Catalyst for preparing aviation kerosene components through one-step hydrodeoxygenation cracking isomerization of grease and preparation method of catalyst

A technology of aviation kerosene and hydrodeoxygenation, which is applied in the field of catalysis, can solve the problems of catalyst poisoning, and achieve the effects of low hydrogen and energy, low viscosity, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

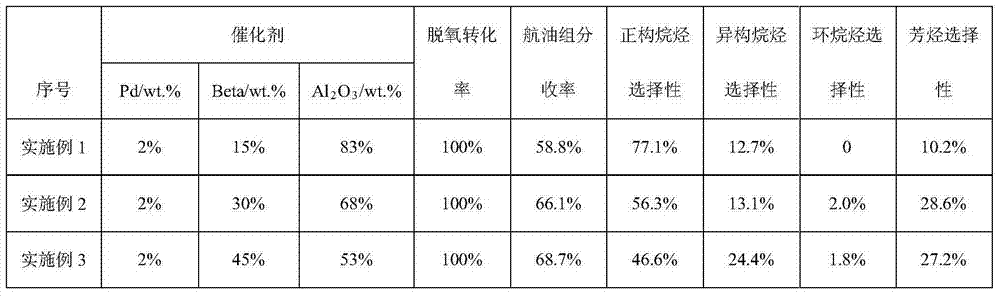

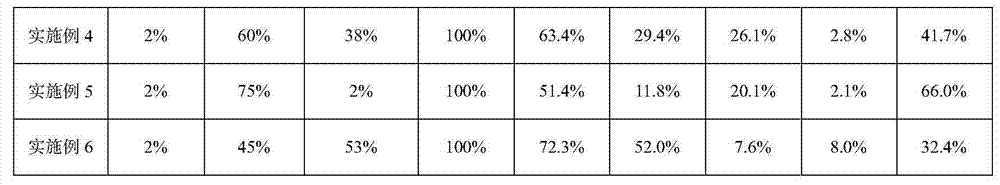

Embodiment 1

[0026] Embodiment 1, Pd / (beta-Al 2 o 3 ) Preparation of catalyst

[0027] (1) 3g H-beta molecular sieve (specific surface area is 526m 2 / g, the pore volume is 0.6ml / g, the crystallinity is 100%, the silicon-aluminum ratio is 25) added to 16.6g Al 2 o 3 (The specific surface area is 200-600m 2 / g, the pore volume is 0.30~0.60ml / g), add 200ml deionized water, stir overnight at room temperature;

[0028] (2) Pd(NO 3 ) 2 The aqueous solution was transferred to (1) the composite carrier aqueous solution, and stood at room temperature for 4 hours, then evaporated to dryness in a water bath at 90°C, then placed in an oven, dried overnight at 120°C, and finally baked in a muffle furnace at 500°C for 5 hours. Finally, it was reduced in an autoclave for 6 hours at 300°C under a hydrogen pressure of 1MPa;

[0029] The prepared catalyst has a mass fraction of Pd of 2%, a mass fraction of beta molecular sieve of 15%, Al 2 o 3 Pd / (beta-Al with a mass fraction of 83% 2 o 3) hydr...

Embodiment 2

[0030] Embodiment 2, Pd / (beta-Al 2 o 3 ) Preparation of catalyst

[0031] (1) 6g H-beta molecular sieve (specific surface area is 526m 2 / g, pore volume is 0.6ml / g, crystallinity is 100%, silicon-aluminum ratio is 25) added to 13.6g Al2O3 (specific surface area is 200-600m 2 / g, the pore volume is 0.30~0.60ml / g), add 200ml deionized deionized deionized water, and stir overnight at room temperature;

[0032] (2) Move the Pd(NO3)2 aqueous solution accounting for 2% of the mass fraction of the catalyst to (1) the composite carrier aqueous solution, let it stand at room temperature for 4 hours, evaporate to dryness in a water bath at 90°C, and then put it in an oven and dry it at 120°C Overnight, then roasted in a muffle furnace at 500°C for 5h, and finally reduced in an autoclave at 300°C under a hydrogen pressure of 1MPa for 6h;

[0033] The prepared catalyst has a mass fraction of Pd of 2%, a mass fraction of beta molecular sieve of 30%, Al 2 o 3 Pd / (beta-Al with a mass f...

Embodiment 3

[0034] Embodiment 3, Pd / (beta-Al 2 o 3 ) Preparation of catalyst

[0035] (1) 9g H-beta molecular sieve (specific surface area is 526m 2 / g, the pore volume is 0.6ml / g, the crystallinity is 100%, the silicon-aluminum ratio is 25) added to 10.6g Al 2 o 3 (The specific surface area is 200~600m 2 / g, the pore volume is 0.30~0.60ml / g), add 200ml deionized deionized deionized water, and stir overnight at room temperature;

[0036] (2) Pd(NO 3 ) 2 Move the aqueous solution to (1) the composite carrier aqueous solution, let it stand at room temperature for 4 hours after impregnation, evaporate to dryness in a water bath at 90°C, then put it in an oven, dry it at 120°C overnight, and then bake it in a muffle furnace at 500°C for 5 hours, and finally Reduction in an autoclave for 6 hours at 300°C under a hydrogen pressure of 1MPa;

[0037] The prepared catalyst has a mass fraction of Pd of 2%, a mass fraction of beta molecular sieve of 45%, Al 2 o 3 Pd / (beta-Al with a mass fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com