Non-contact laser surface displacement monitoring device with tilt correction function

A tilt correction and non-contact technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of laser range-finding surface displacement monitoring devices that cannot be used, aggravate laser beam scattering, and large measurement errors, etc., to achieve automatic Correction and self-checking function, high reliability, sufficient observation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

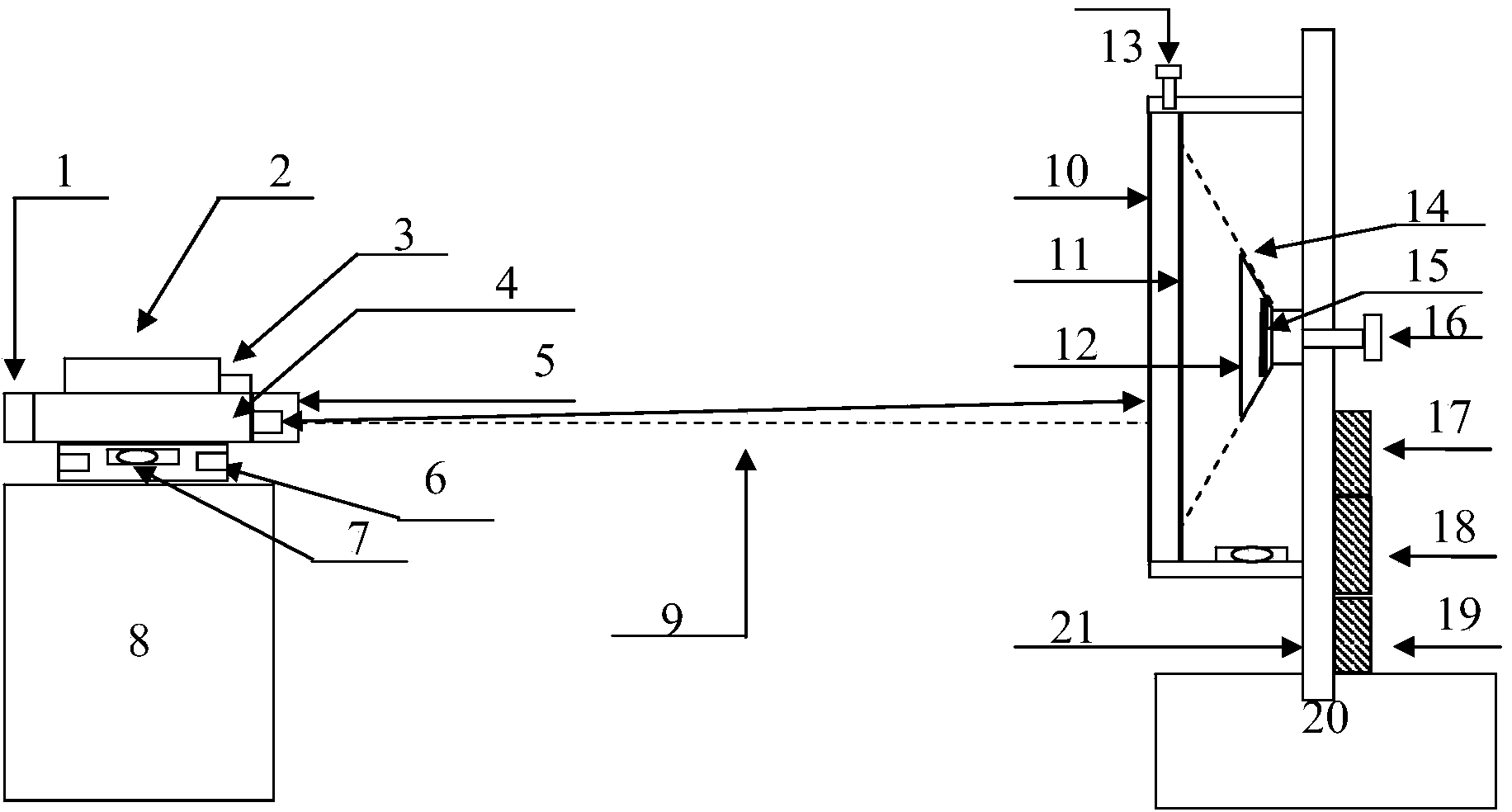

[0017] The specific implementation of the non-contact laser surface displacement monitoring device with tilt correction provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0018] Such as figure 1 As shown, the non-contact laser surface displacement monitoring device with tilt correction includes a laser transceiver terminal, a laser reflection terminal, a corresponding communication module, and host computer software. The laser transceiver terminal is responsible for laser emission and return signal reception to obtain reference points and monitoring points. The laser reflection end is responsible for the laser emission to identify the spot position; the communication module is responsible for the remote communication function of on-site monitoring data; the upper computer software is responsible for monitoring data collection and analysis.

[0019] The installation of the monitoring device is divided into two parts: the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com