Bidimension photoelectric self collimating device based on optical length multiplication compensation method and its measuring method

A photoelectric self-collimation and compensation method technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the difficulty of further improving measurement uncertainty, poor measurement stability of photoelectric autocollimators, and limitations of photoelectric autocollimators. Issues such as the scope of application, to achieve the effect of easy reception and monitoring, easy design, and miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

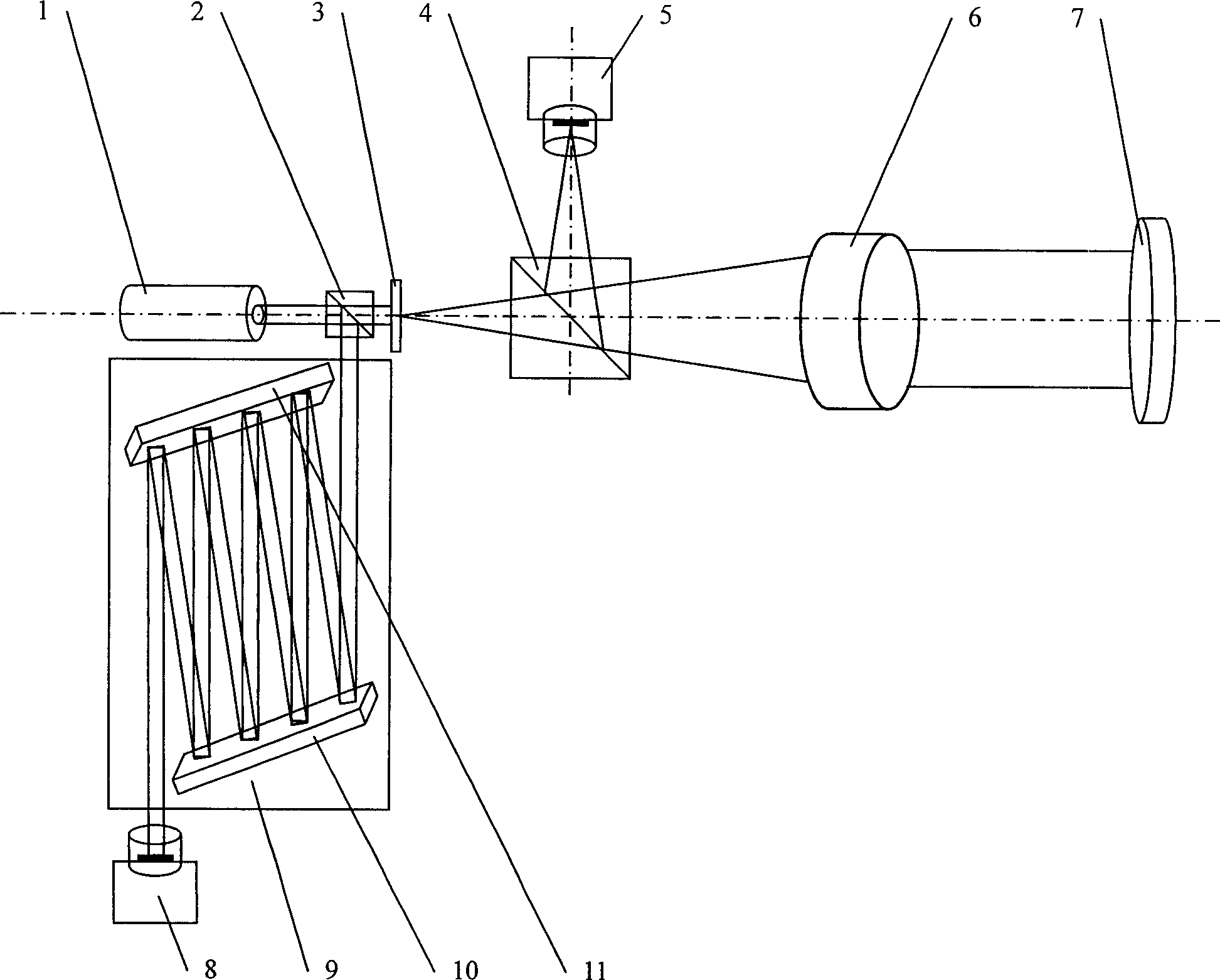

[0067] Such as figure 1 The shown two-dimensional photoelectric self-collimation device first adjusts the optical path multiplication device 9, and here, the optical path multiplication device 9 is as figure 1 As shown, it consists of two relatively parallel plane mirrors 10 and 11. After the adjustment, the optical path multiplication device 9 should be fixed, and then the two-dimensional photoelectric self-collimation device is calibrated. After the calibration is completed, the optical path multiplication device is multiplied during use. Device 9 is no longer adjusted. When measuring, the laser beam emitted by the laser light source 1 is divided into two beams by the pre-beam splitter 2: the transmitted beam becomes the measuring beam, and the reflected beam becomes the reference beam with exactly the same characteristics as the measuring beam; the reference beam enters the optical path multiplication device After 9, the optical path multiplying device 9 reflects the refer...

Embodiment 2

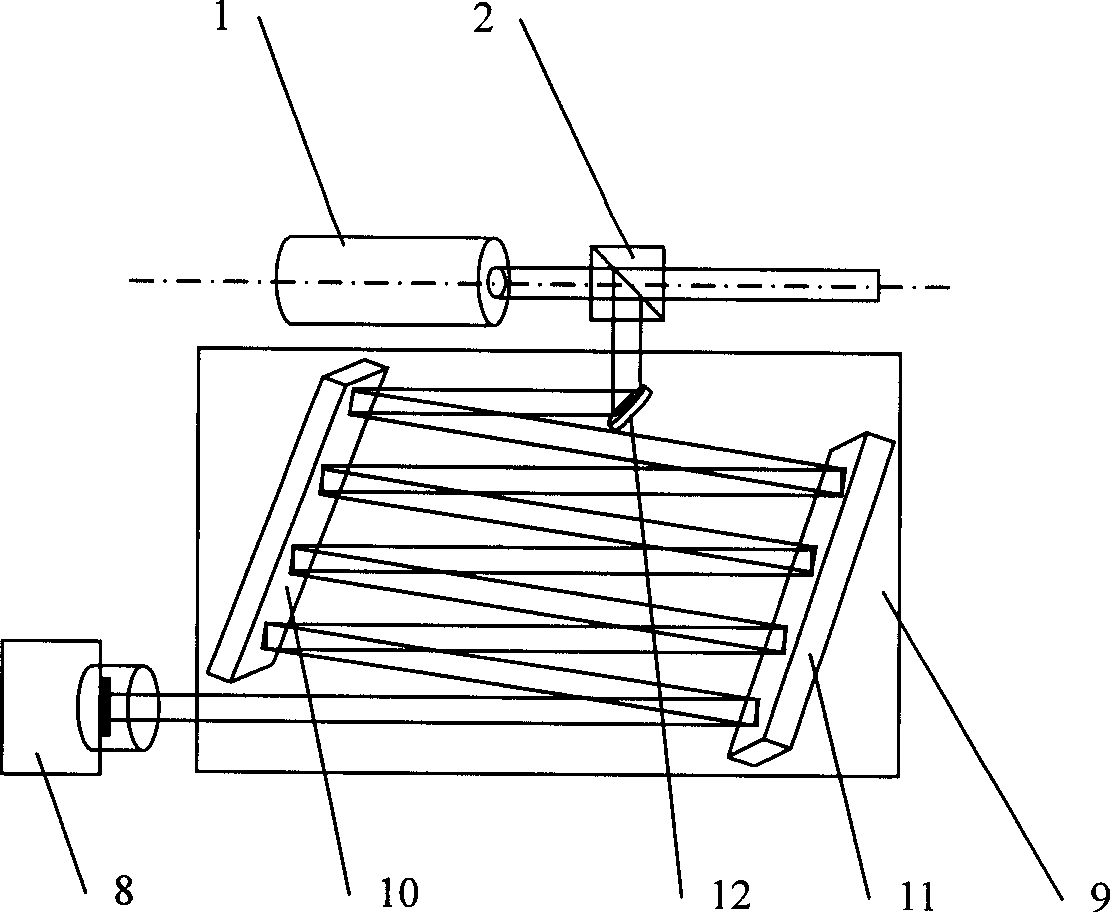

[0072] Such as figure 1 Shown two-dimensional photoelectric self-collimation device, here, the optical path multiplication device 9 is by such as figure 2 The shown two planar mirrors 10 and 11 arranged parallel to each other are composed of an additional planar mirror 12 located in the path of the reference beam. The optical path multiplying device 9 reflects the reference beam multiple times, prolongs the optical path of the reference beam, and amplifies the linear displacement corresponding to the beam angle drift. Other components and working principles of this embodiment are the same as those of Embodiment 1.

Embodiment 3

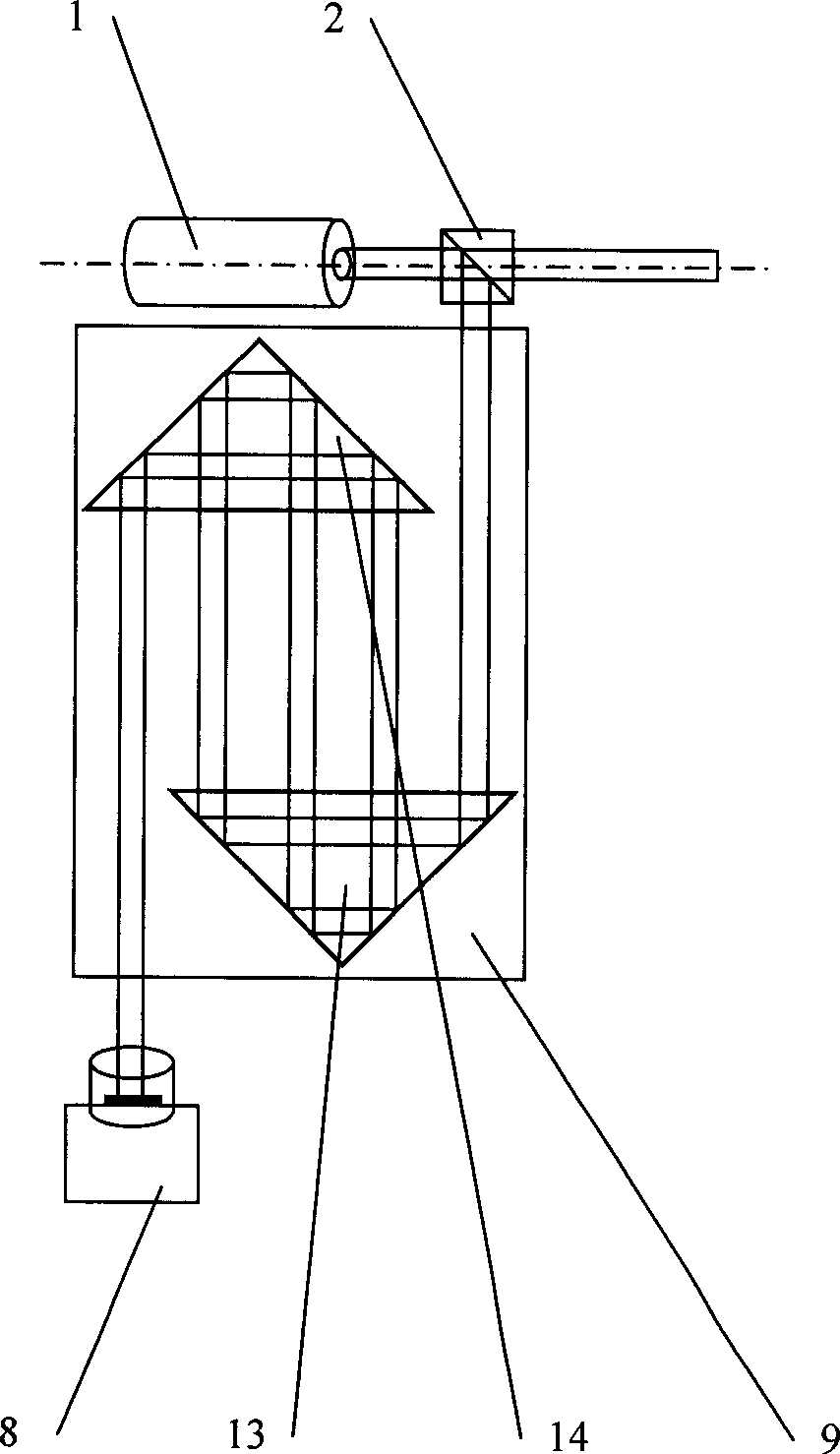

[0074] Such as figure 1 Shown two-dimensional photoelectric self-collimation device, here, the optical path multiplication device 9 is by such as Figure 3a The two rectangular prisms 13 and 14 shown facing each other are formed. The optical path multiplying device 9 reflects the reference beam multiple times, prolongs the optical path of the reference beam, and amplifies the linear displacement corresponding to the beam angle drift. Other components and working principles of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com