Tobacco material wind selection method and device

A technology of tobacco materials and winnowing equipment, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment, and can solve the problems of inability to effectively separate tiny stems and other sundries, bulky winnowing equipment, and low separation accuracy. Achieve the effects of reduced equipment maintenance costs, outstanding separation effects, and improved work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

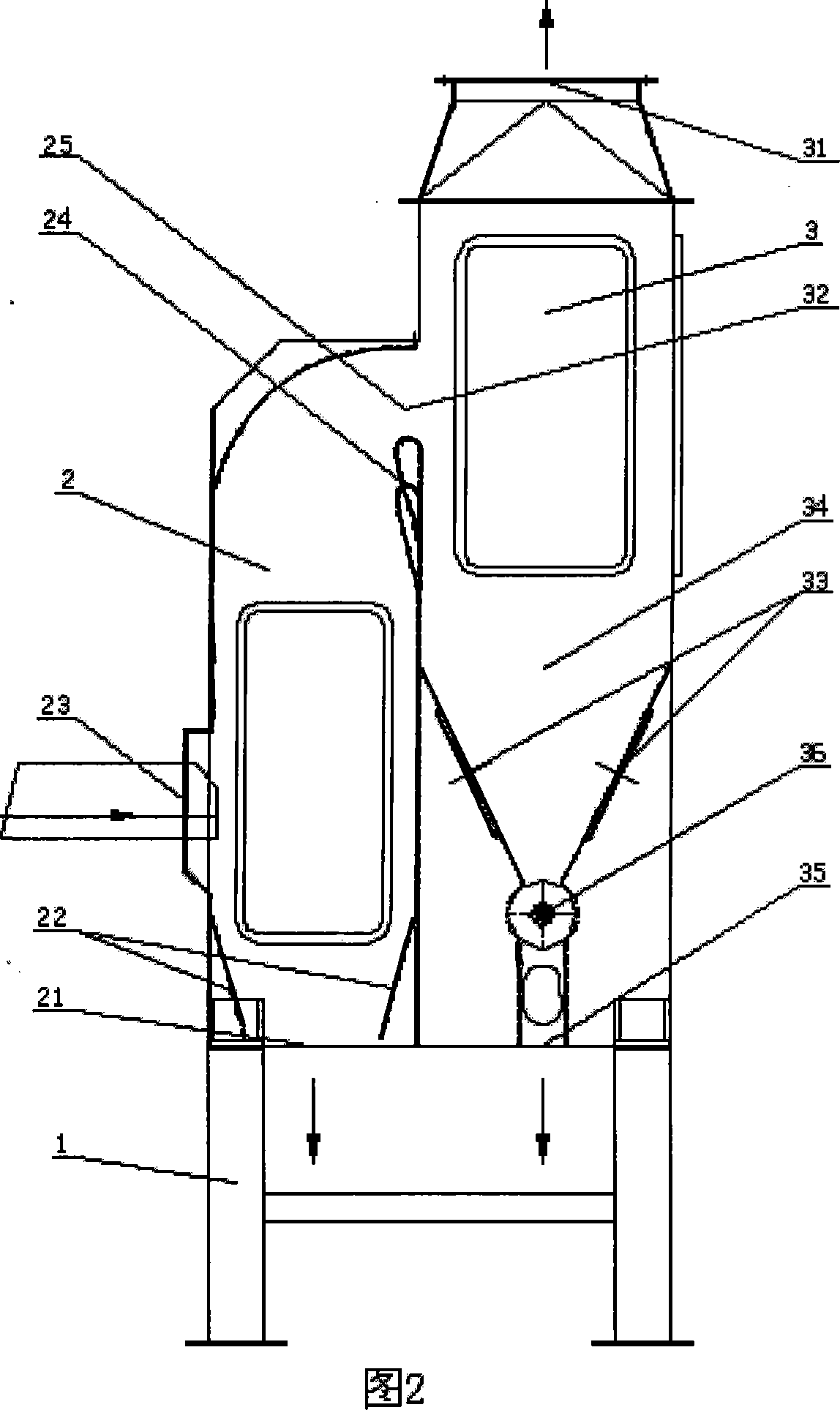

[0026] As shown in Figure 1, the winnowing method of the present invention is, first the tobacco material is sent into the primary wind sub-chamber wind 2 with the higher wind speed of winnowing through conveying equipment 4, separates out the sundry with bigger density, this sundry Discharge from the primary miscellaneous outlet 21; then, the tobacco material after the primary air separation enters the secondary air sub-chamber 3 with a lower wind speed for winnowing, and the air separates the secondary heavy impurities, which are discharged from the secondary miscellaneous outlet 35. The tobacco material after two air separations is output from the discharge port 31 under the action of wind force.

[0027] In the actual operation process, according to the different tobacco materials to be processed, or the different conditions of the same material, the matching primary and secondary wind speeds should be properly selected and adjusted to obtain sufficient sorting accuracy. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com