Nanofiber, organic solar cell using same, and a method for preparing organic solar cell

A solar cell, nanofiber technology, applied in nanotechnology, nanotechnology, fiber processing, etc., can solve the problems of complex operation, low polymer, industrial application limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

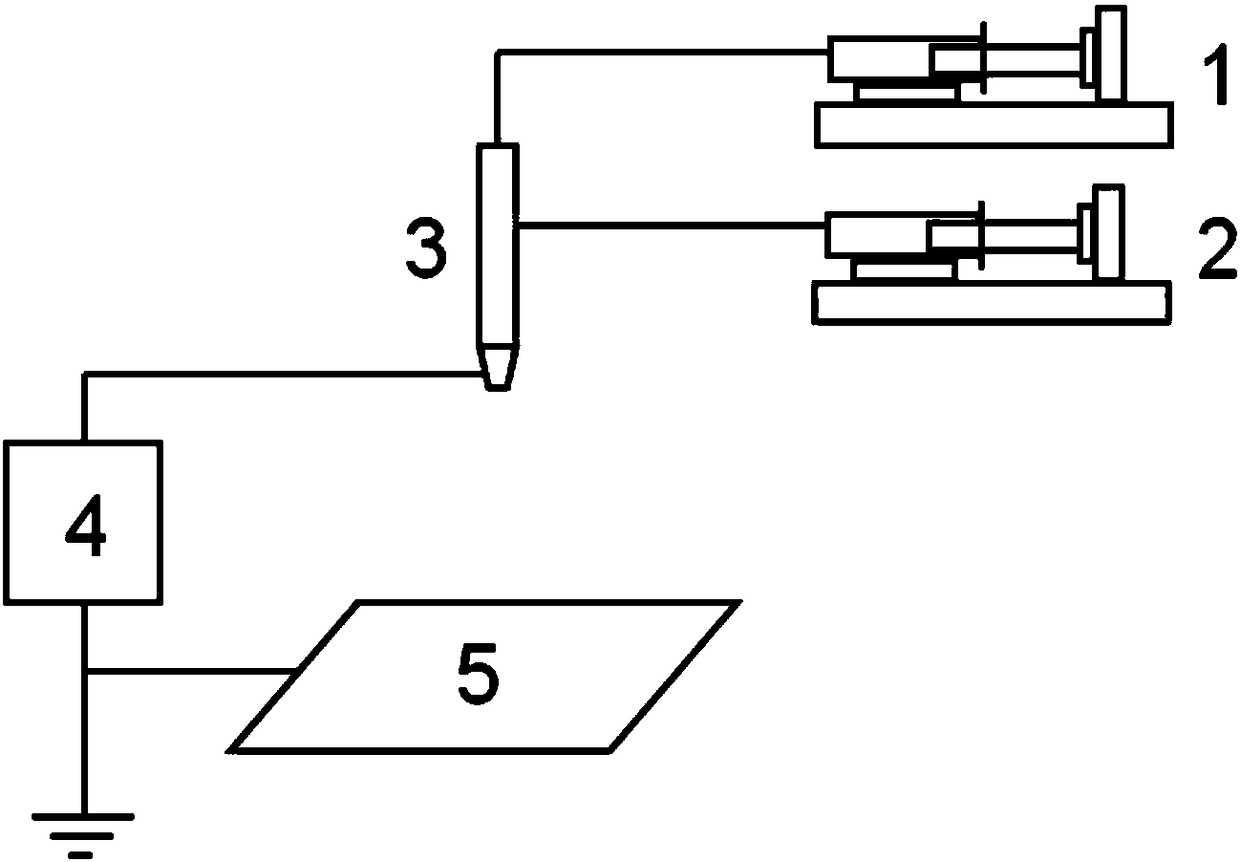

[0063] Embodiment 1: A method for coaxial electrospinning to prepare nanofibers, assisting filamentation of target materials that are difficult to filamentize, comprising the following steps:

[0064] (1) configure the spinning inner tube precursor;

[0065] (2) configure the spinning outer tube precursor;

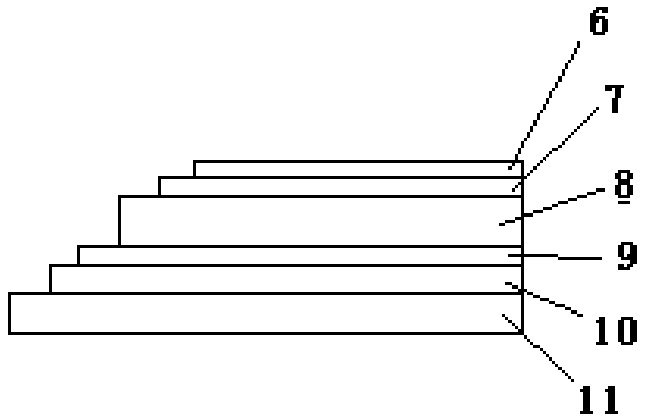

[0066] (3) Add the electrospinning precursor solution configured in steps (1) and (2) into figure 1 In the electrospinning device shown, adjust the receiving distance, set the liquid inlet speed of the constant-current pump, turn on the high-voltage power supply to explore to the critical value, and start electrospinning to obtain high-molecular polymer nanofibers with a core-shell structure;

[0067] (4) Place the nanofibers prepared in step (3) in a centrifuge tube, pour a quantitative cleaning solution, and perform repeated ultrasonic and centrifugal operations to completely remove the shell material, and the dried core layer fiber is the present invention. Target mat...

Embodiment 2

[0086] The amount of basic materials used in this example and the preparation method are the same as in Example 1, the difference is that the voltage of the high-voltage power supply in step 2) is adjusted to 1kV-100kV, and the following sets of data are used respectively: 1kV, 3kV, 6kV, 9kV , 12kV, 15kV, 18kV, 21kV, 24kV, 27kV, 30kV, 50kV and 100kV, but adjusting the high-voltage power supply voltage in the method of the present invention is not limited to the listed values, and other unlisted values within the range of 1kV to 100kV are also applicable.

Embodiment 3

[0088] The amount of basic materials used in this example and the preparation method are the same as in Example 1, except that the adjustment receiving distance in step 2) is 1cm to 100cm, and the following sets of data are used respectively: 1cm, 5cm, 7cm, 10cm, 13cm, 15cm, 17cm, 20cm, 23cm, 25cm, 27cm, 30cm, 50cm and 100cm, but the adjustment of the receiving distance in the method of the present invention is not limited to the listed values, and other unlisted values within the range of 1cm to 100cm are also applicable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com