Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

746 results about "Manufacturing enterprises" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Learn More →. A manufacturing enterprise is a business entity established to produce goods for sale to wholesalers, retailers or end consumers. Some manufacturing enterprises are independent businesses. Others are established as a joint venture between two or more firms.

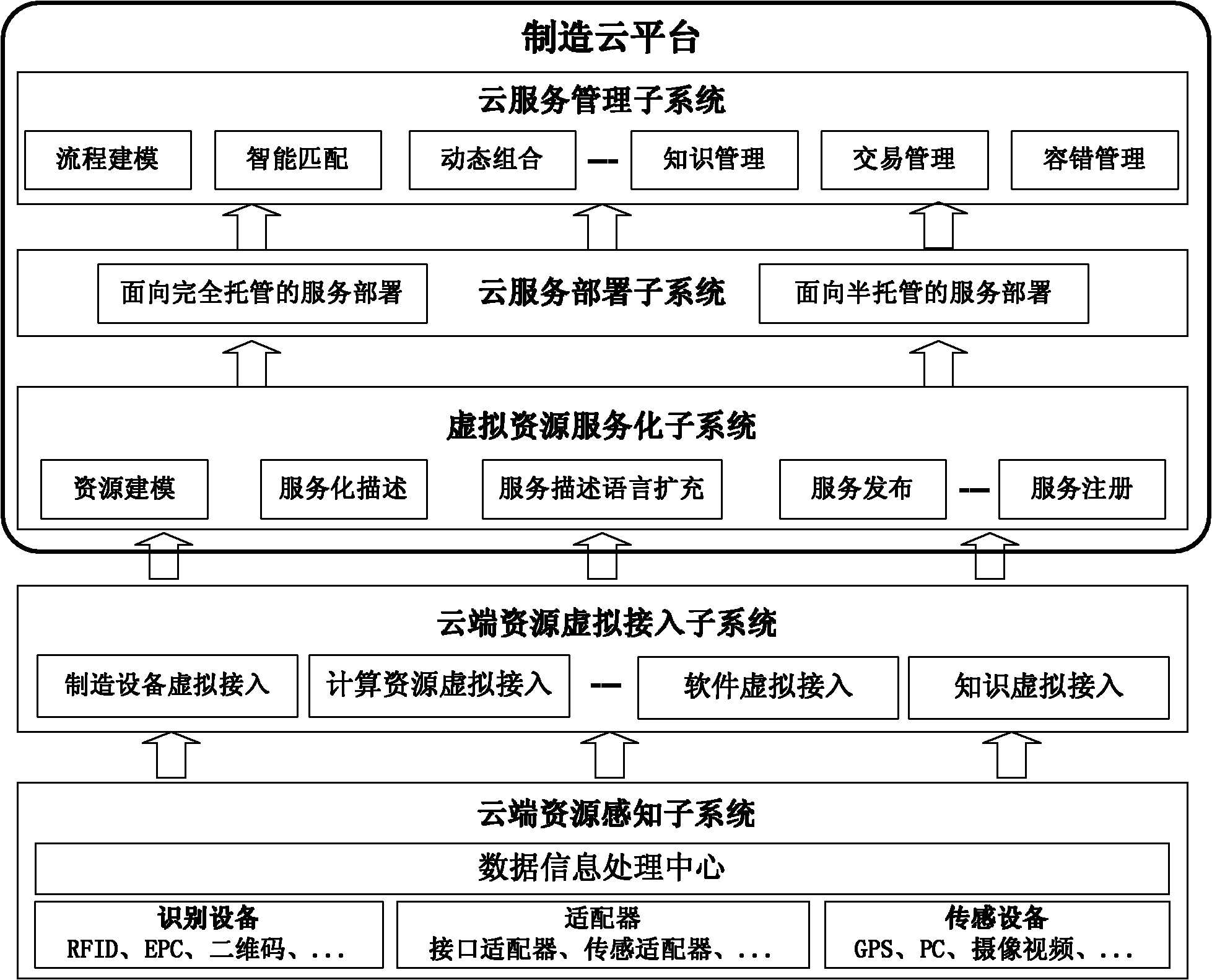

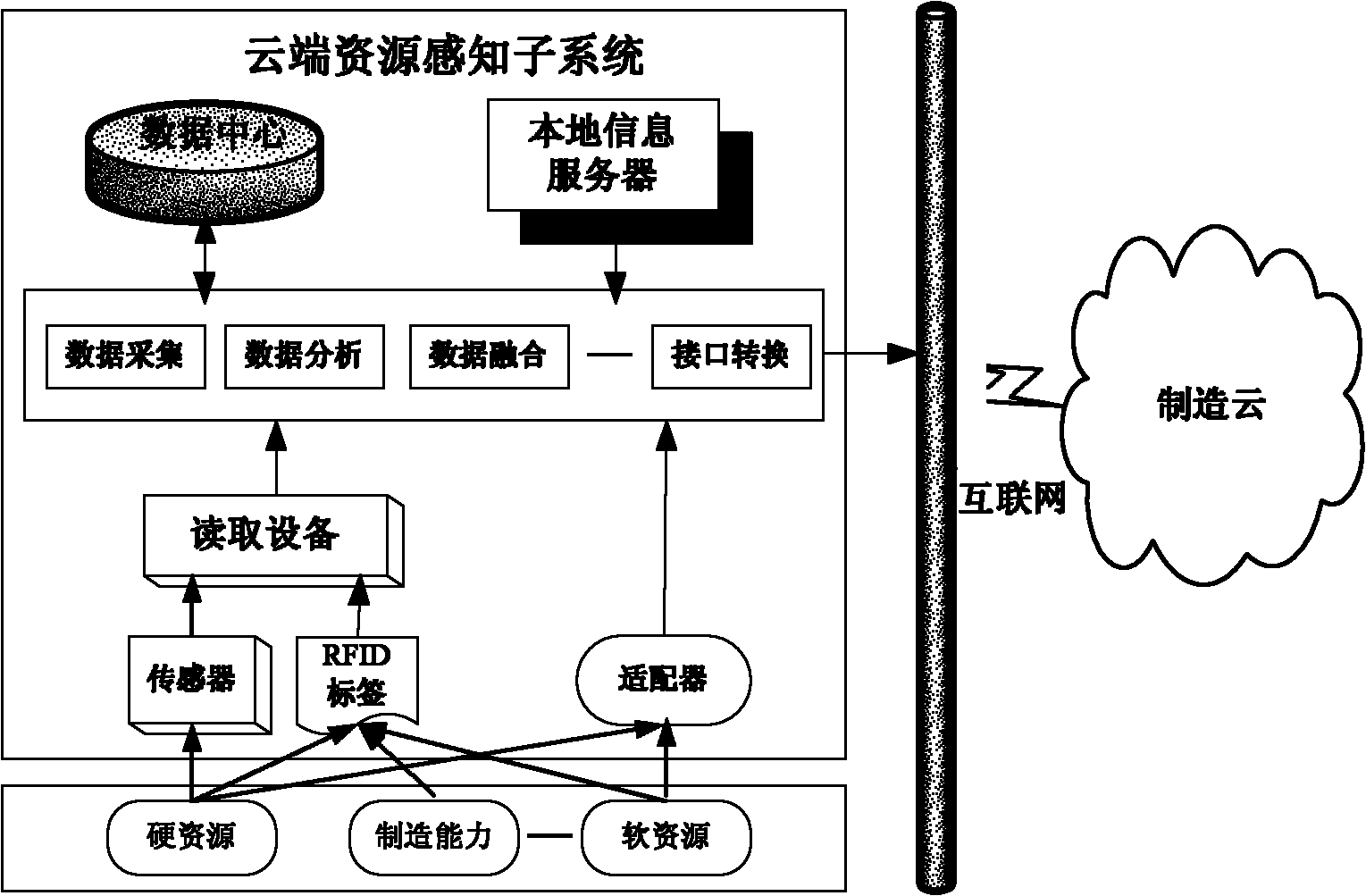

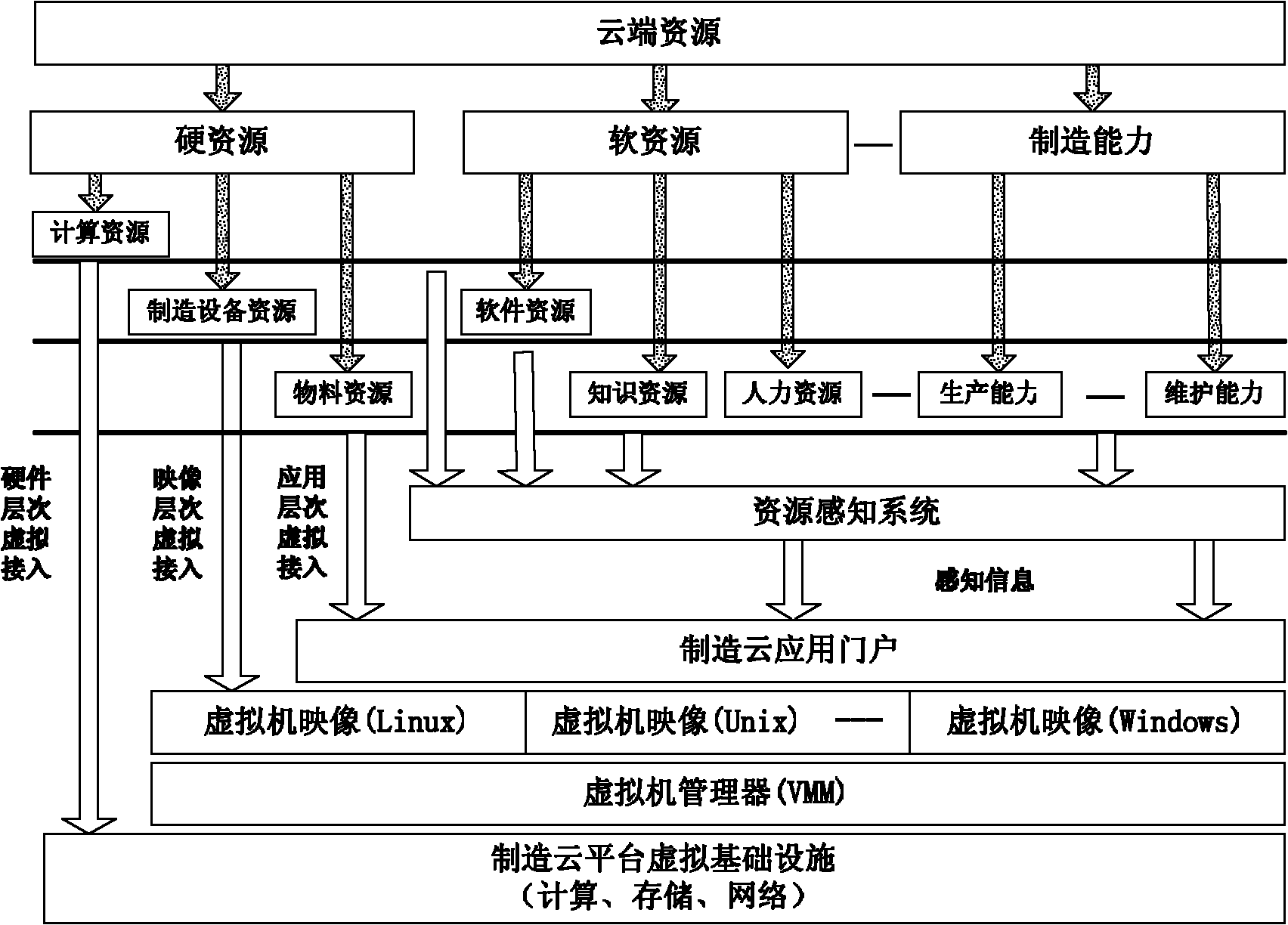

Manufacturing cloud system for supporting on-demand use and dynamic collaboration of manufacturing resources and manufacturing capacities

InactiveCN102176723ARealize analysisAchieving processing powerTransmissionSoftware simulation/interpretation/emulationInformatizationResource utilization

The invention provides a manufacturing cloud system for supporting on-demand use and dynamic collaboration of manufacturing resources and manufacturing capacities, which is used for solving the problems that the use ratio of resources is low, the sharing of the manufacturing capacities is insufficient, effective business operation management measures are short and the like in the process of manufacturing enterprise informatization in China. Aiming at the characteristics of the manufacturing resources and the actual demands of an enterprise for a cloud manufacturing service platform, and according to the lifeline of a cloud service life cycle, the manufacturing resources and the manufacturing capacity in the manufacturing cloud system are designed and stated in five system modules namely intellisense, virtual access, virtual resource servicesation, deployment of cloud services, and integrated management of the cloud services, thus meeting the demand of the on-demand use and the dynamic collaboration of the manufacturing resources and the manufacturing capacities. The manufacturing cloud system has the advantages that the intellisense, the servicesation of the manufacturing capacities and service life cycle demands which are accessed to the manufacturing resources are supported, the intelligence is supported, the services are shared on demand, the system structure is flexible, the levels are distinct, and the expandability is strong.

Owner:BEIHANG UNIV

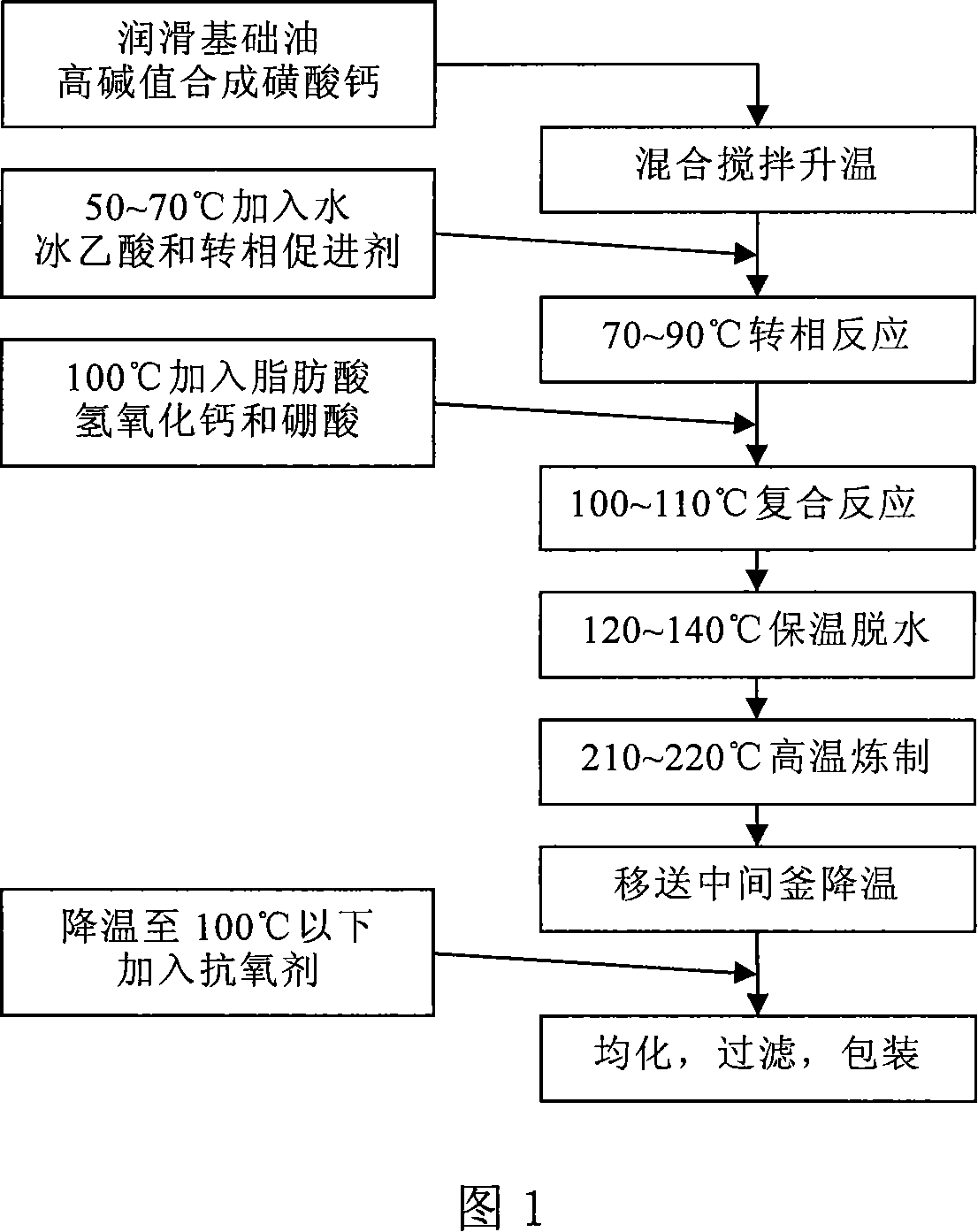

Compound sulphonic acid albany grease and method for producing the same

ActiveCN101153239AImprove performanceImprove water resistanceLubricant compositionAntioxidantManufacturing enterprises

The invention relates to calcium sulfonate complex grease and a manufacture method thereof, in particular to grease producing the thickening agent by synthetic reaction with super-high base value. At first, the lubricating base oil and the calcium sulfonate are added into an opening reaction kettle to be stirred, the phase inversion promoter, the glacial acetic acid and the water are added into the kettle to boost the temperature to make the insulating reaction until the materials are thickened, then the calcium hydroxide, the aliphatic acid and the boric acid are added into make an insulating reaction, a temperature rise, an insulating dehydration and a refining in turn, then the materials are moved into an intermediate kettle, the antioxidant is added to disperse and homogenize, and the finished product is produced after the filtering. The invention has excellent anti-spray performance, excellent high temperature performance, good extreme pressure anti-abrasion performance, prominent anti-shear performance, good pumping performance, anti-rust performance and water adding shear stability; has apparent phase inversion effect and good product performance, decreases the grease exchange times under the same working condition and increases the service life of the equipment, which is proved by the trial applications of a plurality of appliance manufacture enterprises, steel works, paper mills and so on.

Owner:无锡中石油润滑脂有限责任公司

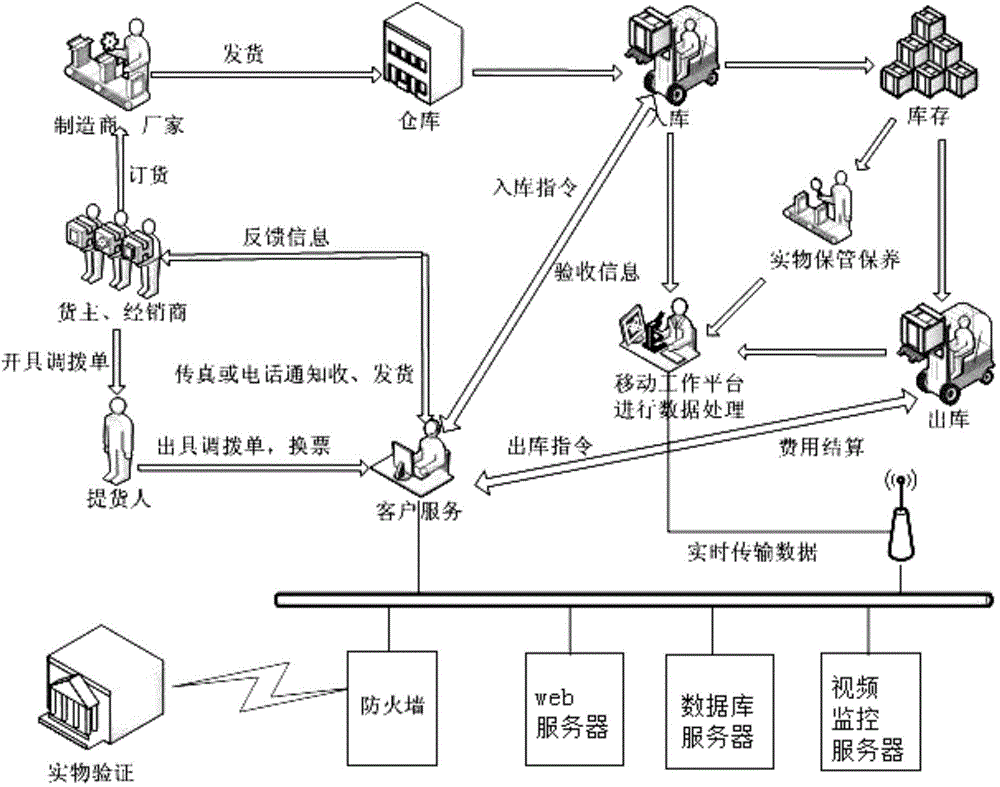

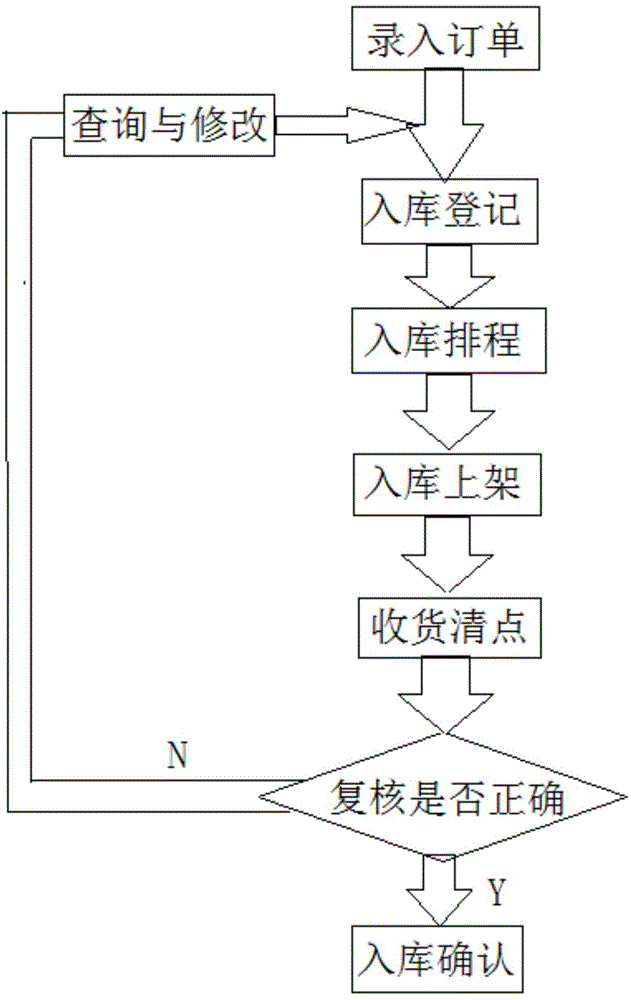

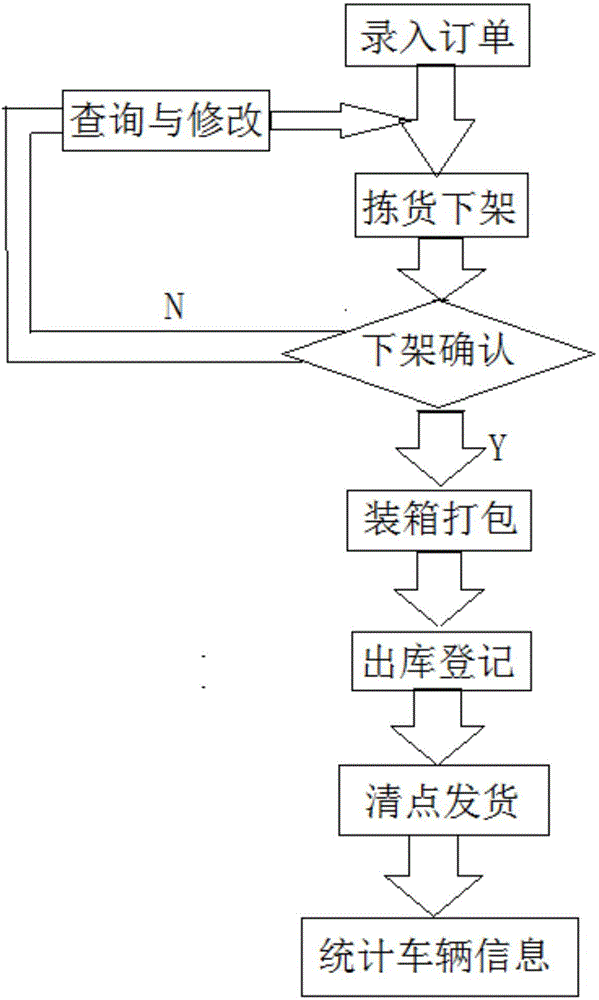

Cold-chain logistics storage supervisory system and method

The invention discloses a cold-chain logistics storage supervisory system and method. The cold-chain logistics storage supervisory system includes a temperature monitoring module, a WMS (Warehouse Management System) management module, an order management module, an in-out stock monitoring module, a three-dimensional planning module, a processing module, an inventory management module and a locating and tracking module. The old-chain logistics storage supervisory system effectively organizes the staff, space and equipment by aid of the WMS for receiving, storing, picking and transporting goods, transporting raw materials and parts to manufacturing enterprises and conveying finished products to wholesalers, distributors and final customers. The main functions of the cold-chain logistics storage supervisory system are managing and controlling all in-out stock dynamic conditions of the warehouse and doing statistic analysis about inventory data, so decision makers can find problems timely, adopt corresponding measures to adjust the inventory structure, shorten the storage period, quicken capital turnover, and further to ensure smooth logistics in enterprise production.

Owner:临沂市义兰物流信息科技有限公司

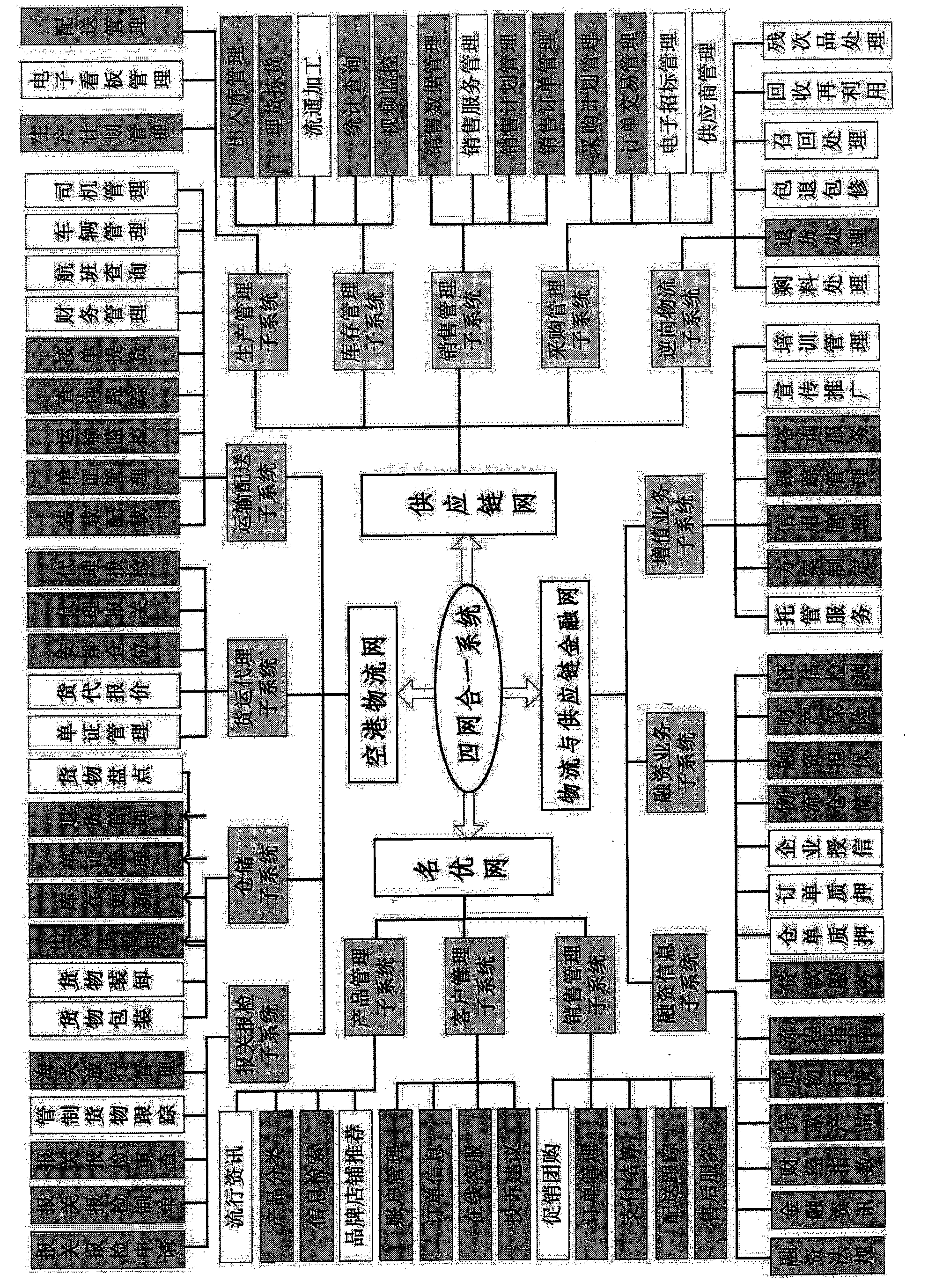

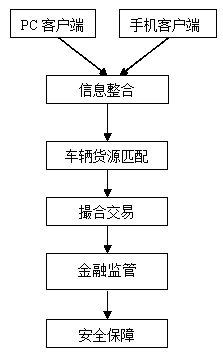

Quadruple net system and work method thereof

InactiveCN104077674AAchieve seamless connectionGood logistics serviceLogisticsInventory managementManufacturing enterprises

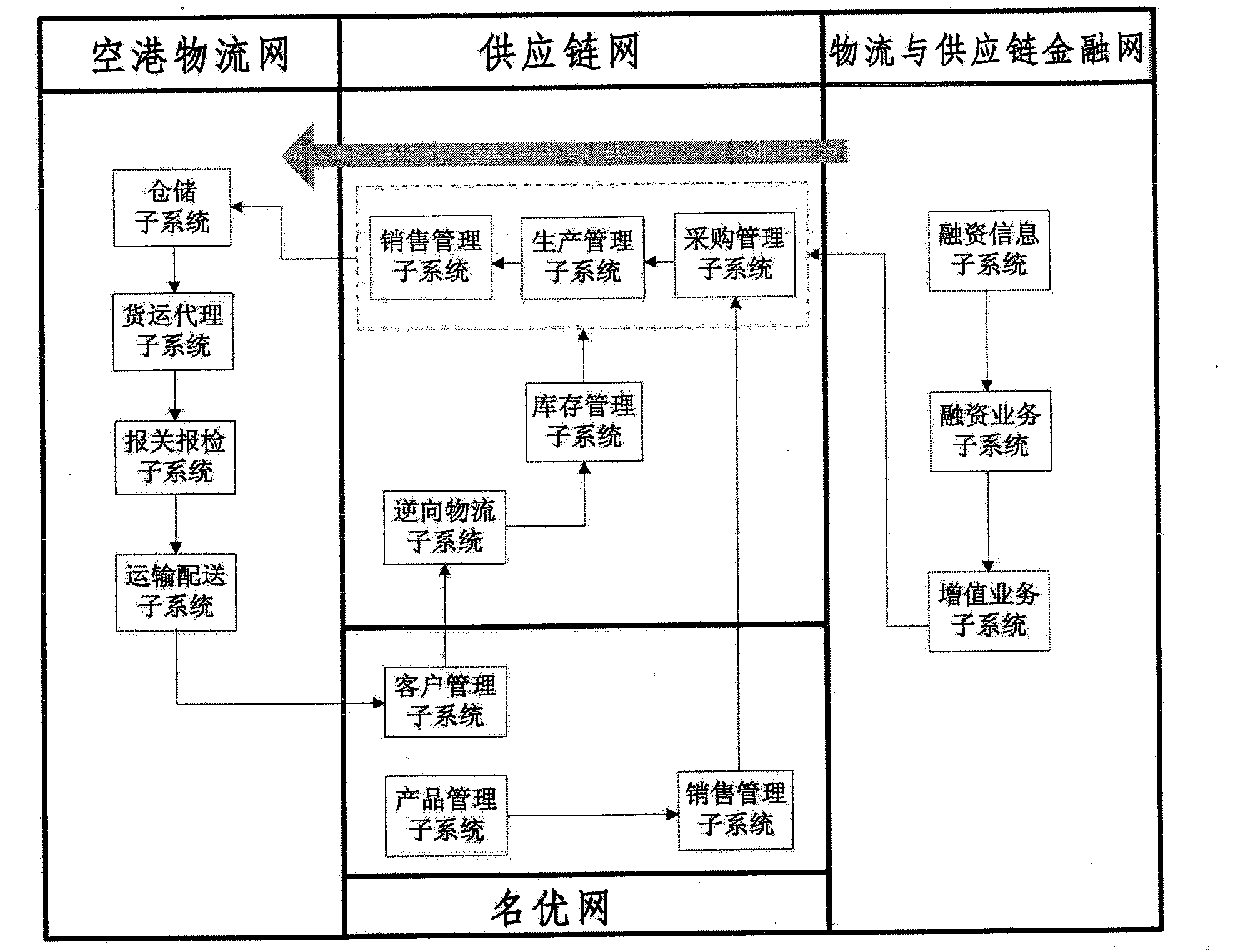

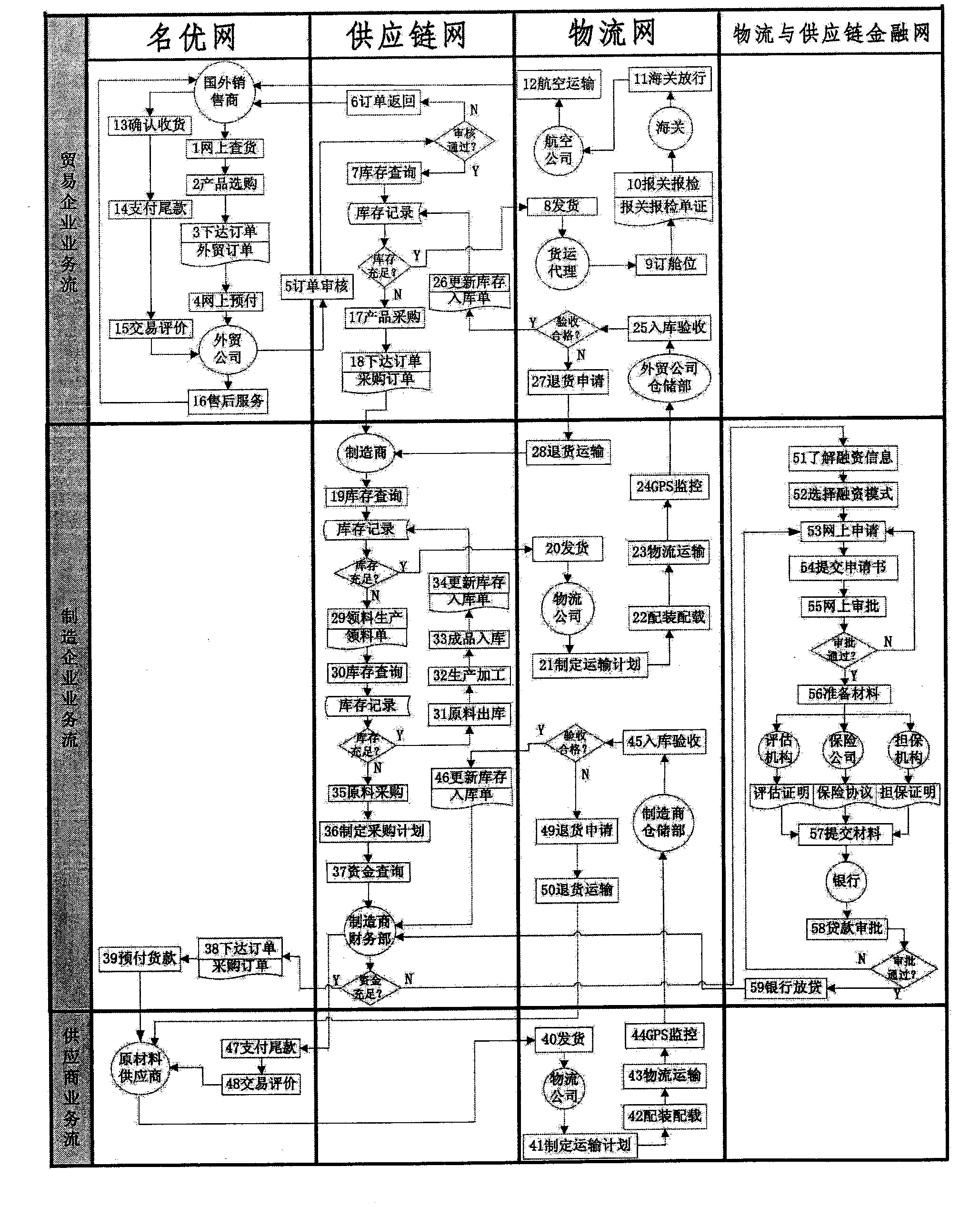

The invention provides a quadruple net system and a work method of the quadruple net system. Logistics, supply chains, electronic commerce and finance are integrated and jointly serve main bodies such as manufacturing enterprises and trade enterprises. The quadruple net system comprises four nets which are the airport logistics net, the supply chain net, the brand-name and high-quality net and the logistics and supply chain financial net. The airport logistics net, the supply chain net, the brand-name and high-quality net and the logistics and supply chain financial net have the unified standard specification and safety authentication and are interconnected through butt joint of platforms. The airport logistics net comprises a storage subsystem, a freight forwarder subsystem, a customs declaration and commodity inspection subsystem and a transport and distribution subsystem. The supply chain net comprises a purchasing management subsystem, a production management subsystem, a marketing management subsystem, an inventory management subsystem, a reverse logistics subsystem and a logistics park management subsystem. The brand-name and high-quality net comprises a product management subsystem, a client management subsystem and a marketing management subsystem. The logistics and supply chain financial net comprises a financing information subsystem, a financing service subsystem and a value added service subsystem.

Owner:桂寿平

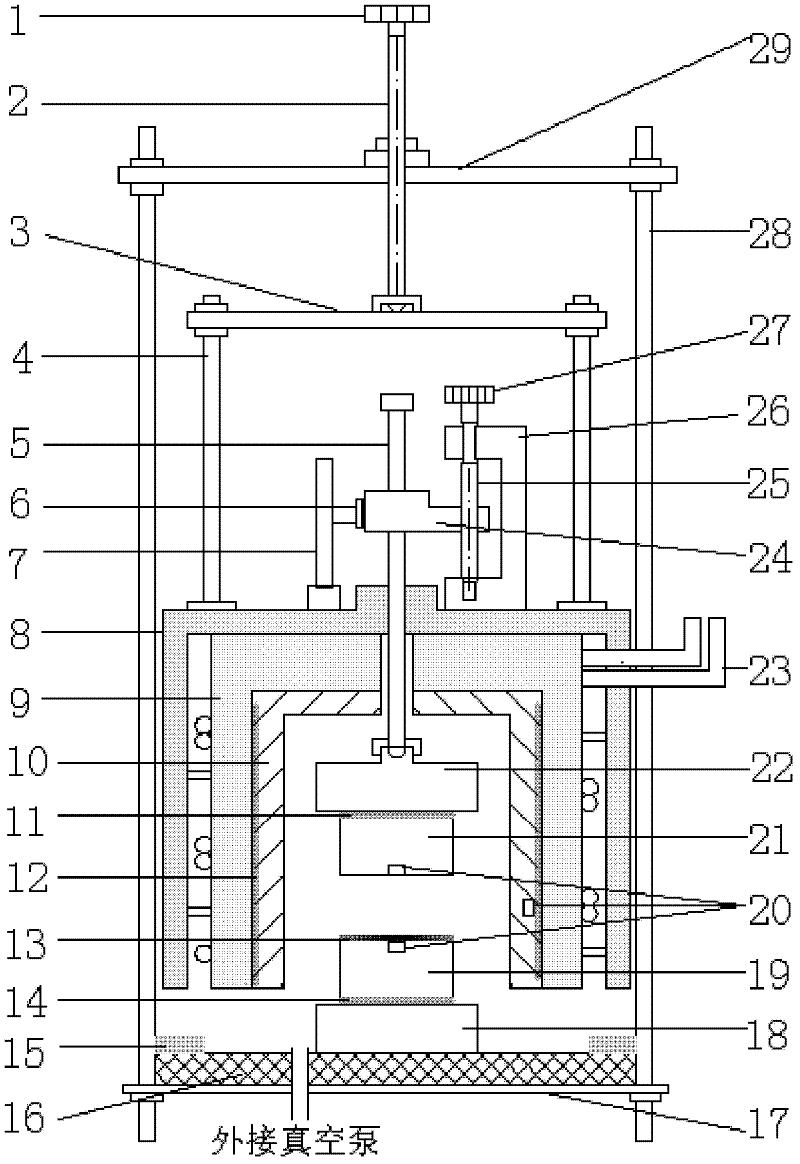

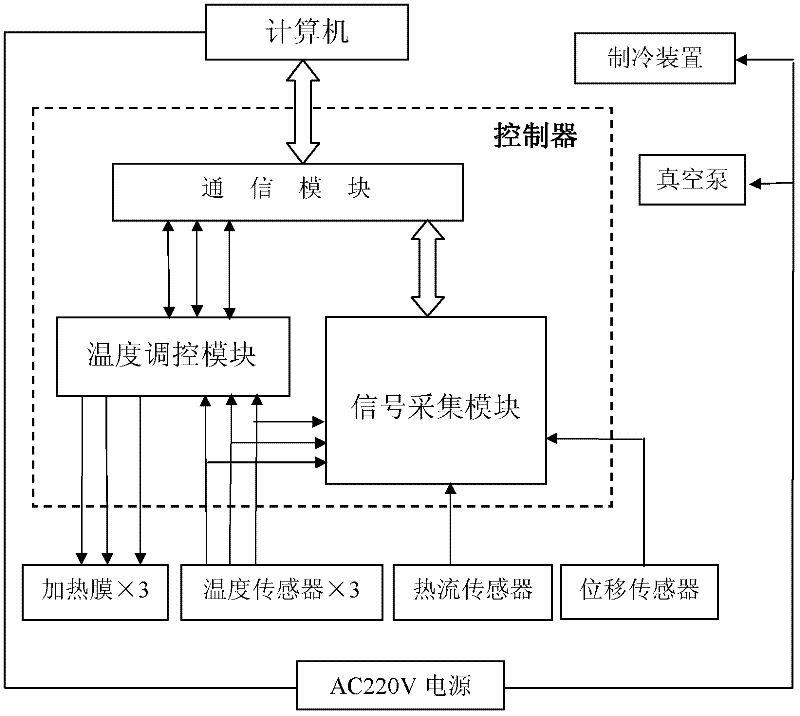

Protective heat flow meter method thermal conductivity coefficient measuring instrument for realizing vacuum insulation and thickness measurement function

InactiveCN102645449AImprove measurement repeatabilityImprove accuracyMaterial heat developmentMeasuring instrumentEngineering

The invention provides a protective heat flow meter method thermal conductivity coefficient measuring instrument for realizing the vacuum insulation and thickness measurement function. A test stack body of the measuring instrument comprises a hot plate and a cold plate, wherein a heating film is clamped between the hot plate and a hot plate fixed seat; and the cold plate is similar to the hot plate in structure. A vacuum system consists of a vacuum box, a vacuum pump, a sealing gasket and a sealing bottom plate; and the vacuum insulation function can be realized through the vacuum pump. A thickness measurement module consists of a displacement sensor capable of outputting an electric displacement signal; the displacement signal enters a controller and realizes the function of automatically measuring the thickness of a test piece; and the whole instrument is measured and controlled by a computer. The protective heat flow meter method thermal conductivity coefficient measuring instrument has the beneficial effects that the influence of environment on measurement stability is avoided through a vacuum chamber; meanwhile, the thickness of the test piece is automatically measured to avoid the personal error caused by manual measurement; and the measuring repeatability, the accuracy and the degree of automation of the instrument are improved. The protective heat flow meter method thermal conductivity coefficient measuring instrument can be widely applied to manufacturing enterprises of heat insulation and heat preservation materials, related quality inspection departments and units, institutes of higher learning, research institutes and other scientific research units.

Owner:TIANJIN UNIV

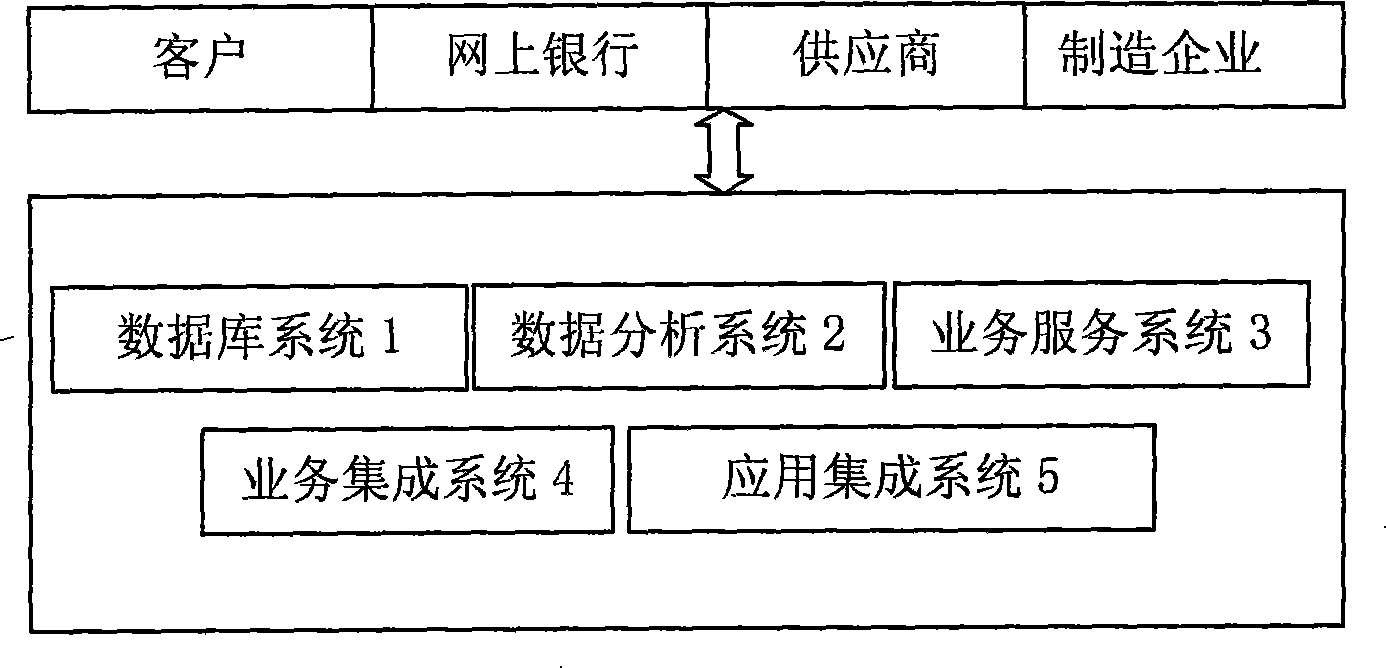

Public platform of collaborative electronic commercial system oriented to business service

A public platform facing synergic electronic business system with database system for collection, calling and storage data, the data analysis system abstracting, classifying and analyzing and digging the data, providing data to the service system, which receives the data for service processing and sealing each service for management, service accumulation system integrating the system organically, realizing the exchange accumulation of the electronic business application system that integrate the basic structure platform of the enterprise service, basic service component, specific service module. It effectively combines the data information, to allow the service exchange of manufacturing enterprise, customer, supplier and bank to improve working efficiency.

Owner:NANJING UNIV OF FINANCE & ECONOMICS

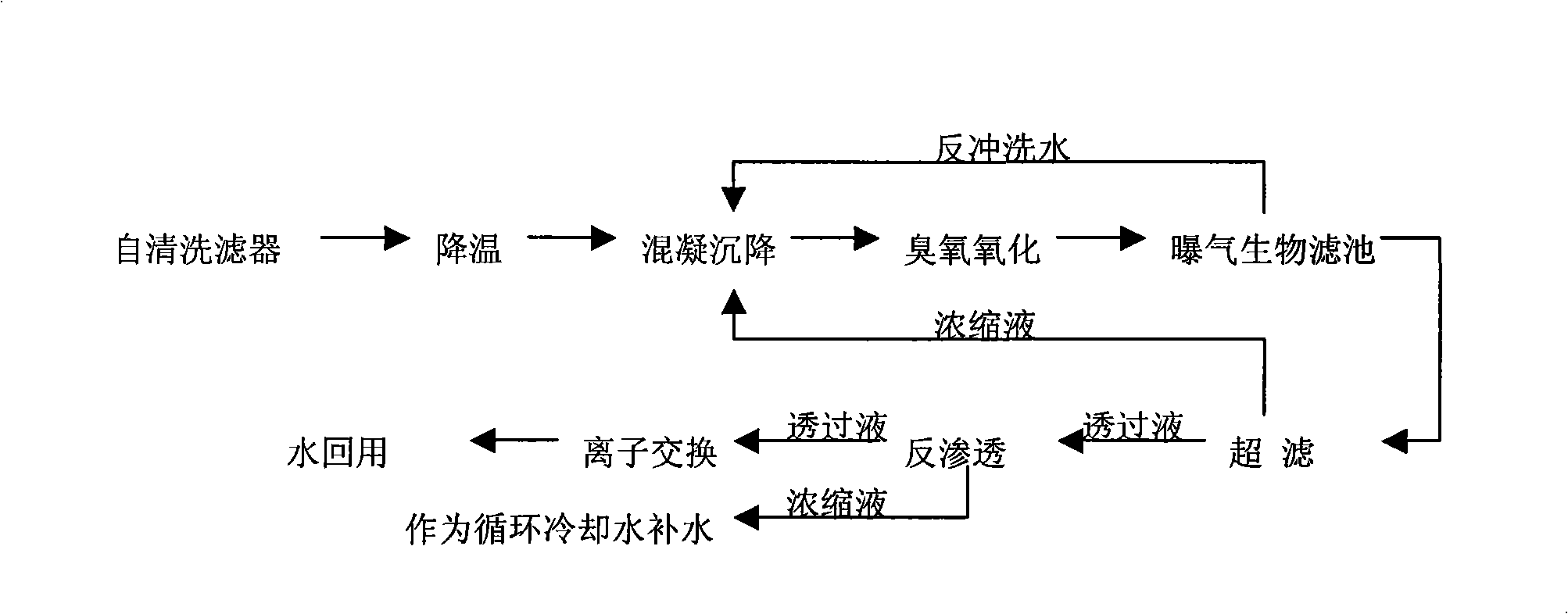

Treatment method for wastewater of polyvinyl chloride (PVC) anticentripetal mother solution

ActiveCN101343132AImprove efficiencySignificant comprehensive benefitsWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisFiltrationUltrafiltration

The invention provides a treatment method of polyvinyl chloride (PVC) centrifugal mother liquor wastewater, sequentially comprising the following treatment steps of: 1) treatment by a self-cleaning strainer, and recovering PVC particles of backwash liquor of the self-cleaning strainer, 2) decreasing temperature treatment, 3) coagulating sedimentation treatment, 4) ozone oxidation, 5) treatment by a biological aerated filter, 6) ultra-filtration treatment, 7) reverse osmosis treatment, and 8) ion exchange treatment. The treatment method realizes the comprehensive treatment to the mother liquor through sequential treatment to the mother liquor, and can realize the high quality recovery to the PVC mother liquor, thereby effectively controlling treatment costs, improving treatment effects, reducing the discharge of COD and quantity of water intake in factories to a great extent, and effectively increasing benefits of PVC manufacturing enterprises.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

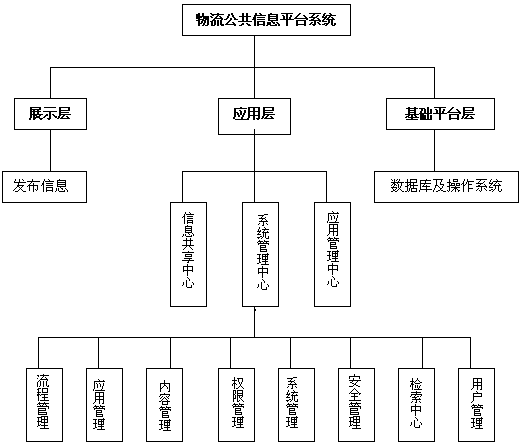

Logistic public information platform system

InactiveCN103699979AEasy to operateRealize human-computer interactionResourcesTransaction managementInformation resource

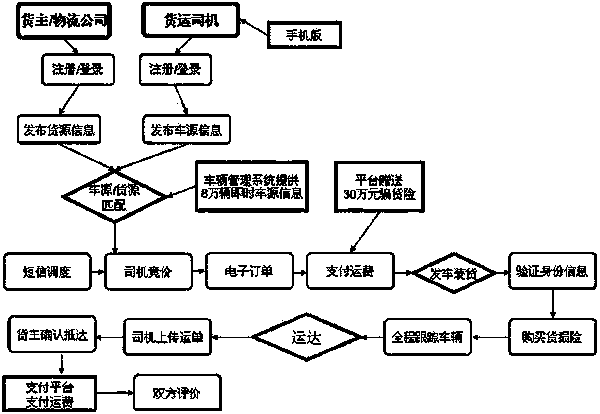

The invention provides a logistic public information platform system, which is oriented towards production and manufacturing enterprises, drivers and logistics companies, has the functions of logistic information management, information retrieval, identity authentication, vehicle positioning, online insurance effecting and online traction, combines with a logistic information system and an electronic business system for realizing logistic information resource sharing and provides online parking lot one-stop service vehicle and cargo marching for a user. The system is an electronic information platform which is based on Internet and is developed by adopting a B2C (Business to Customer) mode, i.e. an enterprise and consumer transaction mode, wherein the electronic information platform comprises a foreground website and a background management system, the user can log in the foreground website for performing user registration, find required vehicle source information or cargo source information through an information searching function of the website, and submitting an electronic order for concluding a transaction, and an administrator can maintain the content of the foreground website through the background management system. The logistic public information platform system is suitable for logistic information transaction.

Owner:JIAN WANJI LOGISTICS TRANSPORTATION

Temperature real-time monitoring and tracing system

InactiveCN103514525AQuality assuranceEliminate Quality Control Blind SpotsTransmission systemsThermometer applicationsTransit networkMedical product

A temperature real-time monitoring and tracing system comprises a detection module and is characterized by further comprising a transit network, a central server and a client-side; the detection module is used for detecting the temperature of an object to be detected, recording temperature data and transmitting detection information to the central server through the transit network, and the central server transmits the detection information to the client-side; the central server can contact a user by sending a message to remind the user to take relevant prevention and control measures; the client-side can send a request to the server to visit the recorded data, trace and analyze the relevant data. The temperature real-time monitoring and tracing system ensures the quality of drugs, vaccine and other medical products of manufacturing enterprises, operation enterprises and retail enterprises in the process of buying and selling, storing, distributing and transporting through enhancing the real-time monitoring on various links of medicine circulation, eliminates quality control blind spots, and achieves whole course traceability. Through the usage of a temperature alarm device and a temperature automatic monitoring device, the quality of the medical products in the circulation process can be guaranteed.

Owner:北京华海隆科技有限公司

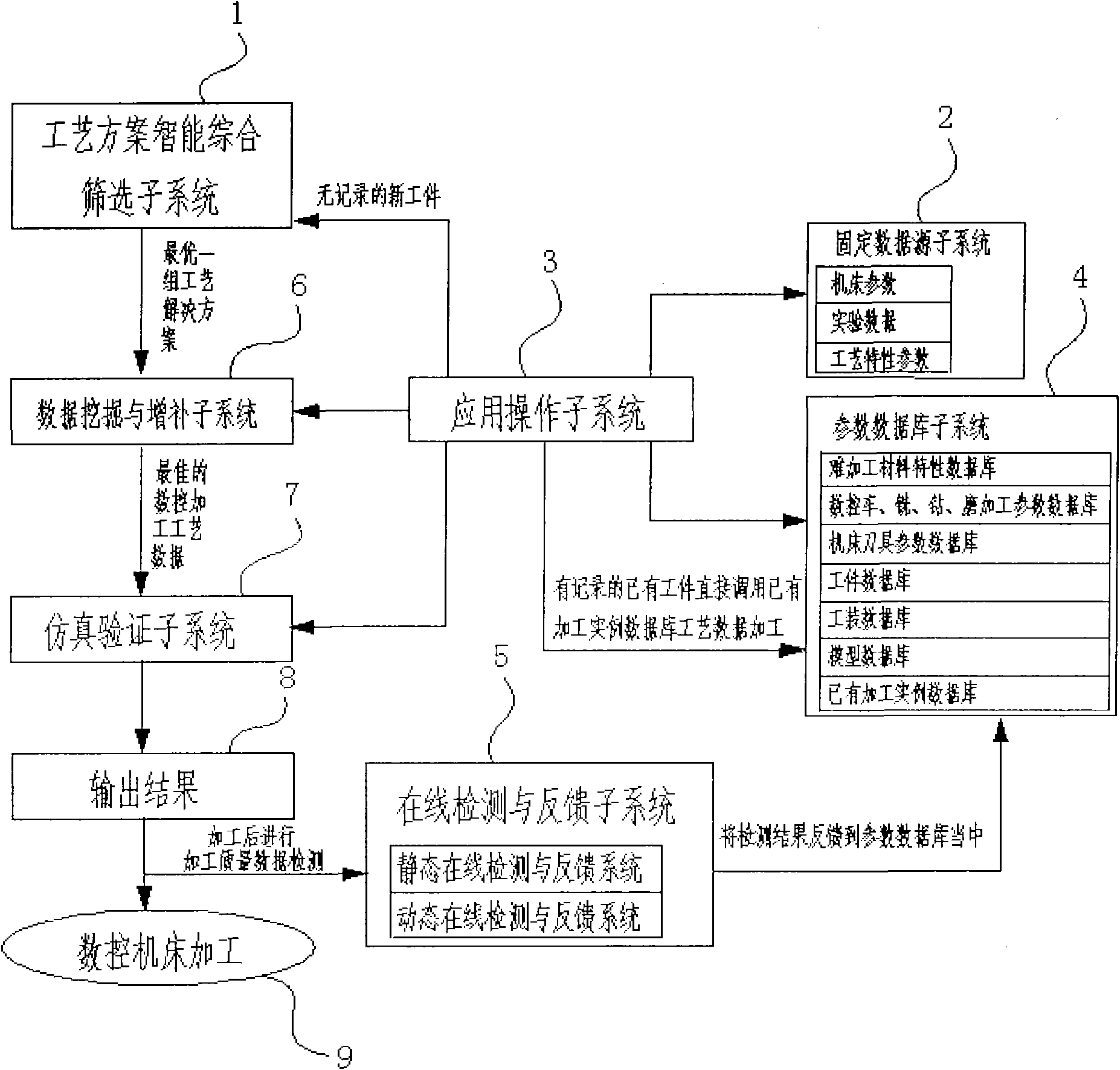

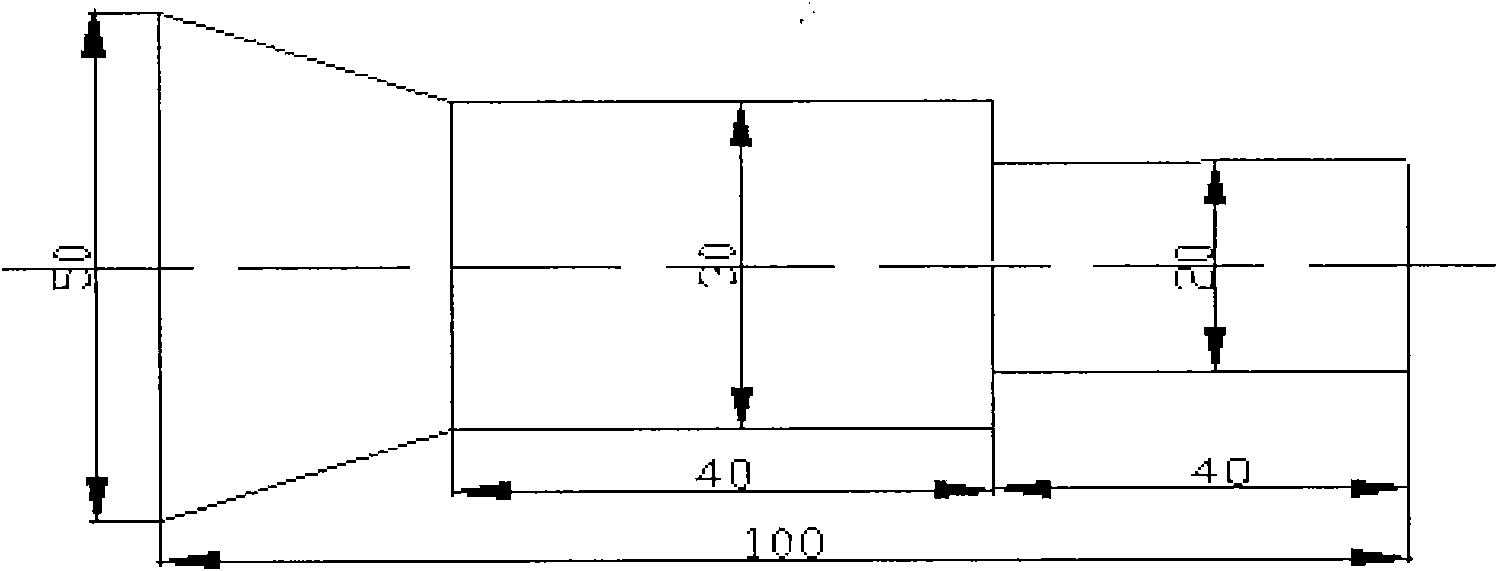

Intelligent screening system based on numerical control processing technology for difficult-to-machine metal

InactiveCN101930223AQuality improvementLow costBiological neural network modelsSpecial data processing applicationsNumerical controlOperational system

The invention discloses an intelligent screening system based on the numerical control processing technology for difficult-to-machine metal, which comprises the following subsystems: a parameter database subsystem, a fixed data source subsystem, an online detection and feedback subsystem, a technology intelligent comprehensive screening optimized scheme system, a data mining and supplementing subsystem, a simulation verification subsystem and an application operating system. The system has the characteristic of recognizing the reasonableness, the advancement and the high efficiency property of each technology scheme in the database, and is used for collecting the processing information of difficult-to-machine metal materials, the machine tool and cutter selection experience and cutting technological parameters accumulated in production practices and experiments. The roughness test data of the optimized cutting technological parameters is selected for processing, so that a reasonable and mature technological scheme is recommended for manufacturing enterprises, and the numerical control processing precision of the difficult-to-machine metal materials is controlled. The purposes of increasing the processing efficiency of the difficult-to-machine materials, reducing processing cost and acquiring high quality products are achieved.

Owner:曾谊晖

Method for rapidly pickling fish by mixed fermentation of microorganisms

ActiveCN103284225AInhibition of denaturationImprove permeabilityFood preparationNitro compoundMicroorganism

The invention discloses a method for rapidly pickling fish by mixed fermentation of microorganisms. According to the method, fresh fish or frozen fish is rapidly prepared into the pickled fish by the procedures of pre-treating fish bodies, pickling by a low-temperature wet pickling method, rinsing, inoculating a mixed microorganism fermenting agent, carrying out gradient low-temperature drying and the like, so that the time for pickling and processing the fishes can be shortened and the flavor of fish pickled products can be improved; nitrite and nitro compounds are prevented from being generated in a process of pickling the fish products, and the edible safety of the fish pickled products is guaranteed; the pickled fish processed by the method is good in flavor, is short in pickling time, low in salt content and free of the nitro compounds; the operation method is simple, the production cost is low, the energy consumption is low, the environmental pollution is small and the product quality is stable; and the economic benefits of manufacturing enterprises can be improved.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Spare parts inventory management

A method for managing spare parts and tools for a manufacturing enterprise is disclosed. Historical demand values are statistically analyzed to determine optimal stocking levels for spare parts based upon required availability percentages, parts lead times, and the statistical distribution parts demand levels. Parts stocking decisions can also be based upon planned and preventative maintenance timeframes with such parts ordered on an as-needed basis in accordance with lead times. Spare parts inventory management can utilize an enterprise-wide computer system to integrate parts demand planning with systems used for engineering and other changes to manufacturing processes and facility maintenance systems. The computer system can perform varying degrees of the parts reordering and planning process and automate certain steps while providing for decision of other issues by parts management personnel.

Owner:CALLAHAN CELLULAR L L C

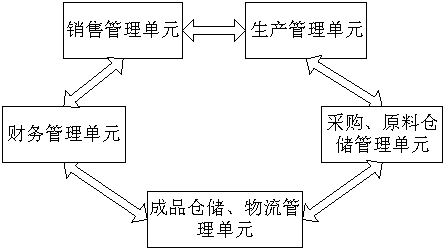

ERP (enterprise resource planning) management system for paperboard manufacturing enterprises

InactiveCN102799979AReduce or eliminate management loopholesLow costLogisticsPaperboardEnterprise resource planning

The invention discloses an ERP (enterprise resource planning) management system for paperboard manufacturing enterprises, which comprises a sales management unit, a production management unit, a purchasing management unit, a warehouse logistics management unit and a financial management unit, wherein the sales management unit is used for carrying out verification, storage and management on orders and sharing data in the system; the production management unit is used for carrying out arrangement on the orders, automatically generating a production plan, carrying out real-time production statistics, and carrying out automatic warehousing after the production is completed; the warehouse logistics management unit is used for performing the warehouse walkthrough of a finished product warehouse according to the orders, carrying out goods delivery after the storage location is full, and generating a delivery table; the purchasing management unit is used for generating a purchasing order according to the real-time storage amount of a raw material storage warehouse; and the financial management unit is used for carrying out management and early warning on costs produced by the units above. The ERP management system for paperboard manufacturing enterprises disclosed by the invention can be suitable for the operating management of paperboard manufacturing enterprises, and can reduce or eliminate management vulnerabilities, reduce the costs and improve the production efficiency.

Owner:常熟市宏华外贸包装有限责任公司

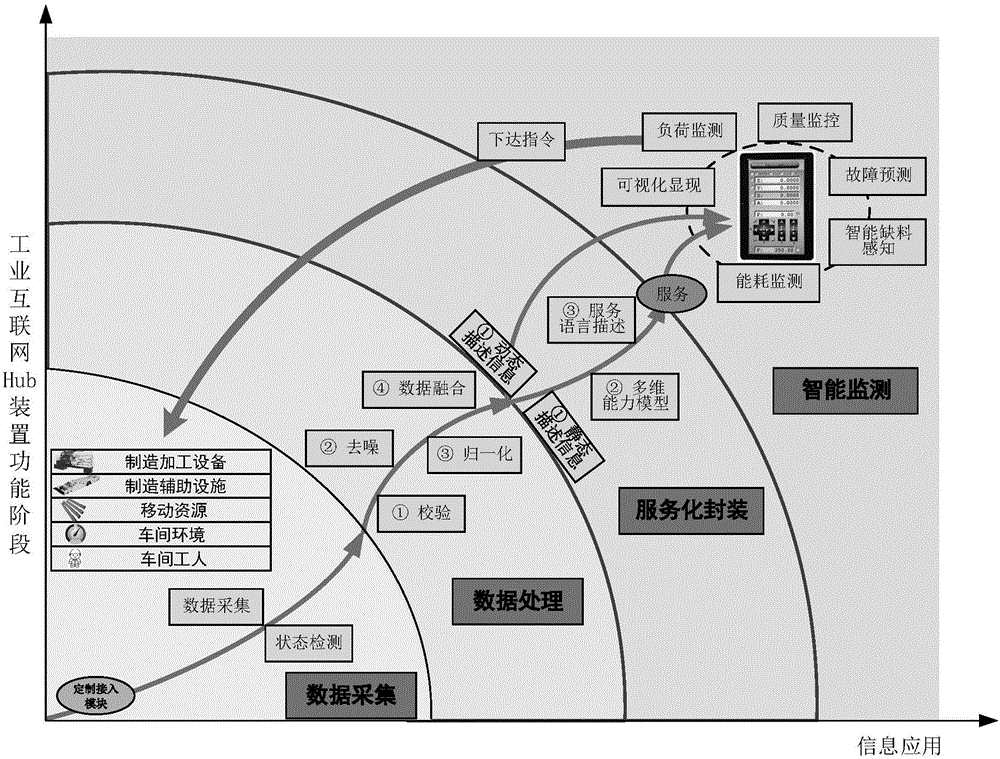

Industrial Internet Hub apparatus

InactiveCN106094777AVarious visualizationsImprove scalabilityTotal factory controlProgramme total factory controlThe InternetData acquisition

An industrial Internet Hub apparatus aims to realize interconnection and fusion of man-machine-environment of a manufacture site. Target objects of different types are packed into virtual services of uniform format according to man-machine-environment state and various parameter data acquired from the manufacture site and processed to realize uniform and indiscrimination automatic service packing and publishing of various resources of a manufacture enterprise, and to provide smart monitoring operation for different types of users. The industrial Internet Hub apparatus comprises a data acquisition module, a data processing module, a service packaging module and a smart monitoring module, and has excellent expansibility and base layer transparency. Heterogeneity of accessing and service process for different man-machine-environment objects can be effectively prevented, the utilization rate of enterprise resources can be maximized, and smart level of various resources of an enterprise can be improved. Undifferentiated network accessing of various heterogeneous resources of a manufacture enterprise can be realized, on-line service packaging of various physical resources can be supported, and service level and smart level of a production process can be effectively increased.

Owner:BEIHANG UNIV

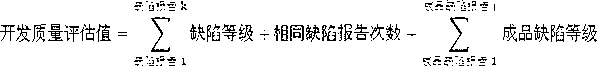

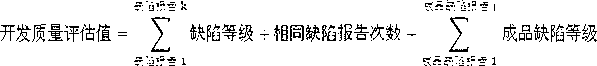

Method for achieving management system for evaluating software test quality and development capacity

ActiveCN103279831AEasy statisticsDone successfullySoftware testing/debuggingResourcesTest qualityData acquisition

The invention discloses a method for achieving a management system for evaluating software test quality and development capacity, and relates to the field of software test management. The management system is composed of a data acquisition system, an algorithm management system, a budget management system and a report management system. According to acquisition of a software test plan and test data, a specific algorithm is used for evaluating the quality and the budget of software testing links. A data acquisition link, an algorithm configuration link, a budget configuration link and a report generation link are mutually independent. Different algorithms and budget managements can be configured according to different software test projects, the method for achieving the management system for evaluating the software test quality and the development capacity can be matched with all test tools in the prior art for use, a tool for continuously improving application software development and the test quality is offered to software industrialized manufacturing enterprises and fields, and the method for achieving the management system for evaluating the software test quality and the development capacity has the advantages of being safe, reliable, rapid in popularization and easy and convenient to maintain.

Owner:中天智领(北京)科技有限公司

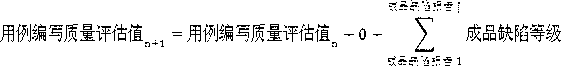

B/S framework based manufacturing enterprise office automation system

InactiveCN105303364AImprove office efficiencyQuality improvementOffice automationInformatizationWork plan

The invention discloses a B / S framework based manufacturing enterprise office automation system. The system is based on a B / S framework and runs on a browser. The system comprises a login management module, a department information management module, a staff management module, a position information management module, a notice information management module, a fixed asset management module, a daily work report module and a work plan module, and is characterized in that the login management module is used for selecting different login identities to log in, the department information management module is used for editing department information, the staff management module is used for checking staff information and carrying out management, the position information management module is used for carrying out position adjustment according to attendance checking information of the staff, the notice information management module is used for publishing information of an enterprise by an administrator and is capable of editing the content and adding an appendix, and fixed asset management module is used for distributing fixed assets to the company staff by the administrator and carrying out management, the daily work report module is used for checking and editing a daily work report, and the work plan module is used for checking and editing a work plan. The system disclosed by the invention is low in cost and convenient to use, can meet requirements of manufacturing enterprises, enables an office environment of the manufacturing enterprises to realize automation and informationization, and improves the office efficiency of the enterprises.

Owner:YANCHENG INST OF TECH

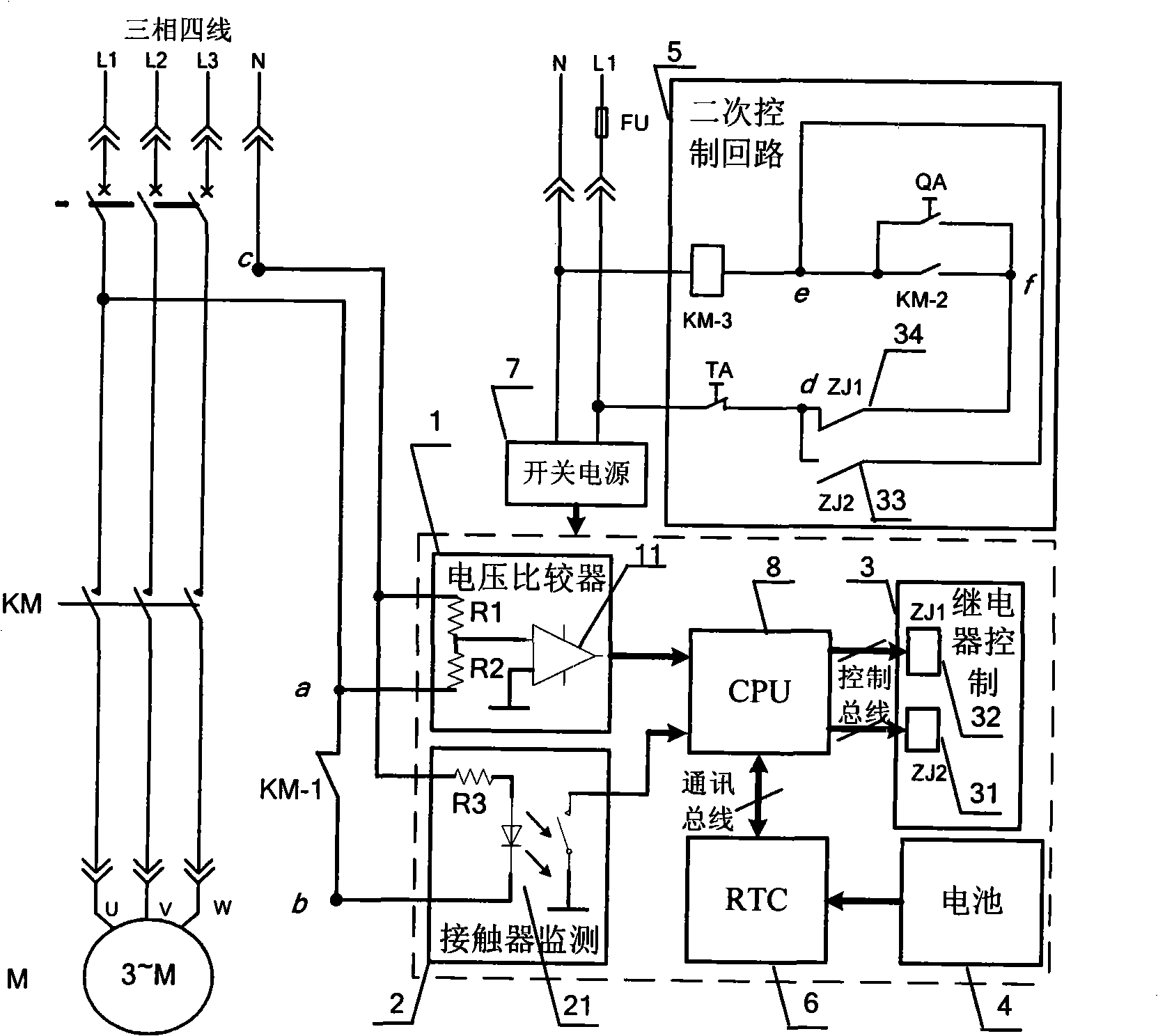

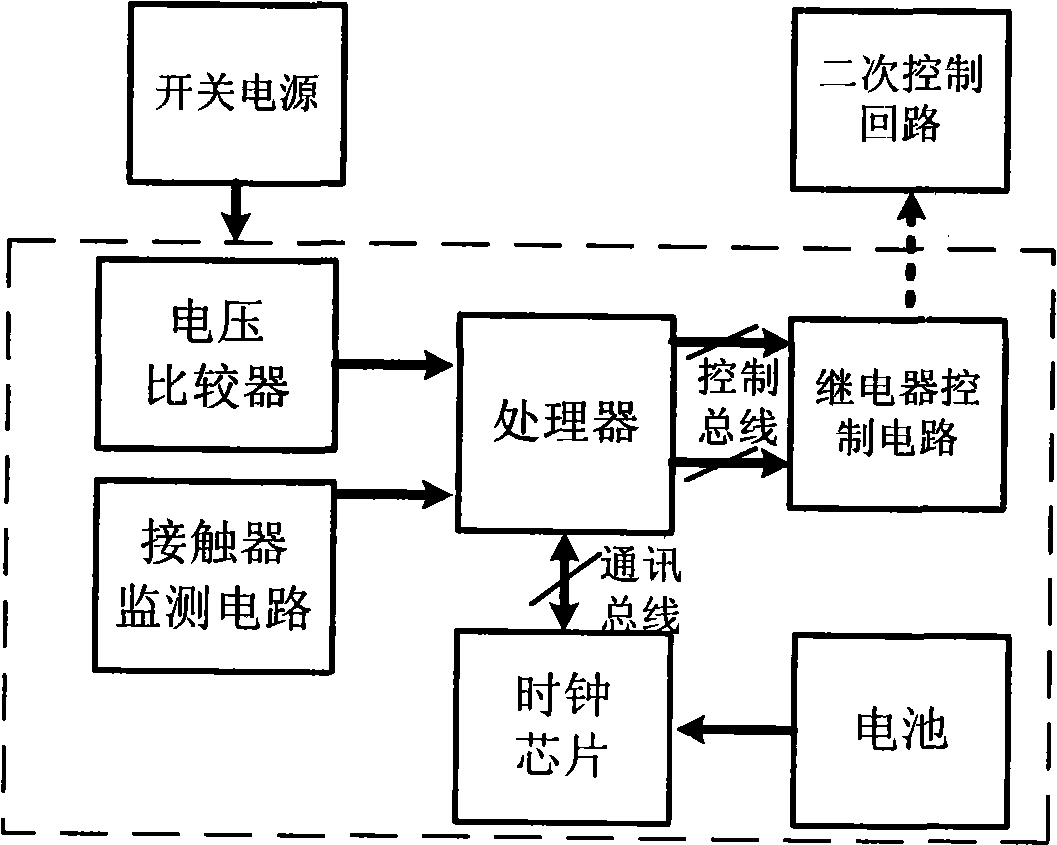

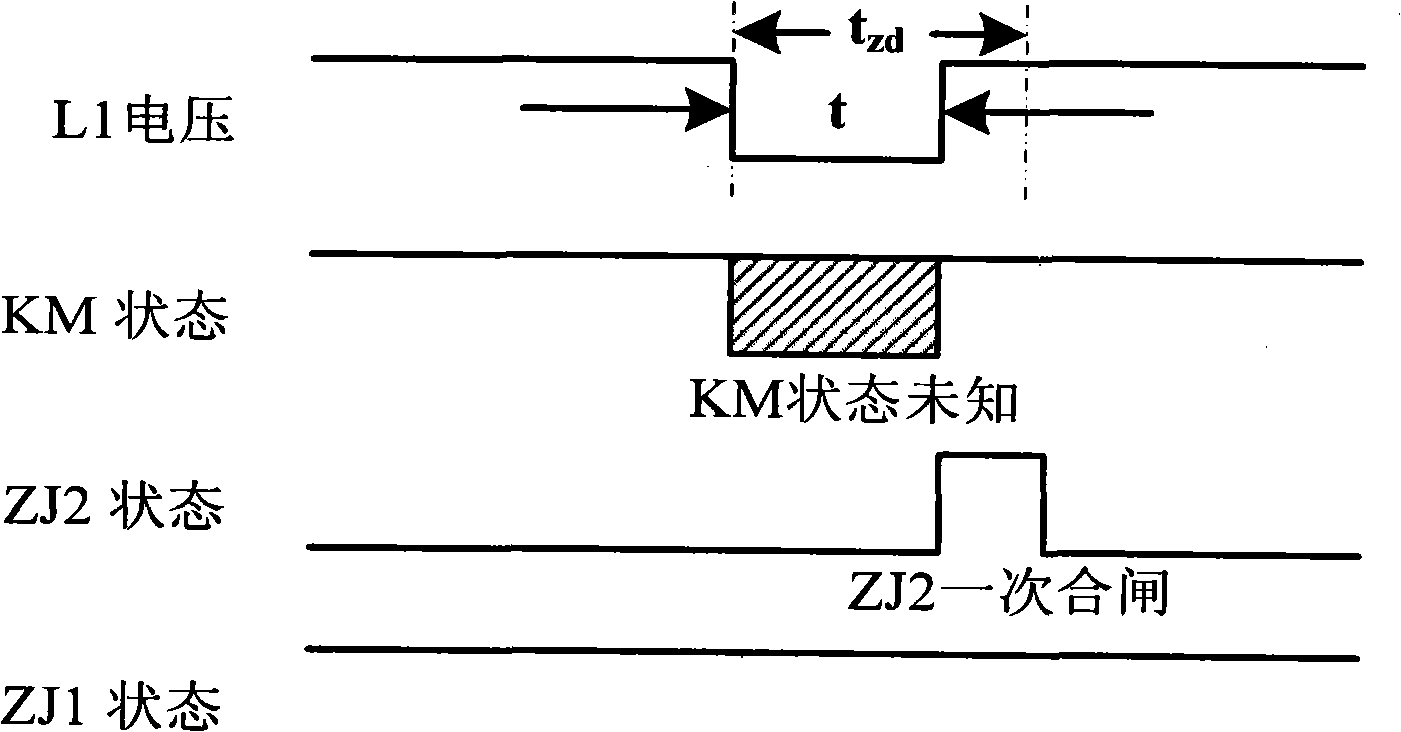

Synthetic apparatus of anti-flashover and protection for low-voltage three phase asynchronous motor

InactiveCN101309003AImprove setting accuracyGood repeatabilityArrangements responsive to undervoltageThree phase asynchronous motorLow voltage

Disclosed is an anti-interference and comprehensive protection device for a low voltage three-phase asynchronous motor, which can realize the restarting of the low voltage three-phase asynchronous motor when the motor is shut down by the fluctuation of the low voltage power network, thereby solves the problem that the product line of industry manufacture enterprise can be shut down abnormally by the power-shaking. The invention is composed of the follows: 1, a processor, 2, a clock chip, 3, a battery, 4, a voltage comparator circuit, 5, a monitor circuit of a contactor, 6, a control circuit of a relay 7, a second control loop, 8, a switching power supply, and 9, a wire connection terminal. The invention can restart the motor when the power is switched on after the motor is shut down due to the power-shaking of the power network, can distinguish two different failures of power-shaking and long-time under-voltage, and can judge whether the motor is working before power-shaking. The anti-interference and comprehensive protection device of the invention has the advantages of high setting accuracy, good repeatability and accurate action time, and does not need external equipment to provide high power backup power supply.

Owner:江苏冠顺电机有限公司 +1

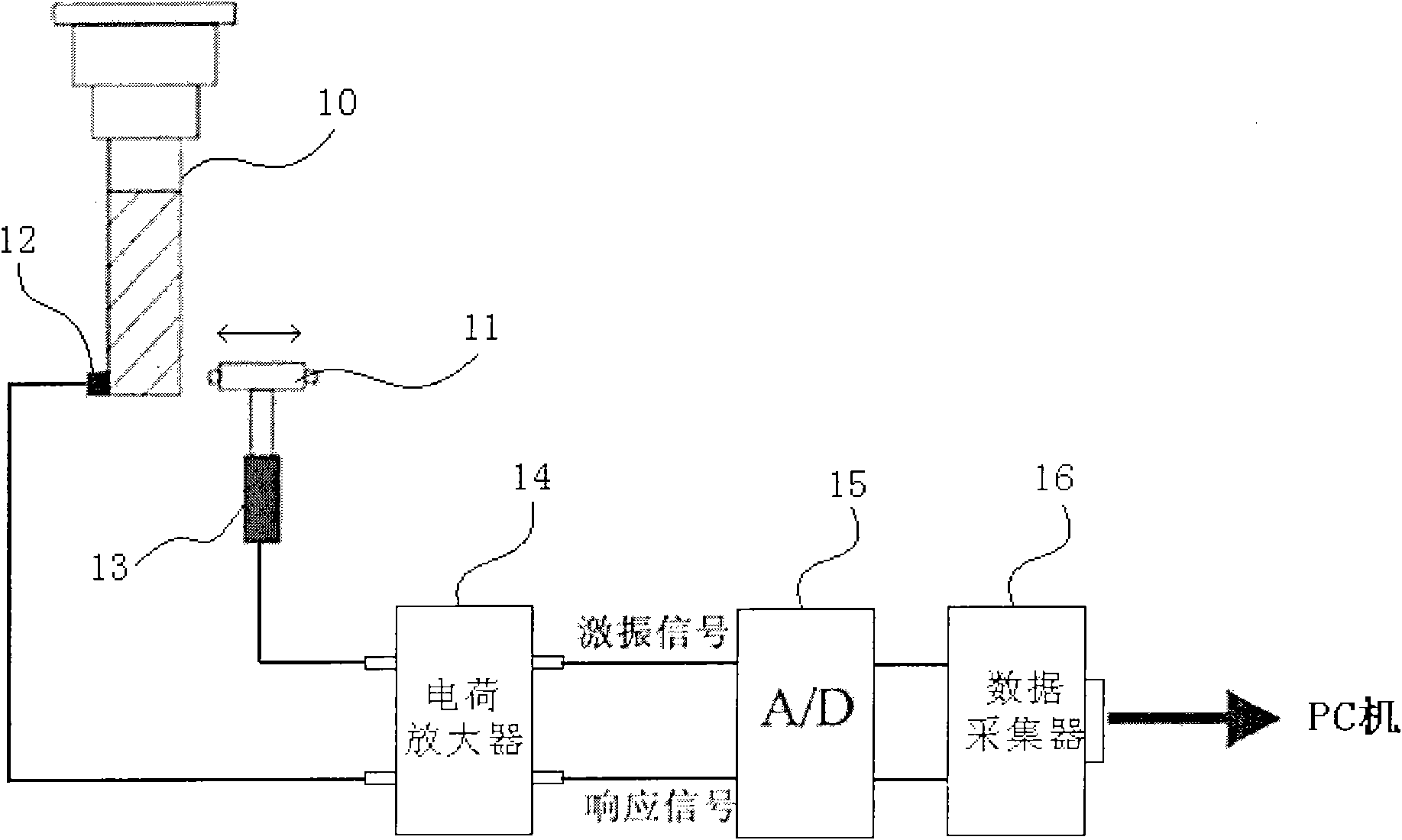

Monitoring and diagnosing system of operation and process state of numerically controlled cylindrical grinding machine

ActiveCN102975119AImprove operational efficiencyHigh precisionGrinding feed controlControl systemComputer module

A monitoring and diagnosing system of operation and a process state of a numerically controlled cylindrical grinding machine comprises a monitoring device of the operation and the process state of a grinding machine and a diagnosing device of the operation and the process state of the grinding machine. The monitoring device of the operation and the process state of the grinding machine comprises a monitoring sensor, a data collecting platform and a computer, the monitoring sensor is connected with the data collecting platform which is connected with the computer, and the monitoring device of the operation and the process state of the grinding machine is connected with the diagnosing device of the operation and the process state of the grinding machine. The functions of the diagnosing device of the operation and the process state of the grinding machine are achieved on the basis of the computer, the monitoring and diagnosing system of the operation and the process state of the numerically controlled cylindrical grinding machine carries out diagnosis according to measuring and analysis of the key signals in a grinding machine processing process, improves the quick response ability of a machine tool manufacturing enterprise to user malfunctions, and achieves the diagnosing of machine on-line faults by integrating an intelligent diagnosing module with the numerically controlled system part of an existing precision machine tool.

Owner:TSINGHUA UNIV

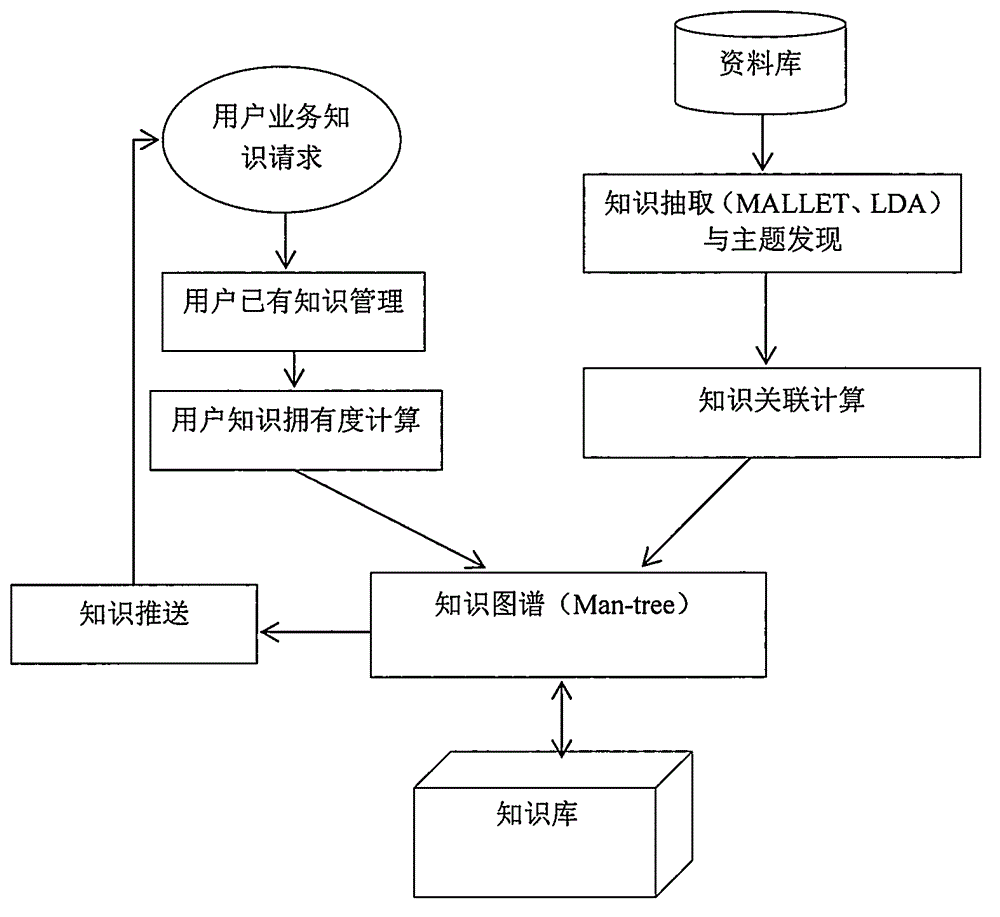

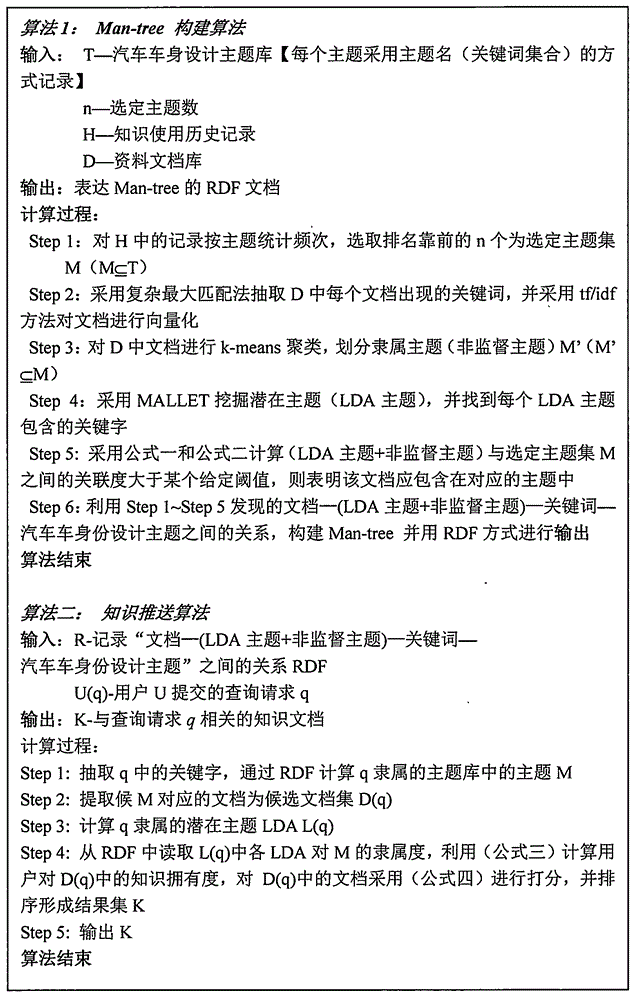

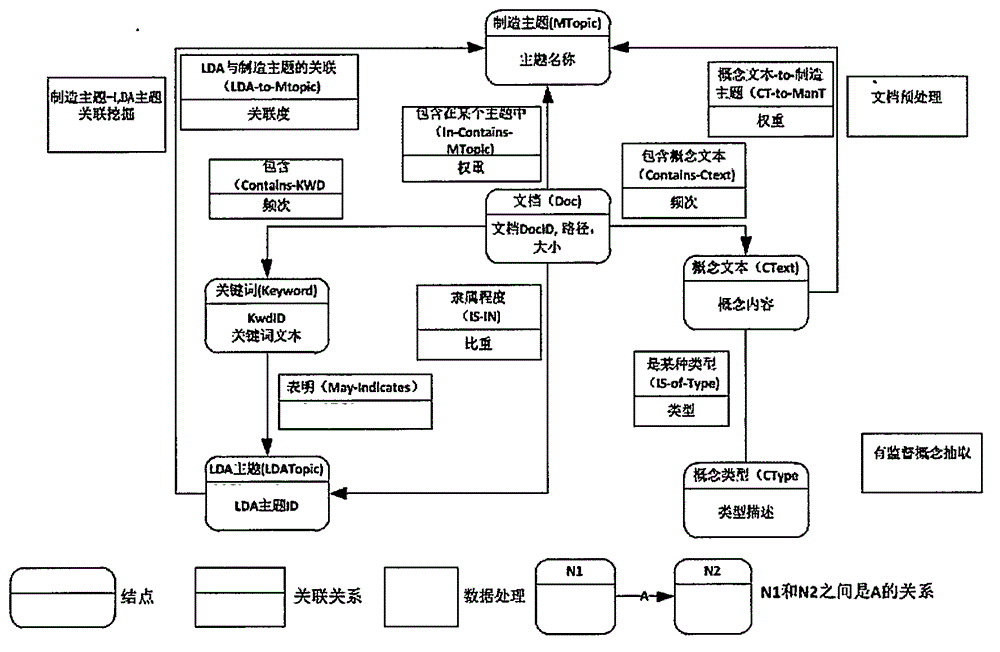

Manufacturing design knowledge individualized pushing method based on knowledge graph (Man-tree)

InactiveCN106156090AGood answerProof of feasibilitySpecial data processing applicationsPersonalizationKnowledge modelling

The invention belongs to the technical field of knowledge management and knowledge pushing oriented to manufacturing enterprises, particularly relates to a novel and efficient knowledge management and knowledge pushing method based on a knowledge graph and discloses a knowledge pushing method based on a manufacturing design knowledge graph structure (Man-tree). By means of the method, the comprehensiveness and accuracy of enterprise knowledge pushing can be effectively improved. The knowledge pushing method comprises the step that a knowledge modeling module, a knowledge extracting and subject discovering module, a knowledge graph Man-tree establishing module, a user knowledge possess degree calculation module and a knowledge pushing module are established by introducing an LDA method. By quantitatively evaluating the degree of the knowledge processed by a user, the knowledge graph is expanded, and semantic association between knowledge and the user is established. According to the specific technology, formation of a database, extraction of knowledge, discovery of knowledge association, knowledge storage design, and a quantitative calculating method for the degree of the knowledge processed by a user are included. The novel method for knowledge pushing in the manufacturing design field is given on the basis that the manufacturing design graph is proposed.

Owner:上海宽文是风软件有限公司

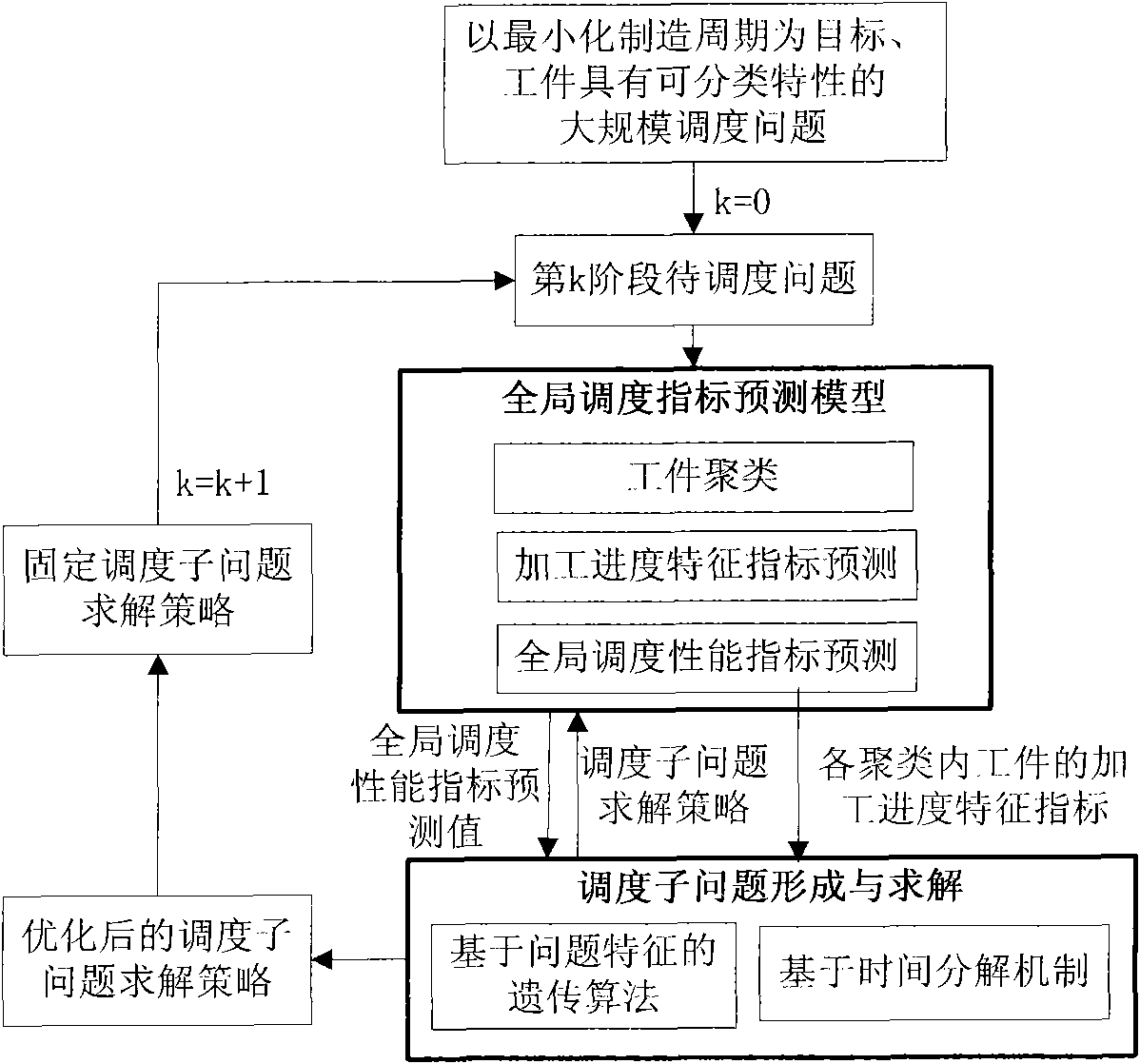

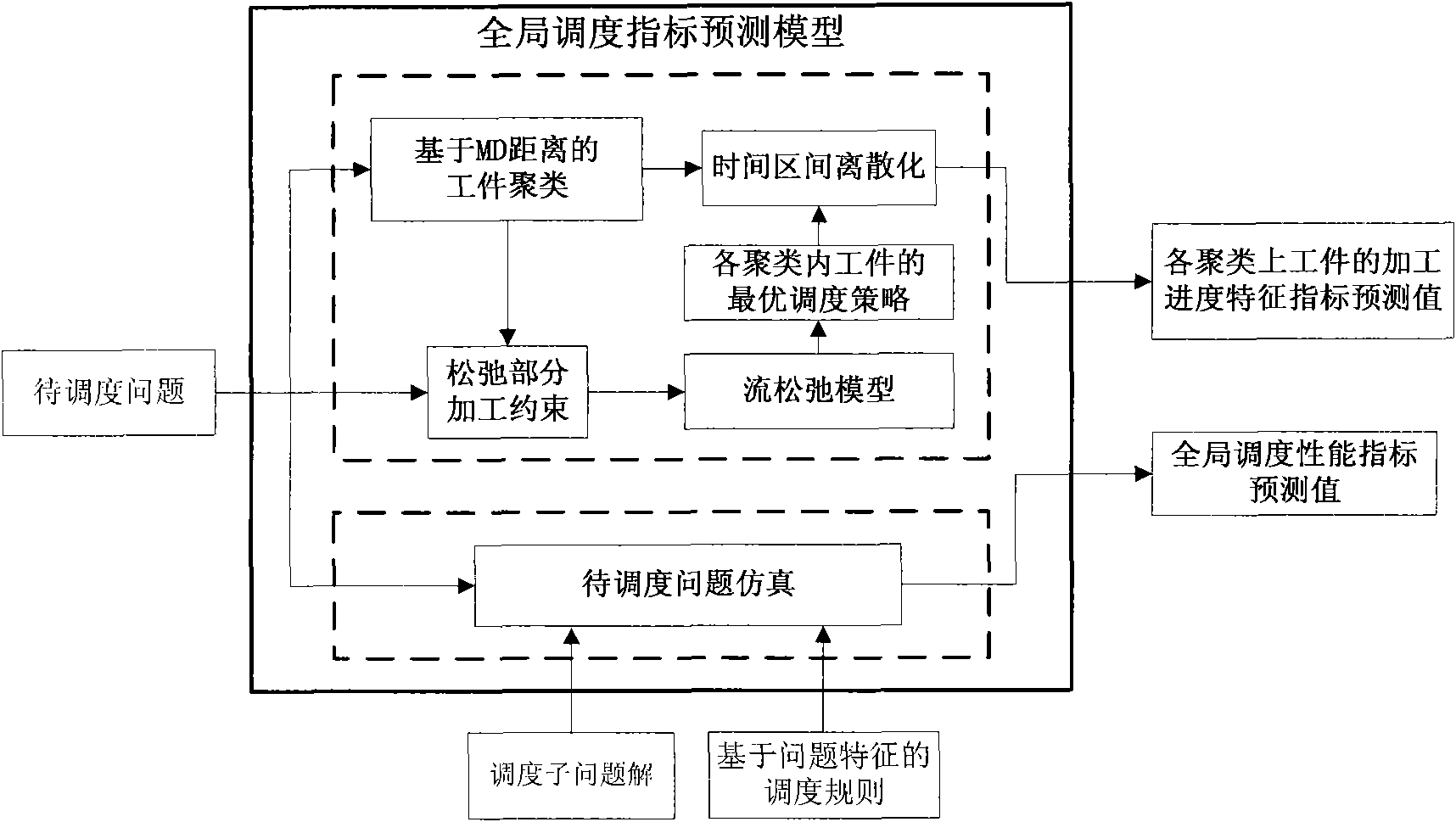

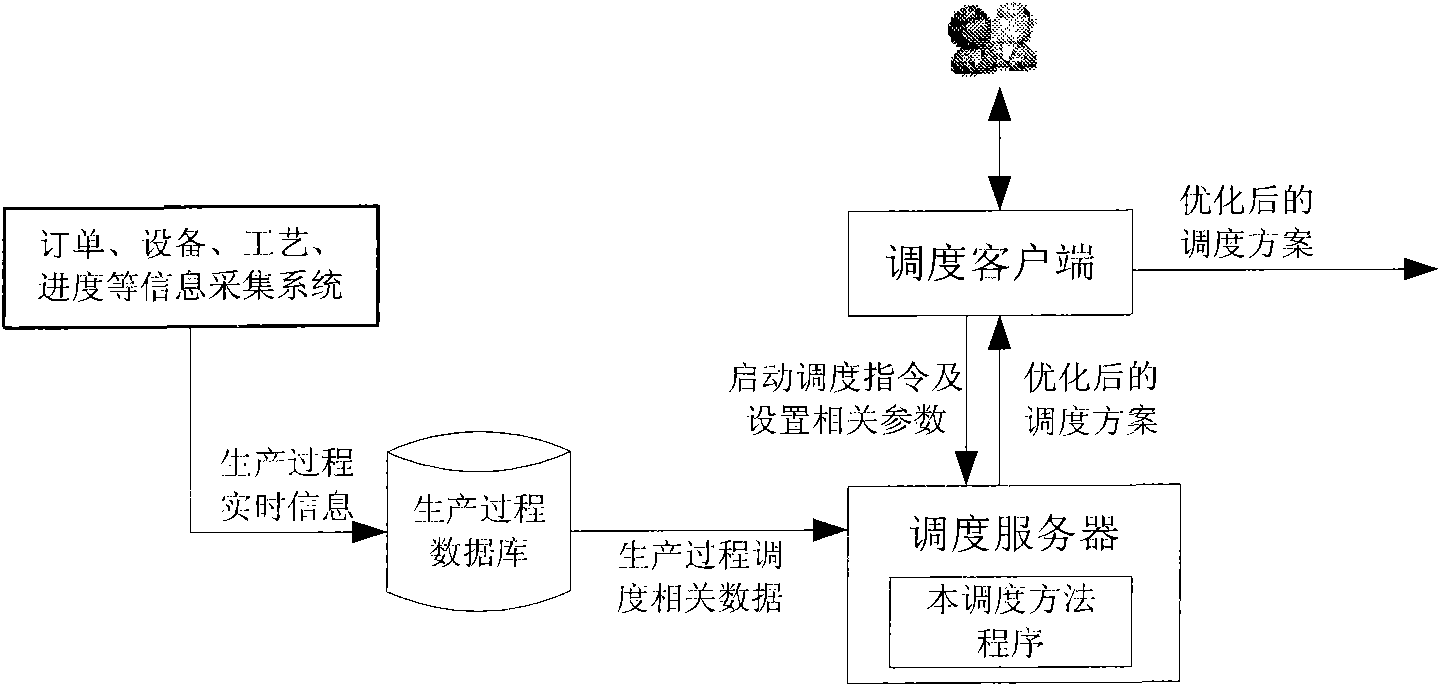

Dispatching method based on iterative decomposition and flow relaxation in large-scale production process

InactiveCN101788819AShorten the manufacturing cycleIncrease productivityTotal factory controlProgramme total factory controlDecompositionMachine utilization

The optimizing dispatch of the production process plays an important role in shortening the manufacture period, improving the utilization ratio of a machine, reducing the production cost, and the like of a manufacture enterprise. The invention discloses a dispatching method based on iterative decomposition and flow relaxation aiming at a large-scale production process by using a minimized manufacture period as a dispatching target and producing the workpiece with the gradable characteristics widely in the discrete industries, such as micro-electronics, machinery, and the like. In the method, the original dispatching problem is iteratively decomposed into a plurality of stages for solving by adopting an iterative decomposition algorithm structure based on a prediction mechanism; at the solving stage, firstly, a global dispatching index predicting model is established on the basis of a workpiece clustering and flow relaxation approach; and then, the formation and optimizing solution of a dispatching subproblem are carried on under the guide of a global dispatching index predicting value obtained by the predicting model. After being applied to the large-scale production process by adopting a minimized manufacture period as the dispatching target and producing the workpiece with the gradable characteristics, the invention can effectively shorten the manufacture period and improve the production efficiency.

Owner:TSINGHUA UNIV

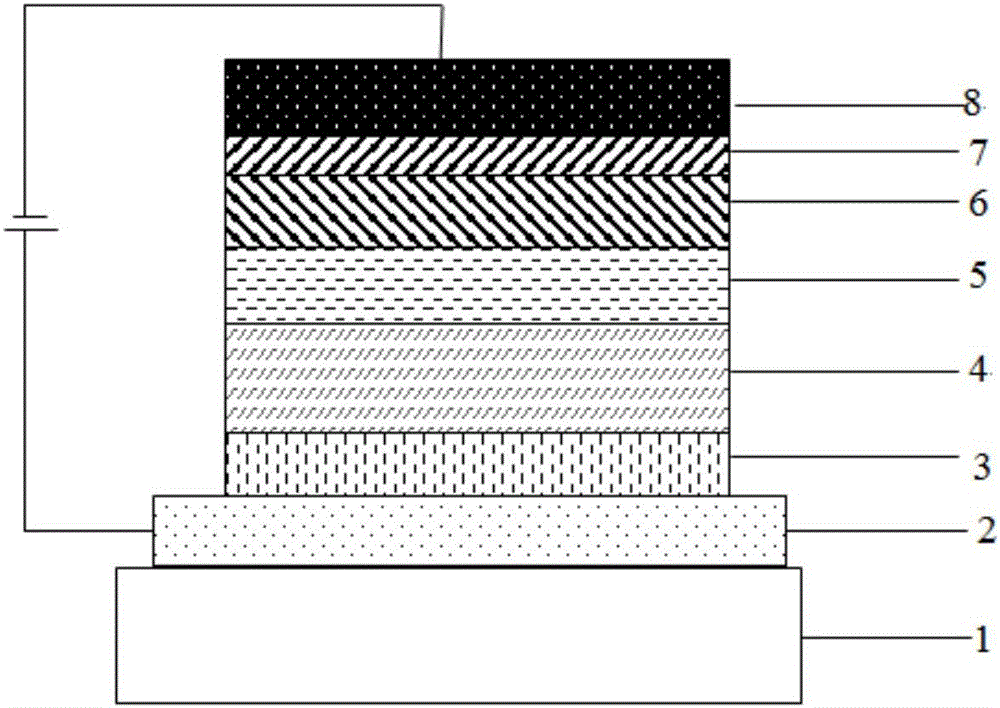

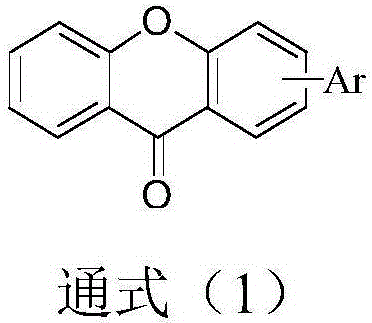

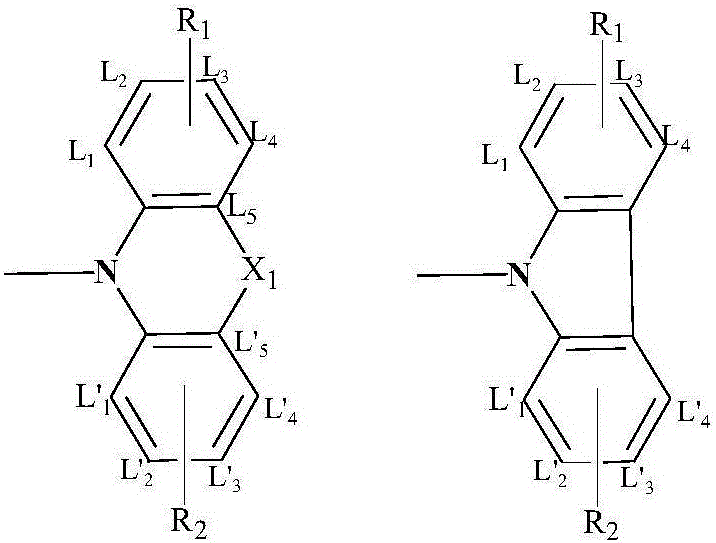

Compound based on xanthone and application thereof

ActiveCN106220638AInhibit aggregationImprove thermal stabilityOrganic chemistrySolid-state devicesChemical compoundMolecular symmetry

The invention discloses a compound based on xanthone and application thereof. The compound uses xanthone as a parent nucleus, which is connected to a heteroaromatic group, so as to destroy the molecular symmetry, and thus further destroy the crystallinity of molecules and avoid the aggregation between molecules. The compound based on xanthone has good film-forming property, and can be applied to organic light emitting diode as a luminescent layer; and the OLED device using the compound based on xanthone has good photoelectric property, and can meet the requirements of panel manufacturing enterprises.

Owner:JIANGSU SUNERA TECH CO LTD

Recycle treatment method for wafer rinse waste liquor

InactiveCN101780998ARealize resource processingReduce pollutionWater softeningWater/sewage treatment bu osmosis/dialysisLiquid wasteSocial benefits

The invention relates to a treatment method for rinse waste water of silicon wafer cutting, which not only can fully recover and utilize polyethylene glycol and water in waste water, but also can reduce the treatment amount of the waste water to realize resource recovery. The method comprises the following steps: preliminarily filtering the rinse waste water of the silicon wafer cutting, carrying out softening process, filtering to remove mechanical impurities and sticky materials by one or the combination of a microfiltration membrane and a superfiltration membrane, entering a multi-level membrane separation device to obtain pure water and polyethylene glycol solution, and refining the polyethylene glycol solution to obtain polyethylene glycol the mass percent of which is larger than 95%. The invention has the advantages that the obtained pure water can be used for the rinse waste water of the silicon wafer cutting and the obtained polyethylene glycol is used for the preparation of cutting fluid of the silicon wafer; by the implementation of the invention, water can be recycled, and the polyethylene glycol in the waste water also can be recycled, thus realizing the source treatment of the waste water, greatly saving the cost, reducing the environmental pollution for silicon wafer manufacturing enterprises, and having considerable economic benefit and social benefit.

Owner:HANGZHOU TIAN CHUANG ENVIRONMENTAL TECH

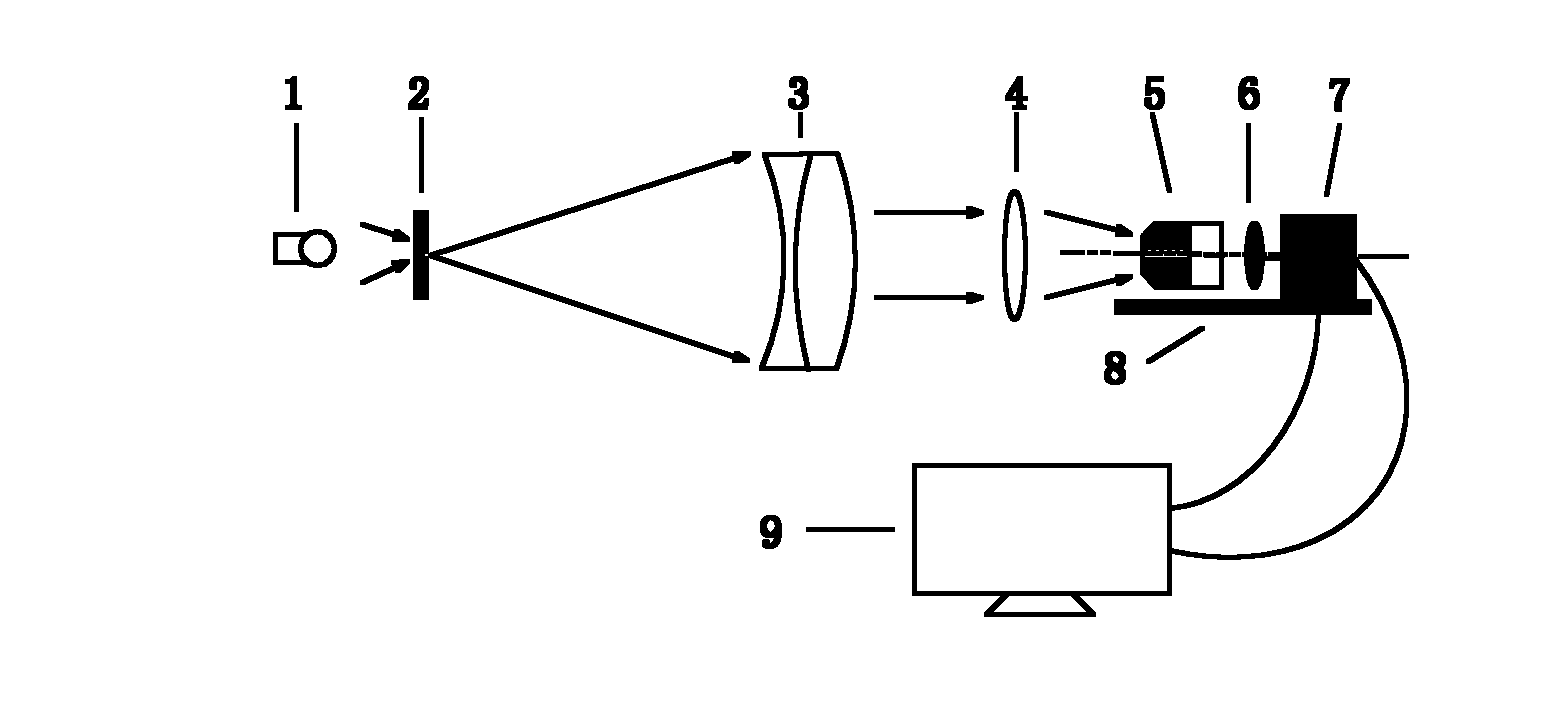

Single focal plane high-precision testing method for optical wavefront of optical imaging system

InactiveCN102252763ASolve for uniformitySolve the errorOptical measurementsPupil functionCalculation error

The invention discloses a single focal plane high-precision testing method for optical wavefront of an optical imaging system, relates to the technical field of optical testing, solves the problems that exit pupil amplitudes are not distributed uniformly and calculation errors are introduced by fast Fourier transform in the conventional phase retrieval algorithm, and provides the scheme for eliminating the influence of vibration in the process of image acquisition on detection accuracy. The method comprises the following steps of: establishing a detection platform of the optical imaging system; detecting the position of the focal plane of a lens to be detected by using a detection device in the detection platform and acquiring an out-of-focus stellar image of the lens to be detected by the detection device; selecting effective data according to the acquired out-of-focus stellar image and calculating a pupil function of an optical system; and extracting the phase of the acquired pupil function to obtain the optical wavefront of the optical imaging system. The pupil function of the optical system is calculated by a Zernike multinomial, an extended Nijboer-Zernike multinomial, and a generalized inverse matrix. The single focal plane high-precision testing method is low in cost, and high in accuracy and is suitable for manufacturing enterprises, scientific research and detection units of the optical imaging system.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

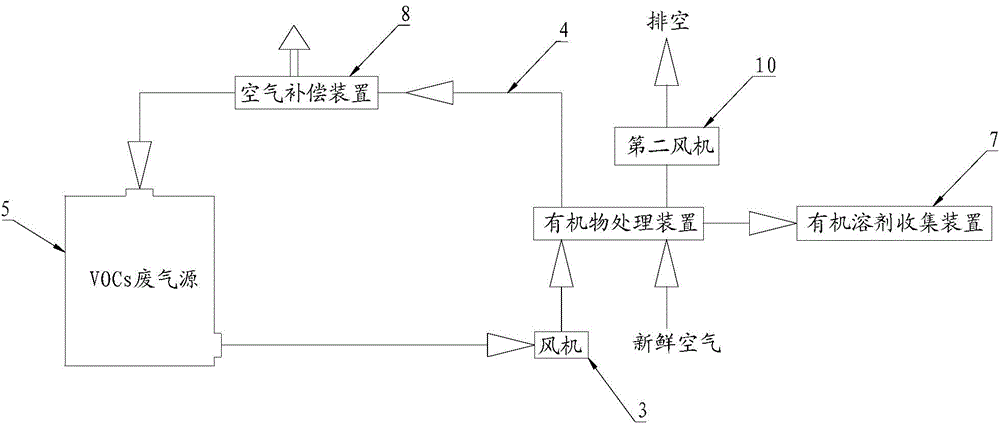

VOCs (volatile organic compounds) waste gas treatment method

ActiveCN104083988AEliminate emission pollutionSatisfy energy savingDispersed particle separationIncinerator apparatusCombined methodOrganic matter

The invention relates to a VOCs (volatile organic compounds) waste gas treatment method. The treatment method comprises the following steps: a step of treating organic matters: carrying out organic matter treatment on waste gas generated by a VOCs waste gas source, wherein the treatment for the organic matters is to remove VOCs in the waste gas by adopting one or a combined method of an absorption recycling method, an adsorption recycling method, a condensation recycling method, a burning method, a catalytic burning method, a plasma method and a biological method; a step of recycling the tail gas: returning the waste gas after the organic matter treatment to the VOCs waste gas source. By adopting the VOCs waste gas treatment method, zero emission of VOCs waste gas is realized, the technical difficulty in realizing zero emission of VOCs waste gas, which needs to be solved but still can not be solved by environment protection equipment manufacturing enterprises for years, can be solved, and the environmental pollution caused by the emission of the VOCs waste gas can be thoroughly eliminated; the entire treatment process is simple and easy to operate, the treatment efficiency is high, few equipment is needed, the energy consumption of equipment is small, the requirement of modern enterprises on energy conservation, emission reduction and production effectiveness improvement can be well satisfied, and great significance on saving the energy and reducing the cost can be achieved.

Owner:FUJIAN LEBEN ENVIRONMENTAL PROTECTION TECH & EQUIP

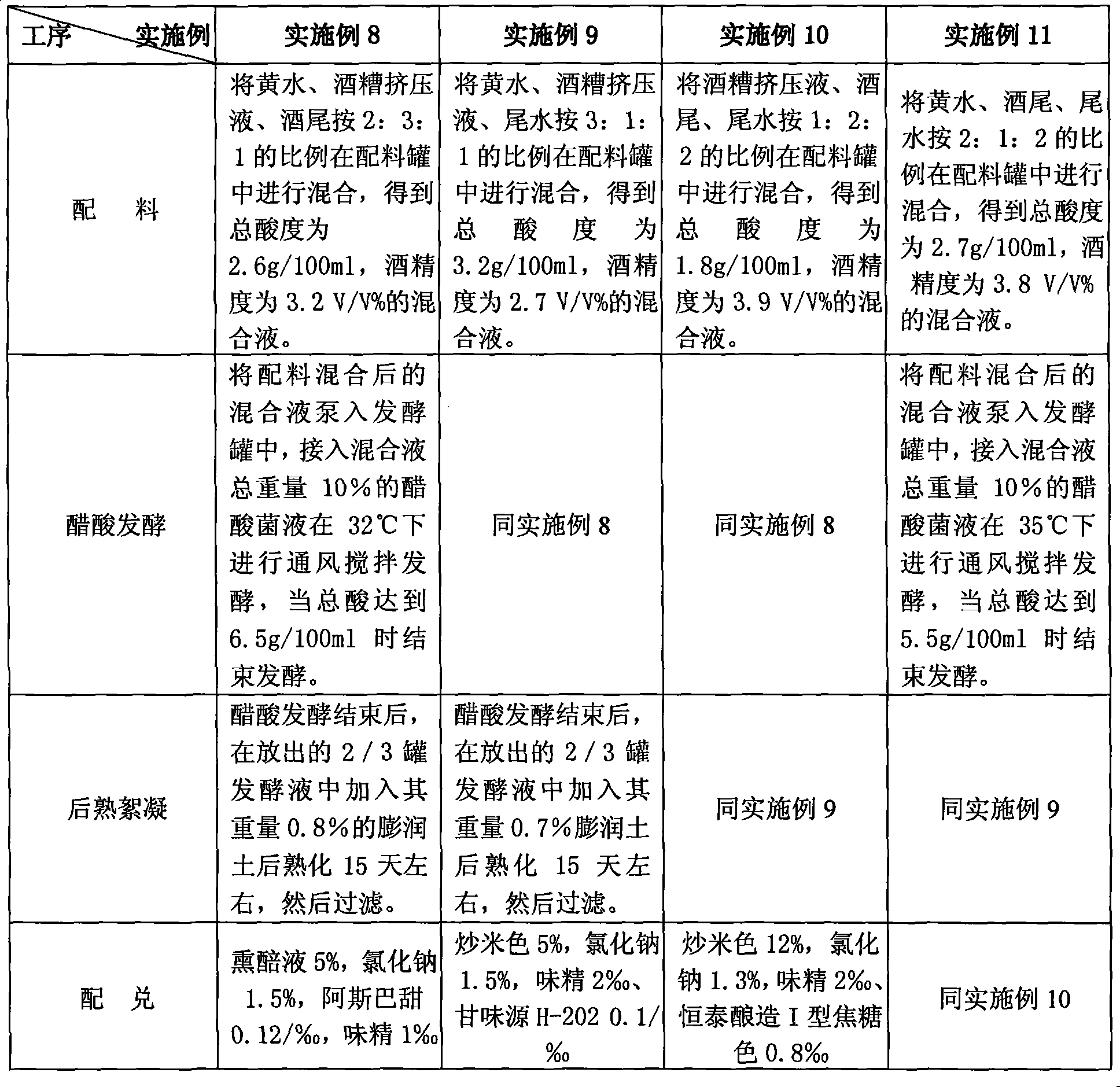

Zero grain consuming full liquid state method for producing vinegar with solid state fermentation flavor

ActiveCN101168715AGreat tasteHigh nutritional valueVinegar preparationNutritive valuesSodium Bentonite

The invention discloses a production method of table vinegar with zero grain consumption and complete liquid state and solid fermentation flavor. The method comprises a material blending process, an acetic fermentation process, a post maturation flocculation process, a refining sterilization process, and a mixing process, wherein, the material blending process adopts the steps that at least two of solid state liquor making concomitant flavoring liquid, grain stillage squeezed fluid, ending liquor, and ending water are blended, and the total acid content of acetometer in the mixed liquor is 0.48 to 6.5 g / 100 ml, and the alcohol content is 0 to 6.5 V / V percent; the acetic fermentation process adopts the steps that that the mixed liquor is accessed into acetic acid bacteria liquor, the weight of the mixed liquor is 10 percent of the weight of the acetic acid bacteria, and the mixed liquor is ventilated to be fermented at 32 to 36 DEG C, and the fermentation is finished when the total acid content of acetometer reaches 5.5 to 6.5 g / 100 ml; the post maturation flocculation process adopts the steps that that the fermentation liquor is accessed into aged bentonite abstracted filter liquor, and the weight of the fermentation liquor is 0.7 to 0.8 percent of the weight of the bentonite; then the vinegar is prepared according to the regular refining sterilization process and the mixing process. The invention has the advantages that the process period is short, the cost is low, the grain consumption is zero, the vinegar tastes good, the nutritive value is high, and the vinegar meets the the primary standard of the national value fermentation GB2719-2003. The effective constituents in the flavoring liquid, the grain stillage squeezed fluid, the ending liquor and the ending water can be fully used, the vinegar can effectively protect the environment from pollution, and the invention can be popularized in liquor manufacturing enterprises.

Owner:SICHUAN TUOPAI SHEDE WINE

Sample preparation method of oxygen content measurement of steels

InactiveCN101769835AMeet measurement needsOvercome limitationsPreparing sample for investigationHardnessManufacturing enterprises

The invention relates to a sample preparation method of the oxygen content measurement of steels, which comprises sample preparation methods of pipes, sheets and high-hardness steels and can satisfy the requirements on the oxygen content measurement on the steels in a bearing manufacturing enterprise according the technical requirements of products. Especially for thin-wall pipes, thin sheets, high-hardness steels, and other steels, samples can not be manufactured according to rules in a standard, therefore, the oxygen content of steels at key parts of a bearing can not be measured; and the samples can be manufactured by adopting the sample preparation method in the invention, and the oxygen content can also be measured according to procedures, devices, and methods in an GB / T11261-2006 standard. The samples manufactured by using the sample preparation method can not only be used for measuring the steels, but also be used for measuring the oxygen contents of other metals, thereby overcoming limitations of the sample preparation method in the standard, broadening the usable range and ensuring that more steel products can be all subjected to the oxygen content measurement by using the standard method; and the sample preparation method provides reliable basis and guarantees especially for analyzing and searching early failure reasons of bearing products.

Owner:胡先根

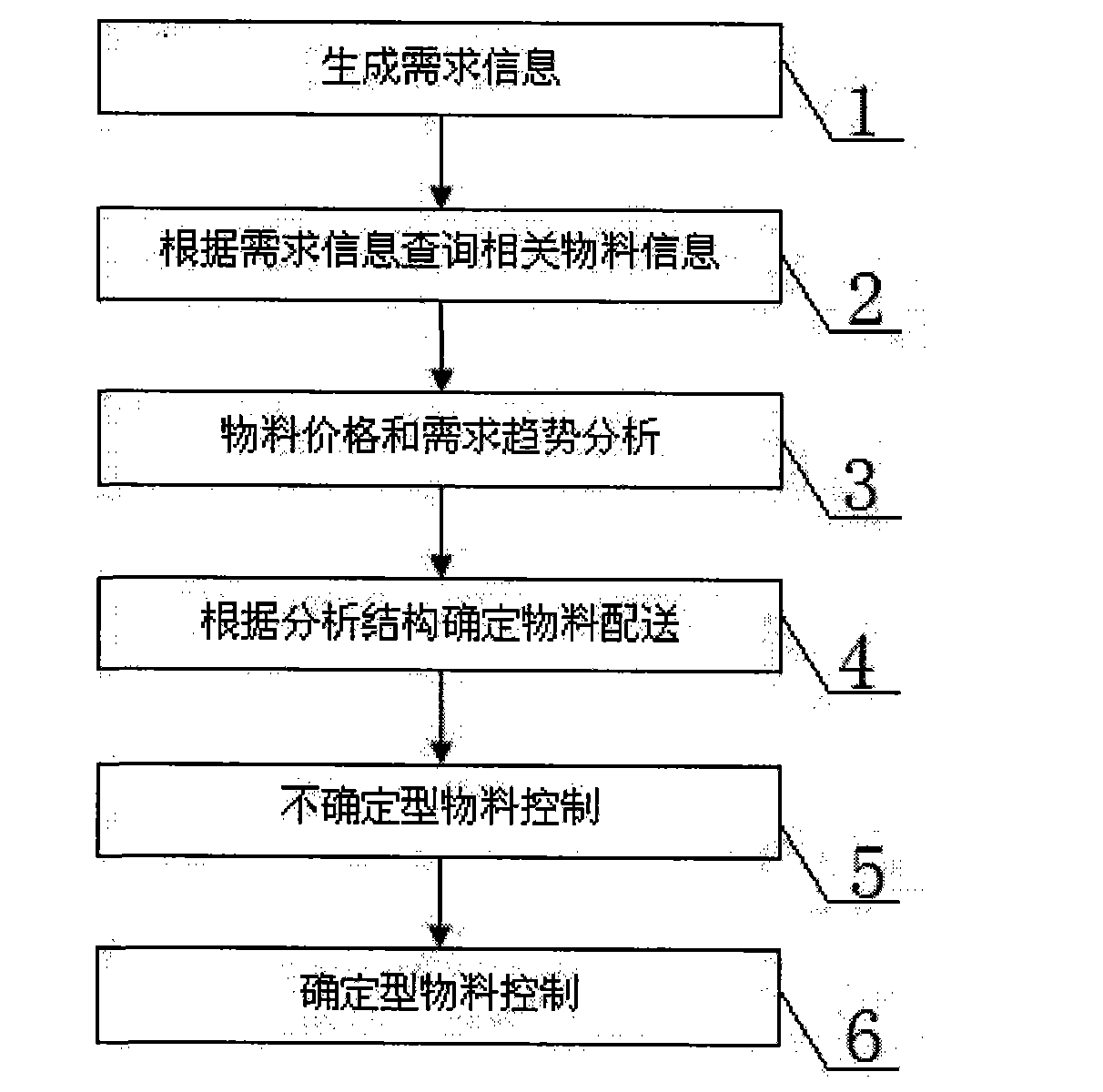

Virtual inventory management system for harbor equipment manufacturing enterprise

InactiveCN101493911ALow costLift the size constraintsBeacon systems using radio wavesPosition fixationInformation processingData warehouse

The invention discloses a virtual inventory management system for port equipment manufacturing enterprises. The system consists of functional modules such as goods supply market information management, in-transit inventory management, local inventory management, virtual inventory control, demand triggering management, data warehouse / data analysis and production planning management. The system applies wireless communication technology, GIS / GPS technology, automatic identification technology, and intelligent information processing technology and the like, takes full advantage of real-time data and triggers inventory replenishment and distribution by real-time inventory status and customer demands.

Owner:SHANGHAI MARITIME UNIVERSITY

Enterprise procurement business management system

InactiveCN106251082AAchieve pinningSolve procurement management challengesResourcesLogisticsBusiness managementSystem maintenance

The invention relates to a management system, which is an enterprise procurement business management system, including a system maintenance module, which manages users and authority control, and records operation records; a project management module, which completes bidding projects, pre-qualification of bidding units, bidding fees, performance And quality tracking, expert management, document management; price verification project management module; bidder management module, establish bidder database, select bidder's reserve when managing bidding projects; price management module, manage previous bidding prices; special mining projects The management module manages some specially approved projects; the transaction processing module realizes daily OA functions; the information query module provides data query, data statistics, data export, and report output for operators. Through the mutual cooperation of these modules, the procurement problems of large-scale joint manufacturing industries are solved, so that various resources in the procurement can be used effectively, efficiently and comprehensively to the maximum extent.

Owner:QINGDAO JINZHI HIGH NEW TECH

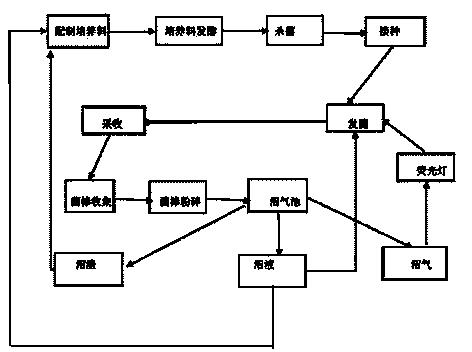

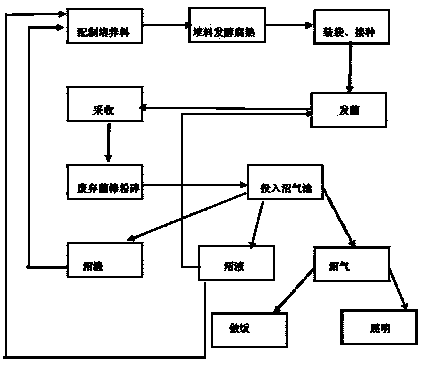

Circular production method for edible mushrooms

The invention discloses a circular production method for edible mushrooms. The circular production method is characterized in that: after edible mushroom compost is subjected to primary production of edible mushrooms, generated mushroom residue is put into a methane tank to generate methane, the generate methane is supplied to edible mushroom manufacturing enterprises or mushroom farmers for cooking, lighting, warming and the like, generated biogas residue is used as the main component of the edible mushroom compost to put into the production of edible mushrooms again, and biogas slurry can be directly added into the compost and also can be sprayed in the production of edible mushrooms; thereby, nutritional ingredient content of the edible mushroom compost is improved, and stress resistance of hyphae or sporocarps in the production of edible mushrooms are also improved. The method can be used for producing 350 kinds of known and naturalized edible mushrooms which can be artificially cultivated, and thus the purpose of comprehensively utilizing resources, saving cost and improving economic performance can be achieved.

Owner:黑龙江昌林盛业生物科技有限公司

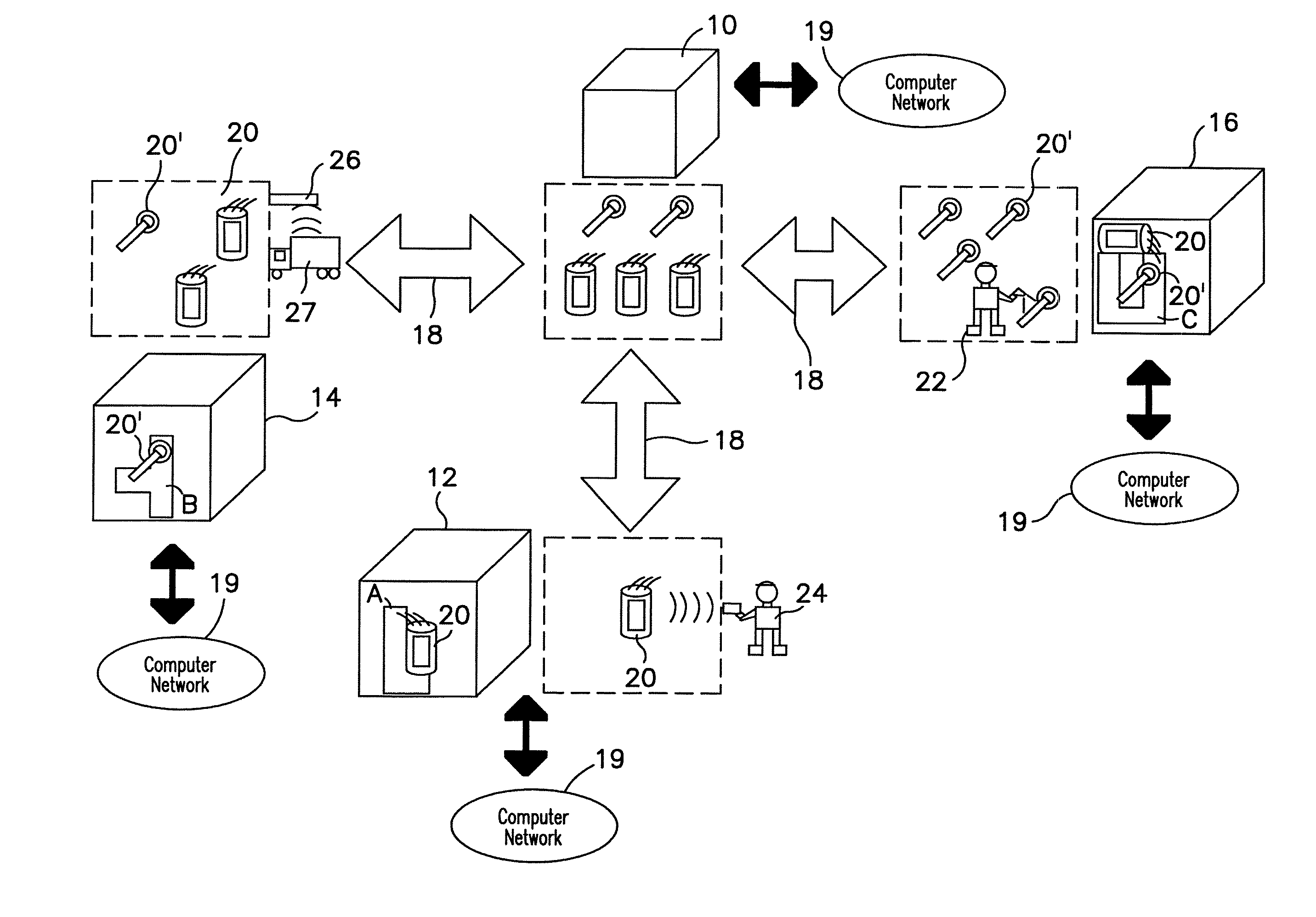

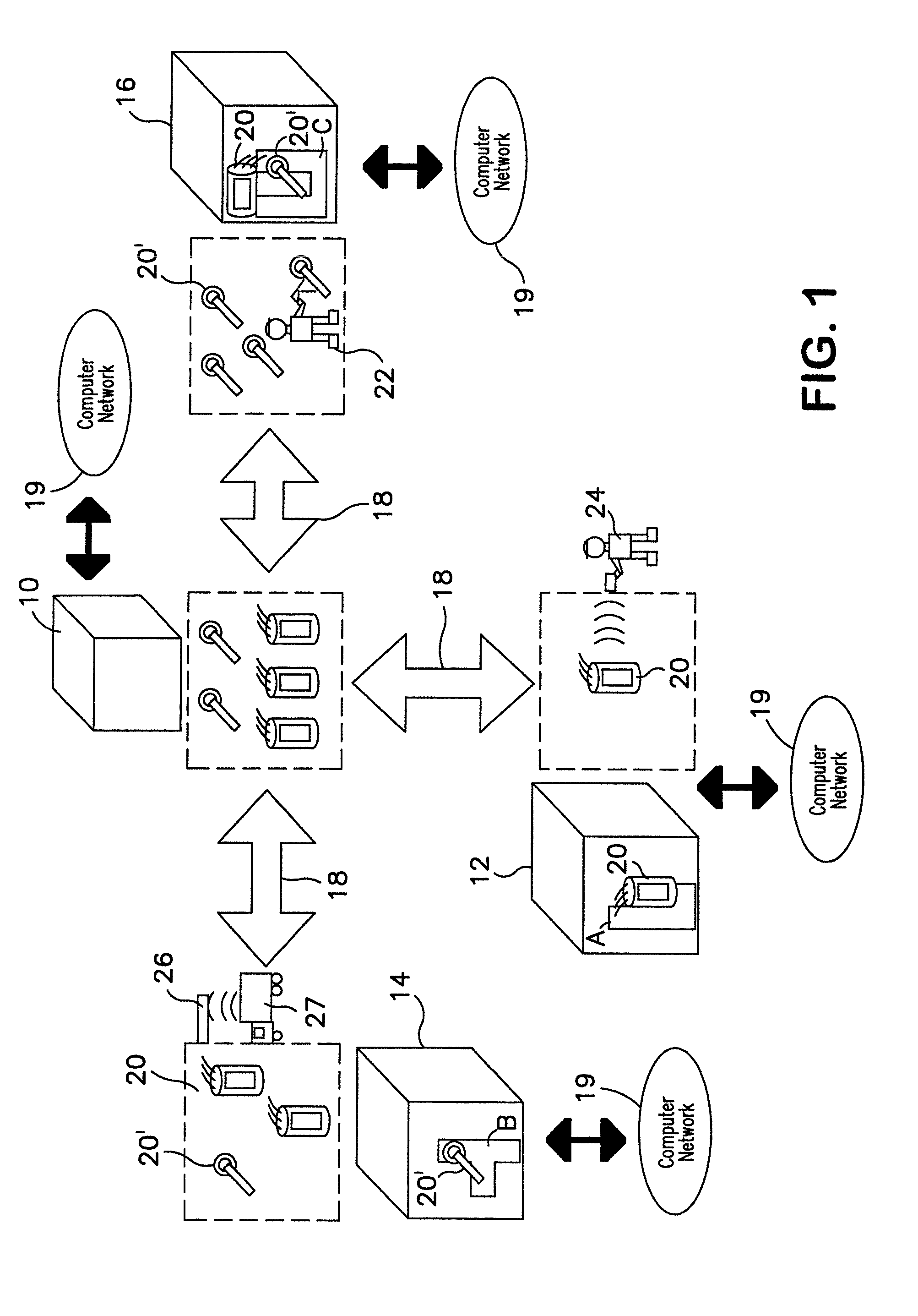

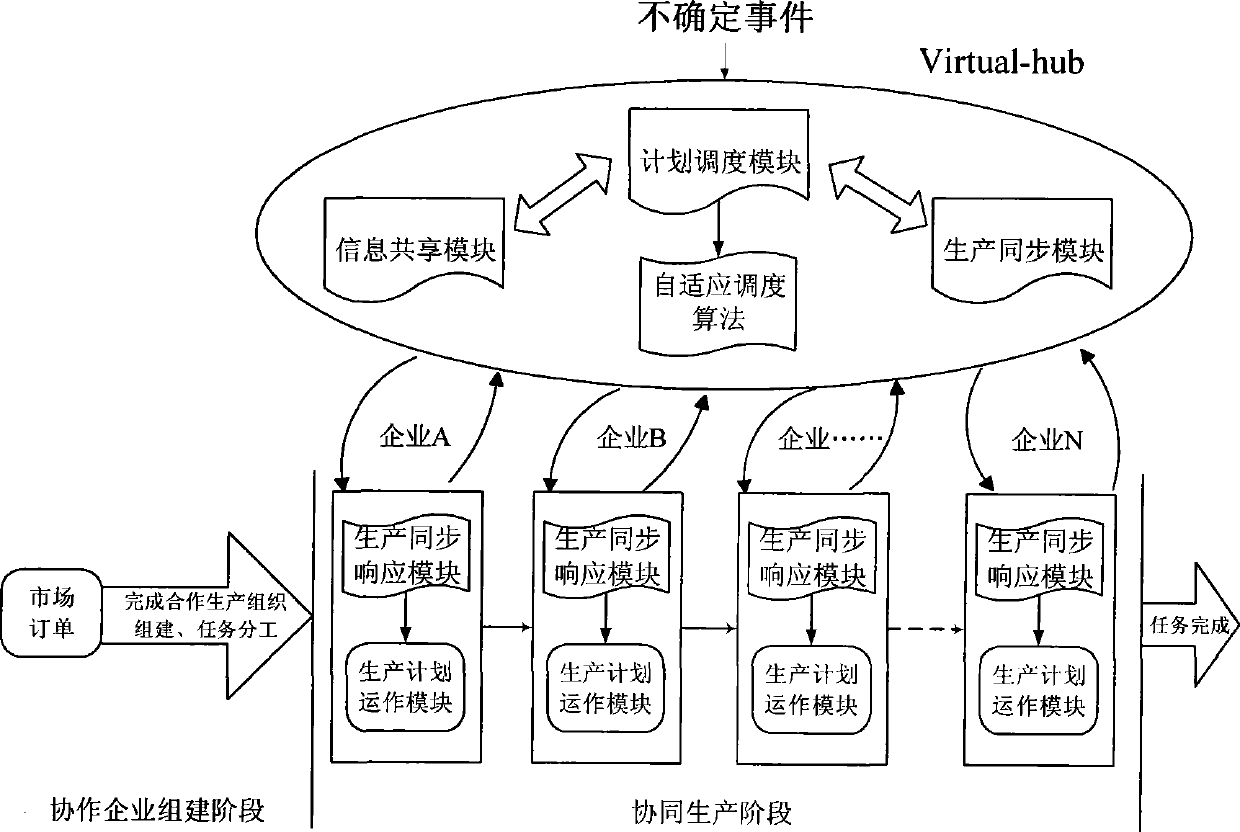

Network coordinative production scheduling system based on Virtual-Hub and self-adapting scheduling method thereof

InactiveCN101441468ASolve collaborative productionCollaborative production is easyTotal factory controlProgramme total factory controlSelf adaptiveDecomposition

The invention relates to a Virtual-hub-based network coordinated production scheduling system, which comprises an information sharing module, a plan scheduling module and a Virtual-Hub of a production synchronization module, wherein the information sharing module comprises an enterprise basic information module, a product material information module, and a plan scheduling information module; the plan scheduling module comprises plan decomposition, task distribution and dynamic scheduling; and the production synchronization module is used to send latest production information commands to other manufactures on a production chain to ensure the longitudinal synchronization of enterprises in coordinated production plan. A self-adaptive scheduling method based on network coordinated production aims to obtain a better or good plan scheduling policy at cost as low as possible when an uncertain event happens in an enterprise at a time T during coordinated production, so as to readjust internal production plan dynamically.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com