Machine-made sand wind power winnowing system and winnowing method

A technology of machine-made sand and wind power, which is applied to chemical instruments and methods, solid separation, and separation of solids from solids with airflow, etc., which can solve problems such as the inability to reproduce dust-free machine-made sand and the inability to realize machine-made sand winnowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

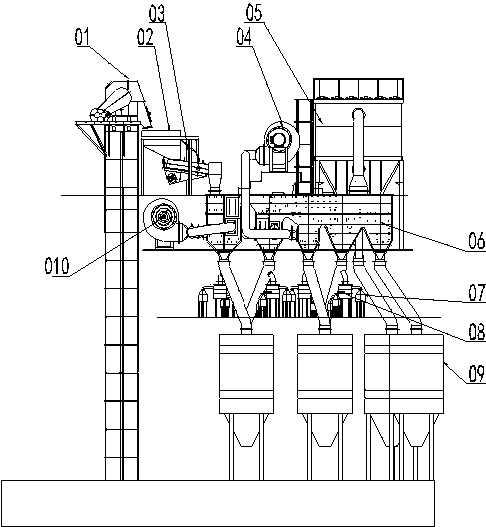

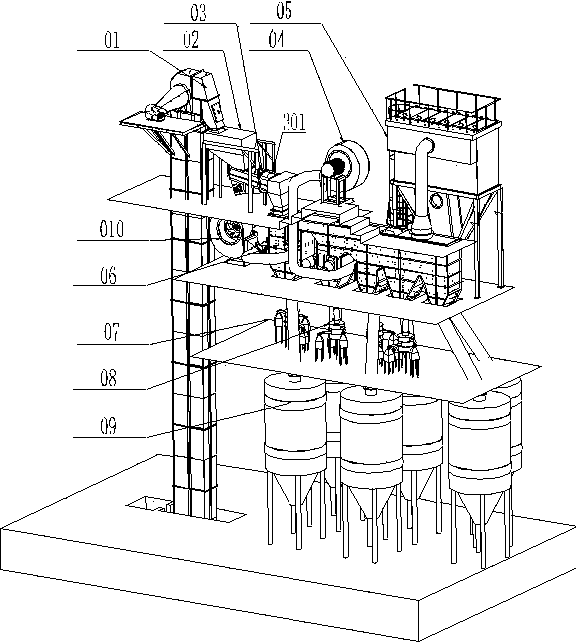

[0019] Embodiment 1: with reference to attached Figure 1-8. A machine-made sand wind-force winnowing system, including a PLC controller, the discharge port of the mixed product lifter 01 is directly connected to the inlet of the buffer bin 02, the discharge port of the buffer bin 02 is directly connected to the inlet of the feeder 03, and the feeder 03 The outlet is connected with the feed inlet of machine-made sand air separator cabin 06, and the multi-stage outlets of machine-made sand air separator cabin 06 are respectively connected with the inlets of respective grading storage tanks 09 through feeding pipes, and the outlet of the main fan 010 is The tuyere is communicated with the main tuyere 21 in the machine-made sand wind-force wind separator cabin body 06, the air outlet of the auxiliary blower fan 04 is communicated with the auxiliary wind outlet 22 in the machine-made sand wind-force winnower cabin body 06, and The dust removal port 6 communicates with the dust co...

Embodiment 2

[0021] Embodiment 2: on the basis of embodiment 1, with reference to appended Figure 9 . A method for wind-force wind separation of machine-made sand, starting the main blower 010 and the auxiliary blower 04, the machine-made sand is lifted to the upper part of the mixed finished product lifter 01 through the hopper in the mixed finished product lifter 01 and passed through the mixed finished product lifter 01 The feed port enters the buffer bin 02, and the buffer bin 02 transports the machine-made sand in the bin to the feeder 03, and the feeder 03 evenly sends the machine-made sand into the first section of strong wind of the air separator cabin 06 The feed port of the compartment:

[0022] The machine-made sand located in the feeding chamber of the first section of strong wind cabin adjusts the size of the wind power of the main fan 010 and the size of the wind power of the auxiliary fan 04 according to the size and weight of the selected particle size. Under the action,...

Embodiment 3

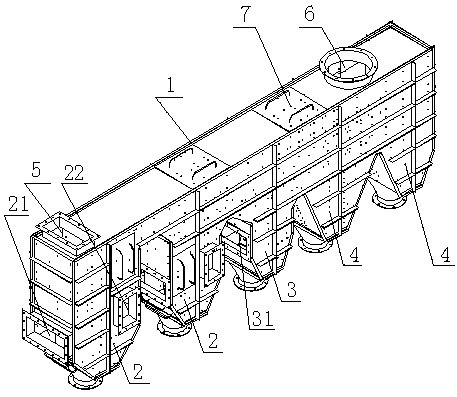

[0025] Embodiment 3: On the basis of Embodiment 2, the main tuyere located at the lower end of the feed port of the first strong wind cabin 2 is strongly supplied with wind under the action of the main fan 01, and the machine-made sand is fed by the feed chamber 23 of the first strong wind cabin. Blow into the adjacent first stage boiling chamber 24, because the two sides of the first stage boiling chamber 24 are provided with auxiliary air outlets 04 to supplement the air volume, so that the machine-made sand is continuously blown from bottom to top in the first stage boiling chamber. The wind blowing on both sides, during which the quality of the large-grained machine-made sand exceeds the blowing of the wind, so the machine-made sand of this level enters the first-stage grading storage tank 09 from the outlet 25 of the first-stage strong wind cabin, and the quality The machine-made sand that is less than the wind force is blown up through the boiling chamber into the first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com