Photoluminescent wafer as well as preparation method and application thereof

A technology of photoluminescence and wafers, which is applied in chemical instruments and methods, crystal growth, self-solidification, etc., can solve the problem of rising chip temperature, affecting the service life of the fluorescent powder layer, reducing the light efficiency of the light-emitting layer, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

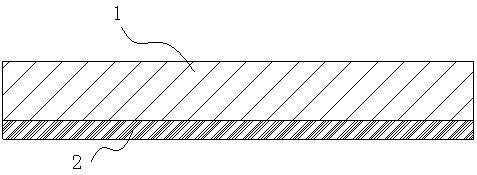

[0077] like Figure 5 As shown, the raw material Y with a purity higher than 4N is selected 2 O 3 , Tb 4 O 7 , Dy 2 O 3 , CeO 2 , Al 2 O 3 , press (Y 0.60 Tb 0.26 Dy 0.20 Ce 0.04 ) 3 Al 5 O 12 The stoichiometric ratio is weighed and mixed. 1.4% cosolvent BaF based on the total weight of the mixture 2 and 0.1% H 3 BO 3 , compression molding, burning at 900 ° C for 2h to shrink the volume and then placing it in the iridium crucible 7, heating to 1970 ° C in the high-frequency induction furnace 8 of the single mold 11 melt casting equipment in an argon atmosphere, and melting at 1980 ~ 1990 ℃ superheated temperature for 8min. Under the pressure of 20 mmHg, the melt flows through the crucible mouth slit 9 to a single mold 11 with a distance of 0.2 mm from the lip 10 and a moving speed of 8.2 m / s to form a polycrystalline photoluminescent wafer 1 with a thickness of 30 μm. like figure 1 shown, SiO was then deposited by high-frequency reactive sputtering 2T...

Embodiment 2

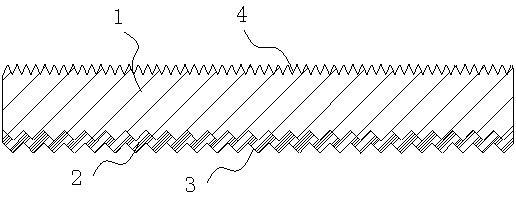

[0079] like Image 6 As shown, the raw material Y with a purity higher than 4N is selected 2 O 3 ,Gd 2 O 3 , CeO 2 , Al 2 O 3 , Ga 2 O 3 , press (Y 0.72 Gd 0.26 Ce 0.02 ) 3 (Al 0.80 Ga 0.20 ) 5 O 12 The stoichiometric ratio is weighed and mixed. Then mix in 0.2% of cosolvent H based on the total weight of the above mixture 3 BO 3 , compression molding, after burning at 900 ° C for 2h to shrink the volume, it is placed in an iridium crucible 7, heated to 1970 ° C in an argon atmosphere in a high-frequency induction furnace 8 of a single mold melt casting equipment, and melted at 1980 ~ 1990 ℃ superheat temperature, keep for 10min. Under the pressure of 20mmHg, the melt flows through the crucible mouth slit 9 to a single mold 11 with a distance of 0.2mm from the lip 10 and a moving speed of 6.4m / s to form a polycrystalline photoluminescent wafer 1 with a thickness of 46µm. like Image 6 As shown, the single mold 11 is engraved with punches 12 arranged in...

Embodiment 3

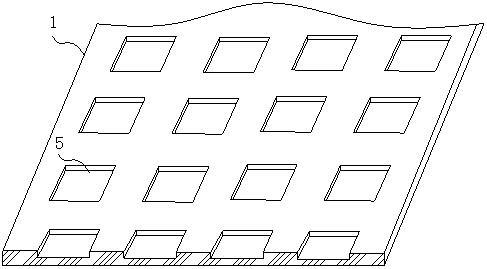

[0081] like Figure 7 , Figure 8 As shown, the raw material Y with a purity higher than 4N is selected 2 O 3 , CeO 2 , Tb 4 O 7 , Pr 6 O 11 , Al 2 O 3 , press (Y 0.54 Tb 0.40 Ce 0.04 Pr 0.02 ) 3 Al 5 O 12 The stoichiometric ratio is weighed and mixed. 1.4% of cosolvent H based on the total weight of the above mixture was mixed 3 BO 3 , compression molding, burning at 900 ° C for 2h to shrink the volume and then placing it in an iridium crucible 7, heated to 1970 ° C in an argon atmosphere in a high-frequency induction furnace 8 of a double mold melt casting equipment, and melted at 1980 ~ 1990 ℃ superheat temperature, keep for 10min. Under the pressure of 20 mmHg, the melt flows through the slits of the crucible mouth 9 at the lower part of the iridium crucible 7 and flows through the slits of the two counter-rotating casting molds 13 to form molten pools and solidify into wafers. The distance from the crucible mouth lip 10 to the narrowest point of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com