Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

382results about How to "High in fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

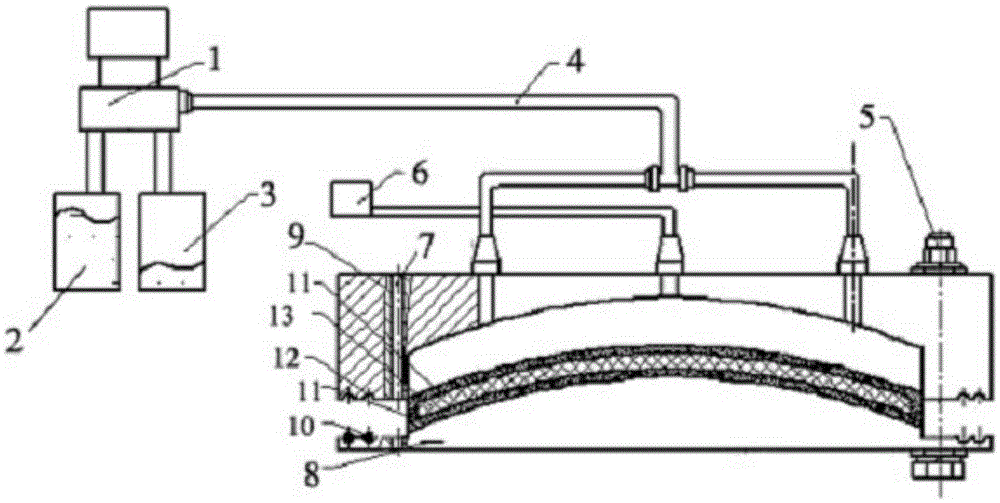

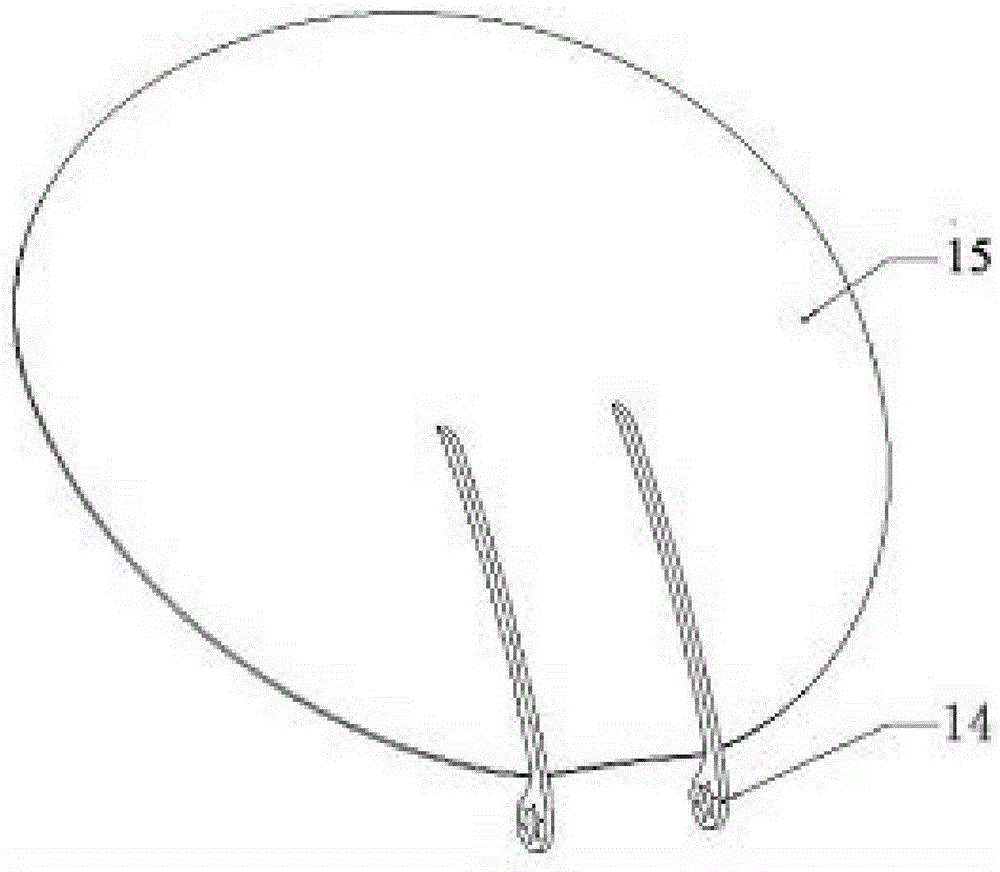

Manufacturing method for carbon fiber antenna surface

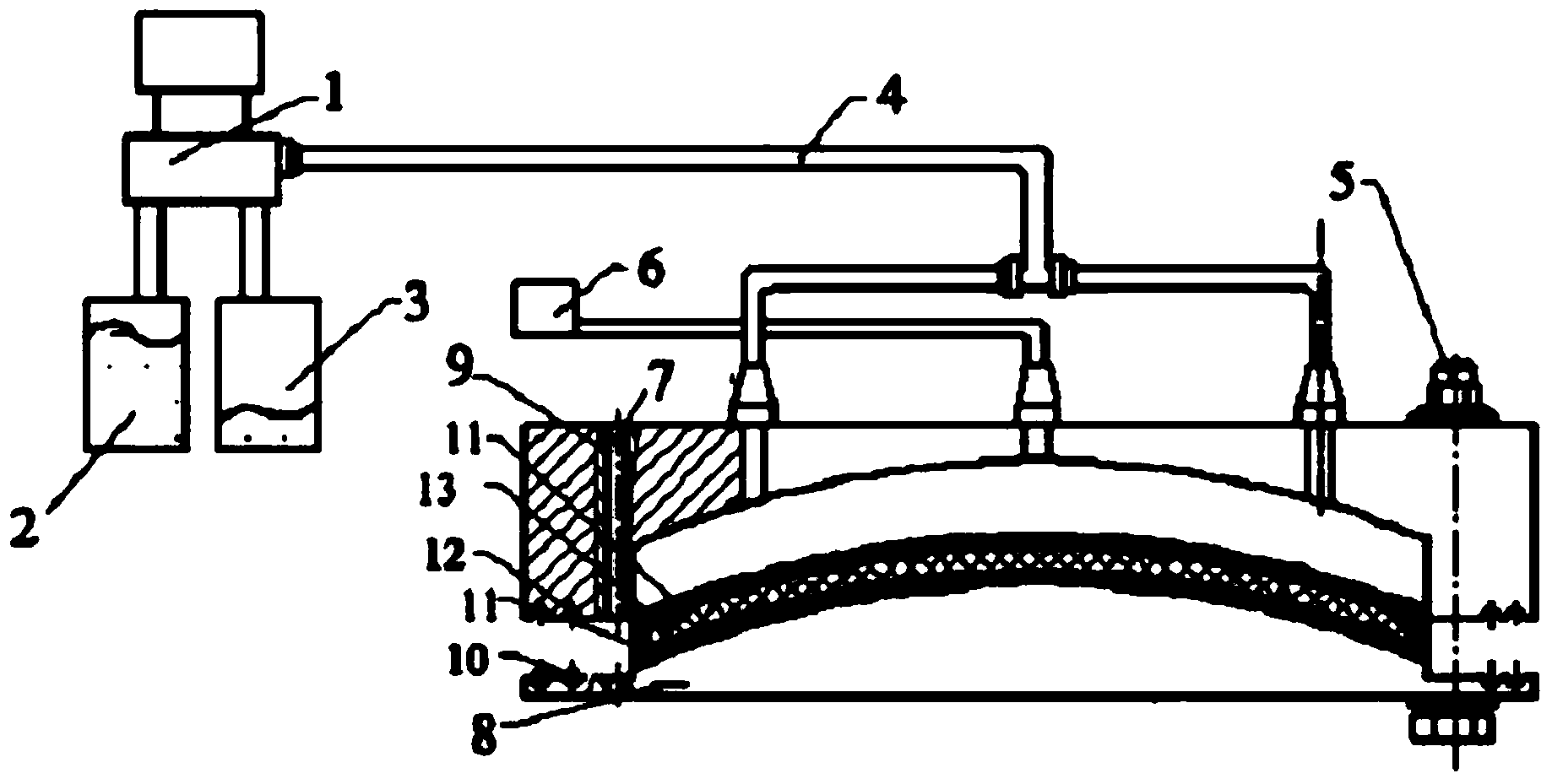

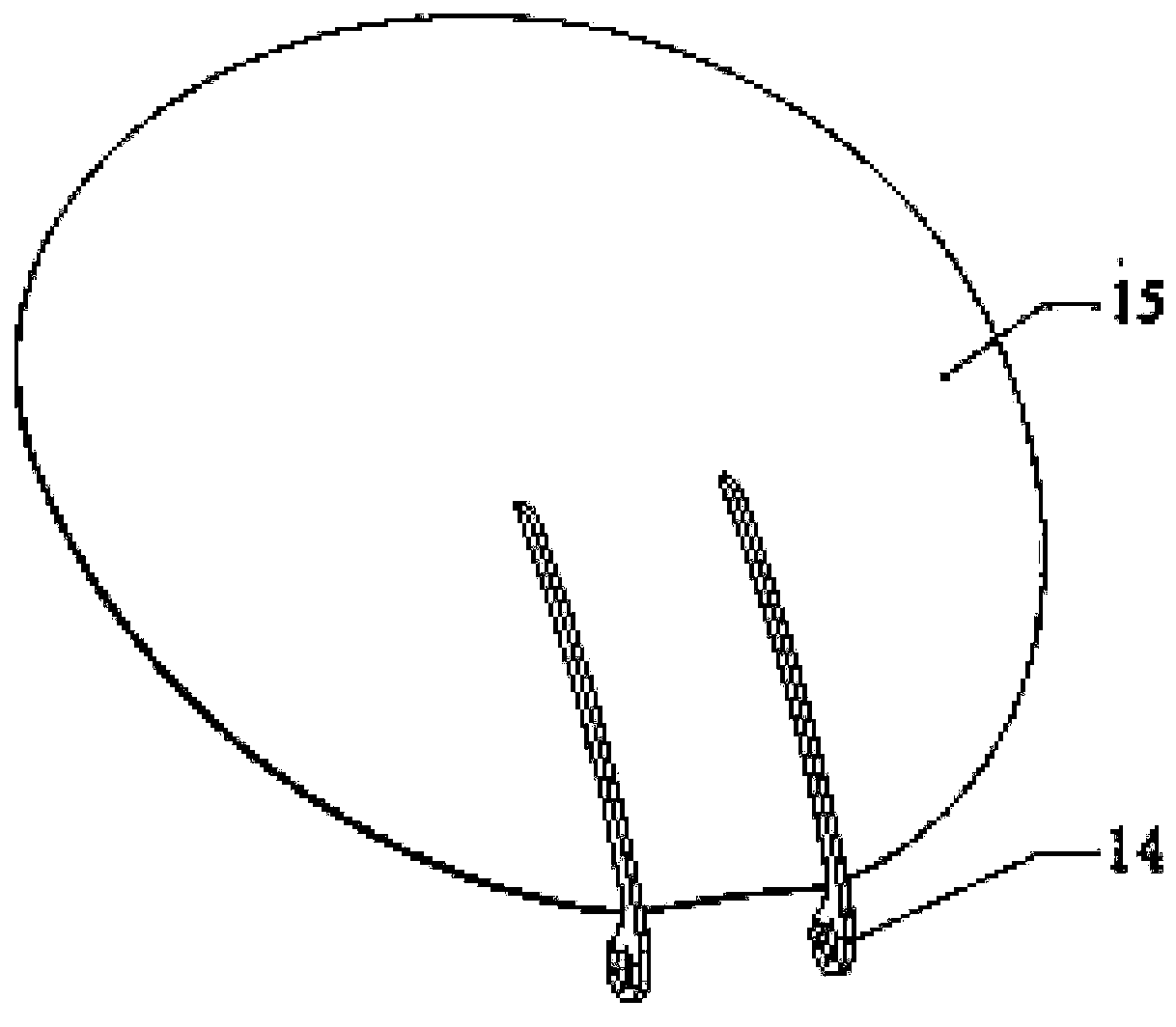

The invention relates to a manufacturing method for a carbon fiber antenna surface. The manufacturing method comprises the following steps of 1, prefabricating a die; 2, polishing the die; 3, chemically electroplating the die; 4, measuring the precision, and clearing away impurities; 5, coating a demolding agent; 6, paving carbon fiber cloth on a male die; 7, paving PVC foams on the surface of the male die; 8, paving carbon fiber cloth on the surface of the male die; 9, assembling the male die and a female die, and sealing and fastening the male die and the female die; 10, vacuumizing to enable the vacuum degree in the die to be smaller than -0.096MPa; 11, injecting epoxy resin and a solidifying agent from a material inlet of the female die; 12, sticking a layer of glass paper to the outer surface of a blank after the appearance gets through inspection and is qualified; 13, performing perforation and assembling; and 14, obtaining the carbon fiber antenna surface after the product is qualified through inspection. The carbon fiber antenna surface manufactured by the manufacturing method is smooth, and the precision can reach 0.1R.M.S; and due to normal-temperature solidification, energy is saved, and the cost is lowered.

Owner:XIAN TUOFEI COMPOSITE MATERIAL

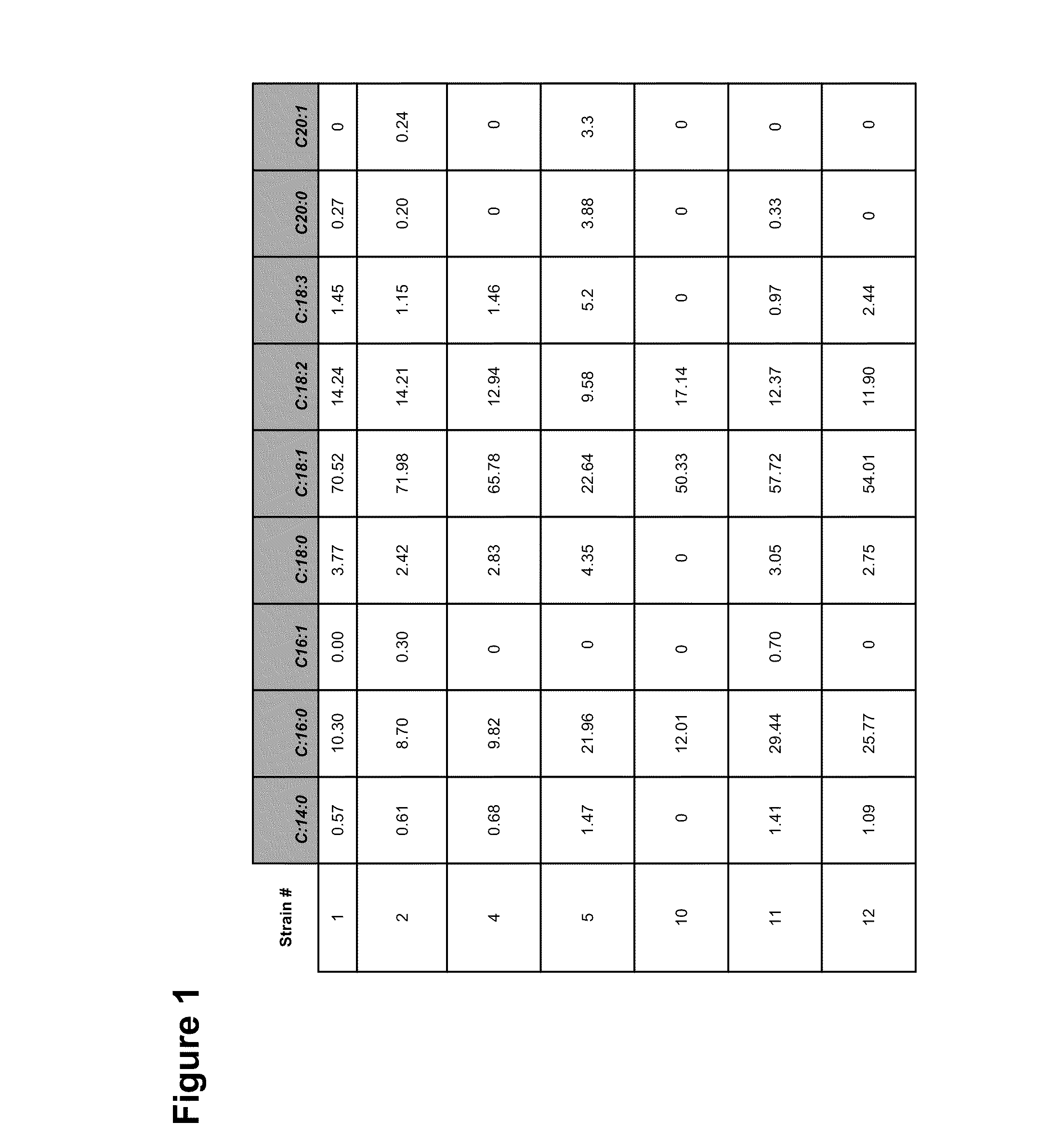

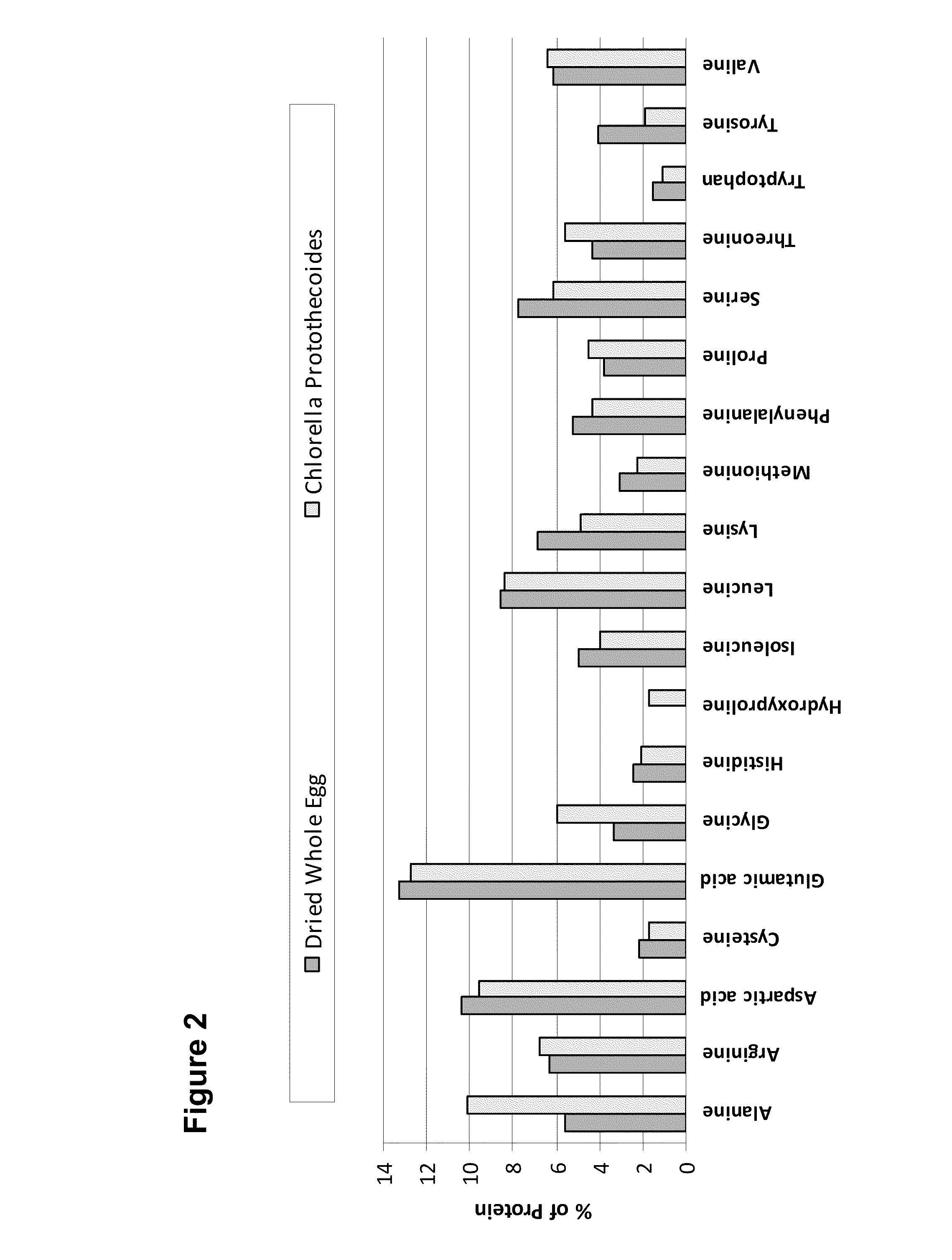

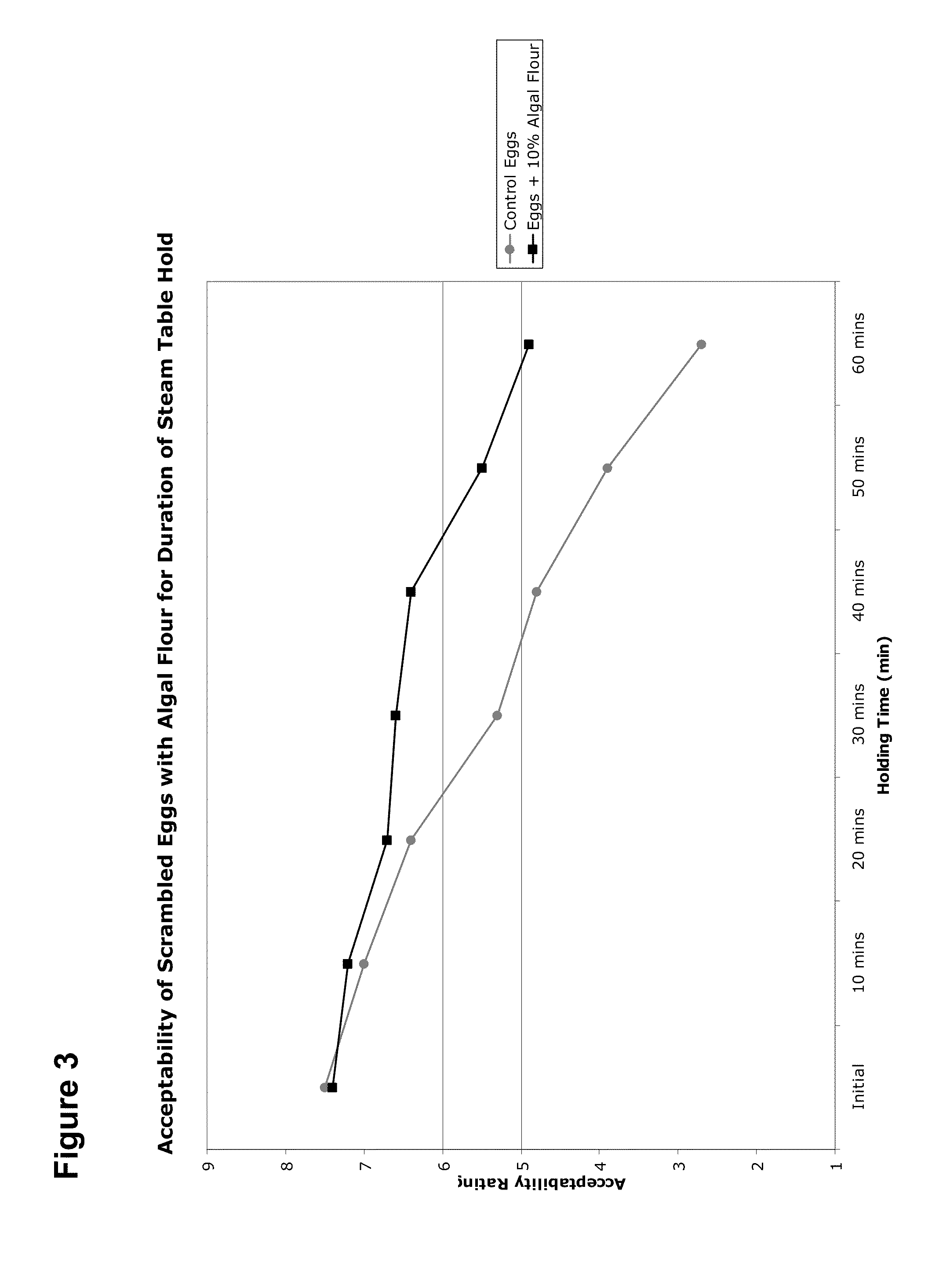

Healthier Baked Goods Containing Microalgae

Provided herein are microalgae-containing baked goods with novel properties compared to preexisting products of the same type. Methods of formulating and manufacturing these foods to deliver reduced fat, reduced cholesterol, and increased fiber content are disclosed herein. Various embodiments include elimination or reduction of eggs, butter, animal fat, and saturated oils in favor of healthy oil-containing microalgae biomass and oils, including the manufacture of foods with lower calories than preexisting products of the same type. Methods of producing raw materials for the manufacture of novel processed baked foods and intermediates such as cake and bead mixes are also provided.

Owner:TERRAVIA HLDG INC

A method of manufacturing a carbon fiber antenna surface

The invention relates to a manufacturing method for a carbon fiber antenna surface. The manufacturing method comprises the following steps of 1, prefabricating a die; 2, polishing the die; 3, chemically electroplating the die; 4, measuring the precision, and clearing away impurities; 5, coating a demolding agent; 6, paving carbon fiber cloth on a male die; 7, paving PVC foams on the surface of the male die; 8, paving carbon fiber cloth on the surface of the male die; 9, assembling the male die and a female die, and sealing and fastening the male die and the female die; 10, vacuumizing to enable the vacuum degree in the die to be smaller than -0.096MPa; 11, injecting epoxy resin and a solidifying agent from a material inlet of the female die; 12, sticking a layer of glass paper to the outer surface of a blank after the appearance gets through inspection and is qualified; 13, performing perforation and assembling; and 14, obtaining the carbon fiber antenna surface after the product is qualified through inspection. The carbon fiber antenna surface manufactured by the manufacturing method is smooth, and the precision can reach 0.1R.M.S; and due to normal-temperature solidification, energy is saved, and the cost is lowered.

Owner:XIAN TUOFEI COMPOSITE MATERIAL

Fiber mat bound with a formaldehyde free binder, asphalt coated mat and method

Fibrous, nonwoven mats are disclosed that are bound with a formaldehyde-free, heat resistant resin in direct contact with the fibers. The heat resistant resin is capable of withstanding coating with a hot, molten material like asphalt or a mixture containing asphalt having a temperature of at least about 300 degrees F. and up to 450 degrees F. or higher. The preferred heat resistant resins are epoxies and urethanes, or mixtures thereof. The methods of making these mats with wet processes are also disclosed.

Owner:MANVILLE JOHNS

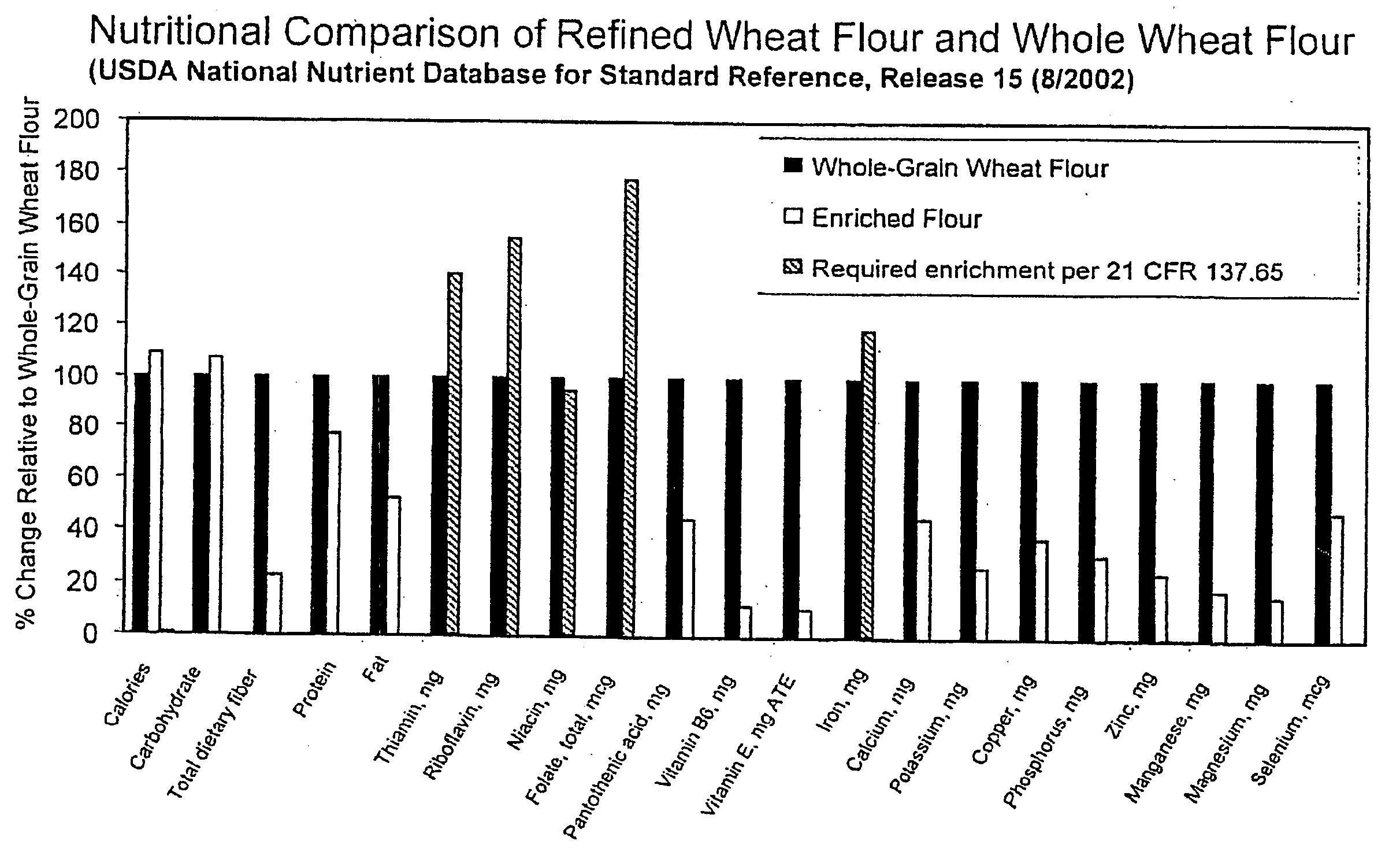

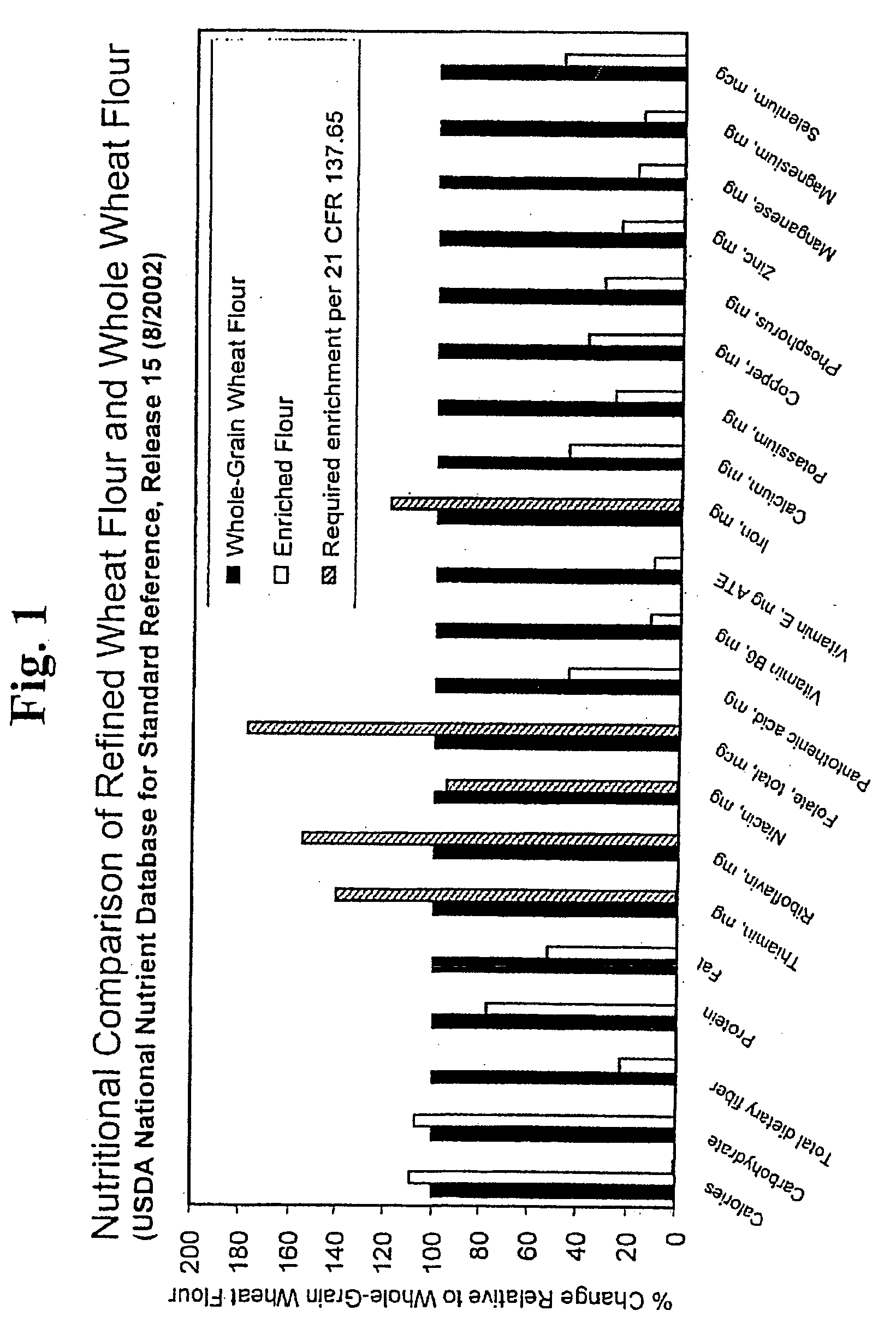

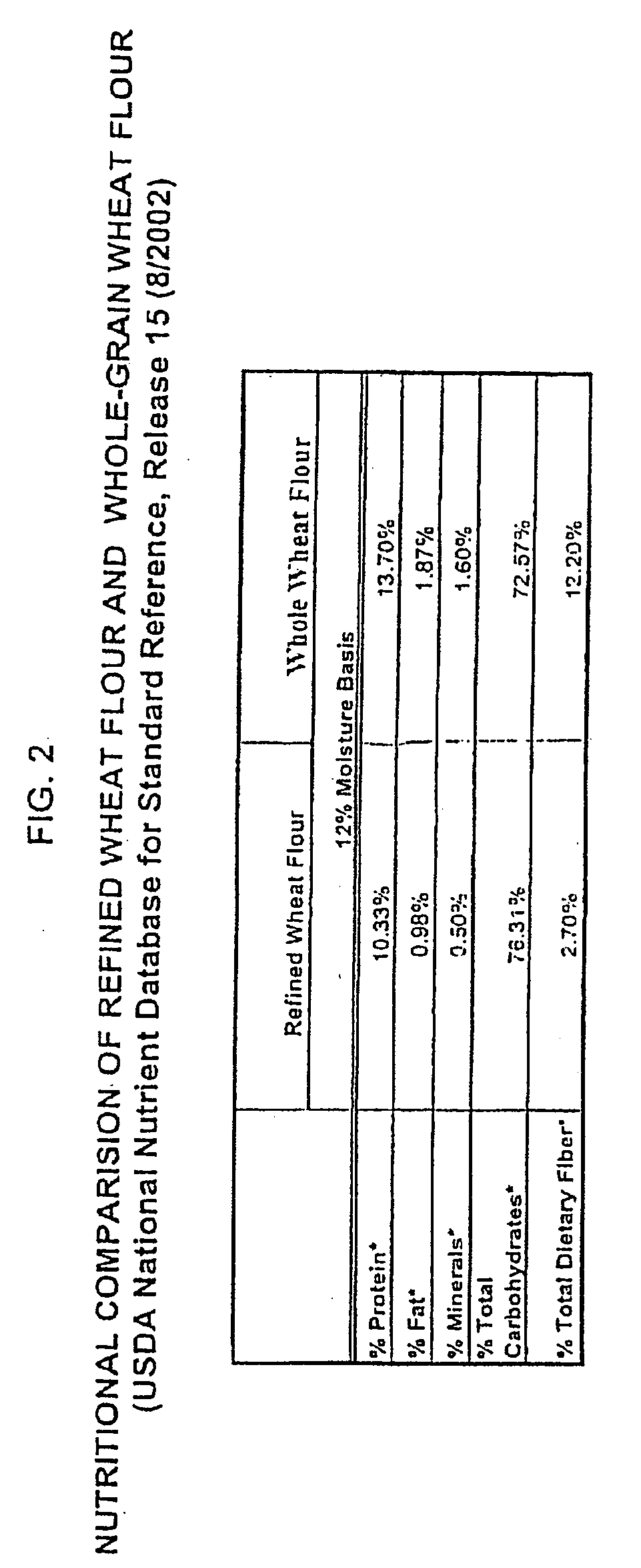

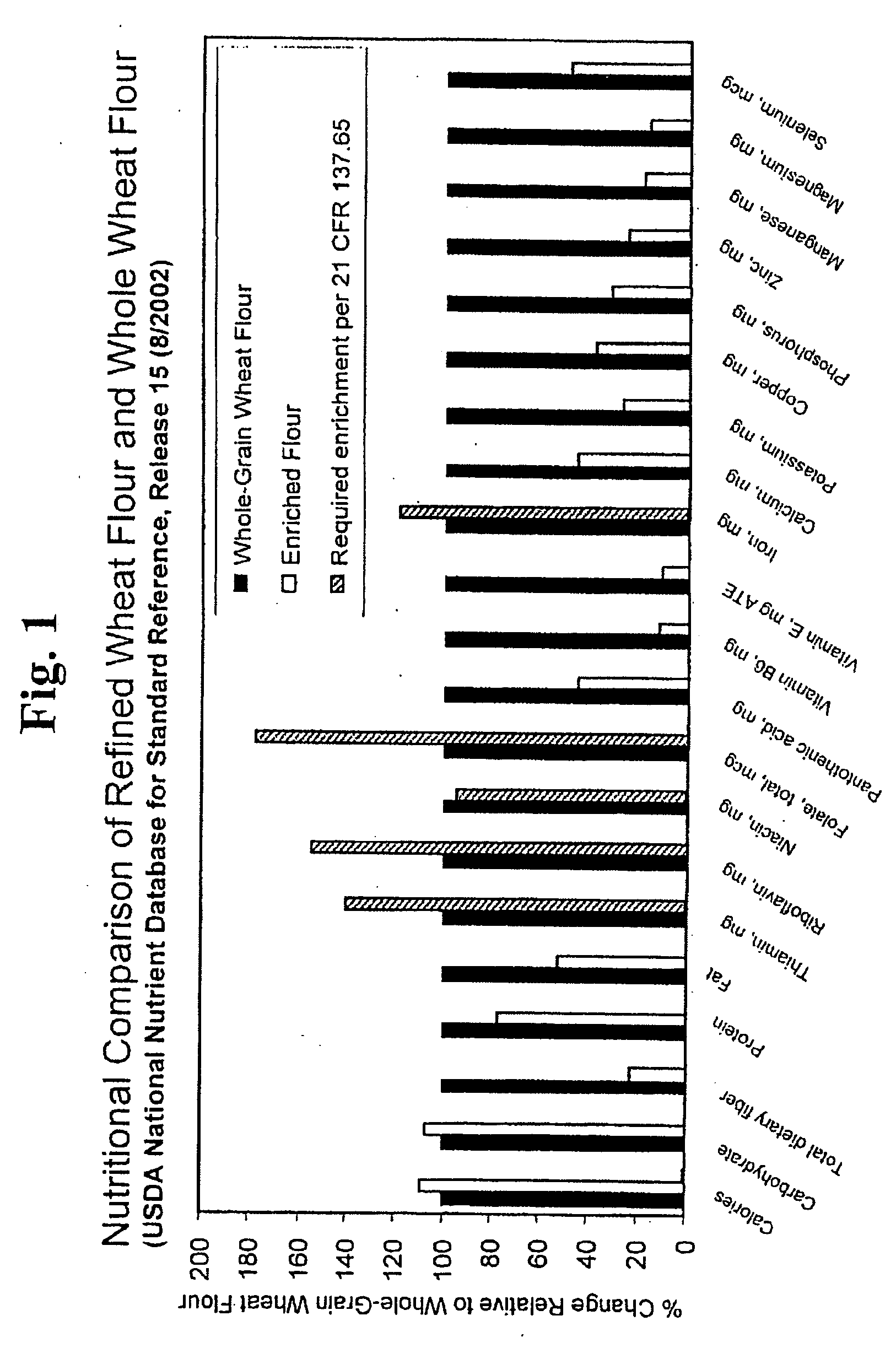

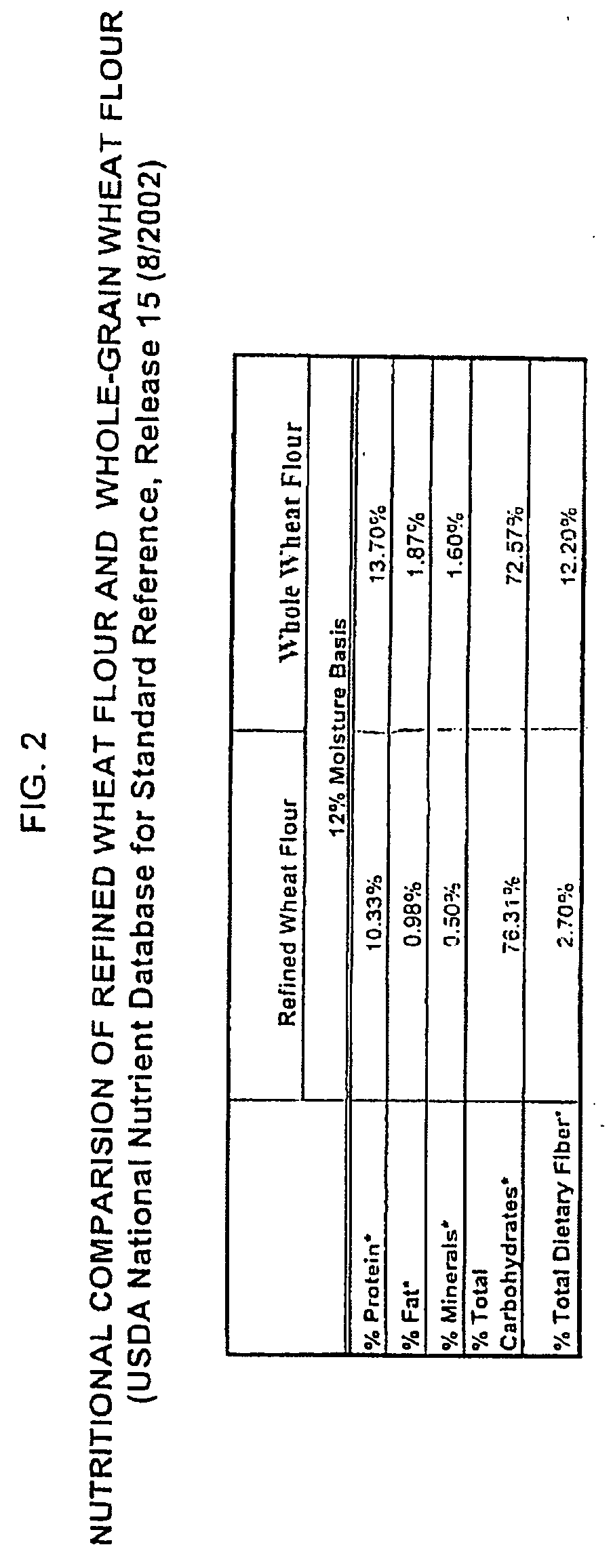

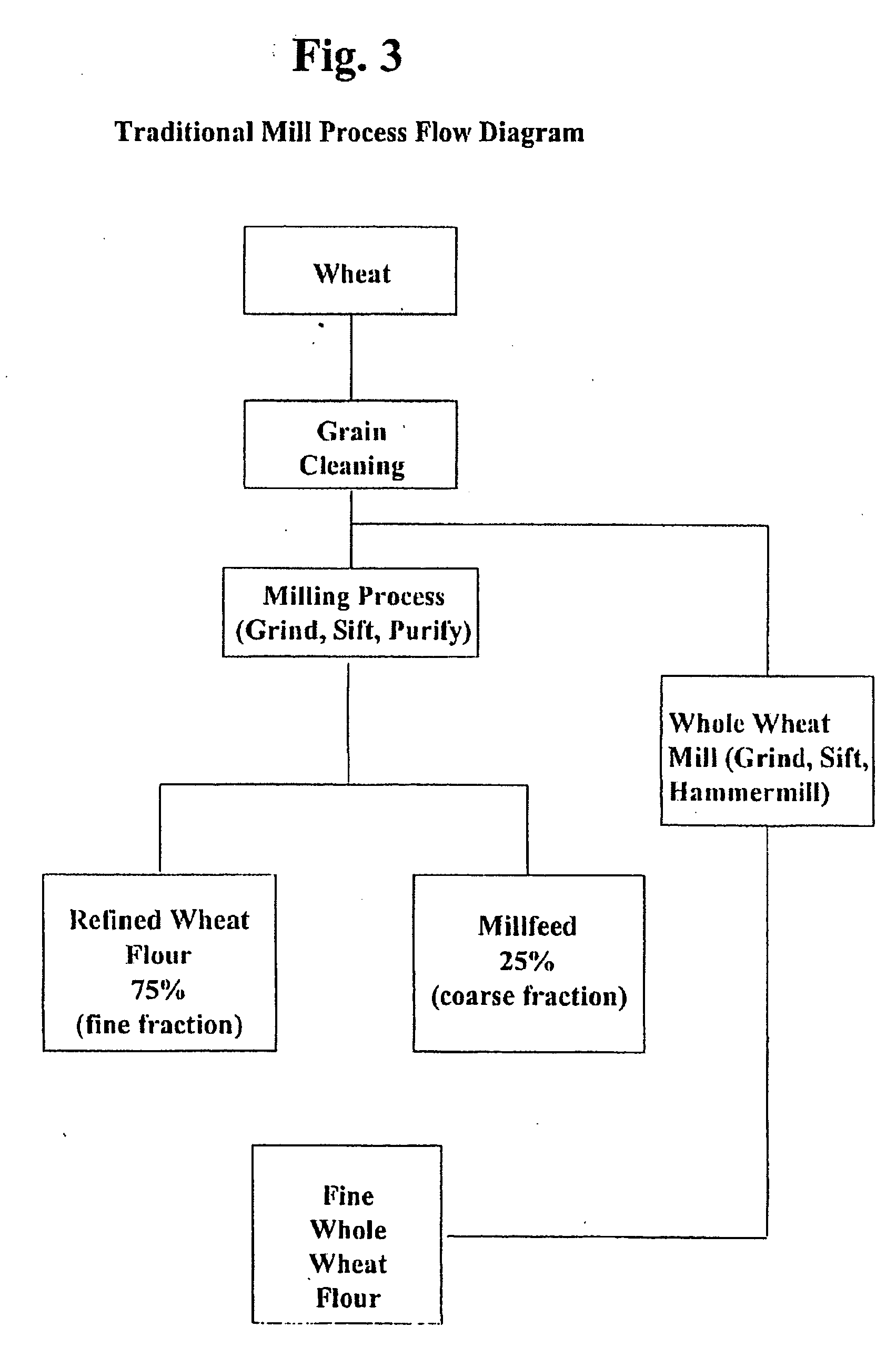

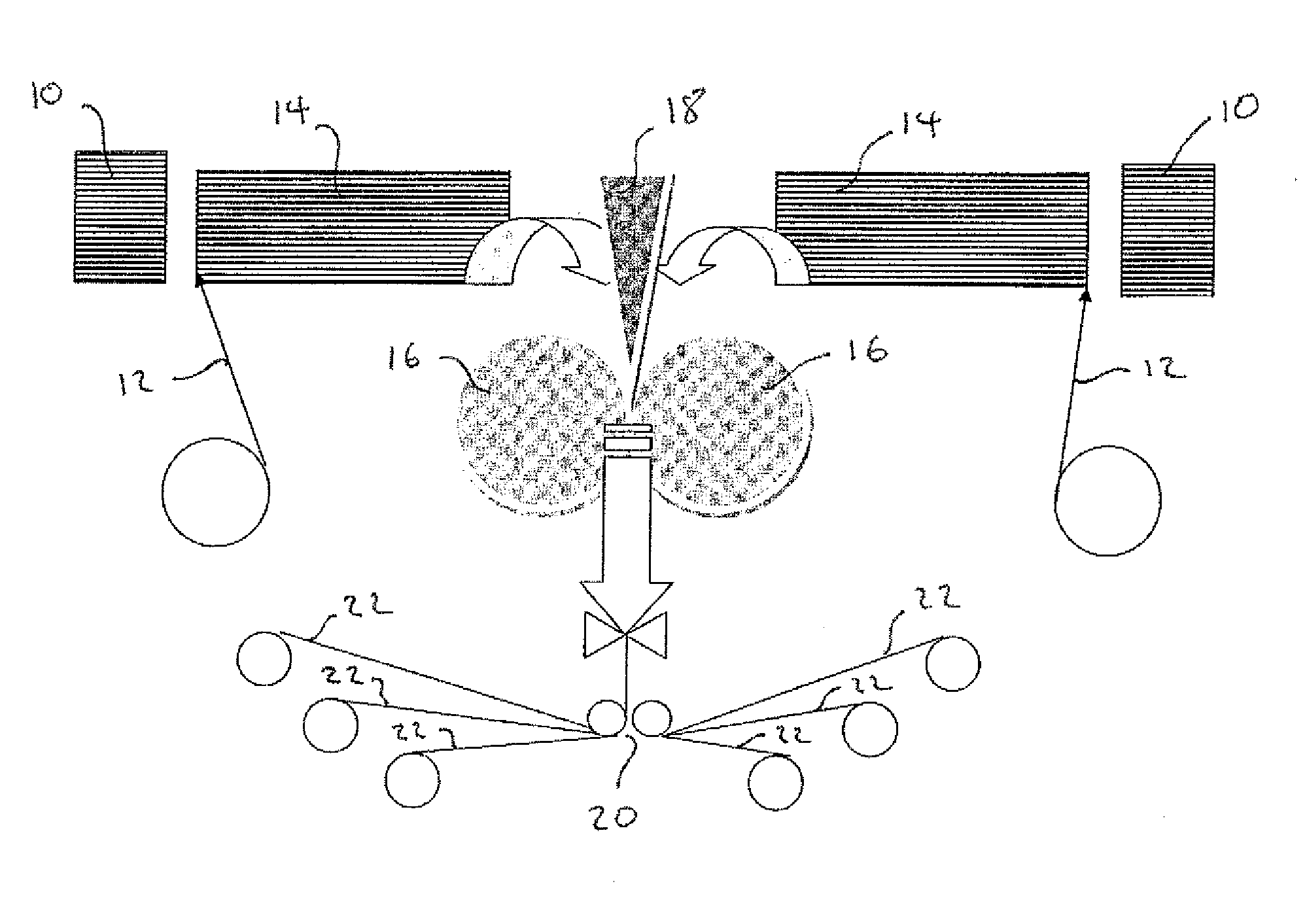

Process for producing an ultrafine-milled whole-grain wheat flour and products thereof

InactiveUS20060073258A1High nutritional valueHigh in fiberDough treatmentGrain treatmentsSnack foodUltra fine

A process for producing an ultrafine-milled whole-grain wheat flour which has the full nutritional value of wheat kernels, while retaining the texture of refined wheat flour and an appearance similar to refined wheat flour, and the products which can be made from the ultrafine-milled whole-grain wheat flour. The process can also be used for producing an ultrafine-milled coarse fraction, which can be used as a replacement and to fortify refined wheat flour. The ultrafine-milled coarse fraction can be used in bakery products, snack products and food products.

Owner:CONAGRA FOODS

Molding material, prepreg and fiber-reinforced composite material, and method for producing fiber-reinforced molding substrate

InactiveUS20100068518A1Increase productivitySatisfactory dispersionCoatingsYarnPolymer scienceFiber bundle

This invention relates to: a molding material comprising a bundle of continuous reinforcing fibers (A), a polyarylene sulfide prepolymer (B) comprising at least 50% by weight of cyclic polyarylene sulfide and having the weight average molecular weight of less than 10,000 or polyarylene sulfide (B′) having the weight average molecular weight of 10,000 or greater and the degree of dispersion of 2.5 or lower, and thermoplastic resin (C); a prepreg comprising a resin composition comprising the polyarylene sulfide prepolymer (B) impregnated into a reinforcing fiber; and a method for producing a fiber-reinforced molding substrate comprising step (I) of continuously feeding a bundle of continuous reinforcing fibers, step (II) of combining cyclic polyarylene sulfide with the reinforcing fiber bundle, step (III) of heating the composite obtained in step (II) to subject the cyclic polyarylene sulfide to ring-opening polymerization to convert into polyarylene sulfide, and step (IV) of cooling the composite obtained in step (III) and withdrawing the same.

Owner:TORAY IND INC

High fiber and high protein baked goods production

InactiveUS20100303991A1Pleasant tastePotential healthDough/pre-mixesConfectioneryStarch gelatinizationHigh protein food

Substantially uniform hydration and dispersion of high amounts of protein and fiber are achieved while avoiding lump formation, hard textures, and off-tastes in the continuous, mass production of high protein and high fiber content sheetable doughs, and baked goods such as crackers, snacks, and cookies made from the sheeted doughs, by hydrating the protein and fiber with water at a temperature below the denaturization temperature of the proteins, and steaming the hydrated mixture without substantial gelatinization of starch during dough production. The steamed, hydrated mass may be admixed with ingredients comprising at least one flour comprising starch to obtain a dough while avoiding substantial gelatinization of starch of the at least one flour during mixing. The baked goods may have a protein content of at least about 4 g, a fiber content of at least about 4 g, and a whole grain flour content of at least about 4 g per 30 g serving.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

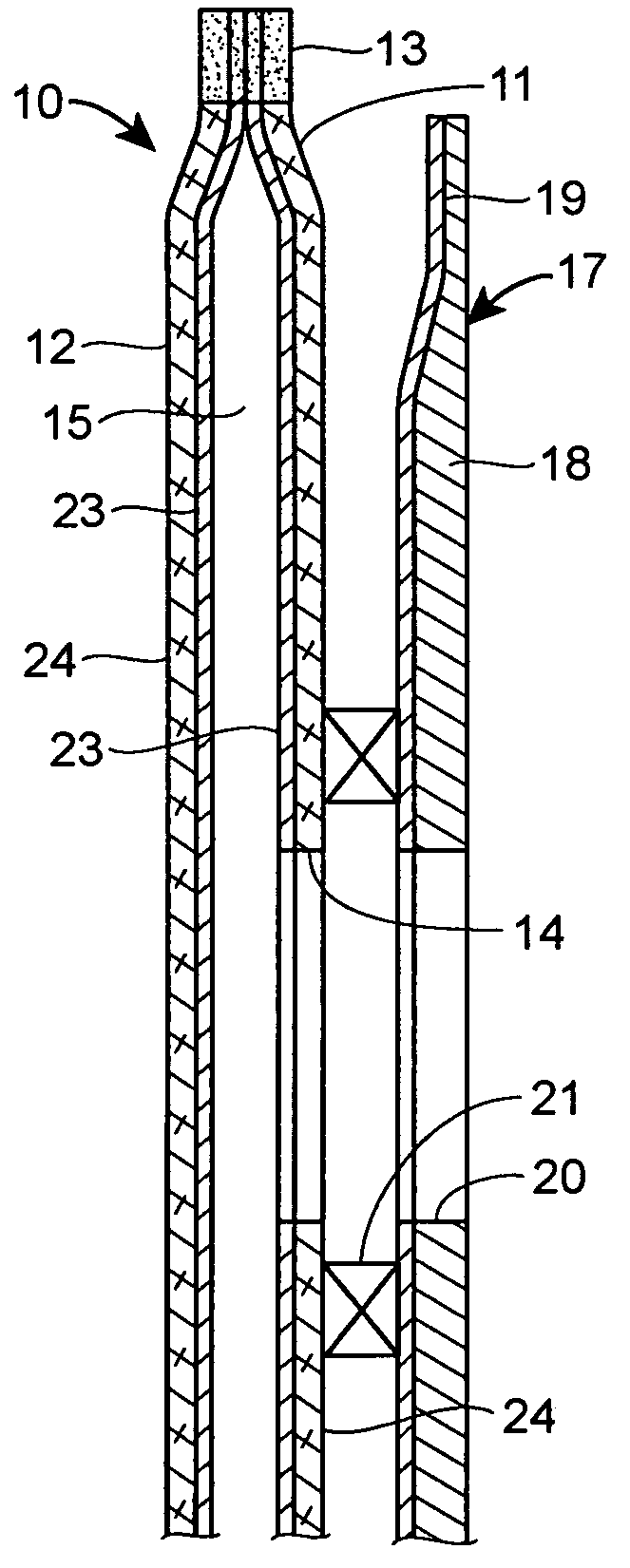

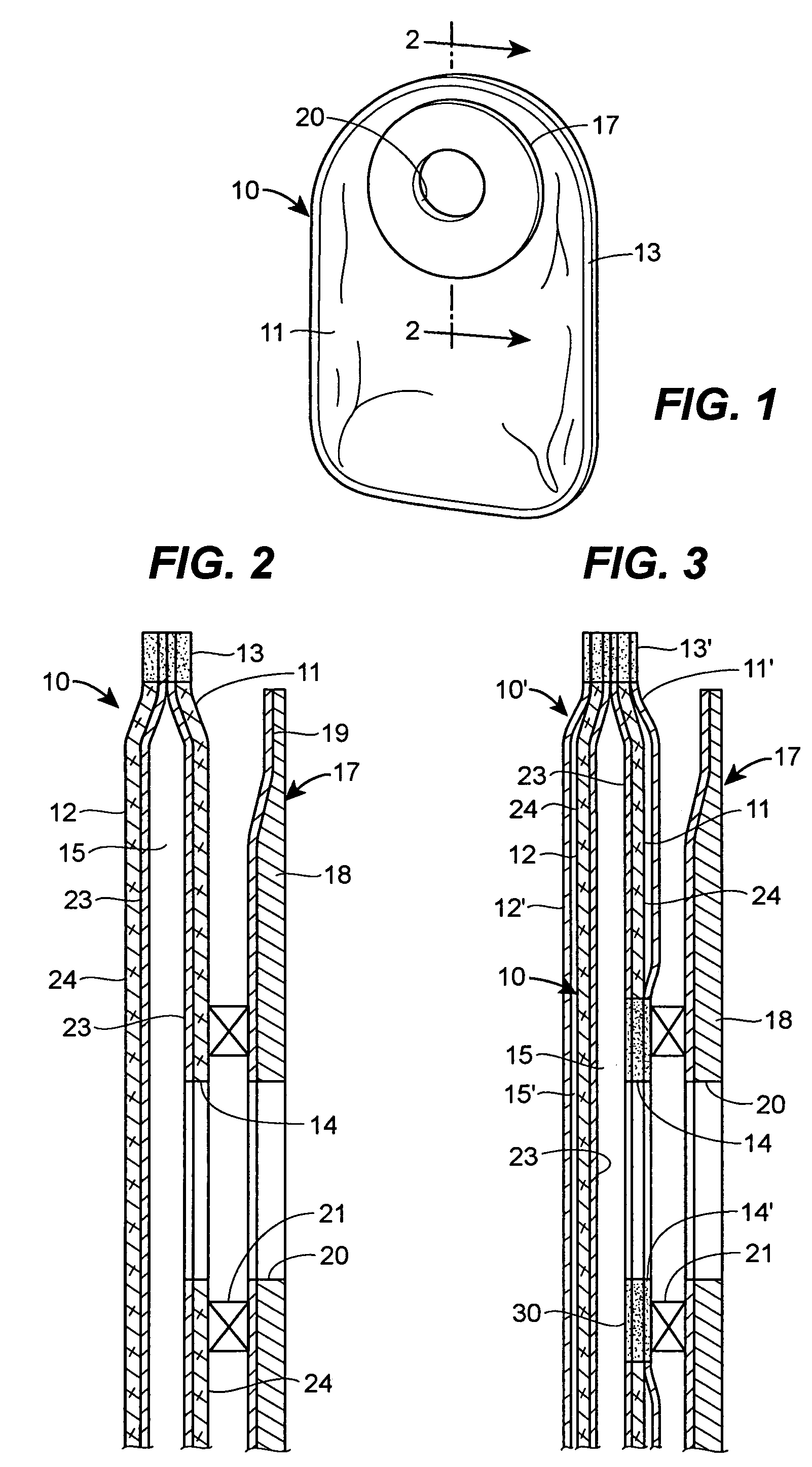

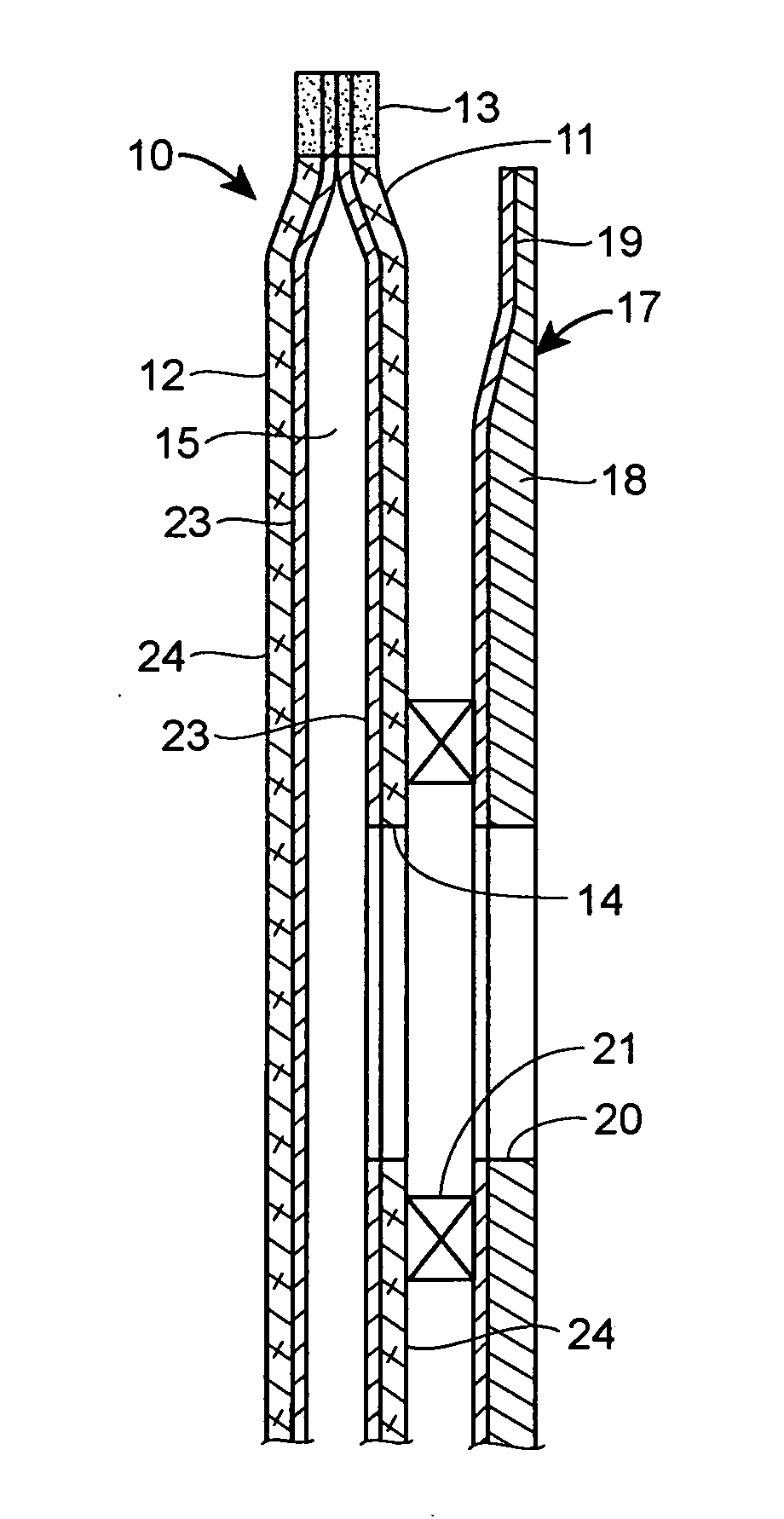

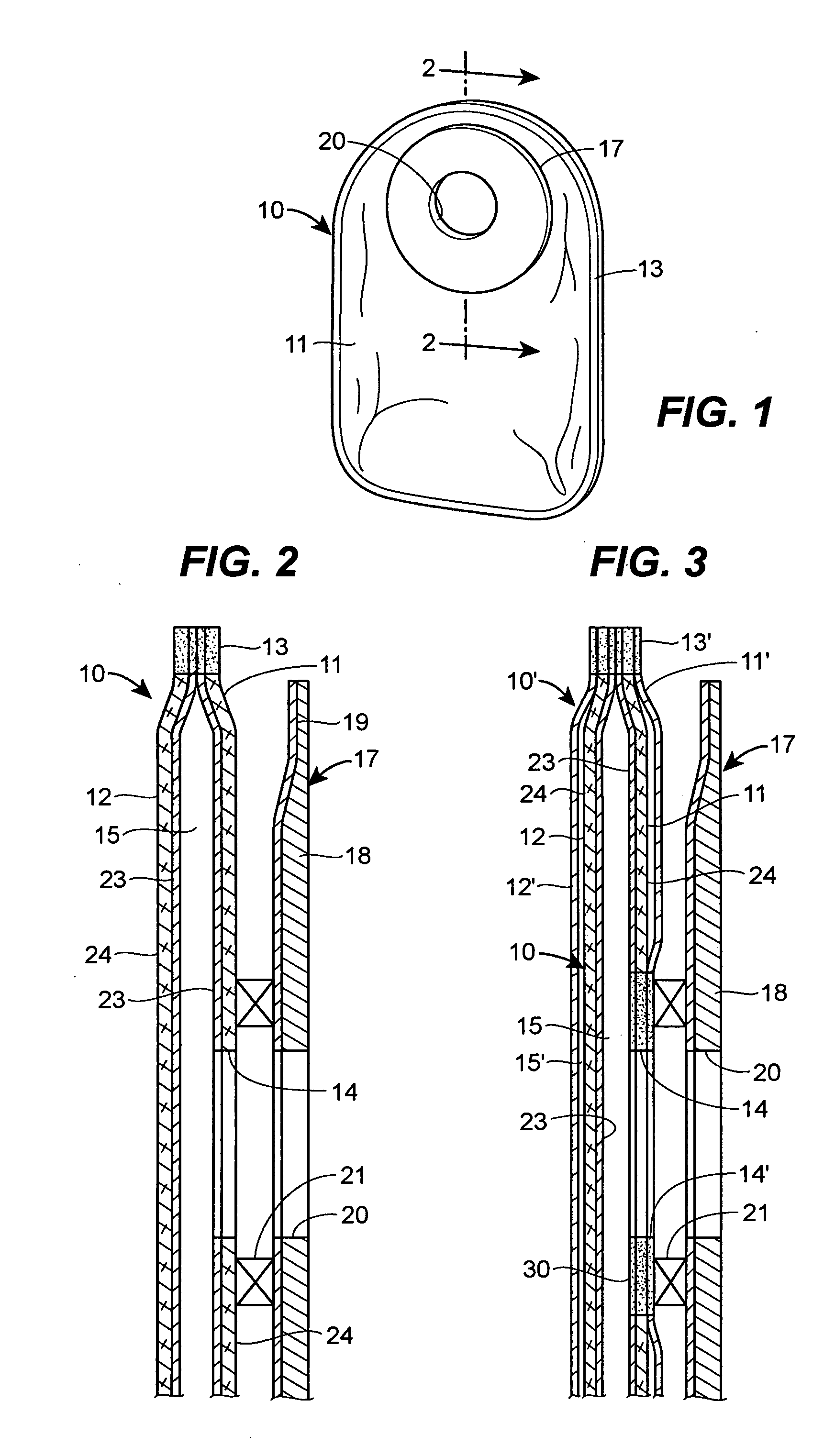

Flushable body waste collection pouch, pouch-in-pouch appliance using the same, and method relating thereto

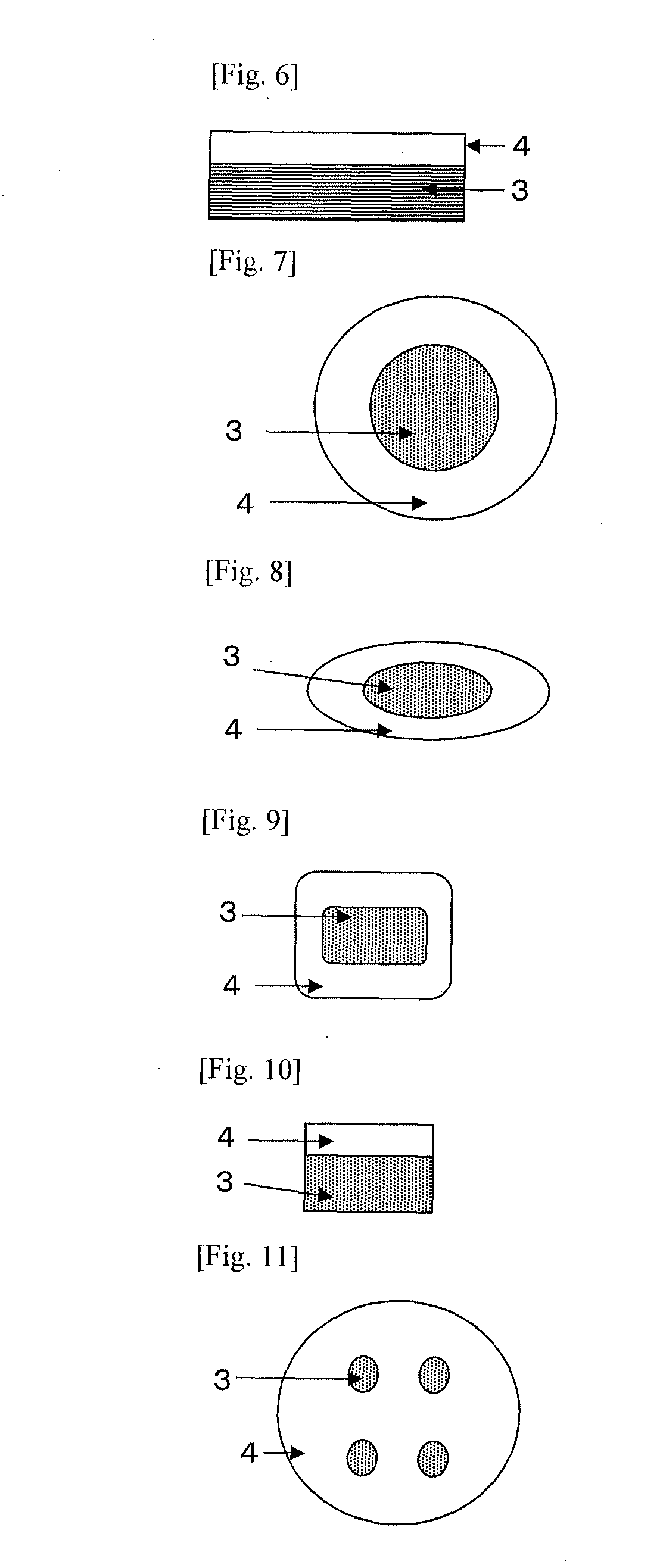

InactiveUS7179245B2Limited biodegradabilityReduce noiseSynthetic resin layered productsNon-surgical orthopedic devicesFiberPolymer science

A biodegradable and toilet-flushable body waste collection pouch, and an appliance in which such pouch constitutes the inner pouch of a peelably separable pouch-in- pouch system, are disclosed. The walls of the inner pouch are composed of an ultra-thin, heat-sealable film impermeable to body wastes comprising a plasticized biodegradable polyester or copolyester externally covered by a soft, porous, water-disintegratable cover layer of biodegradable and water-dispersible fibers.

Owner:HOLLISTER INCORPORAED

High-fiber dairy product

A process for producing a fermented dairy product supplemented with fiber, especially a purified digestion resistant fiber such as maltodextrin, inulin or oligofructose. This process takes advantage of the naturally acidic nature and enzymatic properties of fermented milk products such as yogurt and specific mixing and blending steps which produce a product having a superior organoleptic and textural properties. A fermented dairy product supplemented with at least 1-5% fiber, especially, a purified digestion-resistant fiber such as maltodextrin, inulin or oligofructose.

Owner:DANNON COMPANY INC THE

Process of twice fermenting garbage-sludge mixture to produce microbial fertilizer

ActiveCN1974492ASolve pollutionPromote growthBio-organic fraction processingClimate change adaptationMicroorganismSludge

The present invention is process of twice fermenting garbage-sludge mixture to produce microbial fertilizer. The production process can eliminate environment pollution caused garbage and sludge while providing environment friendly efficient microbial fertilizer. The produced microbial fertilizer has high fertility, beneficial bacteria content up to 10<8>-10<10> / g and various bioactive matters. The produced microbial fertilizer can promote the growth of crop, strengthen the disease resistance of crop and raise yield of crop.

Owner:陕西文岭微生物科技有限公司

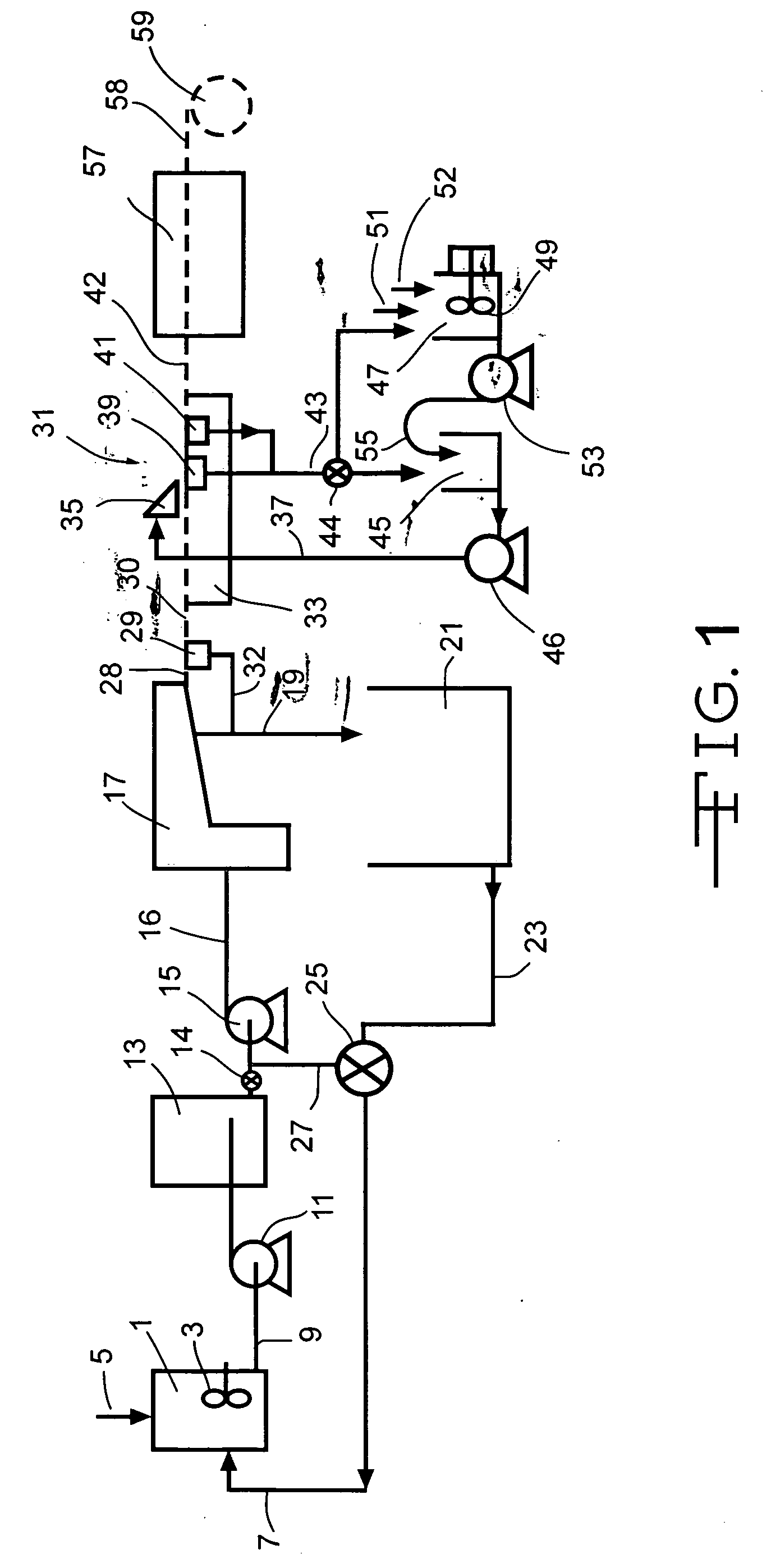

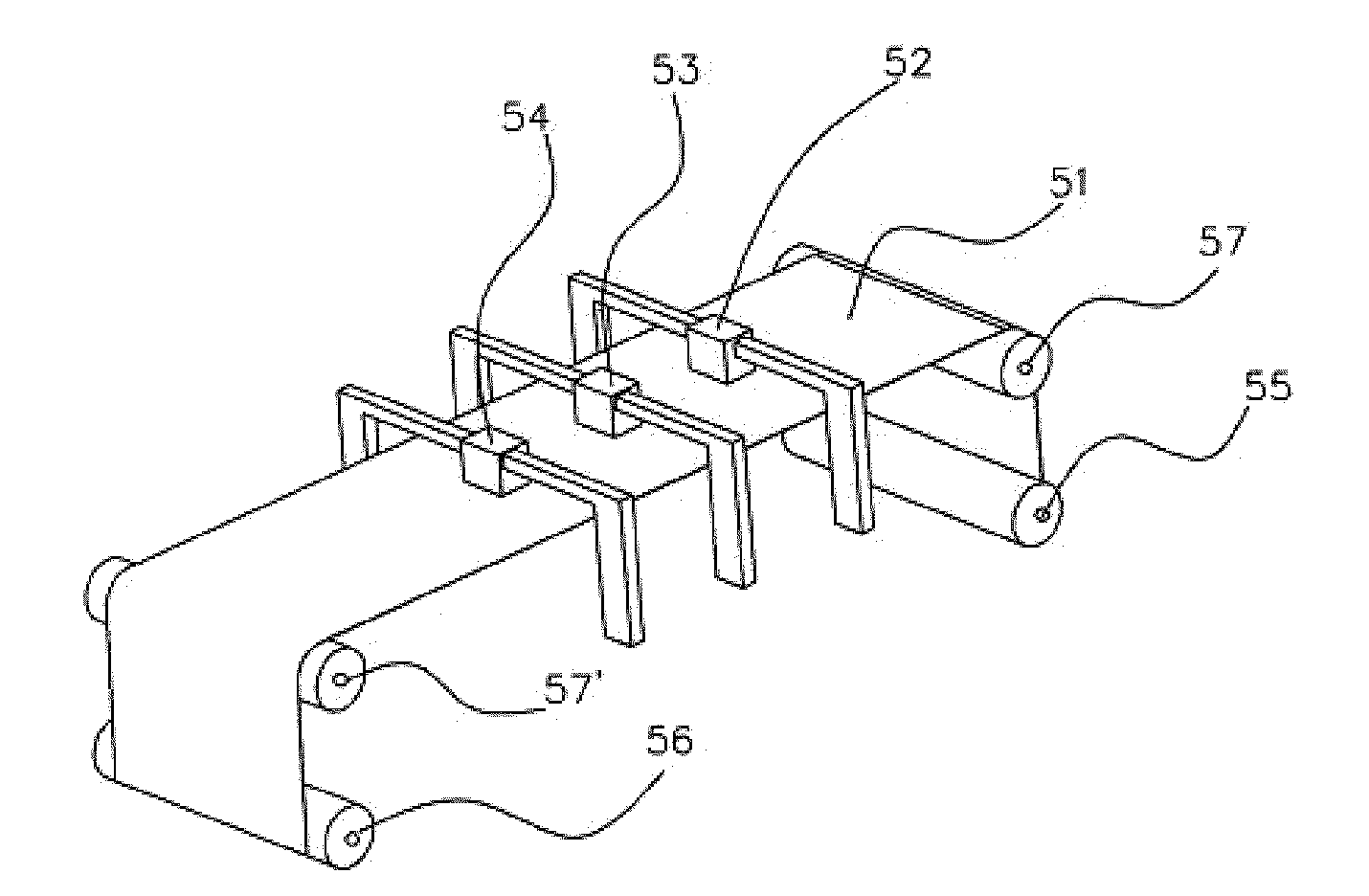

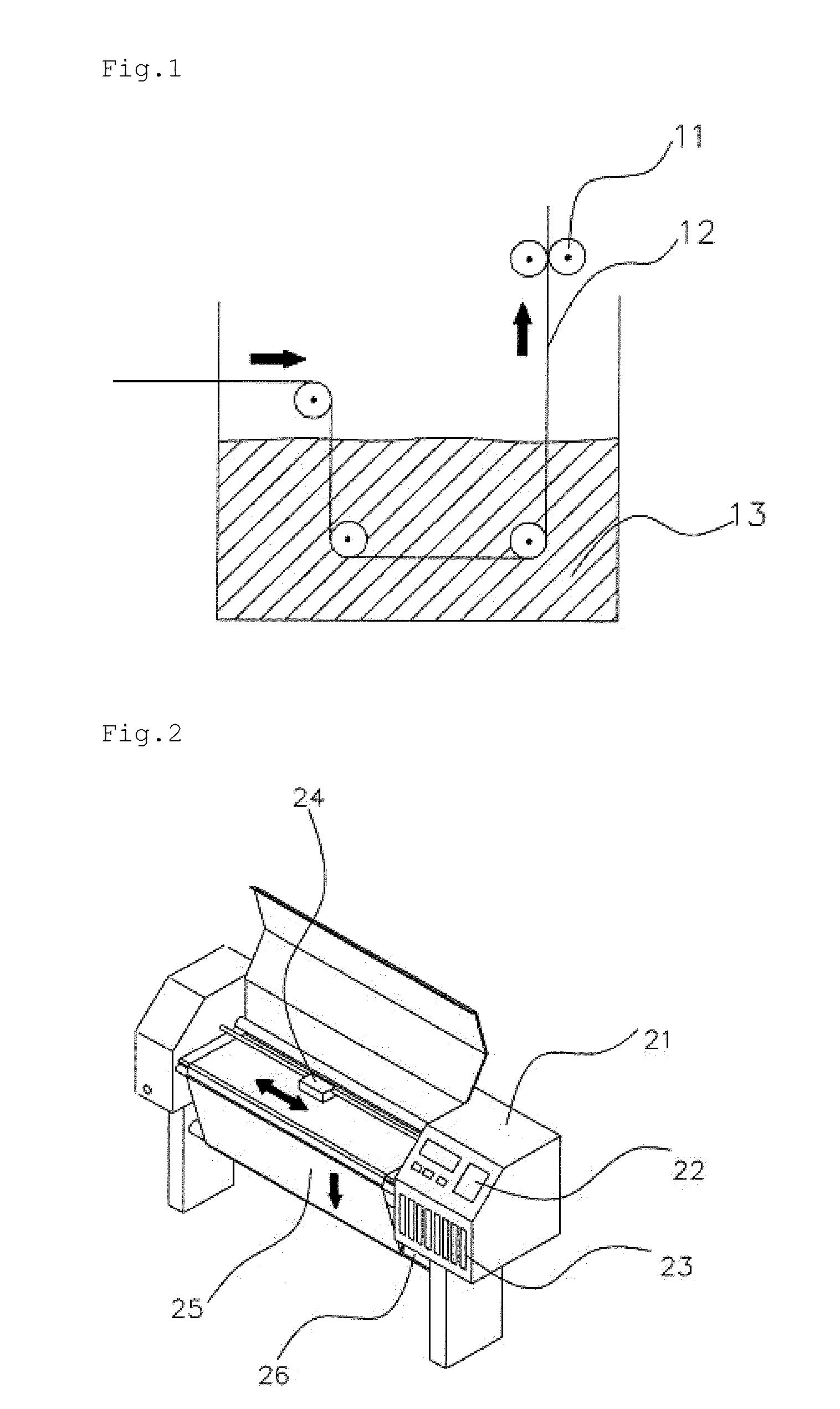

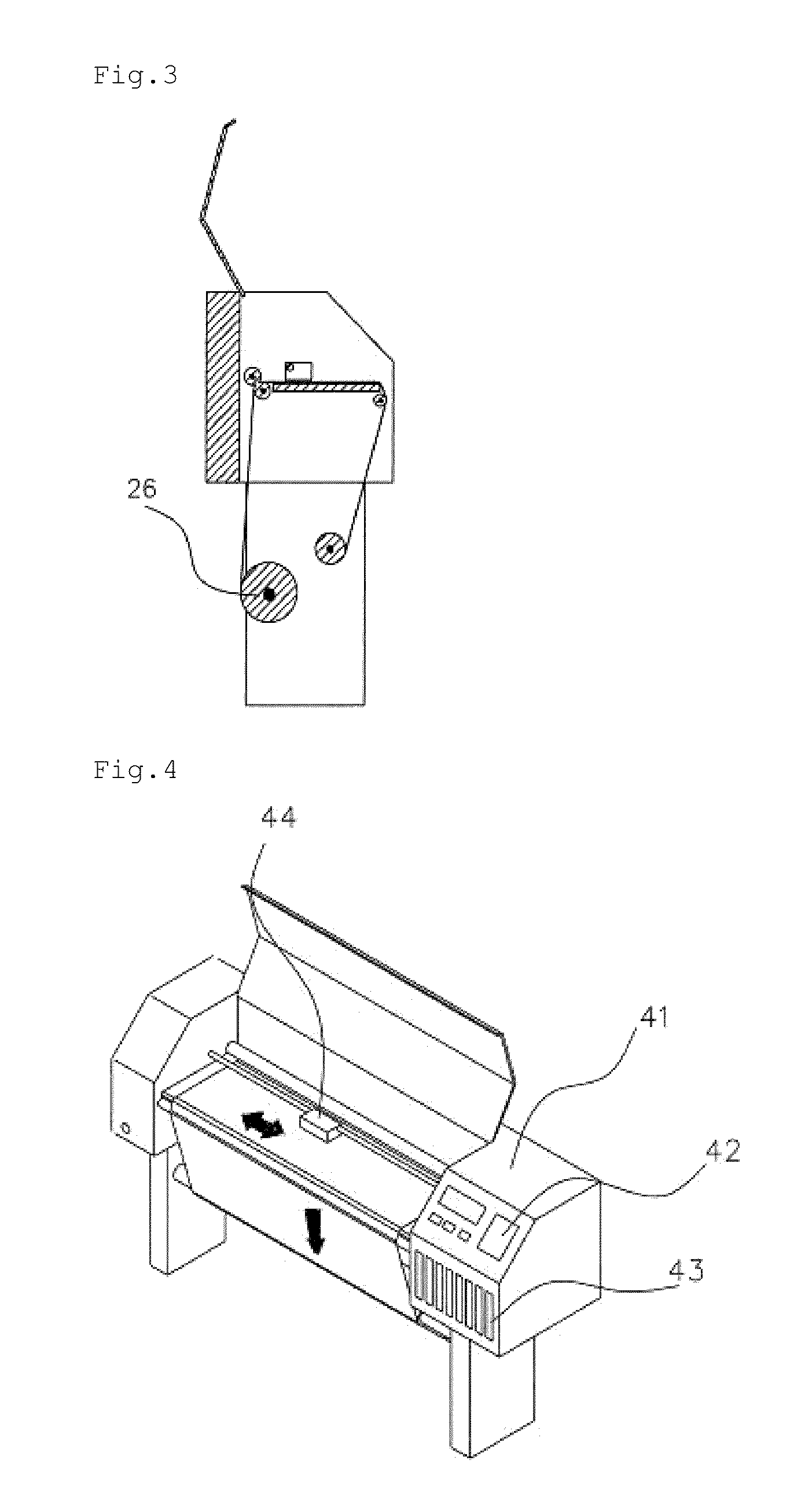

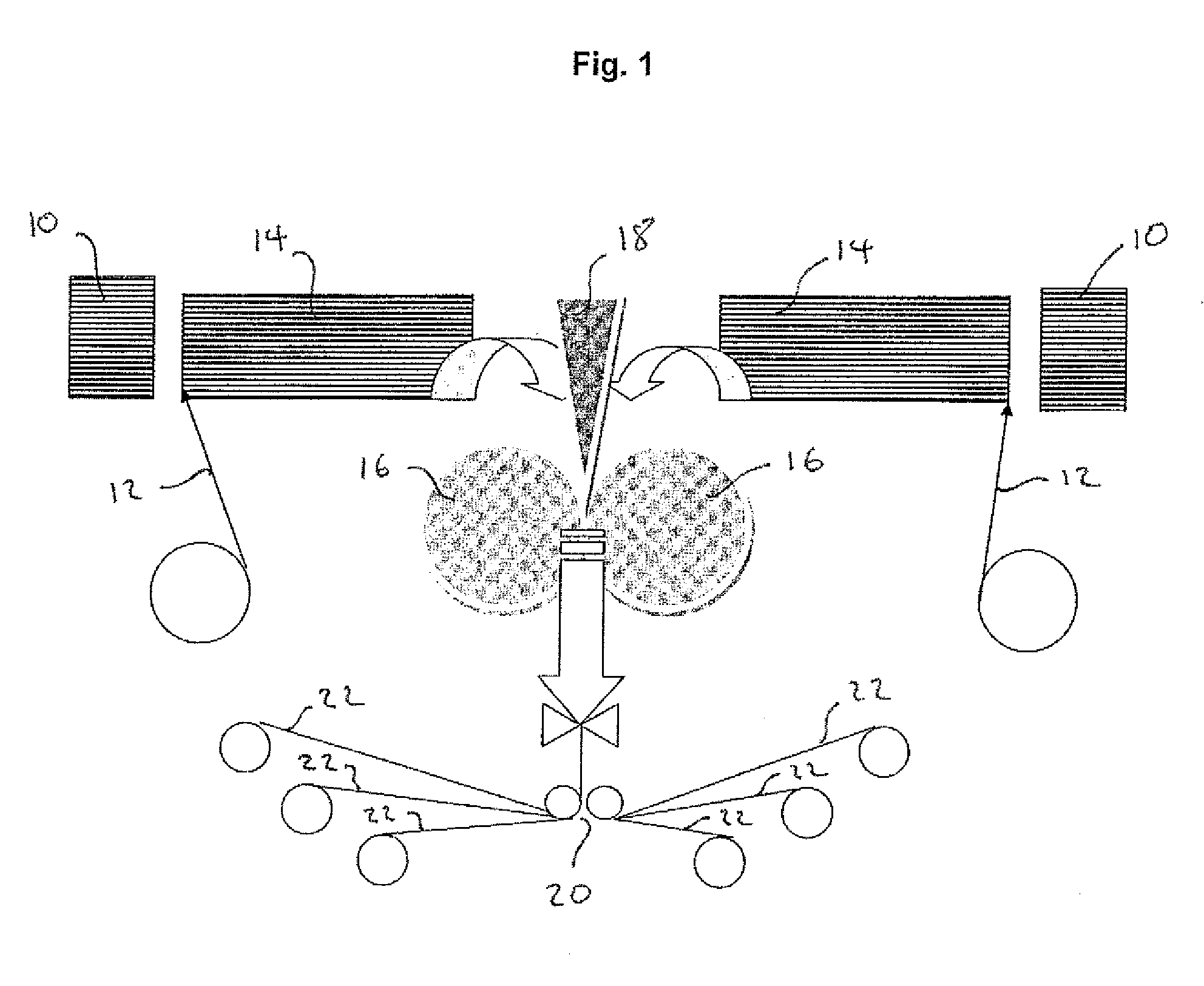

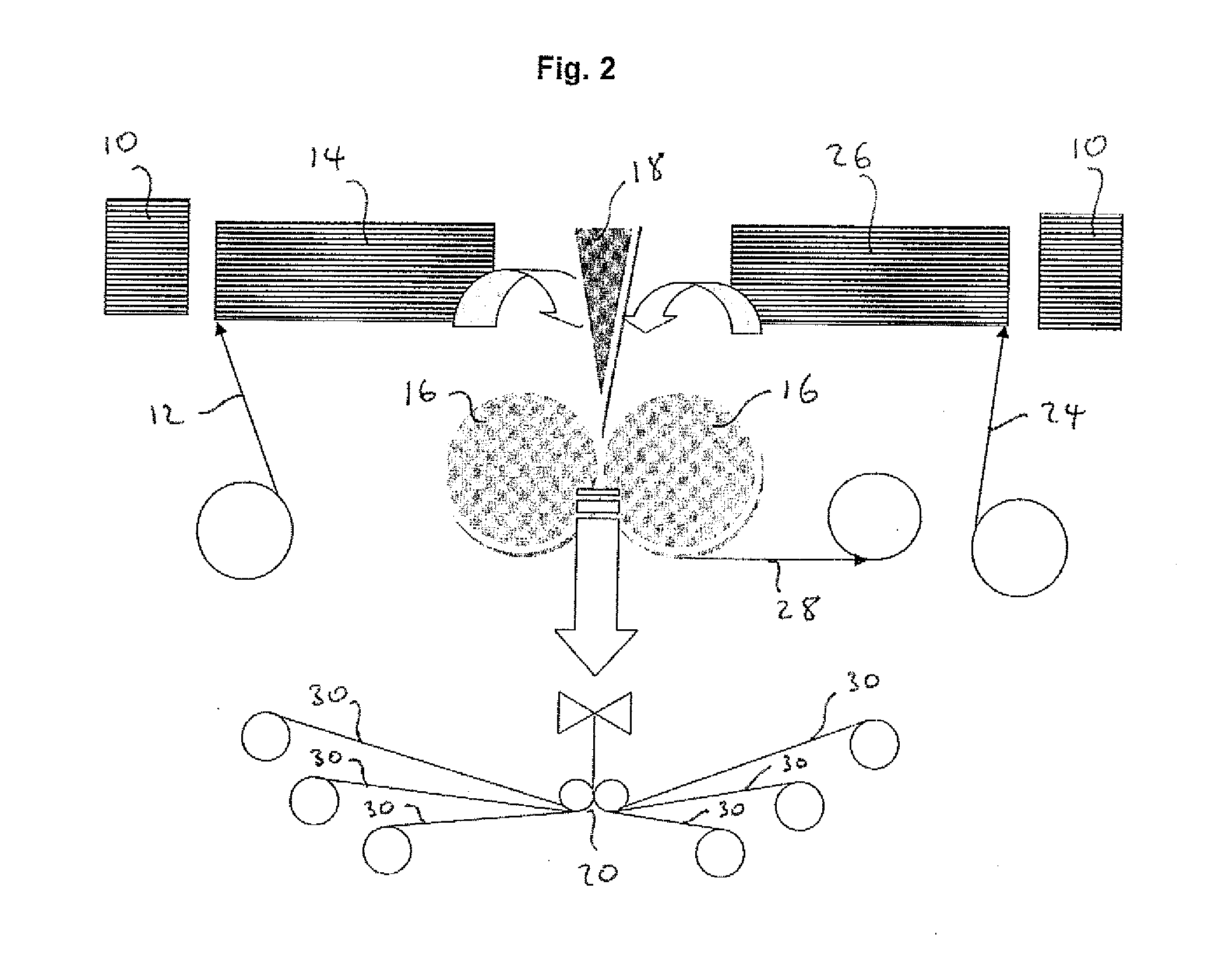

Textile printing method and apparatus applying inkjet printer

InactiveUS20090293209A1Good colorDeterioration in feelingTypewritersDyeing processTextile printerPre treatment

A textile printing method applying inkjet printer comprises the steps for feeding a fabric by a fabric feed roller, applying a pretreatment liquid to the fabric by jetting the pretreatment liquid installed in a pretreatment liquid reservoir installed respective containers filled with individual compositions of a pretreatment liquid, so that such individual compositions are concurrently mixed and applied on the fabric surface to pretreat the fabric by operation of a control unit depending upon the fabric material through a pretreatment head, drying the pretreatment liquid applied to the fabric through a drier, and printing on the dried fabric by jetting the ink installed in a ink reservoir through the printing head. The pretreatment head, the drier and the printing head are serially arranged so that the steps for applying a pretreatment liquid, drying the pretreatment liquid and printing on the dried fabric are concurrently performed.

Owner:INTEC CO LTD

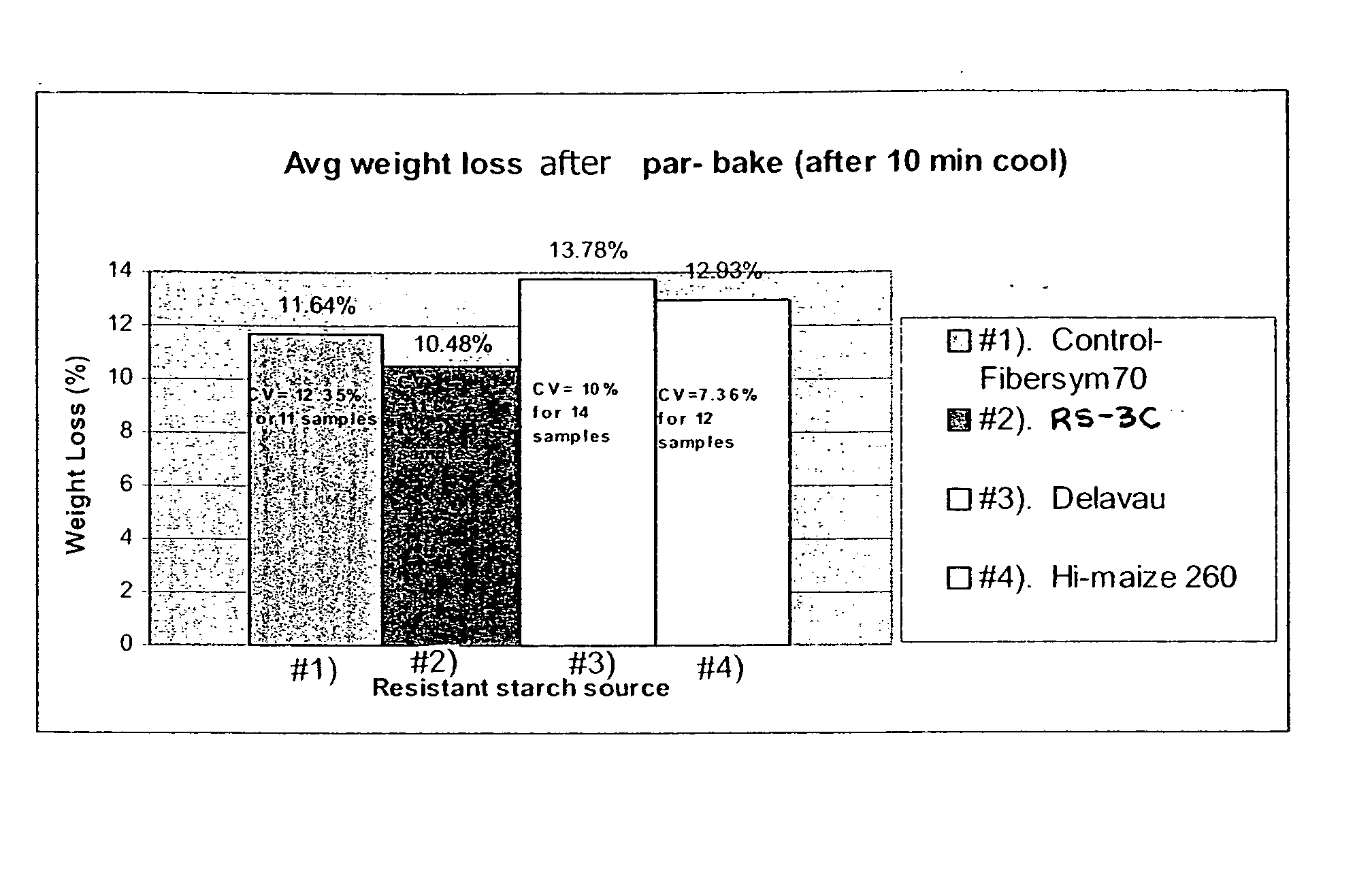

High moisture, high fiber baked products and doughs thereof, and methods

InactiveUS20070207240A1Rapidly and easilyIncrease moistureBakery product refreshing by heating/thawingConfectioneryWater contentMoisture retention

A high moisture, high fiber baked product is provided comprising a high moisture baked component, such as a bread component, comprising a crystalline polysaccharide of a type and amount effective to increase total dietary fiber content retention and reduce firmness as determined by penetration and compression force, of the high moisture baked component as compared to a similar baked product lacking the crystalline polysaccharide. Improved moisture retention can also be obtained. Bread doughs containing the selected crystalline polysaccharide materials and methods of making food products incorporating the dough are also provided.

Owner:KRAFT FOODS GLOBAL BRANDS LLC

Molding material, prepreg, fiber-reinforced composite material, fiber-reinforced composite material laminate, and process for production of fiber-reinforced molding base material

InactiveUS20130295806A1Economical efficiencyEconomical productivityPretreated surfacesWoven fabricsProduction rateFiber-reinforced composite

A molding material is provided including a composite having 1 to 50 wt % of (A) a bundle of continuous reinforcing fibers and 0.1 to 40 wt % of (B) a polyarylene sulfide prepolymer or (B′) a polyarylene sulfide; and 10 to 98.9 wt % of (C) a thermoplastic resin adhered to the composite; wherein the composite further has (D) a zero-valent transition metal compound or (E) a low-valent iron compound in an amount of 0.001 to 20 mol % based on the amount of sulfur atoms contained in the component (B) or (B′). A prepreg and a method of producing a fiber-reinforced molding base material is also provided. By using the molding material according to the present invention which exhibits excellent economic efficiency and productivity, a molded article having excellent mechanical characteristics can be easily produced.

Owner:TORAY IND INC

Food products containing legume products and processes for producing the food products

InactiveUS20070087107A1Increase awarenessIncrease contentFood shapingFood preparationFood productsLegume

Food products containing legume products, as well as processes for producing the food products are disclosed.

Owner:ARCHER DANIELS MIDLAND CO

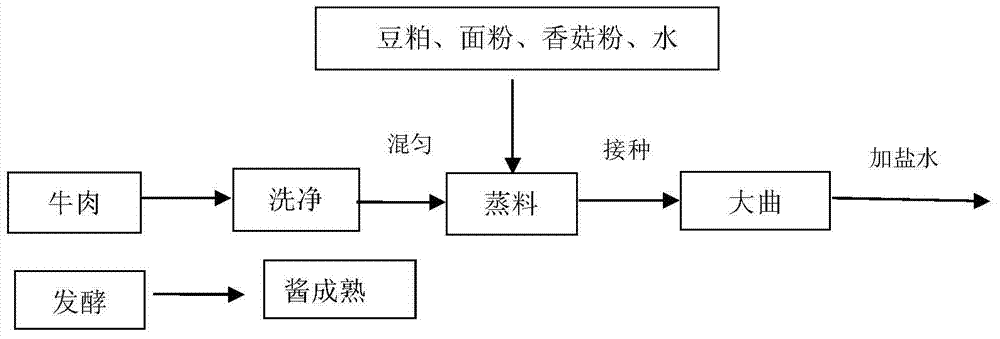

Fermentation type beef sauce and preparation method thereof

InactiveCN103478683ASpecial flavorSpecial colorYeast food ingredientsFood ingredient functionsFlavorYeast

The invention relates to a preparation method of a beef sauce. According to the preparation method, raw materials comprise beef, bean pulp, flour, lentinus edodes powder, salt and water. A production process adopts a low-salt solid-state fermentation method; fermentation strains adopt aspergillus oryzae A100-8, a salt-tolerant yeast S3-2 and salt-tolerant lactobacillus. The specific steps comprise preparation of aspergillus oryzae A100-8 koji, preparation of beef sauce yeast and fermentation of the beef sauce. According to the preparation method, the beef and the bean pulp are mixed and fermented to according to different nutritional characteristics of animal proteins and plant proteins so as to prepare a sauce product with abundant nutrition and unique flavor; the beef sauce has a prominent aroma and a delicious mouth feel, and also has the nutrition supplementary effects of the animal proteins and the plant proteins; the beef sauce is favored by consumers.

Owner:TIANJIN UNIV OF SCI & TECH

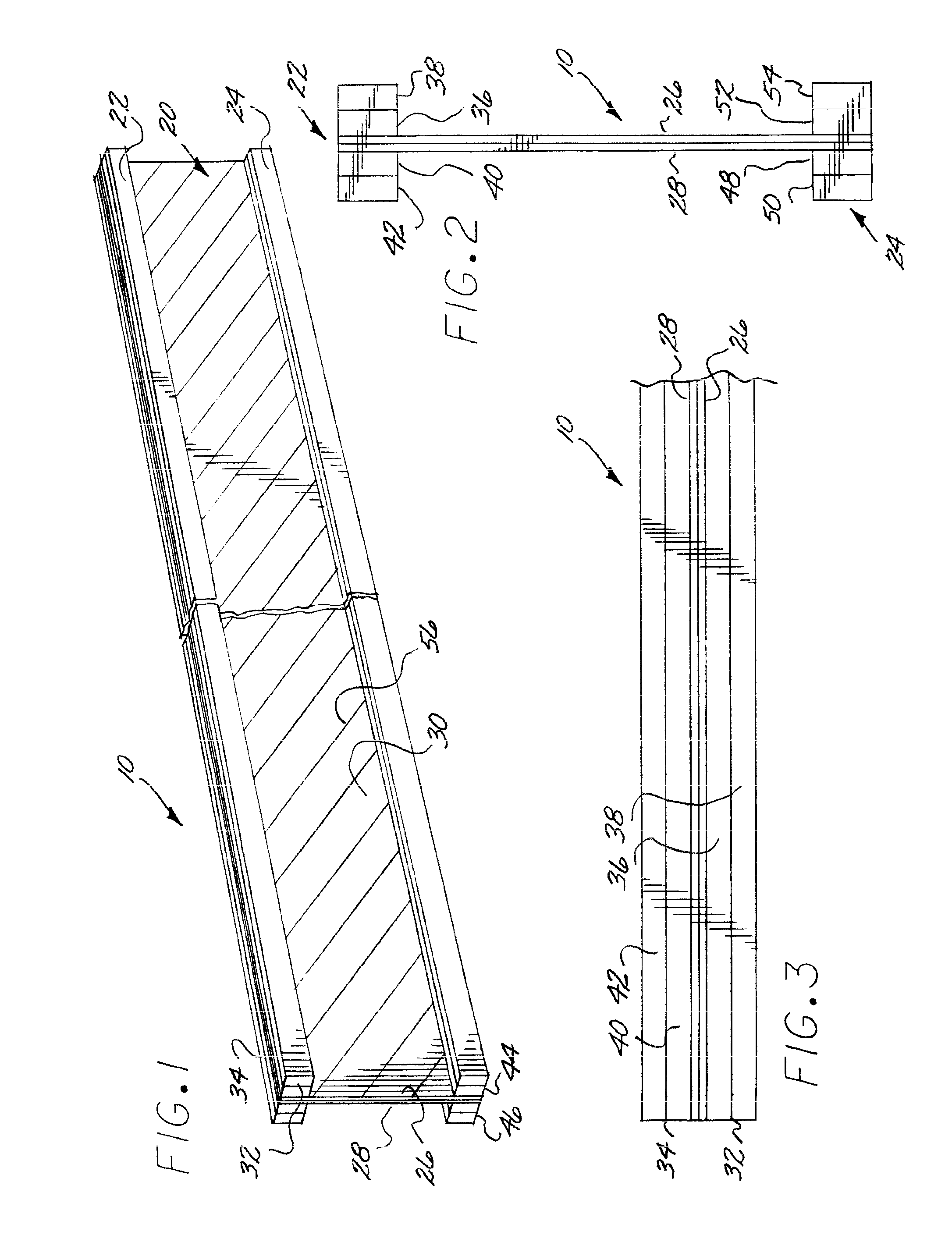

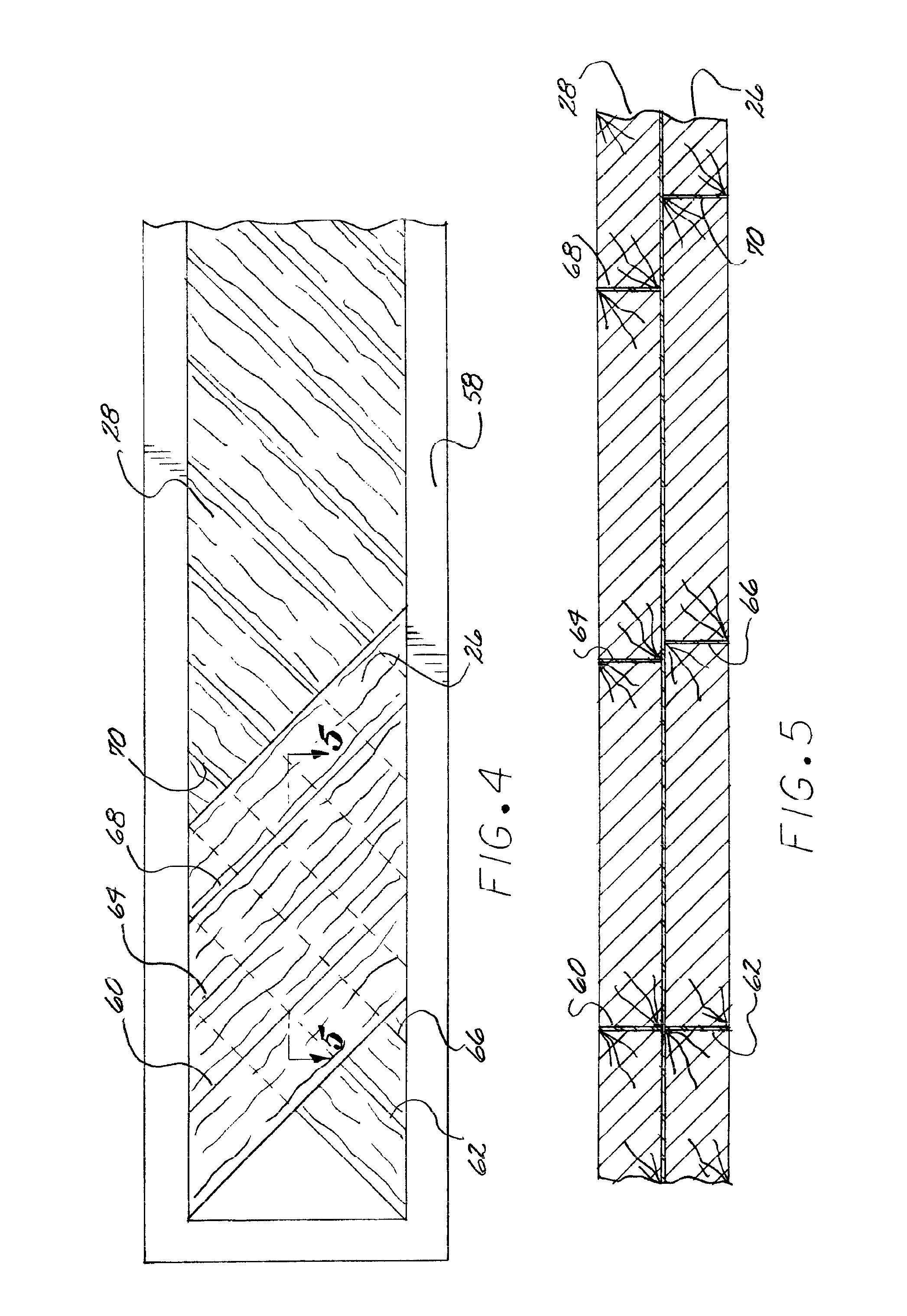

Bamboo I-beam with laminated web and flanges

A high strength bamboo I-beam is provided comprising a bamboo web formed from bamboo boards formed by splaying, pressing and planing bamboo culm and having flanges laminated to the top and bottom of the web. The I-beam flanges each comprise a laminated bamboo flange element on either side of the web portion wherein the top and bottom edges of the web portion are flush with the top and bottom flanges of the I-beam. The flange elements are formed from laminated strips of splayed, pressed and planed bamboo culm. The I-beam is bonded with non-formaldehyde adhesives. Orientation of the high fiber cortex regions of the bamboo boards imparts structural characteristics to the beam. The bamboo I-beam provides a lightweight, low cost, high strength, and fire resistant load bearing construction component.

Owner:BAMCORE

Process for producing an ultrafine-milled whole-grain wheat flour and products thereof

ActiveUS20050136174A1High nutritional valueHigh in fiberDough treatmentFood shapingWheat flourFood products

A process for producing an ultrafine-milled whole-grain wheat flour which has the full nutritional value of wheat kernels, while retaining the texture of refined wheat flour and an appearance similar to refined wheat flour, and the products which can be made from the ultrafine-milled whole-grain wheat flour. The process can also be used for producing an ultrafine-milled coarse fraction, which can be used as a replacement and to fortify refined wheat flour. The ultrafine-milled coarse fraction can be used in bakery products, snack products and food products.

Owner:ARDENT MILLS

Composite materials

ActiveUS20120114899A1High in fiberEliminate the problemFinal product manufactureBaby linensTurbine bladeWork in process

A curable prepreg or semipreg material comprising a layer of fibres and a substantially non-flowable curable resin having a layer of porous sheet material on an outer surface, the material allows automatic lay-up of high fibre content prepregs or semiprepregs typically used in industrial applications such as wind turbine blades.

Owner:HEXCEL COMPOSITES LTD (GB)

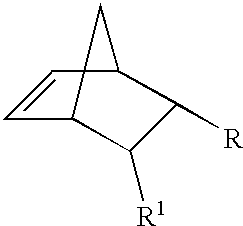

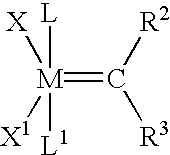

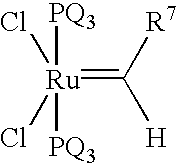

Catalyzed reinforced polymer composites

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Flushable body waste collection pouch, pouch-in-pouch appliance using the same, and method relating thereto

InactiveUS20050084634A1Limited biodegradabilityReduce noiseSynthetic resin layered productsNon-surgical orthopedic devicesFiberPolymer science

A biodegradable and toilet-flushable body waste collection pouch, and an appliance and method in which such pouch constitutes the inner pouch of a peelably separable pouch-in-pouch system, are disclosed. The walls of the inner pouch are composed of an ultra-thin, heat-sealable film impermeable to body wastes comprising a plasticized biodegradable polyester or copolyester externally covered by a soft, porous, water-disintegratable cover layer of biodegradable and water-dispersible fibers. The cover layer and film are weakly bonded together in such a way as to avoid pinholes in the film that might otherwise be caused by the fibers. When used as the inner pouch of a pouch-in-pouch system, the film of the outer pouch is selected to have a melting temperature higher than that of the inner pouch film, with the result that a peripheral heat seal joining the walls of the two pouches together will allow the walls of the outer pouch to be peeled away without delaminating the film and cover layers of the inner pouch.

Owner:HOLLISTER INCORPORAED

Pretreatment method and apparatus of textile applying inkjet printer, digital textile printing method and apparatus comprising it

InactiveUS20070040879A1Good colorDeterioration in feelingMeasurement apparatus componentsTypewritersPretreatment methodProcess engineering

The present invention is to provide a method and an apparatus for overcoming complication of the pretreating process due to diversification of materials by digitalizing a method for pretreating a fabric in an inkjet printing process by using an inkjet device, and further, an inkjet printing method and an inkjet printing apparatus for enabling the inkjet printing work to be continuously conducted on the basis of the said pretreatment. The present invention comprises a pretreatment liquid reservoir for enabling the pretreatment mixed liquid to be applied or respective containers to be filled with individual component compositions of a pretreatment liquid, a control unit for controlling application of the pretreatment liquid and a pretreatment head for applying the pretreatment liquid to the fabric, and it may additionally comprise a dryer for drying the pretreated fabric and a printing head for performing the actual printing work. The present invention can solve the problems incidental to the conventional pretreating method and further provide a method and an apparatus for enabling a continuous process to be executed.

Owner:INKTEC CO LTD

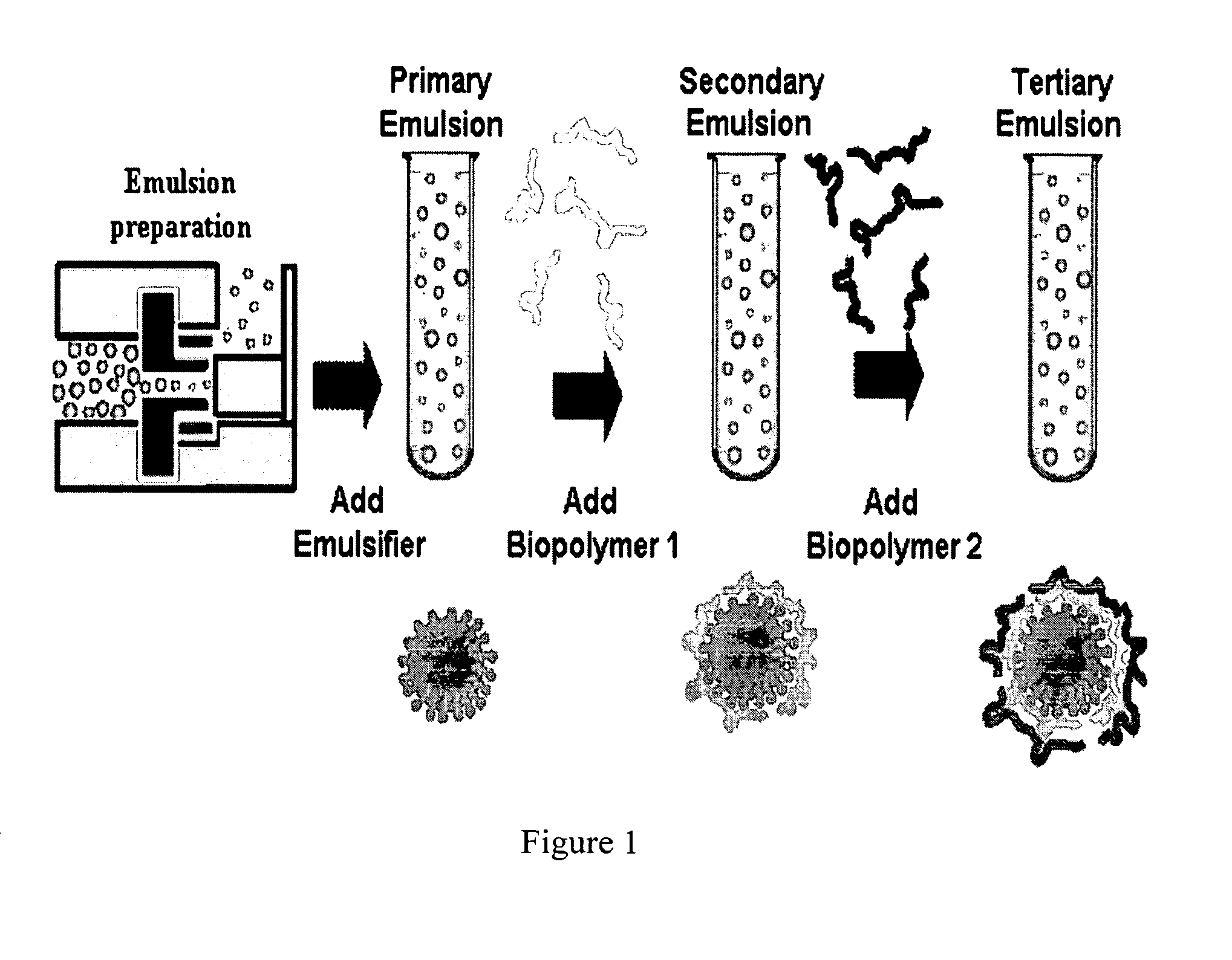

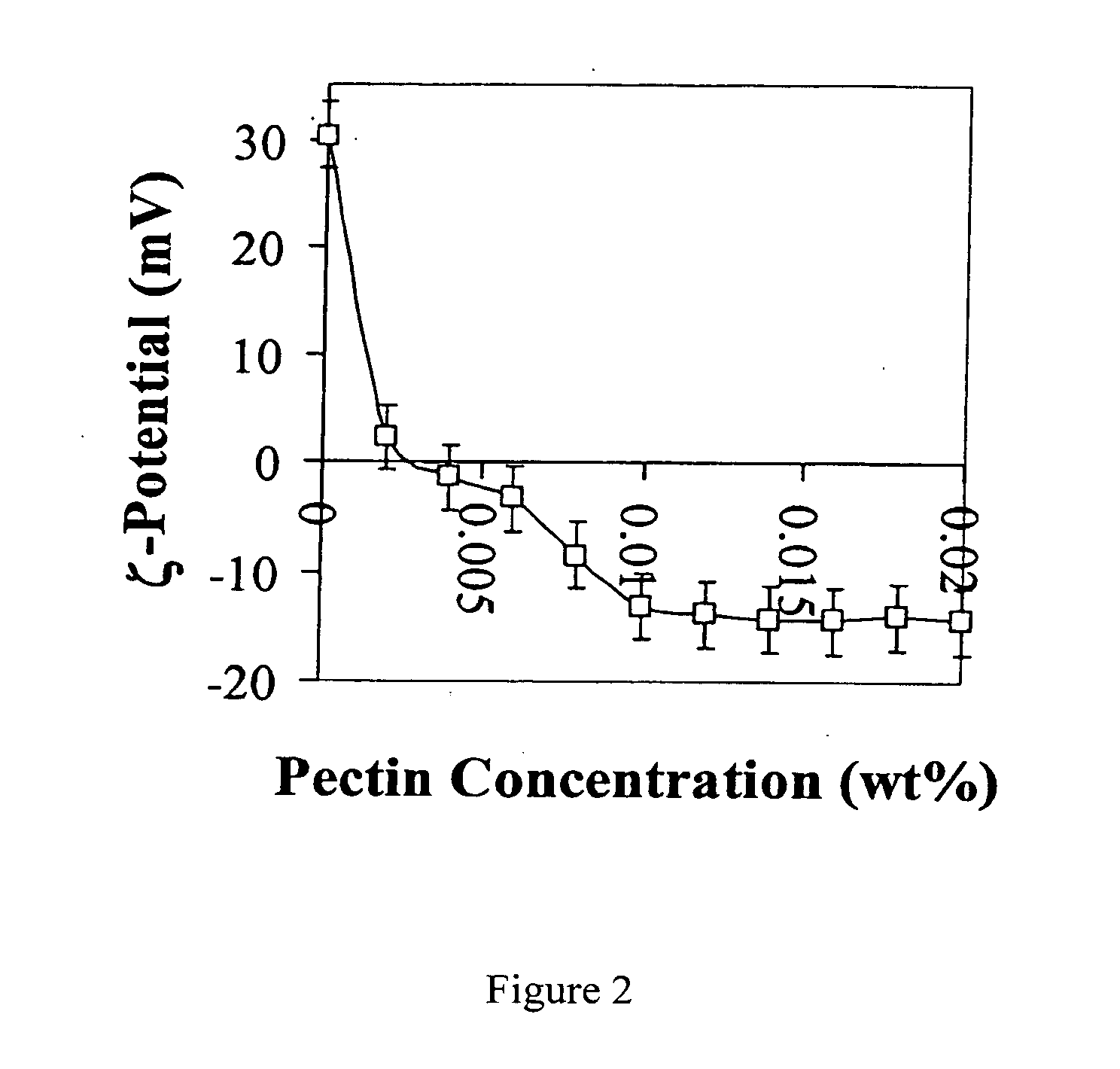

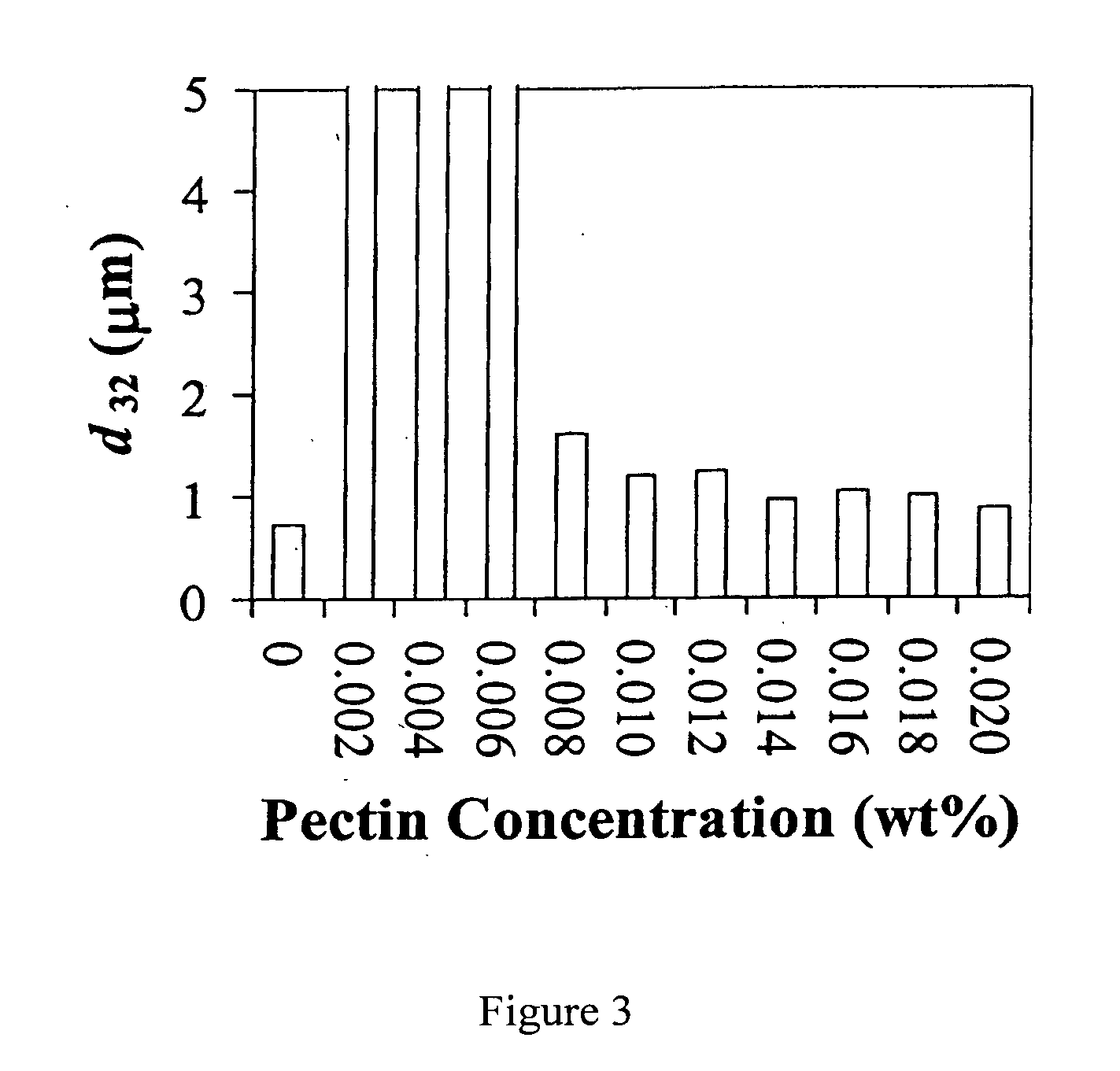

Biopolymer encapsulation and stabilization of lipid systems and methods for utilization thereof

ActiveUS20050202149A1Easily substitutedImpacting tasteMicroballoon preparationFood preparationLipid formationFood grade

An emulsion system and method for controlling the digestion of a fat or an oil component is provided including a substantially hydrophobic food-grade component, and at least one of an emulsifier component, and one or more of polymeric components, wherein at least one of the emulsifier component and the polymeric component comprises a substantially indigestible food-grade material, such as an indigestible dietary fiber. The emulsifier component and / or the polymeric component can be selected so that the overall interfacial membrane is indigestible to humans and / or animals.

Owner:UNIV OF MASSACHUSETTS

Sweet potato compositions

InactiveUS20060286242A1Desired propertyHigh in fiberDough treatmentBaking mixturesSnack foodChip fracture

A sweet potato snack chip which is made by cooking dough that contains a sweet potato flour composition that includes sweet potato powder, sweet potato flakes and mixtures of these. The sweet potato snack chip has a chip density of from about 0.6 g / ml to about 2.0 g / ml, and a chip fracture strength of from about 400 gf to about 900 gf. The preferred dough formed from the sweet potato flour composition is sheetable and cohesive. Fabricated snacks made from this dough have desirable taste and texture characteristics.

Owner:KELLOGG NORTH AMERICA

Fermented product based on an oat suspension

InactiveUS7160564B2Low in proteinReduce fiber contentMilk preparationTea extractionProduct baseSoured cream

A fermented product selected from yogurt, yogurt drink, smothie, crème fraiche, sour cream, and spread is disclosed. The fermented product is based on an oat suspension essentially free from soy and dairy milk. Also disclosed is a process for preparing the product, and a starter culture useful in the process.

Owner:OATLY AB

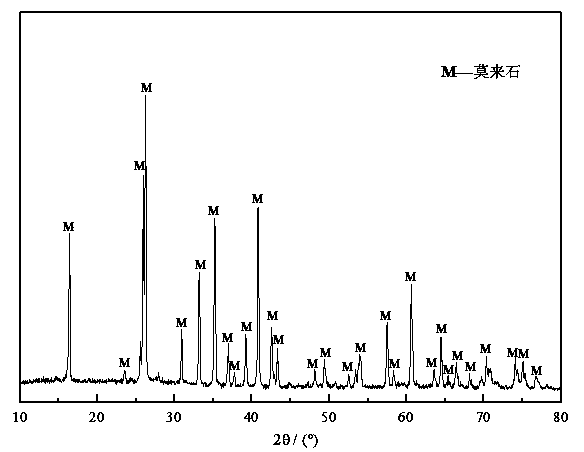

Preparation method of self-reinforced mullite porous ceramic

The invention relates to a preparation method of self-reinforced mullite porous ceramic. The preparation method comprises the following technical steps: carrying out dosing on 30-50% by mass of a mineral or solid waste containing Al2O3 and SiO2, 25-55% by mass of industrial alumina powder and 0.5-30% by mass of starch, adding 1-30% by mass of ammonium salt additives in total mass of the mixture, regulating the molar ratio of Al2O3 to SiO2 in the raw materials to be 3:2, and carrying out mixing, carrying out ball milling and forming; sintering a formed biscuit for 1-6 hours at the temperature of 1400-1600 DEG C, so as to obtain the self-reinforced mullite porous ceramic. The self-reinforced mullite porous ceramic prepared by utilizing the preparation method is in-situ fiber-reinforced mullite porous ceramic having the characteristics that mullite is taken as a primary crystalline phase, the strength is high (40-80MPa), the porosity is high (30-60%), and the aperture is small.

Owner:NORTHEASTERN UNIV

High fibre high calorie liquid or powdered nutritional composition

The present invention relates to a nutritional composition which is liquid and shelf-stable or powdered and reconstitutable. The composition has a fiber content of more than 2.5 g / fibber per 100 ml of the composition. Furthermore, it has an energy content of 1.3-1.8 kcal / ml. The composition is useful to improve and maintain gut comfort, restoring a well-balanced gut flora, especially in an elderly patient prone to malnutrition. The invention further relates to a process for preparing the nutritional composition.

Owner:NESTEC SA

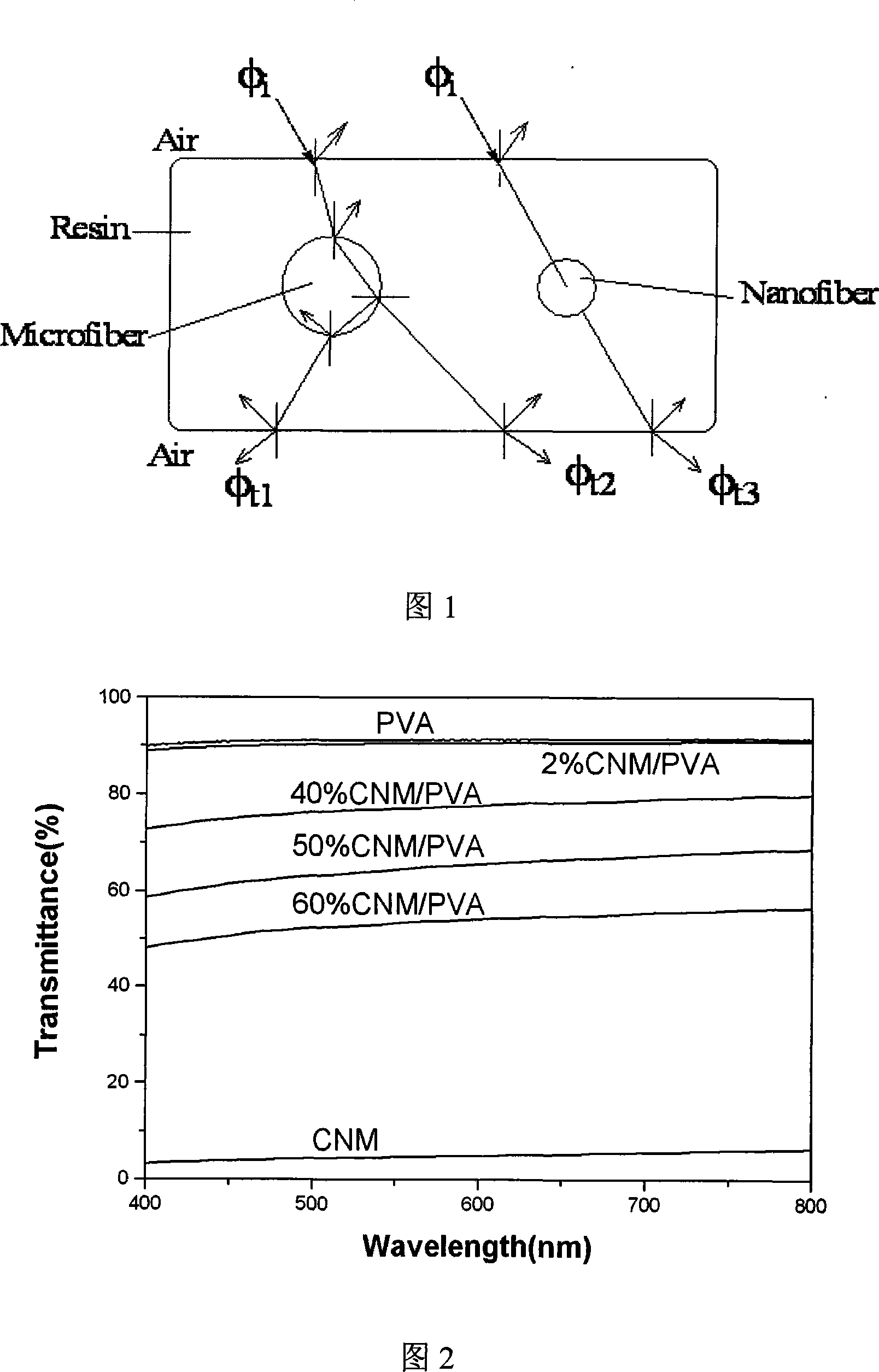

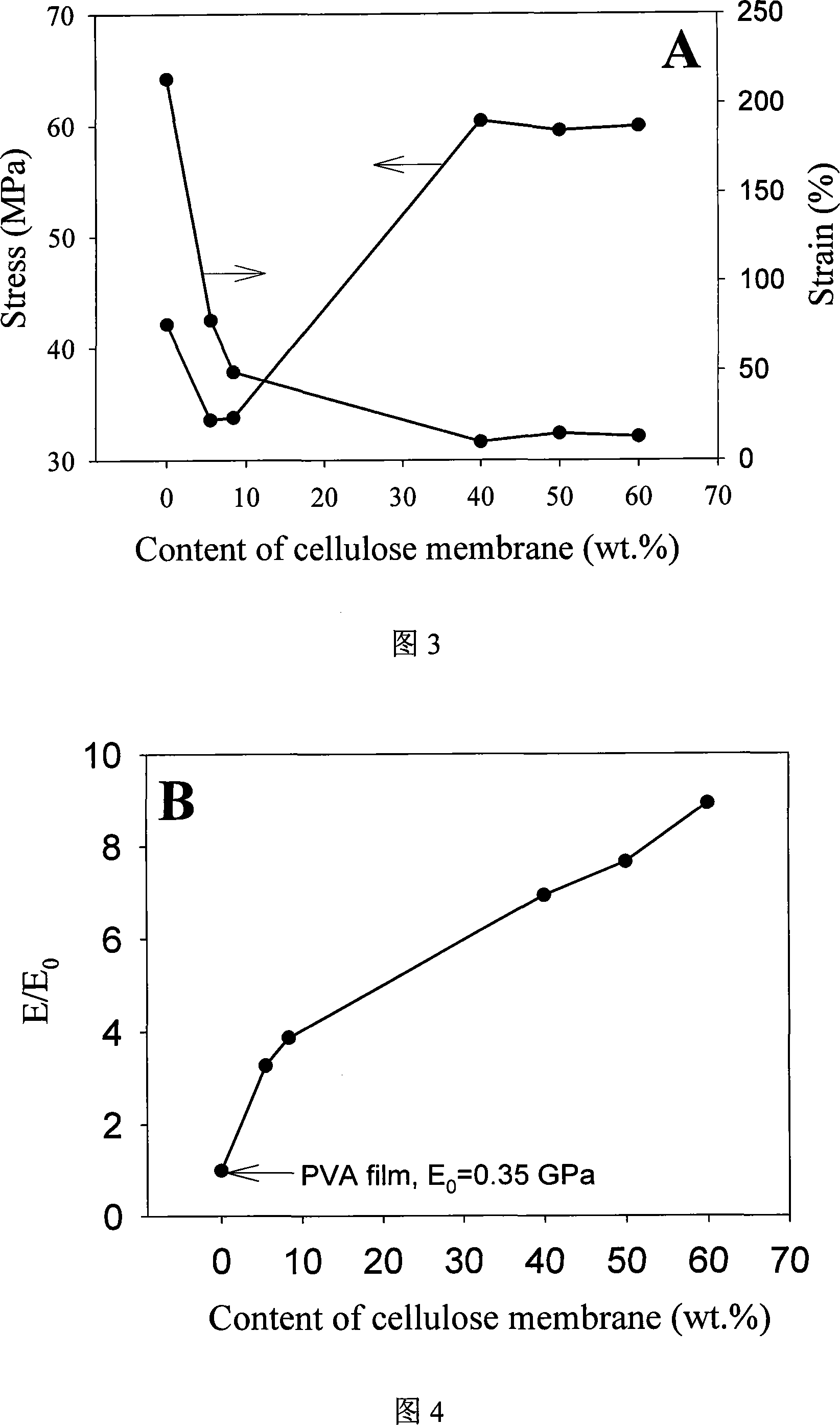

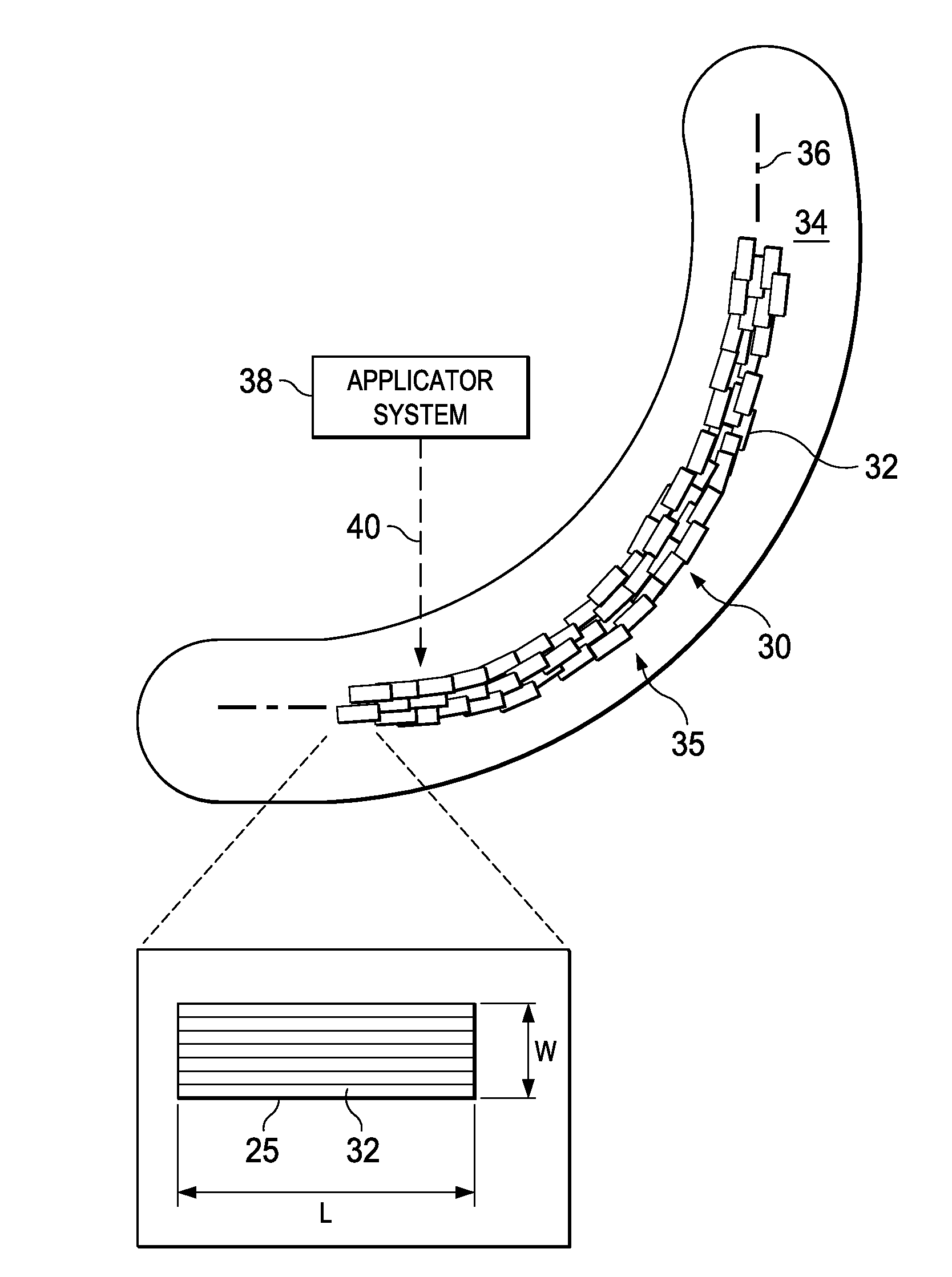

Preparation of nano fibre reinforcement composite resin with high transmittance

The invention relates to the nano composite material field, in particular to a nano-fiber reinforced composite colophony material with high transmittance. The invention adopts the technical proposal that the macromolecule nano-fiber membrane is arranged in transparent colophony dilute solution and fully dipped and dried in order to obtain nano-fiber reinforced composite colophony with high transmittance. The fiber membrane has the thickness of 15 to 160 Mum and the mass percentage of 2 to 60%; the consistency of the colophony solution is 3 to 15% and the dipping time is 8 to 18 hours. The macromolecule nanofiber is cellulose nanofiber, nylon nanofiber, polyester carbonate nanofiber, glass nanofiber or carbon nanofiber. The transparent colophony is polyvinyl alcohol, soja separation albumen, acrylic resin, epoxy resin or polycarbonate. The invention adopting the dipping method has the advantages of simple equipment and process, easy forming and being suitable for the preparation in large scale. The fiber content in the composite material is high, which can reach 40%; the invention has good transmittance and mechanic performance, in particular to excellent tensile strength, tension strength and modulus.

Owner:FUJIAN NORMAL UNIV

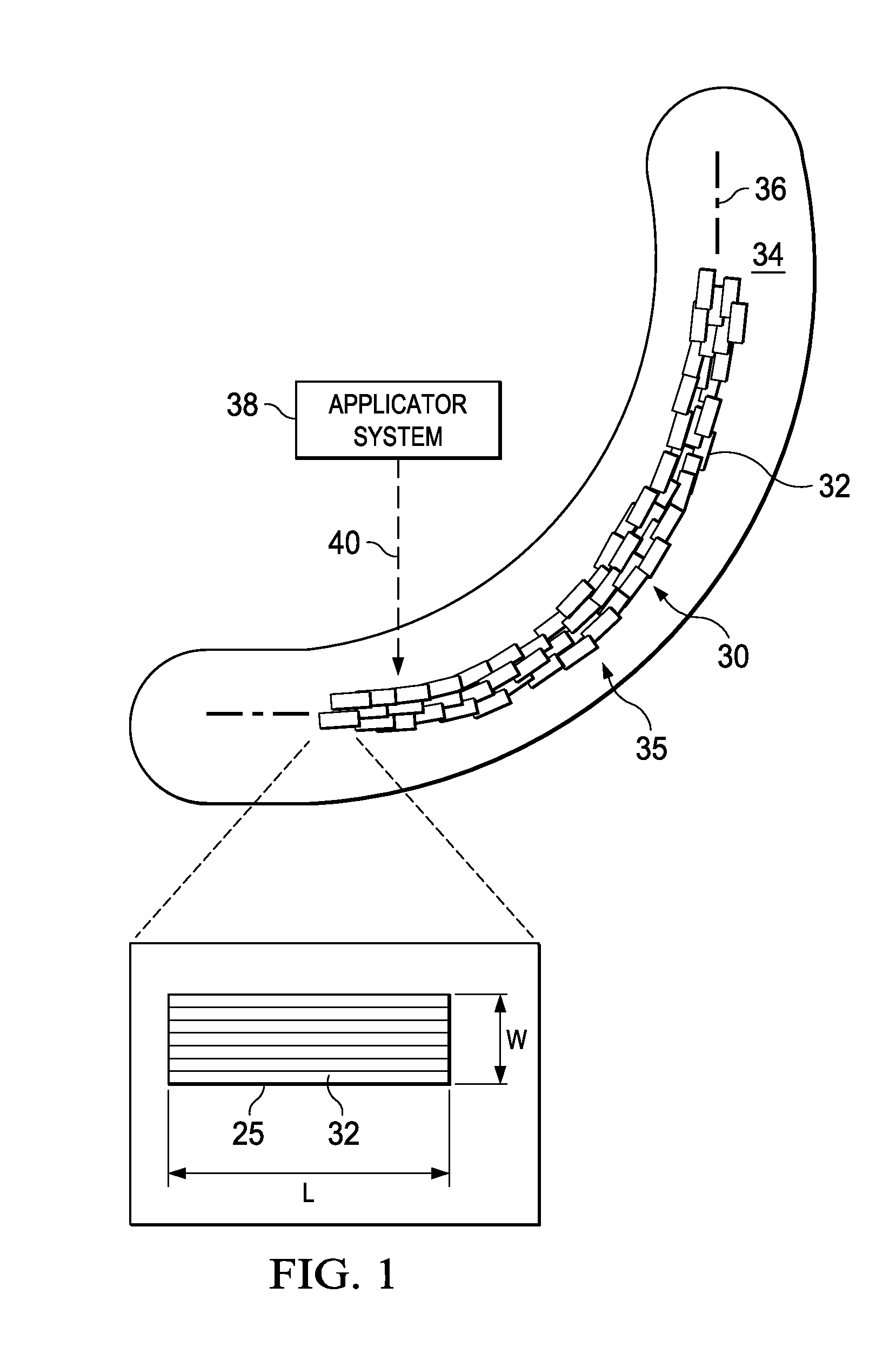

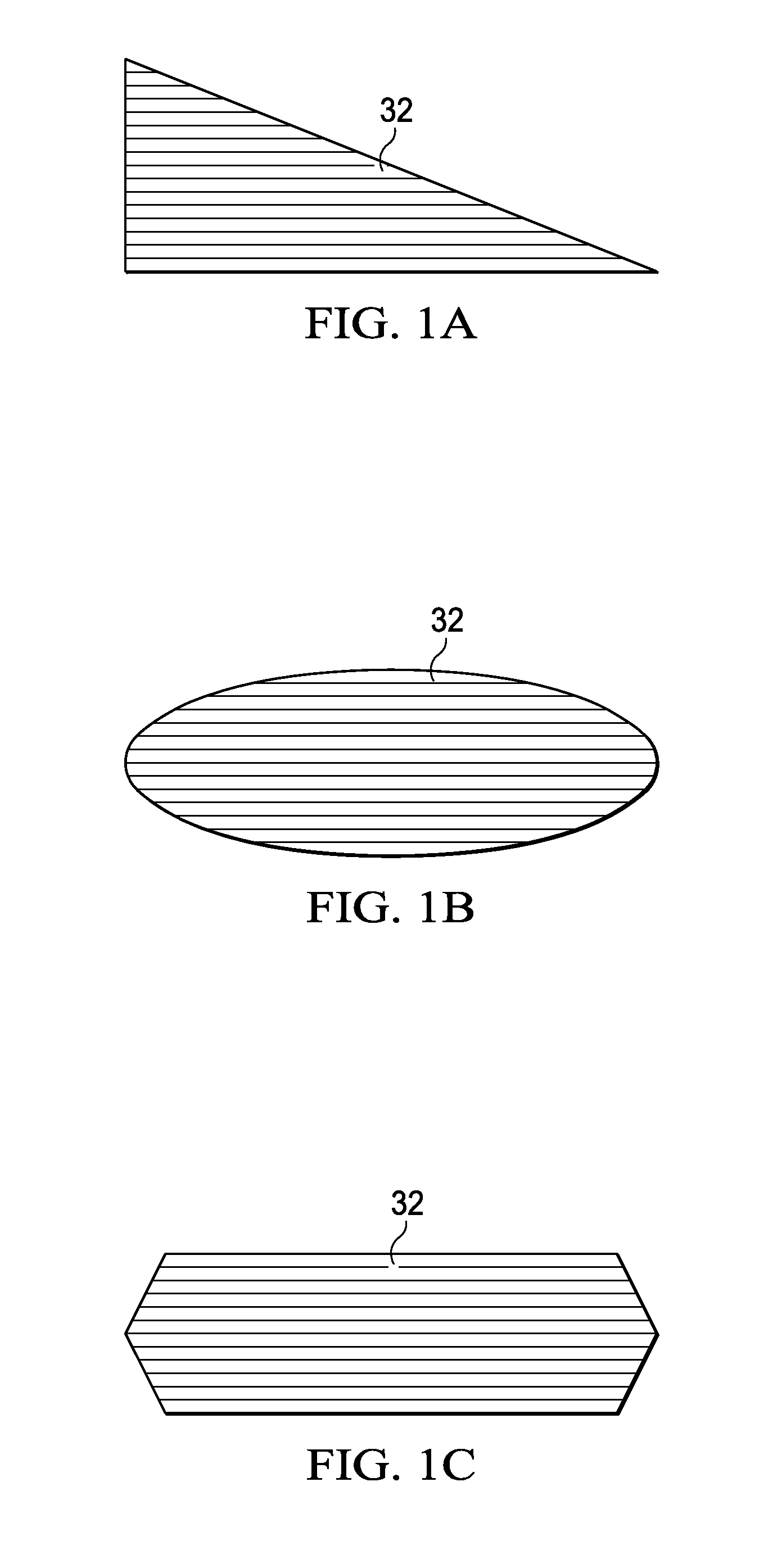

Forming Composite Features Using Steered Discontinuous Fiber Pre-Preg

InactiveUS20140255646A1Easy to controlImprove attributesLamination ancillary operationsControlling laminationMaterials scienceComposite structure

Interlaminar features of a composite structure are laid up by placing and steering individual chopped fiber pre-preg segments onto a substrate.

Owner:THE BOEING CO

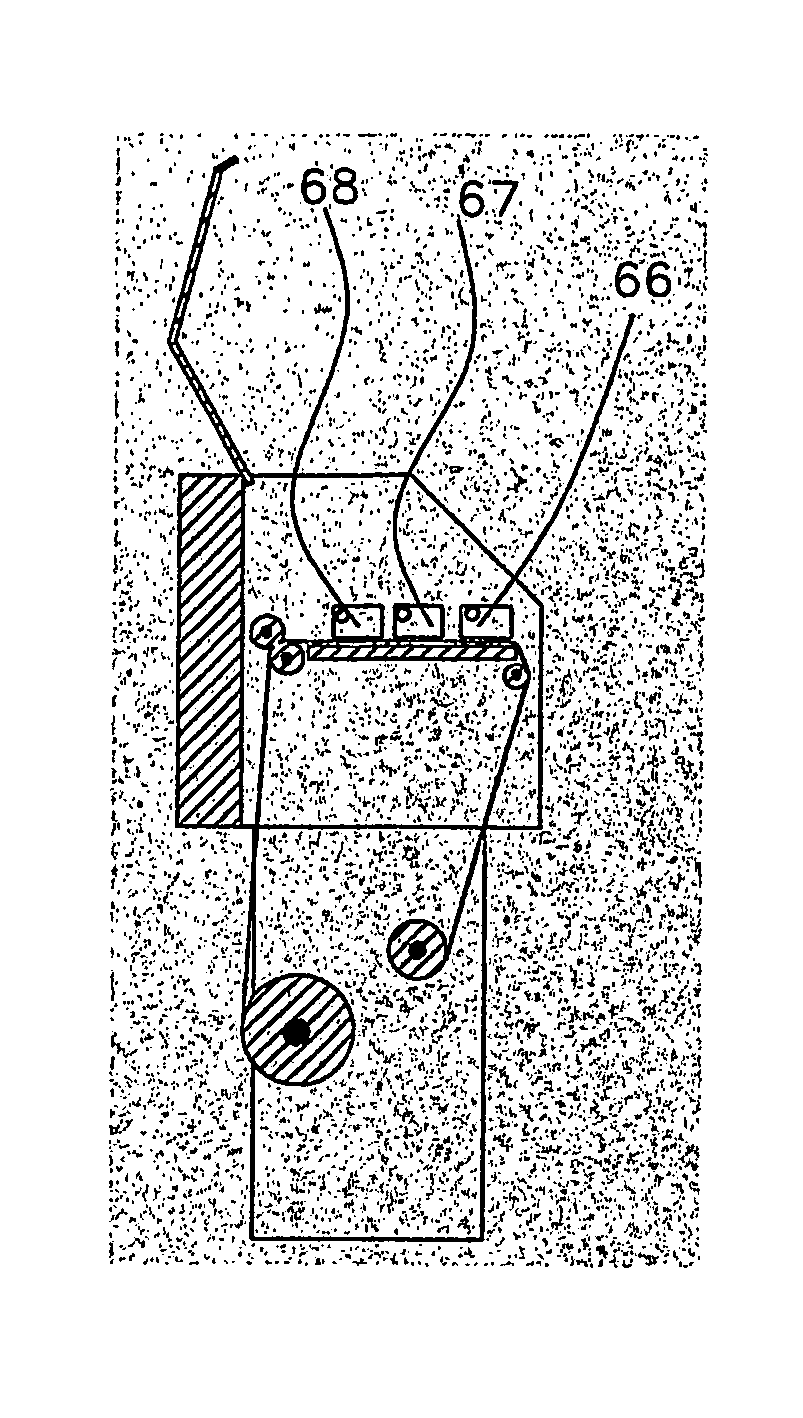

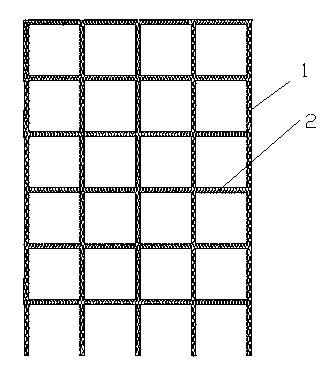

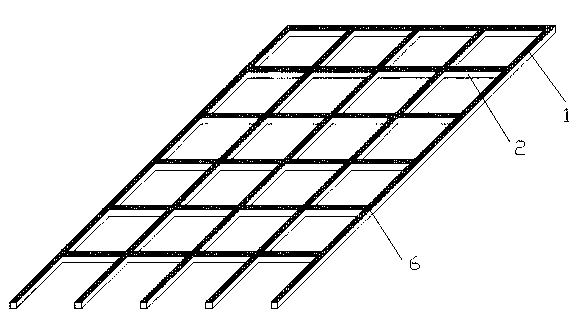

Plane grid rib for structure reinforcement, mould and manufacturing method of plane grid rib

ActiveCN103216041AAvoid crackingNot easy to peel offBuilding repairsBridge erection/assemblyStructural engineeringFibrous composites

The invention discloses a plane grid rib for structure reinforcement. The plane grid rib comprises longitudinal composite ribs and horizontal composite ribs, wherein the longitudinal composite ribs and the horizontal composite ribs are fixedly connected on a same plane to form a plane grid; and the cross sections of the longitudinal and horizontal composite ribs are rectangular. The invention also discloses a mould for manufacturing the plane grid. The mould comprises a male mould and a female mould, wherein the male mould is a first platform; the lower part of the first platform is provided with criss-cross convex ridges; the female mould is a second platform; the upper part of the second platform is provided with criss-cross grooves; and the grooves of the second platform are matched with the convex ridges of the first platform. The invention also discloses a manufacturing method of the plane grid rib. The method comprises the following steps of: 1, manufacturing fibrous composite materials; 2, distributing the fibrous composite materials; and 3, applying pressure to the fibrous composite materials to manufacture the plane grid rib. The plane grid rib disclosed by the invention has the advantages of regularity in section and high tensile strength and elastic modulus.

Owner:江苏绿材谷新材料科技发展有限公司 +2

Method for preparing carbon fiber reinforced inorganic polymer based composite material

InactiveCN101182152AOvercome reunionOvercome the problem of breakingCement productionFiberPolymer science

A preparation method of carbon fiber reinforced inorganic polymer composite relates to a preparation method of inorganic polymer composite. The method solves following problems: low mechanical strength, low ductility, low bearing capacity, low application reliability of the inorganic polymer composite; large aspect ratio, easiness to be winded and agglomerated even be fractured during the preparation process, uneven distribution in an inorganic polymer composite matrix and low strengthening effect of existing carbon fiber. The preparation method of the invention is: firstly, to prepare batch of the inorganic polymer and regulate the viscosity of the batch through deionized water; secondly, to prepare chopped carbon fiber prefabrication; thirdly, to prepare a composite green body which includes a plurality of carbon fiber prefabrication layers; fourthly, to add vacuum pressure on the green body and dry the green body to produce the carbon fiber reinforced inorganic polymer composite. The invention overcomes the carbon fiber agglomeration and fracture problems of a conventional strong agitation method. The composite prepared through the invention has the advantages of high carbon fiber content, even distribution, high material strength and good ductility.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com