Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Satisfactory dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

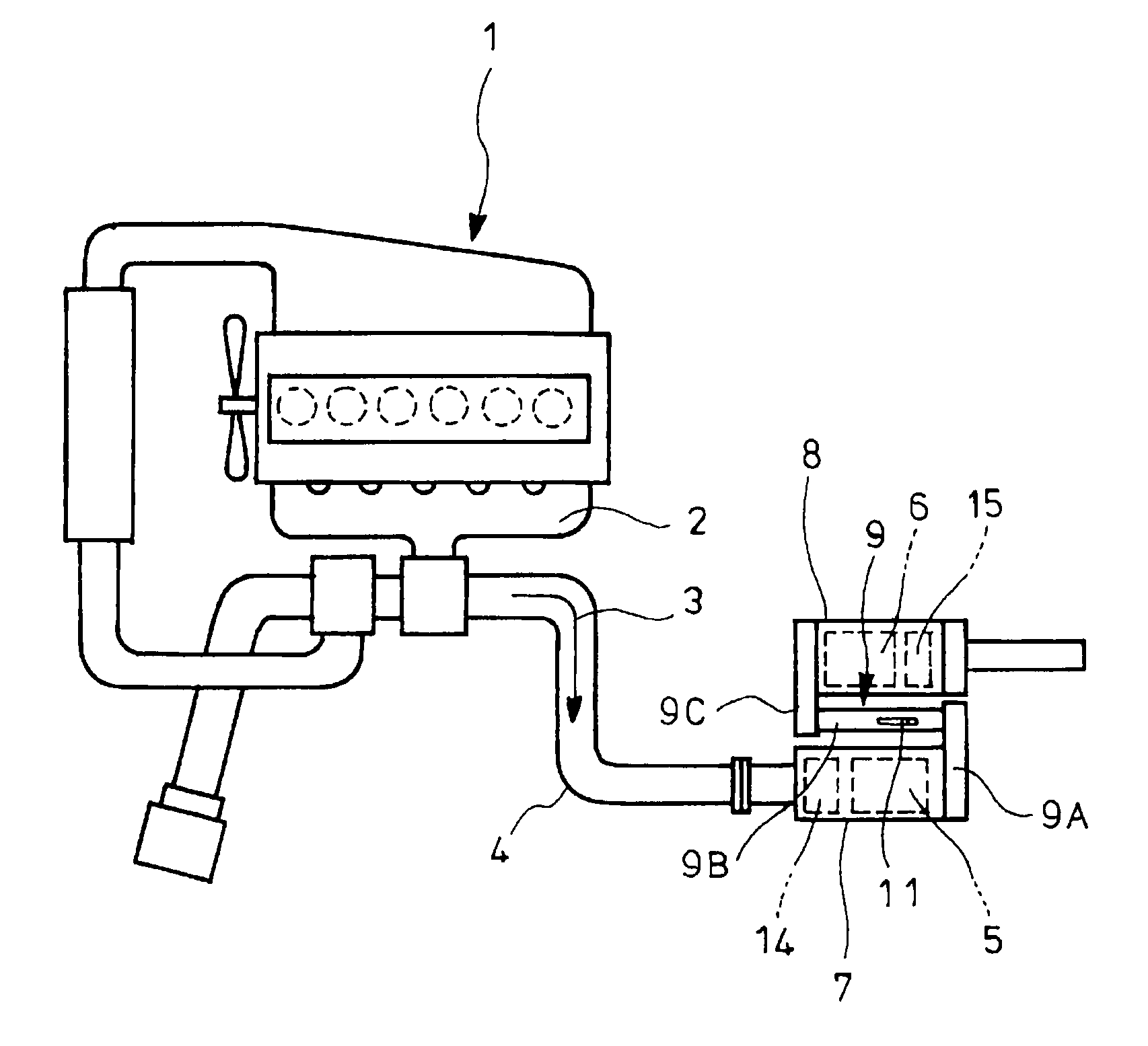

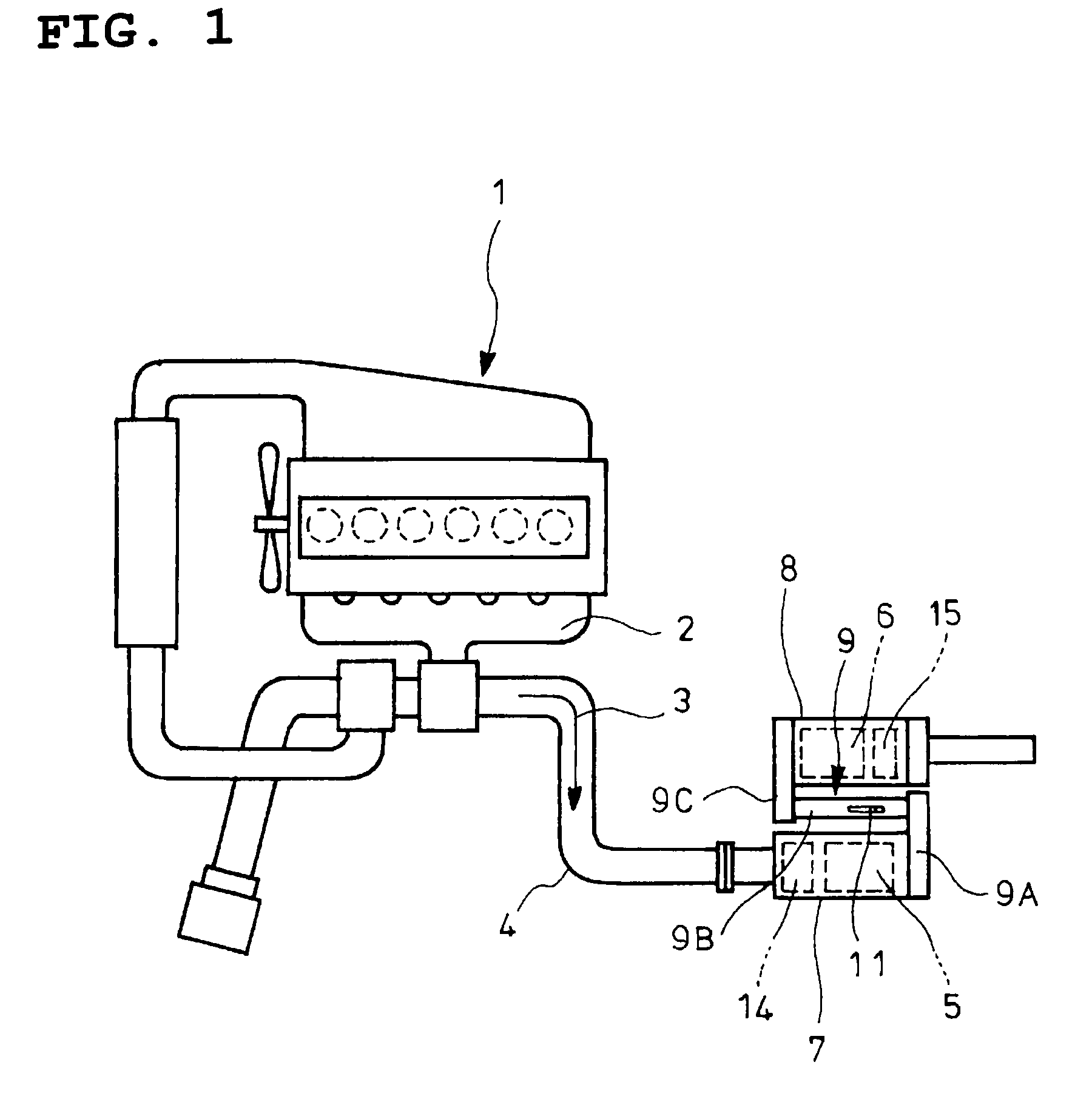

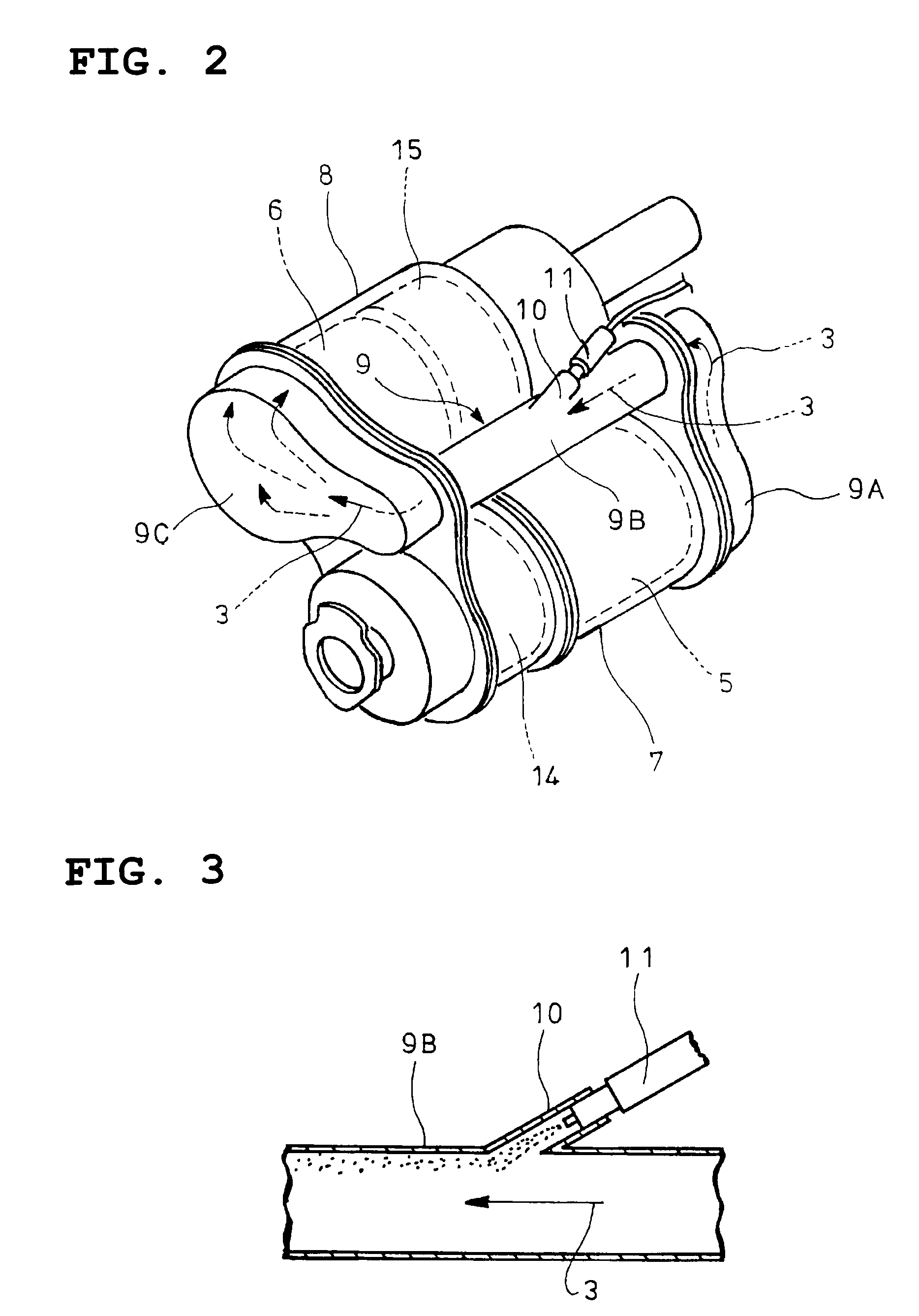

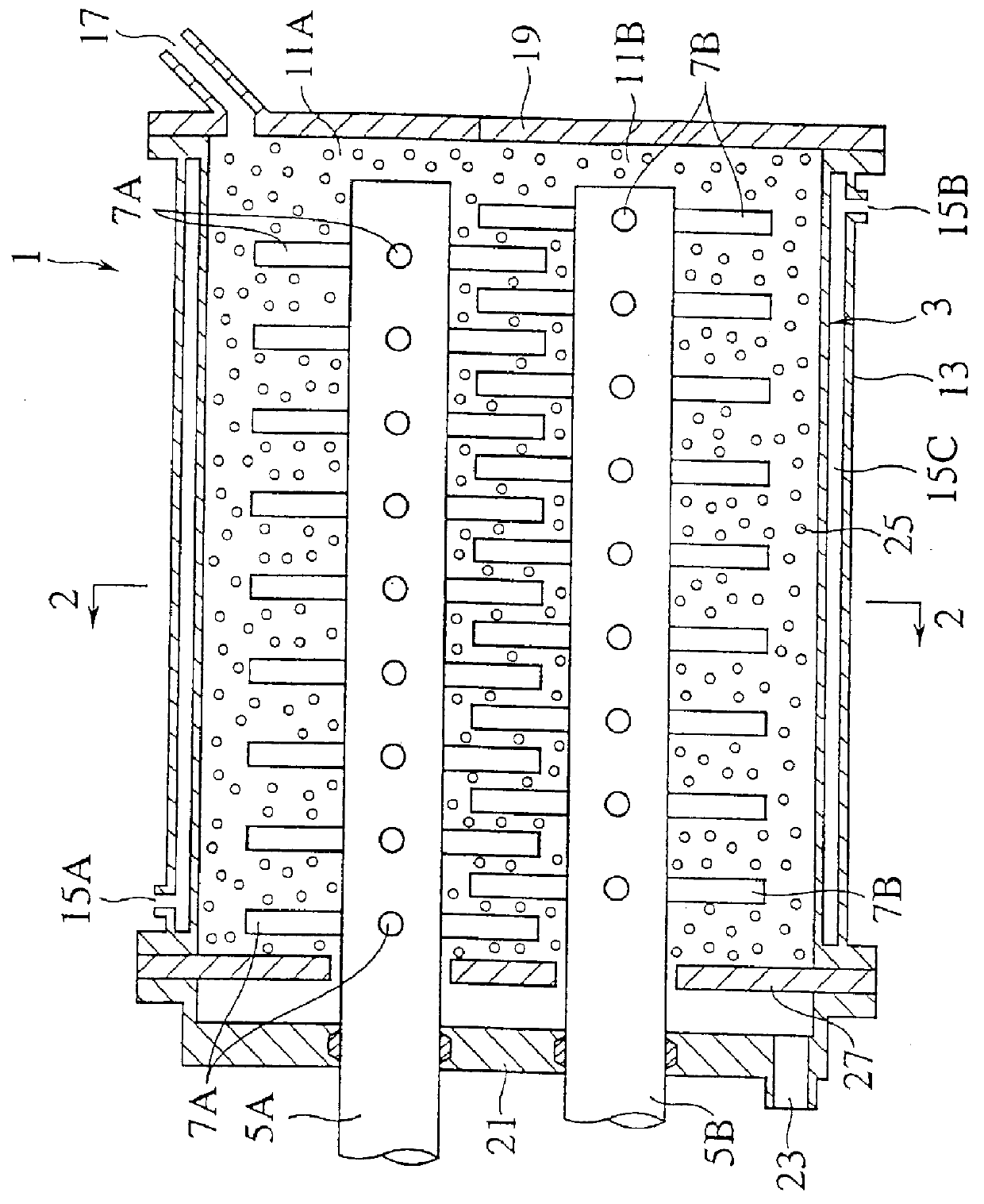

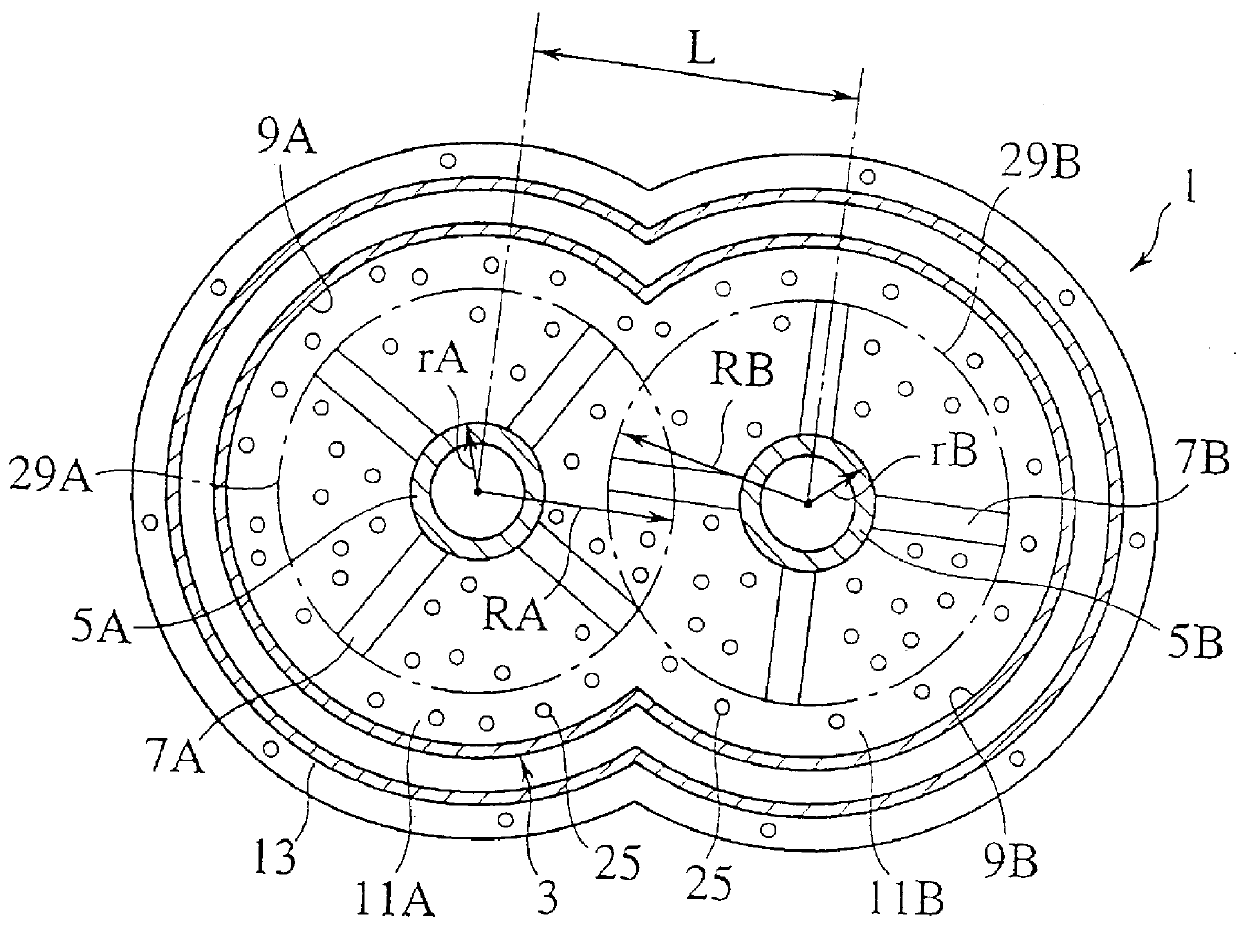

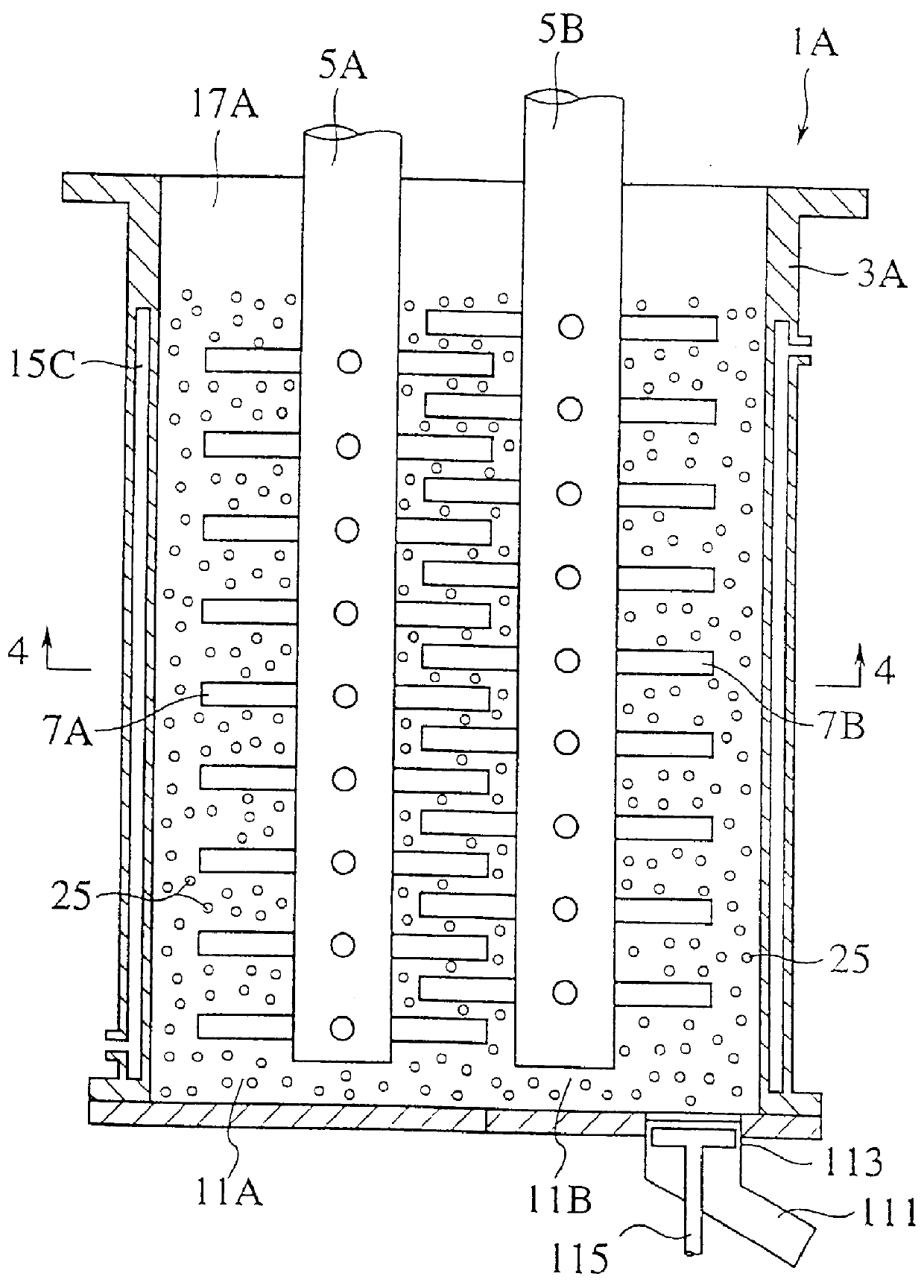

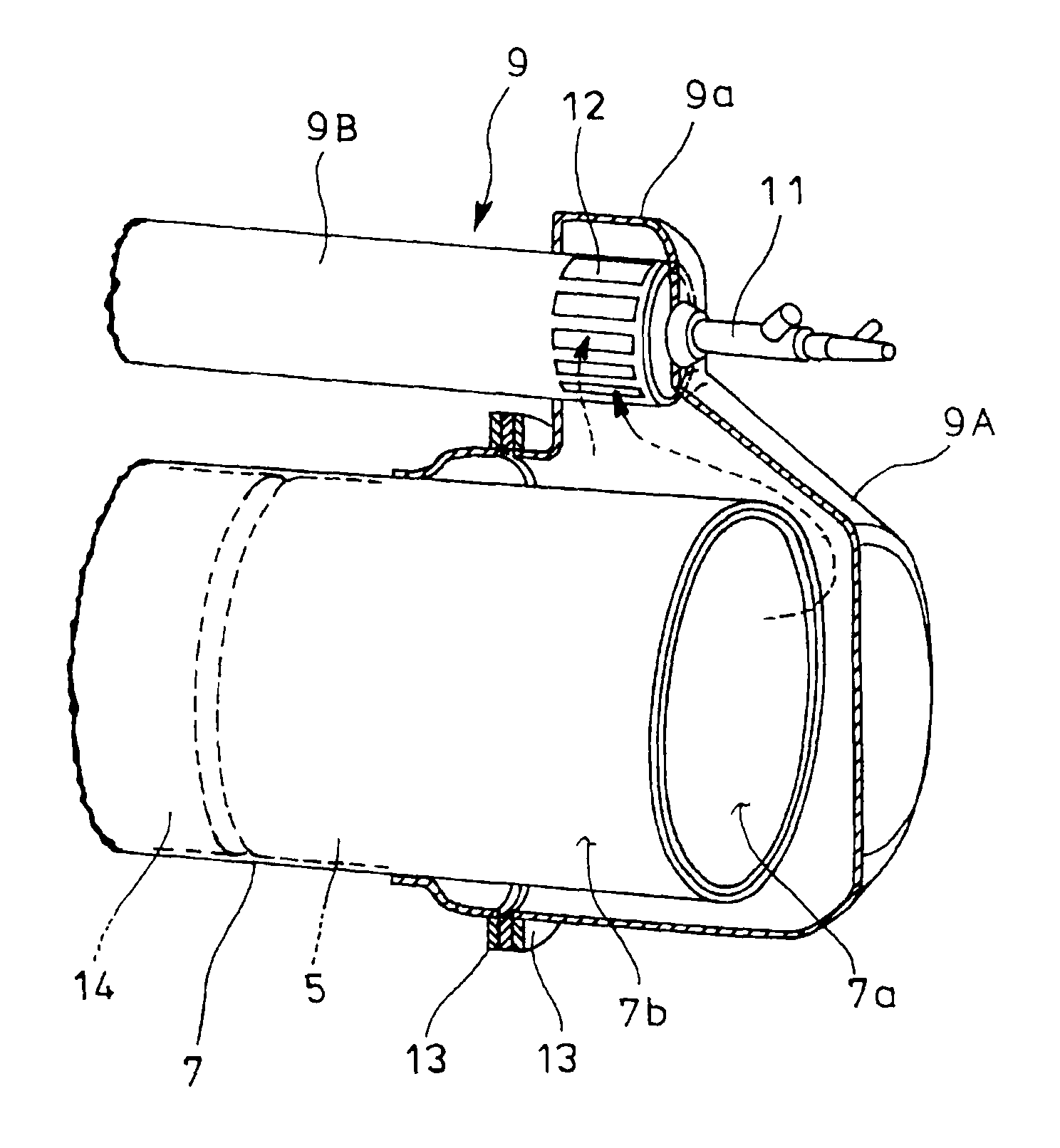

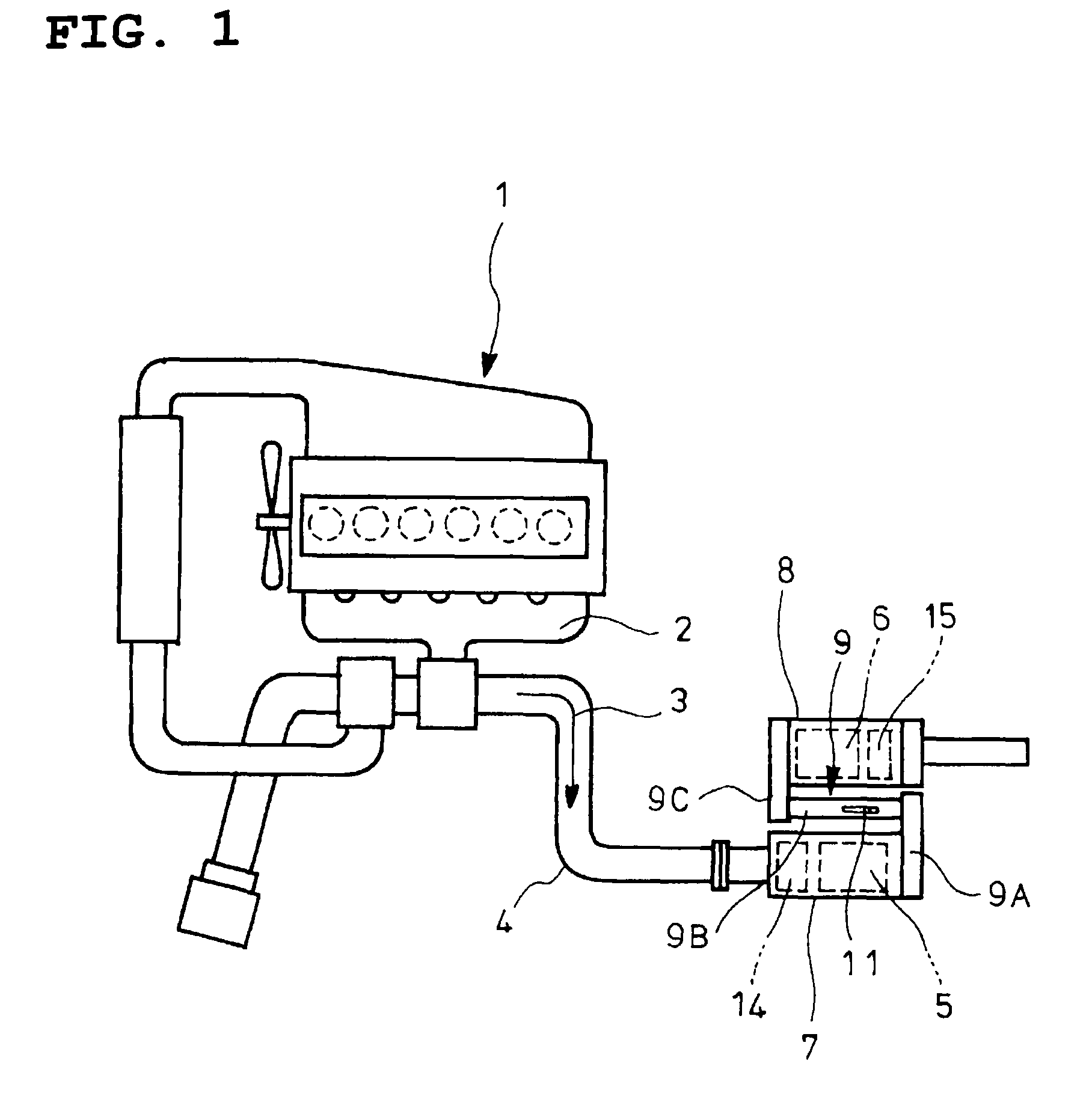

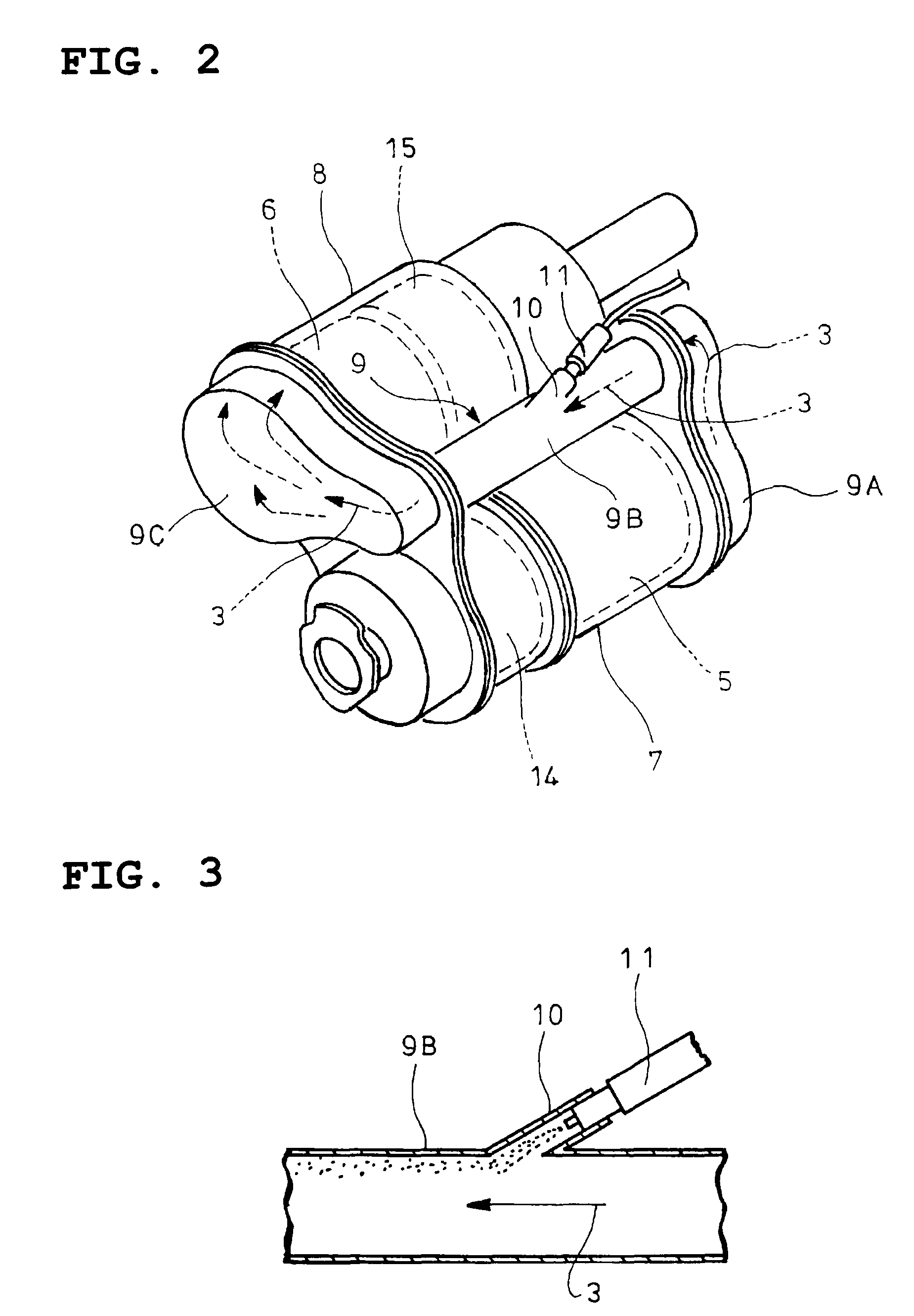

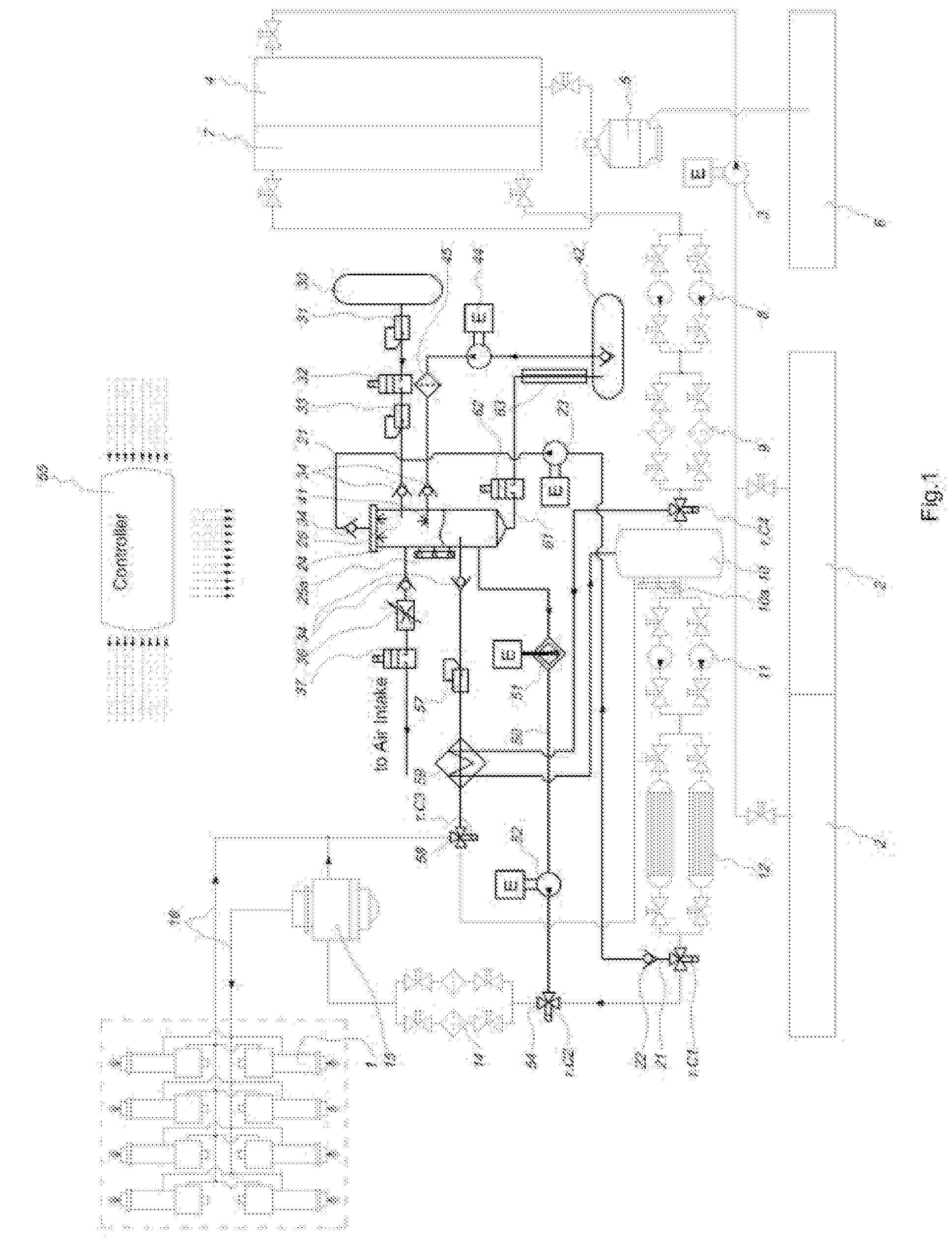

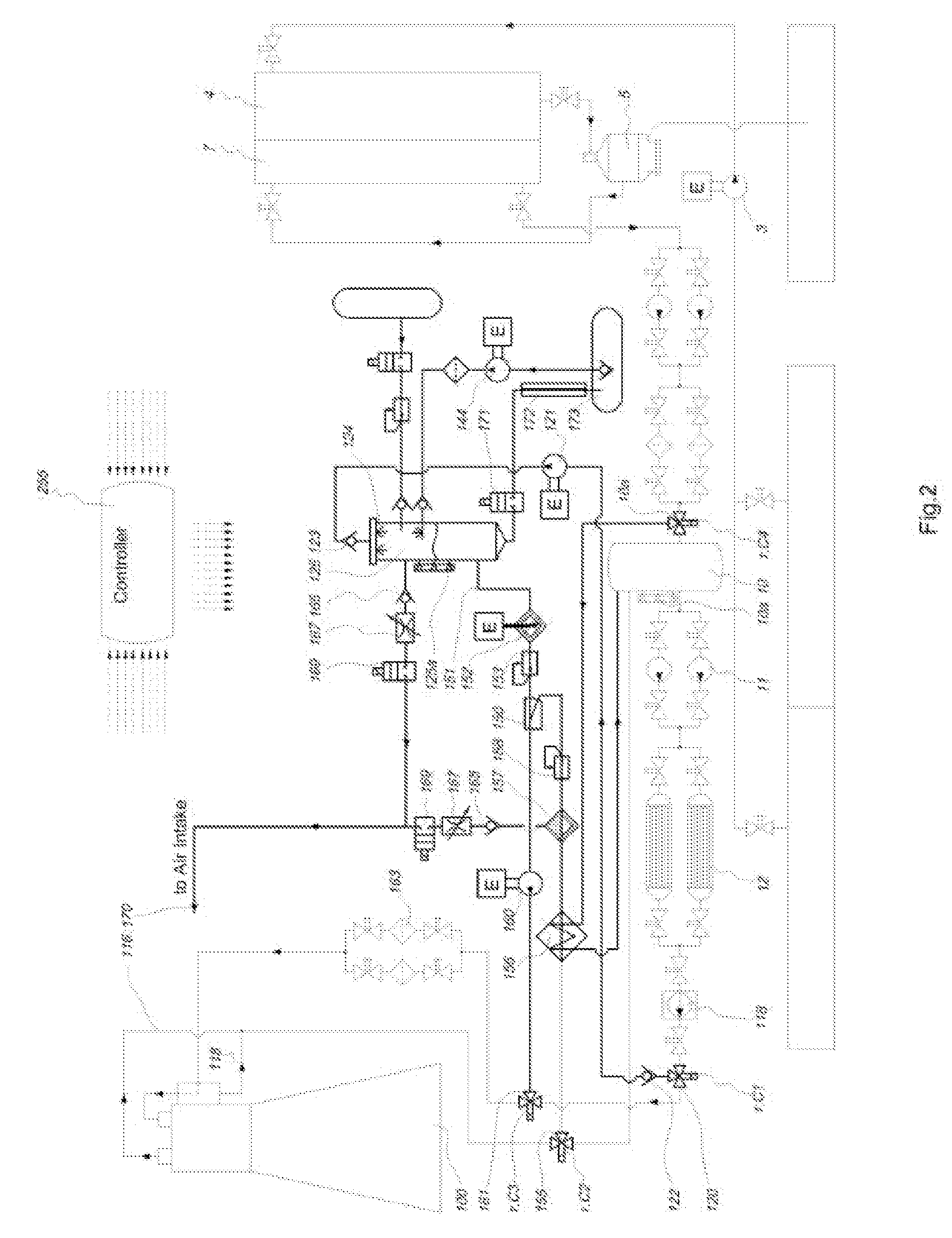

Exhaust emission control device

ActiveUS20090313979A1Well mixedIncrease flow rateGas treatmentInternal combustion piston enginesParticulatesEnvironmental engineering

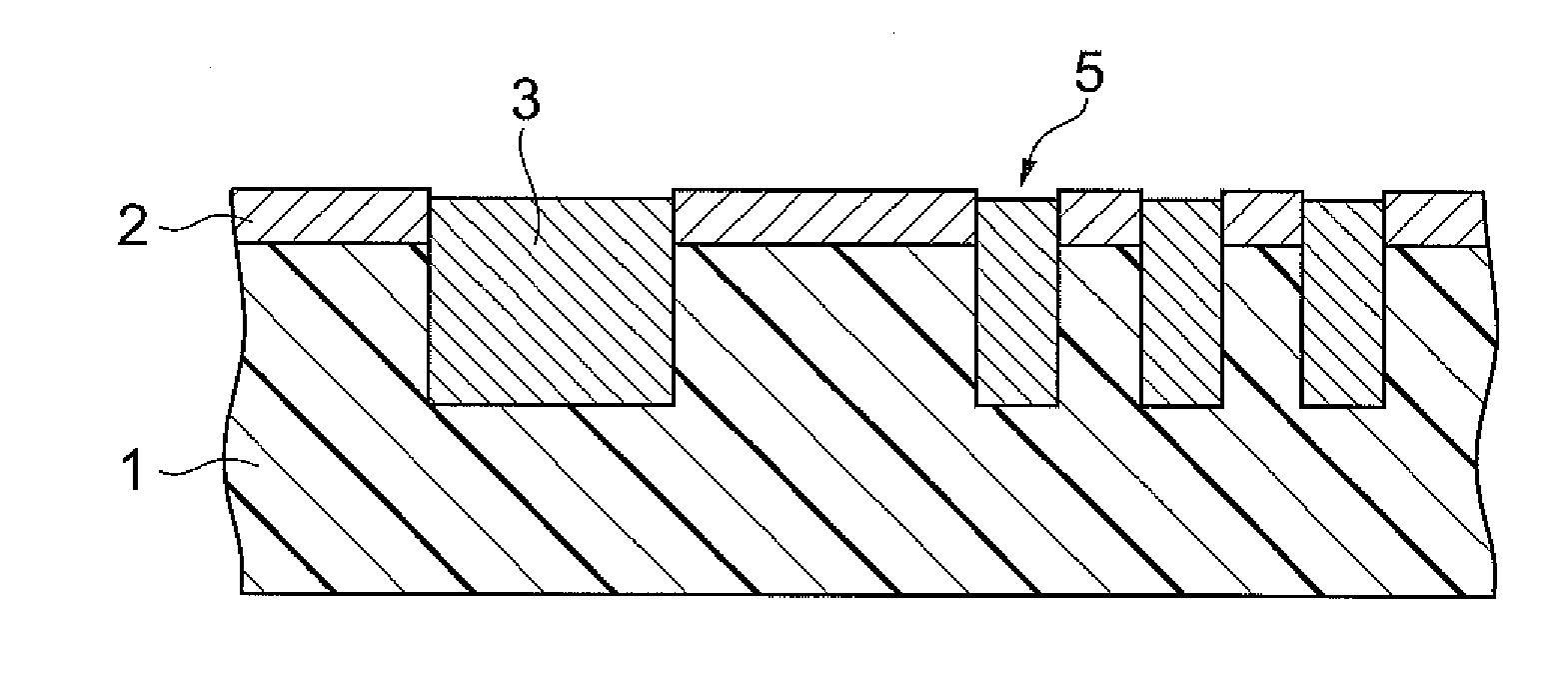

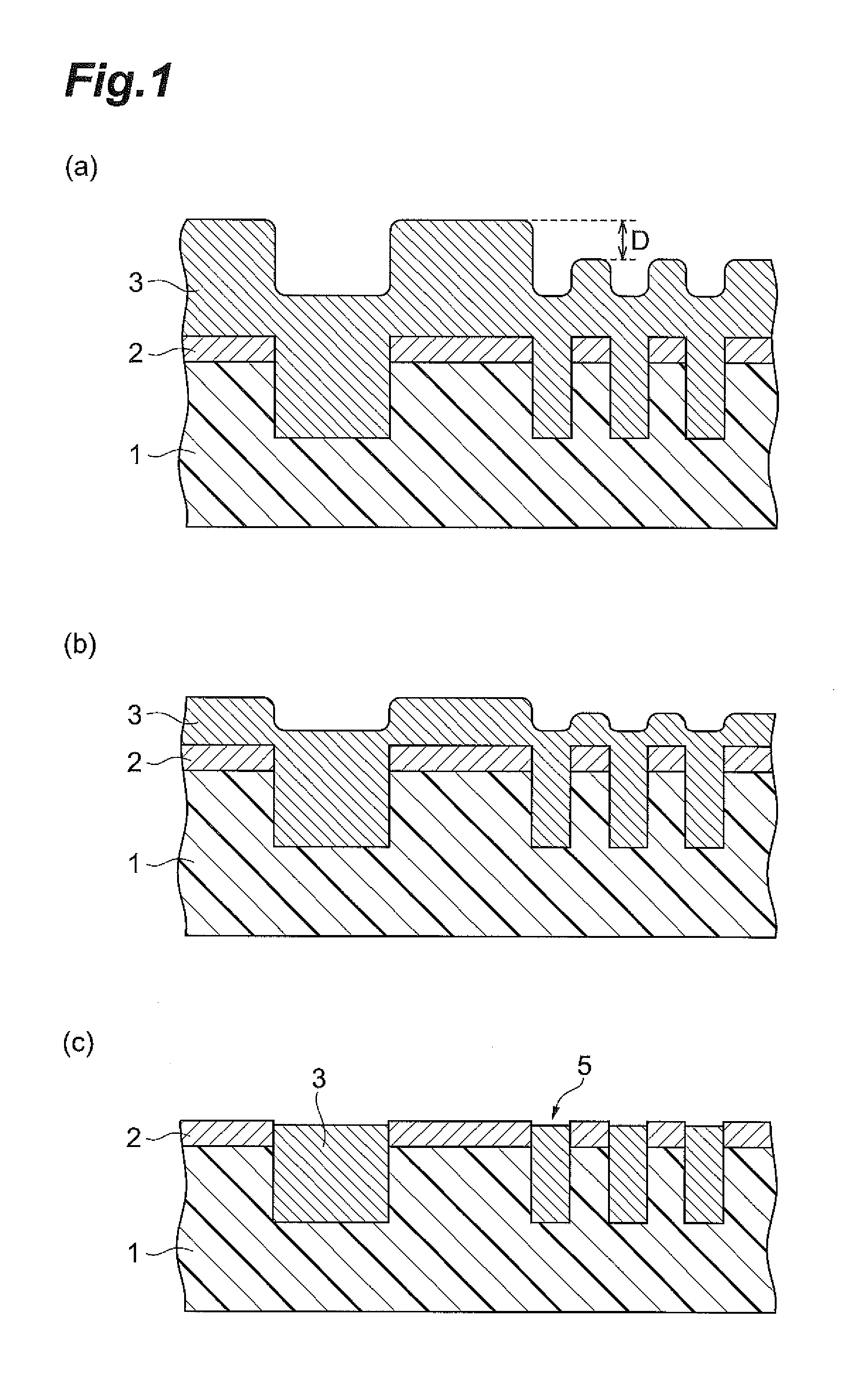

An exhaust emission control device has a particulate filter 5 and a selective reduction catalyst 6 arranged side by side. An S-shaped communication passage 9 is arranged for introduction of exhaust gas 3 from a rear end of the filter 5 to a front end of the adjacent catalyst 6 in a forward fold-back manner and with a urea water addition injector 11 arranged midway of the passage 9. In order to satisfactorily disperse the urea water with enhanced mixing with the exhaust gas 3 even if the flow rate is increased, slits 12 are formed in circumferentially spaced positions on a rear end of a mixing pipe 9B constituting an upstream portion of the communication passage 9 so as to introduce the exhaust gas 3. A downstream end 9a of a gas gathering chamber 9A is connected to the rear end of the mixing pipe 9B such that the slits 12 are encased and the rear end of the mixing pipe 9B is closed.

Owner:HINO MOTORS LTD

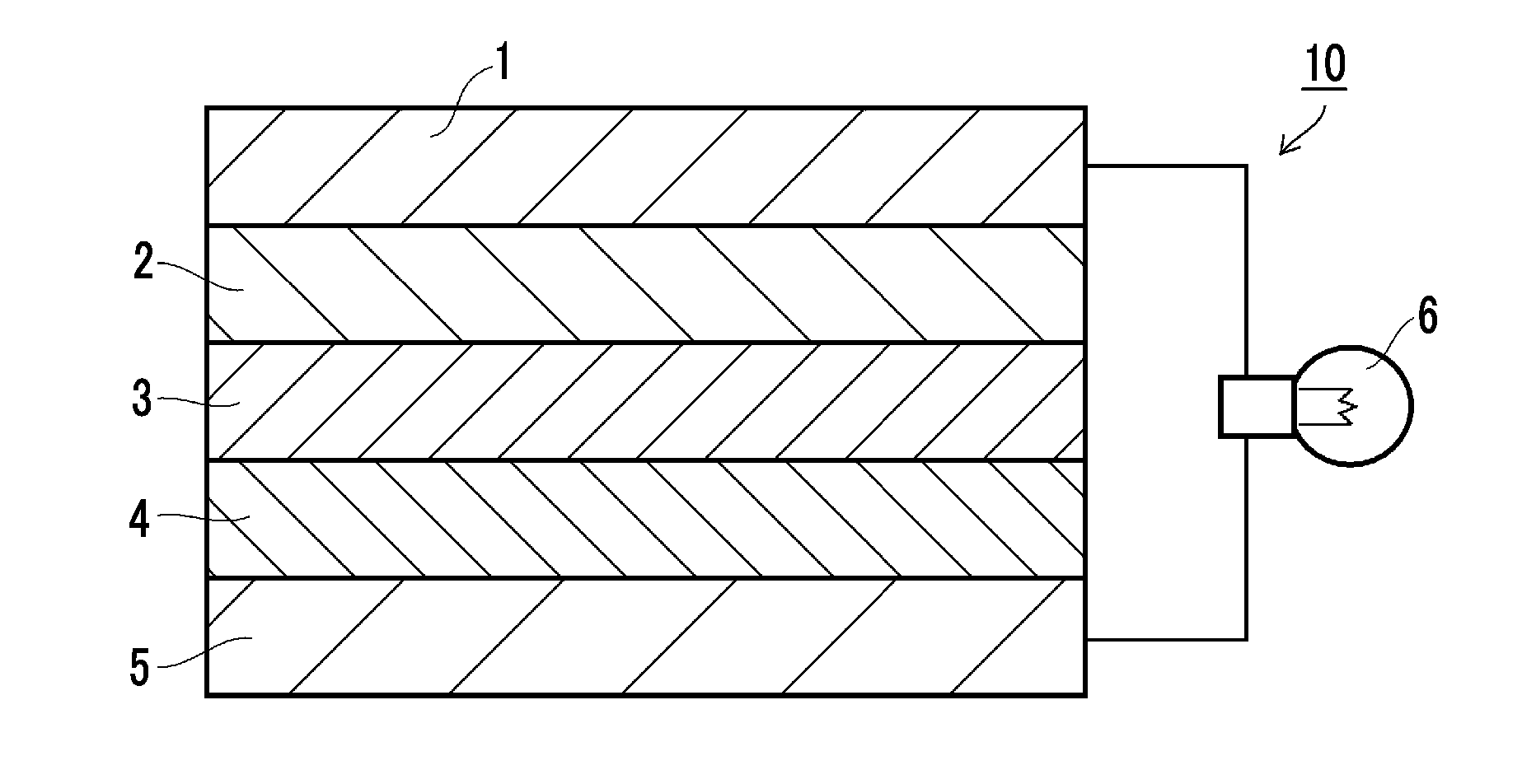

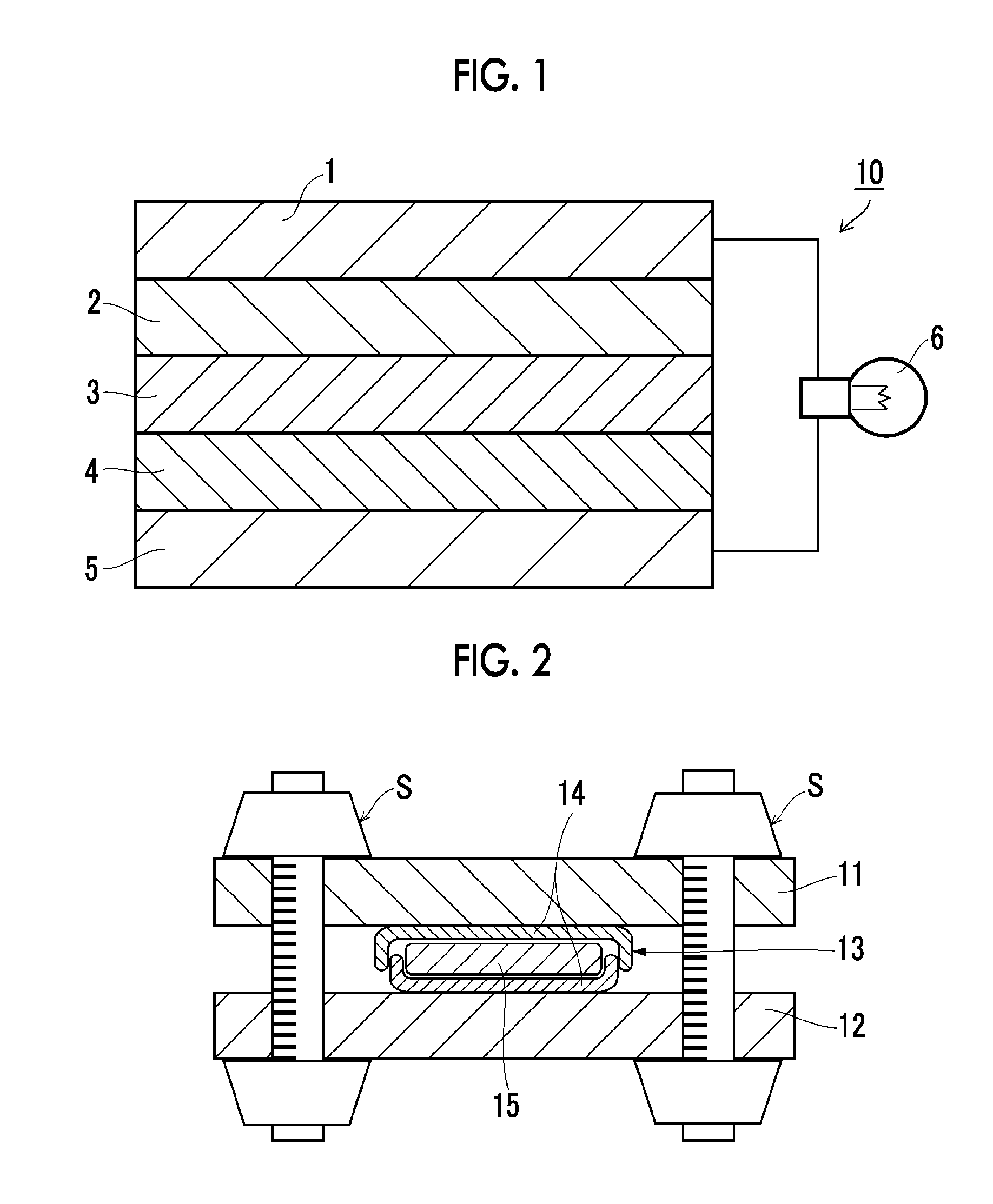

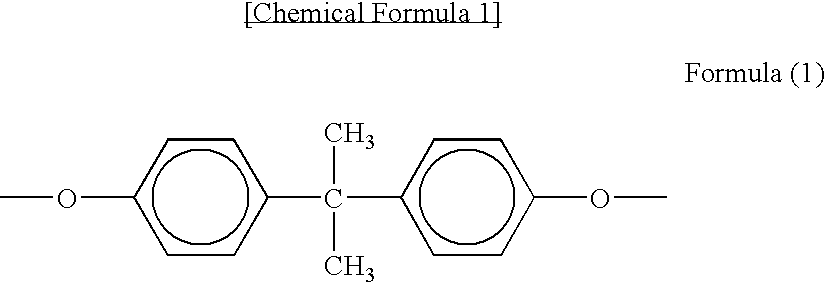

Molding material, prepreg and fiber-reinforced composite material, and method for producing fiber-reinforced molding substrate

InactiveUS20100068518A1Increase productivitySatisfactory dispersionCoatingsYarnPolymer scienceFiber bundle

This invention relates to: a molding material comprising a bundle of continuous reinforcing fibers (A), a polyarylene sulfide prepolymer (B) comprising at least 50% by weight of cyclic polyarylene sulfide and having the weight average molecular weight of less than 10,000 or polyarylene sulfide (B′) having the weight average molecular weight of 10,000 or greater and the degree of dispersion of 2.5 or lower, and thermoplastic resin (C); a prepreg comprising a resin composition comprising the polyarylene sulfide prepolymer (B) impregnated into a reinforcing fiber; and a method for producing a fiber-reinforced molding substrate comprising step (I) of continuously feeding a bundle of continuous reinforcing fibers, step (II) of combining cyclic polyarylene sulfide with the reinforcing fiber bundle, step (III) of heating the composite obtained in step (II) to subject the cyclic polyarylene sulfide to ring-opening polymerization to convert into polyarylene sulfide, and step (IV) of cooling the composite obtained in step (III) and withdrawing the same.

Owner:TORAY IND INC

Solid electrolyte composition, electrode sheet for batteries using same and all-solid-state secondary battery

InactiveUS20160204465A1Interface resistance increaseGood effectNon-metal conductorsSolid electrolytesIonSide chain

Provided is a solid electrolyte composition including: an inorganic solid electrolyte (A) having conductivity of an ion of metal belong to Group 1 or 2 in the periodic table; binder particles (B) which is formed of a polymer combined with a macromonomer (X) including a side chain component having a number average molecular weight of 1,000 or greater, and which has an average diameter of 10 nm to 1,000 nm, and a dispersion medium (C).

Owner:FUJIFILM CORP

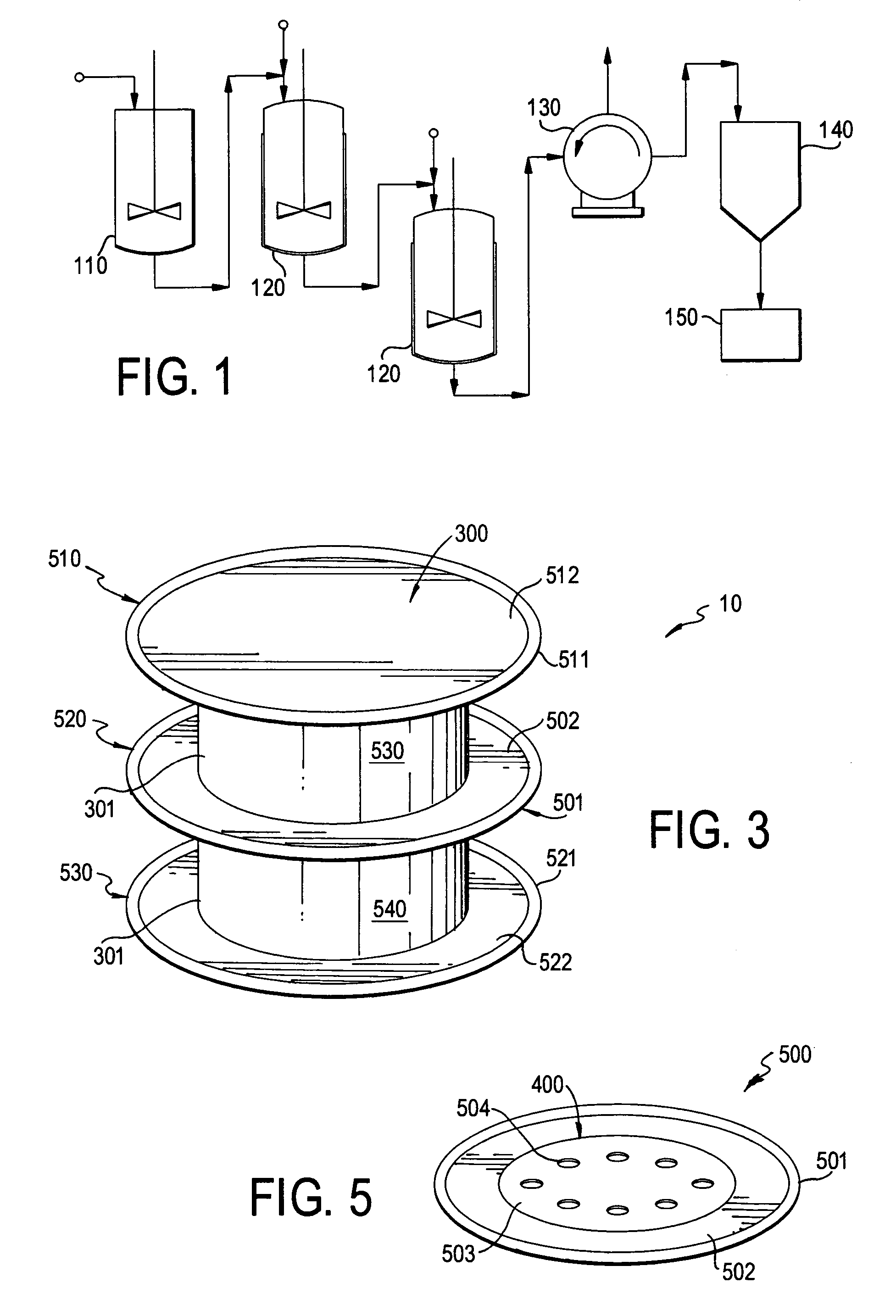

Mixing vessel and method of use

ActiveUS7431837B2Reduce in quantityReduce likelihood of entranceShaking/oscillating/vibrating mixersFlow mixersEngineering

Owner:ILC DOVER LP

Polishing solution for cmp and polishing method using the polishing solution

ActiveUS20110275217A1Good water solubilitySatisfactory maintenance of dispersibilityOther chemical processesSemiconductor/solid-state device manufacturingMetallurgySilicon oxide

The polishing solution for CMP of the invention comprises abrasive grains, a first additive and water, wherein the first additive is at least 1,2-benzoisothiazole-3(2H)-one or 2-aminothiazole. The polishing method of the invention is a polishing method for a substrate having a silicon oxide film on the surface, and the polishing method comprises a step of polishing the silicon oxide film with a polishing pad while supplying the polishing solution for CMP between the silicon oxide film and the polishing pad.

Owner:RESONAC CORP

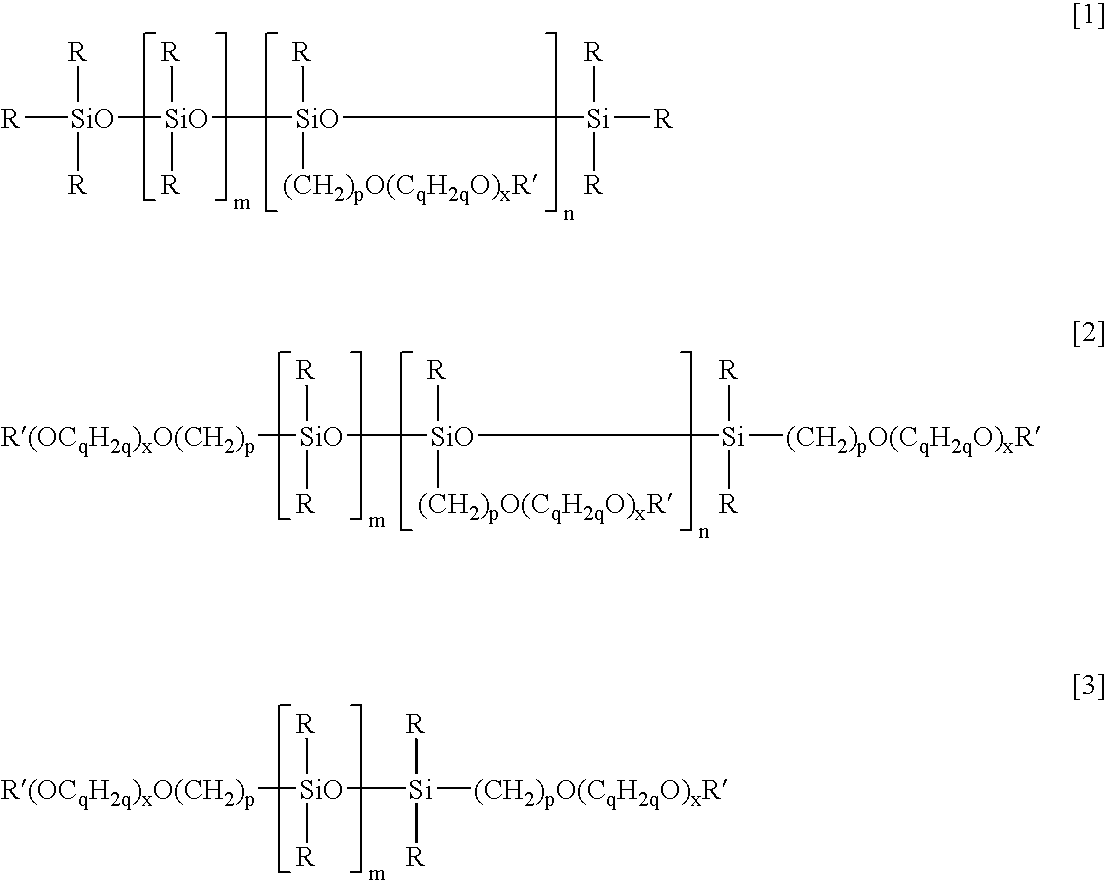

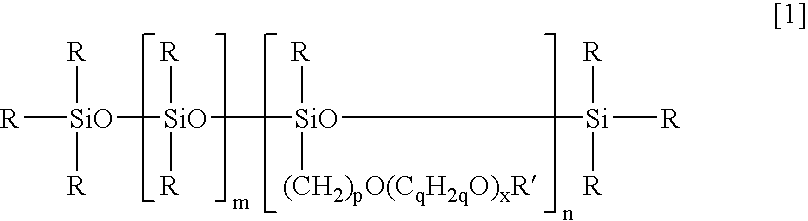

Cosmetic sunscreen preparation

InactiveUS6749838B1Excellent in ultraviolet rays protection effectStable transparencyCosmetic preparationsBody powdersWater useUltraviolet

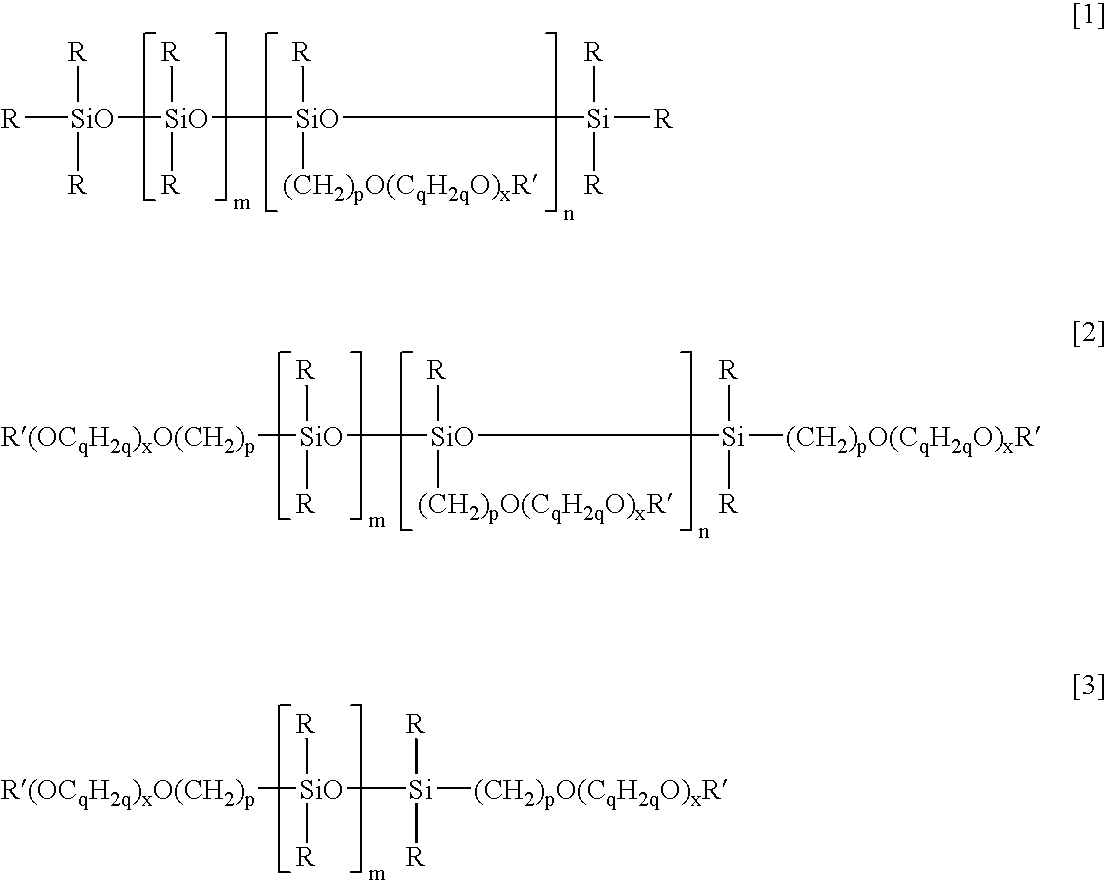

An object of the present invention is to provide a sunscreen cosmetic in which a micro particle zinc oxide is dispersed satisfactorily and which is excellent in the ultraviolet rays protection effect as indicated by SPF and PFA, and also in the finish transparency and the system stability.A sunscreen cosmetic obtained by means of an incorporation of a composite powder of a micro particle zinc oxide having a particle size of 0.1 mum or less which is coated with a silicic anhydride at a coating rate of 5 to 30 wt % and whose surface is treated with a silicone of 3 to 12 wt %, a dispersing treatment of said composite powder in an oil or water using a media-agitating mill or a high pressure dispersing machine and / or an incorporation of a polyoxyalkylene-modified polysiloxane.

Owner:SHISEIDO CO LTD

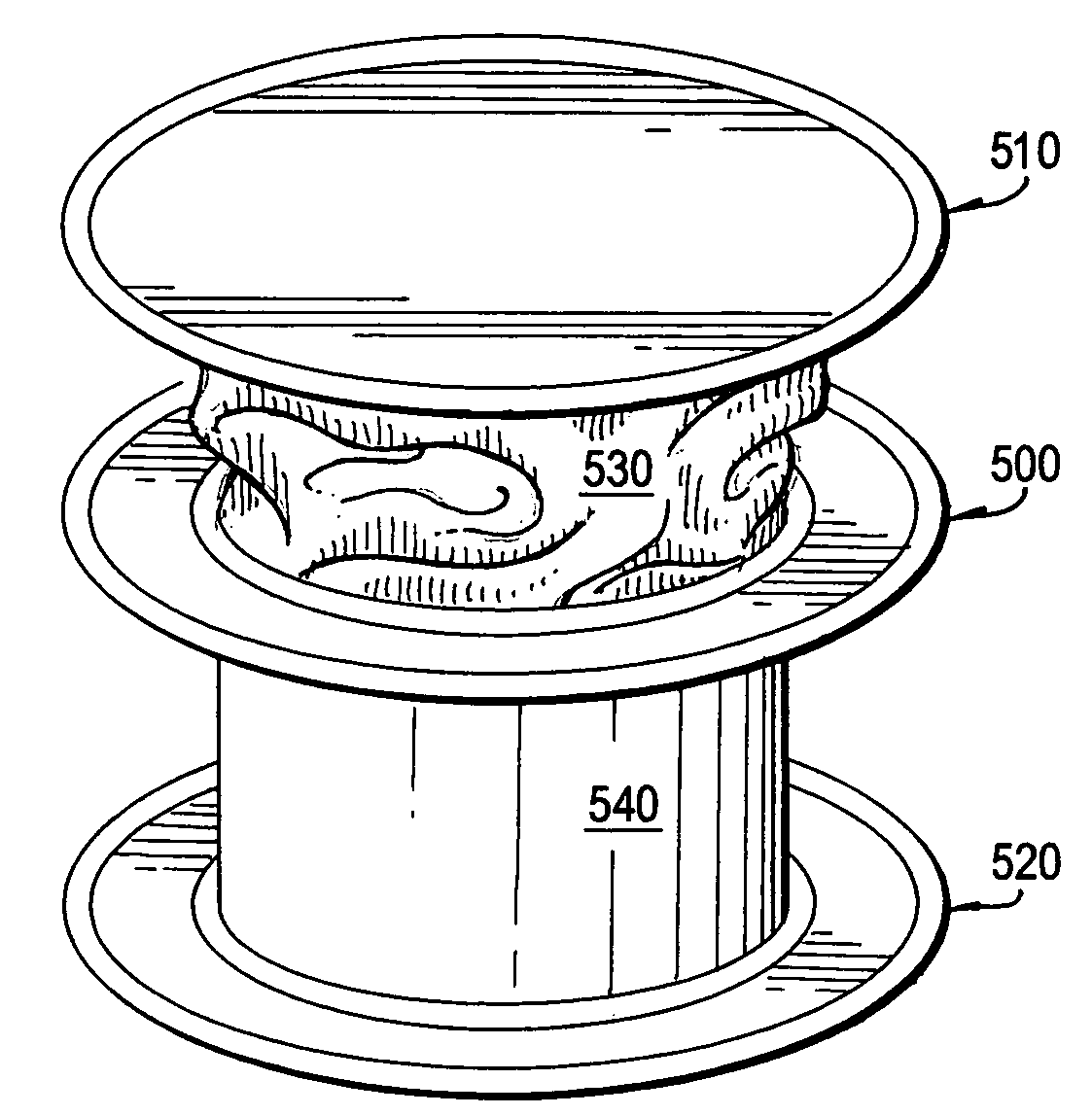

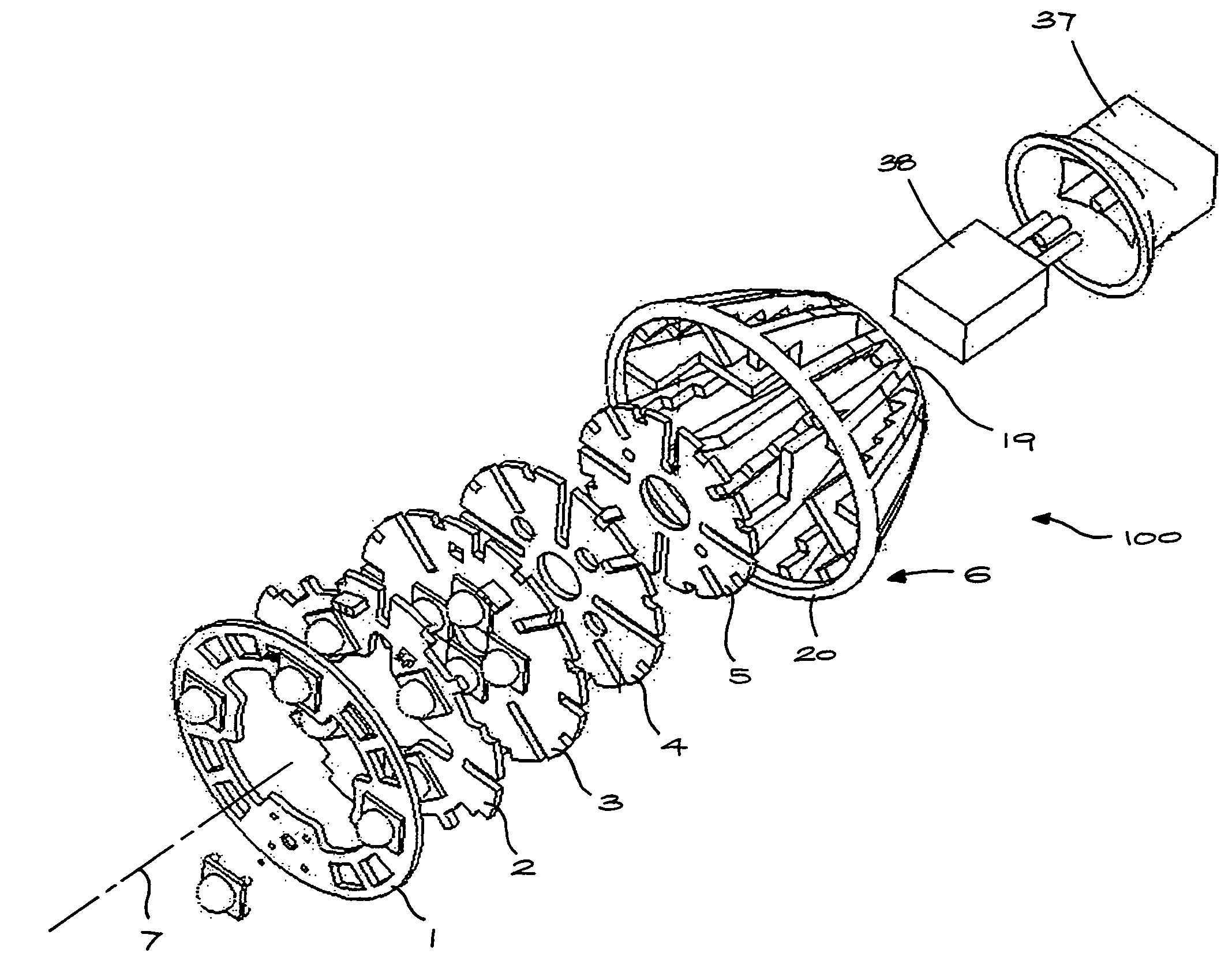

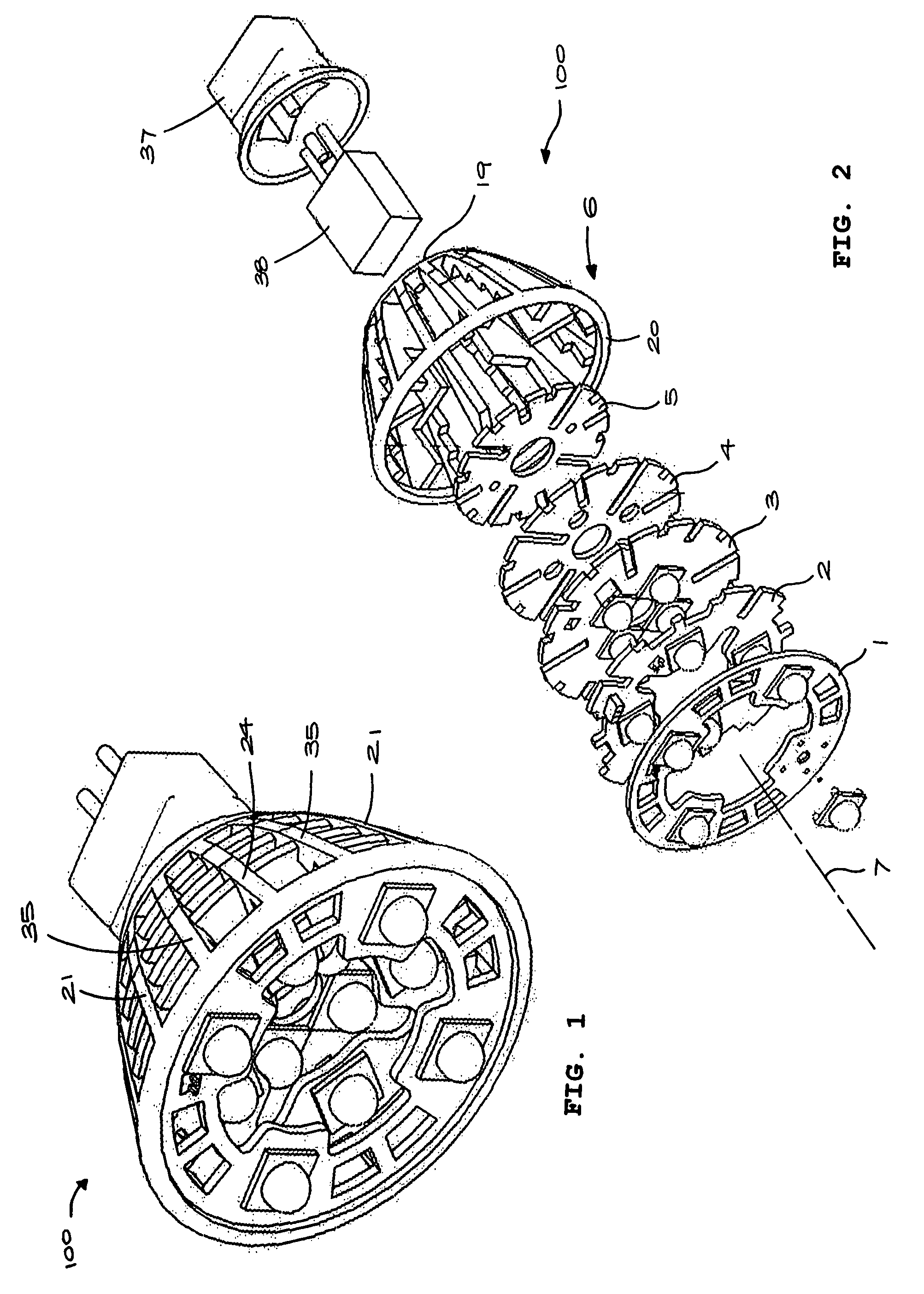

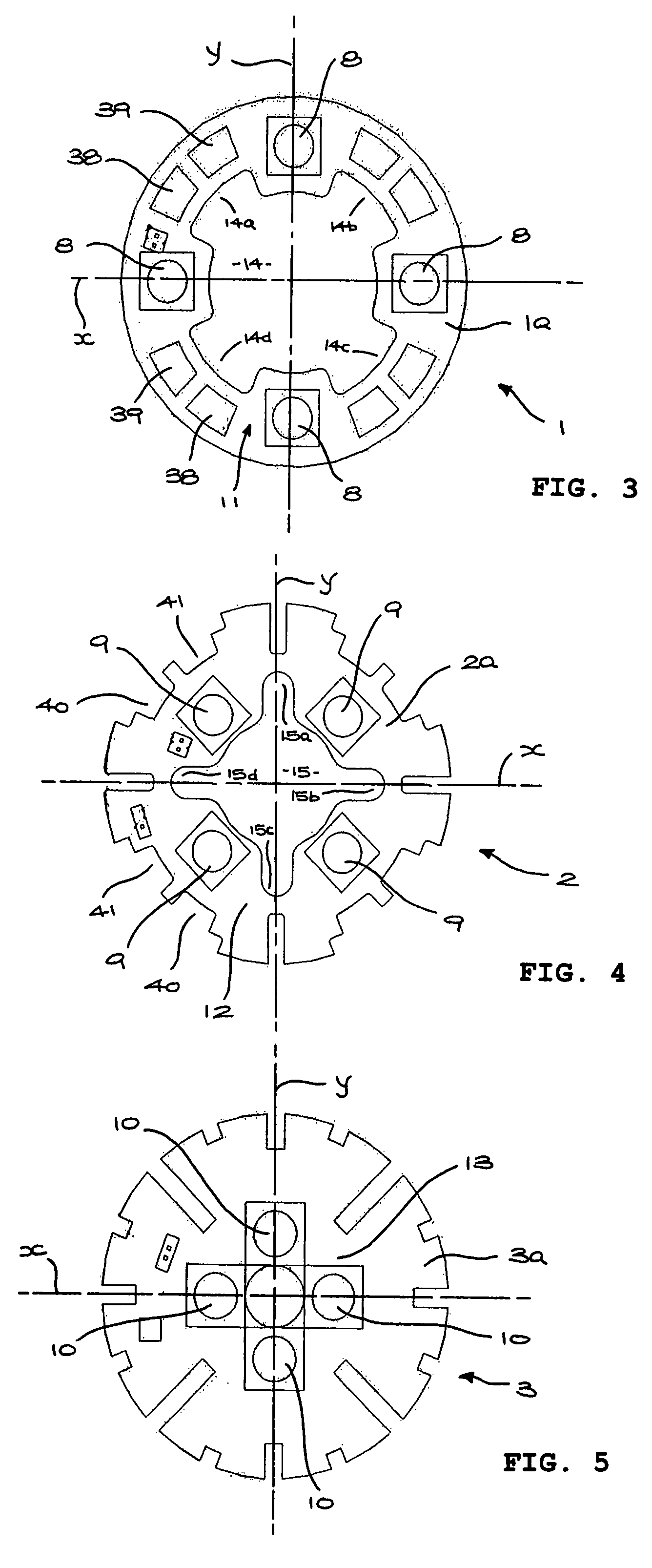

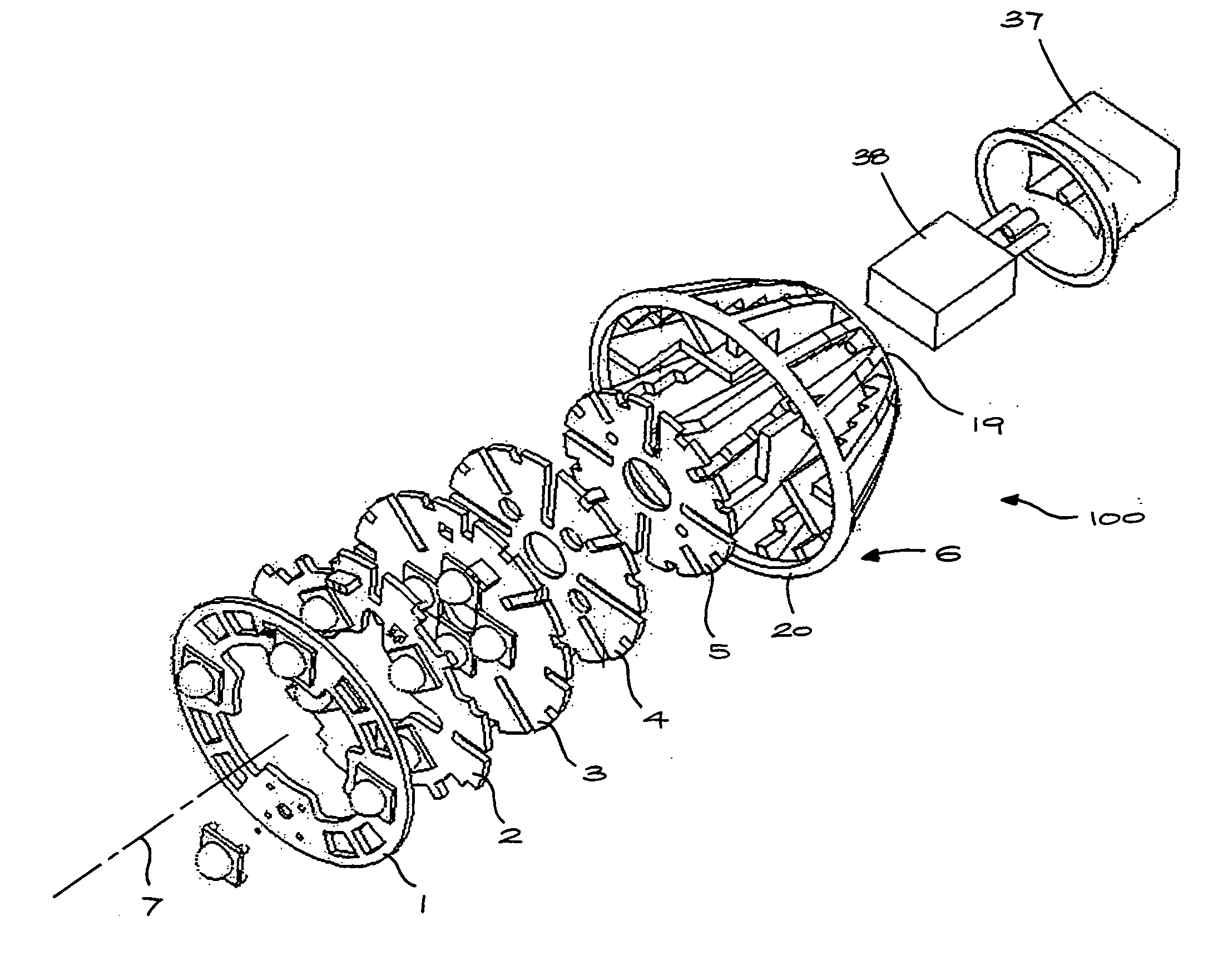

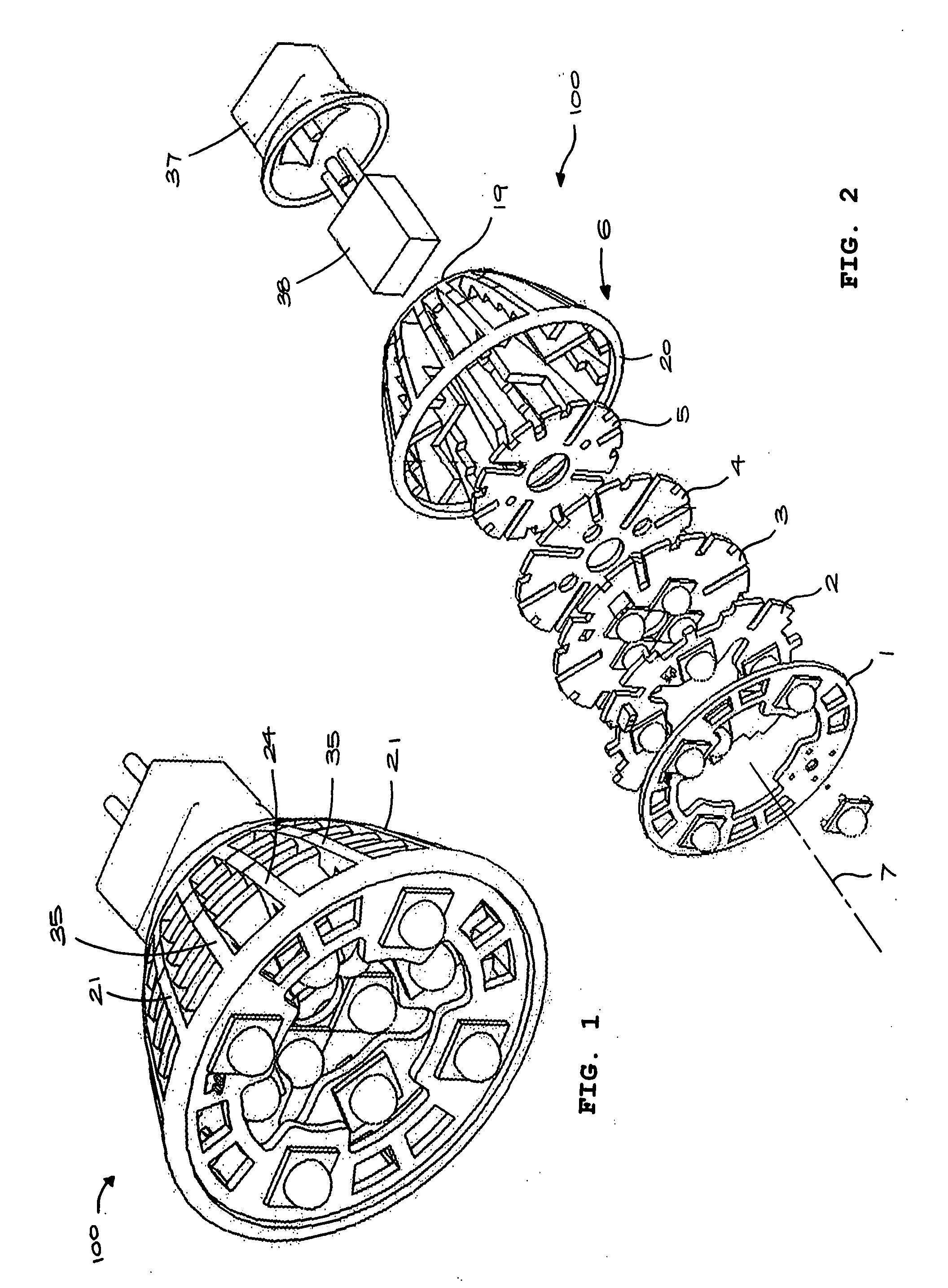

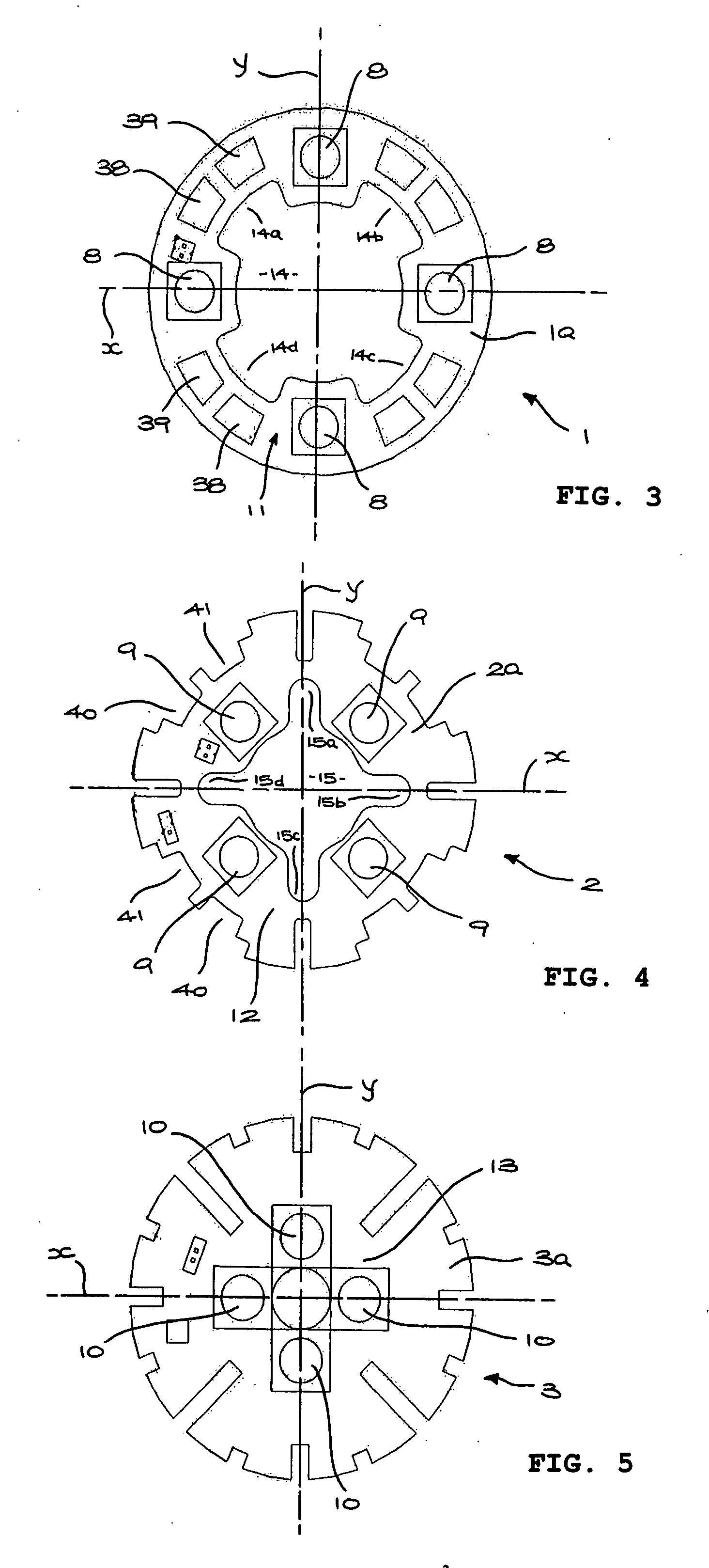

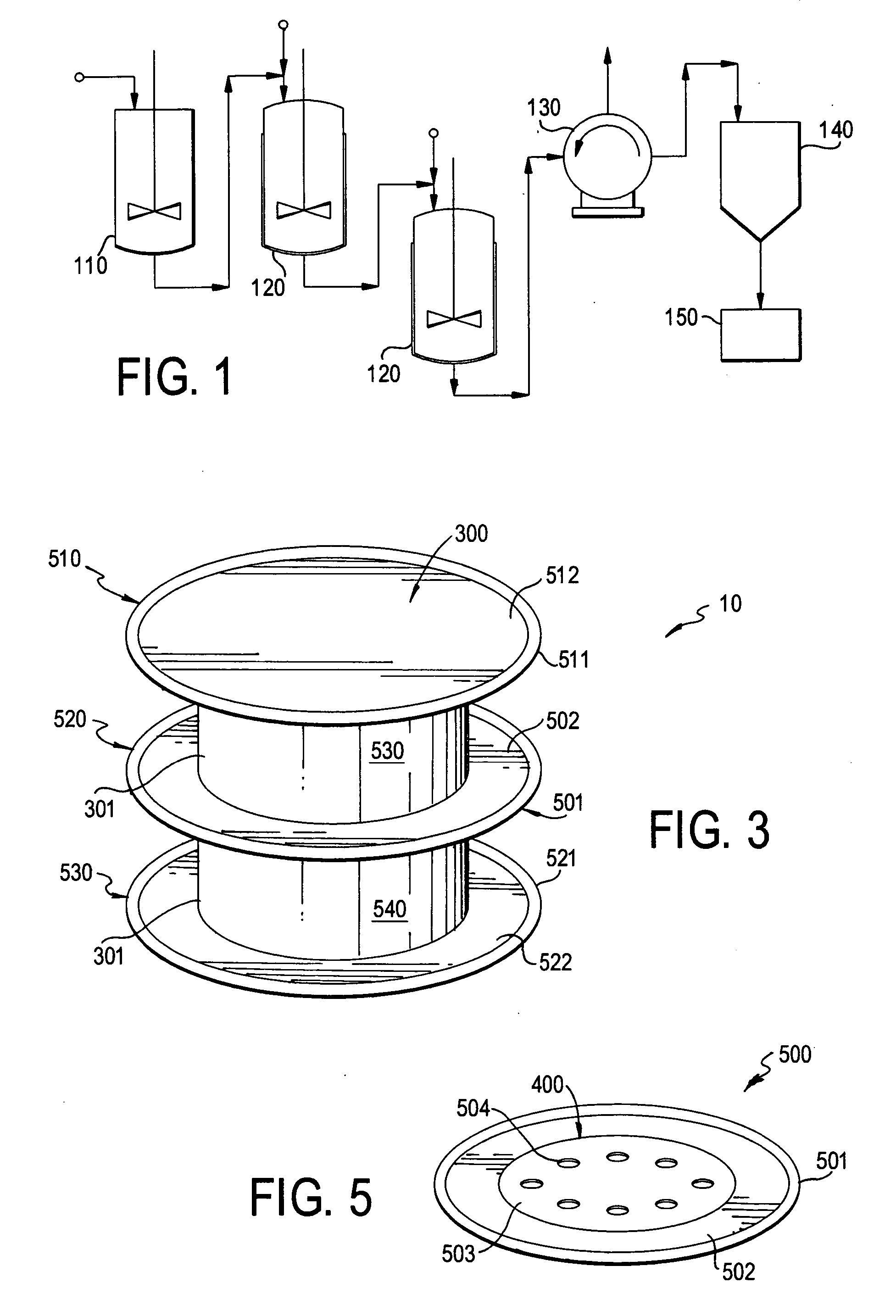

Light emitter assembly

ActiveUS7701055B2Satisfactory dispersionSatisfactory radiationPoint-like light sourceSemiconductor/solid-state device detailsEngineeringLight emitter

A plurality of disc-shaped substrates carry light emitters and are axially stacked, spaced apart, in a metal housing to dissipate the heat produced by the light emitters. The housing comprises mutually connected elongate planar ribs that abut the light emitters or substrates for thermally connecting the light emitters to the housing. The ribs have shoulders. The substrates are received between the ribs and abut the shoulders. The shoulders are positioned proximate each light emitter in intimate contact with the substrate for efficient heat dissipation.

Owner:HONG KONG APPLIED SCI & TECH RES INST

Core-shell carbon black pellets and method of forming same

InactiveUS7651772B2Reduce manufacturing costGood dispersionSynthetic resin layered productsCellulosic plastic layered productsCore shellComposite material

A carbon black pellet comprising an inner core of de-aerated carbon black and an outer surrounding shell of an encapsulating material, the shell of the encapsulating material having an average thickness of from about 1% to about 10% of the average thickness of the pellet.

Owner:BANK OF AMERICA NAT TRUST & SAVINGS ASSOC

Patch containing nonsteroidal antinflammatory and analgesic agent

ActiveUS20060172002A1Excellent long-term storage stabilityImprove solubilityBiocideAntipyreticPolyethylene glycolNon steroidal anti inflammatory

An adhesive patch containing a non-steroidal anti-inflammatory agent, comprising a support and an adhesive layer laminated on this support, wherein the adhesive layer contains a non-steroidal anti-inflammatory agent having a carboxyl group or its salt, and polyethylene glycol having an average molecular weight of 1000 or more.

Owner:HISAMITSU PHARM CO INC

Light emitter assembly

ActiveUS20080121900A1Satisfactory light dispersionSatisfactory radiation patternPoint-like light sourceSemiconductor/solid-state device detailsLight emitter

A plurality of disc-shaped substrates carry light emitters and are axially stacked, spaced apart, in a metal housing to dissipate the heat produced by the light emitters. The housing comprises mutually connected elongate planar ribs that abut the light emitters or substrates for thermally connecting the light emitters to the housing. The ribs have shoulders. The substrates are received between the ribs and abut the shoulders. The shoulders are positioned proximate each light emitter in intimate contact with the substrate for efficient heat dissipation.

Owner:HONG KONG APPLIED SCI & TECH RES INST

Dispersing apparatus

InactiveUS6029920AHigh glossImprove performanceRotary stirring mixersGrain treatmentsEngineeringPigment

Owner:TOYO INK SC HOLD CO LTD

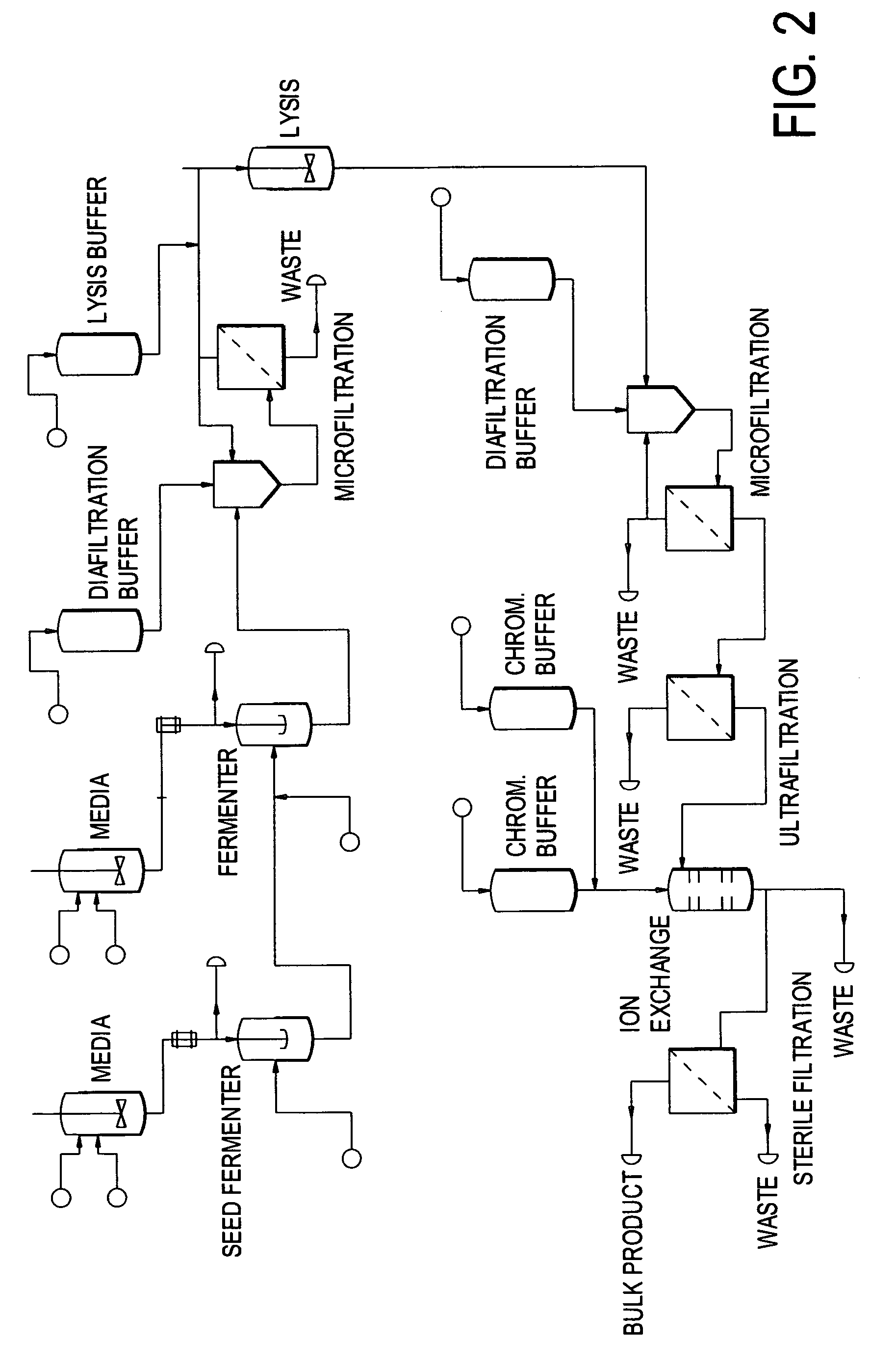

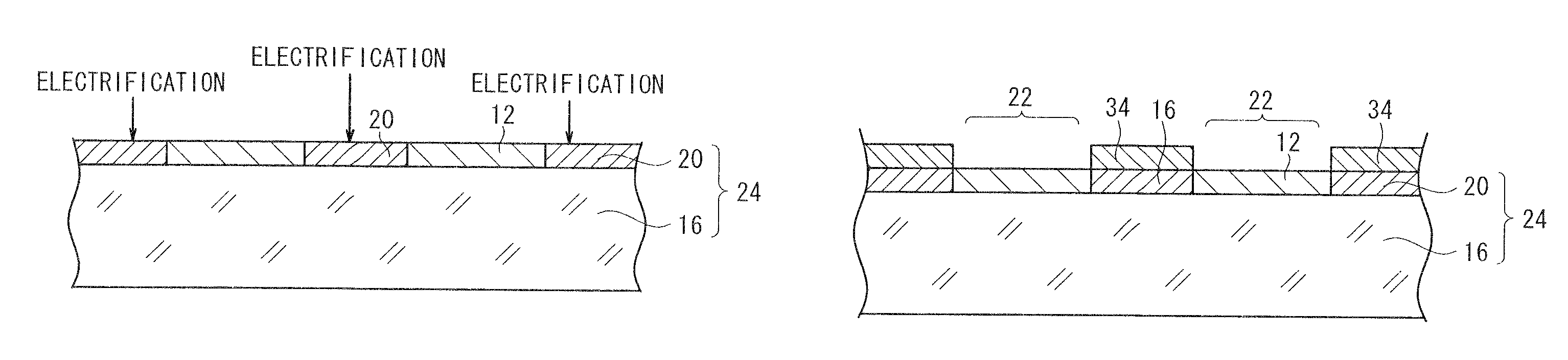

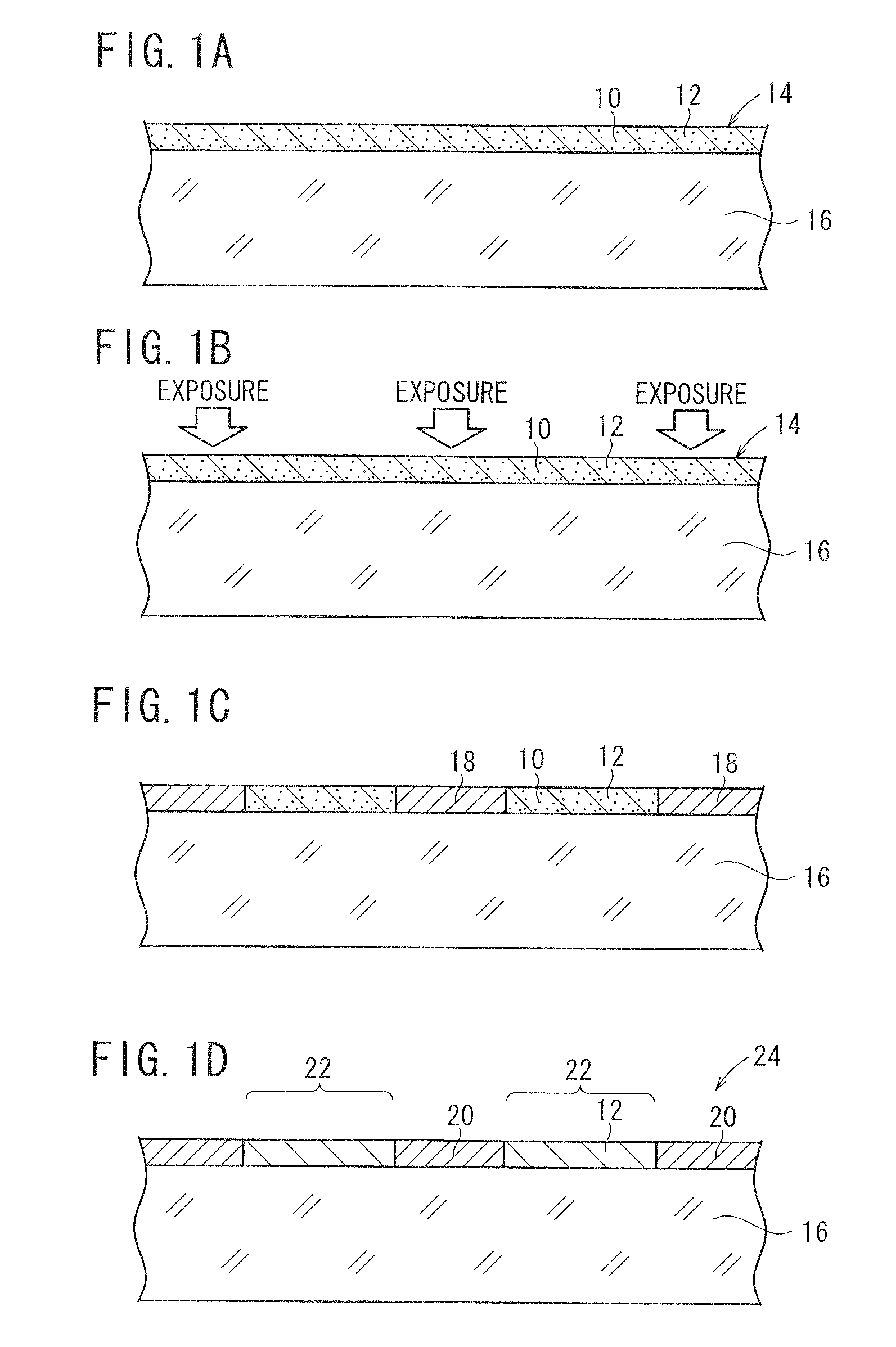

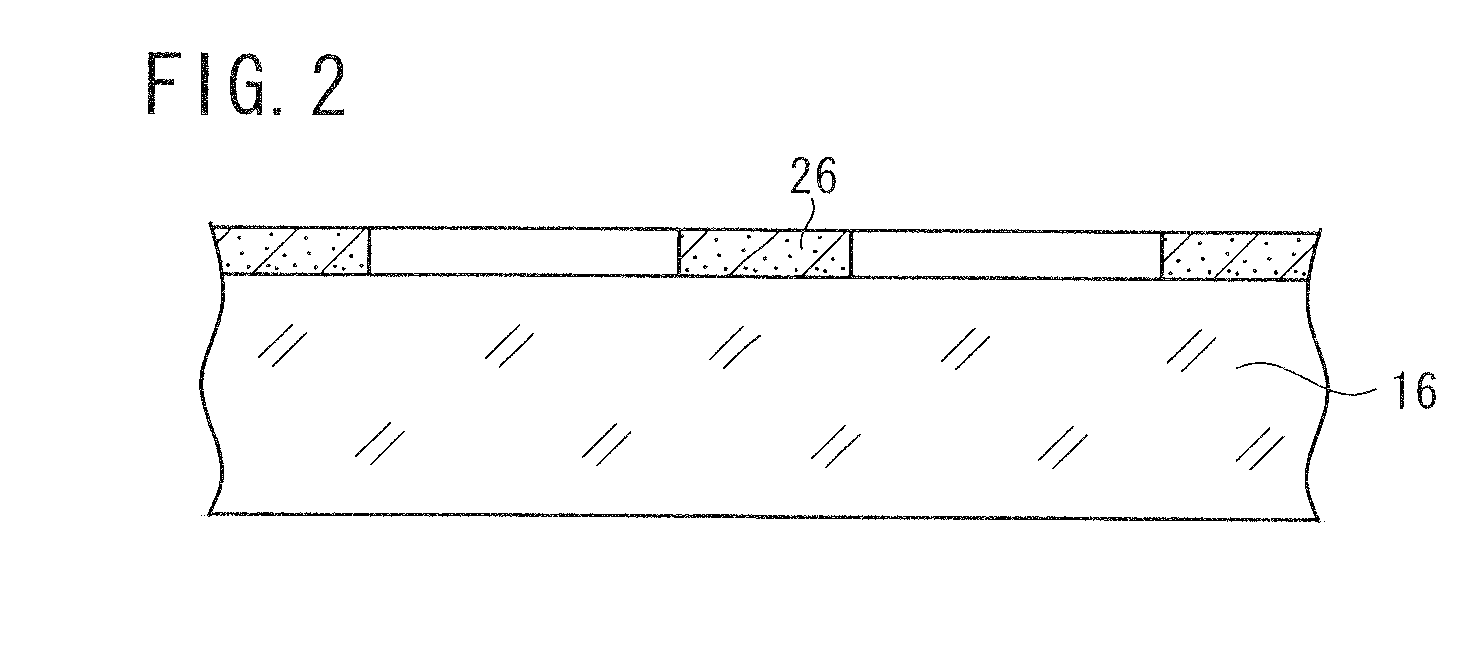

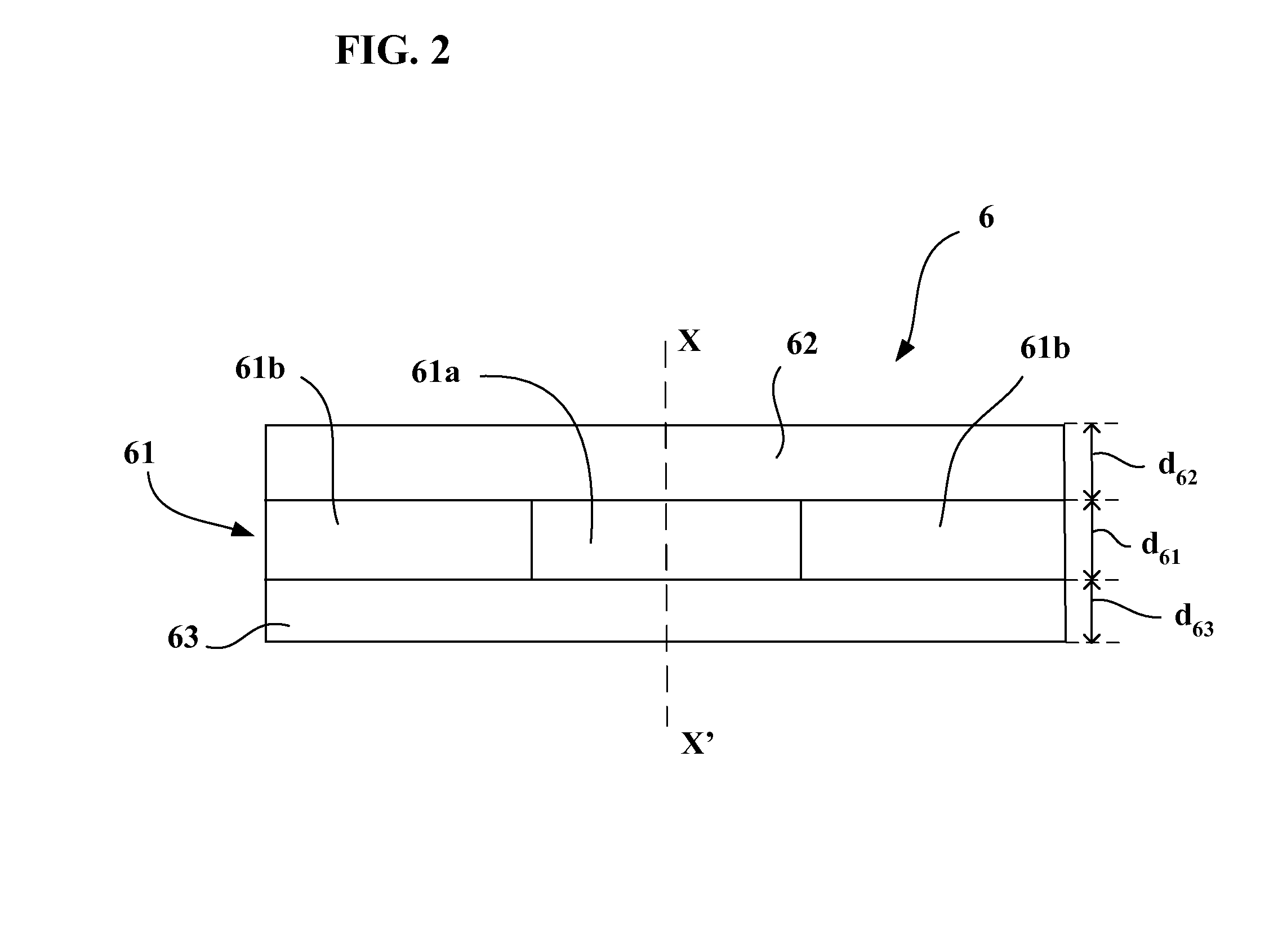

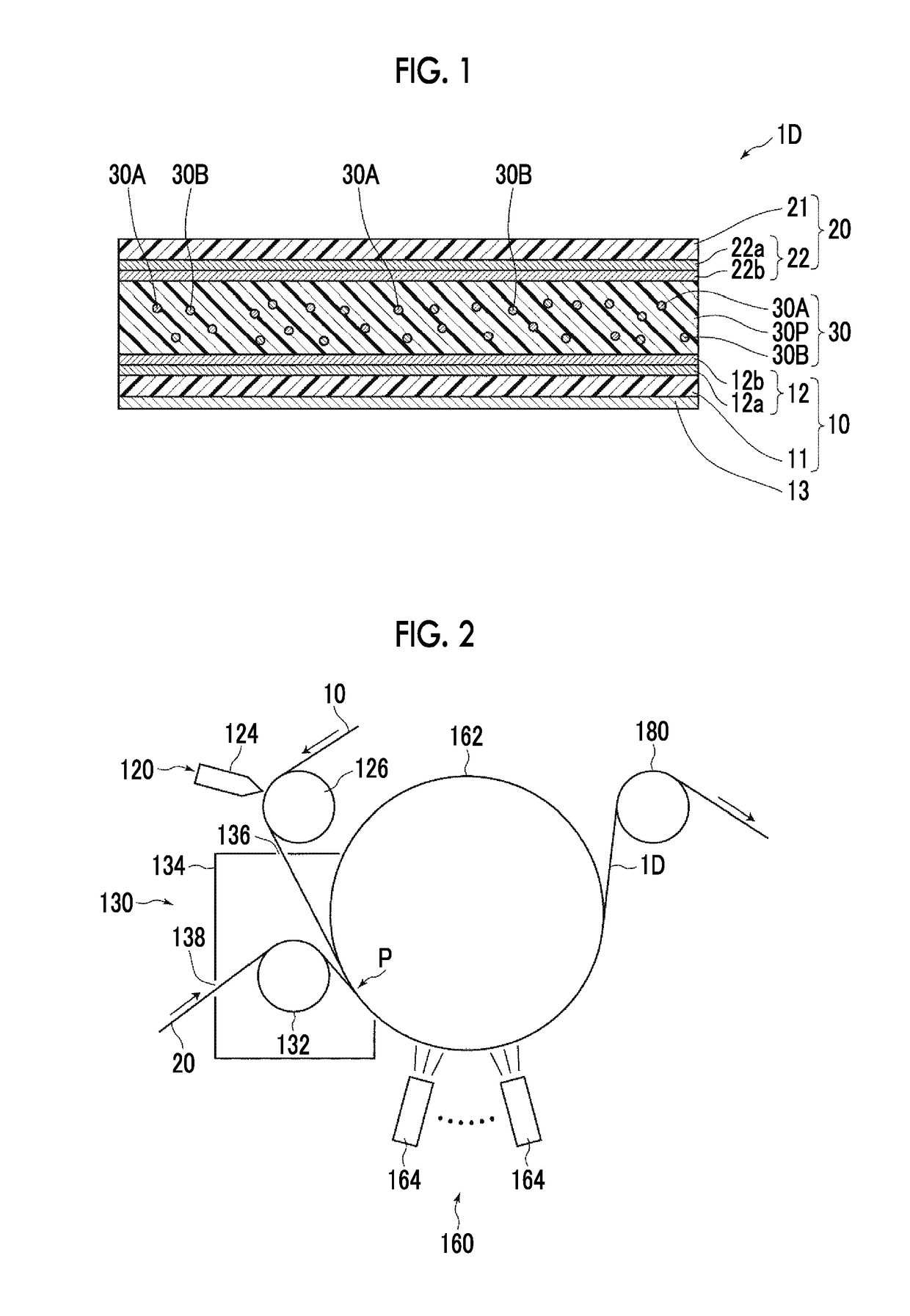

Method and apparatus for producing conductive material

InactiveUS8268400B2Low electroless plating activityHigh electroless plating activityPrinted circuit aspectsPhotomechanical apparatusEmulsionConductive materials

A photosensitive film, which has a transparent support and a silver salt emulsion layer containing a silver salt formed thereon, is exposed and developed to form a metallic silver portion. The base material to be plated is electrified in a solution containing a metal ion, using the metallic silver portion as a cathode. Then, the electrified base material is subjected to an electroless plating treatment to form a plated layer only on the metallic silver portion. The metal ion in the solution is preferably an ion of copper, nickel, cobalt, or tin.

Owner:FUJIFILM CORP

Power supply antenna and power supply method

InactiveUS20060027168A1Satisfactory dispersionGenerate efficientlyElectric discharge tubesRadiating elements structural formsEngineeringElectric field

A power supply antenna comprises a plurality of coils disposed concentrically. Power supply portions formed at opposite ends of the respective coils are located in different phases on the same plane such that spacing between the adjacent power supply portions is equal. The power supply antenna can generate a uniform electric field and a uniform magnetic field, although it has the plural coils.

Owner:MITSUBISHI HEAVY IND LTD

Exhaust emission control device

ActiveUS8347610B2Well mixedIncrease flow rateGas treatmentInternal combustion piston enginesParticulatesEnvironmental engineering

Owner:HINO MOTORS LTD

Golf ball

InactiveUS20060046871A1Enhance ball distanceExcellent shot feelingSynthetic resin layered productsGolf ballsEngineeringHardness

The golf ball includes a core, an intermediate layer for covering the core and a cover layer for covering the intermediate layer, wherein the cover layer,is formed of a resin composition having a Shore D hardness of 52 or higher and the intermediate layer is formed of a resin composition containing a cation-treated phillosilicate and having a Shore D hardness of lower than 55. This combination provides the golf ball with an enhanced ball distance even in a slow swing speed as well as an improved shot feeling.

Owner:DUNLOP SPORTS CO LTD

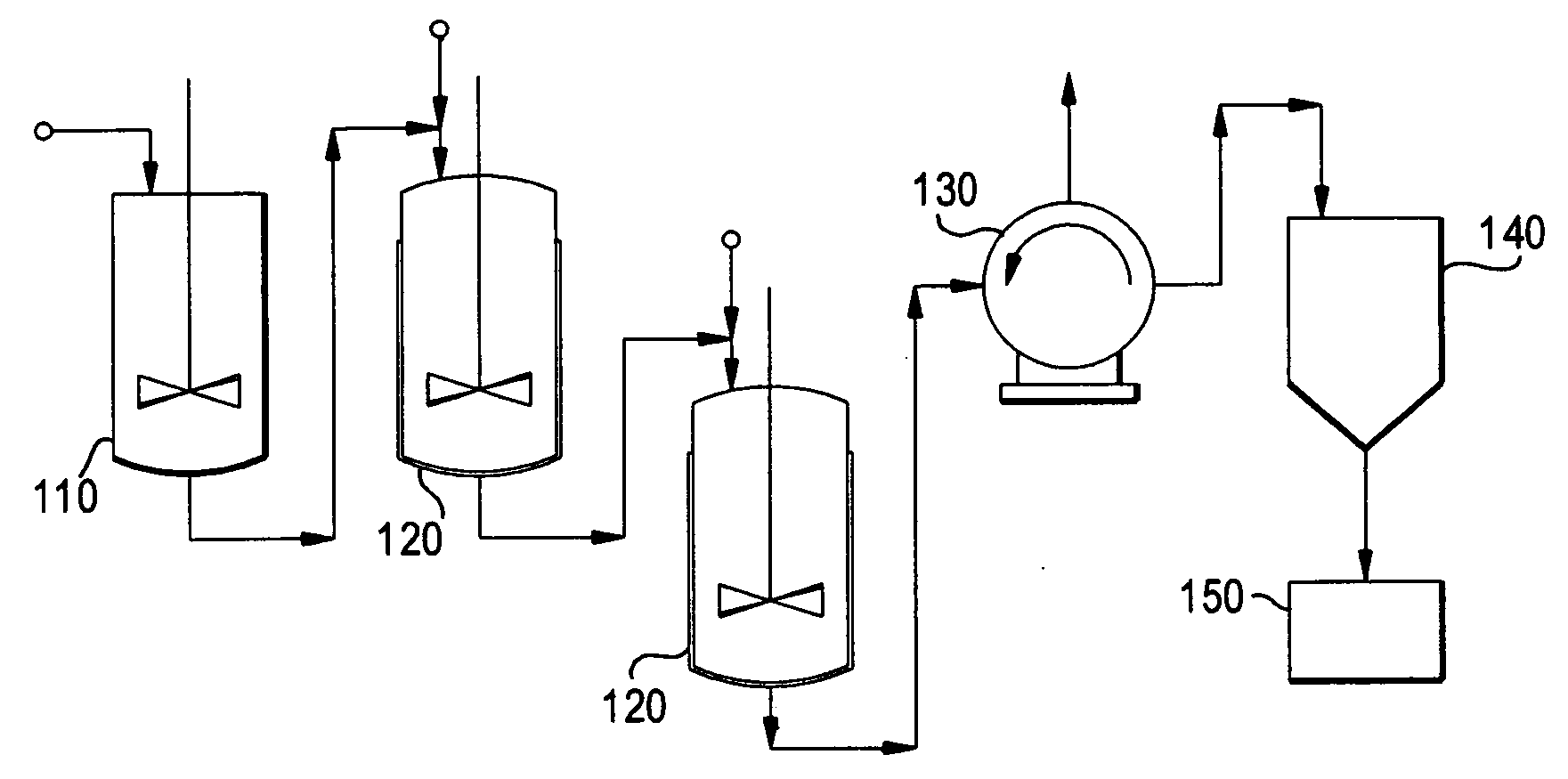

Resin microparticle as raw material for toner, aqueous dispersed system thereof and toner

InactiveUS20070082285A1Improve image qualitySatisfactory dispersionDevelopersPolymer scienceOrganic solvent

A resin microparticle for a toner raw material that has a small particle diameter and a narrow particle diameter distribution and has a low odor is provided. The resin microparticle for a toner raw material has the following requirements (i) to (iii) satisfied: Requirement (i): A particle diameter of 50% volume (D50) satisfies the relationship 0.05 μm≦D50≦1 μm; Requirement (ii): A particle diameter of 10% volume (D10) and a particle diameter of 90% volume (D90) satisfy the relationship D90 / D10≦7; and Requirement (iii): The content of an organic solvent is not more than 70 ppm.

Owner:MITSUI CHEM INC

Carbon black pellets and method of forming same

InactiveUS20080182107A1Reduce manufacturing costGood dispersionSynthetic resin layered productsCellulosic plastic layered productsComposite materialCarbon black

A carbon black pellet comprising an inner core of de-aerated carbon black and an outer surrounding shell of an encapsulating material, the shell of the encapsulating material having an average thickness of from about 1% to about 10% of the average thickness of the pellet.

Owner:BANK OF AMERICA N A

Mixing Vessel and Method of Use

ActiveUS20060254983A1Reduce in quantityRemoval costShaking/oscillating/vibrating mixersFlow mixersEngineering

Owner:ILC DOVER LP

Golf ball

InactiveUS7264559B2Enhanced ball distanceFeel goodSynthetic resin layered productsGolf ballsHardnessEngineering

The golf ball includes a core, an intermediate layer for covering the core and a cover layer for covering the intermediate layer, wherein the cover layer is formed of a resin composition having a Shore D hardness of 52 or higher and the intermediate layer is formed of a resin composition containing a cation-treated phillosilicate and having a Shore D hardness of lower than 55. This combination provides the golf ball with an enhanced ball distance even in a slow swing speed as well as an improved shot feeling.

Owner:DUNLOP SPORTS CO LTD

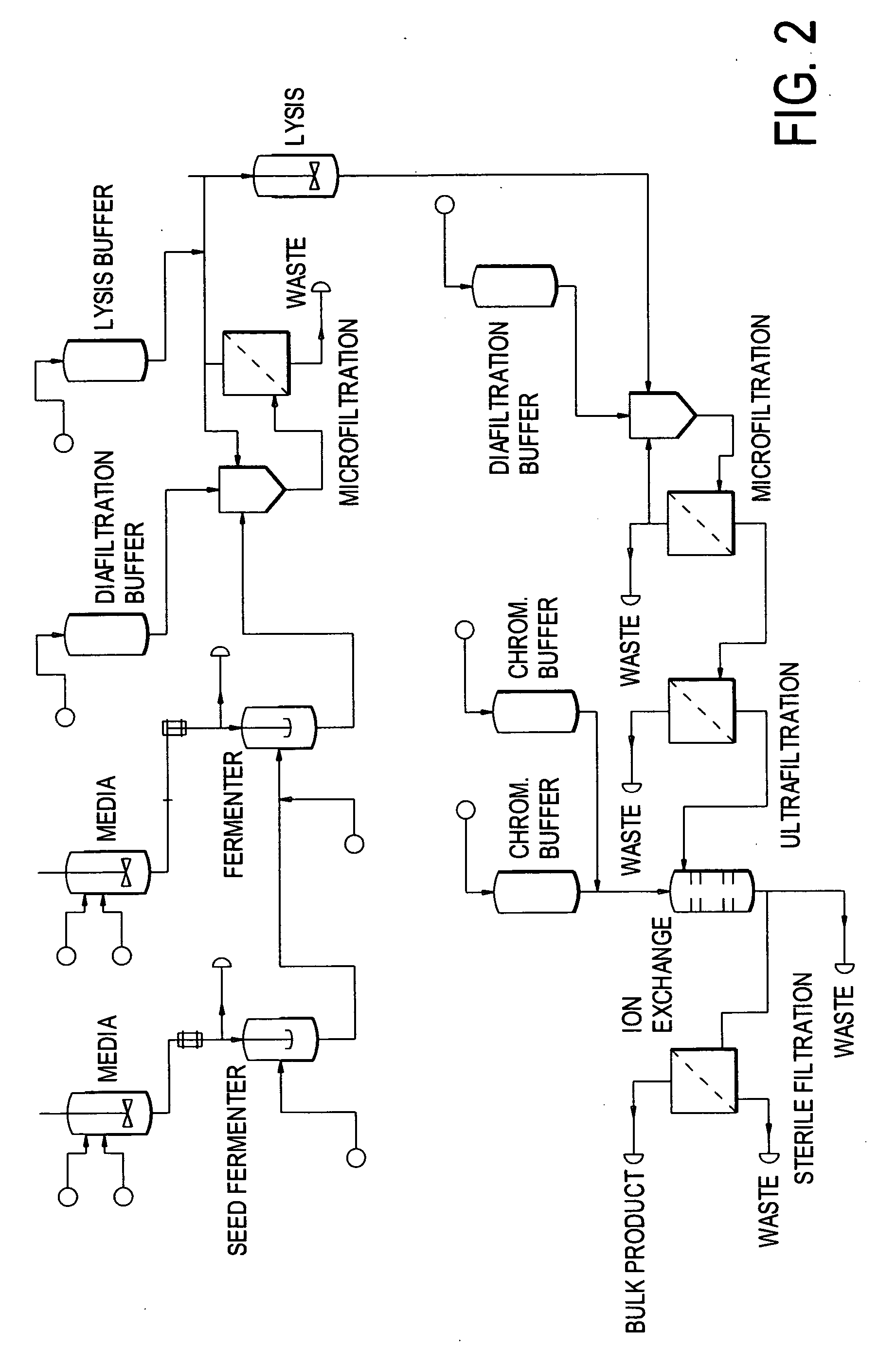

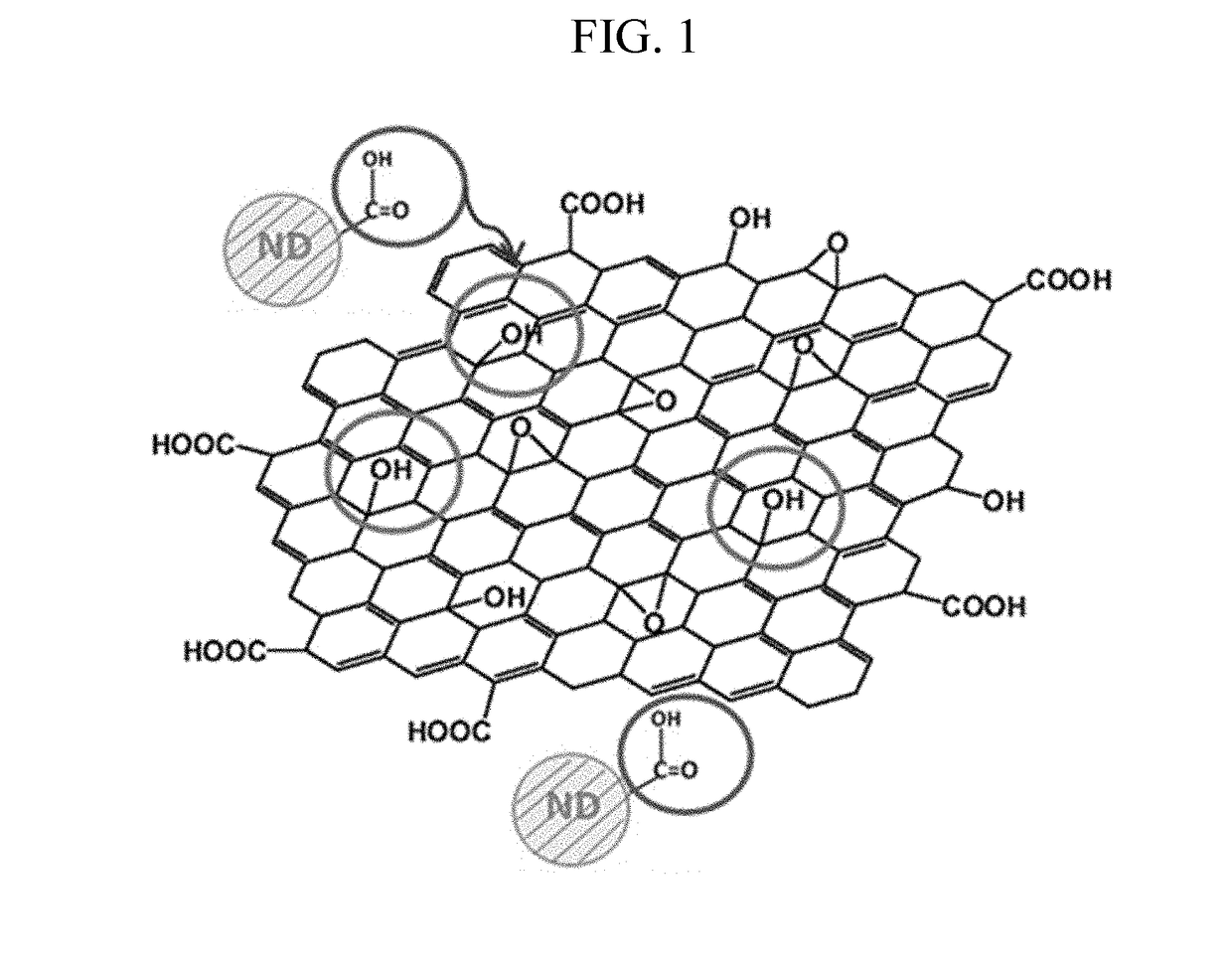

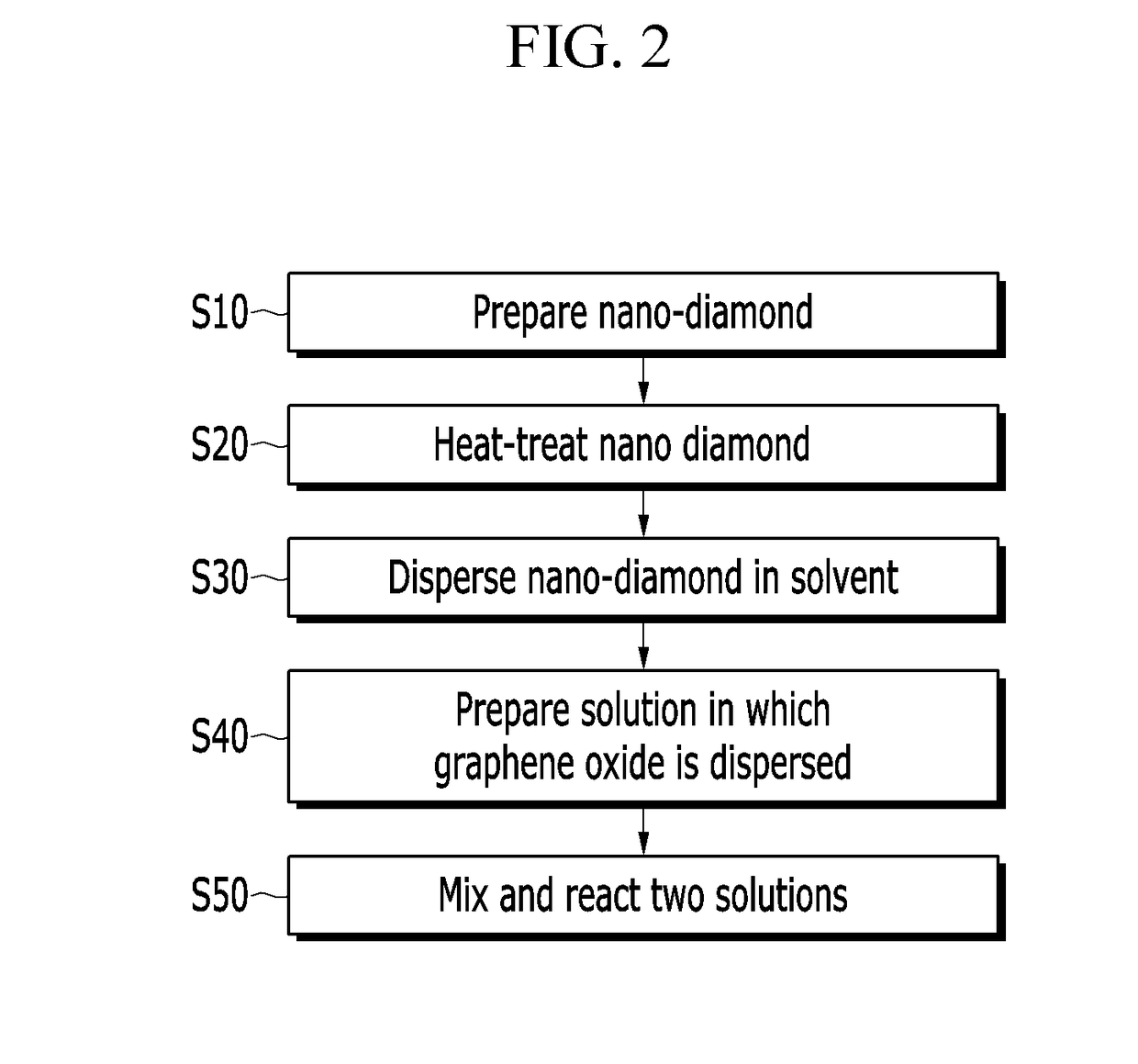

Graphene oxide-nanodiamond composite, manufacturing method thereof, and nanofluid including the same

ActiveUS20180237677A1Improved dispersion stability and corrosion stabilityGood dispersionOrganic compound preparationDiamondNanofluidGraphene

Disclosed herein is a composite comprising a graphene oxide and a nanodiamond that is chemically bonded on a surface of the graphene oxide.

Owner:HYUNDAI MOTOR CO LTD +1

Golf ball

InactiveUS7390542B2Improve controllabilityIncrease distanceEnvelopes/bags making machineryImpression capsEngineeringHardness

The golf ball includes a core, an intermediate layer for covering the core and a cover layer for covering the intermediate layer, wherein the intermediate layer is formed of a resin composition containing a cation-treated phillosilicate and having a Shore D hardness of 56 or higher. This intermediate layer provides the golf ball excellent in ball distance at a driver shot and in controllability at an iron shot.

Owner:DUNLOP SPORTS CO LTD

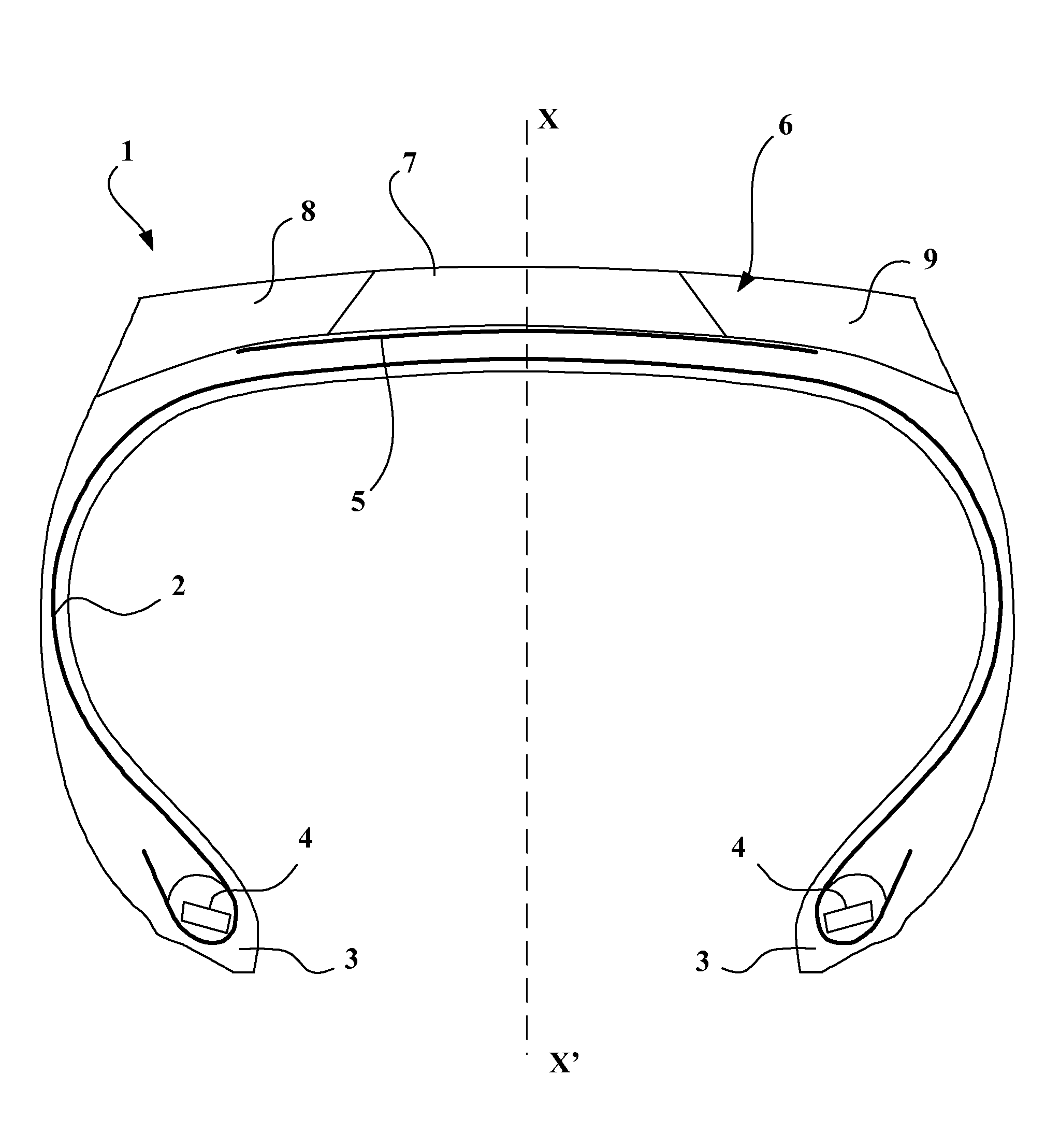

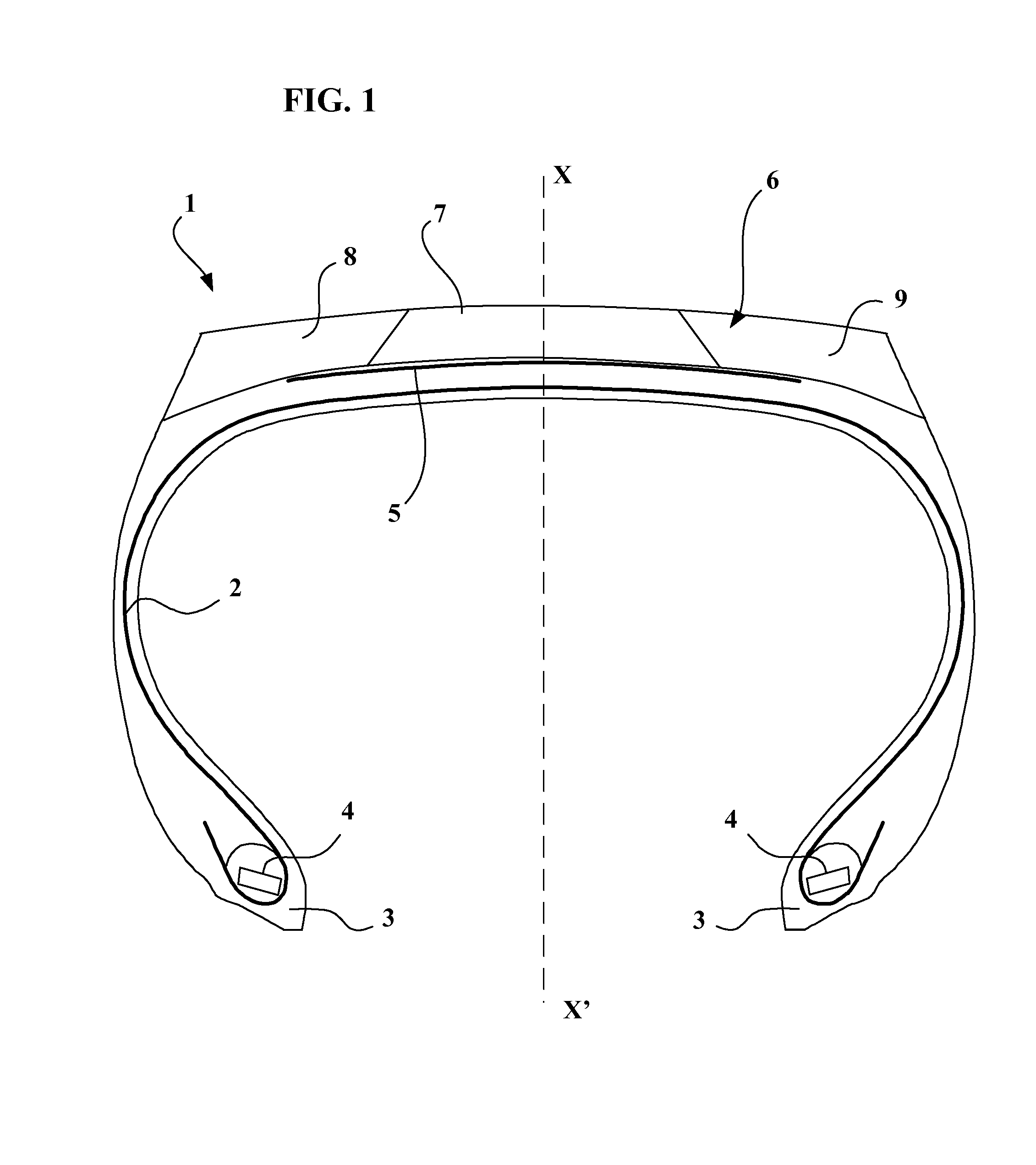

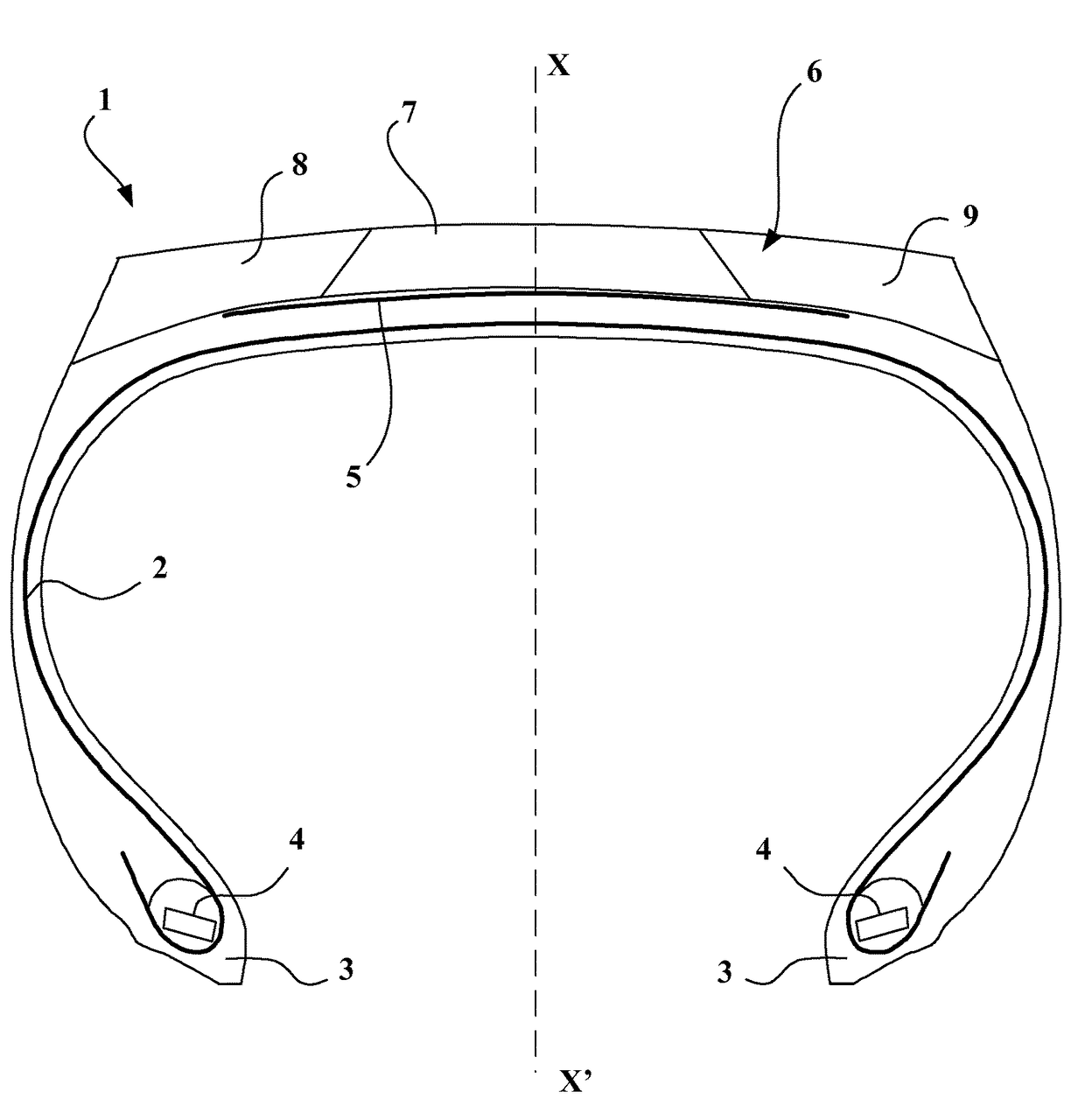

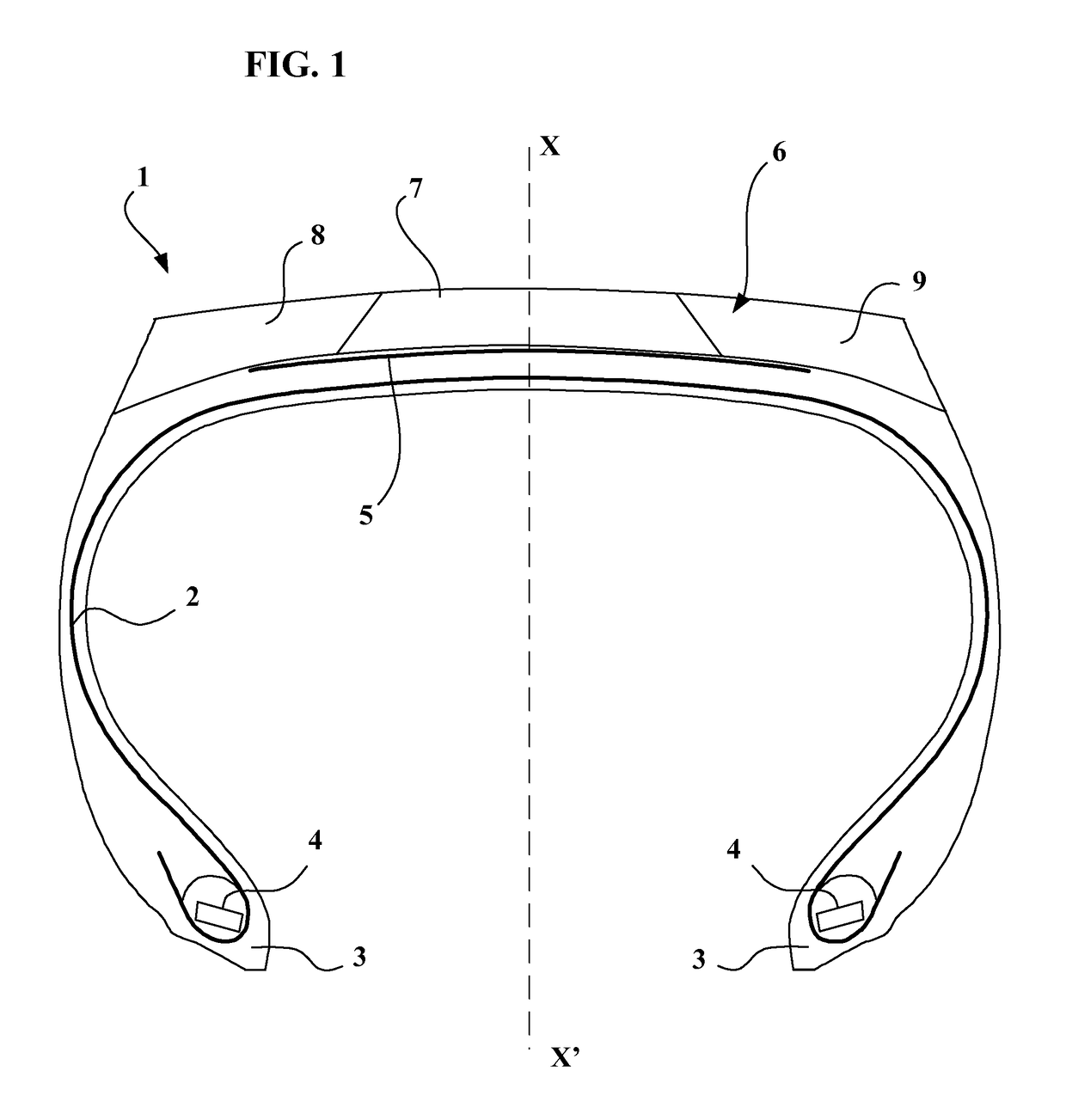

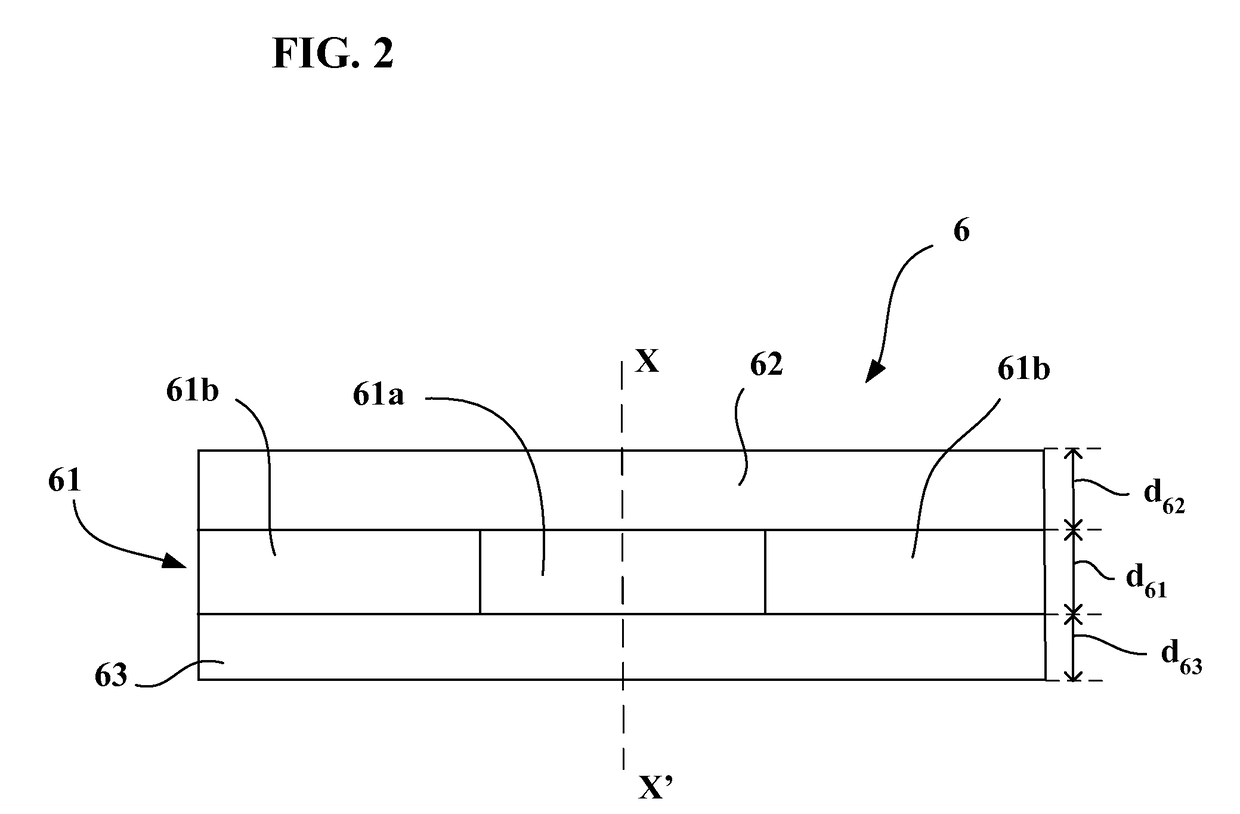

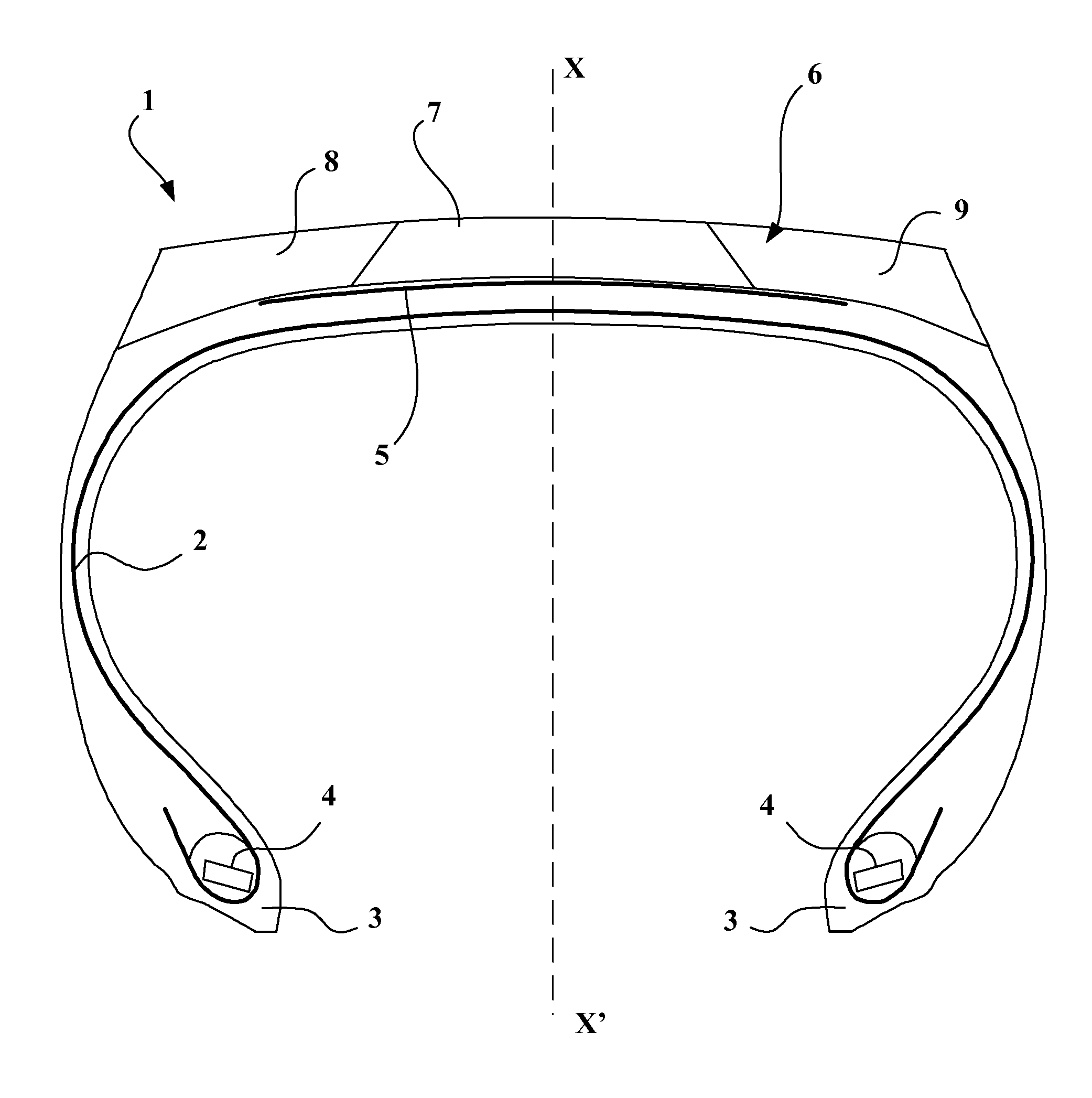

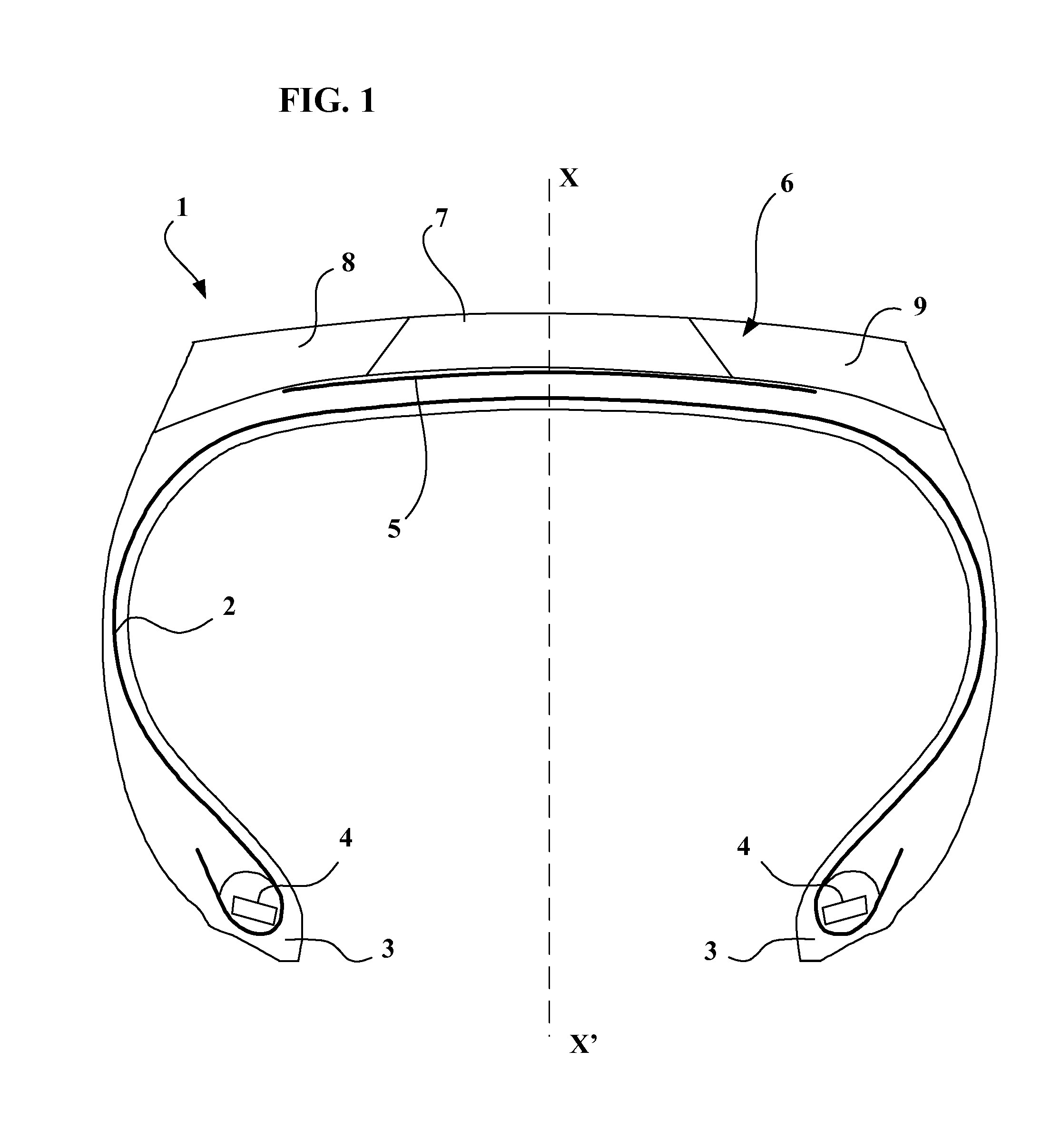

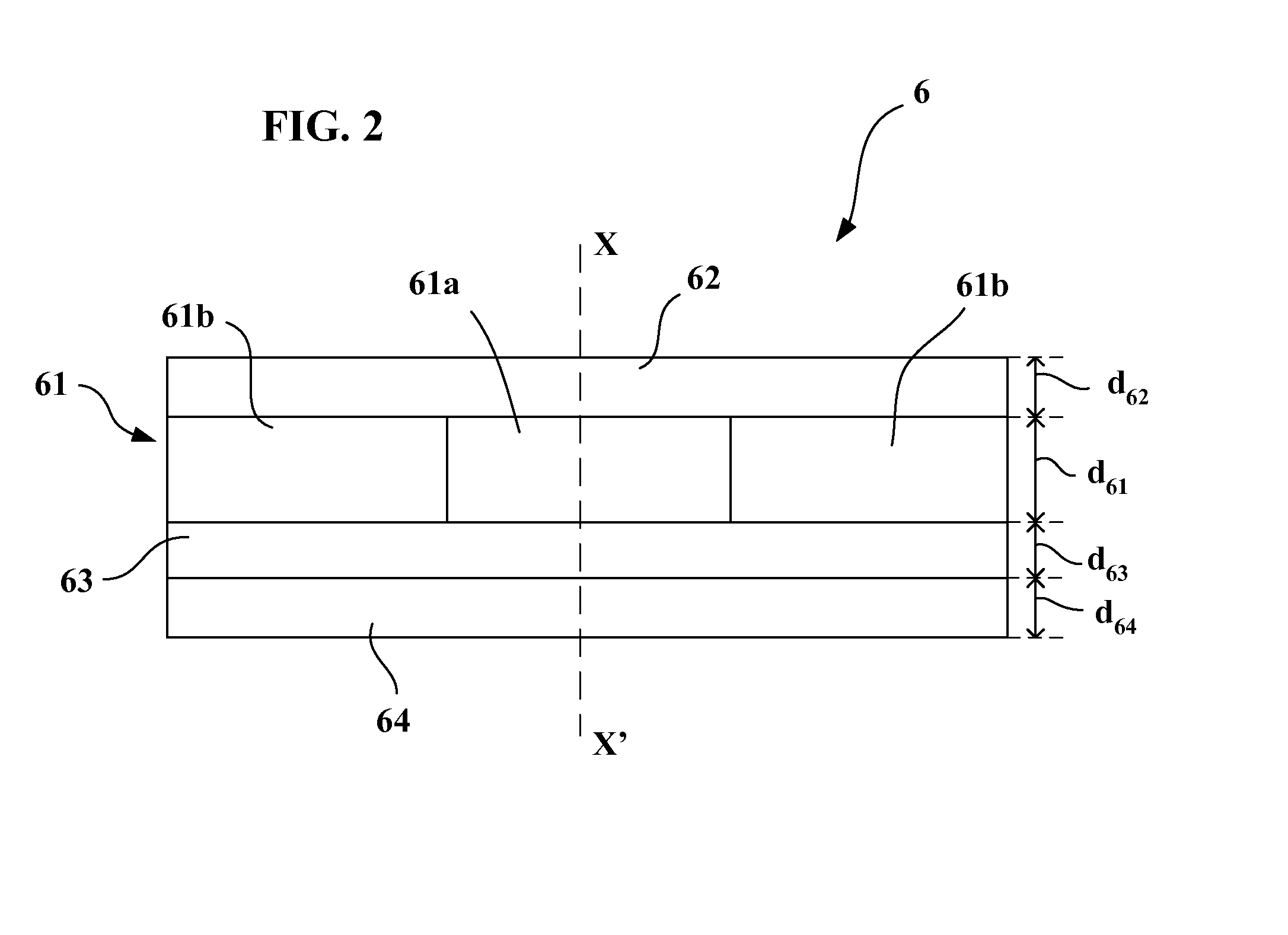

Tire comprising a tread formed by multiple elastomer blends

ActiveUS20150151580A1Increase temperatureImprove staminaSpecial tyresTyre tread bands/patternsElastomerHybrid compound

A tire of which the tread contains at least two layers of blended elastomeric compounds that are radially superposed and has a voids ratio that is lower in the central part than at the axially outer parts thereof. A first layer of blended elastomeric compounds of the tread is made up of a first blended elastomeric compound forming a central part, and of two outer parts formed of a second blended compound, the first blended compound having a Z-value higher than 55, the first blended compound and the second blended compound having a tan(δ)max value lower than 0.110, the modulus G* of the second blended elastomeric compound having a value at least 10% higher than that of the modulus G* of the first blended elastomeric compound, a second layer of the tread, radially the outermost, being made up of a third blended compound of which the modulus G* has a value at least 10% higher than that of the modulus G* of the first blended elastomeric compound and the elongation at break of the third blended compound having a value at least 10% higher than those of the elongations at break of the first and second blended compounds.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

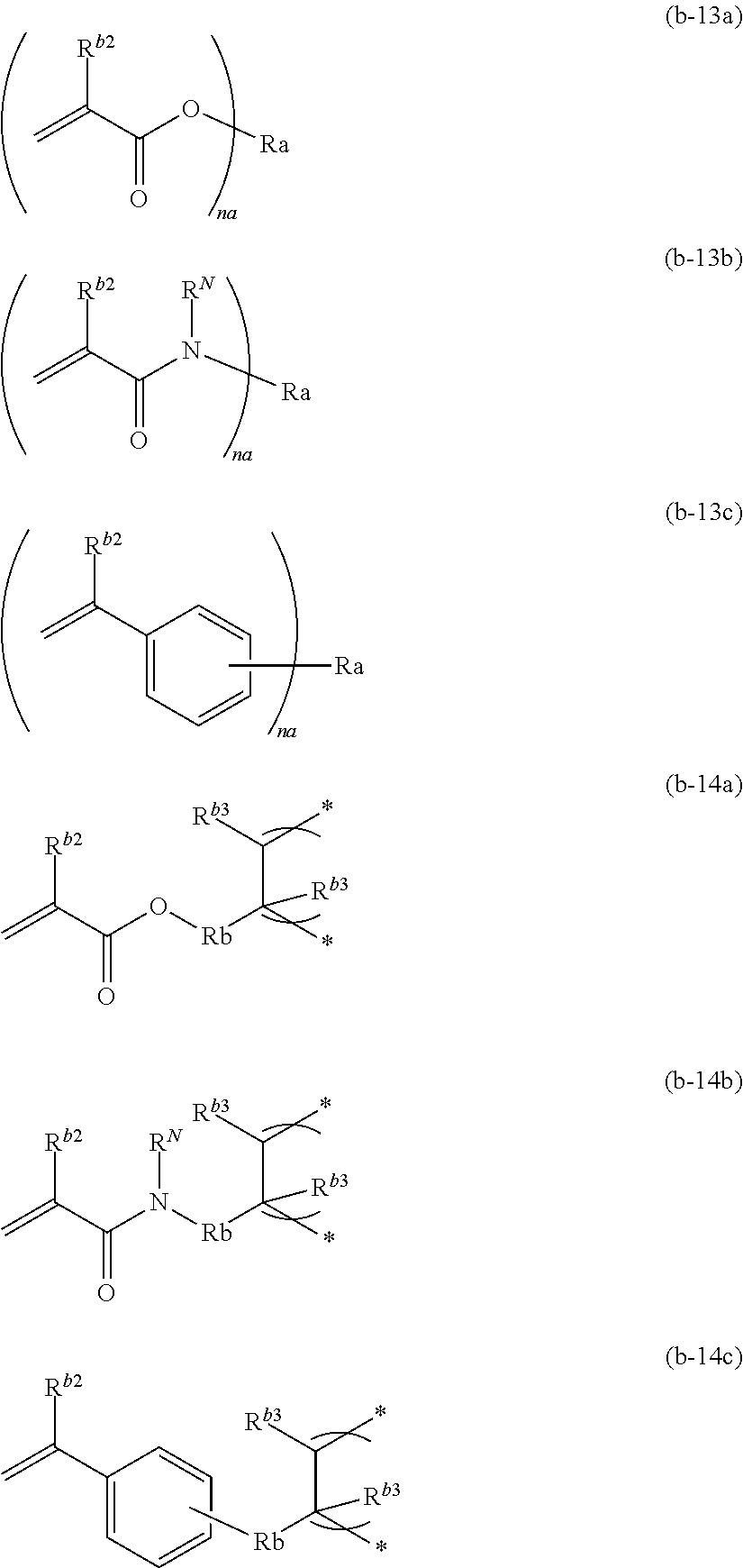

Polymerizable composition, wavelength conversion member, backlight unit, and liquid crystal display device

InactiveUS20180081236A1Satisfactory dispersionSatisfactory brightnessLiquid crystal compositionsMaterial nanotechnologySolubilityPolymer science

A polymerizable composition includes a quantum dot, a monomer having an epoxy group or an oxetanyl group, and a polymer dispersant, in which the polymer dispersant is a compound represented by Formula I. In Formula I, A is an organic group having a coordinating group coordinated with a quantum dot, Z is an (n+m+l)-valent organic linking group, X1 and X2 are a single bond or a divalent organic linking group, R1 represents an alkyl group, an alkenyl group, or an alkynyl group each of which may have a substituent, P is a polymer chain which has a polymerization degree of 3 or greater and which includes a polymer skeleton and of which the solubility parameter is 17 MPa1 / 2 to 22 MPa1 / 2. n and m are each independently the number of 1 or greater, l is the number of 0 or greater, n+m+l is an integer of 2 to 10.

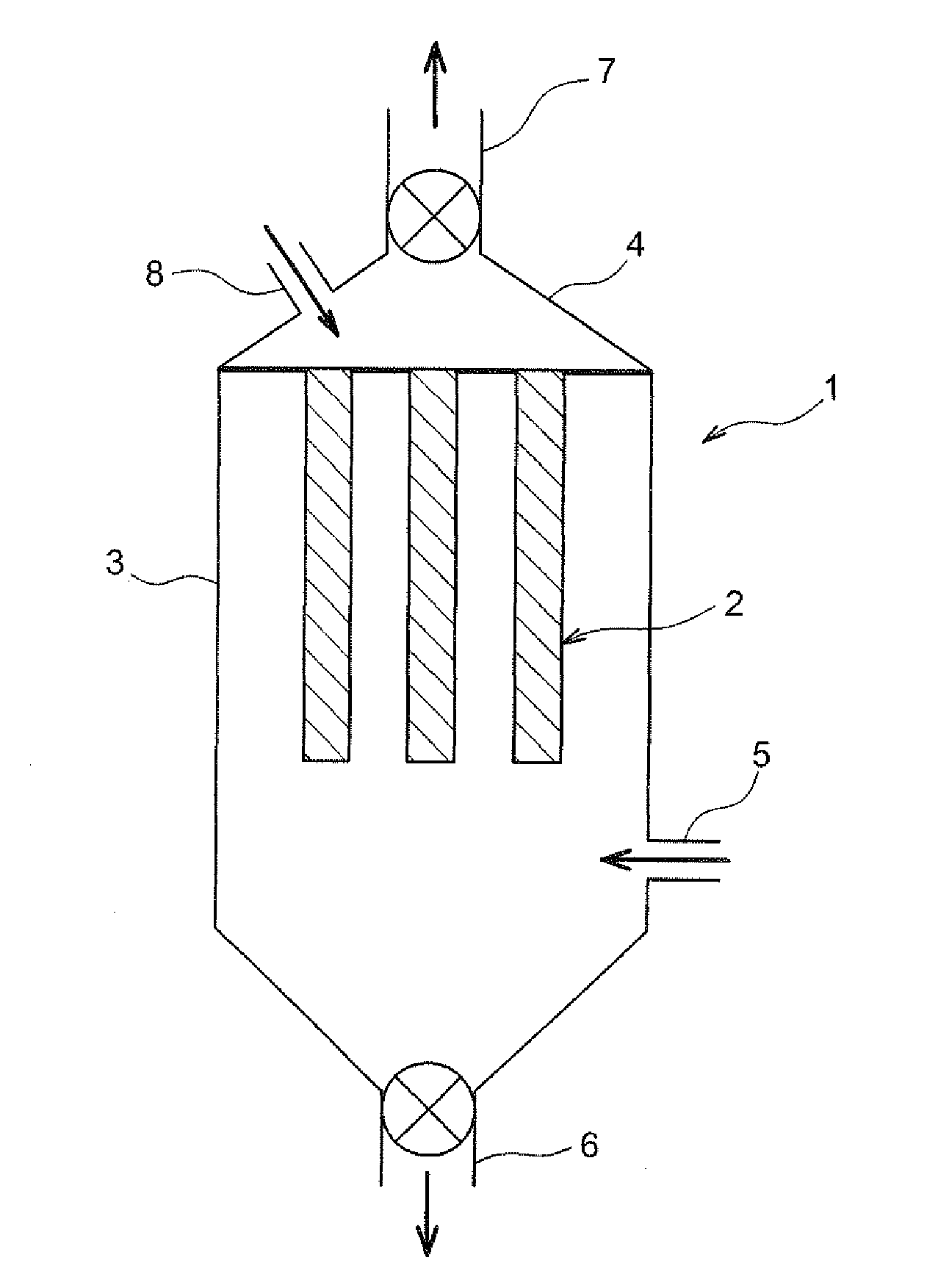

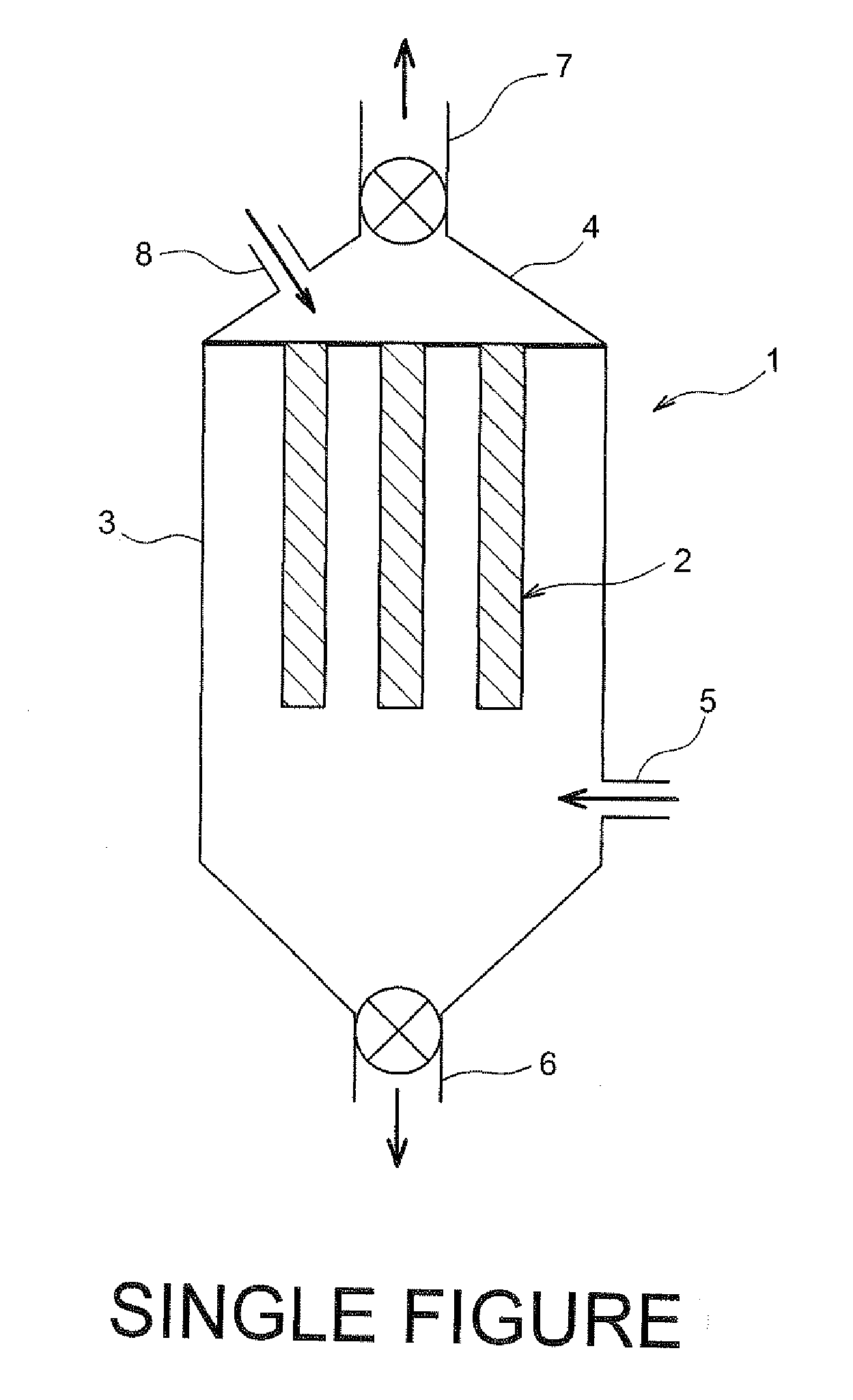

Device and method for producing suspensions or wet pastes of nanopowders or ultra-fine powders

ActiveUS20130248614A1Less costlySatisfactory dispersionFlow mixersTransportation and packagingNanoparticleUltra fine

A device and a method for producing suspensions or wet pastes of nanoparticles or ultra-fine particles. The method comprises: introducing a flow of particles of nanometric or submicronic size into a first compartment of a chamber having a bulk density between 15 and 100 g / L; forming, in the first compartment, a spray of droplets between 1 and 10 micrometres in size, by injecting a solvent in liquid or gas form into a second compartment of the device and passing said solvent through the filtering means, the solvent being chosen from the solvents which are liquid at ambient temperature and at atmospheric pressure; stopping the formation of the spray when the entire quantity of particles contained in the first compartment forms, as required, with the solvent, a suspension comprising between 80 and 99.9% solvent, if the solvent is introduced into the second compartment in liquid form, or a wet paste comprising between 1 and 10% solvent, if the solvent is introduced into the second compartment in gas form; recovering the suspension or wet paste formed.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Method for producing porous film, method for producing composition for producing porous film, and porous film

ActiveUS20200199322A1Large specific surface areaGood effectPretreated surfacesSpecial surfacesImidePolymer science

To provide a method for producing a porous film in which even when minute fine particles are used, fine particles can be satisfactorily dispersed, a method for producing a composition for producing a porous film, and a porous film that can be produced by the method for producing a porous film. When a porous film is formed using a varnish including at least one resin component selected from the group consisting of polyamide acid, polyimide, a polyamide-imide precursor, polyamide-imide and polyethersulfone, and fine particles, varnish is produced by dispersing the fine particles by using a pressure device that pressurizes slurry including the fine particles and a dispersing device provided with a flow path whose cross-sectional area is 1960 μm2 or more and 785000 μm2 or less, and allowing the slurry pressurized to 50 MPa or more to pass through the flow path.

Owner:TOKYO OHKA KOGYO CO LTD

Method and system to improve atomization and combustion of heavy fuel oils

InactiveUS20150122216A1Improve fuel efficiencyImprove combustion processNon-fuel substance addition to fuelInternal combustion piston enginesMixed fuelFuel oil

Presented a method and a system for improving atomization of heavy fuel oil or diesel fuel in heavy duty diesel engines, e.g. marine engines, wherein before injection into a combustion chamber the fuel is treated by gas / gases under elevated pressure of about 500 psi in an absorber; the heavy fuel oil / diesel fuel is fed to the absorber's dispensing means at a pressure of 1100 psi; a resulted fuel solution without a free gas phase is further mixed with a recirculating fuel stream forming a mixed fuel stream; the mixed fuel stream is directed for injection into a combustion chamber.

Owner:HELPFUL TECH

Tire comprising a tread formed by multiple elastomer blends

ActiveUS9701161B2Good dispersionSatisfactory dispersionSpecial tyresTyre tread bands/patternsElastomerHybrid compound

A tire of which the tread contains at least two layers of blended elastomeric compounds that are radially superposed and has a voids ratio that is lower in the central part than at the axially outer parts thereof. A first layer of blended elastomeric compounds of the tread is made up of a first blended elastomeric compound forming a central part, and of two outer parts formed of a second blended compound, the first blended compound having a Z-value higher than 55, the first blended compound and the second blended compound having a tan(δ)max value lower than 0.110, the modulus G* of the second blended elastomeric compound having a value at least 10% higher than that of the modulus G* of the first blended elastomeric compound, a second layer of the tread, radially the outermost, being made up of a third blended compound of which the modulus G* has a value at least 10% higher than that of the modulus G* of the first blended elastomeric compound and the elongation at break of the third blended compound having a value at least 10% higher than those of the elongations at break of the first and second blended compounds.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Tire comprising a tread formed by multiple elastomer blends

ActiveUS20150151579A1Good dispersionSatisfactory dispersionHeavy duty tyresTyre tread bands/patternsElastomerShear modulus

A tire with a radial carcass reinforcement, having a crown reinforcement, itself capped radially by a tread connected to two beads by two sidewalls, the tread having at least two layers of blended elastomeric compounds that are radially superposed and have a voids ratio that is lower in the central part than at the axially outer parts. A first layer of blended elastomeric compounds of the tread is made up of a first blended elastomeric compound forming a part extending at least into the region of the equatorial plane and of at least two axially outer parts formed of a second blended elastomeric compound, the first blended elastomeric compound having a macro dispersion Z-value higher than 65 and a maximum tan(δ) value, denoted tan(δ)max, lower than 0.120, and the complex dynamic shear modulus G* 1% at 100° C. of the second blended elastomeric compound having a value at least 10% higher than that of the complex dynamic shear modulus G* 1% at 100° C. of the first blended elastomeric compound.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Power supply antenna and power supply method

InactiveUS7520246B2Satisfactory dispersionGenerate efficientlyElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringElectric field

Owner:MITSUBISHI HEAVY IND LTD

Magnetic recording medium

InactiveUS20050118459A1Improve recording densityReduce error rateRecord information storageMagnetic recordingHigh densityNon magnetic

A magnetic recording medium contains a non-magnetic substrate, a non-magnetic layer arranged on or above one side of the non-magnetic substrate and containing a non-magnetic powder, a carbon black and a binder resin, and a magnetic layer being arranged on or above the non-magnetic layer and containing a ferromagnetic powder and a binder resin, in which the binder resin of the non-magnetic layer contains an electron-beam-curable resin having an adsorption with respect to the non-magnetic powder of less than 2.2 mg per square meter in terms of a specific surface area determined according to a BET method. The magnetic recording medium can carry out high-density recording and exhibits improved electromagnetic conversion properties and a reduced error rate.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com