Method for non-contact laser cutting of quartz glass product and device thereof

A quartz glass and laser cutting technology, applied in glass cutting devices, glass manufacturing equipment, laser welding equipment, etc., can solve problems such as damage to quartz glass tubes, low production efficiency, and reduced qualification rate, and reduce waste and labor intensity. , the effect of reducing the crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

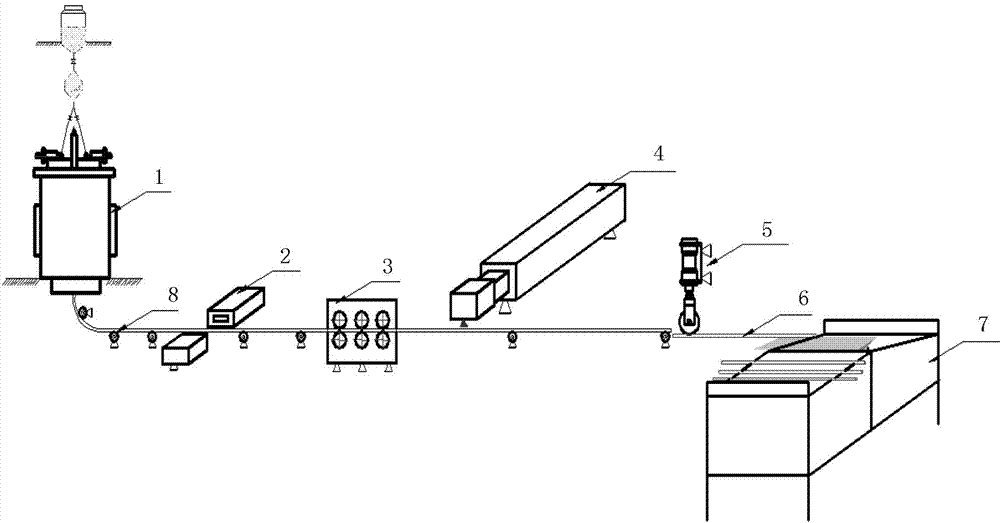

[0027] The present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention and implement it, but it is not intended to limit the present invention.

[0028] The invention provides a non-contact laser cutting method for quartz glass products and its cutting device, especially suitable for cutting quartz glass tubes or quartz glass rod products. In this embodiment, a method suitable for quartz glass tubes or quartz glass rods is provided. The non-contact laser cutting method and its cutting device, wherein the non-contact laser cutting method mainly includes the following steps:

[0029] Step 1: The quartz glass tubes and quartz glass rods continuously produced in the continuous melting furnace 1 are outputted after being shaped by the former, and are continuously transported to the horizontal tube drawing machine 3 under the action of the guide wheel 8, and are drawn by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com