Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

874results about "Diamond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

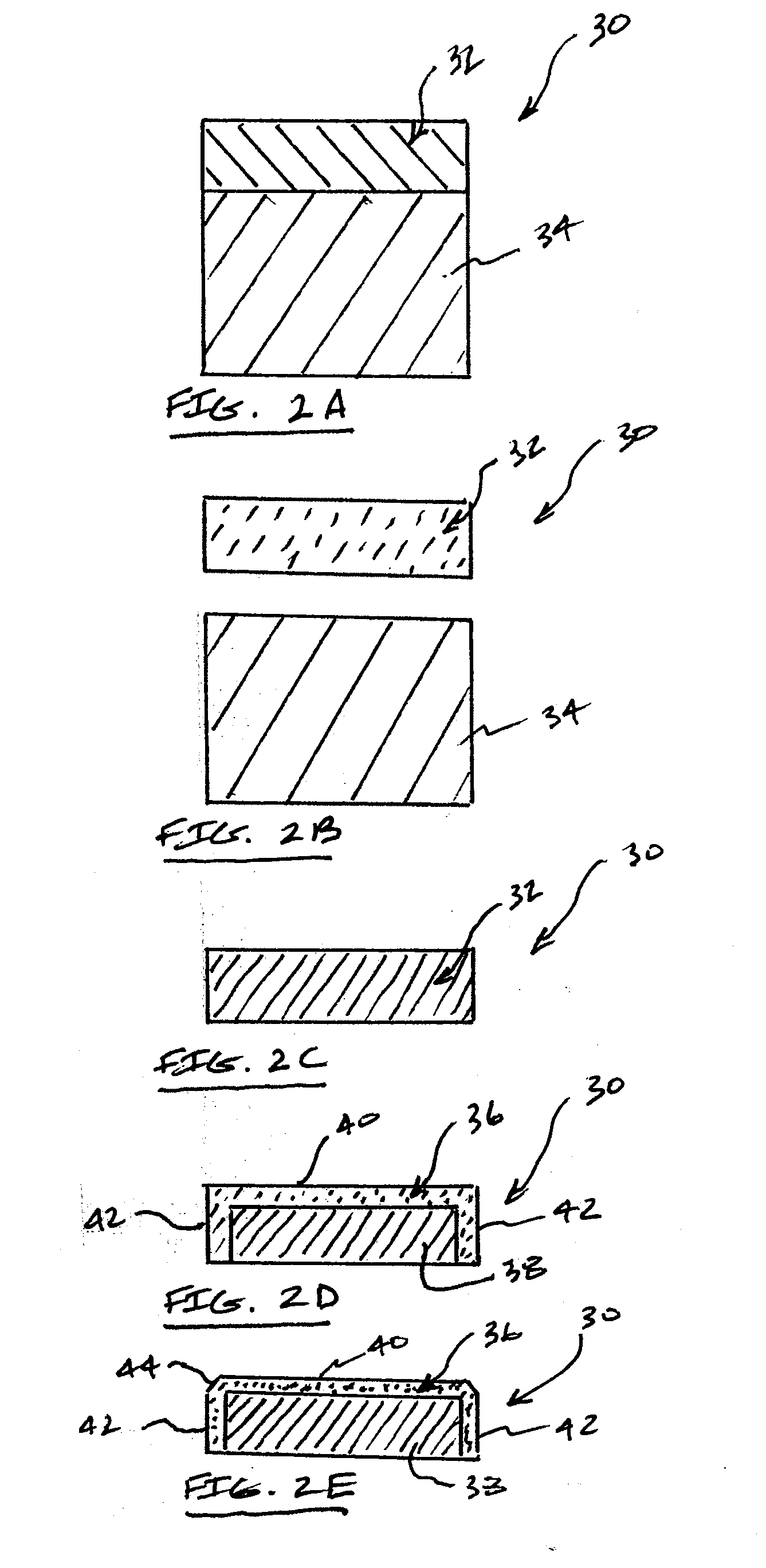

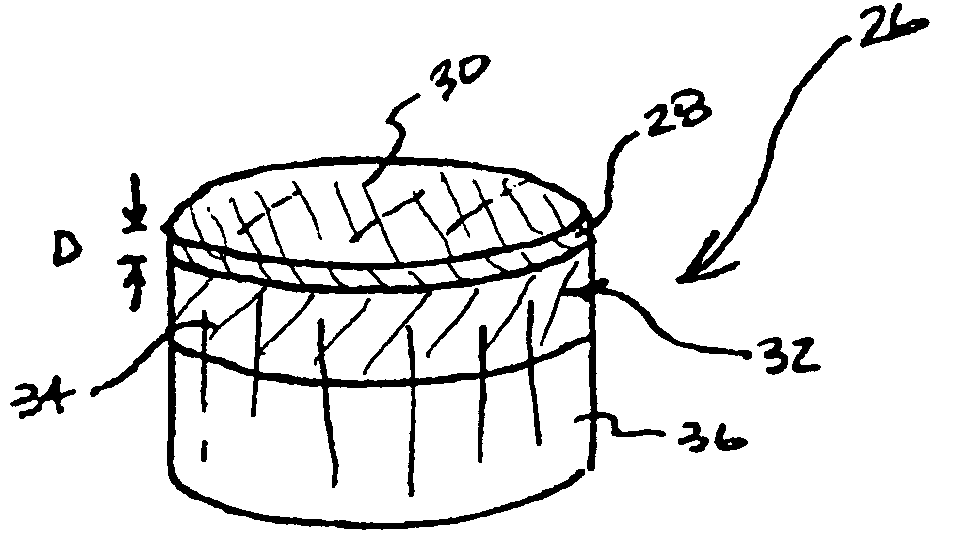

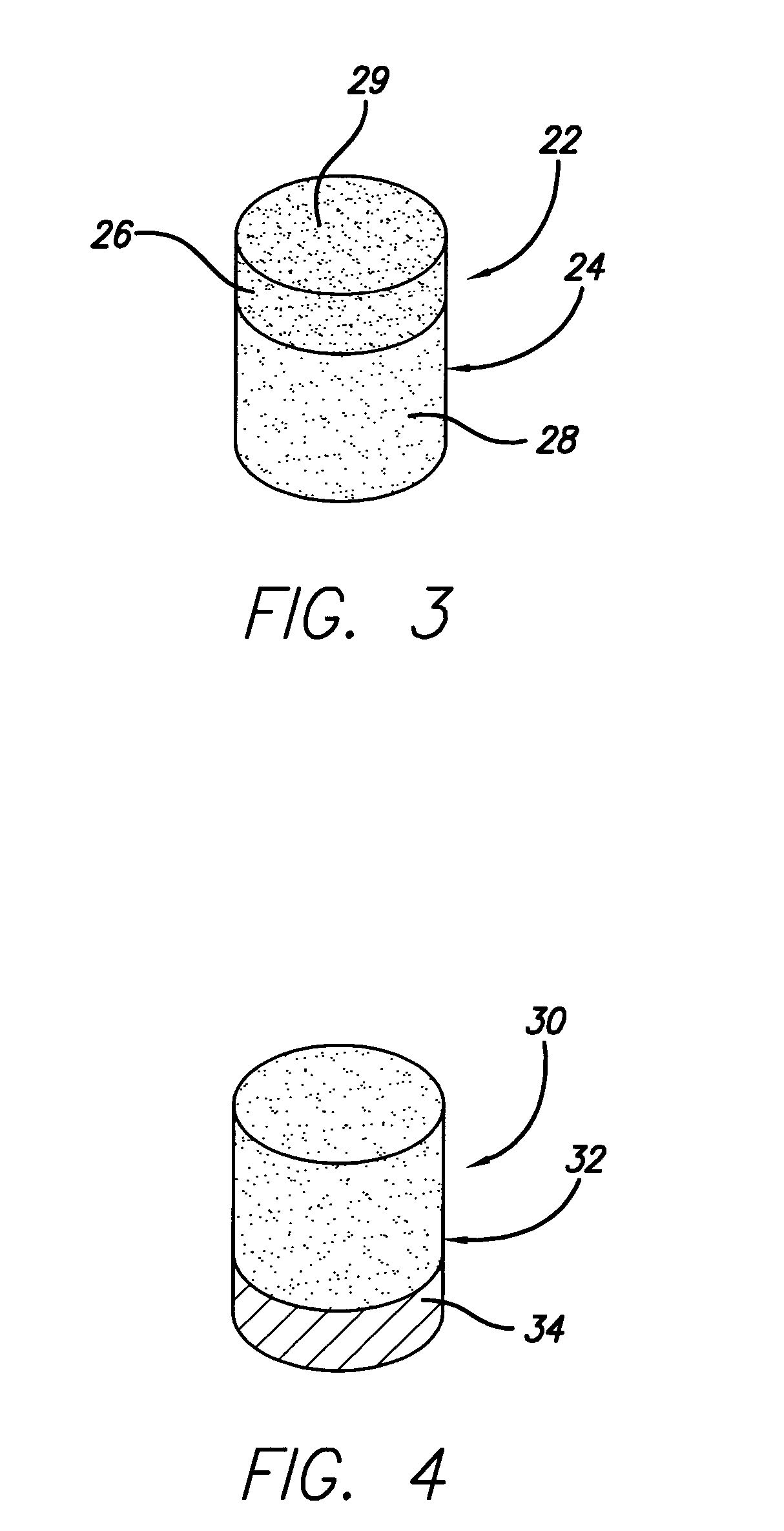

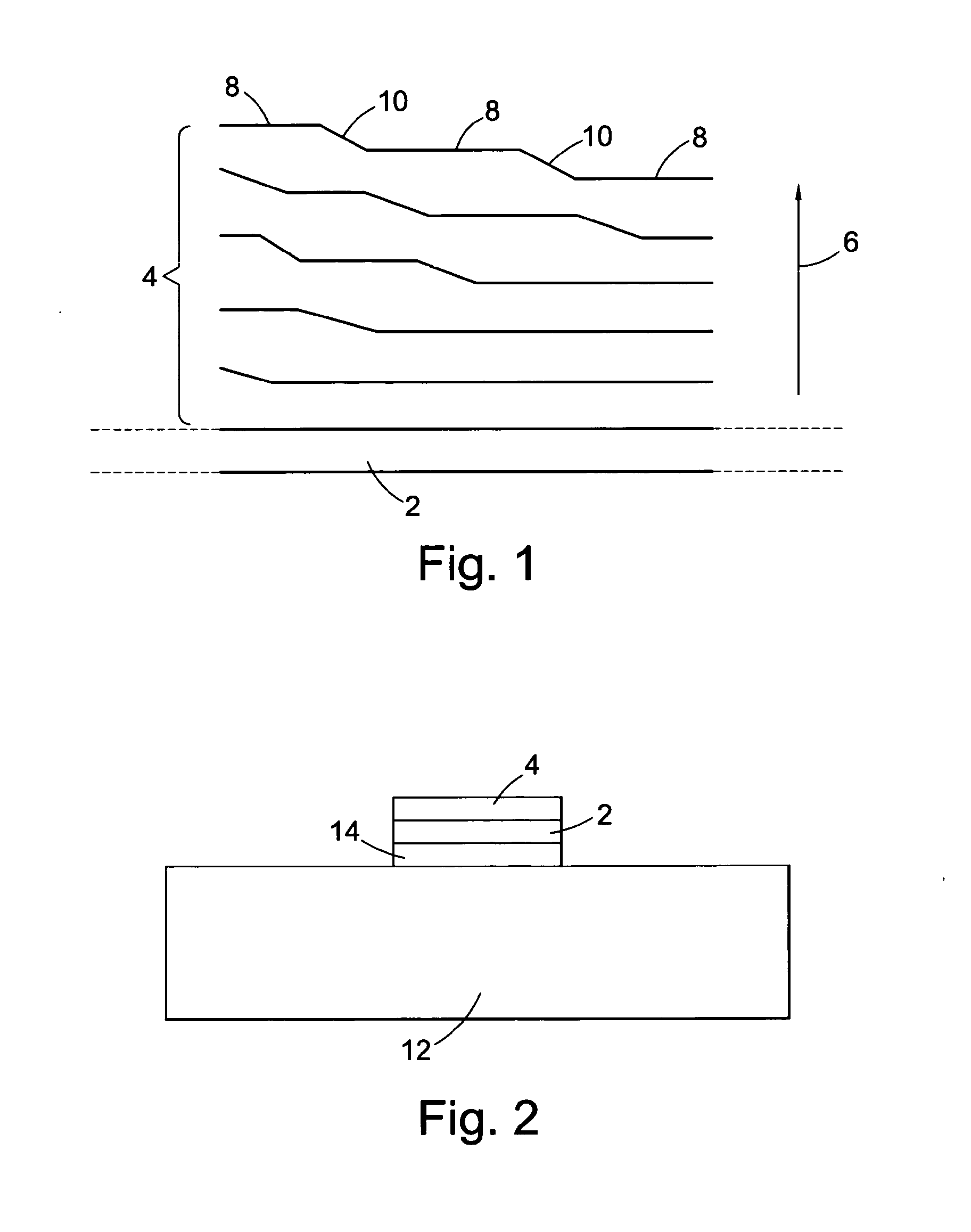

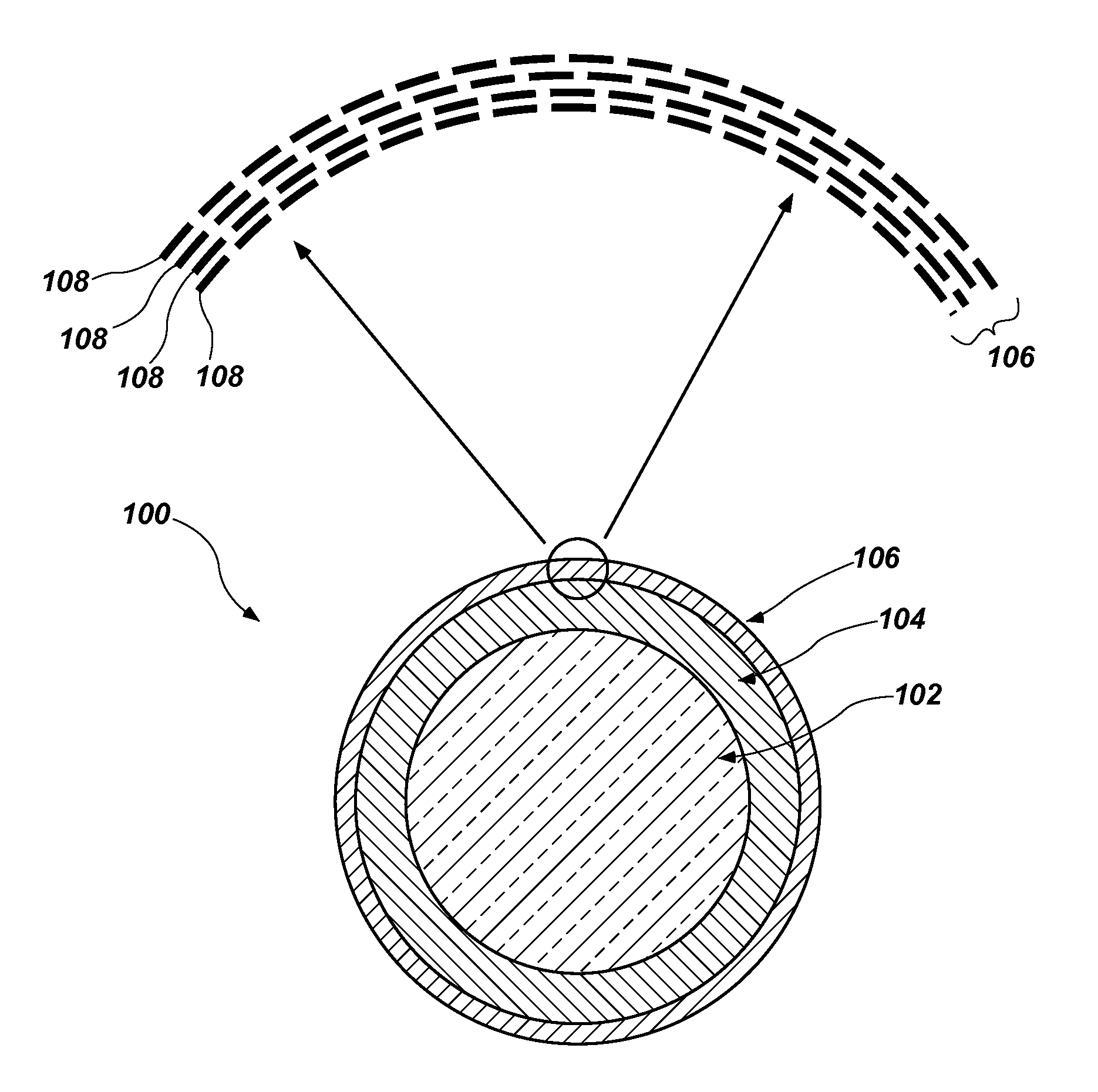

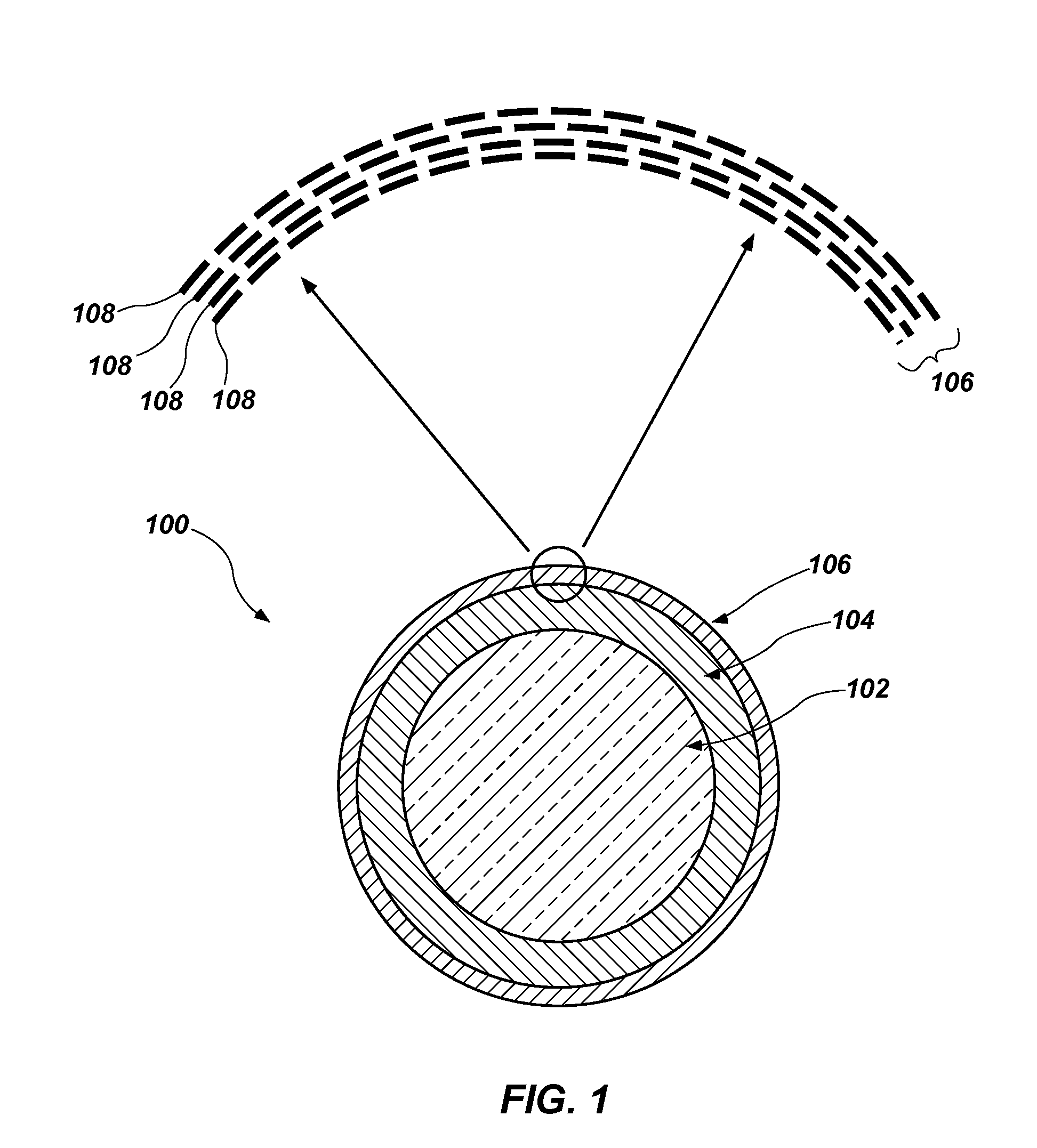

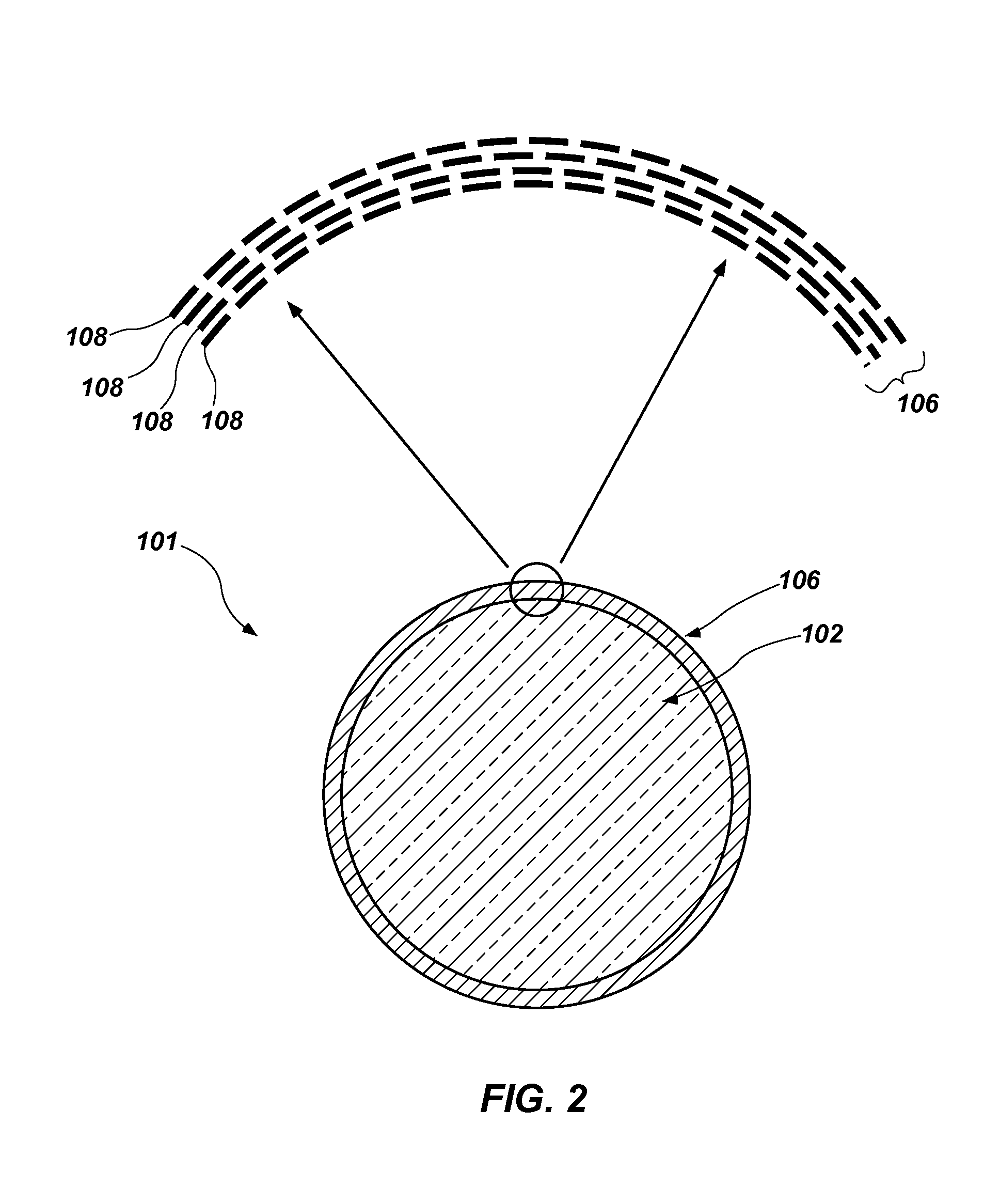

Polycrystalline diamond having improved thermal stability

InactiveUS20080230280A1Improved thermal characteristic and mechanical propertyAvoiding unwanted deteriorationDrill bitsConstructionsPolycrystalline diamondThermal stability

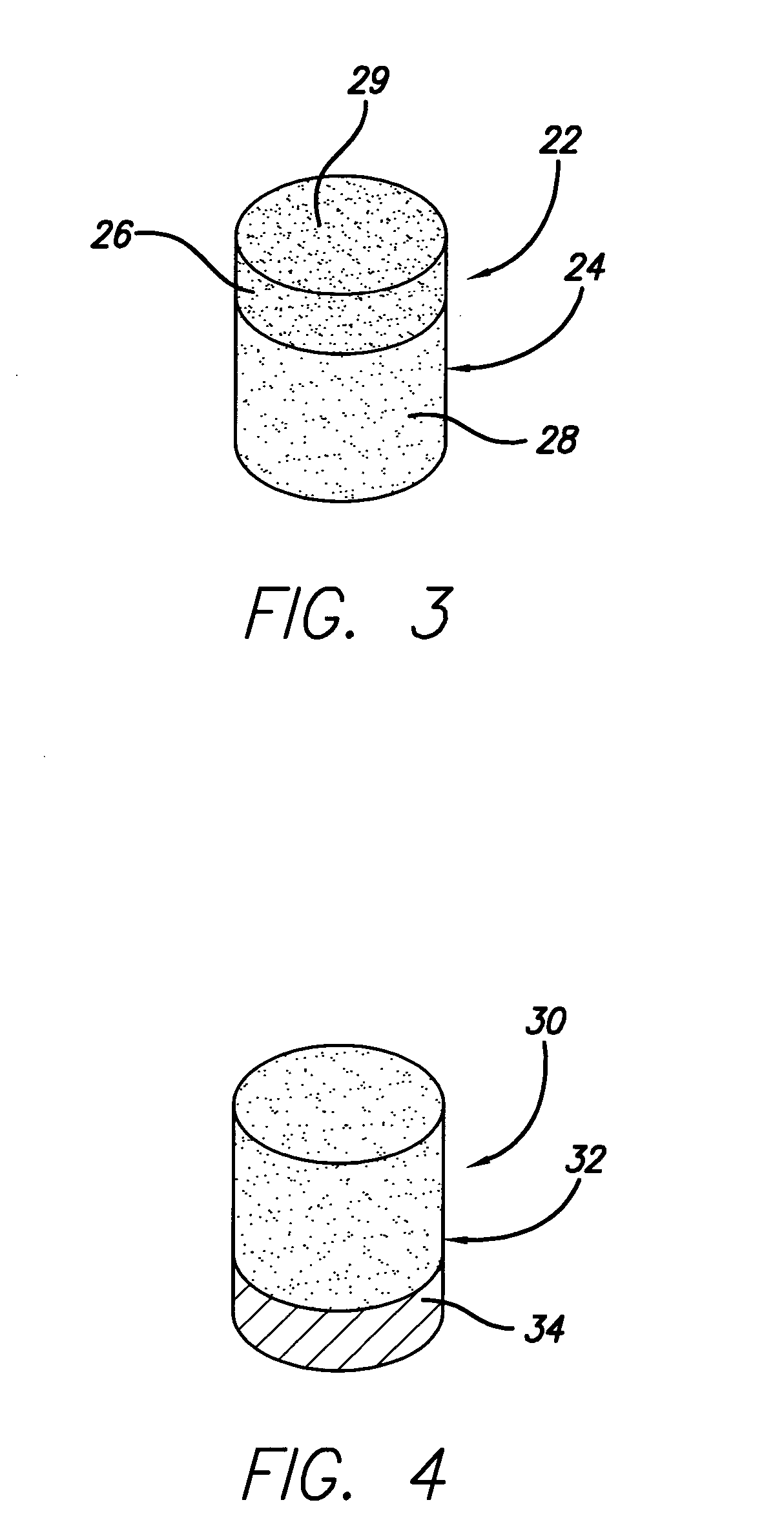

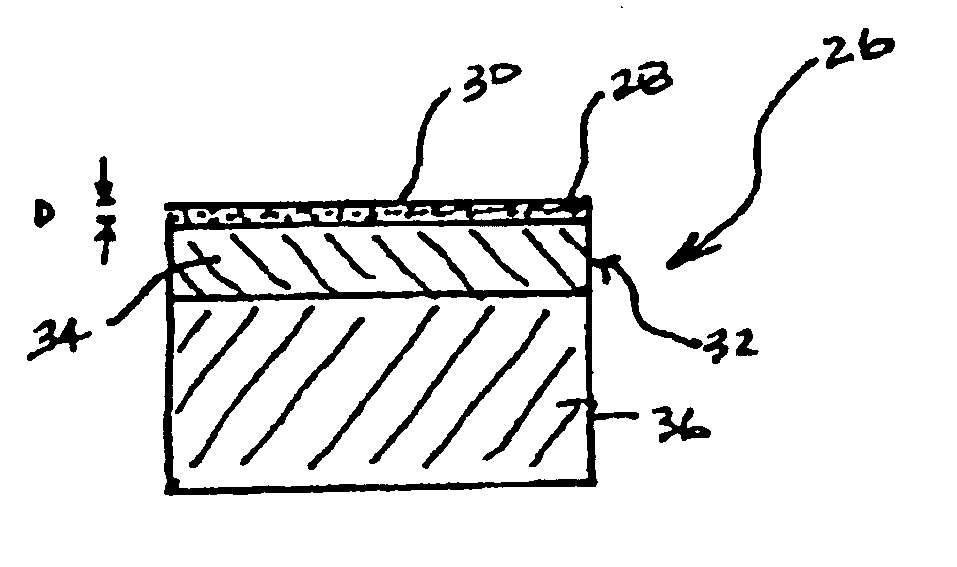

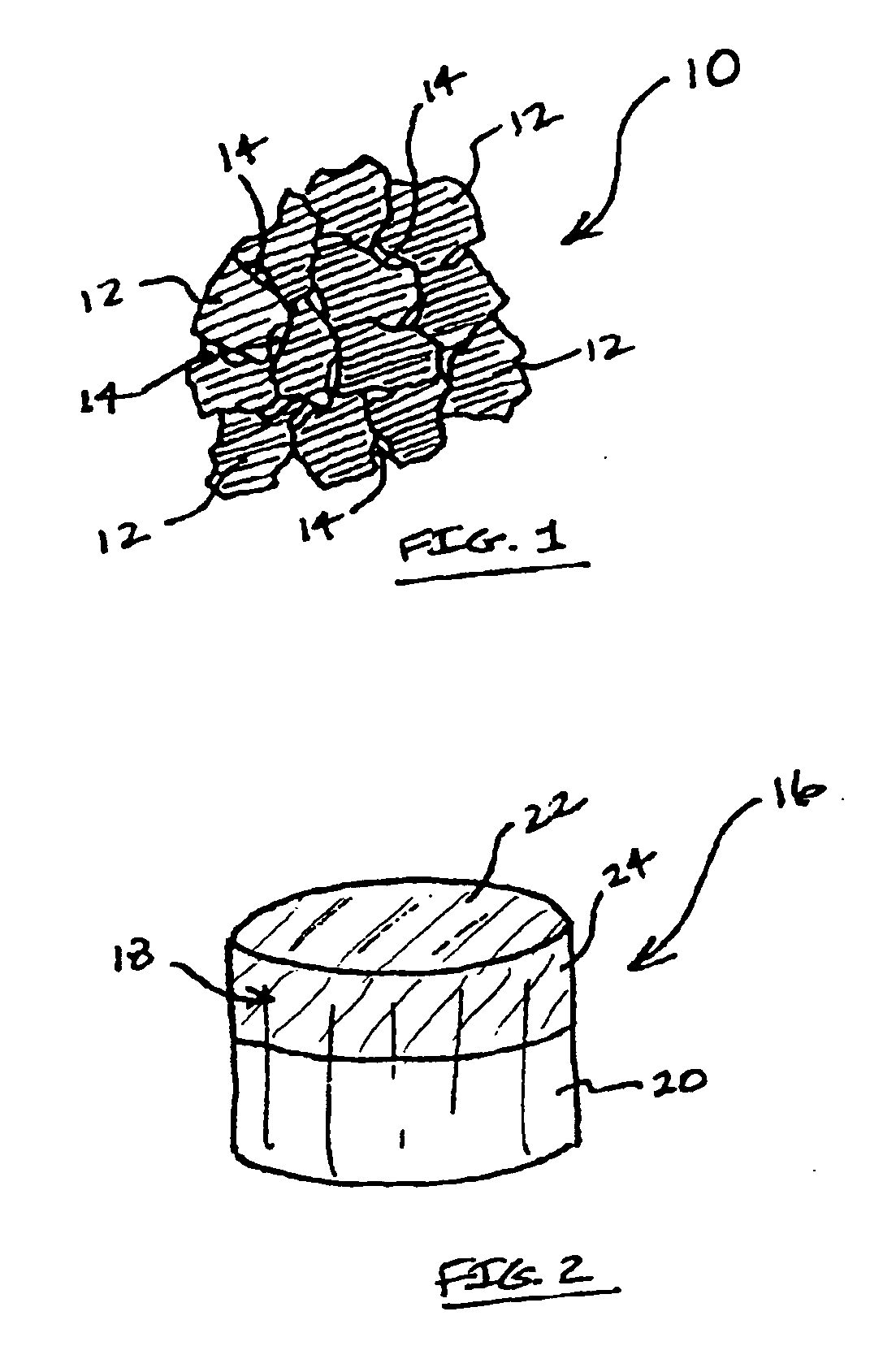

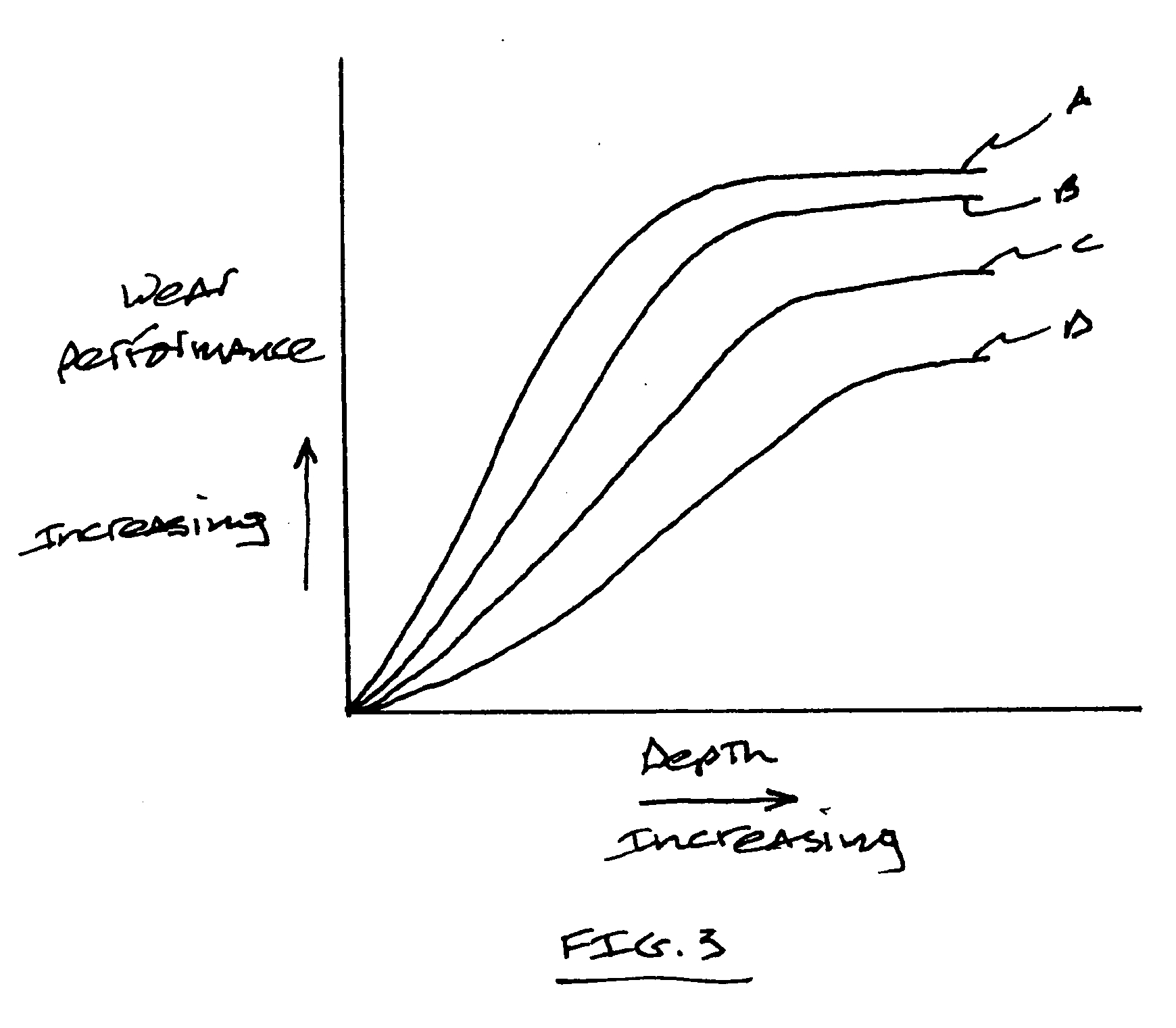

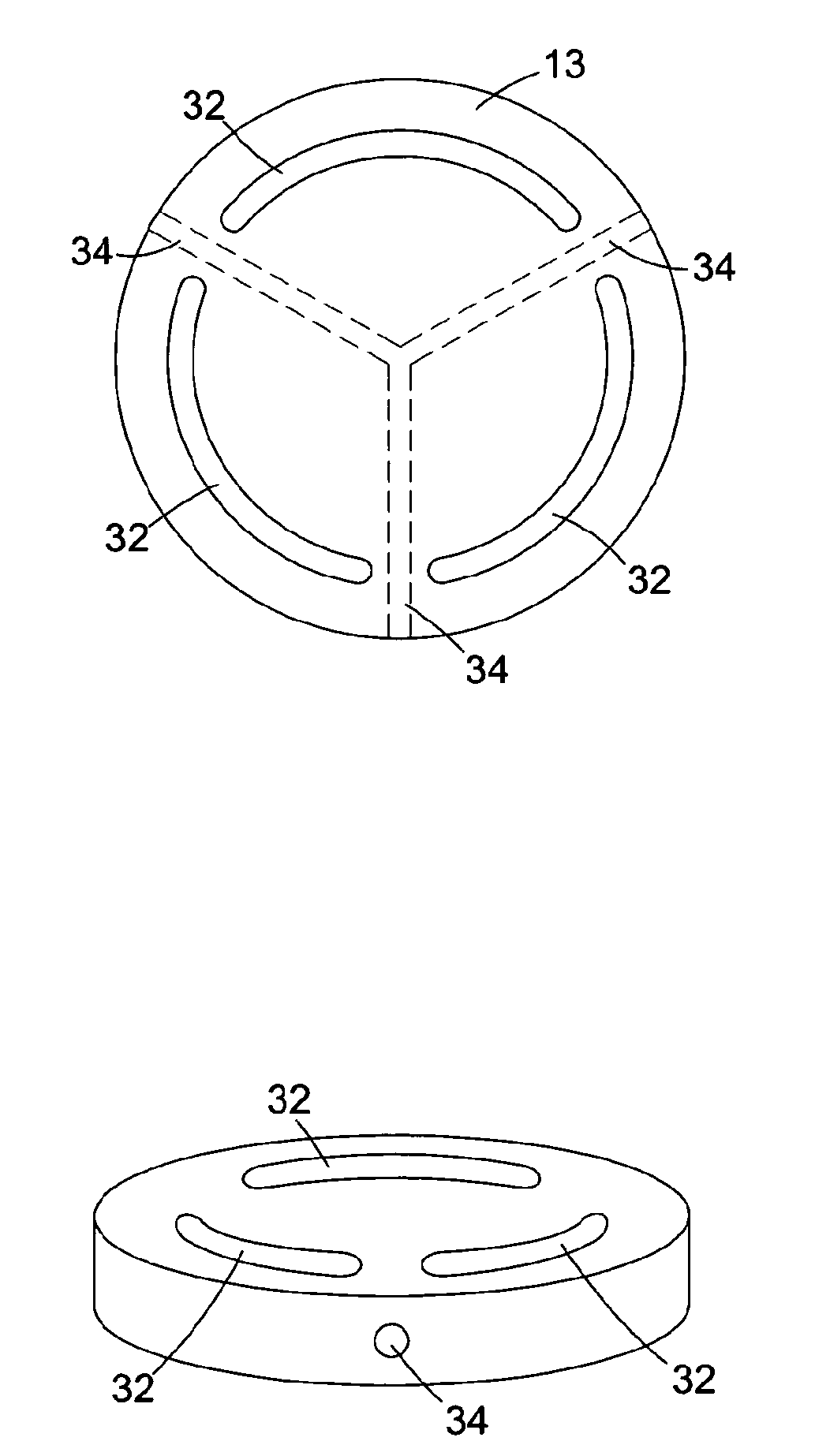

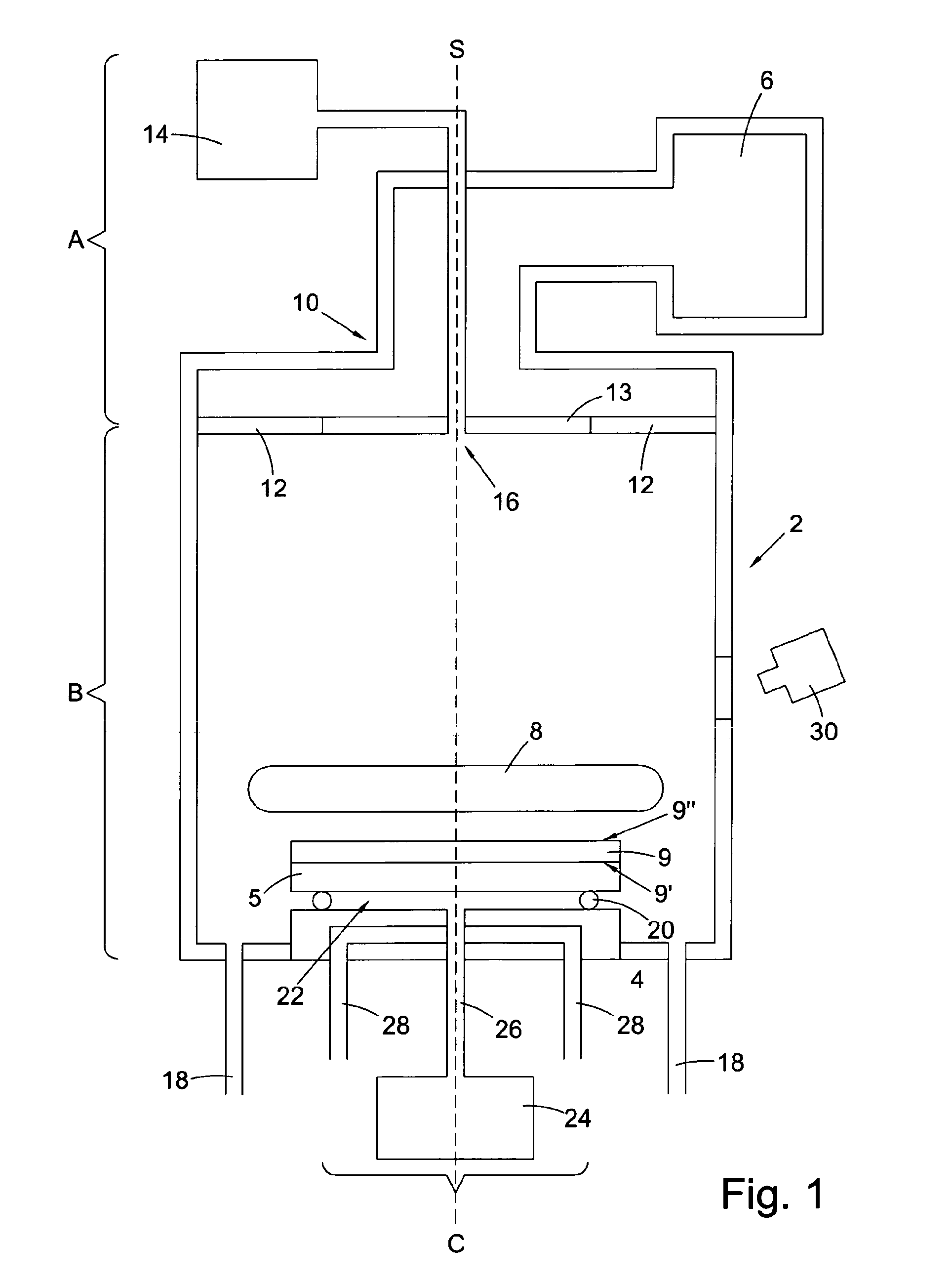

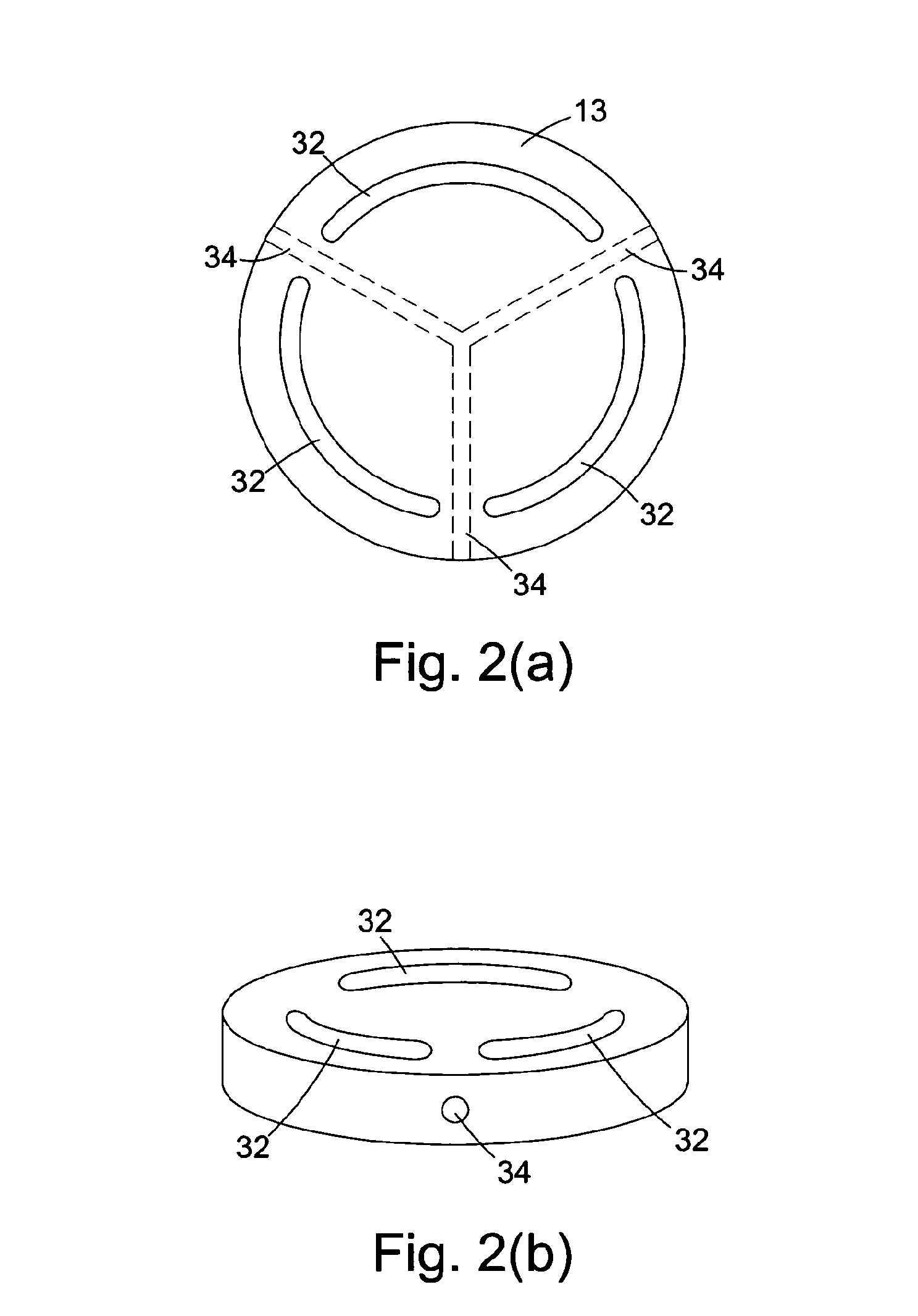

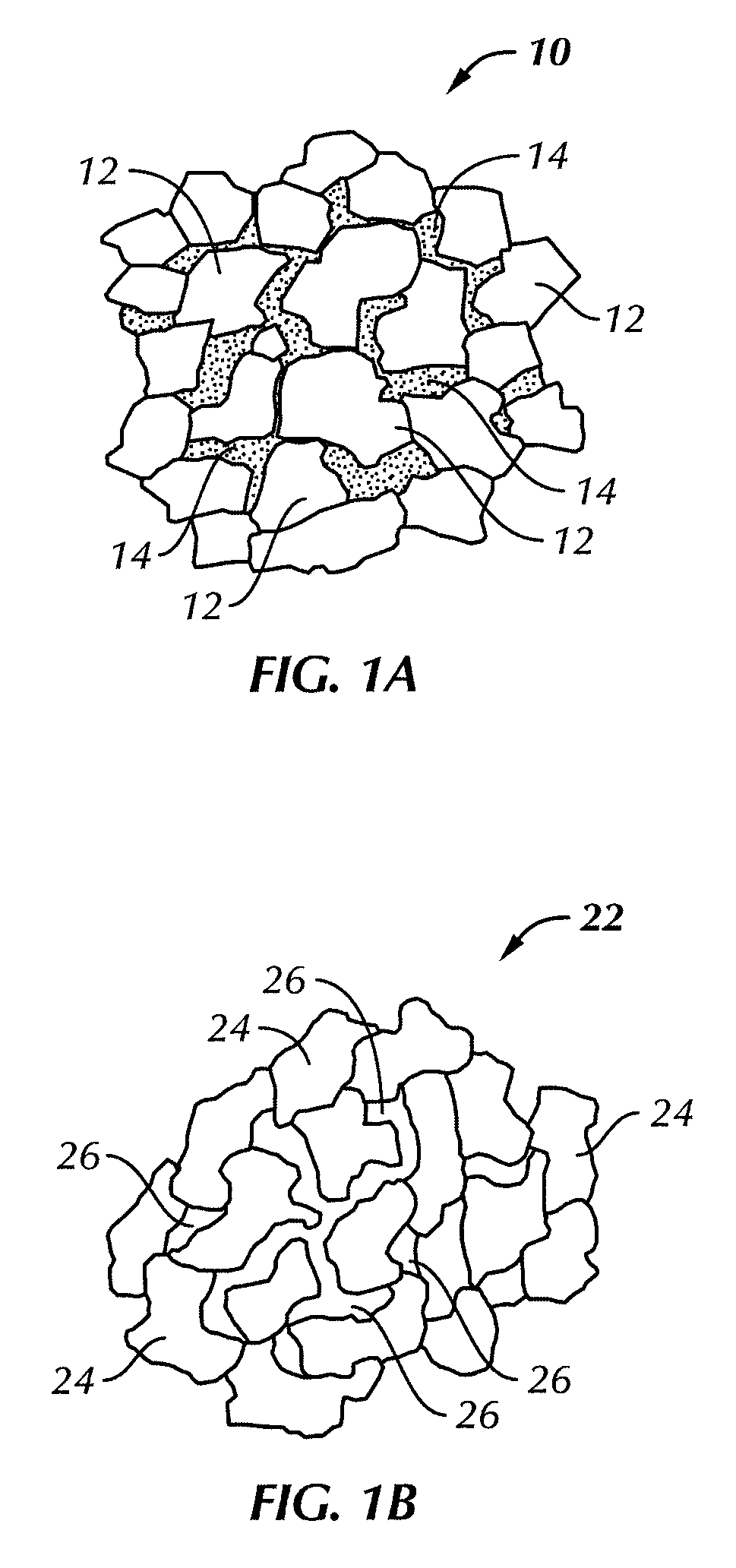

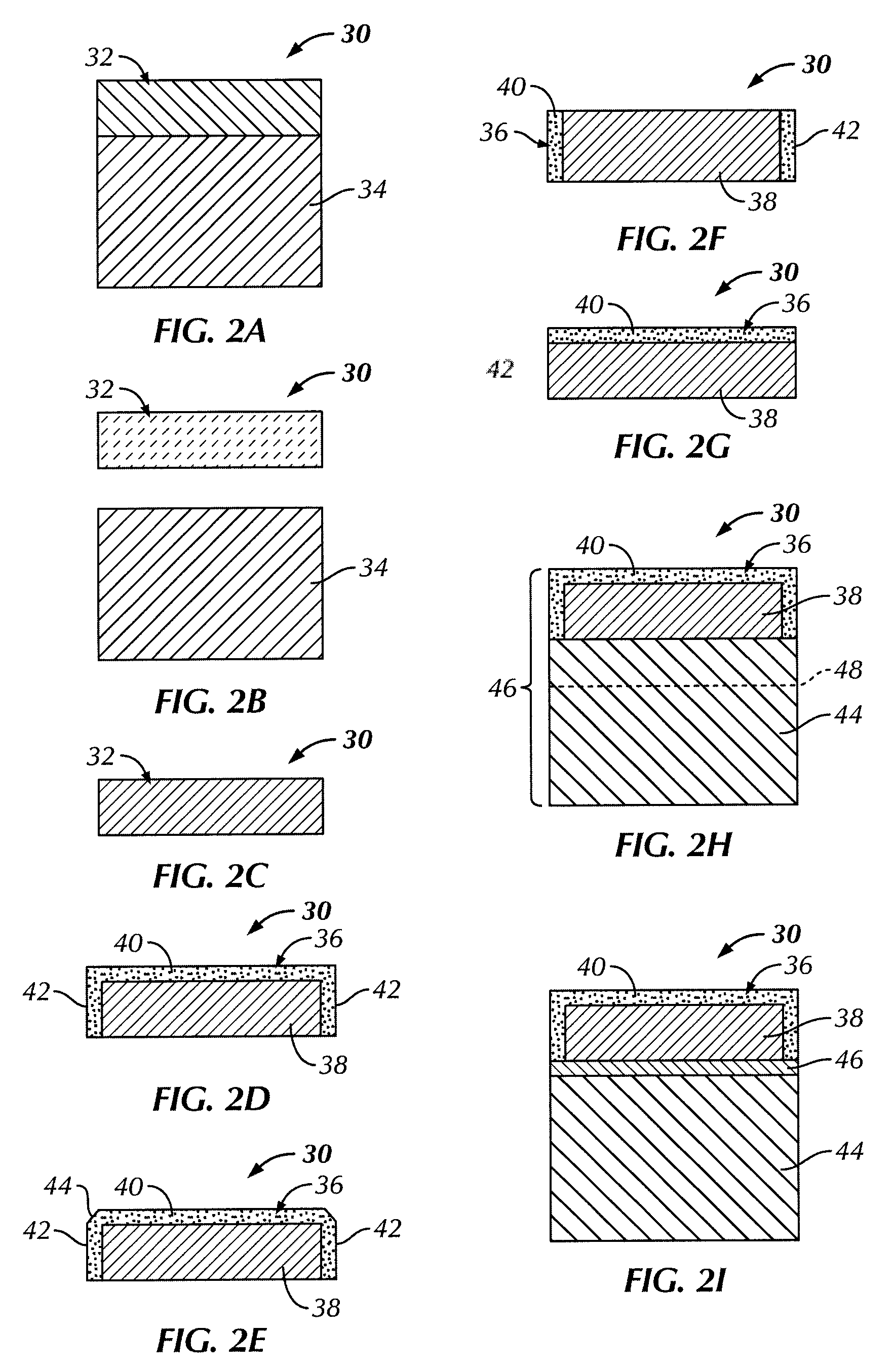

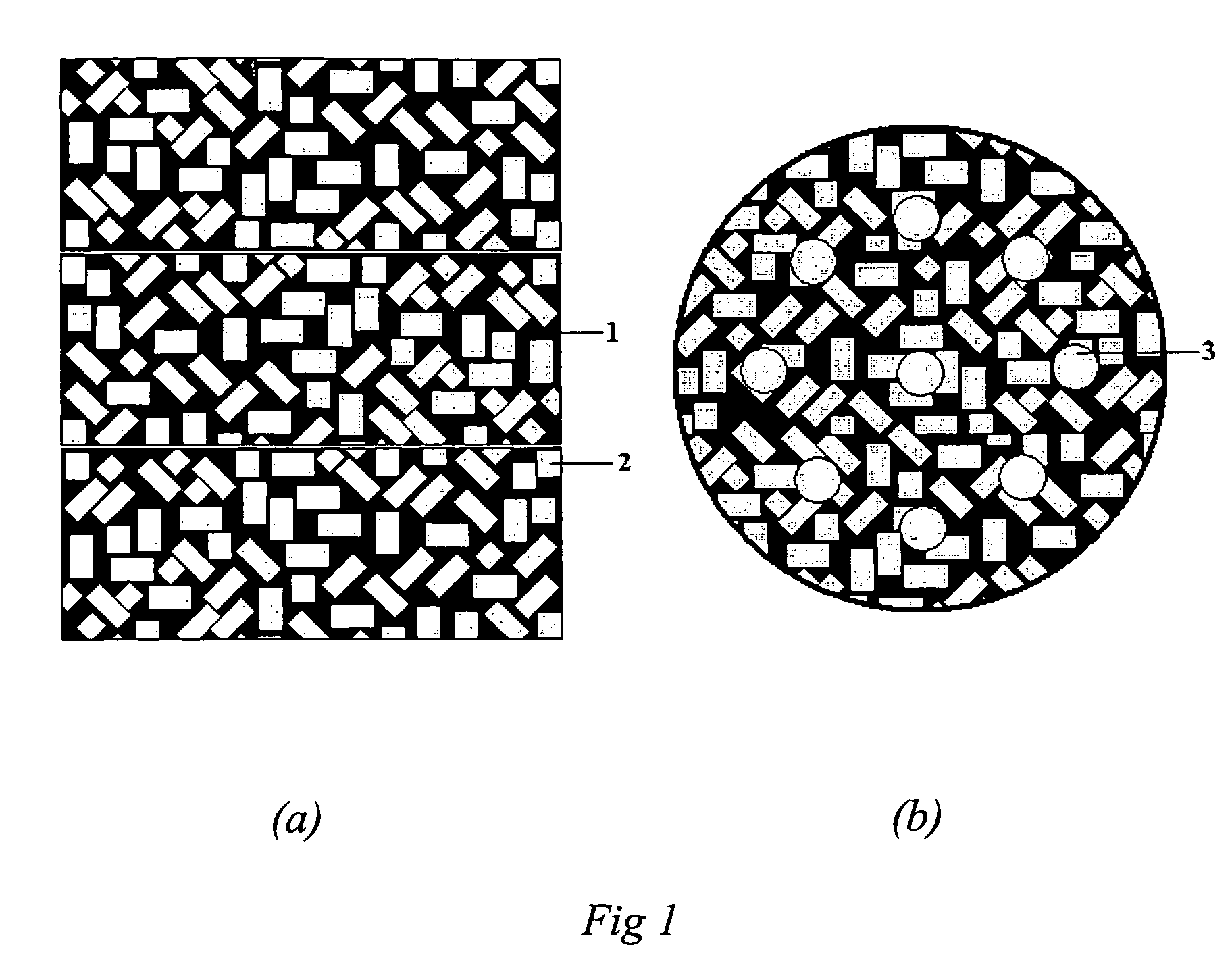

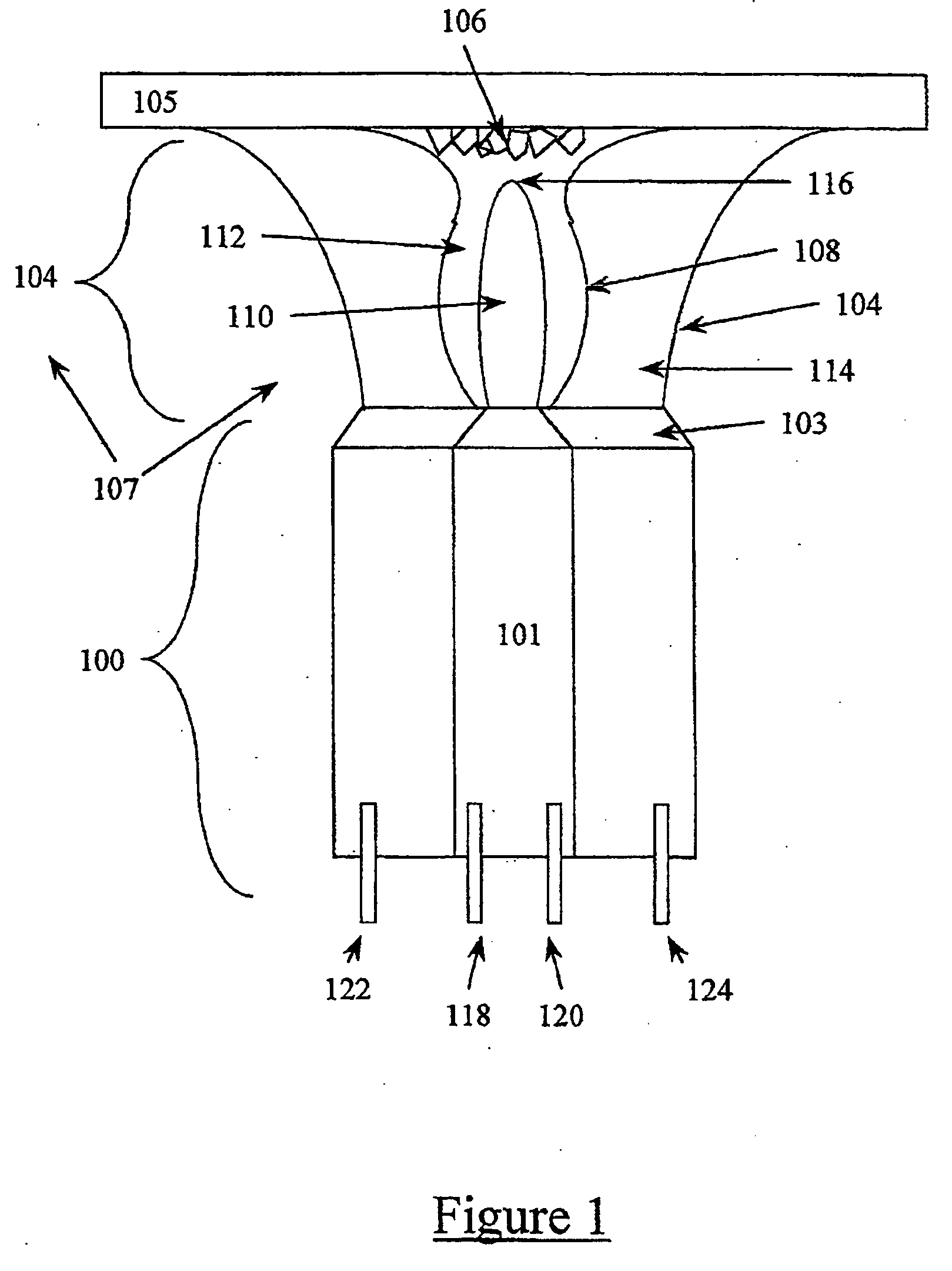

PCD constructions include a PCD body comprising a polycrystalline matrix region, a first region that includes a replacement material positioned remote from a body surface, and a second region that is substantially free of the replacement material and that extends a depth from the body surface. The PCD construction can further include a substrate that is attached to the body. The PCD body is formed by removing a solvent catalyst material used to form the body, replacing the removed solvent catalyst material with a replacement material, and then removing the replacement material from a region of the body to thereby form the second region. The replacement material can be introduced into the PCD body during a HPHT process, and the substrate may or may not be the source of the noncatalyzing material.

Owner:SMITH INT INC

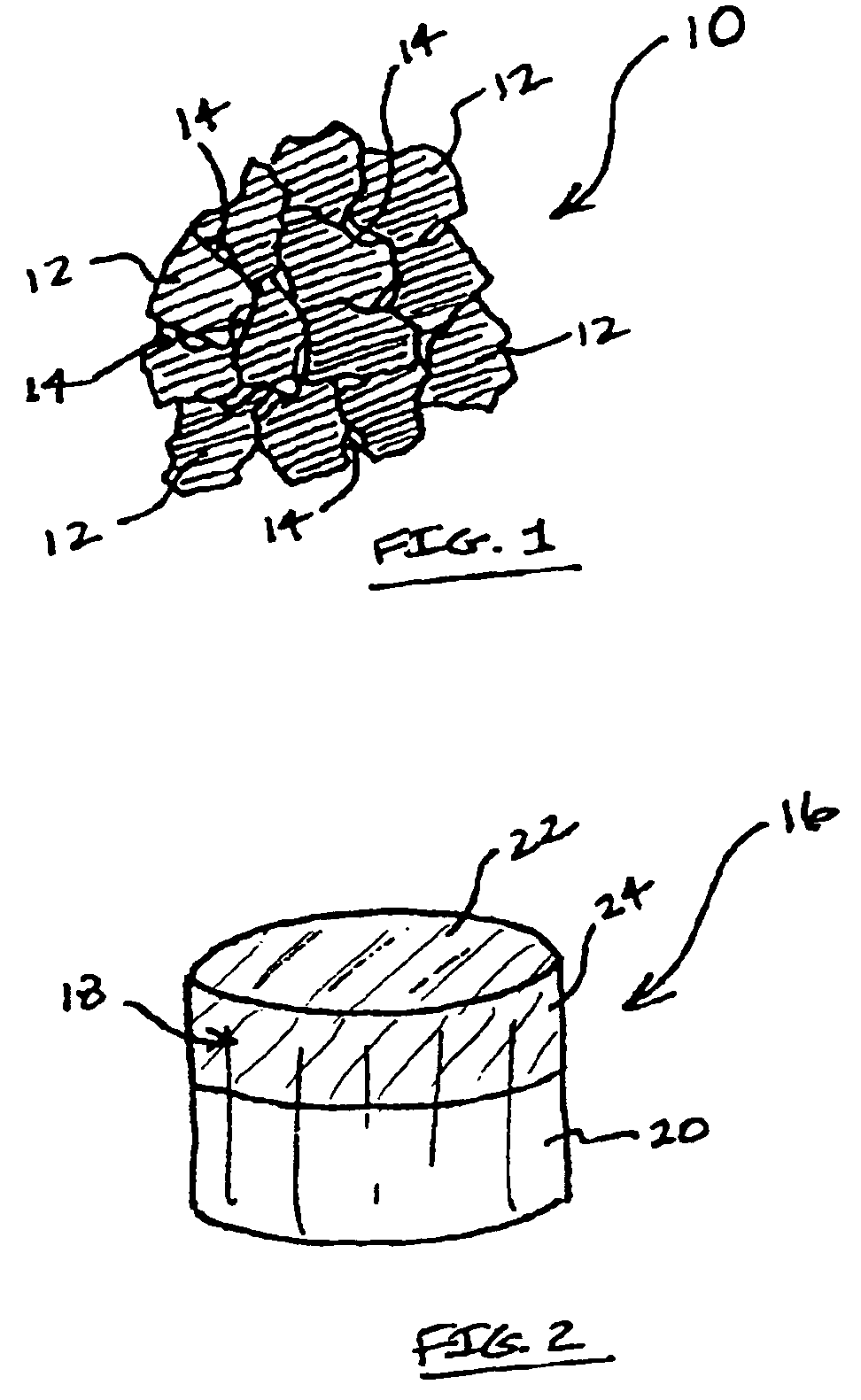

Thermally-stable polycrystalline diamond materials and compacts

InactiveUS20050230156A1Improve thermal stabilityImprove bindingDrill bitsConstructionsDiamond crystalPolycrystalline diamond

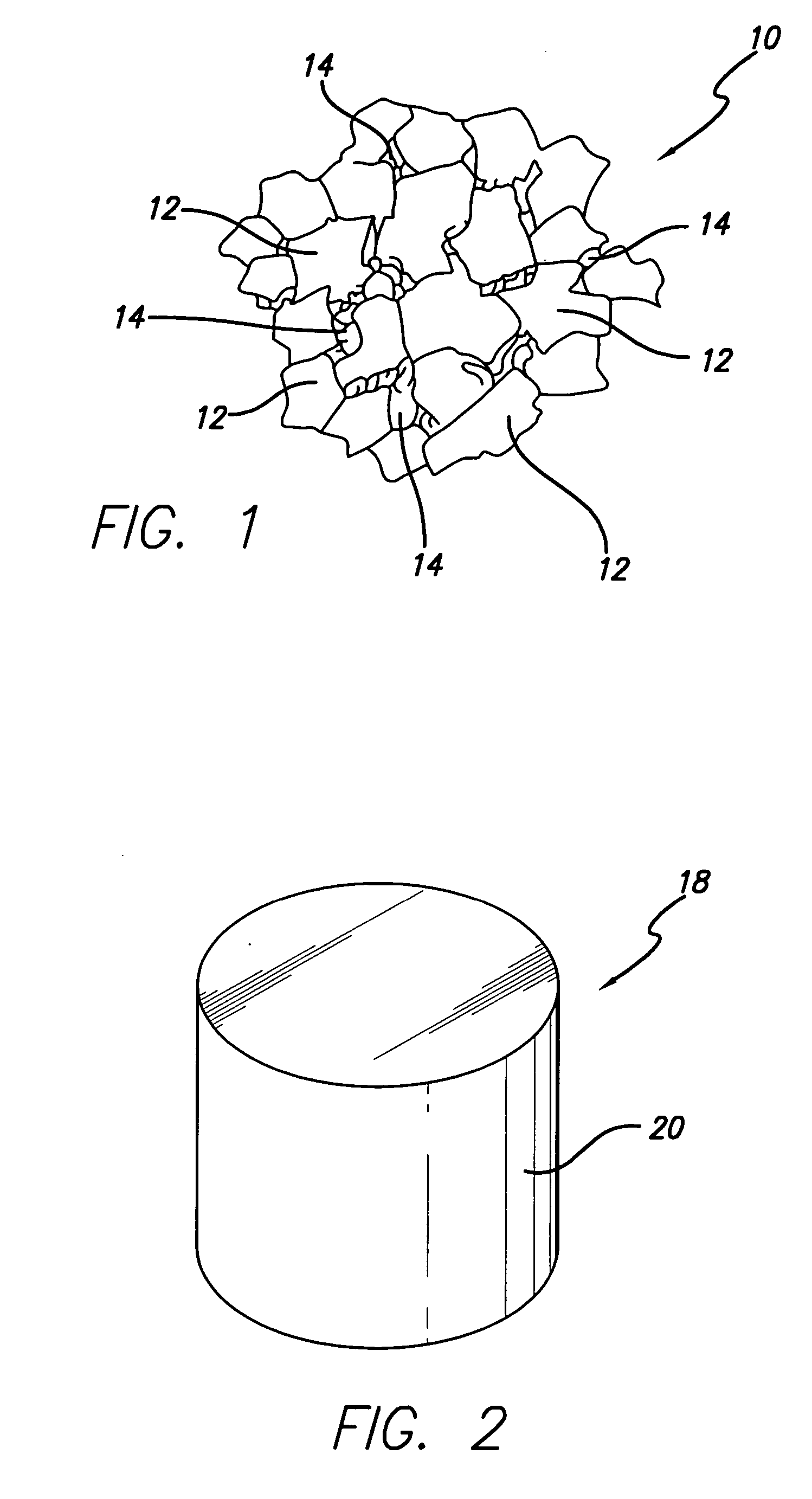

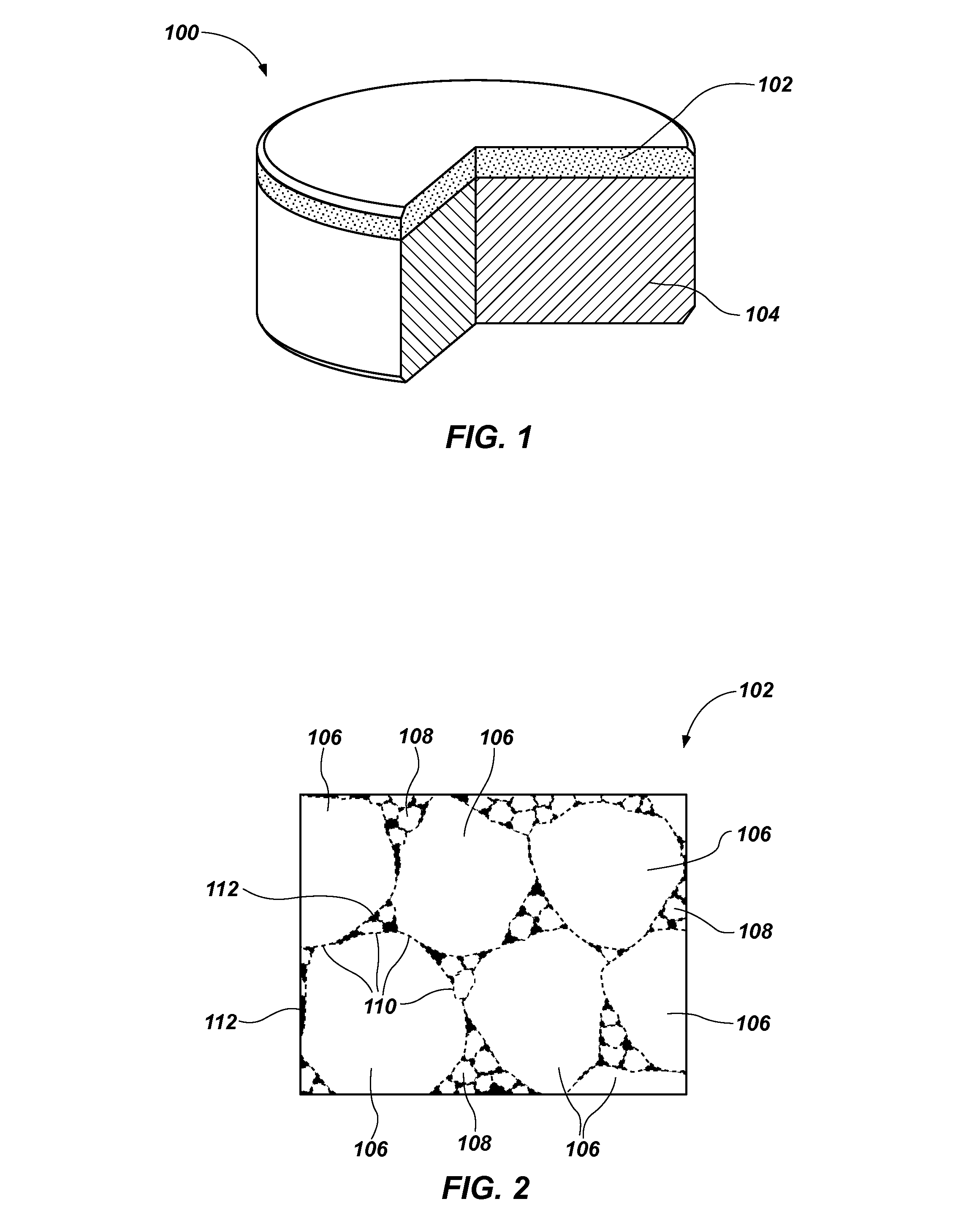

Thermally-stable polycrystalline diamond materials of this invention comprise a first phase including a plurality of bonded together diamond crystals, and a second phase including a reaction product formed between a binder / catalyst material and a material reactive with the binder / catalyst material. The reaction product is disposed within interstitial regions of the polycrystalline diamond material that exists between the bonded diamond crystals. The first and second phases are formed during a single high pressure / high temperature process condition. The reaction product has a coefficient of thermal expansion that is relatively closer to that of the bonded together diamond crystals than that of the binder / catalyst material, thereby providing an improved degree of thermal stability to the polycrystalline diamond material.

Owner:SMITH INT INC

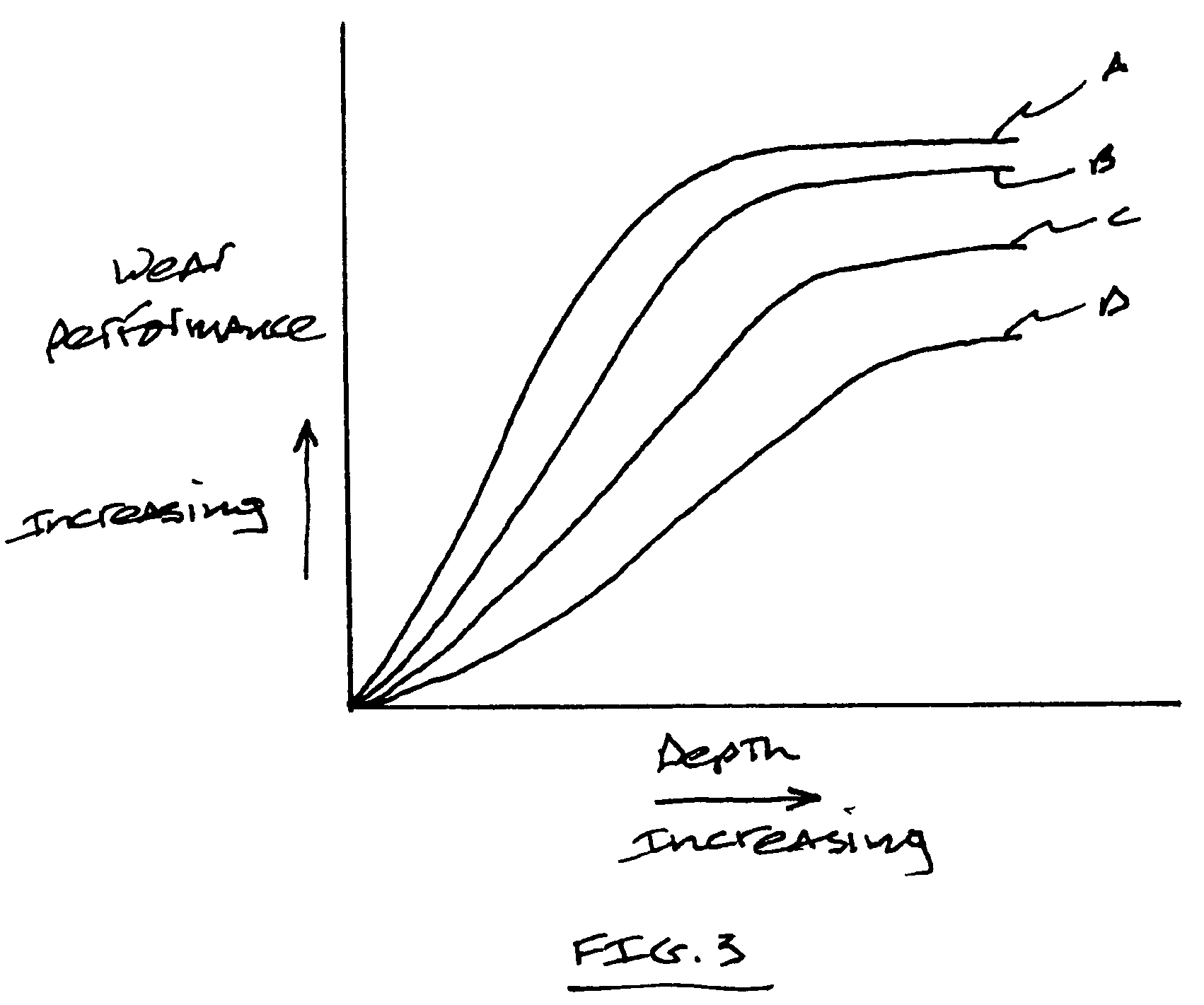

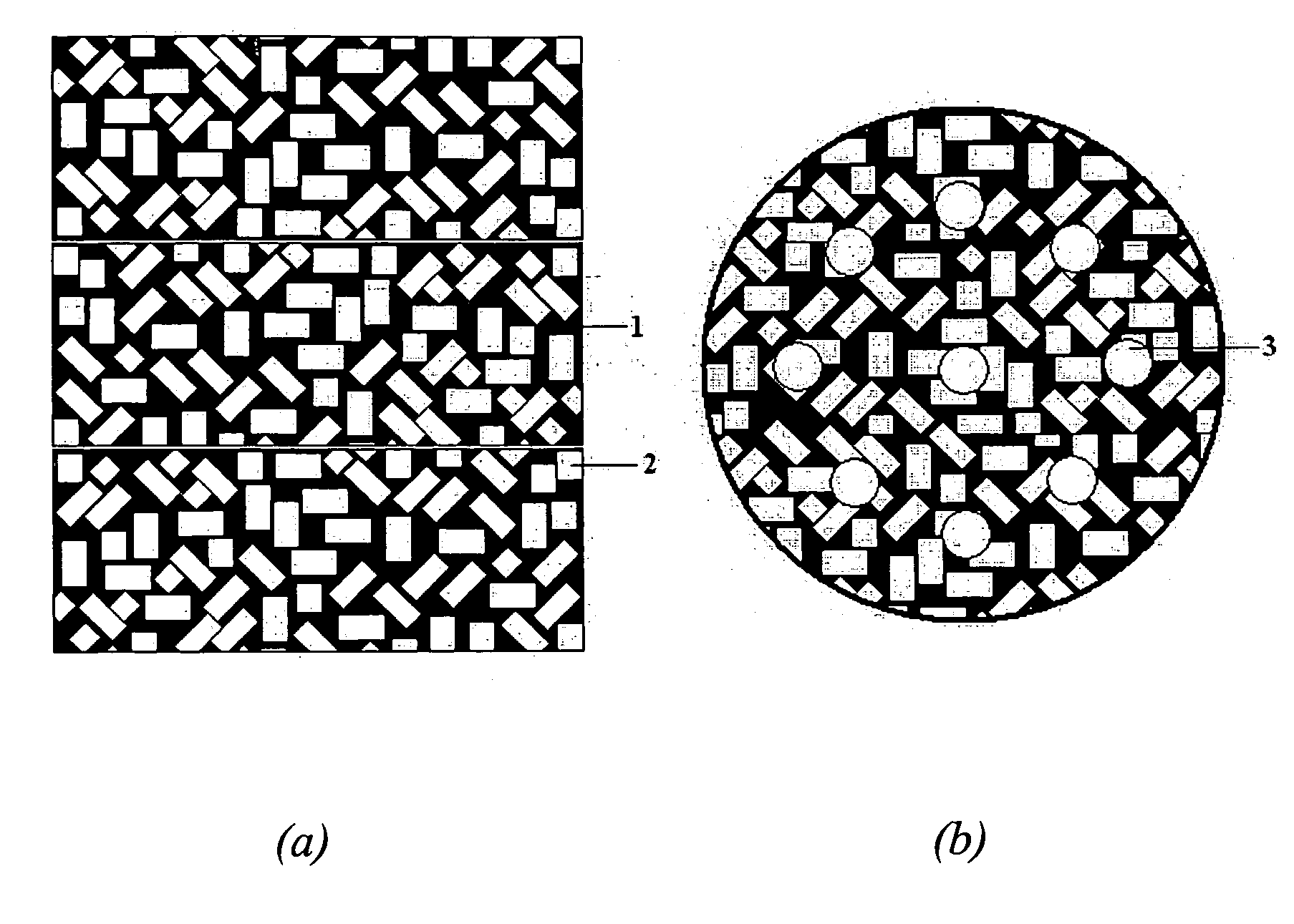

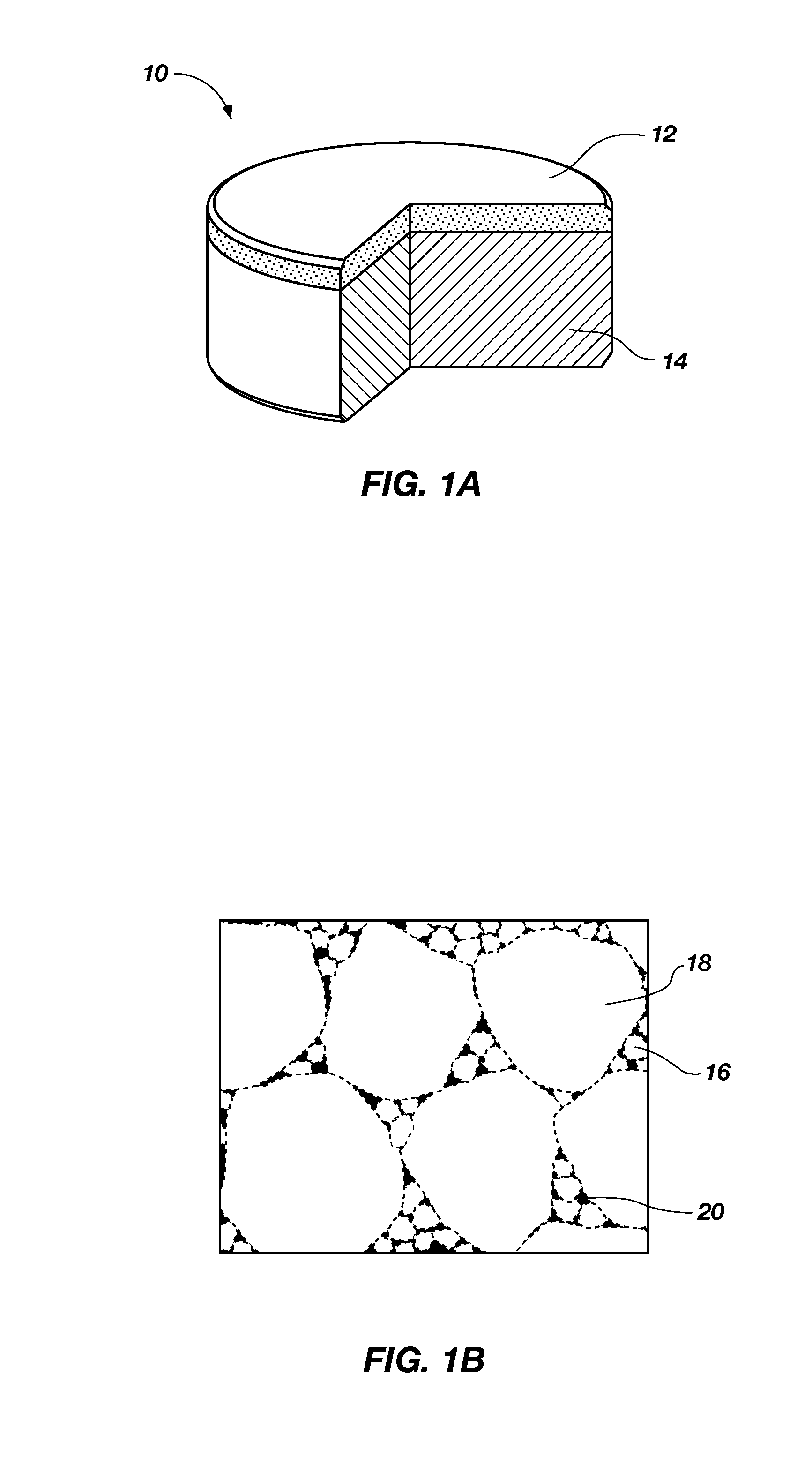

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

ActiveUS20060266559A1Improve propertiesDrill bitsConstructionsDiamond crystalPolycrystalline diamond

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

Large area optical quality synthetic polycrystalline diaond window

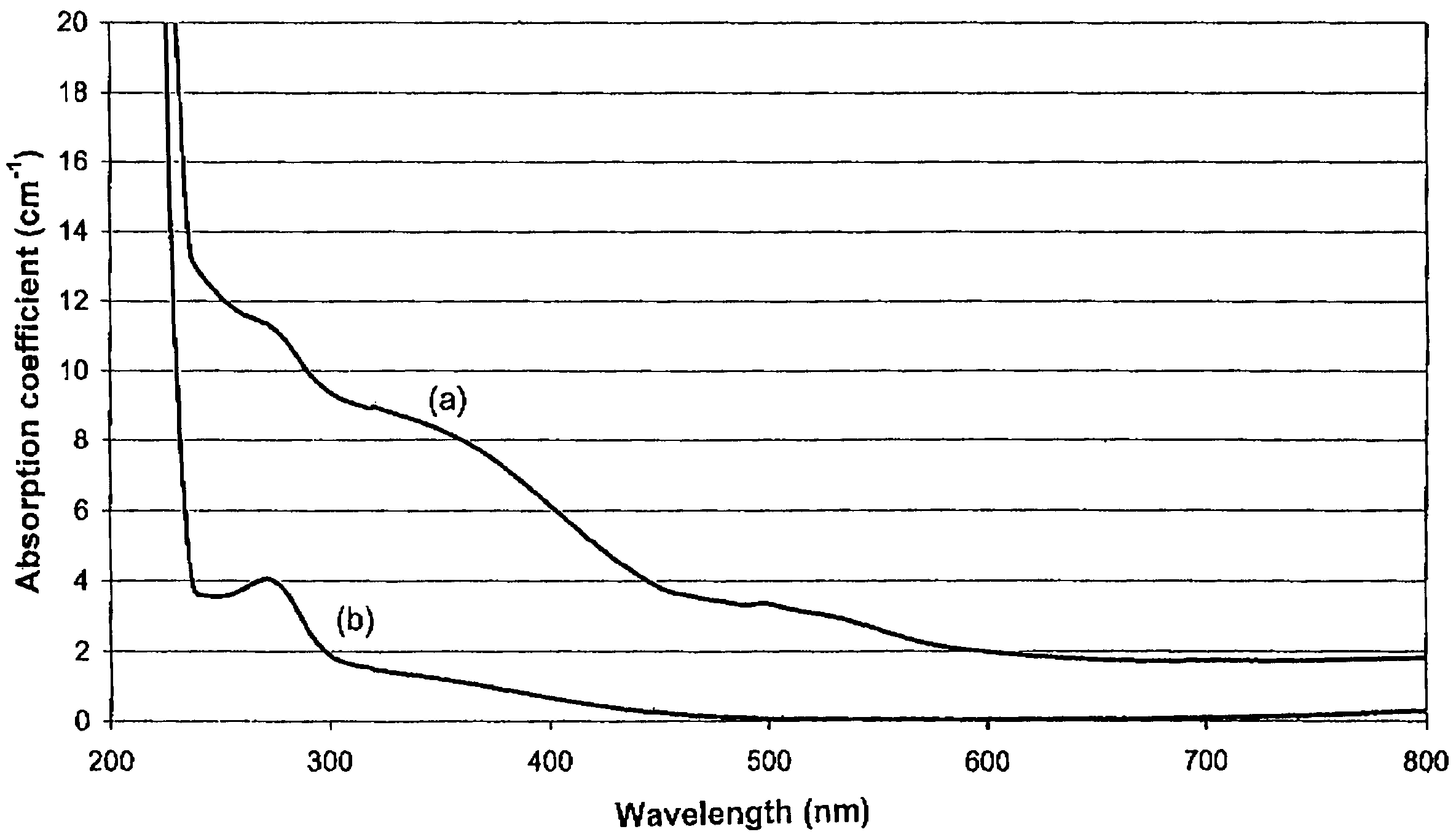

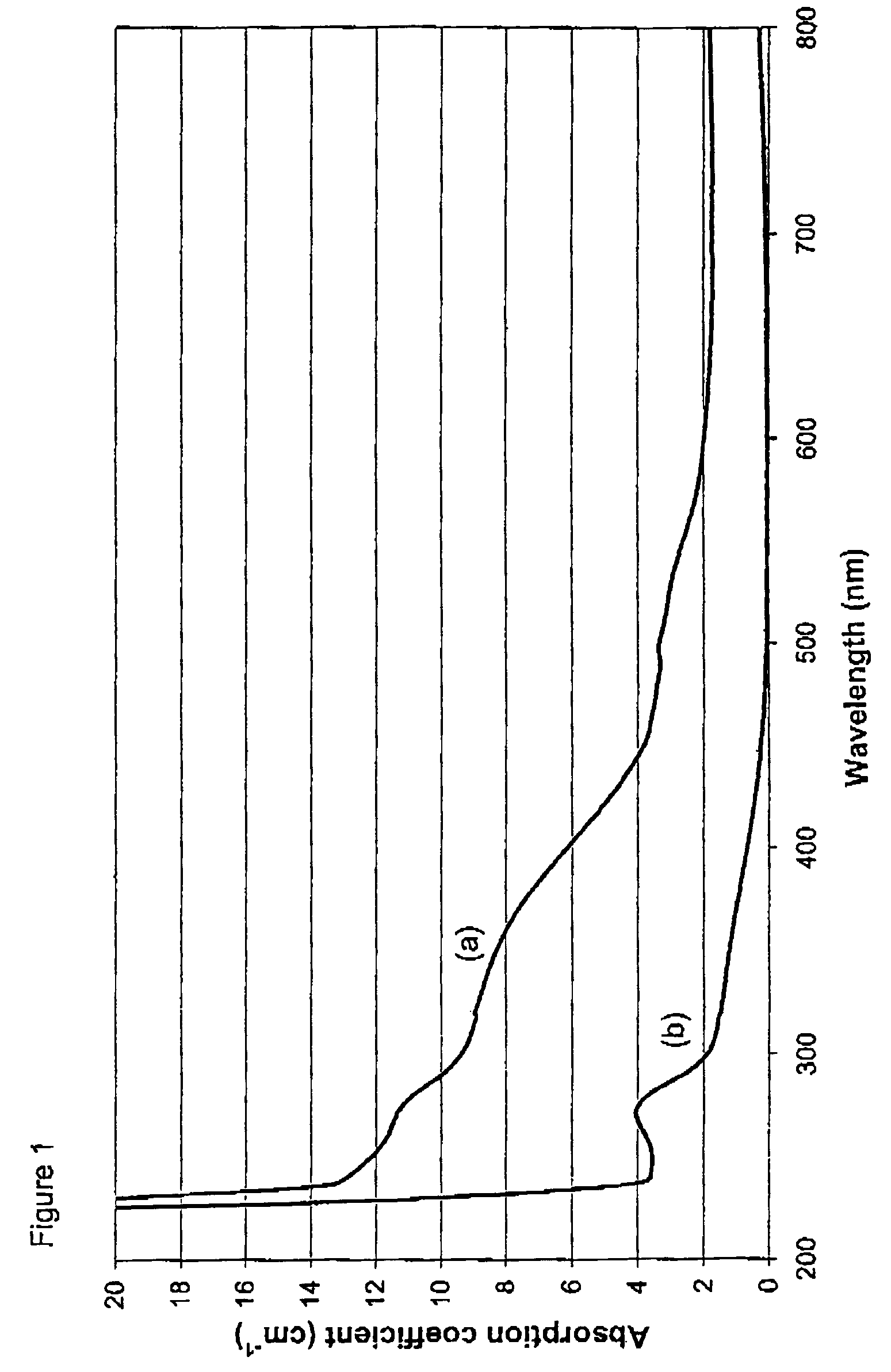

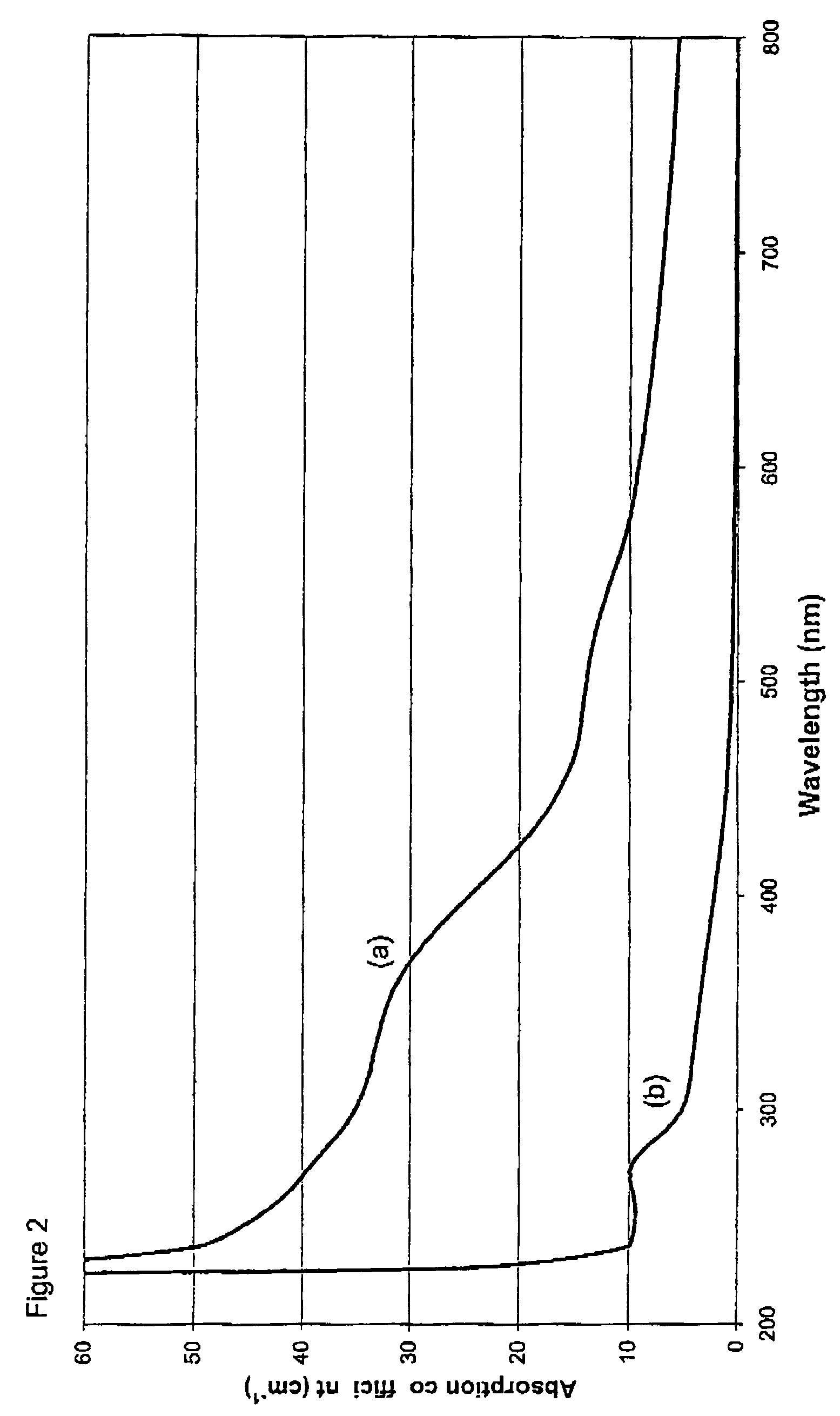

ActiveUS20140349068A1Improve optical qualityPrecise design toleranceSynthetic resin layered productsDiamondDielectric lossRoom temperature

A polycrystalline chemical vapour deposited (CVD) diamond wafer comprising: a largest linear dimension equal to or greater than 70 mm; a thickness equal to or greater than 1.3 mm; and one or both of the following characteristics measured at room temperature (nominally 298 K) over at least a central area of the polycrystalline CVD diamond wafer, said central area being circular, centred on a central point of the polycrystalline CVD diamond wafer, and having a diameter of at least 70% of the largest linear dimension of the polycrystalline CVD diamond wafer: an absorption coefficient ≦0.2 cm−1 at 10.6 μm; and a dielectric loss coefficient at 145 GHz, of tan δ≦2×10−4.

Owner:ELEMENT SIX TECH LTD

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

Thermally-stable polycrystalline diamond materials and compacts

InactiveUS7473287B2Improve thermal stabilityImprove bindingPigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Thermally-stable polycrystalline diamond materials of this invention comprise a first phase including a plurality of bonded together diamond crystals, and a second phase including a reaction product formed between a binder / catalyst material and a material reactive with the binder / catalyst material. The reaction product is disposed within interstitial regions of the polycrystalline diamond material that exists between the bonded diamond crystals. The first and second phases are formed during a single high pressure / high temperature process condition. The reaction product has a coefficient of thermal expansion that is relatively closer to that of the bonded together diamond crystals than that of the binder / catalyst material, thereby providing an improved degree of thermal stability to the polycrystalline diamond material.

Owner:SMITH INT INC

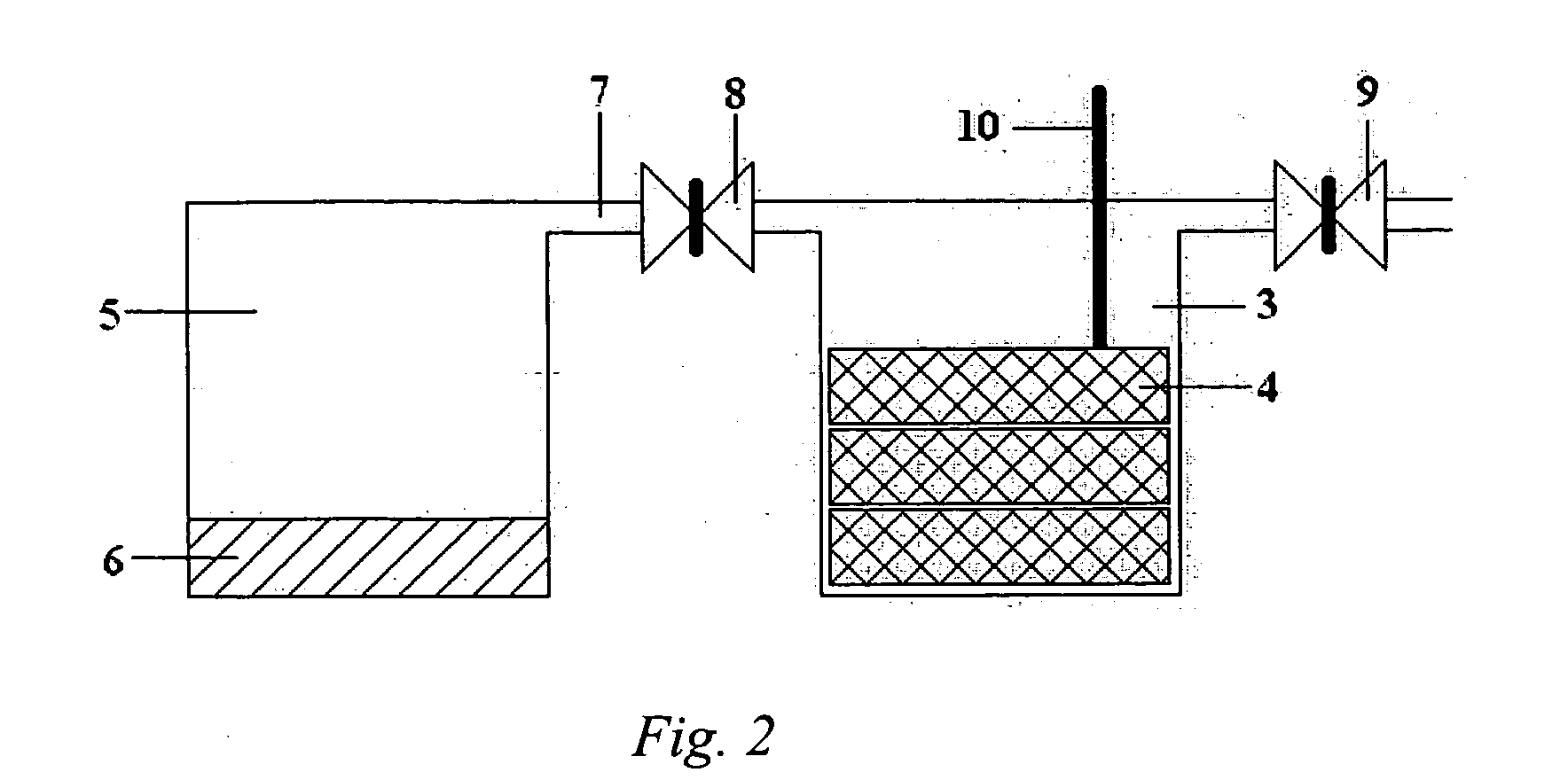

Increased thermal conductivity monolithic zeolite structures

A monolith comprises a zeolite, a thermally conductive carbon, and a binder. The zeolite is included in the form of beads, pellets, powders and mixtures thereof. The thermally conductive carbon can be carbon nano-fibers, diamond or graphite which provide thermal conductivities in excess of about 100 W / m·K to more than 1,000 W / m·K. A method of preparing a zeolite monolith includes the steps of mixing a zeolite dispersion in an aqueous colloidal silica binder with a dispersion of carbon nano-fibers in water followed by dehydration and curing of the binder is given.

Owner:UT BATTELLE LLC

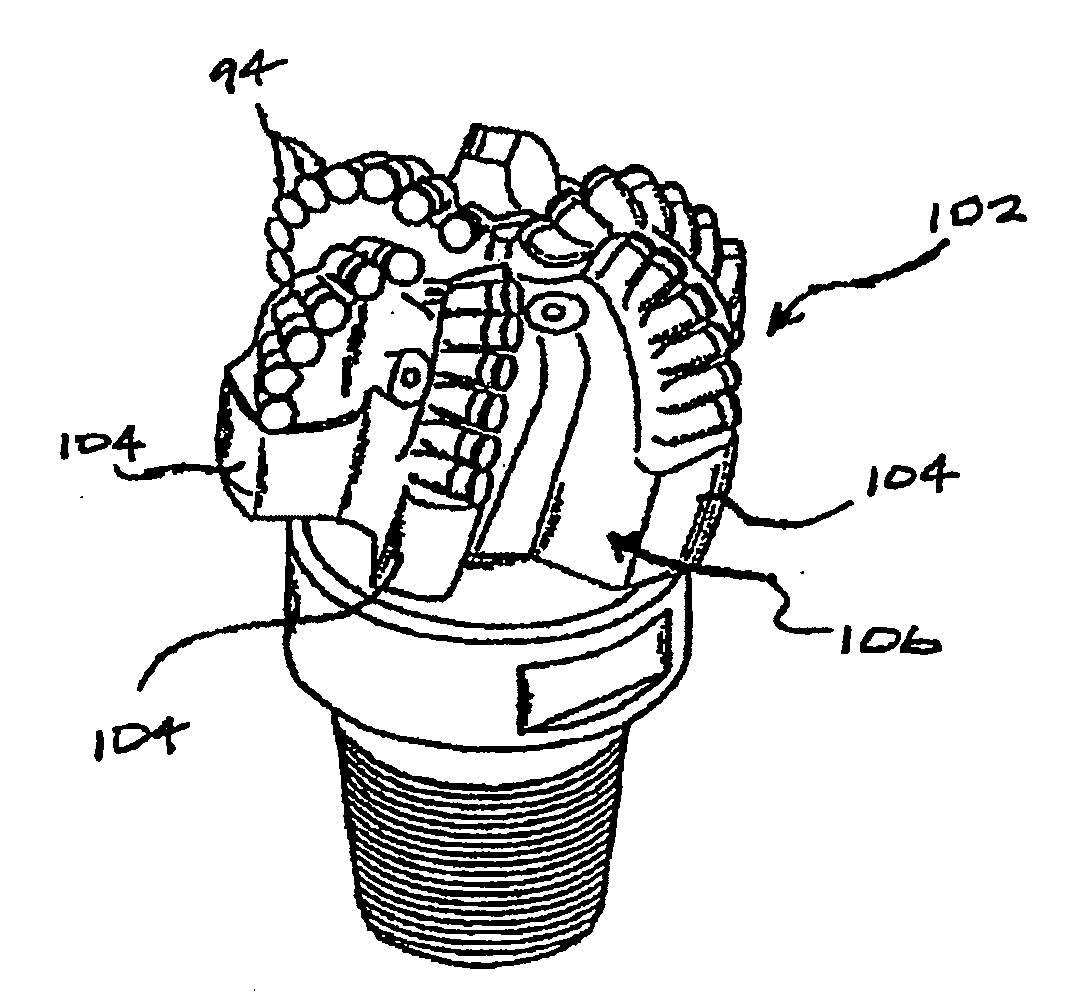

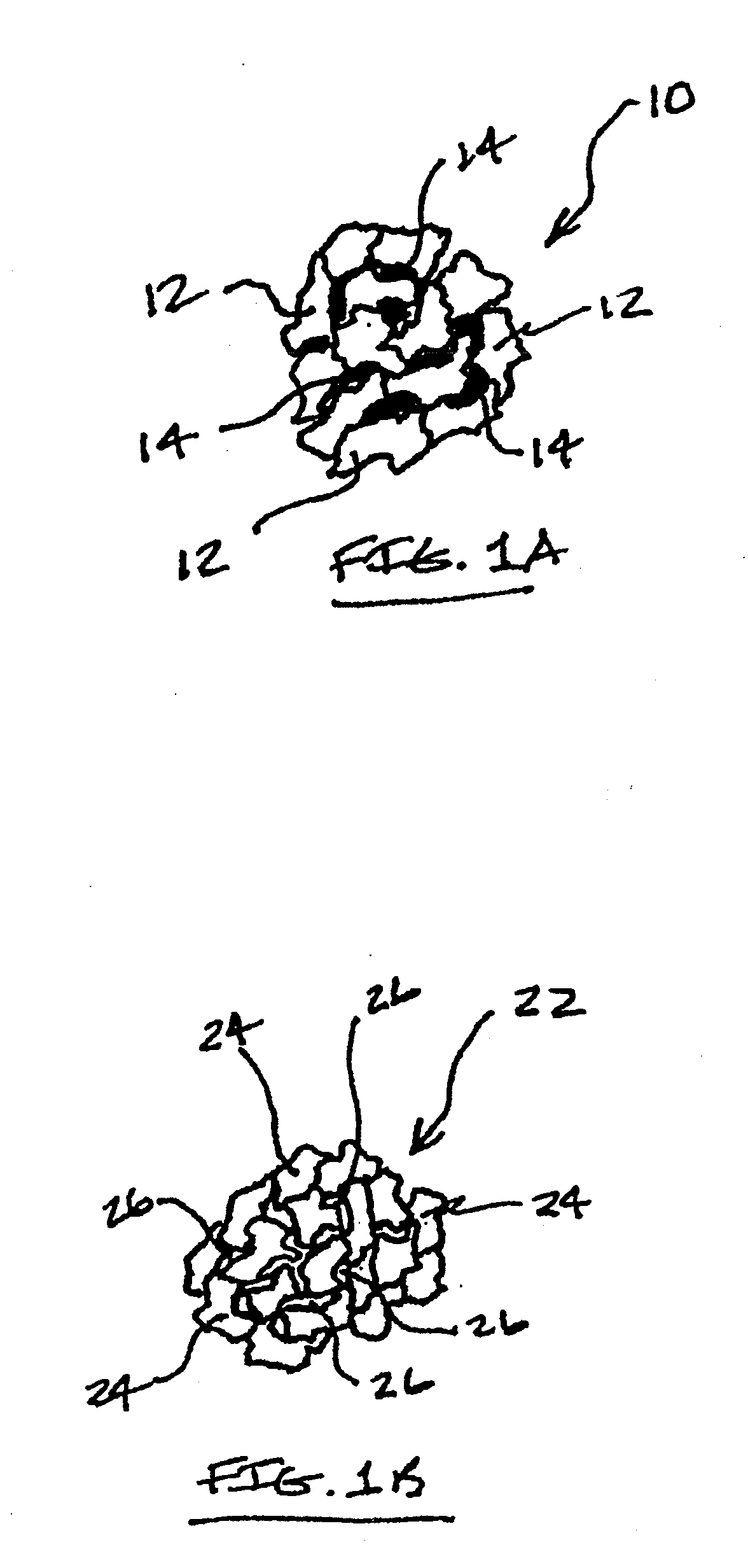

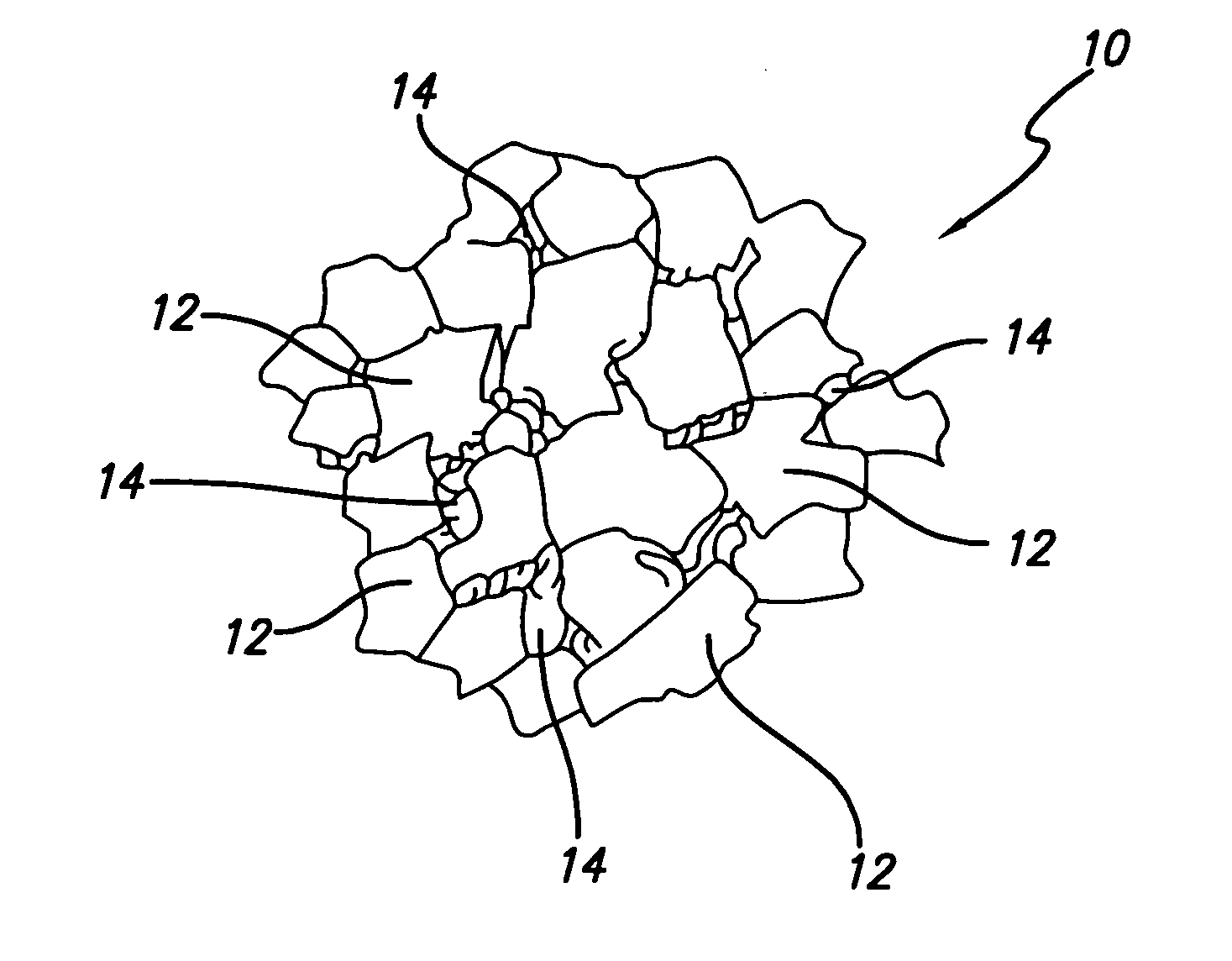

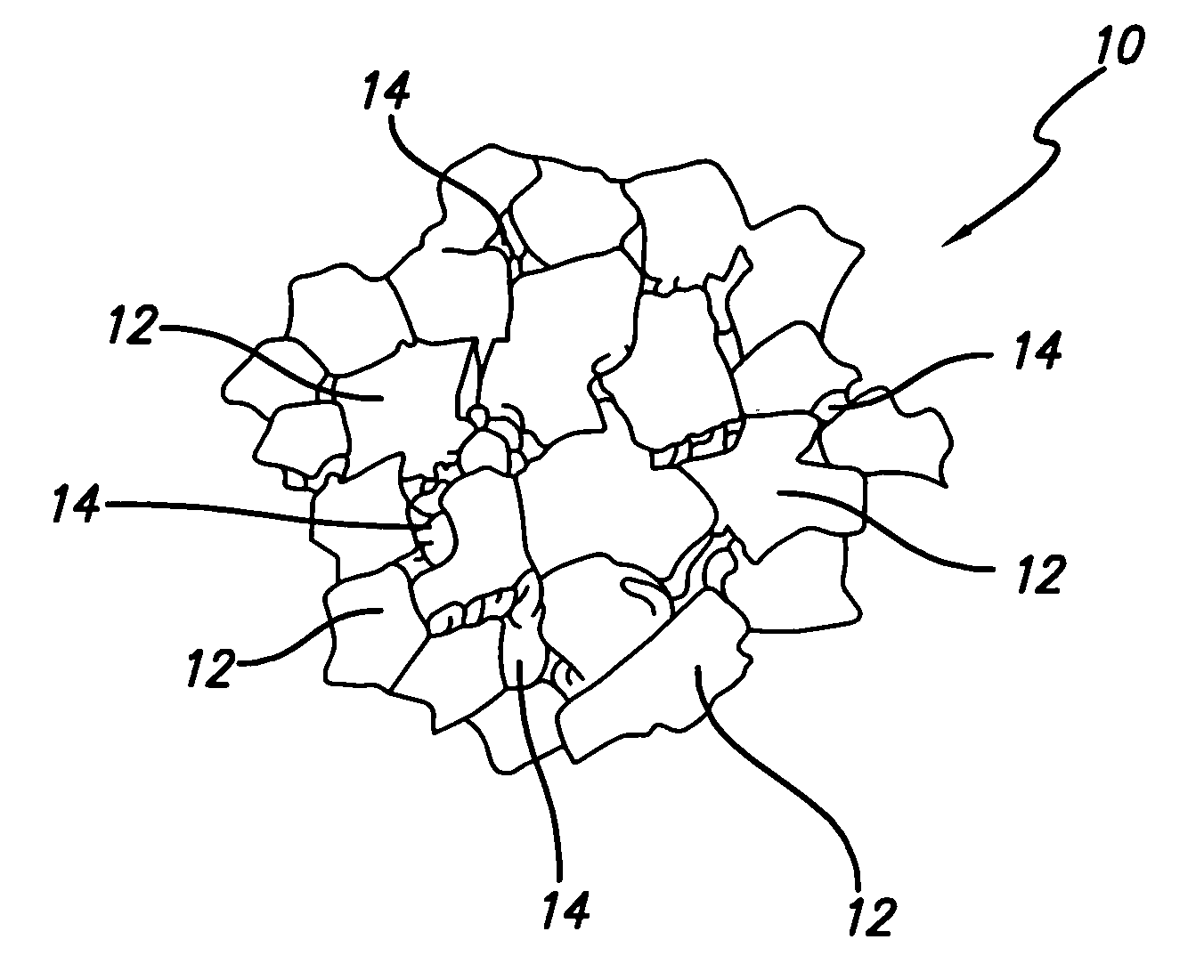

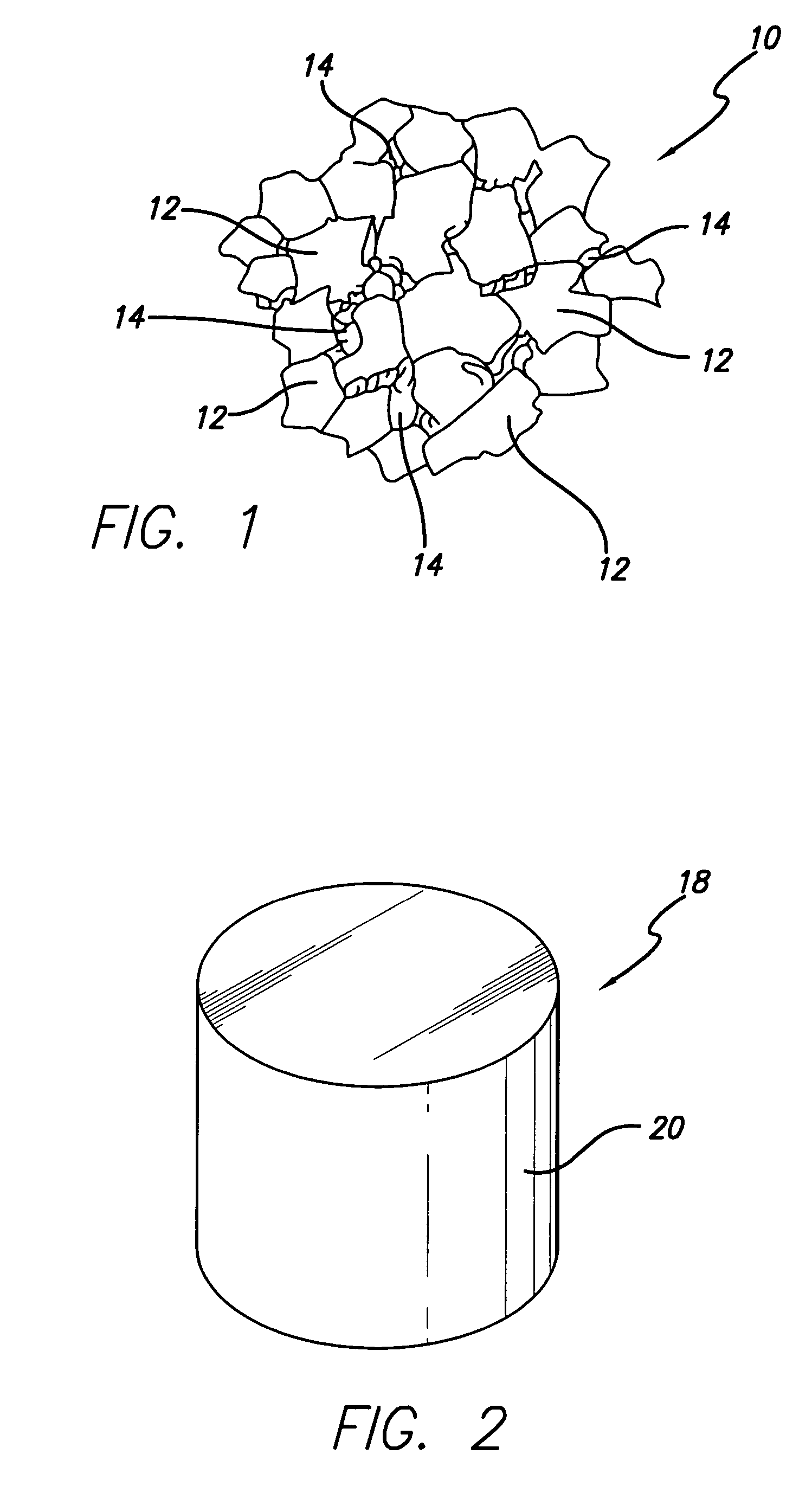

Polycrystalline compacts including in-situ nucleated grains, earth-boring tools including such compacts, and methods of forming such compacts and tools

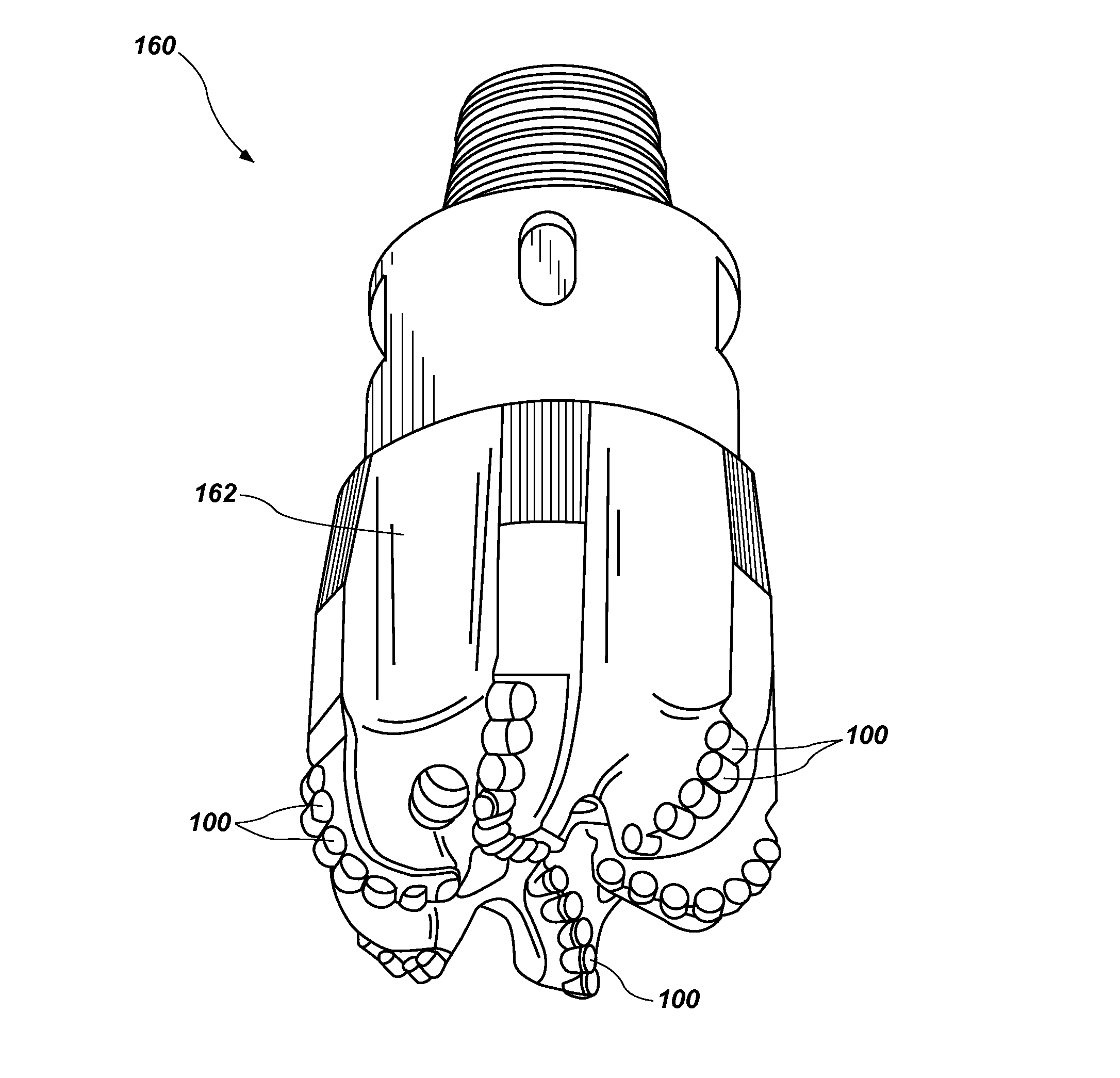

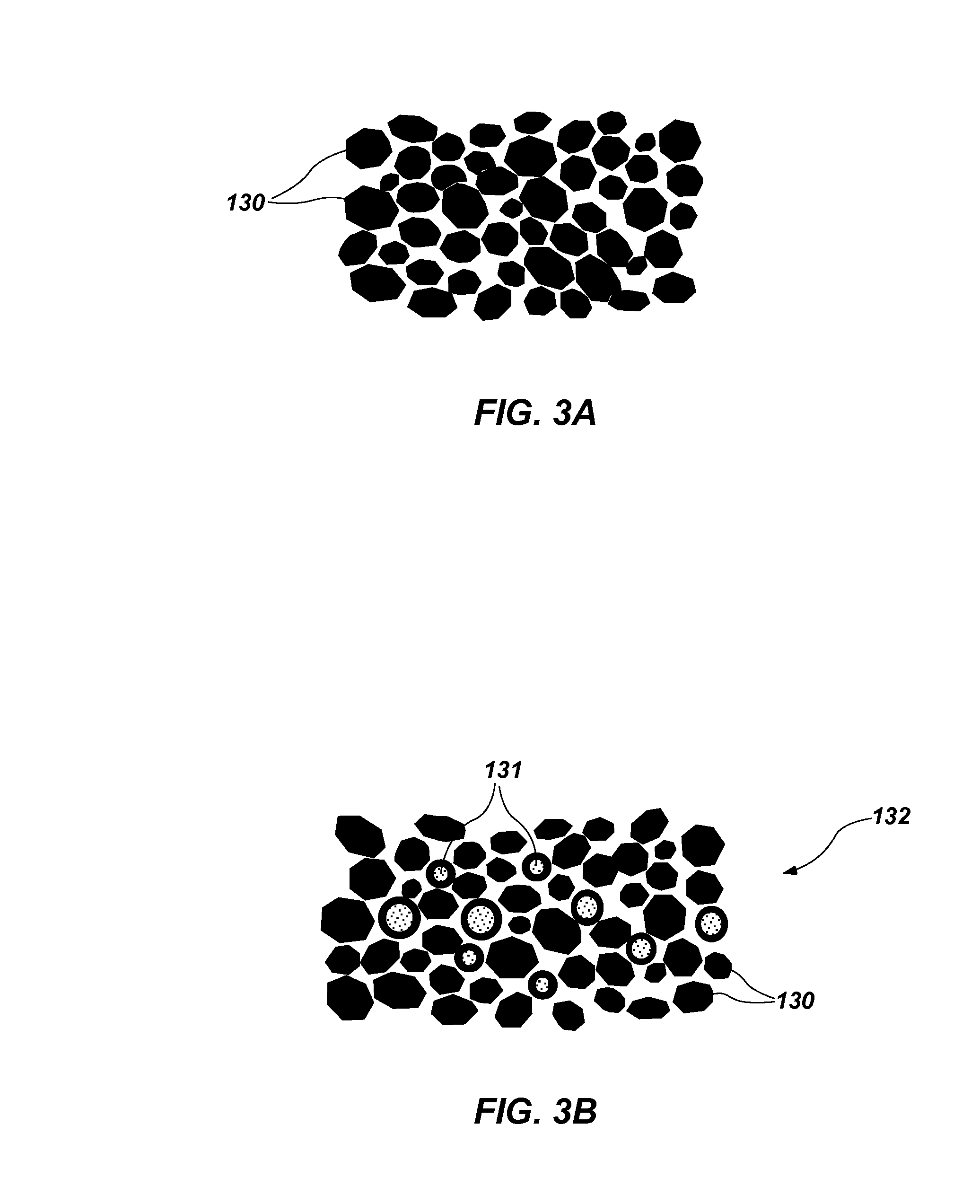

Polycrystalline compacts include hard polycrystalline materials comprising in situ nucleated smaller grains of hard material interspersed and inter-bonded with larger grains of hard material. The average size of the larger grains may be at least about 250 times greater than the average size of the in situ nucleated smaller grains. Methods of forming polycrystalline compacts include nucleating and catalyzing the formation of smaller grains of hard material in the presence of larger grains of hard material, and catalyzing the formation of inter-granular bonds between the grains of hard material. For example, nucleation particles may be mixed with larger diamond grains, a carbon source, and a catalyst. The mixture may be subjected to high temperature and high pressure to form in smaller diamond grains using the nucleation particles, the carbon source, and the catalyst, and to catalyze formation of diamond-to-diamond bonds between the smaller and larger diamond grains.

Owner:BAKER HUGHES INC

Method for synthesizing solids such as diamond and products produced thereby

InactiveUS6342195B1Enhanced interactionIncreasing amount of possibleUltra-high pressure processesDiamondHydrogenBoron nitride

The present invention relates generally to methods for the synthesis of various solids such as diamonds, diamonds films, boron nitride and other similar materials. This invention specifically relates to utilizing novel sources of reaction species (e.g., in the case of diamond formation, novel sources of carbon and / or hydrogen and / or seeds) for the manufacture of various materials and the use of such materials for various commercial purposes.

Owner:PENN STATE RES FOUND

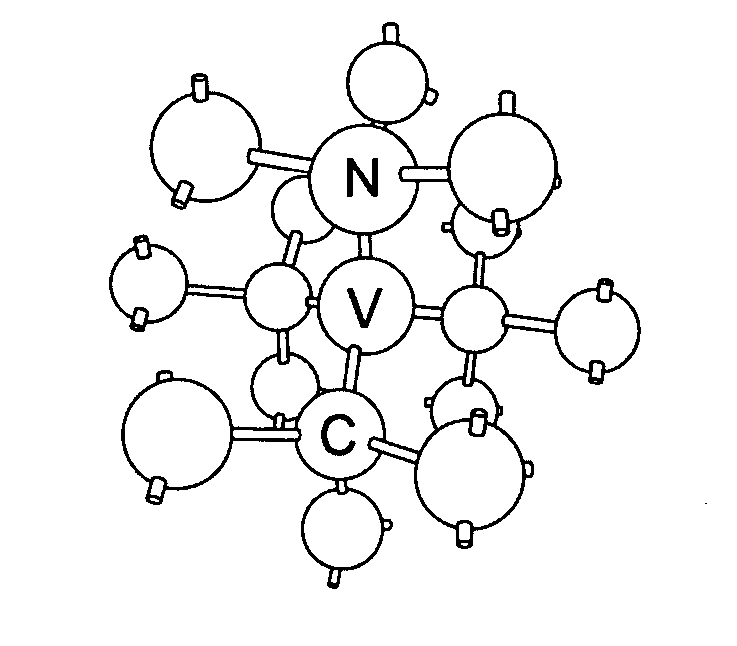

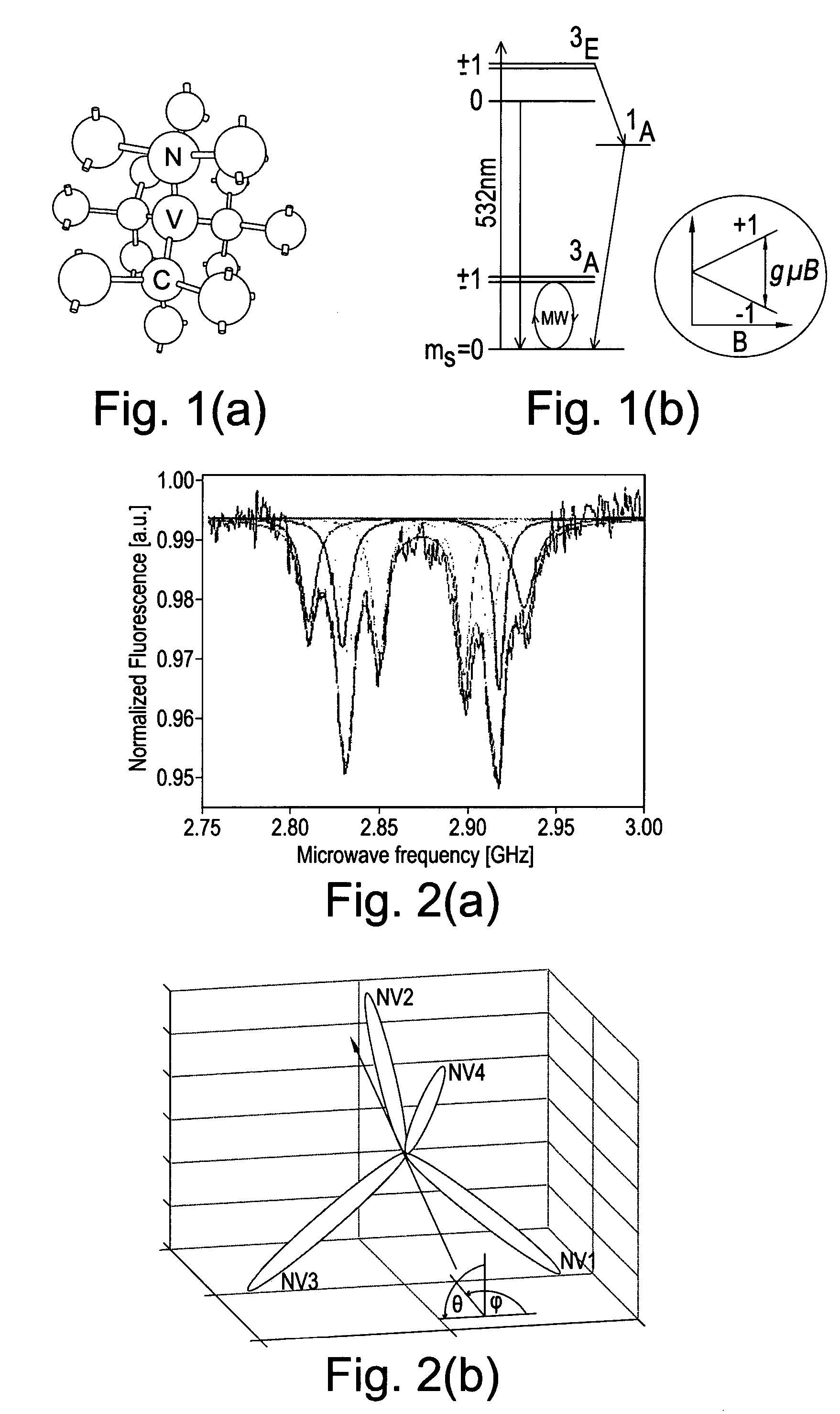

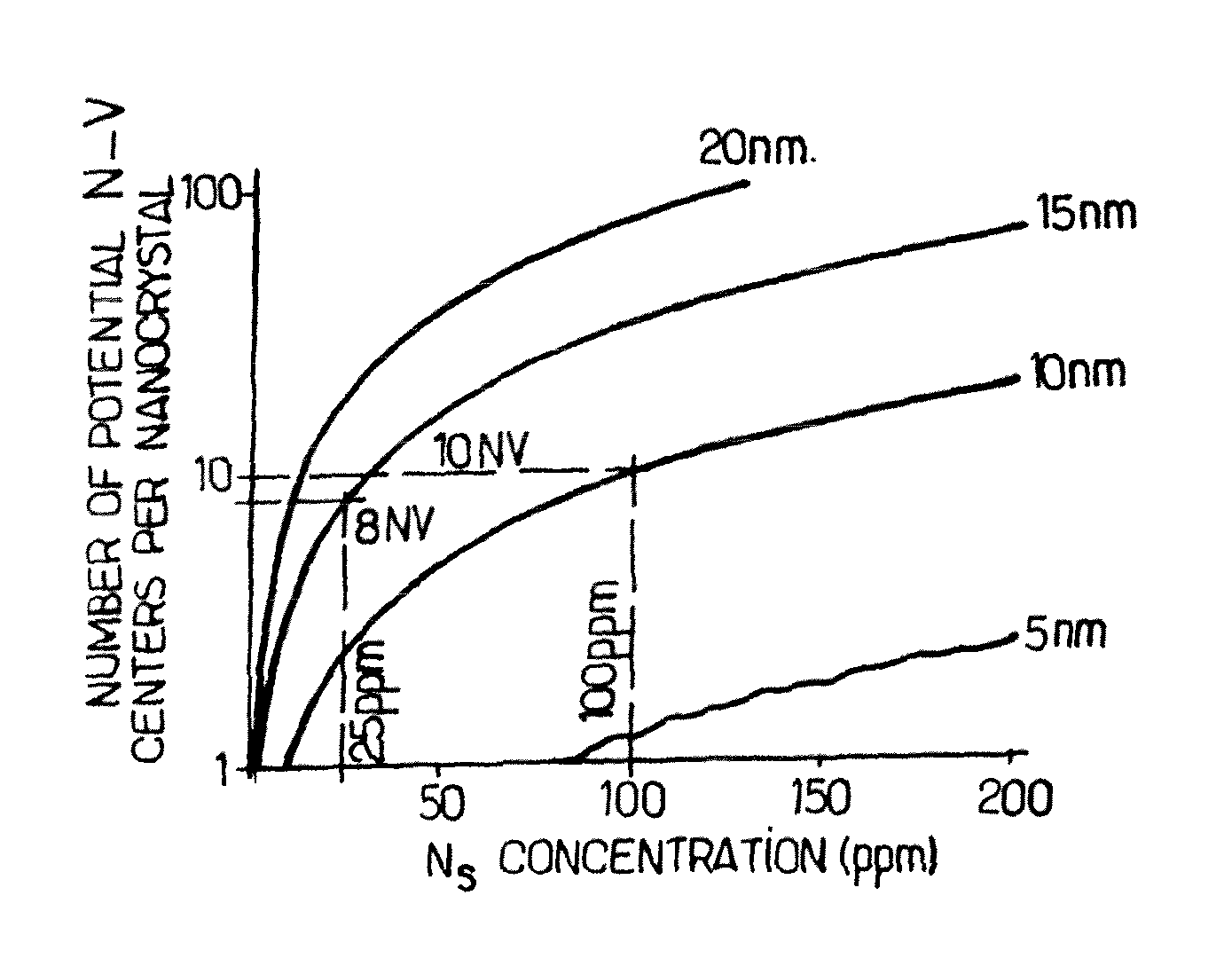

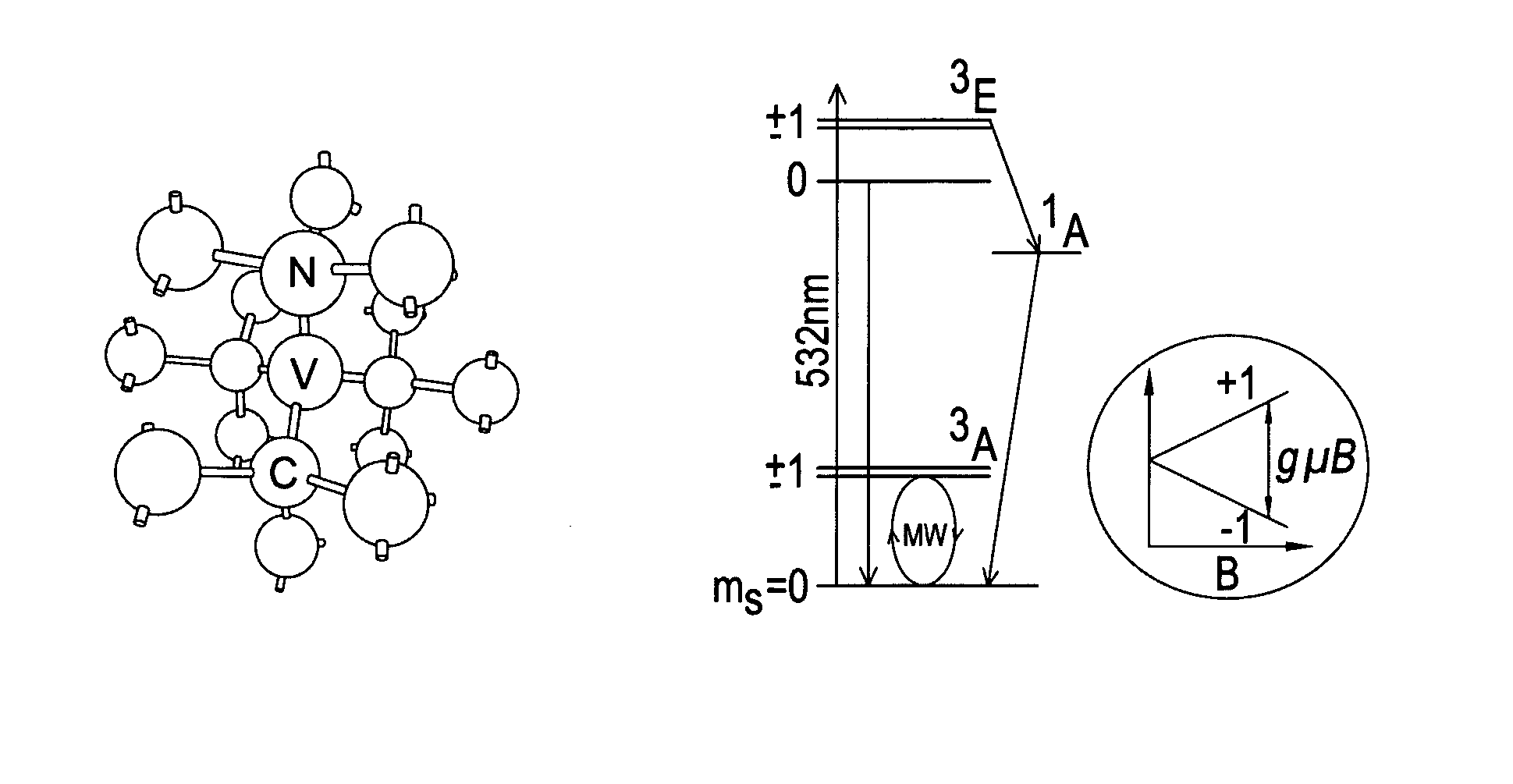

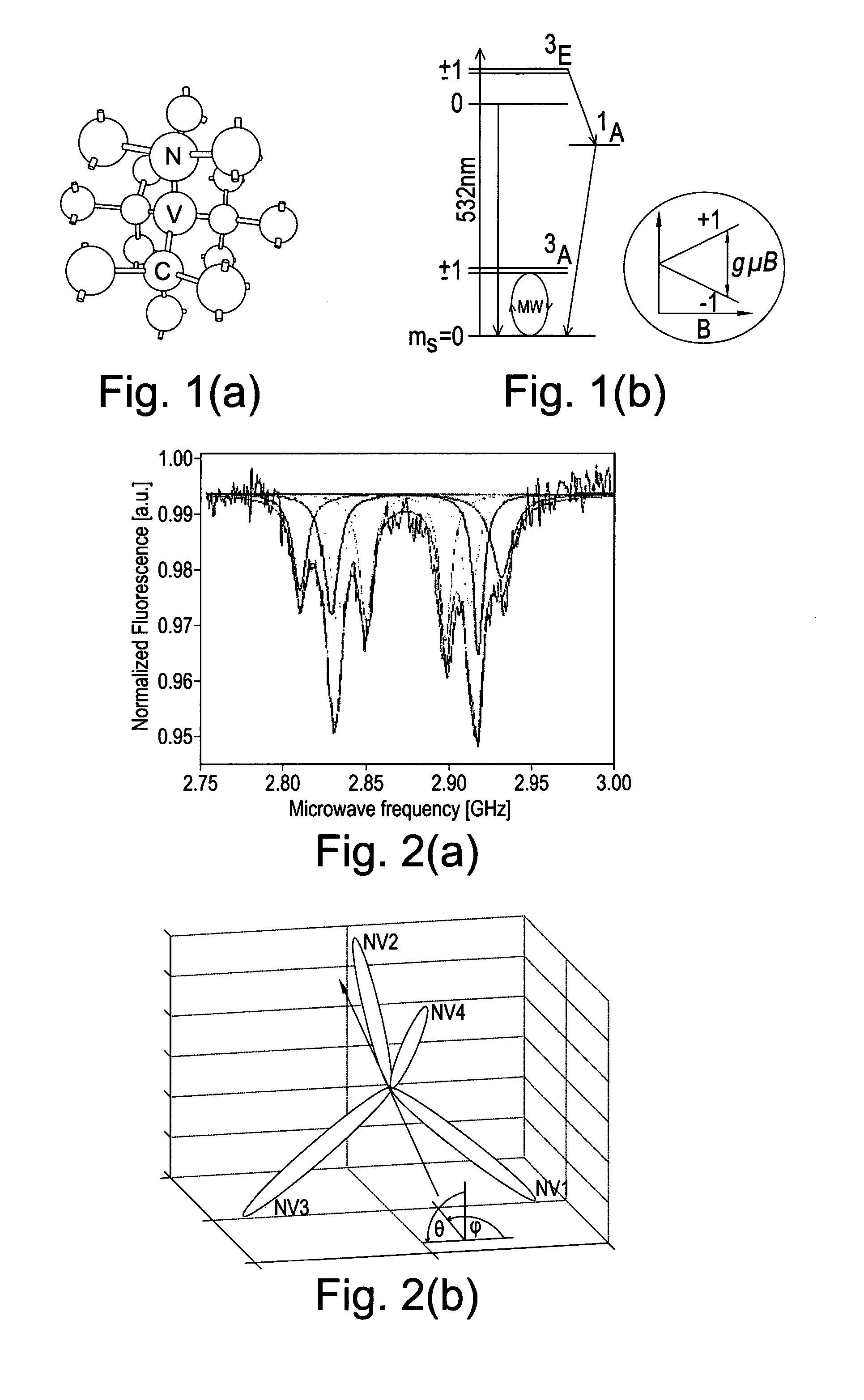

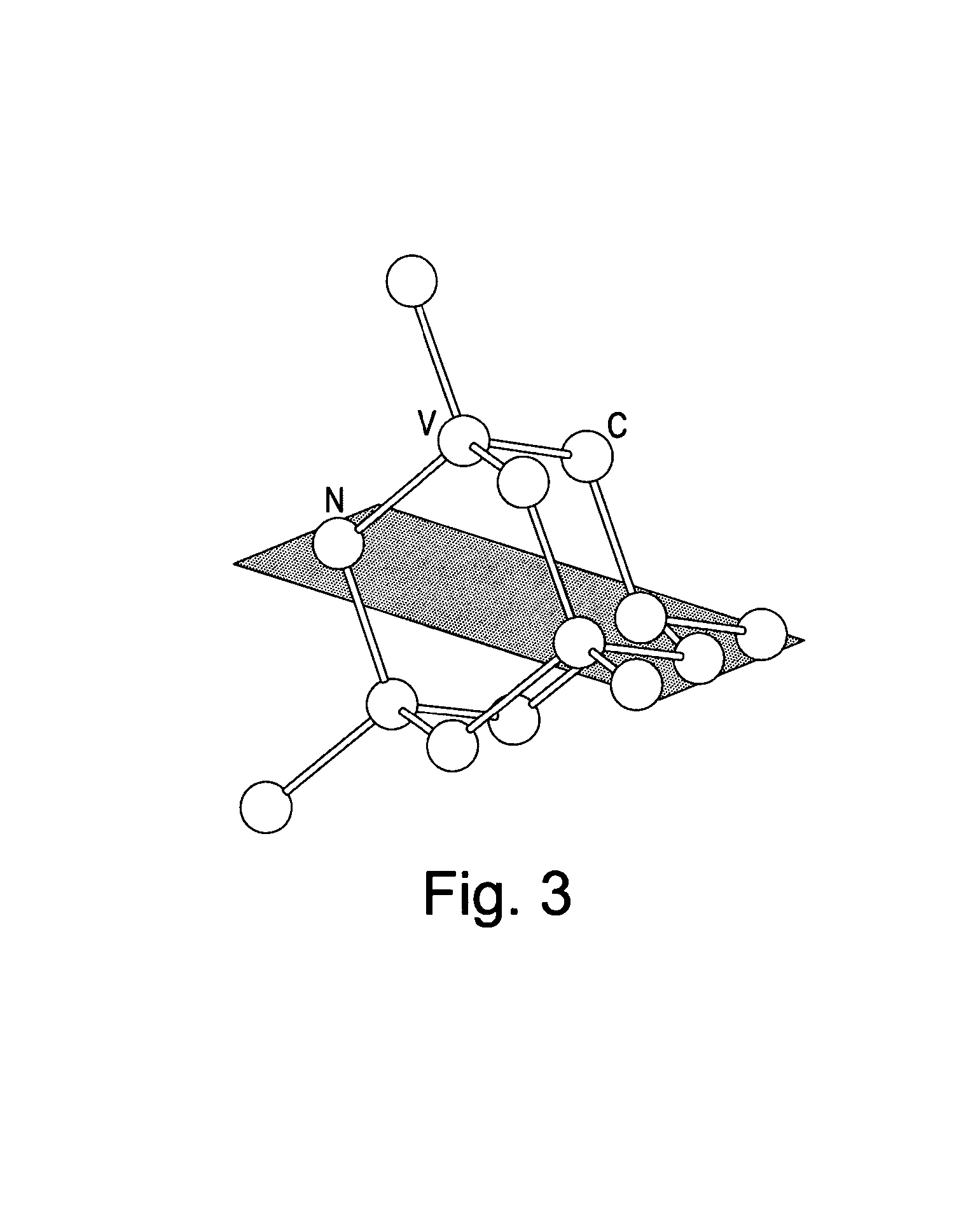

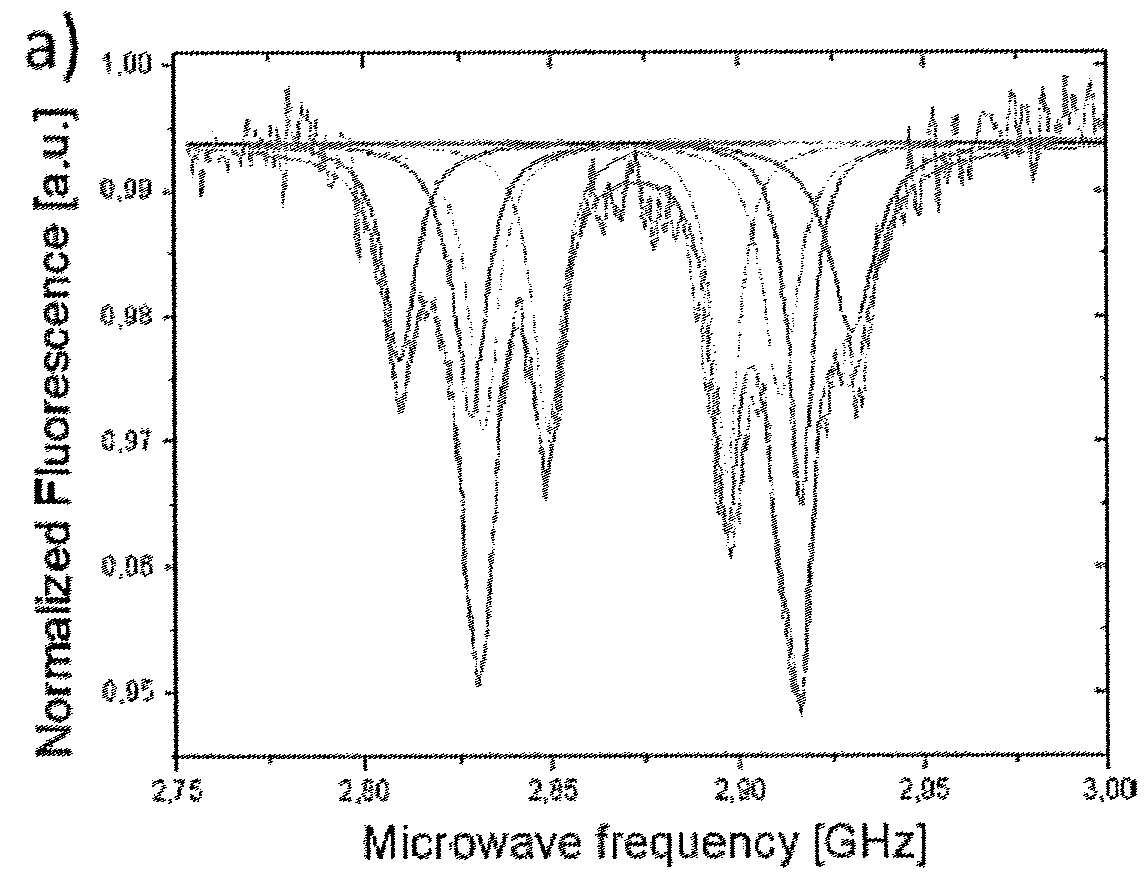

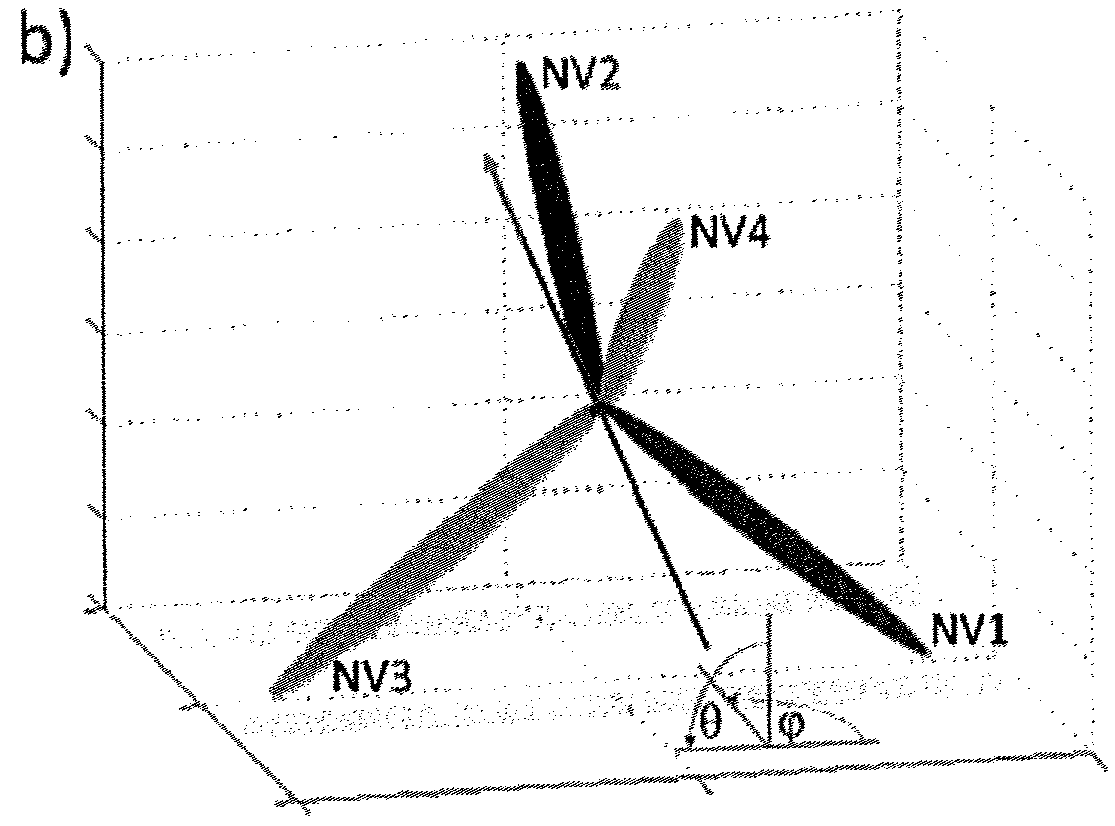

Diamond sensors, detectors, and quantum devices

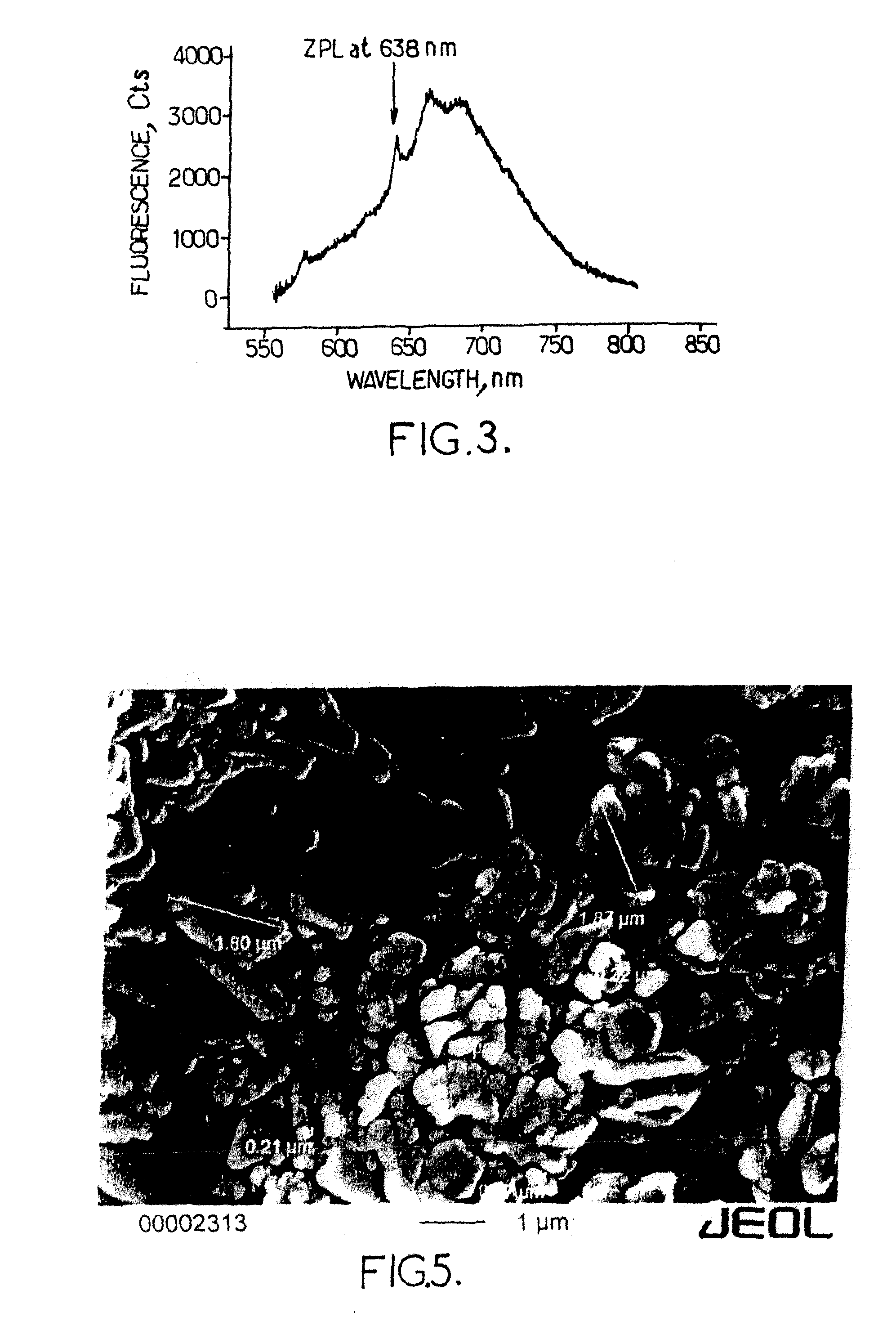

ActiveUS20140061510A1Improve light outcoupling efficiencyEnhanced couplingPolycrystalline material growthUltra-high pressure processesVacancy defectPreferential alignment

A single crystal synthetic CVD diamond material comprising: a growth sector; and a plurality of point defects of one or more type within the growth sector, wherein at least one type of point defect is preferentially aligned within the growth sector, wherein at least 60% of said at least one type of point defect shows said preferential alignment, and wherein the at least one type of point defect is a negatively charged nitrogen-vacancy defect (NV−).

Owner:ELEMENT SIX LTD

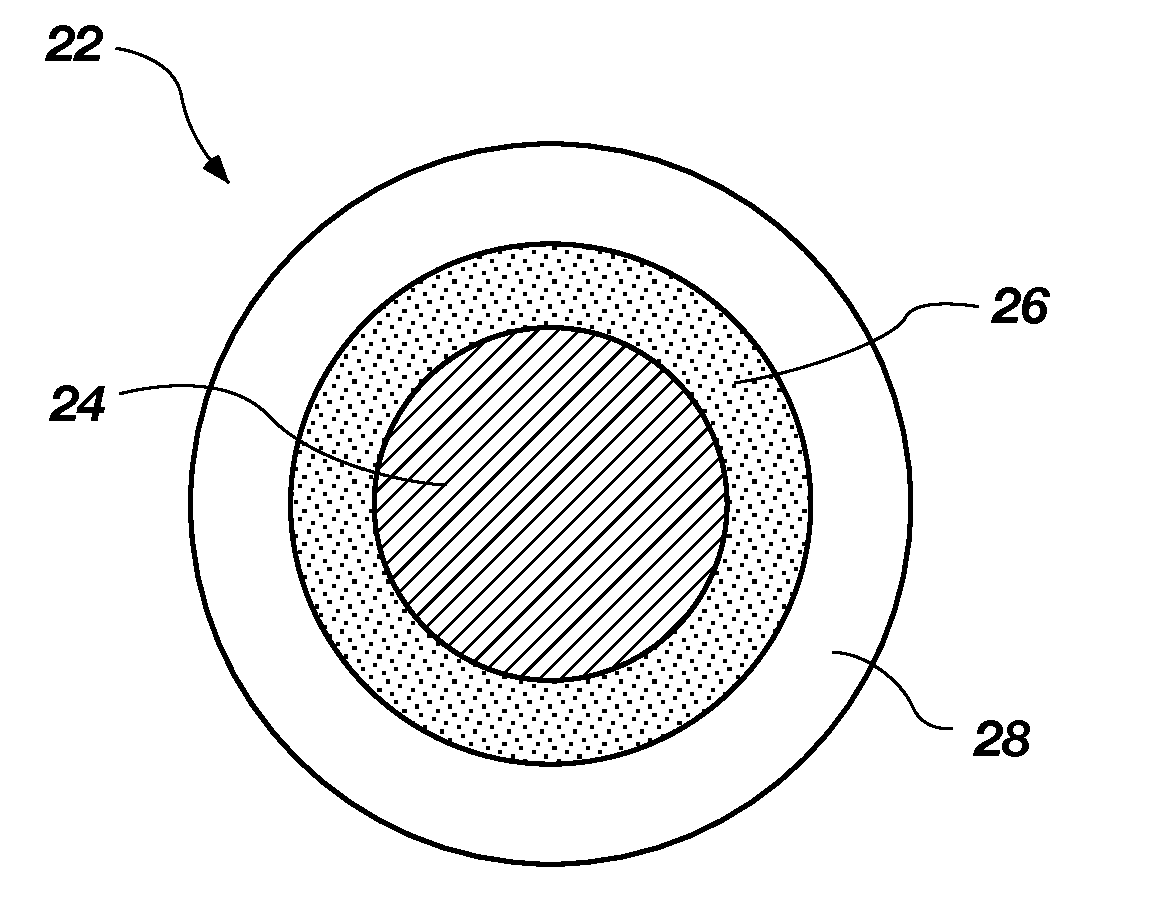

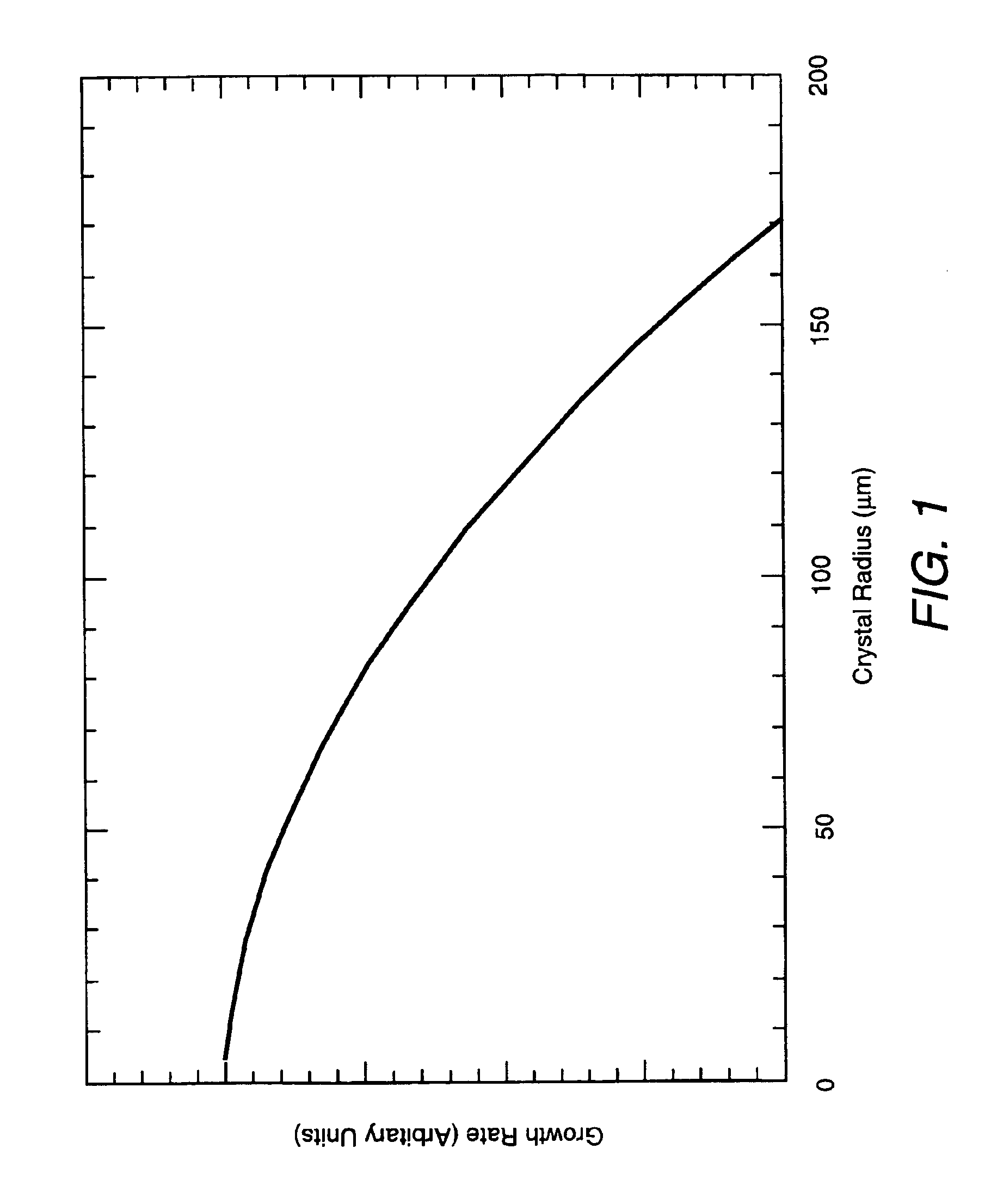

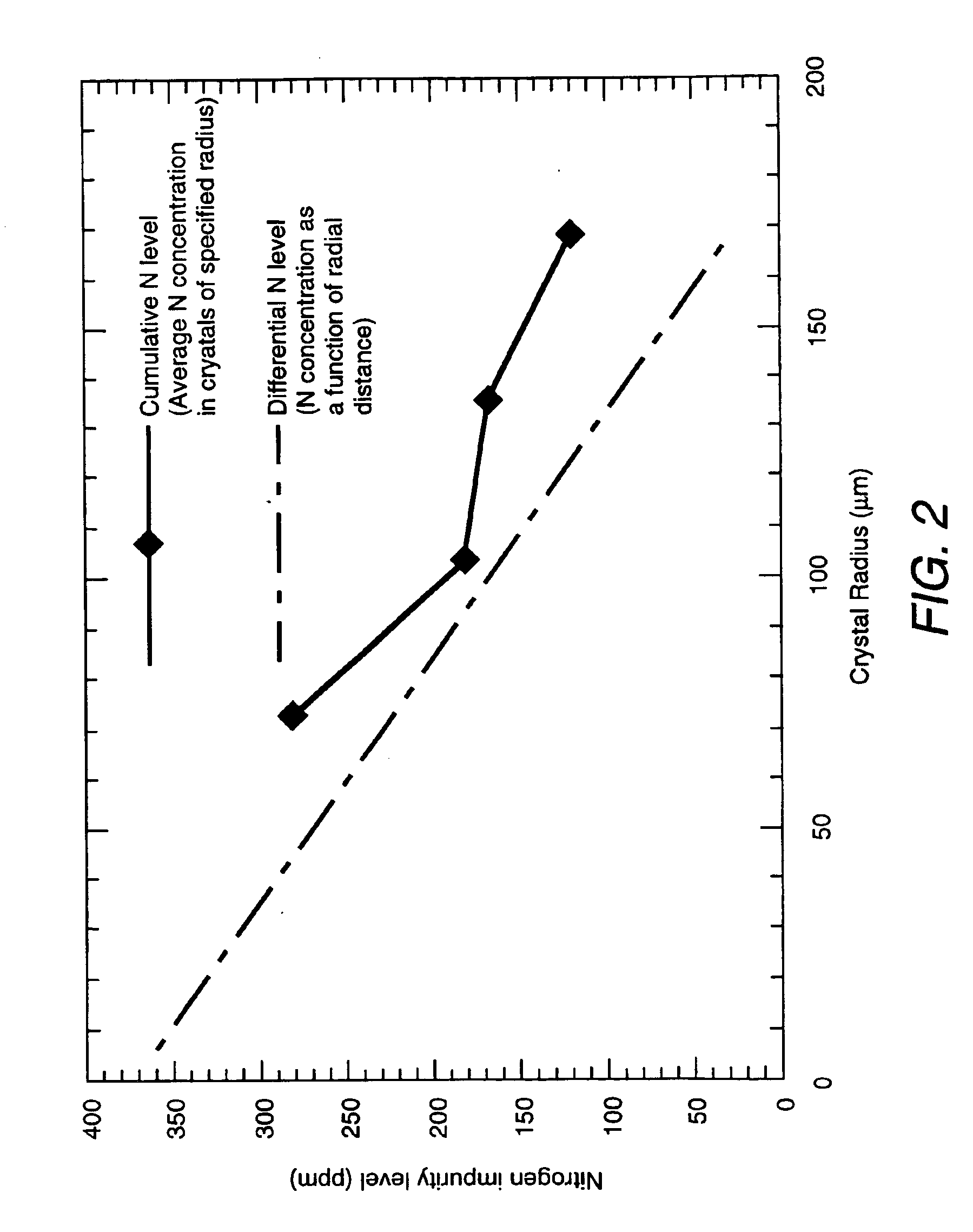

Surface impurity-enriched diamond and method of making

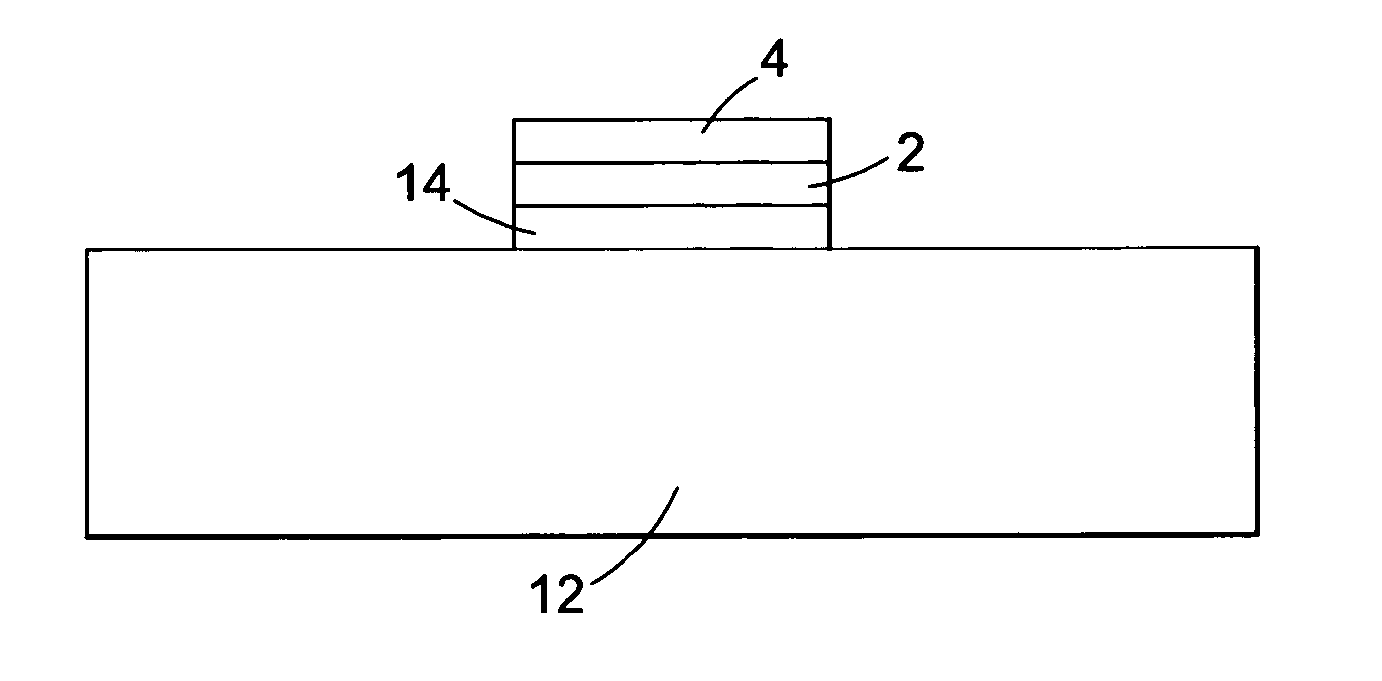

InactiveUS6887144B2Increases compressive fracture strengthHigh breaking strengthPolycrystalline material growthUltra-high pressure processesDopantMicrometer

An element-doped diamond crystal is disclosed herein. The crystal includes at least one dopant element which has a greater concentration toward or near an outermost surface of the crystal than in the center of the crystal. The concentration of the dopant element is at a local minimum at least about 5 micrometers below the surface. The concentration-profile of the dopant element for these diamond crystals causes an expansion of the diamond lattice, thereby generating tangential compressive stresses at the surface of the diamond crystal. These stresses beneficially increase the compressive fracture strength of the diamond.

Owner:DIAMOND INNOVATIONS INC

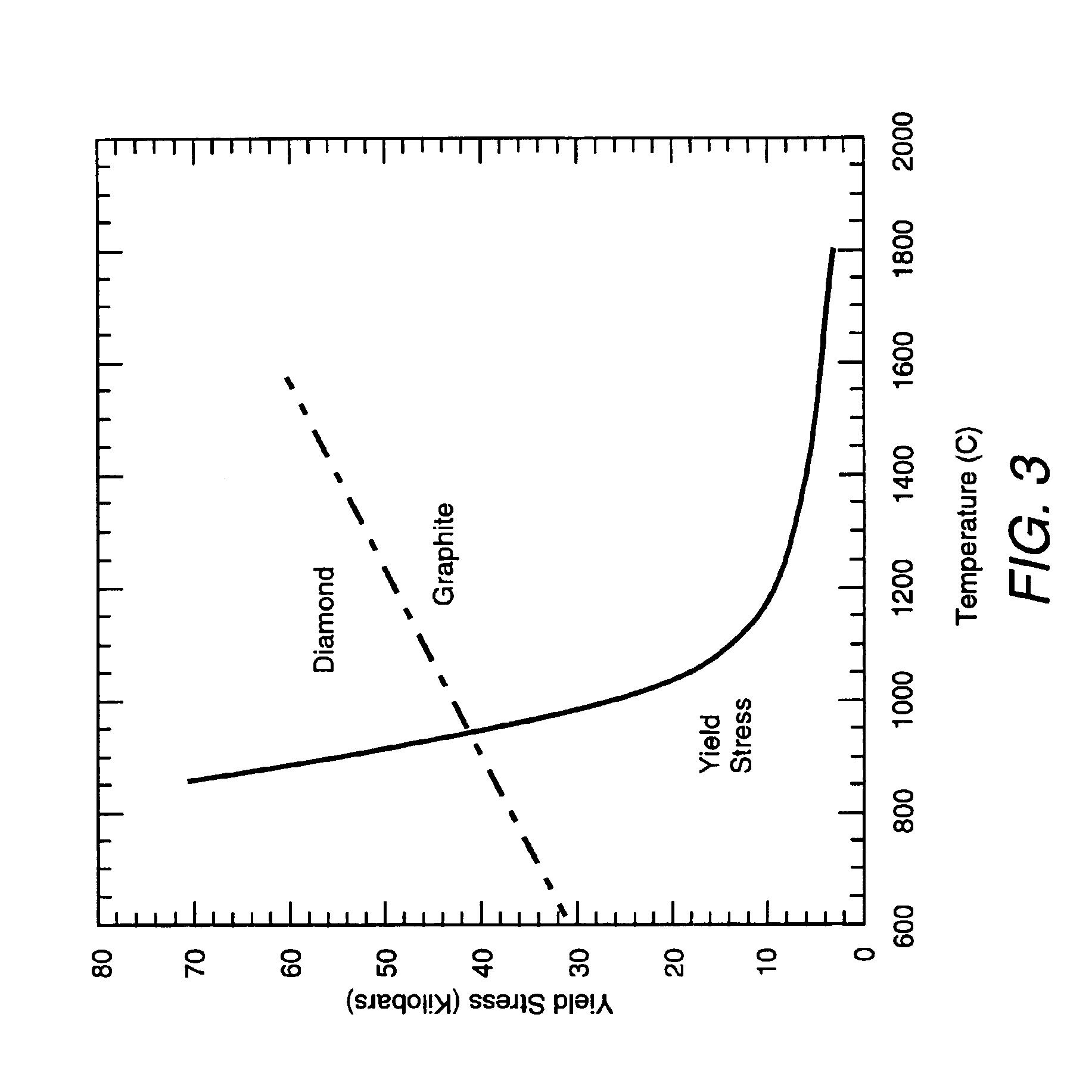

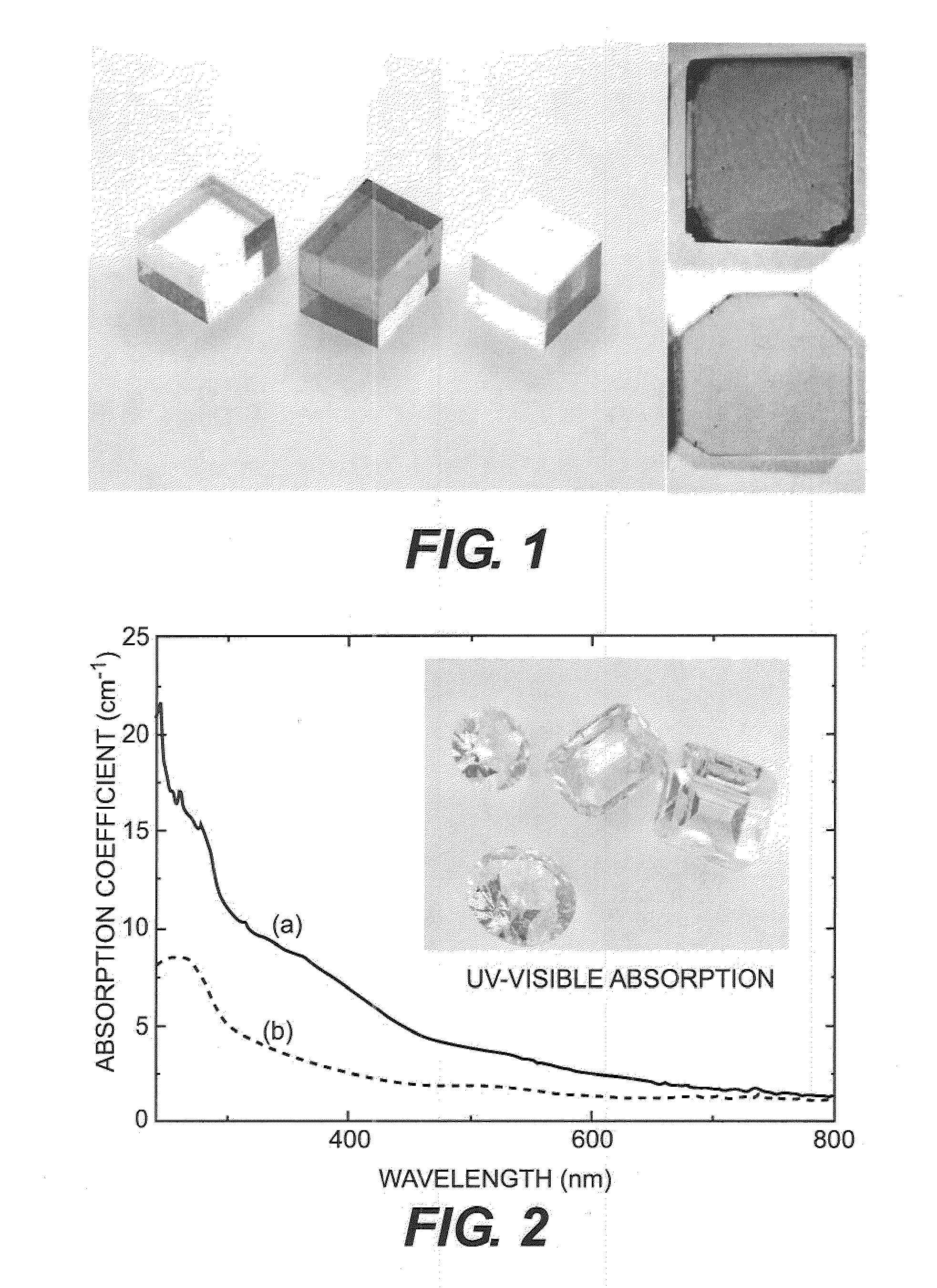

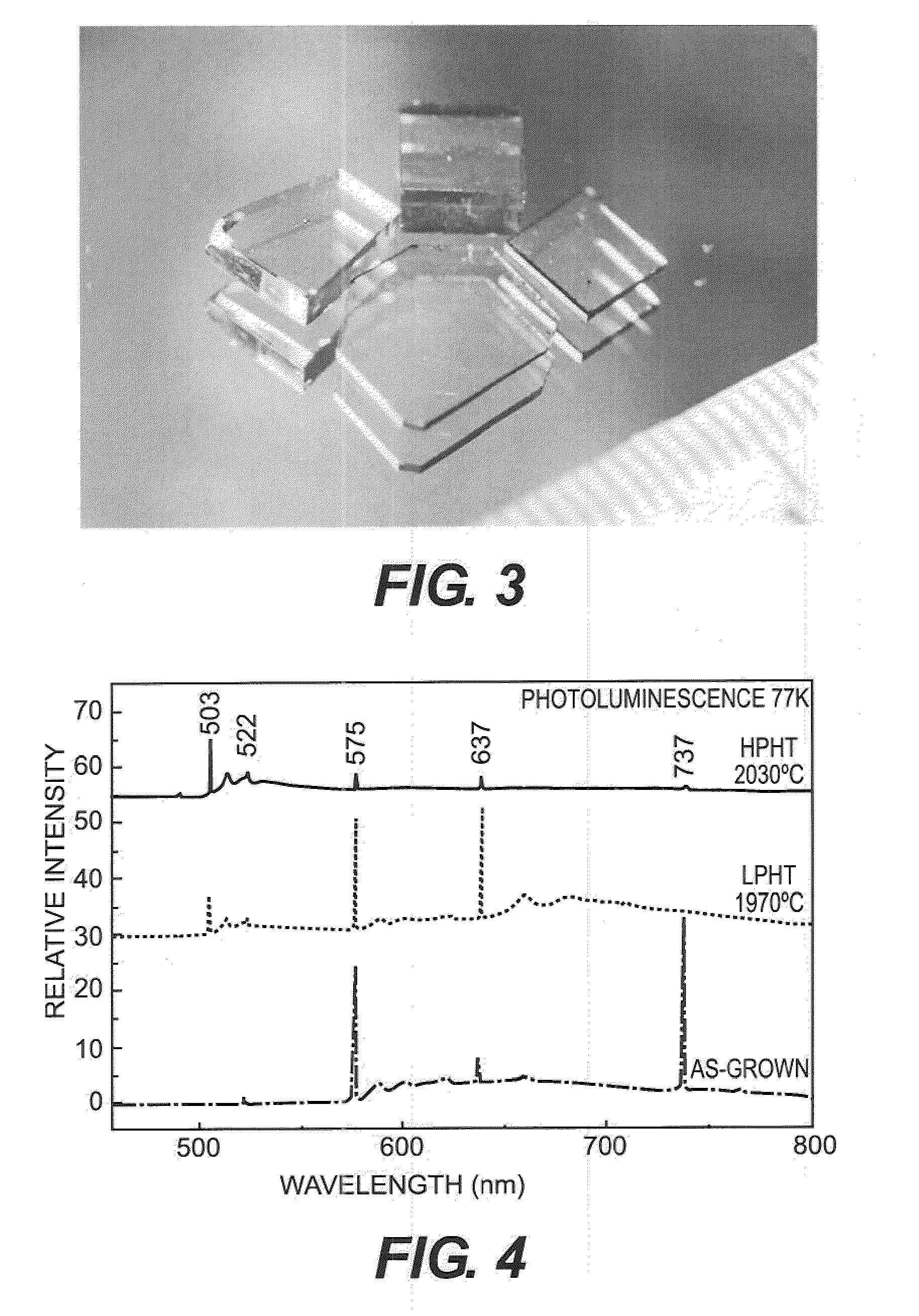

Enhanced Optical Properties of Chemical Vapor Deposited Single Crystal Diamond by Low-Pressure/High-Temperature Annealing

InactiveUS20100104494A1Good optical performanceIncrease probabilityPolycrystalline material growthCyanogen compoundsOptical propertyGas phase

The method of improving the optical properties of single crystal CVD diamond which comprises annealing the crystals at a temperature of up to 2200° C. and a pressure below 300 torr.

Owner:CARNEGIE INSTITUTION OF WASHINGTON

Optical quality diamond material

ActiveUS7740824B2Prevent or reduce local strain generating defectsPrevent and reduce absorptionPolycrystalline material growthAfter-treatment detailsOptical reflectionGrating

Owner:ELEMENT SIX TECH LTD

Polycrystalline diamond constructions having improved thermal stability

InactiveUS7942219B2Improved thermal characteristic and mechanical propertyAvoiding unwanted deteriorationDrill bitsConstructionsPolycrystalline diamondThermal stability

PCD constructions include a PCD body comprising a polycrystalline matrix region, a first region that includes a replacement material positioned remote from a body surface, and a second region that is substantially free of the replacement material and that extends a depth from the body surface. The PCD construction can further include a substrate that is attached to the body. The PCD body is formed by removing a solvent catalyst material used to form the body, replacing the removed solvent catalyst material with a replacement material, and then removing the replacement material from a region of the body to thereby form the second region. The replacement material can be introduced into the PCD body during a HPHT process, and the substrate may or may not be the source of the noncatalyzing material.

Owner:SMITH INT INC

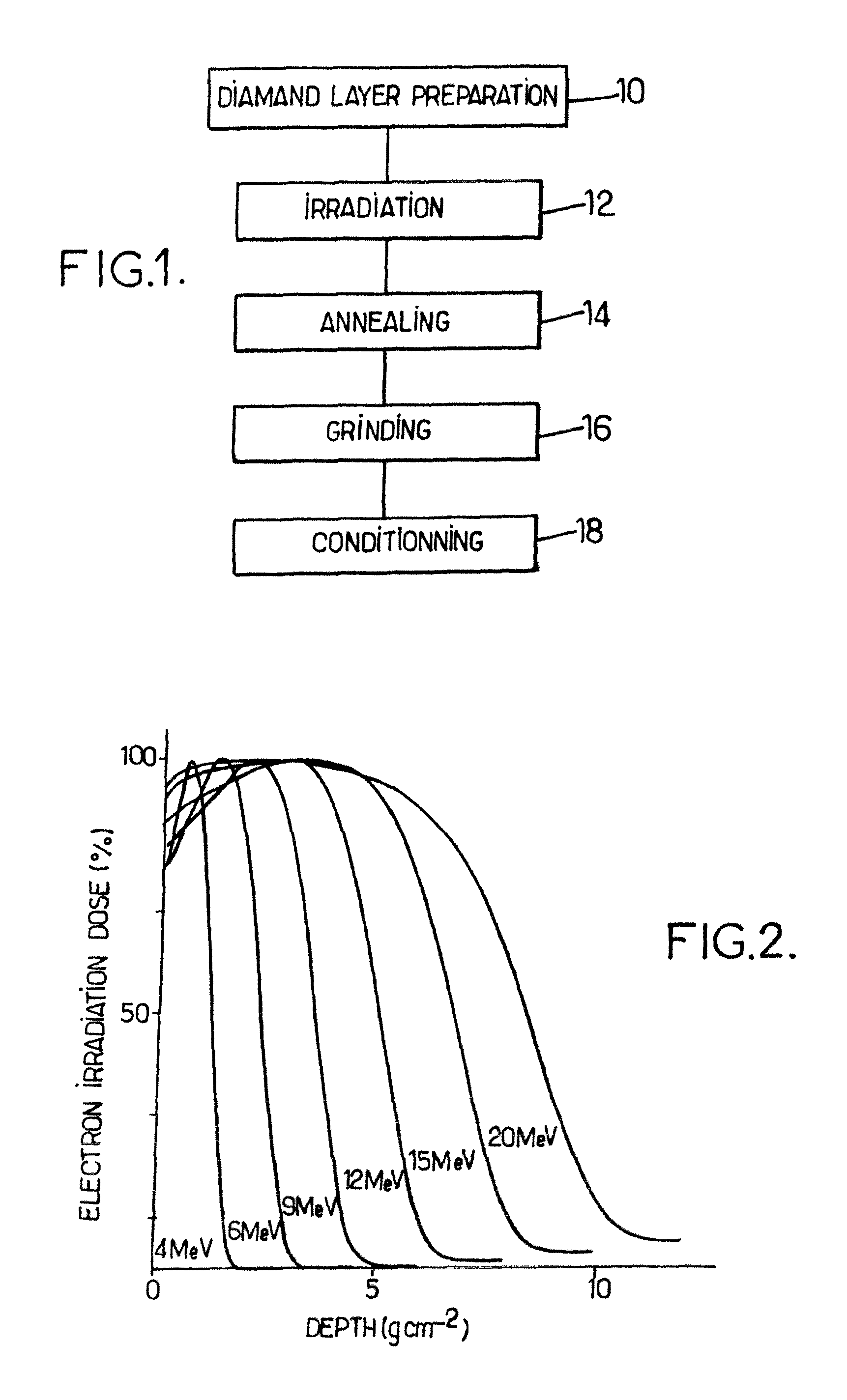

Method to produce light-emitting nano-particles of diamond

Owner:INST NAT DE LA SANTE & DE LA RECHERCHE MEDICALE (INSERM)

Single crystal CVD synthetic diamond material

ActiveUS20140335339A1Improve optical qualityReduce concentrationPolycrystalline material growthSynthetic resin layered productsPhotoluminescenceSingle crystal

A single crystal CVD synthetic diamond material comprising: a total as-grown nitrogen concentration equal to or greater than 5 ppm, and a uniform distribution of defects, wherein said uniform distribution of defects is defined by one or more of the following characteristics: (i) the total nitrogen concentration, when mapped by secondary ion mass spectrometry (SIMS) over an area equal to or greater than 50×50 μm using an analysis area of 10 μm or less, possesses a point-to-point variation of less than 30% of an average total nitrogen concentration value, or when mapped by SIMS over an area equal to or greater than 200×200 μm using an analysis area of 60 μm or less, possesses a point-to-point variation of less than 30% of an average total nitrogen concentration value; (ii) an as-grown nitrogen-vacancy defect (NV) concentration equal to or greater than 50 ppb as measured using 77K UV-visible absorption measurements, wherein the nitrogen-vacancy defects are uniformly distributed through the synthetic single crystal CVD diamond material such that, when excited using a 514 nm laser excitation source of spot size equal to or less than 10 μm at room temperature using a 50 mW 46 continuous wave laser, and mapped over an area equal to or greater than 50×50 μm with a data interval less than 10 μm there is a low point-to-point variation wherein the intensity area ratio of nitrogen vacancy photoluminescence peaks between regions of high photoluminescent intensity and regions of low photolominescent intensity is <2× for either the 575 nm photoluminescent peak (NV0) or the 637 nm photoluminescent peak (NV); (iii) a variation in Raman intensity such that, when excited using a 514 nm laser excitation source (resulting in a Raman peak at 552.4 nm) of spot size equal to or less than 10 μm at room temperature using a 50 mW continuous wave laser, and mapped over an area equal to or greater than 50×50 μm with a data interval less than 10 μm, there is a low point-to-point variation wherein the ratio of Raman peak areas between regions of low Raman intensity and high Raman intensity is <1.25×; (iv) an as-grown nitrogen-vacancy defect (NV) concentration equal to or greater than 50 ppb as measured using 77K UV-visible absorption measurements, wherein, when excited using a 514 nm excitation source of spot size equal to or less than 10 μm at 77K using a 50 mW continuous wave laser, gives an intensity at 575 nm corresponding to NV0 greater than 120 times a Raman intensity at 552.4 nm, and / or an intensity at 637 nm corresponding to NV− greater than 200 times the Raman intensity at 552.4 nm; (v) a single substitutional nitrogen defect (Ns) concentration equal to or greater than 5 ppm, wherein the single substitutional nitrogen defects are uniformly distributed through the synthetic single crystal CVD diamond material such that by using a 1344 cm−1 infrared absorption feature and sampling an area greater than an area of 0.5 mm2, the variation is lower than 80%, as deduced by dividing the standard deviation by the mean value; (vi) a variation in red luminescence intensity, as defined by a standard deviation divided by a mean value, is less than 15%; (vii) a mean standard deviation in neutral single substitutional nitrogen concentration of less than 80%; and (viii) a colour intensity as measured using a histogram from a microscopy image with a mean gray value of greater than 50, wherein the colour intensity is uniform through the single crystal CVD synthetic diamond material such that the variation in gray colour, as characterised by the gray value standard deviation divided by the gray value mean, is less than 40%.

Owner:ELEMENT SIX LTD

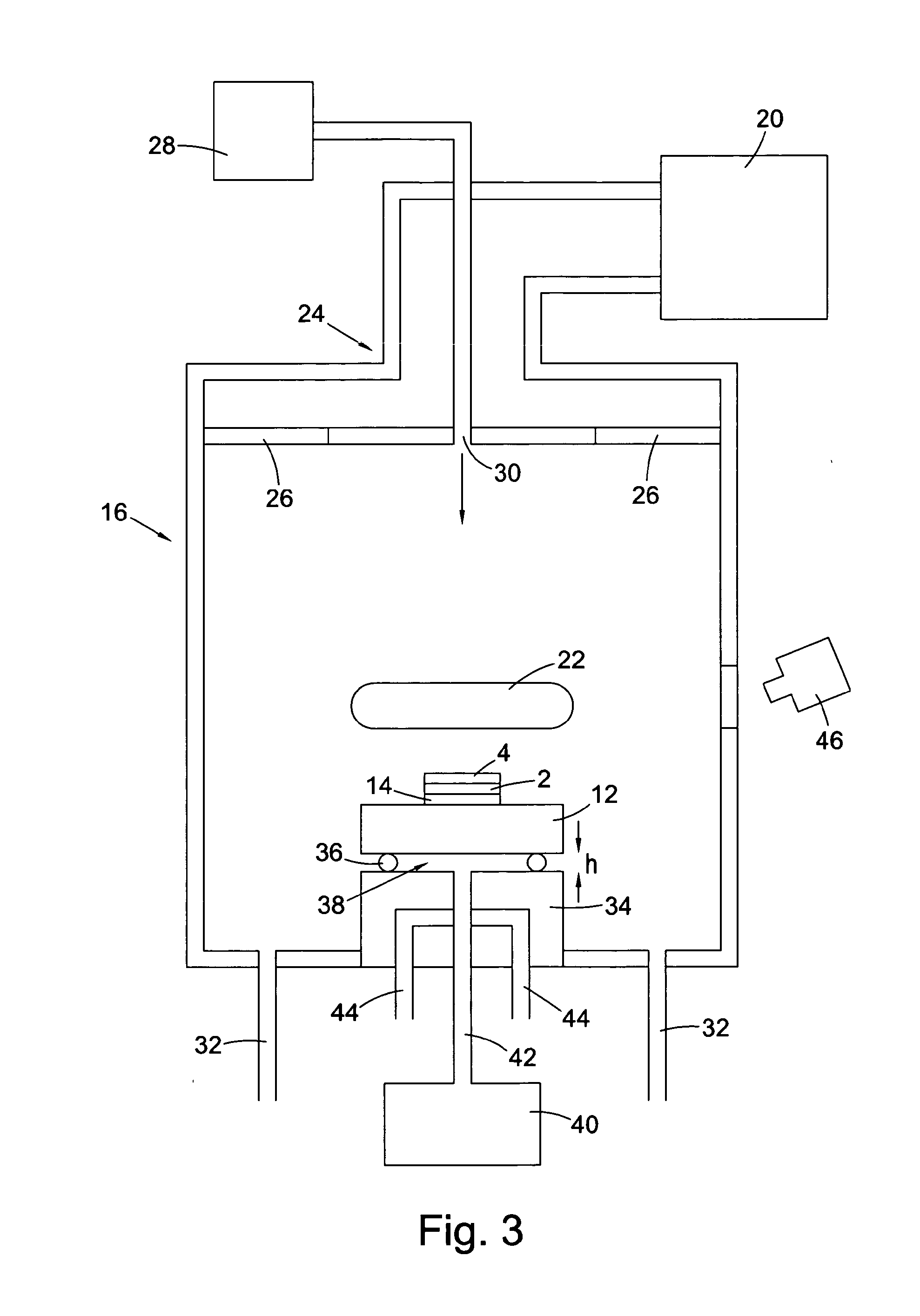

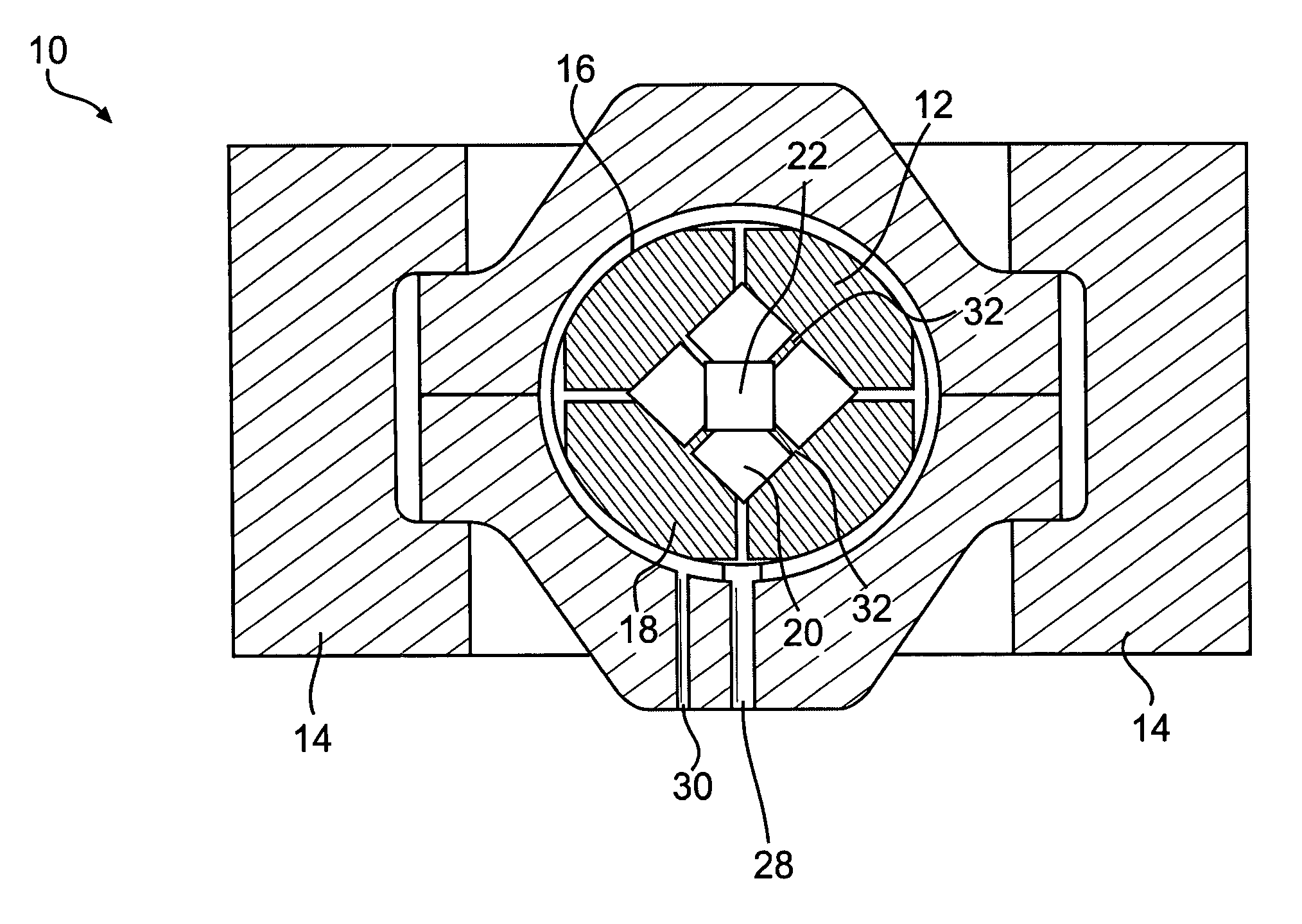

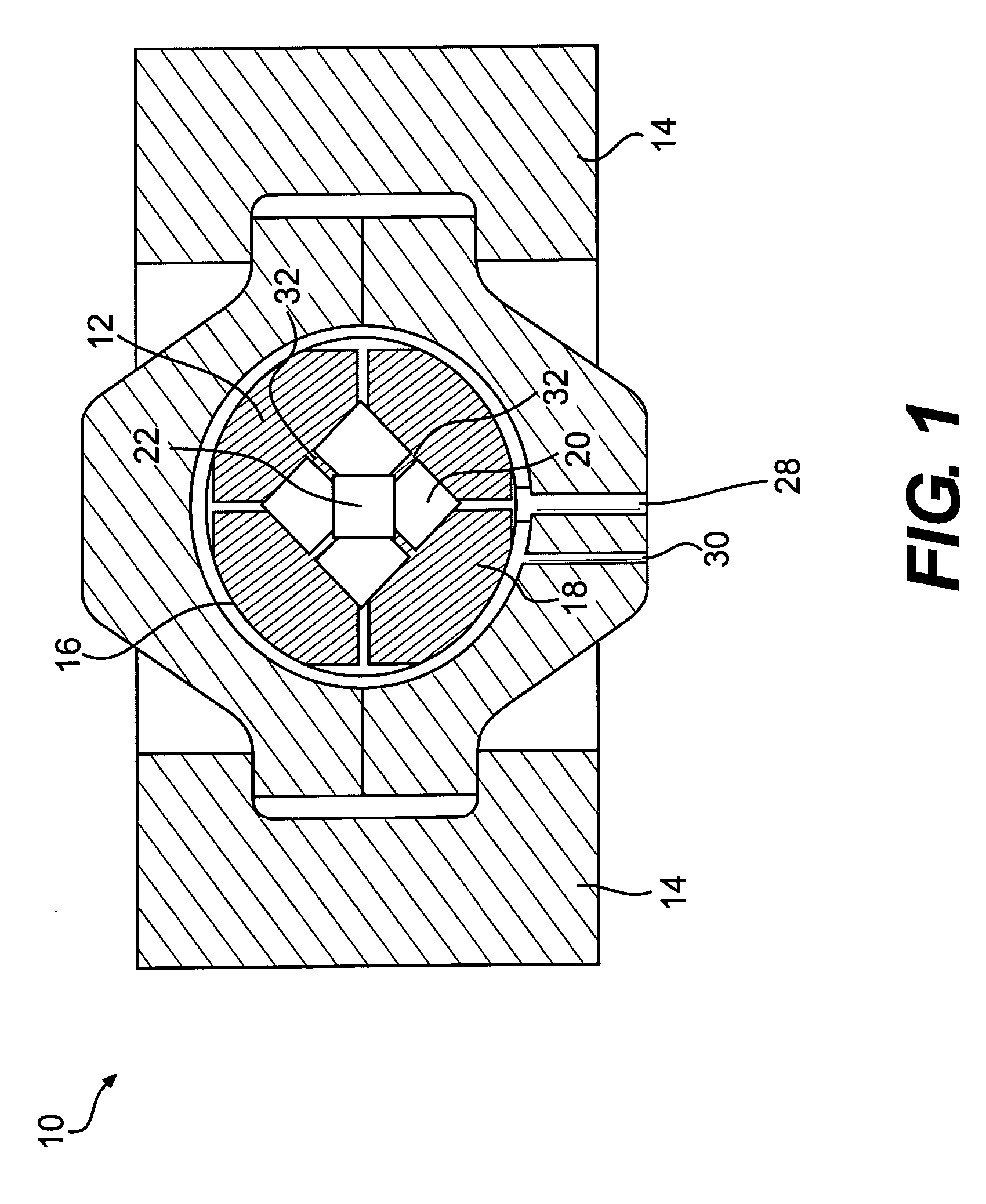

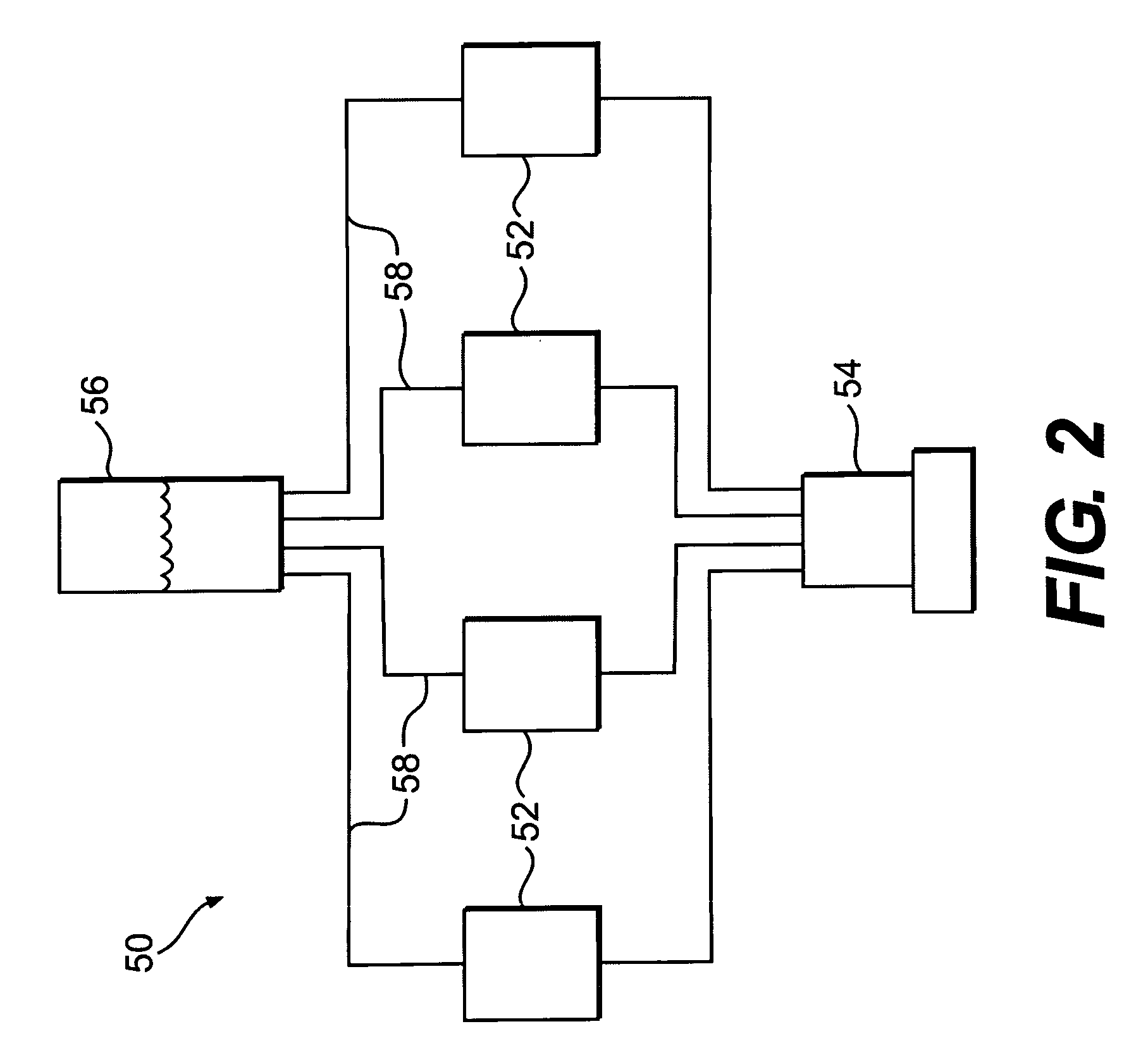

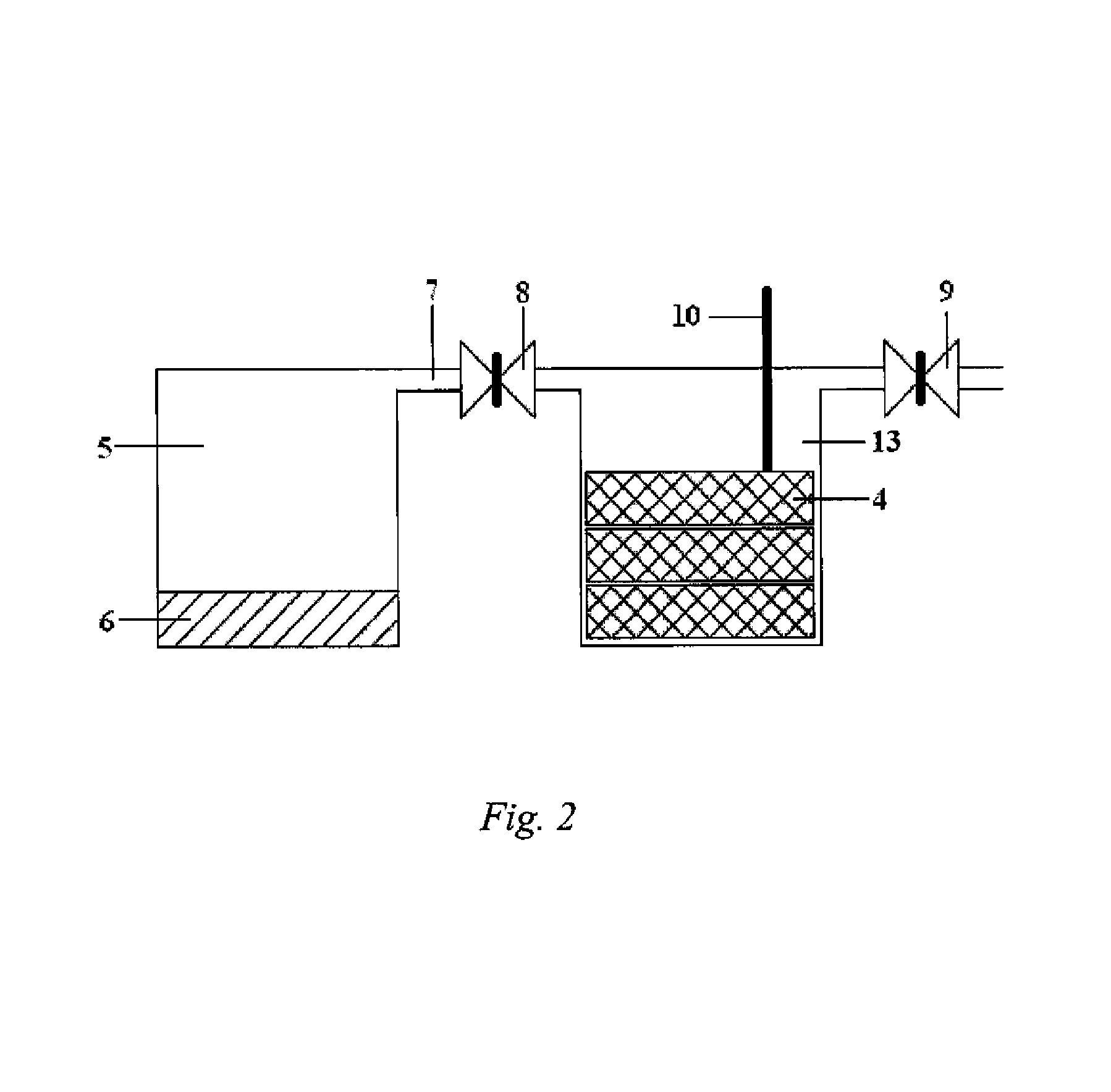

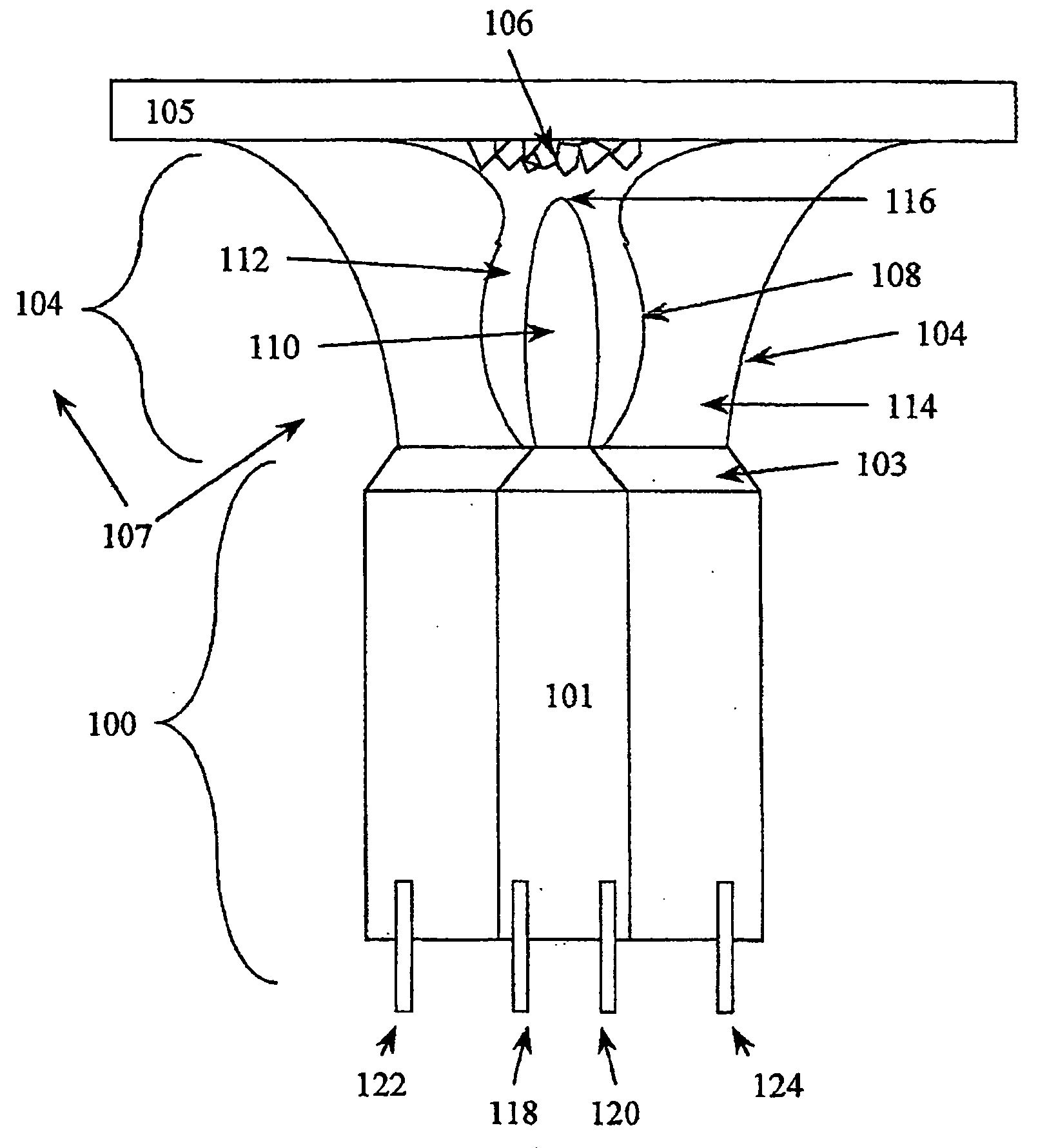

System and high pressure, high temperature apparatus for producing synthetic diamonds

An apparatus for growing a synthetic diamond comprises a growth chamber, at least one manifold allowing access to the growth chamber, and a plurality of safety clamps positioned on opposite sides of the growth chamber; wherein the growth chamber and the plurality of safety clamps are comprised of a material having a tensile strength of about 120,000-200,000 psi, a yield strength of about 100,000-160,000 psi, an elongation of about 10-20%, an area reduction of about 40-50%, an impact strength of about 30-40 ft-lbs, and a hardness greater than 320 BHN.

Owner:THE GEMESIS CORP

Diamond components for quantum imaging, sensing and information processing devices

ActiveUS20160348277A1Reduce surface damageLong spin coherence timePolycrystalline material growthDiffusion/dopingInformation processingSurface roughness

A single crystal CVD diamond component comprising: a surface, wherein at least a portion of said surface is formed of as-grown growth face single crystal CVD diamond material which has not been polished or etched and which has a surface roughness Ra of no more than 100 nm; and a layer of NV− defects, said layer of NV− defects being disposed within 1 μm of the surface, said layer of NV− defects having a thickness of no more than 500 nm, and said layer of NV− defects having a concentration of NV− defects of at least 105 NV− / cm2.

Owner:ELEMENT SIX TECH LTD

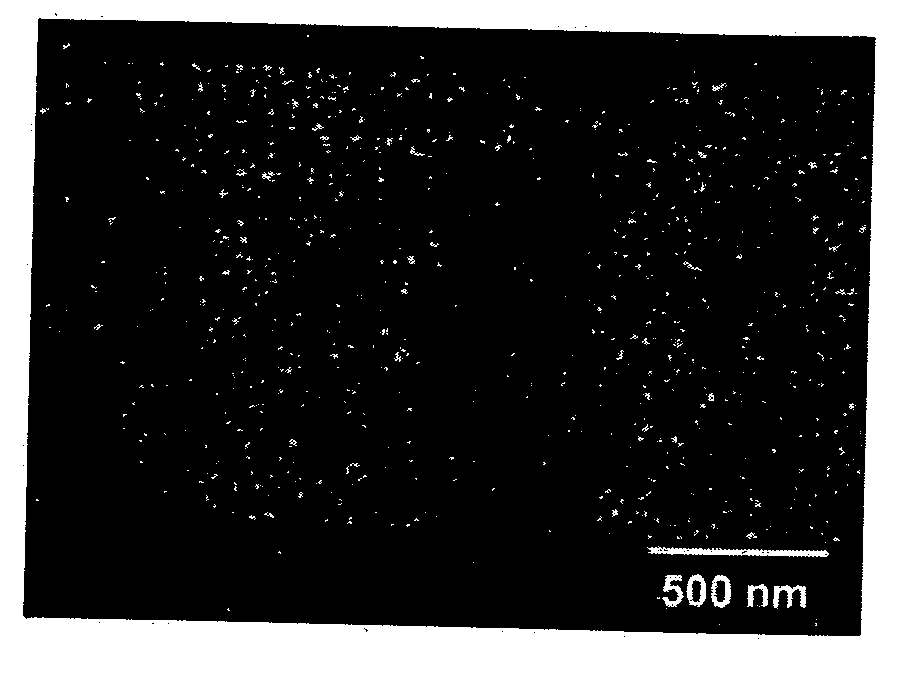

Boron-doped nanocrystalline diamond

InactiveUS20050110024A1Simple methodDiamondSemiconductor/solid-state device manufacturingCharge carrierRedox

A conductive boron doped nanocrystalline diamond is described. The boron doped diamond has a conductivity which uses the boron in the crystals as a charge carrier. The diamond is particularly useful for electrochemical electrodes in oxidation-reduction reactions and decontamination of aqueous solutions.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

Diamond sensors, detectors, and quantum devices

ActiveUS8686377B2Convenient lightingHigh strengthDiamondNanoopticsVacancy defectPreferential alignment

Owner:ELEMENT SIX LTD

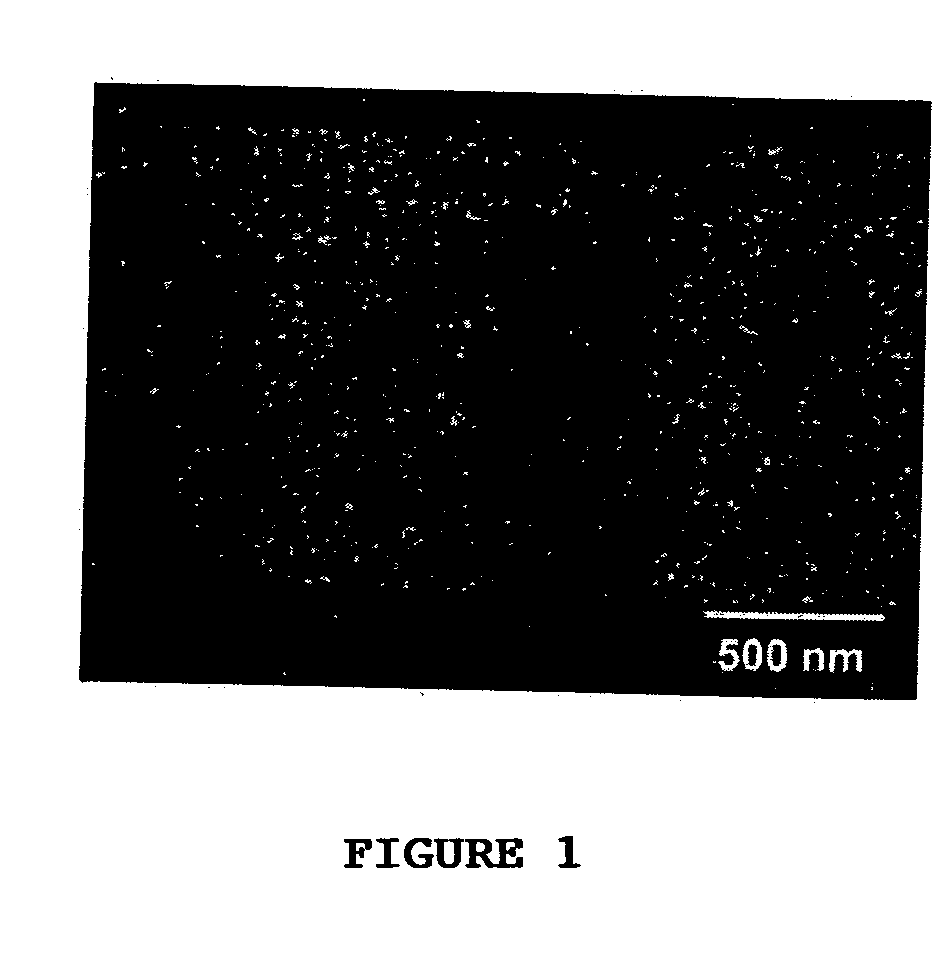

Diamond particles having organic compounds attached thereto, compositions thereof, and related methods

ActiveUS20120034464A1Material nanotechnologyPressurized chemical processSimple Organic CompoundsActive agent

A substance includes diamond particles having a maximum linear dimension of less than about 1 μm and an organic compound attached to surfaces of the diamond particles. The organic compound may include a surfactant or a polymer. A method of forming a substance includes exposing diamond particles to an organic compound, and exposing the diamond particles in the presence of the organic compound to ultrasonic energy. The diamond particles may have a maximum linear dimension of less than about 1 μm. A composition includes a liquid, a plurality of diamond nanoparticles dispersed within the liquid, and an organic compound attached to surfaces of the diamond nanoparticles. A method includes mixing a plurality of diamond particles with a solution comprising a liquid solvent and an organic compound, and exposing the mixture including the plurality of diamond nanoparticles and the solution to ultrasonic energy.

Owner:BAKER HUGHES INC

Increased thermal conductivity monolithic zeolite structures

A monolith comprises a zeolite, a thermally conductive carbon, and a binder. The zeolite is included in the form of beads, pellets, powders and mixtures thereof. The thermally conductive carbon can be carbon nano-fibers, diamond or graphite which provide thermal conductivities in excess of about 100 W / m·K to more than 1,000 W / m·K. A method of preparing a zeolite monolith includes the steps of mixing a zeolite dispersion in an aqueous colloidal silica binder with a dispersion of carbon nano-fibers in water followed by dehydration and curing of the binder is given.

Owner:UT BATTELLE LLC

Diamond sensors, detectors, and quantum devices

ActiveUS9249526B2Minimizes strainShorten the timeQuantum computersPolycrystalline material growthElectron donorQuantum devices

A synthetic single crystal diamond material comprising: a first region comprising electron donor defects; a second region comprising quantum spin defects; and a third region between the first and second regions. The second and third regions have a lower concentration of electron donor defects than the first region. The first and second regions are sufficiently close to allow electrons to be donated from the first region to the second region, thus forming negatively charged quantum spin defects in the second and positively charged defects in the first region, and sufficiently far apart to reduce other coupling interactions between the first and second regions which would otherwise unduly reduce the decoherence time of the plurality of quantum spin defects and / or produce strain broaden of a spectral line width of the plurality of quantum spin defects in the second region.

Owner:ELEMENT SIX LTD

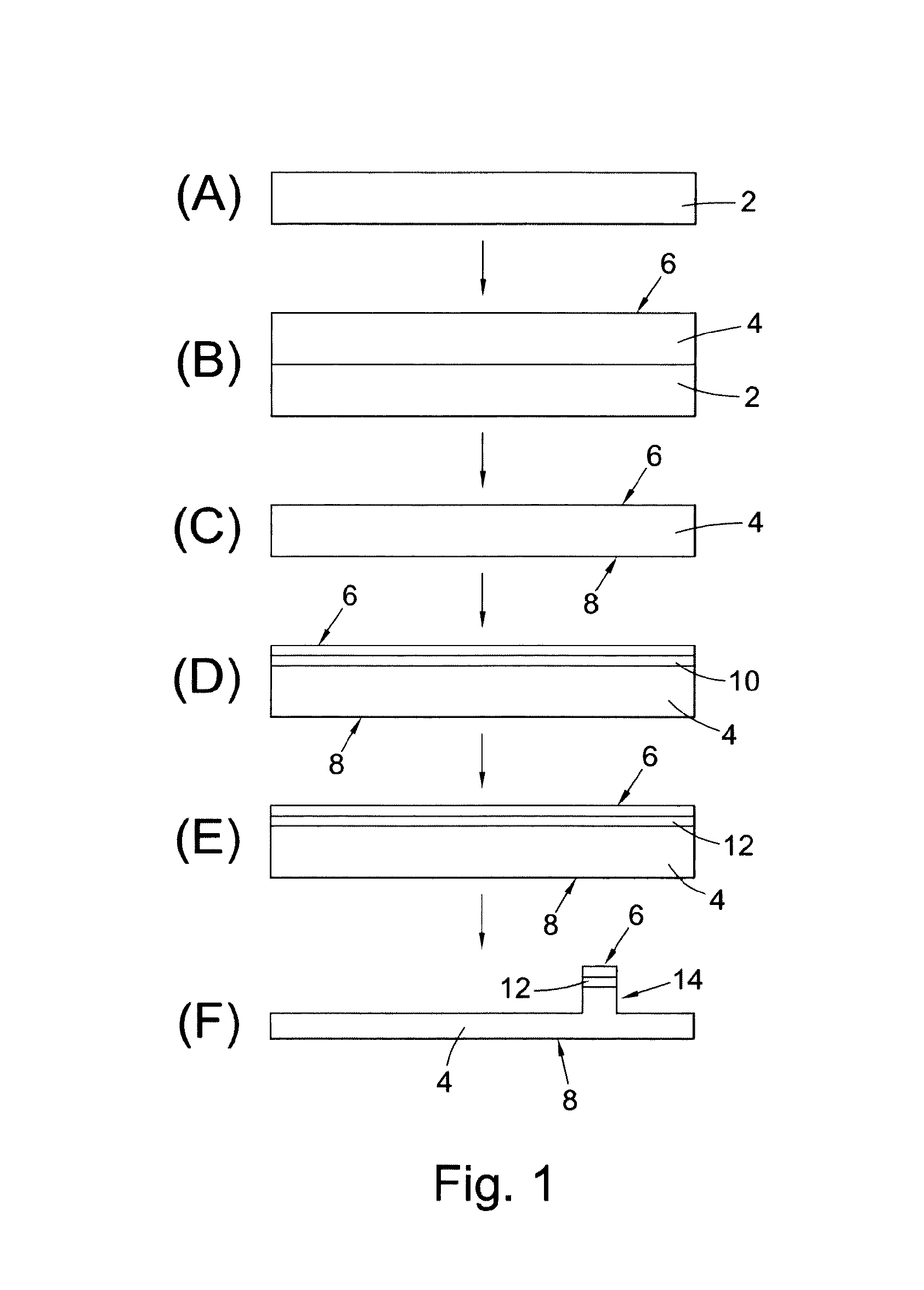

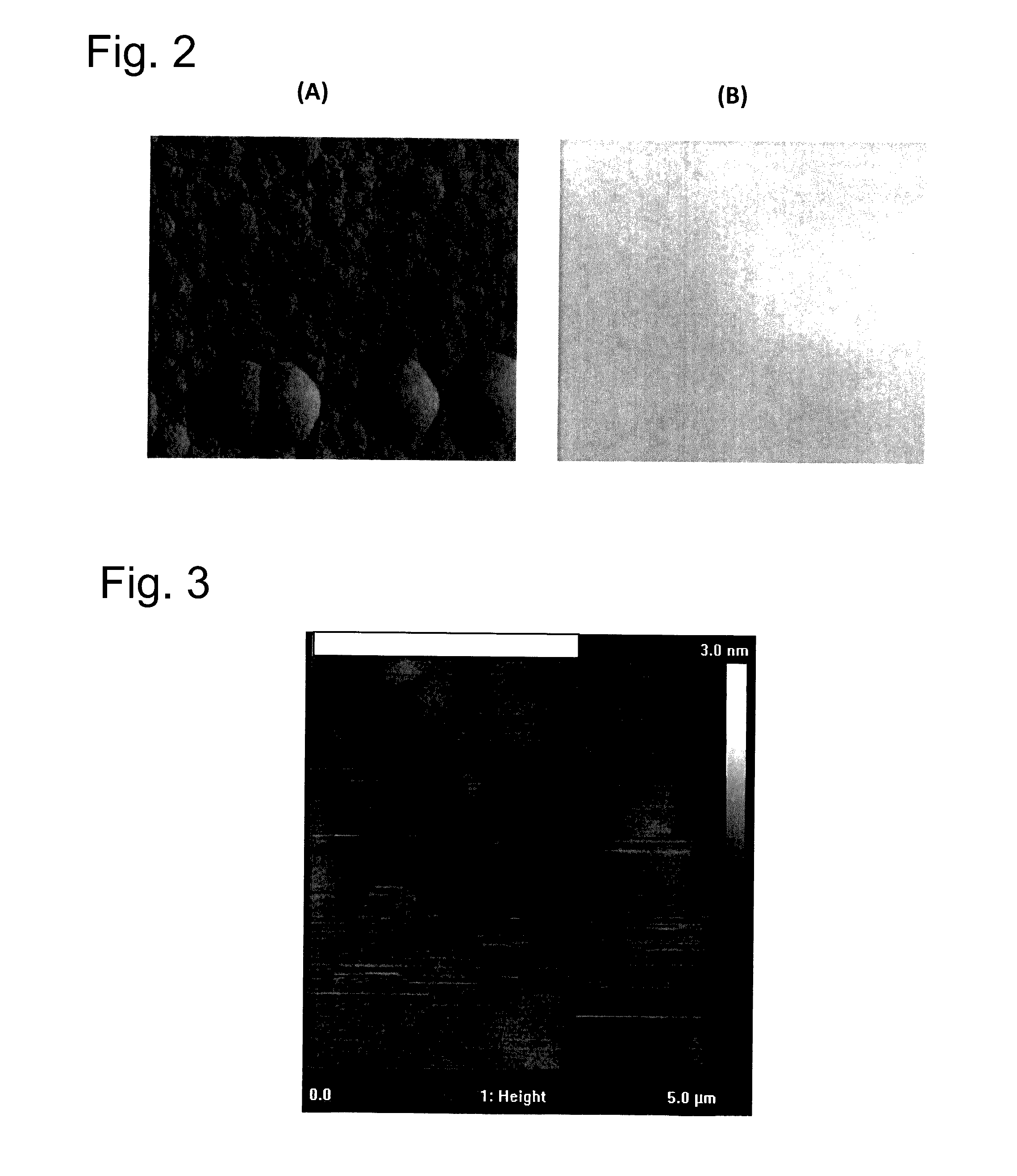

Method For Treating Surface Of Material, Surface-Treated Material, Medical Material, And Medical Instrument

A diamond-like carbon film (DLC film) is formed on the surface of a base material made of an inorganic material, such as ceramics, or the like, or an organic material, such as resin, or the like. The surface of the resultant DLC film is treated with plasma, or the like, so as to be activated. Various monomers having biocompatibility, etc., are graft-polymerized to the activated surface of the DLC film, whereby a polymer layer is formed from the monomers grafted to the surface of the DLC film. Thus, the base material coated with the DLC film modified with a polymer which does not readily separate can be realized.

Owner:TOYO ADVANCED TECH CO LTD

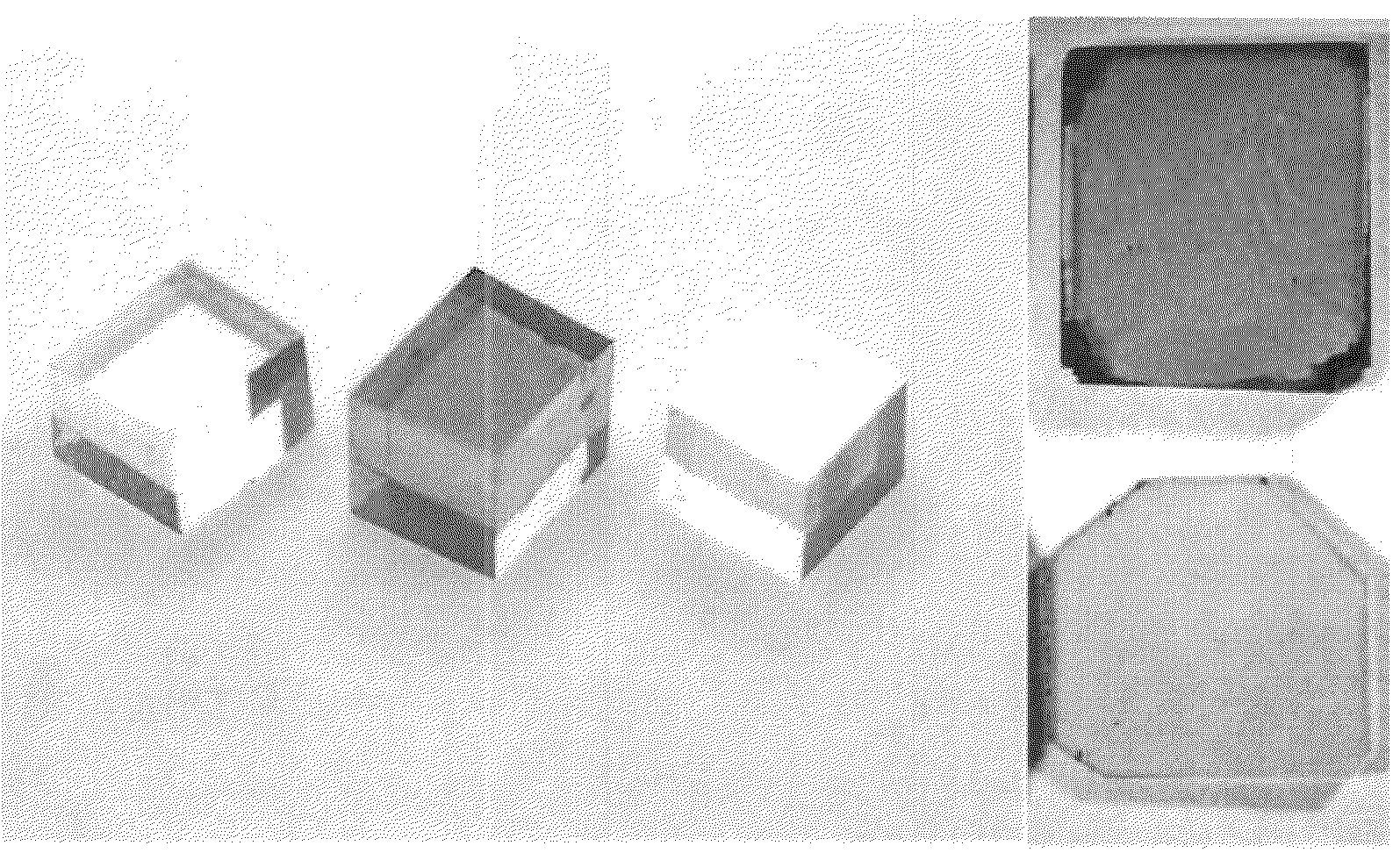

Colored diamond

ActiveUS7172655B2Simple to achieve pressureEasy accessFrom gel stateUltra-high pressure processesSingle crystalMaterials science

A method of producing a single crystal CVD diamond of a desired color which includes the steps of providing single crystal CVD diamond which is colored and heat treating the diamond under conditions suitable to produce the desired color. Colors which may be produced are, for example, in the pink-green range.

Owner:ELEMENT SIX TECH LTD

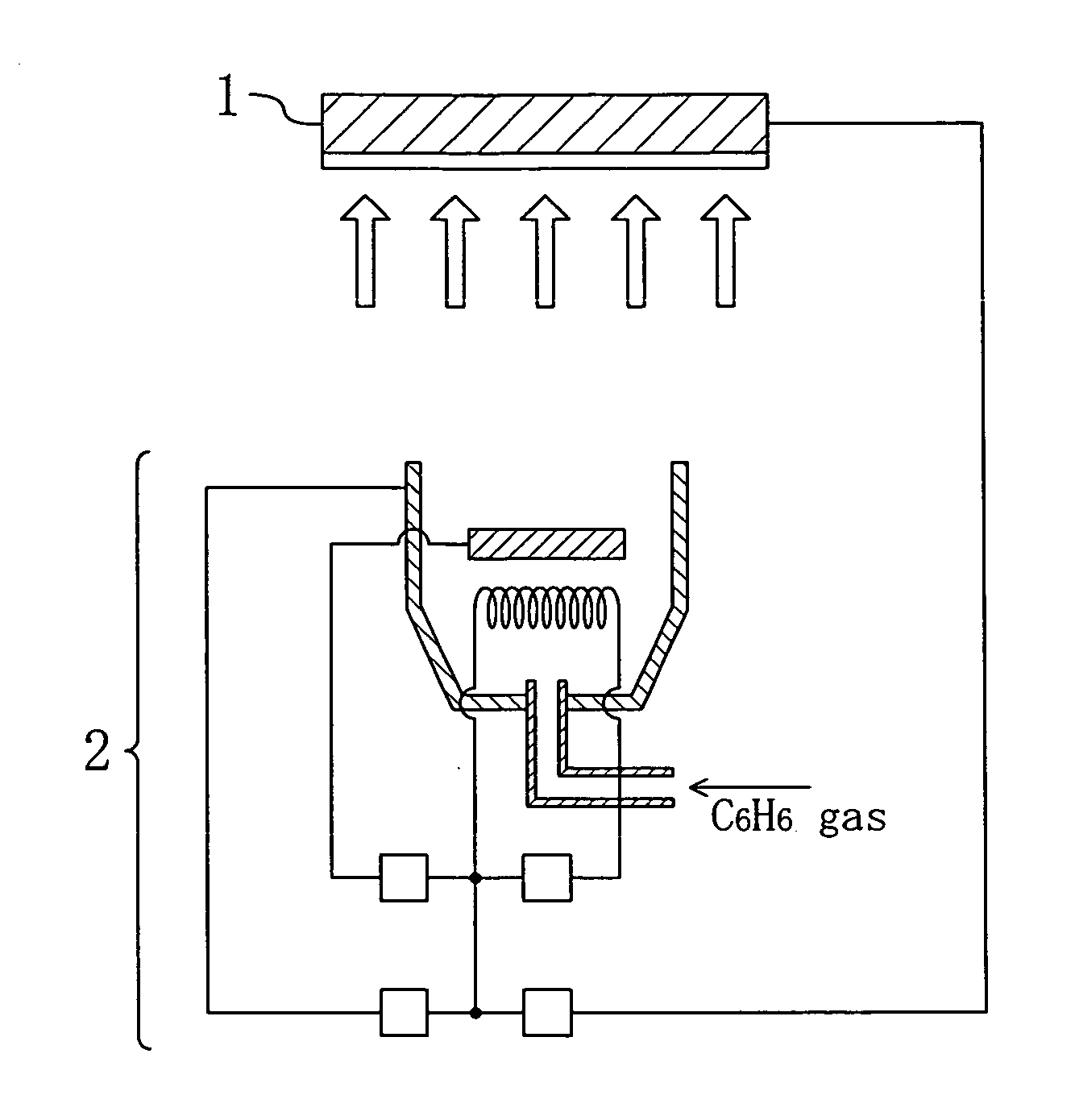

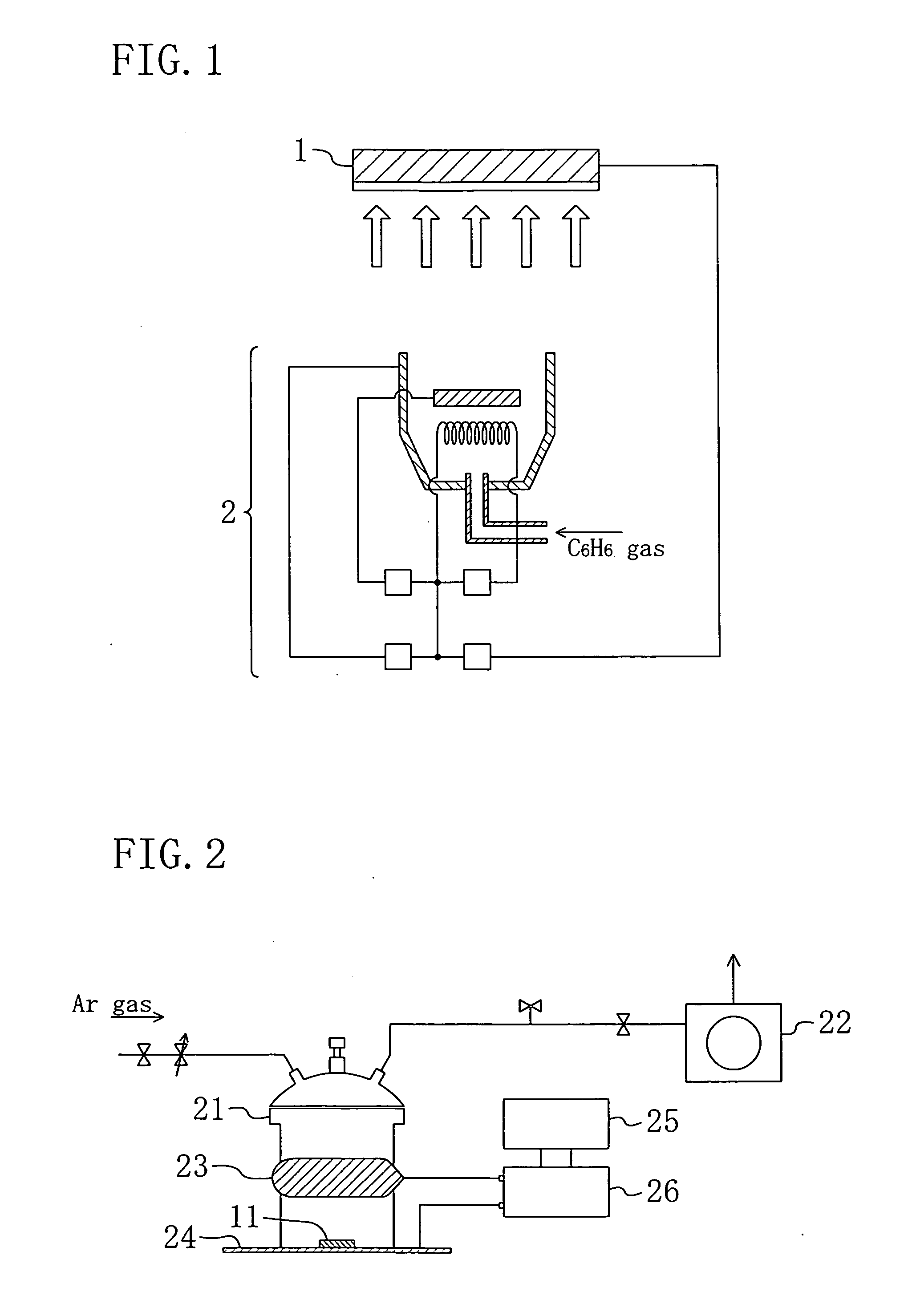

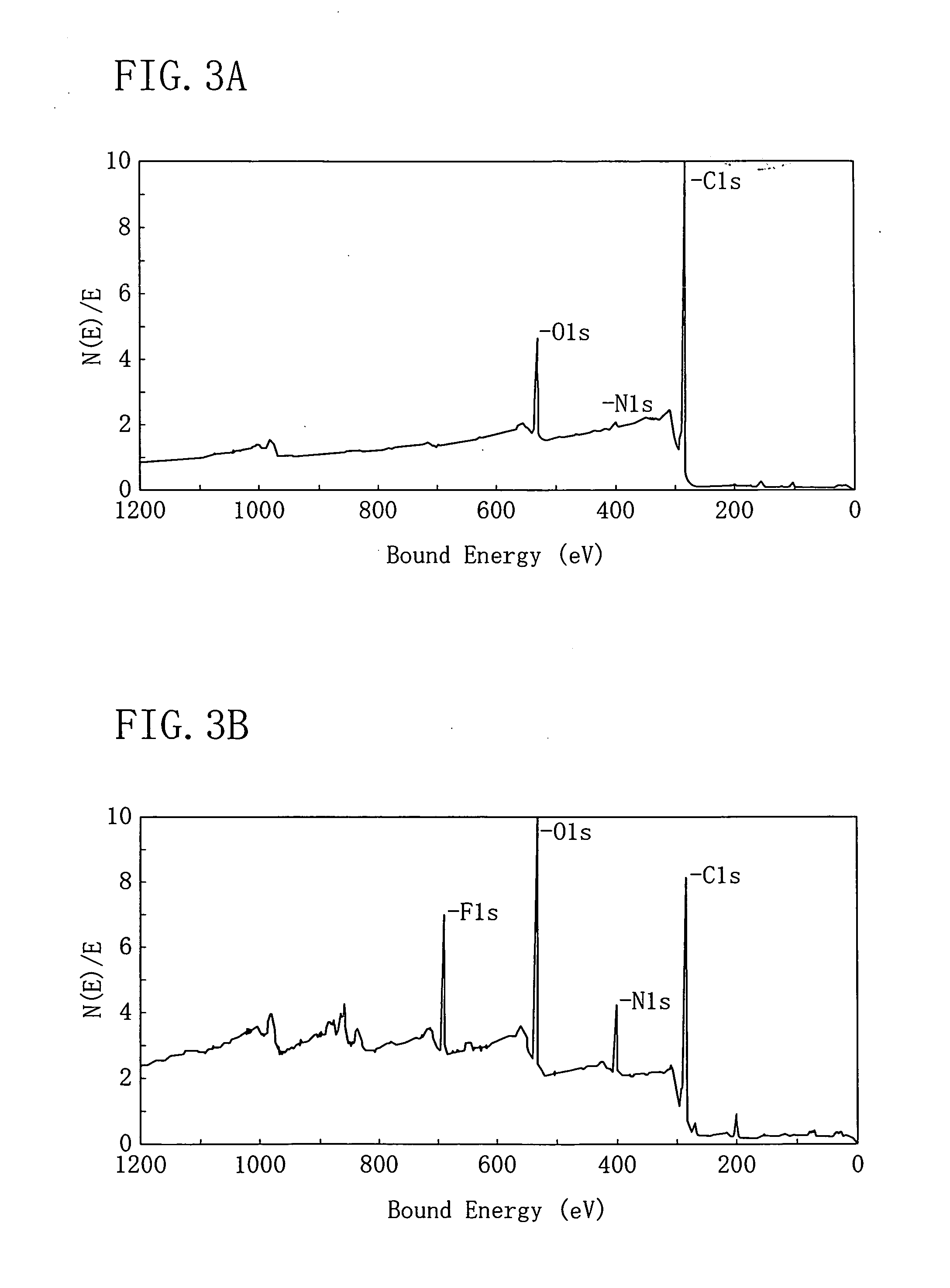

Process and apparatus for preparing a diamond substance

InactiveUS20060127599A1Easy to useUltra-high pressure processesSemiconductor/solid-state device detailsHydrogenOxygen

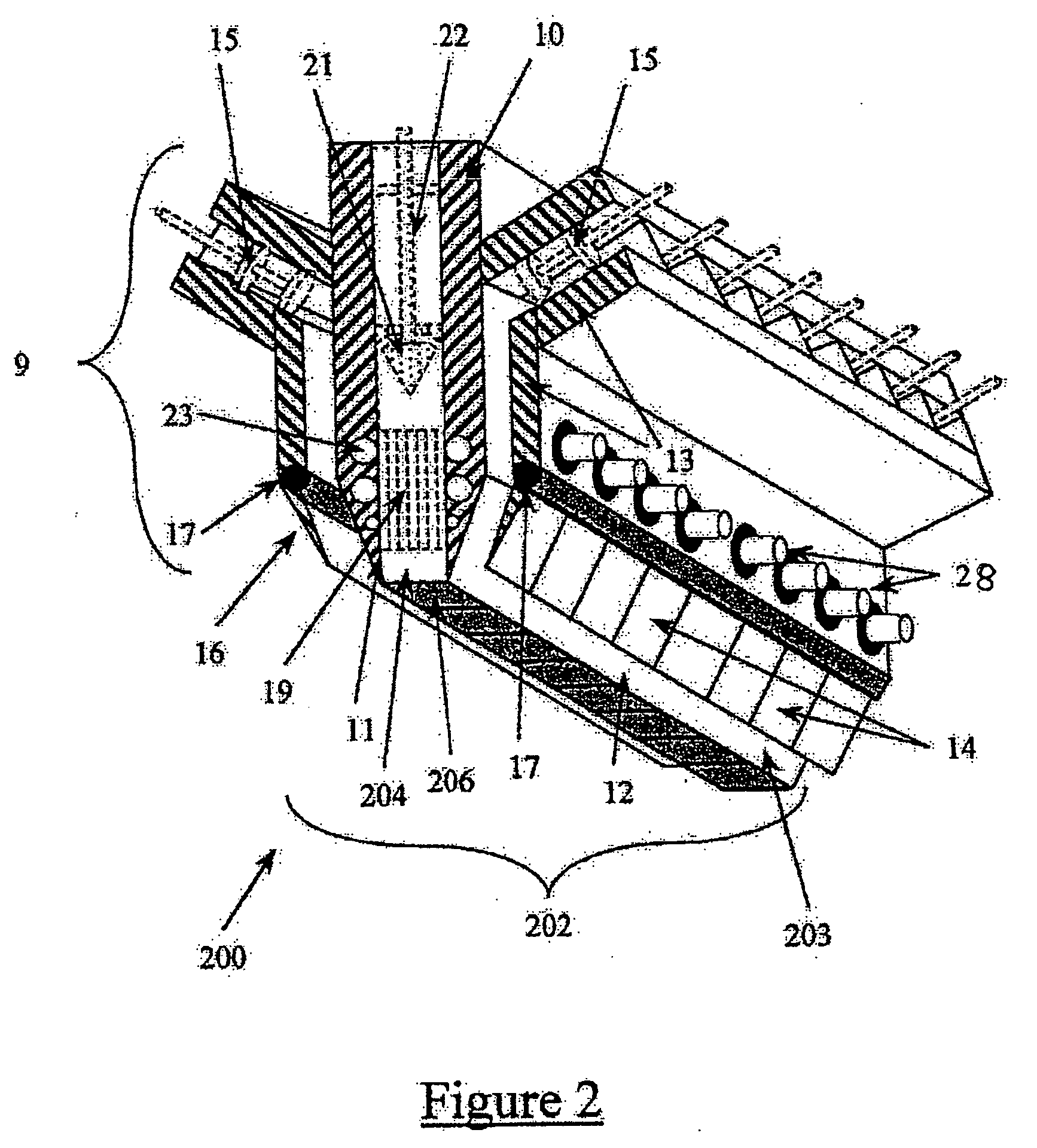

Disclosed in this specification is a process and apparatus for producing a diamond substance. A first mixture comprised of oxygen and a hydrocarbon gas is formed in the first inner nozzle. The first mixture is ignited to produce a flame core. A second mixture comprised of hydrogen and oxygen is formed in an outer nozzle; the second mixture is ignited to produce a flame sheath. The flame sheath is disposed around the flame core so that the flame sheath surrounds the flame core and shields the flame core from the ambient atmosphere; thereby producing a composite flame; and the composite flame is contacted with a substrate.

Owner:WOJAK GREGORY J

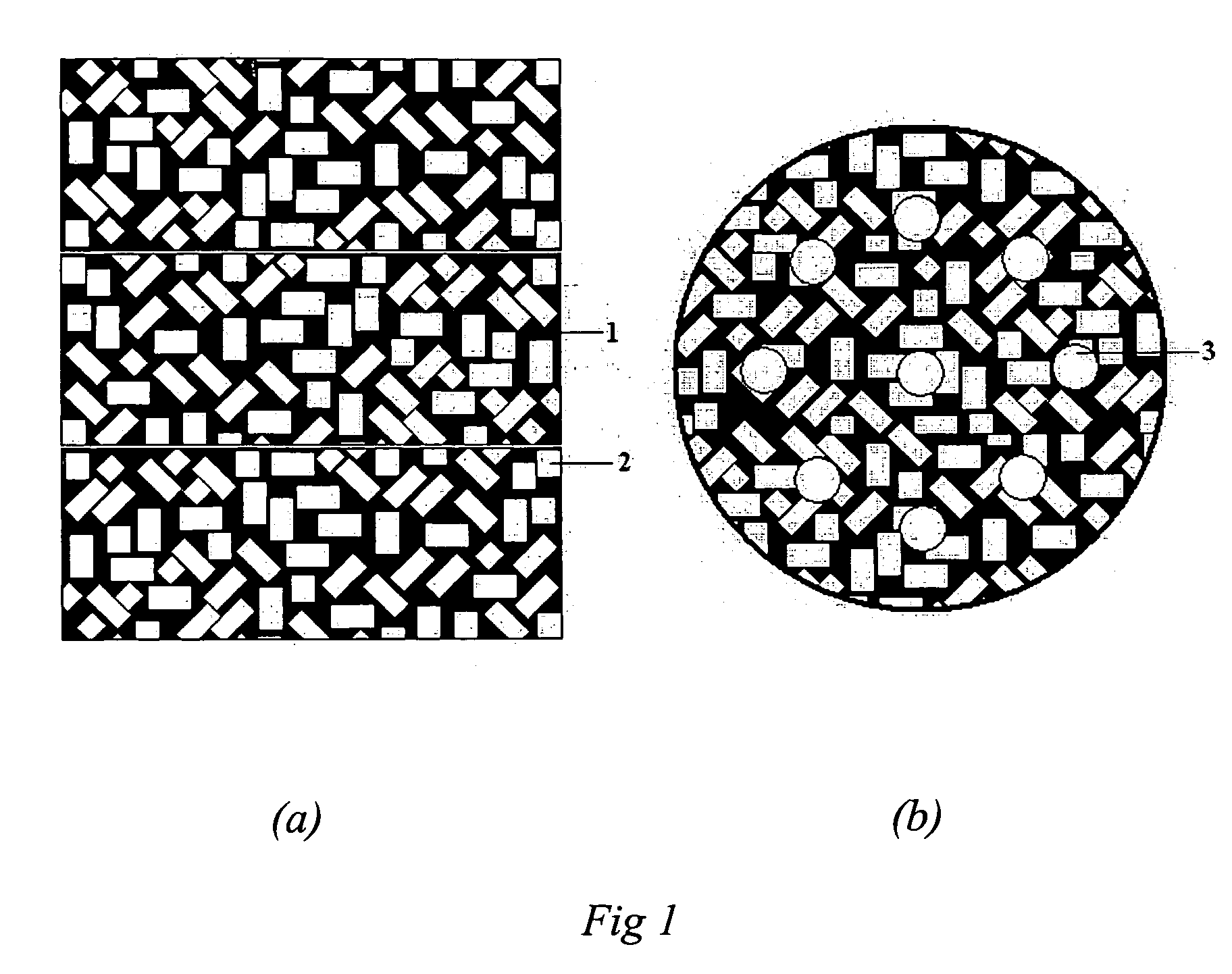

Methods of fabricating polycrystalline diamond, and cutting elements and earth-boring tools comprising polycrystalline diamond

Methods of fabricating polycrystalline diamond include functionalizing surfaces of carbon-free nanoparticles with one or more functional groups, combining the functionalized nanoparticles with diamond nanoparticles and diamond grit to form a particle mixture, and subjecting the particle mixture to high pressure and high temperature (HPHT) conditions to form inter-granular bonds between the diamond nanoparticles and the diamond grit. Cutting elements for use in an earth-boring tool includes a polycrystalline diamond material formed by such processes. Earth-boring tools include such cutting elements.

Owner:BAKER HUGHES INC

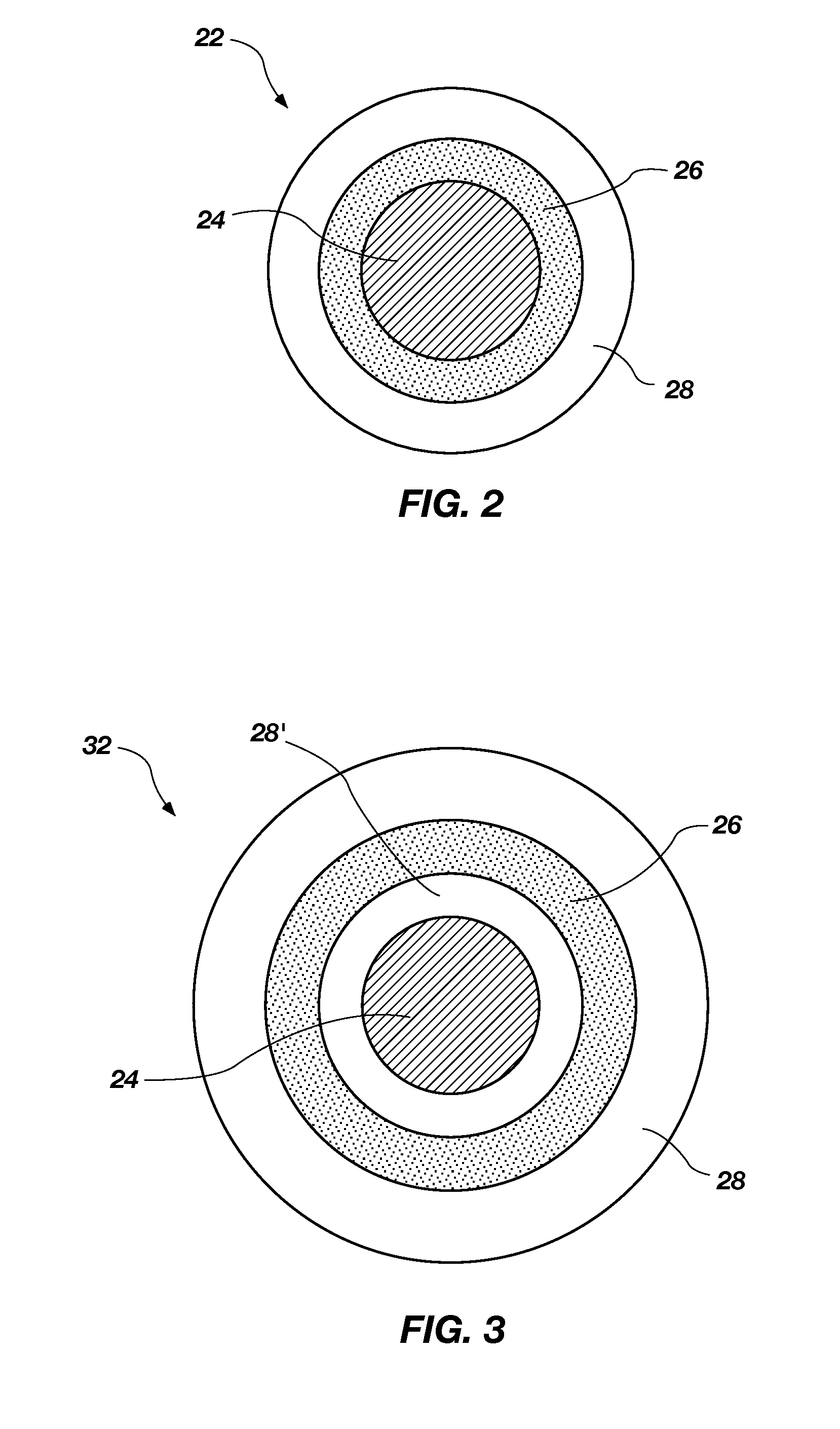

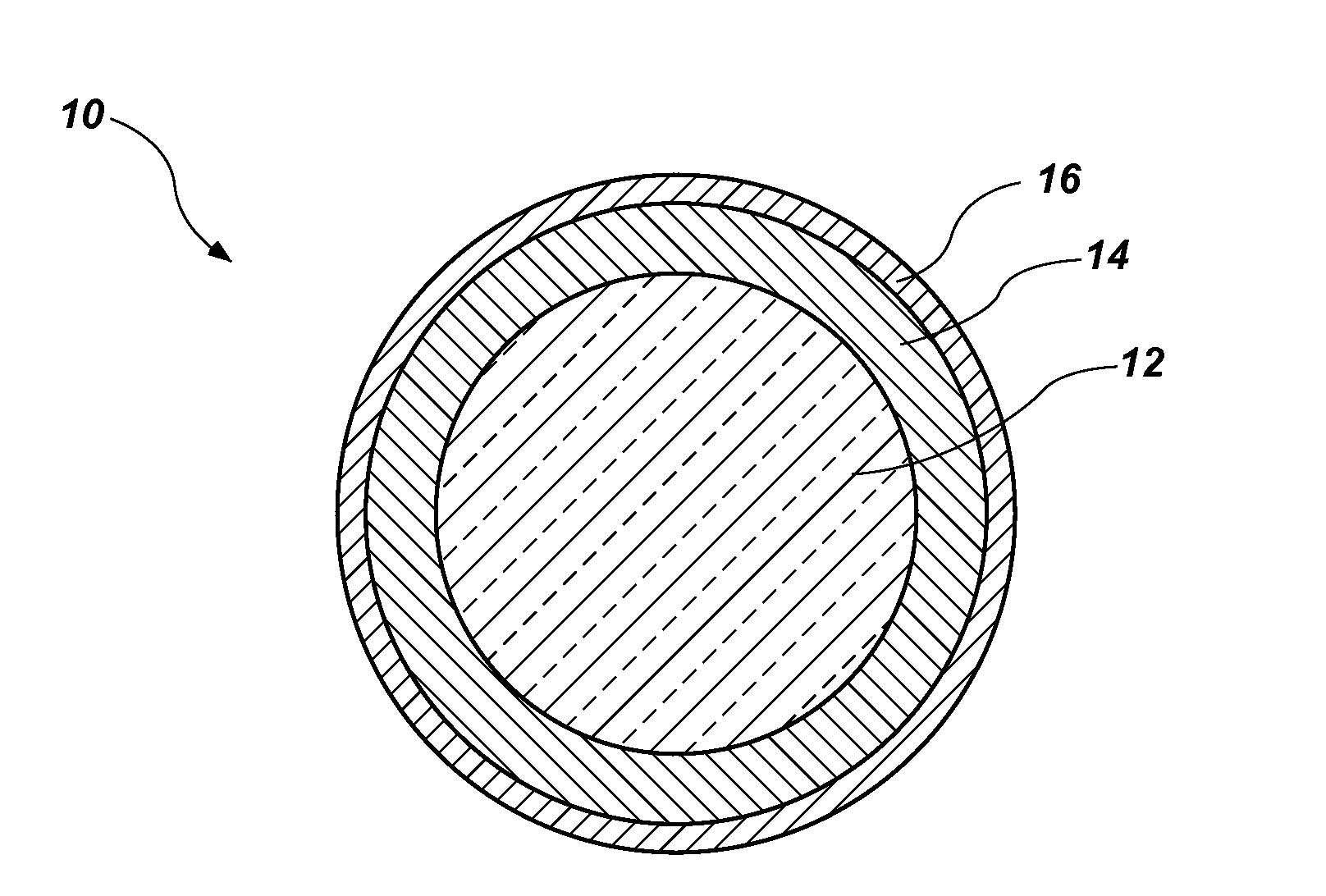

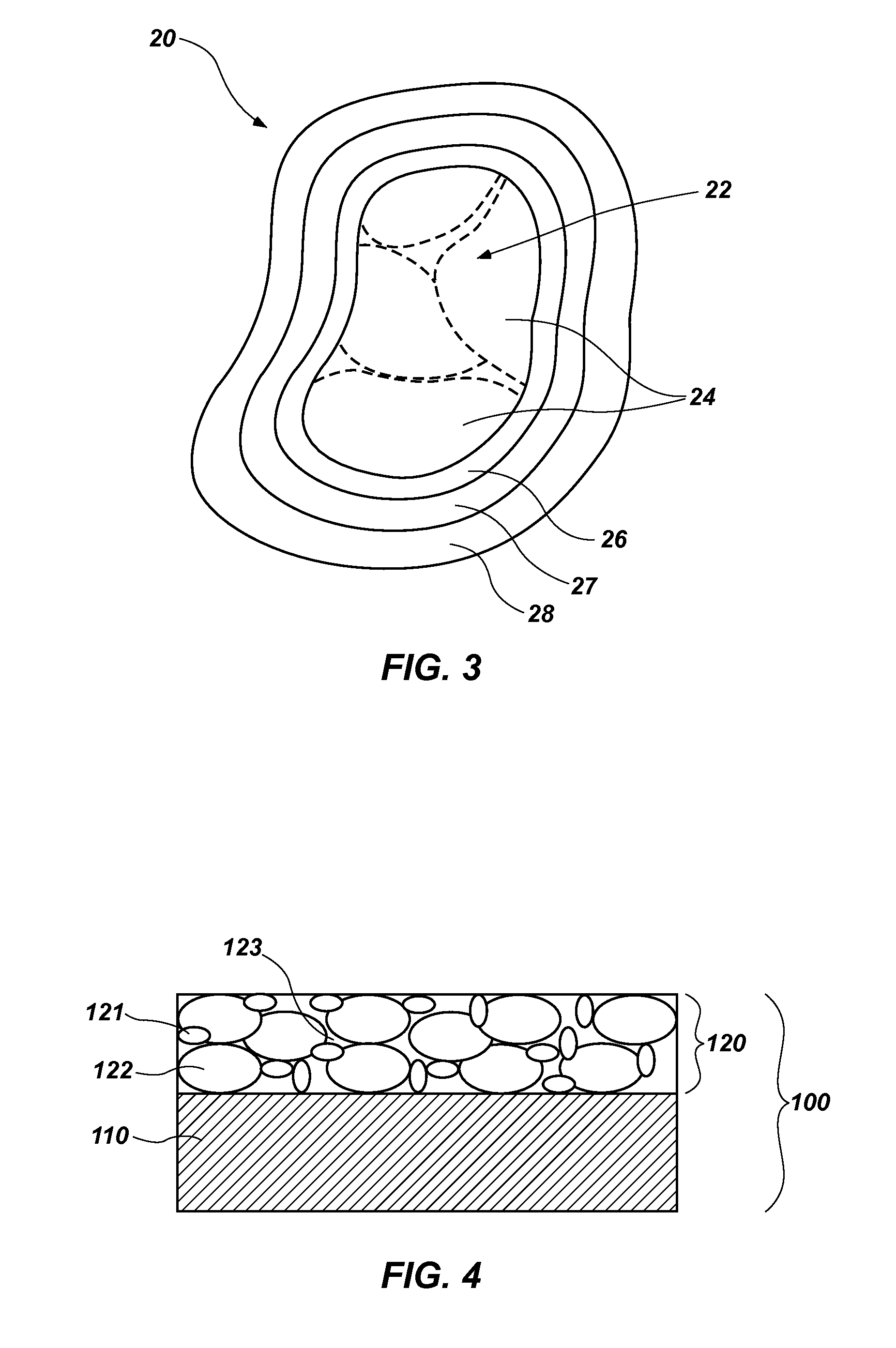

Graphene-coated diamond particles, compositions and intermediate structures comprising same, and methods of forming graphene-coated diamond particles and polycrystalline compacts

InactiveUS20120102843A1Pigmenting treatmentLiquid surface applicatorsCvd grapheneIntermediate structure

Coated diamond particles have solid diamond cores and at least one graphene layer. Methods of forming coated diamond particles include coating diamond particles with a charged species and coating the diamond particles with a graphene layer. A composition includes a substance and a plurality of coated diamond particles dispersed within the substance. An intermediate structure includes a hard polycrystalline material comprising a first plurality of diamond particles and a second plurality of diamond particles. The first plurality of diamond particles and the second plurality of diamond particles are interspersed. A method of forming a polycrystalline compact includes catalyzing the fox of inter-granular bonds between adjacent particles of a plurality of diamond particles having at least one graphene layer.

Owner:BAKER HUGHES INC

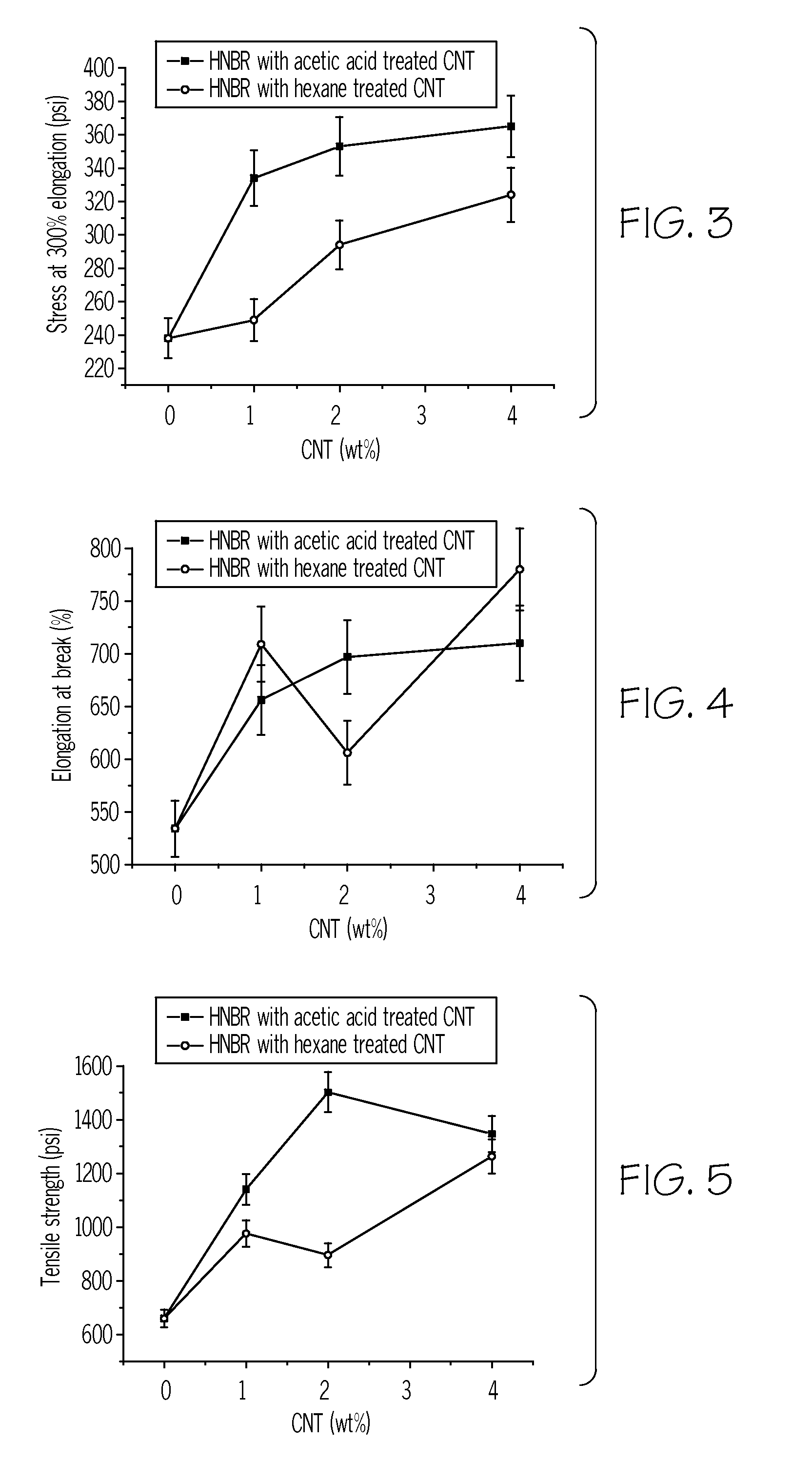

Method of modifying carbon nanomaterials, composites incorporating modified carbon nanomaterials and method of producing the composites

A polymer-carbon nanomaterial composite. The composite includes a polymer matrix; and plasma-modified carbon nanomaterials having surface functional groups attached thereto, wherein the carbon nanomaterial is selected from carbon nanotubes, carbon nanofibers, carbon nanoparticles, carbon black, nanodiamond, fullerenes, or combinations thereof. The invention also involves a method of making a polymer-carbon nanomaterial composite, and a method of modifying carbon nanomaterials.

Owner:UNIV OF DAYTON

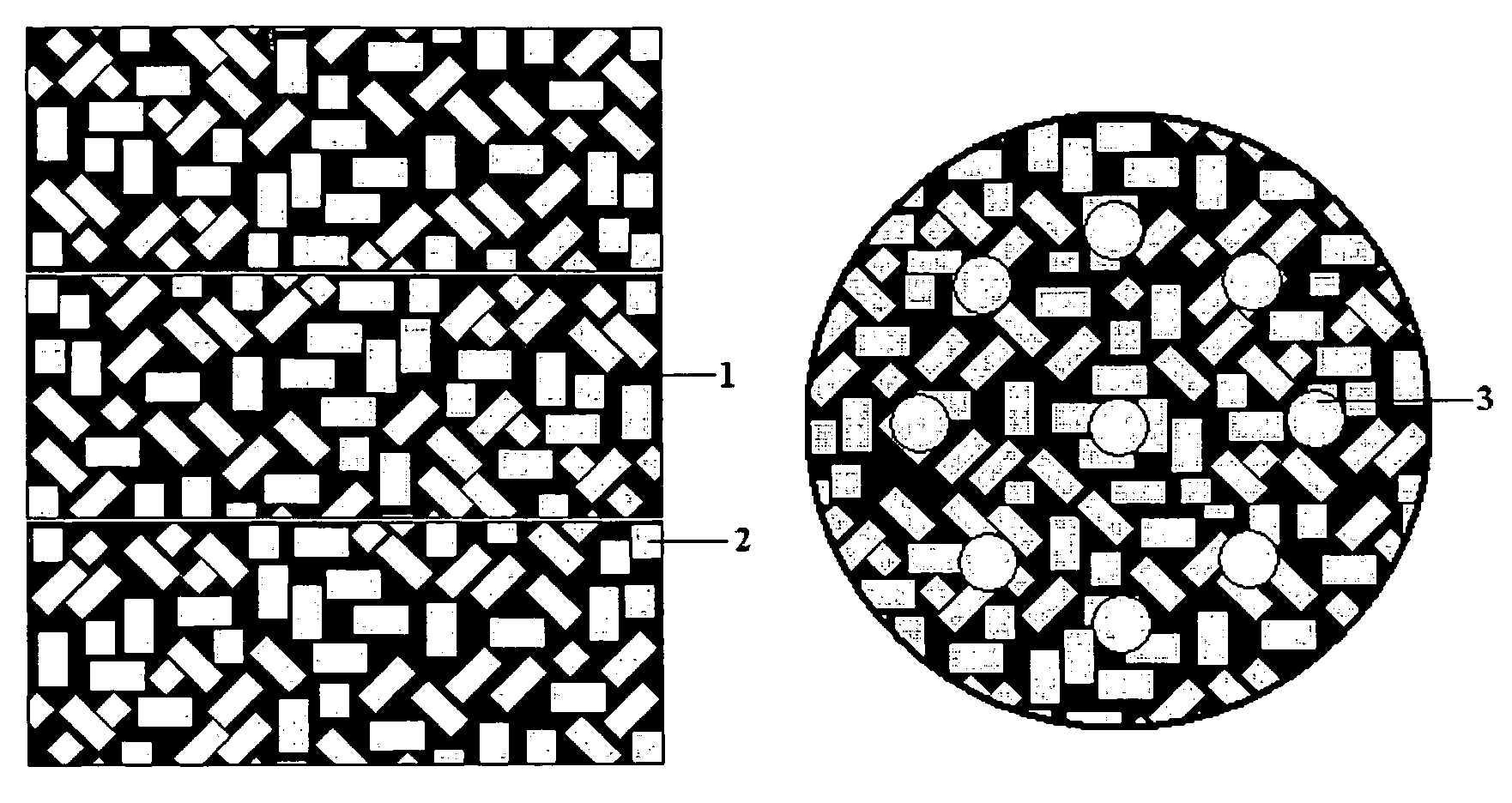

Polycrystalline Grits and Associated Methods

A method for forming polycrystalline grits can include forming an abrasive dough, including a plurality of abrasive particles, into a sheet. The sheet can be divided into a plurality of abrasive precursors. By placing the sheet on a stretchable surface, separations among the plurality of abrasive precursors can be revealed by stretching the stretchable surface. The stretchable surface can include a particulate separating agent, and additional particulate separating agent can be distributed in the separations. The abrasive precursors can be sintered to form polycrystalline grits.

Owner:SUNG CHIEN MIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com