Industrial functional chinlon 66 fibre and preparation method thereof

A functional and industrial technology, applied in the field of fiber production, can solve the problems of rough technology, simple drying process, incomplete and reasonable structure of spinning box of equipment and equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

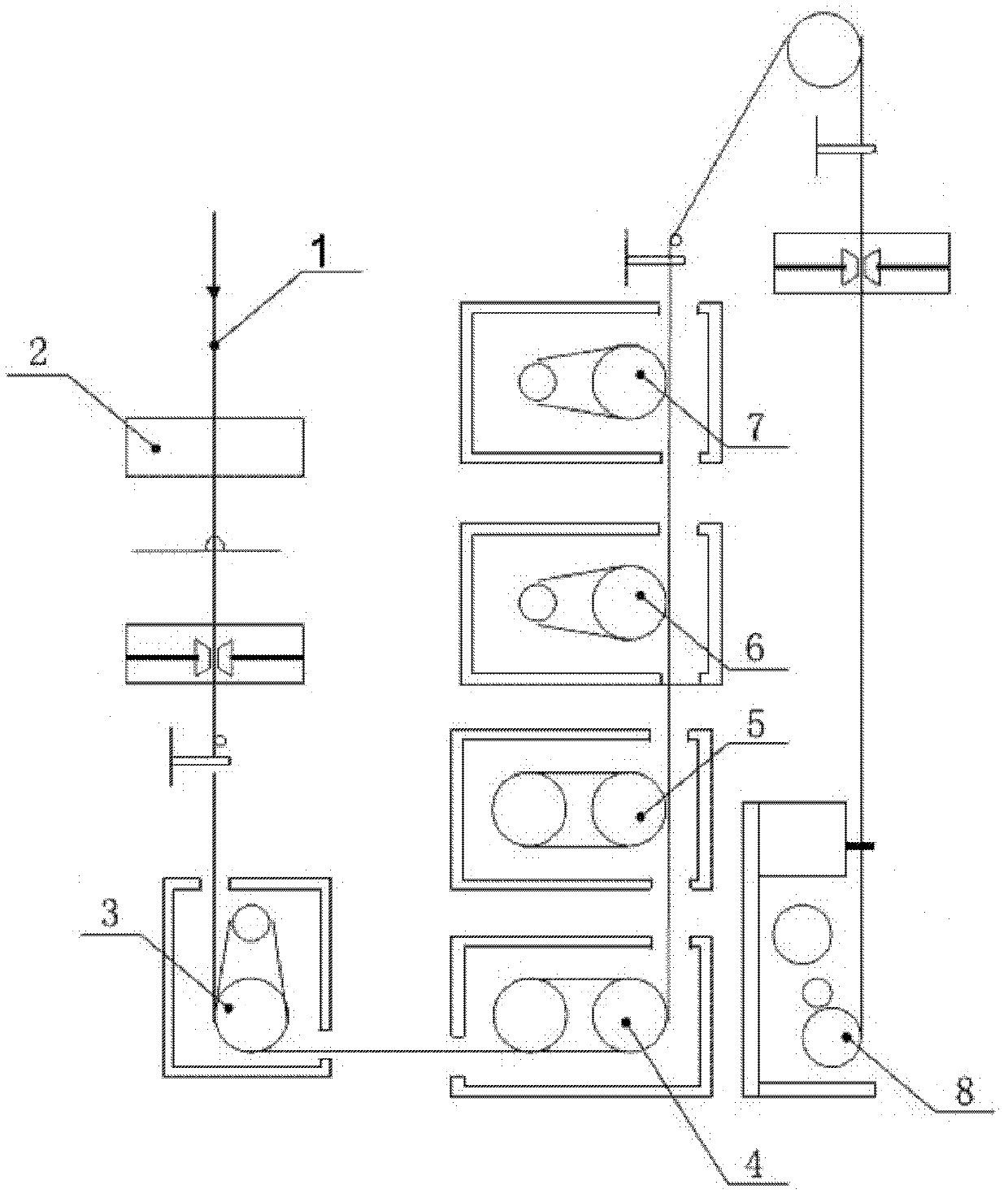

Method used

Image

Examples

Embodiment

[0035] The specific process for producing functional FDY fibers for medium and low denier nylon 66 industrial use:

[0036] 1. Add ordinary filament-grade nylon 66 slices (relative viscosity of slices is 2.5-3.0, sulfuric acid method) into the vacuum drum type solid-phase polymerization kettle, seal and heat up, vacuumize (residual pressure < 0.2mmHg) and heat up at 2- Rotate at 10 rpm, solid phase polymerization temperature is 100-160°C, and the time is 4-8 hours.

[0037] 2. The relative viscosity of the slices is determined to be above 3.3 by sampling. Stop heating and lower the temperature. When the temperature of the kettle drops to 40-50°C, fill the kettle with nitrogen to eliminate the vacuum discharge.

[0038] 3. Send the solid-phase thickened chips into the pre-spinning silo, and then send them to a separate screw extruder with a pin-type mixing head for melting and extrusion. The melt temperature is controlled at 280-285°C.

[0039] 4. The spinning melt is sent to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com