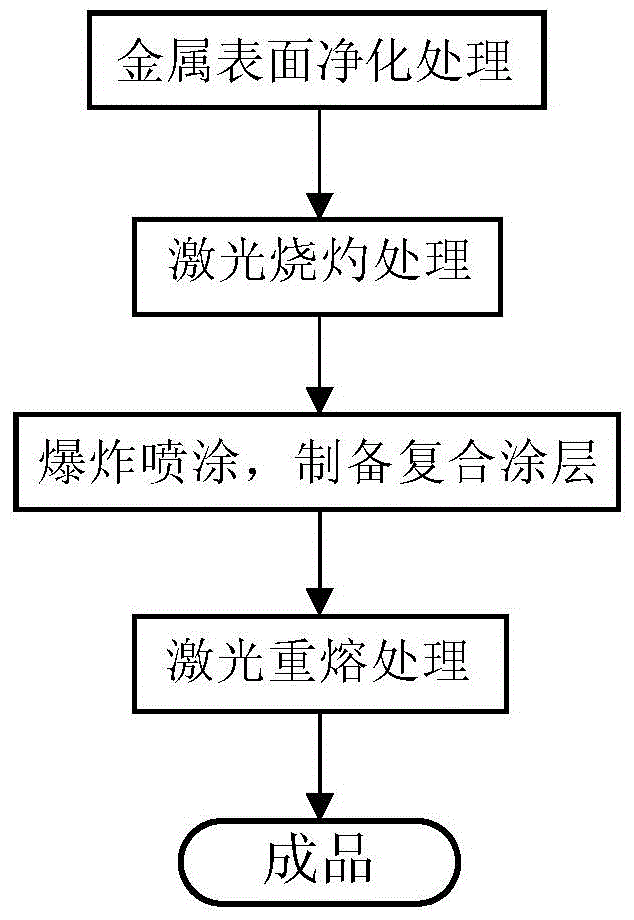

Process for spraying composite coating on metal surface

A metal surface and composite coating technology, which is applied in the direction of metal material coating process, coating, fusion spraying, etc., can solve the problems of the decrease of fatigue performance of the base material, the adverse effect of the bonding strength of the coating and the substrate, etc., and achieve the reduction of inclusions The effect of avoiding the significant decline in the fatigue performance of the base material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) After cleaning the surface of the 45# steel sample to be sprayed with acetone, the laser ablation treatment was performed on the surface of the 45# steel sample by short pulse Nd:YAG. The laser wavelength is 1064nm, the power is 80W, the frequency is 10HZ, and the number of laser pulses is 10-250.

[0027] (2) After the 45# steel sample was preheated, the WC-12% Co coating was prepared by detonation spraying on the surface of the sample. Explosive spraying process parameters are: the average particle size of the spraying material is 30-60 microns WC-12%Co mechanically mixed powder, oxygen flow: 42L / min, acetylene gas flow: 38L / min, nitrogen flow: 30L / min, oxygen acetylene The gas ratio is 1.1, the explosion frequency is 5 times / s, the spraying distance is 150mm, and the coating thickness is 0.05-0.3mm.

[0028] (3) The WC-12%Co coating on the surface of 45# steel sample prepared by detonation spraying process was remelted by semiconductor laser. Laser remelting pr...

Embodiment 2

[0031] (1) After cleaning the surface of the 316 stainless steel sample to be sprayed with acetone, the laser ablation treatment was performed on the surface of the 316 stainless steel with short pulse Nd:YAG. The laser wavelength is 1064nm, the power is 80W, the frequency is 10Hz, and the number of laser pulses is 10-250.

[0032] (2) After preheating the 316 stainless steel sample, detonation spraying was carried out on the surface of the sample to prepare Cr 3 C 2 -NiCr coating. Explosive spraying process parameters are: the spraying material is Cr with an average particle size of 30-60 microns 3 C 2 Mechanically mixed powder with NiCr, Cr 3 C 2 Powder accounts for 75%, NiCr powder accounts for 25%, oxygen flow rate: 42L / min, acetylene gas flow rate: 38L / min, nitrogen gas flow rate: 30L / min, oxygen acetylene gas ratio is 1.1, explosion frequency: 5 times / s, spraying distance : 150mm, the coating thickness is 0.05~0.3mm.

[0033] (3) The surface of 45# steel sample wa...

Embodiment 3

[0036] (1) After cleaning the surface of the 45# steel sample to be sprayed with acetone, the laser ablation treatment was performed on the surface of the 45# steel sample by short pulse Nd:YAG. The laser wavelength is 1064nm, the power is 80W, the frequency is 10HZ, and the number of laser pulses is 10-250.

[0037] (2) After preheating the 45# steel sample, detonation spraying was carried out on the surface of the sample to prepare Al 2 o 3 -Ni60 coating. The parameters of the detonation spraying process are: the spraying material is Al with an average particle size of about 40-80 microns 2 o 3 powder and 80-100 micron Ni60 powder mechanically mixed powder, where Al 2 o3 Powder accounts for 75%, Ni60 powder accounts for 25%, oxygen flow rate: 42L / min, acetylene gas flow rate: 38L / min, nitrogen gas flow rate: 30L / min, oxygen acetylene gas ratio is 1.1, explosion frequency: 5 times / s, spraying distance : 150mm, the coating thickness is 0.05~0.3mm.

[0038] (3) The surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com