Preparation method of durable super-hydrophobic super-oleophylic foamy copper for oil and water separation

A technology of oil-water separation and copper foam, which is applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., can solve problems such as shedding, affecting the long-lasting oil-water separation and circulation separation characteristics of foam copper, and being easily damaged, so as to increase the combination force, increase thickness, and increase oil absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A method for preparing durable super-hydrophobic super-oleophilic copper foam for oil-water separation, said method comprising the steps of:

[0037] (1) Foamed copper pretreatment: Put the foamed copper with a pore size of 400-1500 μm into ethanol and acetone solution in turn, ultrasonically clean it for 10 minutes, take it out and then put it in 2mol / L hydrochloric acid aqueous solution for 10 minutes to remove oil and scale and finally use it Rinse with deionized water repeatedly and dry for later use;

[0038] (2) Pre-roughening of the foamed copper skeleton: chemical etching or electrochemical deposition or a combination of the two methods are used to pre-roughen the foamed copper skeleton; the chemical etching method is to remove oil and descale the foam Copper is put into 2-5mol / L nitric acid aqueous solution, and etched at room temperature for 1-2h. The electrochemical deposition method uses foamed copper as the cathode, and pure copper sheets of the same size a...

Embodiment 1

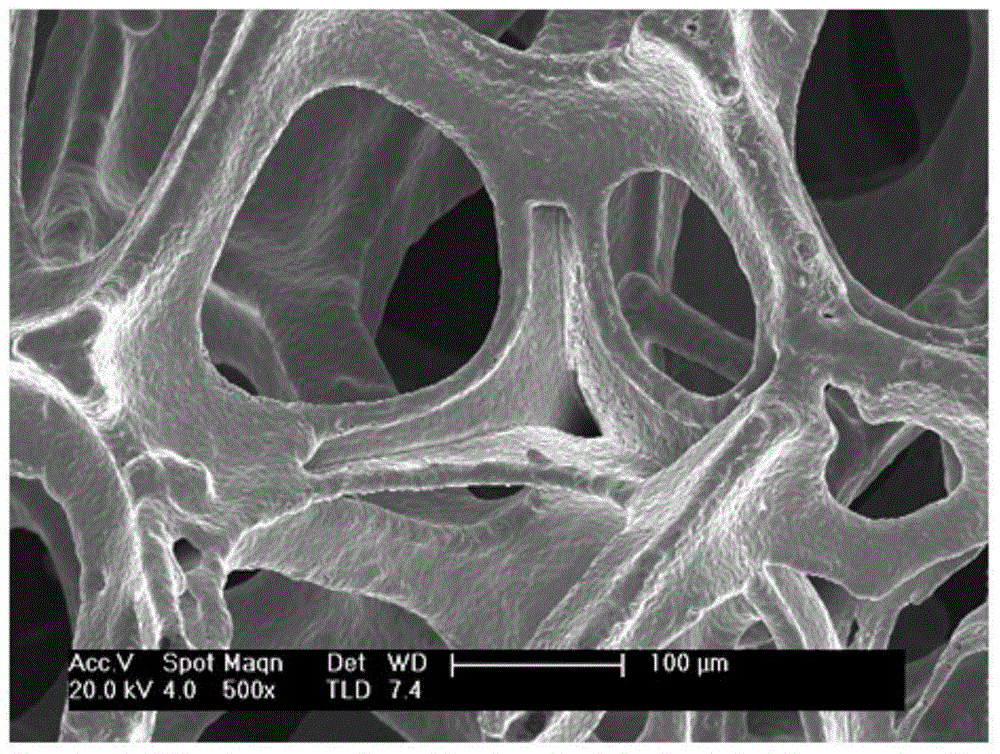

[0042] Copper foam with a pore size of 400 μm (such as figure 1 shown) into ethanol and acetone solutions in turn, ultrasonically cleaned for 10 minutes, and then put into 2mol / L hydrochloric acid aqueous solution for 10 minutes to remove oil and scale, and finally rinsed repeatedly with deionized water and dried for later use. Put the degreased and descaled copper foam into 2mol / L nitric acid aqueous solution, and etch at room temperature for 2 hours to obtain a rough copper foam skeleton. Subsequently, a ZnO seed layer was obtained on the surface of the skeleton by an immersion pulling-sintering method, and then a dense ZnO array nanostructure was grown by a chemical bath method. After 3 minutes, the ZnO precursor sol was pulled out at a speed of 1mm / s, blown with hot air at 60°C for 30s, and then blown with cold air at 20°C for 3 minutes until the foamed copper was completely dry, and then repeatedly dipped and pulled up and down for 3 times. Then vacuum reaction at 350° C...

Embodiment 2

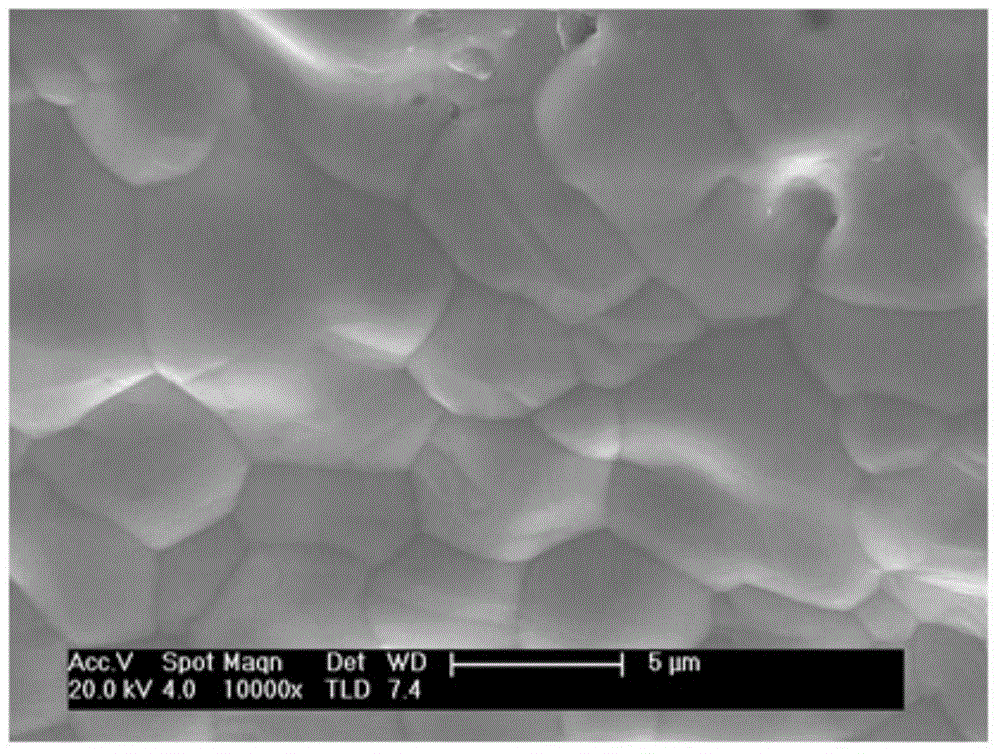

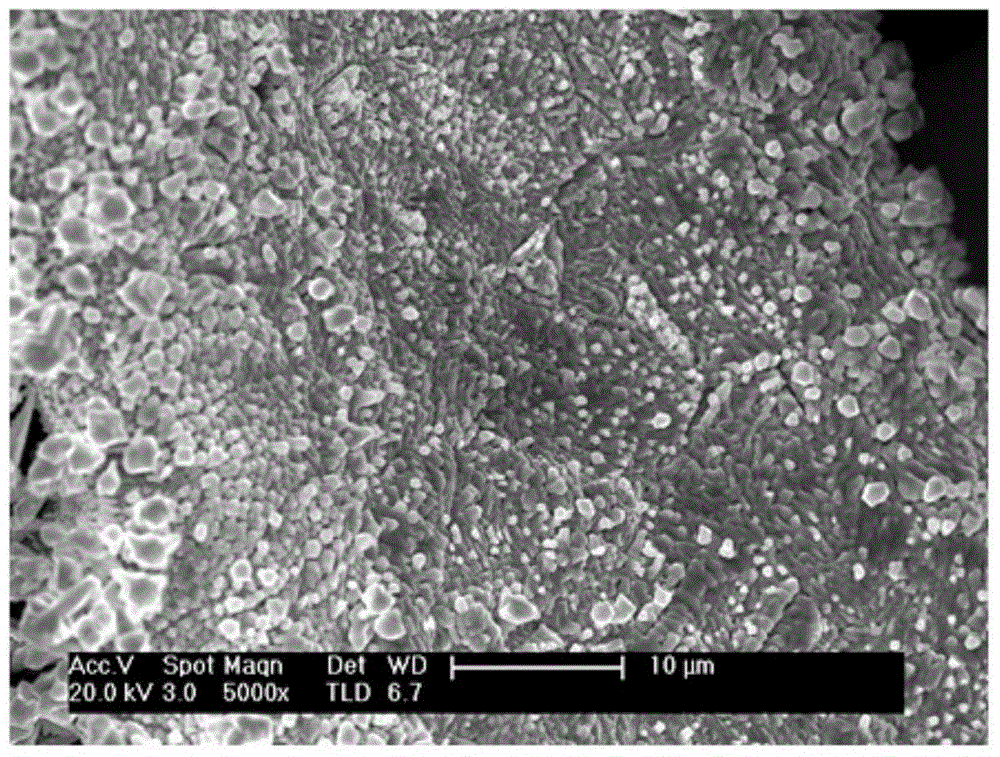

[0044] Put copper foam with a pore size of 600 μm into ethanol and acetone solutions in turn, ultrasonically clean it for 10 minutes, take it out and put it in 2mol / L hydrochloric acid aqueous solution for 10 minutes to remove oil and scale, and finally rinse it repeatedly with deionized water and dry it for later use. Copper foam is used as the cathode, and pure copper sheets of the same size are used as the double anode, the distance between the two poles is 5cm, and 0.2mol / L CuSO 4 and 1.5mol / L H 2 SO 4 The mixed aqueous solution is the electrolyte solution, adding 5g / L sodium dodecylbenzenesulfonate as a wetting agent, at room temperature, 800r / min magnetic sub-stirring, first at a current density of 0.005A / cm 2 Under the conditions of electrodeposition for 5min, and then at 0.01A / cm 2 Electrodeposition at current density for 5min, finally at 0.02A / cm 2 Electrodeposition at current density for 5 min. The original smooth foam copper skeleton ( figure 2 ), after the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com