Preparation of nano fibre reinforcement composite resin with high transmittance

A nanofiber and reinforced composite technology, which is applied in the field of nanofiber reinforced composite resin materials, achieves the effects of high fiber content, good light transmittance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

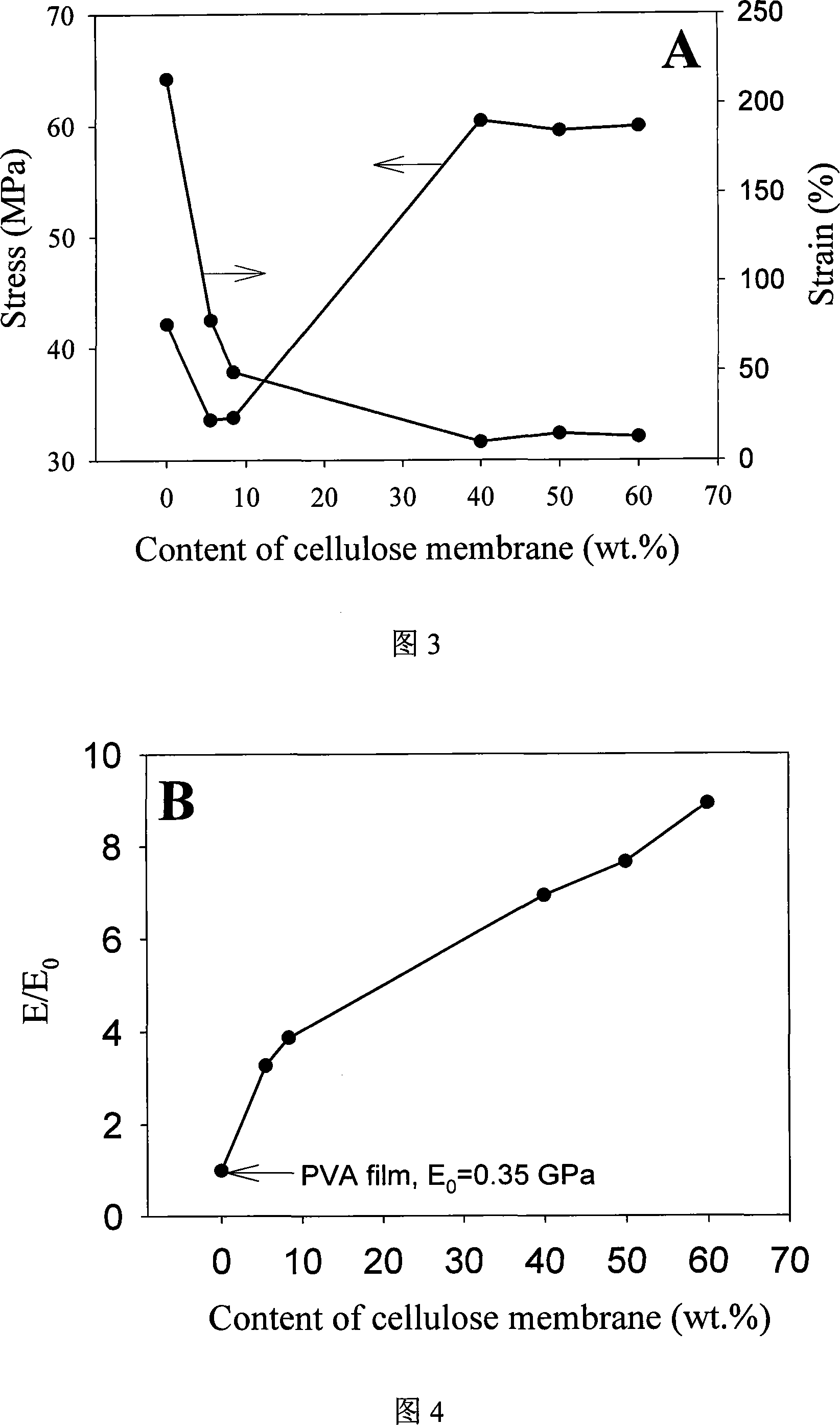

[0026] Will size 5×1cm 2 , The mass per unit area is 0.54g / cm 2 A nylon nanofiber membrane with a thickness of 13μm and a fiber diameter of 100-300nm is immersed in a glass tank containing 10g of a 3% polyvinyl alcohol solution, soaked for 8 hours, and then vacuum dried at 50°C for 24 hours. A composite membrane with a fiber content of 2% was obtained, and the thickness of the composite membrane was 196 μm. The light transmittance of the film is about 90%, which is equivalent to a pure polyvinyl alcohol film.

Embodiment 2

[0028] Will size 5×1cm 2 , The mass per unit area is 9.2g / cm 2 The carbon nanofiber membrane with a thickness of 152μm and a fiber diameter of 100-300nm is immersed in a glass tank containing 10g of acrylic resin solution with a concentration of 8%, soaked for 14 hours, and then vacuum dried at 50°C for 24 hours. A composite membrane with a fiber content of 40% was obtained, and the thickness of the composite membrane was 210 μm. The light transmittance of the film is about 85%. The tensile strength is increased by 100% compared to the acrylic resin film, and the Young's modulus is increased by 8 times.

Embodiment 3

[0030] Will size 5×1cm 2 , The mass per unit area is 4.5g / cm 2 A polycarbonate nanofiber membrane with a thickness of 86μm and a fiber diameter of 100-350nm is immersed in a glass tank containing 10g of 15% soy protein isolate solution, soaked for 18 hours, and then vacuum dried at 50°C for 24 hours . A composite membrane with a fiber content of 20% was obtained, and the thickness of the composite membrane was 130 μm. The light transmittance of the film is about 75%. The tensile strength is increased by 50 times than that of pure soy protein isolate film, and the Young's modulus is increased by 20 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com