Natural nanometer fiber preparation method

A nanofiber, natural technology, applied in fiber processing, spinning solution preparation, textile and paper making, etc., can solve the problems of complex process, high energy consumption and large power involved in the equipment of electrospinning method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

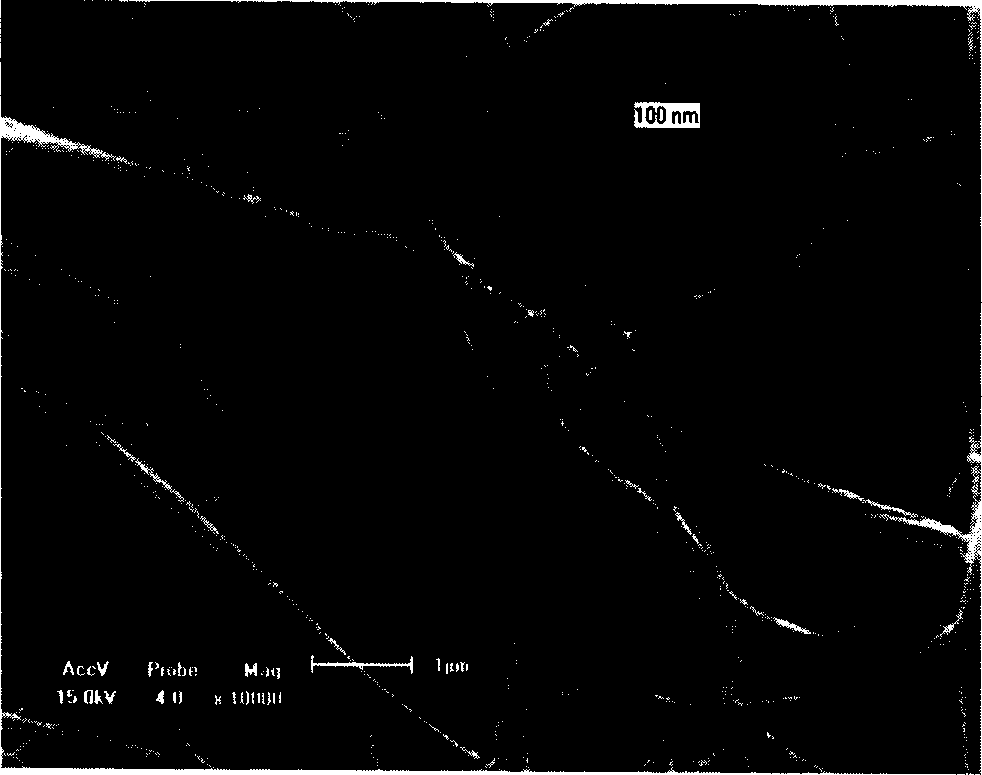

[0030] use as figure 1 The device shown is used to prepare natural nanofibers: soak the spider silk in a beaker filled with ultrapure water; the power of the ultrasonic wave is 600 watts, and the frequency is 20 kHz. In 2.5 hours, natural spider silk nanofibers of 30 to 120 nanometers can be prepared, such as figure 2 shown.

Embodiment 2

[0032] use as figure 1 In the device shown, the spider silk is soaked in a beaker filled with formic acid solvent; the power of the ultrasonic wave is 600 watts, and the frequency is 20 kHz, and the probe of the ultrasonic generator is deep into the beaker, and the ultrasonic cavitation is performed for 2.0 hours, namely Natural spider silk nanofibers of 30-120 nanometers can be prepared.

Embodiment 3

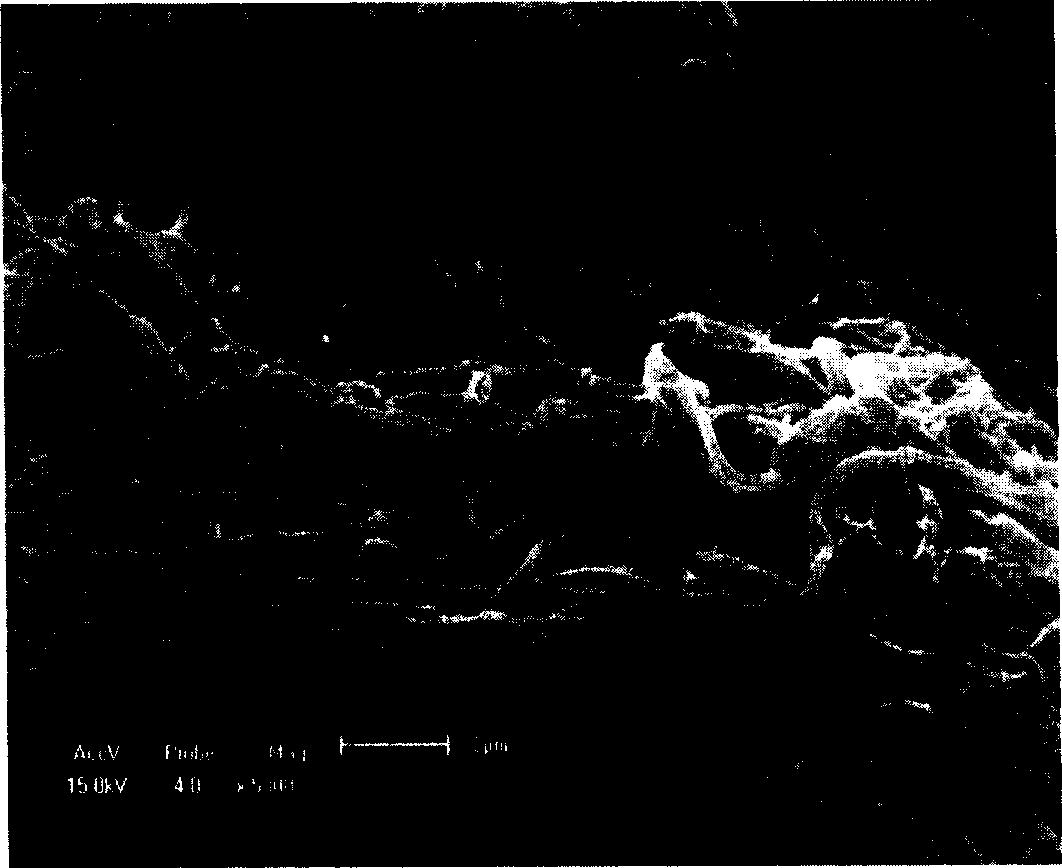

[0034] use as figure 1 In the device shown, the degummed mulberry silk is soaked in a beaker filled with ultrapure water; the power of the ultrasonic wave is 600 watts, the frequency is 20 kHz, the probe of the ultrasonic generator is deep into the beaker, and the ultrasonic cavitation is performed for 2.5 hours , can prepare natural silk nanofibers of 30-120 nanometers, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com