Silage crushing, rubbing filamentation and packing integrated operation machine

A technology of silage and working machine, which is applied in the field of silage machinery, can solve the problems of low rubbing rate, pollute the environment, and low operating efficiency, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with the best example shown in the accompanying drawings, further describe:

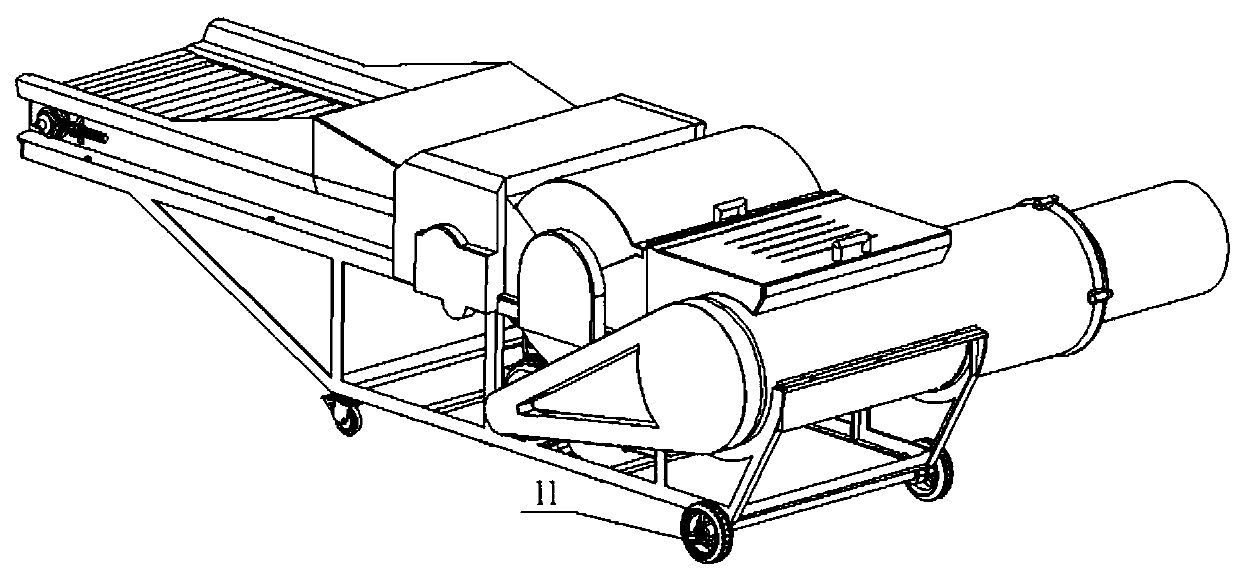

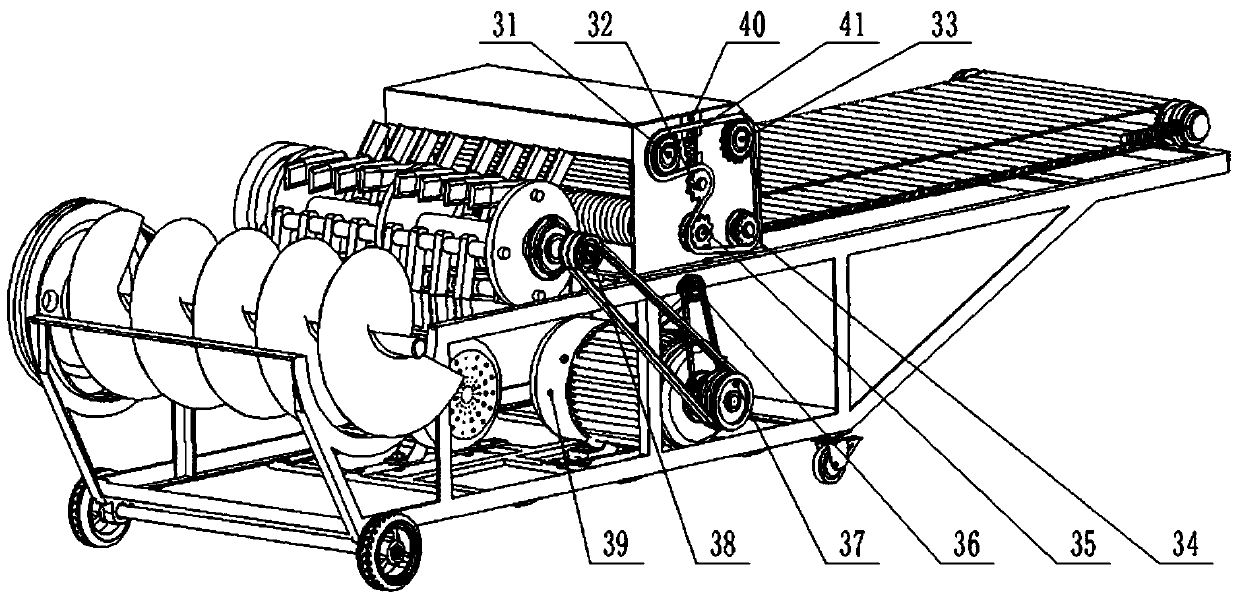

[0031] Such as figure 1 , 2 As shown in , 3, a kind of silage crushing, kneading and packaging integrated operation machine includes a frame 1 and a transmission mechanism, and a walking wheel 11 and a guide wheel 8 are installed under the frame 1 to facilitate the movement of the machine tool and the change of direction during the movement process . Feeding and conveying mechanism 12 is installed at the rear end above frame 1, and conveyor belt protective cover 6 is installed on both sides of feeding and conveying mechanism 12. An extruding and marking mechanism 5 is installed at the front end of the feeding conveying mechanism 12 above the frame 1 . On the frame 1 of extruding and drawing silk mechanism 5 places ahead, crushing and kneading silk chamber 4 is installed, and on the frame 1 of crushing and kneading silk mechanism 4, extruding and packing mechanism 2 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com