Building rubbish screening equipment and screening method

A technology for construction waste and screening equipment, which is applied in the direction of chemical instruments and methods, solid separation, and separation of solids from solids with airflow, etc. The separation effect and other issues can be improved to achieve the effect of improving winnowing efficiency, good screening effect and reducing equipment load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below through specific embodiments.

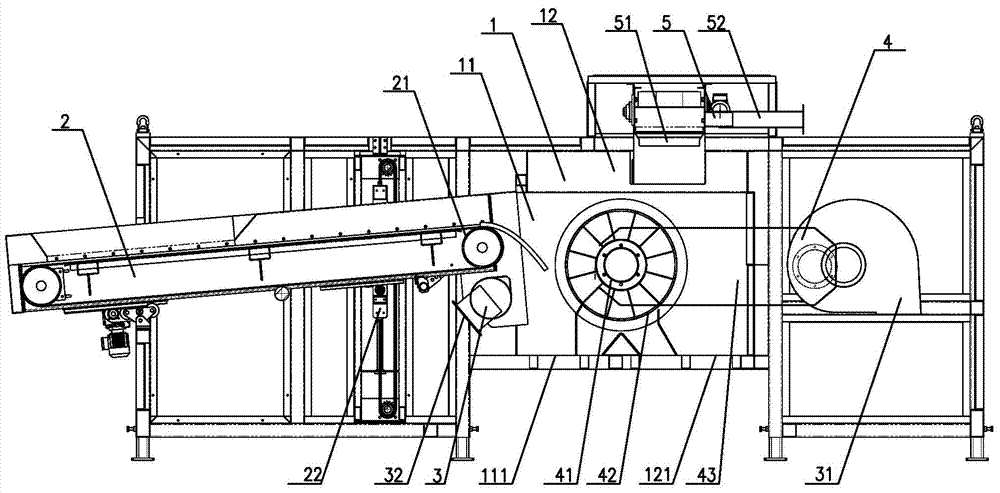

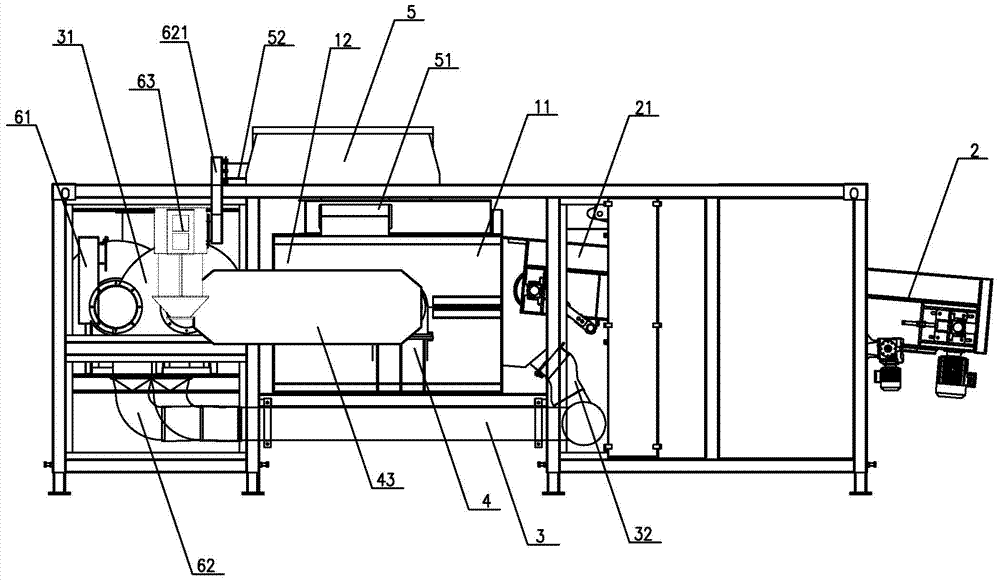

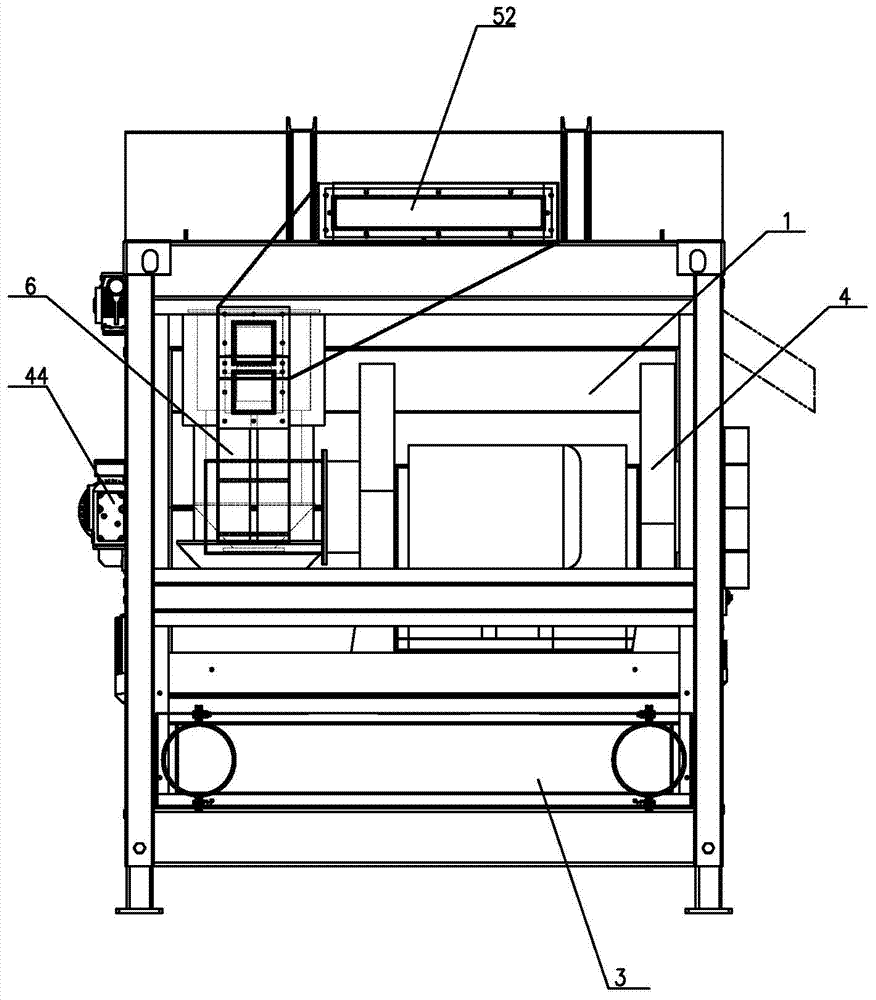

[0027] refer to Figure 1 to Figure 6 As shown, a construction waste screening equipment includes a sorting chamber 1, a throwing device 2, a wind device 3, a medium and heavy object sorting device 4, a light and heavy material sorting device 5, and a dust removal device 6;

[0028] The separation chamber 1 has a first separation zone 11 and a second separation zone 12, the first separation zone 11 has a heavy material outlet 111 at the lower end, and the second separation zone 12 has a medium and heavy material outlet 121 at the lower end;

[0029] The throwing device 2 includes a belt conveyor 21 and a position adjustment mechanism 22. One end of the belt conveyor 21 leads into the winnowing chamber 1 to transport materials to the first separation zone 11. The position adjustment mechanism 22 is a driving mechanism arranged under the belt conveyor 21. Cylinder, adjust the relative p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com