Ultrathin Ni-Fe-MOF nanosheet, preparation method and application thereof

A nano-sheet and ultra-thin technology, applied in the field of ultra-thin Ni-Fe-MOF nano-sheets and its preparation, can solve the problems of difficult removal of surfactants, difficulty of 2D ultra-thin MOF nano-sheets, etc., and achieve excellent catalytic performance, Uniform shape and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: Preparation of ultrathin Ni-Fe-MOF nanosheets

[0045] Weigh respectively 24.8mg (0.1mmol) of nickel acetate tetrahydrate and 7.38mg (0.03mmol) of ferrous sulfate heptahydrate solid dissolved in 6mL deionized water to form solution A, and weigh 8.3mg of organic ligand terephthalic acid Dissolve in 6mL DMAC to form solution B. Slowly add solution B to solution A and mix evenly under stirring conditions, then transfer the mixed solution into a stainless steel reaction kettle with a polytetrafluoroethylene liner, seal it and place it in an oven , reacted at 150°C for 3 h, cooled naturally to room temperature after the reaction, washed with deionized water and ethanol, centrifuged and dried to obtain yellow powder ultrathin Ni-Fe-MOF nanosheets, abbreviated as Ni- Fe-MOF NSs.

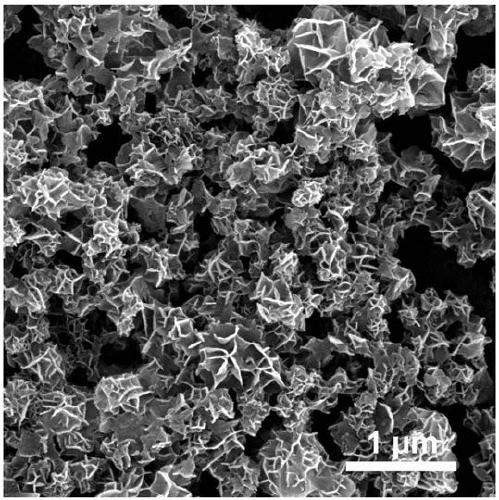

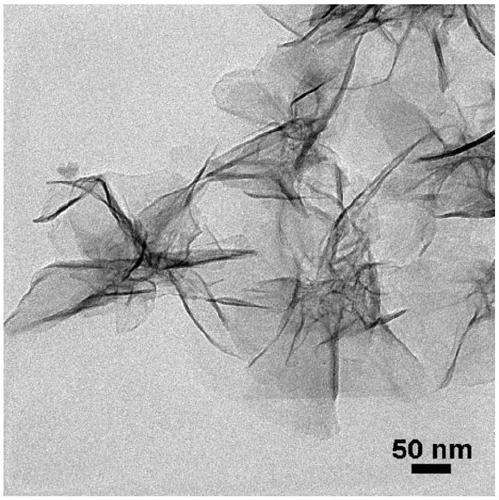

[0046] Such as figure 1 and figure 2 As shown, the ultrathin Ni-Fe-MOF nanosheets have uniform morphology and high quality and yield.

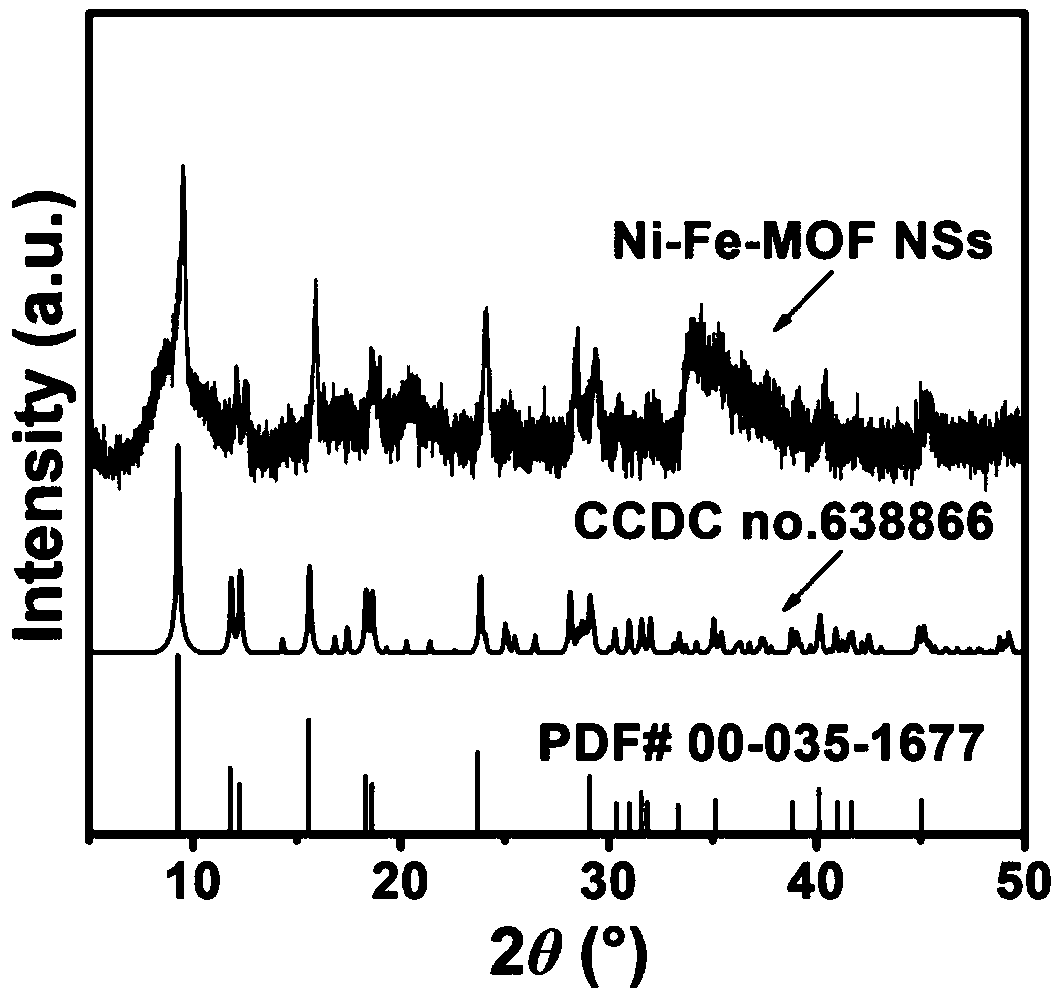

[0047] Such as image 3 As shown, the powder d...

Embodiment 2

[0058] Example 2: Mass preparation of ultrathin Ni-Fe-MOF nanosheets

[0059] Weigh 2.48g (10mmol) of nickel acetate tetrahydrate and 0.738g (3mmol) of ferrous sulfate heptahydrate solid and dissolve them in 300mL deionized water to form solution A, and weigh 0.830g (5mmol) of the organic ligand terephthalate Dissolve formic acid in 300mL DMAC to form solution B. Slowly add solution B to solution A and mix evenly under stirring conditions, then transfer the mixed solution into a 1000mL thick-walled reaction bottle, seal it and place it in an oven at 150°C The reaction was carried out for 3 hours. After the reaction, it was naturally cooled to room temperature, washed with deionized water and ethanol, centrifuged and dried to obtain yellow powdery ultrathin Ni-Fe-MOF nanosheets with a mass of 1.7486g, such as Figure 12 shown.

[0060] Such as Figure 13 As shown, the mass-synthesized ultrathin Ni-Fe-MOF nanosheets have uniform morphology and high quality and yield.

[0061]...

Embodiment 3

[0062] Embodiment 3: the preparation of electrocatalyst

[0063] Weigh 2.5 mg of ultra-thin Ni-Fe-MOF nanosheet solid powder and 2.5 mg of commercial carbon black for mixing, add 970 μL of isopropanol and 30 μL of 5wt.% Nafion solution, and ultrasonically disperse it for 1 h to form an ink-like solution . Take 20 μL of the above solution and add it dropwise to the surface of the polished glassy carbon electrode in batches, and let it dry naturally before use.

[0064] As a comparison, 2.5 mg of Ni-MOF solid powder and 2.5 mg of commercial carbon black were weighed and mixed, 970 μL of isopropanol and 30 μL of 5 wt.% Nafion solution were added, and ultrasonically dispersed for 1 h to form an ink-like solution. Take 20 μL of the above solution and add it dropwise to the surface of the polished glassy carbon electrode in batches, and let it dry naturally before use.

[0065] As a comparison, weigh 5.0 mg of commercial Ir / C (5wt.% Ir), add 970 μL of isopropanol and 30 μL of 5wt....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com