Grindstone tool

a technology of grinding stone and tool, which is applied in the direction of gear teeth, gear teeth, gear-teeth manufacturing apparatus, etc., can solve the problems of difficult to find the cause of damage, the quality of the grinding stone cannot be checked at the time of manufacture, and the inability to check the characteristic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

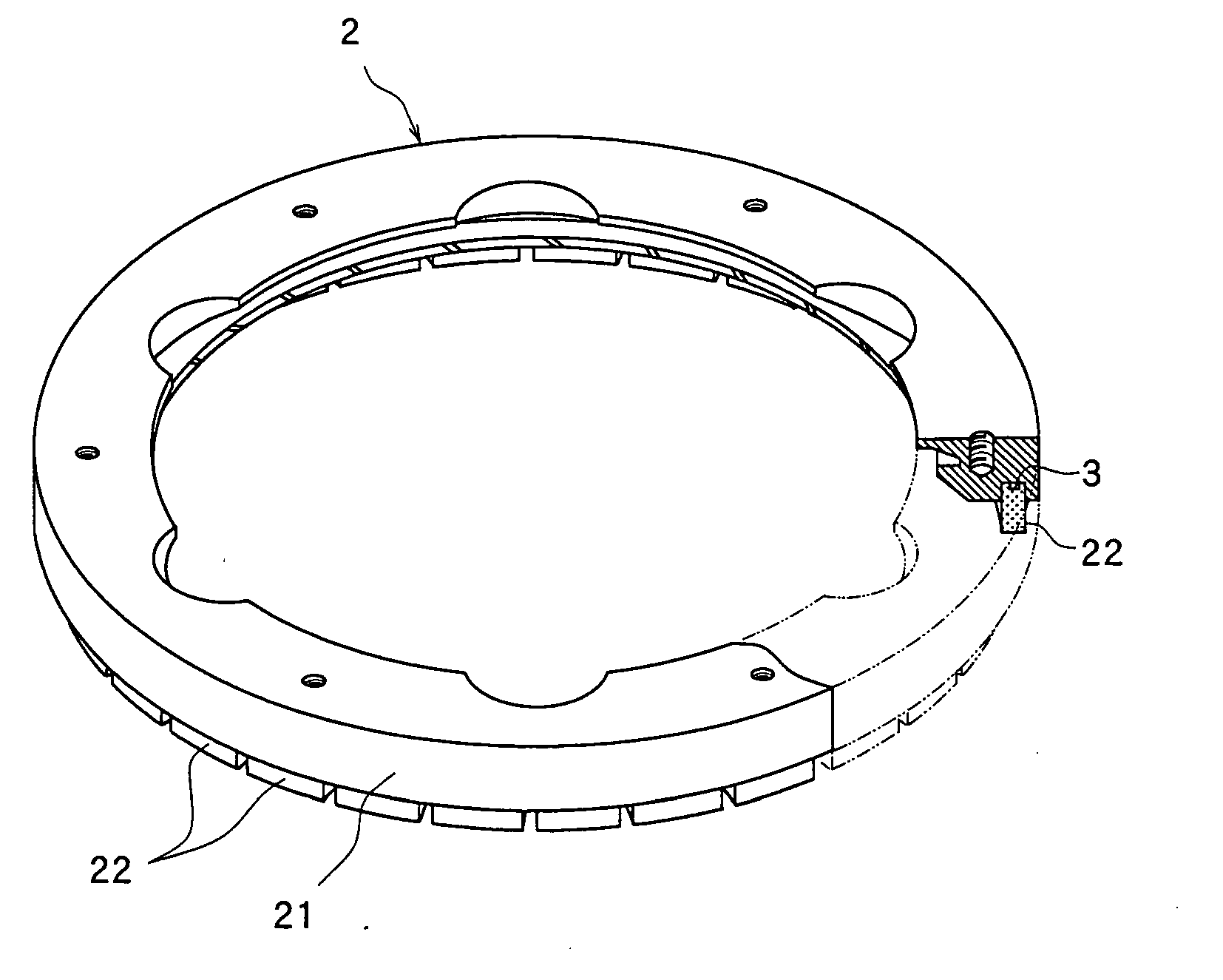

[0021]FIG. 1 shows a grinding wheel having a grindstone as a grindstone tool according to the present invention.

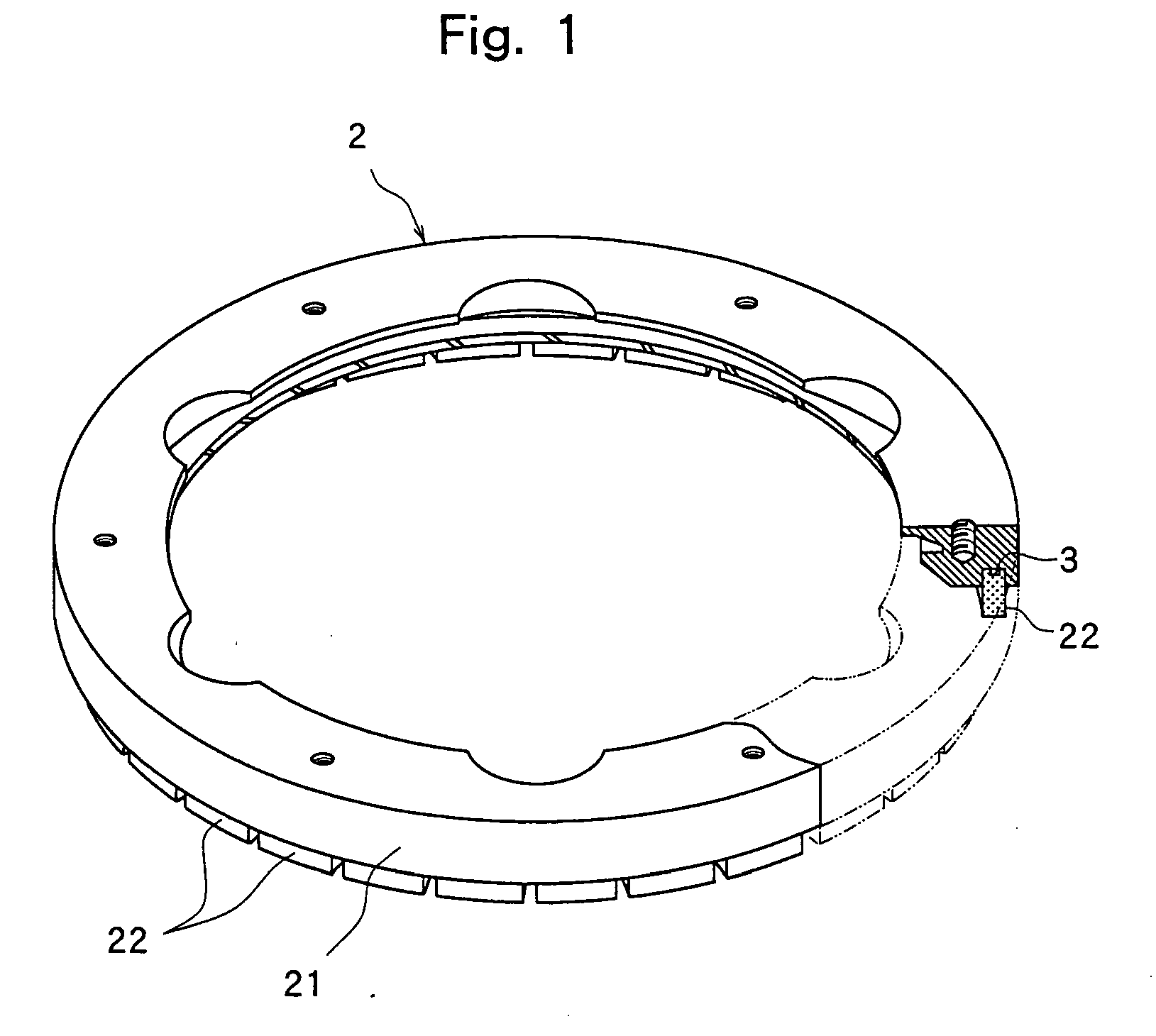

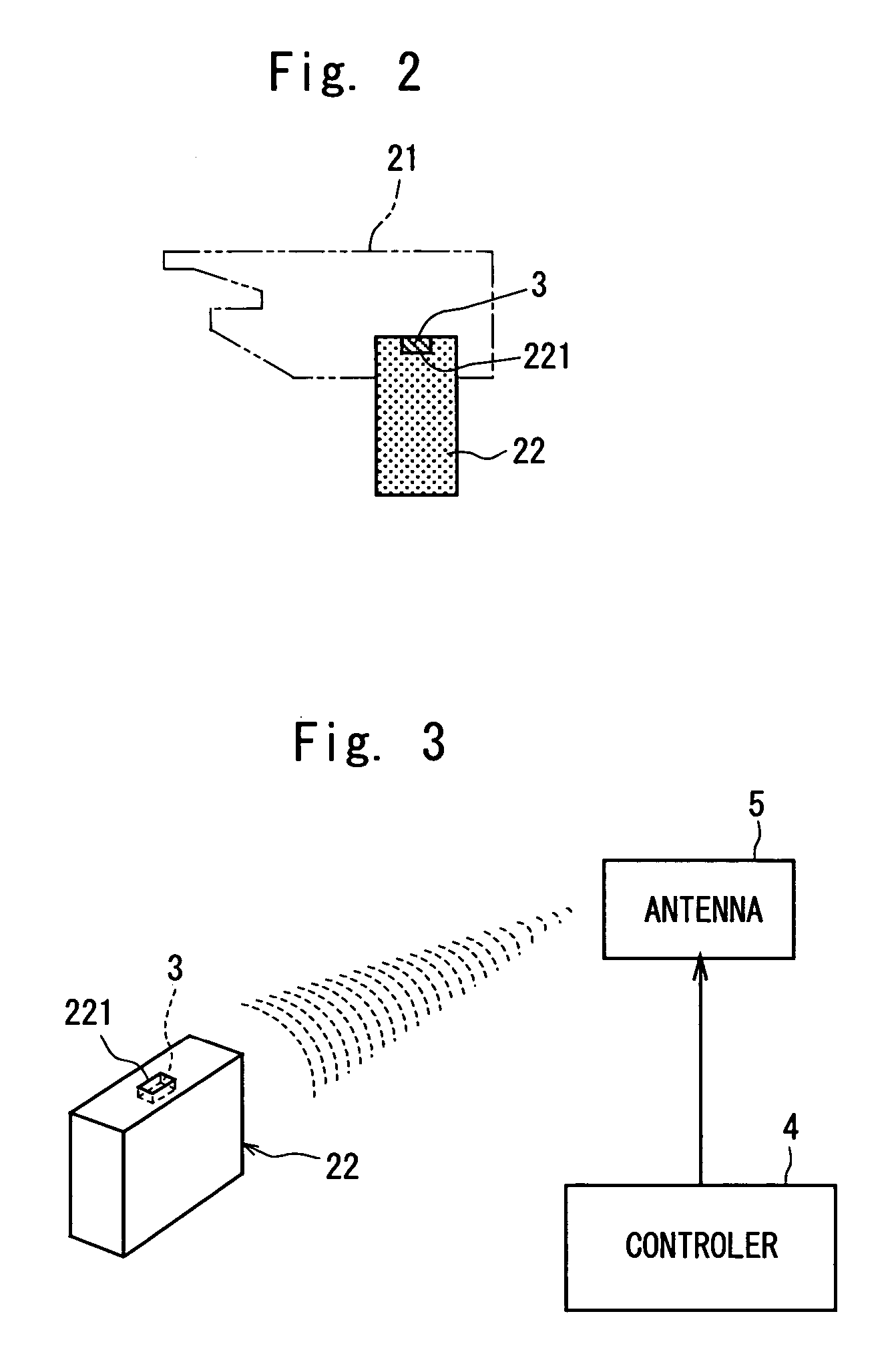

[0022] The grinding wheel 2 shown in FIG. 1 is constituted by an annular grindstone base 21 andapluralityof grindstones 22 mounted on the undersurface of the grindstone base 21. Each of the grindstones 22 is composed of a resinoid grindstone manufactured by kneading abrasive grains with a resin bonding material, molding the kneaded product into a rectangular parallelpiped form and baking it. One of the grindstones 22 each composed of a resinoid grindstone has a recessed portion 221 in the top end face that is an unused area as shown in FIG. 2, and a radio IC tag 3 is embedded in this recessed portion 221. The radio IC tag 3 comprises a memory from, and to, which information can be read, and written, with no contact, by means of electric waves or electromagnetic waves.

[0023] Data on the characteristic properties of the resinoid grindstone are stored in the radio IC tag 3 e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com