Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2744results about How to "Thorough response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ceramsite water permeable brick and preparation method thereof

The invention provides a ceramsite water permeable brick, which comprises the following components by weight: 80-100 parts of ceramsite, 10-15 parts of silicon sand, 20-40 parts of cement, a setting accelerator accounting for 2-4% of the weight of the ceramsite, and a water reducing agent accounting for 2-4% of the weight of the ceramsite. According to the invention, silicon sand dust made ceramsite is combined with a small quantity of cement, the setting accelerator, the water reducing agent and a silicon sand fabric to manufacture the ceramsite water permeable brick. One the one hand, the water permeable brick has a beautiful appearance, and on the other hand it combines the lightweight and high strength characteristics of ceramsite. At the same time, ceramsite is round stone rather than polygonal, and usually the gap between round objects is larger than that between polygonal objects, so that the prepared water permeable brick has good permeability effect. The water permeable brick prepared by the method has compressive strength of greater than or equal to 30Mpa and a permeability coefficient of greater than or equal to 0.05cm / s, and the other properties of the brick meet the JCT945-2005 industrial standard.

Owner:RENCHSAND ECO ENVIRONMENT PROTECTION SCI & TECH CO LTD

Low-density ceramic proppant and preparation method thereof

The invention relates to a low-density ceramic proppant and a preparation method thereof, which belong to the field of exploring petroleum and natural gas. The preparation method of the low-density ceramic proppant comprises the steps of forming an inner core made of bauxite and coal gangue and a shell made of bauxite and trimanganese tetroxide into a ball and sintering to obtain low-density ceramic. The ceramic has higher strength and low density and is applicable to a ceramic proppant for fracturing a deep-level oil-gas well with high closed pressure and low permeability; the sintering temperature is relatively reduced in the range of 1,300-1,380DEG C, so that thus the energy consumption is effectively reduced and the energy can be saved by 20 percent; and meanwhile, the effect with low crushing rate can be achieved.

Owner:阳泉市长青石油压裂支撑剂有限公司

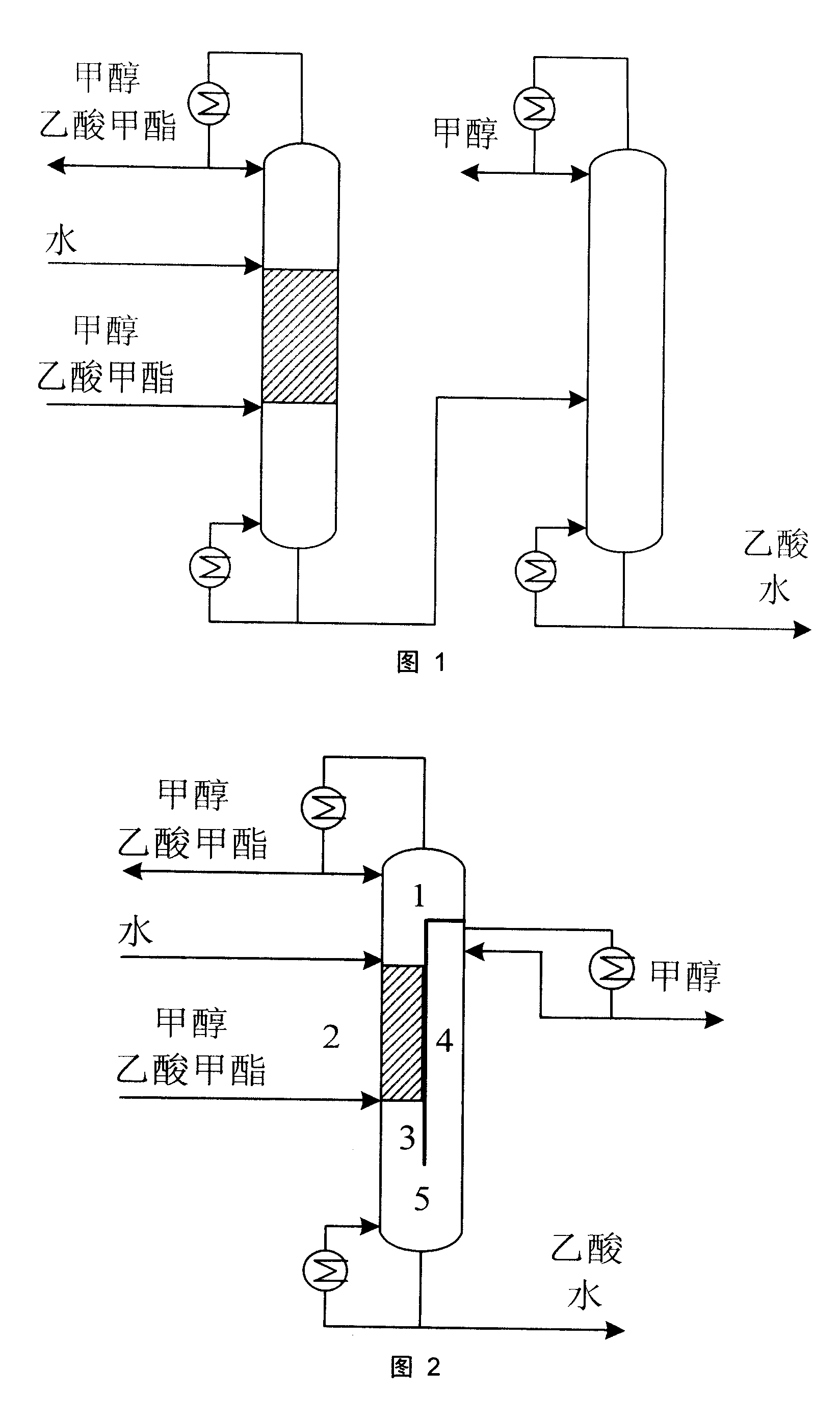

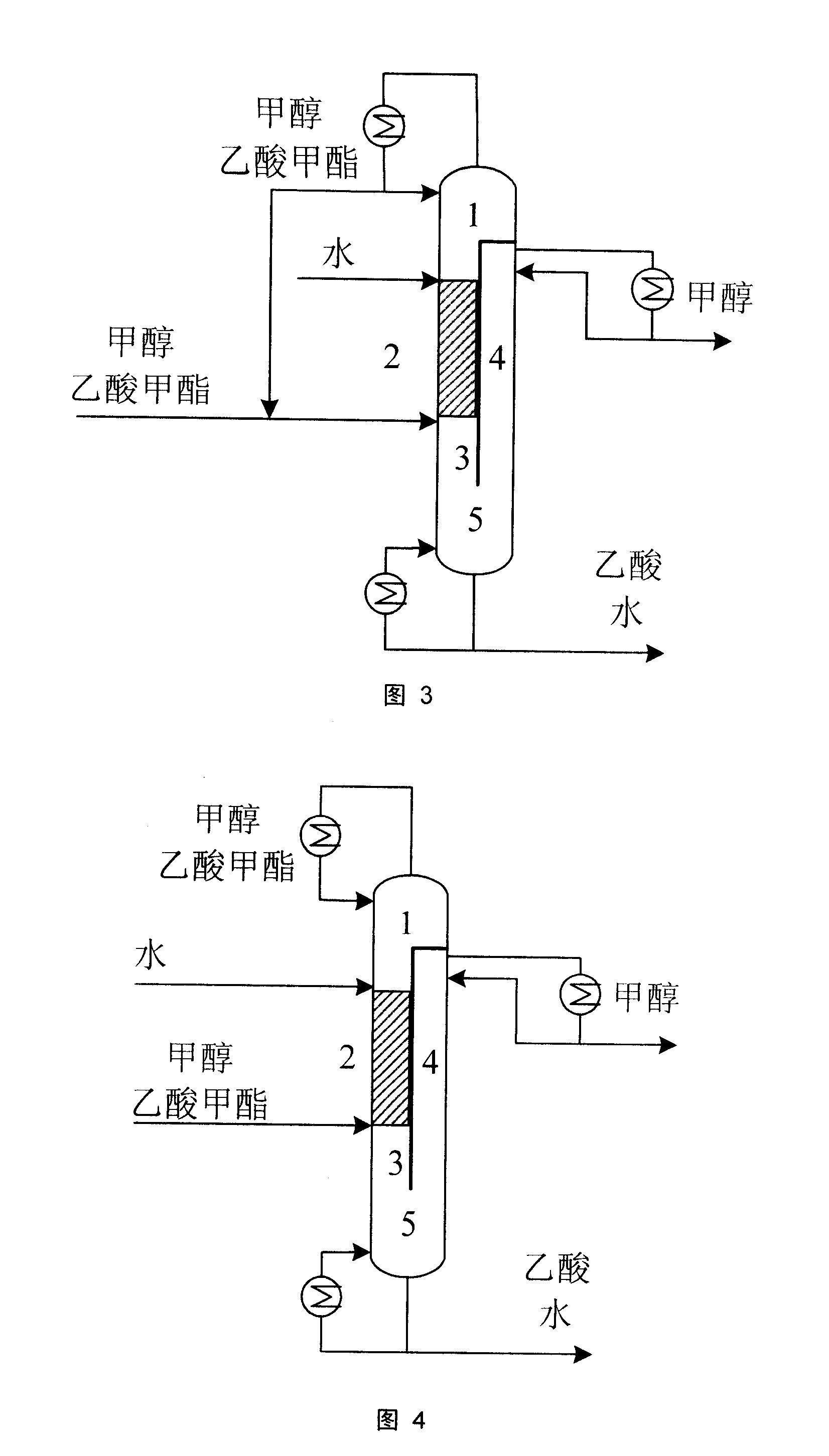

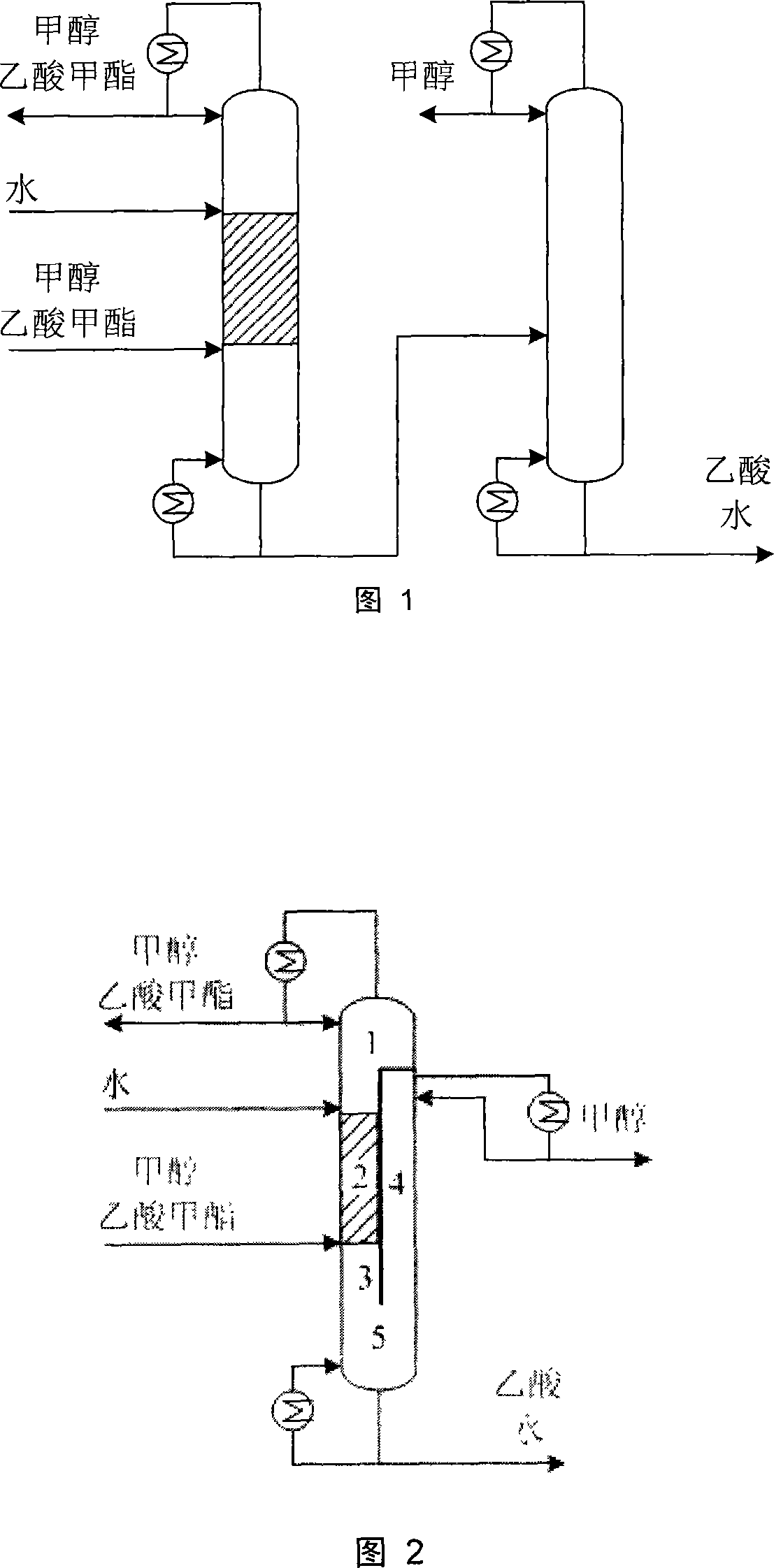

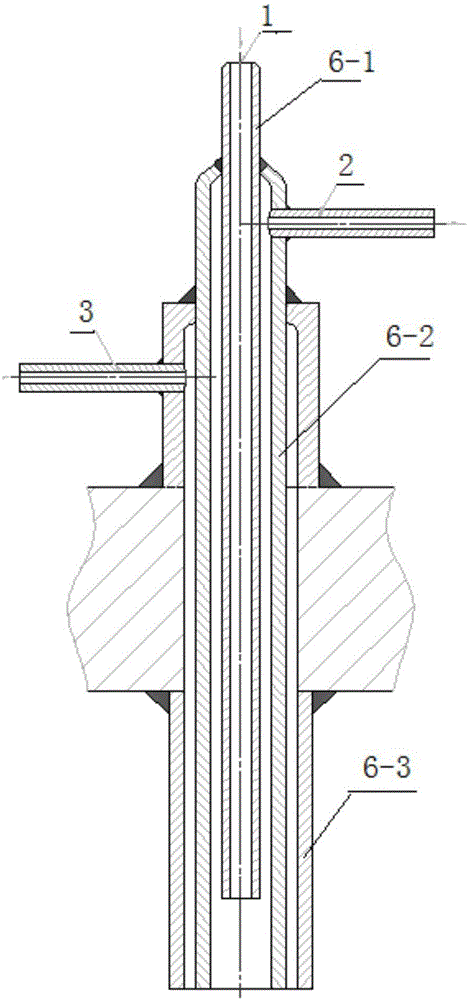

Hydrolyzation separation apparatus for methyl acetate and technique

InactiveCN101244982AIncrease hydrolysis rateAvoid remixingOxygen-containing compound preparationOrganic compound preparationSide effectDistillation

The invention provides a hydrolyzing and separation device of methyl acetate and a technique method thereof, which more particularly relates to a novel technique to catalyze and hydrolyze methyl acetate by a reaction bulkhead distillation tower, which can organically combine reaction process, product separation and recovery of no reactant into the tower. A separator extending from the upper part of the tower to the lower part of the tower is arranged on the vertical direction in the conventional distillation tower, the upper part of one side of which is covered and the other side of which is filled with a catalyst; therefore, the inner space of the reaction bulkhead distillation tower is divided into five regions with different functions. The hydrolyzing and separation device of methyl acetate can fully unleash the advantage of bulkhead tower and reaction distillation, and can cause hydrolysis reaction, product separation and recovery of non reactant to be realized in the same tower. The device provided by the invention and the technique process thereof can obtain the methyl acetate with 60 percent to 99.99 percent hydrolysis rate and products with high purity, restrain side effect effectively, reduce the volume of equipment markedly, simplify process, and reduce energy consumption and operation cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Solid propping agent for oil-gas well fractrue

InactiveCN1508390ALess types of raw materialsSimple ingredientsFluid removalCeramic particleAluminium

The invention is about to improve the solid ceramic particle proppant of deep oil and gas well fracturing technique, the solid proppant composed of crude bauxitic clay fine powder and 6-10wt% manganese dioxide mineral fine powder. The manganese dioxide reacts with the bauxitic clay main material more completely under high temperature, largely reducing glass phase, and beneficial to raise the compactness of the resultant at the same time, able to largely heighten the guide-flow ability. The solid proppant: bulking density 1.65-1.8g / cu cm, apparent density 3.0-3.15g / cu cm, and breaking resistance (SY / T5108-1997) 86MPa not greater than 10%, the maximum able to reach 100MPa not greater than 10%.

Owner:宜兴东方石油支撑剂有限公司

Method for recycling metal from waste catalyst containing molybdenum and nickel

ActiveCN102041388AReduce the introductionIncrease valueProcess efficiency improvementOperabilityAmmonia

The invention relates to a method for recycling metals from a waste catalyst containing molybdenum and nickel, which comprises the following steps of: roasting and smashing the waste catalyst containing the molybdenum and nickel; mixing with an alkaline substance and roasting; leaching by using a mixed acid liquid; depositing by using an alkaline solution, wherein molybdenum is deposited out in the form of ammonium molybdate; further dissolving the ammonium molybdate by using ammonia water; regulating a pH value to obtain ammonium molybdate deposition; and drying to obtain an ammonium molybdate product. The method is particularly suitable for extracting high-purity ammonium molybdate from the aluminum-based waste catalyst containing the molybdenume, and has the advantages of simple process, strong operability, low energy consumption, and stable produced product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vanadium slag treatment method capable of saving energy and reducing emission

InactiveCN102086487ARelieve the pressure of dephosphorizationEnergy savingProcess efficiency improvementWater solubleOxide

The invention belongs to the field of rare metal extraction, and particularly relates to a vanadium slag treatment method capable of saving energy and reducing emission. The method comprises the following concrete steps: first, placing high-temperature liquid vanadium slag with the temperature of higher than 1200 DEG C, which is separated from molten iron, in a slag tank; then, adding a sodium compound into the slag tank according to the grade of the vanadium slag; and supplying oxygen to the slag tank with a water-cooling supersonic speed or subsonic speed oxygen lance to produce a strong oxidizing atmosphere while realizing a stirring effect to promote quick generation of water-soluble sodium vanadate in the vanadium slag, wherein in order to ensure that the supplied oxygen is more than the oxygen required for totally oxidizing all components in the slag into the highest-valence oxides, FeO / T.Fe in the slag is taken as an index for checking the oxidation degree, V2O5 generated in the vanadium slag reacts with the added sodium compound to generate the water-soluble sodium vanadate, and finally the obtained slag containing the water-soluble sodium vanadate is treated to obtain V2O5. The method provided by the invention realizes vanadium extraction and steelmaking at the same time; and by adopting the method, tremendous economical and environmental benefits can be produced.

Owner:UNIV OF SCI & TECH BEIJING +1

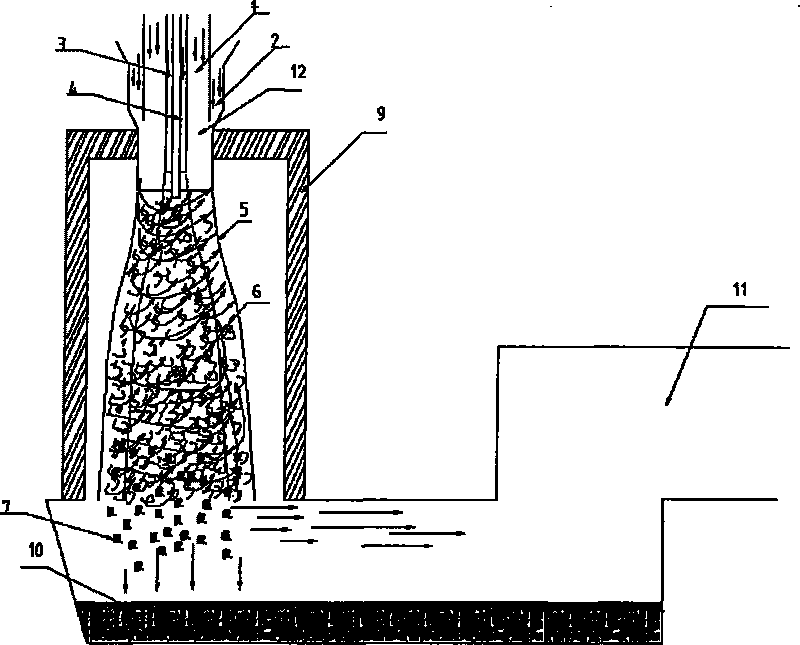

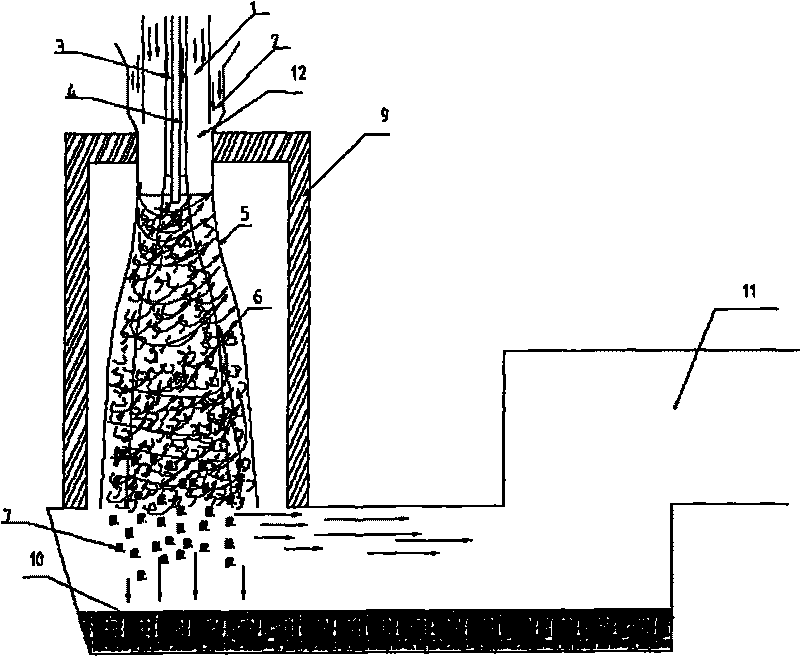

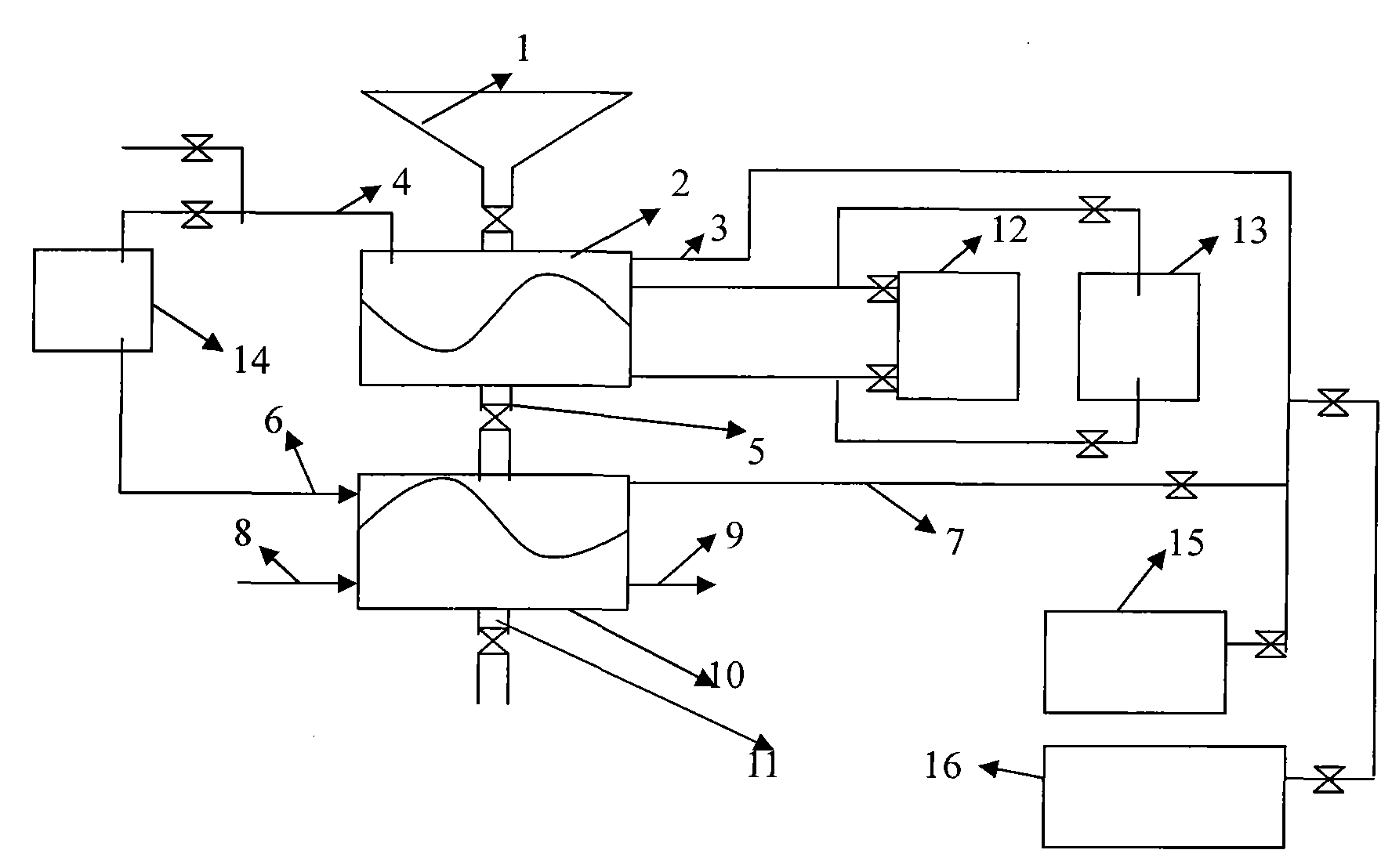

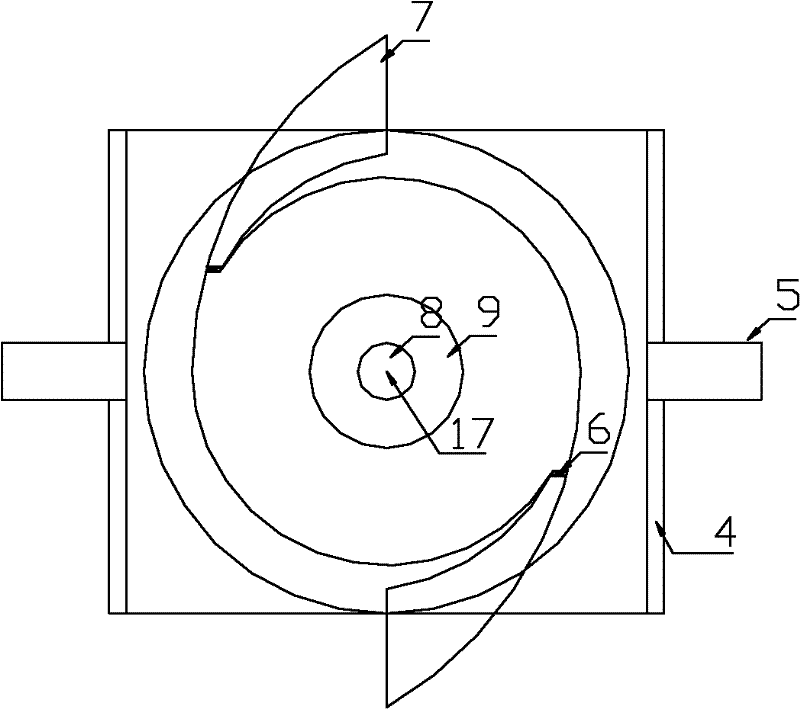

Process and device for smelting copper by pulsation vortex method

ActiveCN101705369AIncreased chance of collisionHigh oxygen utilizationRotary drum furnacesCrucible furnacesSlagProcess engineering

The invention relates to a process and a device for smelting copper by a pulsation vortex method. The process comprises the following steps of: mixing dry copper concentrate powder or matte powder with oxygen-enriched air, and putting the mixture in a reactor to form high-speed vortex taking an axis as a center; introducing pulsation oxygen into the center of the high-speed vortex, performing pulsation combustion to generate pulsation turbulent flow in the high-speed vortex so as to promote particles to collide with one another, then forming a pulsation vortex reaction area with a high-temperature field, a high oxygen field and a high particle field, and completing a reaction of manufacturing the matte and slag from the copper concentrate or manufacturing crude copper and slag from the matte; after the reaction, precipitating fused materials in a fusing pool at the bottom of the reactor, and then separating the matte and slag or the crude copper and slag; and sending SO2 gas fume to an acid preparation process. The process and the device have the advantages of: 1, high reaction efficiency, high oxygen utilization efficiency and low fume yield; 2, high capacity, low energy consumption, small reaction space, centralized heat energy reacted, low loss of a refractory material of a furnace body, no need of a huge metallurgical hearth and low investment cost; and 3, environmental protection and simple, convenient and reliable technological operation.

Owner:YANGGU XIANGGUANG COPPER

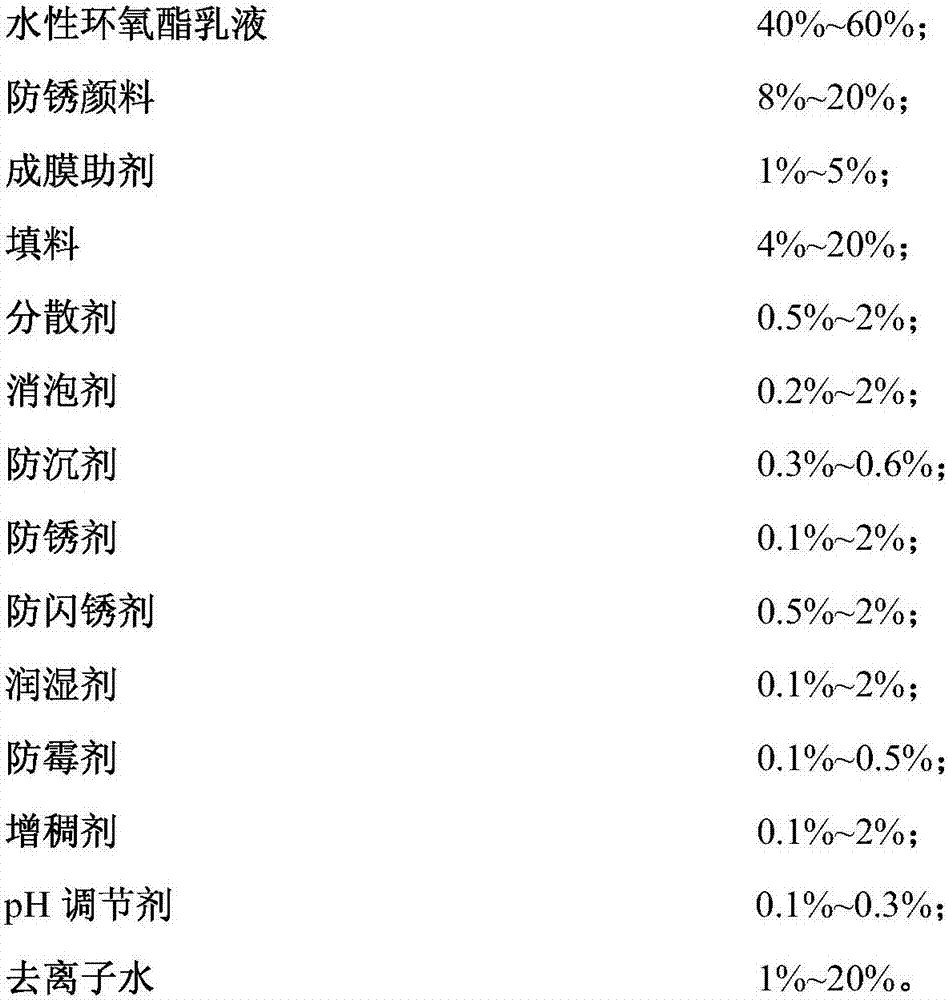

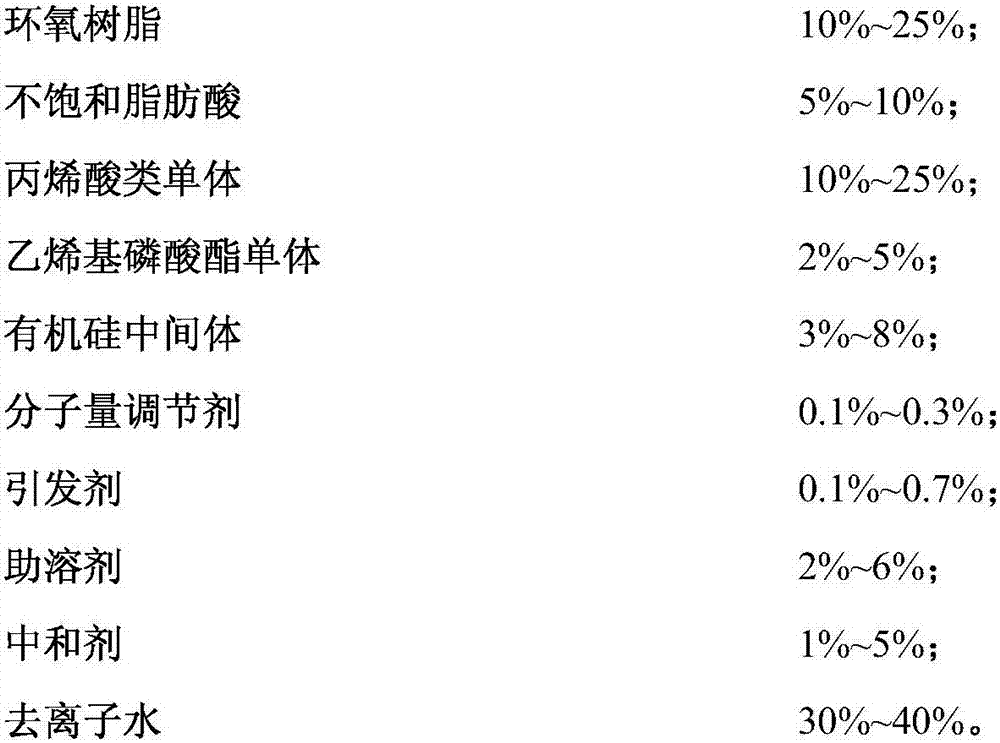

Salt-spray-resistant and anti-aging water-based paint and preparation method thereof

ActiveCN107286798AGood storage stabilityImprove water resistanceAntifouling/underwater paintsPaints with biocidesWater basedEpoxy

The invention discloses salt-spray-resistant and anti-aging water-based paint and a preparation method thereof. The salt-spray-resistant and anti-aging water-based paint is prepared from components in percentage by weight as follows: 40%-60% of a water-based epoxy ester emulsion, 8%-20% of an anti-rust pigment, 1%-5% of a coalescing agent, 4%-20% of filler, 0.5%-2% of a dispersant, 0.5%-2% of a defoaming agent, 0.3%-0.6% of an anti-settling agent, 0.1%-2% of an anti-rust agent, 0.5%-2% of a flash-rust inhibitor, 0.1%-2% of a wetting agent, 0.1%-0.5% of a mildew preventive, 0.1%-2% of a thickening agent, 0.1%-0.3% of a pH conditioning agent and 1%-20% of deionized water. The water-based paint can resist neutral salt spray for 550 H and resist QUV aging for 600 H, has the advantages of high water resistance, good storage stability, contamination resistance, fast drying, safety, environment-friendliness, simple preparation process and the like, is environment-friendly, accords with the environmental protection development trend and is suitable for industrial production.

Owner:HUNAN BANFERT NEW MATERIALS TECH

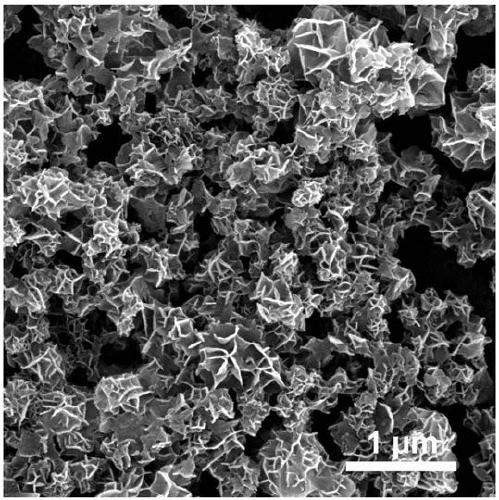

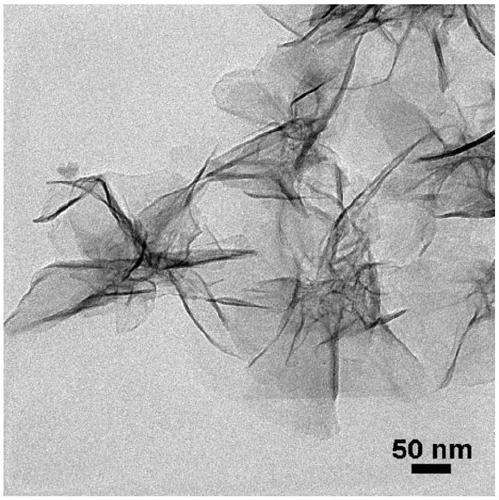

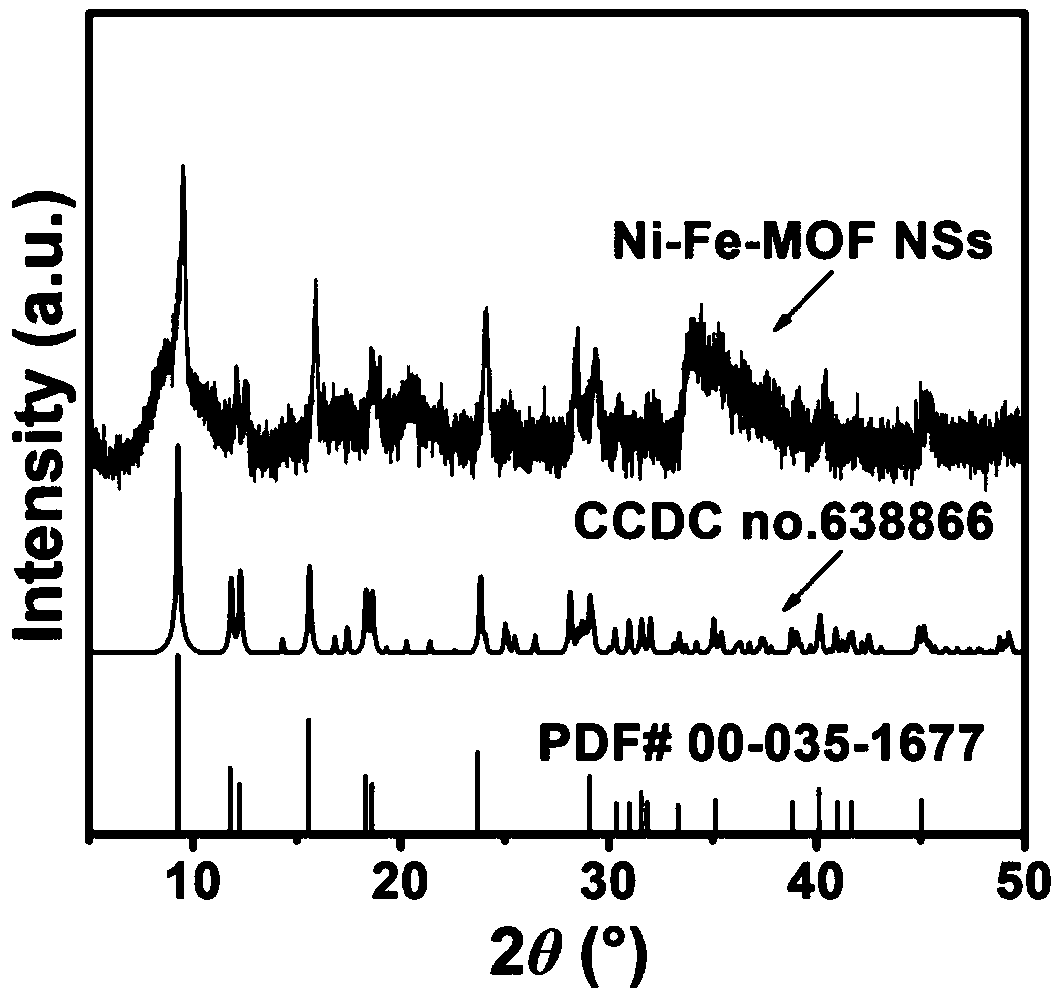

Ultrathin Ni-Fe-MOF nanosheet, preparation method and application thereof

ActiveCN109267093AEasy to operateShort reaction timeNickel organic compoundsNanotechnologyN dimethylformamideIron salts

The invention discloses a preparation method of an ultrathin Ni-Fe-MOF nanosheet. The preparation method comprises the following steps of dissolving an organic ligand in an organic solvent, dripping the obtained solution into a water solution with nickel and iron salts dissolved, mixing uniformly, then reacting for 3-6 hours at 140-160 DEG C, so as to obtain the ultrathin Ni-Fe-MOF nanosheet, wherein the organic ligand is p-phthalic acid and / or disodium terephthalate, and the organic solvent is N,N-dimethylacetamide and / or N,N-dimethylformamide. The invention further discloses the ultrathin Ni-Fe-MOF nanosheet and application thereof. The preparation method needs no surfactant, and can synthesize a large quantity of 2D ultrathin MOF material. The product has a clean surface and is easy toclean.

Owner:SUZHOU UNIV

Synthesis method of imidazoline compound

ActiveCN102093296AReasonably determine the ratioReasonably determine the dosageOrganic chemistryTransportation and packagingEthylenediamineSynthesis methods

The invention discloses a synthesis method of an imidazoline compound. The method comprises the following steps of: heating fatty acid and hydroxyethyl ethylenediamine which are used as raw materials to 80-150 DEG C in the presence of a catalyst in a nitrogen atmosphere, and then rising the temperature to 190-220 DEG C in a gradient mode for carrying out a nitrogen acylation reaction to form alkyl amide; and carrying out gradient pressure reduction, dewatering and cyclization on the formed alkyl amide to prepare the imidazoline compound. The synthesis method has simple process and low requirement on production equipment; by adopting the method of the invention, the generation quantity of bi-amide which is a side product can be reduced, and the content of the bi-amide in the prepared imidazoline compound can be reduced to be below 0.5 percent by mass; and meanwhile, the prepared imidazoline compound has stable quality and can be placed for a long time without turbid phenomena.

Owner:广州星业科技股份有限公司

High-efficiency formaldehyde scavenging agent

InactiveCN101181677AThorough responseTo achieve the purpose of removing formaldehydeDispersed particle separationWastewaterSURFACTANT BLEND

The invention discloses a high effect formaldehyde dispelling agent. The formaldehyde dispelling agent of the invention comprises formaldehyde dispelling factors, a stabilizing agent, a synergistic agent, surfactants and water, etc. The product is nonpoisonous and tasteless, safe and environmental friendly, which can quickly and thoroughly dispel free formaldehyde in air, waste water and various boards and furniture, and a dense protecting film is formed on the surface of solid, working for a long time. The method of the invention is characterized by simple production technique and devices, no three wastes pollution and low production cost.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

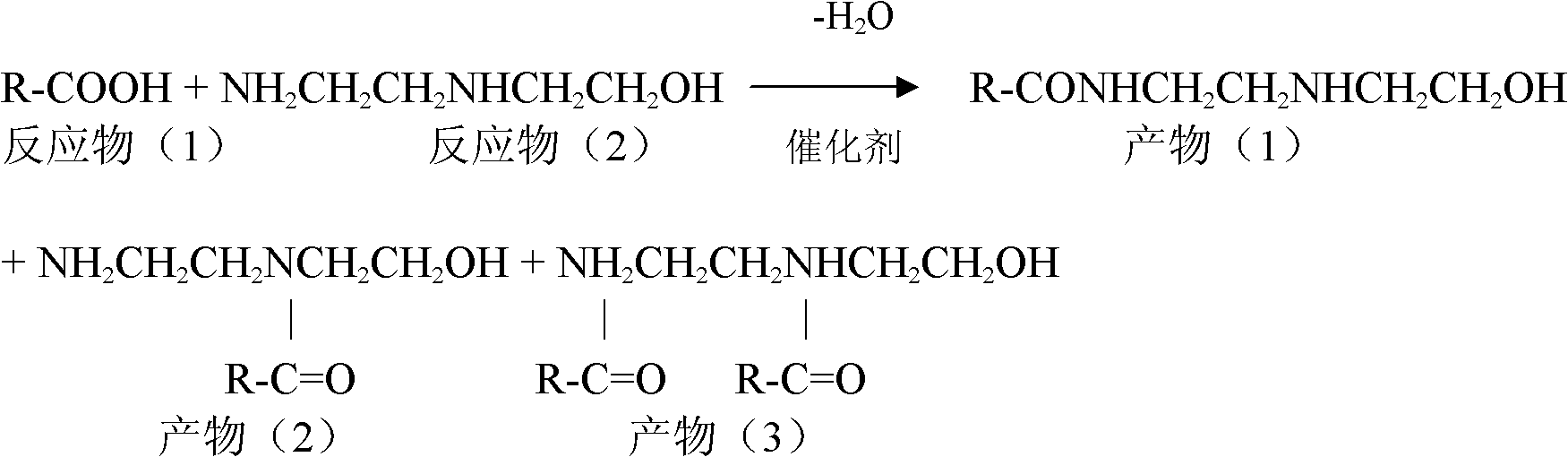

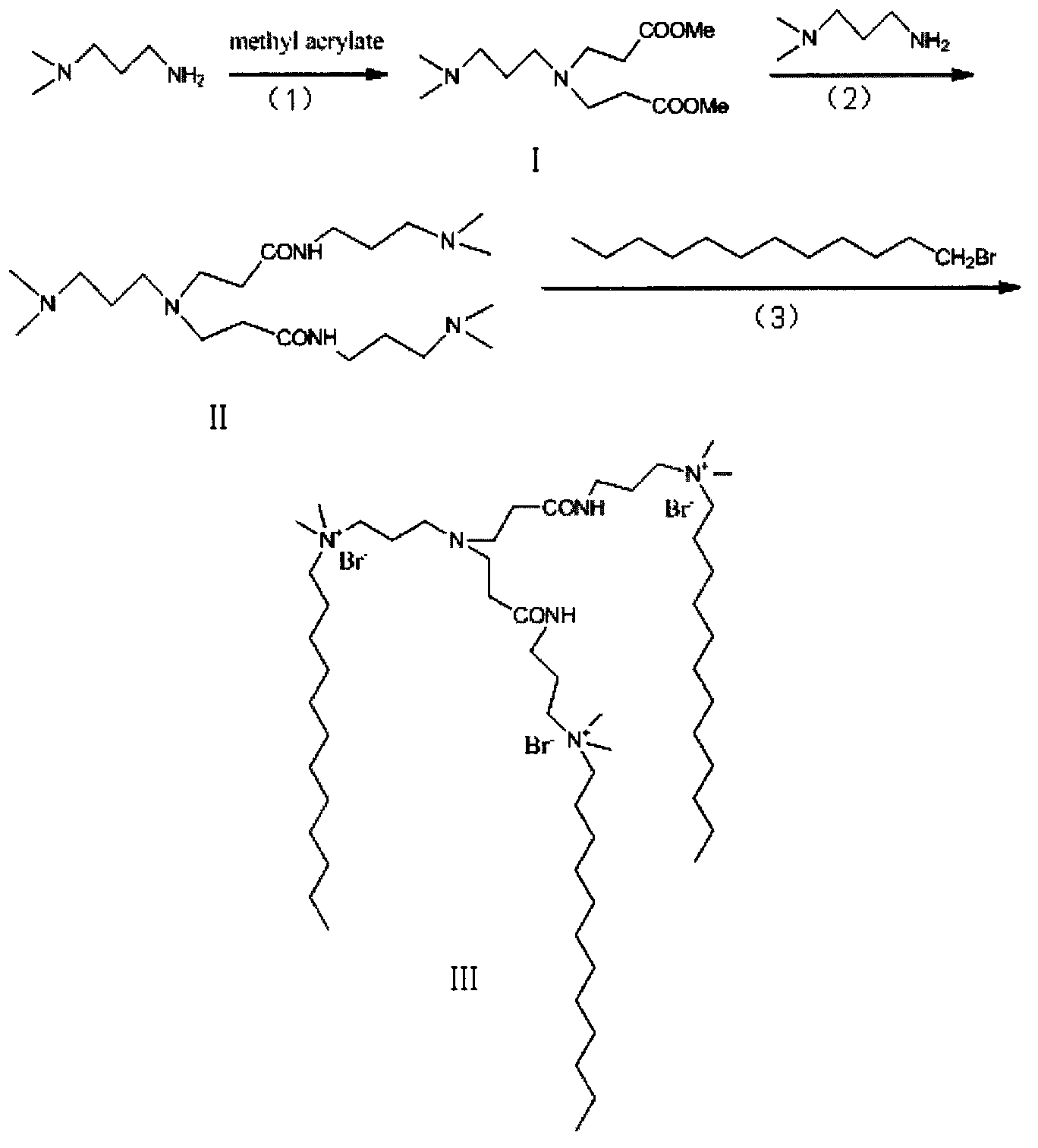

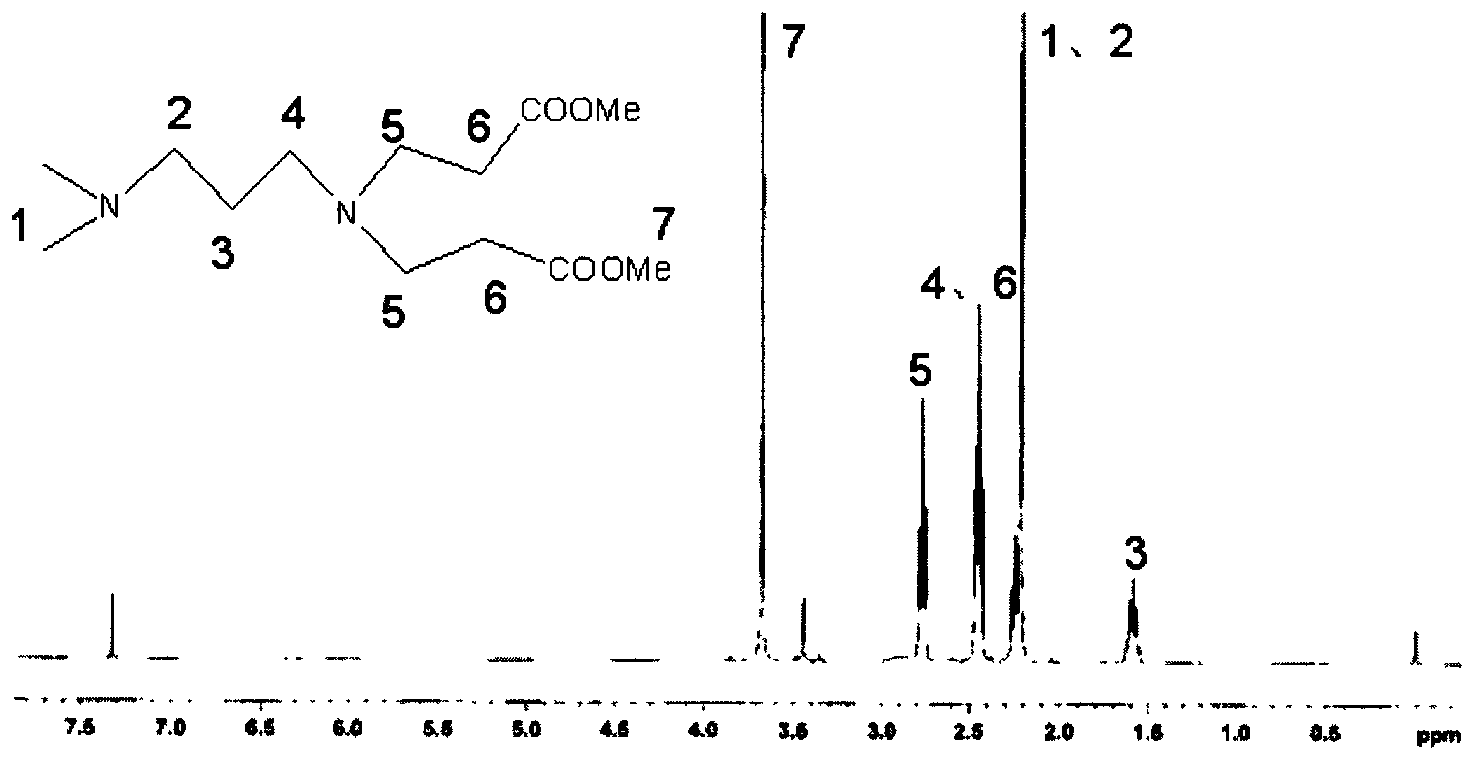

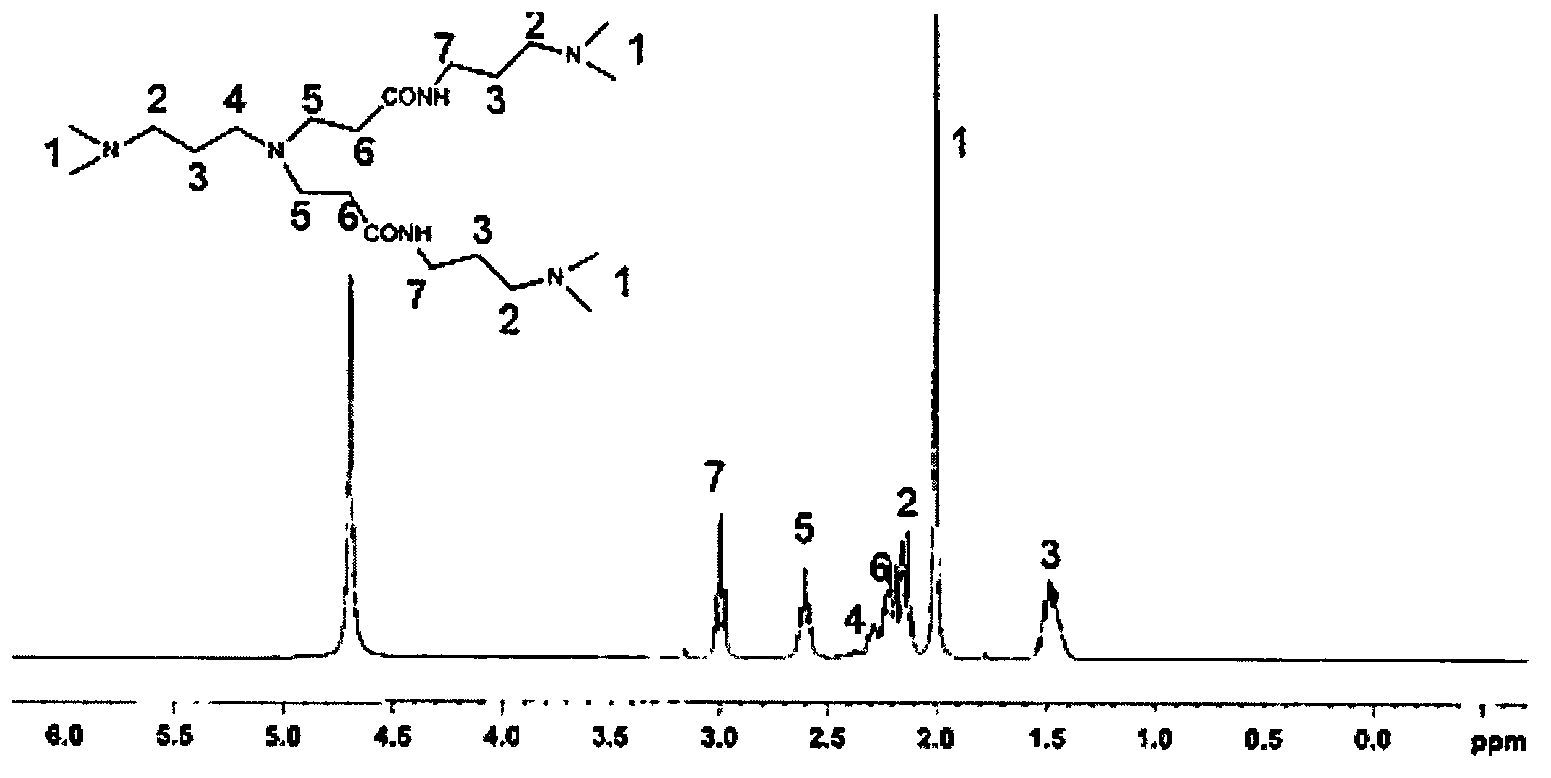

A preparation method for a novel dendritic oligomeric quaternary ammonium surfactant

InactiveCN103288672ALow critical micellar concentrationImprove surface activityOrganic compound preparationTransportation and packagingQuaternary ammonium surfactantChemistry

The present invention provides a preparation method for a novel dendritic oligomeric quaternary ammonium surfactant. The method comprises the following steps: (1) N, N-dimethyl-1,3 - propanediamine and an excess amount of methyl acrylate are subjected to a Michael addition reaction to generate a compound (I); (2) the compound (I) and an excess amount of N, N-dimethyl-1 ,3 - propanediamine are subjected to an amidation reaction to obtain a compound (II); and (3) the compound (II) and bromododecane are subjected to a quaternization reaction to obtain the final product of a compound (III). The surfactant prepared by using the method of the invention has excellent performances, and can be widely used in fields such as daily chemicals, water treatment, paper making and oilfield development.

Owner:山东大学(威海)

Rapid preparation methods of graphene oxide and graphene

InactiveCN106430175AImprove integrityReduced interlayer forceSingle layer grapheneCvd grapheneEnergy consumption

The invention provides a preparation method of graphene oxide. The method comprises the following steps: firstly, mixing graphite, an intercalator and an oxidizing agent under an airtight condition and then carrying out a reaction to obtain a reaction mixture; separating the reaction mixture obtained in the previous step to obtain a reaction product; finally, stripping the reaction product, obtained in the previous step, in a dispersing agent to obtain graphene oxide dispersion liquid. According to the preparation method, the intercalator is inserted into the parts among graphene sheet layers under the action of pressure and under the airtight condition, so that the acting force among layers is reduced, and the distances among the layers are increased; then, the oxidizing agent enters the parts among the graphene sheet layers and has an oxidation reaction, so that the graphene oxide is formed; due to the action of the pressure, the intercalator and the oxidizing agent are enabled to enter the parts among graphene layers more rapidly, and the reaction is promoted to be completed within a short time, so that first-order intercalating for the graphite is realized; furthermore, the preparation method is less in energy consumption in a reaction process, environmentally-friendly, convenient and fast to operate as well as safe and controllable, thus being more suitable for industrial mass production.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

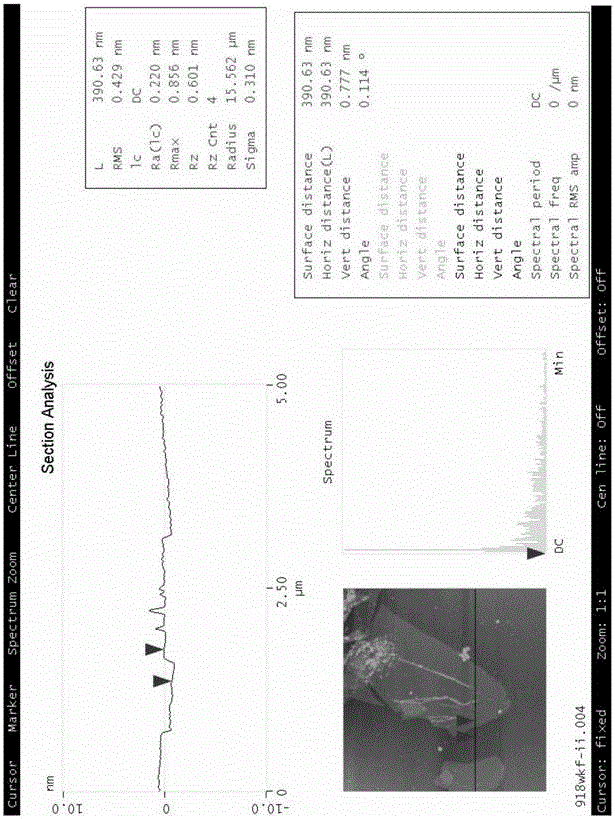

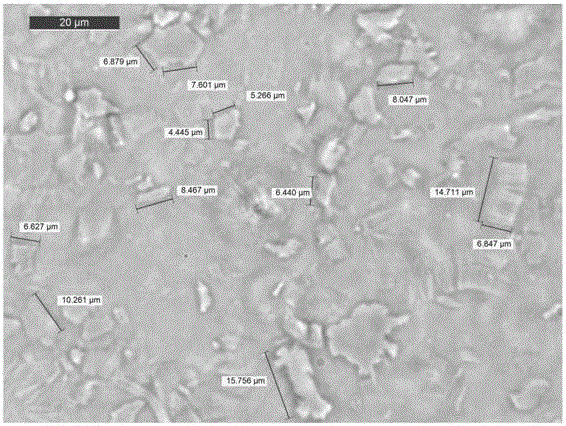

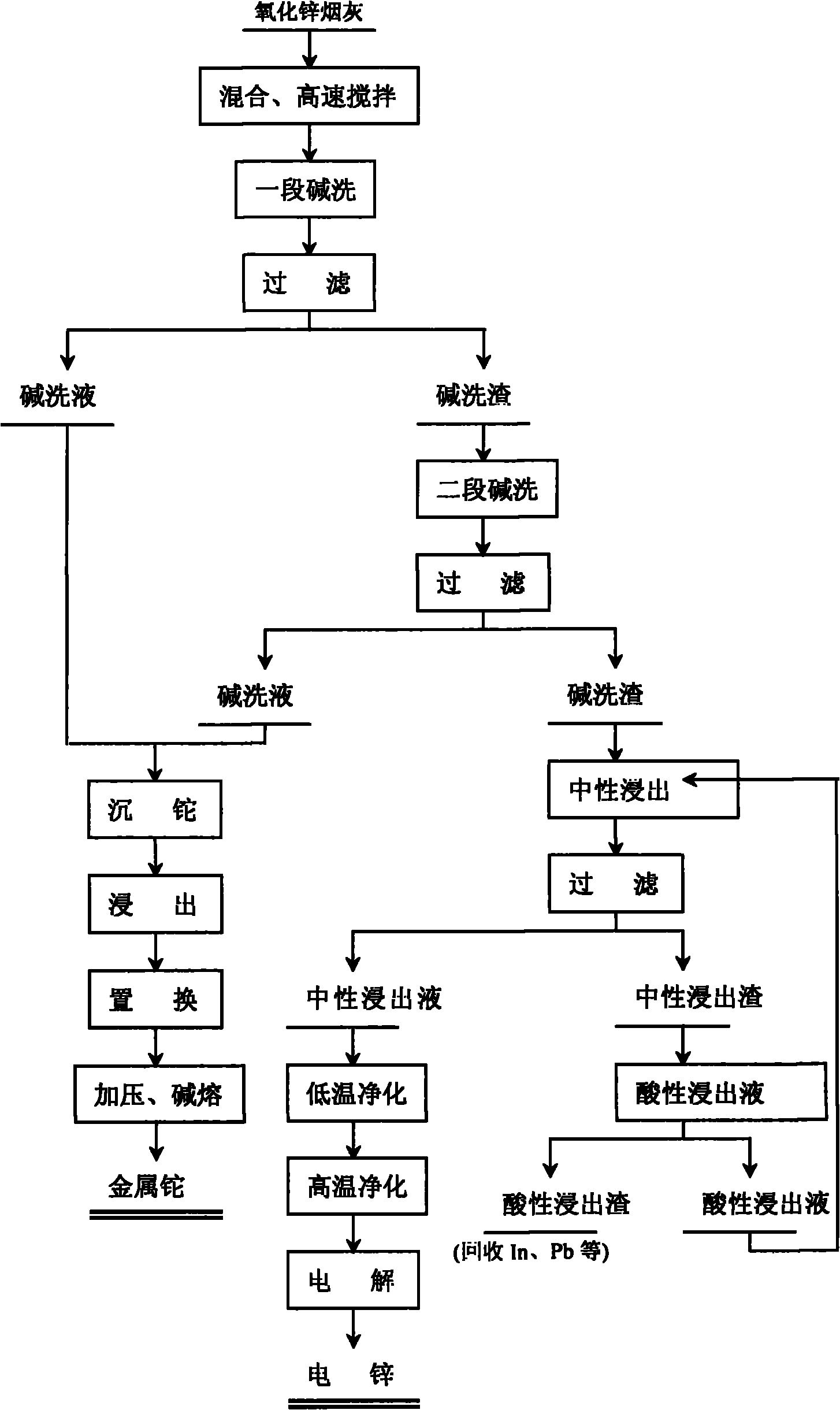

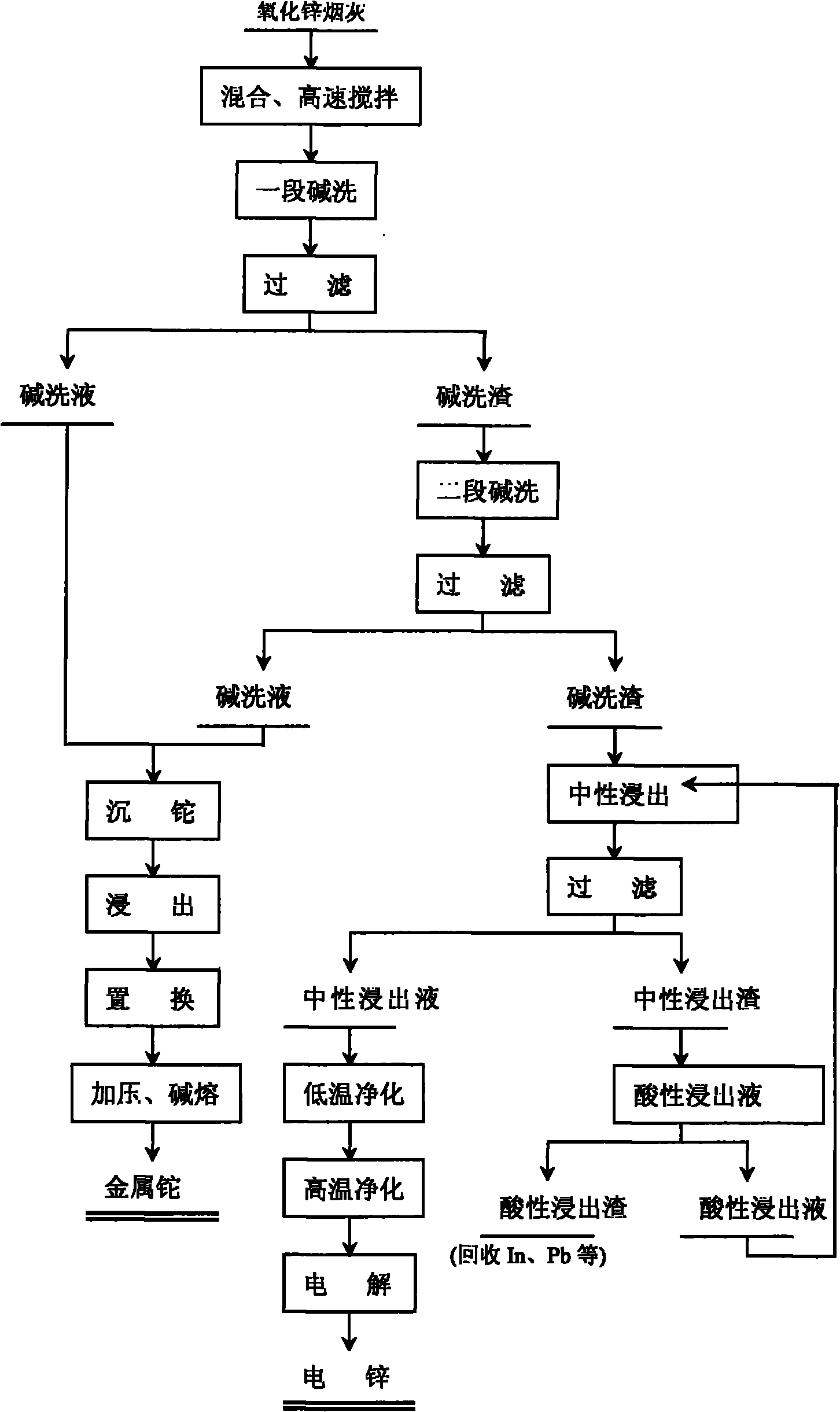

Comprehensive recovery method of zinc oxide fume dust

The invention relates to a comprehensive recovery method of zinc oxide fume dust. The method comprises the following steps: 1. performing alkali-washing on zinc oxide fume dust with Na2CO3 and NaOH in different stages: in the first stage of alkali wash, evenly mixing the zinc oxide fume dust and solid Na2CO3, adding water, stirring at high speed to dissolve the solid into solution with slag, and filtering to obtain first-stage alkali wash liquid and alkali wash slag; in the second stage of alkali wash, adding solid Na2CO3 and NaOH into the first-stage alkali wash slag, adding water, stirring to dissolve the solid, regulating the pH value, and filtering to obtain second-stage alkali wash liquid and alkali wash slag; and carrying out neutral leaching on the second-stage alkali wash slag, purifying and electrodepositing to obtain electric zinc; 2. leaching, displacing and the like to process the low temperature purified slag to obtain sponge cadmium; and 3. processing acid leached slag to obtain coarse indium, using high-temperature high-acidity leached slag as the raw material for recovering lead, and using alkali wash liquid for recovering thallium. In the invention, metals in ZnCl2, ZnF2 and PbCl2 form carbonate solid slag, chlorine and fluorine are dissolved in solution in the form of sodium salts, the slag and the liquids are respectively processed subsequently, and the products in every stage are refined processed to comprehensively recover zinc, cadmium, lead, thallium and indium.

Owner:ZHUZHOU SMELTER GRP

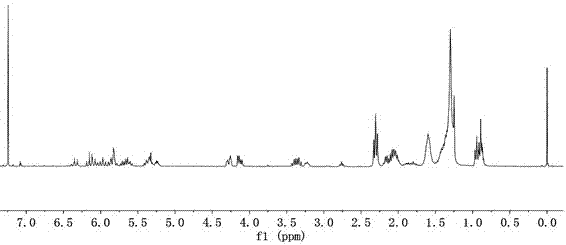

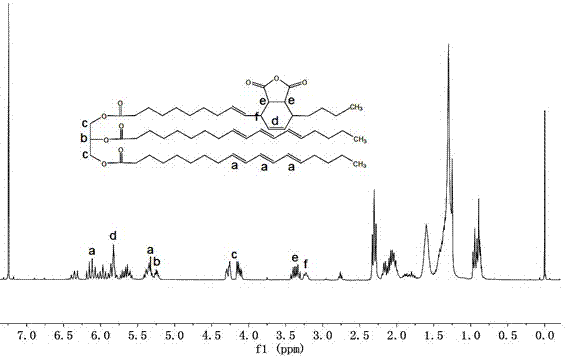

Preparation method of urethane modified tung oil vinylite

The invention discloses a preparation method of urethane modified tung oil vinylite, belonging to the field of modified tung oil vinylite preparation. The method comprises the following steps: (1) carrying out microwave heating in the presence of a catalyst so that maleic anhydride reacts with tung oil so as to obtain anhydride modified tung oil; (2) carrying out ring-opening esterification on urethane diol and anhydride modified tung oil in the presence of a tertiary amine catalyst so as to obtain urethane modified tung oil resin; and (3) when the urethane diol is abundant, directly adding monomer with an epoxy group for reacting with a carboxyl group in a resin structure so as to obtain the vinylite containing urethane modified tung oil, when anhydride is left due to lack of urethane diol after the reaction in the step (2) is completed, adding hydroxyl (methyl) acrylate monomer to react with residual anhydride group for ring-opening esterification so as to obtain the vinylite containing urethane modified tung oil. The preparation method has the advantages that process is simple, and time is saved, thus the preparation method has wide application prospects and can be used in the fields of paint, oil ink, adhesives and the like.

Owner:SUN YAT SEN UNIV

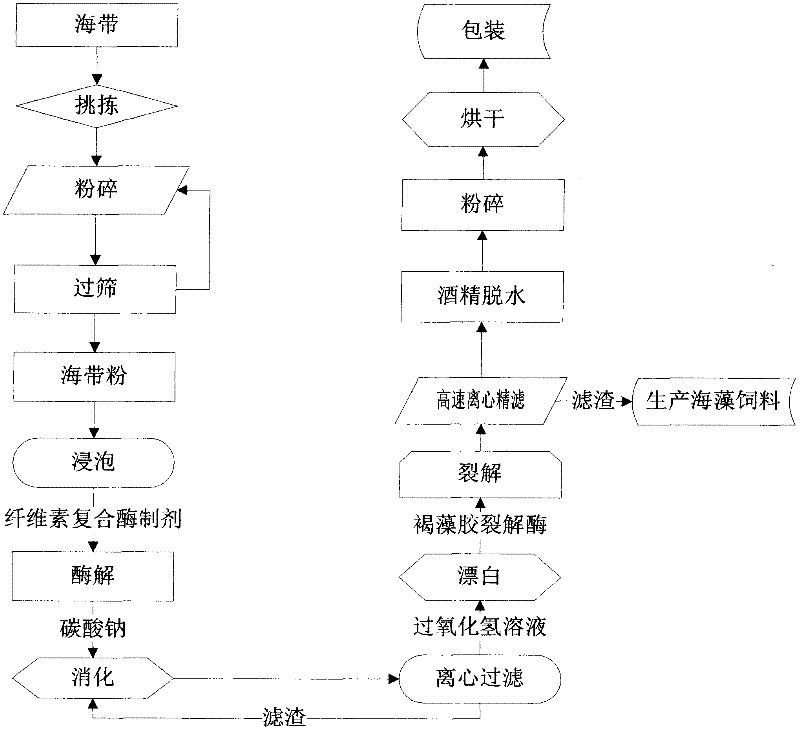

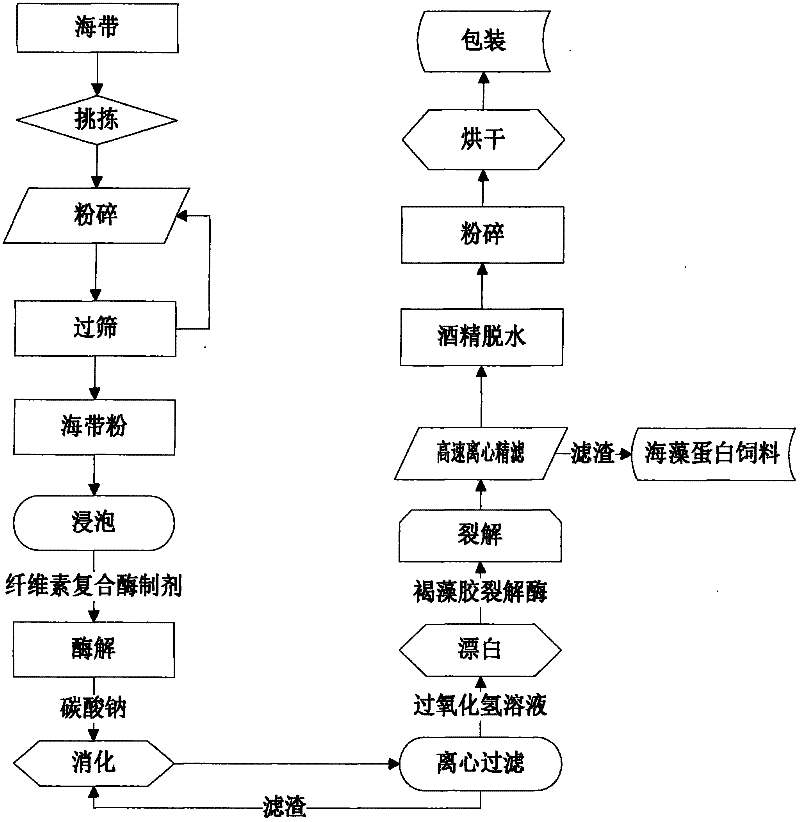

Novel process for extracting alginate-derived oligosaccharide from sea tangles by enzyme hydrolysis method

By aiming at the problems in the existing alginate-derived oligosaccharide extraction, the invention provides a production process for extracting alginate-derived oligosaccharide from sea tangles. A novel process for extracting alginate-derived oligosaccharide from sea tangles by an enzyme hydrolysis method comprises the nine steps of sea tangle powder preparation, soaking, cellulose enzymolysis, digestion, centrifugal filtration, bleaching, sodium alginate lyase enzymolysis, high-speed centrifugal fine filtration and alcohol dehydration. Compared with the existing alginate-derived oligosaccharide extraction process with the yield being 14-15 percent, the novel process has the advantages that the yield is 17-18 percent and is improved by 3 to 4 percent, meanwhile, the process steps are simplified, the use of chemical reagents is reduced, and the product appearance is more attractive.

Owner:青岛聚大洋藻业集团有限公司

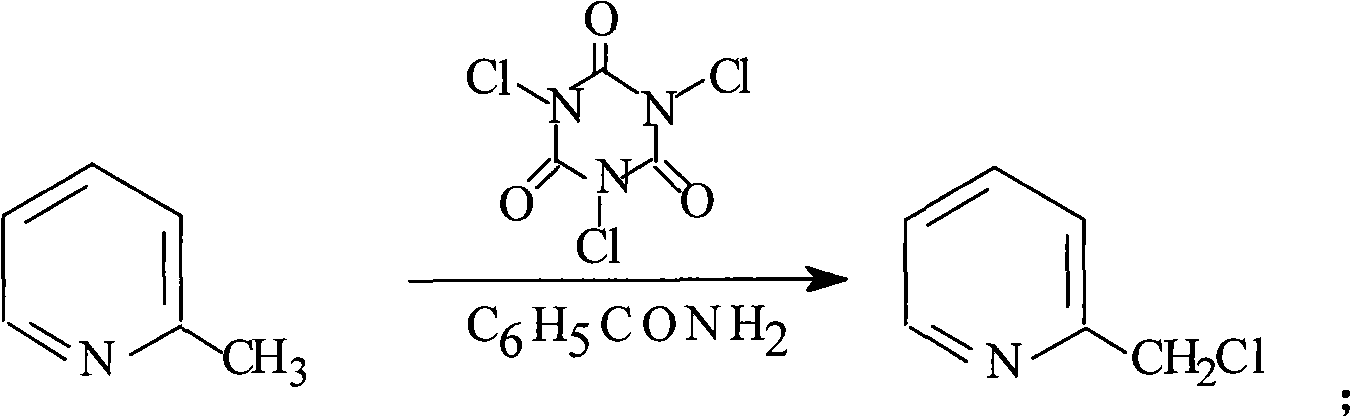

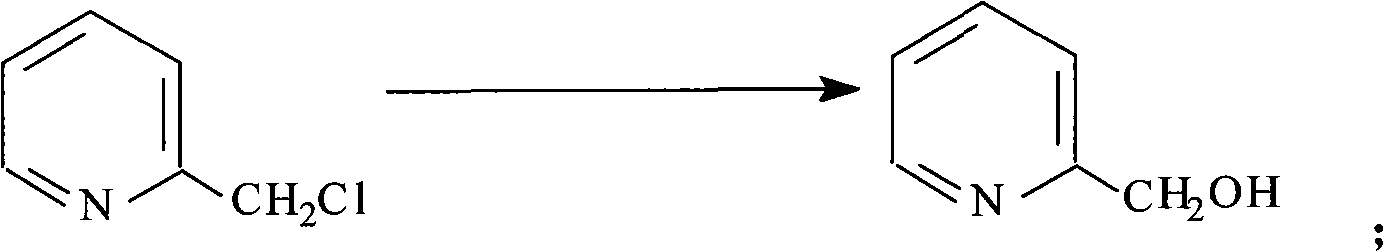

Preparation method of 2-pyridine carboxaldehyde

InactiveCN101906068AMild oxidation conditionsThorough responseOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsNitric oxide2-Methylpyridine

The invention provides a preparation method of 2-pyridine carboxaldehyde, which comprises the following steps of: (1) carrying out the temperature rise reflux reaction of 2-methylpyridine in the presence of halohydrocarbon used as a solvent, benzoyl amide used as a catalyst and trichloro isocyanate used as a chlorinating agent to obtain 2-chloromethyl pyridine; (2) carrying out hydrolysis on 2-chloromethyl pyridine under the alkalinity condition and rising the temperature to obtain 2-pyridinemethanol; (3) cooling 2-pyridinemethanol to -10-0 DEG C in presence of halohydrocarbon used as a solvent and 2,2,6,6-tetramethylpiperidine nitric oxide and potassium bromide used as catalysts, dipping 10 percent by weight of sodium hypochlorite solution used as a oxidizing agent, and keeping the temperature at 10-25 DEG C after the dipping to obtain 2-pyridine carboxaldehyde. The preparation method provided by the invention has the advantages of high yield, low cost, mild reaction condition and easy industrialization production.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

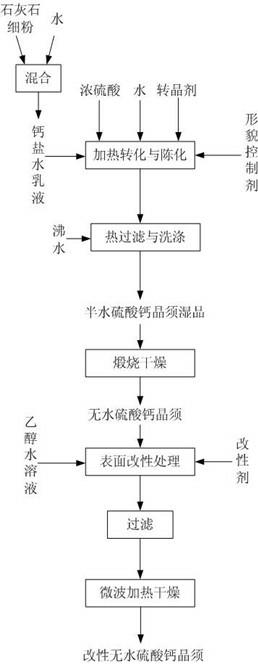

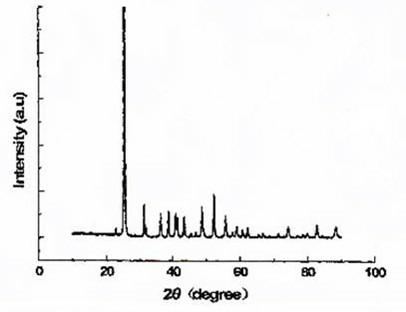

Production method of high-reinforcement modified anhydrous calcium sulfate crystal whiskers

InactiveCN102534773ASimple processThorough responsePolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateCalcium EDTA

The invention discloses a preparation method of high-reinforcement modified anhydrous calcium sulfate crystal whiskers. The method comprises the following steps that: firstly, limestone powder is added into stirred water to be prepared into calcium salt aqueous emulsion; then, sulfuric acid and crystal modifiers are sequentially added into the stirred water to be prepared into sulfuric acid water solution; next, the calcium salt aqueous emulsion containing 1 mol part of Ca<2+> is added into the sulfuric acid water solution containing 2 mol parts of SO4<2-> with the temperature reaching 100 to 110 DEG C, then, morphology control agents are added, the materials are subjected to stirring and aging for 2 to 3.5 hours under the temperature condition being 110 to 120 DEG C, leaching and washing are carried out, and calcium sulfate hemihydrate crystal whisker wet products are obtained; the calcination drying finally is carried out under the temperature condition higher than 200 DEG C to obtain the anhydrous calcium sulfate crystal whiskers; and then, the surface modification treatment is carried out to finally obtain the high-reinforcement modified anhydrous calcium sulfate crystal whiskers. The preparation method has the advantages that the product quality is high, the cost is low, the preparation process is short, the reaction condition is mild, and in addition, green and environmental-friendly effects can be realized.

Owner:四川万润非金属矿物材料有限公司

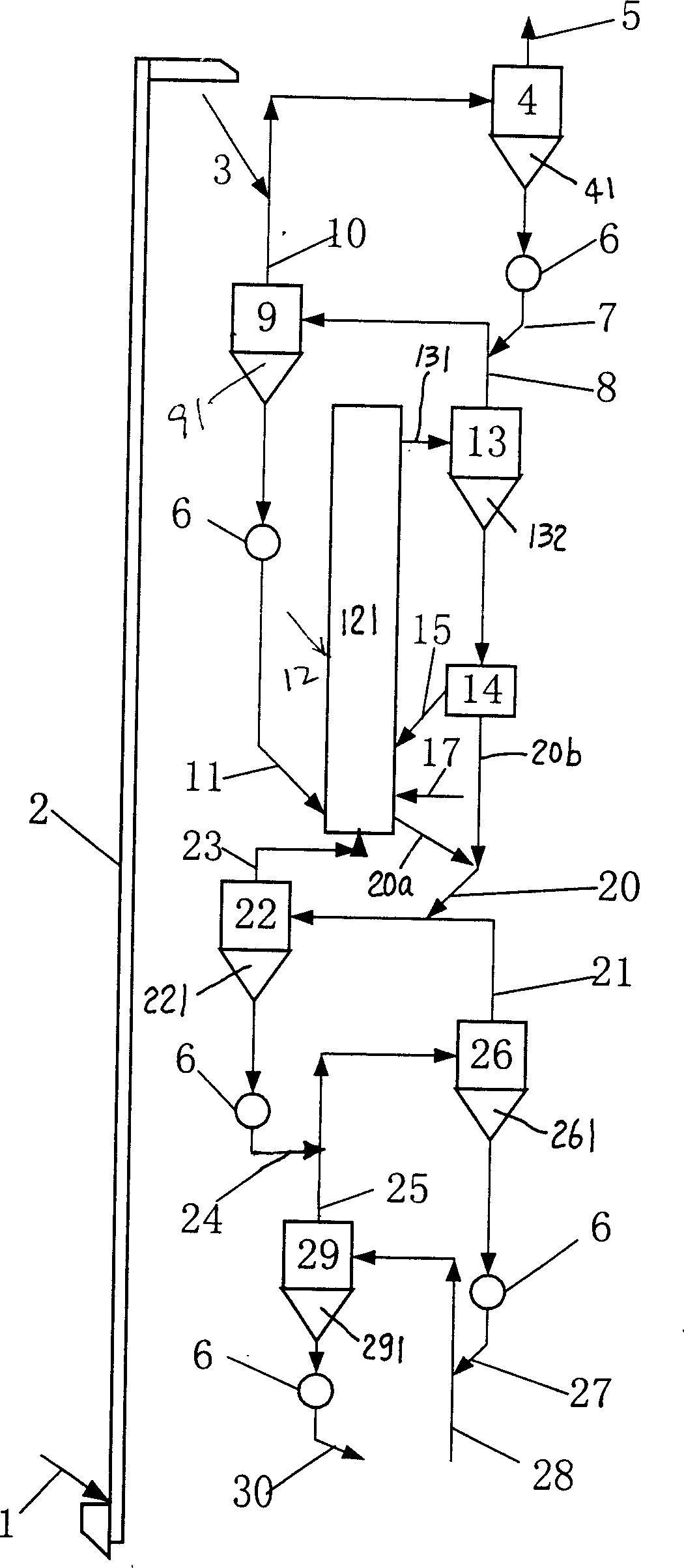

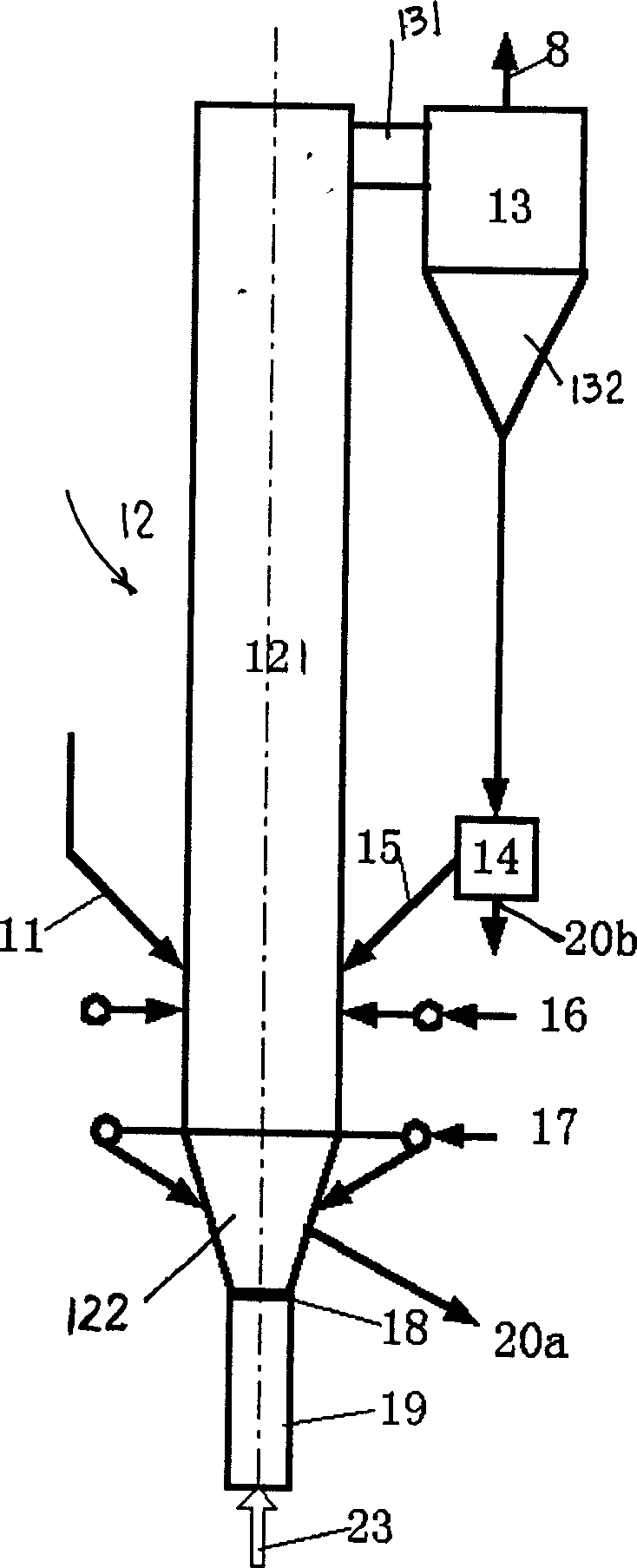

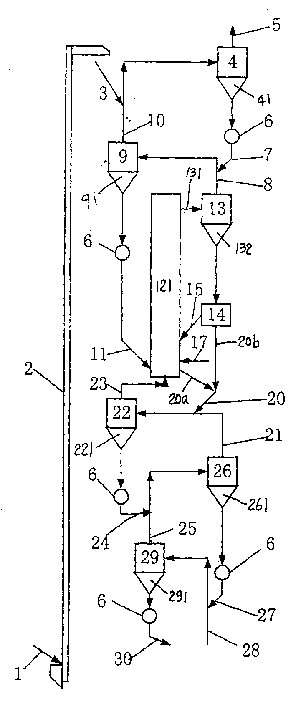

Rapid cycled fluidized calcining procedure for superfine kaolin and equipment

InactiveCN1600687AIncrease productivityImprove thermal efficiencyPigmenting treatmentAluminium silicatesCycloneEngineering

The invention relates to superfine Kaolin calcining process and device, the prodn, method includes; preheating kaolin raw powder material, then putting it in fluidization calcining furnace from the bottom, at same time, sending fuel into the furnace, preheated primary air is sent from plenum under the furnace burns with the fuel and to form a reducibility atmosphere calcining area in the lower section, the volume content of CO+H2 in reduction area is 0-10 percent, secondary air is sent from top of the reduction area to burn residual CO+H2 completely, airflow speed is 1-6m / s in the furnace, raw powder material is in fluidization, kaolin is circularly burned for 0.3-3 hours in temp. 700-1100 deg.C, then is sent into cyclone cooling system to be cooled to obtain superfine kaolin by mixer-grinding and depolymerizing.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

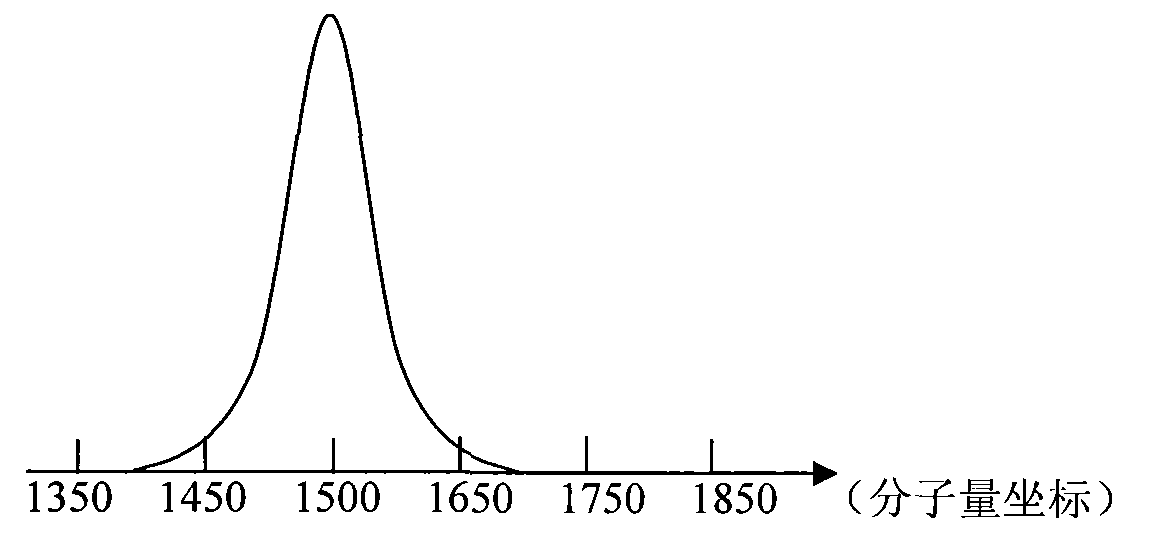

Method for preparing crystal II-type ammonium polyphosphate with distribution of high polymerization degree and narrow molecular weight

ActiveCN101597044AEliminate the effects ofTemperature controlPhosphorus compoundsSolubilityPolymerization

The invention discloses a method for preparing crystal II-type ammonium polyphosphate with distribution of high polymerization degree and narrow molecular weight. The method comprises the following steps: putting phosphorus pentoxide and diammonium phosphate which have equal molar ratio into a malaxator which can accurately control a temperature and heated by conducting oil for mixing; under the protection of inert gas, heating the materials in the malaxator to between 100 and 250 DEG C through the circulatory conducting oil; stopping introducing the inert gas; performing ammonification on the materials and heating the materials under an atmosphere of ammonia gas till the materials are totally molten down; stopping introducing the ammonia gas; after homogenization, introducing the ammonia gas again and heating the materials; throwing a surface treating agent into the malaxator; after material throwing is completed, continuously introducing the ammonia gas, keeping warm and mixing the materials; after reaction is finished, transferring the materials to a closed vessel and reducing the temperature; simultaneously, continuously introducing the ammonia gas till the temperature of the materials is below 100 DEG C; and obtaining a finished product. The method can prepare the crystal II -type ammonium polyphosphate with the distribution of the high polymerization degree and the narrow molecular weight; and the product has the characteristics of uniform granularity shape, small water-solubility, good heat resistance, high polymerization degree, narrow distribution of molecular weight and high crystal II-type purity.

Owner:GUANGDONG JUSHI CHEM CO LTD

Steel slag treating method

ActiveCN102559960AEliminate hazardsSafe useRecycling and recovery technologiesThermal energyCalcium silicate

The invention provides a steel slag treating method comprising the following steps of: directly mixing thermal-state revolving furnace steel slag with blast furnace slag in an arc furnace in proportion, adjusting the molten slag in the furnace into a proper temperature by virtue of the arcing of the arc furnace, and stirring the molten slag by virtue of arc disturbance, so that acidic oxide and basic oxide in the molten slag are sufficiently reacted with each other; reacting free calcium oxide and free magnesium oxide in the raw steel slag with silicon dioxide component and low-calcium calcium silicate in the blast furnace slag to generate safe calcium silicate and magnesium silicate, quenching the molten slag to form glass-state solid slag which is higher in hydration reactivity and free of short-term or long-term inflation harm, and further finely grinding the solid slag into slag powder which can be safely used for related building material as the blast furnace slag. According to the method, the damage caused by the free calcium oxide and free magnesium oxide in the steel slag can be removed, and a basis is provided for the whole use of the steel slag. The heat energy of the thermal-state molten slag can be sufficiently used, so that the energy source can be saved, the energy consumption can be reduced, the cost can be reduced, and the discharge of CO2 can be reduced, and the method is extremely high in social meaning and economic meaning.

Owner:北京联合荣大工程材料股份有限公司

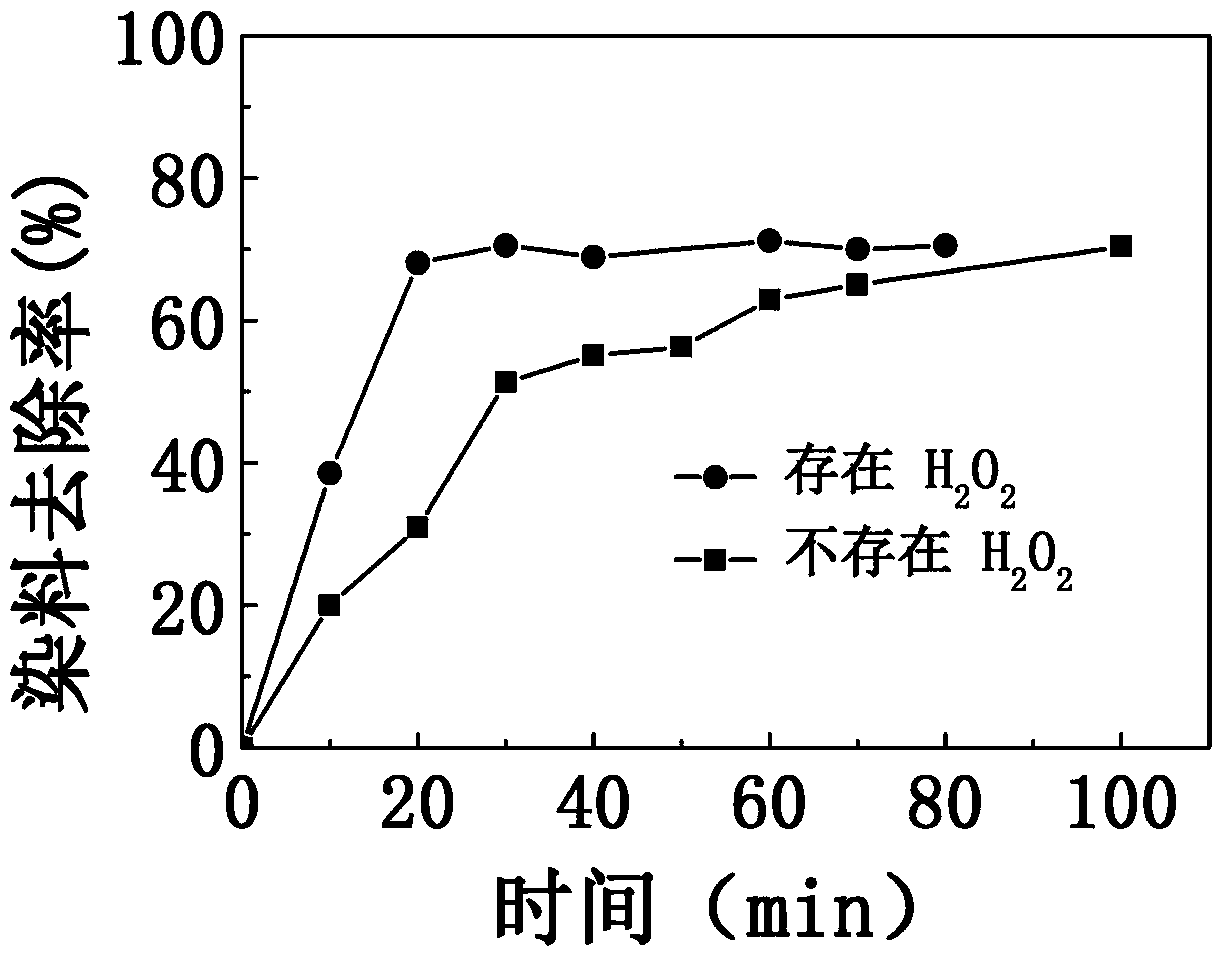

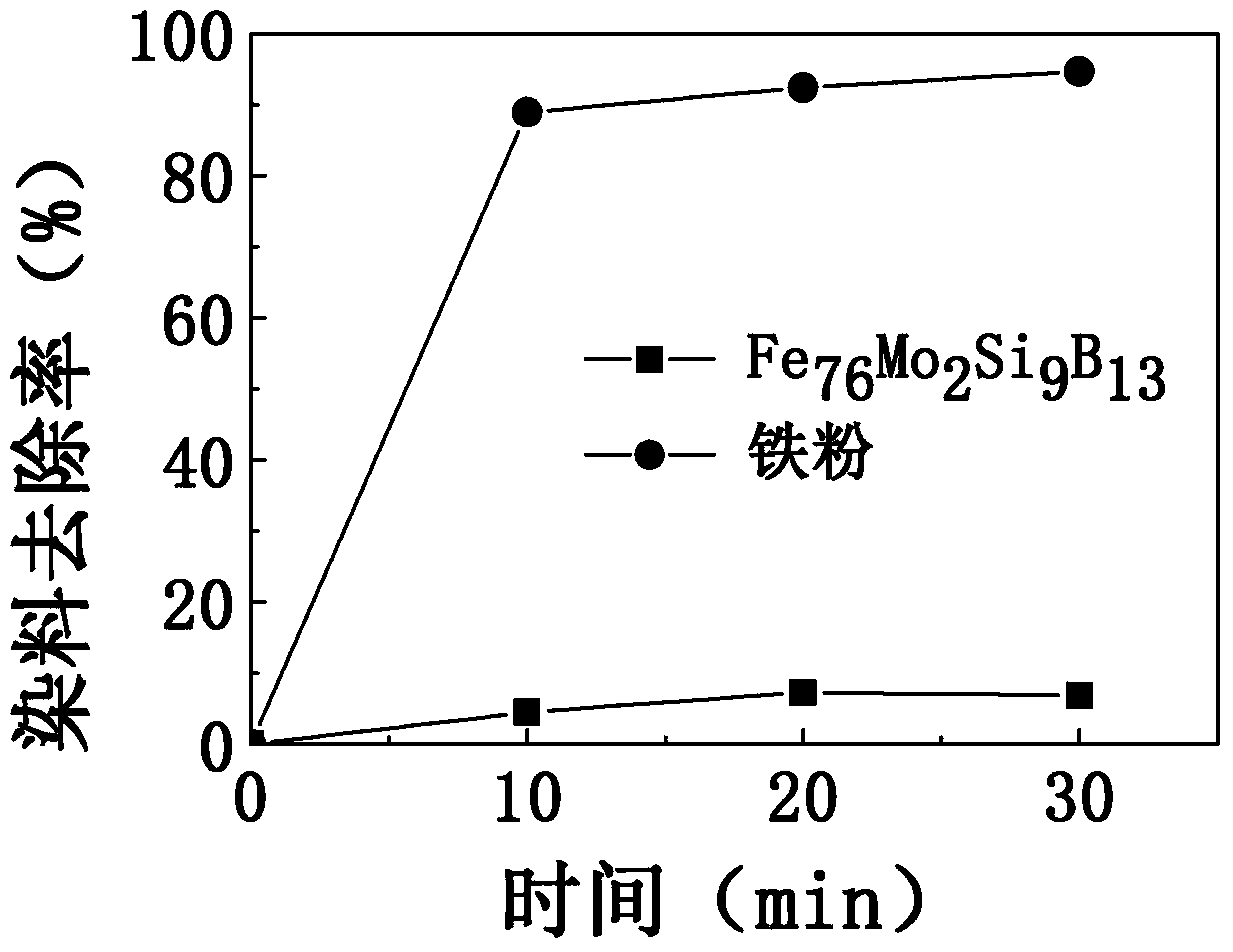

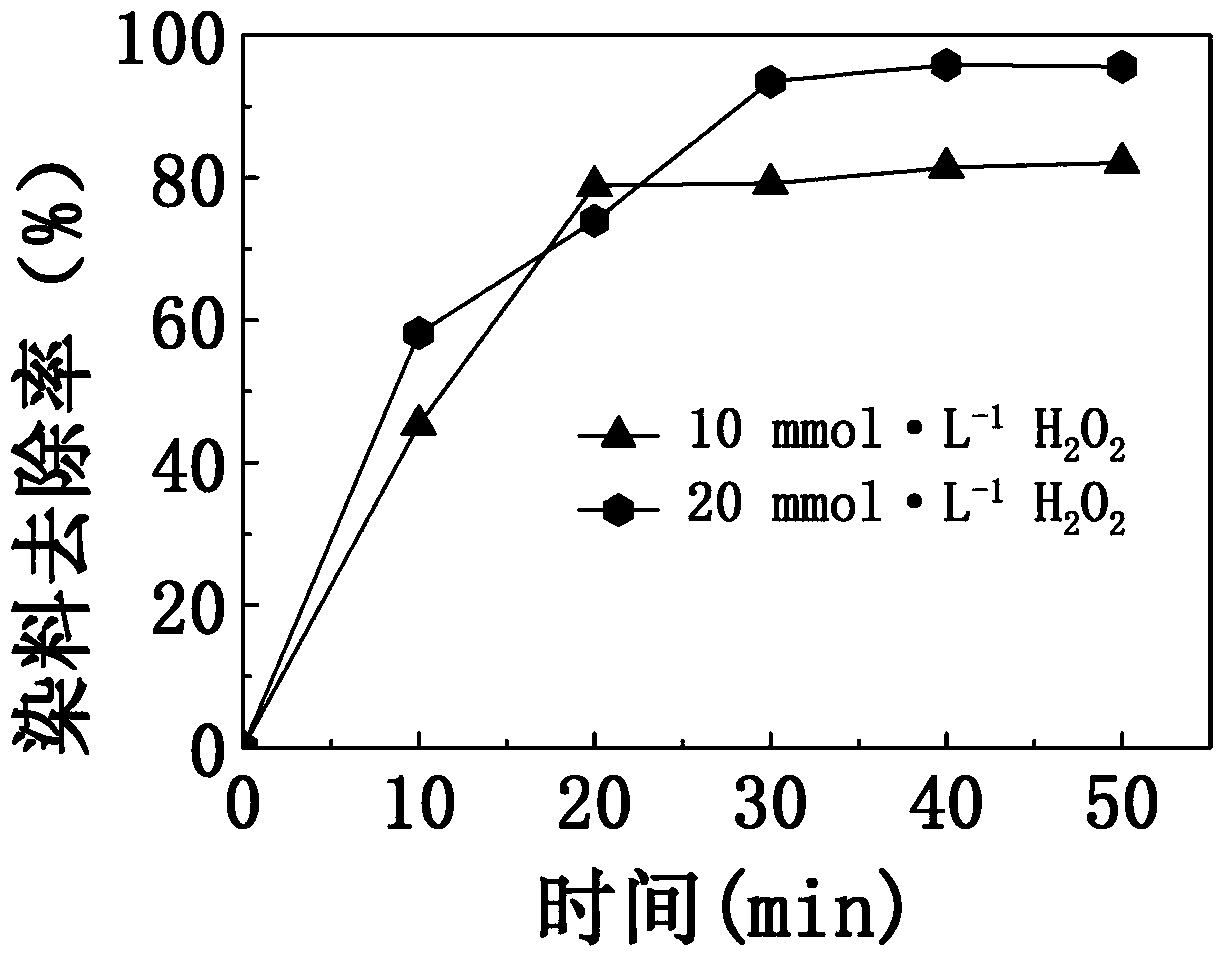

Method of degrading dye wastewater by iron-based amorphous alloy/hydrogen peroxide Fenton-like system

InactiveCN103880149APromote generationThorough responseWater/sewage treatment by reductionWater/sewage treatment by oxidationSewageAlloy

The invention provides a method of degrading dye wastewater by an iron-based amorphous alloy / hydrogen peroxide Fenton-like system. The method is characterized by comprising the following steps: inputting iron-based amorphous alloy ribbon slices and hydrogen peroxide into the dye wastewater; then mixing and stirring, wherein the weight ratio of the dye wastewater and the iron-based amorphous alloy ribbon slices is 100:1, the mass fraction of H2O2 in hydrogen peroxide is 20-30%, and the molar concentration of H2O2 in the dye wastewater is 10-20mmol / L. According to the method of degrading dye wastewater by the iron-based amorphous alloy / hydrogen peroxide Fenton-like system provided by the invention, the dye is initially degraded to Fe<2+> by reducing action of the iron-based amorphous alloy to accelerate growth of OH. free radicals which further oxidize and degrade macromolecules of the dye to micromolecules, and finally, the micromolecules are mineralized to CO2 and H2O. The method is high in degradation rate and thorough in reaction.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method for recycling molybdenum of molybdenum-contained waste catalyst

ActiveCN101724758AThe process is simpleSimple equipmentProcess efficiency improvementAmmonium molybdateChemistry

The invention relates to a method for recycling molybdenum of a molybdenum-contained waste catalyst, which comprises the following steps of: roasting and pulverizing the molybdenum-contained waste catalyst; then mixing and roasting with an alkaline substance; extracting by using mixed acid; depositing by using an alkaline solution; depositing the molybdenum in an ammonium molybdate way; further dissolving the ammonium molybdate by using ammonia water and readjusting the pH value to obtain an ammonium molybdate sediment; and drying to obtain the ammonium molybdate product. The method is particularly suitable for the process of extracting high-purity ammonium molybdate by using a aluminium-based molybdenum-contained waste catalyst, and has simple process, high maneuverability, low energy consumption and stable quality of the prepared product.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP

Unsaturated polyester resin for pultrusion and preparation method for same

The invention discloses unsaturated polyester resin for pultrusion and a preparation method for the same. The resin is mainly made of, by weight, 6400-6800 parts of phthalic anhydride, 4000-4800 parts of maleic anhydride, 1700-2000 parts of 1,2-propylene glycol, 4000-4400 parts of ethylene glycol, 8000-9000 parts of styrene, 1-5 parts of polymerization inhibitor, 1-5 parts of antioxidant and 0.01-1 part of retarding agent. Compared with the prior art, the unsaturated polyester resin has the advantages that the heat distortion temperature of the unsaturated polyester resin is higher than 88 DEG C on the premise of meeting a pultrusion process requirement, and performances such as stretching, compression strength and the like of the unsaturated polyester resin are remarkably enhanced.

Owner:宜兴市兴合树脂有限公司

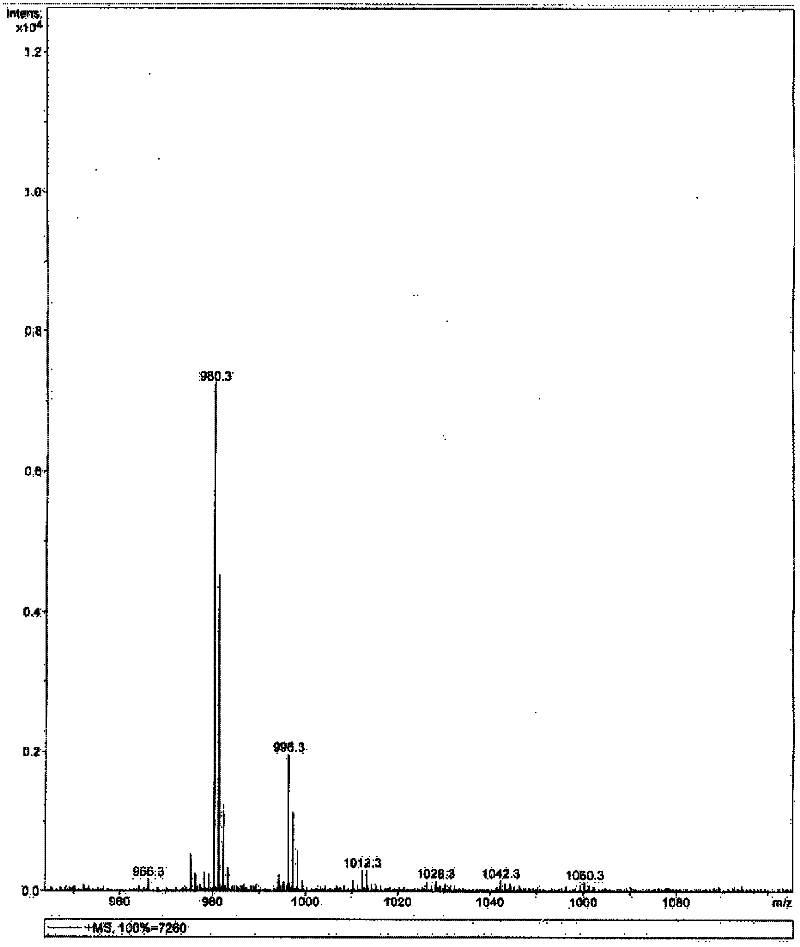

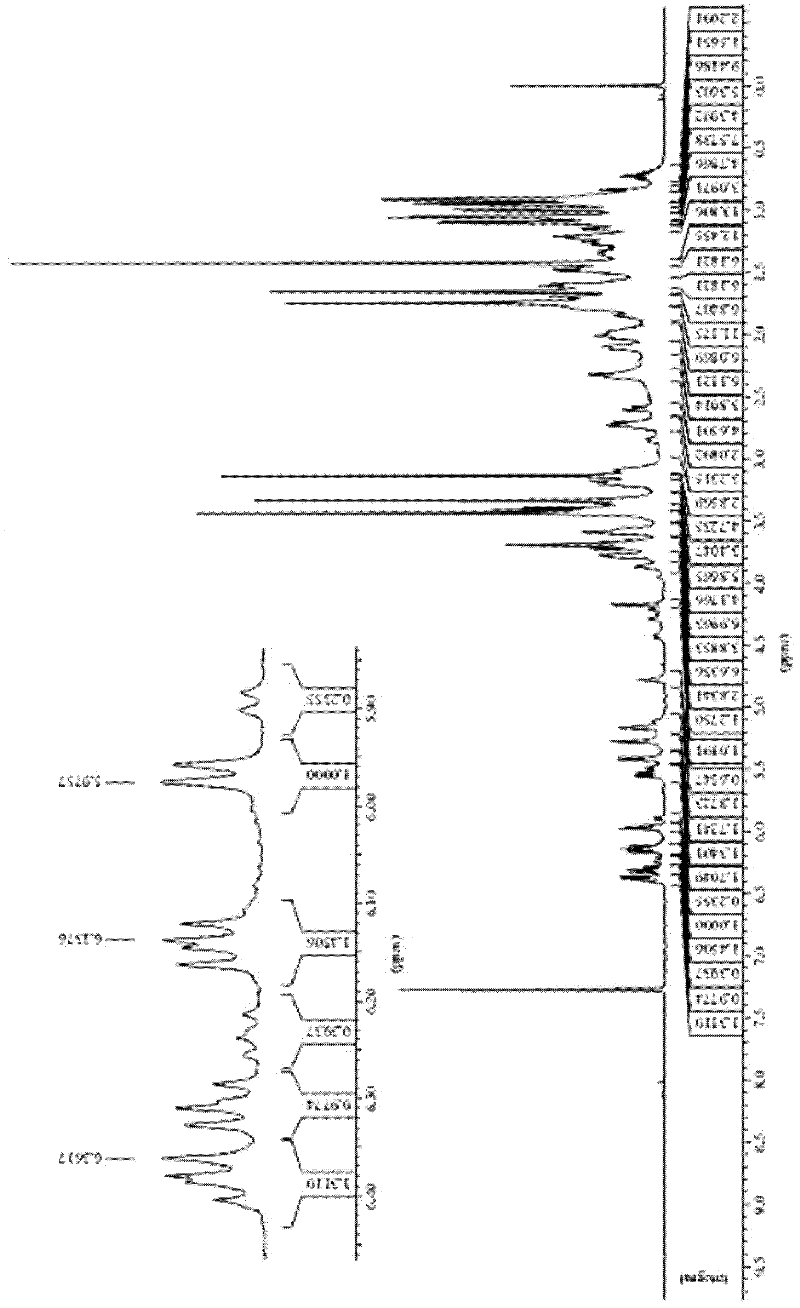

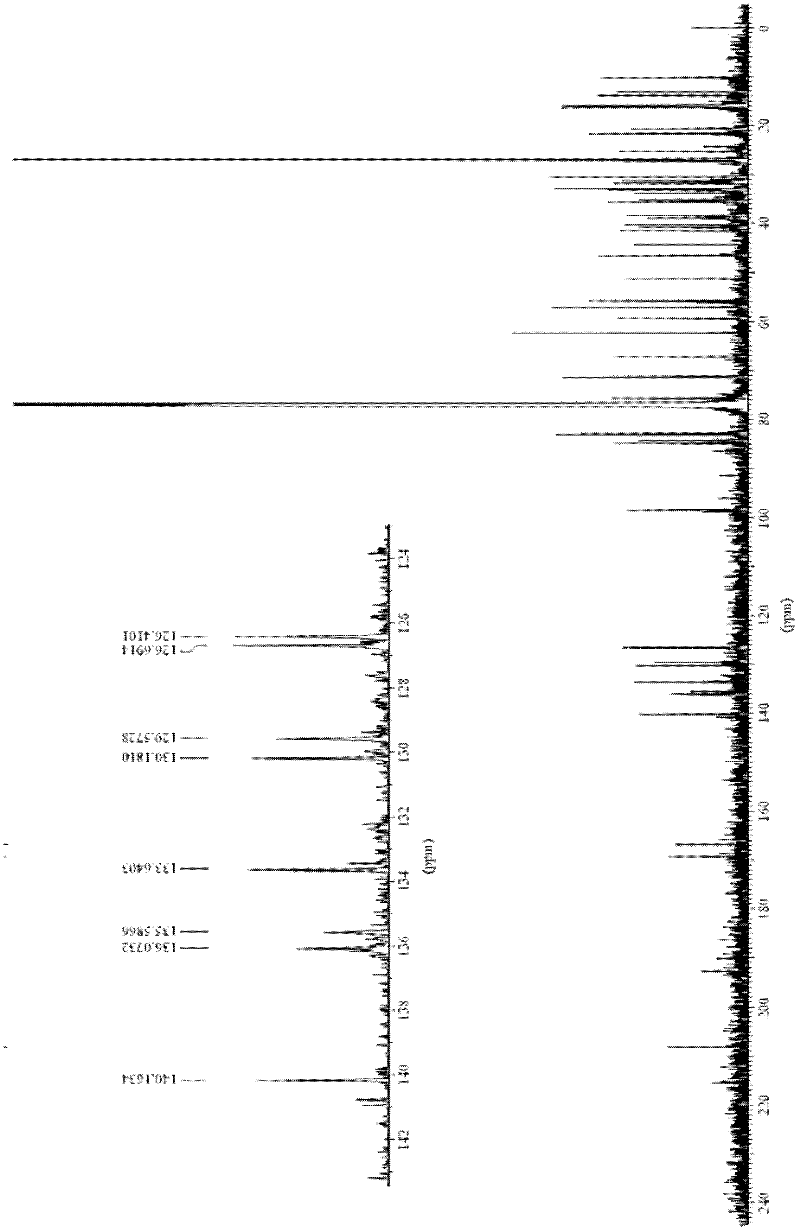

A kind of synthetic method of everolimus

ActiveCN102268015AFully convertedThorough responseOrganic chemistryTrifluoromethanesulfonic anhydrideEverolimus

The invention discloses a synthesis method of everolimus. The synthesis method of the everolimus comprises the following steps: based on rapamycin or a rapamycin derivative the 31-hydroxy of which is protected as a raw material, firstly carrying out a reaction on the raw material with triflic anhydride so as to obtain an intermediate 02; then carrying out a reaction on the intermediate 02 with mono-protected glycol so as to obtain an intermediate 03; and de-protecting the intermediate 03 so as to obtain the everolimus. In the process in the invention, the raw material can be fully converted into the intermediate 02 through reacting with triflic anhydride, and the intermediate 02 can be fully converted into the intermediate 03 through reacting with mono-protected glycol; and each step reaction can be fully carried out, and the total yield is greatly improved to above 50%.

Owner:四川摩尔生物制药有限公司

Jet combustion device and method for super-critical water oxidization of organic matter

InactiveCN105782995ARapid temperatureIncrease reaction rateIncinerator apparatusMesosphereInorganic salts

The invention provides a jet combustion device and method for super-critical water oxidization of organic matter. The device comprises an inner sleeve and an outer sleeve which are arranged together in a coaxial sleeving manner; a coaxial jet combustor extending into the reactor inner sleeve is coaxially installed at the top of the reactor inner sleeve; the coaxial jet combustor is of a three-layer coaxial sleeve structure, an auxiliary heat source access channel is located on the innermost layer, an oxidant access annular channel is located on the middle layer, and a waste liquid access annular channel is located on the outermost layer; and a process water jacket region, a super-critical water oxidization region and a subcritical water region capable of dissolving inorganic salt are formed in a reactor.

Owner:SHANDONG UNIV

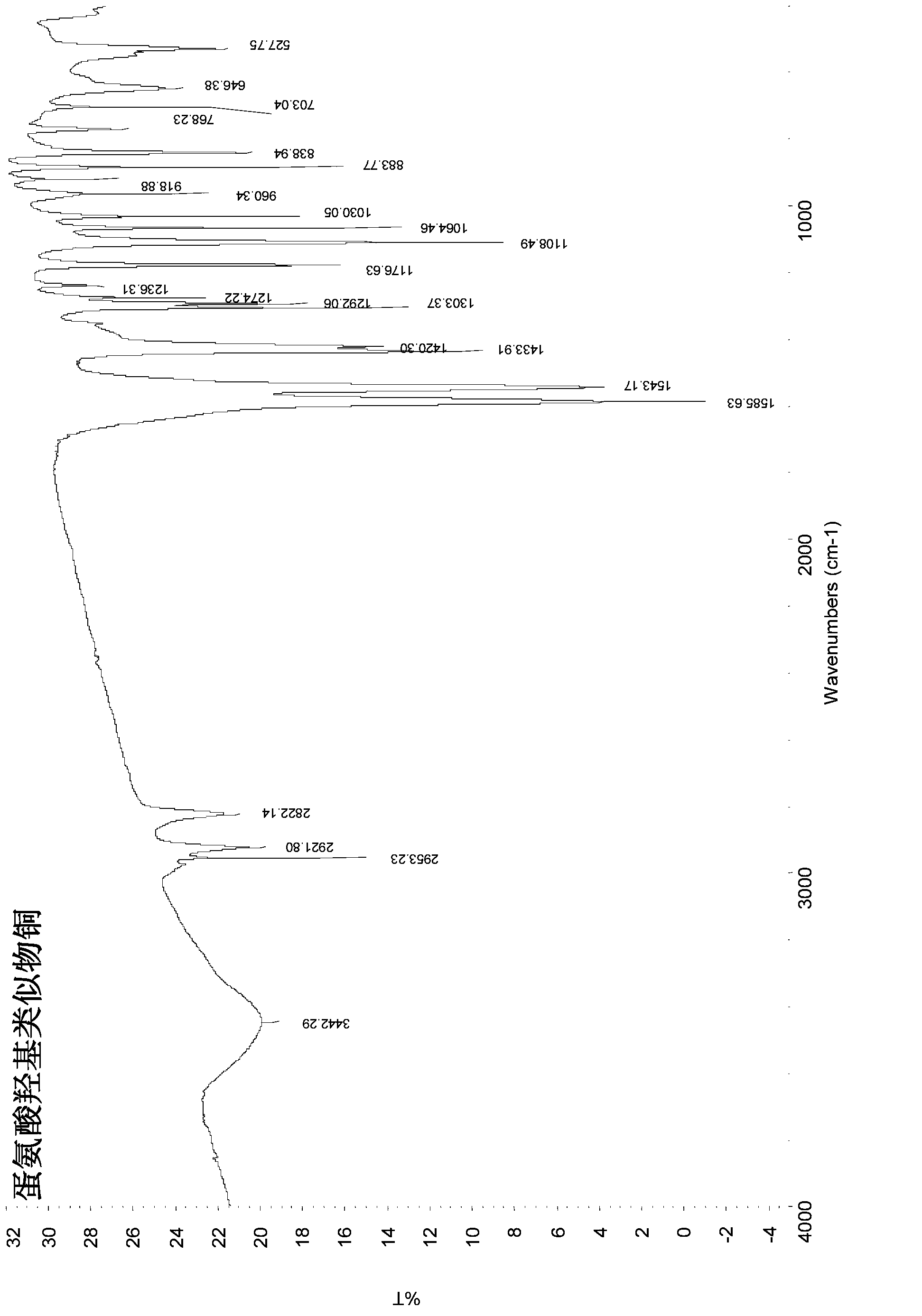

Preparation method of microelement methionine hydroxy analogue chelate additive

ActiveCN103254104AIncrease contentEasy to processAnimal feeding stuffSulfide preparationMethionine hydroxy analogMethionine biosynthesis

The invention discloses a preparation method of a microelement methionine hydroxy analogue chelate additive, which comprises the following steps: 1) respectively putting a mixed solution of a methionine hydroxy analogue solution and water or a mixed solution of organic substances and water into a closed reaction kettle which is protected by an inert gas atmosphere, starting to stir, performing hydrolysis reaction, adding an alkaline solution, and controlling the pH value at the end point of the reaction; 2) adding basic salt or acidic salt or amphoteric salt of trace metal elements into the liquid obtained by the reaction in the step 1), further reacting, and controlling the pH value at the end point of the reaction at 5-8, thus obtaining a liquid containing a microelement methionine hydroxy analogue chelate; and 3) removing water from the liquid obtained after the reaction in the step 2) is finished, drying, and screening to obtain the microelement methionine hydroxy analogue chelate. The method disclosed by the invention maximally lowers the start-up cost, improves the production efficiency and lowers the production cost, can produce qualified products and is suitable for popularization in a wide range.

Owner:XINGJIA BIO ENG CO LTD

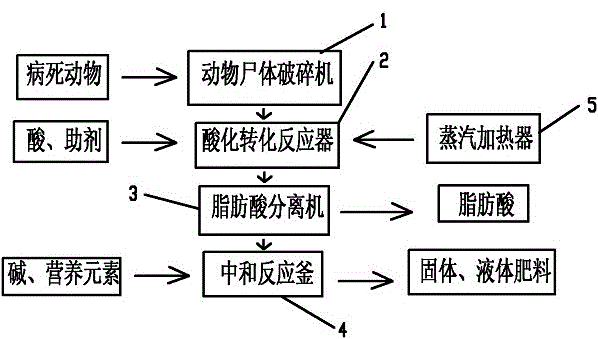

Method for harmlessly preparing fertilizer through carcasses and special equipment

InactiveCN105084986AGood effectImprove fertilizer efficiencyAnimal corpse fertilisersClimate change adaptationPhosphateWater soluble

The invention discloses a method for harmlessly preparing fertilizer through carcasses. The method comprises the steps that carcass fragments are firstly subjected to heat treatment conversion in an acid environment, the reaction environment is controlled to enable animal fat to be converted into fatty acid, and animal skin, fur and meat are converted into amino acid and humic acid, and animal bones are converted into water-soluble calcium salt and phosphate; the fatty acid is separated, and alkali is added to left amino acid and humic acid mixed liquid for neutralization. Special equipment of the method comprises a carcass crusher, an acidizing reaction kettle, a fatty acid separator and a neutralization reaction kettle which are connected in sequence. The method has the advantages of free of pollution, fast, thorough, efficient, high in quality and the like.

Owner:高洁

Method for recovering high-purity molybdenum from molybdenum-containing dead catalyst

The invention relates to a method for recycling the high purity molybdenum from the molybdenum bearing spent catalyst. The method comprises the steps that the molybdenum bearing spent catalyst is roasted and comminuted, then the molybdenum bearing spent catalyst is leach and filter by adopting alkaline solution bearing ammonia, ammonium bicarbonate and oxyful, and the secondary roasting and leaching are performed to the solids after filtration, the twice leaching solution is acidified and the aluminum is precipitated out, then is acidified continuously to precipitate out the molybdenum in the form of molybdic acid, the molybdic acid is dissolved by using ammonia water further, the pH value is adjusted again to obtain ammonium molybdate deposition, and the ammonium molybdate product is obtained after dryness. The method is particularly suitable for the process for extracting the high purity ammonium molybdate with the aluminum based molybdenum-bearing spent catalyst, the operation is simple, the operability is better, and the quality of the prepared product is stable.

Owner:CHINA PETROLEUM & CHEM CORP +1

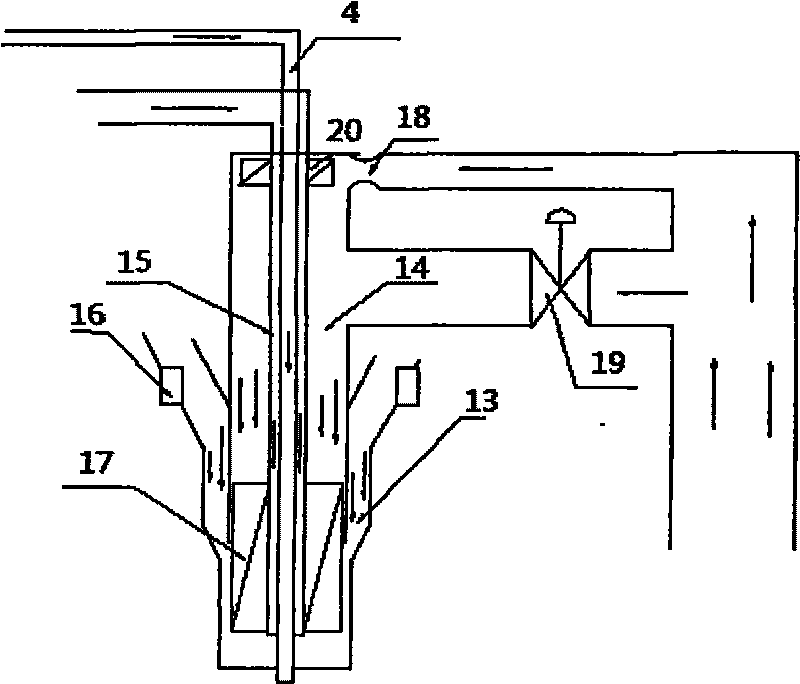

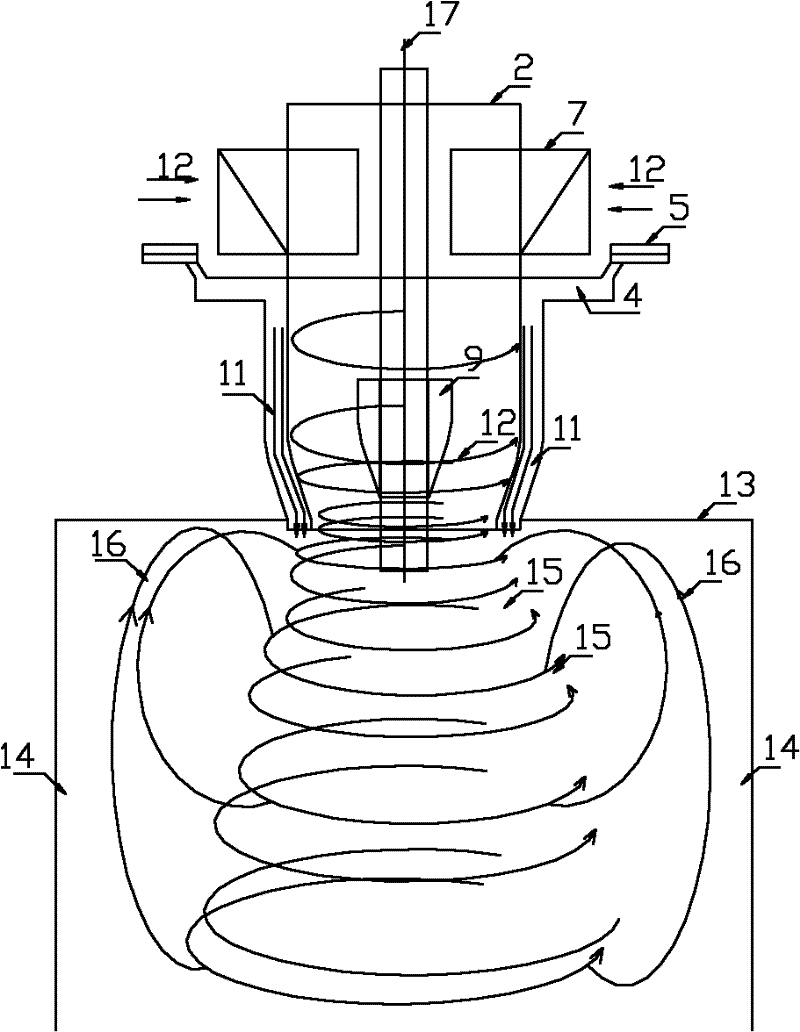

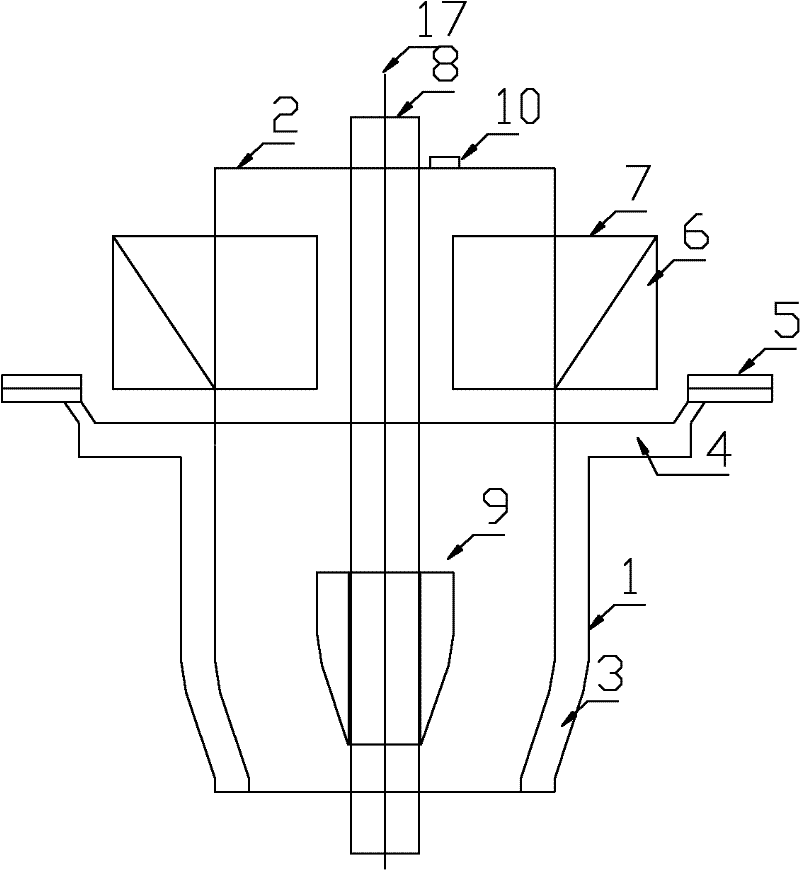

A spin-floating entrainment metallurgical process and its reactor

The invention relates a floating entrainment metallurgical process. In this process, the reaction gas and the powdery materials are injected into the reaction furnace, aiming to obtain a controllable highly rotating and floating state and reach the ignition point under the high-temperature radiation of the reaction furnace to combust intensely. Meanwhile, the rotating fluid injected in the reaction furnace will drive the furnace gas, and forms a relatively low-temperature circular backflow protection area around the rotating fluid. The reaction gas is tangentially fed into the rotating generator along numbers of rotary channels to form a controllable rotating airflow, in addition, a conical exit air controller that can be moved up and down is adopted to control the exit area of the rotating generator, thus controlling the velocity of the reaction gas into the reaction furnace; the powdery materials fall freely around the reaction gas and are involved in the high-speed rotating airflow, forming a rotating fluid, of which the powdery materials are highly dispersed into the reaction gas, moving downwards along the radial high-speed rotating axle. For the purpose of this invention, a steplessly adjusted reactor is as well referred to in this invention.

Owner:YANGGU XIANGGUANG COPPER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com