Mechanism Natural Sand Wind Separation Method

A technology of natural sand and machine-made sand, applied in chemical instruments and methods, cleaning methods and utensils, solid separation, etc., can solve the problems that machine-made sand cannot be selected by winnowing, dust-free machine-made sand cannot be reproduced, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

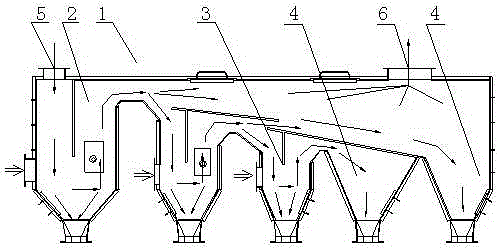

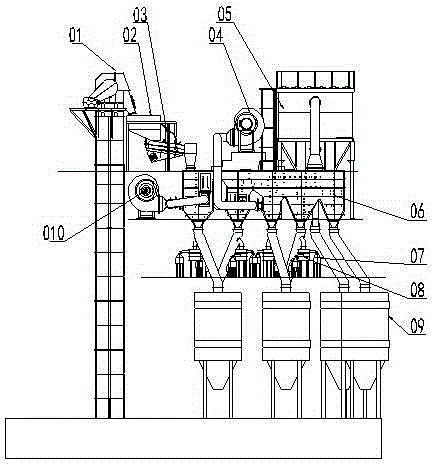

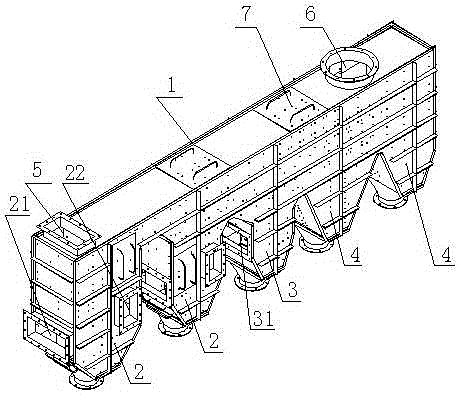

[0013] Embodiment 1: with reference to attached figure 1 . A wind separation method for machine-made natural sand, the external wind source is blown into the strong wind chamber 2 by the front lower air inlet or the front lower air inlet and the side lower air inlet of the strong wind chamber 2, and the machine-made natural sand is fed from the upper end of the wind separation chamber 1 The machine-made natural sand entering the strong wind chamber 2 from port 5 is tossed from bottom to top, the dust in the machine-made sand is sucked by the vacuum cleaner from the dust suction port 6, and the large-grained machine-made sand exceeding the wind force is discharged from the discharge port at the lower part of the strong wind chamber. The machine-made natural sand that is less than the wind force is blown into the second section of strong wind cabin or blown into the middle wind cabin; The air inlet and the lower side air inlet are blown into the second section of strong wind ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com