A method of manufacturing a carbon fiber antenna surface

A manufacturing method and antenna surface technology, applied to other household appliances, household appliances, household components, etc., can solve the problems that autoclave equipment cannot be applied in large quantities, the production equipment occupies a large area, and the price is difficult for consumers. , to achieve the effect of high flexibility in mold manufacturing and material selection, small investment in equipment and molds, and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

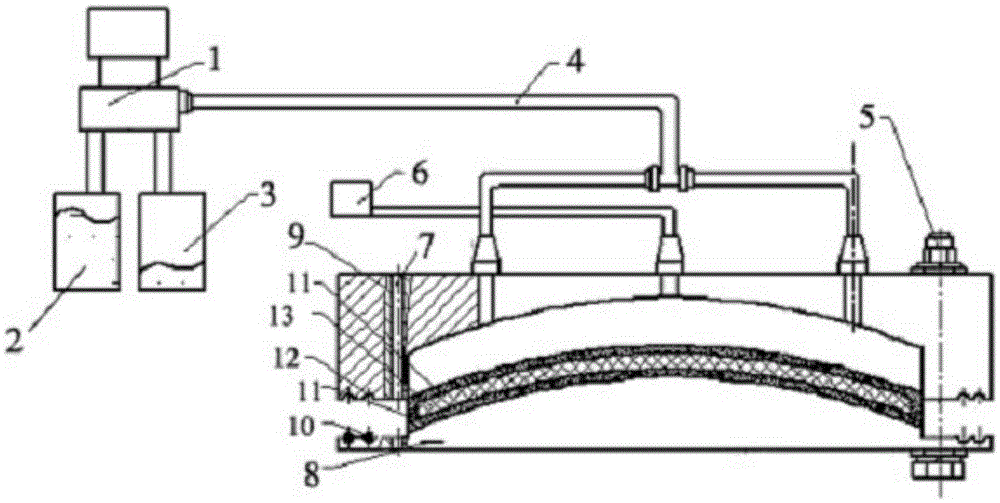

[0042] A method for manufacturing a carbon fiber antenna surface, comprising the following steps:

[0043] (1) The mold for prefabricating the carbon fiber antenna surface, the mold is divided into a female mold 9 and a male mold 8;

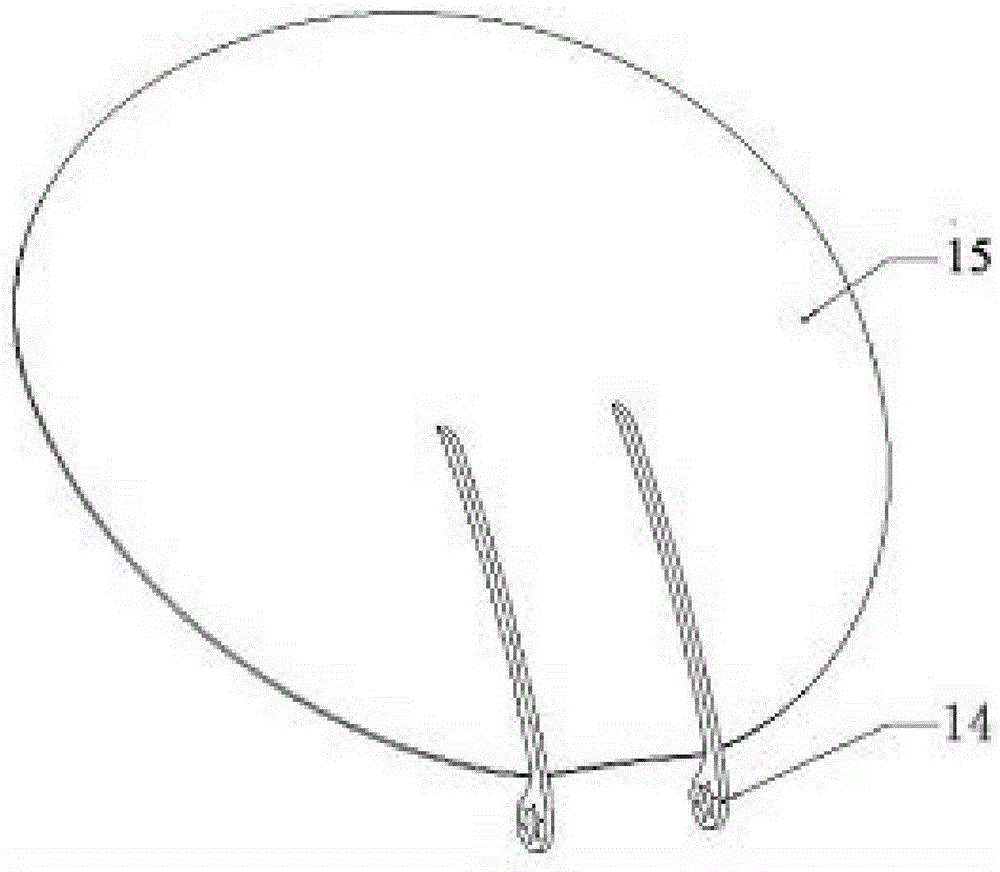

[0044] Due to the high requirement for the face-to-face accuracy of the carbon fiber antenna, (1) the material of the mold is 45# steel, and its thickness, length and width are determined according to the chord height and size of the carbon fiber antenna surface; It is the female mold 9 and the male mold 8), and two sealing grooves 12 for placing ∮10 rubber sealing strips 10 are processed along the 100mm outside the mold cavity. If the sealing is not good and the air leaks, the product is easy to be scrapped. Sealing is a key step in the entire mold making process. figure 1 ).

[0045] (2) polishing the mould of step (1);

[0046] For manual polishing, first use 320# whetstone to roughly throw the mold to remove burrs; then use 600# whetstone,...

specific Embodiment 2

[0070] It is roughly the same as the specific embodiment 1, the difference is:

[0071] 1. Step (6): Lay 4 layers of 3K carbon fiber cloth 11 on the male mold 8 of the mold in step (5) in turn, and reserve about 100mm on the edge of the 3K carbon fiber cloth 11;

[0072] 2. The thickness of the PVC foam 13 in step (7) is 14.8mm;

[0073] 3. Step (11): inject epoxy resin and curing agent (ethylenediamine, the content of which is 10% of the mass of epoxy resin) from the feeding port of female mold 9 using epoxy resin glue injection machine 1, epoxy resin The pressure of the mixing glue injection of the glue injection machine is 4.5 bar, and the carbon fiber antenna surface blank is obtained after the reaction at 30 ° C for 120 min and demoulding.

specific Embodiment 3

[0074] It is roughly the same as the specific embodiment 1, the difference is:

[0075] Step (11): use the epoxy resin glue injection machine 1 to inject epoxy resin and curing agent (hexamethylene diamine, its content is 12% of the epoxy resin mass) from the feeding port of the female mold 9, and the epoxy resin is injected with glue The mixing pressure of the machine was 4 bar, and the carbon fiber antenna surface blank was obtained after the reaction at 25 °C for 135 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com