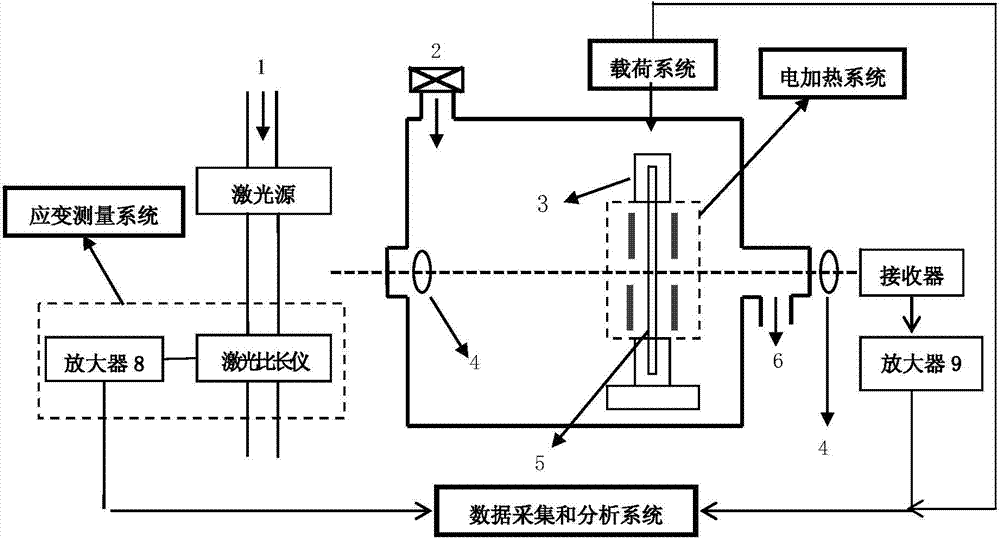

Non-contact high-temperature thermophysical property parameter measurement device and non-contact high-temperature thermophysical property parameter measurement method

A non-contact, physical performance technology, applied in the direction of measurement device, strength characteristics, material thermal development, etc., can solve the problems of low reliability of measurement results, complex measurement process, high measurement cost, and improve the measurement temperature range and measurement results. Accurate, reduced measurement time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Four graphite rods are used as heating elements, the diameter of the graphite rod is 20mm, the power of the laser generator is 6W, the laser frequency is 10kHz, the machining accuracy of the slideway and the laser generating system is 5.0μm, the minimum pressure of the vacuum pump is 0.05Pa, and the measurement temperature is 1500 ℃, using the equipment of the present invention to measure the thermophysical properties of the hafnium diboride sample, the size of the sample is 30mm×2mm×2mm (length×width×height).

[0035] The slide rail module is placed in the laser source module, and the thermal conductivity of hafnium diboride is measured by the national standard (GB / T22588-2008), and the time t for the back of the sample to reach half of the maximum temperature rise is measured. 1 / 2 , using the formula by computer: α=0.13879L 2 / t 1 / 2 The calculated thermal diffusivity is 0.2862cm 2 the s -1 , and use the formula: λ=αC p ρ calculates that the thermal conductivity of...

Embodiment 2

[0041] Five graphite rods are used as heating elements, the diameter of the graphite rod is 18mm, the power of the laser generator is 20W, the laser frequency is 20kHz, the machining accuracy of the slideway and the laser generating system is 8μm, the minimum pressure of the vacuum pump is 0.1Pa, and the preset measurement temperature is At 1600°C, use the equipment of the present invention to measure the thermophysical properties of hafnium diboride samples with known thermophysical properties. T22588-2008) to measure the thermal conductivity of hafnium diboride.

[0042] The testing and calculation process is the same as in Example 1. The test results are compared with the known results: the accuracy rate of mechanical properties is >98.3%, and the accuracy rate of thermal conductivity is >99.1%.

Embodiment 3

[0044] Six graphite rods are used as heating elements, the diameter of the graphite rod is 14mm, the power of the laser generator is 30W, the laser frequency is 30kHz, the machining accuracy of the slideway and the laser generating system is 15μm, the minimum pressure of the vacuum pump is 0.3Pa, and the preset measurement temperature is At 1700°C, use the equipment of the present invention to measure the thermophysical properties of hafnium diboride samples with known thermophysical properties. T22588-2008) to measure the thermal conductivity of hafnium diboride.

[0045] The testing and calculation process is the same as in Example 1. The test results are compared with the known results: the accuracy rate of mechanical properties is >99.4%, and the accuracy rate of thermal conductivity is >99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com