Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Strong membrane binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of durable super-hydrophobic super-oleophylic foamy copper for oil and water separation

ActiveCN104888498ALarge specific surface areaImprove bindingLiquid/solution decomposition chemical coatingLiquid separationNano structuringEtching

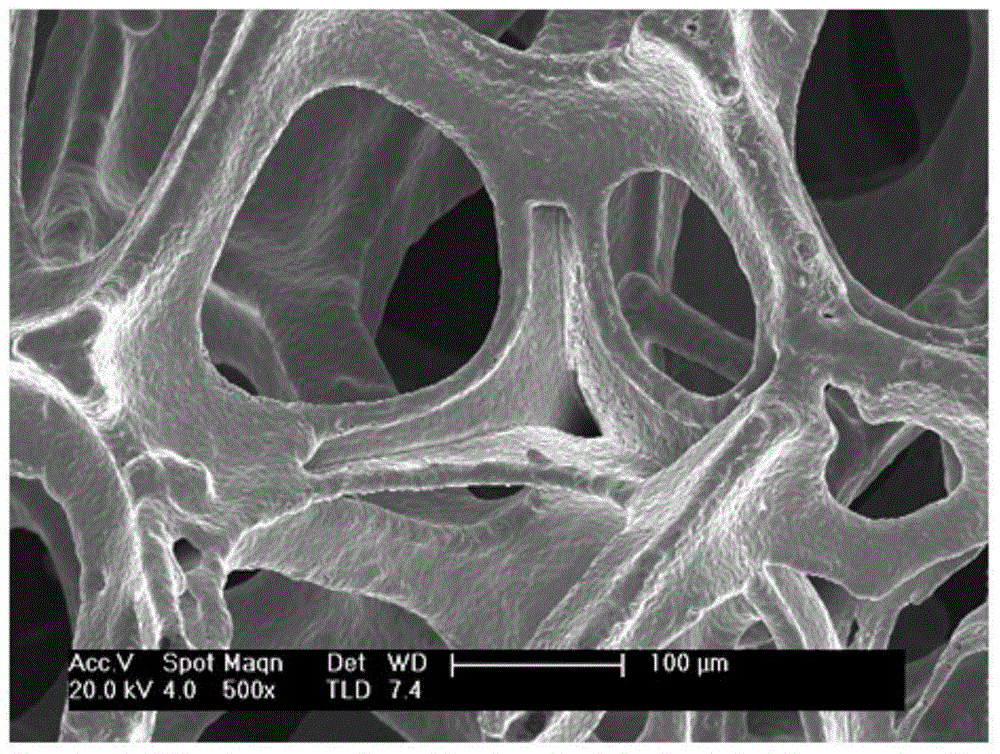

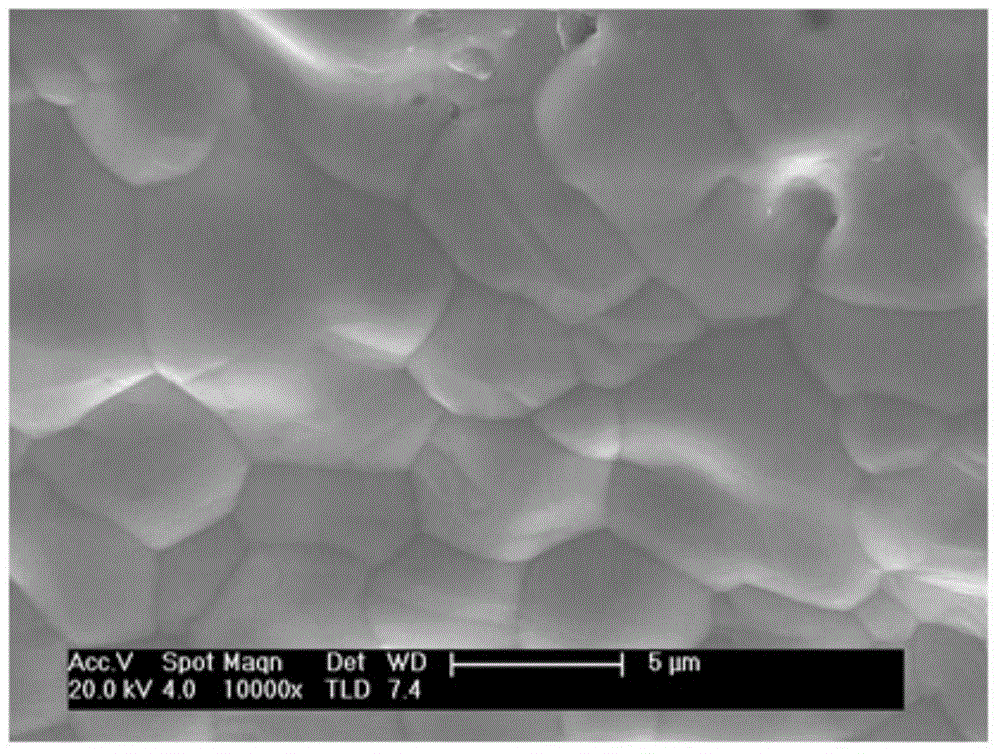

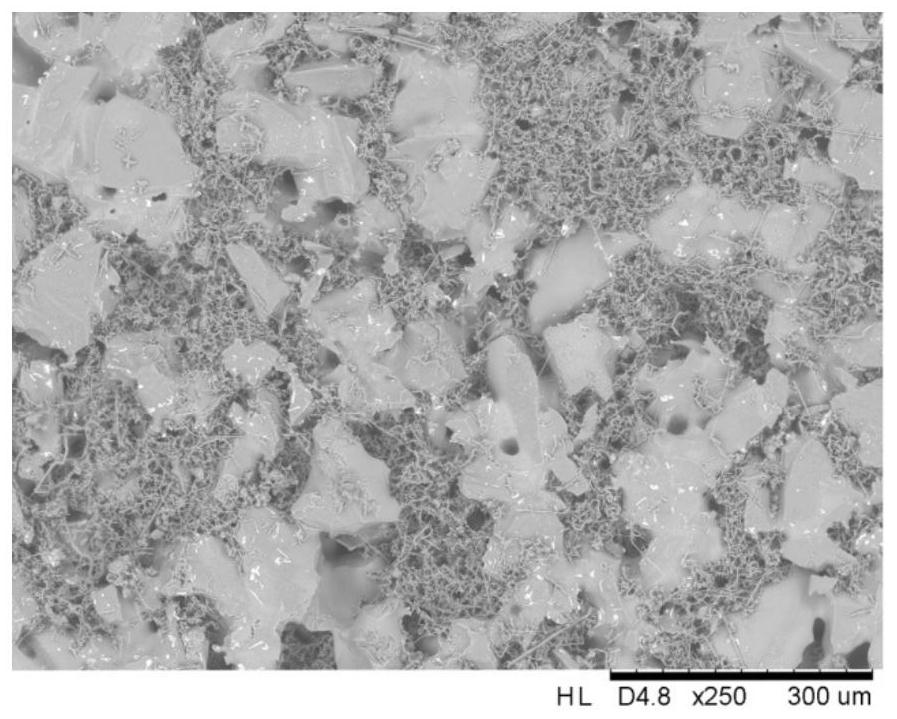

The invention provides a preparation method of durable super-hydrophobic super-oleophylic foamy copper for oil and water separation. The preparation method comprises the followings steps: firstly, the foamy copper is sequentially put in an ethanol solution and an acetone solution for ultrasonic cleaning and treated with a hydrochloric acid aqueous solution to remove oil stain and oxide skin; for the cleaned foamy copper, a chemical etching or electrochemical deposition method is used to pre-roughen a foamy copper framework so as to improve the membrane-based binding force; then, a dip-coating-sintering method is adopted to obtain a ZnO crystal seed layer on the surface of the framework, and a compact ZnO array nano structure grows in an oriented manner through a chemical bath manner so as to improve the strength and stability of a film layer; finally, fluoridation is performed on the foamy copper to realize the super-hydrophobic super-oleophylic feature and the oil and water separation function. Through the pre-roughening of the foamy copper framework and the compactly arranged zinc oxide nano structure, the strength of the film layer and the membrane-based binding force can be improved, and the damaging and falling behavior of the film layer during oil and water separation by the foamy copper can be reduced, so that the durable oil and water separation capacity of the foamy copper can be improved.

Owner:SOUTHEAST UNIV

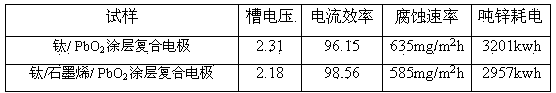

Titanium/graphene/oxide combined electrode

ActiveCN103526235APerfect quantum tunnelingImprove conductivityElectrodesCharge carrier mobilityTitanium

The invention relates to a titanium / graphene / oxide combined electrode, which belongs to the technical field of electroplating. The combined electrode is such structured that graphene and an oxide coating are successively coated on a matrix, wherein the oxide coating is an oxide of Mn, Pb or La, and the matrix is a titanium or titanium alloy plate or screen plate. A plurality of layers of graphene are coated on the matrix, each layer being 0.4 to 1.0 mm thick. The thickness of the oxide coating is 150 mu m to 700 mu m. The titanium or titanium alloy plate is 0.5 to 10 mm thick, and the mesh diameter of the screen plate is 0.1 to 5 mm. According to the invention, overall performance of the electrode is improved by using a stable lattice structure and high carrier mobility of graphene, advantages of each layer of graphene are performed, so the electrode has the advantages of high strength, good conductivity, high corrosion resistance, a long service life and the like.

Owner:KUNMING UNIV OF SCI & TECH

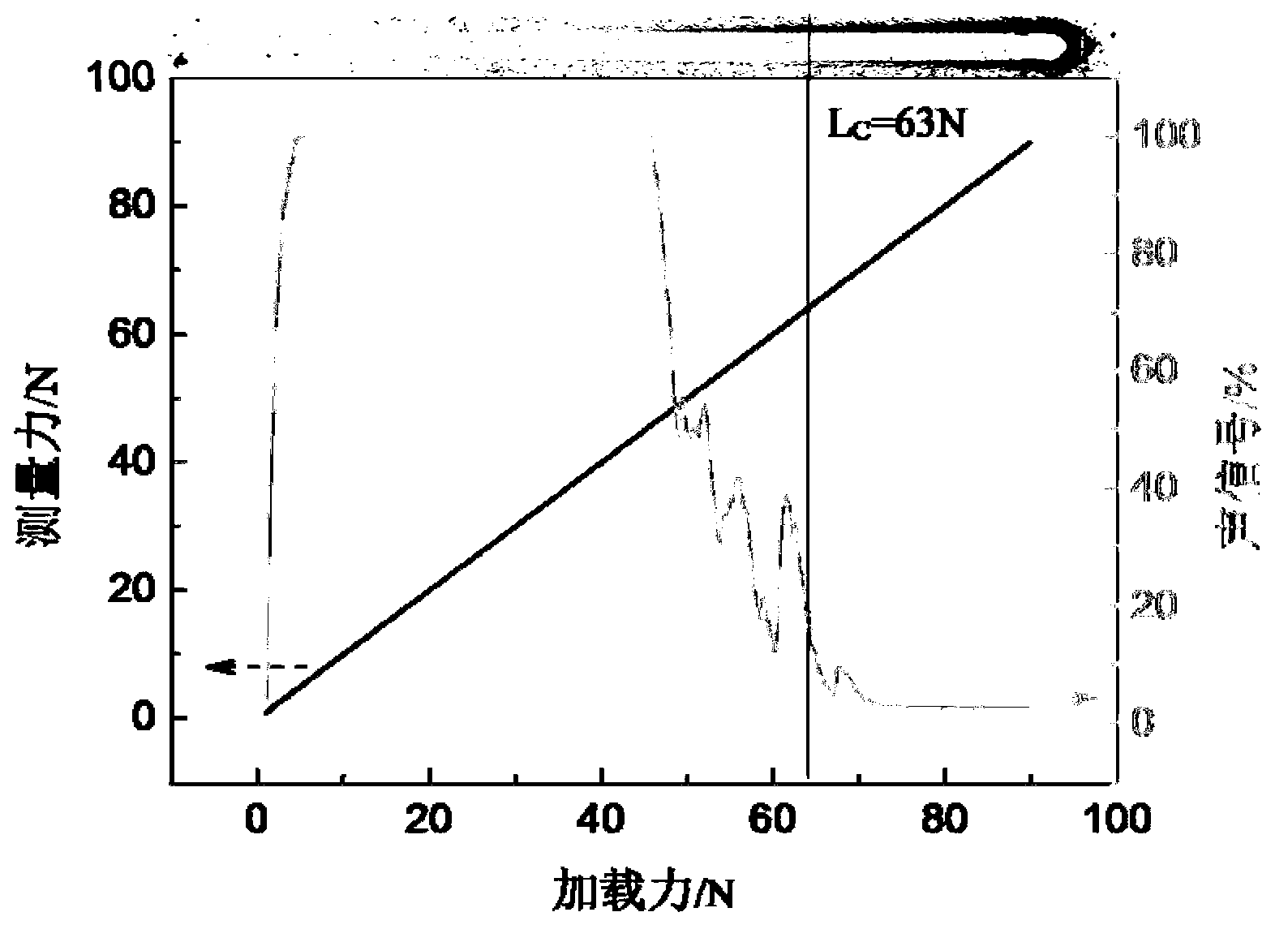

Preparation method of MoS2 composite thin film with high hardness and loss abrasion on surface of substrate

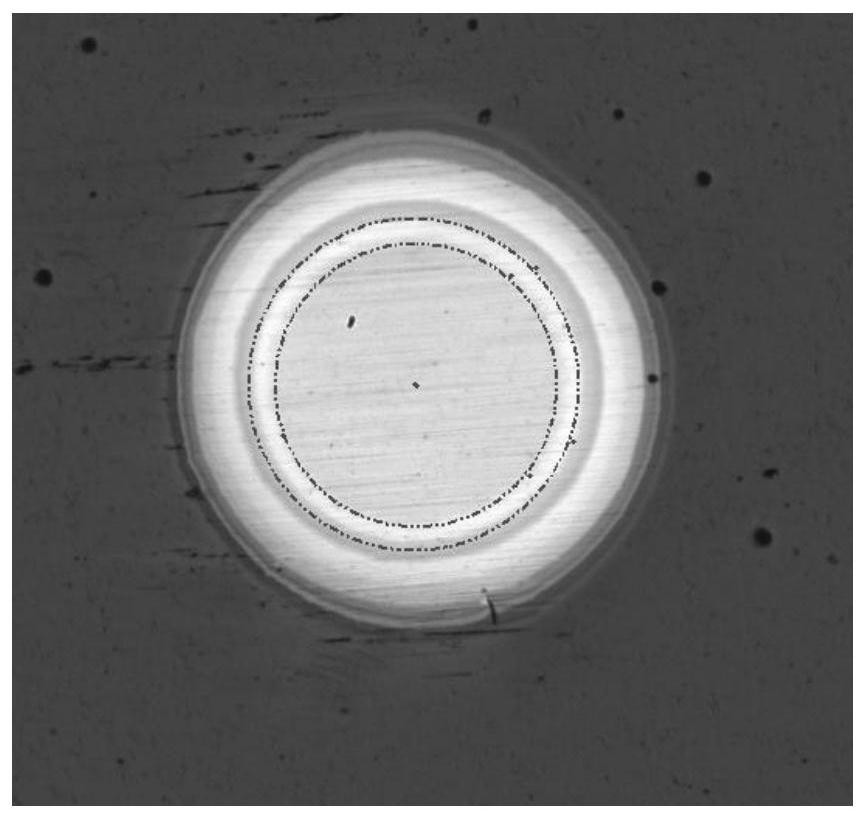

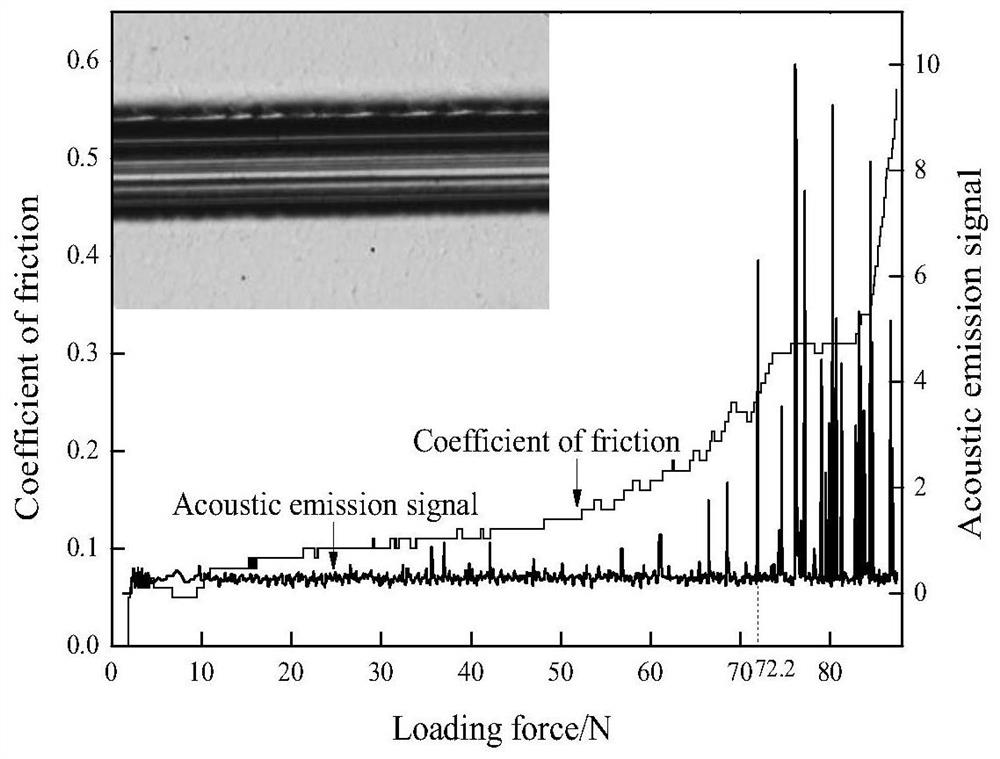

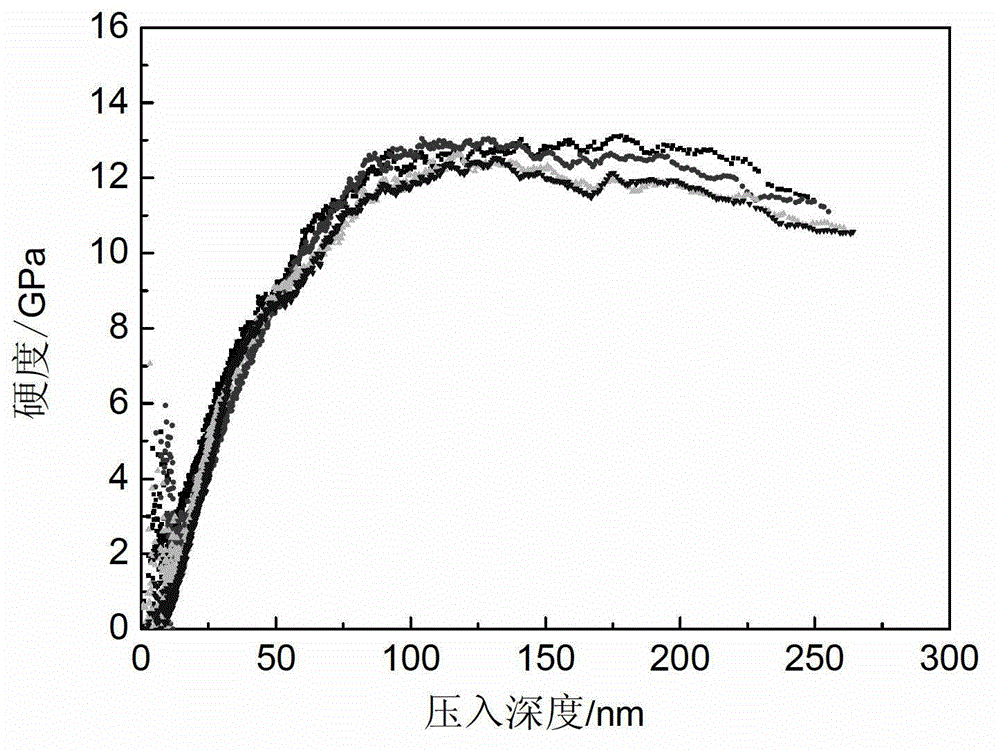

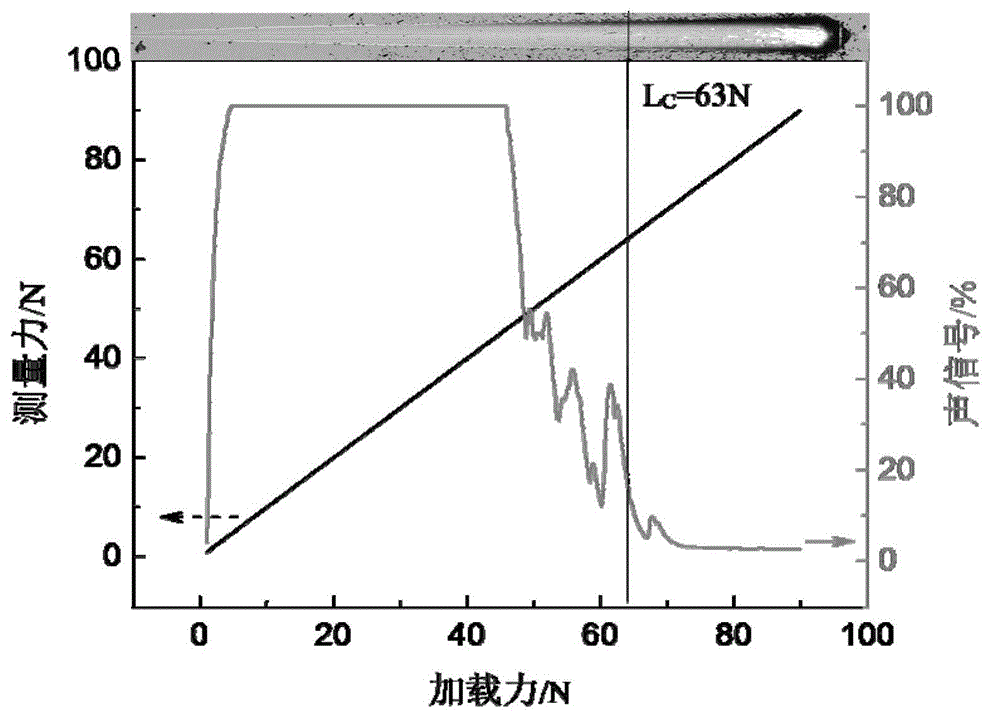

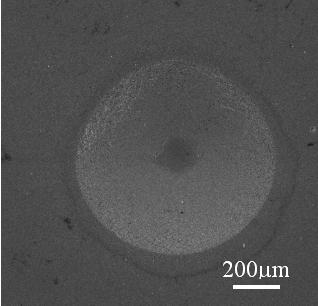

ActiveCN103060765AFast sputtering rateIncrease ionization rateVacuum evaporation coatingSputtering coatingComposite filmCritical load

The invention discloses a preparation method of a MoS2 composite thin film with high hardness and loss abrasion on a surface of a substrate. The method comprises the following step: sequentially depositing a metal Ti priming coat, a TiN transitional layer and a Ti / MoS2 composite thin film on the surface of the substrate by using a high power pulse magnetron sputtering technology combined with optimized process conditions to obtain the MoS2 composite thin film which is strong in film binding force and high hardness and has low frictional coefficient and wear rate in various frictional environments. The nano hardness of the composite thin film is over 11GPa, the critical load value is over 60N, and the frictional coefficients in room-temperature air with relative humidity of 30%, 50% and 70%, an N2 atmosphere and a hydraulic oil environment are below 0.055. Therefore, the substrate is effectively protected in frictional reduction, and the composite thin film has a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for raising common steel antibiotic and rust resisting performance

InactiveCN101067196AImprove adhesion strengthHigh deposition rateVacuum evaporation coatingSputtering coatingFood sectorCopper

The process of raising antibiotic and antirust performance of common steel product belongs to the field of material surface treating technology. The process includes: grinding and polishing the surface of steel product to mirror finishing, ion plating to deposit Ni-Cr film, and implanting Cu or Ag ion. The ion plating and the ion implanting make the common steel product possess both antibiotic performance and antirust performance. Thus treated steel may be used in door handle, kitchenware, household appliance, etc.

Owner:SHANGHAI JIAO TONG UNIV

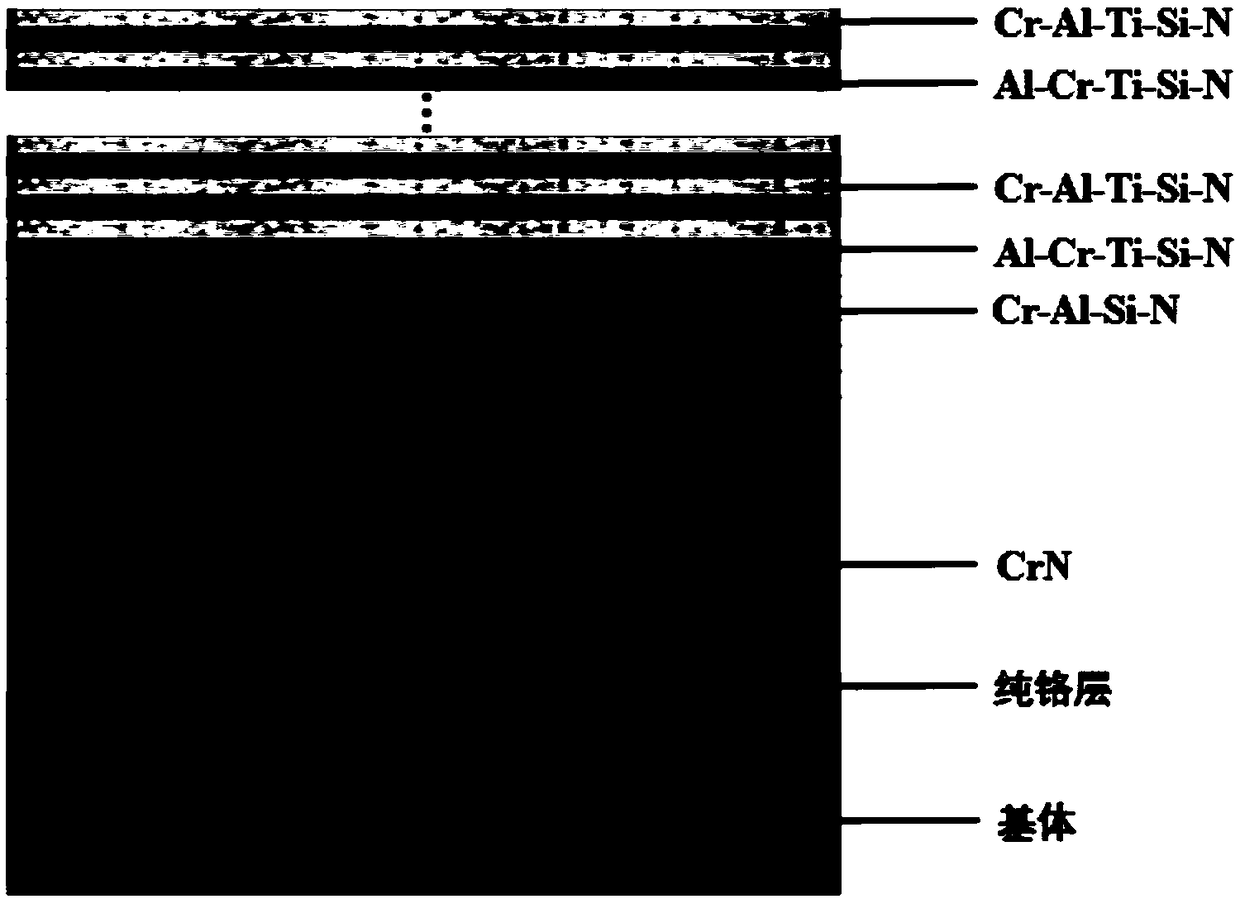

Cr/CrN/CrAlSiN/CrAlTiSiN nano-multilayer gradient film and preparation method thereof

ActiveCN109295425ASmall coefficient of thermal expansionReduce coefficient of frictionVacuum evaporation coatingSputtering coatingTotal thicknessAlloy steel

The invention discloses a Cr / CrN / CrAlSiN / CrAlTiSiN nano-multilayer gradient film and a preparation method thereof, and belongs to the technical field of nitriding films. The Cr / CrN / CrAlSiN / CrAlTiSiN nano-multilayer gradient film is composed of a Cr base layer, a CrN transition layer, a CrAlSiN transition layer and a CrAlTiSiN film layer which are sequentially deposited on a low-alloy steel or mould steel base body by adopting a multi-arc ion plating method; the total thickness of the nano-multilayer gradient film is 1.5 [mu]m-4.2[mu]m; total content ranges of Cr, Al, Ti and Si elements are correspondingly 30at%-34at%, 20at%-28at%, 10at%-14at% and 3at%-5at%; and film base adhesion force of the nano-multilayer gradient film is 35-45N, the friction coefficient is 0.01-0.02, and nano-hardnessis 35-40 Gpa. According to the preparation method, by changing the base body negative bias and deposition time of middle layers and converting targets, the nano-multilayer gradient film with high tenacity, low friction coefficient and good abrasion performance is obtained.

Owner:深圳市奥美特纳米科技有限公司 +1

Composite coating with anti-corrosion lubricating property of surface of magnesium alloy, preparation method thereof

ActiveCN102758201AImprove performanceSimple processSuperimposed coating processMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a composite coating with anti-corrosion lubricating property of the surface of magnesium alloy, which takes an MgO porous membrane as a transition layer, and the MgO porous membrane is positioned on the surface of a magnesium alloy substrate and is used for leading magnesium atoms of the surface layer of the magnesium alloy substrate to be formed in situ by adopting a micro-arc oxidation technology, and comprises (Si, N)-DLC or (Ti, N)-DLC multi-element nano-composite coating arranged on the surface of the transition layer. Compared with the prior art, the composite coating greatly improves the corrosion resistance and the wear resistance of the surface of the magnesium alloy substrate, has the nano-indentation hardness of 21-30GPa and the frictional factor with a steel ball of less than 0.15 or even less than 0.1, and is good in corrosion resistance, so that the composite coating with the anti-corrosion lubricating property has a good application prospect.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Long-term firm durable hydrophobic coating as well as preparation method and application thereof

ActiveCN108977782AEnhanced condensation heat transferIncrease ionization rateVacuum evaporation coatingSputtering coatingRare earthMechanical property

The invention relates to the technical field of hydrophobic coatings, in particular to a long-term firm durable hydrophobic coating as well as a preparation method and application thereof. The long-term firm durable hydrophobic coating comprises a rare earth metal transition layer and a rare earth oxide coating, wherein the rare earth metal transition layer is deposited between a base and the rareearth oxide coating, the material of the rare earth metal transition coating is a rare earth metal which is corresponding to the rare earth oxide coating, and the base is a metal base or a nonmetal base. The hydrophobic coating provided by the invention has a good mechanical property, a thermodynamic property, corrosion resistance and a long-term firm durable characteristic, and particularly canbe applied in a severe environment, so that the application of a hydrophobic rare earth oxide coating is greatly promoted in different fields.

Owner:HANGZHOU DIANZI UNIV

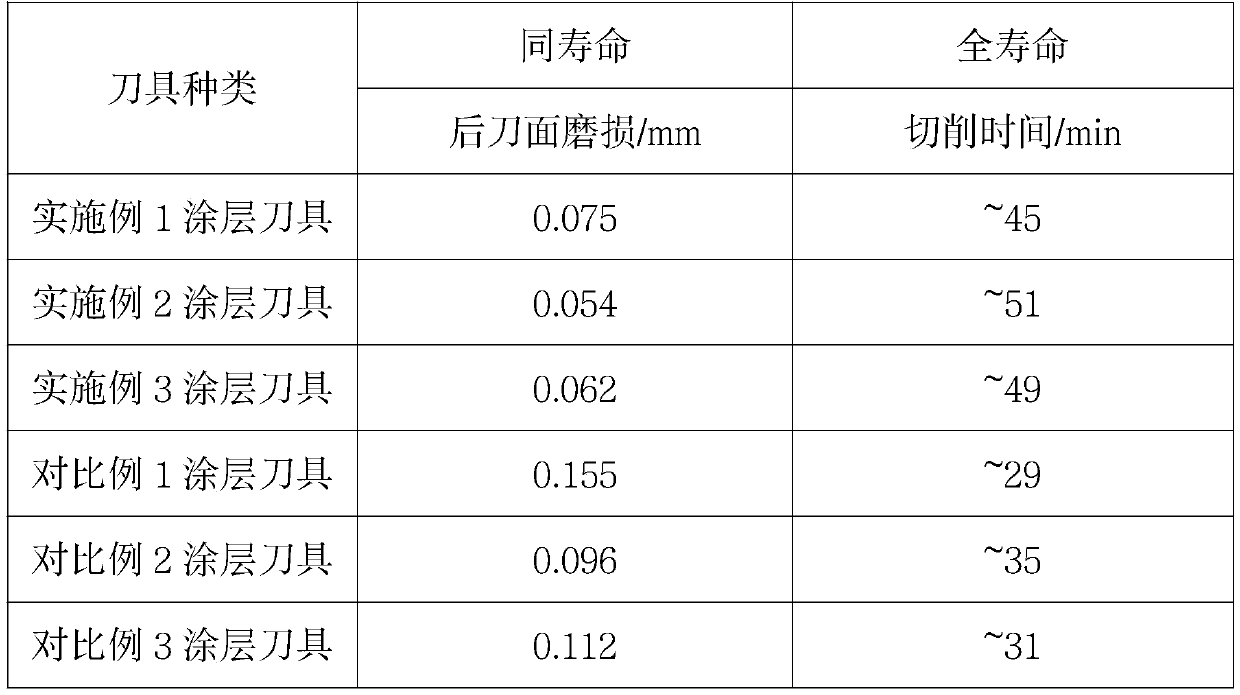

Preparation method for composite coating of cutter

ActiveCN106756841AReduce internal stressImprove compactnessVacuum evaporation coatingSputtering coatingHigh-power impulse magnetron sputteringHigher Power

The invention provides a preparation method for a composite coating of a cutter. The preparation method for the composite coating of the cutter specifically comprises the steps that (A) the cleaned cutter is clamped on a workpiece rack of a high-power pulsed magnetron sputtering instrument, after vacuumizing, an electric heater is started, and then the electric heater is adjusted; (B) inertia gas is fed into a cavity of the high-power pulsed magnetron sputtering instrument, a bias power supply is started, and then glow cleaning is conducted on the cutter; (C) after glow cleaning is ended, the vacuum degree of the cavity of the high-power pulsed magnetron sputtering instrument is adjusted, and a titanium target is started for depositing a Ti layer; and (D) after bombarding is completed, a nitrogen flowmeter valve is opened, a TiN layer and a TiSiN layer are deposited, and the coating of the cutter is obtained after cooling. According to the preparation method for the composite coating of the cutter, the TiSiN nanometer composite coating is prepared through a high-power pulsed magnetron sputtering technology, and the preparation technology of the TiSiN-based coating of the cutter is stable, reliable and high in repeatability and has important application value for high-speed machining of materials difficult to machine, the improvement of the performance of various mechanical part products and the development of the equipment manufacturing industry.

Owner:GUANGDONG UNIV OF TECH

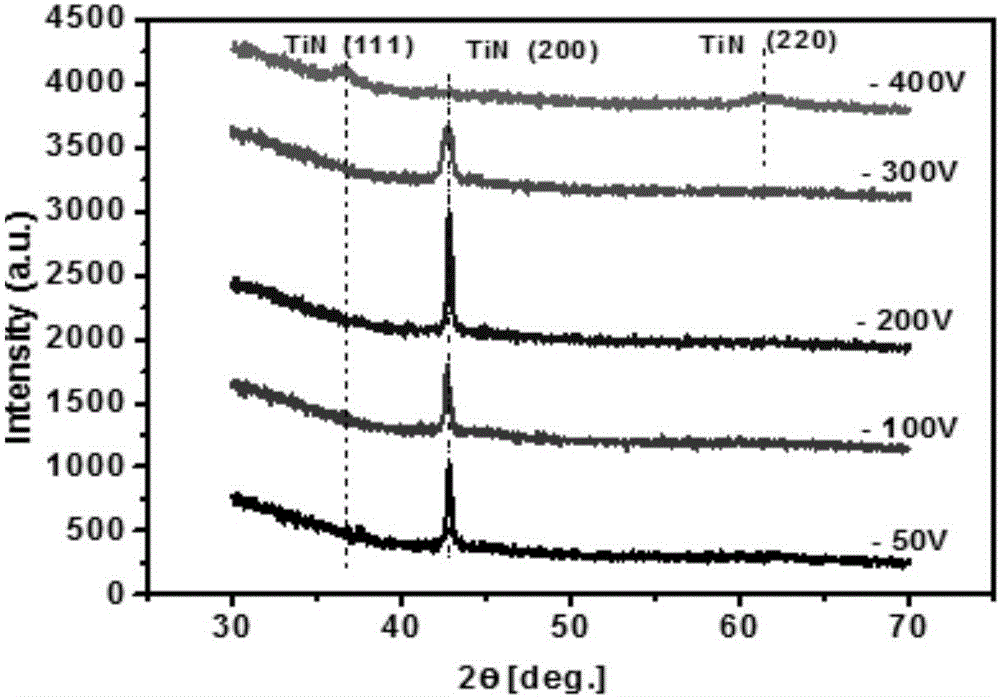

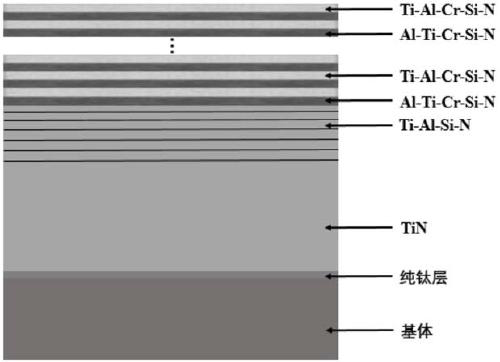

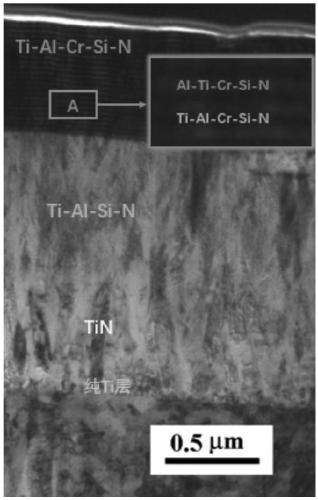

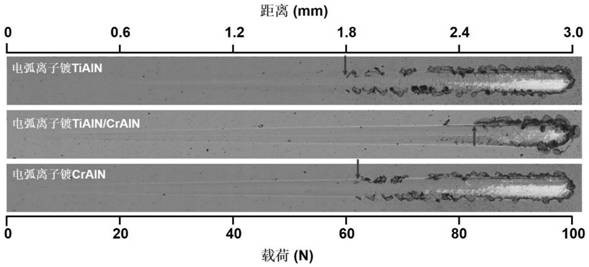

Ti/TiN/TiAlSiN/TiAlCrSiN nanometer multi-layer gradient film and preparation method thereof

ActiveCN109207938AImprove wear resistanceExtended service lifeVacuum evaporation coatingSputtering coatingMicrometerHardness

The invention provides a Ti / TiN / TiAlSiN / TiAlCrSiN nanometer multi-layer gradient film and a preparation method thereof, and belongs to the technical field of nitriding films. The nanometer multi-layergradient film is composed of a Ti priming coat, a TiN transition layer, a TiAlSiN transition layer and a TiAlCrSiN film layer which are sequentially deposited on a low-alloy steel or mold steel matrix through a multi-arc ion plating method. The total thickness of the nanometer multi-layer gradient film is 1.8-3.6 micrometers; the total content ranges of Ti, Al, Cr and Si elements are 30-34 at%, 20-24 at%, 5-10 at% and 3-5 at% separately; and the film-matrix combination force of the nanometer multi-layer gradient film is 36-48 N, the friction coefficient is 0.02-0.03, and the nanometer hardness is 32-36 Gpa. The method obtains the nanometer multi-layer gradient film which is high in toughness, low in friction coefficient and good in abrasion resistance by changing the negative bias voltageof the matrix, the depositing time of each middle layer and target switching.

Owner:TSINGHUA UNIV

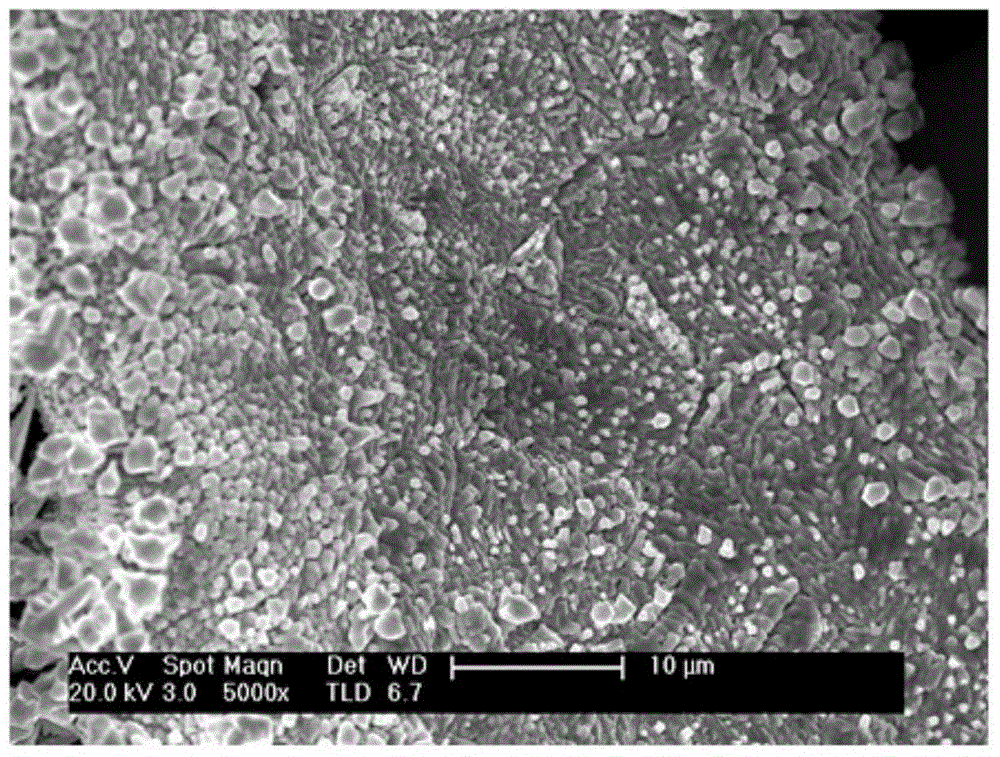

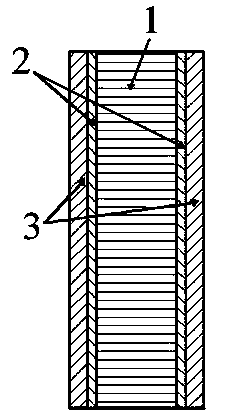

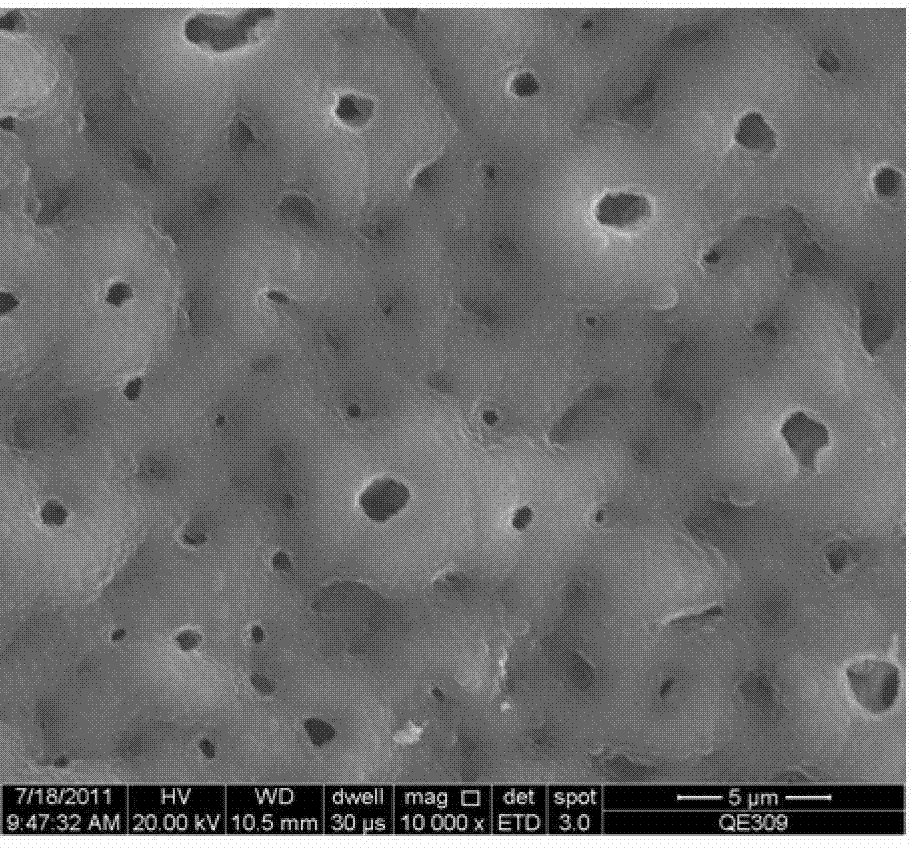

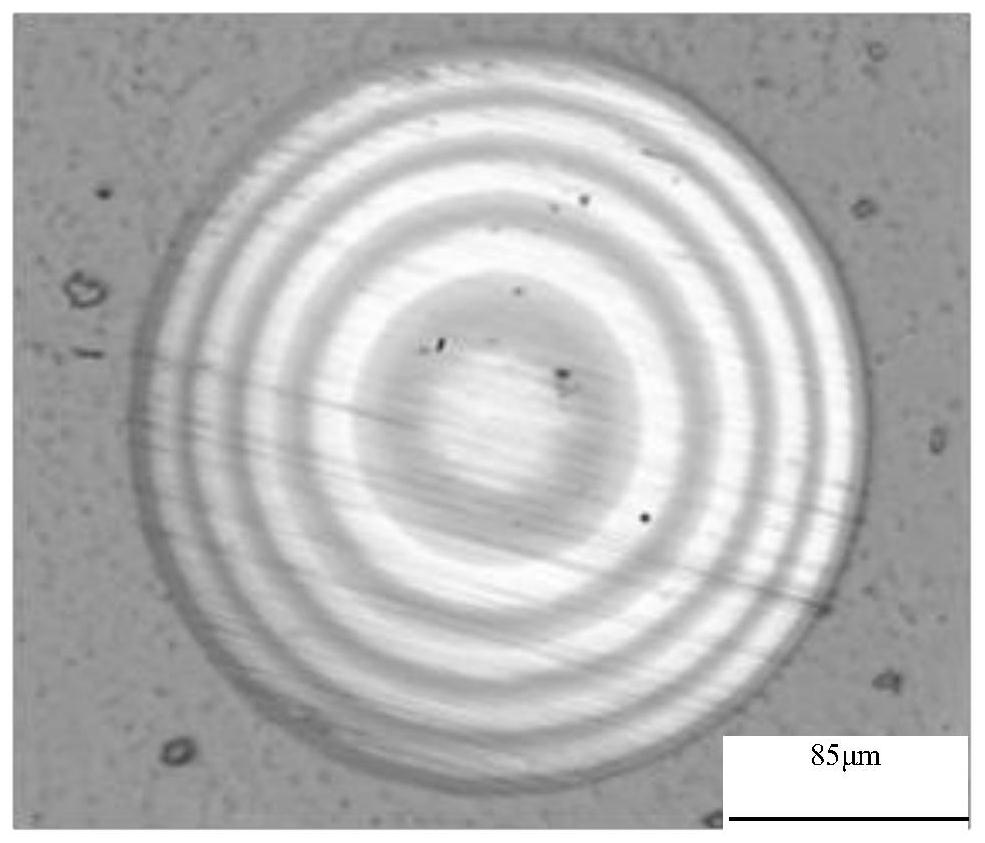

Preparation method of silicon carbide nano-fiber membrane

ActiveCN108176249AStrong membrane bindingHigh separation precisionPhysical/chemical process catalystsUltrafiltrationIonOxide

The invention relates to a high-performance silicon carbide nano-fiber membrane and a preparation method thereof. The preparation method comprises the following steps: adding a certain amount of silicon carbide nano-fibers into de-ionized water; stirring and carrying out ultrasonic mixing to prepare a uniform and stable membrane preparation solution; uniformly spraying the membrane preparation solution on a porous ceramic matrix by adopting a spray coating method; after drying at constant temperature, immersing the porous ceramic matrix into metal oxide sol; then carrying out negative-pressuresuction to enable a pore channel of the matrix to be fully filled with a sol solution; drying the porous ceramic matrix adsorbed with the sol again at constant temperature; finally, raising the temperature through a program and sintering to obtain the silicon carbide nano-fiber membrane. The silicon carbide nano-fiber membrane prepared by the preparation method can be effectively embedded into the surface-layer pore channel of the matrix; the binding force between the nano-fiber membrane and the porous ceramic matrix is strong. The separation membrane provided by the invention has the advantages of good thermal shock resistance, great gas flux and the like, can be used for purification treatment of industrial tail gas and has a wide application prospect in clean production of fields including cement, glass, metallurgy, energy sources and the like.

Owner:NANJING UNIV OF TECH +1

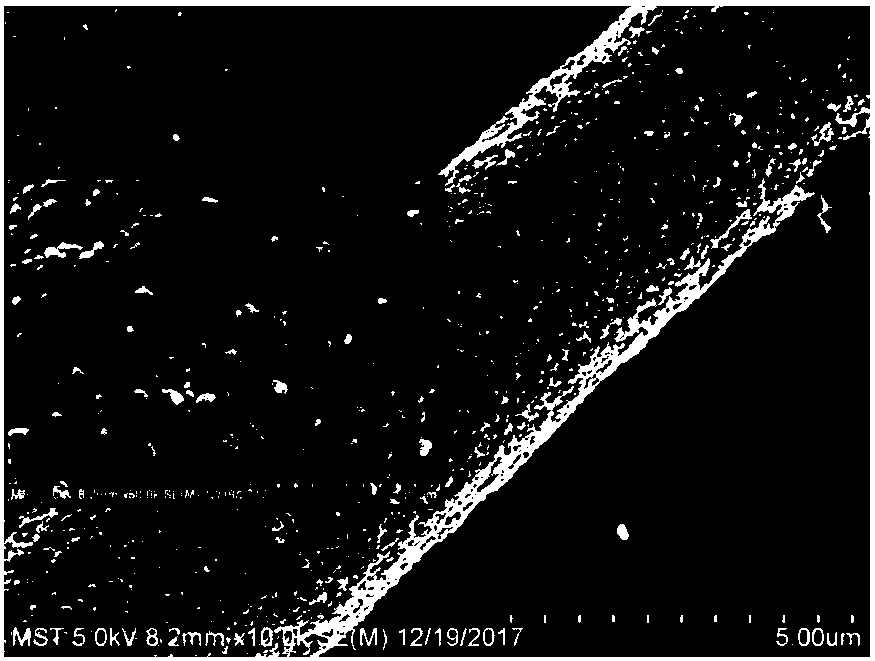

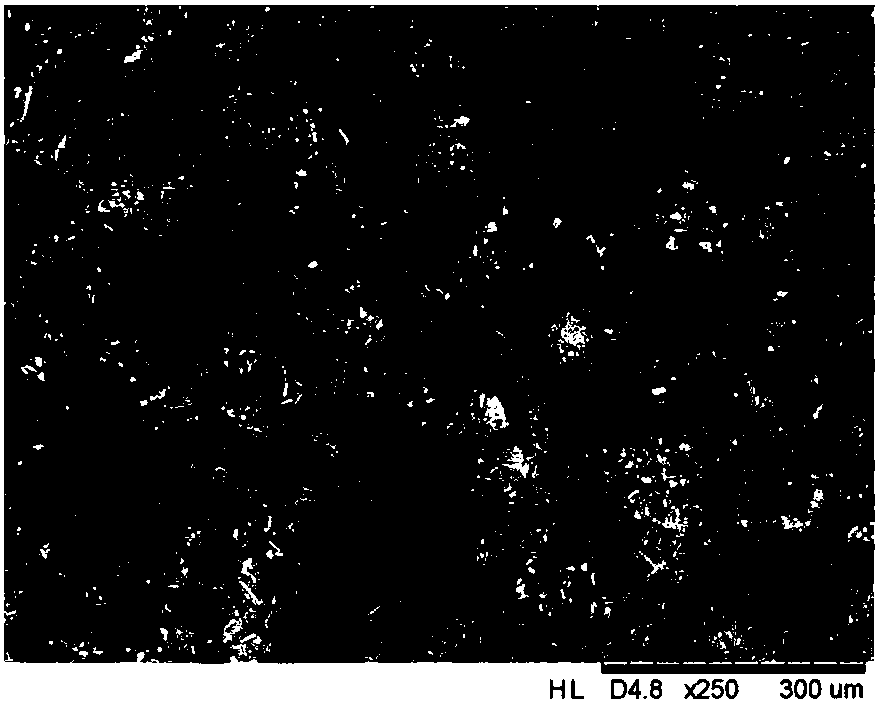

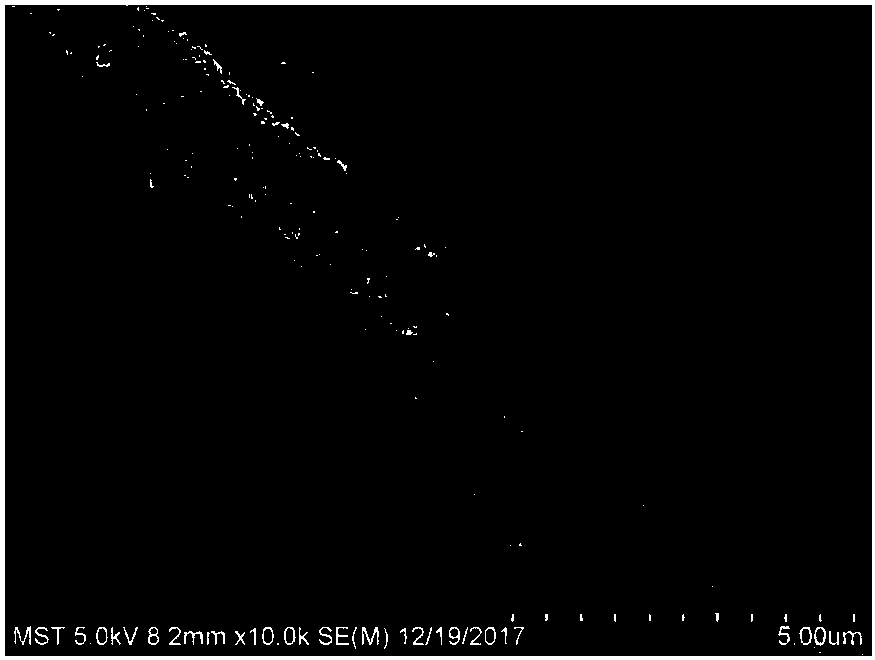

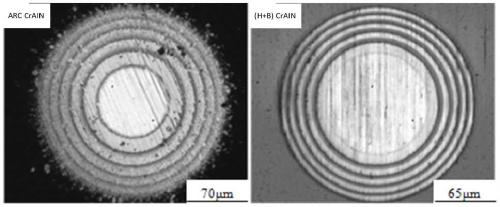

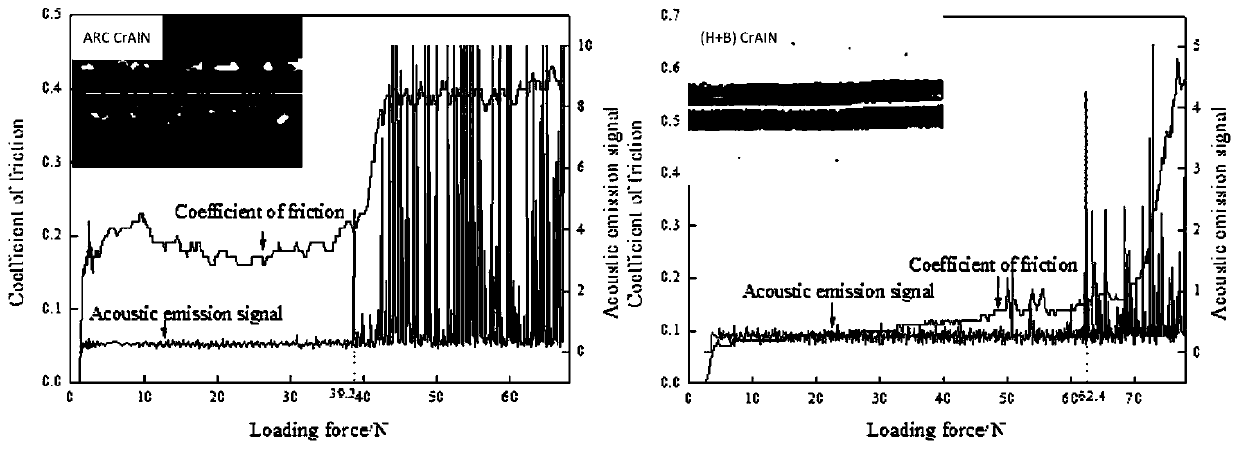

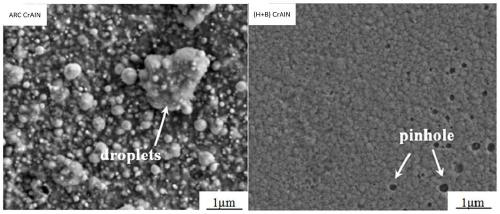

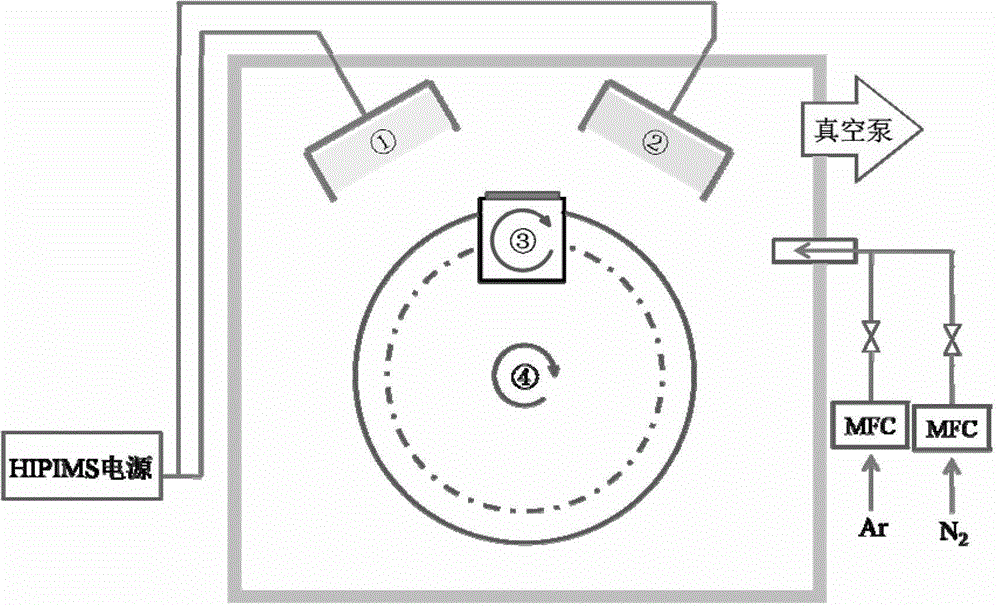

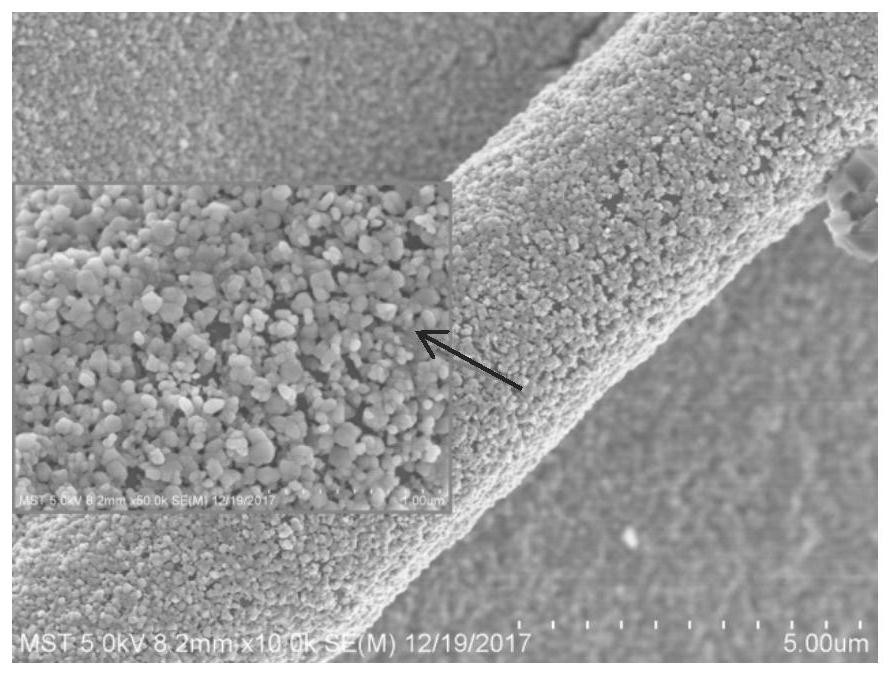

Preparation method of CrAlN coating based on HIPIMS technology

InactiveCN110241387AGood high temperature oxidation resistanceHigh critical loadVacuum evaporation coatingSputtering coatingCritical loadX-ray

The invention discloses a preparation method of a CrAlN coating based on a HIPIMS technology. The high-power pulse magnetron sputtering technology (High Power Impulse Magnetron Sputtering, HIPIMS) is adopted, a method for co-sputtering by using a high-power pulse target (High pulse power cathode) and a bipolar pulse target (Bipolar pulsed sputtering cathodes) is used, and a (H+B) CrAlN coating is deposited; and meanwhile, an ARC CrAlN coating is deposited by adopting a fourth-generation arc ion plating technology (ARC evaporators). The performance of all aspects of the coating is analyzed through a scratch test, an X-ray diffraction, a microscopic morphology observation, an electrochemical corrosion test and the like, and the binding force of a (H+B) CrAlN coating film is stronger, and the maximum critical load can reach 62.4N; the surface crystal grains are smaller, the defects are few, and the section tissues are compact; meanwhile the high-temperature oxidation resistance of the CrAlN coating prepared by the (H+B) method is optimal; and the coating prepared by co-sputtering in the aspect of coating corrosion resistance is more corrosion-resistant than the coating prepared by electric arc ion plating.

Owner:HENAN UNIV OF SCI & TECH

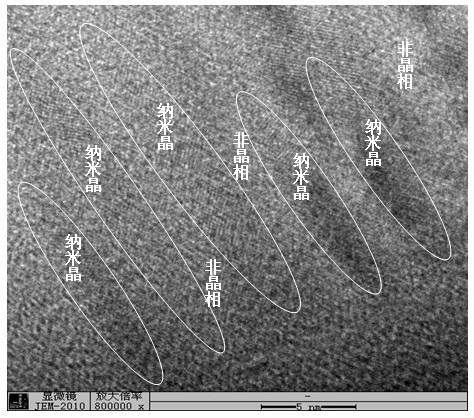

A kind of preparation method of nanocomposite superhard film

InactiveCN102277556AFlexible Density ControlFlexible regulation of energyVacuum evaporation coatingSputtering coatingCombined useIon beam

The invention belongs to the field of film material preparation, and in particular relates to a method for preparing a nanocomposite superhard film. The method first deposits MeN on a substrate by means of magnetic filter arc ion plating to form a 50-nanometer-thick MeN film as a transition layer, and then continues MeN is deposited by magnetic filtered arc ion plating, and Si3N4 is co-deposited on the substrate by ion beam sputtering. During the co-deposition process, a negative DC bias of -100V is applied to the substrate to obtain nanocrystalline MeN / amorphous Si3N4 Nanocomposite superhard film. The invention combines magnetic filter arc ion plating with ion beam sputtering, utilizes the characteristics of similar working pressures of the two to make up for each other's deficiencies, and obtains nanocrystalline MeN / amorphous Si3N4 nanocomposite superhard films with good film base binding force.

Owner:HENAN UNIVERSITY

Transition metal nitride coating with nano multilayer structure as well as preparation method and application thereof

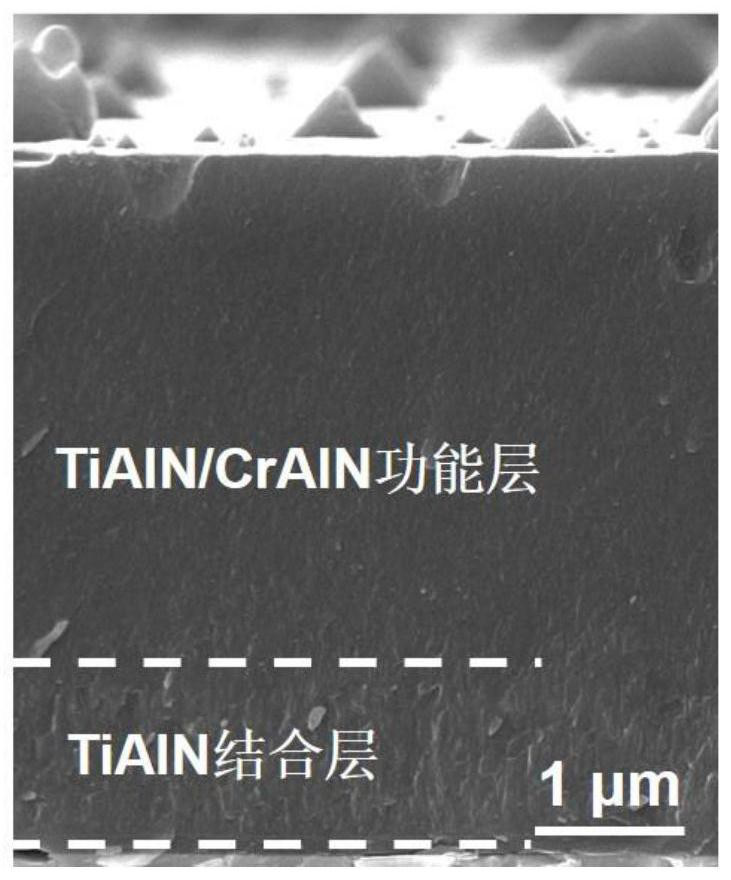

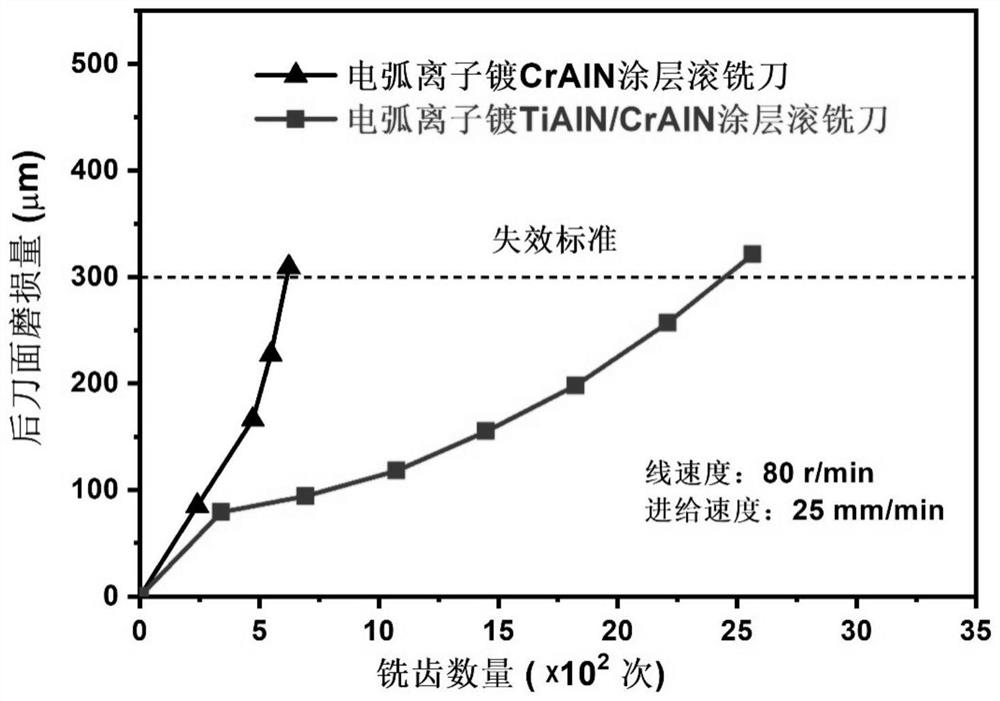

PendingCN113416926AStrong membrane bindingWear-resistant and anti-friction milling gear processing lifeMilling cuttersVacuum evaporation coatingMicrostructureMilling cutter

The invention relates to a transition metal nitride coating with a nano multilayer structure as well as a preparation method and application thereof. The transition metal nitride coating with the nano multilayer structure comprises a nitride bonding layer deposited on the surface of a hobbing cutter base body, wherein a nano multilayer nitride functional layer is deposited on the surface of the nitride bonding layer; the nano multilayer nitride functional layer comprises a TiAlN modulation layer and a Cr (Al) N modulation layer, and is prepared by alternately stacking and depositing the TiAlN modulation layer and the Cr (Al) N modulation layer. Through the microstructure design of a coating material, different modulation layers of the transition metal nitride coating with the nano multilayer structure form a coherent or semi-coherent interface, the hardness, toughness, film-substrate binding force, wear resistance, friction reduction and high-temperature performance of the coating are all improved, and the coating is mainly used for the field of gear milling machining of bimetal band saw blades.

Owner:BICHAMP CUTTING TECH (HUNAN) CO LTD

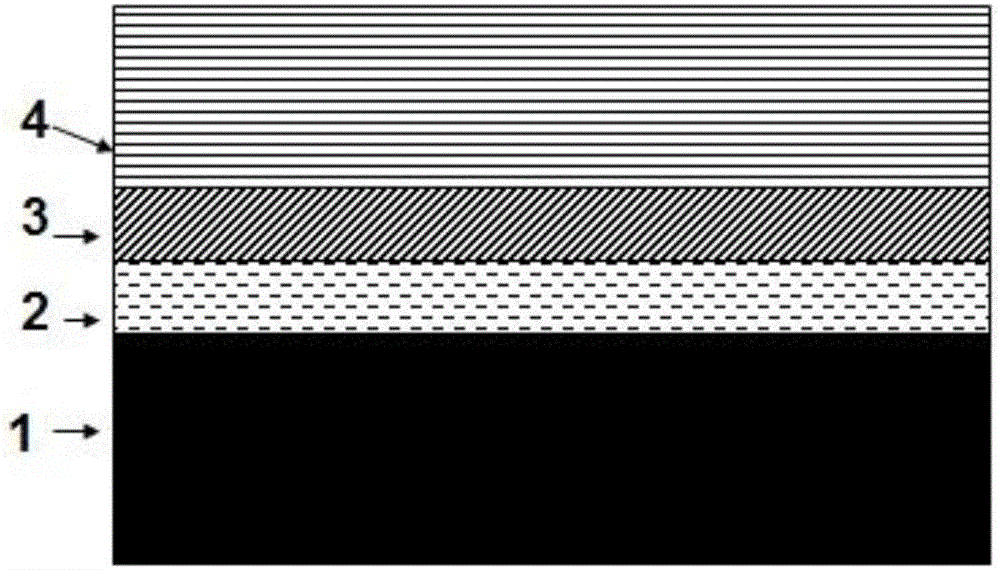

Micro-drill for copper alloy processing and preparation method thereof

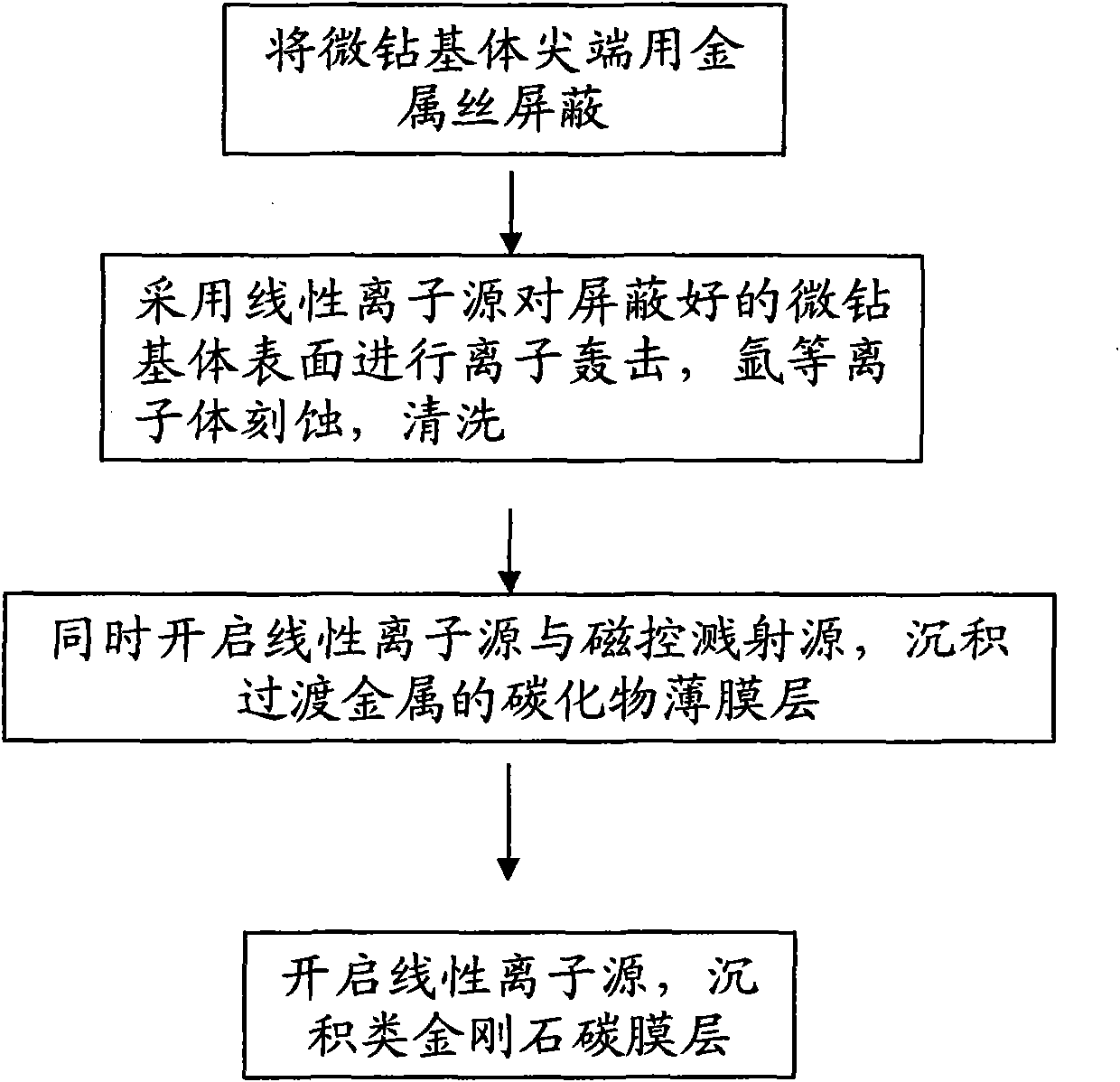

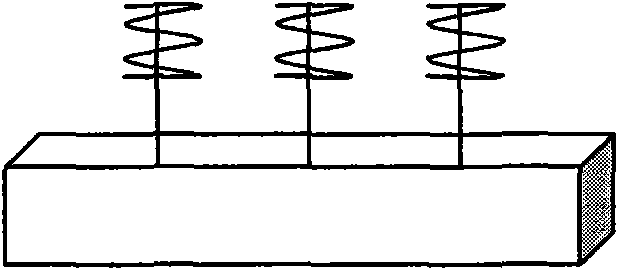

ActiveCN101775587AImprove protectionExtended service lifeLayered productsVacuum evaporation coatingCarbon filmDiamond-like carbon

The invention discloses a micro-drill for copper alloy processing and a preparation method thereof. The micro-drill comprises a micro-drill base body and a thin film deposited on the surface of the micro-drill base body; and the thin layer consists of three film layers; a transitional metal element film layer, a transitional metal carbide film layer and a diamond-like carbon film layer are arranged on the surface of the micro-drill base body in sequence from inside to outside. The preparation method comprises the step that: after the tip of the micro-drill base body is shielded by metal wires, the deposition of three film layers is carried out on the micro-drill base body by a linear ion source or / and a magnetic control sputtering source. The invention takes the shielding measures with metal wires on the tip of the high-speed steel micro-drill, and then carries out deposition of a plurality of layers of films, thus greatly improving the wear resistance and anti-adhesion performance, service life and processing quality of the micro-drill for copper alloy processing.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Component structure double-gradient functional coating for cutting tool and preparation method of component structure double-gradient functional coating

ActiveCN111270202AImprove performanceObvious performance advantageVacuum evaporation coatingSputtering coatingComposite effectHeat stability

The invention provides a component structure double-gradient functional coating for a cutting tool and a preparation method of the component structure double-gradient functional coating. The coating is formed by alternately depositing two performance variation layers, namely a Ti<1-x-y>Al<x>Me'<y>N layer and a Ti <1-x-y>Al<x>Me"<y>N layer, on the surface of a tool base body in thickness progressive decreasing and processing increasing trends. The preparation method comprises the following steps that the tool base body is prepared; the tool base body is pretreated; and the Ti<1-x-y>Al<x>Me'<y>Nlayer and the Ti <1-x-y>Al<x>Me"<y>N layer are alternatively deposited on the tool base body in the different progressively decreasing and progressively increasing trends by adopting a cathodic arc ion plating technology to obtain the component structure double-gradient functional coating for cutting. Compared with a common-structure multi-element coating, the component structure double-gradientfunctional coating for the cutting tool has the advantages that the multi-element composite effect is maximized, the gradient structure design is optimized, the stress of the coating is reduced, the good film-base and film-film binding force is guaranteed, meanwhile, the wear resistance, the impact resistance and the thermal stability of the coating are further improved, the machining life of a correspondingly coated tool is also greatly prolonged, and the service reliability of the corresponding coated tool is also greatly improved.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

Preparation method of multilayer nano-composite-class diamond films on surface of camshaft

InactiveCN103160780AReduce coefficient of frictionReduce wear rateVacuum evaporation coatingSputtering coatingComposite filmMicrometer

The invention discloses a preparation method of multilayer nano-composite-class diamond films on the surface of a camshaft. Due to the adoption of a high-frequency and high-power impulse magnetron sputtering technology, the multilayer nano-composite-class diamond films are deposited on the surface of the camshaft. The thicknesses of the composite films are 0.2-0.5 micrometer, the thickness of a bearing layer of the composite films is 1-3 micrometers, and the surface thickness of the composite films is 1-3 micrometers. The surface binding force of the composite film camshaft is up to 60N.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

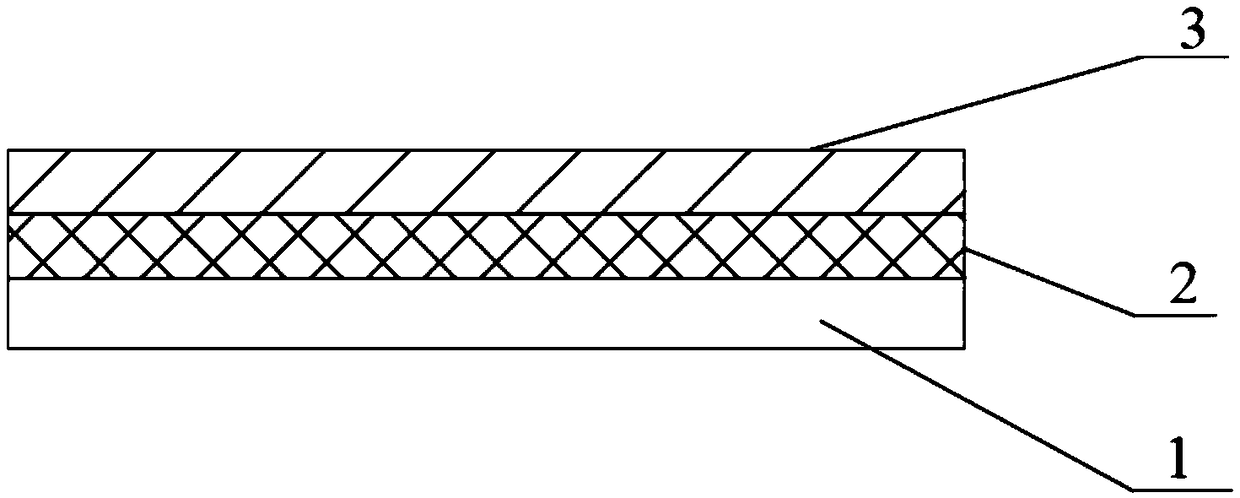

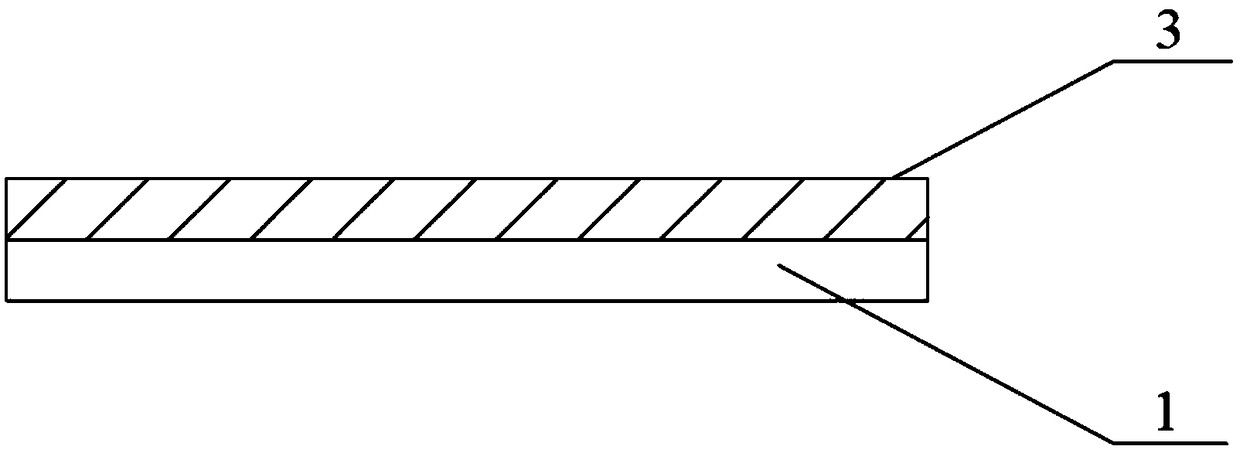

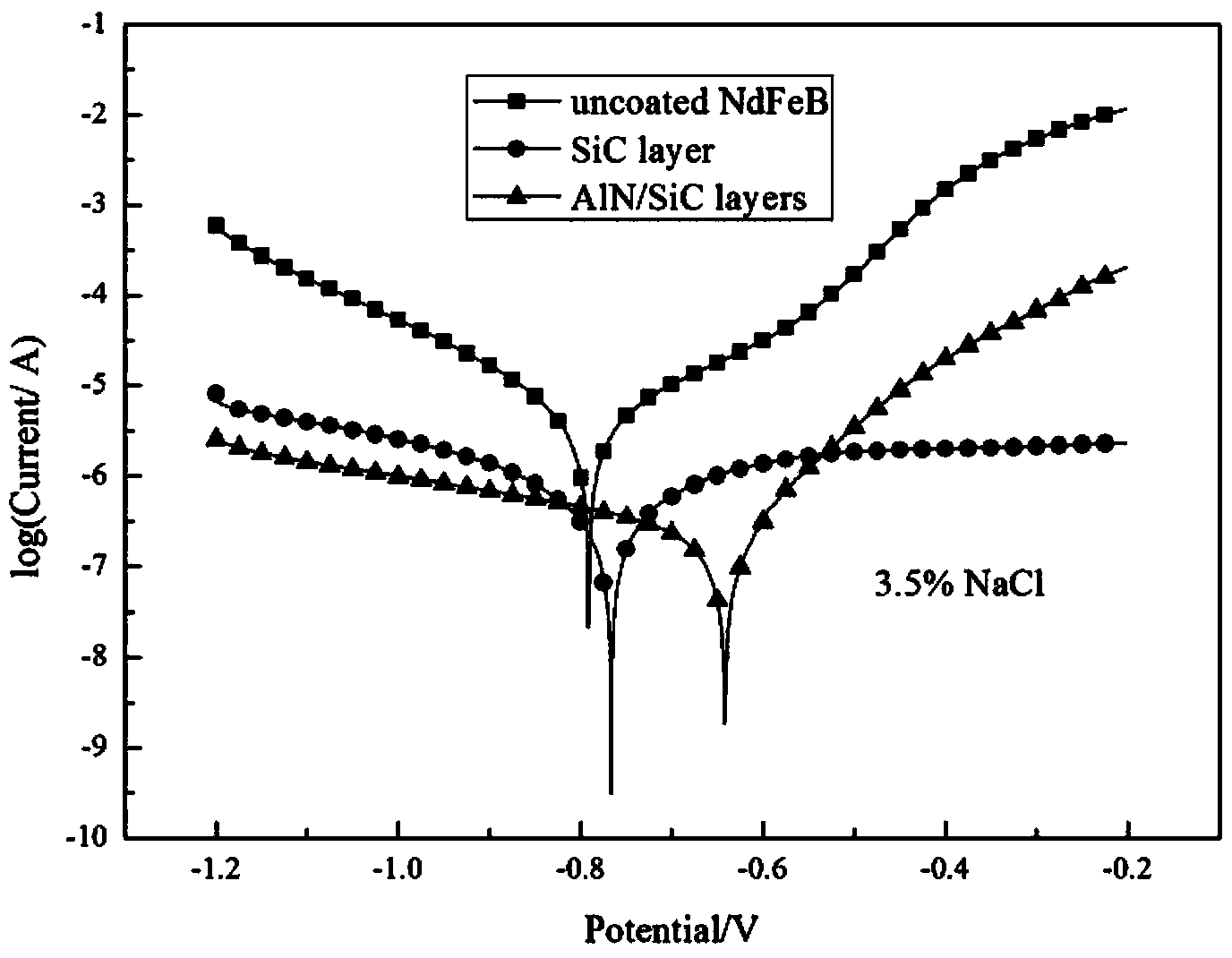

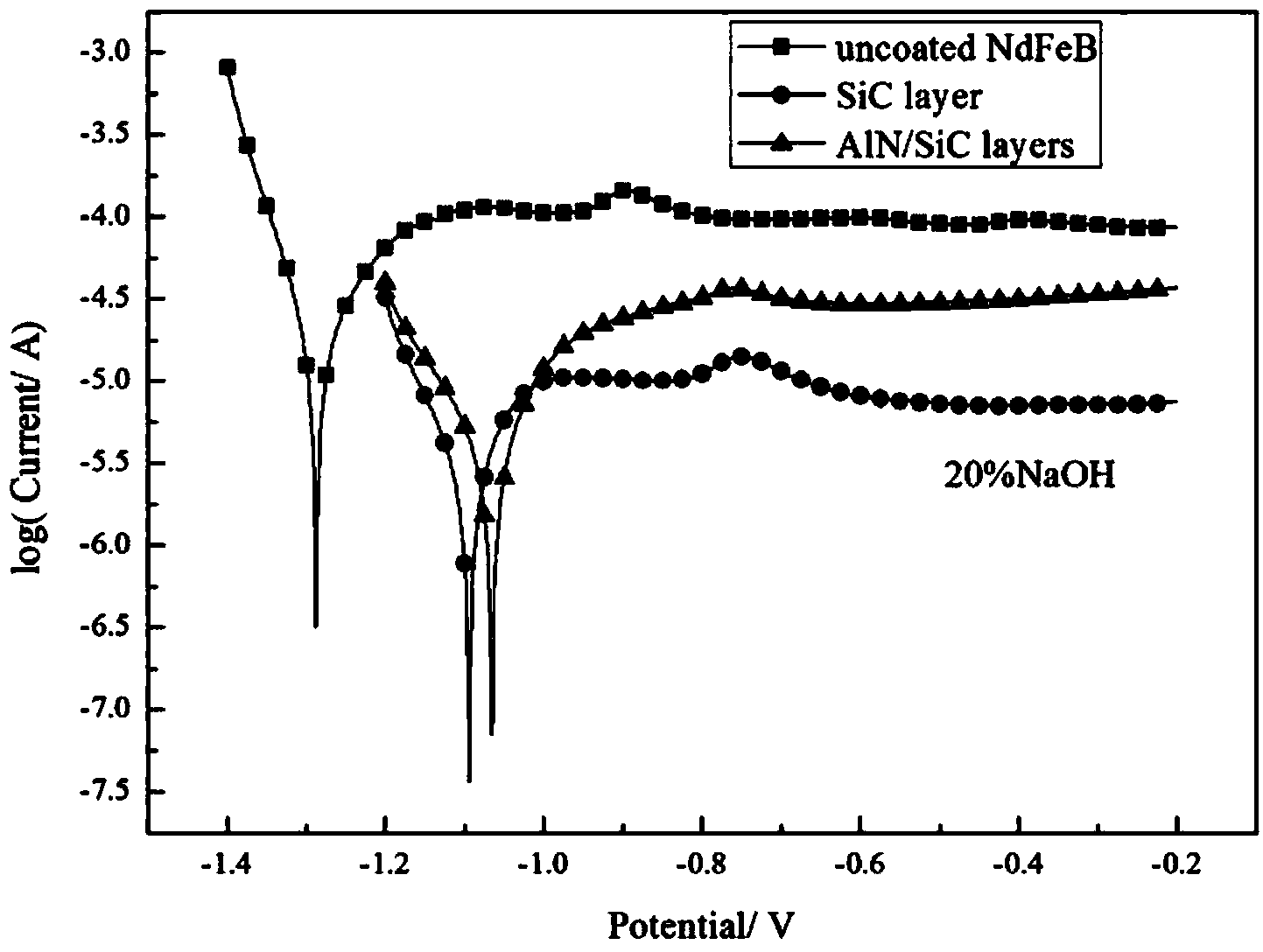

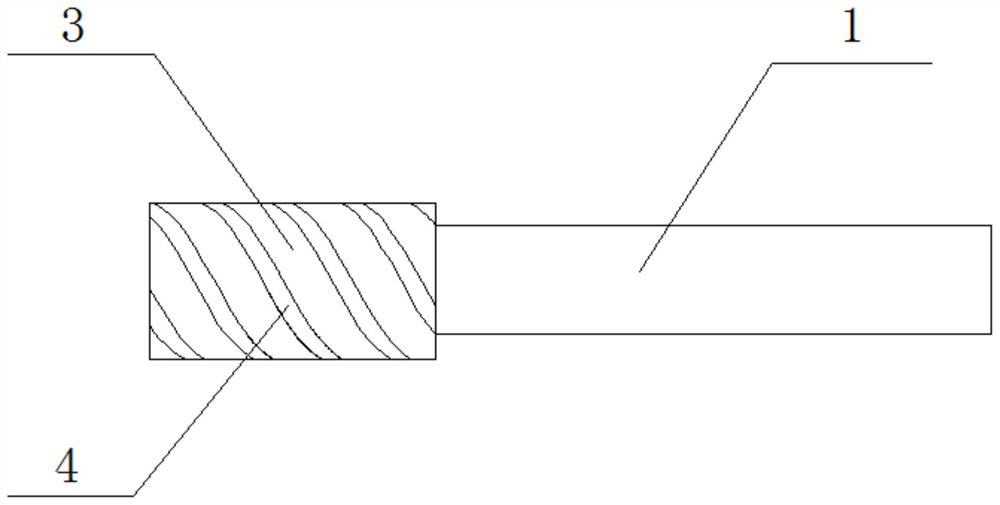

Neodymium iron boron magnetic material with composite coating layer and preparation method for neodymium iron boron magnetic material

ActiveCN104015425AReduce internal stressStrong membrane bindingVacuum evaporation coatingSputtering coatingCorrosionInternal stress

The invention discloses a neodymium iron boron magnetic material with a composite coating layer. A vacuum aluminum nitride plated thin film and a vacuum silicon carbide plated thin film are attached to the surface of the neodymium iron boron magnetic material in sequence from inside to outside; the vacuum aluminum nitride plated thin film is 100-500nm thick, and the vacuum silicon carbide plated thin film is 200-500nm thick. The surface of the neodymium iron boron magnetic material is provided with aluminum nitride and silicon carbide in vacuum plating manner; after the aluminum nitride is arranged in the vacuum plating manner, the roughness of the plated layer is changed, and the internal stress of the plated film layer is reduced; then the silicon carbide is arranged in the vacuum plating manner, so that a film base is high in bonding force. The corrosion resistance and the acid-alkali resistance of the neodymium iron boron magnetic material are obviously improved; the service life is prolonged, and the conventional market requirement is met.

Owner:黄山旺荣汽车电子有限公司

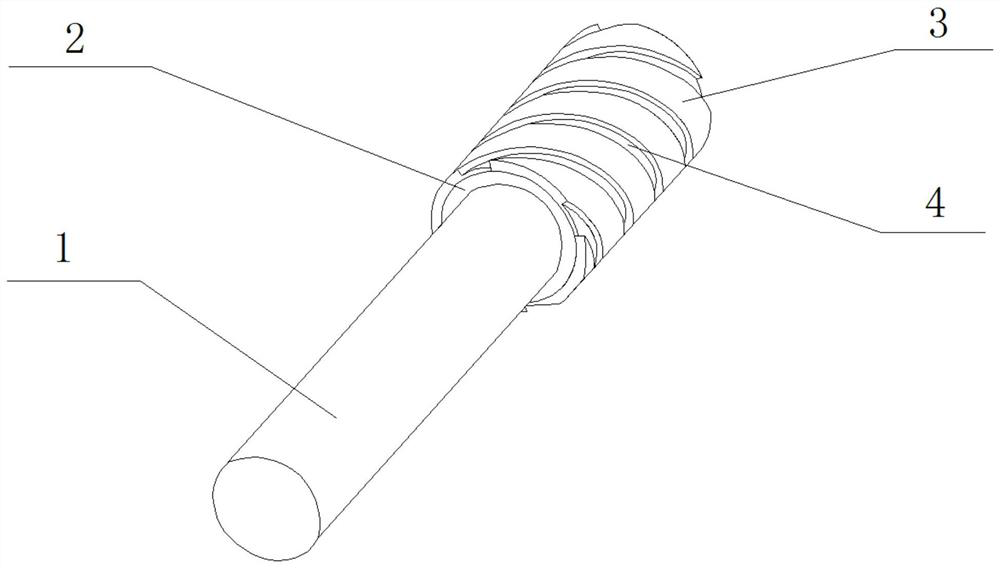

Small deep hole inner wall ultrasonic vibration machining cutter and a preparation method thereof

ActiveCN113732366AHigh strengthStable structureNuclear energy generationTransportation and packagingCooling effectEngineering

The invention discloses a small deep hole inner wall ultrasonic vibration machining cutter and a preparation method thereof, and belongs to the technical field of small deep hole inner wall machining. The tool and the method solve the technical problem that in the small deep hole inner wall high-frequency ultrasonic vibration machining process, a cutter is prone to abrasion due to the fact that heat is generated by friction and the cooling effect is poor. A cutter handle and a cutter base are integrated cylindrical connectors with different diameters, the cutter base is coated with a CVD diamond coating, a spiral groove is formed in the CVD diamond coating, and the cutter handle and the cutter base are both made of SiC. The CVD diamond coating on the surface of the cutter has higher abrasive particle density and does not contain any binding agent, so that the cutter has higher hardness and better wear resistance; and the spiral groove increases a chip containing space and can effectively improve the grinding performance and the chip removal and heat removal capacity, the machining stability of the cutter is improved, the service life of the cutter is prolonged, and high-efficiency, high-precision and high-quality ultrasonic vibration machining of the inner wall of a micro hole is achieved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

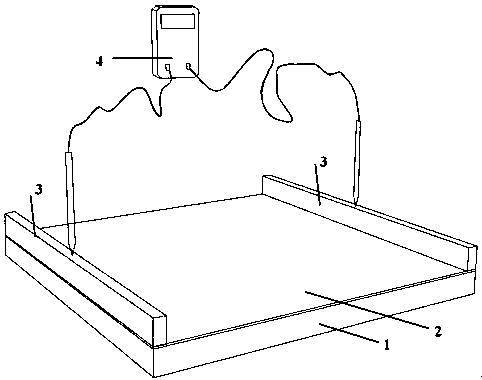

A kind of preparation method of resistive diamond-like carbon base film material

ActiveCN108707863BImprove thickness uniformityStrong membrane bindingVacuum evaporation coatingSputtering coatingDiamond-like carbonFilm base

The invention discloses a preparation method of a resistive diamond-like carbon-based thin-film material. The method is suitable for preparing the diamond-like carbon-based thin-film material sequentially through high energy plasma bombardment, etching and sputtering of a high-purity graphite target on the surface of a micro-structure gas detector electrode substrate by means of a non-equilibriumdirect-current magneto-sputtering deposition technology. By means of the method, the diamond-like carbon-based thin-film material which is good in thickness uniformity and high in film base binding force can be prepared, and meanwhile the surface resistivity of a diamond-like carbon-based thin film can be regulated and controlled. The resistive diamond-like carbon-based thin-film material preparedthrough the method is suitably used for manufacturing a resistive electrode of a micro-structure gas detector and is excellent in application prospect and value.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

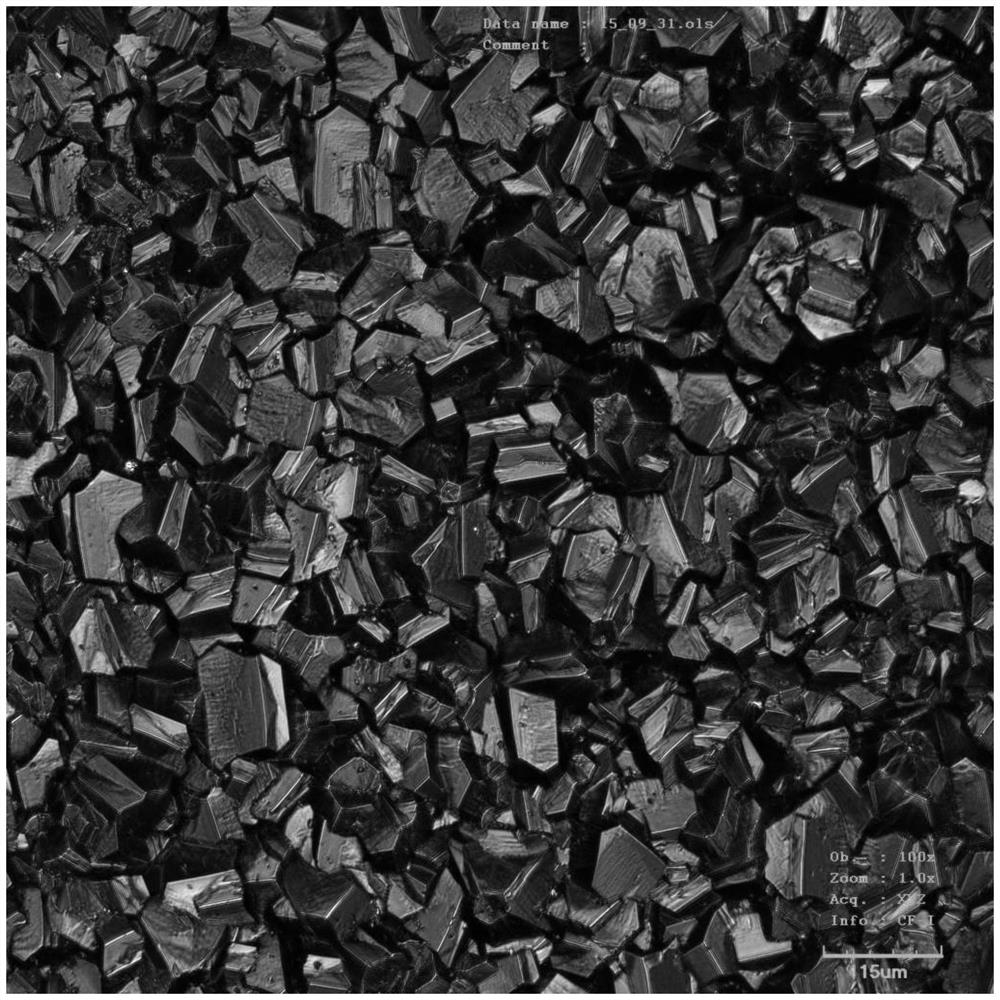

Method for preparing CrN coating on surface of intaglio printing plate based on GIS and HIPIMS technologies

PendingCN112779493AIncrease brightnessImprove compactnessVacuum evaporation coatingSputtering coatingCoated membraneScratch test

The invention discloses a method for preparing a CrN coating on the surface of an intaglio printing plate based on GIS and HIPIMS technologies. According to the method, a high-quality Cr+CrN coating is plated on the surface of the intaglio printing plate by adopting a Gas Ion Source Etching (GISETCH) technology and a High Power Impulse Magnetron Sputtering (HIPIMS) technology, and an original water electroplating technology is replaced; after the performance of the coating in all aspects is analyzed through a ball pit test, a roughness test, a scratch test, a hardness test, surface topography observation and the like, it is found that the Cr+CrN coating prepared through the GISETCH technology and the HIPIMS technology is higher in film-substrate binding force, smaller in surface crystal grain, few in defect and compact in section structure; and through an actual printing test, the printing resistance rate exceeds the water electroplating level.

Owner:北京丹普表面技术有限公司

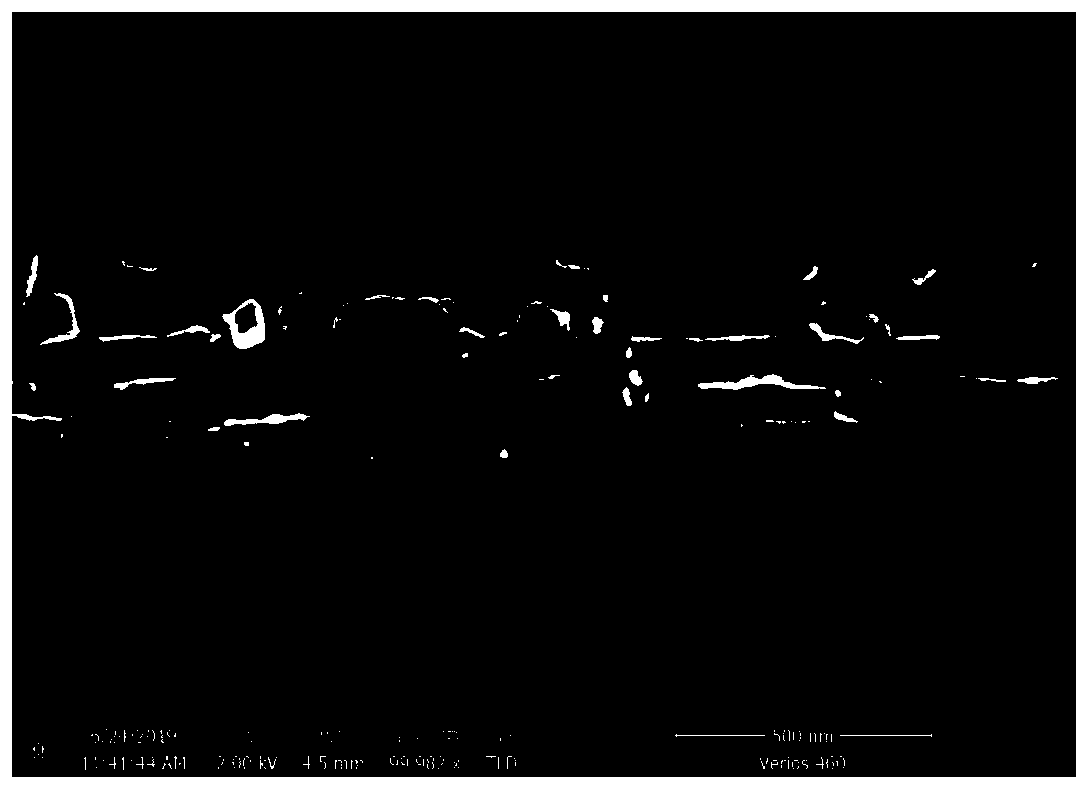

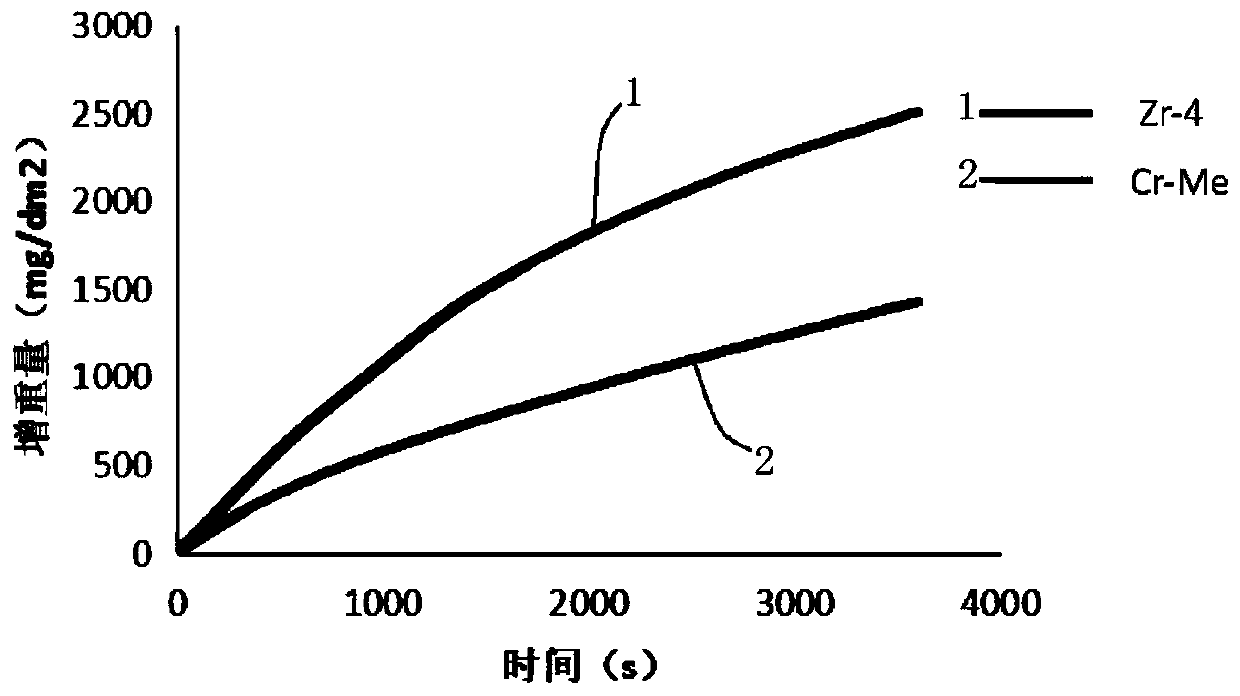

Cr-Me multilayer film based on Zr as substrate and preparation method thereof

PendingCN110499495AImprove efficiencyImprove securityOptical rangefindersNuclear energy generationGas phaseWater vapor

The invention discloses a Cr-Me multilayer film based on Zr as a substrate and a preparation method thereof and belongs to the field of plating of physical vapor deposition. By taking a Zr-4 alloy (prepared from 1.20-1.70% of Sn, 0.18-0.24% of Fe, 0.07-0.13% of Cr and 0.03-0.08% of Ni) as the substrate, the Cr-Me multilayer film is coated to the surface of Zr by means of a magnetron sputtering method. The modulation ratio of the Cr-Me multilayer film (Zr, Al, Mg and Nb) is 1: (0.1-10). The total number of layers of the Cr-Me multilayer film based on Zr as the substrate is 2-100 and the thickness is 0.5-50 [mu]m. The plated Cr-Me multilayer film can improve high-temperature water vapor corrosion resistance and oxidizing performance of a zirconium alloy tubular product, so that the service life of a zirconium alloy pressure pipe is prolonged, the nuclear leakage accident is reduced, and the economical benefit and the safety guarantee of nuclear industry are further improved.

Owner:XI AN JIAOTONG UNIV

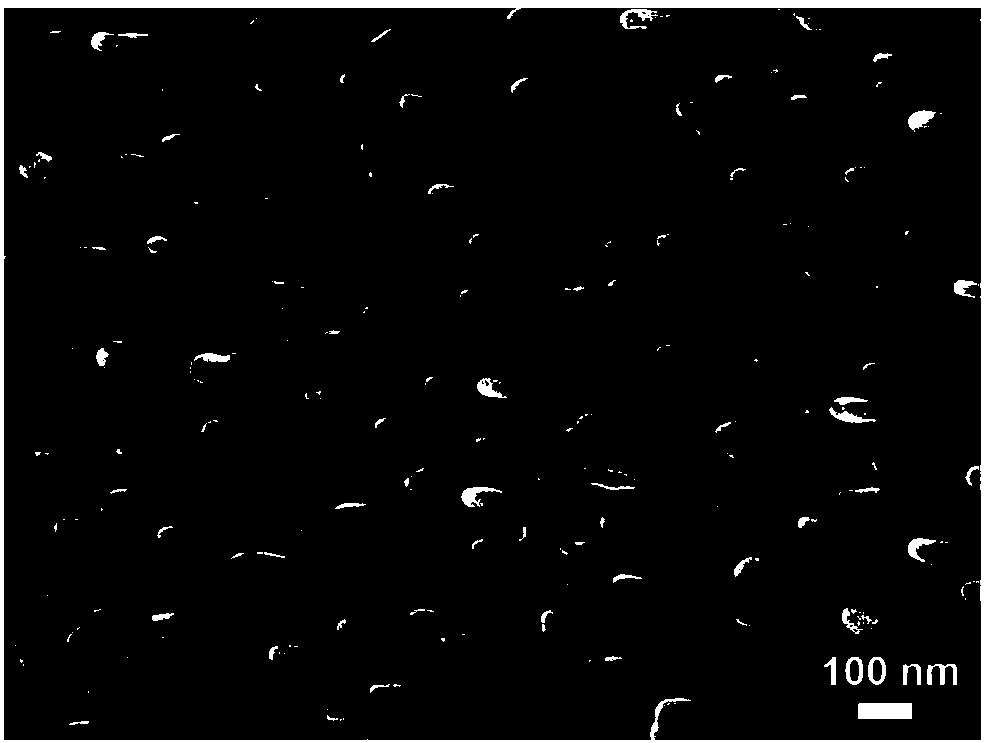

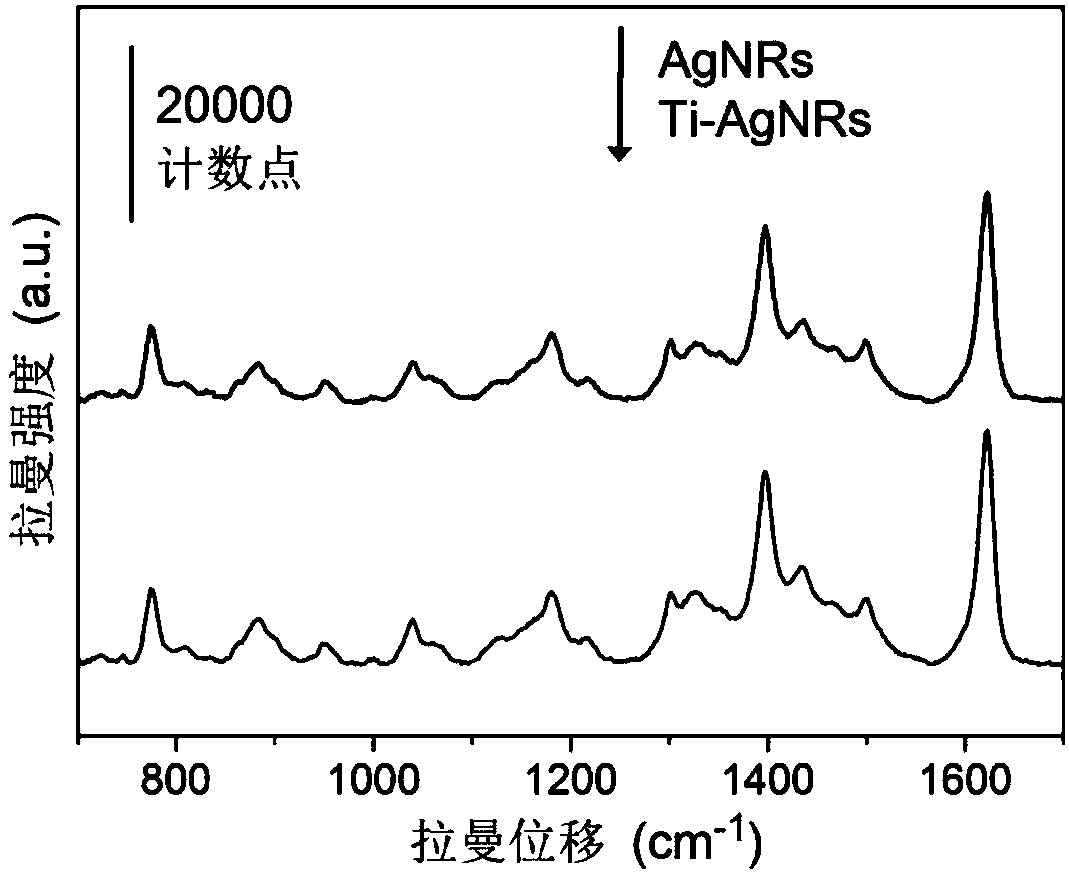

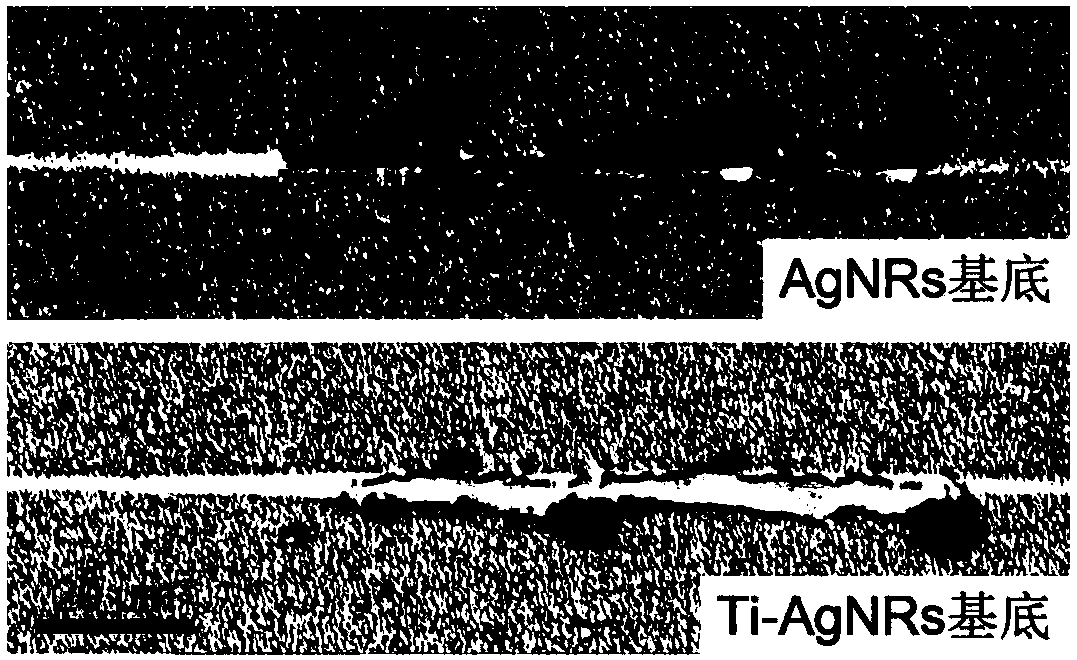

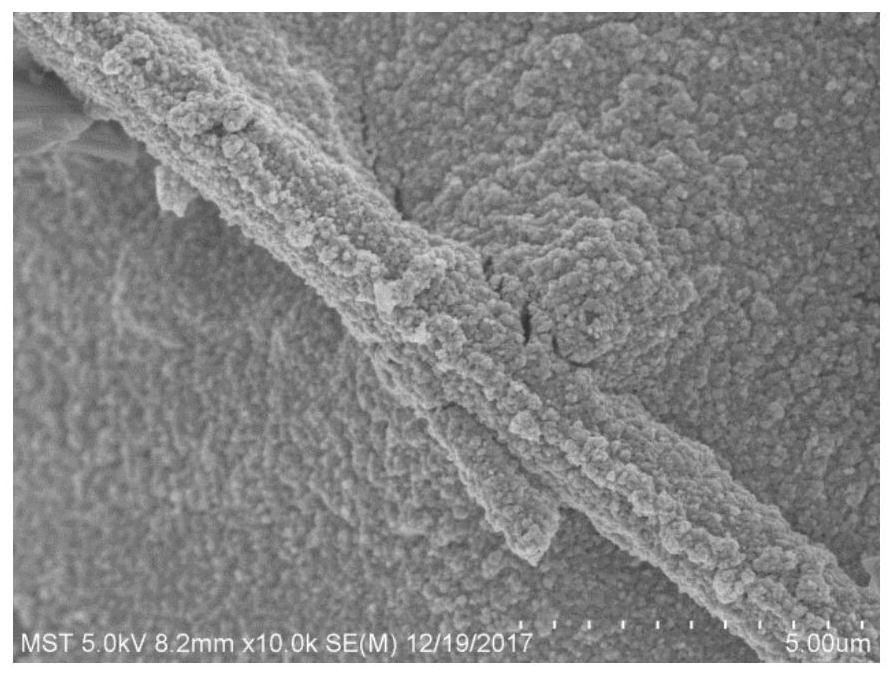

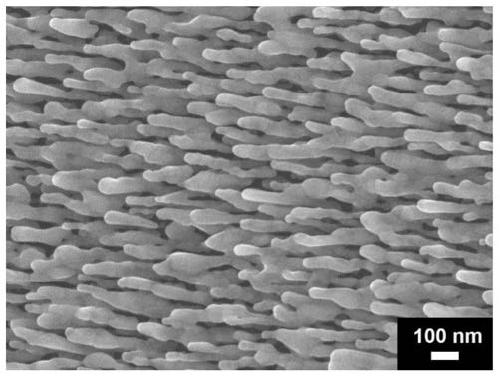

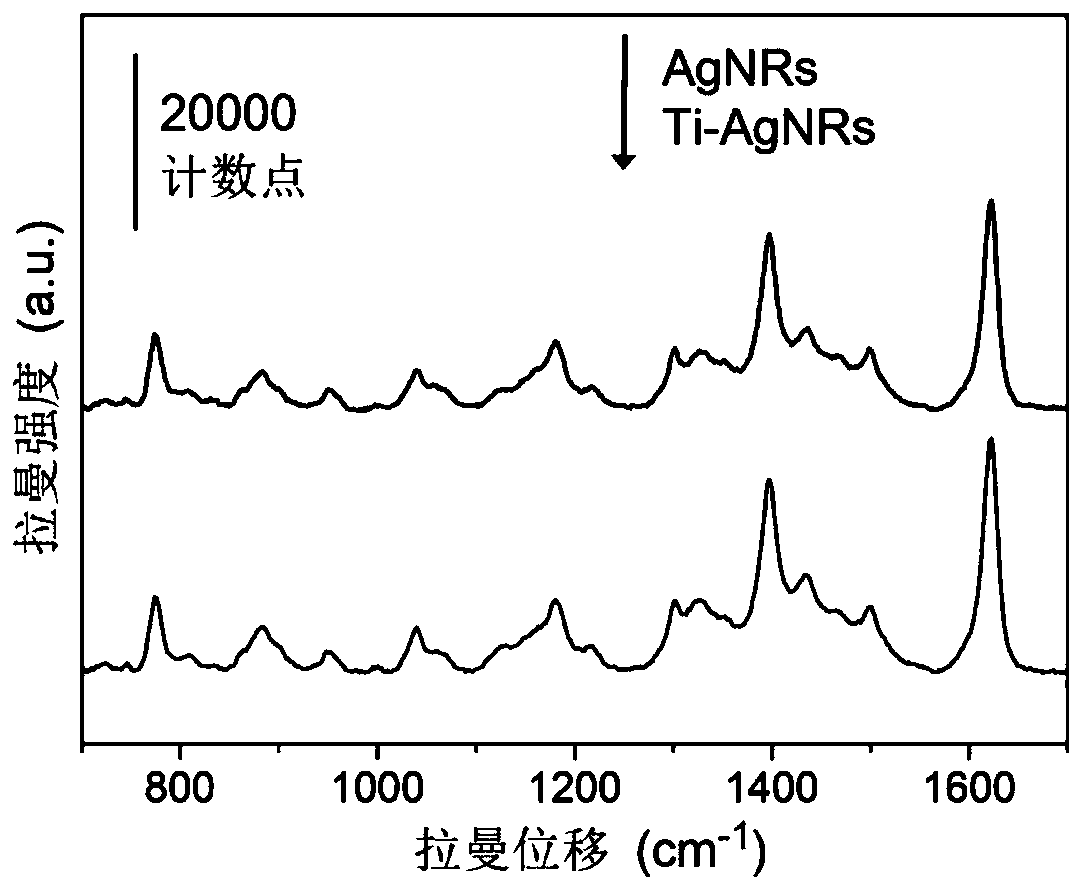

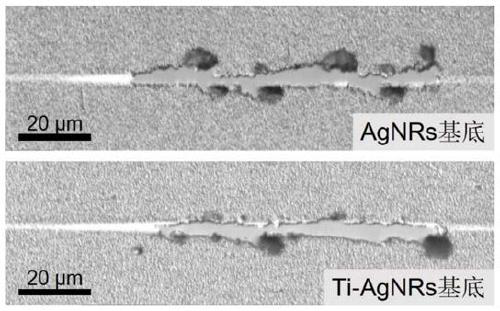

Method for preparing surface-enhanced Raman substrate by improving film-substrate bonding force

ActiveCN108330441AImprove adhesionImprove thermal stabilityVacuum evaporation coatingSputtering coatingPorosityNanostructure

The invention relates to a method for preparing a surface-enhanced Raman substrate by improving film-substrate bonding force. The method comprises the following steps of firstly, growing a flat transition layer on a substrate; growing a silver nanorod array thin film on the transition layer; uniformly covering the surface of silver with an ultrathin oxide film; heating the composite nanometer structure, so as to obtain the surface-enhanced Raman substrate with excellent film-substrate bonding force. The method has the advantages that the mismatching factor between the noble metal thin film andthe substrate is relieved by the transition layer, and the stress distribution and atom bonding in the whole film-substrate range are regulated; the good SERS (surface enhanced Raman scattering) sensitivity and thermal stability of the substrate are ensured by the ultrathin oxide layer at the surface of the silver nanorod; the substrate can be further heated, the atom diffusion between the thin film and the substrate can be promoted, the porosity at the interface is reduced, and the adhesion force is increased. The surface-enhanced Raman substrate with excellent film-substrate bonding force has the advantages that the easiness in falling is avoided, the stability is good, the transportation, storage and use are convenient, and the practicality of surface-enhanced Raman technique is enhanced.

Owner:广西三环高科拉曼芯片技术有限公司

Preparation method of MoS2 composite thin film with high hardness and loss abrasion on surface of substrate

ActiveCN103060765BFast sputtering rateIncrease ionization rateVacuum evaporation coatingSputtering coatingComposite filmCritical load

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for raising bacteria-resistance and rust resisting performance for ordinary carbon steel

InactiveCN100494474CImprove adhesion strengthHigh deposition rateVacuum evaporation coatingSputtering coatingFood sectorCopper

The process of raising antibiotic and antirust performance of common steel product belongs to the field of material surface treating technology. The process includes: grinding and polishing the surface of steel product to mirror finishing, ion plating to deposit Ni-Cr film, and implanting Cu or Ag ion. The ion plating and the ion implanting make the common steel product possess both antibiotic performance and antirust performance. Thus treated steel may be used in door handle, kitchenware, household appliance, etc.

Owner:SHANGHAI JIAO TONG UNIV

A method for preparing diamond film on stainless steel surface with Cr/Craln as transition layer

ActiveCN110629194BStrong membrane bindingNo sheddingVacuum evaporation coatingSputtering coatingMetallurgySS - Stainless steel

The invention discloses a method for preparing a diamond film on the surface of stainless steel with Cr / CrAlN as a transition layer, which is characterized in that it comprises the following steps: S1: pretreatment of stainless steel samples: sanding the stainless steel samples with acetone and absolute ethanol Ultrasonic treatment, drying and standby; S2: Deposit Cr / CrAlN transition layer on the surface of stainless steel: put the stainless steel sample in the S1 step into the sample stage of the magnetron sputtering equipment, install the Cr and Al targets on the target holder, and place the Cr / CrAlN transition layer on the stainless steel Deposit a Cr film and a CrAlN film on the surface of the substrate to obtain a stainless steel sample containing a Cr / CrAlN transition layer; S3: Prepare a diamond film on the stainless steel surface: perform ultrasonic seeding on the stainless steel sample containing a Cr / CrAlN transition layer in step S2, and use a hot wire HFCVD is used to deposit diamond films to realize the preparation of diamond films on the surface of stainless steel containing Cr / CrAlN as a transition layer. Adopting the technology of the invention, the binding force between the diamond film and the stainless steel is high, and the film does not fall off under the action of a load of 150 kg on a Rockwell hardness tester.

Owner:ZHEJIANG UNIV OF TECH

A kind of preparation method of silicon carbide nanofiber film

ActiveCN108176249BStrong membrane bindingHigh separation precisionPhysical/chemical process catalystsDispersed particle separationFiberCarbide silicon

Owner:NANJING TECH UNIV +1

A method for preparing surface-enhanced Raman substrates by improving the binding force of membrane substrates

ActiveCN108330441BImprove adhesionImprove thermal stabilityVacuum evaporation coatingSputtering coatingChemical physicsFilm base

The invention relates to a method for preparing a surface-enhanced Raman substrate by improving film-substrate bonding force. The method comprises the following steps of firstly, growing a flat transition layer on a substrate; growing a silver nanorod array thin film on the transition layer; uniformly covering the surface of silver with an ultrathin oxide film; heating the composite nanometer structure, so as to obtain the surface-enhanced Raman substrate with excellent film-substrate bonding force. The method has the advantages that the mismatching factor between the noble metal thin film andthe substrate is relieved by the transition layer, and the stress distribution and atom bonding in the whole film-substrate range are regulated; the good SERS (surface enhanced Raman scattering) sensitivity and thermal stability of the substrate are ensured by the ultrathin oxide layer at the surface of the silver nanorod; the substrate can be further heated, the atom diffusion between the thin film and the substrate can be promoted, the porosity at the interface is reduced, and the adhesion force is increased. The surface-enhanced Raman substrate with excellent film-substrate bonding force has the advantages that the easiness in falling is avoided, the stability is good, the transportation, storage and use are convenient, and the practicality of surface-enhanced Raman technique is enhanced.

Owner:广西三环高科拉曼芯片技术有限公司

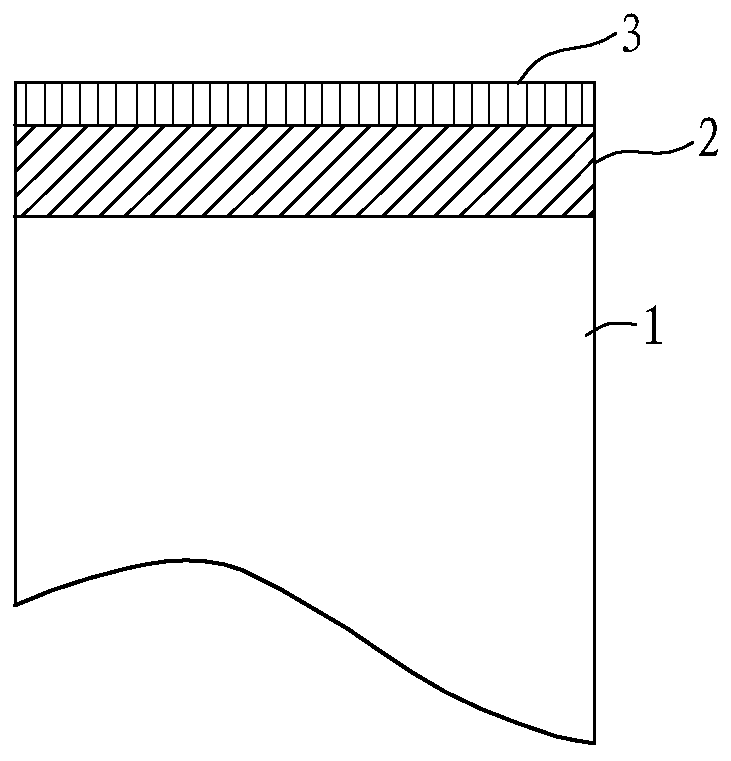

Preparation method of diamond-like carbon film on magnesium alloy surface

ActiveCN106702339BImprove performancePromote engineering applicationVacuum evaporation coatingSputtering coatingCarbon filmDiamond-like carbon

The invention provides a preparation method of a diamond-like carbon film on the surface of magnesium alloy. The preparation method is characterized by comprising the following steps that (1) the surface of a magnesium alloy base material is cleaned and is subjected to sand-blasting roughening treatment, so that the treated base material is obtained; (2) a metal or metal ceramic coating is sprayed on the surface of the base material through cold spraying, and thus a cold-spayed intermediate layer is obtained on the surface of the magnesium alloy base material; (3) the cold-sprayed intermediate layer is polished, so that the set roughness is obtained; and (4) the polished magnesium alloy base material provided with the cold-sprayed intermediate layer is placed in magnetron sputtering deposition equipment, and a diamond-like carbon film is prepared on the surface of the cold-sprayed intermediate layer after coating technological parameters are set. Compared with the prior art, the cold-sprayed metal or metal ceramic coating is used as the intermediate layer, so that the heat effect on the magnesium alloy base material is small, oxidization and deformation of the base material are avoided, and the coating is compact in bonding and has high bonding strength; and the preparation method is simple in process and environmentally friendly, and the structure of the coating can be controlled.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Preparation Technology of Composite Nitride Coating on Tool and Die Surface

ActiveCN106967977BImprove wear resistanceEfficient preparationVacuum evaporation coatingSputtering coatingSputteringEvaporation

Owner:CHENGDU REALLY SHARP COATING TECH CO LTD +2

A kind of treatment method of polymer surface

ActiveCN107151780BImprove surface bindingImprove wear resistance and corrosion resistanceVacuum evaporation coatingSputtering coatingPolymeric surfaceSputtering

The invention relates to a polymer surface treatment method. The method uses arc ion plating to deposit a chromium film on the surface of the polymer substrate, and the obtained chromium film has a silver-white appearance, which is similar to the appearance of the hexavalent chromium film prepared by electroplating. And the use of magnetron sputtering to deposit a nitride hard film layer technology greatly improves the film-base bonding force and the wear-resistant and anti-corrosion performance of the film layer, and obtains strong film-base bonding force on the polymer surface, and is wear-resistant and scratch-resistant The imitation electrochrome plating film layer with excellent properties such as corrosion resistance and corrosion resistance can realize the decoration and protection function of the polymer substrate, and it is a completely dry green surface treatment method without waste water discharge.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com