Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1273 results about "Winnowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wind winnowing is an agricultural method developed by ancient cultures for separating grain from hay. It can also be used to remove pests from stored grain. Winnowing usually follows threshing in grain preparation.

Tobacco hitting and redrying homogenizing processing technology

InactiveCN103653227AImprove the level of homogenization production and processingQuality improvementTobacco preparationTobacco treatmentChemical compositionEngineering

The invention relates to a tobacco hitting and redrying homogenizing processing technology. The tobacco hitting and redrying homogenizing processing technology includes the following steps that raw tobaccos are laid according to a single variety, a single grade and a single product or different varieties, different grades and different production places; the laid tobaccos are arranged in boxes and stored respectively; according to the requirements of a production formula list, the corresponding tobaccos are selected from the stored tobaccos and orderly delivered according to the grades, the varieties and the production places, box overturning and feeding are performed according to the material dispensing ratio of the production formula list, and the tobaccos of all grades are pre-mixed after box overturning and feeding are performed; the tobaccos which are pre-mixed sequentially receive the processing of one-time tobacco moistening, sand sieving, winnowing, impurity removing, manual selecting and secondary tobacco moistening. The tobaccos receive the processing of tobacco hitting and wind dividing; the tobaccos are mixed after receiving the processing of tobacco hitting and wind dividing, and after the on-line chemical component detection shows that the tobaccos are qualified, the redrying processing is performed. The tobaccos which are redried are packaged after the on-line chemical component detection shows that the tobaccos are qualified. The tobacco hitting and redrying homogenizing processing technology solves the problem that formula homogenization is difficult to control in the producing and processing processes of the tobaccos of original tobacco hitting and redrying enterprises.

Owner:FUJIAN WUYI TOBACCO

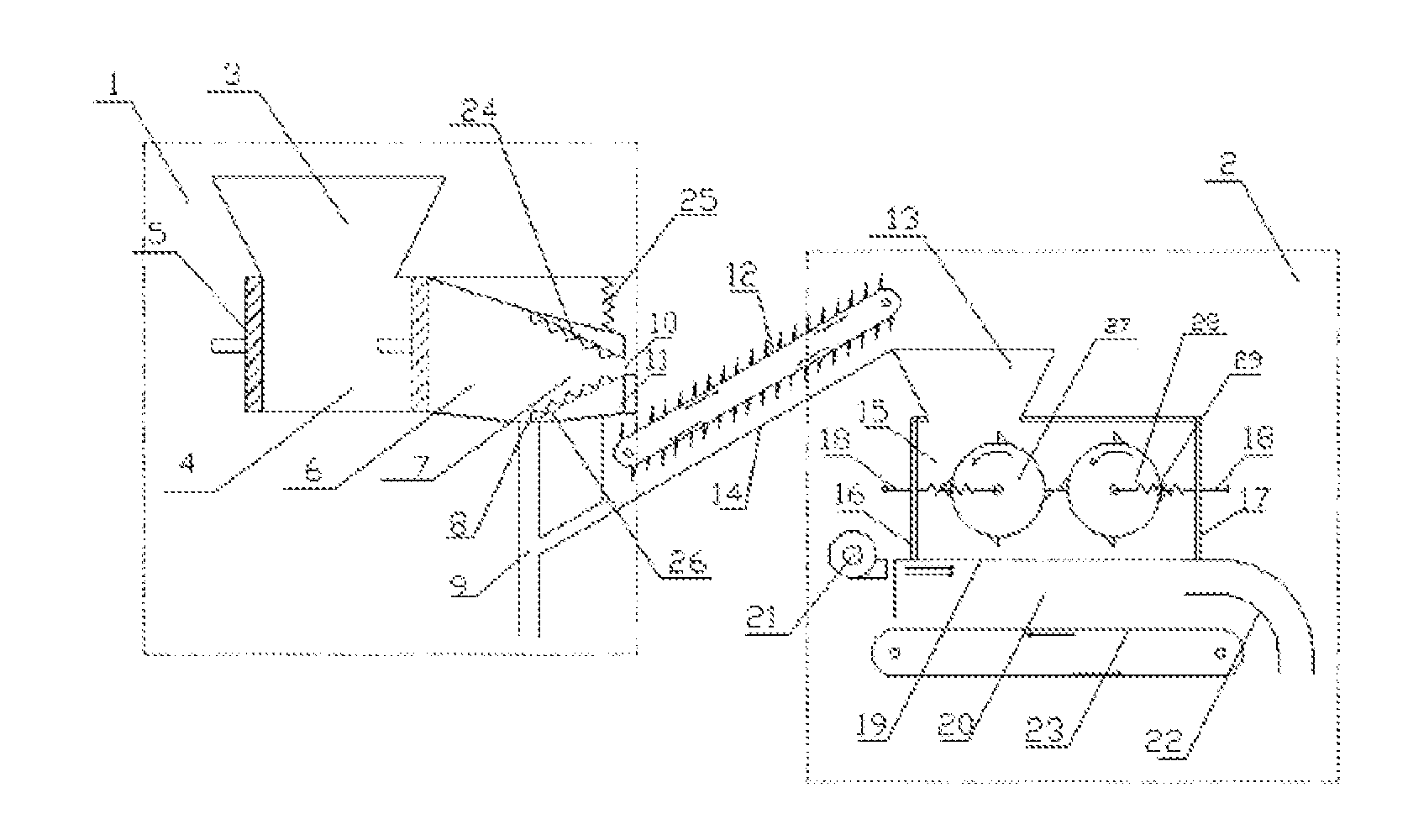

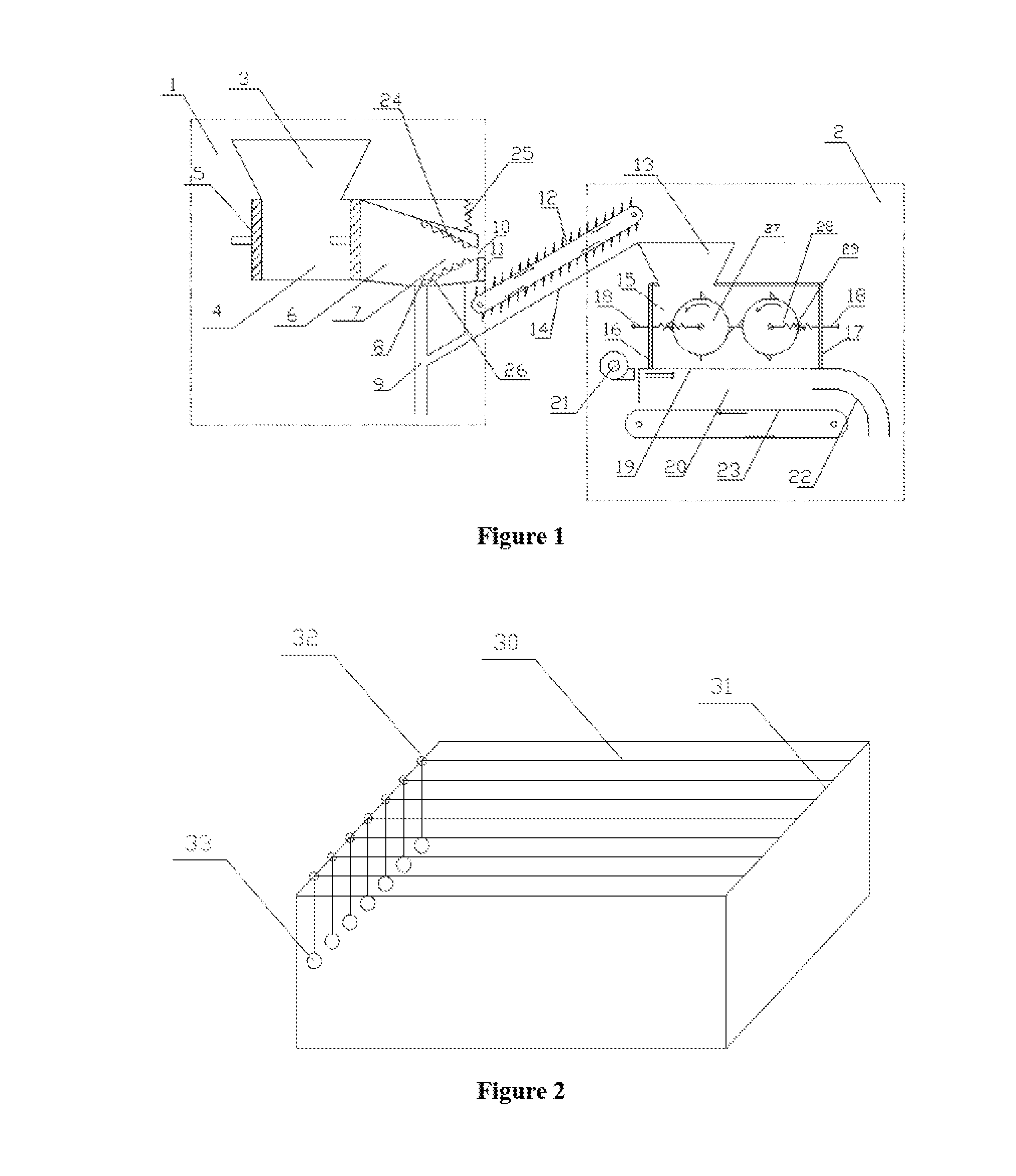

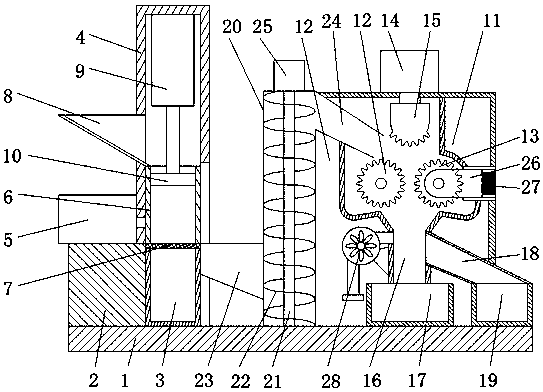

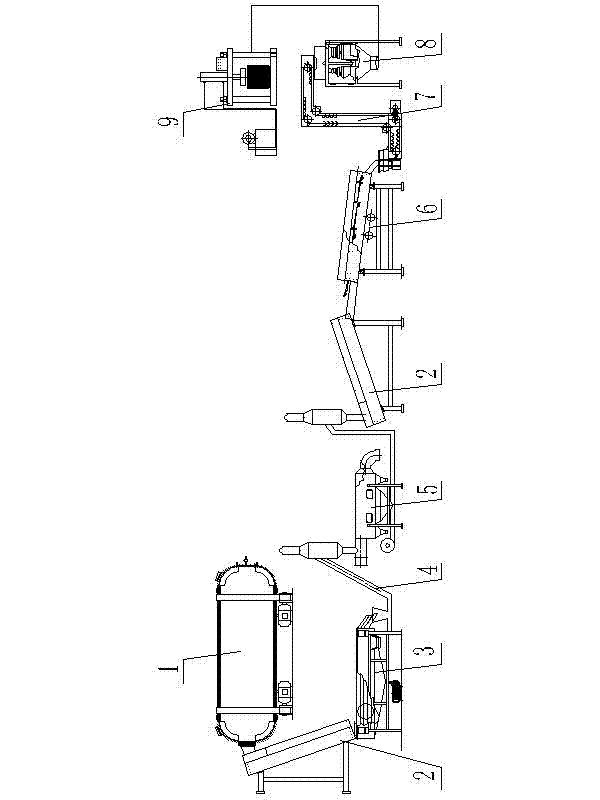

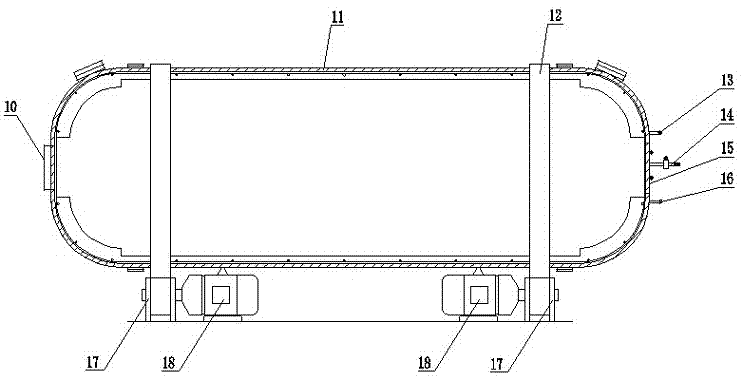

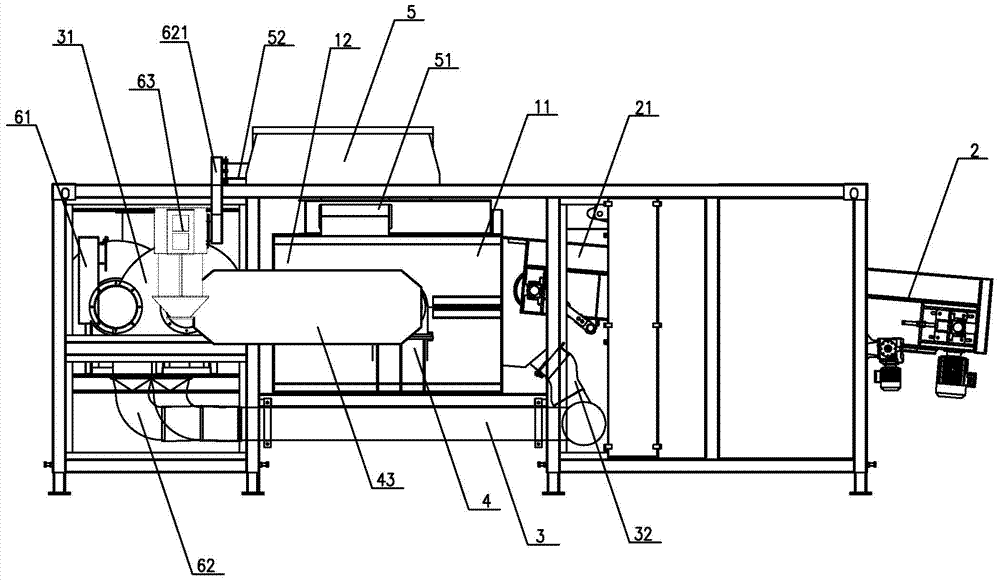

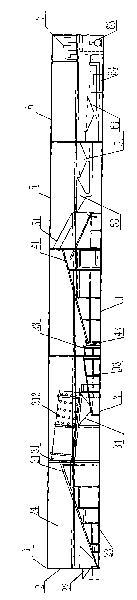

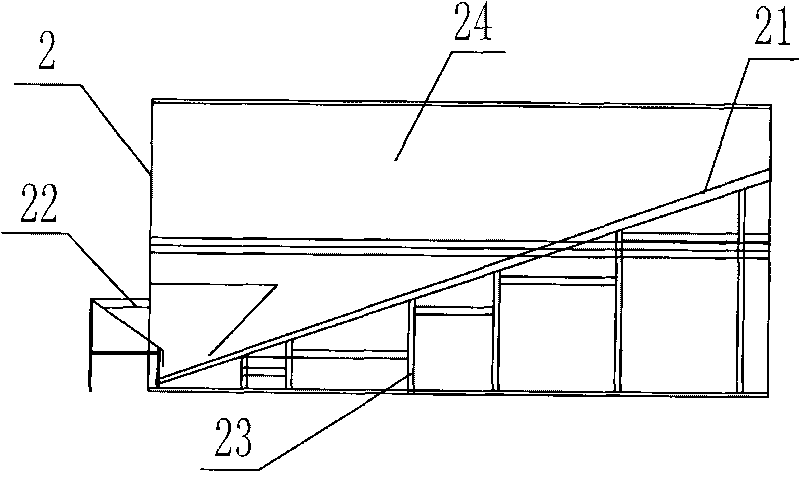

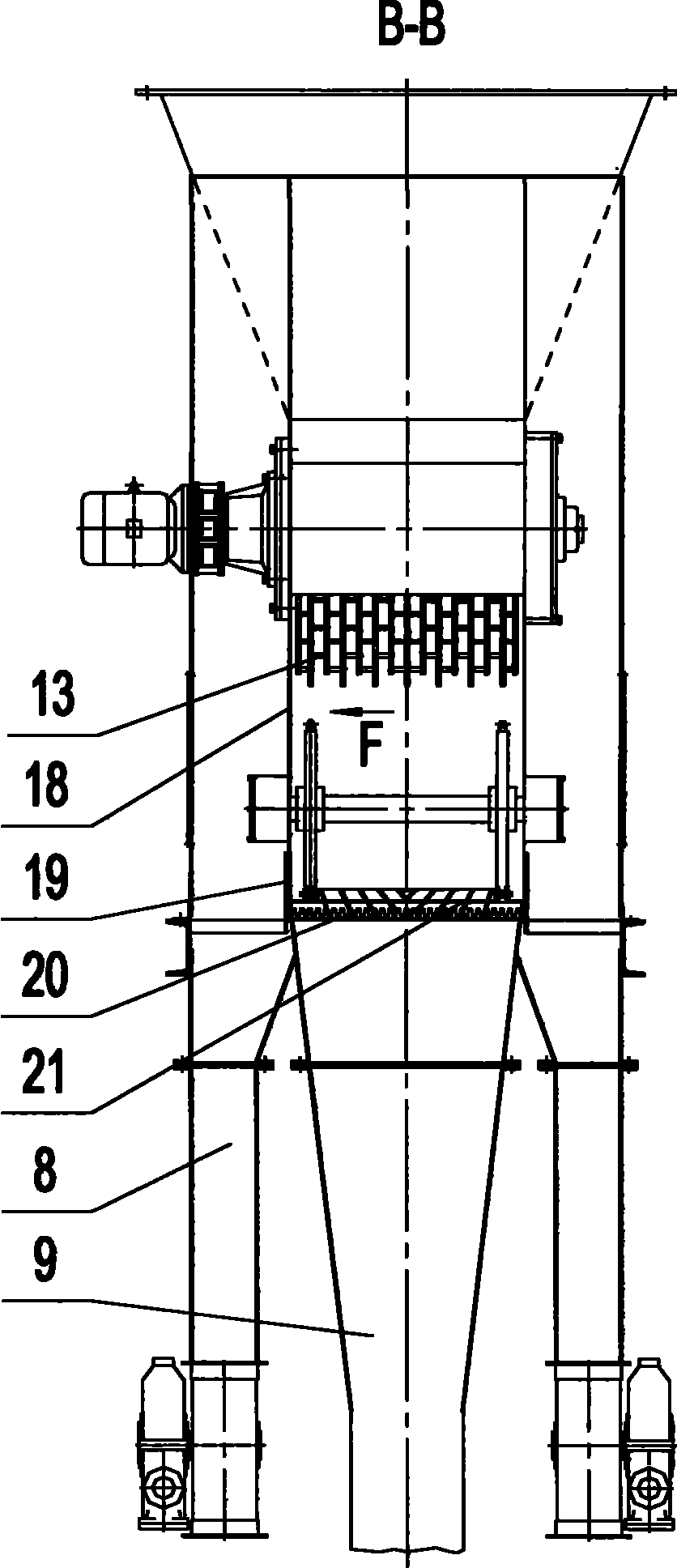

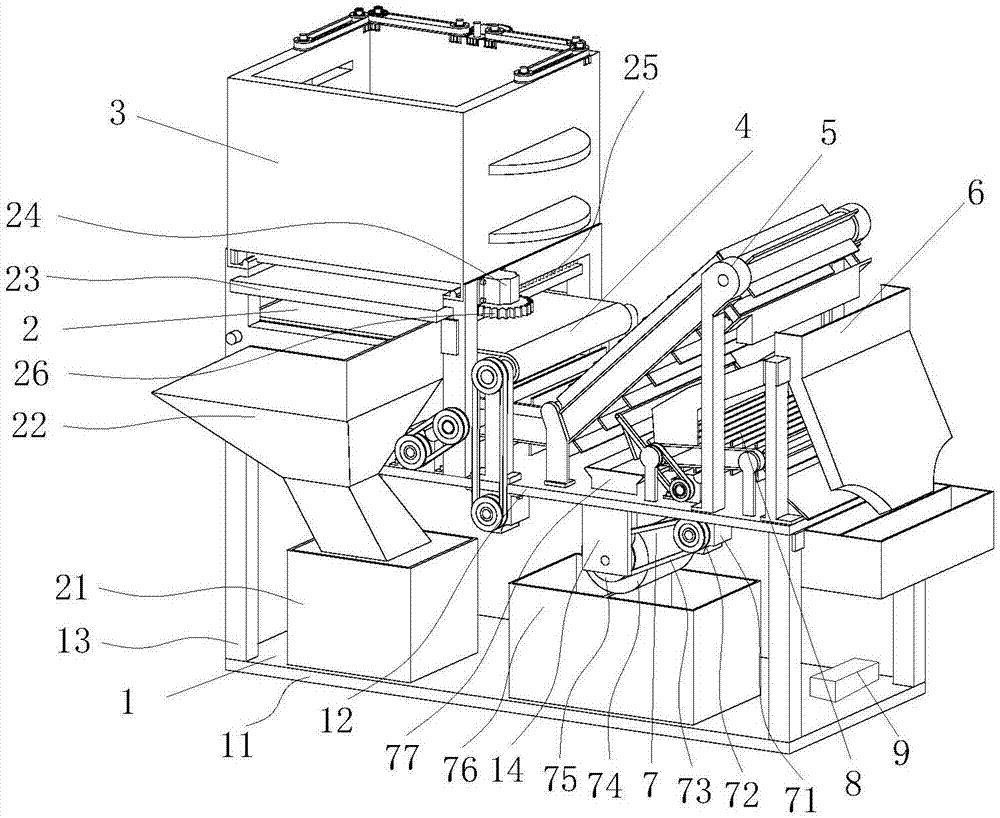

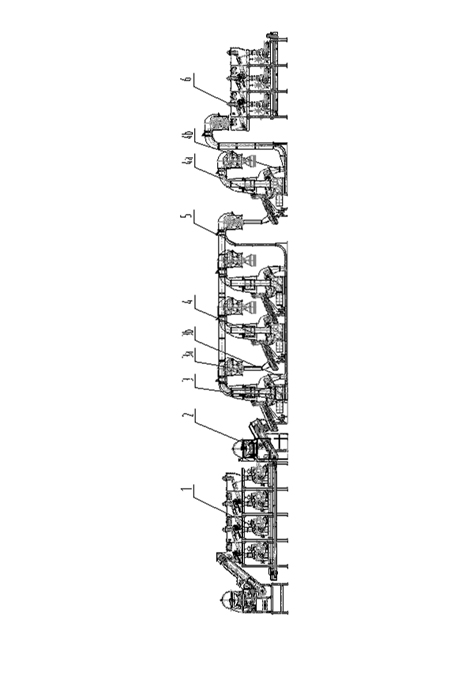

System for squeezing, smashing and winnowing municipal solid waste

ActiveUS20160250648A1Good effect in squeezingGood effect in smashingSievingGas current separationLitterCrusher

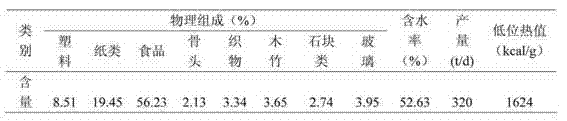

The invention discloses a system for squeezing, smashing and winnowing municipal solid waste (MSW). The system comprises a primary squeezing and smashing, device and a secondary smashing and winnowing device. The system of the invention has good effect m squeezing, smashing and winnowing, can greatly reduce the water content of MSW and efficiently separate the MSW into combustible matters and non-combustible matters, so as to facilitate further subsequent utilization of the municipal waste; moreover, an upper jaw of a jaw crusher is connected with a spring device, so that the squeezing pressure, smashing effect and processing capacity of the jaw crusher can be adjusted according to the amount of the MSW. In addition, the system of the invention is further provided with emergency brake switches, spring protection devices and a sieve, so as to ensure the stability and the reliability of the system.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

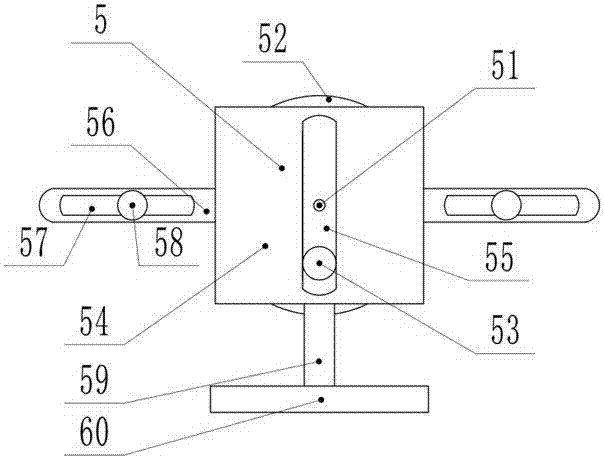

Tobacco material wind selection method and device

ActiveCN101053868AReduce breakageReduce winnowing costTobacco preparationTobacco treatmentAir volumeVolumetric Mass Density

The invention provides a tobacco material winnowing method and an equipment thereof. The tobacco material enters through a transportation equipment into a primary winnowing room to choose sundry goods of larger density by the primary winnowing room having higher wind speed; the tobacco material which is wind separated by the primary winnowing enters into a secondary winnowing room having lower wind speed to choose sundry goods with less larger density; the tobacco material which is wind separated by the two winnowing processes is output via a discharge opening. The equipment implementing the method comprises two winnowing rooms connecting with each other in parallel, supplementation wind gap of each winnowing room is provided with a damper to obtain proper air quantity and air speed for winnowing. The equipment is capable of achieving winnowing the tobacco material for two times with enhanced winnowing efficiency, simple structure and convenient maintenance.

Owner:ZHISI HLDG GRP

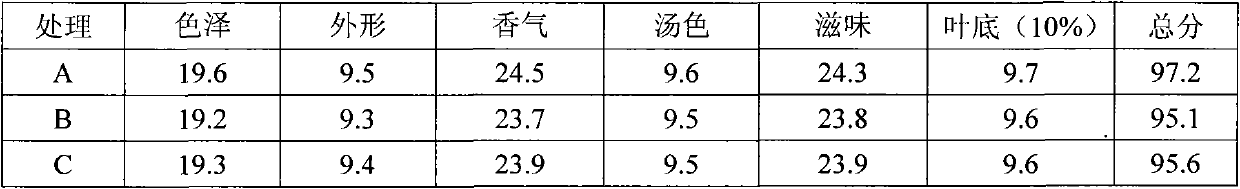

Tea green-preserving and fragrance-increasing process

InactiveCN101946832AChange "color is not emeraldChange colorPre-extraction tea treatmentMicrowaveOptical processing

Owner:四川省叙府茶业有限公司

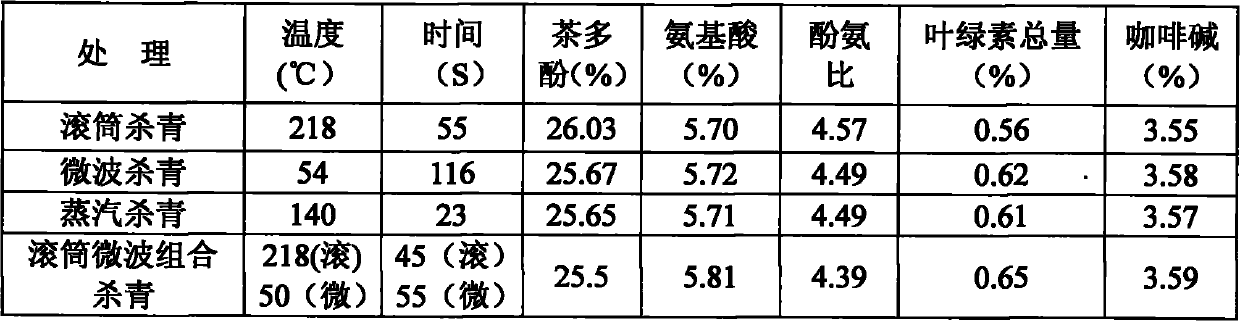

Water washing garbage cleaning production treatment method

InactiveCN102896135ANo emissionsEasy dischargeBio-organic fraction processingWaste processingRefuse DisposalsFermentation

The invention relates to a water washing garbage treatment method, wherein a purpose of the invention is to achieve urban garbage resource comprehensive utilization. According to the method, urban garbage is cleaned by using a running water washing manner, processes of dehydration, drying, winnowing, ??fine sorting and the like are performed, and classification centralization comprehensive utilization is performed; the water washing garbage sewage is treated through a sewage purifier to be rapidly recycled; and the production process adopts a cleaning production process, and no secondary pollution is generated. According to the present invention, the integrated design comprises water washing garbage sorting classification, fertilizer production through organic matter fermentation, heat supply through combustible combustion, a biogas engineering technology, a sewage treatment system and a plurality of mature application technologies; the urban garbage is adopted as a new urban mineral resource, and a water washing garbage resource comprehensive utilization workshop is established in a garbage landfill collection field so as to eliminate garbage pollution hazards; and sustainable development of large-scale garbage treatment industry is promoted, high economic benefits, social benefits and environmental benefits are generated, and good benefits are provided for humans.

Owner:唐义龙

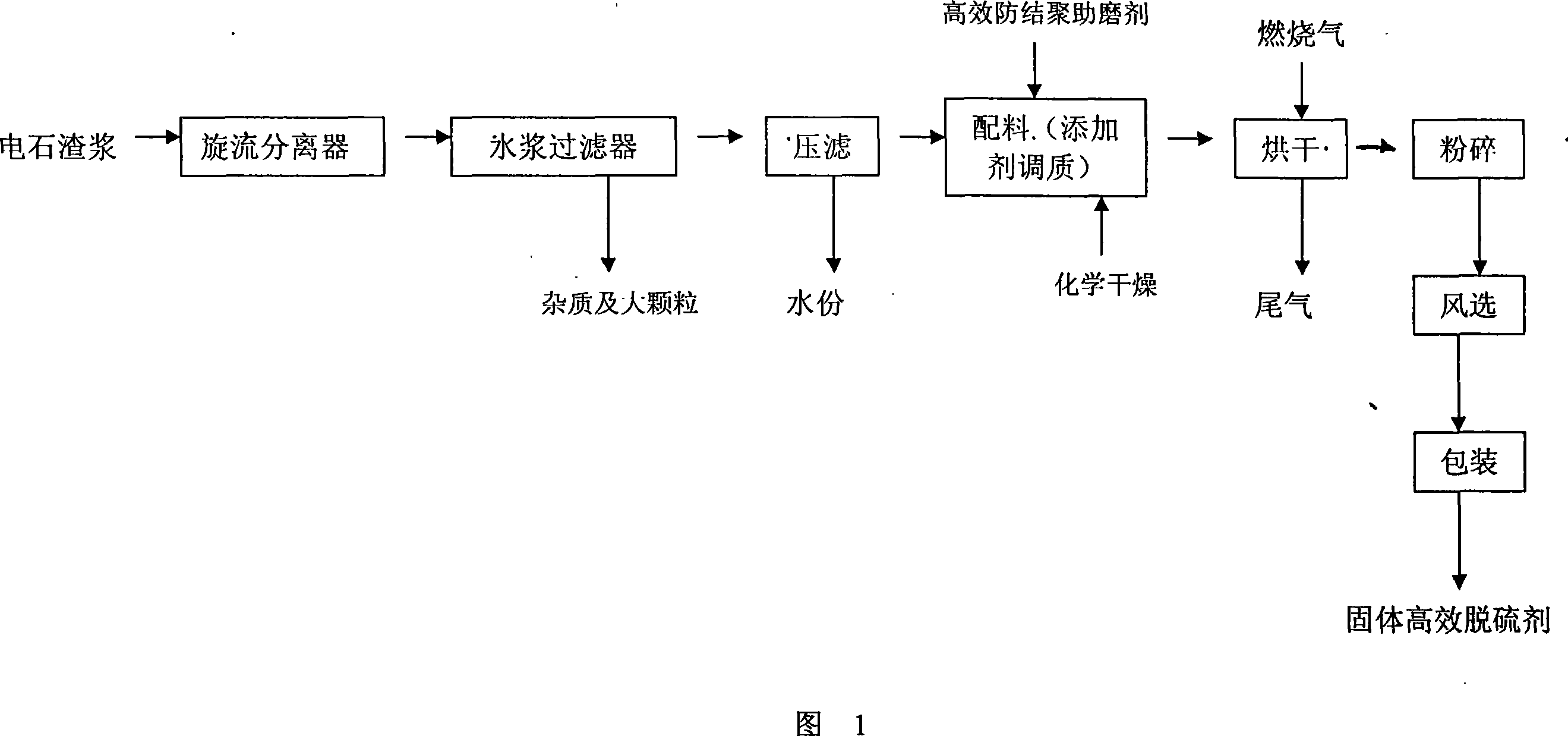

Method for preparing high-performance solid desulfurizing agent by carbide slag slurry

InactiveCN101168117AHigh activityStrong desulfurization abilityDispersed particle separationWinnowingFilter cake

The invention relates to a method of producing a highly-effective solid desulfurizer by carbide slag grout. The invention is characterized in that the carbide slag grout is centrifugally separated, filtered and filter-pressed, then a desiccating agent and a highly-effective anti-coalescing grinding aid are added to a gotten filter cake, and then the filter cake is ground, consequently the process is finished after being packed. The invention produces the highly-effective solid desulfurizer with high activity, high desulfurization and fine grain size by processing purifying, separation, tempering, drying, abrading, winnowing, packing and the like to calcium hydrate which is the main component of the carbide slag grout, thereby achieving the purpose of changing the waste into valuable, realizing the effect of recycling economy, simultaneously saving land resources and eliminating one serious factor of environmental pollution.

Owner:国能英力特能源化工集团股份有限公司 +1

Method for preparing mulberry leaf tea

The invention discloses a method for preparing mulberry leaf tea. The method comprises the following processing steps that: 1, mulberry leaf picking; 2, air-drying and withering; 3, rotating; 4, desiccating at high temperature; 5, spreading for cooling; 6, secondary desiccation at high temperature; 7, rolling; 8, initial drying; 9, winnowing; 10, chopping; and 11, baking. The invention provides the method for preparing mulberry leaf tea without physical and chemical pollution of plant diseases and insect pests, mud, faecal pollution of birds and insects, pesticide pollution, air pollution and the like.

Owner:GUANGDONG XINDA CHRYSALIS SILK

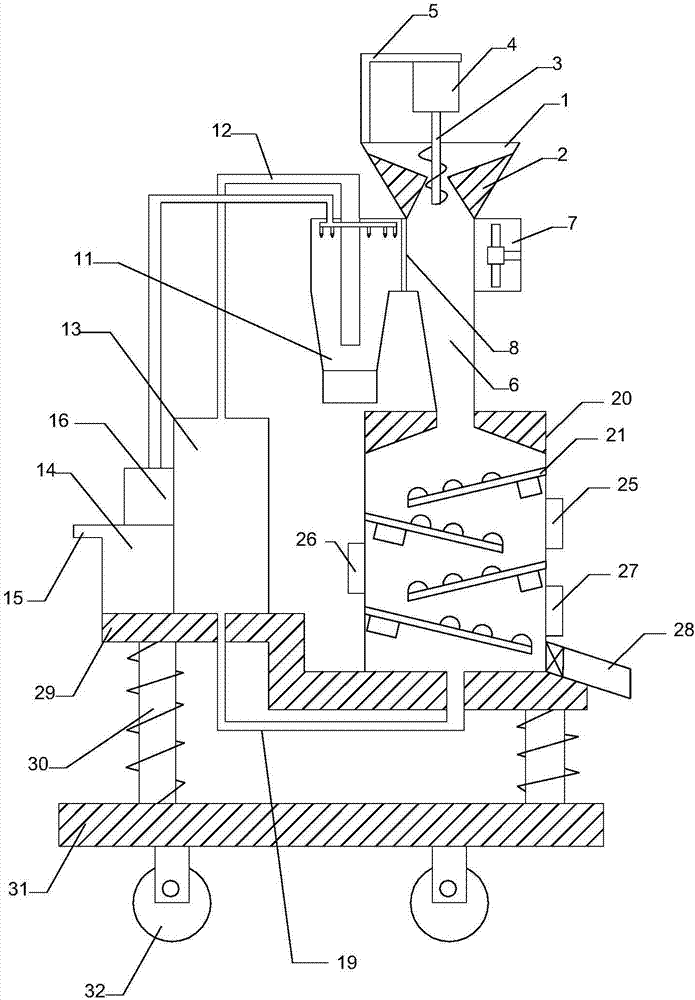

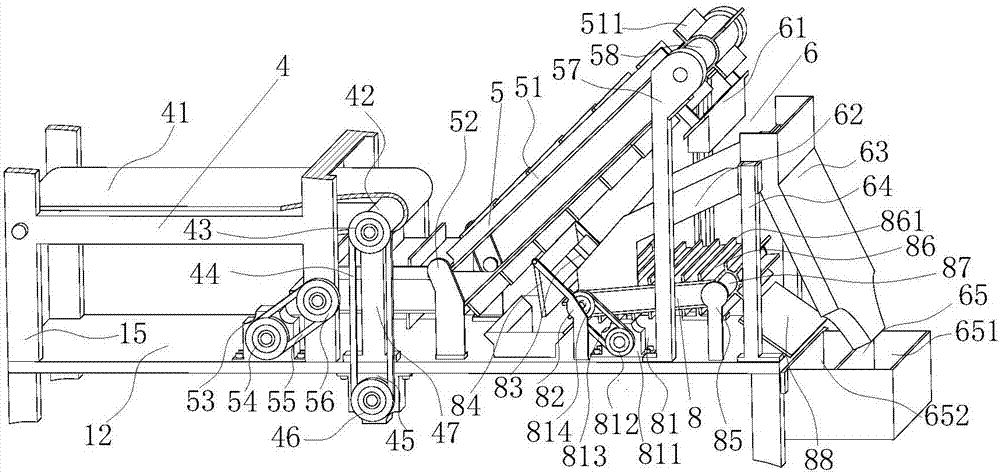

Municipal domestic waste squeezing, crushing and winnowing device and working method thereof

InactiveCN107627654AEfficient removalRealize automatic separationGrain treatmentsPressesHydraulic cylinderFixed frame

The invention discloses a municipal domestic waste squeezing, crushing and winnowing device and a working method thereof. The device comprises a bottom seat, a squeezing unit positioned at the left end of the top face of the bottom seat and a crushing unit positioned at the right end of the top face of the bottom seat, and a material lifting unit is arranged between the squeezing unit and the crushing unit; the squeezing unit comprises a base fixed on the top face of the bottom seat and a liquid storage barrel positioned on the right side of the base, a fixing frame is fixed to the top of thebase, an air cylinder is installed on the left side face of the fixing frame, and a squeezing barrel is arranged on the right side of the fixing frame; the left side face of the squeezing barrel is fixedly connected with the output end of the air cylinder, and a filtering plate is arranged at the top of the liquid storage barrel; and a feeding hole is formed in the side face of the fixing frame, the top of the fixing frame is provided with a squeezing hydraulic cylinder, and the output end of the bottom of the squeezing hydraulic cylinder is connected with a pressing plate. According to the device, squeezing, crushing and winnowing are continuously and automatically carried out; and the device is simple and reasonable in structure, convenient to use, practical and efficient.

Owner:陈彬

Tartary buckwheat full-nutrition rice and preparation method

InactiveCN103704578AThe surface of whole nutritional rice grains is transparentBright surface of full nutritional rice grainsFood preparationBiotechnologyFagopyrum tataricum

The invention provides tartary buckwheat full-nutrition rice and a preparation method. The tartary buckwheat full-nutrition rice is prepared by the following steps: carrying out screening, winnowing, stone removing and magnetic separation cleaning on tartary buckwheat; then carrying out a heat-moisture treatment procedure; in the heat-moisture treatment procedure, finishing a three-in-one production process including a pressurizing and wheat moisturizing process, a normal-pressure steaming process and a low-temperature vacuum drying process in a container; and then, carrying out unshelling and separation on the tartary buckwheat, rolling rice, and polishing and grading. The tartary buckwheat full-nutrition rice prepared by the preparation method is transparent, bright, clean, sanitary and attractive in appearance; the shelf life is easy to prolong.

Owner:KUNMING WUGUWANG FOOD

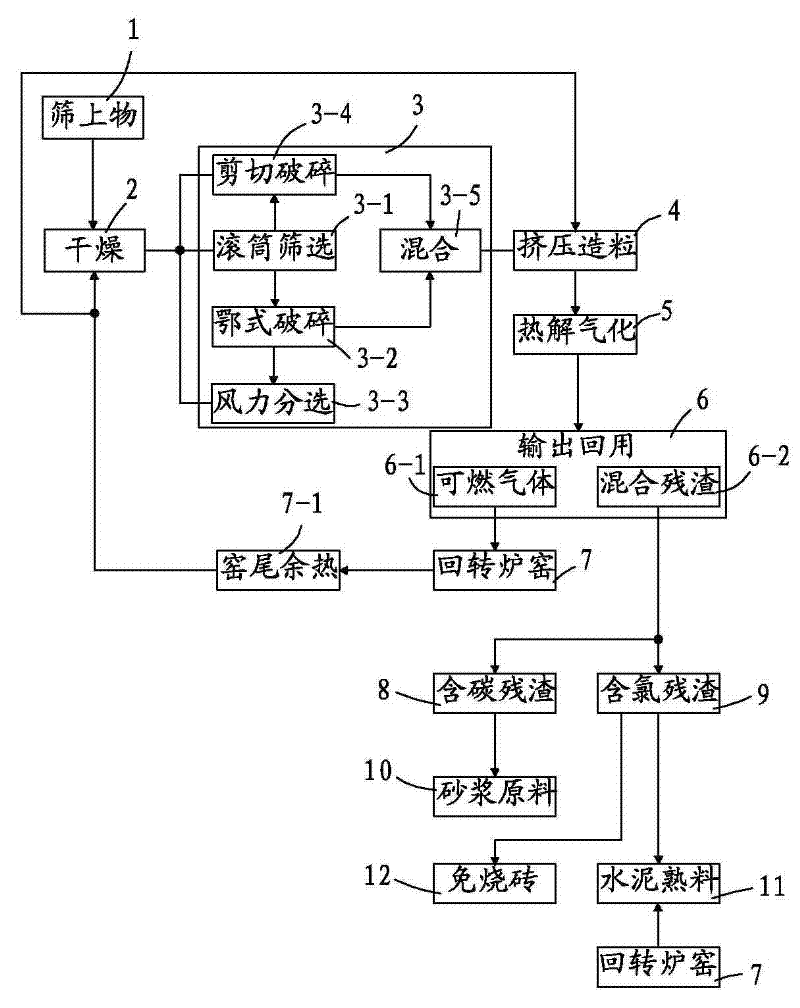

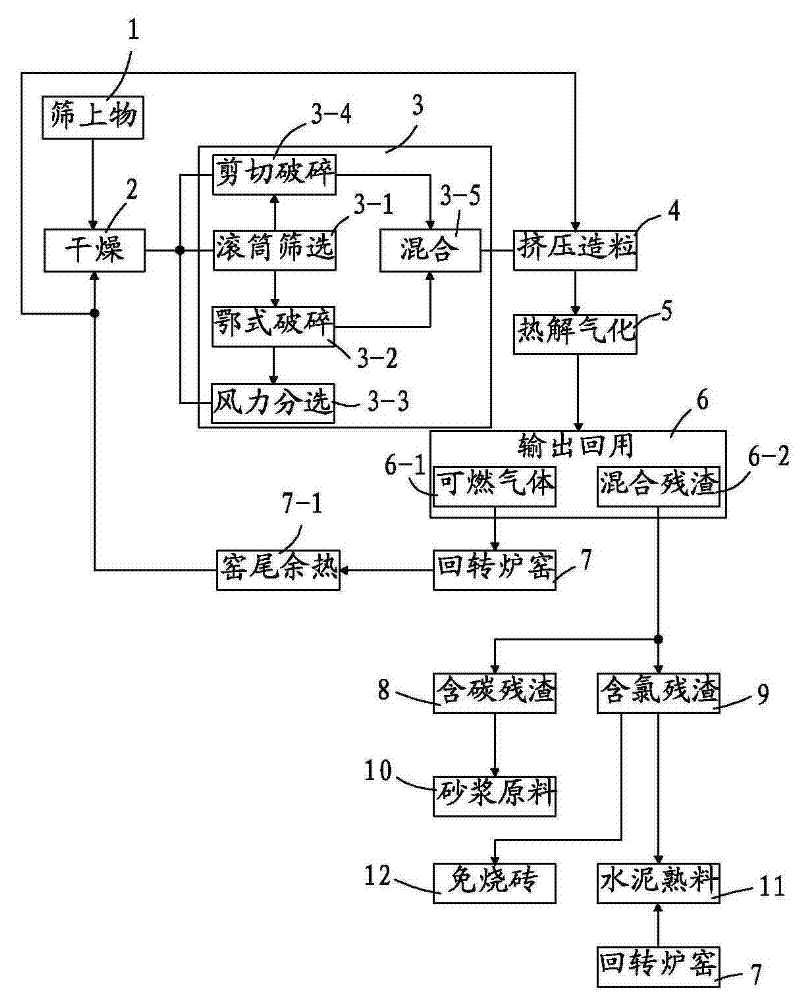

Method for performing pyrolysis uniting building-material utilization to rubbish oversize products

InactiveCN102500607AReduce moisture contentHigh calorific valueSolid waste disposalRefuse-derived fuelCement kiln

The invention discloses a method for performing pyrolysis uniting building-material utilization to rubbish oversize products. First rubbish undersize products with granularity smaller than 15mm are conveyed into a rubbish composting plant to perform composting or conveyed into a refuse landfill to serve as covering soil, and a treatment flow of the rubbish oversize products sequentially comprises drying, screening, crushing, winnowing, mixing, extrusion granulation, pyrolysis gasification and output recycling. Rubbish is processed into a refuse derived fuel (RDF) after waste heat drying at first, and not only are heat value and burning performance improved, but also secondary pollution of percolate, dioxin and the like is avoided. Combustible gas generated by a pyrolysis method enters into a cement kiln to be combusted, part of fuel required for cement clinker production can be replaced, and a stable high-temperature environment in the cement kiln can fully degrade dioxin generated by rubbish incineration. Ash residues serve as different building-material raw materials according to different heterogeneities, waste discharge is avoided, and no influence is caused on building-material production and product quality.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

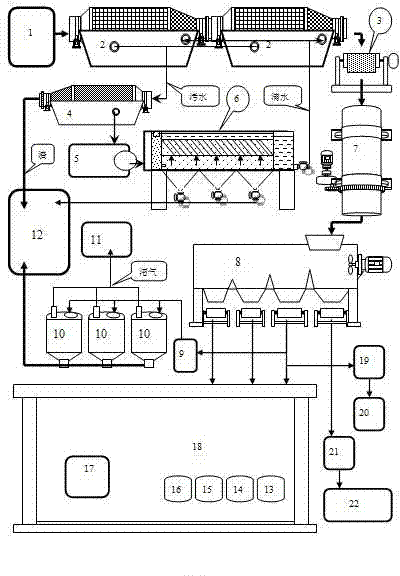

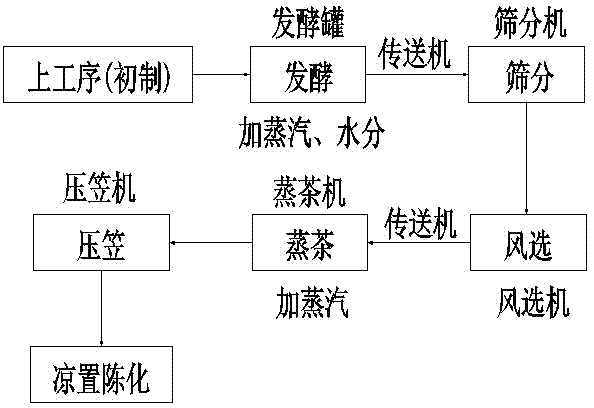

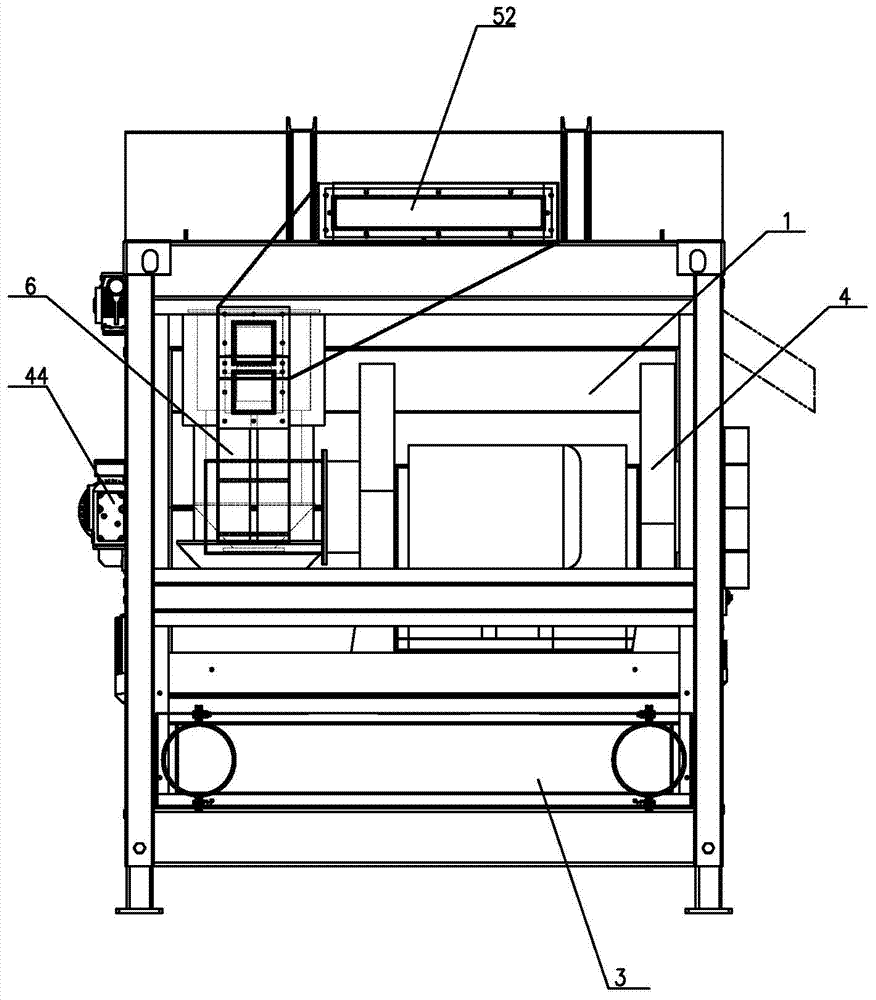

Technology and device for making Liupu tea

ActiveCN103202356AReduce labor intensityHigh degree of automationPre-extraction tea treatmentPulp and paper industryFermentation

The invention discloses a technology and a device for making Liupu tea; the invention is characterized by adopting the mechanical making technology, and the technology comprises the steps of fermenting, screening, winnowing, streaming tea, pressing a bamboo hat, cooling, ageing and the like; the device comprises a fermentation tank, a screening machine, a winnowing machine, a tea steaming machine, a bamboo hat press machine and a conveying machine, wherein the fermentation tank, the screening machine, the winnowing machine, the tea steaming machine and the bamboo hat press machine are sequentially connected by the conveying machine; the fermentation tank is connected with the screening machine by a conveying frame; the screening machine is connected with the winnowing machine by a material pipe; and the front end of the bamboo hat press machine is connected with an automatic electronic weighing machine. The technology and the device for making Liupu tea have the characteristics of being high in degree of automation, safe, sanitary, good in tea quality and the like.

Owner:广西梧州业胜茶叶有限公司

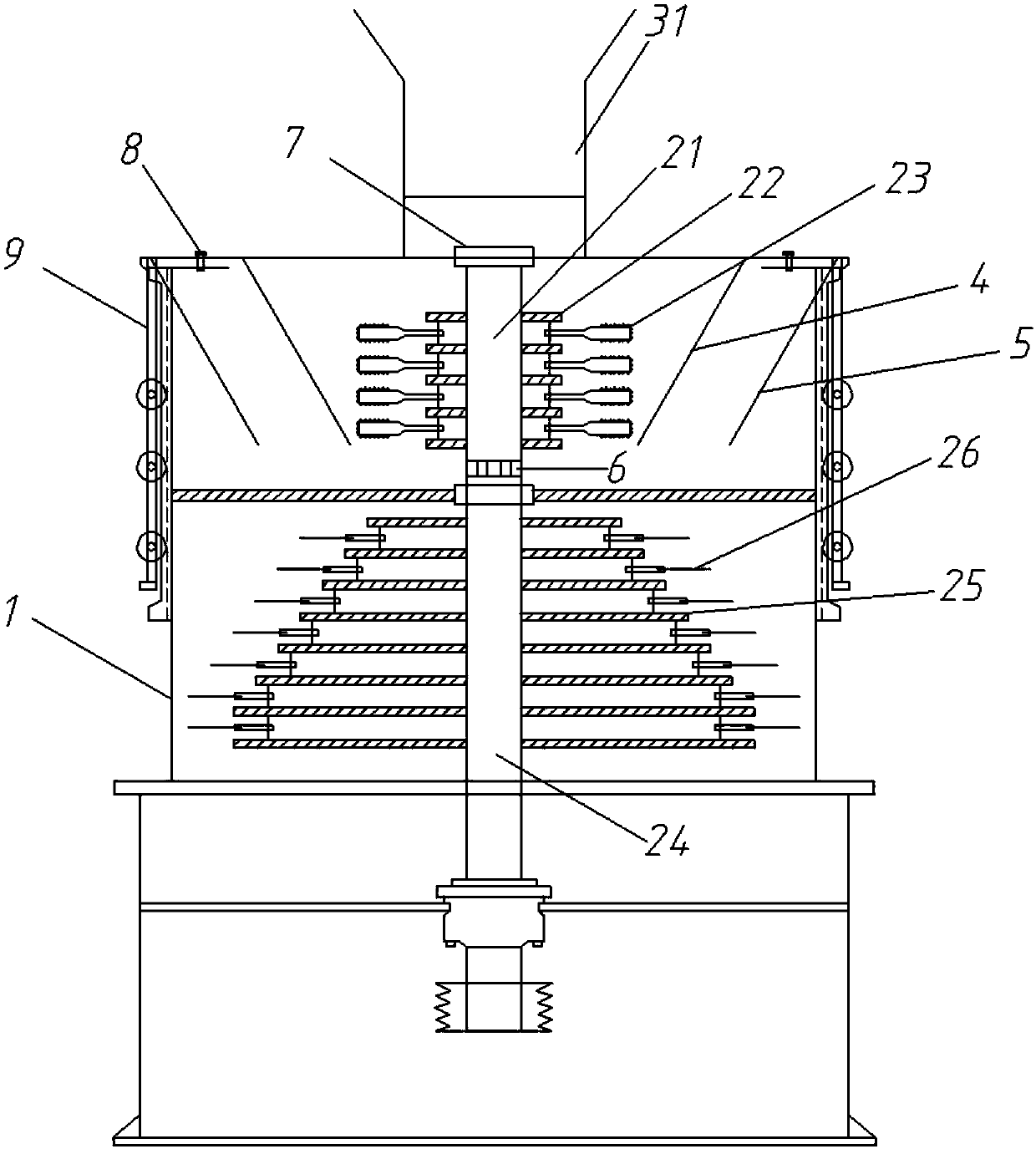

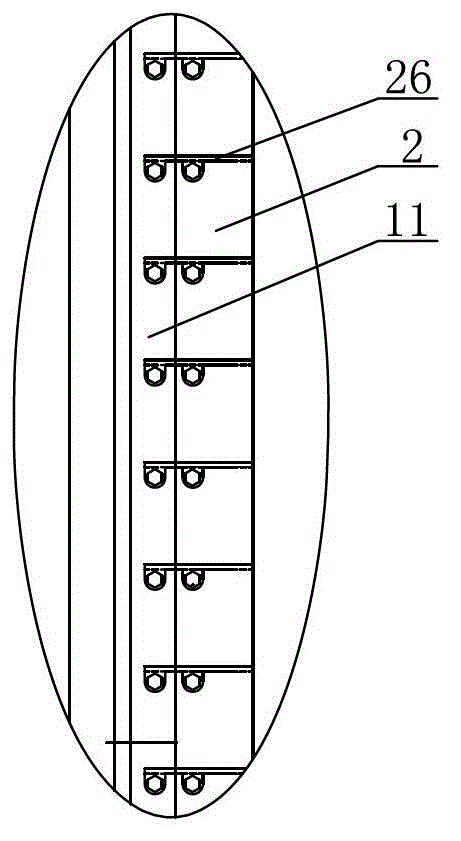

Hot air circulation grain drying device

InactiveCN107156291AImprove qualityReduce churnDrying gas arrangementsSeed preservation by dryingEngineeringHeat losses

The invention discloses a hot gas circulation grain drying equipment, which comprises a dehumidifier and a drying box; a dust removal channel is arranged above the drying box, and a winnowing device is arranged on the right side of the dust removal channel; the dust removal channel is connected with a cyclone dust collector A drying box is connected under the dust removal channel; a drying plate is arranged in the drying box; a first hot air blower, a second hot air blower and a third hot air blower are arranged between the drying plates. The present invention realizes the full utilization of the hot air and separate drying of the grains with different drying degrees by providing a circulating hot air drying device and hot air blowers with different powers, reducing heat loss and saving energy; the present invention is provided with staggered distribution The drying plate improves the drying efficiency and the drying effect; the invention is equipped with a high-school dust removal device to remove dust and shriveled grains in the grain, improves the quality of the grain, and saves storage space.

Owner:惠安益源信息技术咨询有限公司

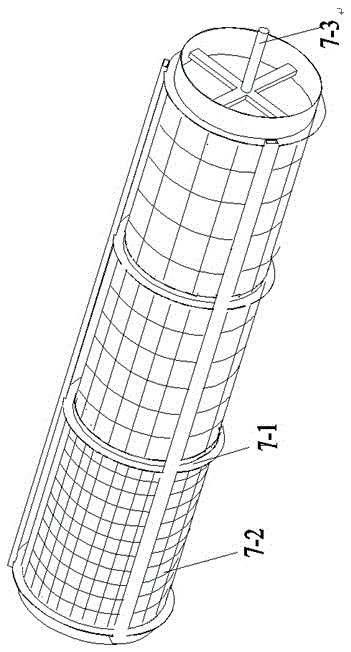

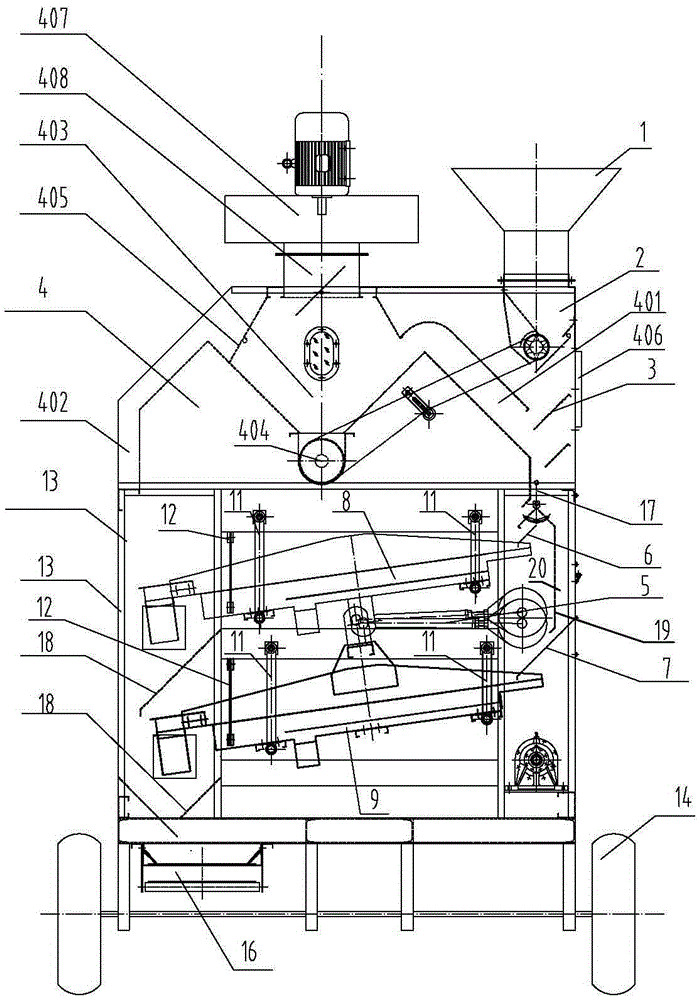

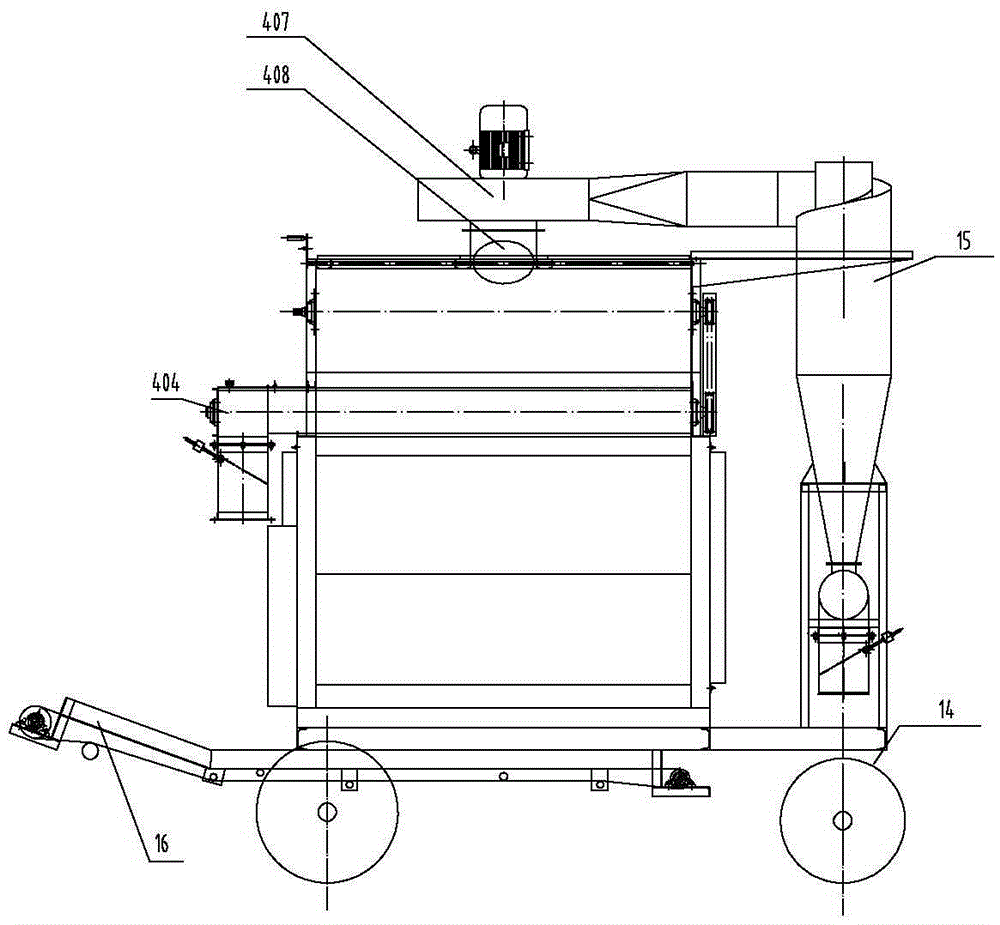

Building rubbish screening equipment and screening method

ActiveCN104759413AExtended service lifeImprove screening effectGas current separationScreening effectScreening method

The invention relates to the field of building rubbish recycling, in particular to building rubbish screening equipment and screening method. The building rubbish screening equipment comprises a sorting chamber, a throwing device, a wind power device and a medium-heavy object sorting device, and a first separation region and a second separation region are arranged in the sorting chamber; the throwing device conveys material to the first separation region; the wind power device uses the wind power to lift the material thrown from the first separation region; the medium-heavy object sorting device comprises a double-layer sorting barrel, a negative pressure mechanism, a fan and a barrel body drive mechanism. The building rubbish screening equipment can separate the building rubbish into heavy substance, medium-heavy substance and light substance according to the need, and the screening effect is good; the heavy material does not collide with the double-layer sorting barrel in the screening process, and the service life of the double-layer sorting barrel is prolonged; the material throwing angle and power of the throwing device can be regulated according to the need in the screening process, and the adaptive capacity of the equipment is greatly improved; the building rubbish screening equipment is capable of effectively lowering the equipment load and improving the winnowing efficiency.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

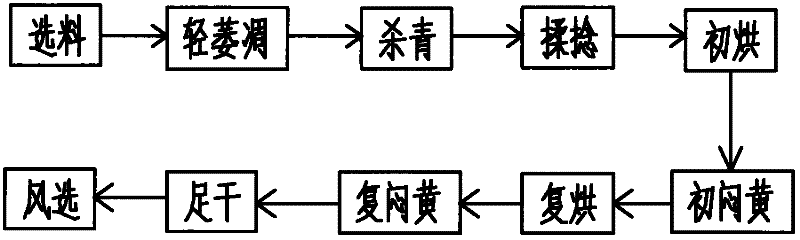

Method for processing yellow soup tea

InactiveCN102388993AControl quality balanceQuality and beautiful appearancePre-extraction tea treatmentBudEqualization

The invention discloses a method for processing a yellow soup tea. The method for processing the yellow soup tea comprises the steps as follows: selecting materials; lightly withering; removing water; kneading; primarily drying; primarily braising; secondarily drying; secondarily braising; sufficiently drying; and winnowing. The method has the advantages as follows: the conversion of substances in the tea is precisely controlled by allocating the temperature and the time, so that all aspects of the finished tea are optimal; the quality equalization of the tea is controlled by controlling the stacking thickness of the tea in the processing process, so that the processed tea is high in quality, attractive in curved appearance, slightly yellow in color and luster, tidy, fat and tender in buds and leaves, yellow, green and bright in soup color, sweet and fragrant in smell and sweet and mellow in taste; and the leaf bottoms are clustered, bright yellow and tidy.

Owner:夏成鹏 +1

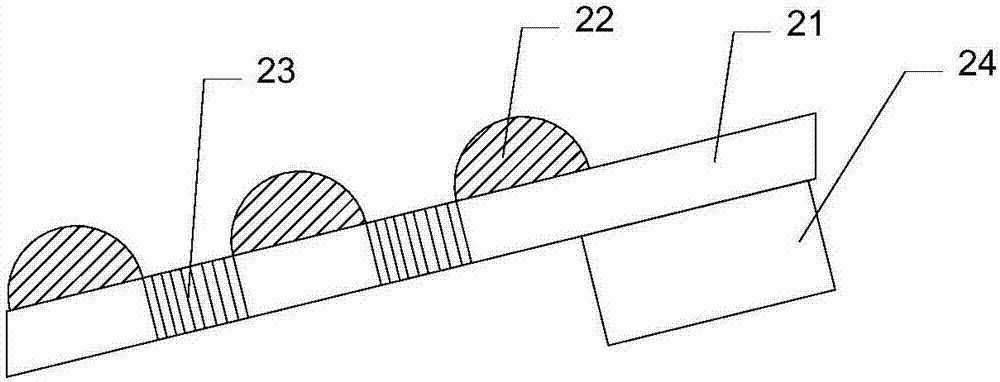

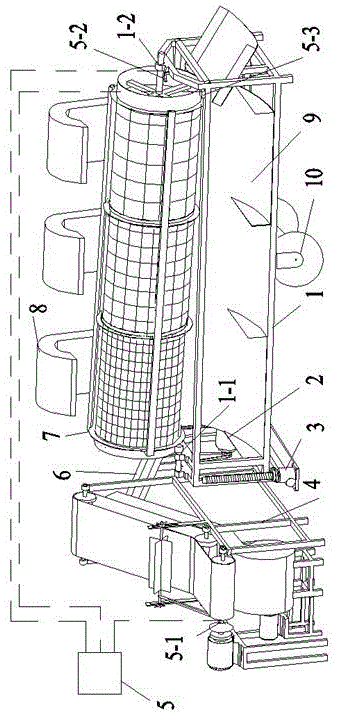

Equal-diameter roller type fresh tea grading device and method

InactiveCN105562345AIncrease profitLarge diameterSievingGas current separationAgricultural engineeringAgricultural machinery

The invention discloses an equal-diameter roller type fresh tea grading device and method, and belongs to the field of agricultural machinery and equipment. According to the equal-diameter roller type fresh tea grading device, a roller is installed in an inclined manner, each segment of the roller is equal in diameter and length, working parameters can be displayed and adjusted, an air outlet of an air separation fan is located below a feeding belt of a feeding mechanism, and an air outlet of a screen cleaning fan is located above the roller. Due to the equal-diameter structural design, the grading rate and grading speed are improved; and a controller is used for monitoring the working process, so that the grading precision is improved, and the labor intensity is reduced. The air separation fan is used for separating leaves and buds to realize primary grading; the screen cleaning fan is used for blowing the fresh tea leaves blocking the meshes to the roller, so that the screen blockage rate is reduced, and the grading rate and grading speed are increased. The screen mesh can be replaced so as to adapt to different grading requirements. The equal-diameter roller type fresh tea grading device can realize regulation and control of the roller inclination angle, the roller rotation speed and the feeding rate.

Owner:JIANGSU UNIV

Module-assembly type domestic waste sorting device

InactiveCN101716586ACreate pollutionSmall footprintSolid waste disposalClimate change adaptationMagnetic separatorSlide plate

The invention discloses a module-assembly type domestic waste sorting device which comprises a box body and also comprises a domestic waste feeding section, a broken bag winnowing section, a magnetic separating section, a water content sorting section and an organic matter section which are arranged in the box body. The box body is externally provided with different domestic waste collecting boxes which correspond to all the sections; the domestic waste feeding section is provided with a domestic waste inlet and an automatic conveying belt which is arrange at the bottom of the domestic waste inlet; the broken bag winnowing section is provided with a knife-type multipurpose roller screen, a domestic waste hopper, an automatic conveying belt and a winnowing machine which is arranged on the side part of the broken bag winnowing section; the magnetic separating section is provided with a magnetic separator and an automatic conveying belt; the tail end of the automatic conveying belt in the broken bag winnowing section extends to the top of the magnetic separator; the water content sorting section comprises a slide plate and water tanks which are connected in sequence by pipes and are used for separating solid from liquid; the organic matter section comprises a water tank and an automatic conveying belt, wherein the water tank is connected with the water tank in the water content sorting section by pipes, and the automatic conveying belt is used for conveying the domestic waste to the domestic waste collecting boxes. The module-assembly type domestic waste sorting device has novel structure, adopts the totally-sealed Module-assembly type and is convenient to install and transport.

Owner:SHANGHAI BILI ENVIRONMENTAL PROTECTION TECHCO

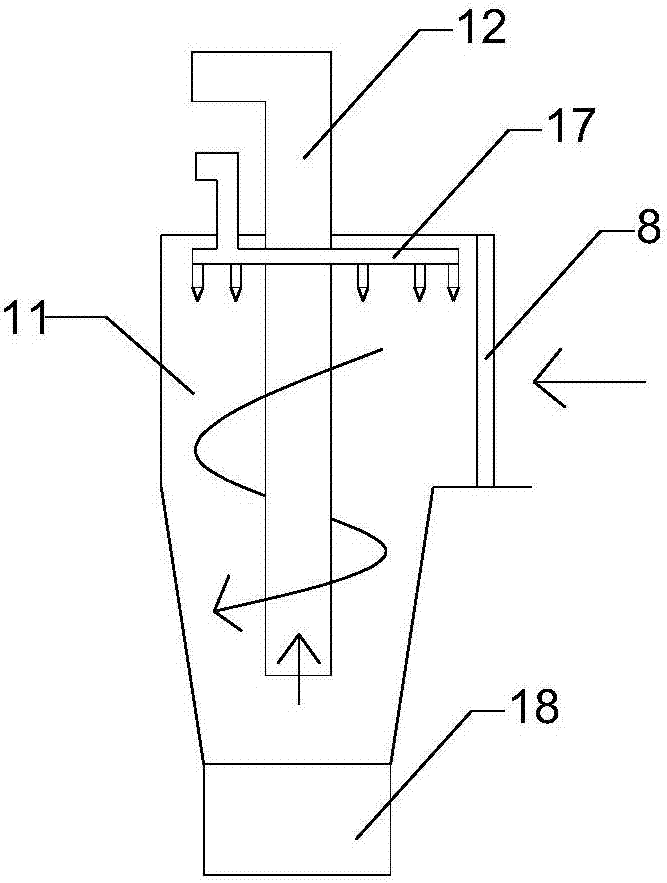

Fluidized bed winnowing and moisture controlling machine and new winnowing and moisture controlling process

InactiveCN101786080AReduce moistureRaise the initial temperatureDrying solid materials with heatGas current separationGranularityFluidized bed

The invention relates to equipment and a process for adjusting the moisture of granular materials and grading the granularity, in particular to a fluidized bed winnowing and moisture controlling machine and a new winnowing and moisture controlling process which can simultaneously realize the reduction of water content of the granular materials and the grading according to the granularity of the granulated materials. Fine granular materials of the granular materials in the fluidized state are centrally discharged through a fine granule discharge pipe and other rough granular materials are scraped to a rough granule discharge pipe for centralized discharge, so the proper reduction of the water content can be realized while grading the granularity. The equipment and the process are applied to the field of coal moisture control in the coking industry, the dryness and quality improvement of lignitous coal in coal industry and the like.

Owner:长沙通发高新技术开发有限公司

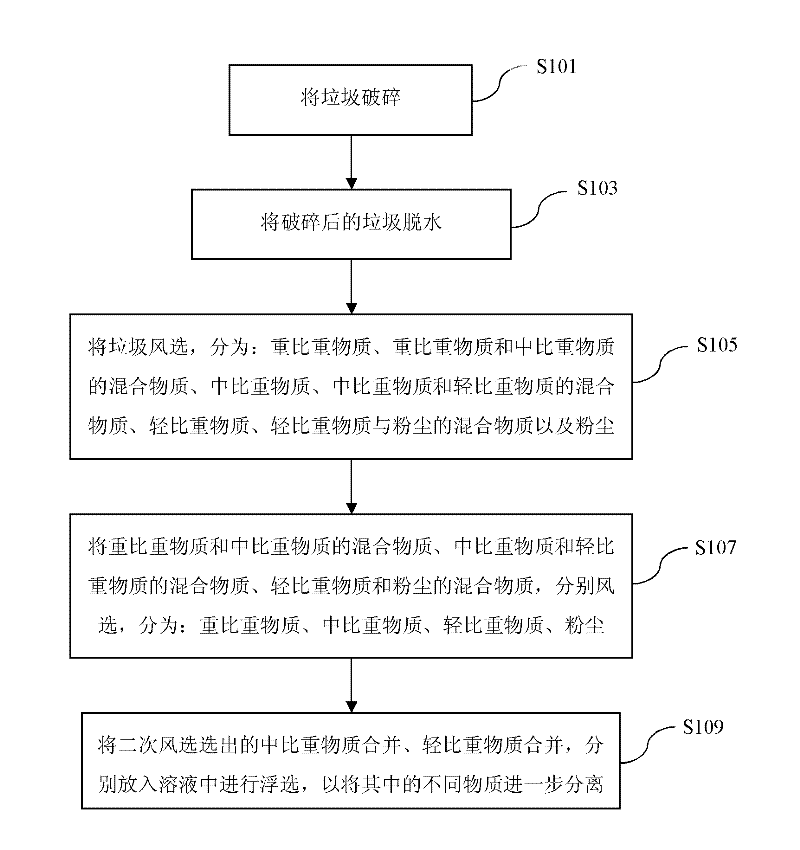

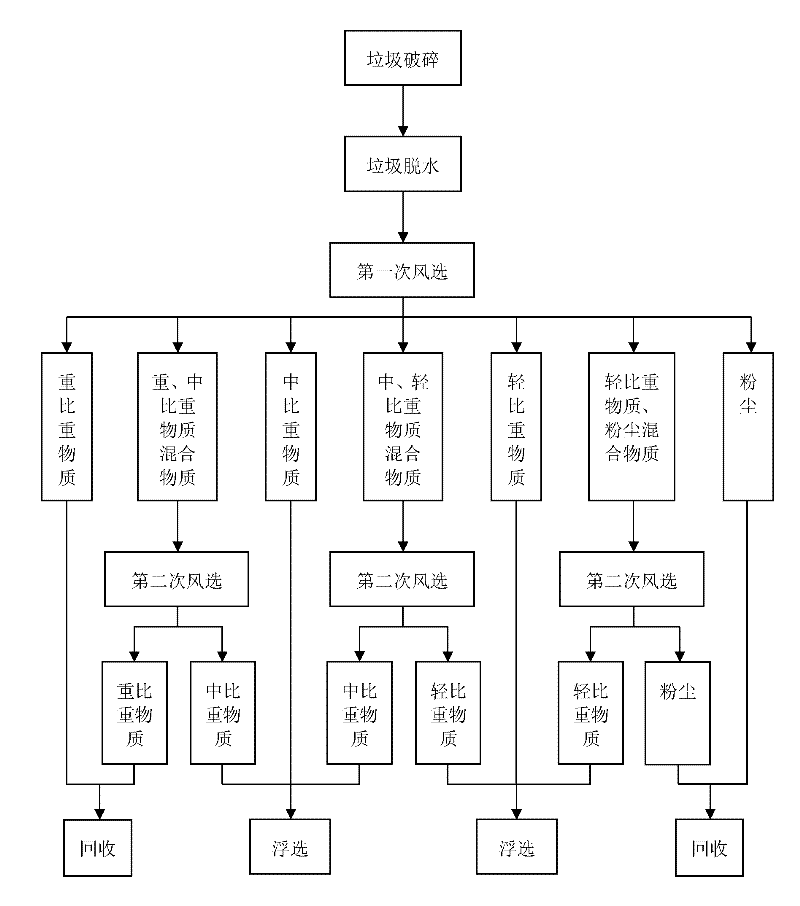

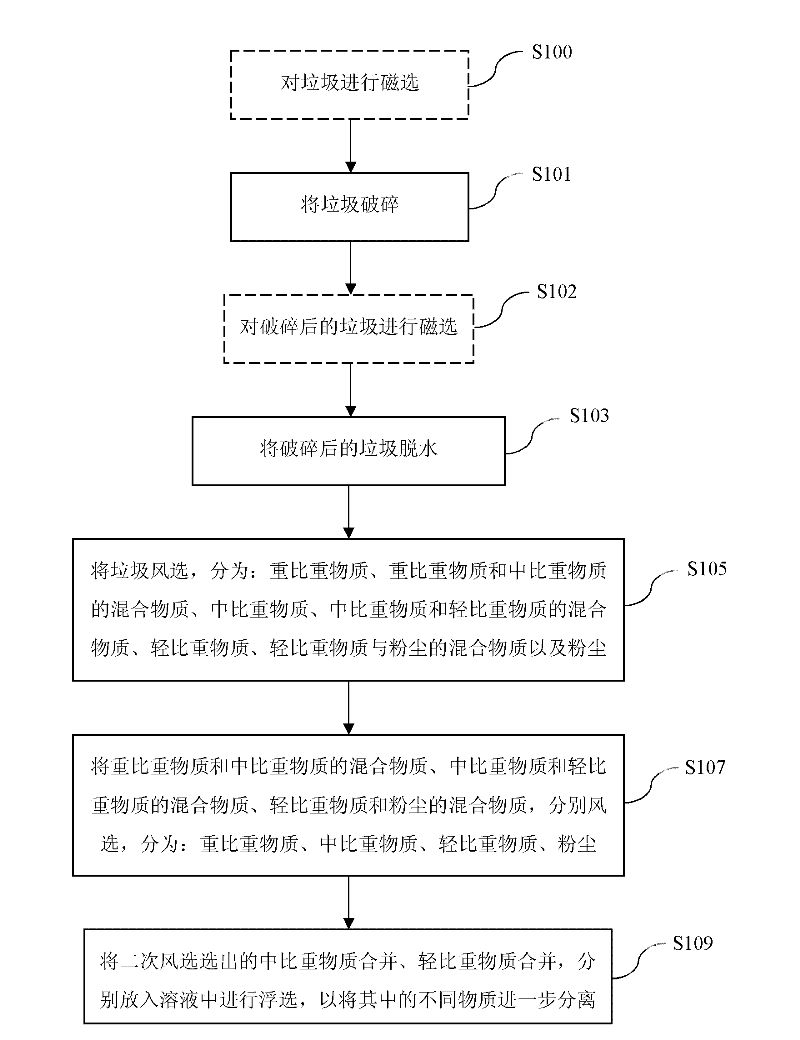

Method and device for treating garbage

InactiveCN102225416ASolve pollutionSolve the problem of garbage occupying landSolid waste disposalWet separationLitterEngineering

The invention relates to a method and a device for treating garbage. The method comprises the following steps of breaking garbage, dehydrating the broken garbage, winnowing the dehydrated garbage to separate them into matters with a large specific gravity, matters with a middle specific gravity, matters with a low specific gravity, dust and their mixtures, winnowing further the mixtures obtained from the previous step to separate them into matters with a large specific gravity, matters with a middle specific gravity, matters with a low specific gravity and dust, putting the matters which haverespectively a middle specific gravity and a low specific gravity and are winnowed by the above steps into a solution to carry out a flotation process to separate further the matters into different substances. The device for treating garbage comprises a garbage breaking device, a garbage dehydrating device, a garbage winnowing device and a garbage flotation device. Through the method and the device, household garbage and medical garbage of which treatments are difficult greatly can be carried out processes of treatment, classification, recovery and utilization thus problems of pollution and land occupation of garbage are solved.

Owner:崔稷宁

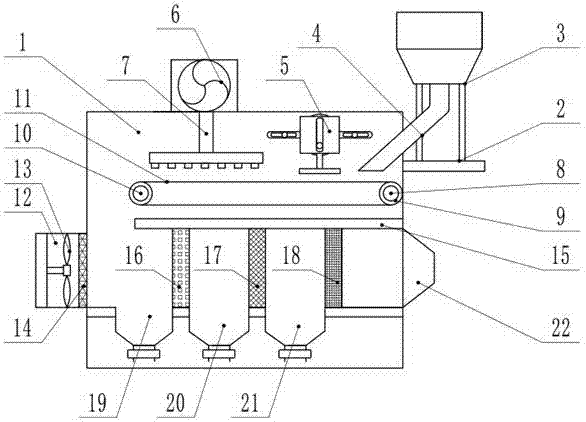

Melon seed drying and screening apparatus

InactiveCN107411140AImprove qualityAvoid affecting the drying effectGas current separationFood treatmentEngineeringAir blower

The invention discloses a drying and screening device for melon seeds, which comprises a machine casing, a paving device, a hot air blower, a casing wind separator, a first sieve plate, a second sieve plate and a third sieve plate. There is a paving device, a hot air blower is fixedly installed on the upper side of the casing, and a hot air pipe is connected to the air outlet of the hot air blower; a wind separation device chamber is installed on the left side of the casing, and a wind separation device cavity is installed inside the wind separation device cavity. A sorting machine, the first sieve plate, the second sieve plate and the third sieve plate are fixedly installed between the upper and lower sets of partitions. Compared with the ordinary paving device, the device indirectly drives the paving plate to move left and right through the drive motor, so that the melon seeds can be evenly spread on the conveyor belt, preventing the melon seeds from being fed and accumulated to affect the drying effect. The sieve plate with aperture can fall into the corresponding outlet according to the particle size of melon seeds, so as to realize the automatic grading and screening of the particle size of melon seeds, and at the same time, it is more efficient than manual selection.

Owner:盐城千之诺机械有限公司

Multistage precision garbage sorting device

ActiveCN107225143AReduce labor pressureEasy to operateSolid waste disposalEngineeringMagnetic separation

The invention discloses a multistage precision garbage sorting device and relates to the technical field of environmental protection machinery. The multistage precision garbage sorting device comprises a rack, a crushing device, a magnetic separation device, a first conveying device, a first sorting unit, a winnowing device, a metal sorting device, a control device and the like. The crushing device is connected to the upper portion of the rack through bolts. The magnetic separation device is located below the crushing device and connected to the rack through bolts. The first conveying device is connected to the lower portion of the magnetic separation device through bolts. The first sorting unit is located on the right of the first conveying device. The winnowing device is connected to the tail end of the first sorting unit through bolts. The multistage precision garbage sorting device has the characteristics of being easy to operate, thorough in sorting and high in efficiency, is high in safety performance and reliability and can conduct precision sorting on various types of garbage. The labor pressure of people is relieved.

Owner:凤阳县易天成模具有限公司

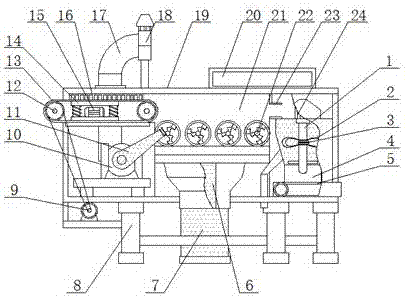

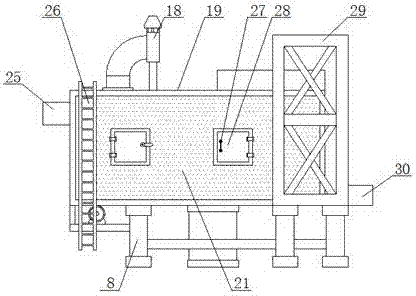

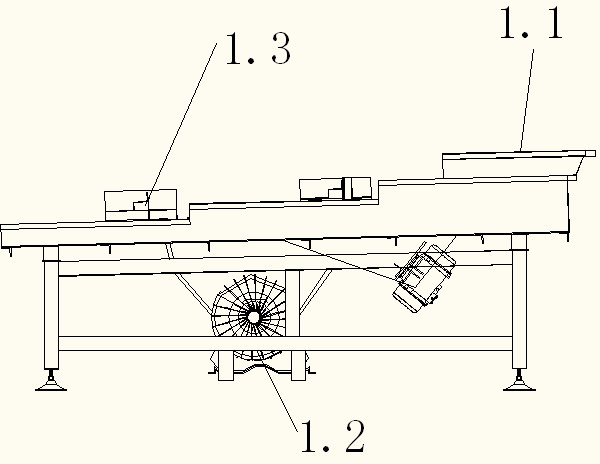

High-efficiency cleaning device for turbo multi-duct blower

InactiveCN104226598AReduce energy lossAvoid generatingSievingGas current separationAir velocityAgricultural engineering

The invention discloses a high-efficiency cleaning device for a turbo multi-duct blower. The device mainly comprises a material conveying uniform distribution device, a grain and impurity conveyer device, a cleaning device and a transmission device, and meets the requirement on high-efficiency cleaning of crops in a large feed quantity; the turbo multi-duct blower is large in flow, uniform in air speed at an air outlet, stable in airflow, high in anti-attenuation capacity, compact in structure and high in energy efficiency ratio; through the vibration of a material vibrating screen and multiple winnowing of the turbo multi-duct blower, clean grains fall into a grain auger and enter a grain box, and partial impurities fall into a secondary impurity auger, are uniformly distributed by a return plate and enter a screen surface to realize recleaning. The high-efficiency cleaning device can meet the requirement on high-efficiency high-performance cleaning operation of wheat, rice, rape, corn, soybean and other crops in the feed quantity of 5-8kg / s, and is small in cleaning loss, low in impurity rate, high in operating efficiency and compact in structure.

Owner:JIANGSU UNIV

Household garbage winnowing machine with ferromagnetic attraction function

ActiveCN107570421AEasy to recycleImprove pollutionCombination devicesGas current separationElectromagnetic generatorSpray nozzle

The invention discloses a household garbage winnowing machine with a ferromagnetic attraction function. The household garbage winnowing machine comprises a winnowing machine body, a dust removal bentthrough part, a feeding port, an electromagnetic generator and spray nozzles. A belt wheel is arranged at the left end of the winnowing machine body and provided with a feeding conveyor belt. A plurality of screen cylinders are arranged in an original winnowing machine, substances with the small weights are screened multiple times by the screen cylinders and then are directly discharged to a lightsubstance treatment area through a clean fan, heavy substances are directly collected into a solid waste pipe, precious metal in garbage of the solid waste pipe is attracted by magnetic selectors through magnetic guiding columns, and thus recycling of the garbage is facilitated; and meanwhile lots of smoke dust generated in the winnowing process is filtered in the dust removal bent through part,the dust is subjected to impurity removal through atomized water drops sprayed by a water spraying device, separation is conducted in a stirring chamber, and the dust is discharged through a liquid discharging pipe, so that pollution of the smoke dust on the environment is reduced, corrosion of the smoke dust on internal parts of the winnowing machine is reduced, and clearing by workers is facilitated.

Owner:温岭市三利音视器材厂

Heating and drying device and seed screening device

PendingCN109916164ADry evenlyGood effectGas current separationDrying solid materials without heatEngineeringWinnowing

The invention relates to a heating and drying device and a seed screening device. The seed screening device comprises the heating and drying device and a winnowing unit. The heating and drying devicecomprises a shell. A heating and drying cavity for drying seeds is formed in the shell. At least two guide plates are arranged in the heating and drying cavity in a staggered manner and an up-and-downspaced manner. In every two adjacent guide plates, the material falling end of the guide plate on the upper portion is higher than that of the guide plate on the lower portion. The motion track of the seeds in the heating and drying cavity is a reciprocating bending curve. The heating and drying device further comprises a vibration unit for driving the guide plates to vibrate. When the guide plates vibrate, the seeds can be evenly distributed on the guide face. The drying efficiency is high. The motion track of the seeds in the heating and drying cavity is the reciprocating bending curve, themotion track in the heating and drying cavity becomes longer, and the drying effect is quite good. Vibration conveying and drying of the seeds can be completed in one set of equipment, and the cost of the whole heating and drying device is reduced.

Owner:HENAN UNIV OF SCI & TECH

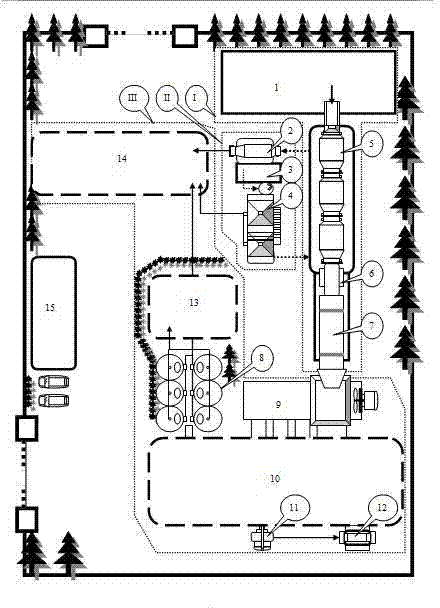

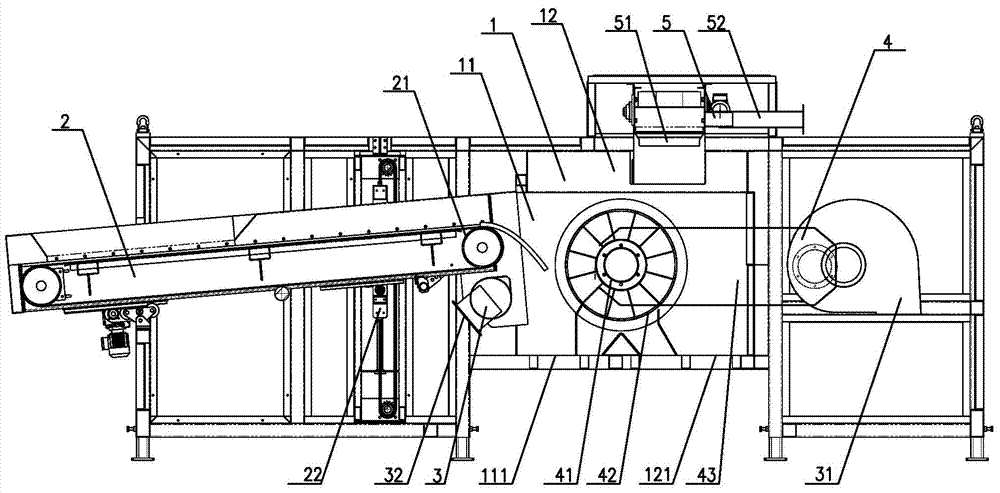

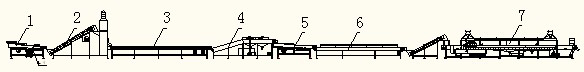

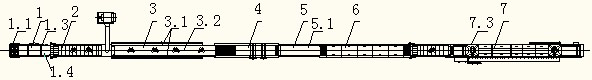

Production line for date palm

ActiveCN102429181AImprove product qualityCreate pollutionFood preparationFood treatmentProduction linePulp and paper industry

The invention relates to a production line for date palm, comprising a vibrating screen, a lifting winnowing machine, a selecting conveyor, a rollarounds type cleaning machine, a vibration draining machine, an ultraviolet sterilization machine and a hot nest type drying machine, which are sequentially connected, wherein the vibrating screen is used for scattering raw materials and screening the data palm; the winnowing machine is used for removing leaves and granulated impurities; the selecting conveyor is used for selecting the data palm; the rollarounds type cleaning machine is used for cleaning the data palm; the vibration draining machine is used for draining the data palm, the ultraviolet sterilization machine is used for sterilizing the data palm, and the hot nest type drying machine is used for drying the data palm. The production line for the data palm, provided by the invention, has the beneficial effects that: the processing steps of winnowing, impurity elimination, cleaning, drying and the like can be carried out without manual work, so that the participation of mass labor is avoided, the product quality of the data palm is higher, and the line production and the production efficiency are very high.

Owner:山东瑞帆果蔬机械科技有限公司

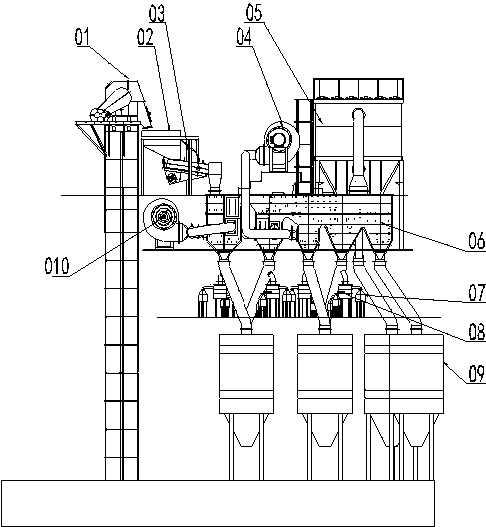

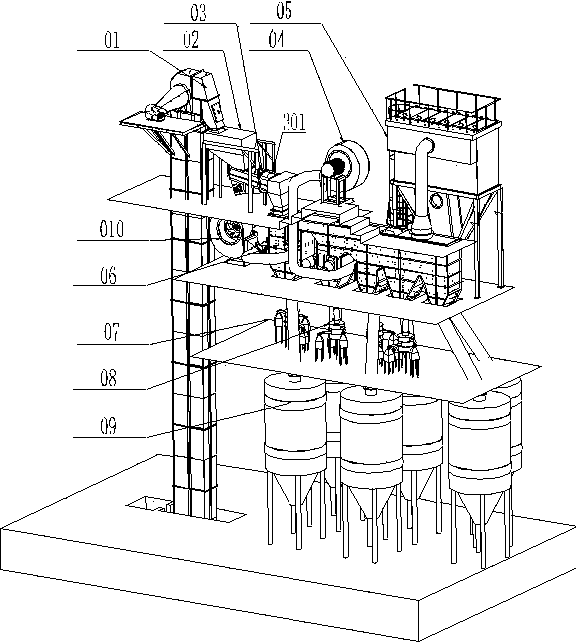

Machine-made sand wind power winnowing system and winnowing method

ActiveCN103357577ATo achieve the purpose of dust-freeTo achieve the purpose of winnowingGas current separationProgrammable logic controllerEngineering

The invention relates to a machine-made sand wind power winnowing system and a winnowing method, which not only can adopt wind power to realize selection of machine-made sand with different particle sizes, but also realizes dustlessness. The machine-made sand wind power winnowing system comprises a PLC (Programmable Logic Controller), wherein a discharge opening of a mixing finished product bucket elevator directly faces to the inlet of a buffer stock bin; a discharge opening of a buffer stock bin directly faces to the inlet of a feeding machine; the outlet of the feeding machine is communicated with a feed opening of a machine-made sand wind power air separator cabin; multiple stage discharge openings of the machine-made sand wind power air separator cabin are communicated with respective material storage cylinders in each stage through material conveying tubes; the air outlet of a main air blower is communicated with a main wind opening of the machine-made sand wind power air separator cabin; the air outlet of an assistant blower is communicated with assistant wind openings in the machine-made sand wind power air separator cabin; a dedusting opening in the machine-made sand wind power air separator cabin is communicated with the inlet of a dust remover.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

Adjustable type household garbage crusher

InactiveCN107737640ASimplify the classification processReduce wearGas current separationGrain treatmentsCrusherKnife blades

The invention discloses an adjustable type household garbage crusher. The adjustable type household garbage crusher comprises a housing, a charging, horizontal-throwing and winnowing mechanism, a crushing mechanism and a power mechanism, wherein the crushing mechanism comprises a hammer head crushing combined cutter crushing group; and the charging, horizontal-throwing and winnowing mechanism comprises a housing, a charging and throwing conveyor belt, a resistance fan, a light material outlet and a heavy material outlet. Compared with the prior art, the adjustable type household garbage crusher has the advantages that: labor power is saved through the charging, horizontal-throwing and winnowing mechanism, and garbage sorting programs are simplified; materials with relatively great hardnessare subjected to secondary treatment, so that abrasion, on blades, of hard materials is alleviated, and crushing efficiency is improved; generally, the materials are only crushed by blades, so that equipment burden is alleviated; and when no hard materials and heavy materials are added, a hammer head crushing mechanism can be separated from a main shaft, so that electric energy is greatly saved,and equipment burden is also alleviated.

Owner:HEFEI UNIV OF TECH

Multipurpose maize enriched flour and production method thereof

ActiveCN103519060AImprove nutritional statusImprove bindingMulti-step food processesFood ultrasonic treatmentAdditive ingredientBiological activation

The invention relates to multipurpose maize enriched flour and a production method thereof, belonging to food processing technology. The production method comprises the steps of performing winnowing, magnetic separation, spraying washing on flowing water to remove impurities, and carrying out nutrient ultrasonic activation induction and increment, peeling, high-shear crushing and grinding, variable-frequency microwave drying, sterilization, high-frequency vibration ultrafine crushing and other treatment to produce multipurpose maize flour which is rich in vitamin, amino acid and soluble saccharides, amylase and other nutrients and bioactive constituents, and the multipurpose maize enriched flour product has thick maize fragrance, and can be used as raw materials for processing cooked wheaten food such as bread, biscuits, steamed bread, dumplings, noodles, steamed cake and the like. The production conditions of the product are mild to well maintain the natural nutrients therein; no pollution and harmful substances are generated in the production process, any chemical and artificial synthesis additives are not used, so that the multipurpose maize enriched flour is safe to eat.

Owner:吉林省长吉图开发建设现代农业投资有限公司

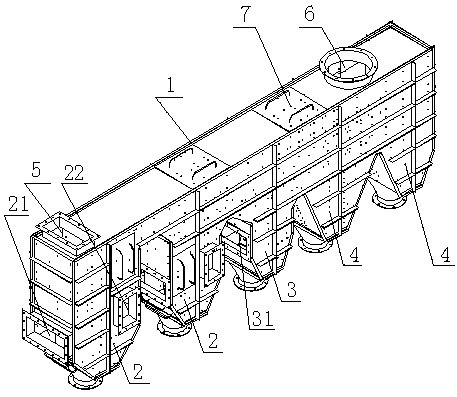

Grain winnowing and stone and impurity removing separator

The invention relates to a grain winnowing and stone and impurity removing separator. The separator comprises a frame, an air supply system, and a storage box and a winnowing separation box which are arranged on the frame, wherein a vibrating feeding plate which is inclined downwards is arranged below the discharge port of the storage box; a vibrating motor is arranged at the bottom of the vibrating feeding plate; the top of the vibrating feeding plate is hinged to the frame; the bottom of the lower blanking end of the vibrating feeding plate is connected with a compression spring; the compression spring is arranged on the frame through a spring seat; the blanking end of the vibrating feeding plate is opposite to the feed port of the winnowing separation box; the air supply system comprises a fan and an air supply channel; the air outlet of the air supply channel is communicated with the feed side of the winnowing separation box; a heavy impurity discharge port, a grain discharge port and a light impurity discharge port are sequentially formed at the bottom of the winnowing separation box along the air inlet direction; an air closer is arranged at the light impurity discharge port; an exhaust regulating port is formed on the top of the winnowing separation box; and a cloth filter bag is arranged in the exhaust regulating port. The separator has a reasonable structure and is obvious in separation effect and high in material treatment capacity, and the material cleaning range is wide under the action of air.

Owner:SHANDONG YIKAI STORAGE ENG

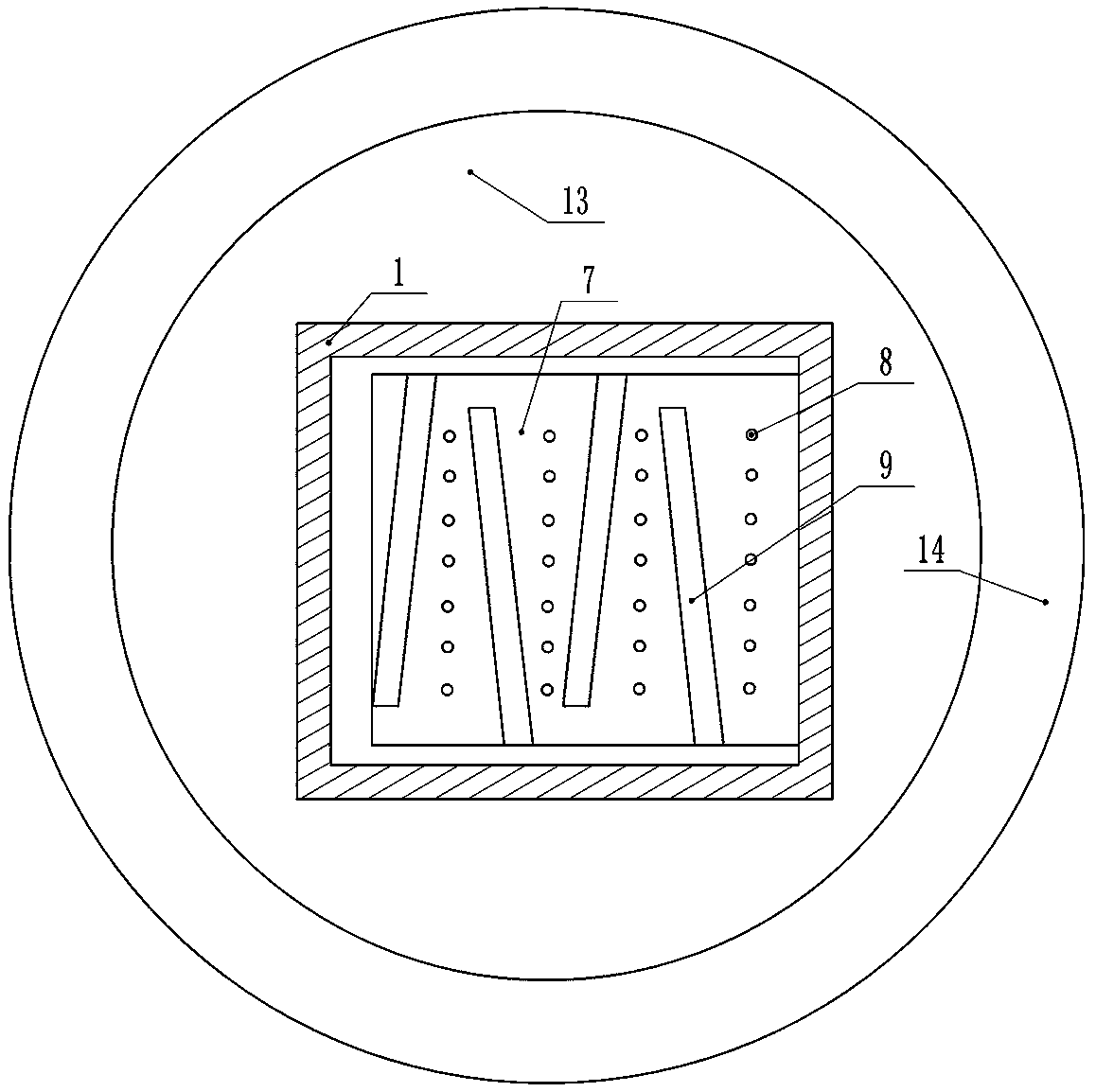

Grain winnowing vibration screen

InactiveCN105268641AIncrease productionGuaranteed uptimeSievingGas current separationEngineeringImpurity

The invention discloses a grain winnowing vibration screen. According to the structure of the grain winnowing vibration screen, a feeding hopper (1) is arranged on the top of a rack (13), an air closing material evening device (2) is arranged below the feeding hopper (1), a discharging flowing plate (3) is arranged below the air closing material evening device (2), and the lower end of the discharging flowing plate (3) is located at a suction opening of a front suction channel (401) of a winnowing cleaning device (4); a material distributing device (17) is arranged below the discharging flowing plate (3), an upper screen feeding flowing plate (6) and a lower screen feeding flowing plate (7) are arranged below the material distributing device (17), and the lower end of the upper screen feeding flowing plate (6) and the lower end of the lower screen feeding flowing plate (7) are located on an upper screen (8) and a lower screen (9) respectively; and a discharging belt conveyor (16) is arranged below the discharging end of the upper screen (8) and the discharging end of the lower screen (9). The grain winnowing vibration screen can effectively remove dust and all impurities such as light impurities, large impurities and small impurities in grain, and it is guaranteed that the impurity rate of the cleaned grain meets the storage requirement.

Owner:沈一青 +1

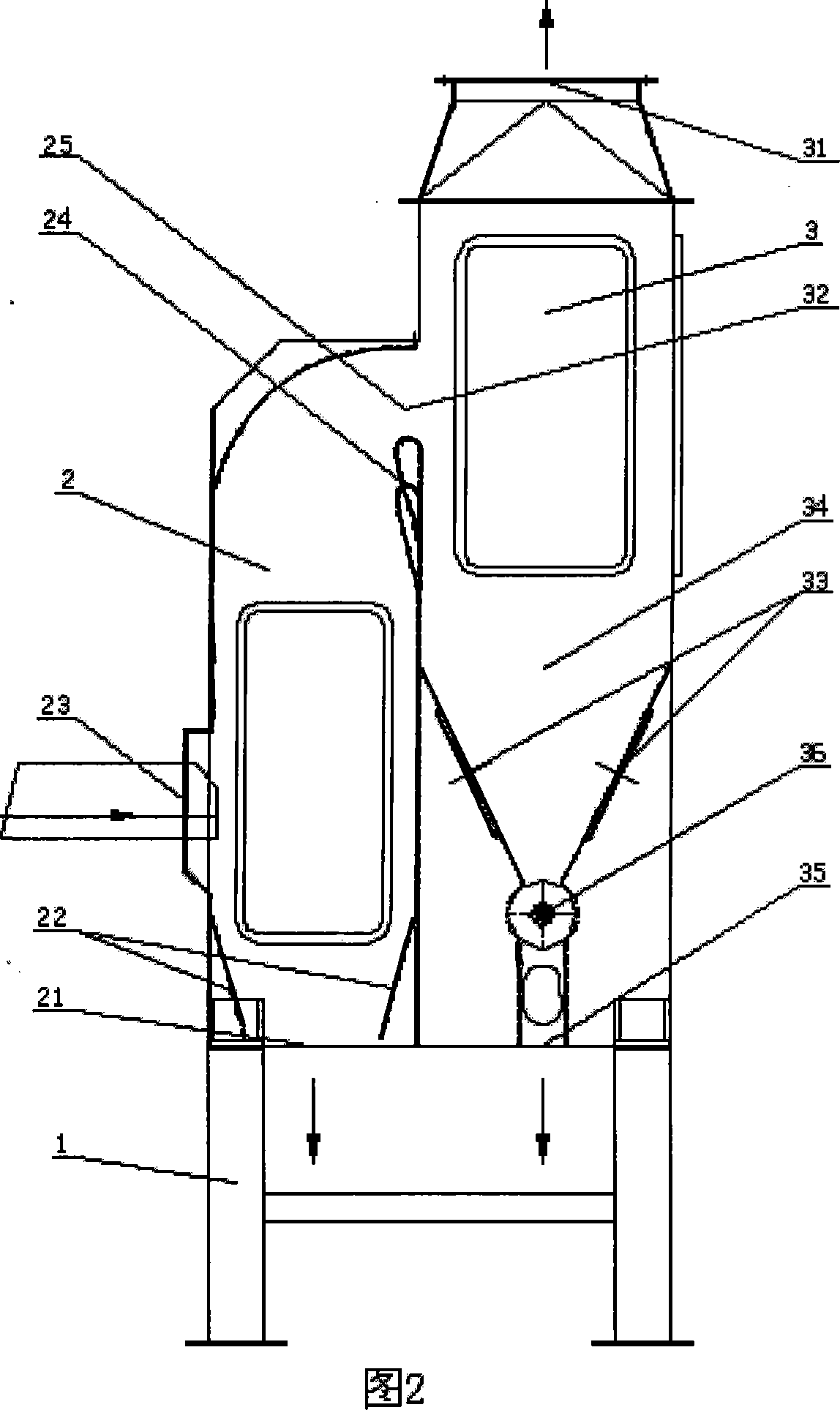

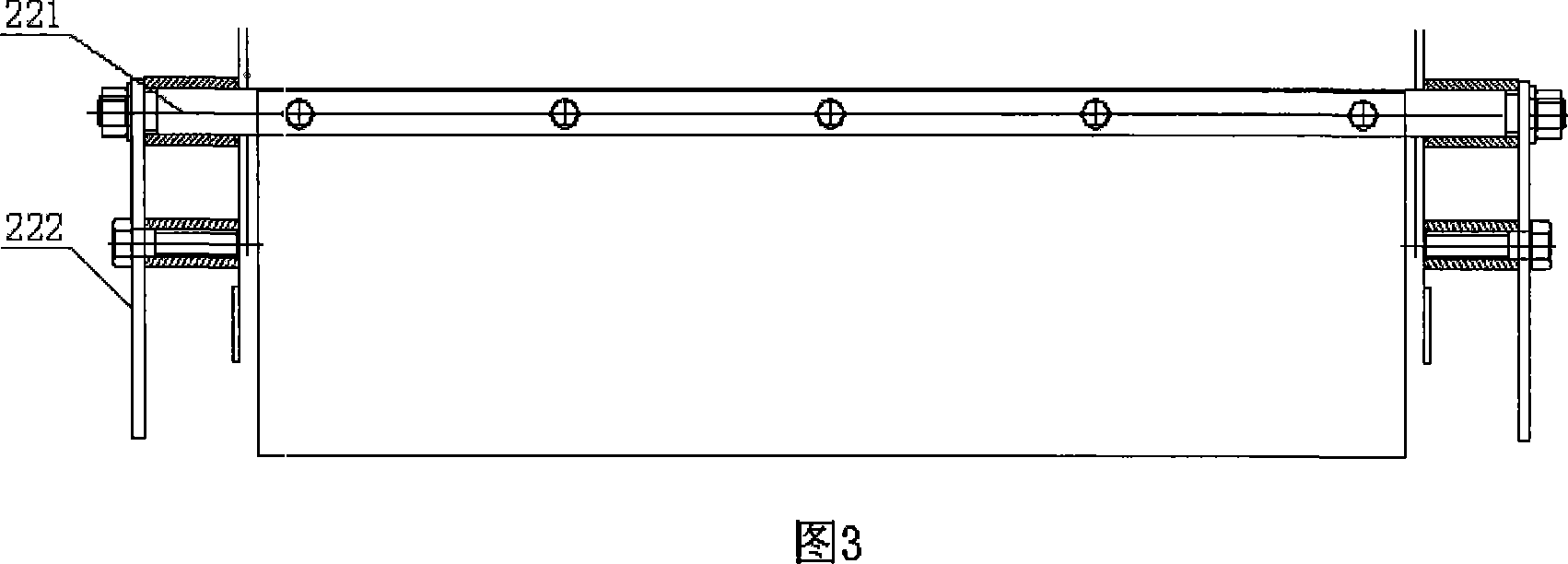

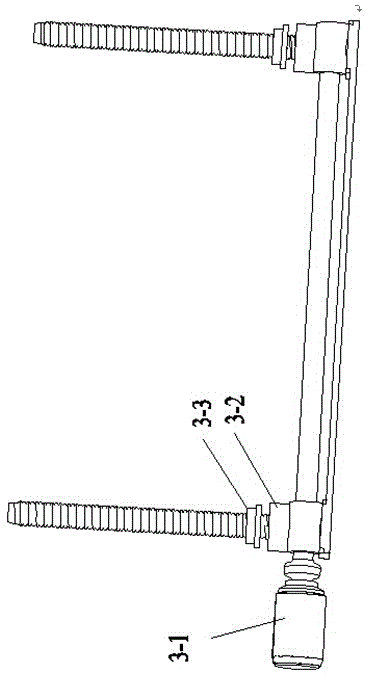

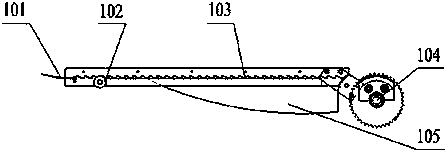

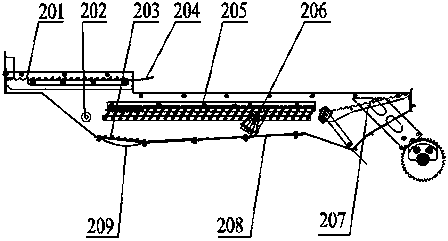

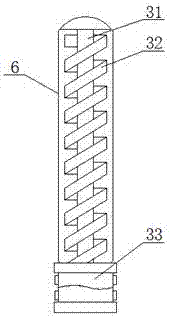

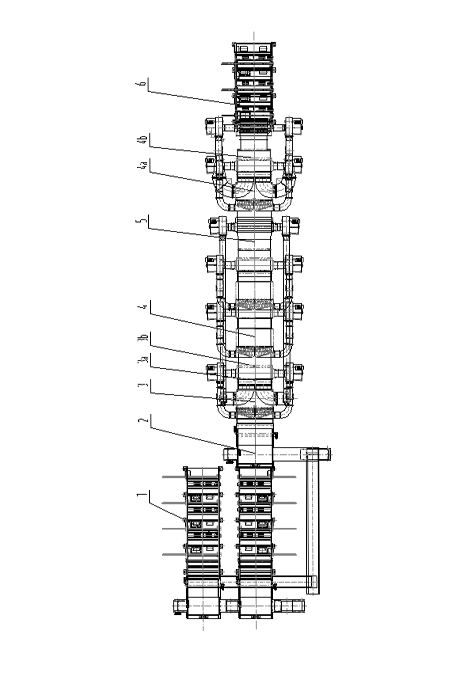

Divided winnowing method and system for tobacco leaf threshing

ActiveCN102048237AShorten delivery timeShorten the conveying distanceTobacco preparationProcess engineeringMutual influence

The invention relates to a divided winnowing method and system for tobacco leaf threshing. The winnowing system consists of a leaf threshing machine (1), a primary-selection winnowing unit (3), a multi-stage fine-selection air distributing unit (4) and a secondary leaf threshing machine (6) that are sequentially arranged, wherein the leaf threshing machine and the primary-selection winnowing unitare connected via auxiliary communicated conveying equipment (2), a blanking hole (3a) of a blanking device of the primary-selection winnowing unit is arranged above a feeding device of the multi-stage fine-selection air distributing unit, and the part between the discharge hole (3b) of the primary-selection winnowing unit and the secondary leaf threshing machine is connected with a collecting air blowing pipeline (5) or a conveyor. By virtue of the winnowing system, materials obtained after leaves are threshed can be reasonably divided and winnowed, lighter materials and heavier materials are effectively separated so as to avoid the mutual influence caused by mixing different materials during winnowing, the load entering a winnowing classifier is reduced, the winnowing precision of the fine-selection air distributing unit is improved, the stalk-content index in leaves is reduced, the leaf threshing effect is enhanced, the breakage of tobacco leaves is lowered, and the resource waste is reduced.

Owner:YUNNAN KUNCHUAN TOBACCO EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com