Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

482 results about "Precision testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

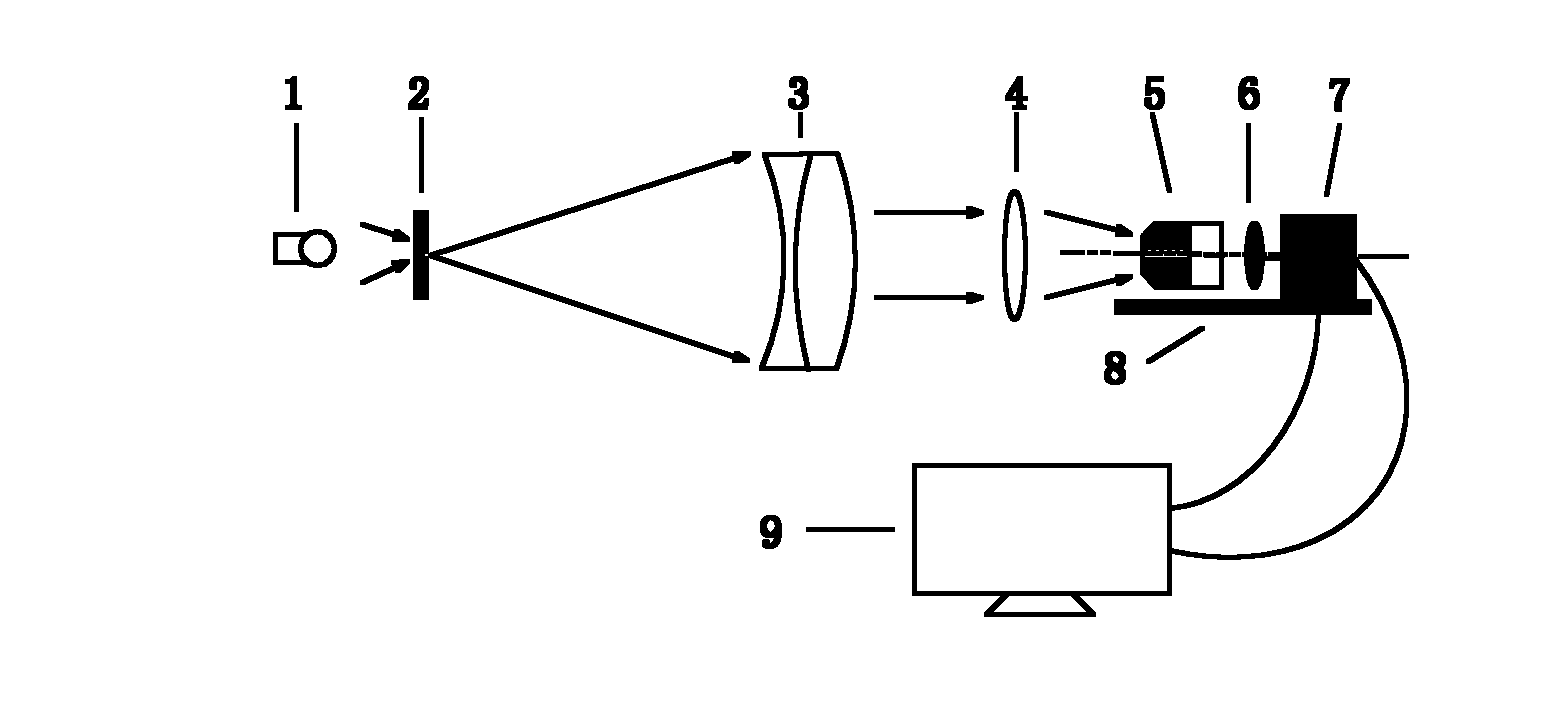

2D photoelectric auto collimation equipment and measuring method based on dynamic differential compensation process

ActiveCN1687702AAccurately measure the amount of changeGood effectUsing optical meansBeam splitterPrism

The invention belongs to the precise instrument manufacturing and detecting technology, especially relates to the bidimensional photoelectric self-alignment equipment and method based on dynamic differentiation compensation method. The equipment comprises the light source, the calibrated board, the CCD image sensor, the beam splitter prism, the aligning object lens, the measuring reflecting lens and the beam splitter between the aligning object lens and the reflecting lens. The two faces of the beam splitter are separately plated with the splitting film and the reflection reducing coating; the surface coarseness of the photic base plate is more than 0.08 um, and paralleling degree of the two faces is smaller than 10'; the light splitting ratio is 52 / 48 is less than or equal to T / R is less than or equal to 72 / 28 and the reflection reducing coefficient alpha is greater than or equal to 99%. The invention improves the stability and the repetition of the measuring.

Owner:日照大象房屋建设有限公司

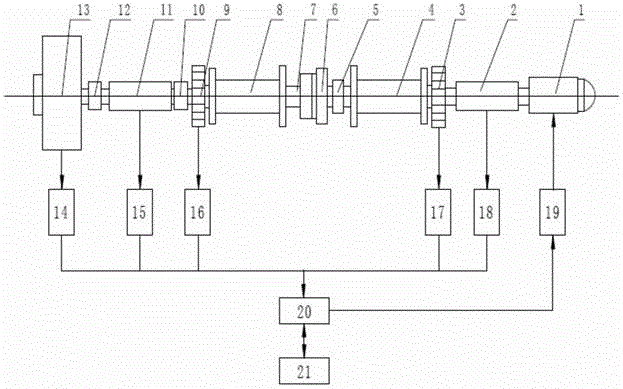

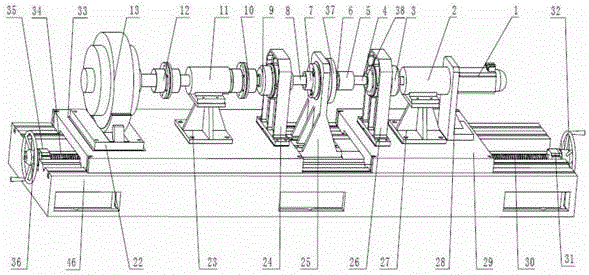

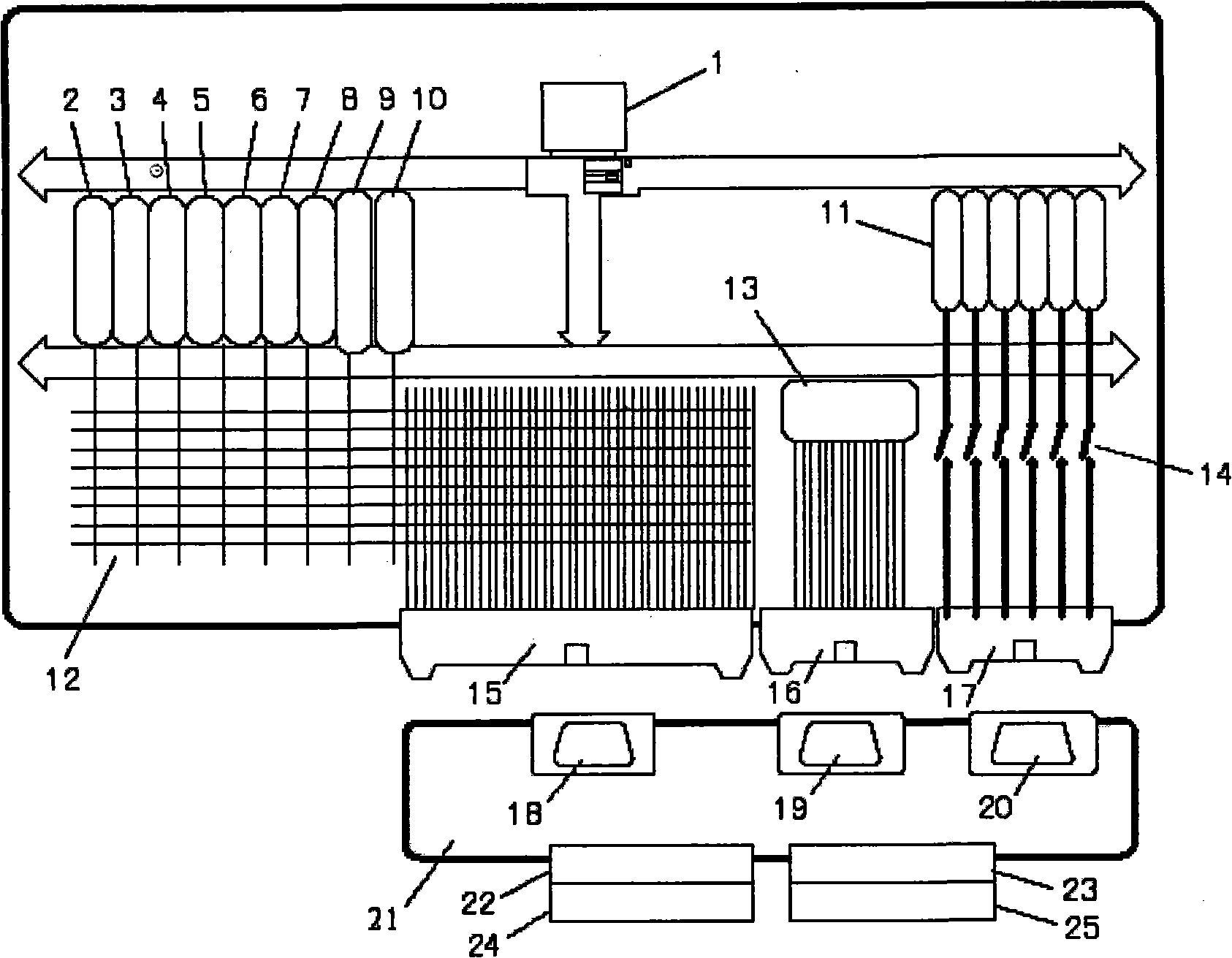

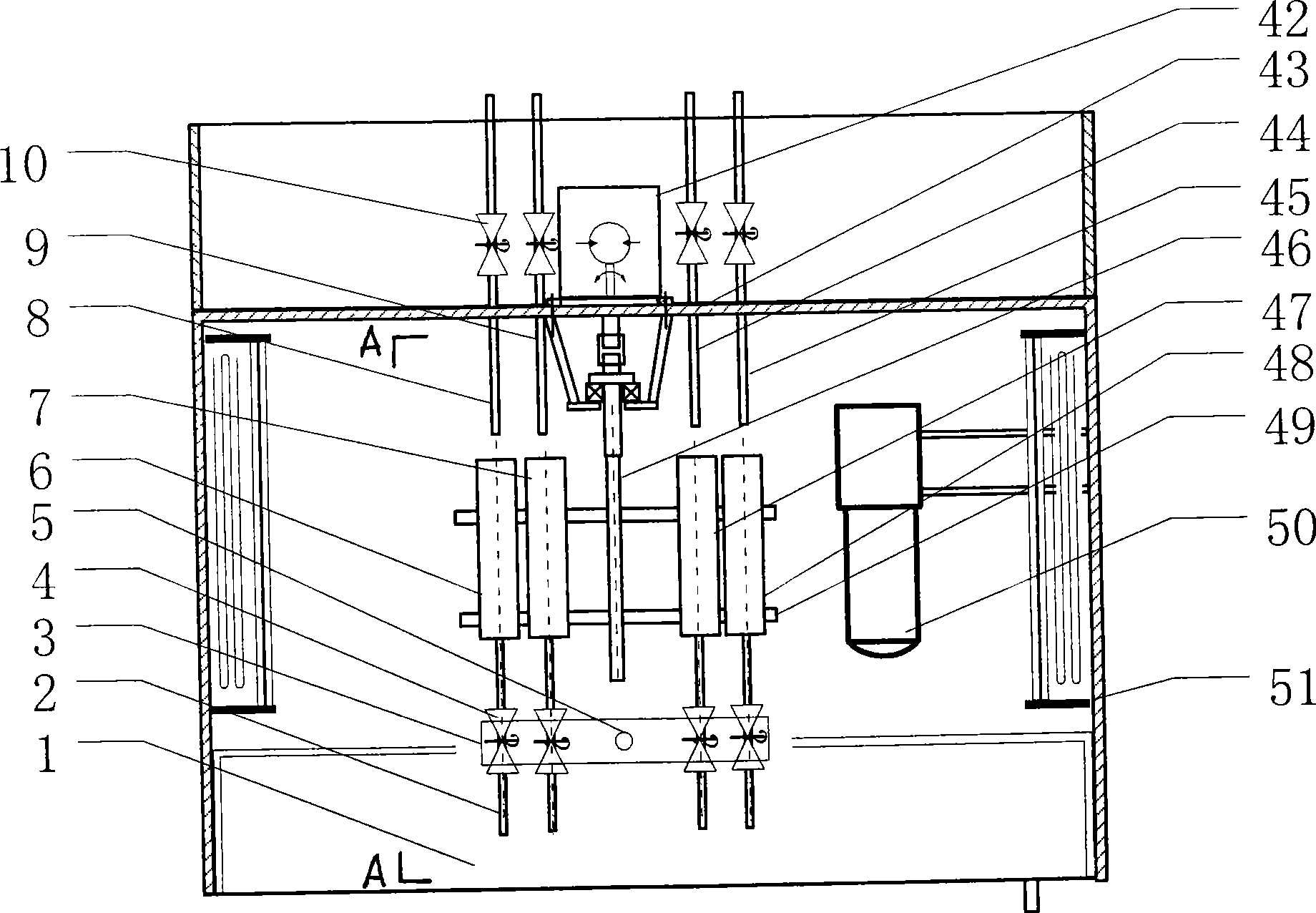

Measuring instrument for comprehensive performances of RV (rot-vector) reducer

InactiveCN104568428ASimplified installation stepsMachine gearing/transmission testingMeasuring instrumentTorque motor

The invention relates to a measuring instrument for comprehensive performances of an RV (rot-vector) reducer and belongs to the technical field of precision testing and metering. The measuring instrument comprises two major parts, wherein a mechanical part mainly comprises a precision mounting support of the RV reducer, an input shaft system, an output shaft system, a torque motor, a shaft coupling, a torque sensor, a magnetic powder brake and a brake mounting support; a measuring and controlling part mainly comprises the torque motor, a controller, a driver, an encoder, a subdivision device, a DSI (digital speech interpolation) card, a data acquisition card and an industrial personal computer. The measuring instrument provided by the invention fills in the blank in testing tables for the comprehensive performances of the RV reducers at home and abroad, and has the advantages of reliable performances, good measurement repeability and accurate measured parameters.

Owner:BEIJING UNIV OF TECH

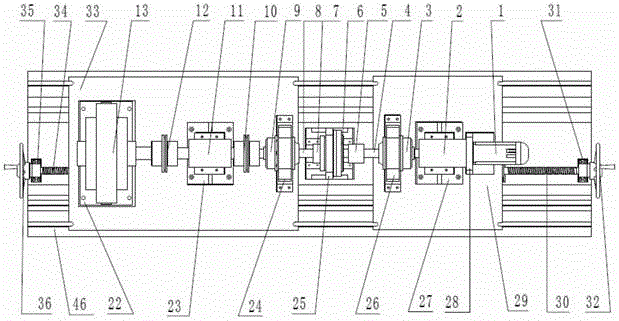

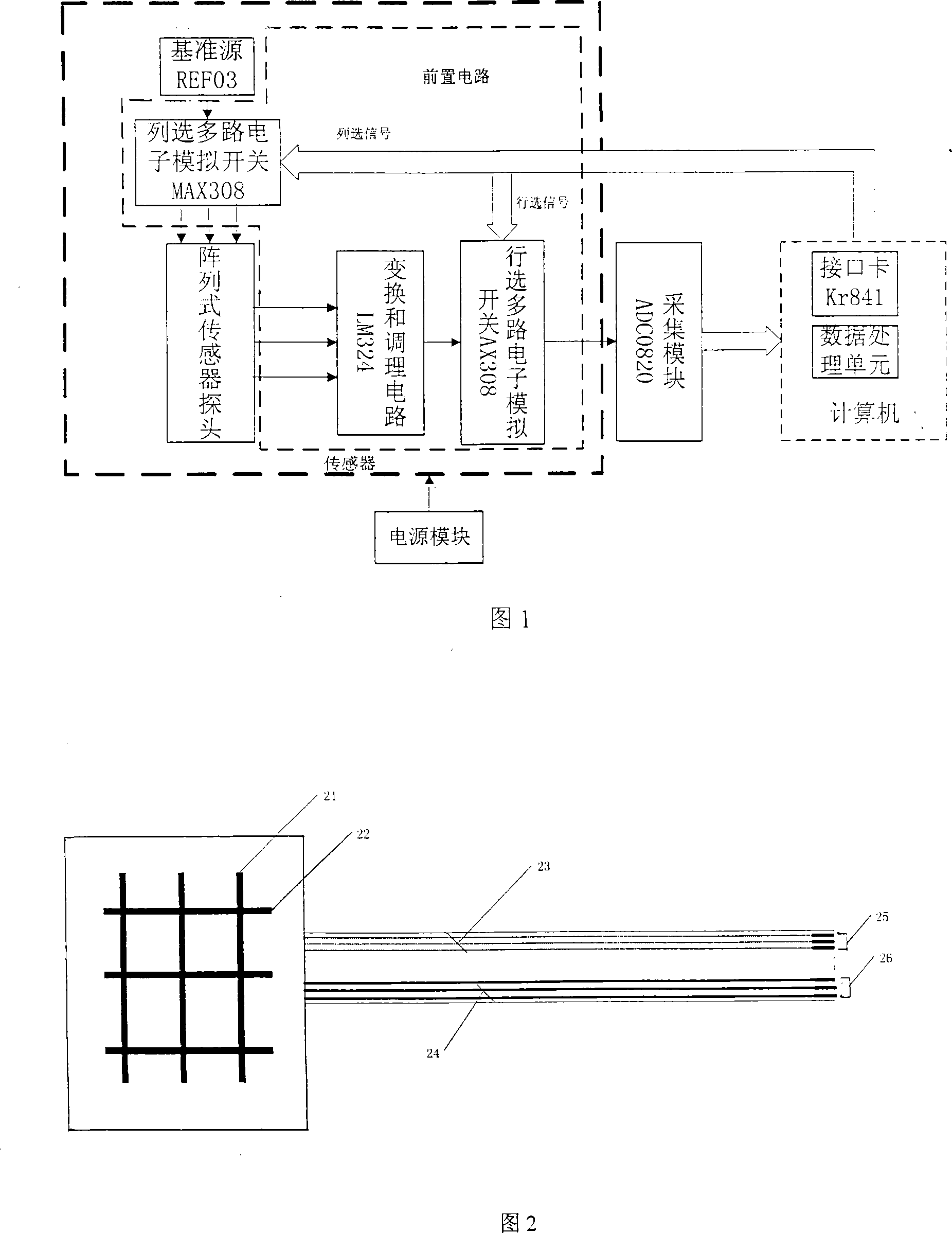

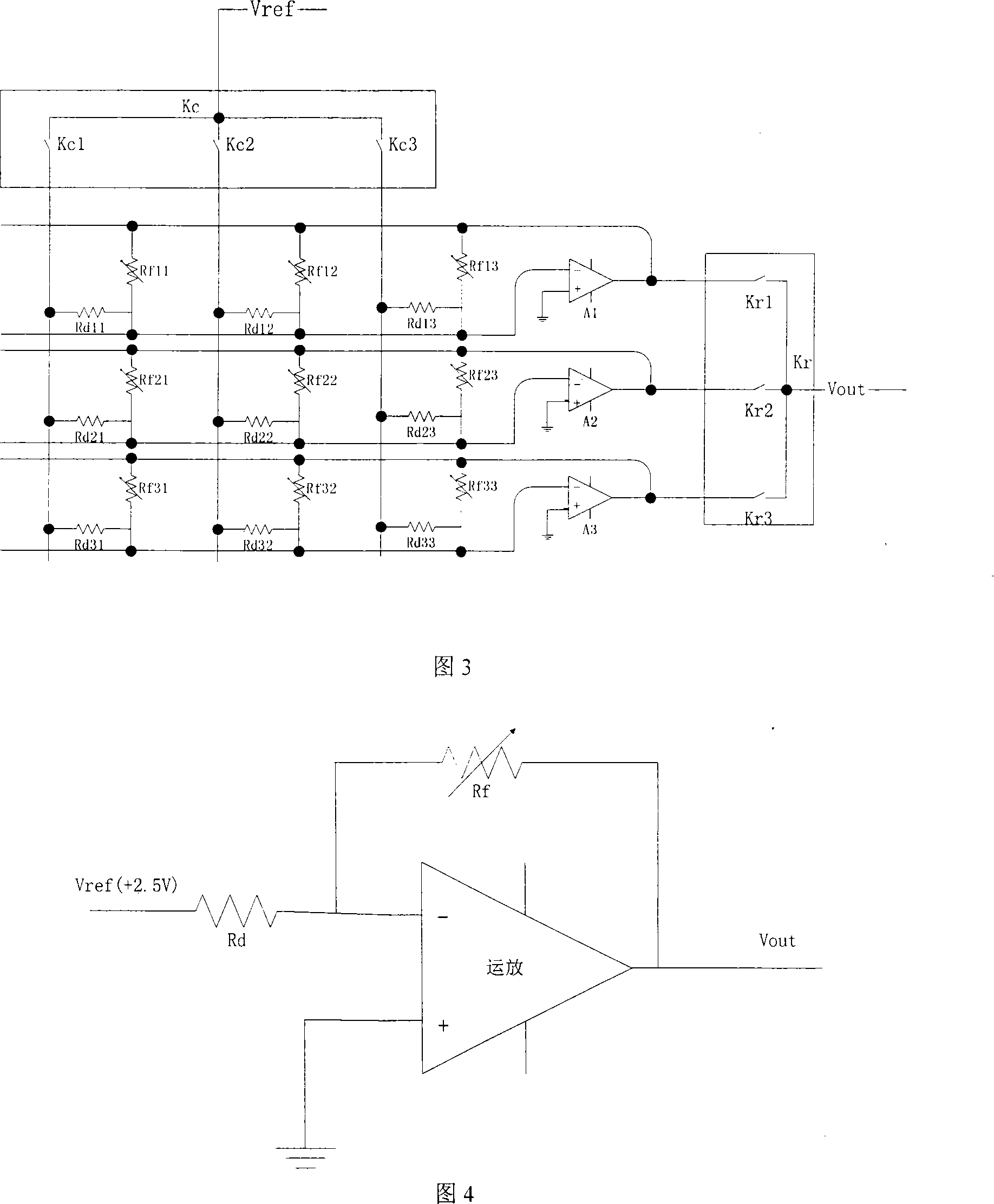

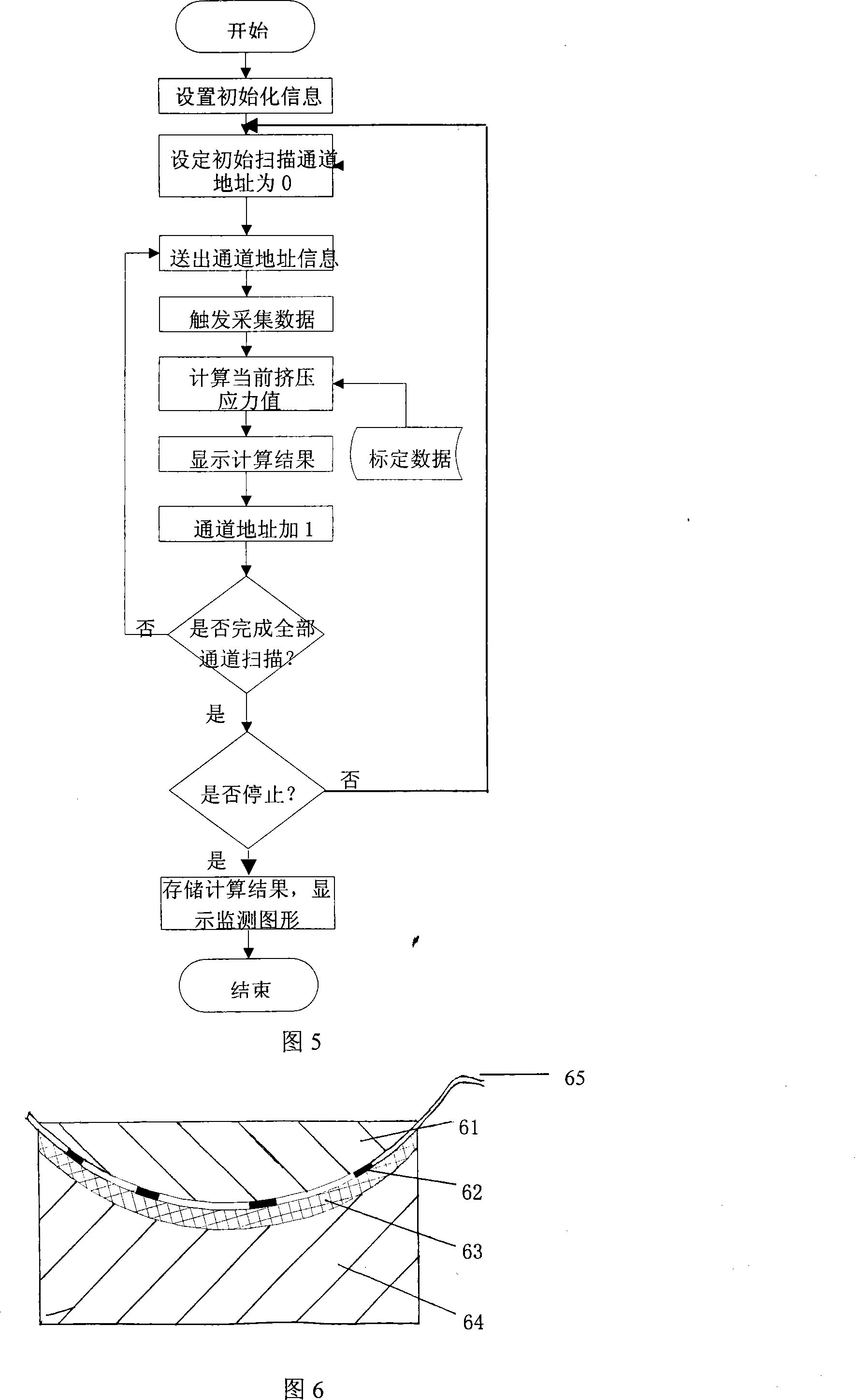

System for monitoring curved surface interlaminar extrusion pressure based on array type ultra-thin submissive force sensor

InactiveCN101201278AImprove flexibilityImprove temperature stabilityForce measurement using piezo-resistive materialsDiagnostic recording/measuringSurface layerComputer module

The invention relates to an inter-curved surface layer extrusion pressure monitoring system based on an array-type ultrathin compliant force sensor, and belongs to the technical field of precise measurement. The system comprises an array-type sensor consisting of an array-type ultrathin compliant force sensing probe and a front end circuit; a reference source; a collection module; a computer comprising an interface card and a data processing unit; and a power supply module. The power supply module is connected with the sensor and the collection module. The reference source is connected with the array-type sensing probe through line multi-route electronic simulation switches. The front end circuit is connected between the array-type sensing probe and the collection module. The interface card is connected with the row and line multi-route electronic simulation switches, respectively. The invention has the characteristics of simple structure, high antijamming capability, high accuracy of measurement, and capability of on-line monitoring of data processing in real time. The invention can monitor the extrusion pressure between face layers on line in real time.

Owner:TSINGHUA UNIV

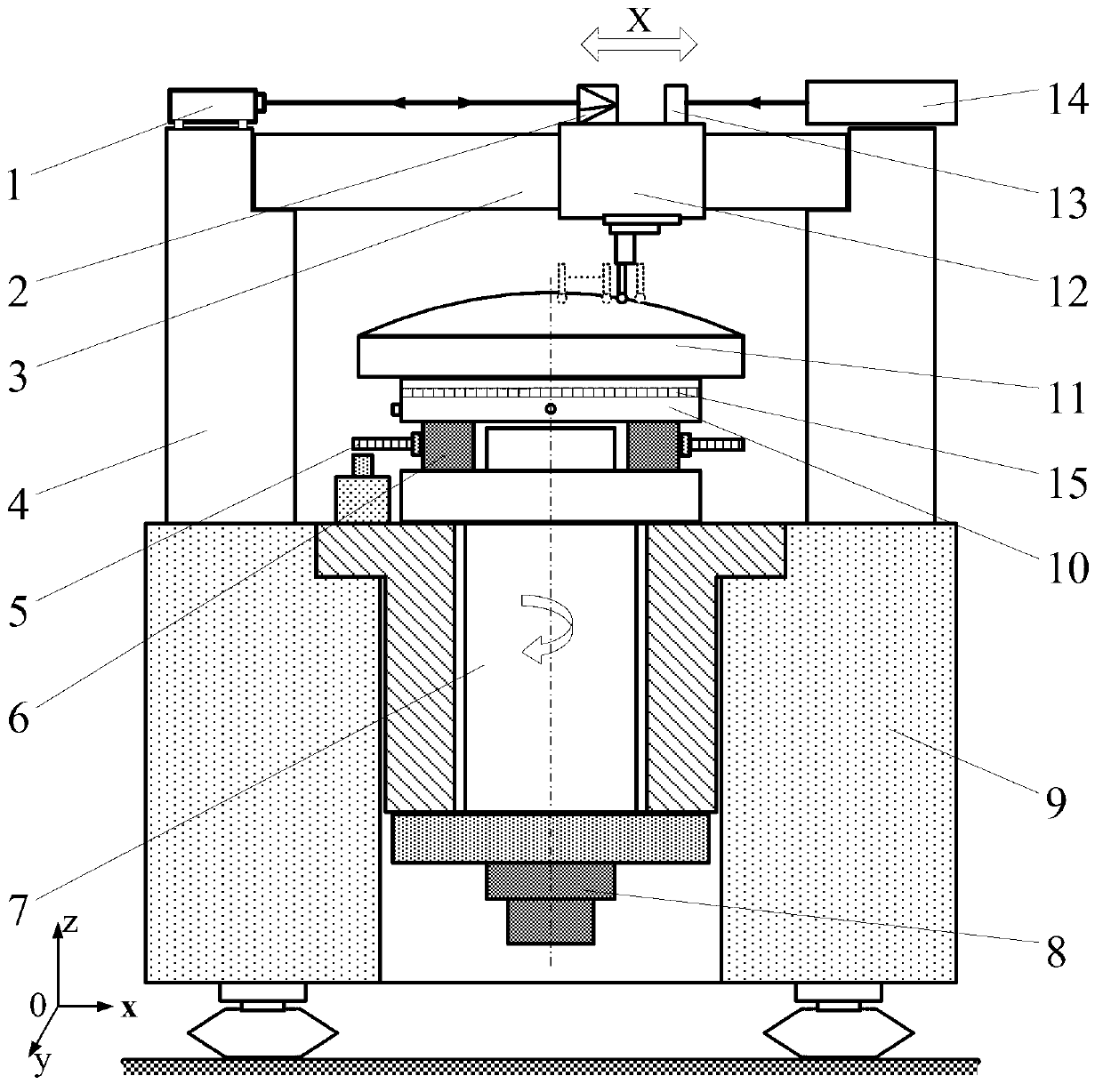

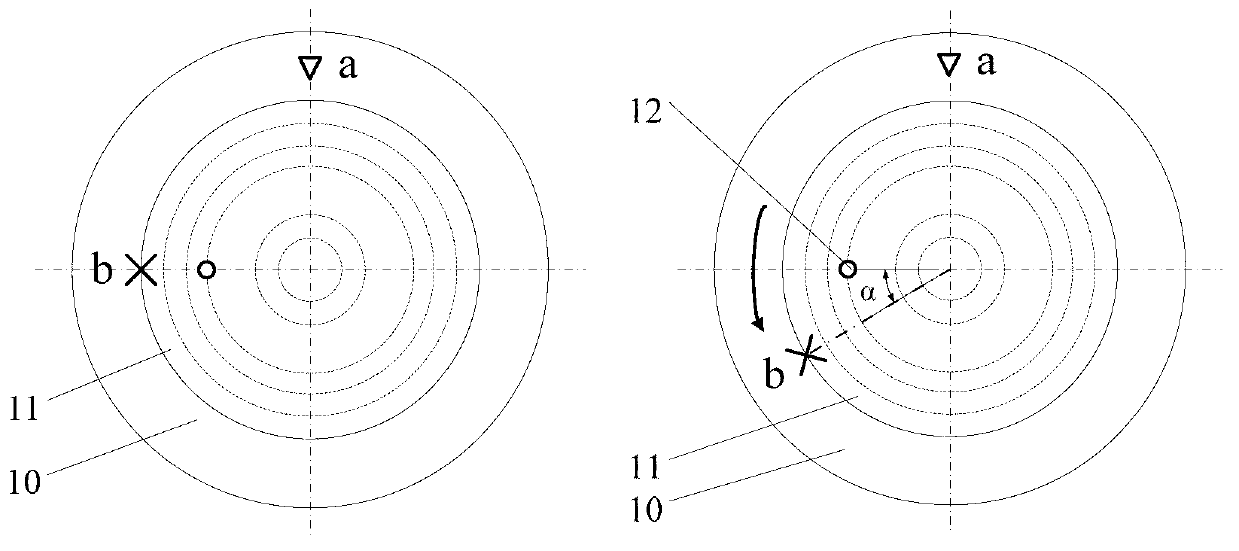

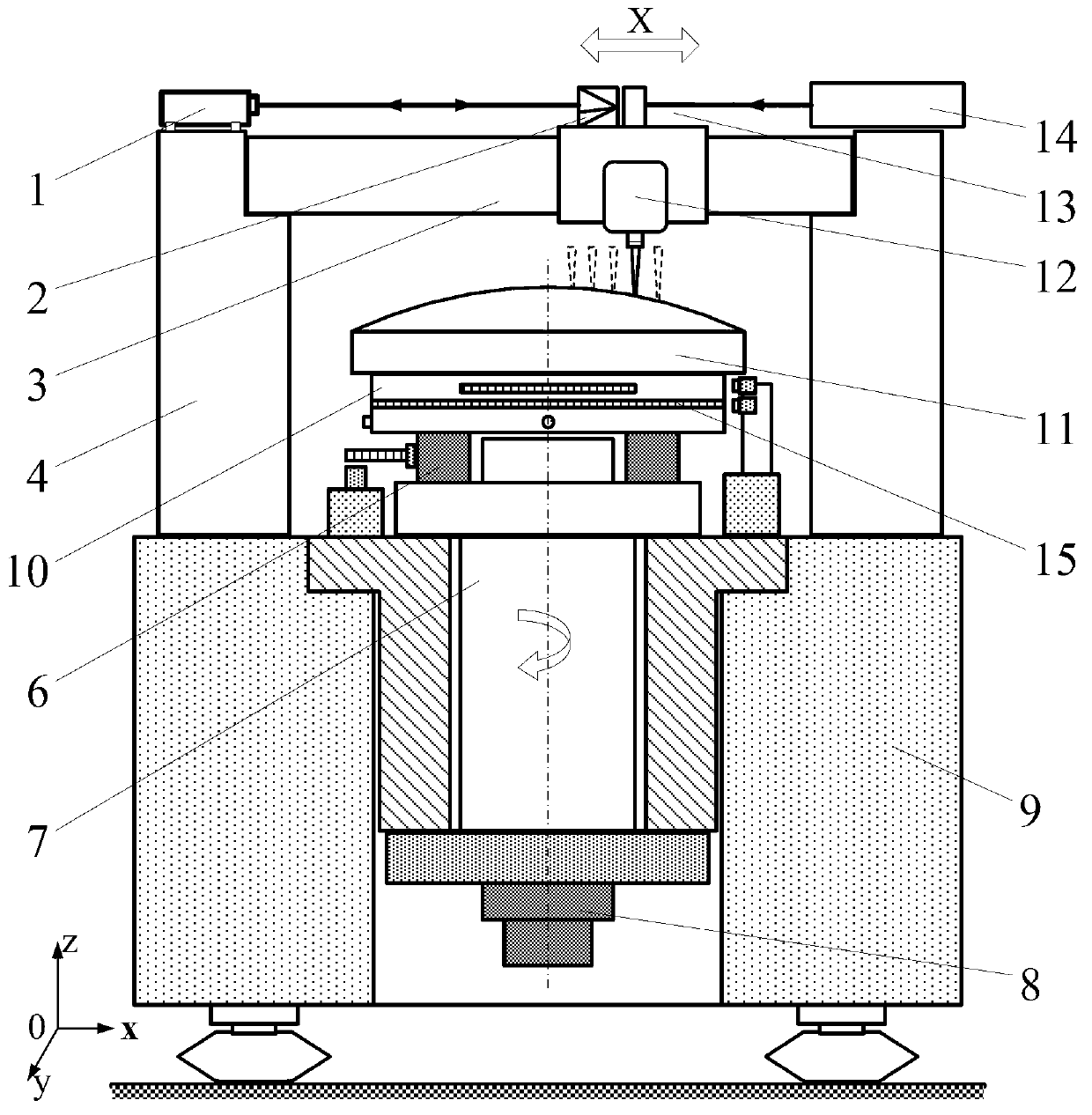

Outline scanning measuring method and device of large-scale sphere and aspheric surface

InactiveCN103105141AAvoid distractionsRealize high-precision measurementUsing optical meansDrive shaftSurface roughness

The invention mainly aims at precision testing of characteristic parameters such as facial form and surface roughness of a large-scale sphere and an aspheric surface and particularly relates to an outline scanning measuring method and a device of the large-scale sphere and the aspheric surface. The large-scale sphere and the aspheric surface can separate an axial end jump error and a rectilinear motion guide rail error in an X direction in real-time, achieve real-time self-detaching of the axial end jump error of a drive shaft system and an aspheric surface outline measurement value, adopt a reference beam with high direction stability to monitor and compensate a guide rail motion error in real-time and be capable of conduct autonomous detaching and real-time compensation on the high-precision large-scale sphere and the aspheric surface such as the axial end jump error of the drive shaft system and the rectilinear motion guide rail error in the X direction. The outline scanning measuring method and the device of the large-scale sphere and the aspheric surface provides a new method and a new technology for high-accuracy measurement of parameters such as the facial forms of the large-scale sphere or aspheric surface, surface roughness, radius of curvature and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

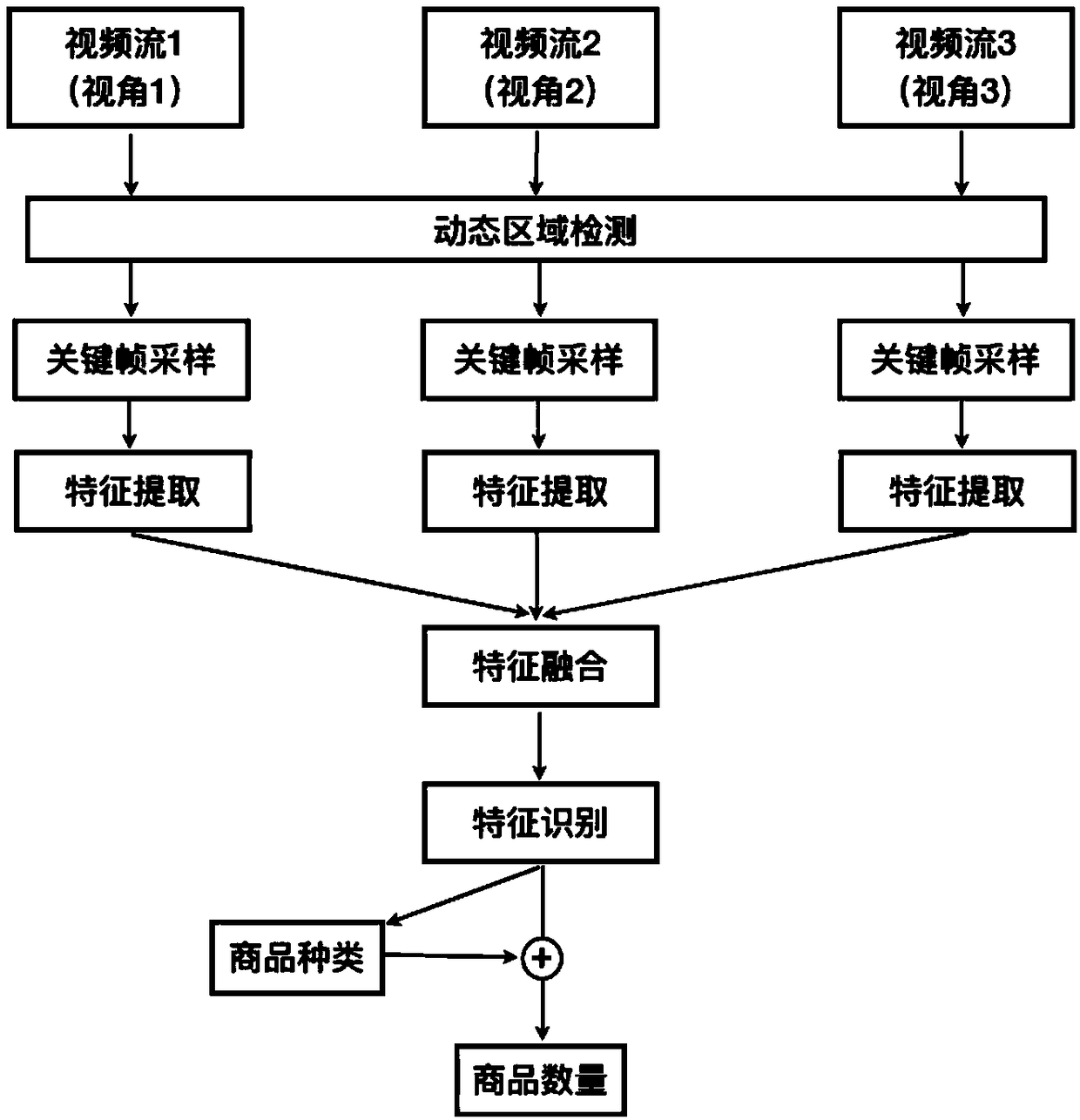

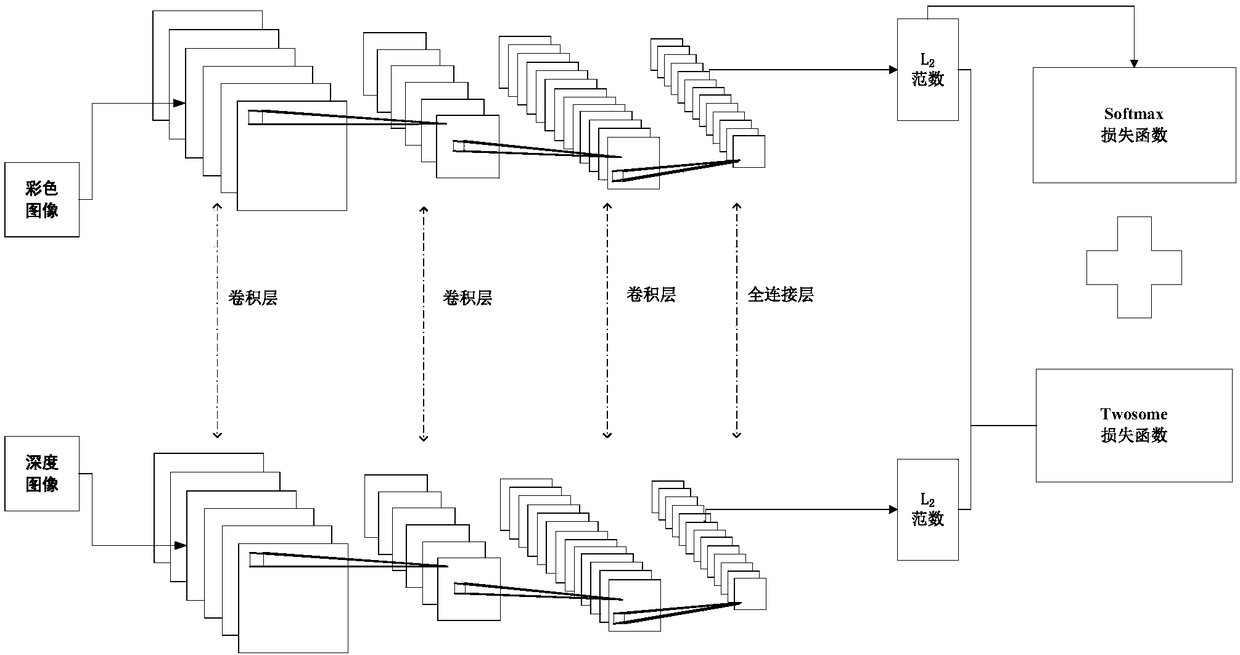

Multi-angle video fusion commodity identification algorithm for unmanned vending counter

ActiveCN108960119AImprove recognition efficiencyImprove recognition accuracyCharacter and pattern recognitionNeural learning methodsRecognition algorithmFeature recognition

The invention provides a multi-angle video fusion commodity identification algorithm for an unmanned vending counter. The algorithm comprises the following steps: pre-processing collected video data;performing key frame sampling on video frames in the video data; building a deep convolutional neural network model; and performing training and precision testing on the model by utilizing the sampledkey frames, and, after accuracy of commodity identification reaches expectation, deploying the model. The algorithm further comprises: feature extraction, feature fusion, feature identification. Thealgorithm further comprises the step that the video data from cameras at different angles of the unmanned vending counter are subjected to pre-processing and key frame sampling and then are input intothe model to obtain identified commodity types and identified corresponding commodity quantities. Through the multi-angle video fusion technology, rich information brought by multi-source data is fully used to reduce the impact of blocking goods, and then the accuracy of commodity identification is improved.

Owner:武汉市哈哈便利科技有限公司

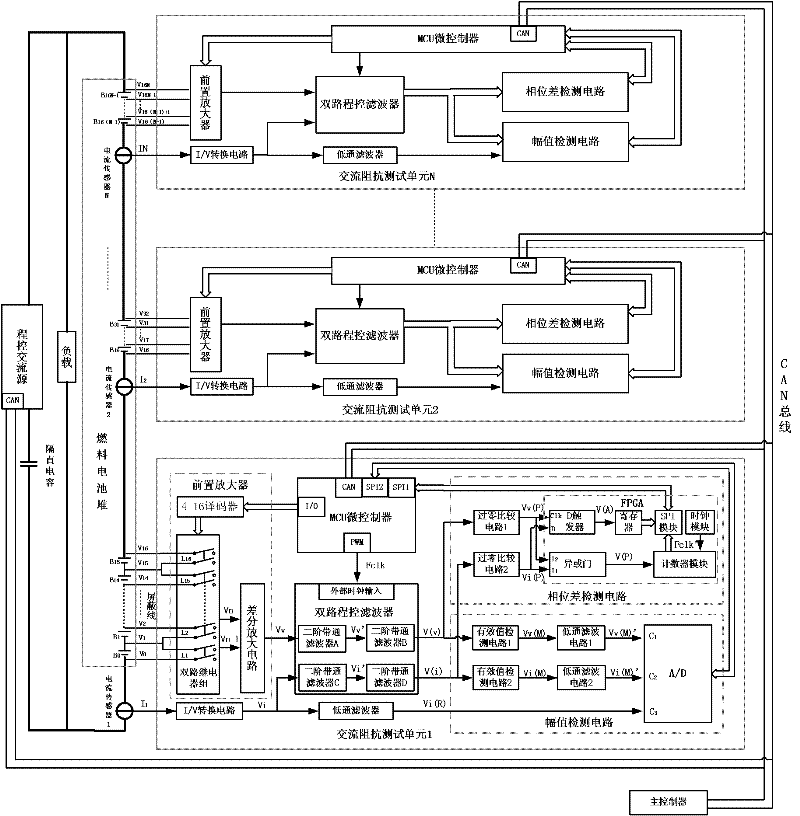

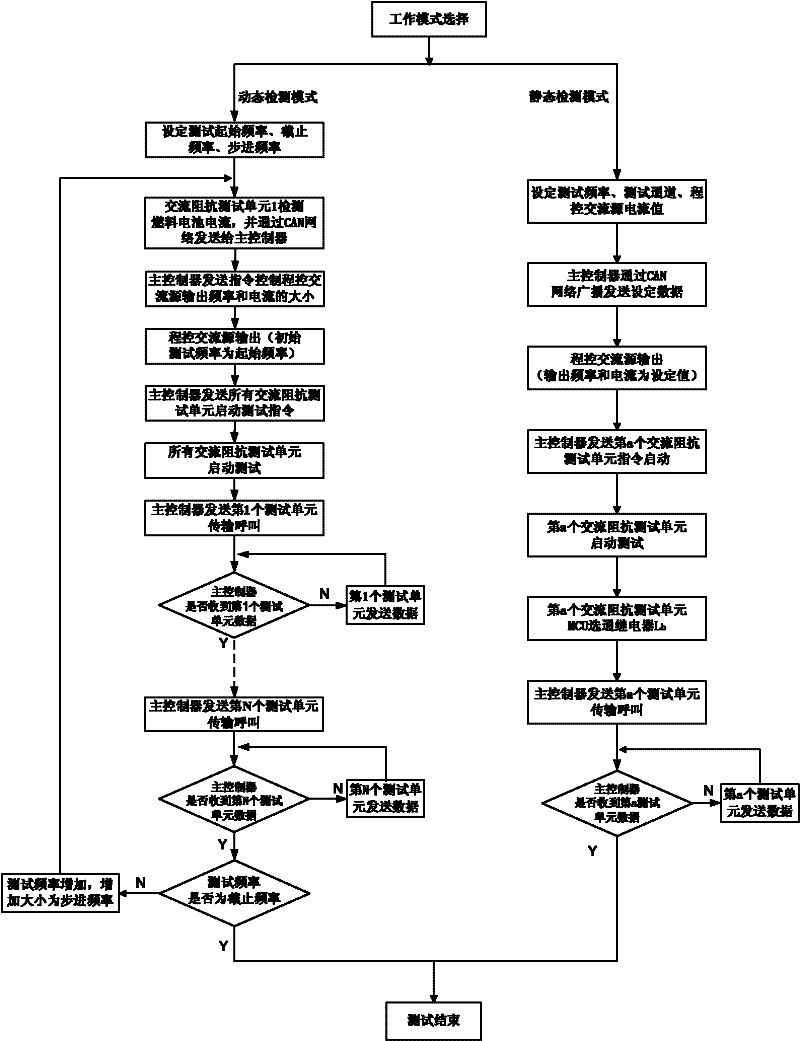

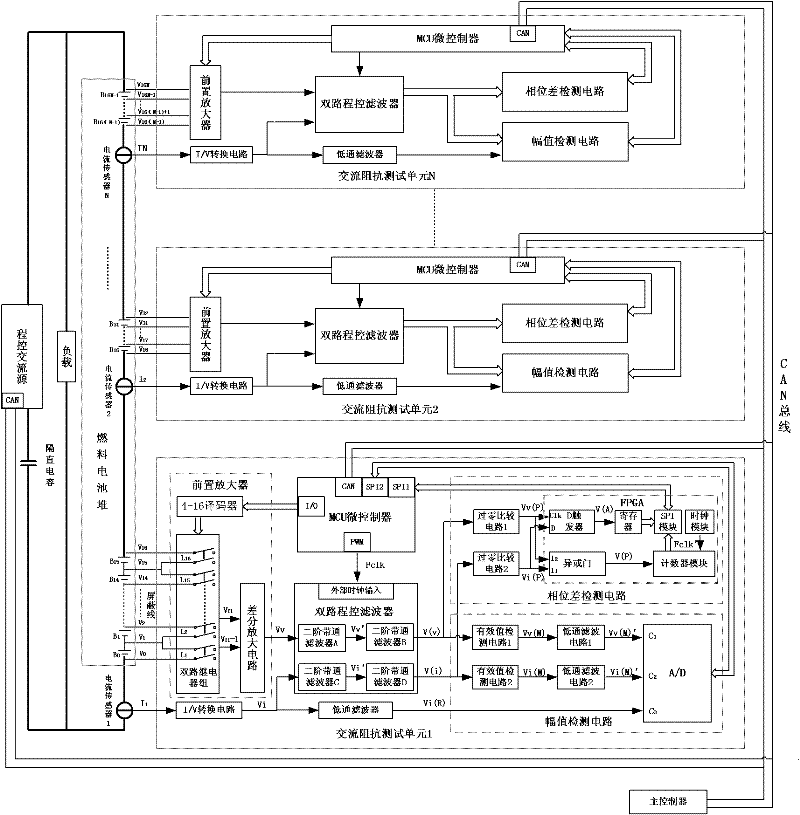

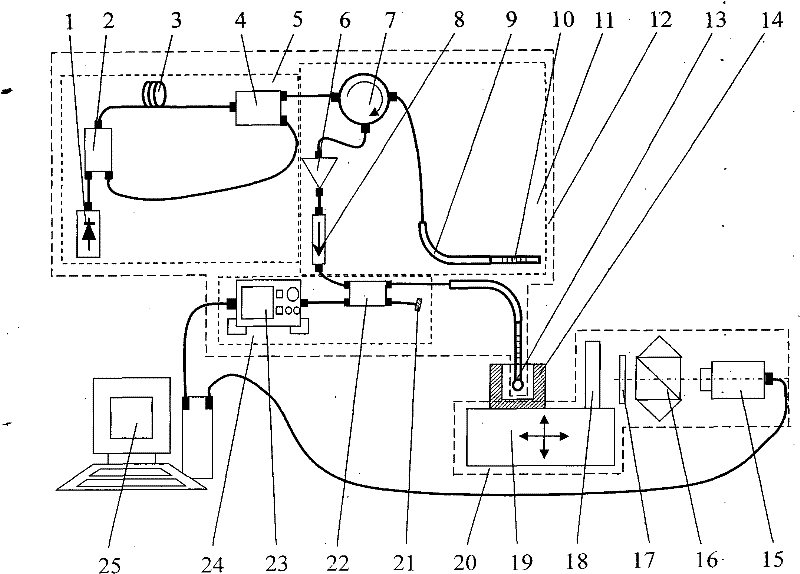

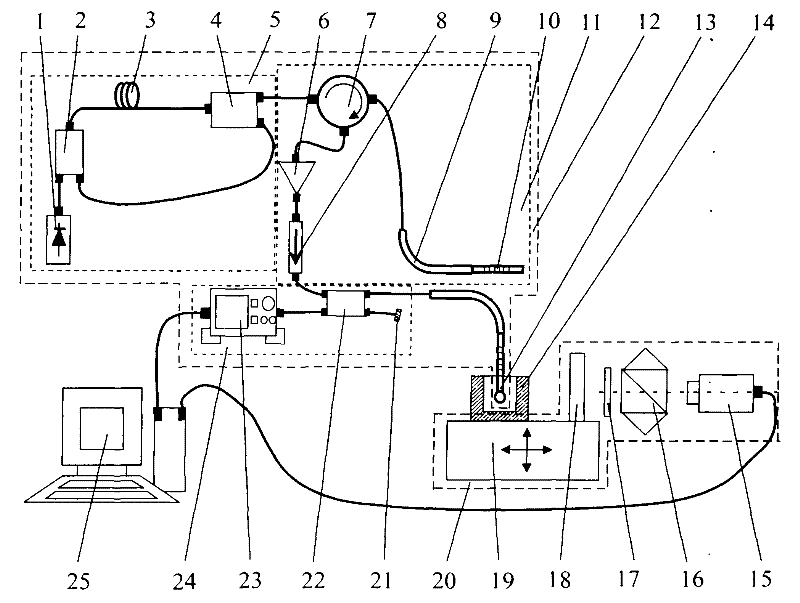

Fuel cell AC impedance on-line testing system and measuring and controlling method

ActiveCN102508035AImprove reliabilityLow costResistance/reactance/impedenceElectrical testingAlternating currentElectrical impedance

The invention relates to a fuel cell AC impedance on-line testing system and a measuring and controlling method thereof. The system comprises a program-controlled alternating current (AC) source, a blocking capacitor, a main controller, a CAN bus and a plurality of AC impedance testing units. Each AC impedance testing unit is used for detecting n chips of fuel cell AC impedances connected in series. The measuring and controlling method of the system has two working modes, which are a dynamic measuring and controlling mode and a static measuring and controlling mode. Under a dynamic measuring and controlling mode, when a fuel cell stack generates power, the main controller controlls the AC source and the AC impedance testing units through the CAN bus, measurement is carried out, measurement data is collected, such that AC impedance spectrums of all the single-chip fuel cells are obtained. Under the static measuring and controlling mode, when the fuel cell stack does not generate, the testing upon AC impedance of fuel cells with any number at a certain fixed frequency point is set manually. The system and the method provided by the invention are advantaged in simple circuit, high measurement precision, and high reliability. With the system and the method, real-time and high-precision testing requirements of fuel cell AC impedance can be satisfied.

Owner:武汉海亿新能源科技有限公司

Device and method for measuring micro-pore size based on fiber Bragg grating

InactiveCN102564309AMeet the measurement requirementsImprove adaptabilityUsing optical meansMeasurement deviceGrating

The invention provides a device and method for measuring a micro-pore size based on a fiber Bragg grating and belongs to the technical fields of precision instrument manufacture and precision test metering. The device consists of an aiming and signaling device for generating aiming signals, a length measuring device for measuring the movement distance of a micro-pore to be measured within a time interval of measuring measurement starting and stopping signals which are sent by the aiming and signaling device, and a computer for controlling a measurement process of the entire measuring device. The method comprises the following steps of: continuously moving a working table along a direction vertical to a length measurement direction, and moving the working table along a measurement line to obtain a maximum displacement, relative to the micro-pore to be measured, of a probe, so as to obtain the diameter of the micro-pore to be measured. According to the device and method disclosed by the invention, the adaptability of the aiming and signaling device to the environment is greatly improved. The device disclosed by the invention has the characteristics of simple structure, good real-time capability and easiness for actual application, and has obvious advantage of carrying out rapid and ultra-precise measurement and aiming on the size of the micro-pore.

Owner:HARBIN INST OF TECH

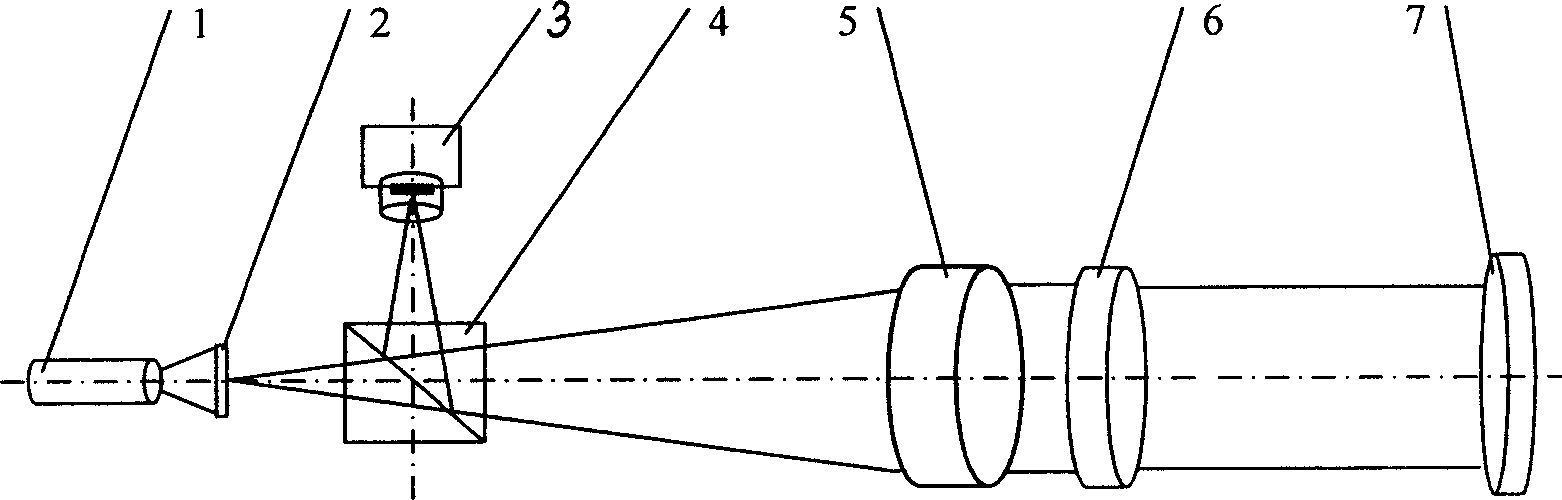

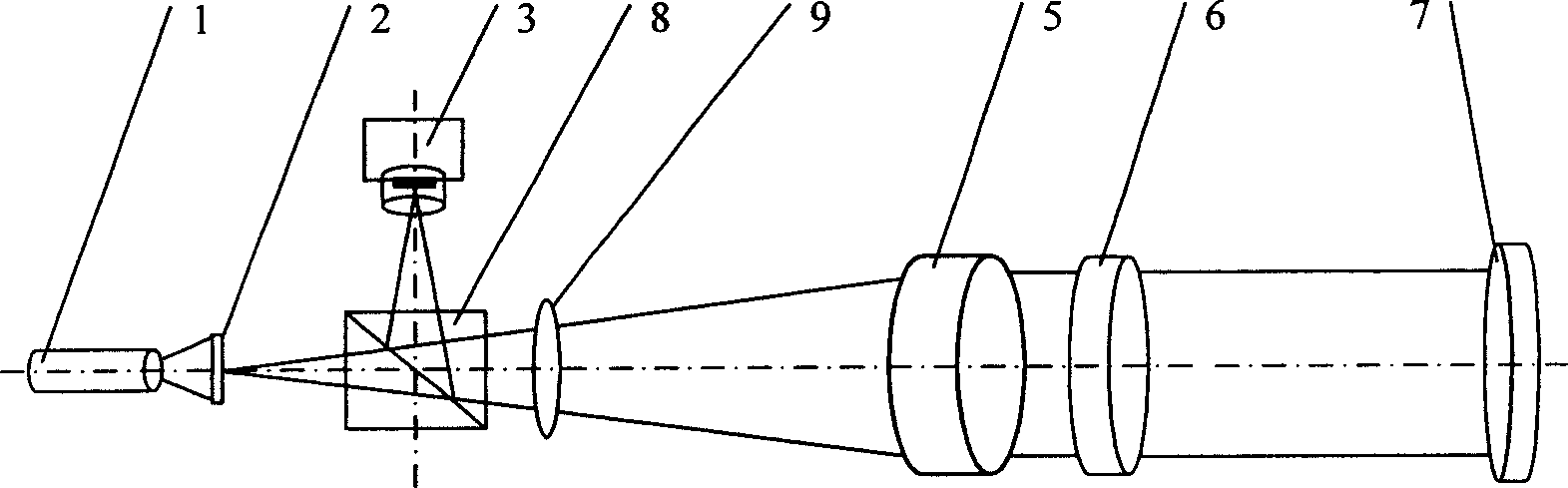

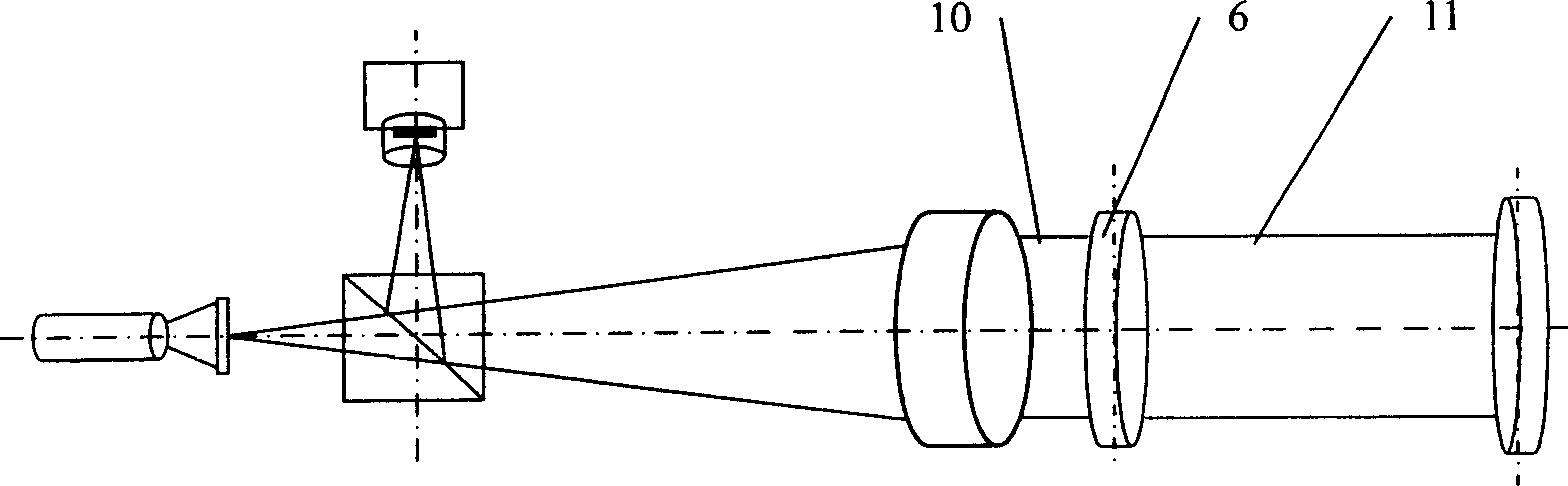

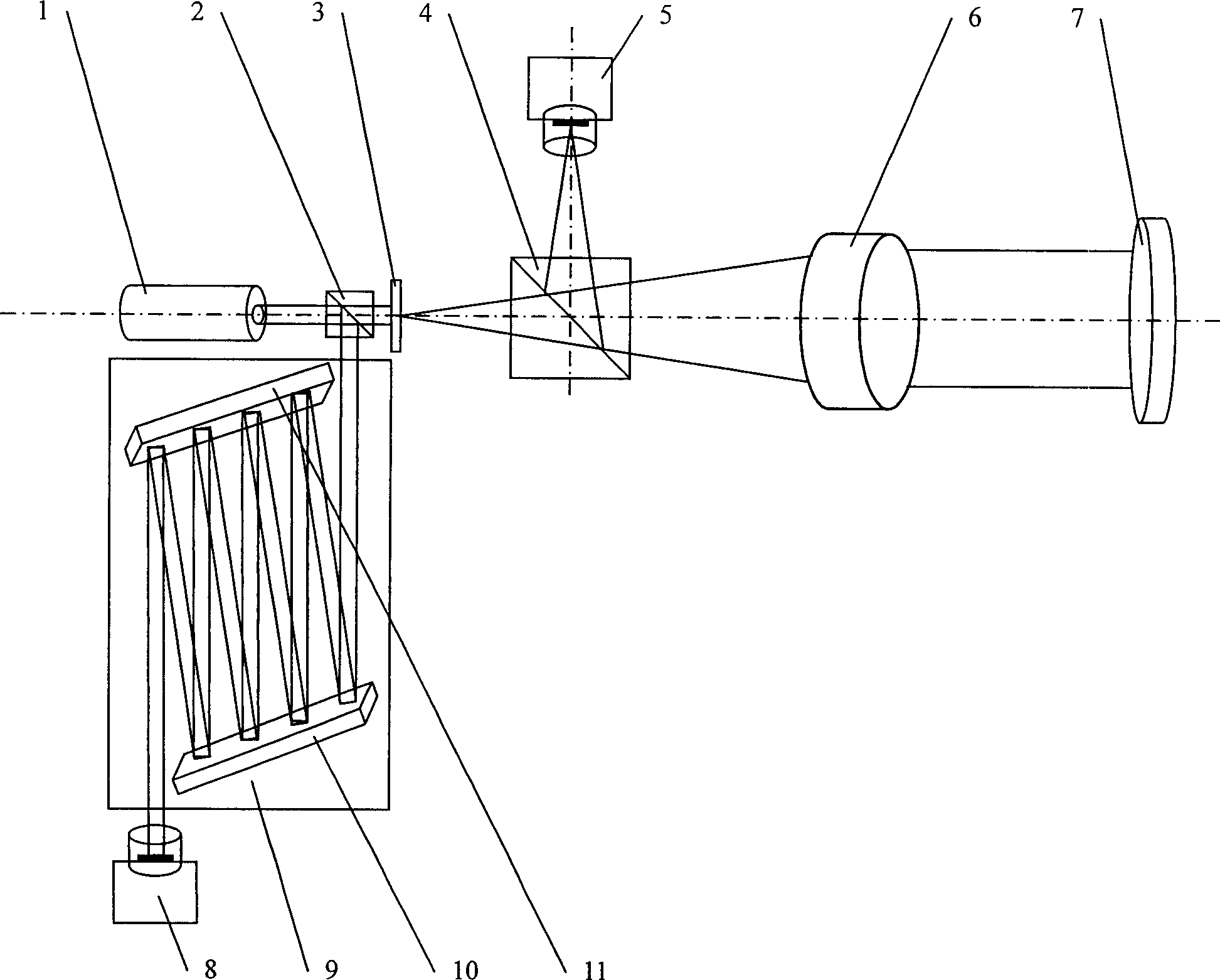

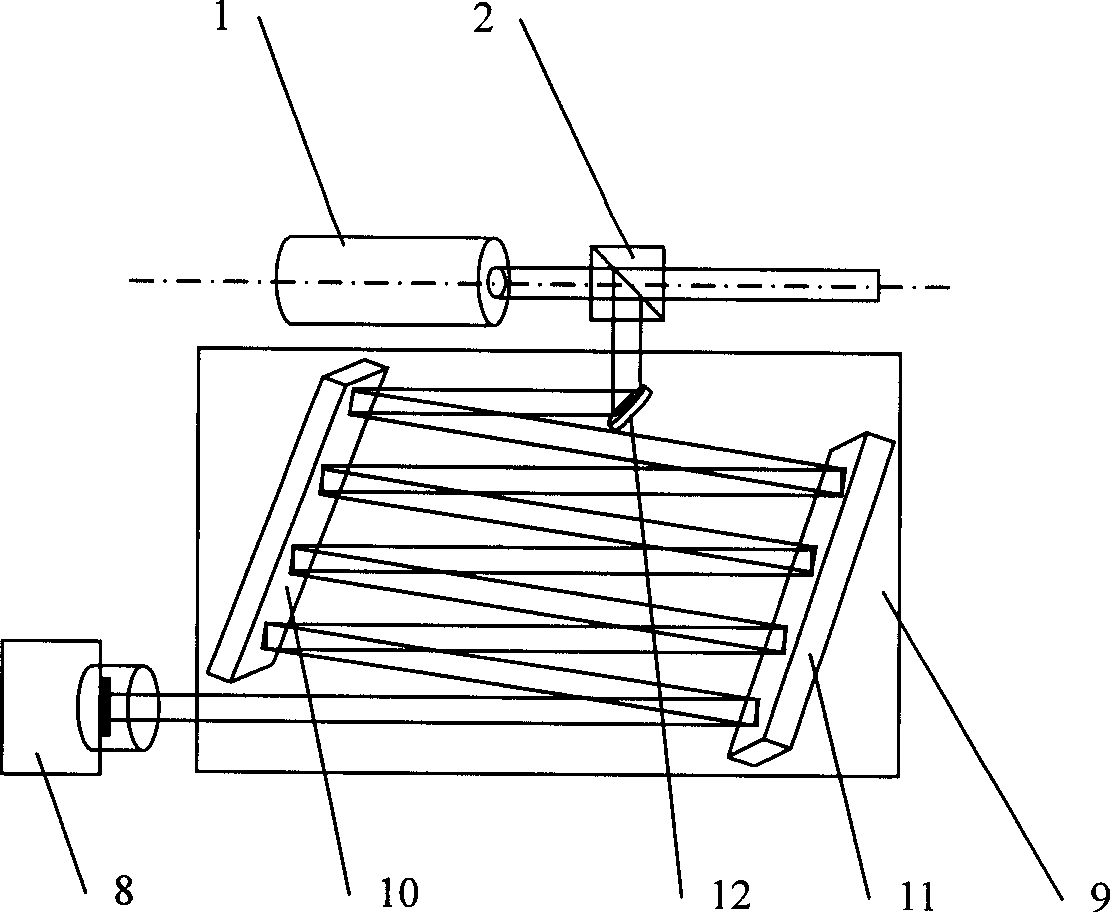

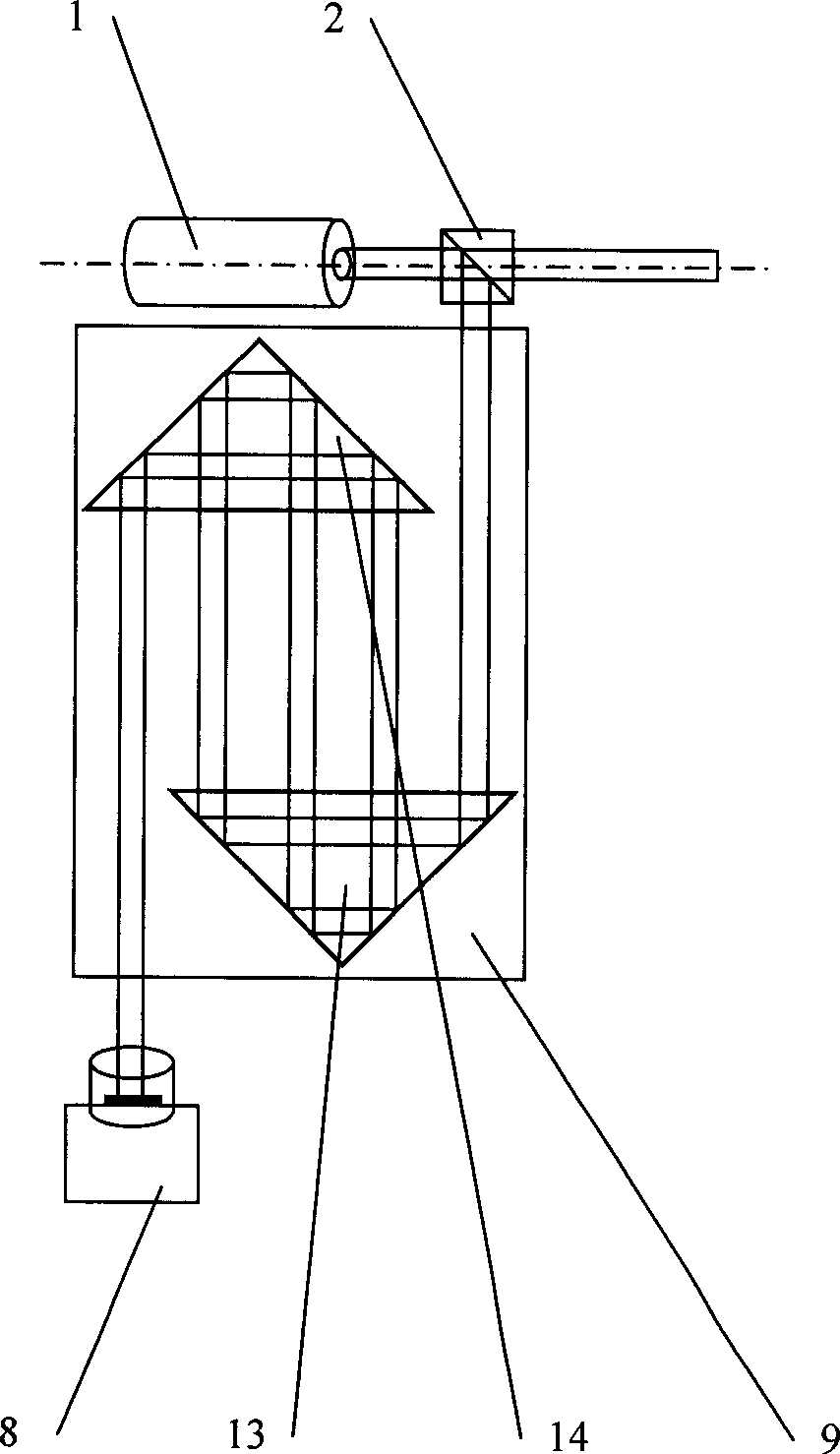

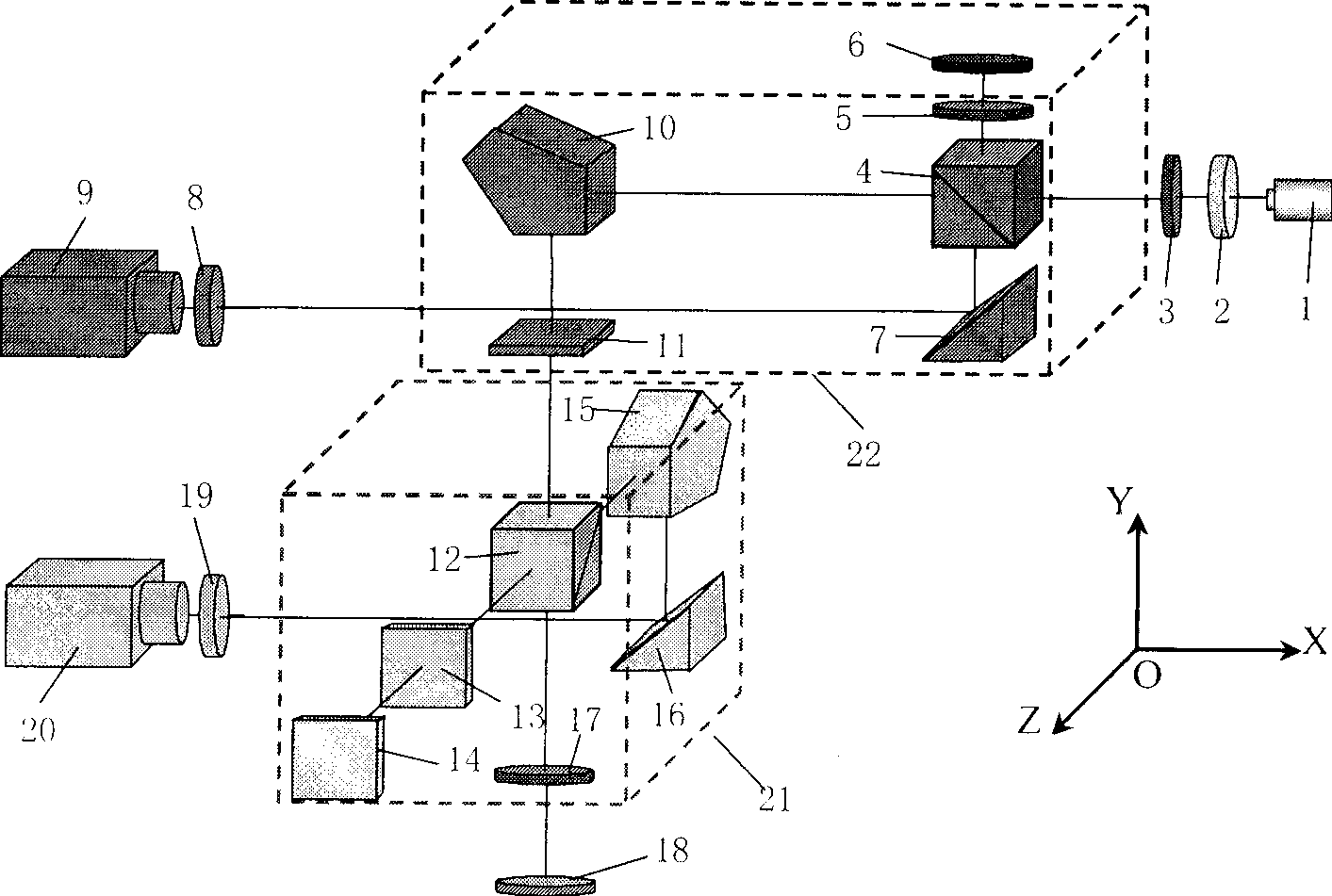

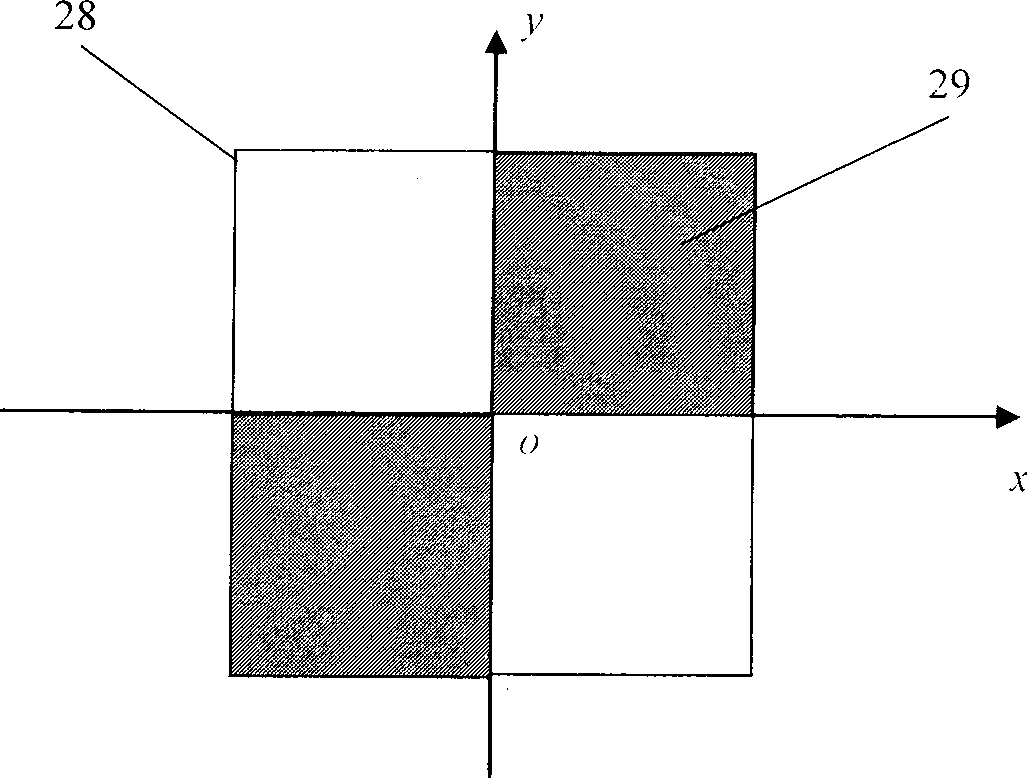

Bidimension photoelectric self collimating device based on optical length multiplication compensation method and its measuring method

InactiveCN1719192AIncrease the optical pathEasy to receiveUsing optical meansLaser lightOptoelectronics

The present invention relates to high precision 2-D photoelectric autocollimating equipment based on optical path multiplication compensation method. Said equipment successively includes laser light source, calibrated plate, main spectroscope, main CCD image sensor, collimating objective and measurement reflector. Besides, said invention also provides its measurement method and concrete steps.

Owner:HARBIN INST OF TECH

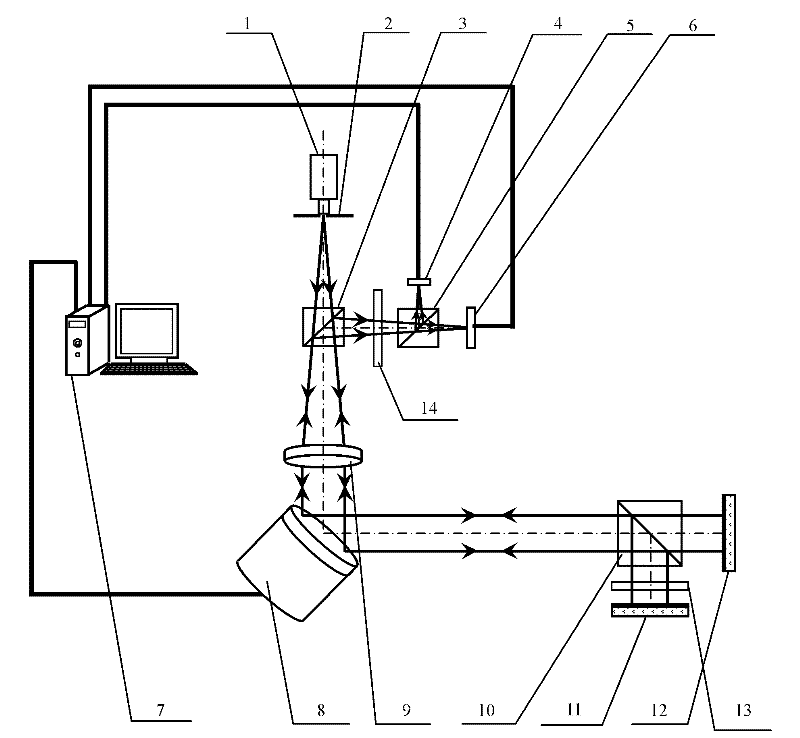

Two-dimensional photoelectric auto-collimation method and device of polarized light plane mirror reference common-path compensation

InactiveCN102176086AAccurately reflect the amount of driftSame characteristicsUsing optical meansOptical elementsBeam splitterPlane mirror

The invention discloses a two-dimensional photoelectric auto-collimation method and device of polarized light plane mirror reference common-path compensation, and the method and device provided by the invention belong to the technical field of precision instrument manufacture and precision measurement. According to the invention, high-precision photoelectric autocollimation angle measurement is realized for solving the defects in the existing method and device. The method comprises: a plane mirror reference common-path shift quantity monitoring separating device can be used for separating a reference light beam with the feature identical to the that of a measurement light beam, especially the reference light beam which is in the common-path transmission with the measurement light beam, while obtaining measurement light beam in a two-dimensional angle variation by using the polarization feature of the laser and using a polarizing beam splitter and a reference plane reflector; and a controller can be used for controlling a two-dimensional light beam deflection device in real time according to the shift quantity reflected by the reference light beam so as to inhibit the shift quantity coupled in the measurement light beam, thus the precision measurement on the two-dimensional angle variation is realized. The device for realizing the method comprises a two-dimensional photoelectric auto-collimation tube, the plane mirror reference common-path shift quantity monitoring separating device, the controller and the two-dimensional light beam deflection device.

Owner:HARBIN INST OF TECH

Calibration device for optical system wave aberration and calibration method for test error of the device

InactiveCN102261985AAchieve ultra-high precision detectionTesting optical propertiesFiberWavefront sensor

An optical system wave aberration calibration apparatus and a calibration method of using the apparatus to test an error relate to the optical measurement technology field. The current optical system can not evaluate whether the test error satisfies a detection precision requirement before detecting an optical element and the current optical system can not select an appropriate phase shifting algorithm to process collected data. The above problems can be solved by using the invention. The method comprises the following steps: a light splitting system emits two beams of common-optical-path orthogonal-line polarized lights and after being emitted by a polarization splitting prism, the polarized lights are coupled to a reference fiber through a coupling lens; two spherical waves diffracted by the reference fiber perform interference and an interferogram can be acquired; a photoelectric detector is used to collect the interferogram and to transmit to a computer; piezoelectric ceramics areused to carry out phase shifting and the photoelectric detector collects the interferogram several times; a thirteen step phase shifting algorithm is used to carry out data processing analysis so as to obtain the test error. By using the invention, ultrahigh precision testing of the optical system wave aberration can be realized.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

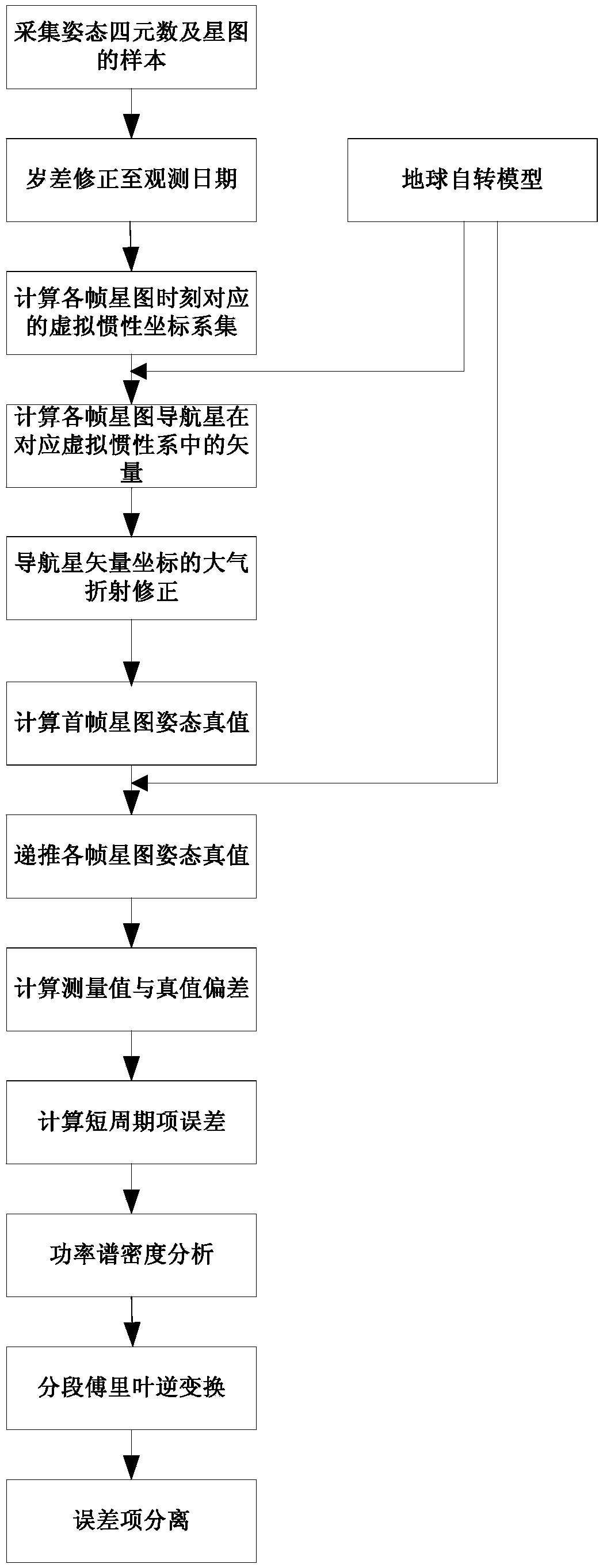

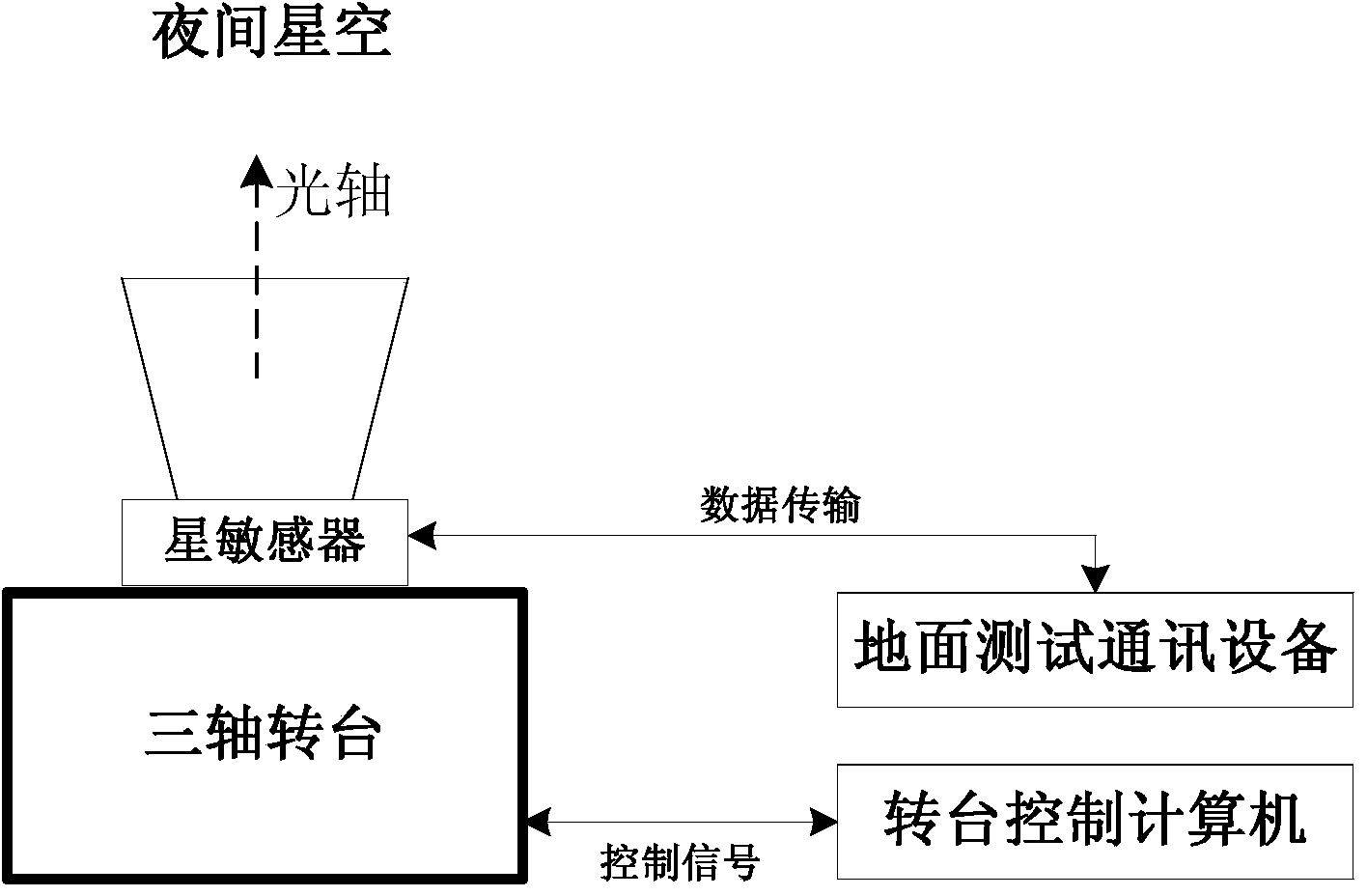

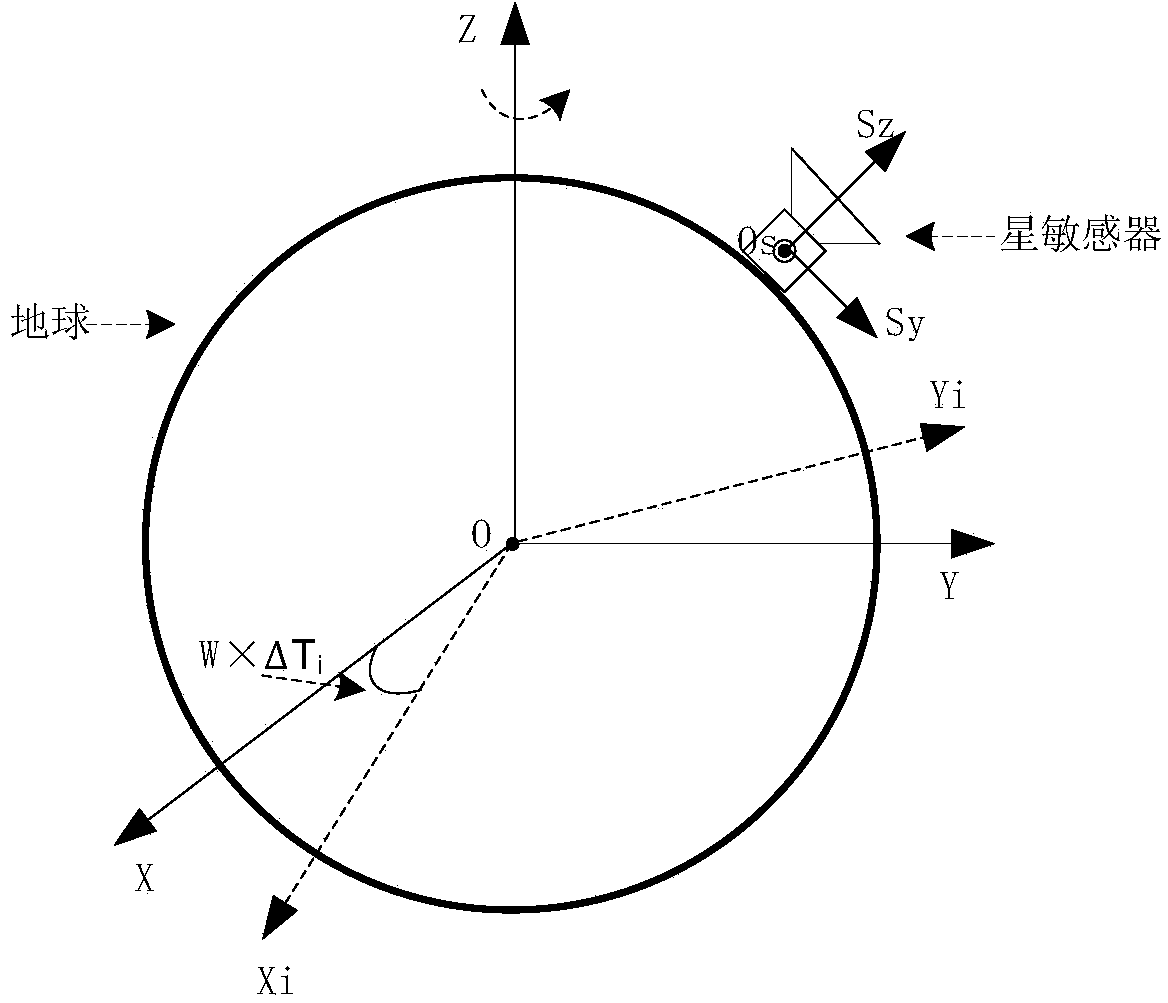

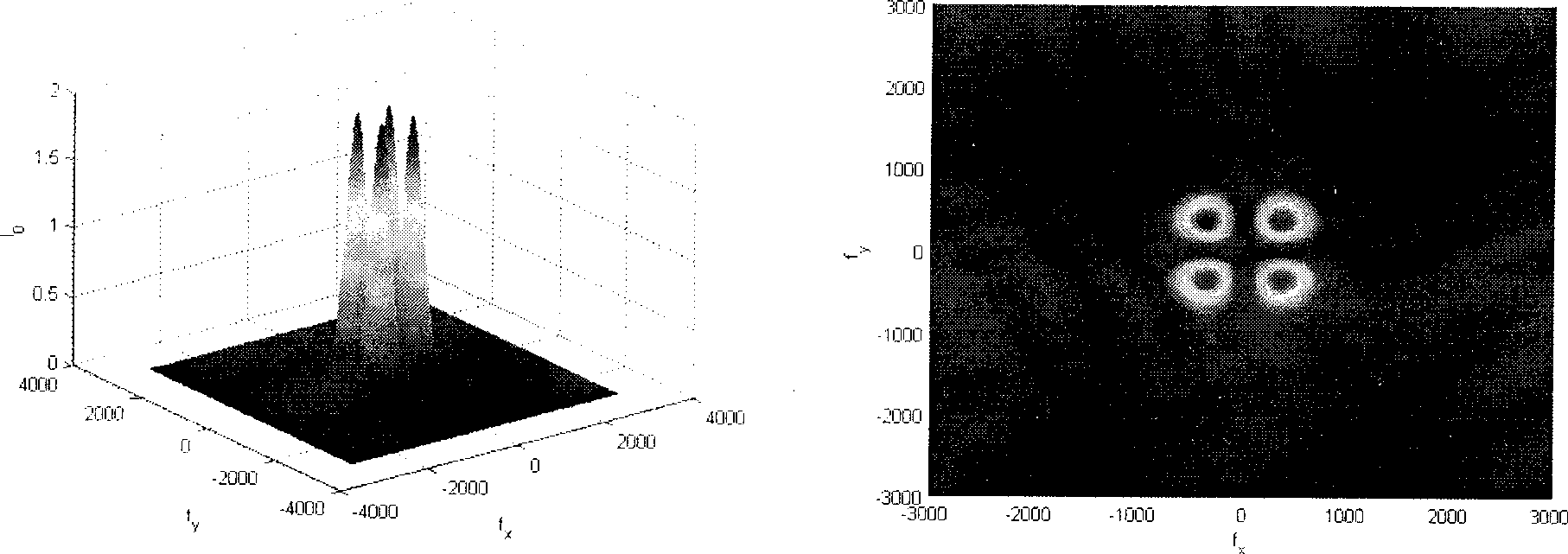

Outfield precision testing method for high-precision star sensor

ActiveCN104280049AAchieving Frequency Domain StrippingAccurate calculationNavigation by astronomical meansStar patternObservational error

The invention discloses an outfield precision testing method for a high-precision star sensor. Accuracy in calculation of a star pattern posture of the star sensor and frequency domain stripping of short-period error terms of the posture are realized by utilizing a procession correction formula, an earth rotation model, an atmosphere correction model and a power spectral density formula, and the posture measuring error of the star sensor can be rapidly and effectively analyzed and evaluated. According to the method, the hardware resource is not occupied, the method is realized by utilizing software and does not need the ground intervention. According to the method, by combining the posture identification principle of the star sensor and adopting a data smoothing method, the posture truth value of each frame star pattern moment is calculated, so that a foundation is established for the subsequent analysis on the posture measuring error; by adopting the method for combining the time domain and the frequency domain, the short-period error term is decomposed into an airspace low-frequency error, a high-frequency error and a time-domain error by virtue of the power spectral density analysis, so that reasonable data support is provided for further evaluation of the precision indexes of the star sensor, and the index performance of the star sensor can be improved.

Owner:BEIJING INST OF CONTROL ENG

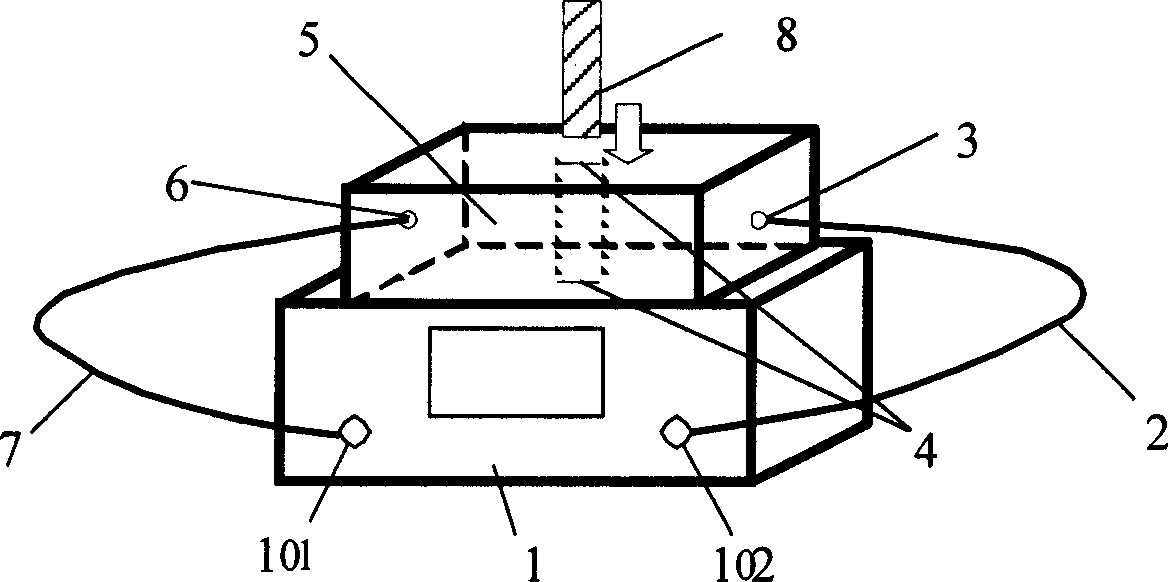

In-situ tester for micromechanical property of material under combined tension and torsion

ActiveCN103926160AReveal mechanical propertiesReveal damage mechanismInvestigating material ductilityMicro nanoEngineering

The invention relates to an in-situ tester for the micromechanical property of a material under combined tension and torsion, and belongs to the field of precise instruments. The tester comprises a base, a tension and torsion loading unit, a test-piece clamping unit, and a displacement and loading force precision testing unit, wherein the torsion loading unit drives two-level worm wheel and worm driving mechanisms to apply a torsion load to one end of a moving clamp through a precision motor, so that the torsion load is applied to a tested test-piece sample; a fixed clamp end is arranged on a precision guide rail sliding block; one end of the moving clamp is provided with a precision tension and torsion sensor for used for detecting the tension and torsion born by a testing workpiece, and a motor encoder can detect the tension strain and torsion angle. The in-situ tester provided by the invention has the characteristics that the structure is compact and exquisite, the volume is small, the weight is light, in-situ testing in micro-nano precision for the micromechanical property of the material under combined tension and torsion can be realized, and a novel testing method is provided for analytical investigation of a material deformation damage mechanism under the serving approaching condition.

Owner:JILIN UNIV

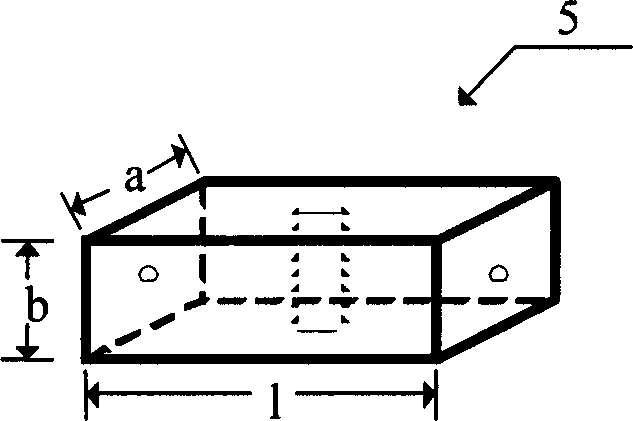

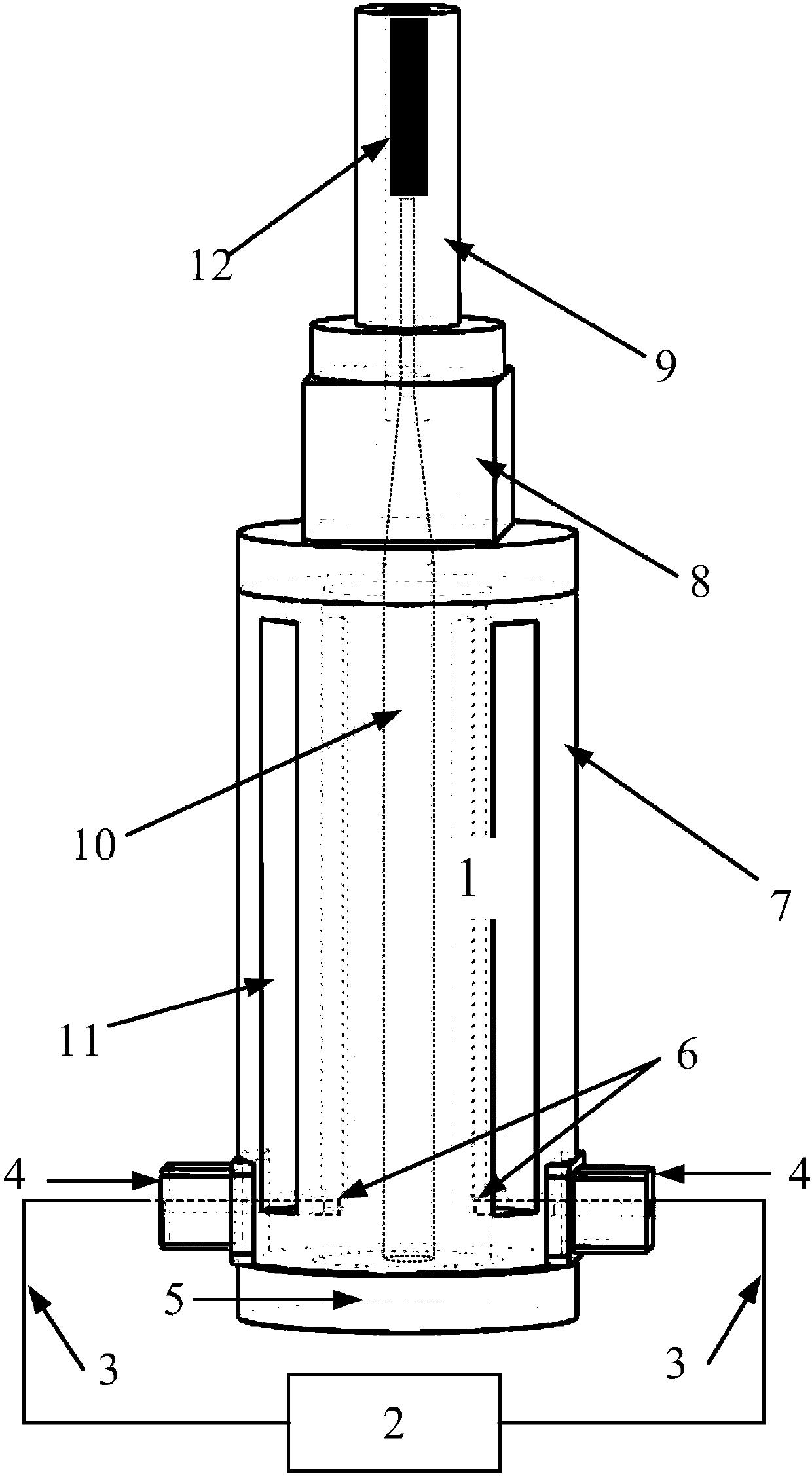

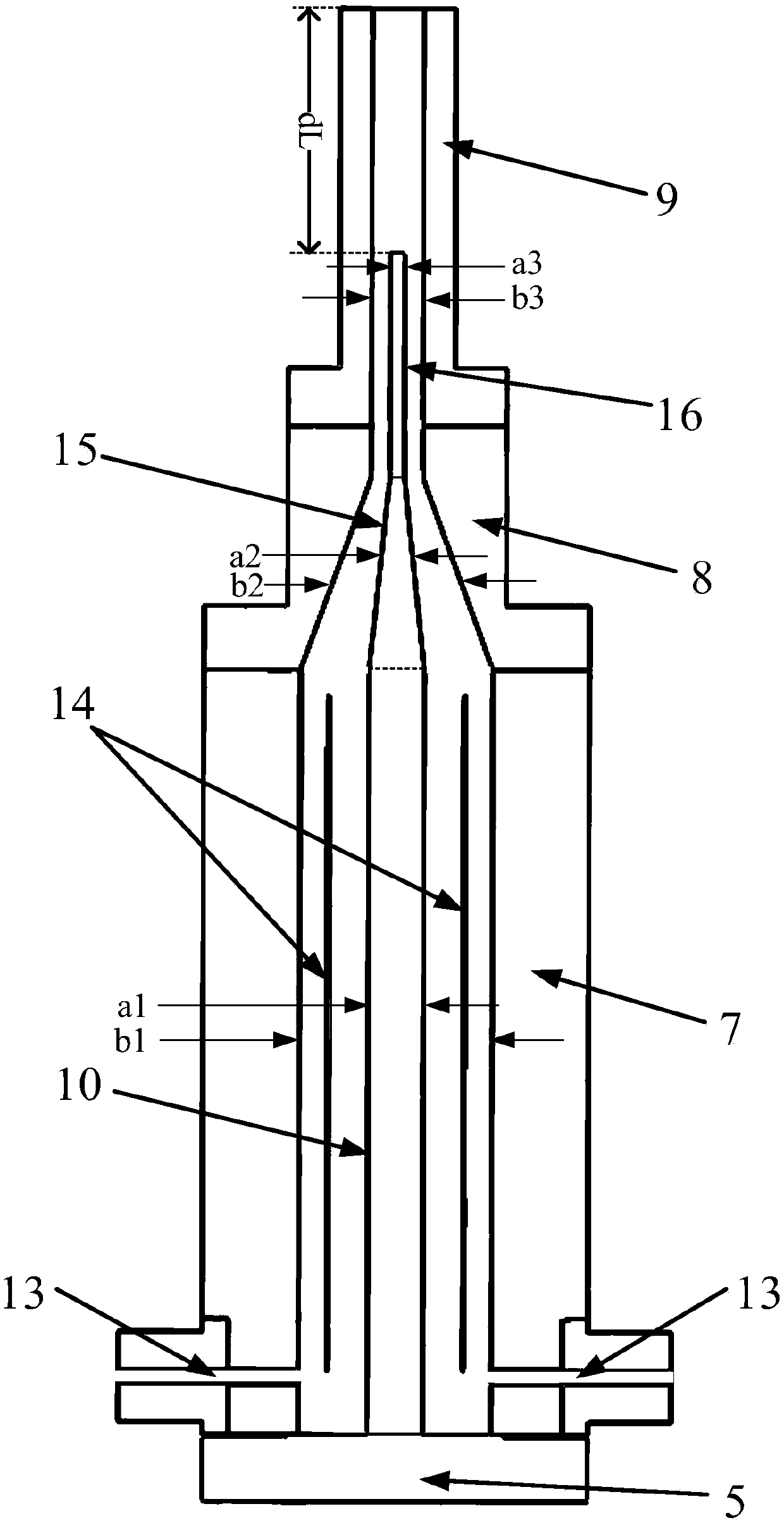

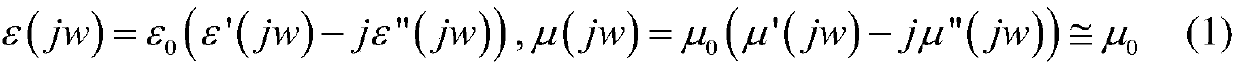

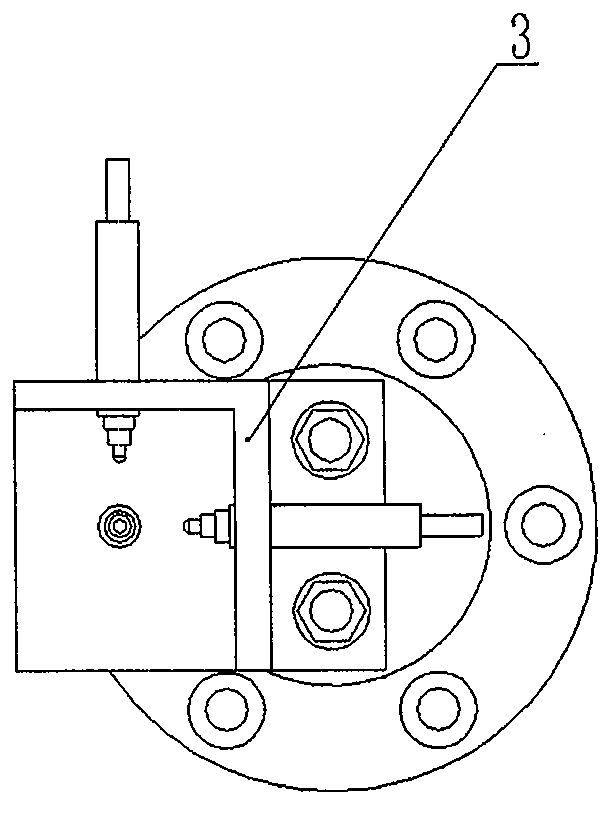

Measurer of dielectric film microwave complex dielectric permittivity

This invention relates to testing equipment of nm order thickness medium thin film microwave complex dielectric permittivity. It includes resonant cavity, net analyzer and medium substrate. Radiofrequency interconnection devices are set on both ends of the cavity, through hole is set in middle part, the substrate is used to burdening medium thin film, the through hole can be through in it and its two ends are out of the cavity. The input and output ends of the analyzer are connected to the two couplers of the cavity. Substrate coated and uncoated can be separately inserted into the through holes of the cavity to get two groups of resonance frequency and quality factor value. Then the medium thin film complex dielectric permittivity can be got by the two data combined with the cavity, substrate and rectangular protractor of the film. The permittivity includes real part and loss angle tangent. So this invention is a general, precision testing device of medium thin film microwave complex dielectric permittivity.

Owner:ZHEJIANG UNIV

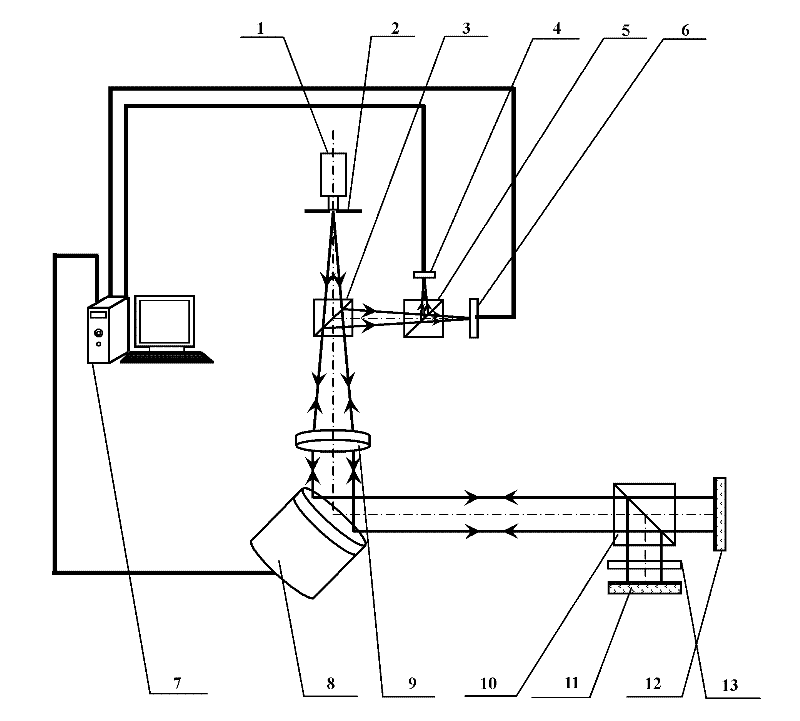

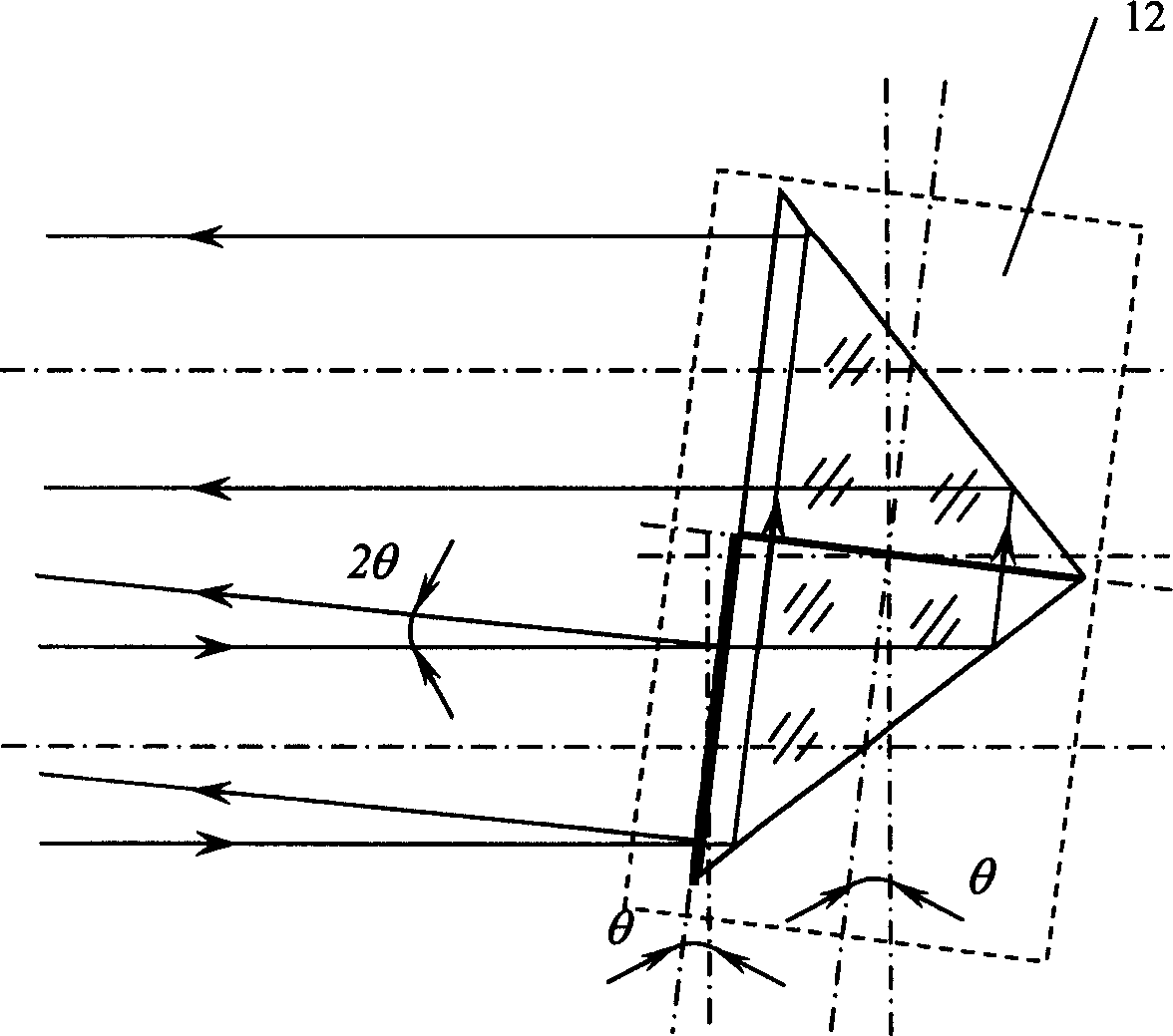

Long-distance 2D polarized photoelectric autocollimation device and method for drift quantity returned from feedback of target drone

Combination of polarized laser source, polarized beam splitter mirror and quarter Lambda wave plate is adopted in the 2D photoelectric autocollimation tube, which uses characteristic of polarization to avoid that measuring light beam feeds back laser source so as to prevent further angle drift of the measuring light. Obtaining measurement signal of 2D variance in small angle, beam splitter type target detector also obtains angle drift component of separated and fed back light beam. The said component is identical to inherent component of laser source. Monitoring device monitors quantity of angle drift. Based on quantity of angle drift obtained, computer control 2D optical beam deflection device in real time to adjust the measuring light beam according to direction opposite to quantity of angle drift. The invention restrains and eliminates quantity of angle drift coupled in measuring light beam in propagation path of the measuring light beam.

Owner:严格集团股份有限公司

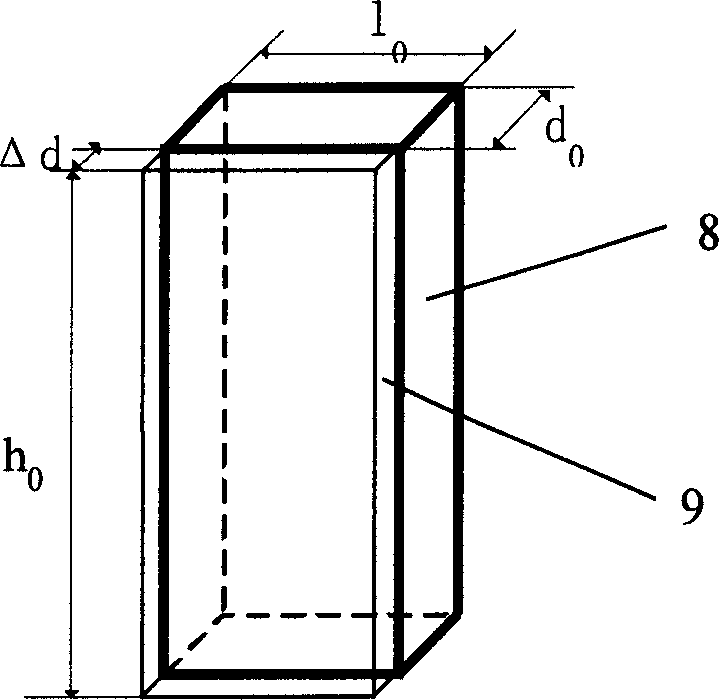

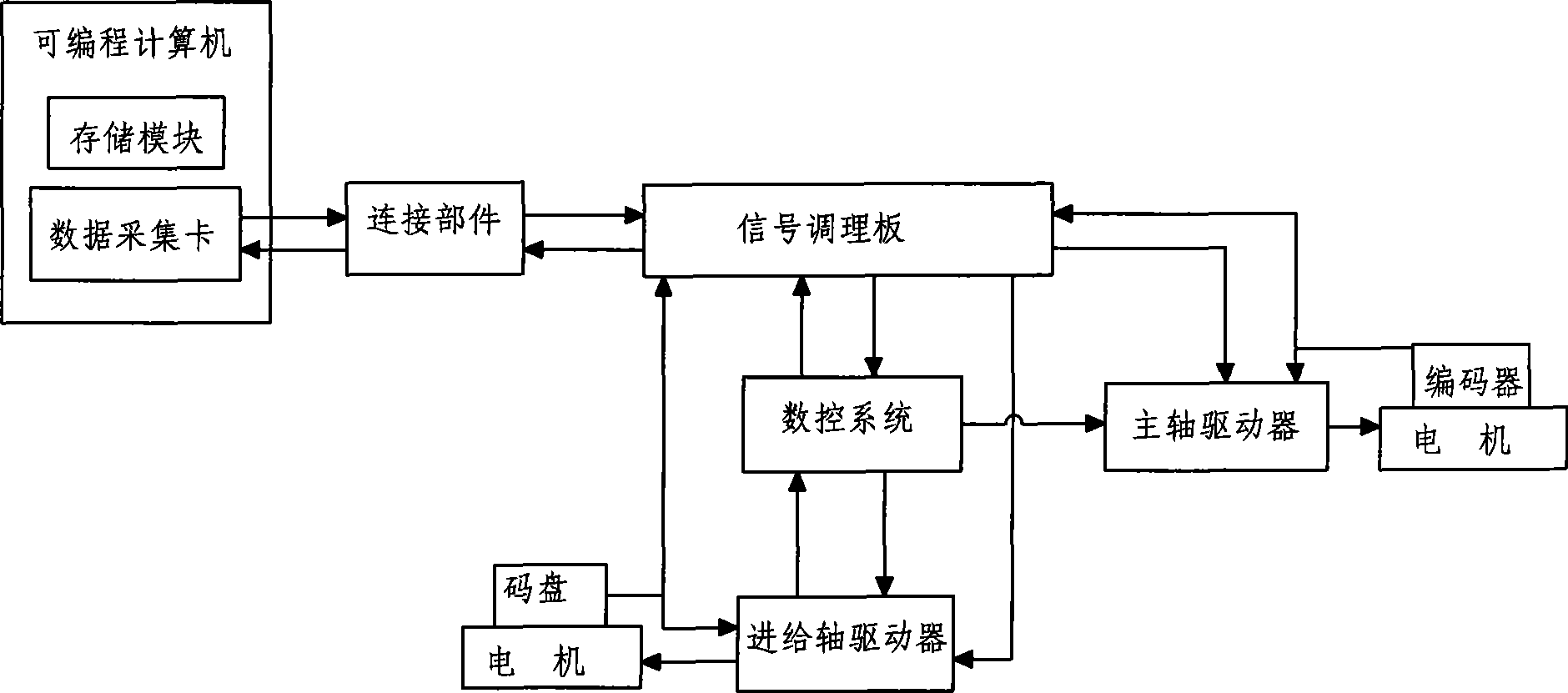

Numerical control equipment moving precision test device and test method

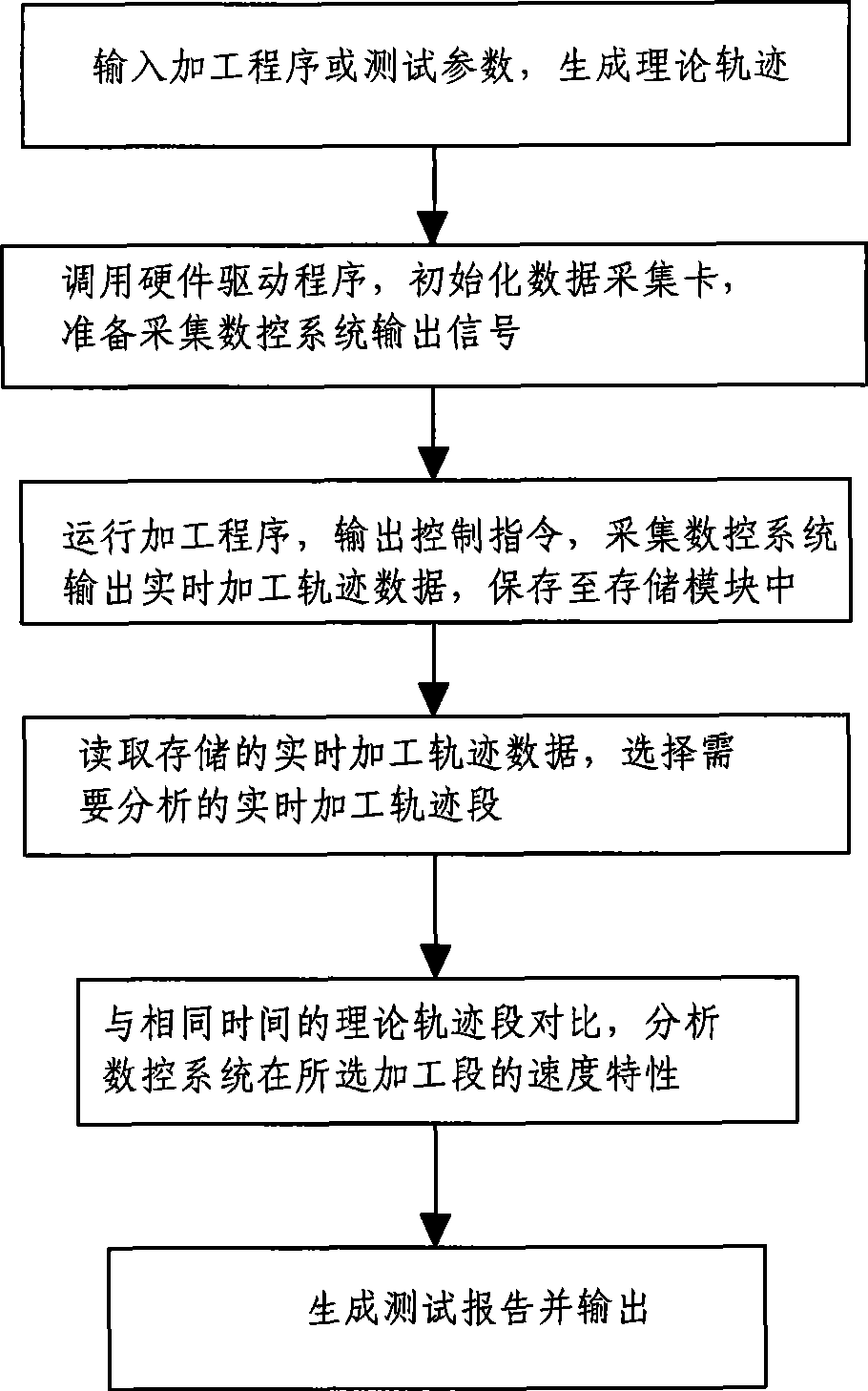

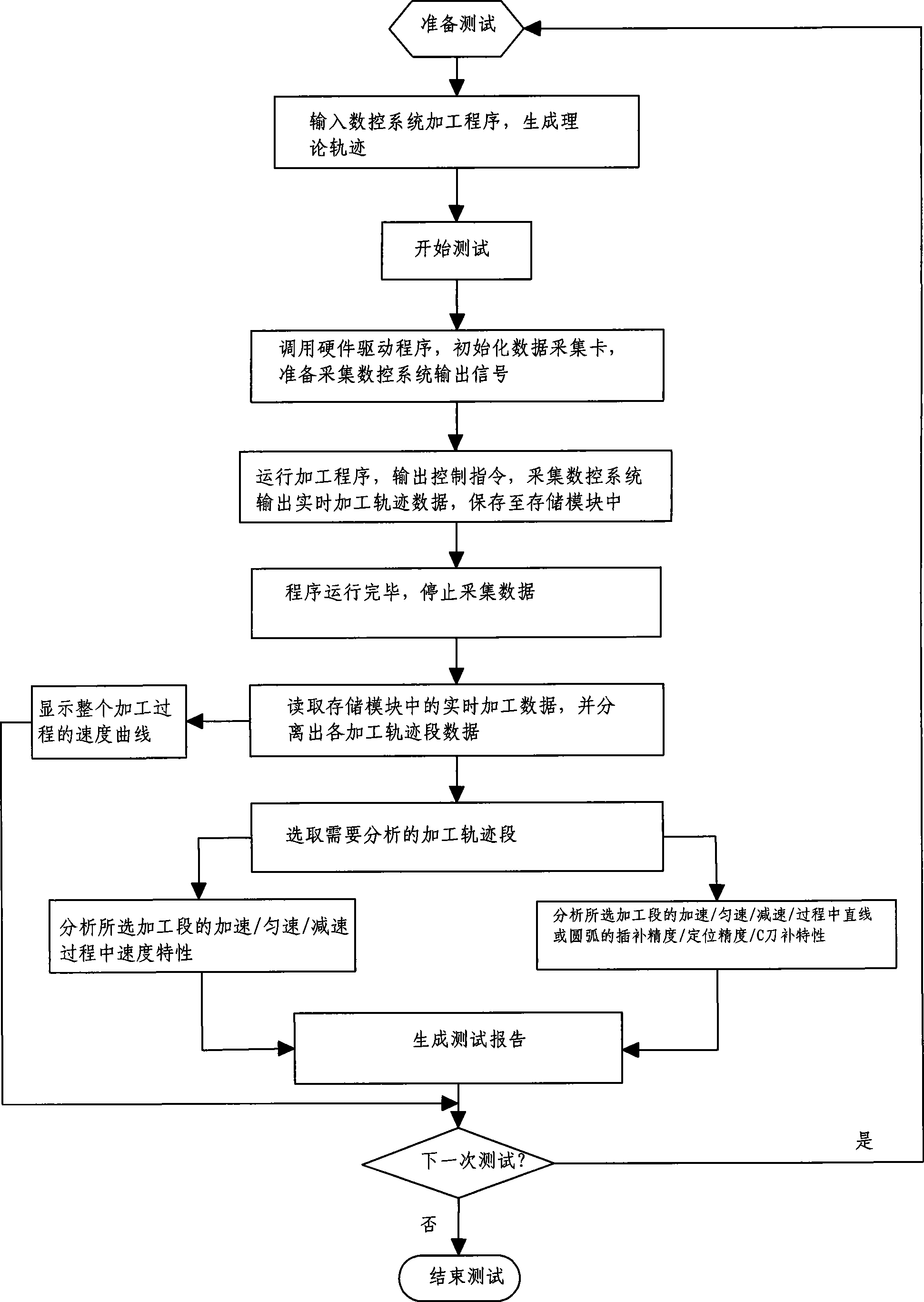

ActiveCN101387879AImprove efficiencyImprove test accuracyElectric testing/monitoringNumerical controlNumerical controlControl signal

The invention discloses a motion precision testing device for numerical control devices, which comprises a signal conditioning plate connected with a numerical control device, a data collecting card and a programmable computer, wherein level conversion or input-output conversion of pulse signals or feedback signals which are real-time received and outputted by the numerical control device can becarried out by the signal conditioning plate, the data collecting card receives signals input by the signal conditioning plate at real time to convert the signals into computer readable signals and outputs control signals to the numerical control device, and the programmable computer equipped with a storage module stores processing procedures or operating parameters of the numerical control device and then builds up the theoretical trace, controls the data collecting card to output control signals, reads pulse signals or feedback signals of the numerical control device which are inputted by the data collecting card, builds up the real-time operating trace, and displays the theoretical trace and the real-time trace to output. The invention constructs a software and hardware platform according to motion characteristics of the numerical control device, and tests the motion characteristics of the numerical control device via simulated operation, which has high efficiency, simple operationwith various testable contents, wide application scope and high testing precision.

Owner:GSK CNC EQUIP

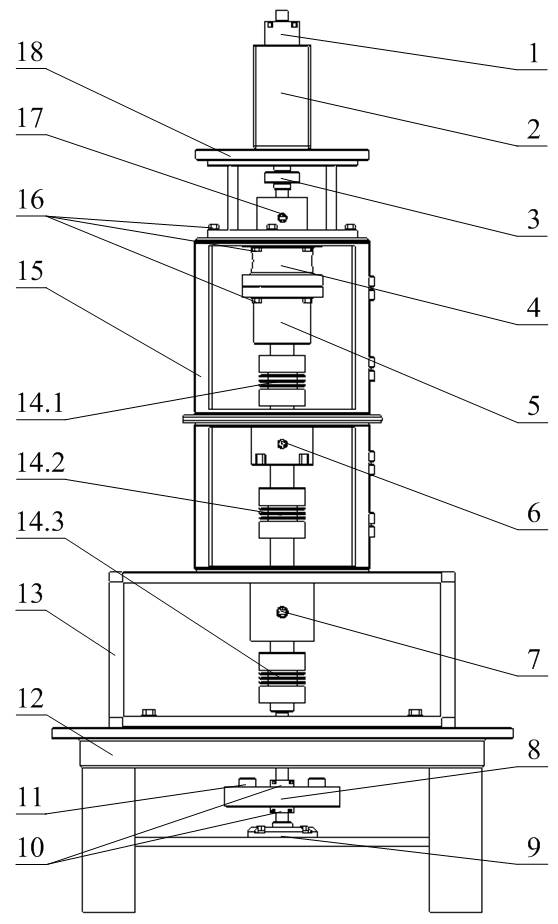

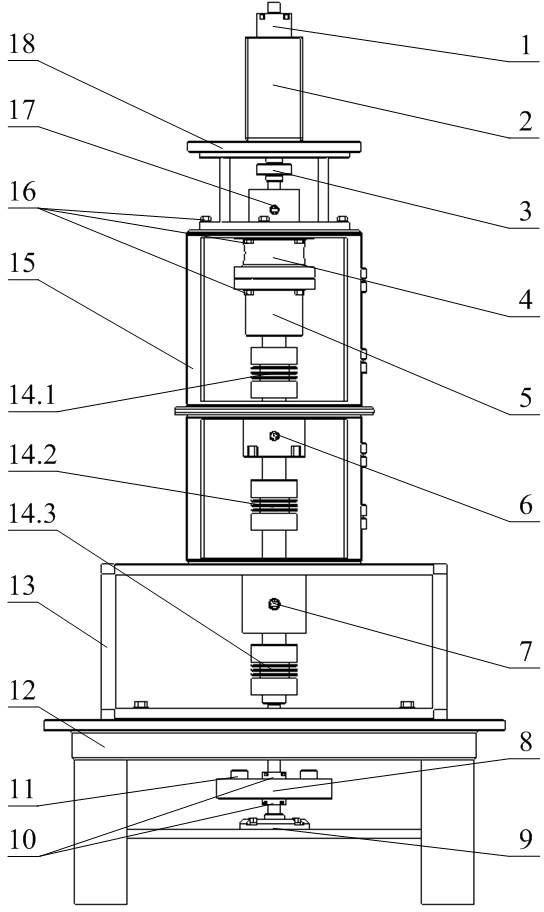

Vertical experiment table for precise performance test of small-tooth-difference planetary reducer

InactiveCN102607844AAvoid assembly errorsEasy to install and debugMachine gearing/transmission testingReduction driveCoupling

The invention discloses a vertical experiment table for a precise performance test of a small-tooth-difference planetary reducer. The vertical experiment table comprises a mounting bracket, a drive motor, an input end torque instrument, an output end angle encoder, an output end torque instrument and a thrust disc, wherein the drive motor is vertically mounted on the mounting bracket; the input end torque instrument is connected with the output shaft of the drive motor and the input shaft of the tested reducer respectively; the output end angle encoder is connected with the output shaft of the tested reducer; the output end torque instrument is connected with the output shaft of the output end angle encoder; the thrust disc is connected with the output shaft of the output end torque instrument; the drive motor is provided with a motor end angle encoder; and the drive motor and the input end torque instrument are connected through a rigid coupling. By vertically arranging the drive motor, the tested reducer, the output end angle encoder and the output end torque instrument, the vertical experiment table effectively avoids the assembly error caused by gravity, is convenient to mount and debug, is high in degree of automation, high in test precision and great in generality, and can test multiple dynamic characteristics of the tested reducer at the same time.

Owner:重庆奔腾智能装备技术有限公司

Single focal plane high-precision testing method for optical wavefront of optical imaging system

InactiveCN102252763ASolve for uniformitySolve the errorOptical measurementsPupil functionCalculation error

The invention discloses a single focal plane high-precision testing method for optical wavefront of an optical imaging system, relates to the technical field of optical testing, solves the problems that exit pupil amplitudes are not distributed uniformly and calculation errors are introduced by fast Fourier transform in the conventional phase retrieval algorithm, and provides the scheme for eliminating the influence of vibration in the process of image acquisition on detection accuracy. The method comprises the following steps of: establishing a detection platform of the optical imaging system; detecting the position of the focal plane of a lens to be detected by using a detection device in the detection platform and acquiring an out-of-focus stellar image of the lens to be detected by the detection device; selecting effective data according to the acquired out-of-focus stellar image and calculating a pupil function of an optical system; and extracting the phase of the acquired pupil function to obtain the optical wavefront of the optical imaging system. The pupil function of the optical system is calculated by a Zernike multinomial, an extended Nijboer-Zernike multinomial, and a generalized inverse matrix. The single focal plane high-precision testing method is low in cost, and high in accuracy and is suitable for manufacturing enterprises, scientific research and detection units of the optical imaging system.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

System and method of testing complex dielectric constant of material based on gradient coaxial resonator

ActiveCN108594023AReduce sizeSave materialDielectric property measurementsResonant cavityCoaxial resonators

The invention provides a system and method of testing complex dielectric constant of a material based on a gradient coaxial resonator. The system comprises the gradient coaxial resonator and a coupling device. The method comprises the steps: 1) testing and recording resonant frequency f0 and quality factor Q0 in a corresponding cavity working mode when no sample is loaded; 2) measuring diameter DSand thickness dS of a sample under test, placing the sample in a sample area, and testing and recording resonant frequency fS and quality factor QS in the corresponding cavity working mode when the sample is loaded; 3) using resonator perturbation theory to calculate complex dielectric constant of the material under test. The system and method have the advantages that high-precision testing of complex dielectric constant at normal temperature is achieved for a microwave dielectric material, required cavity size and sample size for low frequency testing can be reduced, a sealed-bottom tube clamp can also be used to test the complex dielectric constant of liquid and powdery materials.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Method for testing locomotive general-purpose circuit board function

InactiveCN101281231AEasy to testImprove scalabilityElectronic circuit testingGeneral purposeFunctional testing

The invention relates to a locomotive general-purpose circuit board function test method, which aims at the multiple electric pluggable unit kinds and complicated debug method debug method features of the locomotive. In the test process, all apparatuses in the test system are divided into different kinds of objects, each kind of objects have their property and method, different methods of all objects of the test system are combined into a plurality of states, executing combined ordering to the a plurality of states, and mounting property of different objects, and preserving all these information, and then invoking the preserved information when the check program runs. The invention adopts a method which combines using the measurement desk type apparatus to execute authoritative metering and using the corresponding matrix switch and general-purpose switch to execute self checking, provides a locomotive general-purpose circuit board automatization test method with favorable human-machine interaction interface, high precision testing and intellectualized locomotive.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

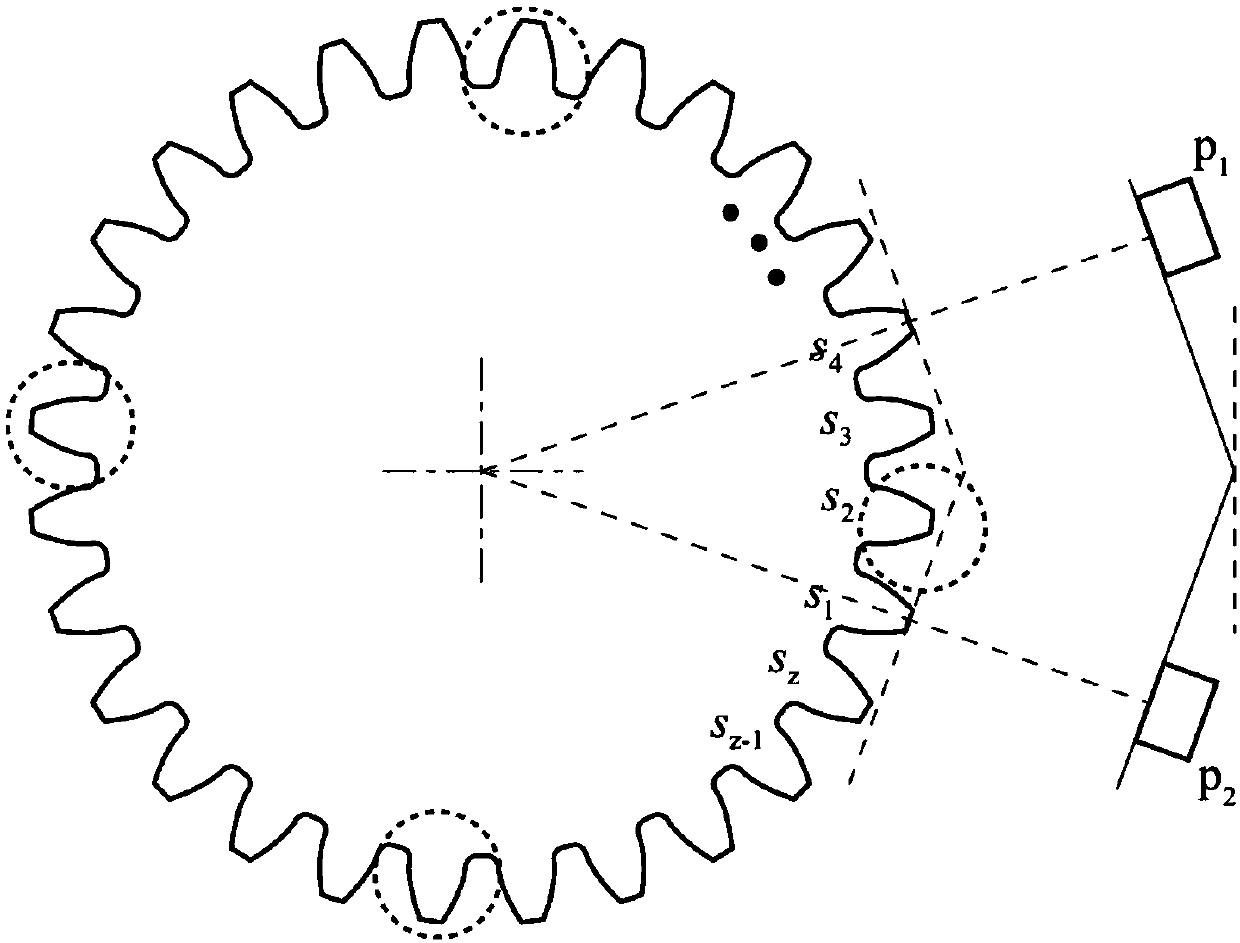

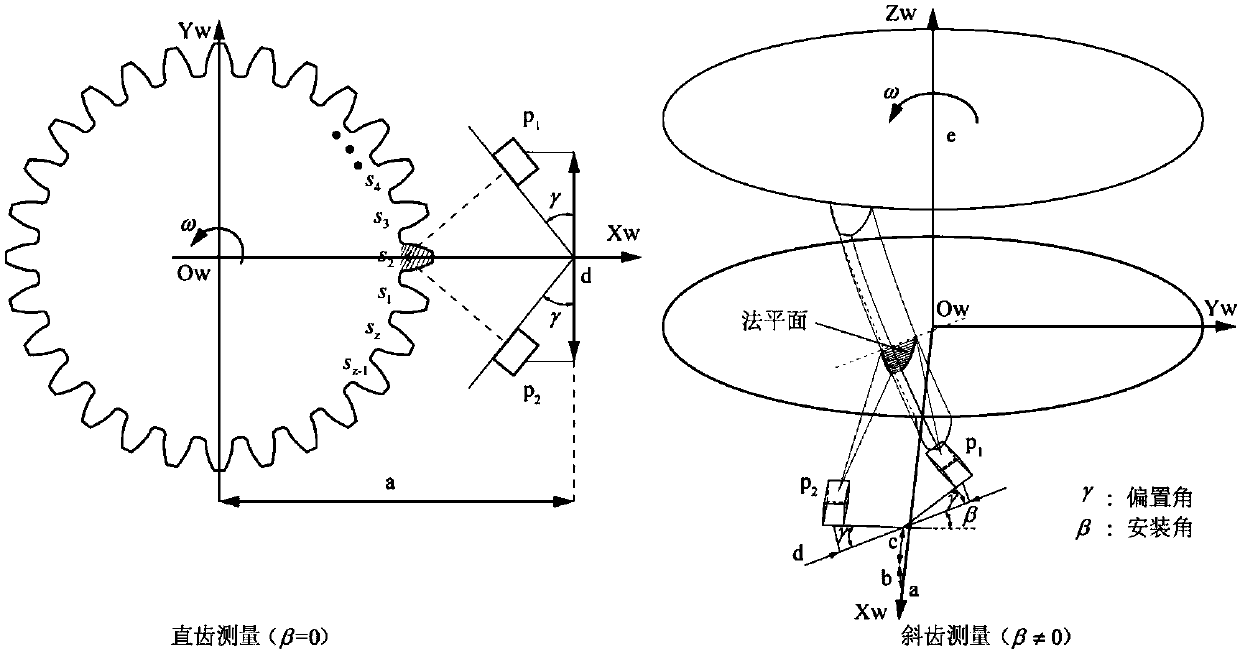

Gear teeth thickness measurement method based on line structured light

ActiveCN108050946AReduce the impactReduce adverse effectsUsing optical meansLaser probeData acquisition

The invention discloses a gear teeth thickness measurement method based on line structured light and belongs to the field of the precision test technology and instruments and the gear detection technology. After a detected gear is embedded, the center of a coordinate system is calibrated through a line laser probe, the design reference of the detected gear is selected as the reference for measurement, according to gear parameters, more than 4 gears uniformly distributed on the detected gear are selected, and three uniformly-distributed cross sections of each gear are taken as measurement positions; data acquisition, mounting parameters required by two probes and the relationship among the parameters are calculated according to the parameters of the detected gear, two line structured lightprobe coordinate systems are established, and data of two side surfaces of the detected gear is acquired; according to each mounting parameter and the measurement data, a space coordinate conversion formula for data acquisition is established, and each set of measurement values of the probe coordinate systems is converted to the gear design center. The method is advantaged in that a tooth thickness deviation mathematic model is established, and high precision measurement of tooth thickness deviation, string tooth thickness measurement and separate-tooth thickness average deviation is further realized.

Owner:BEIJING UNIV OF TECH

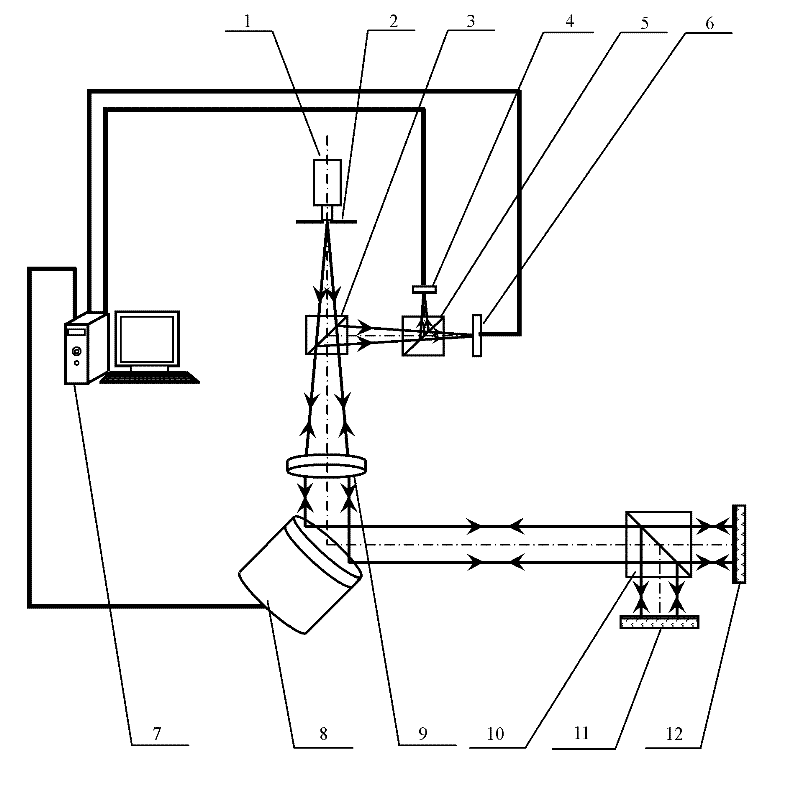

Apparatus and method for measuring two-dimensional small angle based on light beam angle drift dynamic compensation

InactiveCN101377414AIncrease contrastImprove anti-interference abilityUsing optical meansLight beamRepeatability

The invention discloses a two-dimensional small angle measuring device and a method based on light beam angle floating state compensation, belonging to the precision instrument production and precision testing and measuring technical field. The tangential angle measuring unit and the radial angle measuring unit of the instrument are arranged respectively in an orthogonal plane YOZ and an orthogonal plane XOY, and both comprise a light beam angle floating error compensation light path. For the measuring method, the light beam which returns from a self-testing point and has the information of the two-dimensional angle is adopted. The reflected light beam and transmitted light beam produced by a polarization spectroscope are used as the measuring light beam of the tangential angle measuring unit and the radial angle measuring unit. The invention adopts dynamic light beam angle floating error compensation light path, changes the angle floating amount of the light beam into common mode error, separates in real time and compensates dynamically the angle measuring error caused by light beam angle floating, improves repeatability, stability of the two-dimensional small angle during measuring, and reduces the uncertainty of measurement.

Owner:江苏双聚智能装备制造有限公司

Spring plate rigidity precision testing instrument

InactiveCN101556229AStiffness test is accurateEnsure accuracy andMaterial strength using tensile/compressive forcesTester deviceEngineering

The invention discloses a spring plate rigidity precision testing instrument which measures the rigidity of a spring plate on an electronic balance. The same kinds of spring plates on the same electronic balance have to possess the same rigidity. The rigidity of the prior spring plate is difficult to precisely measure due to the lack of a precision testing instrument, therefore, the accuracy and the stability of the electronic balance are affected. The lower part of the spring plate (2) to be measured is provided with a stress application rod (3); one end of a lever (4) acts on the stress application rod (3), and the other end is connected with a weight (6); an eccenter (5) is arranged close to the weight (6); and the upper part of the spring plate (2) to be measured is connected with a non-contact type displacement sensor (7) and a digital displayer (8). A weight rack (9) is arranged on the lever (4), and the middle part of the lever (4) is provided with a lever support (10). The invention has the advantages that the rigidity of the spring plate is accurately measured, the accuracy and the stability of the electronic balance can be ensured, and the spring plate rigidity precision testing instrument has convenient operation, simple structure, small volume and low cost.

Owner:SHANGHAI SUNNY HENGPING SCI INSTR

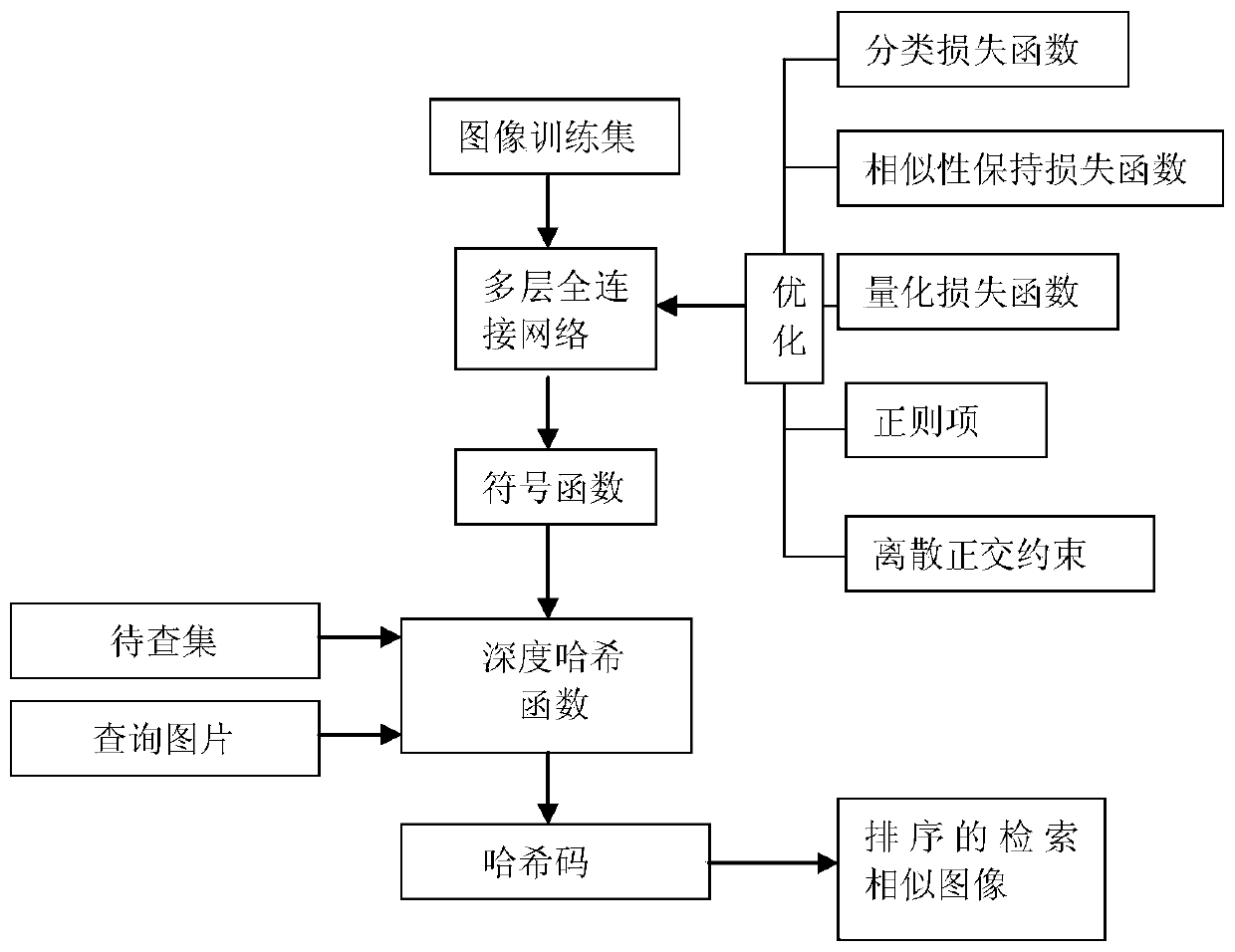

An image retrieval method based on deep Hash learning optimization

ActiveCN109766469AImprove retrieval accuracyIncrease independenceDigital data information retrievalNeural architecturesData setHash function

An image retrieval method based on deep Hash learning optimization comprises the following steps of 1, constructing a multi-layer full connection network firstly, connecting a panh function behind each layer of full connection, and finally conducting the sign operation on the network output; 2, constructing a semantic retention loss function obtained by a classification loss function and a weighted semantic similarity matrix, and a target function with discrete orthogonal constraint obtained by a quantitative loss function and a regular item; 3, optimizing an objective function; 4, dividing the obtained feature data set into a query set Q and a to-be-searched set D, taking a part of data in the to-be-searched set D to form a training data set P, inputting depth characteristics and label information of the training data set P, initializing a weight coefficient and a binary code, performing iterative optimization on the step 3 in sequence to obtain an optimal network weight coefficient,and obtaining a depth hash function by the step 2; and step 4, carrying out the image retrieval and precision testing. The method is relatively higher in precision and relatively higher in retrieval efficiency.

Owner:ZHEJIANG UNIV OF TECH

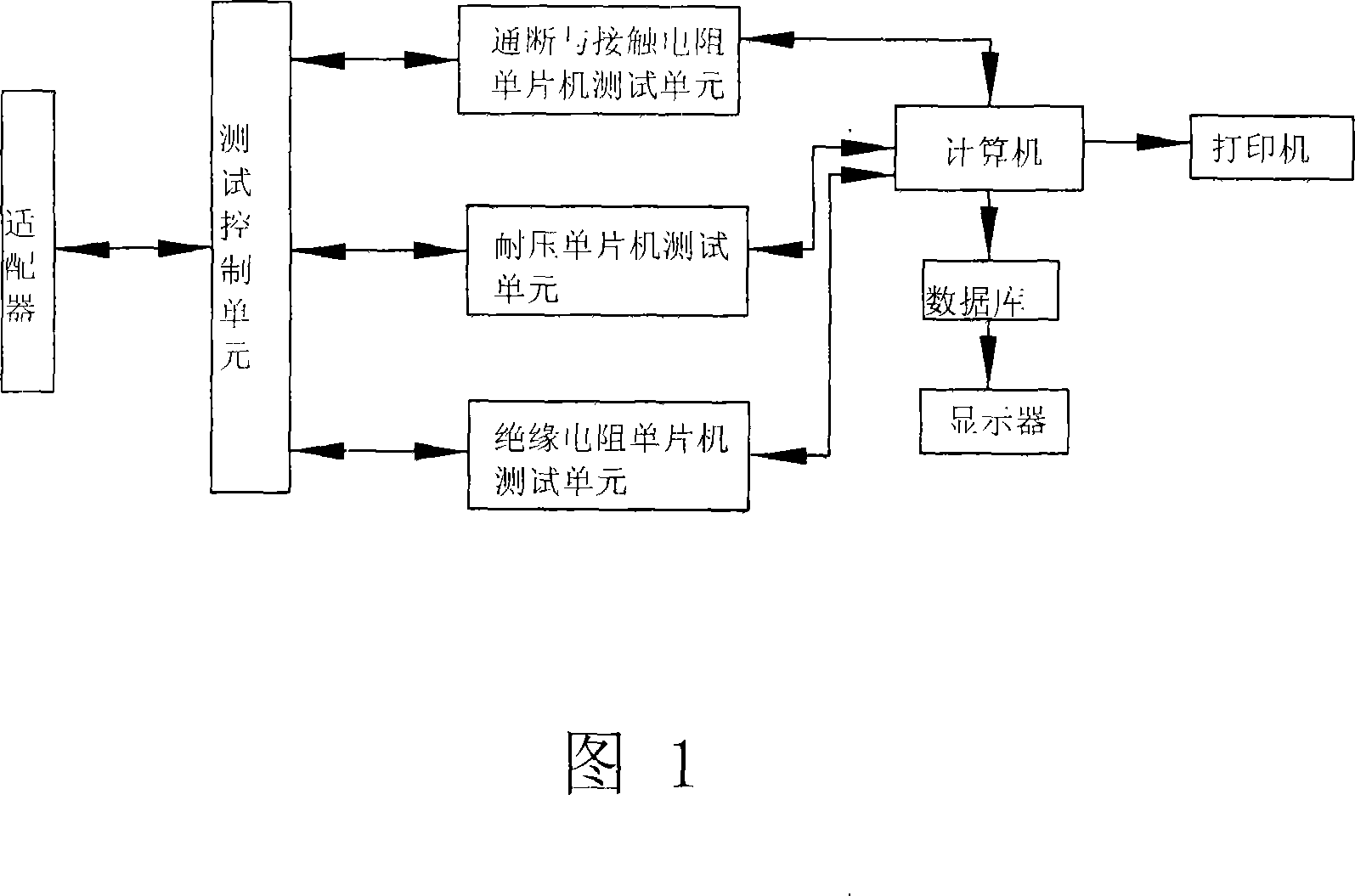

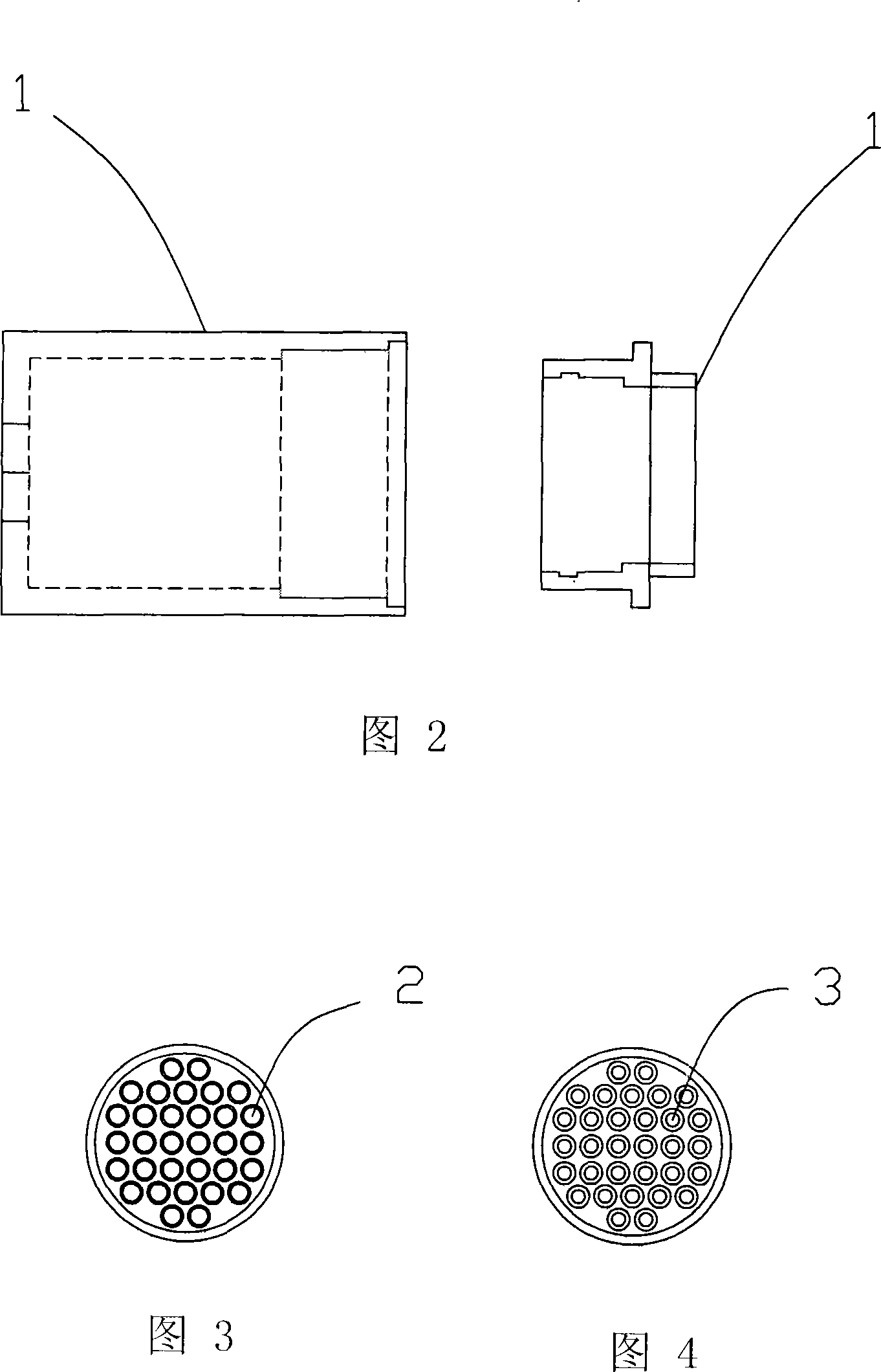

Intelligentized test system for electric coupler

InactiveCN101201367AFunction increaseTest accurateTesting dielectric strengthCurrent/voltage measurementElectrical resistance and conductanceElectricity

An intelligent test system for the electrical connector comprises a computer, a test control unit and an adaptor for the electrical connector. The adaptor comprises two retractable casings, one casing is equipped with an insulating core, and the other casing is equipped with a testing needle. The test control unit comprises a test unit for on-and-off resistance microcontroller, a test unit for withstanding voltage microcontroller and a test unit for the insulation resistance microcontroller. A control device of the microcontroller and a control device of the matrix switching and driving are positioned between the test control unit and the computer. The invention is suitable for the precise test of various parameters of various kinds of the electrical connector, has the advantages of complete function, accurate test and high efficiency.

Owner:陕西永辉测控技术有限公司

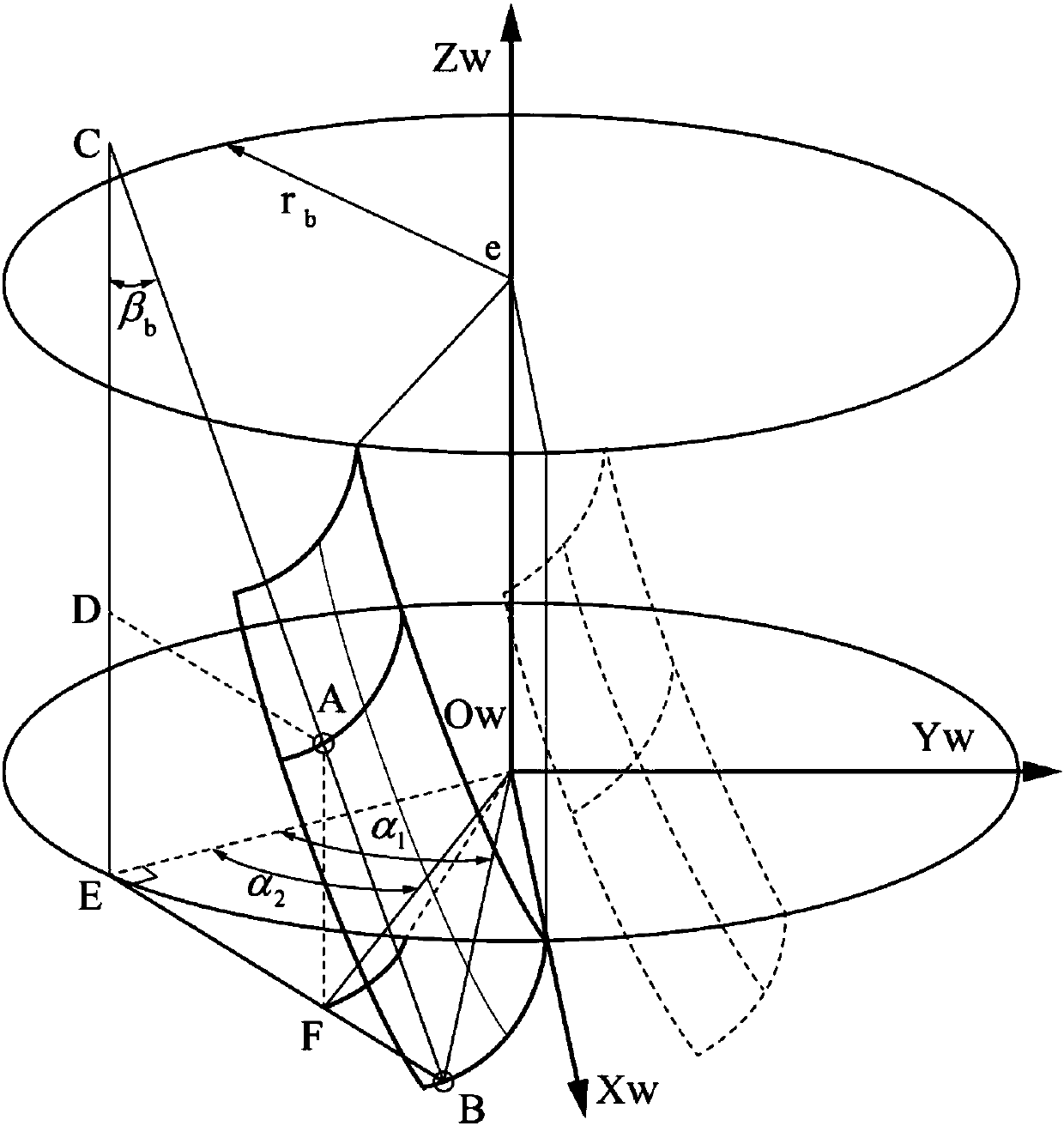

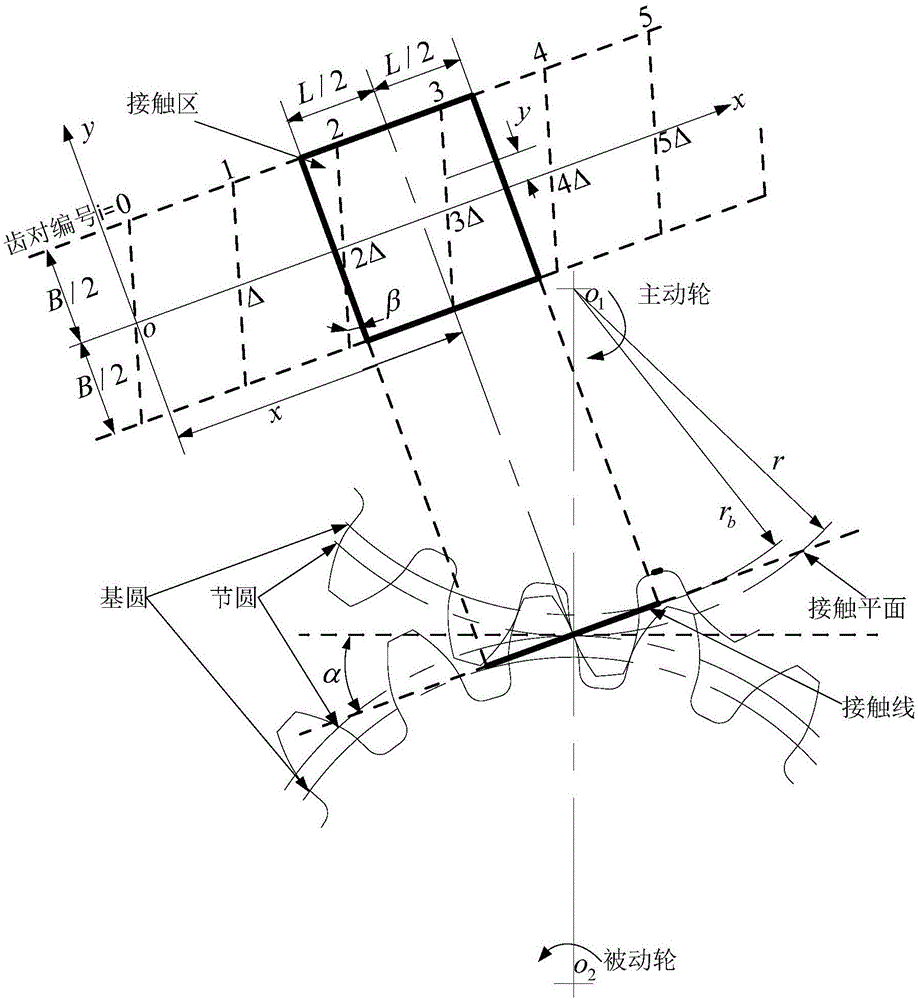

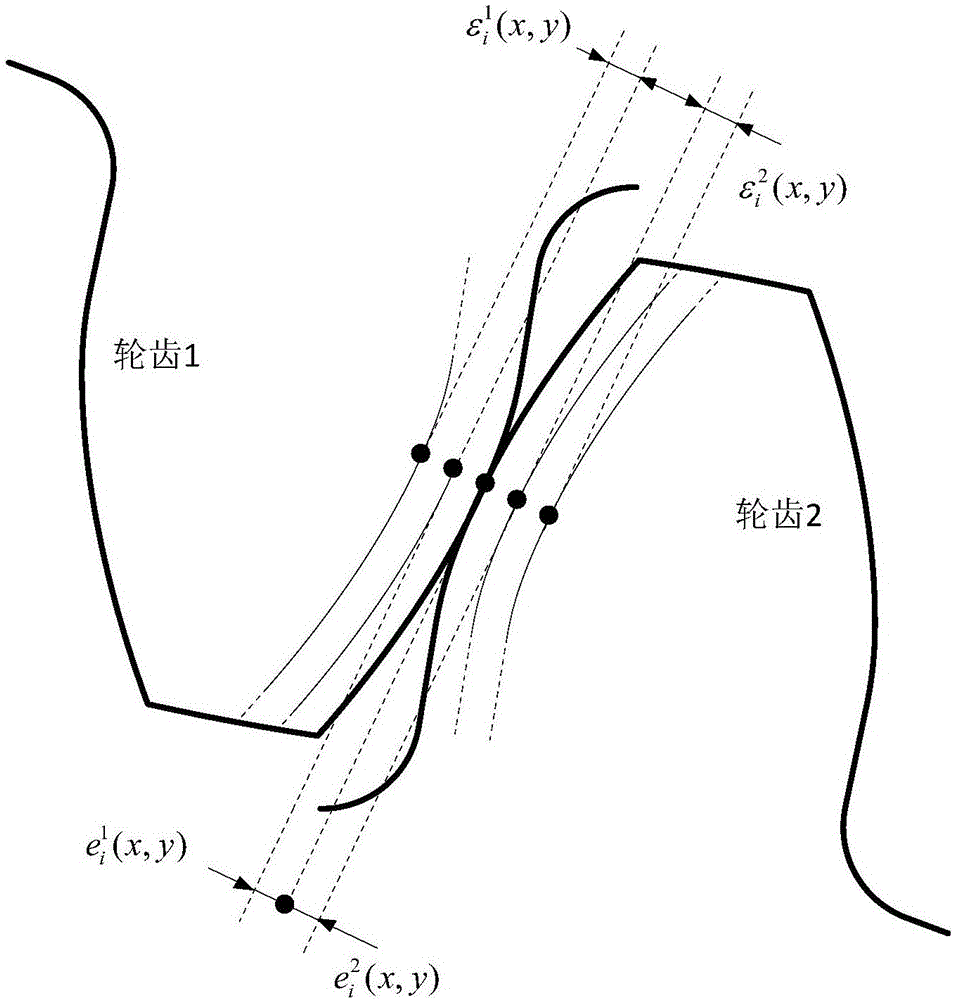

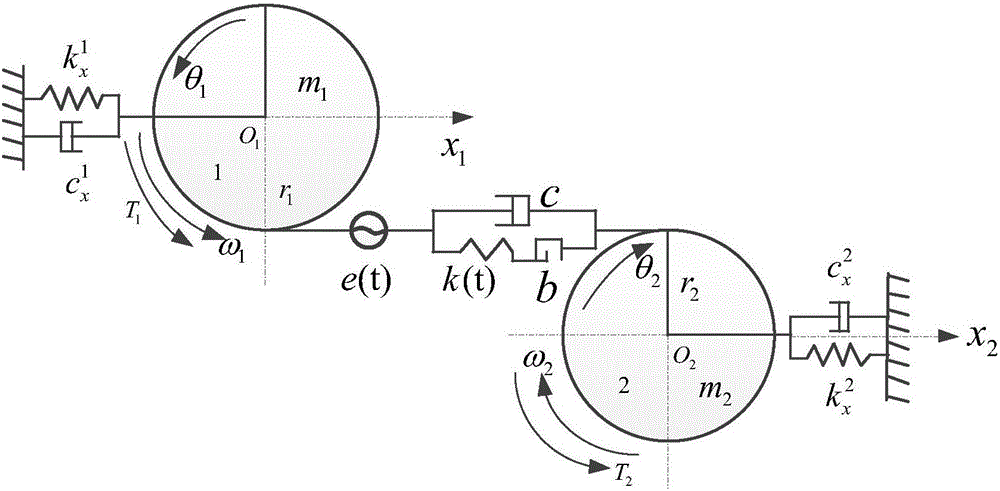

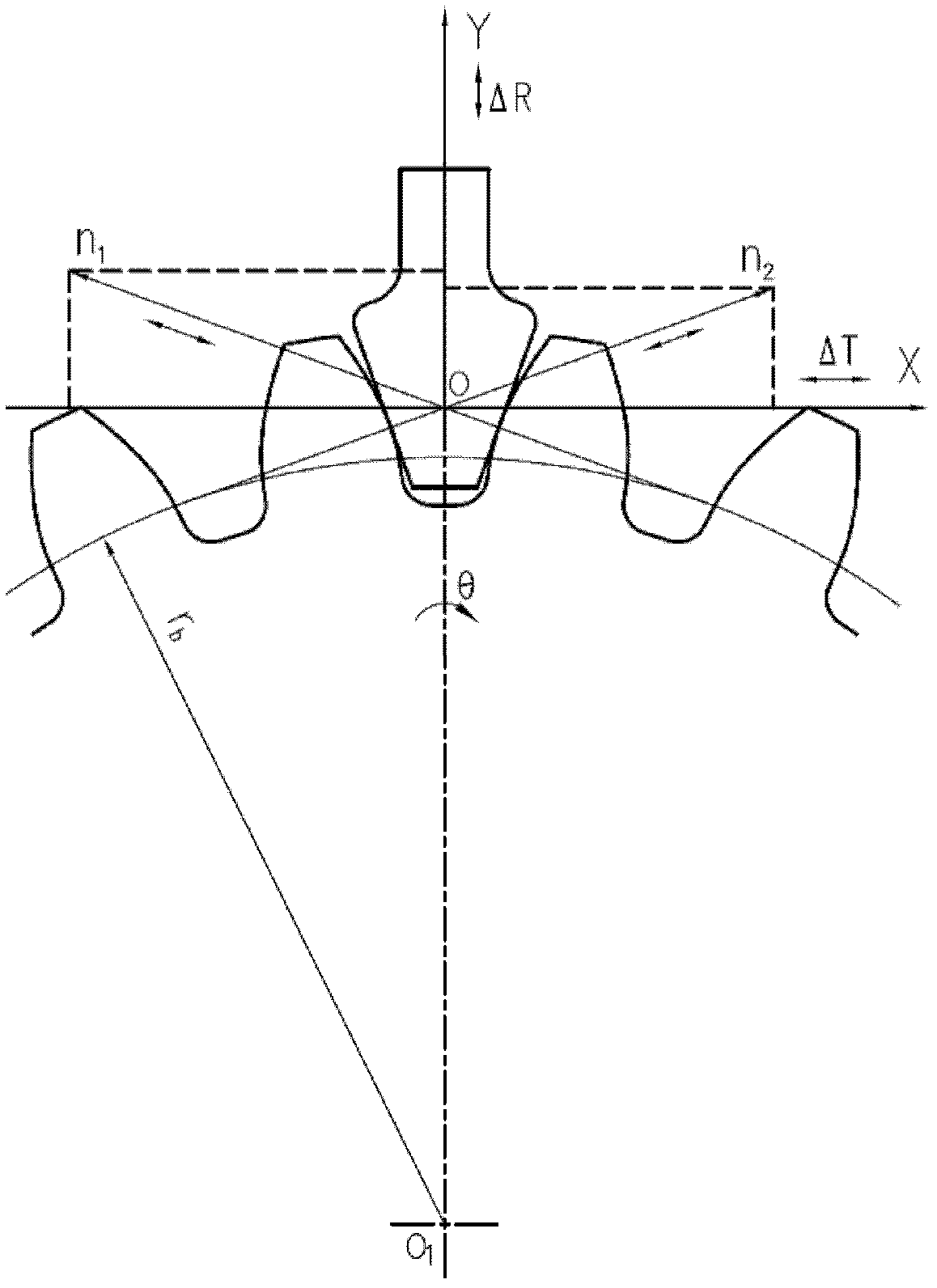

Dynamic transmission error prediction method based on gear integrated error

ActiveCN106840652AAccurate dynamic transmission error indexGet Dynamic Transmission ErrorMachine gearing/transmission testingCouplingNon linear dynamic

The invention discloses a dynamic transmission error prediction method based on a gear integrated error and belongs to the technical fields of gear transmission precision measurement, precision tests and instrument and mechanical transmission. On the basis of obtaining integrated error data of a gear by an integrated error measurement technology, interaction coupling of errors and working conditions is taken into consideration, and a non-linear dynamics prediction model of gear dynamic transmission prediction is constructed. Firstly, a coordinate system is established according to a gear meshing transmission principle, gear integrated error measurement data is used for obtaining gear static transmission errors. Then, dynamic displacement of the prediction model is acquired by the usage of a numerical solution method. Finally, an interaction principle of gear errors is used for compounding gear dynamic transmission errors. The dynamic transmission error prediction method based on the gear integrated error can not only meet the requirements of a complicated environment, but also meet the requirements for consideration of the interaction coupling between the errors and the working conditions.

Owner:BEIJING UNIV OF TECH

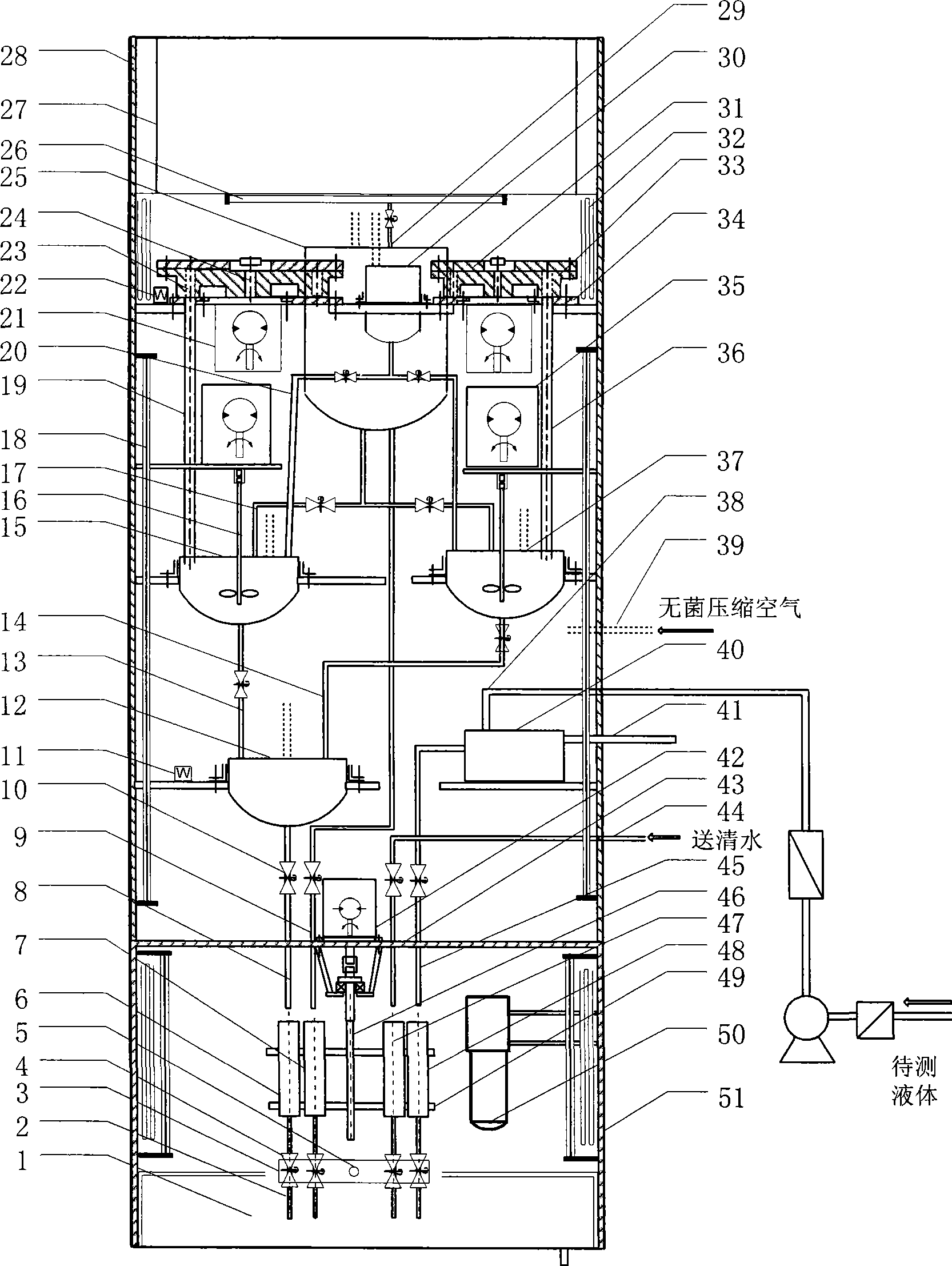

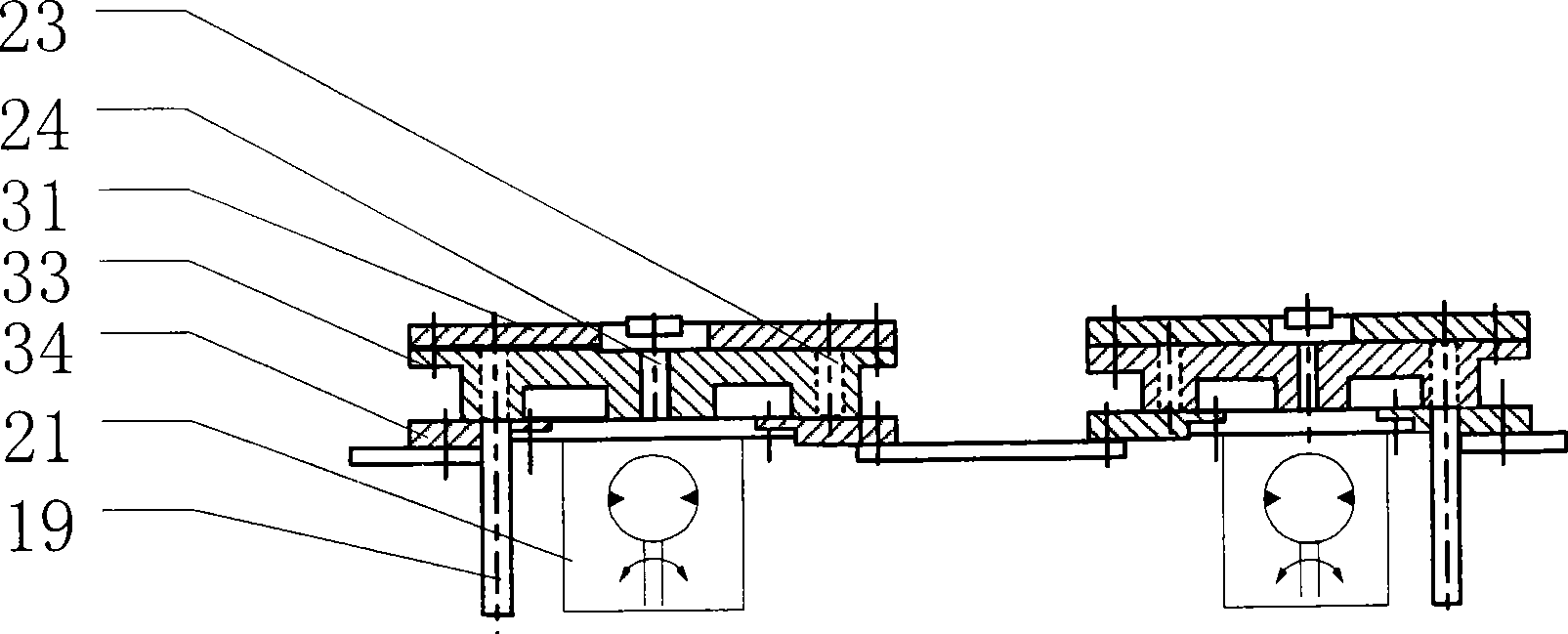

On-line automatic analyzer for synthetic biological toxicity in water and its use method

InactiveCN101477131ARealize online activationImprove accuracyChemiluminescene/bioluminescenceTwo temperatureWater quality

The invention relates to a water quality integrated bio-toxicity on-line automatic analyzer and a method for using the same. The analyzer is characterized in that the interior of the analyzer is provided with two temperature control areas, wherein one temperature area at a temperature of between 0 and 4 DEG C mainly comprises a freezing dry powder storing device, a sterilizing device, a freezing dry powder definite quantity control device and a nutrient solution storing device; and the other temperature area at a temperature of between 20 and 25 DEG C mainly comprises a photogenic bacterium activating reaction storing kettle, a buffering liquid storing device, a regulation and control device for water to be tested, a clear water flow rate transmission and control pipeline, a delicate testing device and a rotary long shaft fixing round plate in a dark box, wherein a test tube is assembled on the round plate; the dark box cover is connected with the photogenic bacterium activating reaction storing kettle, the buffering liquid storing device, the control device for water to be tested and an analyzer externally connected washing pipe through the flow rate transmission and control pipeline; and the interior of the dark box is provided with a photoelectric probe. The analyzer has the advantages of on-line test achievement for water quality integrated bio-toxicity, simple operation and high automation degree in the aspect of maintenance, and can obtain reasonable cost performance and be suitable for the on-line monitoring of abominable environment. The analyzer can be used as a single machine, and can also be used as a front-end product of a monitoring network system.

Owner:ZHEJIANG SCI-TECH UNIV

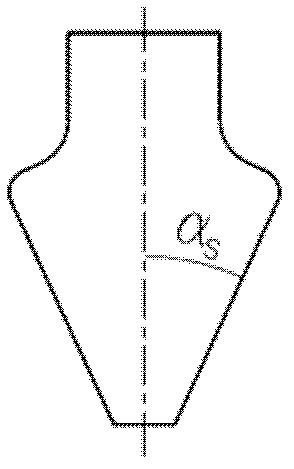

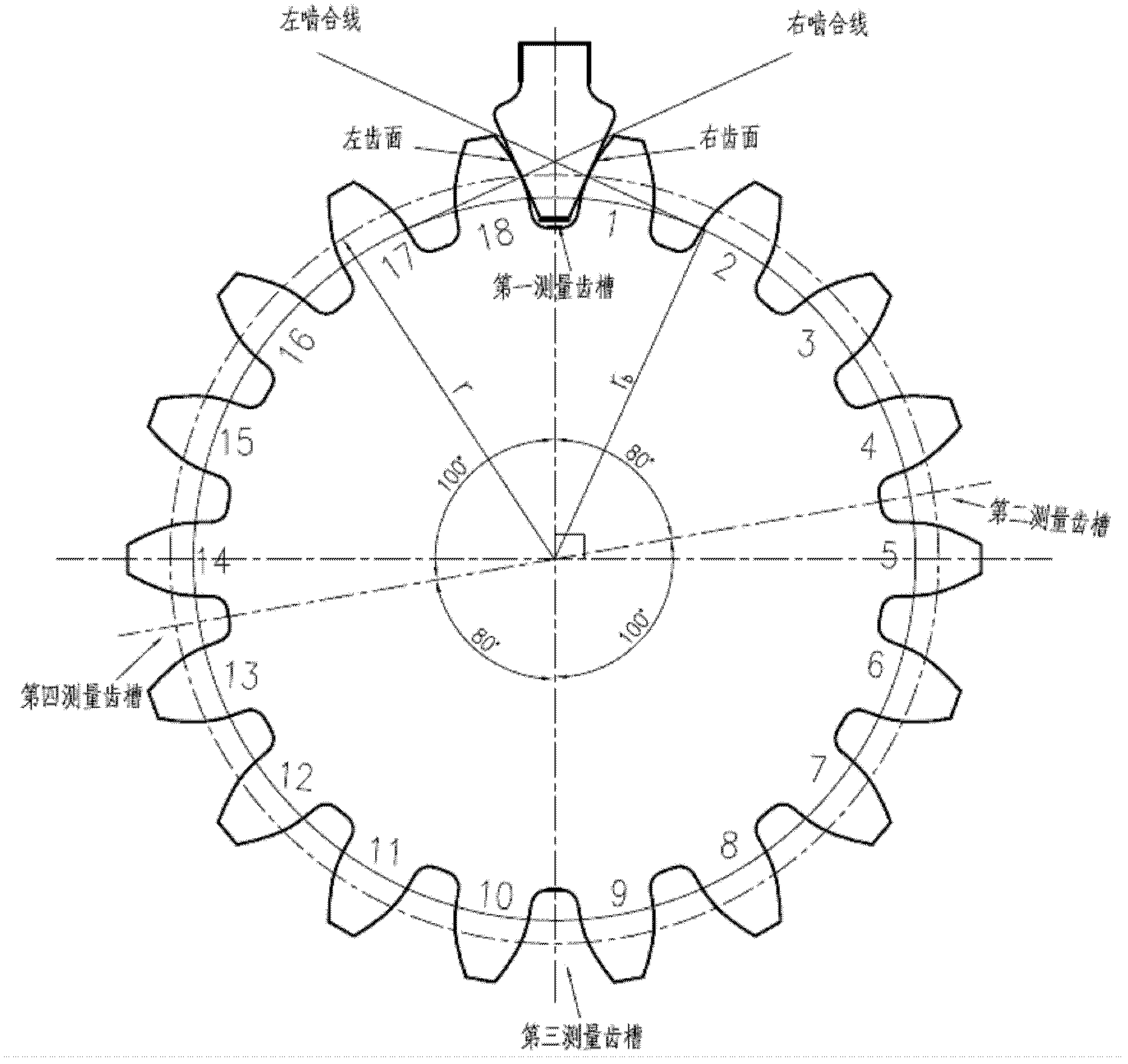

Method for measuring tooth profile deviation of gear based on double-side meshing

ActiveCN102636097AAchieving tooth profile deviationImprove measurement efficiencyMechanical counters/curvatures measurementsMathematical modelGear wheel

The invention relates to a method for measuring a tooth profile deviation of a gear based on double-side meshing and belongs to a precise measuring technique and the technical field of instrument and mechanical transmission. According to the method, a rack measuring head is adopted for measuring the tooth profile deviation of the to-be-measured gear based on double-side meshing, wherein the rack measuring head only has a tooth and the tooth profile is a straight line. Four tooth sockets of each to-be-measured gear are measured. During the measuring process of each tooth socket, the rack measuring head enters the tooth socket of the to-be-measured gear and is in close contact with left and right tooth surfaces of the to-be-measured gear; the rack measuring head and the tooth socket move in a double-side meshing manner and the position of the rack measuring head is measured and obtained; and lastly, the tooth profile deviation of the to-be-measured gear is solved and obtained through a mathematical model. Specific to the requirement for on-site quick measurement of the gear, the invention provides the method for measuring the tooth profile deviation of the gear through the meshing of the rack measuring head and the to-be-measured gear based on the double-side meshing, so that the tooth profile deviations of the left and right tooth surfaces of the to-be-measured gear are simultaneously obtained through once measurement.

Owner:BEIJING UNIV OF TECH

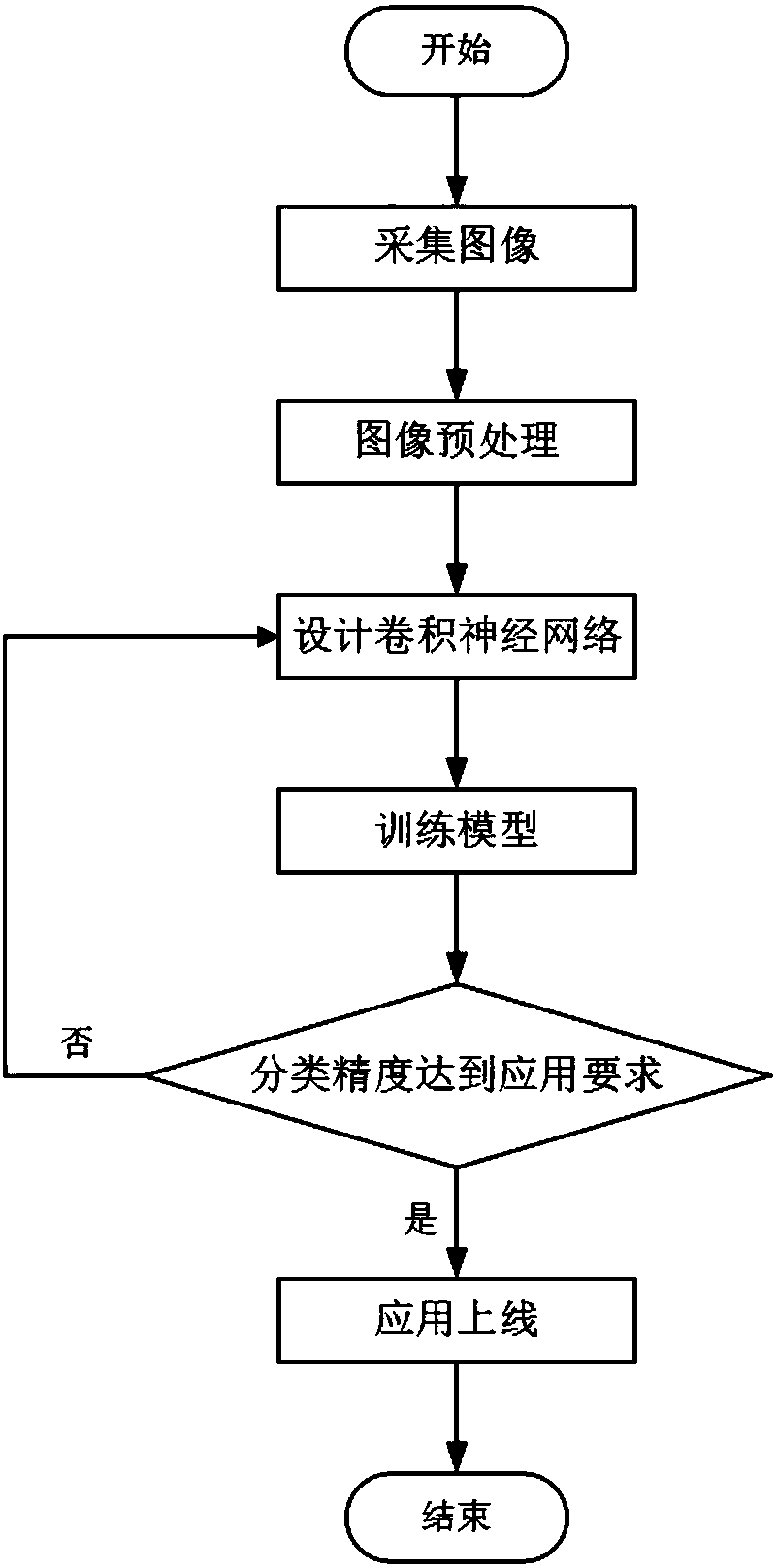

Poultry animal behavior recognition method based on deep convolutional neural network

InactiveCN108182423AMeet management requirementsAvoid errorsBiometric pattern recognitionNeural architecturesAnimal behaviorComputer science

The invention discloses a poultry animal behavior recognition method based on a deep convolutional neural network. The method comprises the steps of (1) collecting all poultry animal behavior images to be monitored, (2) preprocessing the collected images, (3) designing a deep convolutional neural network structure with the combination of characteristics of the poultry animal behavior images to bemonitored, (4) taking the images obtained in step (2) as training data and training a poultry animal behavior recognition model by using the deep convolutional neural network structure in step (3), (5) carrying out precision testing on the trained poultry animal behavior recognition model in step (4), returning to step (3) if the test precision does not reach a standard, and carrying precision outtesting until an application standard is reached, and (6) deploying the recognition model to be applied to the process of poultry animal farming and ending the step. According to the method, the recognition efficiency and accuracy of poultry animal behaviors can be effectively improved, and the simplification of the management work of aquaculture is facilitated.

Owner:SHANDONG UNIV OF SCI & TECH

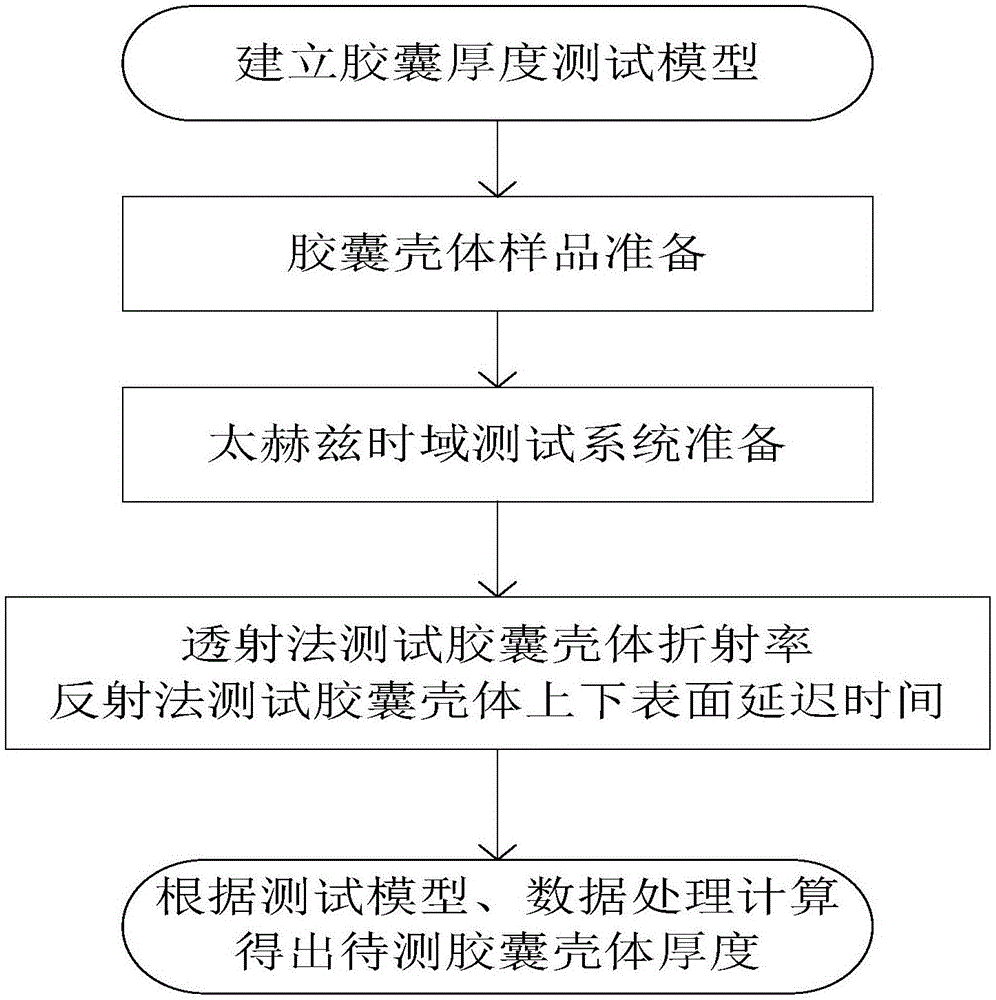

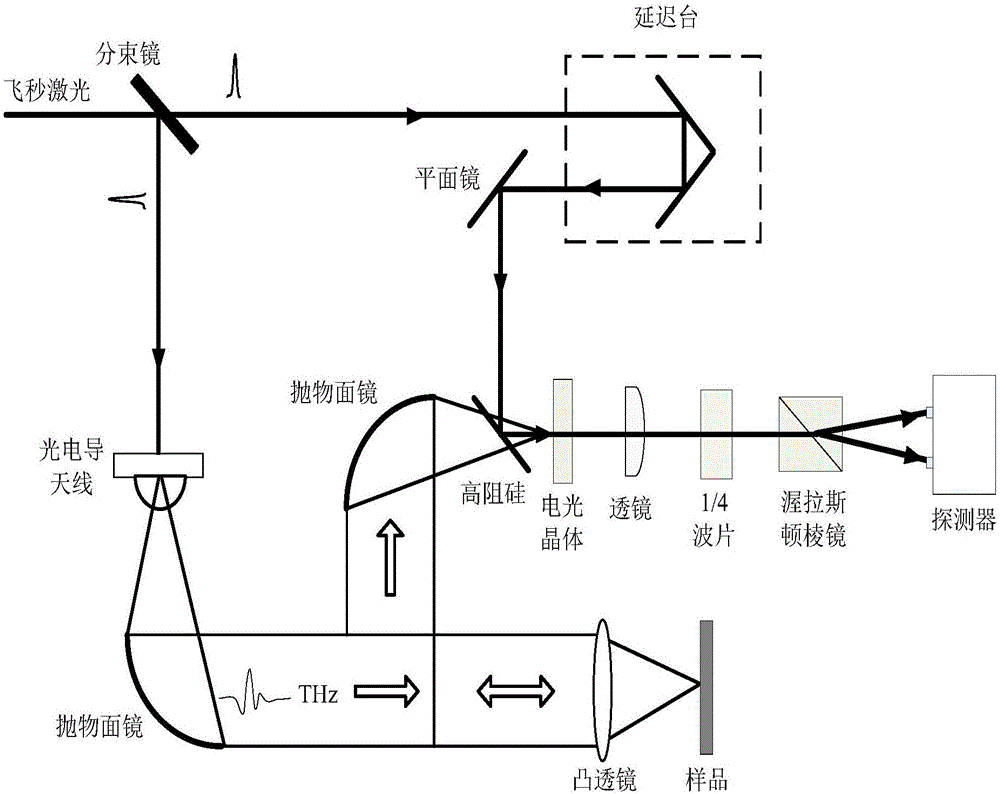

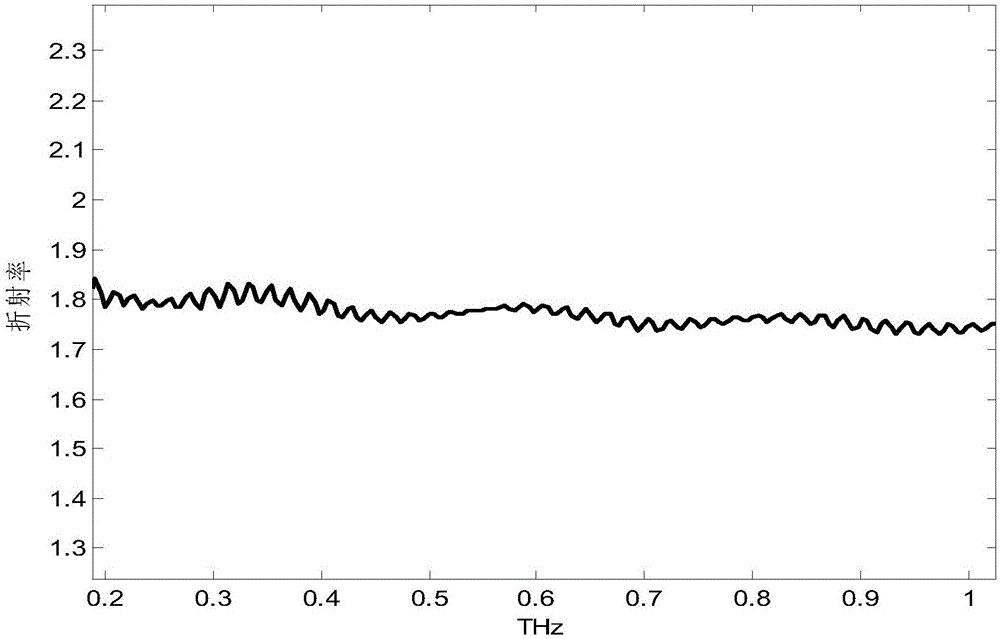

Method for measuring thickness of capsule housing based on terahertz time domain spectrum technology

InactiveCN106482651ALess susceptible to interferenceMeet testing needsUsing optical meansTime domainRefractive index

The invention discloses a method for measuring thickness of a capsule housing based on terahertz time domain spectrum technology. The method comprises the following steps of establishing a capsule housing thickness measuring model; on the condition that refractive index of the to-be-measured capsule housing is known, preventing testing for the refractive index of the to-be-measured capsule housing, and otherwise, testing the refractive index of the to-be-measured capsule housing; measuring a delay time difference deltat between an upper-surface reflection peak and a lower-surface reflection peak of the to-be-measured capsule housing; and calculating the thickness of the to-be-measured capsule housing according to an established capsule housing thickness measuring model d=c*deltat / 2n. The method of the invention realizes high-precision testing for the thickness of the capsule housing without damage of the capsule housing or contact with the capsule housing. The method supplies technical supports for online monitoring and management for quality of the capsule housing and better serves a medicine quality inspection industry.

Owner:SHANDONG ACAD OF SCI INST OF AUTOMATION

Detection device for knife point dynamic characteristics of numerical control machine tool and method of detection device

ActiveCN105269404ALow costSimple structureMeasurement/indication equipmentsNumerical controlData information

The invention discloses a detection device for knife point dynamic characteristics of a numerical control machine tool and a method of the detection device. Mainly the problems that detection performance indexes of knife point dynamic characteristics of an existing numerical control machine tool are not comprehensive or accurate, and detection cost of instruments and cutting test pieces is high are solved. The detection device for the knife point dynamic characteristics of the numerical control machine tool comprises a supporting base, a connecting plate and an L-shaped supporting wall plate. The top of the supporting base is provided with displacement sensors in a penetrating manner through holes, wherein the displacement sensors are arranged in the manner that every two displacement sensors are perpendicular to each other; meanwhile, acquired temperature data of main heat sources of the machine tool are integrated so that a main shaft can acquire real-time location and posture information of a point of a knife point in the swinging or rotating process, and correlation calculation of accuracy and generation of compensating data are completed by automatically obtaining fused data information through a data collector and transmitting the fused data information to a computer at high speed to be recorded and analyzed. The detection device is ingenious in structural design, the knife point characteristic testing functions are comprehensive, universality is high, numerical control machining precision testing cost is greatly reduced, and good practical and popularization value is achieved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com