Numerical control grinding machine capable of quickly removing cooling liquid for machining

A CNC grinding machine and coolant technology, applied in the direction of grinding machines, grinding beds, metal processing equipment, etc., can solve the problems of affecting the cooling effect of the grinding mechanism, unable to cool down quickly, and temperature rise, etc., to achieve good cleaning effect of impurities and increase filtration Difficulty, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Such as figure 1 As shown, a numerically controlled grinding machine for rapid cleaning and processing of coolant includes a grinding machine 1, a grinding mechanism 2 installed on the grinding machine 1, a cooling mechanism 3 arranged on one side of the grinding mechanism 2, a cooling mechanism 3 arranged on the grinding mechanism 2 below and installed on the grinding machine 1, an adsorption mechanism 5 arranged under the carrying mechanism 4 and used to collect impurities on the carrying mechanism 4, and two groups are arranged symmetrically on the Screening mechanisms 6 on both sides of the carrying mechanism 4;

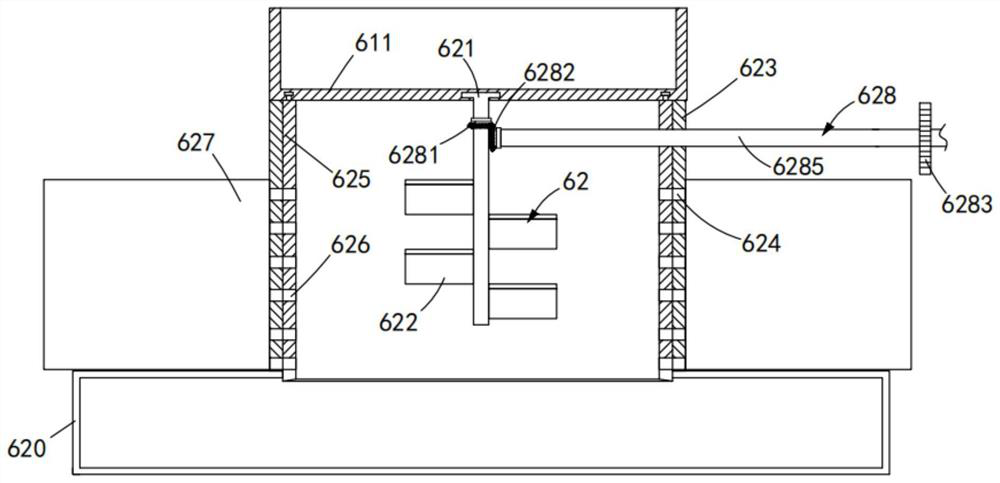

[0074] The screening mechanism 6 includes an iron filings collection assembly 61, a clean water output assembly 62 arranged below the iron filings collection assembly 61, arranged under the clean water output assembly 62 and cooperates with the clean water output assembly 62 to complete clean water throwing A working grindstone particle collection assembl...

Embodiment 2

[0122] Such as Figure 14 to Figure 23As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0123] further, such as Figure 14 to Figure 23 As shown, the iron filings collection assembly 61 includes:

[0124] The installation frame a611, the installation frame a611 is installed on the frame 41 and its lower end is provided with several groups of blanking holes a612, and the lower end of the installation frame a611 is provided with an elastic material structure;

[0125] A rotating shaft 613, the rotating shaft 613 is installed at the lower end of the installation frame a611 and is located at the outer end of the installation frame a611;

[0126] Filter plate 614, the filter plate 614 is matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com