Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110 results about "Laser burn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

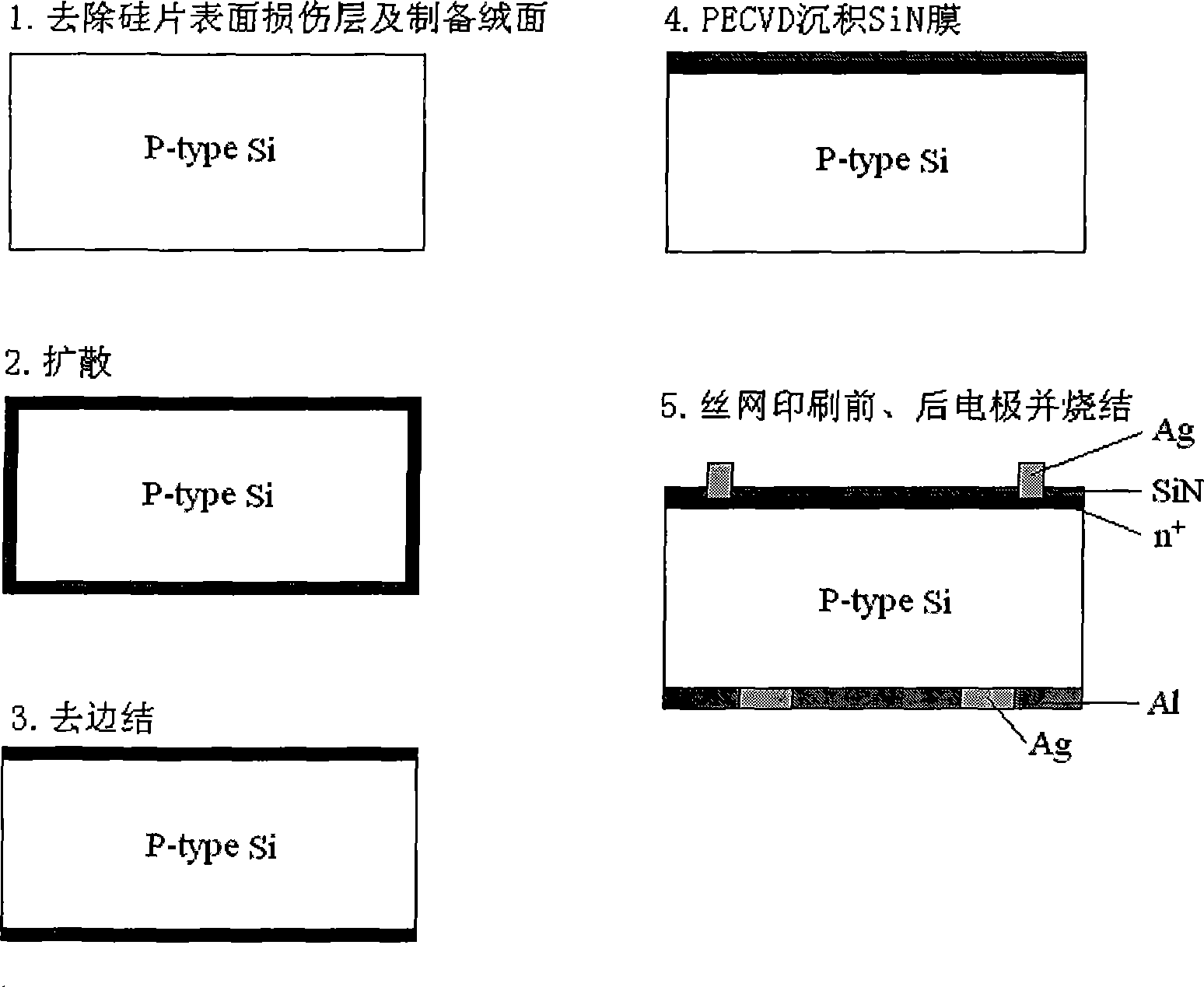

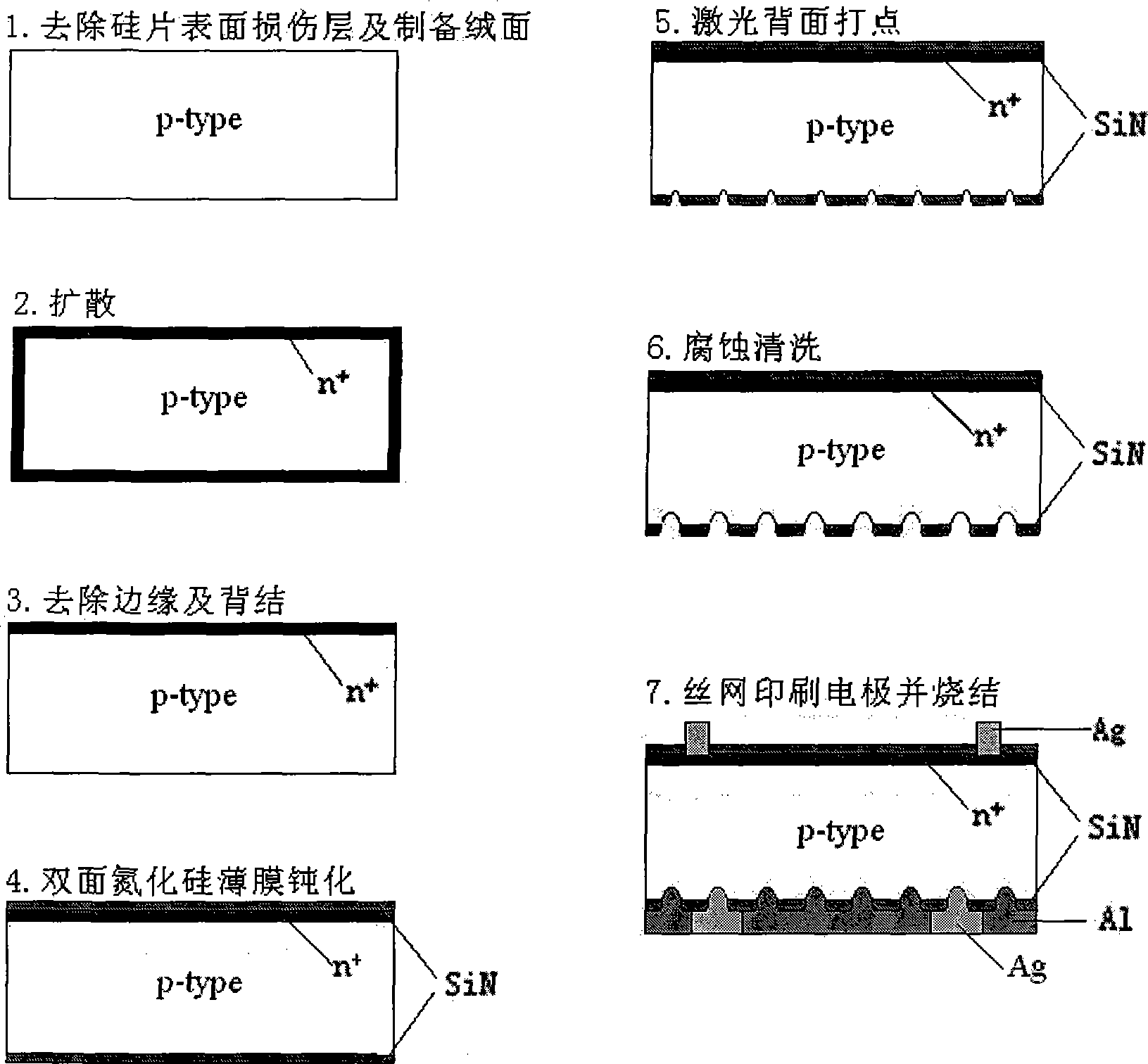

Method for preparing antapex contact crystalline silicon solar cell by utilizing passivation on double surfaces and laser dotting

InactiveCN101447528AImprove conversion efficiencyReduce compound rateFinal product manufactureSemiconductor devicesLaser burnProduction line

The invention discloses a method for preparing an antapex contact crystalline silicon solar cell by utilizing passivation on double surfaces and laser dotting. In the method, on the basis of a conventional crystalline silicon solar cell preparation process, both the front and the back surfaces of the solar cell are passivated; then a passivation layer on the back surface of the solar sell is quickly dotted by lasers, and then a back electrode local contact window is formed; and after screen printing or electrode magnetron sputtering, the antapex contact crystalline silicon solar cell with relative high efficiency is prepared. The method utilizes the technology of directly opening a passivation layer window by lasers, so that whether compared with traditional photolithography or a laser burning thawing aluminum electrode method, process steps, process time and preparation costs of the method are greatly reduced; screen printing and the mode of using magnetron sputtering to prepare back electrode adopted by the method are highly beneficial to mass production; and especially, screen printing has a low cost and a high output, and is consistent with the current production line, thereby profitably pushing the industrialization of screen printing.

Owner:上海晶澳太阳能光伏科技有限公司

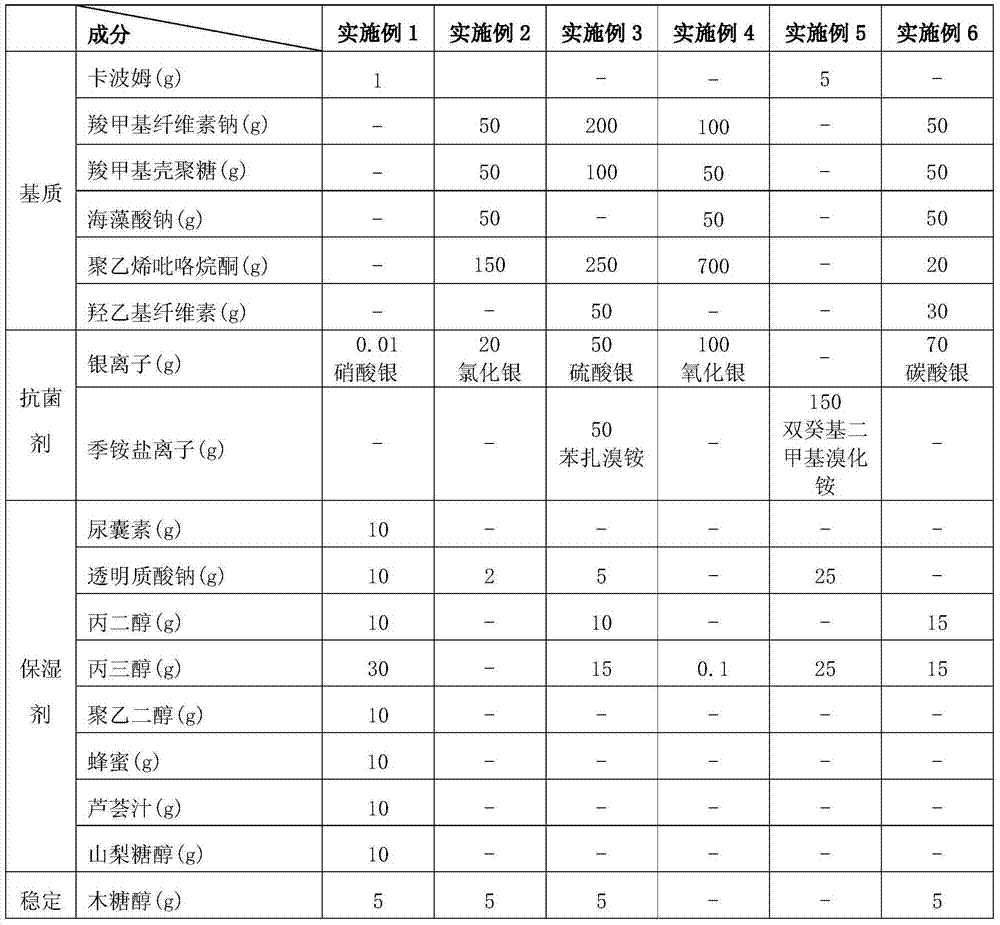

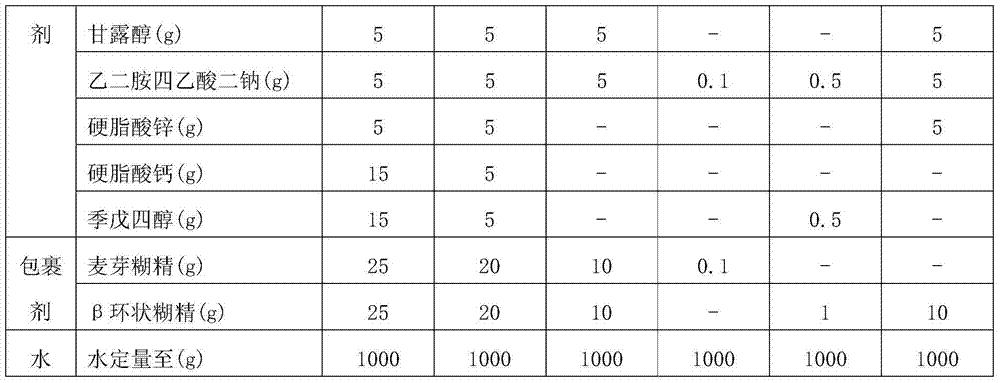

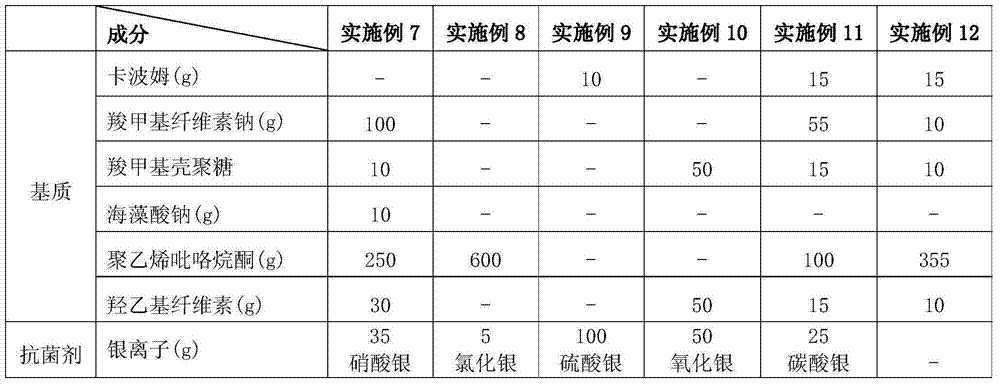

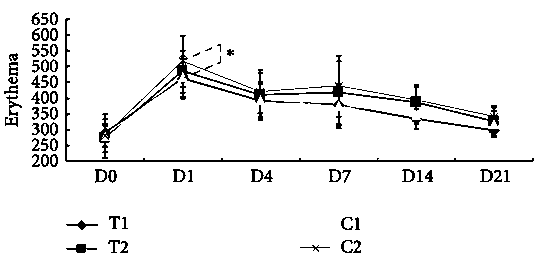

Hydrogel wound dressing for treating laser cauma and burns and scalds as well as preparation method thereof

ActiveCN103495199APromote wound healingImprove antibacterial propertiesAbsorbent padsBandagesBurned skinLaser burn

The invention relates to hydrogel wound dressing for treating laser cauma and burns and scalds. The active components of the hydrogel wound dressing include an antibacterial agent, a humectant and a stabilizer, wherein the antibacterial agent inhibits adhesion and growth of the wound of laser cauma and surrounding bacteria and can kill various pathogenic bacteria at the cauma part, so as to effectively promote union of the laser cauma. The antibacterial agent adopted by the invention does not generate drug resistance, the humectant can maintain moisture of the wound, promote union of the wound surface, prevent formation of scars and alleviate wound pain. With the adoption of the stabilizer, the hydrogel maintains long-time antibacterial effectiveness. Experiments verify that the hydrogel dressing provided by the invention has the effects of effectively relieving wound pain, controlling local infection, maintaining moisture of wound skins, protecting skins, accelerating and promoting union of wound surface and wound and preventing formation of scars, and can be used for healing laser-burned skin wound surfaces (such as laser mole removal and the like) and wound surfaces of burns and scalds.

Owner:SAIKE SAISI BIOTECH CO LTD

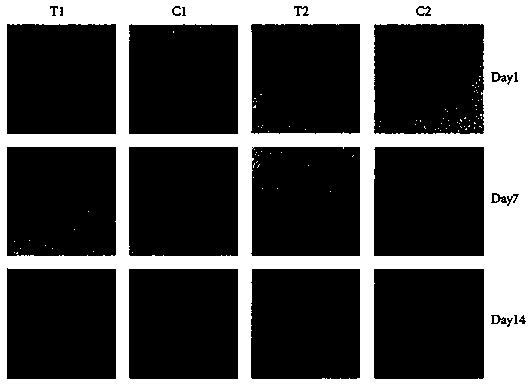

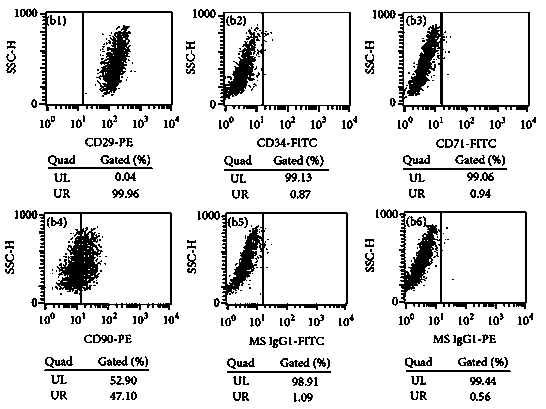

Application of human umbilical cord mesenchymal stem cell complex cell factor in preparing biological agent for repairing skin injury

ActiveCN104027794APromote growth and healingRegulate immune responsePeptide/protein ingredientsDermatological disorderLaser burnCold injury

The invention provides an application of a human umbilical cord mesenchymal stem cell complex cell factor in preparing a biological agent for repairing skin injury. The skin injury includes laser burn, thermal burn, cold injury or common trauma skin physical and chemical injury. According to the application, an umbilical cord stem cell complex growth factor is firstly used for the treatment of human skin laser injury; the human umbilical cord mesenchymal stem cell complex cell factor can be preserved in maximal activity and plays a maximal role of injury repair and treatment under a certain preservation condition.

Owner:徐妍

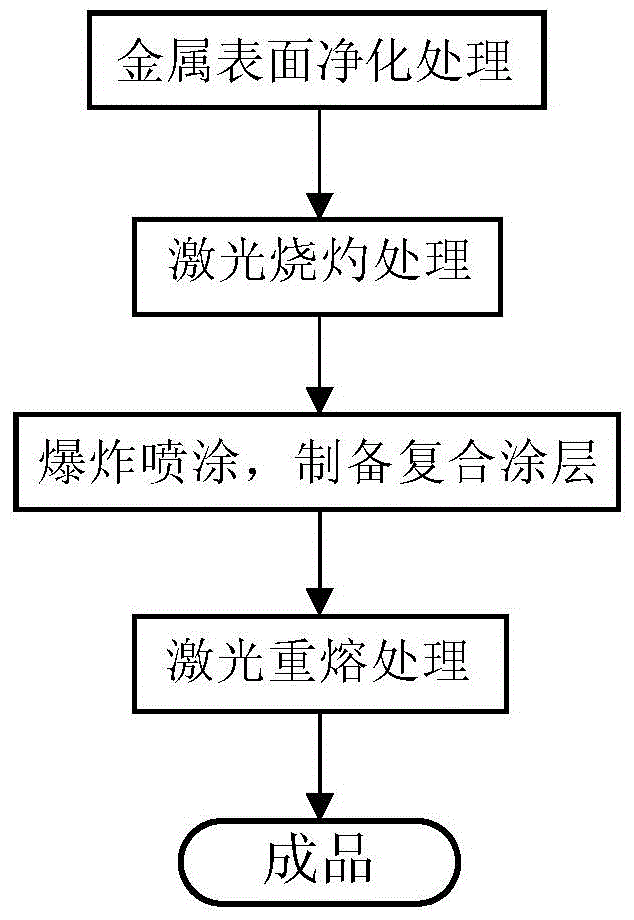

Process for spraying composite coating on metal surface

InactiveCN104789921AReduce porosityImprove microstructureMolten spray coatingWear corrosionLaser burn

The invention discloses a process for spraying a composite coating on a metal surface. The process comprises the following steps: carrying out purification treatment on the metal surface; carrying out laser burning treatment on the metal surface; carrying out explosion spray treatment on the metal surface, and preparing the composite coating; carrying out laser re-melting treatment on the composite coating prepared by an explosion spray process, on the metal surface. According to the combined process for spraying the composite coating on the metal surface, the explosion spray process is compounded with two laser heat treatment processes, so that the binding force of the coating and a matrix can be effectively improved, and the performances of corrosion resistance, wear corrosion and the like of the coating can be further improved.

Owner:上海市机械制造工艺研究所有限公司

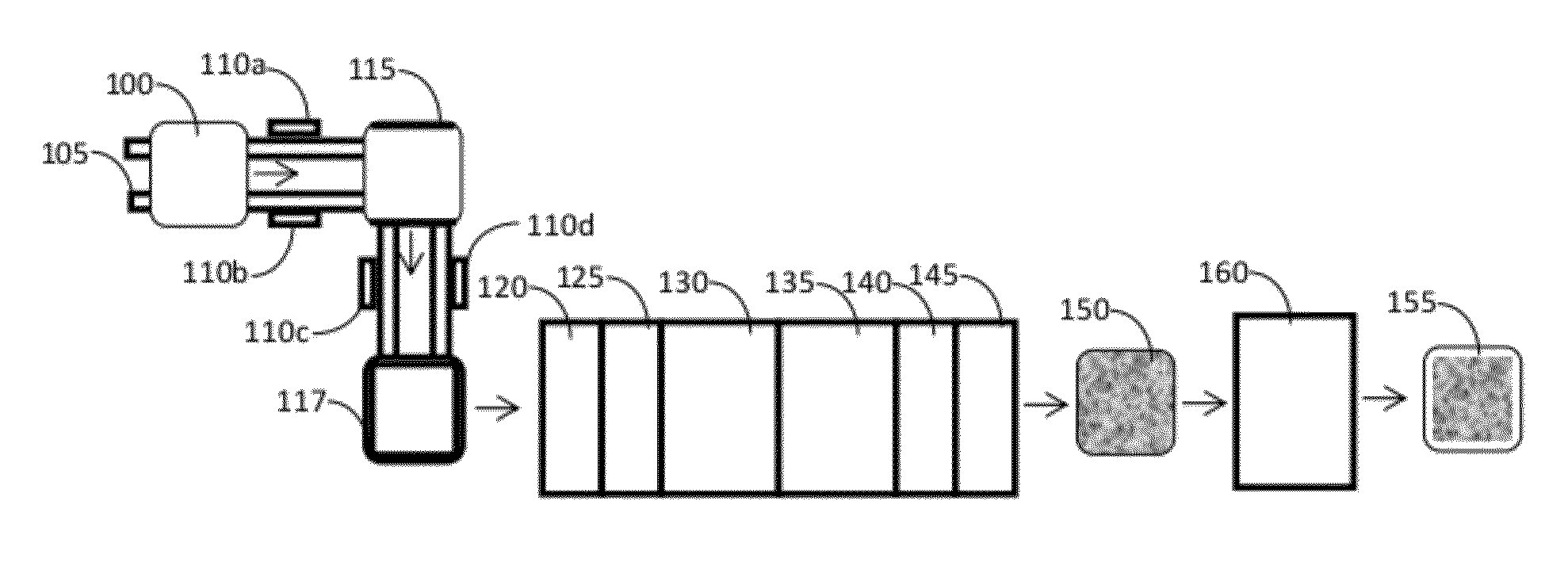

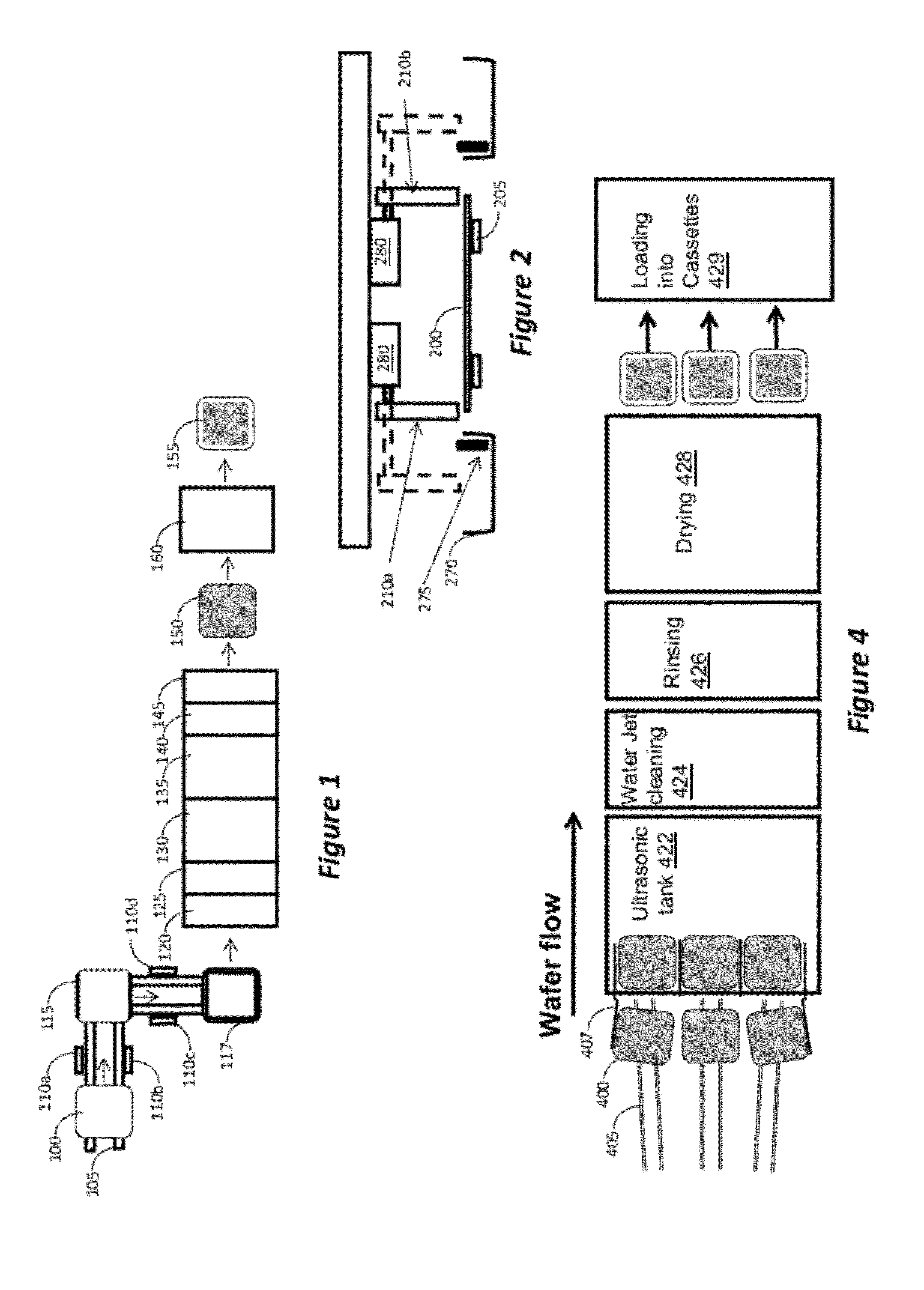

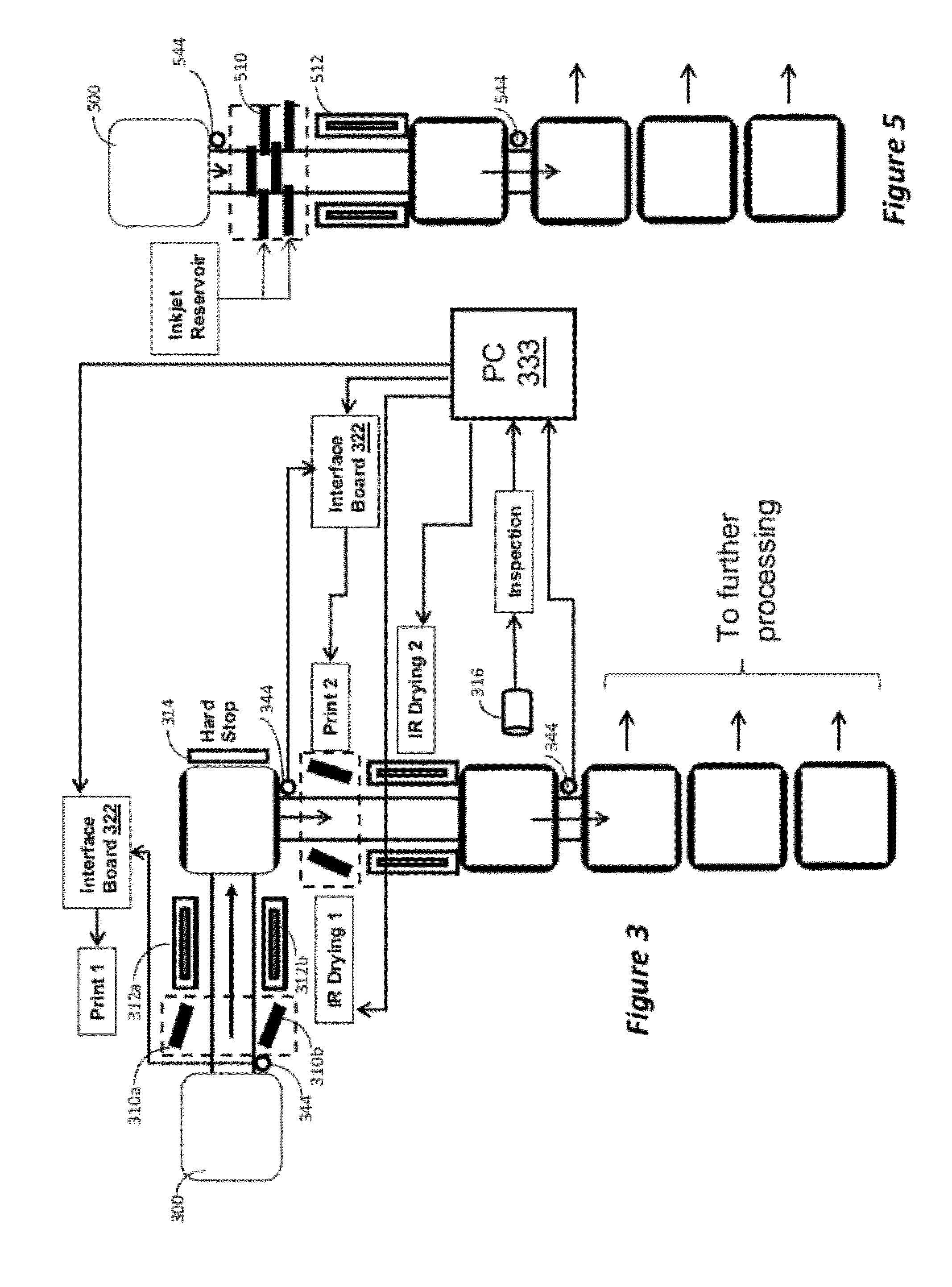

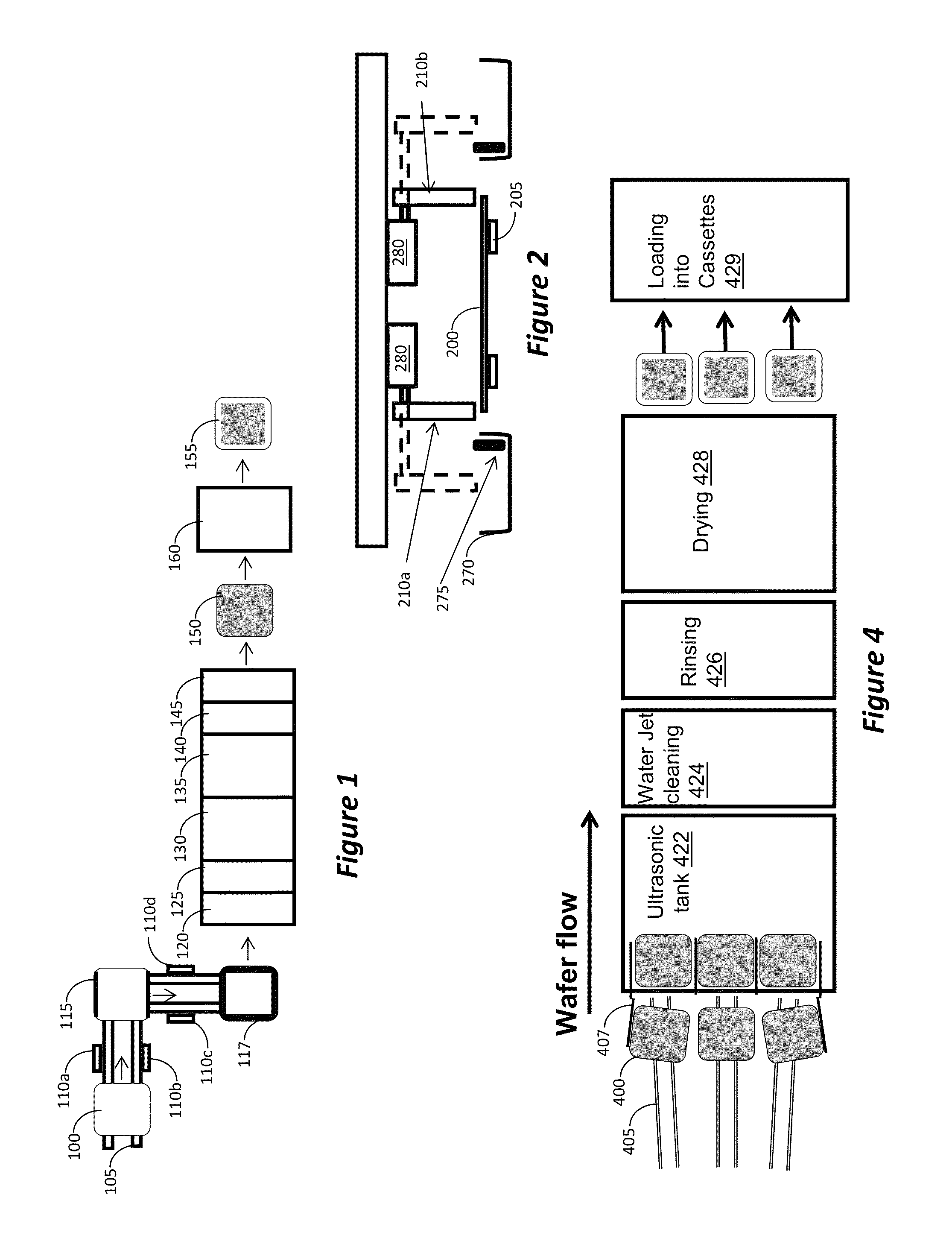

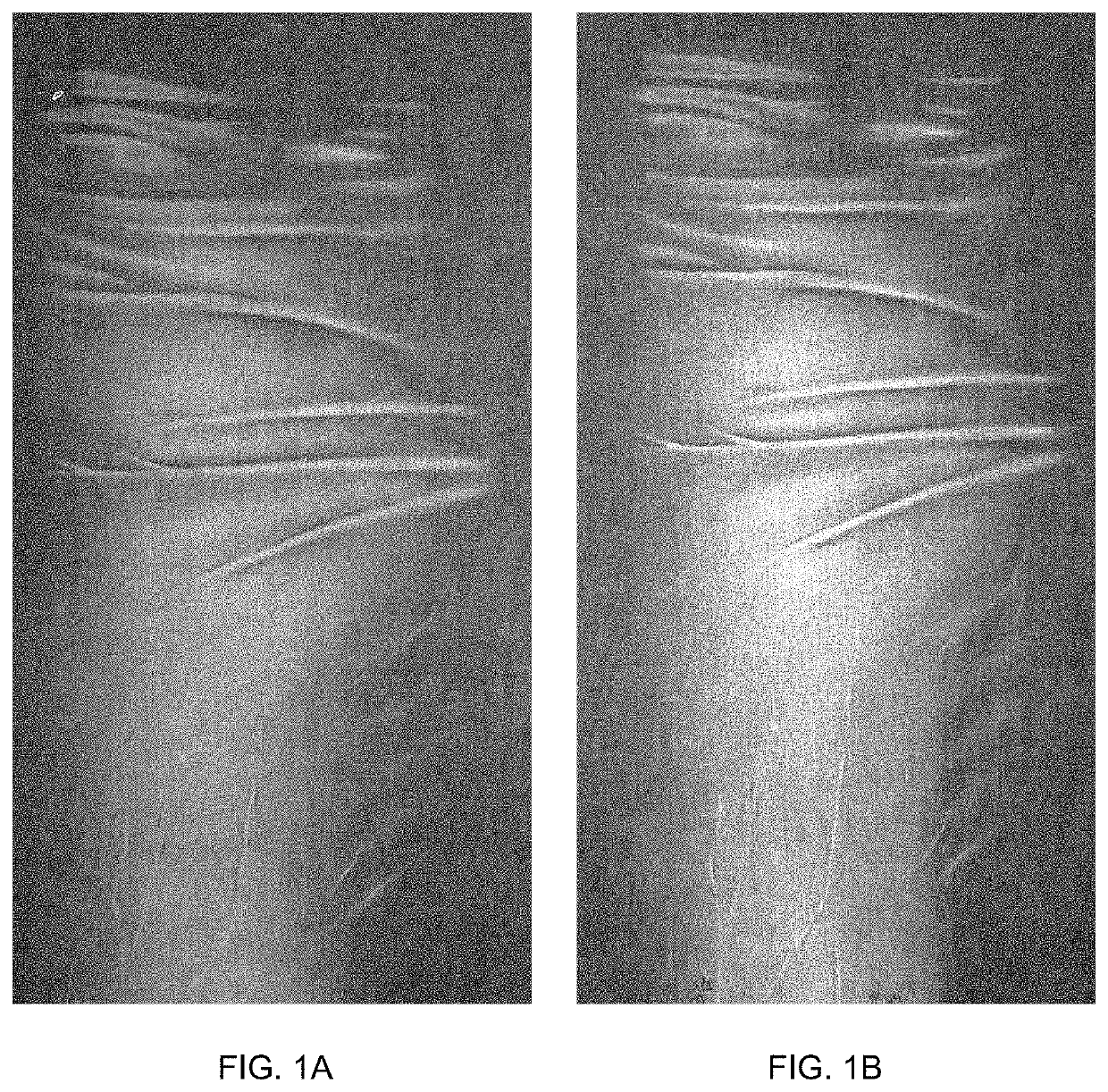

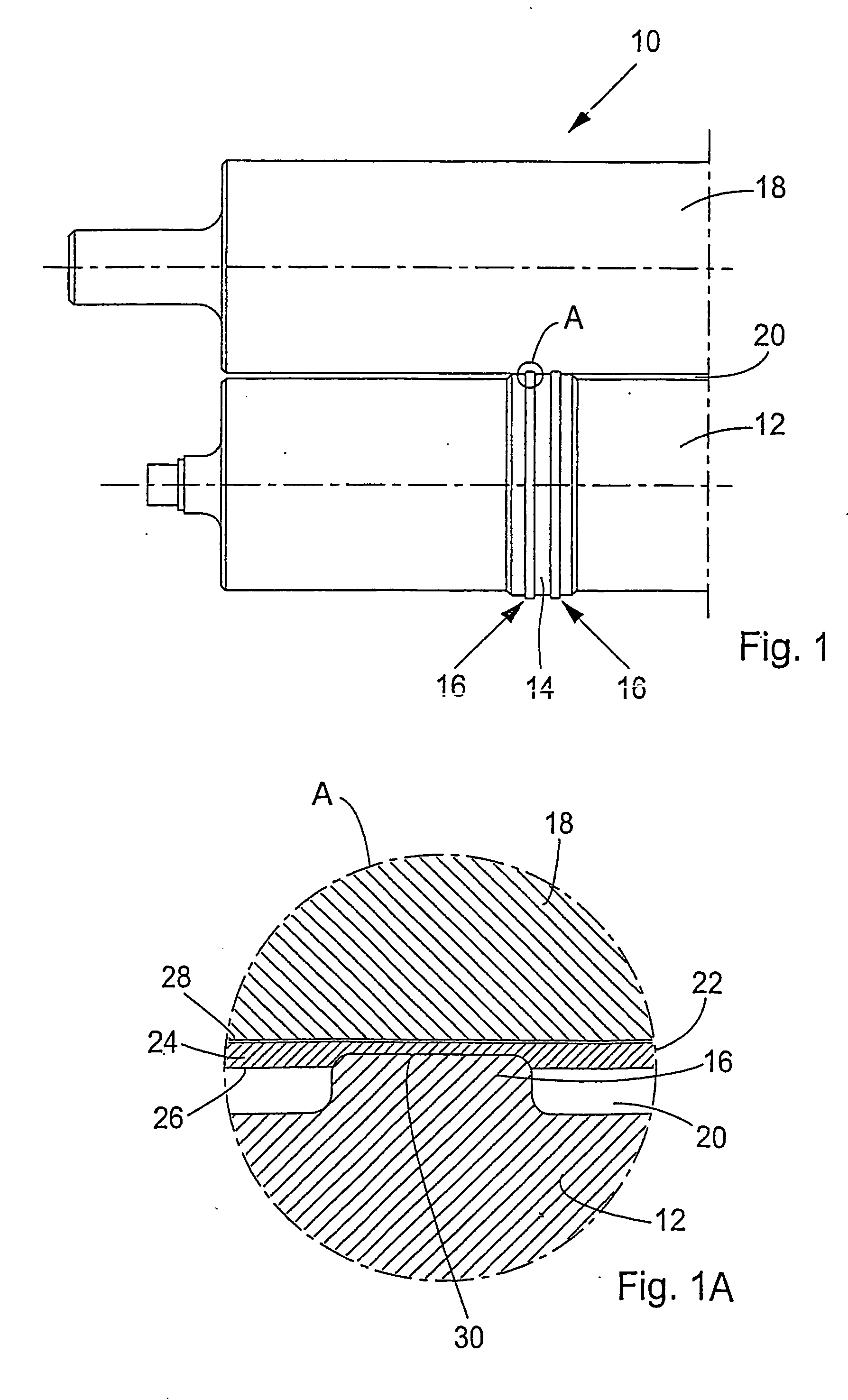

Method and apparatus for masking substrates for deposition

InactiveUS20120171807A1Short curing timeHigh equipment throughputLiquid surface applicatorsFinal product manufactureLaser burnEngineering

Disclosed are methods and apparatus for masking of substrates for deposition, and subsequent lifting of the mask with deposited material. Masking materials are utilized that can be used in high temperatures and vacuum environment. The masking material has minimal outgassing once inside a vacuum chamber and withstand the temperatures during deposition process. The mask is inkjeted over the wafers and, after deposition, removed using agitation, such as ultrasonic agitation, or using laser burn off.

Owner:INTEVAC

Laser paint-removing system and method

InactiveCN102059457AAccurate removalEasy to operateLaser beam welding apparatusLaser burnEngineering

The invention provides a laser paint-removing system and method. The system comprises a control device, a laser marking machine, a detecting device and a cleaning device, wherein the control device is internally provided with laser marking software which sets the shape of paint to be removed and the position of removing the paint; the laser marking machine is connected with the control device and used for carrying out laser burning according to the set of the laser marking software; the detecting device is connected with the laser marking machine and is clung to the stream line and used for detecting the motion position of a product to be subjected to paint removal and controlling the laser marking machine to send laser; and the cleaning device is positioned at the downstream station of the laser marking machine and used for cleaning the incompletely dropping paint part. The laser paint-removing method comprises the steps of: 1, determining the shape of the paint to be removed and the position of removing the paint; 2, regulating the laser swinging speed; 3, detecting the position of a product; and 4, cleaning the paint removing surface. The invention has the advantages of achieving the paint-removing function by adopting a non-contact laser burning manner without damaging the internal material of the product, and being simple in operation.

Owner:HANS LASER TECH IND GRP CO LTD

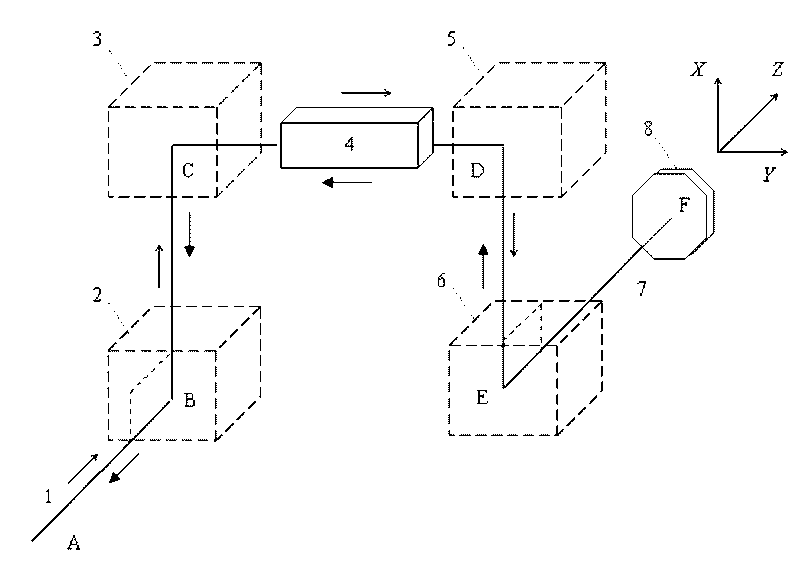

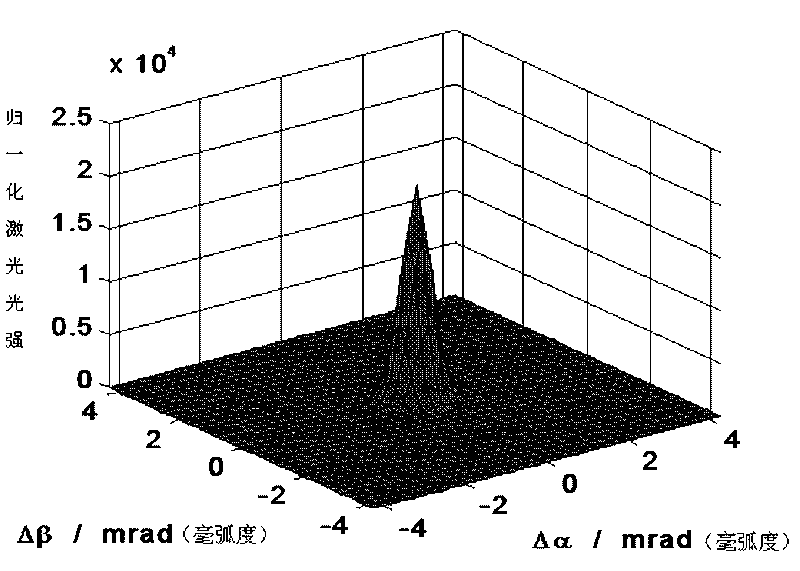

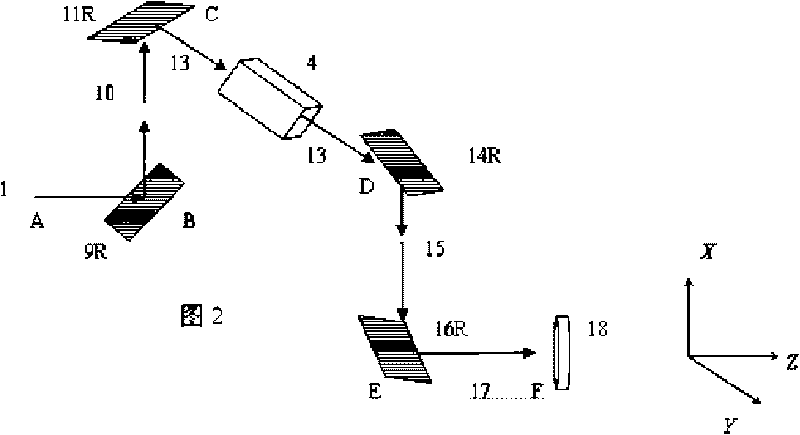

High-power laser diffraction type spatial filter

InactiveCN101738739AImproved angular spectral selectivityIncreased bandwidthOptical elementsLaser burnGrating

The invention discloses a high-power laser diffraction type spatial filter. The left side of the high-power laser diffraction type spatial filter is provided with an interstage isolation filter of which the central axis is a vertical line BC, the middle of the high-power laser diffraction type spatial filter is provided with a group of gain medium of which the central axis is a transverse line CD, the right side of the high-power laser diffraction type spatial filter is provided with a multi-pass cavity filter of which the central axis is a vertical line DE, the central axis of the entire device forms a BCDEF broken line, one optical grating which enables light beams to be deflected at 90 degrees is respectively arranged at a point B, a point C, a point D and a point E, the optical gratings are separate type volume Bragg optical gratings or double-piece integrated type optical gratings, and one reflecting mirror is arranged at a point F. The invention uses an optical grating double-pass spatial filter component which does not have a lens and a pinhole and has compact appearance to replace a pinhole filter in a multi-pass amplifier, can realize the wider width of a diffraction frequency band and can meet the requirement of short-pulse and ultrashort-pulse spatial filtering; the borne laser power is higher, and the requirement of high-power laser spatial filtering can be met, thereby eliminating the probability that laser burns out the filter component because of no lens and no pinhole in the device.

Owner:谭吉春

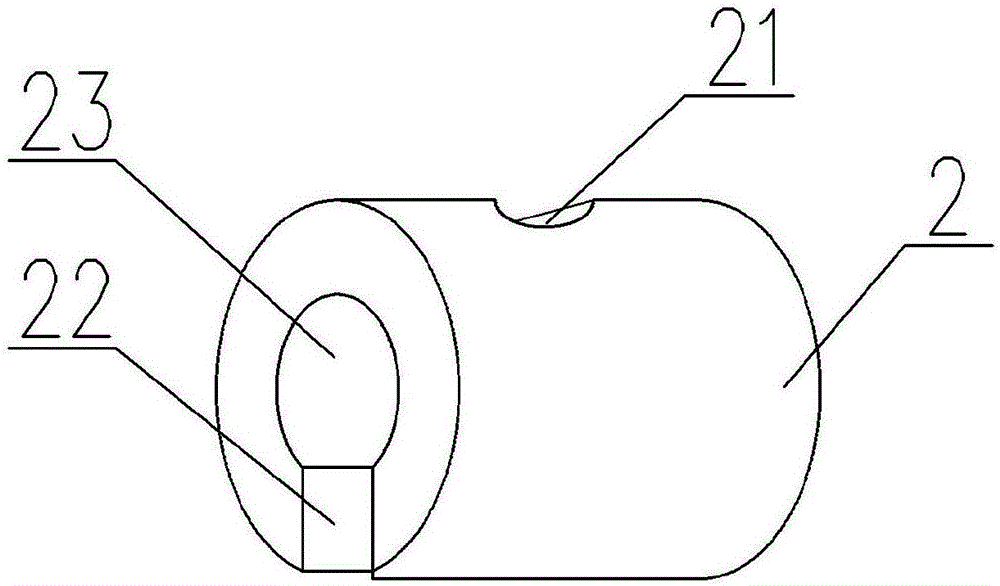

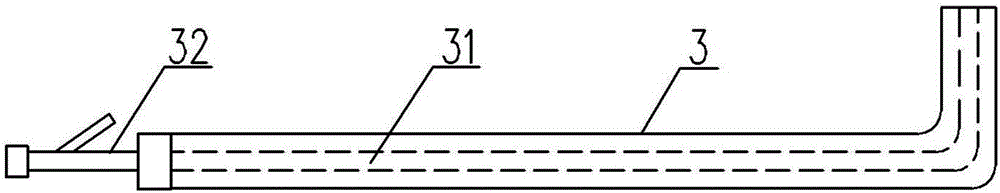

Wafer cutting device

InactiveCN104526892ASmall heat affected zoneIncrease cutting rateFine working devicesBeam expanderLaser burn

The invention discloses a wafer cutting device. The wafer cutting device comprises a laser, a beam expander, a reflector, a focus system, a water guide system and a worktable, wherein a wafer to be cut is arranged on the worktable, laser light generated by the laser sequentially passes through the beam expander and the reflector and enters the focus system, and focused laser emitted by the focus system is changed into a laser water pillar through the water guide system and emitted onto the worktable for wafer cutting. The focus system is a double-focus system, a front focus and a rear focus are generated on the surface and inside the wafer, the cutting speed is improved, the focused light beam is emitted from a spraying nozzle along with deionized water through the water guide system, the focused laser burns only within the diameter of the water pillar and cuts the wafer, the heat influence is small, the machining quality is improved, and the cutting speed is high.

Owner:SUZHOU KAIDE MICRO ELECTRONICS CO LTD

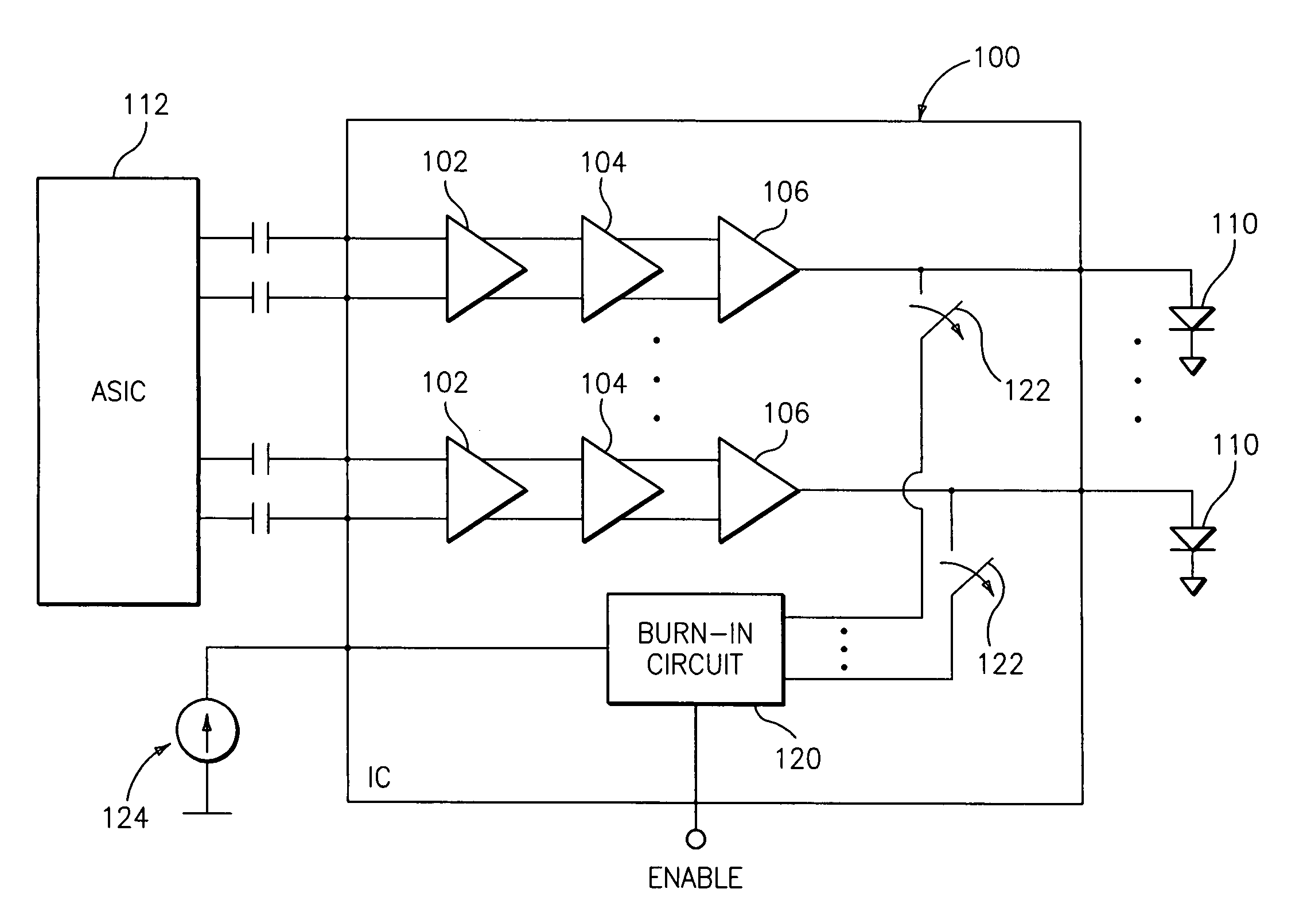

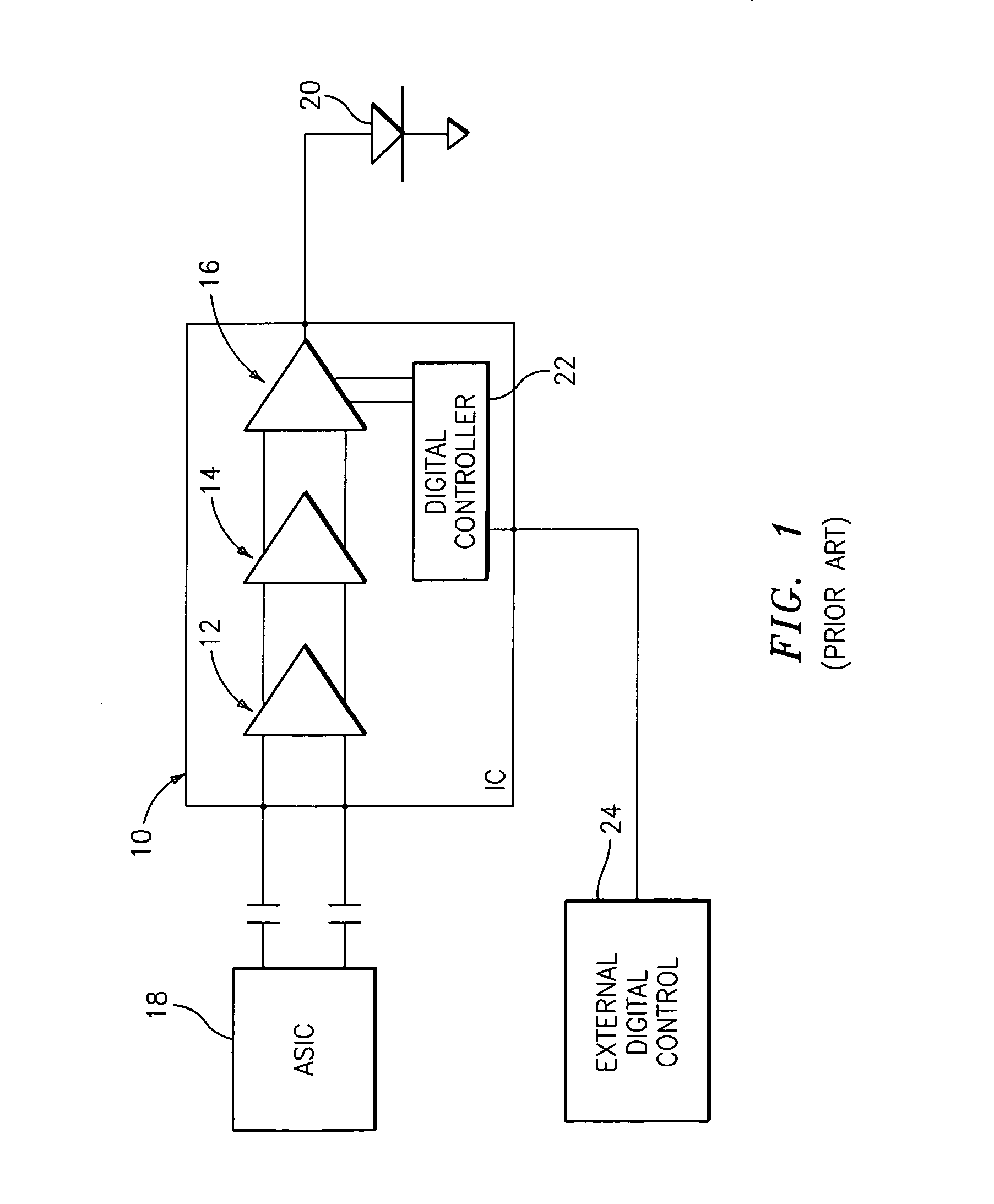

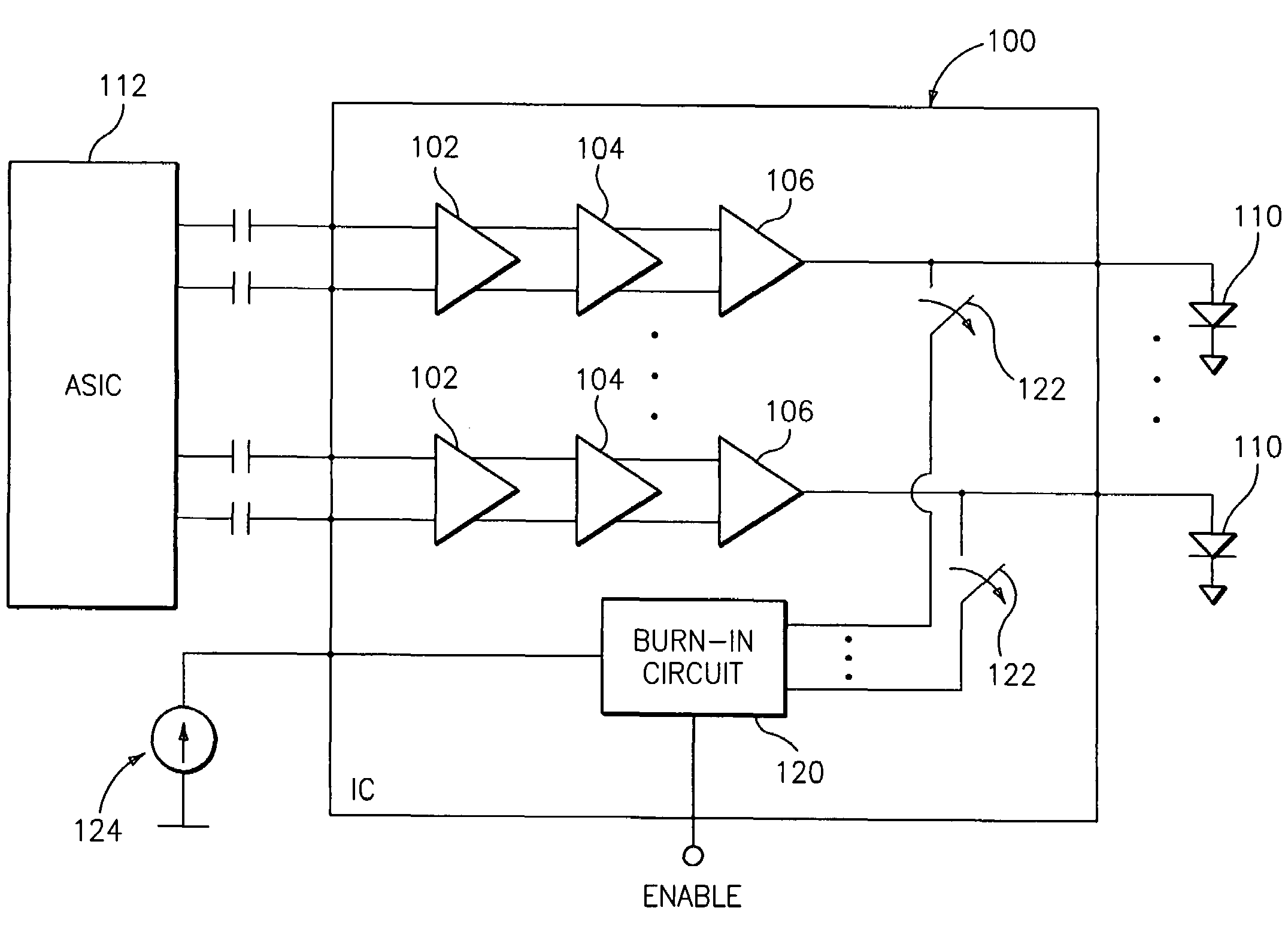

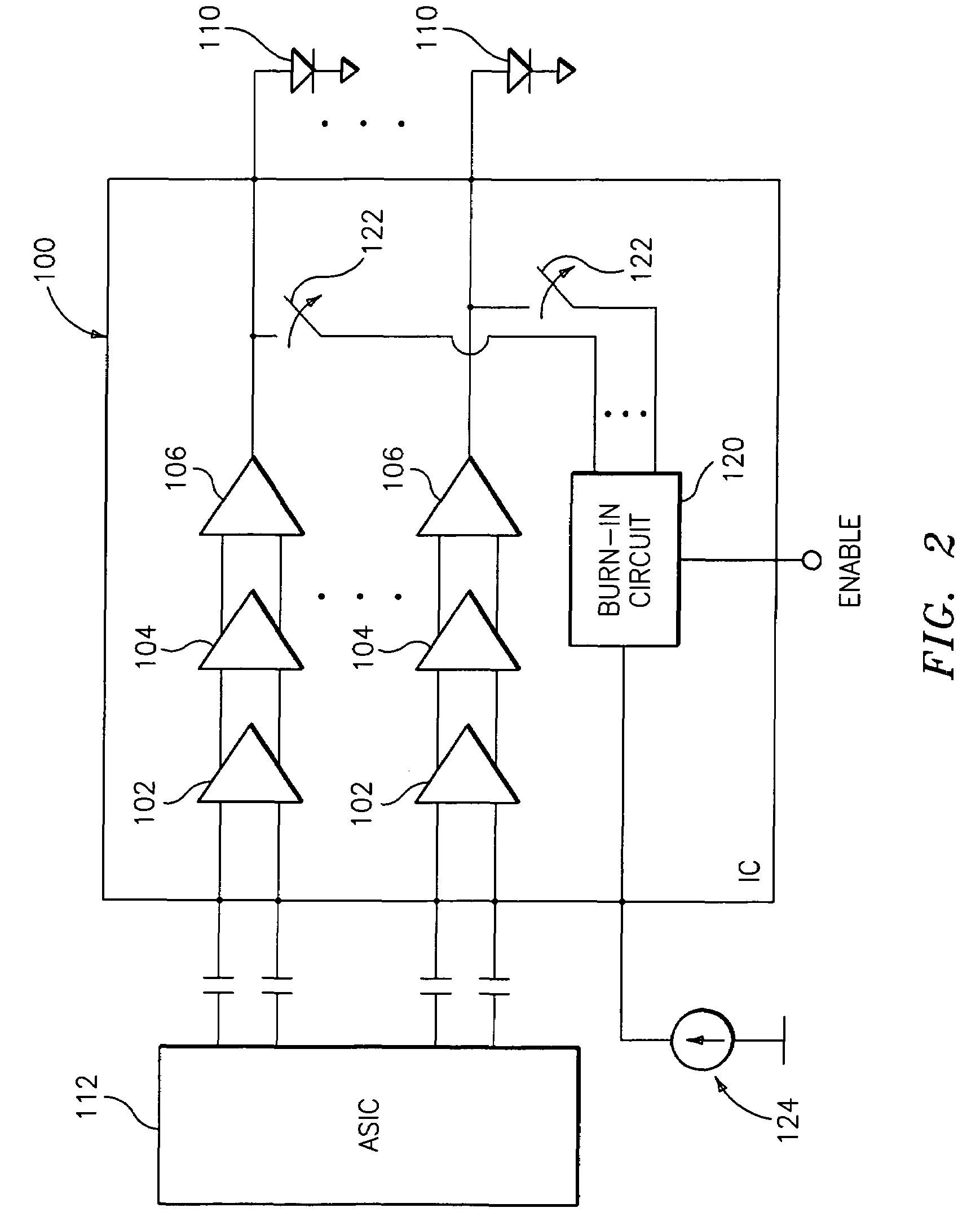

Integrated circuit having on-chip laser burn-in circuit

An integrated circuit for providing burn-in current to a laser diode. The integrated circuit includes a laser driver having an output for connection to the laser diode. Burn-in circuitry is formed on the integrated circuit and generates a burn-in current. A switch is formed on the integrated circuit and couples the burn-in current to the laser diode in response to an enable signal.

Owner:BROADCOM INT PTE LTD

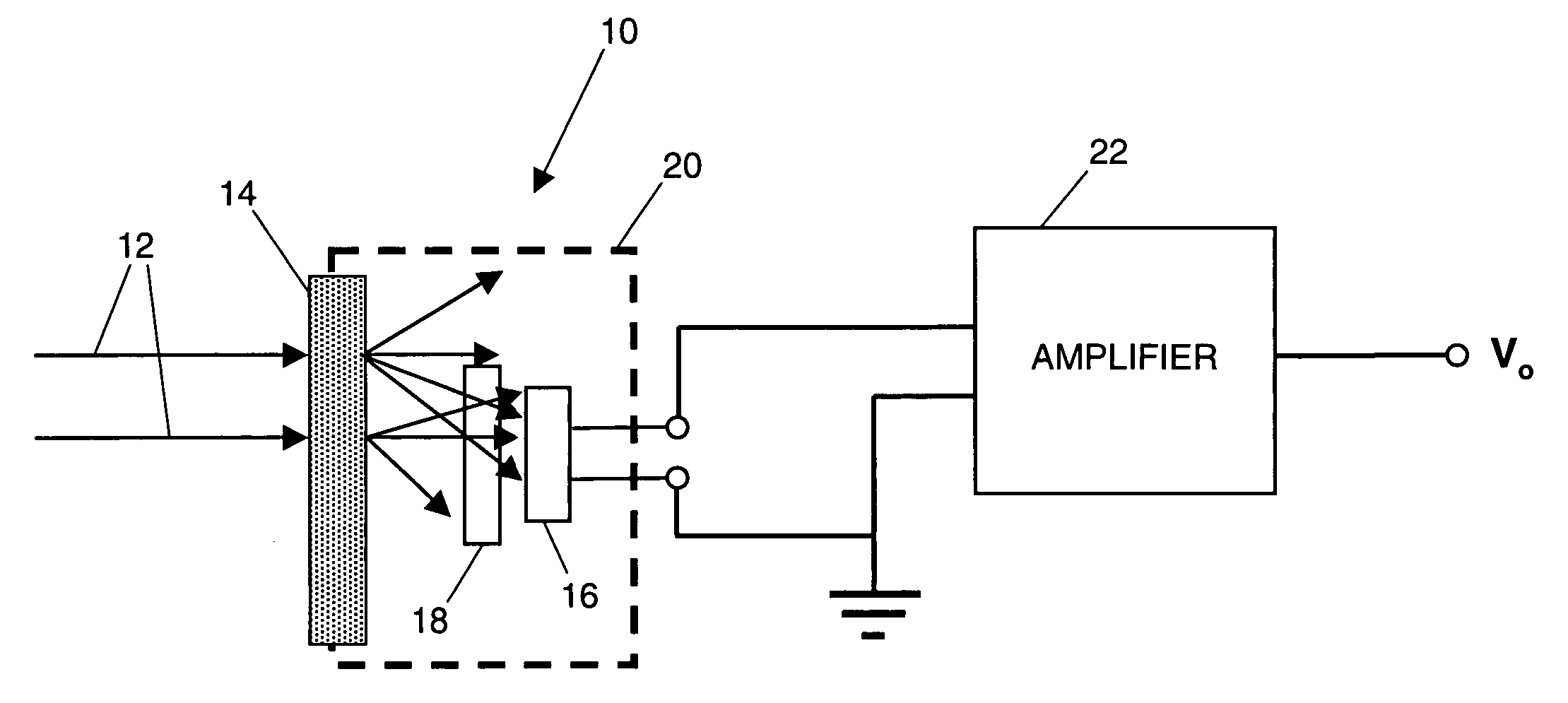

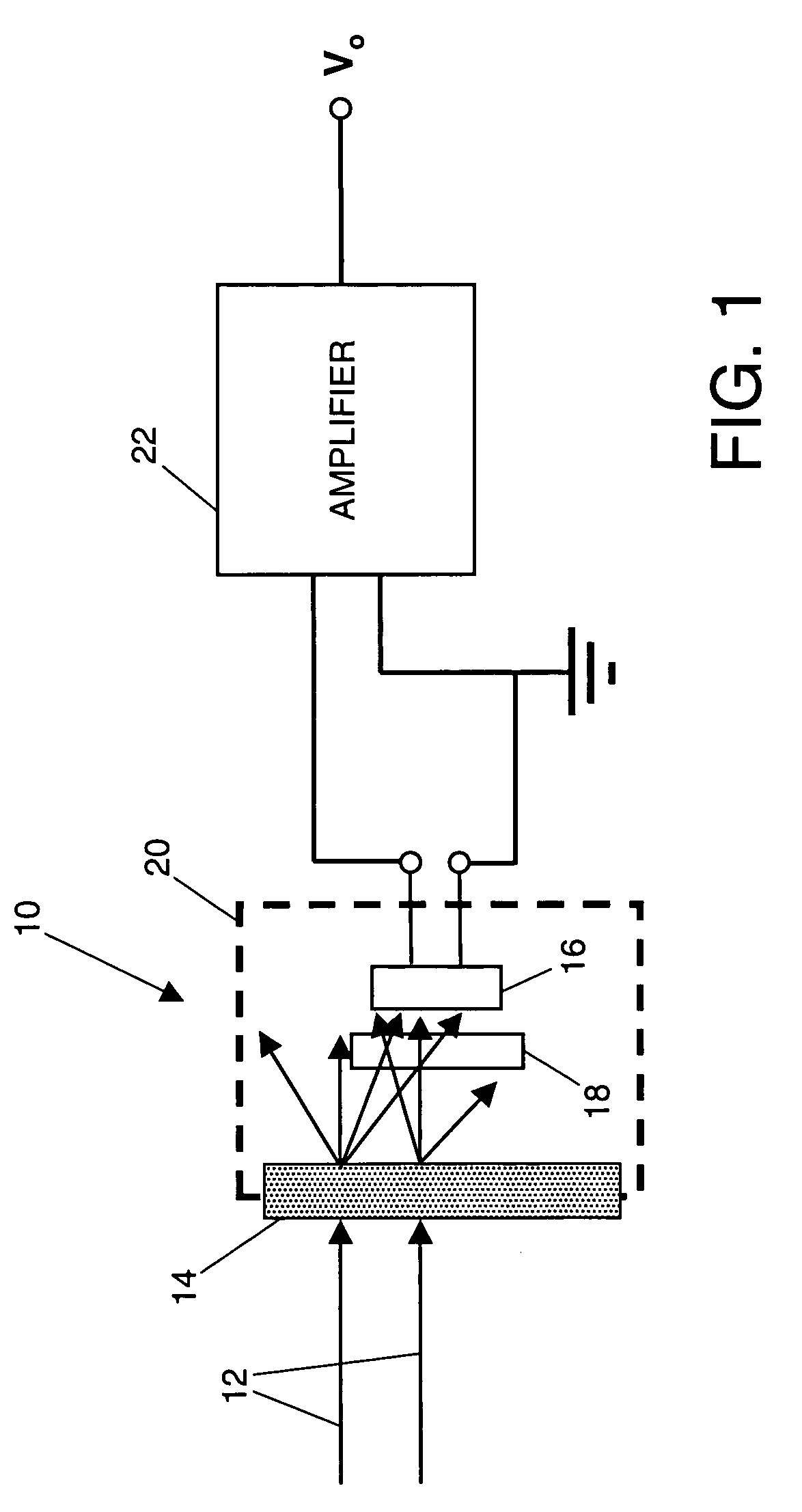

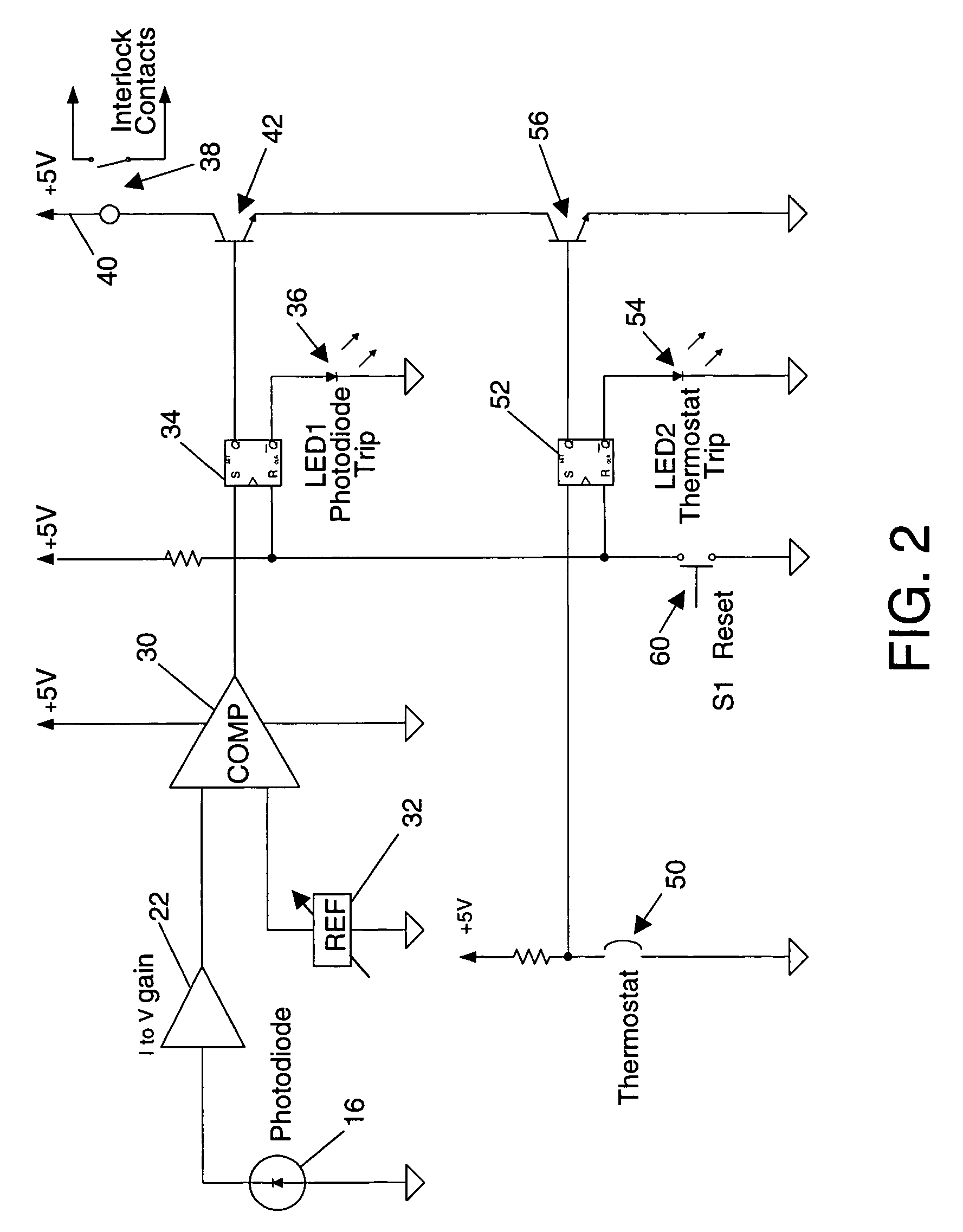

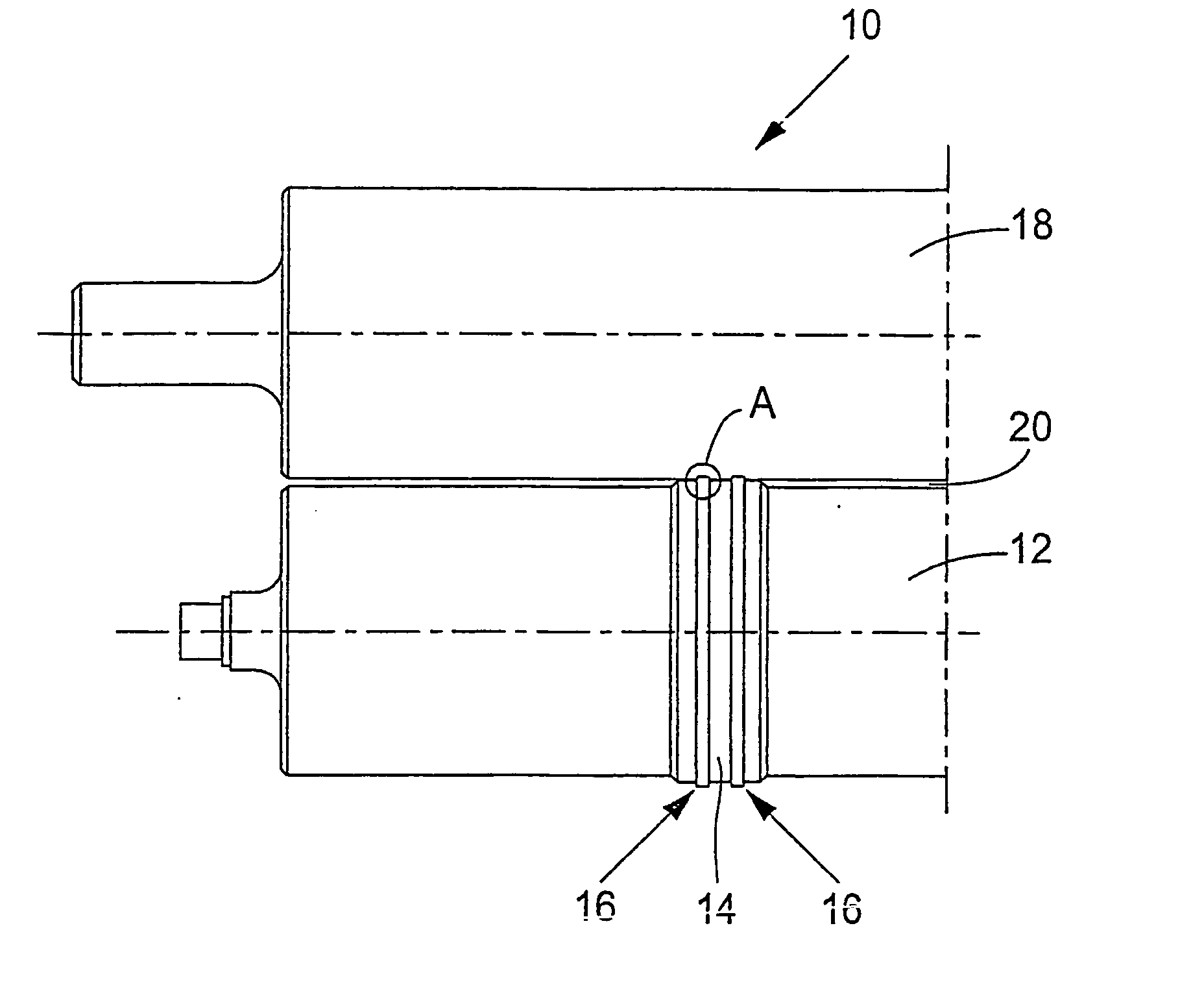

Laser burn through sensor

An optical sensor for detecting the presence of laser radiation in locations outside an intended optical path in a high energy laser device. An optical sensor, such as a photodiode, is positioned to receive light through an optical component when it fails to operate properly and laser light burns through the component. The optical sensor preferably includes a diffuser, an optical filter, and electrical circuitry to compare the signal generated by the photodiode with a selected reference signal, and to use the photodiode signal to actuate an alarm indicator and to disable power to the laser source. A thermal detector may be employed as a backup detection device.

Owner:NORTHROP GRUMMAN CORP

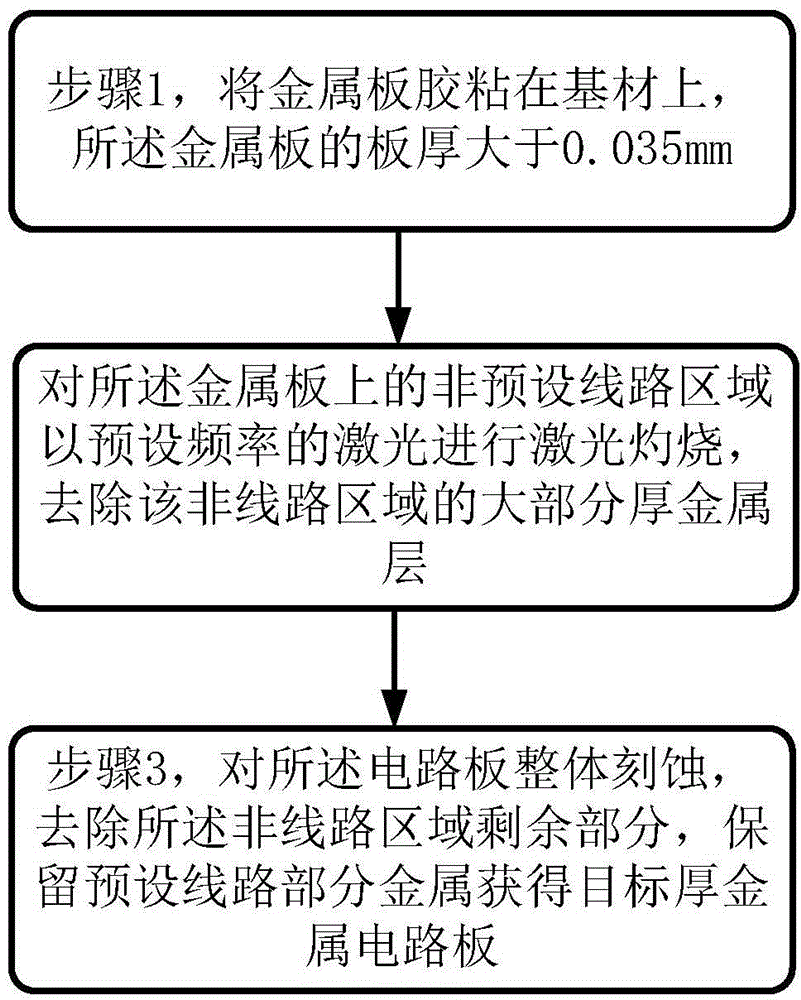

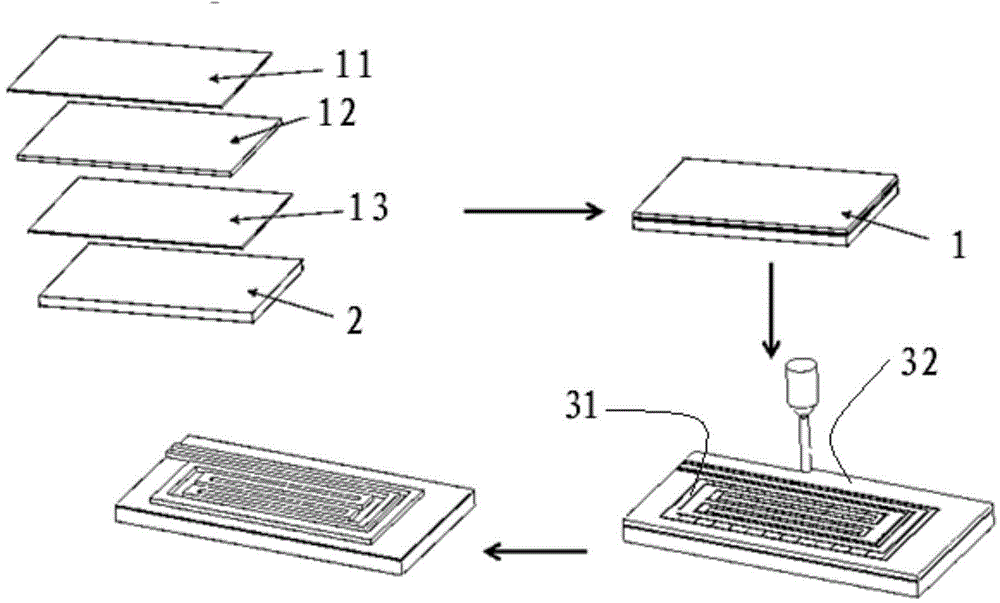

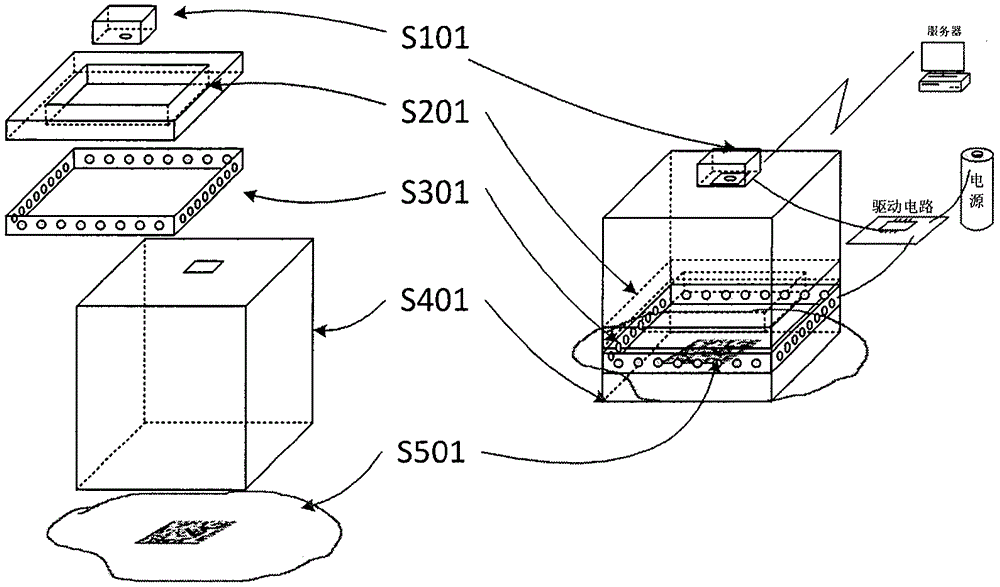

Thick metal circuit board in NFC or wireless charging technology and manufacturing method thereof

ActiveCN104837300AEasy to controlSimple stepsConductive material chemical/electrolytical removalCircuit precursor manufactureLaser burnMaterials science

The invention provides a manufacturing method of a thick metal circuit board in an NFC or wireless charging technology, which is characterized by comprising the steps 1, adhering a metal plate to a base material, wherein the thickness of the metal plate is greater than 0.035mm; 2, carrying out laser burning on a non-preset circuit region on the metal plate by laser with preset frequency, and removing most of a thick metal layer on the non-circuit region; and 3, carrying out etching on the whole circuit board, removing residue of the non-circuit region, and retaining a preset circuit portion so as to acquire the target thick metal circuit board. Application of the method provided by the invention can enable manufacturing of an NFC or wireless charging antenna to be not restricted in base material selection, and can also realize accurate control for an interval of adjacent wires through controlling a laser burning region. The thick metal circuit board in the NFC or wireless charging technology and the manufacturing method thereof are simple in step and high in practicability.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

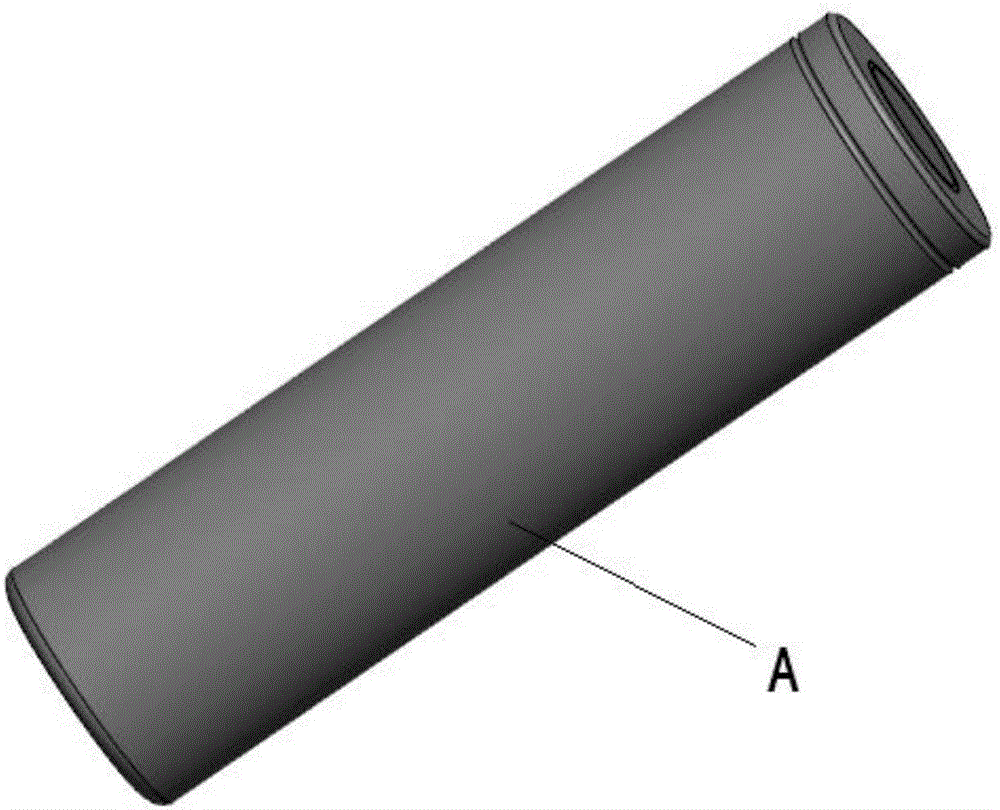

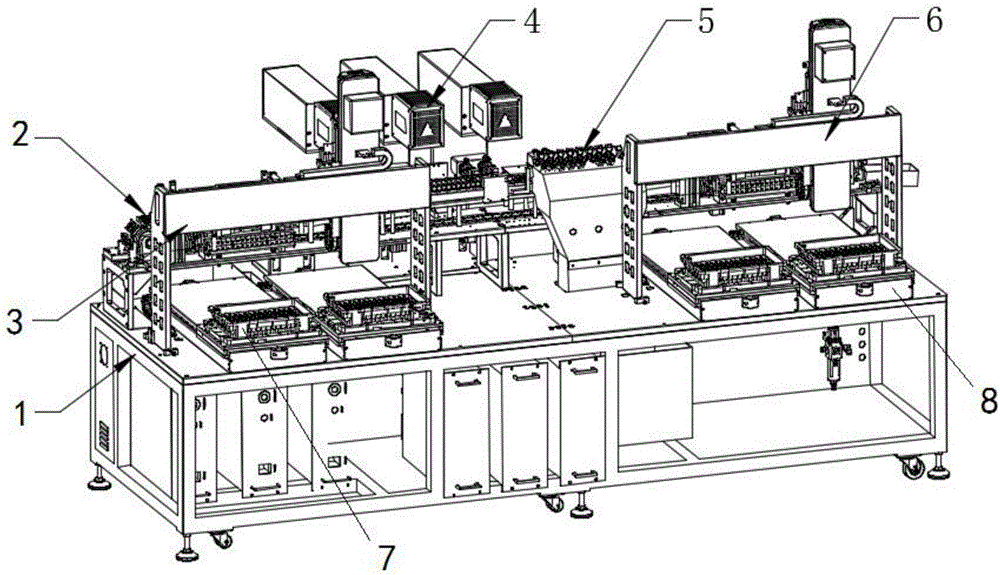

Heat shrink tube burning mechanism and full-automatic ring cutting machine with same

InactiveCN106374133AImprove circumcision removal efficiencyWon't hurtPrimary cell manufactureAssembling battery machinesLaser burnEngineering

The invention discloses a heat shrink tube burning mechanism and a full-automatic ring cutting machine with the same to improve the ring cutting efficiency of a battery heat shrink sleeve. The heat shrink tube burning mechanism comprises a battery clamping component, a rotatable driving component, a lifting driving component and a laser burning and cutting component, the battery clamping component is mounted on a frame and can clamp and release a battery; the rotatable driving component is connected with the battery clamping component and drives the battery clamping component to rotate around a central axis of the battery clamped by the battery clamping component; the lifting driving component is connected with the battery clamping component and drives the battery clamping component to rise and fall; and the laser burning and cutting component is arranged near the battery clamping component and fixed relative to the frame.

Owner:苏州灵米自动化设备科技有限公司

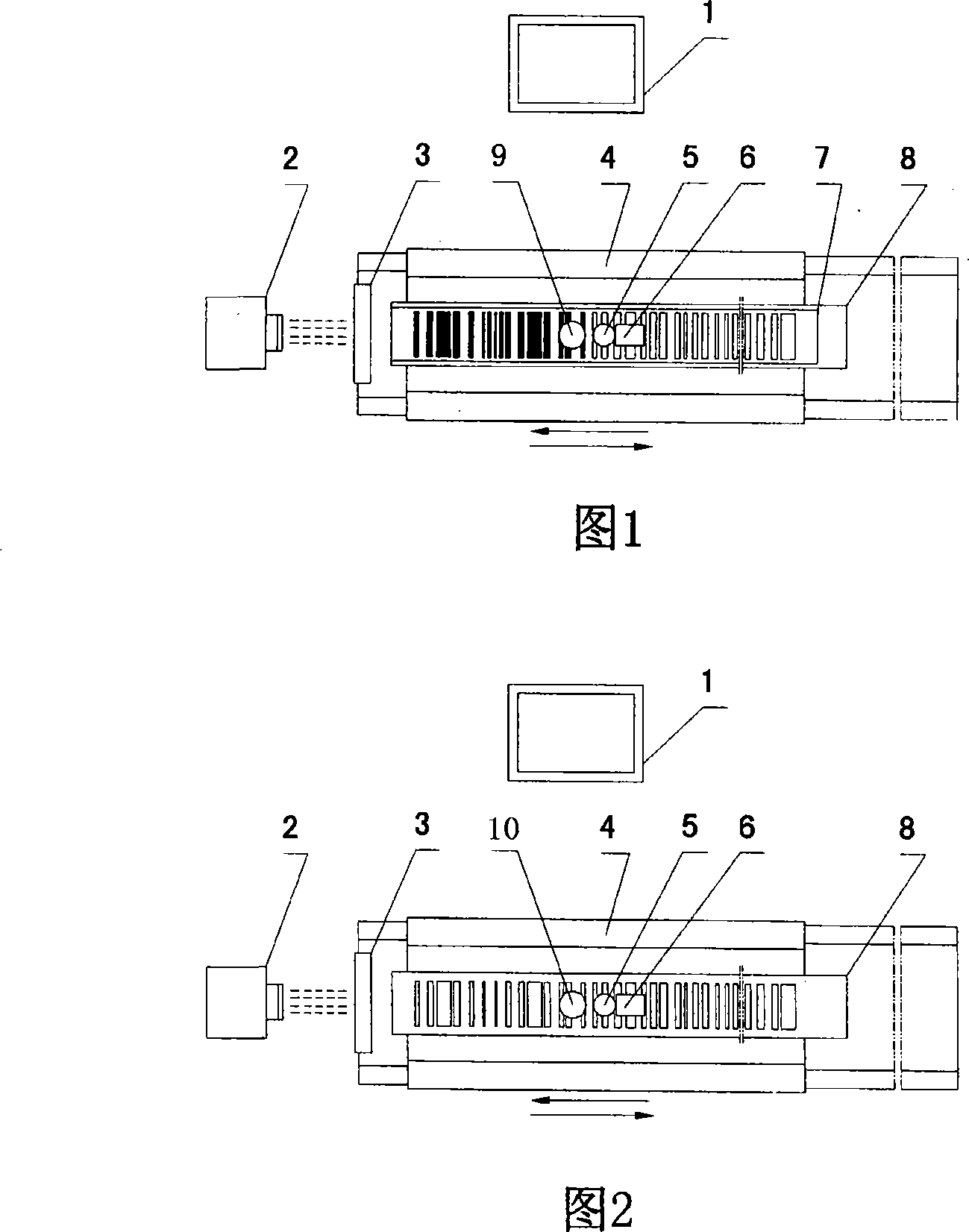

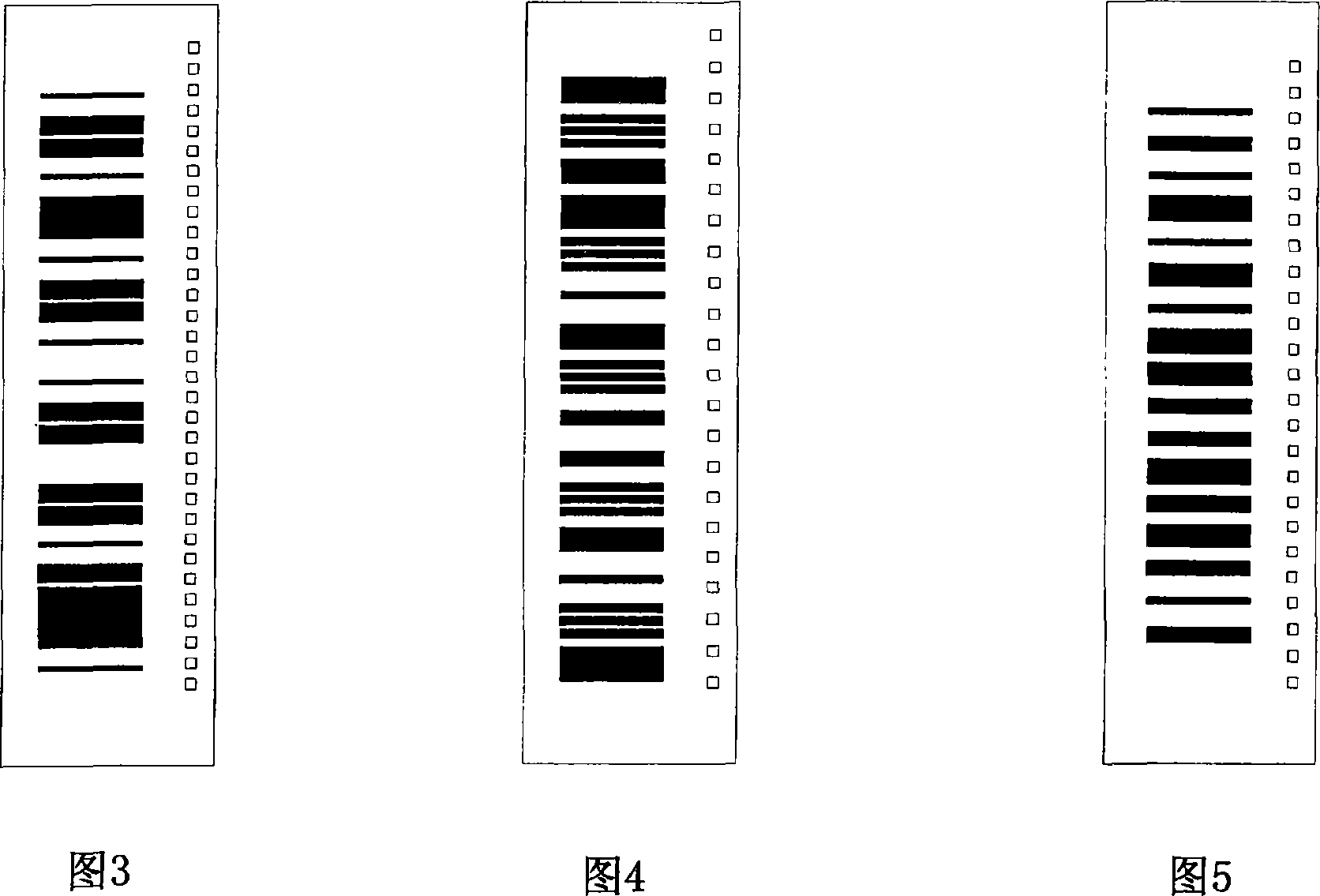

Bar code scaleplate production process

InactiveCN101122458AHigh precisionHigh degree of automationHeight/levelling measurementNumerical controlNumerical controlLaser burn

A bar code scale production technique is characterized in that a template spray process, a laser burning process, a screen-printing process and an etching are adopted to make bar codes on a scale panel to be processed. The main process steps of the screen-printing process are that designed bar code graphs, sizes, precision standards and making process program instructions are stored in a computer. And the computer is connected with a signals collecting and actuating mechanism. A template is compounded on the scale panel to be processed and is fixed to a numerical control machine motion system. The bar code making process instruction in the computer is operated. An automatic spray system sprays bar code painting materials on the template to finish the spray task of the scale bar code. The bar code scale produced by the method of the invention has a high precision and solves a hard problem of requiring for the bar code scale during the upgrade from a traditional level to an electronic level.

Owner:戴进武 +1

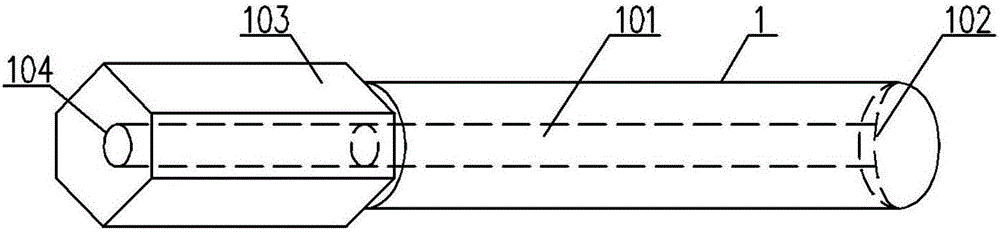

Positioning device for in-situ windowing of endovascular stent-graft

ActiveCN106333766ASimplify window opening stepsLower requirementStentsBlood vesselsLaser burnPunching

The invention relates to a positioning device for in-situ windowing of an endovascular stent-graft. The positioning device comprises a push piece, a conveying sheath and a guiding wire, wherein a first through hole is formed in the push piece, a first magnetic piece is arranged at the first end of the push piece, and a guiding wire hole communicated with the first through hole is formed in the first magnetic piece; a second through hole is formed in the conveying sheath, a second magnetic piece is arranged at the first end of the conveying sheath, a third through hole communicated with the second through hole is formed in the second magnetic piece, and the first magnetic piece is connected with the second magnetic piece in a magnetic attracting manner; and the guiding wire is used for conveying the first magnetic piece and the second magnetic piece. The positioning device provided by the invention has the benefits as follows: after folding of the magnetic pieces, windowing is achieved through guided laser burning punching or a puncture needle method, the step of windowing is simplified, operating difficulty and risks are lowered, the operation time is saved, equipment customization is avoided, and moreover, the operation cost is lowered.

Owner:董红霖

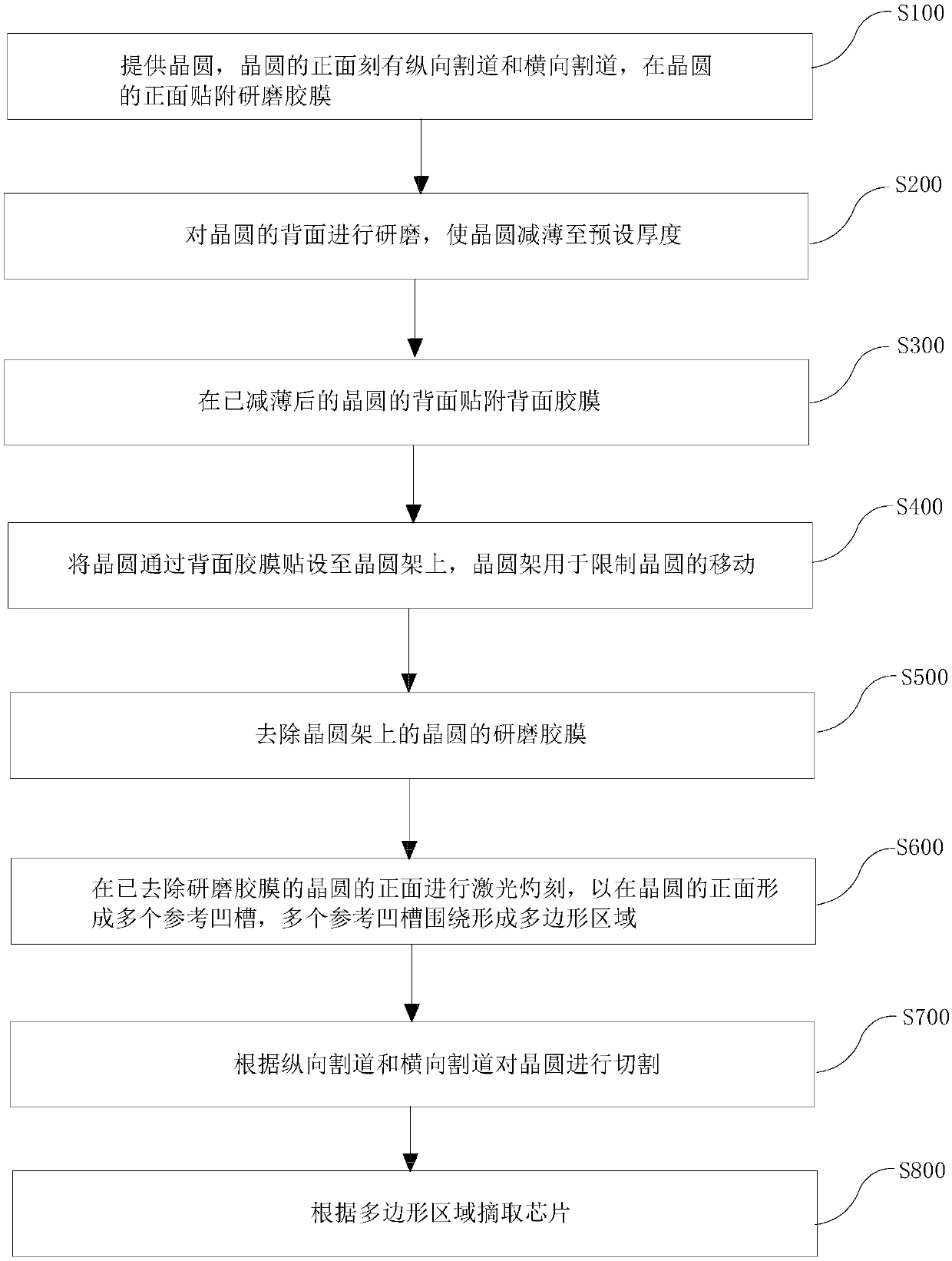

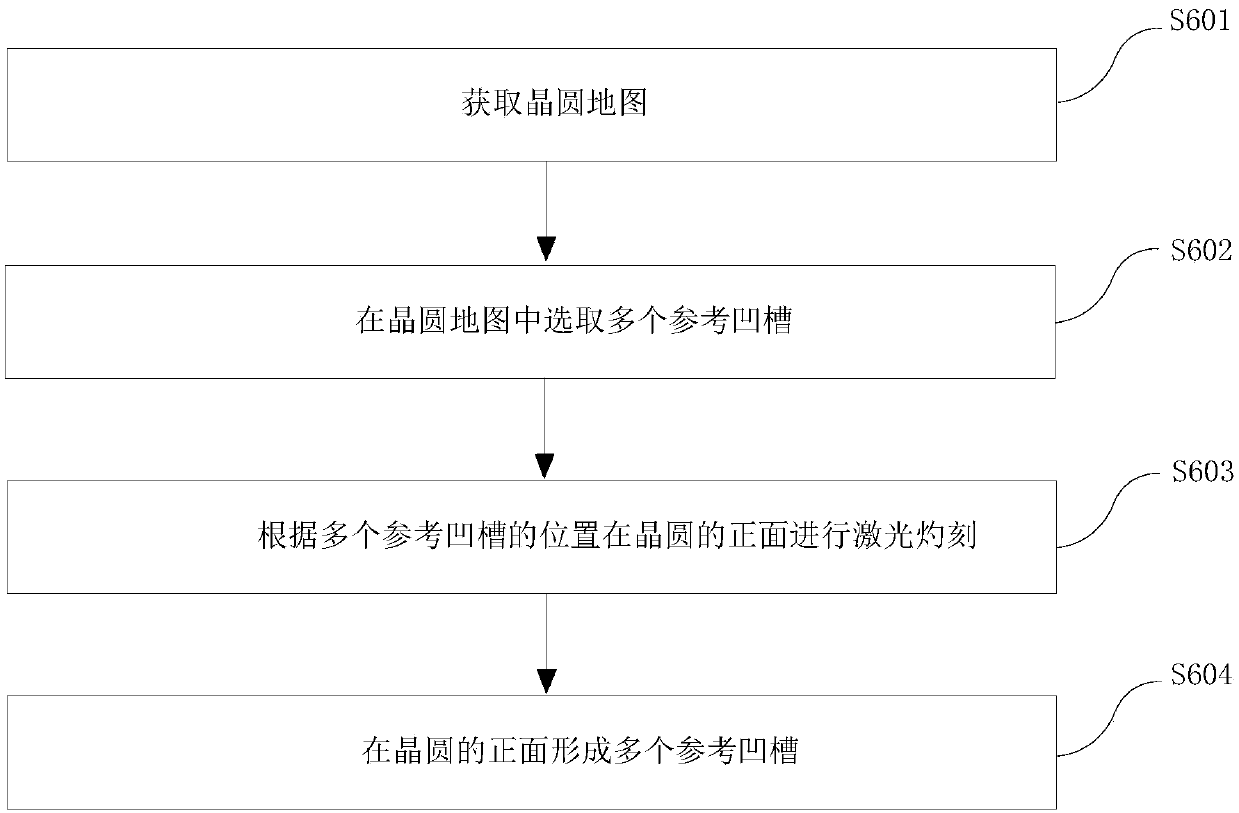

Wafer cutting process

ActiveCN109545678AAvoid dopingAvoid scratchesSemiconductor/solid-state device manufacturingLaser beam welding apparatusLaser burnEngineering

The invention discloses a wafer cutting process, and the process comprises the steps: providing a wafer with a longitudinal cut way and a lateral cut way on the front, attaching a grinding film on thefront surface of the wafer to perform the back surface of the wafer till the wafer is thinned to preset thickness, attaching a back film to the back surface of the thinned wafer, and attaching the wafer to a wafer holder through the back film, wherein the wafer holder is used to limit the movement of the wafer; removing the grinding film of the wafer on the wafer holder, and performing laser burning on the front surface of the wafer from which the grinding film has been removed to form a plurality of reference grooves on the front surface of the wafer, wherein the reference grooves surroundsa polygonal region; cutting the wafer according to the longitudinal and lateral cut ways, and taking down a chip according to the polygonal region. The wafer cutting process disclosed by the inventioncan accurately mark the position of a front reference point, improves the cutting accuracy of the wafer, and avoids the doping of the unqualified chip product into a qualified product.

Owner:CHIPMOS TECHSHANGHAI

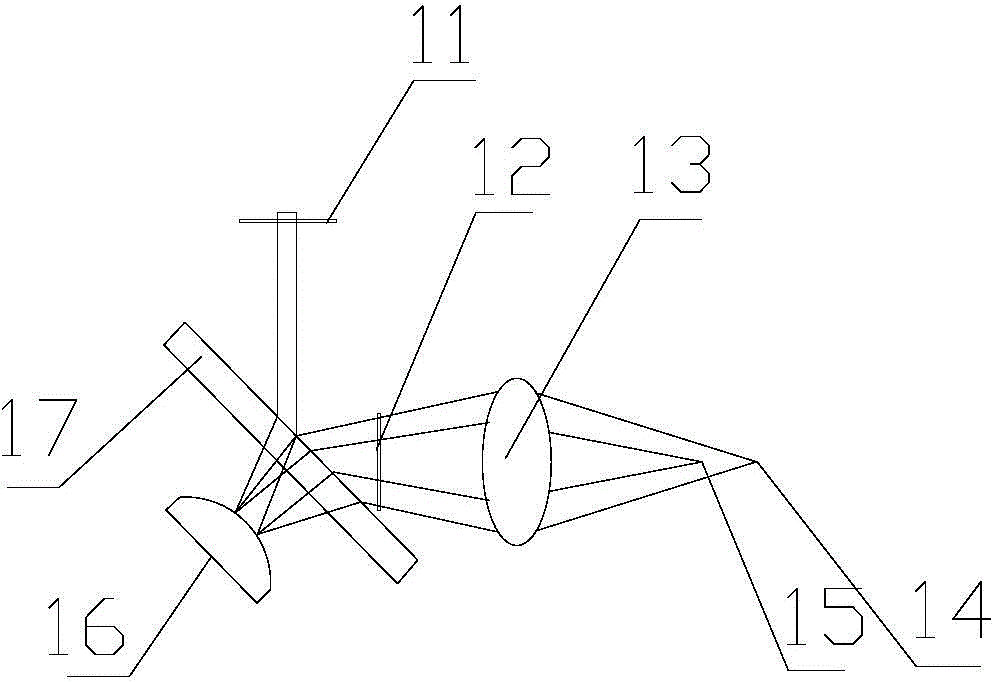

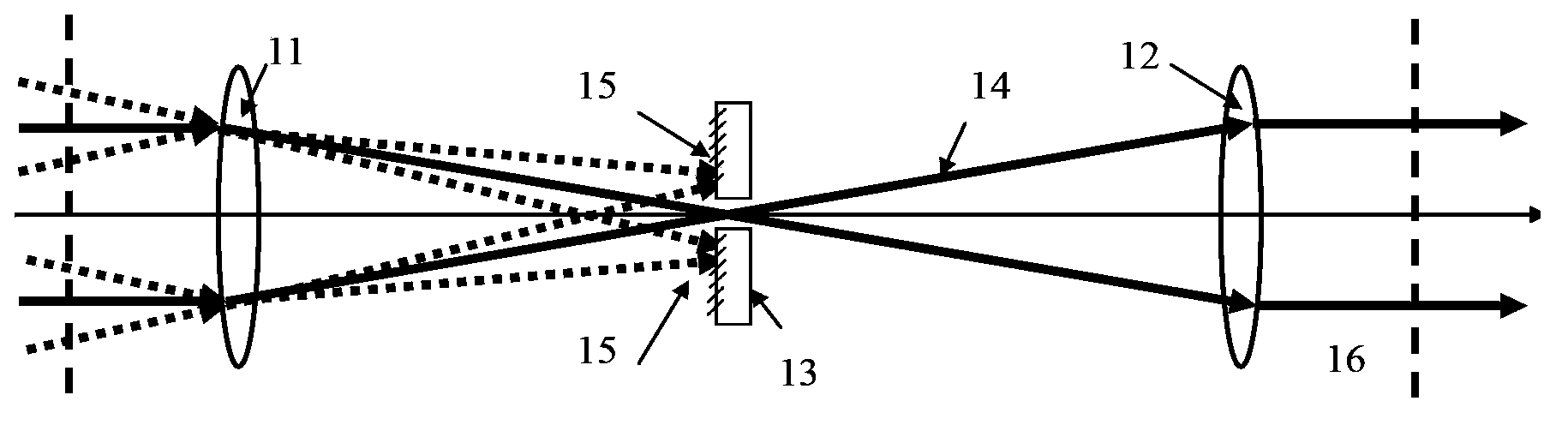

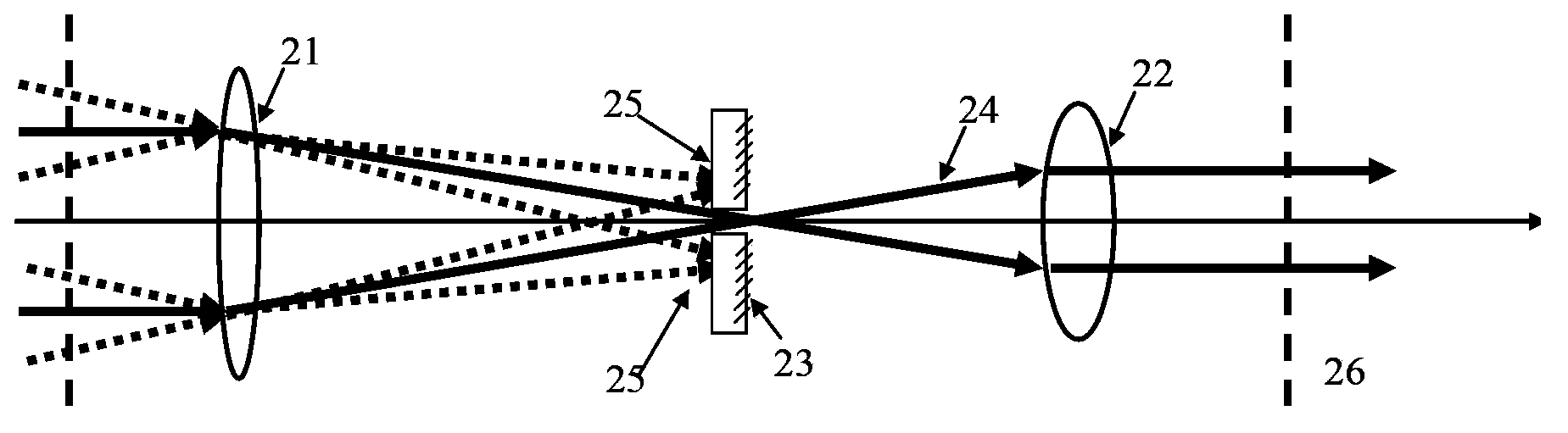

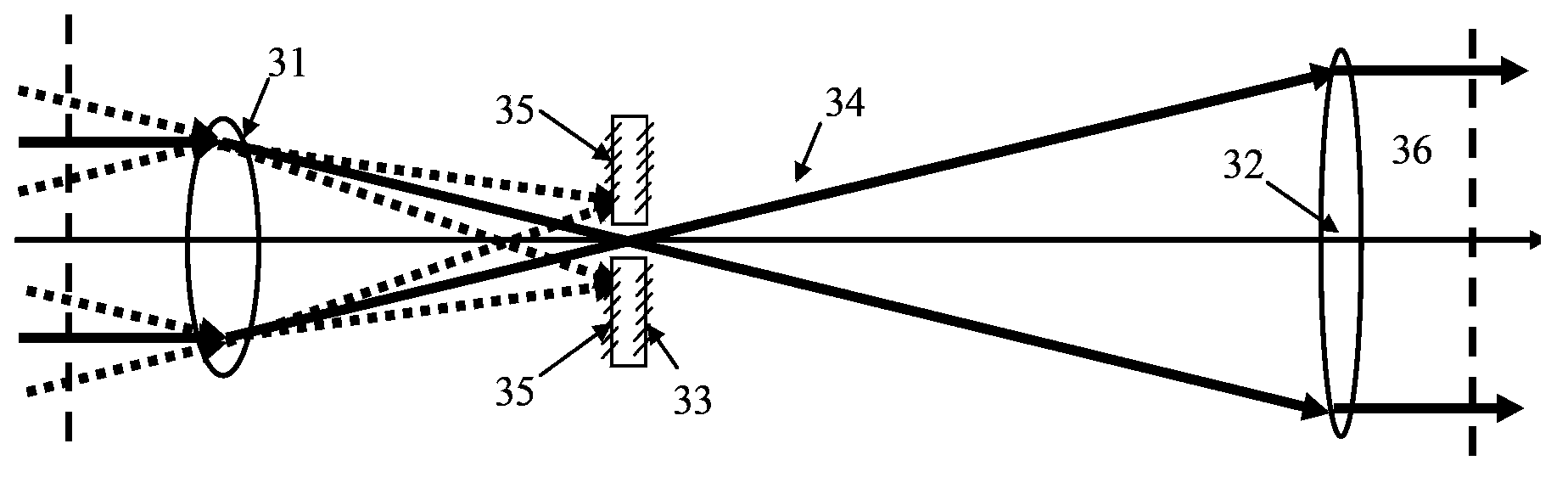

High-power laser image transfer space filtering device

ActiveCN103676187AHigh frequency component energy reductionSimple structureOptical elementsLaser burnHigh power lasers

The invention discloses a high-power laser image transfer space filtering device. The device is characterized in that the device comprises a frequency division lens, a recovery lens and a filtering small hole, wherein the frequency division lens and the recovery lens form a confocal optical system; and the filtering small hole is positioned at the focal point of the confocal optical system between the frequency division lens and the recovery lens. The device can realize image transfer by adjusting focal distances of the frequency division lens and the recovery lens; and the host material of the filtering small hole only absorbs few laser power, so that the filtering small hole is not required to be subjected to water cooling, the structure of the filtering small hole is simplified, the damage threshold is improved, the possibility that laser burns the filtering small hole is basically eliminated, simultaneously by adopting the scattering effect on laser beam of the roughed surface of the filtering small hole, the high-frequency component energy of the laser beam can be rapidly reduced, and the low-frequency component energy is hardly changed, and a low-pass space filtering function is better realized.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

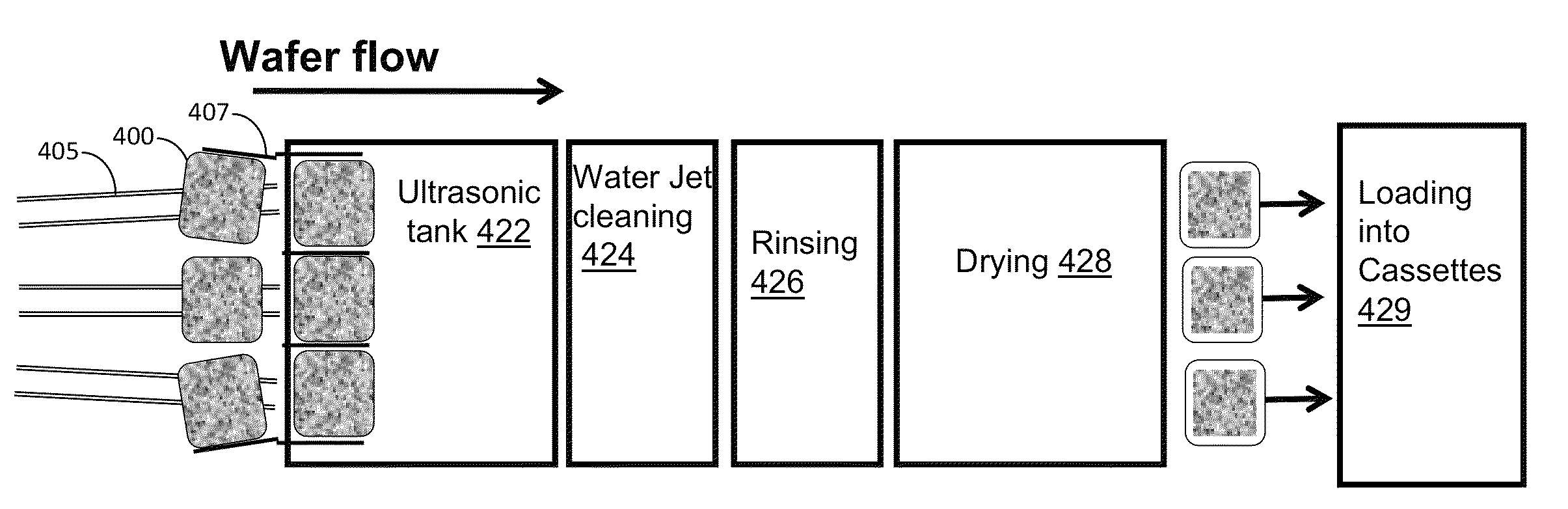

Method and apparatus for masking solar cell substrates for deposition

InactiveUS8677929B2UV curableShort curing timeLiquid surface applicatorsPV power plantsLaser burnEngineering

Disclosed are methods and apparatus for masking of substrates for deposition, and subsequent lifting of the mask with deposited material. Masking materials are utilized that can be used in high temperatures and vacuum environment. The masking material has minimal outgassing once inside a vacuum chamber and withstand the temperatures during deposition process. The mask is inkjeted over the wafers and, after deposition, removed using agitation, such as ultrasonic agitation, or using laser burn off.

Owner:INTEVAC

Method for laser engraving on clothing and corresponding machine

ActiveUS20190345658A1Reducing final cost of productSimplify the design processPattern makingTrousersLaser burnLaser engraving

A method for laser engraving on clothing and to a corresponding machine. Using an image, a laser burns, for each pixel, a corresponding point on the clothing, with a laser energy level that is a function of the pixel value. This function has a first zone with a first average gradient and a second zone with a second average gradient. The first zone corresponds to laser energy values less than the second zone, the absolute value of the second average gradient being greater than the absolute value of the first average gradient. The laser engraving machine comprises a laser source, means for conducting the laser on specific points of the clothing, means for controlling the energy supplied by the laser, and control means configured to carry out the method.

Owner:JEANOLOGIA

Electric-arc-push-welding and laser-rear-mounted hybrid welding method and device for aluminum alloy

ActiveCN105458509AImproved Solder Bridging CapabilityAvoid interferenceLaser beam welding apparatusLaser burnLight beam

The invention discloses an electric-arc-push-welding and laser-rear-mounted hybrid welding method and device for aluminum alloy. The method includes the steps that a welding gun is arranged in the manner that the welding gun inclines by 5-10 degrees relative to the direction perpendicular to the surface of a workpiece, and therefore arc flame can point to a to-be-welded part; and laser beams are on the rear portion of the welding gun in the welding direction. The welding gun and an optical fiber focus lens are assembled together in a hybrid manner, and the electric-arc-push-welding and laser-rear-mounted hybrid heat source configuration is achieved. By means of the method, the welding and bridging capacity of aluminum alloy can be improved by about 20%, pore defects are remarkably relieved, and meanwhile the surface quality of weld joints is ensured; focusing is achieved through the light beam focus lens, and therefore a hybrid welding head can be more compact and simpler, and interference of laser beams and the welding gun is avoided during large-amount focusing; by means of laser beams which are obliquely emitted, it is avoided that perpendicularly-emitted lasers burn the light beam focusing lens when reflected; and an opening is formed in the rear side of the welding gun, and therefore interference of laser beams and the welding gun can be prevented, and the tail portion of a molten pool can be better protected.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Laser engraving method for jewelry product and laser engraving jig for ringlike jewelries

ActiveCN103878487AAchieve exquisite shapeAchieve deflectionWelding/cutting auxillary devicesAuxillary welding devicesLaser burnLaser engraving

The invention discloses a laser engraving method for a jewelry product and a laser engraving jig for ringlike jewelries. The method includes the first step of processing the surface of the jewelry product to be a specular smooth and clean surface, and the second step of carrying out laser burning on the smooth and clean surface according to a preset pattern region through a laser burning mode, wherein the laser burning depth ranges from 0.02 millimeter to 0.03 millimeter, and the burning frequency is at least twice. According to the laser engraving method, twice or more laser engraving processes are adopted, the depth of patterns or stripes formed through laser burning ranges from 0.02 millimeter to 0.03 millimeter, the delicate appearance effect is achieved, no raw materials are redundantly consumed, the delicate modeling of the jewelry product is achieved, and low-cost processing of laser burning of the jewelry product is guaranteed. According to the laser engraving jig for the ringlike jewelries, a motor is adopted to control the rotational speed of the ringlike jewelries, and the motor and a laser burning device are controlled synchronously, so rotation and laser burning are simultaneously carried out on the ringlike jewelries, the laser burning speed and production output of the ringlike jewelries are improved, and the cost is reduced.

Owner:SHENZHEN BOFOOK JEWELRY

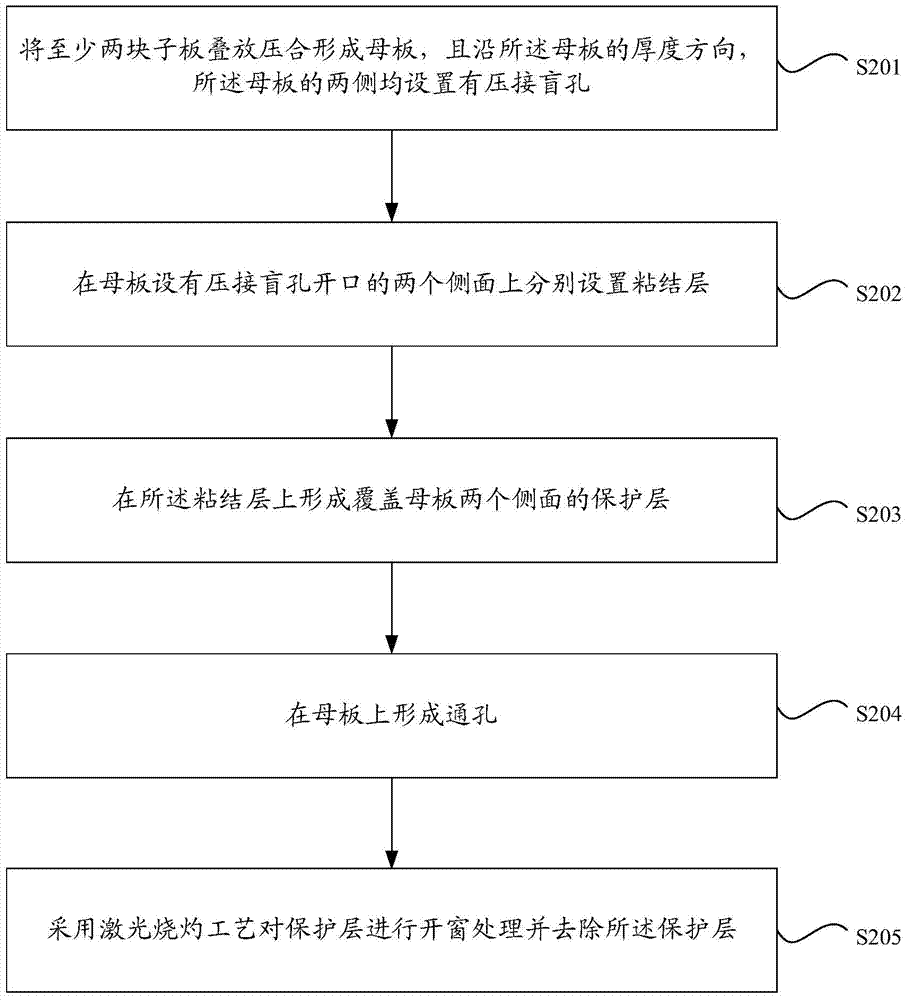

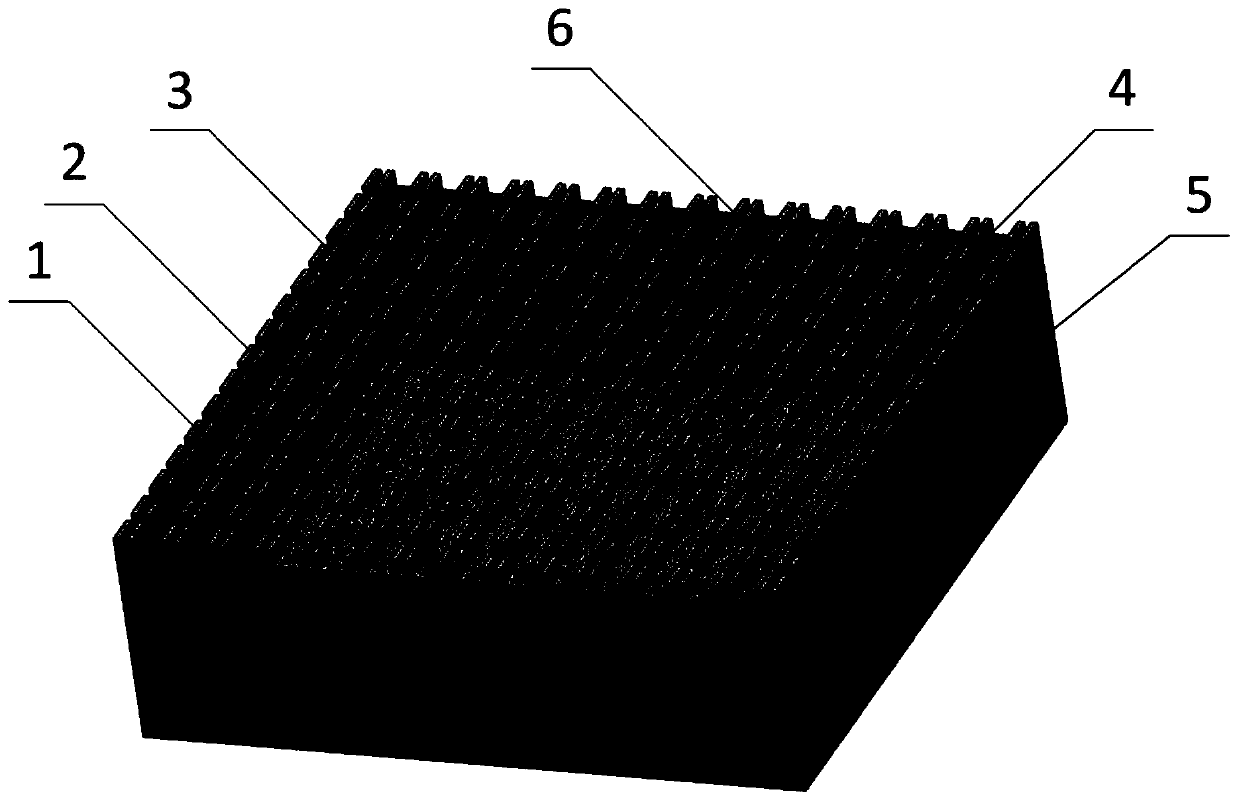

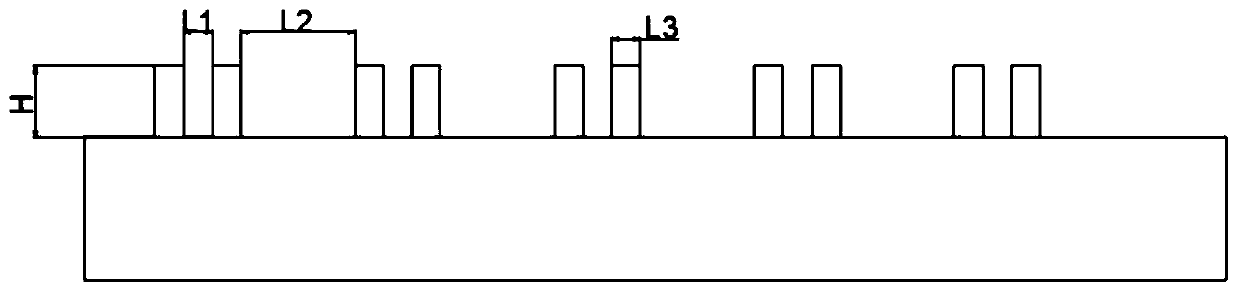

Preparation method for back plate

InactiveCN104767096AImprove product qualityFacilitates high-density setupsContact member assembly/disassemblyLaser burnHigh density

The invention relates to the technical field of communication, and discloses a preparation method for a back plate. The preparation method for the back plate comprises the steps that two or more daughter boards are pressed to form a mother board, and crimping blind holes are formed in the two sides of the mother board in the thickness direction of the mother board. Bonding layers are arranged on the two side faces, provided with openings of the crimping blind holes, of the mother board respectively. Protecting layers covering the two side faces of the mother board are formed in the bonding layers. Through holes are formed in the mother board. Windowing treatment is conducted on the protecting layers by laser burning technology and the protecting layers are removed. According to the preparation method for the back plate, when removing the protecting layers is needed, the windowing treatment is conducted on the protecting layers through the laser burning technology, etching liquid and medical liquid are not utilized, and thereby considering the windowing position, the bonding size between the protecting layers and the bonding layers and the size and standard of windowing and the like are not needed, so that the preparation method for the back plate is convenient to achieve the high-density arrangement of the crimping blind holes in the back plate conveniently, damage on the crimping blind holes during preparing of the back plate can be reduced, and the product quality of the back plate is improved.

Owner:HUAWEI TECH CO LTD

Micro-scale collaborative surface structure for enhancing boiling heat transfer

InactiveCN109974513AAccelerated disengagementReduced escape diameterHeat transfer modificationLaser burnEnhanced heat transfer

The invention belongs to the technical field of enhanced heat transfer, and provides a micro-scale collaborative surface structure for enhancing boiling heat transfer. The structure comprises a largegroove, a small groove, a connecting groove, a micro rib, a base surface and a super-hydrophobic coating; the base surface of the structure for enhancing boiling heat transfer is subjected to mechanical cutting, structure electroplating or laser burning to form a synergistic scale surface; the surface of the base surface is divided into the large groove, the small groove and the connecting groovethrough ribs. According to the structure, the micro-scale collaborative surface structure can achieve the capillary force effect, so that a liquid can reach a vaporization core point faster, the requirement of the boiling heat transfer vaporization process on the scale can be further met under the condition of different superheat degrees, the connecting groove between the large groove and the small groove enables liquid between the grooves to interact, so that steam is easier to discharge, and then the boiling heat transfer is enhanced.

Owner:DALIAN UNIV OF TECH

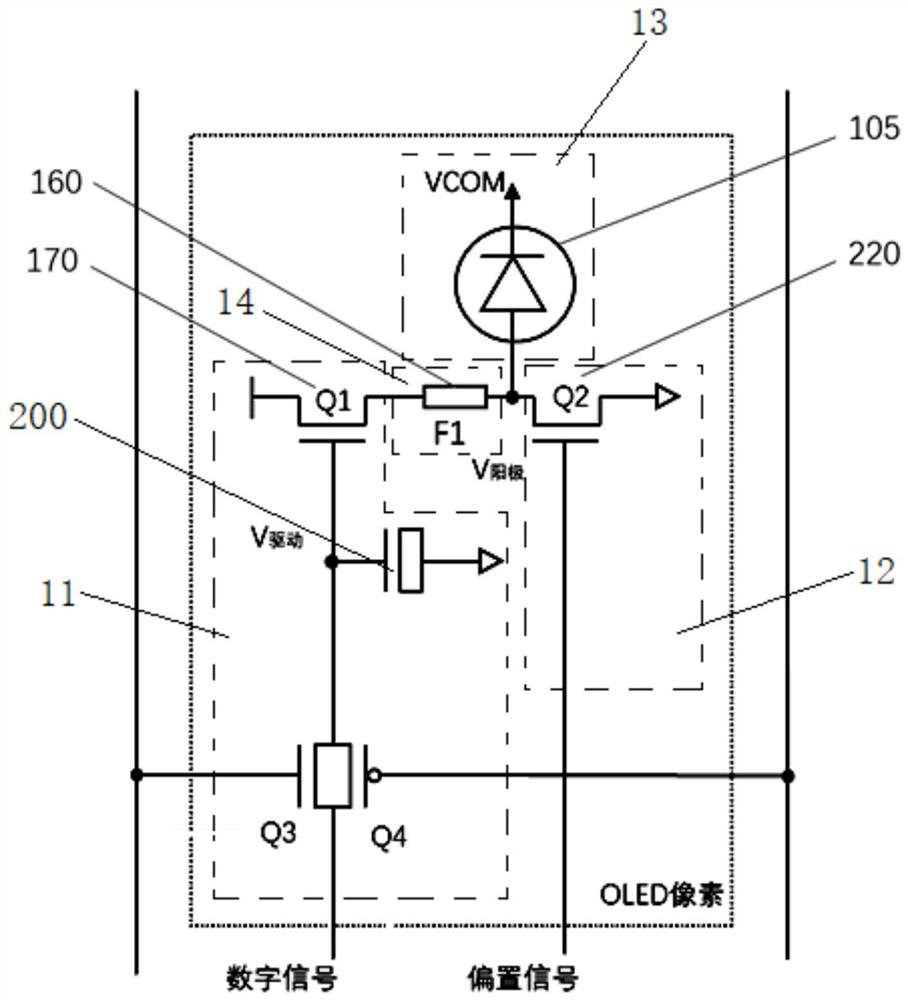

Driving circuit and repairing method for repairing normally-on OLED pixel, and display device

InactiveCN112509521AQuick fix for always bright defectsStatic indicating devicesLaser burnDisplay device

The invention relates to a driving circuit and method for repairing normally-on OLED pixels and a display device. The circuit comprises a first driving module, a second driving module, a light emitting module and a fusing module. The light-emitting module comprises an OLED pixel light-emitting unit. The first driving module is connected with the light emitting module and provides a driving signal;the fusing module is connected between the first driving module and the anode of the light emitting module; the second driving module is connected between the fusing module and the anode of the lightemitting module, wherein the second driving module is used for providing bias current, so that the fusing module is fused. The beneficial effects are that laser burning is not needed, and the fusingelement and the bias circuit are additionally arranged in the drive circuit so that the normally-on defect can be rapidly repaired.

Owner:深圳市智联汇网络系统企业(有限合伙)

Silicon chip classification method by means of laser code printing discrimination

InactiveCN108417479AAvoid picking mistakesSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingLaser burnClassification methods

The invention provides a silicon chip classification method by means of laser code printing discrimination, and belongs to the technical field of classification of monocrystalline silicon chips. The silicon chip classification method by means of laser code printing discrimination includes the following steps: 1) a silicon rod inspector detects a silicon rod and makes marks for adverse length intervals; 2) laser burning code printing is performed on the adverse length intervals marked on the surface of the silicon rod; 3) the silicon rod is sliced; 4) according to the laser codes on silicon chips, adverse silicon chips are selected; and 5) qualified silicon chips and adverse silicon chips are packaged after classification. The silicon chip classification method by means of laser code printing discrimination makes permanent laser codes on the surface of the unqualified intervals of the photoelectric parameters of the silicon rod through laser burning and code printing, and after the silicon rod is sliced into silicon chips, the laser codes are maintained on the silicon chips with unqualified photoelectric parameters and do not disappear because of washing and polishing of the siliconchips, thus avoiding the selection error caused in the flowing process.

Owner:XINGTAI JINGLONG ELECTRONICS MATERIAL

Integrated circuit having on-chip laser burn-in circuit

An integrated circuit for providing burn-in current to a laser diode. The integrated circuit includes a laser driver having an output for connection to the laser diode. Burn-in circuitry is formed on the integrated circuit and generates a burn-in current. A switch is formed on the integrated circuit and couples the burn-in current to the laser diode in response to an enable signal.

Owner:BROADCOM INT PTE LTD

Method in the manufacture of a packaging laminate, a plant in the manufacture of the packaging laminate, and the thus manufactured packaging laminate

InactiveUS20050053738A1Improve accessibilityImprove integrityWrappersThin material handlingLaser burnPaperboard

A method in the manufacture of a web-shaped packaging laminate (22) comprising a core layer (24) of paper or paperboard, the method including the steps of coating (38) a first side of a material web (40) of paper or paperboard with an outer layer (26) of thermoplastic material, an thereafter forming, with the aid of laser burning (46, 48) on the thus thermo-plastic coated first side of the packaging laminate (22), a perforation line (32) through said thermoplastic layer (26) and said core layer (24). After said coating (38) with the thermoplastic material but before the formation of the perforation line, the packaging laminate (22) is compressed (44, 10) on said first side for the formation of a compression line (30) in which said core layer (24) is compressed, whereafter said perforation line (32) is formed in said compression line (30). The present invention also relates to a plant in the manufacture of the packaging laminate, as well as the thus produced packaging laminate (22).

Owner:TETRA LAVAL HLDG & FINANCE SA

Novel environment-friendly machining method for removing rare and precious metal oxide skin through laser burn washing method

The invention discloses a novel environment-friendly machining method for removing rare and precious metal oxide skin through a laser burn washing method. The process technology is adopted for production, no adverse influence is produced on workpieces, and no loss is caused to material substrates almost. The working environment is clean, the production efficiency is relatively high, particularly in rare and precious metal pipe and special-shaped material surface treatment machining, since laser can automatically adapt to special-shaped surfaces such as a circular arc, the polishing and grinding workload can be greatly reduced, grinding apparatus grinding materials for polishing and grinding are saved, the loss of the rare and precious metal material substrates is effectively reduced, and the production cost is greatly reduced.

Owner:安徽宝泰特种材料有限公司

University physical education teaching material management system

ActiveCN106157208ARecord receiptImprove management abilityData processing applicationsRecord carriers used with machinesPhysical educationLaser burn

The invention provides a university physical education teaching material management system. The system comprises a laser burning device used for etching a physical education teaching material to form a two-dimensional code, a wrapping device which is used for wrapping a transparent wear layer on the two-dimensional code formed on the physical education teaching material, a scanning device which is used for scanning the two-dimensional code formed on the physical education teaching material, and a calculation device which is used for calculating recorded two-dimensional codes scanned by the scanning device and recording the taking condition of physical teaching materials when being used for calculating the two-dimensional codes. The university physical education teaching material management system has the beneficial effects that the physical education teaching material taking condition can be quickly recorded, recording can be completed when the teaching material is taken, and paper recording is not required, so that the physical education teaching material management effect can be improved.

Owner:JILIN BUSINESS & TECH COLLEGE

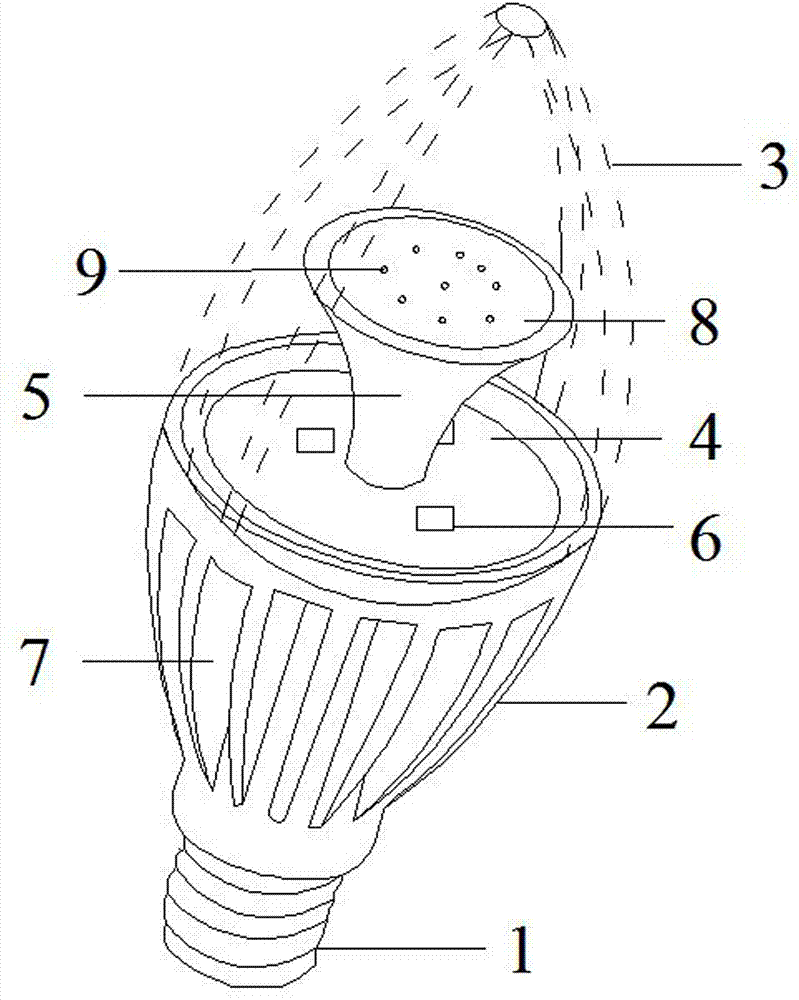

LED (Light-Emitting Diode) candle lamp

InactiveCN102829363AOvercoming directivity problemsImprove reflection efficiencyPoint-like light sourceLighting heating/cooling arrangementsLaser burnCandle

The invention discloses an LED (Light-Emitting Diode) candle lamp, comprising a light source fixing board and a reflector. The light source fixing board is an aluminum base board; the reflector is horn-shaped; LED light sources are distributed along the outer side of the reflector; the reflector is made of an acrylic material; a continuous arc surface plated with a silver surface is formed at the open end of the reflector; transmitting points are formed on the silver surface; and the transmitting points are formed through laser burn-off. The LED candle lamp provided by the invention has the following beneficial effects: the projection direction of light emitted by an LED light source is determined according to the height and the size of an opening of the horn-shaped reflector, so that the light-emitting angle can be enlarged, and the LED lamp light directivity problem can be overcome; and the reflector is made of acrylic material and the silver surface is plated on the arc surface, so that the light-emitting amount above the reflector is controlled by the transmitting points formed on the silver surface. Therefore, the ratio of the light-emitting amount above the reflector and the light-emitting amount at the lateral direction of the reflector can be controlled, so that the light projection direction and the light amount of the LED candle lamp can be adjusted; the reflection efficiency is high and the energy conversation can be realized; and the light source fixing board uses the aluminum base board, so that the heat dissipation effect is good, and the service life of the LED candle lamp can be prolonged.

Owner:SUZHOU JINKE XINHUI PHOTOELECTRIC TECH

Collecting device and method of pork laser burning codes

InactiveCN103999923AClearly obtainedImprove signal-to-noise ratioMeat/sausages markingLaser burnImaging processing

The invention discloses an image collecting device and a collecting method aiming at pork skin laser burning codes. The characteristic that a laser burning part on the pork has weak fluorescence reaction on light with specific wavelengths is utilized, through shielding visible light and installing an ultraviolet light source with the specific wavelengths on collecting equipment, the laser burning part on the pork can give out fluorescence, and the fluorescence is collected by an image sensor, so the image collection of the laser burning codes is realized. The image collecting device has the advantages that very strong noise resistance performance is achieved, and the obtaining of machine-readable code information in images can be realized through further image processing and analysis.

Owner:BEIJING YIDAO BOSHI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com