Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

216 results about "Contact laser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for non-contact laser cutting of quartz glass product and device thereof

InactiveCN102898014AEnsure consistencyReduce labor intensityGlass severing apparatusLaser beam welding apparatusCrevasseEngineering

The invention discloses a method for non-contact laser cutting of a quartz glass product and a device thereof. The method comprises the following steps: firstly firing the quartz glass product with a laser beam emitted by a laser generator to form a groove, and then cutting off by using a pneumatic unit. The device provided by the invention comprises a laser automatic cutting unit and the pneumatic unit. According to the invention, the product quality can be guaranteed, crevasses can be reduced, the consistency of the kerf and the kerf section can be guaranteed, waste is reduced, thus the operation is safe; and the laser cutting has noncontact with the quartz glass tube or quartz glass rod, thus the speed of drawing is raised, the production cost is reduced, the labor intensity is reduced, and the yield is raised.

Owner:JIANGSU PACIFIC QUARTZ

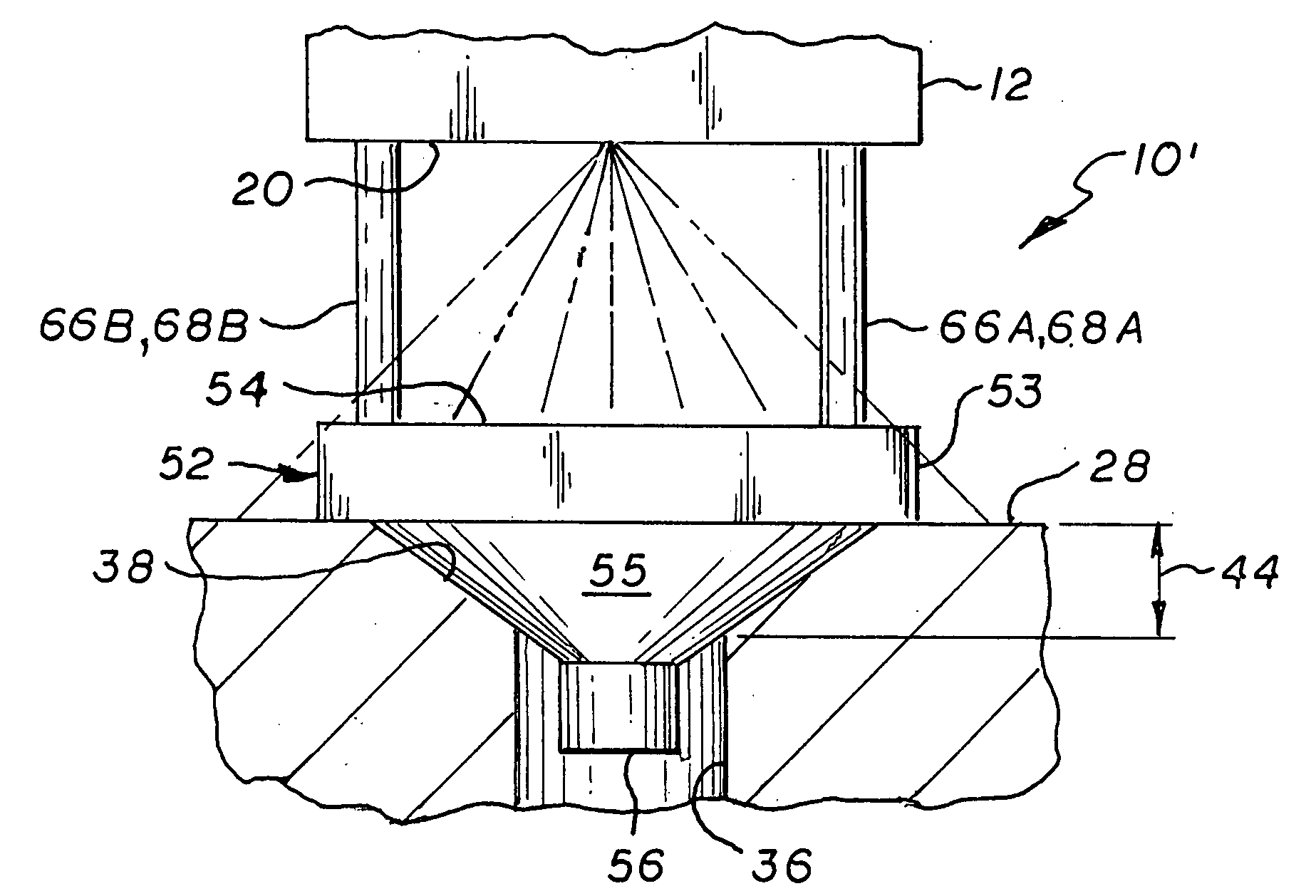

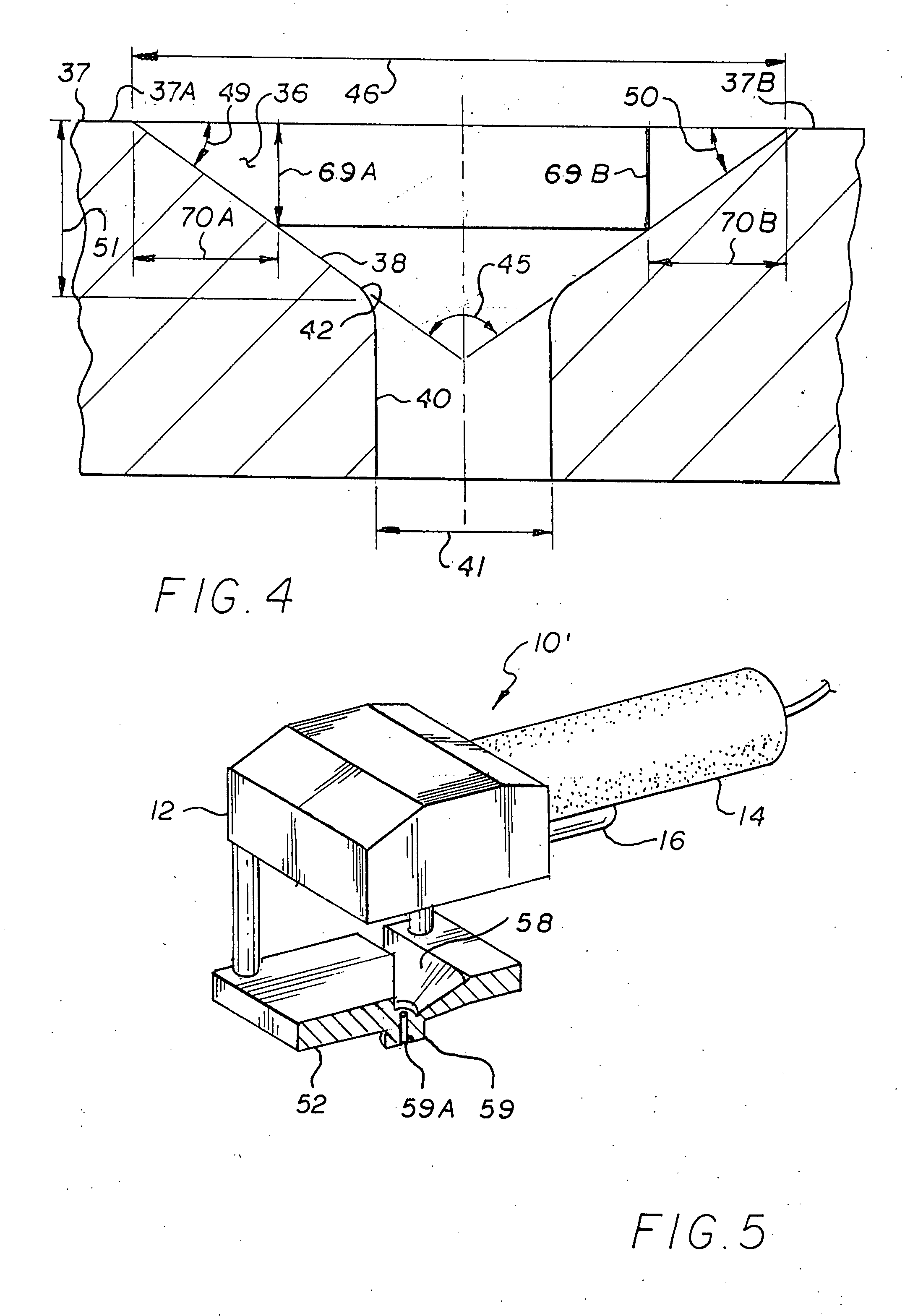

High precision optical imaging systems and related systems

InactiveUS20050053113A1High precision alignmentRadiation pyrometryMaterial analysis by optical meansLaser scanningEngineering

This disclosure describes the design and construction of high-precision off-axis optical imaging systems. The disclosure also describes the design and construction of high-precision mounting structures for rigidly holding optical elements in an optical imaging system. The disclosure further describes both a mechanism for highly stable mounting and a technique for high precision focusing of a detector in a complex optical setup. The disclosure even further describes both tooling and a technique used for focusing high precision optical imaging systems. The theory and use of at least these concepts are introduced by examining how these concepts aid the construction and use of a non-contact laser scanning system.

Owner:METRON SYST

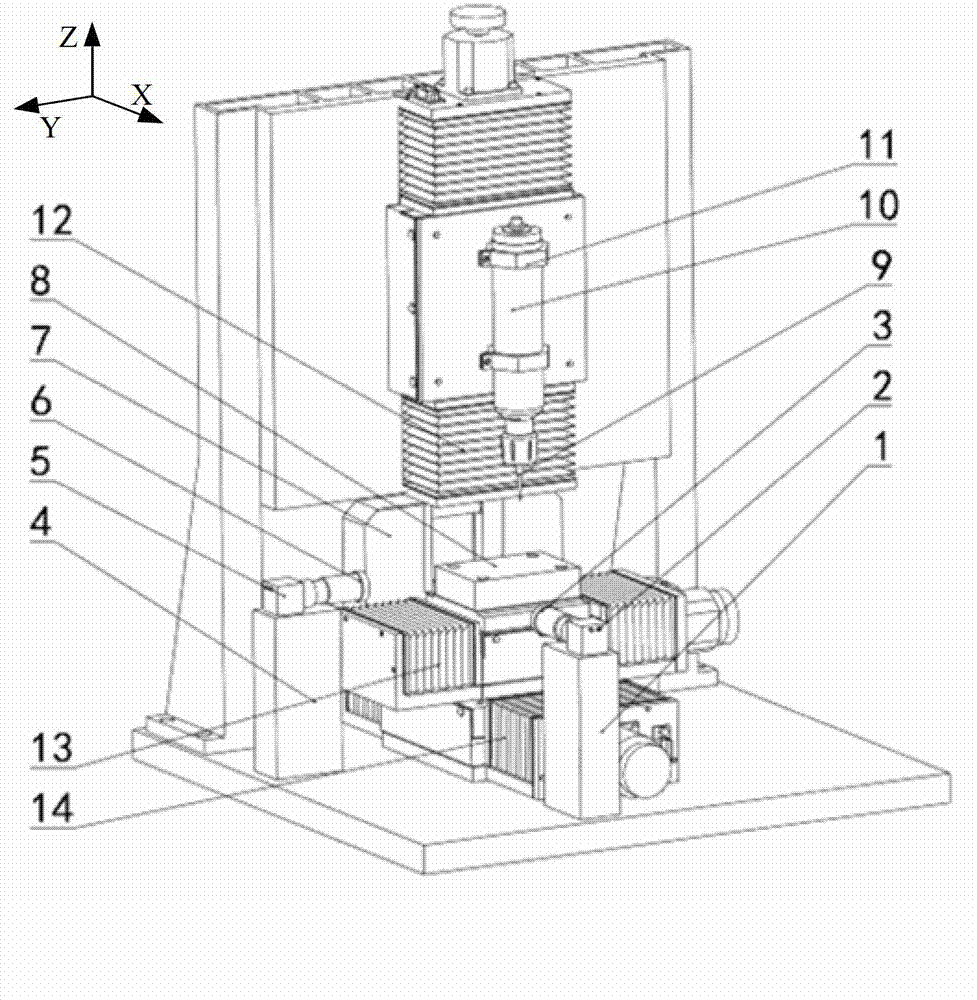

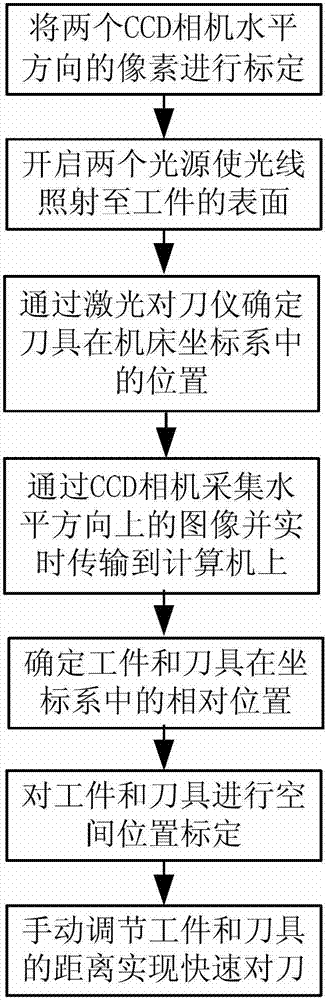

Tool setting device and method of mini-type numerical control milling machine

ActiveCN103029004AHigh precisionEasy to processAutomatic control devicesMeasurement/indication equipmentsNumerical controlAutomatic control

The invention provides a tool setting device and method of a mini-type numerical control milling machine, belongs to the field of a machine tool automatic control technology and aims to solve the problems in the prior art that the tool setting precision and the tool setting efficiency are low. The tool setting device comprises CCD (Charged Coupled Device) cameras, light sources and a laser tool setting instrument, wherein the two CCD cameras are orthogonally placed; the two light sources are respectively sleeved at the front ends of the two CCD cameras to illuminate a workpiece; after light is reflected, the light is received by the CCD cameras and is transmitted to an outer computer, so as to determine the positions of the workpiece and a tool in a machine tool coordinate system; the laser tool setting instrument and the workpiece are placed in parallel; a tool nose contacts laser emitted by the laser tool setting instrument and a signal generated by the laser tool setting instrument is transmitted to the outer computer, so as to further determine the position of the tool in the machine tool coordinate system; and data processing is carried out through computer program software so as to realize rapid tool setting. According to the tool setting device and method of the mini-type numerical control milling machine, the tool nose and the workpiece to be machined do not need to be actually contacted to carry out trial cutting, so that an error caused by contacting the tool nose with the workpiece to be machined is avoided, and the tool setting precision and the tool setting efficiency of the workpiece are improved.

Owner:CHANGCHUN UNIV OF SCI & TECH

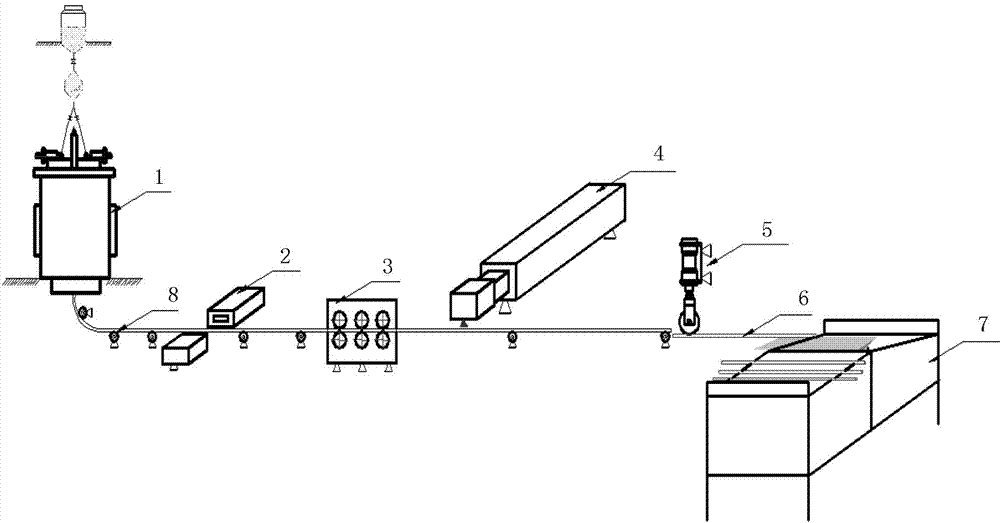

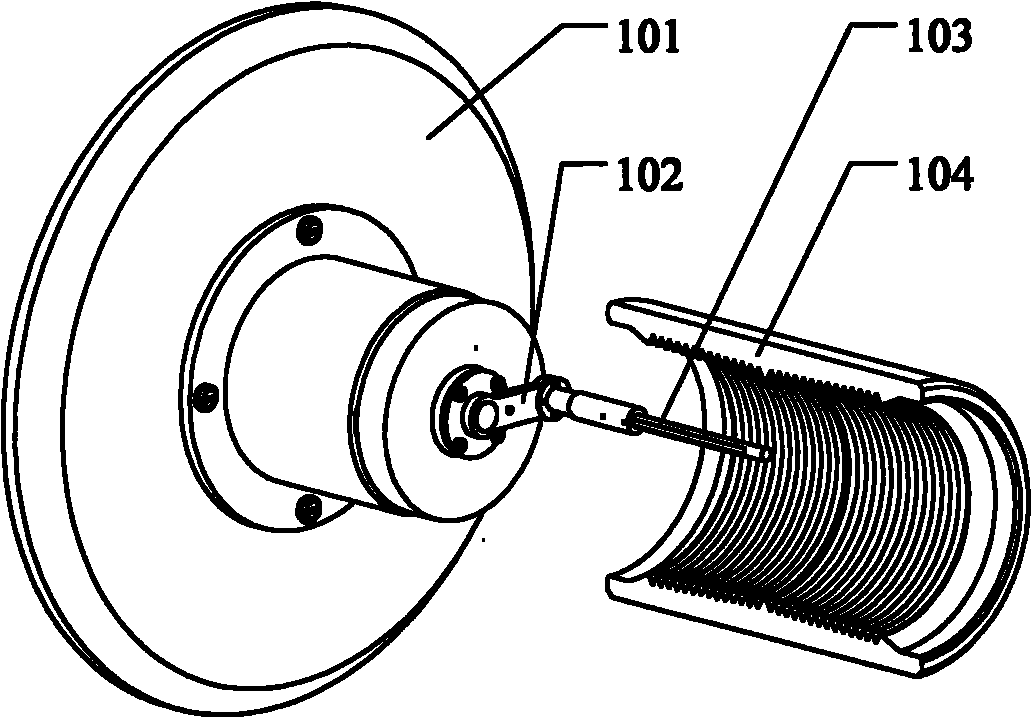

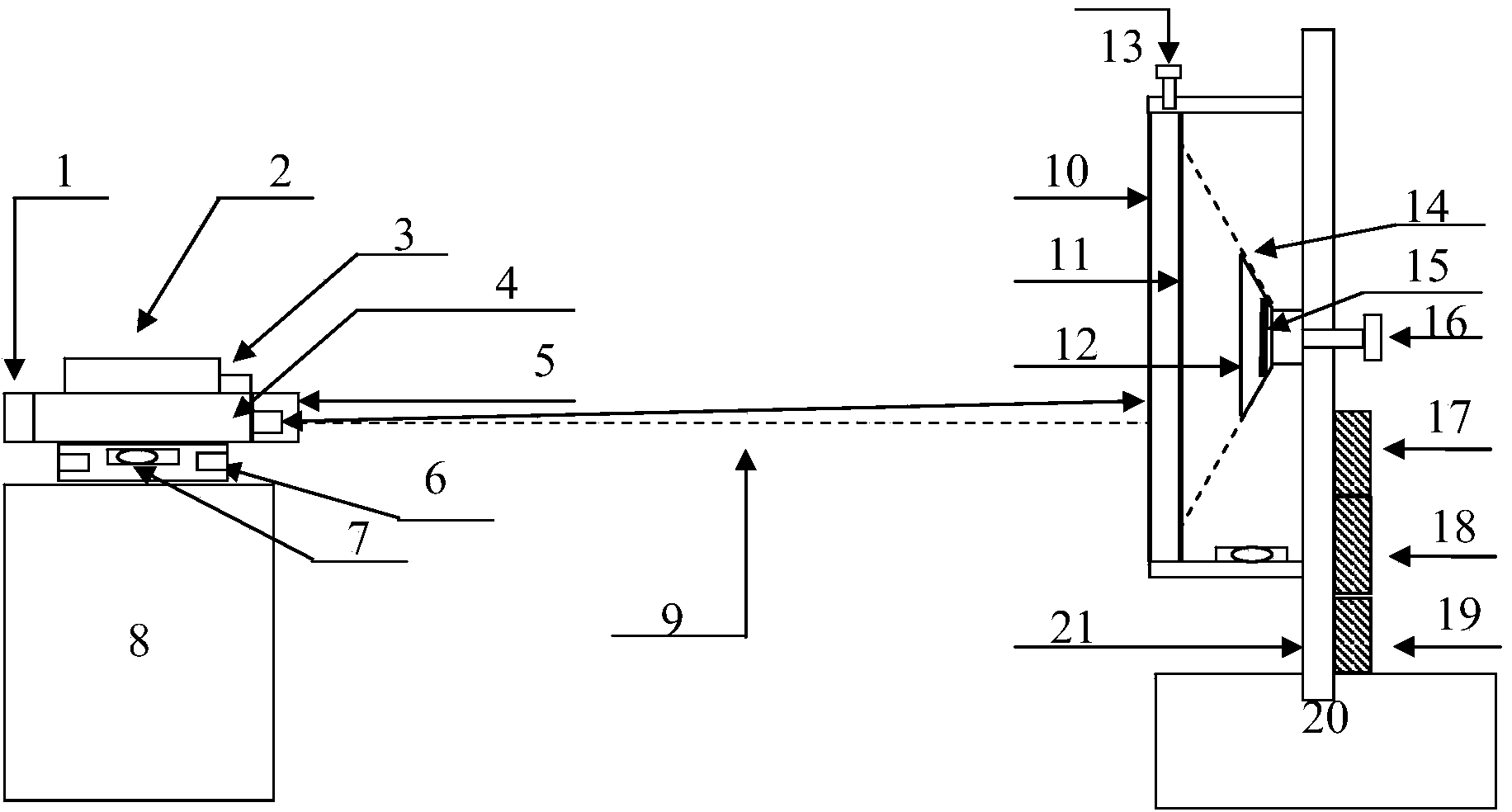

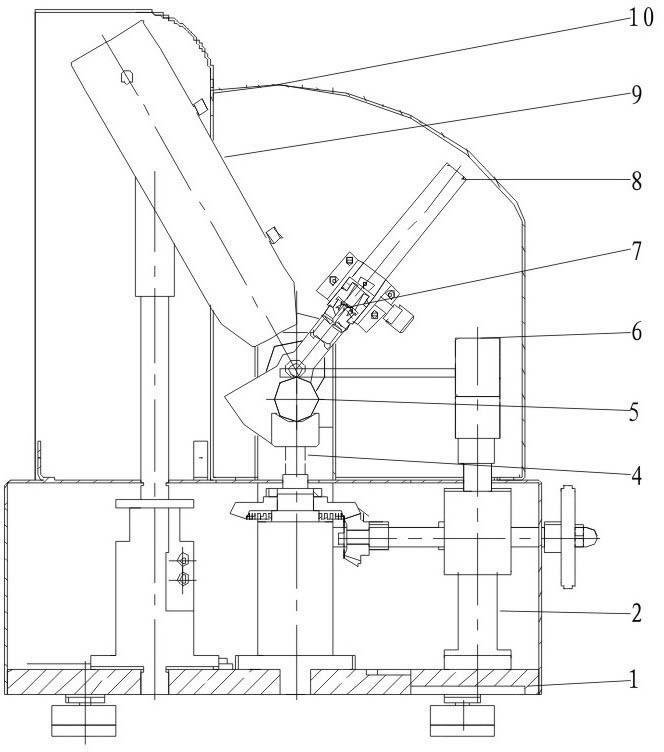

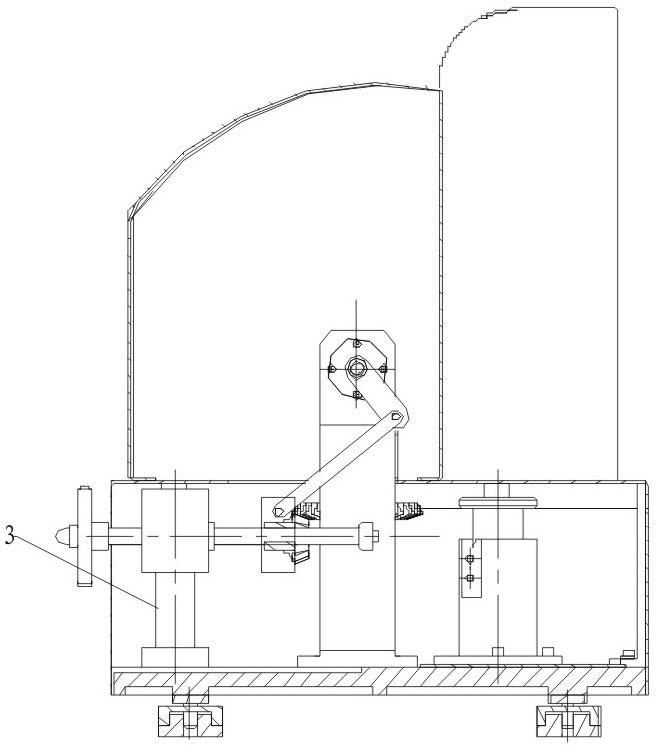

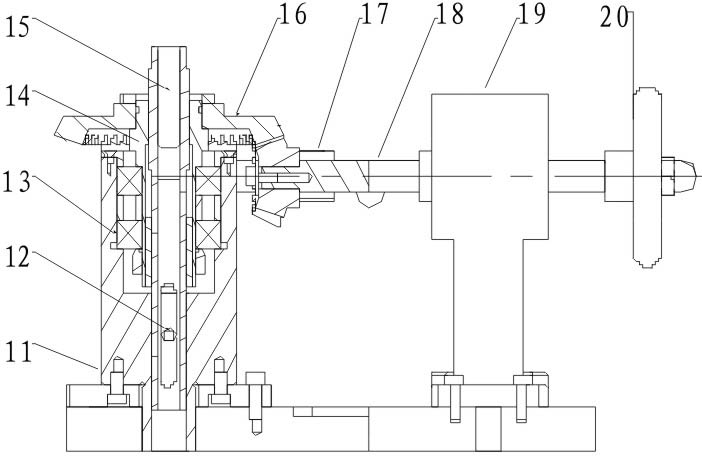

On-line non-contact laser stereo scanning detection device for internal screw threads of tubing coupling

InactiveCN101797701AImprove detection accuracySolve the detection speed is slowMeasurement/indication equipmentsUsing optical meansCouplingEngineering

The invention relates to an on-line non-contact laser stereo scanning detection device for the internal screw threads of a tubing coupling, which is used for carrying out one-by-one all-around dynamic on-line three-dimensional stereo scanning detection on the tooth profile parameters of all the internal screw threads to be processed in the processing process of special purpose machine tools, suchas a threading machine tool of the tubing coupling and the like, to the internal screw threads. The on-line non-contact laser three-dimensional scanning detection device comprises an axial movement mechanism assembly, a radial rotation mechanism assembly and a laser detection probe assembly. The radial rotation mechanism assembly is fixedly connected with the end of the axial movement mechanism assembly, and the laser detection probe assembly is fixedly connected at the end of the radial rotation mechanism assembly. The invention has a three-dimensional stereo scanning detection function, cancarry out high-speed high-accuracy on-line laser stereo scanning on the tooth profiles of the sections of different radial axles of the internal screw threads of the tubing coupling and obtains the three-dimensional stereo geometric information of the tooth profiles of the internal screw threads of the tubing coupling. The invention can enhance the detection accuracy and speed of the parameters of the internal screw threads, lightens the labor strength of a detection worker greatly and avoids the influence of human factors to the measurement accuracy. Moreover, the invention can be used for on-line quality monitoring and prediction and enhances the product quality.

Owner:BEIHANG UNIV

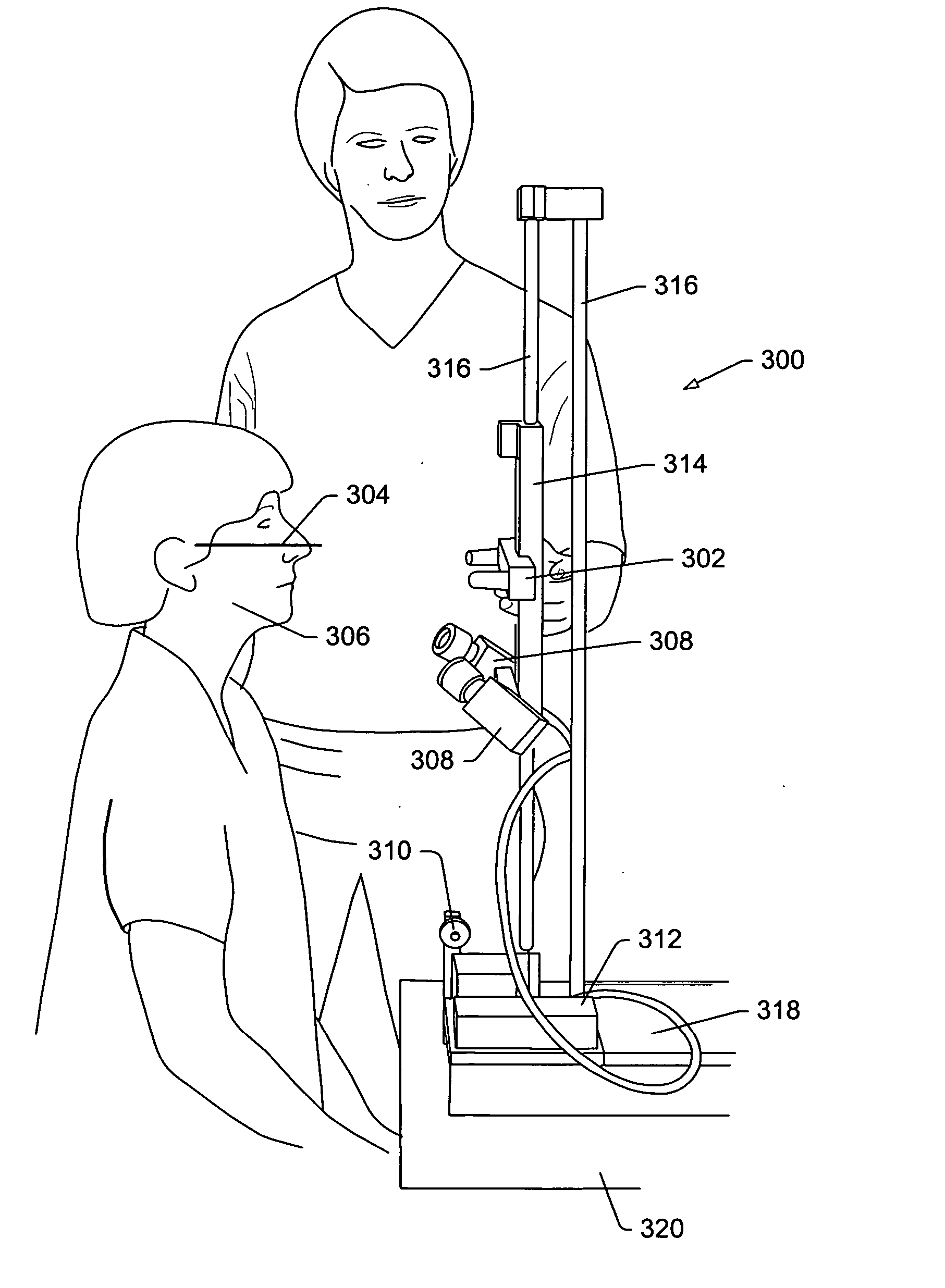

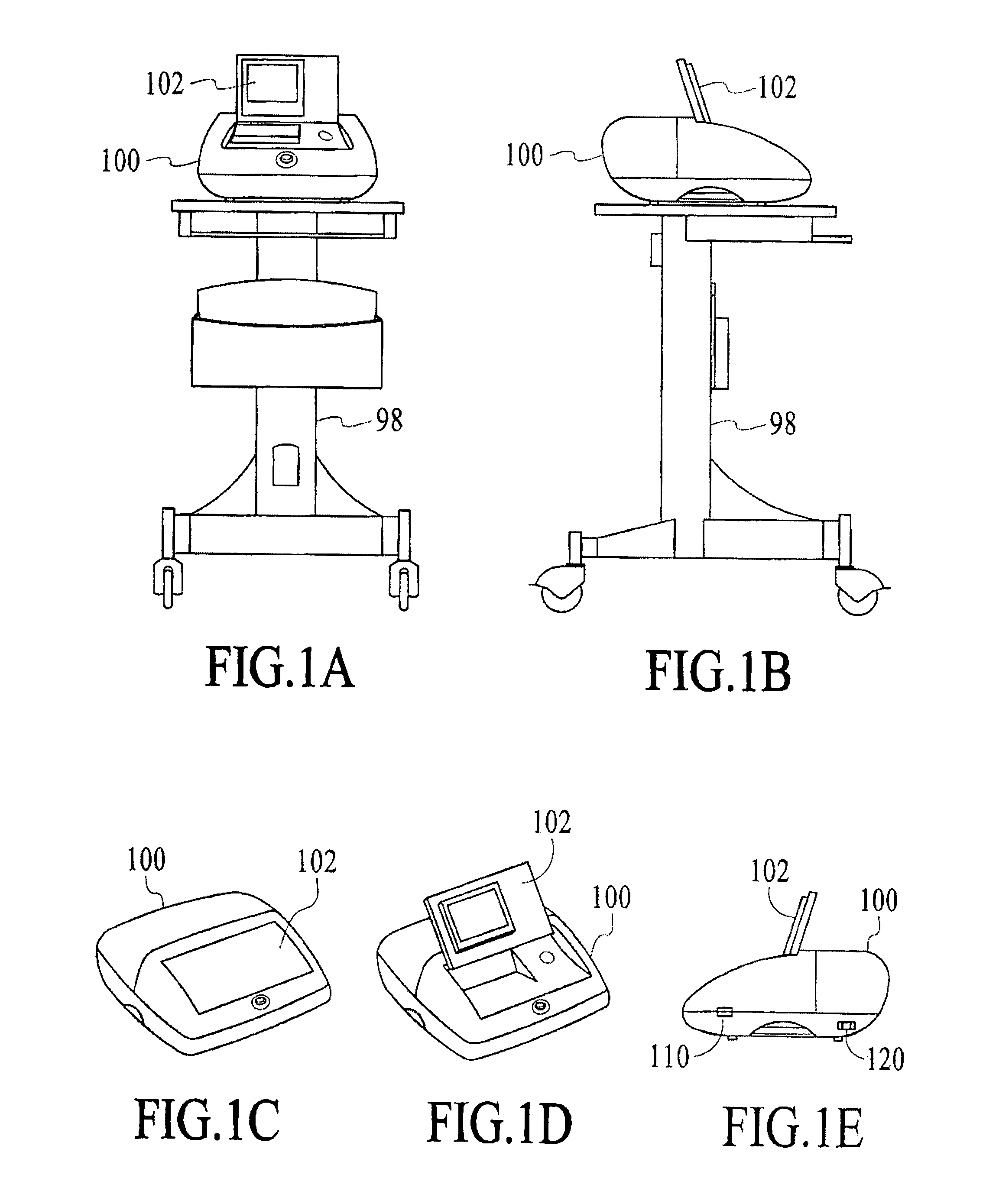

System and method for design and manufacture of custom face masks

Methods and systems for forming face masks are disclosed. Embodiments may utilize computer-aided design and computer-aided manufacturing to form custom fitted face masks. System software may be configured to acquire facial topography information, design a mask based on the topography information, and send mask information to a computerized manufacturing device. The software may communicate with a scanning device for facial topography acquisition and a milling machine for pattern fabrication. In an embodiment, the scanning device may include a linear scan non-contact laser imager. In an embodiment, the scanning device may be manually moved with respect to an individual being scanned, thereby eliminating the need for motive apparatus. In such embodiments, position information may be determined based on data from a position sensor coupled to the scanning device.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

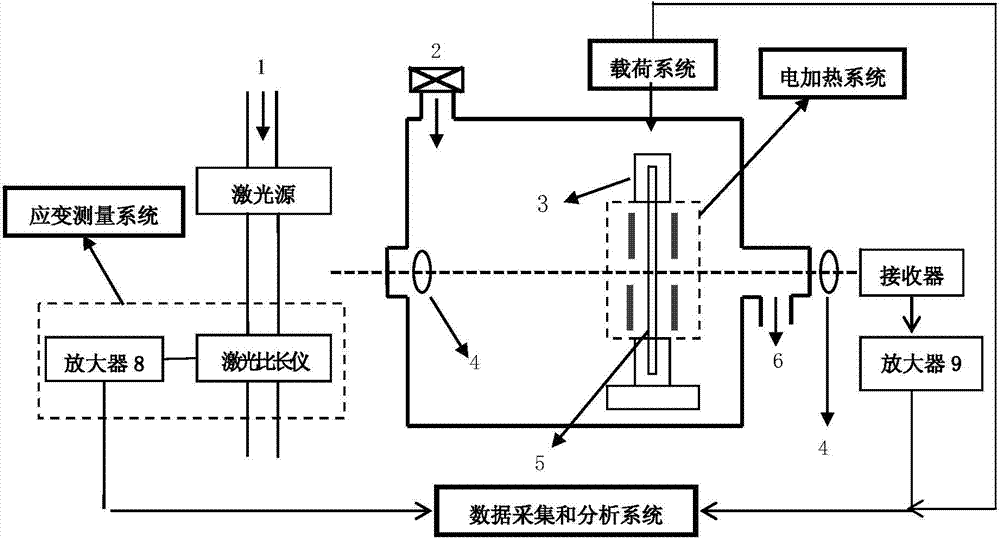

Non-contact high-temperature thermophysical property parameter measurement device and non-contact high-temperature thermophysical property parameter measurement method

ActiveCN103499603AImprove accuracyIncreased measurement temperature rangeMaterial heat developmentStrength propertiesMeasurement deviceData acquisition

The invention discloses a non-contact high-temperature thermophysical property parameter measurement device and a non-contact high-temperature thermophysical property parameter measurement method. The non-contact high-temperature thermophysical property parameter measurement device consists of an electric heating system, a laser generation system, a load system, a strain measurement system and a data acquisition and analysis system. Laser serves as an instant energy source, and the measurement time is shortened; a laser comparator is used for measuring deformation of a material in a high-temperature environment; a non-contact laser comparator is used for measuring a deformation value of the measured material sample under high temperature; therefore, the deformation error caused by thermal expansion can be avoided; the laser comparator can precisely measure a precise displacement or strain of the sample under a condition of high-temperature loading through fine scales, so that the reliability of a measurement result is improved, and the measurement process is simplified and is easy to control. A thermocouple is used for measuring the temperature in a low-temperature stage, and a far infrared temperature measurer is used for measuring the temperature in a high-temperature stage, so that equipment can realize measurement of the thermophysical property of the material within the range from room temperature to 2,000 DEG C. The verification shows that the equipment has the advantages that the running process is easy to control, the measurement time is short, the accuracy is high, and the like.

Owner:DALIAN UNIV OF TECH

Machining method for glass cover plate of mobile phone touch screen

InactiveCN103214174ALow costHigh speedGlass severing apparatusGlass productionNumerical controlGlass cover

The invention relates to the technical field of machining for the glass cover plate of a mobile phone touch screen, and particularly relates to a machining method for the glass cover plate of a mobile phone touch screen. Compared with the traditional mechanical machining method, a laser cutting machine is adopted in the method, the four rectangle right angles of the rectangular glass cover plate are cut into circular angles by laser, and circular holes corresponding to mobile phone keys on the rectangular glass cover plate and a strip-shaped sound hole corresponding to a phone receiver are cut out. Compared with the traditional mechanical contact-type machining method, the adopted non-contact-type machining method has the following advantages that 1, any route curve can be cut by laser, so that the speed is fast and the effect is good during cutting for the circular angles and drilling; 2, laser machining belongs to non-contact machining, so that consumables are not used during the machining process, and the cost is reduced compared with the traditional CNC (computerized numerical control) cutting method; and 3, breakages or cracks are avoided during the non-contact laser cutting process, so that the yield of products is greatly increased.

Owner:东莞光韵达光电科技有限公司

Blade optical rapid measurement method based on double-probe four-axis measurement system

InactiveCN107246849AMake up for incomplete data and other problemsVariety of curvatureUsing optical meansPoint cloudThree dimensional measurement

The invention discloses a blade optical rapid measurement method based on a double-probe four-axis measurement system. According to the method, two non-contact laser displacement sensors are combined on one same four-axis measurement system, in a respective work scope, measurement of a certain special scope of a blade is respectively realized, the measurement results of the two sensors are fused, complete angle three-dimensional point cloud data of an object is acquired, and precise measurement of the blade is lastly realized. The method is advantaged in that a mode of combination of the two non-contact laser measurement probes is employed to carry out three-dimensional measurement of the object, a problem of incomplete data caused by utilizing a single probe for measurement in the prior art is effectively solved, a problem of point cloud data loss of a certain point angle caused by fixed measurement orientation is solved, and measurement precision is improved.

Owner:XIAN CHISHINE OPTOELECTRONICS TECH CO LTD

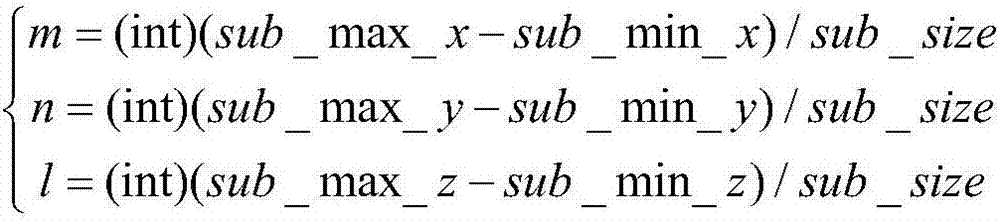

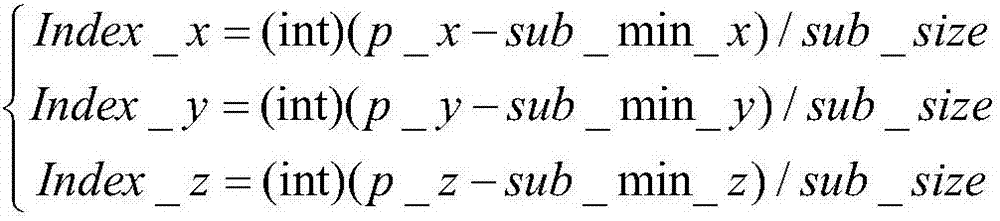

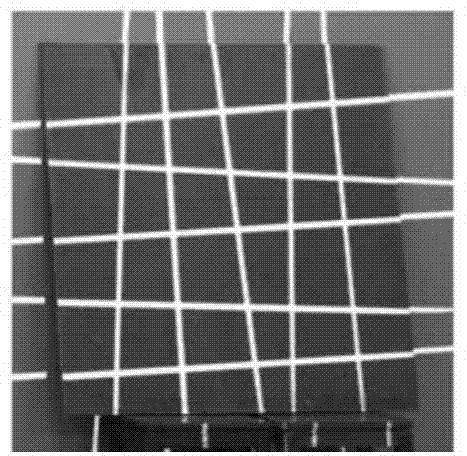

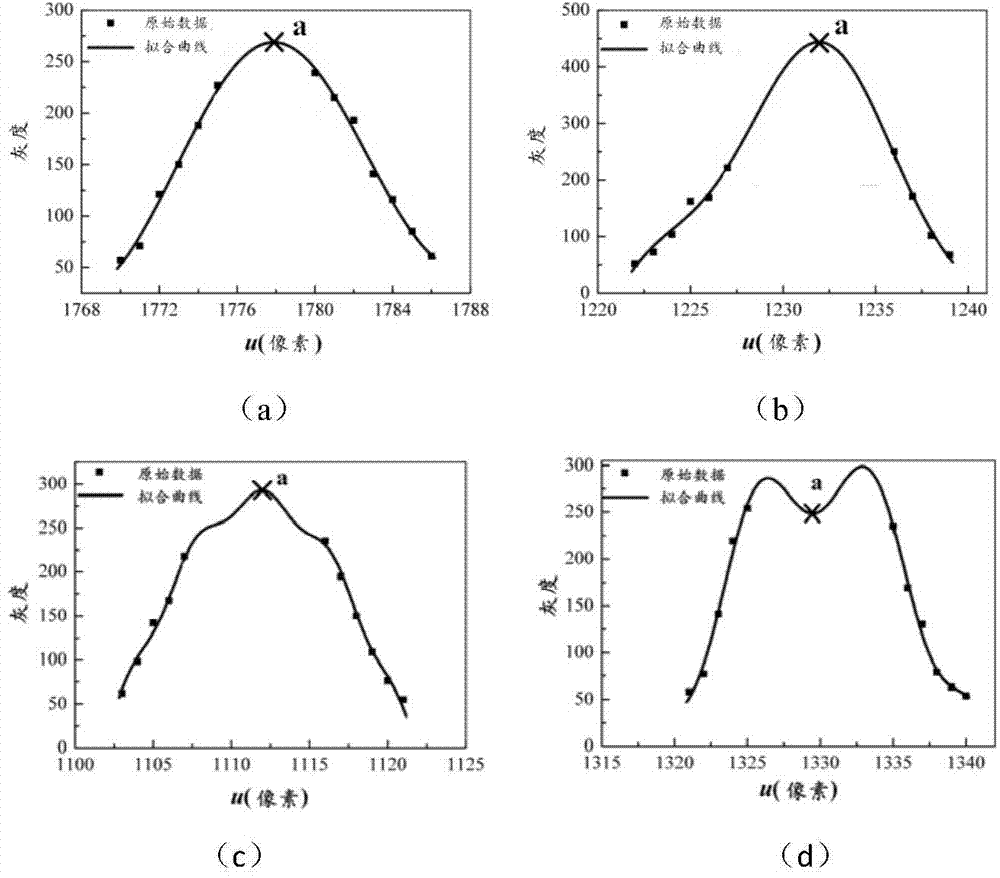

Feature point extraction method based on multiple laser-assisted targets

ActiveCN104732553AImprove extraction efficiencyReduce search areaImage analysisCharacter and pattern recognitionImaging processingLaser array

The invention provides a feature point extraction method based on multiple laser-assisted targets, belongs to the fields of image processing and computer vision detection, especially relates to a data processing method of laser-assisted multi-view data registration, and particularly discloses an extraction method based on a multiple laser-assisted target design and feature points. The method adopts a laser array projection laser strip construction registration target which is composed of multiple non-contact lasers, in the target, intersections of a laser grid are taken as the feature points of the registration, and a coordinate position of the target is extracted through a high-precision target feature point extraction algorithm. According to the feature point extraction method based on the multiple laser-assisted targets, the target based on the laser assistance is adopted, and better adaptability is achieved compared with an adhesive type target; by means of the method of determining a region of interest first and extracting the feature points accurately later, the precision and efficiency of extracting the feature points are effectively improved.

Owner:DALIAN UNIV OF TECH

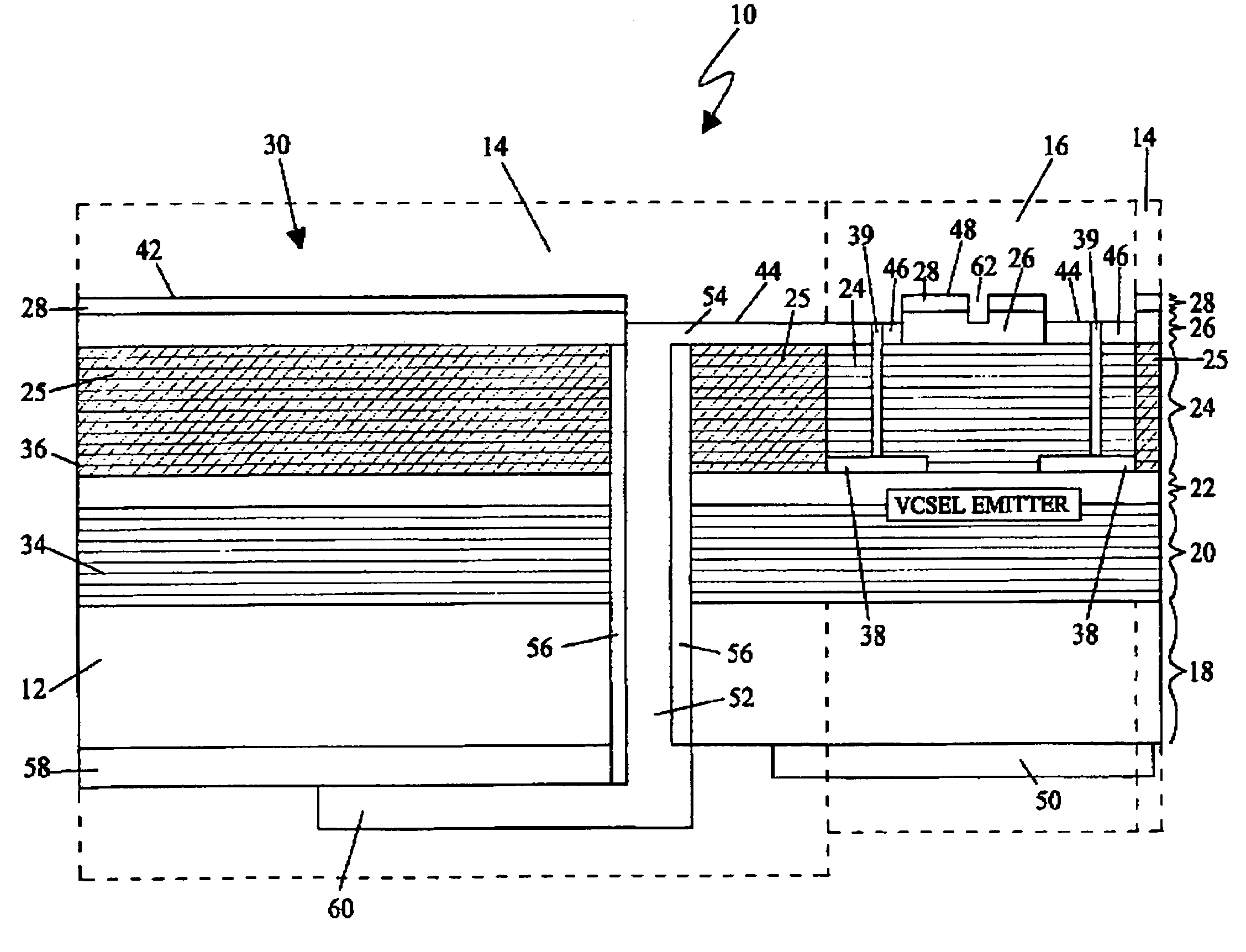

Near-field optical head system with integrated slider and laser

InactiveUS6963530B1Quickly and easily attachedComplex and time-consuming and attachmentCombination recordingOptical flying-type headsSemiconductor materialsAir bearing

A near-field optical apparatus having one or more solid state lasers and an aerodynamically shaped slider which comprise a single integrated, monolithic device fabricated from the same base semiconductor material. The monolithic optical head can be quickly and easily attached to the read arm of an optical read / write device without requiring attachment of separate laser elements, and without micropositioning or use of optical microscopy for positioning the lasers. The optical head comprising a single semiconductor substrate including a first region which defines a slider having an air bearing surface, and at least one second, laser region which defines a diode laser, with the diode laser having an emission face which is substantially co-planar with the air bearing surface. The semiconductor substrate preferably includes an active layer, a p-clad layer or reflective layer adjacent a first side of the active region, an n-clad layer or reflective layer adjacent a second side of the active layer, and an n-semiconductor layer adjacent the n-clad layer. A slider region of the semiconductor substrate includes an air bearing surface, adjacent the p-clad layer, which is aerodynamically structured and configured to define a slider. The integral lasers include a p-electrical contact adjacent to the p-clad layer and proximate to the laser emission face, and an n-electrical contact adjacent to the n-clad layer or an n-semiconductor layer. The laser mode is defined by oxidized or ion-diffusion regions associated with the p-clad layer or n-clad layer of the laser. A conductive via through the substrate allows electrical connection with the p-side contact to be achieved from the n-side of the substrate. The optical head is used in a near-field optical system with an optical medium having a phase change layer.

Owner:RES INVESTMENT NETWORK

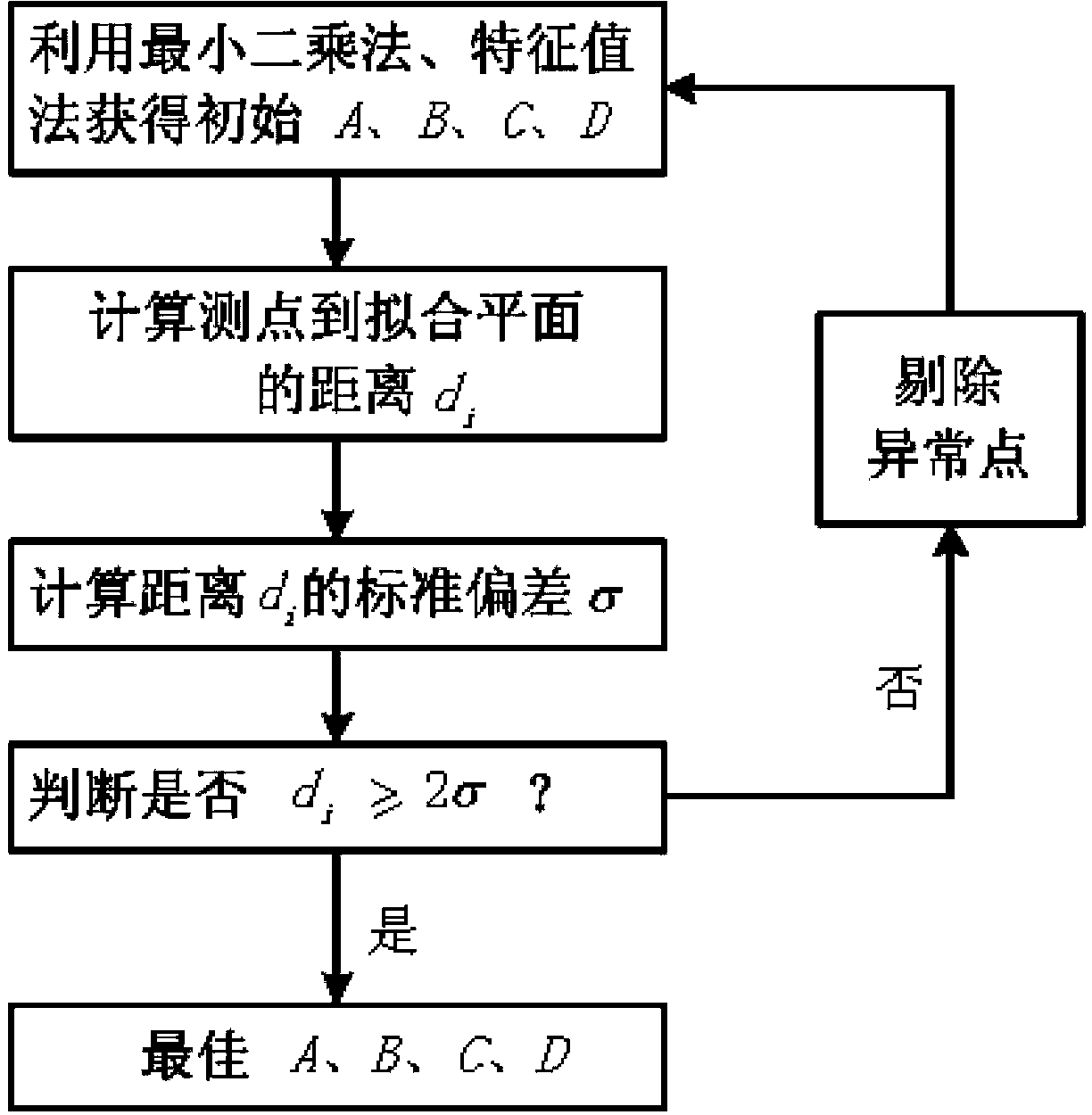

Detection method for three-dimensional space section roundness of large component

ActiveCN103900528AHigh degree of automationSimplify the difficulty of judging the roundness of the sectionUsing optical meansProfile tracingMeasurement pointData acquisition

The invention relates to a detection method for three-dimensional space section roundness of a large component. Non-contact laser measurement is carried out by utilizing a total station instrument, meanwhile measured data is transmitted to a computer for analysis and processing in real time, measurement points are projected to a projection plane calculated by a least square method or an eigenvalue method, and measurement points which are not in conformity with the conditions are eliminated to obtain the best projection evaluation plane, and an evaluation center and the best radius are calculated to obtain a roundness evaluation value of each section measurement point. Data acquisition is high in degree of automation, and acquisition and analysis are in seamless connection; measurement and analysis processes are strong in visualization by utilizing computer aid, and data and graphs are displayed in a correlated manner, so that operators can conveniently and accurately grasp the measurement and analysis processes. The detection method can be used for real-time measurement and detection for any section roundness of the large component, measurement results can be obtained in real time, and according to the measured data, the measurement points also can be increased or decreased at any time or a certain measurement point can be measured again, so that the difficulty in judging the section roundness of the large component is greatly simplified, and the working efficiency is improved.

Owner:NAVAL UNIV OF ENG PLA

Laser paint-removing system and method

InactiveCN102059457AAccurate removalEasy to operateLaser beam welding apparatusLaser burnEngineering

The invention provides a laser paint-removing system and method. The system comprises a control device, a laser marking machine, a detecting device and a cleaning device, wherein the control device is internally provided with laser marking software which sets the shape of paint to be removed and the position of removing the paint; the laser marking machine is connected with the control device and used for carrying out laser burning according to the set of the laser marking software; the detecting device is connected with the laser marking machine and is clung to the stream line and used for detecting the motion position of a product to be subjected to paint removal and controlling the laser marking machine to send laser; and the cleaning device is positioned at the downstream station of the laser marking machine and used for cleaning the incompletely dropping paint part. The laser paint-removing method comprises the steps of: 1, determining the shape of the paint to be removed and the position of removing the paint; 2, regulating the laser swinging speed; 3, detecting the position of a product; and 4, cleaning the paint removing surface. The invention has the advantages of achieving the paint-removing function by adopting a non-contact laser burning manner without damaging the internal material of the product, and being simple in operation.

Owner:HANS LASER TECH IND GRP CO LTD

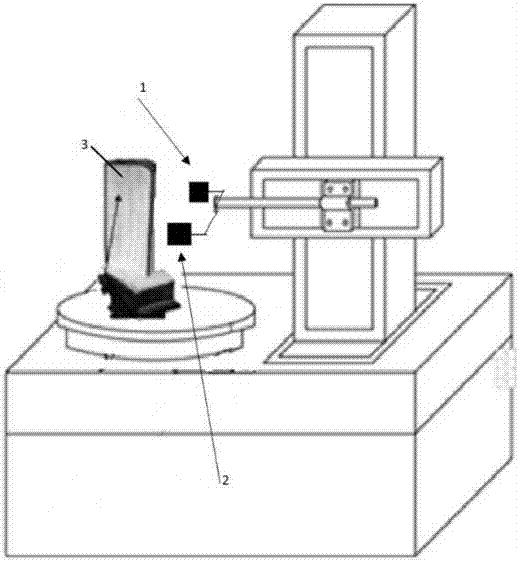

Numerically controlled lathe-based contour laser online measurement device and method for rotary type structure characteristic parts

ActiveCN107238352APrecise positioningImprove adaptabilityUsing optical meansPoint cloudMeasurement device

The invention relates to a numerically controlled lathe-based contour laser online measurement device and a method thereof for rotary type structure characteristic parts, and designs an adjustable and detachable clamp for clamping a sensor. An assembly body is arranged on the tool rest of a lathe in the side edge positioning mode, and the position and orientation calibration of a measuring head is conducted based on a ceramic standard ball. After that, a measuring program is called, and the distance value between the curved-surface discrete point of a part and the measuring head is measured. In combination with the coordinates of the lathe, a one-dimensional distance value is converted into a three-dimensional coordinate value by adopting a compiling algorithm, and then point cloud data are obtained. The point cloud data are analyzed and processed, and a model of the point cloud data is reconstructed. Compared with a theoretical model, an error value and a generation reason thereof are analyzed. Therefore, the high-efficiency precise online measurement of the contour profile of a rotary part is realized. According to the invention, the online measurement and the error analysis for the contours of rotary type structure characteristic parts can be realized. The device and the method are fast in measurement speed and high in precision, thus having a good practical value and an excellent application prospect in the field of non-contact laser online measurement and research.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Amplitude control based aviation engine blade vibration fatigue testing method

InactiveCN108195537AAmplitude real-time monitoringEliminate errorsVibration testingAviationDriving current

The invention discloses an amplitude control based aviation engine blade vibration fatigue testing method. A non-contact laser amplitude monitoring system is adopted. The amplitude of the end parts ofblades of an engine is monitored in real time. The amplitude of the end parts of the blades of the engine is taken as feedback signals. If that the dynamic amplitude deviates from a test preset valueis detected, a measurement and control system sends a modification command in real time. The amplitude constancy of the end parts of the blades of the engine is maintained through adjusting the magnitude of excitation drive current or adjusting excitation frequency. The amplitude control precision is superior to 1%. Therefore, a reliable blade vibration fatigue testing result can be acquired.

Owner:SOUTHEAST UNIV

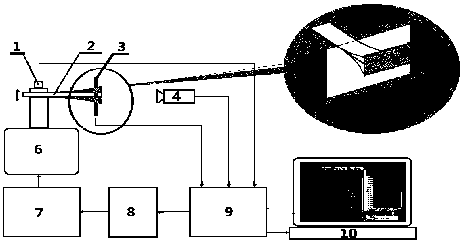

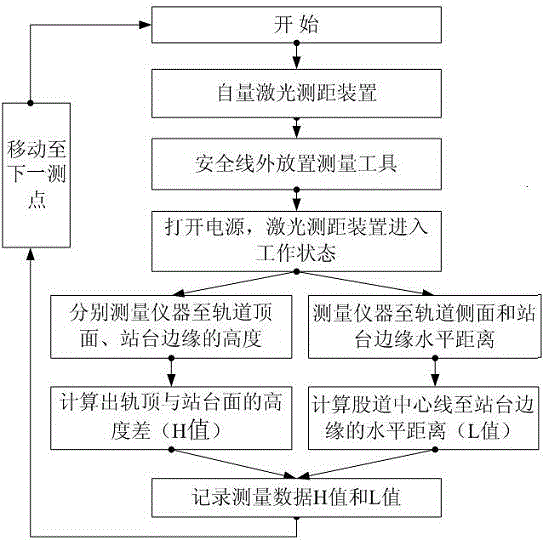

Non-contact laser range finding method of railway platform gauge

InactiveCN105222719AOperation impactDriving safety is not affectedUsing optical meansLaser rangingMeasurement point

The invention relates to a non-contact laser range finding method of a railway platform gauge. The method comprises: (1), a laser range finding device is arranged beyond a railway platform safety line and when a power supply is turned on, the laser range finding device enters a working state; (3), heights of an instrument relative to a track top surface and a platform edge are measured respectively and a height difference value H of the track top and the platform surface is calculated; (4), horizontal distances between the instrument and the track side and between the instrument and the platform edge are measured respectively and a horizontal distance value L between the central line of the track and the platform edge is calculated; and (5), movement to a next measurement point is carried out and then measurement and calculation are carried out according to the above-mentioned steps. According to the invention, the whole measurement system employs a laser non-contact measurement technology; measurement equipment is arranged at the platform and laser signals are transmitted and received remotely; and position boundary line data are calculated precisely. The measurement tools and the staff are in a safety range relative to the train and no influence is caused on the train running during the whole operating process. According to the invention, the method is especially suitable for measurement work of a railway platform building gauge.

Owner:中国铁路南昌局集团有限公司南昌房建生活段

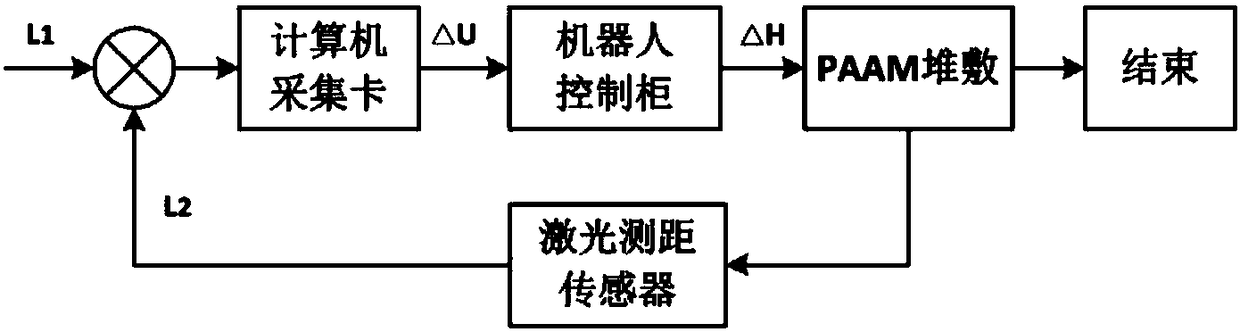

Laser ranging device and measuring and controlling method for plasma arc additive manufacturing of wires

ActiveCN108296618ARealize closed-loop controlAvoid wire pressingPlasma welding apparatusOptoelectronicsTitanium alloy

The invention discloses a laser ranging device and a measuring and controlling method for plasma arc additive manufacturing of wires. The device comprises a working platform, a substrate, a plasma welding gun, a laser displacement sensor and a clamp thereof, a computer and a robot control cabinet. The measuring and controlling method of the laser ranging device comprises the following steps: measuring the distance from the device to an overlaying layer by means of a non-contact laser displacement sensor; calculating the height of the overlaying layer by means of the computer; and communicatingto the robot control cabinet to adjust the height of the welding gun at the moment of arcing of a next overlaying layer. According to the laser ranging device and the measuring and controlling methodfor plasma arc additive manufacturing of wires disclosed by the invention, the heights of the overlay layers for plasma arc additive manufacturing of carbon steel, stainless steel and titanium alloywires can be detected, the height of from a nozzle to a member is controlled in the overlaying process, the height of the nozzle is automatically adjusted in the plasma arc additive manufacturing process, and problems that pressed wires and burned nozzle as the nozzle is too low and splattering and overlaying defects as the nozzle is too high in the overlaying process and the like are solved, so that the molding process is more precise and automatic, and the dimensional precision and the molding quality of molded parts are improved effectively.

Owner:NANJING UNIV OF SCI & TECH

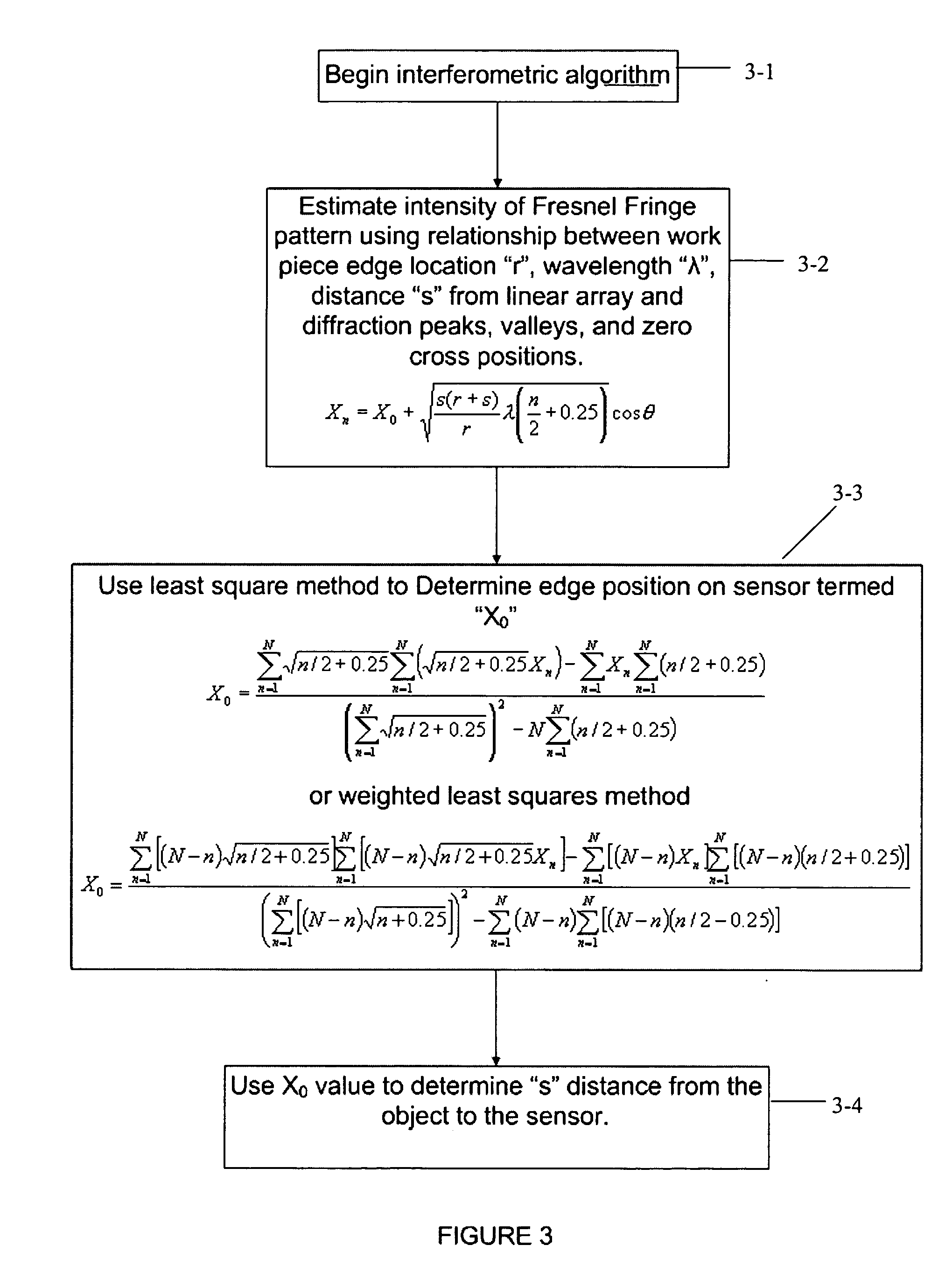

Diffractive non-contact laser gauge

A non-contact gauge and method of use is provided for optical measurement of an object or objects. The apparatus and methods may comprise a laser providing a projected laser beam; a work-piece holder for holding the object to be measured; a light sensitive sensor located to sense the beam as the beam is diffracted by at least one edge of the object and as the beam forms a near field Fresnel diffraction fringe pattern upon elements of the sensor. The laser and the sensor are located to enable near-field Fresnel diffraction. A fringe pattern signal analyzer may be included for computing mathematical algorithms to determine the position (X0) of at least one edge of the object based upon the diffraction pattern sensed by the sensor wherein the fringe pattern signal analyzer is structured to refine sensed fringe pattern edge position data to be more accurate based upon a theoretical diffraction compensation factor.

Owner:PRATT & WHITNEY MEASUREMENT SYST

Non-contact laser surface displacement monitoring device with tilt correction function

InactiveCN104142124ARealize automated monitoringSelf-correctingUsing optical meansData acquisitionOptoelectronics

The invention provides a non-contact laser surface displacement monitoring device with a tilt correction function. The device is characterized in that the monitoring device comprises a laser receiving and emitting end, a laser reflecting end, a corresponding communication module and upper computer software, wherein the laser receiving and emitting end comprises a radio frequency module, a double-axis tilt angle sensor, a temperature sensor, a laser range finder, a laser beam device and a mapping base, the laser reflecting end comprises a two-dimensional PSD displacement sensor, auxiliary parts of the two-dimensional PSD displacement sensor, an installation support, a range adjusting knob, a driving control circuit and a wireless communication module, the communication module is used for remote communication of field monitoring data, and the upper computer software is used for acquisition and analysis of monitoring data. The device has the advantages that automatic monitoring of plane displacement and vertical displacement of deformable bodies can be achieved at the same time, redundant observation quantity is sufficient, self-correction and self-inspection of monitoring data can be achieved, and the reliability of monitoring results is high.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES

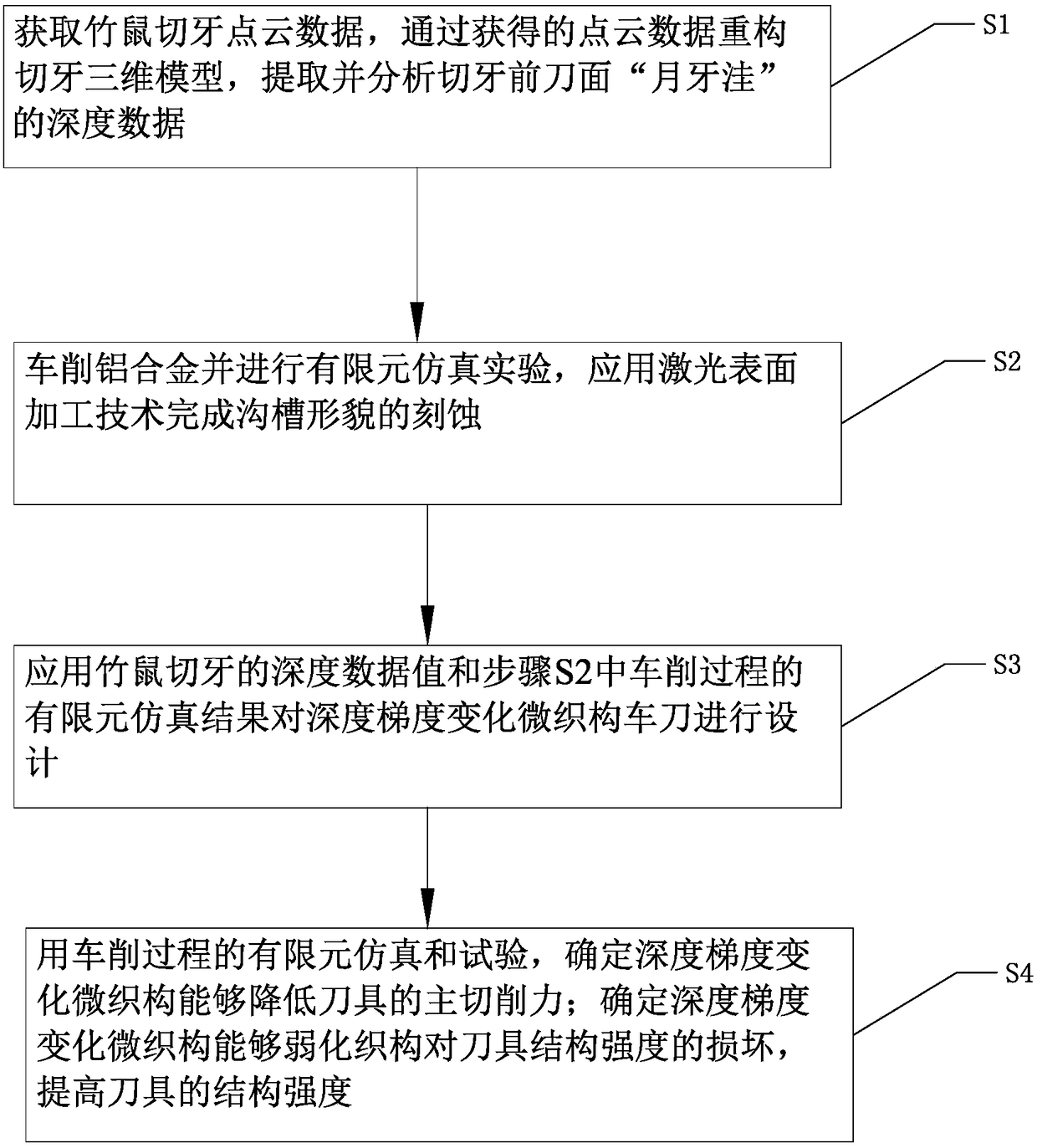

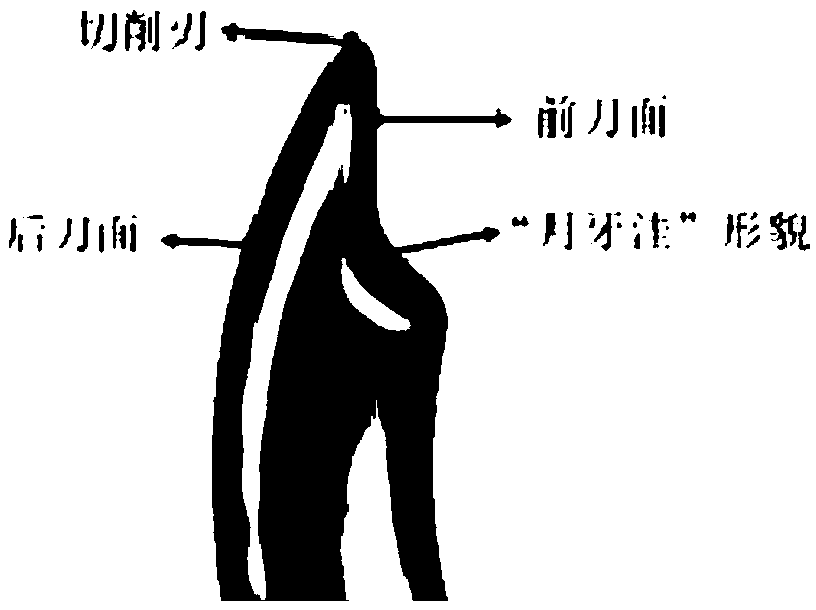

Bionic design method for microtexture turning tool with gradient changed depth

ActiveCN108763702AReduce main cutting forceImprove structural strengthGeometric CADDesign optimisation/simulationGroove widthPoint cloud

The invention discloses a bionic design method for a microtexture turning tool with a gradient changed depth. The method comprises the following steps of using a non-contact laser scanner to acquire bamboo rat incisor point cloud data, reconstructing a three-dimensional incisor model, and extracting crescent-shaped depth data of incisors; aiming at dry turning of aluminum alloy 7075 by using a hard alloy YG6A tool, when the distance of 10 microns from texture to a cutting edge, a groove depth of 7 microns, a groove width of 12 microns, and the groove space of 30 microns are determined by usingfinite element simulation and experiments during a turning process, achieving the best turning characteristic by a texture tool; and in combination with temperature distribution of the front tool plane of the turning tool, using the crescent depth data value to bionically design the microtexture turning tool with the gradient changed depth. When the microtexture with gradient changed depth is close to the cutting edge, the texture depth is small, and the texture depth is firstly increased and then reduced along with the texture that keeping away from the cutting edge. The method provided by the invention reserves the characteristic that the texture is reduced in cutting force of the tool, also improves the structural strength of the tool, and has the advantages of prolonging the service life of the tool and improving economic value of the tool.

Owner:SOUTHWEST JIAOTONG UNIV

Non-contact laser welding technique

InactiveCN101947677AGuarantee welding qualityWelding process solution and realizationSoldering apparatusNitrogen gasContact laser

The invention relates to a non-contact laser welding technique which comprises the following steps: a. placing tin balls in a container filled with nitrogen; b. melting the tin balls with a laser; and c. blowing the molten tin balls to the position to be welded on the workpiece under the pressure of nitrogen. The application of non-contact laser system: common welding techniques, which mainly carry out welding in an electric soldering iron heating mode, are contact welding techniques; and by adopting laser welding, the invention ensures the welding quality, solves and realizes the non-contact welding technique. The invention uses colophony-free welding technique to prevent colophony from polluting an object, thereby enhancing the welding quality; the invention can use an auxiliary image vision system to locate the solder position, and the positioning accuracy can be below 0.015 millimeter, thereby having the advantages of quick positioning and high accuracy; and nitrogen drives tin balls to be ejected out of the tin ball container with high speed and stability, and thus, the invention can also prevent oxidation in the process of high temperature melting and solidification.

Owner:HUIZHOU AOSHENTE PHOTOELECTRIC TECH +1

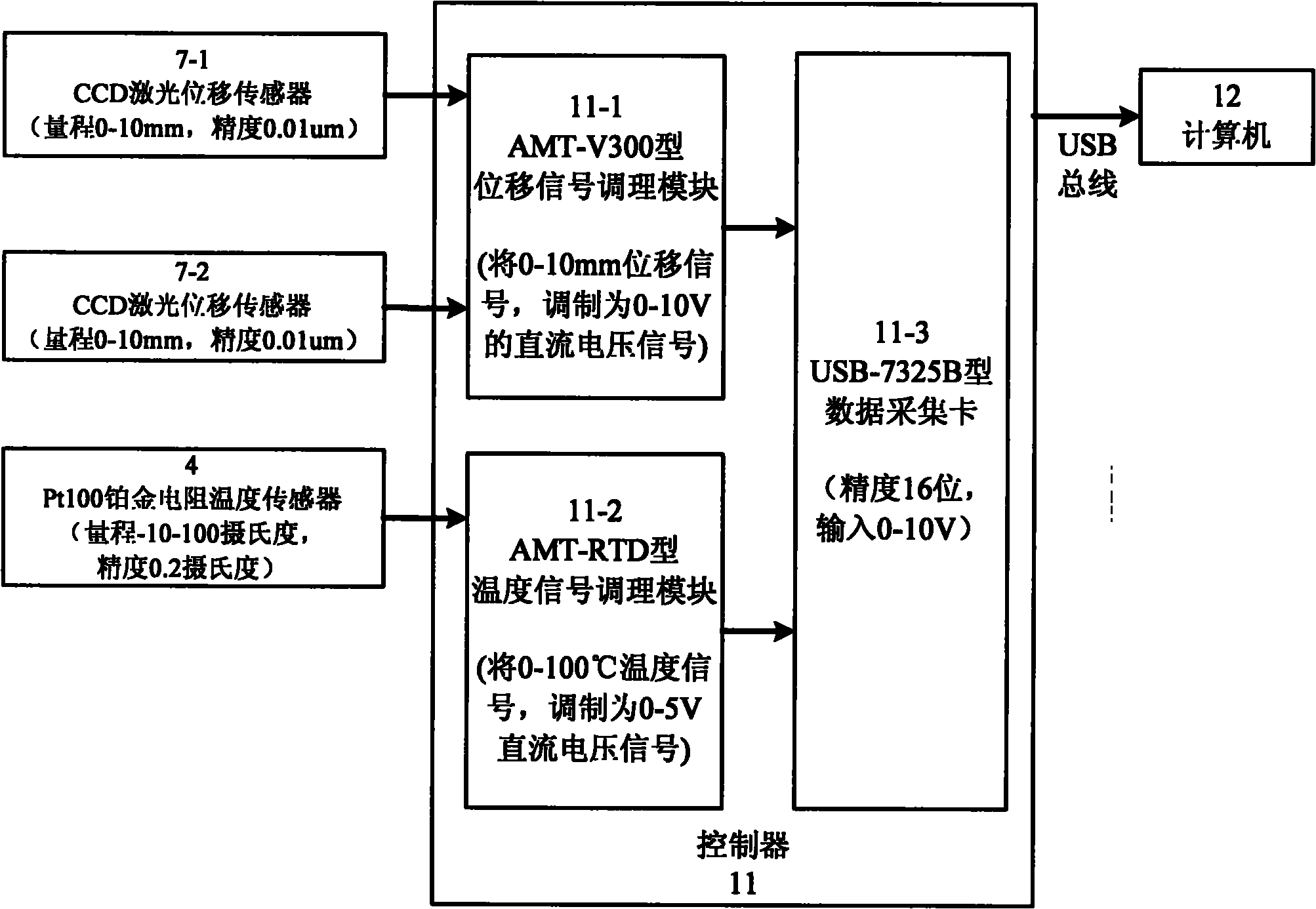

Non-contact laser displacement measurement system used for cement-based materials

ActiveCN102072704AImprove test accuracyFast sampling frequencyUsing optical meansData acquisitionEngineering

The present invention relates to a non-contact laser displacement measurement system used for cement-based materials, which belongs to the strain measurement technique of cement-based gelling materials in processes of hydration as well as dehydration. The system is characterized in that: in the aspect of hardware constitution, the system comprises a laser displacement sensor and fixing supports thereof, a temperature signal sensor, rotary knobs which are used for adjusting positions in horizontal and vertical directions and installed on the fixing supports, a cement-based material mold, tested samples of the cement-based materials, laser signal reflection targets embedded in the tested samples of the cement-based materials, a computer, and a controller which is provided with a displacement signal processing module of the samples, a temperature signal processing module of the samples, and a data collection card; in the aspect of software: the computer is installed with measurement and analysis softwares for calculating strain quantity of the related samples based on temperature variation. The invention has the advantages of being high in testing precision, quick in sampling frequency, free from surrounding electromagnetic interference during the testing process, and impervious to material quality and color of the samples.

Owner:TSINGHUA UNIV

Method for measuring attenuation curve of seismic wave in rock by using laser receiving apparatus

ActiveCN103713050ASmall receiving pointSmall receiving point intervalAnalysing solids using sonic/ultrasonic/infrasonic wavesLaser Doppler vibrometerTransducer

The invention relates to a method for measuring the attenuation curve of a seismic wave in a rock by using a laser receiving apparatus. The method is characterized in that apparatuses used in the invention comprise a routine ultrasonic energy transducer excitation probe belonging to an emission portion, a laser receiver belonging to a reception portion and corresponding excitation and reception matching devices; the emission portion adopts the routine probe, the routine probe is arranged on the surface at one side of a test rock sample and is fixed, and an excitation system emits certain ultrasonic waves; the reception portion adopts a non-contact laser receiving apparatus; there is no hardware contact between the reception portion laser Doppler vibrometer and a detection medium; and the focusing of a laser source on a detection point on a model is small, so enough small spacing measurement can be carried out.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device for inspecting countersunk holes

ActiveUS20080304085A1Thread cutting toolsDrilling/boring measurement devicesLaser transmitterComputerized system

The invention is a non contact laser inspection self centering device to inspect the counter sink portion of a counter sunk fastener hole on a surface. In detail, the self centering and seating device includes a combination laser transmitter and receiver for transmitting a laser bean across a surface and for receiving the return signal from the surface. A self centering device is attached to the combination laser transmitter and receiver for aligning the laser transmitter with the fastener hole such that the transmitted and received laser beam passes across the center of the counter sink portion of the fastener hole. A computer system is connected to the combination laser transmitter and receiver for analyzing the transmitted and returned laser signal from the surface and determining if the counter sink portion of the hole is within tolerance.

Owner:NORTHROP GRUMMAN SYST CORP

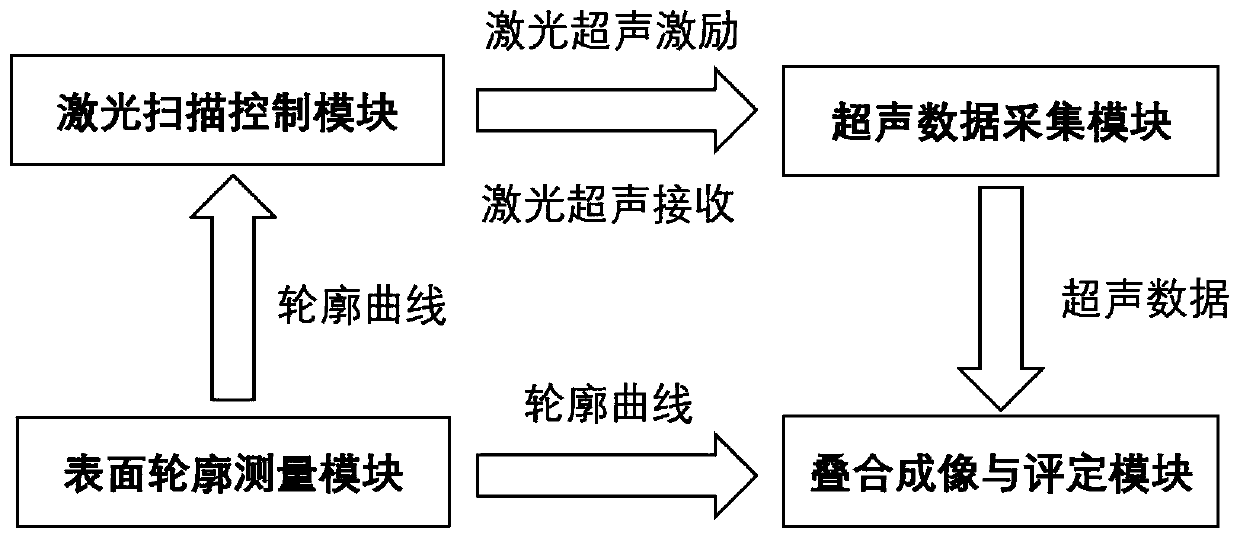

Laser ultrasonic imaging detection system and detection method for self-adaptive irregular surface

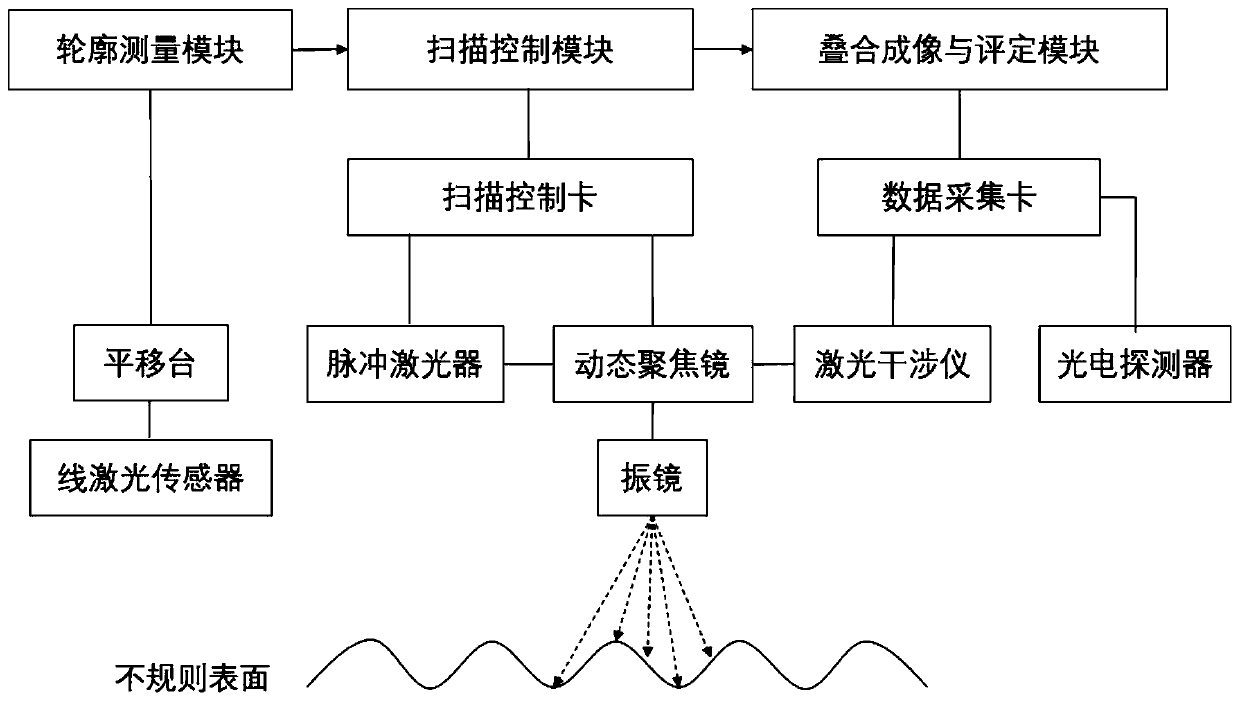

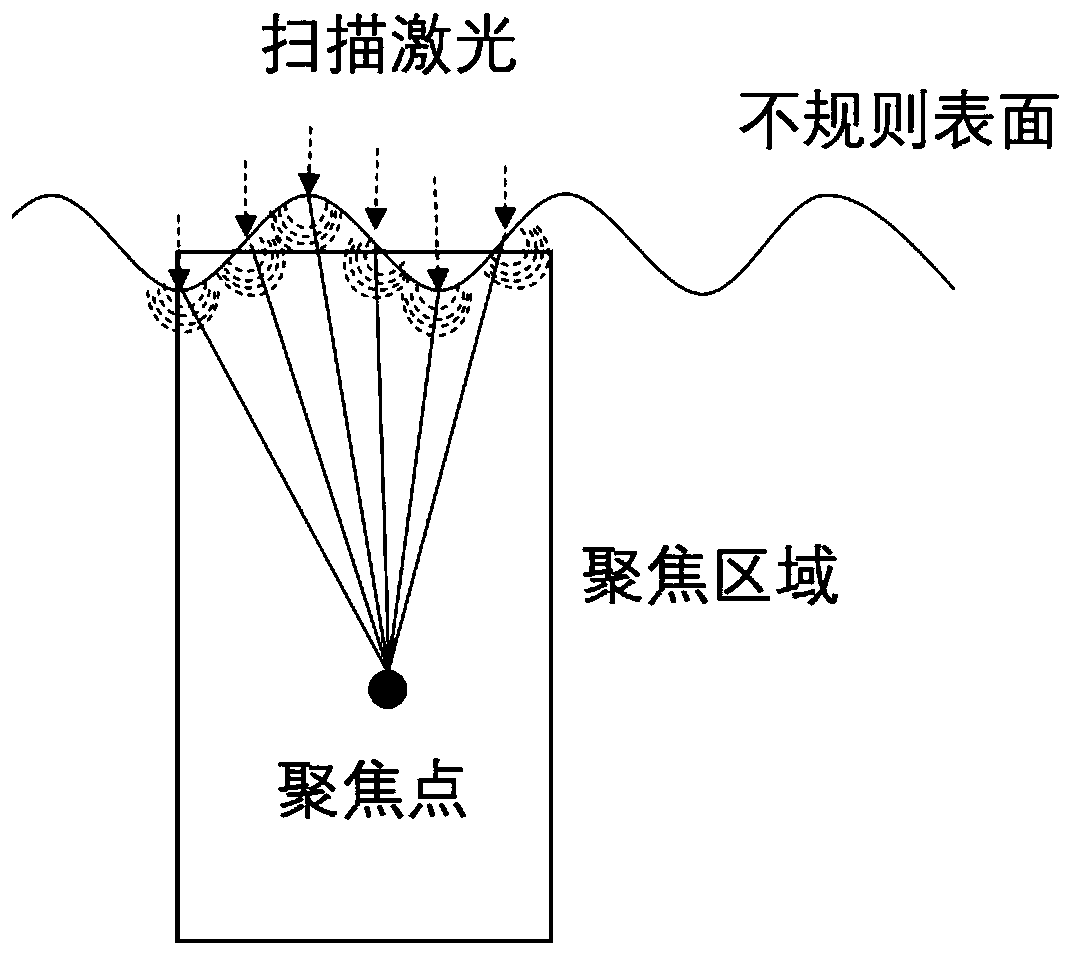

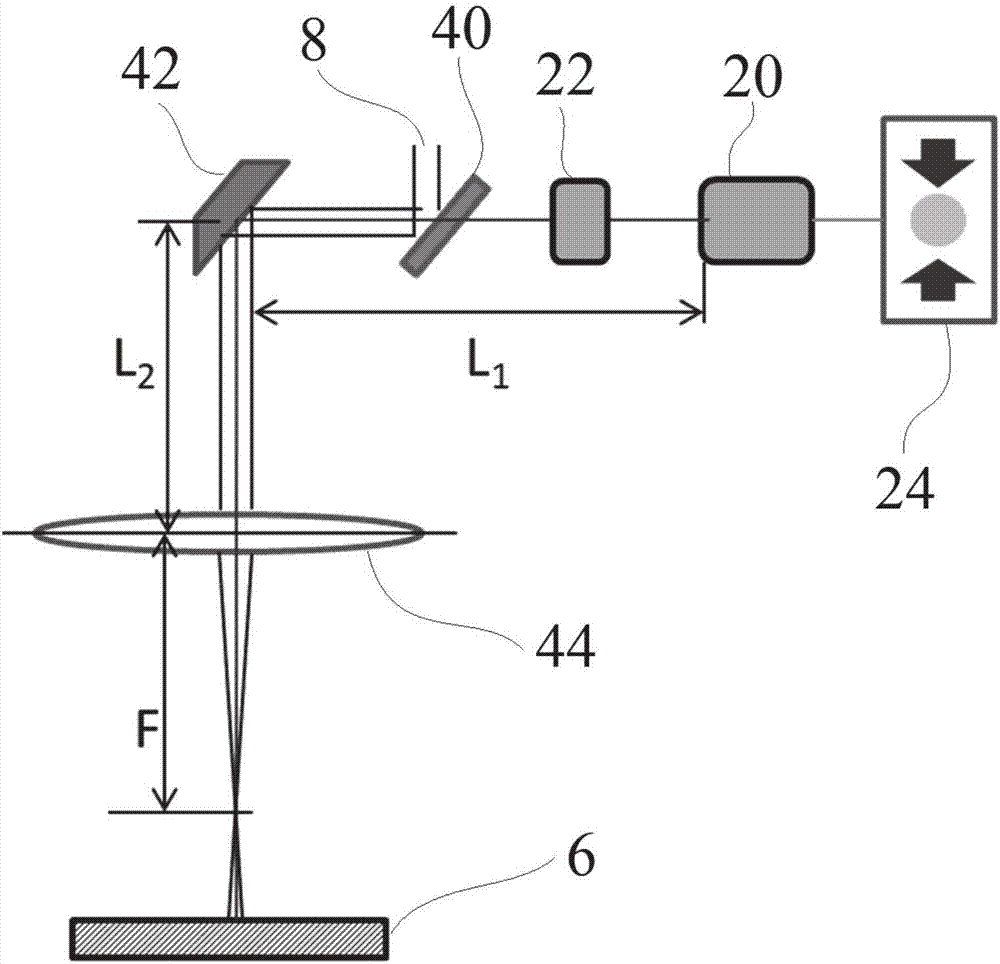

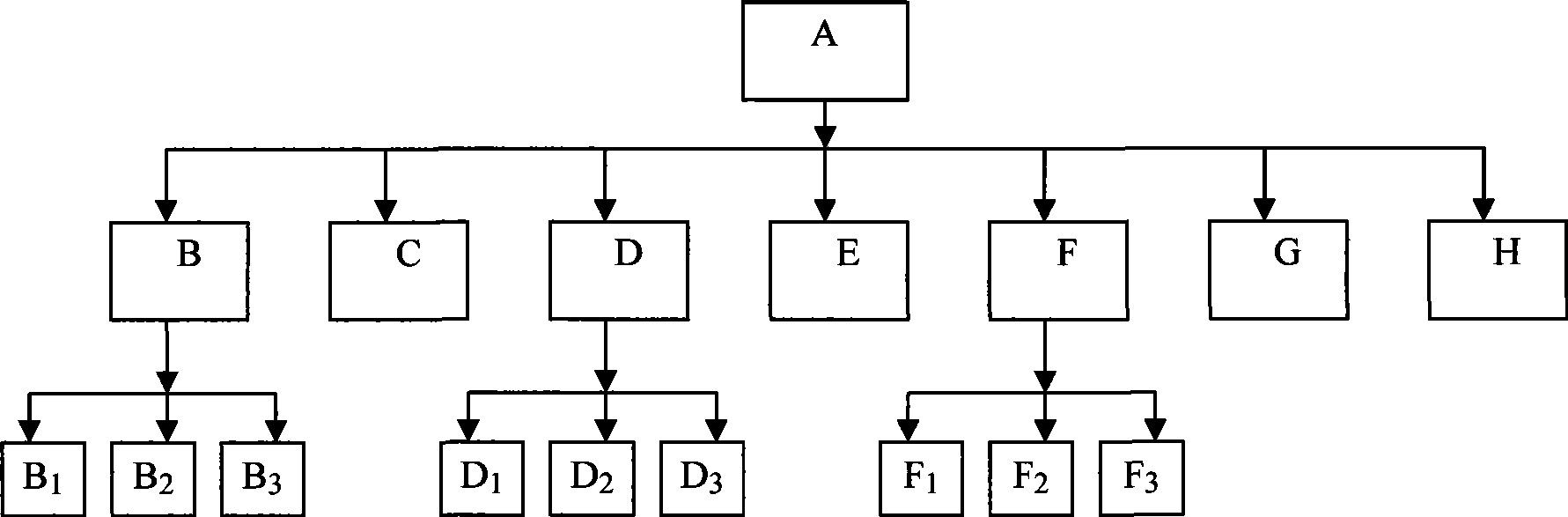

ActiveCN111595949ASolving Ultrasonic Coupling ProblemsRealize visual displayAnalysing solids using sonic/ultrasonic/infrasonic wavesOptically investigating flaws/contaminationLaser scanningContact laser

The invention discloses a laser ultrasonic imaging detection system and a detection method for a self-adaptive irregular surface. The detection system comprises a surface contour measurement module, alaser scanning control module, an ultrasonic data collection module and a lamination imaging and evaluation module, and the surface contour measurement module is connected with the laser scanning control module and the lamination imaging and evaluation module and used for workpiece contour shape and size measurement and data transmission; wherein the laser scanning control module and the ultrasonic data collection module are two independent modules and work synchronously and cooperatively to realize excitation and reception of laser ultrasonic signals respectively; and the overlapping imagingand evaluation module performs virtual focusing processing on the laser ultrasonic signal and overlapping imaging display of the surface contour of the workpiece, and identifies and positions defectsand structural echoes. According to the invention, non-contact laser ultrasonic scanning detection can be carried out on an irregular surface with an unknown geometrical shape, a defect signal can bequickly identified, and the relative position of a defect in an irregular workpiece can be visually displayed.

Owner:WUHAN UNIV

Laser focus control system, application thereof and laser cleaning head

InactiveCN107377530AReal-time monitoring of defocus distanceQuality improvementLaser beam welding apparatusCleaning processes and apparatusElectricityControl system

The invention discloses a laser focus control system, an application of the laser focus control system and a laser cleaning head. The laser focus control system comprises a laser distance measuring meter, a field lens and a calculation and display unit, wherein a distance measuring laser beam sent by the laser distance measuring meter passes through the field lens, then is irradiated onto the surface of a workpiece and measures distance, the laser distance measuring meter is electrically connected with the calculation and display unit, the laser distance measuring meter and the calculation and display unit input a distance measuring result, and the calculation and display unit outputs at least one signal. The laser focus control system can monitor the defocusing distance in real time, is applicable to the field of laser cleaning, can achieve non-contact laser cleaning, particularly cleaning in narrow spaces, and can improve the cleaning quality and efficiency.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Aspheric surface detecting instrument

InactiveCN101464141AMeet the requirements of detection accuracyHigh measurement accuracyUsing optical meansGratingThree dimensional measurement

The invention relates to optical aspheric detecting devices, and provides an aspheric detector, particularly an aspheric detector with higher measuring accuracy, which is obtained by combining the advantages and disadvantages of contact and non-contact measurement, integrating the contact and non-contact measurement as a whole to measure aspheric surfaces and mutually compensating for the two methods of measurement. The aspheric detector comprises a structure rack, a detecting platform, a non-contact laser displacement probe, a grating contact displacement probe, an XYZ three-axis motion mechanism and a control device, wherein, the non-contact laser displacement probe and the grating contact displacement probe are mounted on the Z axis of the XYZ three-axis motion mechanism; the detecting platform is arranged on the X axis motion mechanism; an X-axis motor, a Y-axis motor and a Z-axis motor are mounted on the XYZ three-axis motion mechanism respectively; and the XYZ three-axis motion mechanism is driven by the X axis motor, the Y axis motor and the Z axis motor, thereby realizing the movement of the non-contact laser displacement probe and the grating contact displacement probe, and realizing the three-dimensional measurement of an aspheric surface optical element.

Owner:XIAMEN UNIV

Non-contact laser detecting instrument for displaying roughness of steel ball

The invention relates to a non-contact laser detecting instrument for displaying the roughness of a steel ball, which comprises a base (1), a steel ball adjusting device (2), a swing adjusting device (3), a measuring mandrel (4), a limiting device (6), a photoelectric sensor (7), a swing receiving device (8), a laser tube, a laser tube adjusting device (9) and a shell (10). In the non-contact laser detecting instrument provided by the invention, a laser speckle principle is adopted on a measuring principle; the mechanical structure of the detecting instrument has the key points that the incidence speckle of the laser tube, the top end of the steel ball and the gyration center of the sensor adjusting device are adjusted to one point, i.e. three points are on the same line; simultaneously, the reflected speckles are right positioned in the right center of a photonuclear sensor; and the whole light path is in a good darkroom protection mode, and errors are reduced to the minimum under the condition that the whole light path is in the good darkroom protection mode, thereby reaching measurement standards. The non-contact laser detecting instrument provided by the invention has the advantages of high measuring speed, no damage to the measured steel ball (5), simplified structure of the detecting instrument, cost reduction, appearance improvement, simple and convenient operation and strong detection reliability.

Owner:LUOYANG BEARING SCI & TECH CO LTD

Cylindrical cell laser automatic peeling system

ActiveCN109014601AEffectively cut offGuaranteed performanceLaser beam welding apparatusProduction lineLaser processing

The invention provides a cylindrical cell laser automatic peeling system. The system comprises a loading mechanism, a separation mechanism, a laser cutting and peeling mechanism, a cell conveying line, a finished product unloading mechanism and a finished product transportation mechanism; the loading mechanism is arranged at one end of the cell conveying line; the finished product unloading mechanism and the finished product transportation mechanism are arranged at the other end of the cell conveying line; the separation mechanism, the laser cutting and peeling mechanism, the finished productunloading mechanism and the finished product transportation mechanism are arranged in an operation direction of the cell conveying line in sequence; the separation mechanism is arranged near one end of the loading mechanism; and the laser cutting and peeling mechanism is arranged near one end of the finished product unloading mechanism. The system adopts a non-contact laser machining method to peel cells, meanwhile, adopts double production lines for automatic material separation, realizes full-automatic production through the loading mechanism, the cell conveying line, the finished product unloading mechanism and the finished product transportation mechanism, and greatly improves the machining efficiency on the basis of guaranteeing the performances of cell products.

Owner:深圳华工新能源装备有限公司

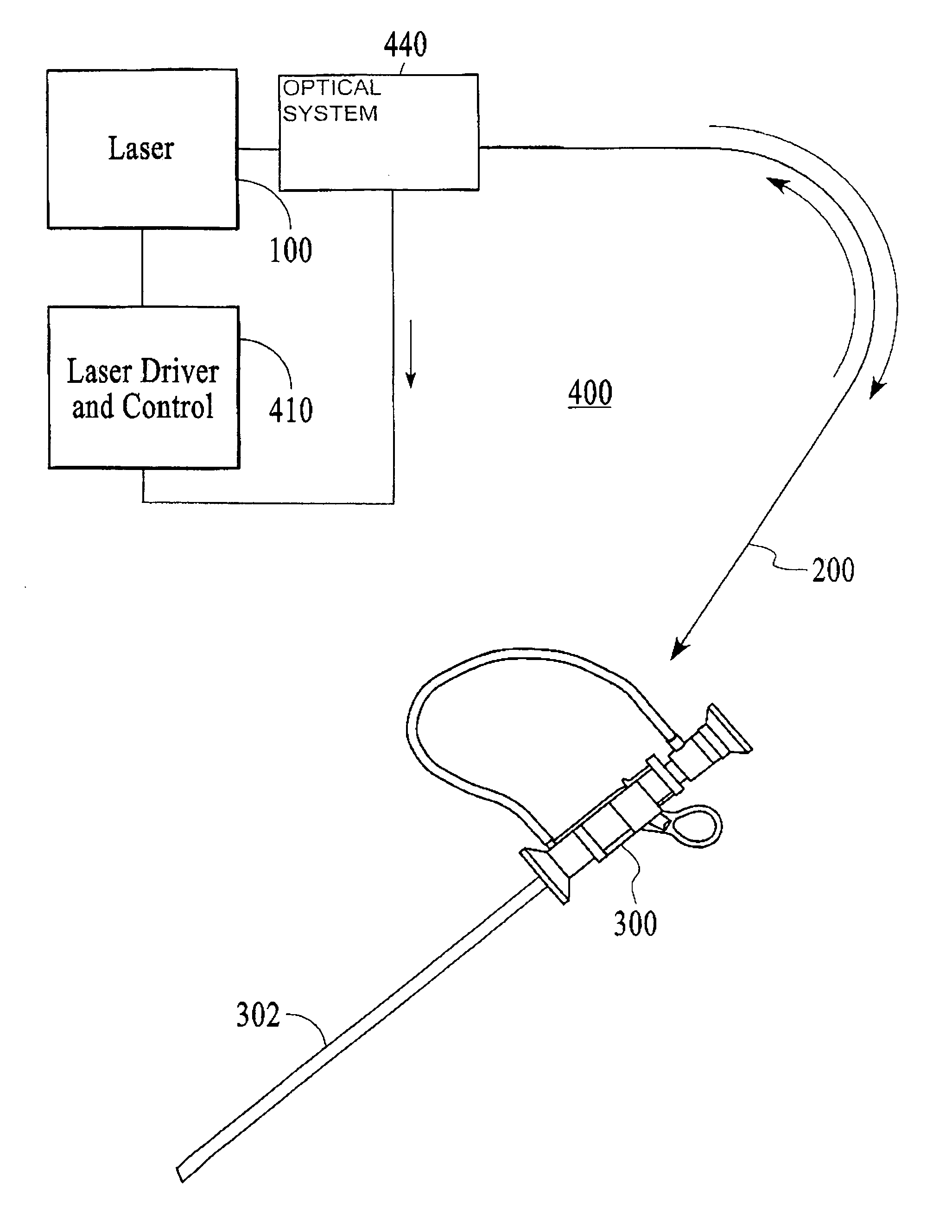

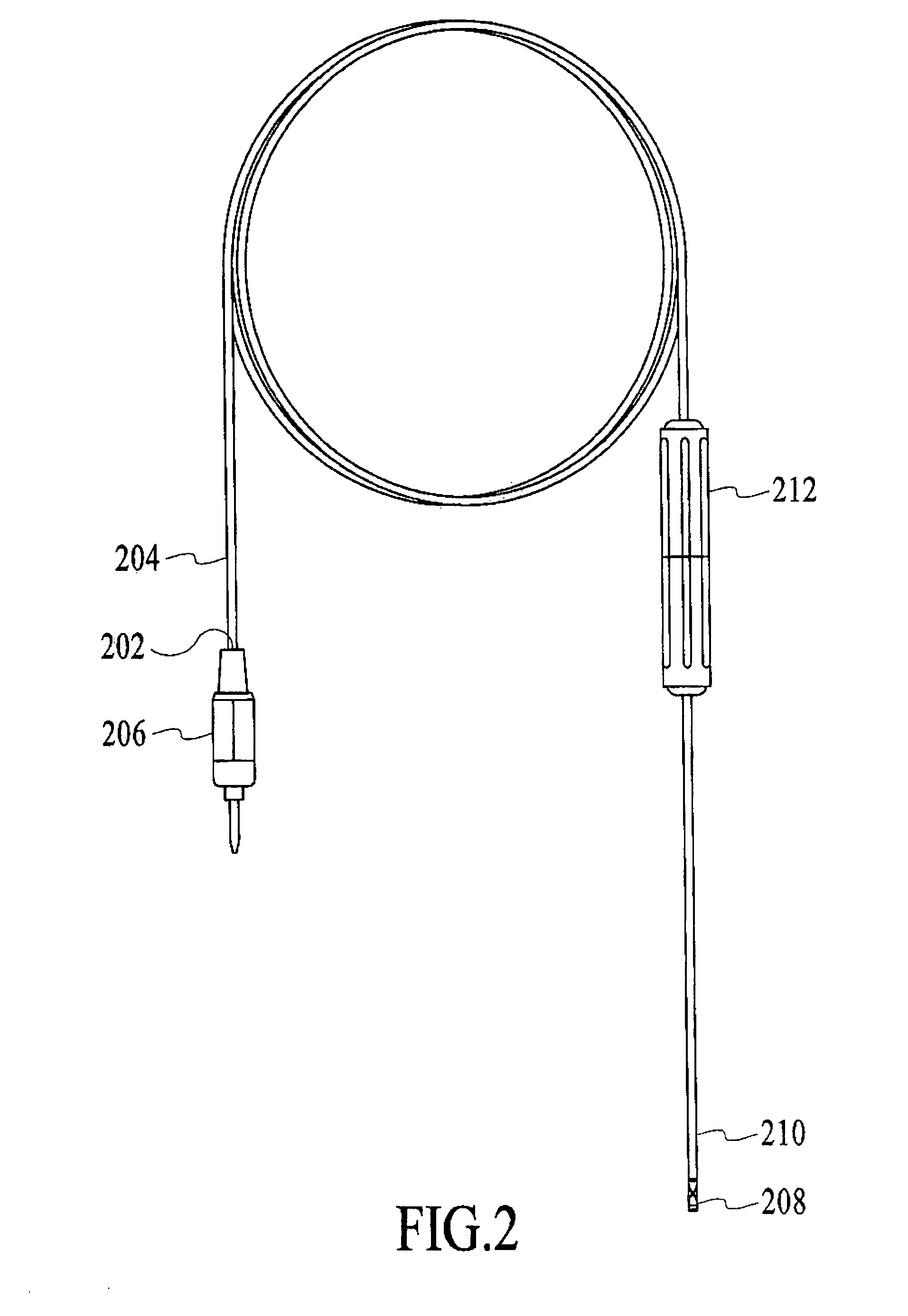

Contact laser ablation of tissue

ActiveUS20110190746A1Effective maintenanceEffective vaporization of tissueSurgical instrument detailsLaser sourceLaser ablation

Apparatus and methods are described for laser ablation of tissue. The apparatus and methods utilize a laser source coupled to a fiberoptic laser delivery device and a laser driver and control system with features for protection of the laser delivery device, the patient, the operator and other components of the laser treatment system. Advantageously, the laser source may utilize laser diodes operating at approximately 975 nm, 1470 nm, 1535 nm or 1870 nm wavelengths with a laser power output of at least 60 watts, preferably greater than 80 watts and most preferably 120-150 watts or higher. The invention, which has broad medical and industrial applications, is described in relation to a method for treatment of benign prostatic hyperplasia (BPH) by contact laser ablation of the prostate (C-LAP).

Owner:XINTEC

Aero-engine labyrinth disc hot list processing thickness information extraction system

InactiveCN101694584AReduce volumeHigh precisionLiquid surface applicatorsUsing optical meansAutomatic controlLaser scanning

The invention relates to an aero-engine labyrinth disc hot list processing thickness information extraction system which consists of an industrial robot, a laser scanning head and an automatic control positioner, wherein the non-contact laser scanning head is connected with the industrial robot by a data cable for transmitting scanning data, and is connected with a control cabinet by a communication cable so as to transfer the scanning data when receiving a motion command; the control cabinet is connected with a computer through a network port and is used for transferring a control command and the scanning data; the computer mainly completes the core tasks such as motion scan path planning, data processing and coating thickness and the like; and the high accuracy automatic control positioner and the industrial robot are connected with the main control computer by data lines, and receive the control command sent out by the main control computer to finish the spraying operation until a spraying aero-engine labyrinth disc is fixed on the positioner. The system can automatically and efficiently acquire comprehensive aero-engine labyrinth disc hot list processing thickness information distribution data, so as to be applicable to the spraying occasion of the aero-engine labyrinth disc hot list processing.

Owner:DALIAN MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com