Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

270results about How to "Reduce surface damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

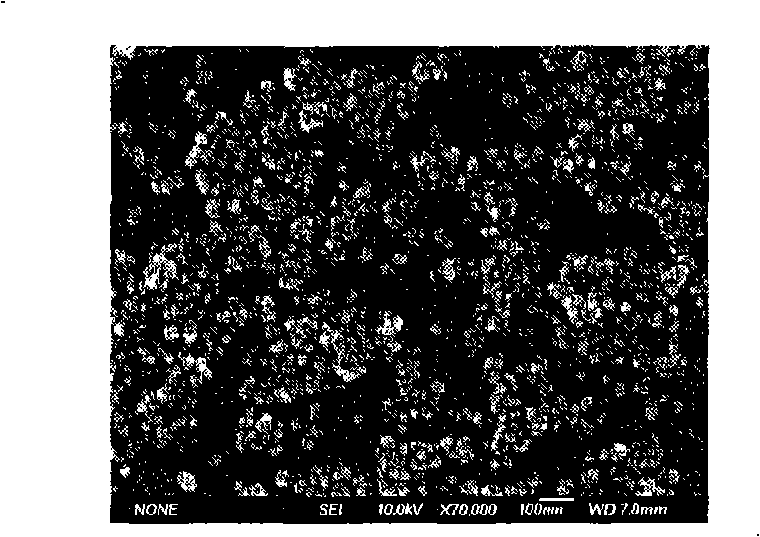

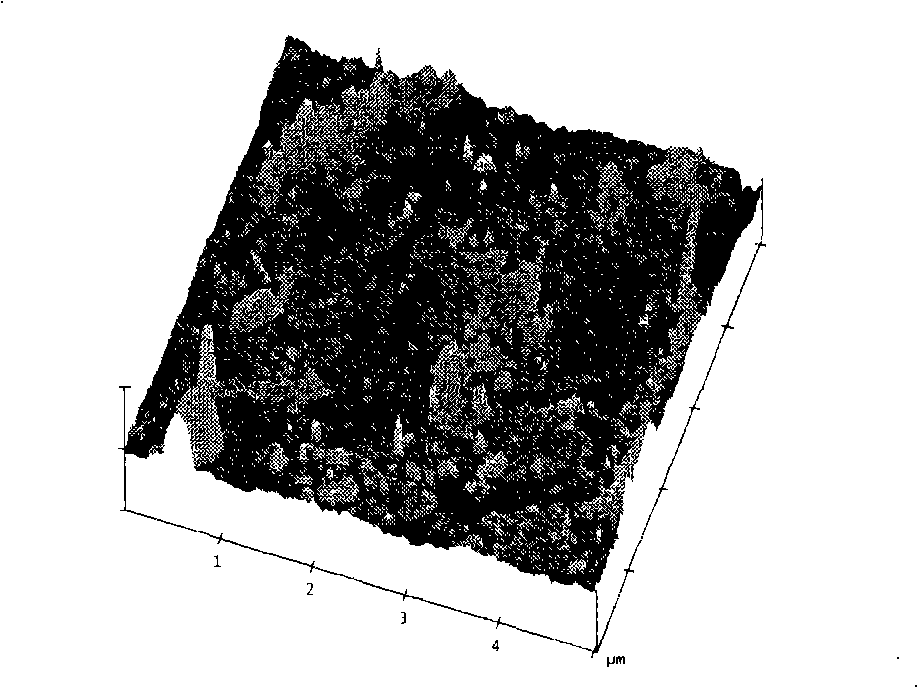

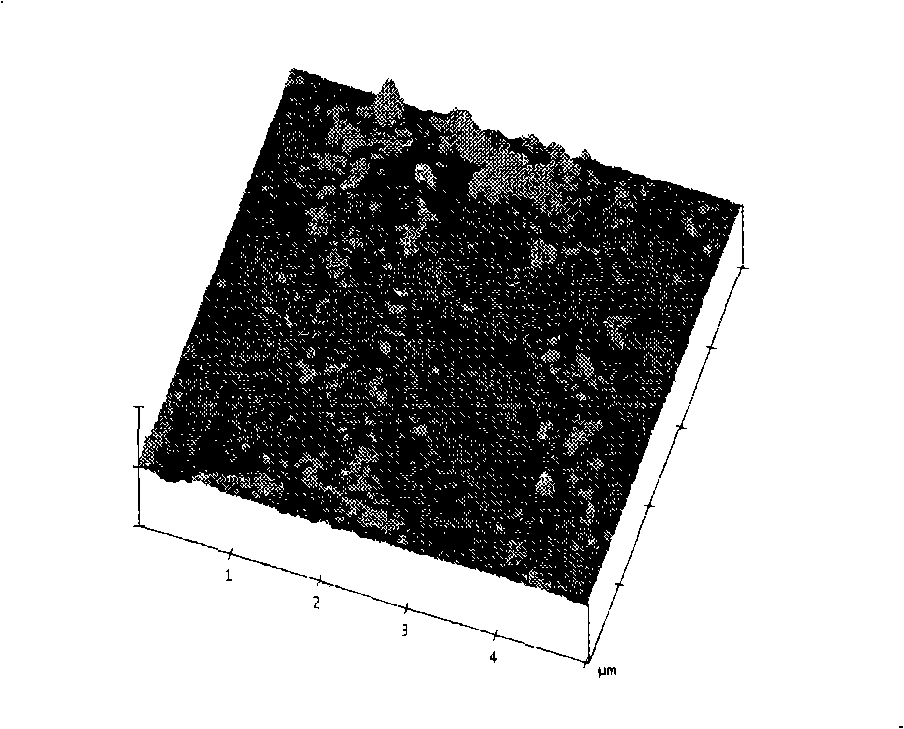

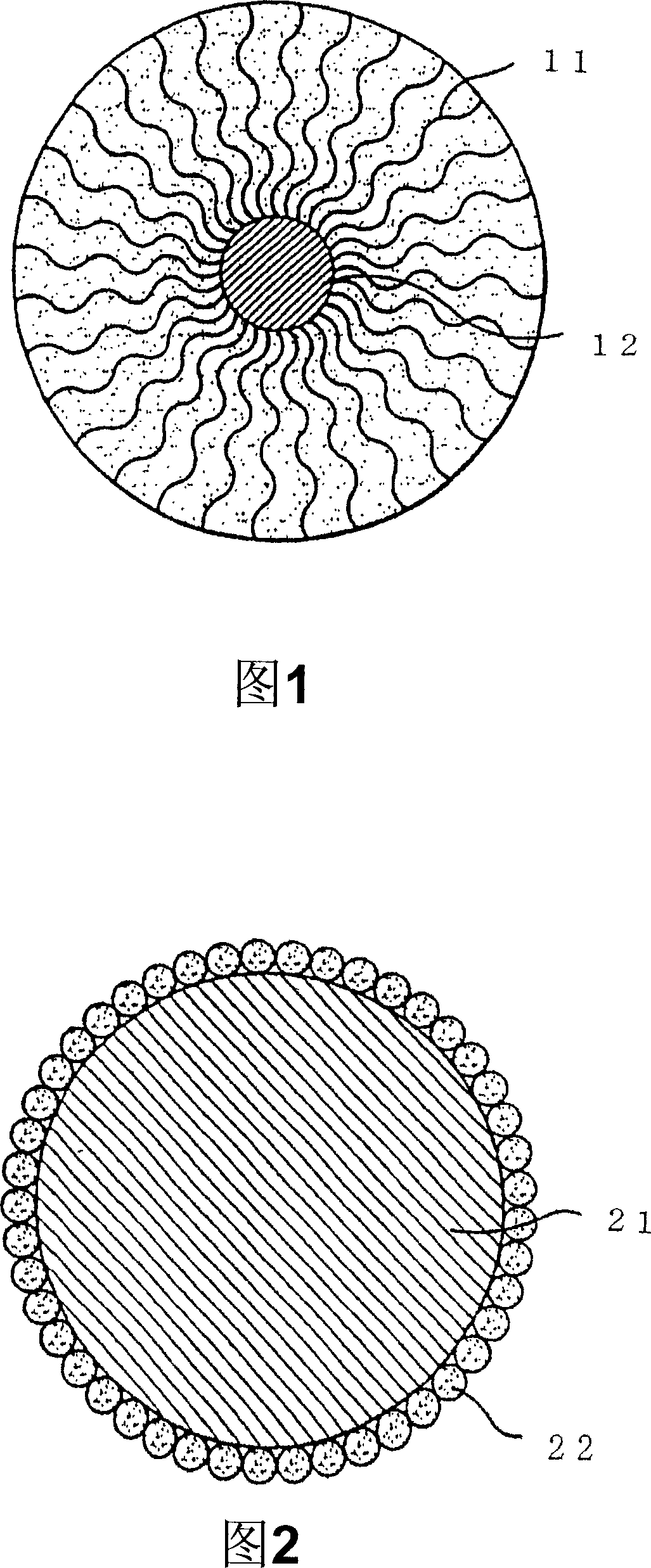

Preparation of nano-cerium oxide composite abrasive grain polishing solution

InactiveCN101302404AGood dispersionReduce surface damagePolishing compositions with abrasivesSmooth surfaceCerium oxide

The invention discloses a method for preparing nano cerium oxide composite abrasive particle polishing solution. The method is characterized by taking inorganic abrasive particles as the inner core and a cerium oxide coating as the shell to form the nano cerium oxide composite abrasive particle polishing solution with a core / shell structure, and belongs to the high-precision polishing material preparation technique technical field. The preparation process of the polishing solution is as follows: firstly, the nano cerium oxide composite abrasive particles are prepared by the homogeneous precipitation method; secondly, the polishing solution is prepared through the cerium oxide composite abrasive particles. During the preparation process of the polishing solution, the weight percent of the cerium oxide composite abrasive particles and water is between 2 and 10 percent, and 0.5 to 2 percent of dispersant is added; after further ultrasonic dispersion or ball milling dispersion of mixture, uniform dispersion liquid is formed; and the nano cerium oxide composite abrasive particle polishing solution is obtained after addition of 0.5 to 5 percent of oxidant, 0.05 to 0.1 percent of corrosion inhibitor and 0.05 to 0.1 percent of lubricant (the addition of various materials takes 100 percent of water as the reference basis). The polishing solution is represented by low surface roughness and scratch level, and then an ultra-smooth surface is obtained.

Owner:SHANGHAI UNIV

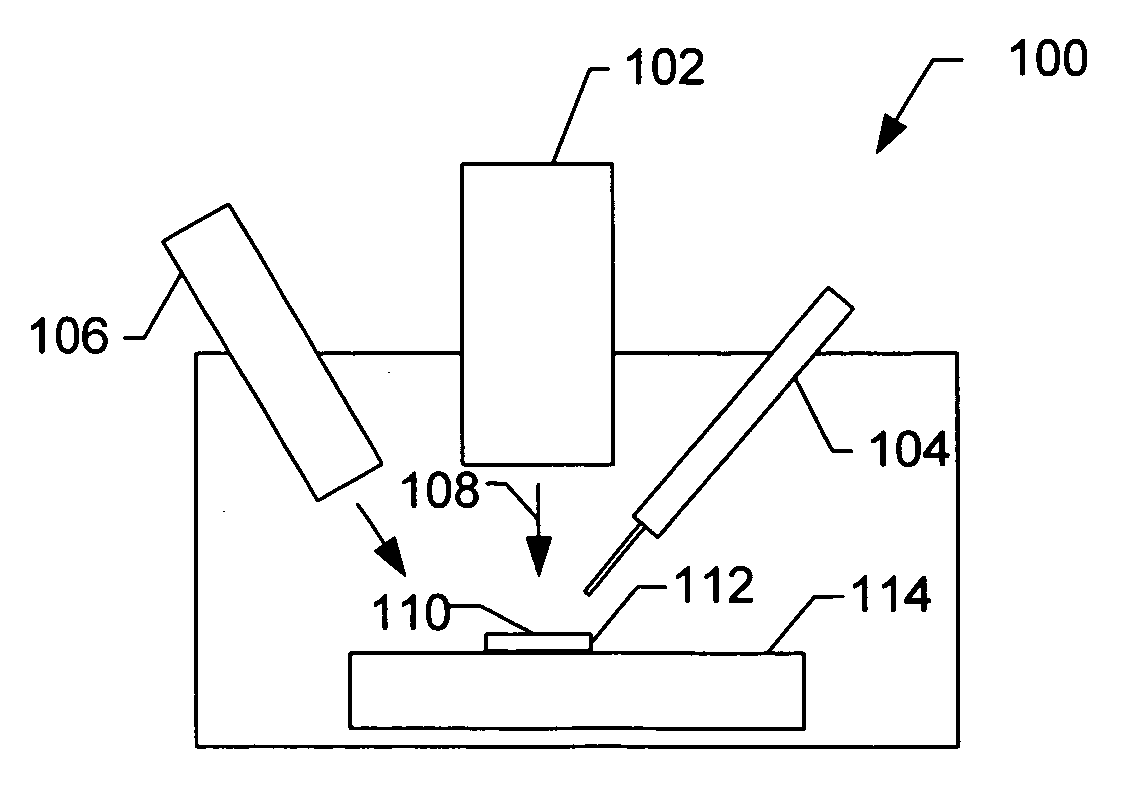

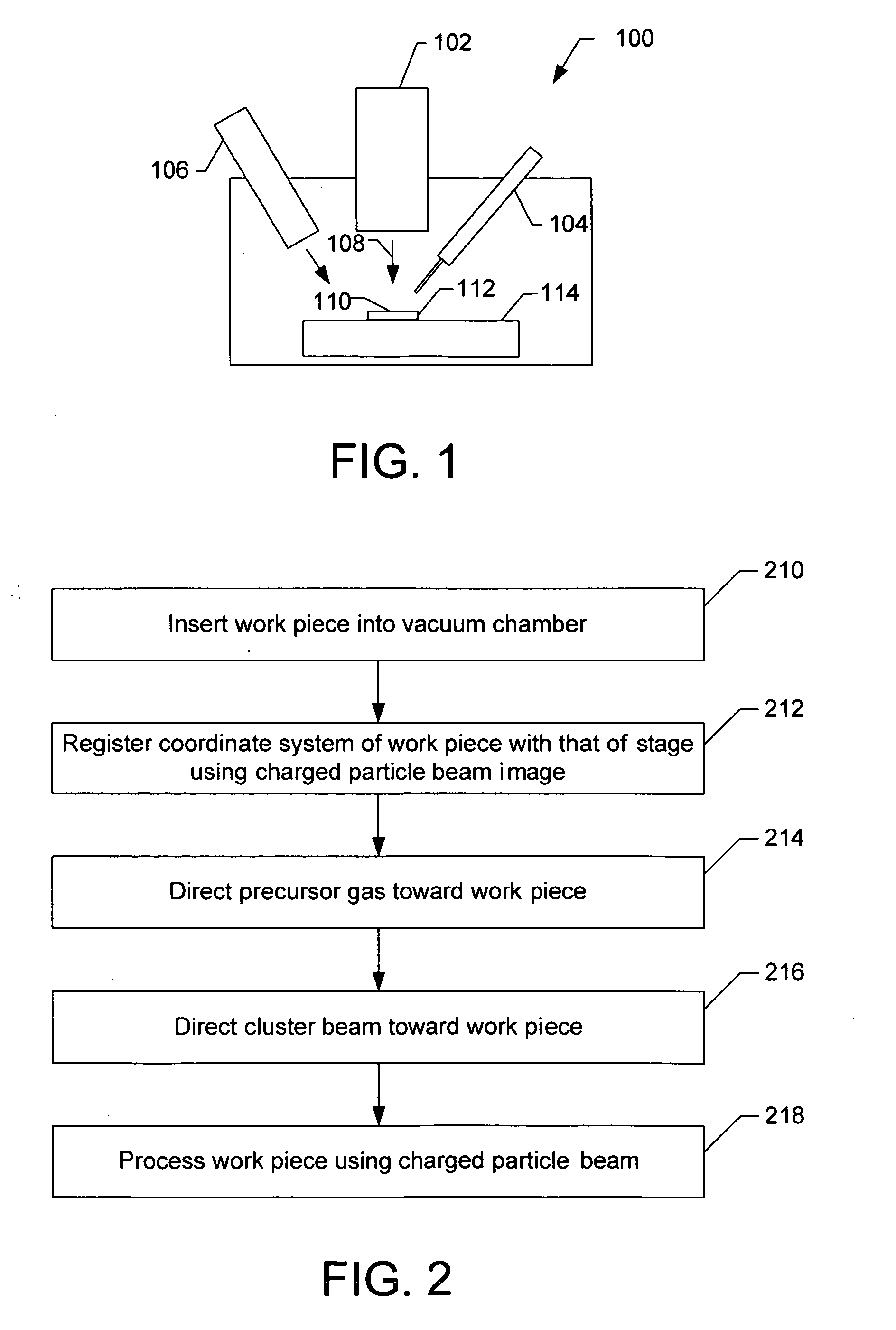

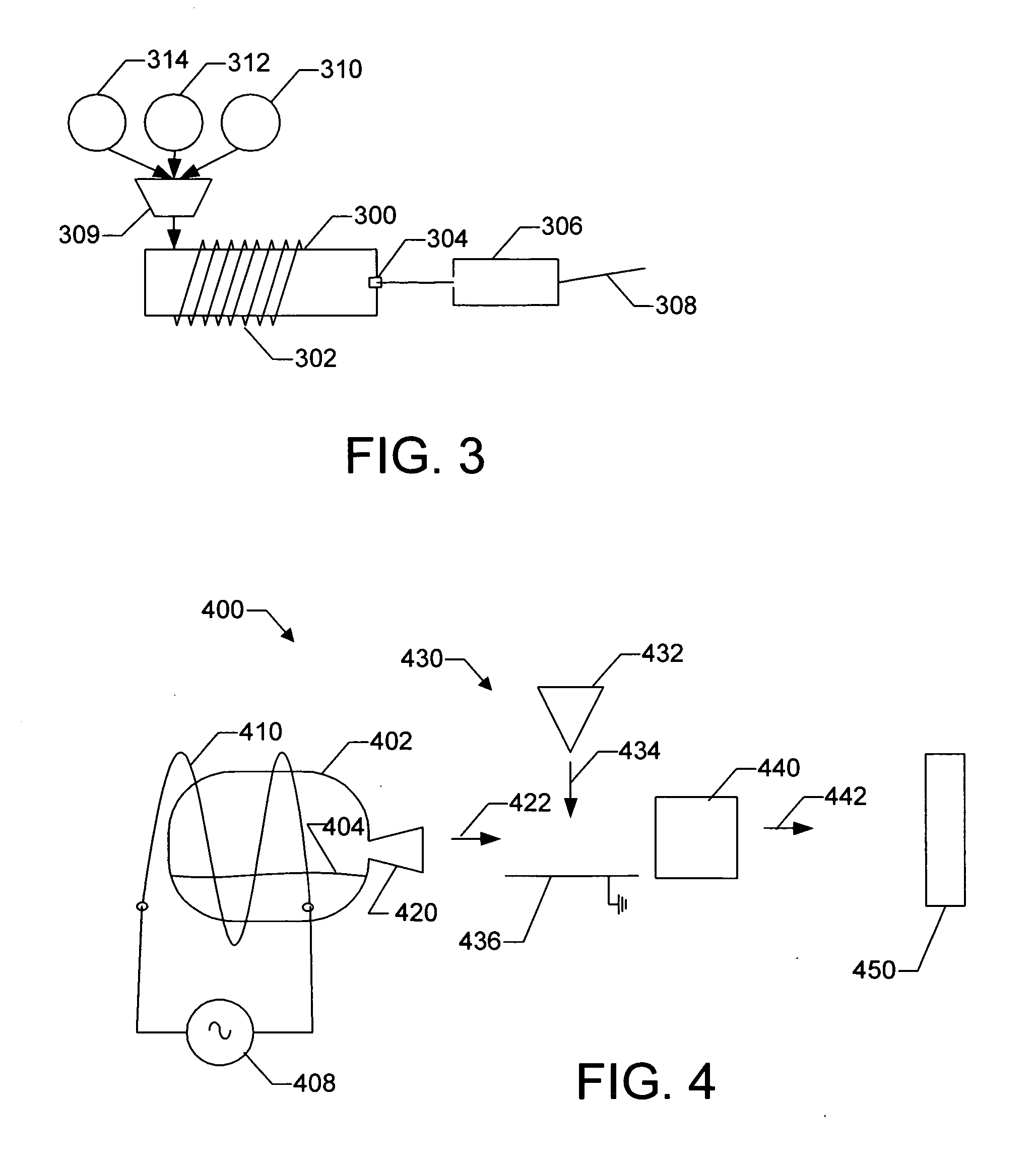

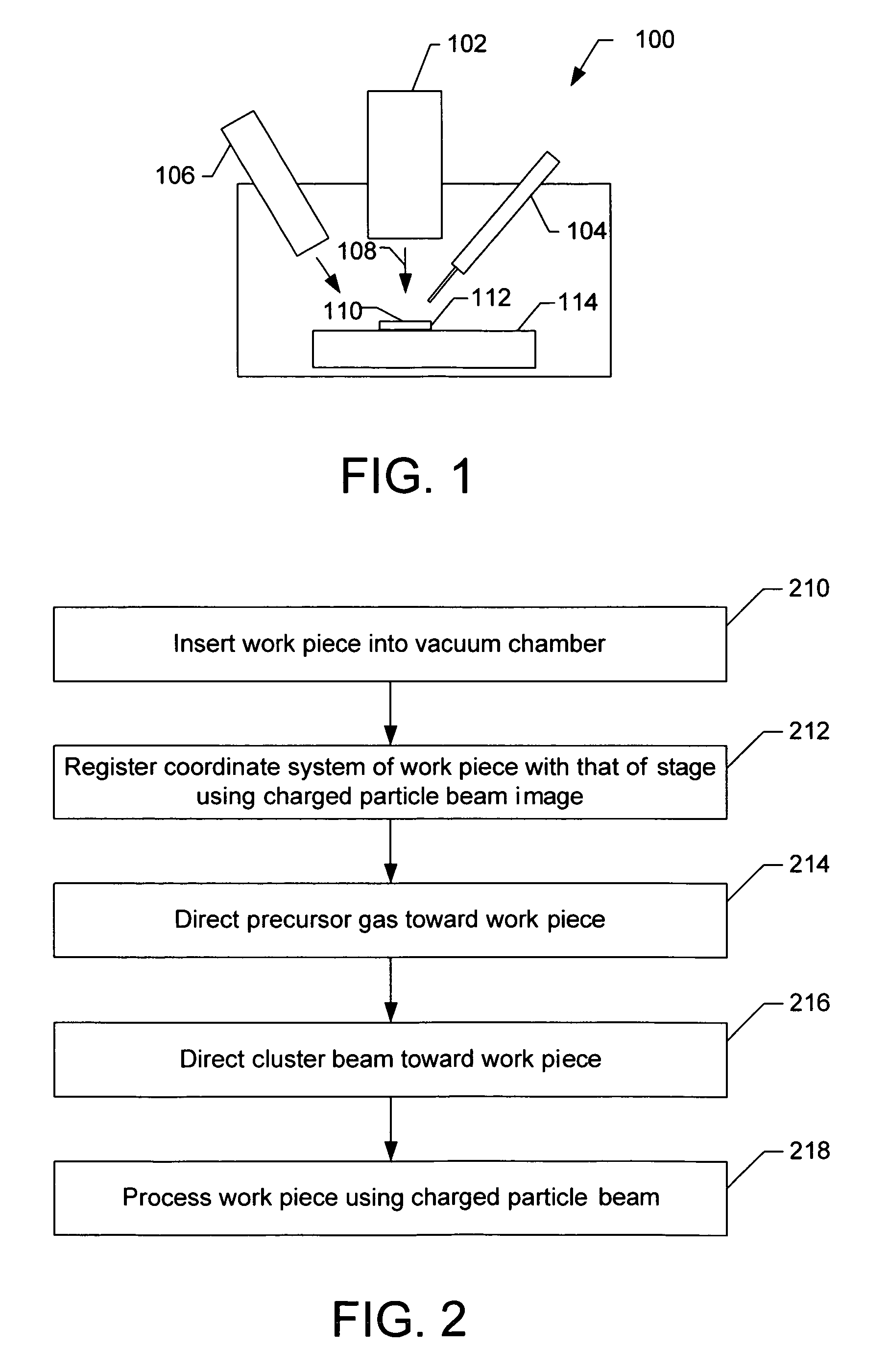

Charged-particle-beam processing using a cluster source

ActiveUS20080142735A1Reduce surface damageReduce harmElectric discharge tubesSemiconductor/solid-state device manufacturingFullereneProtection layer

A cluster source is used to assist charged particle beam processing. For example, a protective layer is applied using a cluster source and a precursor gas. The large mass of the cluster and the low energy per atom or molecule in the cluster restricts damage to within a few nanometers of the surface. Fullerenes or clusters of fullerenes, bismuth, gold or Xe can be used with a precursor gas to deposit material onto a surface, or can be used with an etchant gas to etch the surface. Clusters can also be used to deposit material directly onto the surface to form a protective layer for charged particle beam processing or to provide energy to activate an etchant gas.

Owner:FEI CO

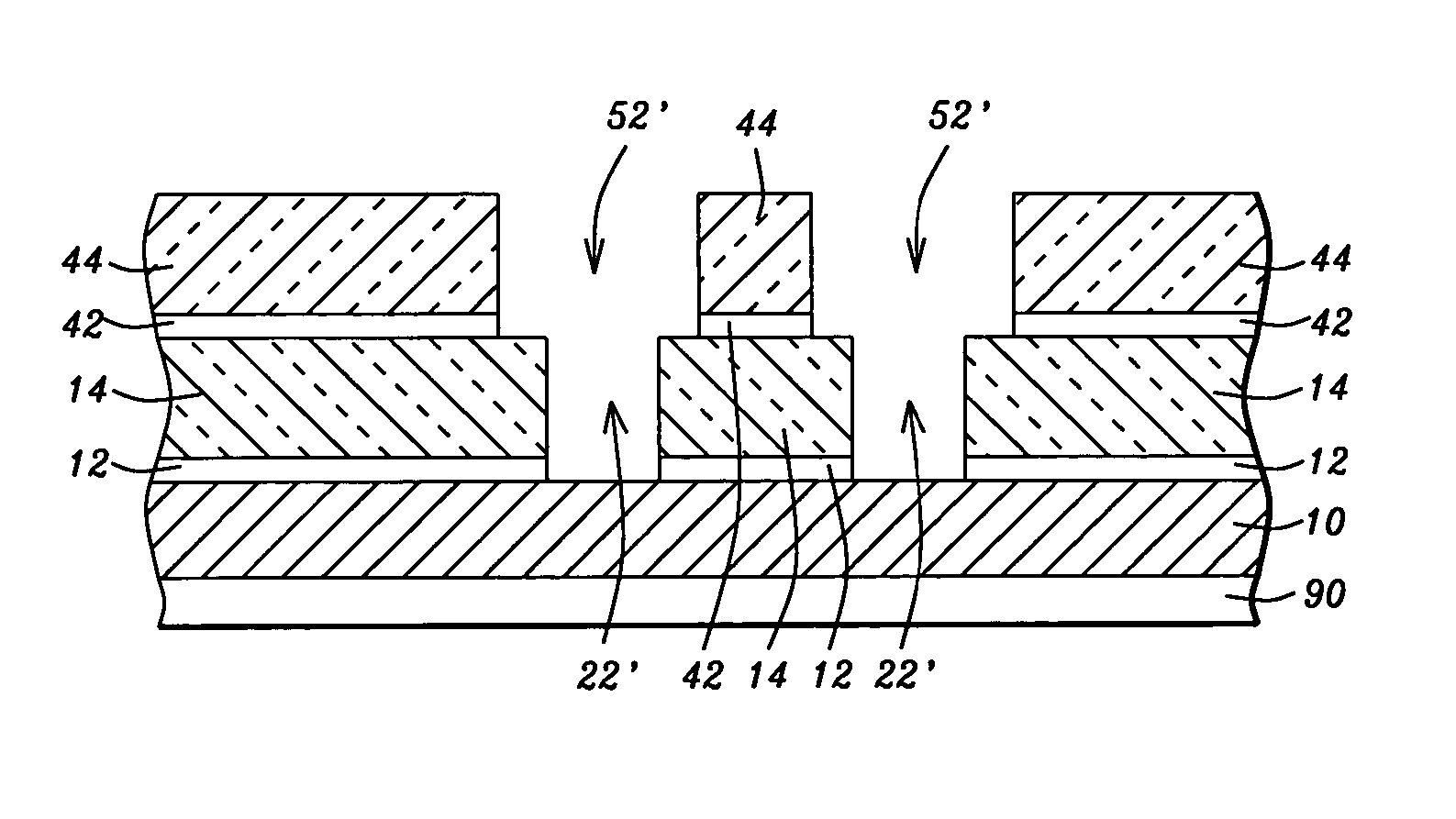

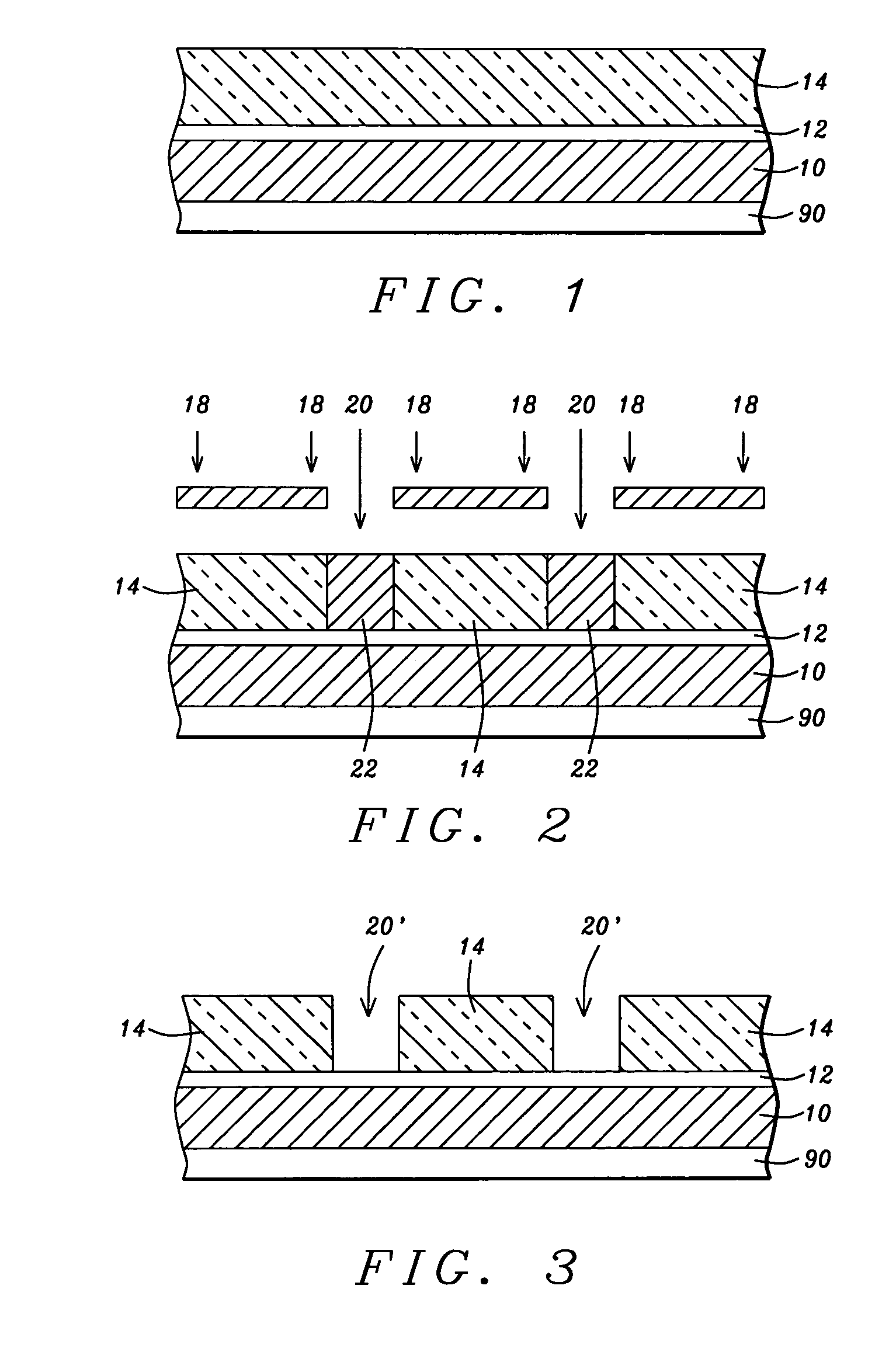

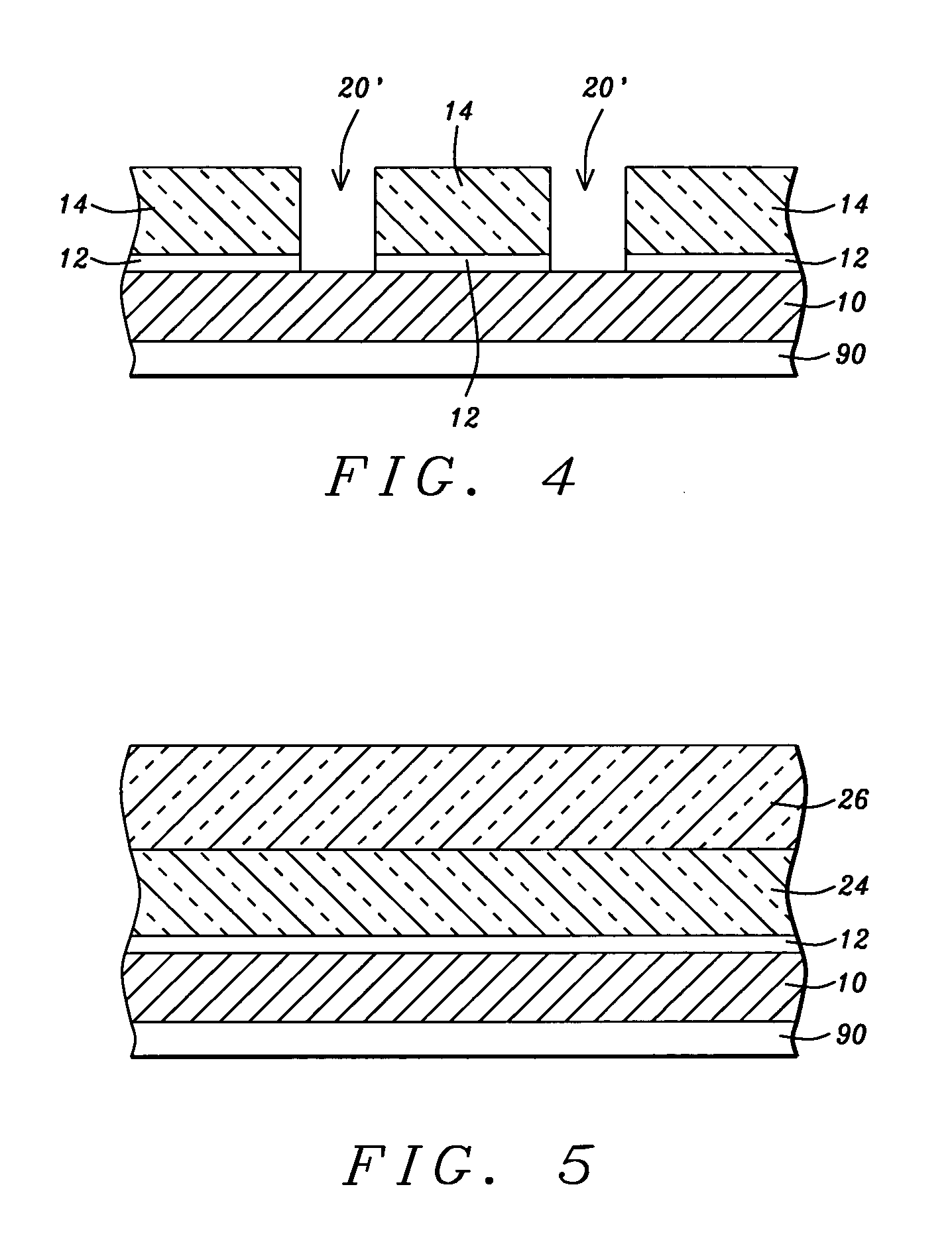

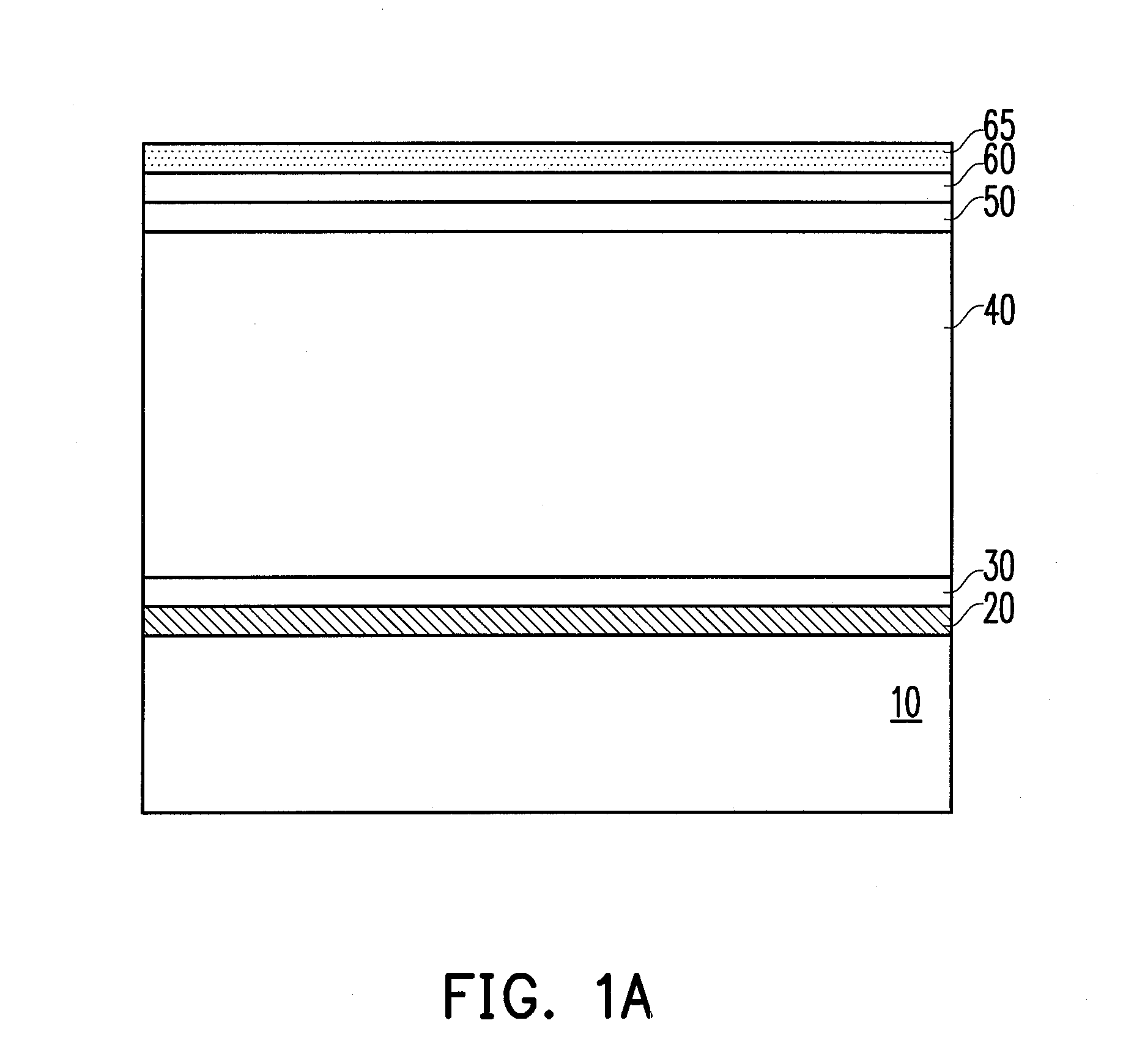

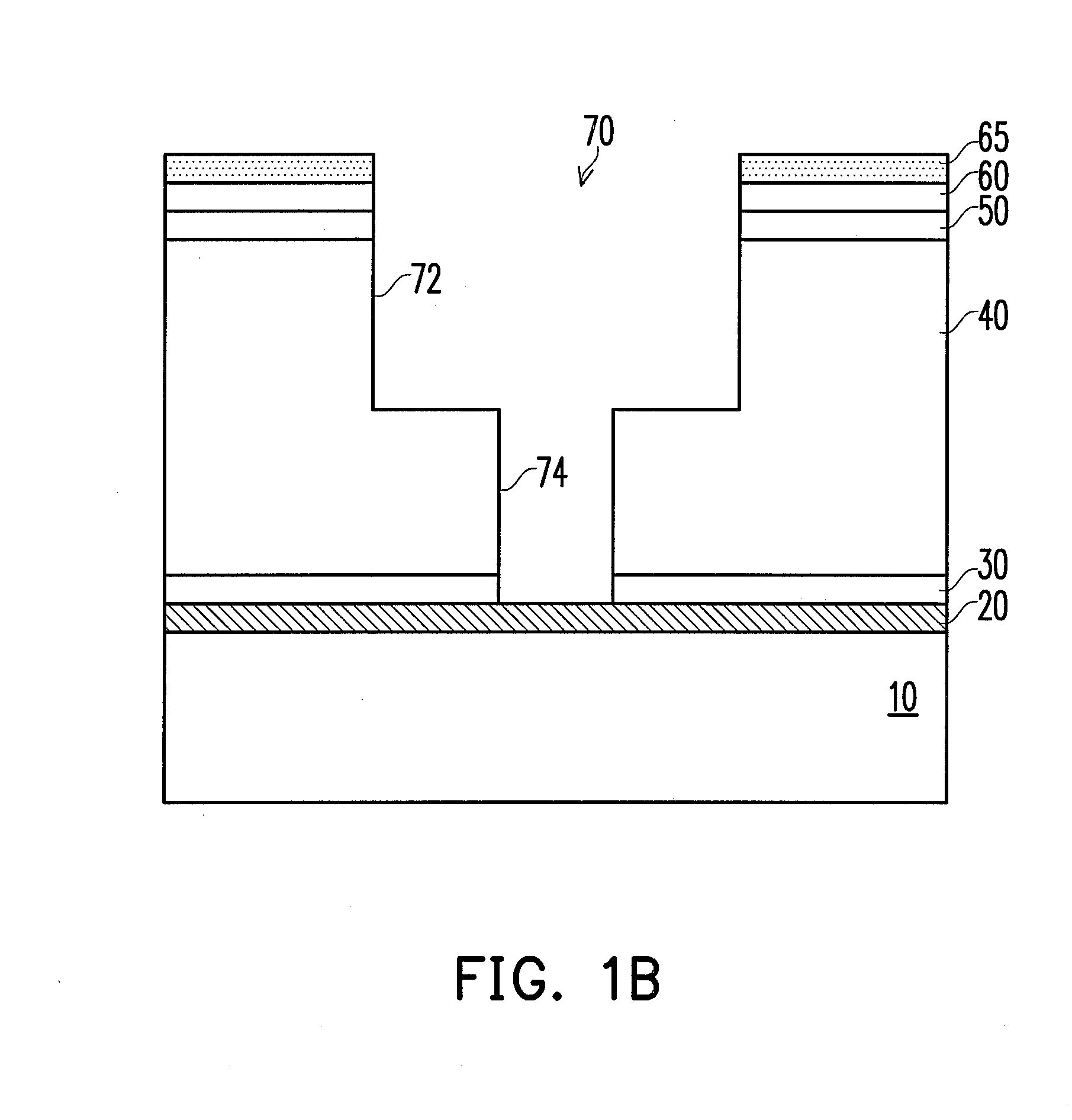

Self-patterning of photo-active dielectric materials for interconnect isolation

InactiveUS20050093158A1Low costReduce creationSemiconductor/solid-state device detailsSolid-state devicesDielectricPhotoresist

In accordance with the objectives of the invention a new method is provided for the creation of an interconnect pattern. The invention provides for a layer of Photo-Active Dielectric (PAD) to be used for the insulation material in which the interconnect pattern is created, this without the use of an overlying exposure mask of photoresist.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

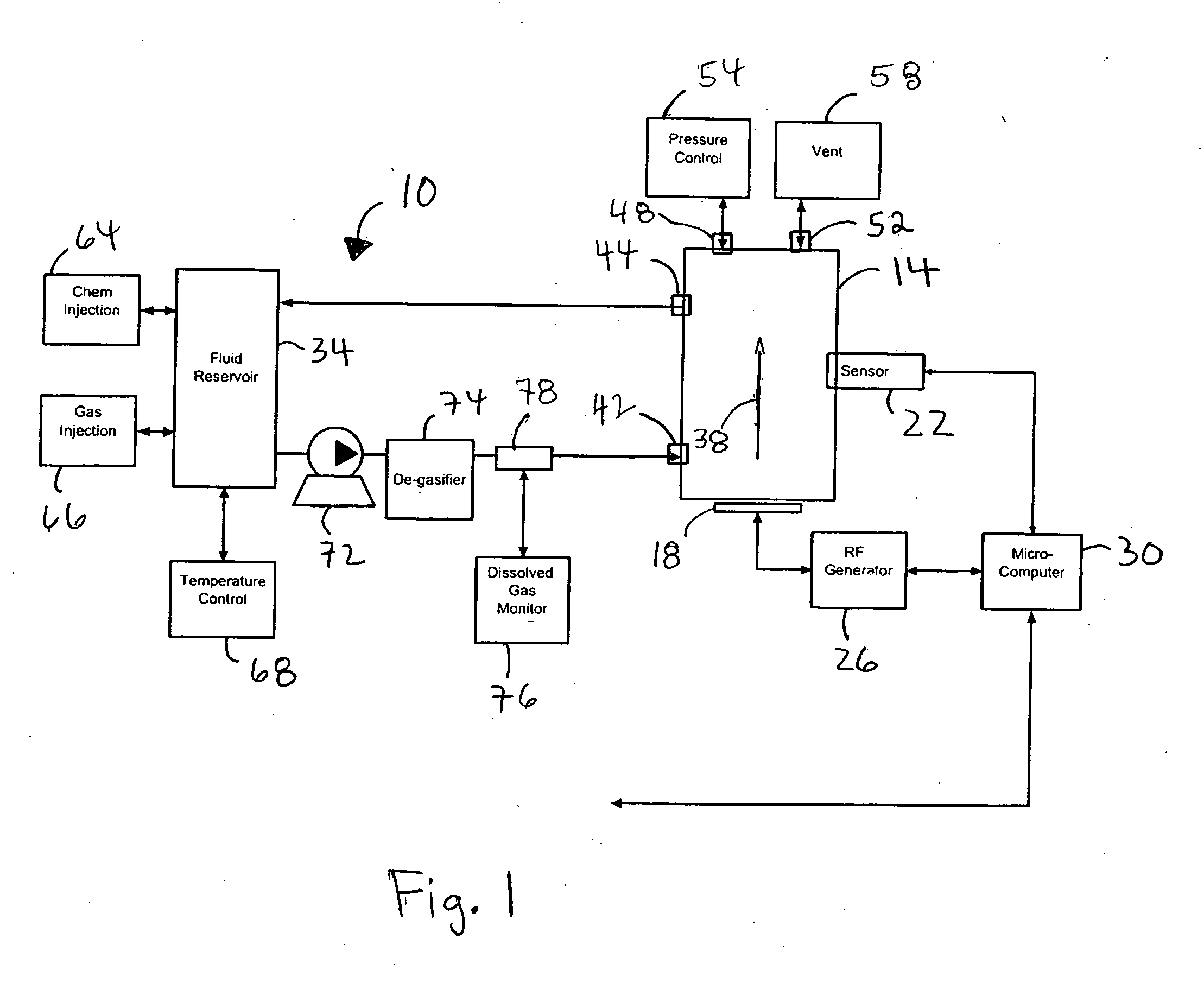

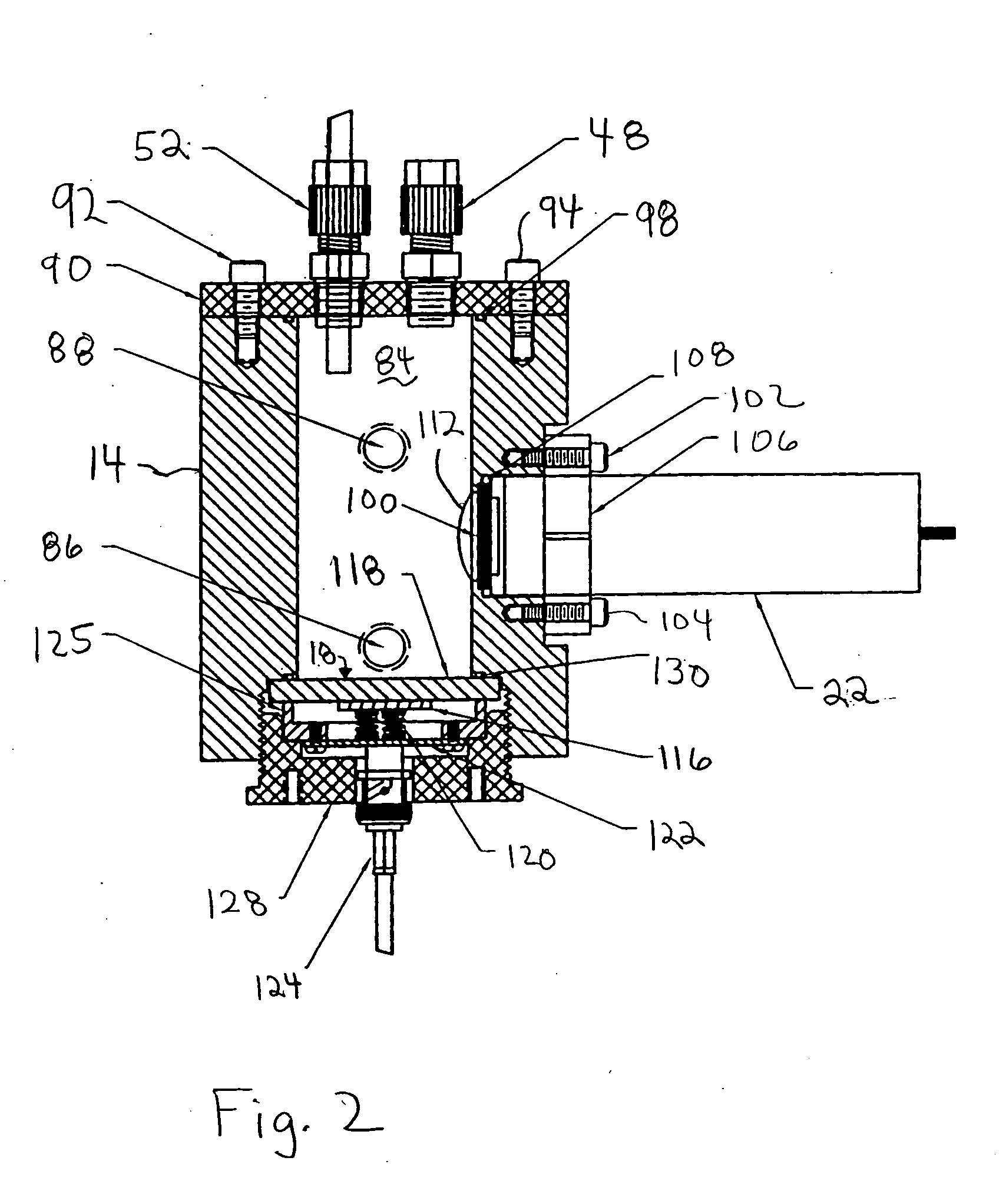

Method and apparatus for cavitation threshold characterization and control

ActiveUS20060061225A1Reduce chemical consumptionAvoid damaging effectsAnalysing solids using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidAcoustic energySonoluminescence

An apparatus and method for characterizing cavitation that occurs in a fluid exposed to acoustic energy. The apparatus comprises a vessel for holding the fluid; an acoustic energy generating means for generating acoustic energy, the acoustic energy generating means being positioned to transmit the acoustic energy into the fluid while the fluid is held in the vessel; and a cavitation detection means for detecting cavitation in the fluid held in the vessel. In a preferred embodiment, the cavitation detection means comprises a light detection means, such as a photomultiplier tube, that detects sonoluminescent emission from the fluid. The method comprises the steps of exposing a volume of process fluid to acoustic energy at a specified power level; measuring the photon output from the fluid over a period of time; and when the photon output deviates from a desired level, initiating a remedial step to bring the photon output back to approximately the desired level.

Owner:PROD SYST

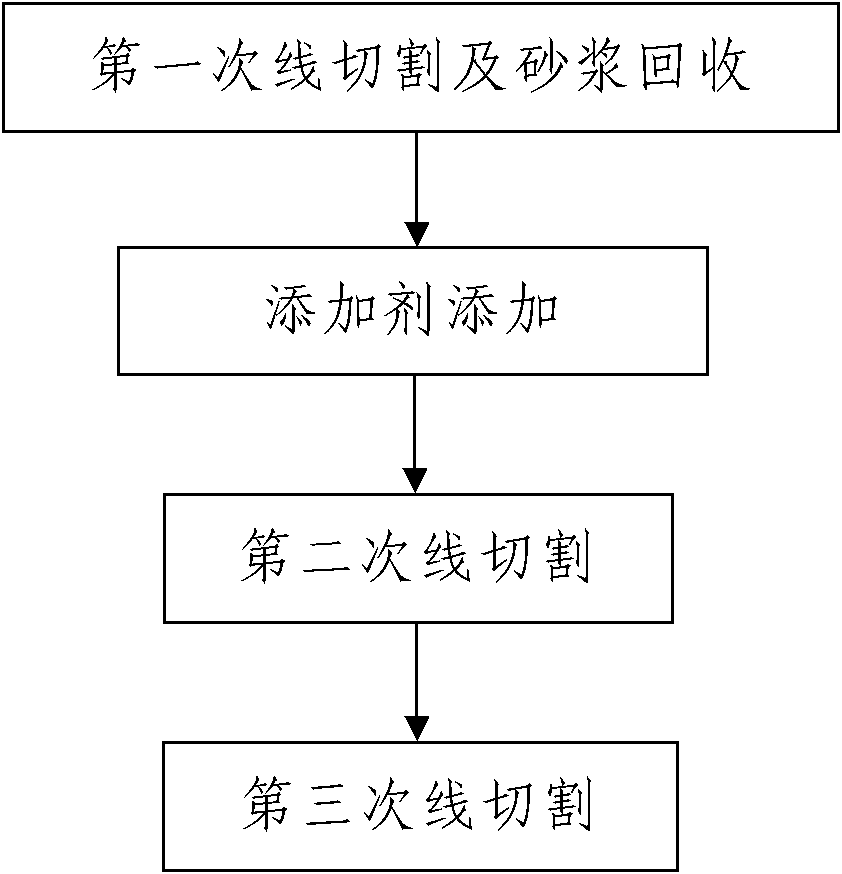

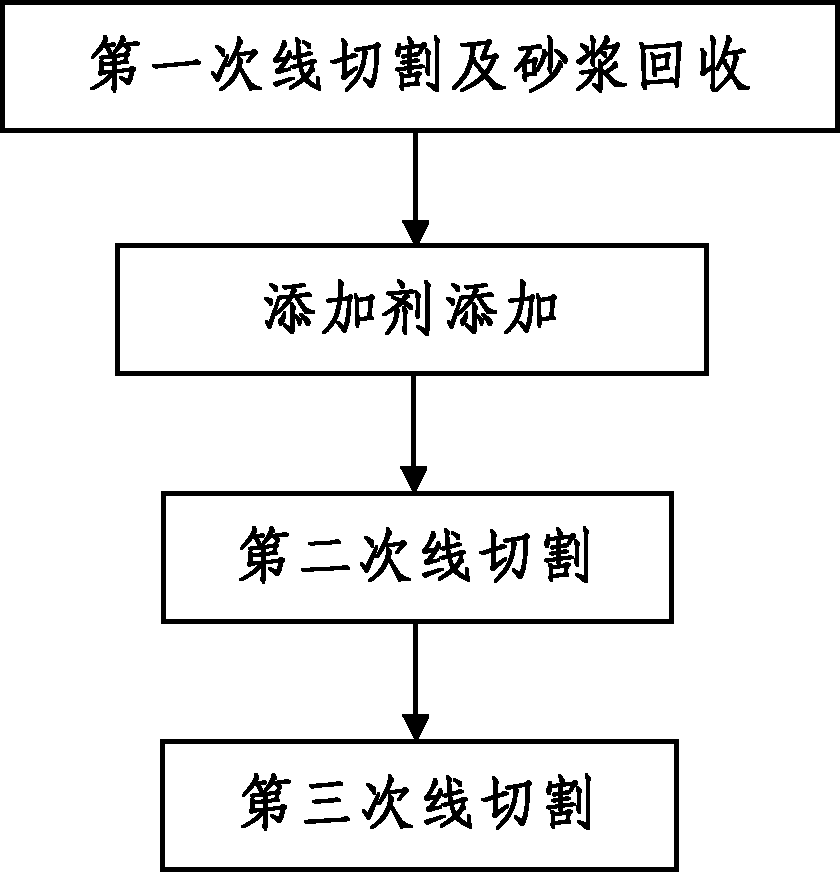

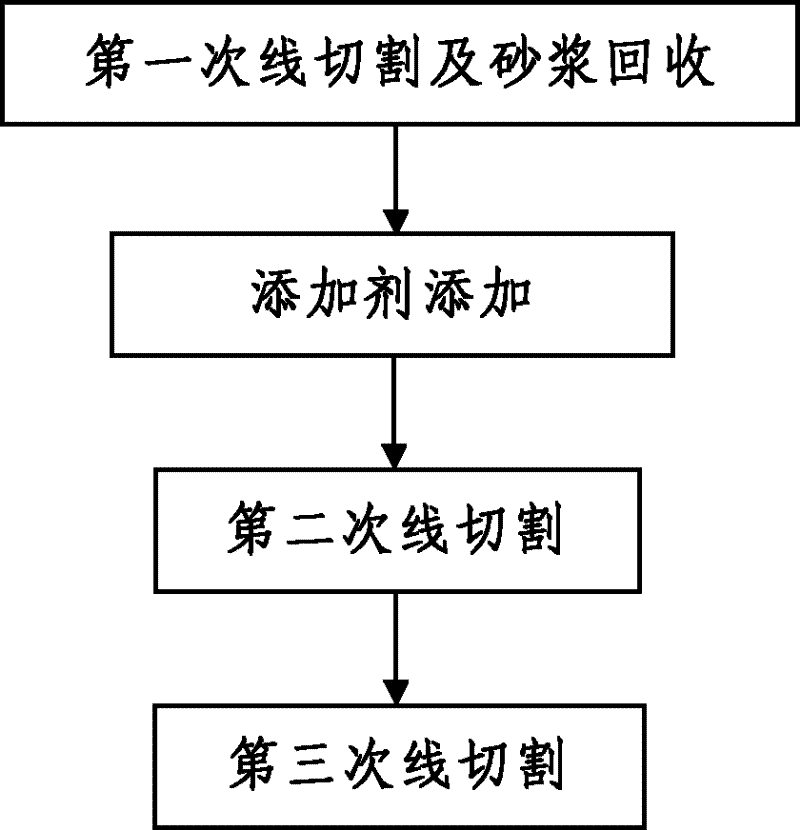

Additive for improving utilization ratio of silicon crystal line cutting mortar as well as preparation method and application method of addictive

InactiveCN102041138AIncrease profitReduce manufacturing costLubricant compositionAlcoholPolyethylene glycol

The invention discloses an additive for improving utilization ratio of silicon crystal line cutting mortar as well as a preparation method and application method of the addictive. The additive is composed of the following raw materials in percentage by weight: 50-96.5% of polyethylene glycol, 1-10% of penetrating agent, 1-20% of ether alcohol surfactant, 0.5-10% of extreme pressure resistant chelator and 1-10% of assistant detergent. The preparation method comprises the steps of weighing and mixing the raw materials. The application process comprises the following steps: 1. carrying out the first line cutting the mortar and recovering the mortar; 2. adding the additive: adding the additive to the recovered mortar after the first linear cutting based on the weight ratio of 1:100 plus / minus 10, and then evenly stirring; 3. carrying out the second line cutting; and 4. carrying out the third line cutting and recovering the mortar. The addictive is reasonable in design and has good use effect and practicable value, addictive preparation and use processes are simple, operation is convenient, and the defects of the existing silicon wafer cutting fluid such as more severe pollution, higher rejection rate, high production cost, low utilization ratio and the like can be overcome.

Owner:XIAN HUAJING ELECTRONICS TECH

Surface protection film for polarizer film

InactiveUS20080166549A1Decrease surface damageLow coefficient of frictionLiquid surface applicatorsSynthetic resin layered productsPolarizerPolythiophene

The present invention provides a film for the protection of the surface of polarizer film. Said film surface has anti-static coated layer. The coating solution contains polythiophene, surfactant, binding resin and water. According to the present invention, said protection film on the surface on the polarizer film has the excellent anti-static, transmittance, anti-foul and water repellence. It is able to prevent the invasion of imbuing with dust, accumulative anti-static and water vapor from the processing of assembling and transportation so as to influence the quality of polarizer film.

Owner:NANYA PLASTICS CORP

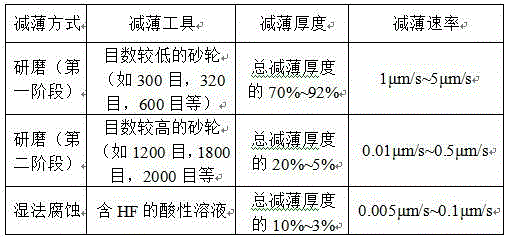

Silicon chip thinning method

ActiveCN103606517AGuaranteed mass productionReduce defectsSemiconductor/solid-state device manufacturingManufacturing technologyEtching

The invention belongs to semiconductor integrated circuit manufacture technology, and especially relates to a silicon chip thinning method. The silicon chip thinning method comprises a step 1 of arranging a protection material on the front side of a silicon chip; a step 2 of thinning the back side of the silicon chip in a phased grinding mode with a specific thinning process being divided into two phases; a step 3 of putting the silicon chip being thinned in the grinding mode into a corrosive liquid, and carrying out wet etching to the silicon chip through an abrasive wheel at a corrosion rate v3; and a step 4 of removing the protection material from the silicon chip. According to the invention, defects, of the silicon chip, generated in the thinning process are reduced, not only can a batch of silicon chips be thinned, but also back side defects and damaged layers caused by the thinning process are effectively reduced; the thickness proportions and the rates in the thinning process and the corrosion process can be subtly controlled, and therefore less defects and damages are generated on the surface of the silicon chip in the thinning process, and the effect of defect reduction is verified through ion implantation after the thinning process.

Owner:中国东方电气集团有限公司

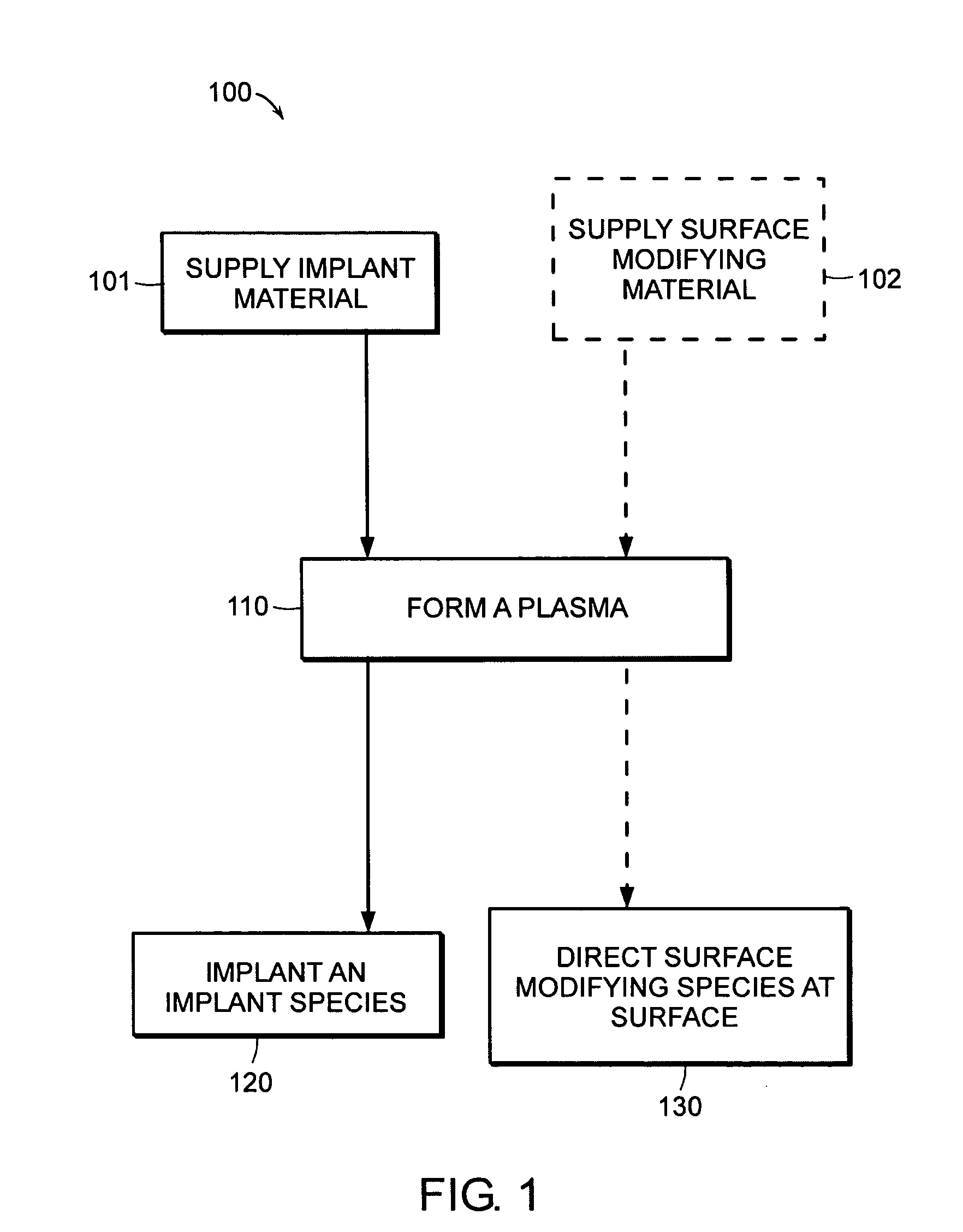

Etch and deposition control for plasma implantation

InactiveUS20050287307A1Reduce surface damageElectric discharge tubesVacuum evaporation coatingIon implantationImplant material

A method for ion implantation of a substrate includes forming a plasma from at least one implant material comprising at least one implant species, implanting the at least one implant species into a surface of the substrate, and directing at least one surface-modifying species at the surface to reduce a surface damage associated with the plasma. An apparatus for ion implantation is configured to implement this method.

Owner:VARIAN SEMICON EQUIP ASSOC INC

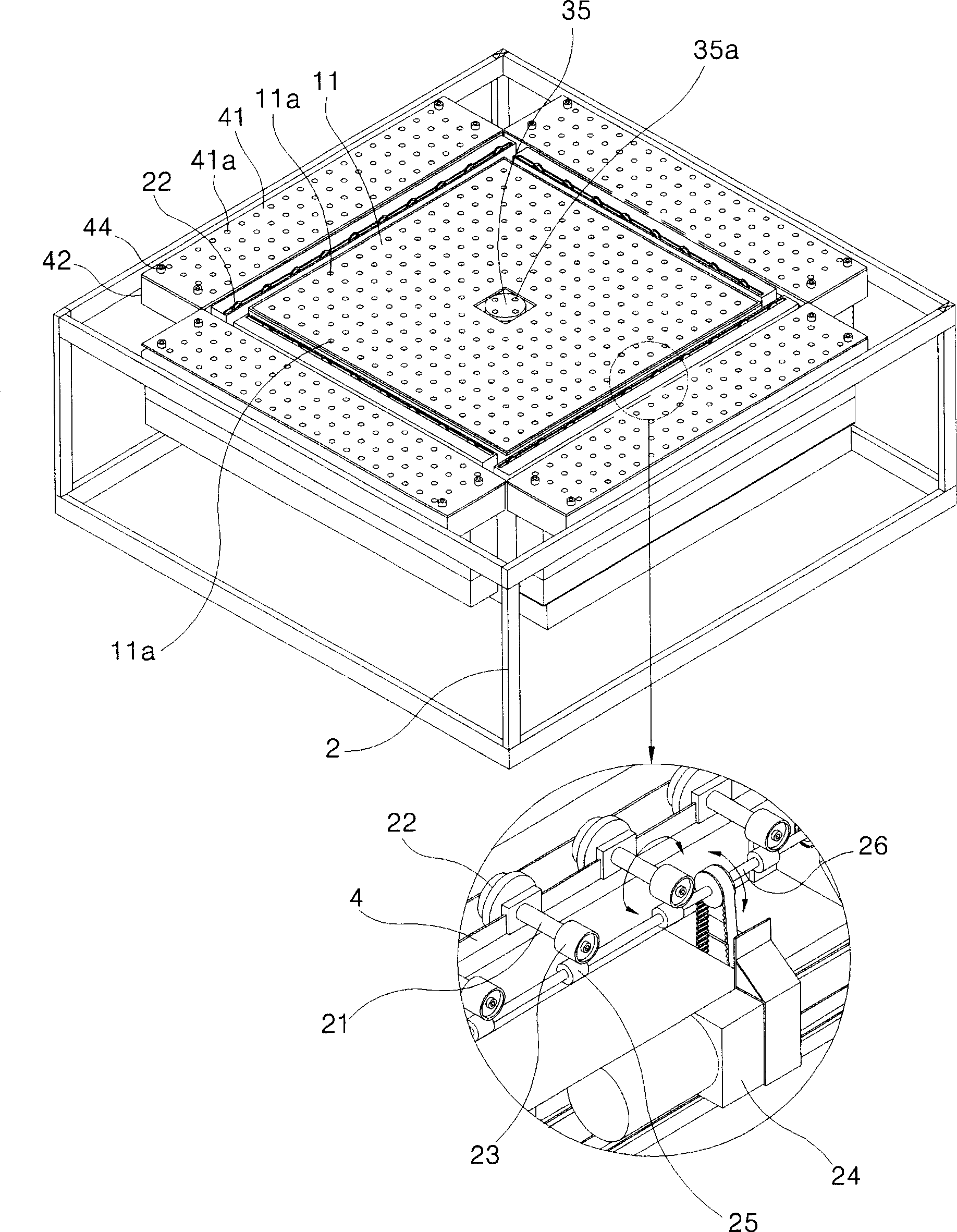

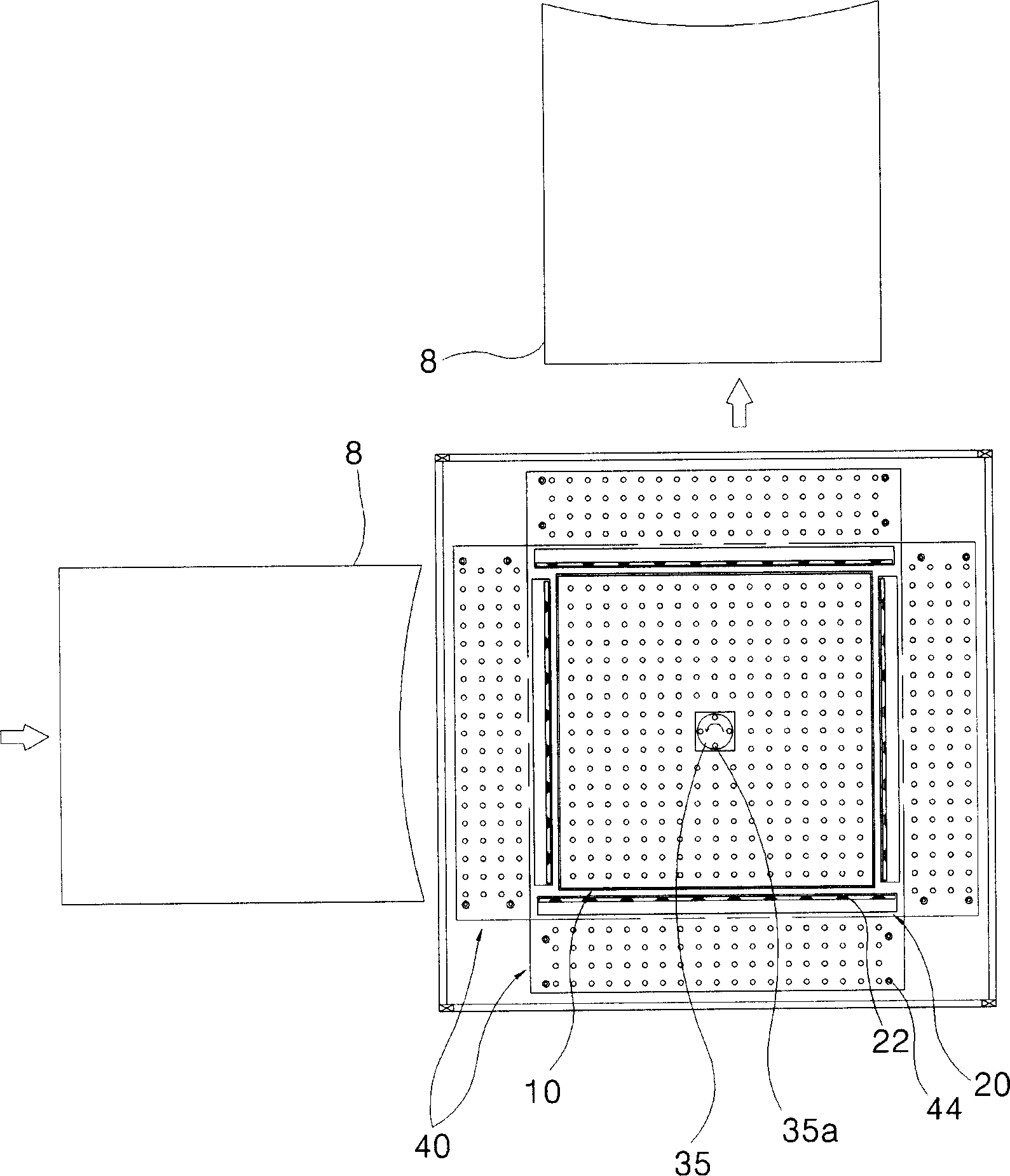

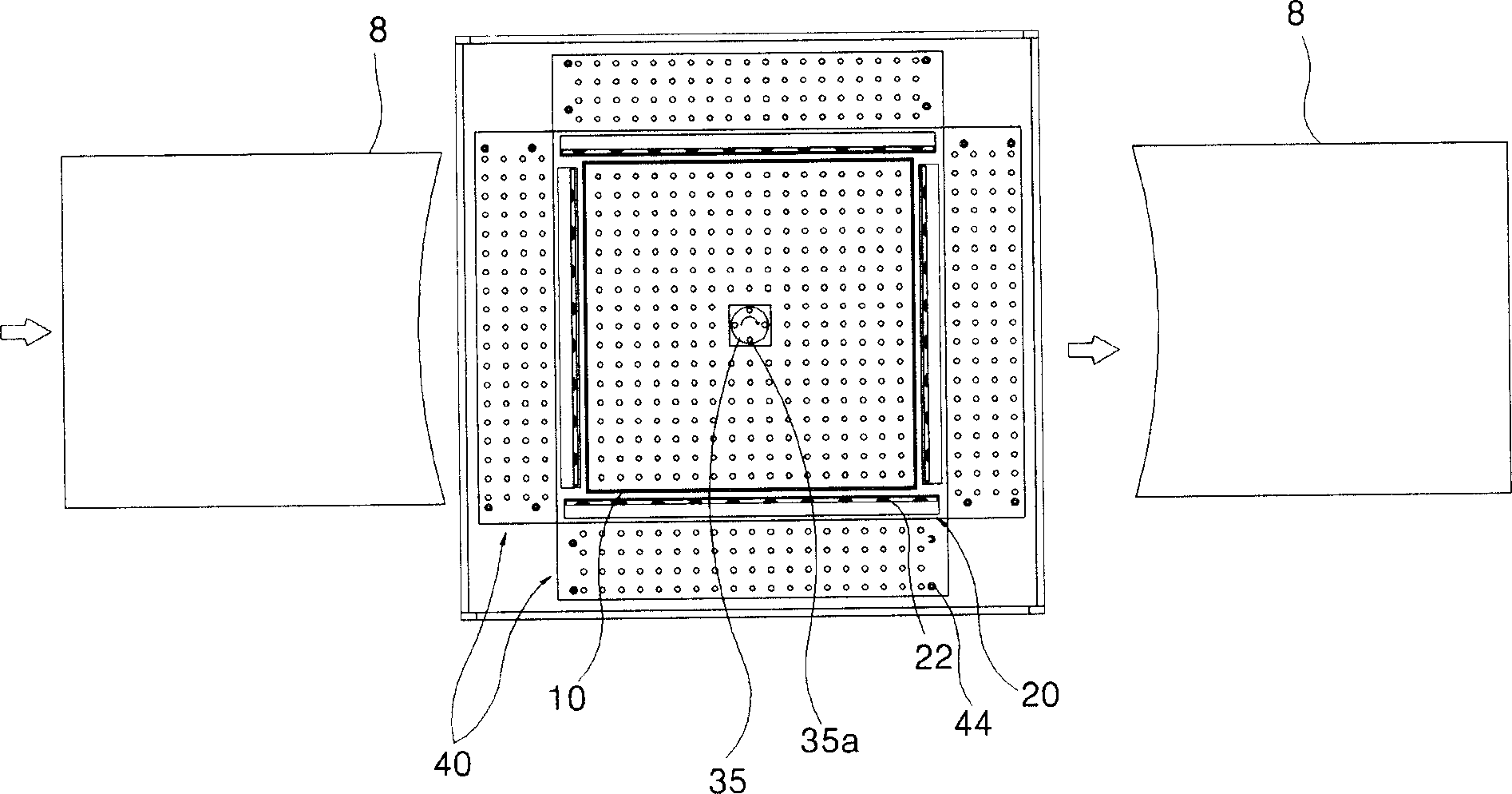

Plate glass direction conversion device

InactiveCN1891648AReduce surface damageSimple structureGlass transportation apparatusBulk conveyorsFlat glassMiniaturization

A direction changing device for flat glass minimizes the load on the flat glass by floating in the air, so that the flat glass is rotated in place and transferred in a specified direction. The flat glass direction changing device of the present invention comprises: an air ejector, comprising an air chamber and a fan box, the air chamber has an ejection plate for the air to float the flat glass, and the fan box is provided with an air jet fan for supplying air to the air chamber The roller transfer machine is arranged on the adjacent part of the outer peripheral surface of the air ejector, and has a plurality of rollers for transferring the flat glass in a prescribed direction; the rotary machine is arranged in the central part of the air ejector, so that the The flat glass is rotated in place. In the state of the flat glass floating in the air, the shaft rotates and transfers the flat glass, which not only minimizes the contact area between the flat glass and the roller and reduces the surface damage of the flat glass, but also simplifies the structure of the direction changing device regardless of the size of the flat glass , thereby miniaturizing the power and structure of the rotating equipment.

Owner:TAE SUNG ENG

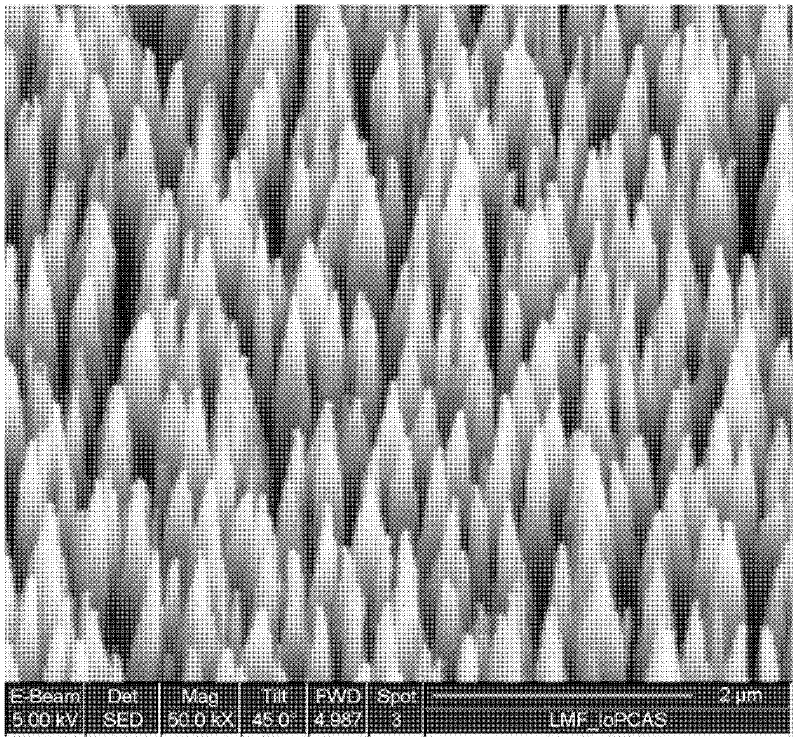

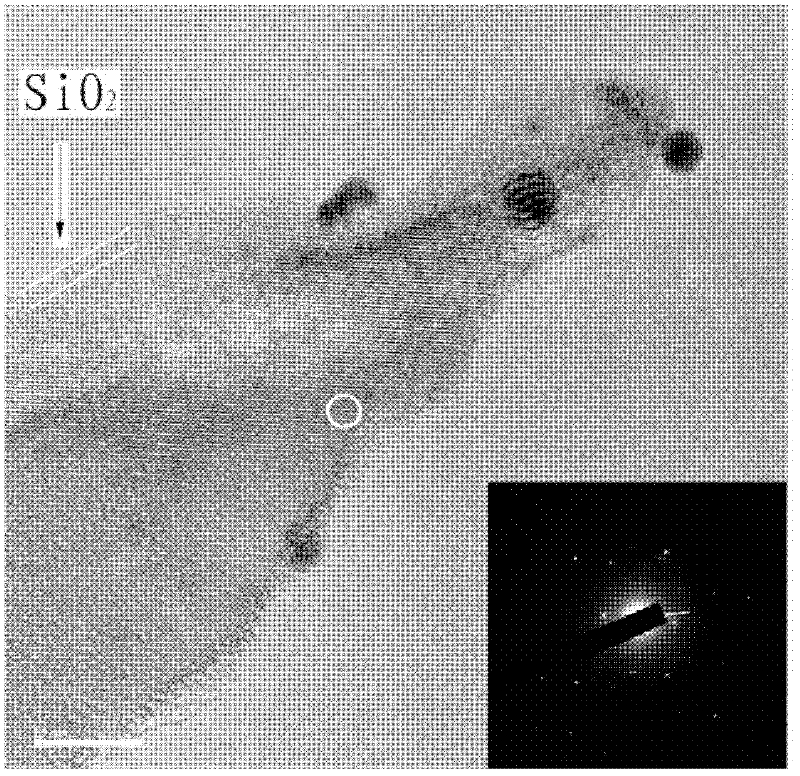

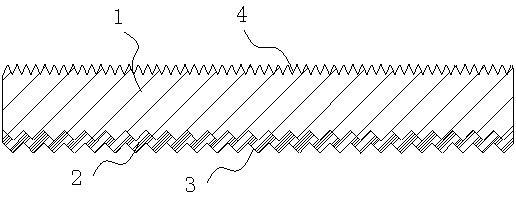

Preparation method for silicon surface anti-reflection nanometer array structure

ActiveCN102351569AOrientation to overcomeReduce light reflectivityInductively coupled plasmaReactive-ion etching

The invention relates to a preparation method for a silicon surface anti-reflection nanometer array structure, which comprises the following steps that: silicon chips are placed into an inductively coupled plasma (ICP) system, and nanometer conical array structures are obtained at the silicon surface under the conditions of the basic vacuum being 1.0*10<-6> Torr, the temperature being -100 DEG C to -140 DEG C, the gas flow rate ratio (SF6 / O2) being 36 / 22 to 44 / 14, the air pressure being 6 to 25mTorr, the reactive ion etching (RIE) power being 3 to 6W and the ICP power being 800 to 1000W. The method adopts a low-temperature etching technology, the masking process is not needed, the large-area silicon surface nanometer conical array structure with the super anti-reflection characteristic is directly prepared through etching, and in addition, the regulation and control on the nanometer conical structure feature is realized through regulating and controlling the corresponding parameters.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Method for processing soft and crisp LBO crystals based on consolidated abrasive polishing pad

InactiveCN102172879AReduce surface damageImprove surface qualityPolishing machinesPolishing compositionsMicrometerGranularity

The invention discloses a method for processing soft and crisp LBO crystals based on a consolidated abrasive polishing pad, which is characterized by comprising the following steps: firstly, roughly polishing and machining LBO crystals by the polishing pad of diamond consolidated abrasive of which the granularity is less than or equal to 14 micrometers, wherein in the polishing and machining process, the polishing pressure is controlled to 50-600g / cm<2>, the revolving speed of a polisher is controlled to 10-200 rpm, the pH value of a polishing solution adopted by polishing is controlled to 2-6, and the temperature of the polishing solution is 20-30DEG C to roughly polish the LBO crystals; and then, finely polishing and machining the LBO crystals obtained from the rough machining by the polishing pad of cerium oxide consolidated abrasive of which the granularity is not more than 3 micrometers, wherein the polishing pressure is controlled to 50-600g / cm<2> in the fine polishing and machining process, the revolving speed for polishing is controlled to 10-200rpm, the pH value of a polishing solution adopted by polishing is controlled to 2-6, and the temperature of the polishing solution is 20-30DEG C until the surface quality satisfies a set requirement. The method has the advantages of high processing efficiency and high finished product rate and does not cause environmental pollution.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

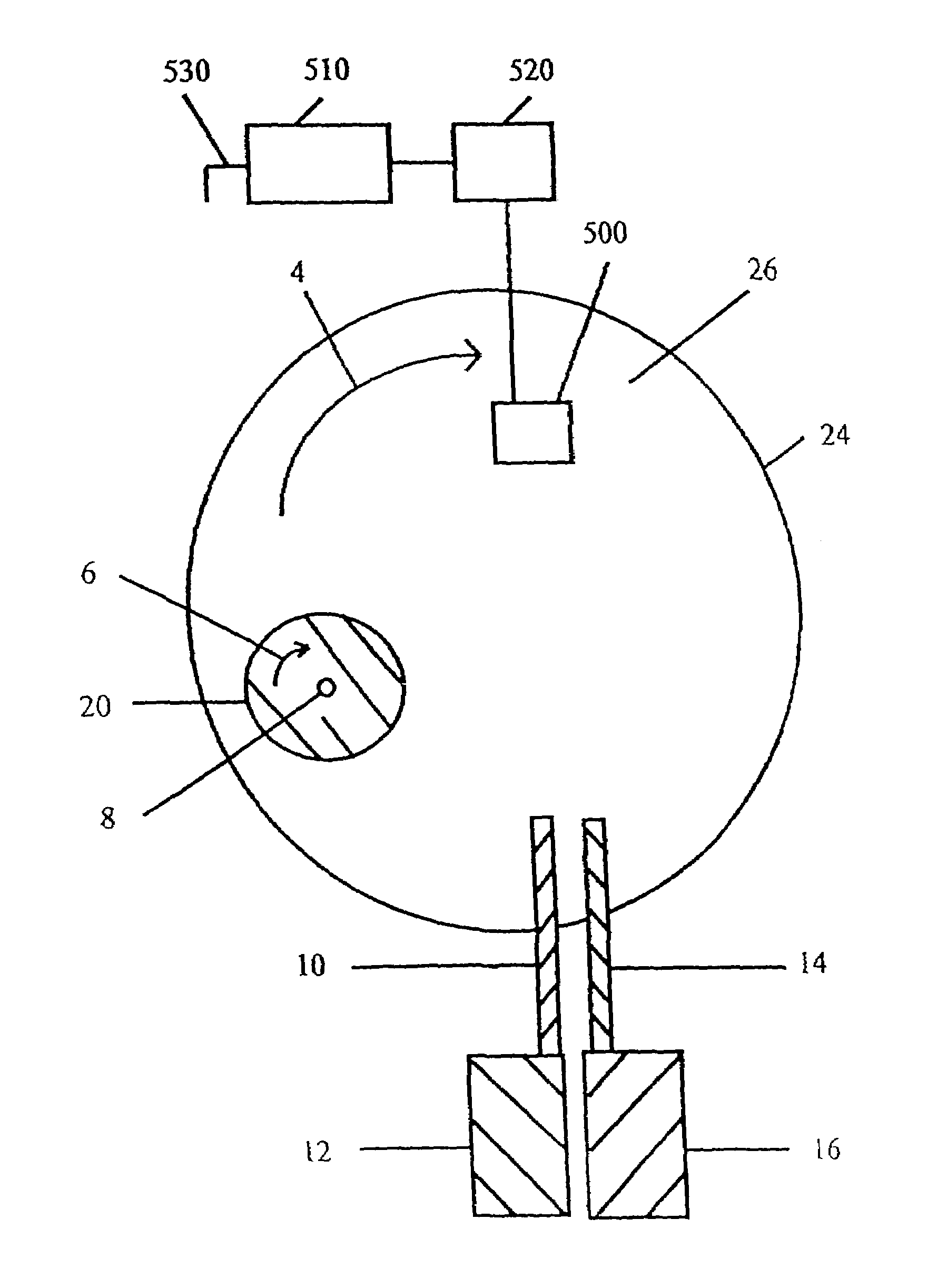

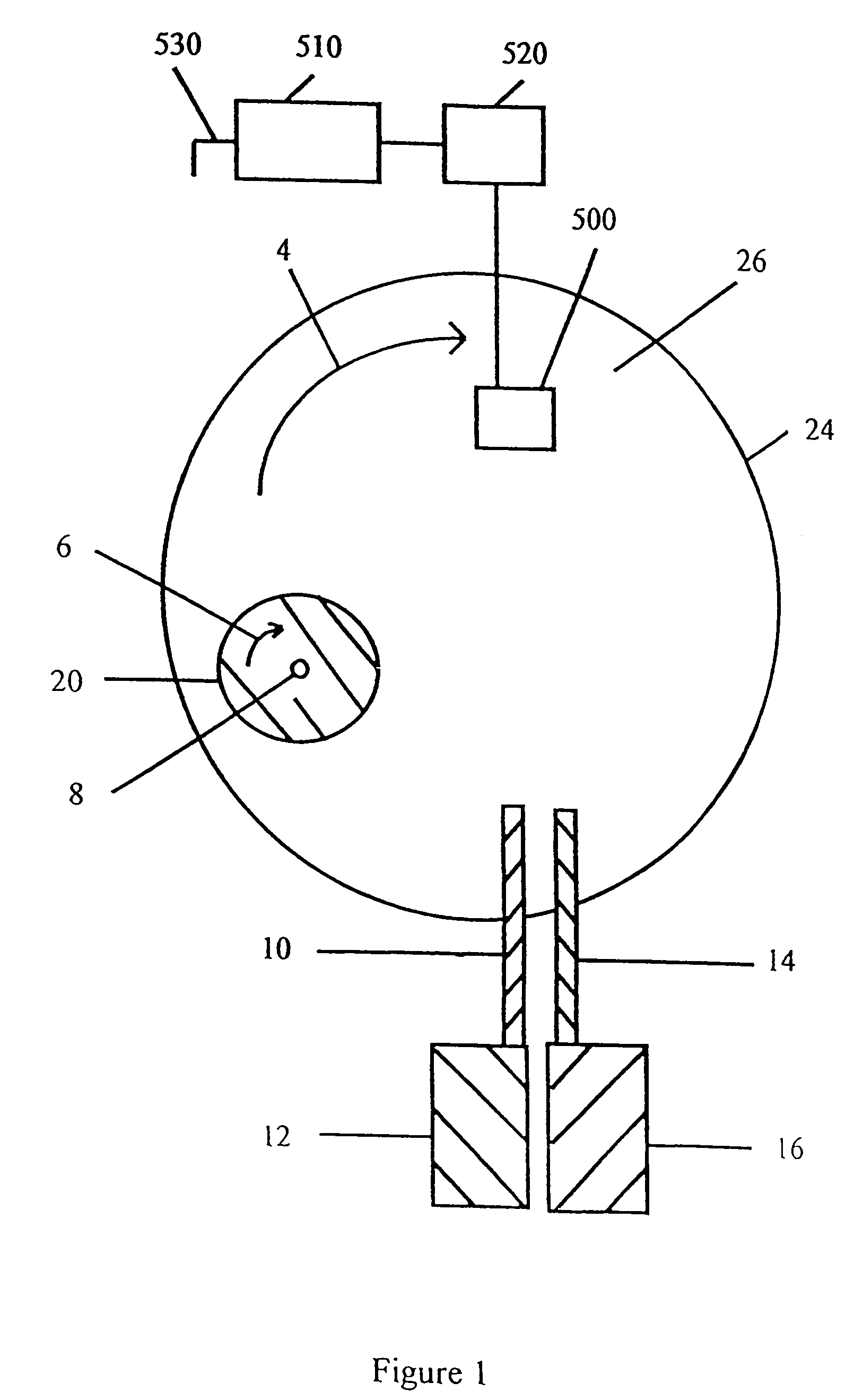

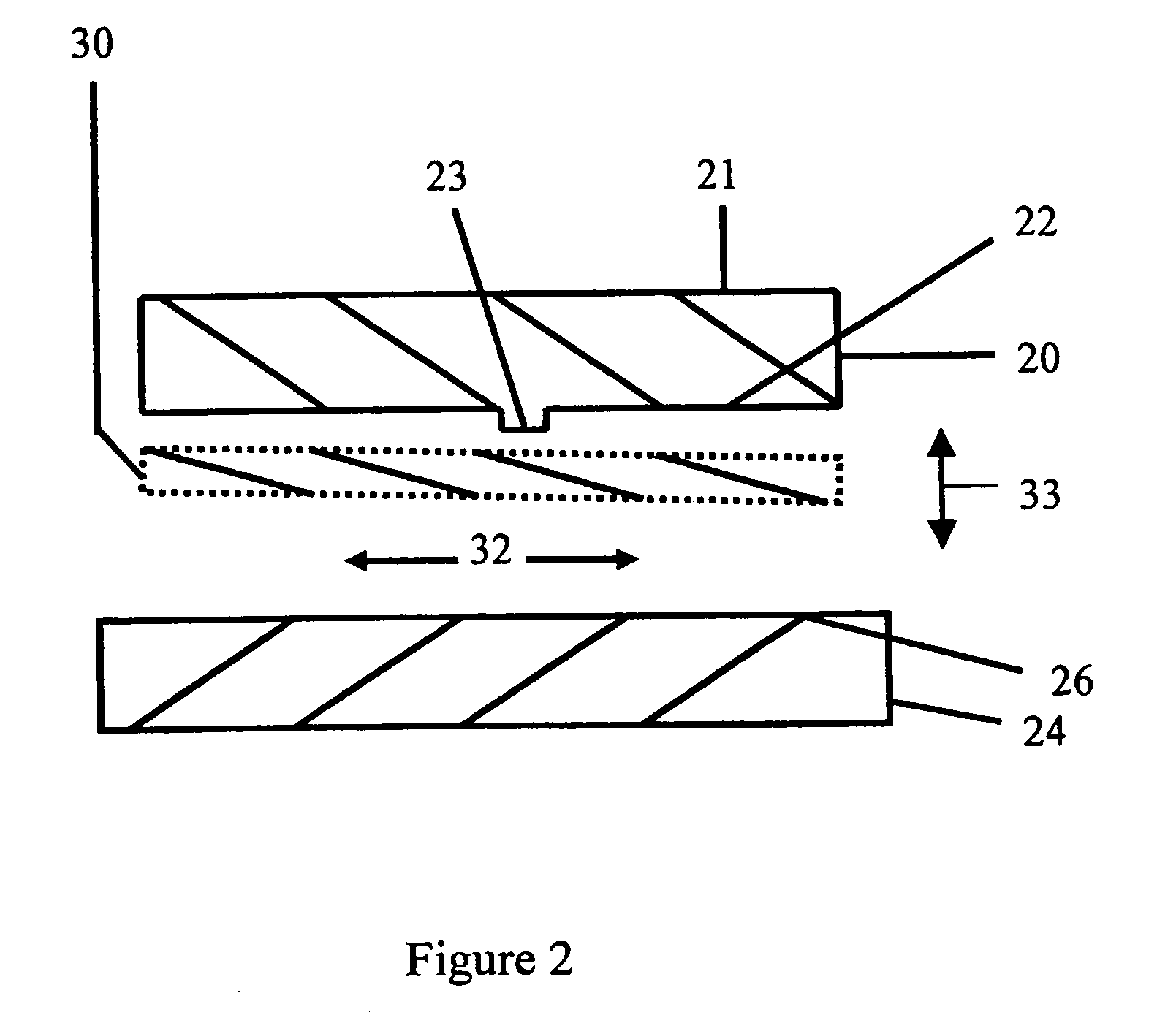

Situ finishing aid control

InactiveUS7156717B2Improve the finishChange frictionPolishing machinesSemiconductor/solid-state device manufacturingProcedure AgentsTangential force

A method of using finishing aids for advanced finishing control is described. A finishing surface is used generally to induce frictional wear. The finishing aids with preferred in situ control can improve control of the coefficient of friction, the tangential force of friction, a finishing rate, a regional finishing rate(s), a differential finishing rate, and help reduce unwanted defects. A finishing aid can reduce friction. A lubricant is an illustrative finishing aid. The method uses finishing control subsystem having a multiplicity of operative process sensors along with tracked information to improve in situ control of finishing. Differential finishing rate methods are described to differentially finish semiconductor wafers. Differential lubricating film methods are described to differentially finish semiconductor wafers. Planarization and localized finishing can be improved using differential lubricating boundary layer methods of finishing with improved real time control.

Owner:SEMCON TECH

Semiconductor silicon material water base cutting liquid

The alkaline water-base cutting liquid for silicon wafer and other semiconductor material consists of polyglycol of molecular weight 200-1000 in 30-90 weight portions, pH regulator 9-30 weight portions, chelating agent 1-10 weight portions and deionized water for the rest. The present invention has the beneficial effects of homogeneous stable chemical splitting effect coexisting with the mechanical effect, less stress, lowered damage of the semiconductor material, raised chip cutting efficiency and quality, simple post-treatment, and avoiding the chemical bonding and adsorption on the surface of silicon wafer.

Owner:HEBEI UNIV OF TECH

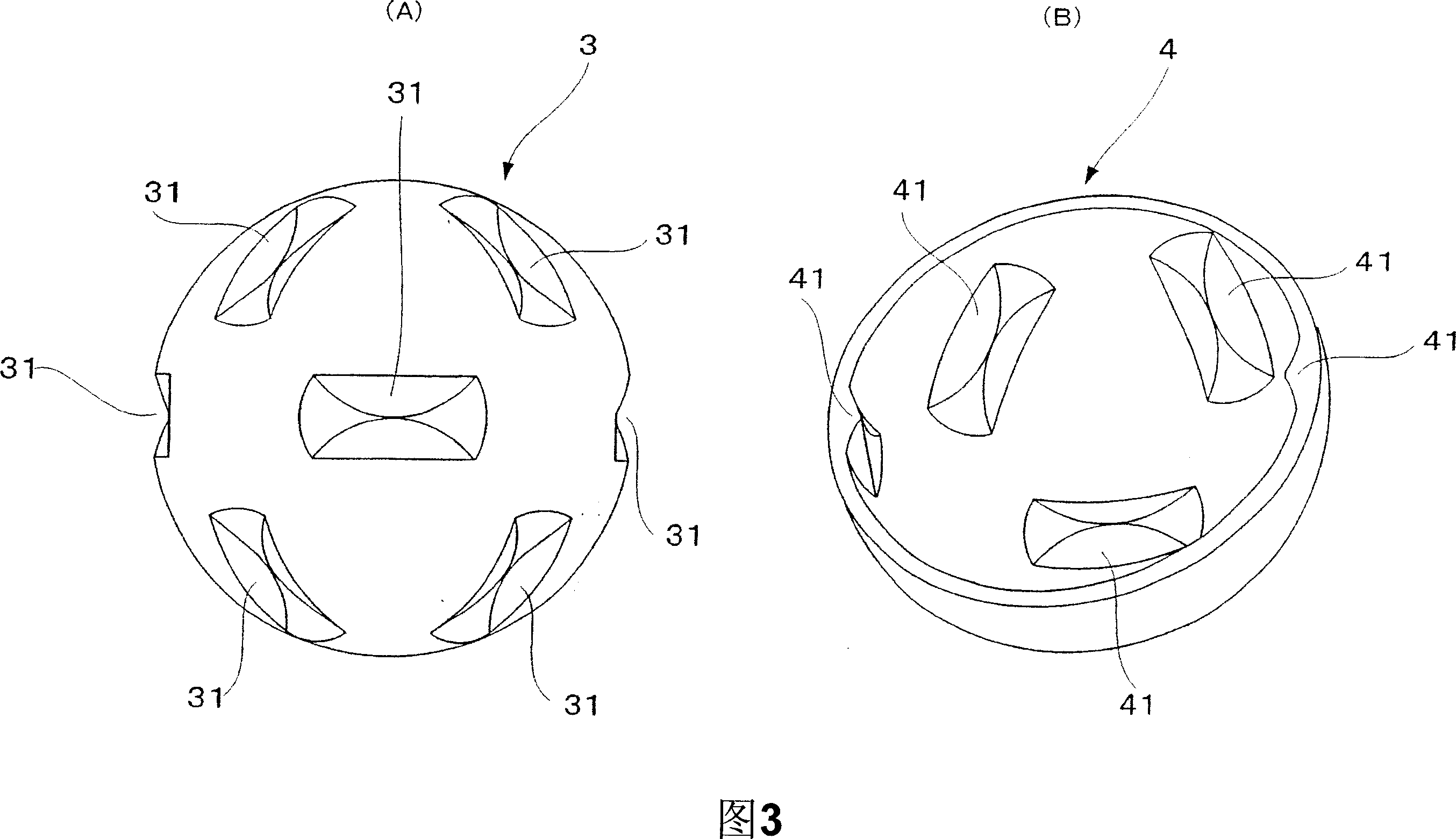

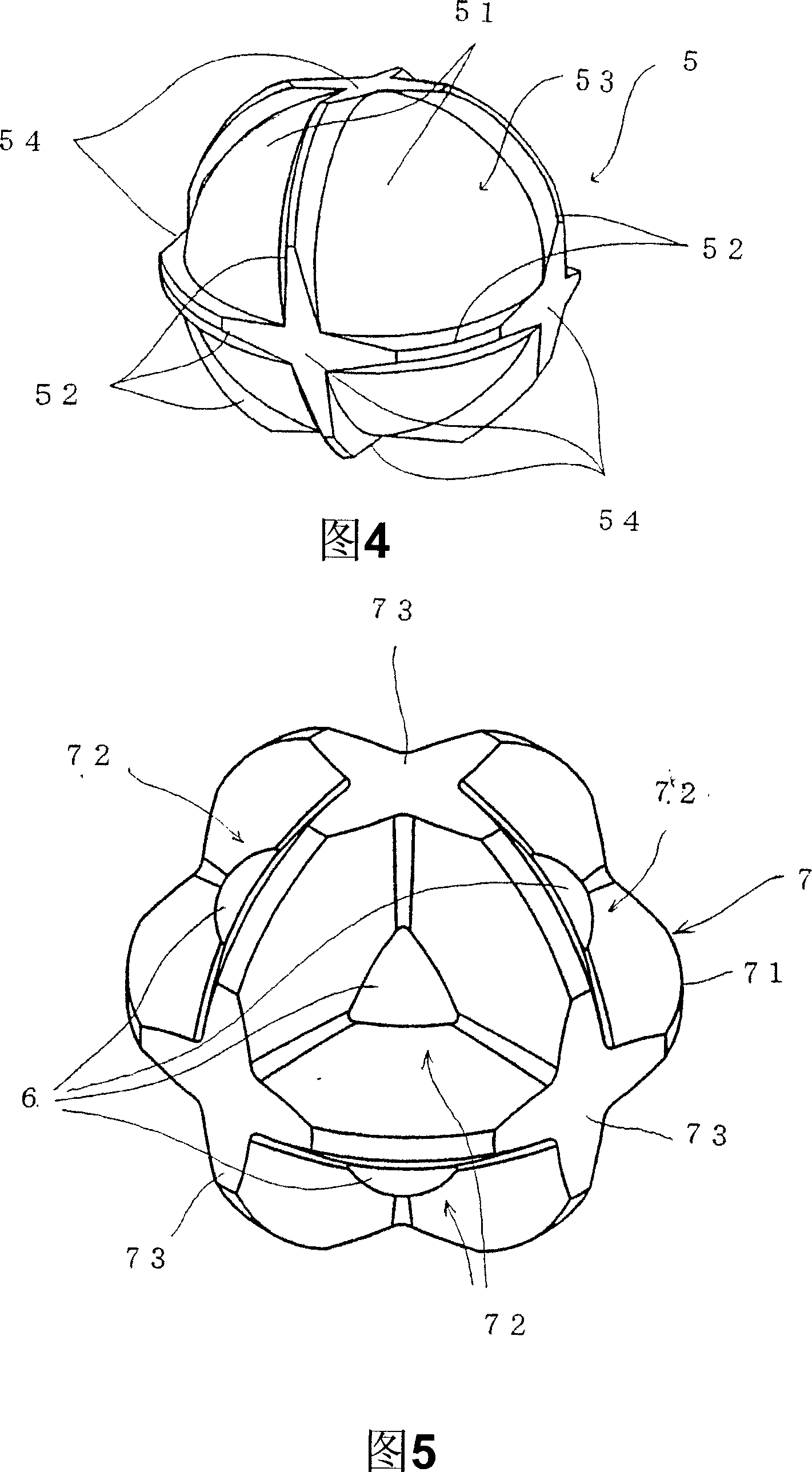

Composition for producing golf balls and multi-piece golf balls

InactiveCN1953790AImprove wear resistanceExcellent adhesionGolf ballsSolid ballsElastomerPolymer science

A composition for golf ball formation which comprises: fine polyurethane gel composite particles comprising fine gel particles of a three-dimensionally crosslinked polyurethane produced from a polyisocyanate compound and a compound containing no polyethylene oxide group but containing active hydrogen, at least either of the compounds having a functionality of 3 or higher, and colloidal polyurea particles which were precipitated from a colloidal solution of a polyurea in a nonaqueous solvent and with which the surface of the fine gel particles has been coated; and at least one base selected from the group consisting of synthetic resins and elastomers. Also provided is a multipiece golf ball any one or more layers of which are layers formed from the composition.

Owner:MIZUNO CORPORATION

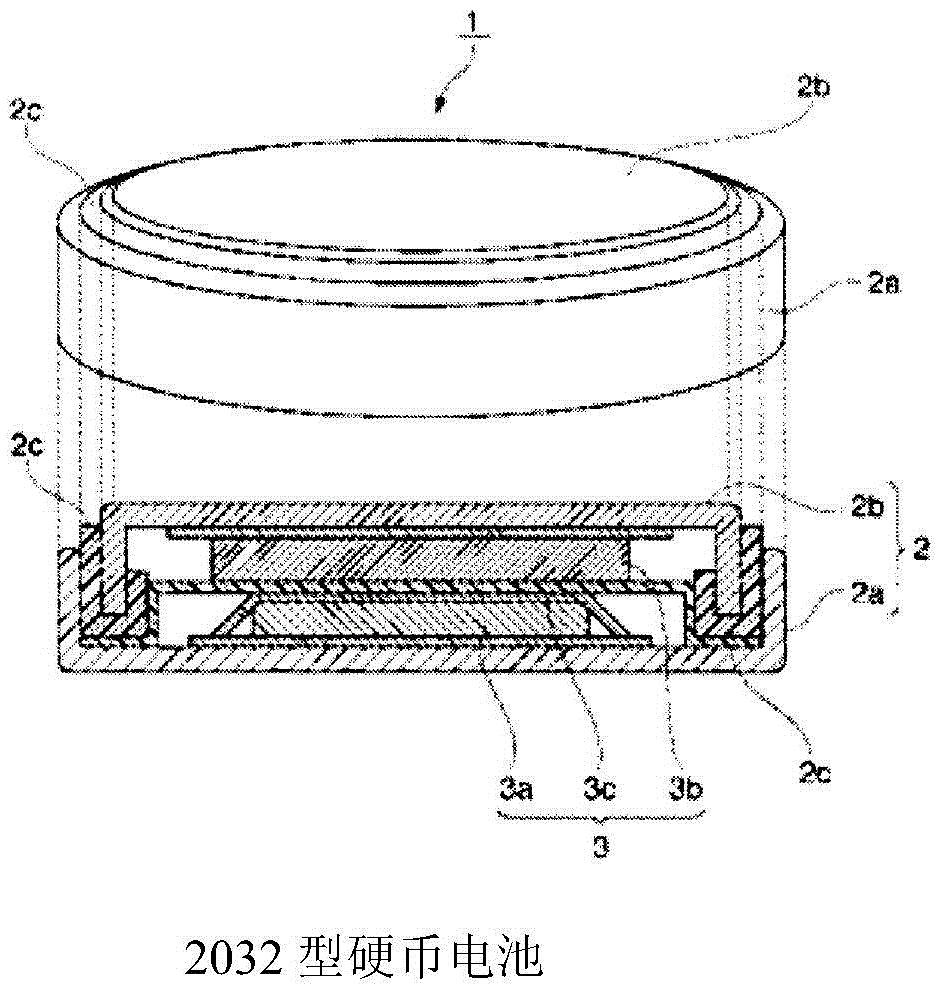

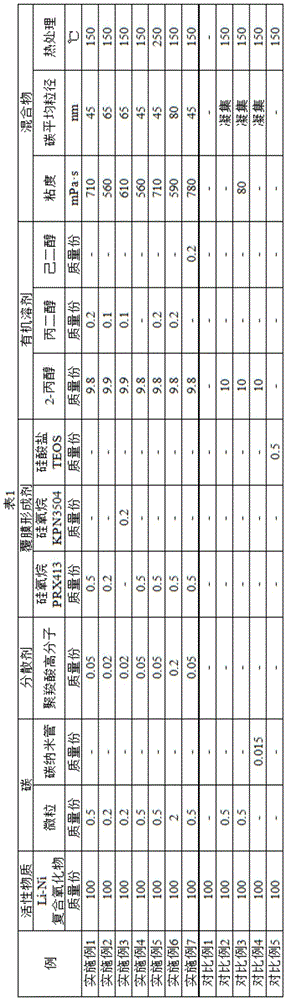

Method for producing positive electrode active material for nonaqueous electrolyte secondary batteries, positive electrode active material for nonaqueous electrolyte secondary batteries, and nonaqueous electrolyte secondary battery

ActiveCN105594024AEasy to operateIncrease internal resistanceElectrode thermal treatmentFinal product manufactureOrganic solventFilm-forming agent

To provide: a method for producing a positive electrode active material, which is capable of improving water resistance of the positive electrode active material and suppressing gelation of a positive electrode mixture paste without deteriorating the original battery performance of the positive electrode active material; and the like. A method for producing a positive electrode active material for nonaqueous electrolyte secondary batteries, which is provided with: a mixing step for preparing a mixture that contains fine carbon particles, an organic dispersant, a hydrophobic coating film-forming agent, an organic solvent and positive electrode active material particles; a drying step for drying the mixture so as to obtain a mixture in which the content of the organic solvent is reduced; and a heat treatment step for subjecting the mixture, in which the content of the organic solvent is reduced, to a heat treatment so as to obtain a coated positive electrode active material.

Owner:SUMITOMO METAL MINING CO LTD

Solar silicon wafer cutting liquid

InactiveCN102093925AGood dispersionGuarantee stabilitySemiconductor/solid-state device manufacturingBase-materialsPolyethylene glycolSlurry

The invention discloses solar silicon wafer cutting liquid. The solar silicon wafer cutting liquid contains polyethylene glycol, a dispersant, a surfactant, a defoamer and a chelating reagent. The solar silicon wafer cutting liquid can improve the dispersibility and the redispersibility of silicon carbide so as to ensure the stability and the durability of slurry, can realize 100 percent recovery of the silicon carbide, greatly reduces the cost, can reduce the surface damage of a slice and the pollution of mechanical stress, thermal stress and metal ions to a silicon wafer, contributes to subsequent cleaning of the silicon wafer, improves the conversion efficiency of a rear-end solar battery, can effectively improve the thickness error of the silicon wafer and improves cutting yield.

Owner:ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Cleaning method of quartz material parts

ActiveCN101204706AAchieve cleaningReduce surface damageInorganic/elemental detergent compounding agentsDrying solid materials with heatOrganic solventCleaning methods

The invention relates to a method for cleaning quartz material parts, which is as follows: wiping with organic solvent, soaking in H2O2, cleaning in solvent containing ammonium persulfate and non-ionic surface active agent such as polyethylene glycol or methoxy polyethylene glycol, etc. wiping again with an emery cloth and ultrasonic cleaning with ultrapure water. In the steps that do not adopt ultrapure water to clean, rinse with ultrapure water needs to be carried out. The invention is a harmless, quick and effective method to clean the surfaces of quartz parts in etching machines, which can realize cleaning of surfaces of quartz material parts and causes little or no harm to the surfaces of parts; the operation thereof is simple and convenient.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Photoluminescent wafer as well as preparation method and application thereof

InactiveCN102140690ALattice integrityReduce surface recombinationPolycrystalline material growthSolid-state devicesRare-earth elementWafering

The invention relates to the manufacturing field of light emitting diodes (LED), in particular to a photoluminescent wafer for the LED as well as preparation method and application thereof. The photoluminescent wafer is a slice-shaped crystal in a garnet structure with a general formula of A3B5O12 without doping any resins and other bonding agents, the thickness of the photoluminescent wafer is not less than 20 um, and the size of the crystal particle is not less than 10 um; moreover, the photoluminescent wafer comprises a first element A, a second element B and an active element, wherein thefirst element A is at least one of rare-earth elements Y, Lu, La, Gd or Sm; the second element B is at least one of the elements Al, Ga or In; and the active element is at least one of the rare-earthelements Ce, Pr, Tb and Dy. The photoluminescent wafer has the characteristics of high light emitting efficiency and good light emitting uniformity; the light transmission of the light emitting layercan not be reduced by light adsorption of the bonding agent; and the surface of the photoluminescent wafer is easy for people to carry out various optical treatments.

Owner:ZHEJIANG SHENDU LIGHTING

Processing method for ultrathin plain glass based on consolidated abrasive

InactiveCN102172859AUniform thicknessImprove flatnessPolishing compositionsPlane surface grinding machinesGranularityMicrometer

The invention discloses a processing method for ultrathin plain glass based on consolidated abrasive, which is characterized by comprising the following steps: firstly, taking ground plain glass of which the thickness is less than or equal to 0.5mm as a raw material; secondly, adopting a polishing pad of diamond consolidated abrasive of which the granularity is less than or equal to 28 micrometers, controlling the polishing temperature to 20-40oC, polishing pressure of 100-1000g / cm<2>, pH value of a polishing solution of 8-11, flow velocity of 100-500ml / min and polishing rotation speed of 10-500r / min to obtain a middle glass product of which the thickness is 0.2-0.3mm; thirdly, polishing the polishing pad of diamond consolidated abrasive of which the granularity is less than or equal to 10 micrometers, controlling the polishing temperature to 20-40oC, polishing pressure of 100-500g / cm<2>, pH value of a polishing solution of 8-11, flow velocity of 100-500ml / min and polishing rotation speed of 10-300r / min; and putting the middle glass product onto a polisher to polish to obtain ultrathin glass of which the thickness is less than or equal to 0.15mm. The processing method has the advantages of simple process, no pollution, high efficiency and low cost, and size material with a larger length or width and thickness ratio can be processed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

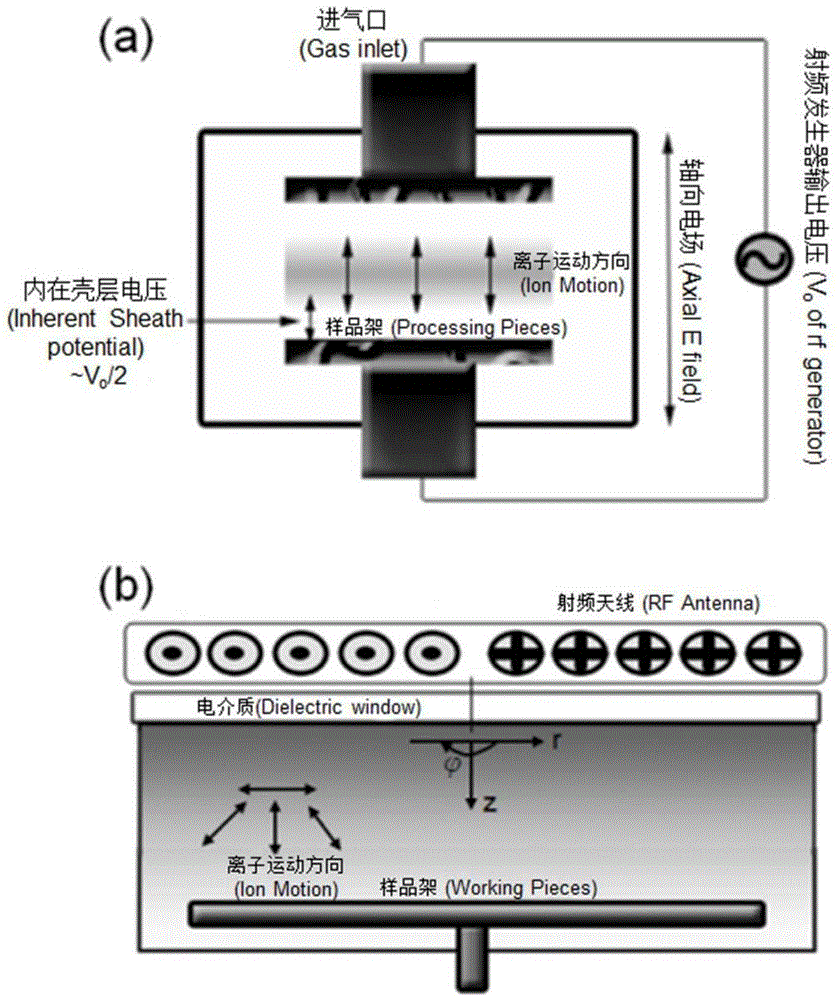

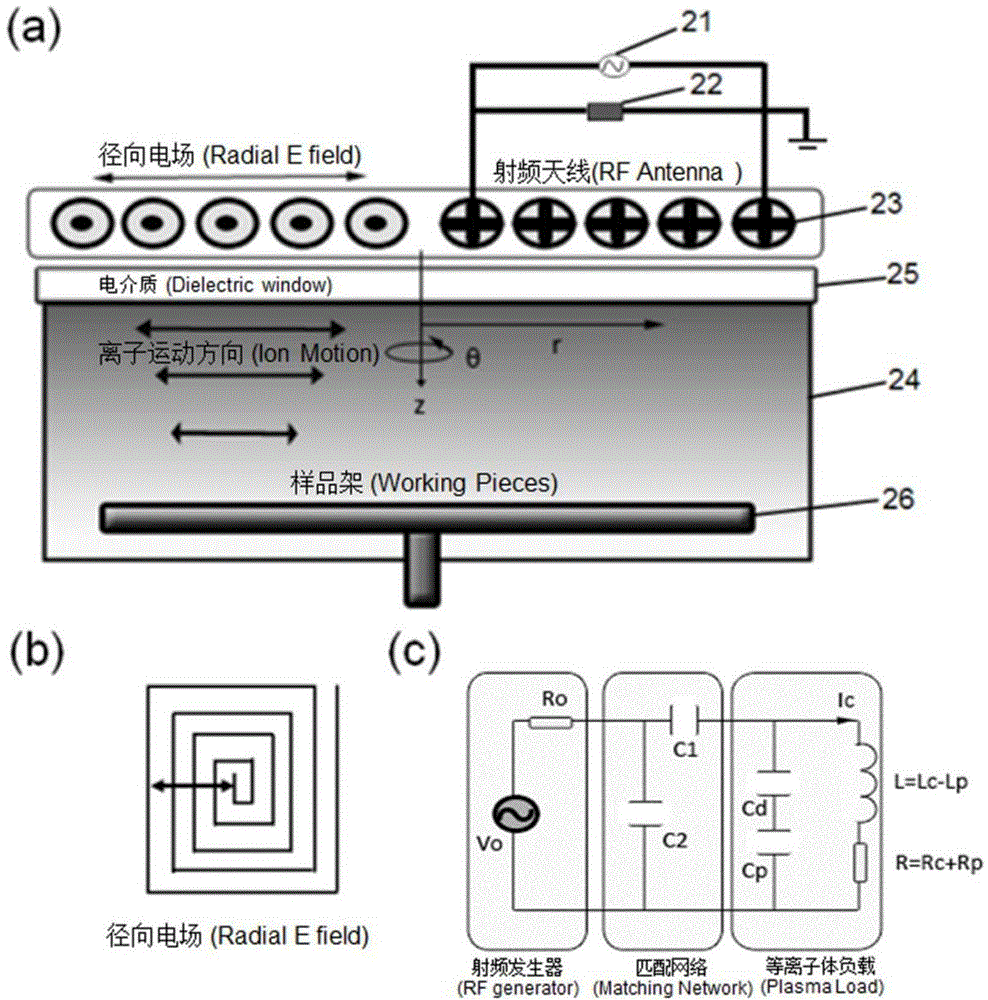

Non-parallel plate type capacitive coupled plasma chemical vapor deposition method

ActiveCN104694906ALow ionization rateAvoid cross contaminationChemical vapor deposition coatingCapacitancePlasma density

The invention relates to a film deposition method, and particularly relates to a non-parallel plate type capacitive coupled plasma chemical vapor deposition method. The method adopts the following components: a planar rectangular spiral inductive antenna, a low-frequency power generator, an impedance matching network, a columnar vacuum chamber, quartz glass and a lining bracket. By controlling radio frequency input power and tuning matched capacitance, the method disclosed by the invention can be used for realizing stable capacitive coupled discharging in the vacuum chamber; the plasma is relatively low in density; a radial electrostatic field which is parallel to the surface of a lining and built by potential difference of the two ends of a coil plays a leading role, so that the motion of positive ions is limited in a direction parallel to the surface of the lining. Therefore, the method disclosed by the invention commences in two aspects, namely reduction of the plasma density and limitation on motion direction of the positive ions, so that bombardment caused by the positive ions to the film surface during a chemical vapor deposition can be remarkably inhibited, and surface damages are reduced. The system can be used for preparing various necessary passivation layers such as non-crystalline silicon and non-crystalline silicon nitride for a high-efficiency crystalline silicon solar cell.

Owner:JIANGNAN UNIV

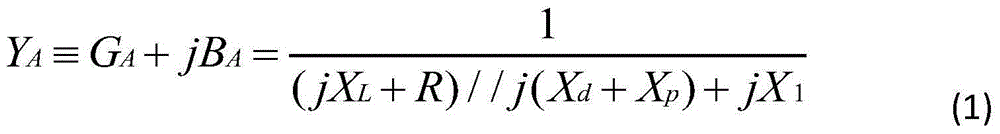

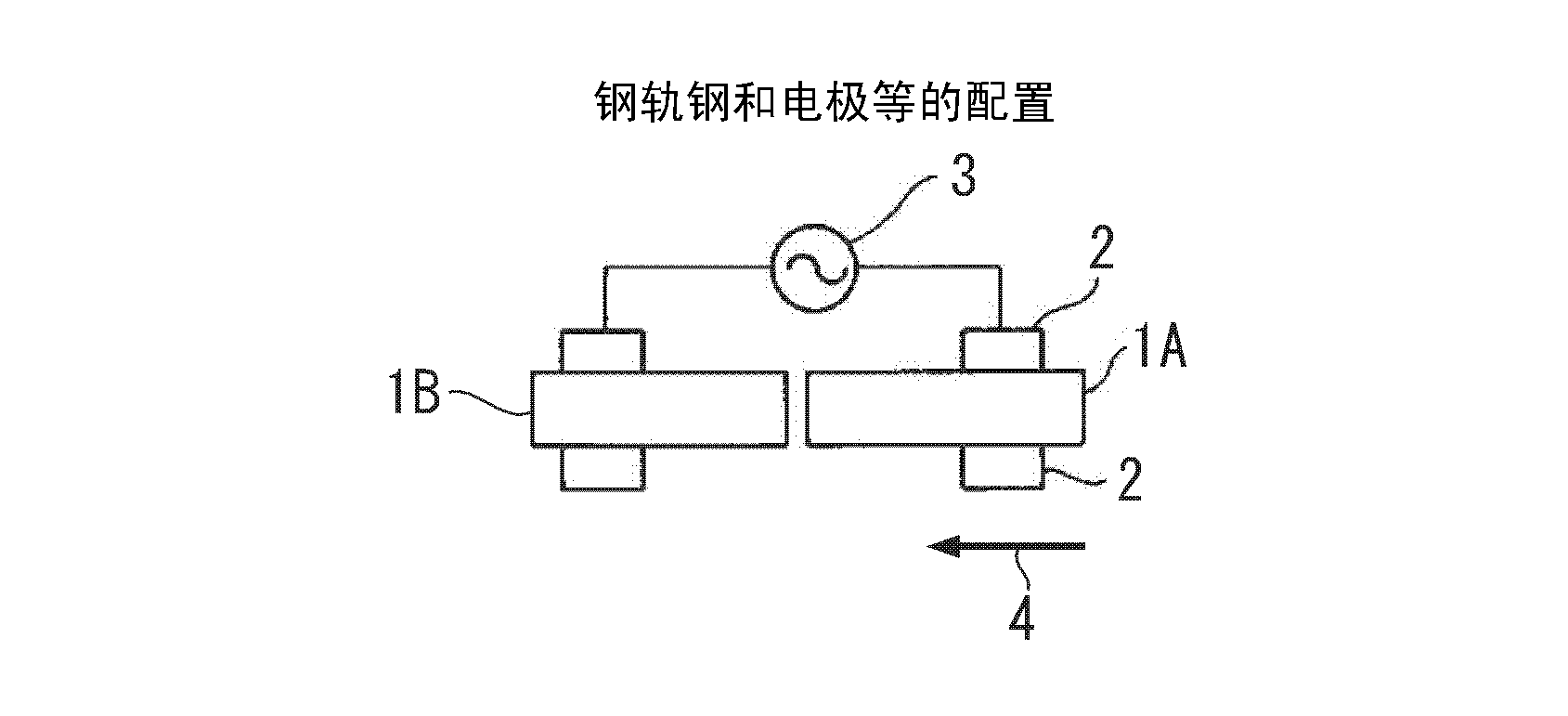

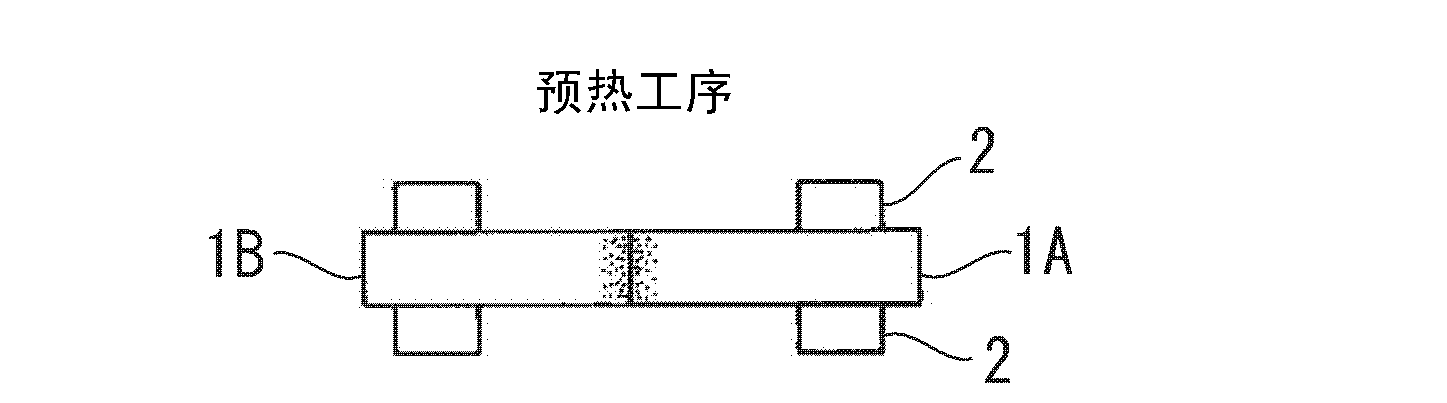

Flash-butt welding method for rail steel

InactiveCN102665994ASteep heat distributionExtend the exchange cycleRailsWelding electric supplyElectrical resistance and conductancePower flow

The invention relates to a welding method. The method is for subjecting a pair of track rail steels to flash- butt welding, which is provided with a preheating step for causing a current to flow for a predetermined time period in a state in which the welding surfaces of the pair of the track rail steels are forced into contact with each other, and heating the vicinity of the welding surfaces by means of resistance heating, a previous flash step for partially generating flash on the welding surfaces, and heating the welding surfaces by means of the resistance heating and electric-arc heating of the flash, and a later flash step for further generating the flash on the entire welding surfaces, and uniformly applying heat to the entire welding surfaces by means of the resistance heating and electric-arc heating of the flash, wherein the later flash speed in the later flash step is 2.1-2.8 mm / sec inclusive.

Owner:NIPPON STEEL CORP

Abrasive material-free polishing fluid for chemical mechanical polishing of rigid fragile material

The invention discloses abrasive material-free polishing fluid free for chemical mechanical polishing of a rigid fragile material. The polishing fluid is characterized by consisting of 0.5 to 40 percent of corrosive, 0.5 to 20 percent of corrosion inhibitor, 0.5 to 15 percent of surfactant, 0.1 to 10 percent of pH regulator and de-ionized water. The abrasive material-free polishing fluid has the advantages of no abrasive material, small damage to the surface of a polished material, capability of obtaining a non-damage super smooth surface, no precipitate, capability of being stored and used for a long time, high stability, difficult volatilization, high fluidity, easy cleaning and small corrosion to equipment. The abrasive material-free polishing fluid is prepared special for the chemical mechanical polishing of the rigid fragile material, so the abrasive material-free polishing fluid has the advantages of conventional abrasive material-free polishing fluid, has high removal ratio for the rigid fragile material, can obtain high surface quality and has low cost and a simple and easy method.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Charged particle-beam processing using a cluster source

ActiveUS8835880B2Reduce surface damageReduce harmElectric discharge tubesSemiconductor/solid-state device manufacturingFullereneProtection layer

Owner:FEI CO

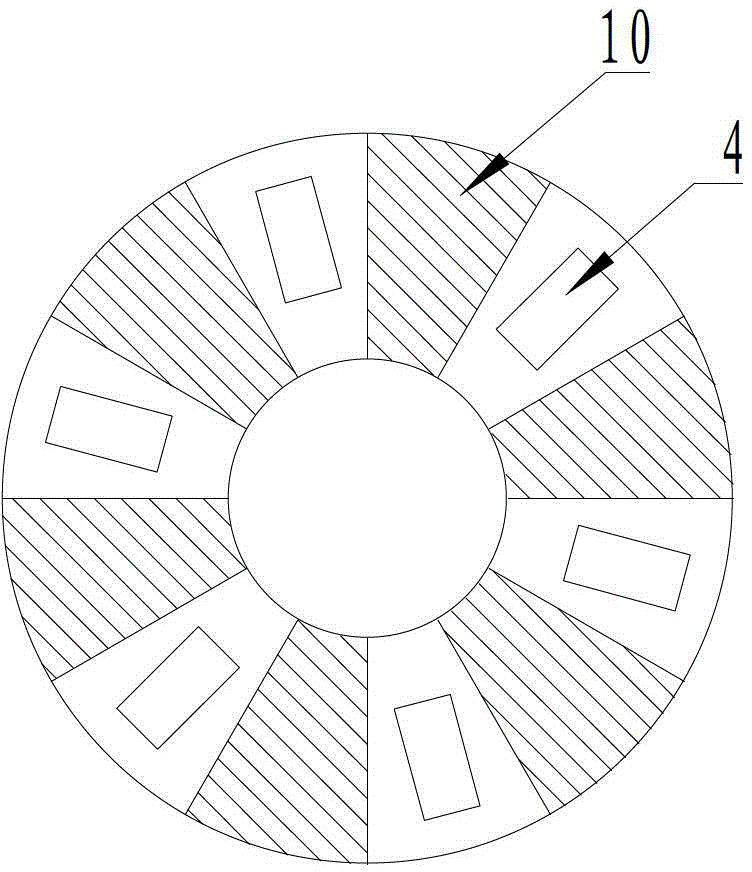

Floating disc suspension polishing device

ActiveCN103331691AAvoid damageImprove machined surface qualityLapping machinesEngineeringMechanical engineering

A floating disc suspension polishing device comprises a polishing base disc and a floating disc, wherein wedge grooves and processing stations for placing workpieces to be processed are formed and arranged on the surface, opposite to the floating disc, of the polishing base disc in the circumferential direction; the wedge grooves are filled with polishing solutions; the wedge grooves and the processing stations are arranged at intervals; the polishing device further comprises a spring, a force sensor, a lifting platform and a master driver; the polishing base disc and the master driver are connected and can rotate around a spindle; the polishing base disc is positioned on the floating disc; the floating disc is connected with the upper end of the spring; the lower end of the spring is connected with the force sensor; and the force sensor is fixedly connected with the lifting platform. The floating disc suspension polishing device presses precisely, grinds stably, and is small in surface damage and high in quality.

Owner:奥特贝(天津)机器人有限公司

Additive for improving utilization ratio of silicon crystal line cutting mortar as well as preparation method and application method of addictive

InactiveCN102041138BIncrease profitReduce manufacturing costLubricant compositionAlcoholPolyethylene glycol

The invention discloses an additive for improving utilization ratio of silicon crystal line cutting mortar as well as a preparation method and application method of the addictive. The additive is composed of the following raw materials in percentage by weight: 50-96.5% of polyethylene glycol, 1-10% of penetrating agent, 1-20% of ether alcohol surfactant, 0.5-10% of extreme pressure resistant chelator and 1-10% of assistant detergent. The preparation method comprises the steps of weighing and mixing the raw materials. The application process comprises the following steps: 1. carrying out the first line cutting the mortar and recovering the mortar; 2. adding the additive: adding the additive to the recovered mortar after the first linear cutting based on the weight ratio of 1:100 plus / minus10, and then evenly stirring; 3. carrying out the second line cutting; and 4. carrying out the third line cutting and recovering the mortar. The addictive is reasonable in design and has good use effect and practicable value, addictive preparation and use processes are simple, operation is convenient, and the defects of the existing silicon wafer cutting fluid such as more severe pollution, higher rejection rate, high production cost, low utilization ratio and the like can be overcome.

Owner:XIAN HUAJING ELECTRONICS TECH

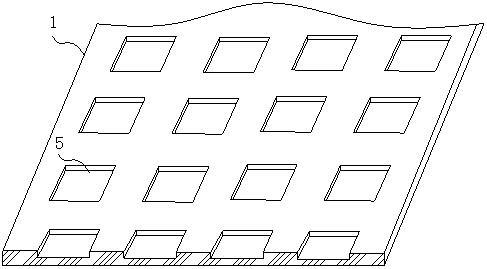

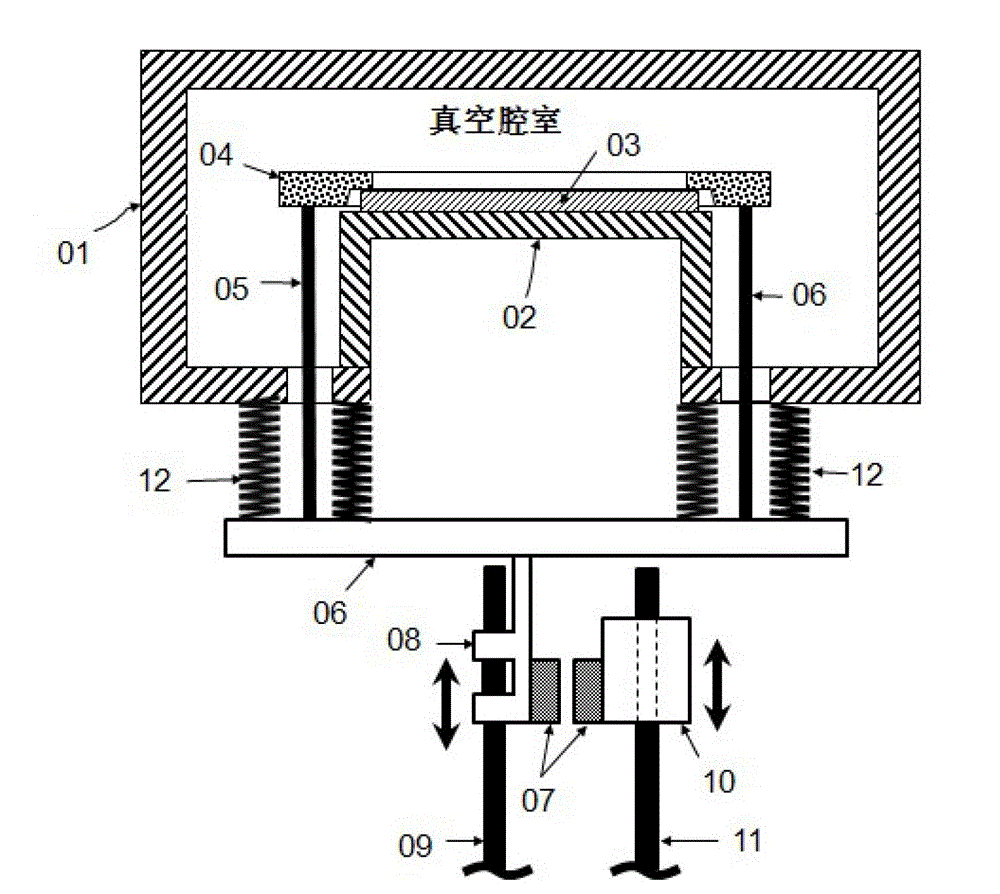

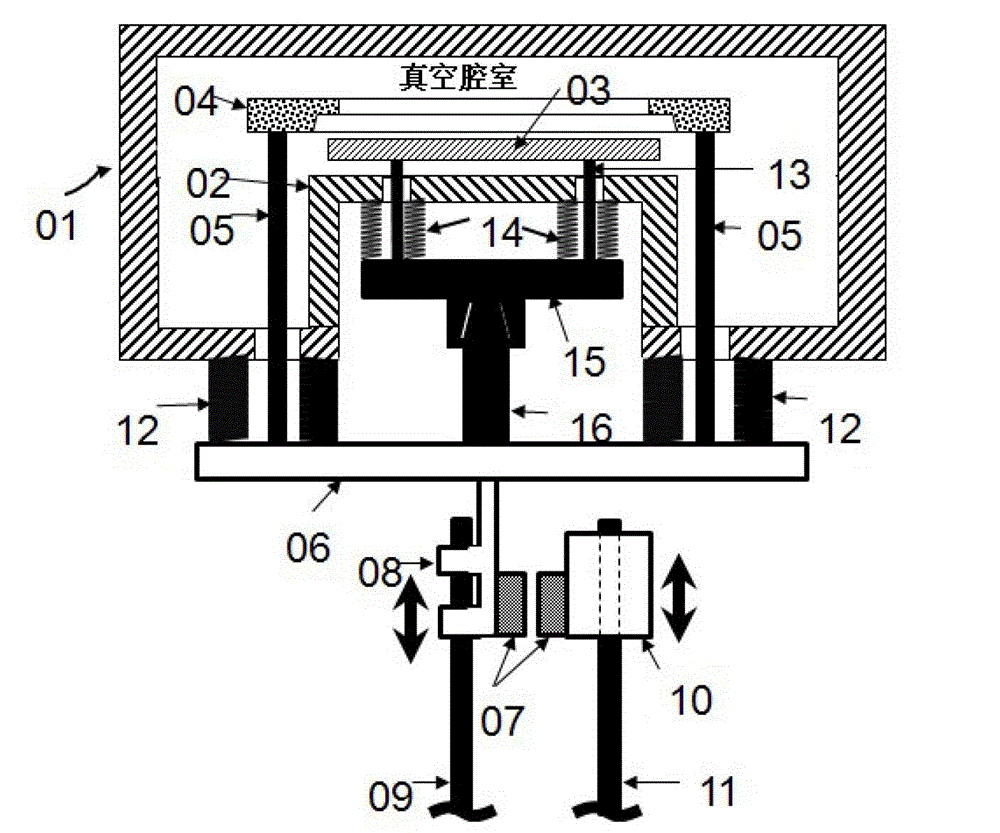

Mechanical-type chip clamping-pressing device for vacuum plasma technology

InactiveCN103066003AImprove use reliabilityReduce surface damageSemiconductor/solid-state device manufacturingMagnetic tension forceCoupling

The invention discloses a mechanical-type chip clamping-pressing device for vacuum plasma technology. The mechanical-type chip clamping-pressing device for the vacuum plasma technology comprises a chip substrate, an electrode, ceramic pressure rings, pressure ring connecting rods, a connecting rod support, a permanent magnet group, a drive motor and a motor support, wherein the chip substrate is positioned on the electrode, the ceramic pressure rings are arranged above the chip substrate and are connected with the connecting rod support through the pressure ring connecting rods, the permanent magnet group comprises a first group of permanent magnets and a second group of permanent magnets, wherein the first group of permanent magnets and the second group of permanent magnets are arranged in a corresponding mode are in magnetic coupling with each other, the first group of permanent magnets is fixedly connected with the connecting rod support, and the second group of permanent magnets is fixed on the drive motor which is movably connected with the motor support. The mechanical-type chip clamping-pressing device for the vacuum plasma technology can overcome the technical defect that an mechanical-type chip clamping-pressing device in the prior art can not be compatible with chip substrates with different thicknesses and surface evenness, is reliable in using, can reduce and eliminate instantaneous impact force generated by the ceramic pressure rings to the chip substrate when the ceramic pressure rings are contacted with the surface of the chip substrate, reduces the probability that the surface of the chip substrate is damaged or cracked, and improves production efficiency.

Owner:赖守亮

Method for mfg negative electrode foil of aluminium electrolytic capacitor

InactiveCN1484260AReduce surface damageIncrease specific volumeElectrolytic capacitorsCapacitor manufactureCorrosionAluminum electrolytic capacitor

This invention relates to a method for manufacturing cathode foils of aluminium electrolytic condensers including corrosion, middle treatment and post treatment characterizing in the technical process: pretreatmentí·corrosioní·burnetí·middle treatmentí·post treatmentí·dried. The burning is done in a dry oven under 300-550deg.c, for 30-80sec. forming and oxide film on the A1 foil surface and solidifying the surface holes eroded on the foil for reducing damage to the surface of the negative foil. Premiddle treatment can beaded after corrosion and before burning, the solution can be applied with0.5~0.9mol / L HNO3 under 28-35deg.c for 25-50sec.

Owner:深圳市东阳光化成箔股份有限公司

Production method for mixed grinding material

ActiveCN102241959AReduce surface damageImprove surface finish qualityOther chemical processesSiphonHybrid type

The invention relates to a novel production method for a mixed grinding material. The method comprises the following steps: mixing zirconium silicate and alumina; carrying out ball milling on the mixture so as to obtain mixed micro-powder; putting the mixed micro-powder, water and a dispersant into a sorting barrel and standing the mixture for settlement after stirring; carrying out sorting, wherein two sub-steps are included, namely, a) sucking out a slurry on the upper layer of the sorting barrel with a siphon, adding clear water to the sorting barrel until the mixture reaches the initial liquid level before siphoning, and carrying out stirring, settling and siphoning so as to obtain particles of a grade, and b) adding the dispersant and clear water into the sorting barrel until the mixture reaches the initial liquid level before siphoning and repeating the steps of stirring, settling and siphoning so as to obtain particles of another grade; drying the obtained particles with different grades so as to obtain a finished product. The mixed grinding material produced in the invention enables damage of micro-powder to the surface of a ground material in grinding to be substantially reduced and plays a very critical role in improving the quality of surface polishing of an object and in reducing polishing cost.

Owner:无锡成旸科技股份有限公司

Blade fastening having safety device for turbine blades

InactiveUS20120177499A1Avoid unwanted looseningAvoid displacementPropellersRotary propellersTurbine bladeUpper limb

A safety device for a turbine blade is provided. The safety device includes a shear pin, a clamping piece and a securing element, wherein the shear pin is arranged in a corresponding bore in the turbine blade foot and the clamping piece is designed having an upper limb and a lower limb, wherein the clamping piece exerts a radial force on the turbine blade foot for radial safeguarding.

Owner:SIEMENS AG

Cleaning solution, cleaning method and damascene process using the same

ActiveUS20120009788A1Efficient removalReduce surface damage (copper loss)Inorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsChemistryStrong acids

A cleaning solution is provided. The cleaning solution includes (a) 0.01-0.1 wt % of hydrofluoric acid (HF); (b) 1-5 wt % of a strong acid, wherein the strong acid is an inorganic acid; (c) 0.05-0.5 wt % of ammonium fluoride (NH4F); (d) a chelating agent containing a carboxylic group; (e) triethanolamine (TEA); (f) ethylenediaminetetraacetic acid (EDTA); and (g) water for balance.

Owner:UNITED MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com