Super-hydrophobic/super-oleophilicity copper wire mesh for oil and water separation and preparation method and application thereof

An oil-water separation and super-hydrophobic technology, applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve problems such as environmental pollution, harsh reaction conditions, and cumbersome processes, and achieve low cost, simple preparation process, and high separation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

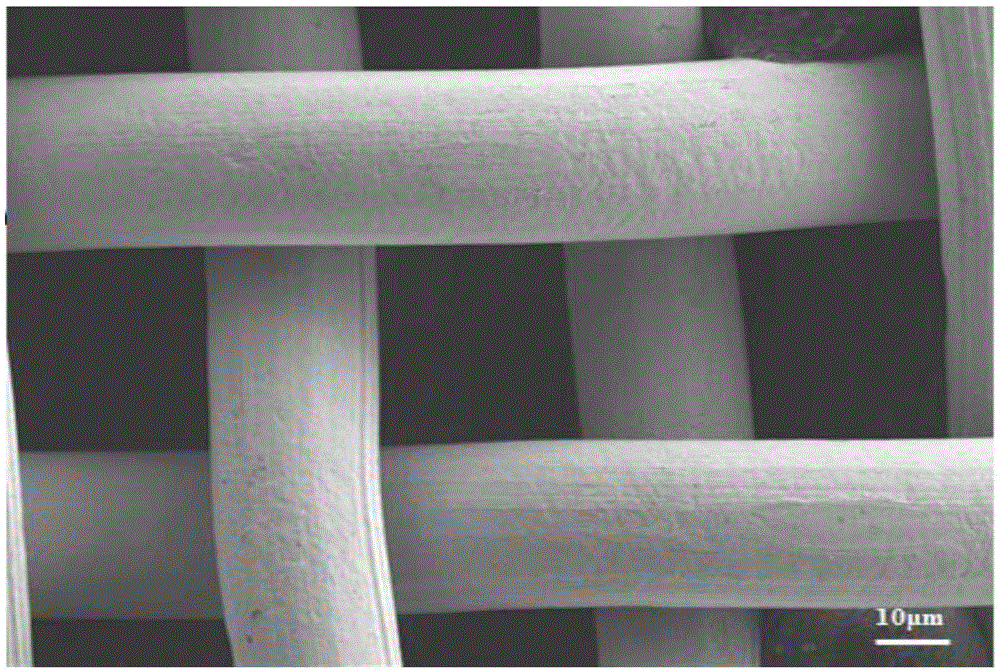

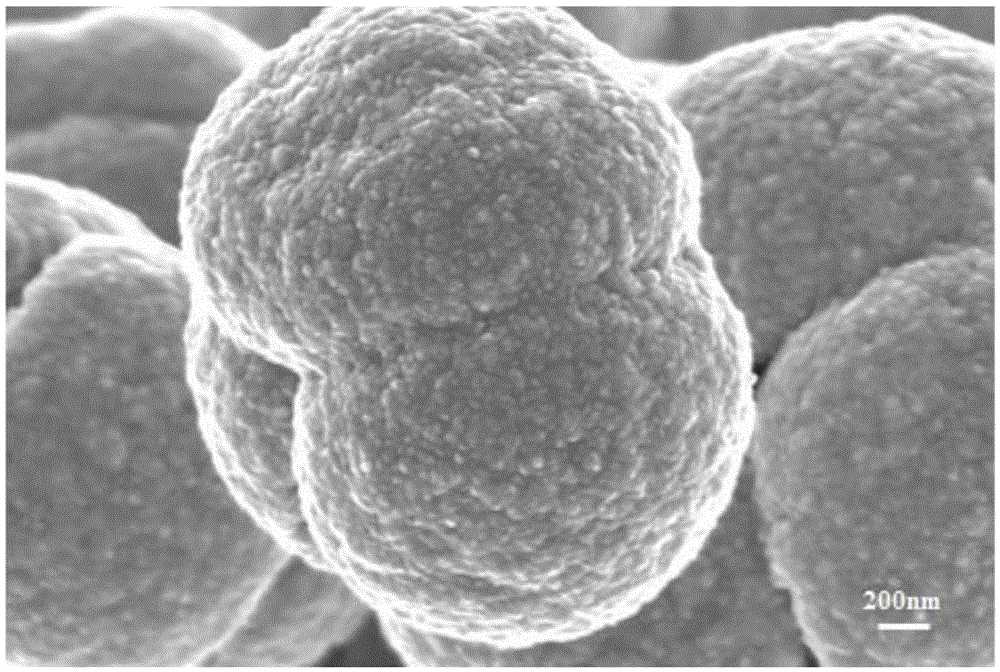

[0042] 300-mesh phosphorus copper mesh (size 3cm×3cm) was used respectively with 1mol·L ‐1 Ultrasonic cleaning with dilute hydrochloric acid, absolute ethanol and deionized water for about 10 minutes, and drying with nitrogen for later use; prepare 1mol L ‐1 Copper sulfate solution and 1mol L ‐1 Sodium thiosulfate solution, in parts by volume, mixes 20 parts of copper sulfate solution and 10 parts of sodium thiosulfate solution respectively, and dilutes with 70 parts of deionized water to obtain chemical deposition solution; the cleaned 300 mesh phosphor copper The grid was placed in the deposition solution at 50°C; after 30 minutes, the copper grid was taken out, washed with deionized water, dried in the air, and finally the dried copper grid was soaked in hydroxyl-terminated polydimethylsiloxane and methyl tributyl ketone Put in the mixed solution of chloroform of oxime-based silane curing agent for 2 hours, take it out and heat it at 80°C for 2 hours to obtain a superhydro...

Embodiment 2

[0047] A 200-mesh brass mesh (3cm×3cm in size) was mixed with 1mol·L ‐1 Ultrasonic cleaning with dilute hydrochloric acid, absolute ethanol and deionized water for about 10 minutes, and drying with nitrogen for later use; prepare 2mol L ‐1 Copper sulfate solution and 1mol L ‐1 Sodium thiosulfate solution, in parts by volume, mixed with 5 parts of copper sulfate solution and 10 parts of sodium thiosulfate solution, and diluted with 85 parts of deionized water to obtain chemical deposition solution; the cleaned 200 mesh brass The grid was placed in the deposition solution at 50°C; after 30 minutes, the copper grid was taken out, washed with deionized water, dried in the air, and finally the dried copper grid was soaked in hydroxyl-terminated polydimethylsiloxane and methyl tributyl ketone Put in the mixed solution of n-hexane of oxime-based silane curing agent for 2 hours, take it out and heat it at 60°C for 4 hours to obtain a super-hydrophobic / super-oleophilic copper mesh for...

Embodiment 3

[0049] A 100-mesh red copper mesh (3cm×3cm in size) was used with 2mol·L ‐1 Ultrasonic cleaning with dilute hydrochloric acid, absolute ethanol and deionized water for about 10 minutes, and drying with nitrogen for later use; prepare 5mol L ‐1 Copper sulfate solution and 3mol L ‐1 Sodium thiosulfate solution, in parts by volume, mixes 10 parts of copper sulfate solution and 10 parts of sodium thiosulfate solution respectively, and dilutes with 80 parts of deionized water to obtain chemical deposition solution; the cleaned 100-mesh copper net Place in a deposition solution at 50°C; after 10 minutes, take out the copper grid, wash it with deionized water, and dry it in the air. Finally, soak the dried copper grid in hydroxyl-terminated polydimethylsiloxane and methyl tributanone oxime The toluene solution of base silane curing agent for 2 hours, took it out and heated it at 80°C for 3 hours to obtain a superhydrophobic / superoleophilic copper mesh for oil-water separation. Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com