Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

587 results about "Grindstone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A grindstone is a round sharpening stone used for grinding or sharpening ferrous tools. Grindstones are usually made from sandstone. Grindstone machines usually have pedals for speeding up and slowing down the stone to control the sharpening process. The earliest known representation of a rotary grindstone, operated by a crank handle, is found in the Carolingian manuscript Utrecht Psalter. This pen drawing from about 830 goes back to a late antique original. The Luttrell Psalter, dating to around 1340, describes a grindstone rotated by two cranks, one at each end of its axle. Around 1480, the early medieval rotary grindstone was improved with a treadle and crank mechanism.

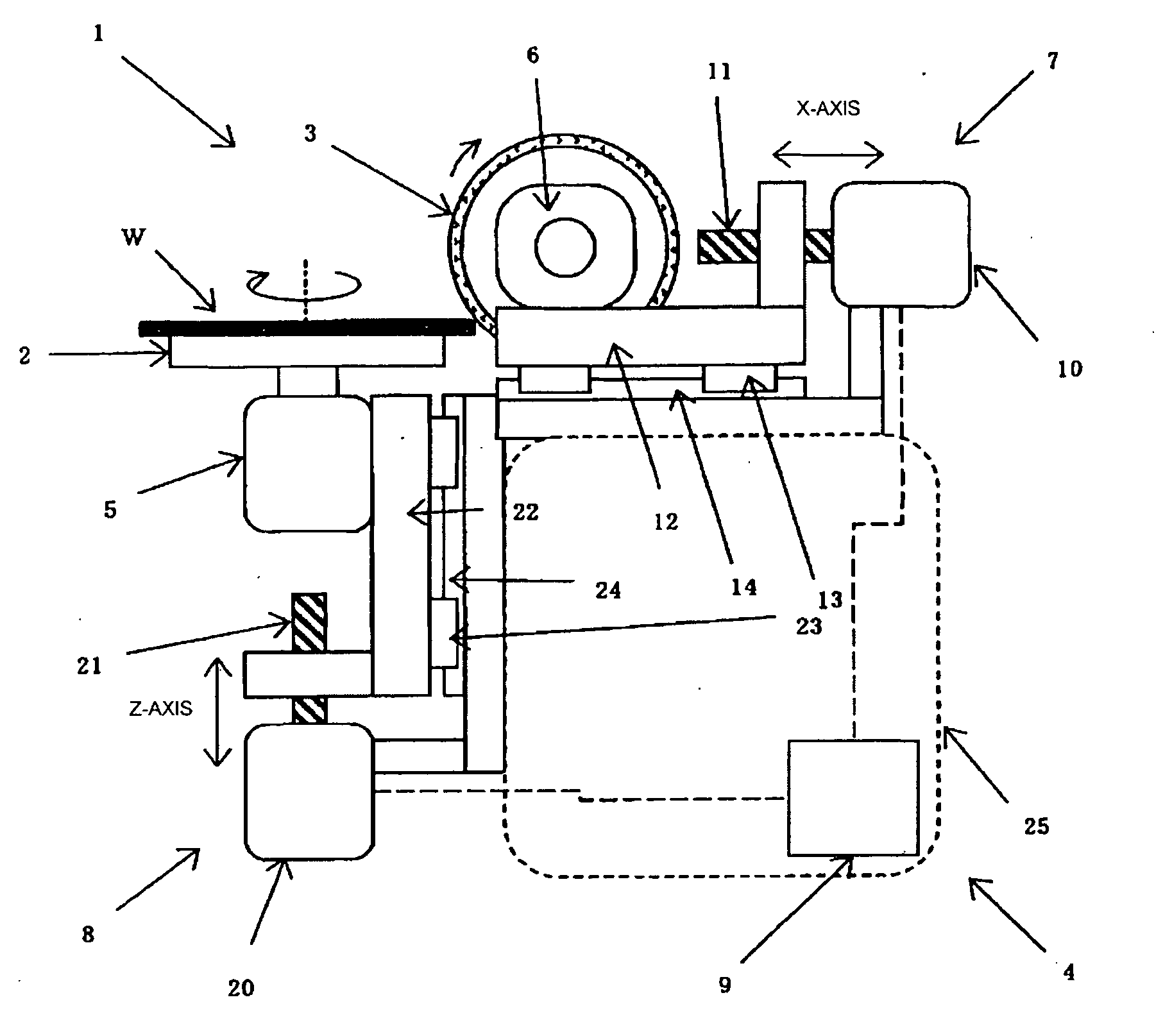

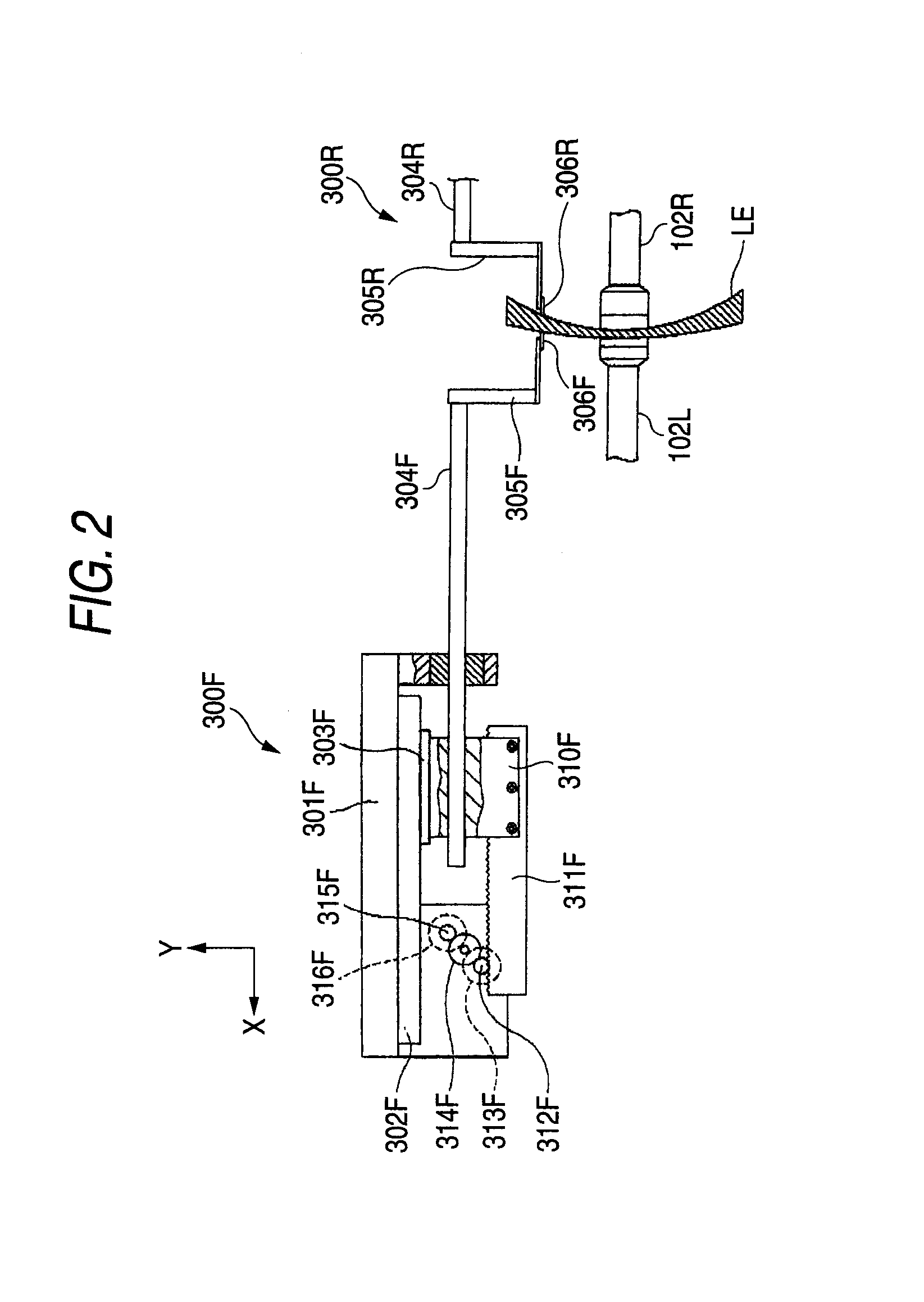

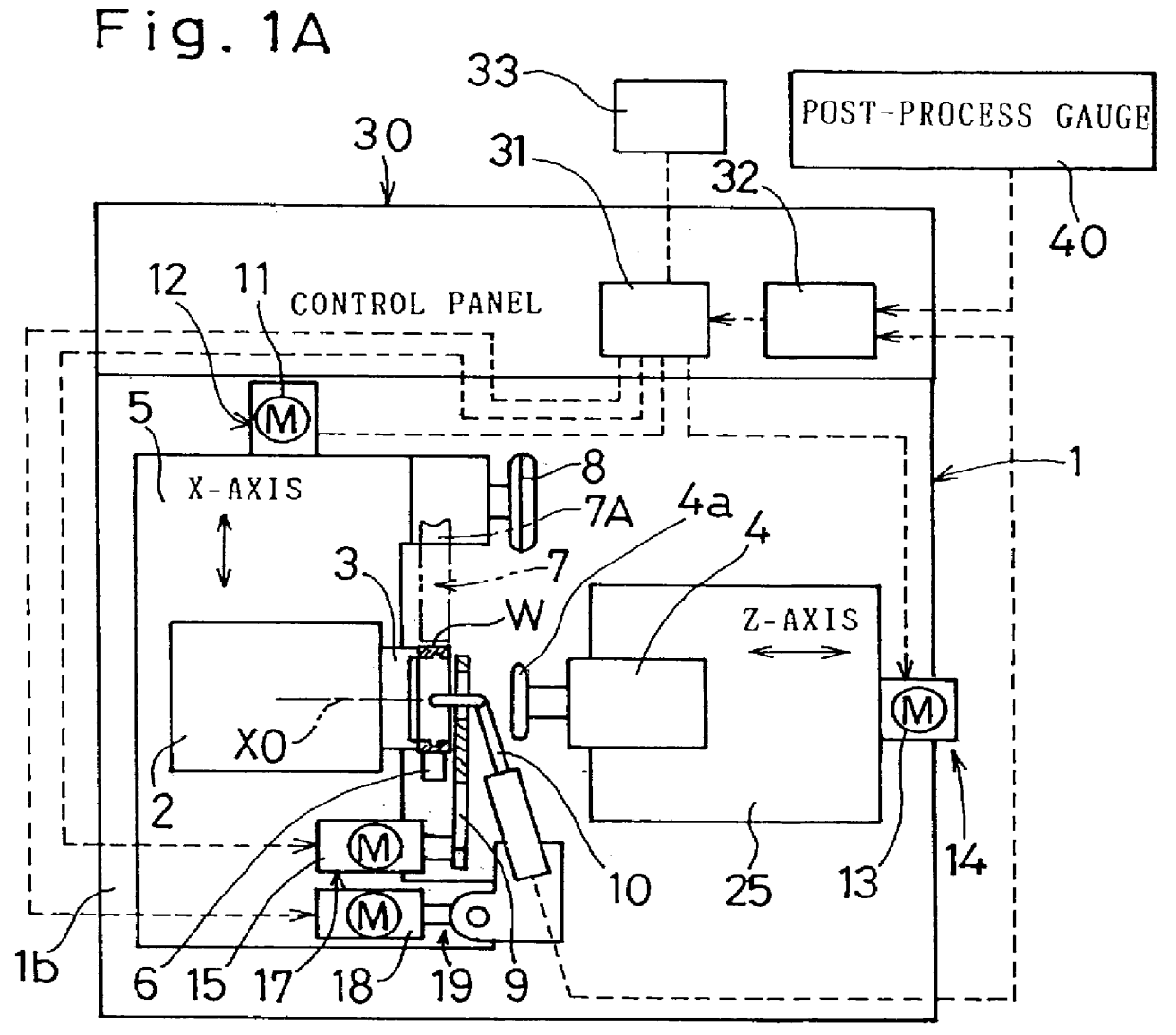

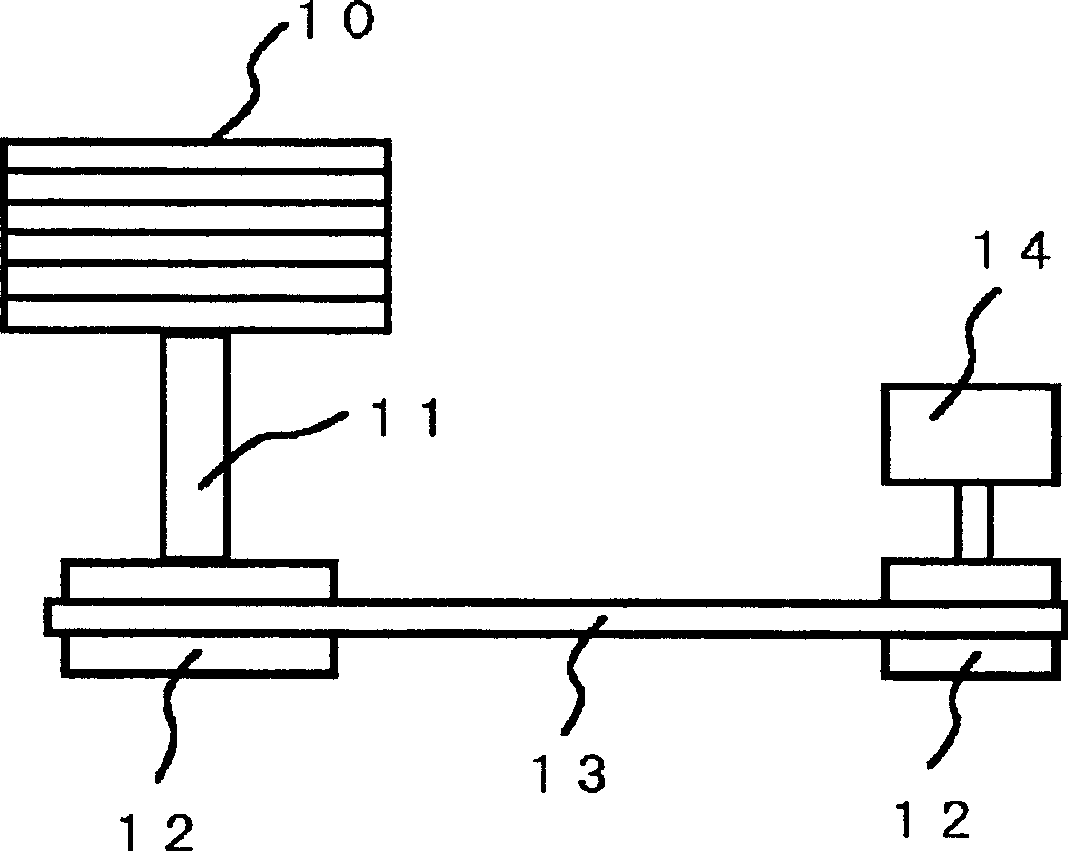

Method of grinding an axially asymmetric aspherical mirror

InactiveUS6537138B2Improve accuracyReliably madeEdge grinding machinesOptical surface grinding machinesNumerical controlSurface roughness

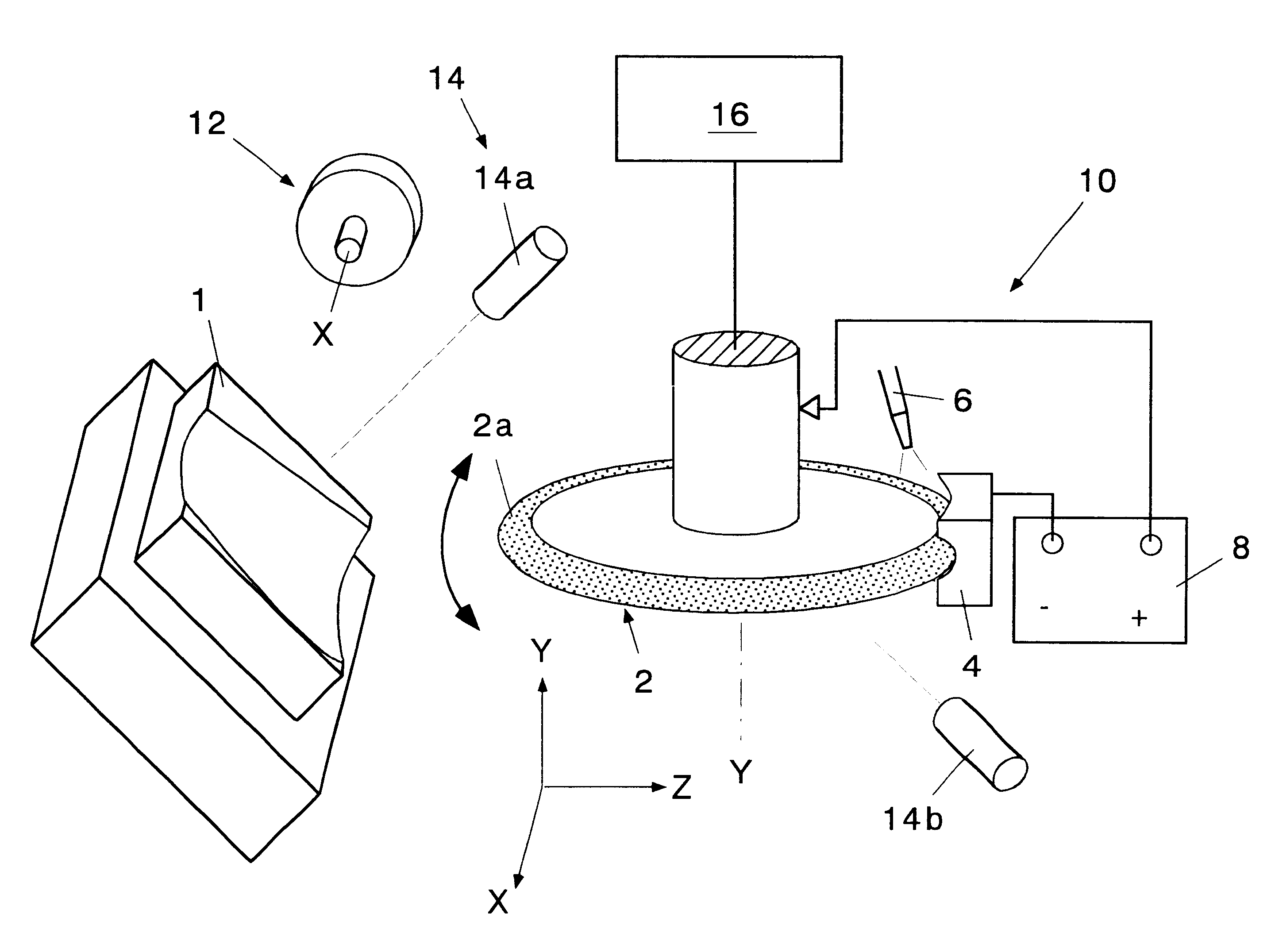

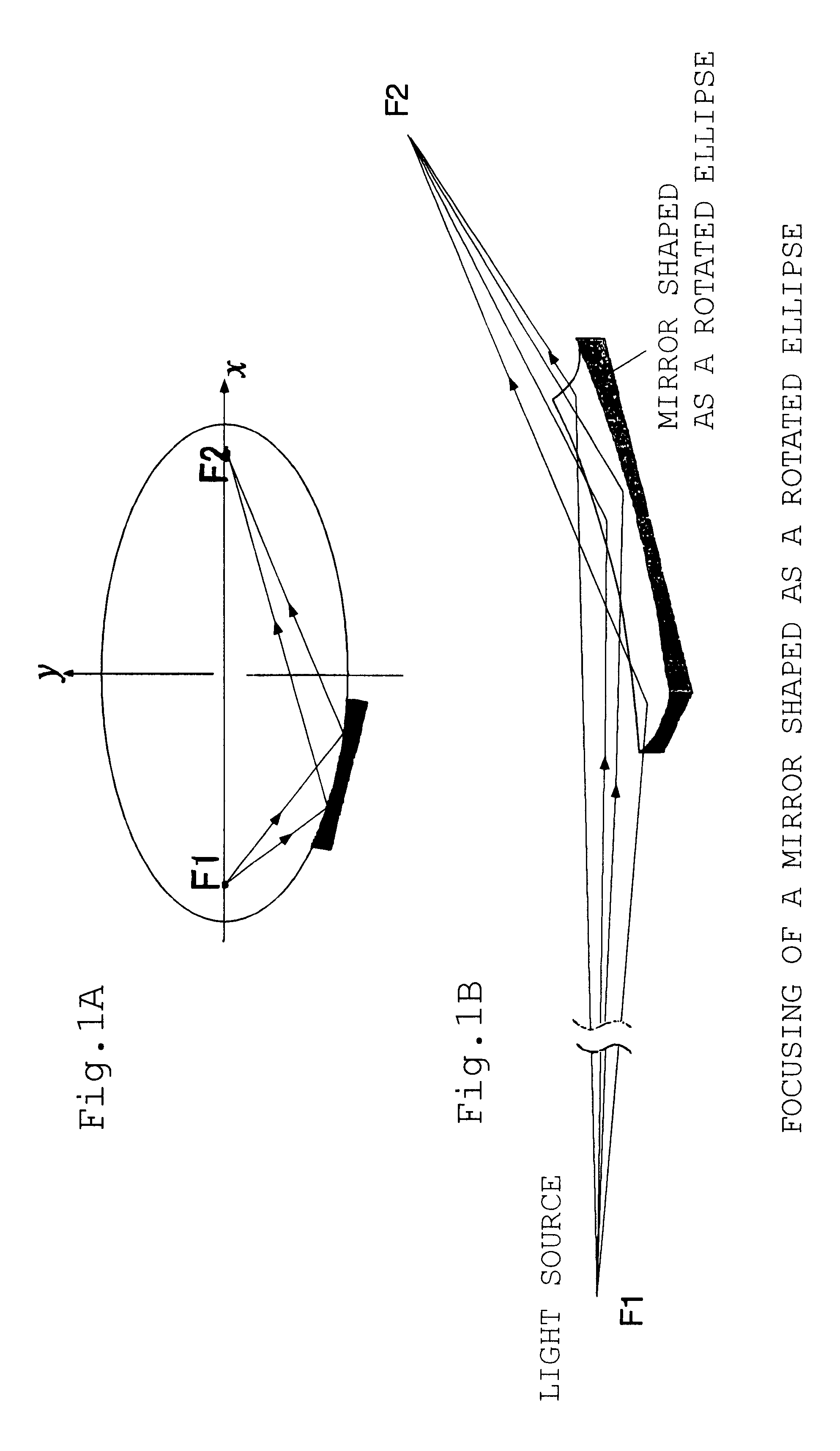

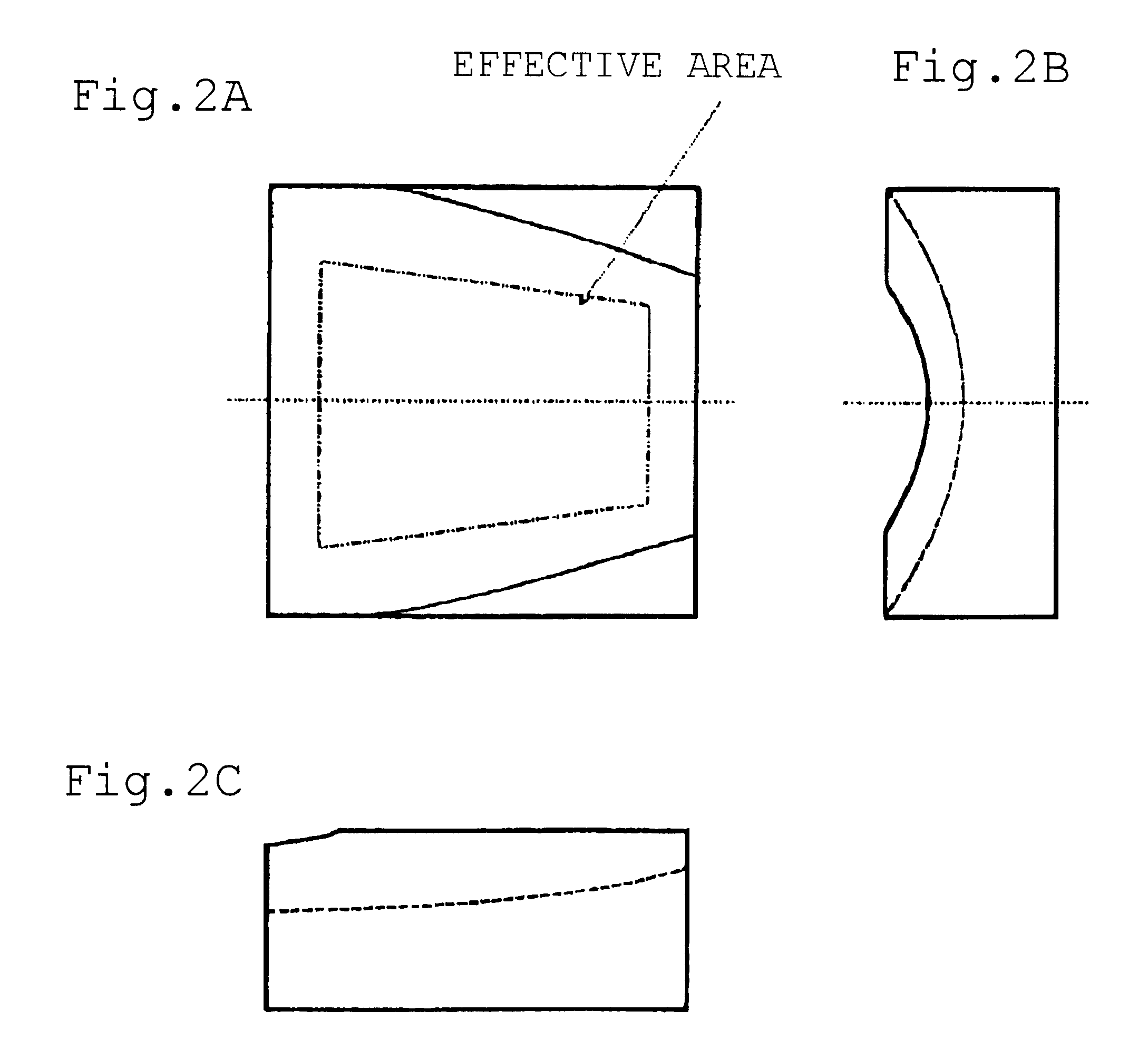

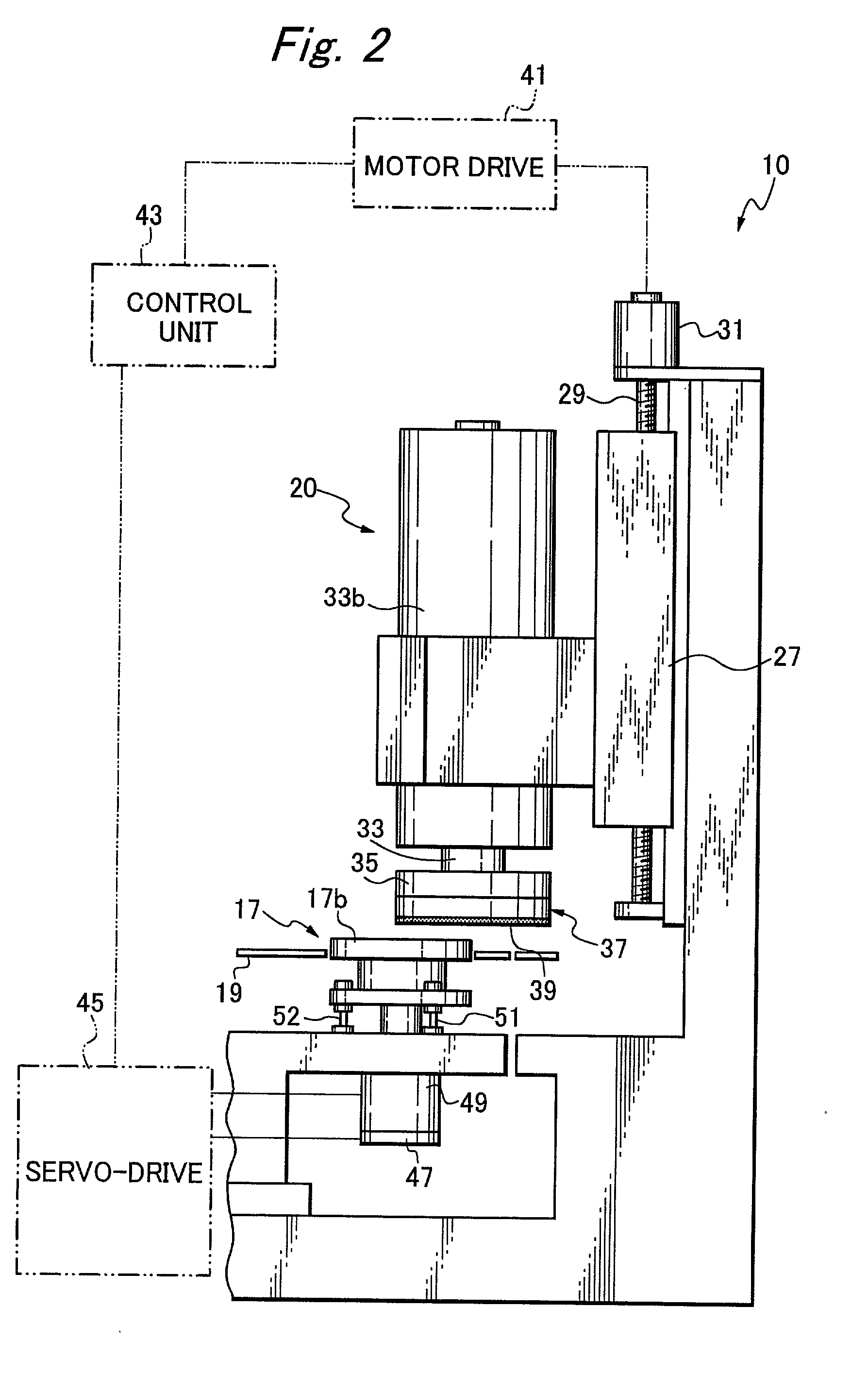

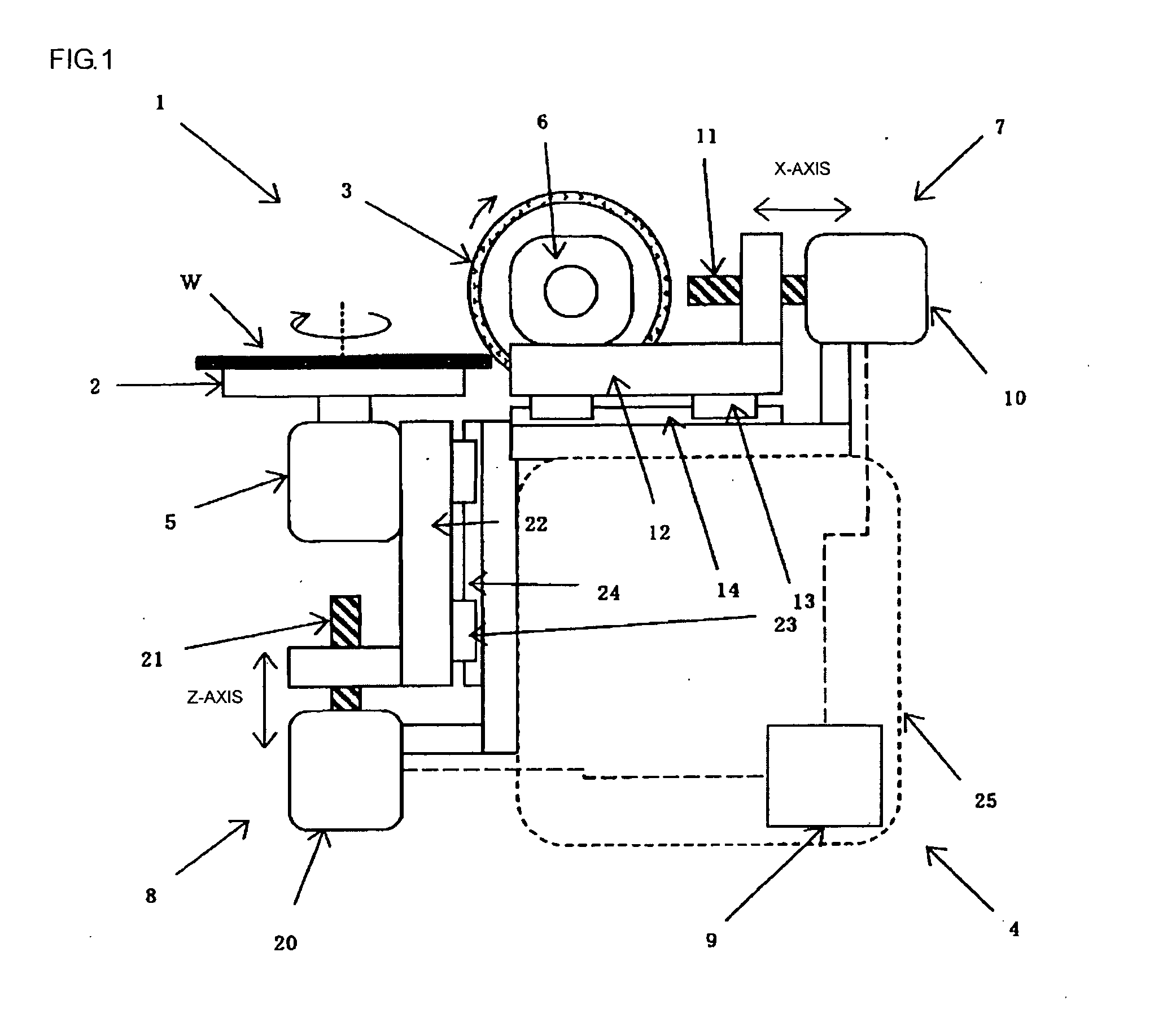

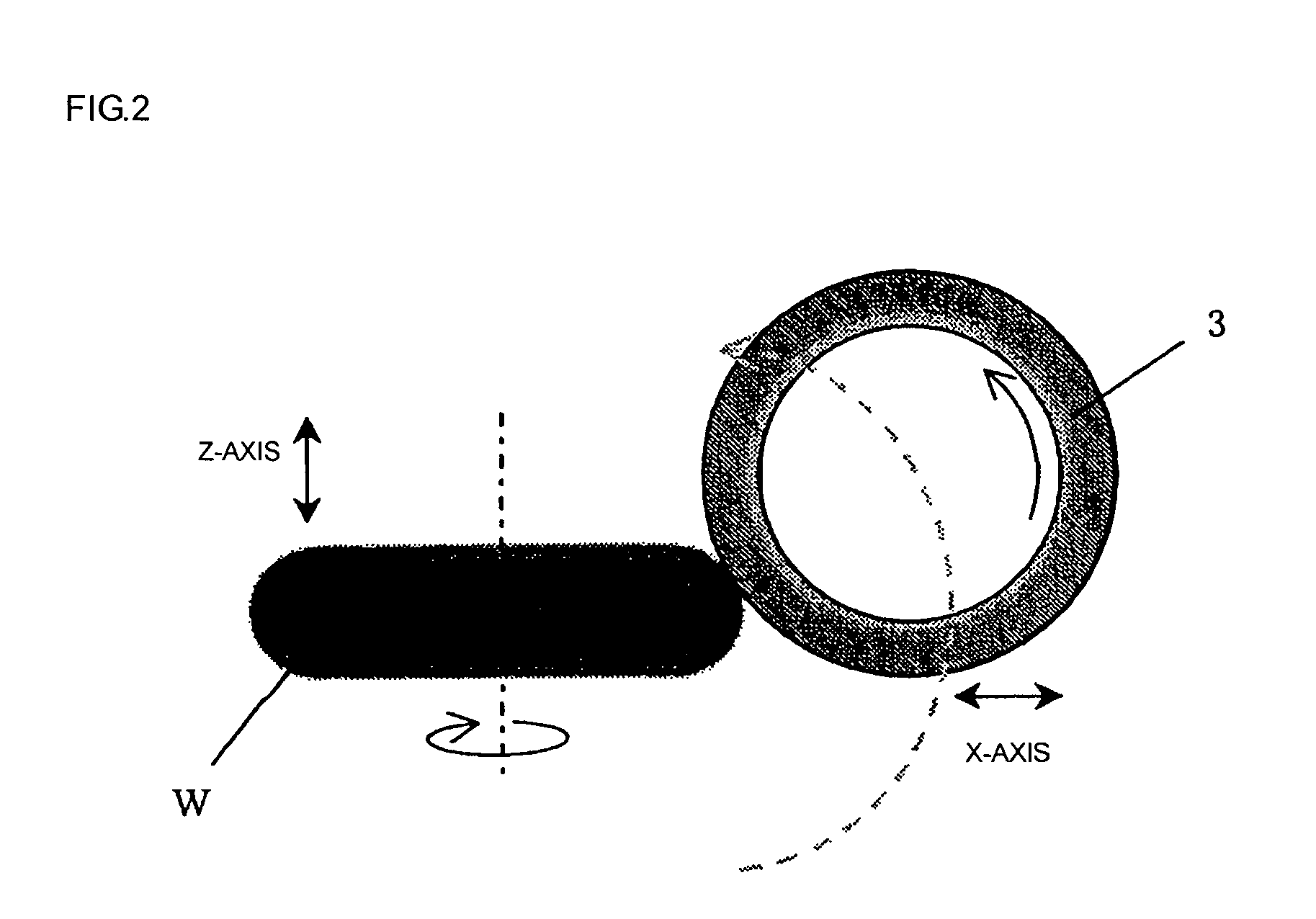

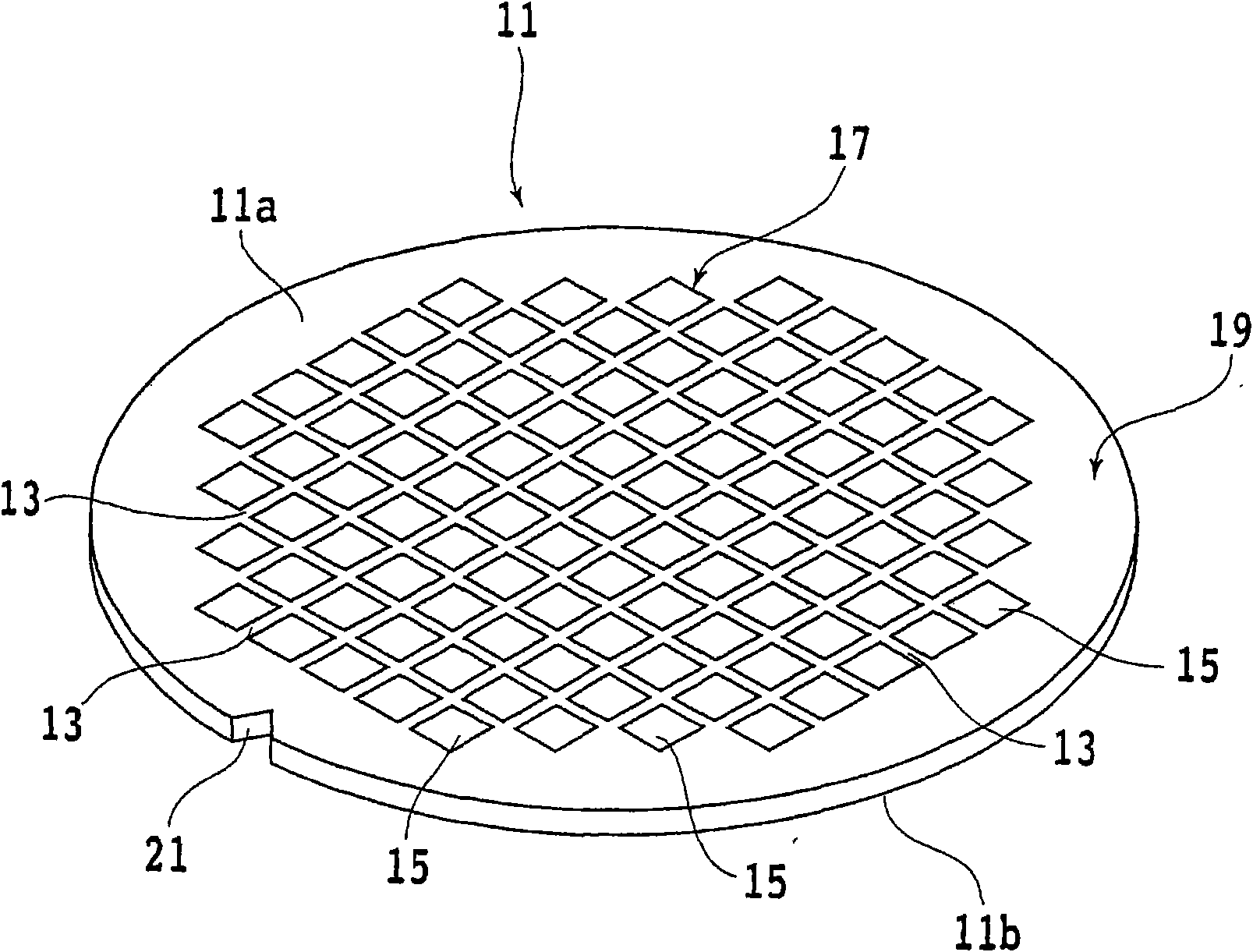

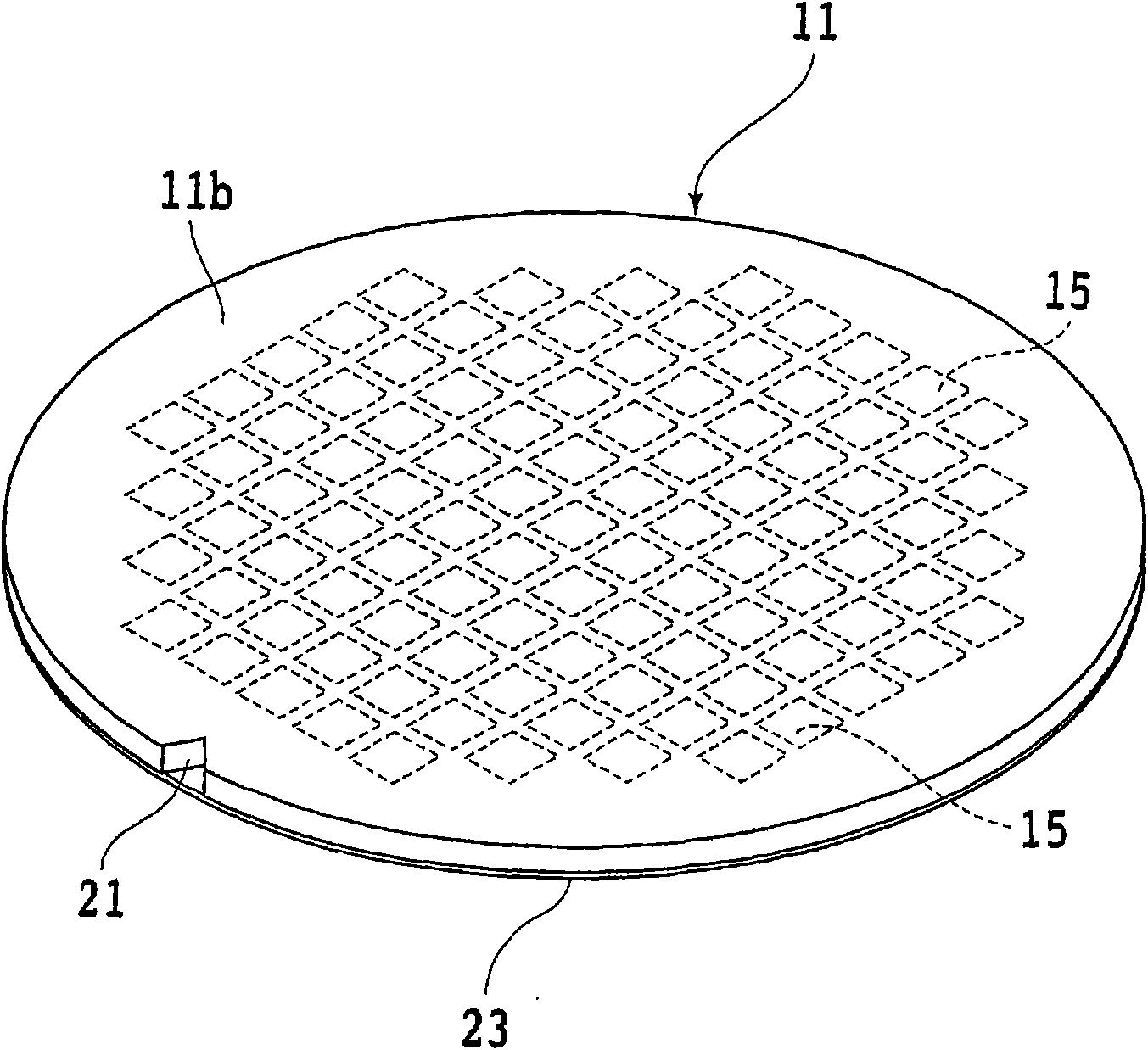

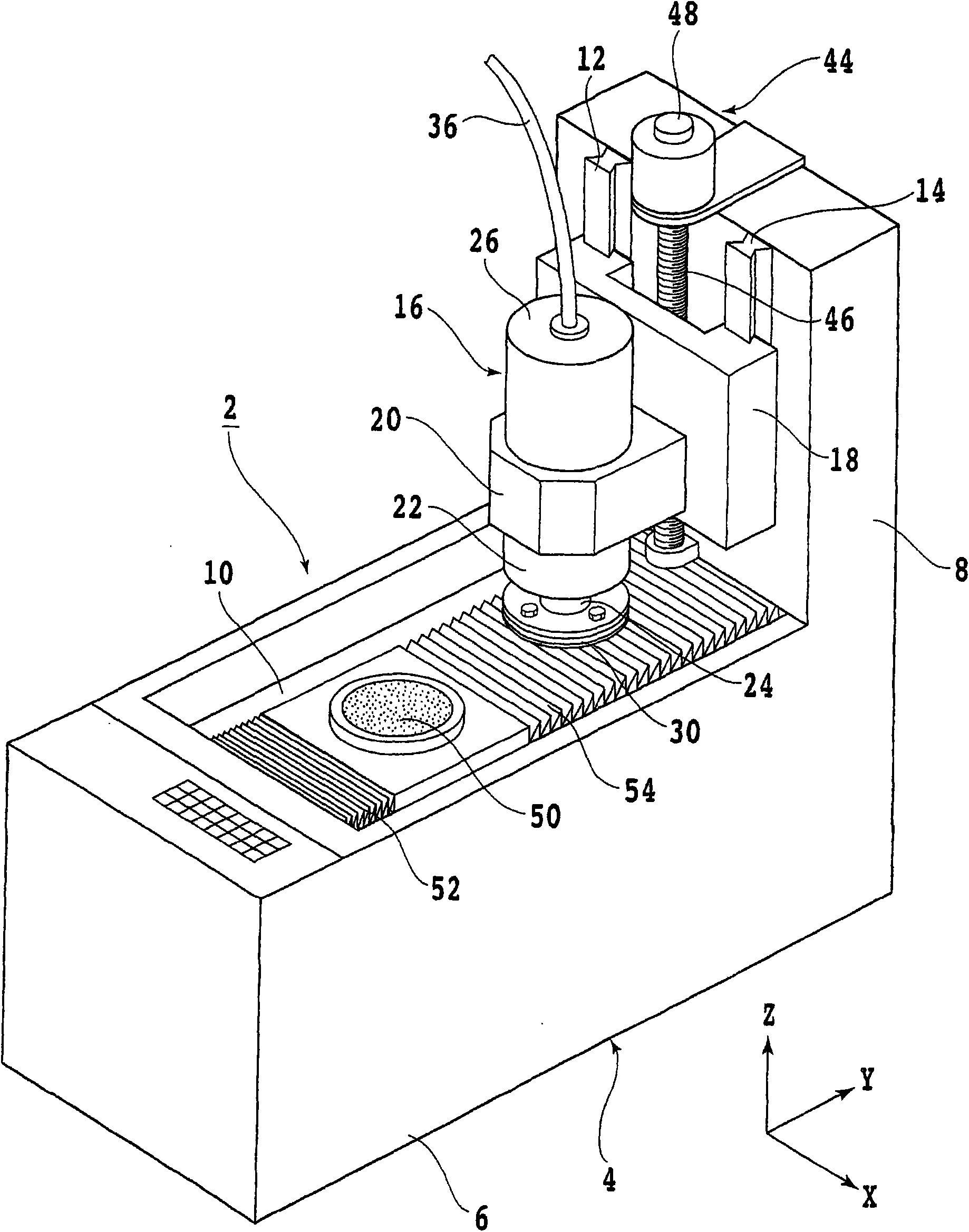

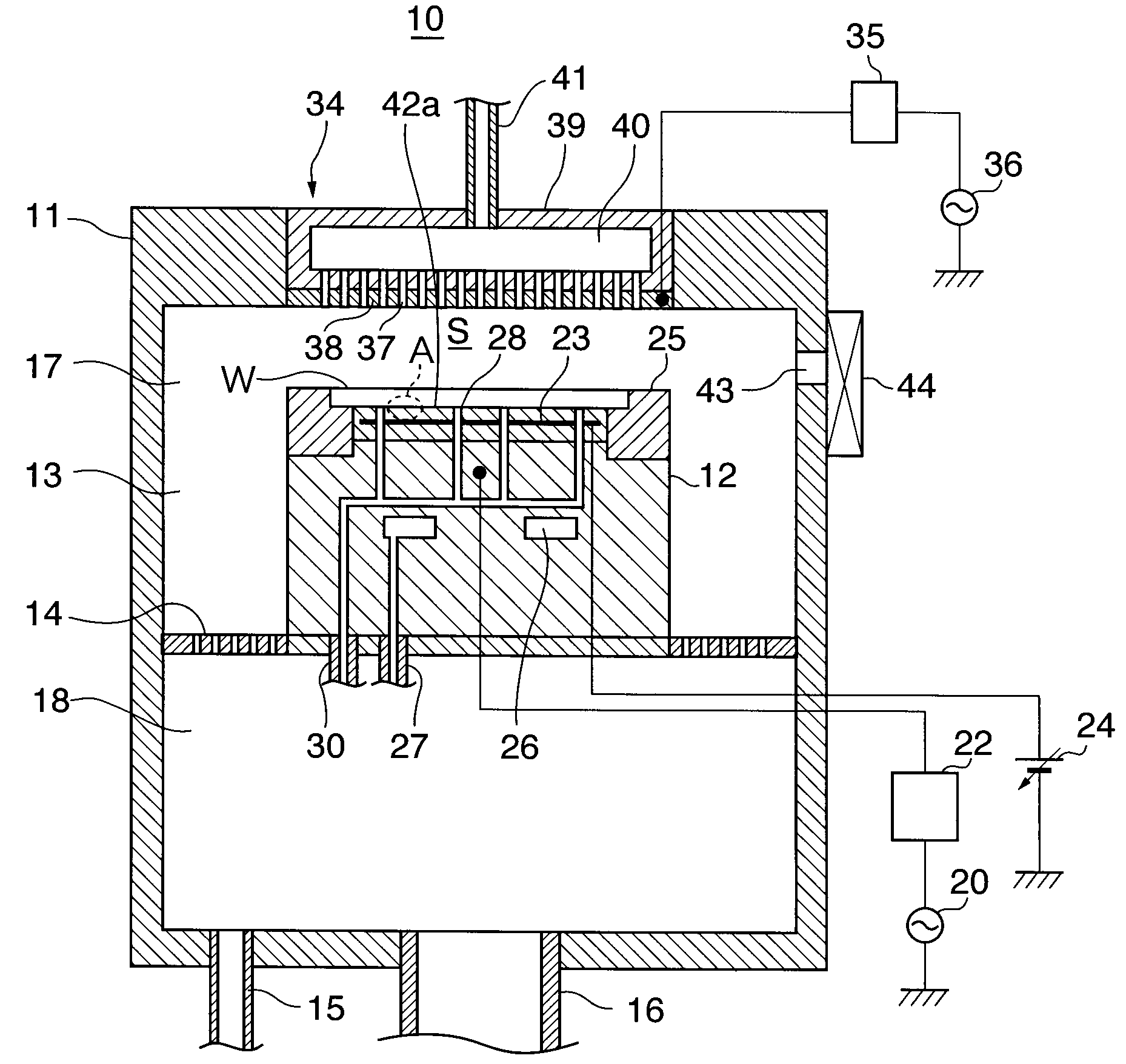

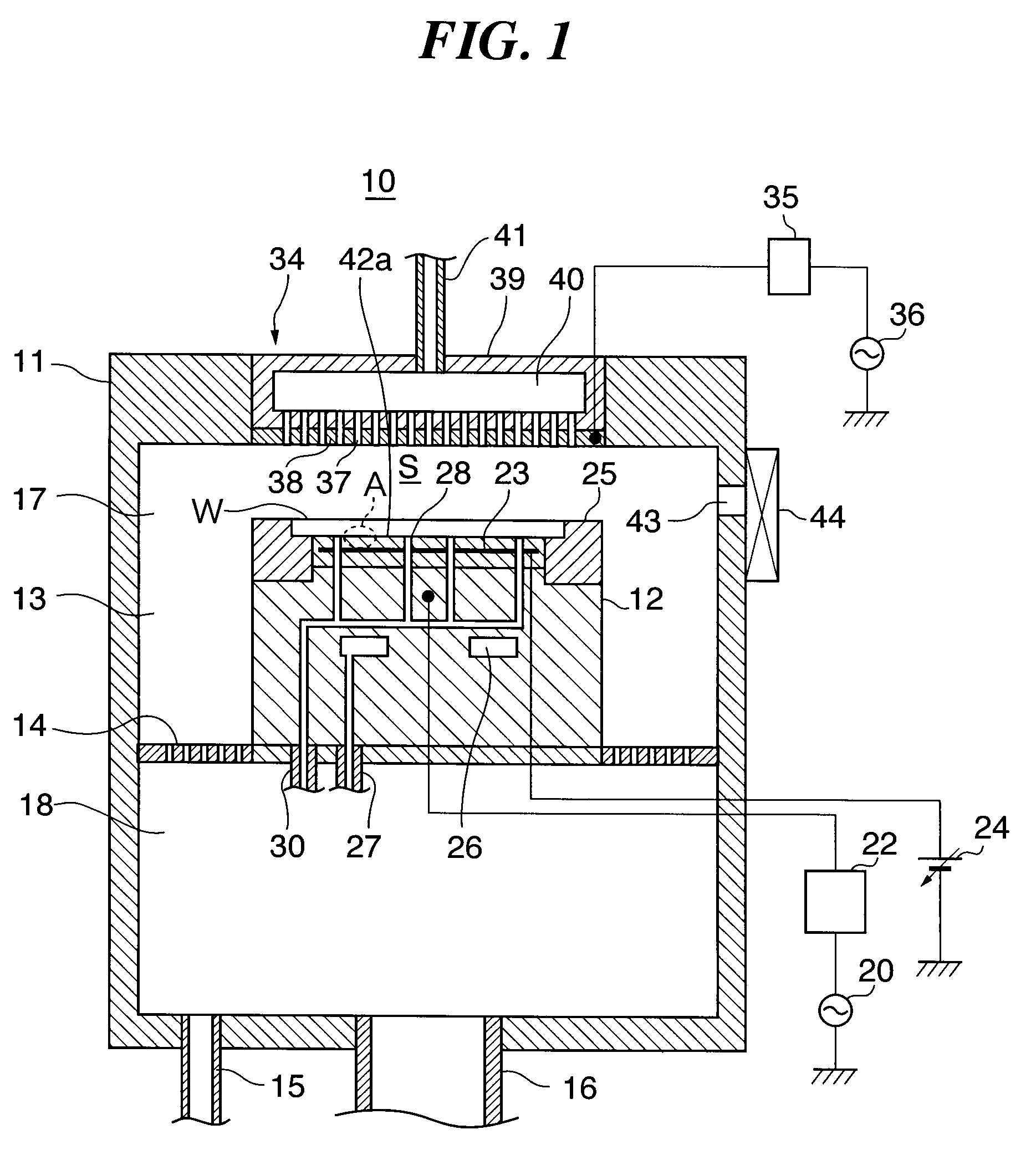

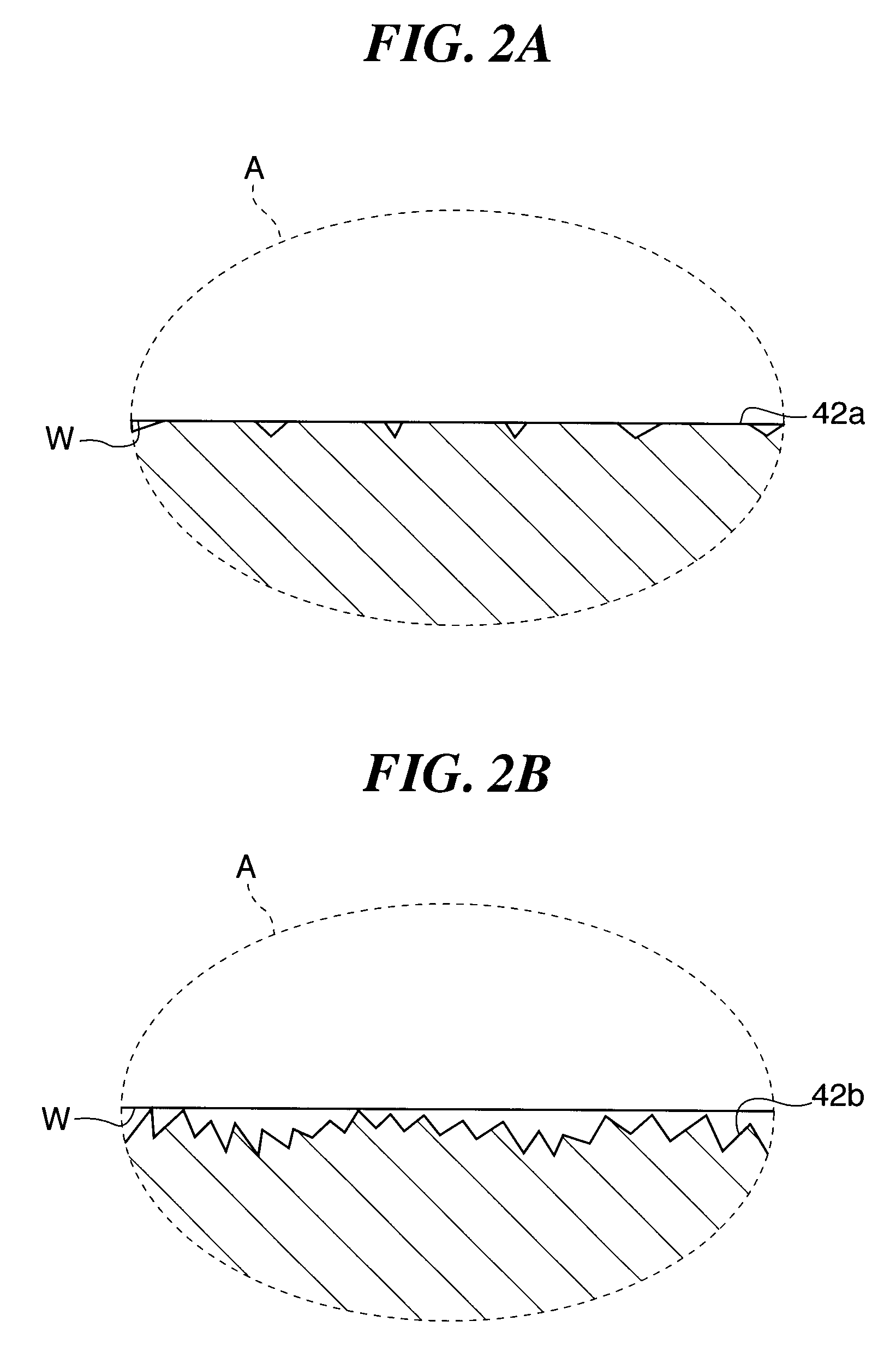

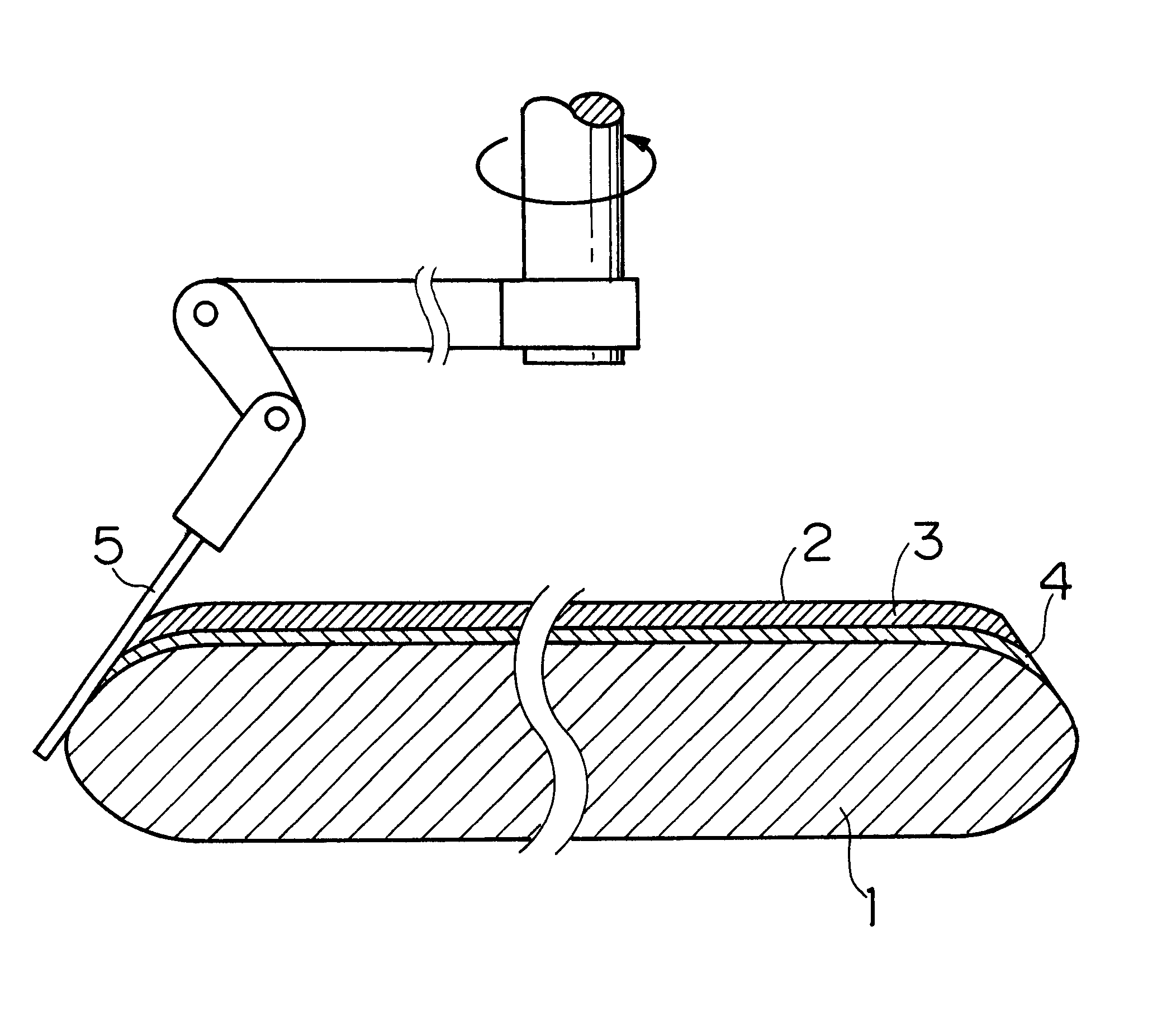

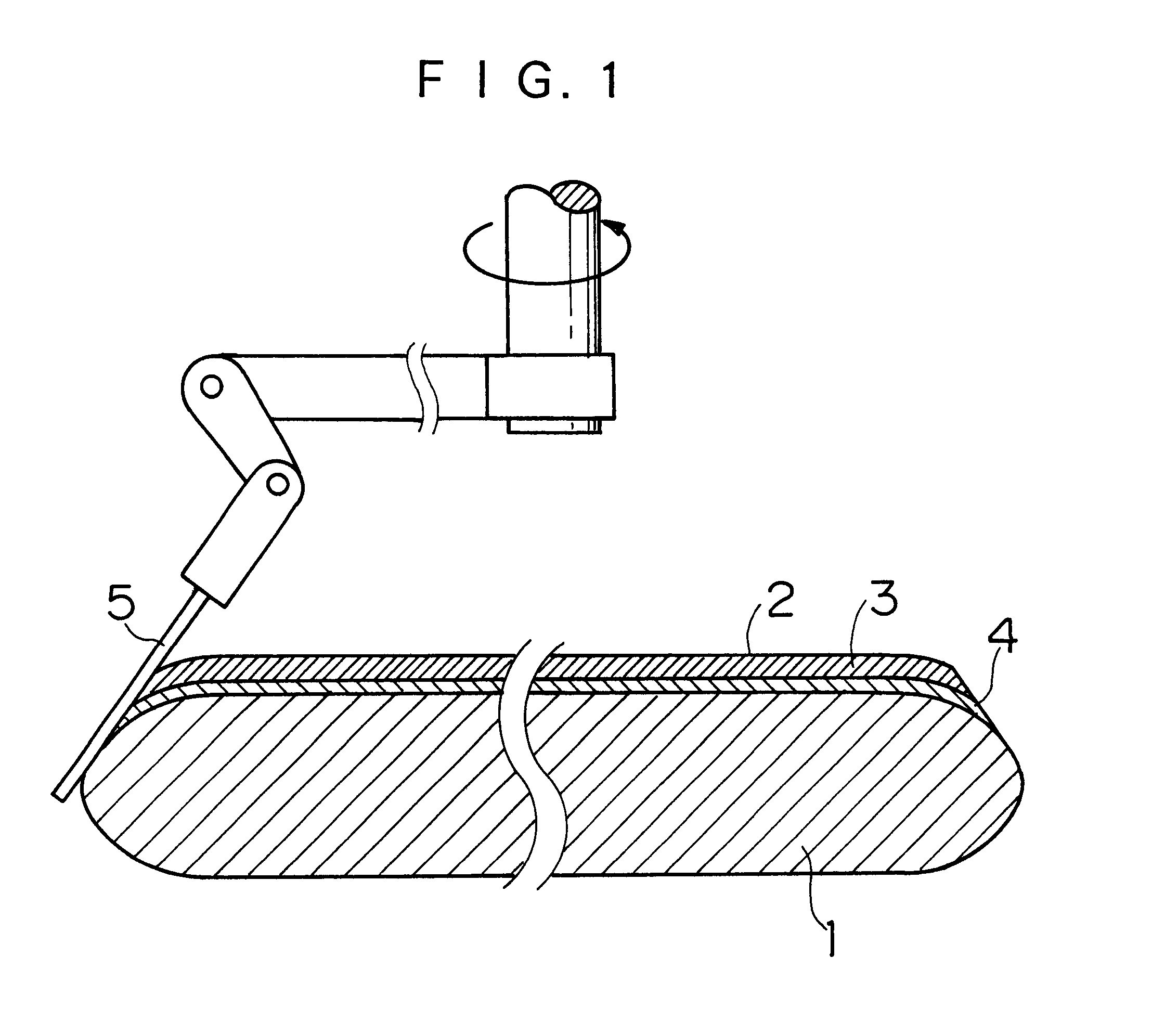

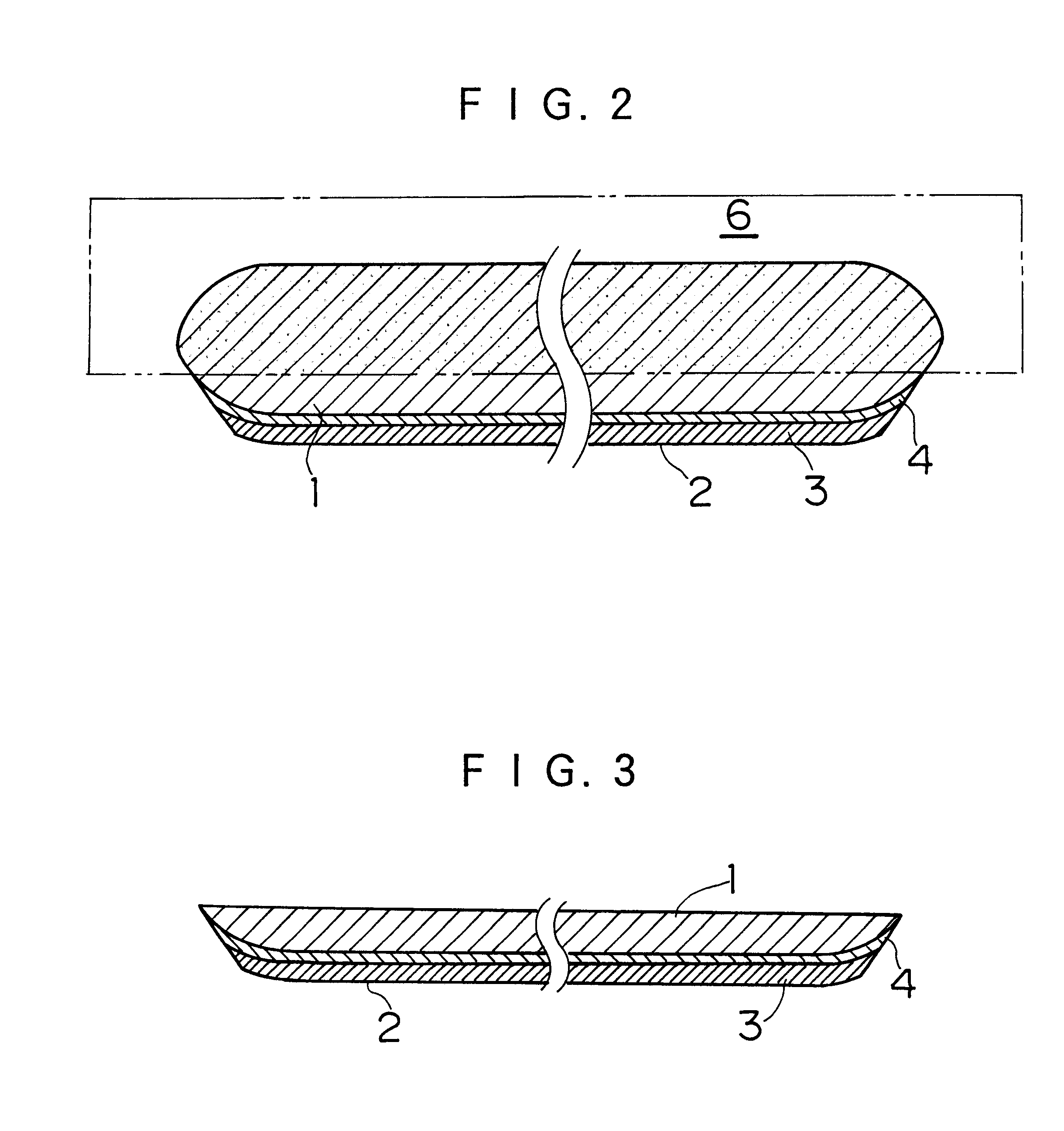

An electrolytic in-process dressing device 10 is provided with a disk-shaped metal-bonded grindstone 2 with a surface 2a with a circular arc shape with a radius R at its outer periphery and a numerical control device 16. The disk-shaped metal-bonded grindstone 2 rotates around an axis Y, and the grindstone is dressed electrolytically while the device 10 grinds the workpiece 1. The numerical control device 16 is provided with a rotary truing device 12 that rotates around the X axis that orthogonally crosses the axis of rotation Y and trues the circular arc surface 2a, a shape measuring device 14 for measuring the shape of the circular arc surface of the grindstone and the shape of the processed surface of workpiece 1 on the machine, and controls the grindstone numerically in the three directions along the axes X, Y and Z. The numerical control device 16 moves the grindstone in three axial directions and repeats the operations of truing, grinding and measurements on-line. Thus, an axially asymmetrical aspheric mirror with a highly accurate shape and extremely low surface roughness, that can precisely reflect or converge light can be manufactured within a short time with a high accuracy.

Owner:RIKEN +1

Substrate flat grinding device

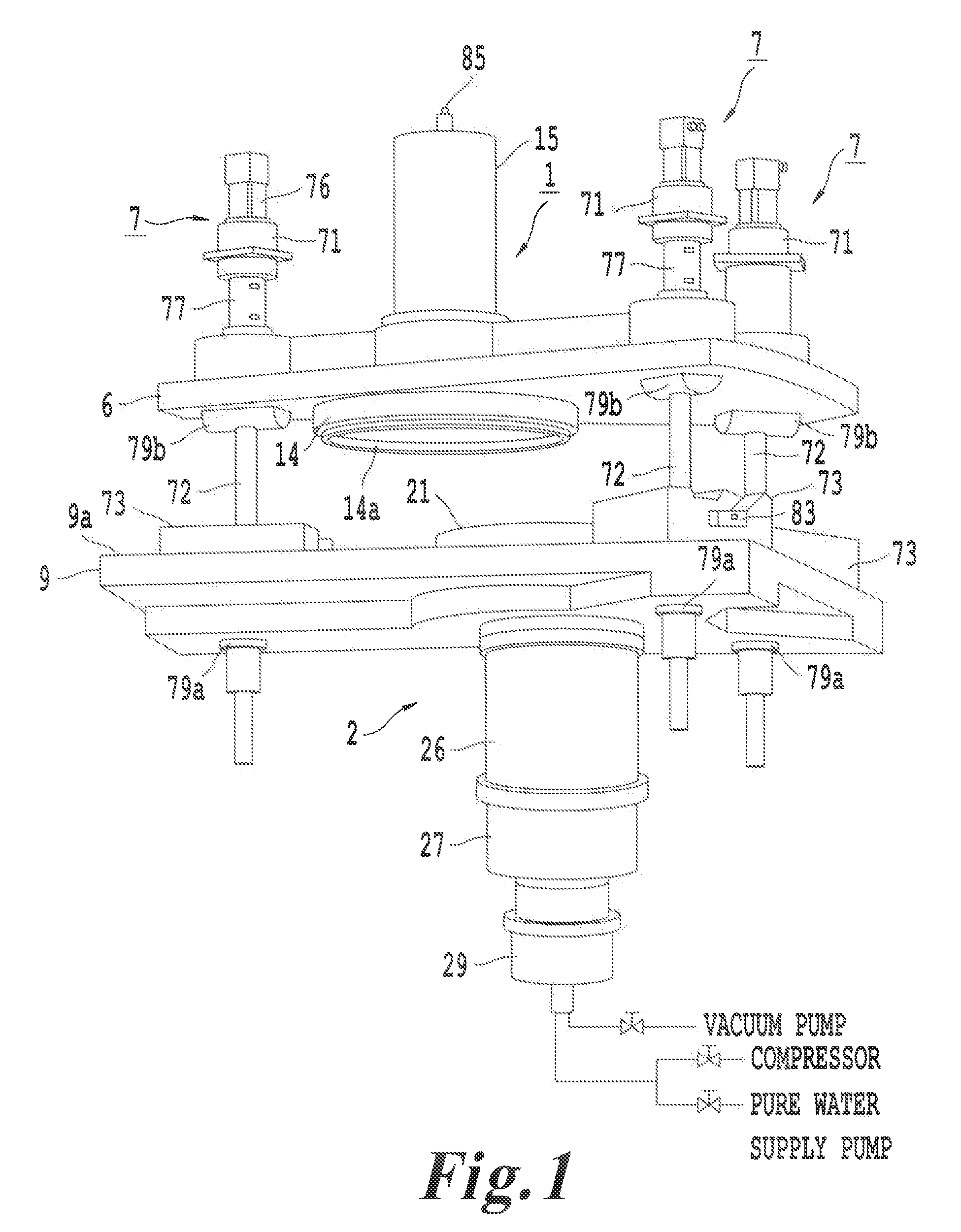

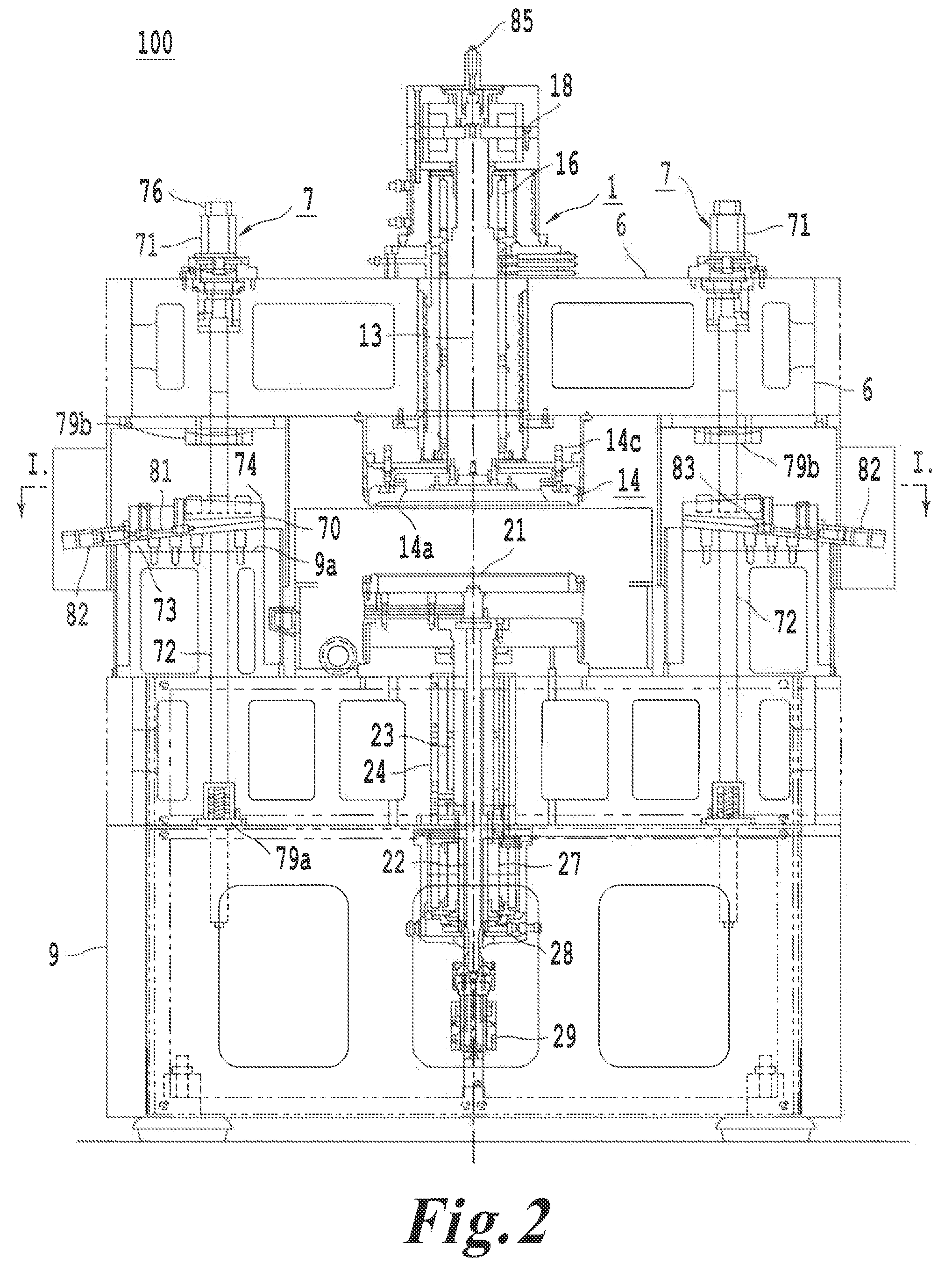

InactiveUS20090203299A1Superior flat thickness distributionImprove rigidityEdge grinding machinesPolishing machinesKinematic couplingEngineering

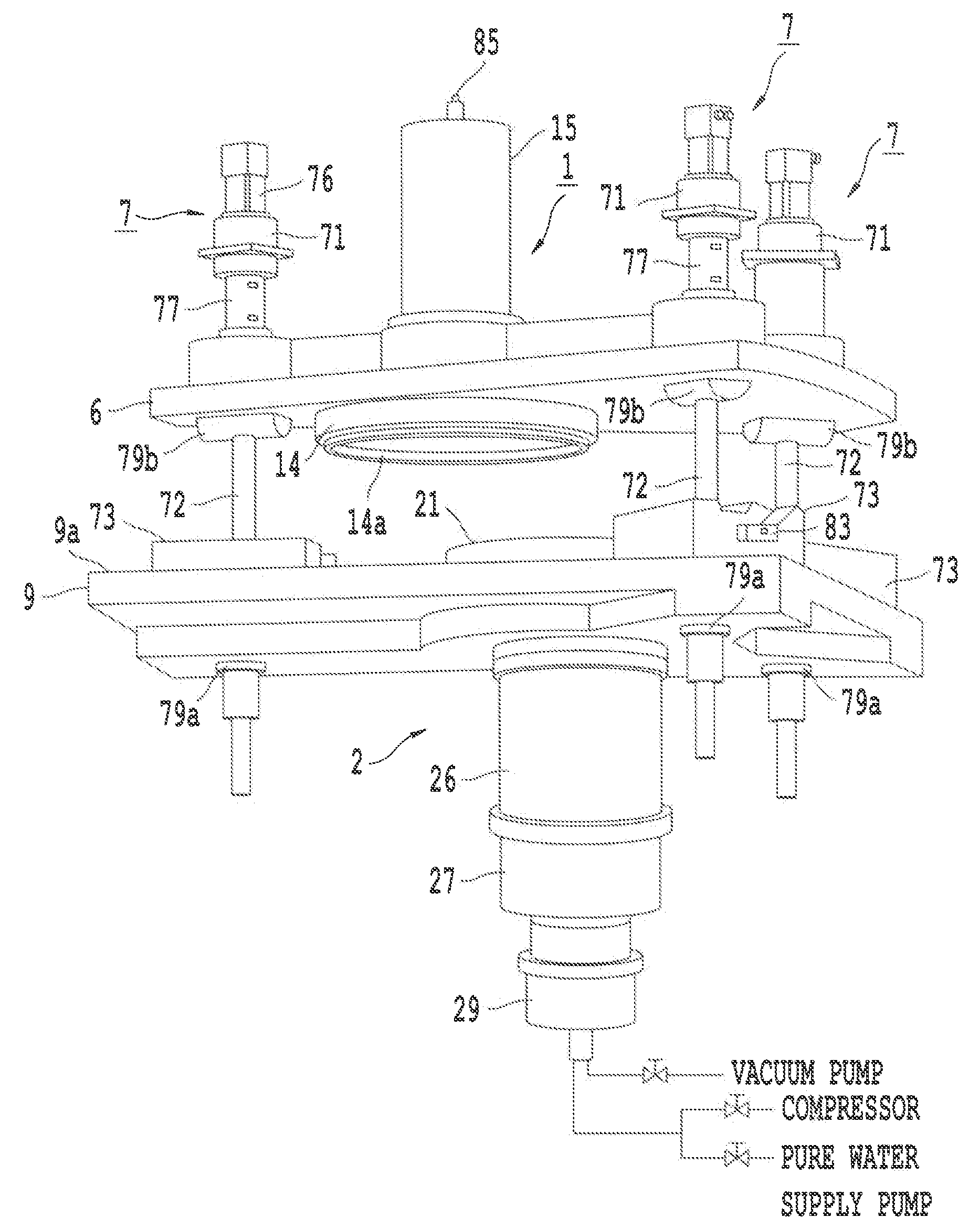

To provide a high-rigidity flat grinding device, a substrate flat grinding device has three fastening plate lifting-and-lowering mechanisms that have kinematic couplings and a cylinder rod that move the fastening plate upward or downward. Being a high-rigidity grinding device in which the load of the fastening plate 6 also is a load on the grindstone 14 that does the grinding, there is little deflection in the thickness distribution of the substrates that are obtained, even if they are semiconductor substrates having a large substrate diameter of 450 mm.

Owner:OKAMOTO MACHINE TOOL WORKS LTD

Grinding machine

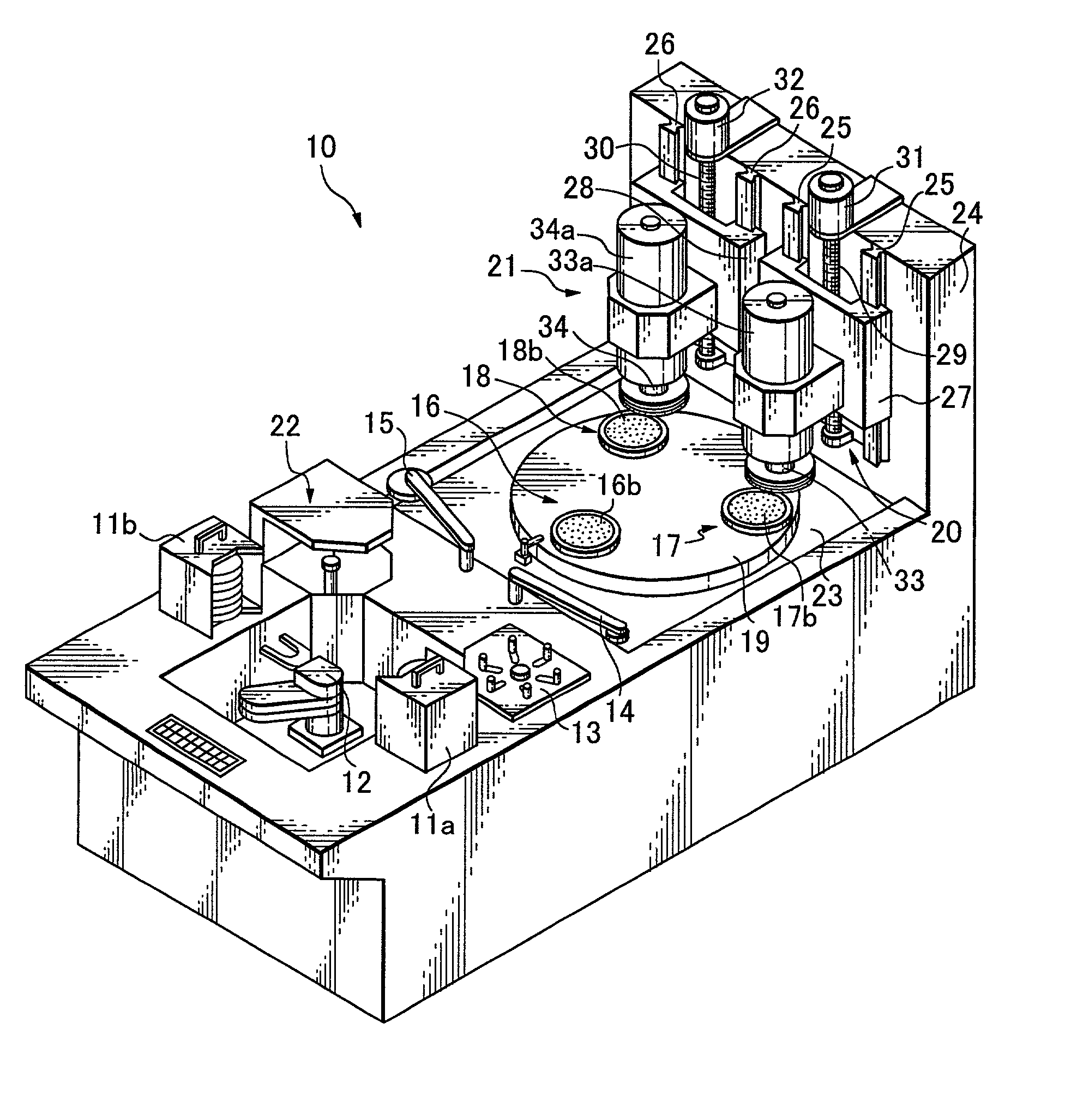

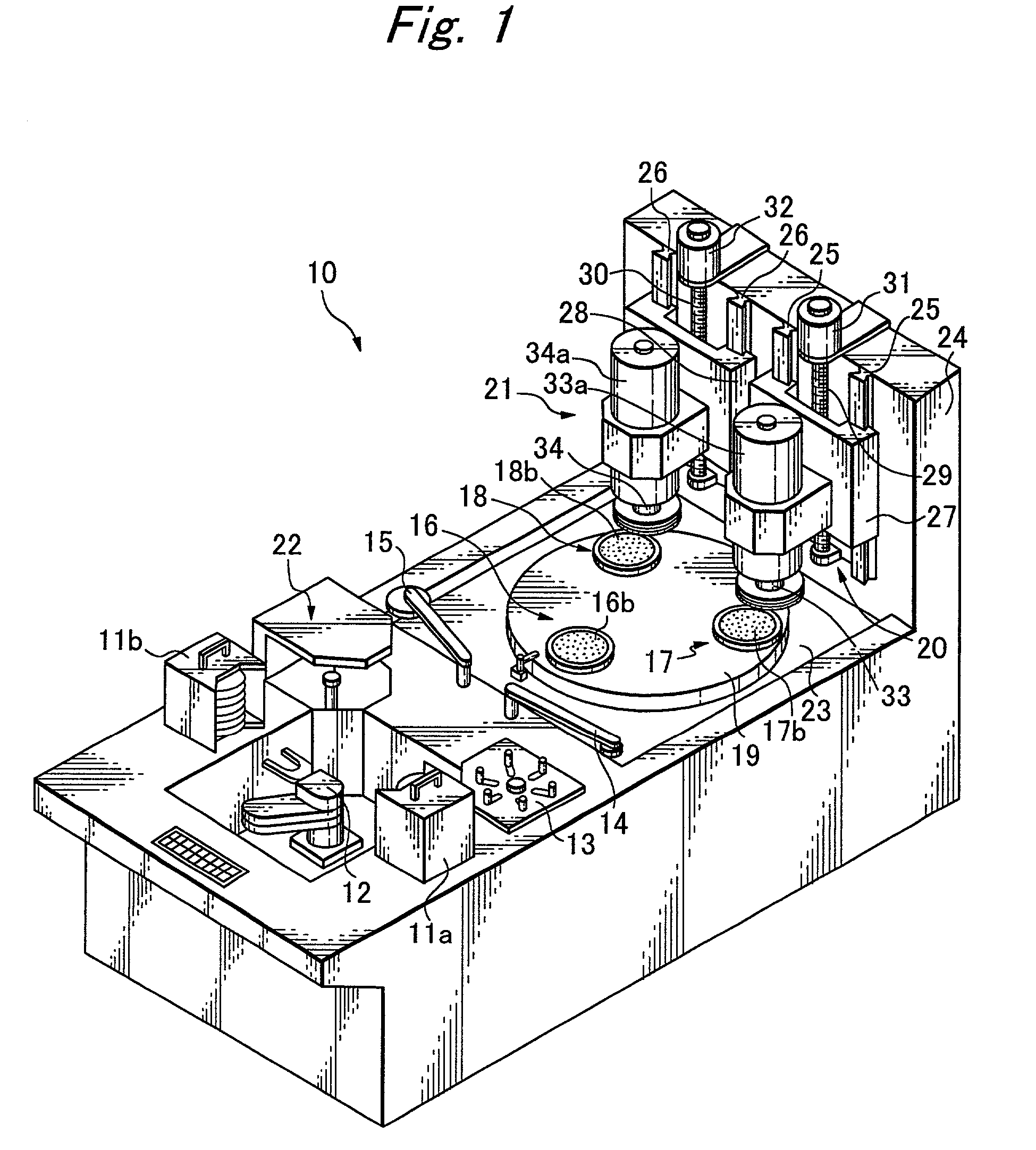

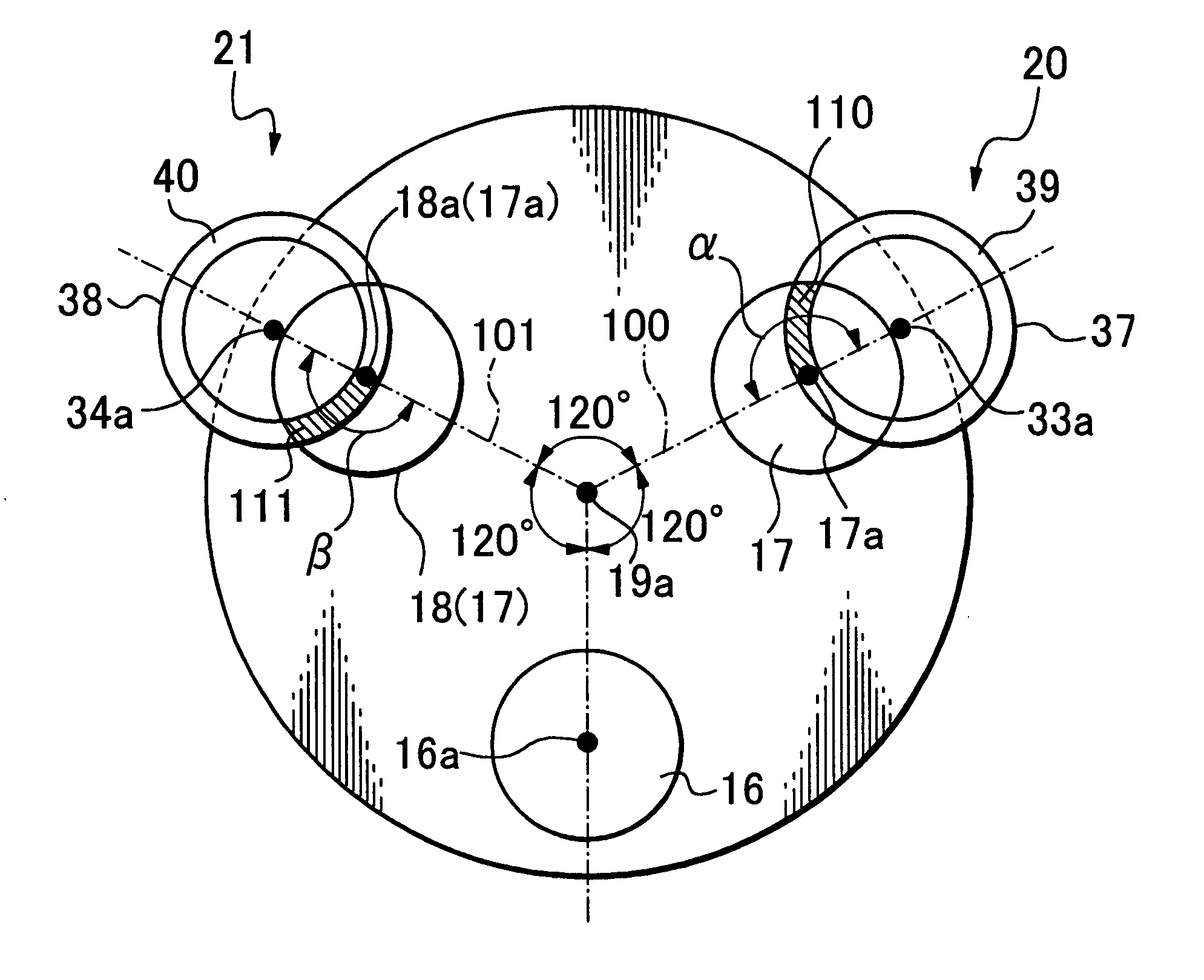

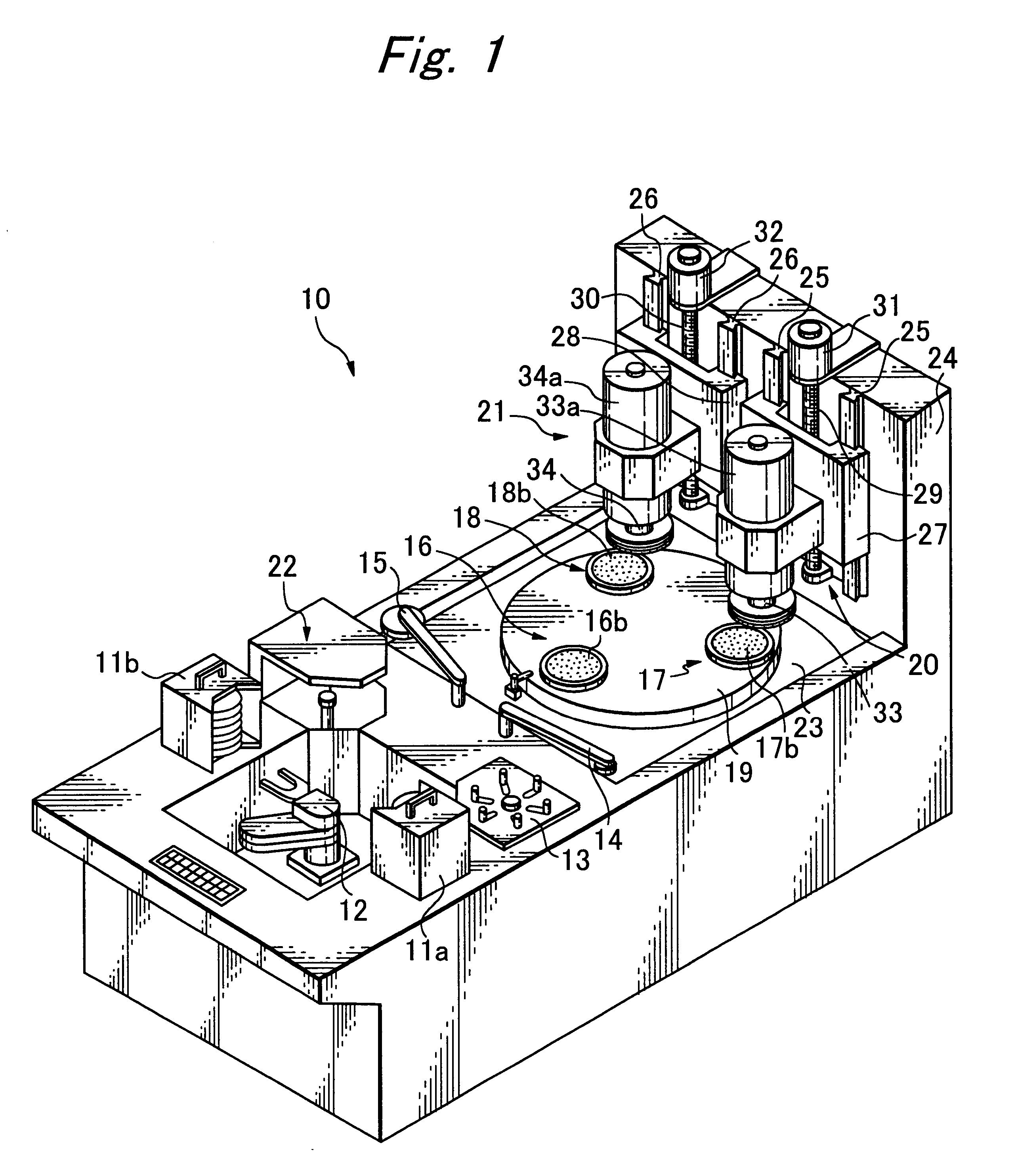

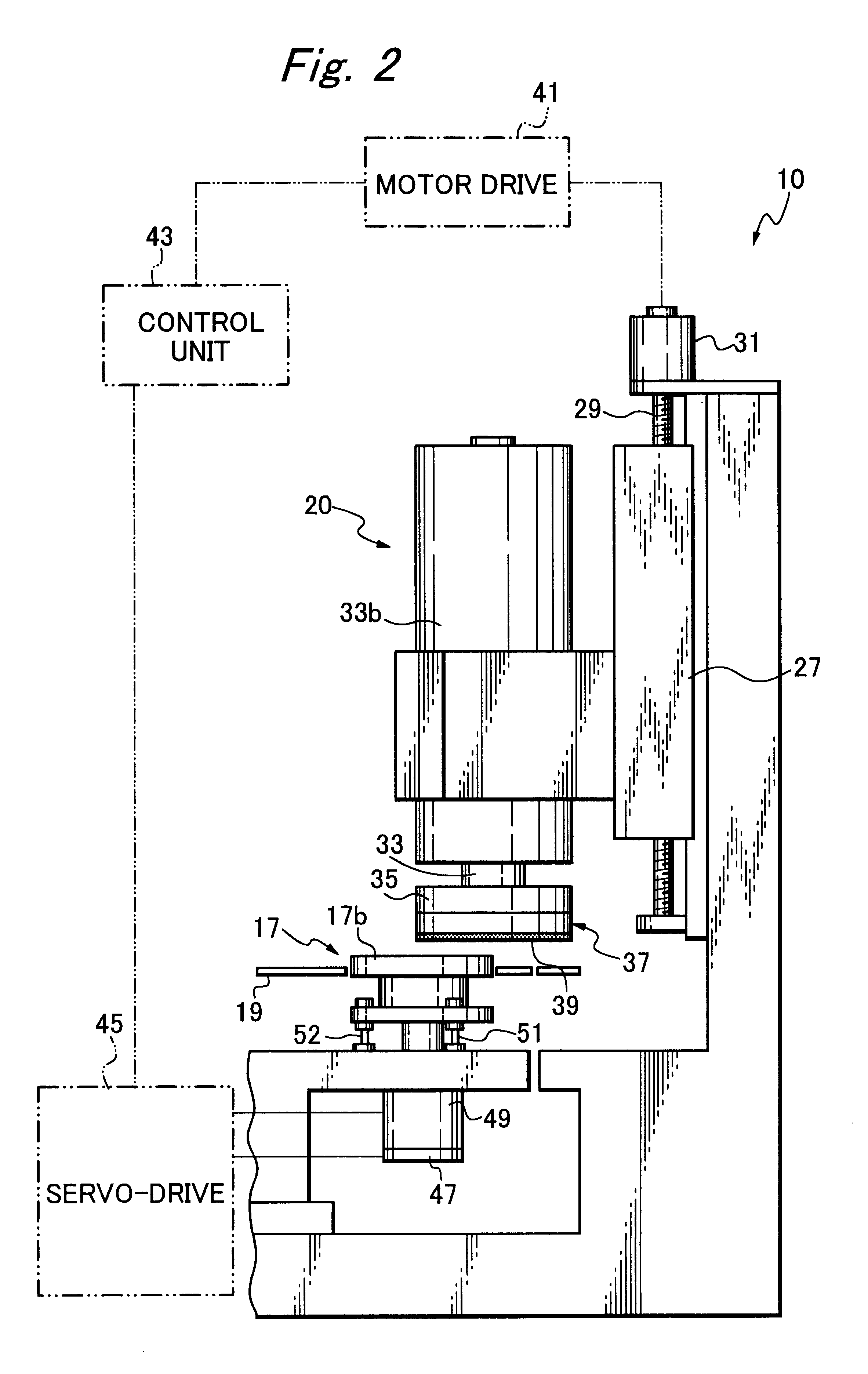

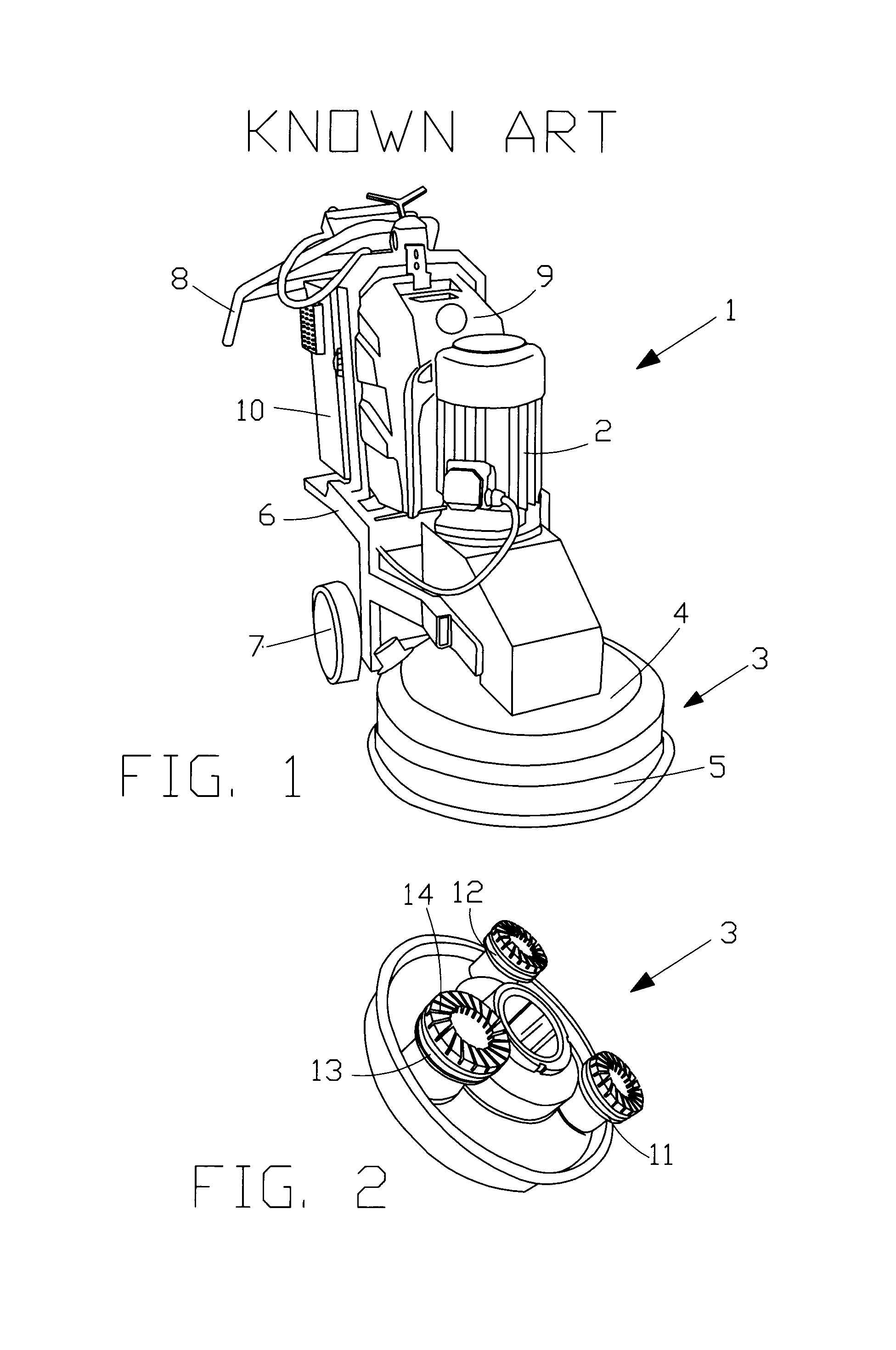

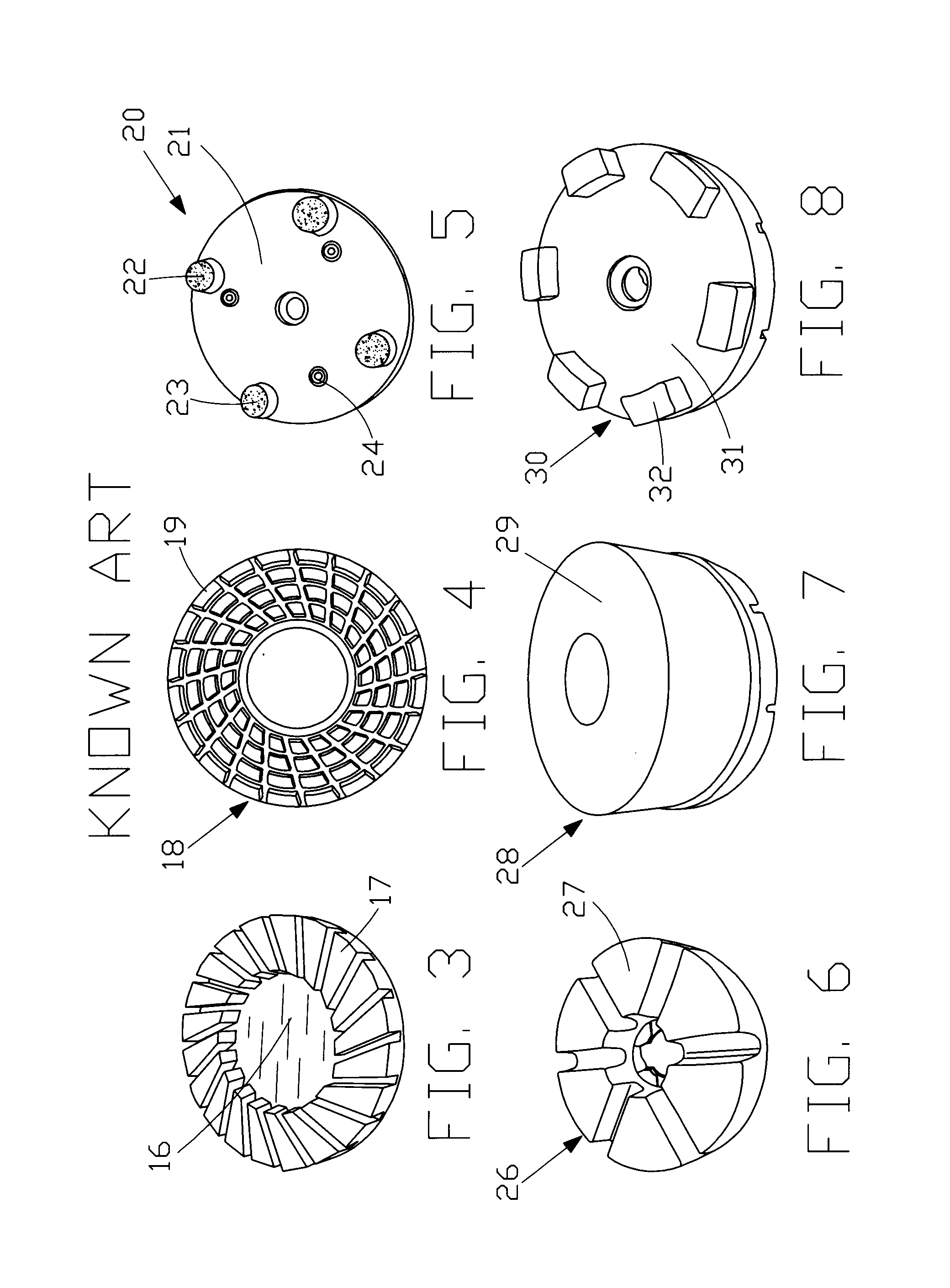

Disclosed is an improvement in a grinding machine comprising at least a turn table, rotary chuck tables for holding work pieces to be machined, a first grinding means for grinding the work piece held on the chuck table and a second grinding means for grinding the first-ground work piece held on the chuck table. The first grinding means comprises at least a first grinding wheel having pieces of grindstone set so as to define together a first grinding plane, and a first spindle fixed to the first grinding wheel. Likewise, the second grinding means comprises a second grinding wheel having pieces of grindstone set so as to define together a second grinding plane and a second spindle fixed to the second grinding wheel. The first and second grinding means are so arranged that the first angle formed between the linear line connecting from the center of rotation of the turn table to the center of rotation of a selected chuck table and the linear line connecting from the center of rotation of the selected chuck table to the center of rotation of the first spindle is equal to the second angle formed between the linear line connecting from the center of rotation of the turn table to the center of rotation of the selected chuck table and the linear line connecting from the center of rotation of the selected chuck table to the center of rotation of the second spindle. This arrangement assures that all finished work pieces have on and same thickness.

Owner:DISCO CORP

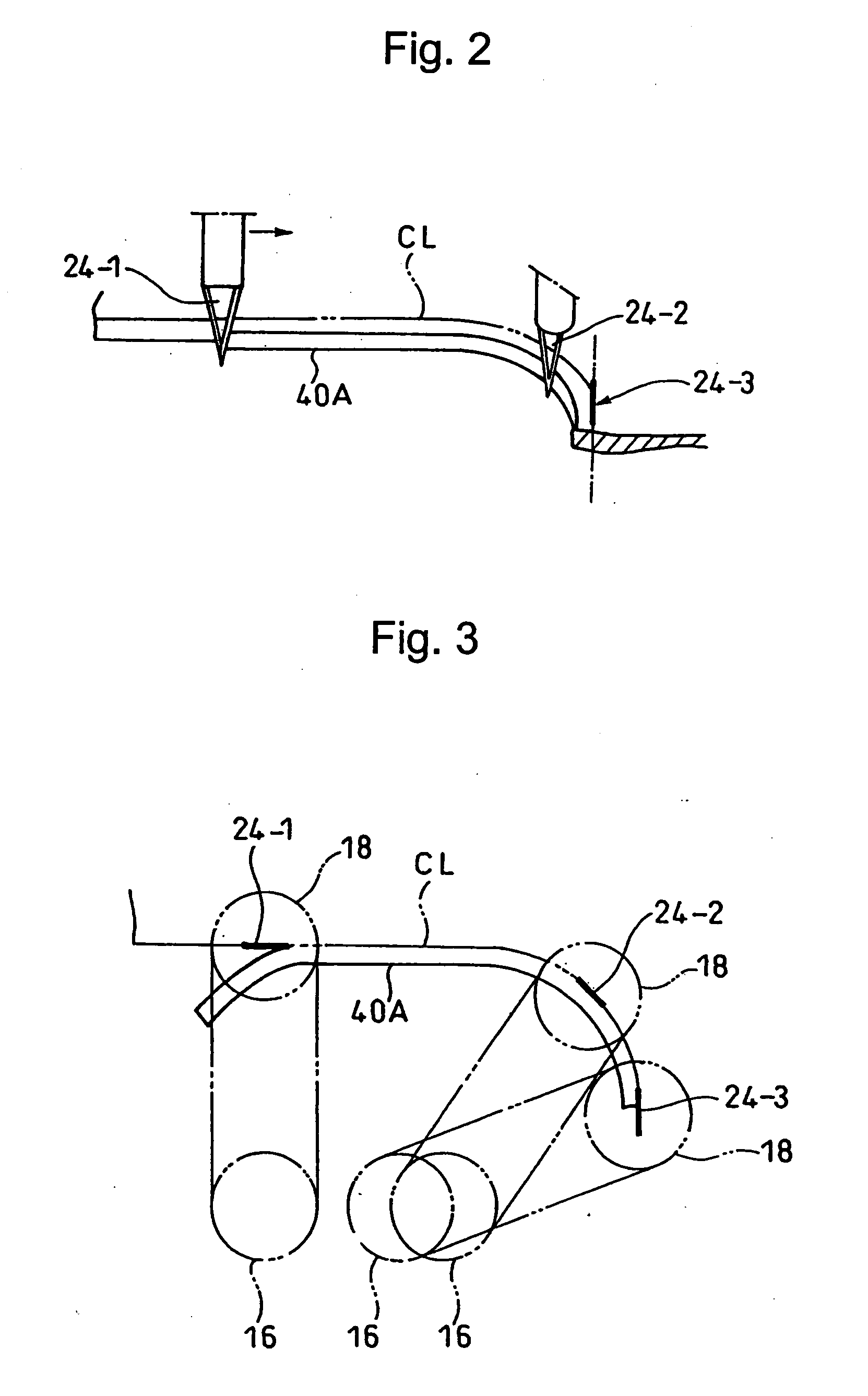

Helical part manufacturing apparatus and control method thereof

InactiveUS20080302156A1Easy to processIncrease productivityShaping safety devicesGrinding feed controlManufactured apparatusEngineering

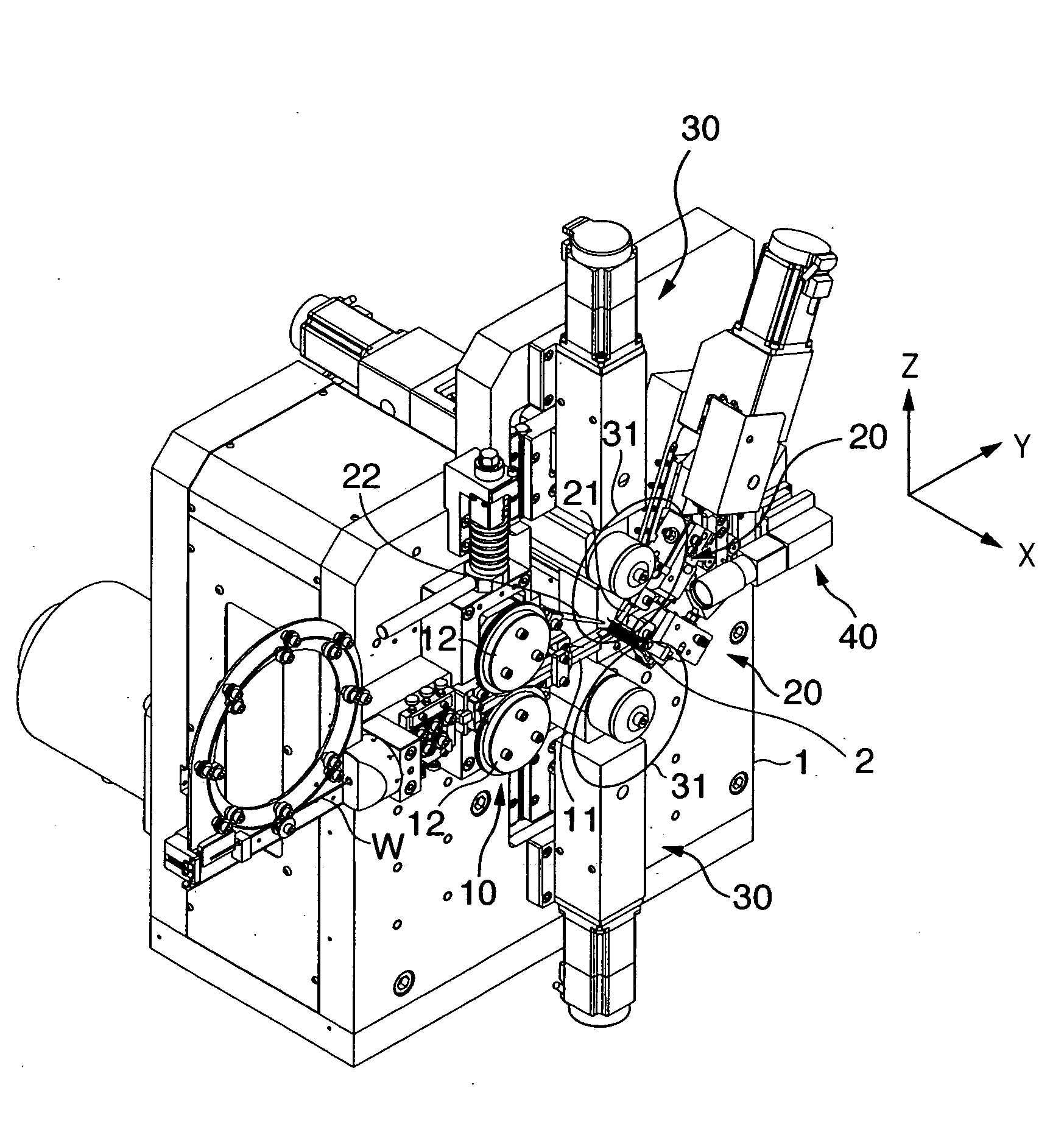

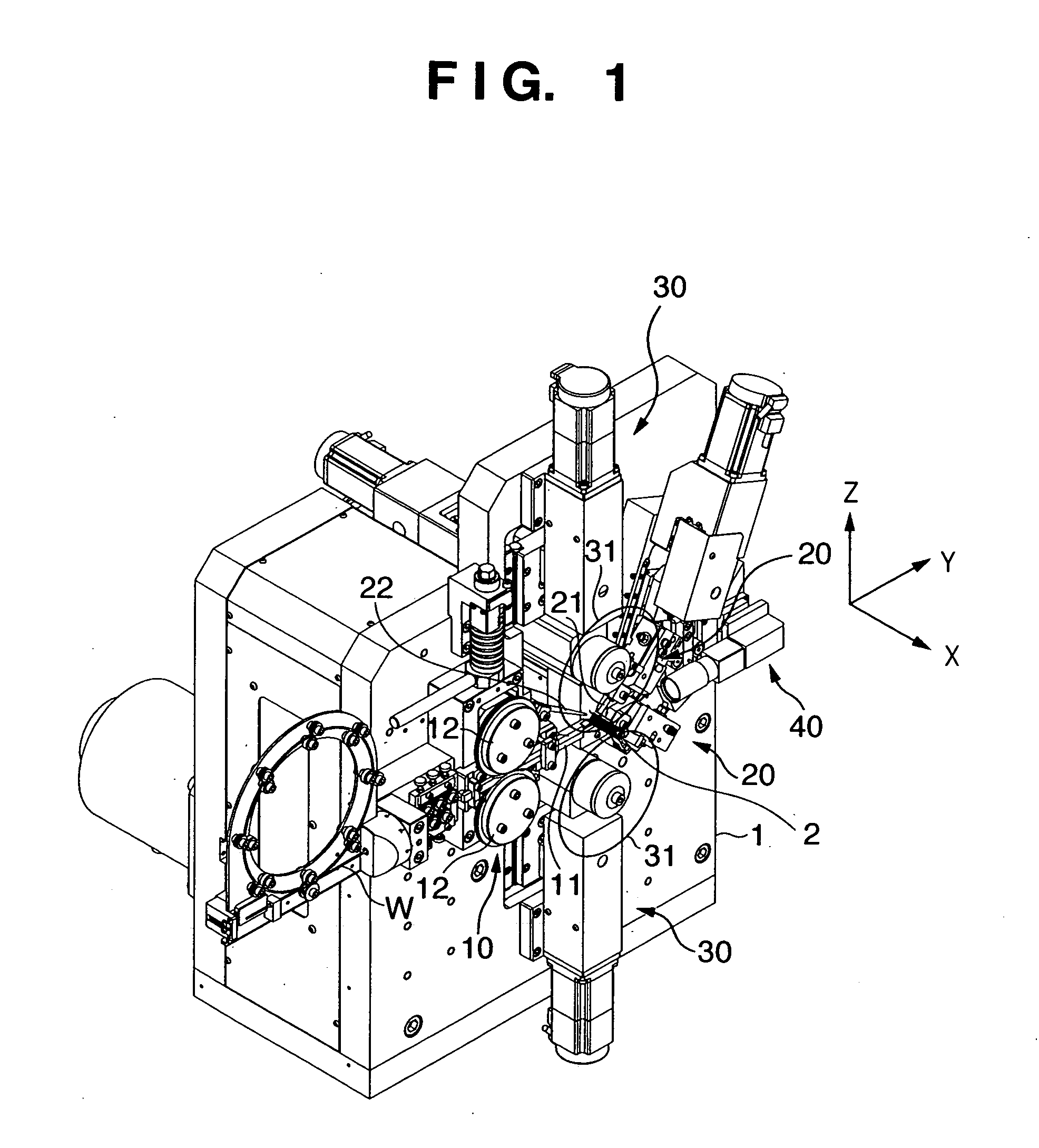

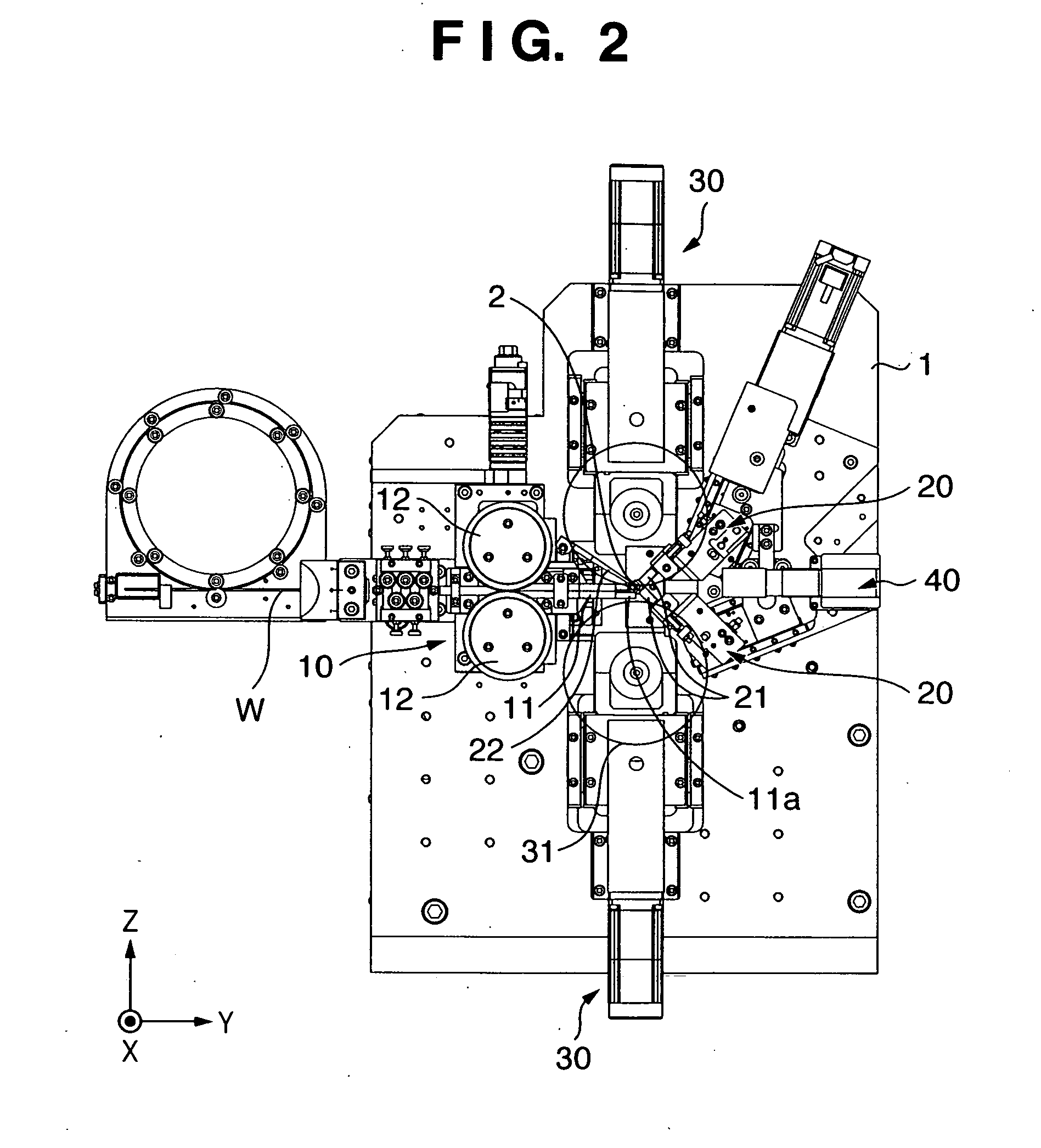

This invention provides an apparatus for manufacturing a helical part by feeding a wire W toward a pointing tool 21 and pushing the wire W against the pointing tool 21 to forcibly wind the wire. The apparatus comprises: a feed roller 12 for feeding the wire W toward the pointing tool 21; a wire feeding motor 111 for rotatably driving the feed roller; a grindstone tool unit 30, which holds a discoid grindstone 31 rotatable and movable, for cutting the wire W by the rotating discoid-grindstone 31; and a CPU 100 for controlling the wire feeding motor 111 and grindstone tool unit 30 to move the discoid grindstone 31 on a plane which is substantially perpendicular to a coil growing direction of the helical part and to cut the wire W in a direction which is substantially perpendicular to the coil growing direction.

Owner:ITAYA SEISAKUSHO

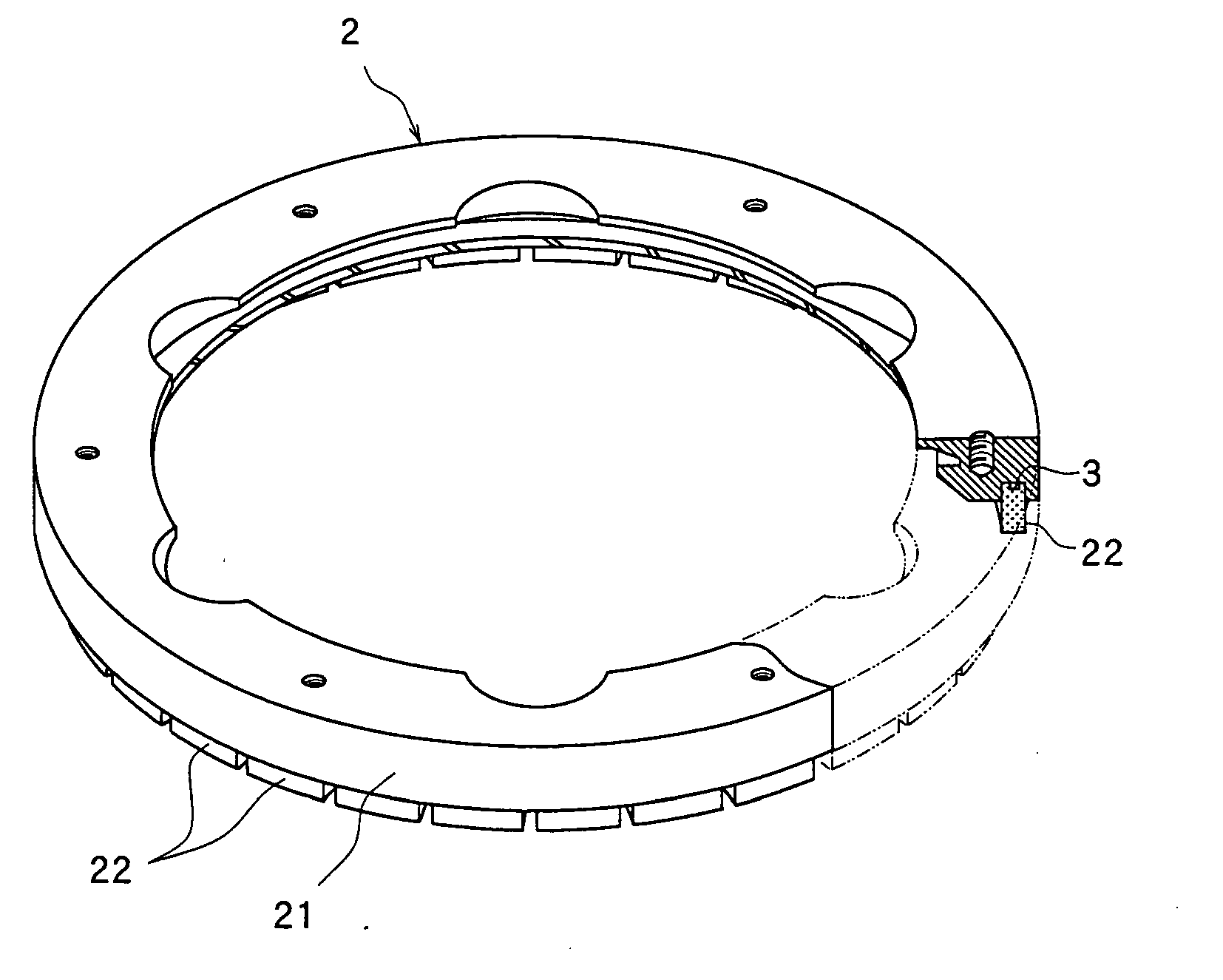

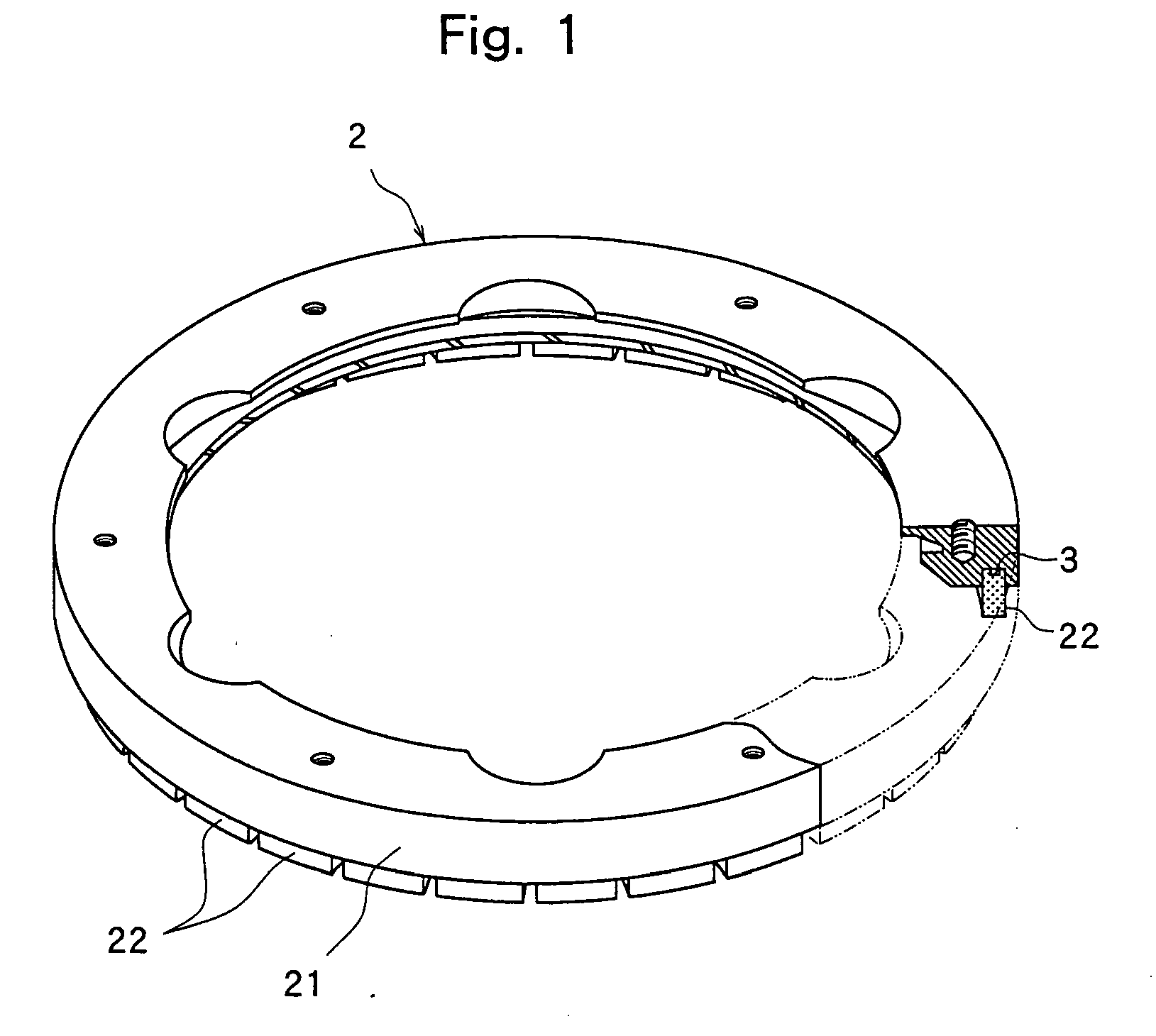

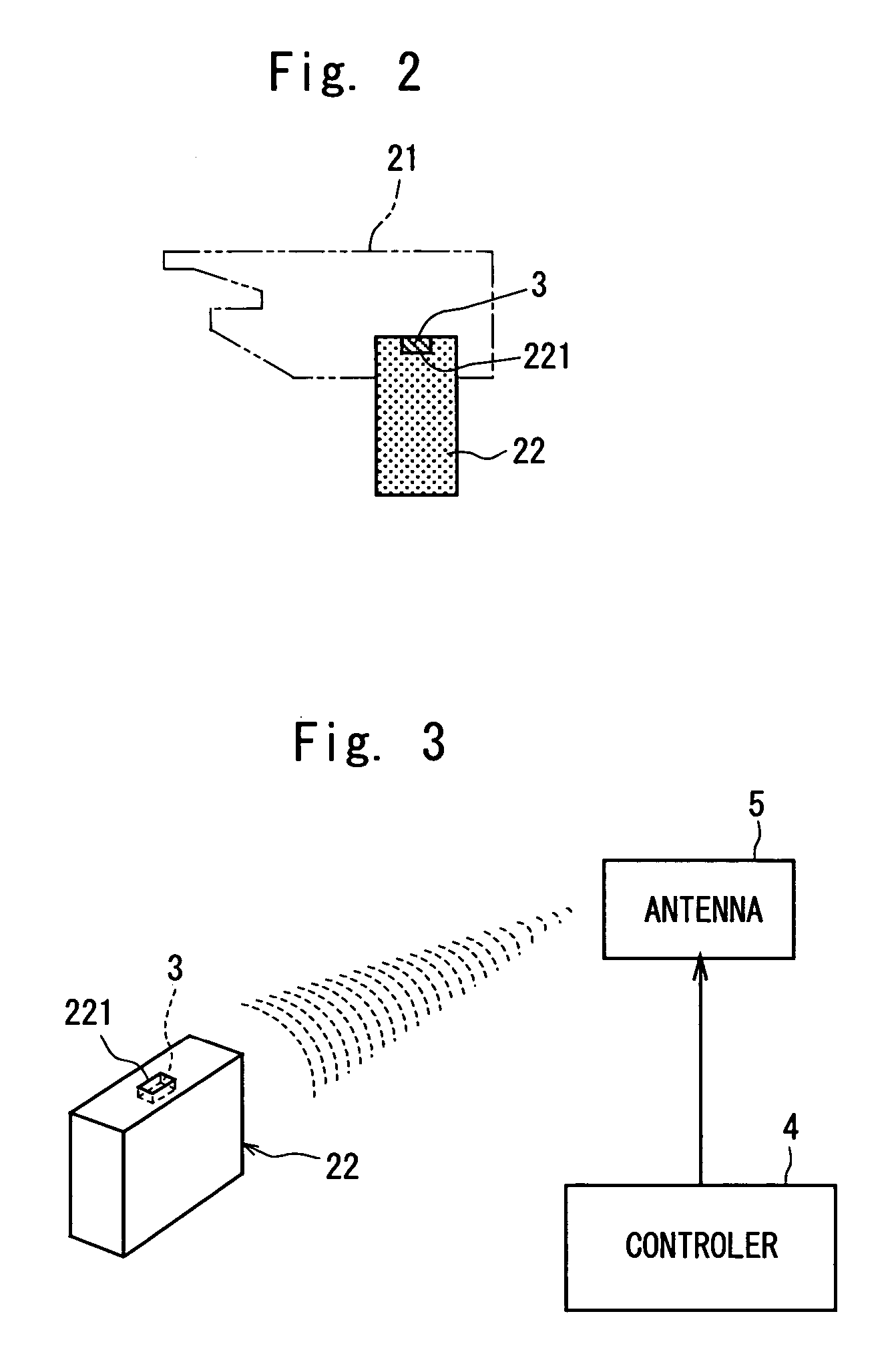

Grindstone tool

InactiveUS20060014475A1Revolution surface grinding machinesAntenna supports/mountingsEngineeringGrindstone

A grindstone tool forperformpredeterminedprocessing on a workpiece, wherein a radio IC tag from, and to, which information can be read, and written, without contact is embedded in the grindstone tool.

Owner:DISCO CORP

Chamfering Apparatus For Silicon Wafer, Method For Producing Silicon Wafer, And Etched Silicon Wafer

ActiveUS20090324896A1Suppress mutationAccurate acquisitionEdge grinding machinesDecorative surface effectsNumerical controlEngineering

The invention is directed to a chamfering apparatus for a silicon wafer to chamfer outer edge of a silicon wafer by using a chamfering grindstone, the chamfering apparatus including at least: a holder holding and rotating a silicon wafer; a chamfering grindstone chamfering the outer edge of the silicon wafer held by the holder; and a control apparatus for controlling a chamfered shape by controlling a relative position of the outer edge of the silicon wafer and the chamfering grindstone by numerical control, wherein the control apparatus controls and changes the relative position of the outer edge of the silicon wafer and the chamfering grindstone at the time of chamfering depending on the circumferential position of the silicon wafer held by the holder, a production method, and an etched silicon wafer. This provides a silicon wafer chamfering apparatus, production method and an etched silicon wafer that can suppress variations in the cross-sectional shape dimensions of a chamfered portion after an etching process.

Owner:SHIN-ETSU HANDOTAI CO LTD

Grinding wheel

InactiveCN101659033AReduces eye cloggingReduce the number of trimmingSemiconductor/solid-state device manufacturingLapping machinesEngineeringGrinding wheel

The invention provides a grinding wheel, which can decrease the finishing time of a grinding tool and prevent a wafer from generating crackles. The grinding wheel is arranged on a wheel seat of a grinding device in the free assemble and unassemble way, the grinding device comprises a grinding fluid supply member for supplying a grinding fluid, a main shaft driven to rotate and the wheel seat connected with the frontend of the main shaft. The grinding wheel is characterized in that the grinding wheel comprises an annular base with an internal wall, an external wall and an installation portion arranged on the wheel seat, and a plurality of grinding tools annularly arranged at the free end of the annular base, wherein a plurality of through holes which are spaced apart at prescribed intervalsare formed on the external wall of the annular base along the circumference direction, the plurality of through holes penetrate through the internal wall for discharging the grindstone dust and the grinding fluid.

Owner:DISCO CORP

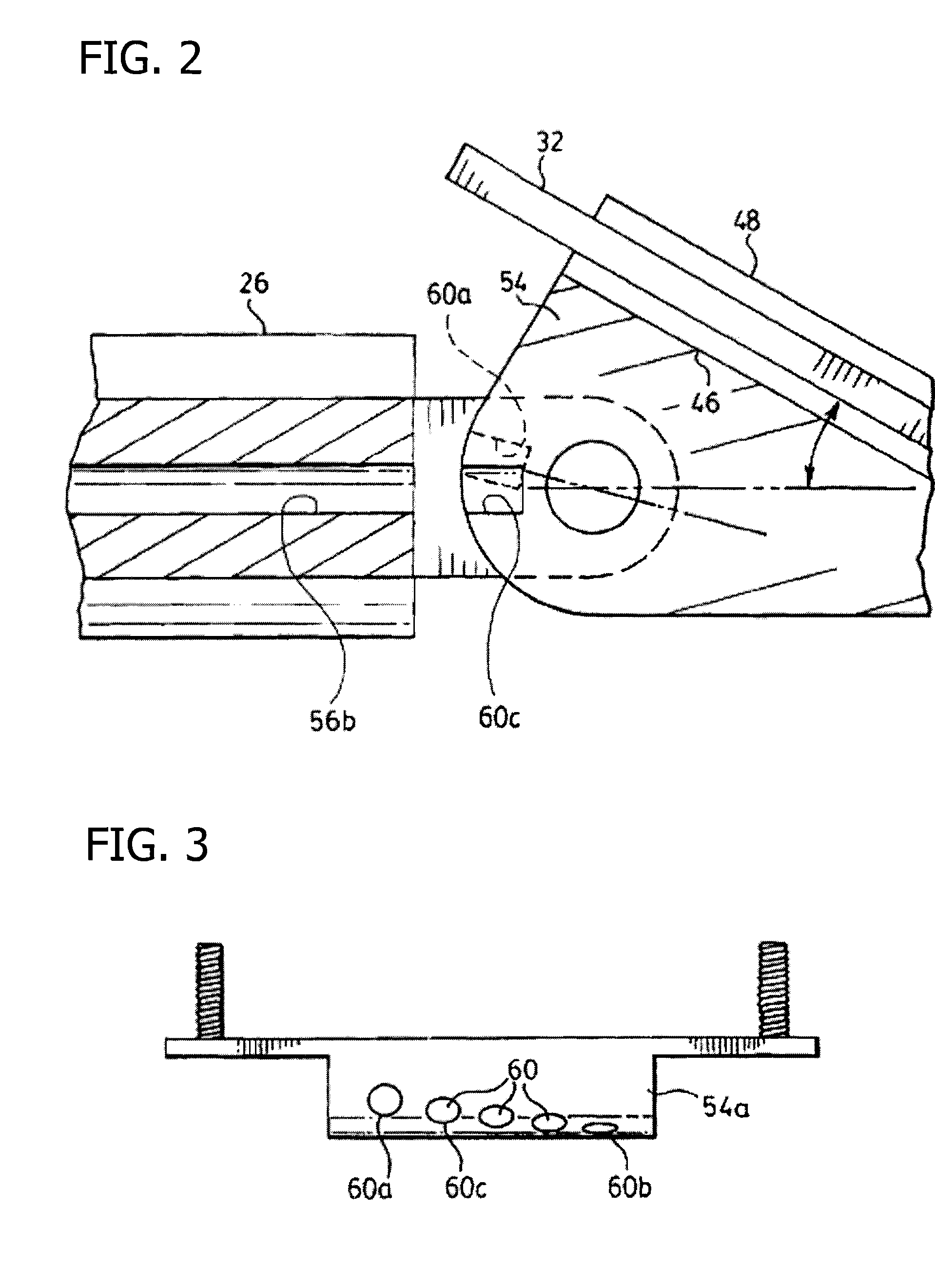

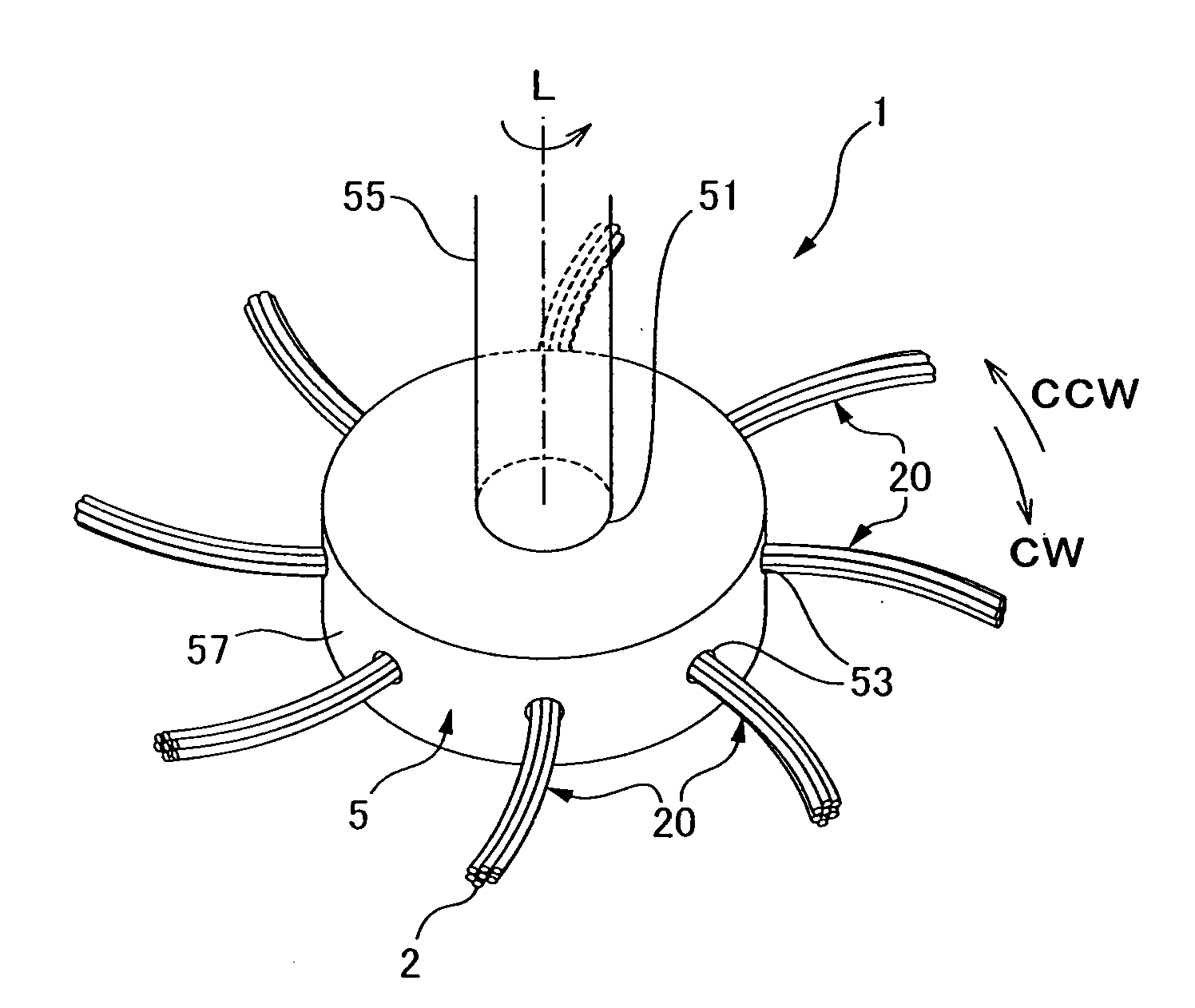

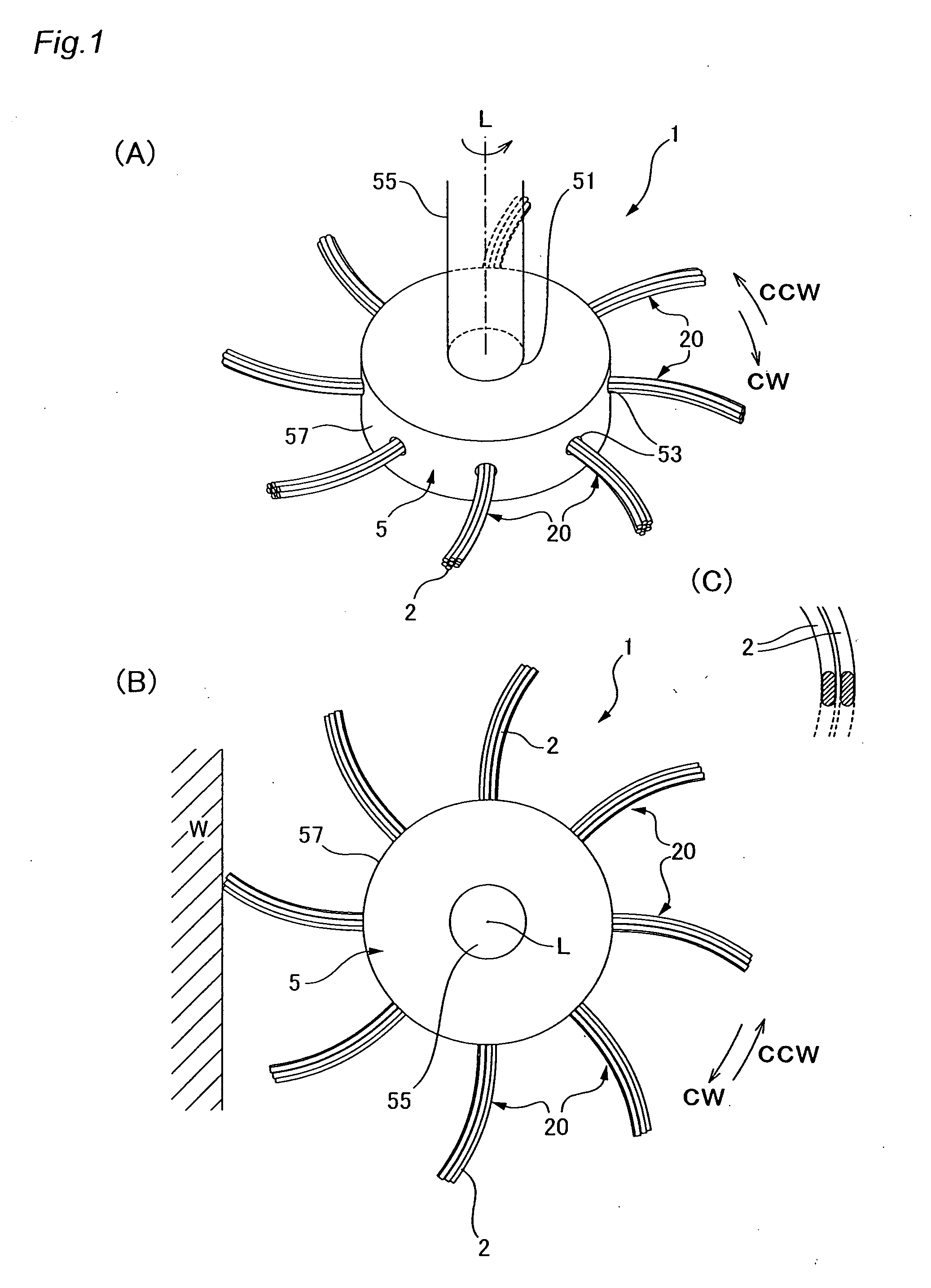

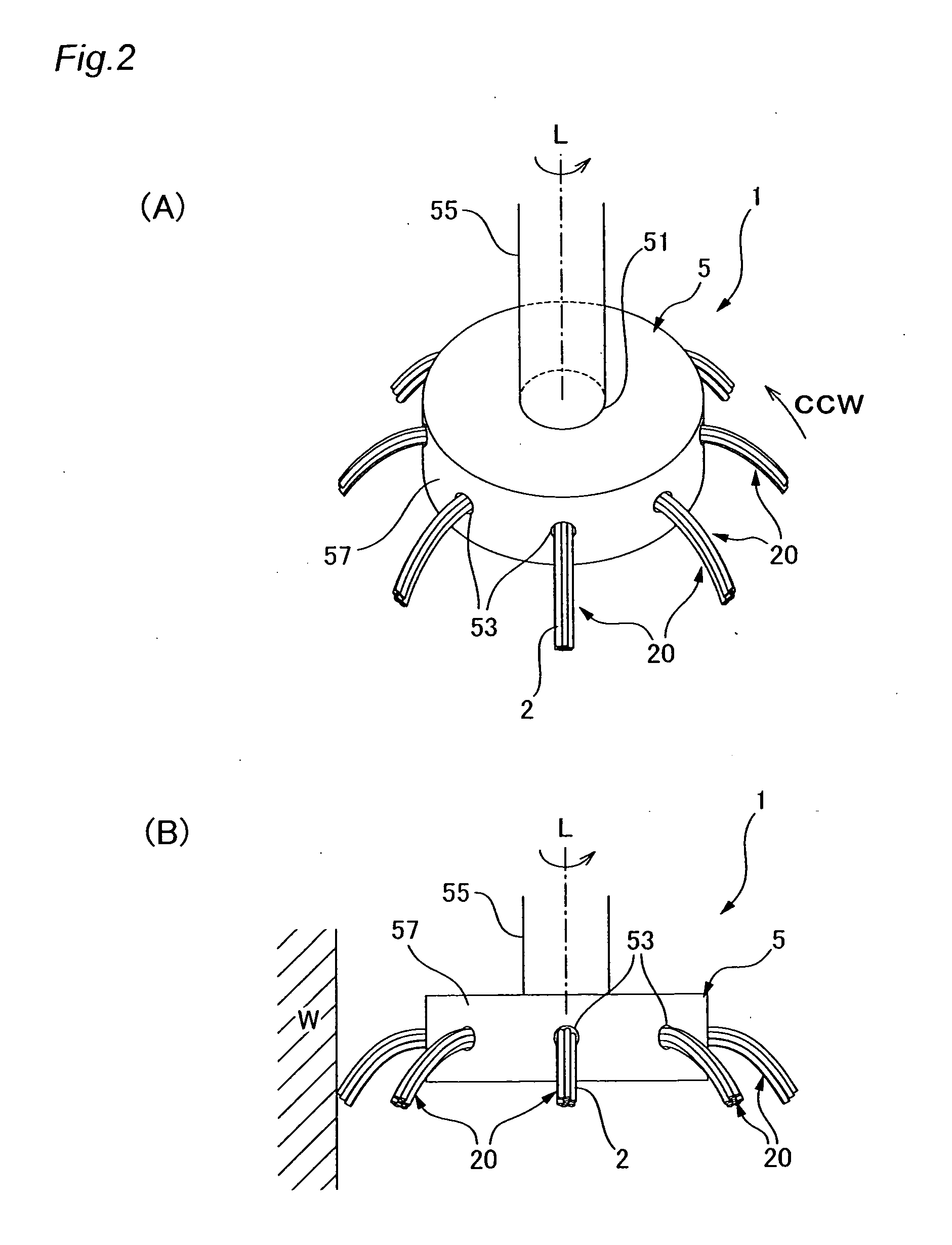

Method of producing brush-like grind stone, the brush-like grind stone, and brush for grind machine

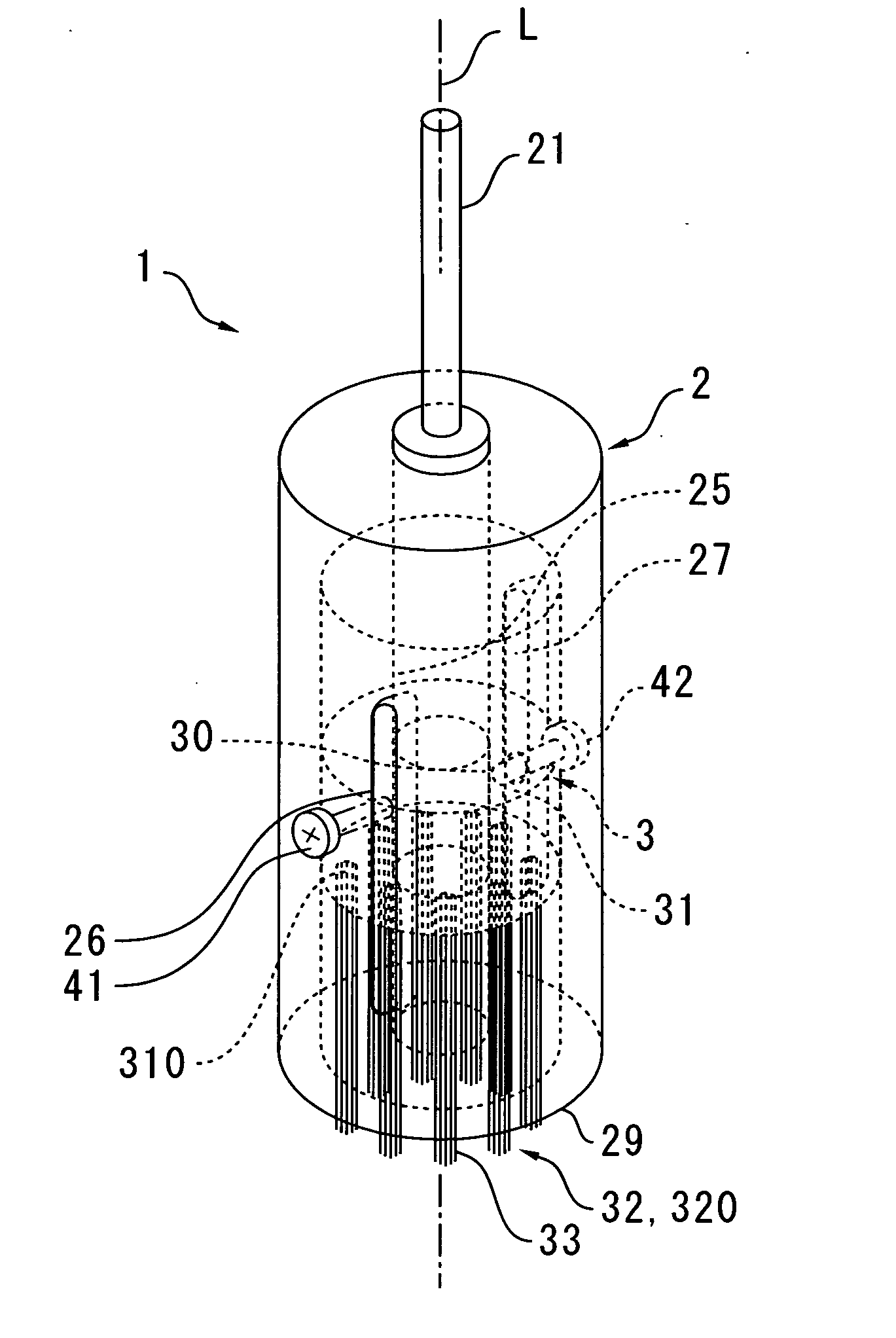

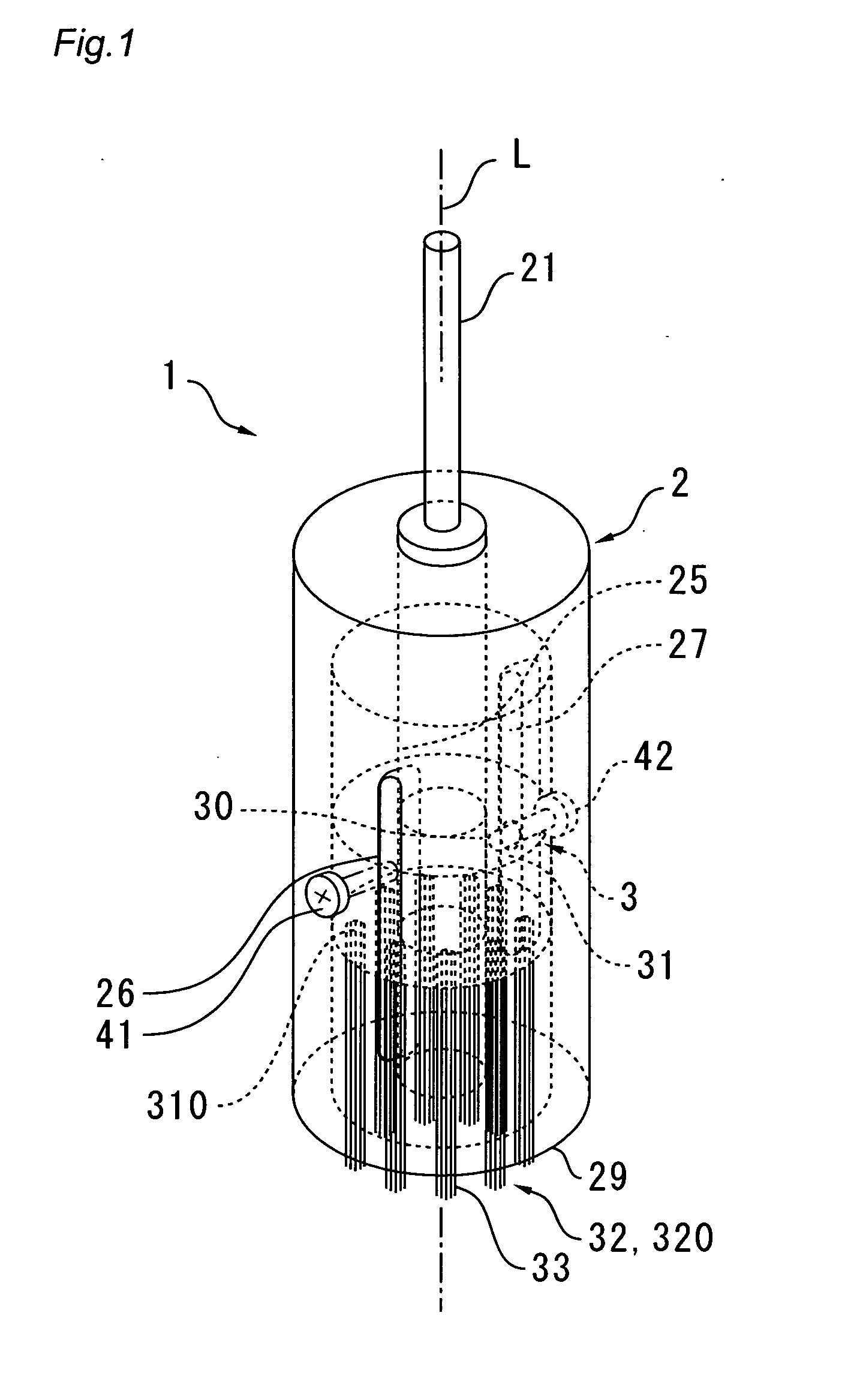

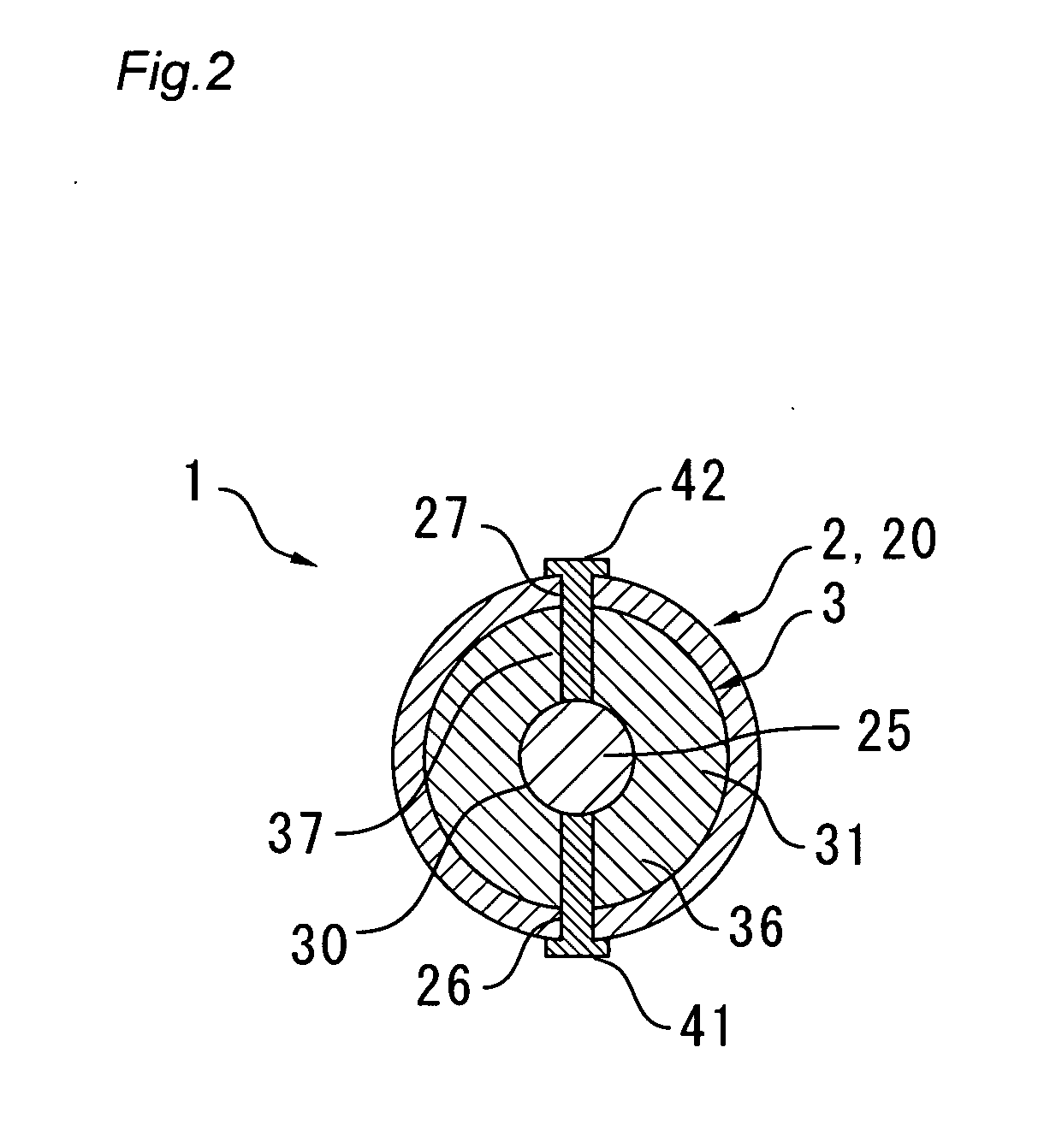

In the manufacture of a brush-shaped grindstone (3), embedding holes (310) are formed in a grinding element holding surface (311) of a holder (31) in mutually separated positions. A base end side of a plurality of wire-shaped grinding elements (32), formed such that a composite yarn composed of inorganic filaments is impregnated and hardened with a resin, is aligned, and rod assemblies (320) are thereafter formed by fixing the base end side of the plurality of wire-shaped grinding elements (32) with adhesive (71) in holes (60) of a die material (6), which is formed to have substantially the same size as the embedding holes (310) of the holder (31). The rod assemblies (320) are thereafter embedded in the embedding holes (310) of the holder (32), and fixed with adhesive (72). Whereby, removing burrs from a precision work component, performing polishing, and the like can be carried out with good efficiency and high precision.

Owner:XEBEC TECH CO LTD +1

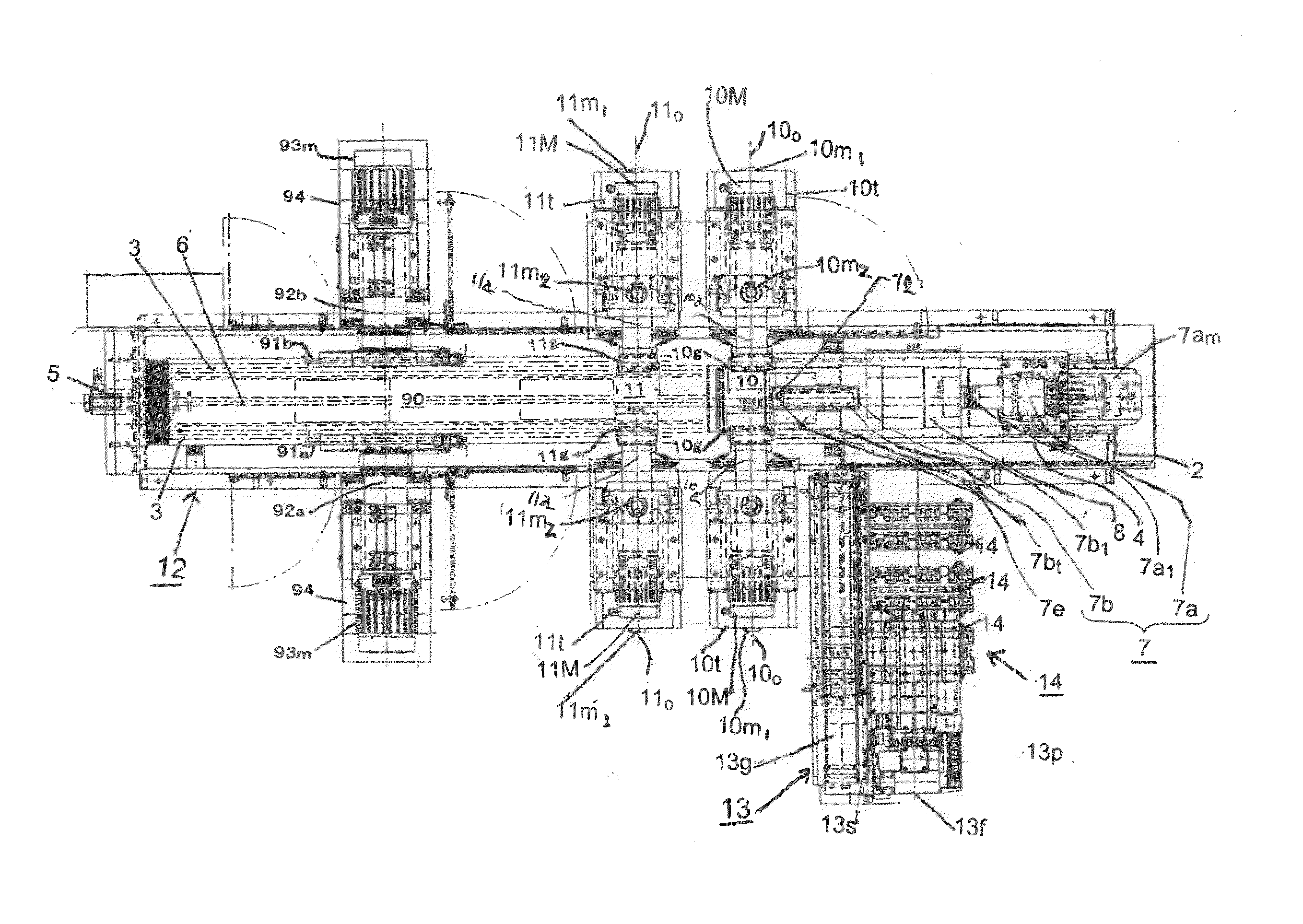

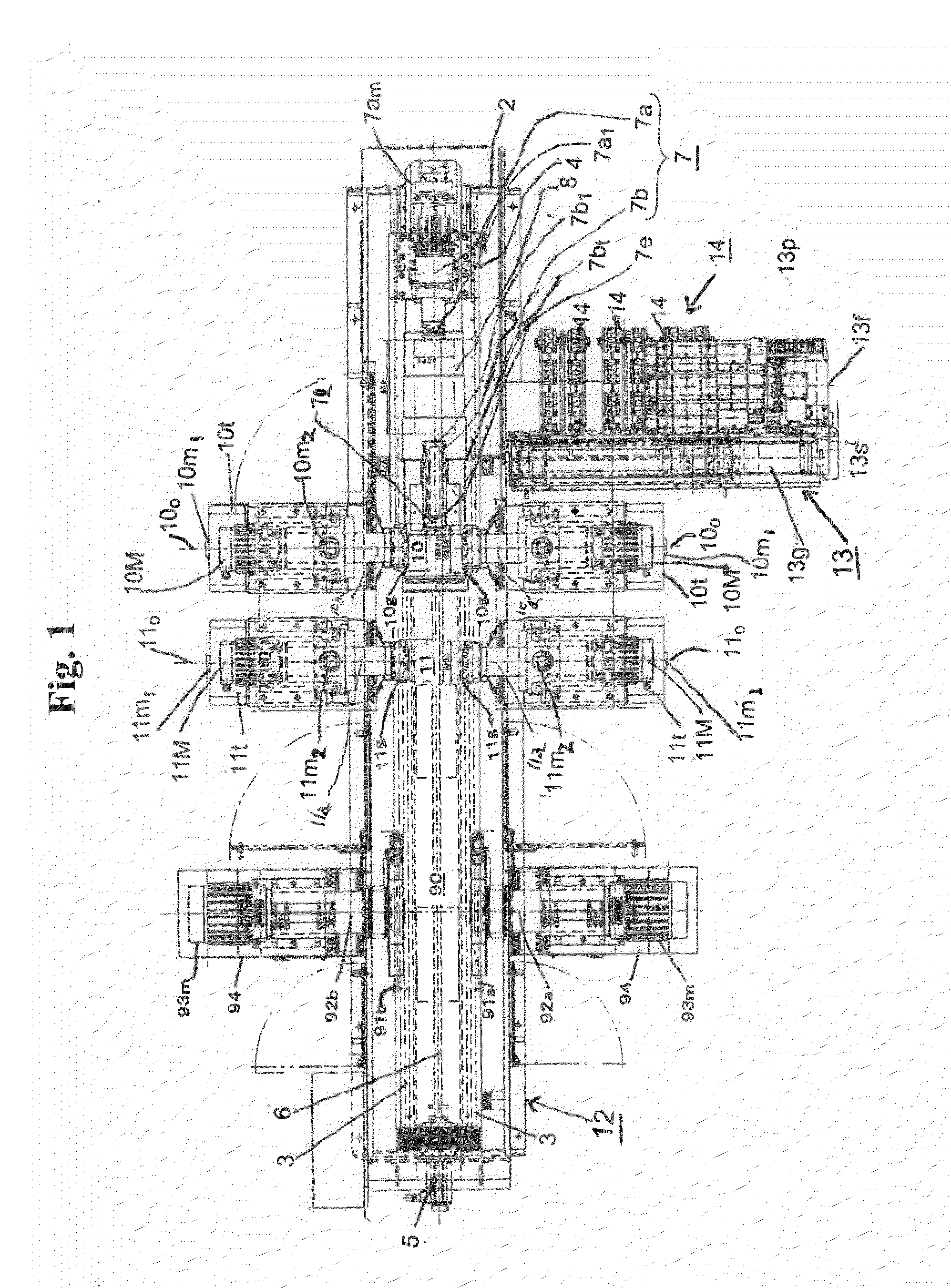

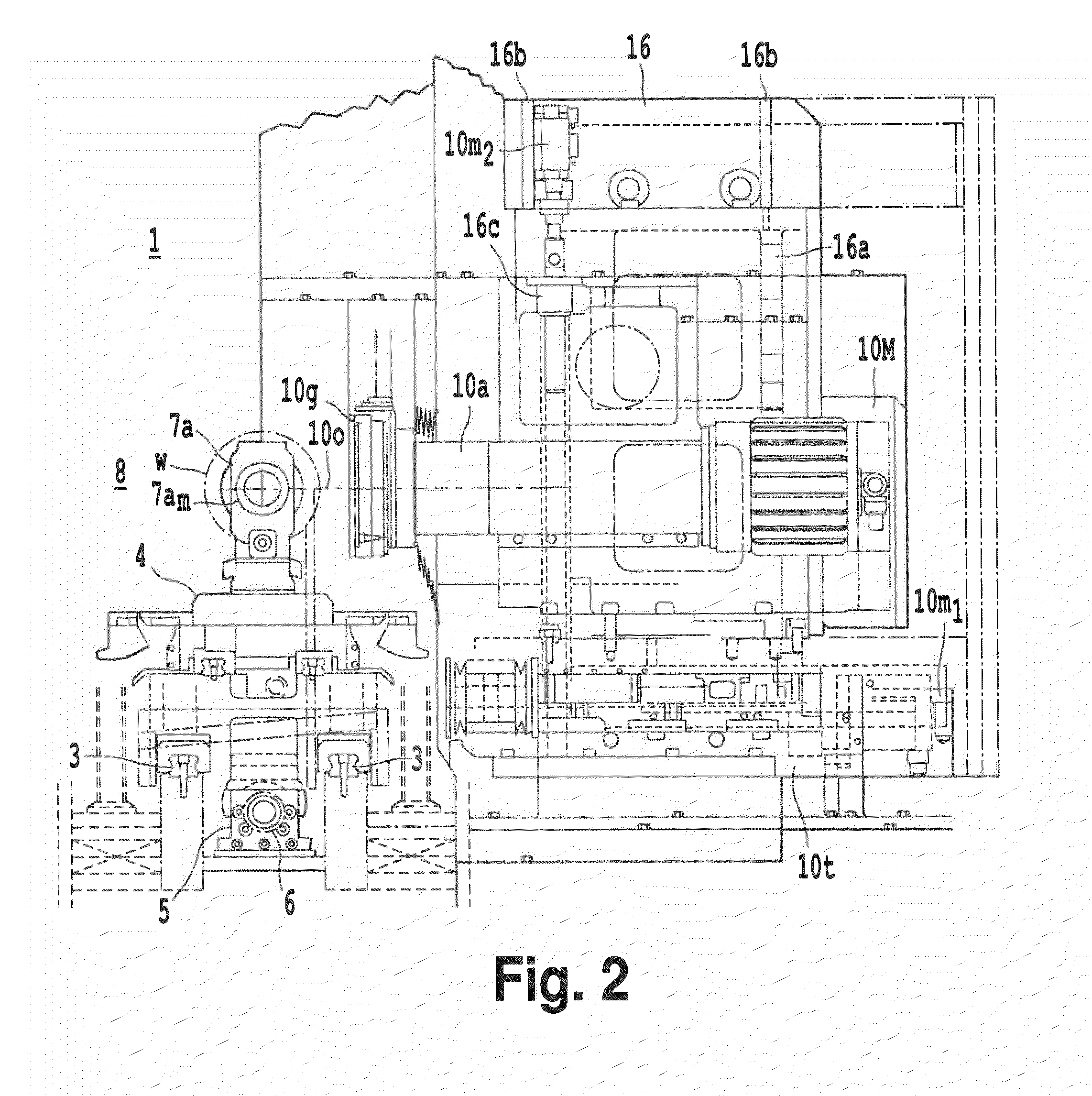

Grinding machine

A grinding machine includes at least a turntable, rotary chuck tables for holding workpieces to be machined, a first grinding device for grinding the workpiece held on the chuck table and a second grinding device for grinding the first-ground workpiece held on the chuck table. The first grinding device comprises at least a first grinding wheel having pieces of grindstone set so as to define together a first grinding plane, and a first spindle fixed to the first grinding wheel. Likewise, the second grinding device comprises a second grinding wheel having pieces of grindstone set so as to define together a second grinding plane and a second spindle fixed to the second grinding wheel. The first and second grinding devices are so arranged that the first angle formed between the linear line connecting from the center of rotation of the turntable to the center of rotation of a selected chuck table and the linear line connecting from the center of rotation of the selected chuck table to the center of rotation of the first spindle is equal to the second angle formed between the linear line connecting from the center of rotation of the turntable to the center of rotation of the selected chuck table and the linear line connecting from the center of rotation of the selected chuck table to the center of rotation of the second spindle. This arrangement assures that all finished workpieces have the same thickness.

Owner:DISCO CORP

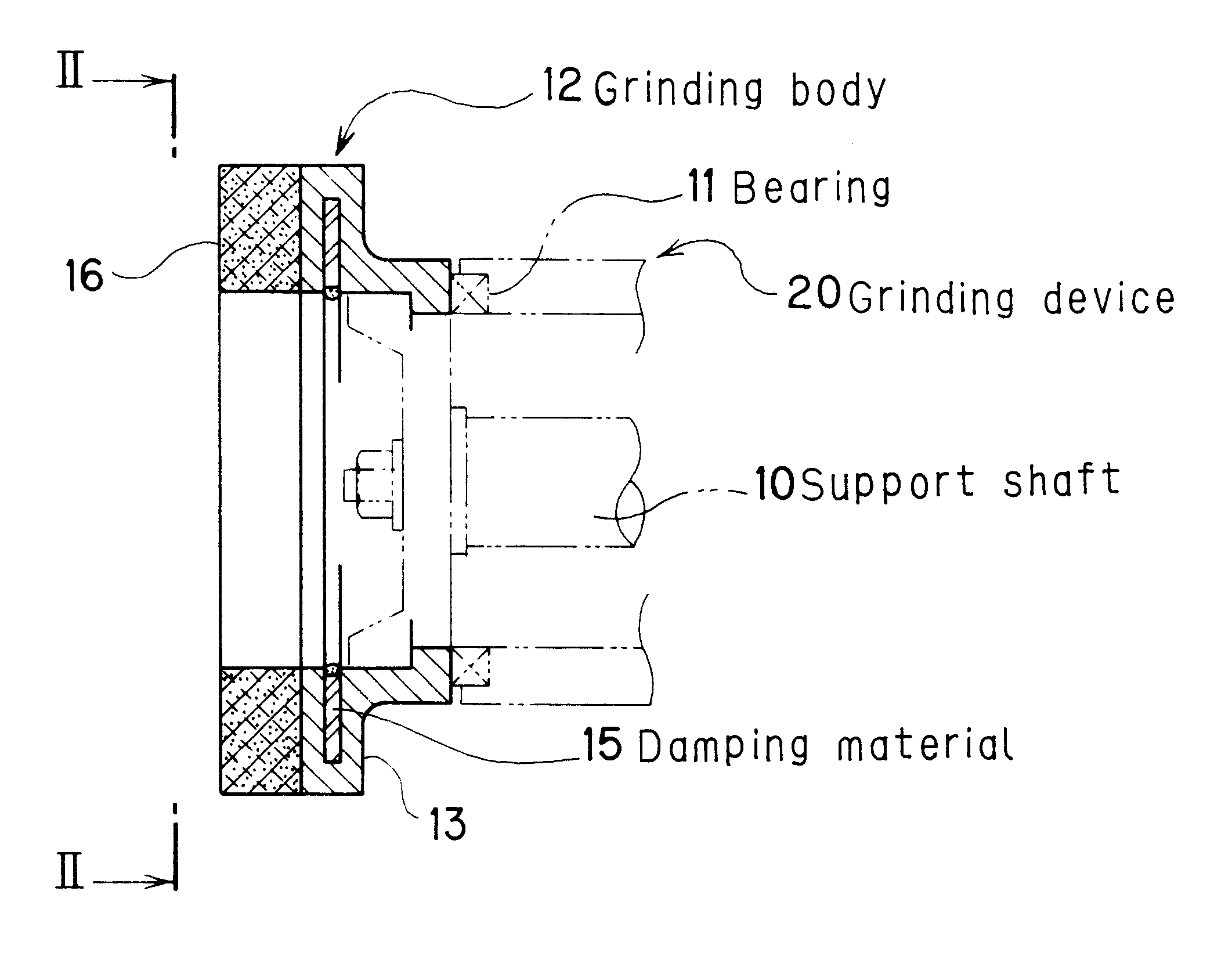

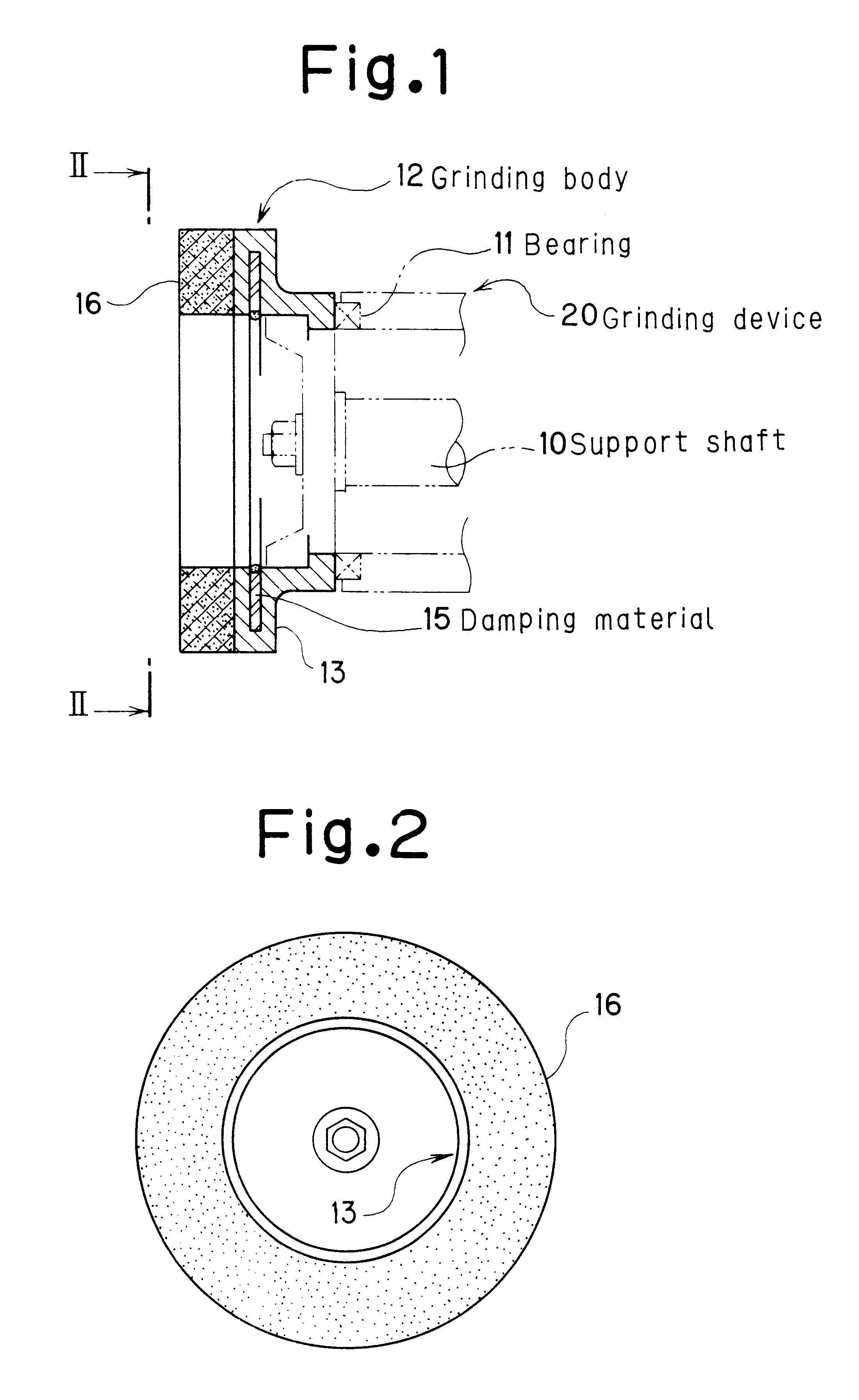

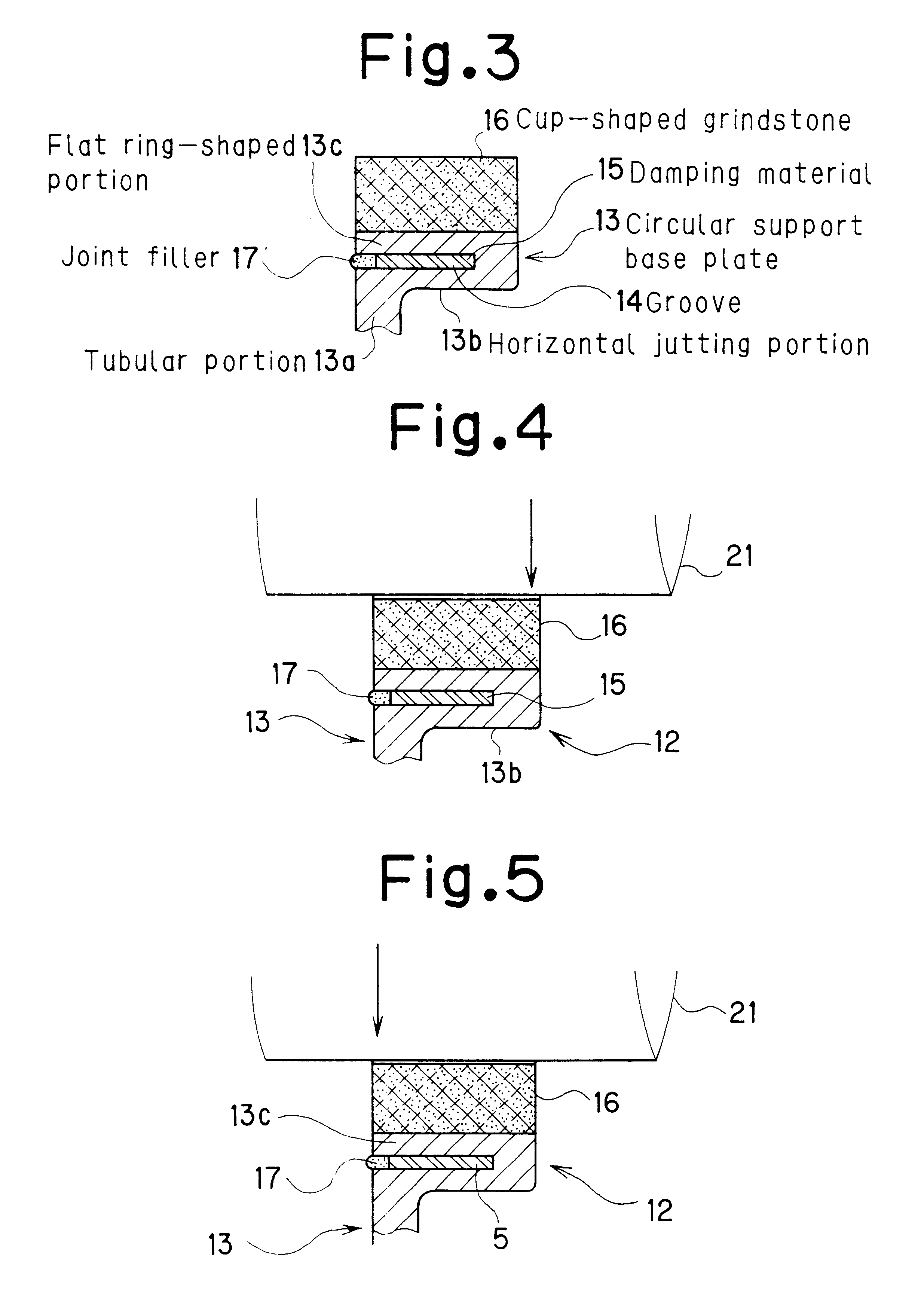

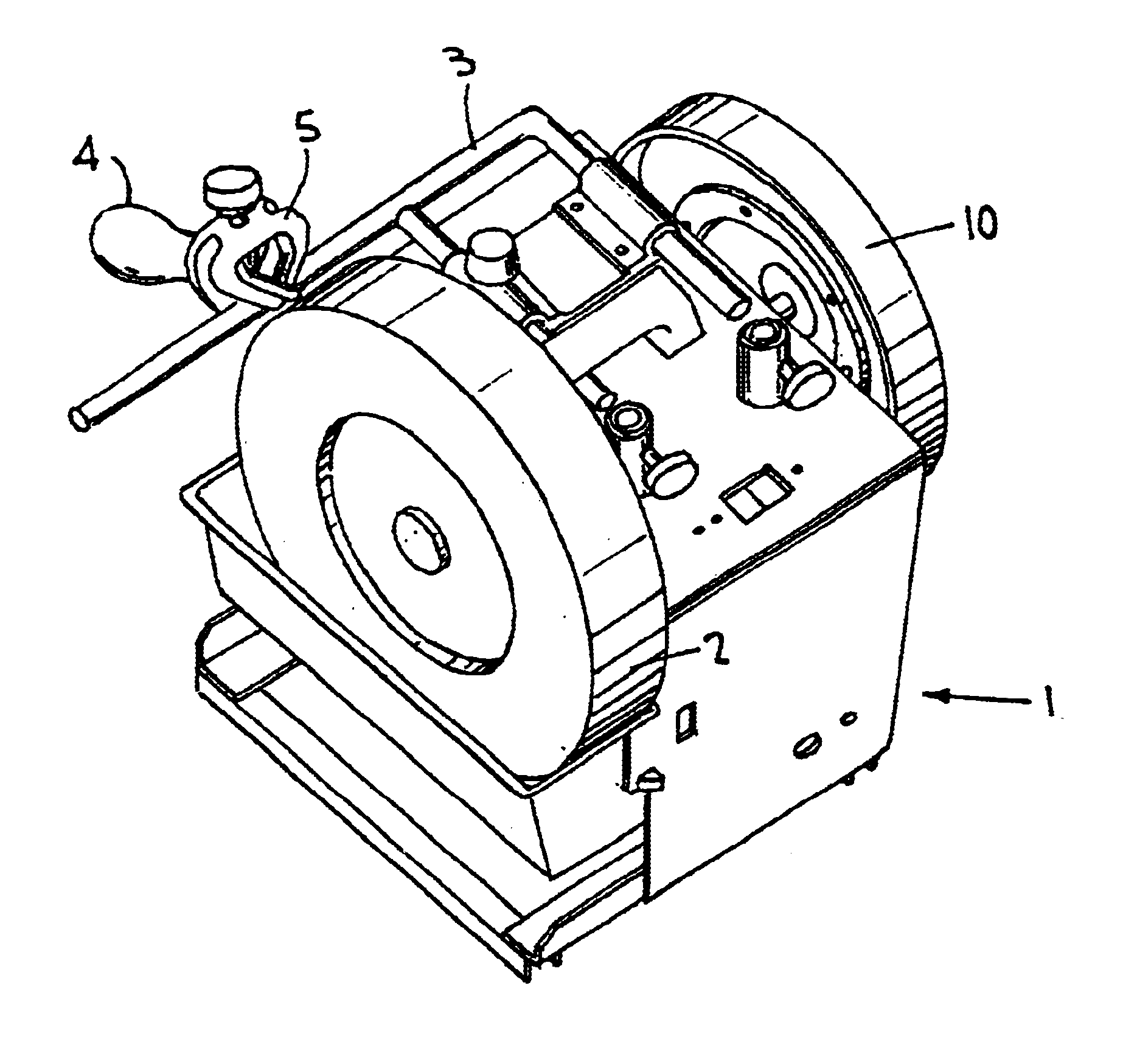

Grinding body for on-line roll grinding

InactiveUS6220949B1Edge grinding machinesRevolution surface grinding machinesEngineeringMechanical engineering

A grinding body for on-line roll grinding has a grindstone of a cup shape. The grindstone is on a surface portion, and near a peripheral edge, of a circular support base plate, so that a peripheral edge portion of the circular support base plate has on a surface side thereof a two-layer structure. This two-layered structure includes a flat ring-shaped portion jutting toward an inner periphery so as to define a groove opening inward. The grindstone is mounted on the flat ring-shaped portion; and a damping material is filled and mounted into the groove. This grinding body can effectively prevent the formation of a spiral mark and a pitching surface mark, improve the grinding power and grinding accuracy, and prolong the life of the grindstone.

Owner:MITSUBISHI HITACHI METALS MASCH INC +2

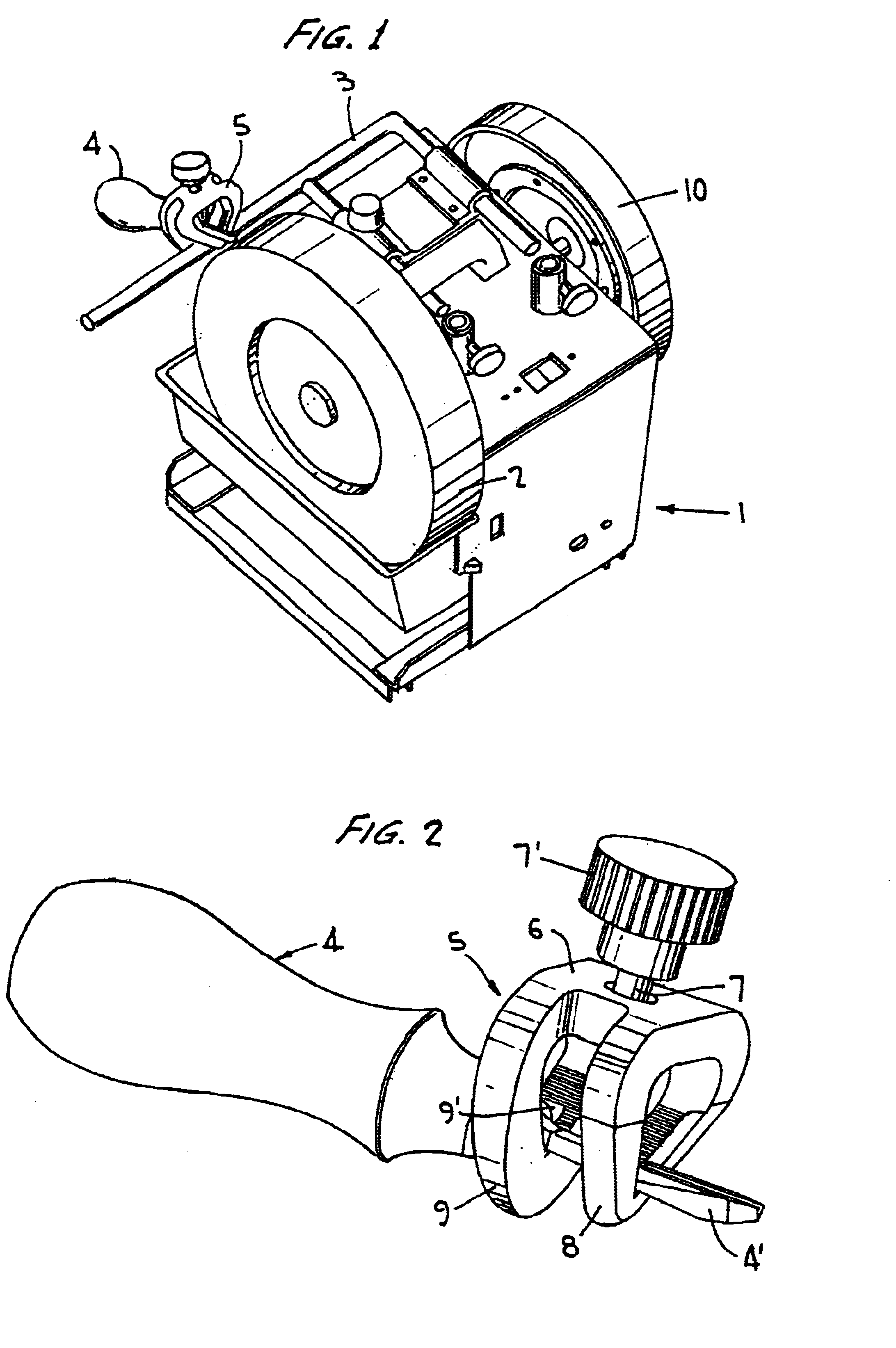

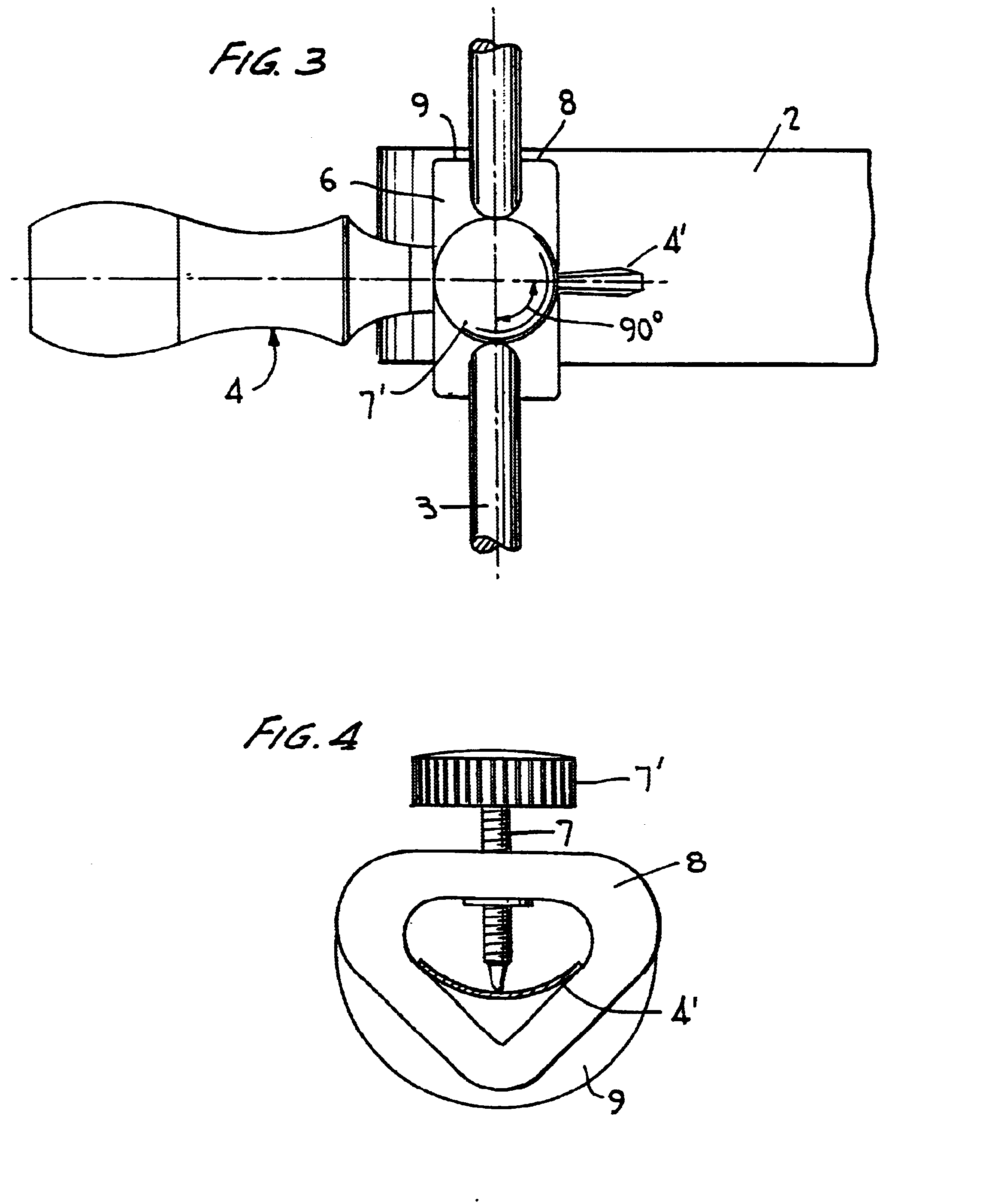

Grinding jig

A grinding jig (5) is to be attached on an edge tool (4) to be ground on a rotating grindstone (2) in a grinding machine (1), having a support means (3) in the vicinity of the grindstone. The jig is split by having a base portion (6) and two parallel open yokes (8, 9) extending therefrom. A screw (7) for clamping the tool (4) against the bottoms of the yokes is provided in the base portion between the two yokes.

Owner:TORMEK

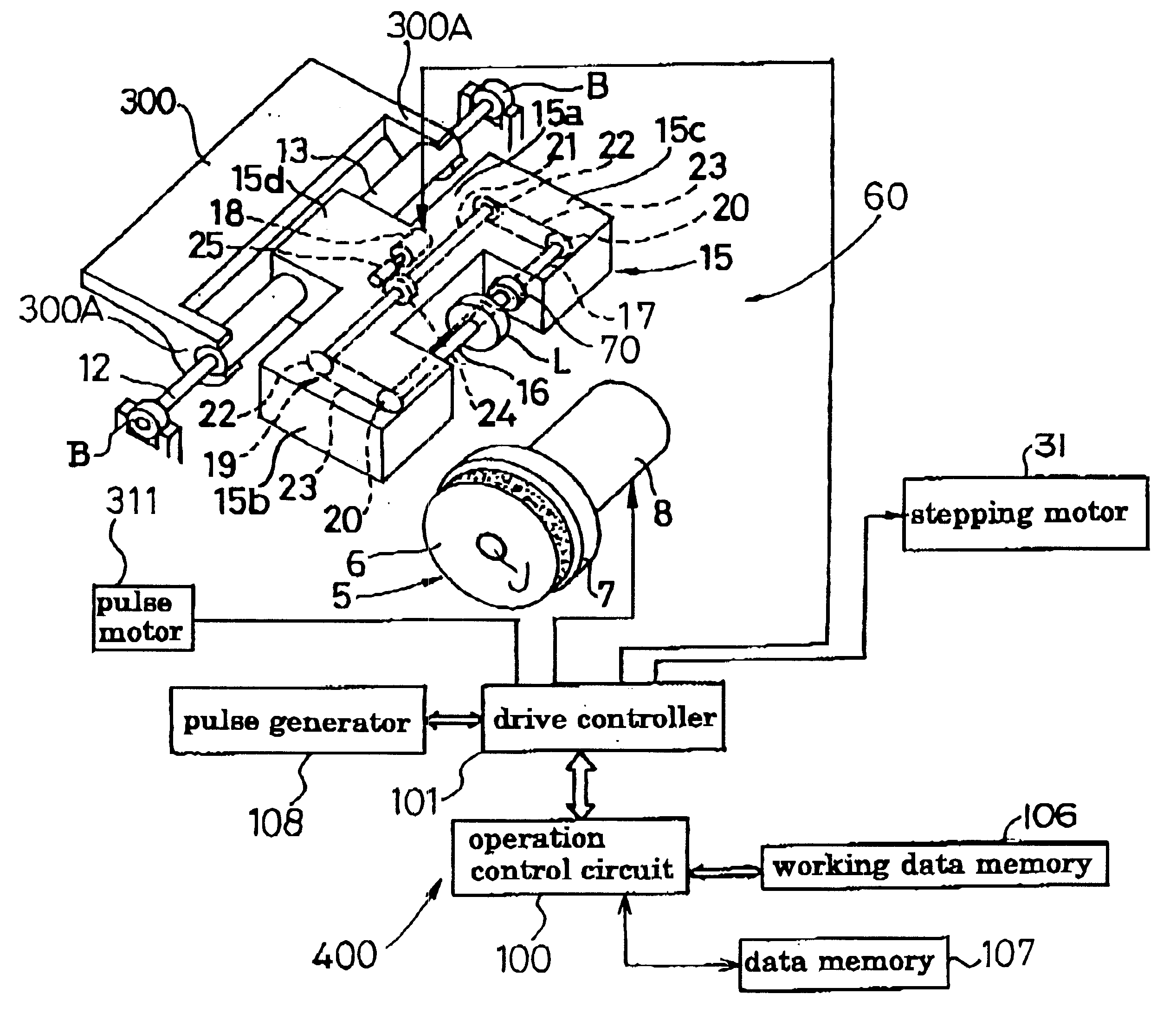

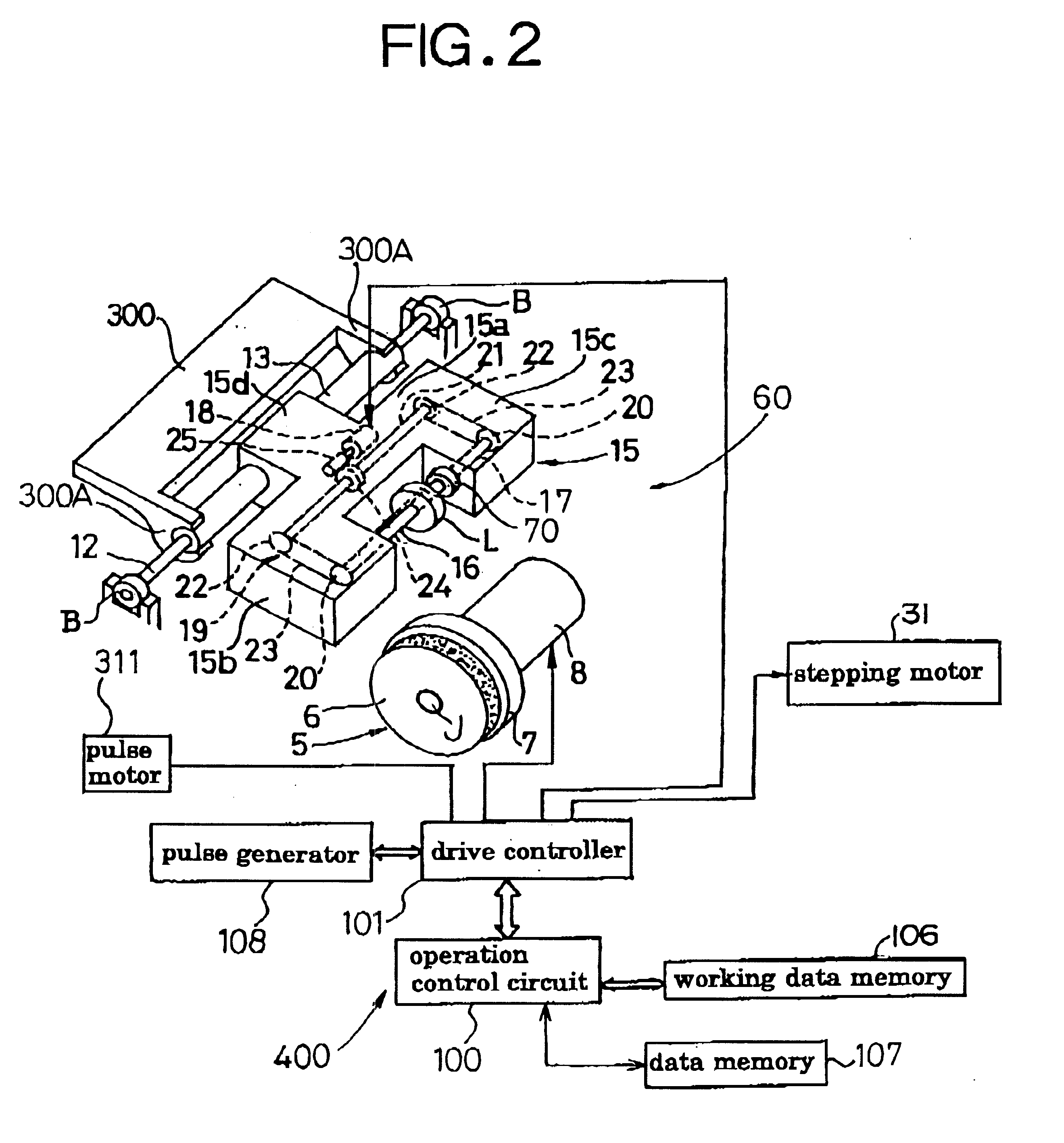

Lens periphery edge processing apparatus

In a lens periphery edge processing apparatus comprising lens rotating shafts 16, 17 for putting and holding an objective lens therebetween, a carriage 15 rotatable around a pivot, and a grindstone rotating shaft 9 provided with a grindstone 5 for grinding the objective lens L, the lens rotating shaft 17 is provided with a reference globe 70 having a predetermined radius.

Owner:KK TOPCON

Polyol composition of the two-part system for foam grindstone, two-part curable composition for foam grindstone, foam grindstone, and process for production thereof

ActiveUS20060122287A1Satisfactory dissolution stabilityHigh yieldOther chemical processesAbrasion apparatusPolyolFoaming agent

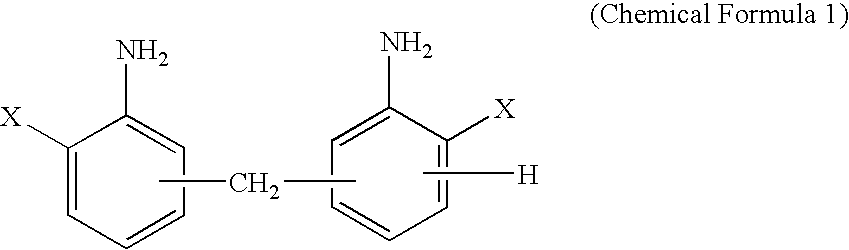

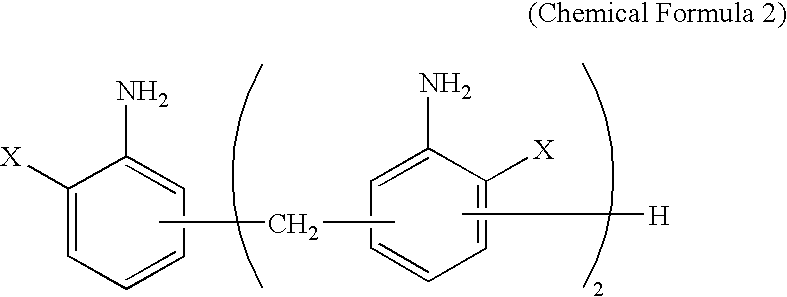

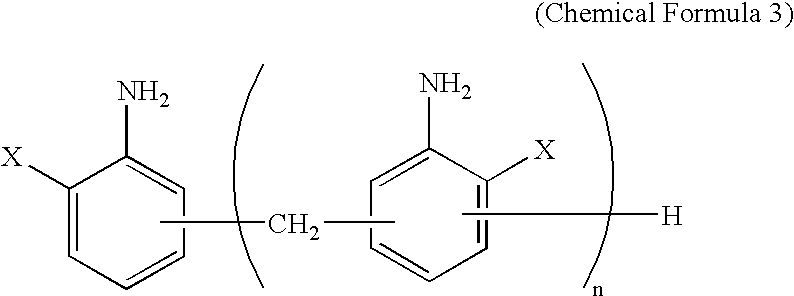

A polyol composition contains a polyaminochlorophenylmethane mixture (A) and a polyol (B), in which the component (A) is uniformly dissolved in the component (A) in a weight ratio of 30 / 70 to 60 / 40. The component (A) includes 50 to 70% by weight of a specific binuclear polyaminochlorophenylmethane compound, 20 to 40% by weight of a specific trinuclear polyaminochlorophenylmethane compound and 5 to 10% by weight of a specific tetranuclear or higher polyaminochlorophenylmethane compound. The polyol composition exhibits excellent miscibility and dissolution stability, is liquid and enables molding of a foamed article for abrasive in a simple two-component mixing casting machine. According to the present invention, water serving as a foaming agent can be added to the polyol composition containing MBOCA, and the composition for a two-component curable abrasive foam can be held to a temperature equal to or lower than the boiling point of water, thus avoiding water from evaporating upon molding. The resulting abrasive foam has a uniform density distribution and exhibits excellent mechanical properties. A method for satisfactorily producing such an abrasive foam is also provided.

Owner:DAINIPPON INK & CHEM INC

Surface treatment method

ActiveUS20080280536A1Improve heat transfer efficiencyImprove flatnessEdge grinding machinesPolishing machinesSusceptorSpray coating

A surface treatment method that enables a surface of an electrostatic chuck to be smoothed, so as to improve the efficiency of heat transfer between the surface of the electrostatic chuck and a substrate. The electrostatic chuck is provided in an upper portion of a susceptor provided in a chamber of a substrate processing apparatus. In the surface treatment of the electrostatic chuck, a sprayed coating film is formed on the surface of the electrostatic chuck, next the surface of the electrostatic chuck is ground by bringing into contact therewith a grindstone, then the surface of the electrostatic chuck is ground flat by bringing into contact therewith a lapping plate onto a surface of which is sprayed a suspension, and then the surface of the electrostatic chuck is ground smooth by bringing into contact therewith a tape of a tape lapping apparatus.

Owner:TOKYO ELECTRON LTD

Ultrasonic trimming apparatus and ultrasonic trimming method

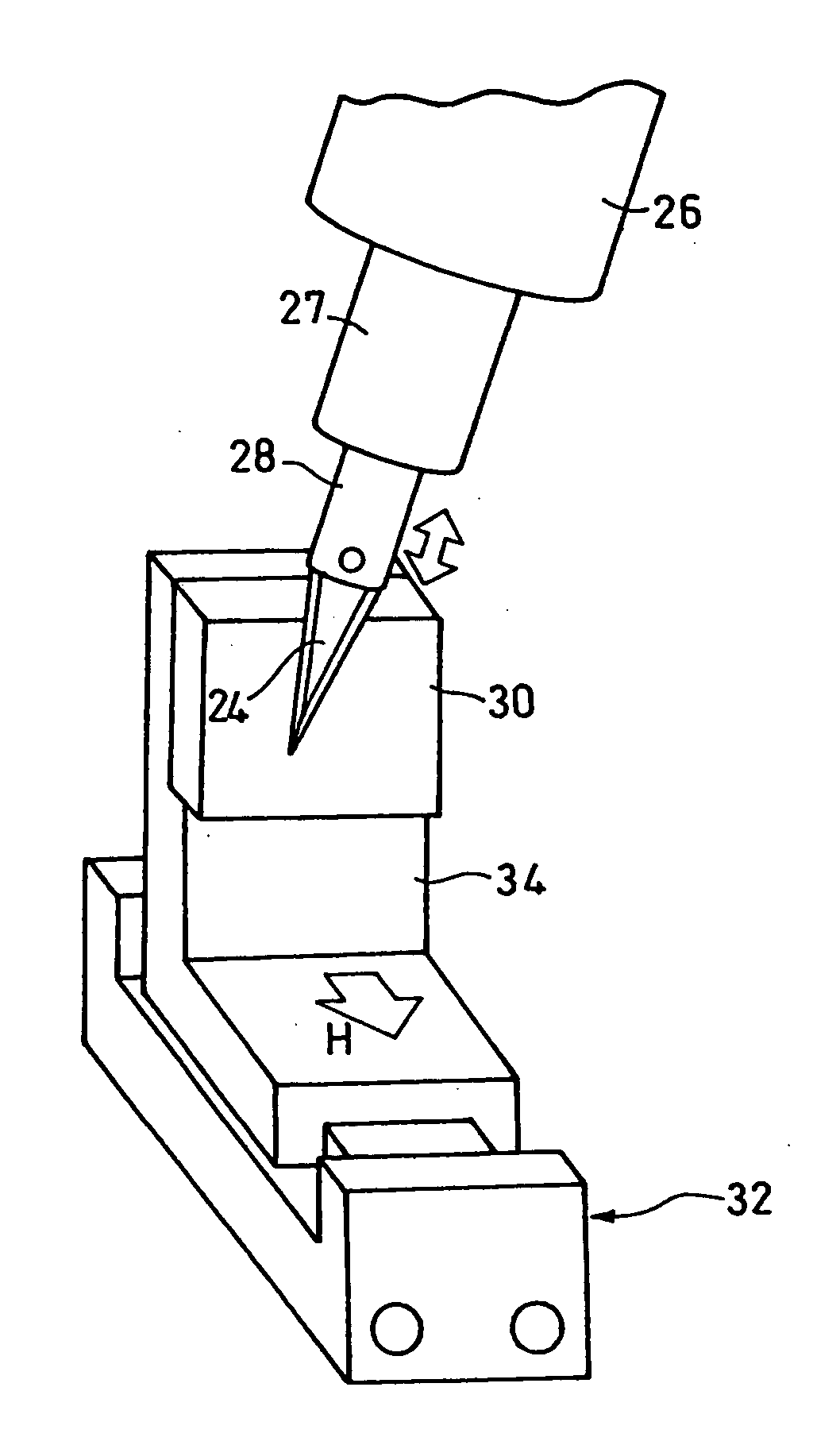

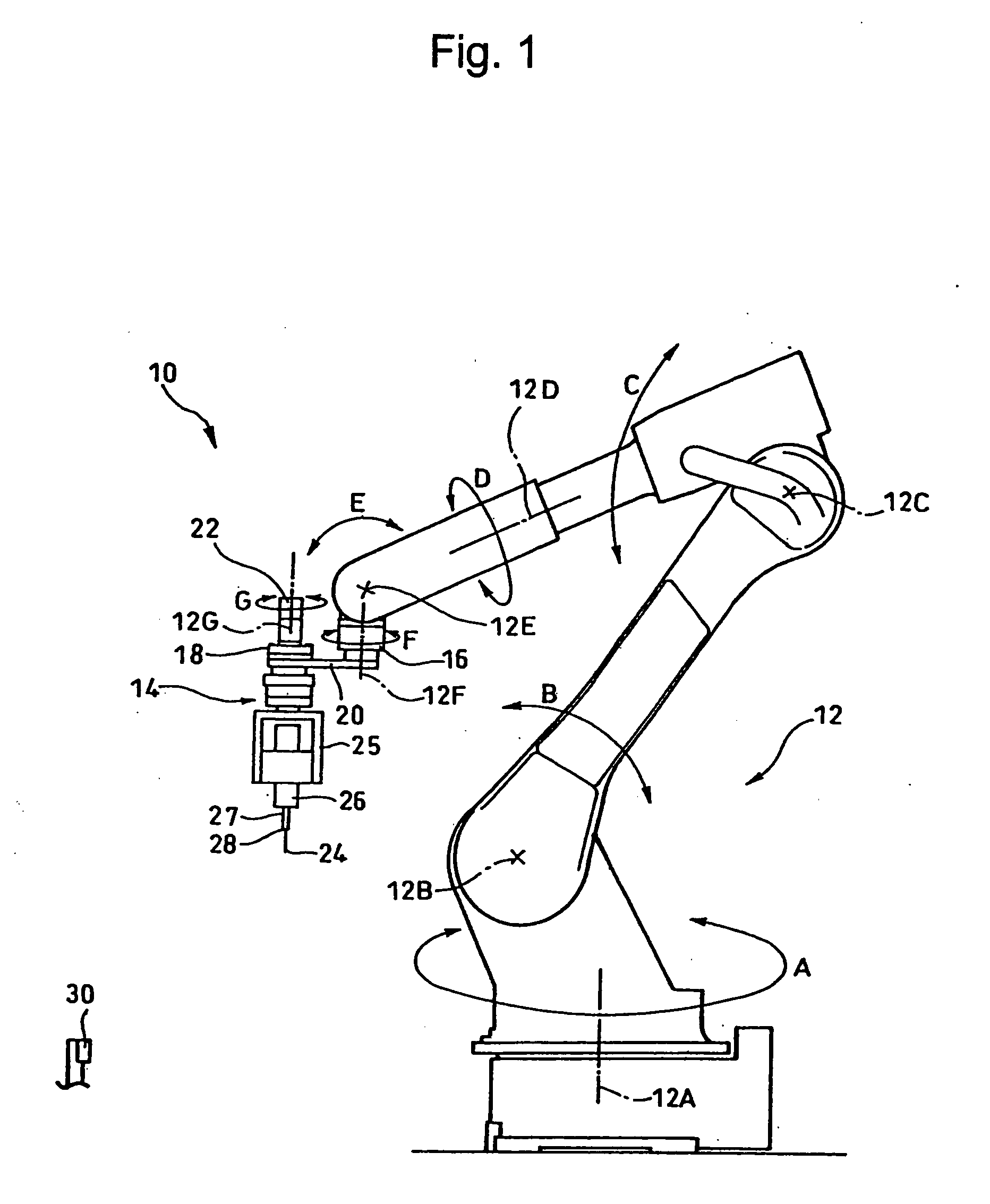

ActiveUS20100043610A1Efficient executionEfficiently grinding a cutter bladeEdge grinding machinesMetal sawing devicesGlass fiberThree dimensional shape

An ultrasonic trimming apparatus is composed of an articulated robot, a cutting apparatus, and a grindstone. The cutting apparatus is composed of an ultrasonic oscillator which is supported by the end portion of the articulated robot, a cutter blade which is supported by the ultrasonic oscillator, and a workpiece securing portion which secures a workpiece. The grindstone serving as a grinding member is disposed within the movable range of the cutter blade driven by the robot and is placed in a position at which the cutter blade can pressure contact the cutter blade. The cutter blade is ultrasonically vibrated by the ultrasonic oscillator and is ground while being pressed against the grindstone by means of the articulated robot. The ultrasonic trimming apparatus efficiently cuts a sheet material composed of soft material such as plastic, fabric, or rubber, a composite material, or a material containing glass fiber by means of an environmentally conscious method even when the material has a three-dimensional shape.

Owner:NIHON SHORYOKU KIKAI

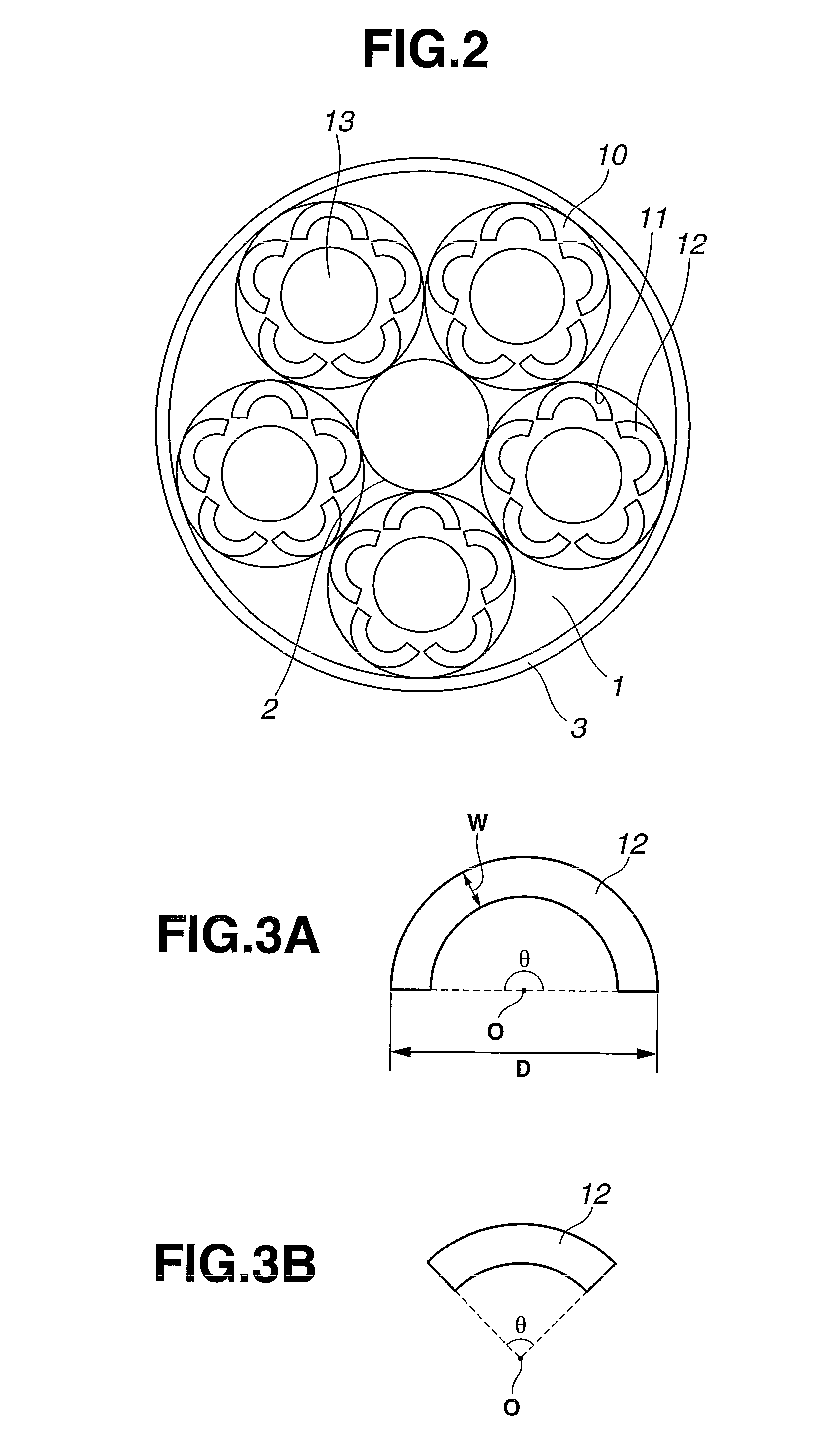

Lapping plate-conditioning grindstone segment, lapping plate-conditioning lapping machine, and method for conditioning lapping plate

InactiveUS20100190418A1Minimal surface roughnessFine surfacePolishing machinesRevolution surface grinding machinesMechanical engineeringGrindstone

In a lapping machine comprising a lapping plate and a conditioning carrier disposed thereon, the carrier being provided with bores for receiving conditioning grindstone segments, the lapping plate is polished and conditioned by cooperatively rotating the lapping plate and the carrier and feeding loose abrasive grains to the lapping plate. The conditioning grindstone segment of a shape of arcuated trapezoid having an included angle of 180°-90° is fitted in the carrier bore.

Owner:SHINANO ELECTRIC REFINING

Complex apparatus and method for polishing an ingot block

InactiveUS20110306277A1Small footprintExtended service lifeEdge grinding machinesGrinding feed controlPrismEngineering

A compound chamfering device that manufactures prism-shaped ingot blocks of excellent surface smoothness is disclosed. The four-corner round surfaces and the four sides of a prism-shaped ingot obtained by using a pair of rotary blades of a slicer to perform four-side peeloff of a cylindrical ingot block are chamfered by rough grinding with a pair of cup wheel type rough grinding grindstones. A pair of cup wheel type finishing grinding grindstones are used to chamfering by finishing grinding the four-corner round surfaces and the four sides of the block.

Owner:OKAMOTO MACHINE TOOL WORKS LTD

Abrasive grains consisting of polycrystalline alumina

The invention relates to an abrasive grain based on electromelted alumina consisting of crystals with a hexagonal structure, of size less than 100 mum, and preferably less than 30 mum, and more preferably less than 5 mum, with density higher than 97%, preferably 98%, of the theoretical density of alumina, and a Knoop hardness higher than 2000. The invention also relates to a method for making abrasive grains based on alumina consisting in melting alumina, casting it at a constant flow rate less than 80 kg / mn, and cooling it by dispersing the melted alumina in fine droplets to obtain articles with size less than 1 mm. The dispersion is preferably performed by ultrasound-assisted spraying, at a frequency ranging between 15 and 50 MHz. The inventive grains are used in particular for making grindstones.

Owner:PEM ABRASIFS REFRACTAIRES

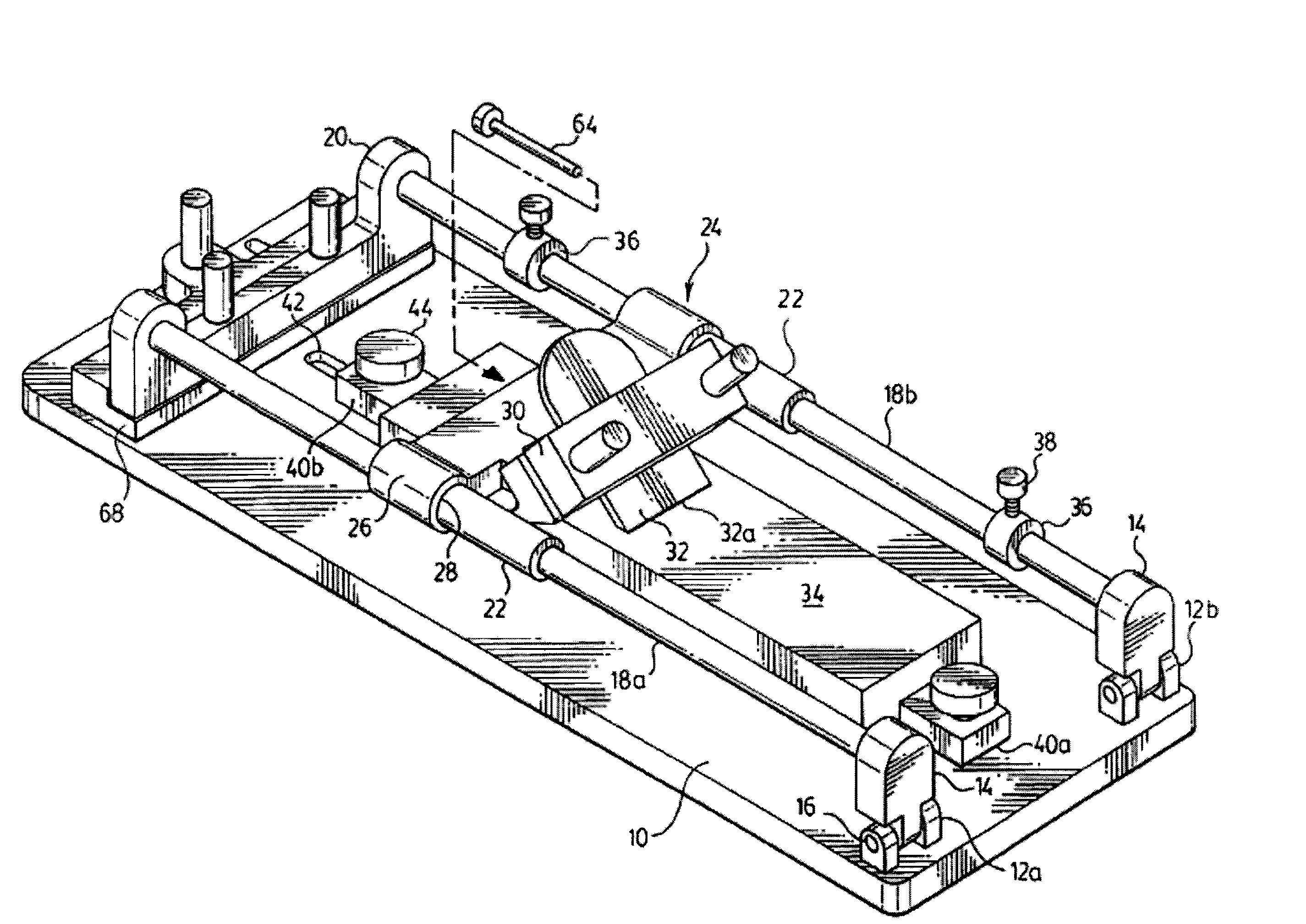

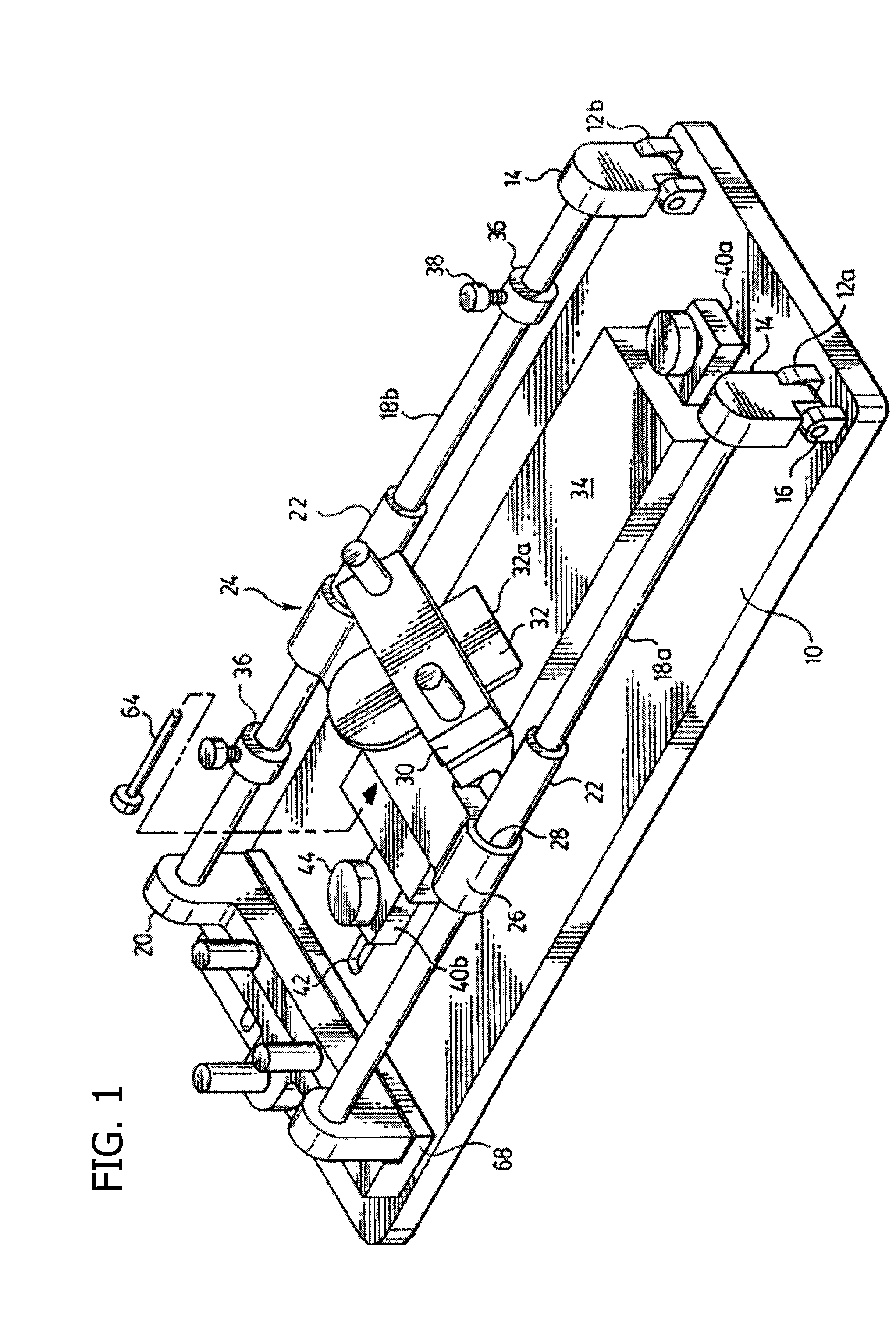

Honing jig

InactiveUS20090004956A1Other manufacturing equipments/toolsGrinding/polishing hand toolsEngineeringMechanical engineering

The honing jig has a base on which a whetstone or other abrasive substance is mounted. A pair of spaced guide rods extends the length of the base. A carriage is mounted to tubes which slide along the rods and through which the guide rods extend. The blade to be sharpened is held to the carriage by a clamp and the clamp swivels on the carriage to allow the inclination of the blade relative to the whetstone to be adjusted. The angle of the guide rods can be adjusted to permit fine adjustment of the inclination of the blade.

Owner:JESSEM TOOL

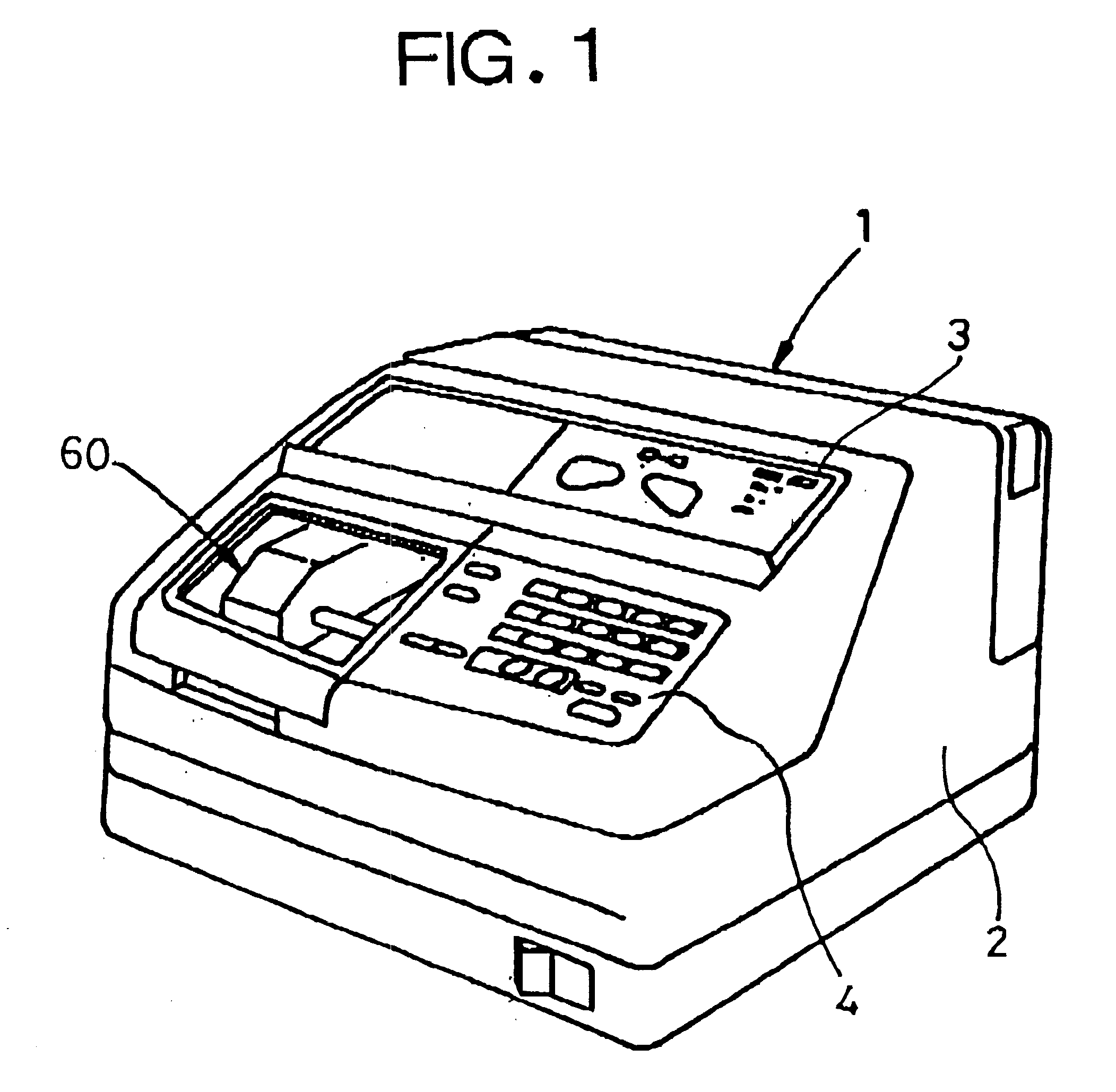

Eyeglass lens processing apparatus

In an eyeglass lens processing apparatus for beveling a peripheral edge of an eyeglass lens, if the high curve lens processing mode is selected by a mode selector, a computing unit acquires a high curve bevel path for locating the bevel apex on a front surface curve of the eyeglass lens or for locating the bevel apex at a position shifted by a predetermined quantity from the front surface curve toward the rear side on the basis of the edge position information acquired by the edge position detector, thereby providing high curve beveling data for the rear surface beveling grindstone, or for the front surface and rear surface beveling grindstones; and a beveling controller bevels the peripheral edge of the eyeglass lens by the rear surface beveling grindstone, or by the front surface and rear surface beveling grindstones on the basis of the high curve beveling data.

Owner:NIDEK CO LTD

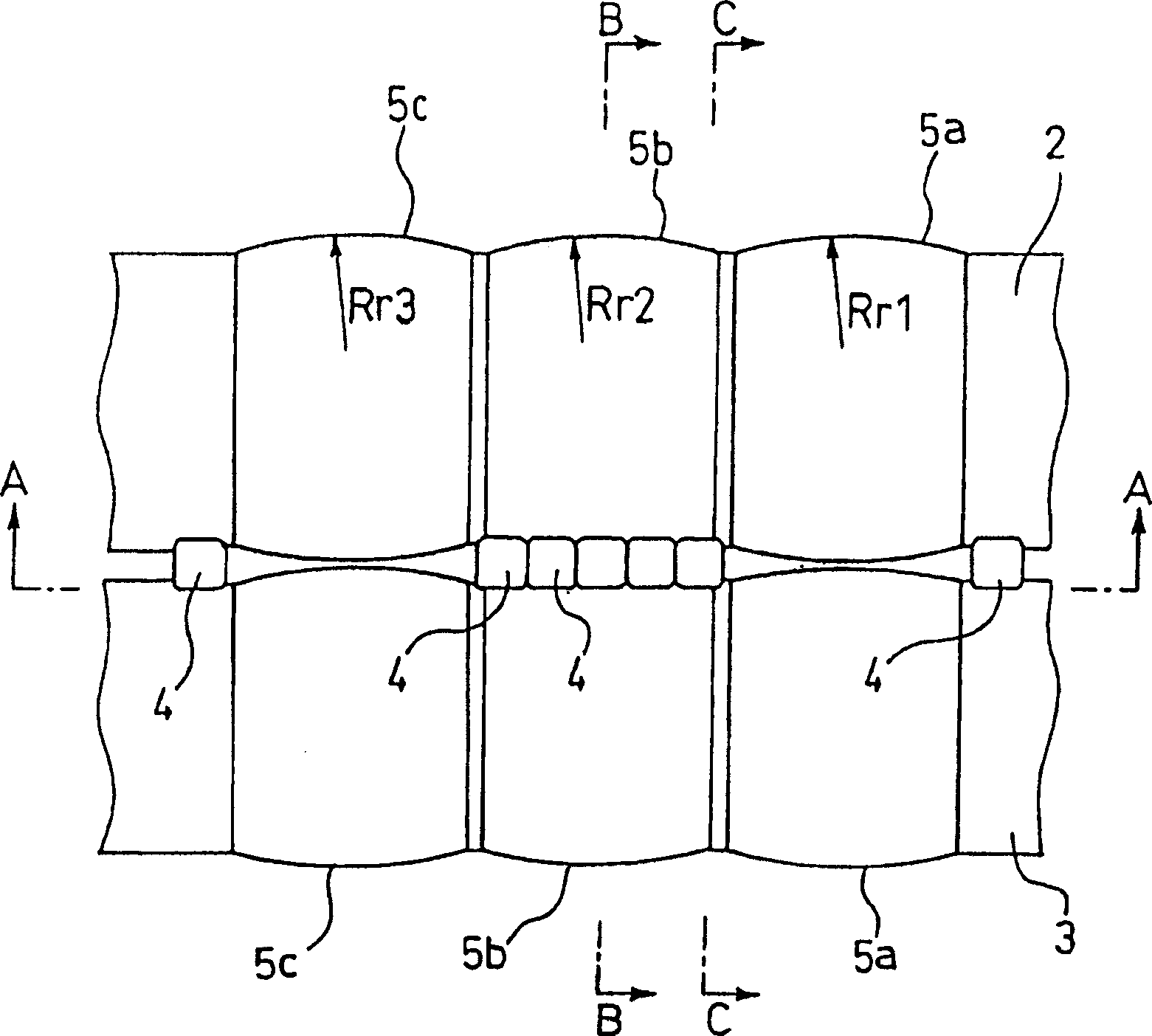

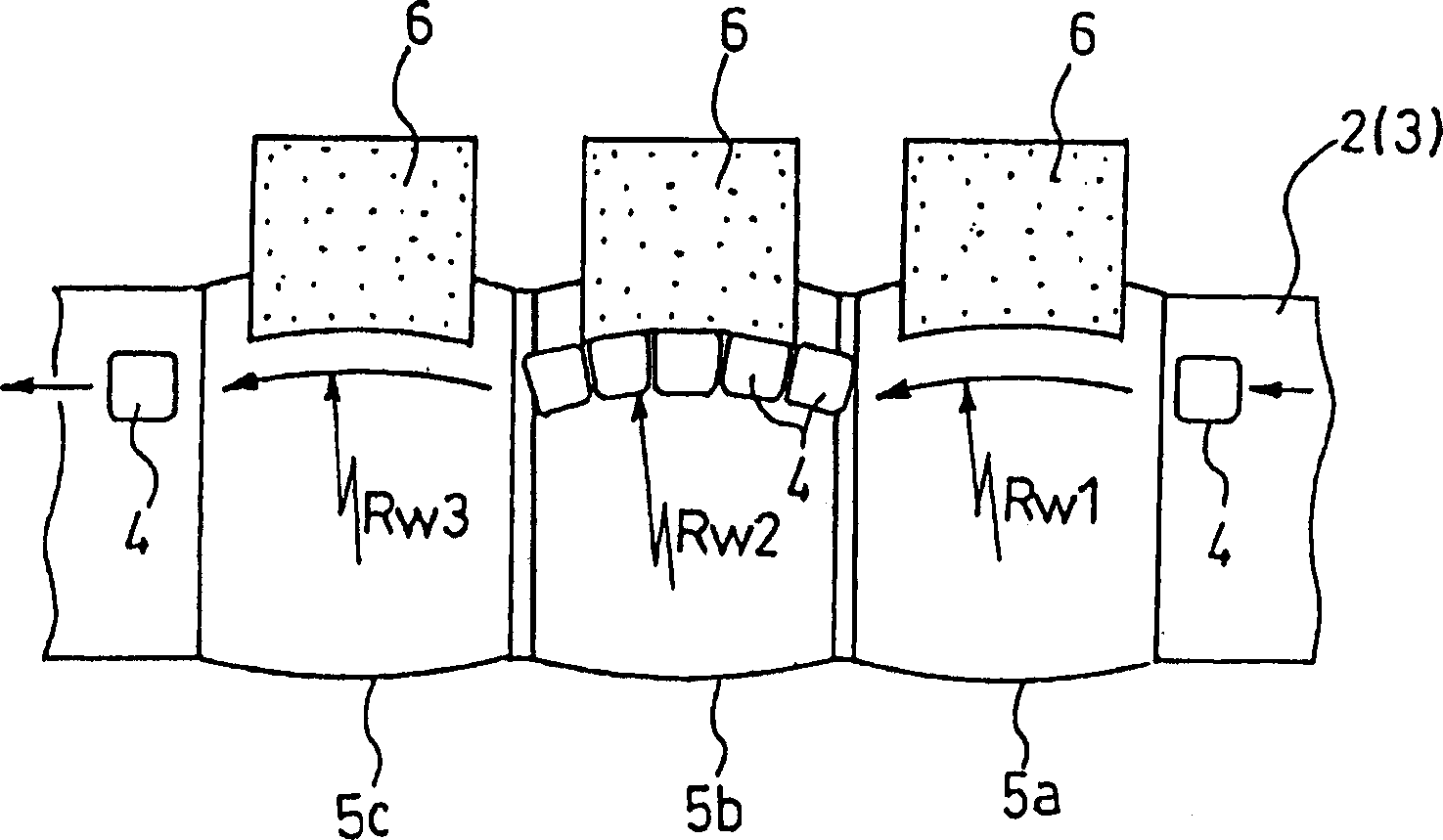

Super grinding machine, super grinding method rolling piece and rolling bearing

InactiveCN1535795ARoller bearingsRevolution surface grinding machinesEngineeringMechanical engineering

Driving rollers 2, 3 which rotate in the same direction are arranged in parallel to each other. A plurality of convex portions 5a, 5b, 5c having different radii of curvature Rr1, Rr2 and Rr3 are formed along the axial direction at opposing positions on the driving rollers 2, 3. A rolling element 4 which is fed into the gap between the driving rollers 2, 3 and rotated is moved along tracks having different radii of curvature Rw1, Rw2 and Rw3 in the axial direction. There is provided a superfinishing grindstone 6 which is pressed on the rolling surface of the rolling element 4 moving on tracks having different radii of curvature to superfinish the rolling surface of the rolling element 4.

Owner:NSK LTD

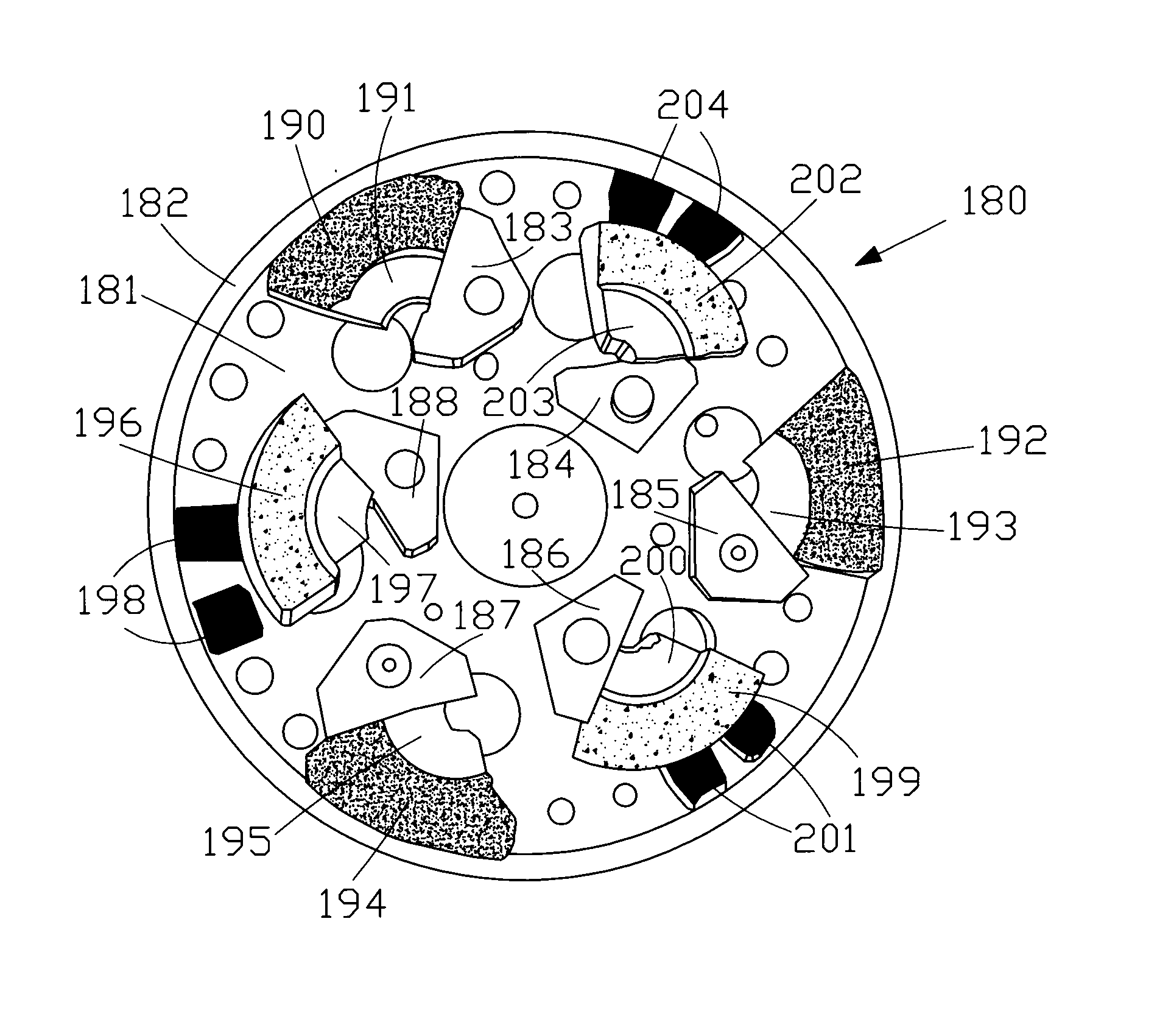

Multi-abrasive tool

ActiveUS20140154961A1Reduce in quantityIncrease speedRevolution surface grinding machinesBonded abrasive wheelsPolishingEngineering

A multi-abrasive tool is constituted by a support on which abrasive elements are present. Such abrasive elements are arranged in a manner so as to form one or more paths along which the successive abrasive elements have grain size sequentially increasing or decreasing by an arbitrary quantity when passing from on element to the next. Such principle gives rise to abrasive tools with different conformation both for polishing machines and for grindstones. For roto-orbital and planetary polishing machines, and optionally orbital, such support is circular and the grain sequence is circumferential, or radial, or in both directions. A first tool is constituted by contiguous (or non-contiguous) circular rings, that are differently abrasive. A second tool comprises differently abrasive elements arranged along the circular peripheral edge. A third tool comprises differently abrasive elements arranged along a spiral path of 360° starting from the edge. A fourth tool comprises two 180° spiral paths with reversed roughness sequences. A fourth tool comprises pairs of differently abrasive small cylinders fixed to a plate on concentric circumferences. A fifth tool is obtained directly on the plate of the polishing machine by means of reliefs and spacers for fixing differently abrasive sectors. For linear polishing machines, the abrasive support is a belt along which differently abrasive rectangular or oblique zones follow each other. For alternative polishing machines, the abrasive support is a plate shaped like the aforesaid belt. For tools to use with grindstones, the multi-abrasive element has a cylindrical rotation symmetry, or conical with rounded tip, or spherical symmetry.

Owner:MA VA SRL

Grinding method utilizing grinding sharpness of grinding element

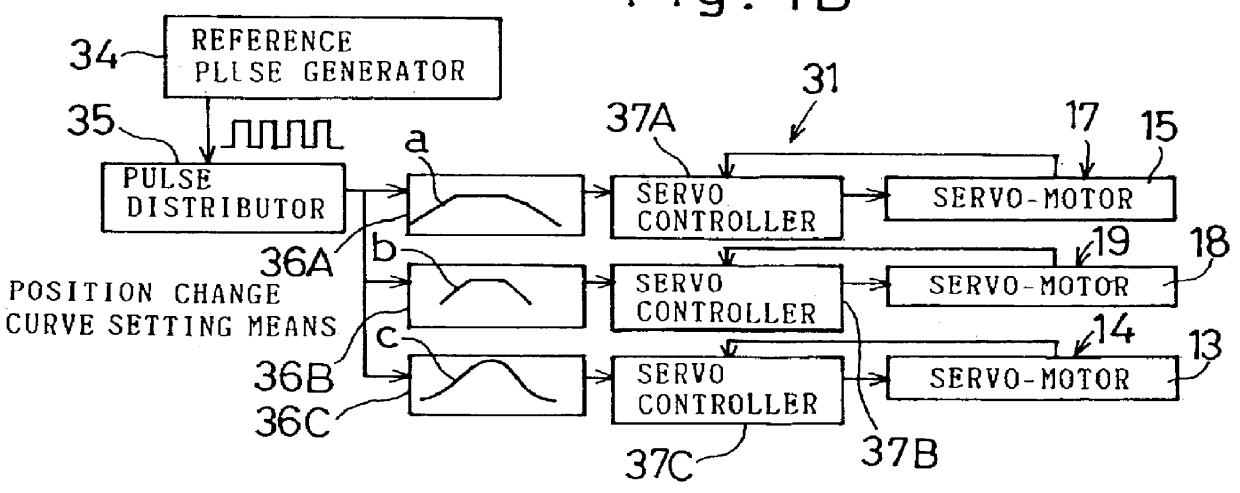

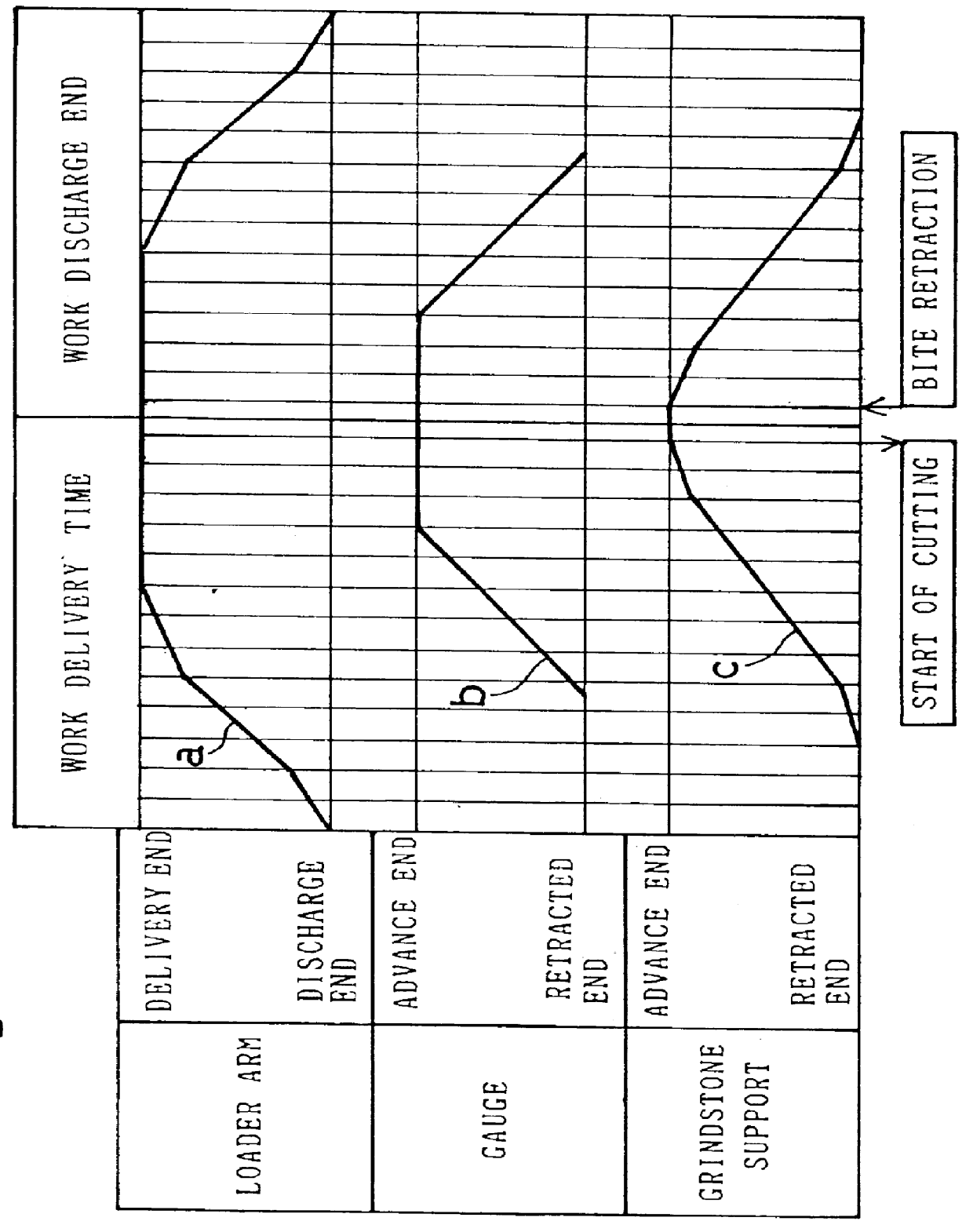

In order to eliminate a delay in a driving system and a control system during sequential operation of various component parts, to thereby realize a high speed and easy multi-axis control, a work delivery and removing device (7), a grindstone retracting device (14) and a gauge retracting device (19) are driven by respective compact electric motors (15, 13, 18) through associated reduction gear units. A reference pulse generator (34) for sequencers for generating reference pulses is provided, which reference pulses are distributed by a pulse distributor (35) to various position change curve setting units (36A, 36B, 36C). The position change curve setting units (36A, 36B, 36C) are a so-called electronic cam and output in response to receipt of the corresponding reference pulses respective position commands representative of predetermined position change curves (a, b, c). Servo-controllers (37A, 37B, 37C) are used for controlling the electric motors (15, 13, 18) in response to these outputs.

Owner:NTN CORP

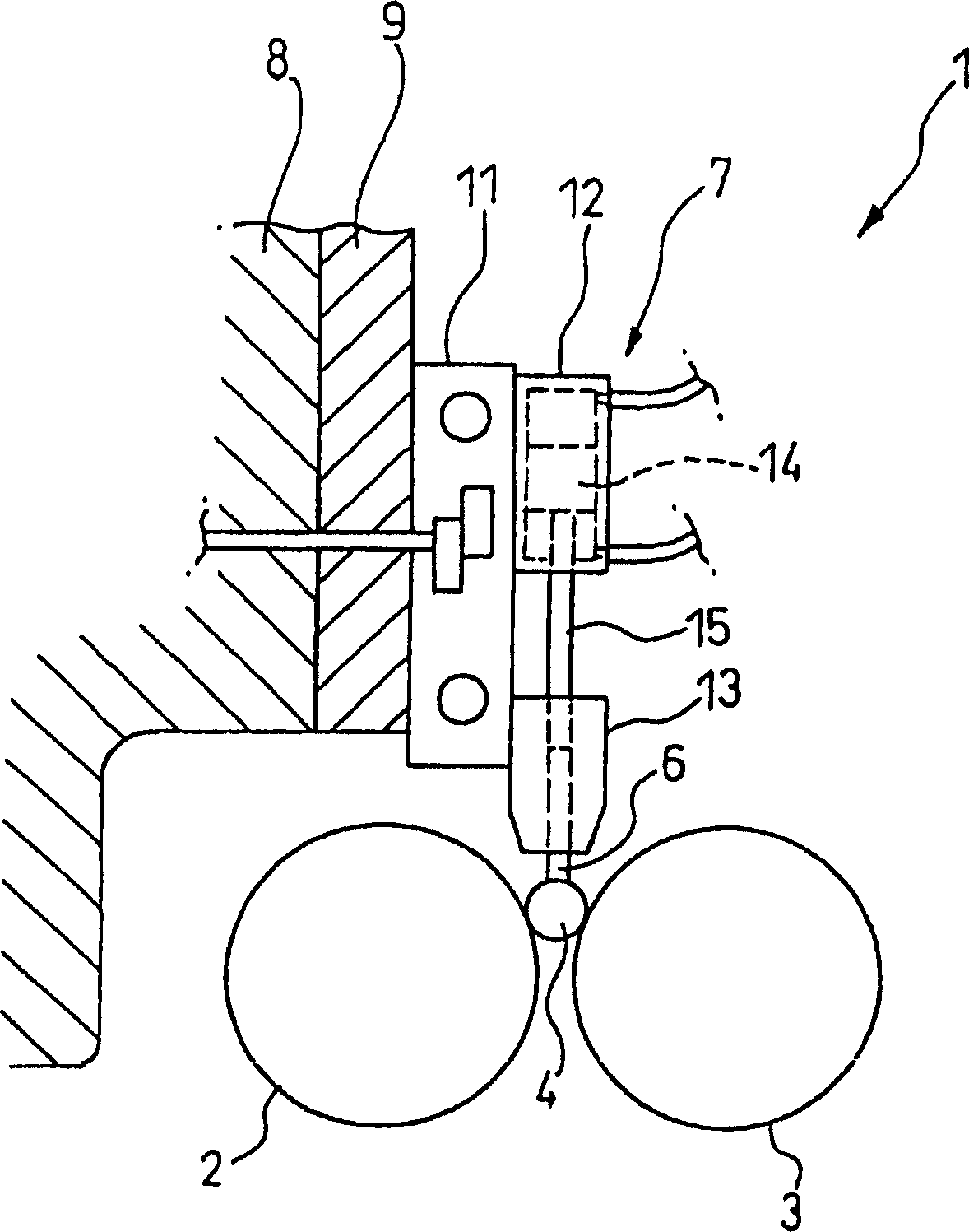

End face grinding apparatus, and method of grinding end face, for glass substrate

ActiveCN101500749AReduce movement speedSuppression of scratchesEdge grinding machinesPlane surface grinding machinesEngineeringGrinding wheel

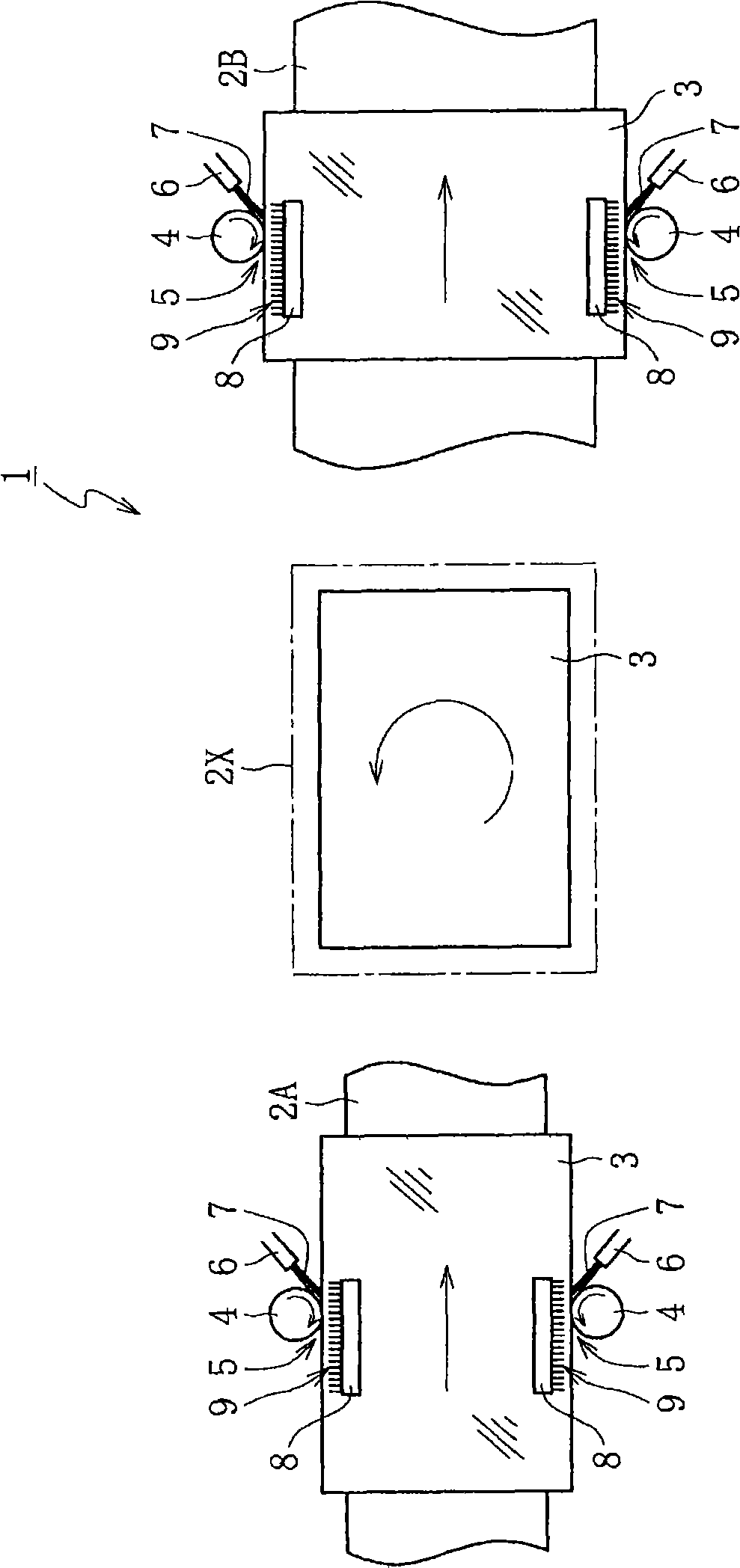

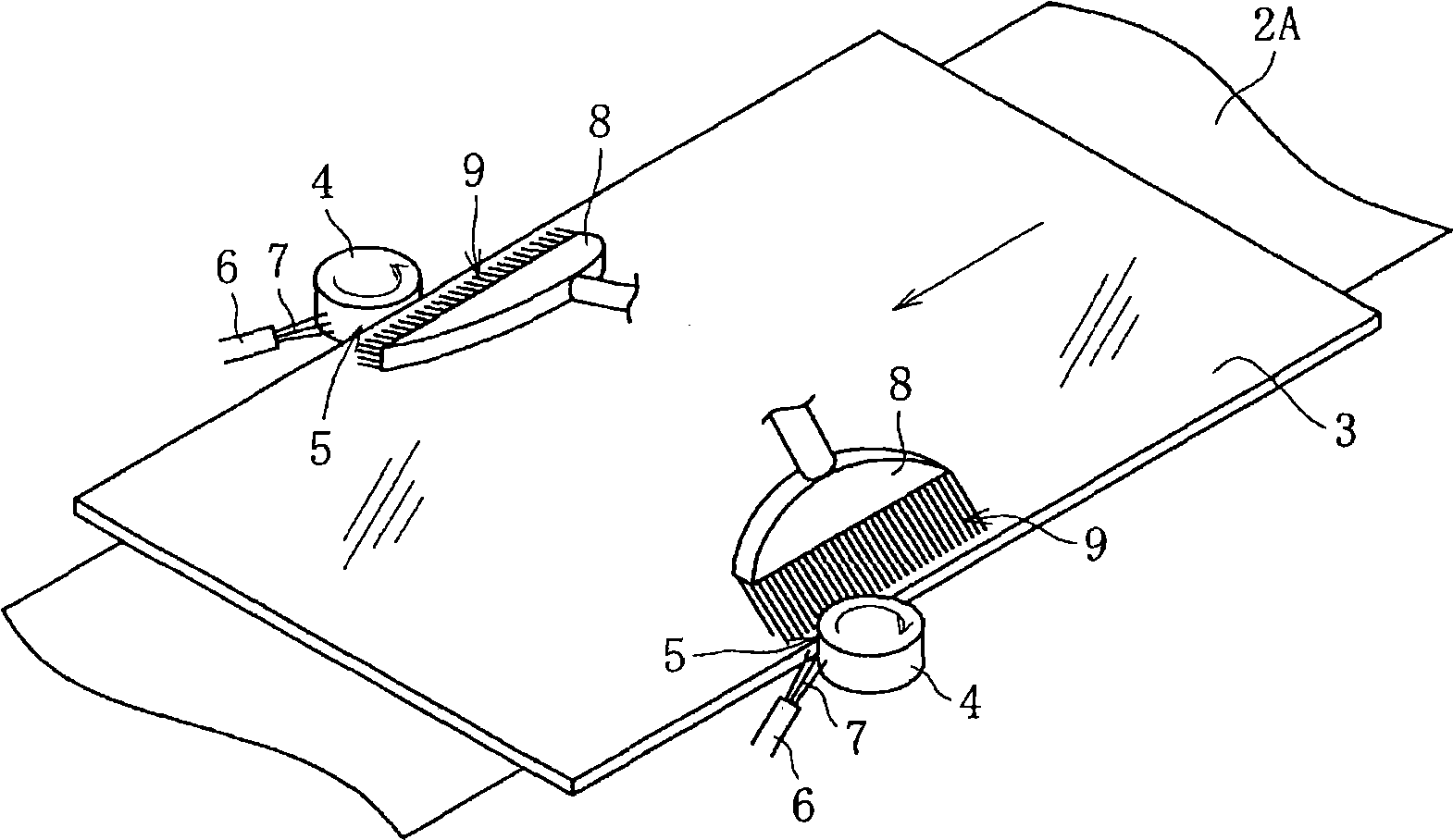

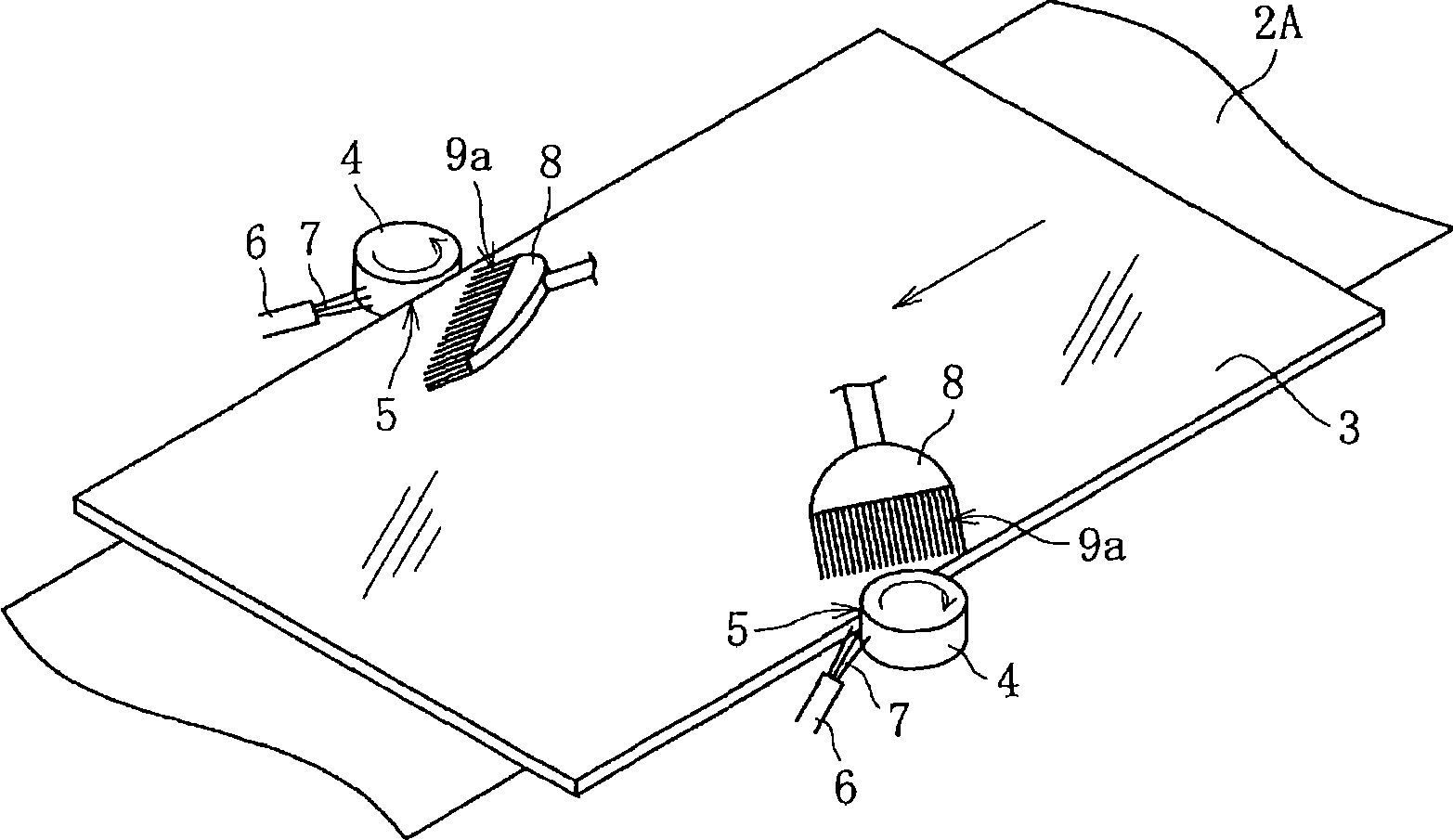

End face grinding apparatus (1) for glass substrate including grindstone (4) for grinding an end face of glass substrate (3) by making relative movement to the glass substrate (3) and including grinding fluid supply means (6) for feeding grinding fluid (7) to an area surrounding a grind location of the glass substrate (3), wherein there is disposed water spouting means (8) for forming water curtain (9) adapted to block the flow along the surface of the glass substrate (3) of any cut dust contained in the grinding fluid (7) scattered in the grinding of the end face of the glass substrate (3) by the grindstone (4).

Owner:NIPPON ELECTRIC GLASS CO LTD

Method for cutting semiconductor wafer protecting sheet

InactiveUS6910403B1Thin thicknessLowered machining efficiencySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringGrinding wheel

To cut a protecting sheet adhered over the obverse of a wafer, an inclination angle of a cutting tool is adjusted according to a form of a chamfered part of the wafer and a finishing thickness of the wafer so that the protecting sheet is cut into the required minimum size for protecting the obverse of the wafer. Thus, the protecting sheet is not included inside a removed portion in a grinding process of the reverse of the wafer with a grindstone even if the wafer is ground to have extremely thin finishing thickness. Hence, the protecting sheet is not ground while the reverse of the wafer is ground, and the grindstone is thus prevented from being clogged up with ground material of the protecting sheet.

Owner:TOKYO SEIMITSU

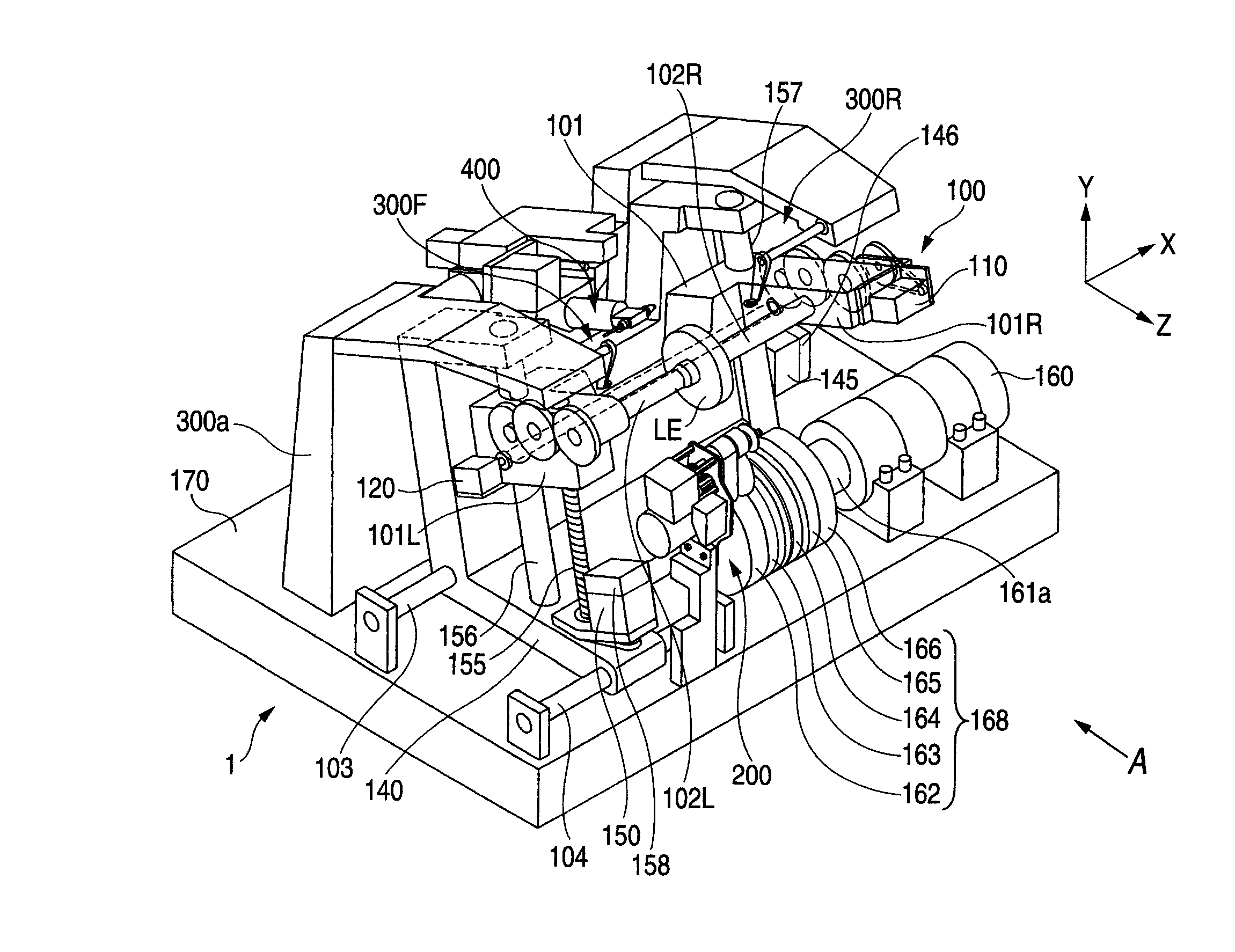

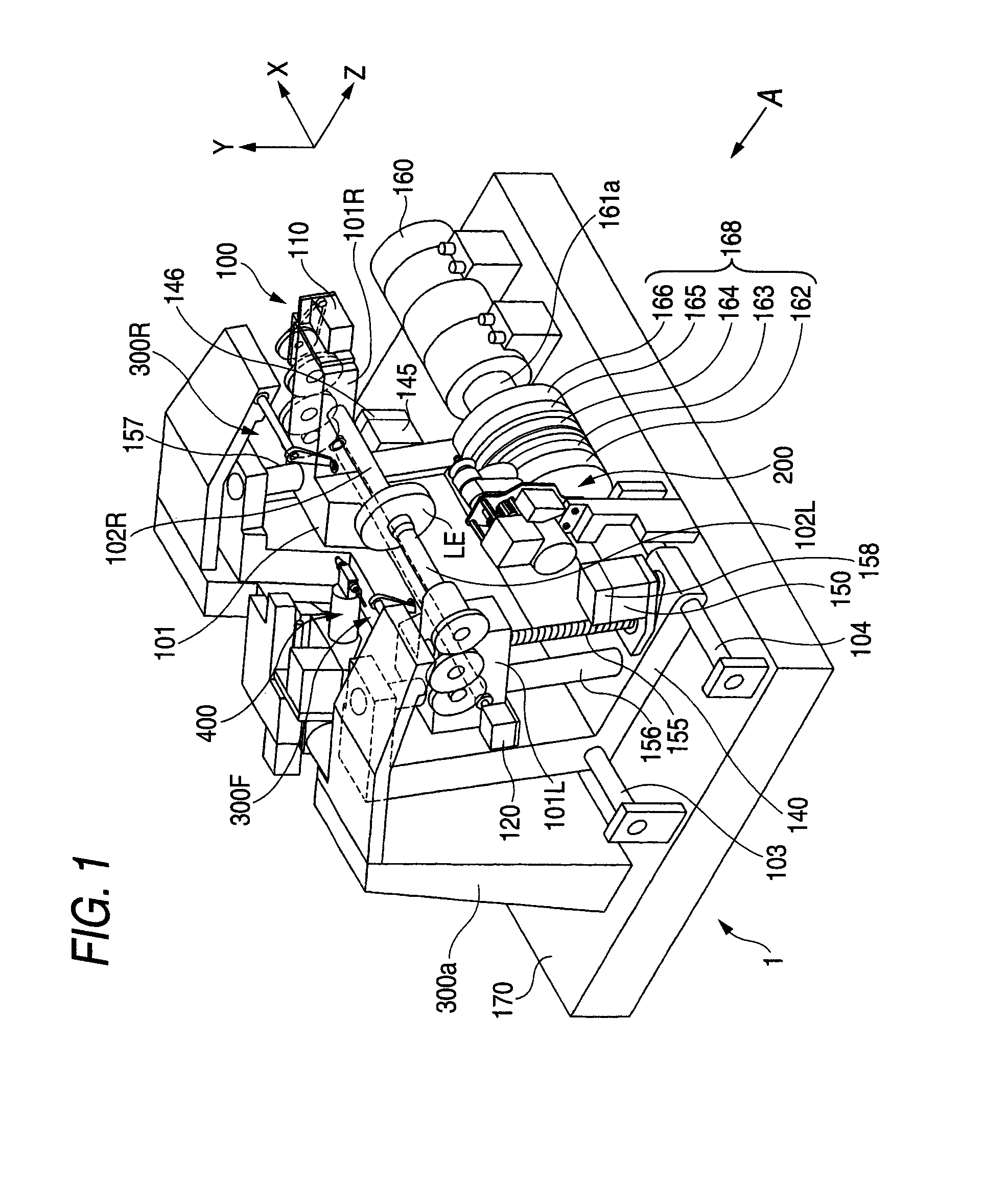

Grinding machine and measurement device

ActiveCN102099155AAccurate measurementSimple and smooth gauge applicationRevolution surface grinding machinesMechanical diameter measurementsMeasurement deviceMeasuring instrument

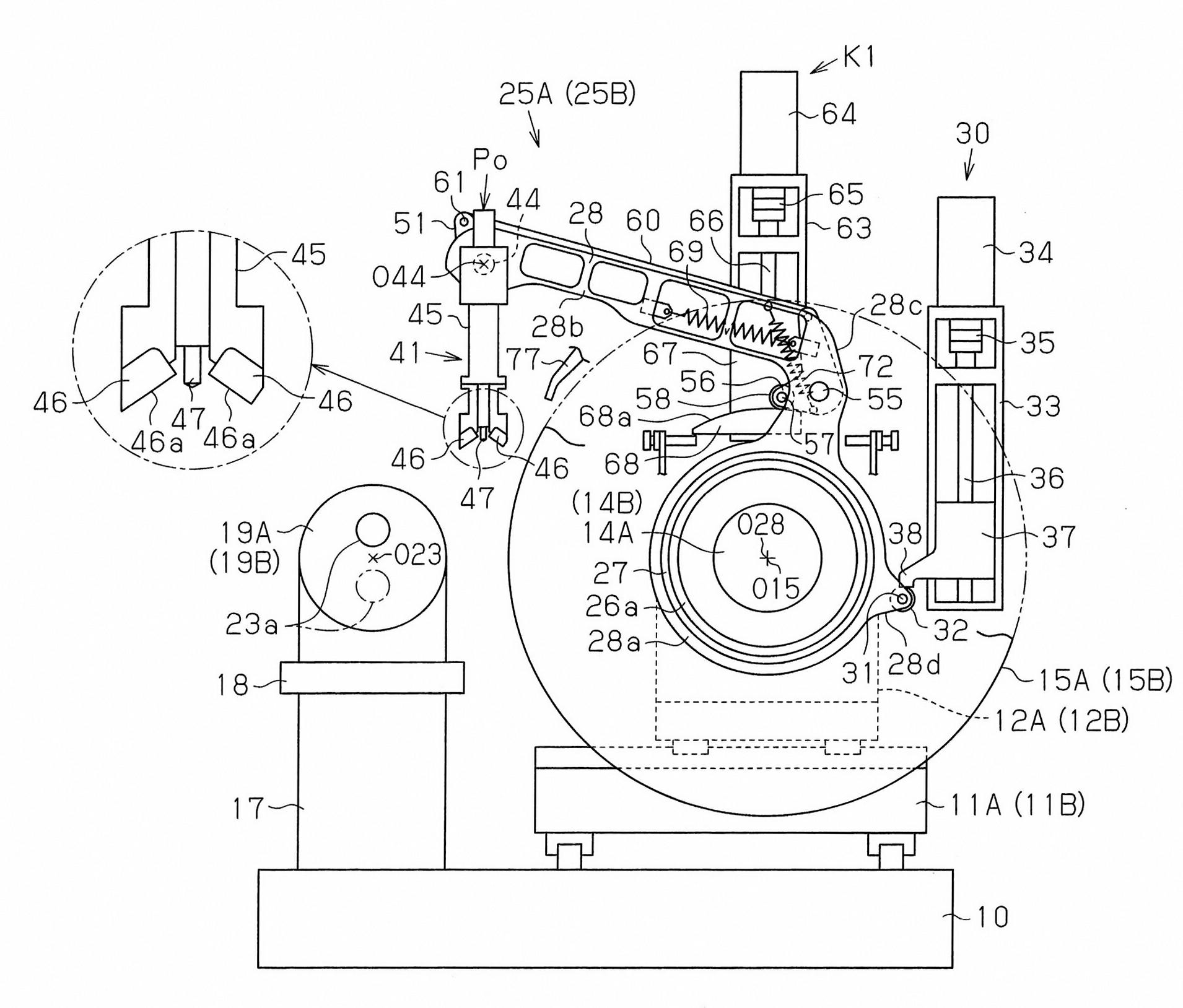

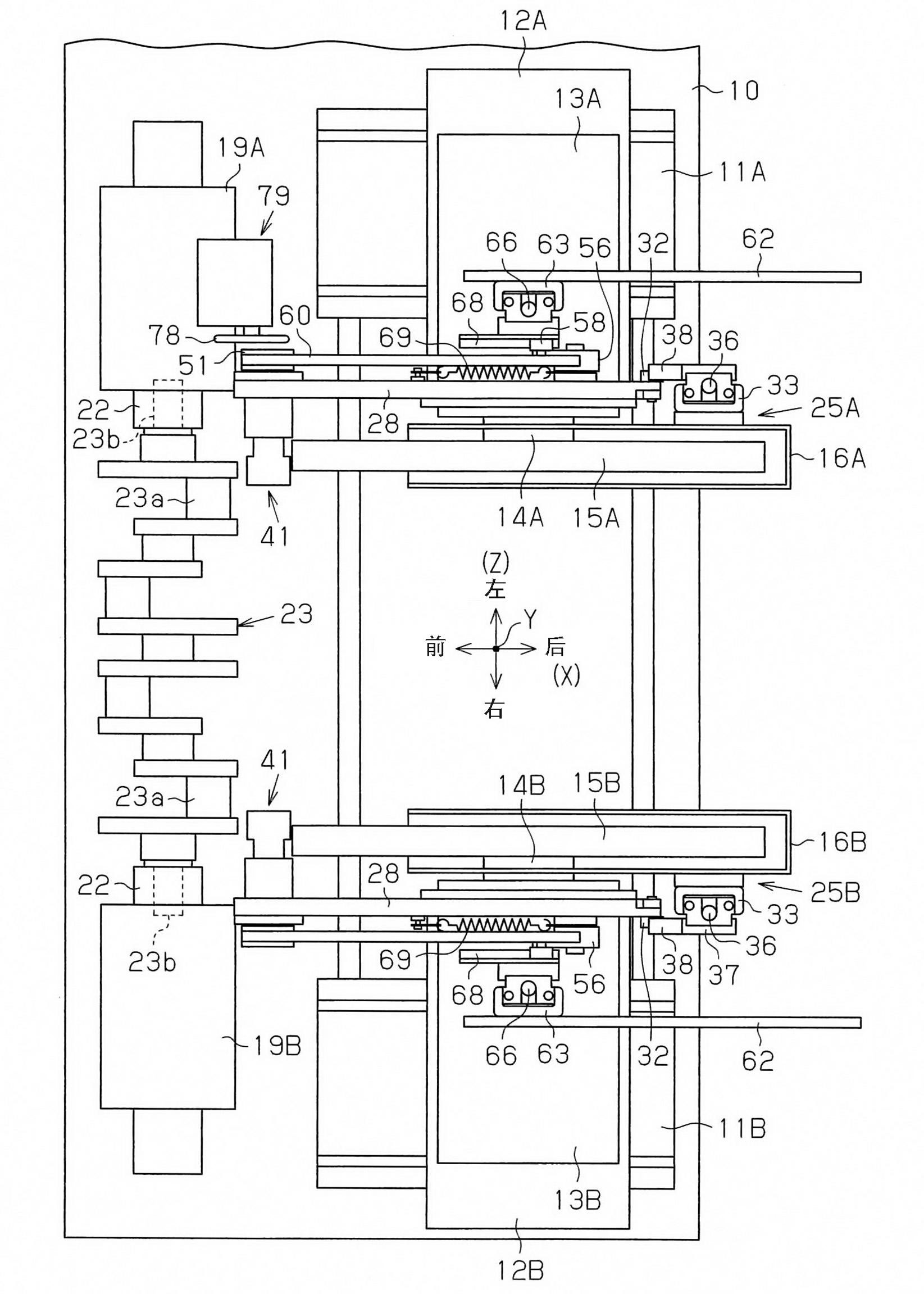

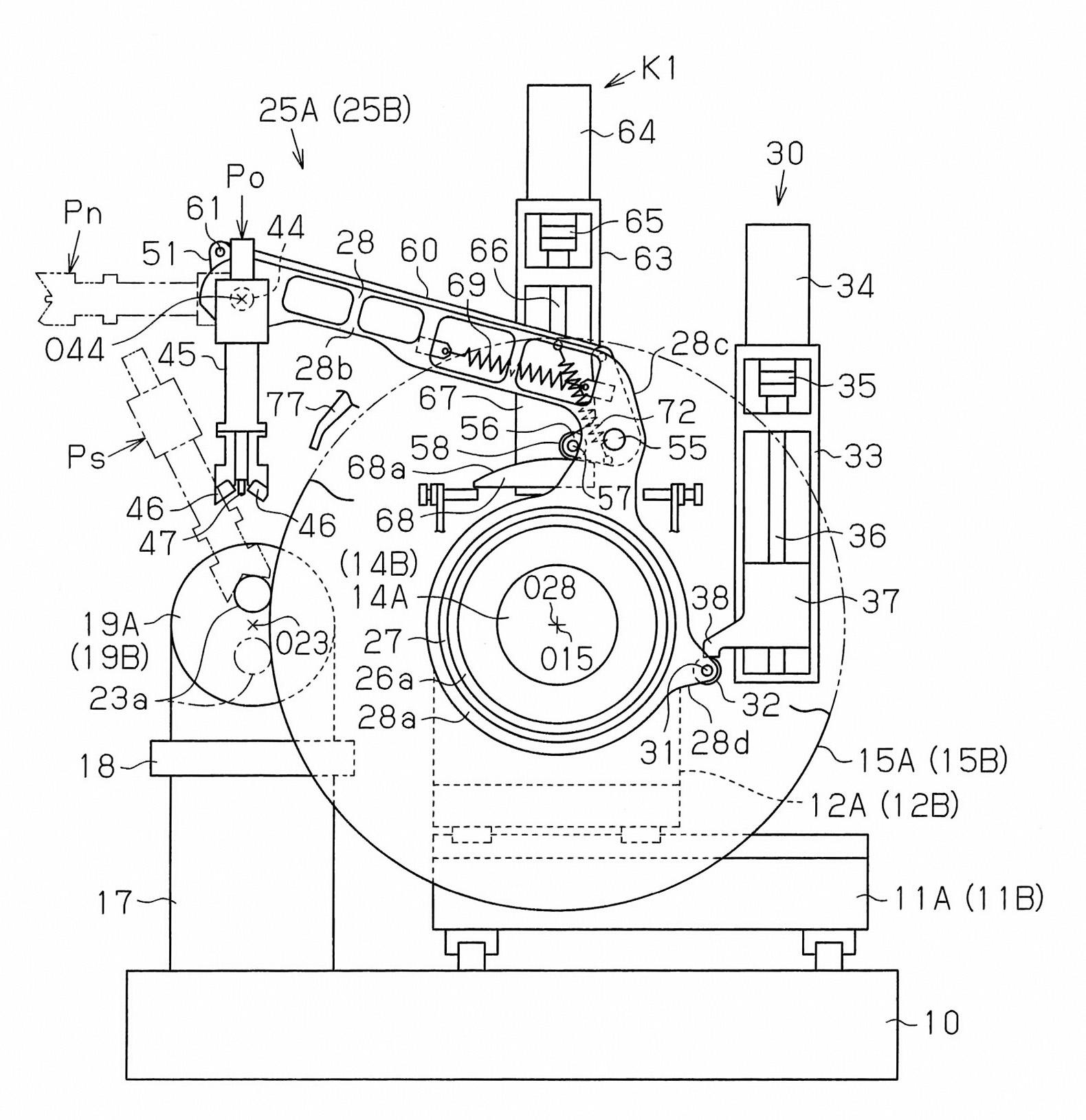

A grinding machine, wherein a first grindstone head is provided to a machine base frame (10) with a first movement body (11A) and a first grindstone base (12A) provided therebetween. The base end of a tilting arm (28) is tiltably fitted to the housing of the grindstone head. A measuring instrument (41) is rotatably connected to the tip of the tilting arm (28). A gage (46) and a measuring pin (47) are connected to the lower end of the measuring instrument (41), and the gage (46) is engaged with a crank pin (23a) of a crankshaft. The center (O28) of tilting of the tilting arm (28) is set on the same axis as the center (O15) of rotation of the first grindstone (15A). Even if the tilting arm (28) is tilted to change the position of the measuring instrument (41), the positional relationship between the first grindstone (15A) and the gage (46) does not change, and this enables the position of the gage (46) to be easily adjusted according to the diameter of the crank pin (23a). As a result, the trajectory of movement of the gage of the measuring instrument is simple and the outer diameter of the workpiece can be measured quickly.

Owner:KOMATSU NTC LTD

Brush-like Grindstone

InactiveUS20100041324A1Avoid breakingSimplified linkageEdge grinding machinesGrinding wheel securing apparatusFiberHardness

A brush-like grindstone (1) has threadlike grinding elements (2) each being a thread that is a collection of long inorganic fibers and is impregnated with resin and solidified. To grind work (W), the grindstone (1) is moved relative to the work (W) with the forward ends of the threadlike grinding elements (2) pressed against the work (W). In order to prevent the grinding elements (2) from breaking, each threadlike grinding element (2) is curved from its base end to its forward end with high hardness of the grinding elements (2) maintained. Also, the grinding elements (2) are formed in an elliptic or oblong cross-sectional shape whose minor axis is aligned with the direction of the curve. Therefore, the grinding elements (2) have extremely high rigidity in the direction perpendicular to the direction of the curve but they easily deform in the direction of the curve. Consequently, the grinding elements (2) softly engages the work (W) at their forward ends and, when excessive force acts on the elements (2), the brush-like grindstone (1) does not break because the elements (2) deform to absorb the force.

Owner:XEBEC TECH CO LTD +1

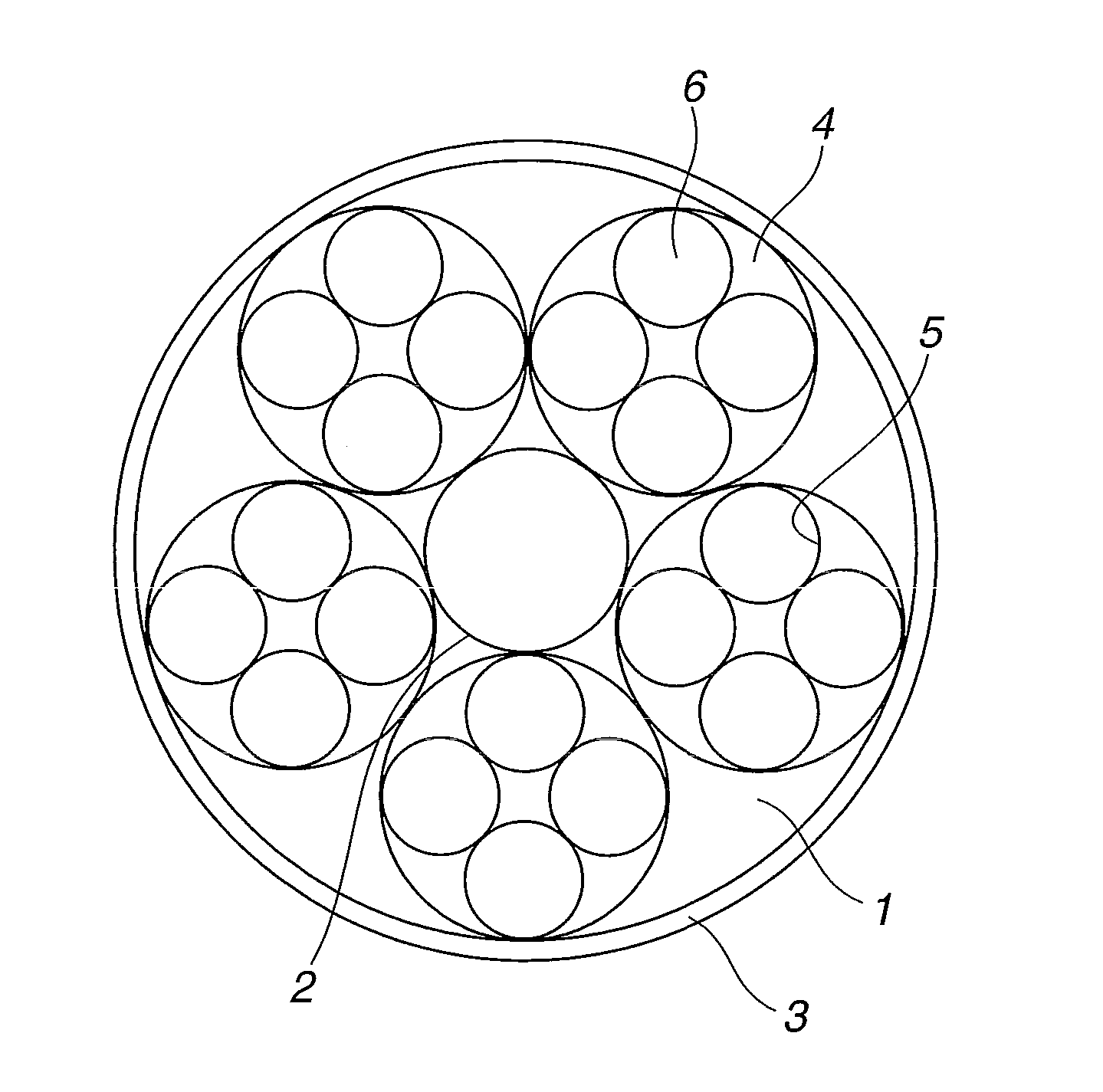

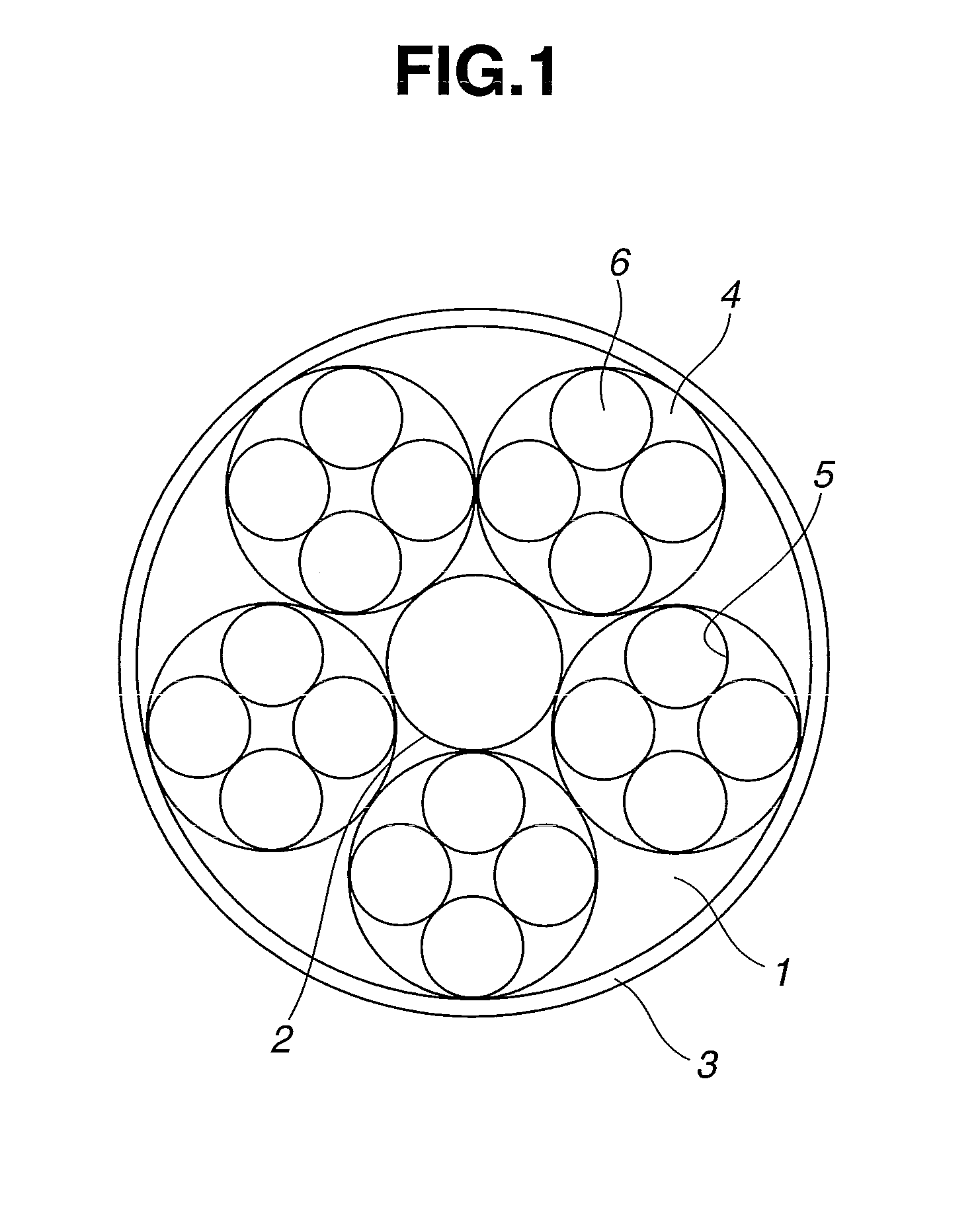

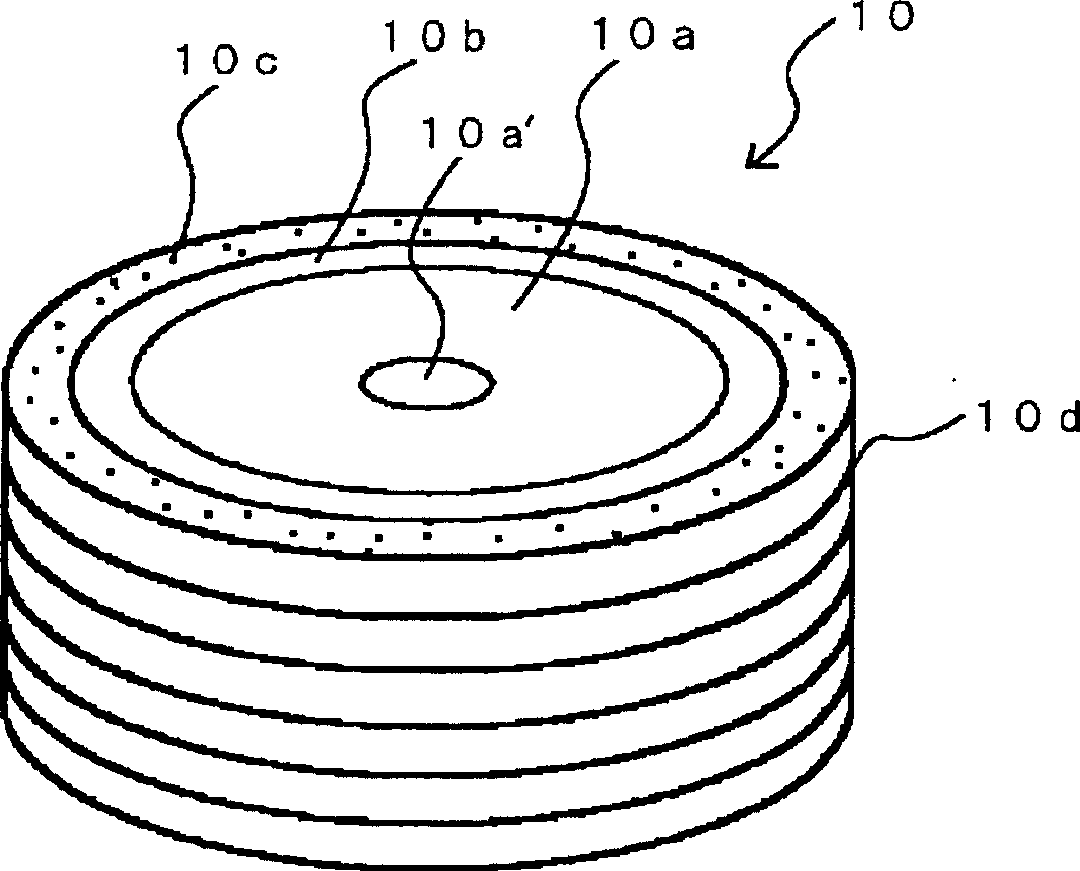

Grindstone

ActiveCN101500755AAvoid defectsAvoid breakingEdge grinding machinesBonded abrasive wheelsEngineeringMachining

To provide a grindstone that even in the event of chamfer machining of an edge portion of plate glass, ensures prevention of any defect or breakage thereof without productivity decrease, and provide a method of machining an end face of plate glass. The grindstone (10) comprises aluminum disk-shaped base metal (10a) provided at its center with hole portion (10a', with 120 mm outside diameter, 80 mm inside diameter and 40 mm thickness); ringlike shock absorption layer (10b, with 10 mm thickness) of, for example, phenolic resin, bonded to the outer circumferential surface of the disk-shaped base metal (10a); and ringlike abrasive grain layer (10c, with 5 mm thickness) bonded to the outer circumferential surface of the shock absorption layer (10b).

Owner:NIPPON ELECTRIC GLASS CO LTD

Surface glued newsprinting paper and manufacturing method thereof

The present invention discloses a surface-sized news-paper and its making method. It includes the following steps: using bleached sulfate needle wood pulp (BKP), beating, then mixing it with Italia poplar alkaline hydrogen peroxide hot-ground mechanical wood pulp (APMP) and bleached mechanical grindstone ground wood pulp (GP), according to mixing ratio blending them into mixed pulp, adding auxiliary material and making them into raw material pulp for making paper. The standard quantity of said news-paper is 45-49 g / sq.m, brightness (ISO) is 57-63%, opaqueness is greater than 91%, transverse tearing index is greater than 5.5mV, sq.m / g, surface strength is greater than 0.5 m / s, and breaking length longitudinal is greater than 4000 m.

Owner:YUEYANG FOREST & PAPER CO LTD

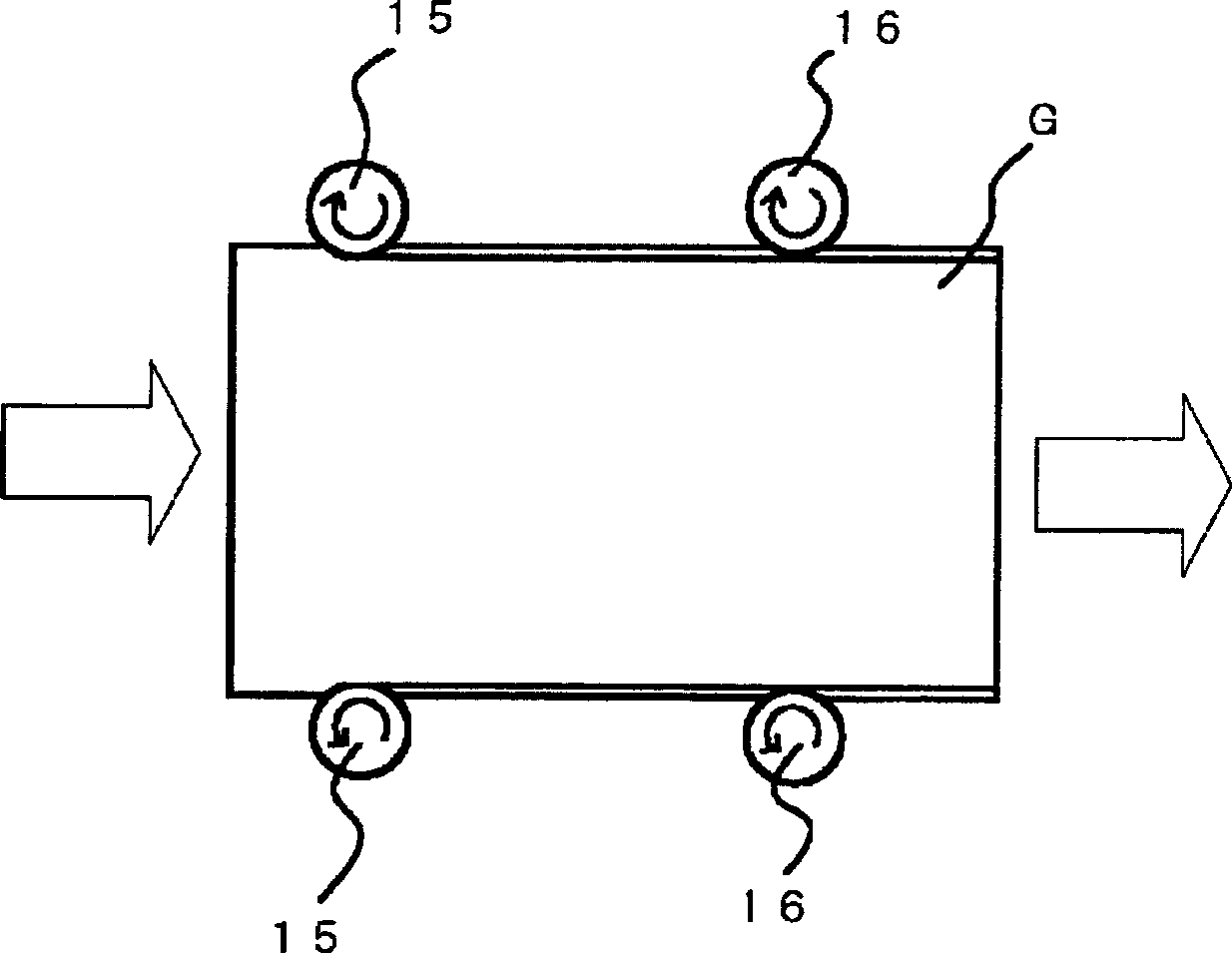

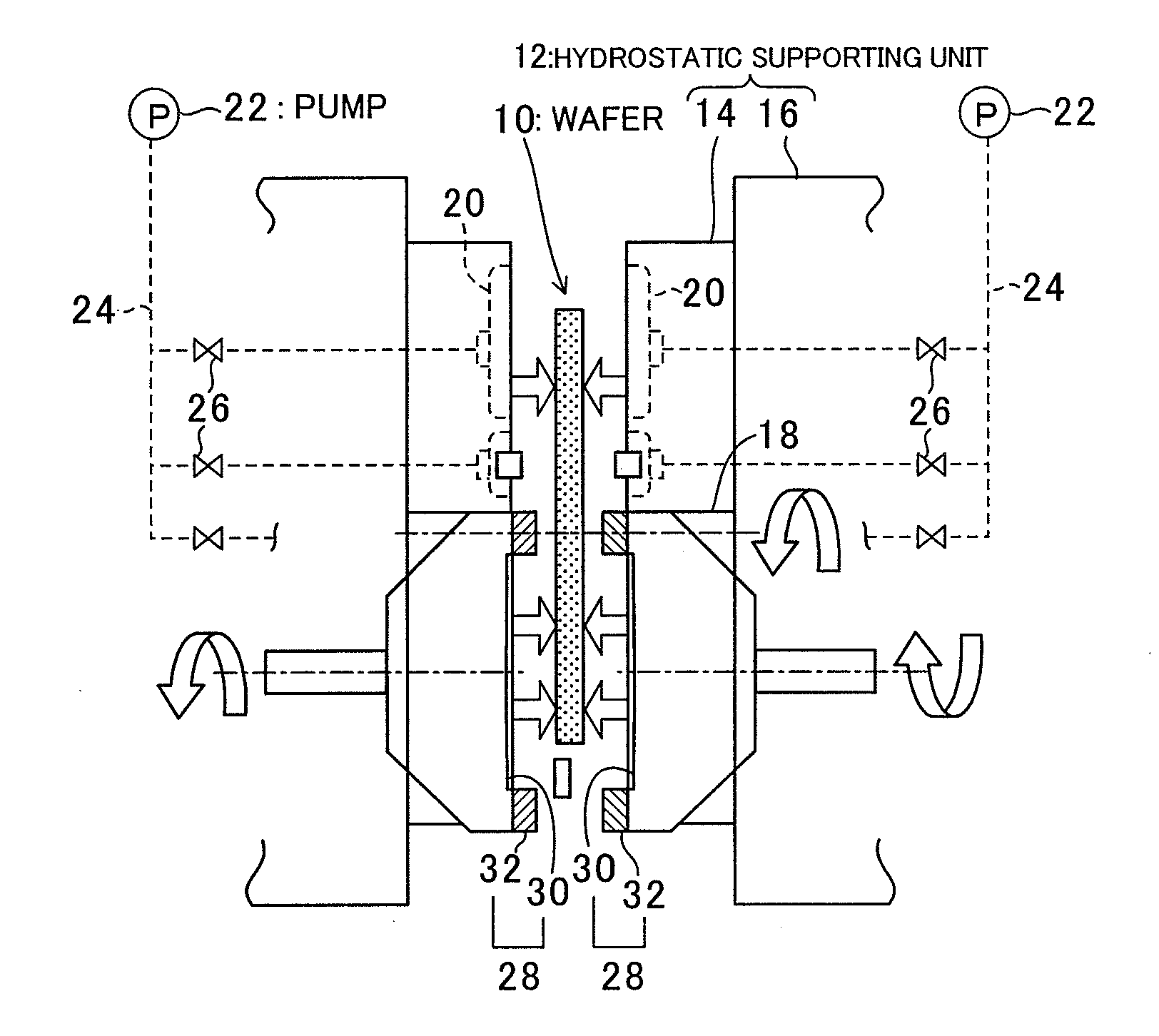

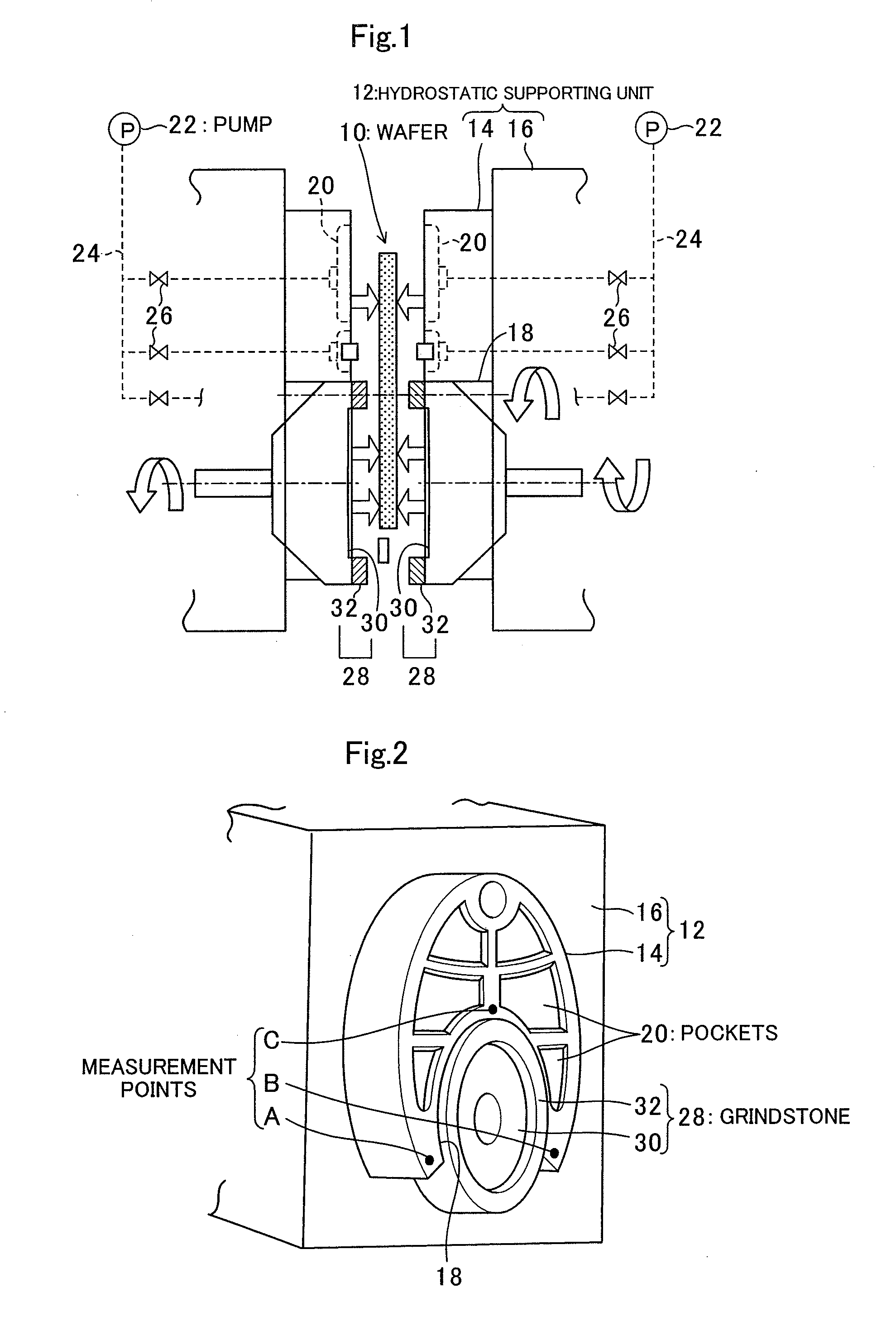

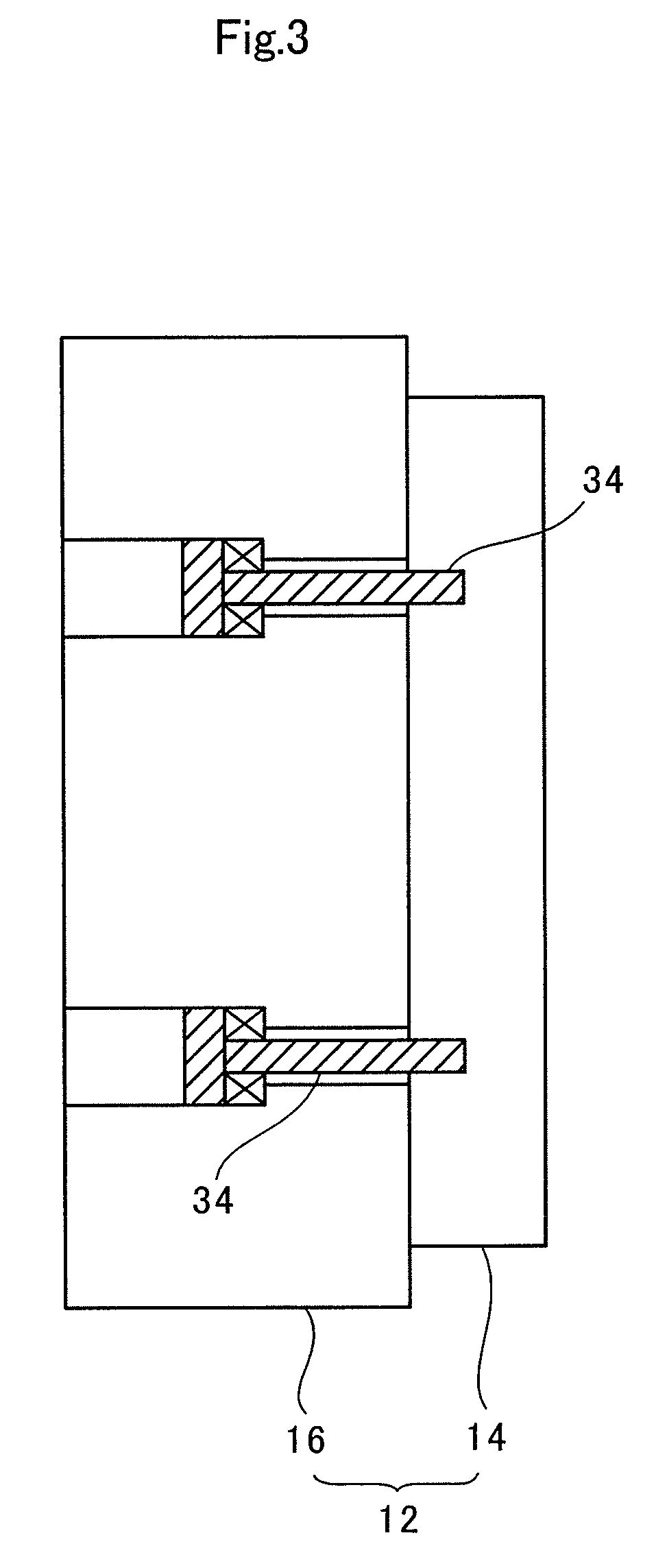

Double-side grinding apparatus for wafer and double-side grinding method

ActiveUS20100144248A1Low thermal expansionEliminate the causeEdge grinding machinesPolishing machinesGrindstoneEngineering

A double-side grinding apparatus is designed to be capable of minimizing thermal expansion of hydrostatic pad members and reducing nanotopography in performing wafer grinding. The double-side grinding apparatus is a double-side grinding apparatus for wafers that can simultaneously grind either surface of a wafer to be ground by pressing a grindstone against either surface of the wafer to be ground while hydrostatically supporting either surface of the wafer to be ground in a noncontact manner. Each hydrostatic supporting unit is formed with a hydrostatic pad member facing the wafer to be ground, and a base member placed on the back surface of the hydrostatic pad member. The hydrostatic pad member is made of a ceramic member, and the base member is made of a metal member.

Owner:SUMCO TECHXIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com