Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2757results about "Baling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

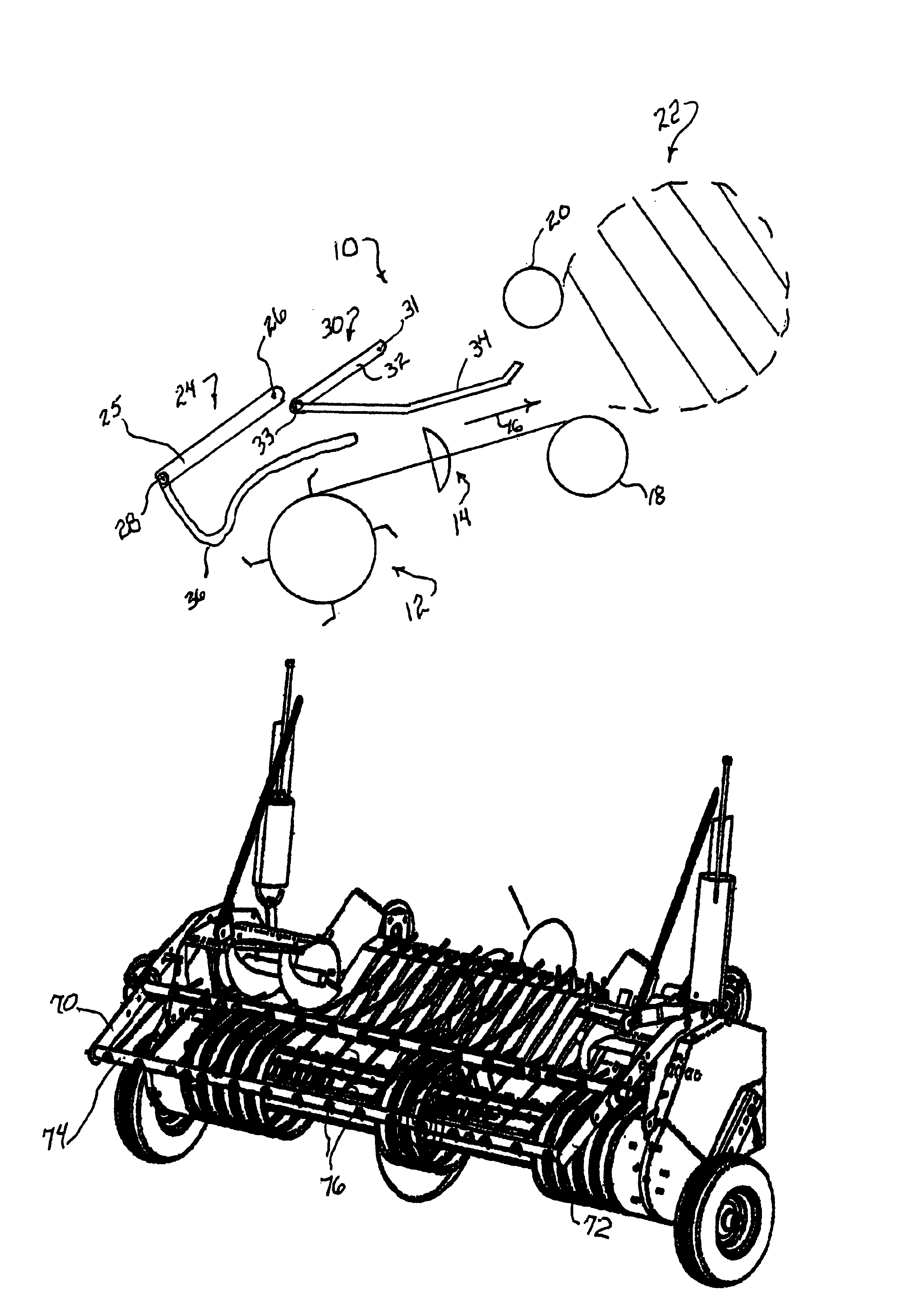

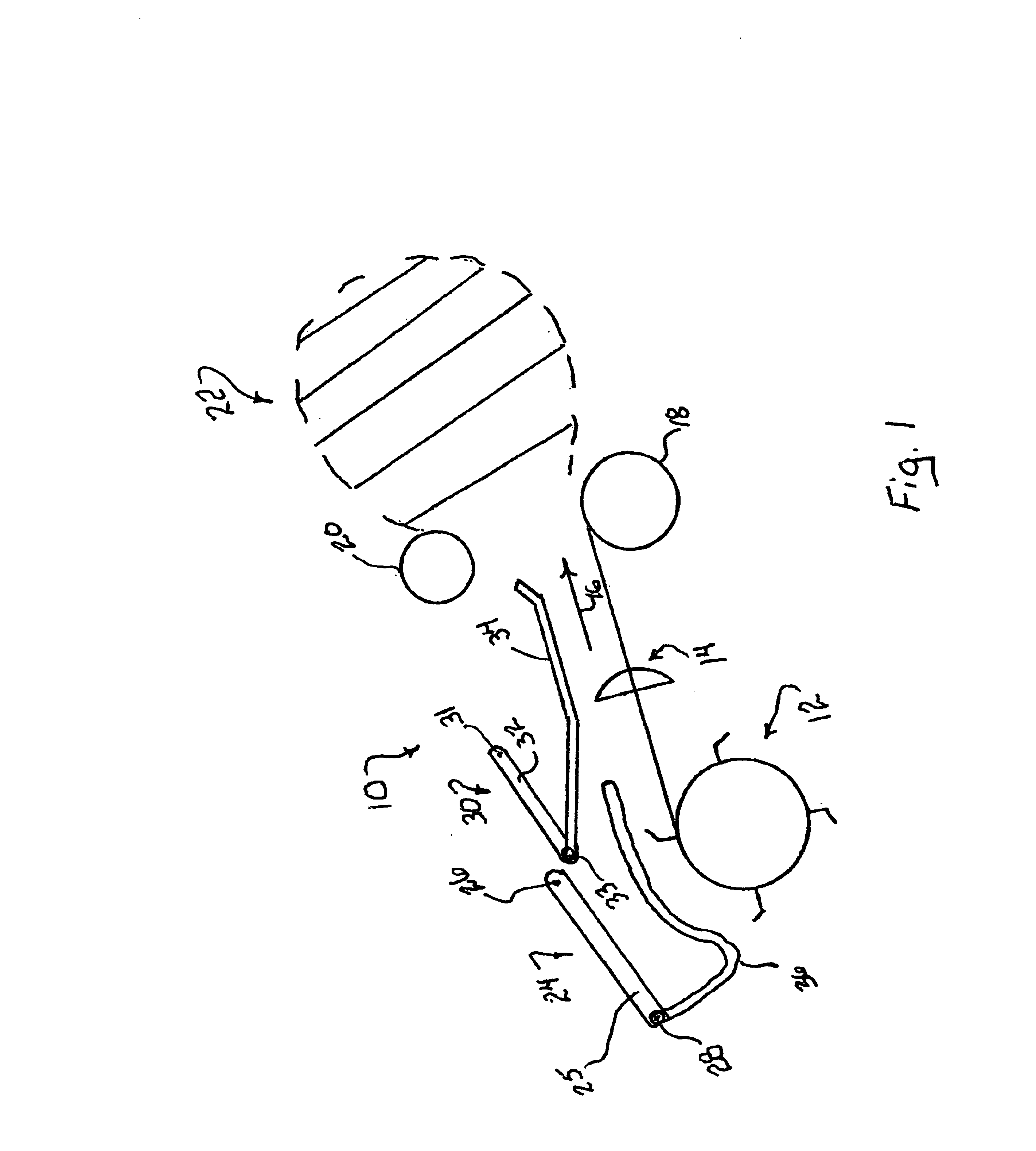

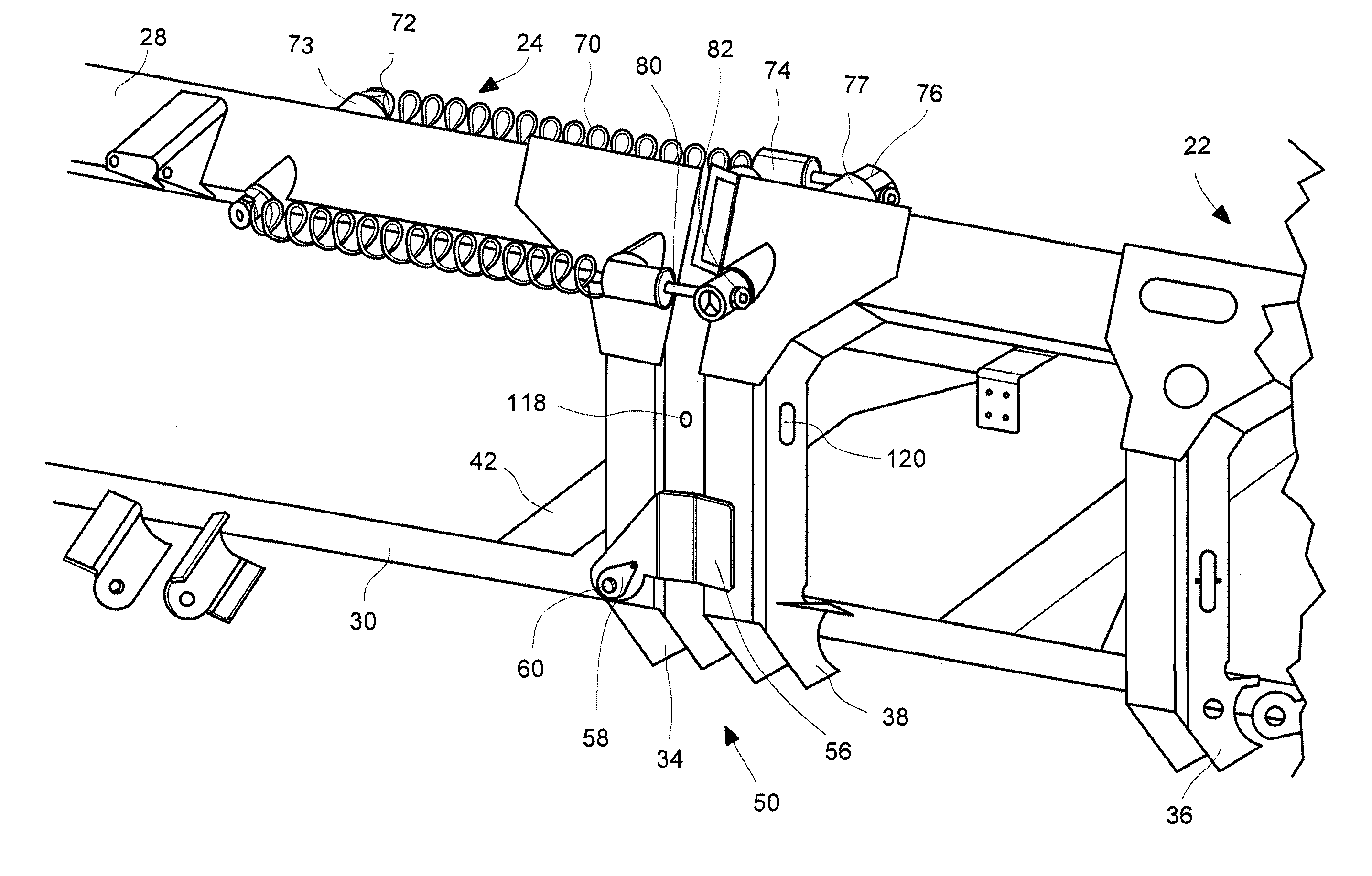

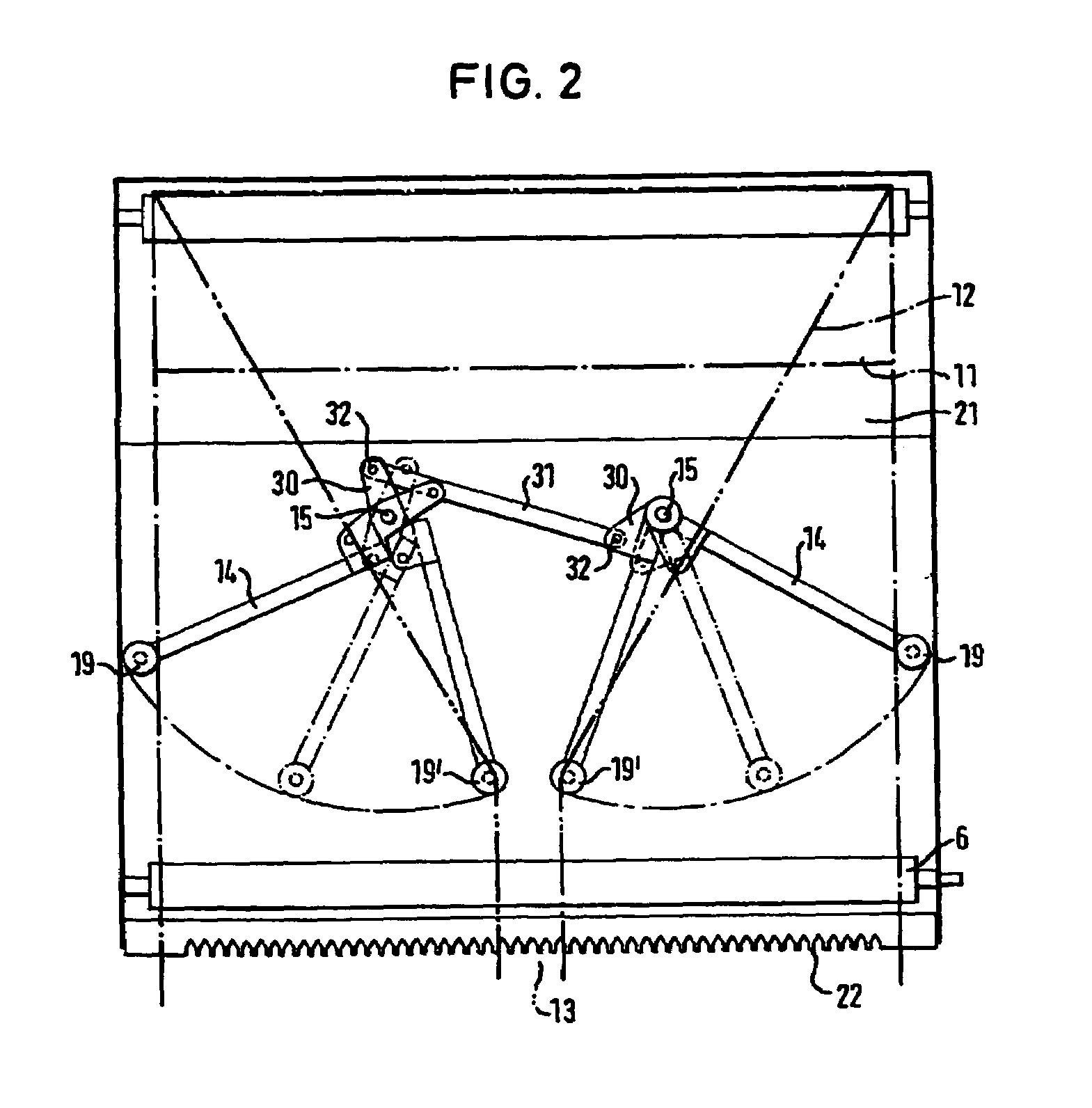

Windguard for round baler

ActiveUS6877304B1Improve versatilityEfficiently and effectively assembleLoadersMowersElectrical and Electronics engineering

Owner:BLUE LEAF I P INC +1

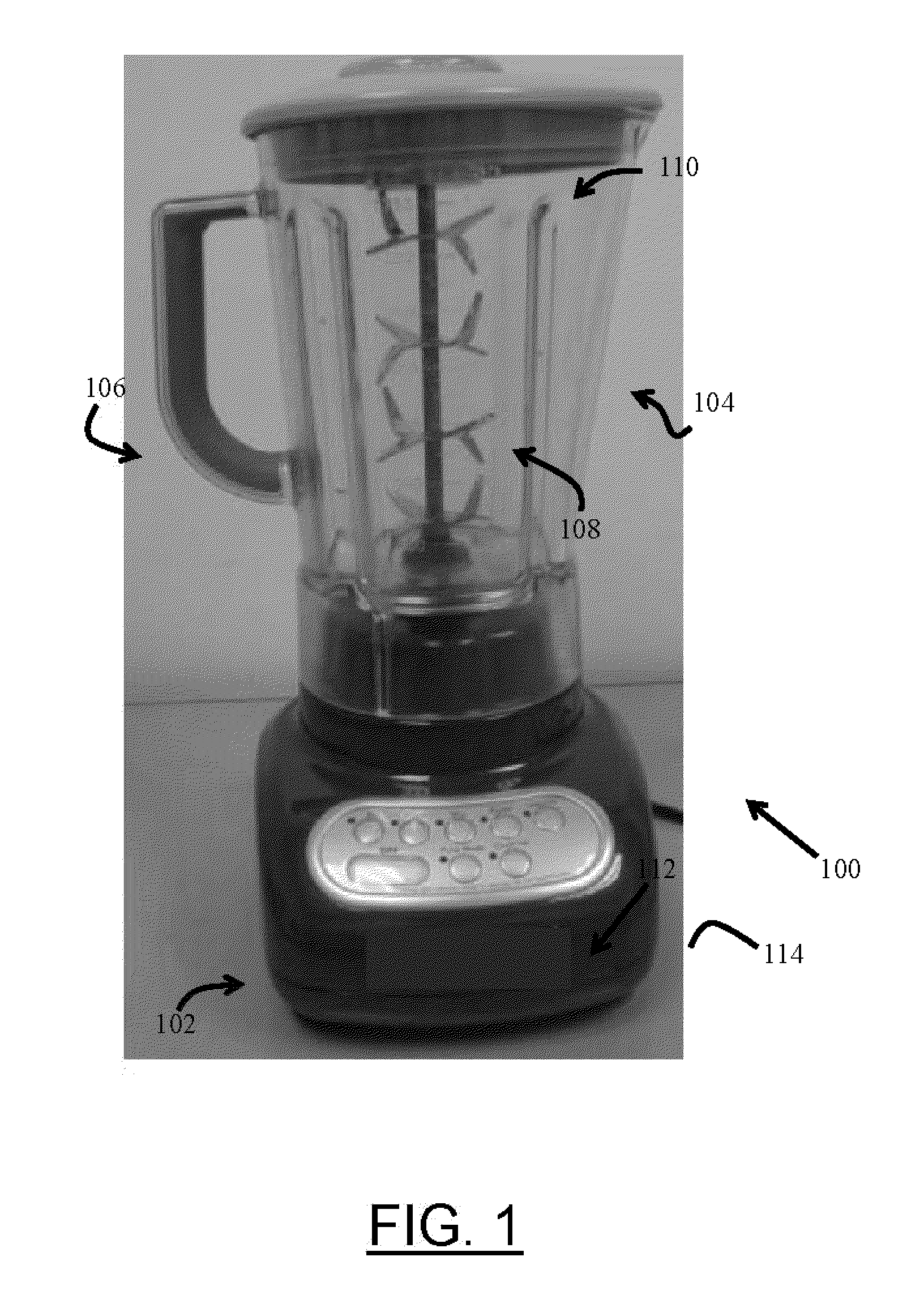

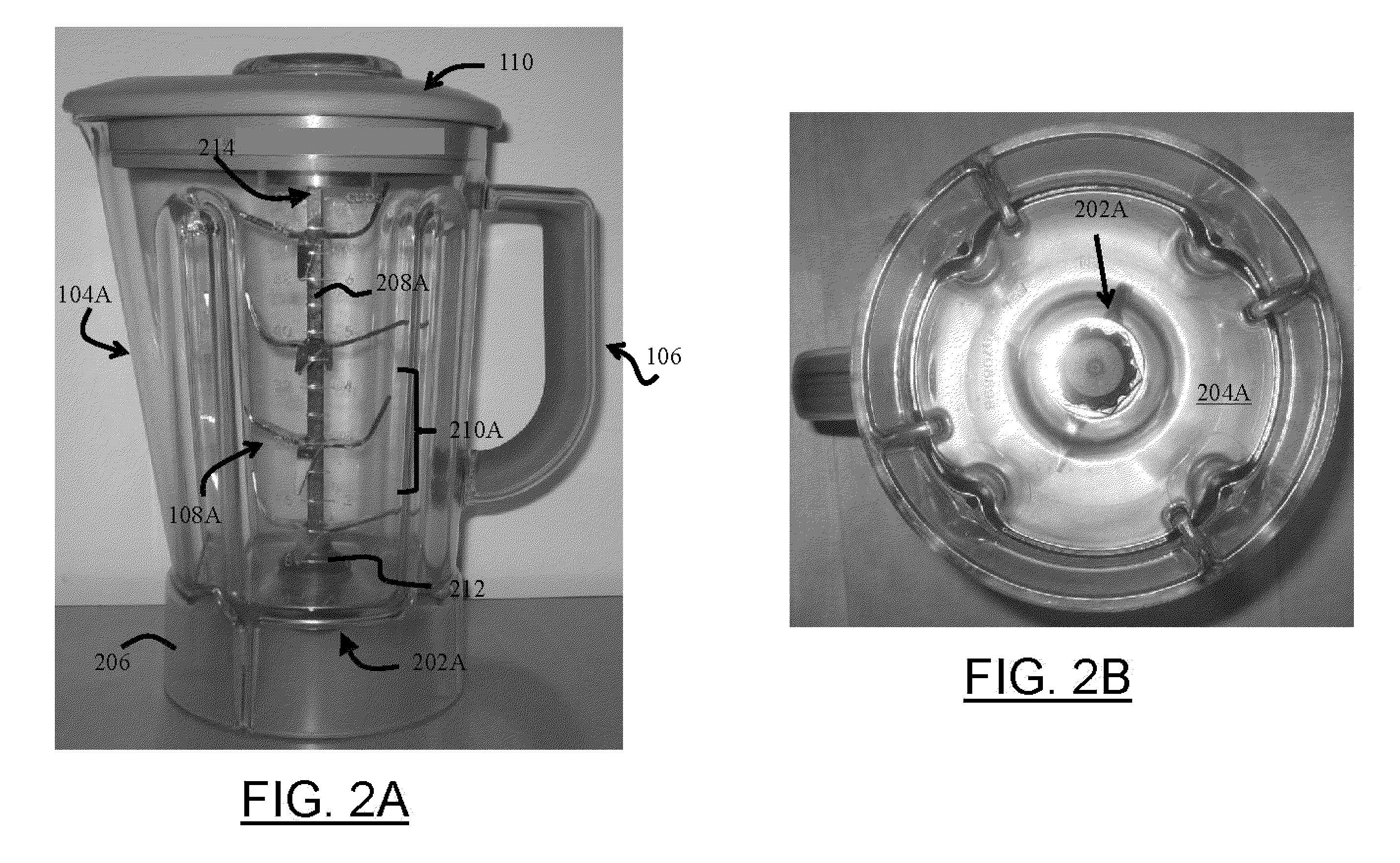

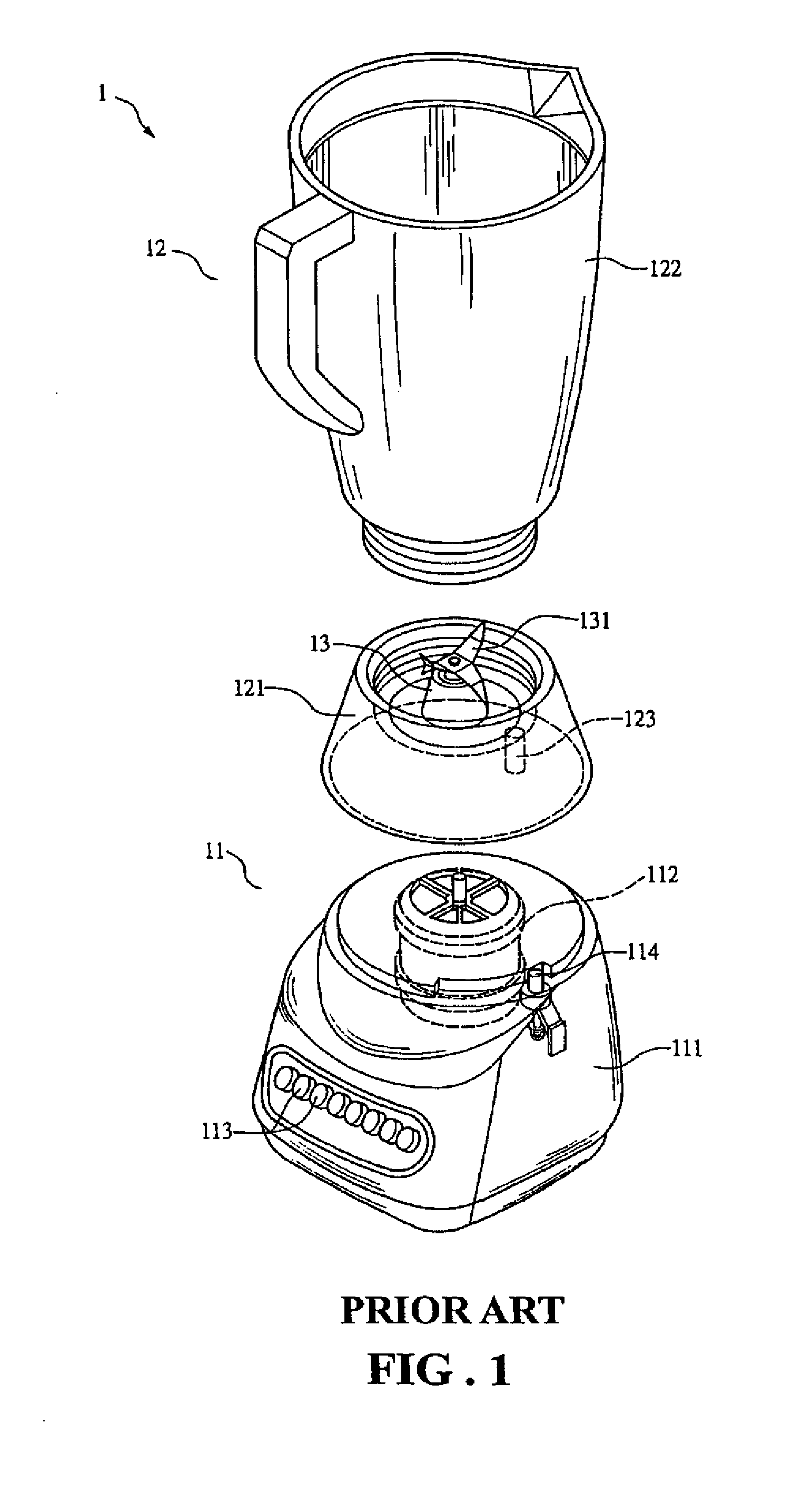

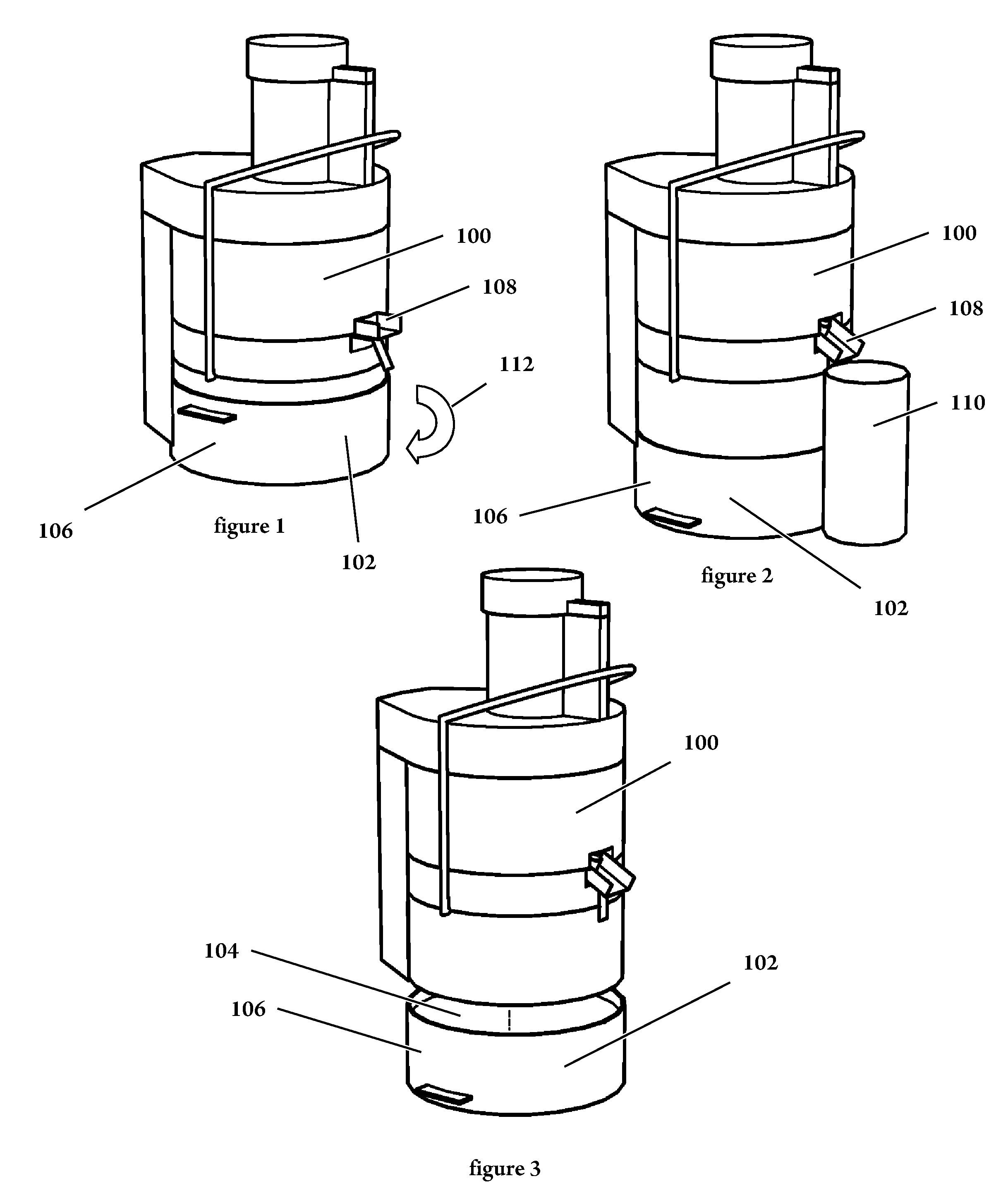

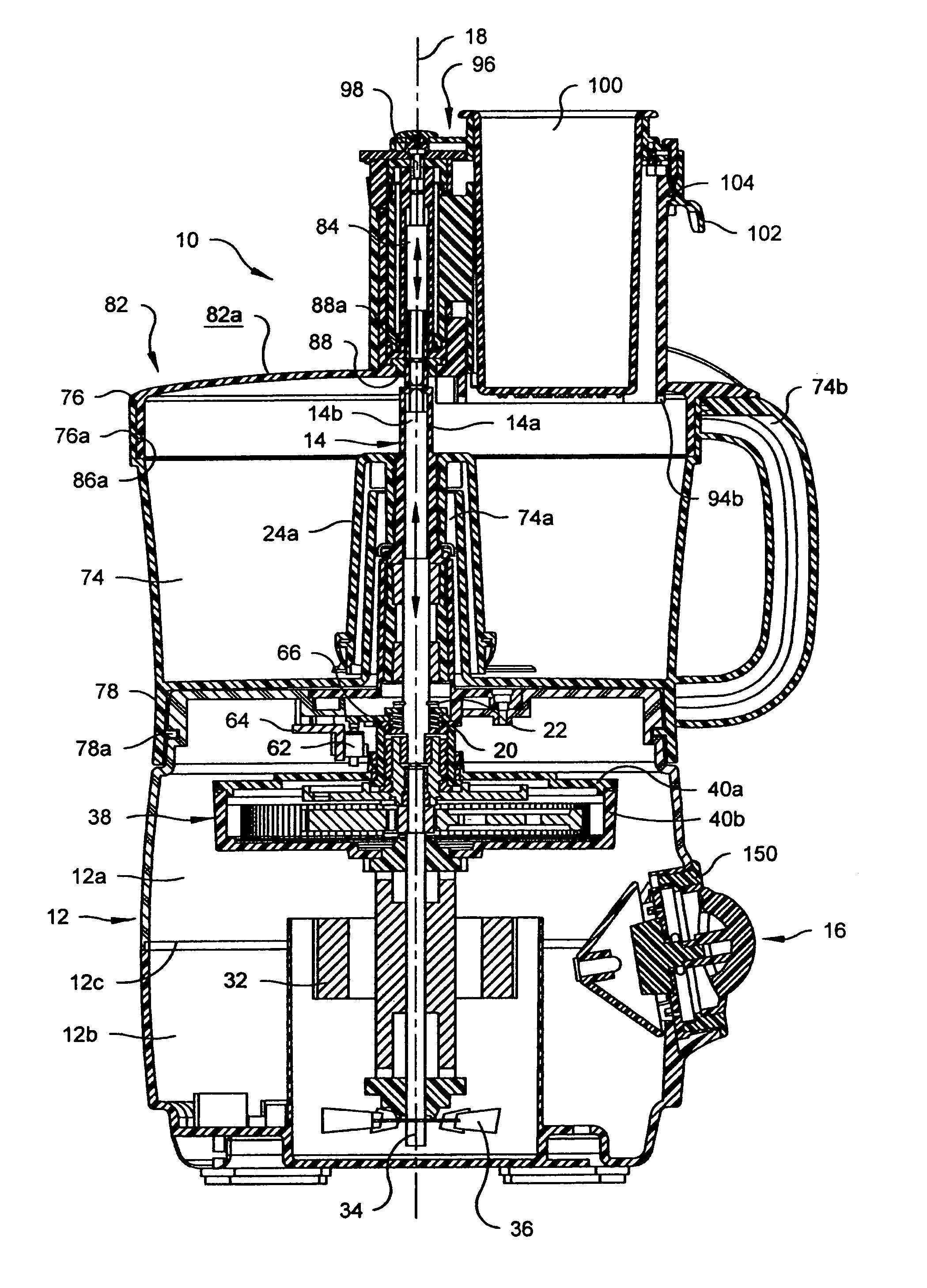

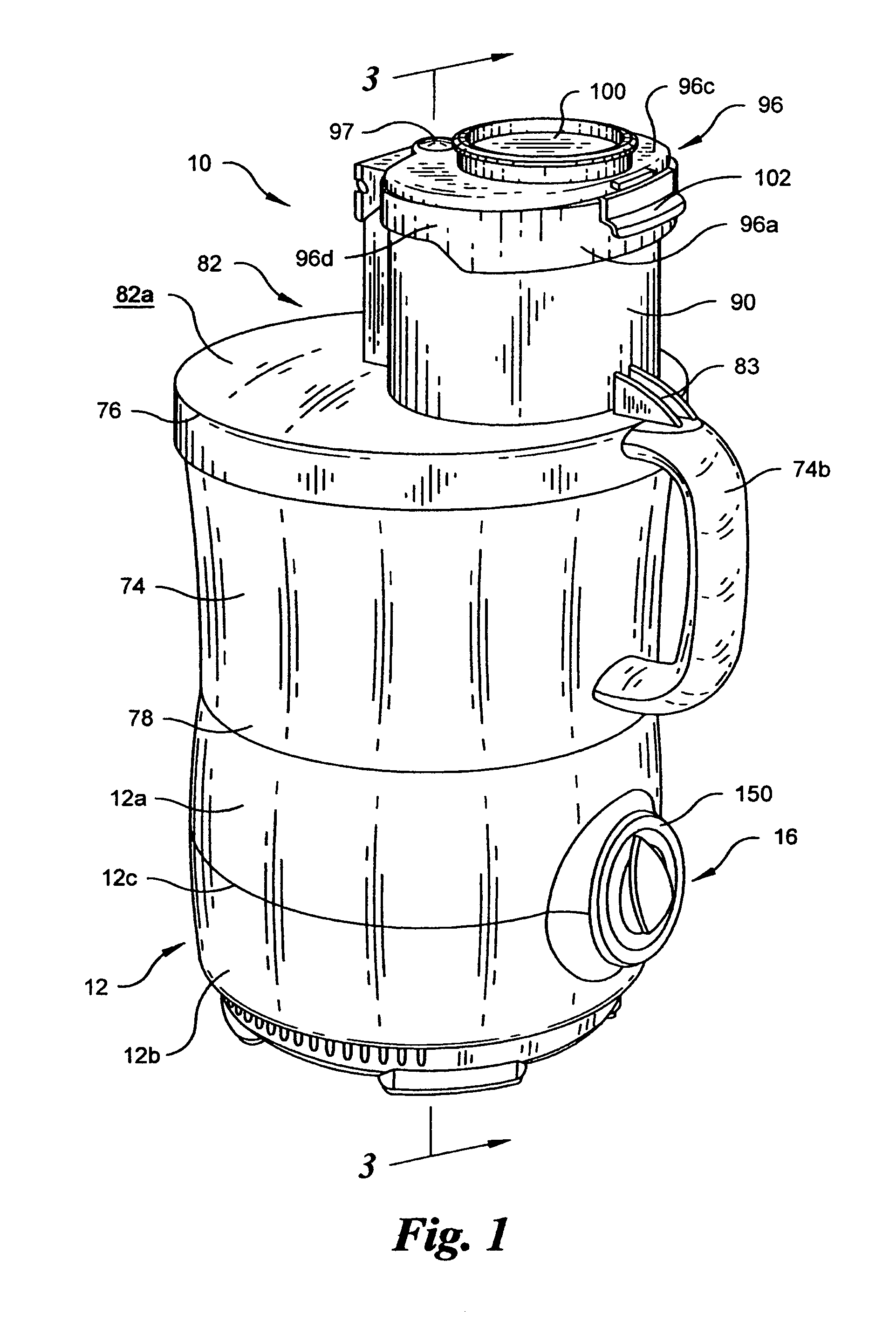

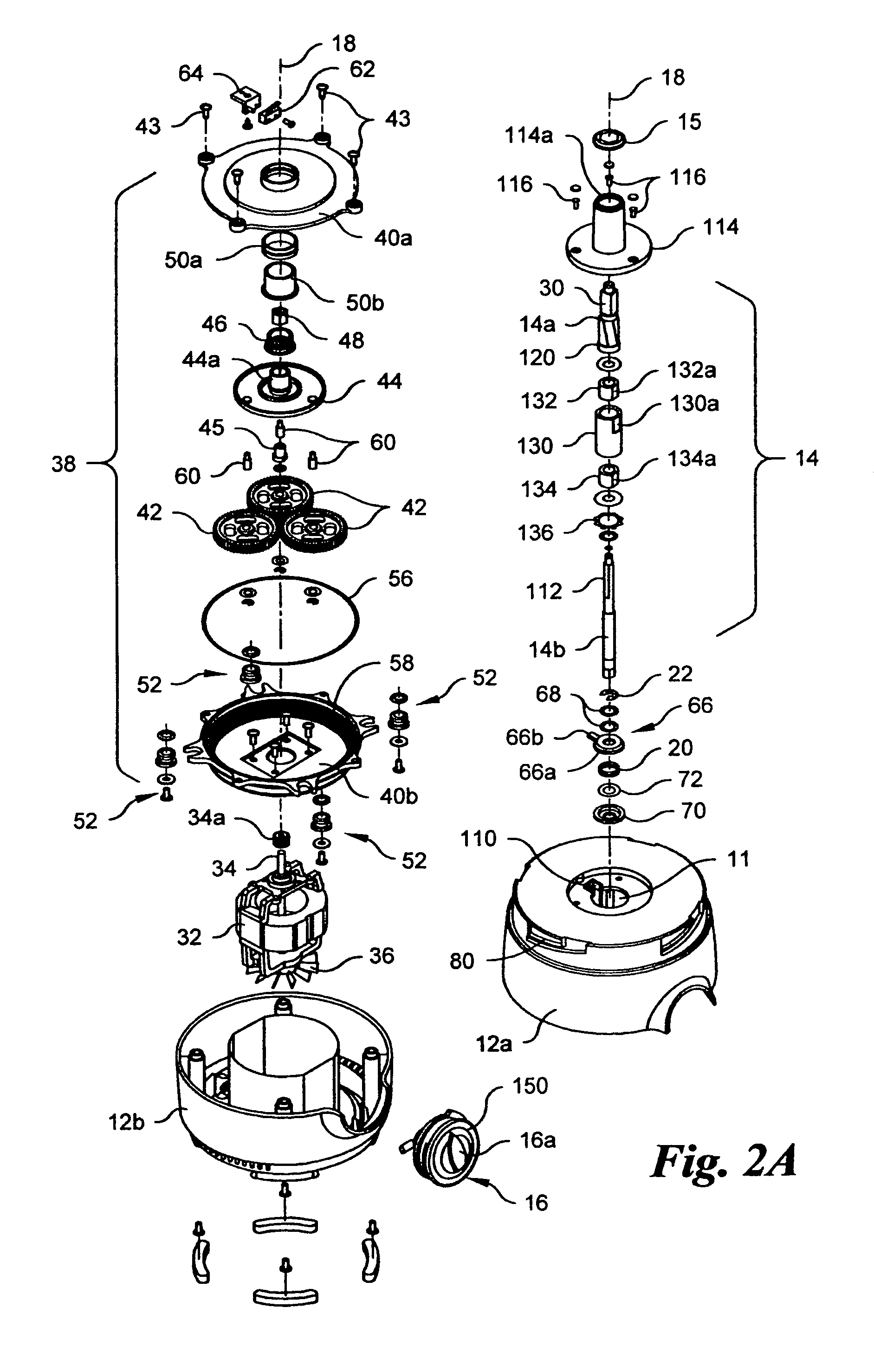

Blender and food processor device

Owner:CARRIERE MARK C

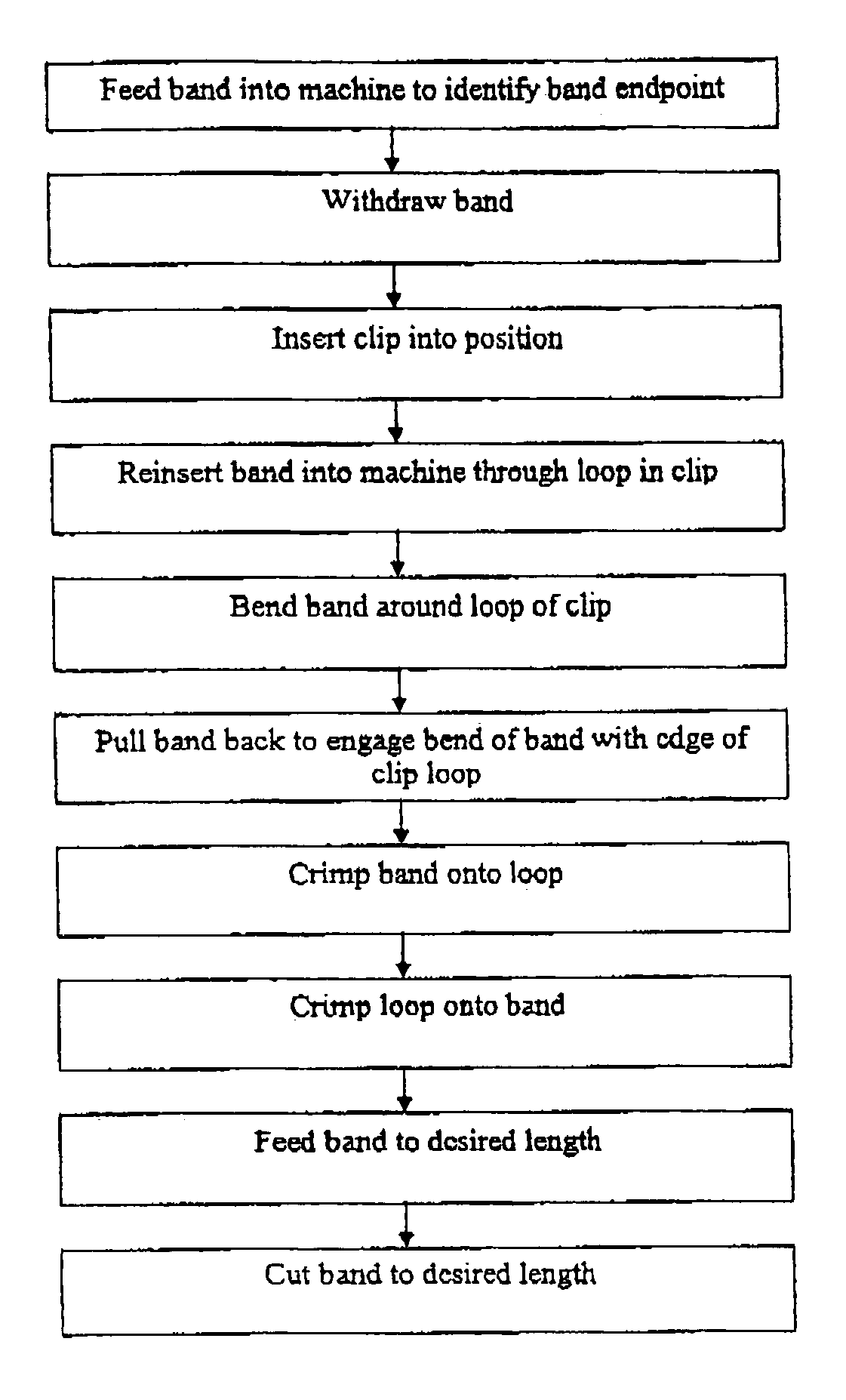

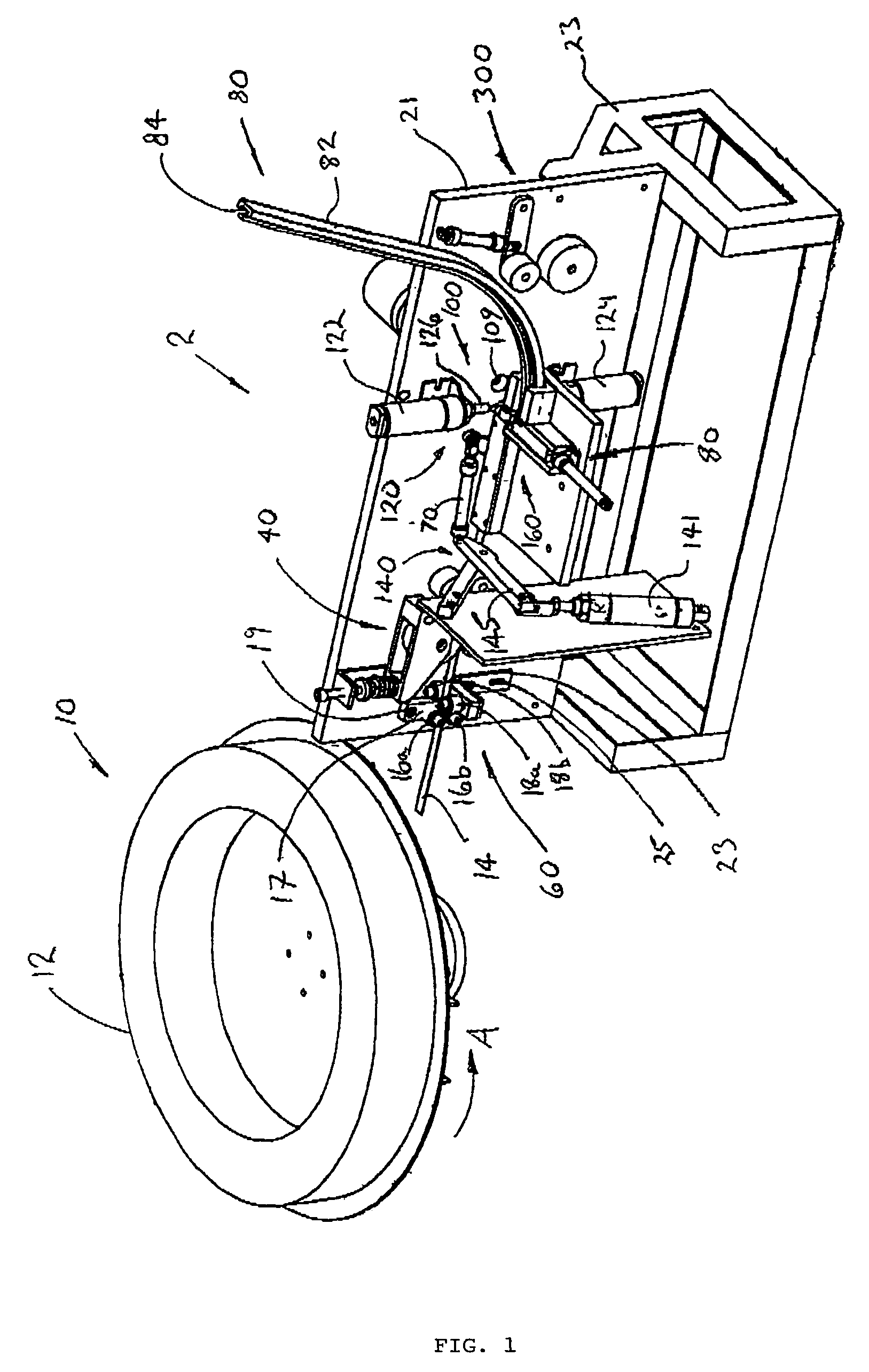

Method of manufacturing a band with a fastener

A device and method is disclosed for manufacturing a band of a desired length with a fastener attached to the band. Generally, metal band material is fed from a spindle on the device until the end of the band material is detected by the device. The device includes a positioning component that places the fastener at the desired location of the band, which is then looped through the fastener. The device then crimps the fastener to the band, positions the band at its desired length, and cuts the band to the desired length.

Owner:VERESCHAGIN LAWRENCE WAYNE

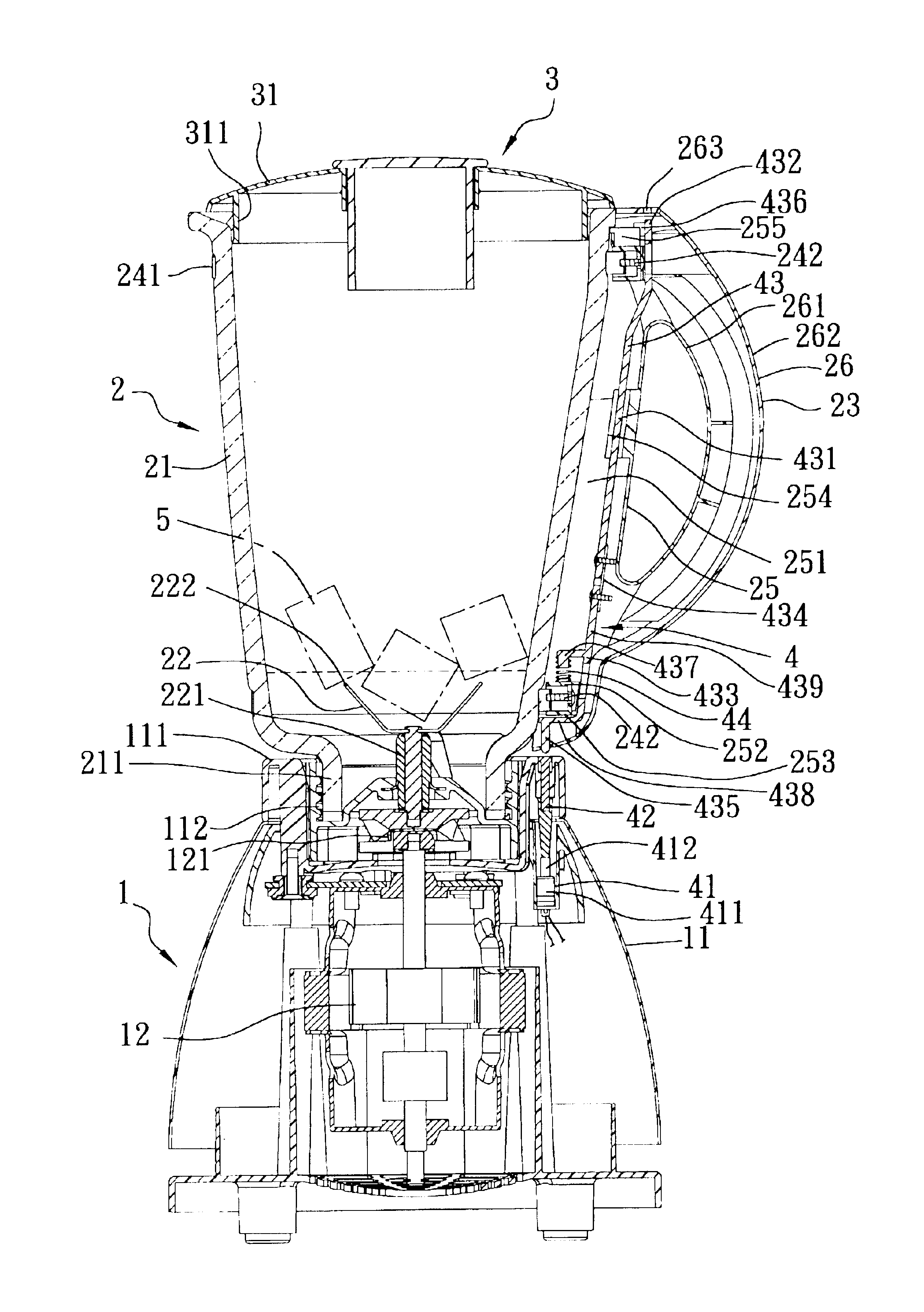

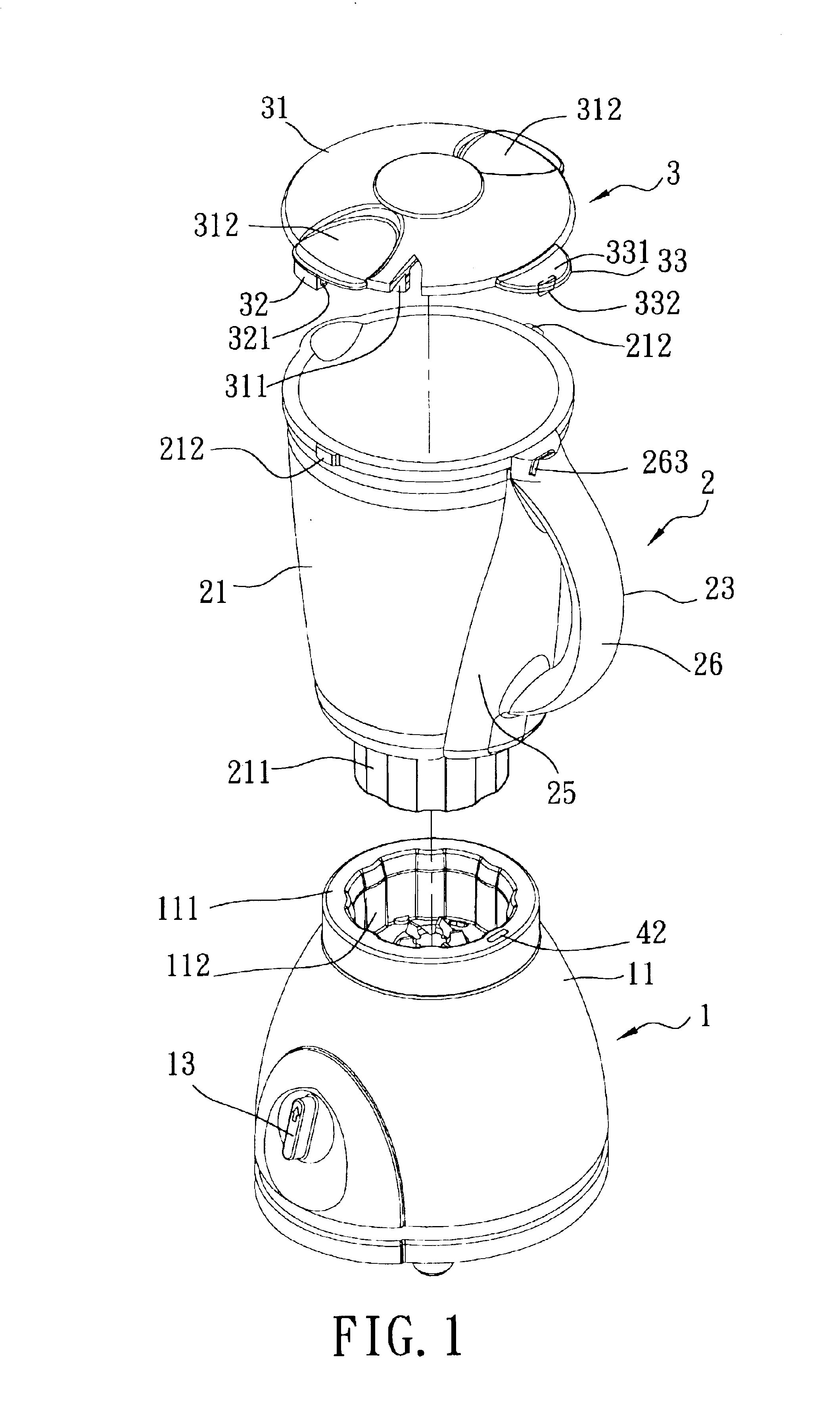

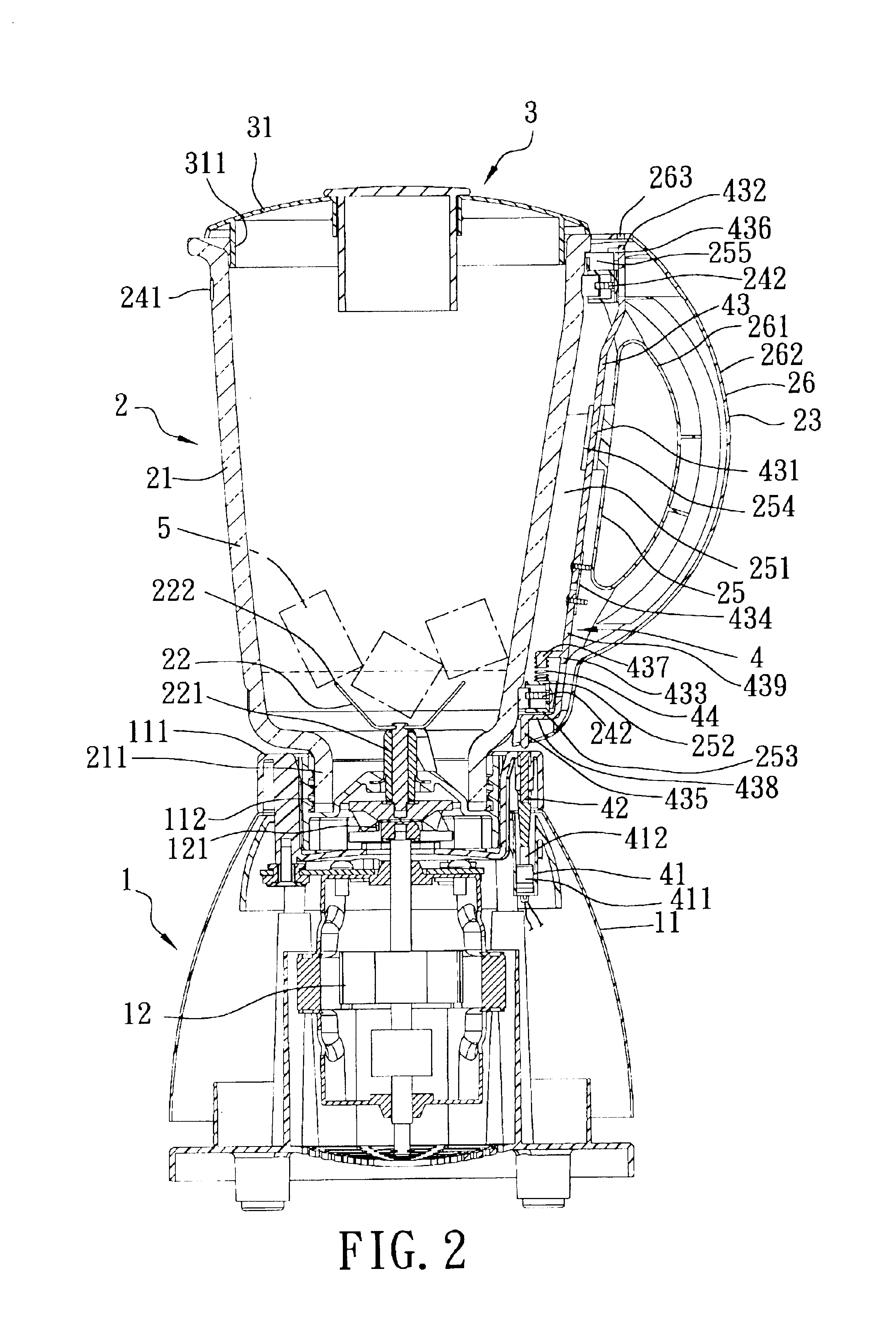

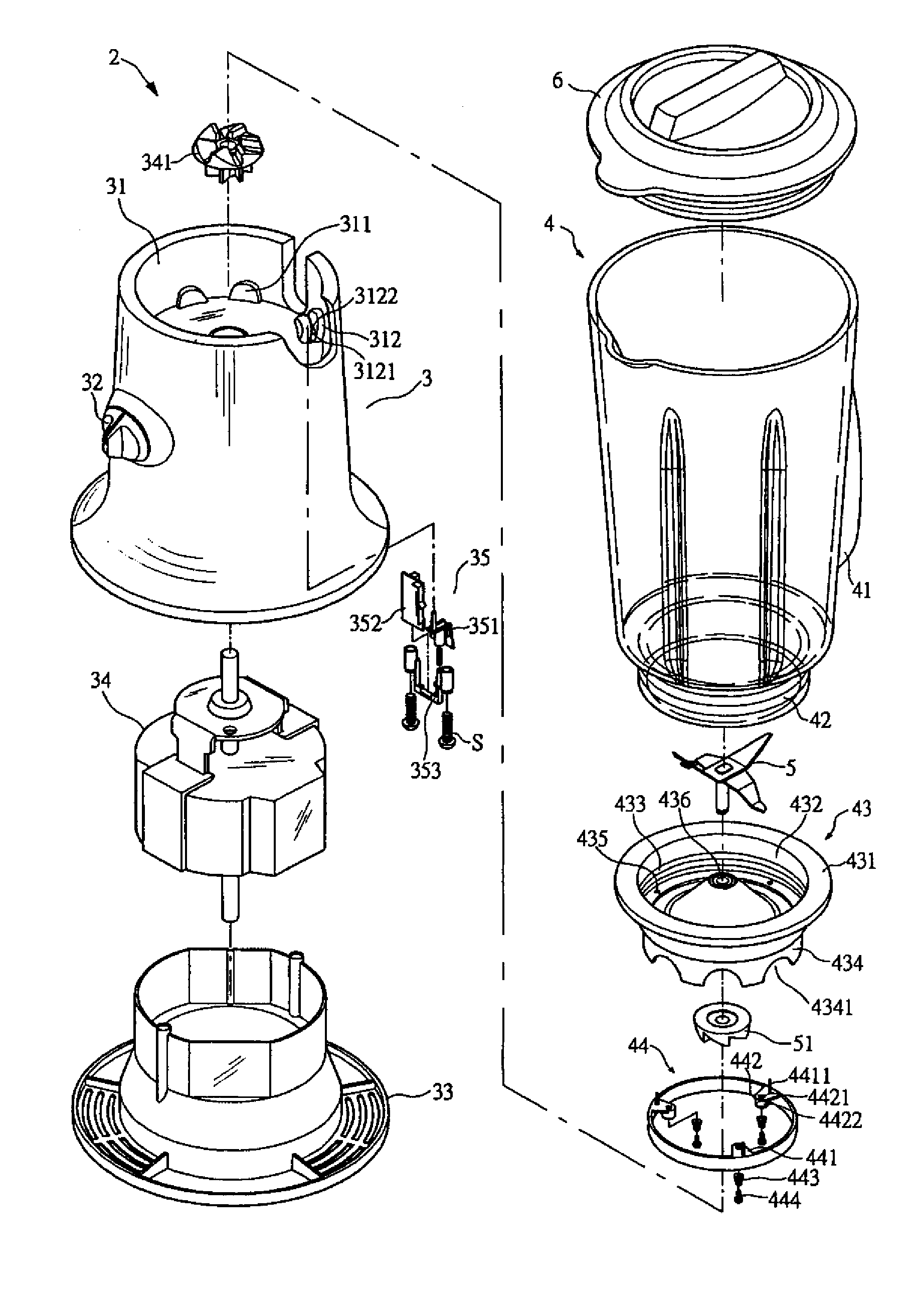

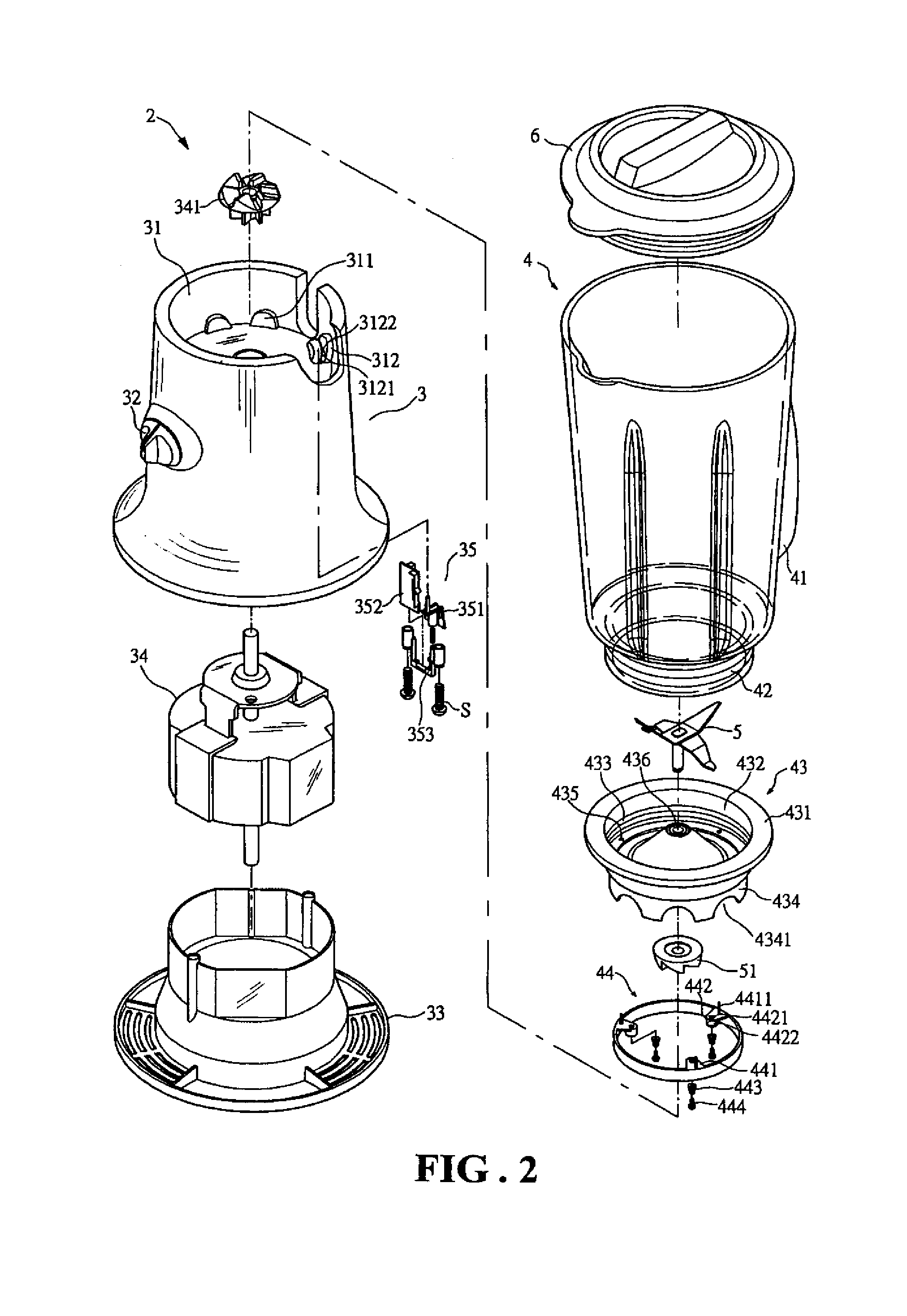

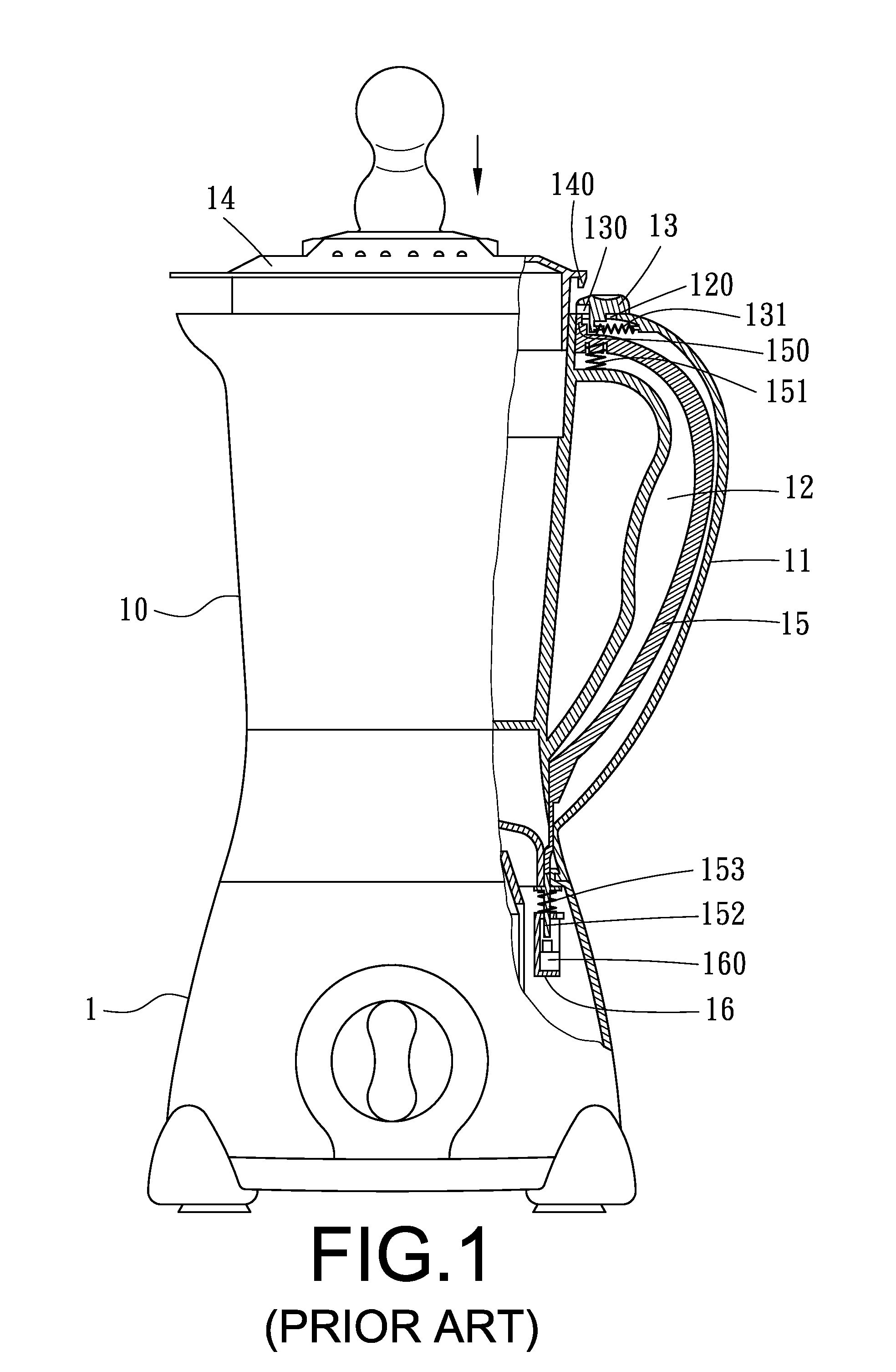

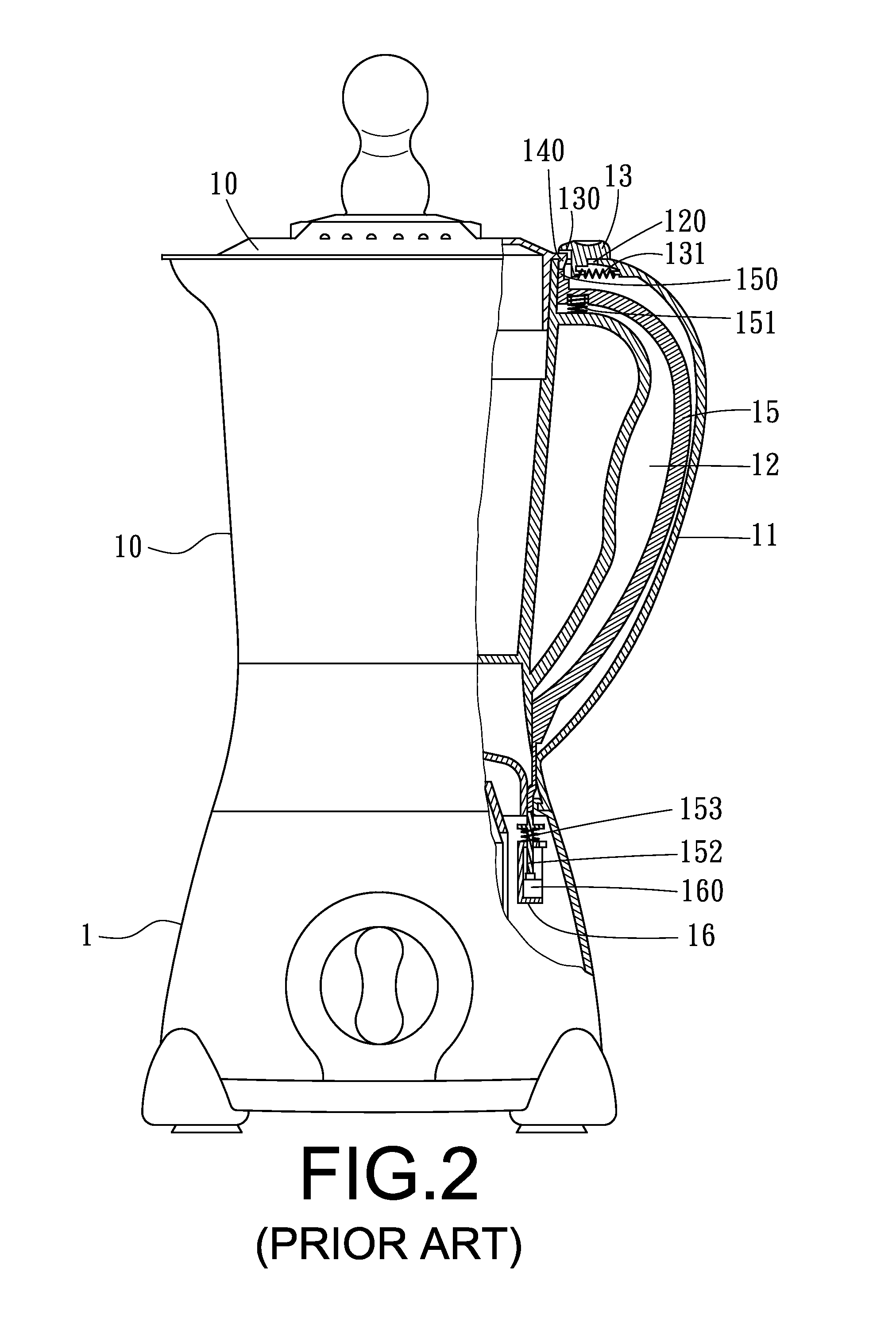

Blender having a top cover provided with a switch actuating block

A blender includes a motor base, a container, and a top cover. The motor base includes a motor unit having a blade driving section, and a contact switch unit connected electrically to the motor unit. The contact switch unit includes a press button that is depressible so as to permit activation of the motor unit. The container has a container bottom provided with a cutting blade unit that is coupled to the blade driving section so as to be driven rotatably by the motor unit. The container has a spring-loaded push rod unit mounted movably thereon. The push rod unit has a bottom rod section associated with the press button of the contact switch unit, and a top rod section depressible by a switch actuating block of the top cover so as to move the push rod unit against biasing action from a deactivating position to an activating position.

Owner:EUPA INT CORP

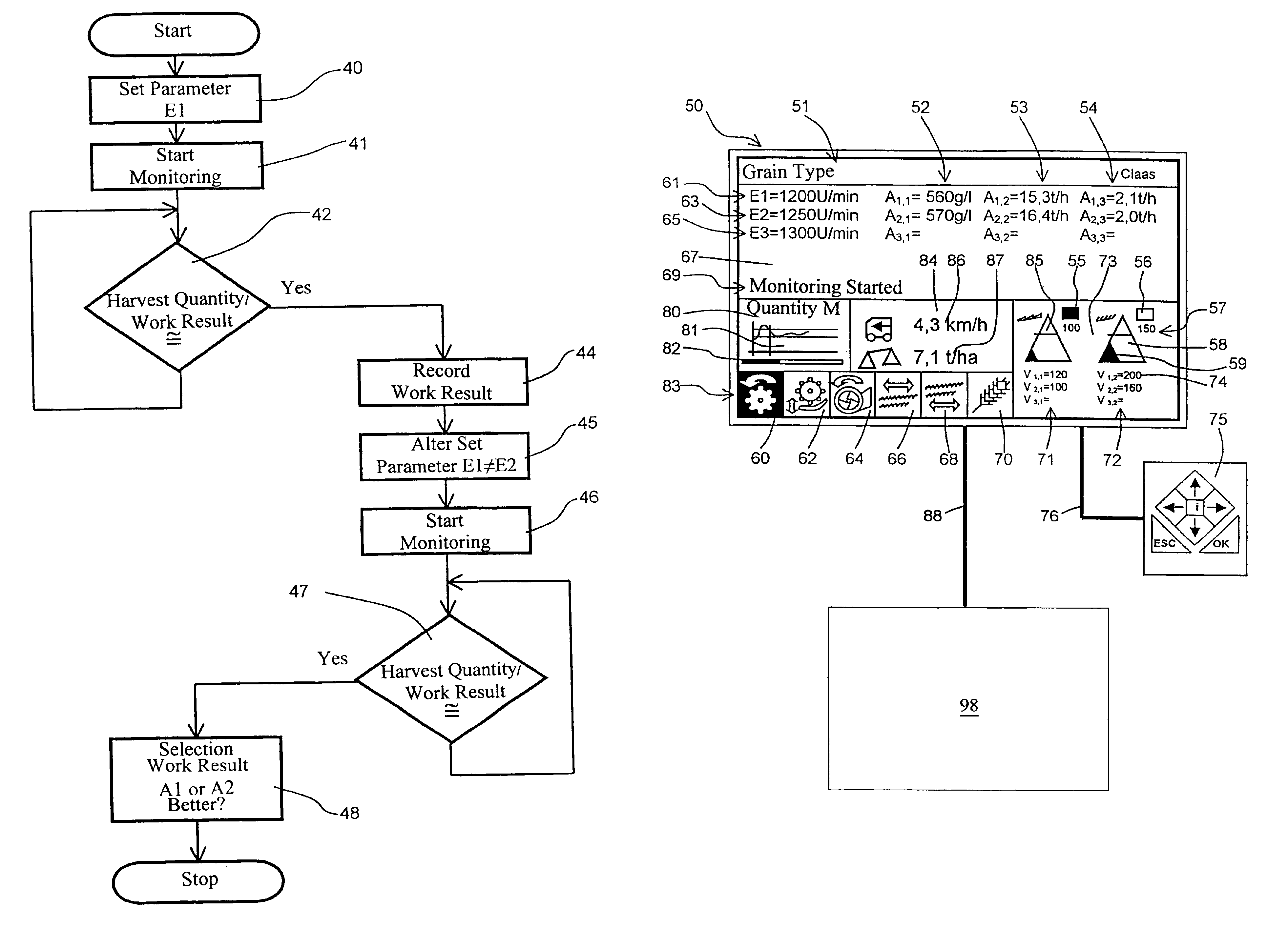

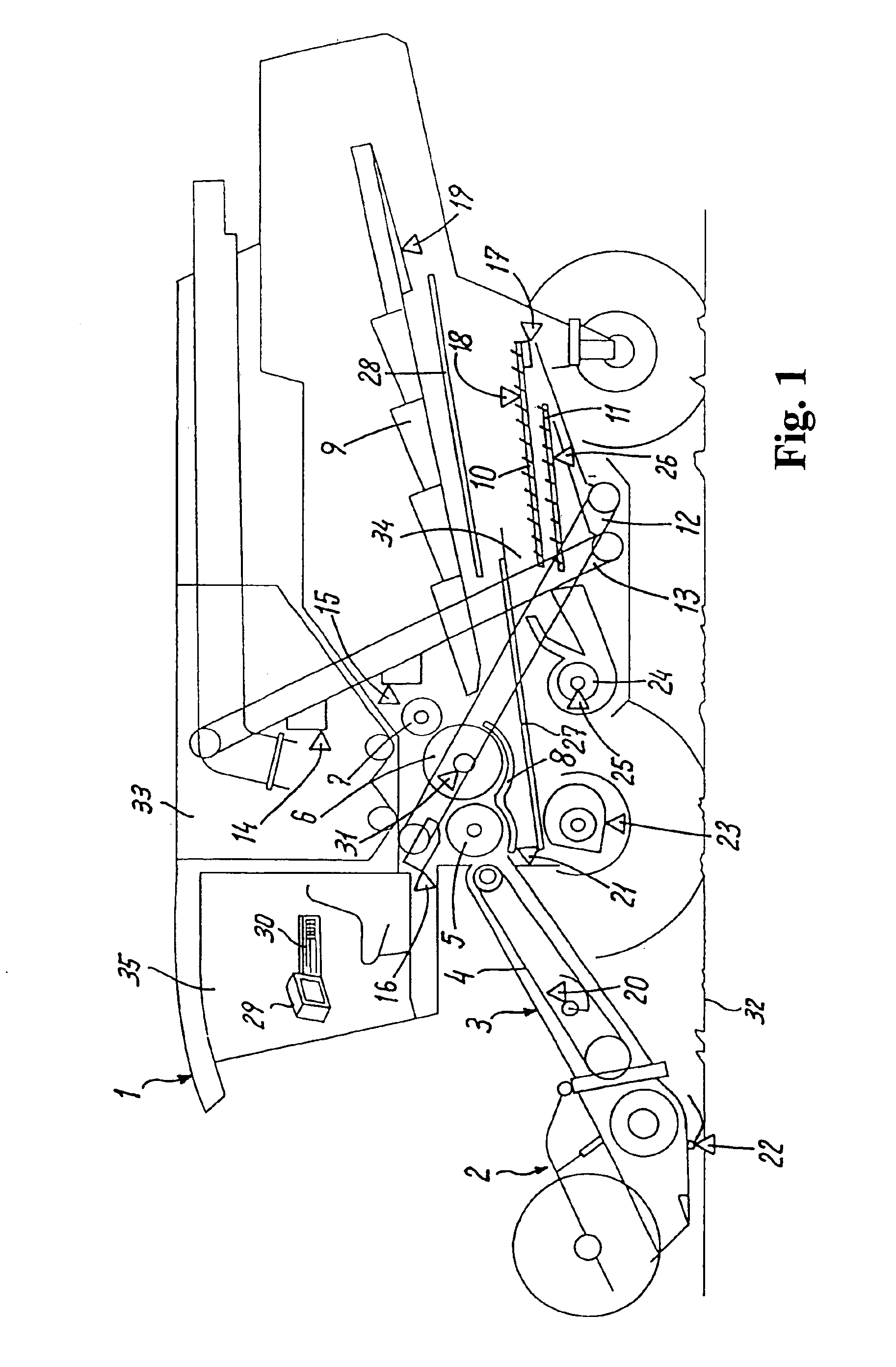

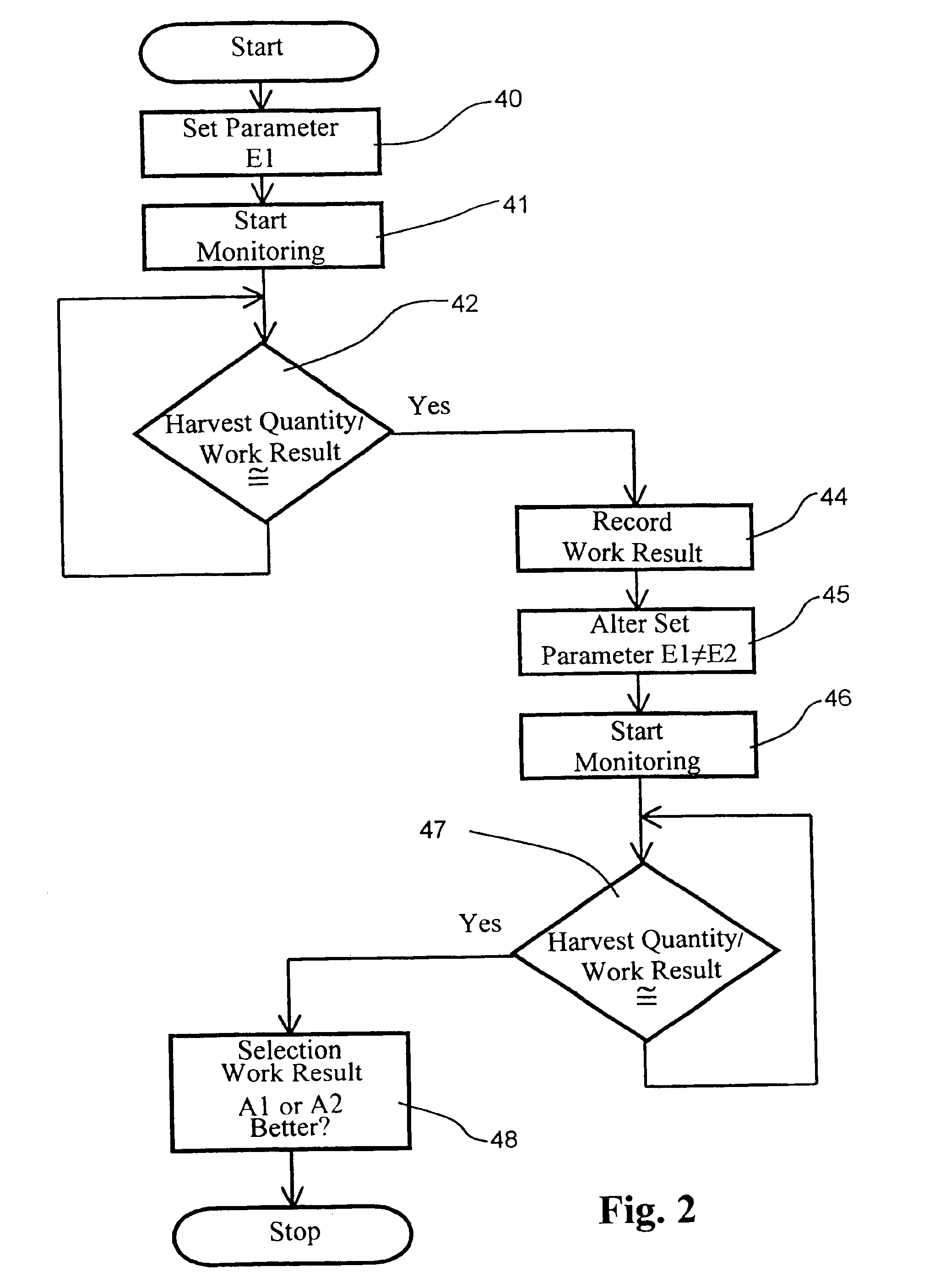

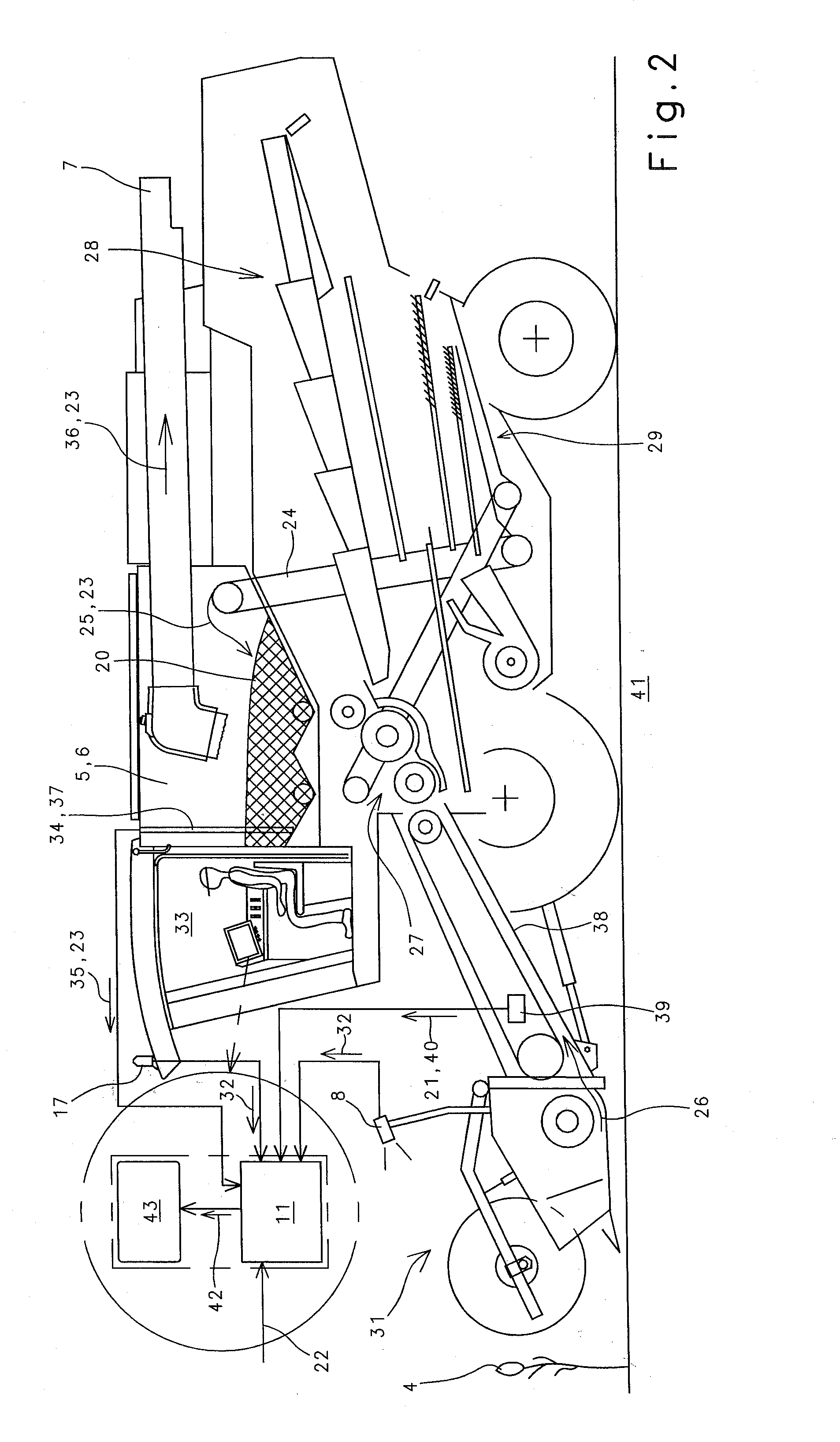

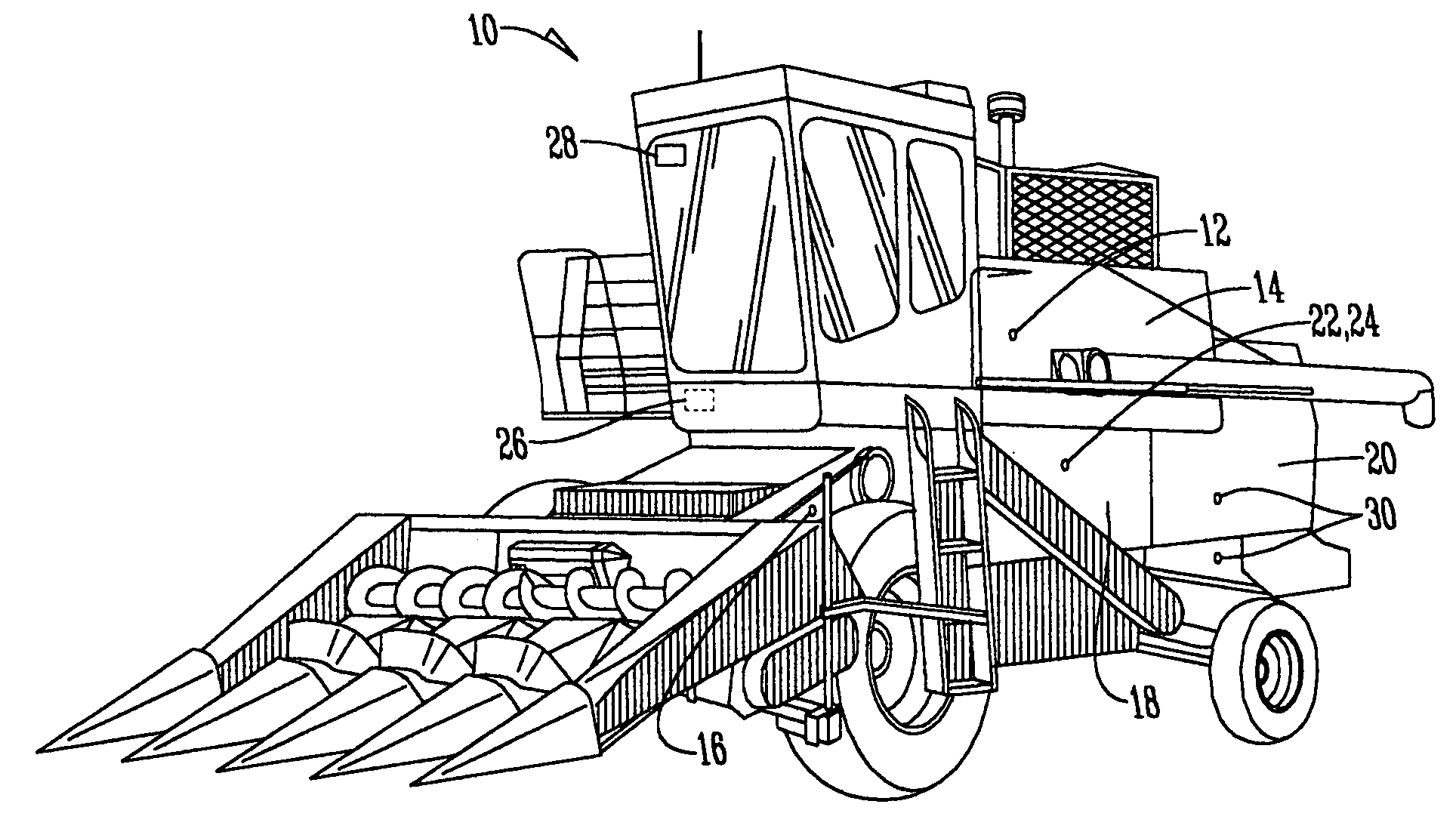

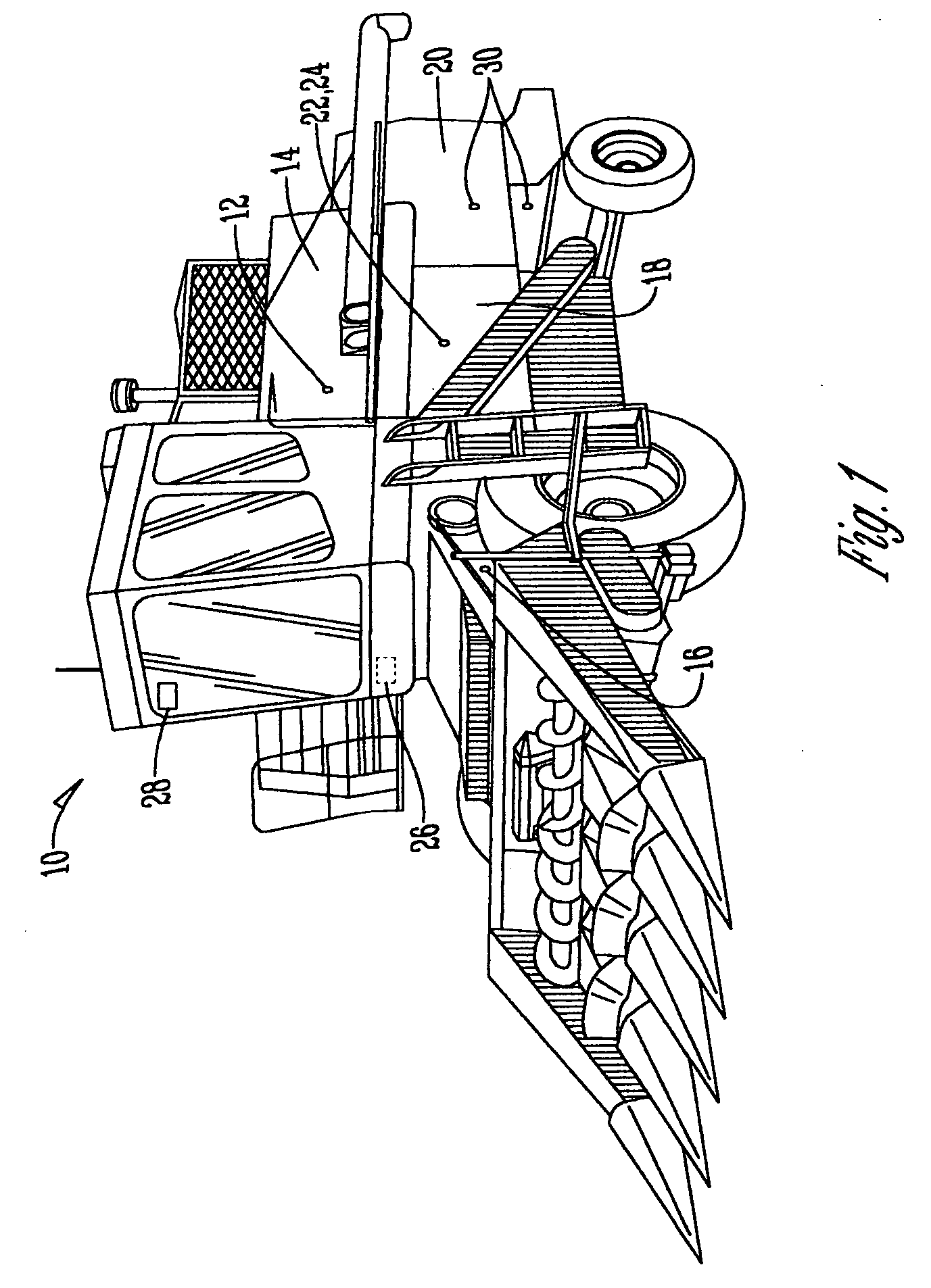

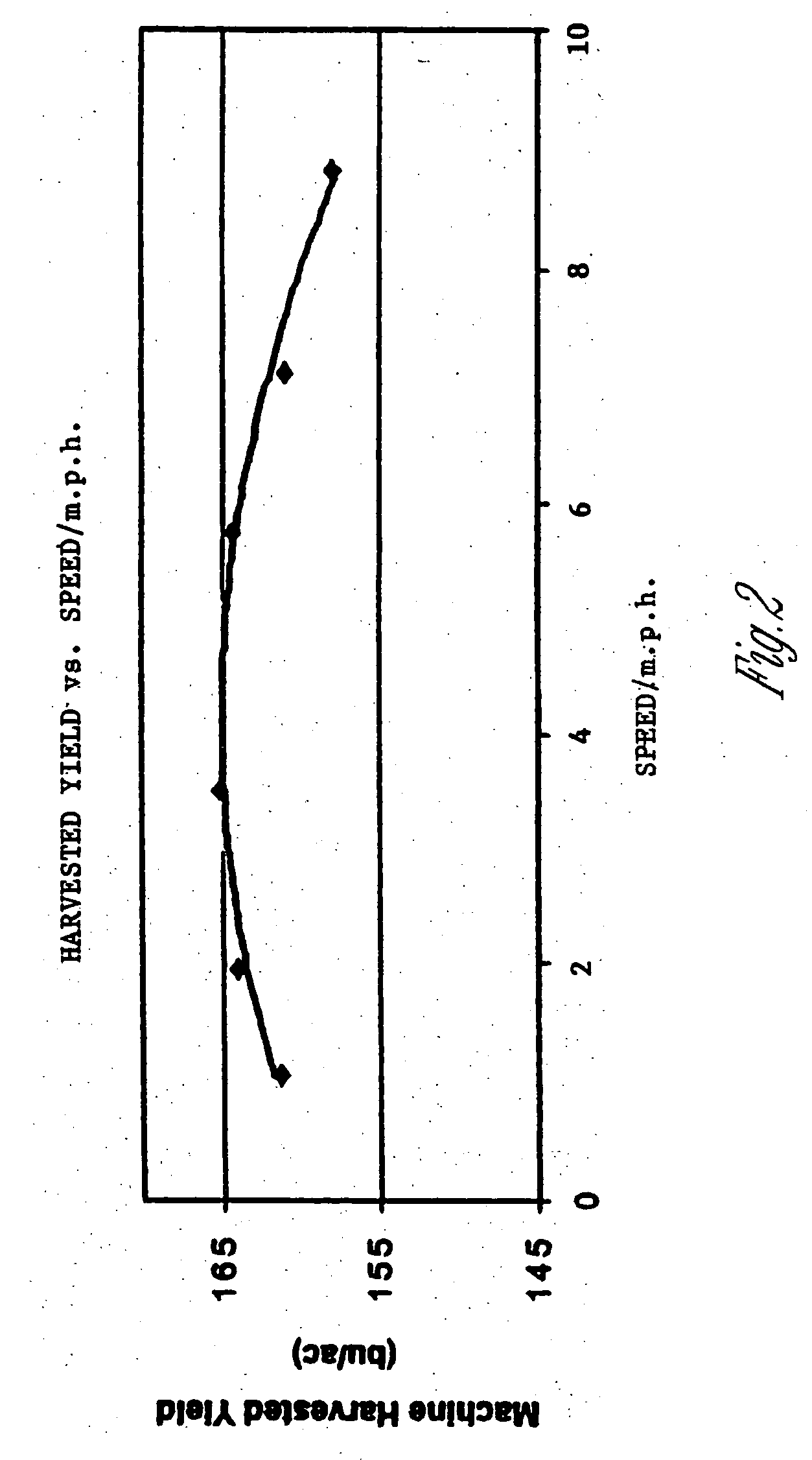

Method and apparatus for determining optimal adjustments of work units in an agricultural harvesting machine

A method for selecting an optimal setting of an adjustable work unit in an agricultural harvesting machine, wherein each setting of the work unit results in a work result, includes adjusting a first set parameter of the work unit on the machine to a first work setting; recording a first, stable work result; adjusting the first set parameter of the work unit to a second work setting; recording a second, stable work result; comparing the first and second work results; and selecting between the first and second work settings based on the comparison of the first and second work results.A device for selecting an optimal setting of an adjustable work unit in an agricultural harvesting machine includes means for adjusting a first set parameter of the work unit to different work settings; a control device to determine a work result as a function of a work setting; and a memory device in communication with the control device to record the work result.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Safety device for blender

InactiveUS7318666B1Reduce riskUnexpected operationRotary stirring mixersBalingEngineeringMechanical engineering

A blender includes a base forming a receiving space in which a positioning seat is formed. The positioning seat defines a through hole. The base houses a motor that is connected to a safety switch. The safety switch has a bar extending through the through hole of the positioning seat. A container has a lower end releasably mounted to a retainer. A movable member is received in the retainer and has pegs extending through the retainer to be engageable and depressible by the lower end of the container when the container is mounted to the container retainer. The container is positionable in the receiving space, and the depressed movable member is fit into the positioning seat to depress downward the bar of the safety switch to thereby actuate the safety switch supplying the power to the motor.

Owner:LIN KUAN CHIH

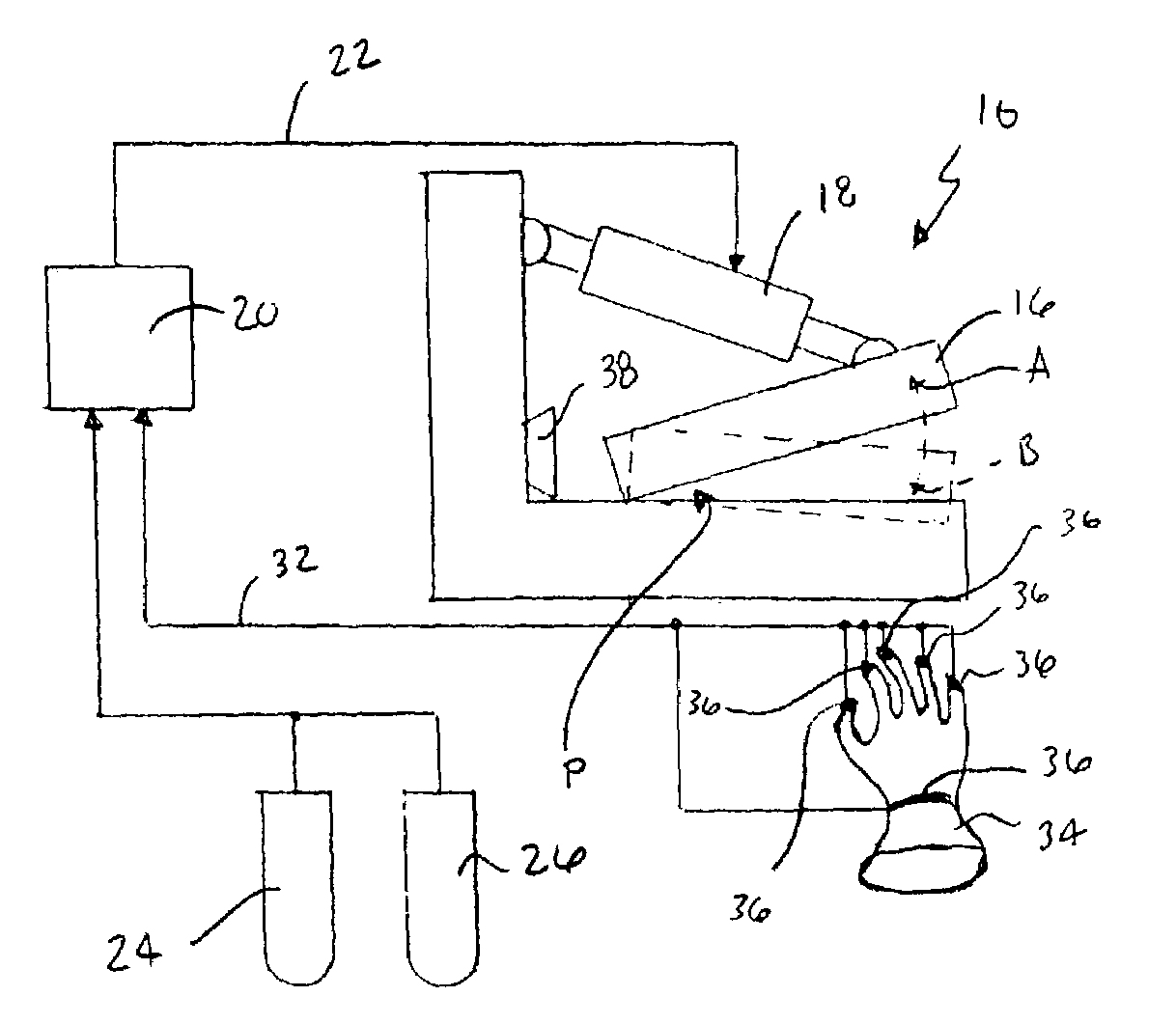

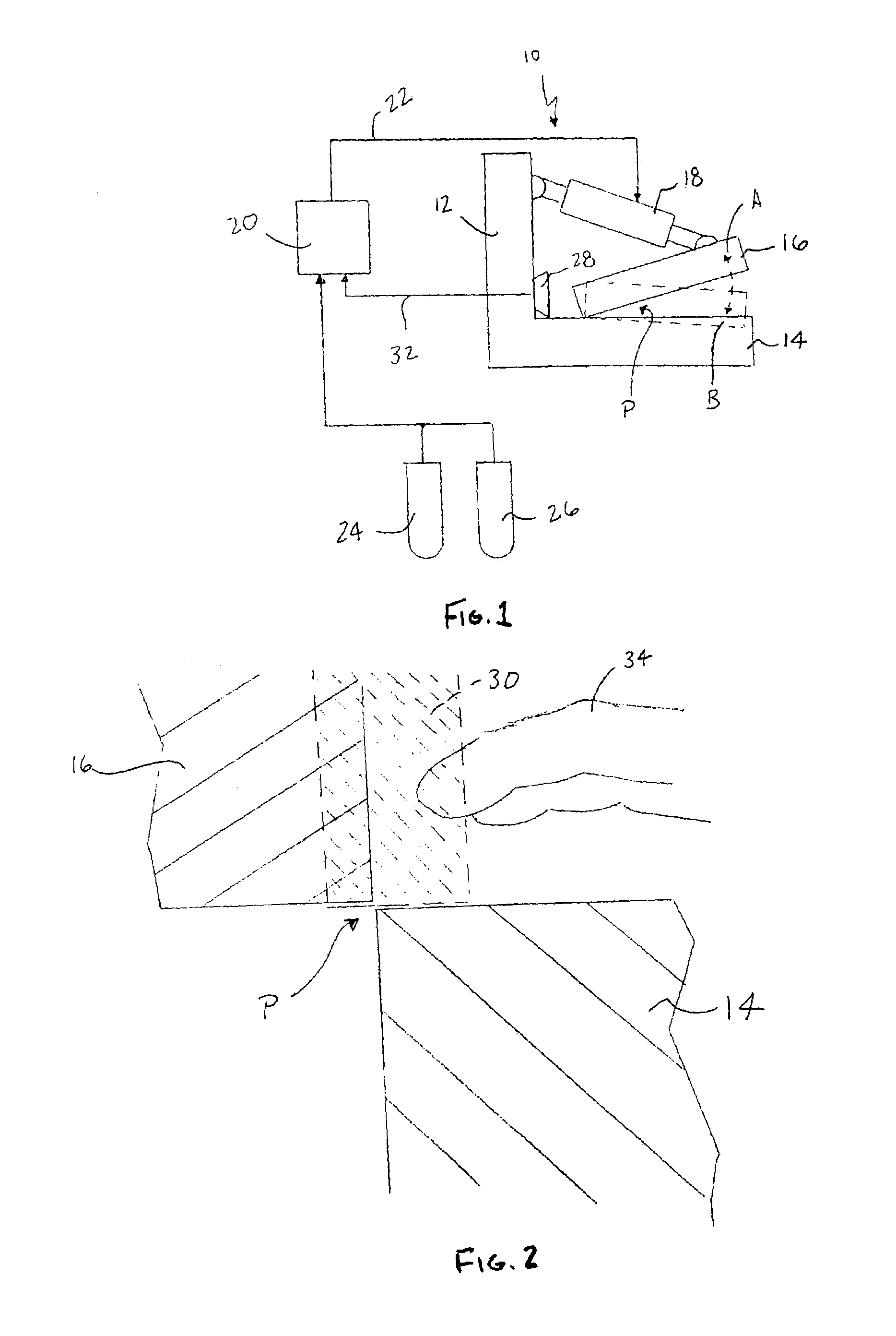

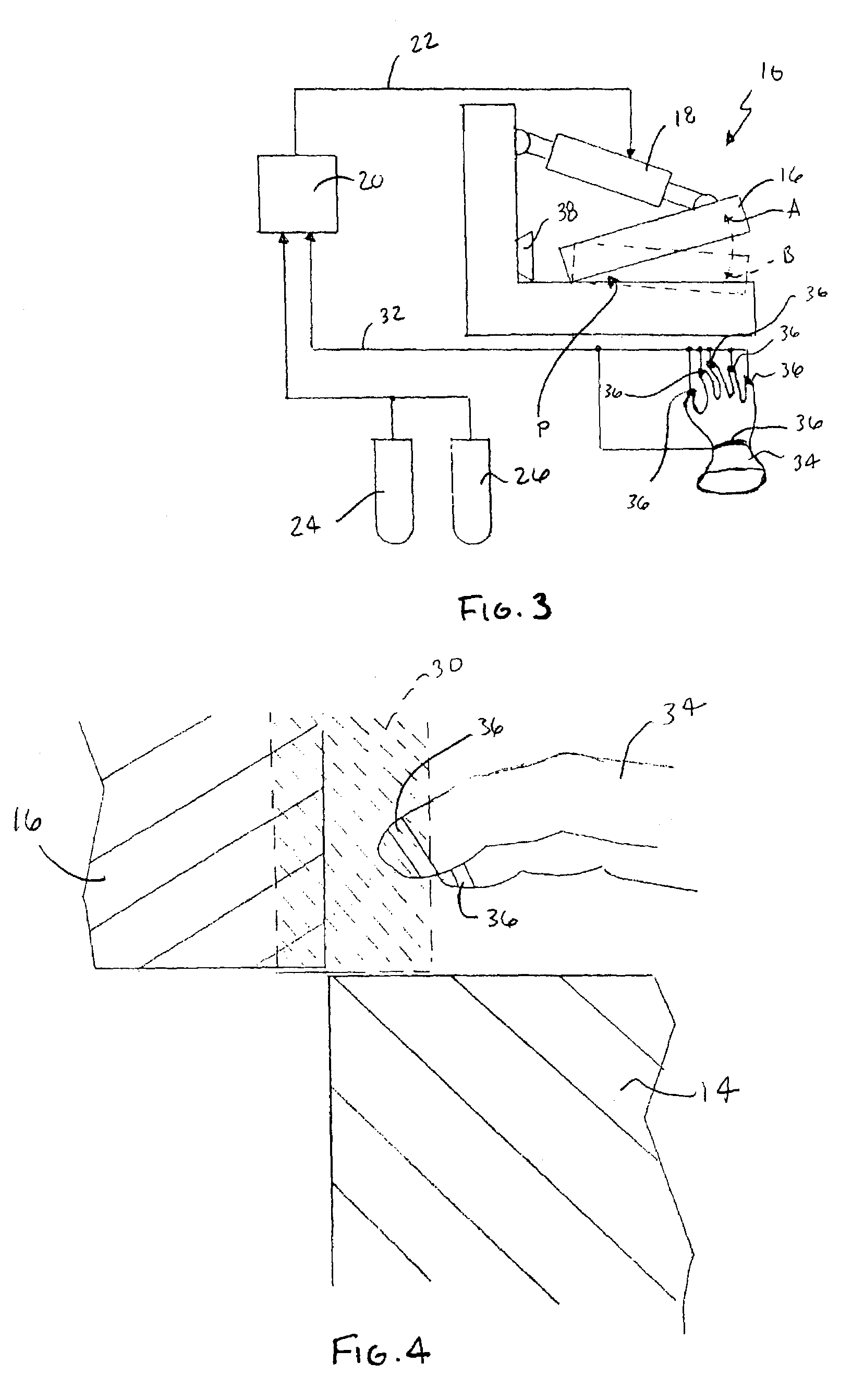

Safety-shutoff device for a manually fed processing machine

InactiveUS6979813B2Operational securityDc network circuit arrangementsMaterial analysis by optical meansComputer scienceFeed processing

An intrusion detection system for altering the operation of an associated machine when an appropriate intrusion is detected, the system comprising: a first detector to detect the presence of a first distinguishing property and to selectively produce an intrusion signal when the first distinguishing property associated with an object is detected within a danger zone approximate a pinch point of a machine, wherein an area approximate the pinch point of the machine does not exhibit the first distinguishing property; and, a controller, operatively coupled to the intrusion detector and the machine, for controlling the operation of the machine, wherein the controller generates a corrective action signal directed toward the machine when intrusion signals are received from the intrusion detector.

Owner:AVRIL JOHN G

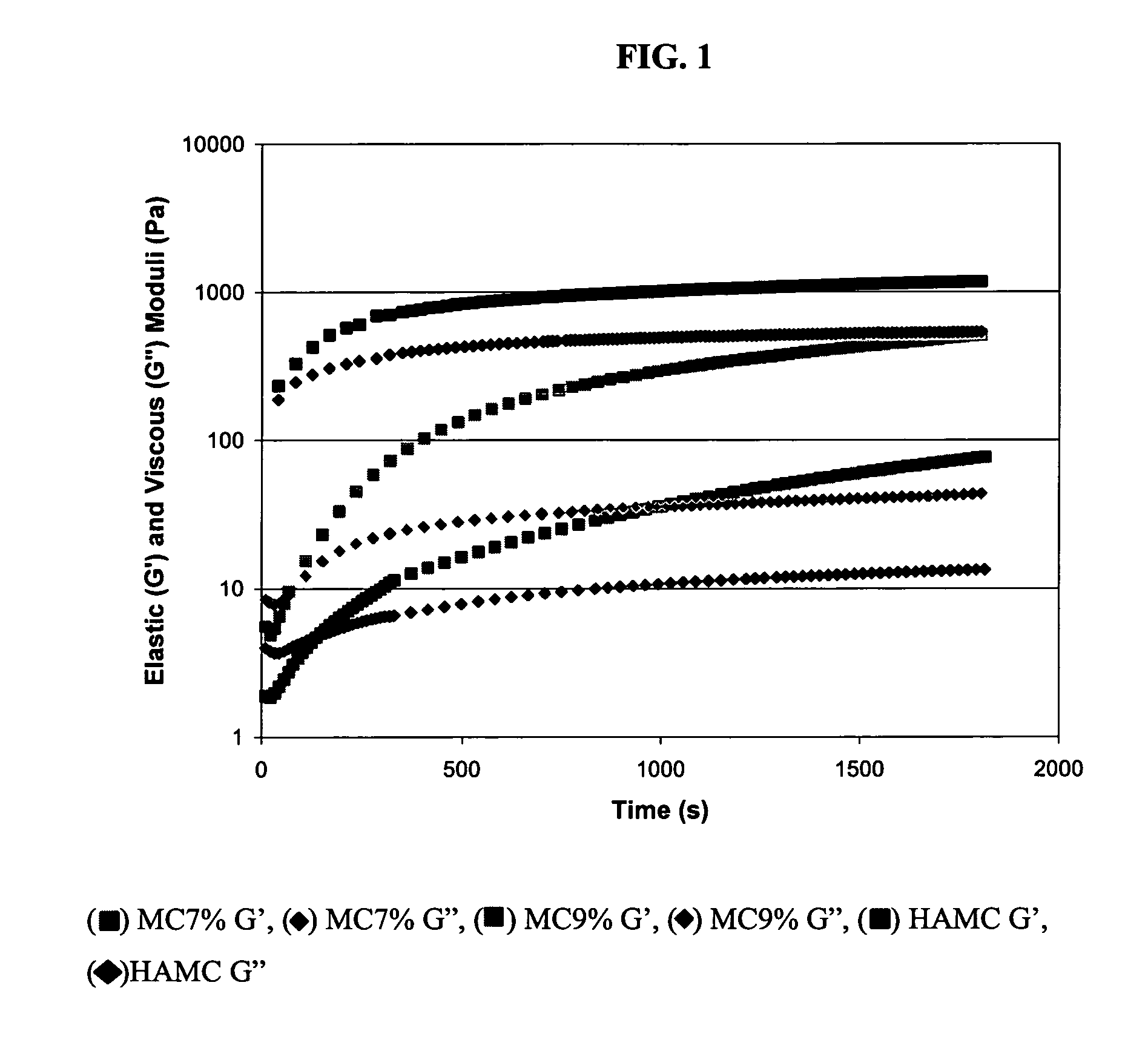

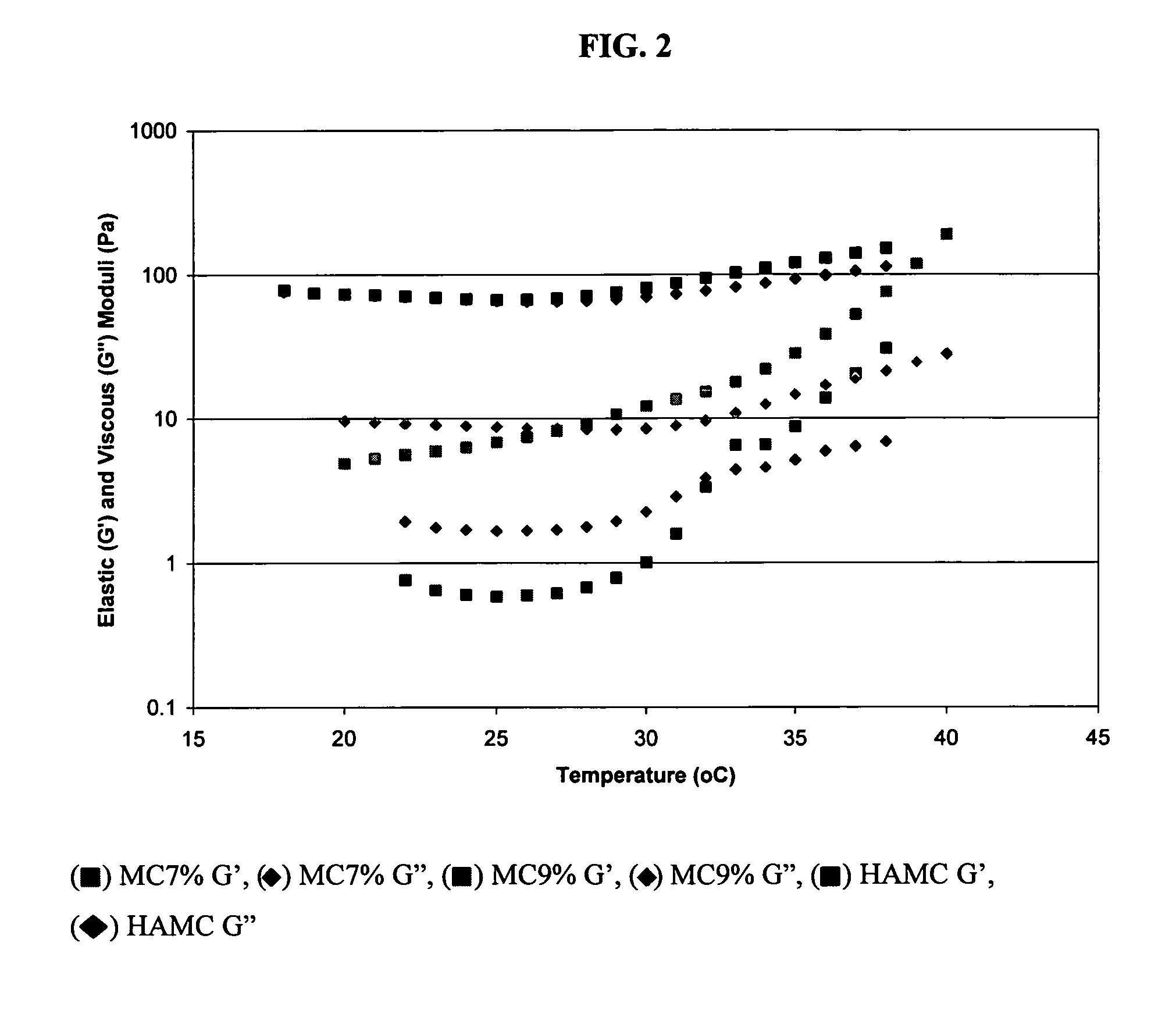

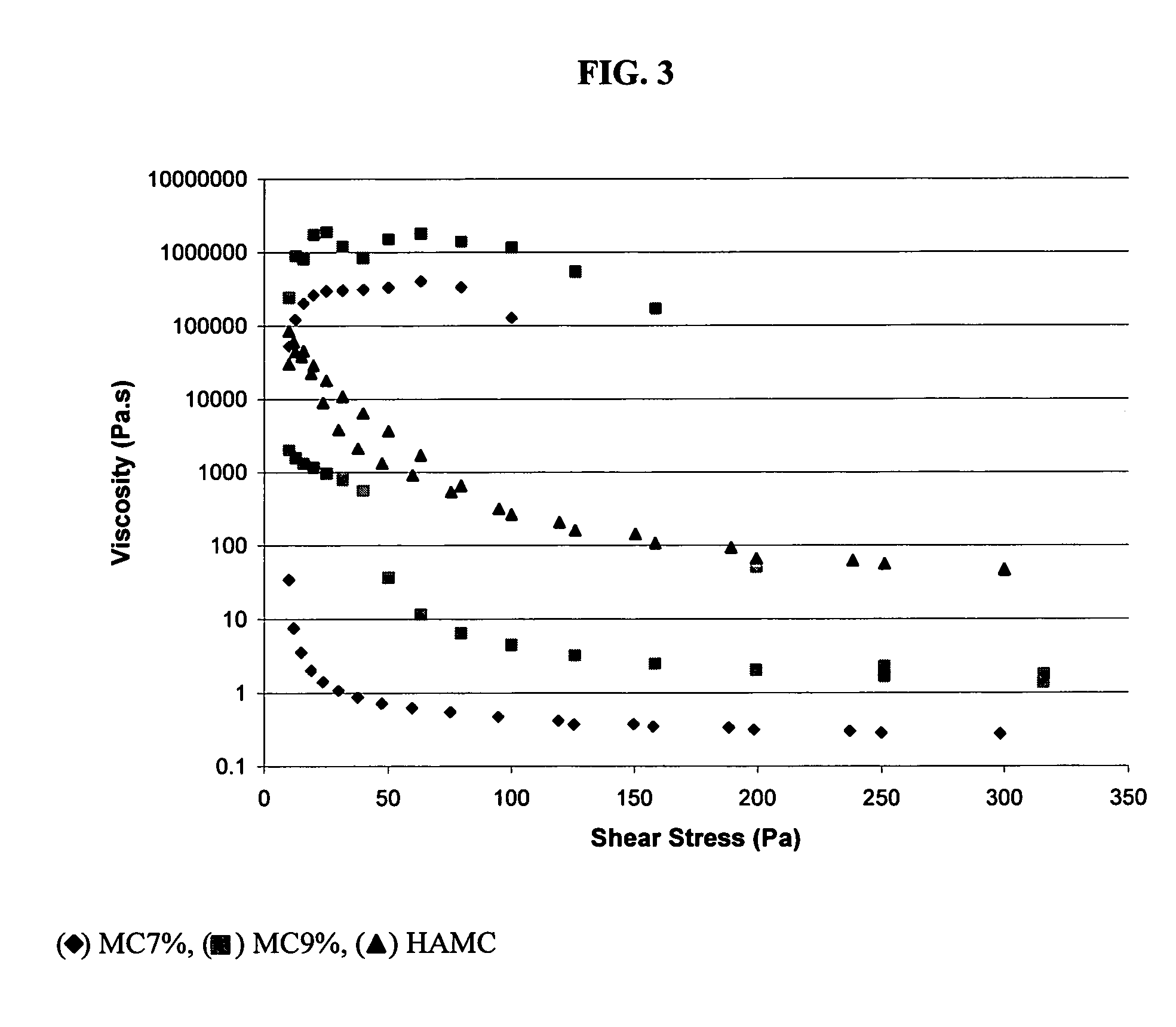

Blends of temperature sensitive and anionic polymers for drug delivery

A physical blend of inverse thermal gelling and shear-thinning, thixotropic polymers that has a lower gelation temperature than the thermal gelling polymer alone is provided. The blend results in an injectable hydrogel that does not flow freely at room temperature, but is injectable due to its shear-thinning properties. The thermal-gelling properties of the polymer promote a more mechanically stable gel at body temperature than at room temperature. The polymer matrix gel has inherent therapeutic benefit and can also be used as a drug delivery vehicle for localized release of therapeutic agents.

Owner:SHOICHET MOLLY S +2

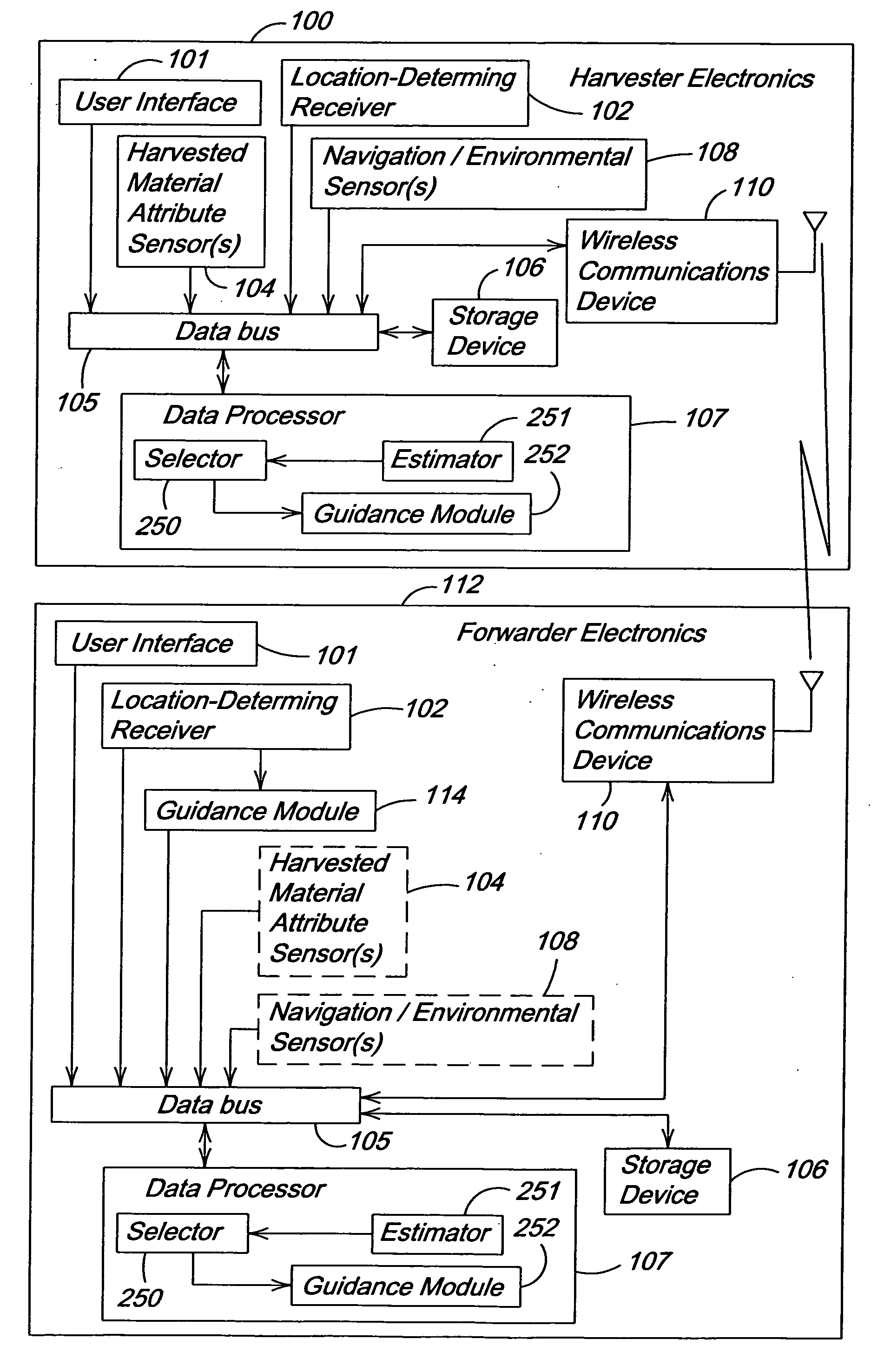

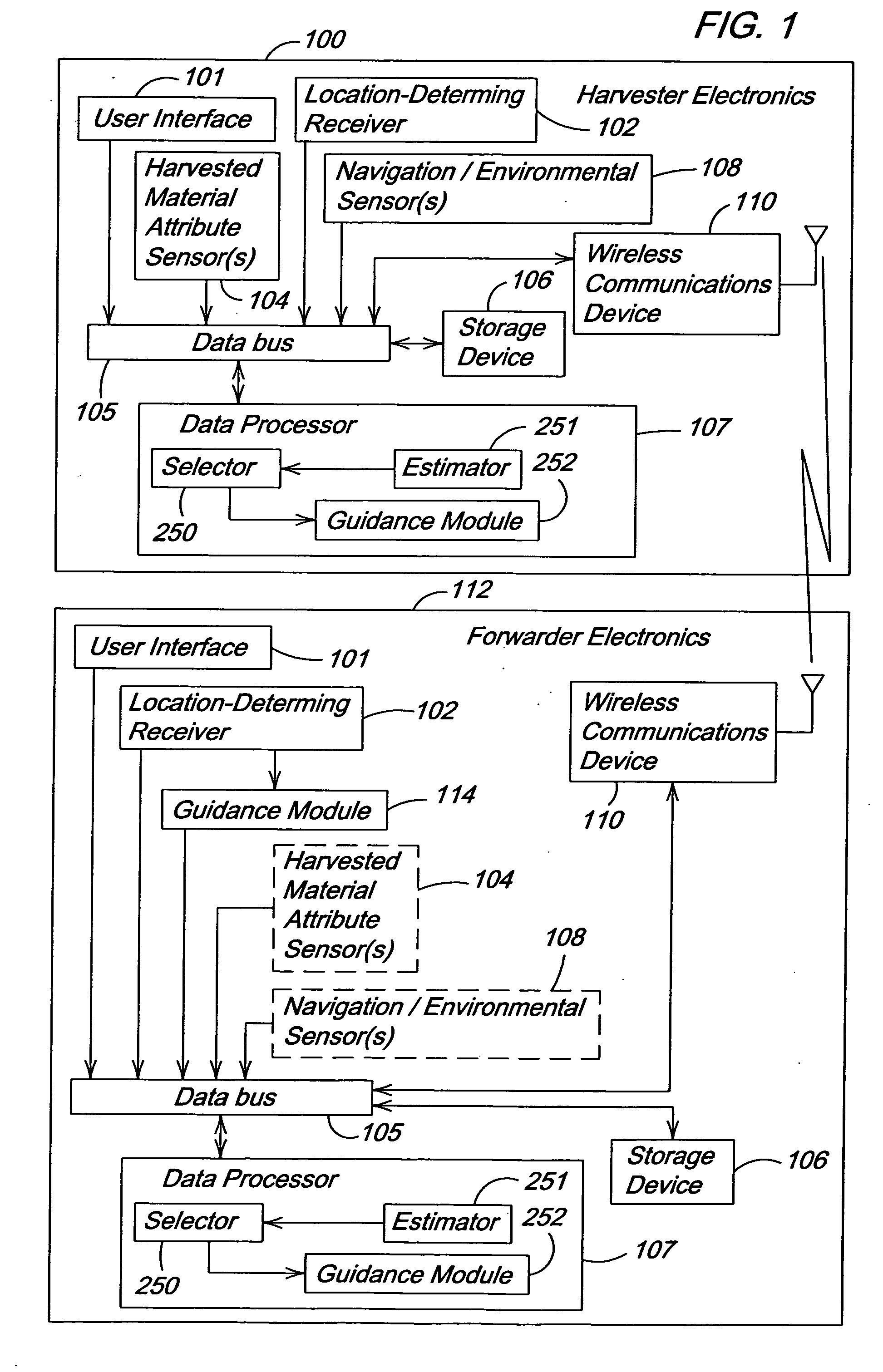

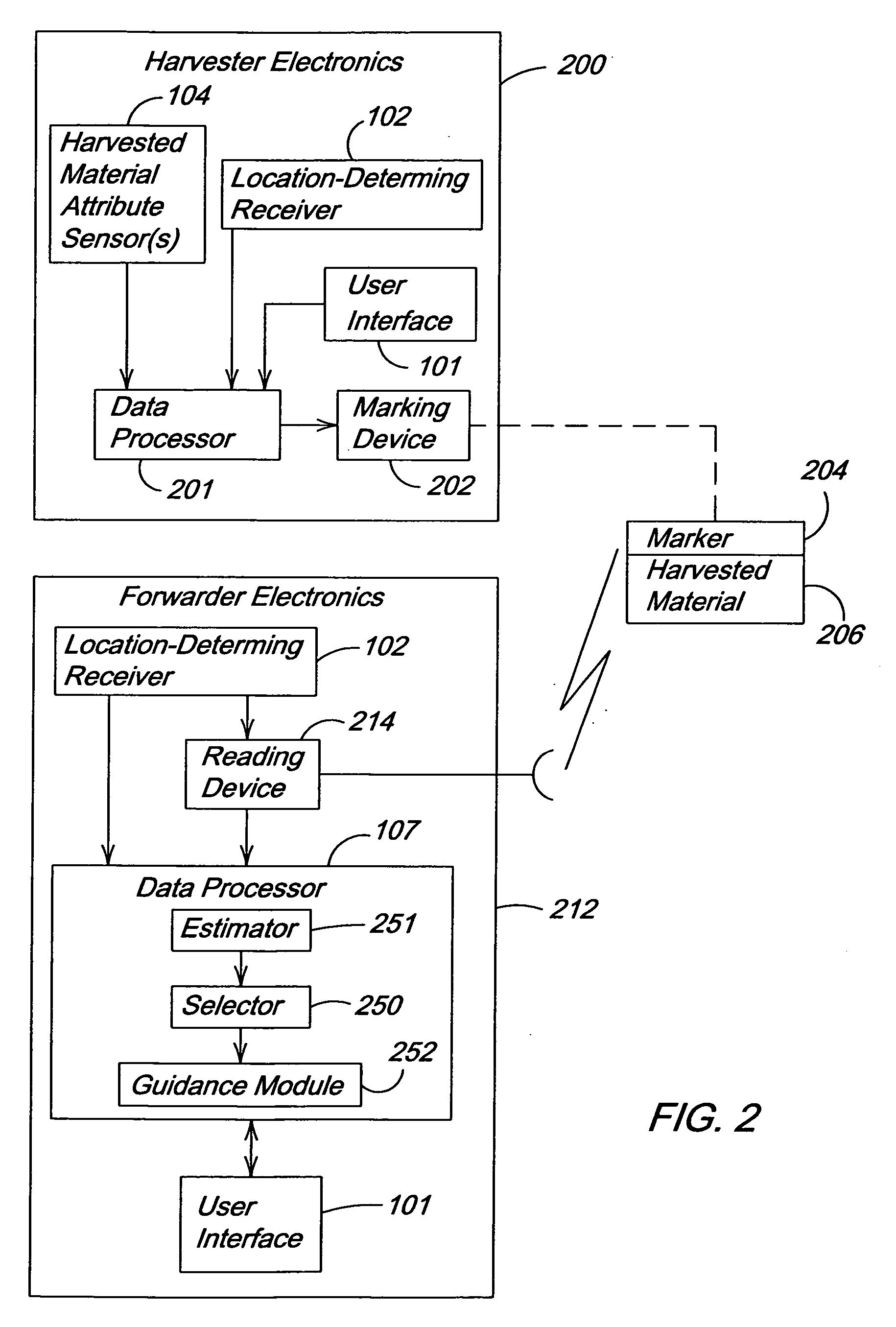

Locating harvested material within a work area

ActiveUS20050197175A1Minimizing economyAnalogue computers for trafficHarvestersForwarderComputer science

A method and system for locating harvested material comprises receiving material data including material location data on a material location of harvested material within a work area. Background data is obtained. A location-determining receiver determines a forwarder location of a forwarder. An estimator estimates economic cost factors associated with corresponding candidate paths or segments of candidate paths between the forwarder location and the material location. A selector selects a preferential planned path between the forwarder location and the material location consistent with the material data, background data, and minimization of the economic cost factors.

Owner:DEERE & CO

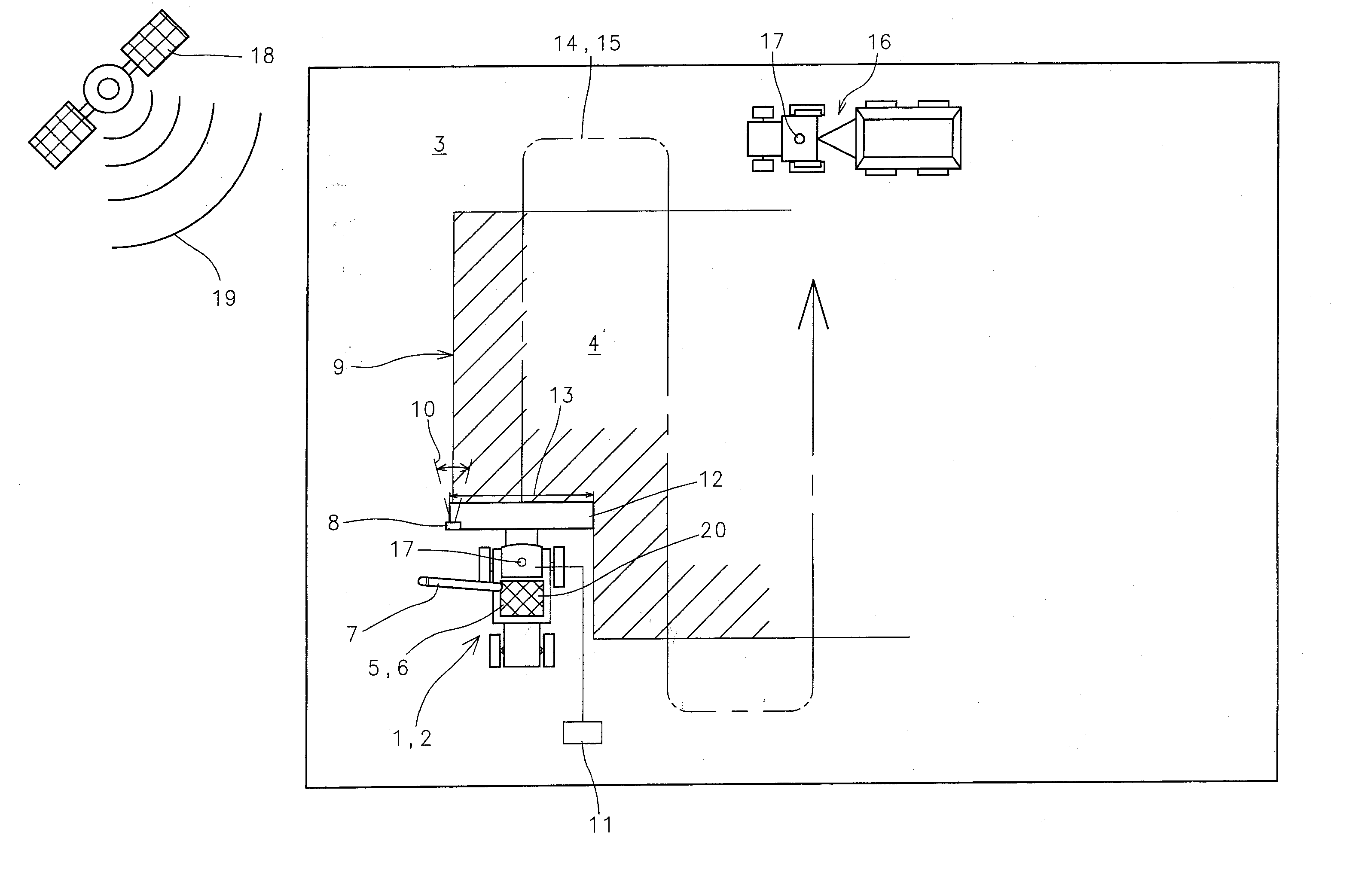

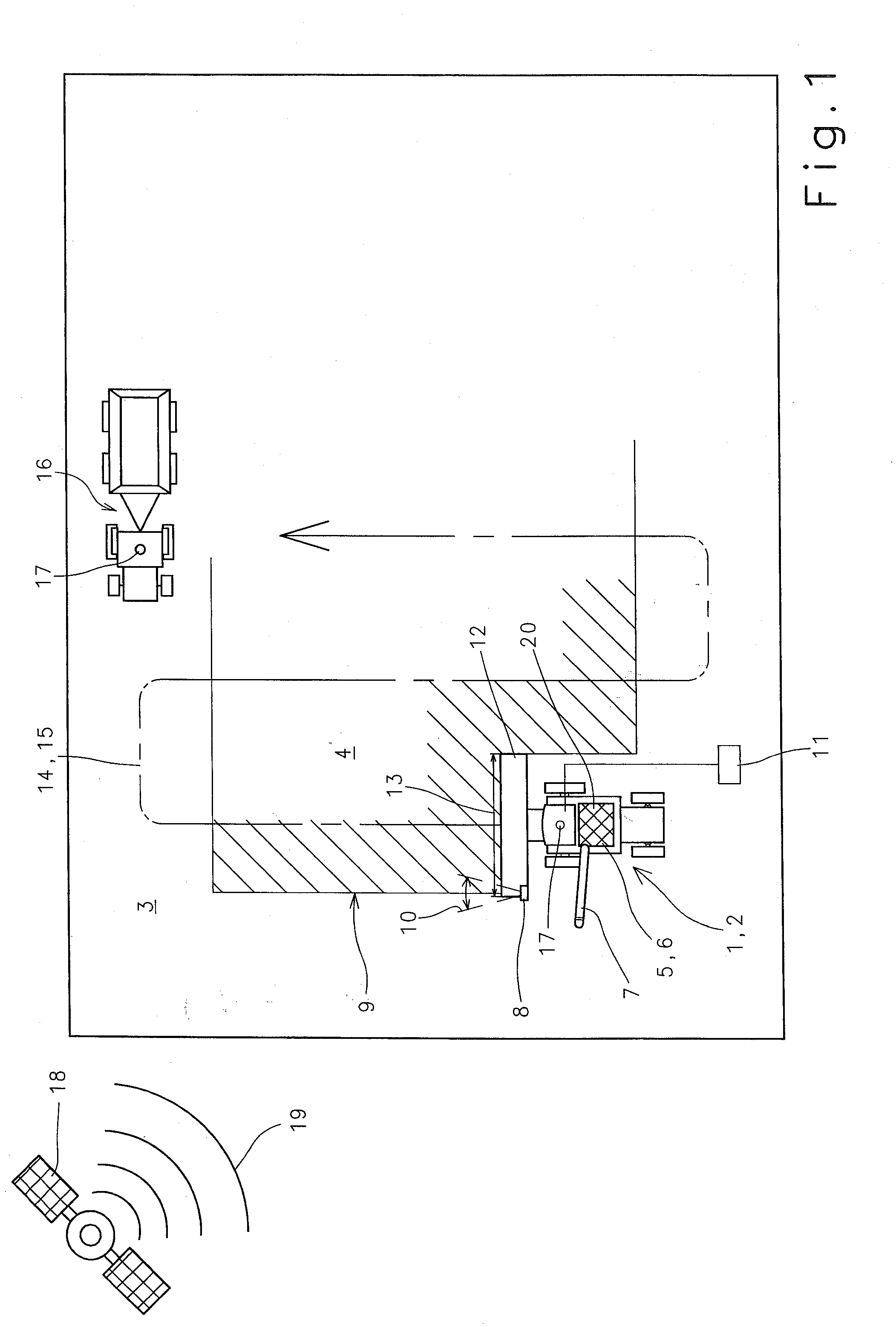

Route planning system for agricultural working machines

A route planning system for an agricultural working machine including at least one crop material storage unit for storing quantities of crop material transferable to forage vehicles, has a unit for generating driving routes in a territory based on a defined working width assigned to the agricultural working machine, a unit for reconciling a crop material quantity stored in the crop material storage unit depending on at least one characteristic parameter, and a unit for dynamically adapting the reconciliation to changes in the at least one characteristic parameter.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Enhanced drug dispensing system

InactiveUSRE40453E1Overcomes drawbackIncrease in sizeCapsControlling coin-freed apparatusAutomatic controlDrug dispensing

In an automated prescription pill dispensing system, a multiplicity of pill dispensers are provided each operable to count out and dispense pills from supply hoppers. The dispensers are controlled by a computer which selects up to five of the dispensers to operate and control the selected pill dispensers to count out pills simultaneously. The pill dispensers dispense the pills into the first set of output hoppers, from which the pills can be released into a second output hopper under the control of the computer. The computer will release the pills from the second output hopper corresponding to a selected pill dispenser through a snout into a pill vial in response to sensing the presence of a pill vial at the snout. The computer controls a prescription label printer to print prescription labels for the pill vials. The computer also controls indicator lights to indicate which dispensing cell is selected and ready to have pills released from the second output hopper corresponding thereto. Automatically controlled security doors control access to supply hoppers for each of the pill dispensers.

Owner:MEDCO HEALTH SOLUTIONS

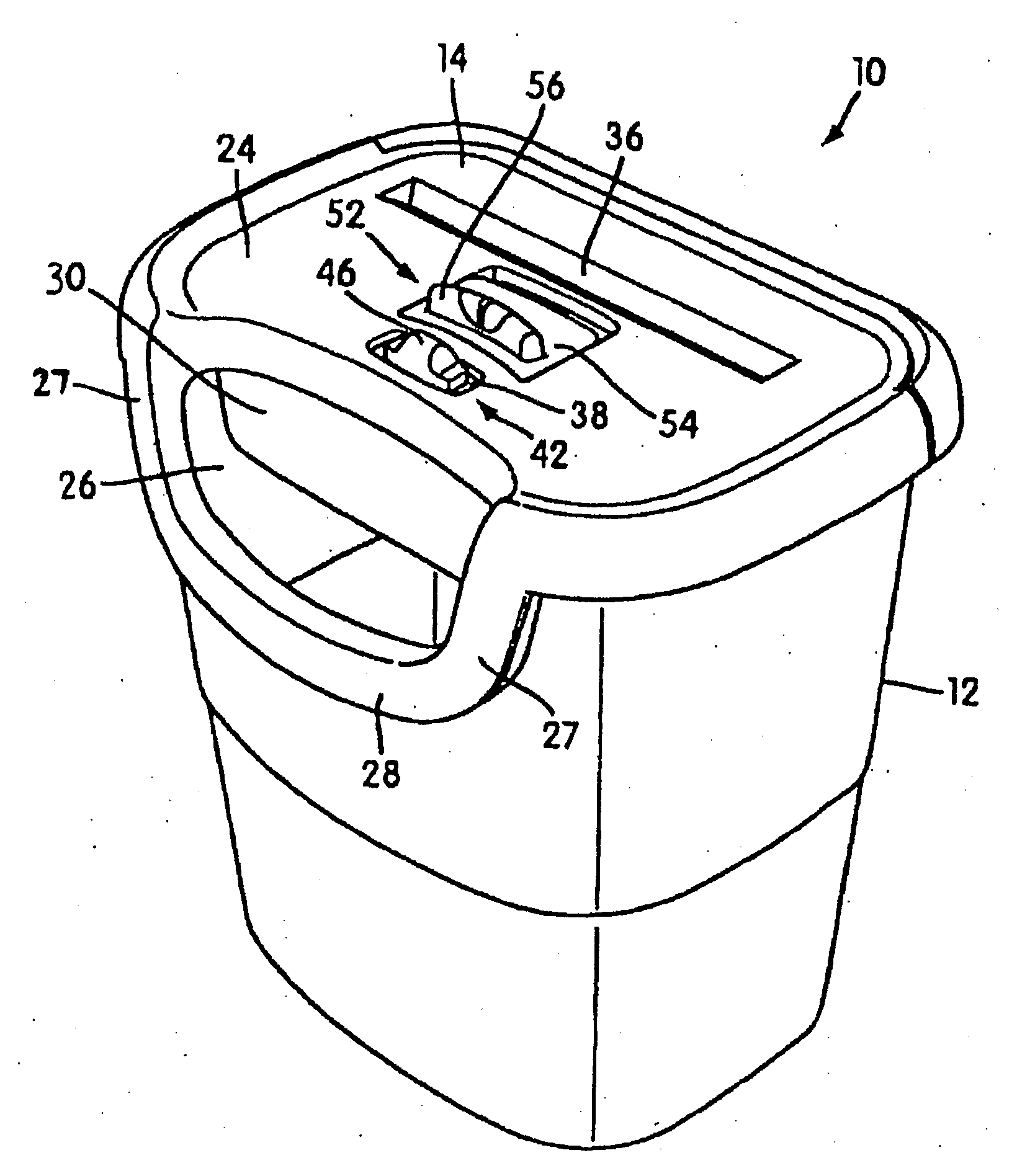

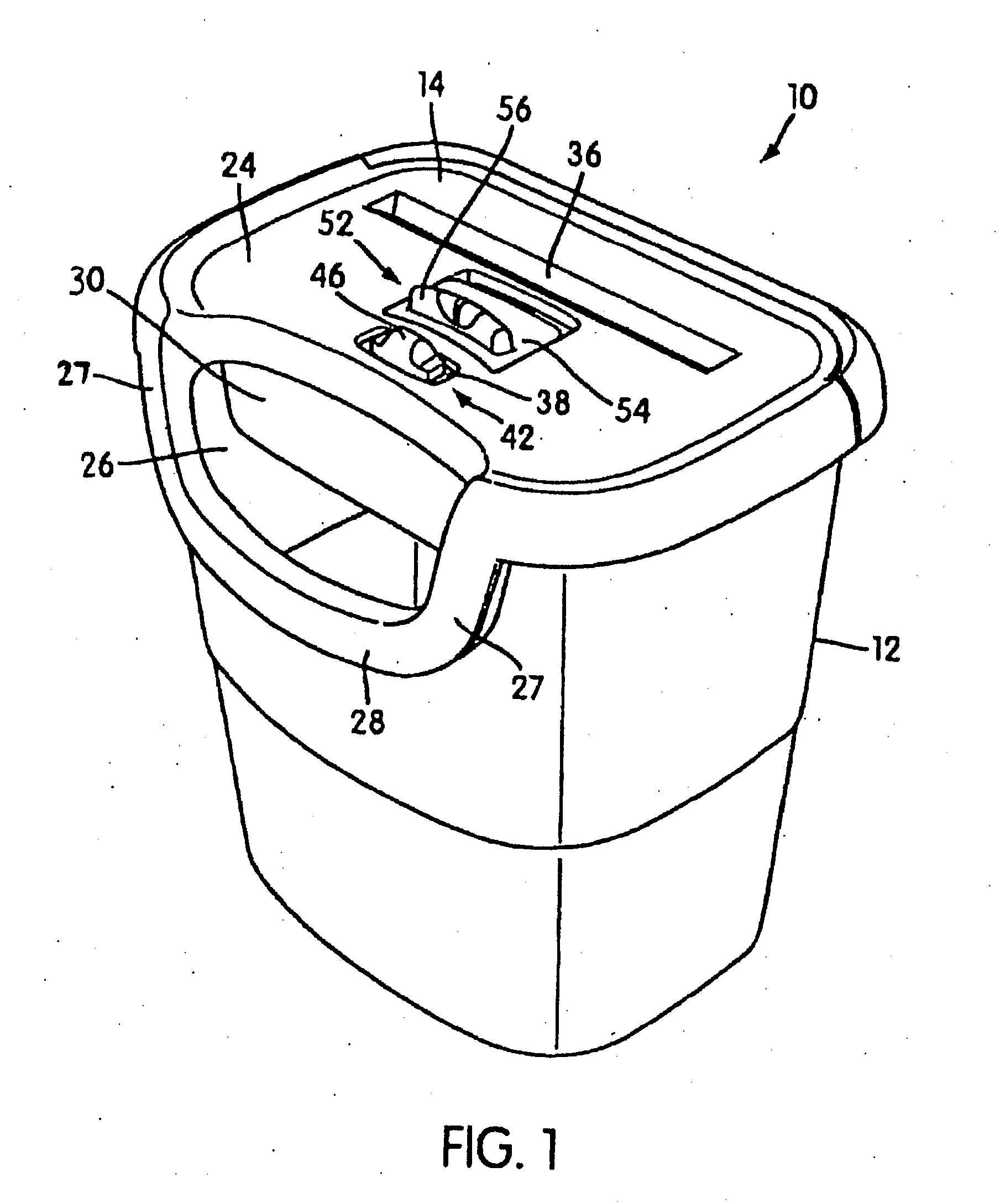

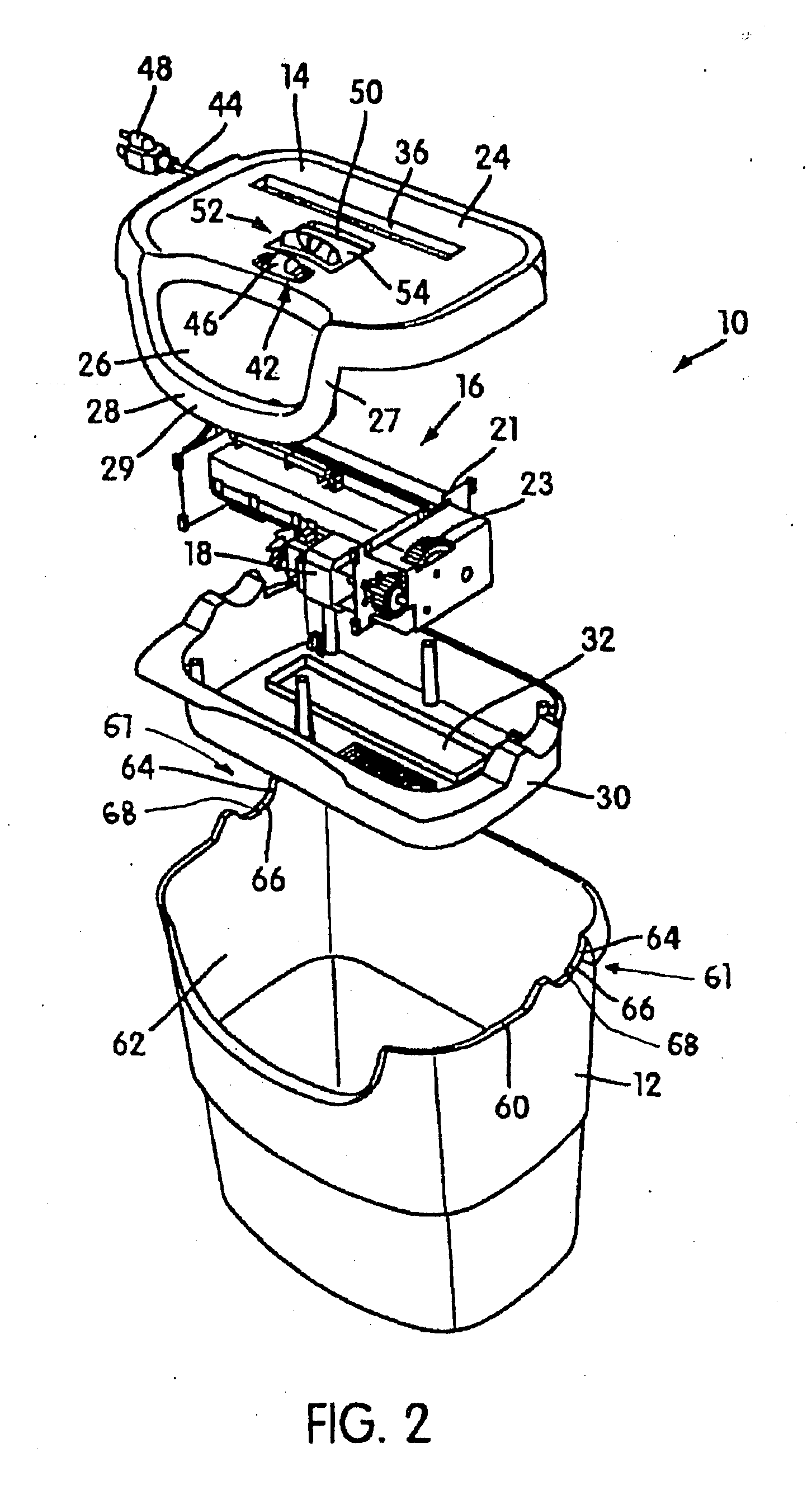

Shredder thickness with Anti-jitter feature

A shredder includes a housing having a throat for receiving at least one article to be shredded, and a shredder mechanism received in the housing and including an electrically powered motor and cutter elements. The shredder also includes a detector that is configured to detect a thickness of the at least one article being received by the throat, and a controller that is configured to operate the motor to drive the cutter elements to shred the at least one article and to set a flutter threshold higher than the predetermined maximum thickness threshold, if the detected thickness is less than a predetermined maximum thickness threshold. The controller is also configured to thereafter continuously detect the thickness of the at least one article being inserted into a throat of the shredder; and to perform a predetermined operation responsive to the thickness detector detecting that the thickness of the at least one article is greater than the flutter threshold.

Owner:FELLOWES INC

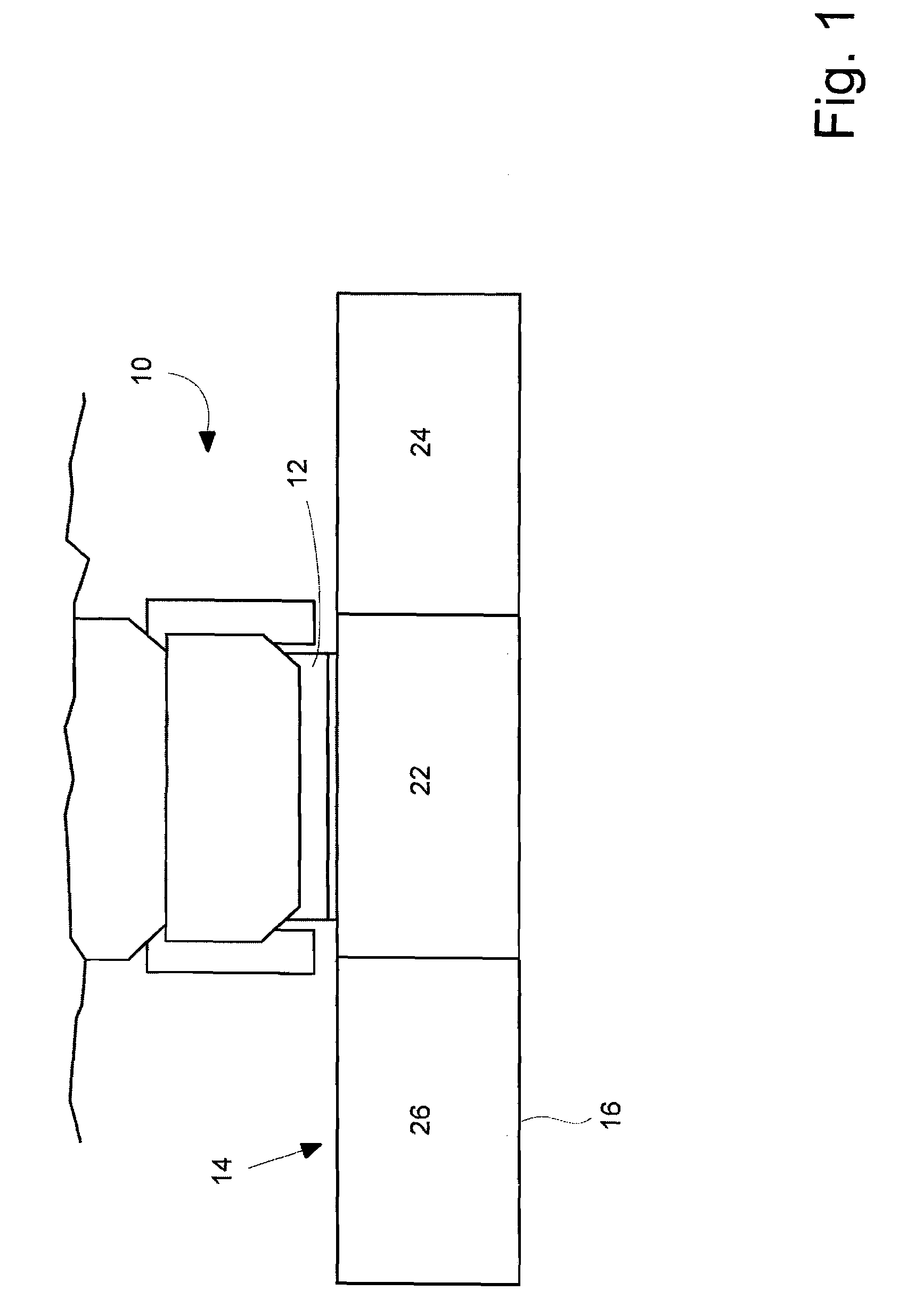

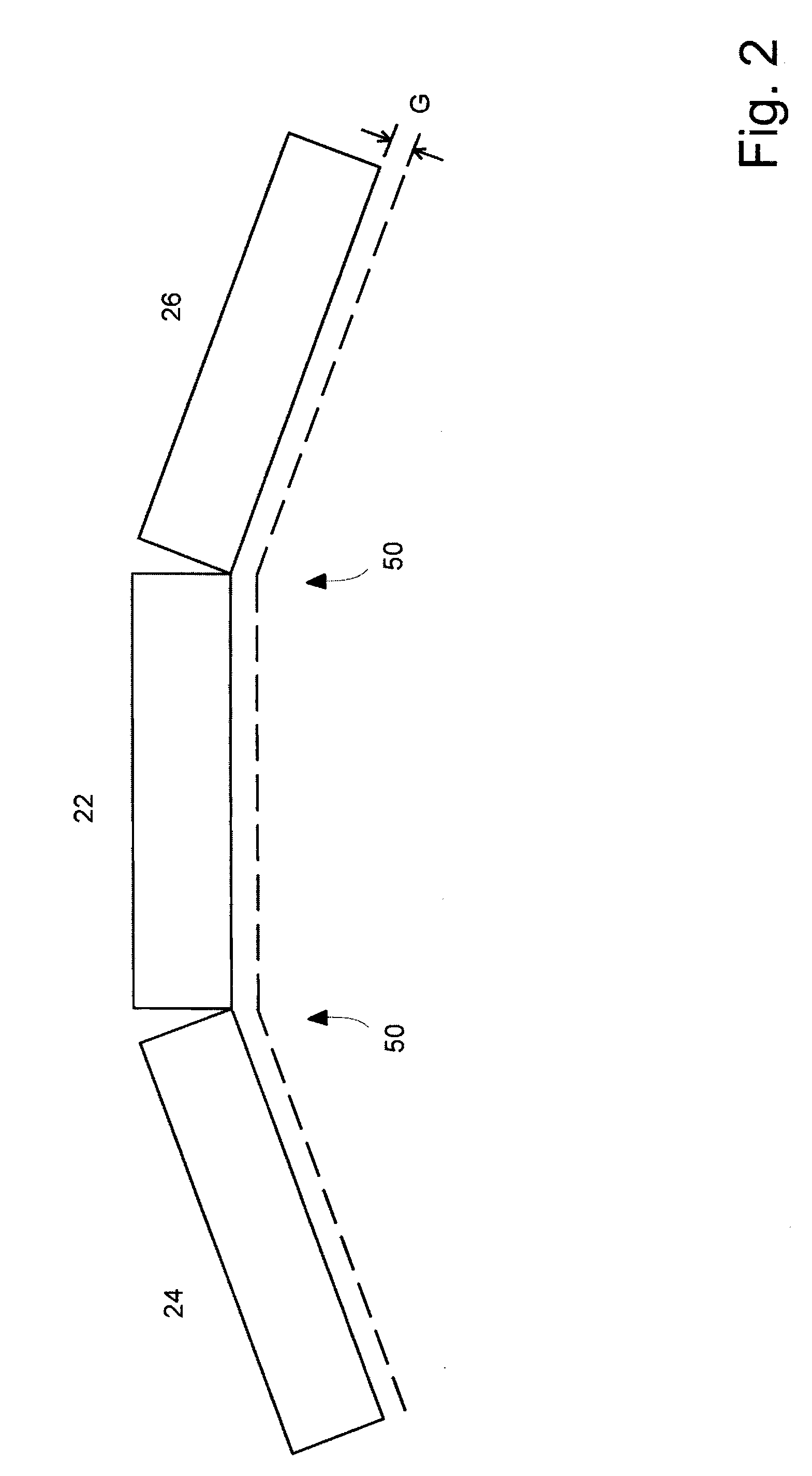

Winged header apparatus and method for a combine

A header for a combine or a harvester comprising a center portion of said header having a feeder house position disposed to direct cut crop from the center portion to a feeder house when the header is mounted on the feeder house. At least one lateral portion of the header is attached to the center portion by a frame hinge. A draper comprised of a frame and a belt disposed to rotate over the frame extends from the lateral portion to the center portion having a draper hinge. A cutter having a curving portion is disposed at a leading aspect of the header to cut crop. The frame hinge, draper hinge and curving portion along the same axis are parallel to a direction of travel of the combine or harvester. The lateral portion can raise and lower relative to the center portion by rotation around the axis.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

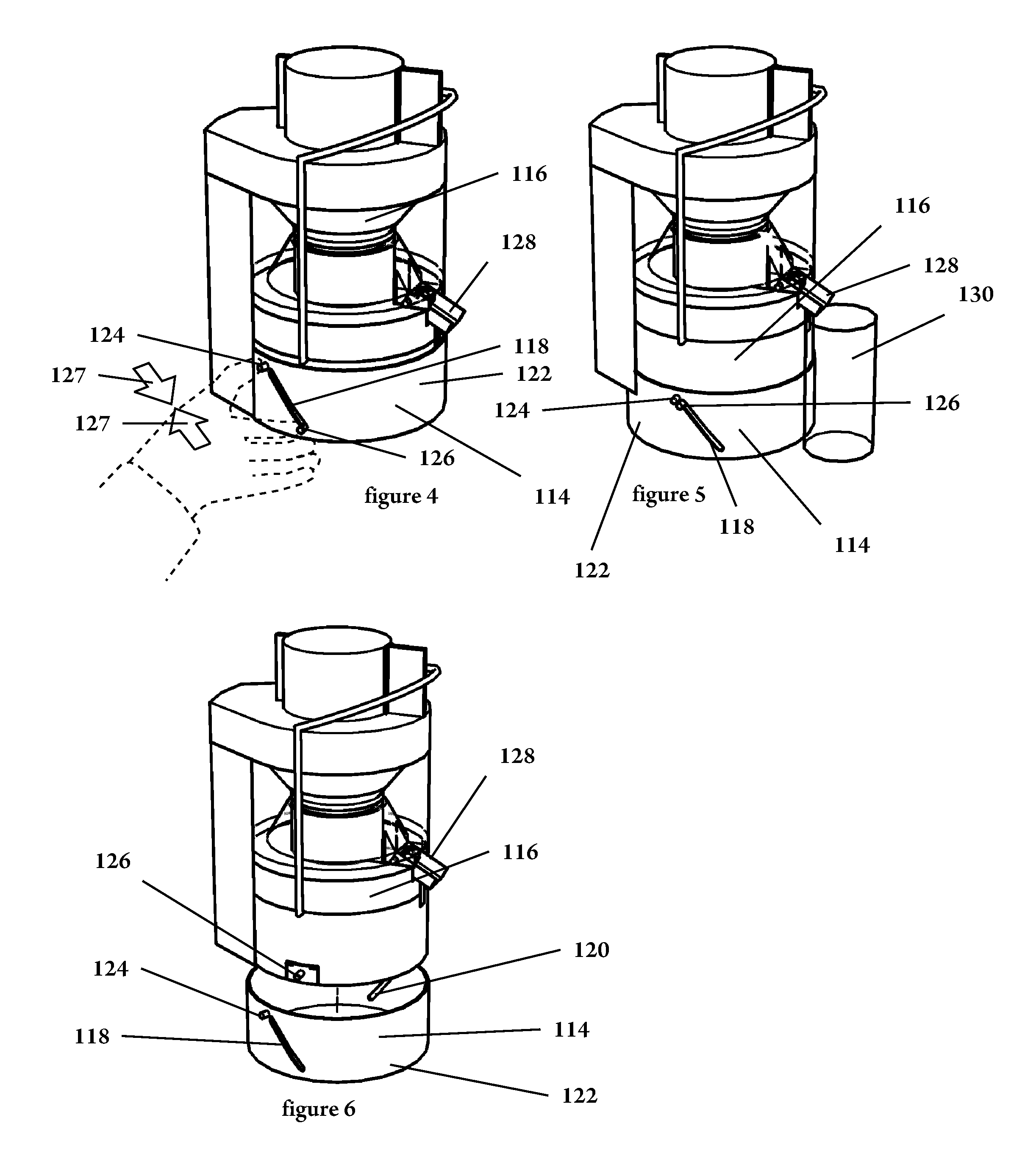

Devices and methods to disintegrate foods

The subject application is directed to a food processing device to extract juice. The device includes an inlet coupled to a disintegrator. The inlet is configured to accept food items and the disintegrator configured to disintegrate food items passed through the inlet. The device further includes a separator that accepts the disintegrated food items and separates out the liquid components from the food item. The device further includes a reservoir that is coupled to the separator for accepting and holding the liquid components. The reservoir includes a translucent member for viewing of liquid levels within the reservoir, and a valved outlet. The valved outlet is configured to allow or prevent the flow of liquid from the reservoir through the valved outlet.

Owner:BACKUS ALAN

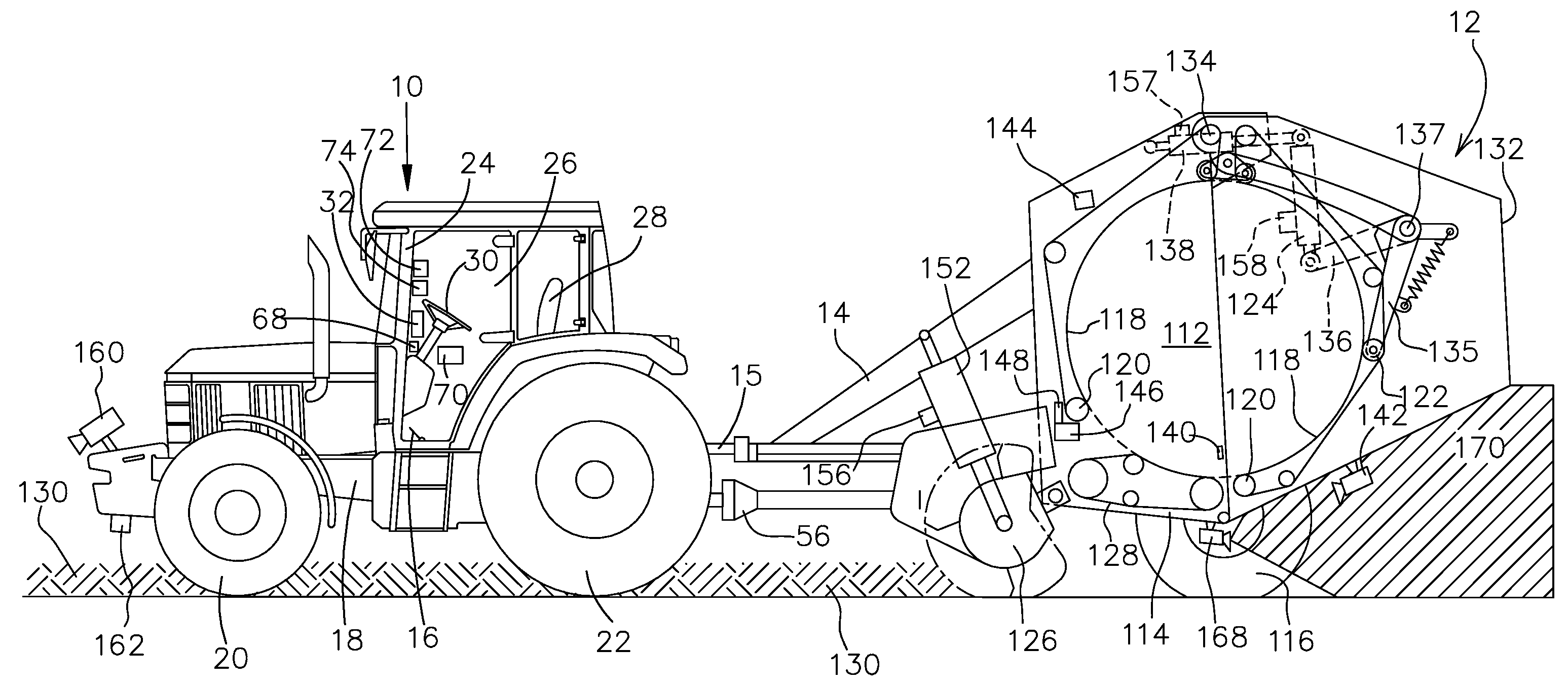

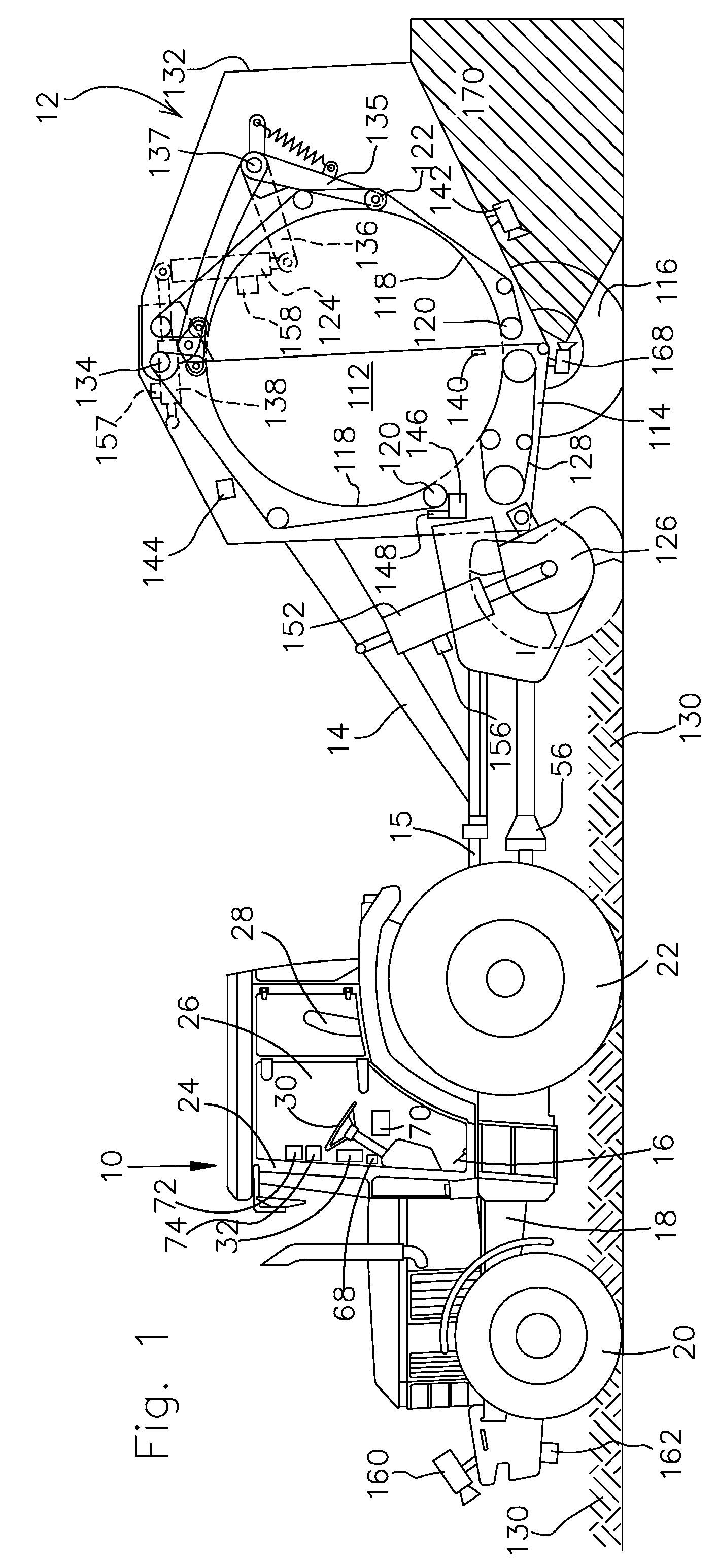

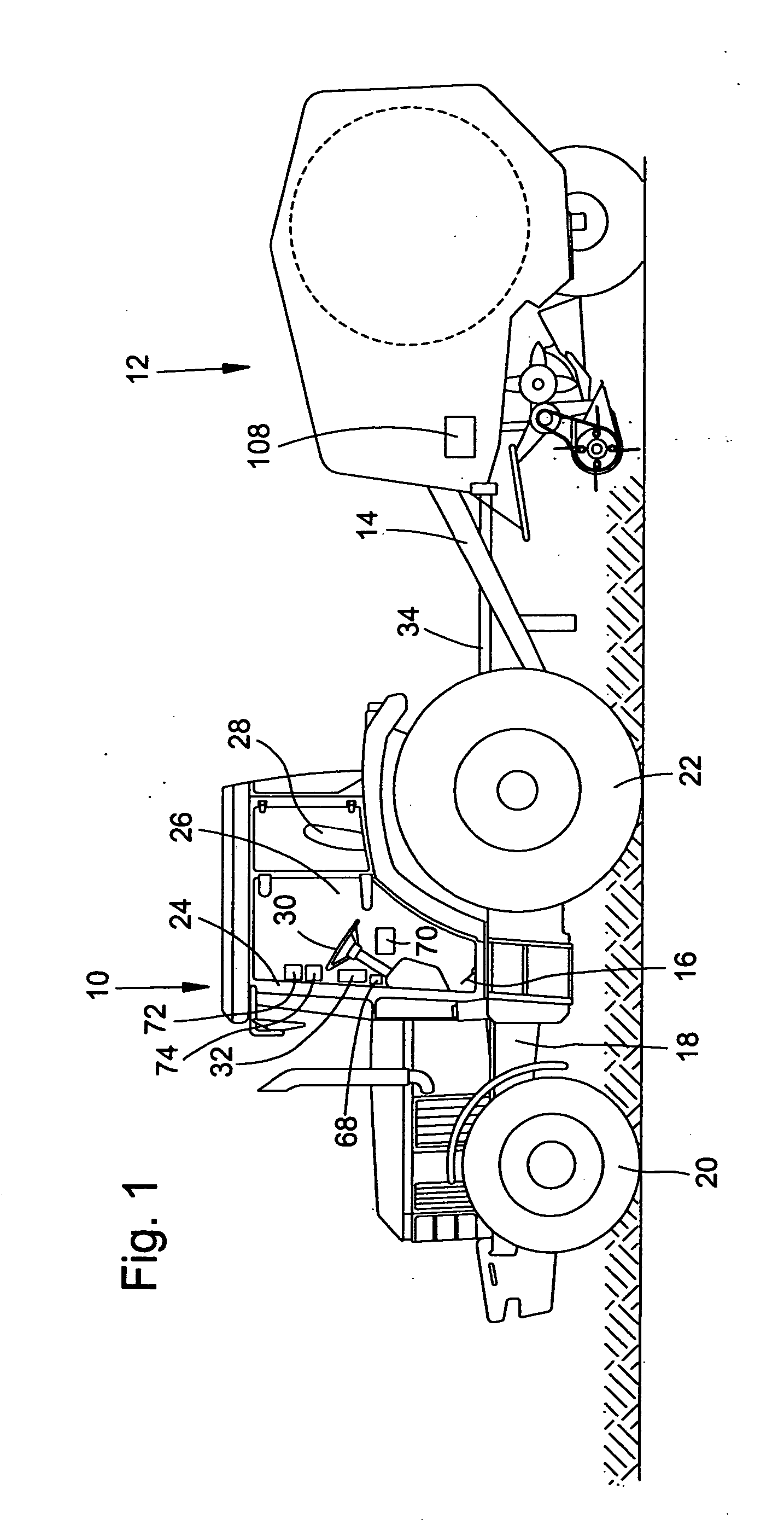

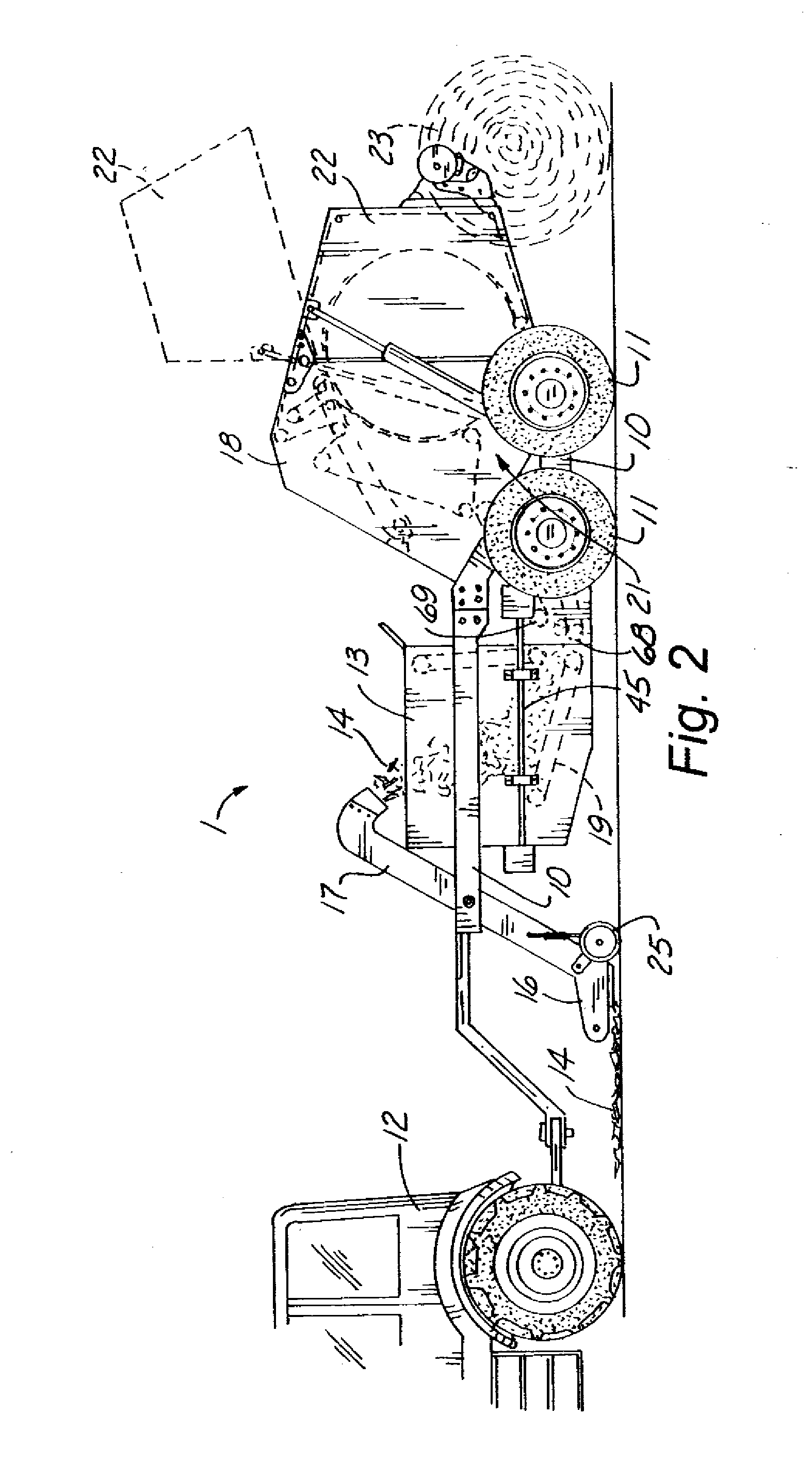

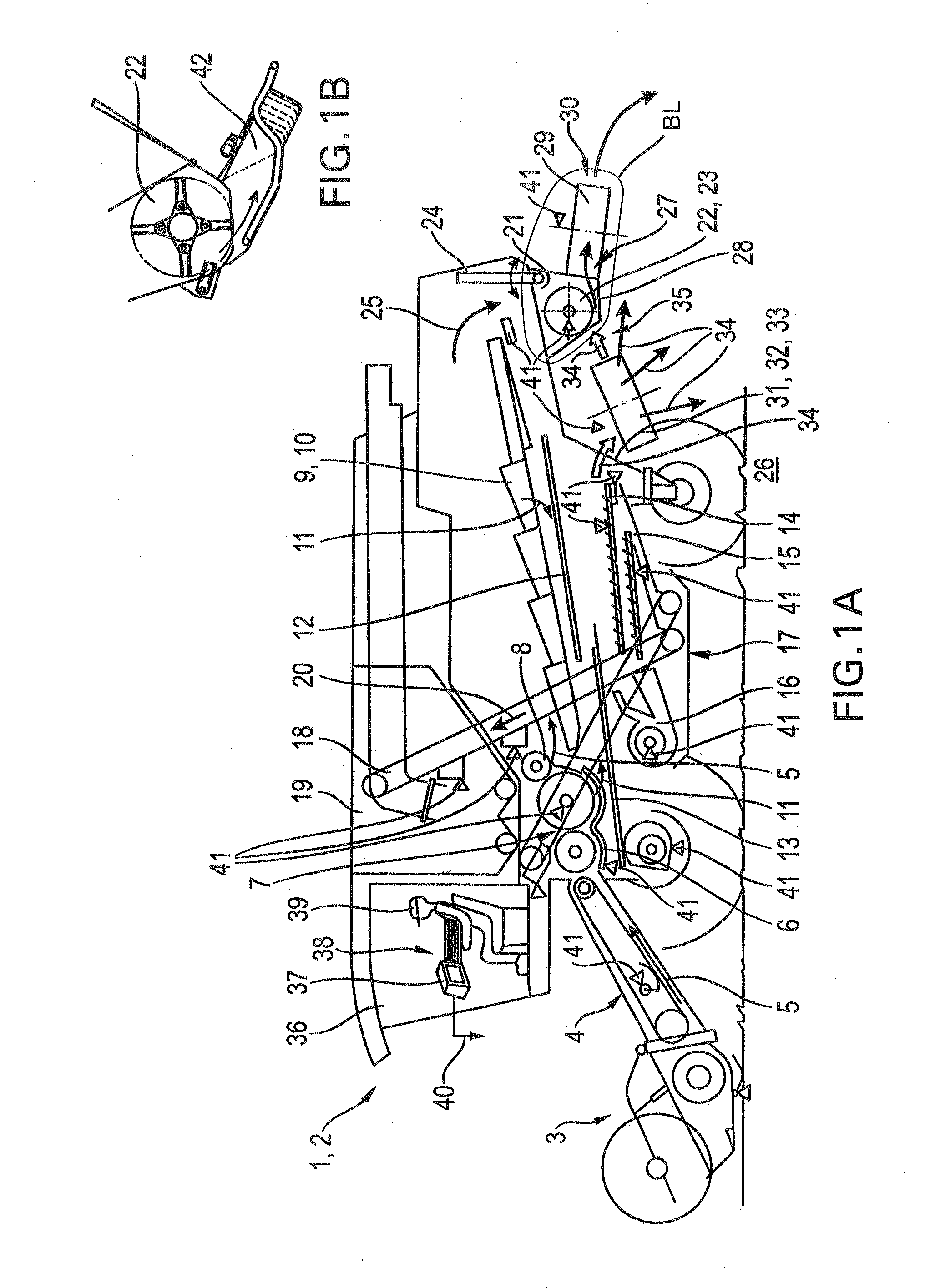

Tractor And Round Baler Combination With Automatic Baling And Automatic Rear Door Opening

A tractor comprises an electronic tractor controller. A baler comprises a crop receiving means, a baling chamber, a rear door, a rear door actuator, a bale size sensor associated with the baling chamber, and an electronic baler controller. The baler controller is operable to submit a halt signal to the tractor controller when a bale size signal provided by the bale size sensor indicates that a bale has reached a size corresponding to a predetermined size. The tractor controller then halts the tractor and the bale is wrapped. The rear door is opened automatically after the bale has been wrapped, but only if an obstacle sensor detects no obstacle in a detection zone behind the baler.

Owner:DEERE & CO

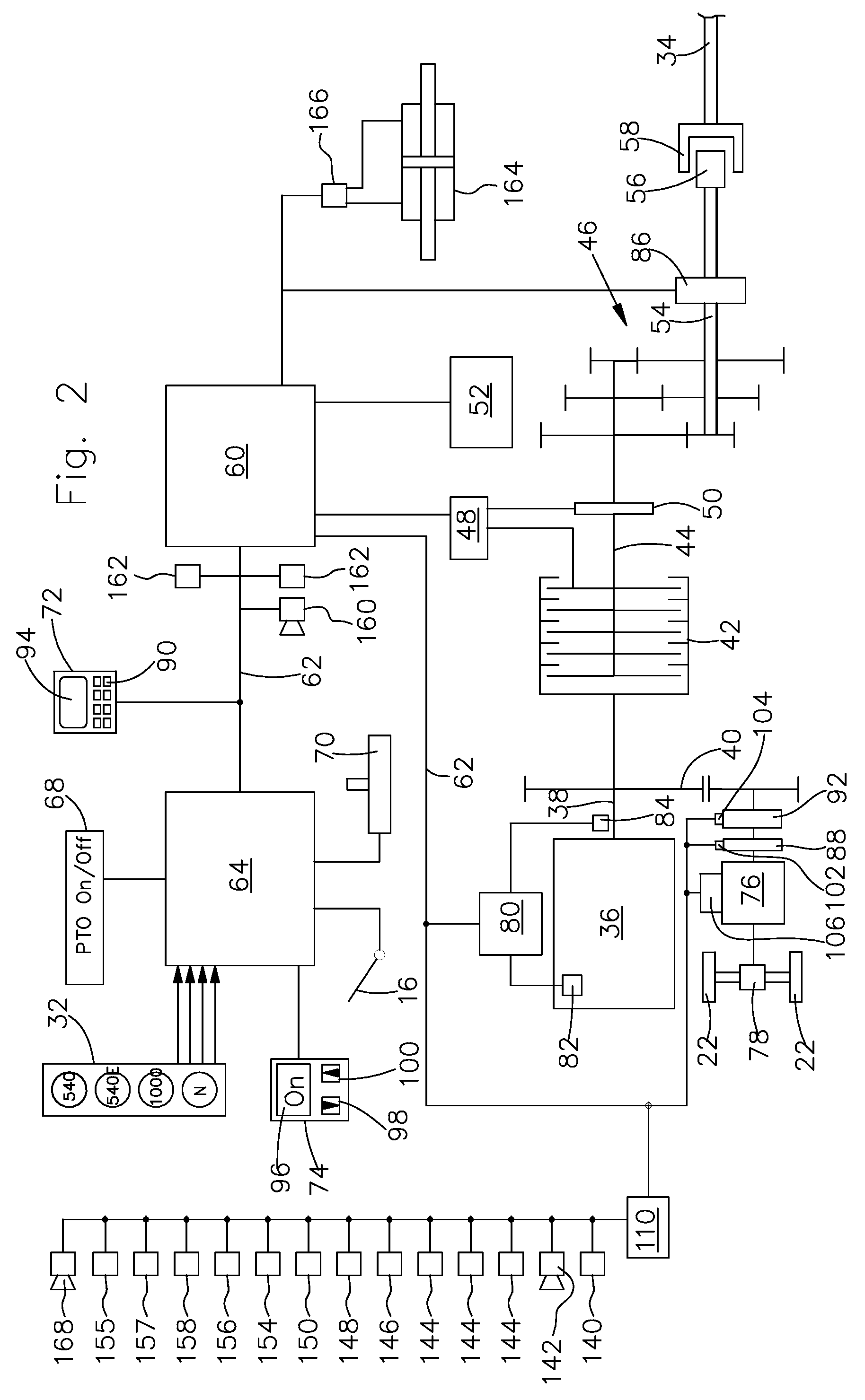

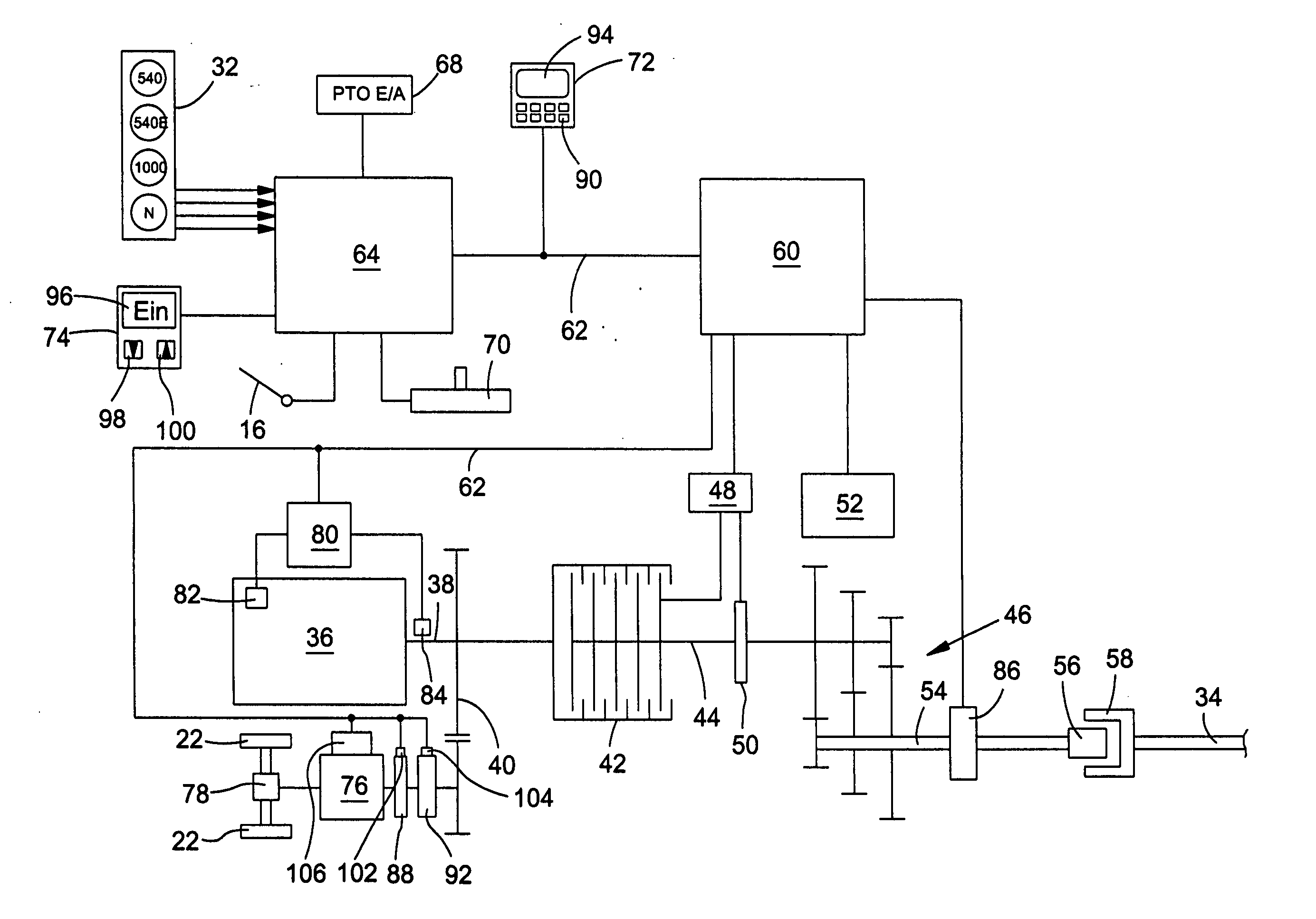

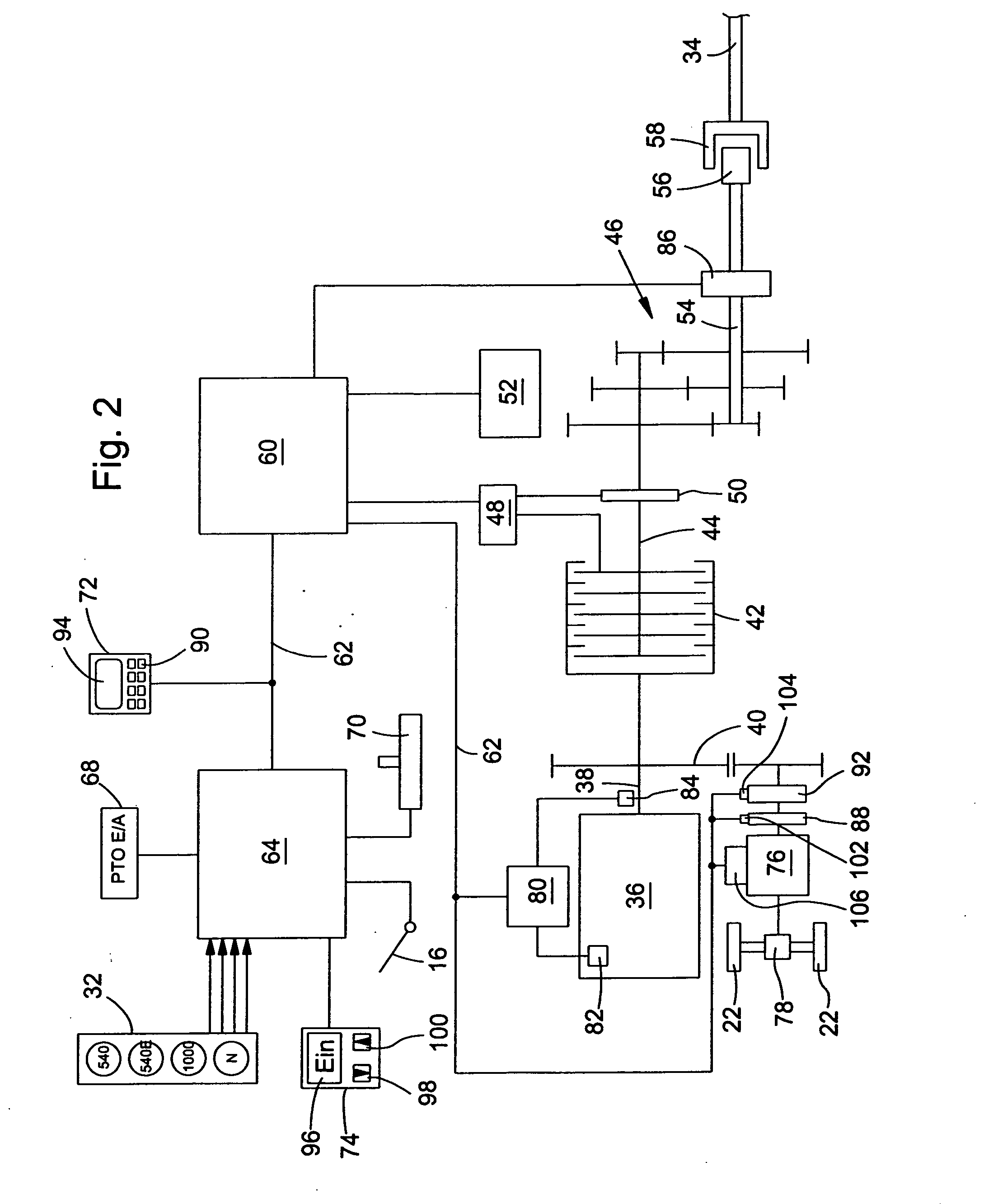

Agricultural machine with PTO torque limiting feature

ActiveUS20060191359A1Shorten speedOverloading can be reducedAgricultural machinesGearingDrive motorActuator

A drive assembly for an agricultural machine. A power take off (PTO) output shaft is connected to a driving motor for driving an attachment. A drive transmission is positioned between and interconnects the driving motor and the support wheels of the agricultural machine. An input device is connected to an electronic control unit. A sensor senses the torque transferred between an attachment and the PTO output shaft, and an actuator is configured to change the transmission ratio of the drive transmission, thereby setting the propulsion speed of the agricultural machine such that the torque transferred between the PTO output shaft and an attachment does not exceed a pre-determined value. The electronic control unit further receives data from the input device and calculates a pre-determined value based on the data received, and thereafter controls the actuator accordingly.

Owner:DEERE & CO

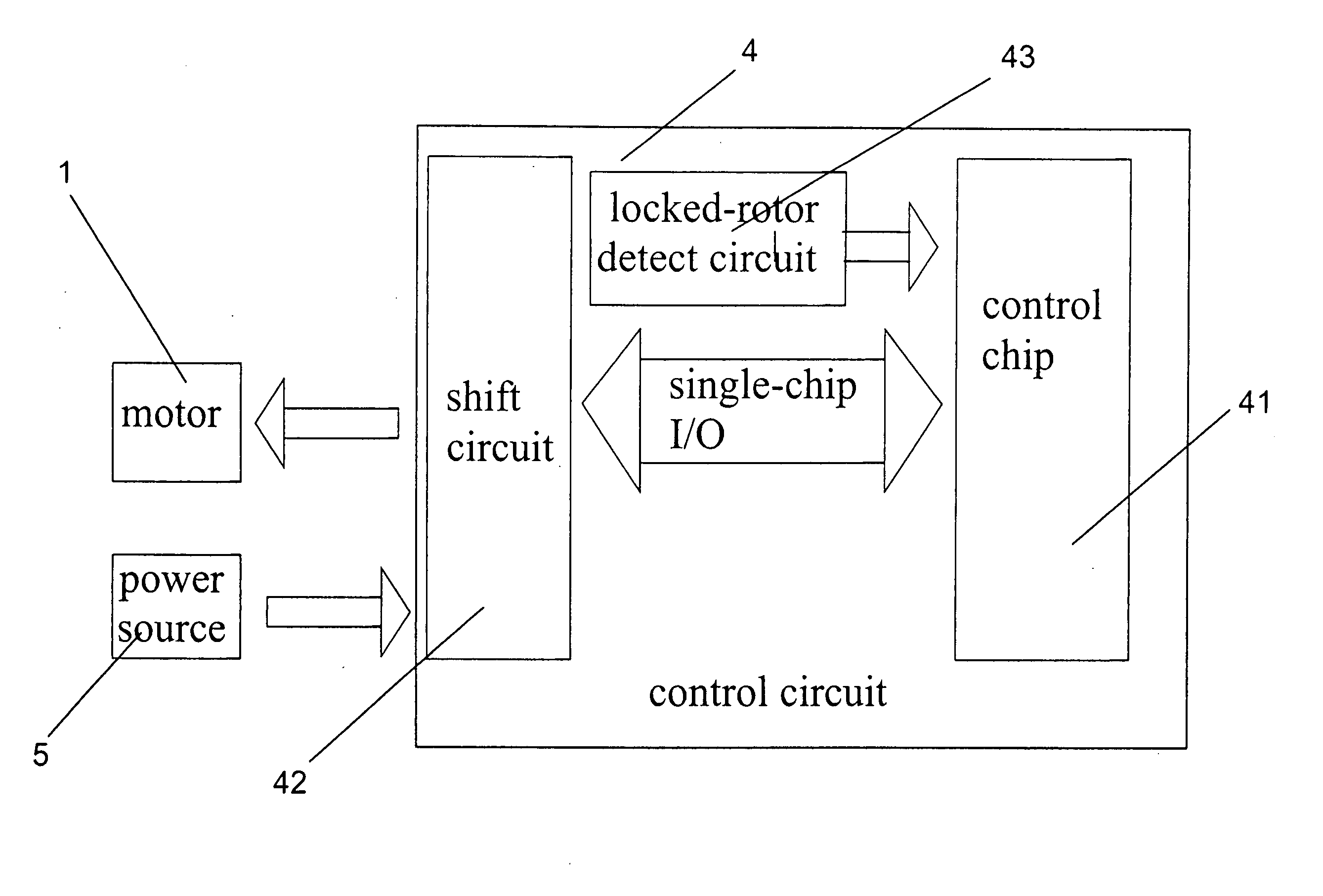

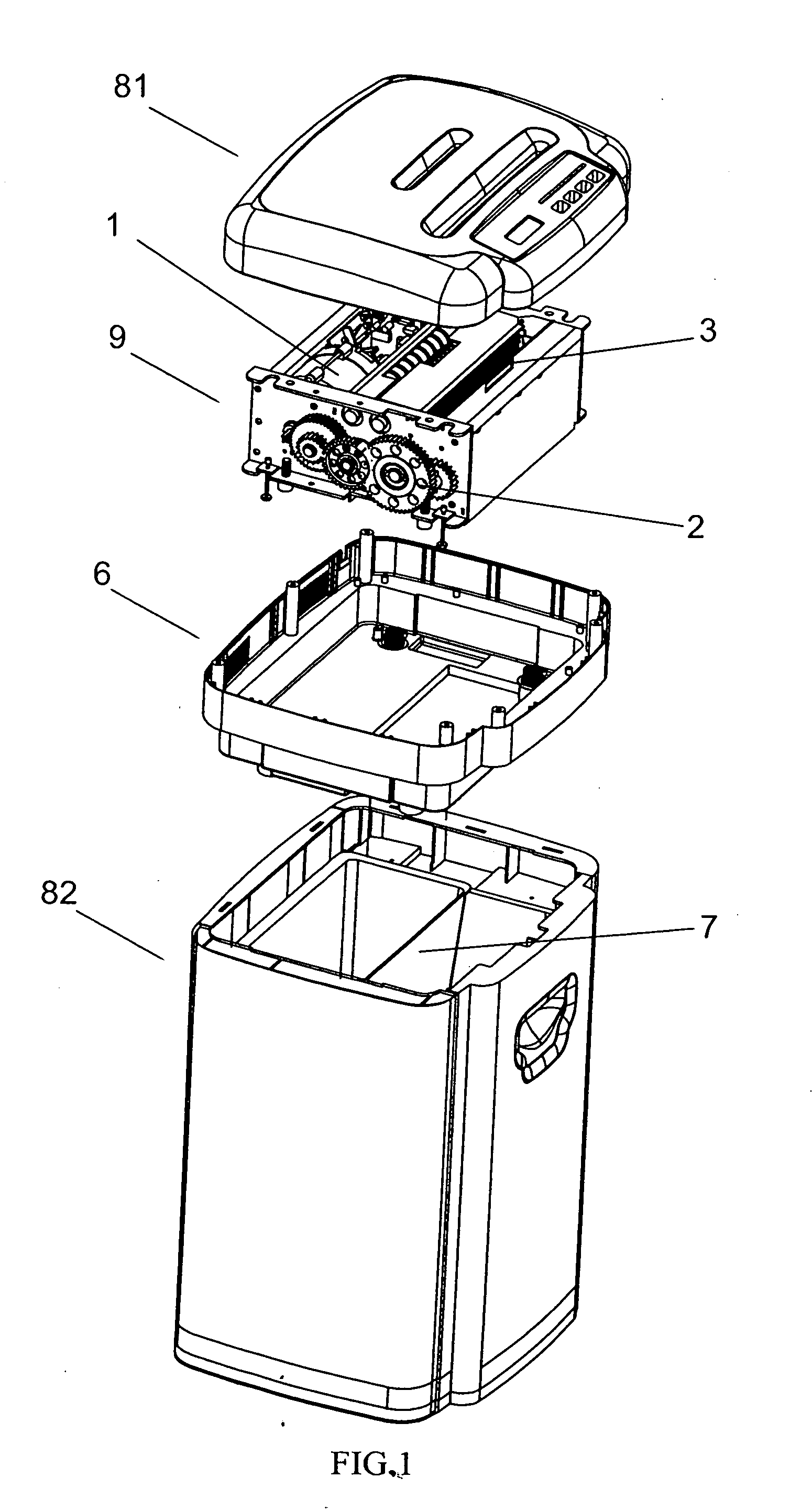

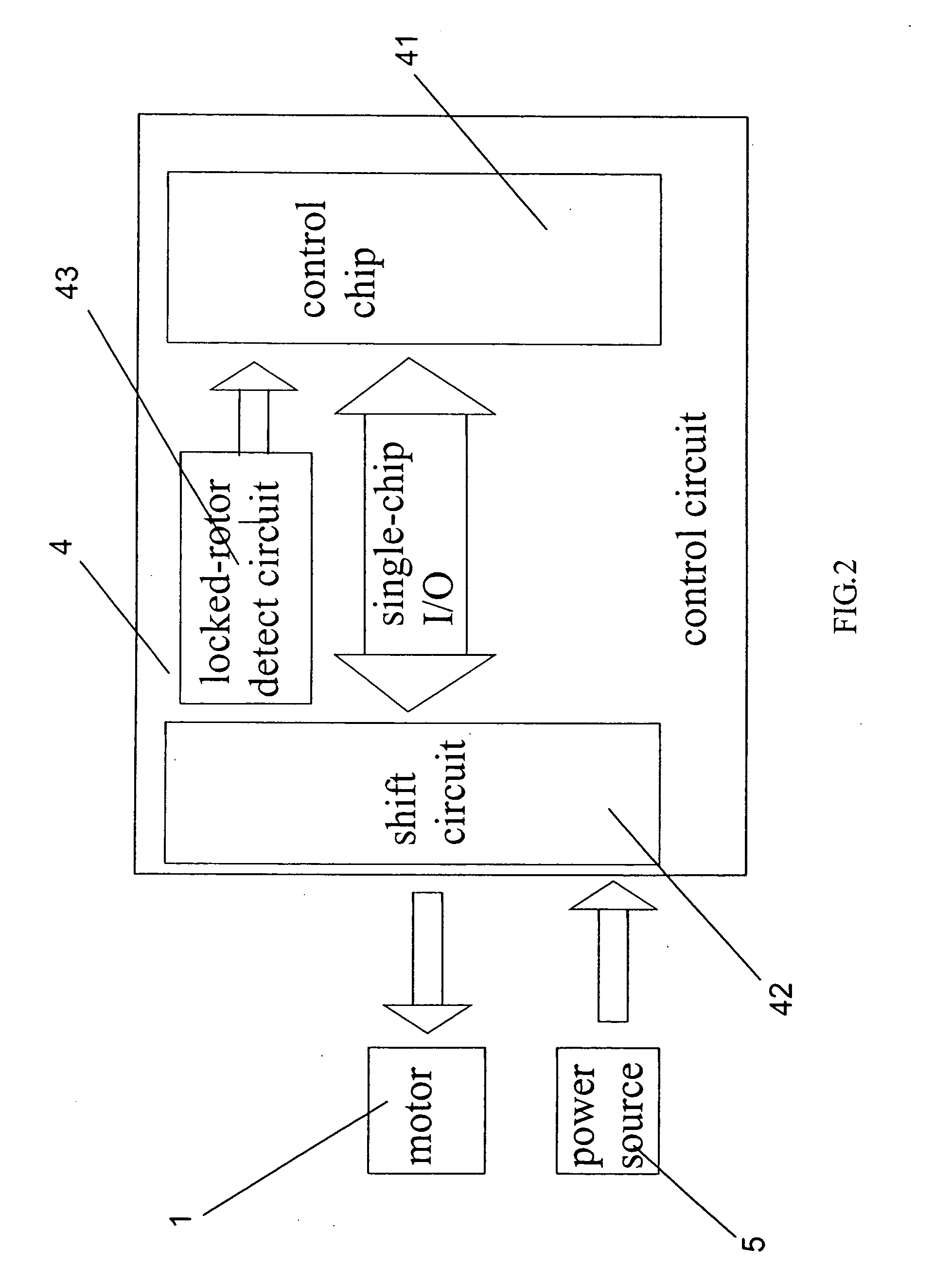

Intelligent shift paper shredding mechanism and method of automatic shift of the same

An intelligent shift paper shredding mechanism and a method of automatic shift of the same in accordance with the present invention includes a control circuit including a control chip electrically connecting with a shift circuit and a locked-stator detect circuit. The shift circuit electrically connects with a motor. The method of adjusting power of the motor includes steps of: a) turning on the highest tap position switch circuit to initiate the motor; b) automatically switching to the lowest tap position switch circuit after a predetermined time delay; c) when the locked-rotor detect circuit detecting the current tap position cannot shred papers, automatically switching to higher tap position switch circuit, repeating this step until to the highest tap position switch circuit, otherwise keeping on the electrical connection to the current tap position switch circuit; d) when the locked-rotor detect circuit detecting a paper jam, automatically turning on a normal-reverse switch circuit and corresponding tap position switch circuit at the same time to exit the jammed papers. The cooperation between the shift circuit and the locked-rotor detect circuit realizes the goal of adjusting power of the motor intelligently according to different quantities of the papers, and thus, makes the paper shredder in which the paper shredding mechanism is used more economic in energy.

Owner:GUANGZHOU COMET

Apparatus and method for monitoring and controlling an agricultural harvesting machine to enhance the economic harvesting performance thereof

A device is provided for monitoring the economic performance of a machine for harvesting an agricultural product, the device having a plurality of sensors mounted on the machine for detecting operational information about the machine. A controller is provided that is connected to the sensors for receiving the operational information to determine settings for the machine that produce maximum economic return. Means are provided for adjusting settings of the machine either by the operator or by an automatic controller based on the determined settings to achieve maximum economic return. A method for adjusting the settings of an agricultural harvesting machine to produce maximum economic return also is provided.

Owner:IOWA STATE UNIV RES FOUND

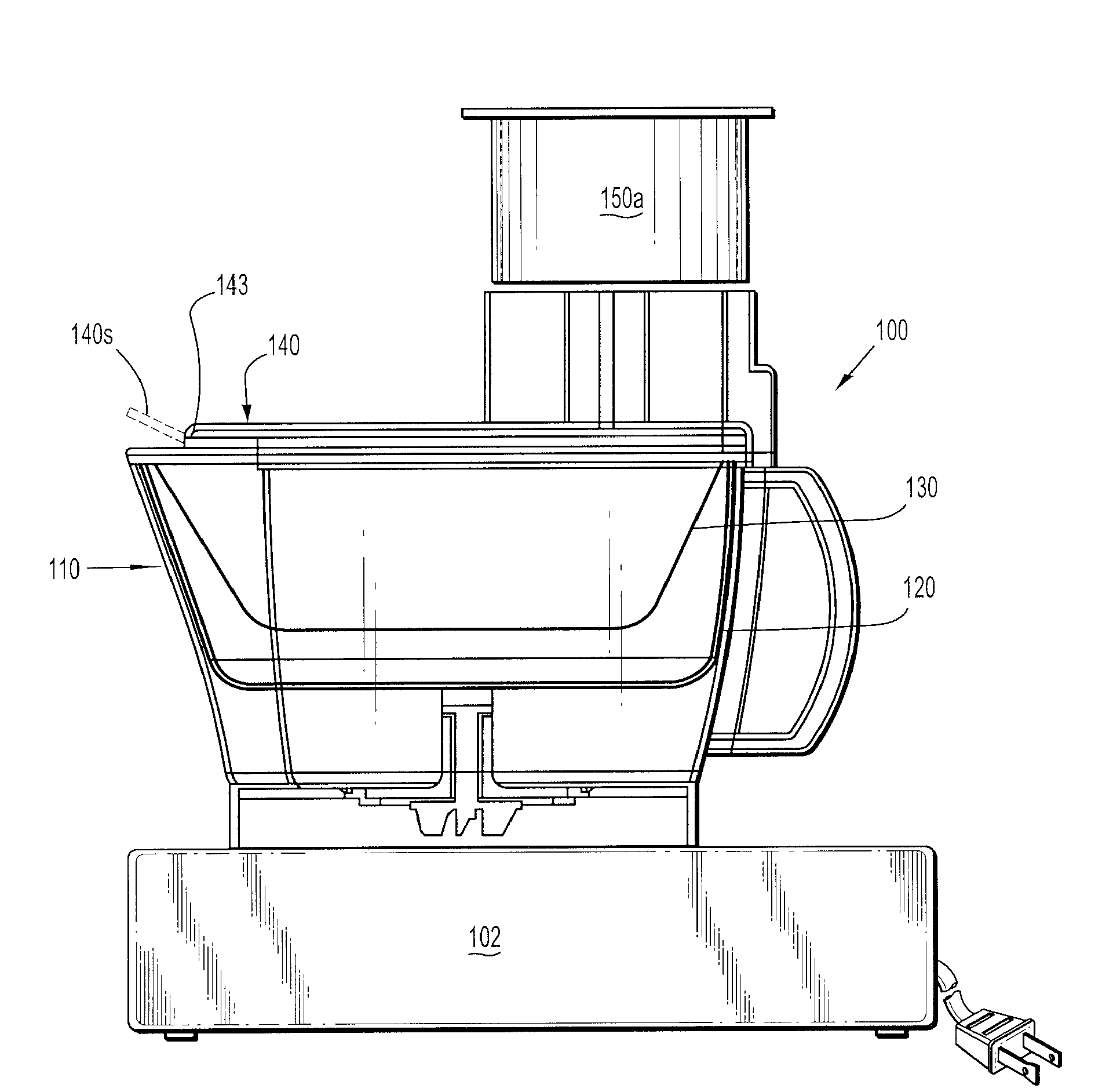

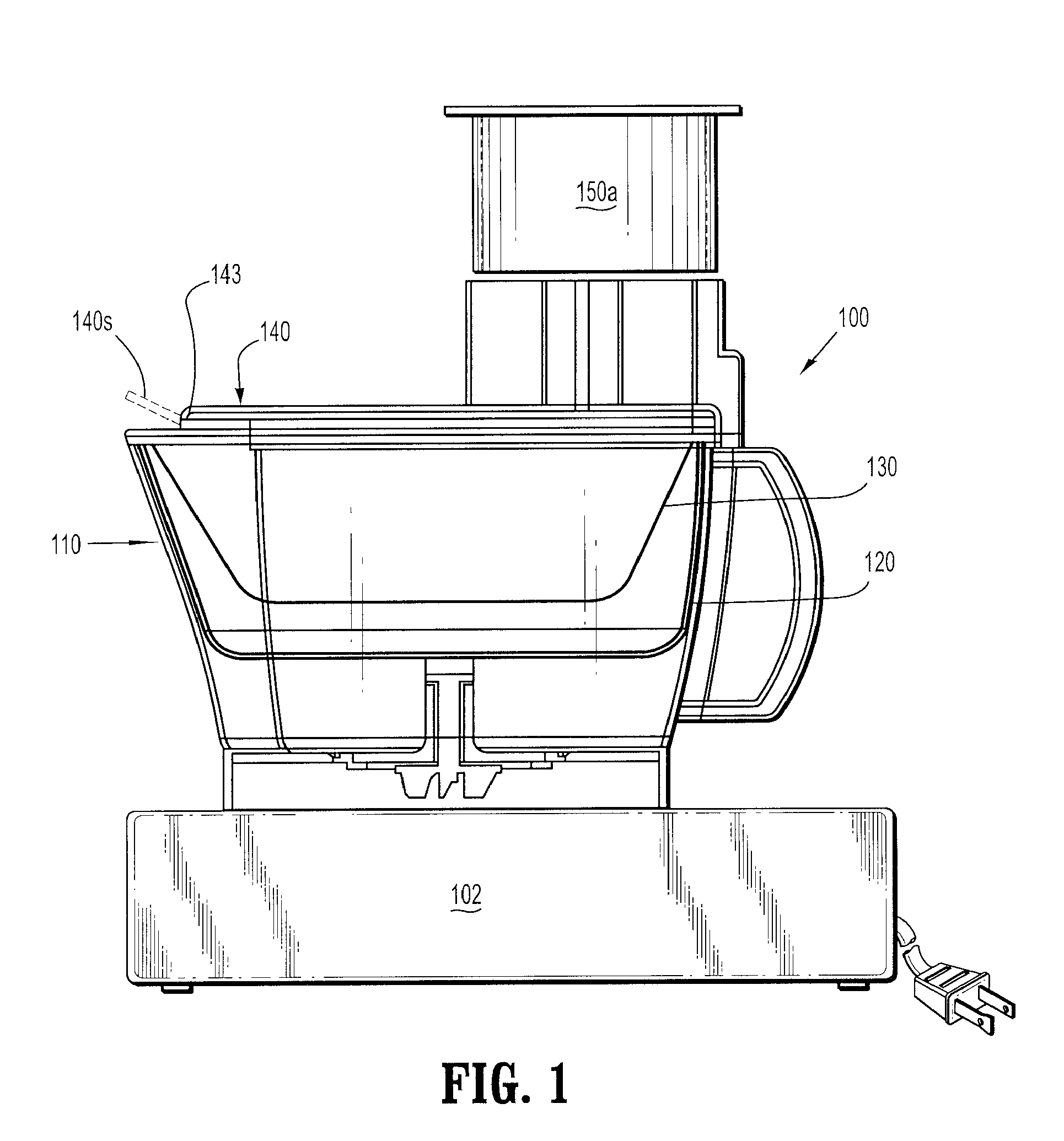

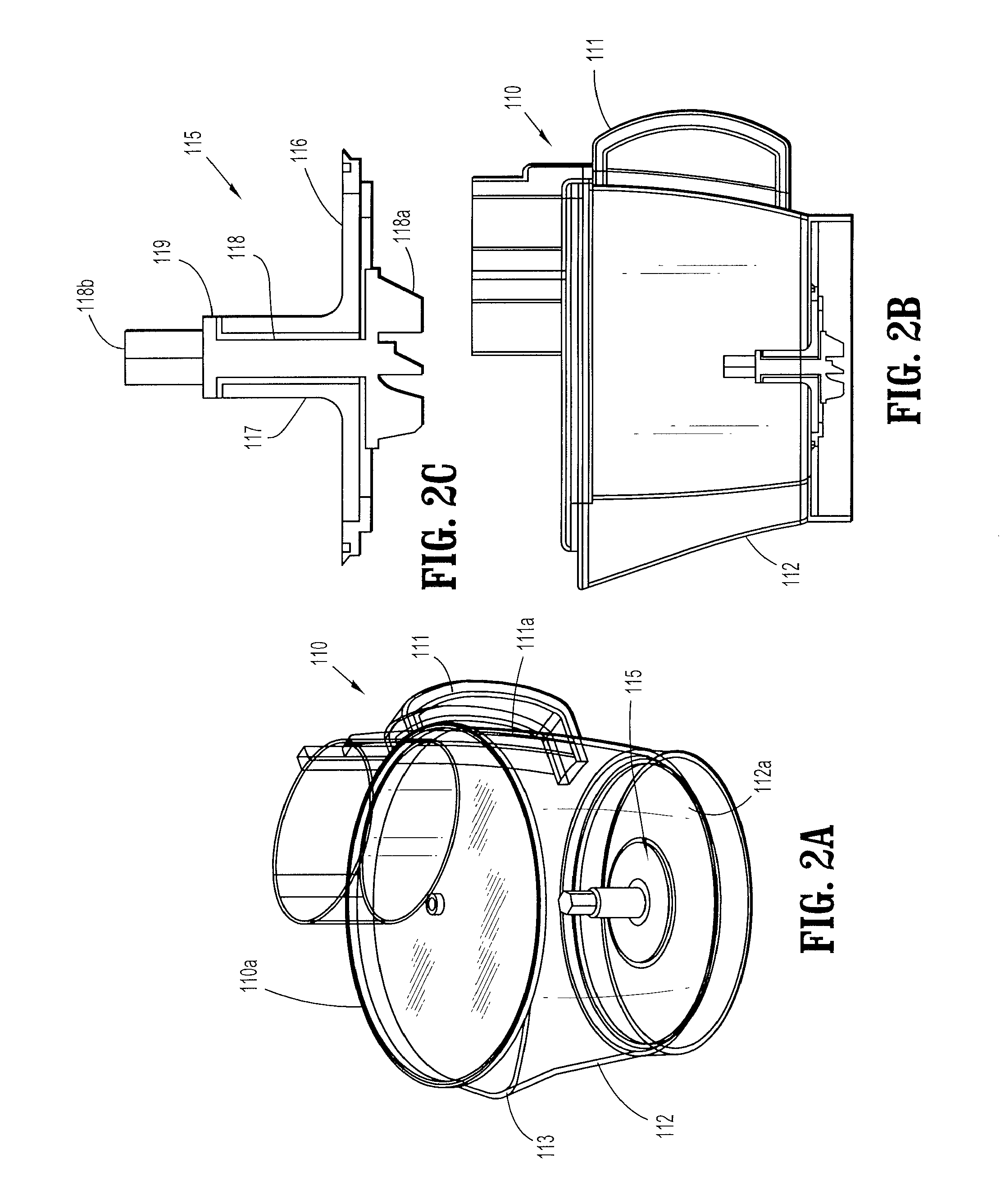

Food processor

A food processor (100) includes one or more of a removable feed tubes (155), a cover or lid (156) for a feed tube opening (154), a double sided grating disc (190), a bowl or receptacle (110) having a pour spout and a complimentary hinged spout lid (140s) on the bowl cover (140), a bowl mounted drive shaft (115), an extensible shaft for mounting various blades or discs at various heights, and an adjustable thickness slicing disc (180).

Owner:CONAIR CORP

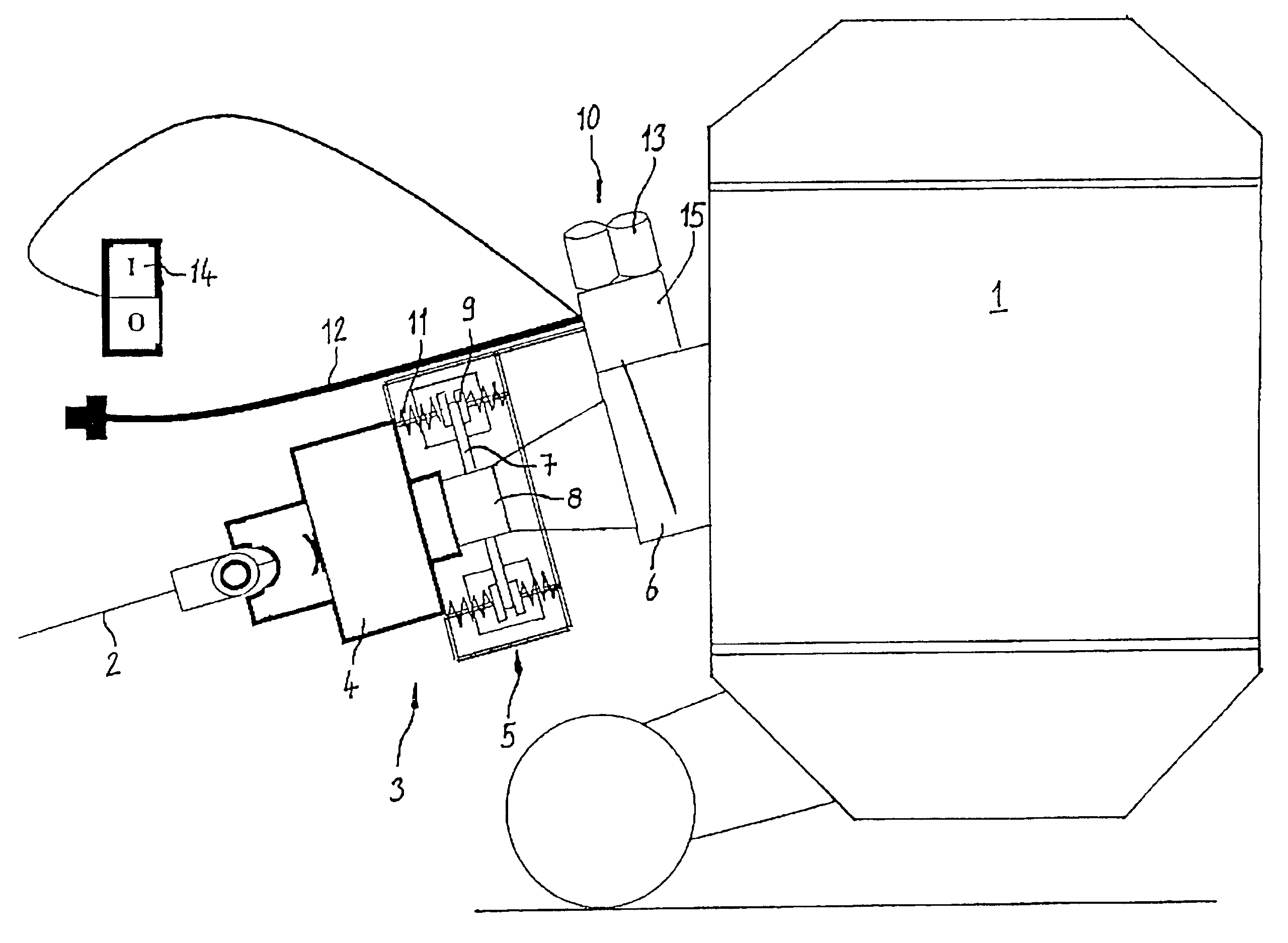

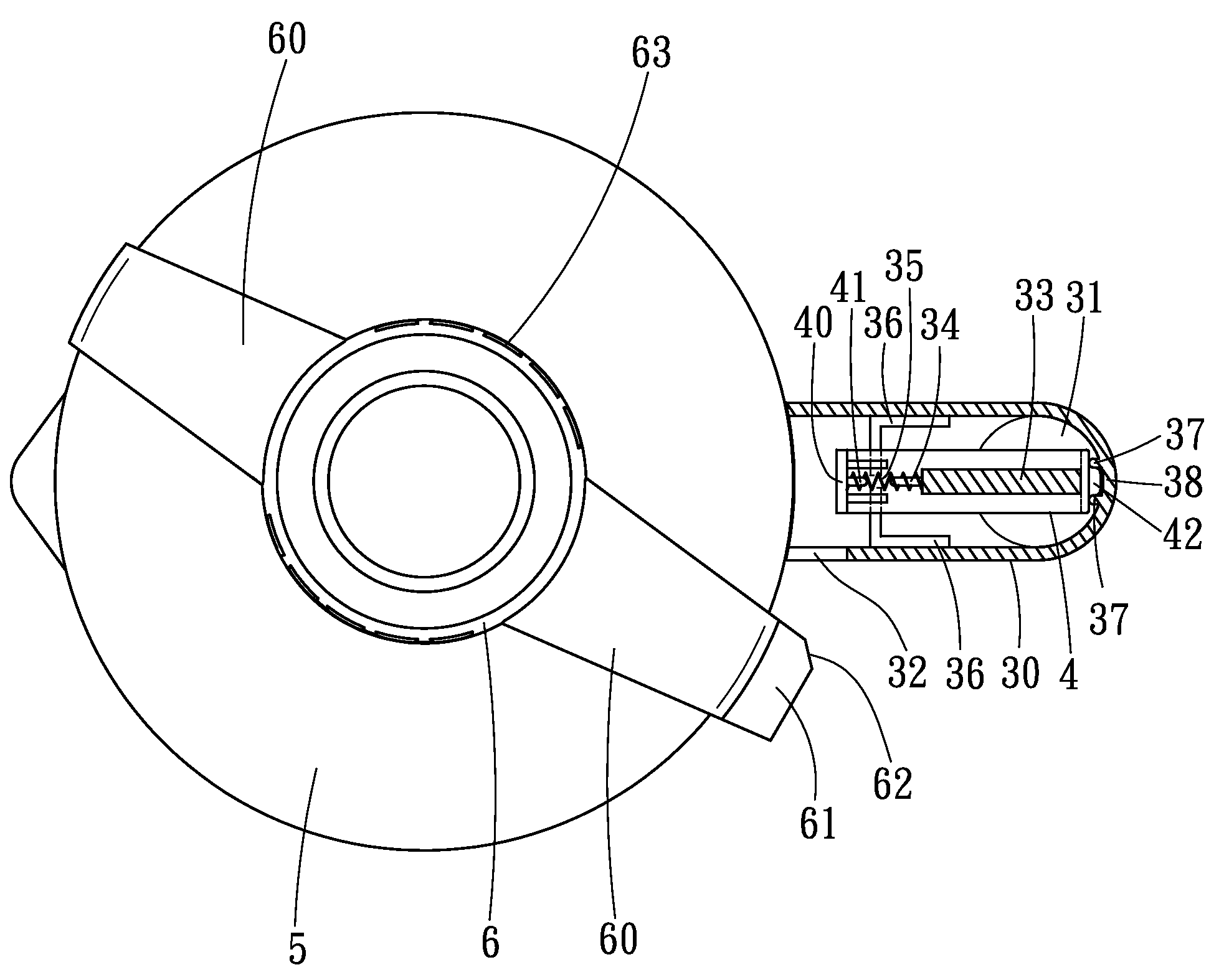

Drive assembly for locking one or several operating units of an agricultural implement or of a self-propelled implement

InactiveUS7464526B2Quick stopAgricultural machinesMechanical actuated clutchesCouplingElectrical and Electronics engineering

A drive assembly driven by a drive unit locks one or several operating units (6) of an agricultural implement (1) or of a self-propelled implement. The operating unit (6) can be locked when switching off the drive unit or upon reaction of an overload coupling (4). The drive assembly (3) has an overload coupling (4) connected to the drive unit and driven by the drive unit in one driving direction of rotation. The overload coupling (4) is also connected to the operating unit (6). The drive assembly (3) further has a brake unit (5) connected to the overload coupling (4). The brake unit (5) is intended to be arranged in the driveline between the overload coupling (4) and the operating unit (6). Actuating mechanism (10) actuates the brake unit (5) when the operating unit is running so that the operating unit is braked and locked. Thereafter, the overload coupling is disconnected.

Owner:JEAN WALTERSCHEID GMBH

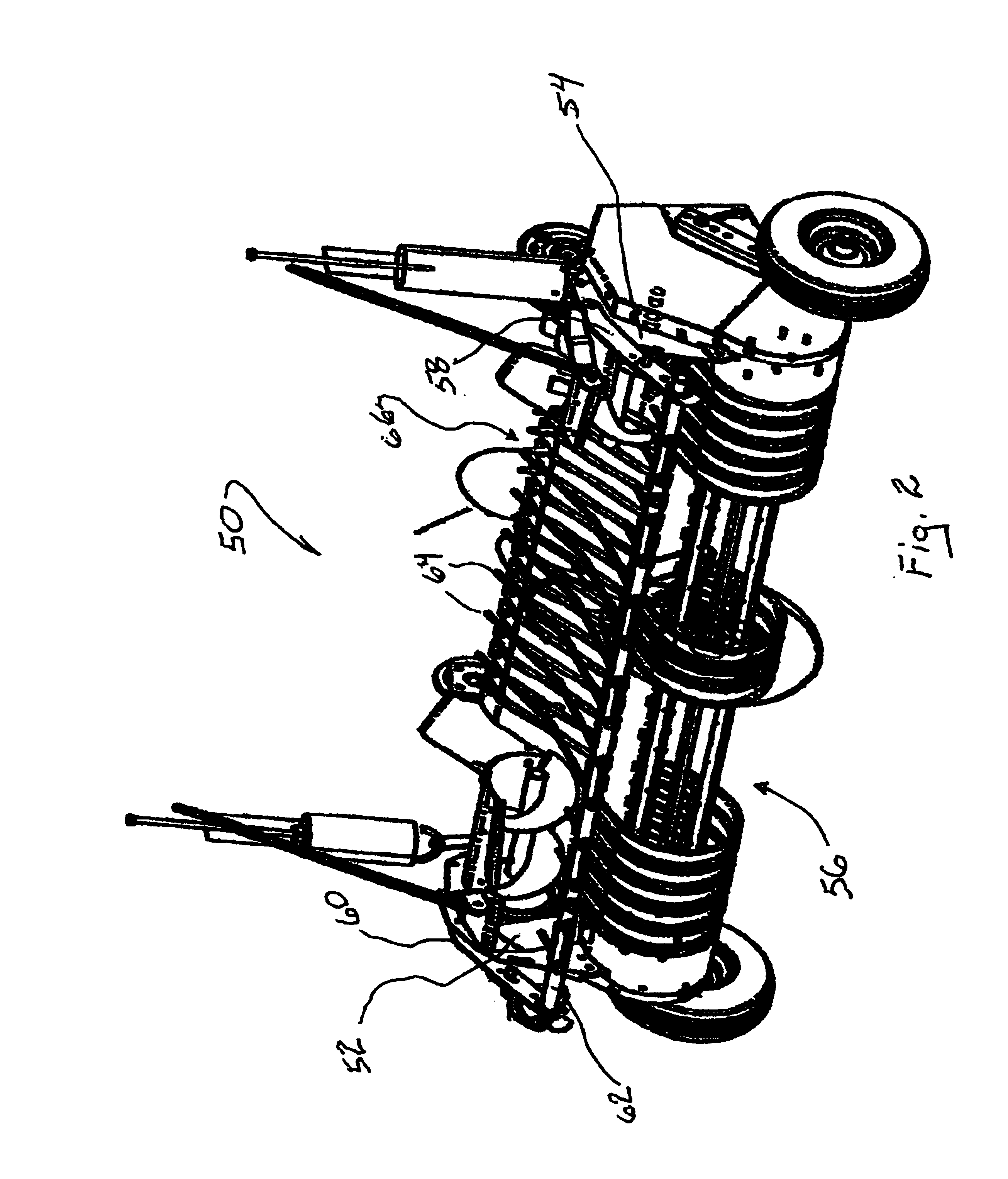

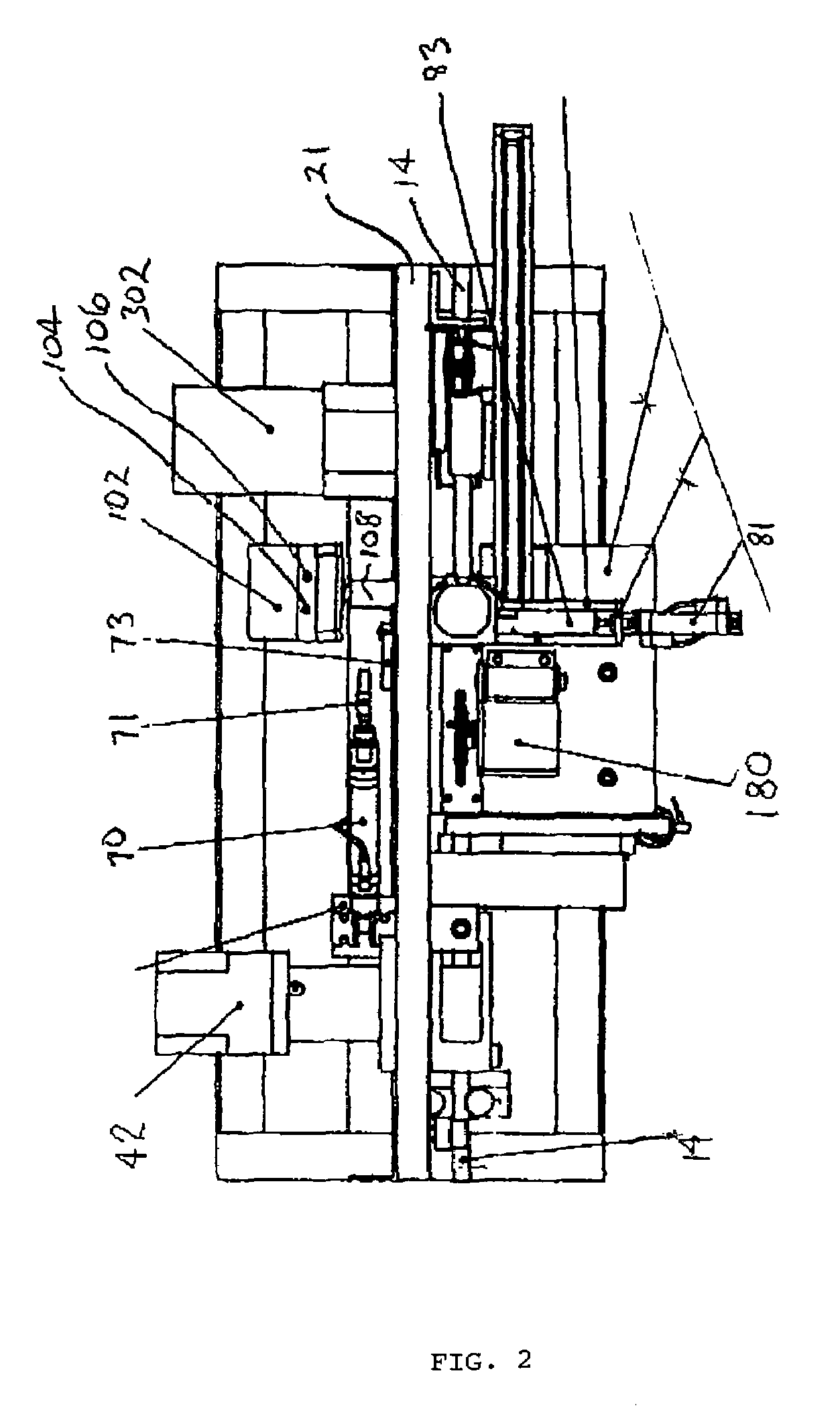

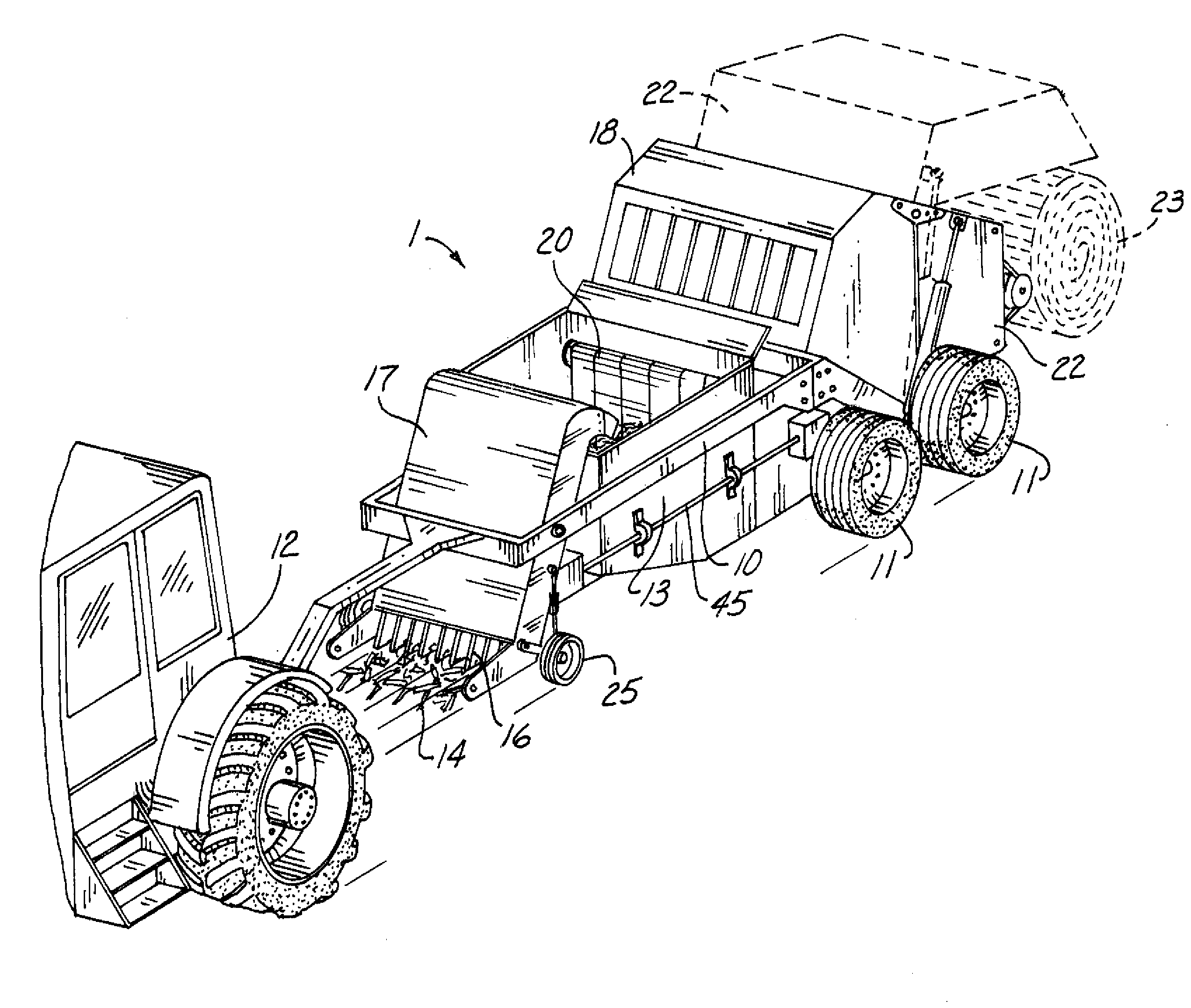

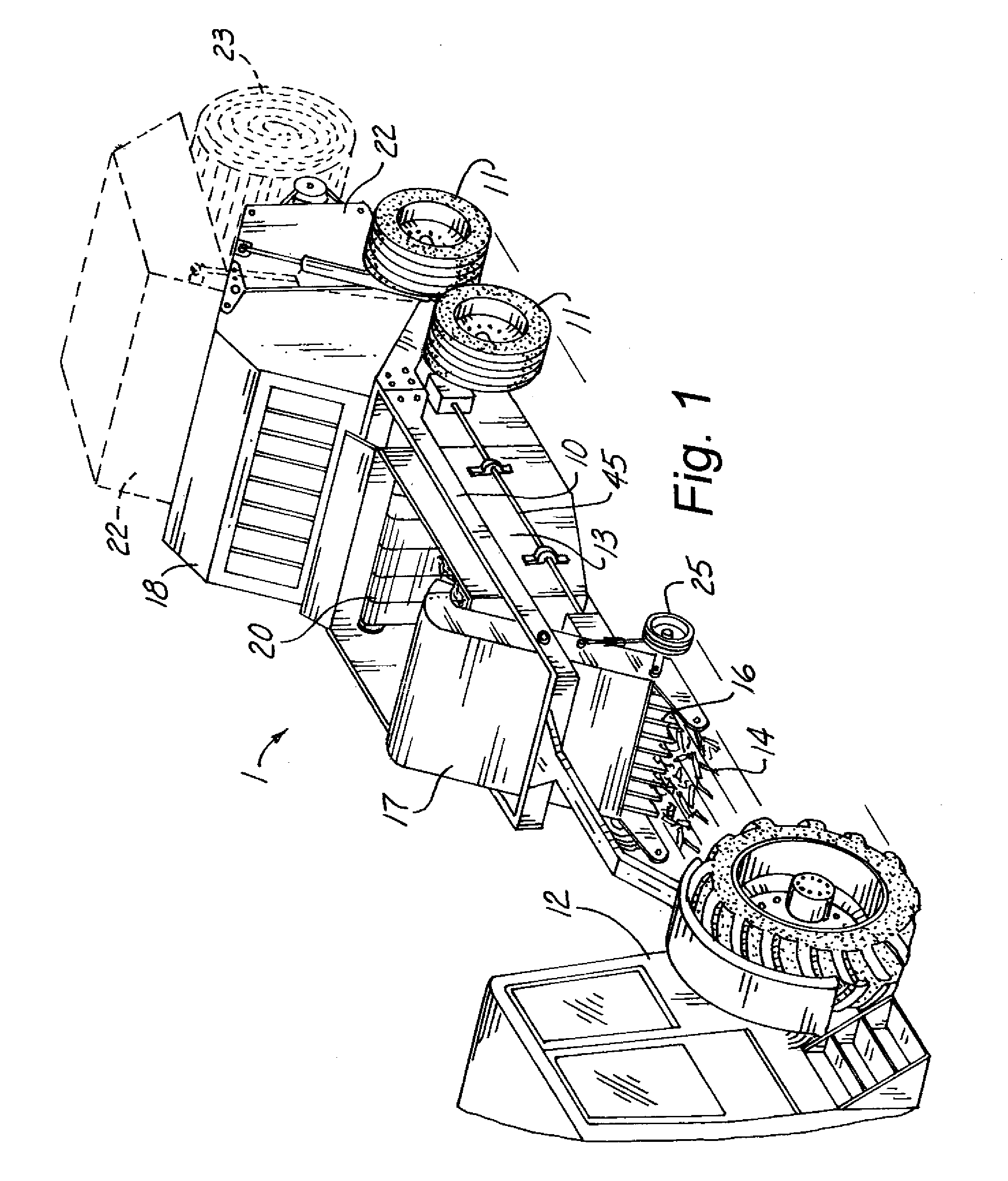

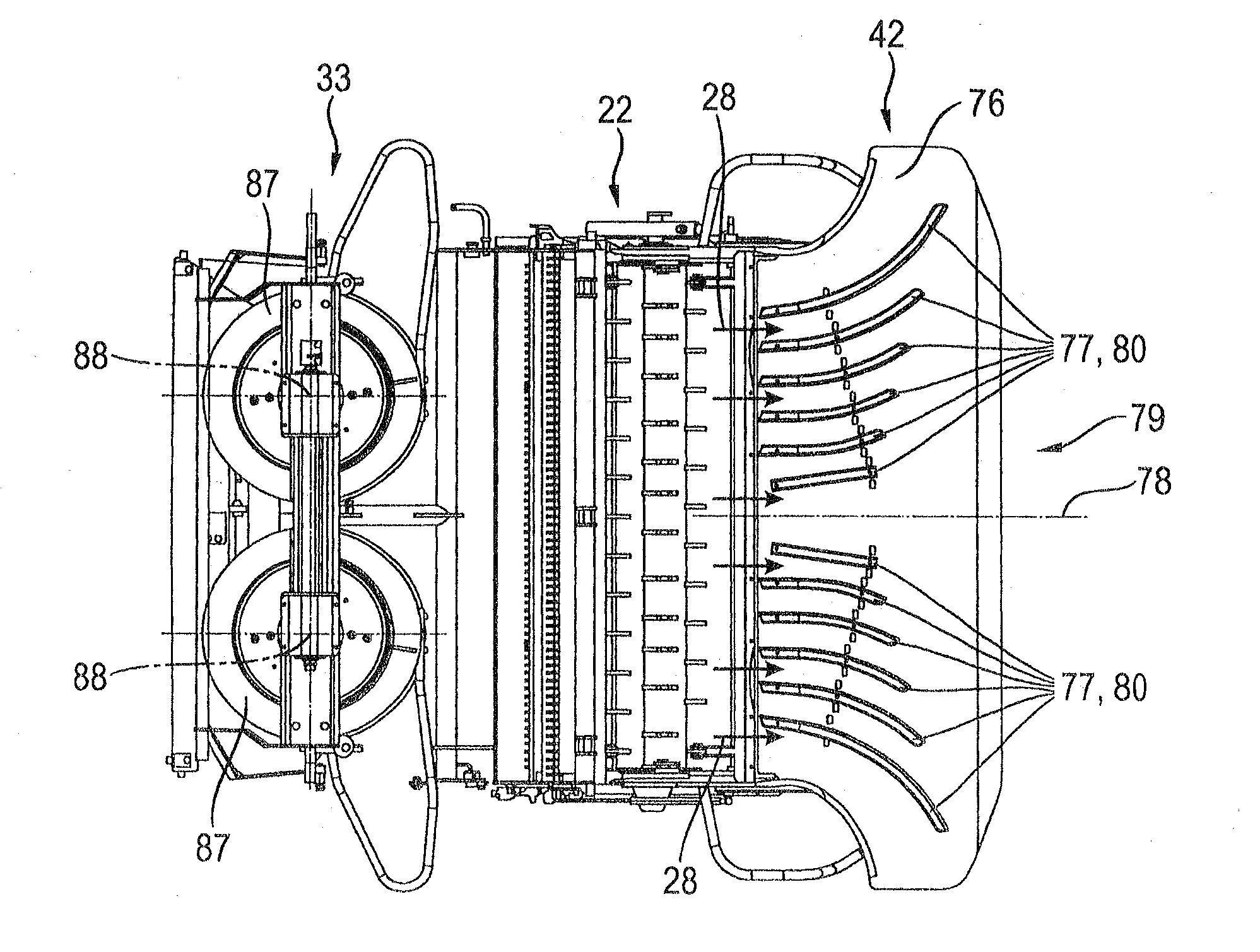

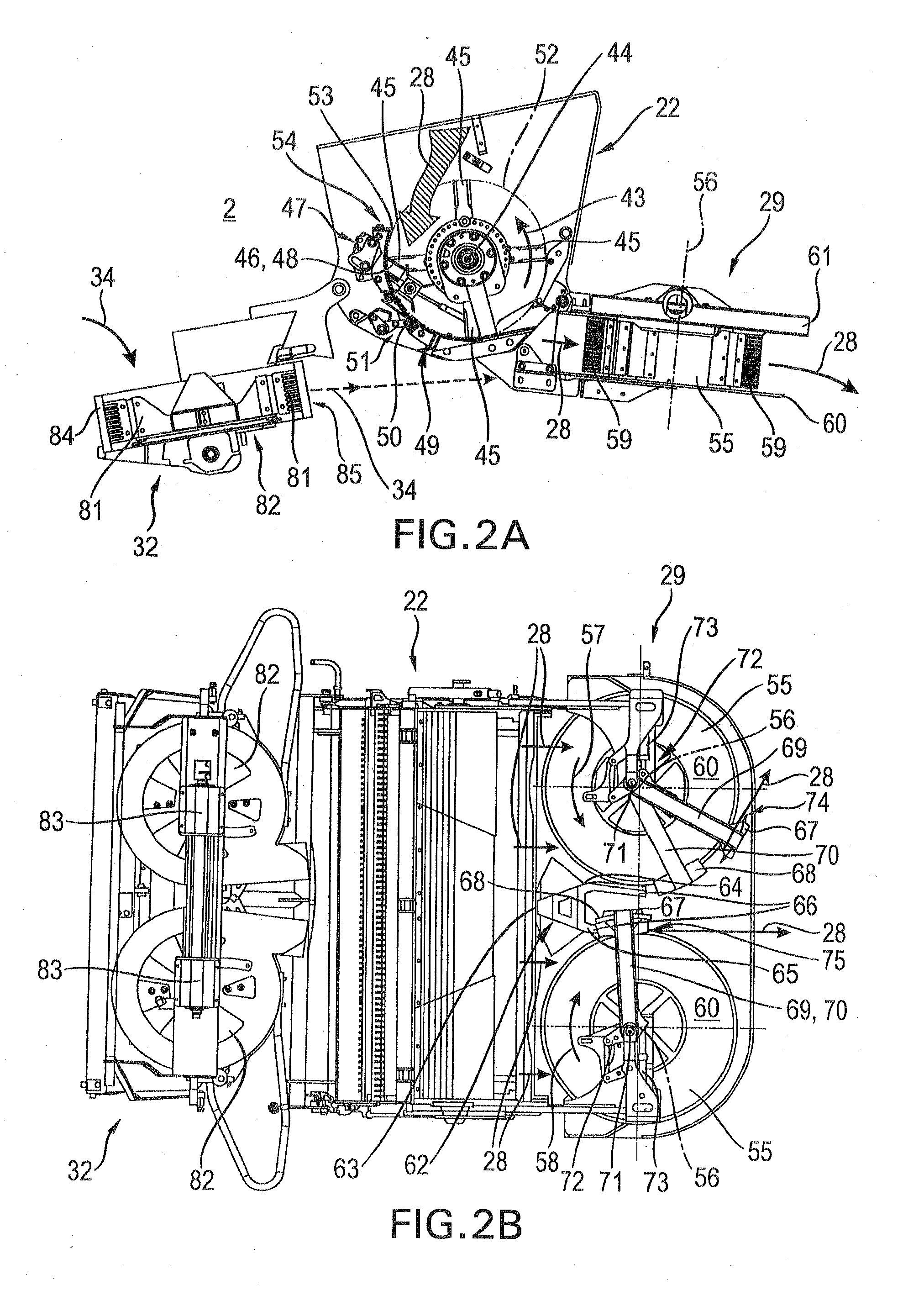

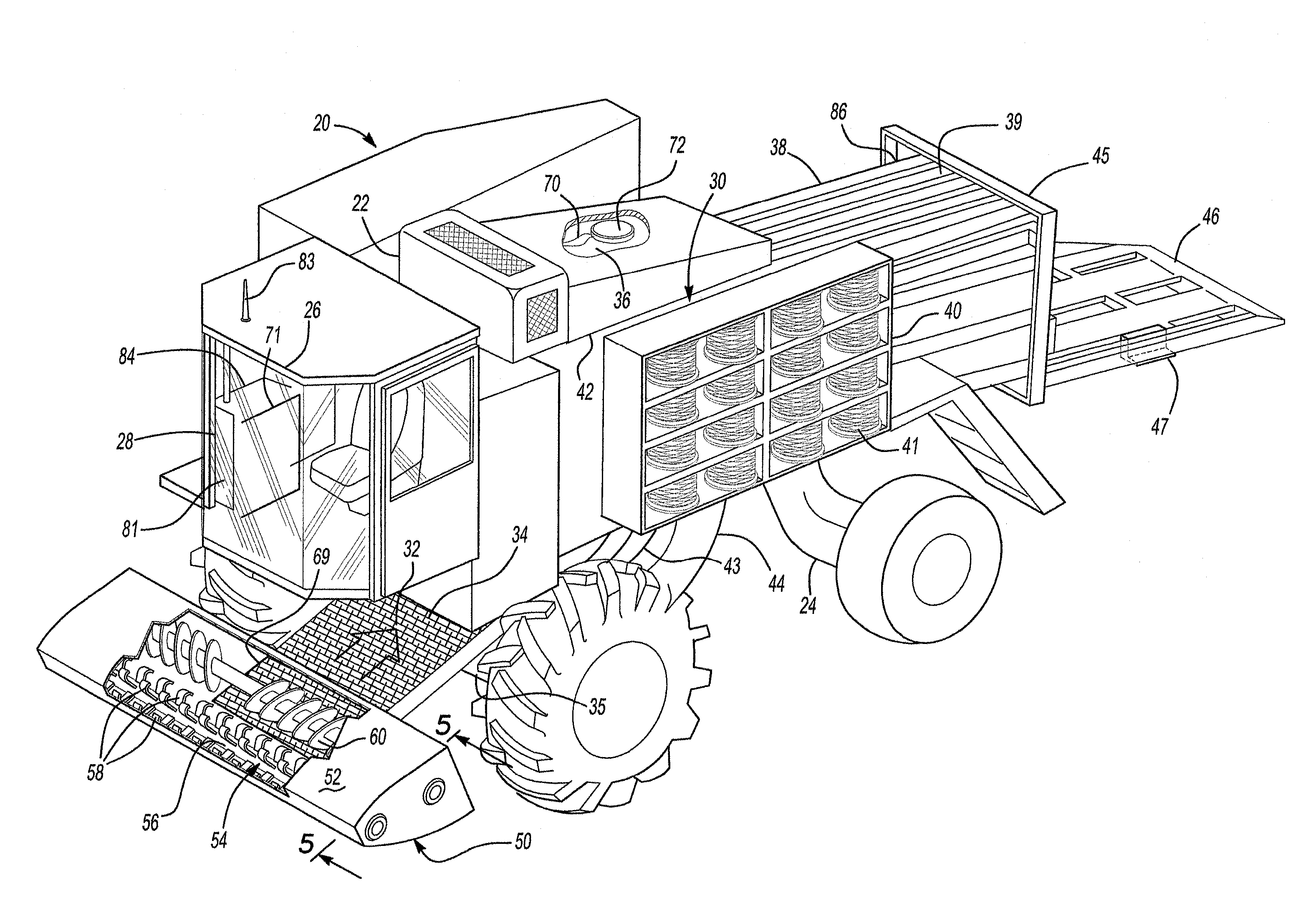

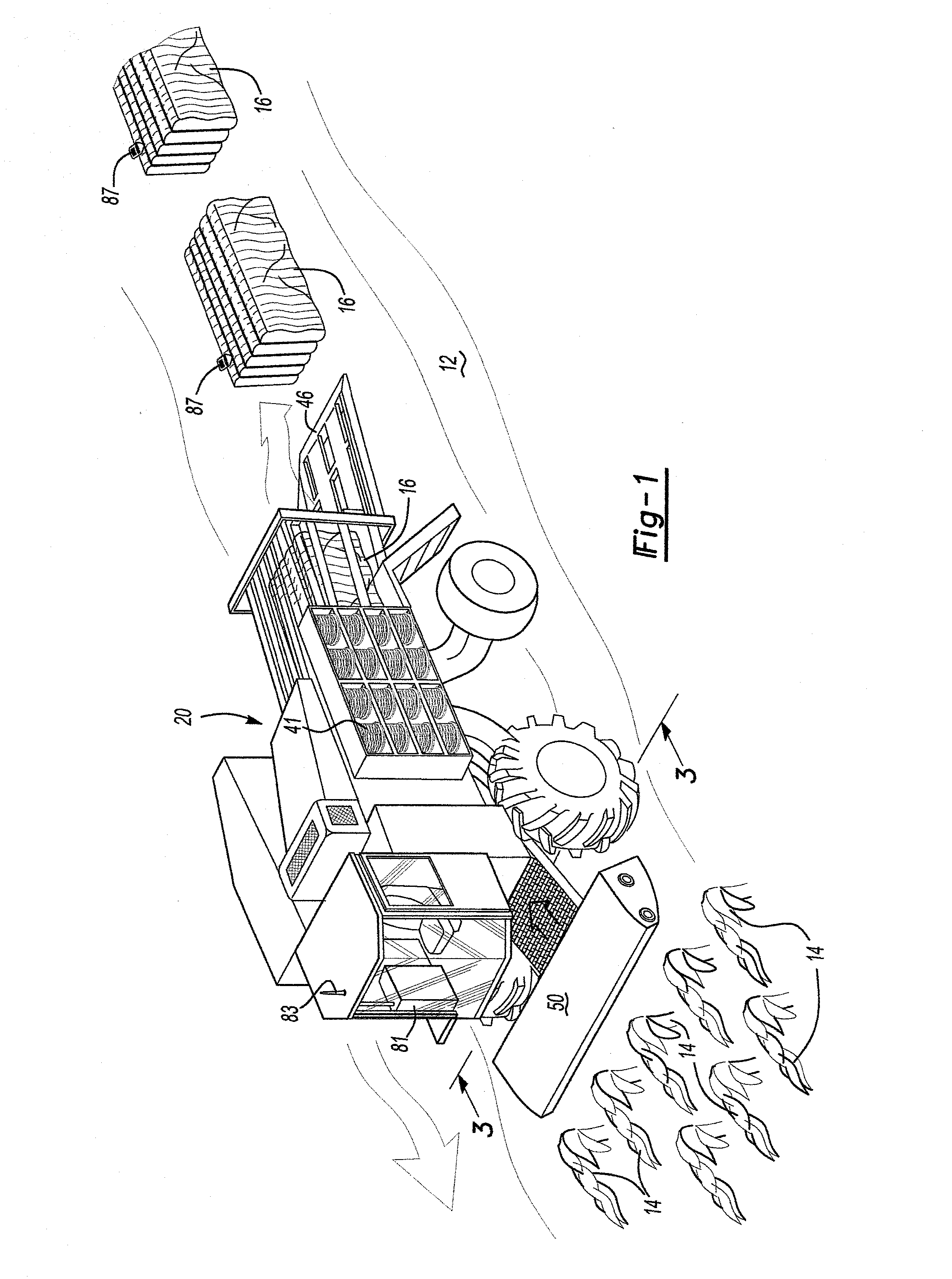

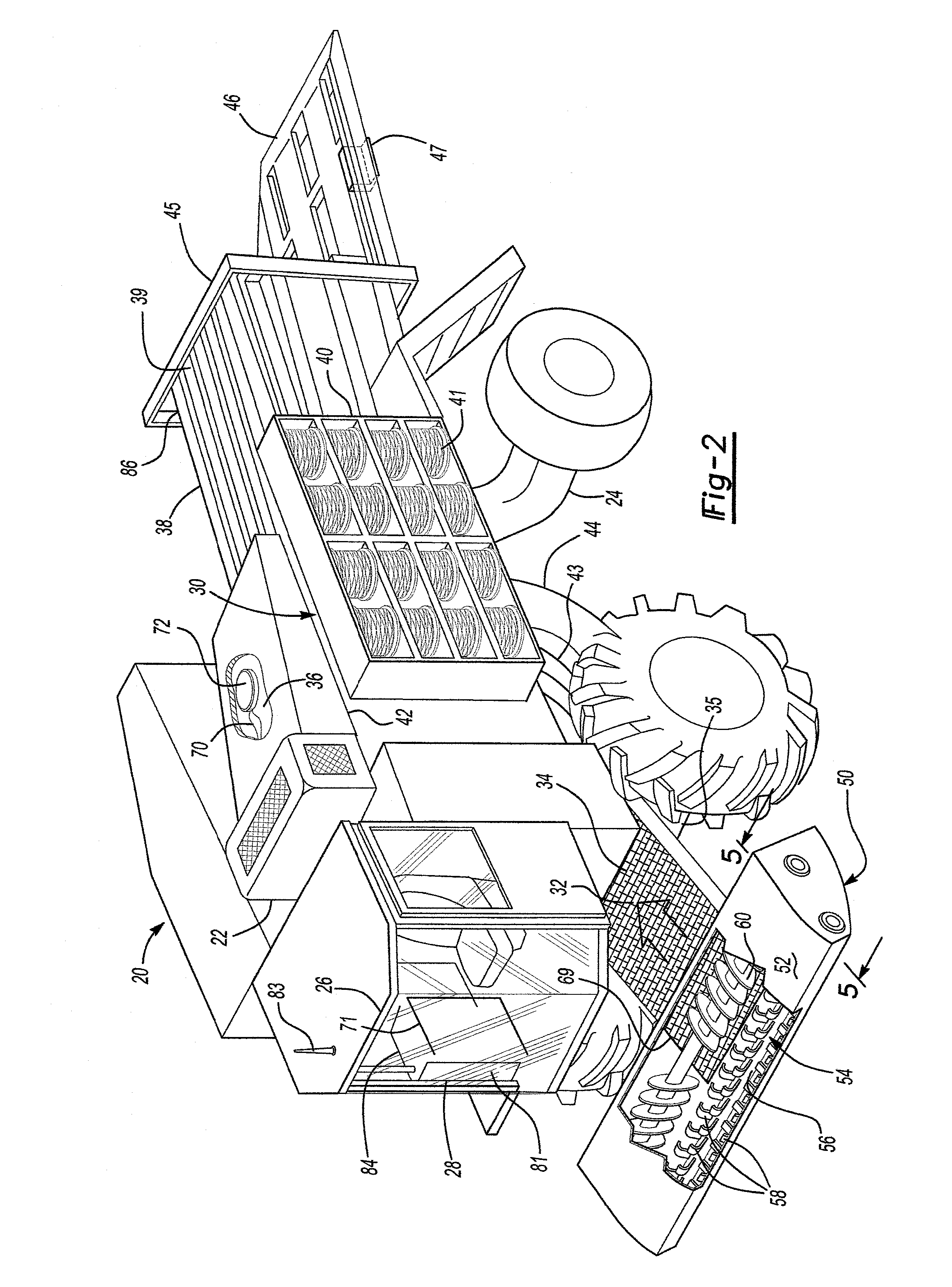

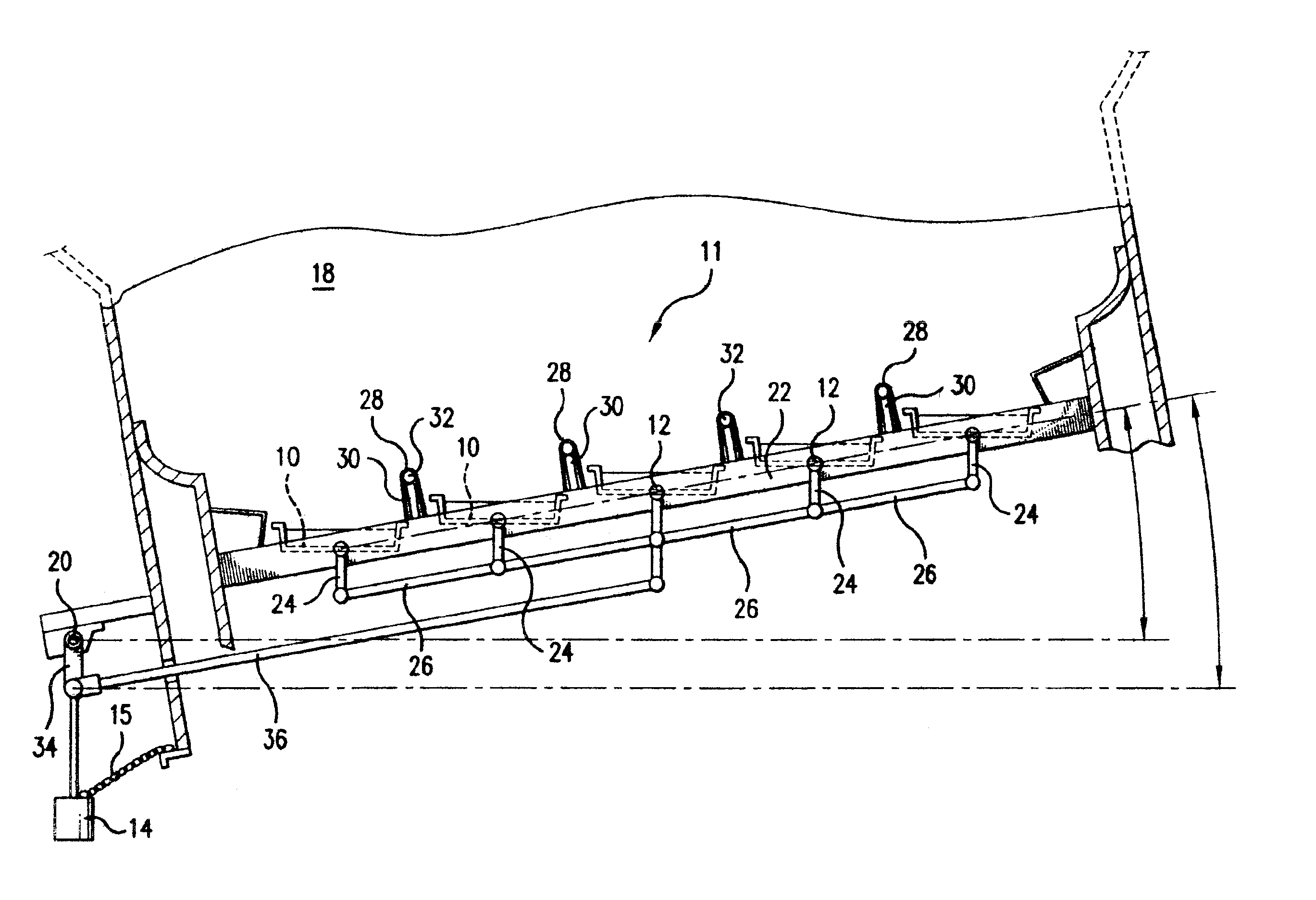

Corn Stalk Baling Method and Apparatus

A method and apparatus for baling a crop with stiff stalks such as corn stalks has a frame with a front and a rear. At least one ground engaging wheel operatively attached to the frame for facilitating movement of the frame in a forward direction. An accumulator is operatively attached to the frame for holding the crop in various amounts. A pickup is operatively attached to the front of the frame for picking up the crop from a field and transferring the crop into the accumulator. A baler is operatively attached to the frame behind the accumulator for transforming a crop into a bale. A transfer mechanism such as a conveyor is provided in the accumulator for moving the crop in the accumulator to the inlet of the baler. In another embodiment, a pickup of a first predetermined width is provided for picking up the crop from a field and transferring the crop into the accumulator. The baler has an inlet and a baling chamber of a second predetermined with that is significantly larger than the first predetermined width of the pickup so that a larger bale can be made. The transfer mechanism can be in segments which are independently operable.

Owner:VERMEER MFG CO

Combine harvester having a driver assistance system

ActiveUS20160088794A1Minimize energy demandConducive to decayMowersBalingCombine harvesterEmbedded system

A combine harvester includes a driver assistance system that regulates a spreading on the ground of a crop flow exiting the combine harvester. The driver assistance system includes spreading strategies that can be selected in order to regulate the spreading of the crop flow exiting the combine harvester.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

Kitchen appliance with a safety interlock

A kitchen appliance with a safety interlock for processing foodstuff includes a housing with a drive shaft extending therefrom. The drive shaft is rotatable about a drive axis and at least one portion of the drive shaft is movable along the drive axis between an extended position and a retracted position. A switch is supported in the housing and a bowl is removably mountable to the housing. The bowl includes a mouth and the drive shaft extends into the bowl when the bowl is secured to the housing in a working position. A bowl lid is removable mountable over the mouth of the bowl. The bowl lid is in a working position when it is mounted over the bowl when the bowl is in the working position. The bowl lid includes a lid shaft extending from the bowl lid that is in an operative relationship with the drive shaft when the bowl and bowl lid are in the working position. The lid shaft urges the at least one portion of the drive shaft into the retracted position when the lid shaft is in an operative position. The at least one portion of the drive shaft closes the switch in a retracted position such that power is able to be provided to the kitchen appliance.

Owner:HAMILTON BEACH BRANDS

Biomass harvesting system

A biomass harvesting system for harvesting agricultural plant growth from agricultural fields comprises a power source for providing mechanical and electric power to the system, a biomass accumulator for producing discrete units of accumulated biomass, a windrower for feeding biomass to the accumulator, a biomass quality analyzer for sensing and transmitting a set of quality characteristics of the biomass, a ground cover residue monitor for sensing and transmitting an optimal quantity of biomass residue to remain on the field, an active tracking system for identifying individual ones of the discrete units of accumulated biomass, and a central processing unit including a memory module storing an executable instruction set therein. The central processing unit executes the instruction set and integrates the sensed biomass quality characteristics and the sensed optimal quantity of biomass residue to remain on the field to determine a biomass quality index of the discrete units of accumulated biomass.

Owner:CROSBY LON OWEN

Juicer safety device

Owner:LIN KUAN CHIH

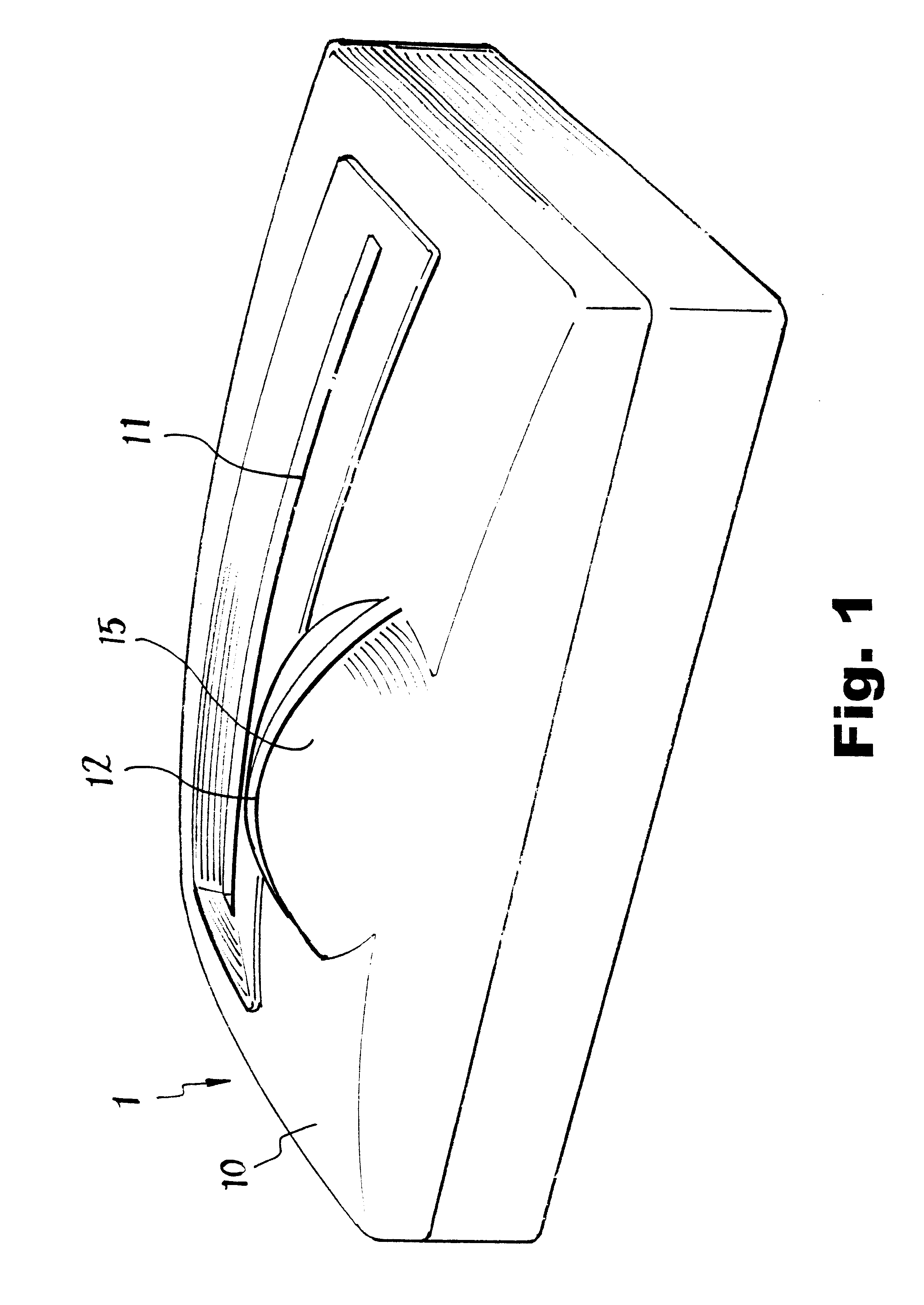

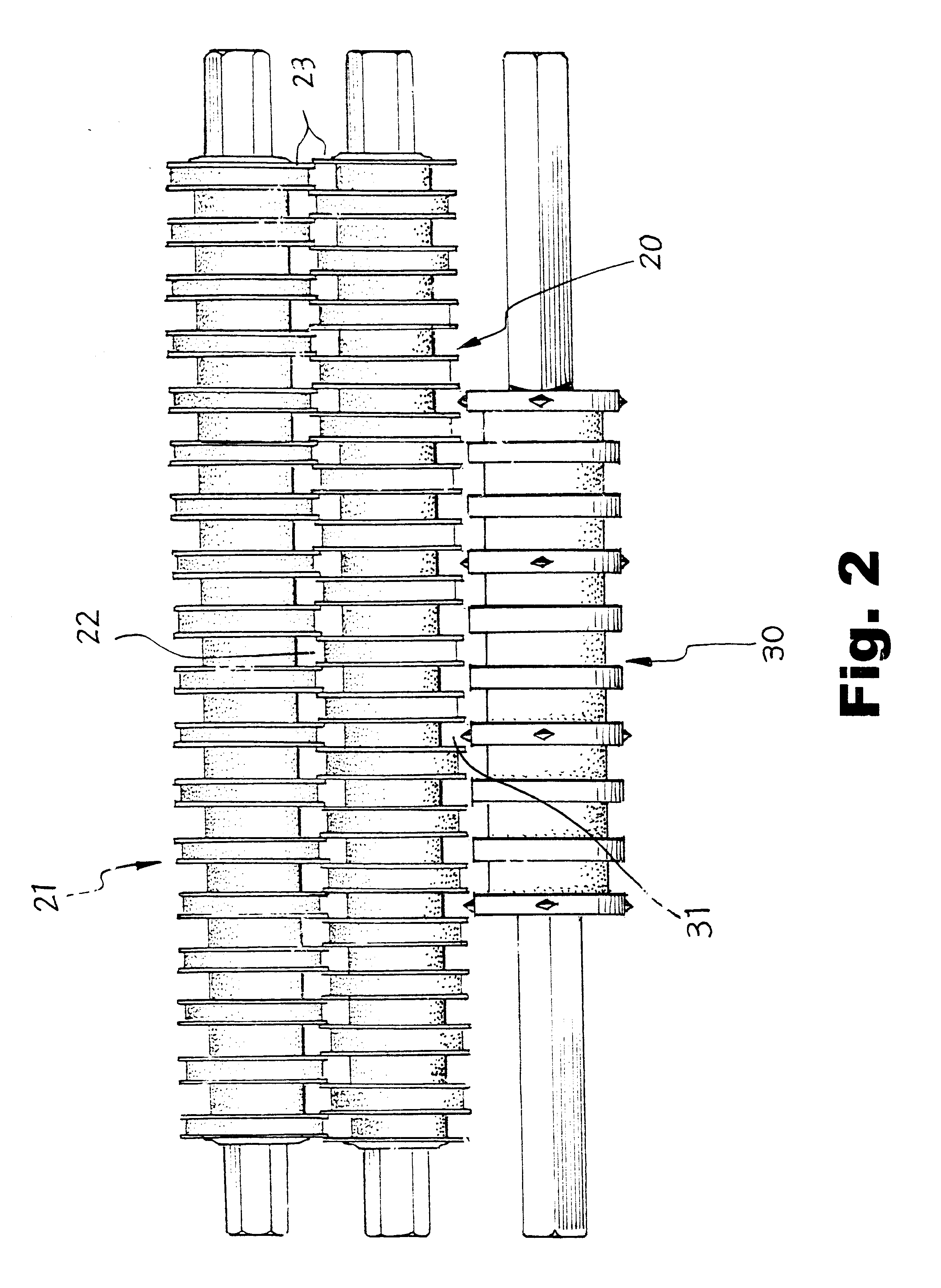

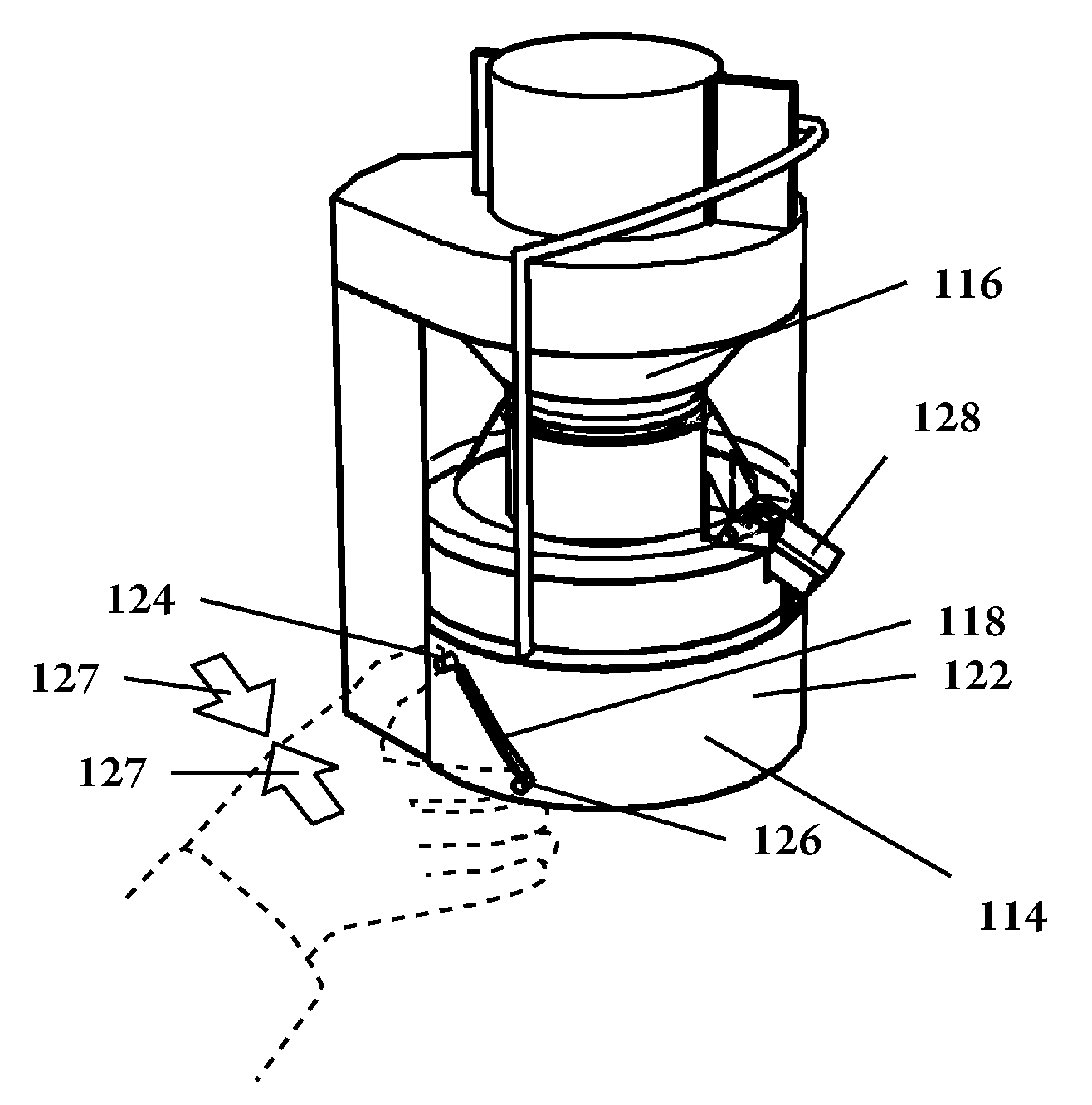

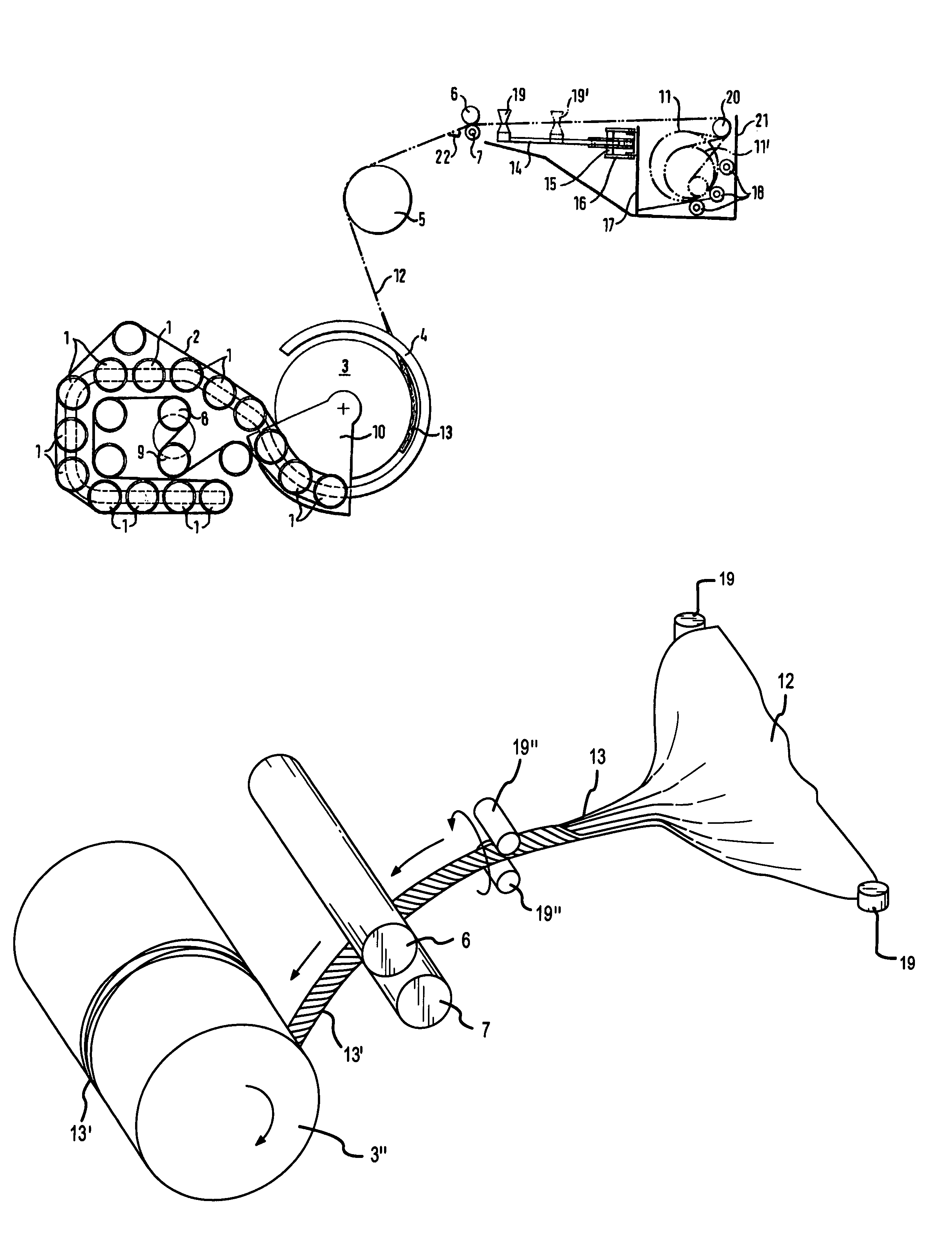

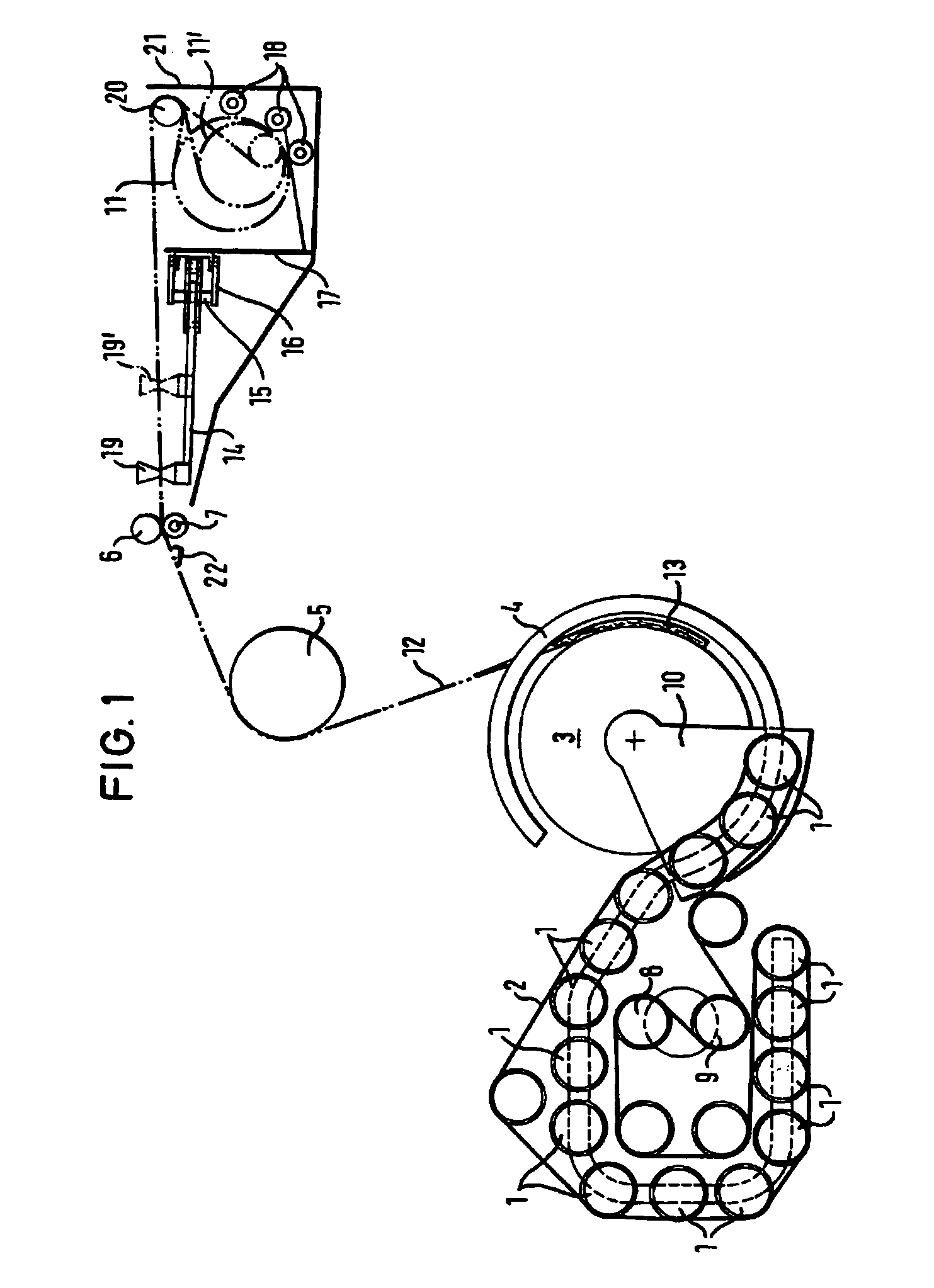

Method of wrapping a round bale compacted by a round baler, film-wrapping device and round baler that is provided with such a film-wrapping device

The invention relates to a method and a device for wrapping a round bale pressed in a round bale press at least about its cylindrical surface area with an at least unilaterally adhesive film (12). With the inventive method, the film (12) is pulled off by means of a pulling-off device (6, 7) from a film roll (11) in its entire width. During a predetermined space o time of said pulling-off operation, a film rope (13) is formed from the film (12). Said film rope (13) is introduced into the gap between the round bales (3) to be wrapped and a device forming the circumferential press chamber wall (2). By setting the round bale (3) into rotation, the film rope (13) present in the gap is carried along. The round bale (3) is so long rotated until the desired number of film layers has formed on the surface area of the round bale.

Owner:RPP AMERICA

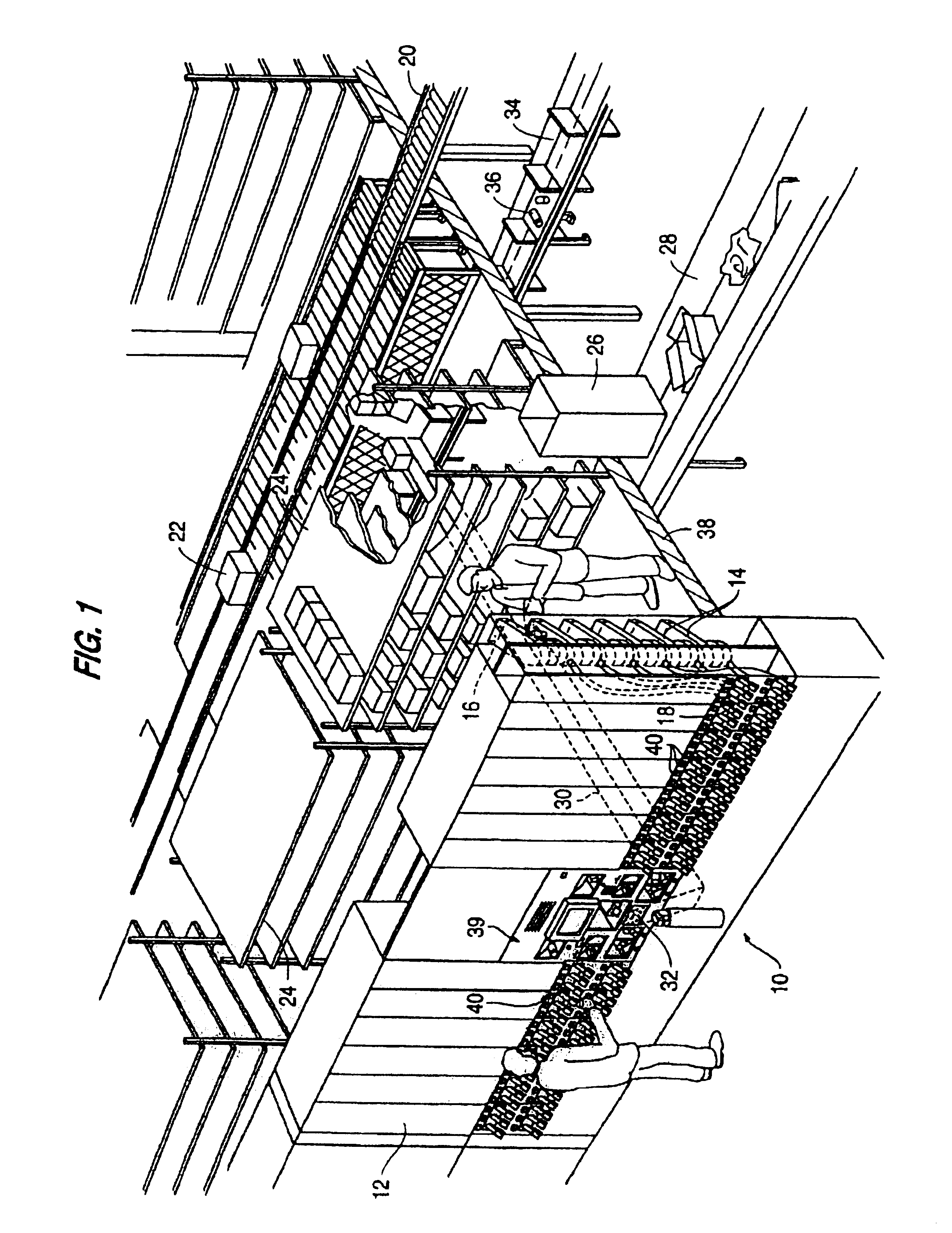

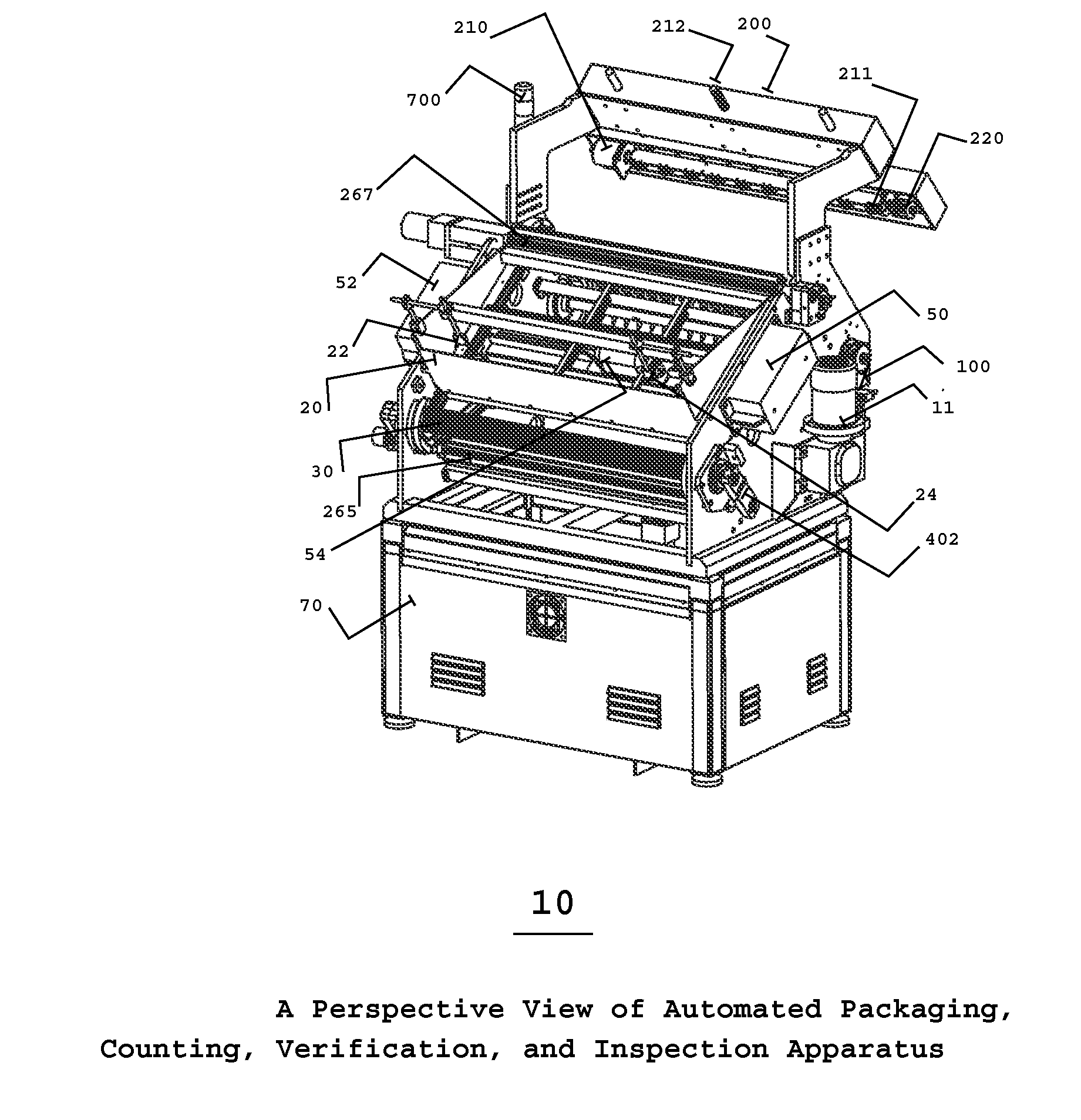

Automated pharmaceutical product packaging, inspection, verification, and counting apparatus

InactiveUS20100175352A1High container filling speedFast filling speedCapsCapping machinery safety/controlProcess engineeringEngineering

The present invention is an automated packaging apparatus utilizing a rotating assembly of elongated slats containing cavities to receive discrete pharmaceutical, vitamin, or food products. Quantities of discrete products such as tablets, capsules, or gels are deposited into the hopper of the apparatus. The apparatus then dispenses the discrete products into containers moving on a conveyor system such that each container receives a predetermined quality and quantity of pharmaceutical, vitamin, or food products. While operating at high speed, the apparatus inspects, counts, identifies and analyzes each product deposited into the containers and maintains electronic records describing the status of each product. In the event any errors occur the apparatus produces various alerts to inform the operator. The presence of foreign products or objects may cause the apparatus to instantly stop the entire system including peripheral equipment. A series of Good Manufacturing Practice protocols can then be enforced as per FDA requirements.

Owner:SOLOMAN SABRIE

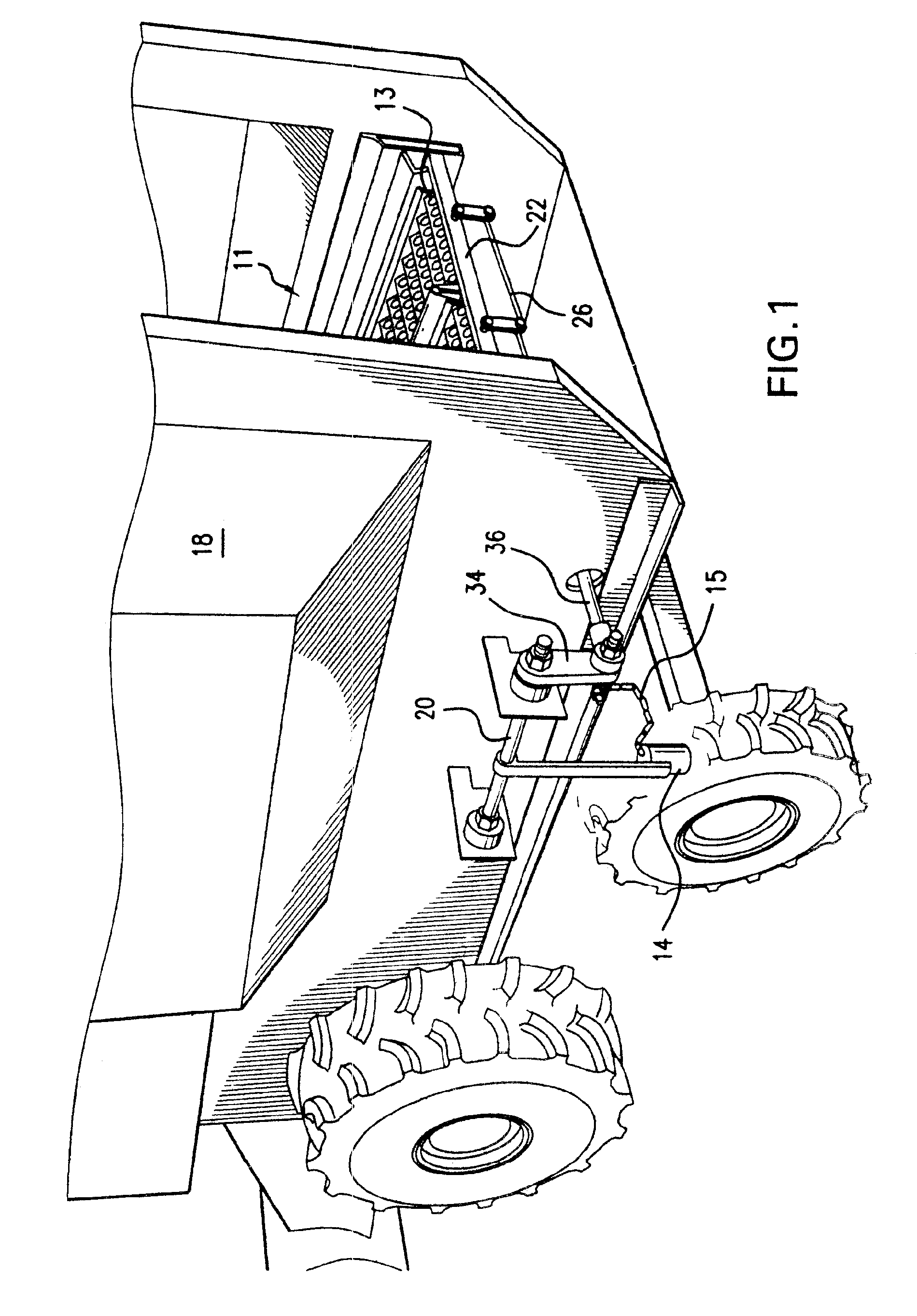

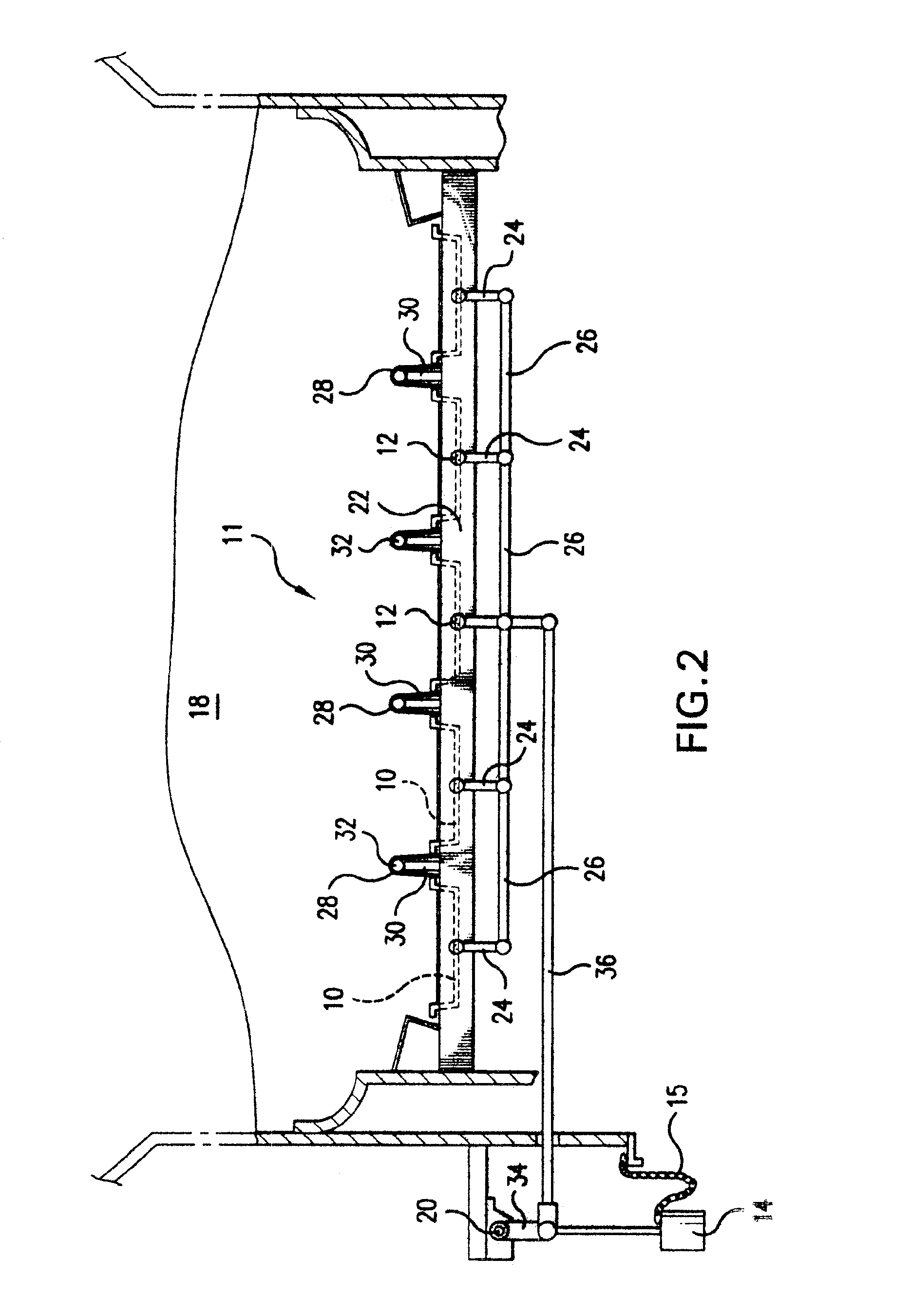

Floating combine sieve assembly

InactiveUS6843719B1Improve efficiencySeparation efficiency can be improvedSievingScreeningEngineeringCombine harvester

A sieve assembly for separating grain from chaff inside of a combine. The sieve assembly comprises a plurality of longitudinal sieve planks that pivot on their longitudinal axis. A hanging weighted member combined with the sieve planks regulates the angle of the sieve planks relative to the combine. As the combine becomes laterally inclined on a hillside, the weighted member changes its angular position relative to the combine. In doing so, the weighted member causes the sieve planks to pivot on their longitudinal axis so that the sieve planks remain level relative to the horizon. Dividers extend between each sieve plank.

Owner:SACQUITNE DAVID

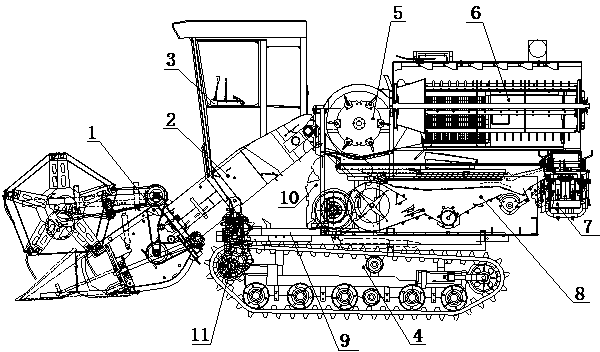

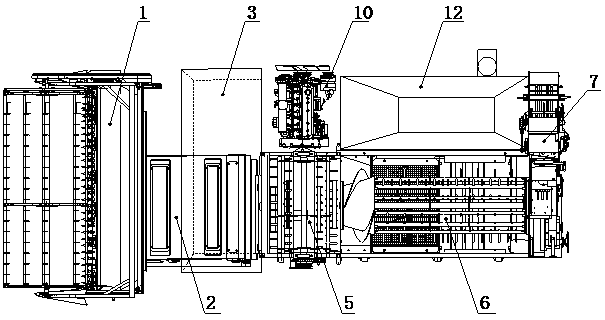

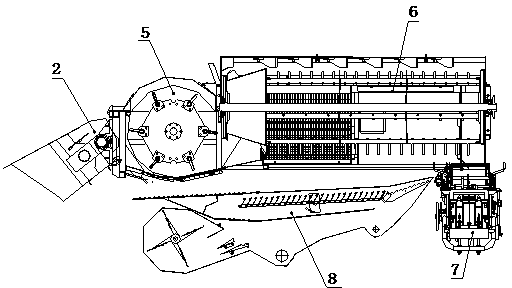

Tangential-longitudinal axial type grain combine harvesting and bundling duplex operation machine

InactiveCN104054449AReduce loss rateImprove work efficiencyMowersBalingAgricultural scienceAgricultural engineering

The invention discloses a tangential-longitudinal axial type grain combine harvesting and bundling duplex operation machine which comprises a grain cutting and conveying system, a seed threshing and separating system, a seed cleaning device, a seed collecting and storing system, a straw compressing and bundling device, a chassis walking system and a driving operation system. When the duplex operation machine harvests grain in the field, firstly, the grain cutting and conveying system cuts stalks of grain and conveys the grain to the seed threshing and separating system, straws where seed threshing and separating are conducted are compressed and bundled through the straw compressing and bundling device, seeds obtained through threshing are cleaned through the seed cleaning device, and seeds obtained through cleaning are conveyed to a grain tank through the seed collecting and storing system. The duplex operation machine can meet the requirements for harvesting seeds of rice and wheat and compressing and bundling threshed straws, and has the advantages of being high in work efficiency, stable in work performance, simple in work procedure and capable of saving time and labor.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com