Composite coating with anti-corrosion lubricating property of surface of magnesium alloy, preparation method thereof

A composite coating, magnesium alloy technology, applied in the direction of metal material coating process, coating, superimposed layer plating, etc., can solve the problem of restricting thick film growth, easy peeling failure of thin film, and poor corrosion resistance of Me-DLC film. Significant improvement and other problems, to achieve the effect of slowing down the electrochemical corrosion of the interface, promoting engineering applications, and excellent film-base adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

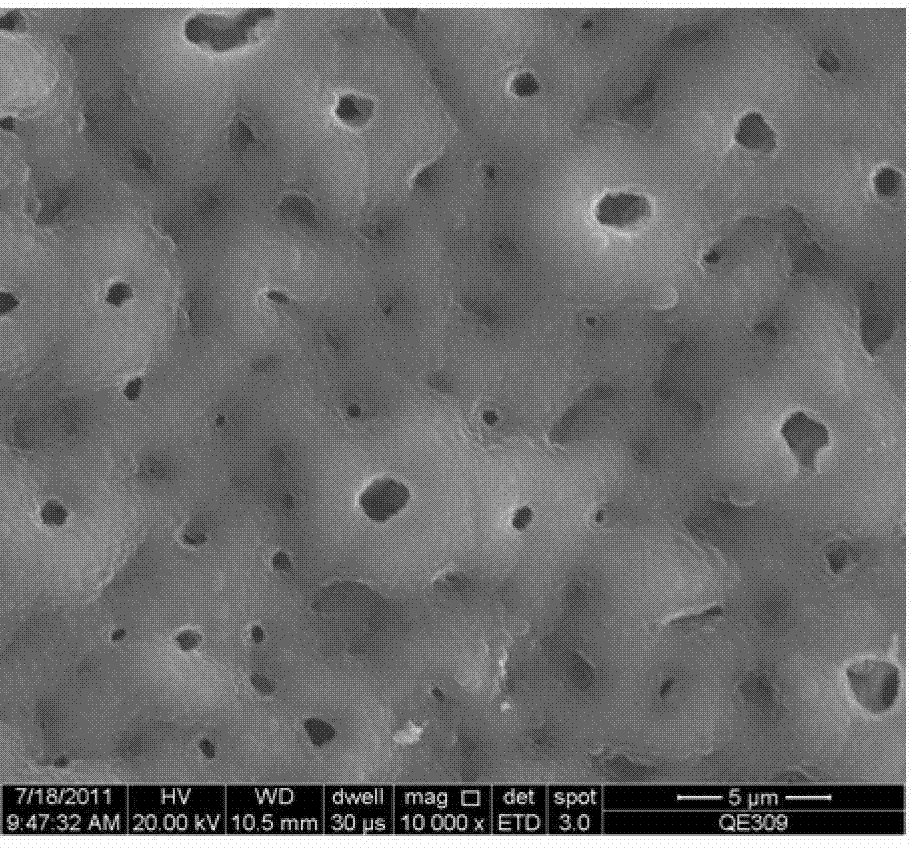

[0031] In this embodiment, the composite coating on the surface of the magnesium alloy consists of a transition layer on the surface of the magnesium alloy substrate, and a DLC film layer co-doped with Si and N elements on the surface of the transition layer, that is, (Si, N)-DLC multi-component Nanocomposite film layer composition. The transition layer adopts the micro-arc oxidation technology to form a MgO porous film in situ on the magnesium atoms on the surface of the magnesium alloy substrate. The maximum surface pore diameter of the MgO porous film is 200 nm and the thickness is 4 μm. The (Si,N)-DLC multi-component nanocomposite film layer has a thickness of 350nm.

[0032] The preparation method of the composite coating on the surface of the above-mentioned magnesium alloy comprises the following steps:

[0033]Step 1: According to the matching principle of magnesium alloy micro-arc oxidation electrolyte, select chemical reagents without the introduction of harmful ele...

Embodiment 2

[0039] In this embodiment, the composite coating on the surface of the magnesium alloy consists of a transition layer on the surface of the magnesium alloy substrate, and a DLC film layer co-doped with Si and N elements on the surface of the transition layer, that is, (Si, N)-DLC multi-component Nanocomposite film layer composition. The transition layer adopts the micro-arc oxidation technology to form a MgO porous film in situ on the magnesium atoms on the surface of the magnesium alloy substrate. The maximum surface pore diameter of the MgO porous film is 500 nm and the thickness is 5 μm. The thickness of the (Si,N)-DLC multi-component nanocomposite film layer is 500nm.

[0040] The preparation method of the composite coating on the surface of the above-mentioned magnesium alloy comprises the following steps:

[0041] Step 1: According to the matching principle of magnesium alloy micro-arc oxidation electrolyte, select chemical reagents without the introduction of harmful e...

Embodiment 3

[0047] In this embodiment, the composite coating on the surface of the magnesium alloy consists of a transition layer on the surface of the magnesium alloy substrate, and a DLC film layer co-doped with Si and N elements on the surface of the transition layer, that is, (Si, N)-DLC multi-component Nanocomposite film layer composition. The transition layer adopts the micro-arc oxidation technology to form a MgO porous film in situ on the magnesium atoms on the surface of the magnesium alloy substrate. The maximum surface pore diameter of the MgO porous film is 500 nm and the thickness is 6 μm. The thickness of the (Si,N)-DLC multi-component nanocomposite film layer is 500nm.

[0048] The preparation method of the composite coating on the surface of the above-mentioned magnesium alloy comprises the following steps:

[0049] Step 1: According to the matching principle of magnesium alloy micro-arc oxidation electrolyte, select chemical reagents without the introduction of harmful e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com