Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117results about How to "Avoid remixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

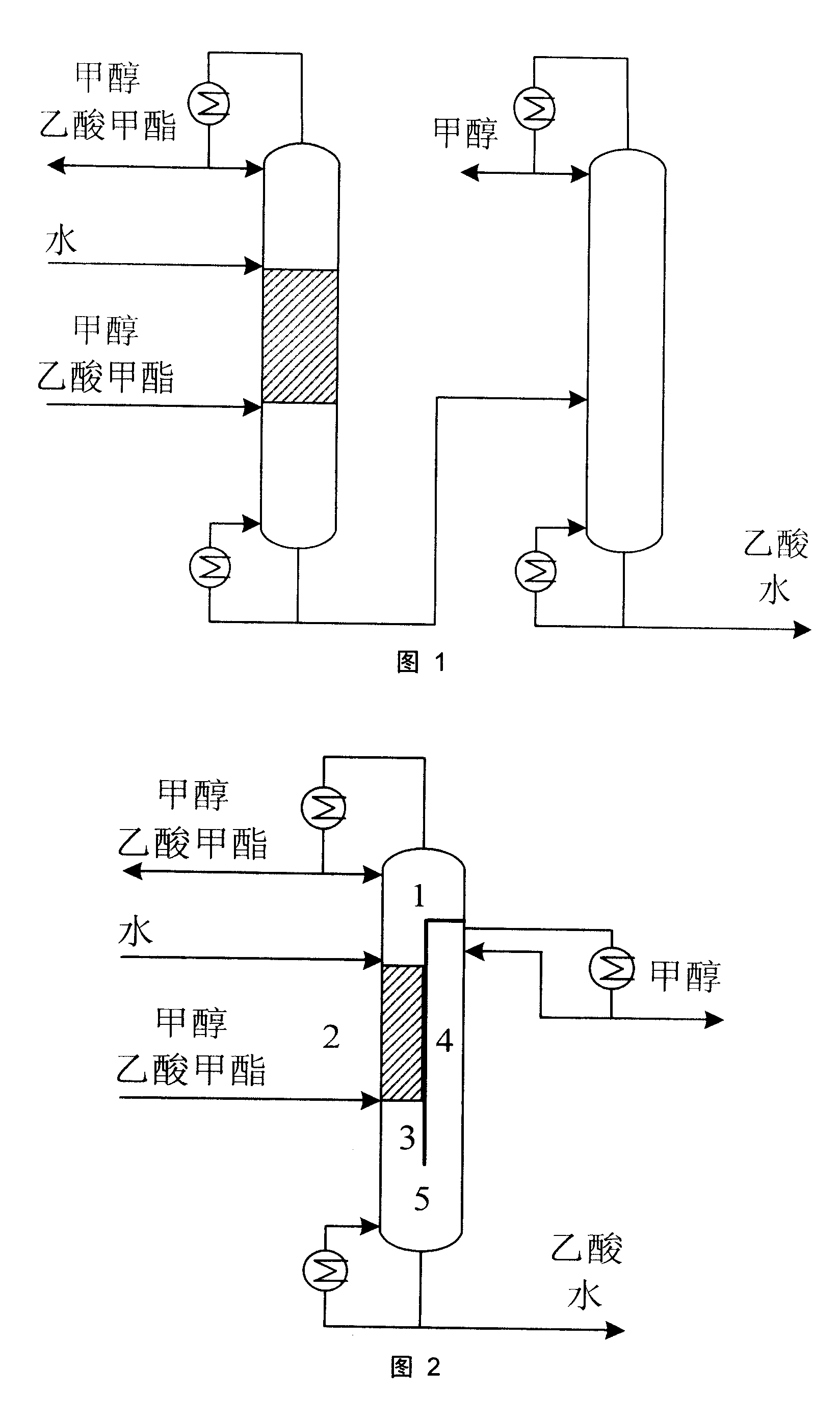

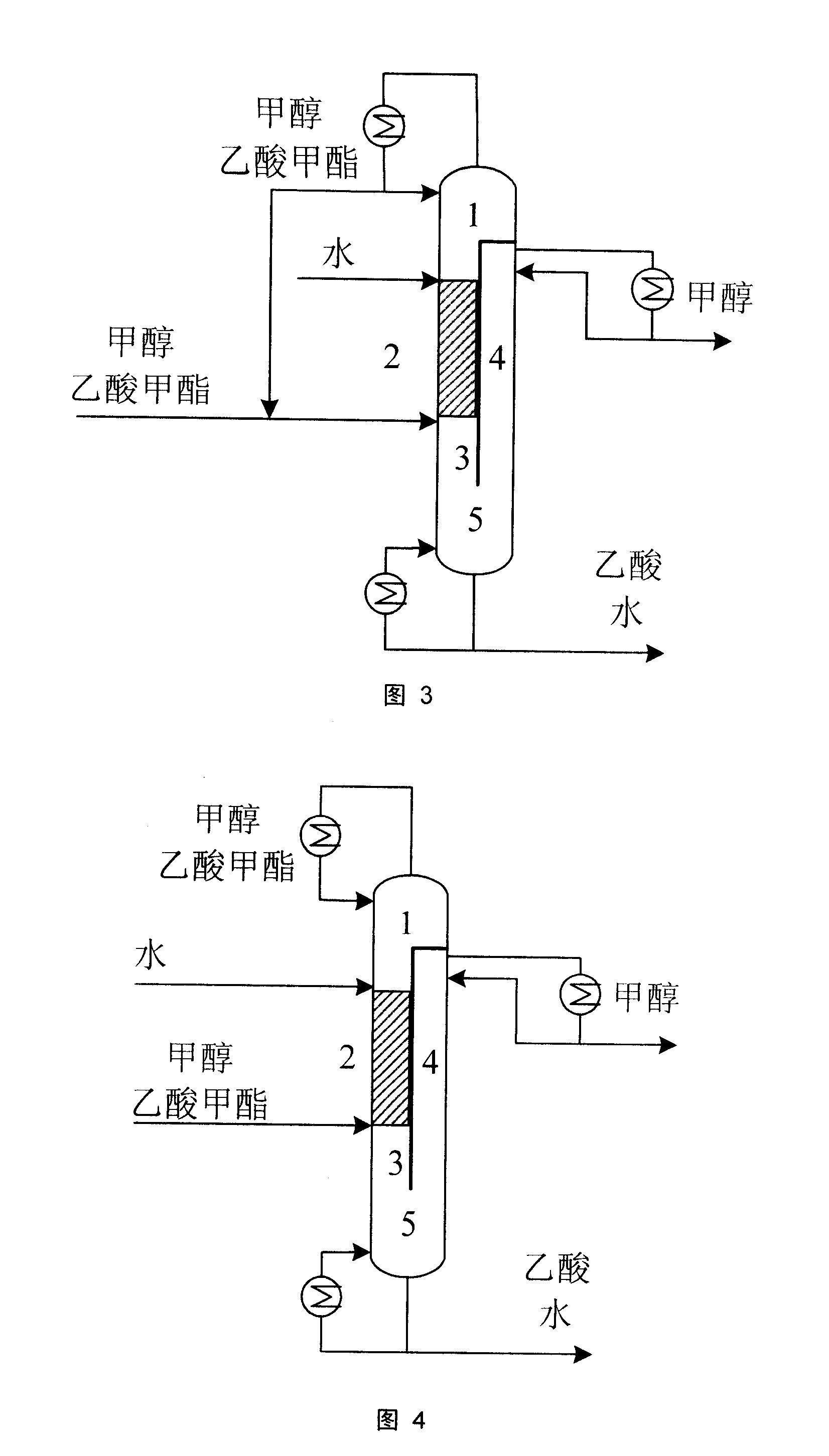

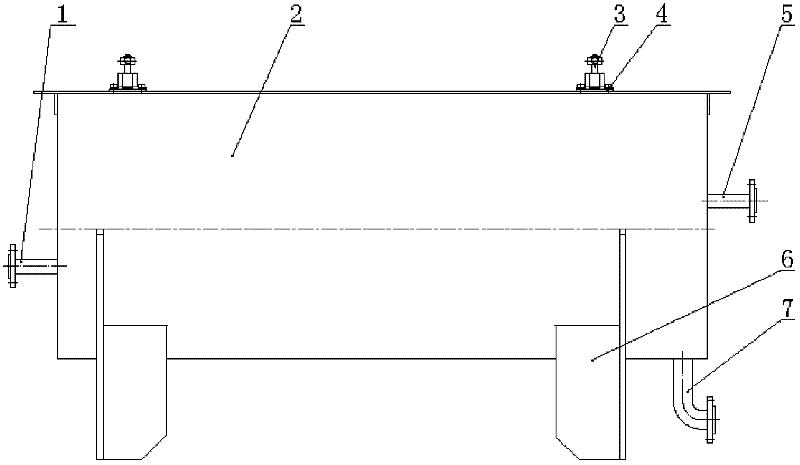

Hydrolyzation separation apparatus for methyl acetate and technique

InactiveCN101244982AIncrease hydrolysis rateAvoid remixingOxygen-containing compound preparationOrganic compound preparationSide effectDistillation

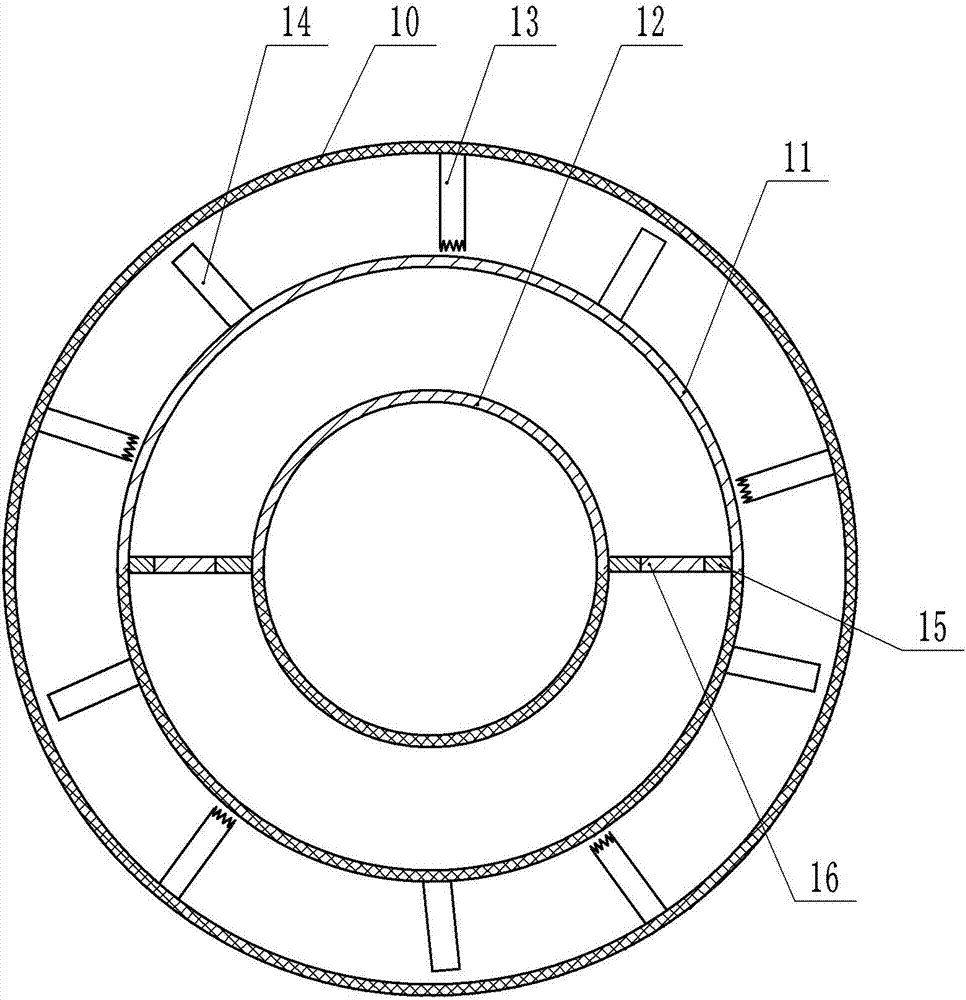

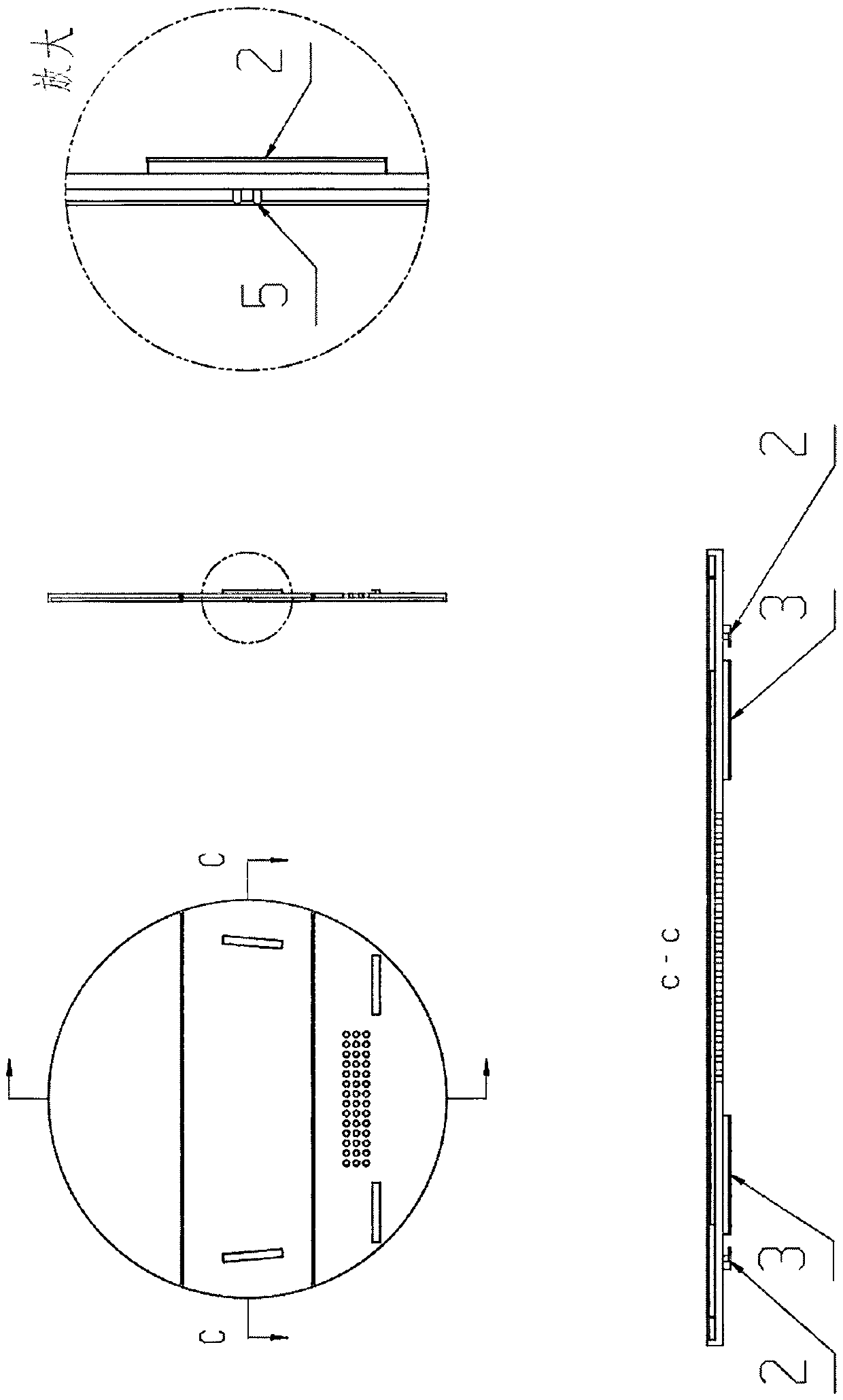

The invention provides a hydrolyzing and separation device of methyl acetate and a technique method thereof, which more particularly relates to a novel technique to catalyze and hydrolyze methyl acetate by a reaction bulkhead distillation tower, which can organically combine reaction process, product separation and recovery of no reactant into the tower. A separator extending from the upper part of the tower to the lower part of the tower is arranged on the vertical direction in the conventional distillation tower, the upper part of one side of which is covered and the other side of which is filled with a catalyst; therefore, the inner space of the reaction bulkhead distillation tower is divided into five regions with different functions. The hydrolyzing and separation device of methyl acetate can fully unleash the advantage of bulkhead tower and reaction distillation, and can cause hydrolysis reaction, product separation and recovery of non reactant to be realized in the same tower. The device provided by the invention and the technique process thereof can obtain the methyl acetate with 60 percent to 99.99 percent hydrolysis rate and products with high purity, restrain side effect effectively, reduce the volume of equipment markedly, simplify process, and reduce energy consumption and operation cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

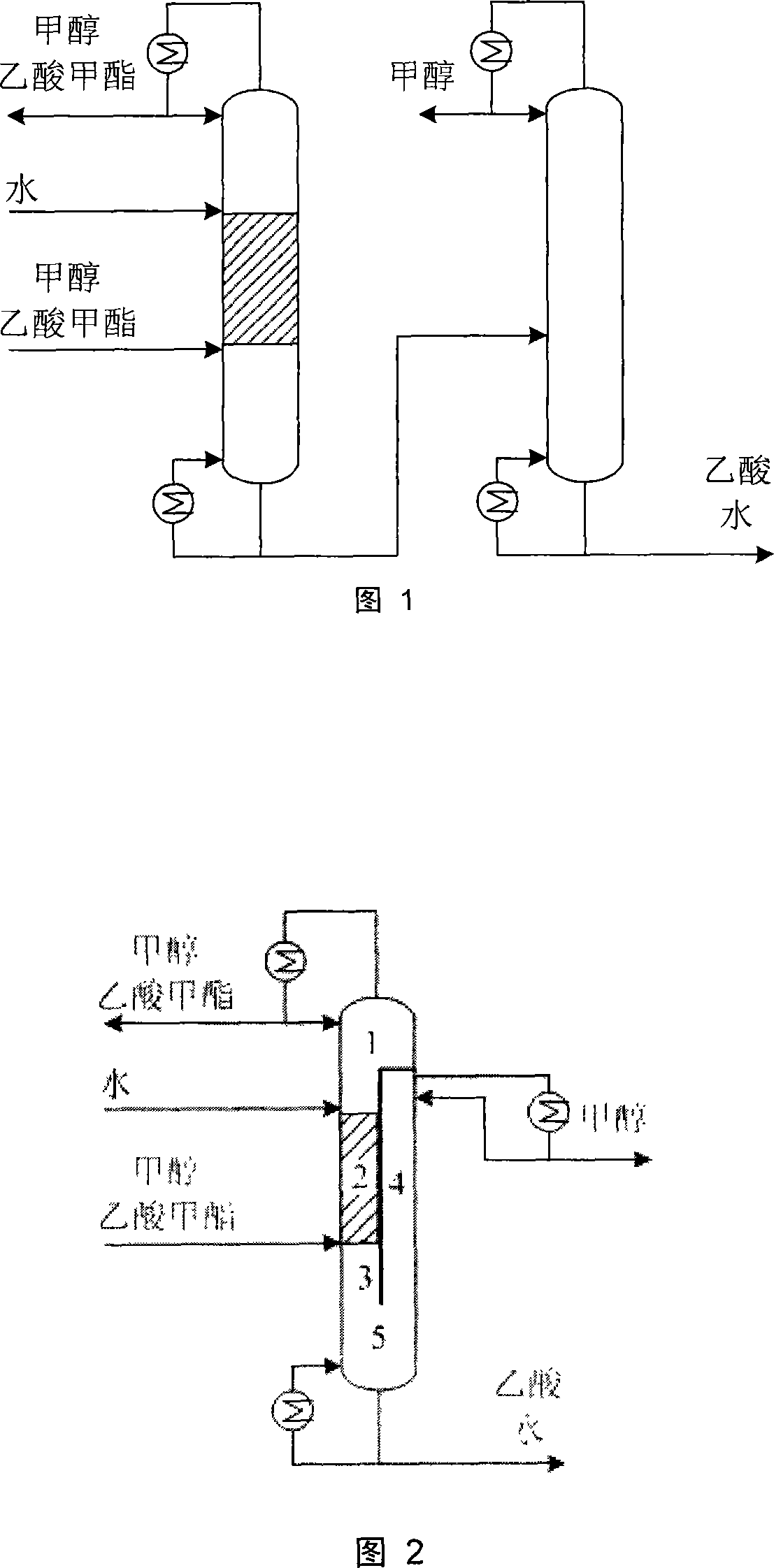

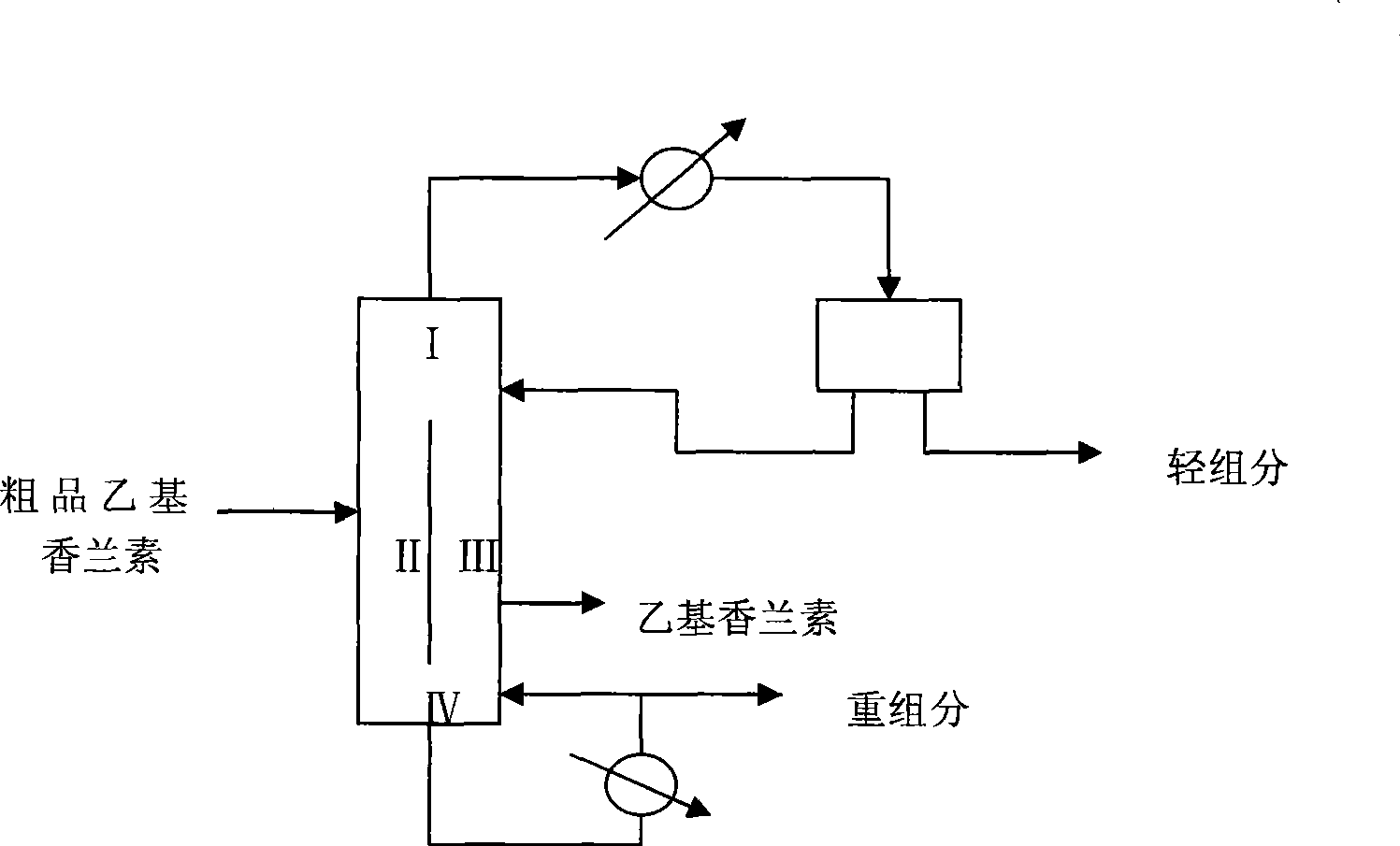

Method and apparatus for separating and purifying ethyl vanillin by decompression and continuous distillation in dividing wall column

InactiveCN101417930AImprove efficiencyShort heating timeCarbonyl compound separation/purificationFractional distillationHigh energyDistillation

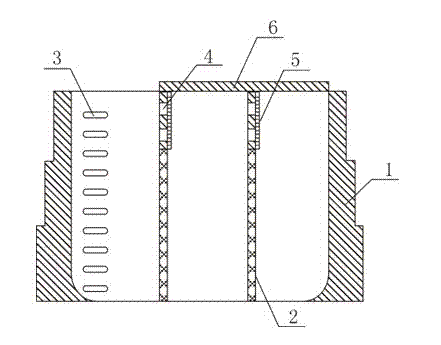

The invention relates to a method and device for separating and purifying vanillin by comparting wall tower to reduce pressure and continuous distillation. A vertical wall which is arranged in the middle and lower part of a distillation tower divides the tower into four areas, which are area one, area two, area three and area four. The coarse ethyl vanillin waiting to be separated, is put in from the middle and upper part of the area two which mainly finishes the separation of ethyl vanillin from the heavy components; the area three is the area in which ethyl vanillin is separated from light components, and the pure components ethyl vanillin is obtained from the lateral line in the middle and lower part of the area three; the area one is the public distillation section of the area two and the area three, and the light components is obtained from the top of the area one; the area four is the public distillation section of the area two and the area three, and the heavy components is obtained from the bottom of the area four. The single column continuous distillation of coarse ethyl vanillin is realized and high-purity ethyl vanillin is obtained from the lateral line. The invention overcomes the disadvantages of the high demand for equipment in the molecular distillation, and high energy consumption and low yield in the double tower pressure reduction continuous distillation method, and has the advantages of 'low invest, low energy consumption, high yield and high purity', large spreading and applying value and high social and economical benefits.

Owner:HUNAN ASTAR BIO CHEM TECH

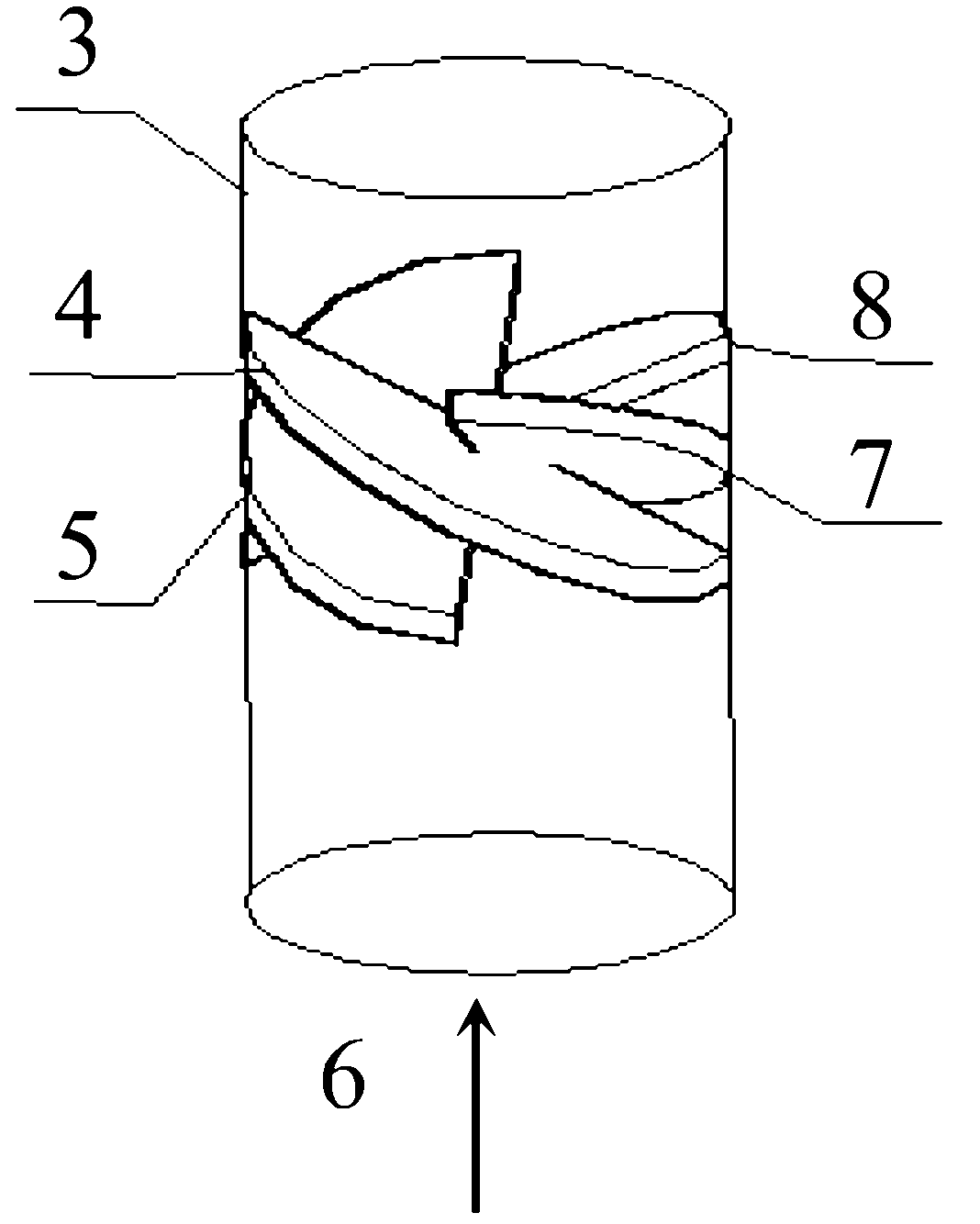

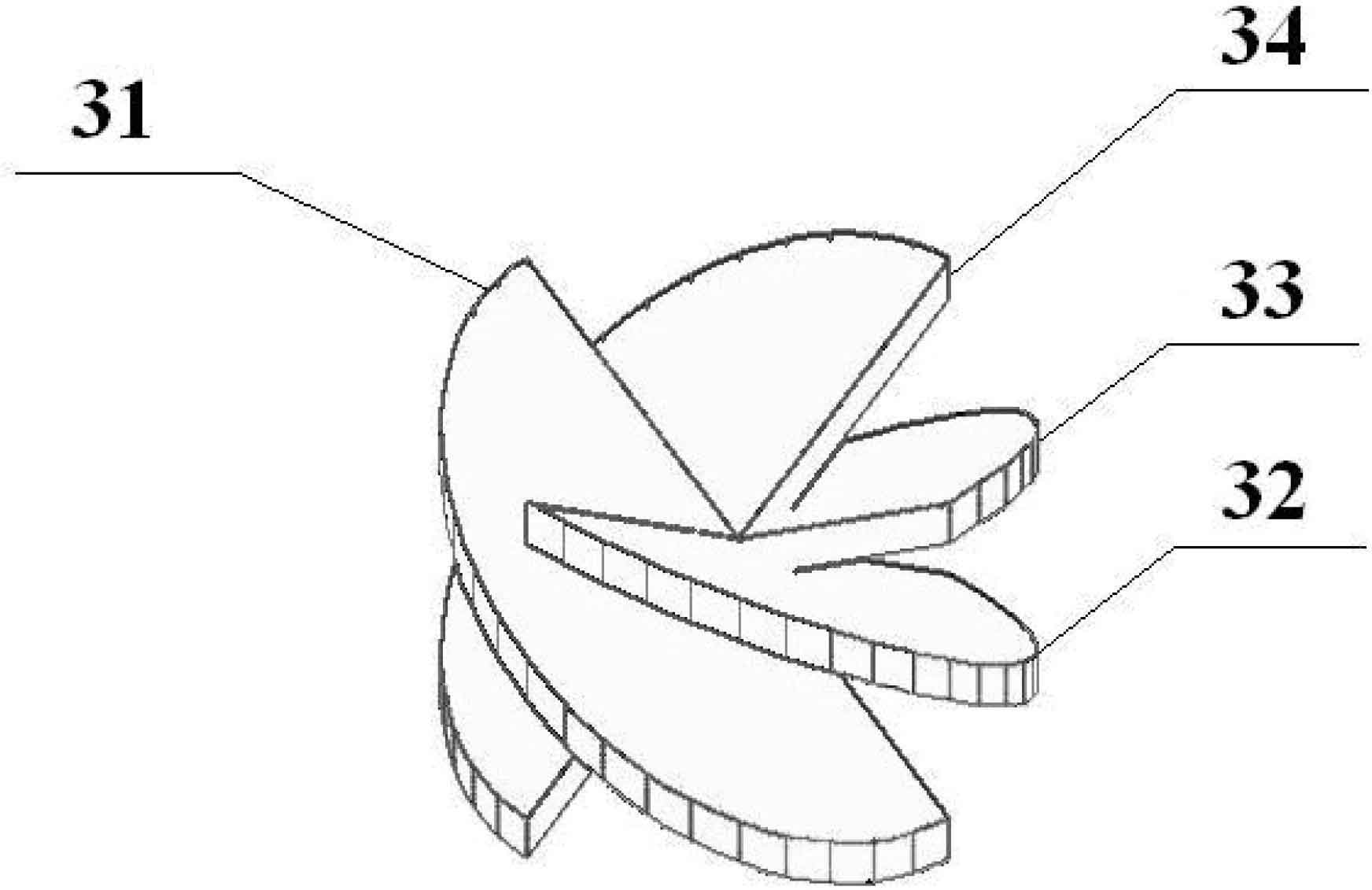

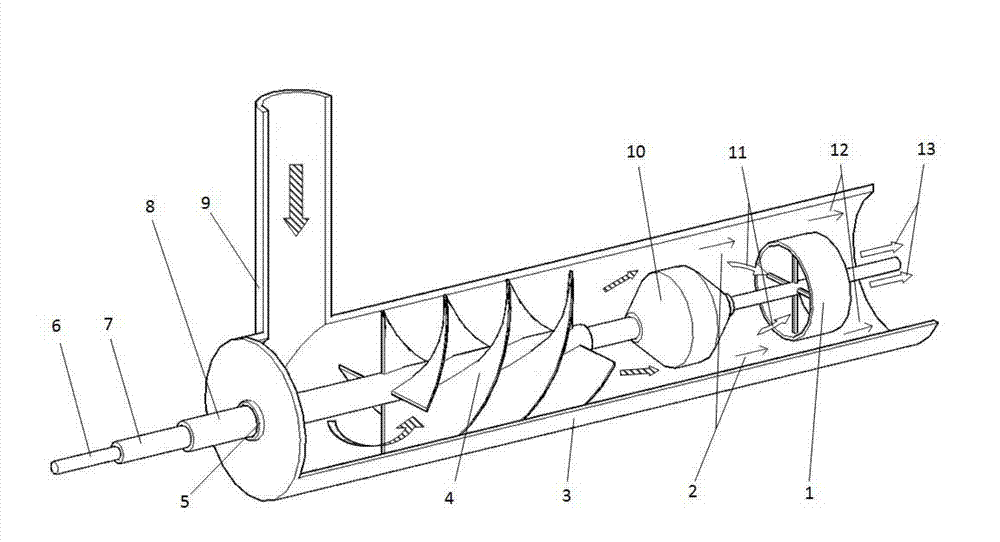

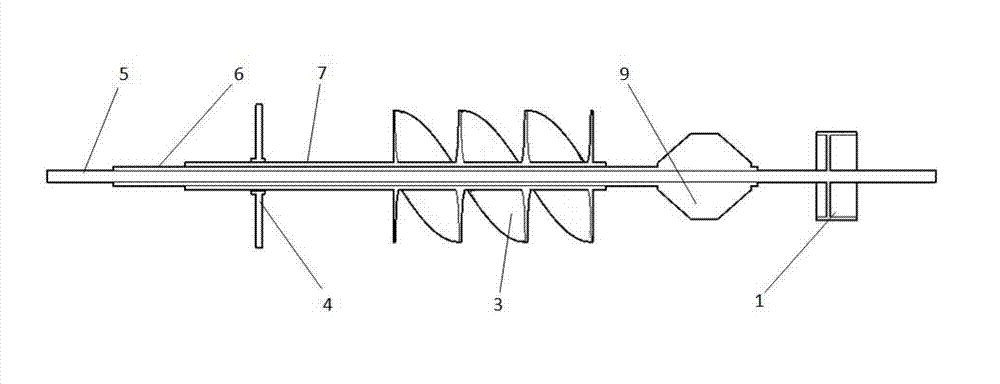

Novel pipeline type flow deflector oil-water separator rotation starting device

The invention discloses a novel pipeline type flow deflector oil-water separator rotation starting device, and the device provided by the invention comprises more than two flow deflectors capable of being fixedly and obliquely mounted in a pipeline, wherein the flow deflectors are uniformly distributed along the circumferential direction of the pipeline and sequentially superposed in the axial direction of the pipeline; and when an oil and water mixed fluid flows by the flow deflectors, a swirling flow field in central symmetry is formed, thus oil and water are further centrifugally separated. The novel rotation-starting device has the following effects: when the oil and the water enter into the rotation-starting device equipped with the oil-water separator in a certain proportion, the oil and the water meet the flow deflectors, as the flow deflectors are circumferentially oblique in the same direction, the flow of the part of the fluid under flow deflection of each flow deflector along the annular direction is bascially same, thus a consistent vortex effect can be achieved and the stronger vortex can be formed; and simultaneously, the flow deflectors which are mounted axially can be used for reducing the radial motion distance of oil drops and enabling the oil drops to move to an axle center faster. Therefore, the better oil-water separation effect can be played.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

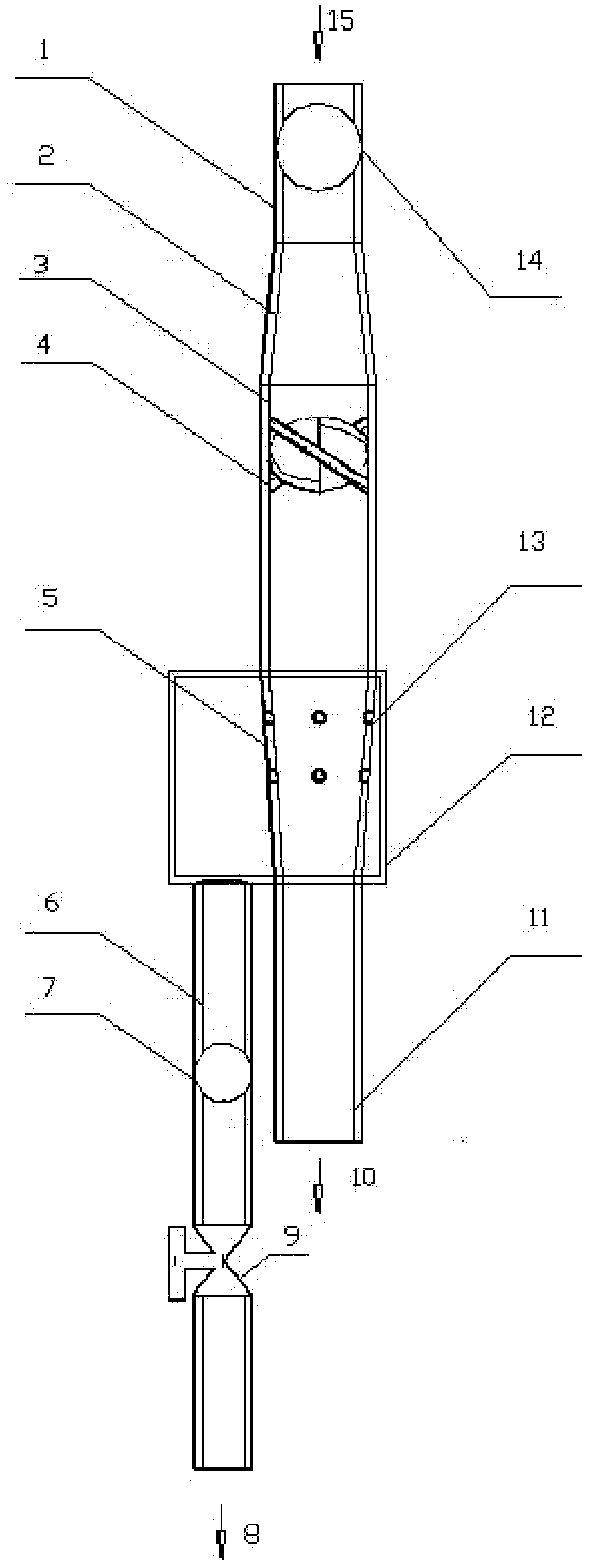

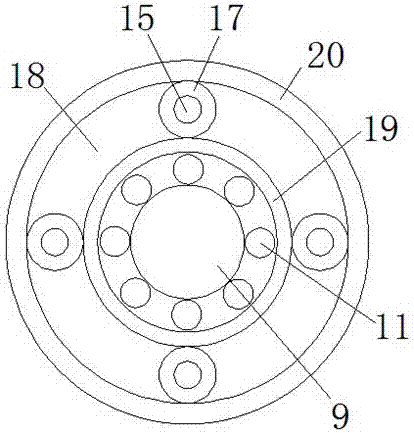

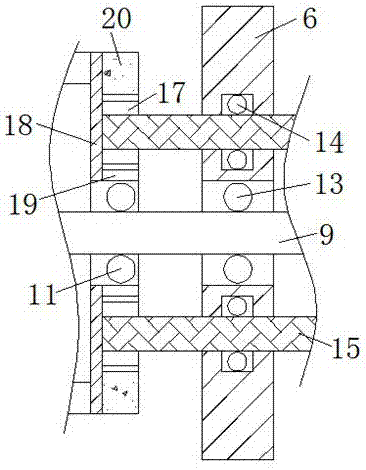

Pipeline flow deflector type oil-water separator and water removing device thereof

The invention discloses pipeline flow deflector type oil-water separator and a water removing device thereof. The pipeline flow deflector type oil-water separator comprises a liquid inlet pipe segment, a gradually-expanding pipe segment, a rotational flow generating pipe segment and a water removing pipe segment which are connected in sequence, wherein the rotational flow generating pipe segment comprises a rotational flow pipeline and more than two flow deflectors which are fixedly and obliquely arranged in the rotational flow pipeline; when an oil-water mixed liquid flows through the flow deflectors, a centrally-symmetrical rotational-flow field is formed, so that oil and water are separated centrifugally; the water removing pipe segment comprises a water removing pipeline; the water removing pipeline is provided with an oil inlet and an oil outlet; and the oil removing pipeline is provided with over one group of water removing holes along the axial direction of the pipe. Due to the adoption of the oil-water separator, the symmetric stability of the rotational flow field can be improved, an oil-water separating technology is improved, the utilization ratio of an underground oil-water separator space is increased, and a good industrial application prospect is achieved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

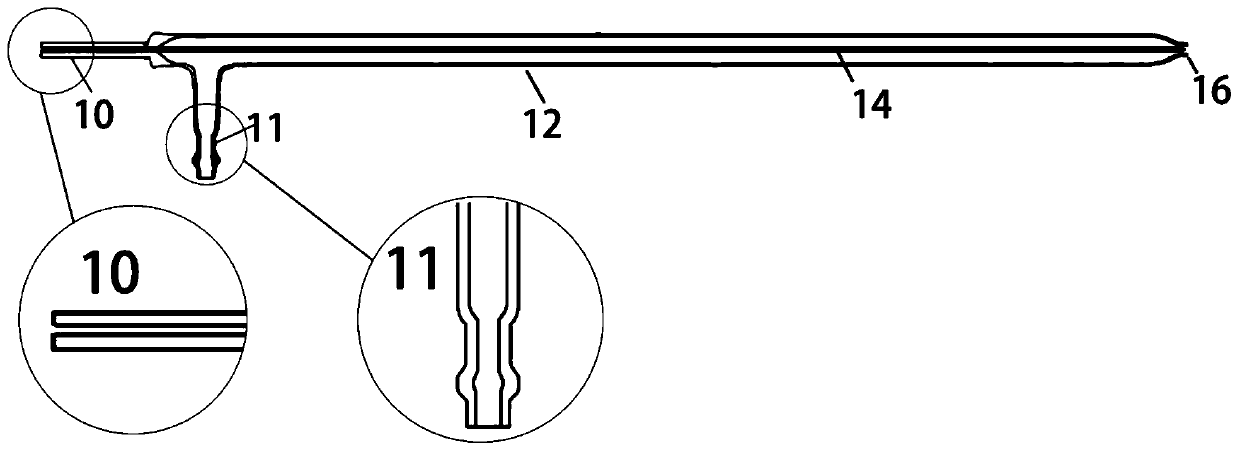

Liquid drop micro-fluidic chip used for detecting diabetes with high sensitivity and detection method

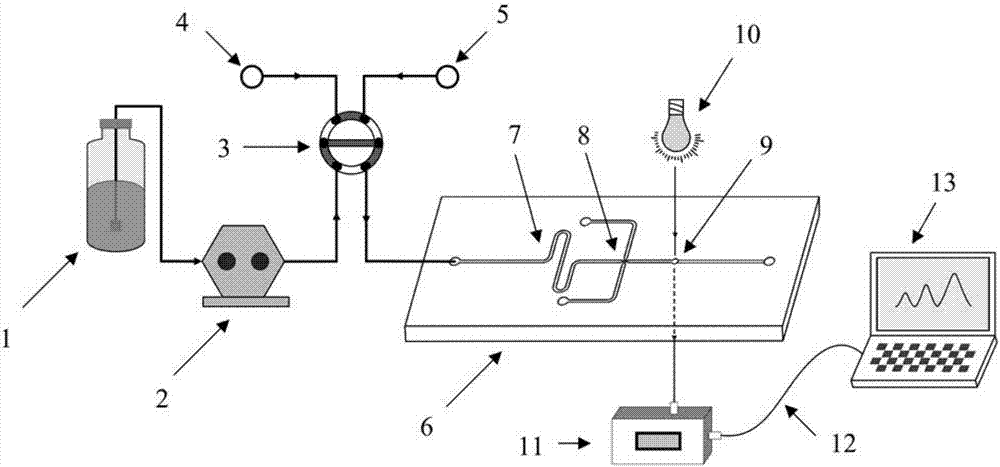

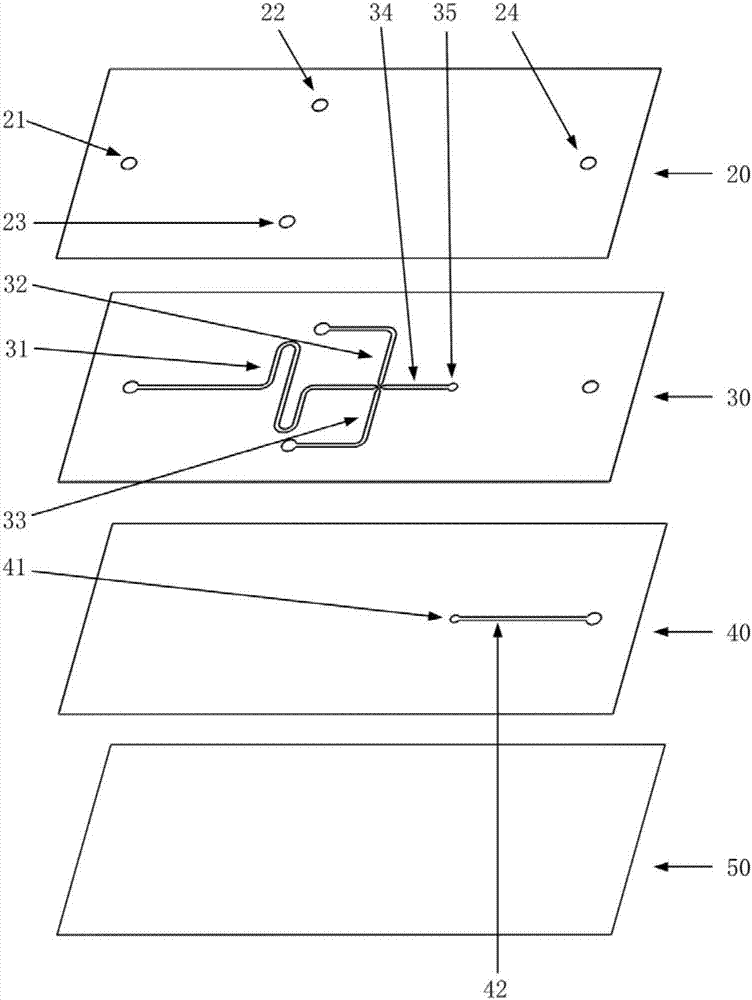

InactiveCN108008032ATolerates a wide pH rangeIncrease the lengthComponent separationInlet valveEngineering

The invention relates to a liquid drop micro-fluidic chip used for detecting the diabetes with high sensitivity and a detection method, and belongs to the technical field of microfluidics. The liquiddrop micro-fluidic chip sequentially comprises a cover glass layer 20, an upper fluid passageway layer 30, a lower fluid passageway layer 40 and a base layer 50; and a liquid drop micro-fluidic chip based high sensitivity diabetes detection device comprises a high pressure liquid phase chromatographic pump 2, a sample inlet valve 3, the liquid drop micro-fluidic chip 6, a deuterium lamp and a halogen tungsten lamp source 10, an ultraviolet-visible light spectrometer 11 and data processing software 13. The provided micro-fluidic chip is small in size, low in cost and simple in operation, and isfavorable for real-time detection on the site. The high sensitivity diabetes detection method is not only suitable for the high sensitivity detection of a sample HbA1c, but also suitable for detection of biomacromolecules like polypeptide, nucleic acid and protein.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

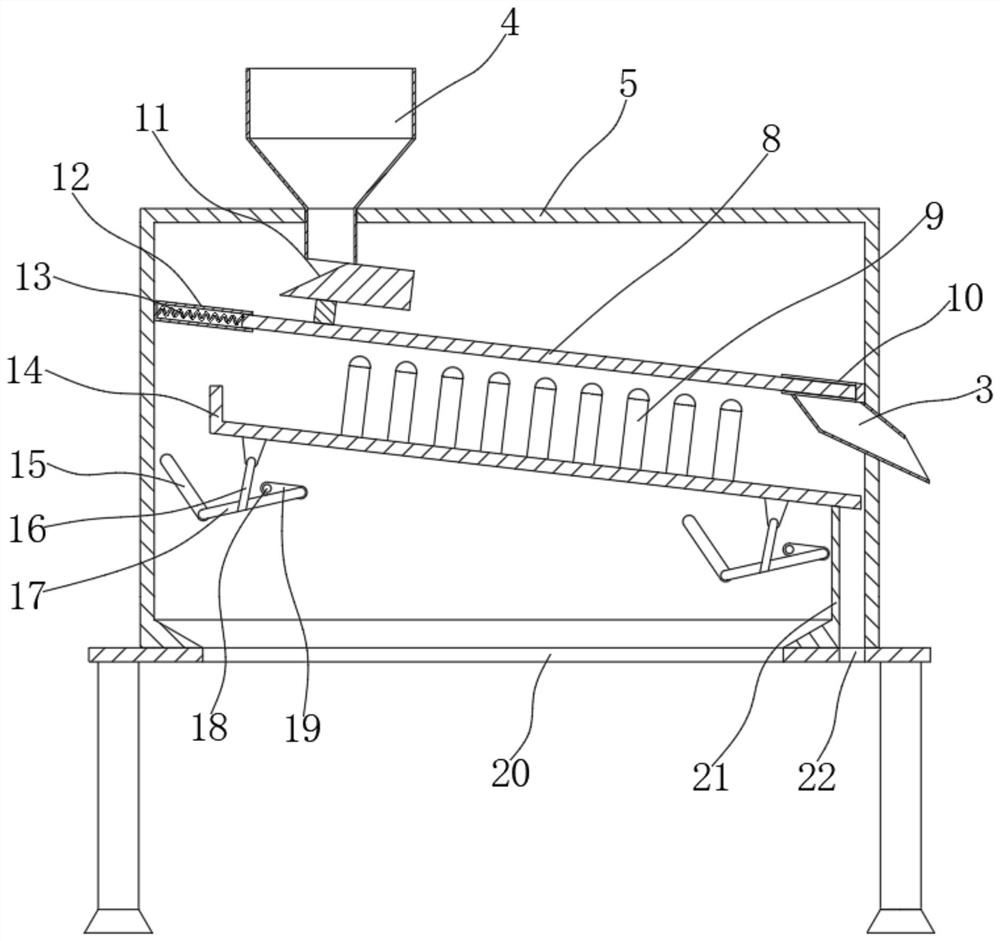

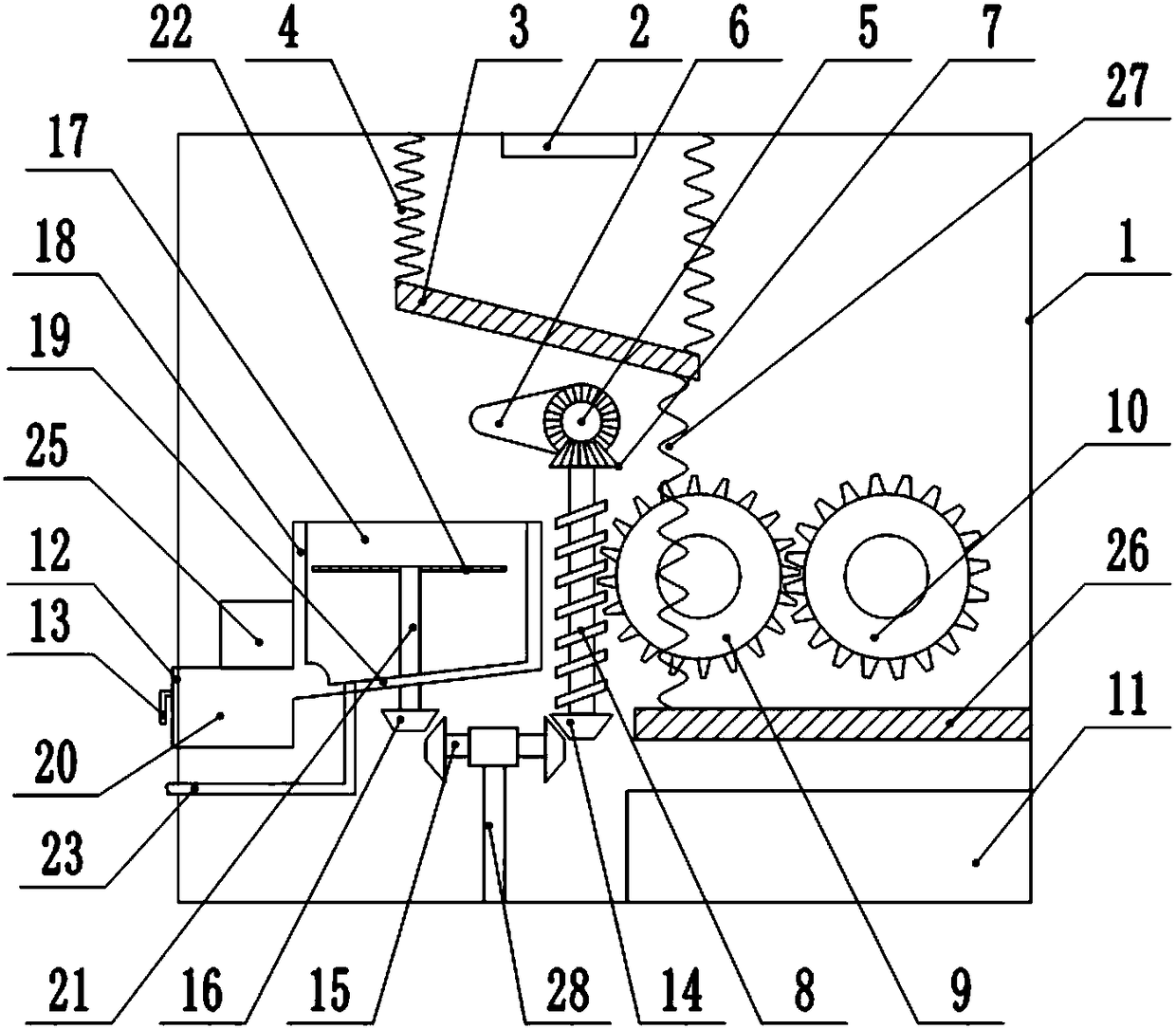

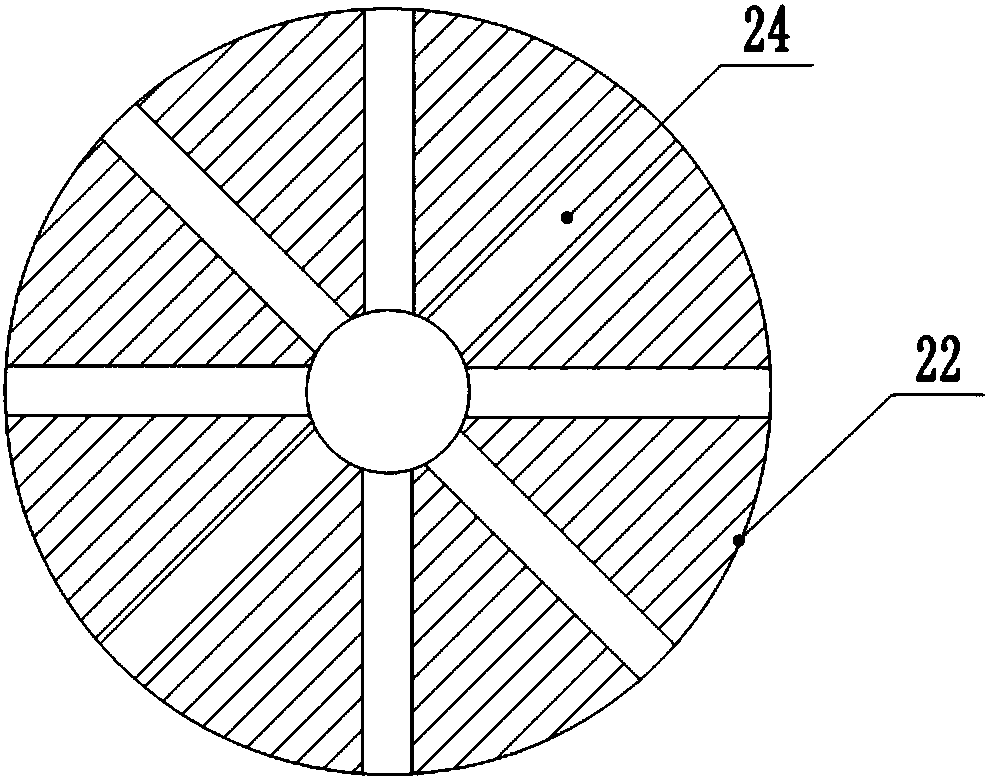

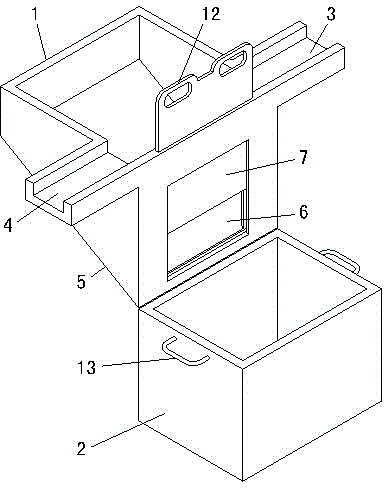

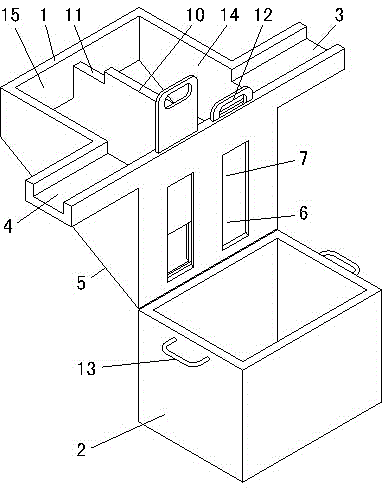

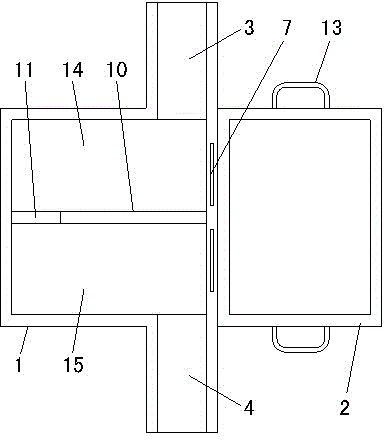

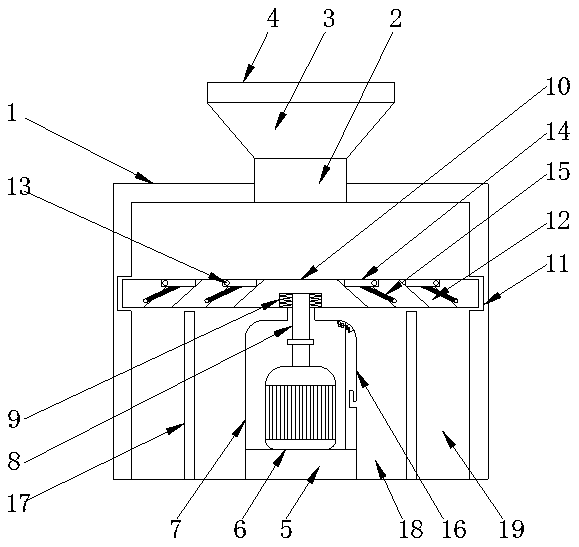

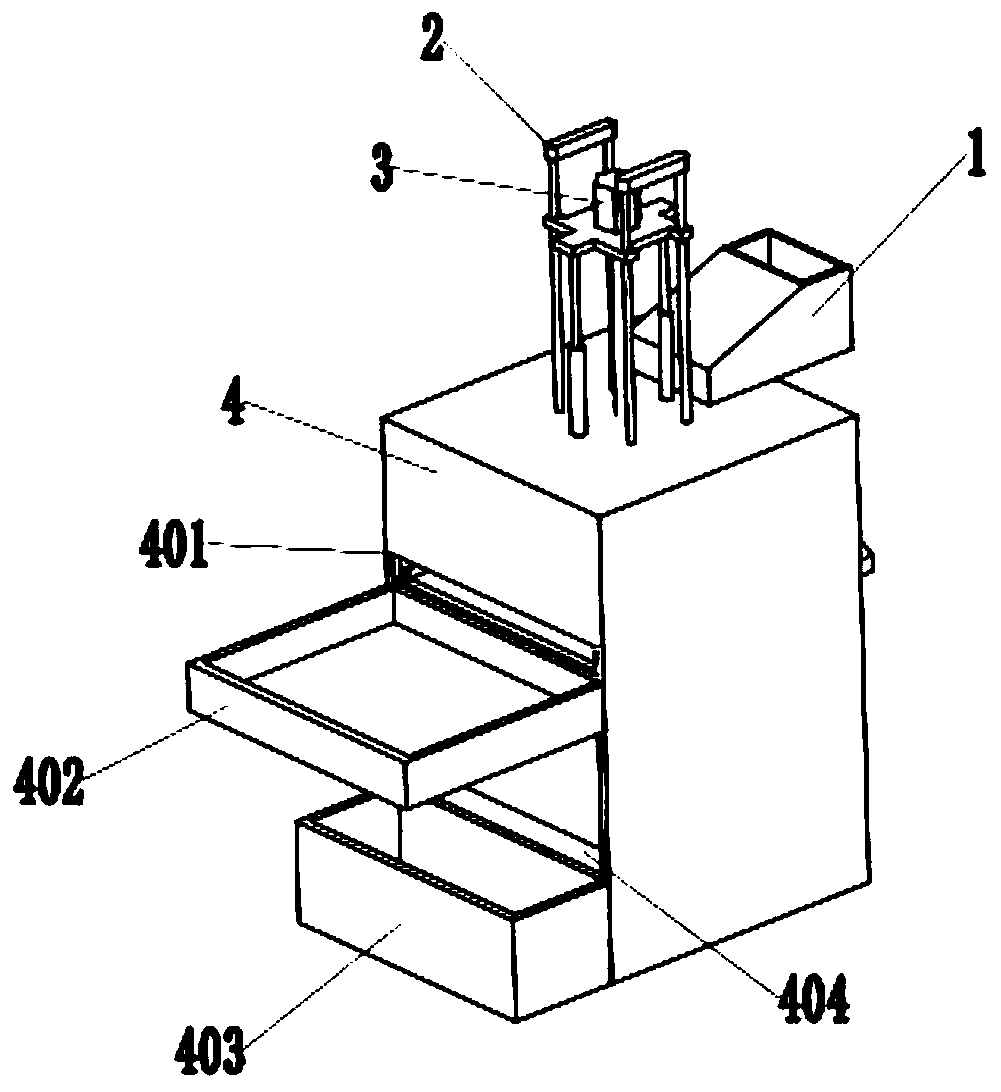

Gravel multi-stage screening machine for building construction

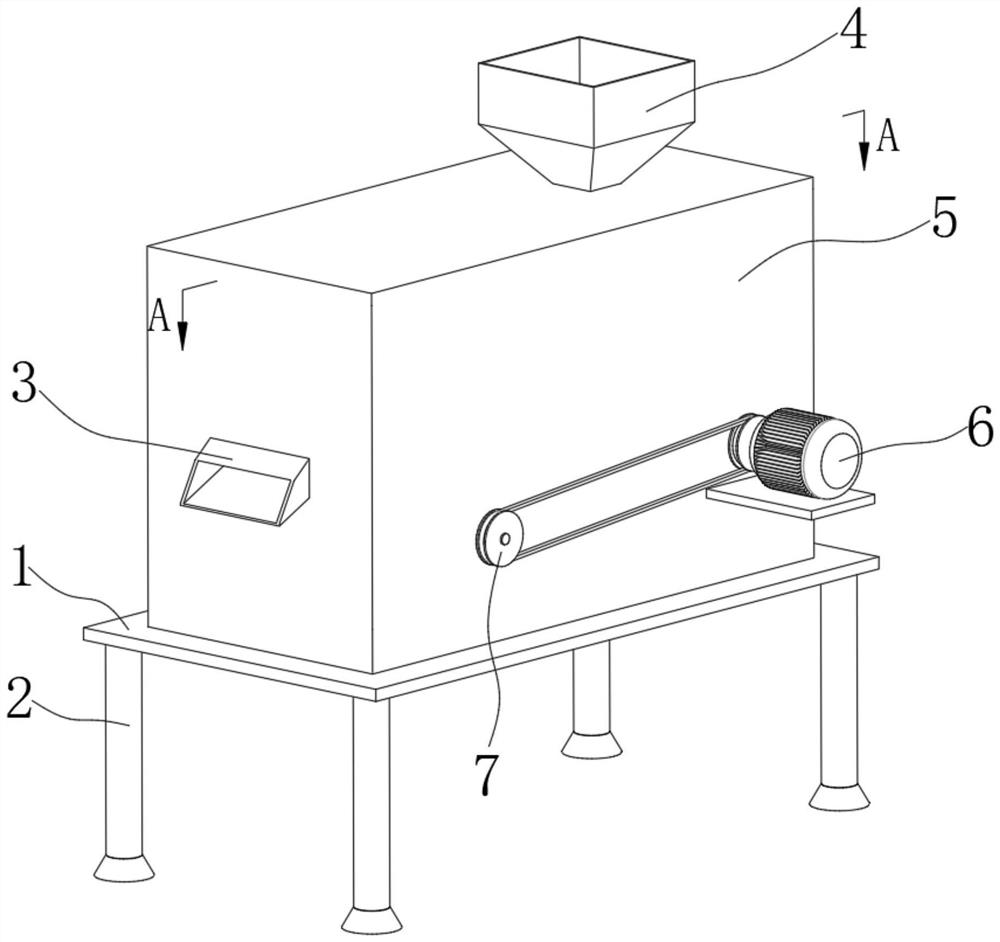

InactiveCN113369130AImprove screening efficiencyAvoid cloggingSievingScreeningArchitectural engineeringEngineering

The invention discloses a gravel multi-stage screening machine for building construction. The machine comprises a bottom plate, wherein, supporting legs are fixed to the bottom of the bottom plate, a screening shell is fixed to the top of the bottom plate, a primary screening mechanism and a secondary screening mechanism are sequentially arranged in the screening shell from top to bottom, the primary screening mechanism comprises a second mounting frame and a first mounting frame, the second mounting frame is fixed to the inner wall of one side of the screening shell, the first mounting frame is fixed to the inner wall of the other side of the screening shell, a first screening plate is jointly slidably arranged between the cavity inner wall of the second mounting frame and the cavity inner wall of the first mounting frame, and the first screening plate is obliquely arranged. According to the machine, by arranging the primary screening mechanism and the secondary screening mechanism, the effect of carrying out multi-stage screening on gravel is achieved, meanwhile, screening holes can be prevented from being blocked, and therefore the screening efficiency is indirectly improved, and the working efficiency is improved.

Owner:赵振伍

Kitchen wastewater treatment device

ActiveCN108483779AAvoid cloggingAvoid dischargeWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesDrive shaftFiltration

The invention relates to the field of sewage treatment, and discloses a kitchen wastewater treatment device. The kitchen wastewater treatment device comprises a shell below a sink. An oblique filtration screen is connected into the shell slidably. Extensible springs are fixedly connected between two ends of the filtration screen and the top wall of the shell respectively. A driving switch is arranged on the side wall of the shell. The filtration screen can be abutted against the driving switch. A driving shaft is arranged below the filtration screen. A cam is fixedly connected with the drivingshaft coaxially. A first bevel gear is fixedly connected to the driving shaft coaxially, and is meshed with a second bevel gear. A threaded rod is fixedly connected to the second bevel gear coaxially. A first runner wheel is meshed with one side of the threaded rod and a second runner wheel. A vertical shaft is fixedly connected with the bottom end of the threaded rod through the bevel gear set.An oil-water separation box is arranged on the other side of the threaded rod. An oil collection groove is formed in the inner wall of the oil-water separation box. The vertical shaft is located in the oil-water separation box, and a filtration plate is fixedly connected to the top end of the vertical shaft. By the kitchen wastewater treatment device, the problems of sewer line being blocked by grease and of inconvenience in manual collection and operation, of conventional wastewater treatment devices, are solved.

Owner:宁波清智环保科技有限公司

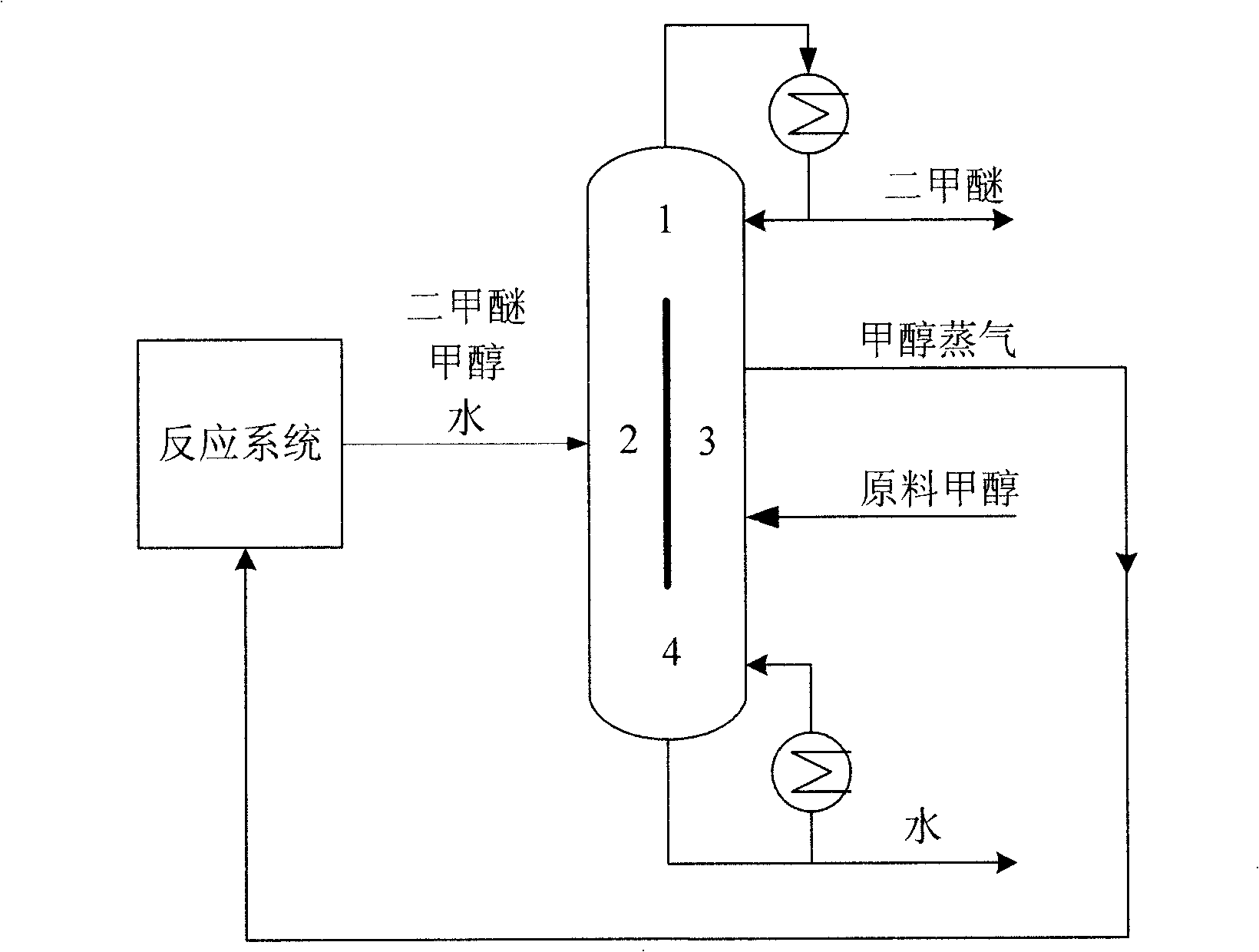

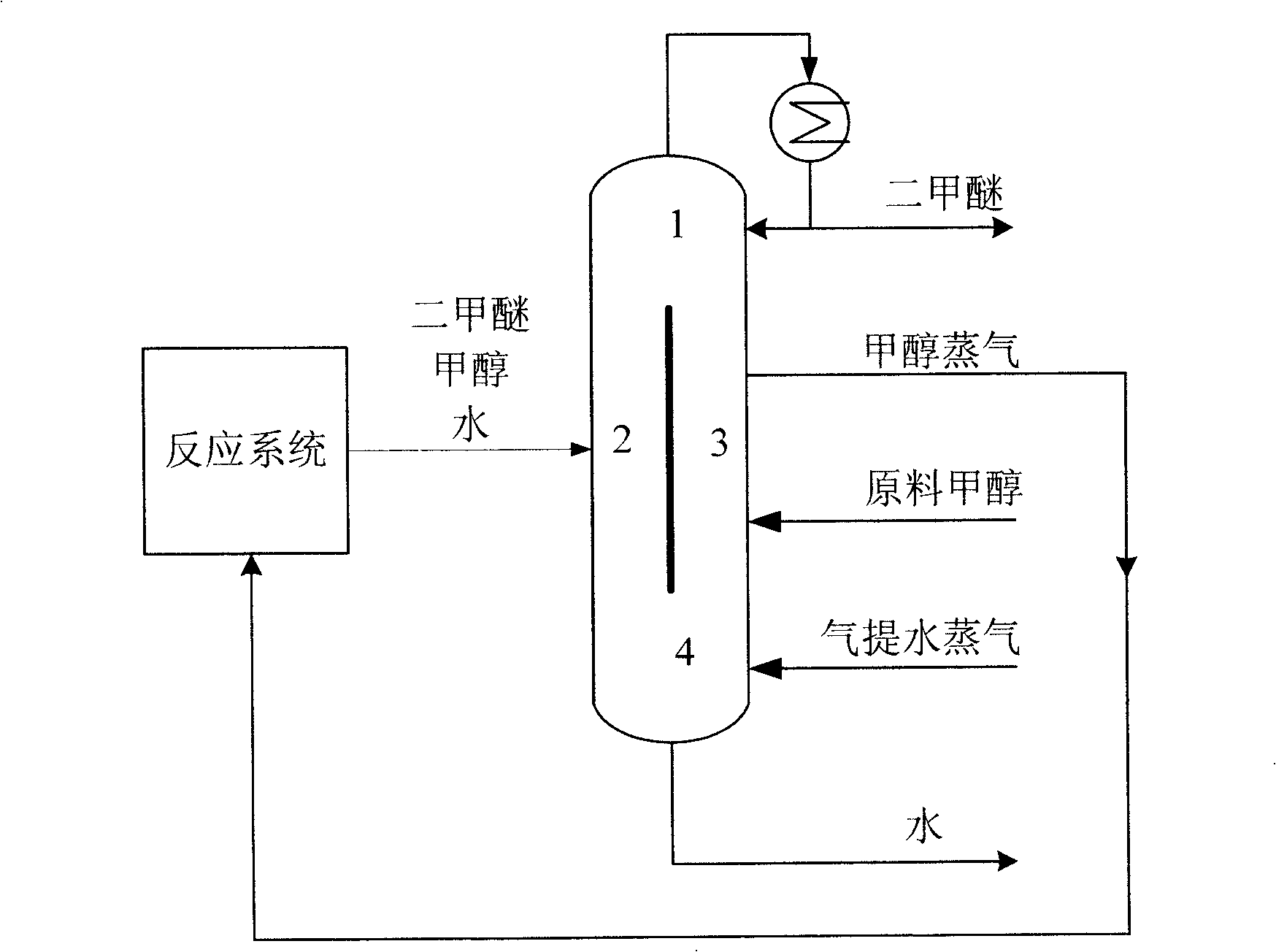

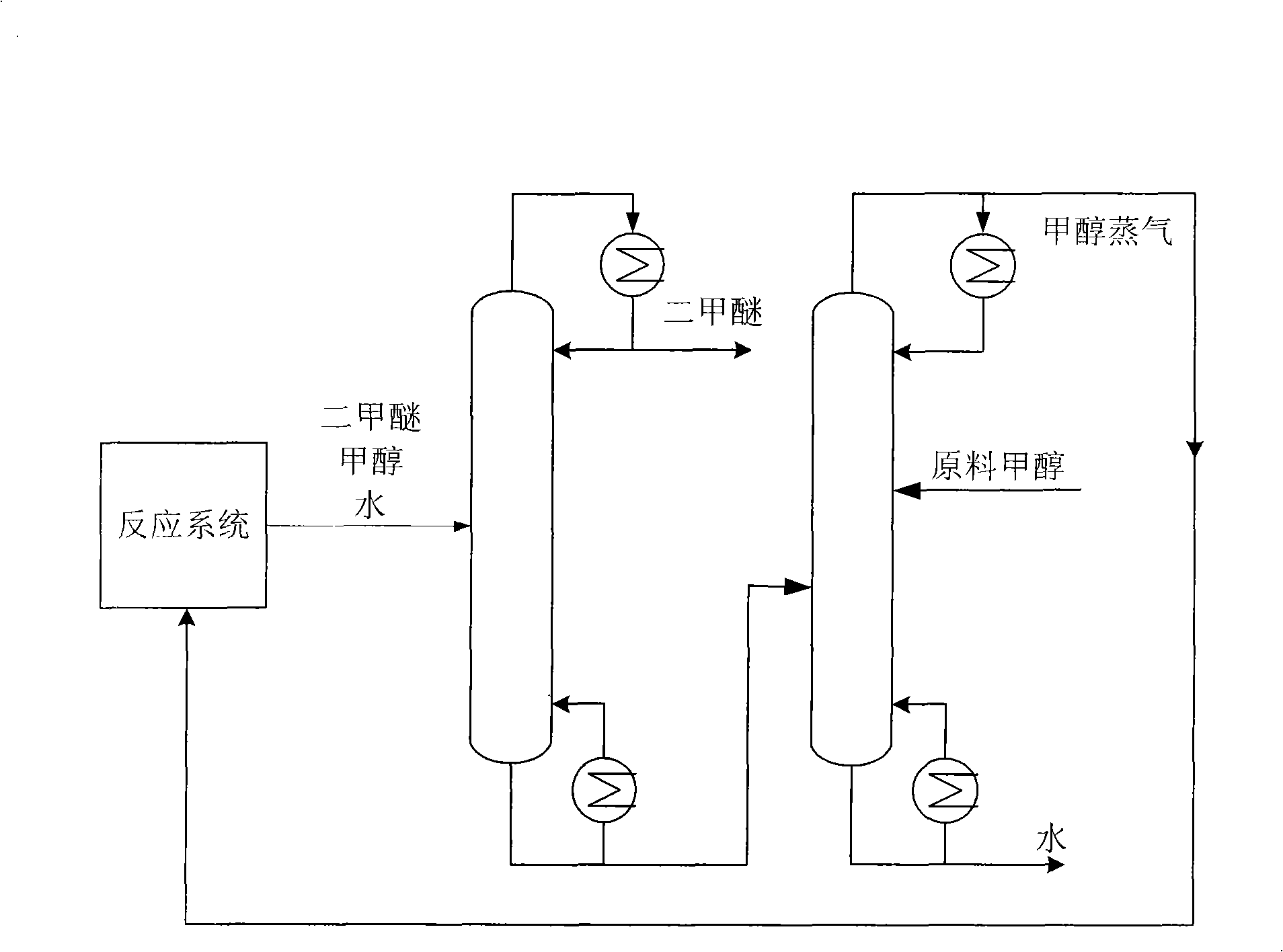

Energy-saving dimethyl ether production flow and apparatus thereof

InactiveCN101298412AImprove thermodynamic efficiencyLess reboiler duty and condenser dutyEther preparation by compound dehydrationChemistryDimethyl ether

The invention relates to a new energy-saving technique and a device for composing dimethyl ether by utilizing carbinol, which is characterized by integrating the separation of a reaction product and a substance not reacted as well as the gasification of the raw materials into a tower to be carried out simultaneously. The device of the invention consists of a reaction system and a dividing wall rectification column; the dividing wall rectification column is provided with a block of clapboard on the vertical direction in a normal rectification column; thereby dividing the inner cavity of the rectification column into four areas which are an upper area, a lower area, a left area and a right area; a dimethyl ether product is obtained from the top parts of the reaction product and the substance not reacted output from the reaction system after being separated by the dividing wall rectification column; a gas phase logistics taking carbinol as a main component is obtained from a side line as the incoming stock of the reaction system; while the water in the system is discharged from the bottom of the rectification column; simultaneously, the raw material, carbinol, containing unpurified water enters the rectification column from the right side of the dividing wall to obtain the carbinol and the water in gas phase. The invention can be used for various manufacture techniques and devices by using the carbinol in gas phase to catalyze and compose the dimethyl ether, can reduce device investment to a large extent, simplify the flows as well as reduce energy consumption and operation cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

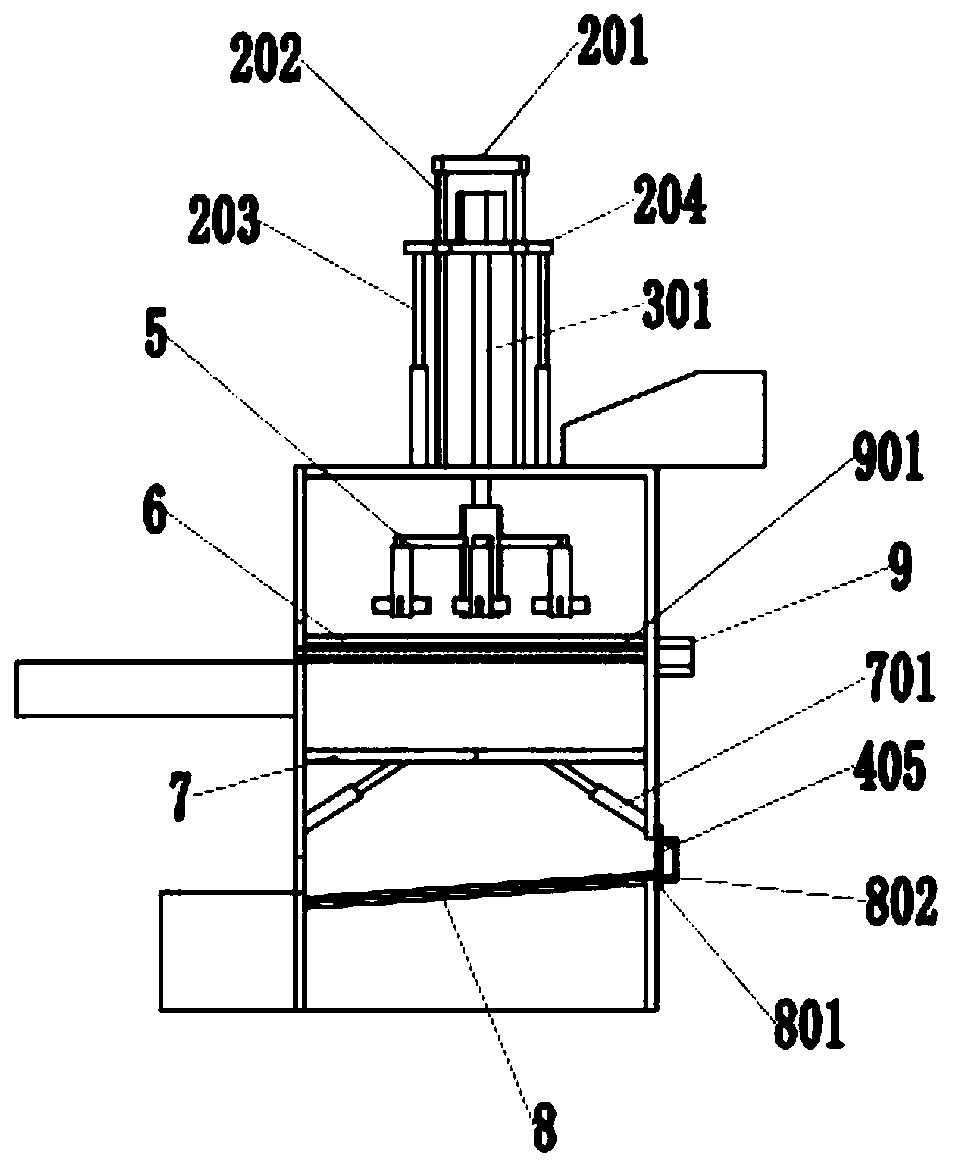

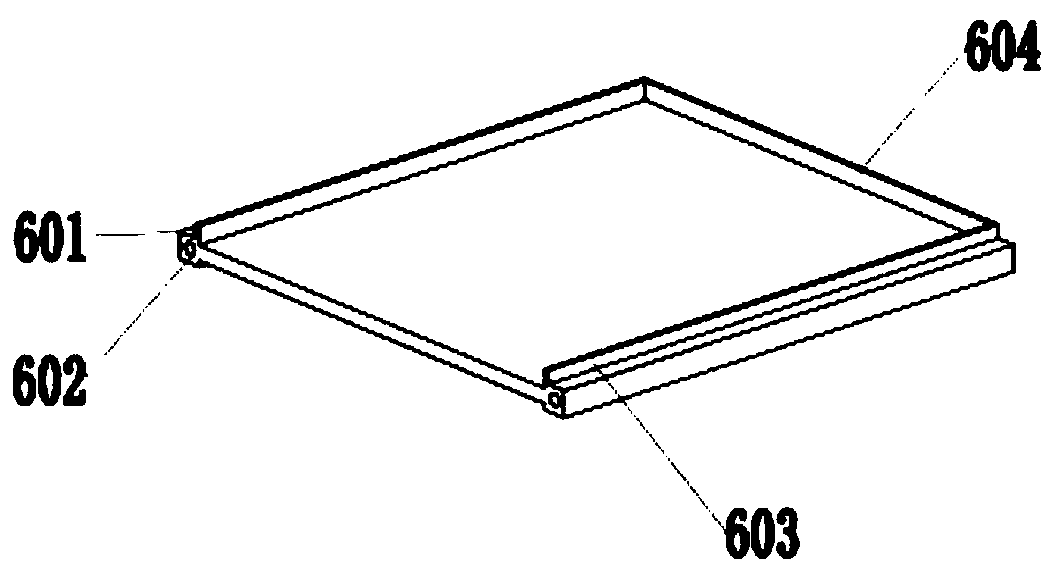

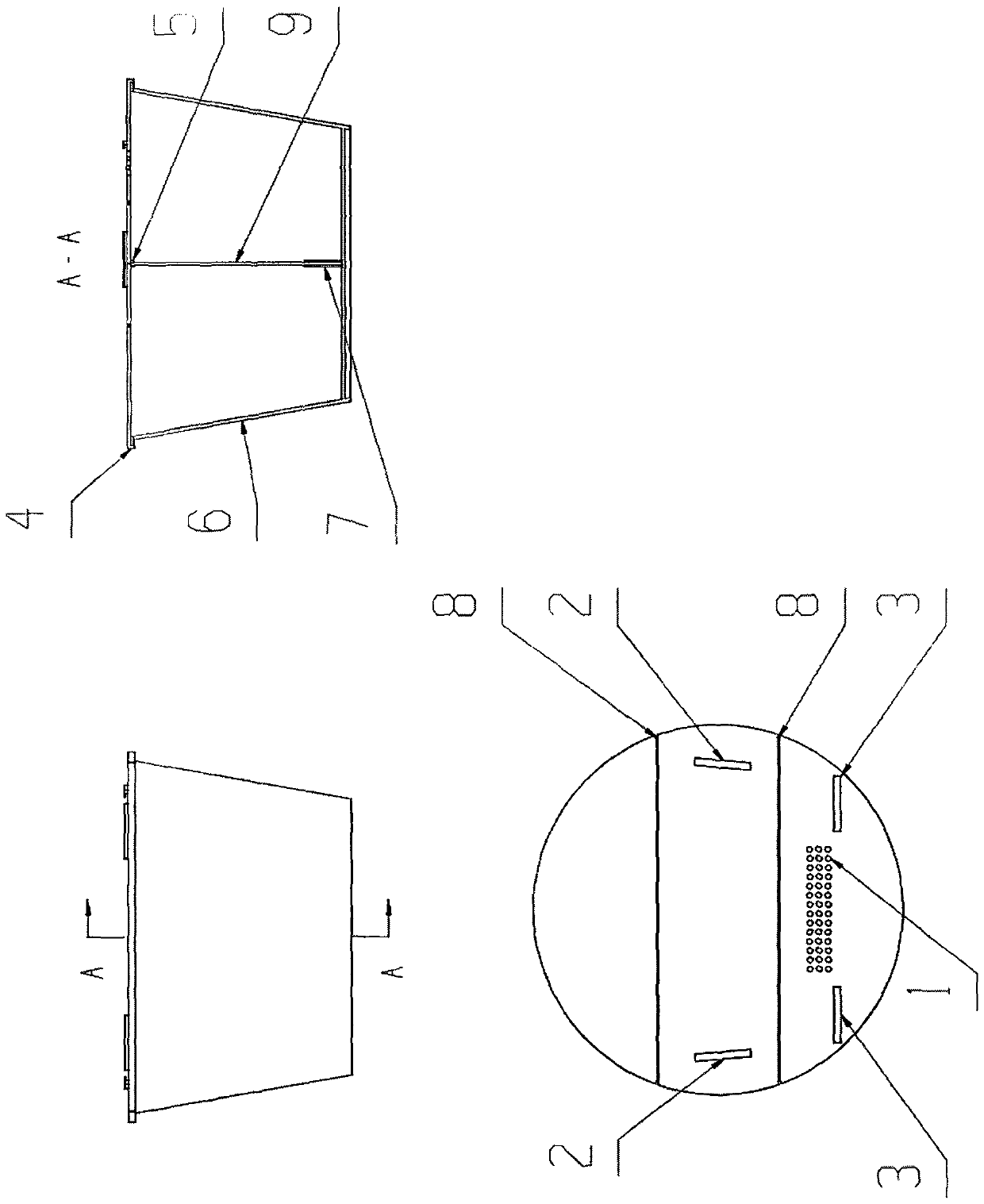

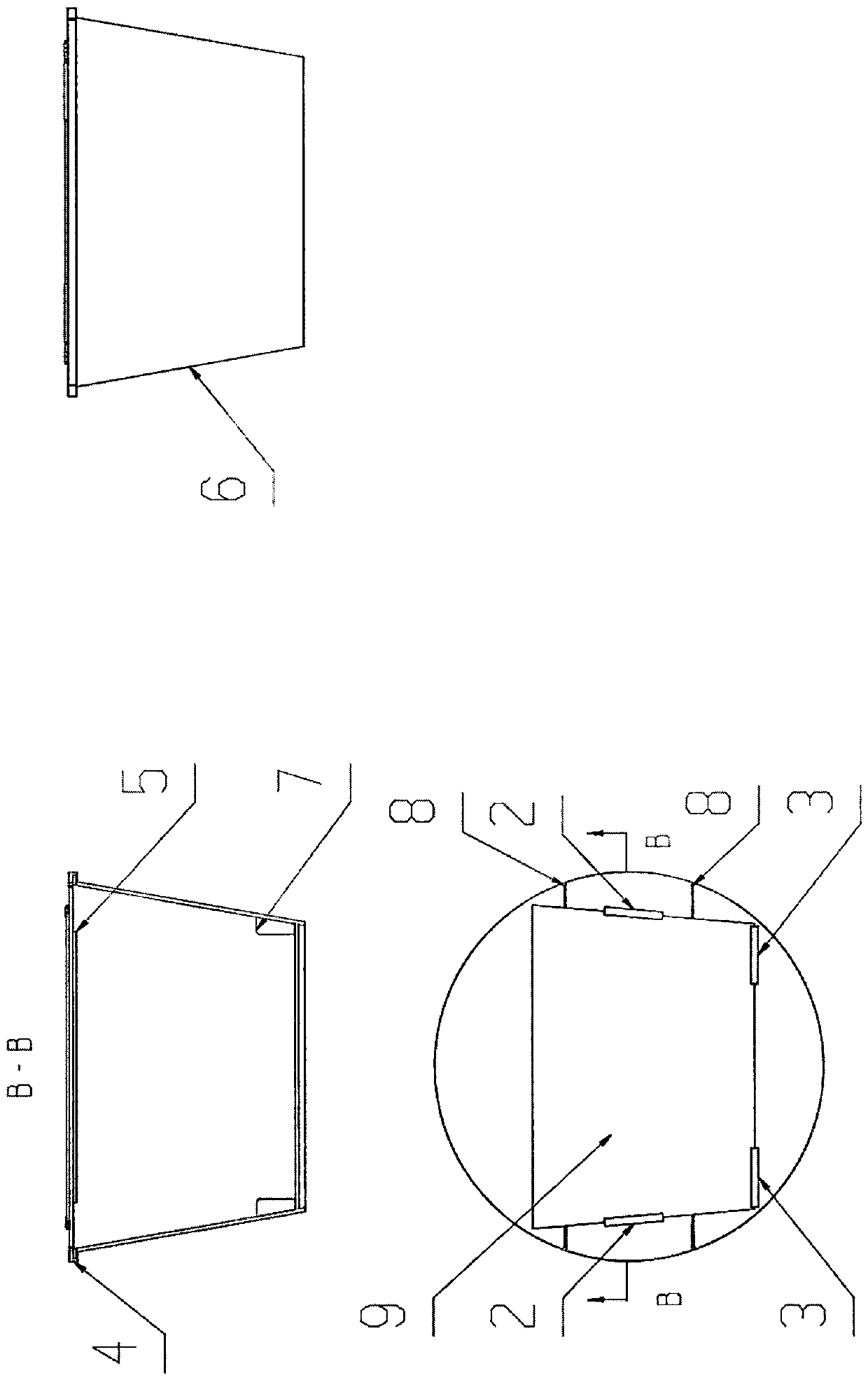

Tilted plate separator with variable inclination

InactiveCN102311158AStrong process adaptabilityGuaranteed axisFatty/oily/floating substances removal devicesLiquid separationEngineering

The invention relates to a tilted plate separator with a variable inclination. The tilted plate separator comprises a housing, a pedestal, a left baffle plate, a right baffle plate, a tilted plate assembly, a feed pipe, a light phase outlet pipe and a heavy phase outlet pipe; the housing is coaxially fixed on the pedestal; the feed pipe is fixedly arranged on a housing fore stand plate; the light phase outlet pipe and the heavy phase outlet pipe are fixedly arranged on a rear-end of the housing; the left baffle plate and the right baffle plate are arranged in a radial direction in the housing; the tilted plate assembly is movably mounted above the left baffle plate and the right baffle plate; a rotating wheel fixing assembly is arranged on the housing; and two movable baffle plates correspond to the left baffle plate and the right baffle plate respectively to have a diversion effect on a flow field. A design of the invention is scientific, reasonable and with a simple structure; an inclination of the tilted plate can be adjusted according to technology requirements to increase working efficiency effectively and enhance technological adaptability of the lifting device; besides, a direction of the tilted plate can be adjusted to effectively guarantee that a lamination chamber parallels with a flow direction, so as to realize a more efficient separation and extraction of an insoluble binary and ternary system based on a prior art.

Owner:TIANJIN UNIV OF SCI & TECH

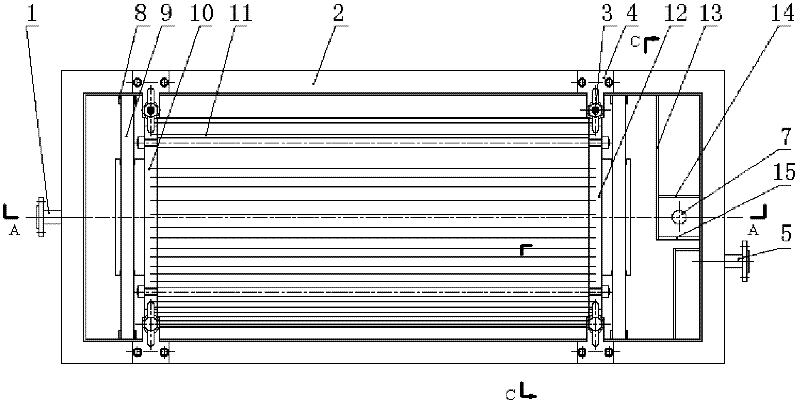

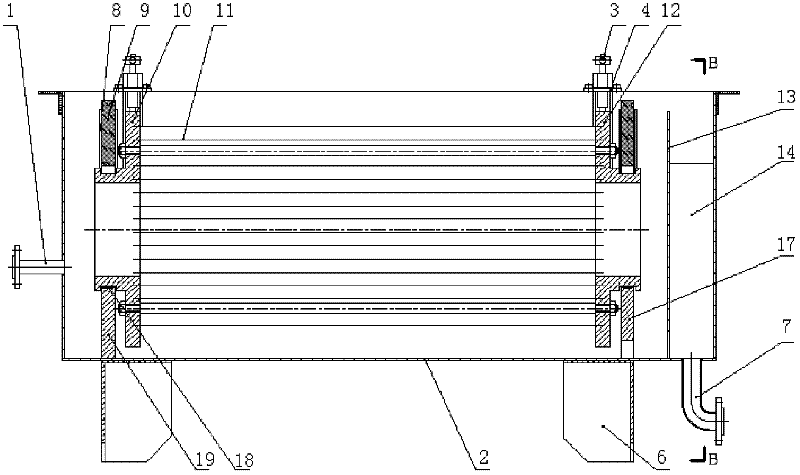

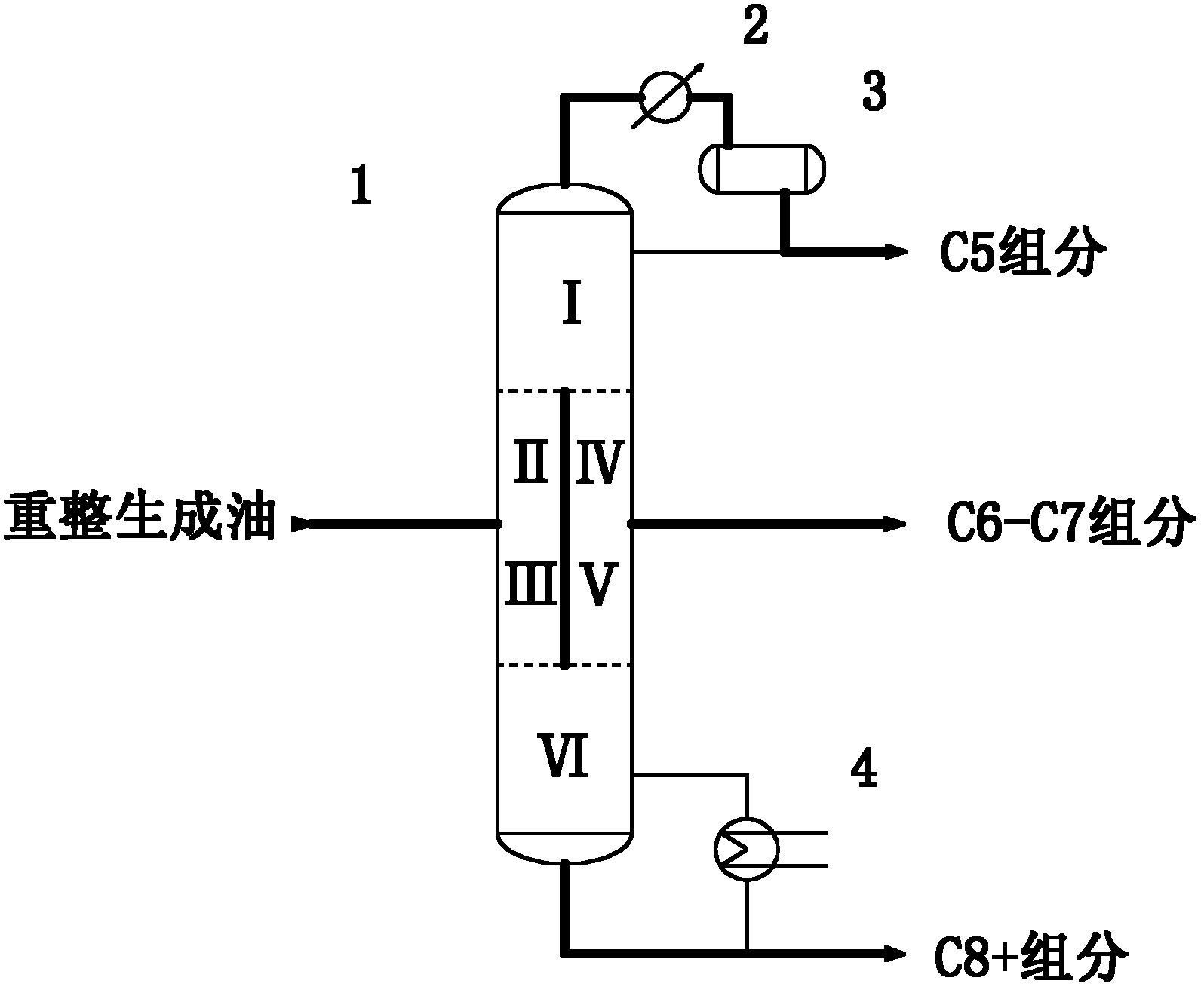

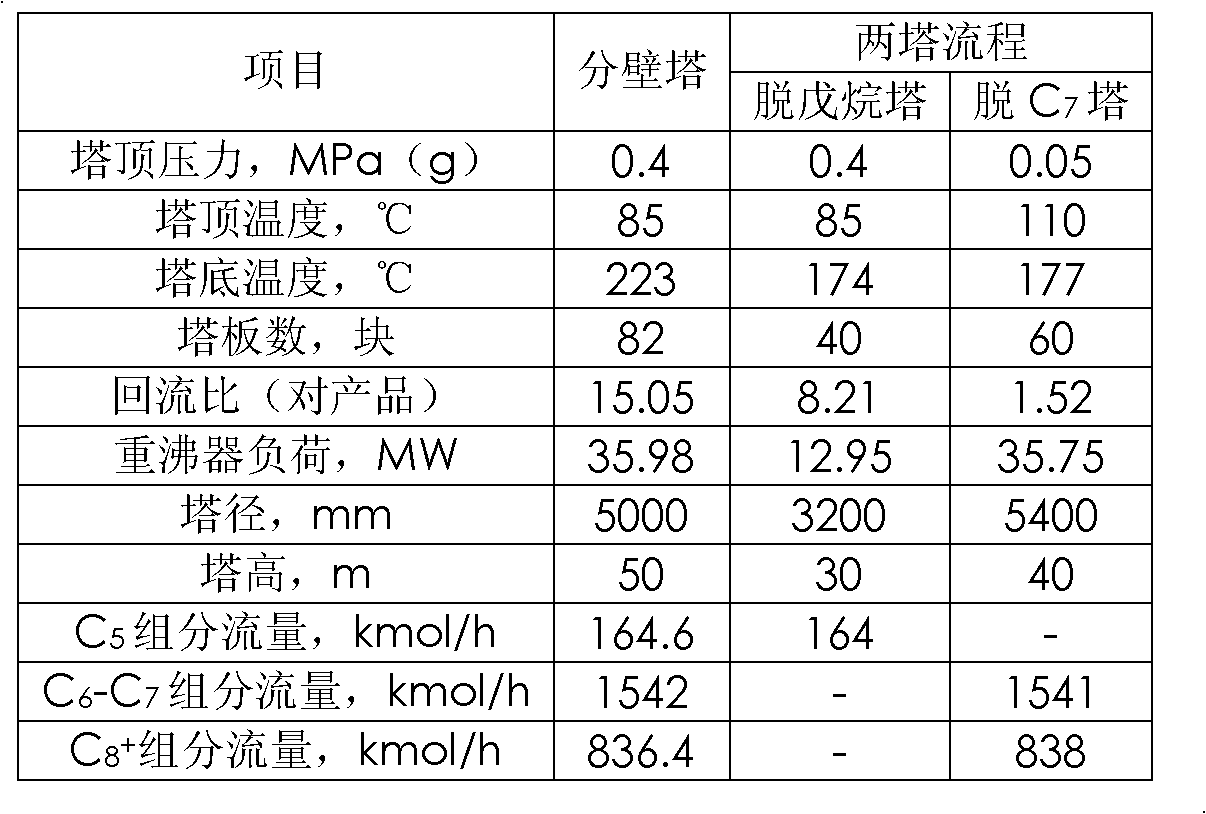

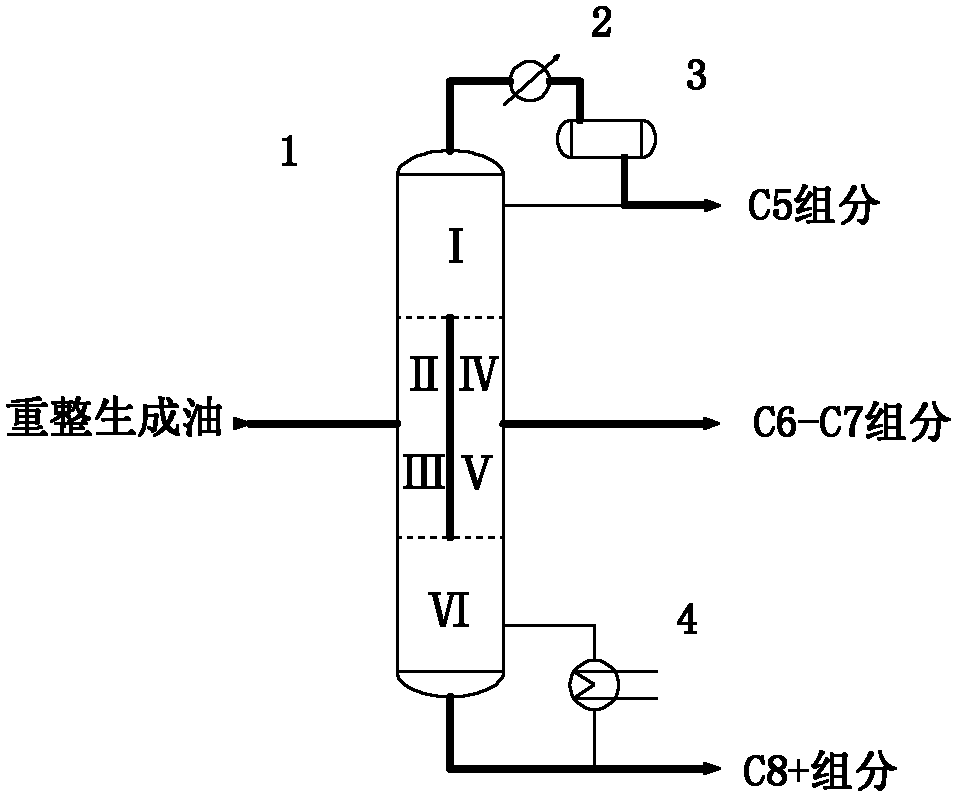

Equipment and method for separating reformed oil

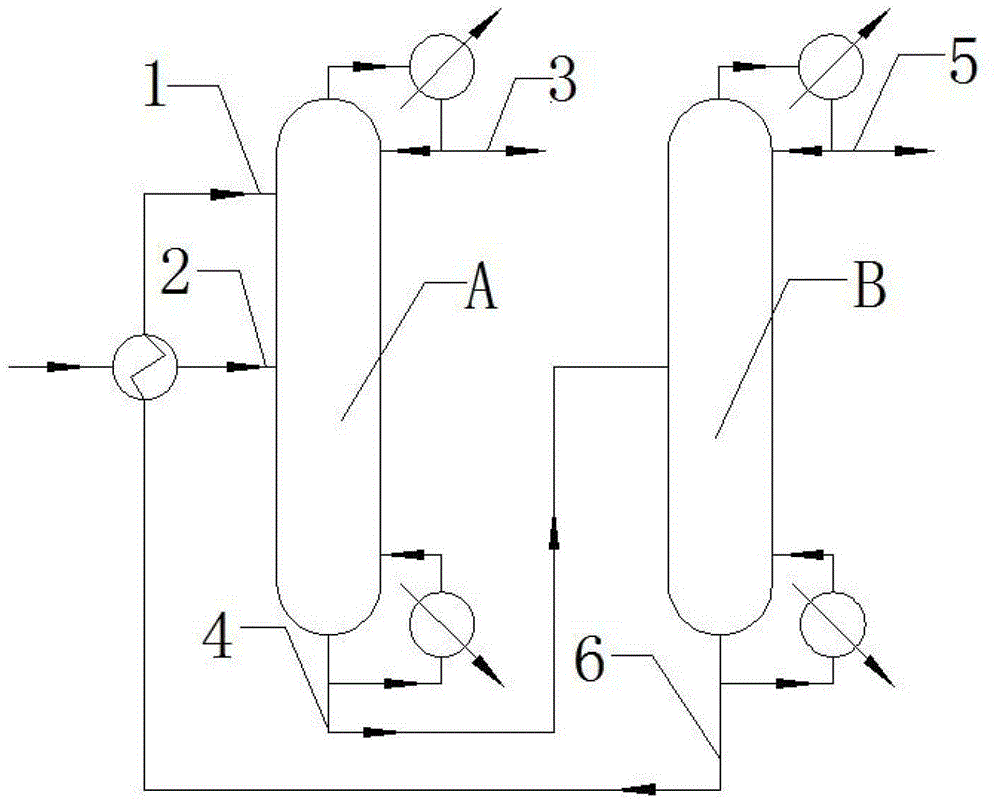

ActiveCN102206504AReduce the number of devicesLow investment costHydrocarbon distillationEngineeringEnergy consumption

The invention relates to equipment and a method for separating reformed oil. The method comprises the following steps of: separating three components, namely C5, C6-C7 and C8<+> in the reformed oil by using a bulkhead rectification column; adding the reformed oil prepared in a reforming device from a rectifying section of a feeding part and the middle part of a stripping section of the feeding part into the bulkhead rectification column; cooling the C5 component on the top of the column by using a condenser, and adding the cooled C5 component into a reflux tank, wherein a liquid phase at the bottom of the reflux tank is partially used as a C5 component product, and the rest liquid phase is used as back flow and flows back to a shared rectifying section on the upper part of the bulkhead rectification column; performing gas-phase side-line extraction on the C6-C7 component from a rectifying section of an extraction part of a side line product and the middle plate of a stripping section on the extraction part of the side line product; and performing condensation cooling and then feeding to an aromatics extraction device, wherein the C8<+> component is arranged at the bottom of the column. The feeding pressure is 0.5MPa (g), the operation pressure of the bulkhead rectification column is 0.4MPa (g), the energy consumption is low, the purity of the C6-C7 component can reach 99.7 percent, floor space is reduced by 40 percent, and the total investment on the equipment is saved by 20 percent.

Owner:PETROCHINA CO LTD +1

Multistage rotating type filtering device used for constructional engineering

InactiveCN106944332ATo achieve the effect of multi-stage filteringImprove filtration efficiencySievingGas current separationArchitectural engineeringElectric machinery

The invention discloses a filter device for multi-stage rotary construction engineering, which comprises a support leg, a support plate is fixedly connected to the top of the support leg, and a first material receiving trough and a second material receiving groove are respectively opened on the upper surface of the support plate. The upper surface of the support plate and the third receiving trough are respectively fixedly connected with a support column and a fixed base, and the upper surface of the fixed base is fixedly connected with a motor. The multi-stage rotary construction filter device achieves the effect of multi-stage filtration of sand, thereby improving the filtration efficiency and achieving the effect of energy saving. At the same time, the rotation direction of the inner filter drum frame and the outer filter cylinder frame is opposite, which improves the filtration efficiency. Efficiency, can make the effect of spirally exporting sand while filtering, avoiding the problem of clogging, and can effectively avoid the problem of sand flowing back out of the sealing cap, which leads to the problem of reducing the filtration efficiency, thus effectively solving the need for a higher level. The efficiency of manual screening is relatively low when the sand is fine.

Owner:章德昌

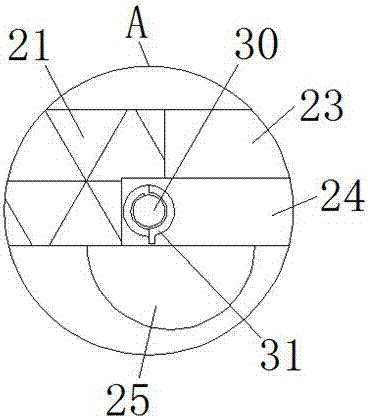

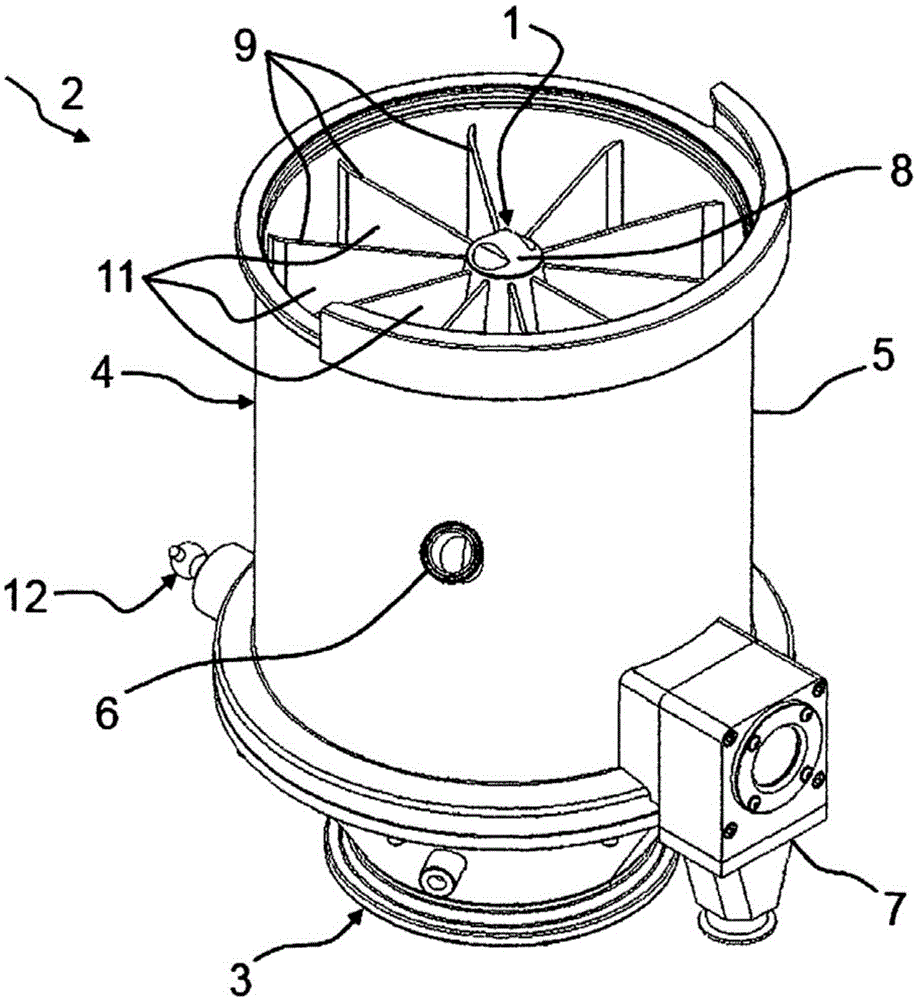

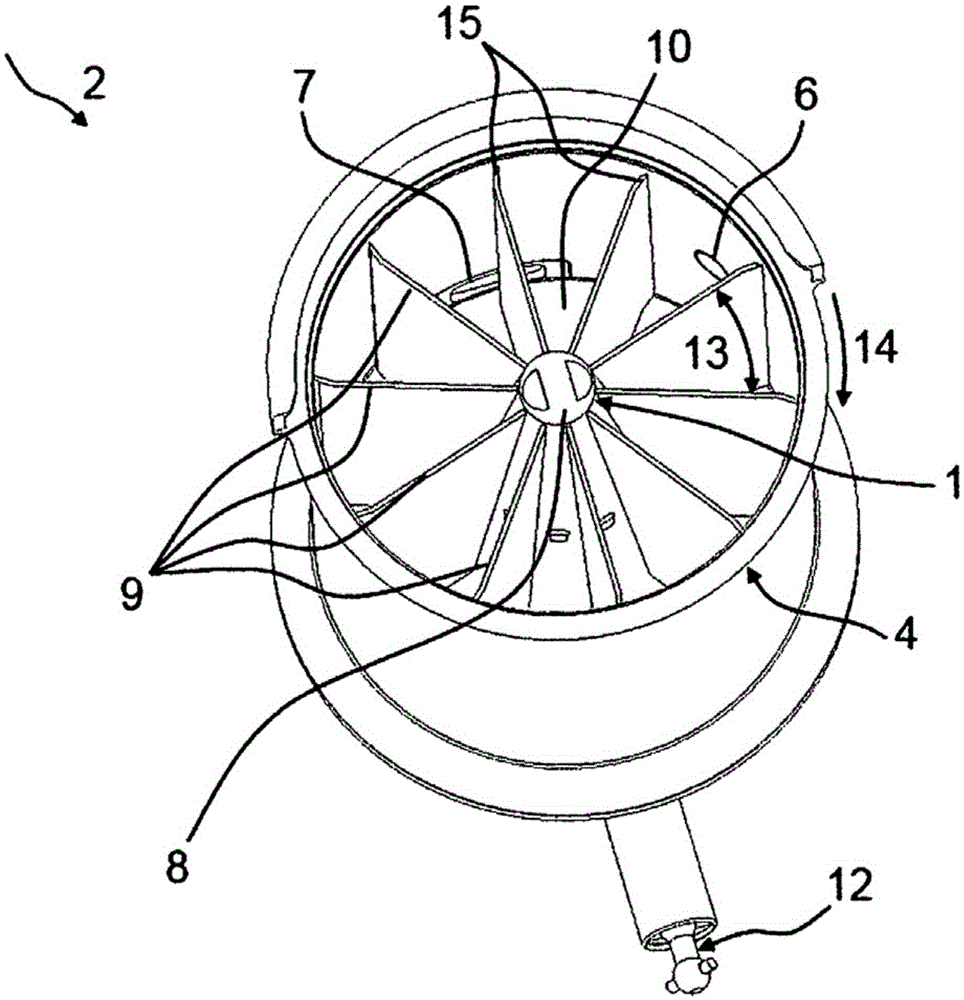

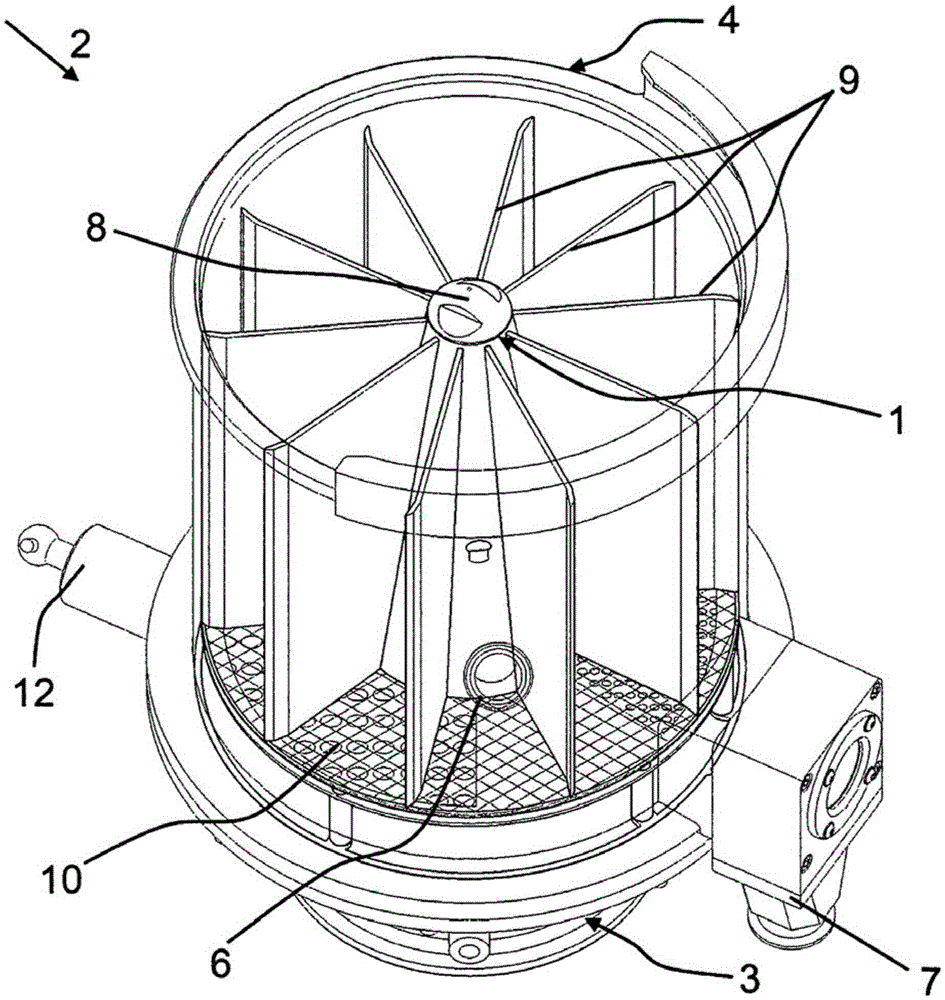

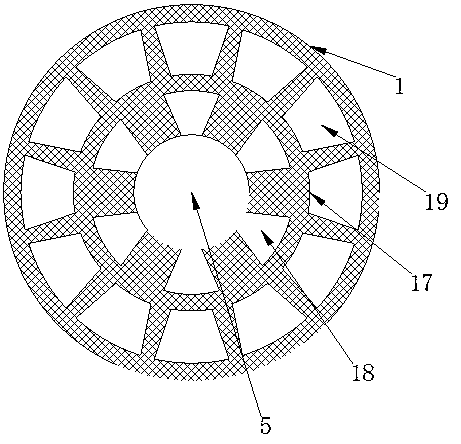

Rotary dryer star and method for treating solid particles

ActiveCN105358244AImprove product qualityPrevent overflowDrying using combination processesGranule coatingEngineeringResidence time

The invention relates to a rotary dryer star (1) for segmenting a vortex chamber (4) into process compartments (11), said rotary dryer star (1) being rotatably arranged and having separating walls (9) or the like to convey solid particles along a conveying path, a flow receiving base (10) being detachably arranged below the rotary dryer star (1). The invention further relates to a method for spraying solid particles for the purpose of agglomeration, coating, layering, spray granulation or pelletization, the spectrum of residence time of the solid particles in the fluidization apparatus (2) being at least in the range of 1:3 (or alternativelytRTD90 less than or equal to 3 tRTD10).

Owner:GLATT INGENIEURTECHNIK GMBH

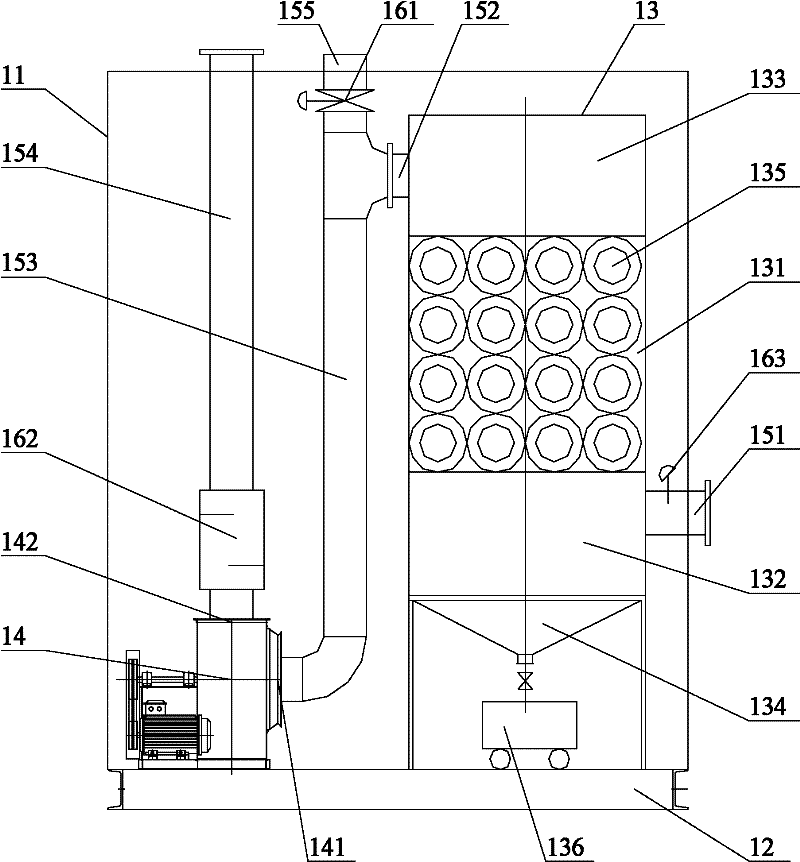

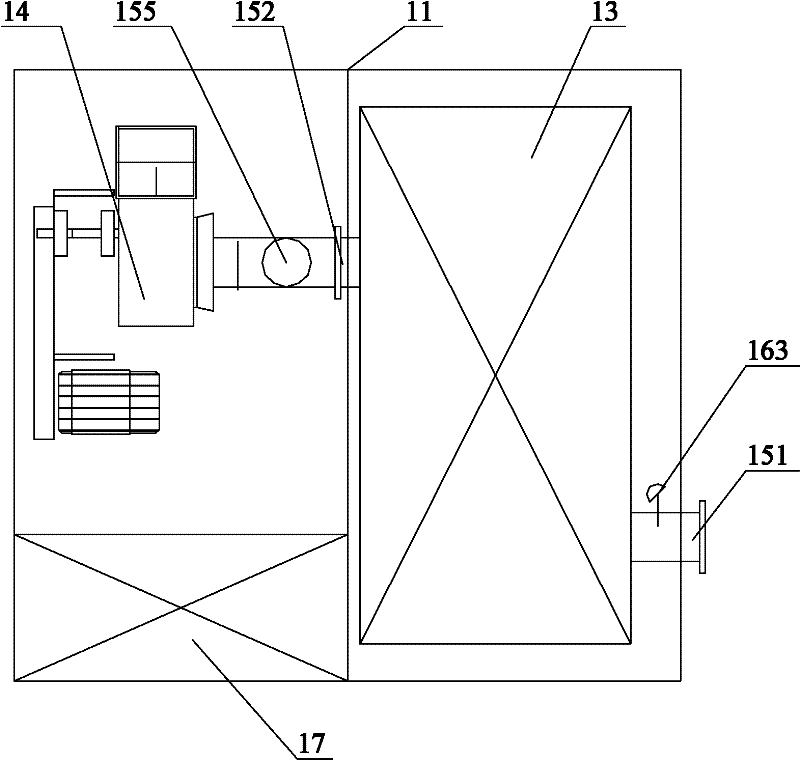

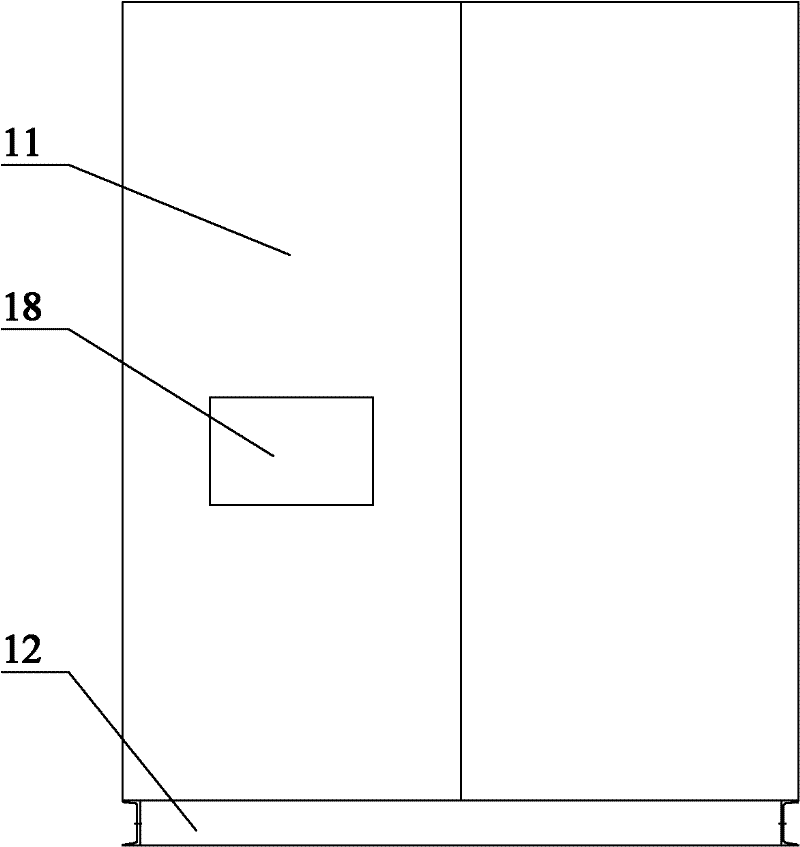

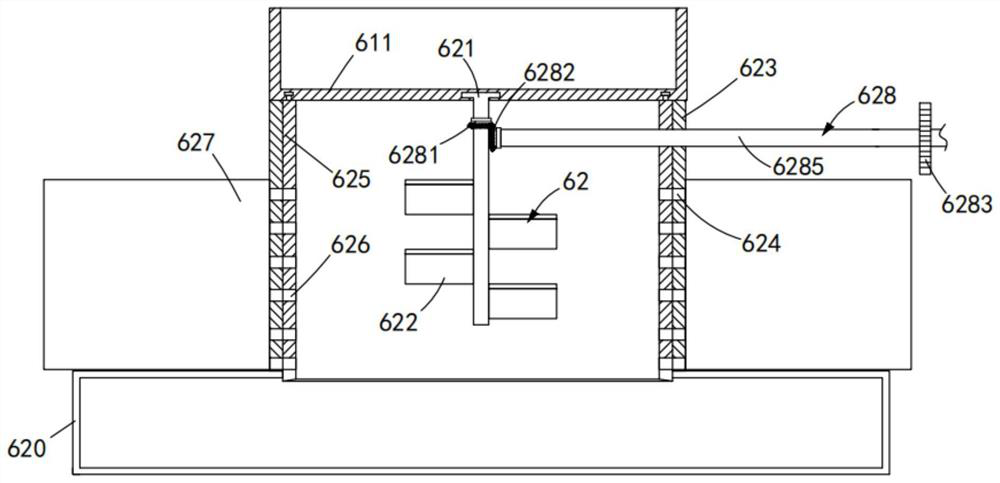

Dedusting equipment and dust collector thereof

InactiveCN102225280AConvenient for centralized processingAvoid remixingDispersed particle filtrationEngineeringProcess efficiency

The invention discloses a dust collector. A deduster is arranged in the casing of the dust collector, and one side of the deduster is provided with an air-supply pipe while the other side of the deduster is provided with an air-discharge pipe; a blower fan is also arranged in the casing of the dust collector and a main airduct is provided between an air inlet of the blower fan and the air-discharge pipe; an air exit of the blower fan is connected with an exhaust pipe communicating with outside air. When the dust collector works, air flow generated by the blower fan enables a vacuum environment to be formed in the dust collector, and therefore air with impurities enters into the dust collector from the air-supply pipe under the action of atmospheric pressure; clear air obtained after the filtering by the deduster is discharged into outside air through internal pipes in the dust collector; processing efficiency in the whole process is high. Furthermore, the invention also discloses dedusting equipment which uses the above-mentioned dust collector; dust processing efficiency of the dedusting equipment is high and the processing is more thorough and effective.

Owner:长沙赛普尔自动化工程设备有限公司

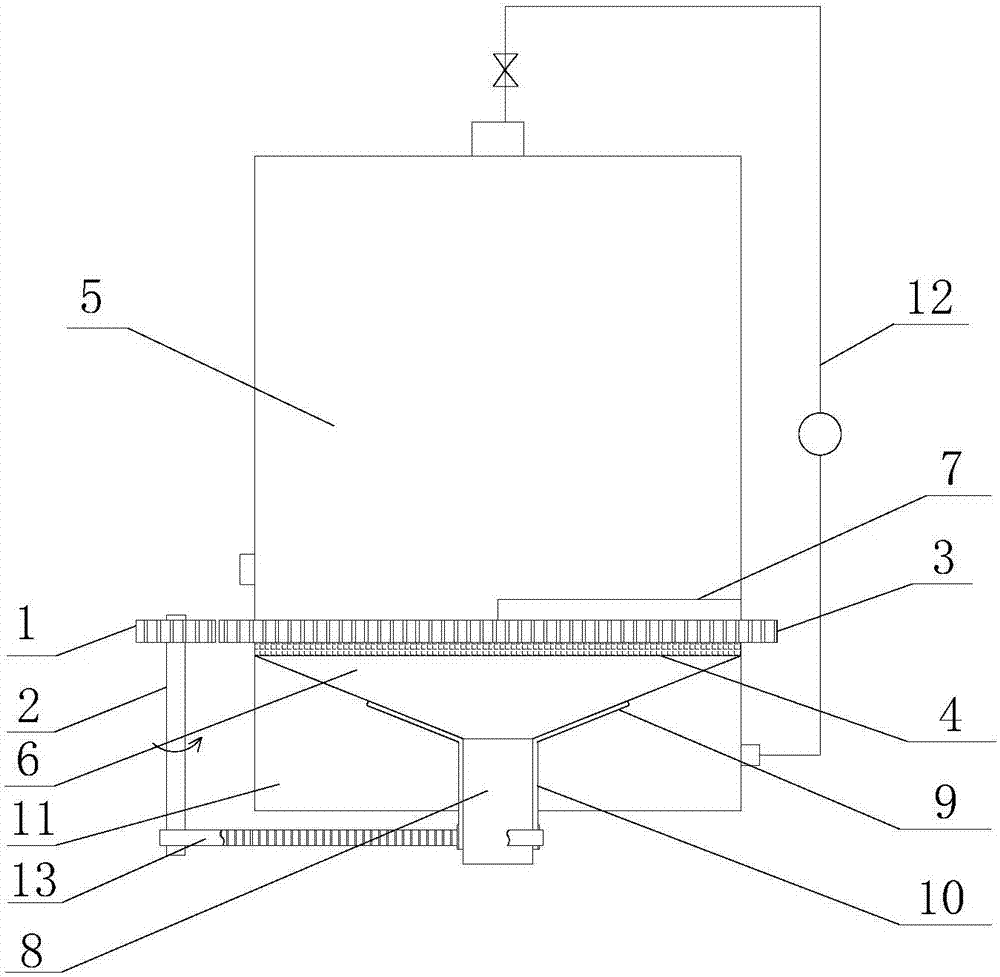

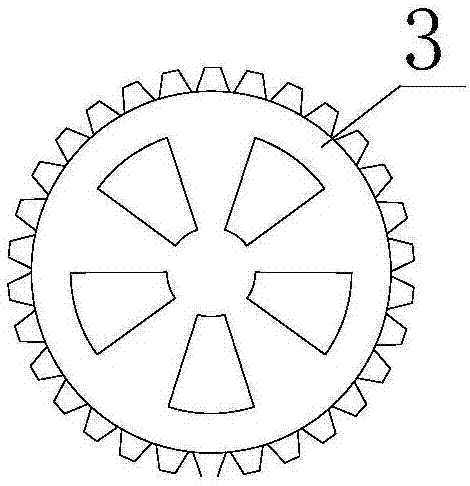

Edible oil storage device capable of regularly and automatically removing residues

ActiveCN107019939AWill not cause circulationGuaranteed stabilitySettling tanks feed/dischargeSedimentation settling tanksEdible oilPetroleum engineering

The invention discloses an edible oil storage device for regular and automatic slag removal, comprising: a storage tank, a transmission gear, a power shaft and a driving mechanism, wherein the storage tank includes an upper tank body, a lower tank body, and an upper tank body and a lower tank body The circular plate and the partition plate between the bodies; the upper tank has an upper chamber; the lower tank has a lower chamber, and the lower chamber has a slag discharge port; the rim of the circular plate is provided with teeth, and the circle There are a plurality of first through grooves on the surface of the shaped plate; second through grooves are arranged on the partition plate; the transmission gear is installed on the power shaft and meshed with the teeth on the rim of the circular plate; the driving mechanism is used The driving power shaft rotates to drive the transmission gear to move the circular plate to rotate. The invention enables preset time intervals for communicating or closing the inner cavities of the upper tank body and the lower tank body, so as to realize the work of communicating or closing the chambers on a regular basis.

Owner:BENGBU QIONGHUAI GRAIN & OIL

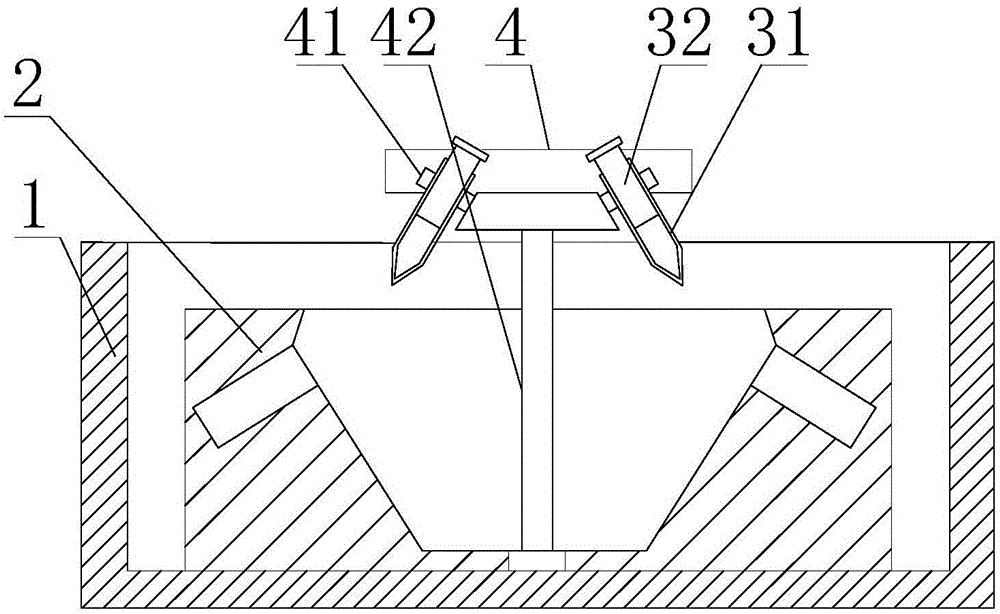

Method and device for arranging highway desilting basin

ActiveCN105089143AIncrease the effect of sinking sandImprove dredging efficiencyFatty/oily/floating substances removal devicesPaving gutters/kerbsSiltEnvironmental engineering

The invention discloses a method and a device for arranging a highway desilting basin. An integral desilting tank is adopted to replace an existing highway desilting basin, the undersurface of the desilting tank is an oblique face, the tank wall on one side of a lowest point of the oblique face is provided with a sand discharging port, a movable sand tank is arranged below the sand discharging port, and a flashboard is arranged at the sand discharging port. When sand discharging is needed, the flashboard is taken away to enable sand which precipitates at the bottom of the desilting tank to slide into the movable sand tank along the oblique face at the bottom of the desilting tank, and then the sand in the movable sand tank is poured away. Desilting effect is improved by means of lowering water flow speed and increasing water flow path, turbidity of water flower due to the fact that silt which is precipitated already is remixed into water flow in the process of desilting can be avoided, and desilting effect is good. A user only needs to clean the sand in the movable sand tank during desilting, so that convenience in cleaning is realized.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Quick construction waste separating device beneficial for environmental protection

The invention discloses a quick construction waste separating device beneficial for environmental protection. The quick construction waste separating device comprises a box body, a feeding port is arranged at the center of the upper wall of the box body, and an upper cover is installed on the outer wall of the upper portion of a feeding hopper; a fixing block is arranged at the center of the bottom of the box body, a motor is installed on the fixing block, a motor protection cover is arranged on the outer side of the motor, and the motor is connected with a rotating rod through a coupler; andan outer gear is connected to the outer wall of the top end of the rotating rod in a sleeving mode, the rotating rod is connected with an inner gear through an outer gear in an engaged mode, the innergear is inlaid to the center of the bottom of a rotating disc, the rotating disc is connected with the side wall of the box body in a matched mode through a groove, and the rotating disc is providedwith discharging ports. According to the quick construction waste separating device beneficial for environmental protection, the motor and the rotating disc are arranged, construction wastes with different components have different weights according to the centrifugal force principle, that is to say, the wastes can rotate under driving of the motor when the wastes fall into the rotating disc, theconstruction wastes made of different materials can fall into the different discharging ports, and then quick separating work is achieved.

Owner:XINXIANG ZHEN YING MACHINERY EQUIP CO LTD

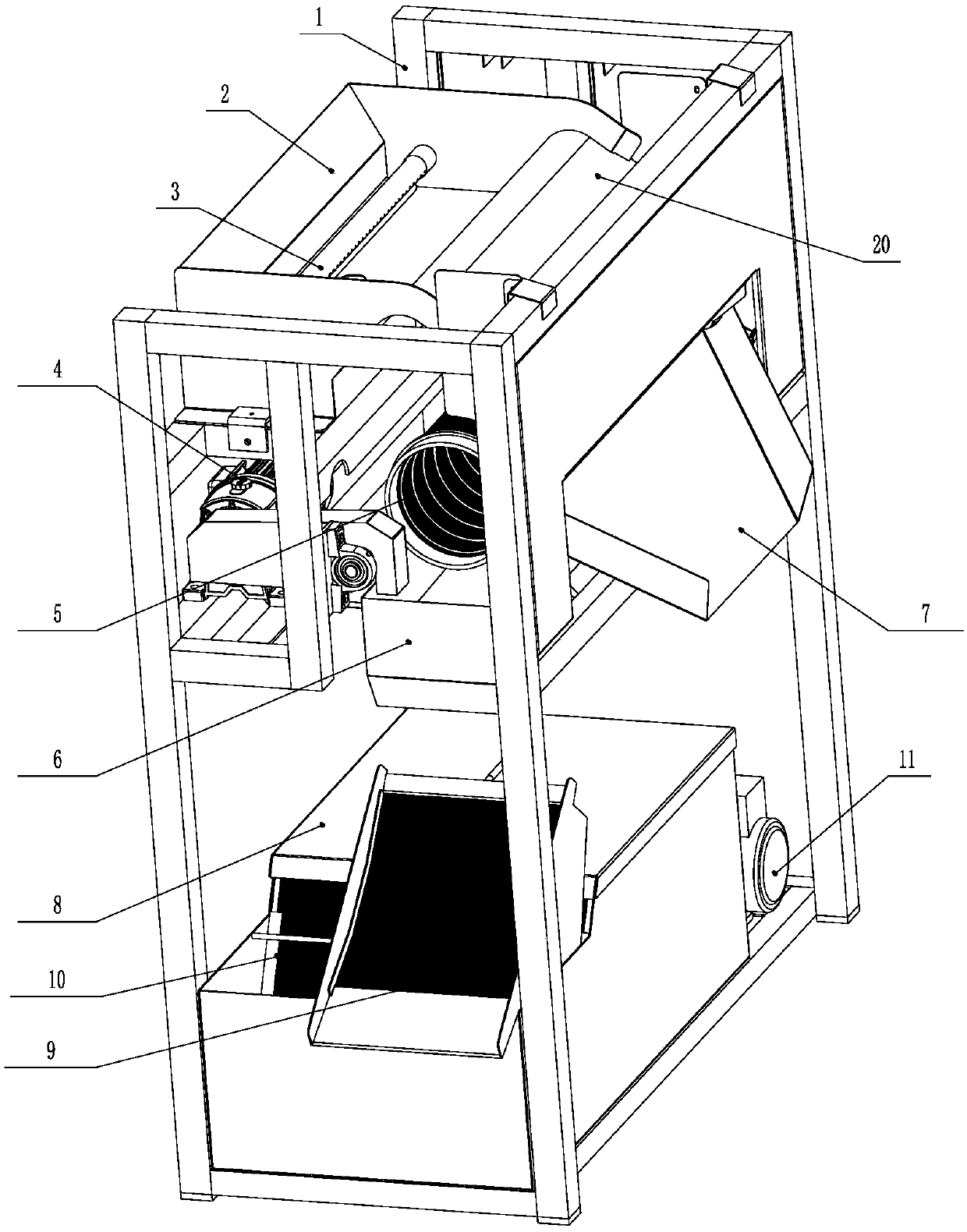

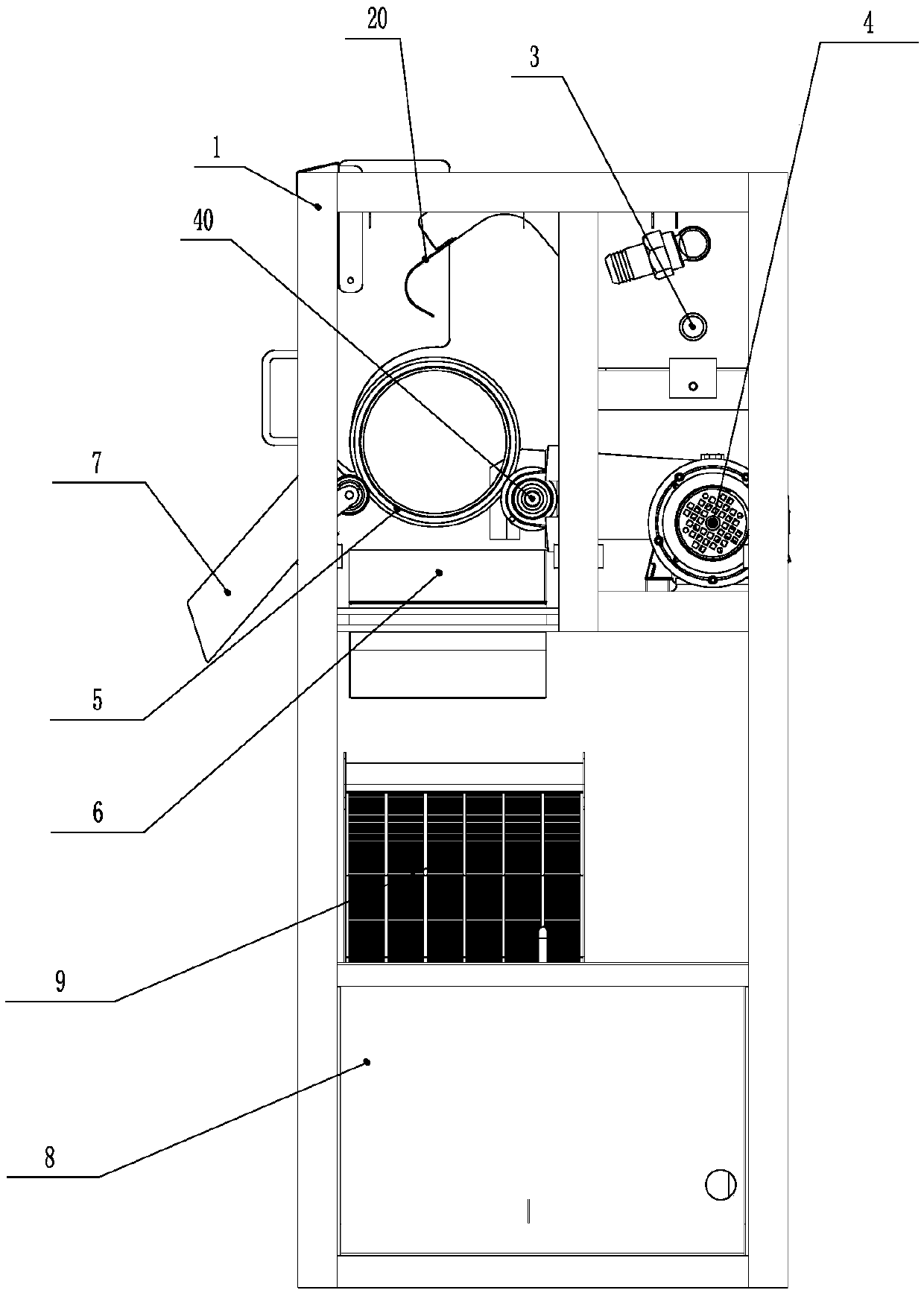

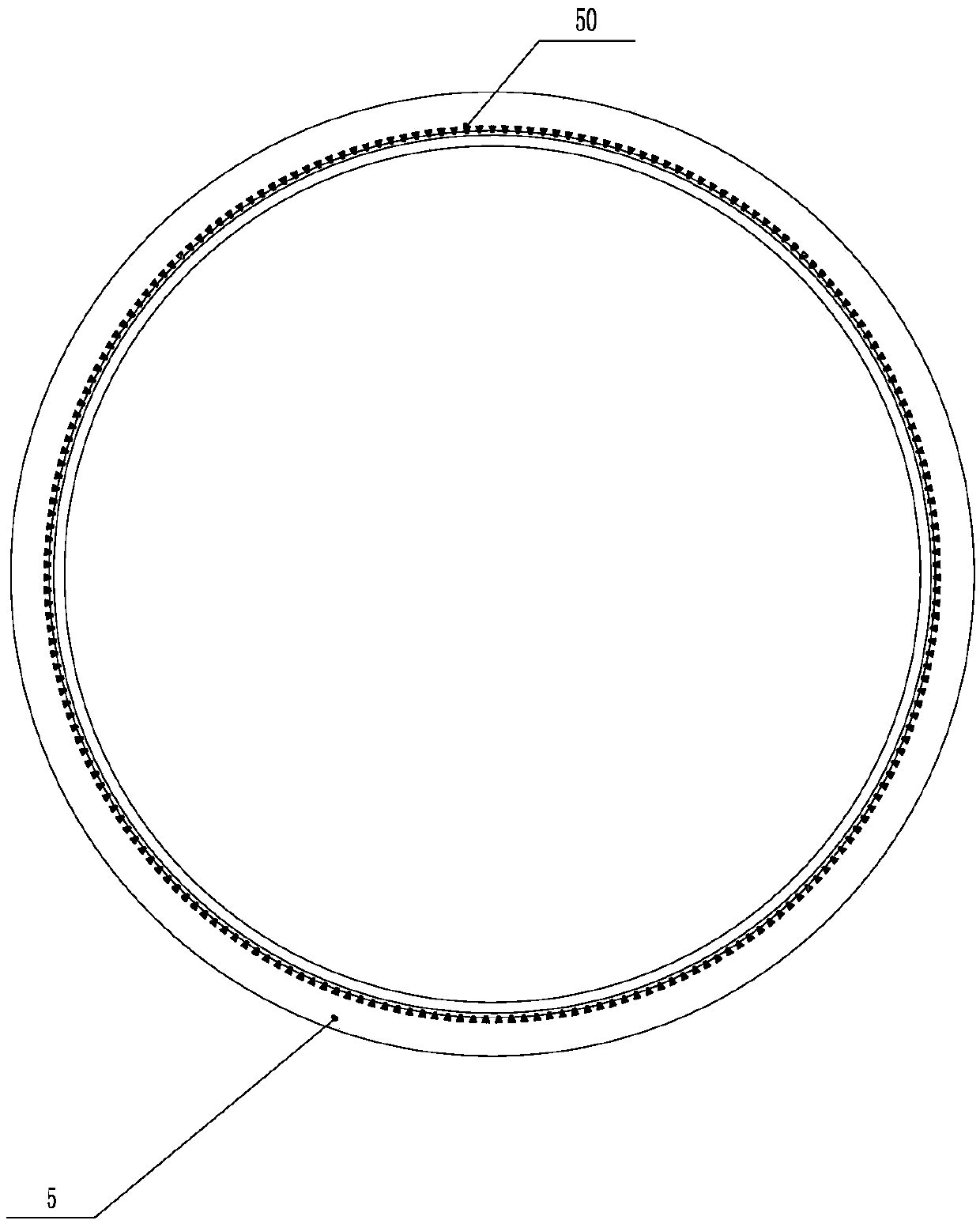

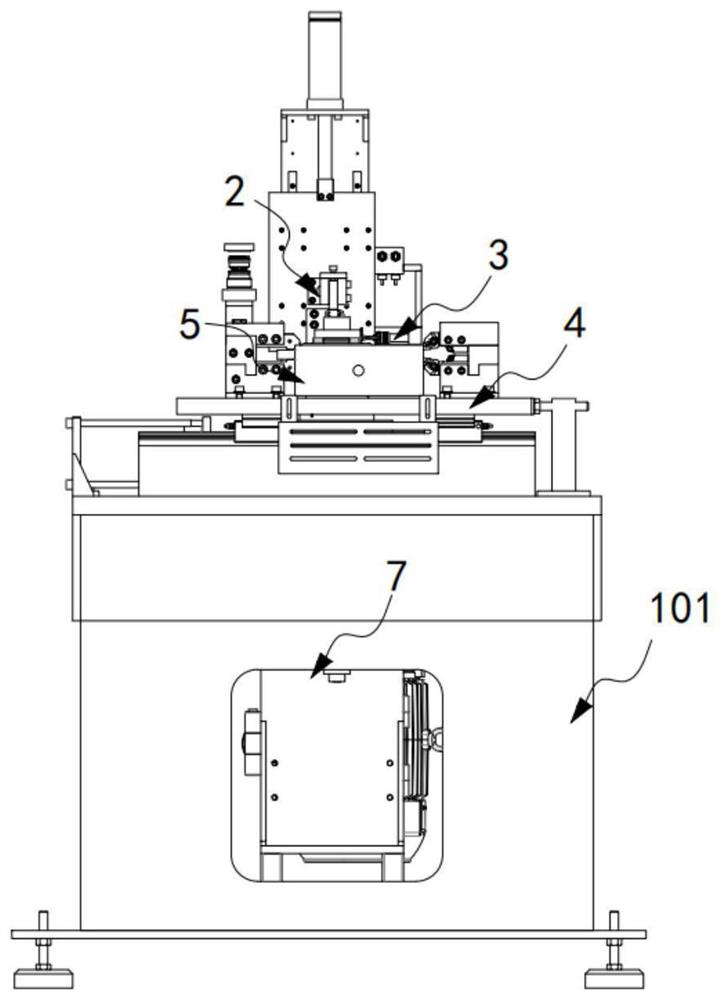

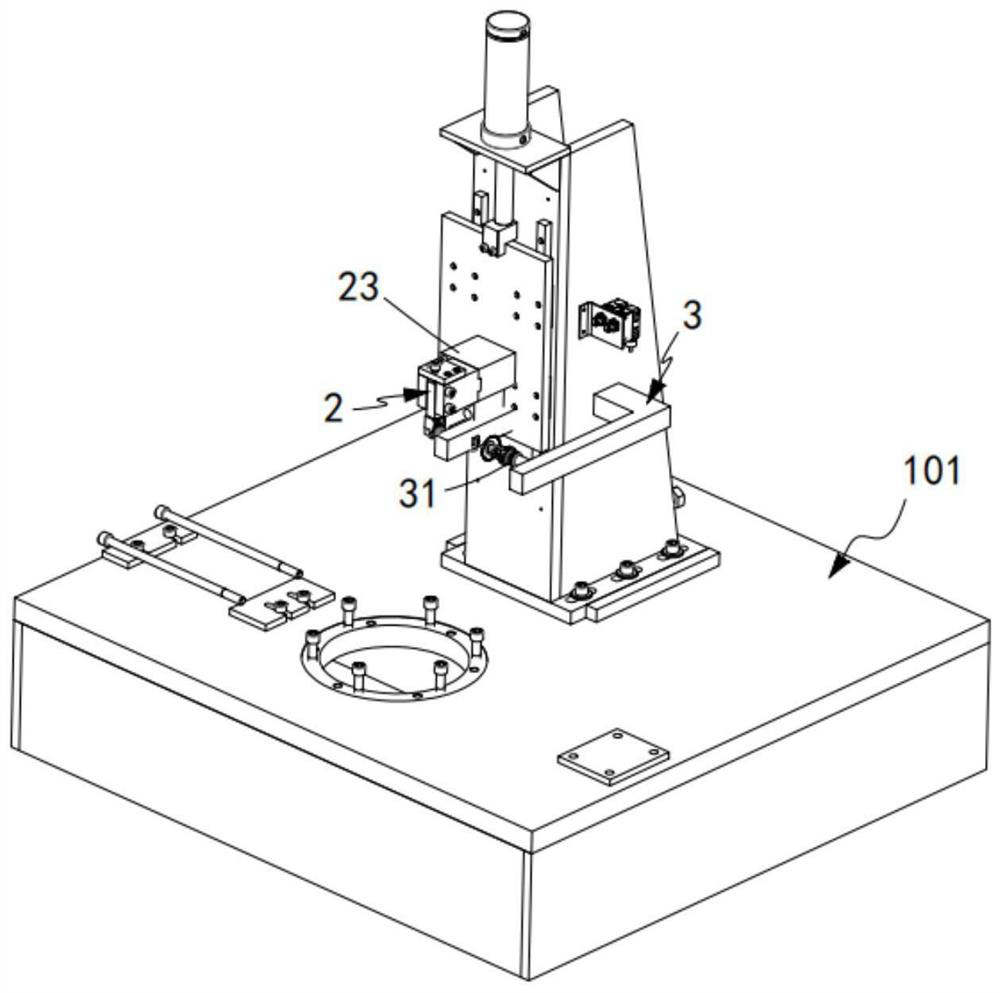

Numerical control grinding machine capable of quickly removing cooling liquid for machining

InactiveCN112536682AGood effect of removing impuritiesImprove the quality of useGrinding carriagesGrinding machinesCooling effectCnc grinding

The invention relates to a numerical control grinding machine capable of quickly removing cooling liquid for machining. The numerical control grinding machine comprises a grinding machine, a grindingmechanism, a cooling mechanism, a bearing mechanism, an adsorption mechanism and a screening mechanism; the screening mechanism comprises a scrap iron collecting assembly, a clear water output assembly arranged below the scrap iron collecting assembly, a grinding stone particle collecting assembly arranged below the clear water output assembly and cooperates with the clear water output assembly tocomplete clear water throwing-out work, and a circulating assembly of which one end of communicates with the grinding stone particle collecting assembly and the other end communicates with the cooling mechanism; and the adsorption mechanism and the grinding mechanism work in a synchronous transmission mode through a first transmission mechanism. The technical problems that when water cools the grinding mechanism, the temperature of the water rises, the water cannot be quickly cooled in the recycling process, and then the cooling effect on the grinding mechanism is affected when circulating water conducts cooling work again are solved.

Owner:张达宇

Experimental cell centrifugal extractor

The invention discloses an experimental cell centrifugal extractor. A rotary drum is vertically arranged in a machine body; a plurality of test tube accommodating cavities on the same circumference are formed in the rotary drum; a mounting plate is horizontally arranged above the rotary drum and is coaxial with rotary drum; a plurality of test tube sealing elements are arranged on the outer circumference of the mounting plate; a storage tube of the extractor is mounted on each test tube sealing element; the extraction end of the storage tube communicates with a test tube; one end of a plunger extends into the storage tube from the upper end of the storage tube, while the other end of the plunger is fixed with the mounting plate; and a driving mechanism is connected with the storage tube and used for driving the storage tube to move towards the plunger. According to the optimally designed experimental cell centrifugal extractor, the structure design is reasonable, on one hand, the test tube sealing elements on the mounting plate seal the open ends of test tubes to ensure that the test tubes cannot swing during centrifugation, on the other hand, the storage tubes extend into the test tubes after centrifugation to achieve in-situ extraction and separation, so that re-mixing, caused by taking out of the test tubes, of layered materials is avoided, and the separation effect is greatly improved.

Owner:ANHUI HUIEN BIOTECH

Improved sewage separation device

InactiveCN106422445AAvoid remixingImprove efficiencyCentrifugal force sediment separationEngineeringCyclotron

The invention relates to an improved sewage separation device, which includes a cyclotron body and a collection body. The lower end of the cyclotron body is connected to the collection body, the side wall of the cyclotron body is provided with a plurality of water inlets, the center of the cyclotron body is provided with a water outlet pipe, the top of the water outlet pipe is communicated with a top cap of the cyclotron body, the periphery of the water outlet pipe and the inner wall of the collection body are all equipped with microporous water collectors, and the bottom of the collection body is equipped with a sewage discharge port. The improved sewage separation device provided by the invention utilizes high speed rotation of the cyclotron body to separate condensed water and impurities between condensed water, the impurity separated condensed water can be pumped out through the water outlet pipe in the cyclotron body from the top cap of the cyclotron body, and impurities can be precipitated in the collection body.

Owner:JIANGSU TEHO METAL IND

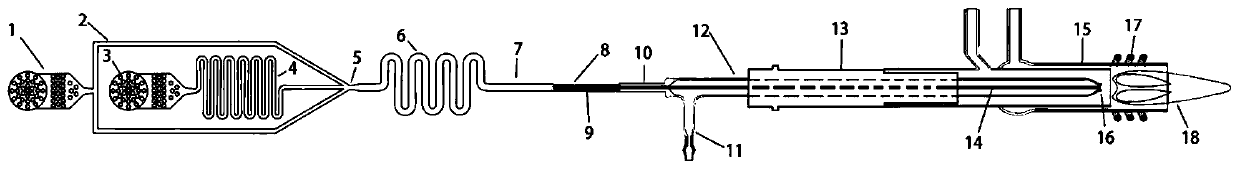

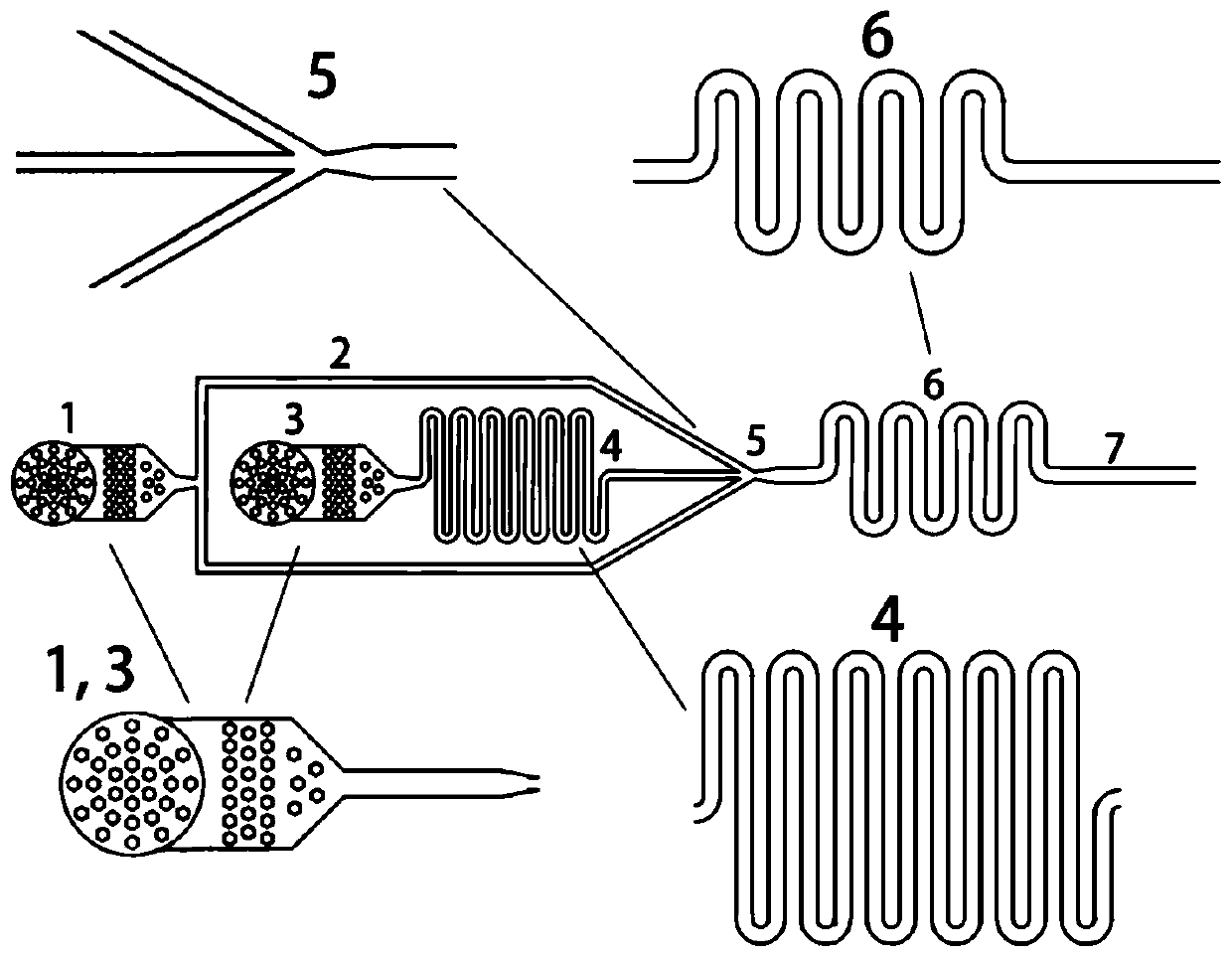

Oil-free sorting-direct injection-ICPMS single cell analysis system

ActiveCN111266140AAdjustable cell intervalAdjust intervalMaterial analysis by electric/magnetic meansLaboratory glasswaresMicrofluidic chipPolyimide

The invention discloses an oil-free sorting-direct injection-ICPMS single cell analysis system, and relates to a single cell analysis platform. A sampling device integrating cell sorting, control andsingle cell direct injection is coupled with ICPMS mass spectrometry detection to perform efficient single cell analysis. The system comprises a double-straight-line-bending-straight-line type micro-fluidic chip body and a direct injection type micro-spraying device. The double-straight-line-bending-straight-line type micro-fluidic chip comprises a buffer solution inlet, a buffer solution channel,a suspension liquid inlet and a two-stage separation channel; a buffer solution and suspension liquid inlet main body is of a cylindrical structure, and a three-fork type connected two-stage separation channel is composed of a plurality of linear-bent-linear structures; the direct injection type micro-spraying device comprises a shell with a carrier gas branch pipe, and the tail end of the shellis gradually thinned to form a nozzle; the sample injection capillary tube is inserted from the tail end of the shell and slightly retracts relative to the nozzle, the polyimide coating on the surfaceof one section of capillary tube is stripped, and a micro cavity is formed on line at the nozzle. An ammonia bicarbonate buffer solution is used in the whole system.

Owner:XIAMEN UNIV

Tea deblocking device

InactiveCN106954695ANot easy to damageNot easy to breakSievingPre-extraction tea treatmentEngineeringMechanical engineering

The invention belongs to the field of tea processing equipment, and specifically discloses a tea deblocking device. The tea deblocking device comprises a machine frame, a hot air generator, a sieve column and a sieve tube; a material inlet and a first air hole are formed on a surface of the sieve tube; one end of the sieve column is connected onto the machine frame, and the other end is located in the sieve tube; the sieve column is a hollow columnar structure; multiple second material inlet holes are formed on an upper surface of the sieve column, and multiple second air holes are formed on a lower surface of the sieve column; one end of the sieve tube is connected with a rotation shaft; the rotation shaft is connected onto the machine frame in a rotary way, and is arranged with rotary blades; an annular sieve net is fixed in the sieve tube, and is located outside the sieve column; multiple first material inlet holes are formed on an upper surface of the annular sieve net, and multiple third air holes are formed on an lower surface of the annular sieve net; a clapboard is arranged at a joint of the upper and lower surfaces of the annular sieve net; multiple one-way gates are arranged on the clapboard; and multiple split combs are fixed on an inner surface of the sieve tube. Being adopted for deblocking tea, the tea deblocking device is not liable to cause damage or extrusion-break on tea leaves; moreover, the tea leaves can be dried during the deblocking process.

Owner:重庆毓堡农业开发有限责任公司

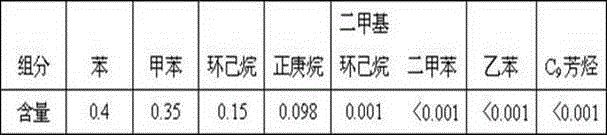

Method for separating benzene and toluene from hydrocarbon mixture

InactiveCN102942433AAvoid remixingHigh purityDistillation purification/separationBenzeneChemical industry

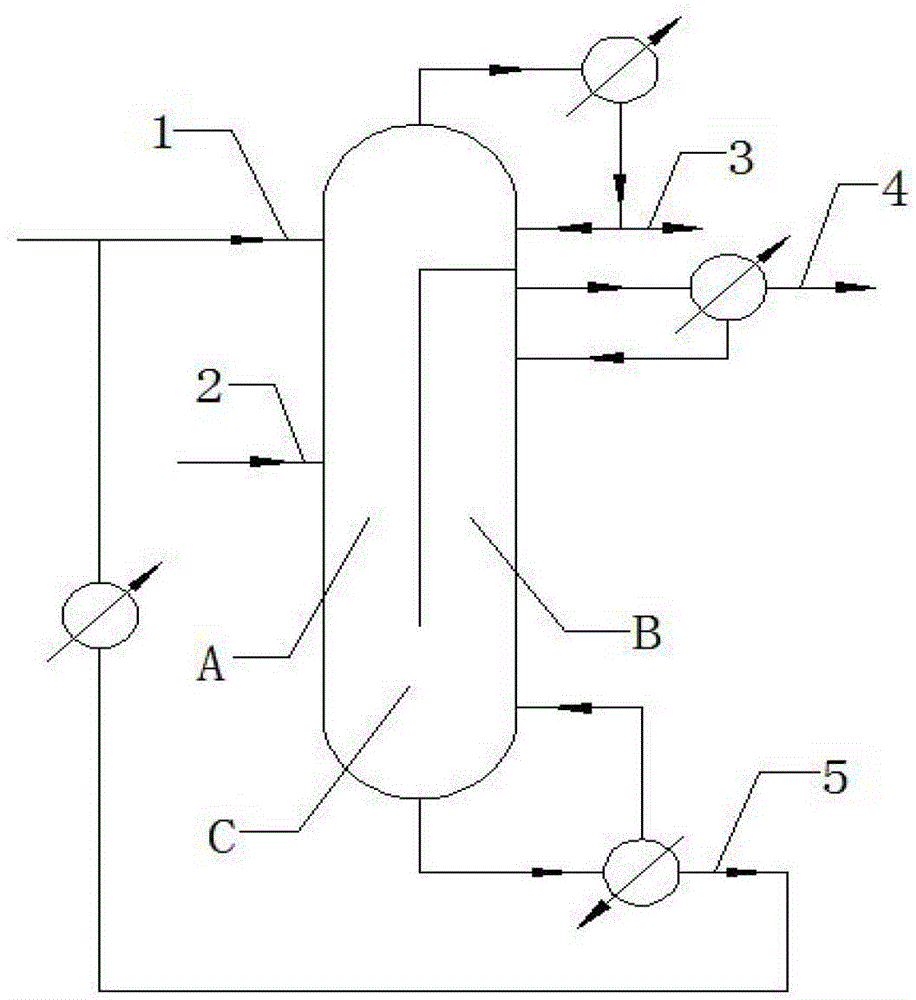

The present invention discloses a method for separating benzene and toluene from a hydrocarbon mixture, and belongs to the technical field of chemical industry. According to the method, the middle portion of a rectification tower for separation of non-aromatic hydrocarbon, benzene and toluene is provided with a vertical wall, the upper portion and the lower portion of the separation wall do not contact the top and the bottom of the tower, the upper portion on a benzene and toluene outlet side of the separation wall is sealed, and is not connected with the top space, the tower is divided into three regions such as A, B and C through the separation wall, non-aromatic hydrocarbons are recovered from the top of the region A, benzene and toluene are recovered from the region B side, the region C is a public stripping section, and column plates or fillers are arranged inside the three regions. According to the present invention, material feeding and side line recovery are separated through the separation wall, and high purity components are respectively obtained from three positions such as tower top, side line recovery and tower kettle of the separation wall extraction rectification tower, wherein the product purity can be more than 99.7%, and energy can be saved by more than 20% compared with the conventional process, such that the process is simple, operation is convenient, investment on one tower is saved, and cost can be significantly reduced.

Owner:CHANGZHOU UNIV

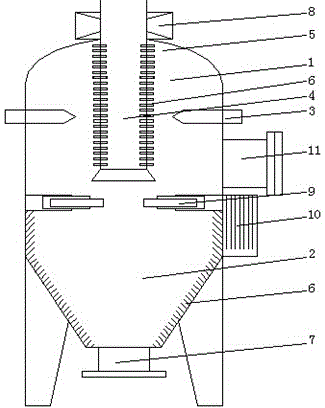

Rotational flow stopping block type pulverized coal concentrator

ActiveCN103162289AImprove concentration efficiencyLow pollution combustionPulverulent fuel combustion burnersCombustionInlet channel

The invention relates to a rotational flow stopping block type pulverized coal concentrator which comprises a cylinder body, a tangential inlet channel, a rotating blade, a double-cone stopping block, a bypass flow stopping ring, a bearing, an inner primary air channel and an outer primary air channel, wherein pulverized coal airflow enters the cylinder body from the tangential inlet channel, rotates by the rotation blade, and then collides with the double-cone stopping block. Pulverized coal concentrates on a wall surface of the cylinder body under effect of centrifugal force and collision to form thin pulverized coal airflow close to the bearing and thick pulverized coal airflow close to an outer wall of the cylinder body, the thin pulverized coal airflow and the thick pulverized coal airflow are respectively sent to the inner primary air channel and the outer primary air channel. The principle of centrifuging and colliding is comprehensively utilized, so that the pulverized coal airflow is concentrated into an outer thick airflow and an inner thin airflow, concentration efficiency of the pulverized coal is improved, and a pulverized coal concentration mode of being thick outside and thin inside is formed by a ring-shaped bypass flow stopping plate and matched with radial thick-thin combustion technology to achieve high-efficiency and low-pollution combustion.

Owner:YANGZHOU CHENGUANG SPECIAL EQUIP

Waste lithium battery powder iron removal device

The invention discloses a waste lithium battery powder iron removal device, which comprises a material feeding box, a supporting frame, a first motor, a case, an electromagnetic iron adsorption device, an iron powder collection plate, a separation door and an iron adsorption plate, wherein the upper end of the case is provided with the supporting frame; the supporting frame is provided with a lifting plate; the lifting plate is provided with the first motor; the first motor is provided with a connecting shaft; the end part of the connecting shaft is provided with the electromagnetic iron adsorption device; one side of the supporting frame is provided with the material feeding box; the material feeding box is arranged on the upper end of the case and is communicated with the inner part of the case; the electromagnetic iron adsorption device is arranged in the case; the case is internally provided with the iron powder collection plate in sliding connection; the separation door is arranged below the iron powder collection plate; and the iron adsorption plate is arranged below the separation door.

Owner:ZHEJIANG XINSHIDAI ZHONGNENG RECYCLING TECH CO LTD

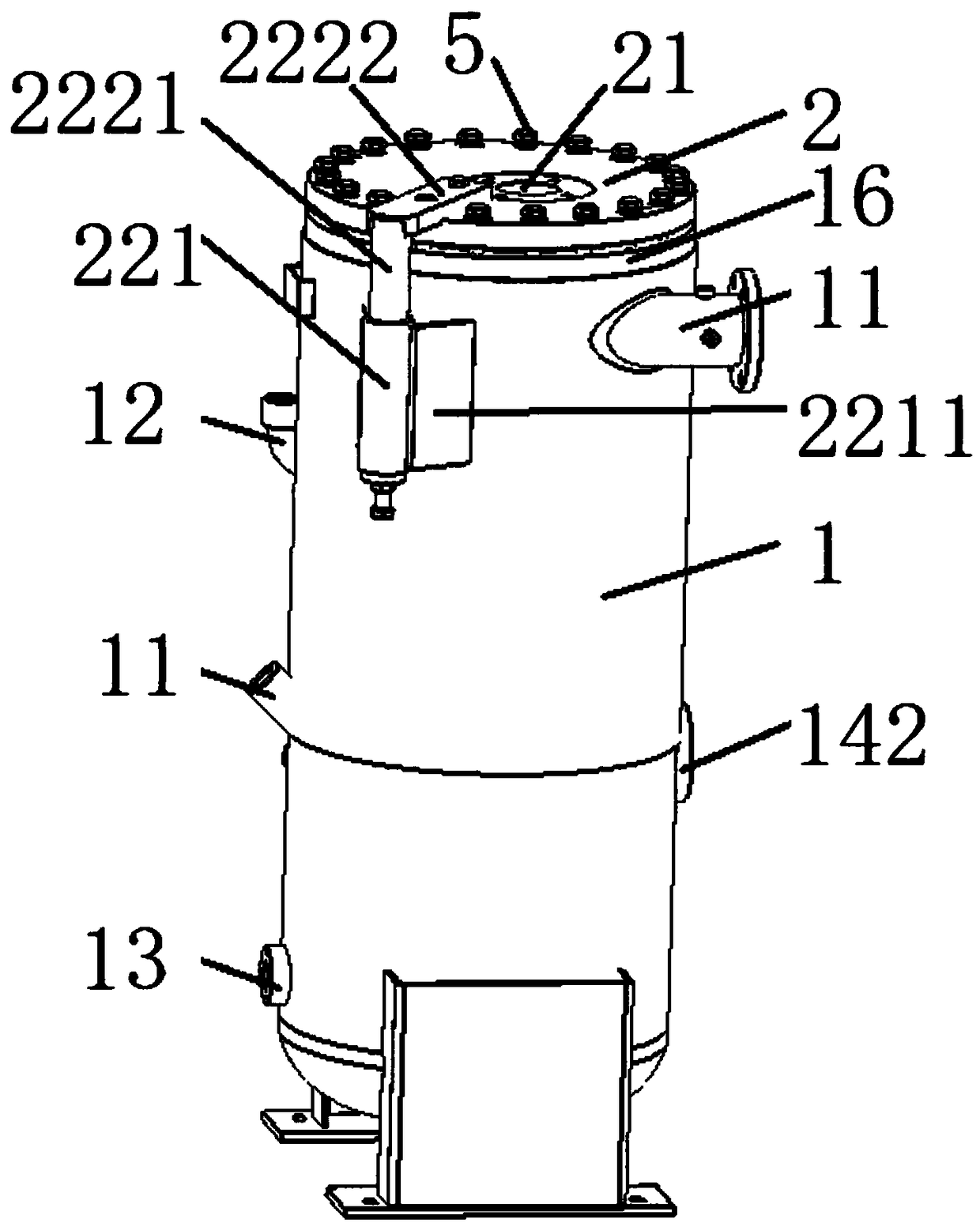

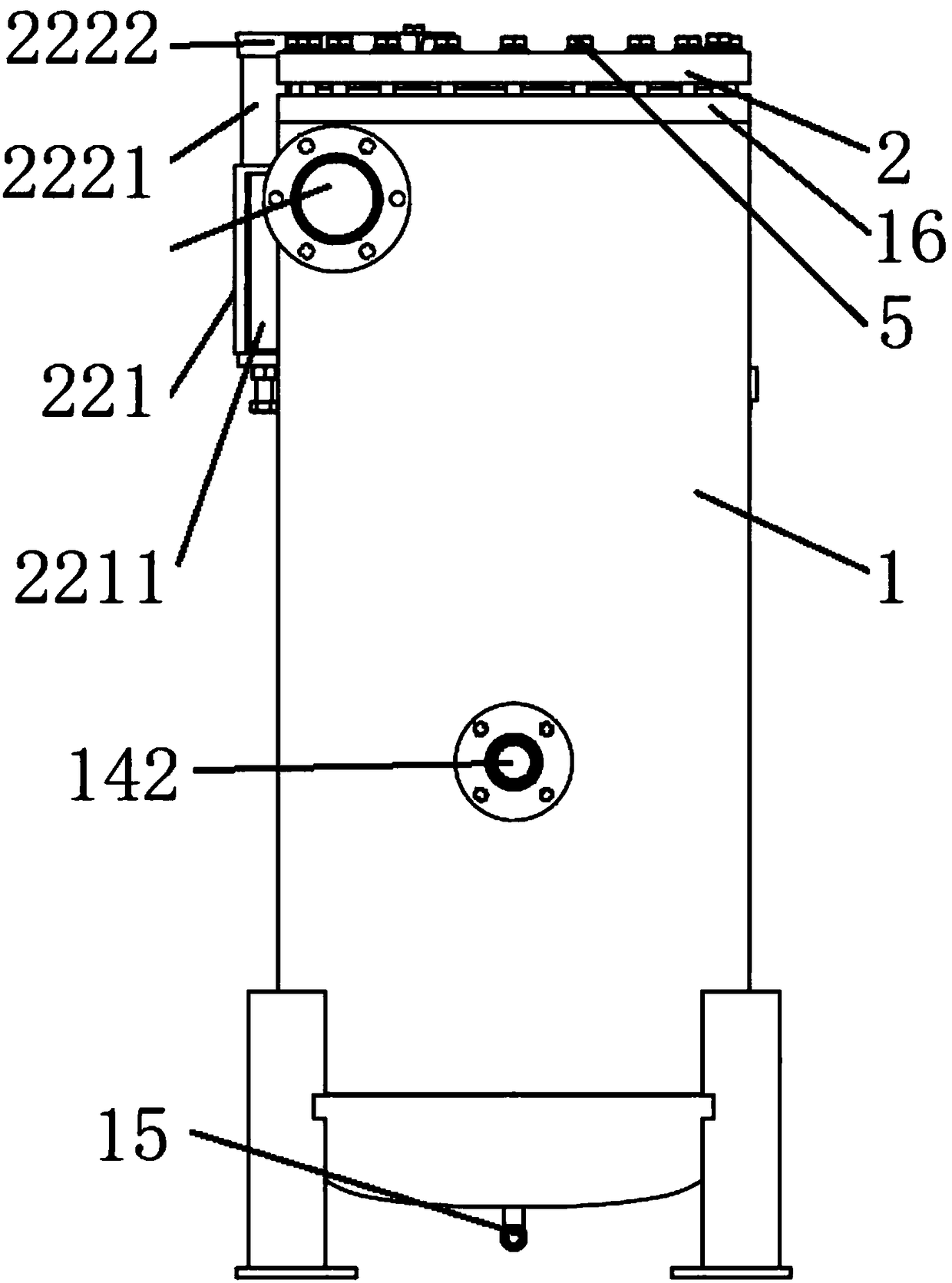

Oil-gas separation device

The invention discloses an oil-gas separation device. The oil-gas separation device comprises an outer barrel and a barrel cover, wherein the outer barrel is provided with a gas inlet channel; the barrel cover is arranged at the top of the outer barrel and is provided with a gas outlet channel communicated with the inner part of the outer barrel; the barrel cover further comprises a fixed unit, wherein the fixed unit comprises a fixed part and a rotary part penetrating through the fixed part; the fixed part is connected to the outer barrel; the rotary part is connected to the barrel cover andthe rotary part does axial linear motion and rotary motion relative to the fixed part so as to move the barrel cover between a sealing position and an opening position. The fixed unit is arranged andis used for connecting the outer barrel and the barrel cover; when parts in the oil-gas separation device need to be replaced, the barrel cover can be moved between the sealing position and the opening position only if the fixed unit is operated, and the barrel cover and the outer barrel are not completely separated; compared with a condition in the prior art that the barrel cover is taken to theother place to completely separate the outer barrel and the barrel cover, the opening and closing of the barrel cover are simpler and more convenient.

Owner:SUZHOU SULLAIR GAS EQUIP

Industrial shrimp shell filtering machine

PendingCN109548850AAvoid damageIntegrity guaranteedShrimp/lobster processingShrimpElectric machinery

The invention discloses an industrial shrimp shell filtering machine. The industrial shrimp shell filtering machine comprises a machine frame, a water tank, a water inlet pipe arranged in the water tank, a filtering roller arranged below the water tank, a shrimp meat guiding groove formed in one side of the roller and a shrimp shell discharging groove formed below the roller, wherein the water tank consists of four side plates and a bottom plate; one of the side plates is an overflow plate of which the upper edge is lower than that of other side plates, and the overflow plate is bent outwardsto form an arc shape; the arc-shaped plate is located above the filtering roller; the filtering roller is connected with a motor; the shrimp meat guiding groove is formed in a position at the lower part of one side of the filtering roller; and the guiding-out direction of the shrimp meat guiding groove is used as a forward direction, the motor is transmitted to drive the filtering roller to rotatebackwards along the upper part of the motor, so that impurities are separated from the materials, and remixing is avoided.

Owner:南通宝泰机械科技有限公司

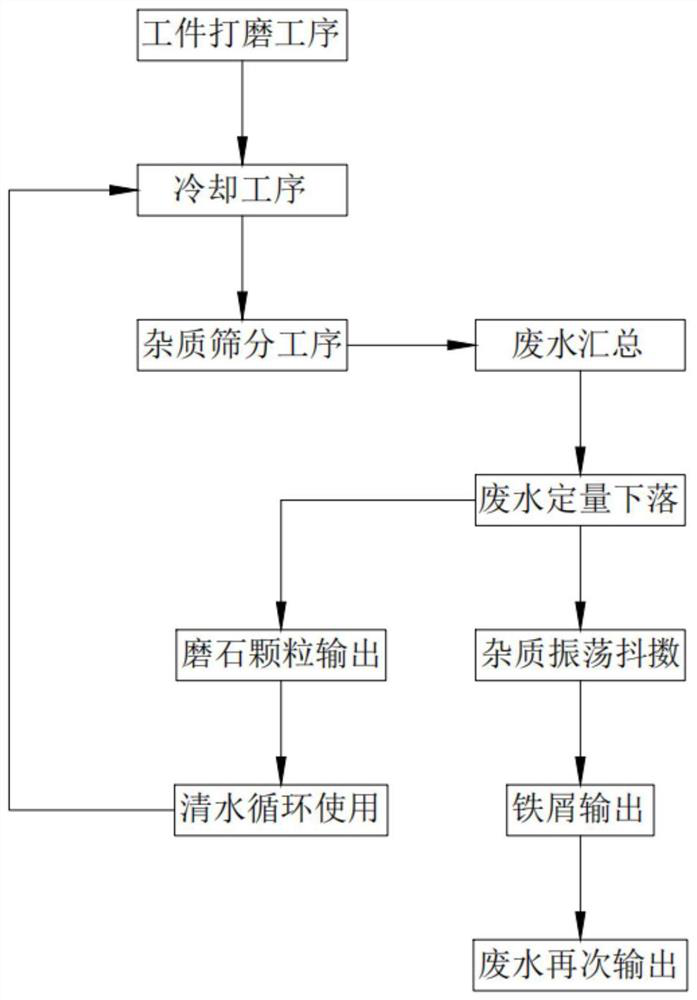

Cooling liquid recovery process for six-axis grinding machine

InactiveCN112621567AEasy to useAchieve clearingGrinding/polishing safety devicesPhysical chemistryWastewater

The invention relates to a cooling liquid recovery process for a six-axis grinding machine. The process comprises a workpiece grinding process, a cooling process and an impurity screening process, wherein the impurity screening process comprises the following steps: 1, gathering wastewater; 2, quantitatively dropping the wastewater; 3, shaking off impurities by oscillation; 4, outputting scrap iron; 5, outputting clean water; 6, outputting millstone particles; and 7, recycling clear water. The technical problems that scrap iron and millstone particles cannot be discharged in time, consequently, the water flow is low, output of much water cannot be achieved, and nearly equal amount of water circulates and flows back in time are solved.

Owner:浙江威步机器人股份有限公司

Take-out box with refuse classification and storage functions

InactiveCN110419839AAvoid remixingAchieve the function of sorting different garbageWaste collection and transferRefuse receptaclesLitterEngineering

The invention, by improving a structure of an ordinary take-out box, enables the ordinary take-out box to have refuse storage and classification functions. On one hand, after a user has a meal, residual liquid in a take-out box can be filtered off by using a leaking hole structure on a take-out box cover. Then, a transverse long card slot, a division plate and a vertical card slot in the take-outbox on a lower surface of the take-out box cover, are assembled. The assembled take-out box structure can simply classify and store refuse generated by different kinds of meals. Therefore, the user can open and close different areas on the take-out box cover when dumping refuse, such that refuse of different types is poured out from a corresponding window, thereby achieving purposes of classifyingrefuse and separating refuse from the take-out box, which is convenient for recycling refuse and the take-out box. On the other hand, when classification space of the take-out box is redundant, the user can use the take-out box to classify and store refuse generated in daily life, thereby reducing usage of a plastic refuse box and other items causing environmental pollution.

Owner:吕英浩 +1

Pressure-proof outdoor water storage device

The invention discloses a pressure-proof outdoor water storage device comprises a pool with the top open. The pool is divided into an upper portion, a middle portion and a lower portion from top to bottom, wall thicknesses of the upper portion, the middle portion and the lower portion increase gradually and sequentially from top to bottom, two platy partitions are arranged in the pool vertically and divide the pool into three mutually non-communicated chambers, a cover is arranged above two adjacent chambers, a ladder from the top to the bottom is arranged in the chamber not provided with the cover, watering passing holes are formed in the upper portion of each partition, and a filter unit is arranged at the positions of the water passing holes of each partition. Requirements on water pressure of different depths are met, water is classified into three different clean classes, different requirements of people are met, and the pressure-proof outdoor water storage device is convenient to clean, simple in structure and convenient and practical.

Owner:CHENGDU COPOO TECH

An apparatus for and a method of processing reproducible data

InactiveCN101099196AAvoid boredomConvenient entertainmentElectrophonic musical instrumentsProcessing elementComputer engineering

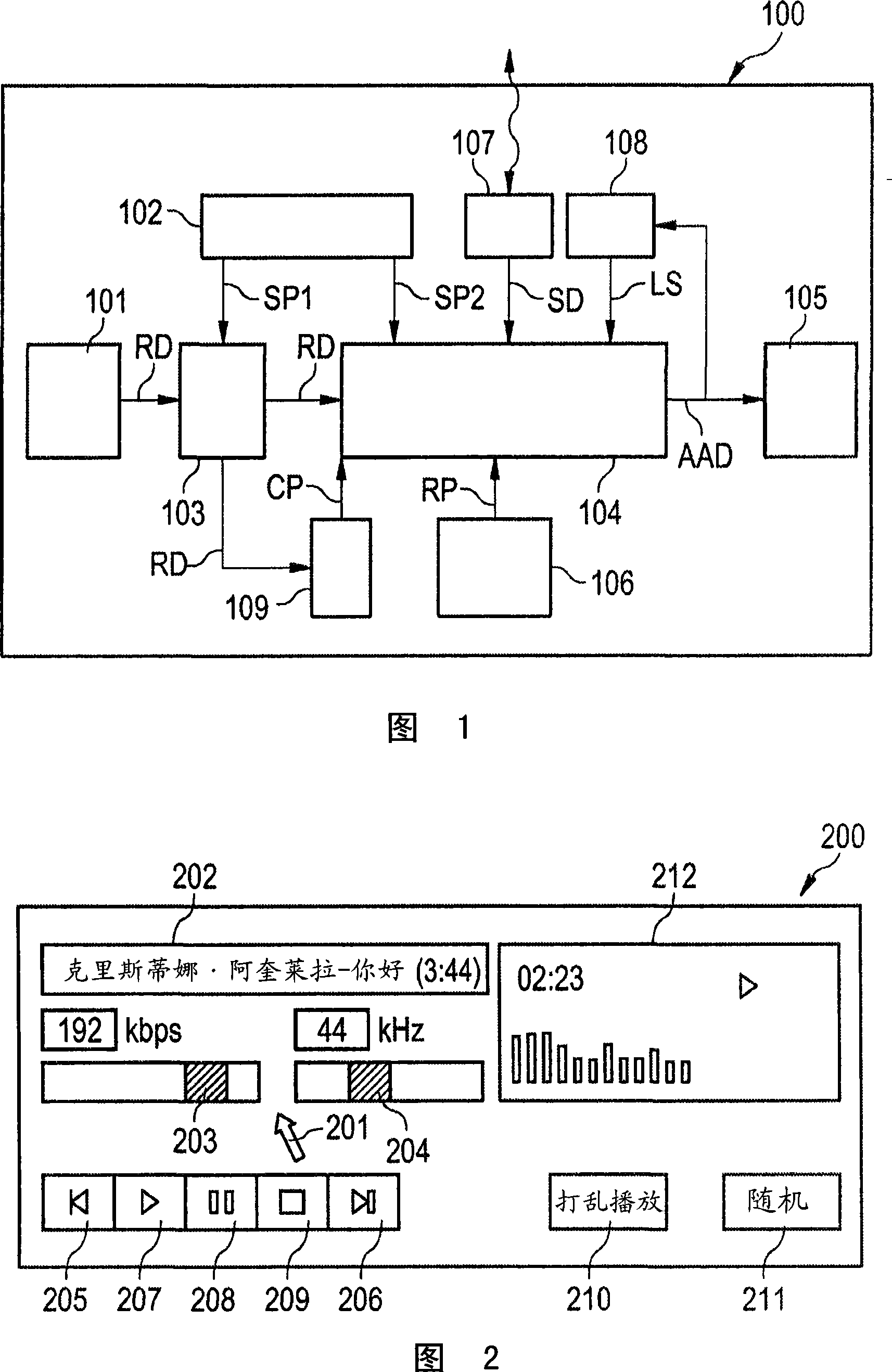

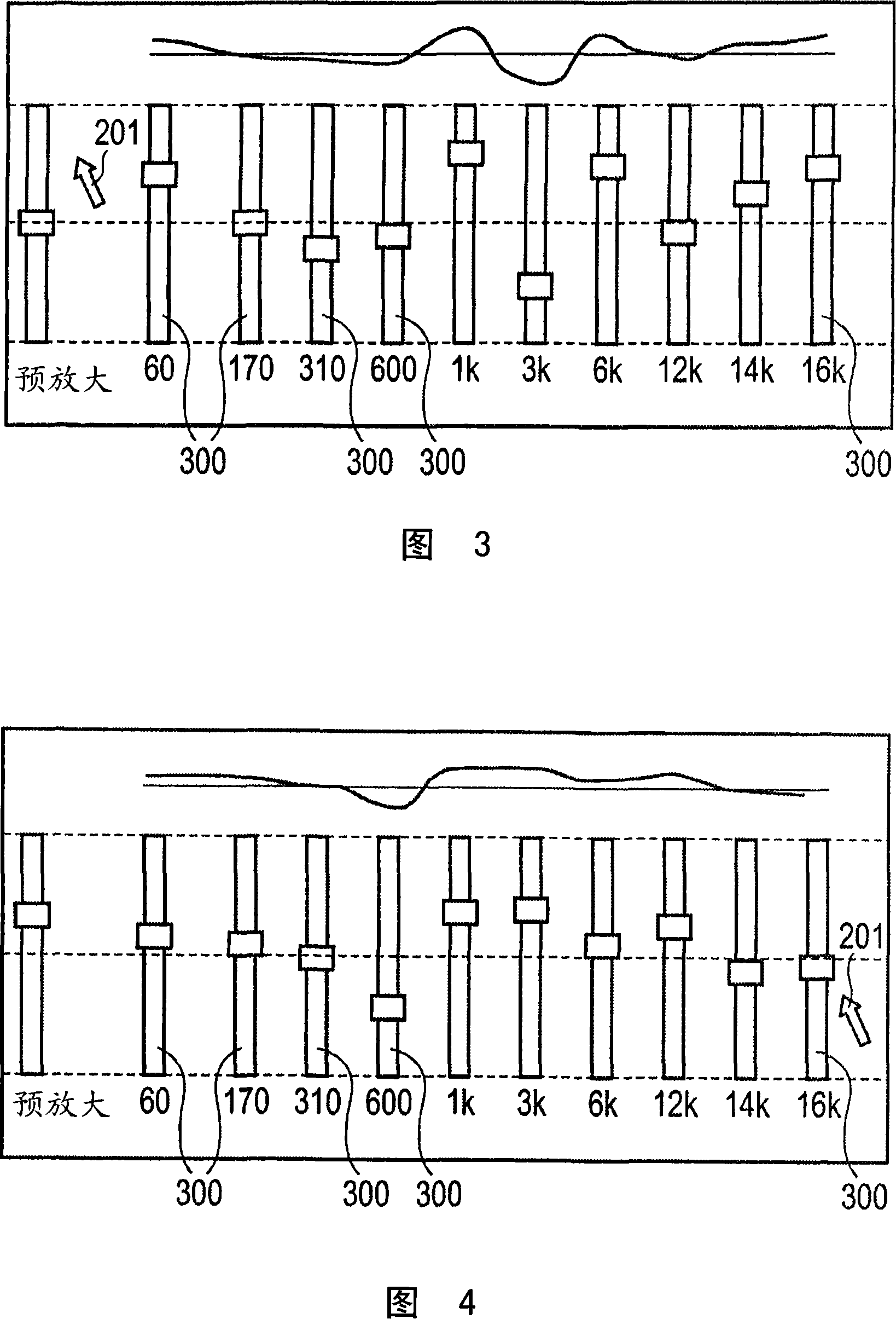

An apparatus (100) for processing reproducible data comprises a receiving unit (103) adapted to receive reproducible data in a given order, and a processing unit (104) adapted to generate altered reproducible data by altering at least one property of received reproducible data in an at least partially random manner, wherein the alteration of at least one property is perceivable by a human sense when the altered reproducible data are reproduced in the given order.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com