Chamfering Apparatus For Silicon Wafer, Method For Producing Silicon Wafer, And Etched Silicon Wafer

a technology of chamfering apparatus and silicon wafer, which is applied in the direction of manufacturing tools, transportation and packaging, and cellulosic plastic layered products, etc. it can solve the problems of liquid tending to leak from the chamfering portion of the wafer, cracks in the wafer, and wafer cracks, etc., to achieve the effect of suppressing variations in cross-sectional shape dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

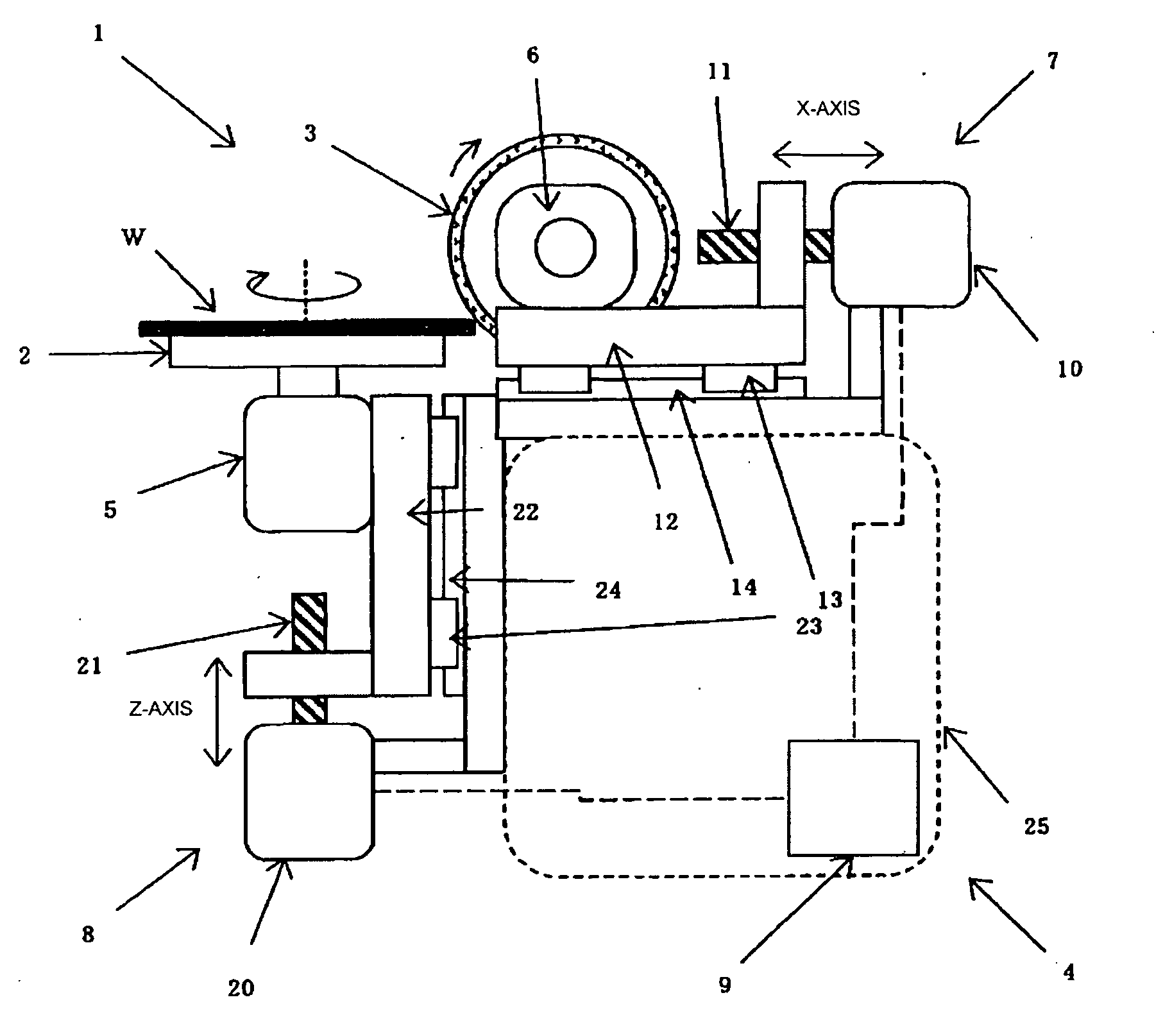

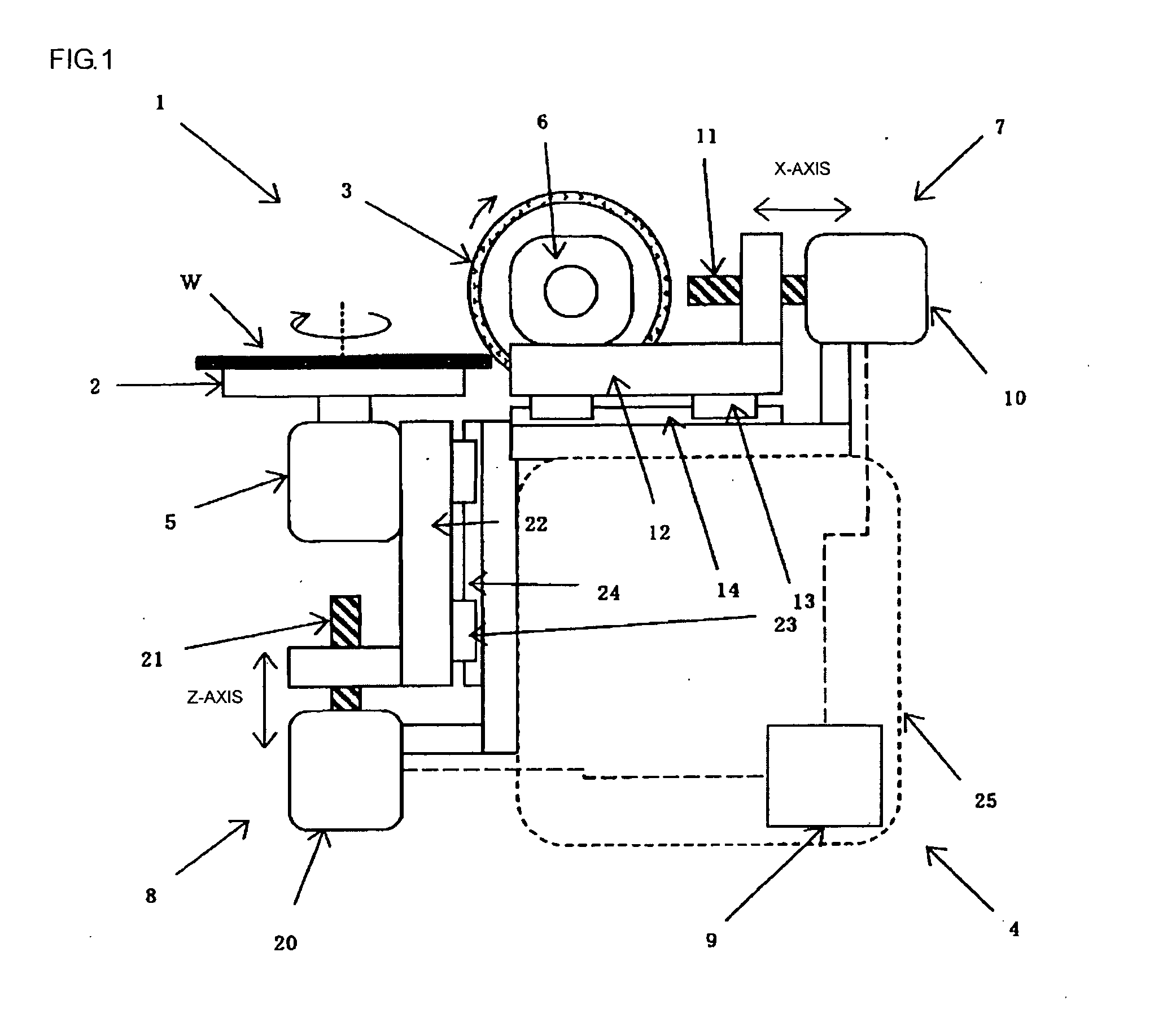

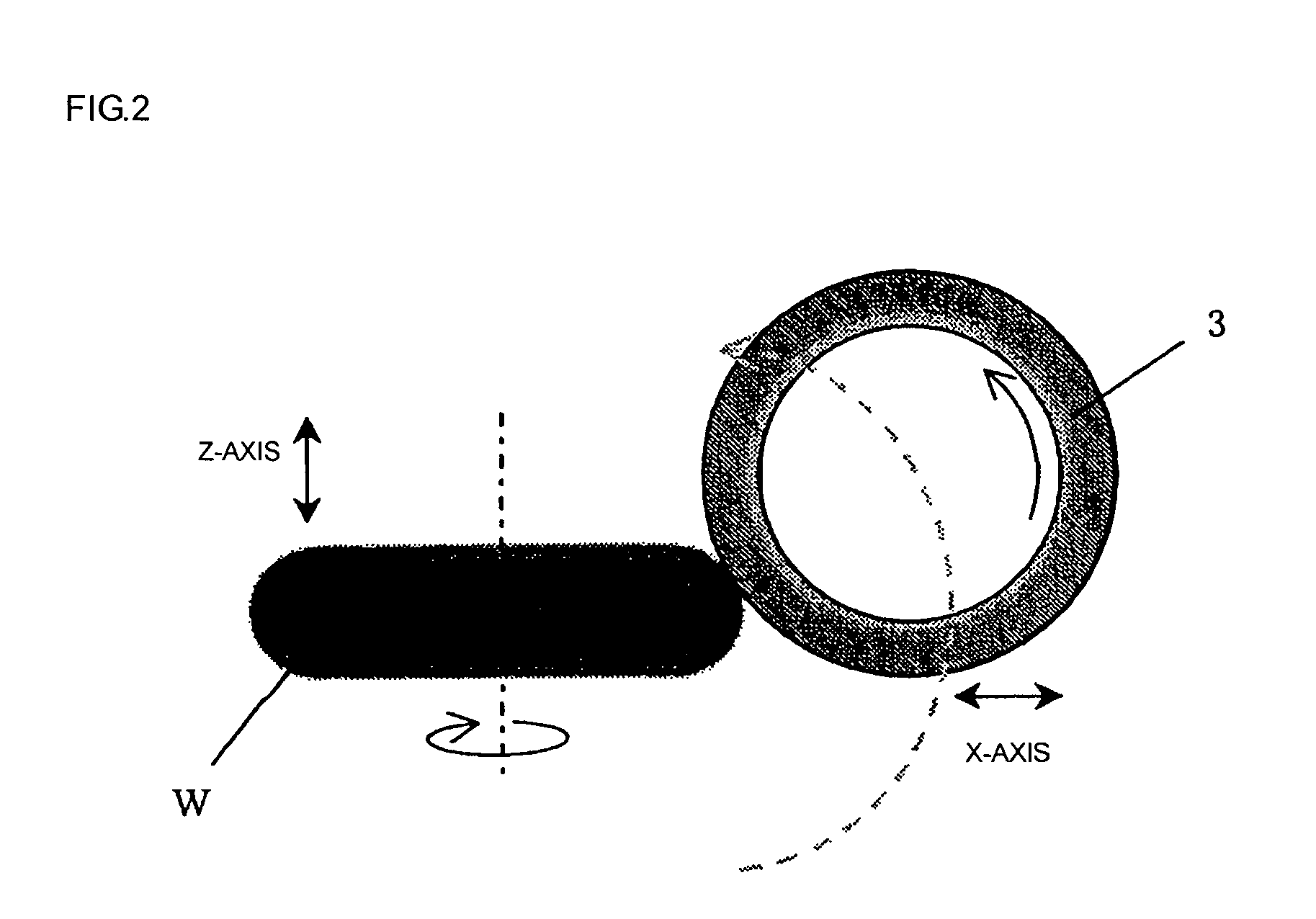

[0054]Hereinafter, an embodiment of the invention is explained; the invention, however, is not limited thereto.

[0055]In a conventional silicon wafer production method, it is common practice to chamfer the outer edge of a silicon wafer in each of circumferential positions into a uniform shape in a chamfering process, and then perform an etching process by alkali etching that is highly capable of maintaining the shape of the principal surface.

[0056]However, even when the uniform chamfered shape is obtained by the chamfering process, in the etching process that follows, due to crystal orientation-dependent etching anisotropy of an alkalie solution, the cross-sectional shape dimensions of the chamfered portion vary. As a result, although the conventional method maintains the flatness of the principal surface, it cannot meet the demands for high-precision cross-sectional shape dimensions of the chamfered portion.

[0057]Therefore, the inventor conducted a study on the chamfering process an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com