Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

382 results about "Intermediate structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intermediate (anatomy), the relative location of an anatomical structure lying between two other structures: see Anatomical terms of location. Intermediate Edison Screw, a system of light bulb connectors. Intermediate goods, goods used to produce other goods. Middle school, also known as intermediate school.

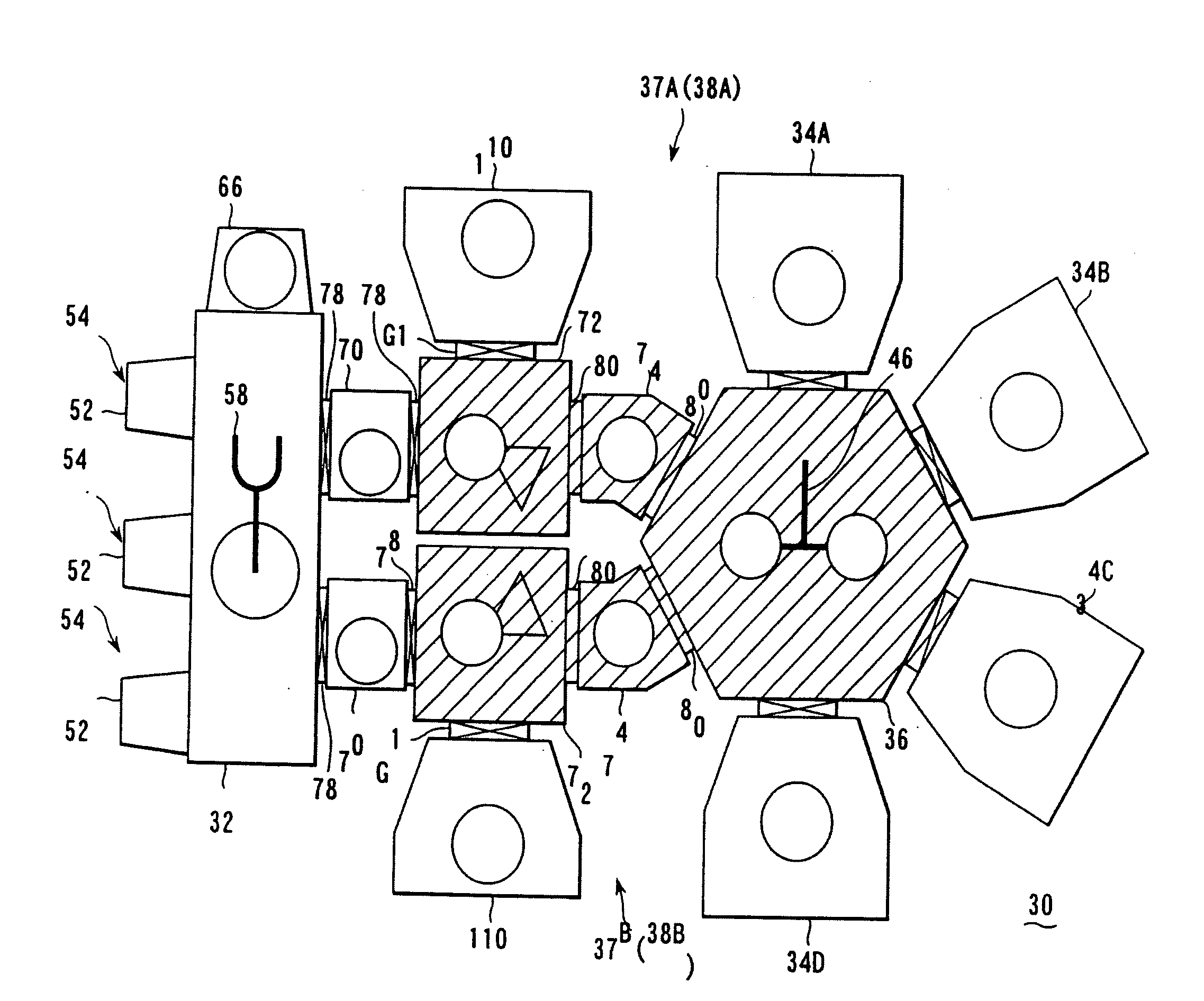

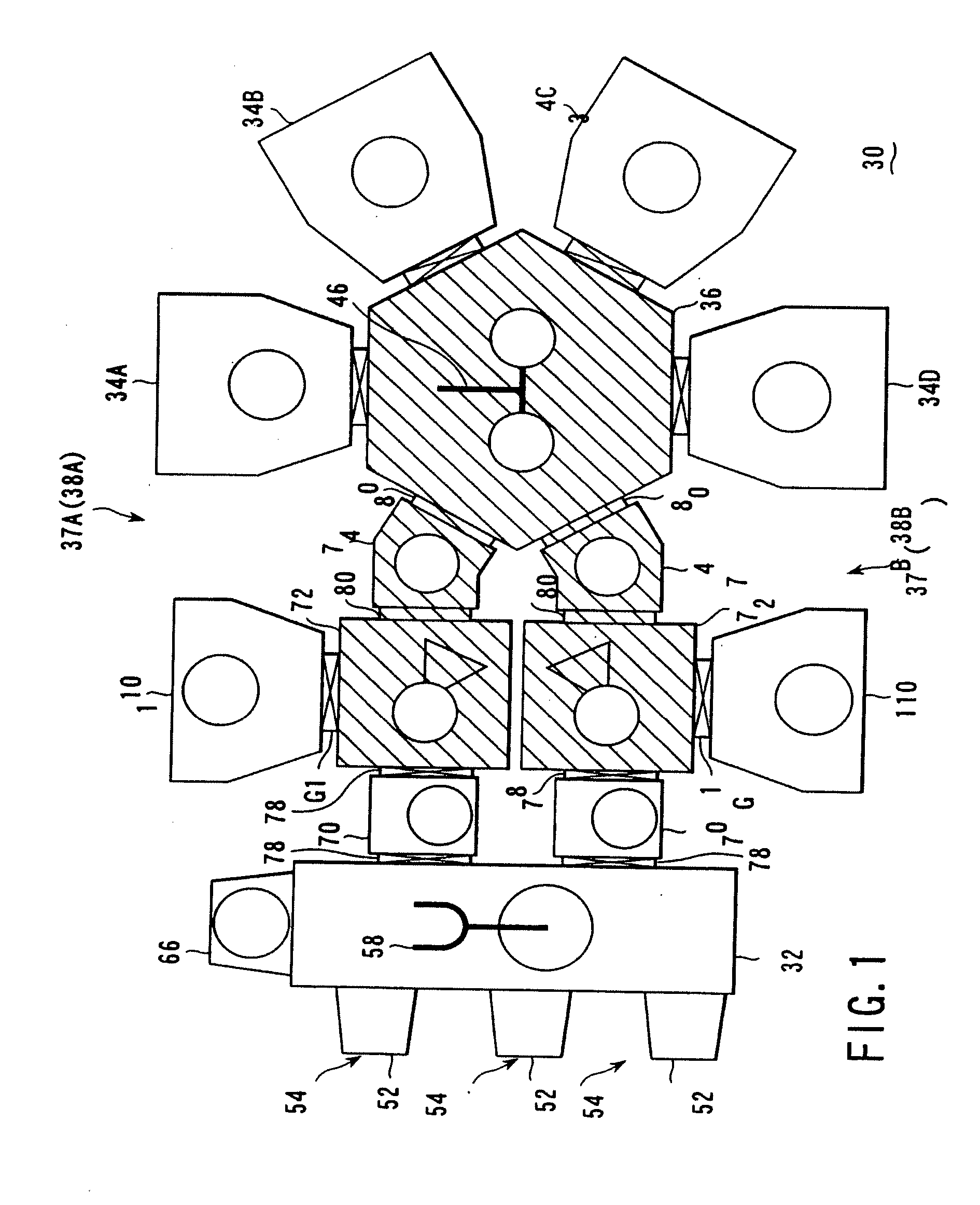

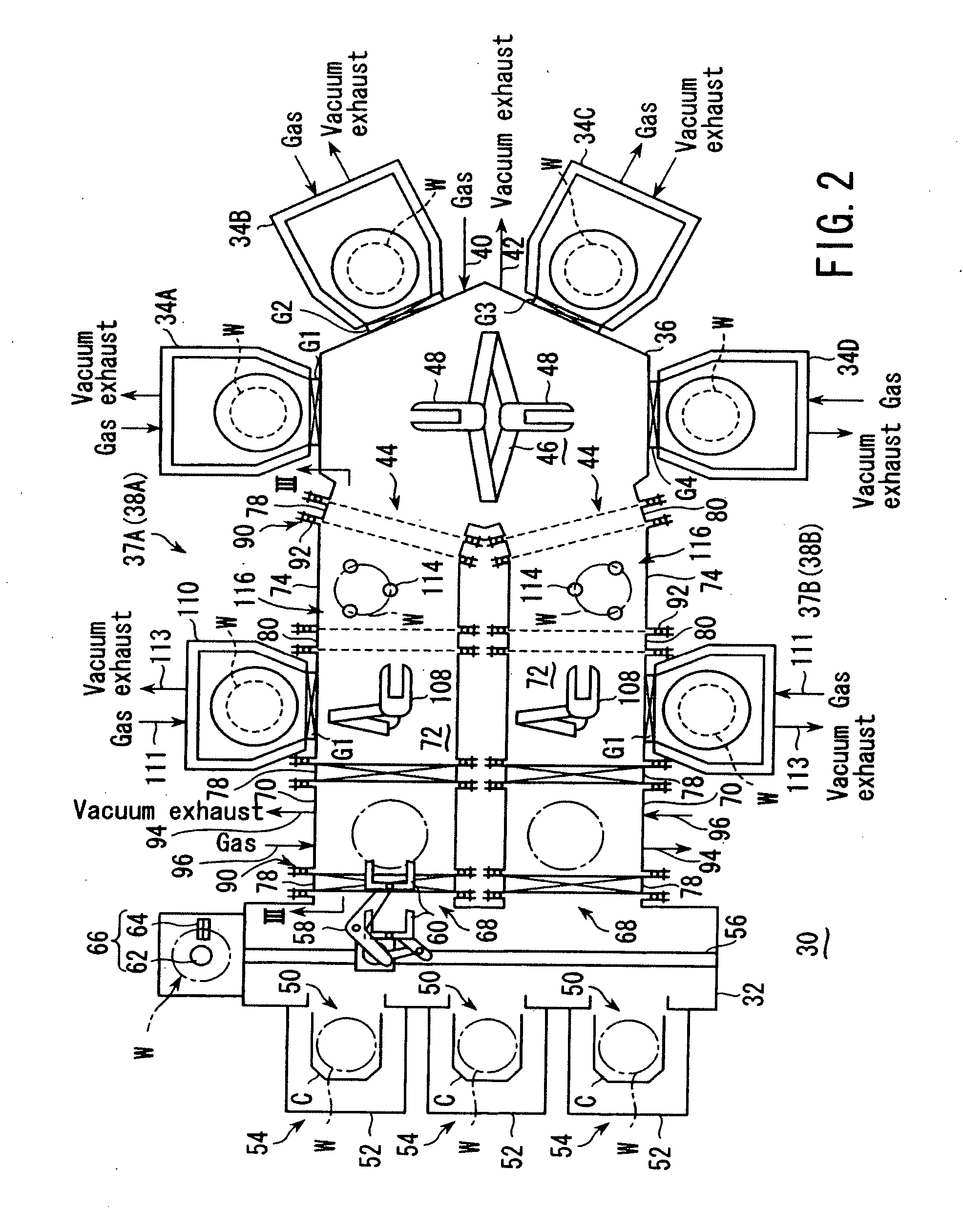

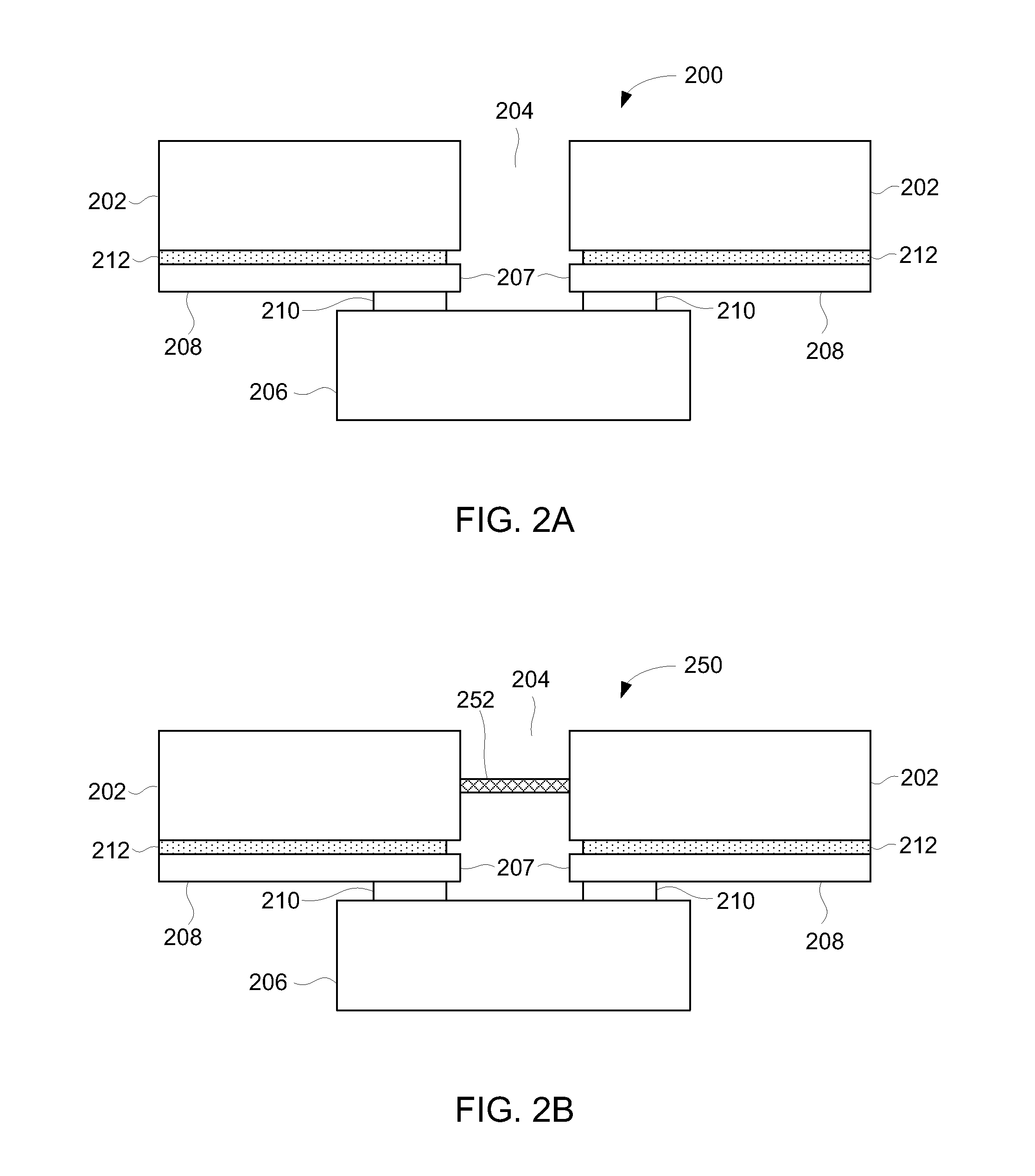

Semiconductor processing system

InactiveUS20070107845A1Easy to mergeSemiconductor/solid-state device manufacturingCharge manipulationAtmospheric pressureIntermediate structure

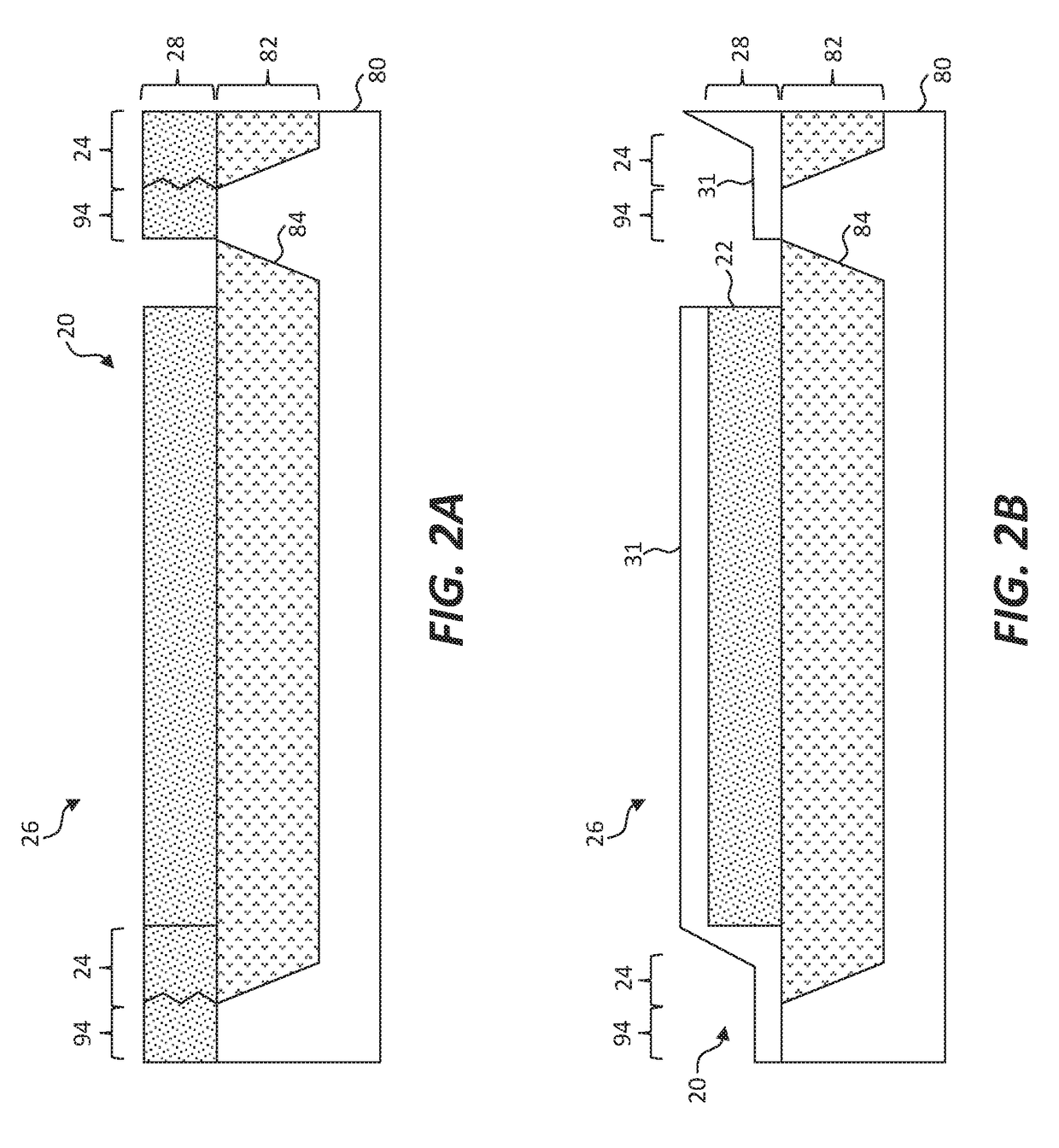

A semiconductor processing system includes an intermediate structure disposed between an atmospheric pressure entrance transfer chamber and a vacuum common transfer chamber. The intermediate structure includes a transfer passage for a target substrate to pass therein. The transfer passage includes a first buffer chamber a middle transfer chamber and a second buffer chamber detachably connected. An additional processing apparatus is detachably connected to the middle transfer chamber. The intermediate structure is selectively arranged in first or second state. In the first state, the additional processing apparatus performs a vacuum process, while the first buffer chamber is a load-lock chamber. In the second state, the additional processing apparatus performs an atmospheric pressure process, while the second buffer chamber is a load-lock chamber.

Owner:ISHIZAWA SHIGERU +6

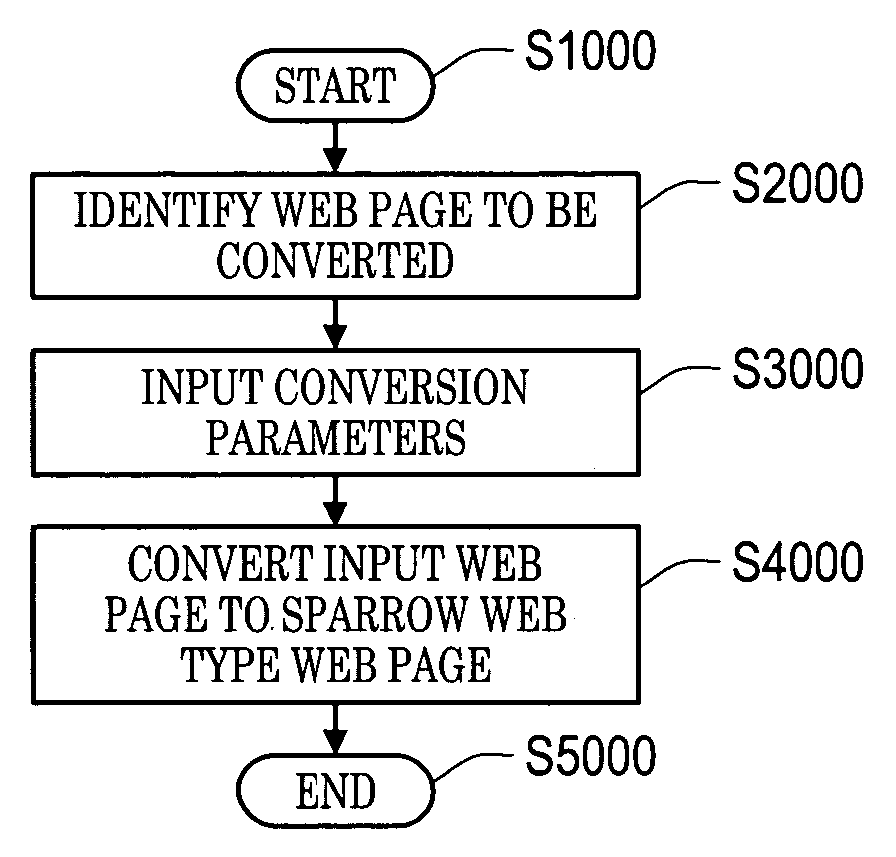

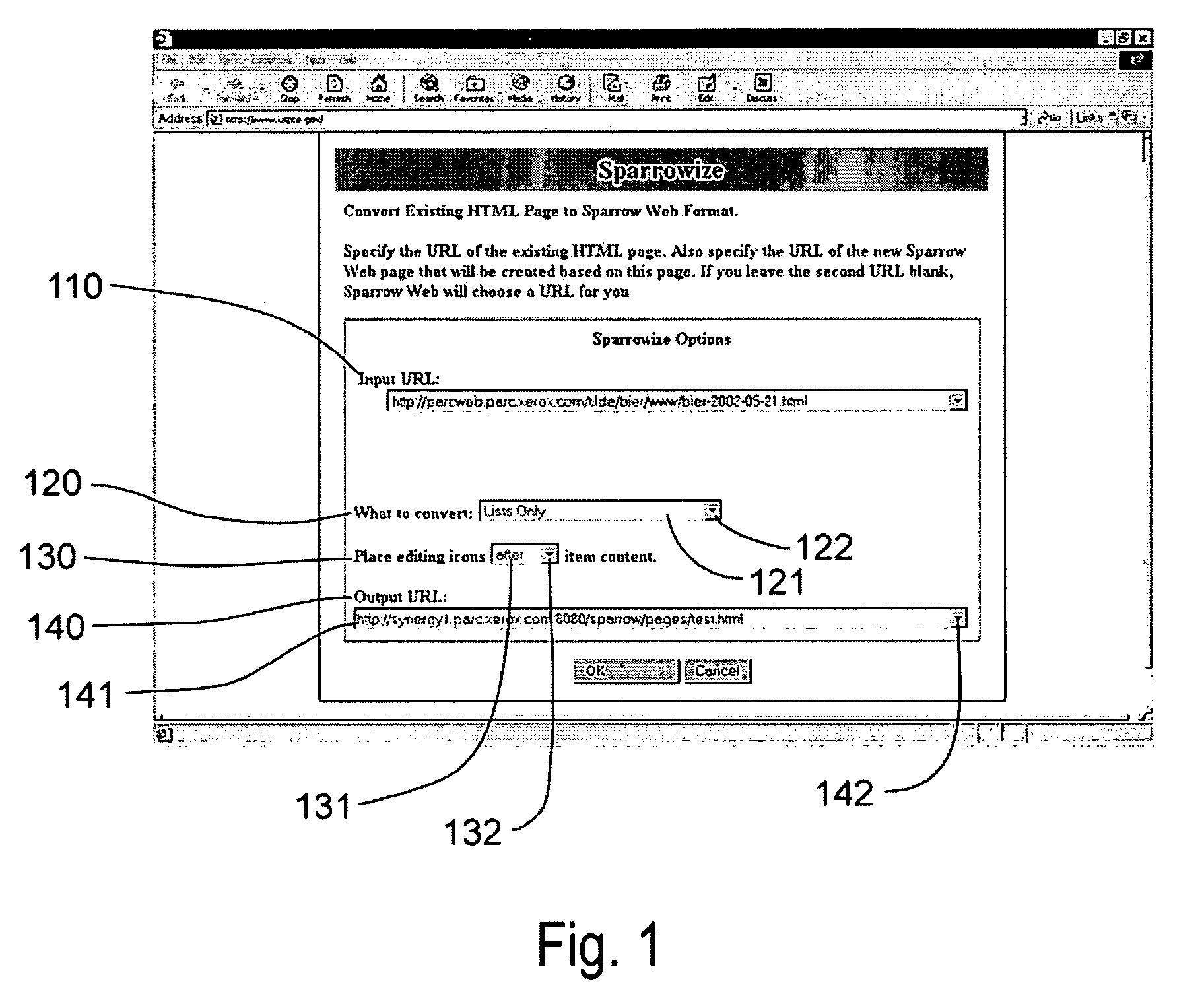

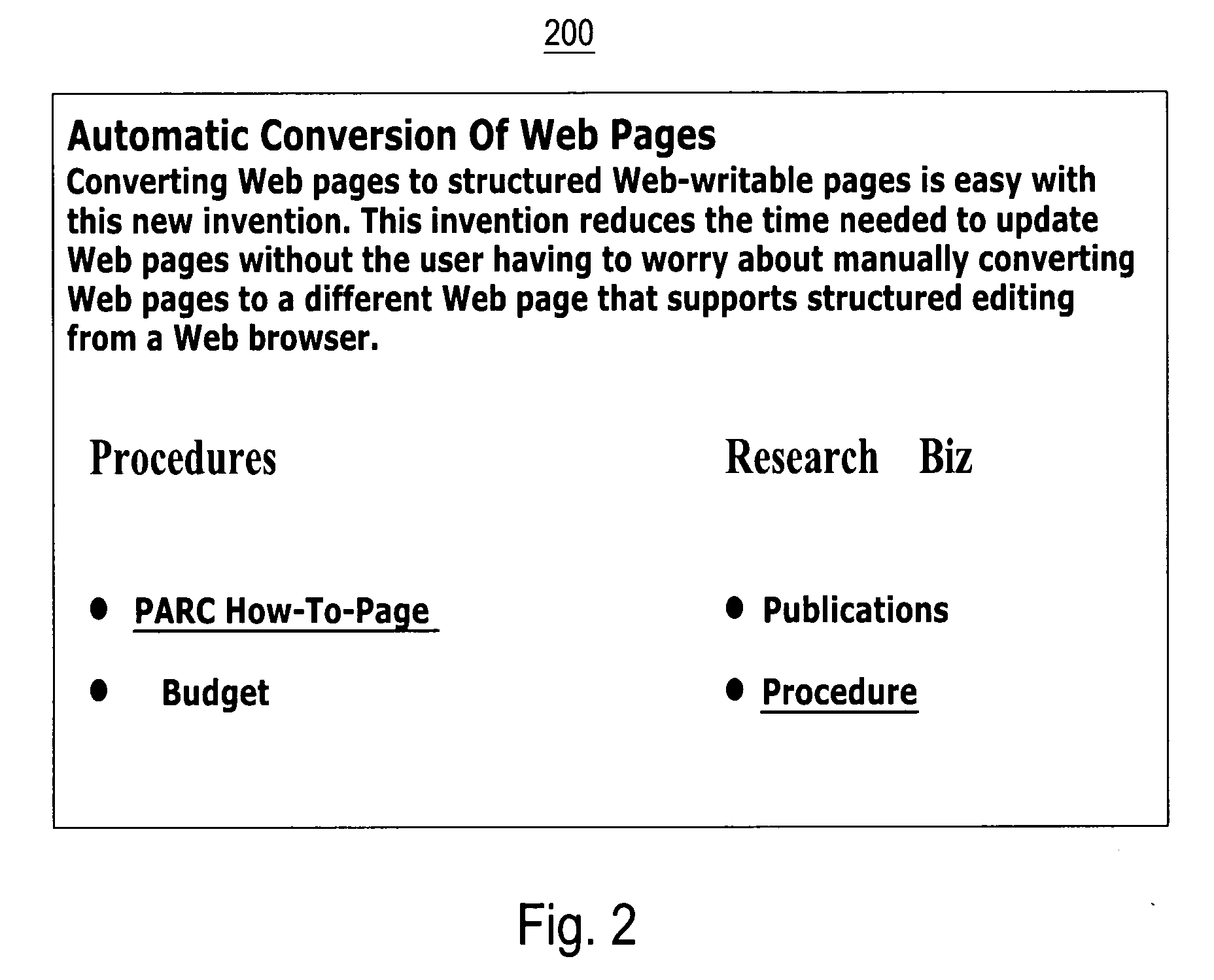

Systems and methods for automatically converting web pages to structured shared web-writable pages

InactiveUS20040261023A1Low costDigital data information retrievalDigital computer detailsIndividual itemWeb page

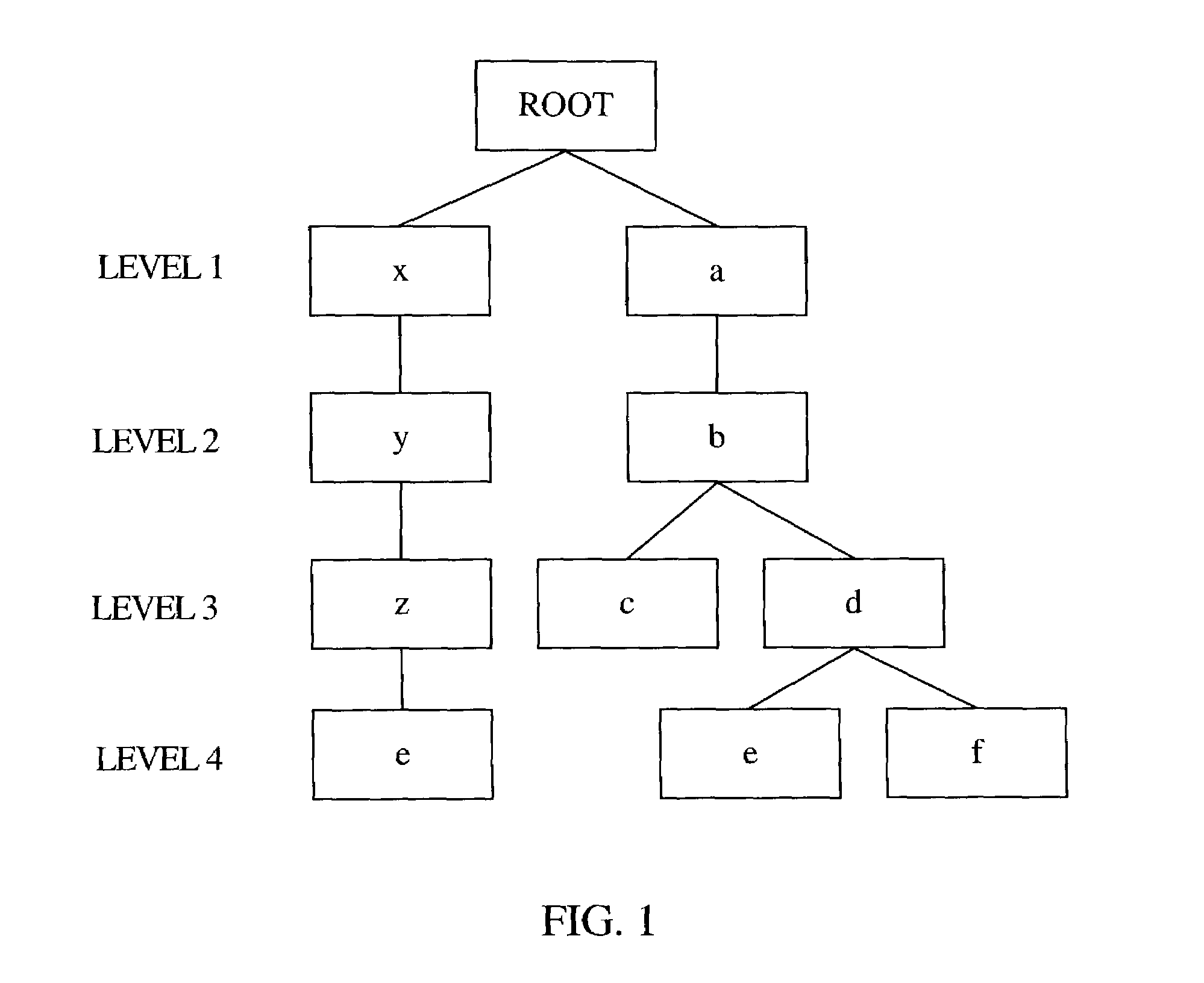

A system and method for an automatic conversion of web pages to shared structured web pages. An input web page is augmented with syntactic elements of a server-based software tool to create and customize group-writeable web pages. Sub-regions of the web page that are to be individually-editable items are identified, and syntactic elements are added to show where these editable regions begin and end, and where clickable buttons will appear that trigger the editing of an individual item, the addition of a new item, or other editing features. Also, syntactic elements are added that act as templates for the layout of any item to be added or modified. The conversion process includes parsing the Web page into an intermediate structure, adding information to individual tokens about the structures in which the tokens play a part, and them generating the new page while making one or more final passes through the intermediate structure from beginning to end.

Owner:PALO ALTO RES CENT INC

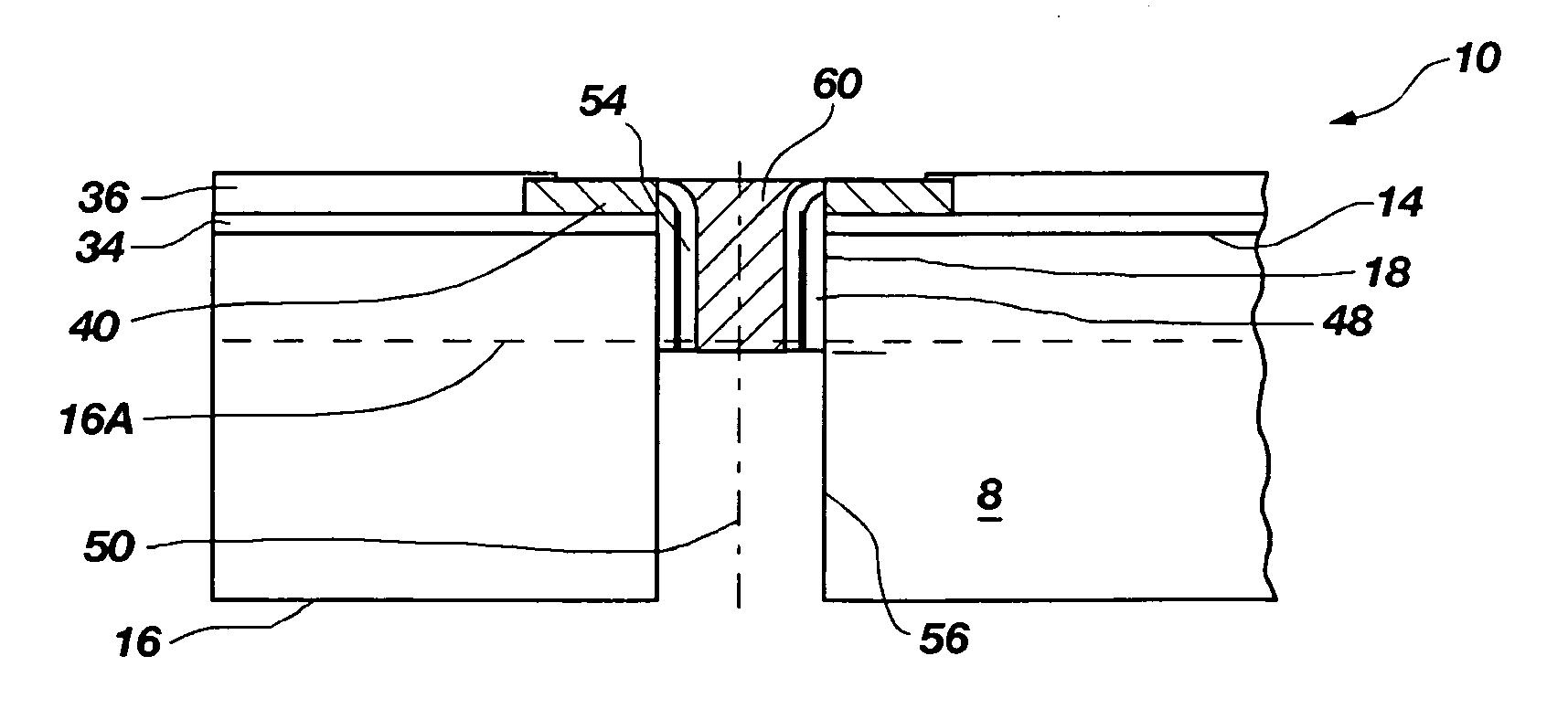

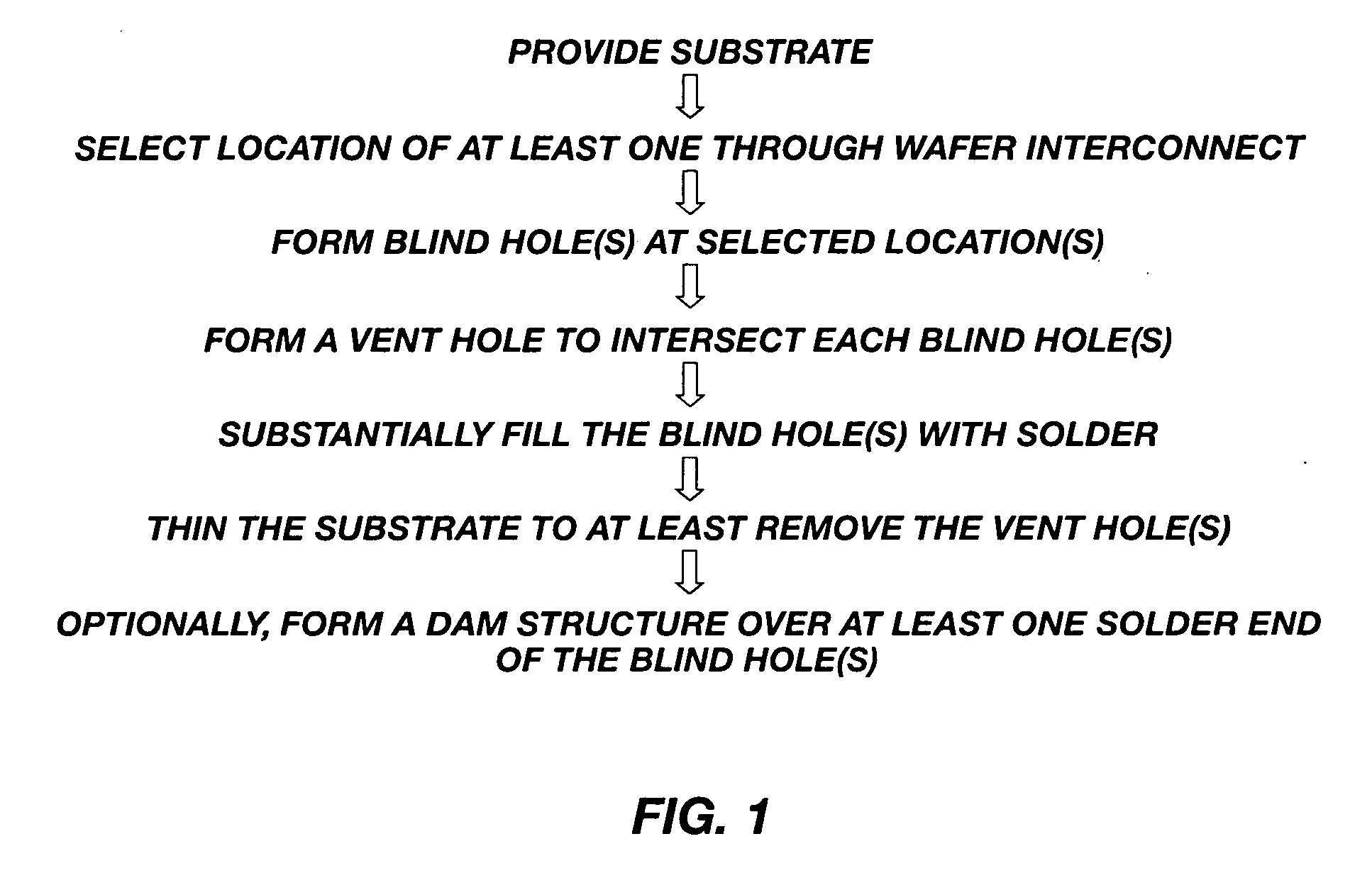

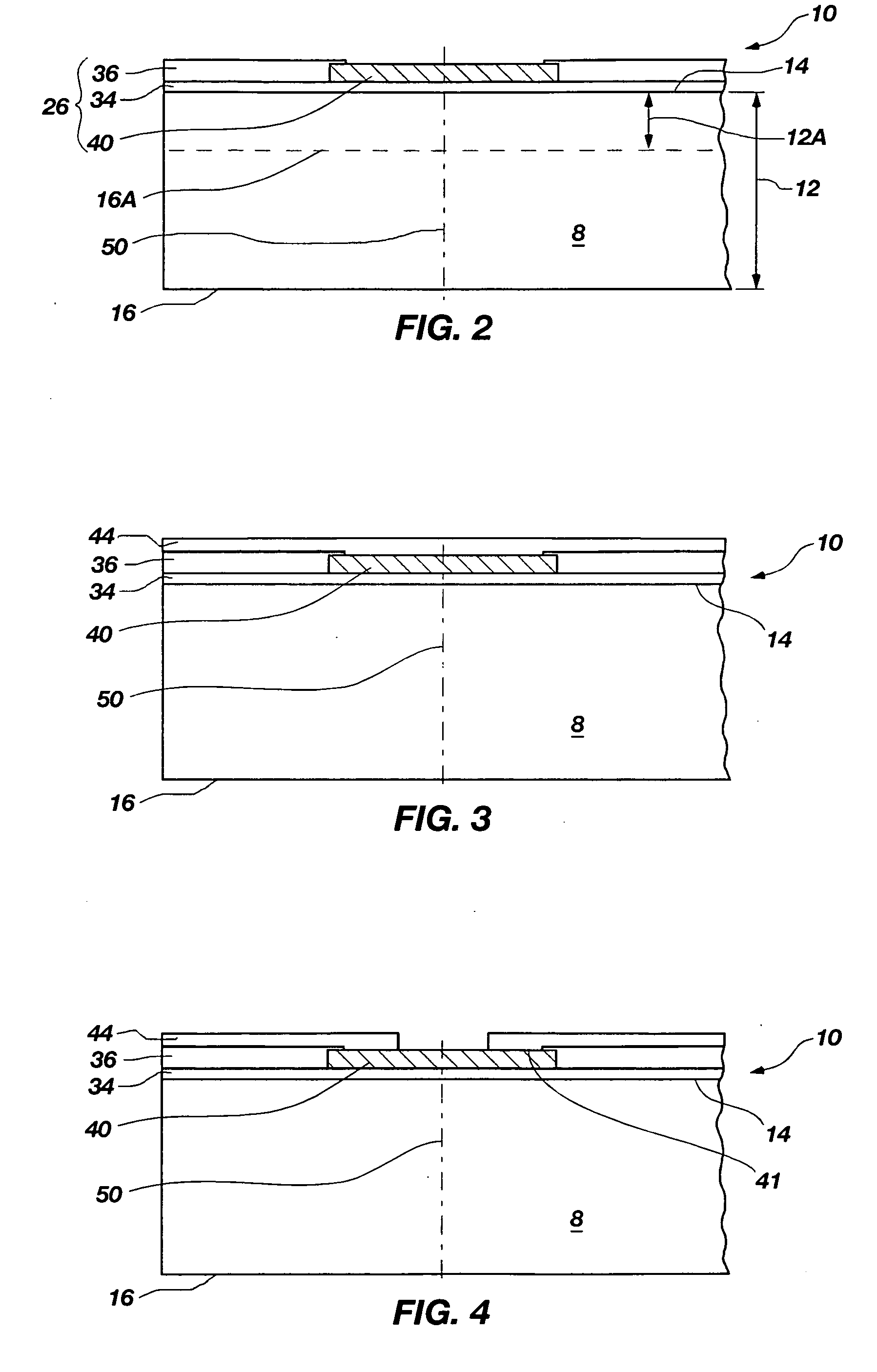

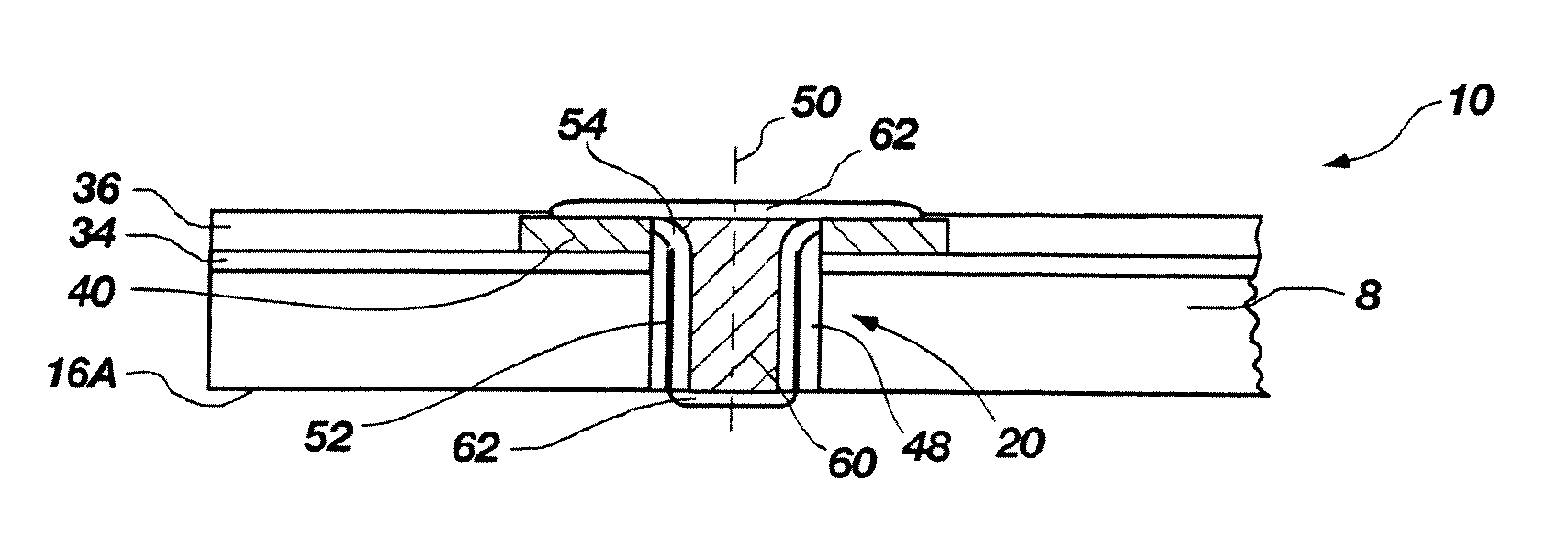

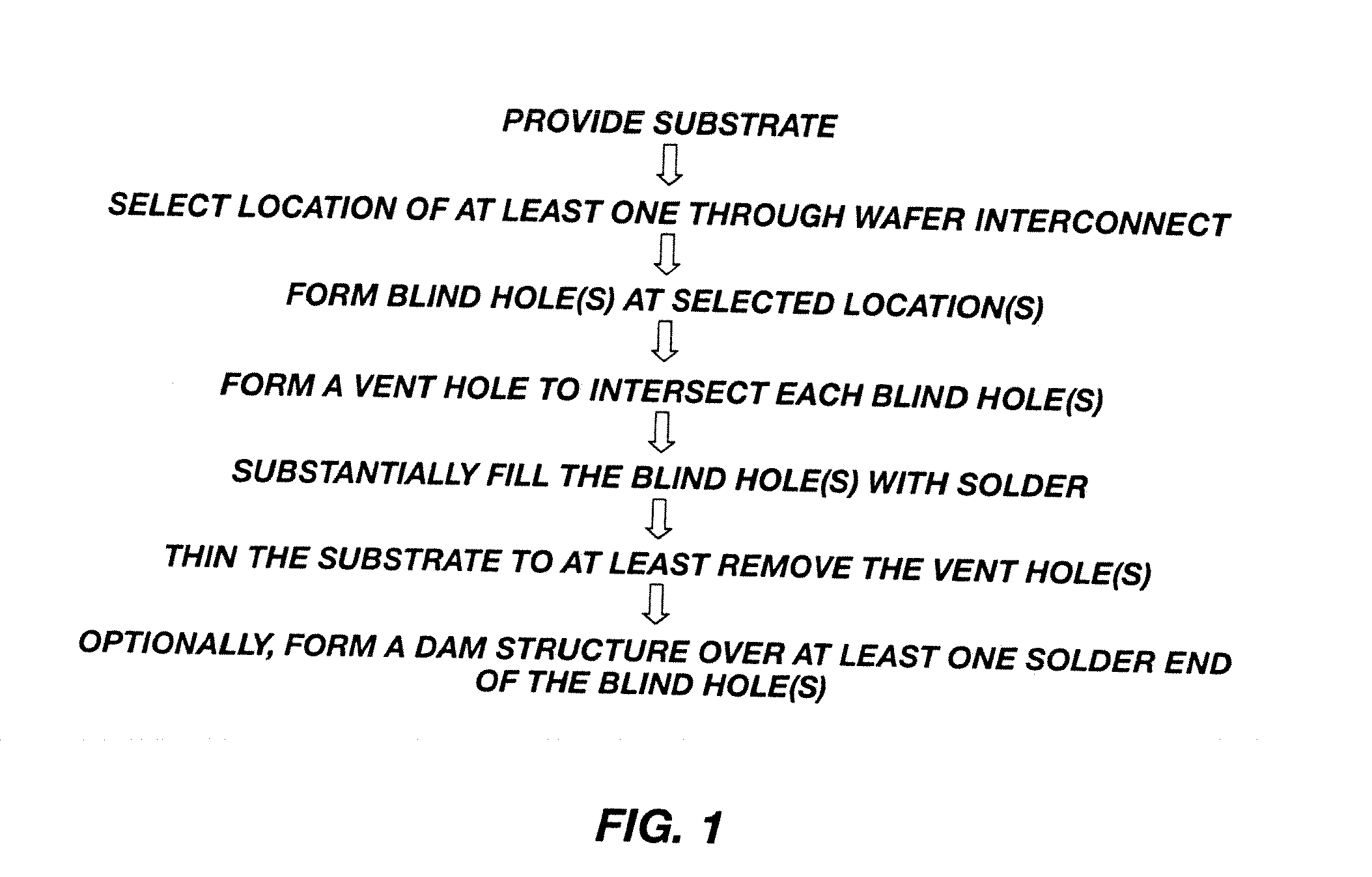

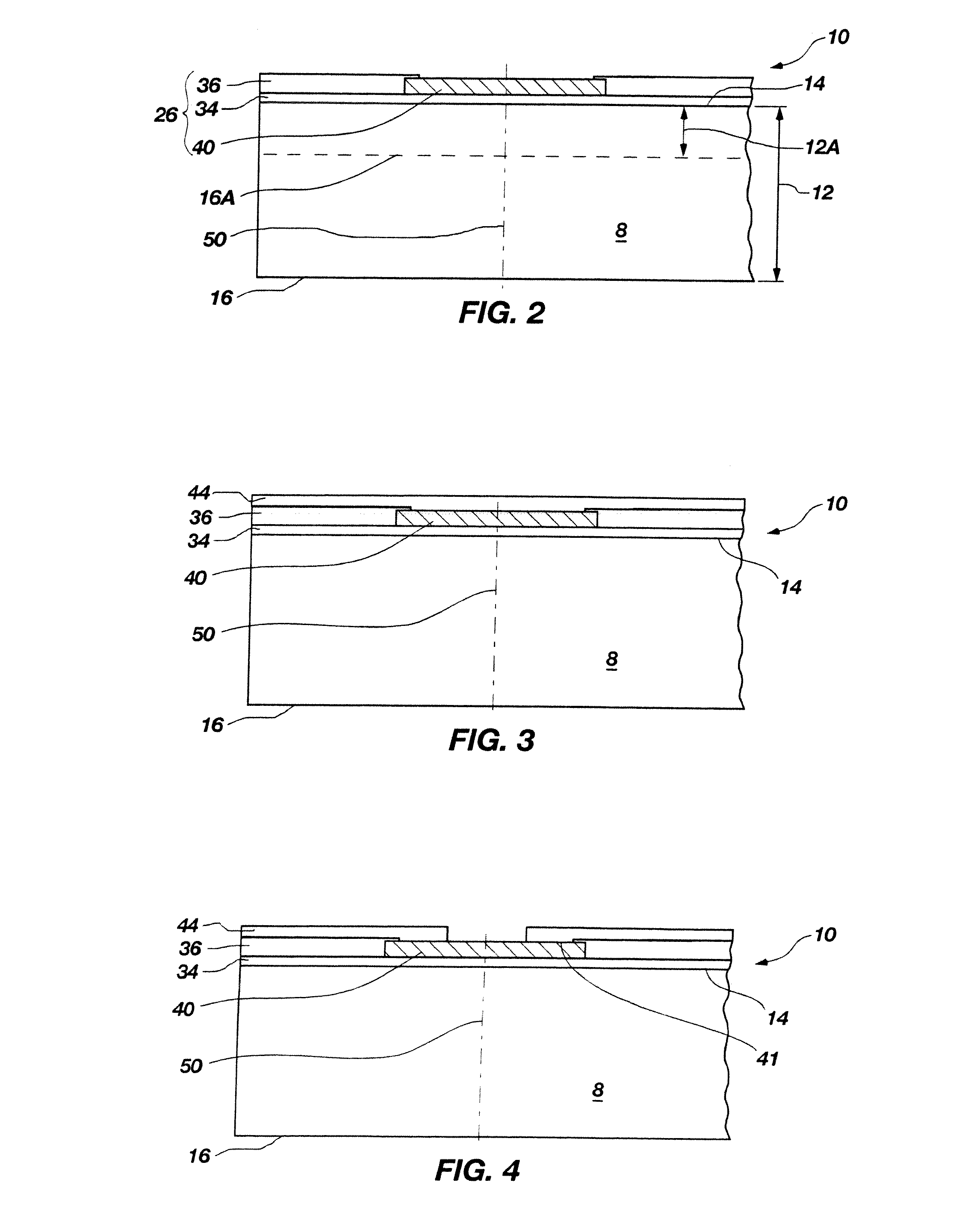

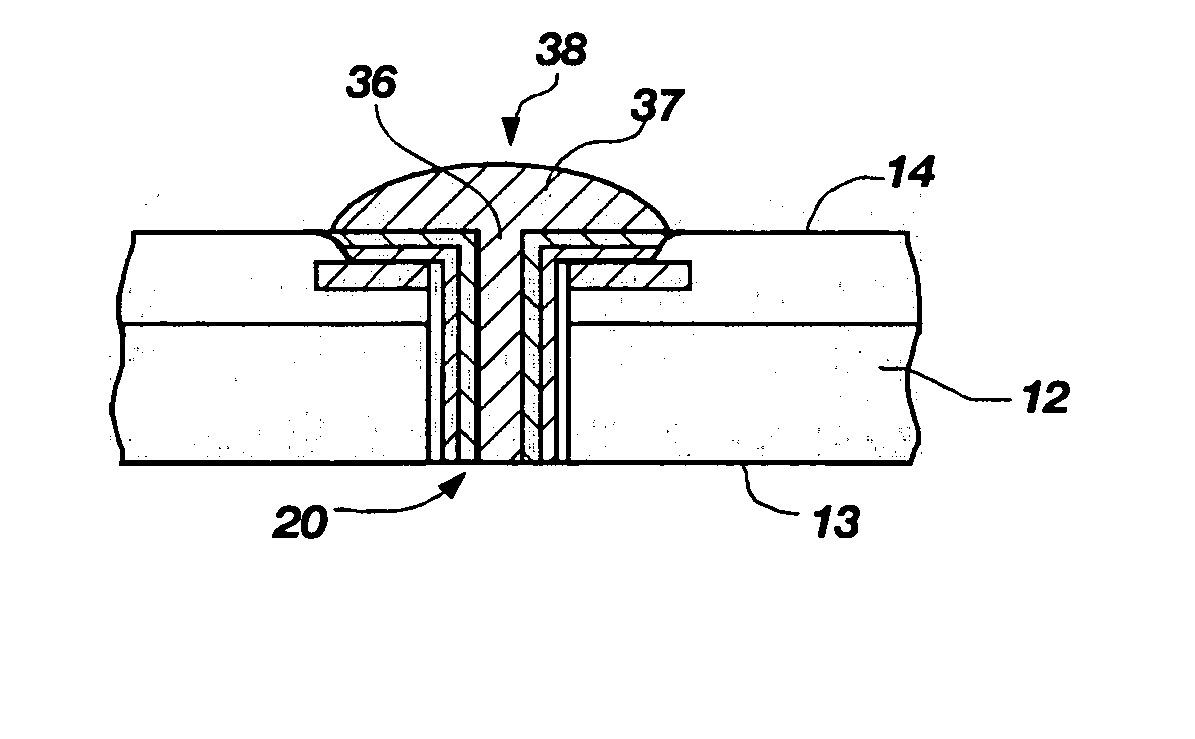

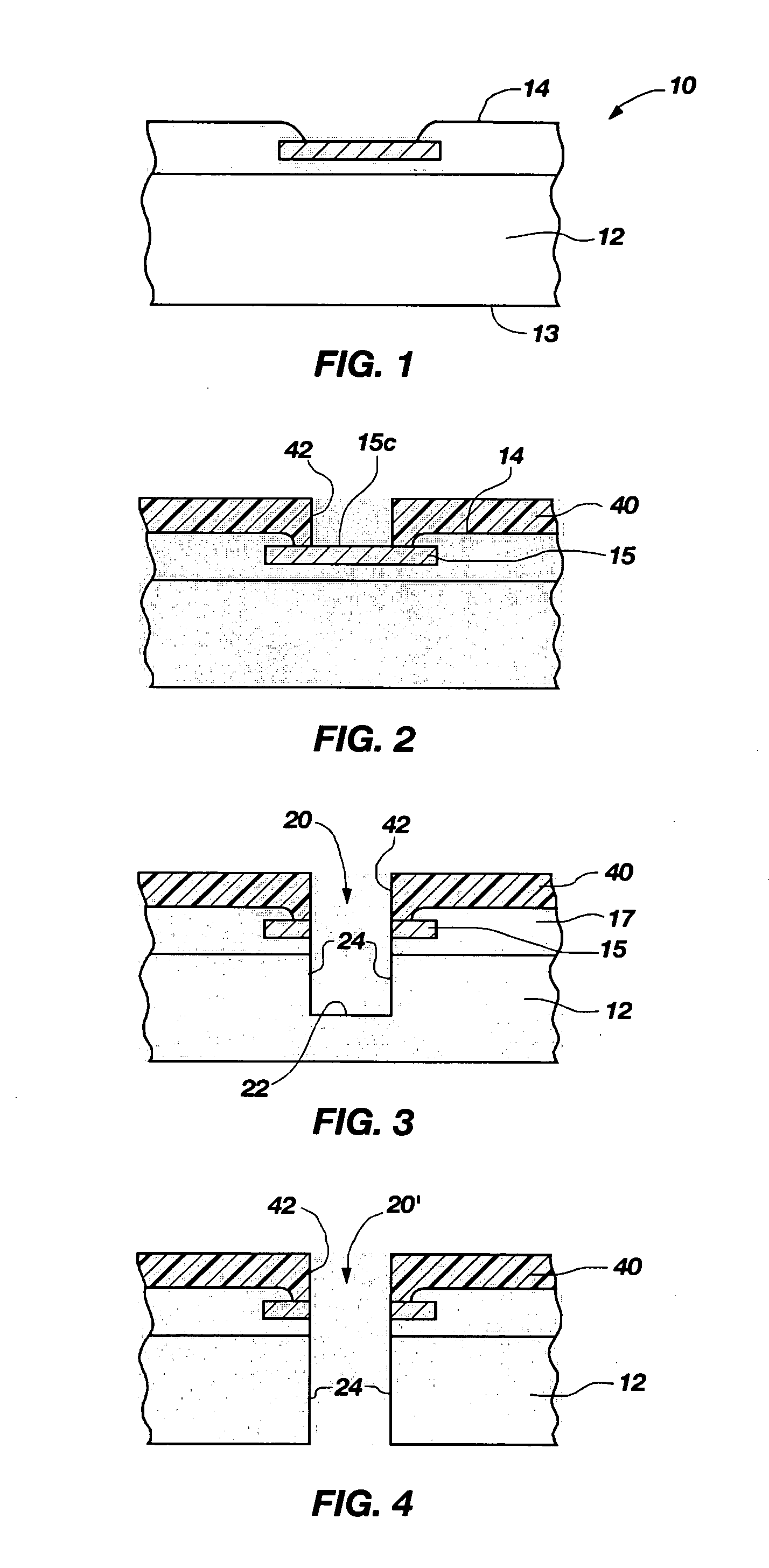

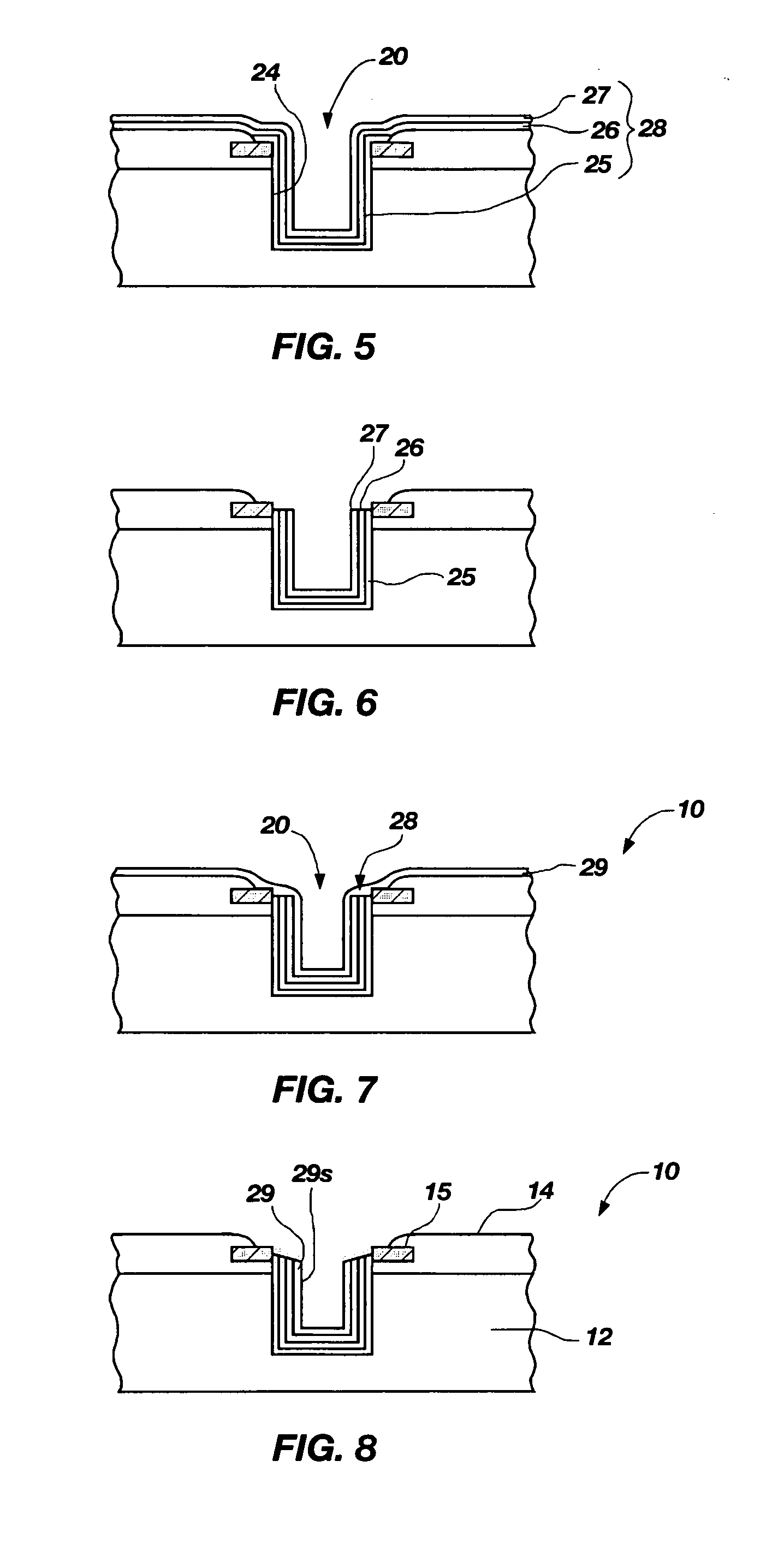

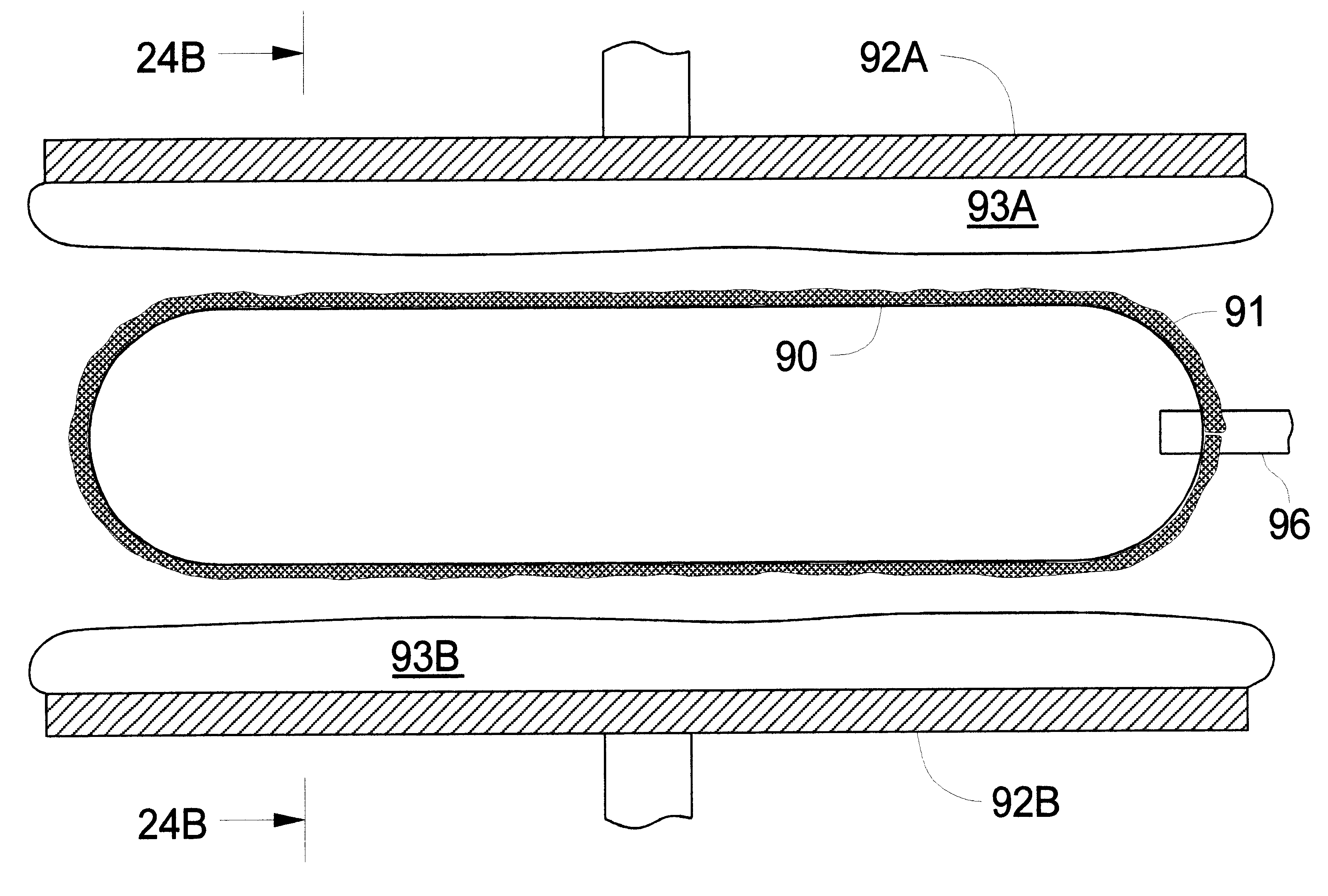

Methods for forming through-wafer interconnects, intermediate structures so formed, and devices and systems having at least one solder dam structure

ActiveUS20070045779A1Conveniently attachedEliminate cross-contaminationSemiconductor/solid-state device detailsSolid-state devicesVitrificationDevice material

A method for forming through-wafer interconnects (TWI) in a substrate of a thickness in excess of that of a semiconductor die such as a semiconductor wafer. Blind holes are formed from the active surface, sidewalls thereof passivated and coated with a solder-wetting material. A vent hole is then formed from the opposite surface (e.g., wafer back side) to intersect the blind hole. The blind hole is solder filled, followed by back thinning of the vent hole portion of the wafer to a final substrate thickness to expose the solder and solder-wetting material at both the active surface and the thinned back side. A metal layer such as nickel, having a glass transition temperature greater than that of the solder, may be plated to form a dam structure covering one or both ends of the TWI including the solder and solder-wetting material to prevent leakage of molten solder from the TWI during high temperature excursions. Intermediate structures of semiconductor devices, semiconductor devices and systems are also disclosed.

Owner:MICRON TECH INC

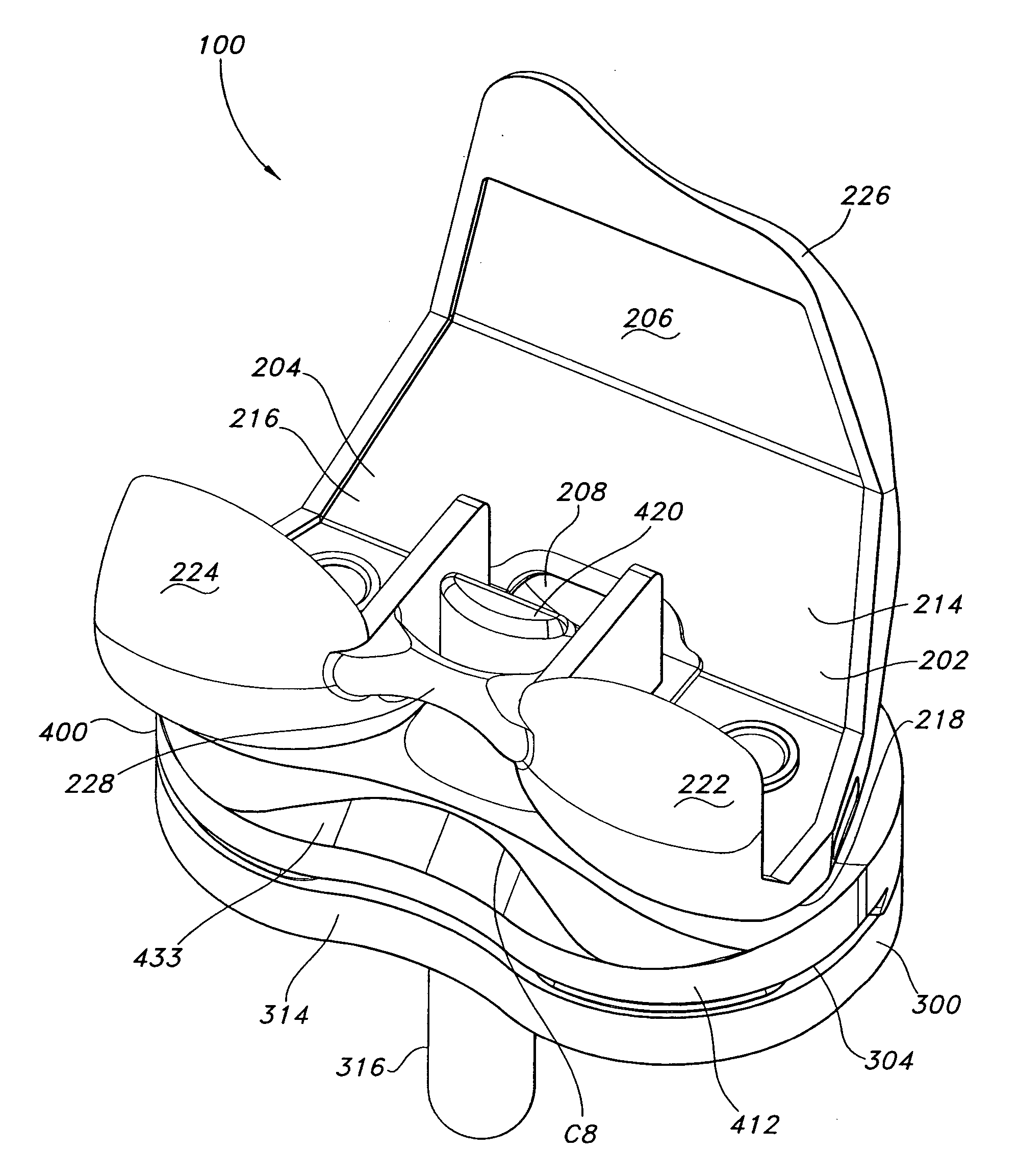

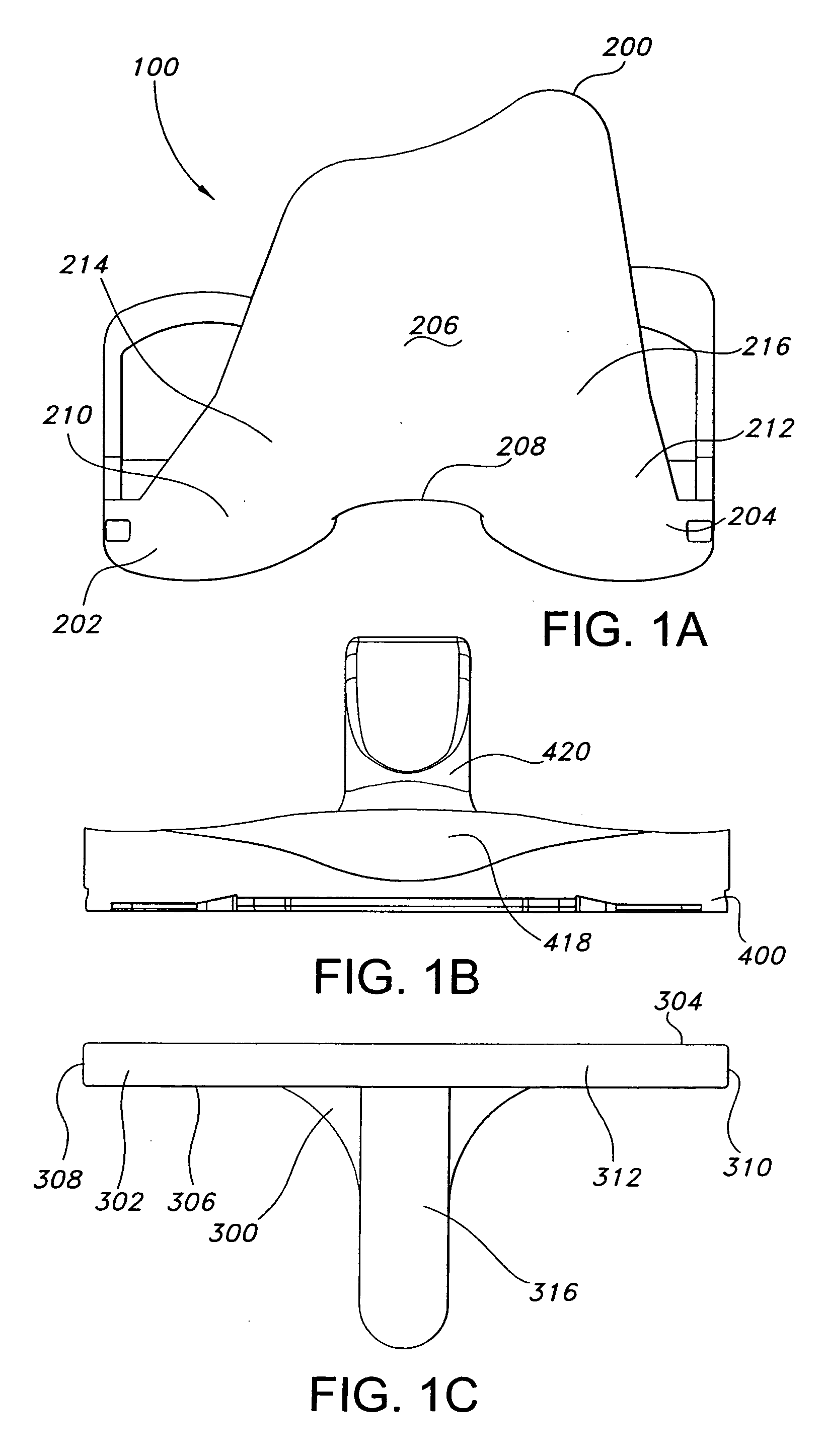

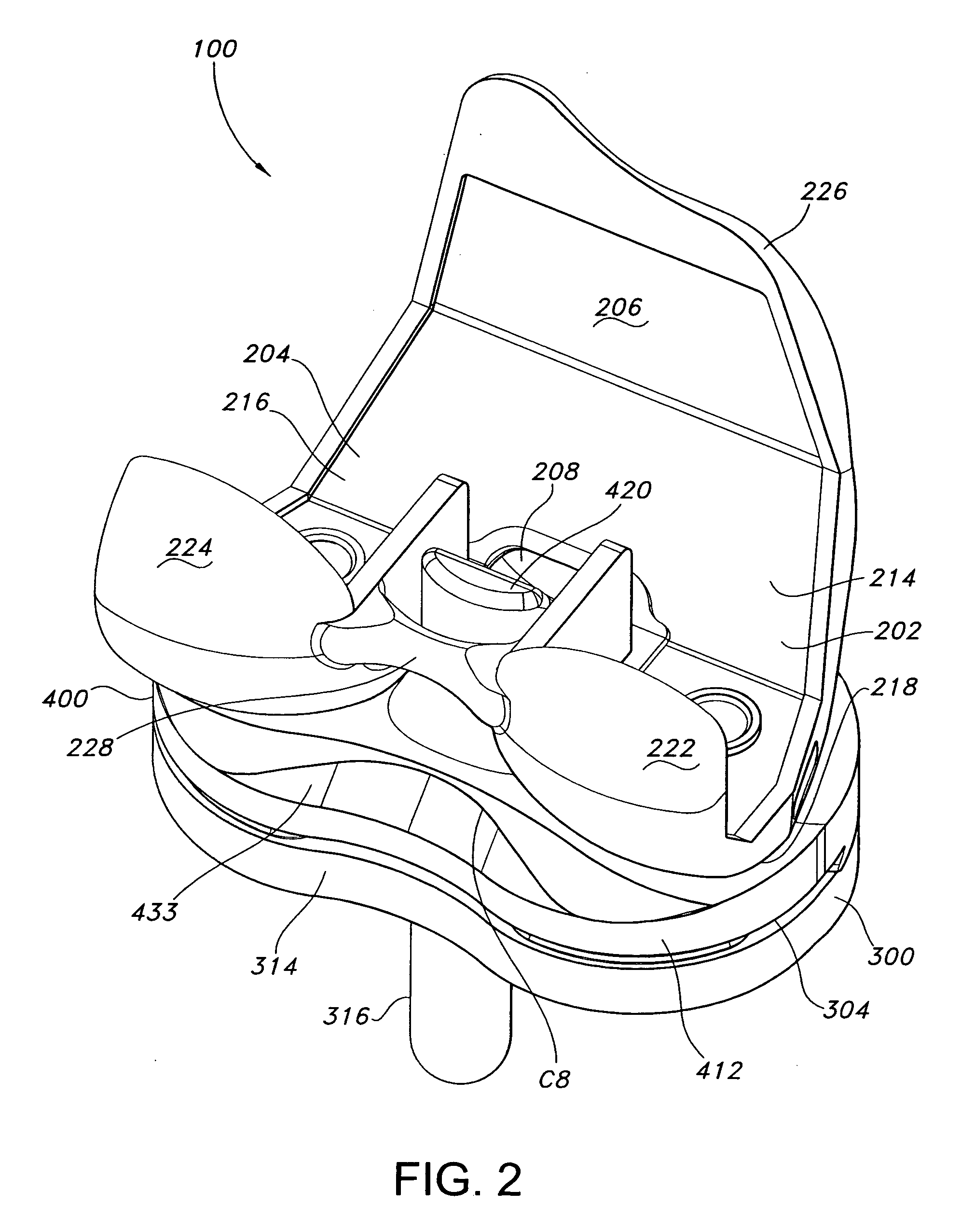

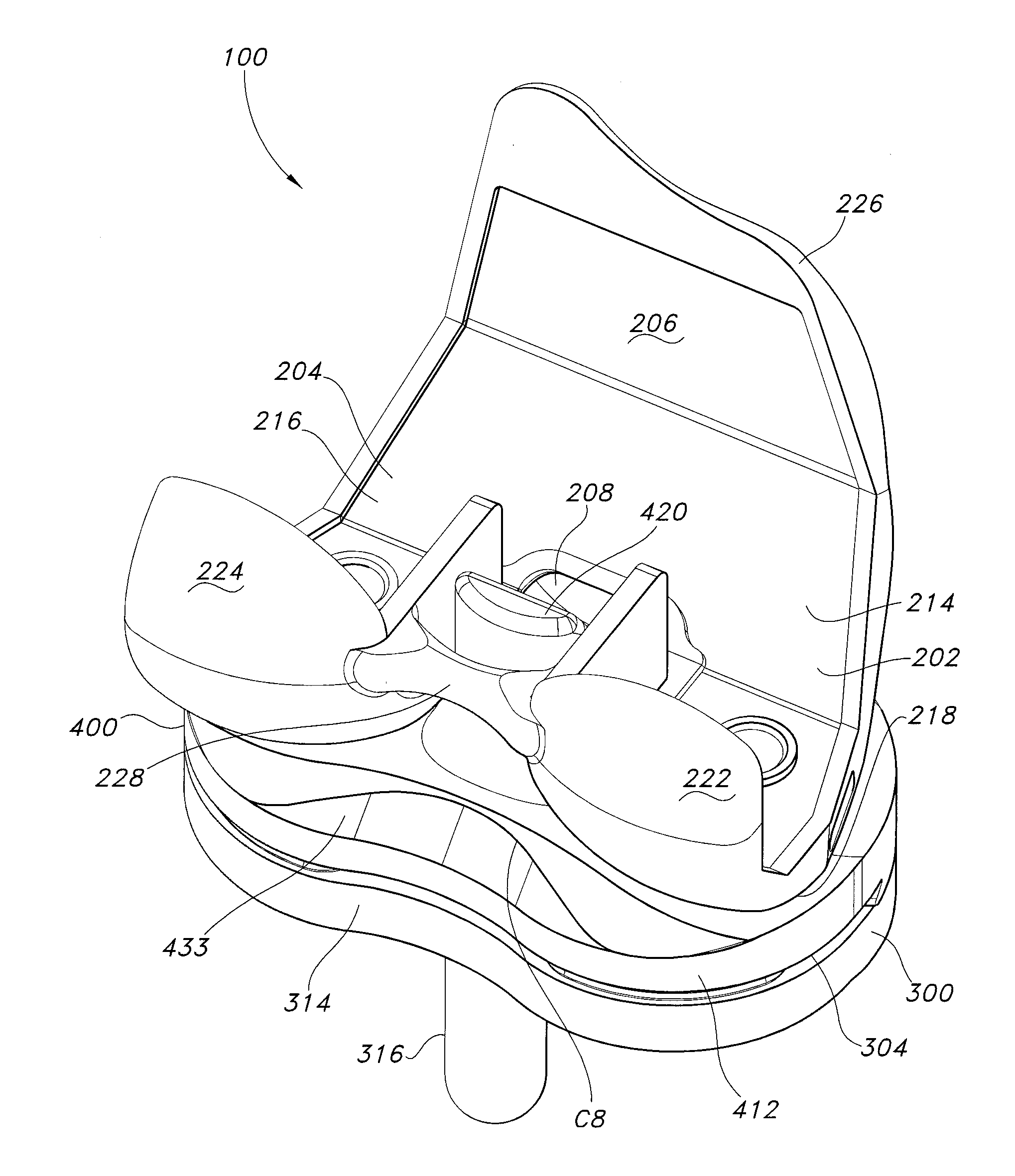

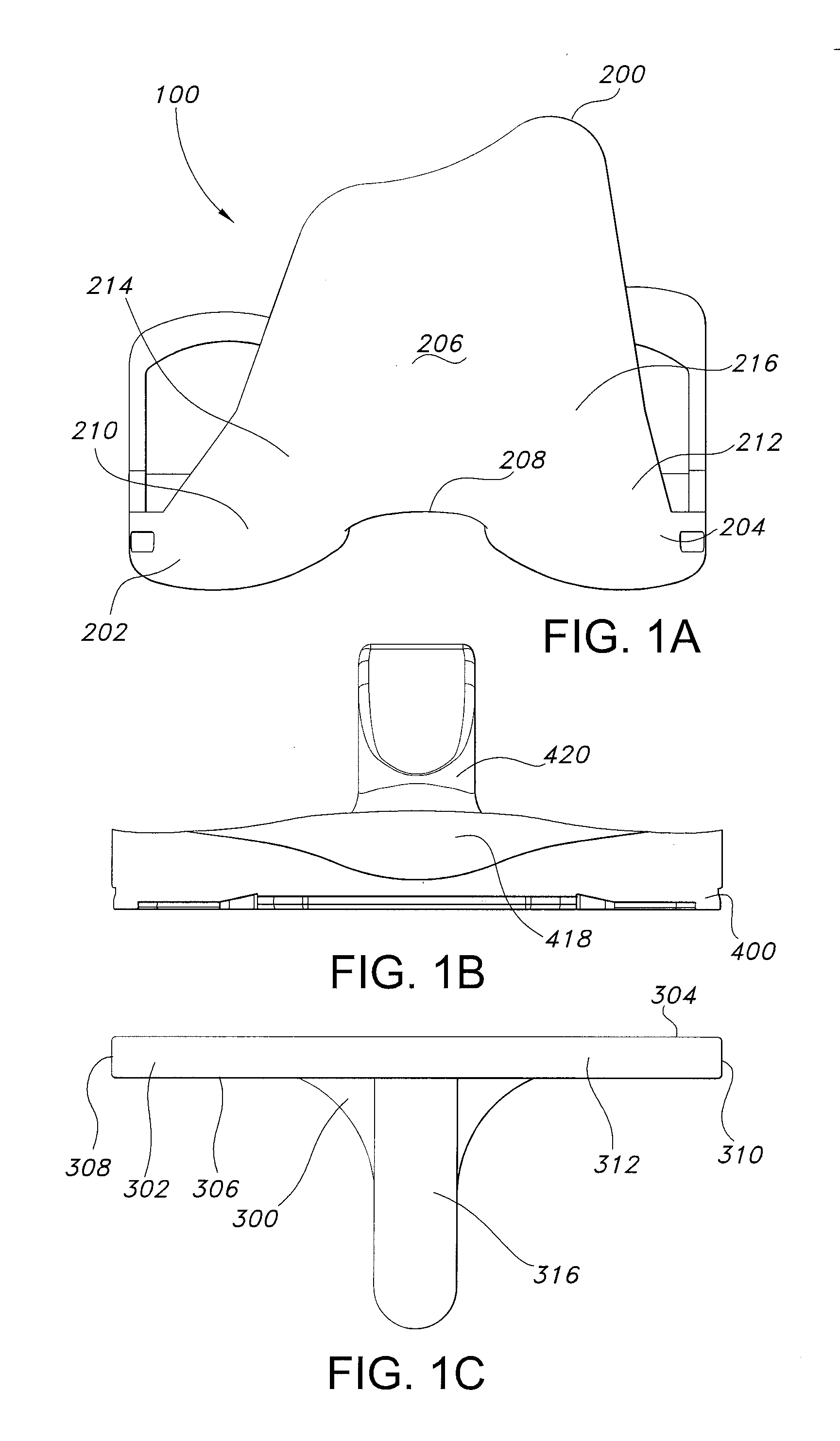

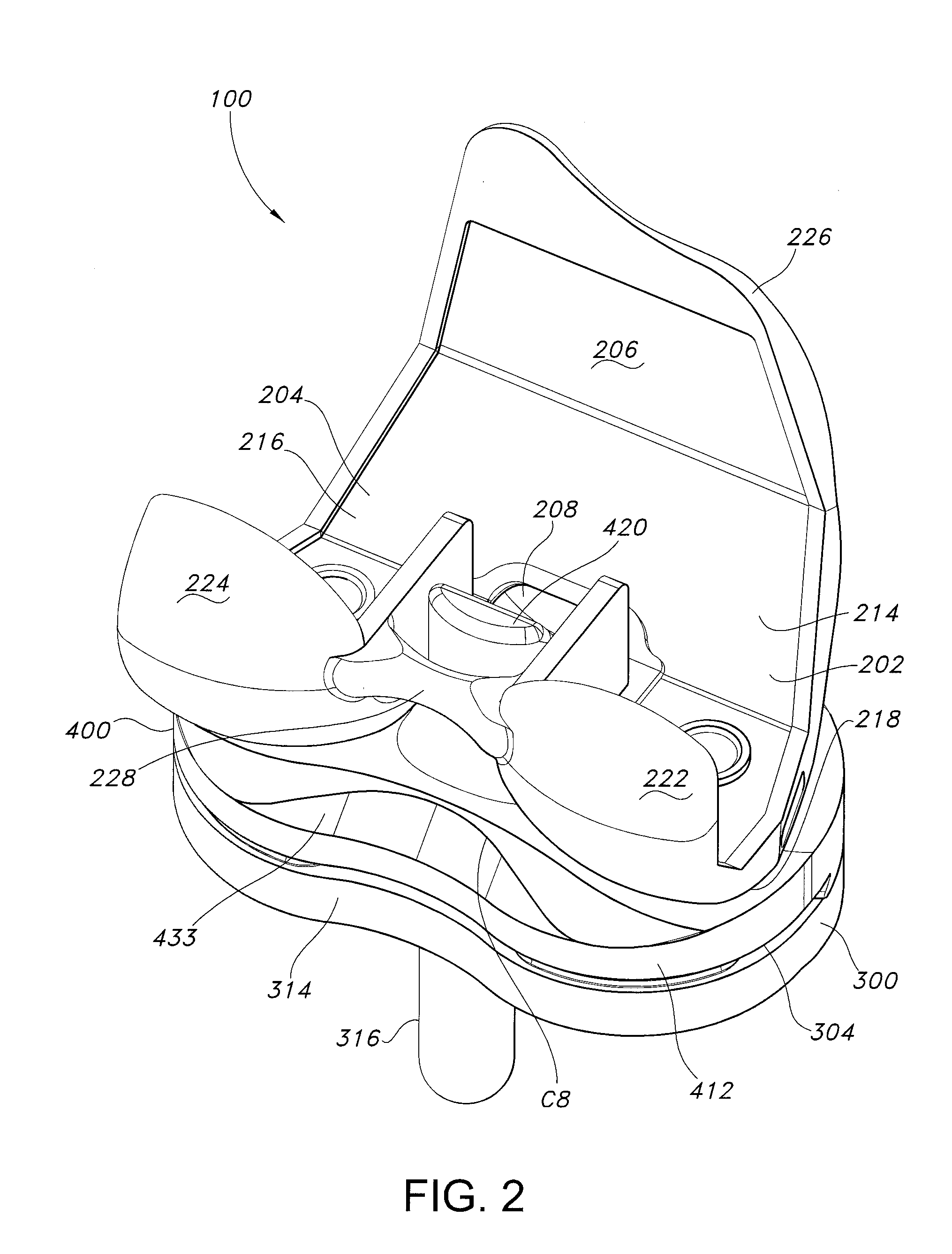

High flexion articular insert

A knee prosthesis is provided that allows for increased flexion. The knee prosthesis includes (a) a femoral component adapted to fit on a distal end of the femur which includes a lateral condylar structure and a medial condylar structure and (b) an intermediate structure configured to cooperate with a femoral component of a knee prosthesis. The intermediate structure includes at least one surface for contacting the femoral component and a transition of a sagittal curvature of the at least one contact surface from a concave surface into a convex surface at the contact interface of the femoral component and the intermediate structure when the knee is flexed at approximately 120° to 140°. The knee prosthesis minimizes impingement on the femoral posterior cortex in deep flexion, increases the dislocation safety factor and allows for easier reengagement of the articular surface should the femoral component externally rotate off of the tibial plateau.

Owner:SMITH & NEPHEW INC

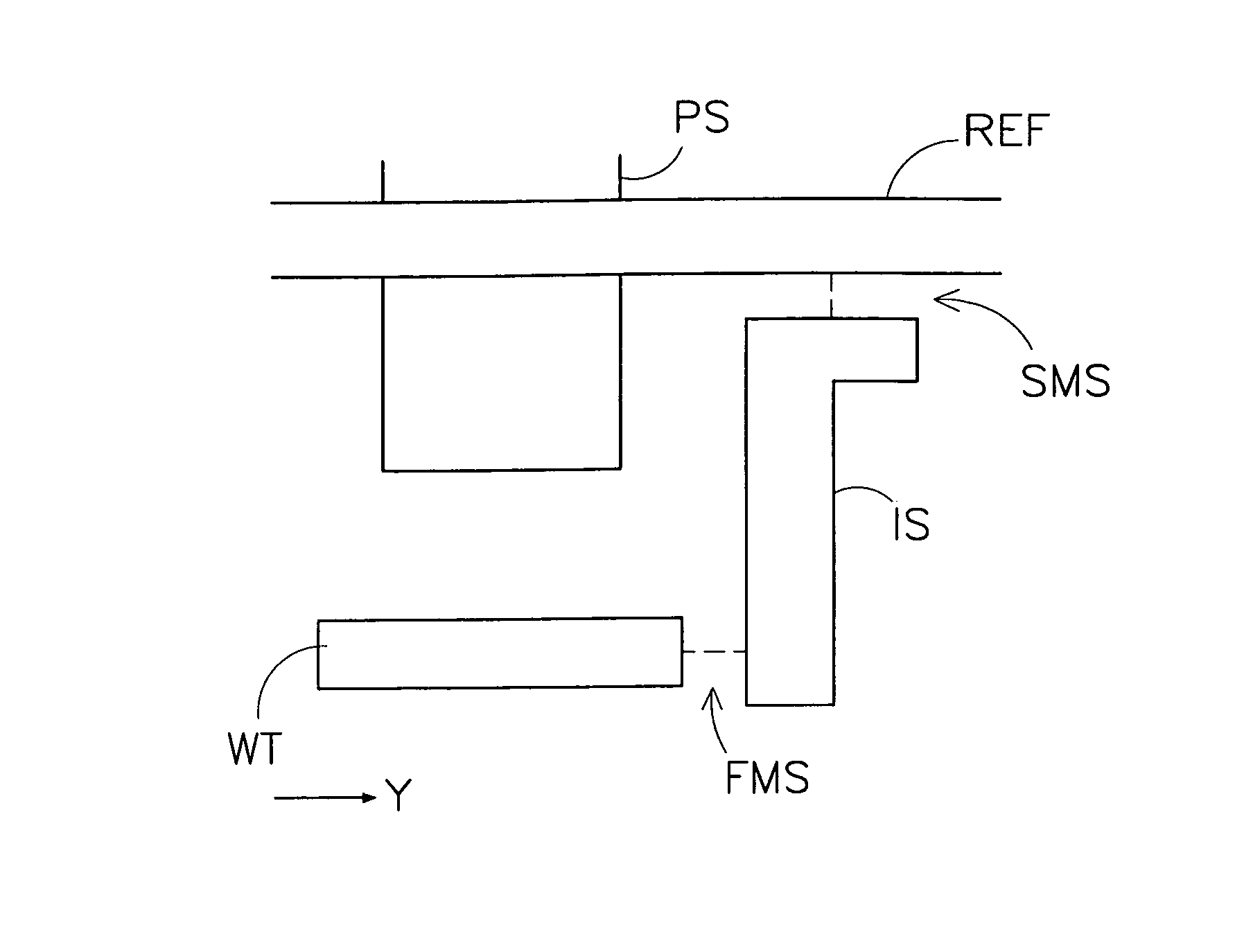

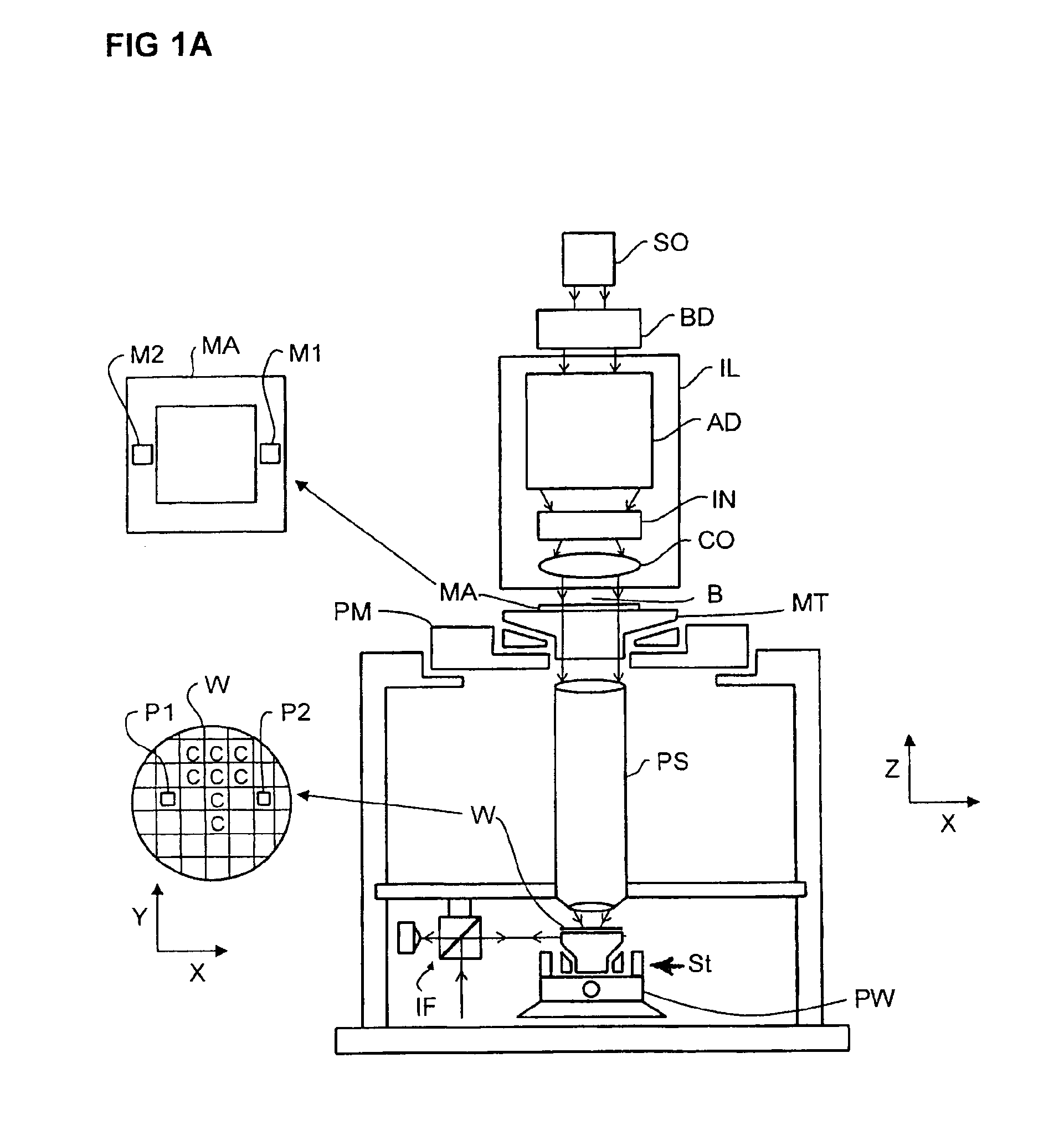

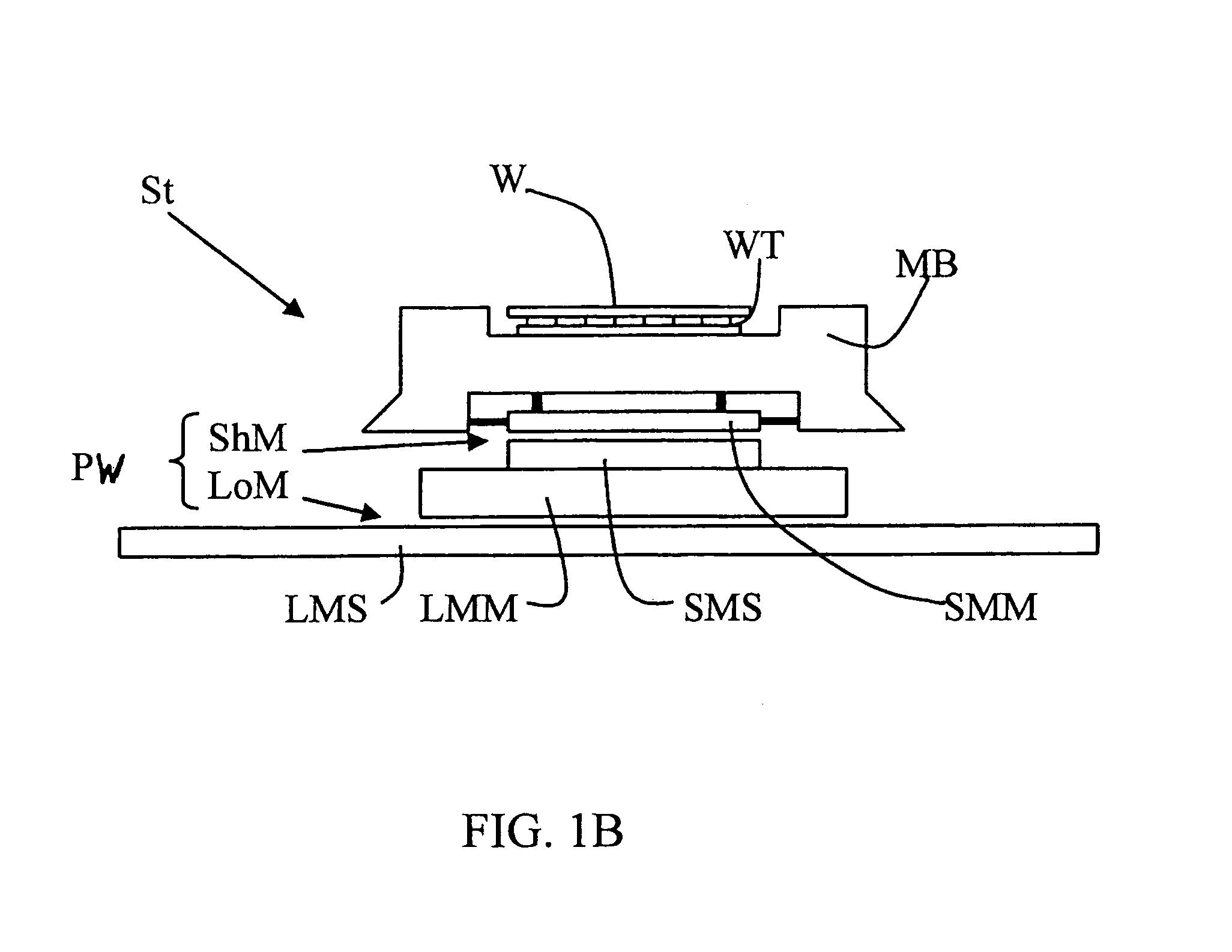

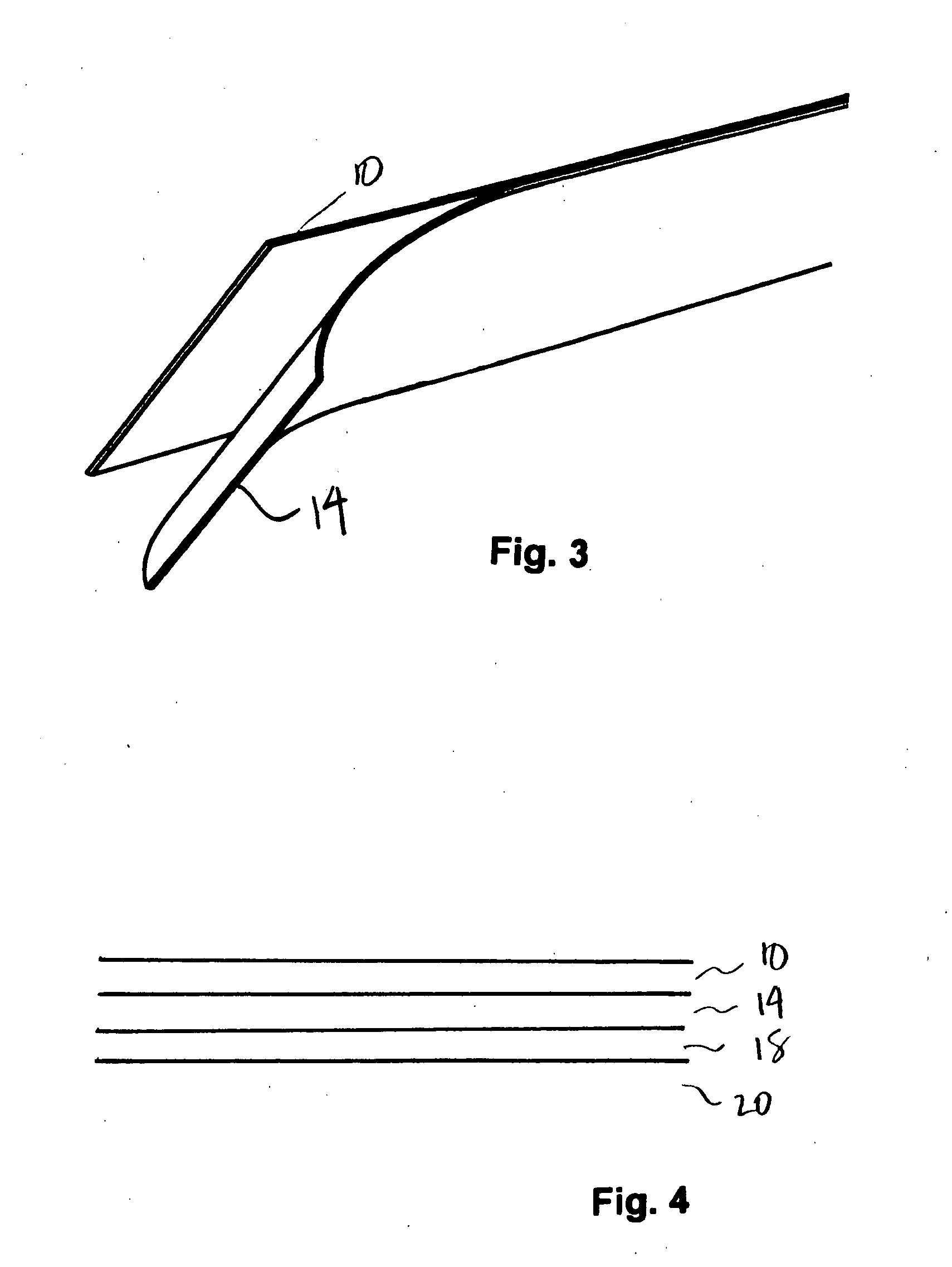

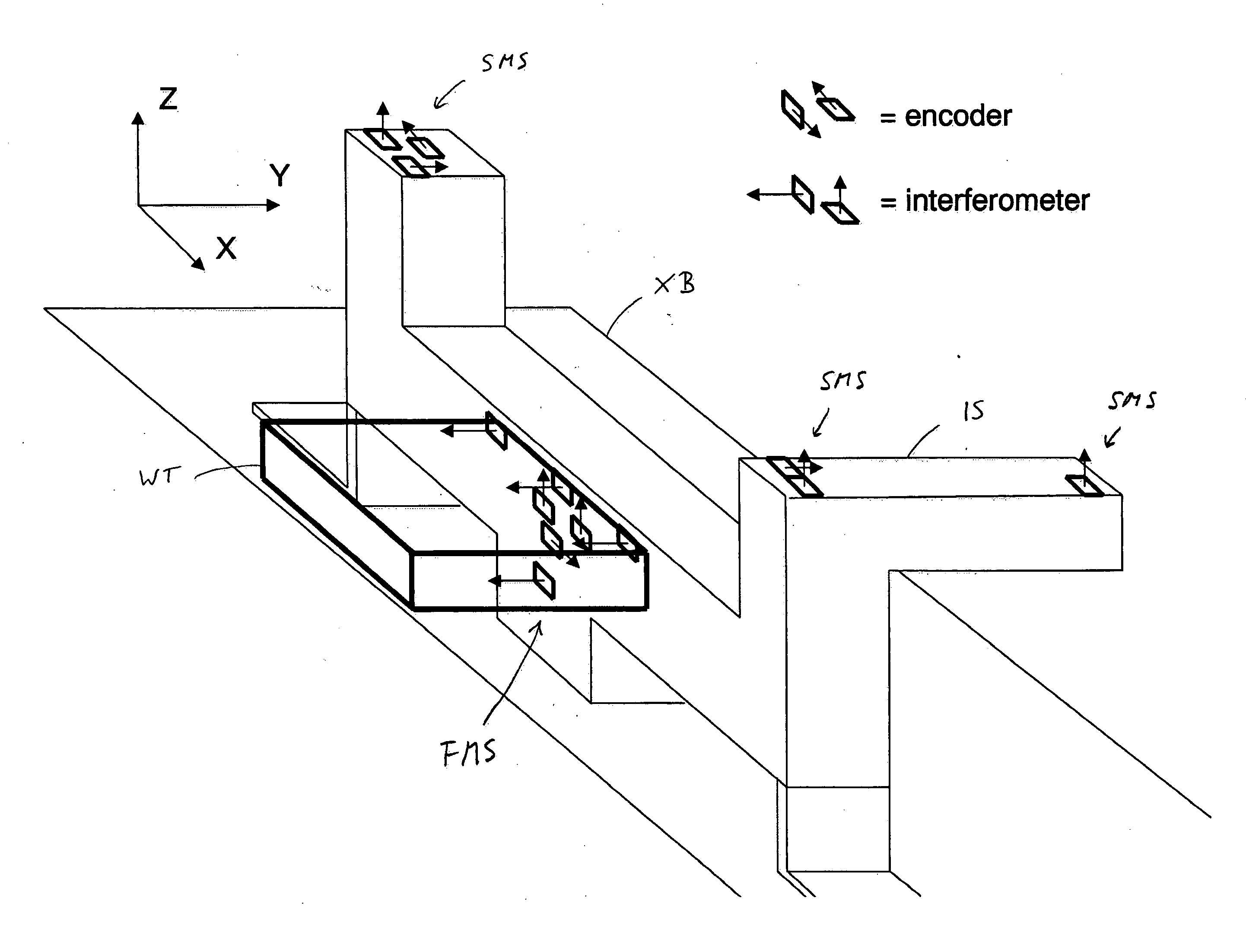

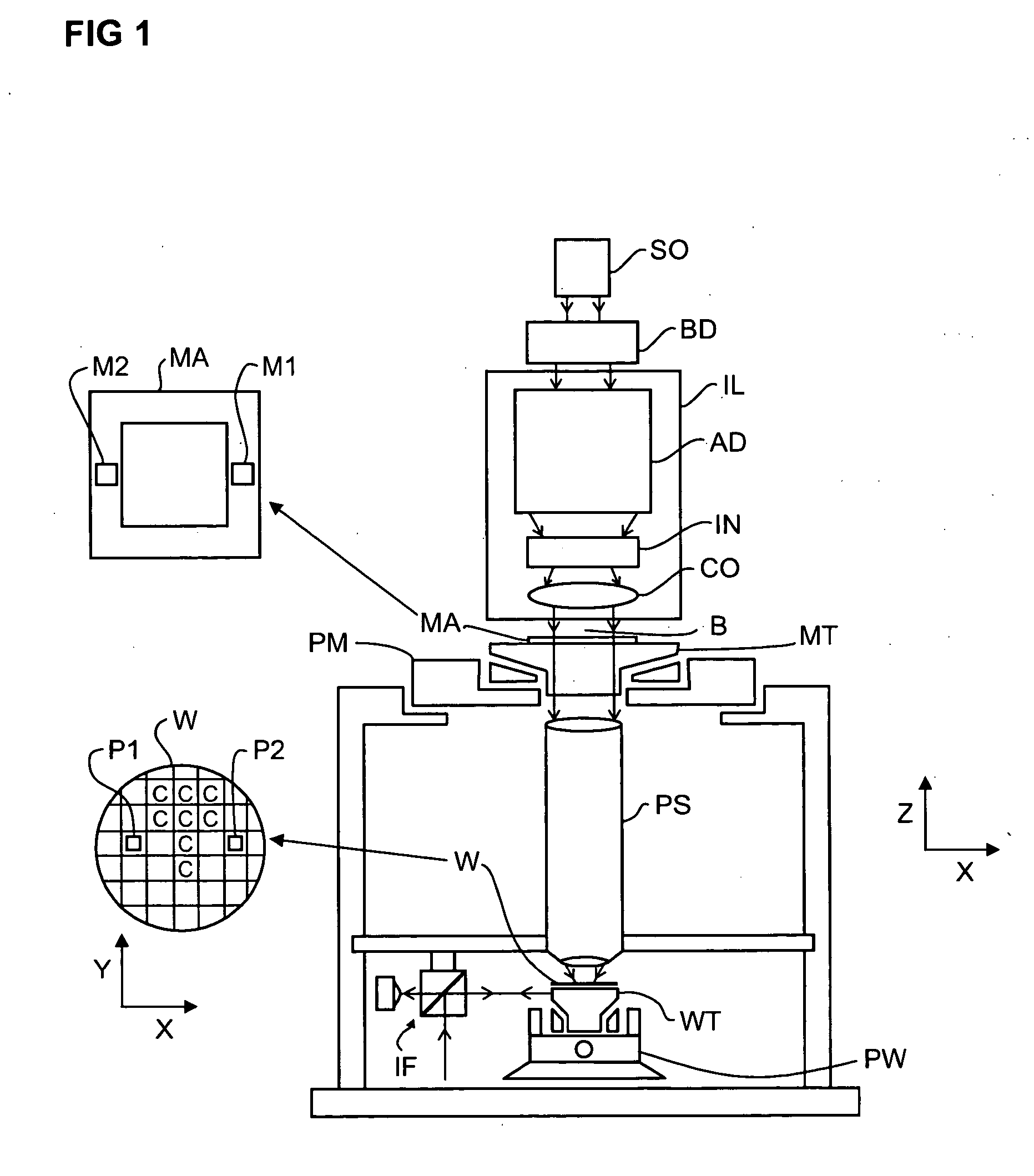

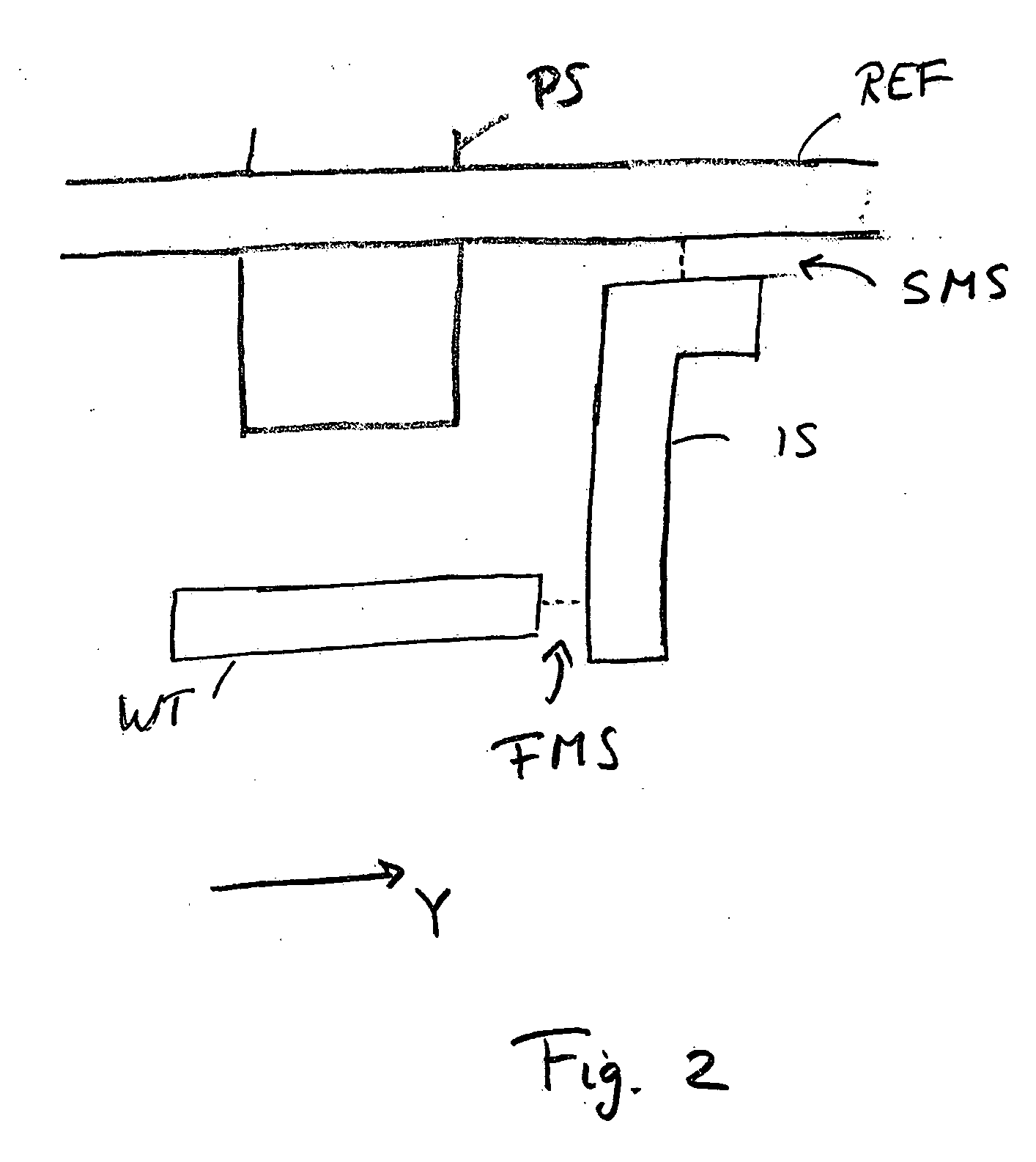

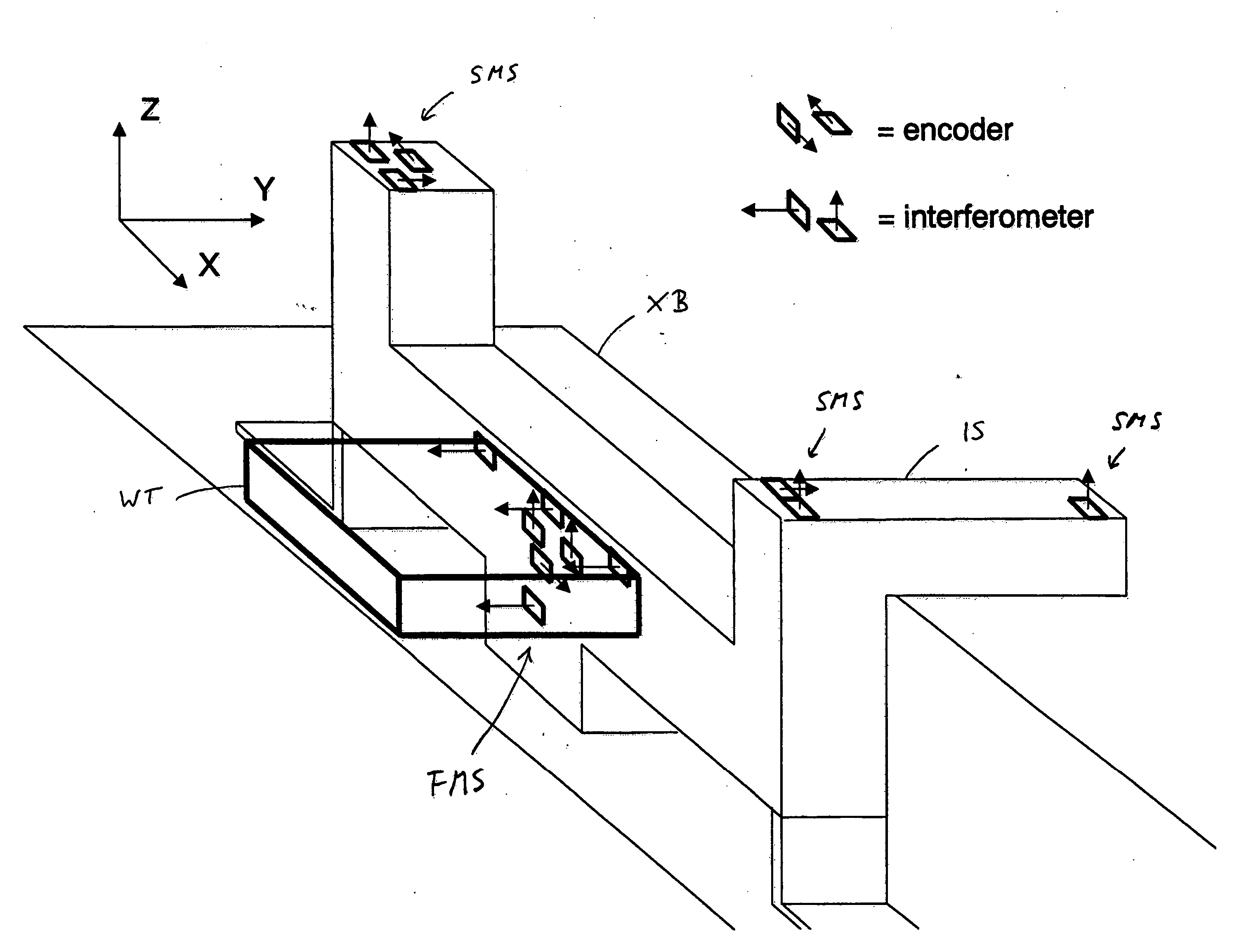

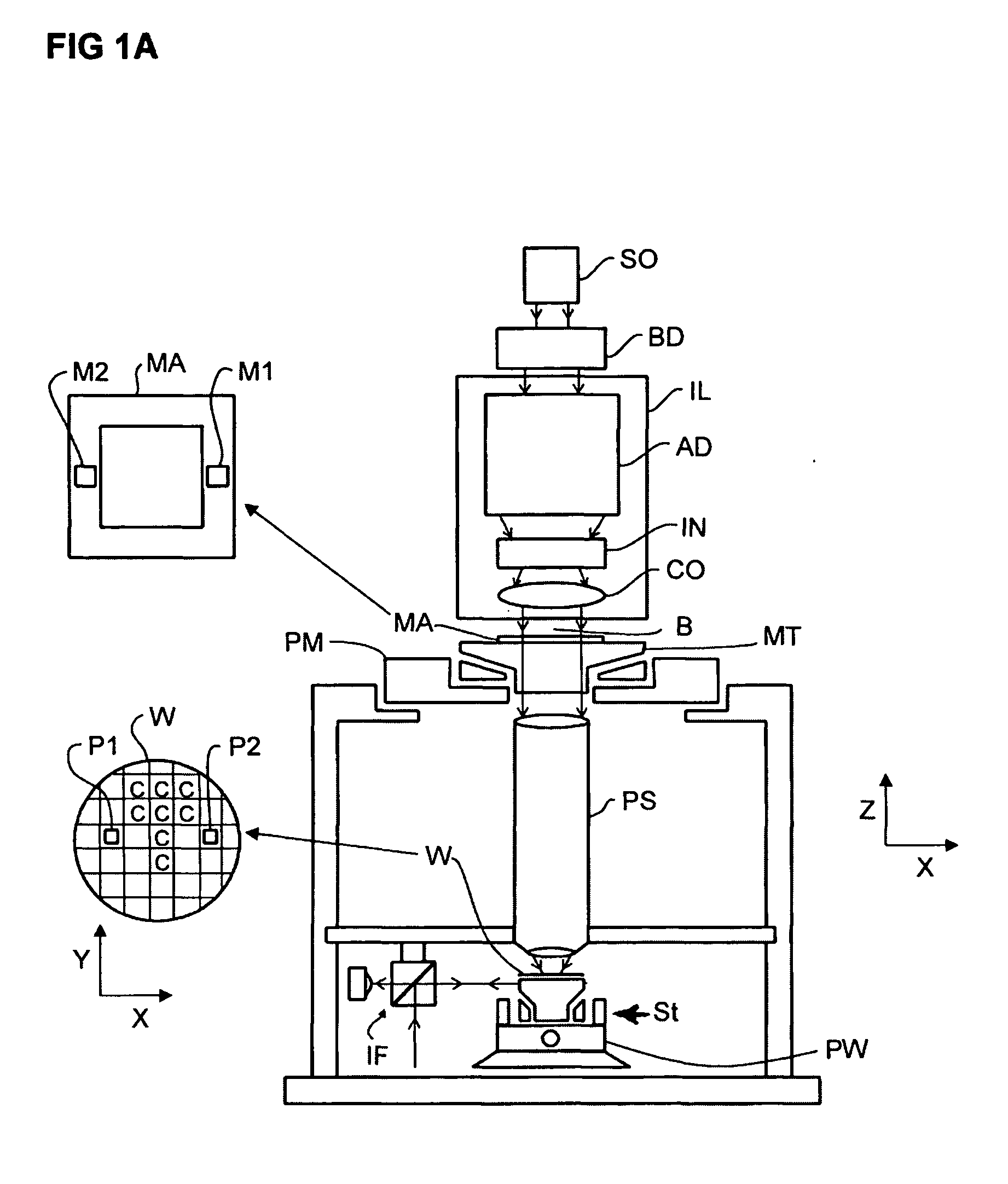

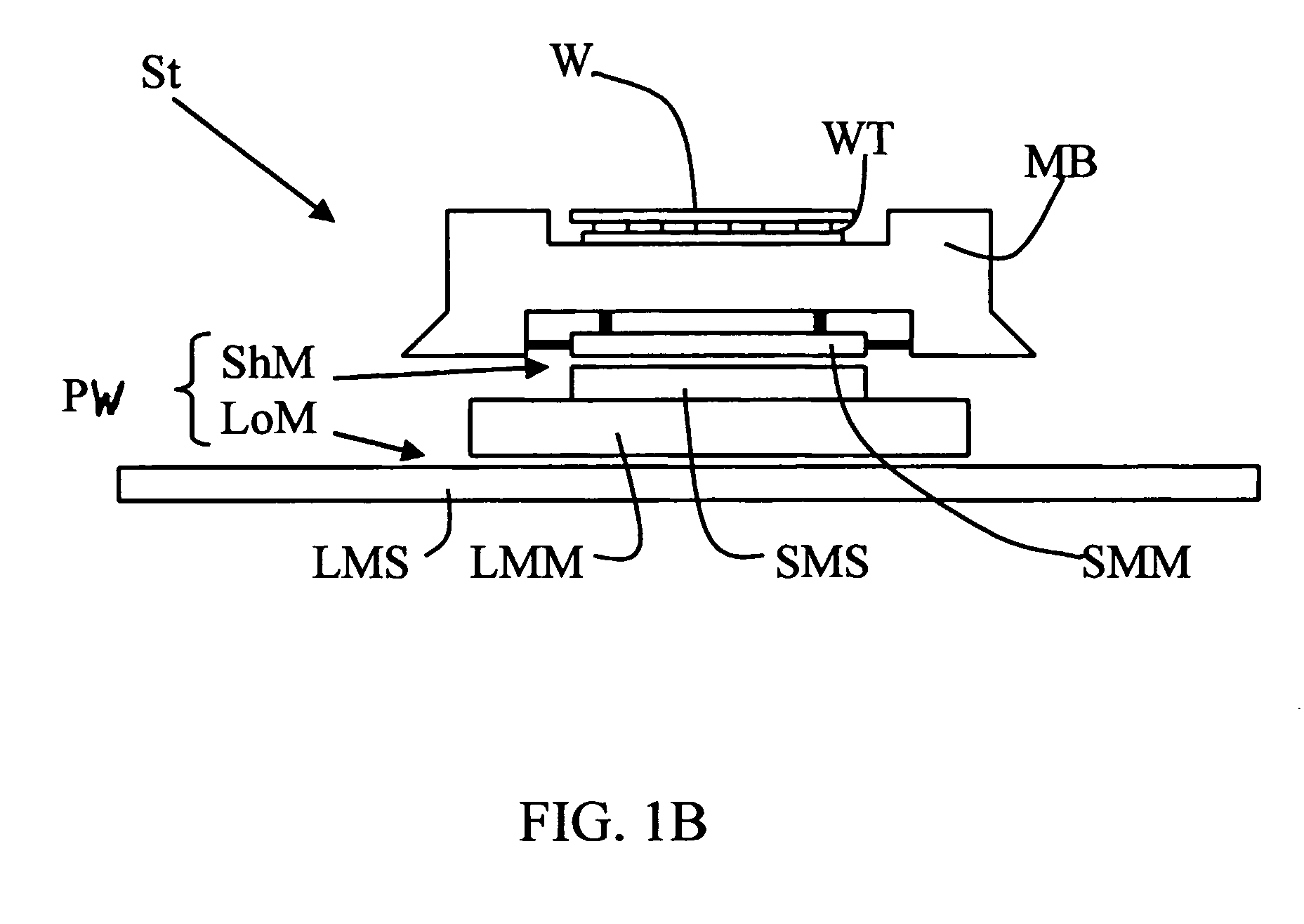

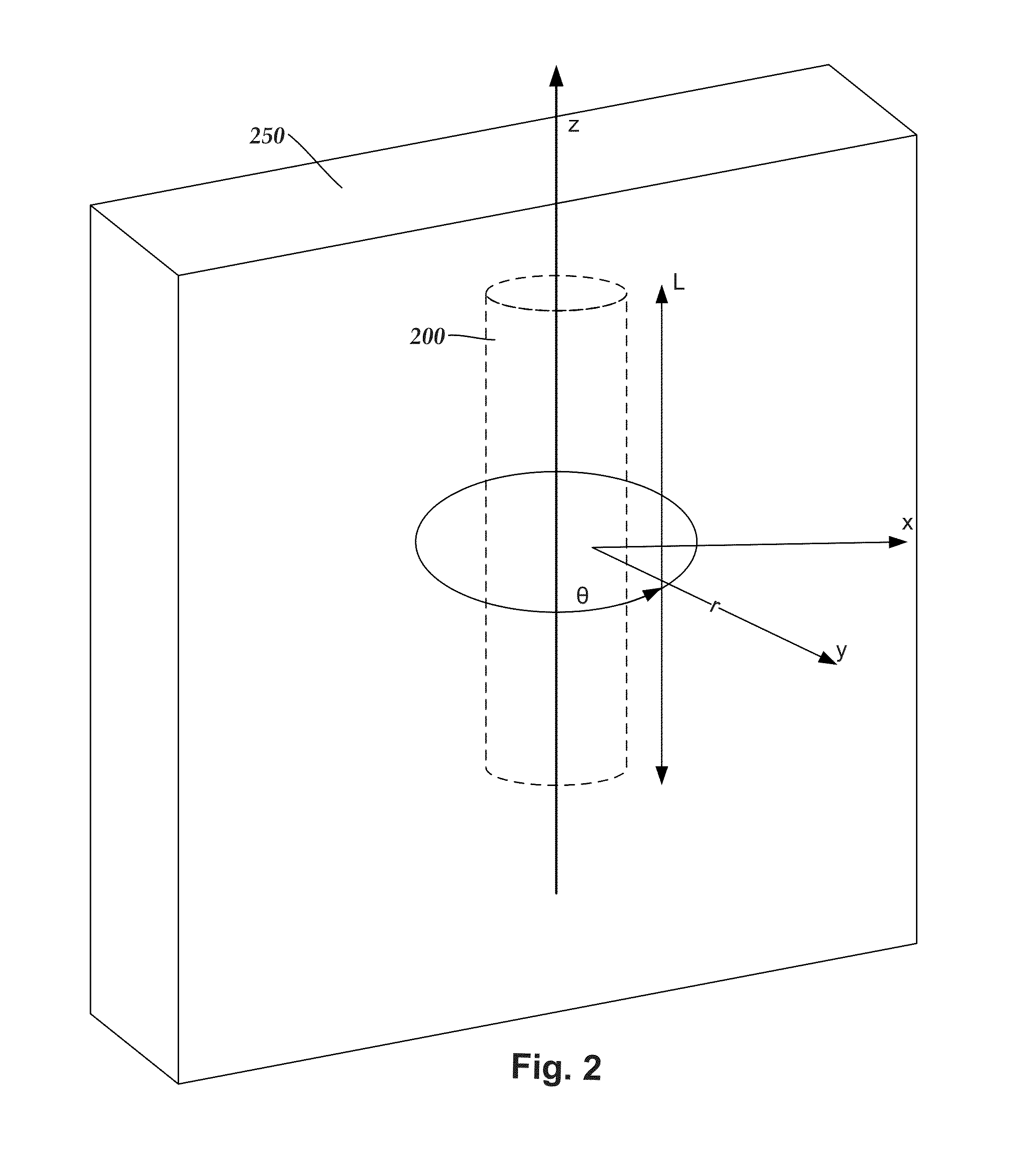

Lithographic apparatus and positioning apparatus

A lithographic apparatus comprises a substrate table to hold a substrate, a reference structure and a measurement system to measure a position of the substrate table with respect to the reference structure. The measurement system comprises a first measurement system to measure a position of the substrate table with respect to an intermediate structure and a second measurement system to measure a position of the intermediate structure with respect to the reference structure. The intermediate structure may be connected or connectable to a drive mechanism to drive the substrate table. A distance between the substrate table and the intermediate structure, resp. a distance between the intermediate structure and the reference structure may be small which results in a highly accurate position measurement.

Owner:ASML NETHERLANDS BV

High flexion articular insert

A knee prosthesis is provided that allows for increased flexion. The knee prosthesis includes (a) a femoral component adapted to fit on a distal end of the femur which includes a lateral condylar structure and a medial condylar structure and (b) an intermediate structure configured to cooperate with a femoral component of a knee prosthesis. The intermediate structure includes at least one surface for contacting the femoral component and a transition of a sagittal curvature of the at least one contact surface from a concave surface into a convex surface at the contact interface of the femoral component and the intermediate structure when the knee is flexed at approximately 120° to 140°. The knee prosthesis minimizes impingement on the femoral posterior cortex in deep flexion, increases the dislocation safety factor and allows for easier reengagement of the articular surface should the femoral component externally rotate off of the tibial plateau.

Owner:SMITH & NEPHEW INC

Lithographic apparatus and positioning apparatus

A lithographic apparatus comprises a substrate table to hold a substrate, a reference structure and a measurement system to measure a position of the substrate table with respect to the reference structure. The measurement system comprises a first measurement system to measure a position of the substrate table with respect to an intermediate structure and a second measurement system to measure a position of the intermediate structure with respect to the reference structure. The intermediate structure may be connected or connectable to a drive mechanism to drive the substrate table. A distance between the substrate table and the intermediate structure, and a distance between the intermediate structure and the reference structure may be small which results in a highly accurate position measurement.

Owner:ASML NETHERLANDS BV

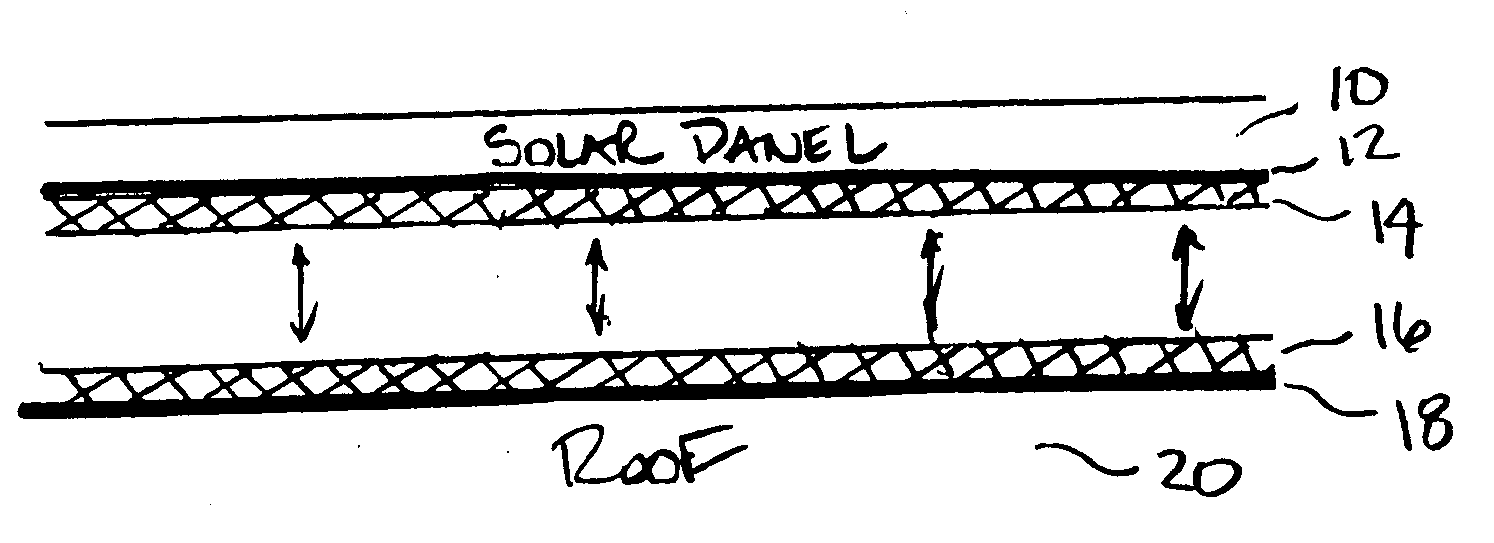

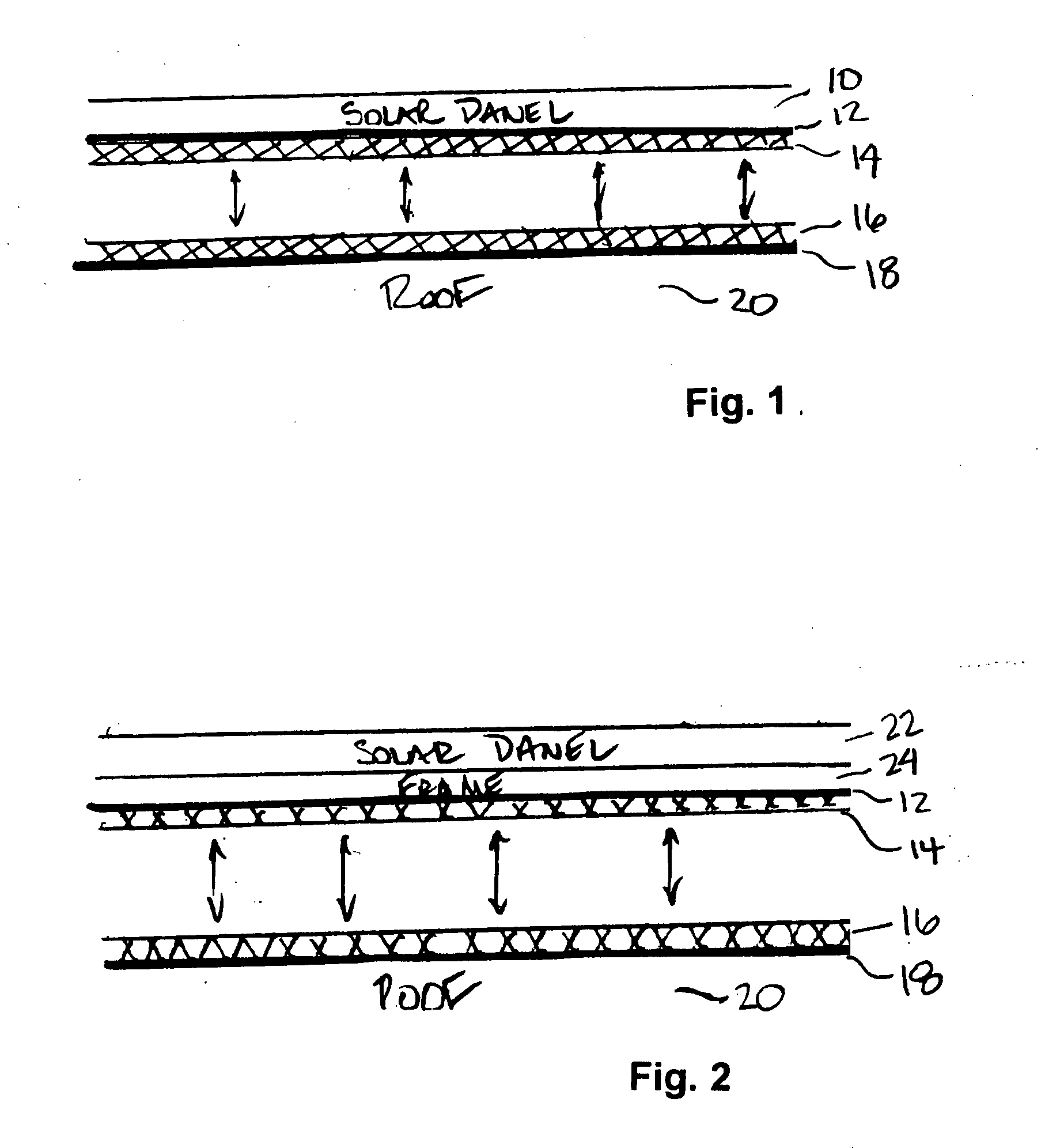

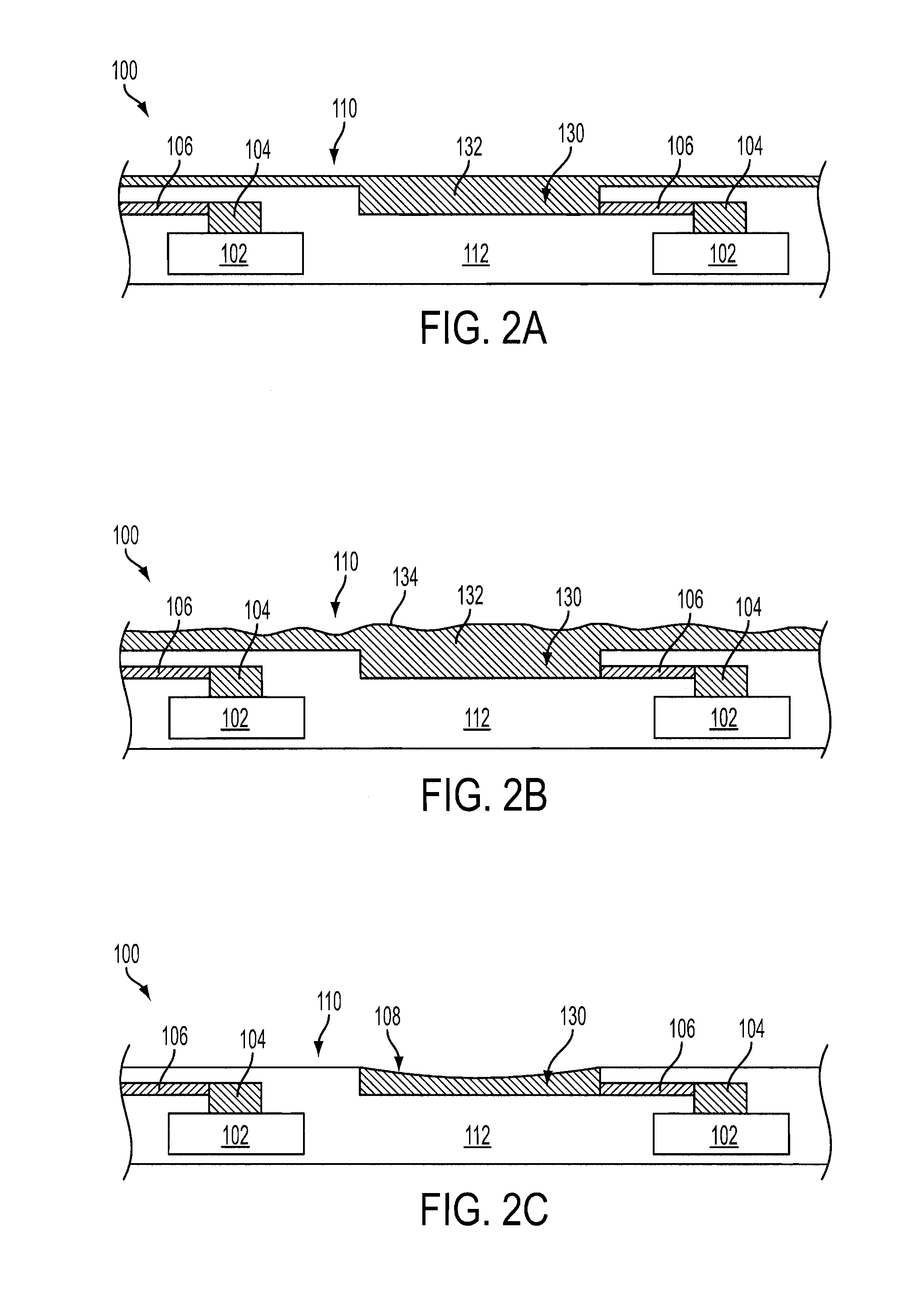

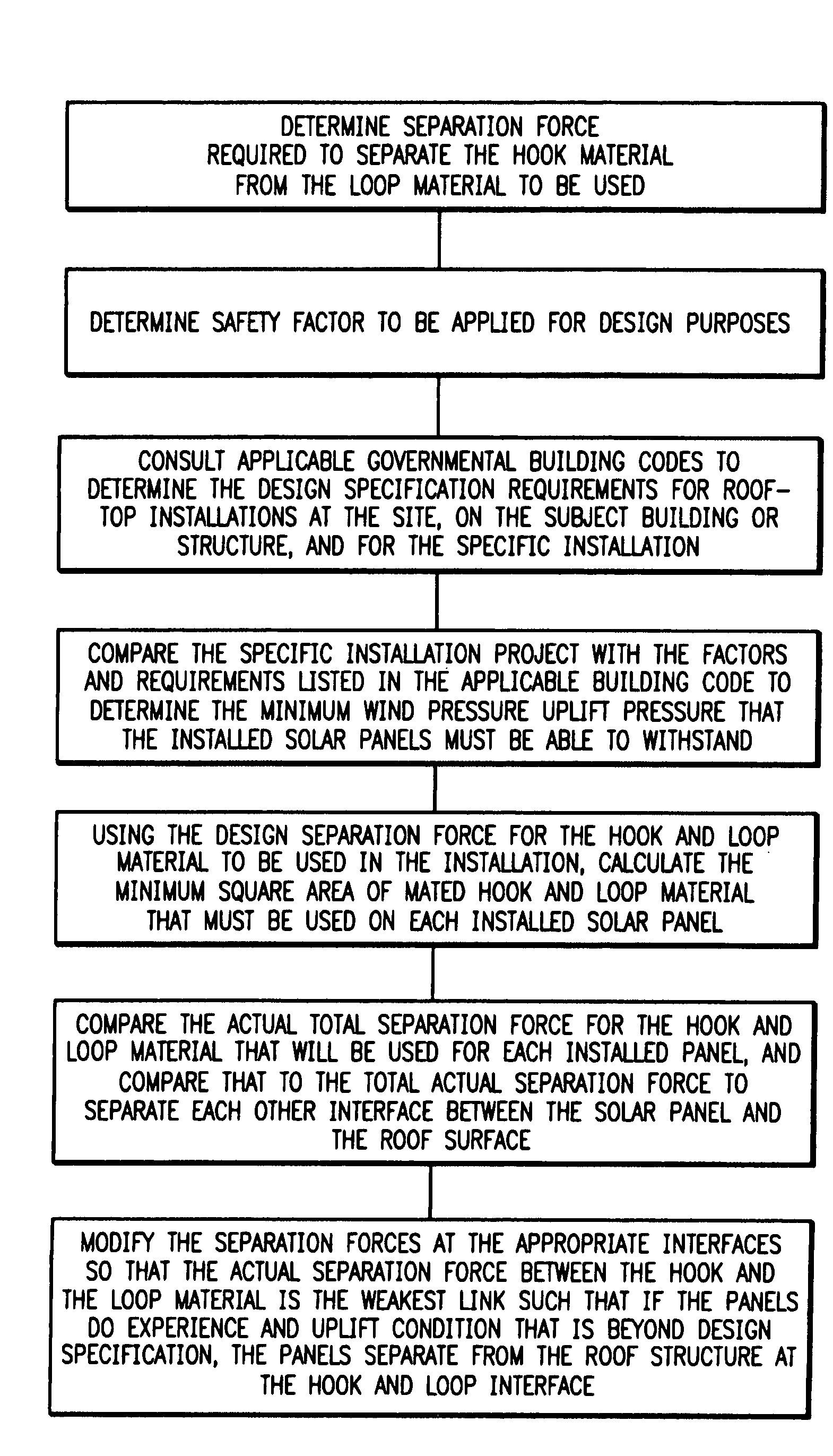

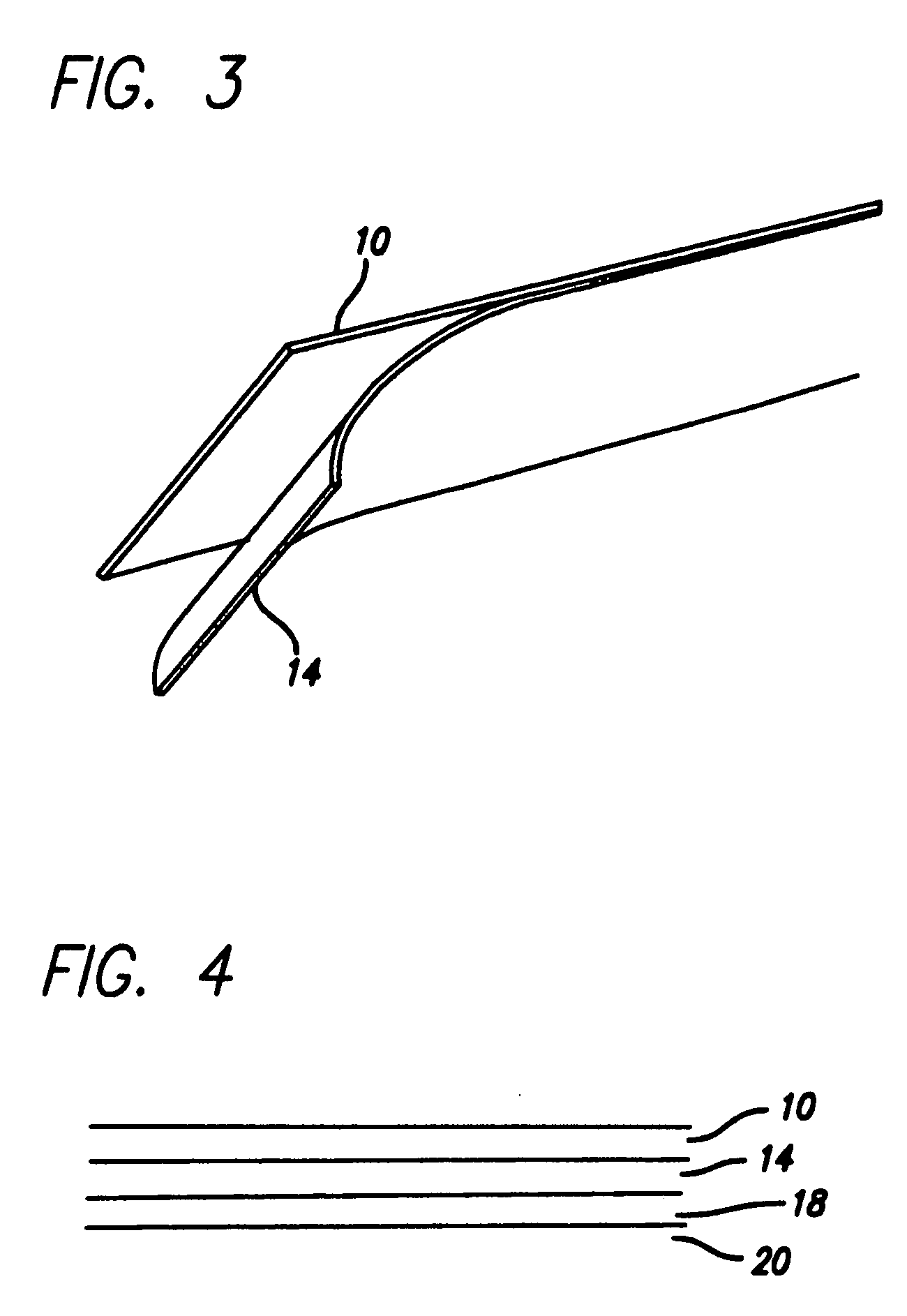

Apparatus and method for attaching solar panels to roof system surfaces

InactiveUS20080245404A1Reduce weightPhotovoltaic supportsSolar heating energyIntermediate structureSystem structure

An apparatus and method for attaching photovoltaic solar panels to a roof system surface. Thin film flexible panels are attached using a hook and loop system in which either the hook or loop material is attached to the underside of panel, and the other of the hook and loop material is attached the roof. Solar panels that are encased in a frame are attached using the hook and loop material directly to the roof system structure, or to an intermediate structure, which is in turn attached to the roof system surface. The method also determines the amount of mated hook and loop material that must be attached to each installed panel to ensure that the installed panels will be able to withstand the wind pressure uplift force required, and to ensure that in the event unexpected and exceessive uplift force is ever encountered, the panels separate at the hook and loop interface

Owner:DELIDDO JACK P

Lithogaphic apparatus and positioning apparatus

InactiveUS20060238731A1Photomechanical apparatusUsing optical meansEngineeringIntermediate structure

A lithographic apparatus comprises a substrate table to hold a substrate, a reference structure and a measurement system to measure a position of the substrate table with respect to the reference structure. The measurement system comprises a first measurement system to measure a position of the substrate table with respect to an intermediate structure and a second measurement system to measure a position of the intermediate structure with respect to the reference structure. The intermediate structure may be connected or connectable to a drive mechanism to drive the substrate table. A distance between the substrate table and the intermediate structure, resp. a distance between the intermediate structure and the reference structure may be small which results in a highly accurate position measurement.

Owner:ASML NETHERLANDS BV

Methods for bonding semiconductor structures involving annealing processes, and bonded semiconductor structures and intermediate structures formed using such methods

InactiveUS8716105B2Semiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor structure

Owner:SONY SEMICON SOLUTIONS CORP

Methods of forming layers of semiconductor material having reduced lattice strain, semiconductor structures, devices and engineered substrates including same

ActiveUS20100109126A1Low viscositySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsSemiconductor structure

Methods of fabricating semiconductor devices or structures include forming structures of a semiconductor material overlying a layer of a compliant material, subsequently changing the viscosity of the compliant material to relax the semiconductor material structures, and utilizing the relaxed semiconductor material structures as a seed layer in forming a continuous layer of relaxed semiconductor material. In some embodiments, the layer of semiconductor material may comprise a III-V type semiconductor material, such as, for example, indium gallium nitride. Novel intermediate structures are formed during such methods. Engineered substrates include a continuous layer of semiconductor material having a relaxed lattice structure.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

Lithographic apparatus and positioning apparatus

InactiveUS20060238733A1Precise processPhotomechanical apparatusPhotographic printingEngineeringLocation Equipment

A lithographic apparatus comprises a substrate table to hold a substrate, a reference structure and a measurement system to measure a position of the substrate table with respect to the reference structure. The measurement system comprises a first measurement system to measure a position of the substrate table with respect to an intermediate structure and a second measurement system to measure a position of the intermediate structure with respect to the reference structure. The intermediate structure may be connected or connectable to a drive mechanism to drive the substrate table. A distance between the substrate table and the intermediate structure, and a distance between the intermediate structure and the reference structure may be small which results in a highly accurate position measurement.

Owner:ASML NETHERLANDS BV

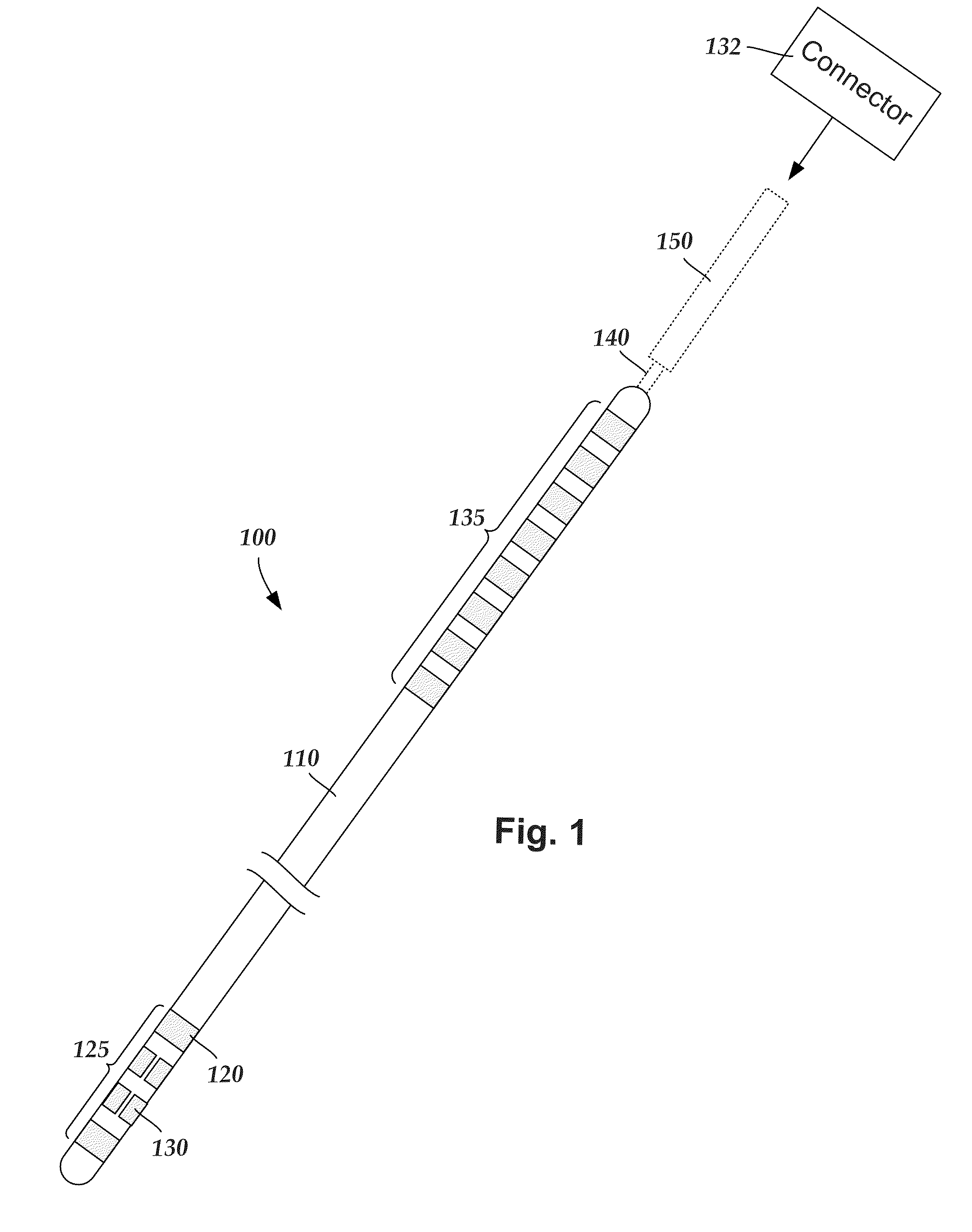

Molded segmented electrode leads and systems and methods of manufacturing and using the leads and systems

A lead with segmented electrodes can be made using one or two mold methods. In one method, segmented electrodes are individually disposed on pins on an interior surface within a mold. Each of the segmented electrodes has at least one opening formed in the exterior surface of the segmented electrode. The lead body is then molded between the electrodes. In a two mold method, segmented electrodes are inserted into electrode slots of a first mold and an interior portion of a lead body is formed. The resulting intermediate arrangement is placed into a second mold to form an exterior portion of the lead body. In another two mold method, a sacrificial ring is formed around the segmented electrodes in a first mold and the resulting intermediate structure is inserted in a second mold to form the lead body. The sacrificial ring is then removed.

Owner:BOSTON SCI NEUROMODULATION CORP

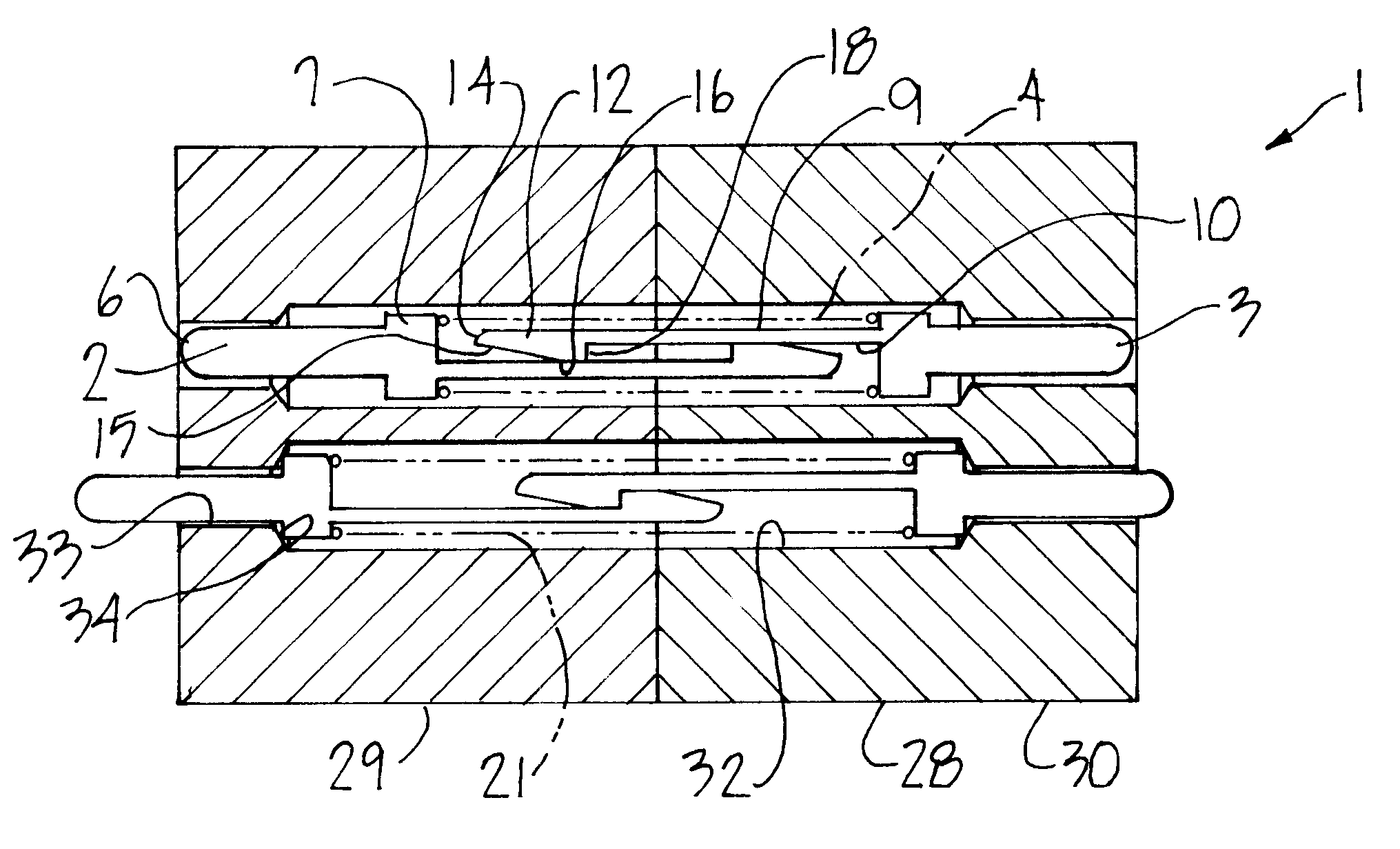

Electrical contact interface

An electrical contact interface consists of a probe formed by a pair of oppositely extending plungers each having a contact tip, an inner shoulder and a rearwardly extending shaft terminating in a lug end. A coil spring is sleeved about the opposed plungers and is positioned between the opposite inner shoulders with the shafts extending toward each other and in constant sliding engagement with each other through the lug ends. The lug ends abut each other at an extreme travel relation of the plungers and prevent mutual disengagement of the plungers from within the coil spring. The probe is mounted in a fixture or other intermediate structure for positioning between circuit contacts. The probe finds particular use in applications requiring robust design and in which electrical contact must be maintained.

Owner:SMITHS INTERCONNECT AMERICAS INC

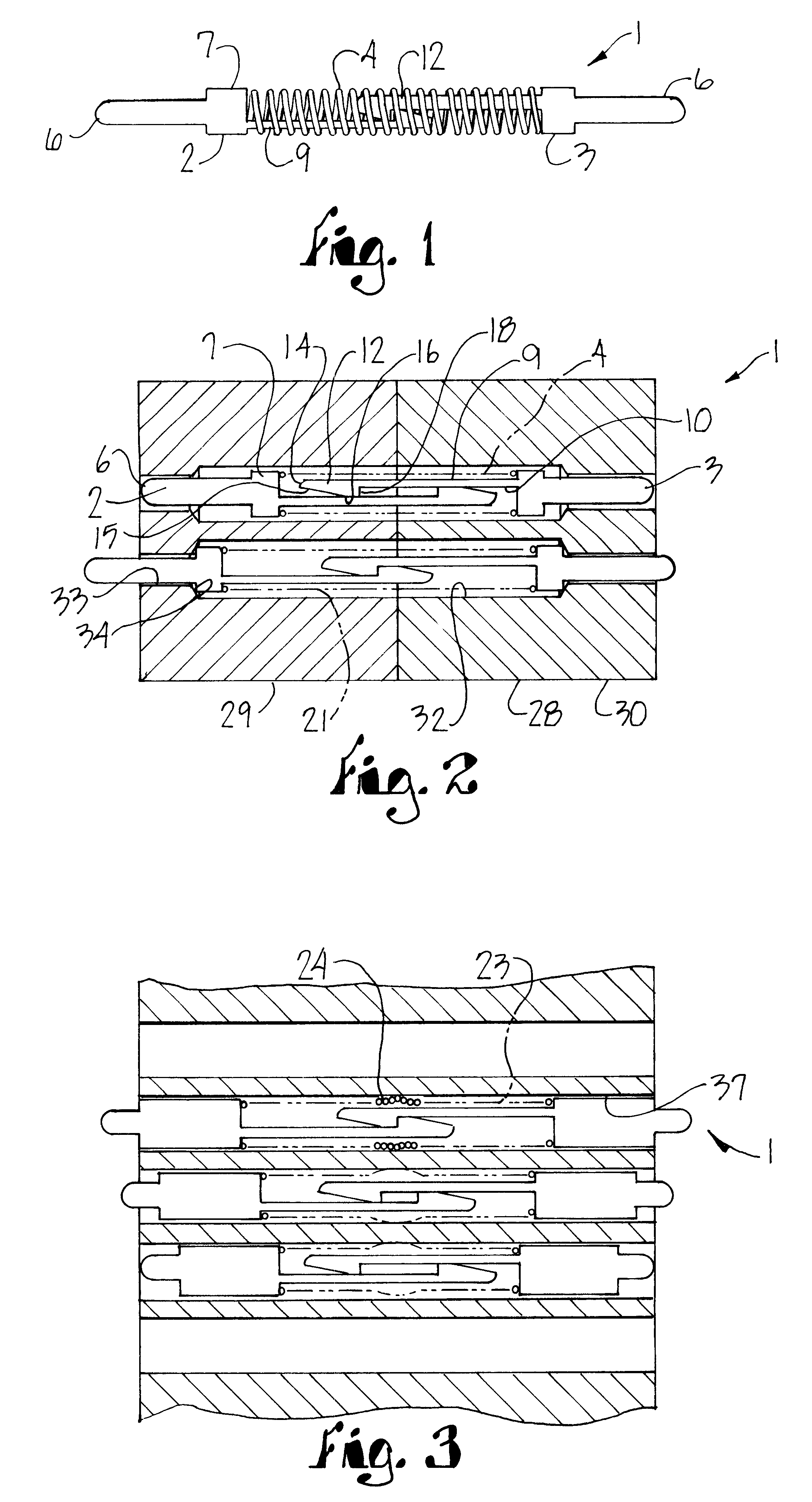

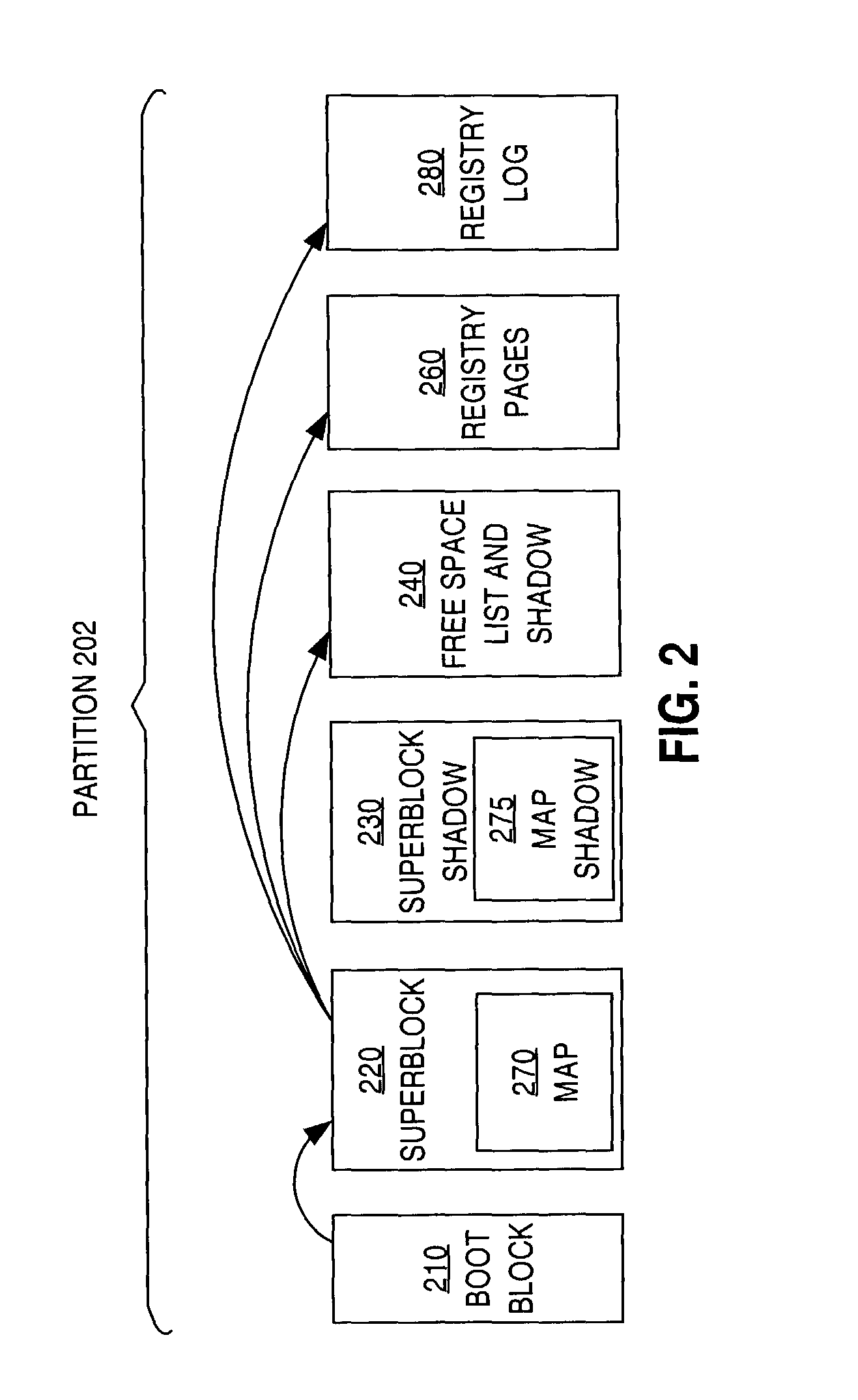

Metadata format for hierarchical data storage on a raw storage device

ActiveUS7136867B1Data processing applicationsDigital data information retrievalArray data structureIntermediate structure

A system and techniques are described for formatting a persistent storage device to store hierarchical data. According to one aspect of the invention, data structures are established, at a base level of the persistent storage device, for storing a hierarchy of key-value pairs. A first structure, which corresponds to a root node of the hierarchy, is established. A second structure, which corresponds to a key-value pair, is established. The second structure stores the value of the key-value pair. Links, which lead from the first structure to the second structure through one or more intermediate structures, are established based on a position, within the hierarchy, of the key.

Owner:ORACLE INT CORP

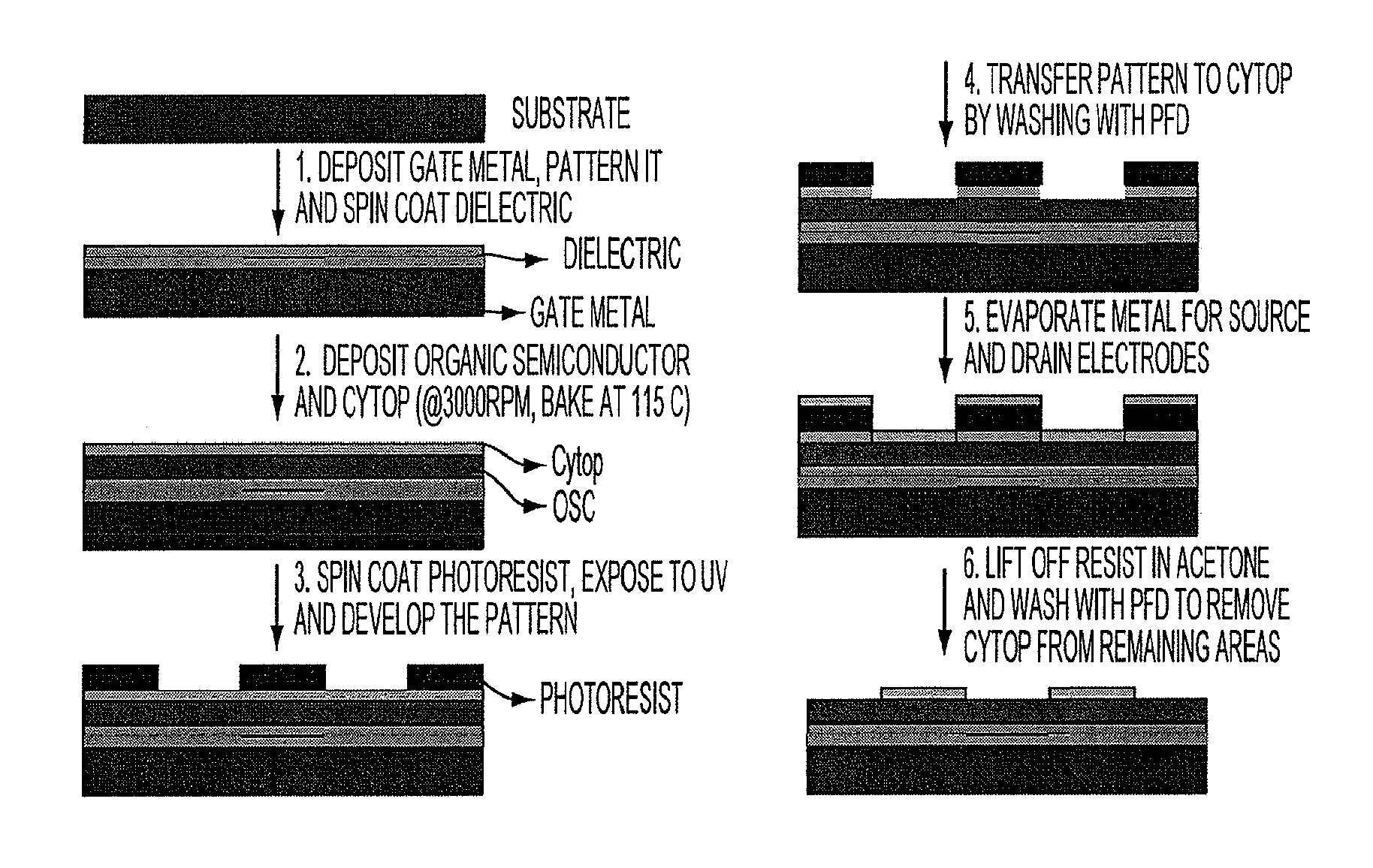

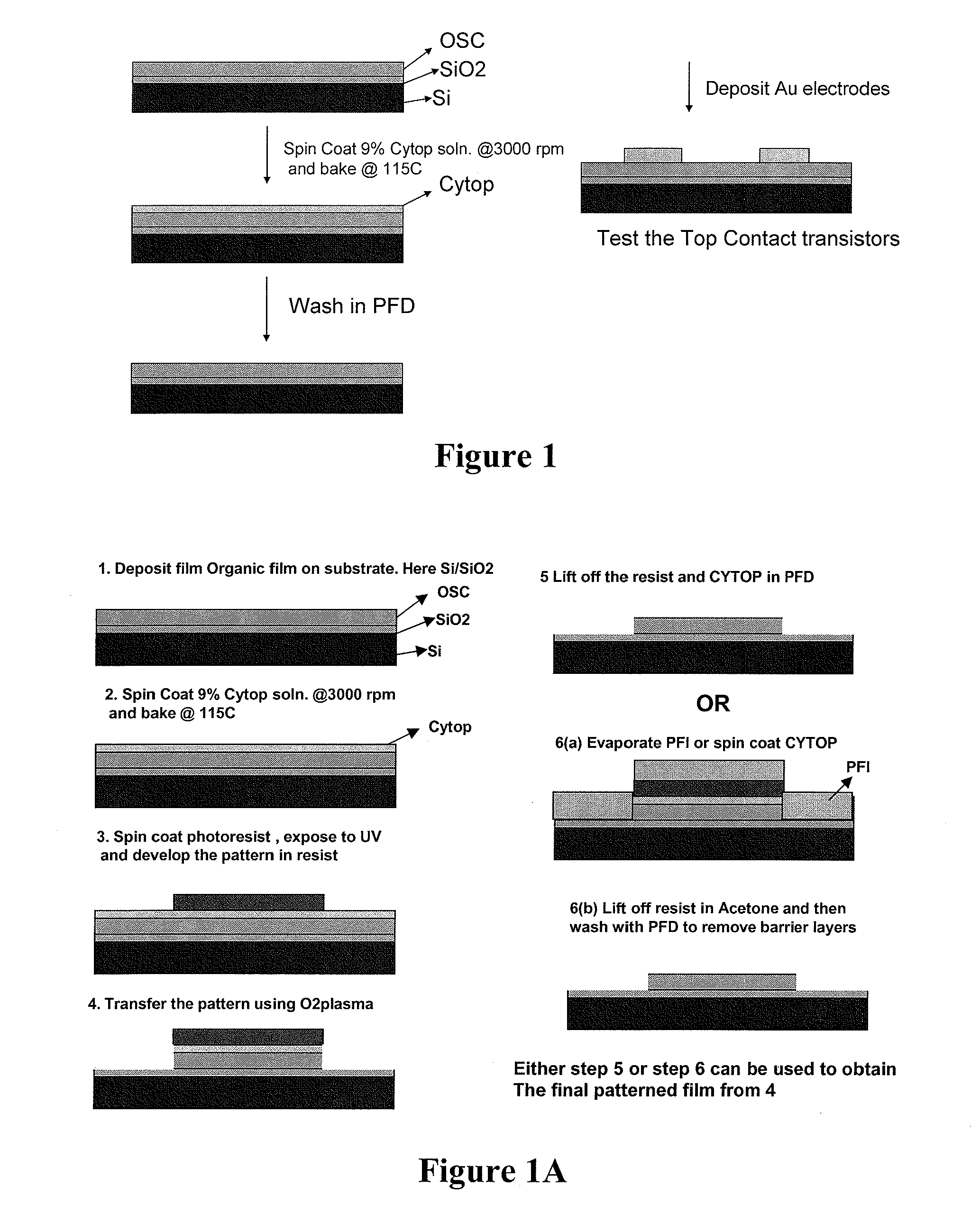

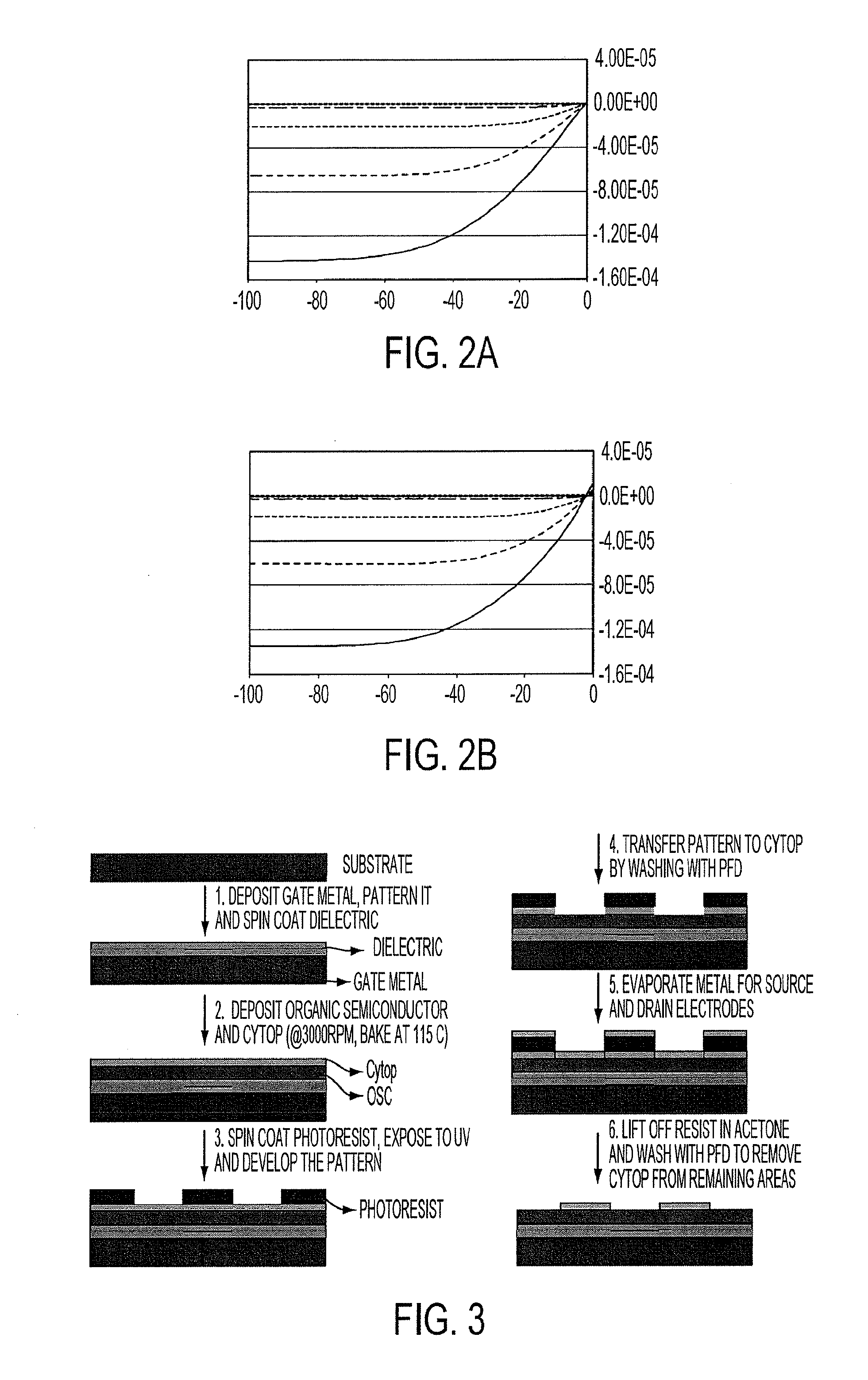

Patterning devices using fluorinated compounds

A method for producing a spatially patterned structure includes forming a layer of a material on at least a portion of a substructure of the spatially patterned structure, forming a barrier layer of a fluorinated material on the layer of material to provide an intermediate structure, and exposing the intermediate structure to at least one of a second material or radiation to cause at least one of a chemical change or a structural change to at least a portion of the intermediate structure. The barrier layer substantially protects the layer of the material from chemical and structural changes during the exposing. Substructures are produced according to this method.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

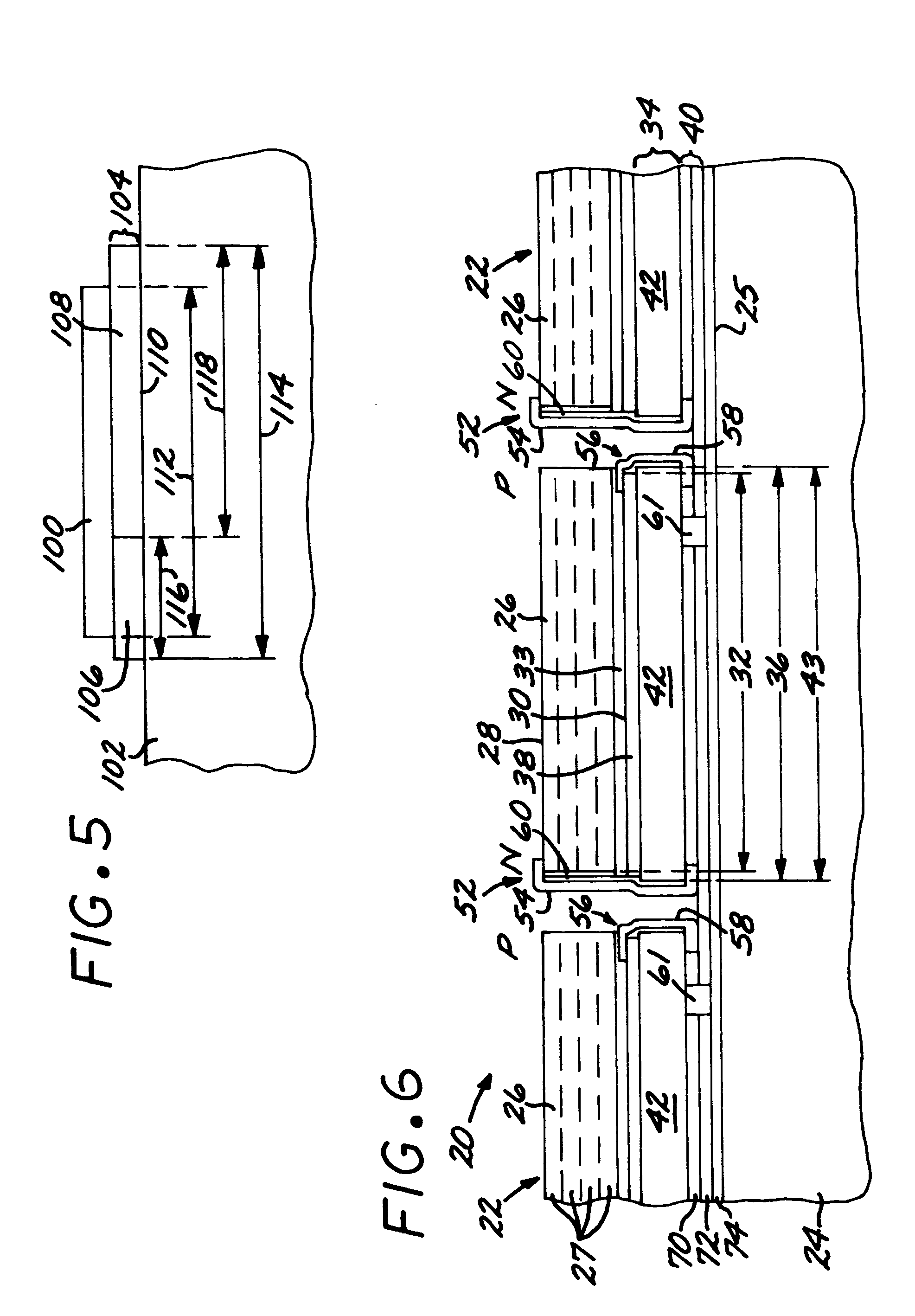

Methods for forming through-wafer interconnects and devices and systems having at least one dam structure

ActiveUS20070262424A1Conveniently attachedEliminate cross-contaminationSemiconductor/solid-state device detailsSolid-state devicesVitrificationDevice material

A method for forming through-wafer interconnects (TWI) in a substrate. Blind holes are formed from a surface, sidewalls thereof passivated and coated with a conductive material. A vent hole is then formed from the opposite surface to intersect the blind hole. The blind hole is solder filled, followed by back thinning of the vent hole portion of the wafer to a final substrate thickness to expose the solder and conductive material at both the active surface and the thinned back side. A metal layer having a glass transition temperature greater than that of the solder may be plated to form a dam structure covering one or both ends of the TWI. Intermediate structures of semiconductor devices, semiconductor devices and systems are also disclosed.

Owner:MICRON TECH INC

Methods for fabricating and filling conductive vias and conductive vias so formed

ActiveUS20070184654A1Improve adhesionEliminating the potential for misalignment between different sectionsSemiconductor/solid-state device detailsSolid-state devicesDevice materialConductive materials

Methods for forming conductive vias include forming one or more via holes in a substrate. The via holes may be formed with a single mask, with the protective layers, bond pads, or other features of the substrate acting as hard masks in the event that a photomask is removed during etching processes. The via holes may be configured to facilitate adhesion of a dielectric coating that includes a low-K dielectric material to the surfaces thereof. A barrier layer may be formed over surfaces of each via hole. A base layer, which may comprise a seed material, may be formed to facilitate the subsequent, selective deposition of conductive material over the surfaces of the via hole. The resulting semiconductor devices, intermediate structures, and assemblies and electronic devices that include the semiconductor devices that result from these methods are also disclosed.

Owner:MICRON TECH INC

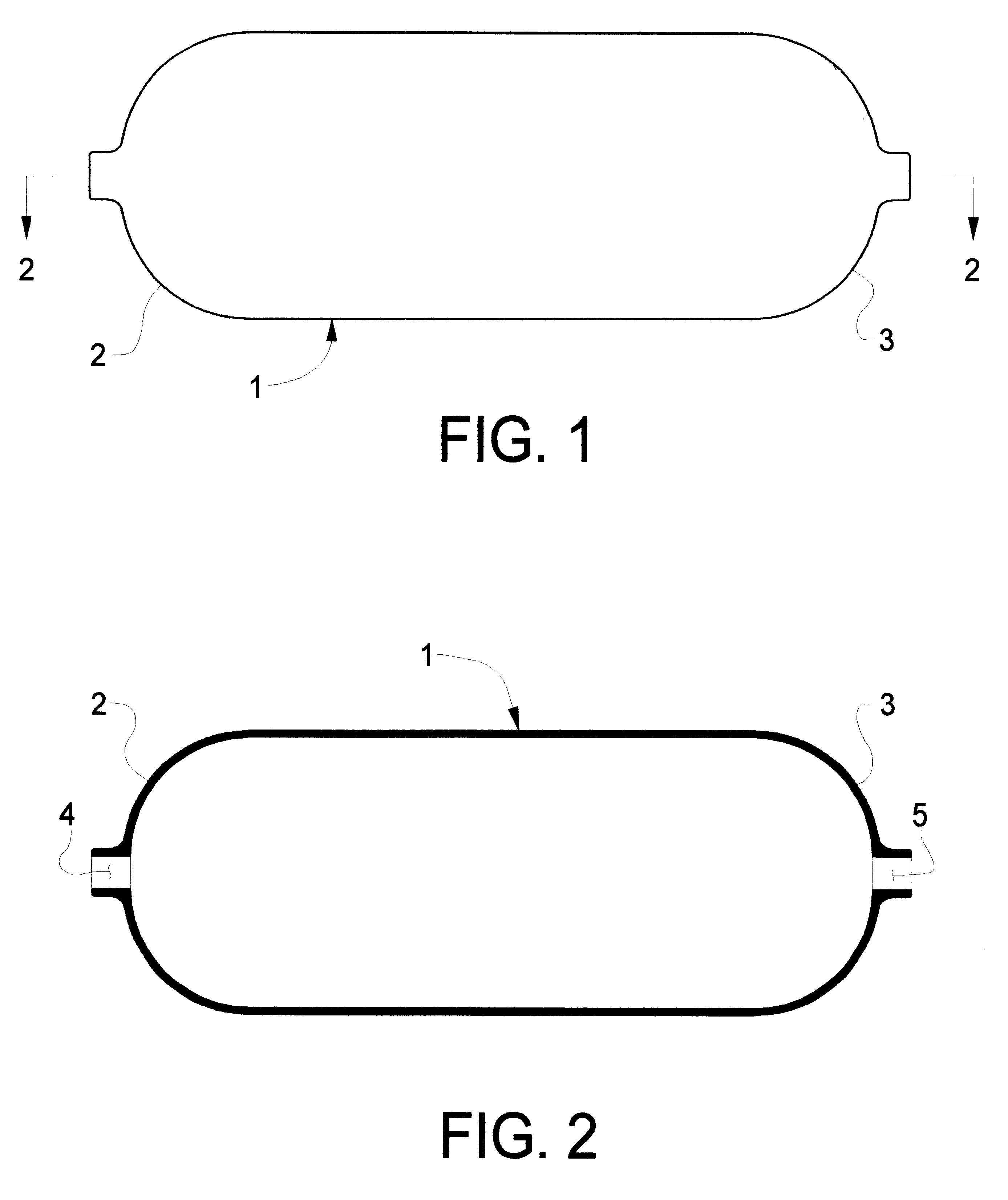

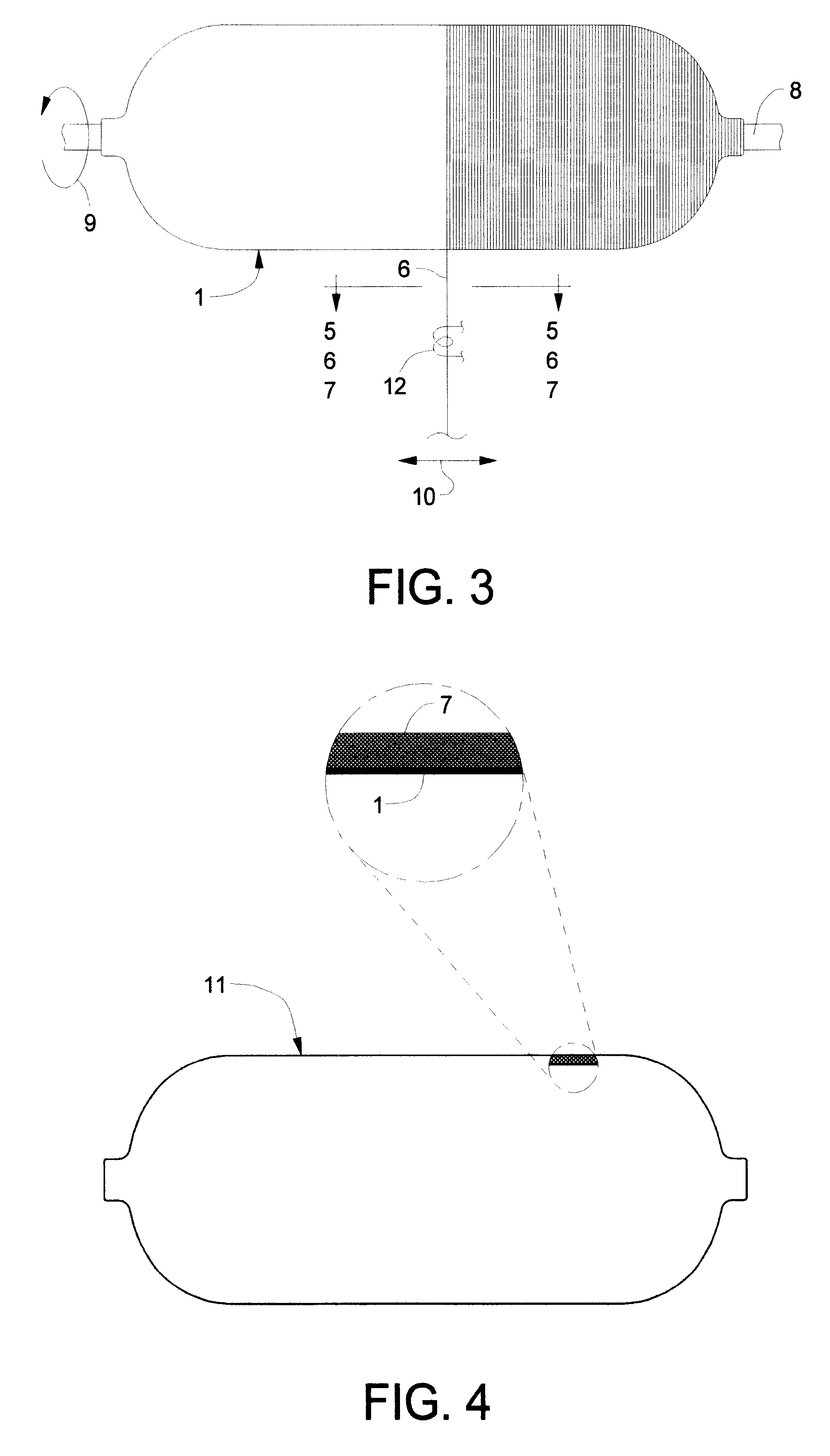

Method for fabricating composite pressure vessels and products fabricated by the method

InactiveUS6485668B1Speed up the processRatio is limitedLabelling non-rigid containersConfectioneryFiberSilicon rubber

A process, and the product thereof, for making a composite vessel having at least one closed end, the process including the steps of: fabricating a thermoplastic liner for the vessel; overlaying onto the liner a layer of commingled fiber and thermoplastic material to obtain a composite intermediate structure; pressing and heating the composite intermediate structure to effect at least partial consolidation in apparatus which includes upper and lower silicon rubber bags, the bags having dimensions such that, during operation, their facing peripheral regions abut to encompass the composite intermediate structure; then placing the composite intermediate structure in a mold; heating the composite intermediate structure in the mold while applying a force, such as internal gas pressure, tending to urge the composite intermediate structure against and into the shape of the interior walls of the mold until the thermoplastic liner and the overlaid layer fully consolidate; cooling the mold and composite vessel until the composite vessel is solidified; and removing the formed composite vessel from the mold. The commingled fiber and thermoplastic material may either be wound onto the liner or laid on the liner in the form of fabric woven from the fiber and threads of the thermoplastic material.

Owner:ESSEF CORP +1

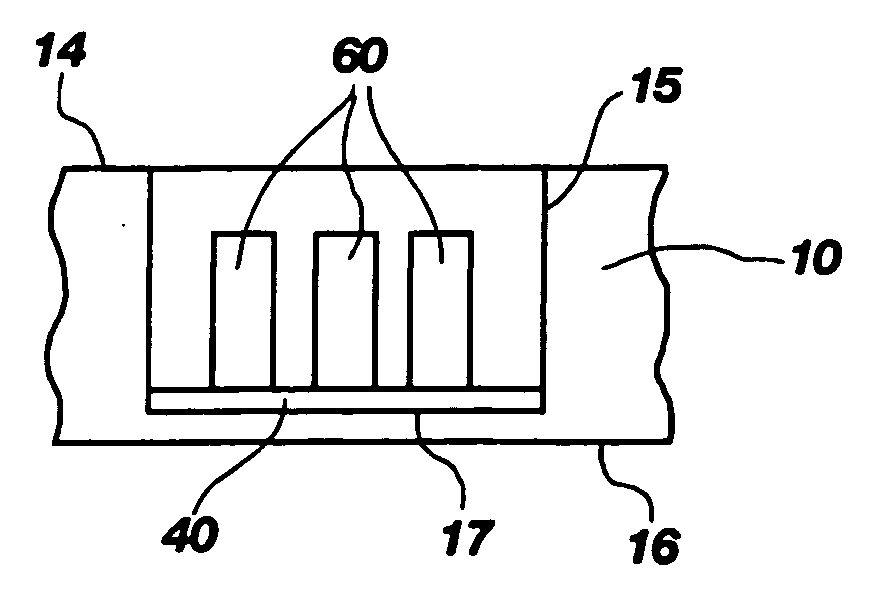

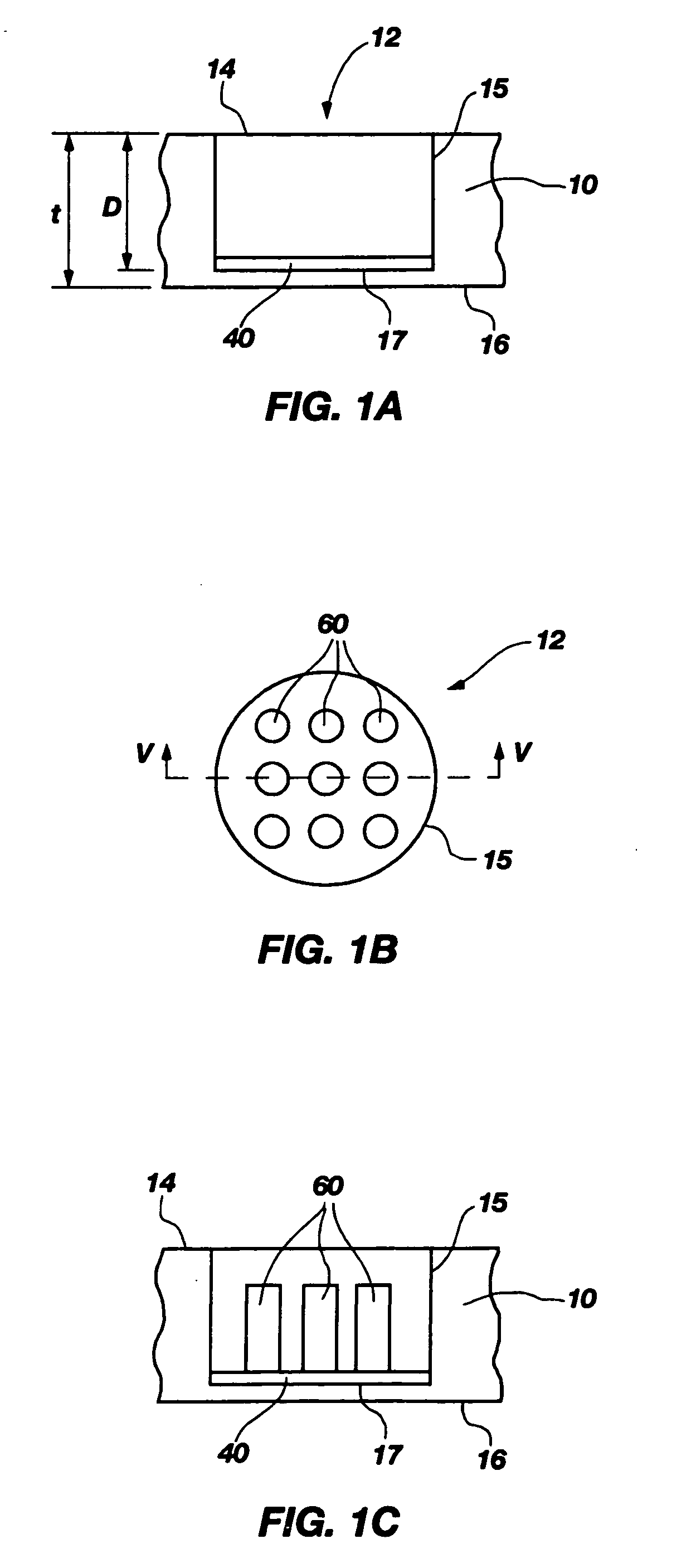

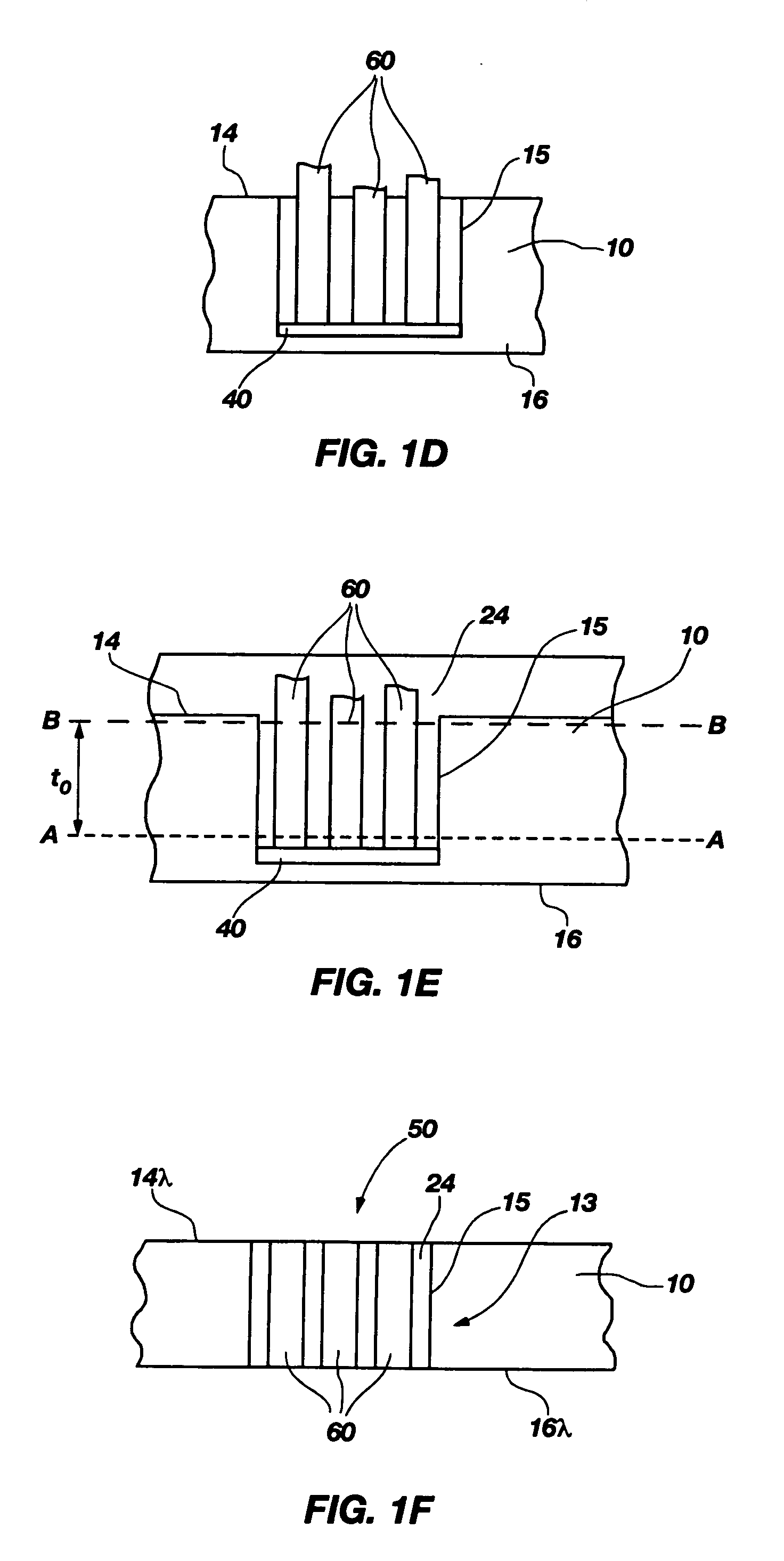

Nanotubes having controlled characteristics and methods of manufacture thereof

A method of forming a plurality of nanotubes is disclosed. Particularly, a substrate may be provided and a plurality of recesses may be formed therein. Further, a plurality of nanotubes may be formed generally within each of the plurality of recesses and the plurality of nanotubes may be substantially surrounded with a supporting material. Additionally, at least some of the plurality of nanotubes may be selectively shortened and at least a portion of the at least some of the plurality of nanotubes may be functionalized. Methods for forming semiconductor structures intermediate structures, and semiconductor devices are disclosed. An intermediate structure, intermediate semiconductor structure, and a system including nanotube structures are also disclosed.

Owner:MICRON TECH INC

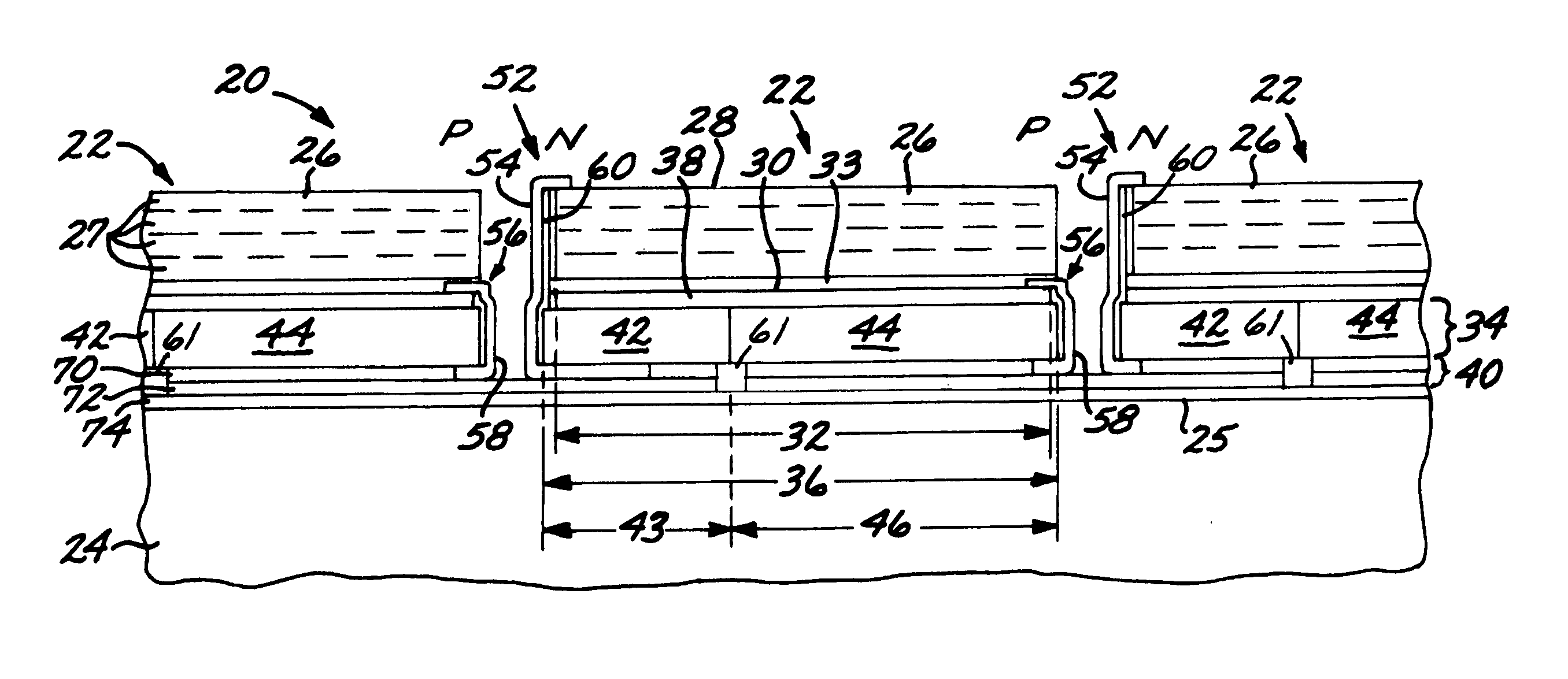

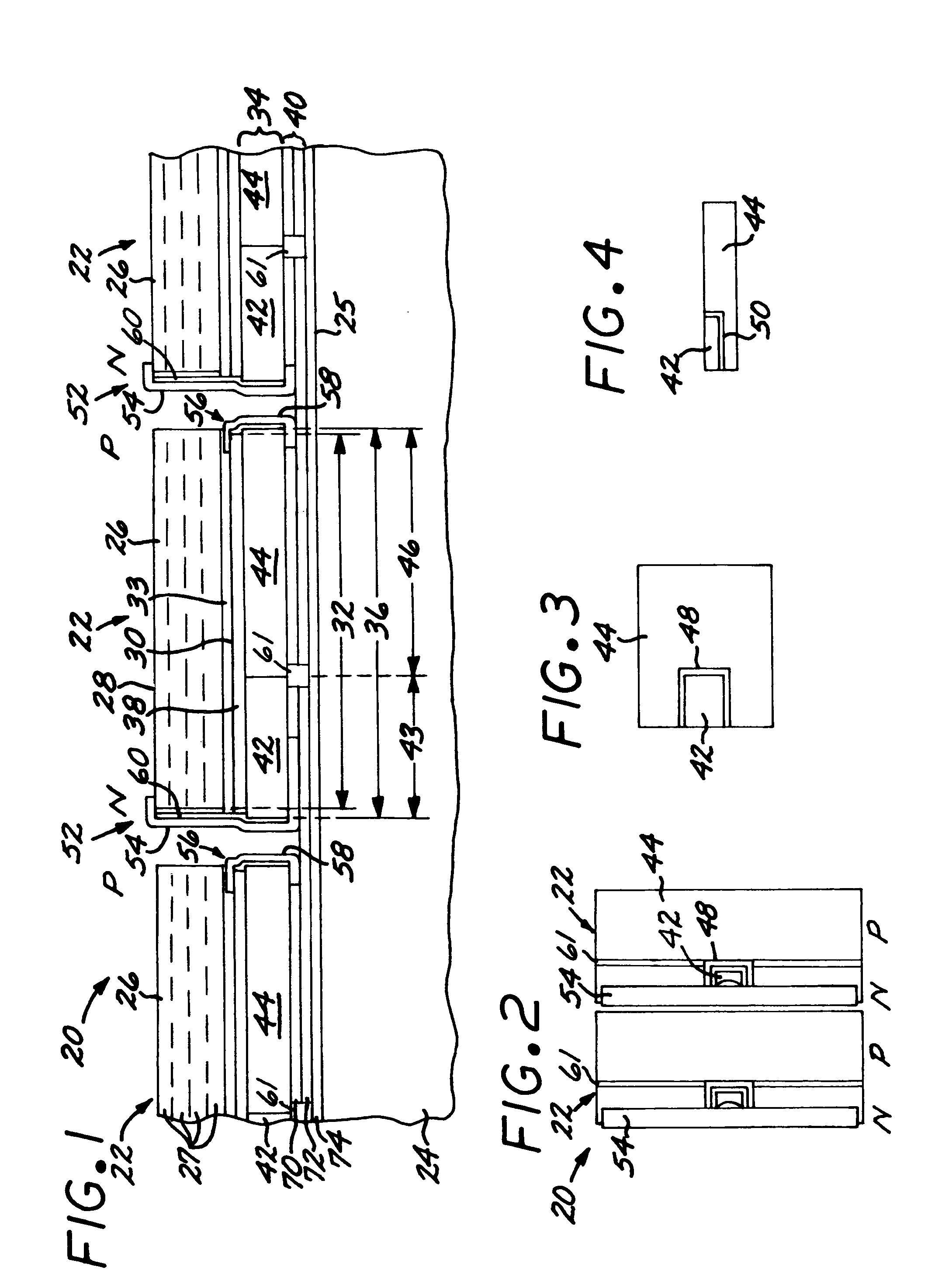

Solar cell structure with integrated discrete by-pass diode

A solar cell structure has a solar cell unit structure including a heat sink, and a solar cell having a front side, a back side, and a solar-cell projected area coverage on the heat sink. The solar cell has an active semiconductor structure that produces a voltage between the front side and the back side when the front side is illuminated. An intermediate structure is disposed between and joined to the back side of the solar cell and to the heat sink. The intermediate structure has an intermediate-structure projected area coverage on the heat sink and includes a by-pass diode having a diode projected area coverage on the heat sink. The diode projected area coverage on the heat sink may be substantially the same as the intermediate-structure projected coverage on the heat sink. Alternatively, the diode projected area coverage on the heat sink maybe less than the solar-cell projected area coverage on the heat sink, and the intermediate structure further includes a substrate coplanar with the by-pass diode.

Owner:THE BOEING CO

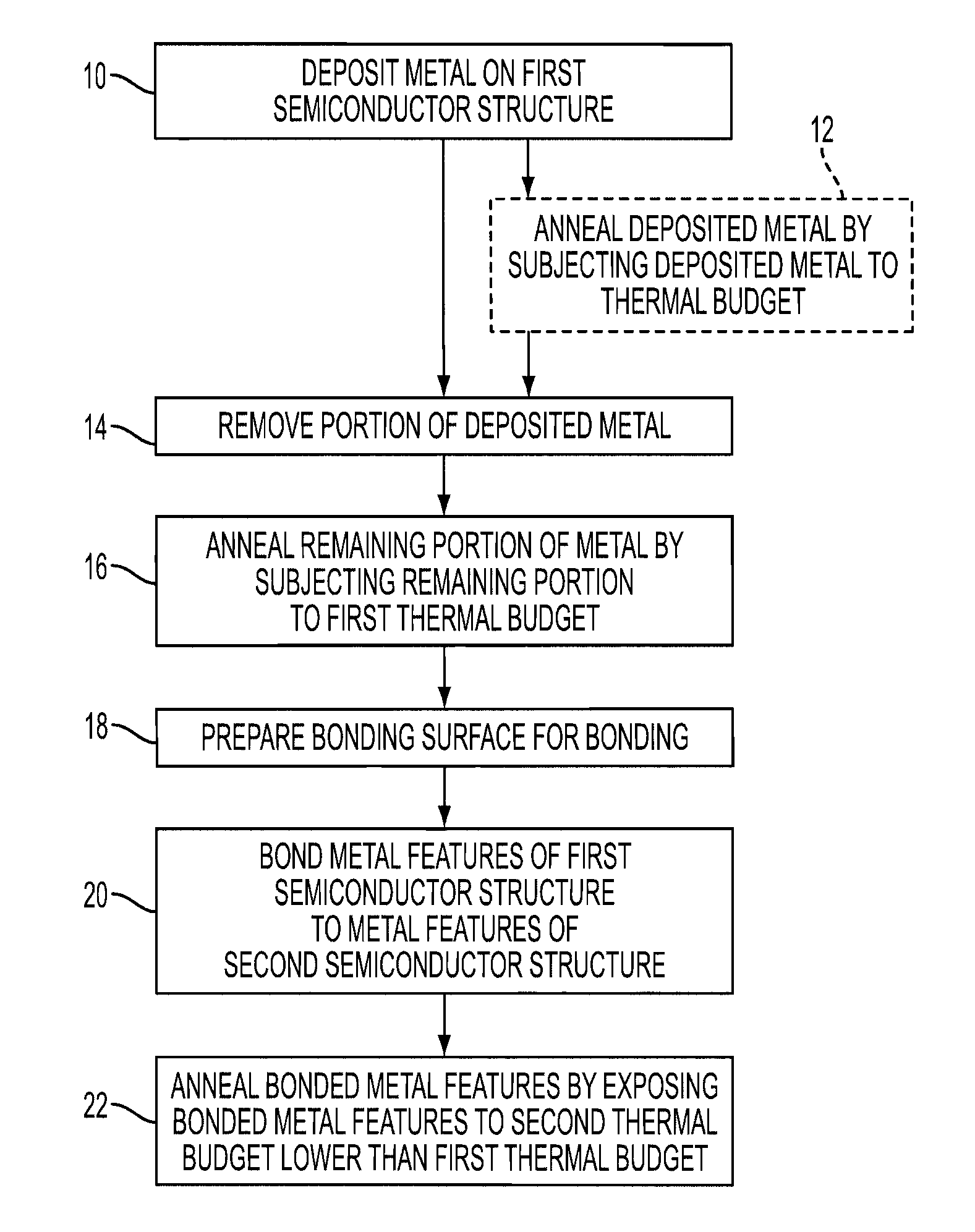

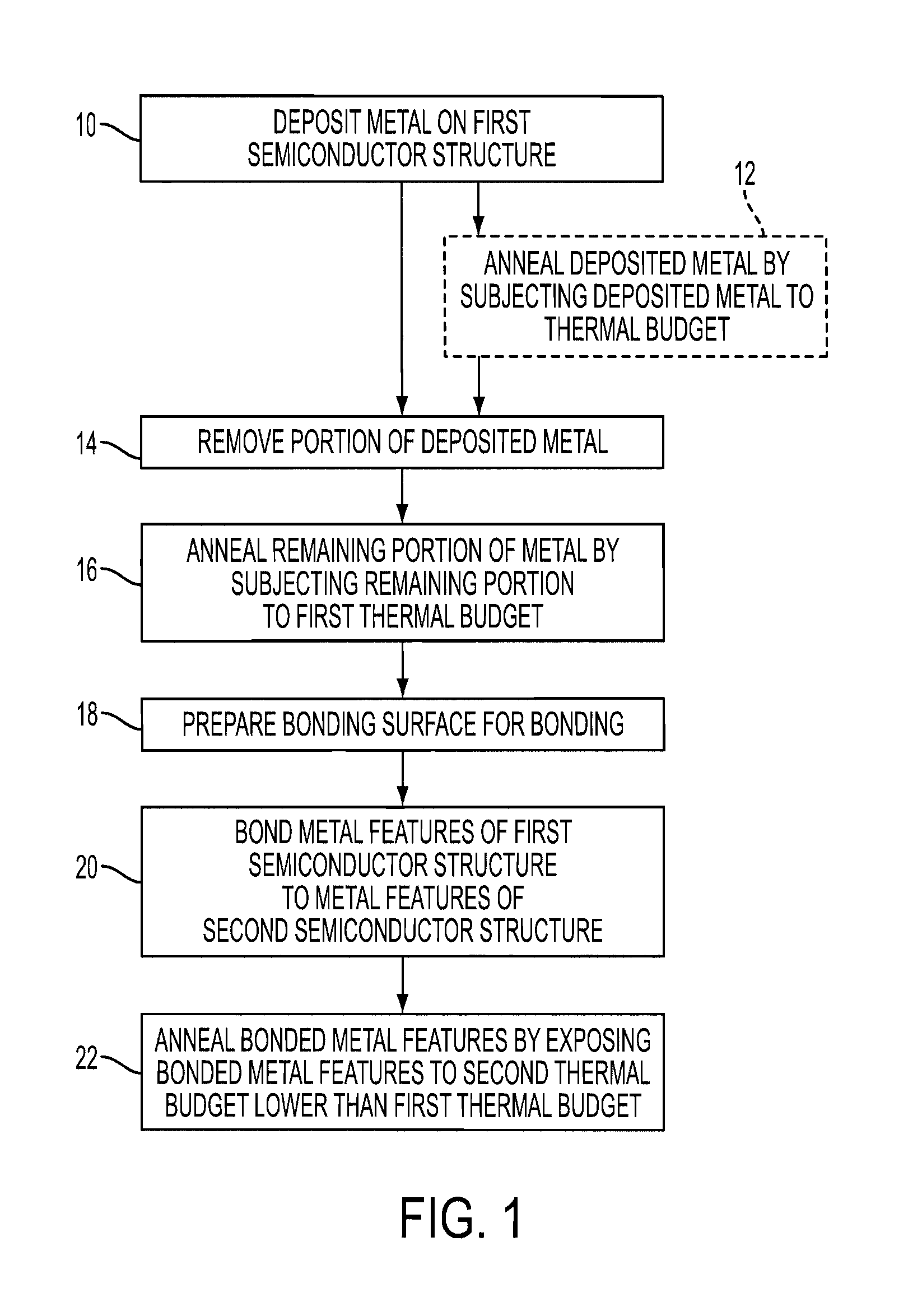

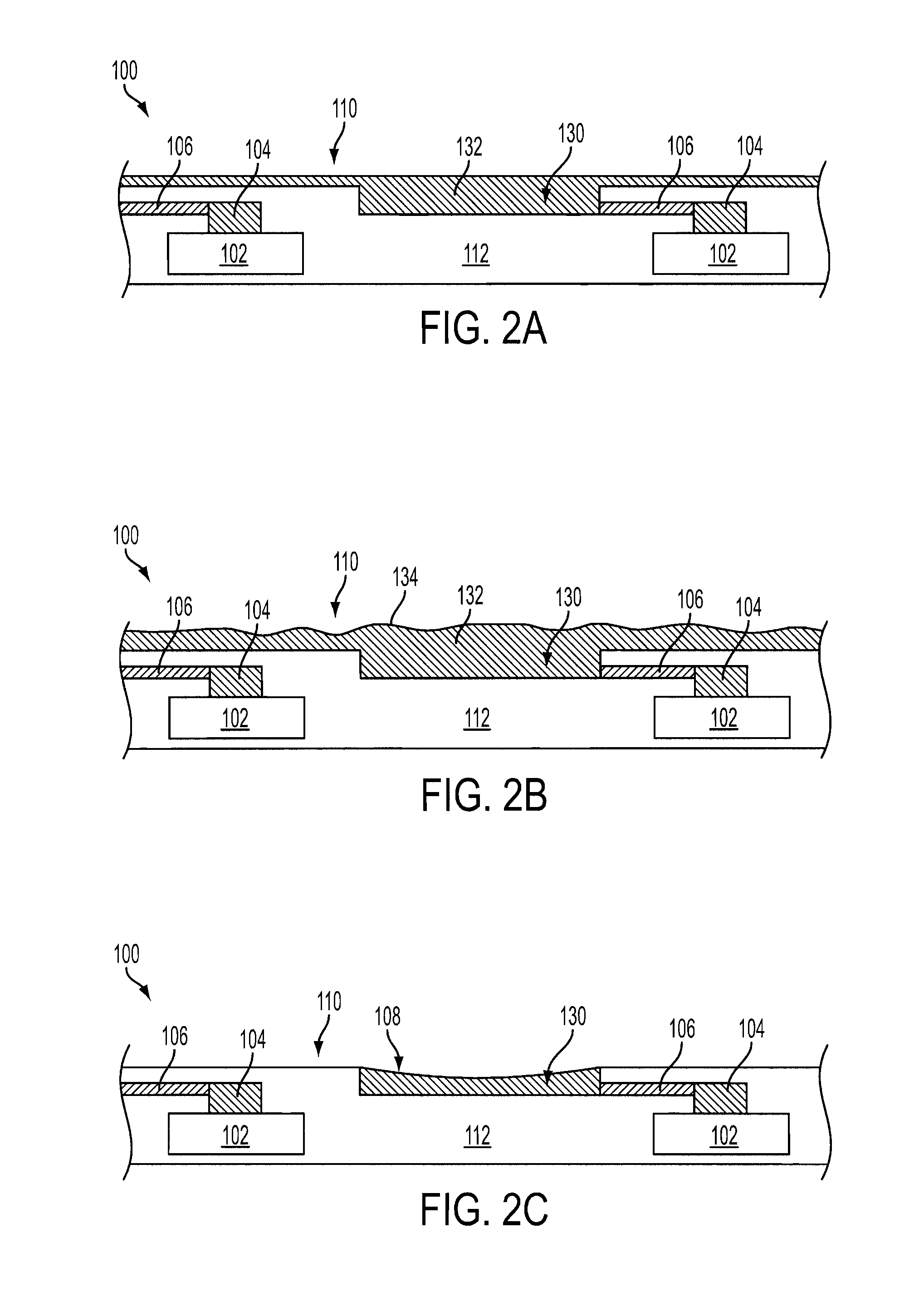

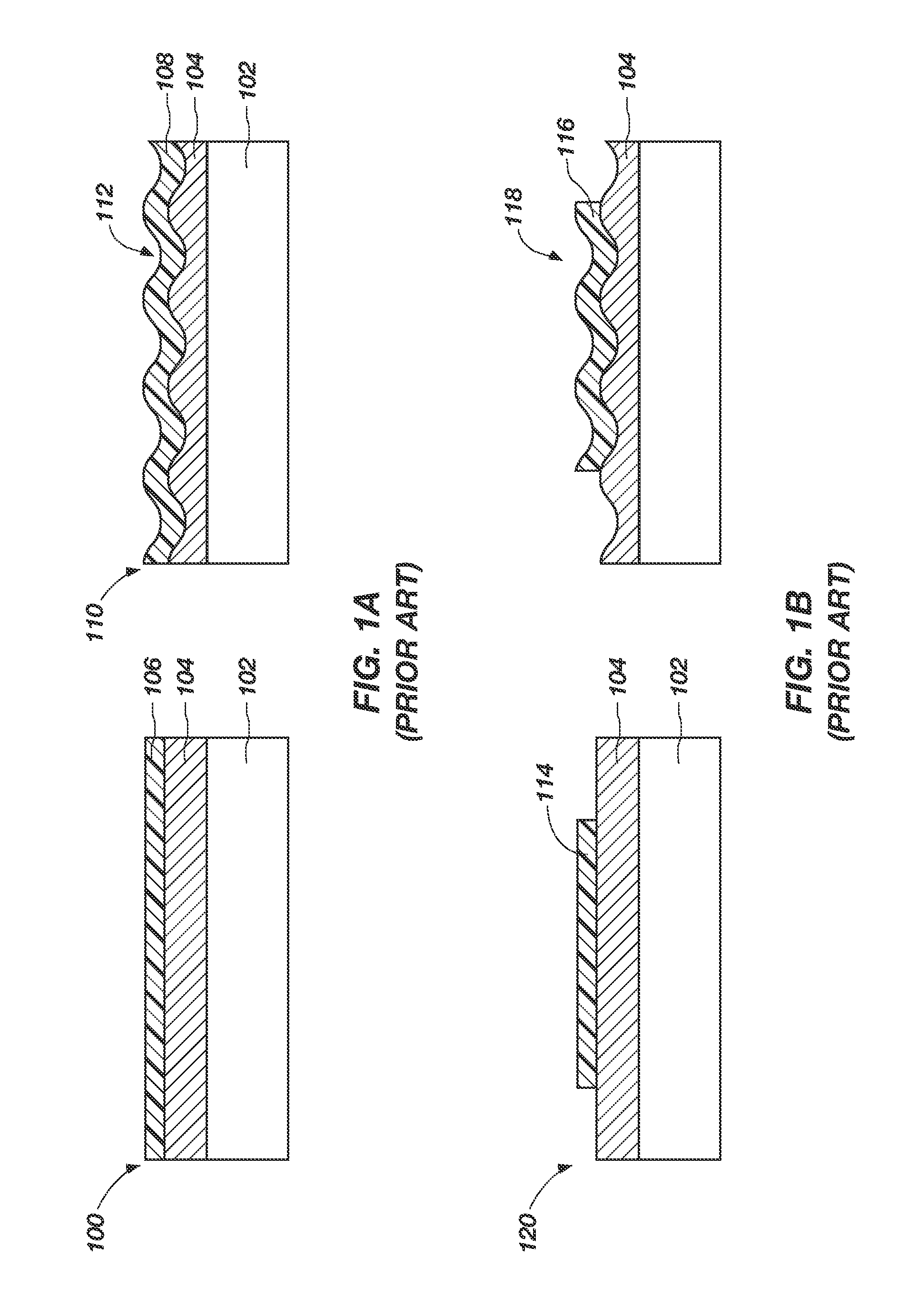

Methods for bonding semiconductor structures involving annealing processes, and bonded semiconductor structures and intermediate structures formed using such methods

InactiveUS20120252189A1Limit scopeSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorSemiconductor structure

Methods of bonding together semiconductor structures include annealing metal of a feature on a semiconductor structure prior to directly bonding the feature to a metal feature of another semiconductor structure to form a bonded metal structure, and annealing the bonded metal structure after the bonding process. The thermal budget of the first annealing process may be at least as high as a thermal budget of a later annealing process. Additional methods involve forming a void in a metal feature, and annealing the metal feature to expand the metal of the feature into the void. Bonded semiconductor structures and intermediate structures are formed using such methods.

Owner:SONY SEMICON SOLUTIONS CORP

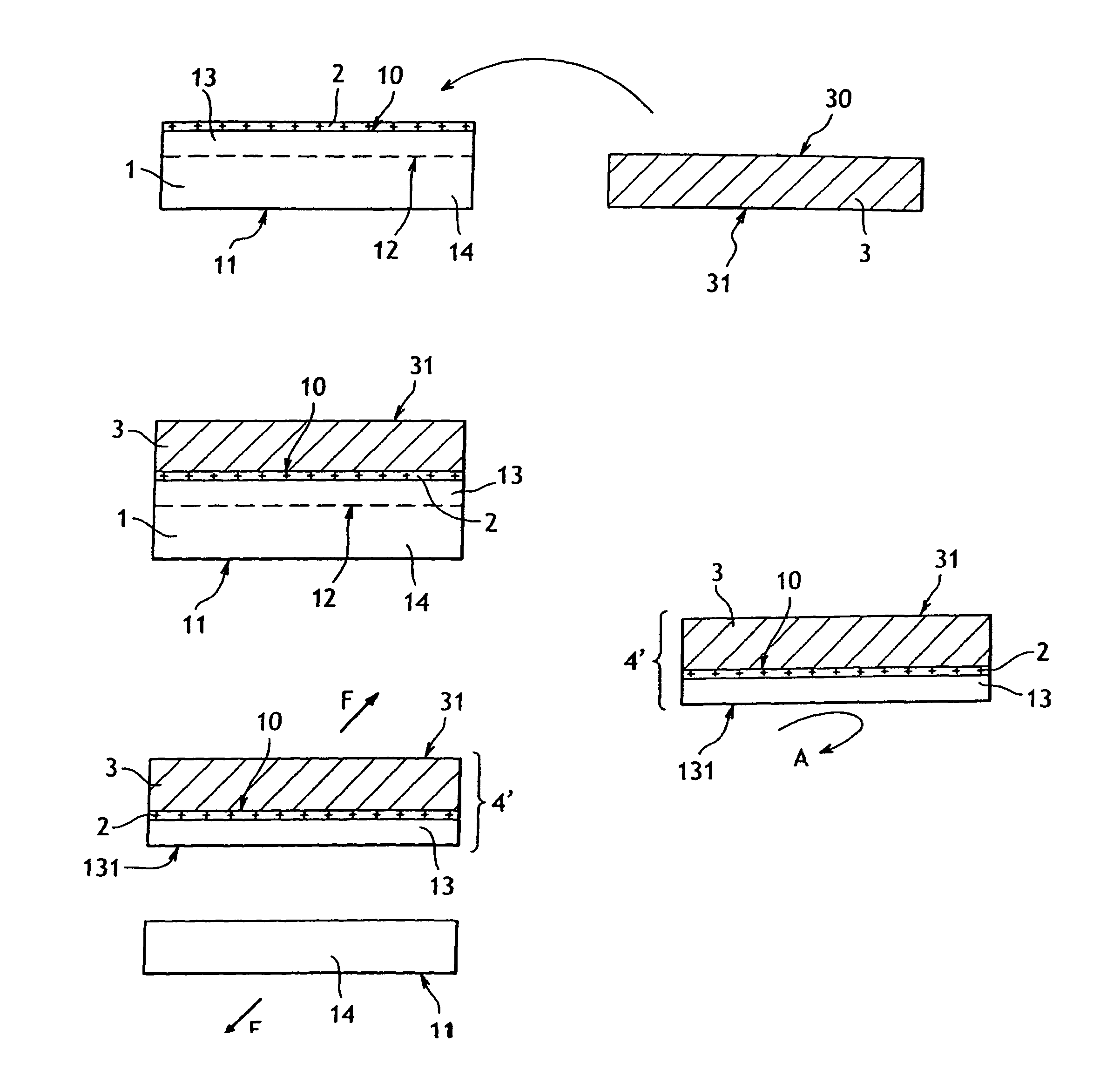

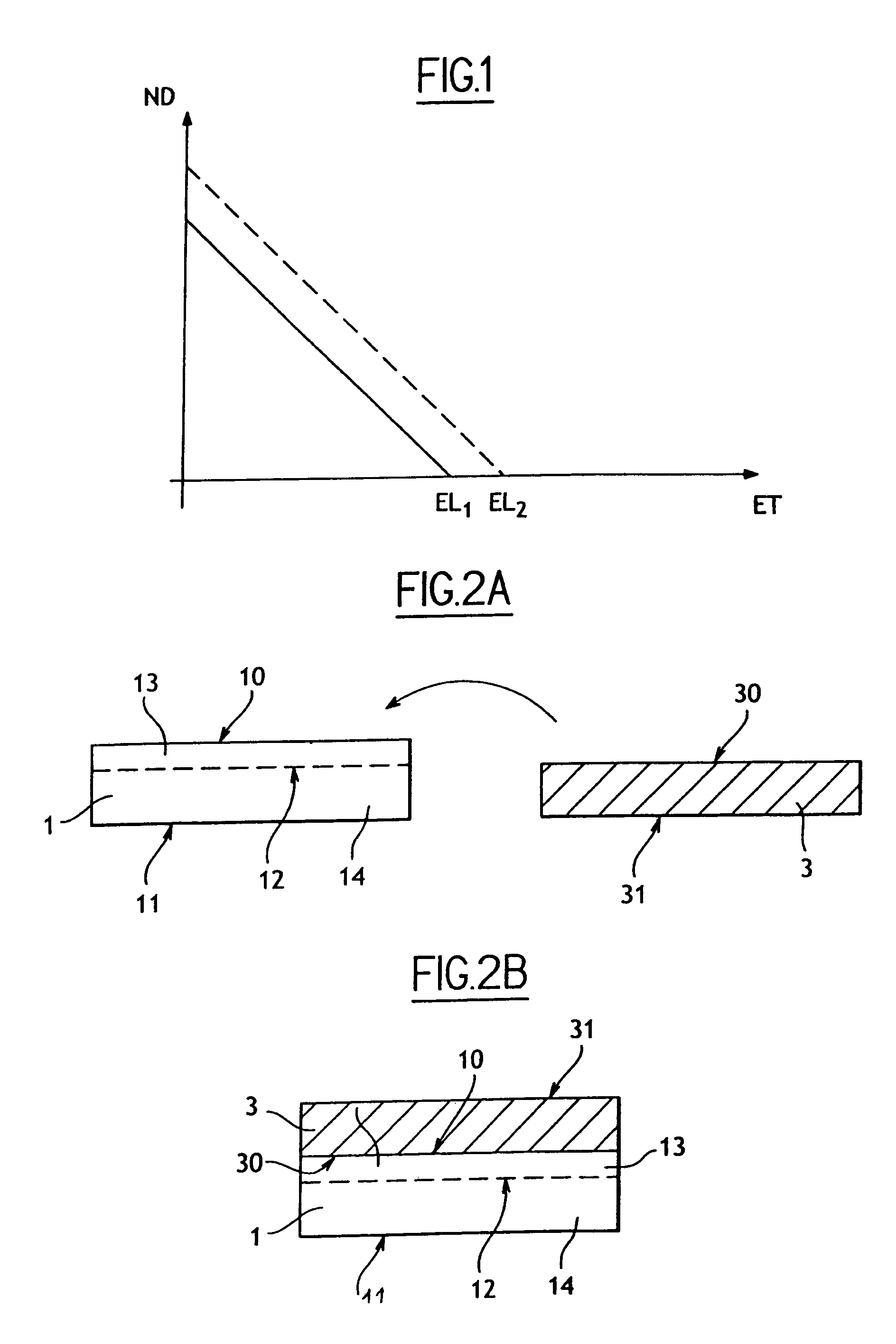

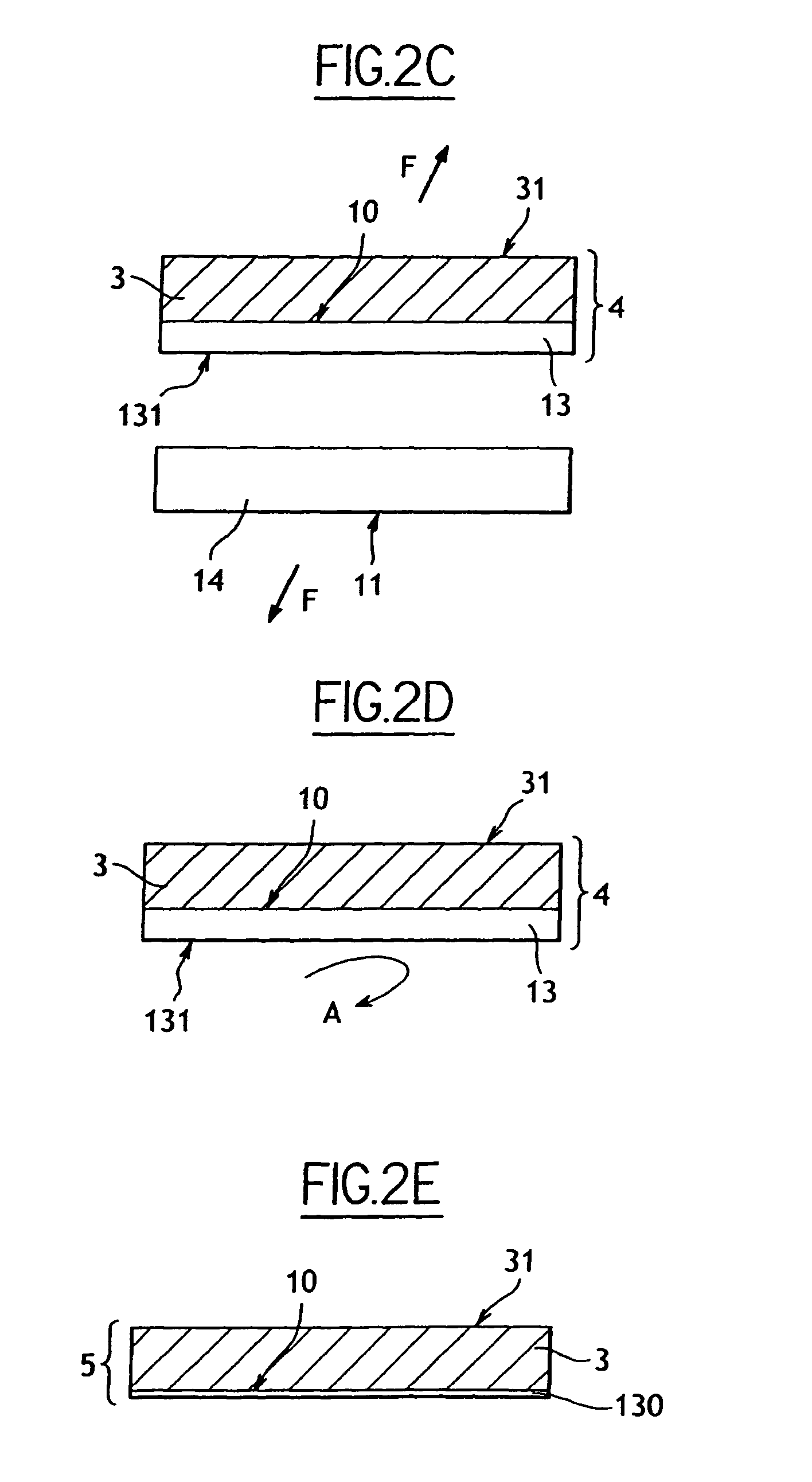

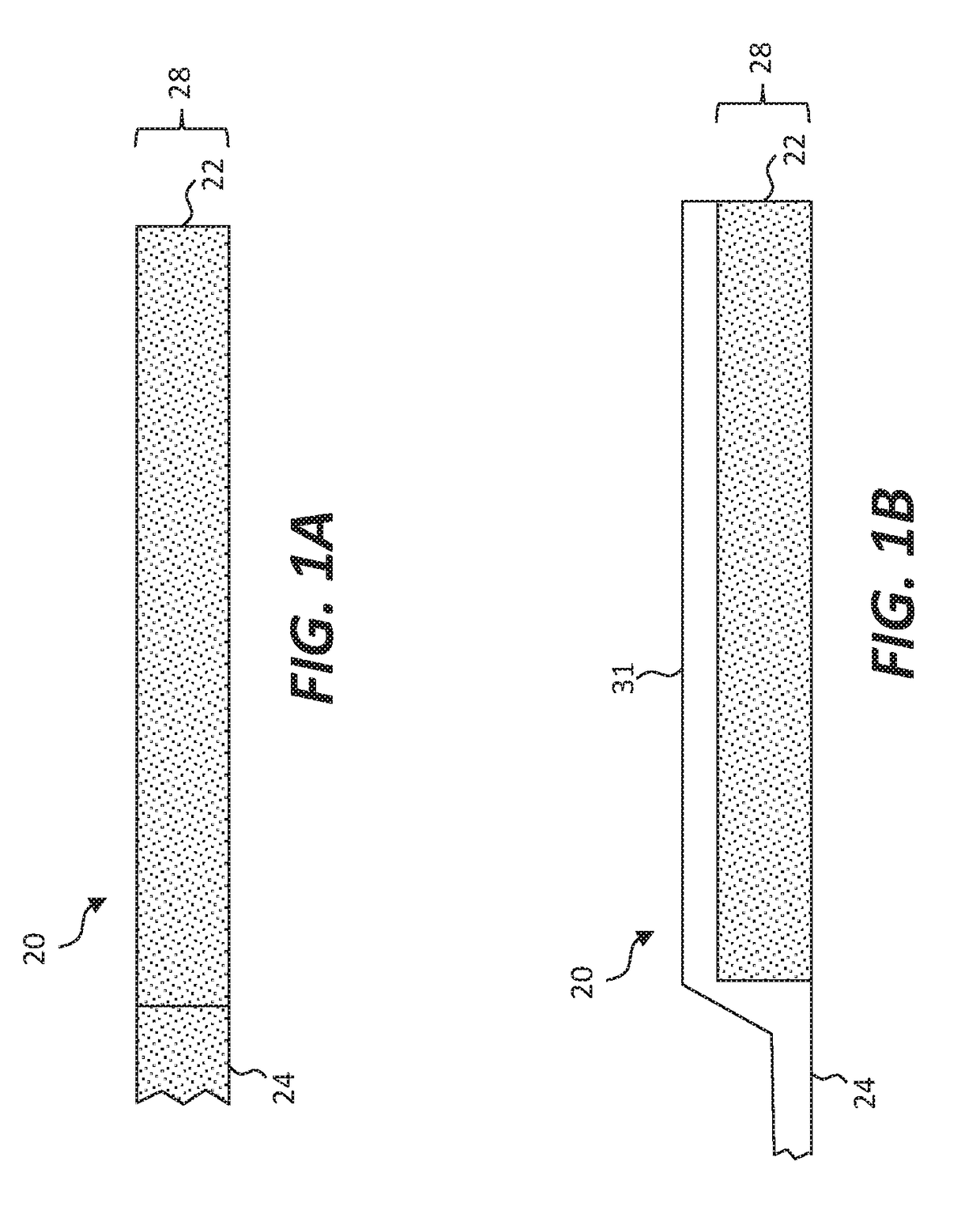

Method of producing a semiconductor structure having at least one support substrate and an ultrathin layer

ActiveUS6991995B2Reduce thicknessSuitable for useSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureIntermediate structure

A method of producing a semiconductor structure having at least one support substrate and an ultrathin layer. The method includes bonding a support substrate to a source substrate, detaching a useful layer along a zone of weakness to obtain an intermediate structure including at least the transferred useful layer and the support substrate, and treating the transferred useful layer to obtain an ultrathin layer on the support substrate. The source substrate includes a front face and a zone of weakness below the front face that defines the useful layer, and the useful layer is sufficiently thick to withstand heat treatments without forming defects therein so that it can be reduced in thickness to form the ultrathin layer. The resulting ultrathin layer is suitable for use in applications in the fields of electronics, optoelectronics or optics.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES +1

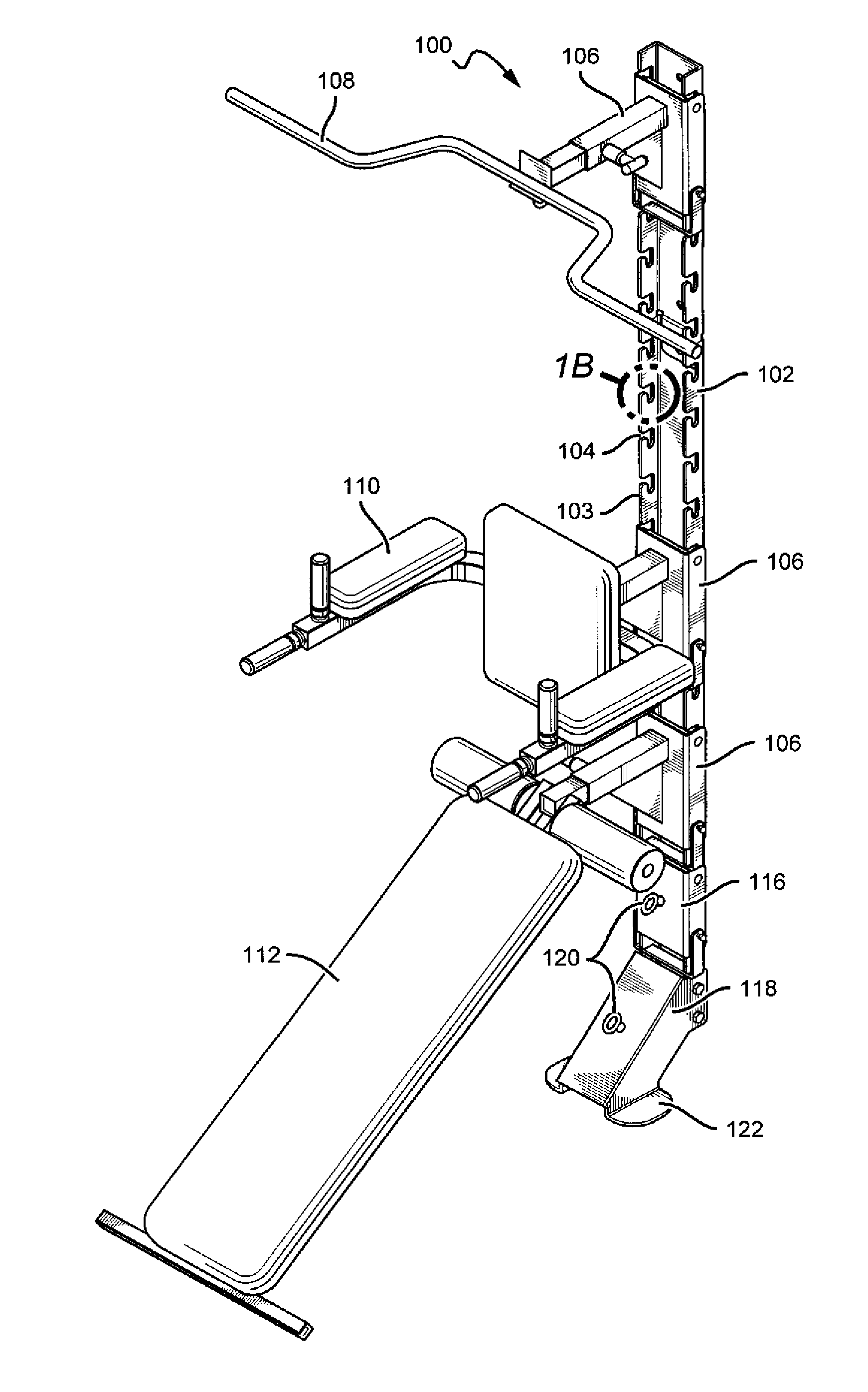

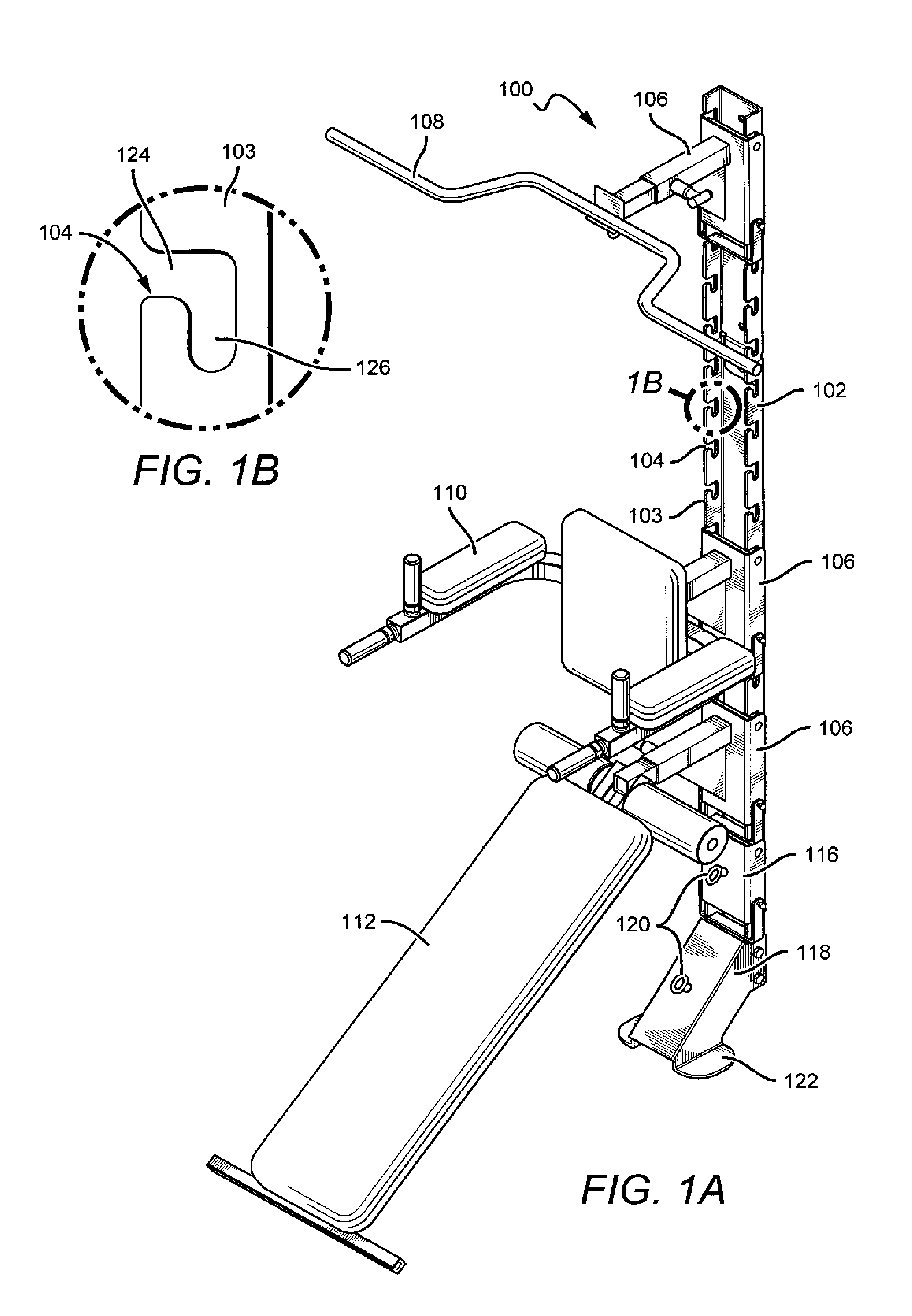

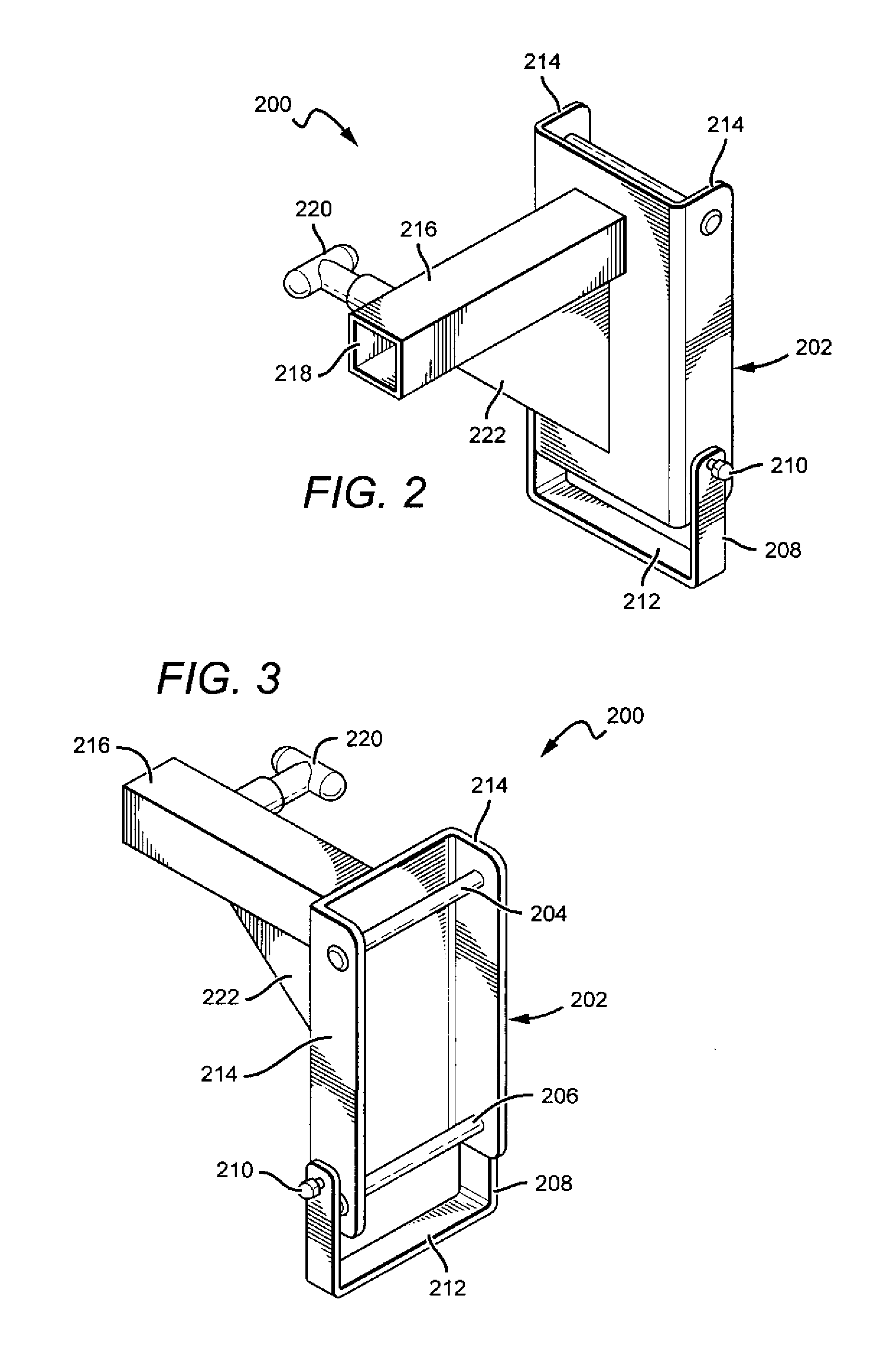

Surface mounted modular exercise device

InactiveUS20150352395A1Easy to adjustLess likely to malfunctionResilient force resistorsSpace saving gamesSurface mountingEngineering

Described herein are devices and methods which incorporate a surface mounted “base structure” for use with one or more components allowing various resistance-based exercises to be performed, for example, exercises incorporating bars, benches, handles and resistance bands. The device can be made modular such that an intermediate structure can interchangeably cooperate with various components allowing a myriad of different exercises to be performed, utilizing the same single intermediate structure. The device can comprise additional designs and features to enhance the safety and stability of the device and the connections of the various components to the device.

Owner:GREGORY TREVER

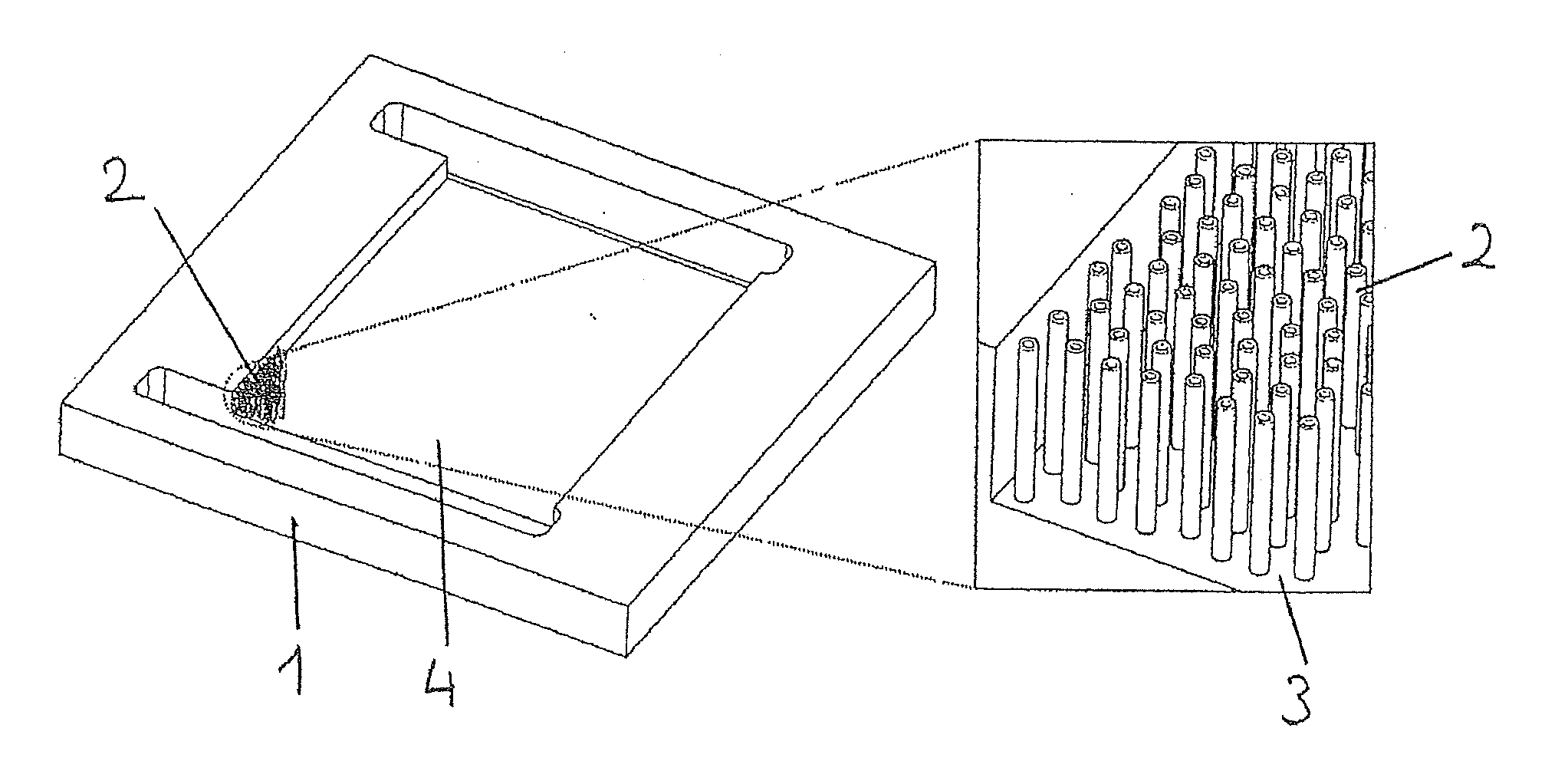

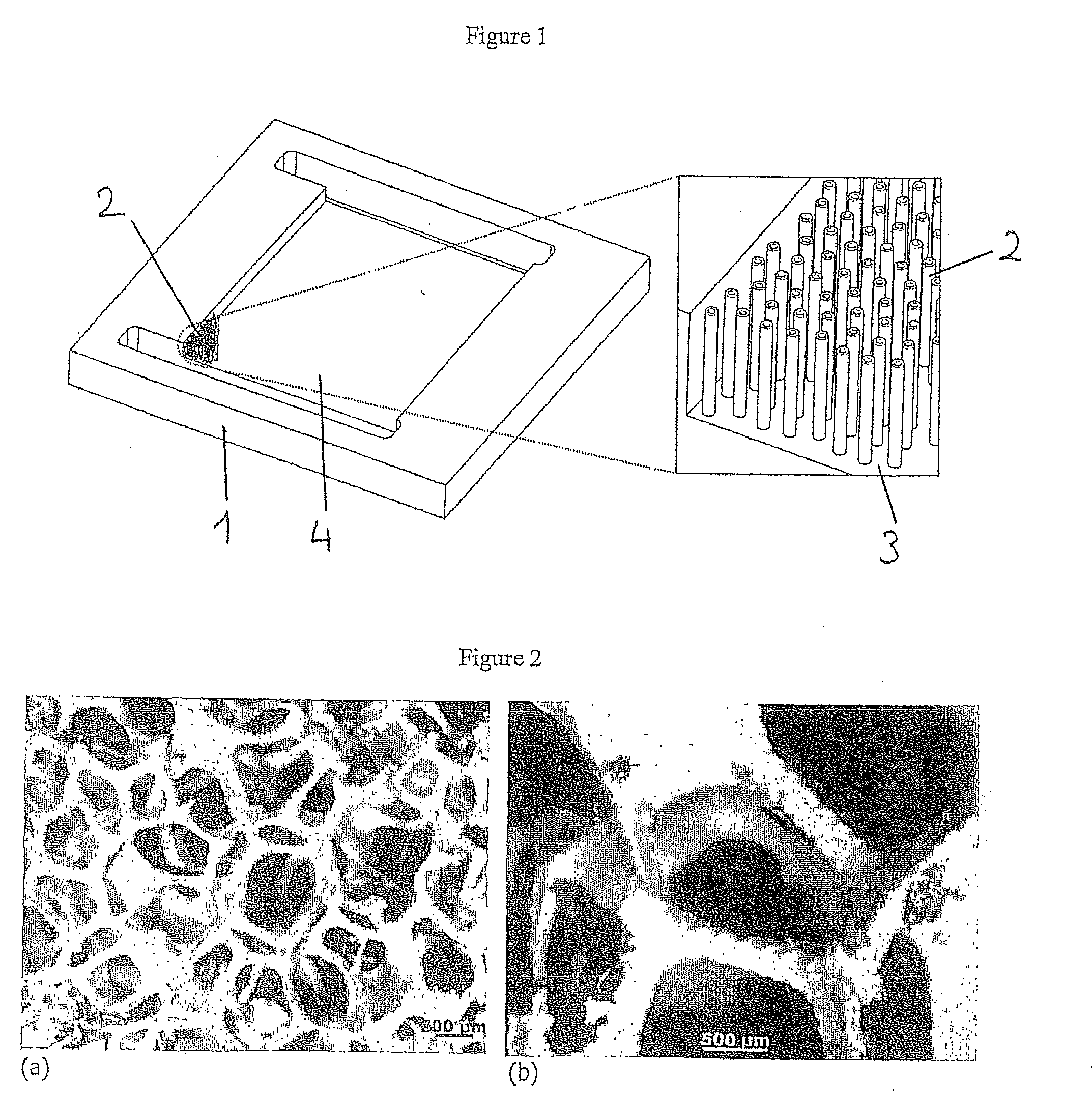

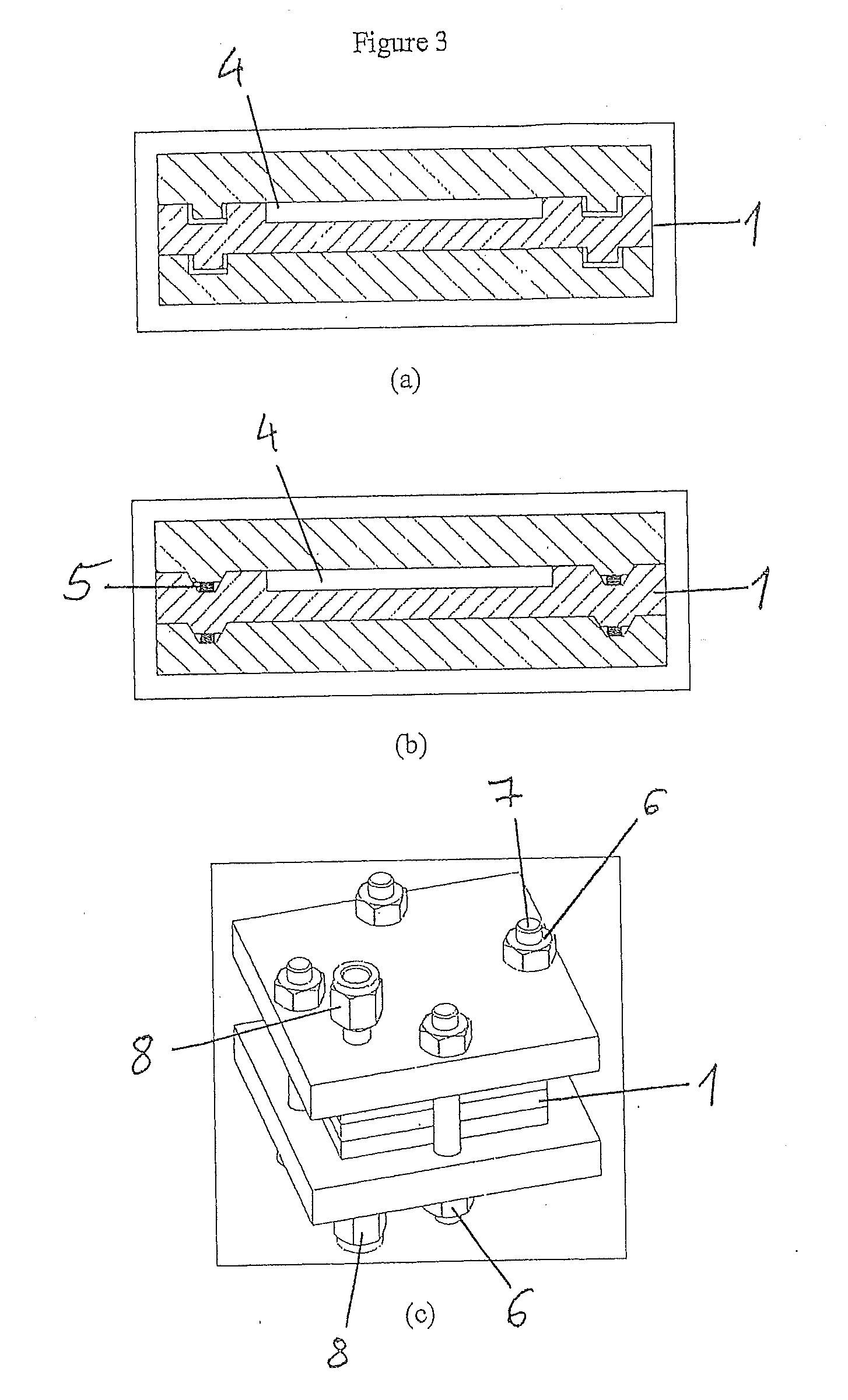

Chemical reactor with nanometric superstructure

InactiveUS20110123409A1Good choiceInhibition formationAnodisationMaterial nanotechnologyGlass fiberCarbon fibers

The invention relates to a chemical reactor with a nanometric superstructure, comprising at least one member wherein at least one reaction chamber is arranged, and said reaction chamber being filled at least partially with a high specific surface area material having a specific surface area greater than 5 m2 / g, and characterised in that said high specific surface area material is selected from nanotubes or nanofibres.These nanotubes or nanofibres are preferably selected in the group consisting of carbon nanofibres or nanotubes, β-SiC nanofibres or nanotubes, TiO2 nanofibres or nanotubes.They may be deposited on an intermediate structure selected in the group consisting of glass fibres, carbon fibres, SiC foams, carbon foams, alveolar β-SiC foams, said intermediate structure filling the reaction chamber of said reactor at least partially.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Apparatus and method for attaching solar panels to roof system surfaces

InactiveUS20080245399A1Reduce weightPhotovoltaic supportsSolar heating energySystem structureIntermediate structure

An apparatus and method for attaching photovoltaic solar panels to a roof system surface. Thin film flexible panels are attached using a hook and loop system in which either the hook or loop material is attached to the underside of panel, and the other of the hook and loop material is attached the roof. Solar panels that are encased in a frame are attached using the hook and loop material directly to the roof system structure, or to an intermediate structure, which is in turn attached to the roof system surface. The method also determines the amount of mated hook and loop material that must be attached to each installed panel to ensure that the installed panels will be able to withstand the wind pressure uplift force required, and to ensure that in the event unexpected and excessive uplift force is ever encountered, the panels separate at the hook and loop interface. For roof system surfaces using a multiply layer membrane material, the hook or loop material can be directly attached to the membrane during its manufacturing process to eliminate the need of doing so at the job site.

Owner:DELIDDO JACK P

Methods of fabricating semiconductor structures or devices using layers of semiconductor material having selected or controlled lattice parameters

ActiveUS20110156212A1Semiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsSemiconductor structure

Methods of fabricating semiconductor devices or structures include bonding a layer of semiconductor material to another material at a temperature, and subsequently changing the temperature of the layer of semiconductor material. The another material may be selected to exhibit a coefficient of thermal expansion such that, as the temperature of the layer of semiconductor material is changed, a controlled and / or selected lattice parameter is imparted to or retained in the layer of semiconductor material. In some embodiments, the layer of semiconductor material may comprise a III-V type semiconductor material, such as, for example, indium gallium nitride. Novel intermediate structures are formed during such methods. Engineered substrates include a layer of semiconductor material having an average lattice parameter at room temperature proximate an average lattice parameter of the layer of semiconductor material previously attained at an elevated temperature.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

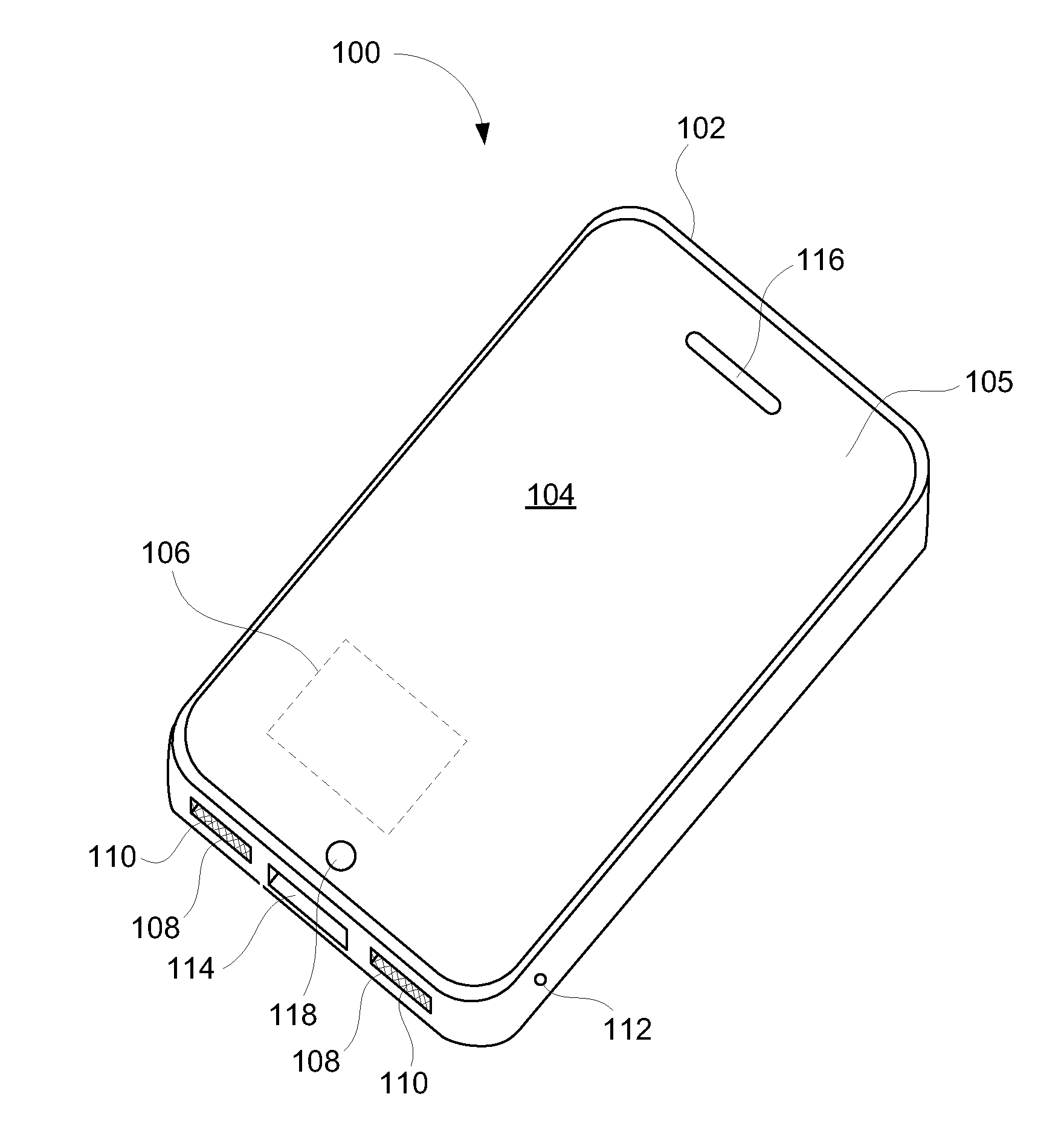

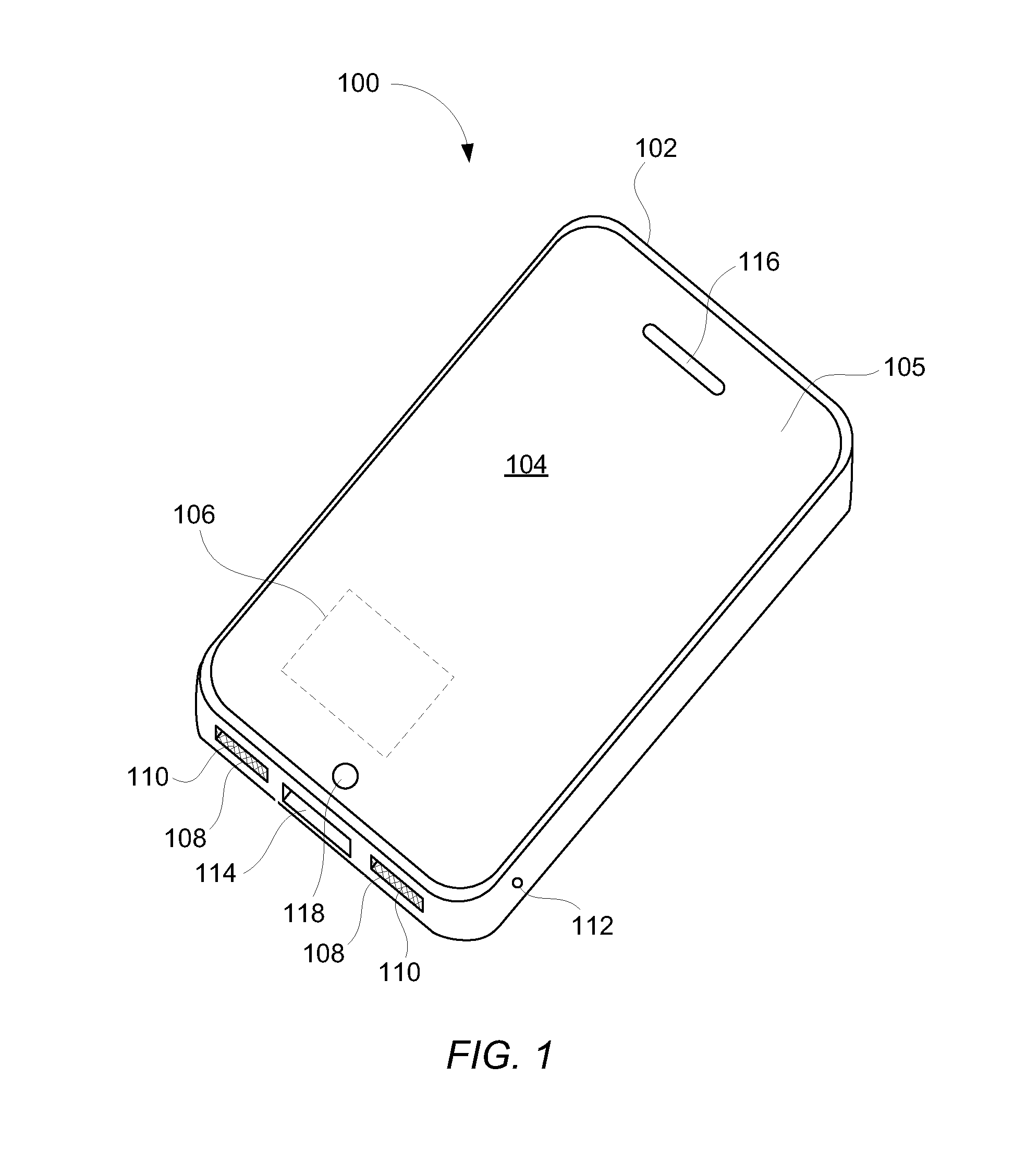

Audio Port Configuration for Compact Electronic Devices

ActiveUS20110255726A1Compact configurationMicrophonesLoudspeaker transducer fixingEngineeringFlexible electronics

A portable electronic device that provides compact configurations for audio elements are disclosed. The audio elements can be drivers (e.g., speakers) or receivers (e.g., microphones). In one embodiment, an audio element can be mounted on or coupled to an intermediate structure (e.g., a flexible electrical substrate) having an opening therein to allow audio sound to pass there through. In another embodiment, an audio chamber can be formed to assist in directing audio sound between an opening an outer housing and a flexible electronic substrate to which the audio element is mounted or coupled thereto. In still another embodiment, a barrier, such as a mesh barrier, can be provided in an opening of an outer housing so that undesired foreign substances can be blocked from further entry into the opening in the outer housing.

Owner:APPLE INC

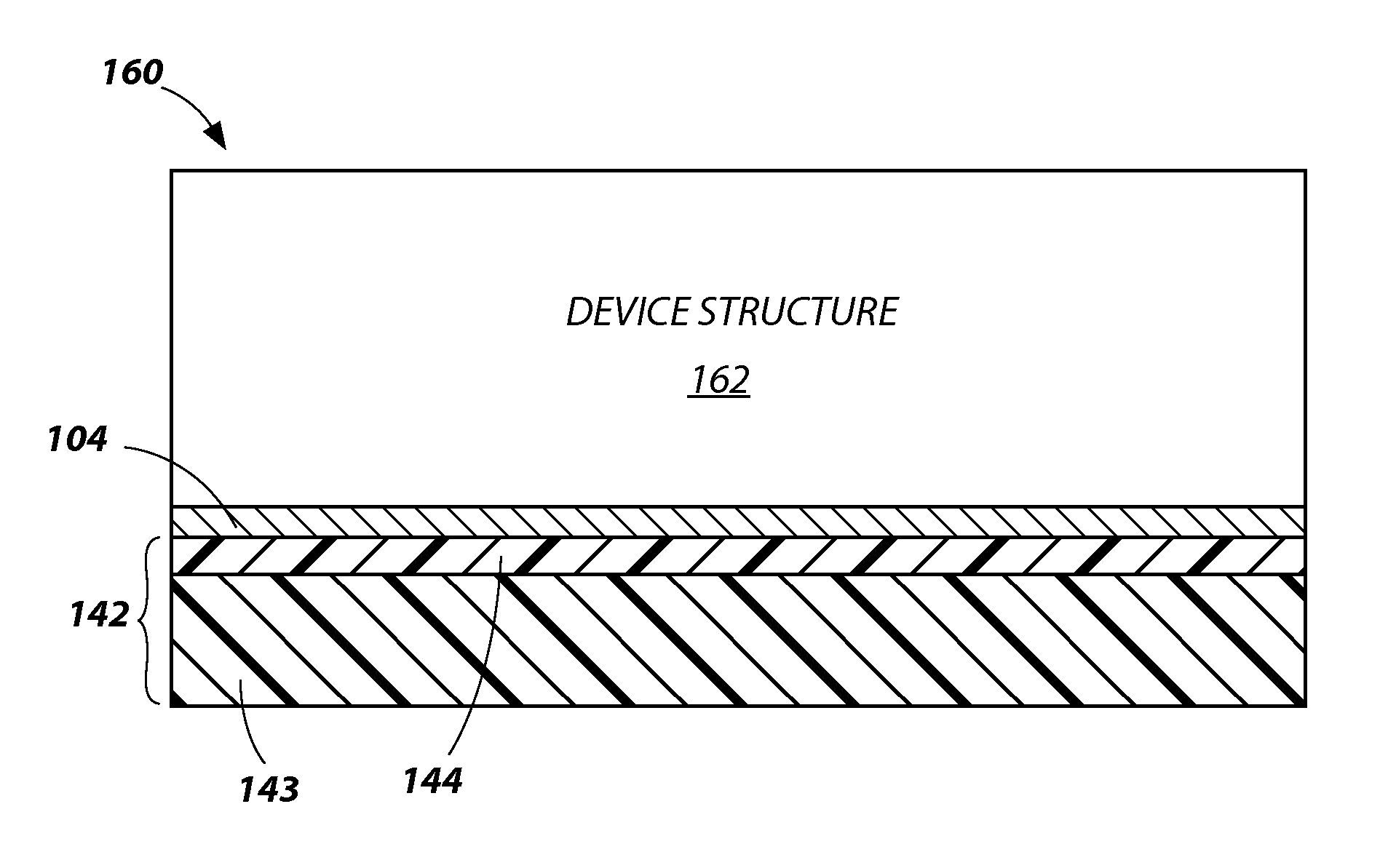

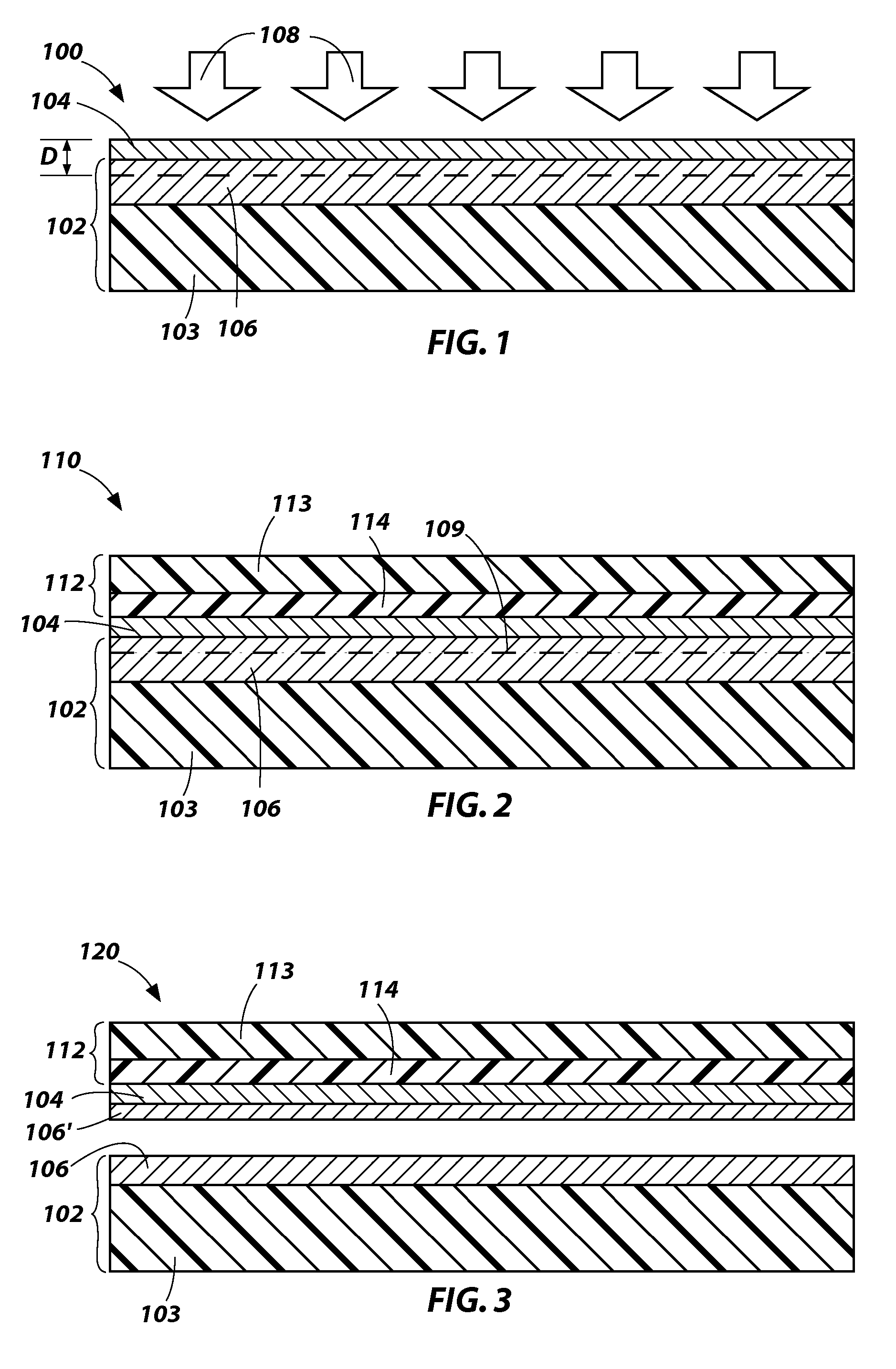

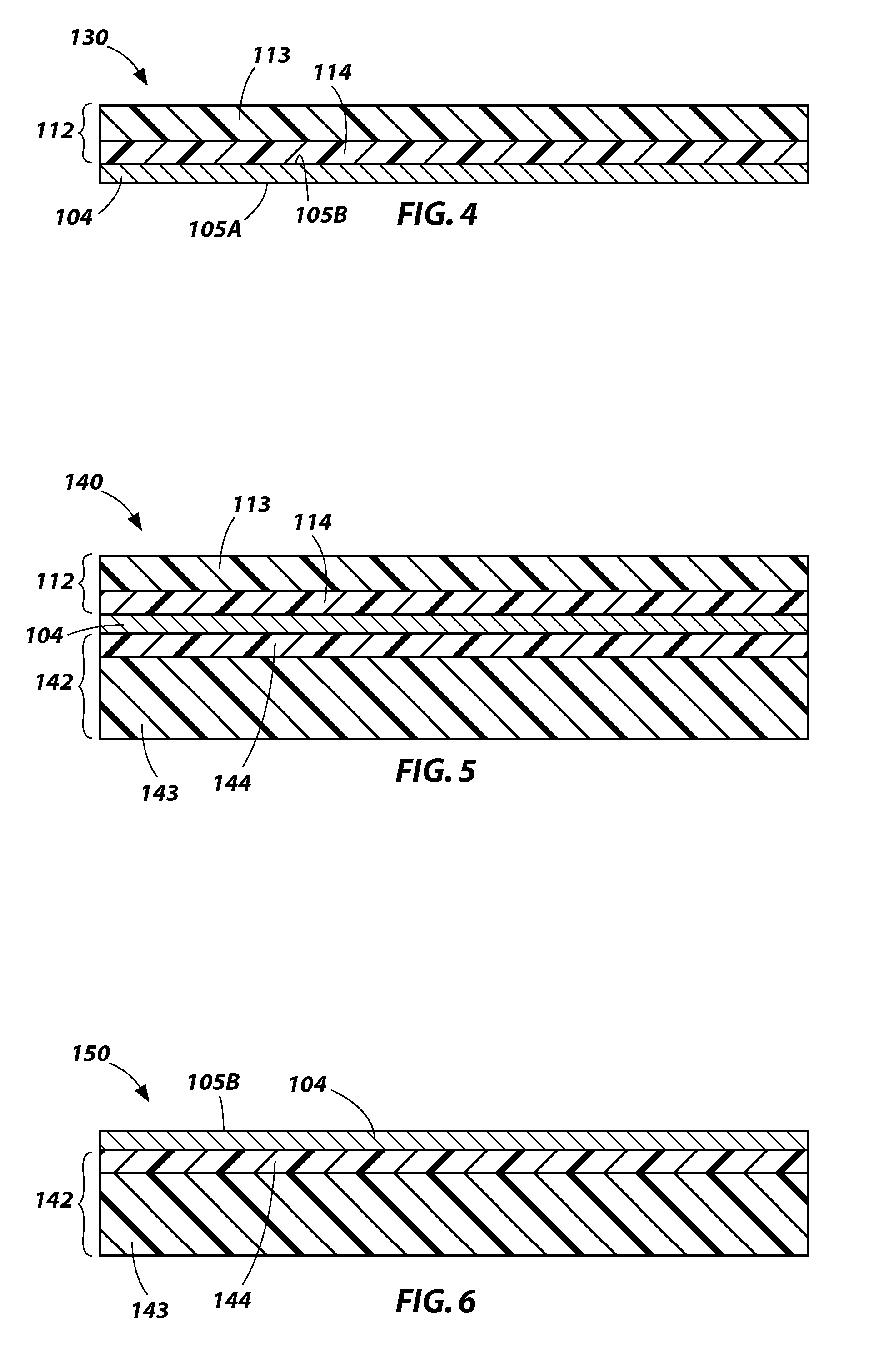

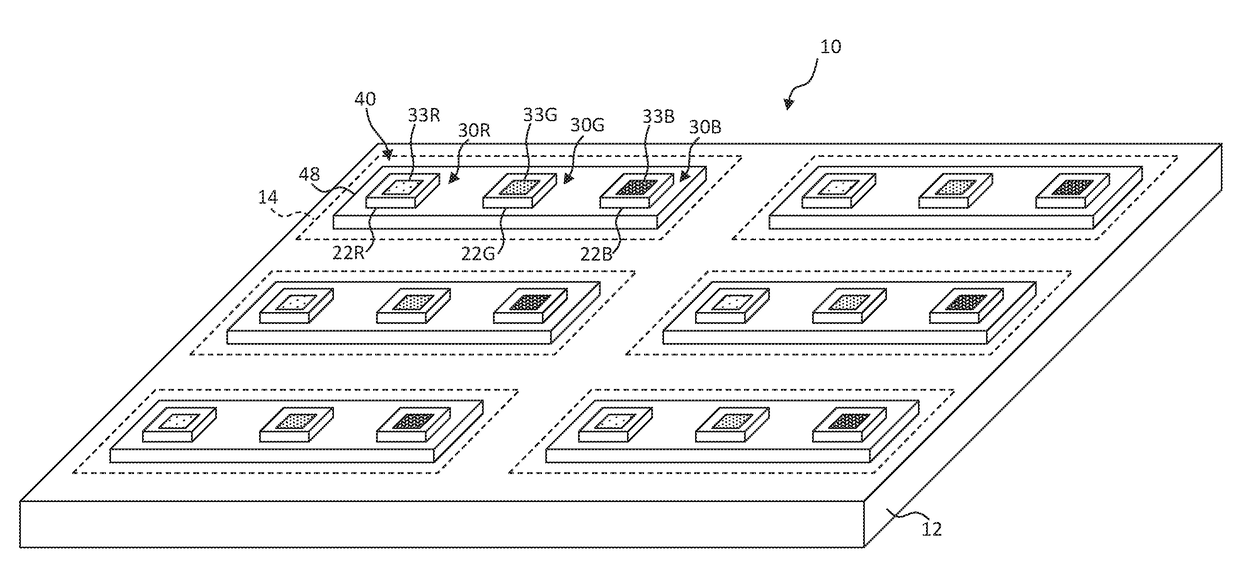

Micro-Transfer Printed LED and Color Filter Structure

ActiveUS20170287882A1Low costReduce the number of materialsSolid-state devicesSemiconductor devicesColor gelEngineering

A micro-transfer printed intermediate structure comprises an intermediate substrate and one or more pixel structures disposed on the intermediate substrate. Each pixel structure includes an LED, a color filter, and a fractured pixel tether physically attached to the pixel structure. A fractured intermediate tether is physically attached to the intermediate substrate. A method of making an intermediate structure source wafer comprises providing a source wafer having a patterned sacrificial layer including sacrificial portions separated by anchors, disposing an intermediate substrate over the patterned sacrificial layer, and disposing one or more pixel structures on the intermediate substrate entirely on or over each sacrificial portion. Each pixel structure includes an LED, a color filter, and a fractured pixel tether physically attached to the pixel structure to form an intermediate structure.

Owner:X DISPLAY CO TECH LTD

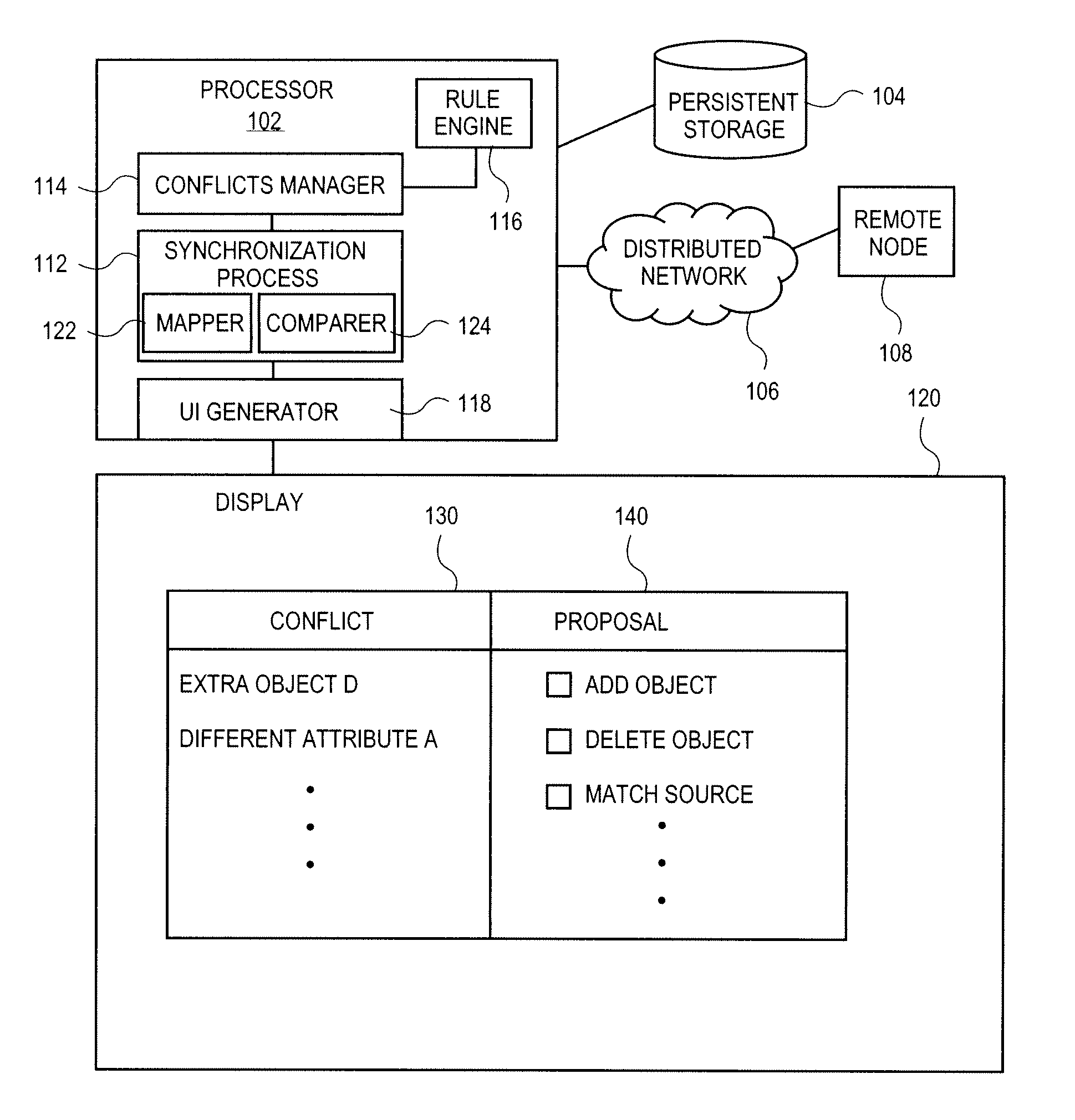

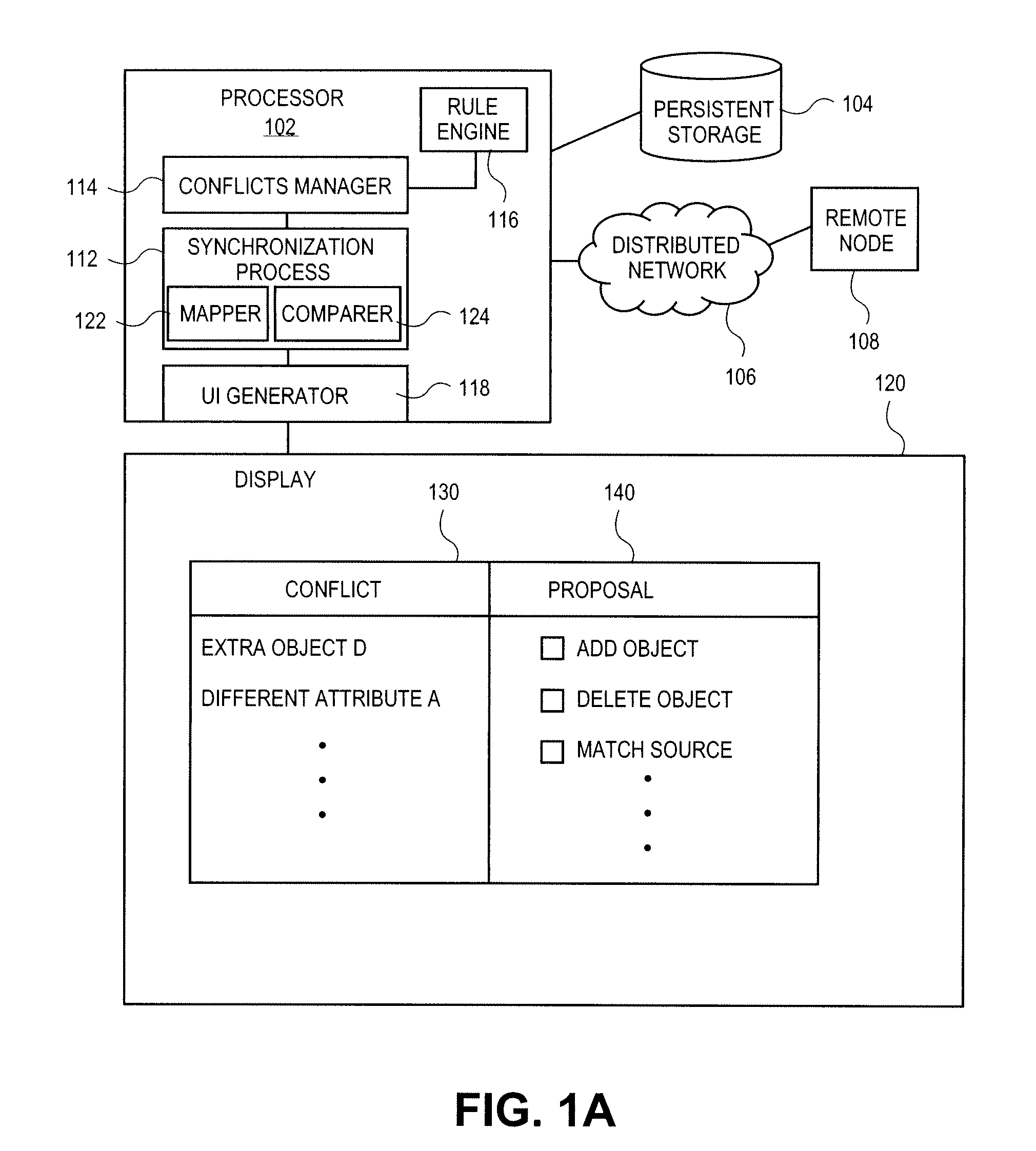

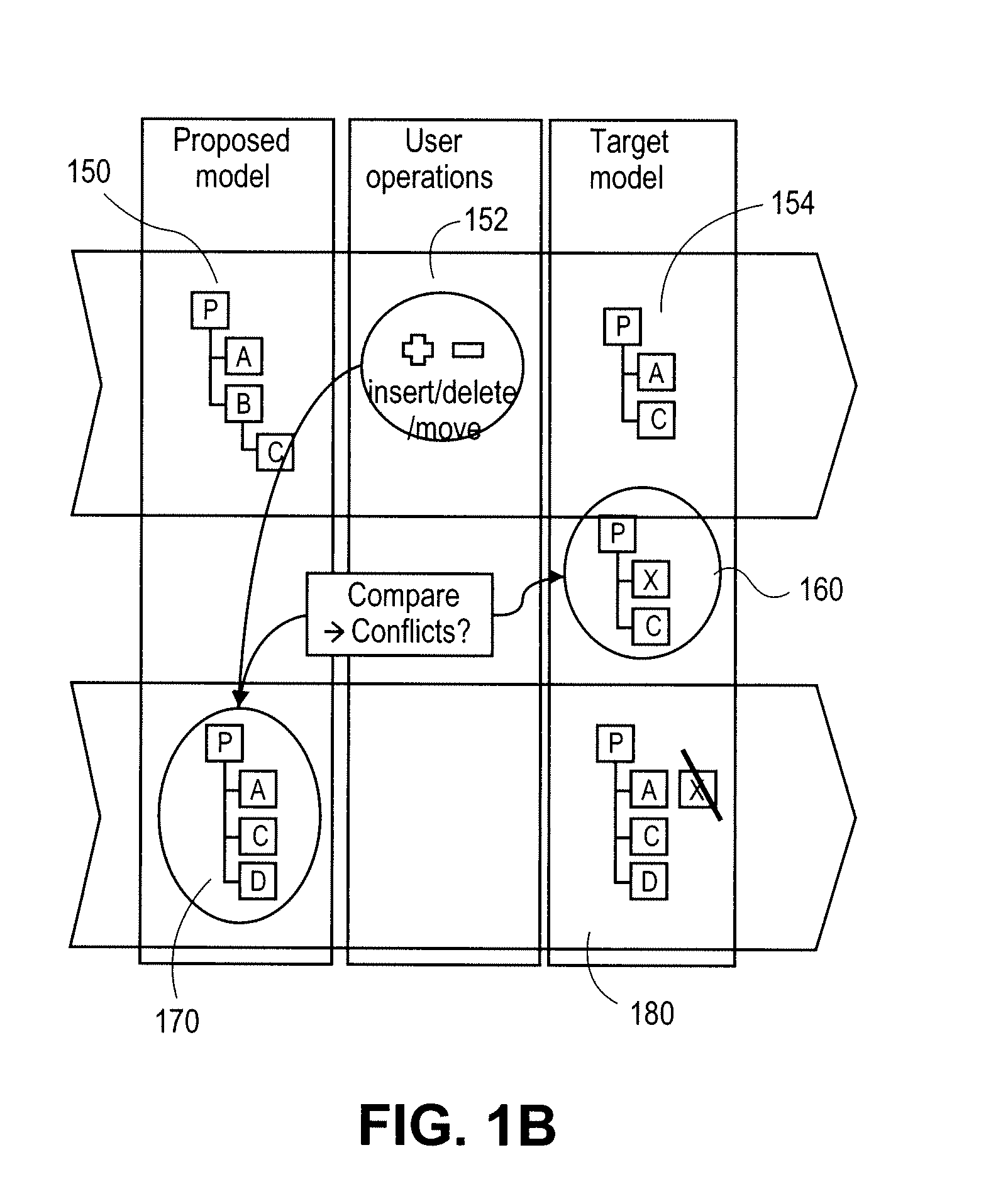

Conflict framework for guided structure synchronization

InactiveUS20110145187A1Digital data information retrievalDigital data processing detailsIntermediate structureComputer science

A system and method for handling conflicts during structure synchronization. Conflicts are identified as the structure moves through the synchronization process. An intermediate structure is generated on a format of a target structure. A proposal for resolution of the identified conflicts is created. The conflicts and proposed resolutions are presented to a user. Proposals accepted by the user are applied to the intermediate structure.

Owner:SAP AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com