Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

136 results about "Filamentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Filamentation is the anomalous growth of certain bacteria, such as Escherichia coli, in which cells continue to elongate but do not divide (no septa formation). The cells that result from elongation without division have multiple chromosomal copies. In the absence of antibiotics or other stressors, filamentation occurs at a low frequency in bacterial populations (4-8% short filaments and 0-5% long filaments in 1- to 8-hour cultures), the increased cell length protecting bacteria from protozoan predation and neutrophil phagocytosis by making ingestion of the cells more difficult. Filamentation is also thought to protect bacteria from antibiotics during patient treatment and is associated with other aspects of bacterial virulence such as biofilm formation. The number and length of filaments within a bacterial population increases when the bacteria are treated with various chemical and physical agents (eg. DNA synthesis-inhibiting antibiotics, UV light). Some of the key genes involved in filamentation in E. coli include sulA and minCD.

Method and apparatus for spiral cutting a glass tube using filamentation by burst ultrafast laser pulses

A method of producing a spiral cut transparent tube using laser machining includes using an ultrafast laser beam comprising a burst of laser pulses and focusing the laser beam on the transparent tube to enable relative movement between the laser beam and the transparent tube by moving the laser beam, the glass tube or both the laser beam and the glass tube. A beam waist is formed external to the surface of the transparent tube wherein the laser pulses and sufficient energy density is maintained within the transparent tube to form a continuous laser filament therethrough without causing optical breakdown. The method and delivery system makes a spiral cut in the transparent tube.

Owner:ROFIN SINAR TECH

Method and apparatus for laser processing of silicon by filamentation of burst ultrafast laser pulses

ActiveUS20150151380A1Easy to separateMinimize distortionLayered productsWelding/soldering/cutting articlesFilamentationPulse energy

A method for laser processing of Silicon includes placing a Kerr material into engagement with the Silicon forming an interface therebetween. A laser beam is applied having at least one subpulse in a burst envelope operating at a first wavelength. The laser beam passes through a distributive lens focusing assembly and to the Kerr material. The first wavelength is modified to a plurality of second wavelengths, some of which are effective for processing Silicon. Photoacoustic compression processing is produced by the laser pulse energy by a portion of second wavelengths delivered through the interface and to the Silcon which initiates Kerr Effect self focusing which is propagated in the Silicon by additional energy input to the Silicon thus producing a filament within the Silicon.

Owner:ROFIN SINAR TECH

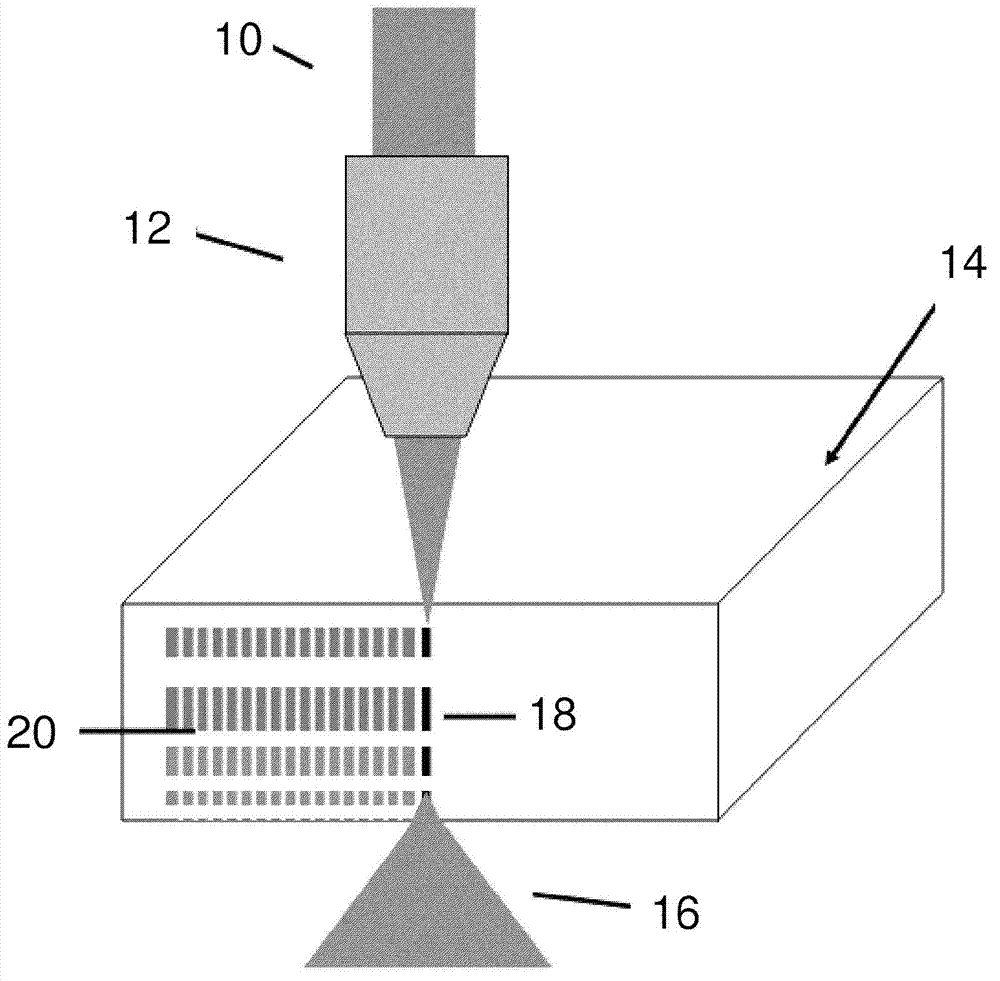

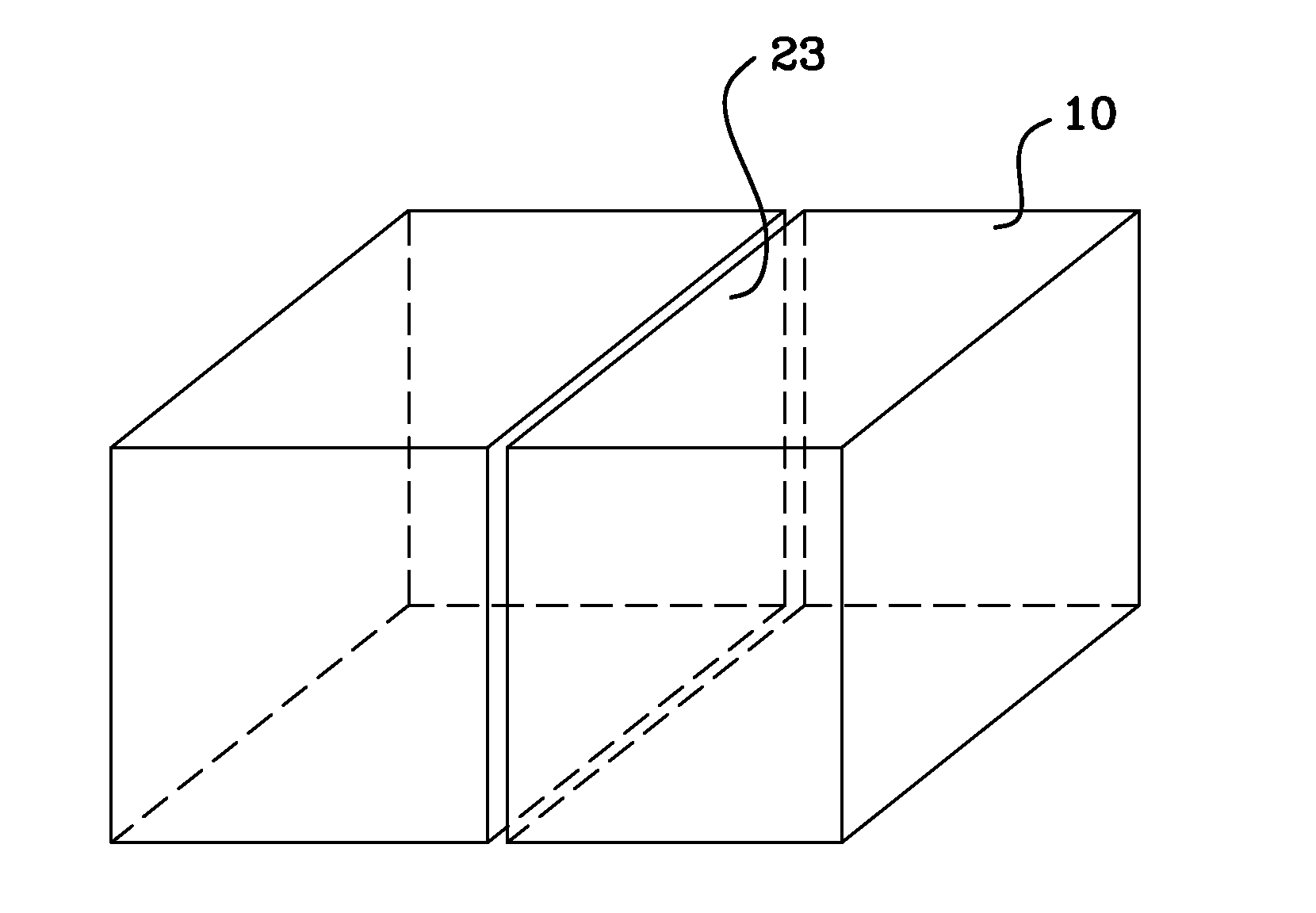

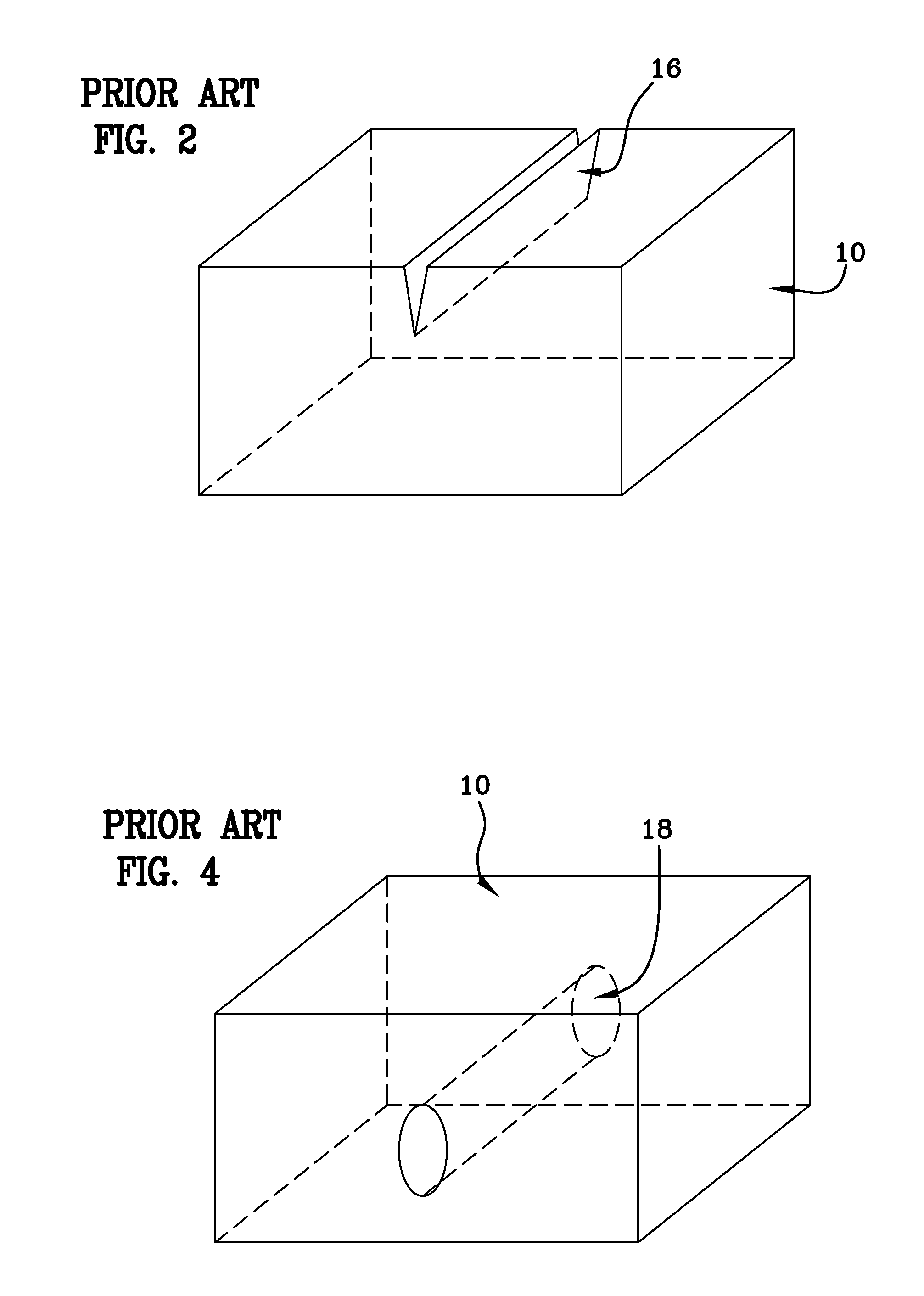

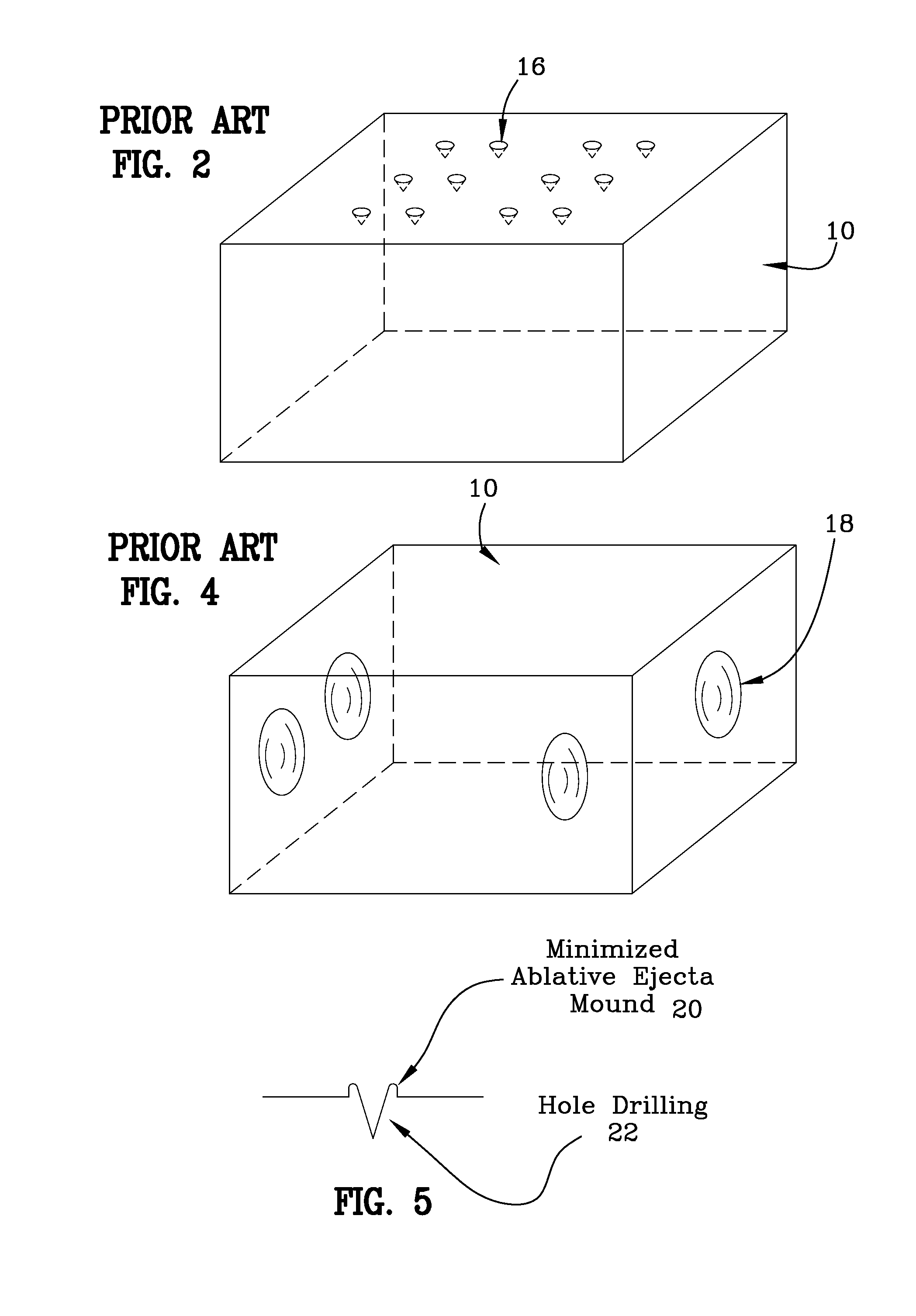

Method of material processing by laser filamentation

ActiveCN103079747ASemiconductor/solid-state device manufacturingGlass severing apparatusFilamentationExtra-location

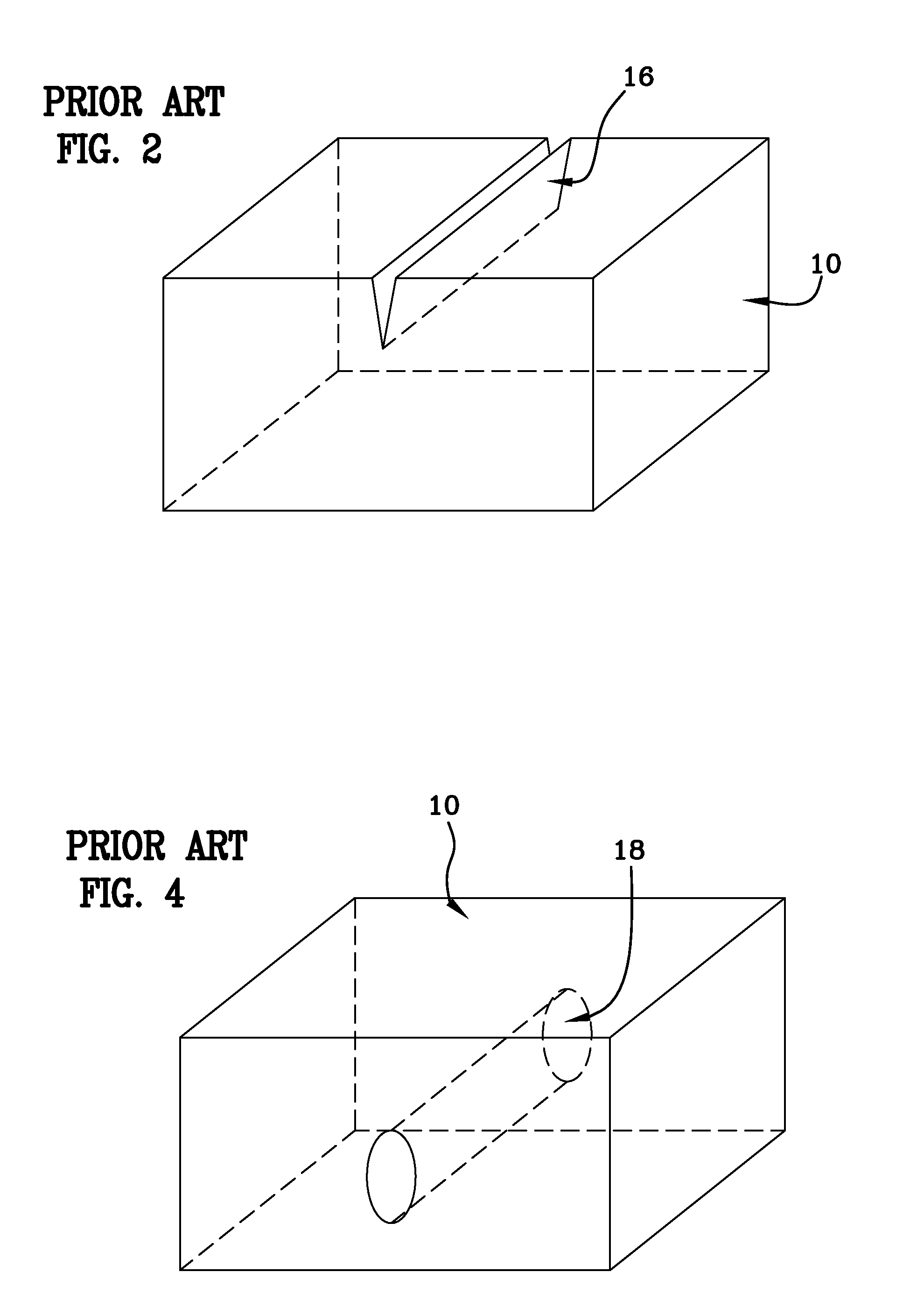

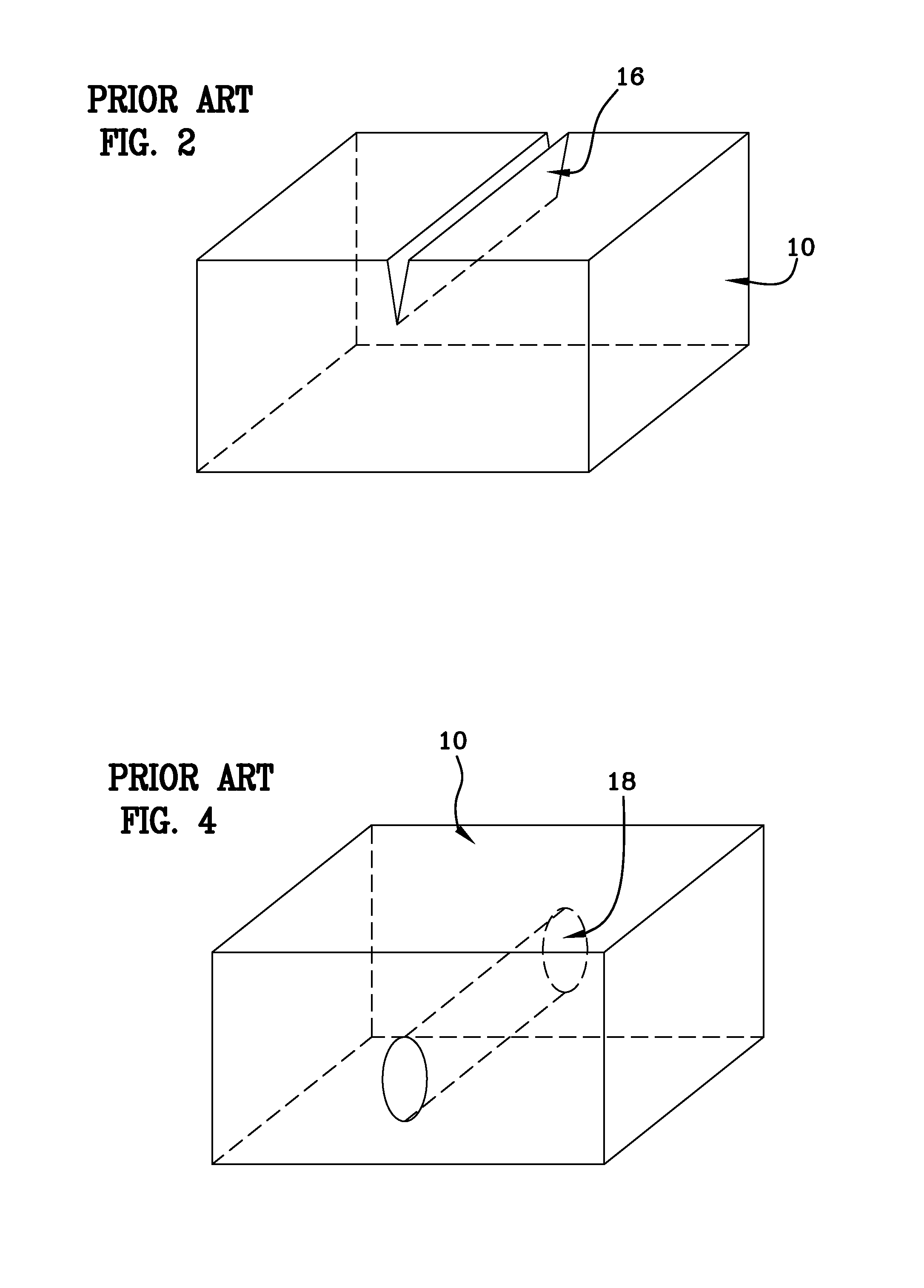

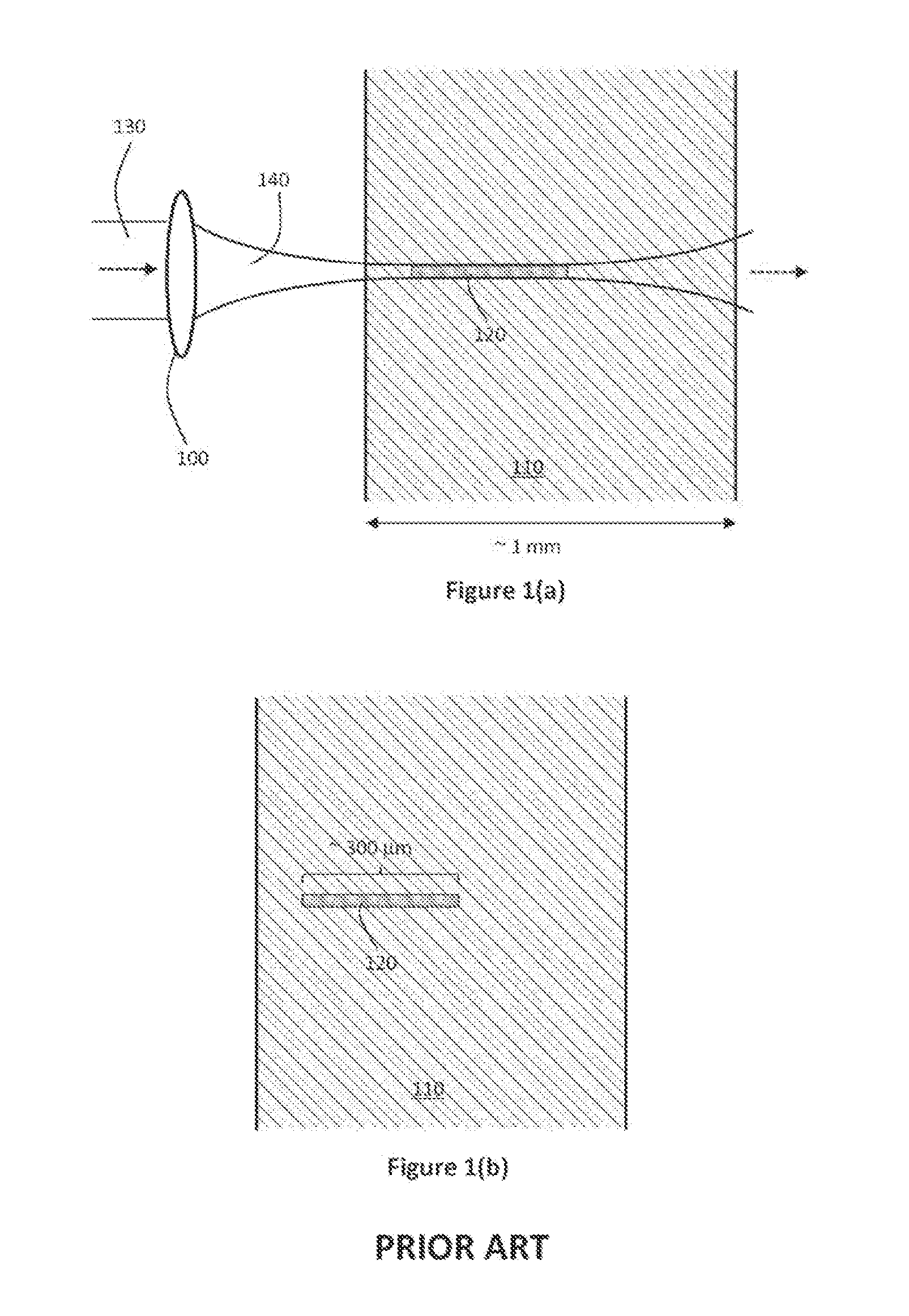

A method is provided for the internal processing of a transparent substrate in preparation for a cleaving step. The substrate is irradiated with a focused laser beam that is comprised of pulses having an energy and pulse duration selected to produce a filament within the substrate. The substrate is translated relative to the laser beam to irradiate the substrate and produce an additional filament at one or more additional locations. The resulting filaments form an array defining an internally scribed path for cleaving said substrate. Laser beam parameters may be varied to adjust the filament length and position, and to optionally introduce V-channels or grooves, rendering bevels to the laser-cleaved edges.; Preferably, the laser pulses are delivered in a burst train for lowering the energy threshold for filament formation, increasing the filament length, thermally annealing of the filament modification zone to minimize collateral damage, improving process reproducibility, and increasing the processing speed compared with the use of low repetition rate lasers.

Owner:ROFIN SINAR TECH

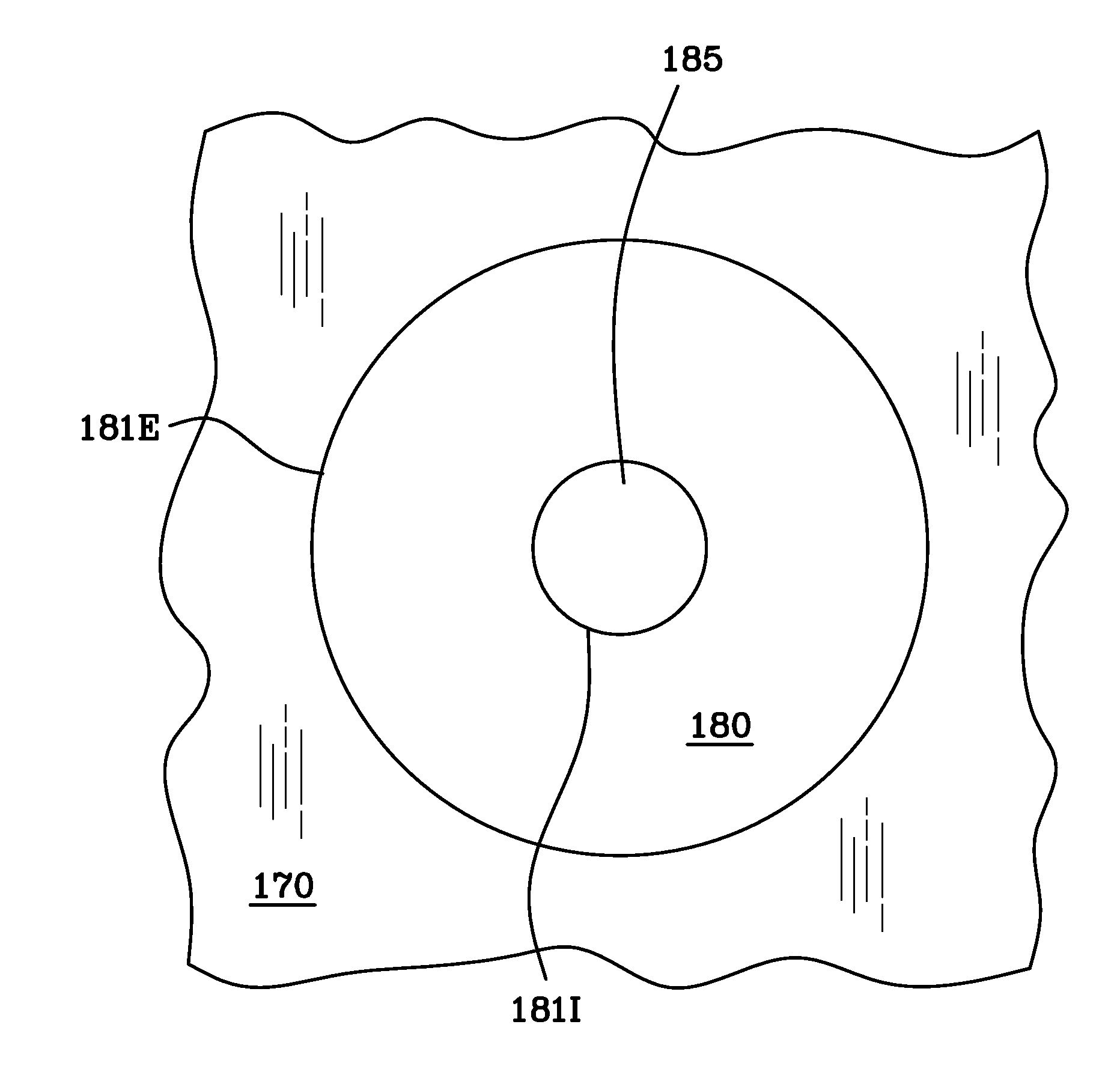

Method of fabricating a glass magnetic hard drive disk platter using filamentation by burst ultrafast laser pulses

ActiveUS20150118522A1Reduce manufacturing costExtreme precisionMagnetic materials for record carriersGlass furnace apparatusHard disc driveNon ablative

A non-ablative method and apparatus for making an economical glass hard disk (platter) for a computer hard disk drive (HDD) using a material machining technique involving filamentation by burst ultrafast laser pulses. Two related methods disclosed, differing only in whether the glass substrate the HDD platter is to be cut from has been coated with all the necessary material layers to function as a magnetic media in a computer's hard drive. Platter blanks are precisely cut using filamentation by burst ultrafast laser pulses such that the blank's edges need not be ground, the platter's geometric circularity need not be corrected and there is no need for further surface polishing. Thus the platters can be cut from raw glass or coated glass. As a result, this method reduces the product contamination, speeds up production, and realizes great reductions in the quantity of waste materials and lower production costs.

Owner:ROFIN SINAR TECH

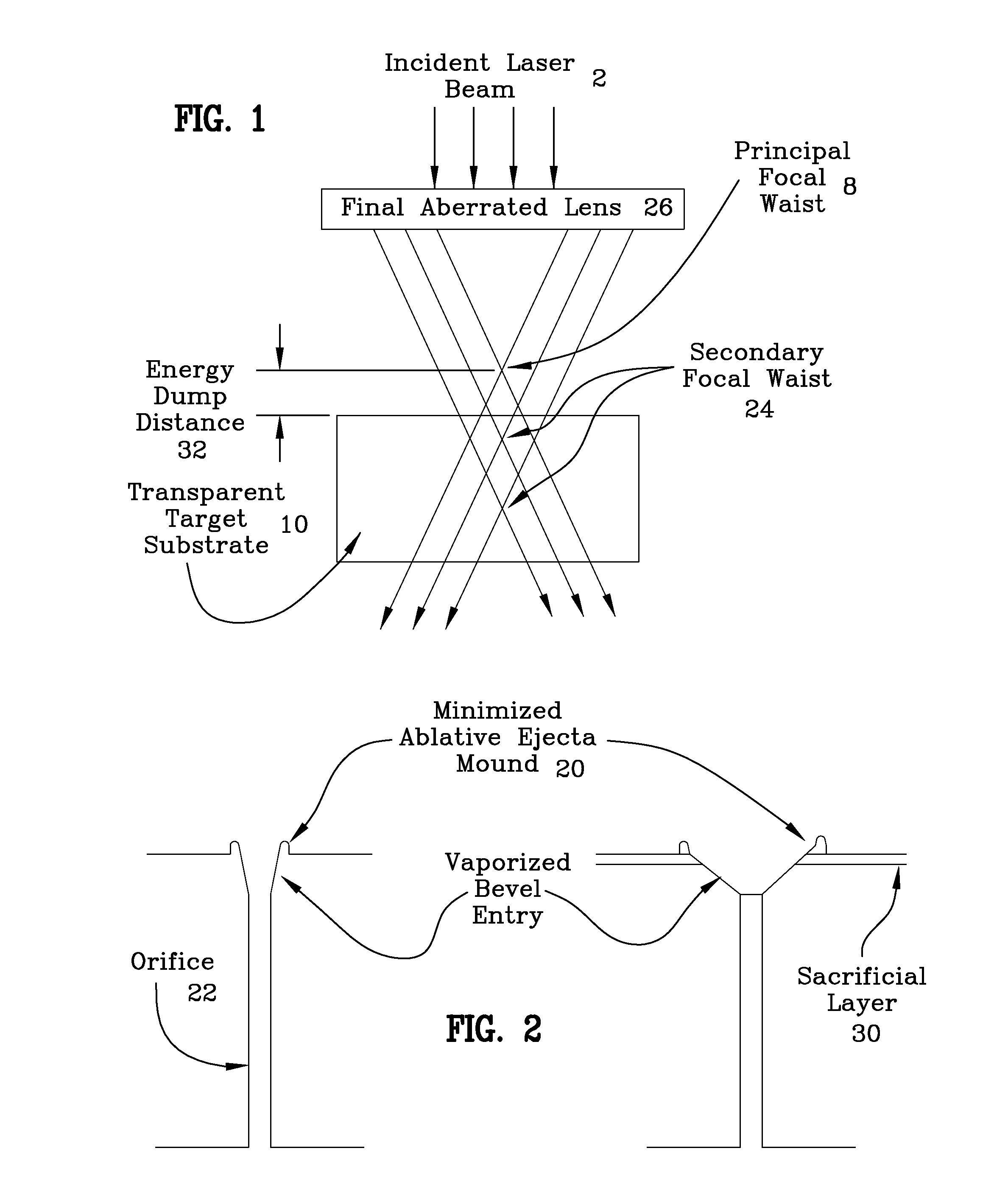

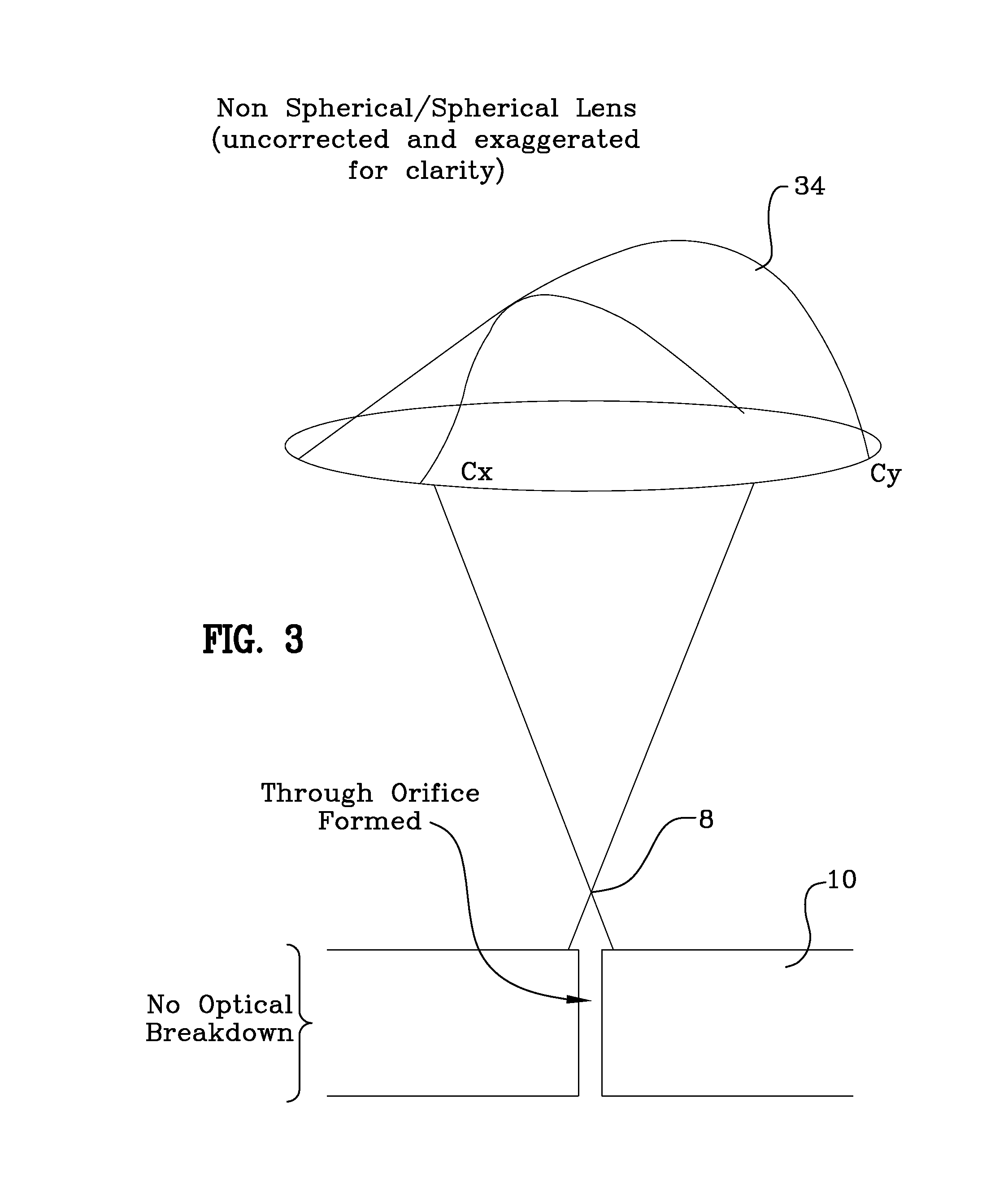

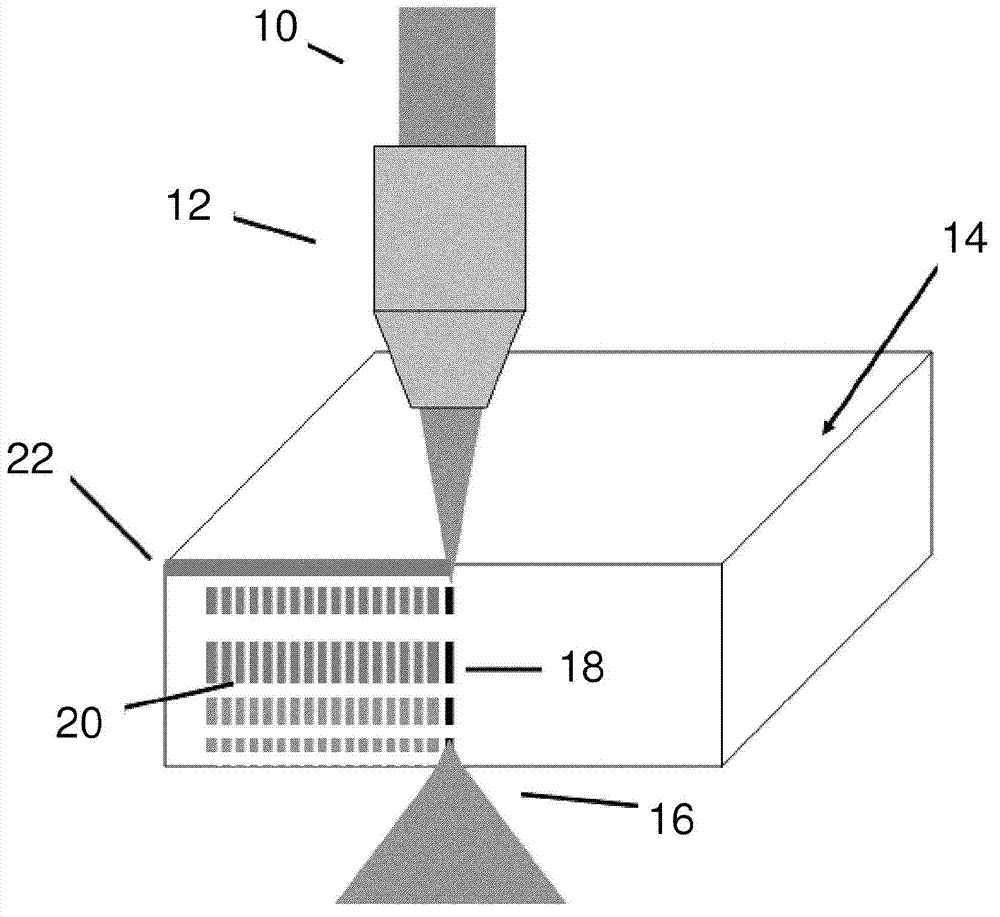

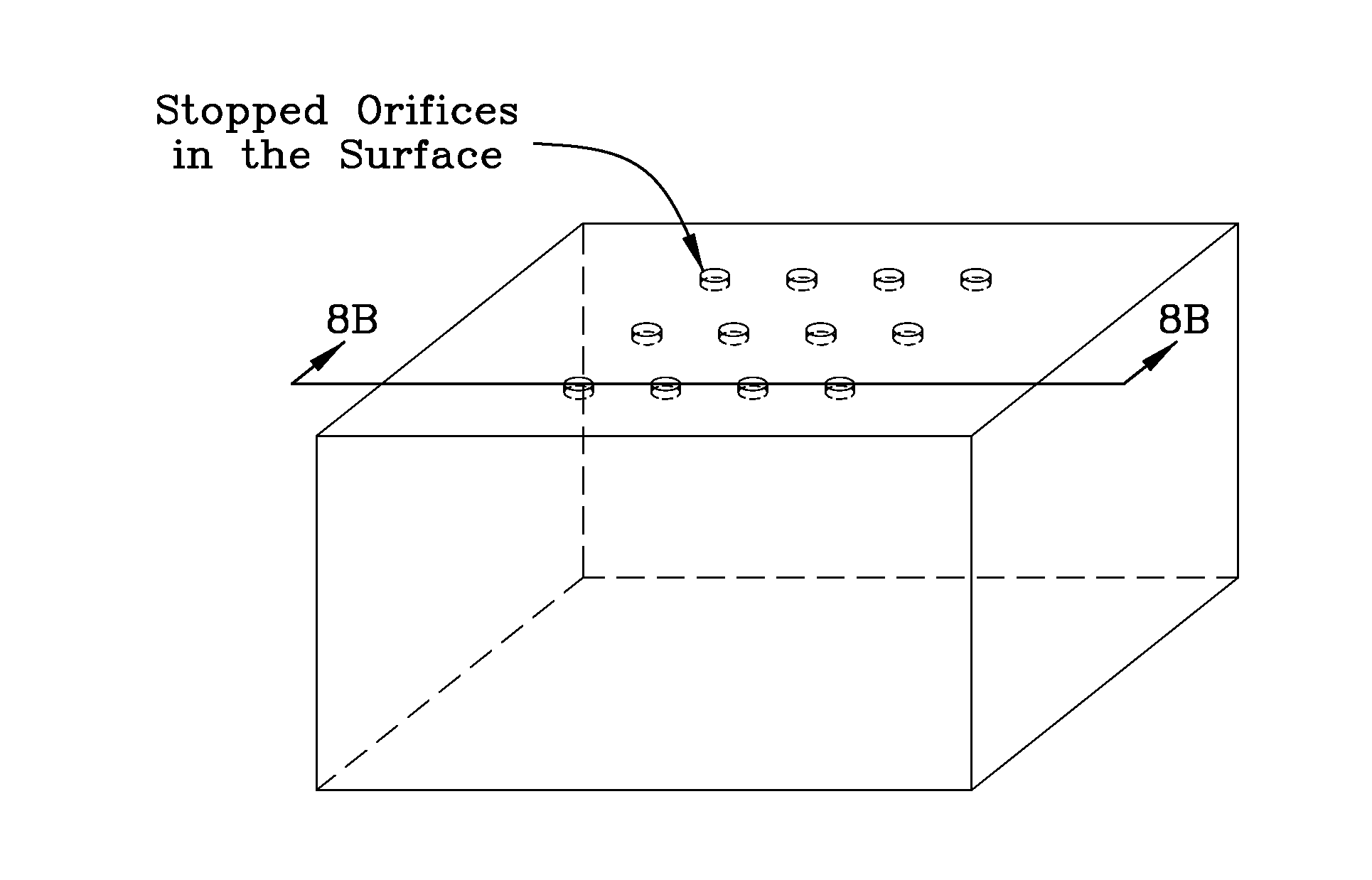

Method and apparatus for non-abaltive, photoaccoustic compression machining in transparent materials using filamentation by burst ultrafast laser pulses

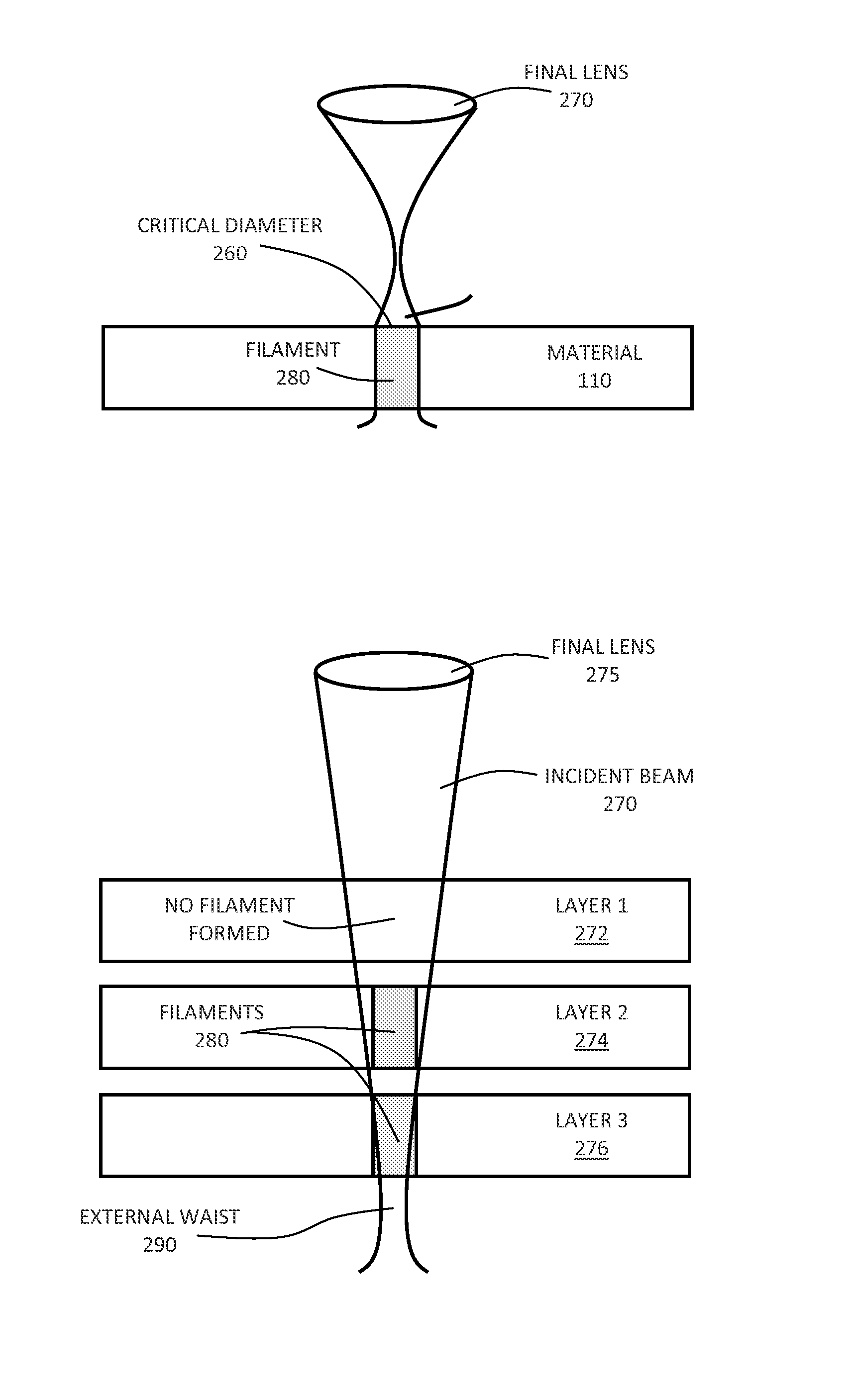

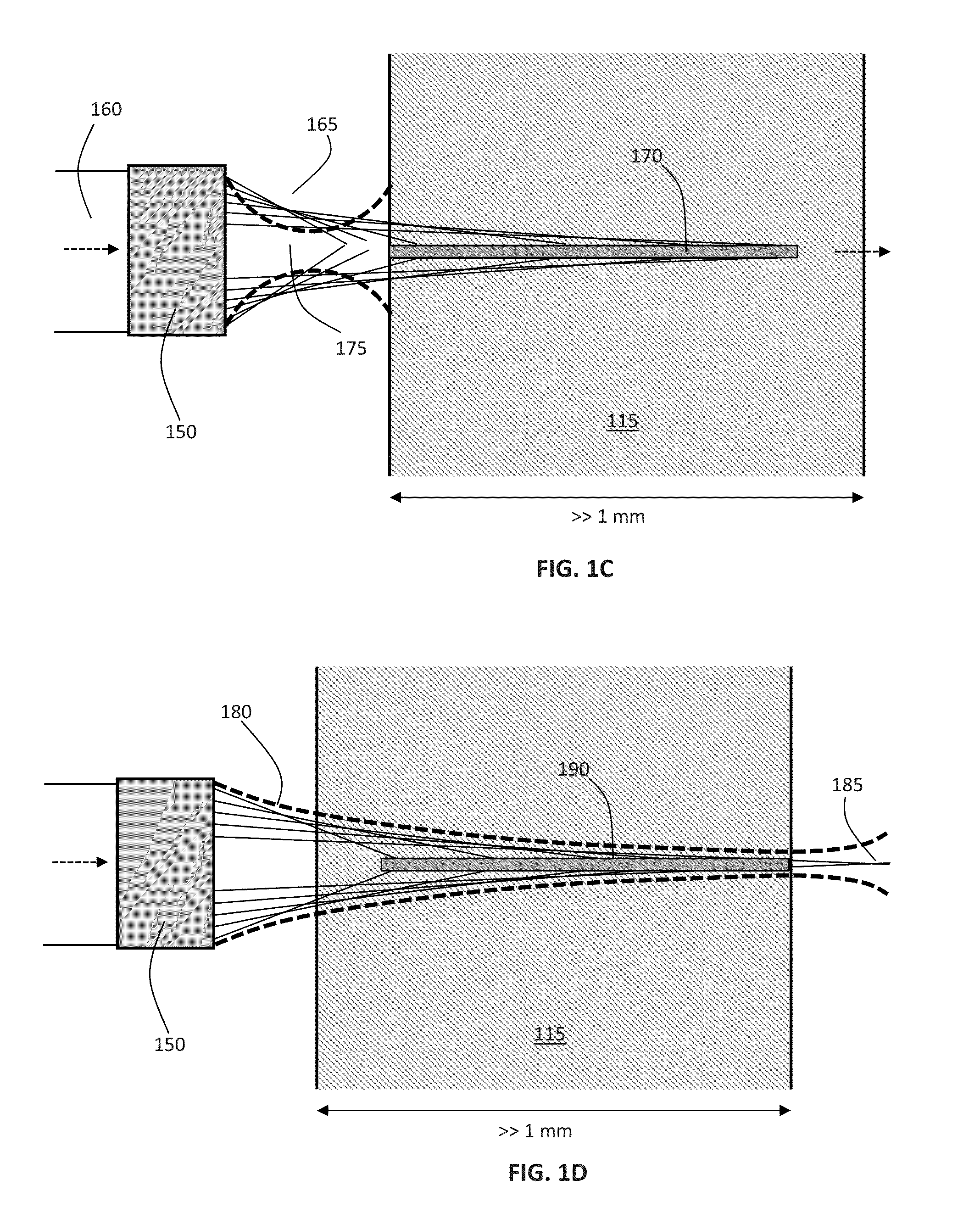

ActiveUS20150034612A1Minimize distortionReduced collateral damageWelding/soldering/cutting articlesThin material handlingFilamentationLight beam

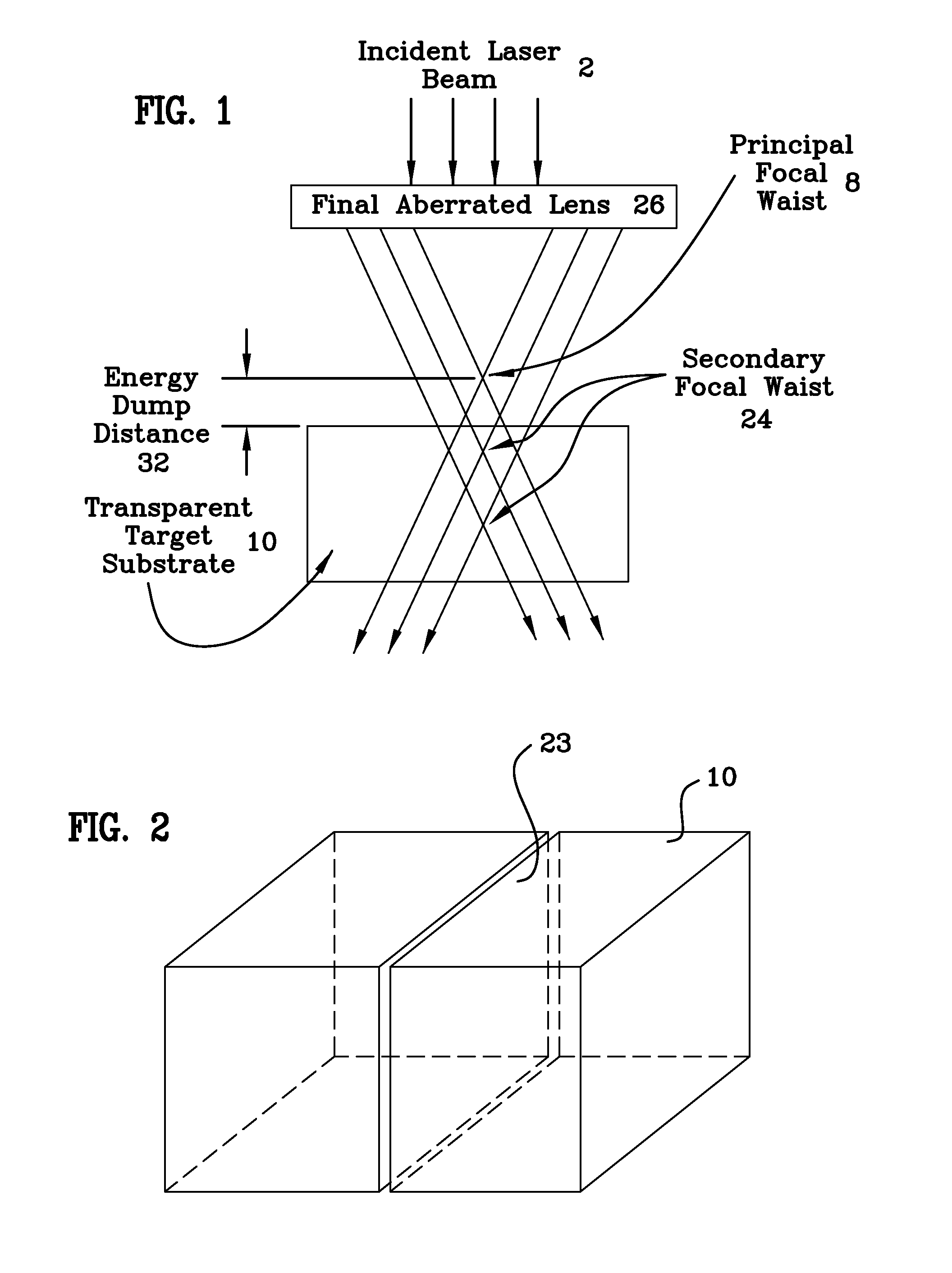

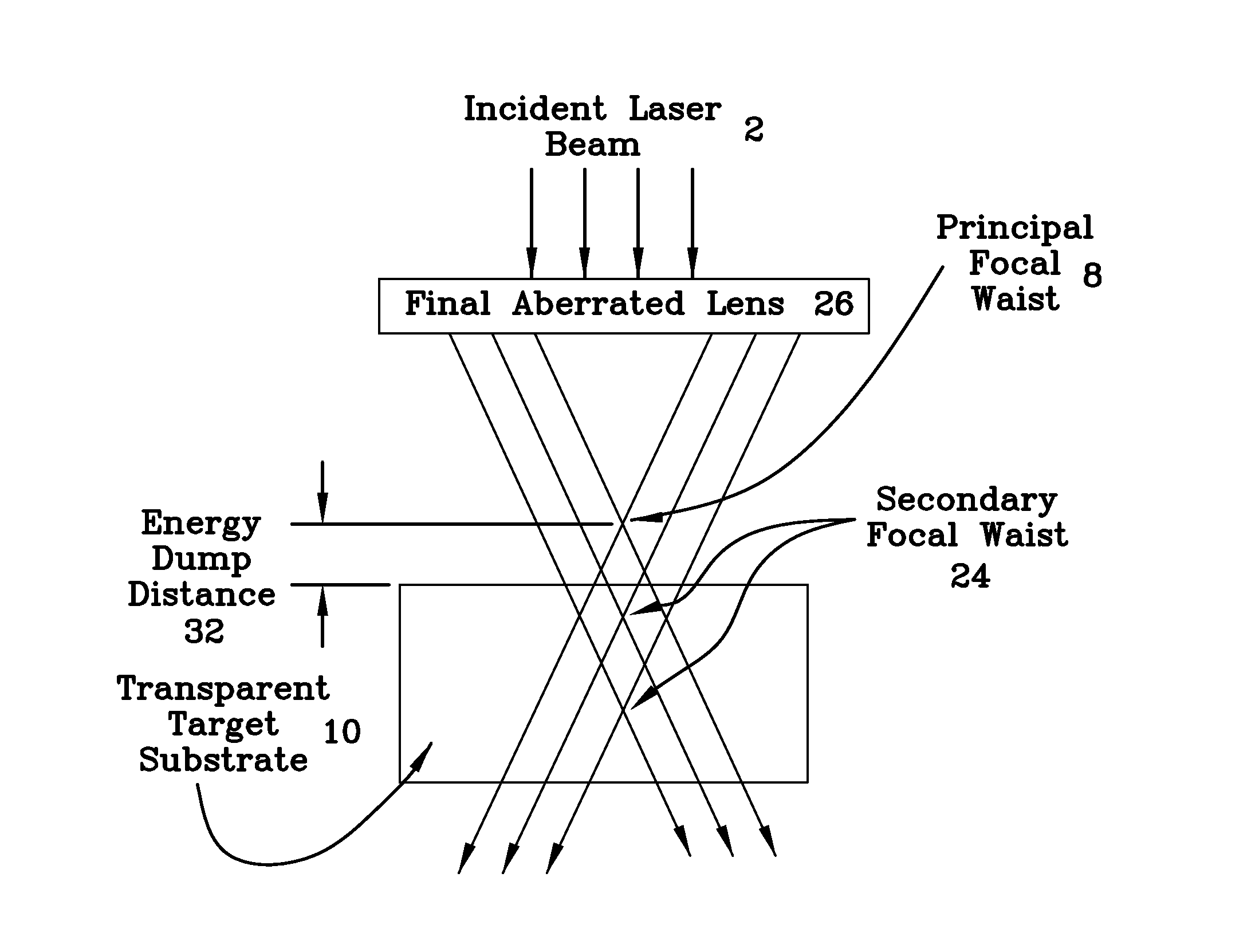

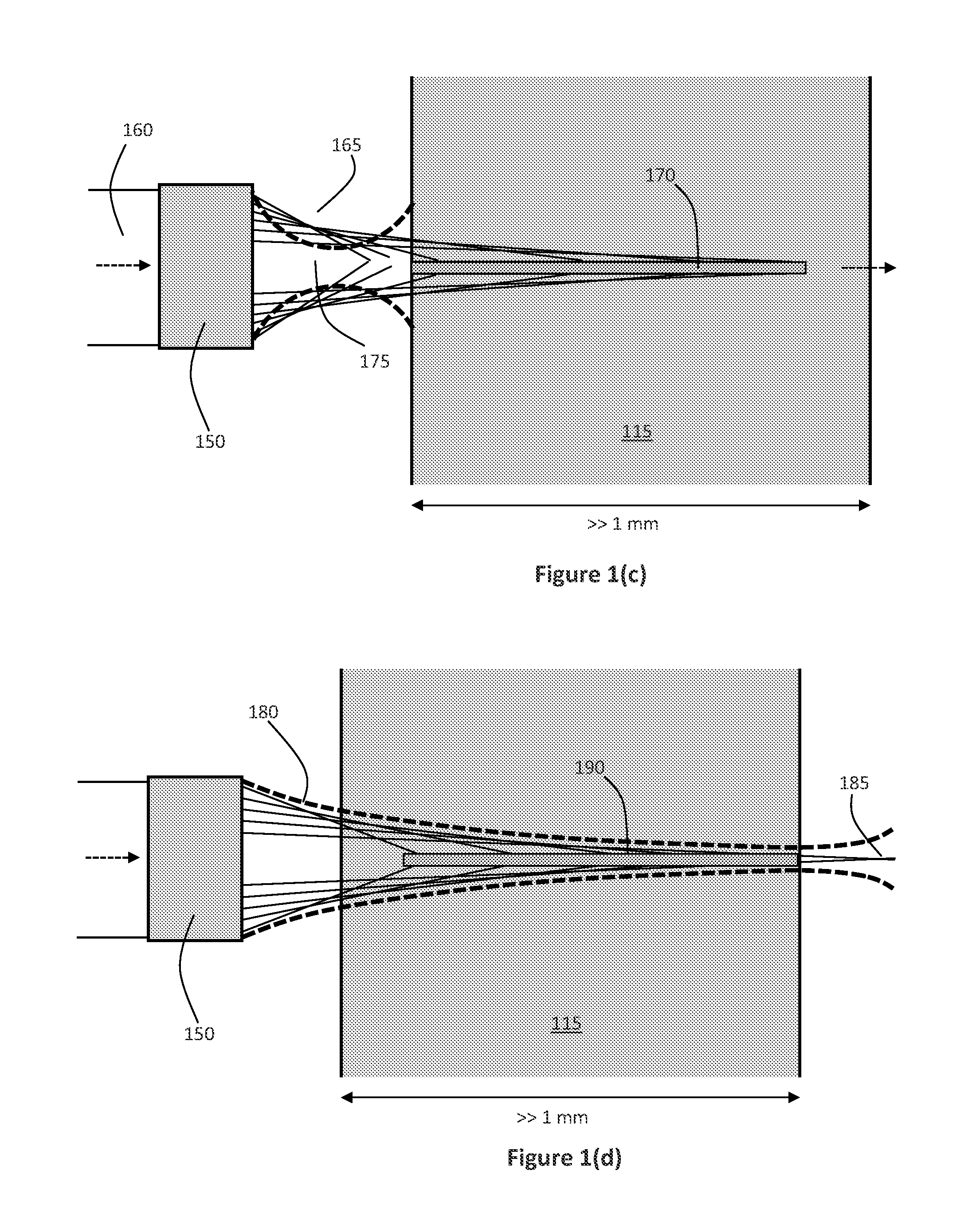

An apparatus, system and method for the processing of orifices in materials by laser filamentation that utilizes an optical configuration that focuses the incident laser light beam in a distributed manner along the longitudinal beam axis. This distributed focusing method enables the formation of filaments over distances, and the laser and focusing parameters are adjusted to determine the filament propagation and termination points so as to develop a single / double end stopped orifice, or a through orifice. Selected transparent substrates from a stacked or nested configuration may have orifices formed therein / therethrough without affecting the adjacent substrate. These distributed focusing methods support the formation filaments with lengths well beyond ten millimeters in borosilicate glass and similar brittle materials and semiconductors.

Owner:KINESTRAL TECH

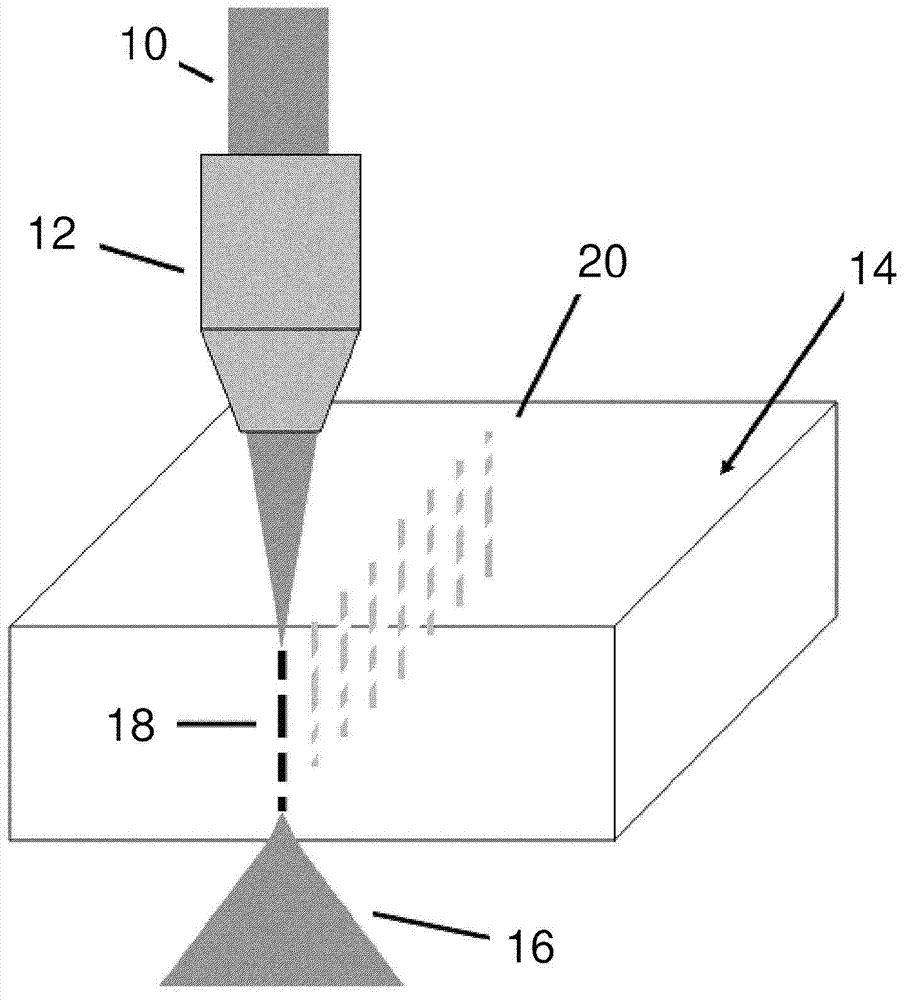

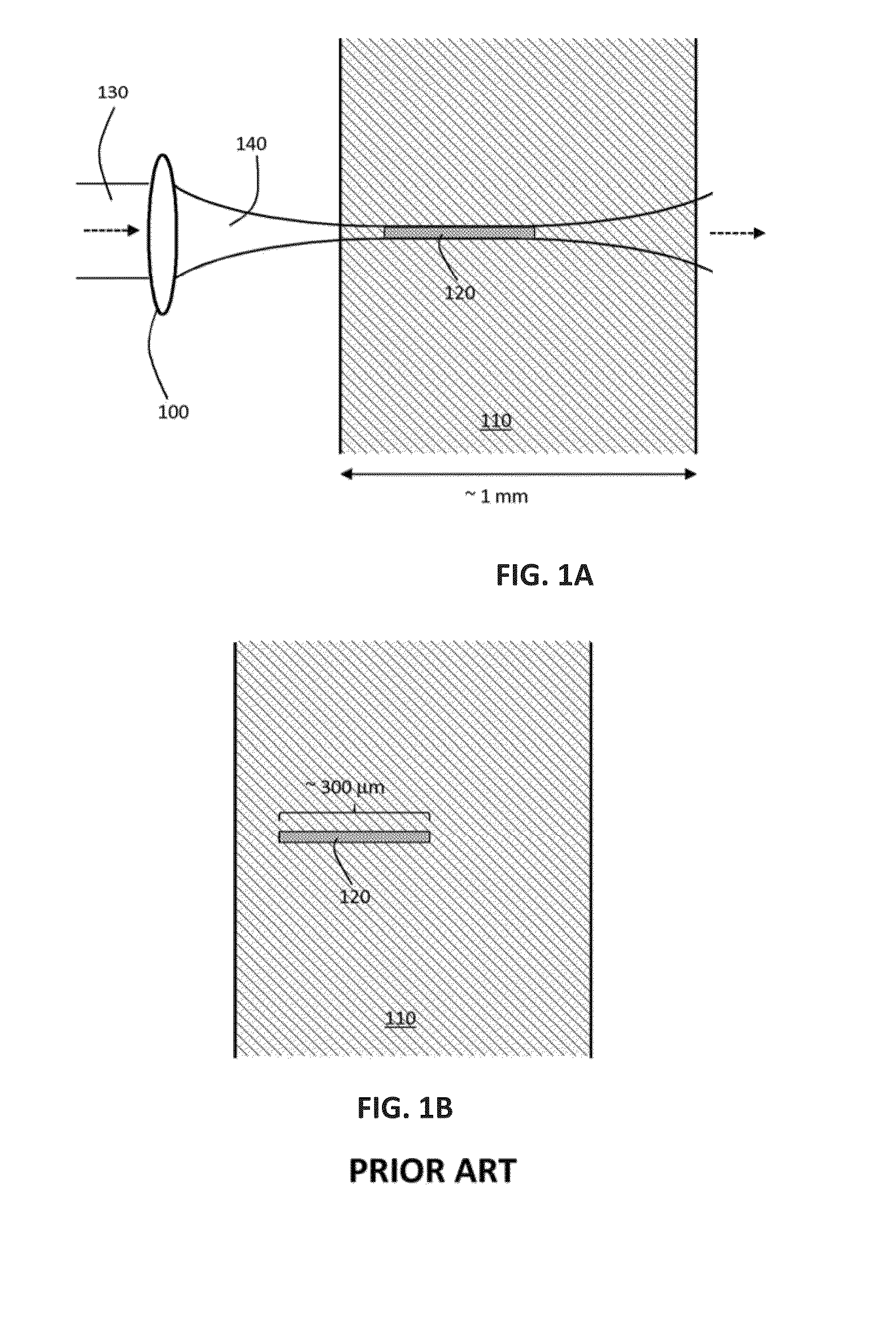

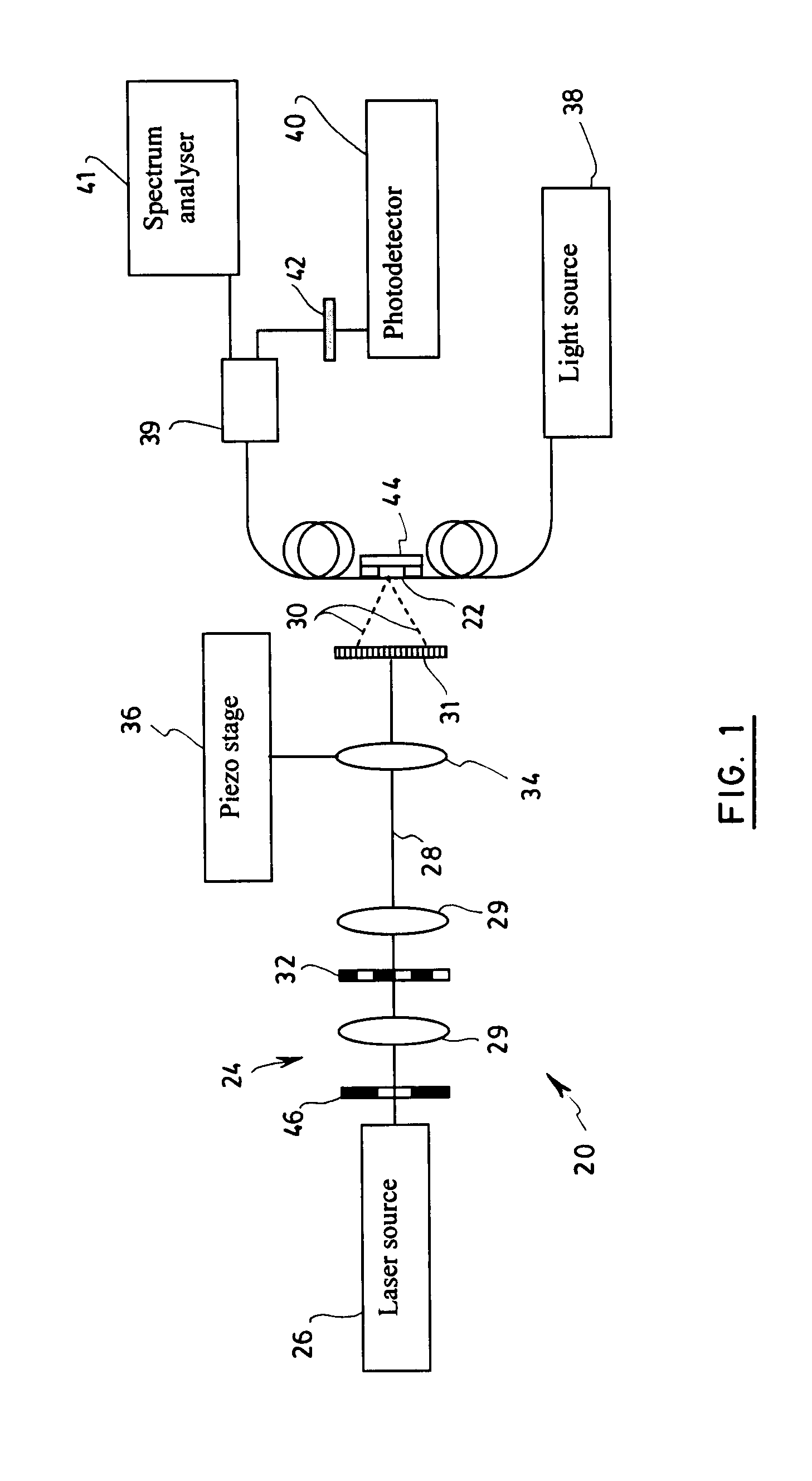

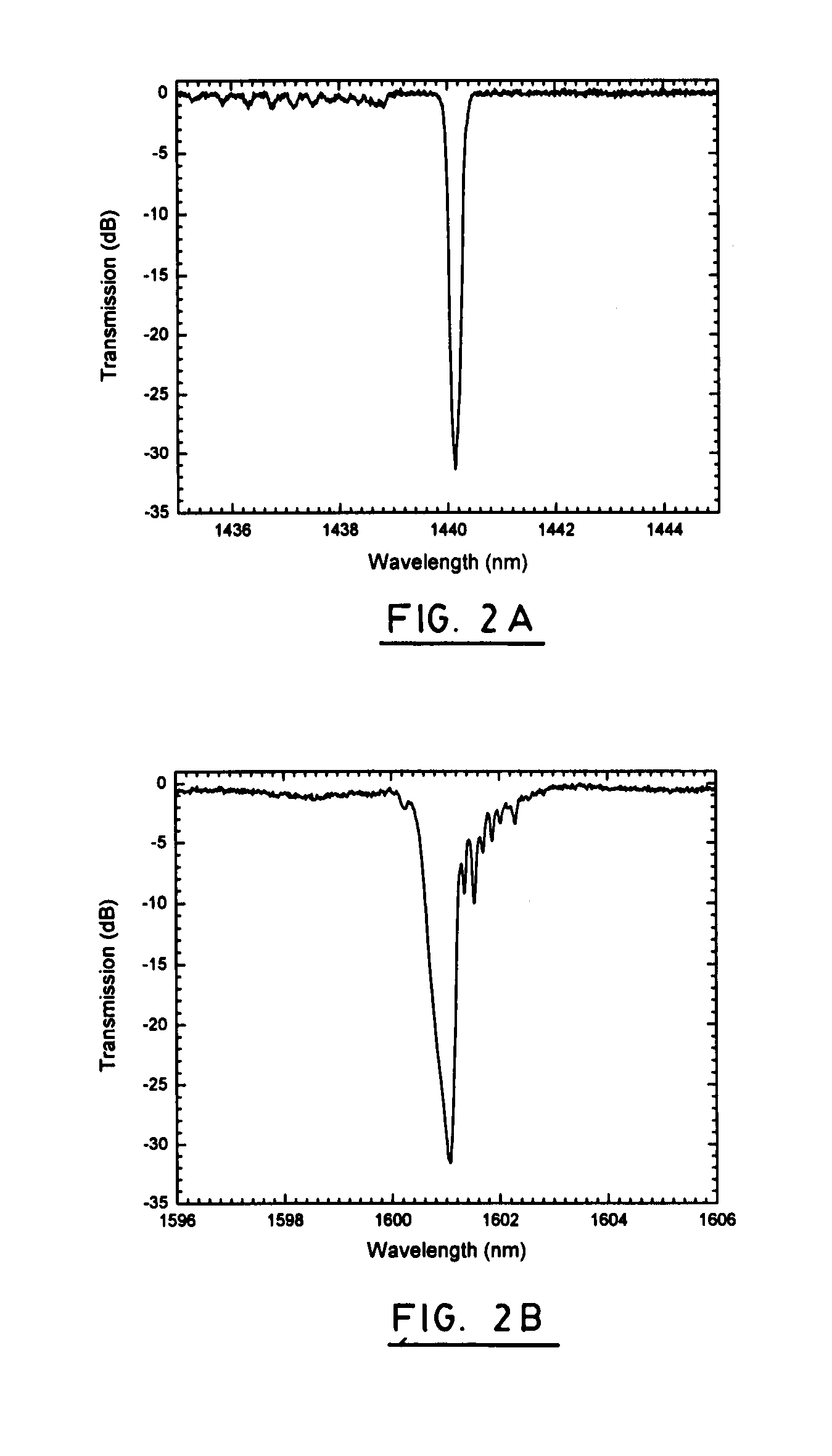

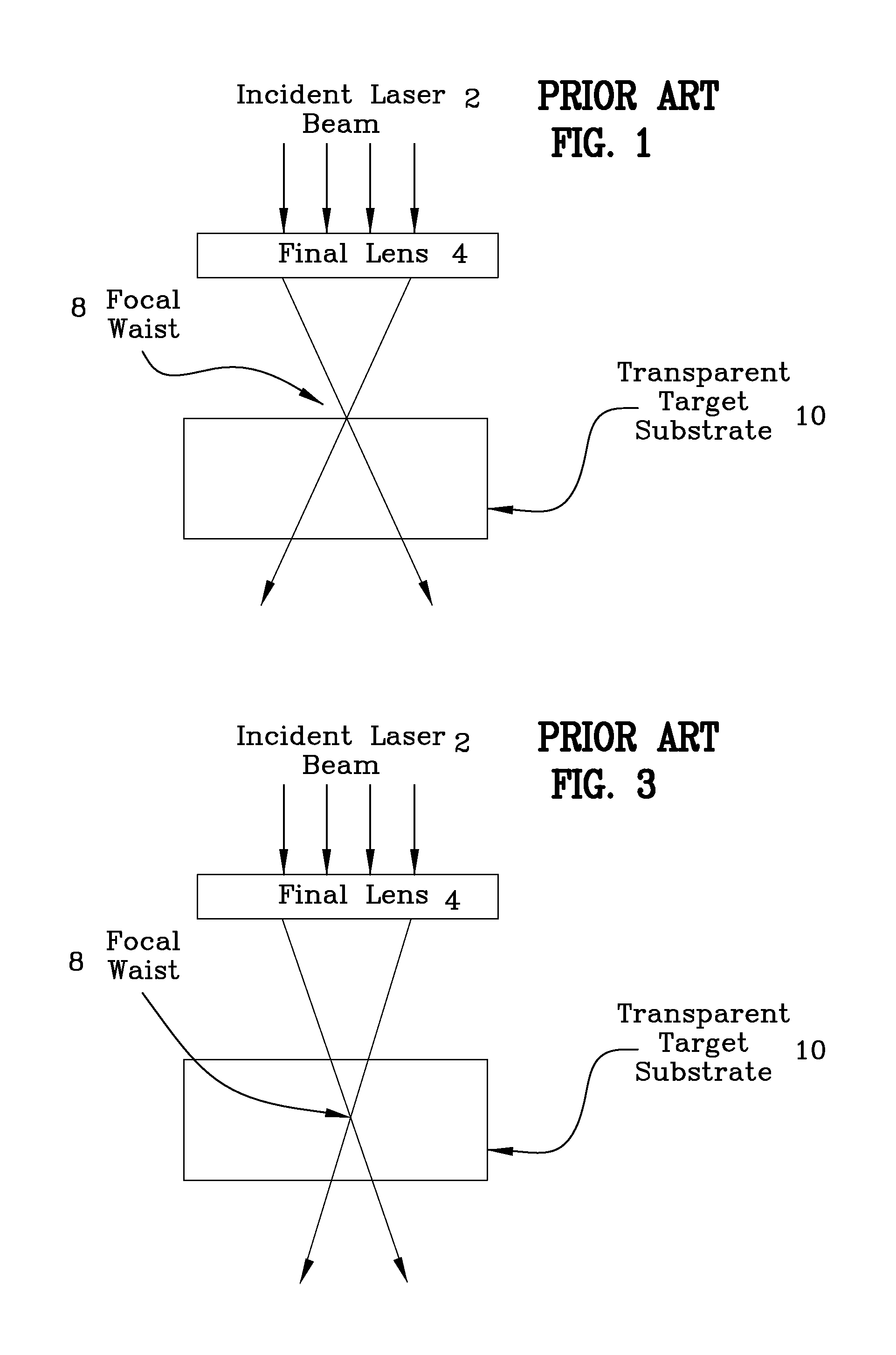

System for performing laser filamentation within transparent materials

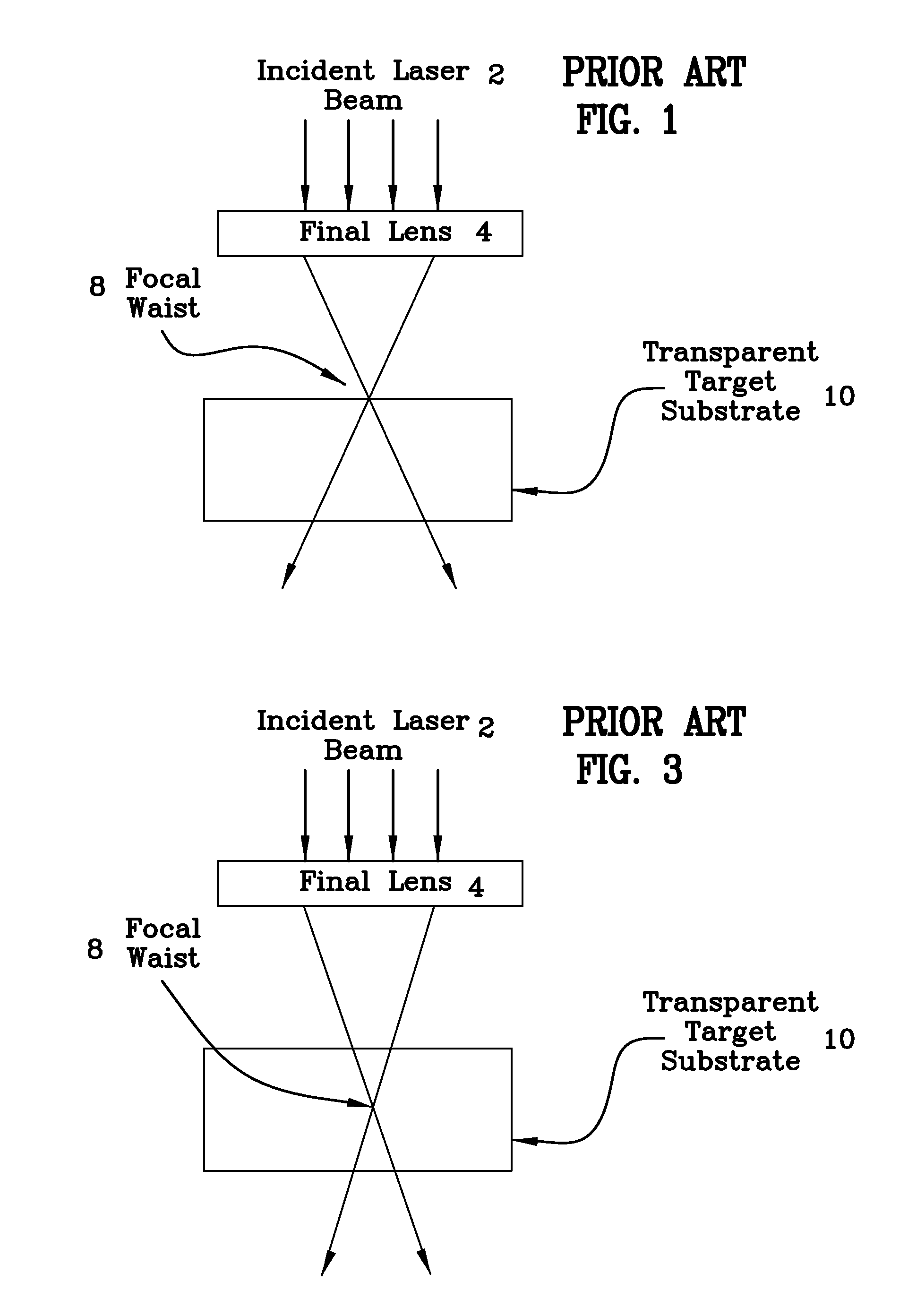

InactiveUS20150034613A1Promote formationEasy to controlSemiconductor/solid-state device manufacturingGlass severing apparatusFilamentationLight beam

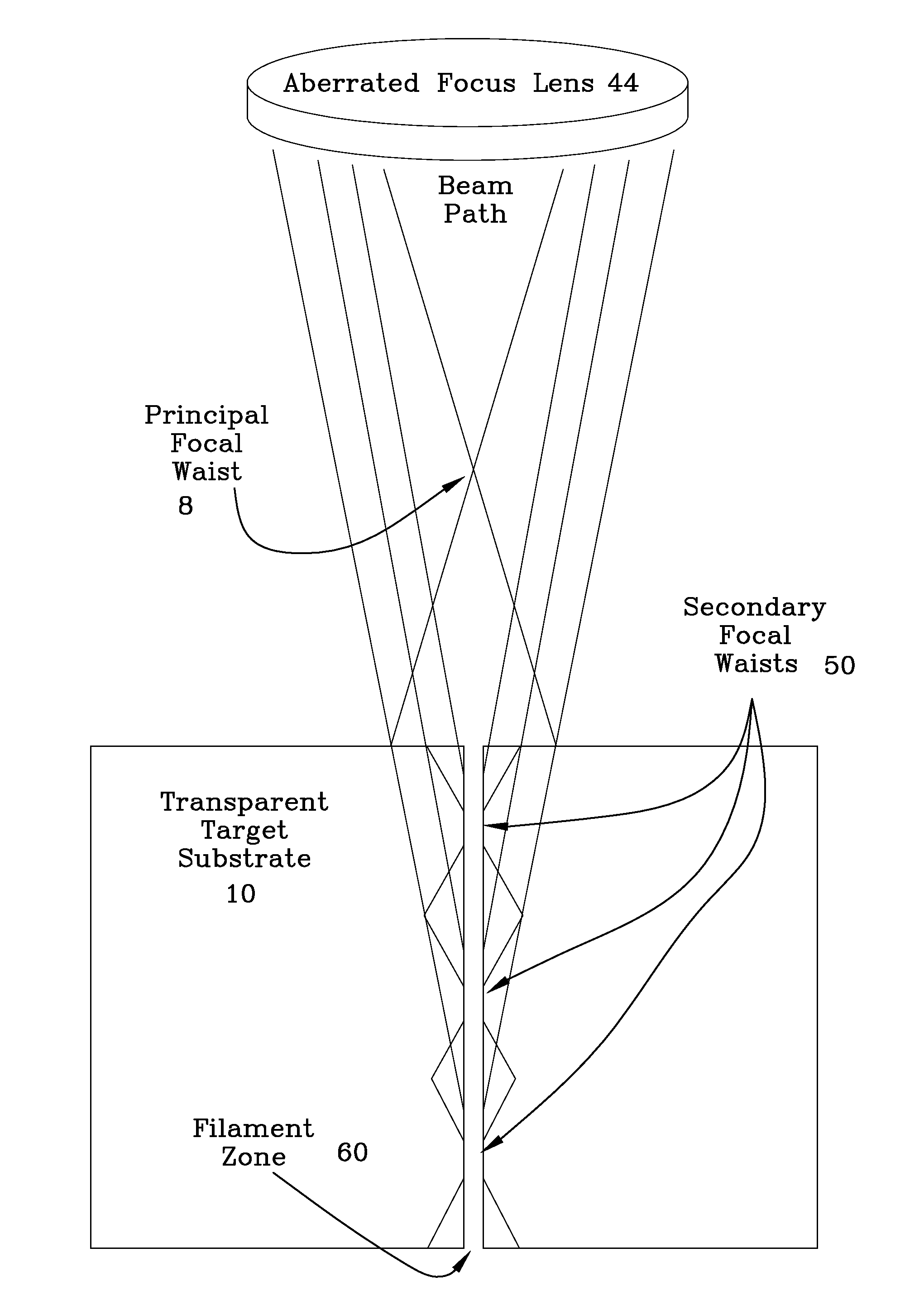

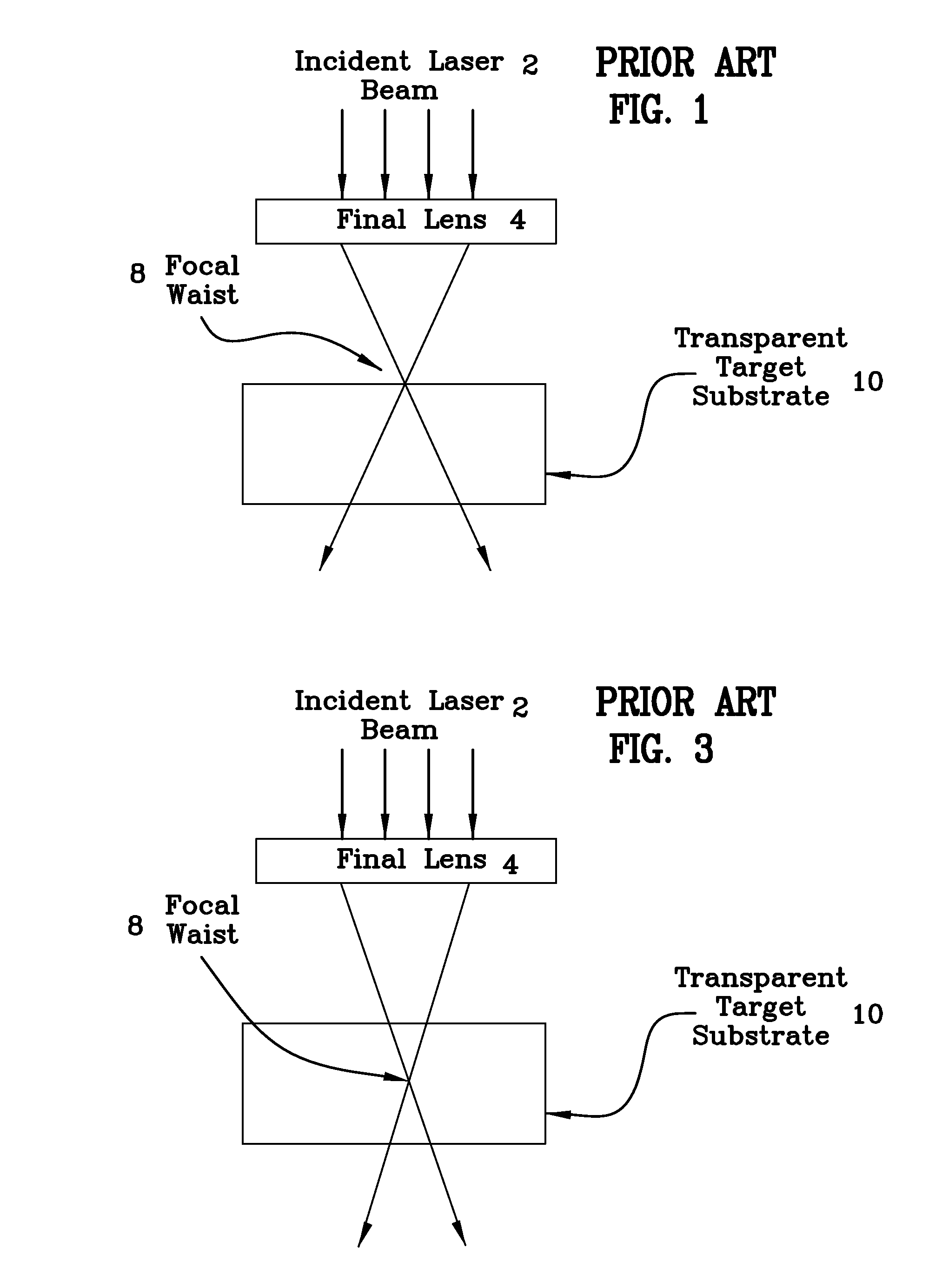

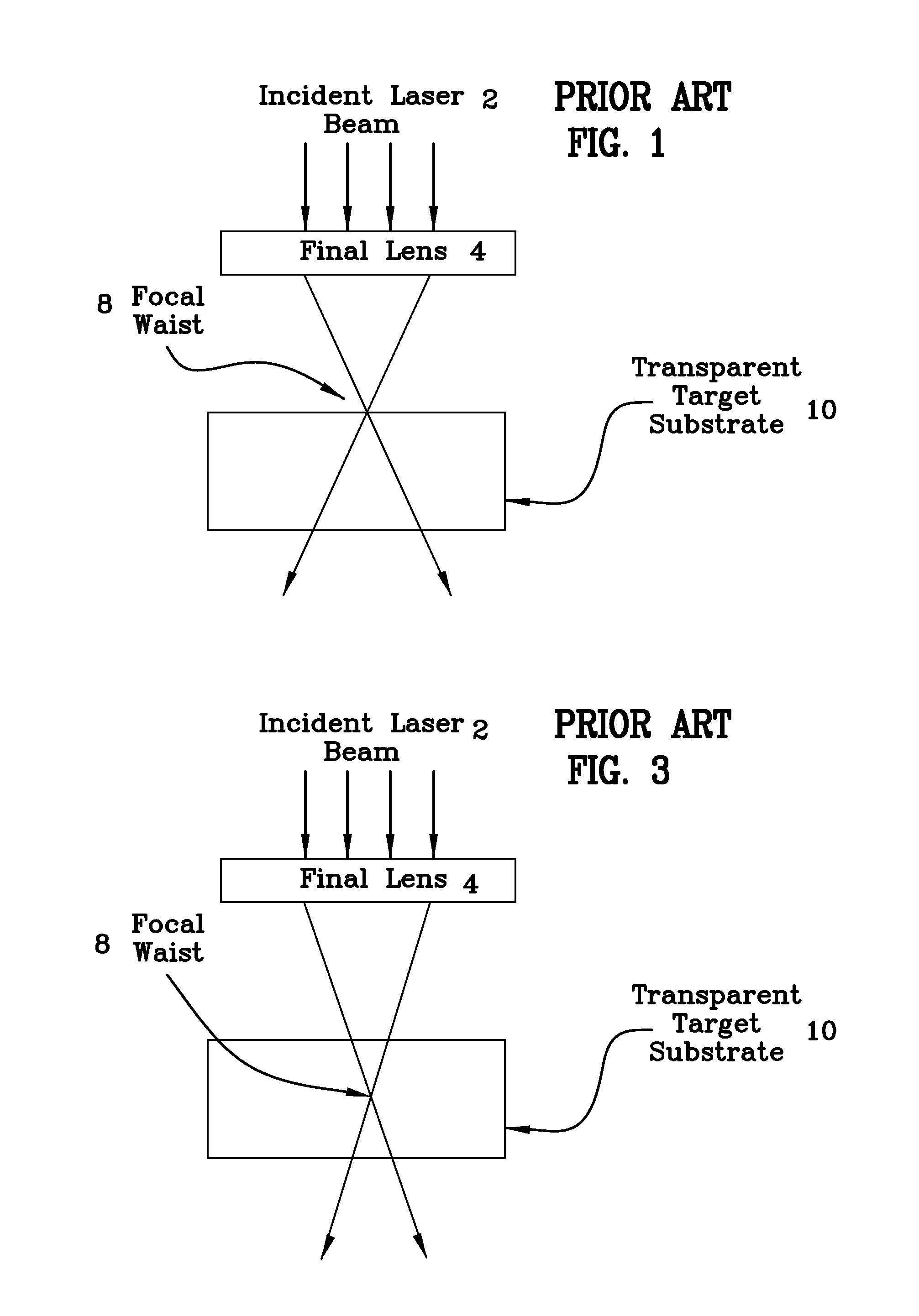

Systems and methods are described for forming continuous laser filaments in transparent materials. A burst of ultrafast laser pulses is focused such that a beam waist is formed external to the material being processed without forming an external plasma channel, while a sufficient energy density is formed within an extended region within the material to support the formation of a continuous filament, without causing optical breakdown within the material. Filaments formed according to this method may exhibit lengths exceeding up to 10 mm. In some embodiments, an aberrated optical focusing element is employed to produce an external beam waist while producing distributed focusing of the incident beam within the material. Various systems are described that facilitate the formation of filament arrays within transparent substrates for cleaving / singulation and / or marking. Optical monitoring of the filaments may be employed to provide feedback to facilitate active control of the process.

Owner:ROFIN SINAR TECH

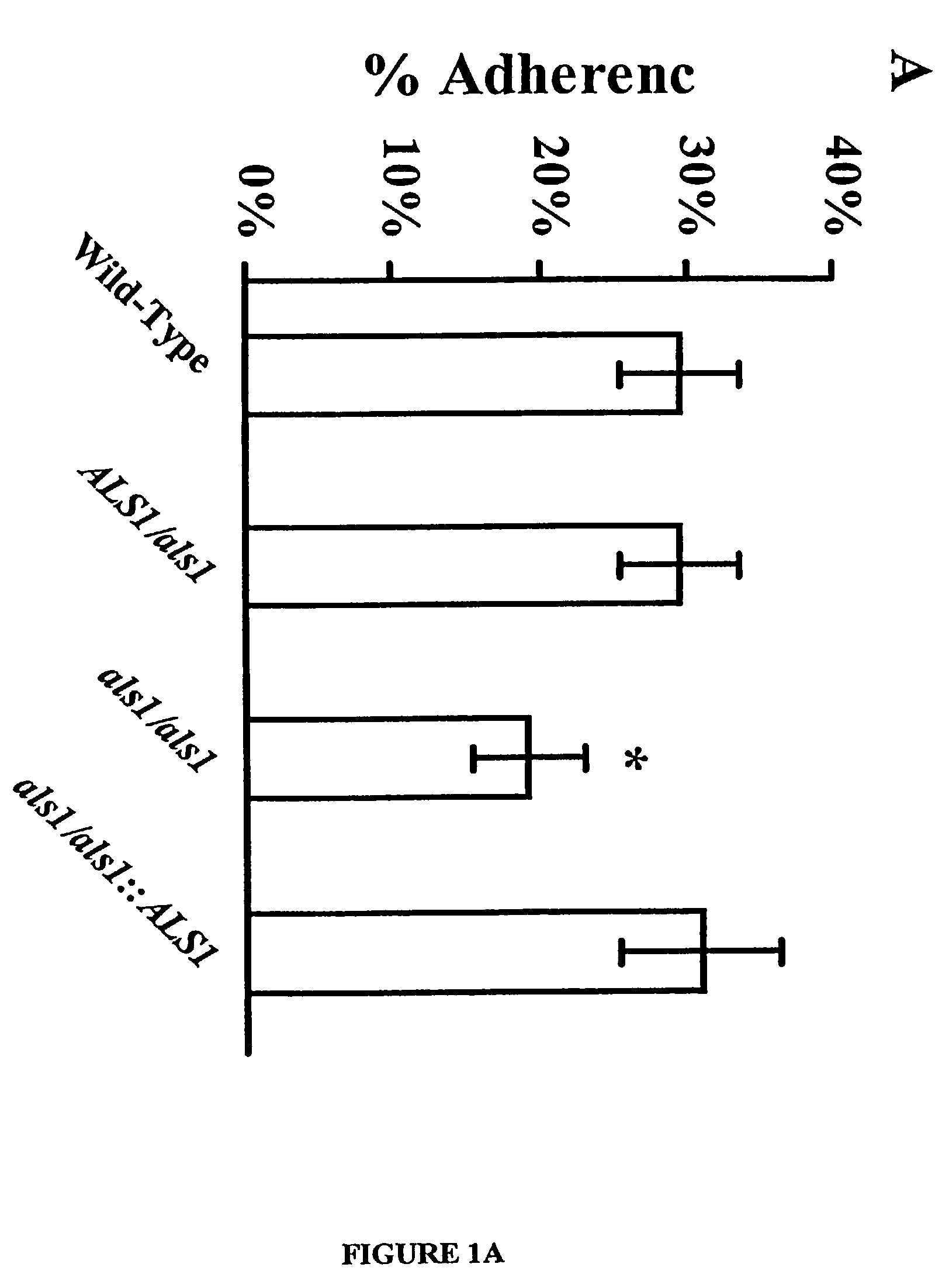

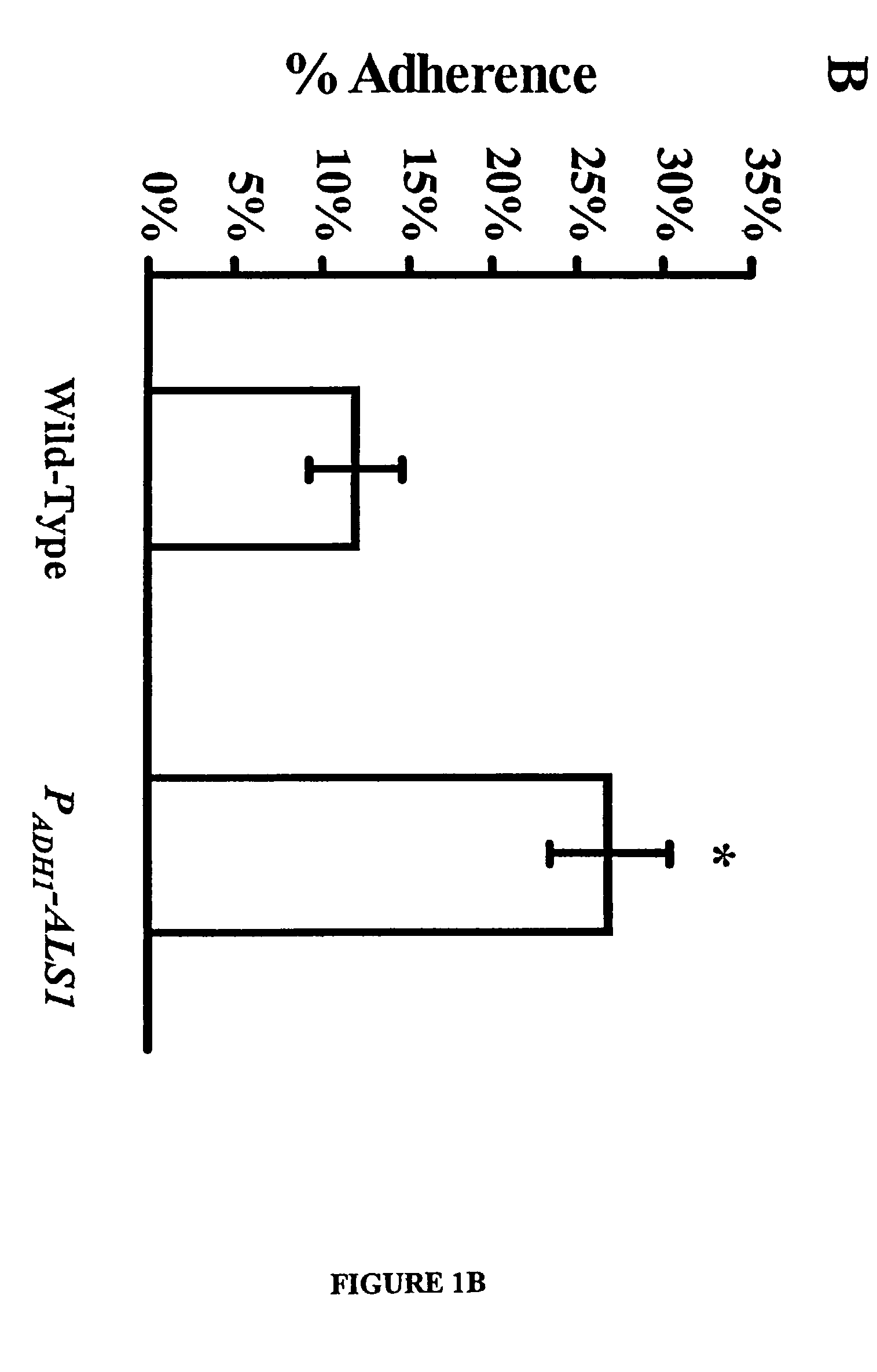

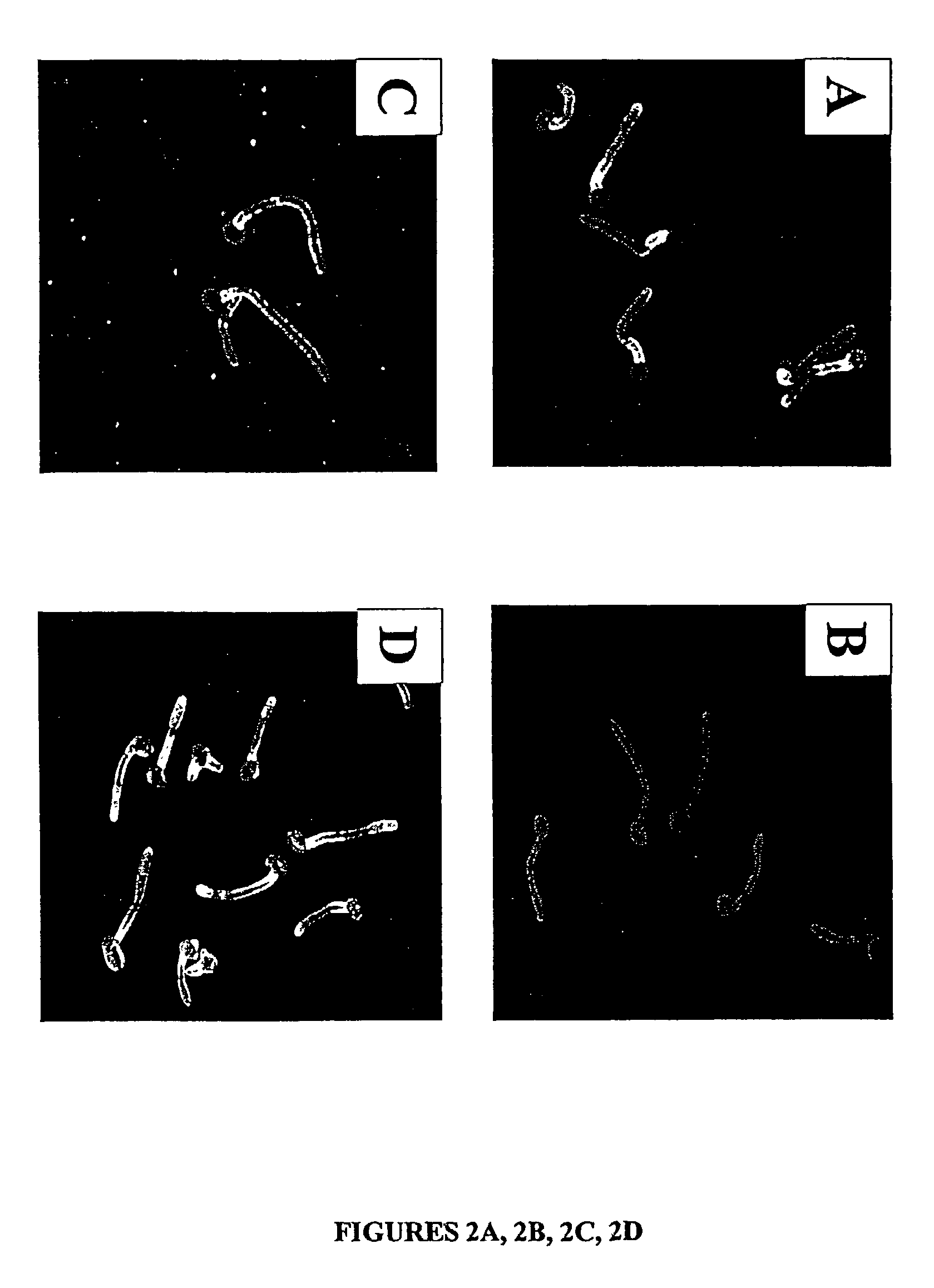

Pharmaceutical compositions and methods to vaccinate against candidiasis

InactiveUS20030124134A1Treat prevent alleviateToxic reductionPeptide/protein ingredientsSnake antigen ingredientsHospitalized patientsVirulent characteristics

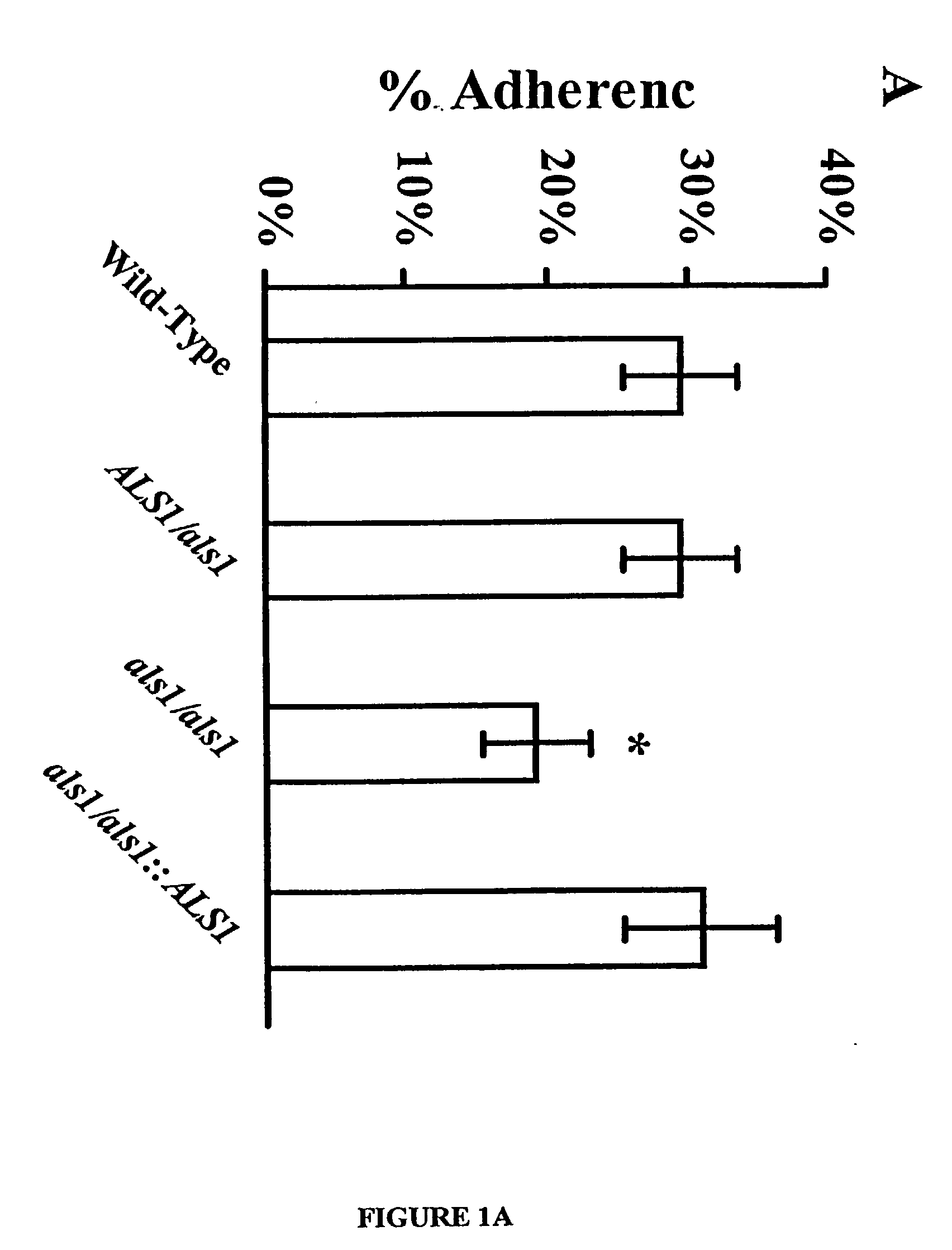

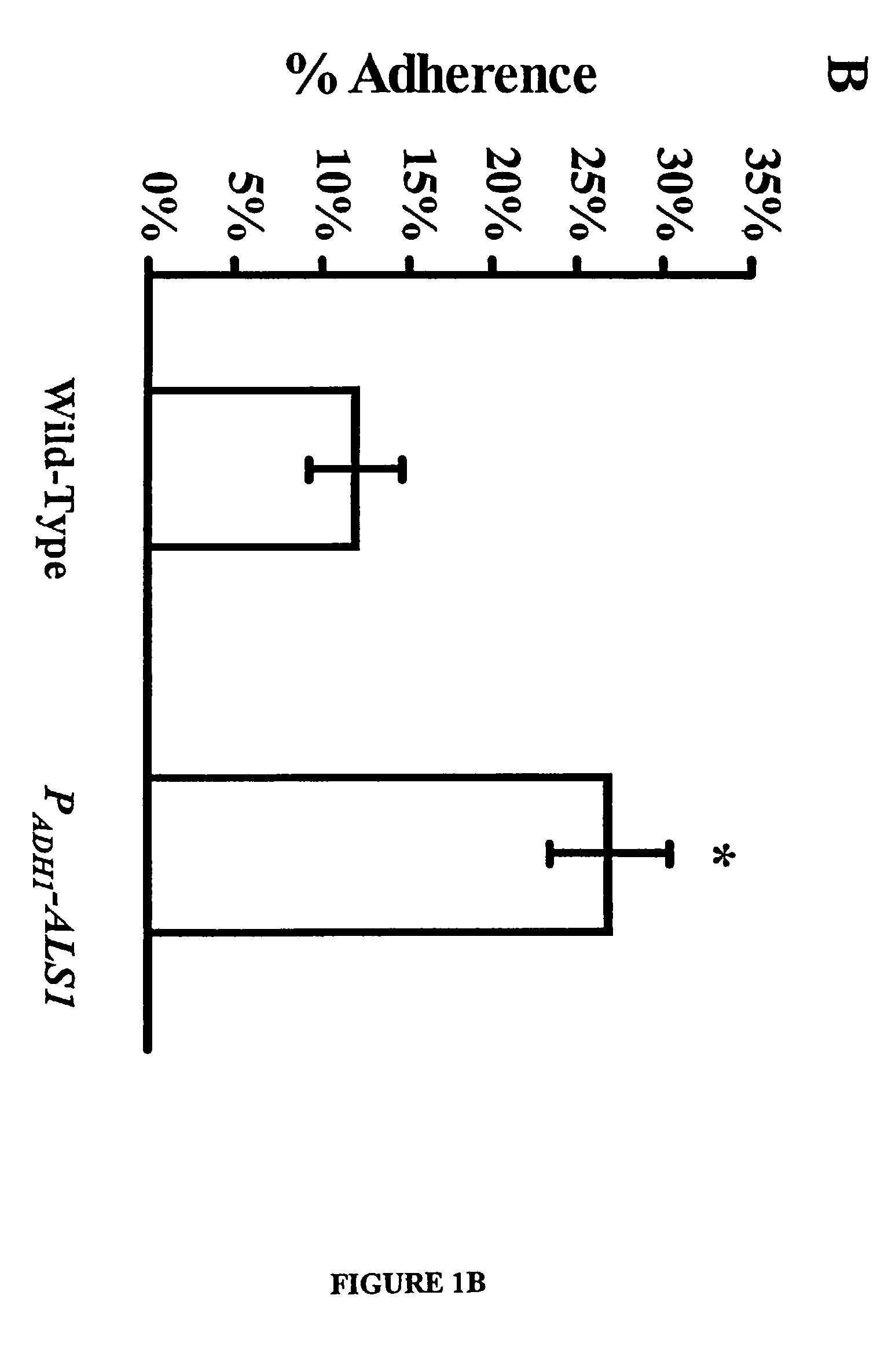

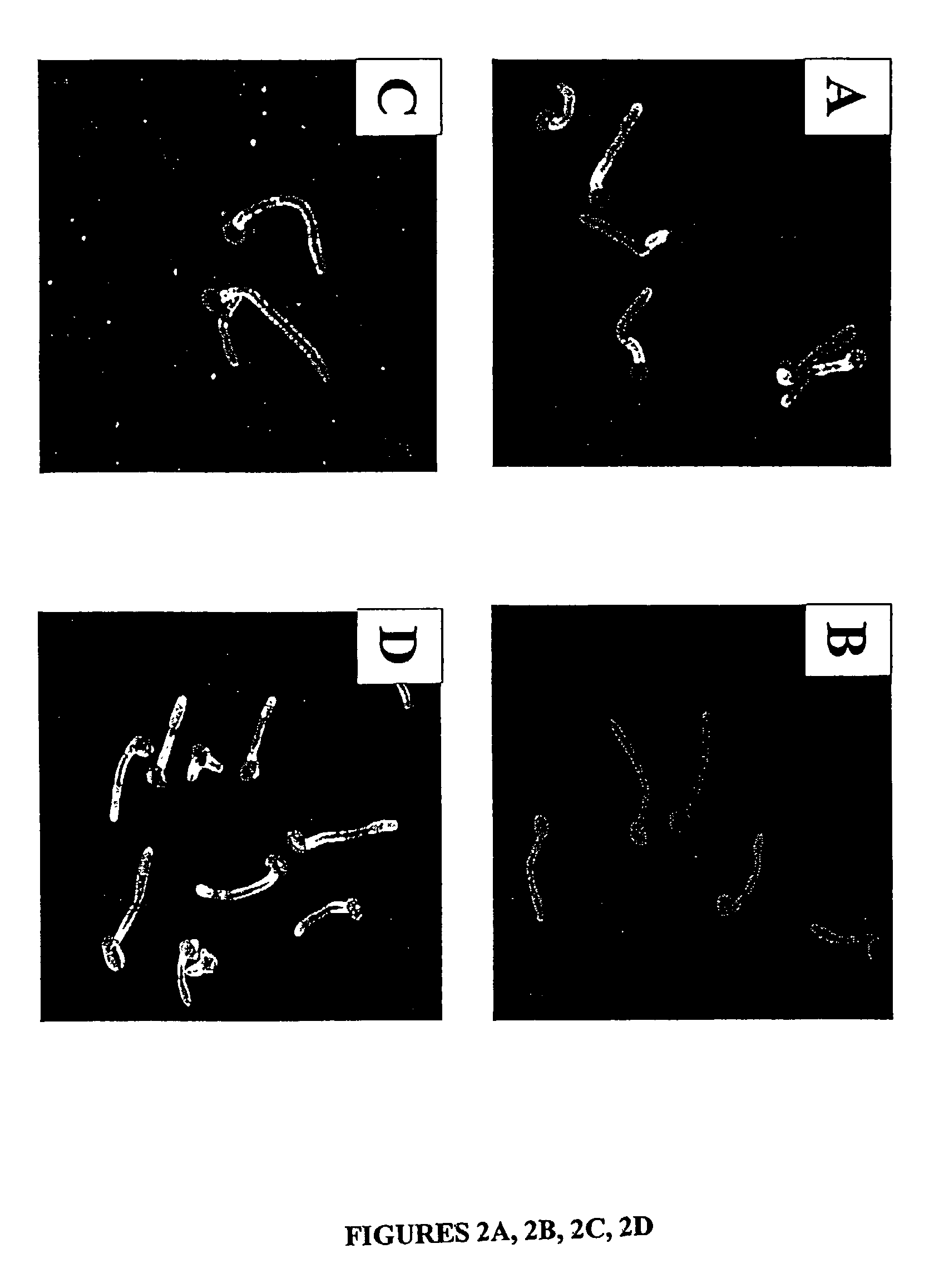

A Candida albicans bloodstream infections cause significant morbidity and mortality in hospitalized patients. Filament formation and adherence to host cells are critical virulence factors of C. albicans. Multiple filamentation regulatory pathways have been discovered, however the downstream effectors of these regulatory pathways remain unknown. The cell surface proteins in the ALS group are downstream effectors of the filamentation regulatory pathway. Particularly, Als1p mediates adherence to endothelial cells in vitro and is required for virulence. The blocking of adherence by the organism is described resulting from the use of a composition and method disclosed herein. Specifically, a pharmaceutical composition comprised of a gene, gene product, or specific antibody to the ALS gene family is administered as a vaccine to generate an immune response capable of blocking adherence of the organism.

Owner:LOS ANGELES BIOMEDICAL RES INST AT UCLA HARBOR MEDICAL CENT +1

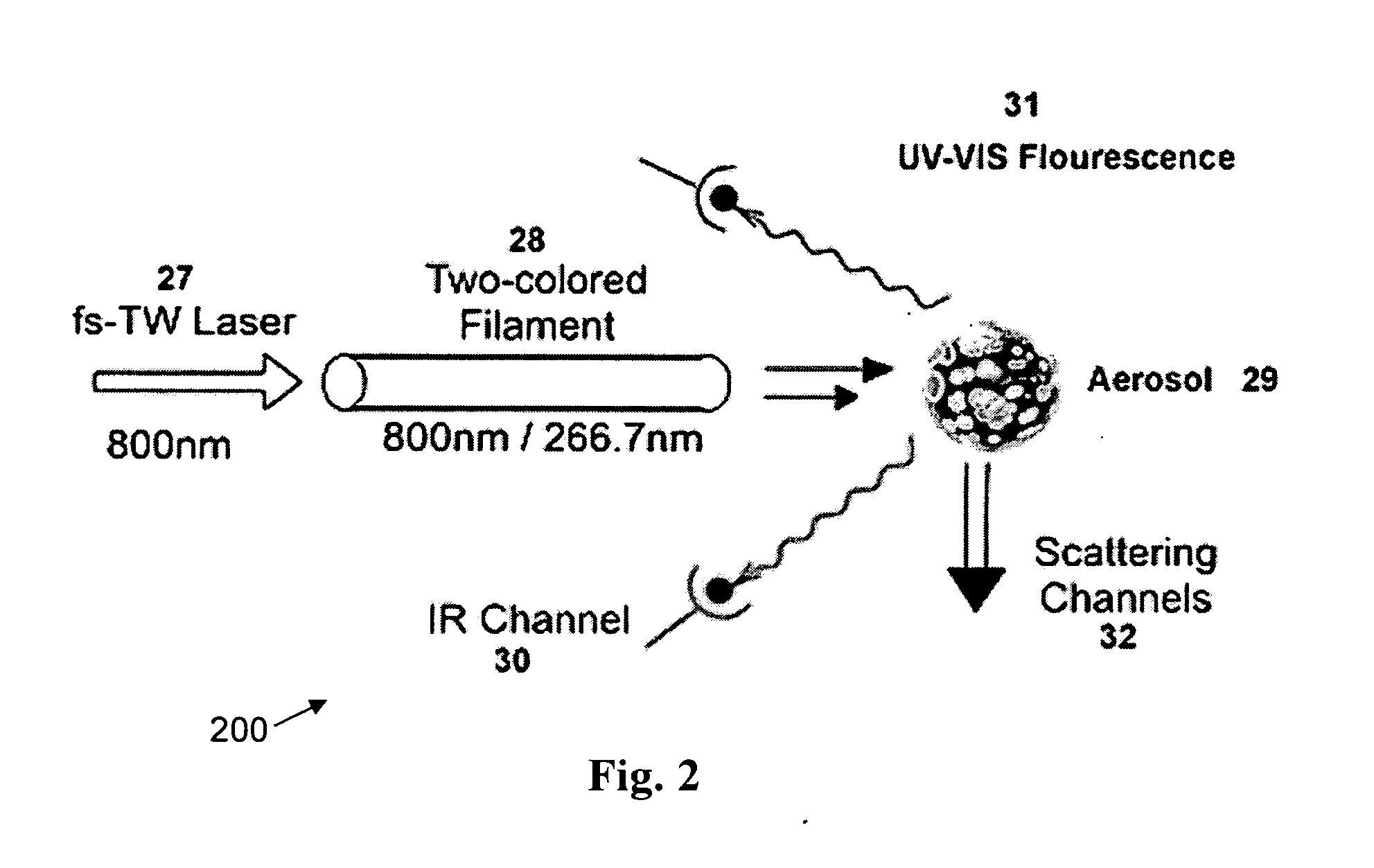

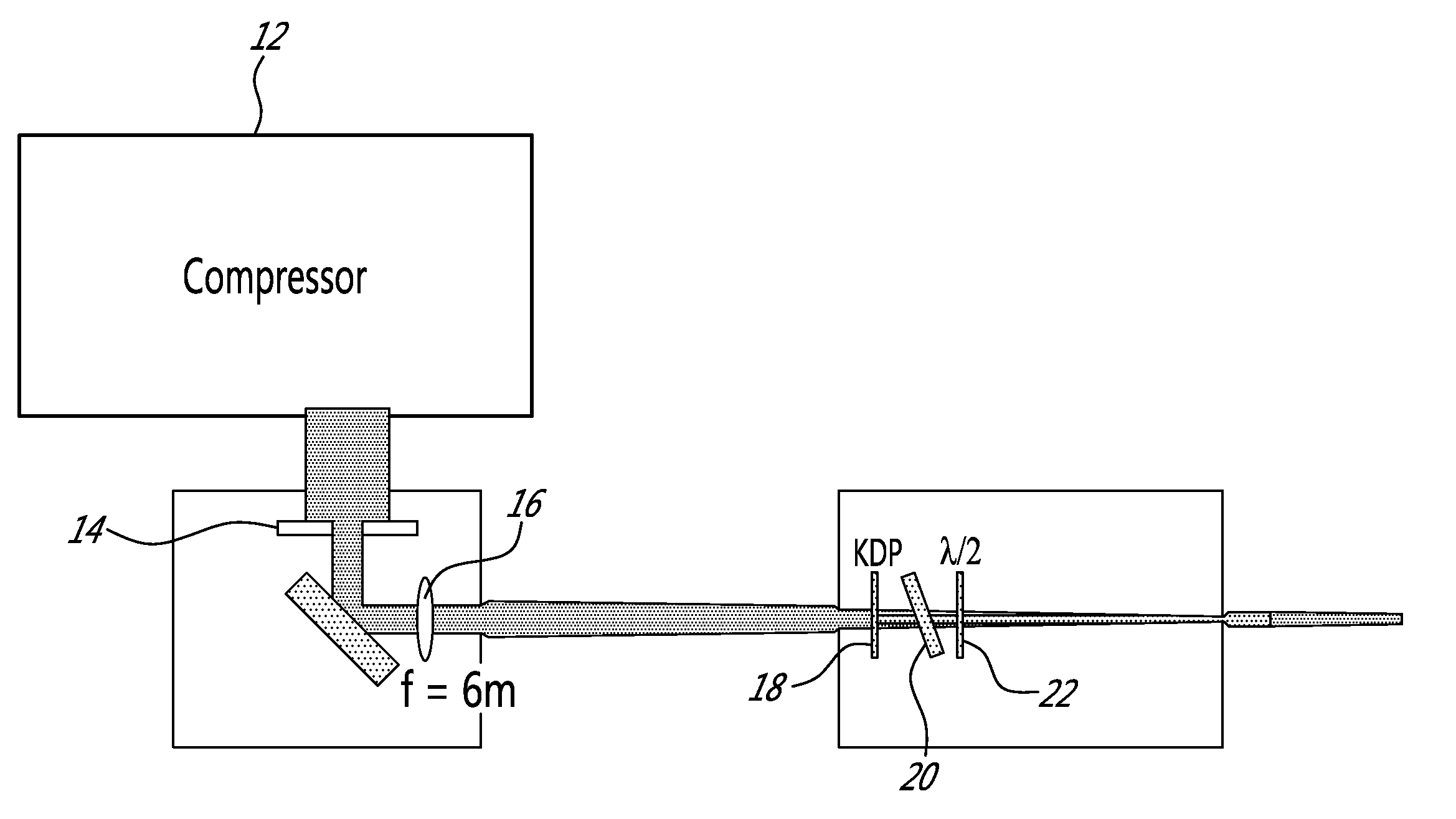

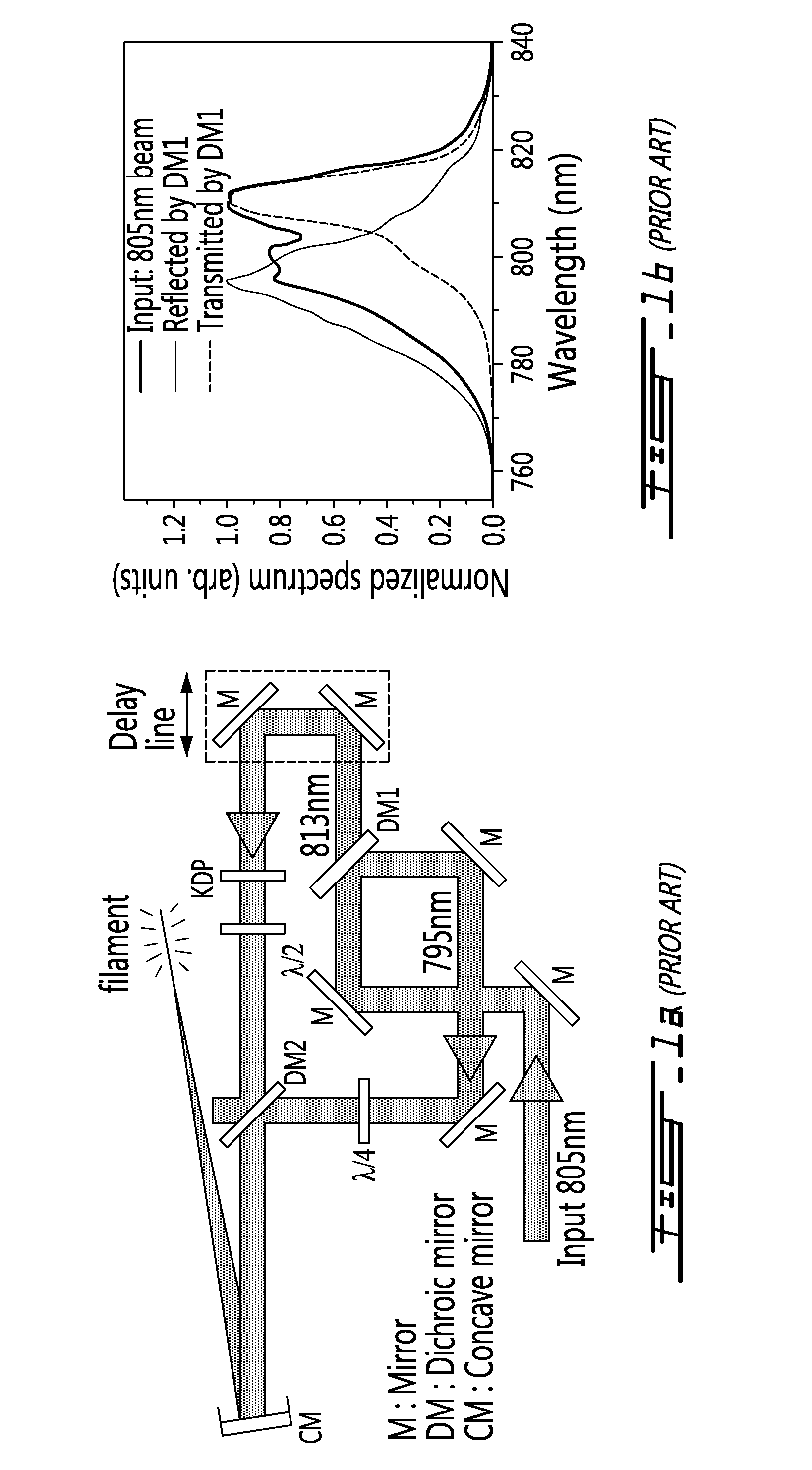

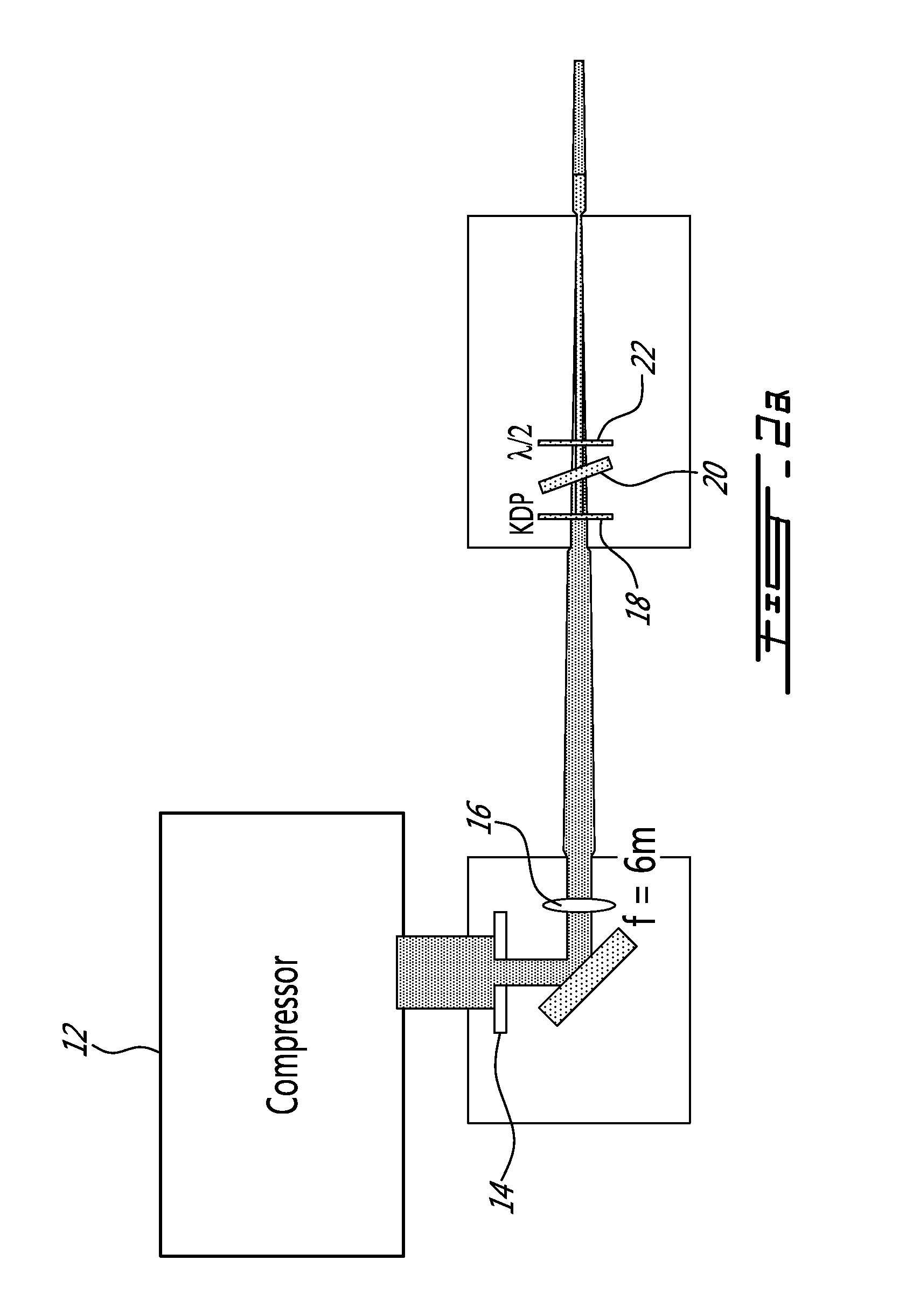

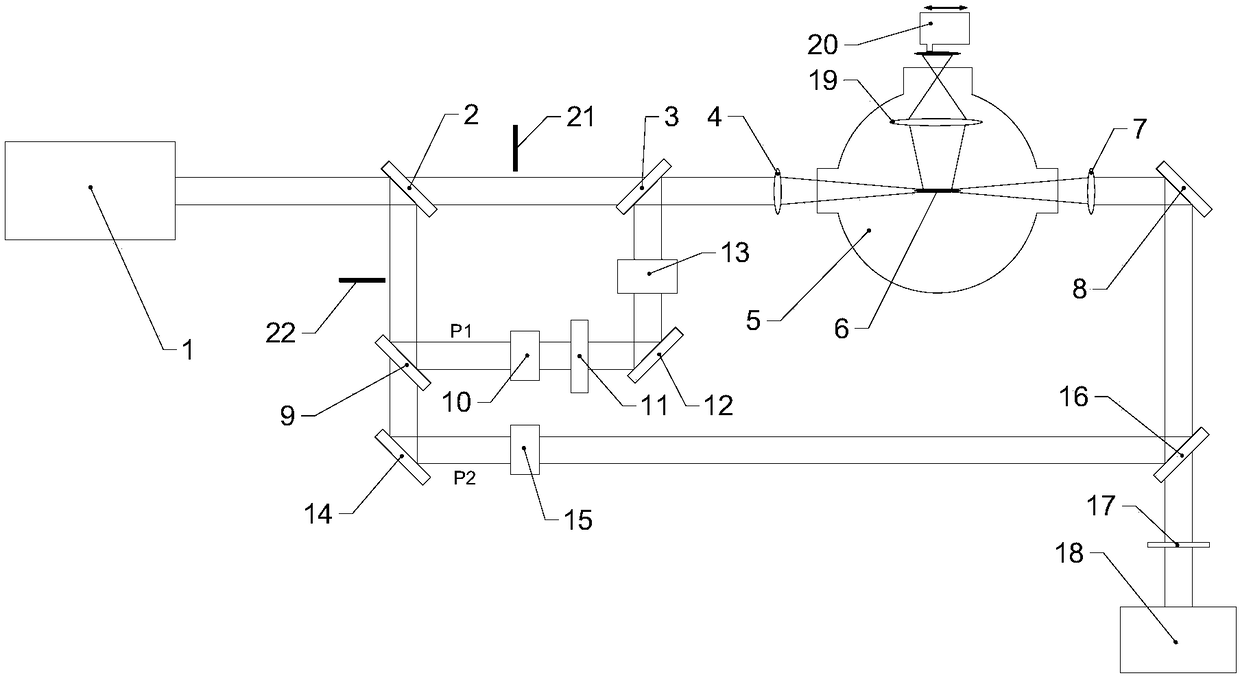

Mobile terawatt femtosecond laser system (MTFLS) for long range spectral sensing and identification of bioaerosols and chemical agents in the atmosphere

InactiveUS7391557B1Reduce probabilitySimultaneous measurementRadiation pyrometryLaser detailsFilamentationUltraviolet

The present invention relates to a system for detection and identification of airborne biological, chemical and / or nuclear threats such as toxins, spores, bacteria, and viruses in real time at distances from a few meters to several kilometers. Compact femtosecond terawatt laser technology is combined with spectroscopic and mathematical methods for spectral sensing of airborne warfare agents such as bio-aerosols. Trigger sensors and standoff devices based on mobile terawatt femtosecond laser systems are provided that may be placed at strategic monitoring locations. Furthermore, the invention relates to the propagation of airborne ultra-short, ultra-intense laser pulses giving rise to plasma channels (filamentation) producing white light supercontinuum ranging from the ultraviolet (UV), visible (VIS), near infra-red (NE) and middle infra-red (MIR). According to this invention, the supercontinuum can be directly produced in a particle cloud and hence is uniquely suitable for multi-spectral long-range atmospheric agent and radioactive isotope detection.

Owner:APPLIED PHOTONICS WORLDWIDE

Method and apparatus for performing laser curved filamentation within transparent materials

ActiveUS20160016257A1Improve bending strengthInhibition formationGlass drawing apparatusGlass transportation apparatusFilamentationPlasma channel

Systems and methods are described for forming continuous curved laser filaments in transparent materials. The filaments are preferably curved and C-shaped. Filaments may employ other curved profiles (shapes). A burst of ultrafast laser pulses is focused such that a beam waist is formed external to the material being processed without forming an external plasma channel, while a sufficient energy density is formed within an extended region within the material to support the formation of a continuous filament, without causing optical breakdown within the material. Filaments formed according to this method may exhibit lengths in the range of 100 μm-10 mm. An aberrated optical focusing element is employed to produce an external beam waist while producing distributed focusing of the incident beam within the material. Optical monitoring of the filaments may be employed to provide feedback to facilitate active control of the process.

Owner:ROFIN SINAR TECH

Method and apparatus for machining diamonds and gemstones using filamentation by burst ultrafast laser pulses

InactiveUS20150121960A1Efficient cuttingLess-waste is producedBlowing machine gearingsFine working devicesNon ablativeFilamentation

A non-ablative laser machining method and apparatus for cutting facets of a diamond, using a material machining technique involving filamentation by burst ultrafast laser pulses well suited to mass production. Coupled with 3D modeling and the computerized laser machining system, complex geometric surfaces can be created on the diamond. The facets of the diamond need not be planar in configuration, and may incorporate acute as well as oblique angles. This method minimizes the need for diamond polishing, speeds up production, and realizes great reductions in the quantity of lost material from the cutting process.

Owner:ROFIN SINAR TECH

Mobile terawatt femtosecond laser system (MTFLS) for long range spectral sensing and identification of bioaerosols and chemical agents in the atmosphere

InactiveUS20080180655A1Reduce probabilitySimultaneous measurementLaser detailsRadiation pyrometryFilamentationUltraviolet

The present invention relates to a system for detection and identification of airborne biological, chemical and / or nuclear threats such as toxins, spores, bacteria, and viruses in real time at distances from a few meters to several kilometers. Compact femtosecond terawatt laser technology is combined with spectroscopic and mathematical methods for spectral sensing of airborne warfare agents such as bio-aerosols. Trigger sensors and standoff devices based on mobile terawatt femtosecond laser systems are provided that may be placed at strategic monitoring locations. Furthermore, the invention relates to the propagation of airborne ultra-short, ultra-intense laser pulses giving rise to plasma channels (filamentation) producing white light supercontinuum ranging from the ultraviolet (UV), visible (VIS), near infra-red (NIR) and middle infra-red (MIR). According to this invention, the supercontinuum can be directly produced in a particle cloud and hence is uniquely suitable for multi-spectral long-range atmospheric agent and radioactive isotope detection.

Owner:APPLIED PHOTONICS WORLDWIDE

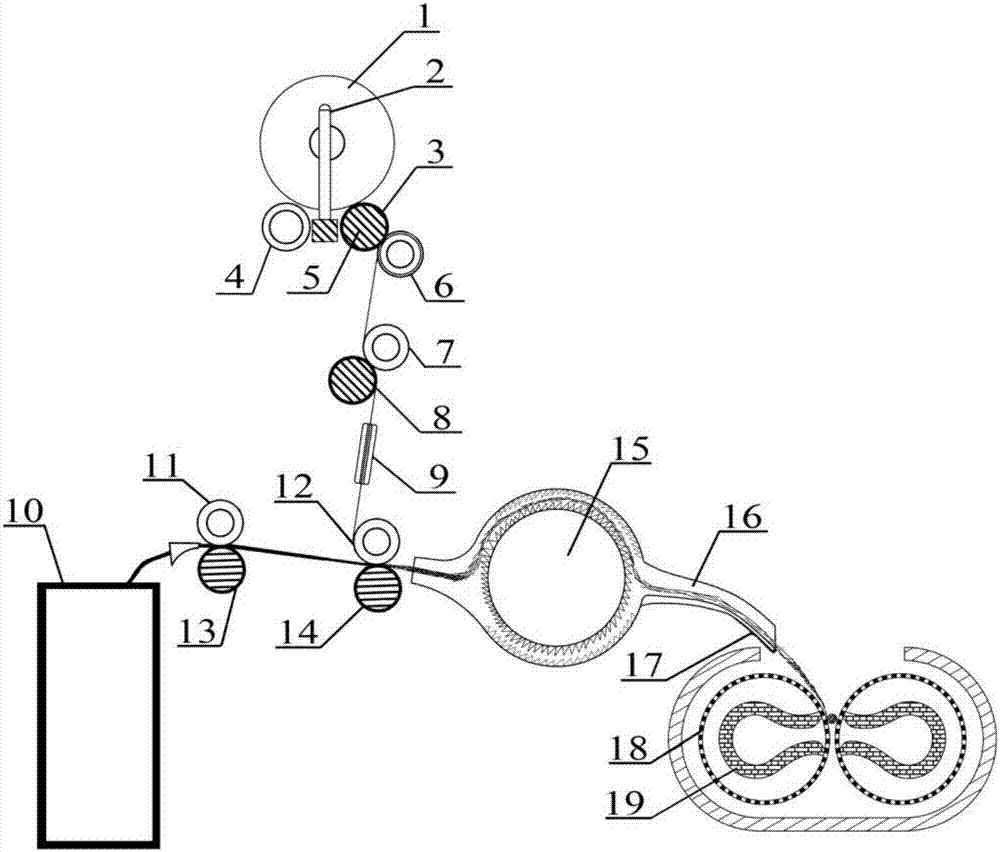

Pulping system and pulping method for environment-friendly mechanical pulp and chemical mechanical pulp of non-woody crops

The invention provides a pulping system for environment-friendly mechanical pulp and mechanical chemical pulp of non-woody crops, which comprises a cutting machine, a hammer filament duster, an impregnating washer, an I-section cracking impregnator, an II-section cracking impregnator, an I-section storage reaction bin, an II-section storage reaction bin, a high-concentration impregnating millstone mill, an III-section storage reaction bin and a pulping machine and screening, purification and concentration equipment in a subsequent process, wherein a steaming spiral conveyer, the I-section storage reaction bin, the II-section storage reaction bin and the III-section storage reaction bin are provided with steam injecting pipelines, and liquid medicine injecting pipelines are also arranged at the impregnating washer, the cracking tail end of the I-section cracking impregnator, the cracking tail end of the II-section cracking impregnator and the input position of the high-concentration impregnating millstone mill. A pulping method comprises the following steps of: preparing raw materials, performing pre-steaming spiral conveying, connecting two physical filamentation treatment sections in series, performing high-concentration disc impregnating filamentation treatment, and performing high-concentration pulping, screening, purifying and dehydrating to obtain commercial pulp. The technical scheme has the technical advantages of high yield, no pollution, low energy consumption and the like.

Owner:刚荣环保科技(上海)有限公司

Trumpet-flared monolithically integrated semiconductor laser amplifier

InactiveUS6130903AIncrease output powerOptimizationLaser detailsLaser optical resonator constructionAudio power amplifierFilamentation

An MFA-MOPA that includes a semiconductor laser with separate master oscillator and trumpet-flared power amplifier regions. Within the trumpet-flared active gain region of the uniformly-pumped power amplifier of the MFA-MOPA device, the density distribution of carriers and reflections of the laser beam are analyzed to determine the output powers at which filamentation and beam degradation due to reflections occur. The shape of the trumpet-flare is optimized to delay the onset of filamentation and the degradation of the output laser beam due to reflections to higher output powers for the MFA-MOPA device.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Adjustment and control device and method for ultra intense and ultra short laser pulse super-continuum spectrum

The invention discloses an adjustment and control device and method for an ultra intense and ultra short laser pulse super-continuum spectrum. After passing through a variable attenuation sheet and a time delay line, a beam of laser G (t) irradiates to a concave mirror in parallel with another beam of laser G (f) passing through a movable reflector; and G (t) and G (f) are reflected through the concave mirror and then crossed and focused. In a plasma channel produced by laser filamentation, a space plasma grating is formed because of double light beam interference; the super-continuum spectrum produced during the filamentation can be enhanced by using the plasma grating; and control and transfer of the energy of the super-continuum spectrum between the two beams of laser can be realized. According to the method and the device provided by the invention, the spectrum of the ultra short pulse can be actively controlled in an ultra intense laser field; and an involved light path has a simple structure and is convenient for adjustment.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

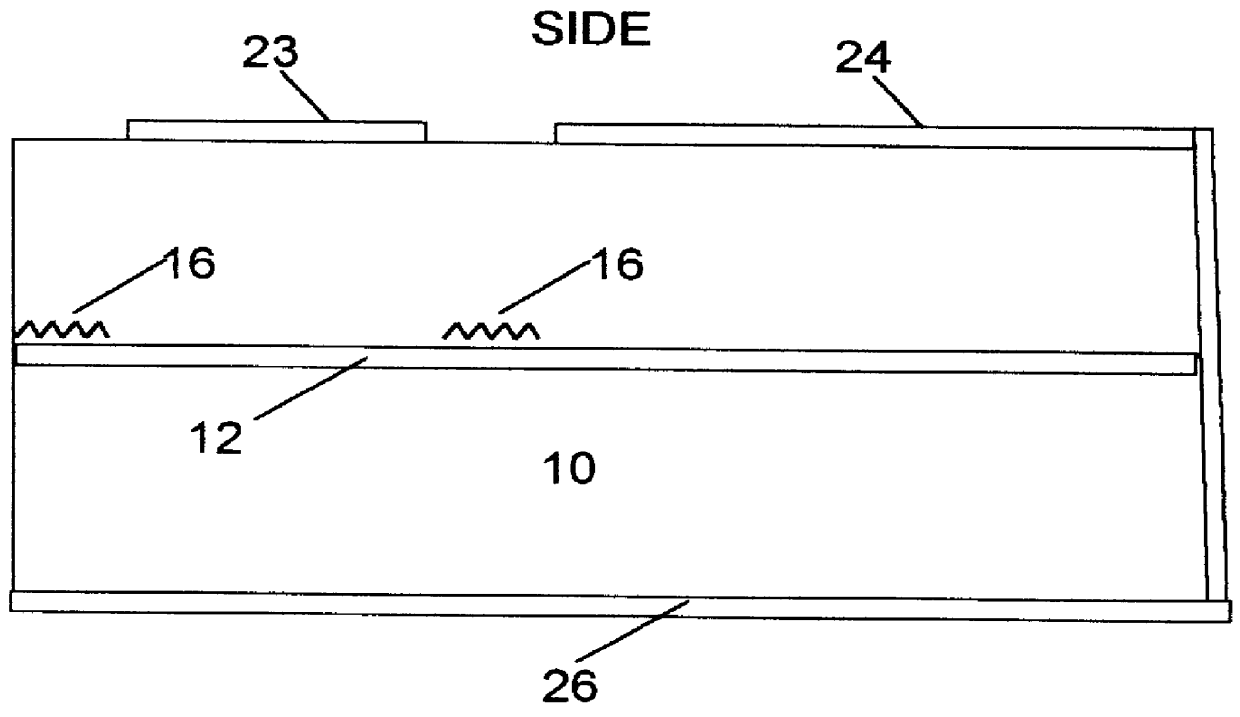

System and Method for Permanently Writing a Diffraction Grating in a Low Phonon Energy Glass Medium

A system and method for permanently writing diffraction gratings in low phonon energy glass waveguides are shown. Ultrashort light pulses are generated and made to form two beams synchronously superimposed in the waveguide, therefore forming an interference pattern corresponding to the desired grating. The light pulses are focussed so that the light intensity in the waveguide exceeds a filamentation threshold. The exposure of the waveguide to these light pulses is controlled temporally and spatially in order to limit detrimental thermal effects induced by the high-intensity pulses in the glass medium of the waveguide.

Owner:UNIV LAVAL

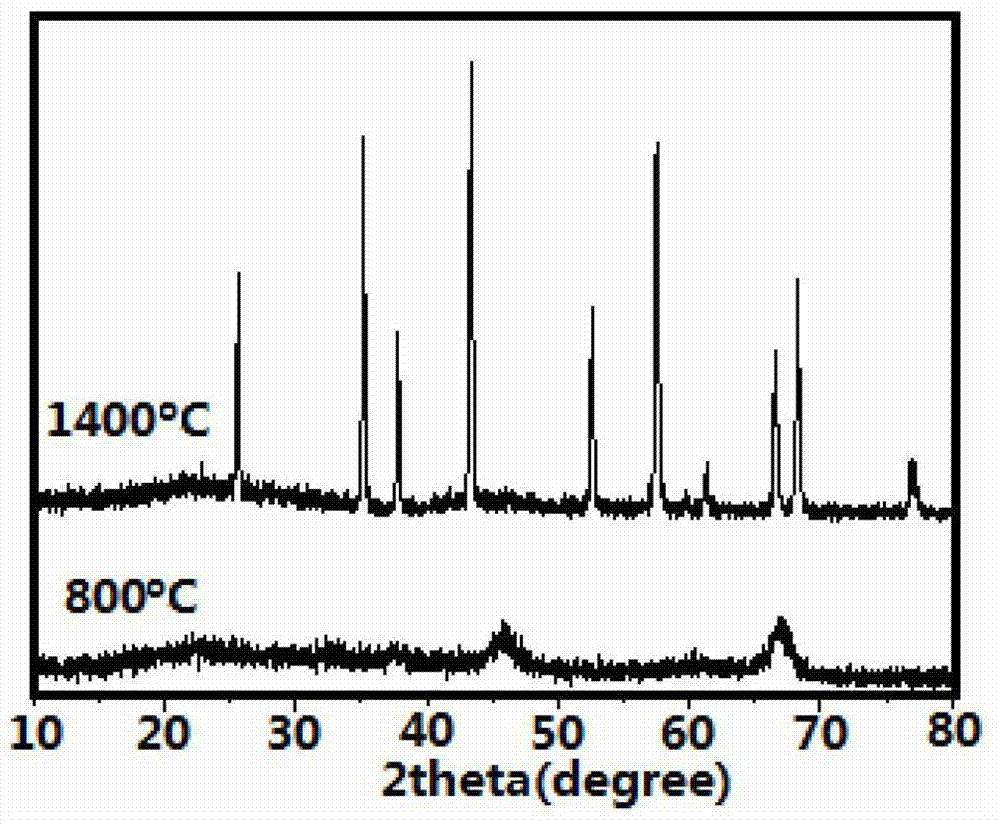

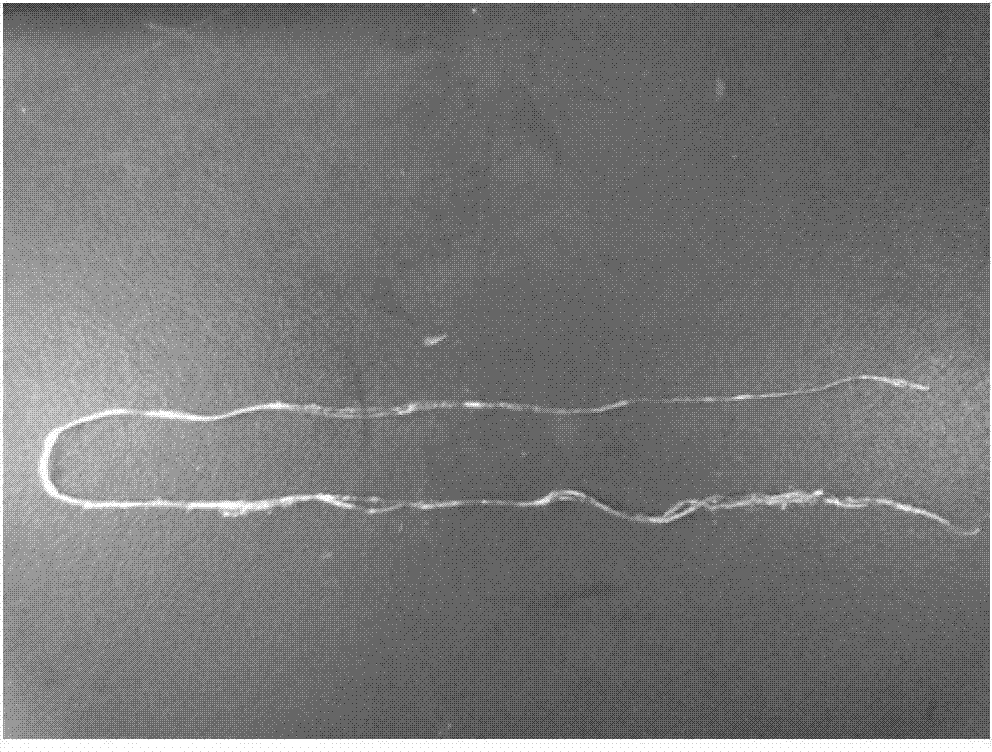

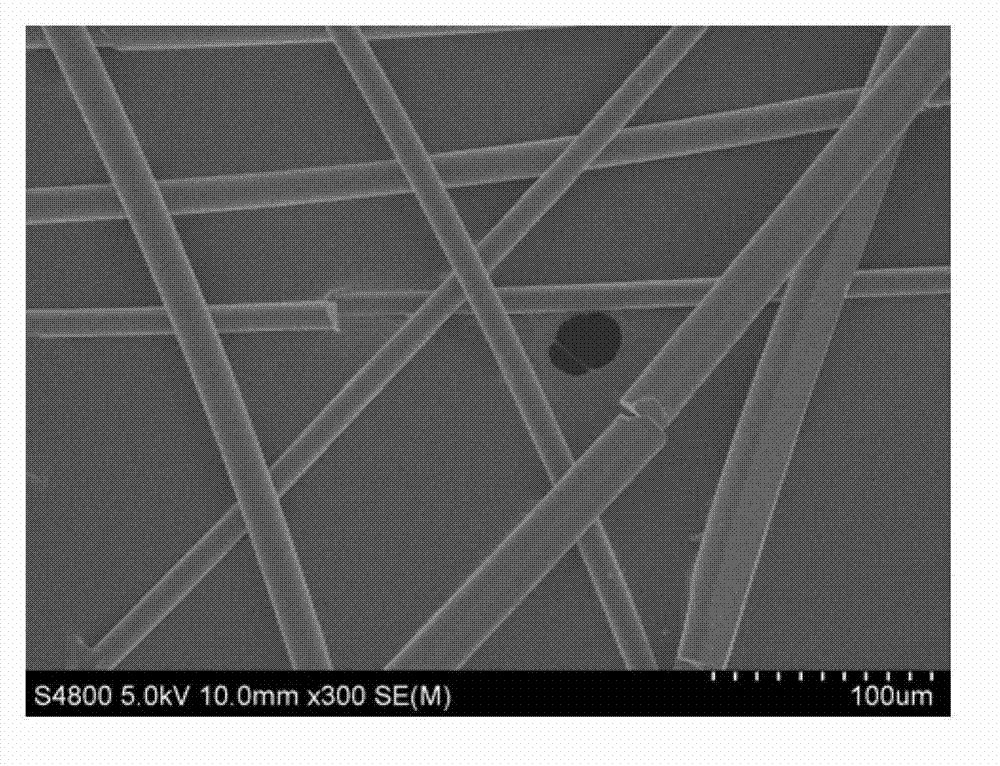

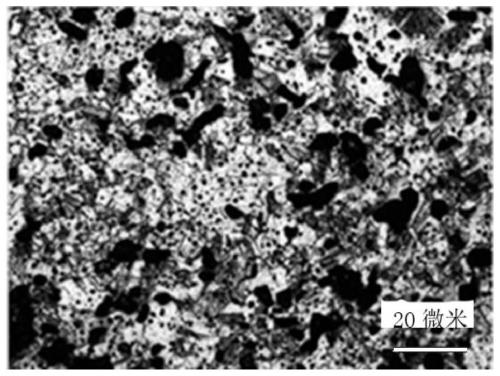

Preparation method of aluminum oxide ceramic continuous fiber

The invention relates to a preparation method of aluminum oxide ceramic continuous fiber, which comprises the following steps of: preparing a sol spinnable precursor by use of inorganic aluminum salt, aluminum powder, aluminum isopropoxide, nitric acid and crystal grain inhibitor; spinning gel fiber by a dry spinning technology; and performing drying and high-temperature calcination to obtain the aluminum oxide ceramic continuous fiber with diameter of 10-60 microns. According to the invention, the prepared sol system is particularly stable, the cost of the raw materials is low, and the preparation process is simple; and the filament can be obtained without adding auxiliaries such as macromolecules and the like. The filamentation environment is mild in the dry spinning. The calcined ceramic continuous fiber has flexibility and can be used as reinforcement in a composite material to improve strength and heat resistance of the material.

Owner:SHANDONG UNIV

Preparation method of zirconic acid lanthanum ceramic fiber

ActiveCN103553596ASmall diameterEvenly distributedInorganic material artificial filamentsFiberFilamentation

The invention relates to a preparation method of a zirconic acid lanthanum ceramic fiber. The method comprises the following steps: preparing a gel fiber through a colloidal sol centrifugal fiber forming technology by using zirconium nitrate as a zirconium source, lanthanum nitrate as a lanthanum source, citric acid as a chelating agent, and water as a solvent, and calcining the gel fiber to form the zirconic acid lanthanum ceramic fiber. A precursor prepared by the invention has stable colloidal sol property and is good in filamentation property with no need of adding a polymer spinning additive. The prepared zirconic acid lanthanum ceramic fiber is good in flexibility, compact in microstructure, good in phase stability an low in heat conductivity coefficient and can be used for high-temperature thermal-insulation material, and the crystal form of the zirconic acid lanthanum ceramic fiber is pyrochlore form.

Owner:SHANDONG UNIV

Micro-optic elements and method for making the same

InactiveUS7531104B1OptimizationDecorative surface effectsPhotosensitive material processingResistHigh power lasers

A method of making micro-optic elements. In one embodiment, photo-resist elements each having predetermined dimensions are transferred onto a substrate. The photo-resist elements are exposed to a reflow process to shape the top surface of the elements into a curved surface. The method also involves a reactive ion etching process having controlled parameters, such as a photo-resist depth and the selectivity between the substrate and photo-resist. A predetermined photo-resist depth and selectivity form a micro-optic element having a predetermined shape, preferably an elliptical or parabolic shape. In another aspect of the present invention, a micro-optic element is used to construct a micro-mirror for eliminating filamentation and promoting single mode operation of high-power broad area semiconductor lasers. The lenses and micro-mirrors produced by methods disclosed herein are configured to collimate the output of high-power lasers and promote a Gaussian intensity profile laser beam from a broad area laser beam.

Owner:HWU RUEY JEN

Method and apparatus for performing laser curved filamentation within transparent materials

ActiveUS9757815B2Inhibition formationImprove bending strengthGlass severing apparatusWelding/soldering/cutting articlesFilamentationLight beam

Owner:ROFIN SINAR TECH

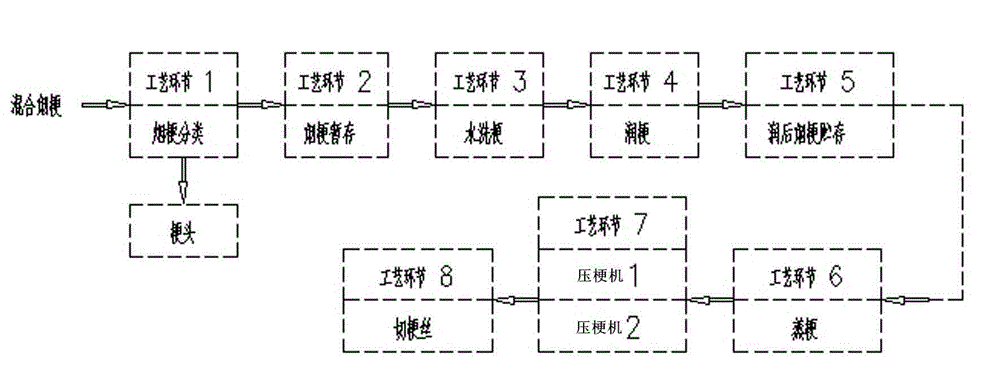

Tobacco stem classifying and processing method

InactiveCN102715645AImprove wetting effectUniform moisture contentTobacco treatmentFilamentationEngineering

The invention relates to a tobacco stem classifying and processing method. The tobacco stem classifying and processing method comprises the following steps of classifying tobacco stems by one or more methods of spectrum pickup classification, multi-stage vibrating screening classification and winnowing classification and removing heads from the tobacco stems; conveying the classified tobacco stems into temporary storage stations respectively, washing and moistening each kind of tobacco stems according to the production requirement, and conveying the tobacco stems into a storage cabinet or box type small-sized three-dimensional elevated library respectively to store; steaming and pressing the tobacco stems sequentially so as to press the tobacco stems into flat shapes; and finally conveying the flattened tobacco stems into the subsequent stem-cutting procedure. According to the invention, the filamentation ratio of the cut stems is increased, the uniformity of the cut stems is improved and the quality of the cut stems is improved.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

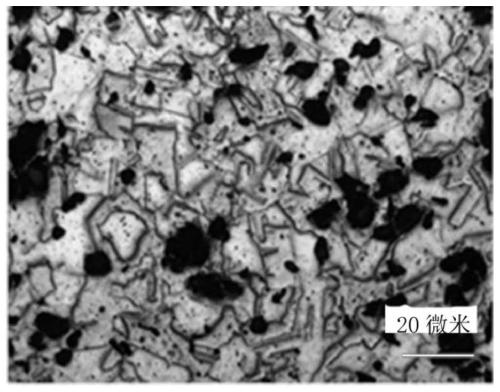

Copper-iron alloy wire rod and preparation method thereof

The invention discloses a copper-iron alloy wire rod. The copper-iron alloy wire rod comprises the following components of, in percentage by mass, 8-50% of Fe and the balance copper and other inevitable impurities, wherein the inevitable impurities comprise the following components of, in percentage by mass, less than or equal to 0.05% of C, less than or equal to 0.1% of H, less than or equal to 0.1% of O, less than or equal to 0.01% of S and less than or equal to 0.5% of other impurities. The invention further provides a preparation method of the copper-iron alloy material. The technical means of spin-strip method powder preparation, crushing and mixing and forming and sintering are combined. According to the copper-iron alloy wire rod and the preparation method of the copper-iron alloy wire, the preparation methods of adopting cooper-iron alloy powder, powder forming and sintering blanking and billet calendar filamentation; and the copper-iron alloy wire rod and the preparation method thereof are provided, the Fe content of the prepared copper-iron alloy wire rod is larger than 8%, the component is uniform, the structure crystal grain is fine and compact, and the copper-iron alloy wire rod has high strength, conductivity and good electromagnetic shielding performance.

Owner:JINTIAN COPPER GROUP CORP NINGBO

Brittle material punching method

ActiveCN106392341AReduce difficultyGuaranteed StrengthWelding/soldering/cutting articlesLaser beam welding apparatusPulse beamHeat-affected zone

The invention relates to the technical field of laser punching, in particular to a brittle material punching method. Filamentation cutting is carried out on a brittle material to be processed with ultrashort laser pulse beams to form round rings penetrating through the brittle material; an ablation area is arranged in each round ring, each ablation area is of an appointed shape, the parts, of the appointed shapes, of the brittle material are removed in a laser ablation manner, and single bodies to be splintered which are not connected with one another and to be subjected to splintering processing are formed; and splintering processing is carried out on the single bodies to be splintered at the same time, so that punching machining on the brittle material is realized. Because filamentation cutting and laser ablation are combined, edge breakage of the brittle material is reduced, the area of the heat affect zone of the brittle material is reduced, the efficiency of punching is improved, the success rate of punching is increased, the cost is reduced, and the problems about efficiency and effect in the machining process are solved.

Owner:WUHAN HGLASER ENG CO LTD

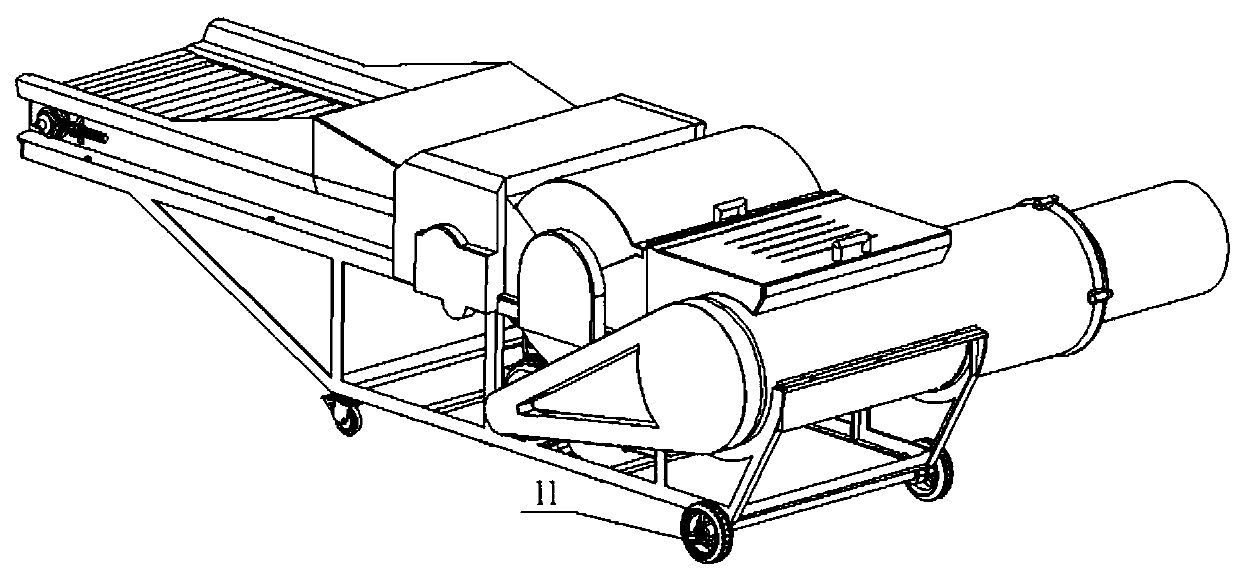

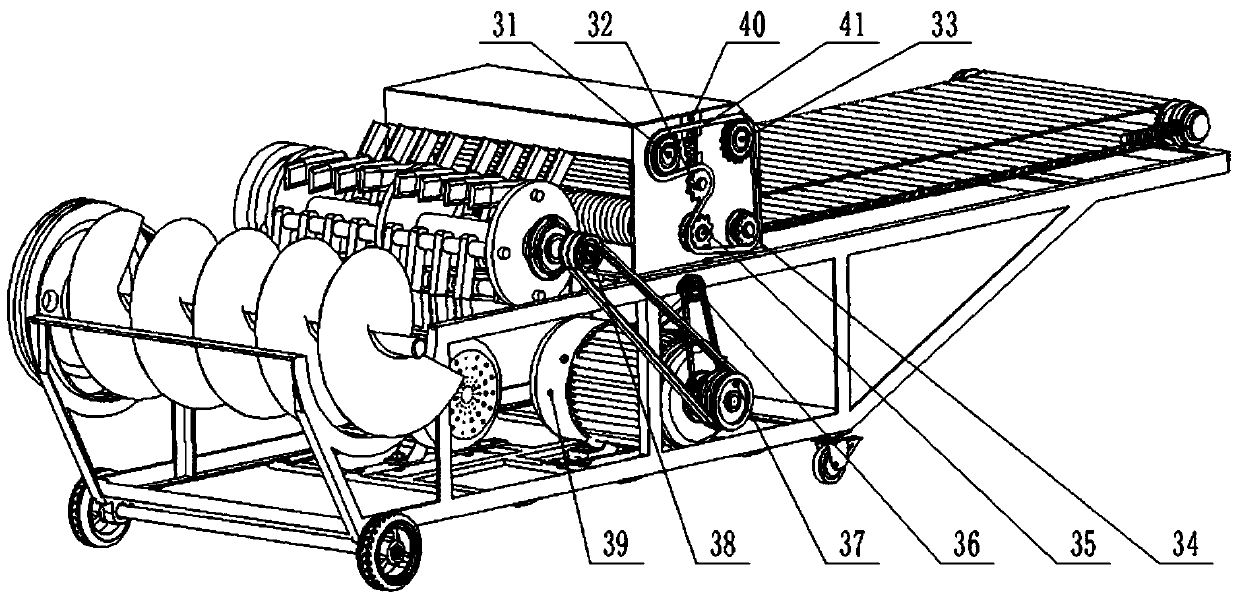

Silage crushing, rubbing filamentation and packing integrated operation machine

A silage crushing, rubbing shedding and packing integrated operation machine comprises a rack and a transmission mechanism, wherein the rear end of the upper portion of the rack is provided with a feeding and delivery mechanism, the rack in front of the feeding and delivery mechanism is provided with an extruding shedding mechanism, the rack in front of the extruding shedding mechanism is provided with a crushing and rubbing shedding chamber, the rack in front of the crushing and rubbing shredding mechanism is provided with an extrusion and packing mechanism, and the transmission mechanism is arranged on the rack and comprises a driving motor. The driving motor is used for power supply of the extruding shedding mechanism and the feeding and delivery mechanism, and the driving motor is used for power supply of the extrusion and packing mechanism. The silage crushing, rubbing shedding and packing integrated operation machine can complete material conveying, extruding shredding, crushing and rubbing shedding and extruding, pushing and variable packing operations at a time.

Owner:GANSU AGRI UNIV

Method and apparatus for material processing using multiple filamentation of burst ultrafast laser pulses

ActiveUS20150246415A1Remarkable effectEnhanced light absorptionGlass drawing apparatusGlass transportation apparatusBeam splittingFilamentation

A method of drilling multiple orifices in and texturing a substrate is disclosed and includes the following steps. Ultrafast laser pulses are passed through a beam splitting diffractive optical element and then multiple beams are passed through a distributive-focus lens focusing assembly. The relative distance and / or angle of said distributive-focus lens focusing assembly in relation to the laser source is adjusted focusing the pulses in a distributed focus configuration creating a principal focal waist and at least one secondary focal waist. The fluence level of the at least one secondary focal waists is adjusted such that it is or they are of sufficient intensity and number to ensure propagation of multiple filaments in the substrate. Photoacoustic compressive machining is performed and forms multiple volume(s) within the substrate.

Owner:ROFIN SINAR TECH

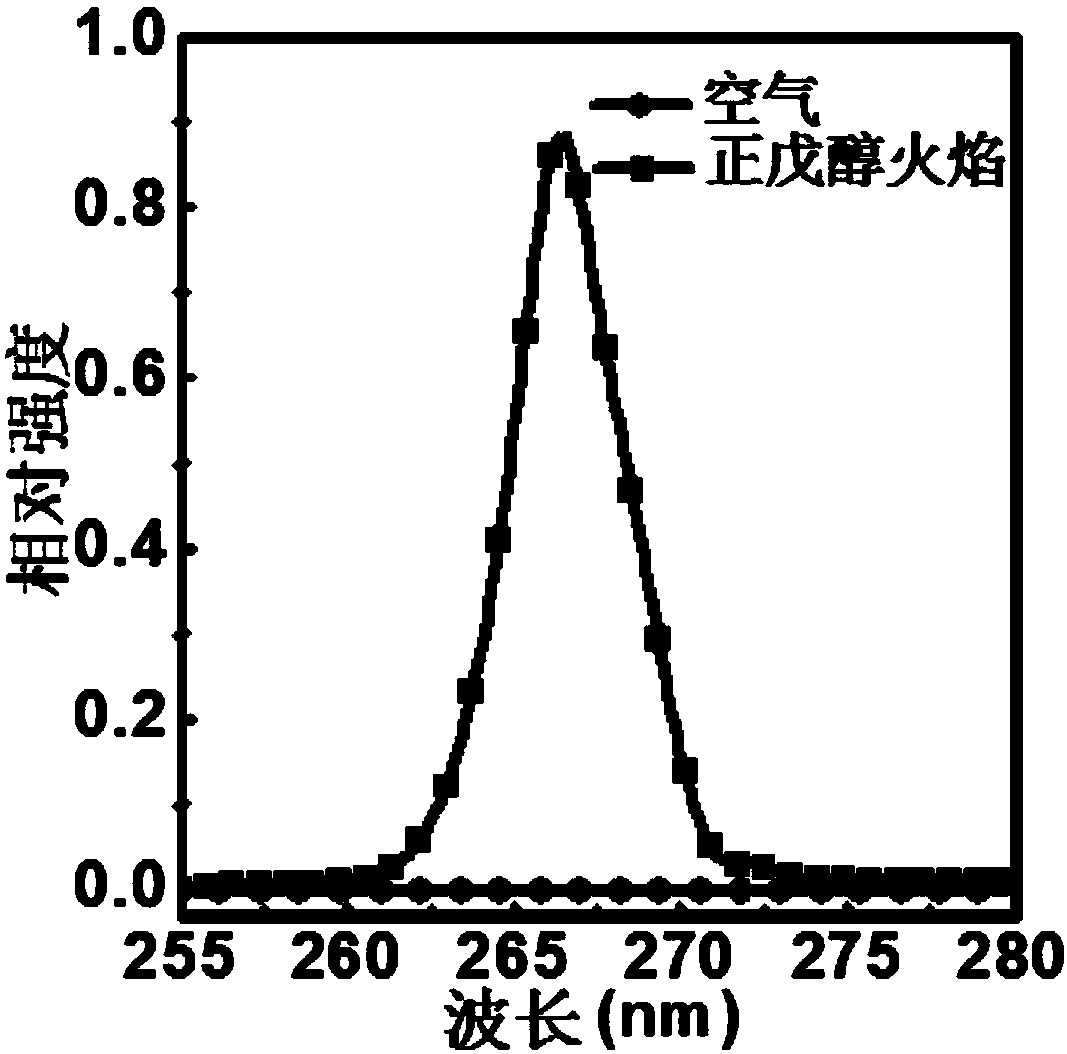

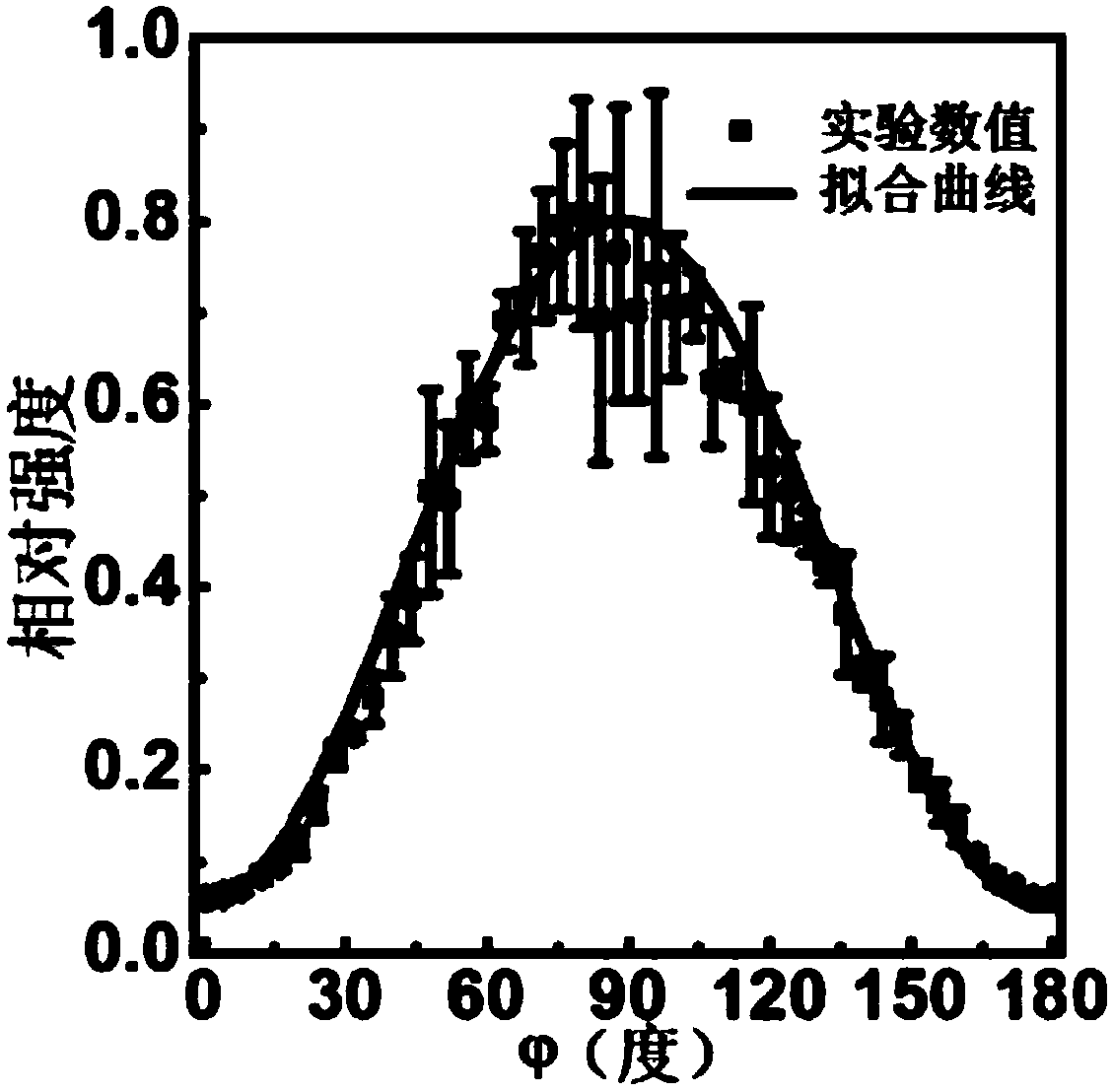

Device and method for detection of particulate matter distribution in flames by strong field laser

Belonging to the technical field of ultrafast laser sensing, the invention discloses a device and method for detection of particulate matter distribution in flames by strong field laser. The high strength characteristics of a femtosecond filament nuclear zone in a combustion field can produce nonlinear frequency conversion for in-situ generation of third harmonic with spectrum located in an ultraviolet region. Particulate matters scatter the third harmonic in the combustion field, and the distribution information of particulate matters in the combustion field can be obtained through the strength of laterally collected scattered signals. The light scattering technology of generating third harmonic as a pumping source based on ultrafast laser filamentation in the combustion field can be applied to the field of remote in-situ monitoring of particulate matters in a combustion environment. The device and method provided by the invention have the outstanding advantages of remote detection and low loss, and are very suitable for analysis of particulate matters in a complex combustion environment like high temperature and high pressure combustion field.

Owner:JILIN UNIV

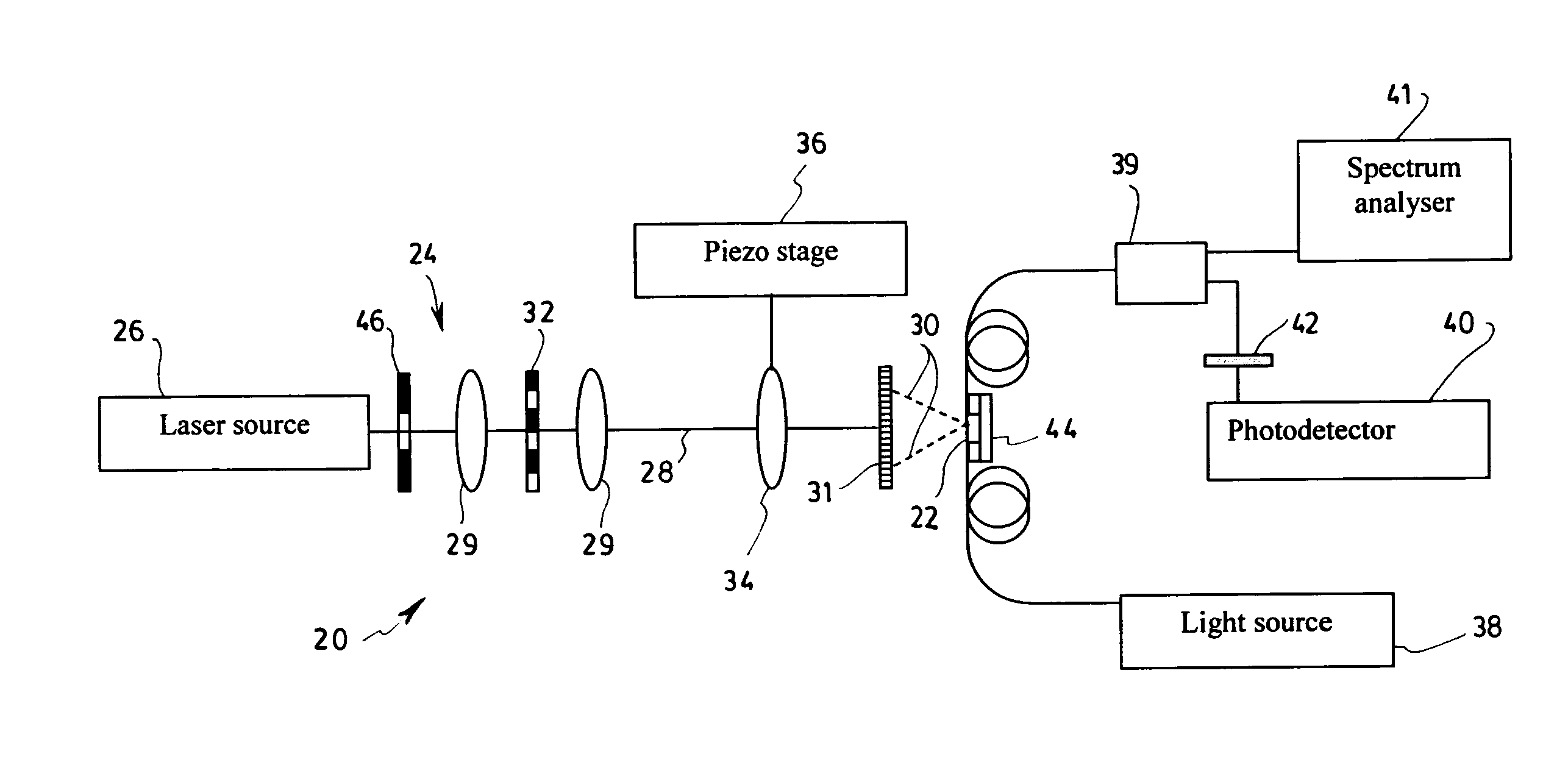

System and method for agile remote generation of a broadband tunable short-pulse emission

ActiveUS20120243564A1Agile remote generationLaser detailsMaterial analysis by optical meansAudio power amplifierFilamentation

A method comprising using a pulse shaper in the spectral domain to generate multiple-color pulses directly at the output of the laser amplifier. The delay can thus be controlled directly in the spectral domain and there is no need for an optical delay line. The method allows reducing the number of optical components and insures insensitivity to alignment, vibrations and turbulence on long distance propagation and filamentation, particularly in air. The method allows programmable and tunable interaction, since the pulse shaper is able to control the laser spectral amplitude and phase.

Owner:INSTITUT NATIONAL DE LA RECHERCHE SCIENTIFIQUE

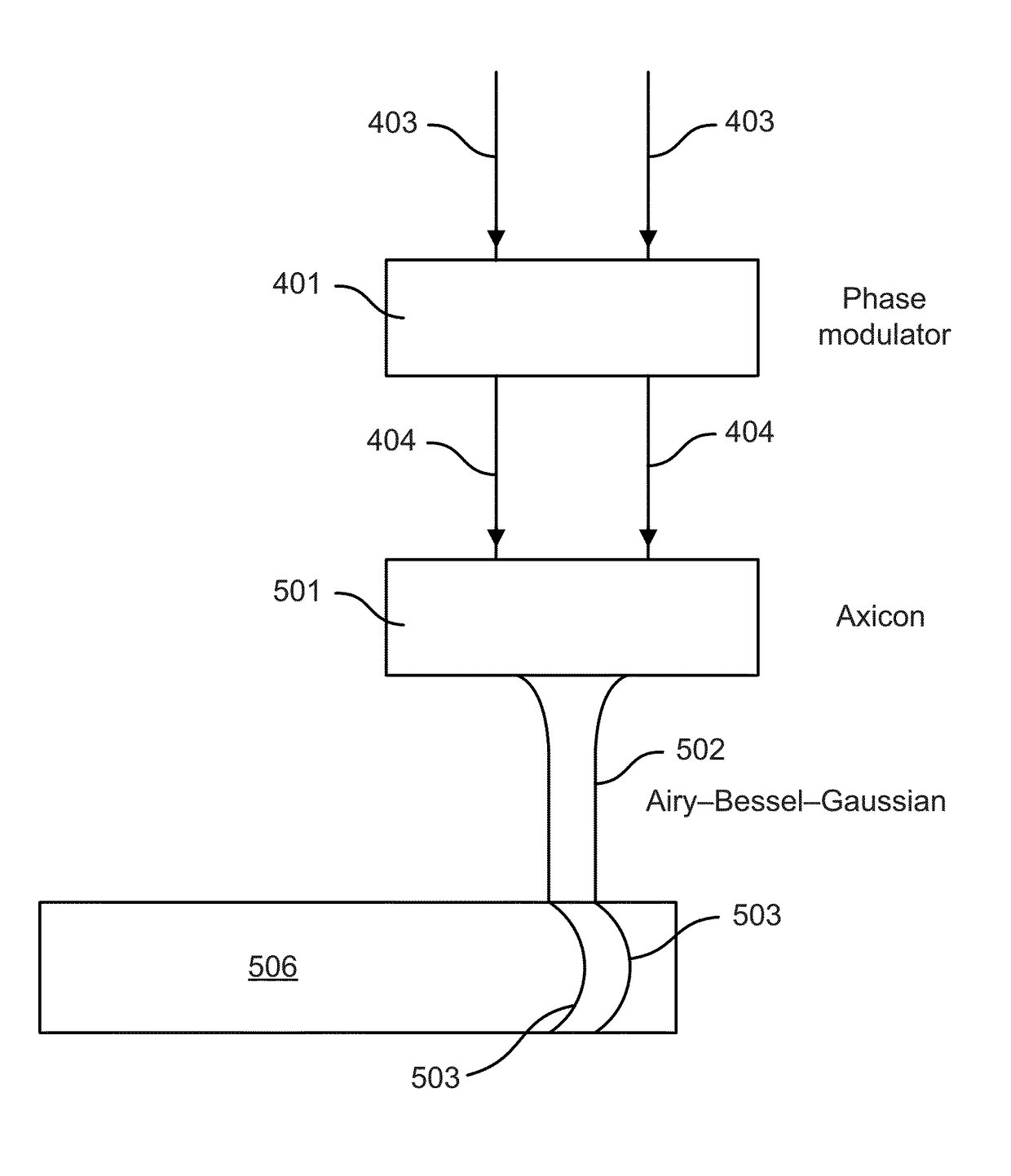

Device and method for increasing filamentation length of femtosecond laser in air

InactiveCN101718937AMulti-deliveryIncrease the lengthNon-linear opticsGaussian beamFemto second laser

The invention provides a device and method for increasing filamentation length of femtosecond laser in the air. The device is characterized in that adjustable apertures, a phase plate and a focusing lens are sequentially arranged on a light path for outputting collimated femtosecond laser. The experiments show that after passing through the phase plate, the high-energy femtosecond laser pulse changes the focusing characteristic of the focused zone due to interference effect, thus greatly increasing the length of the focused zone. Compared with the common Gaussian beam focusing, the method of the invention ensures supercontinuum radiation to focus in the axial direction, thus ensuring more energy to be conveyed to farther places, which is of great significance in laser triggered lightning, remote atmospheric sounding and acquisition of superstrong and supershort few-cycle laser pulse.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Femtosecond laser filamentation plasma density measuring device and measuring method

ActiveCN109100262AImprove time resolutionSolve the problem of uneven vertical distributionSpecific gravity measurementPlasma densityFluorescence

A femtosecond laser filamentation plasma density measuring device and a measuring method, wherein the femtosecond laser is divided into three beams through two beam splitting plates, which are respectively used as pump light, first detecting light P1, and second detecting light P2. The pump light is performed a filamentation in an air cavity to form a plasma channel. The first detecting light P1 passes through the plasma channel to be a carrier for the plasma to introduce a variation. The second detecting light P2 observes the value of the variation through mutual observation so as to obtain the plasma density by reverse derivation. The problem that the longitudinal distribution of the plasma is not uniform is solved through the lateral fluorescence distribution. The femtosecond laser filamentation plasma density measuring device and the measuring method have the advantages of being high in time resolution capability, convenient adjustment and accurate measurement.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Pharmaceutical compositions and methods to vaccinate against candidiasis

InactiveUS8541008B2Toxic reductionReduce adhesionPeptide/protein ingredientsSnake antigen ingredientsHospitalized patientsVirulent characteristics

A Candida albicans bloodstream infections cause significant morbidity and mortality in hospitalized patients. Filament formation and adherence to host cells are critical virulence factors of C. albicans. Multiple filamentation regulatory pathways have been discovered, however the downstream effectors of these regulatory pathways remain unknown. The cell surface proteins in the ALS group are downstream effectors of the filamentation regulatory pathway. Particularly, Als1p mediates adherence to endothelial cells in vitro and is required for virulence. The blocking of adherence by the organism is described resulting from the use of a composition and method disclosed herein. Specifically, a pharmaceutical composition comprised of a gene, gene product, or specific antibody to the ALS gene family is administered as a vaccine to generate an immune response capable of blocking adherence of the organism.

Owner:LOS ANGELES BIOMEDICAL RES INST AT UCLA HARBOR MEDICAL CENT +1

Sectional membrane filamentation friction composite spinning method

ActiveCN106917166ASolve the long process flowSolve complexityFilament/thread formingContinuous wound-up machinesFilamentationNanofiber

The invention relates to a sectional membrane filamentation friction composite spinning method, and belongs to the technical field of textiles. A membrane cutting traction device is arranged above a front roller jaw of each traction mechanism of a friction yarn machine; a cutting region is formed between a cutting-resistant ring and a cutting roller of a membrane putting cutting device; uniform laid and spread belt-shaped multifilaments are formed through cutting; the sectional membrane is filamented; a conventional spinneret orifice linear jetting filamentation method is changed; the multifilaments are tracked through a first traction region and a second traction region; the filament intensity in the multifilaments is enhanced; thinned multifilaments and short fiber strips pass through a carding region of a friction spinning machine to be carded into composite fiber flows with mixed sectioned nanometer and micron filament strips and short fiber strips; the composite fiber flows enter a position between the friction rollers through a fiber conveying passage to be twisted into fine tex friction composite yarns with the uniformly held nanometer and micron filament strips and short fiber; the difficult problem that filament yarns, nanometer fiber and conventional short fiber cannot be uniformly mixed and cannot be sufficiently held during the friction composite spinning are solved; the membrane industry and the textile industry are merged. The operation is convenient; the popularization is easy.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com