Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

254results about "Monocomponent fibroin artificial filament" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

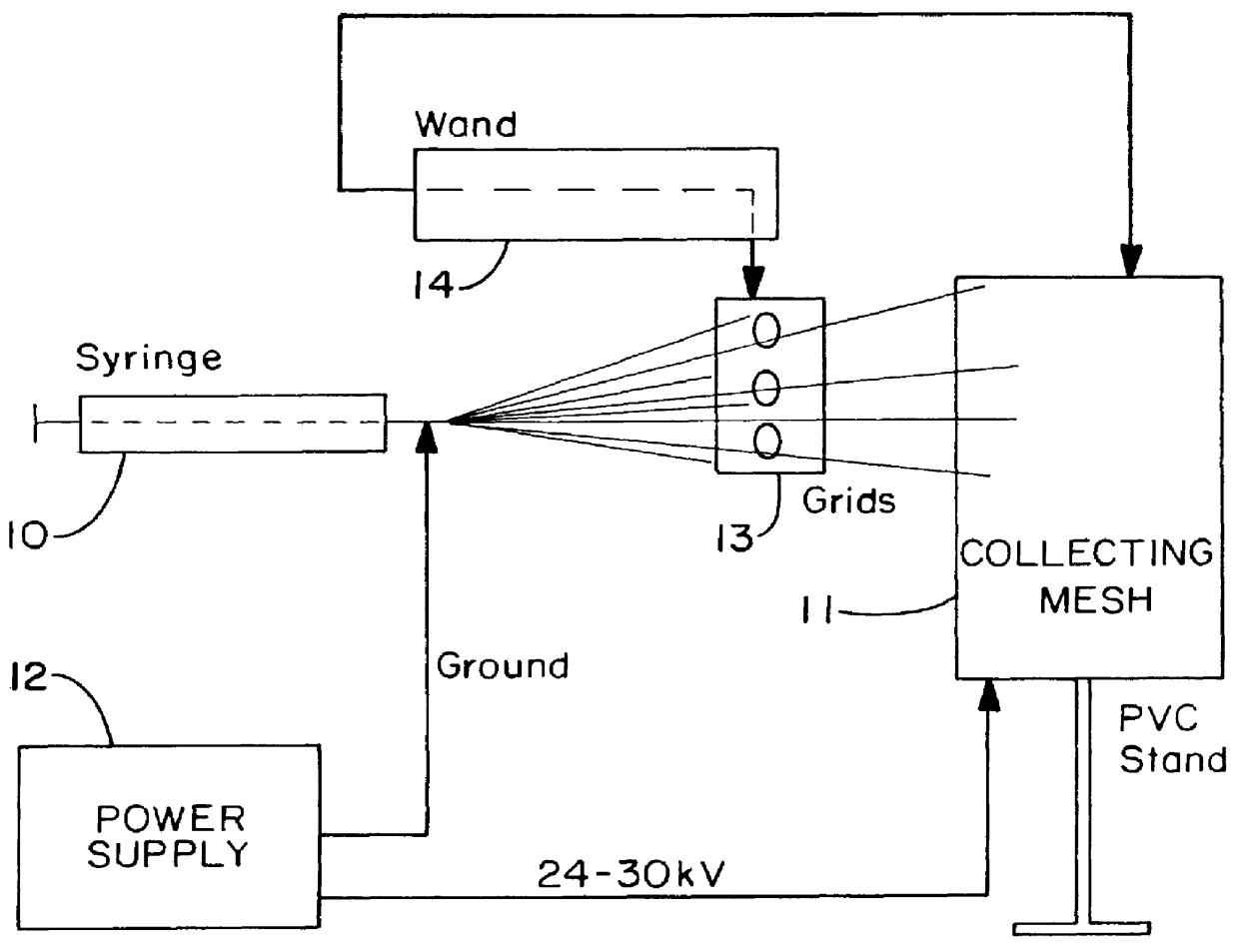

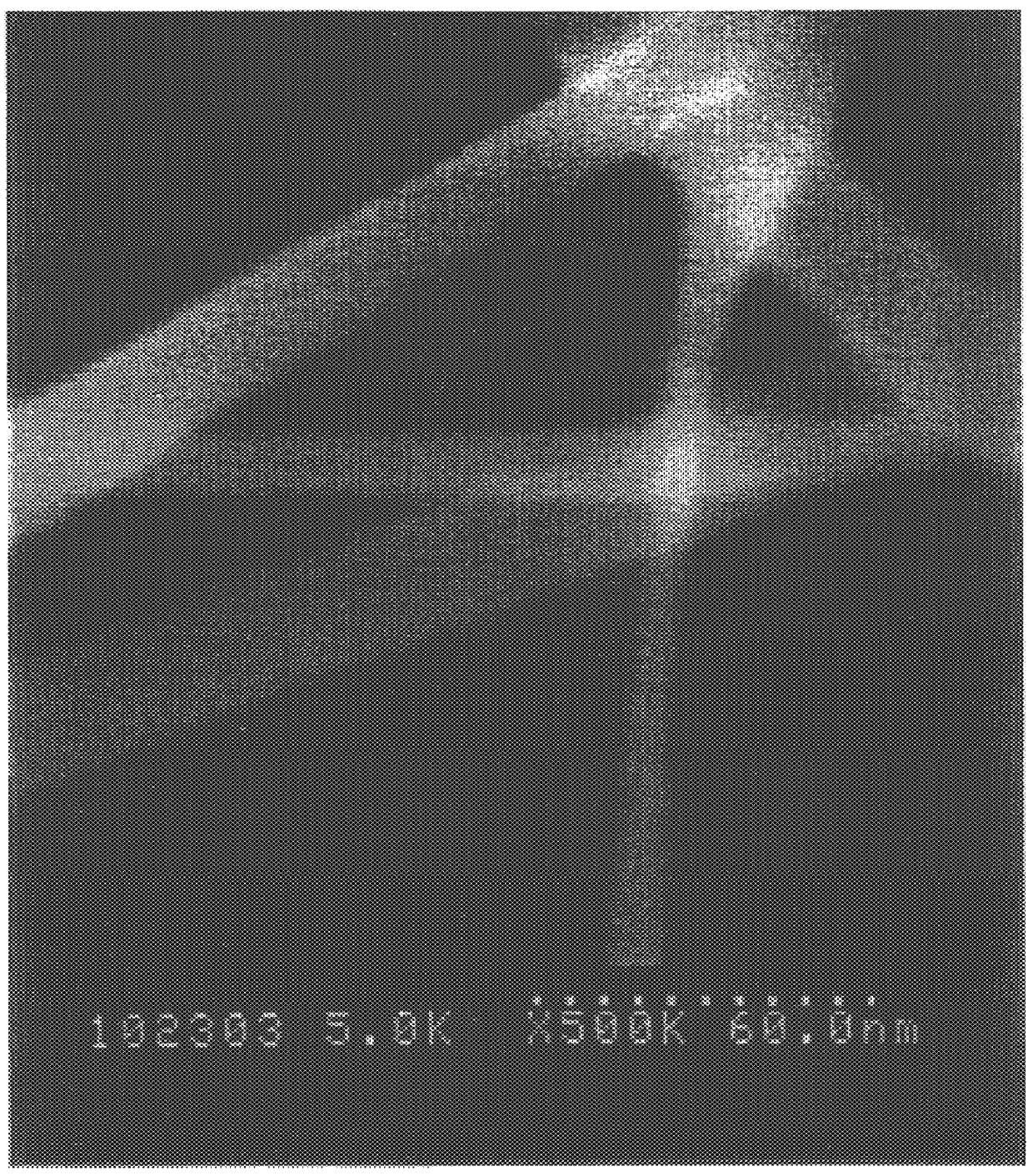

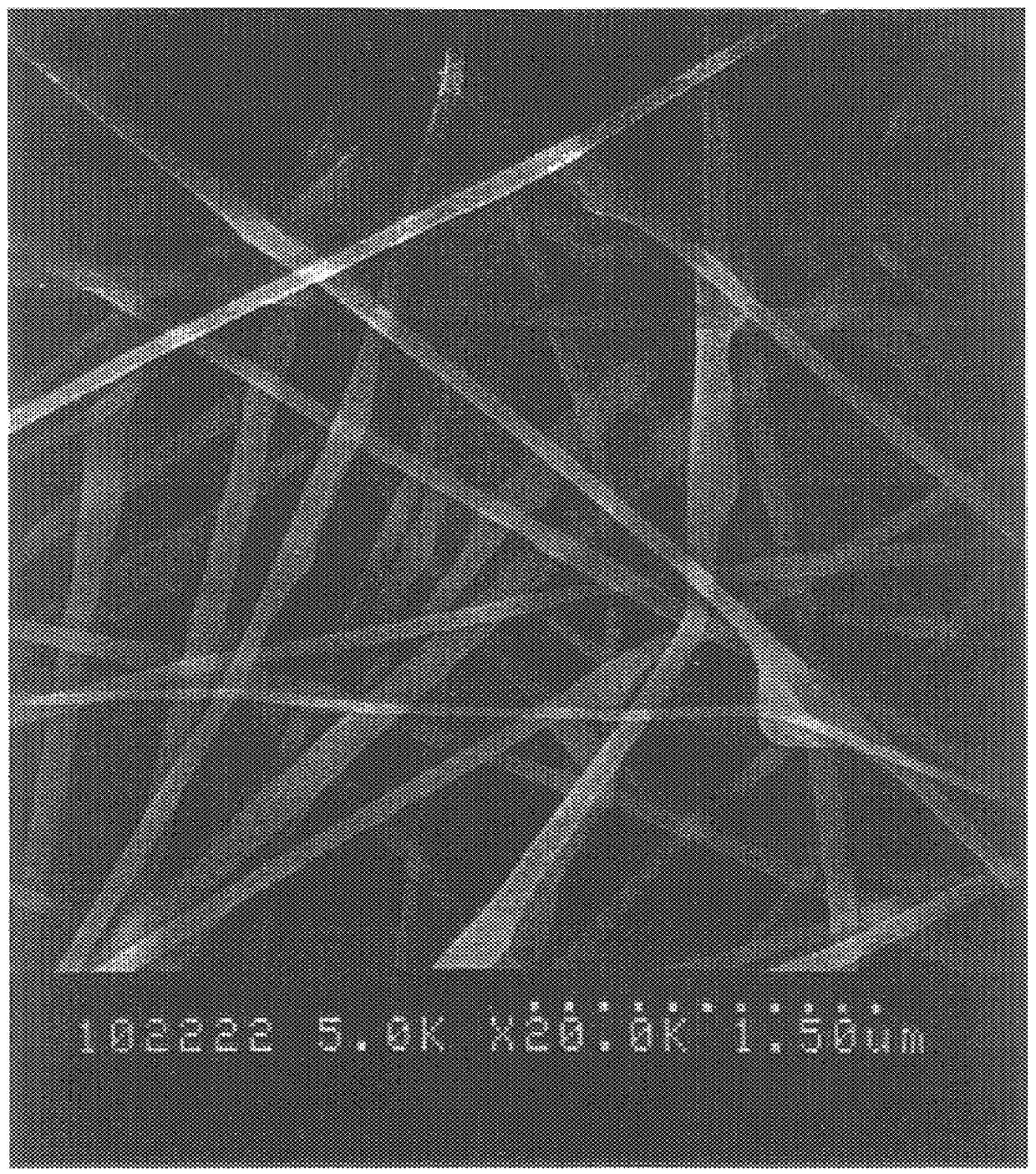

Synthetically spun silk nanofibers and a process for making the same

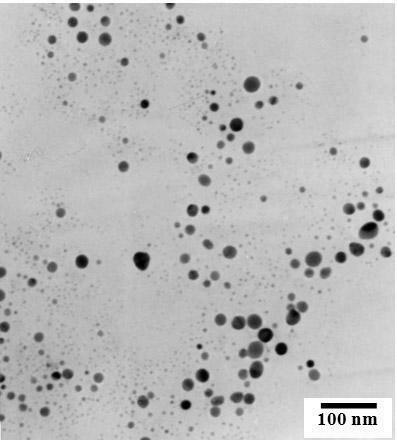

InactiveUS6110590AMonocomponent fibroin artificial filamentFilament/thread formingBombyx moriNanofiber

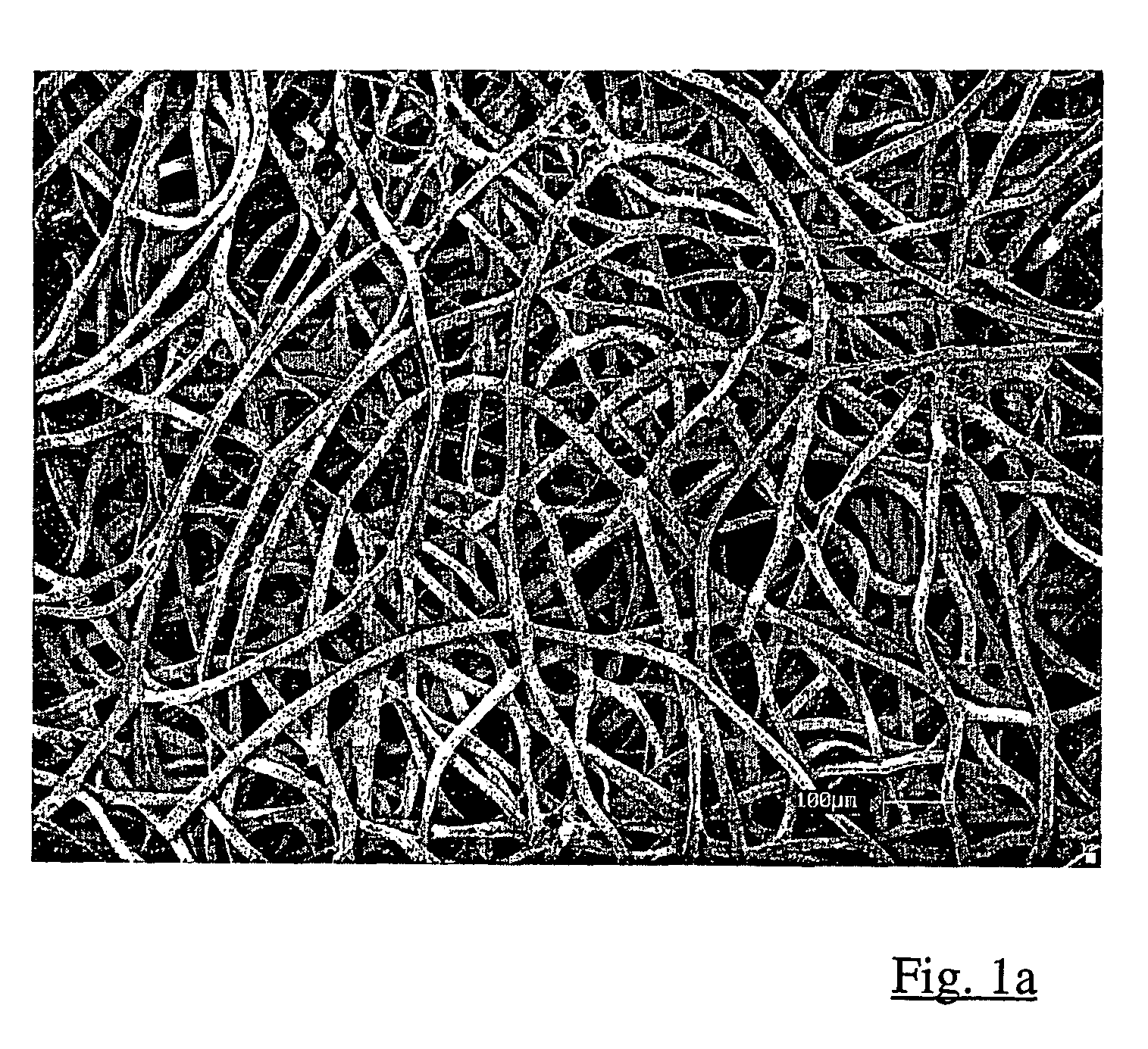

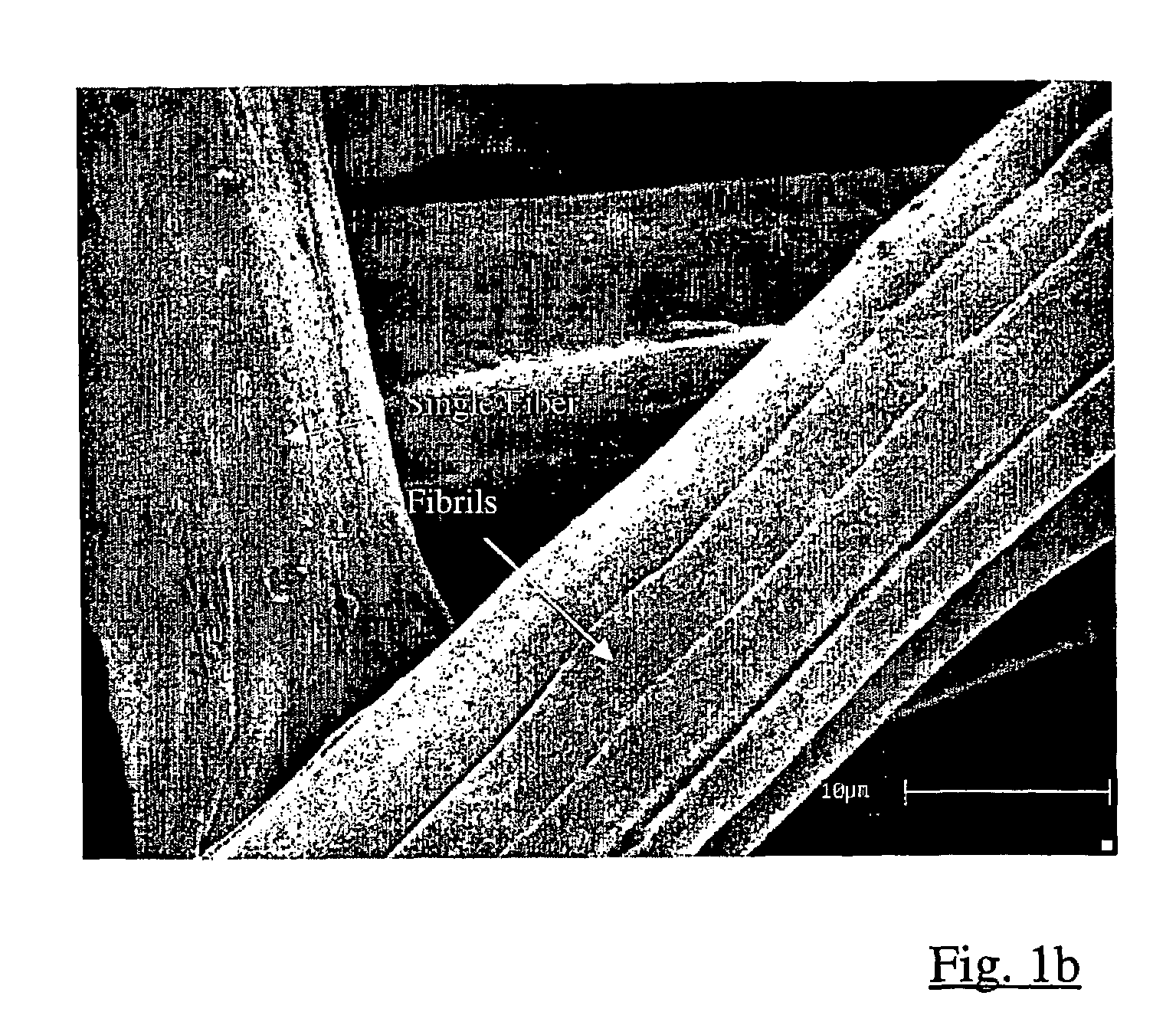

A silk nanofiber composite network produced by forming a solution of silk fiber and hexafluroisopropanol, wherein the step of forming is devoid of any acid treatment, where the silk solution has a concentration of about 0.2 to about 1.5 weight percent silk in hexafluroisopropanol, and where the silk is selected from Bombyx mori silk and Nephila clavipes silk; and electrospinning the solution, thereby forming a non-woven network of nanofibers having a diameter in the range from about 2 to about 2000 nanometers.

Owner:THE UNIVERSITY OF AKRON

Silk fibroin materials and use thereof

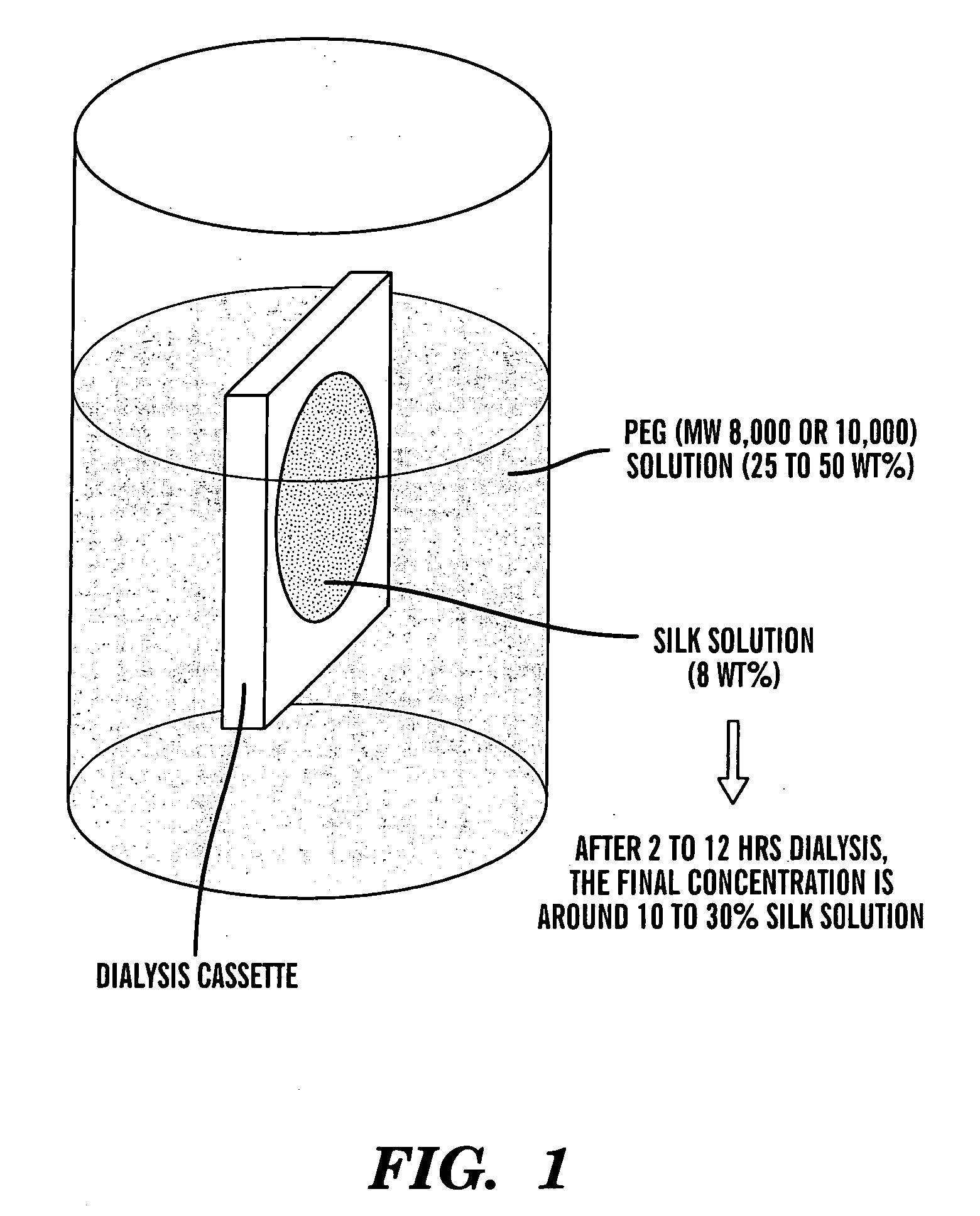

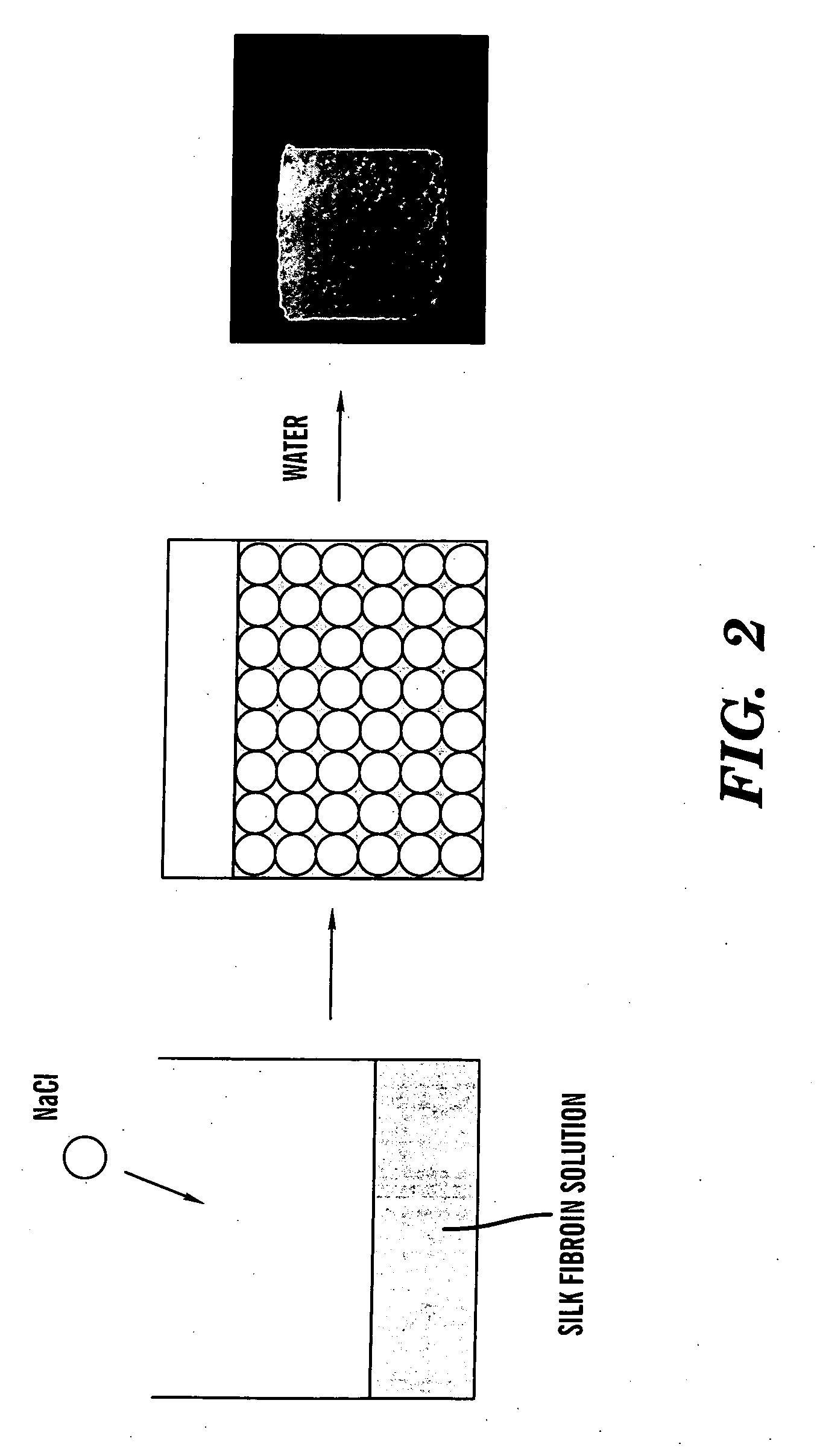

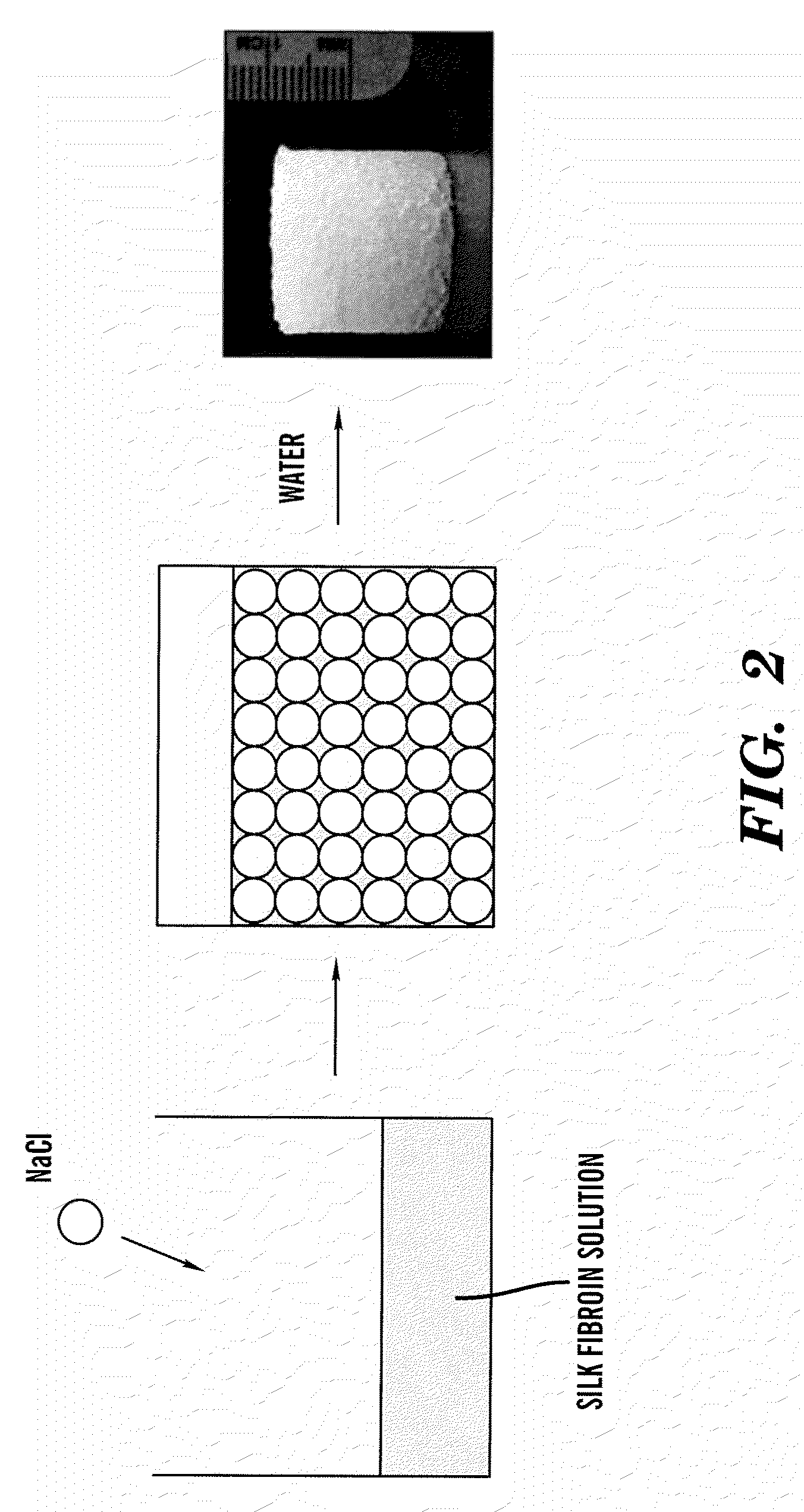

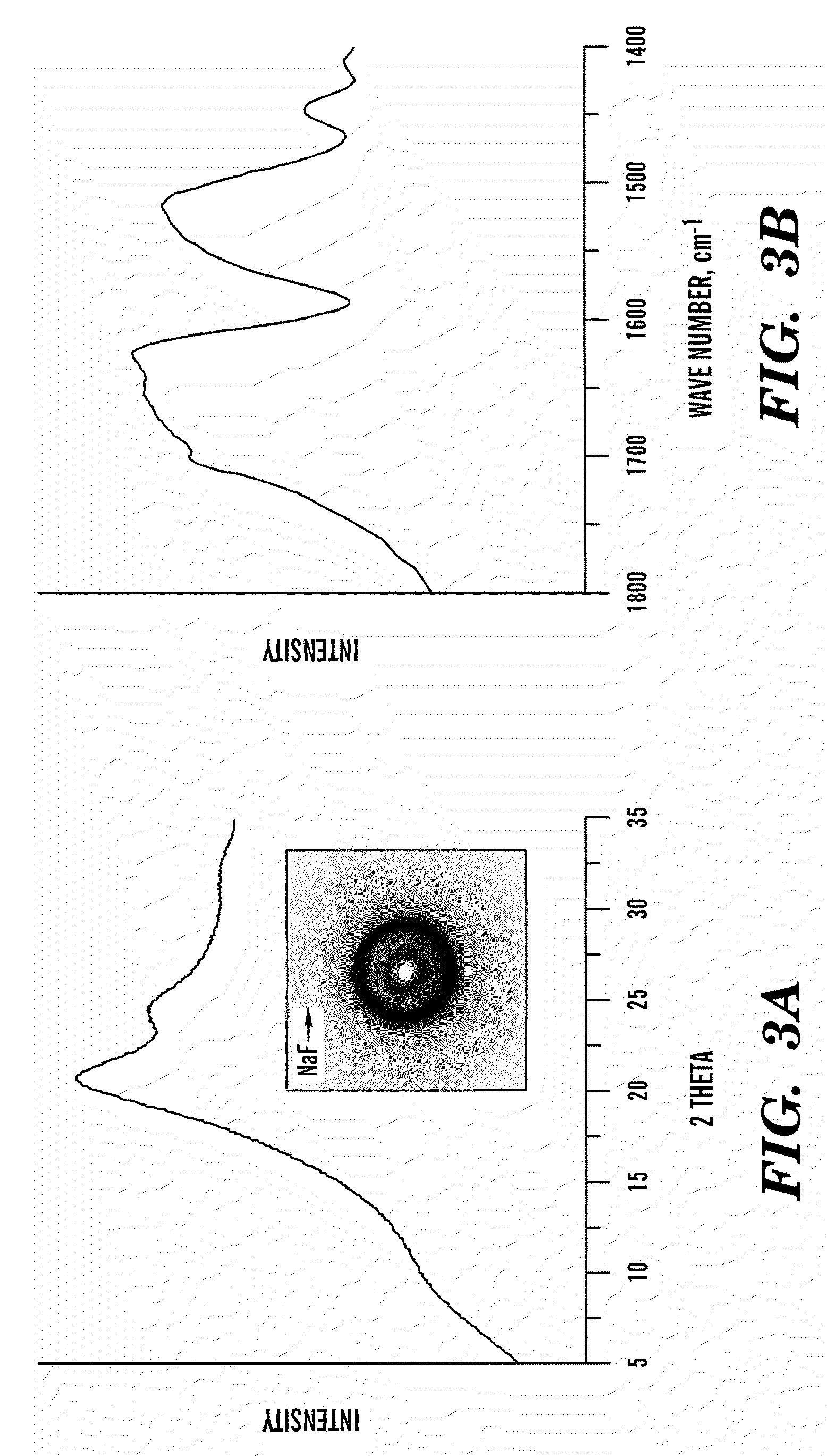

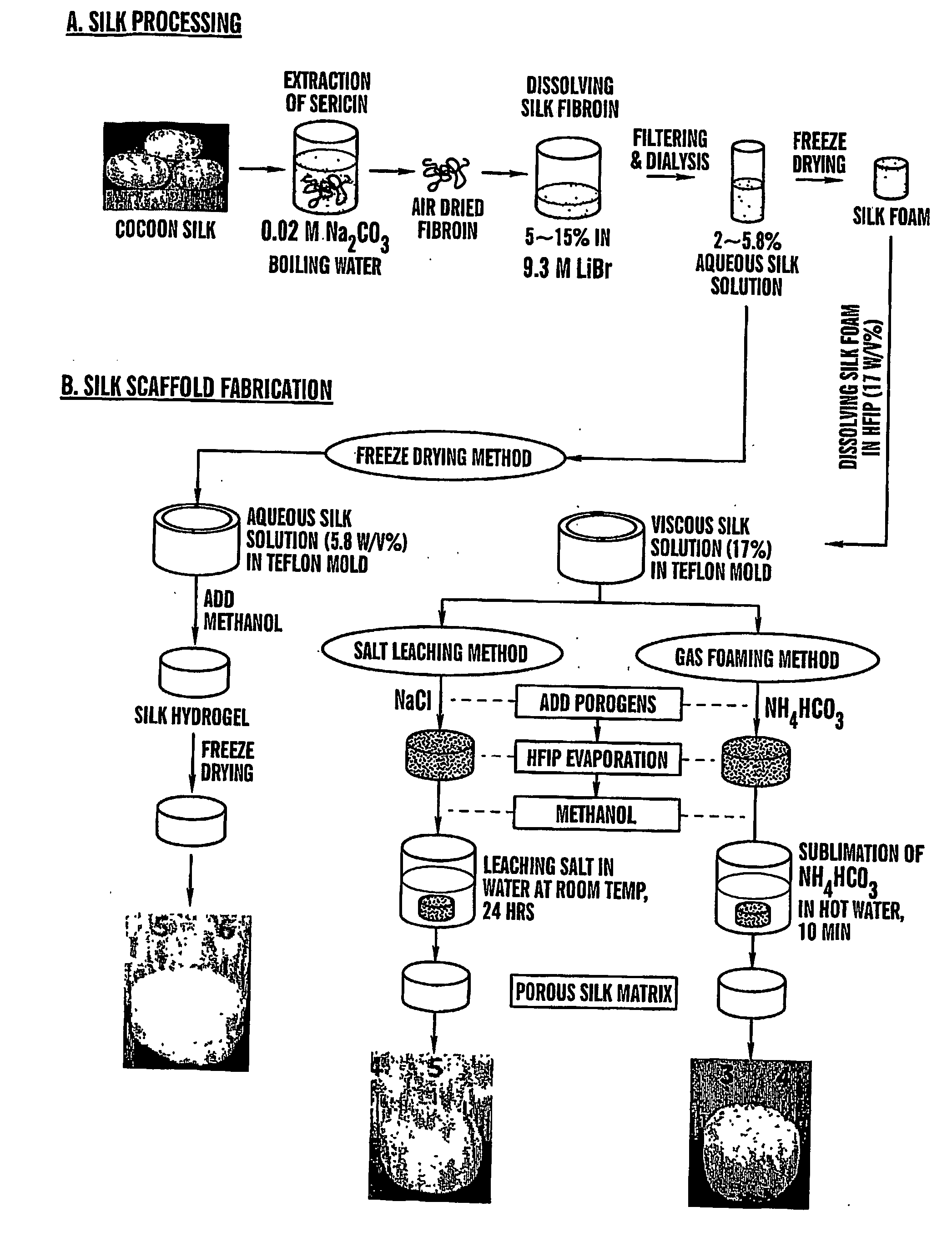

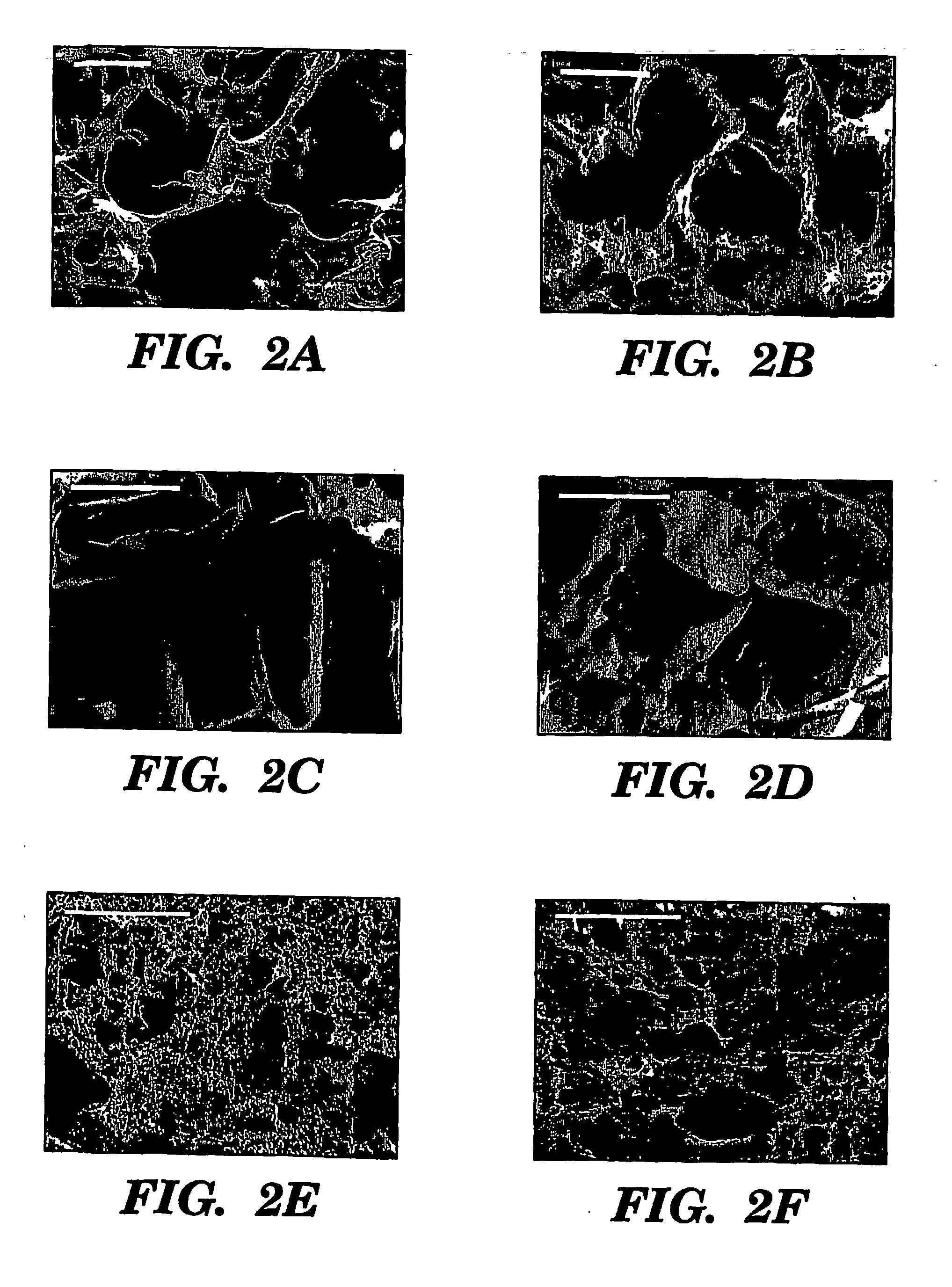

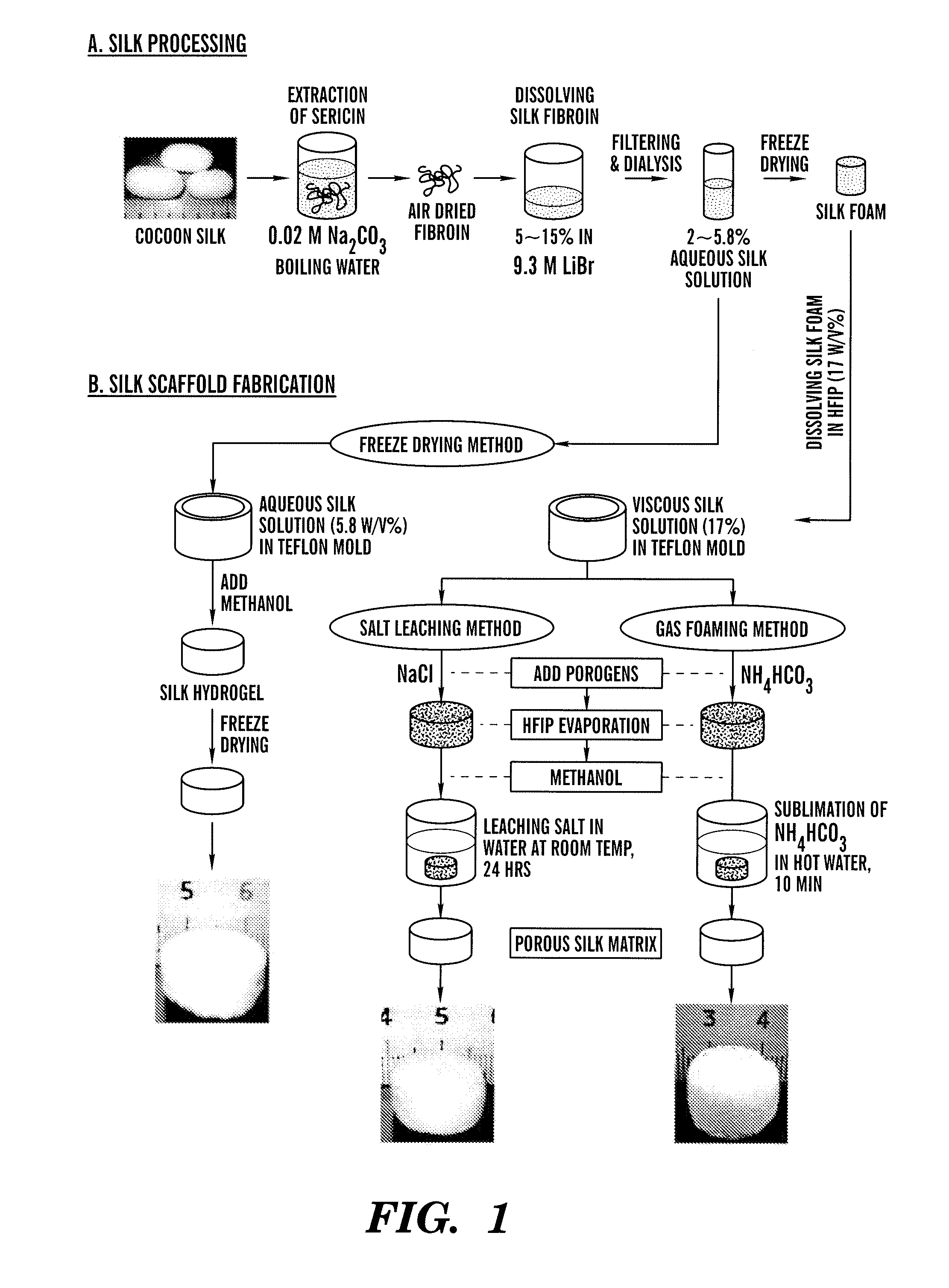

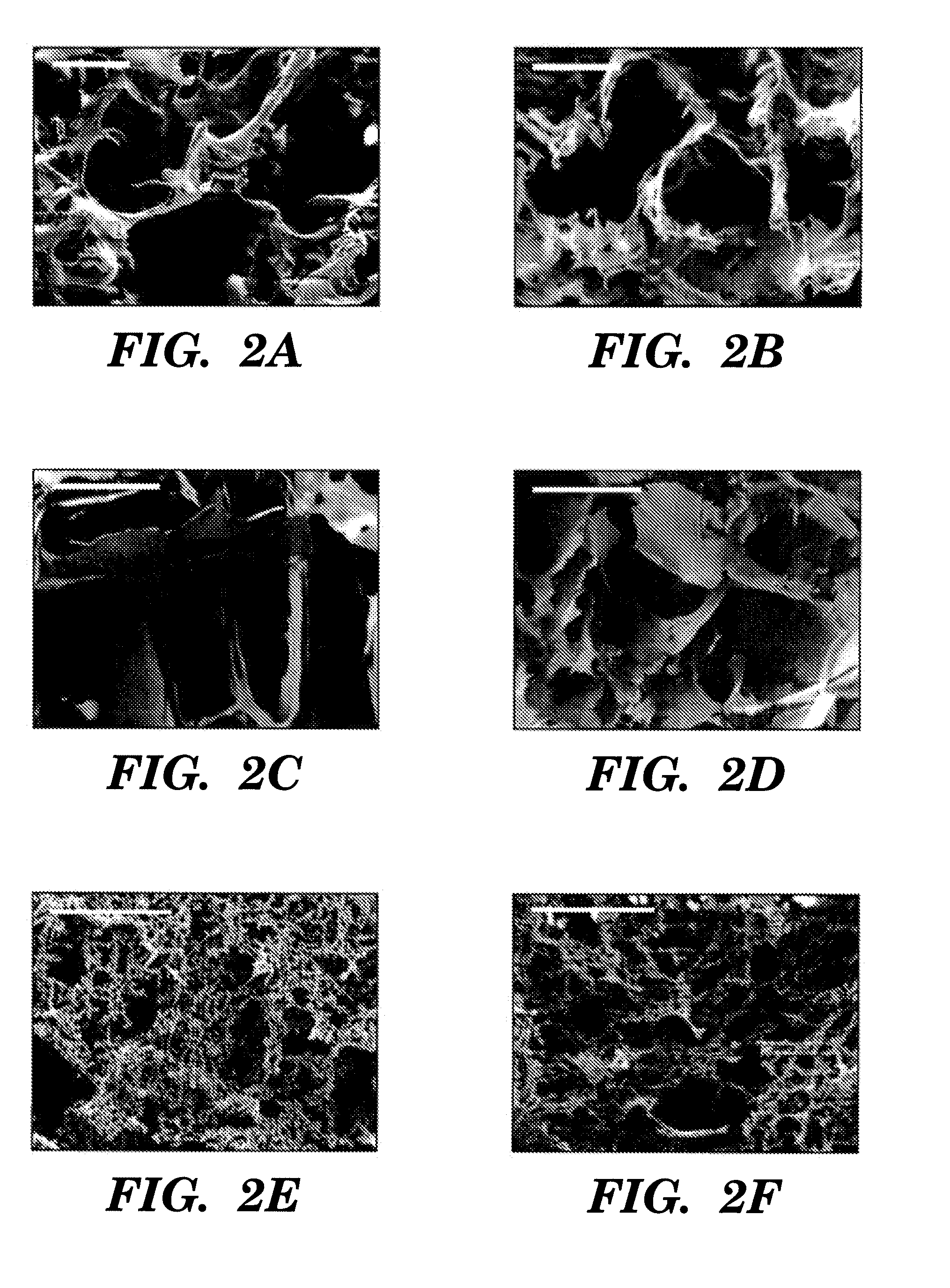

ActiveUS7842780B2Low densityIncreased proliferationPeptide/protein ingredientsMonocomponent fibroin artificial filamentPorosityBiology

The present invention provides processes for producing porous silk fibroin scaffold material. The porous silk fibroin scaffold can be used for tissue engineering. The porosity of the silk fibroin scaffolds described herein can be adjusted as to mimic the gradient of densities found in natural tissue. Accordingly, methods for engineering of 3-dimensional tissue, e.g. bone and cartilage, using the silk fibroin scaffold material are also provided.

Owner:TUFTS UNIV +1

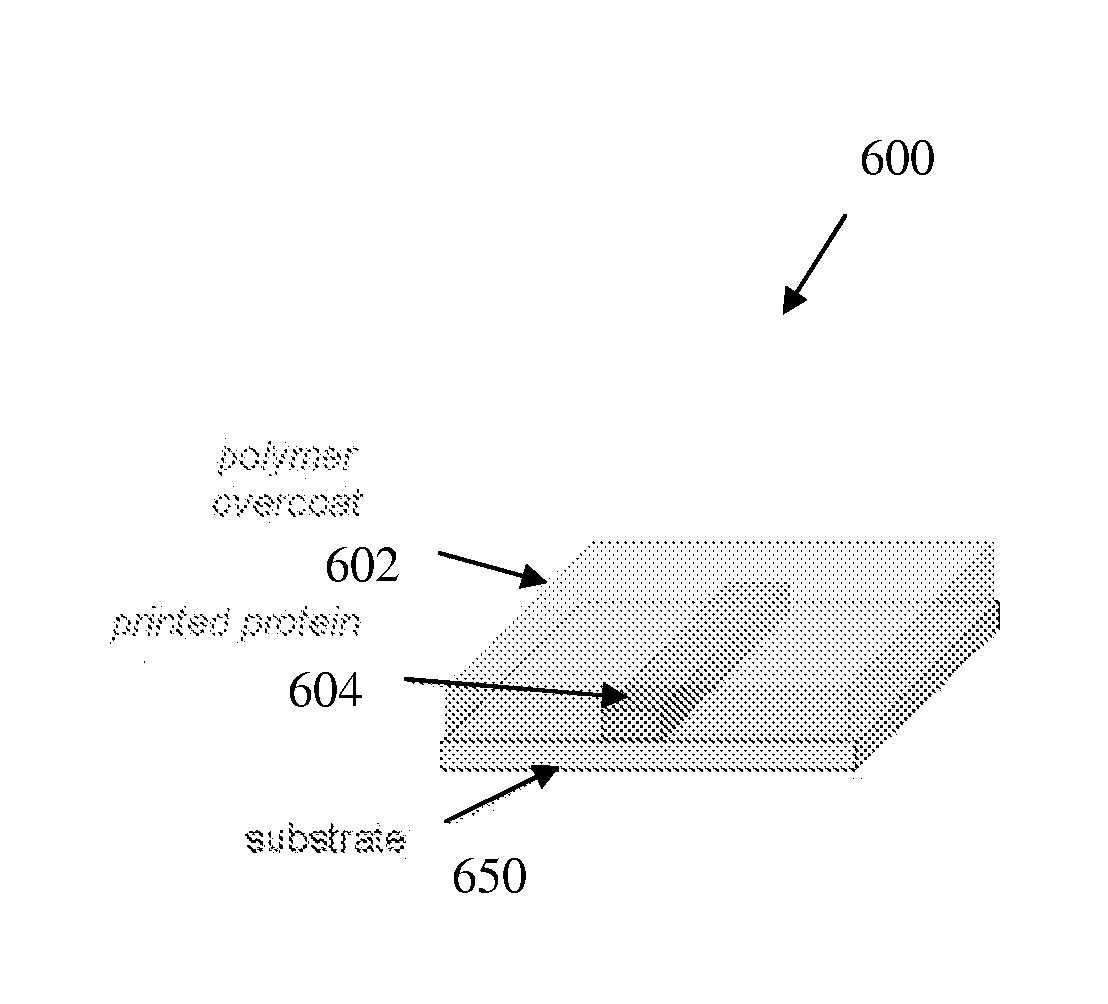

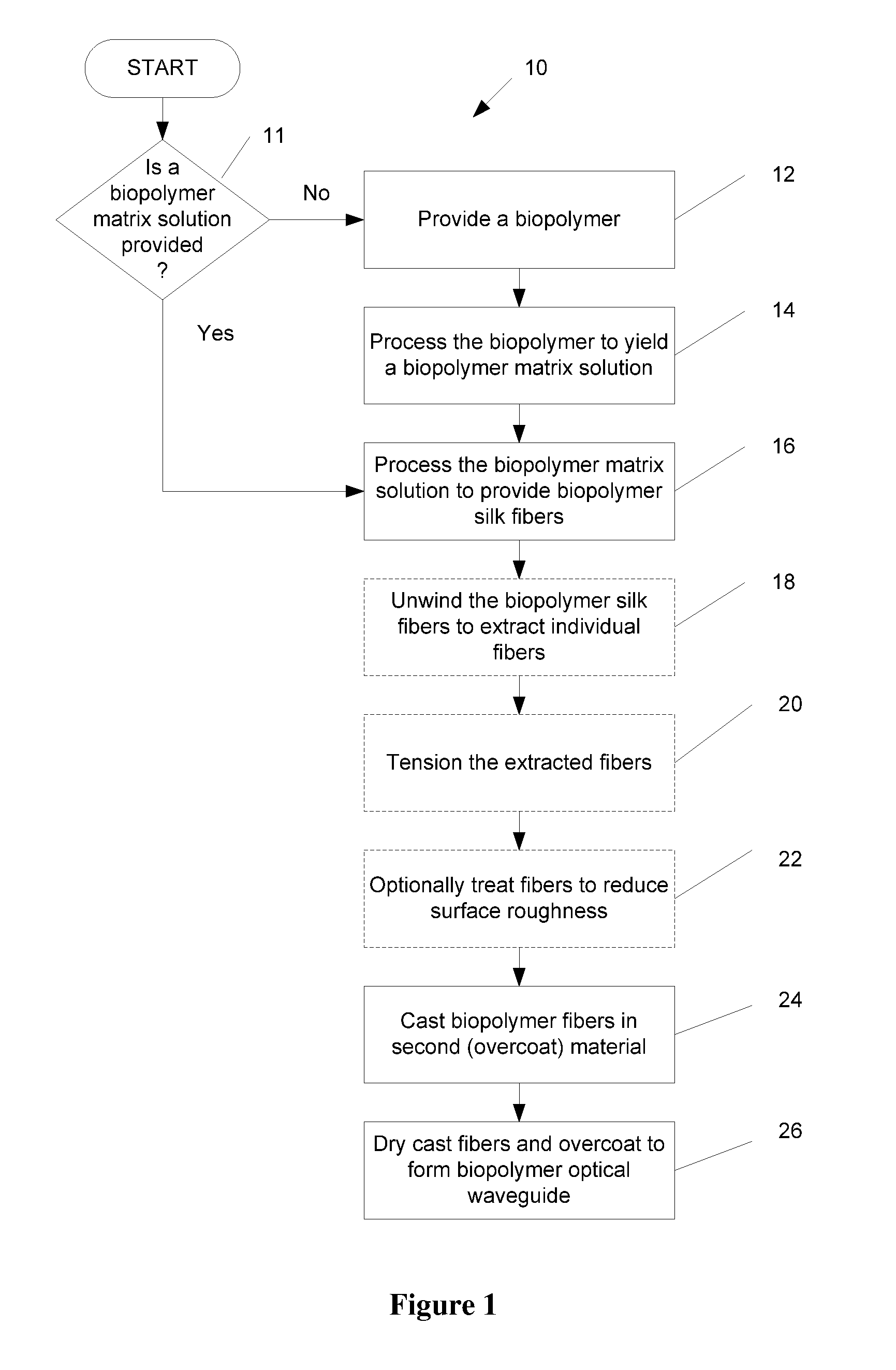

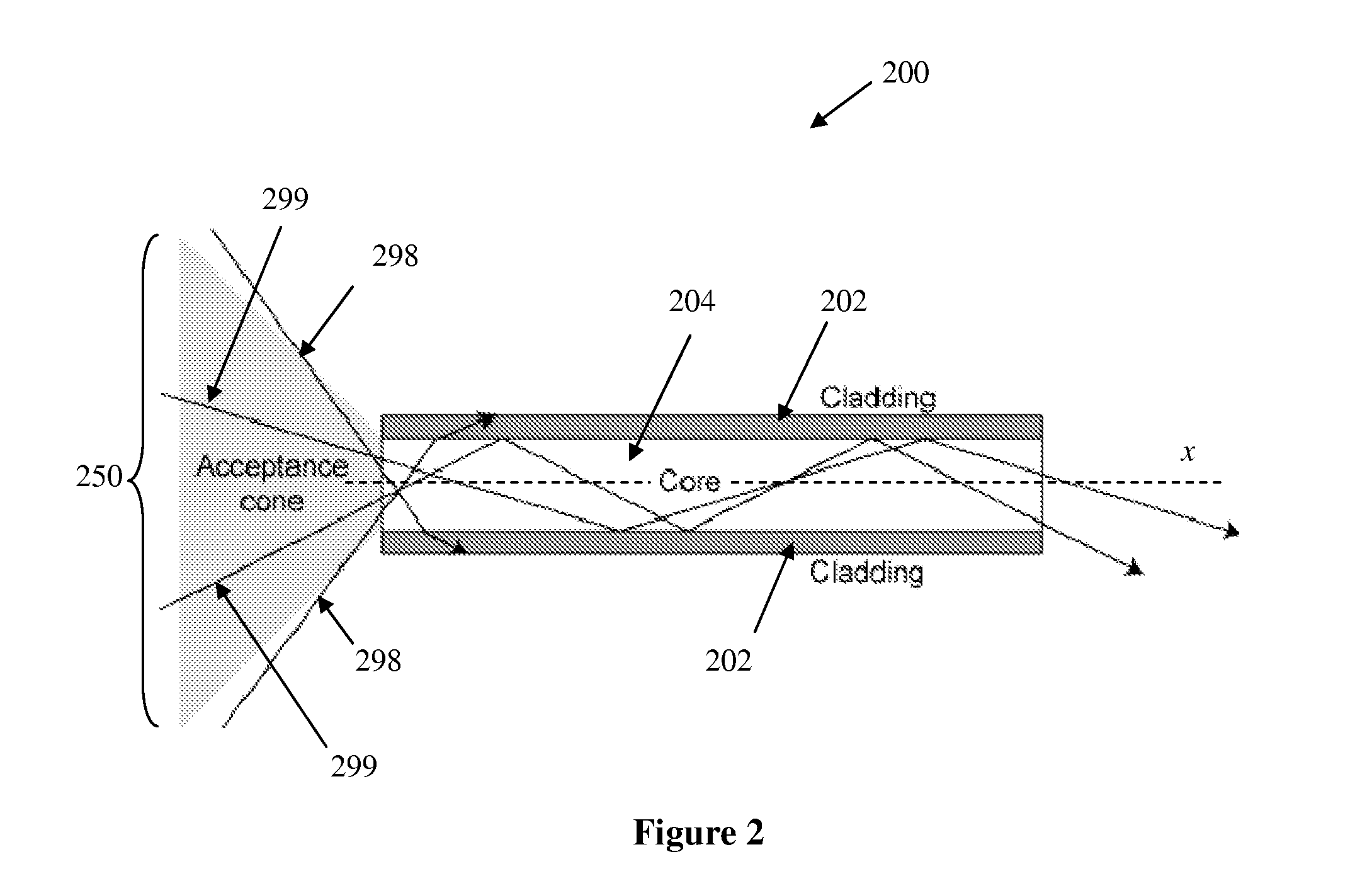

Biopolymer optical waveguide and method of manufacturing the same

ActiveUS20100063404A1Minimize negative impactImprove functional propertiesBiological material analysisMonocomponent fibroin artificial filamentFiberBiopolymer

A method of manufacturing a biopolymer optical waveguide includes providing a biopolymer, unwinding the biopolymer progressively to extract individual biopolymer fibers, and putting the unwound fibers under tension. The tensioned fibers are then cast in a different polymer to form a biopolymer optical waveguide that guides light due to the difference in indices of refraction between the biopolymer and the different polymer. The optical fibers may be used in biomedical applications and can be inserted in the body as transmissive media. Printing techniques may be used to manufacture the biopolymer optical waveguides.

Owner:TRUSTEES OF TUFTS COLLEGE

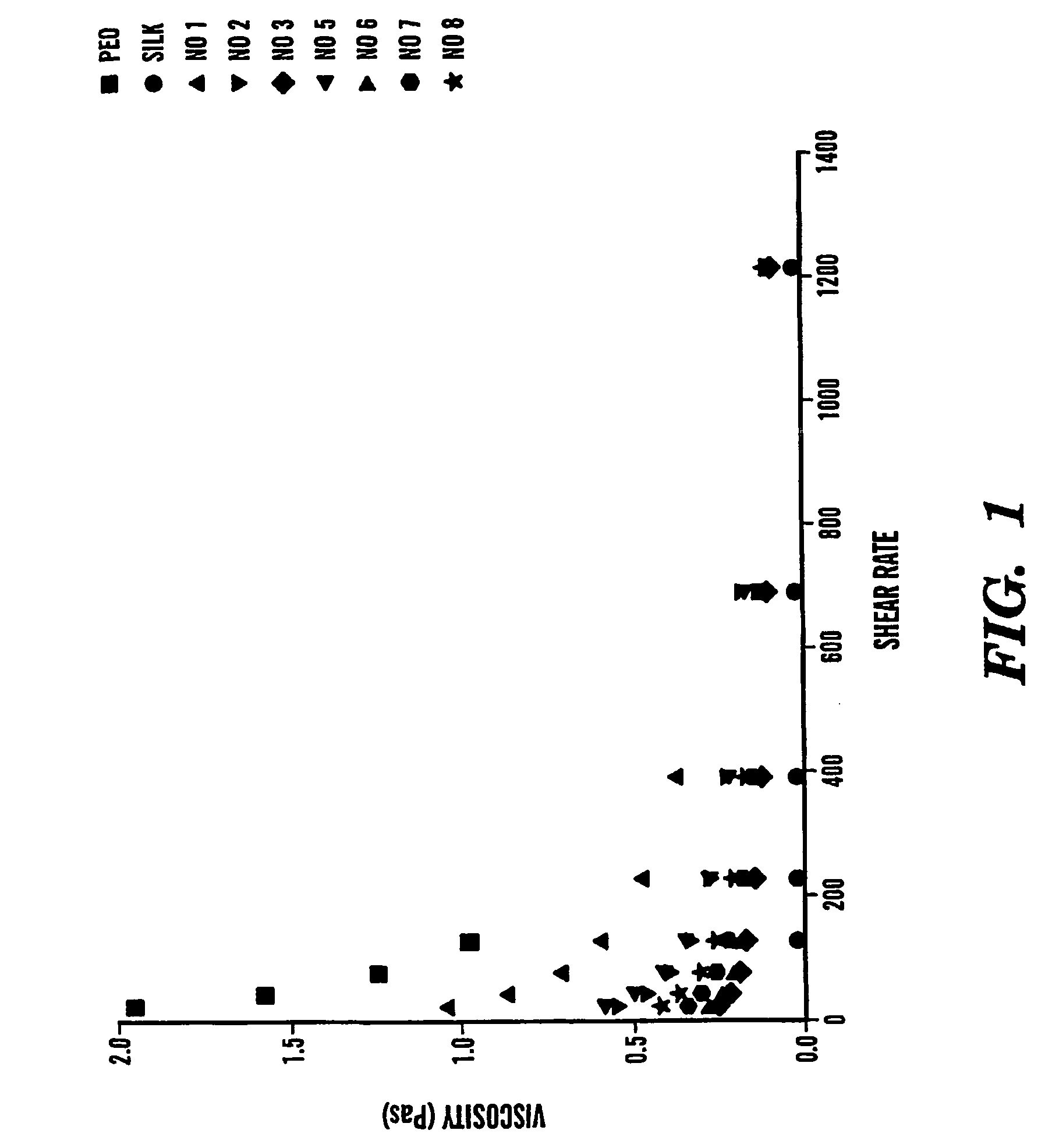

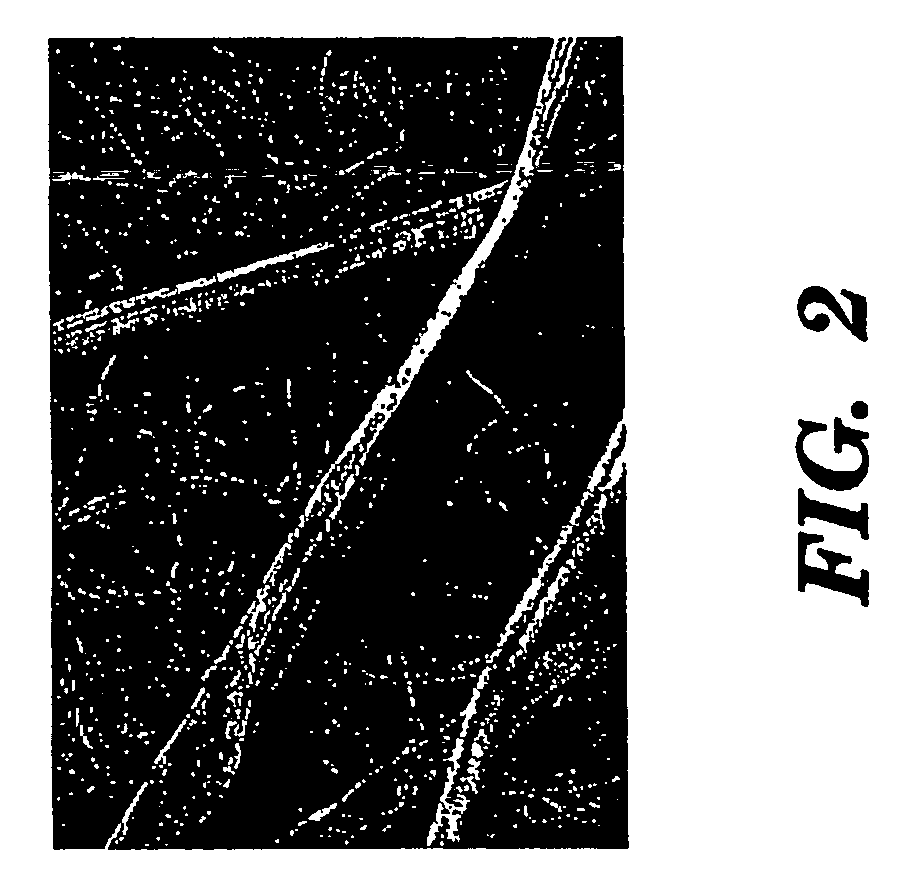

Silk biomaterials and methods of use thereof

ActiveUS7674882B2Avoid problemsReduce usagePeptide/protein ingredientsFilament/thread formingFiberIn vivo

The present invention provides an all-aqueous process and composition for production of silk biomaterials, e.g., fibers, films, foams and mats. In the process, at least one biocompatible polymer, such as poly(ethylene oxide) (PEO) (a well-documented biocompatible material), was blended with the silk protein prior to processing e.g., electrospinning. We discovered that this step avoids problems associated with conformational transitions of fibroin during solubilization and reprocessing from aqueous solution which lead to embrittled materials. Moreover, the process avoids the use of organic solvents that can pose problems when the processed biomaterials are exposed to cells in vitro or in vivo.

Owner:MASSACHUSETTS INST OF TECH +1

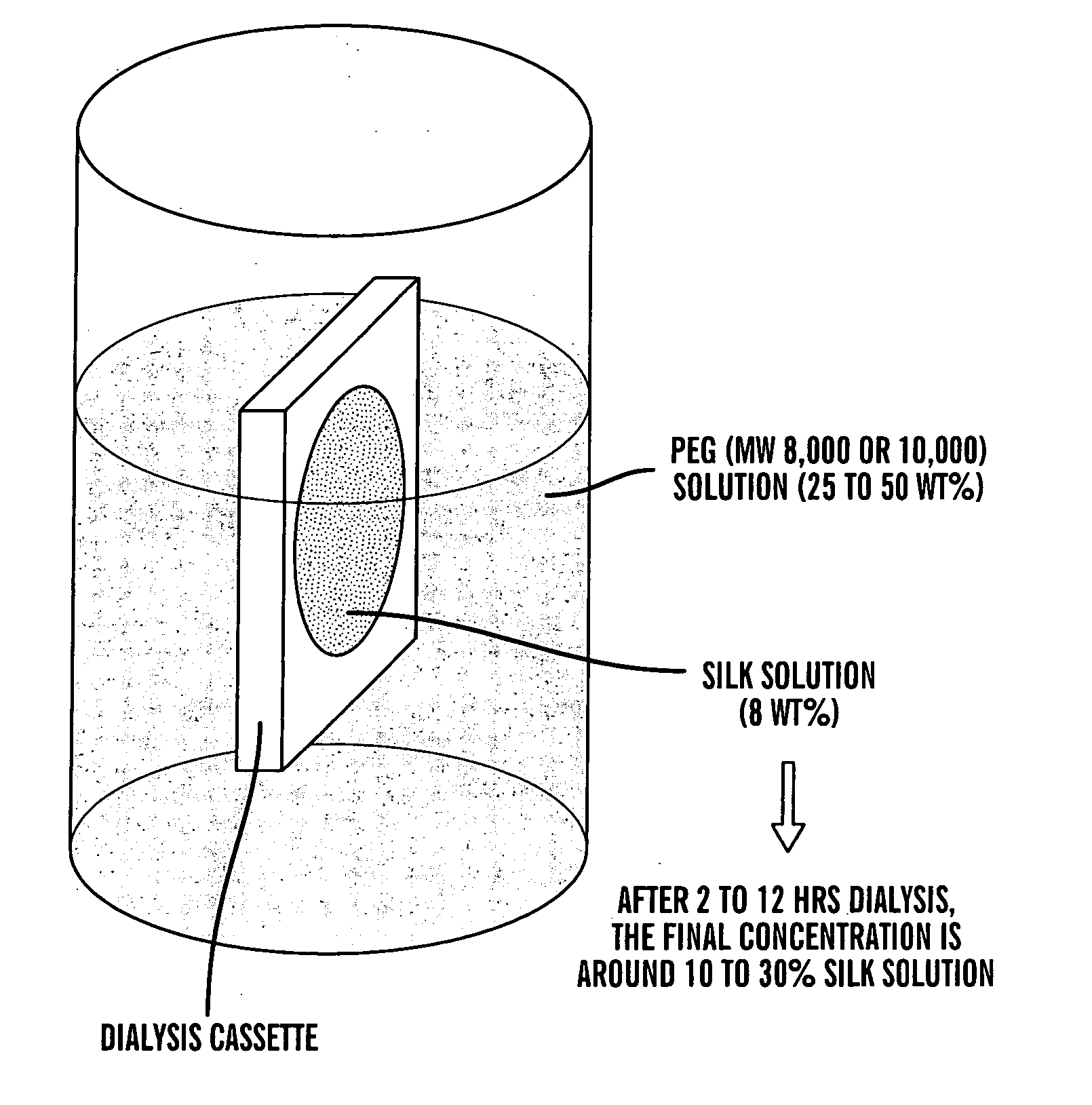

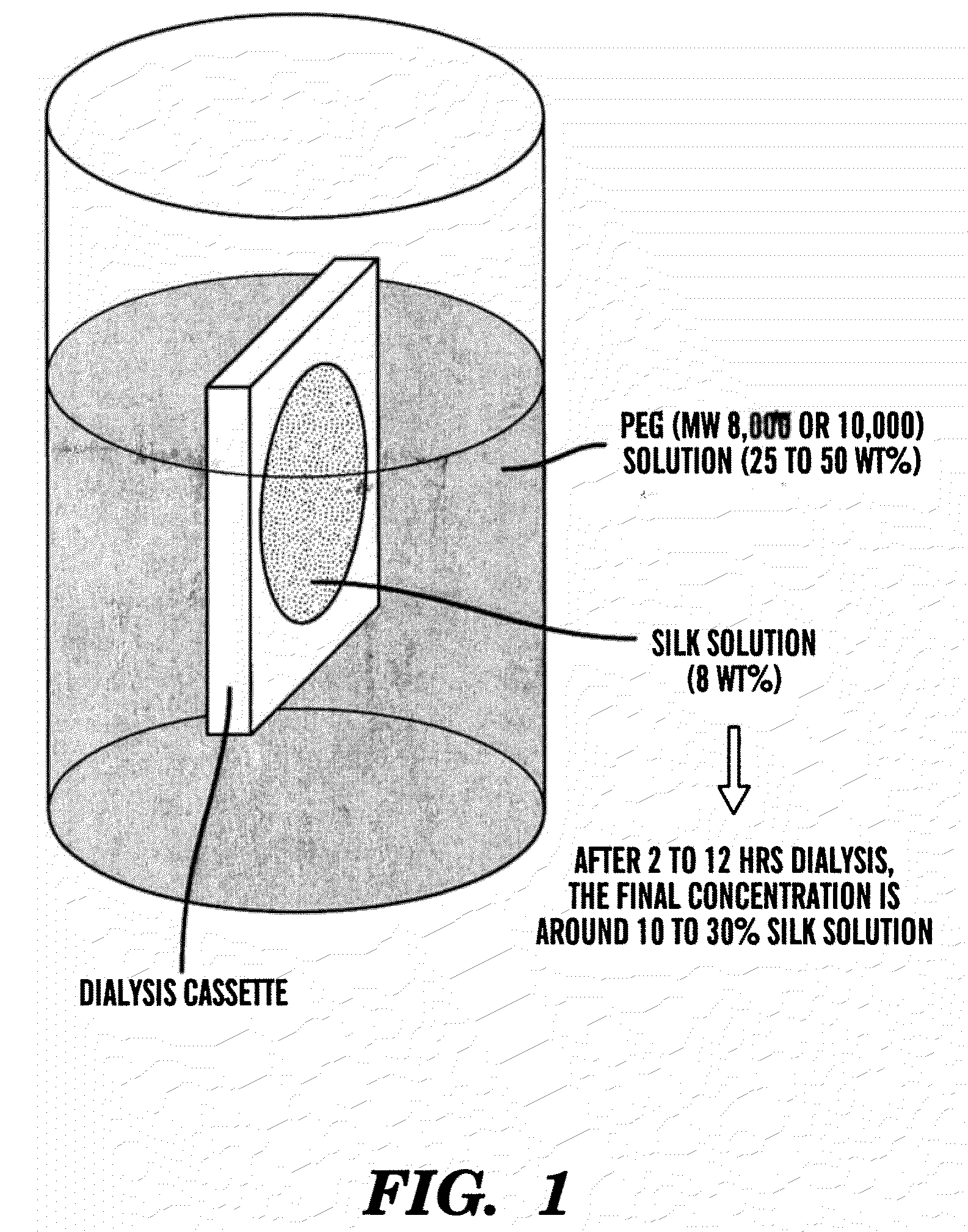

Concentrated aqueous silk fibroin solution and use thereof

ActiveUS20070187862A1Reduce usageConnective tissue peptidesPeptide/protein ingredientsFiberOrganic solvent

The present invention provides for concentrated aqueous silk fibroin solutions and an all-aqueous mode for preparation of concentrated aqueous fibroin solutions that avoids the use of organic solvents, direct additives, or harsh chemicals. The invention further provides for the use of these solutions in production of materials, e.g., fibers, films, foams, meshes, scaffolds and hydrogels.

Owner:TRUSTEES OF TUFTS COLLEGE TUFTS UNIV

Concentrated aqueous silk fibroin solution and use thereof

ActiveUS20090234026A1Reduce usageBiocideMonocomponent fibroin artificial filamentFiberOrganic solvent

The present invention provides for concentrated aqueous silk fibroin solutions and an all-aqueous mode for preparation of concentrated aqueous fibroin solutions that avoids the use of organic solvents, direct additives, or harsh chemicals. The invention further provides for the use of these solutions in production of materials, e.g., fibers, films, foams, meshes, scaffolds and hydrogels.

Owner:TRUSTEES OF TUFTS COLLEGE

Electrospun pharmaceutical compositions

ActiveUS20060273279A1Increased proliferationIncrease differentiationPeptide/protein ingredientsFilament/thread formingPorosityFibroin

The present invention provides processes for producing porous silk fibroin scaffold material. The porous silk fibroin scaffold can be used for tissue engineering. The porosity of the silk fibroin scaffolds described herein can be adjusted to mimic the gradient of densities found in natural tissue. Accordingly, methods for engineering of 3-dimensional tissue, e.g. bone and cartilage, using the silk fibroin scaffold material are also provided.

Owner:TUFTS UNIV +1

Silk fibroin materials and use thereof

ActiveUS20100279112A1Low densityIncreased proliferationPeptide/protein ingredientsFilament/thread formingPorosityBiology

The present invention provides processes for producing porous silk fibroin scaffold material. The porous silk fibroin scaffold can be used for tissue engineering. The porosity of the silk fibroin scaffolds described herein can be adjusted as to mimic the gradient of densities found in natural tissue. Accordingly, methods for engineering of 3-dimensional tissue, e.g. bone and cartilage, using the silk fibroin scaffold material are also provided.

Owner:TRUSTEES OF TUFTS COLLEGE +1

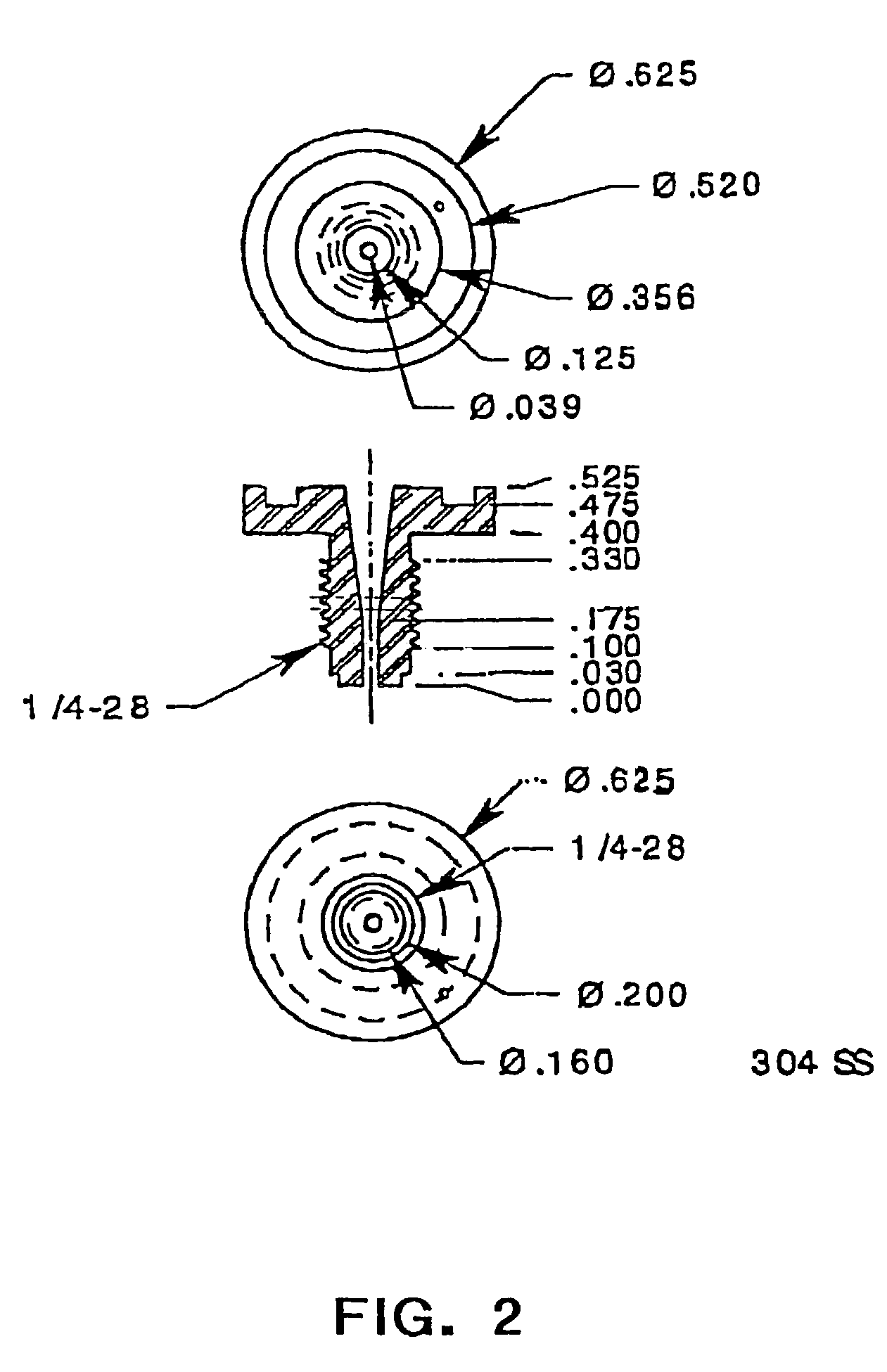

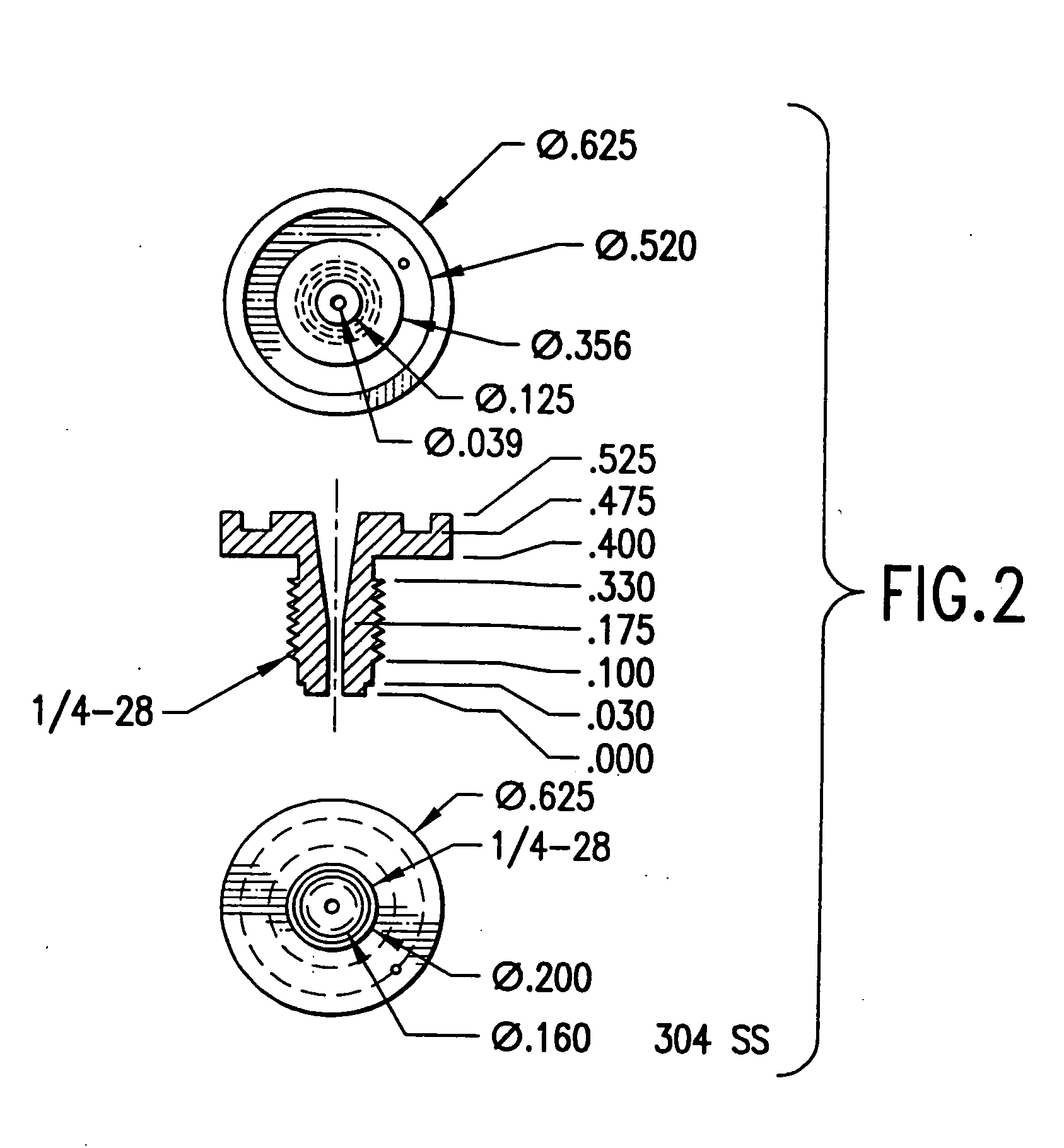

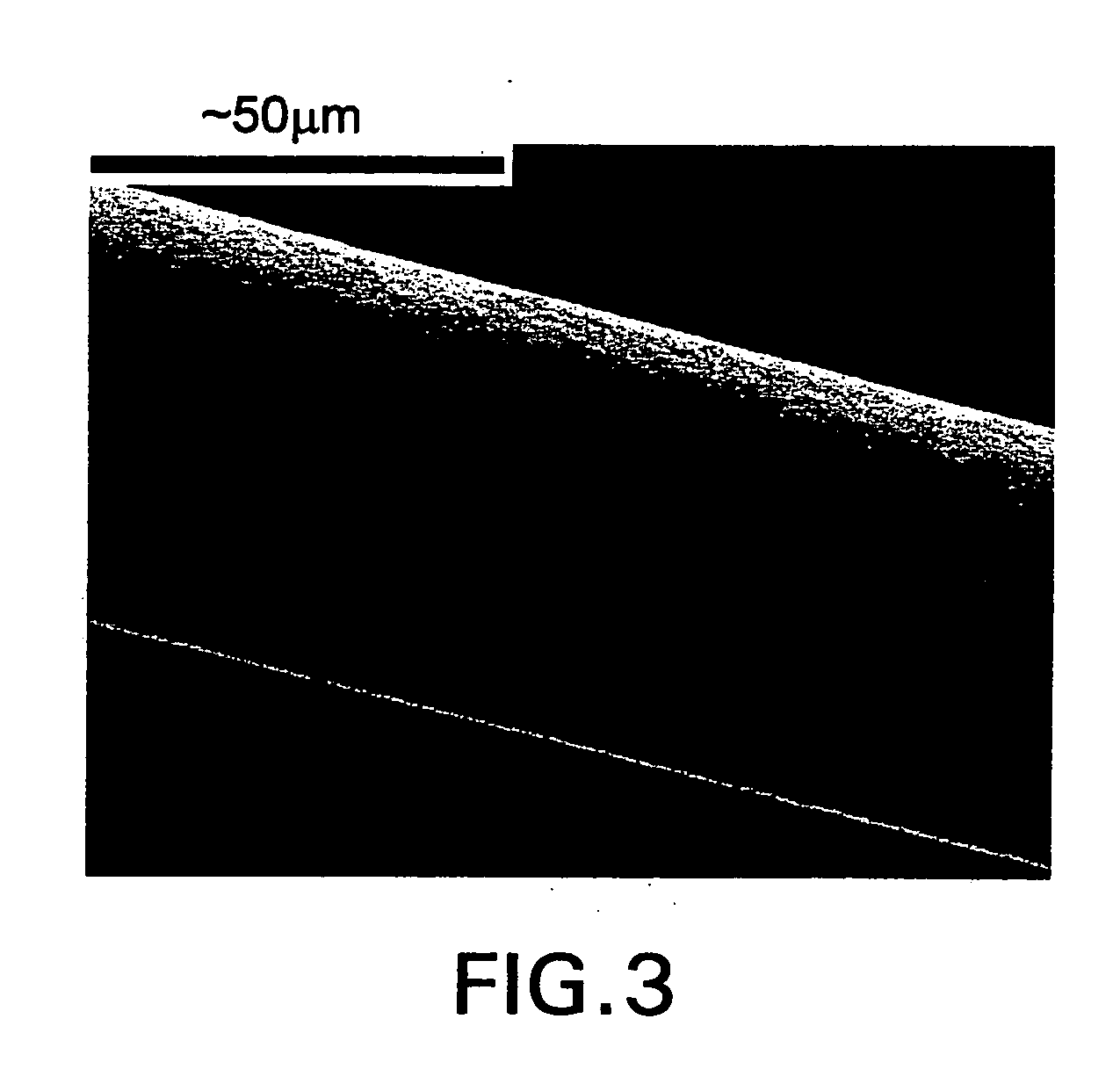

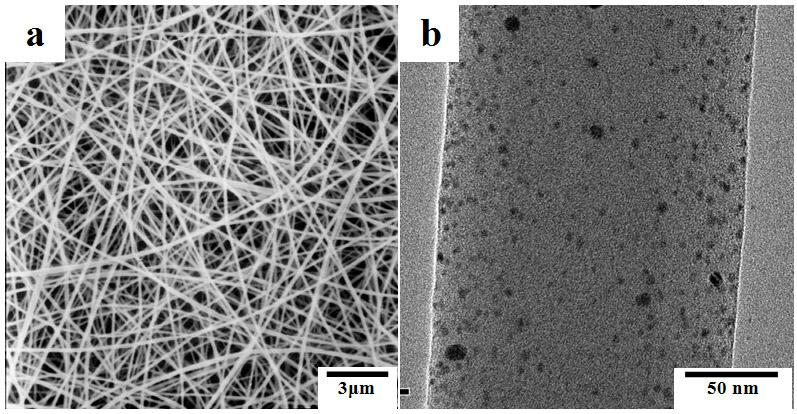

Methods and apparatus for spinning spider silk protein

The invention features methods and apparatuses for spinning silk protein fibers (biofilaments) from recombinant biofilament proteins. The methods are particularly useful for spinning fibers of spider silk or silkworm silk proteins from recombinant mammalian cells and may be used to spin such fibers for use in the manufacture of industrial and commercial products.

Owner:SANTE BIOMATERIALS

Methods and apparatus for spinning spider silk protein

InactiveUS20050054830A1Peptide/protein ingredientsMonocomponent fibroin artificial filamentBiotechnologySpider Proteins

The invention features methods and apparatuses for spinning silk protein fibers (biofilaments) from recombinant biofilament proteins. The methods are particularly useful for spinning fibers of spider silk or silkworm silk proteins from recombinant mammalian cells and may be used to spin such fibers for use in the manufacture of industrial and commercial products.

Owner:NEXIA BIOTECH

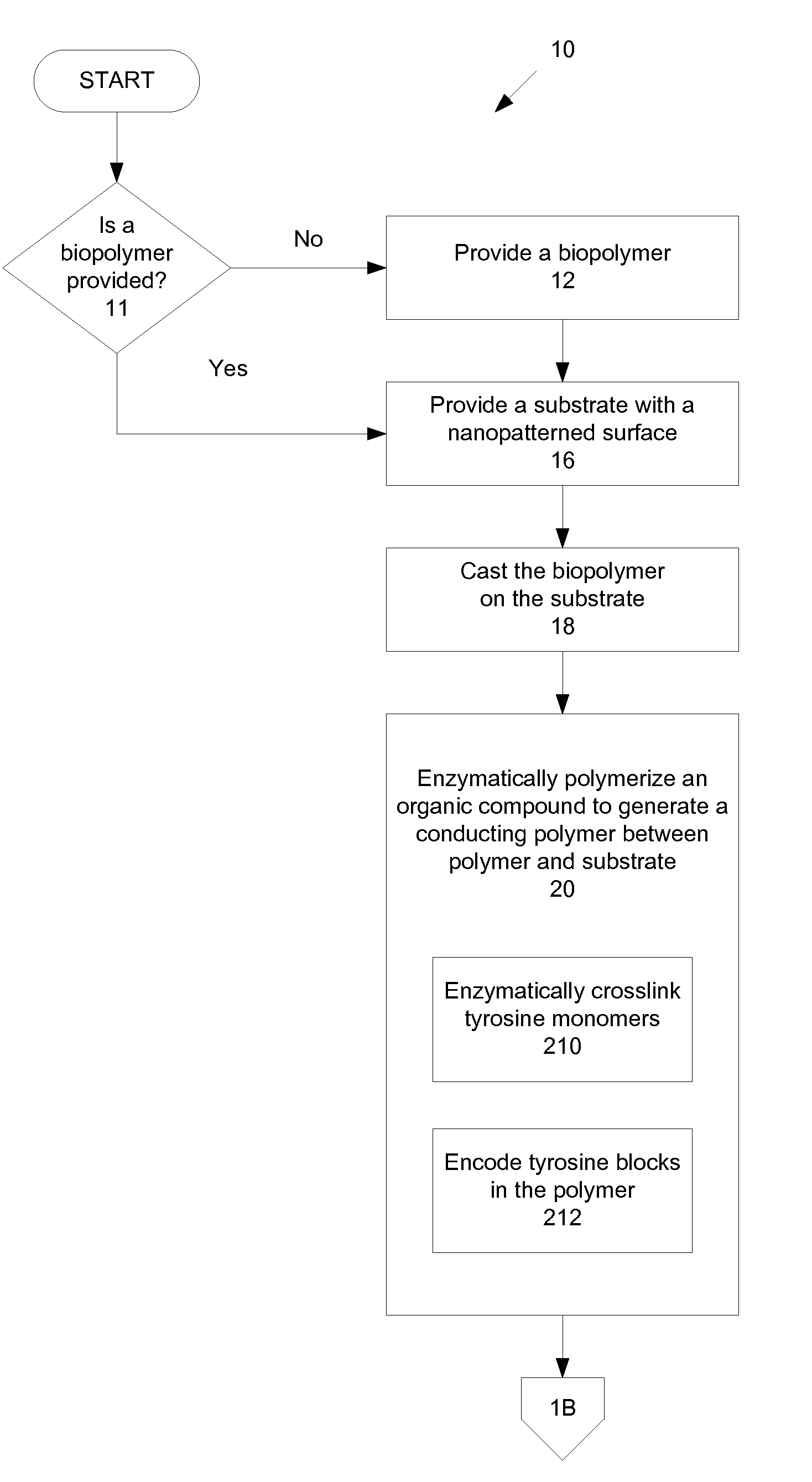

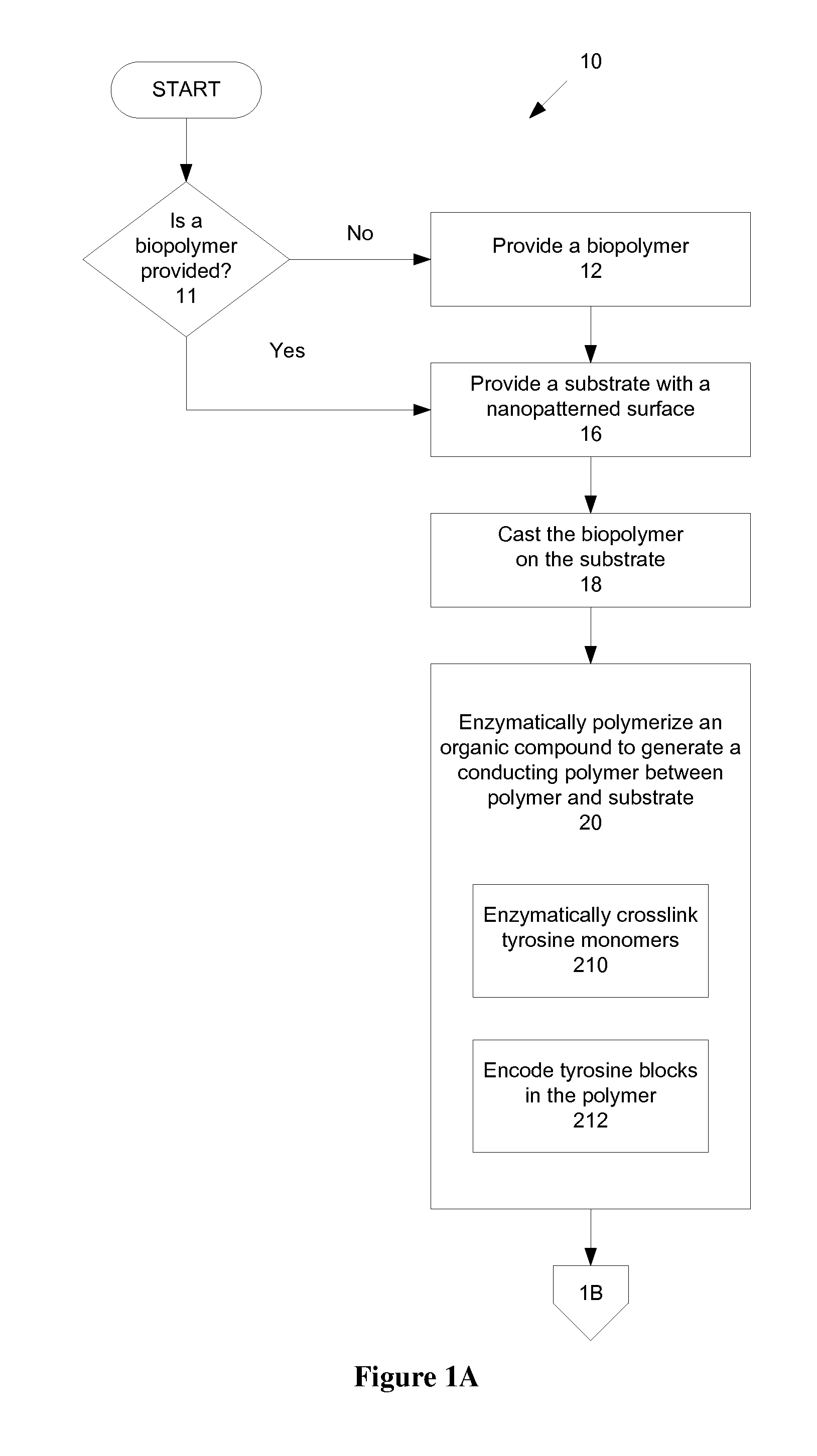

Electroactive biopolymer optical and electro-optical devices and method of manufacturing the same

ActiveUS20100065784A1Minimize negative impactImprove functional propertiesPowder deliveryConductive materialPolymer scienceBiopolymer

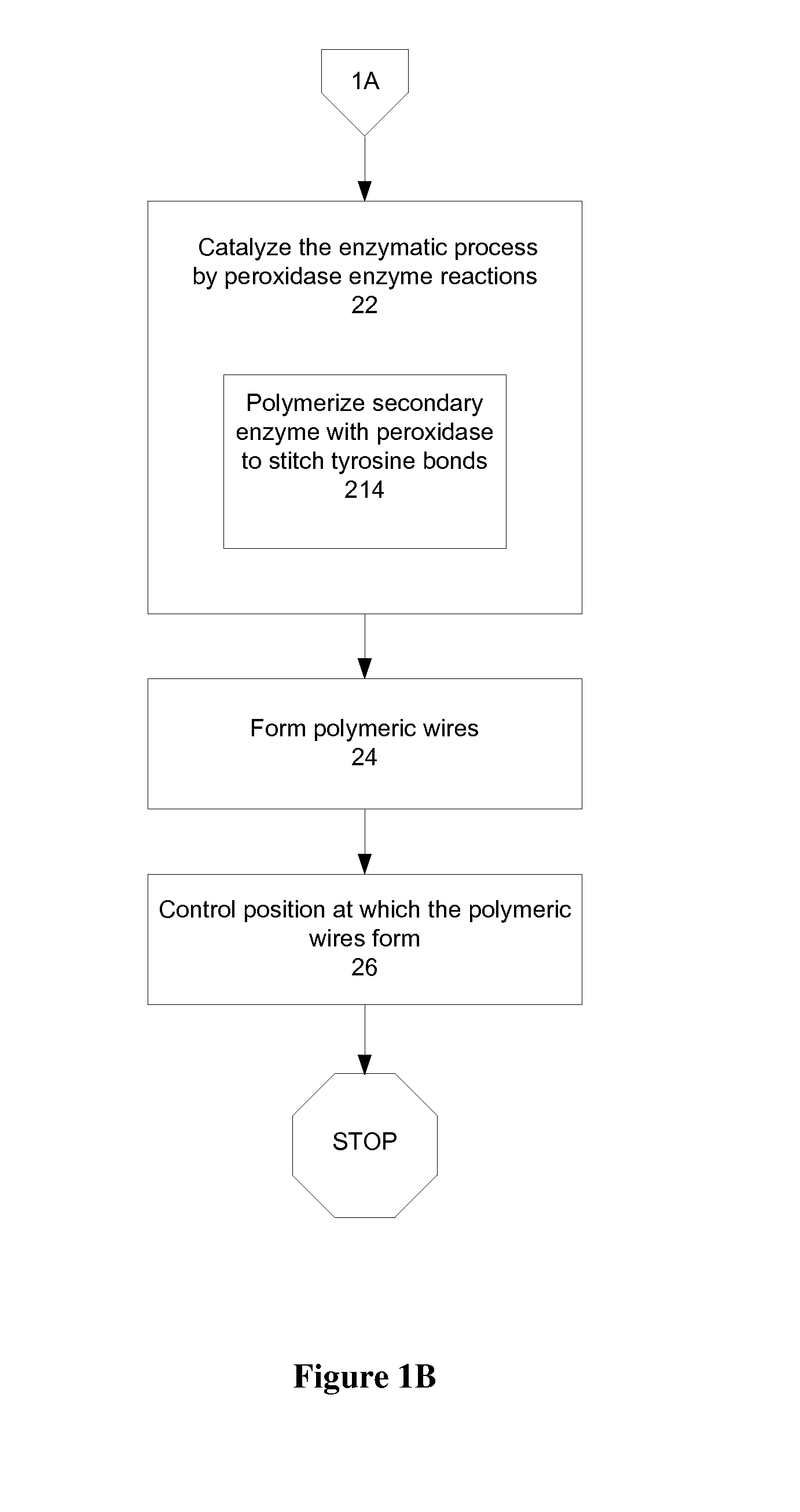

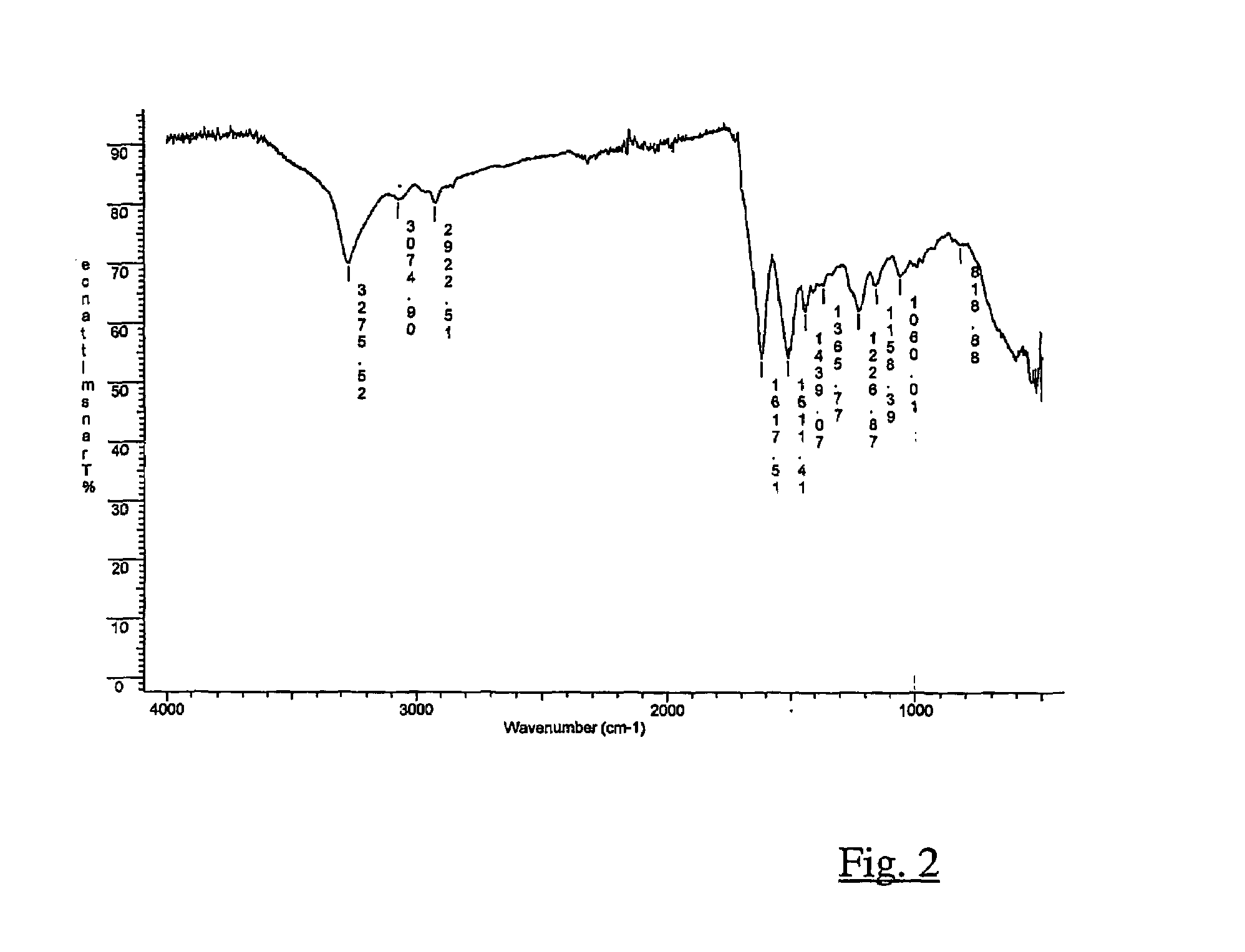

A method of manufacturing a biopolymer optical device includes providing a polymer, providing a substrate, casting the polymer on the substrate, and enzymatically polymerizing an organic compound to generate a conducting polymer between the provided polymer and the substrate. The polymer may be a biopolymer such as silk and may be modified using organic compounds such as tyrosines to provide a molecular-level interface between the provided bulk biopolymer of the biopolymer optical device and a substrate or other conducting layer via a tyrosine-enzyme polymerization. The enzymatically polymerizing may include catalyzing the organic compound with peroxidase enzyme reactions. The result is a carbon-carbon conjugated backbone that provides polymeric “wires” for use in polymer and biopolymer optical devices. An all organic biopolymer electroactive material is thereby provided that provides optical functions and features.

Owner:TRUSTEES OF TUFTS COLLEGE

Method for the preparation of a non-woven silk fibroin fabrics

InactiveUS7285637B2Peptide/protein ingredientsMonocomponent fibroin artificial filamentSericinDisulfide bond

A process for producing non-woven silk fiber fabrics comprises the following steps: a) obtaining silk fibroin, for example either from silk cocoons, or silk textiles or waste silk; b) removing the sericin layer covering the silk fibroin fibers, when present; c) breaking the disulfide bonds between heavy (350 kDa) and light (27 kDa) chains of silk fibroin in order to obtain the production of chain fragments which serve as a specific cellular recognition sites promoting the attachment and growth of cells, d) homogenising of the material resulting from step c).

Owner:CONSORZIO PER GLI STUDI UNIVRI

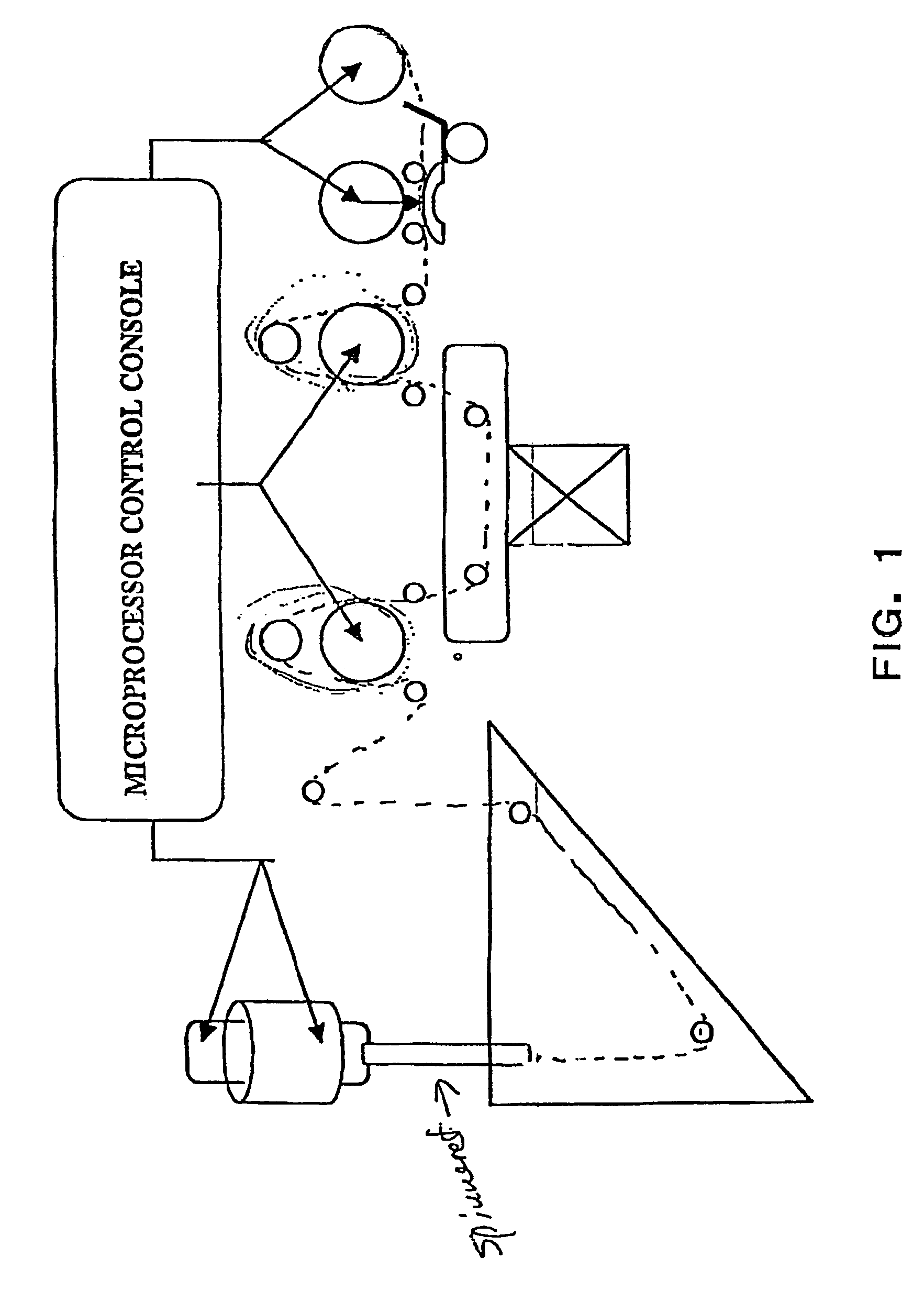

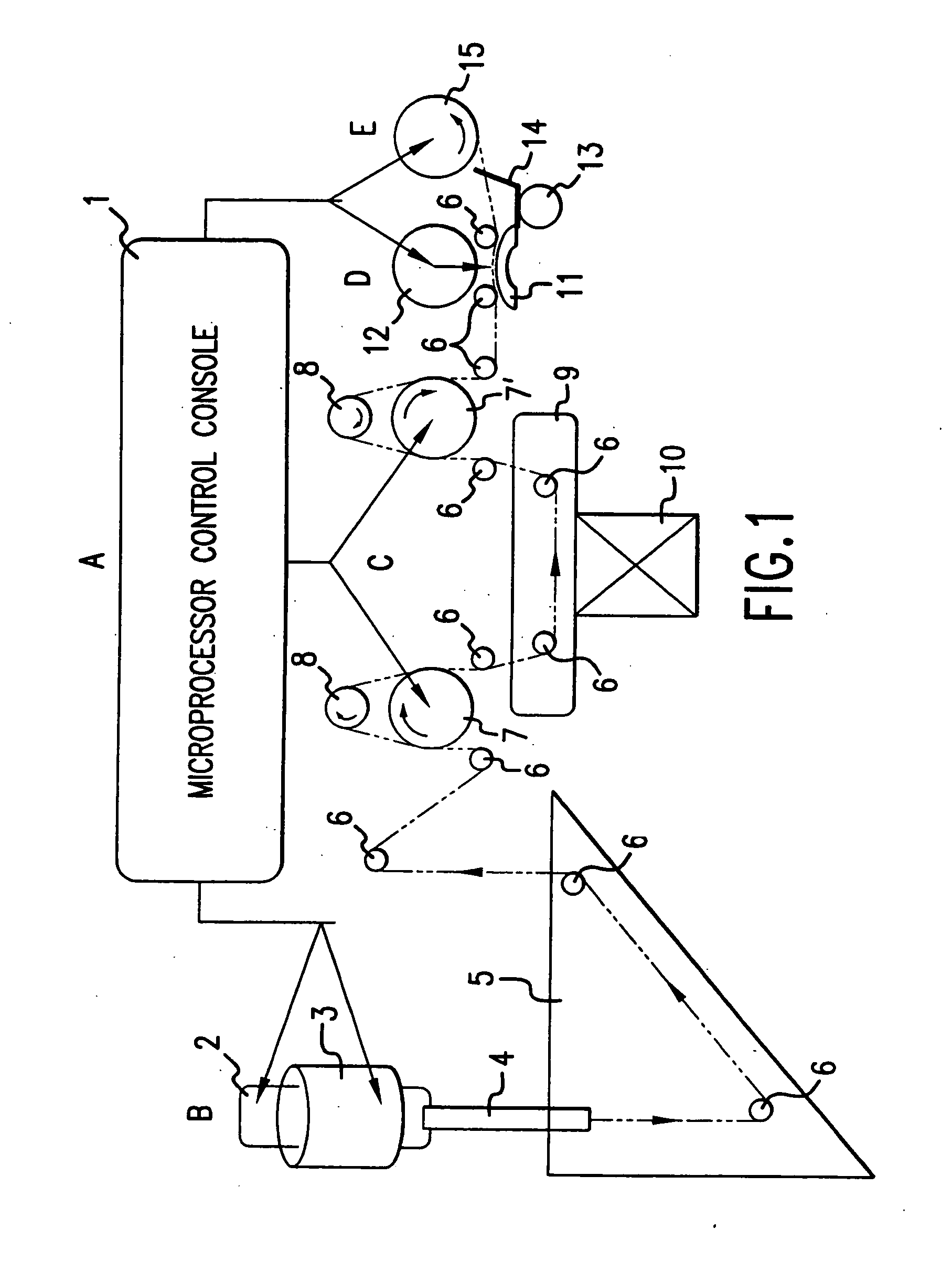

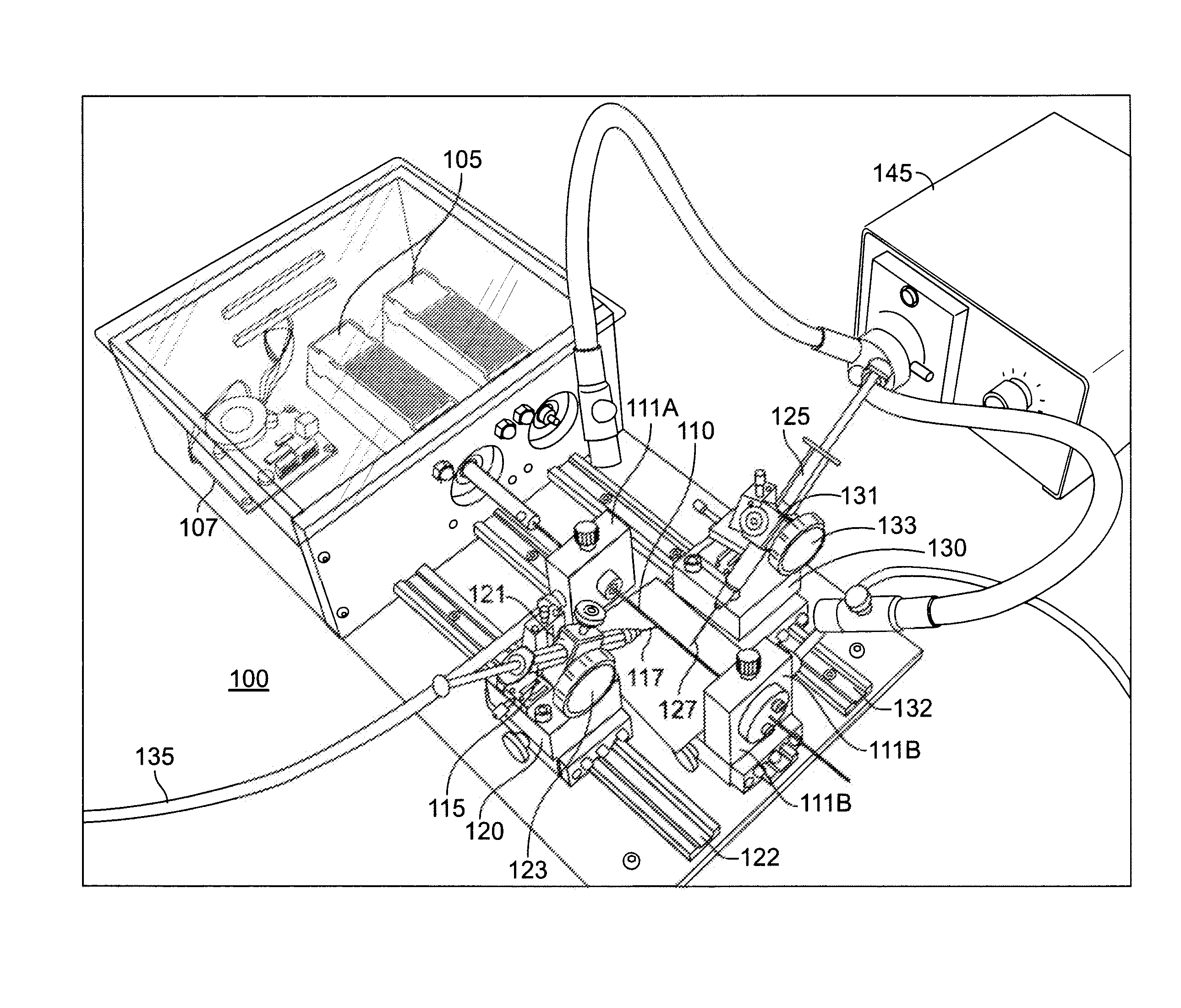

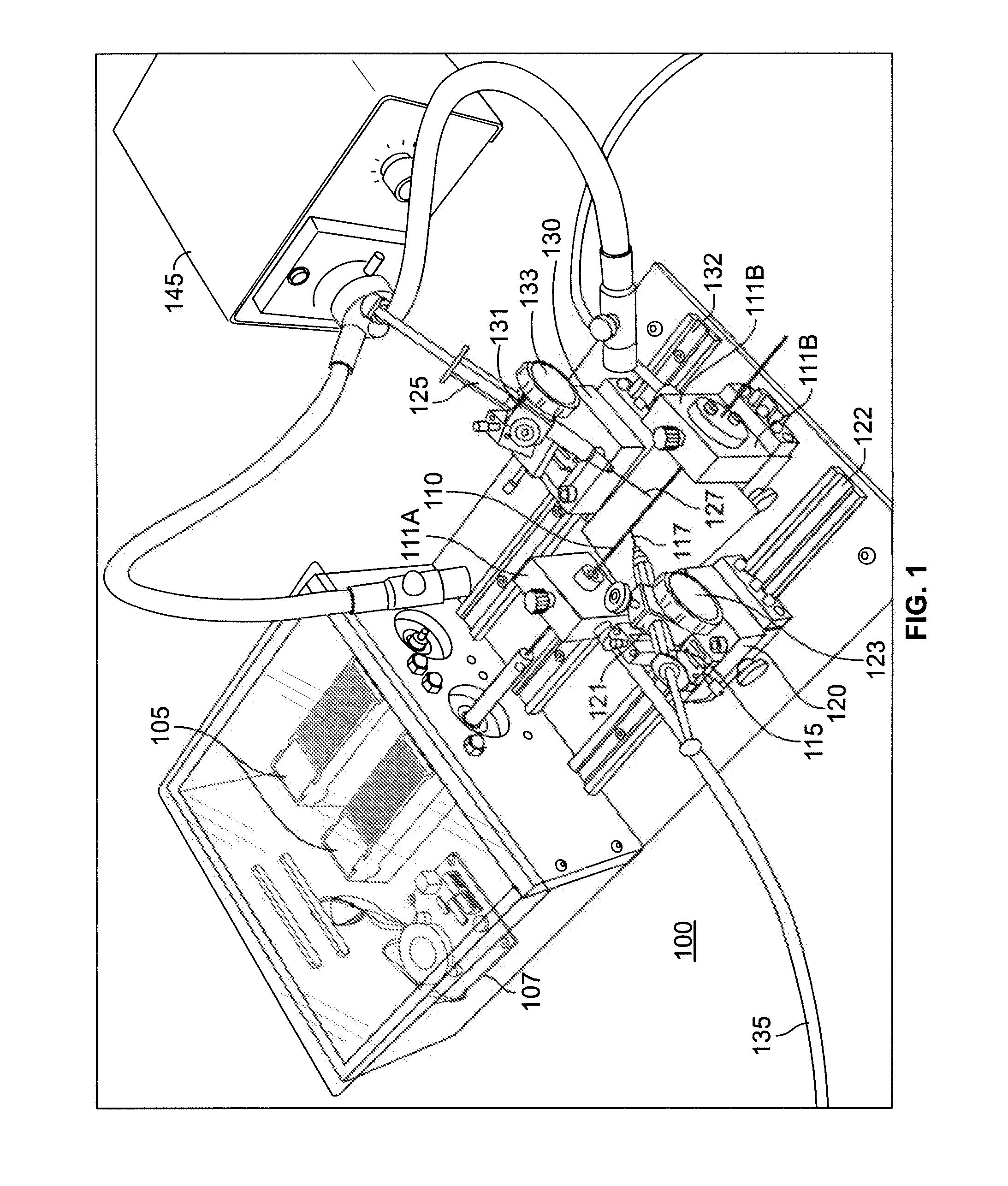

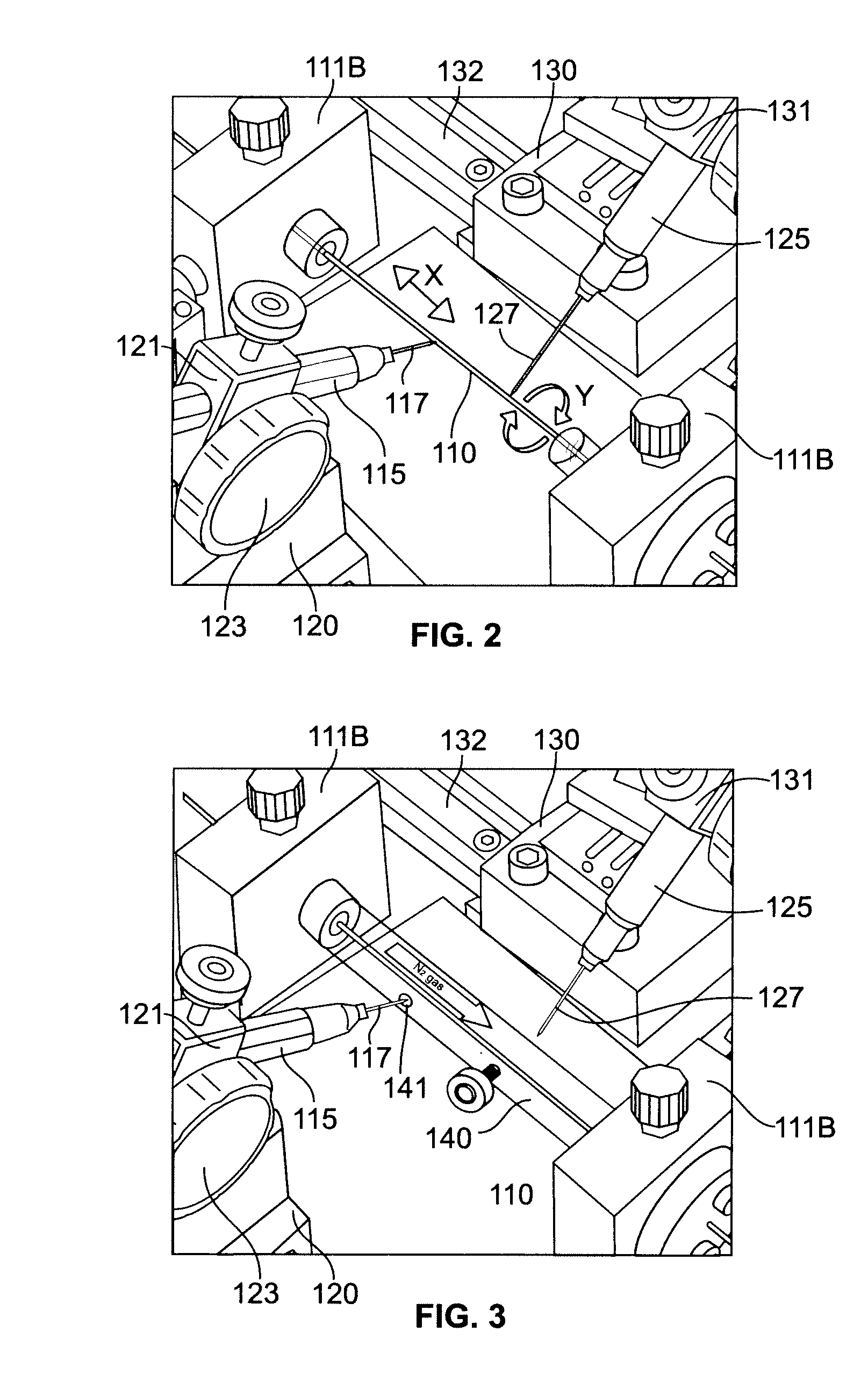

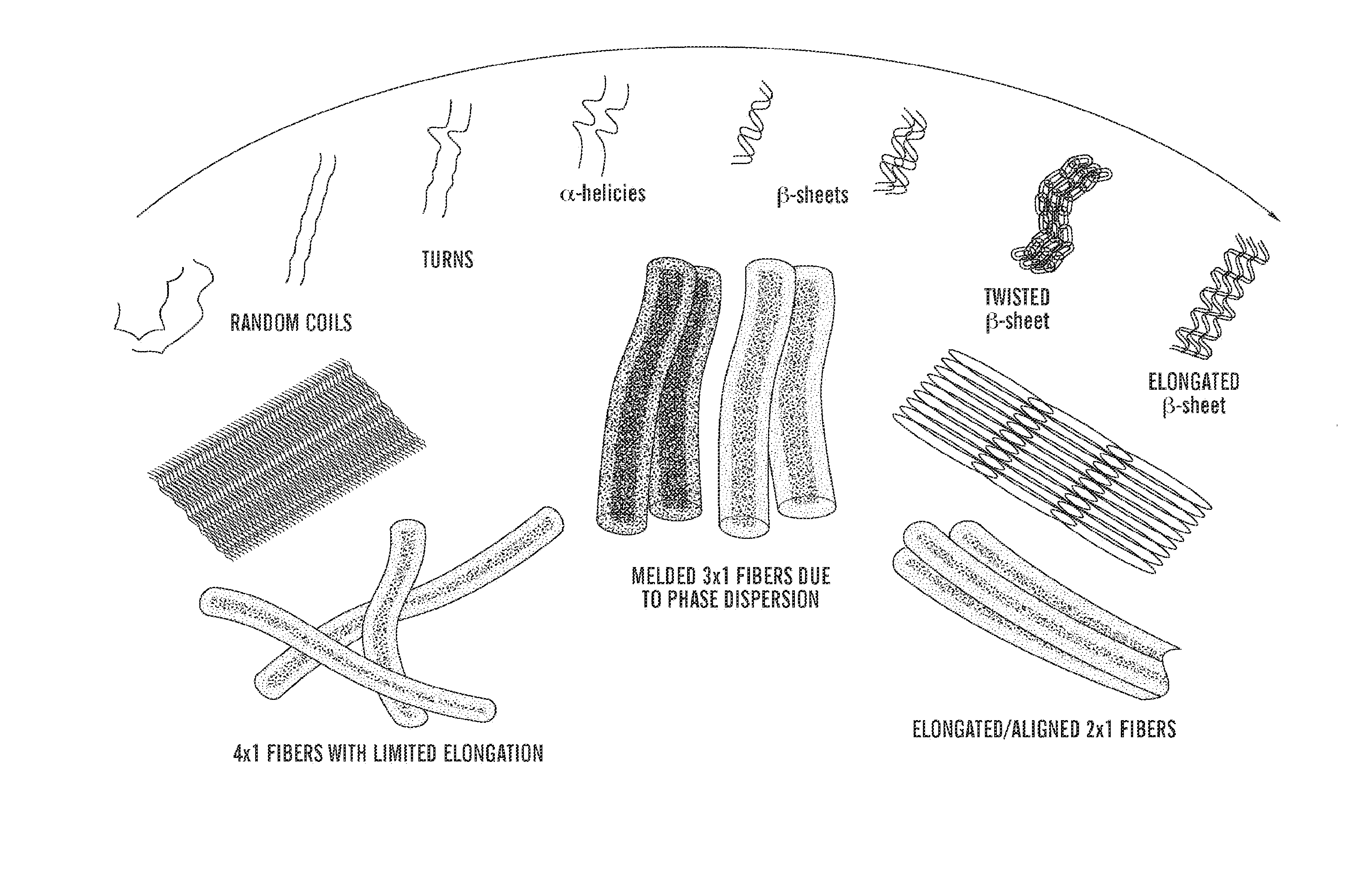

System and method for making biomaterial structures

ActiveUS20110076384A1Unique and robust mechanical propertyProperty is limitedNew-spun product collectionMonocomponent fibroin artificial filamentFiberMaterials processing

A system and method for making a biomaterial device includes a support structure providing a shape for a biomaterial device. At least one applicator has a supply of biomaterial solution and is positioned along the support structure. The at least one applicator forms a biomaterial fiber by applying shear force to the biomaterial solution and delivering the biomaterial fiber to the support structure. A controller causes relative movement between the support structure and the at least one applicator, and the biomaterial fiber is arranged on the support structure according to the relative movement to form the biomaterial device. The biomaterial may be silk fibroin which may be wound onto a reciprocating and rotating mandrel. Control over the properties of the biomaterial device is achieved through appropriate selection of material processing, winding strategy, and post-winding processing.

Owner:TRUSTEES OF TUFTS COLLEGE +1

Precursor silk feedstock for forming filaments

InactiveUS7041797B2Contamination of the silk feedstock solution by other body fluids is substantially reduced or preventedImprove mechanical propertiesPeptide/protein ingredientsMonocomponent fibroin artificial filamentZoologyArthropod

The application relates to a method of obtaining silk feedstock solution from a gland of a silkworm or another silk-producing arthropod in which the body of the silkworm or the other silk-producing arthropod is cut open and the gland removed. The silk feedstock solution is subsequently extracted from the gland and used for extrusion, spinning or moulding of objects.

Owner:SPINTECH ENG

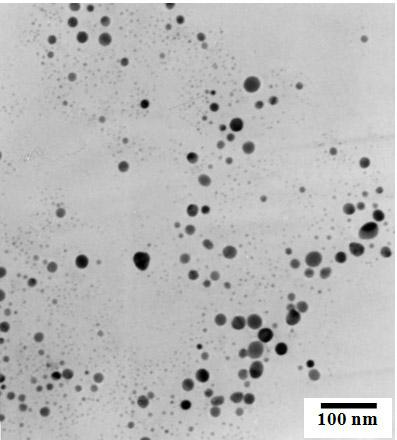

Method for preparing graphene/ silk composite fiber

InactiveCN103173882AHigh strengthImprove toughnessMonocomponent fibroin artificial filamentFilament/thread formingElectrospinningGraphite

The invention provides a method for preparing graphene / silk composite fiber. The method comprises the steps of: oxidizing graphite powder by using acid, and carrying out ultrasonic dispersing and stripping to obtain graphene solution; mixing the obtained graphene solution with degummed silk fibroin and formic acid to obtain spinning solution; and carrying out electrospinning on the spinning solution by an electrostatic spinning device to obtain the graphene / silk composite fiber. The method is simple in preparation technology, can effectively improve the mechanical property of the silk fiber and is easy to popularize and use.

Owner:DALIAN MARITIME UNIVERSITY

Artificial nerve graft prepared by electrostatic spinning and preparation method and special device thereof

InactiveCN101664346AGood biocompatibilityEasy to useSurgeryMonocomponent fibroin artificial filamentFiberHuman body

The invention discloses an artificial nerve graft prepared by electrostatic spinning and a preparation method and a special device thereof, and a product is a catheter-shaped nerve graft which is prepared from polymers by an electrostatic spinning method and consists of nano-fibers. The used materials of the product are all degradable materials and have good biocompatibility with human bodies. Theprepared product does not contain heterotoxin or side-effect substances introduced by a preparation process. A three dimensional structure with plentiful micropores is arranged on a conduit wall, provides a necessary approach for transporting nutritive substances needed in the growth process of nerve cells, has good use effect and provides a necessary induction function and a necessary growing space for the growth of the nerve cells.

Owner:NANTONG UNIVERSITY

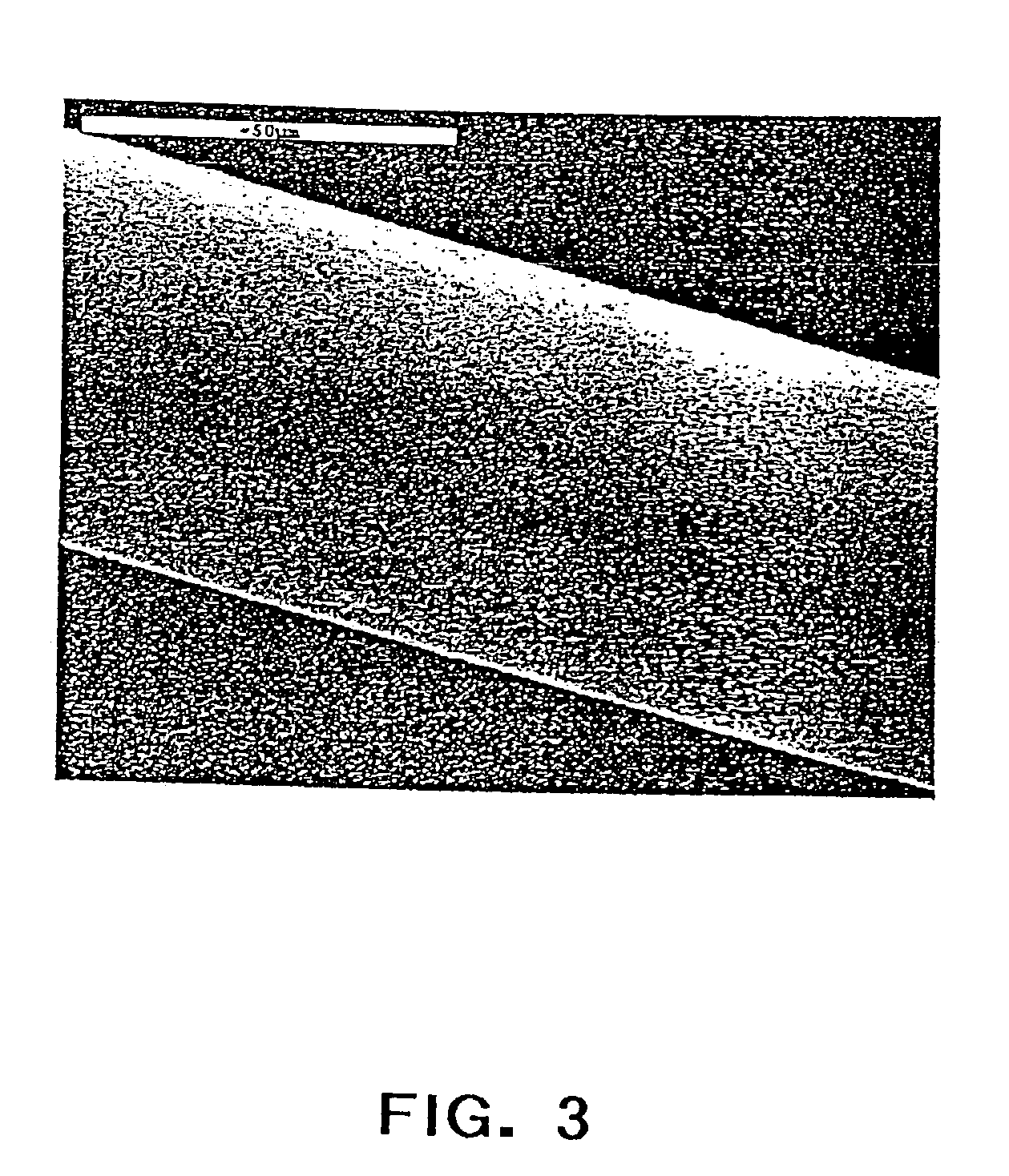

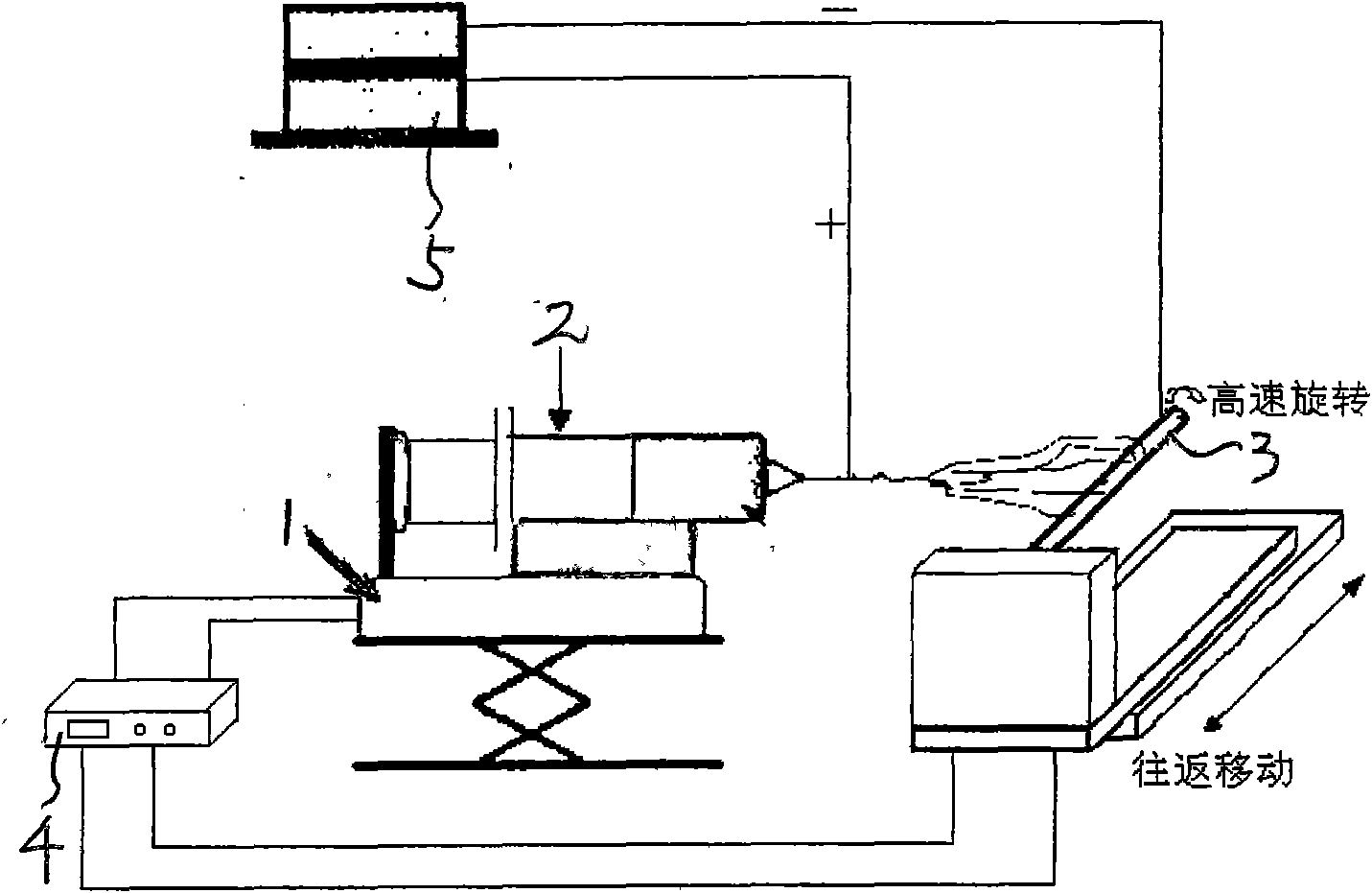

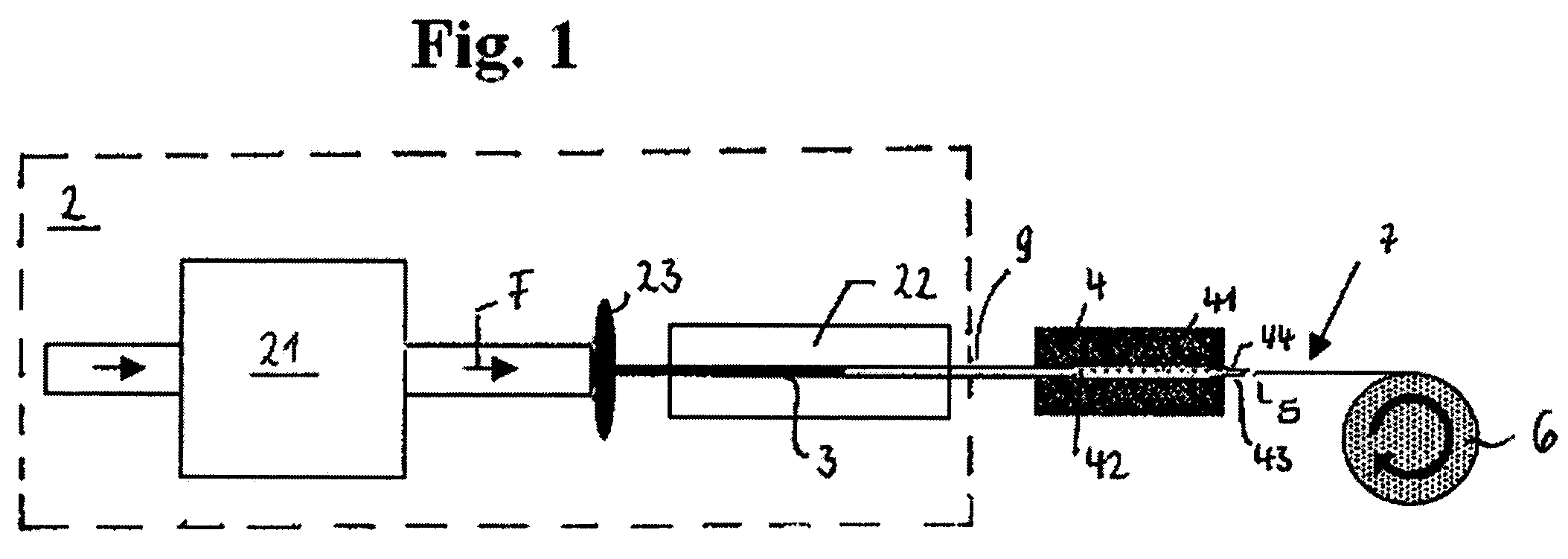

Artificial polypeptide fiber and method for producing the same

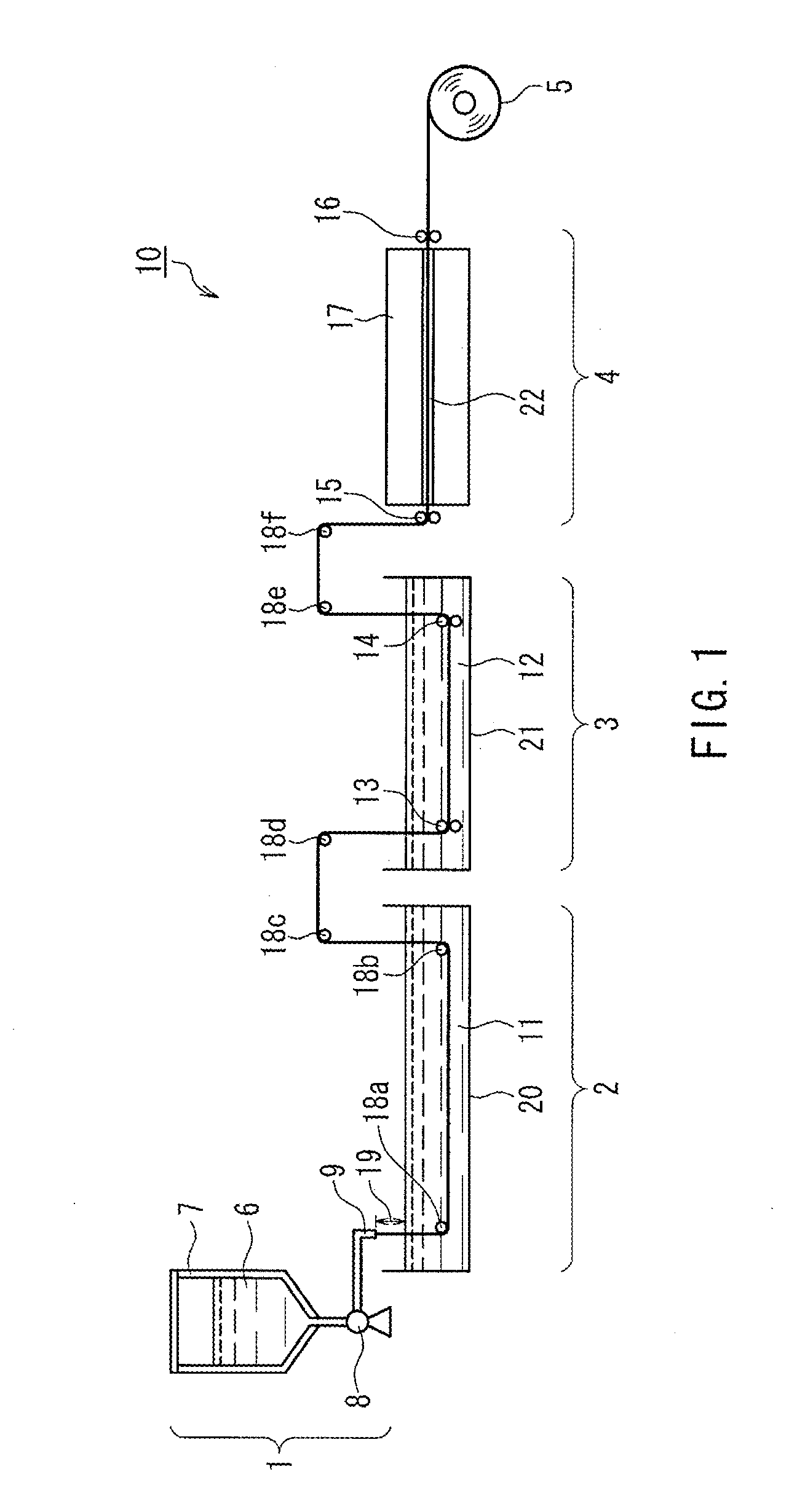

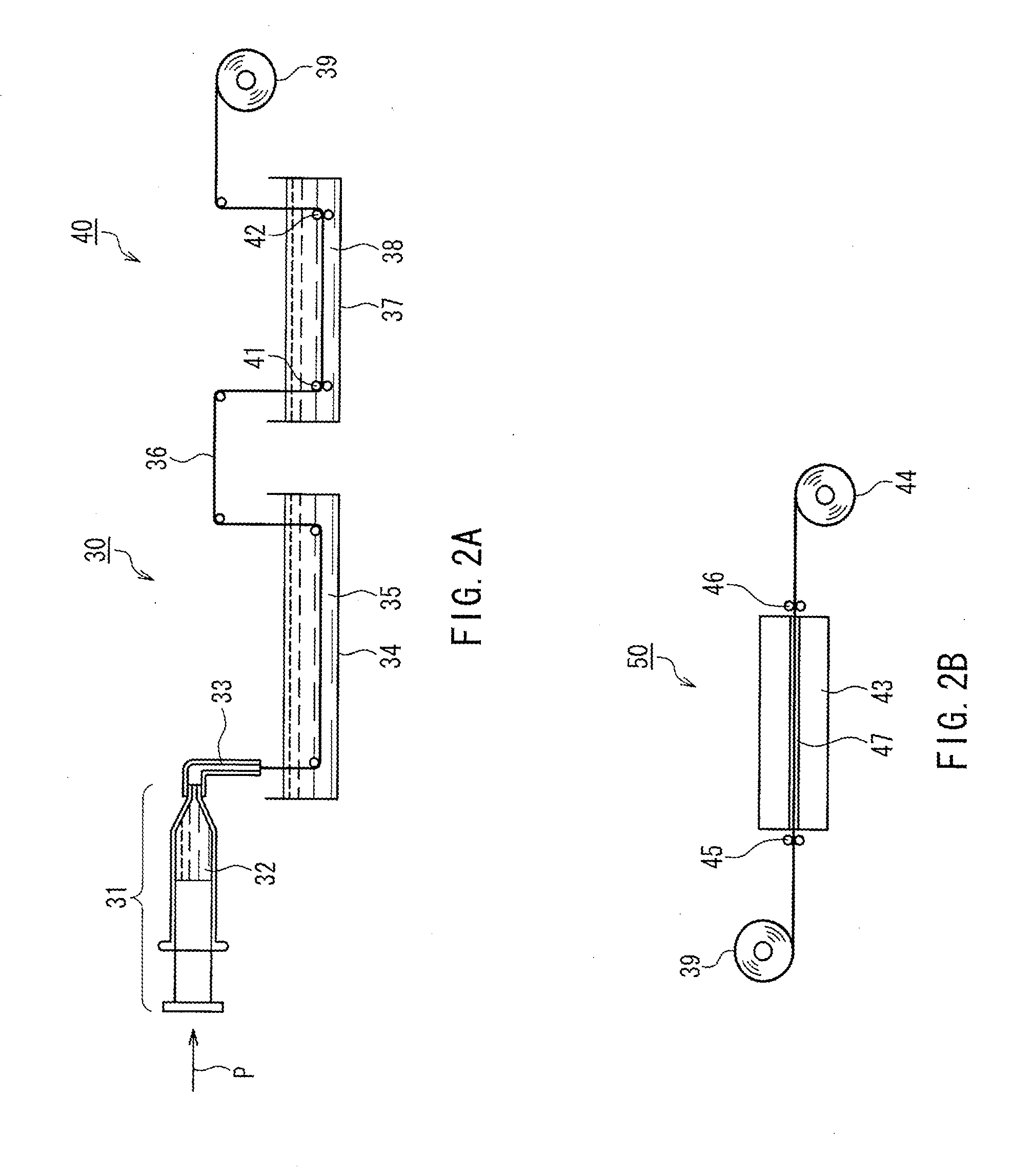

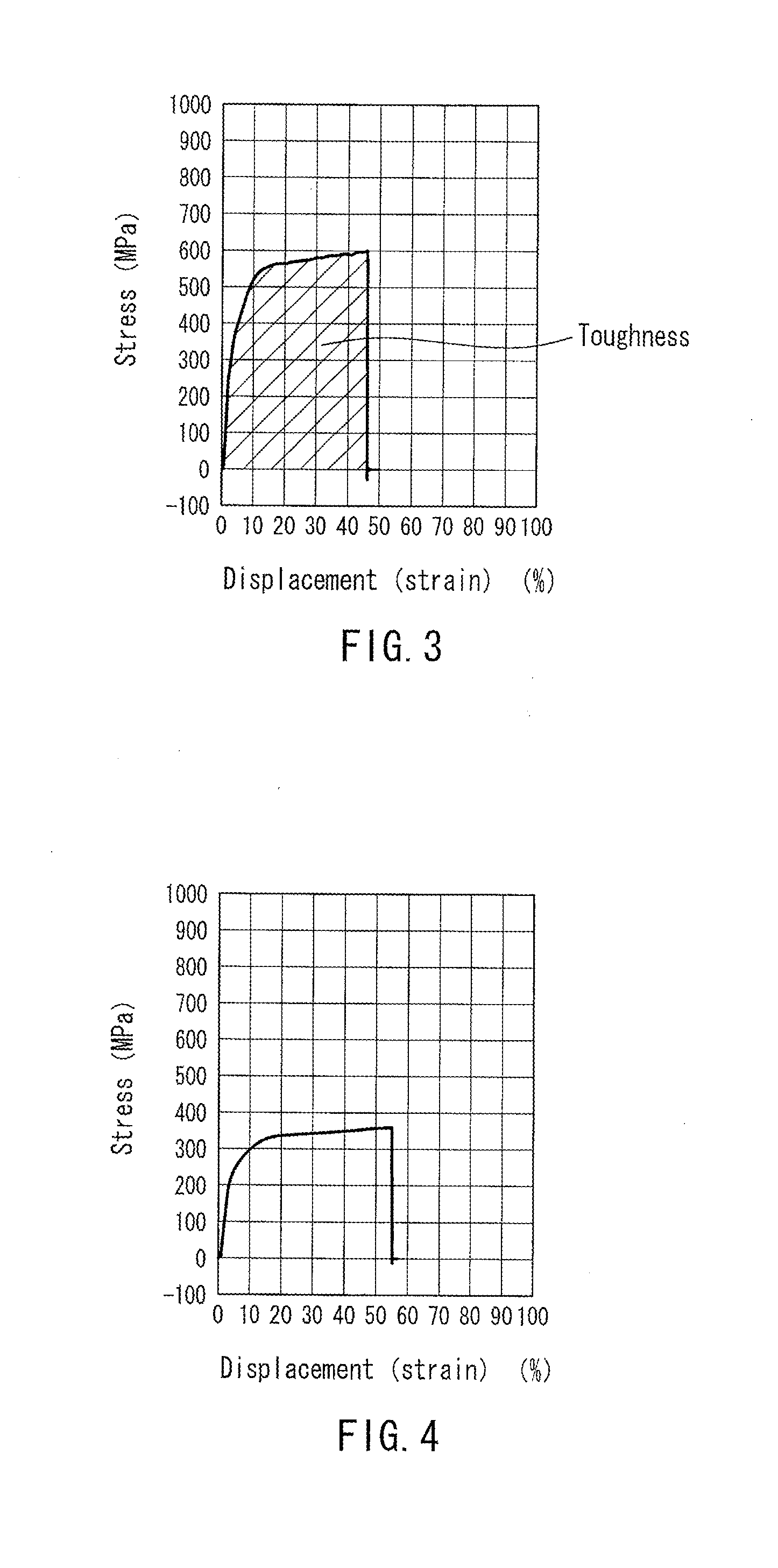

ActiveUS20140058066A1High stressImprove toughnessPeptide/protein ingredientsMonocomponent polypeptides artificial filamentFiberSpider Proteins

An artificial polypeptide fiber of the present invention is an artificial fiber containing a polypeptide as a main component, and has a stress of 350 MPa or more and a toughness of 138 MJ / m3 or more. A method for producing an artificial polypeptide fiber of the present invention is a method for producing the artificial polypeptide fiber obtained by spinning a spinning solution (6) containing a polypeptide derived from natural spider silk proteins and performing drawing of at least two stages. The drawing of at least two stages includes a first-stage drawing (3) in wet heat and a second-stage drawing (4) in dry heat. Thereby, the present invention provides high-toughness artificial polypeptide fibers having favorable stress and rupture elongation, and a method for producing the same.

Owner:SPIBER INC

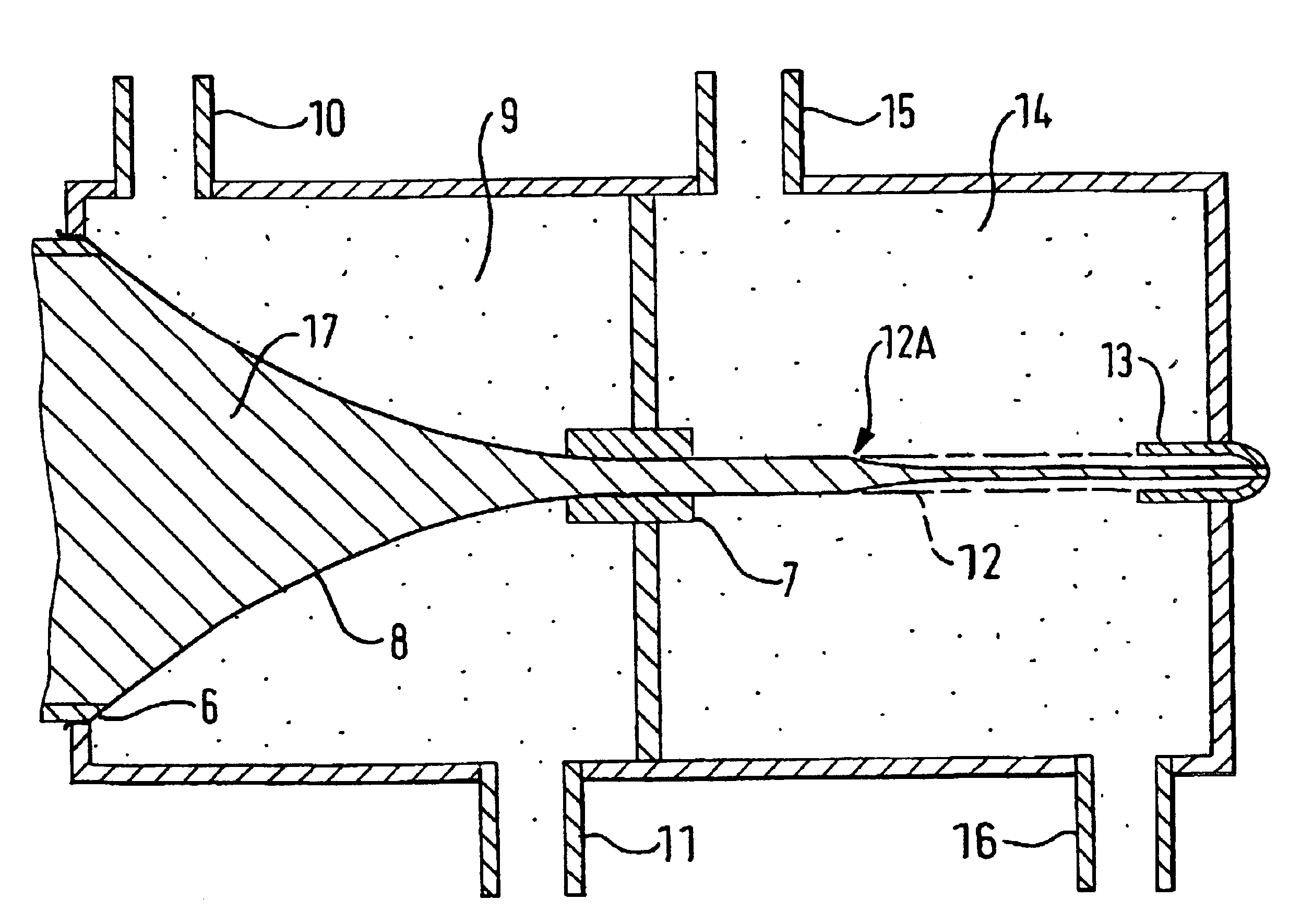

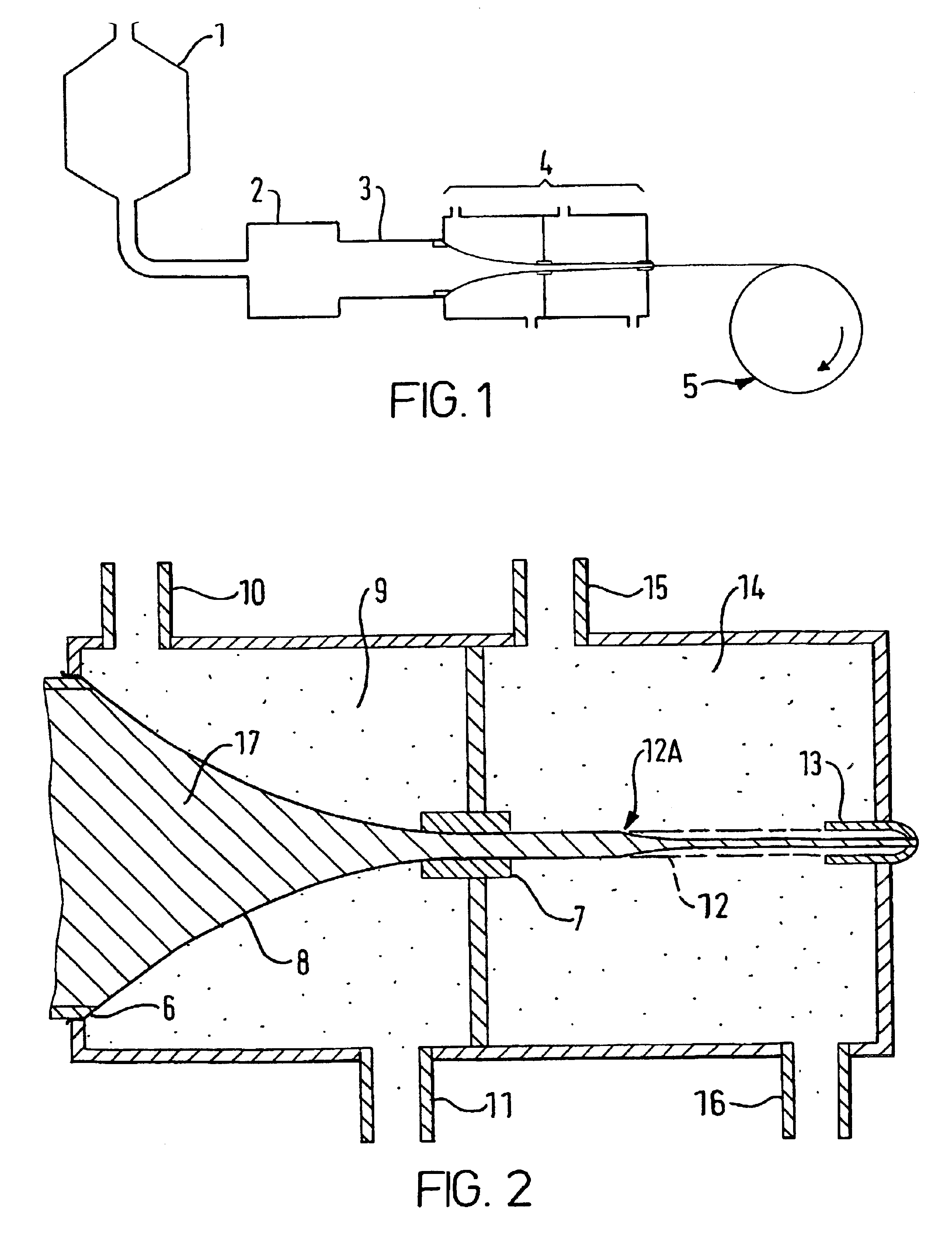

Apparatus and method for forming materials

InactiveUS6858168B1Improves molecular orientationReduce pressure requirementsSpinnerette packsConfectioneryHydrogenSolid mass

An apparatus and method for forming liquid spinning solution into a solid formed product whereby the solution is passed through at least one tubular passage (17) having walls formed at least partly of semipermeable and / or porous material. The semipermeable and / or porous material allows parameters, such as the concentration of hydrogen ions, water, salts and low molecular weight, of the liquid spinning solution to be altered as the spinning solution passes through the tubular passage(s).

Owner:SPINOX LTD

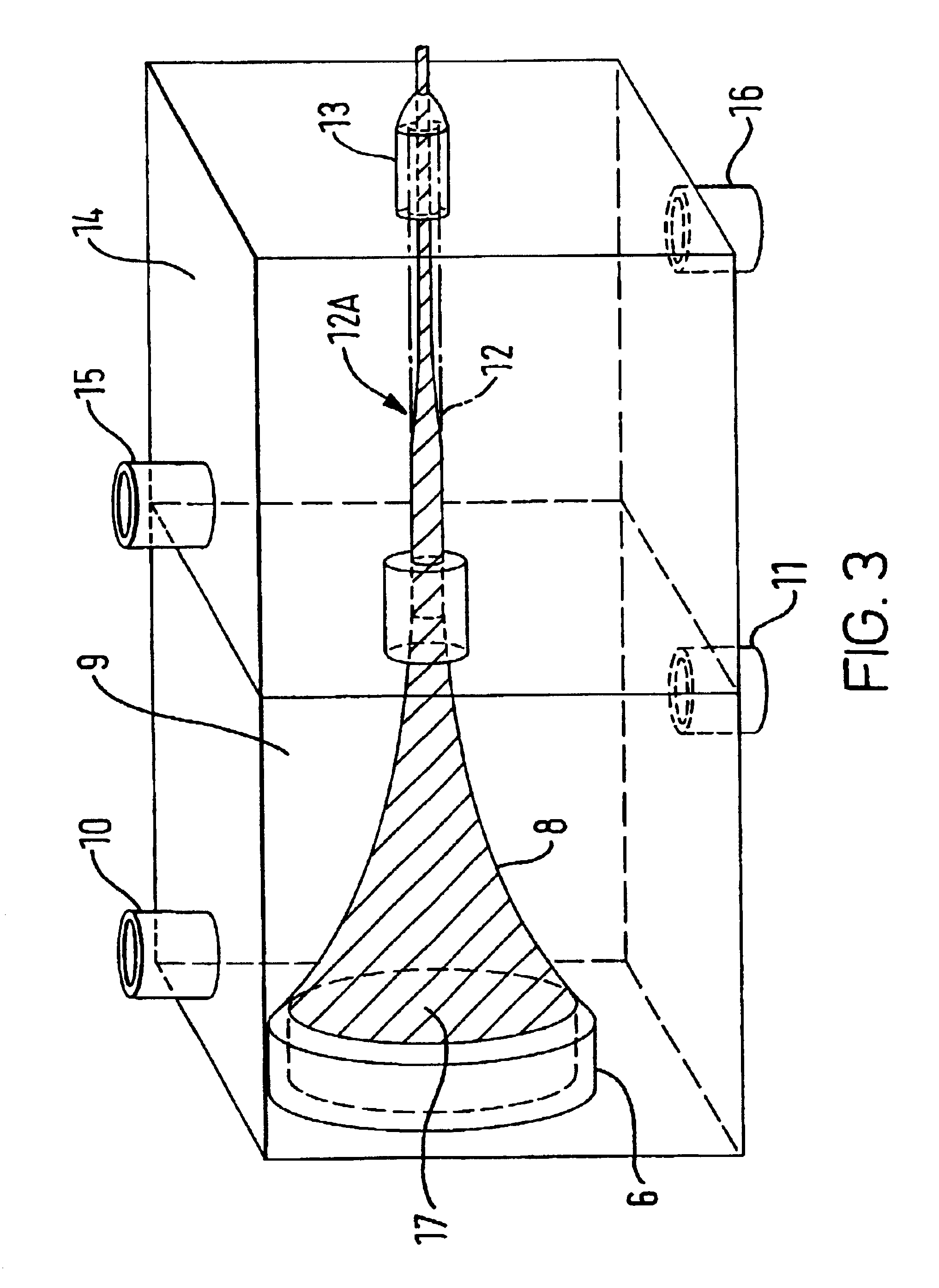

Fibroin-silver-nanoparticle composite material and preparation method thereof

The invention belongs to the technical field of composite materials and particularly provides a fibroin-silver-nanoparticle composite material and a preparation method thereof. The fibroin-silver-nanoparticle composite material comprises fiber (including electrospinning fiber), film, hydrogel and three dimensional porous materials. The preparation method comprises the following steps: after fibroin solution and silver nitrate solution are mixed, the precursor of silver is converted into silver-nanoparticles through in-situ reduction under the irradiation of sunlight or simulated sunlight, and then the material is formed and prepared; or fibroin is prepared into different forms of materials first, then the materials are soaked in silver nitrate water solution, and finally, the precursor of silver is converted into silver-nanoparticles through in-situ reduction under the irradiation of sunlight or simulated sunlight. According to the invention, fibroin is taken as material matrix and the reducing agents and stabilizing agents of silver-nanoparticles, and no other chemical agent is required to be added; and the preparation process is simple, energy-saving and environment-friendly, and the material has various forms.

Owner:FUDAN UNIV

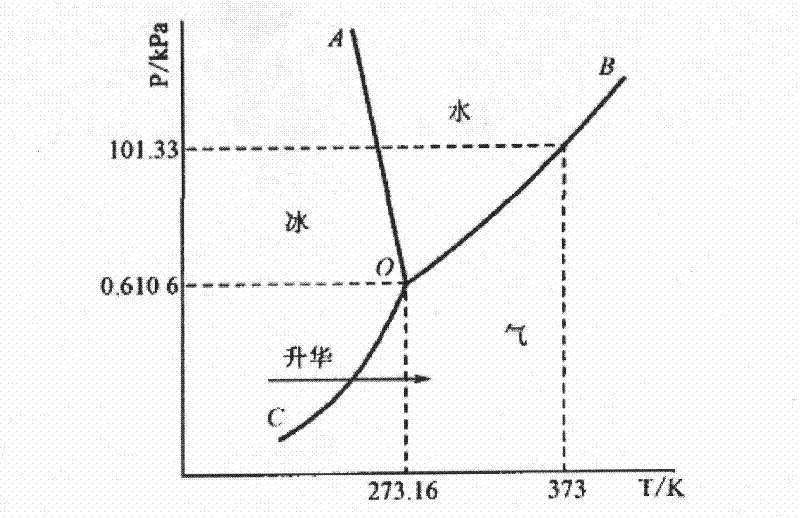

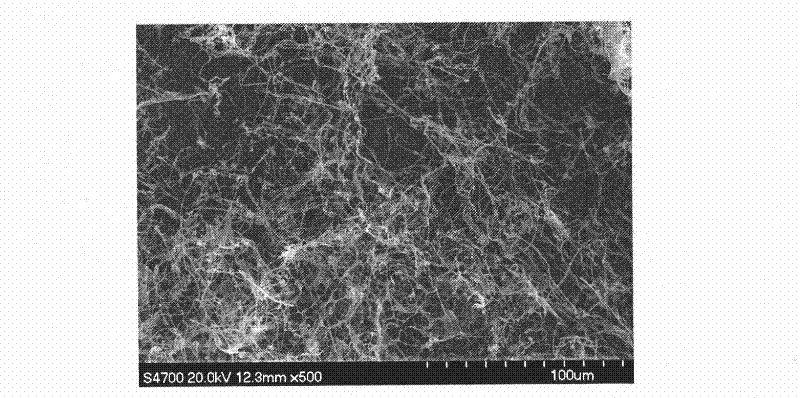

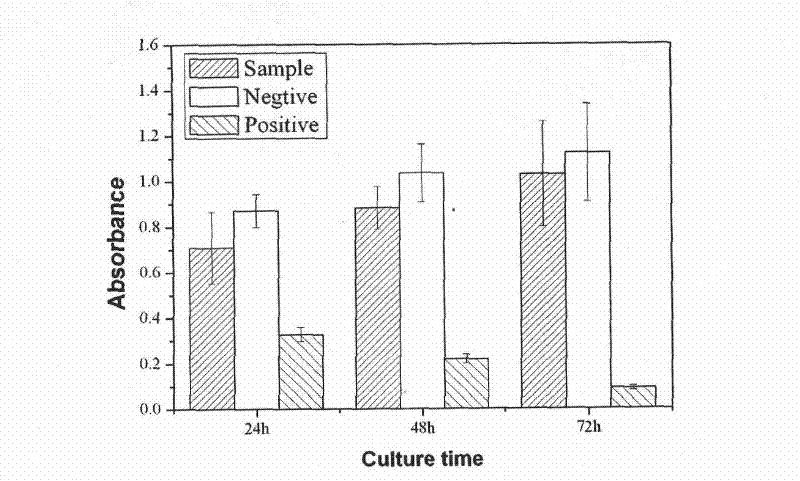

Natural polymer-based nano-fibrous membrane prepared by freeze-drying method

The invention relates a biodegradable and absorbable natural polymer-based nano-fibrous membrane prepared by a freeze-drying method, and the application thereof. The natural polymer-based nano-fibrous membrane is prepared through the following steps of: dissolving natural polymer powder into a corresponding solvent so as to prepare an extremely-dilute solution with the concentration of 0.001-0.1wt %; after the natural polymer powder is completely dissolved in the solvent, transferring the obtained natural polymer solution into a liquid nitrogen refrigerating device, so that the natural polymer solution is rapidly frozen in a liquid nitrogen environment; then, carrying out freeze-drying treatment on the obtained product in a freeze drier for 12-48 hours to obtain natural polymer-based nano fibers; and carrying out cross-linking on the obtained natural polymer-based nano fibers by a corresponding cross-linking agent to obtain a natural polymer-based nano-fibrous membrane, and then carrying out MTT (methyl thiazolyl tetrazolium) cytotoxicity test and cell vaccination experiments on the natural polymer-based nano-fibrous membrane, with the obtained results showing that the obtained fibrous membrane has no toxicity but has excellent cell adhesion and proliferation properties. The natural polymer-based nano-fibrous membrane disclosed by the invention is simple in the operation process, easy to control and low in cost; and by using the nano-fibrous membrane disclosed by the invention, ultra-fine natural polymer-based nano fibers can be prepared continuously on a large scale.

Owner:BEIJING UNIV OF CHEM TECH

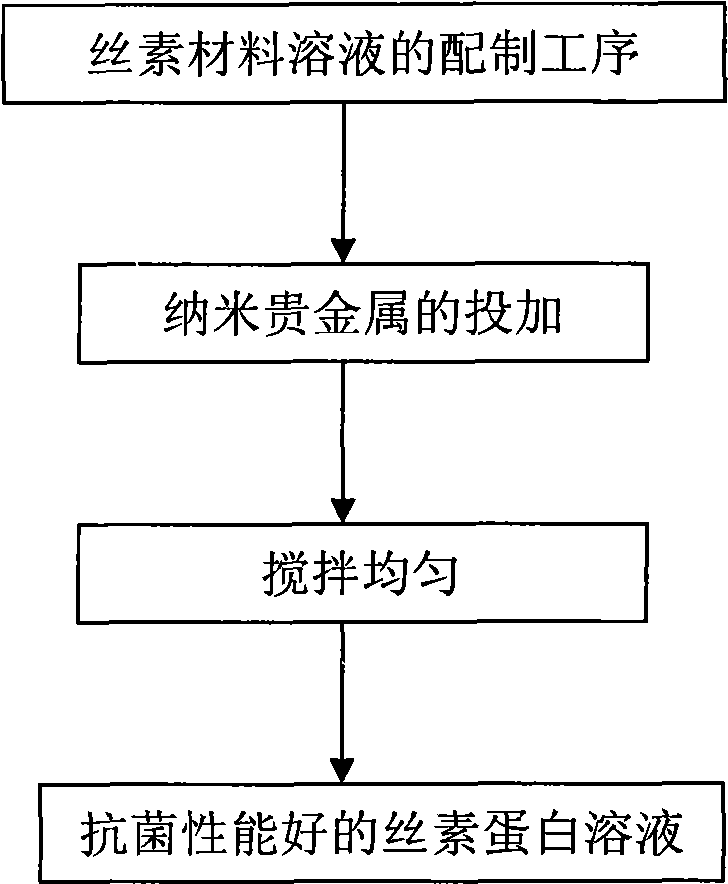

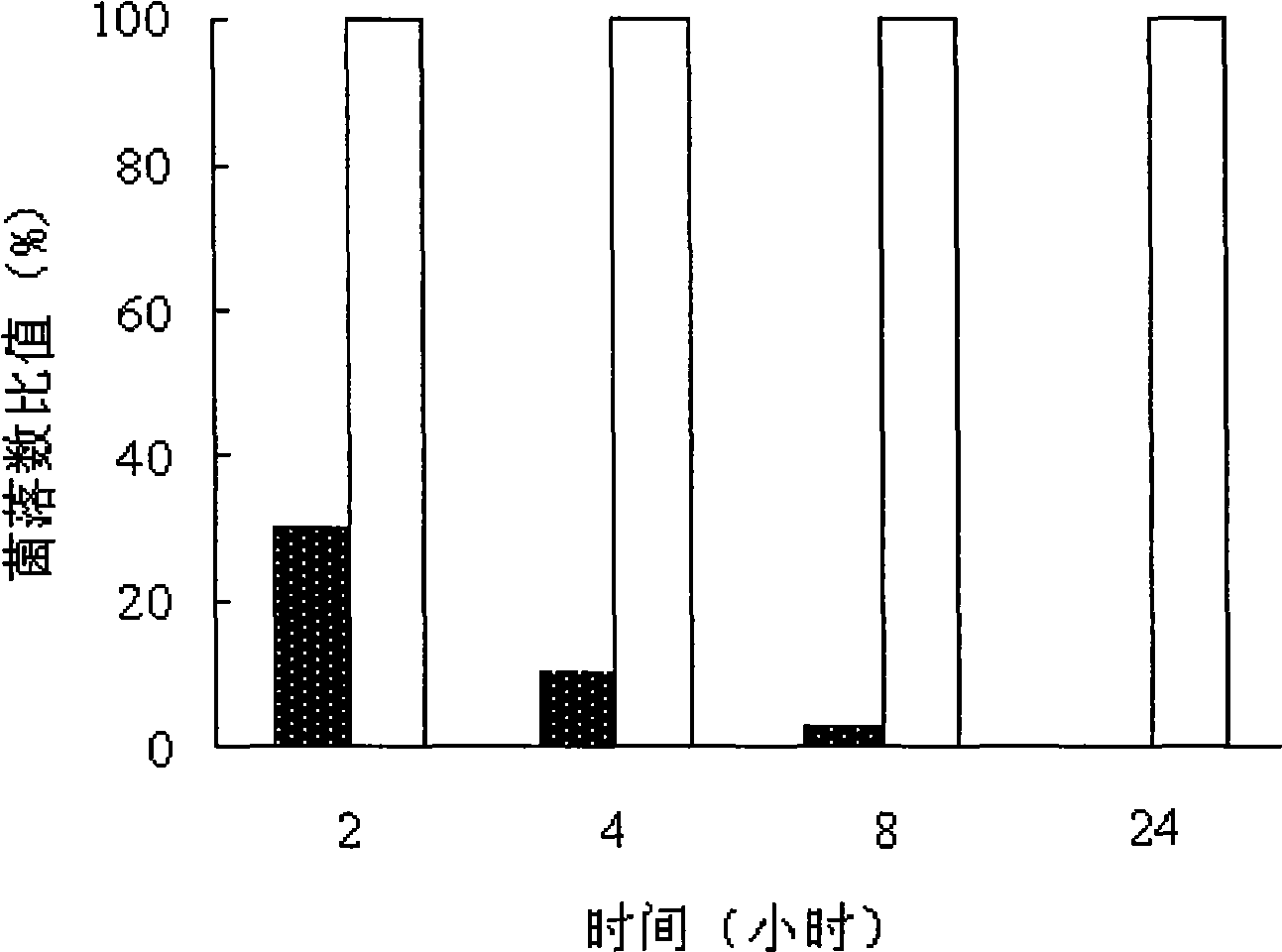

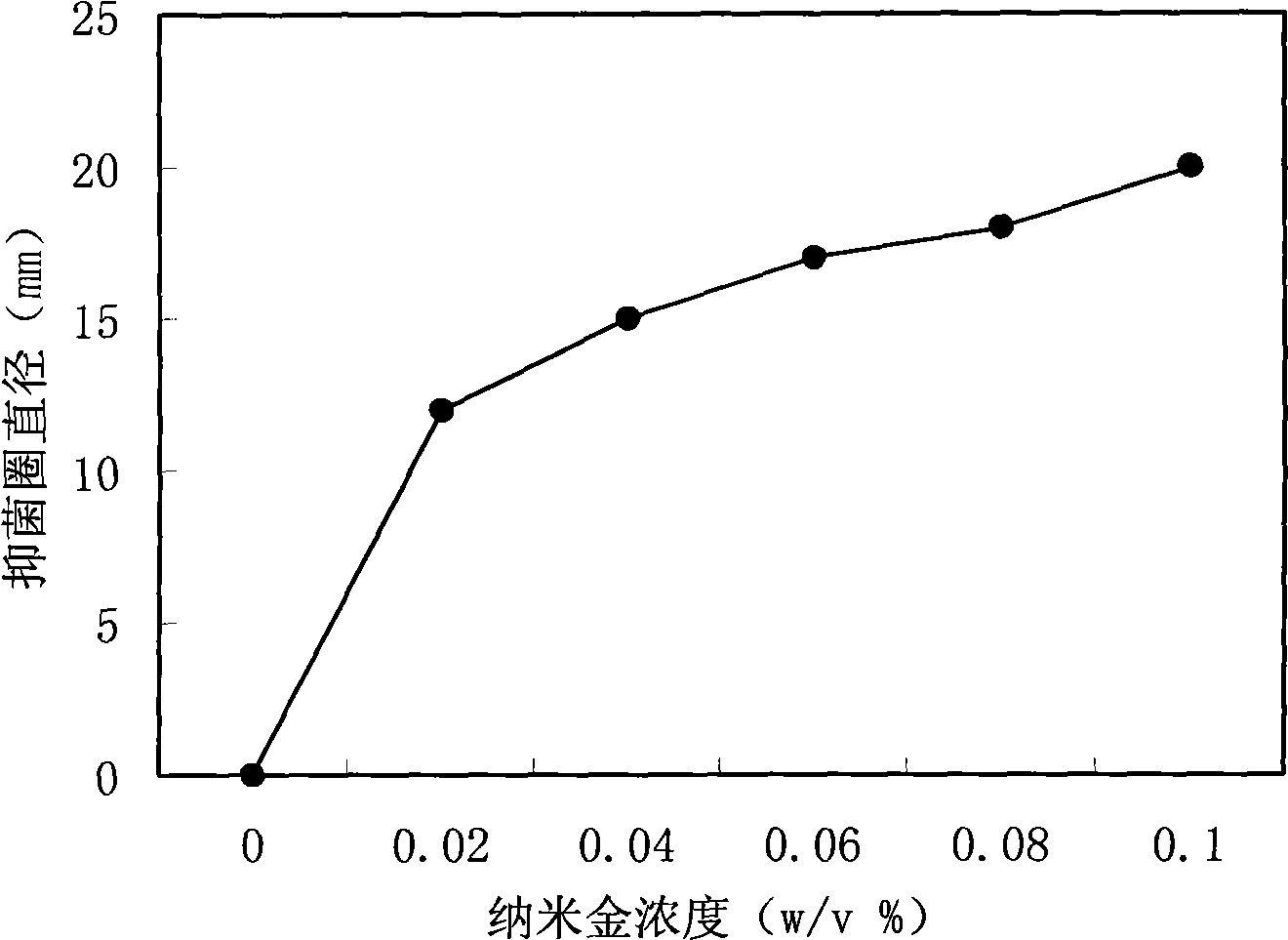

Method for improving antibiosis of silk fibroin material

InactiveCN101498061AEasy to get materialsUniform and effective releaseMonocomponent fibroin artificial filamentArtifical filament manufactureAntibiosisEngineering

The invention relates to a method of improving the bacterinertness of a silk fibroin solution. Silk fibroin material has favorable prospects when applied in biomedicine aspect, and thus the search of a method of improving the bacterinertness of silk material is meaningful. The invention comprises a silk fibroin solution preparing working procedure which adopts silk fibroin to prepare the silk fibroin solution and is characterized by also comprising a nanometer noble metal feeding working procedure by selecting nanometer noble metal with the grain diameter between 5 nanometers to 100 nanometers. When a temperature is between 0 DEG C to 50 DEG C, the nanometer noble metal is fed to a stand-by silk fibroin solution and is stirred at a rotating speed of 100-400 round / min to obtain the silk fibroin solution comprising the nanometer noble metal; the concentration of the silk fibroin is 0.5-15w / v percent, and the concentration of the nanometer noble metal is 0.005-0.2w / v percent. The invention can favorably improve the antibiotic performance of the silk fibroin solution so that the silk fibroin can be more widely applied to biological material.

Owner:ZHEJIANG UNIV

Natural nanometer fiber preparation method

InactiveCN1730734ASuitable for a wide rangeControllableMonocomponent fibroin artificial filamentFilament/thread formingSpider ProteinsLaboratory research

The present invention relates to the preparation process of natural nanometer fiber for tissue engineering, air filtering, clothing material and composite reinforced aeronautical and astronautical material, and is especially the preparation process of natural nanometer spider silk fiber and cocoon silk fiber. Through soaking in certain solution and ultrasonic dissociation, natural nanometer fiber of diameter 30-100 nm may be prepared. The prepared natural nanometer fiber may find its wide application in tissue engineering, air filtering, clothing material and composite reinforced aeronautical and astronautical material. The present invention has simple operation, simple equipment, low power consumption and low cost, and is suitable for both lab preparation and industrial production.

Owner:TSINGHUA UNIV

Process for producing regenerated silk protein super fine fiber

InactiveCN1587459AWide range of choicesImprove performanceMonocomponent fibroin artificial filamentWet spinning methodsHigh concentrationInorganic salts

The production process of superfine regenerated silk protein fiber features that silk protein is first dissolved in inorganic salt, the solution is desalted and concentrated to produce high concentration and high spinnability regenerated silk protein aqua, and the aqua is electrostatically spun directly into the superfine regenerated silk protein fiber. The fiber has excellent performance, has stable silk protein-II crystal structure without need of post-treatment. The present invention uses water without toxicity and harm as solvent to make the superfine fiber good in biocompatibility and suitable for use as biomedicine material. The present invention has wide material source including common silk and silk leftover, and the product of superfine regenerated silk protein fiber has its specification regulated with the use.

Owner:DONGHUA UNIV

Fibre for tissue engineering scaffold and making method thereof

InactiveCN1372023ANatural silk protein is goodGood compatibilityMonocomponent fibroin artificial filamentProsthesisProtein solutionFiber

The natural silk can be used as main raw material, and is undergone the processes of degumming, dissolution and purification to obtain silk extract protein solution, then the wet spinning process is adopted and its controlled degree of crystallization is less than 40% and the fibre which can be made into bio-degradable tissue engineering scaffold can be spun. Said fibre possesses good biological compatibility.

Owner:SUZHOU UNIV

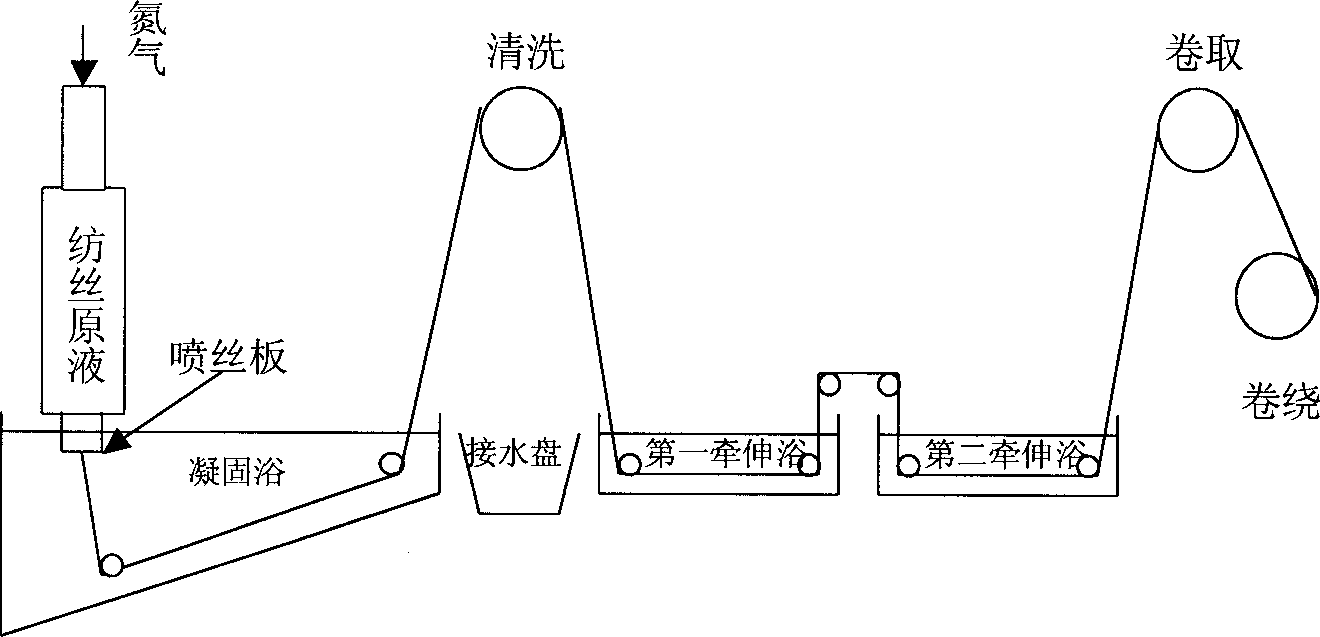

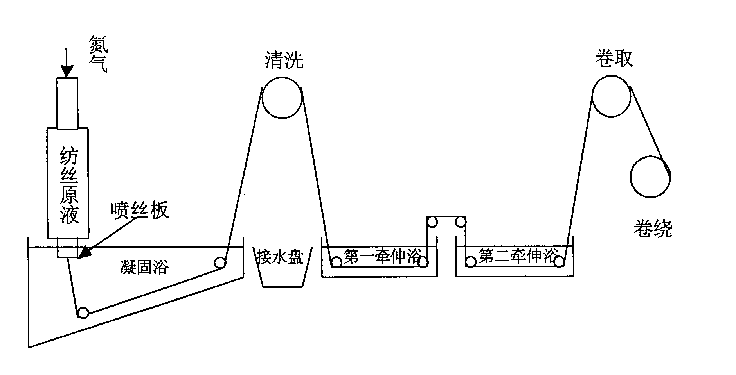

Preparation method for regenerated fibroin fiber

InactiveCN102181957AControl degradationReduce usageMonocomponent fibroin artificial filamentCellulose/protein filament chemical after-treatmentFiberPh regulation

The invention relates to a preparation method for regenerated fibroin fiber, which comprises the following steps: taking regenerated fibroin water solution containing calcium ions as spinning liquid, extruding the spinning liquid out from a spinning nozzle in the temperature range of 5-35 DEG C, then curing the spinning liquid into silk in air directly, taking alcohol-water mixed solution as a finishing agent for post-processing, then taking the silk for drying, and finally obtaining the regenerated fibroin fiber. In the invention, the raw material source is wide, the cost of the raw material is low, and in the whole process, the defects that the traditional wet spinning solvent and the coagulating bath are strong in corrosion, and are toxic; in addition, compared with the other regenerated fibroin fiber dry spinning fiber, the condition of the spinning liquid is optimized, the PH regulation and other complex steps are omitted, and the use of a series of solvent is avoided. Therefore in the method, the cost is saved, and simultaneously the environment is protected. The regenerated fibroin fiber has the advantages of being non-toxic, harmless on human body and the like, is good in biocompatibility, suitable for biological and medical materials, and has good application prospect.

Owner:DONGHUA UNIV

Preparation method of regenerative silk protein fiber with skin-core structure

ActiveCN101748504ANo pollution in the processEasy to prepareMonocomponent fibroin artificial filamentFilament/thread formingElectrospinningCarbon nanotube

The invention relates to a preparation method of regenerative silk protein fiber with skin-core structure, comprising the following steps: (1) silkworm cocoon is degummed and is dissolved in LiBr solution, a multi-wall carbon nano tube, a single-wall carbon nano tube or carbon black is added to obtain the solution with 20-35 percent of concentration; (2) sericin powder is prepared into the solution with 50-70 percent of concentration; (3) the solution is respectively poured into an inner pipe and an outer pipe of a coaxial spinning nozzle to carry out coaxial electrostatic spinning. The preparation method is simple, the operation is convenient, the cost is low, the method has no pollution to environment, and the obtained regenerative silk protein fiber has similar composition and skin-core structure with the natural silk.

Owner:DONGHUA UNIV

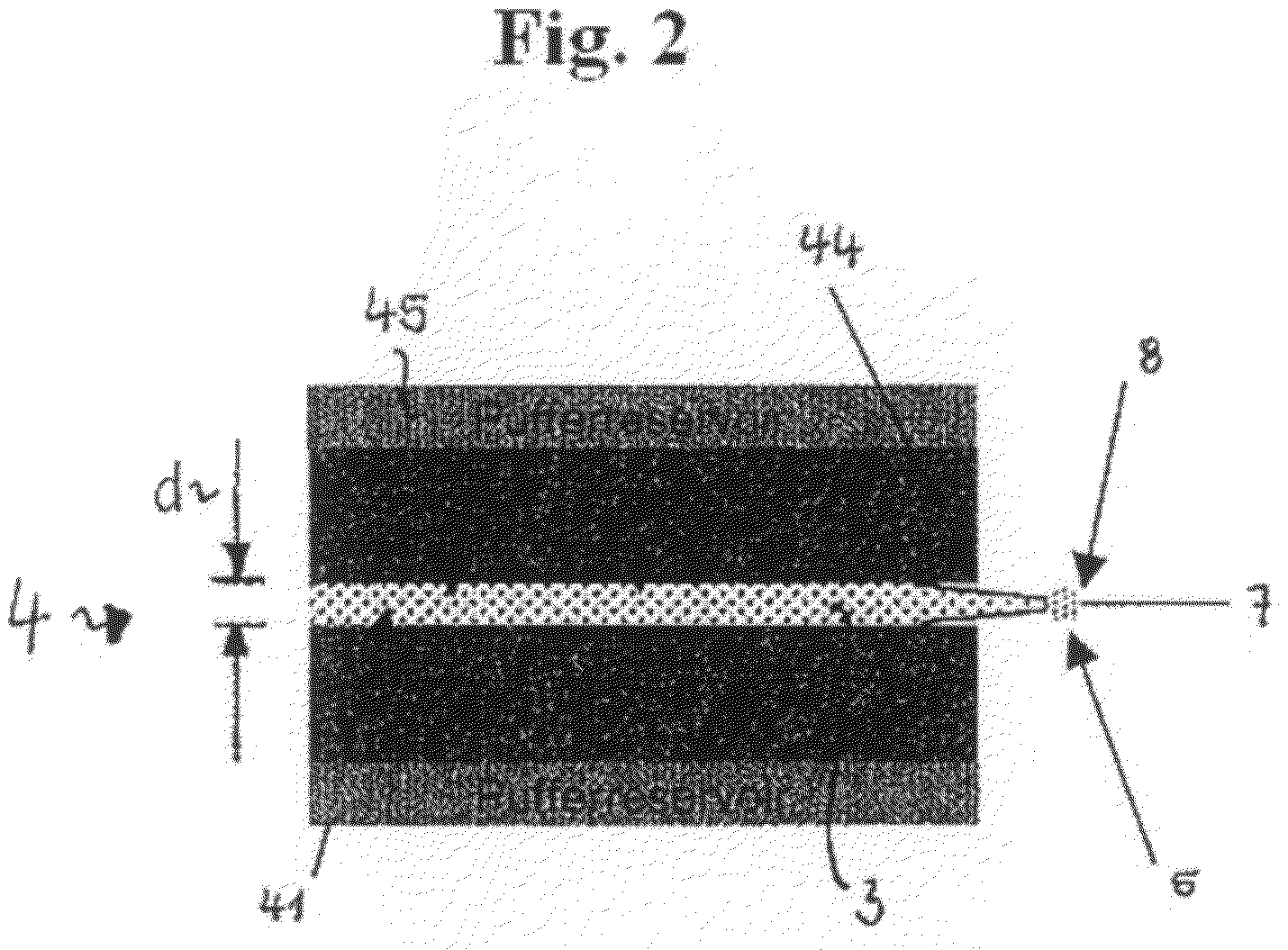

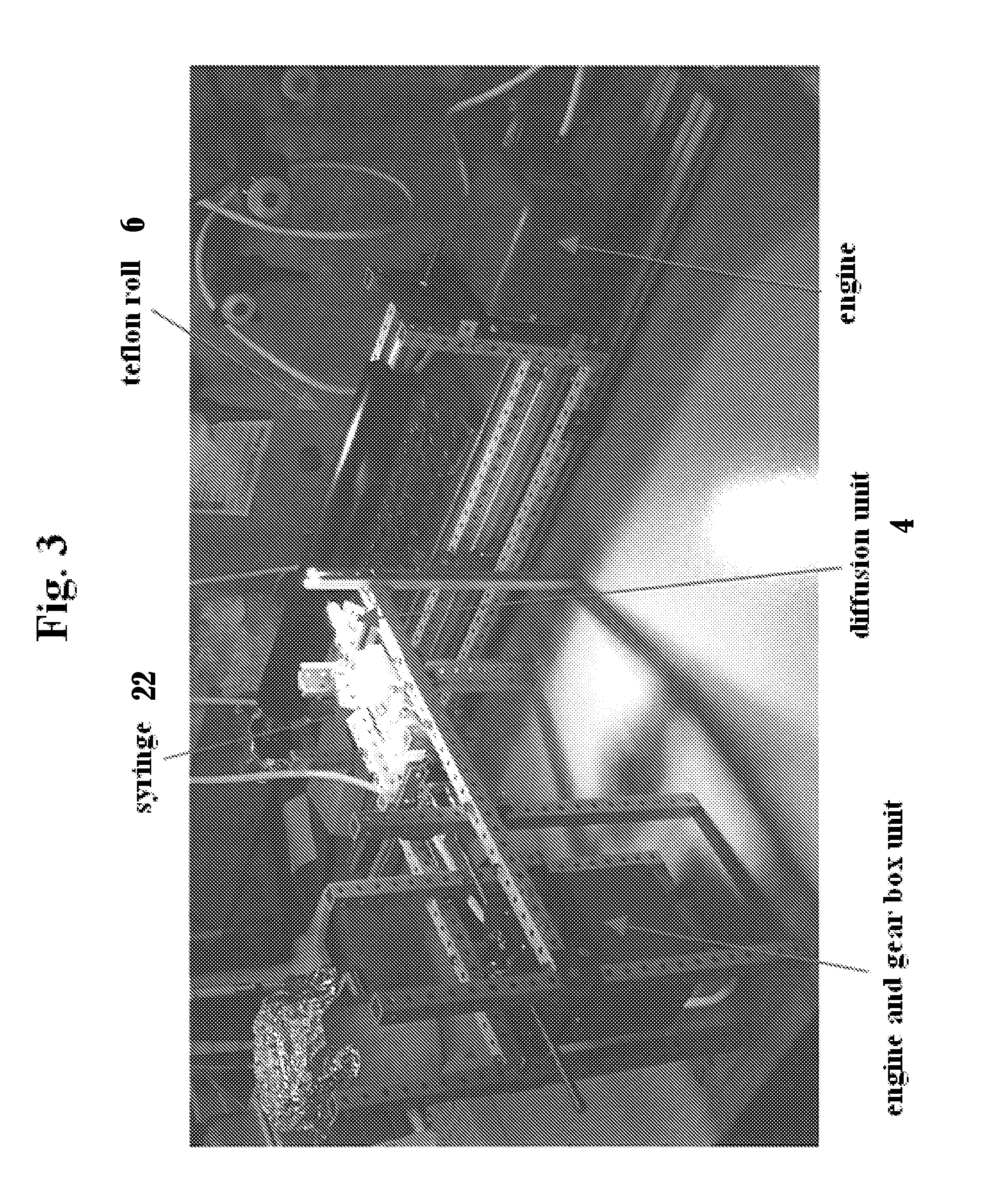

Method and device for producing a thread from silk proteins

ActiveUS7868146B2Enhancing stability and processabilityEnsure continuous processingPeptide/protein ingredientsMonocomponent fibroin artificial filamentProduction lineEngineering

The present invention relates to a thread preparation process from silk proteins including an apparatus which is appropriate for performing the method. Furthermore, the invention is directed to the threads obtained therewith as well as the use thereof. The invention uses a diffusion unit leading to the production of high-quality silk threads with high yield.

Owner:AMSILK

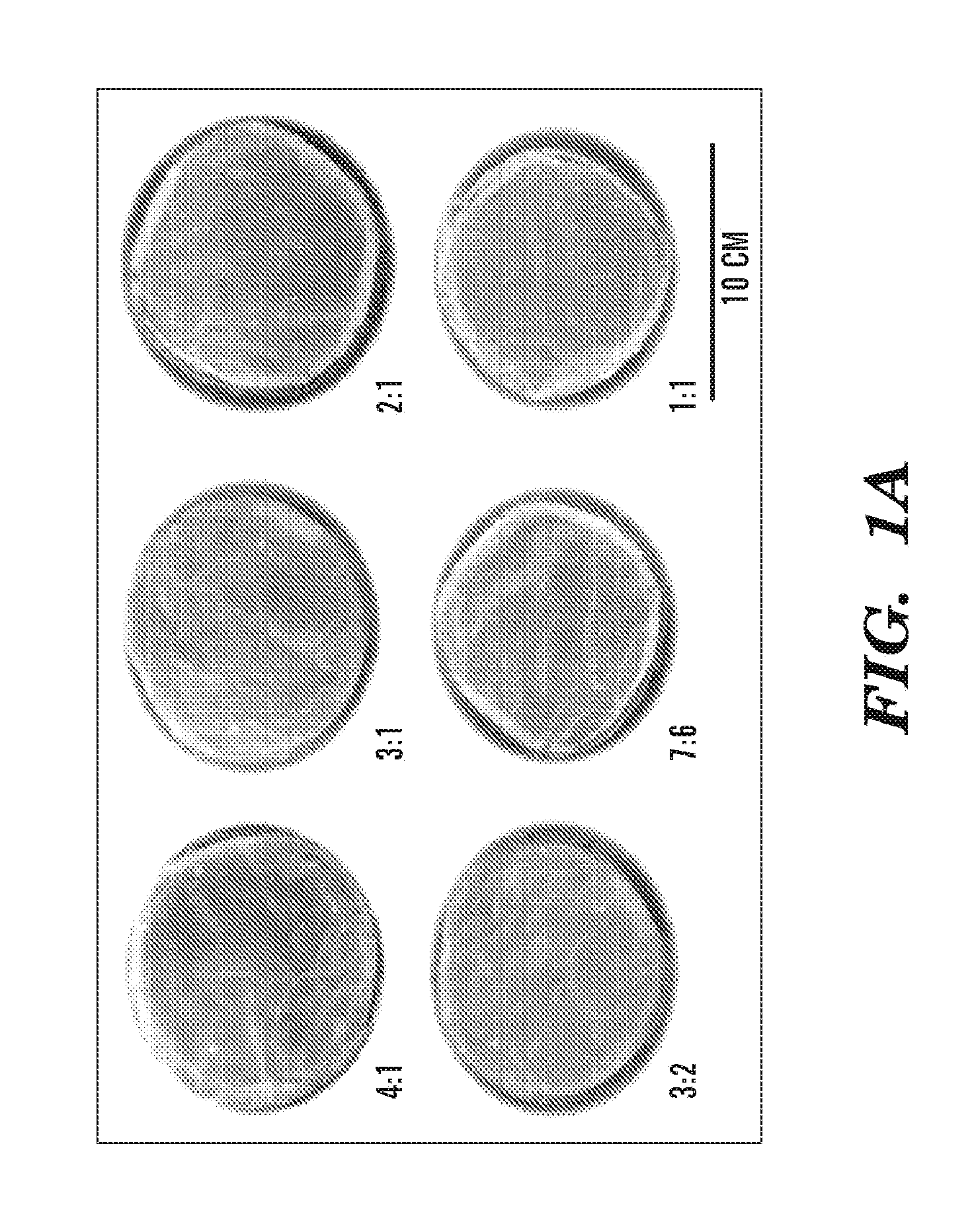

Electrospun silk material systems for wound healing

ActiveUS20120171256A1Organic active ingredientsPeptide/protein ingredientsPolyethylene oxideWound dressing

The present invention relates to the processes of preparing silkfibroin / polyethylene oxide blended materials, and the resulting materials thereof, which are suitable for biomedical applications such as wound healing. In particular, the electrospun silk fibroin / PEO mats with a silk:PEO blend ratio of 2:1 to 4:1, treated with controlled evaporation, constraint-drying techniques, and / or alcohol treatment, and / or PEO extraction, demonstrate suitable physical and biofunctional properties, such as fiber structure, topography, absorption, water vapor transmission rates, oxygen permeation, and biodegradability, relevant to biomaterial systems with utility for wound dressings.

Owner:TRUSTEES OF TUFTS COLLEGE +2

Regenerated silk fiber with alcohols as coagulating bath and method for preparing same

InactiveCN1664184AControl degradationReduce usageMonocomponent fibroin artificial filamentWet spinning methodsGreen environmentPolymer science

This invention is a rebirth silk fibre and preparation method. Silk is broad use because of excellent mechanics capability. But the produce is work force denseness and high cost. This invention take the raw material used high chroma rebirth silk protein water liquor (10-40%) with filature former liquor from industry scrap silk to process wet way filature. And adopt pure compound or multi-pure polymer water liquor to process concreting. This invention have some trait: abroad raw material source, high capability rebirth silk fibre, low cost, blare of nature silk and simple filature process, green environment protecting. In this method, rebirth silk fibre's rupture intention can get 0.1~1.0Gpa and its rupture elongate rate can be 10%-60%.

Owner:FUDAN UNIV

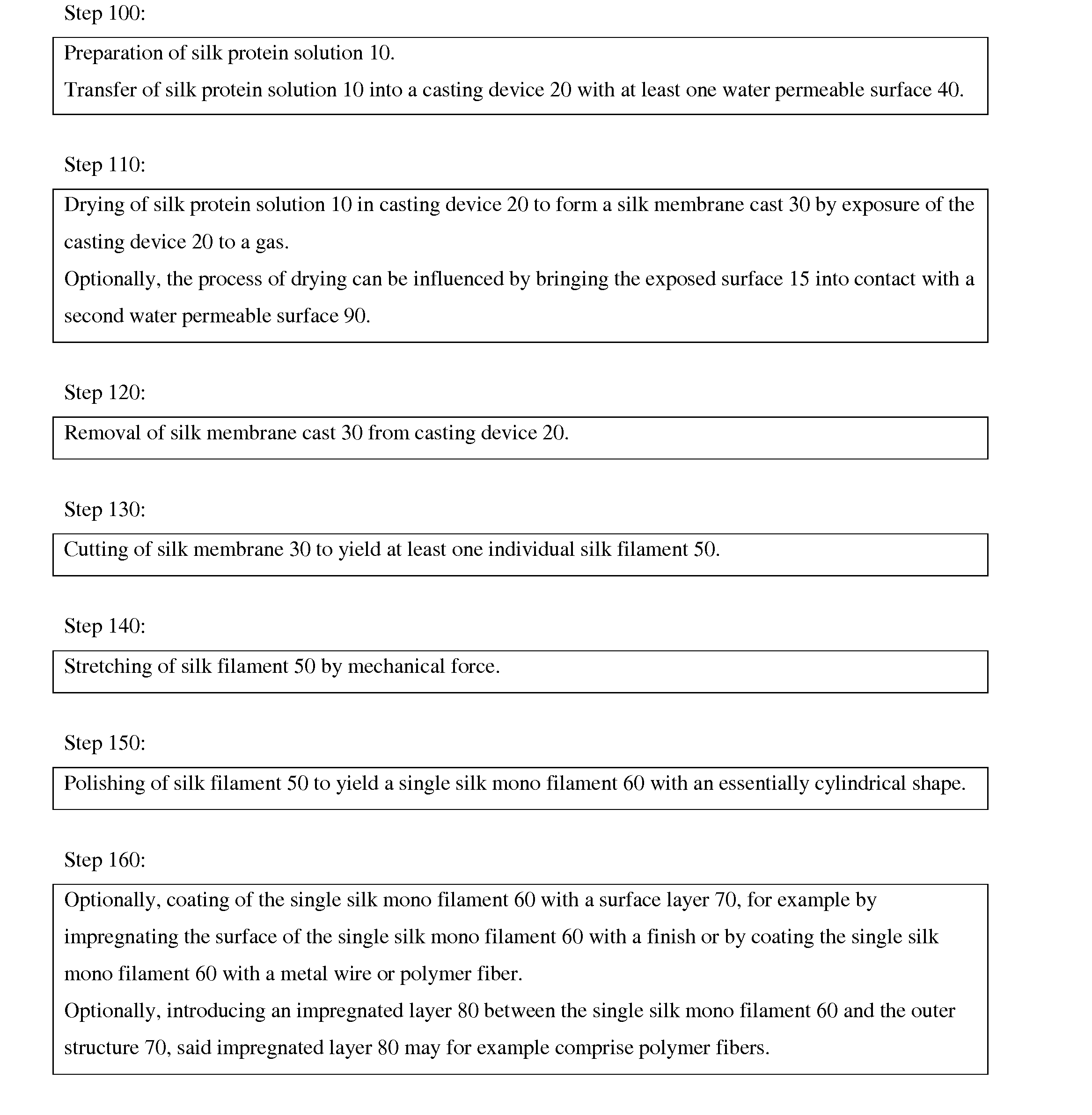

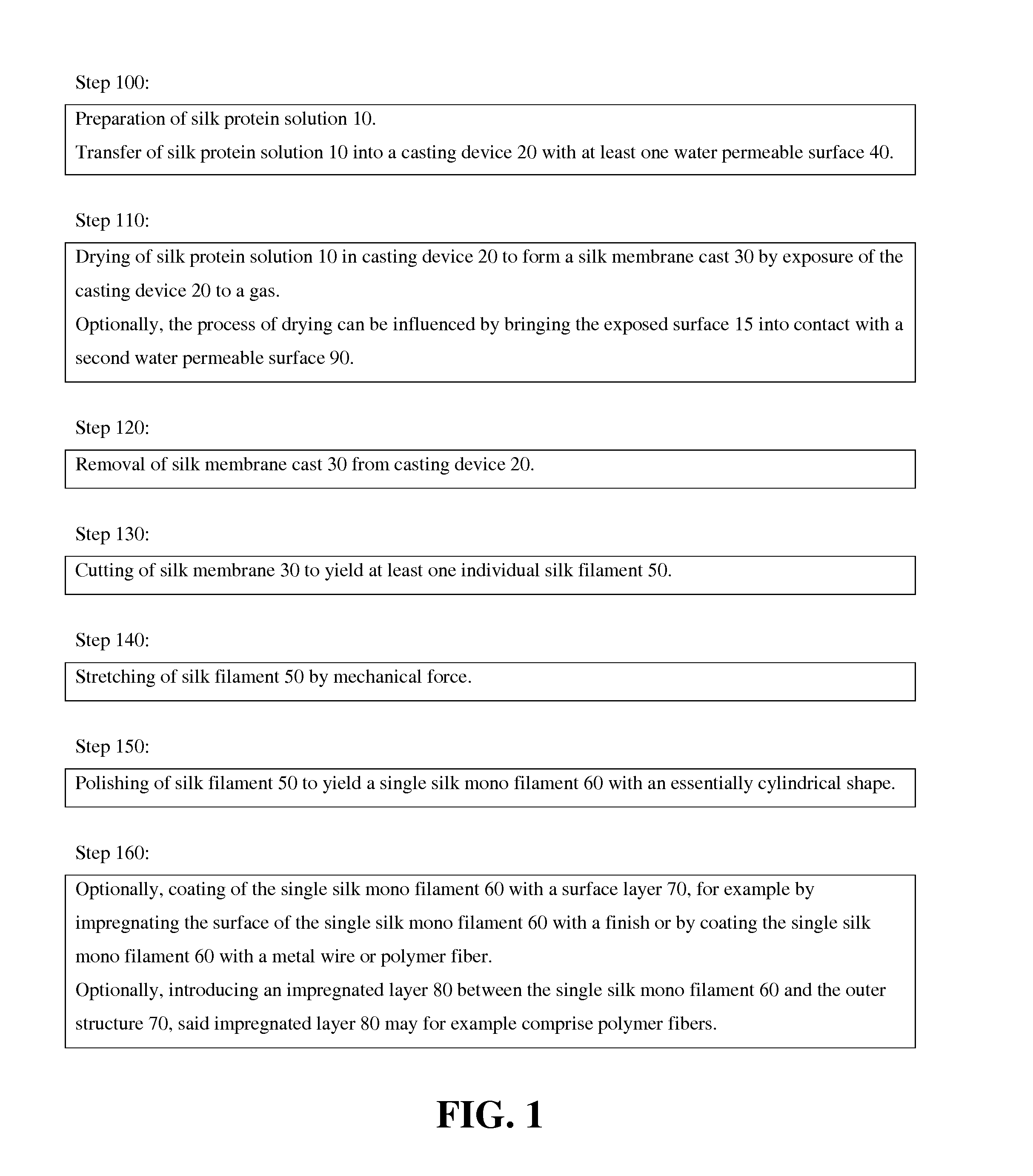

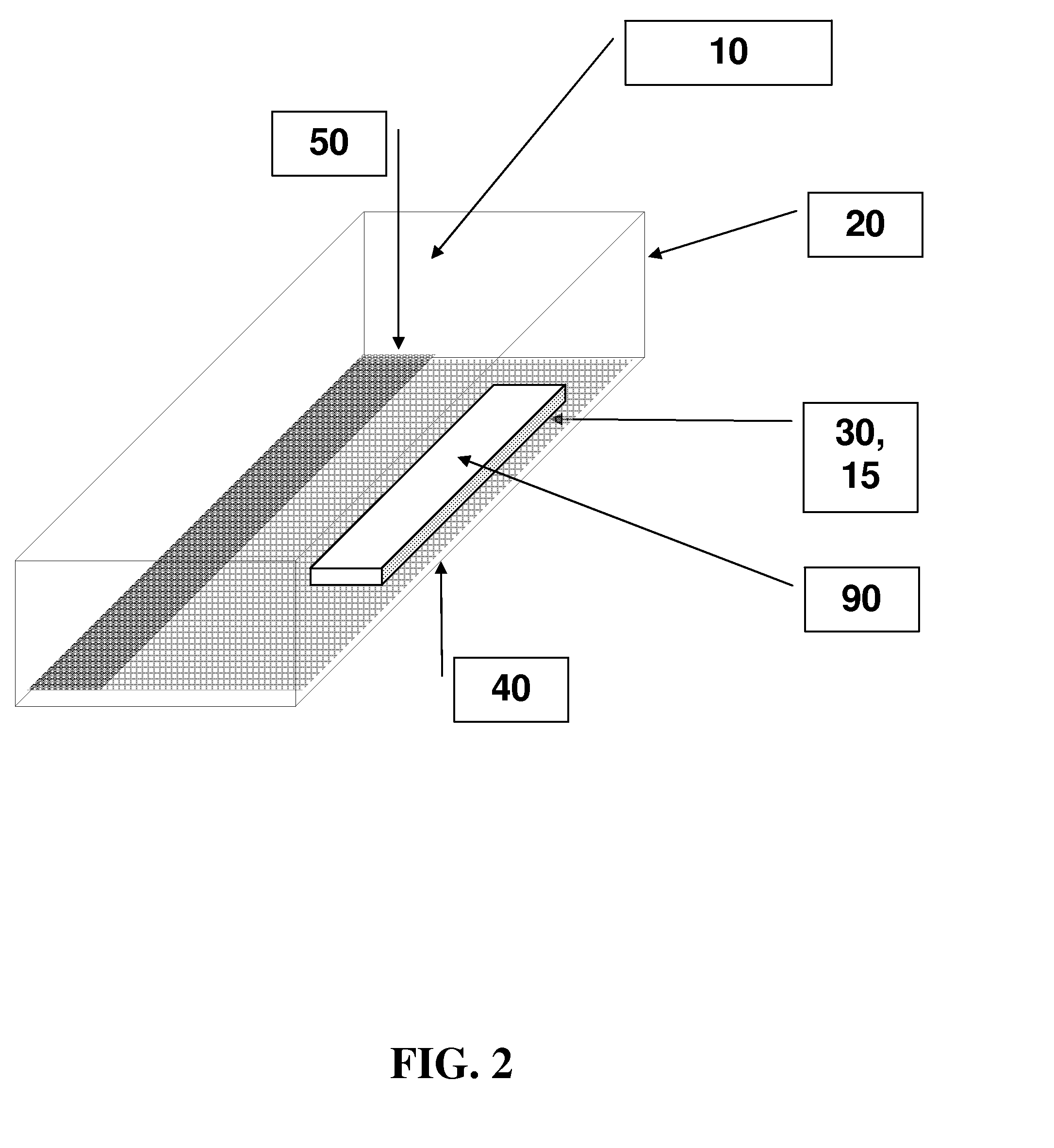

Apparatus and method for the manufacture of a silk mono-filament with a high tensile strength

InactiveUS20100095827A1Expedited drying processAvoid problemsStringed musical instrumentsMonocomponent fibroin artificial filamentUltimate tensile strengthMedical device

A method and an apparatus for the manufacture of a single silk mono-filament. The single silk mono filament has a tensile strength of above 40 Newtons. The single silk mono-filament has applications as a musical string or a medical device.

Owner:SPINTECH ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com