Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Reduce the number of trimming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

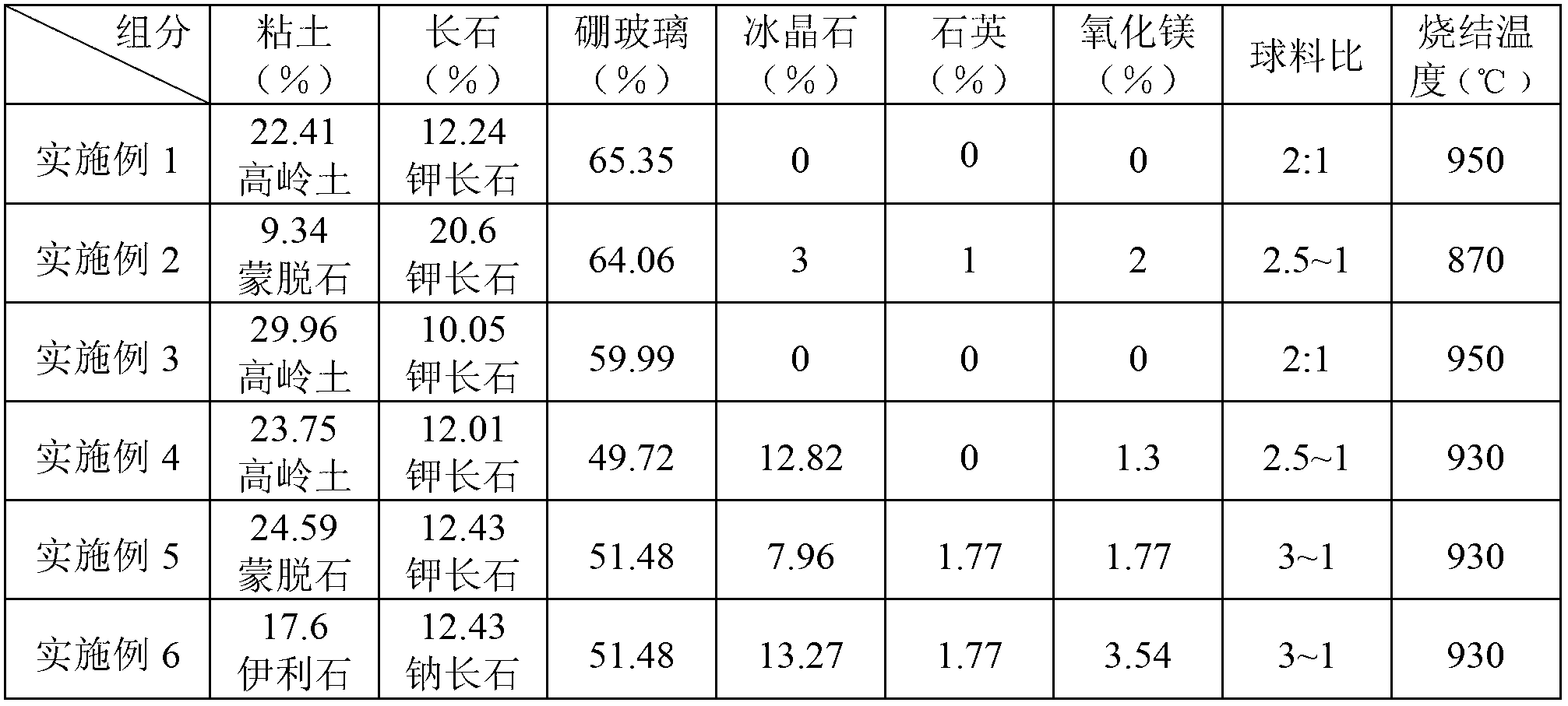

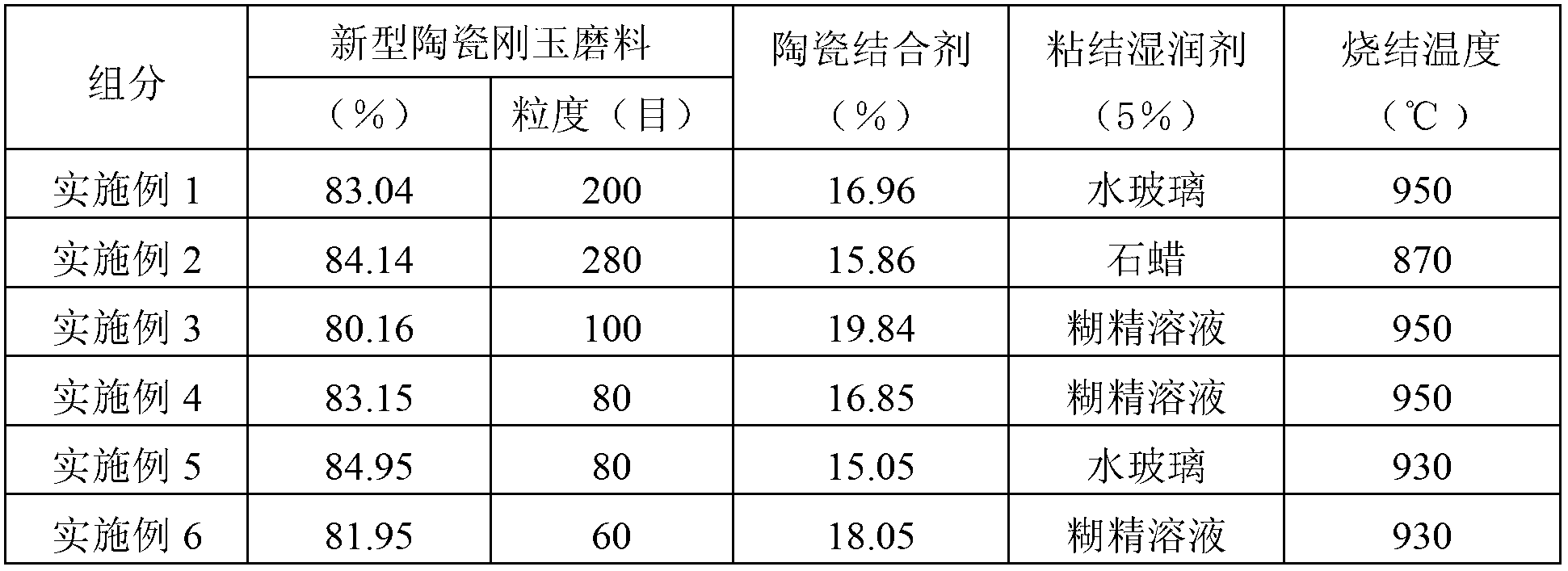

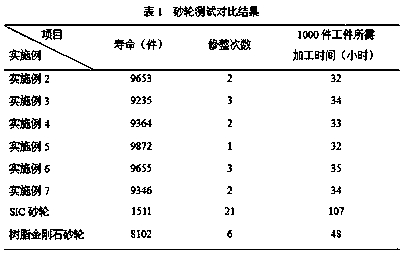

Novel ceramic corundum grinding tool of low-temperature and high-strength ceramic bonding agent and preparation method thereof

InactiveCN102699825ASharp abrasiveStrong cutting forceAbrasion apparatusGrinding devicesGrinding wheelBorosilicate glass

The invention discloses a novel ceramic corundum grinding tool of a low-temperature and high-strength ceramic bonding agent. The grinding tool consists of the following components in percentage by mass: 15 to 20 percent of ceramic bonding agent, 80 to 85 percent of novel ceramic corundum grinding material and 5 percent of bonding wetting agent, wherein the bonding agent consists of the following components in percentage by mass: 10 to 30 percent of clay, 10 to 30 percent of feldspar, 45 to 70 percent of borosilicate glass, 0 to 15 percent of kryocide, 0 to 5 percent of quartz and 0 to 5 percent of magnesium oxide. The novel ceramic corundum grinding tool can be sintered at the sintering temperature of 850 to 980 DEG C, and by the grinding tool, a grinding wheel can be safely used at the rotation speed of 80 to 100m / s. The single-travel feeding amount of the grinding tool can be over 0.3mm, the metal removing rate is over 3 times that of an ordinary corundum grinding wheel, the grinding interval time is 3 to 5 times that of the ordinary corundum grinding wheel, the service life is 5 to 10 times that of the ordinary corundum grinding tool, and the novel ceramic corundum grinding tool is superior to a super-hard grinding tool and the ordinary grinding tool in performance and price.

Owner:TIANJIN UNIV

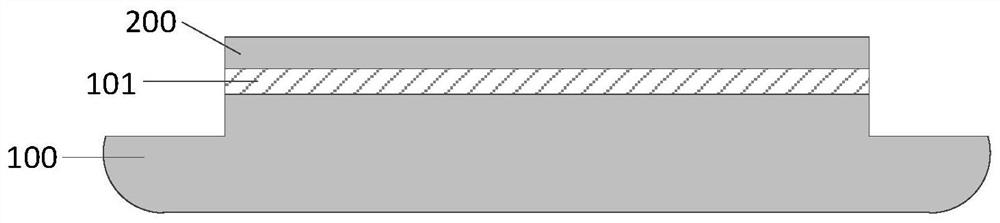

Grinding wheel

InactiveCN101659033AReduces eye cloggingReduce the number of trimmingSemiconductor/solid-state device manufacturingLapping machinesEngineeringGrinding wheel

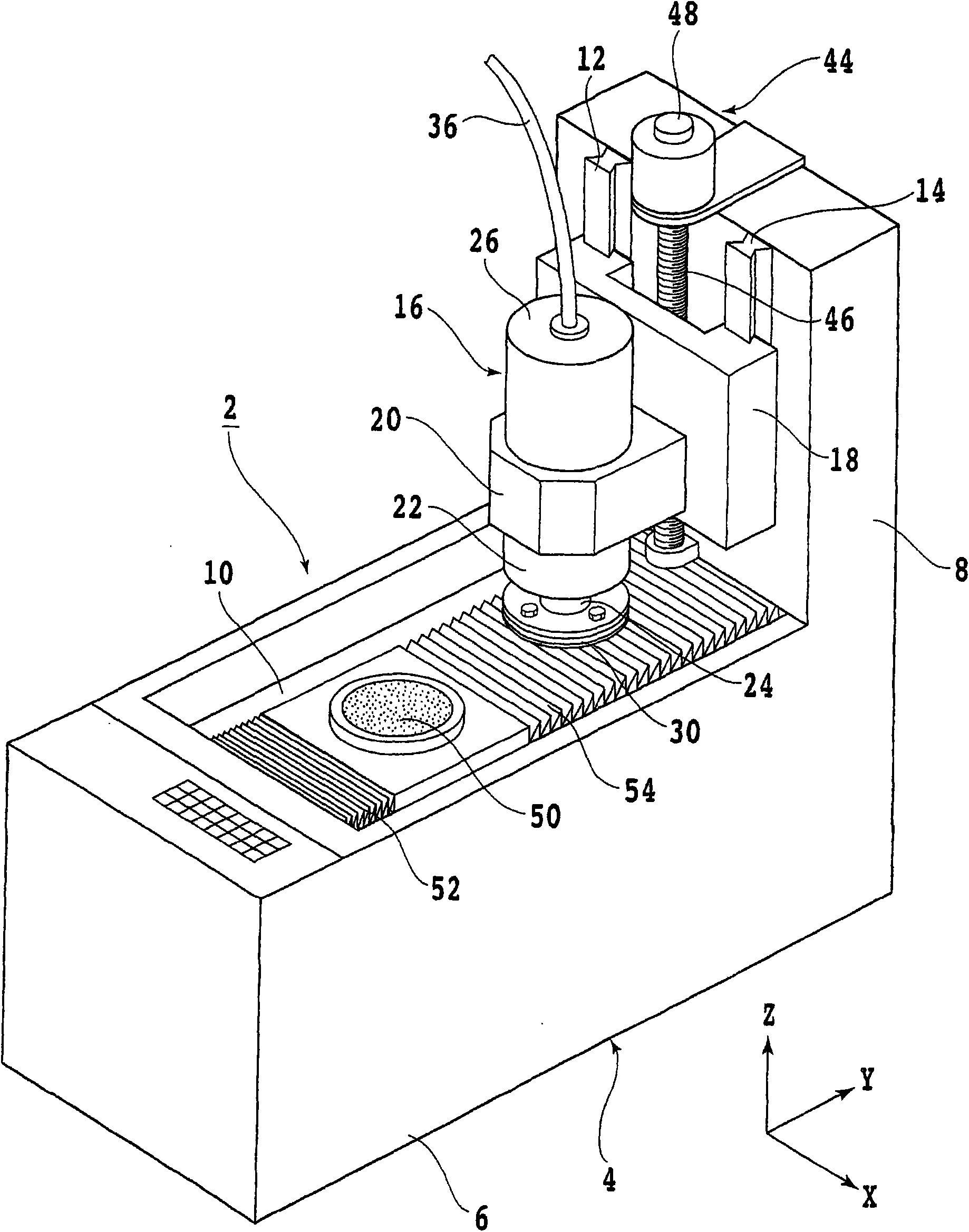

The invention provides a grinding wheel, which can decrease the finishing time of a grinding tool and prevent a wafer from generating crackles. The grinding wheel is arranged on a wheel seat of a grinding device in the free assemble and unassemble way, the grinding device comprises a grinding fluid supply member for supplying a grinding fluid, a main shaft driven to rotate and the wheel seat connected with the frontend of the main shaft. The grinding wheel is characterized in that the grinding wheel comprises an annular base with an internal wall, an external wall and an installation portion arranged on the wheel seat, and a plurality of grinding tools annularly arranged at the free end of the annular base, wherein a plurality of through holes which are spaced apart at prescribed intervalsare formed on the external wall of the annular base along the circumference direction, the plurality of through holes penetrate through the internal wall for discharging the grindstone dust and the grinding fluid.

Owner:DISCO CORP

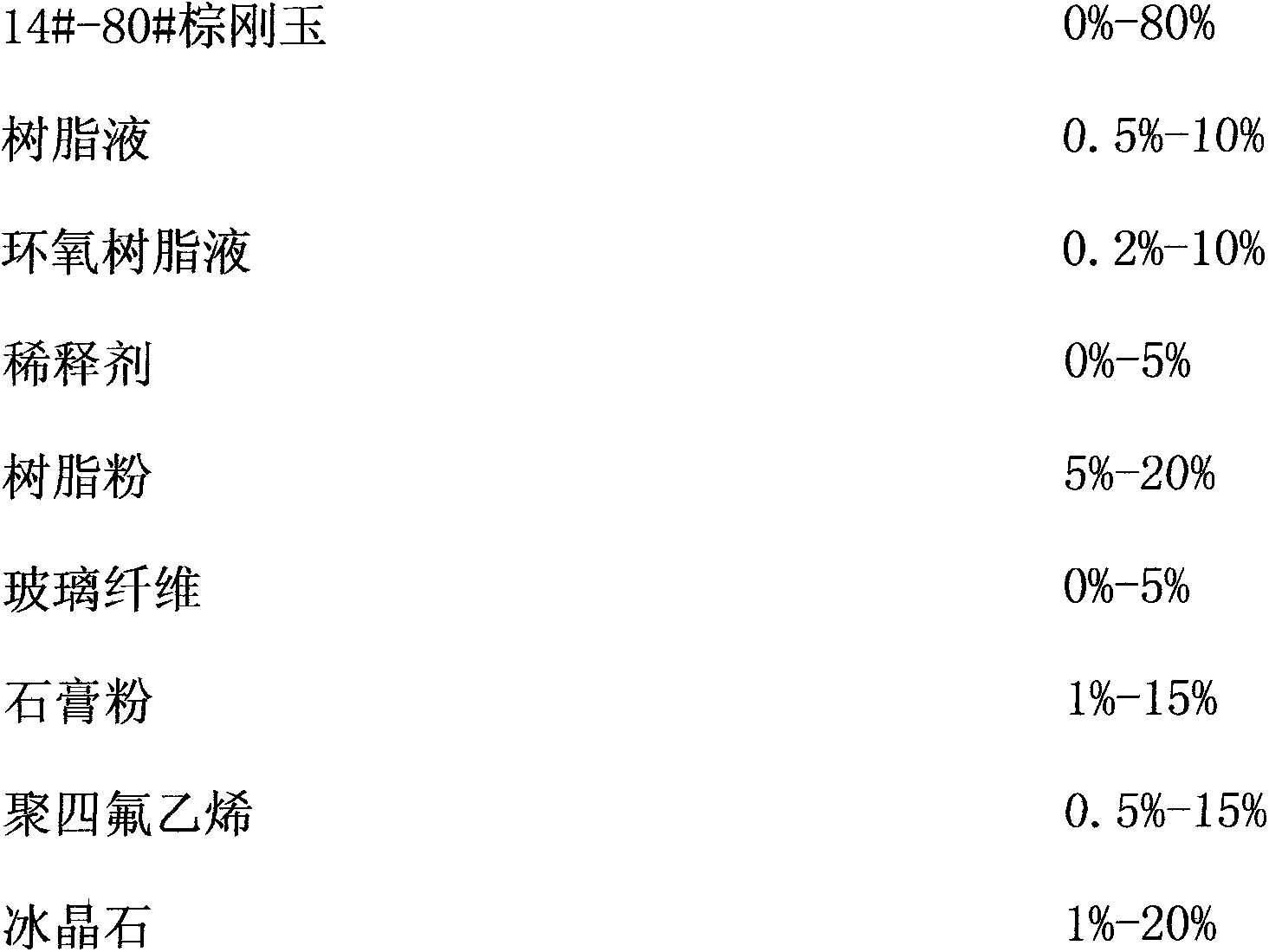

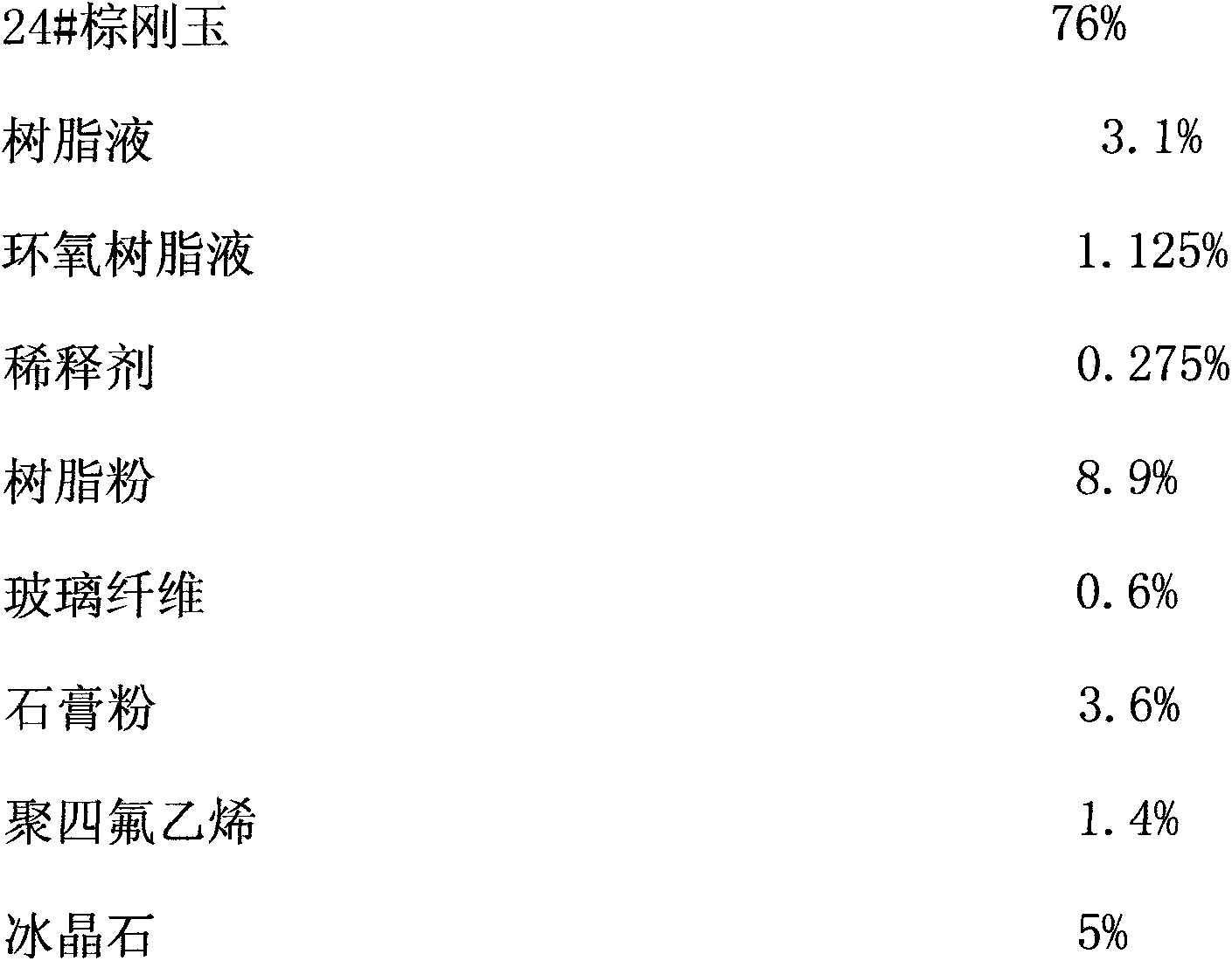

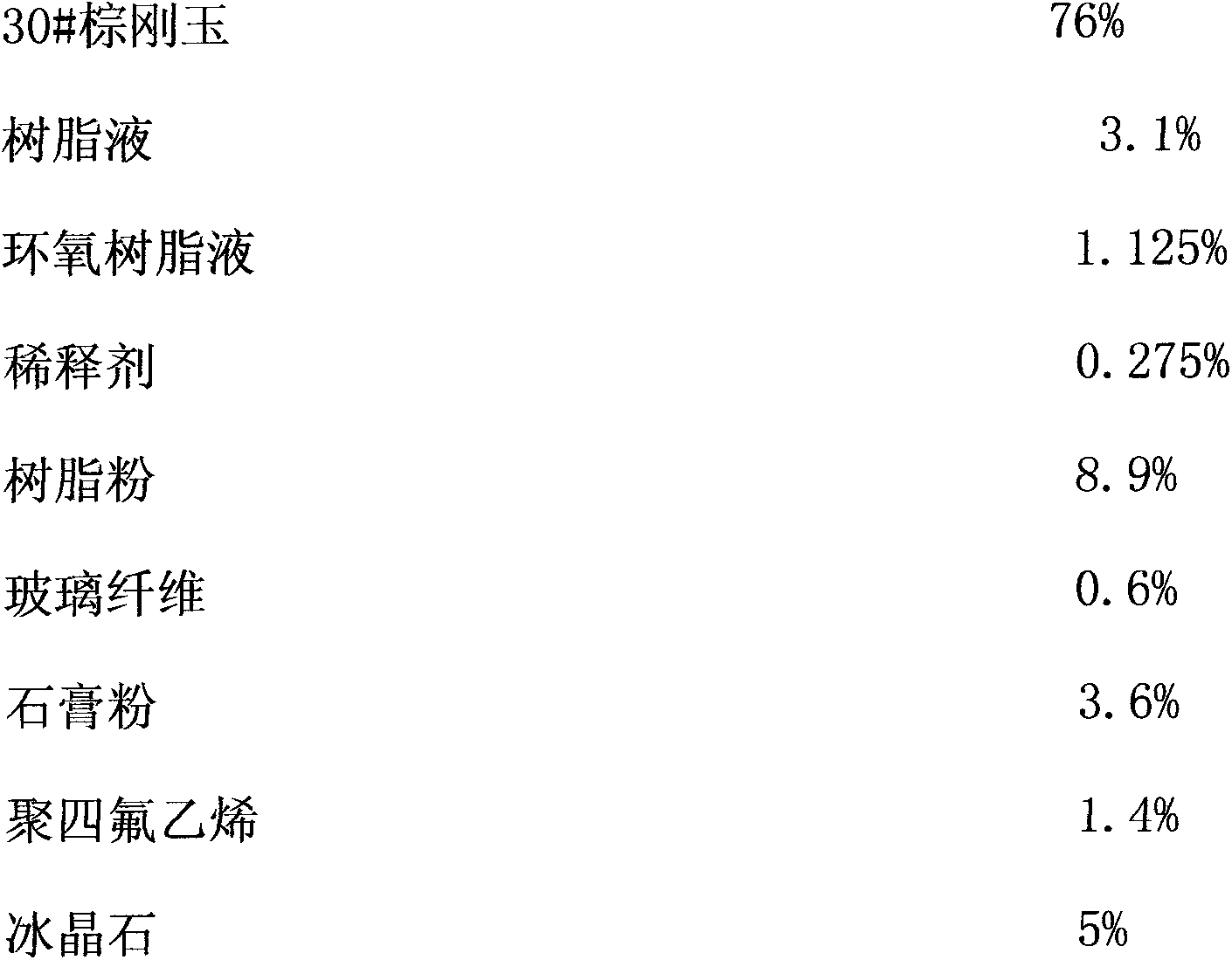

Method for preparing resin grinding wheel containing epoxy resin

InactiveCN103921220AReduce deformationExtended service lifeAbrasion apparatusGrinding devicesEpoxyGlass fiber

The invention discloses a method for preparing a resin grinding wheel containing epoxy resin. The resin grinding wheel containing the epoxy resin comprises 0%-80% of 14#-80# brown aluminum oxide, 0.5%-10% of resin liquid, 0.2%-10% of epoxy resin liquid, 0%-5% of a thinning agent, 5%-20% of resin powder, 0%-5% of glass fibers, 1%-15% of gypsum powder, 0.5%-15% of polytetrafluoroethylene and 1%-20% of cryolite. The resin grinding wheel containing the epoxy resin has the advantages that due to the group resistance of the epoxy resin, the degree of deformation of the grinding wheel can be lowered, the service life of the grinding wheel is prolonged, the repair and maintenance frequency of the grinding wheel can be reduced for a worker when the wheel is used, the production efficiency is improved, the fatigue strength during work is reduced, the grinding wheel contains no resin group or abrasive material group point after being hardened, and the degree of finish of a ground workpiece can be effectively improved.

Owner:武汉法山磨料磨具有限公司

Metallic bond diamond grinding wheel with good self-sharpening performance

InactiveCN102814749AGood self-sharpeningNo pollution in the processAbrasion apparatusCarbideThermal expansion

The invention discloses a metallic bond diamond grinding wheel with good self-sharpening performance, wherein the grinding wheel bond comprises bonding metal, a framework material, a carbide forming element and low-melting glass material filler; the bonding metal is used for bonding and forming various components; the framework material is used for providing a hard point for the bond and improving the strength of the bond; the carbide forming element can react with a diamond and be carbonized at a certain temperature, change mechanical occlusion into metallurgical bonding, and improve the holding force on the diamond; and the low-melting glass material filler has a thermal expansion coefficient close to those of other components, and the mechanical properties of the grinding wheel bond are adjusted by adjusting the added amount of the low-melting glass material filler. Compared with free abrasive powder grinding, the efficiency is doubled, and no dust or waste water pollution is produced; and compared with an ordinary bronze grinding wheel, the self-sharpening performance is good, the grinding efficiency is high and the finishing times are few.

Owner:SHENZHEN CHANGXING TECH

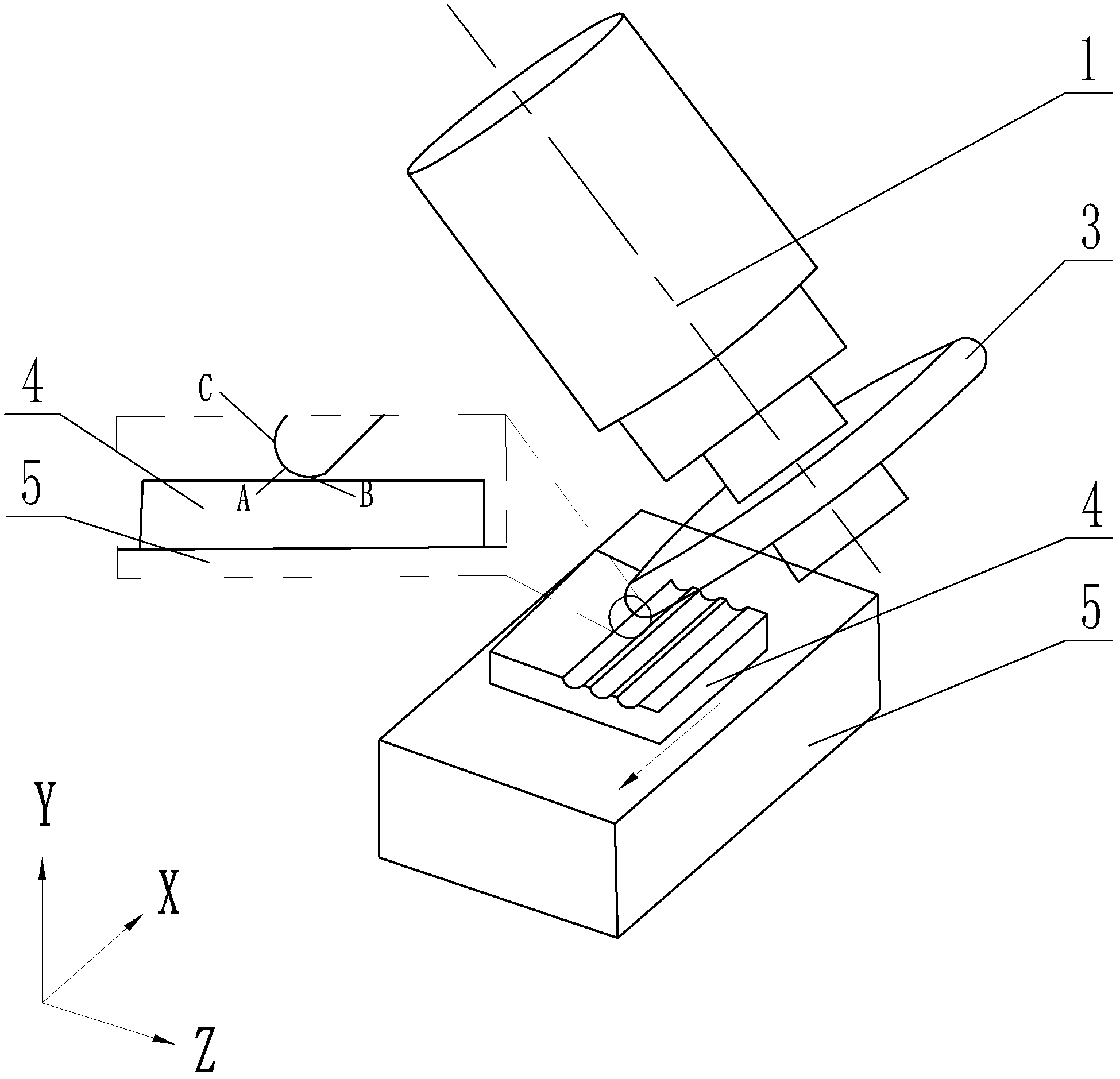

Non-rotation optical array coarse-fine integrated progressive grinding method

ActiveCN108747603ANo wearImprove profile accuracyOptical surface grinding machinesAbrasive surface conditioning devicesUltra fineMachine tool

The invention discloses a non-rotation optical array coarse-fine integrated progressive grinding method. The method comprises the steps that 1, structure outlines of a precision structuring coarse grinding diamond grinding wheel and a precision structuring superfine diamond grinding wheel and the structure of a separating plate are designed and manufactured; 2, the precision structuring coarse grinding diamond grinding wheel, the separating plate and the precision structuring superfine diamond grinding wheel in the step 1 are sequentially installed on a machine tool main shaft, and a machinedworkpiece is fixed to a machine tool working table; 3, grinding wheel in-place correction is carried out; 4, profile modeling coarse grinding is carried out, wherein a profile modeling grinding methodis adopted, and the precision structuring coarse grinding diamond grinding wheel is used for coarse grinding; and 5, tangent track progressive precision operation is carried out, wherein along the progressive grinding track, a precision structuring fine-grit or ultra-fine-grit diamond grinding wheel is used for conducting progressive grinding on the workpiece surface, and semifinishing and finishing of the overall microstructural array surface profile are efficiently completed through one grinding circulation.

Owner:SHANDONG UNIV

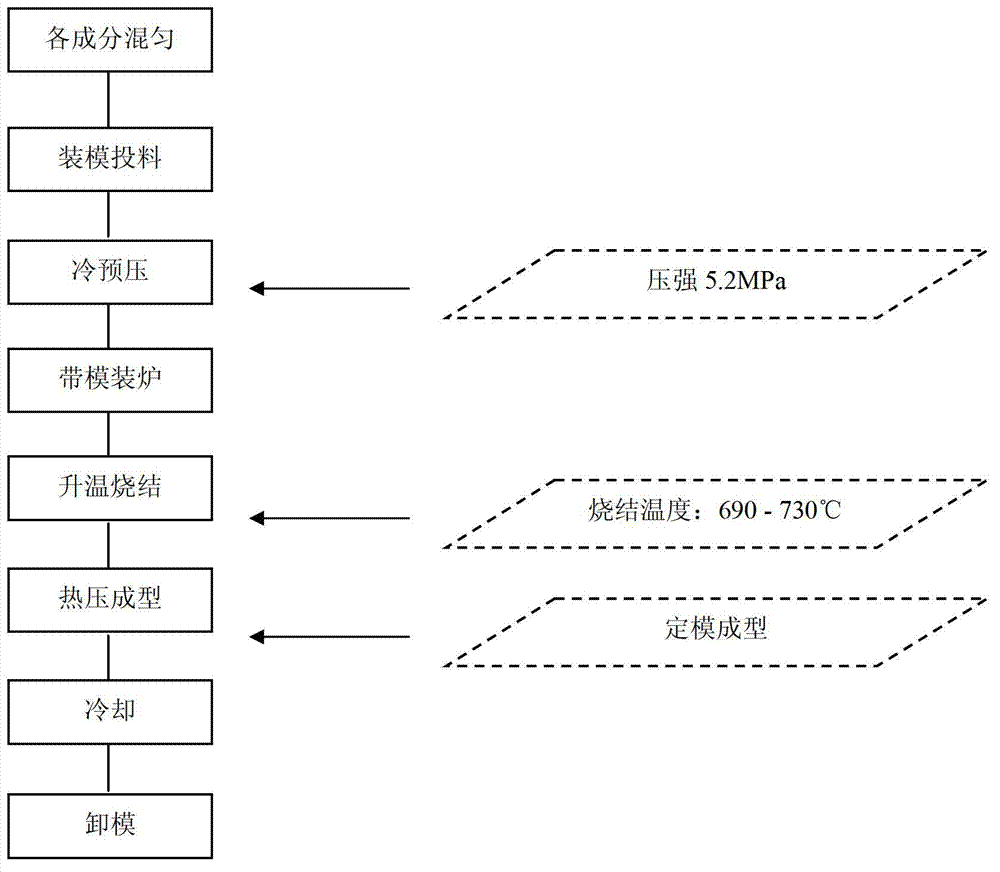

Process for producing ceramic grinding table

The invention discloses a process for producing a ceramic grinding table. The process comprises the following steps: (1) prefabricating a glass material; (2) finely grinding glass powder; (3) mixing; (4) producing green bodies; (5) drying; (6) sintering; (7) molding the grinding table; (8) bonding the grinding table to a basal body; and (9) grinding to form the finished product. In the process for producing the ceramic grinding table, a ceramic binding agent is utilized to replace a traditional bronze binding agent to produce a diamond grinding table, and compared with a diamond grinding table produced by utilizing the bronze binding agent, the ceramic binding agent per se has the characteristics of good brittleness and self-sharpening; in a grinding process, due to the good self-sharpening, diamond in the upper layer quickly falls off after being blunt so that the diamond in the lower layer is exposed to form a new sharp grinding blade, the grinding force can be maintained for a long time, and the grinding table has good sharpening in grinding.

Owner:SHENZHEN CHANGXING TECH

Ceramic bonding agent, preparation method thereof and application in CBN grinding wheel

InactiveCN109465757AImprove gripLower sintering temperatureAbrasion apparatusGrinding devicesGrinding wheelQuenching

The invention discloses a ceramic bonding agent, a preparation method thereof and an application in a CBN grinding wheel, wherein the ceramic bonding agent is prepared from the following components inparts by weight: 41.0 to 44.5 parts quartz, 4.0 to 5.5 parts of alumina, 19.0 to 21.0 parts of boric acid, 3.0 to 5.0 parts of zinc oxide, 6.0 to 8.0 parts of lithium carbonate, 2.5 to 3.5 parts of sodium carbonate, 15.0 to 17.5 parts of barium carbonate, 2.0 to 3.5 parts of strontium carbonate. The preparation method of the ceramic bonding agent comprises the following steps: material preparation step, mixing step, melting step, water quenching step, ball milling step, particle size detection step and drying step. The ceramic bonding agent wets and coats the CBN abrasive particles well, increases the holding force of the bonding agent to the abrasive particles, and improves the strength of the bonding agent.

Owner:广东奔朗新材料股份有限公司 +1

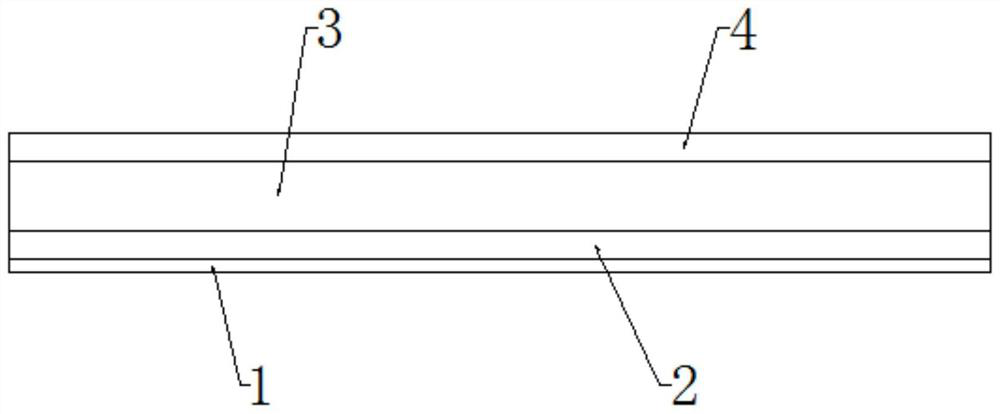

Large-pore CBN grinding wheel for machining sliding vanes of compressor

InactiveCN105598859AExtend the trimming timeGood shape retentionAbrasion apparatusGrinding devicesHeat conductingGrinding wheel

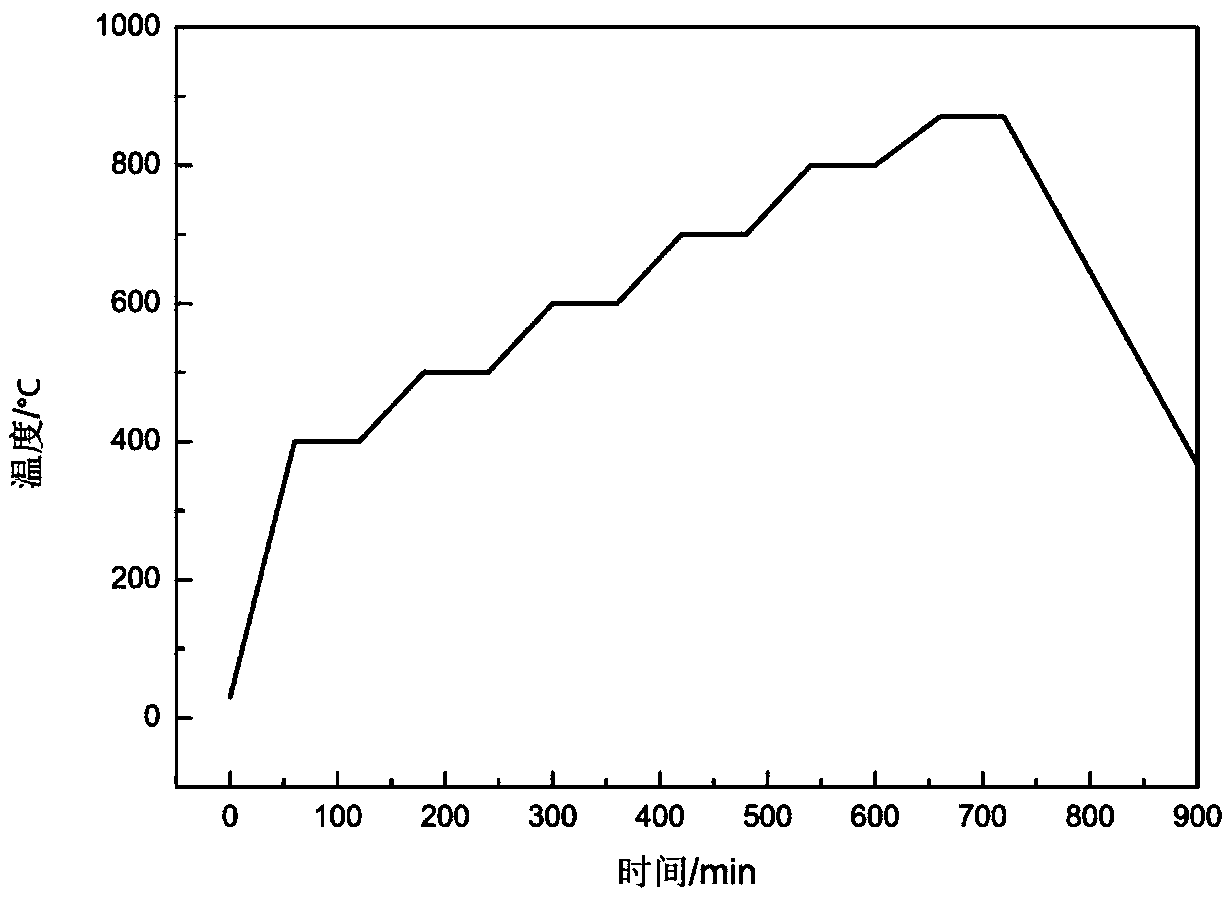

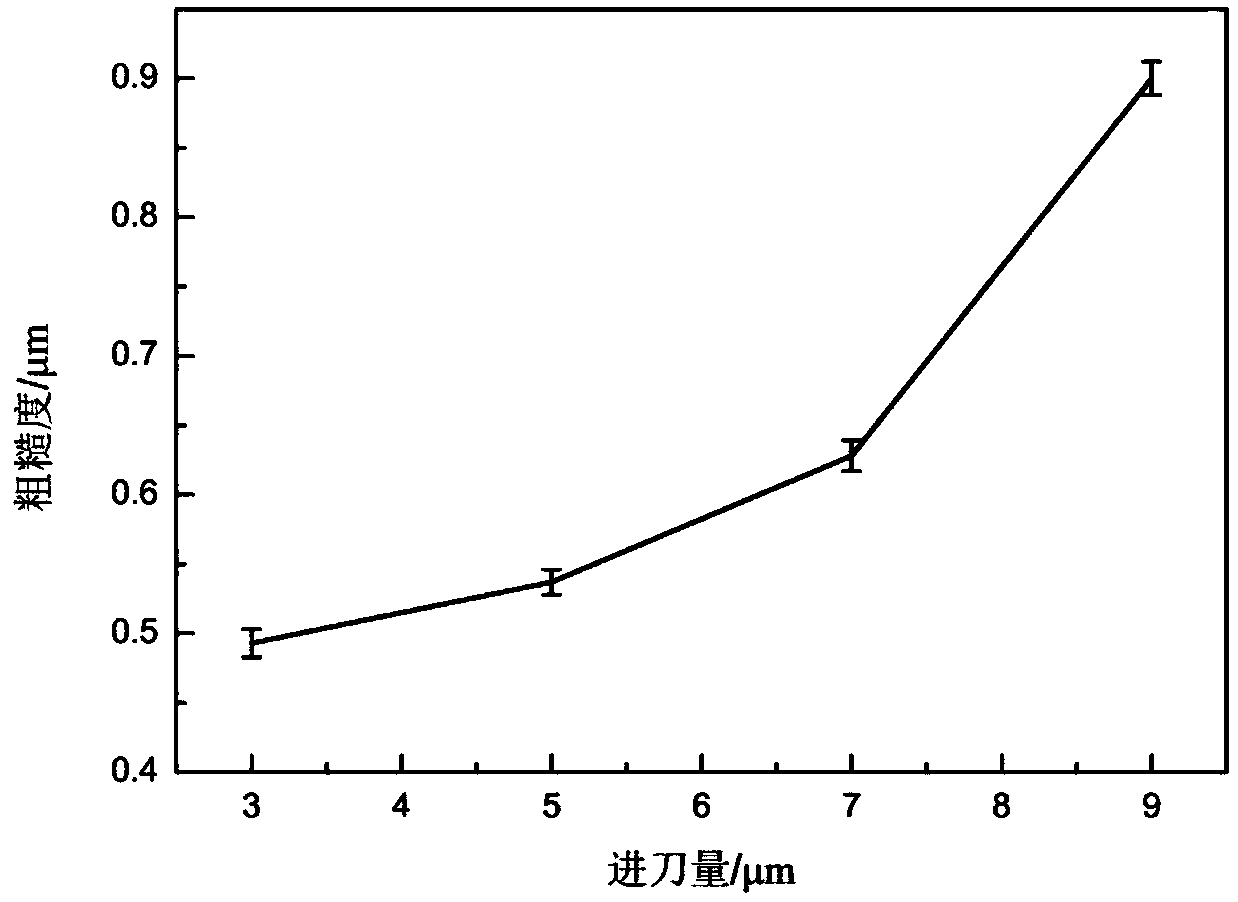

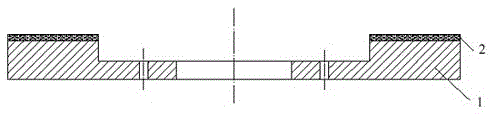

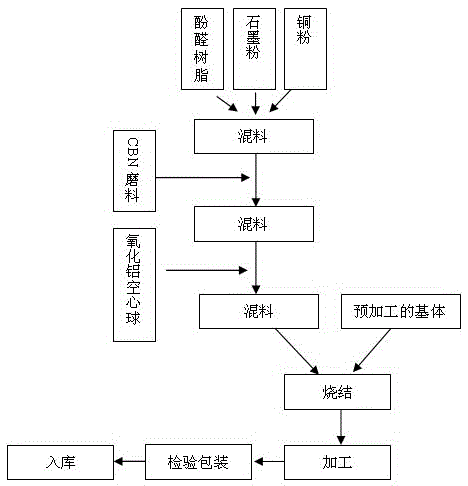

The invention discloses a large-pore CBN grinding wheel for machining sliding vanes of a compressor. The large-pore CBN grinding wheel comprises a base body and a grinding material layer, wherein the grinding material layer comprises 15 to 20 percent of a CBN grinding material, 40 to 50 percent of phenolic resin powder, 12 to 18 percent of a solid lubricating material, 8 to 10 percent of a heat conducting material, and 10 to 15 percent of a pore forming material, wherein the pore forming materials adopts alumina hollow balls of which the average grain diameter is 1.5 to 2.0 mm. Compared with the conventional grinding wheel, the large-pore CBN grinding wheel for machining the sliding vanes has the advantages that the production efficiency is improved; the dressing time of the grinding wheel is prolonged; the manual replacing frequency is reduced; the shape preserving capability of the grinding wheel is improved; the dressing times of the grinding wheel during machining is reduced; the grinding wheel is highly sharp, so as to ensure the workpiece machining precision.

Owner:SUZHOU SAILI PRECISION TOOLS

High-durability ceramic grinding tool

The invention discloses a high-durability ceramic grinding tool which is characterized by comprising the following components in parts by weight: 11-27 parts of zirconite, 31-50 parts of calcite, 3-14 parts of ethylene copolymer elastomer, 1-9 parts of closed-cell perlite, 15-45 parts of borate glass, 5-17 parts of solid paraffin, 11-25 parts of tourmaline concentrate micropowder, 3-4 parts of molybdenum disilicide, 34-61 parts of spodumene, 11-31 parts of mica, 3-5 parts of zinc oxide, 5-12 parts of ferric sodium pyrophosphate, 1-3 parts of calcium hydrogen phosphate and 5-9 parts of cryolite. The high-durability ceramic grinding tool has the advantages of sharp grinding grains, low trimming frequency, favorable sharpness, low grinding temperature, favorable toughness, low abrasion, high durability and long service life, and can be used for high depth, roughing feed, heavy load and high efficiency grinding.

Owner:QINGDAO XIANGHAI ELECTRONICS

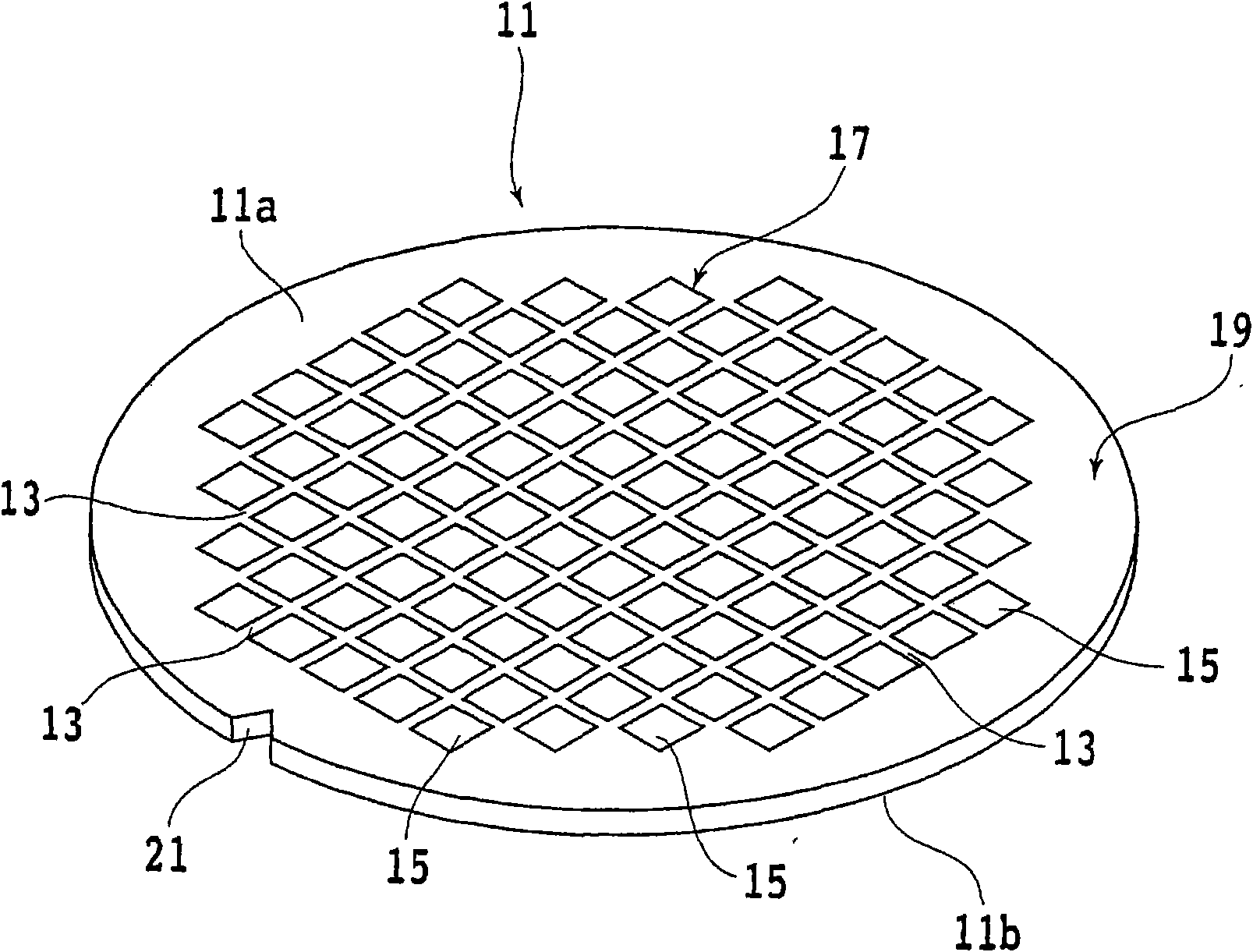

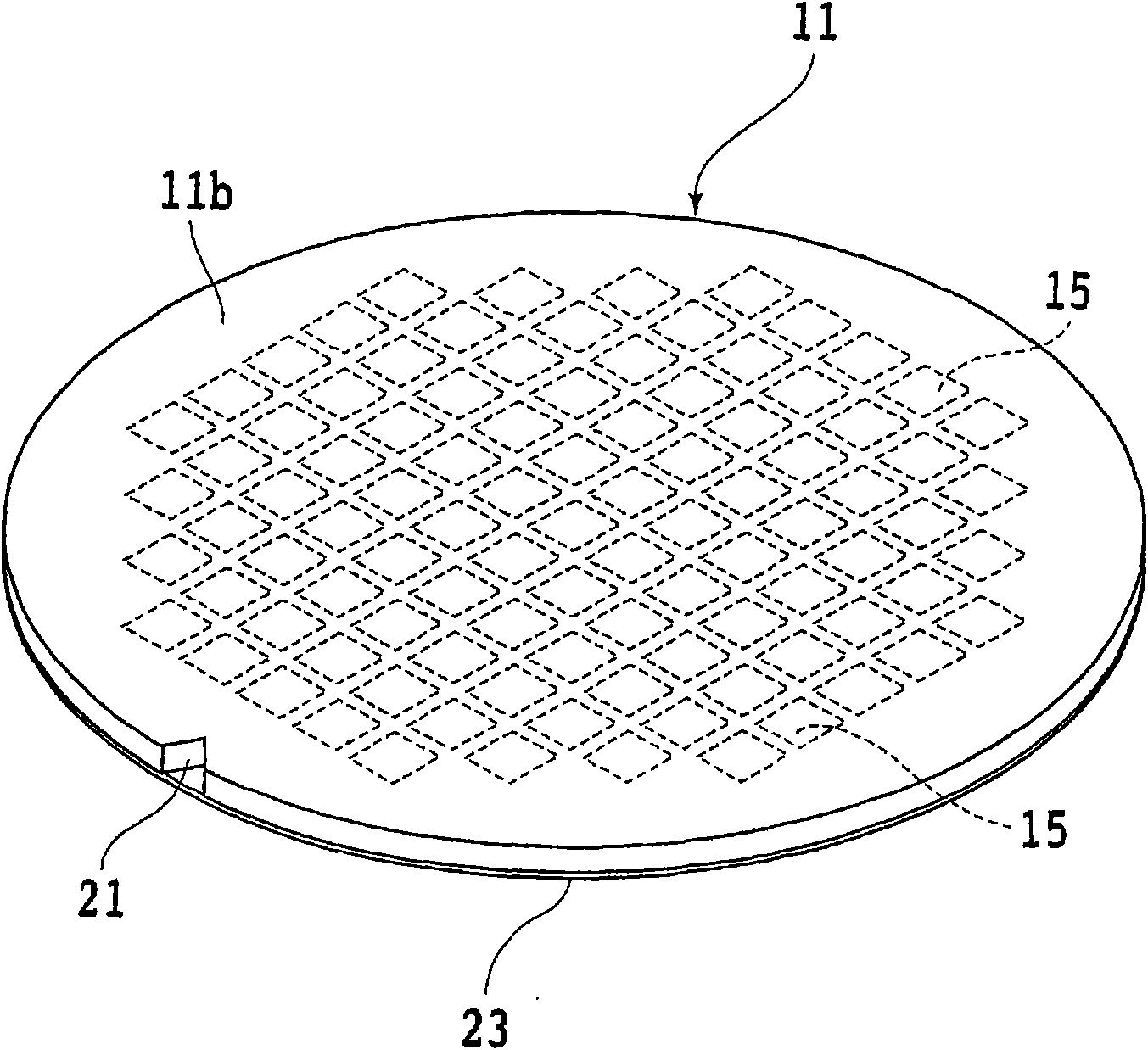

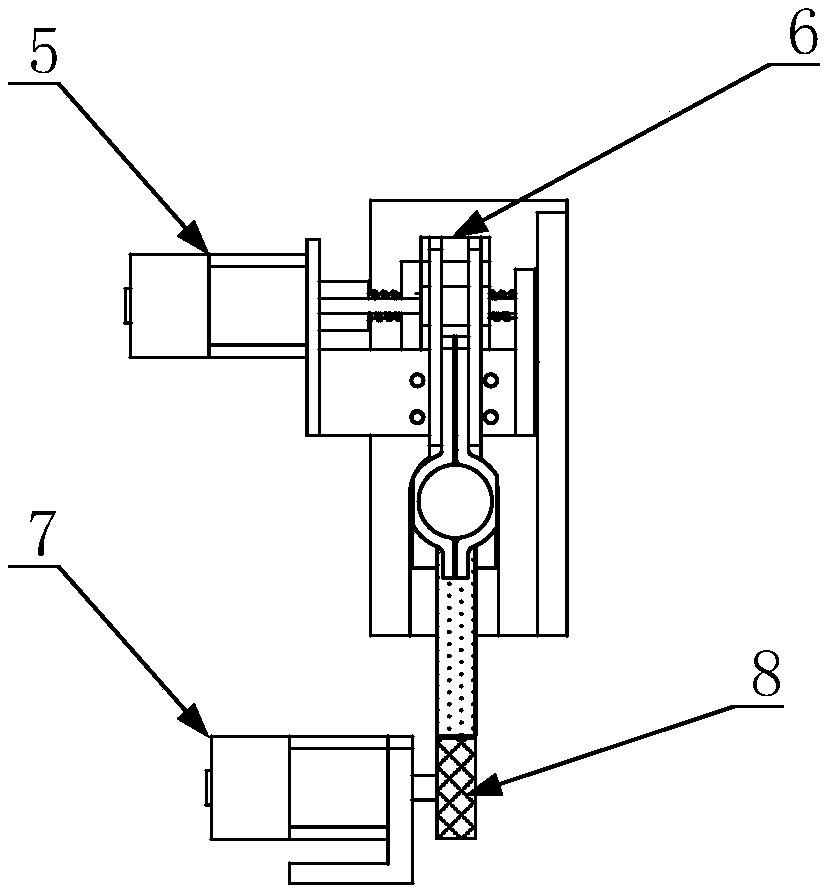

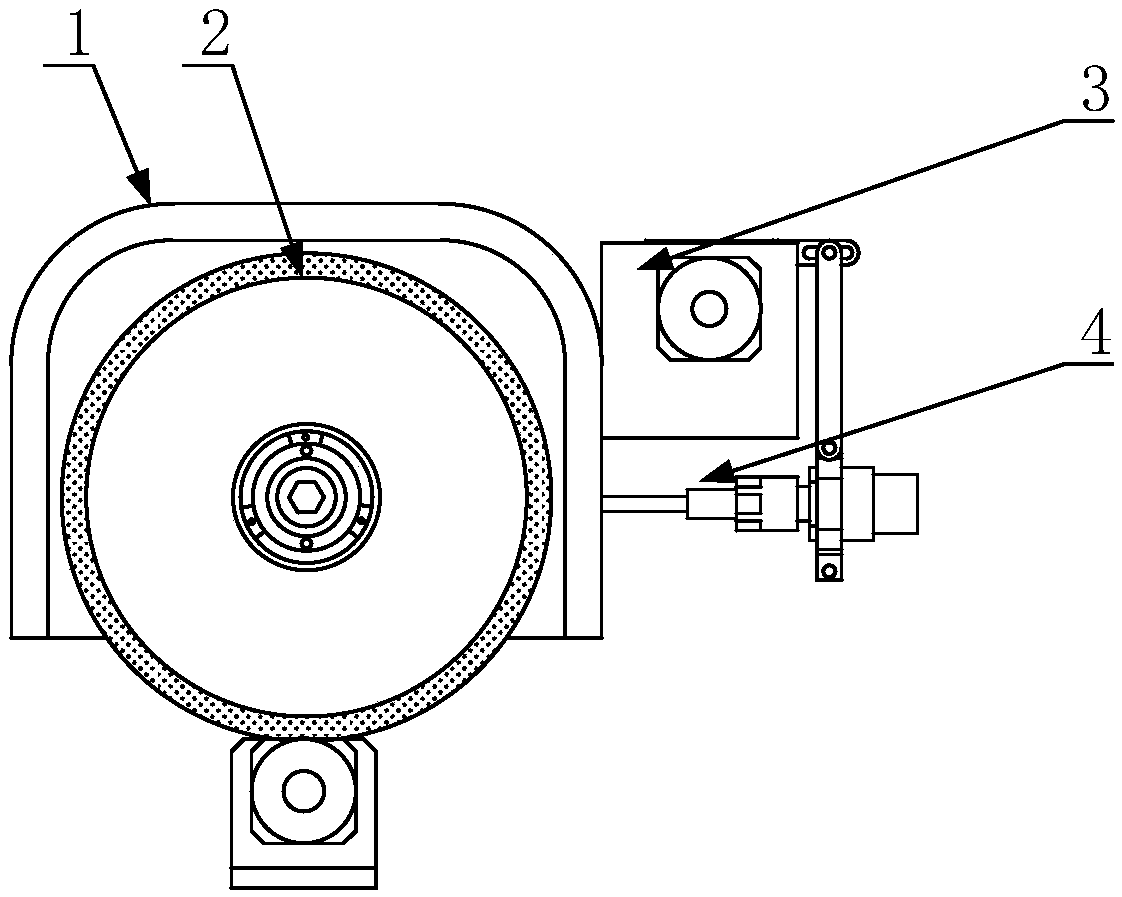

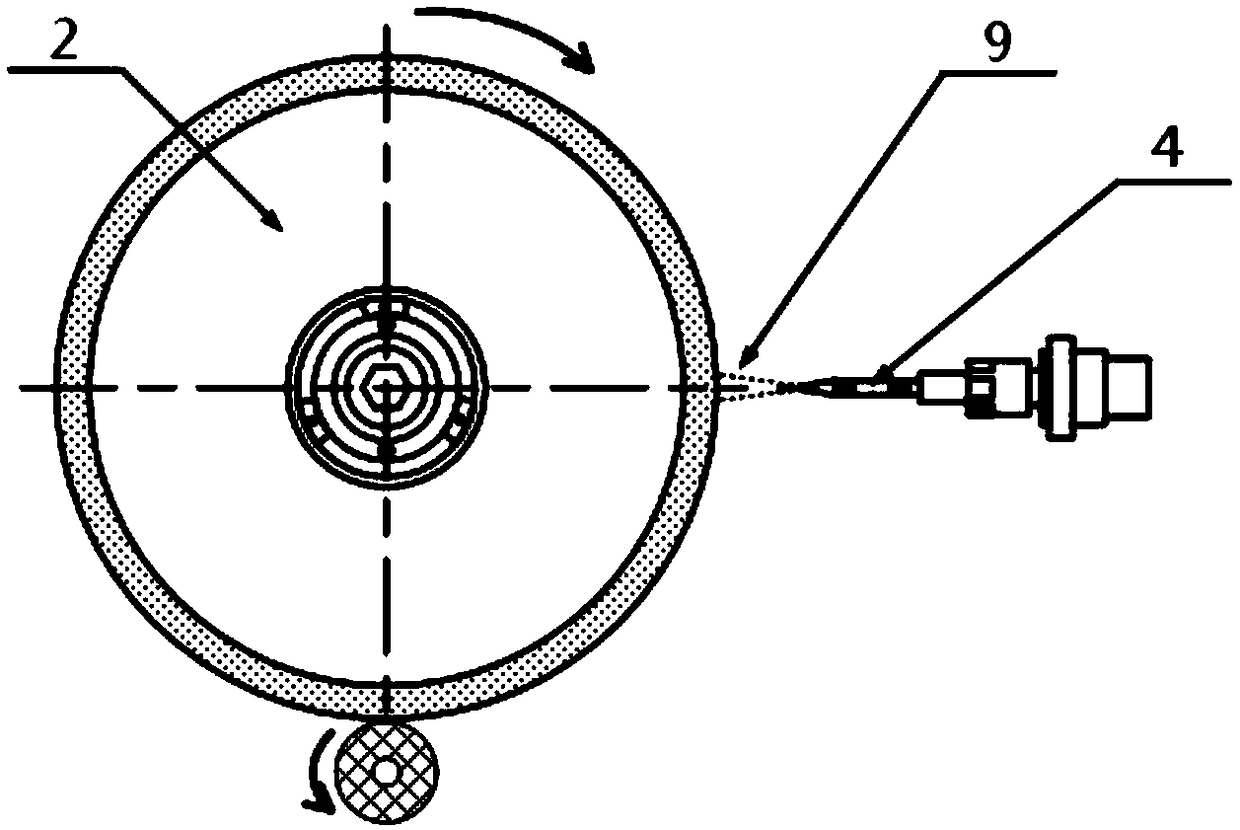

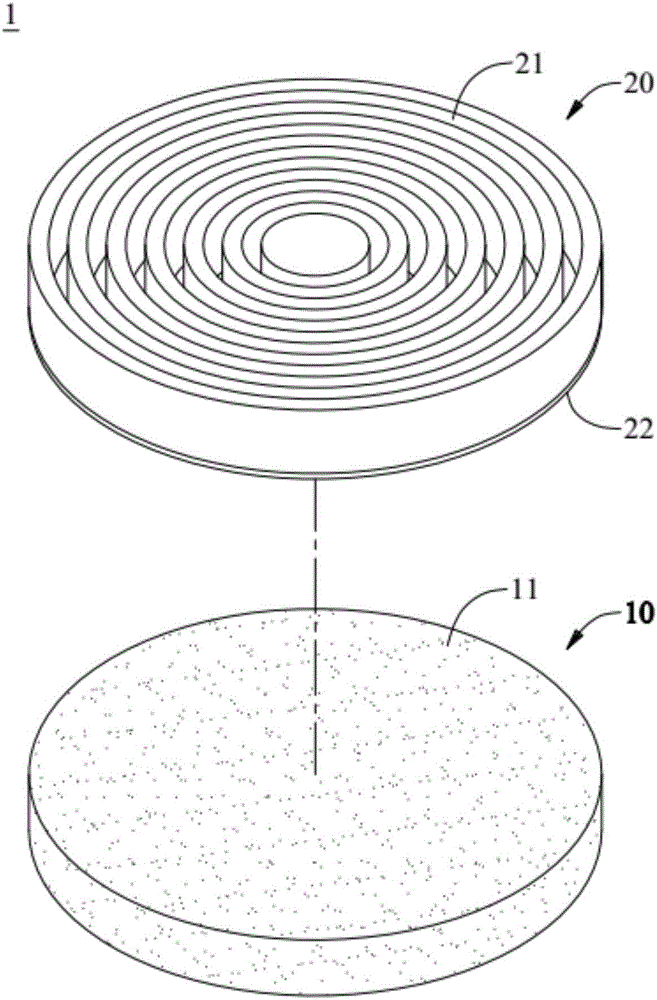

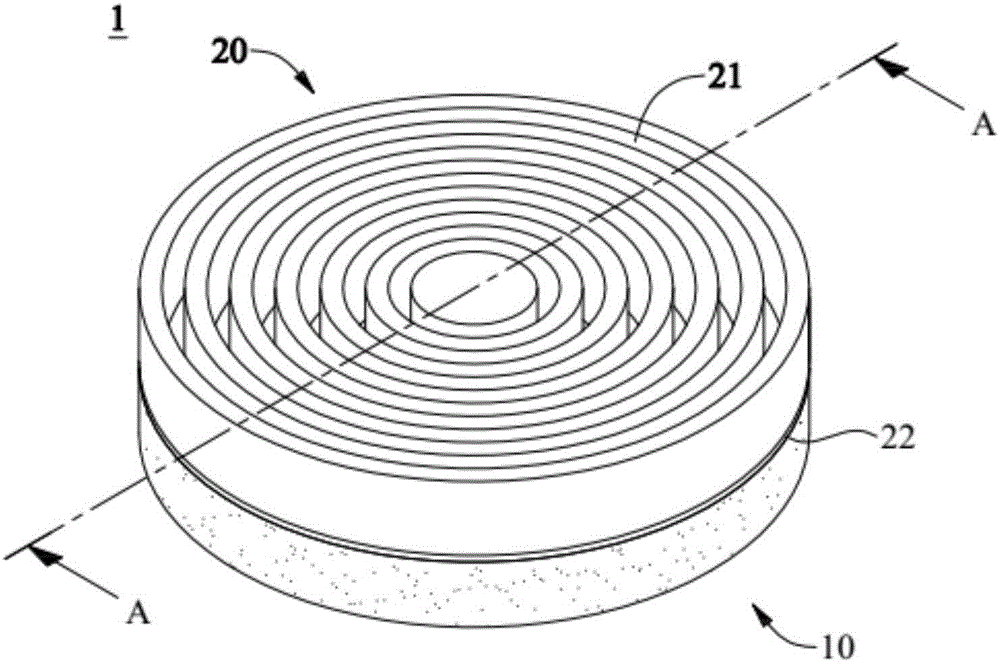

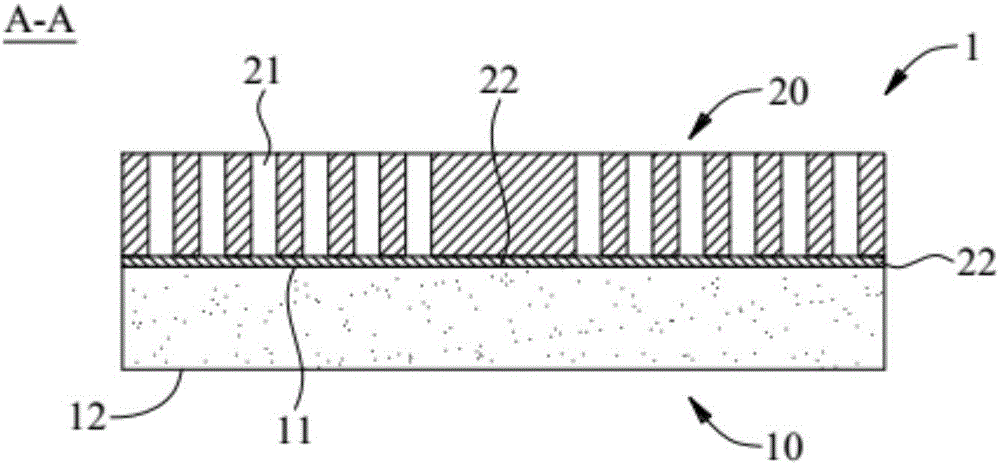

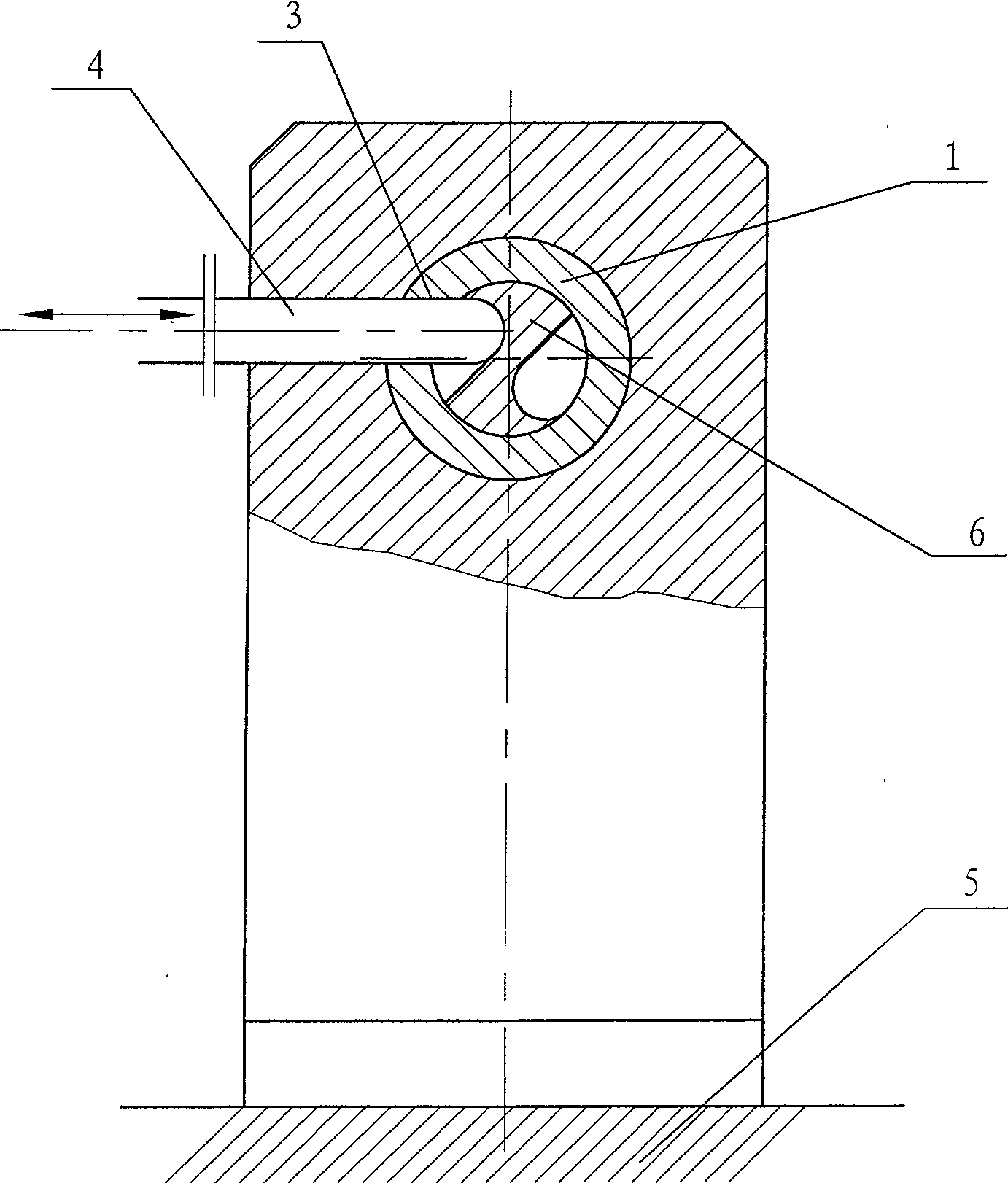

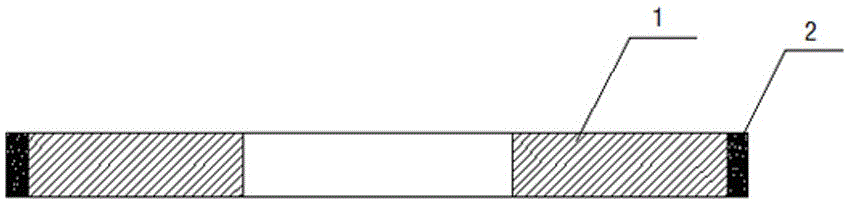

Grinding disc with internal flow supply structure

ActiveCN106607775AReduce distortionReduce the number of trimmingBonded abrasive wheelsEngineeringDrive shaft

The present invention discloses a grinding disc with an internal flow supply structure, and the grinding disc is installed on a drive shaft with a plurality of feed lines and comprises a multi-porous grinding layer and a base. The multi-porous grinding layer comprises a bonding surface and a grinding surface, which are opposite to each other. The base is joined to the bonding surface, and comprises a plurality of channels passing through the base, wherein the channels are arranged in a concentric or radial form and at least a portion of the channels extend to an edge of the bonding surface. Each channel is used for disposing the liquid supply line. Therefore, the grinding disc can adjust the amount of fluid outlet at different positions of the polishing surface of the multi-porous abrasive layer by controlling the supply of the fluid in each channel or the flow rate so as to adjust the amount of consumption in different positions, by effectively reducing the deformation of the grinding surface to reduce the number of dressings.

Owner:KINIK

Preparation method of aluminum foil for automobile radiator

ActiveCN111101035AReduce corrosion potentialReduce solubilityHeat exchange apparatusMetal rolling arrangementsAlloyAluminum foil

The invention discloses a preparation method of an aluminum foil for an automobile radiator. The preparation method comprises the following steps of preparation of an aluminum melt; continuous castingand rolling, wherein during the continuous casting and rolling, a layer of nanometer silica powder is uniformly sprayed on a contact interface between a steel belt and a casting blank of a casting machine; homogeneous annealing; cold rolling; and finished product annealing. Through the adoption of the method for producing the aluminum foil for the automobile radiator by continuous casting and rolling provided by the invention, more options are provided for the production of the aluminum foil for the automobile radiator with a 7072 alloy.

Owner:广西润泰铝业有限公司

Thin-wall special-shaped curved surface polishing device and method based on static pressure principle polishing tool

PendingCN110238730ASame loadImprove uniformityOptical surface grinding machinesLensEngineeringSurface loading

The invention discloses a thin-wall special-shaped curved surface polishing device and method based on a static pressure principle polishing tool. The thin-wall special-shaped curved surface polishing device comprises a nozzle, wherein the nozzle is used for spraying polishing liquid; the device is further comprises a fluid cylinder, wherein a plurality of pistons are connected to the fluid cylinder, and the output directions of the pistons face a polished curved surface, polishing grinding tools is arranged at the output ends of the pistons, and the polishing grinding tools are matched with the polished curved surface. The invention aims to provide the thin-wall special-shaped curved surface polishing device and method based on the static pressure principle polishing tool so as to solve the problems that a polishing method for the thin-wall special-shaped curved surface in the prior art is low in machining efficiency and poor in uniformity and that the initial surface shape is easy to be damaged and the high-precision surface is difficult to obtain, so that the uniform application of the thin-wall special-shaped curved surface loading is realized, the uniformity of removal is ensured, and meanwhile, the edge effect is greatly reduced.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

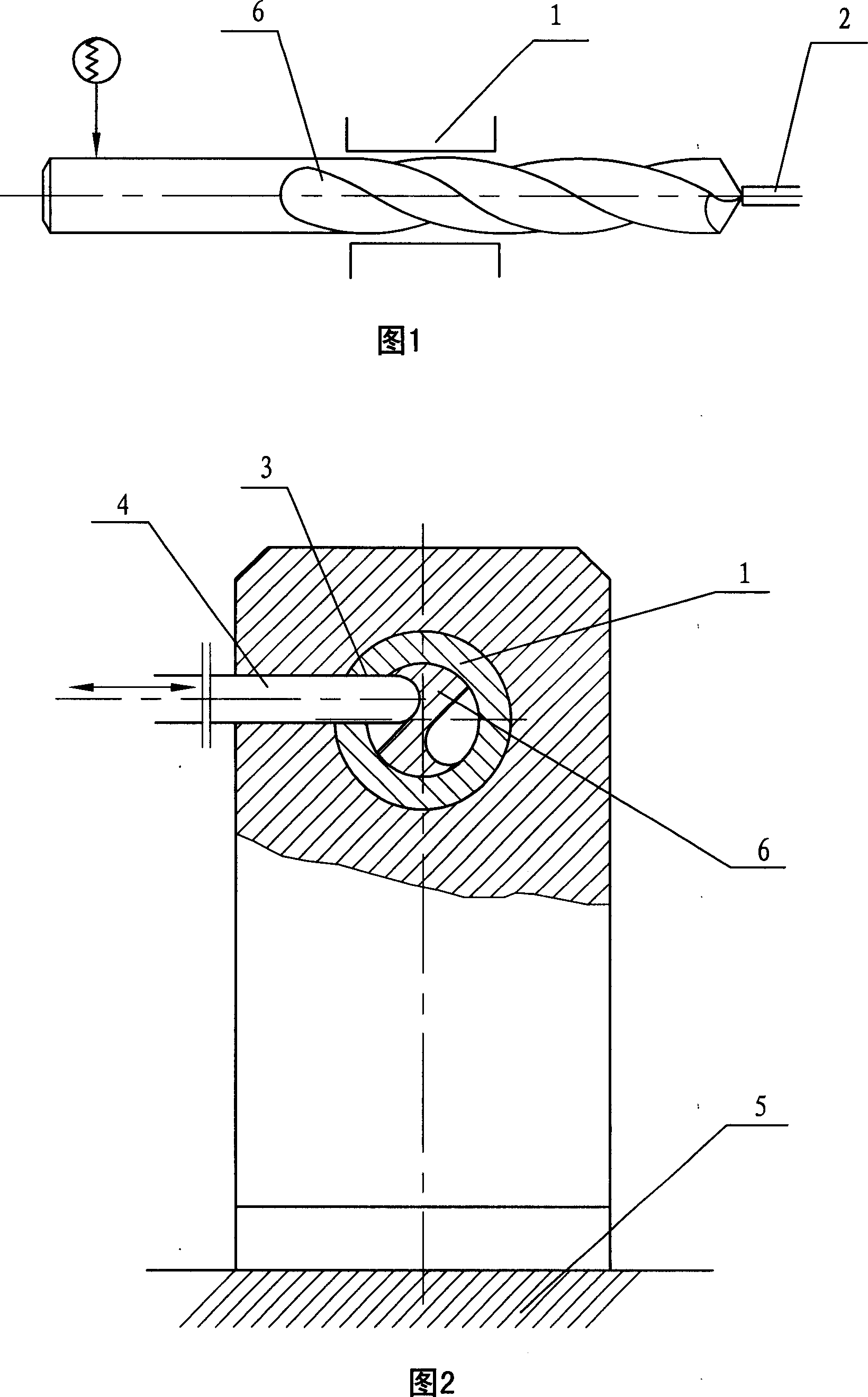

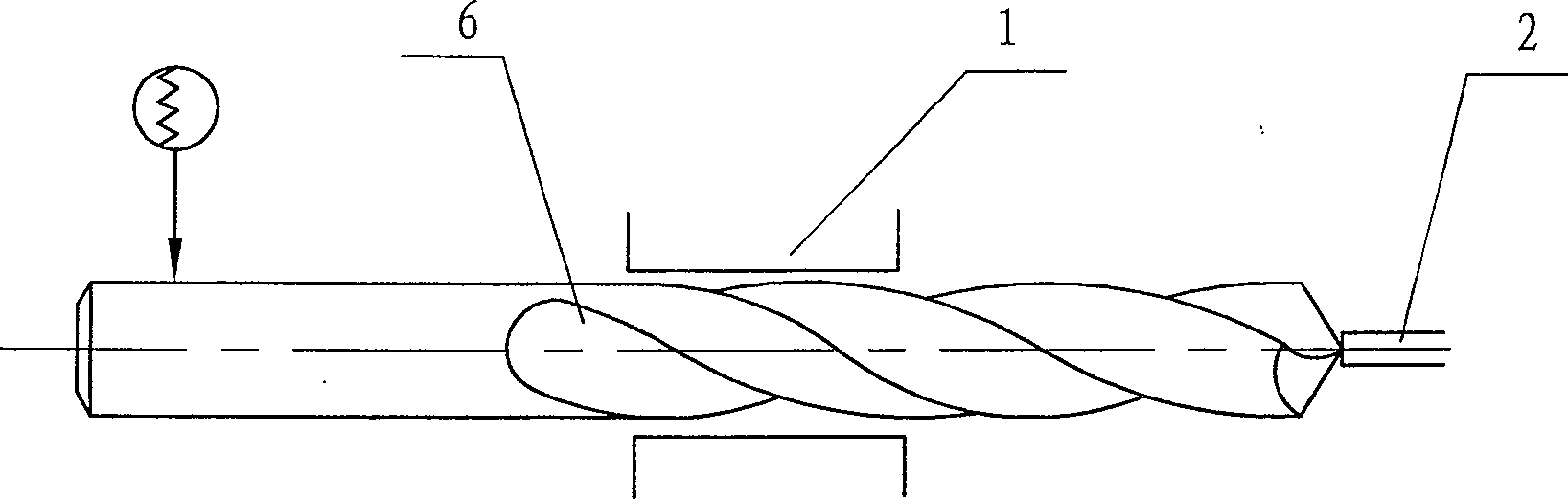

Processing method of full-grinding twist drill after plastic deformation and processing positioning apparatus

ActiveCN101081475ADense material structureGood rigidityPositioning apparatusMetal-working holdersWork in processEngineering

The present invention belongs to the field of making of metal cutting tool, and is especially process and apparatus of plastically deformed and ground twist drill. The process includes the following steps: 1. plastically deforming rod material to make semi-finished drill with grooves possessing grinding allowance; and 2. heat treatment, grinding excircle and grinding groove in a groove grinding machine. The plastically deformed and ground twist drill has high precision and high production efficiency.

Owner:江苏爵克数控刀具有限公司

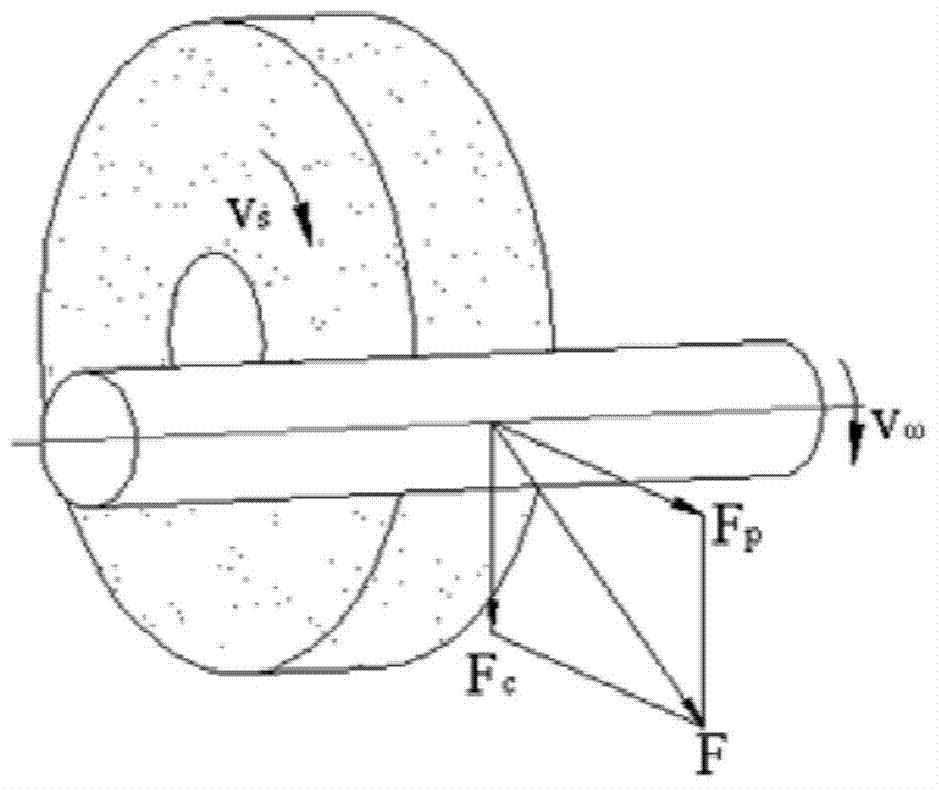

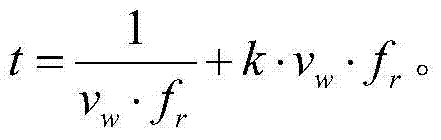

Grinding machining method for outer circle of universal joint pin neck

ActiveCN103522132BImprove processing efficiencyShorten grinding timeRevolution surface grinding machinesUniversal jointMinimum time

The invention relates to a grinding machining method for an outer circle of a universal joint pin neck. The grinding machining method comprises the following steps that optimization variables are designed, and the rotation linear velocity vw of a universal joint pin workpiece and the transverse feeding amount fr of a grinding wheel serve as the optimization variables; the minimum time used for grinding a signal universal joint pin serves as a target function, wherein the target function is t=1 / vw*fr +k*vw*fr, vw is the rotation linear velocity of the universal joint pin workpiece, fr is the transverse feeding amount of the grinding wheel, and k is a correction factor; the optimal rotation linear velocity vw of the universal joint pin workpiece and the transverse feeding amount fr of the grinding wheel are obtained according to the restraining condition; the outer circle of the universal joint pin neck is ground according to the obtained optimal rotation linear velocity vw of the universal joint pin workpiece and the transverse feeding amount fr of the grinding wheel through a crush grinding method. The grinding machining method can obtain an optimal grinding parameter combination and meanwhile takes production efficiency into consideration.

Owner:NANTONG VOCATIONAL COLLEGE

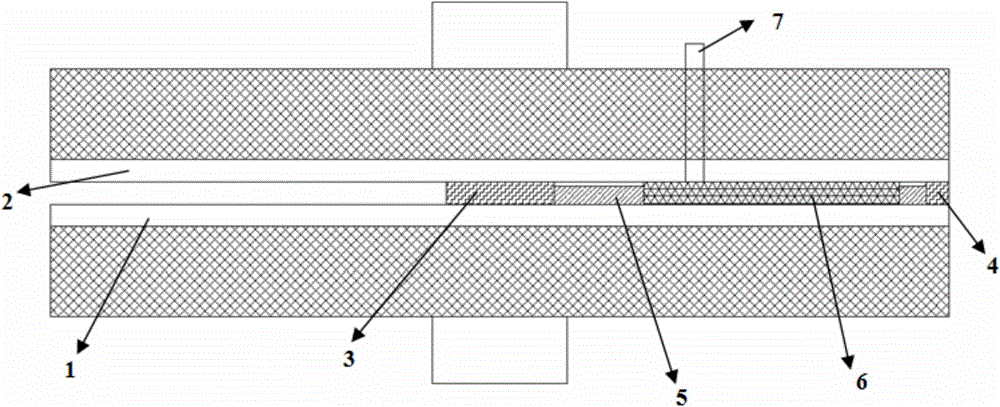

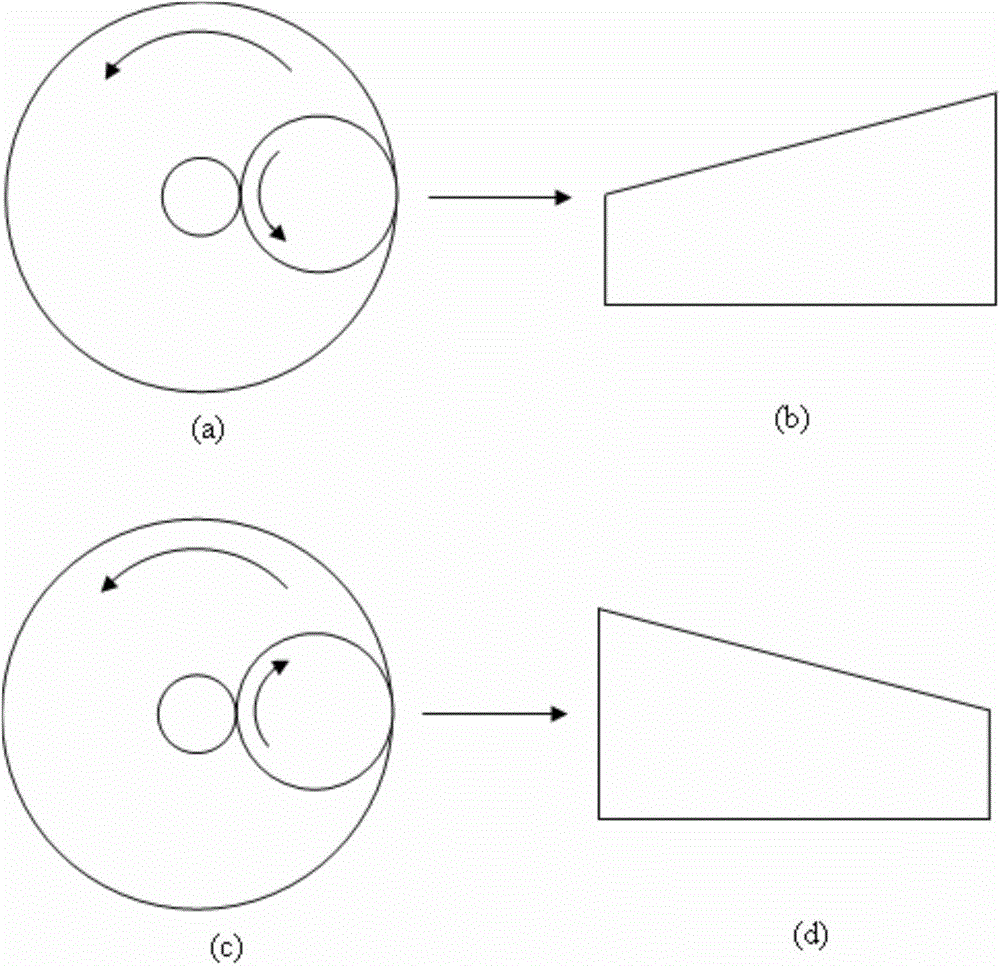

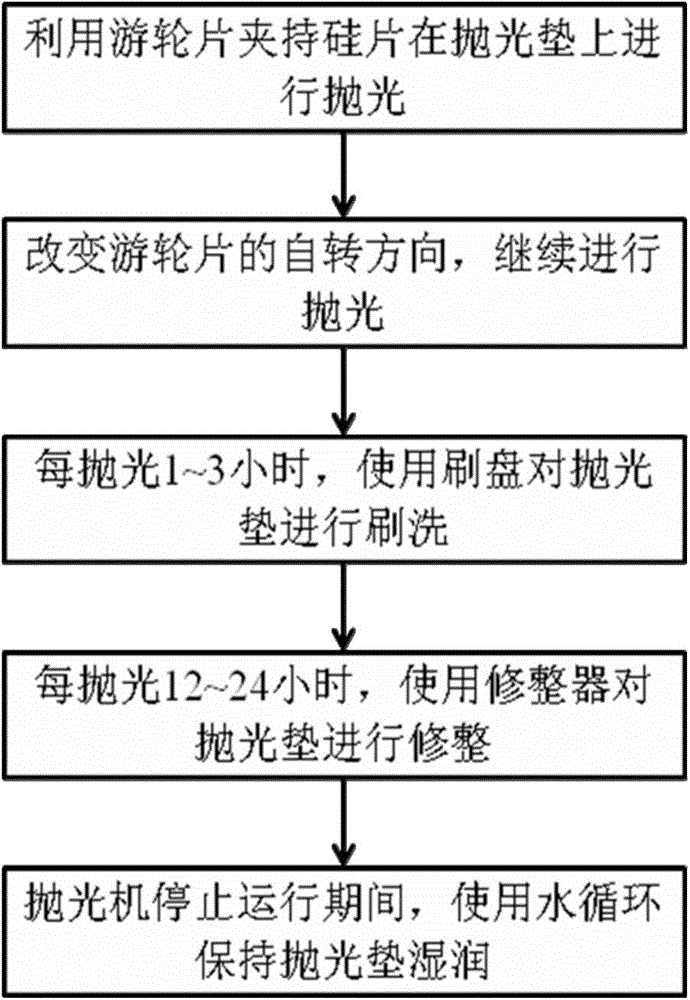

Double-side polishing method of 12-inch silicon wafer

InactiveCN104551961AImprove the phenomenon that the amount of wear variesSlow down the rate of glazingPolishing machinesLapping machinesEngineeringSilicon

The invention provides a double-side polishing method of a 12-inch silicon wafer. The method includes the steps of firstly, placing the silicon wafer in the carrier of a polishing machine, allowing he silicon wafer to move relative to an upper polishing pad and a lower polishing pad under the drive of a sun gear and an outer gear ring, and alternately changing the rotation direction of the carrier so as to polish the surface of the silicon wafer; using a brush plate to brush the upper polishing pad and the lower polishing pad after the silicon water is polished for every 1-3 hours, wherein purified water is sprayed to the polishing pads during the brushing; thirdly, using a diamond trimmer to trim the upper and lower polishing pads after the silicon water is polished for every 12-24 hours, wherein purified water is sprayed to the polishing pads during the trimming. The method has the advantages that the phenomenon that the abrasion loss at the center of the polishing pads is different from that at the edge of the polishing pads can be improved effectively, residual impurities on the surfaces of the polishing pads can be removed effectively by the brush plate, glazing speed of the polishing pads is slowed, heterogeneity in the silicon wafer and between silicon wafers can be lowered, the trimming times of the polishing pads are reduced, polishing stability is increased, and production cost is lowered.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

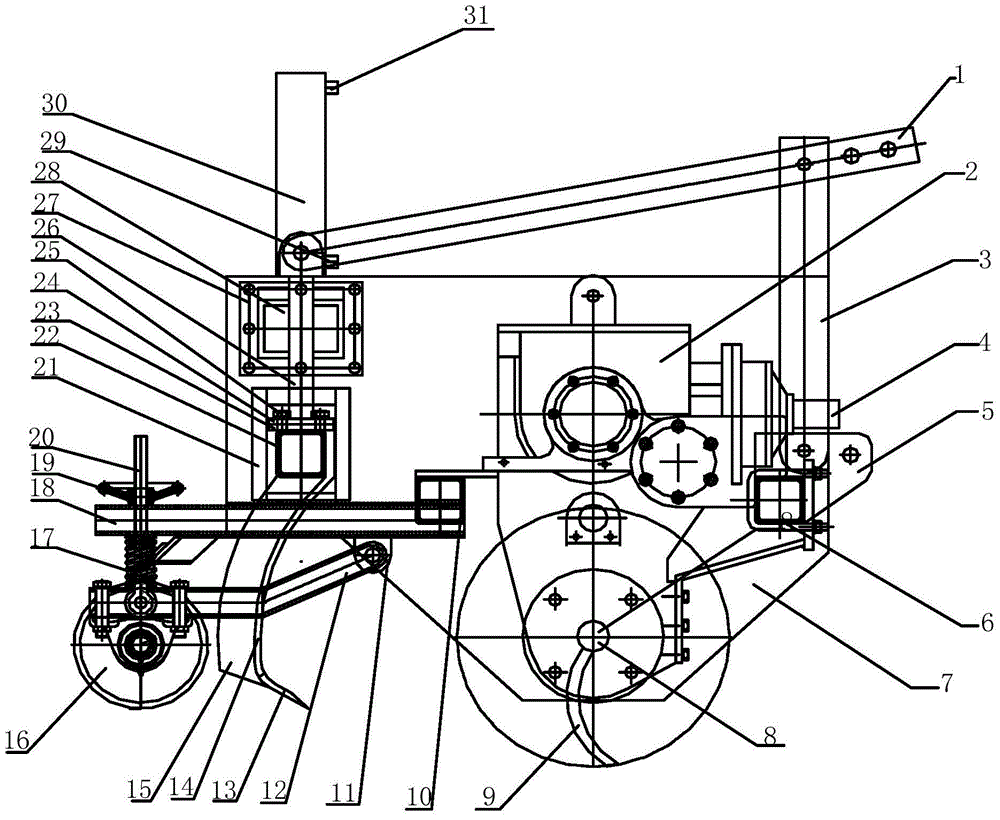

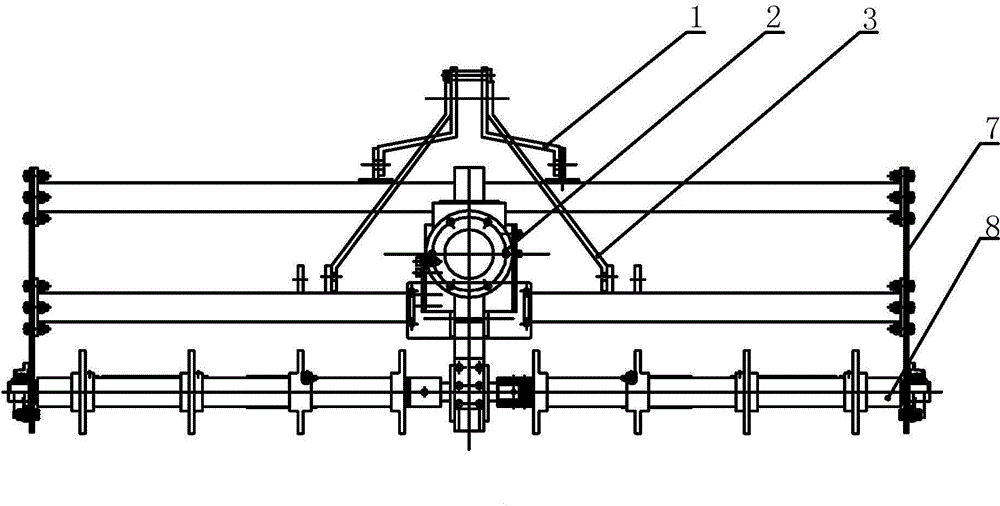

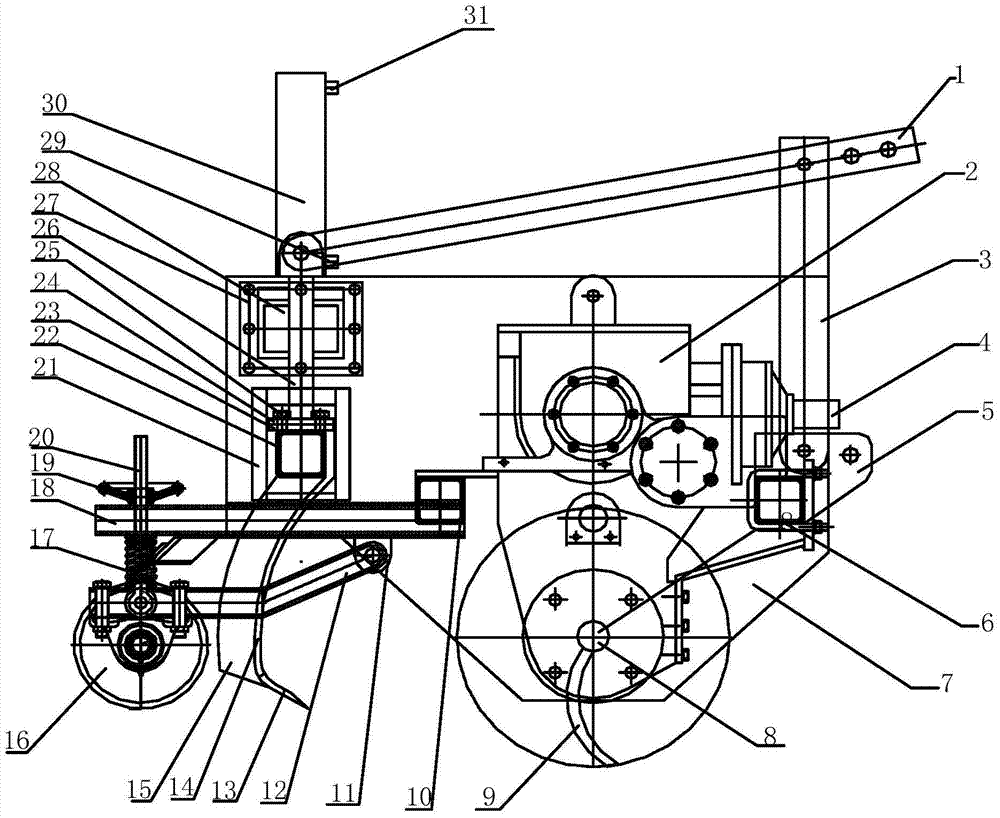

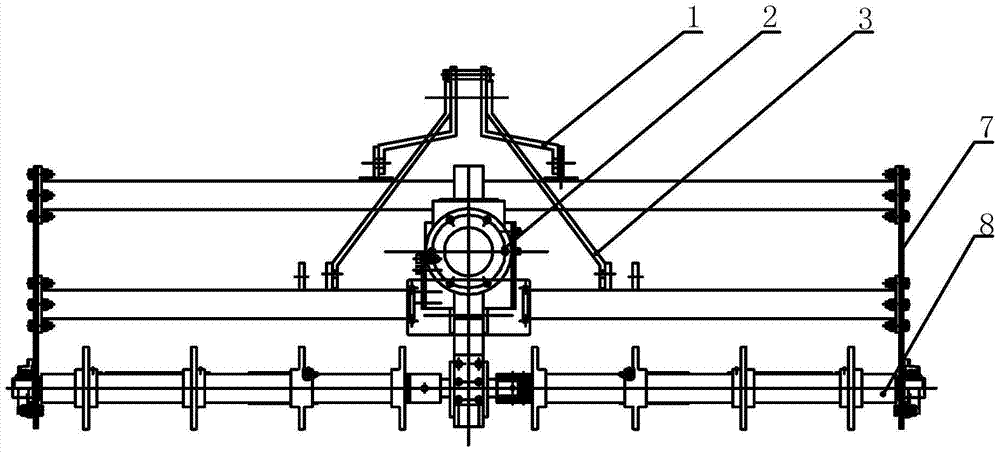

Combined soil preparation machine

InactiveCN104685997AReduce the number of trimmingImprove dressing efficiencySpadesPloughsEngineeringTillage

The invention discloses a combined soil preparation machine. The combined soil preparation soil preparation machine comprises a frame, a power transmission component, a rotary tillage component, a soil flattening component and a soil compacting component, wherein the frame is provided with a mounting portion used for being connected with power machinery by hanging, the power transmission component is fixedly connected on the frame and used for being connected with the output end of the power machinery, the rotary tillage component is connected with the output end of the power transmission component and used for smashing the soil, the soil flattening component is connected with the frame and arranged behind the rotary tillage component, and the soil compacting component is connected with the frame and arranged behind the soil flattening component. The combined soil preparation machine can complete rotary tillage, flattening and compacting of the soil at one step, soil preparation times are effectively reduced, and soil preparation efficiency is improved. In addition, the soil is flat and uniform after soil preparation, and control of sowing depth is facilitated.

Owner:SHIJIAZHUANG XINNONG MACHINERY +1

Ceramic grinding tool for low-temperature high-strength ceramic binder

The invention discloses a ceramic grinding tool for a low-temperature high-strength ceramic binder. The ceramic grinding tool for the low-temperature high-strength ceramic binder is characterized by comprising the following substances in parts by weight: 15-30 parts of dextrin liquor, 6-9 parts of closed cell perlite, 21-40 parts of borax glass, 3-4 parts of molybdenum disilicide, 5-10 parts of calcite, 3-12 parts of magnesite, 1-3 parts of silicate ester, 10-20 parts of potassium feldspar, 1-3 parts of potassium oxide, 5-20 parts of leptynite, 20-34 parts of agate, 3-4 parts of carbide, 10-19 parts of yellow dextrin, 1-3 parts of calcium hydrophosphate, 20-40 parts of calcite and 5-9 parts of cryolite. The ceramic grinding tool of the low-temperature high-strength ceramic binder, which is disclosed by the invention, has the beneficial effects of being sharp in abrasive particle, less in trimming times, capable of carrying out grinding with great cutting depth, great feed, heavy load and high efficiency, good in self-sharpening performance, low in grinding temperature, good in toughness, small in abrasion, high in durability and long in service life.

Owner:QINGDAO GUOHANG XIANGYU TECH SERVICE

Processing method of full-grinding twist drill after plastic deformation, and machining and positioning apparatus

ActiveCN100493823CDense tissueImprove rigidityPositioning apparatusMetal-working holdersEngineeringWork in process

The present invention belongs to the field of making of metal cutting tool, and is especially process and apparatus of plastically deformed and ground twist drill. The process includes the following steps: 1. plastically deforming rod material to make semi-finished drill with grooves possessing grinding allowance; and 2. heat treatment, grinding excircle and grinding groove in a groove grinding machine. The plastically deformed and ground twist drill has high precision and high production efficiency.

Owner:江苏爵克数控刀具有限公司

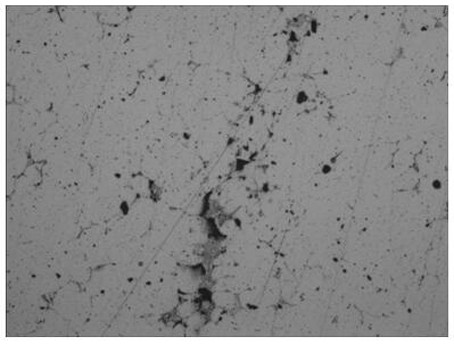

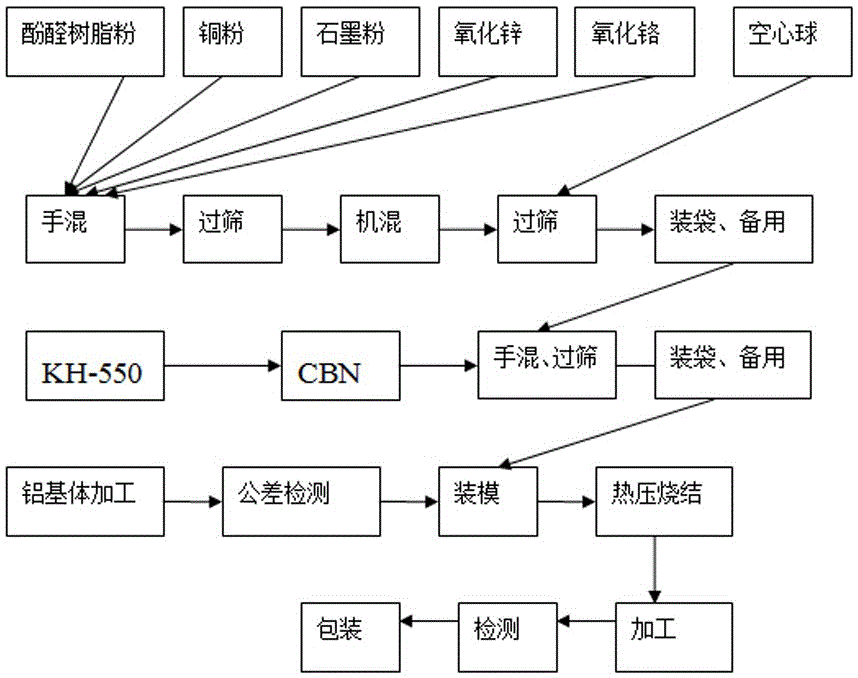

Self-sharpening resin binder diamond grinding wheel and preparation method thereof

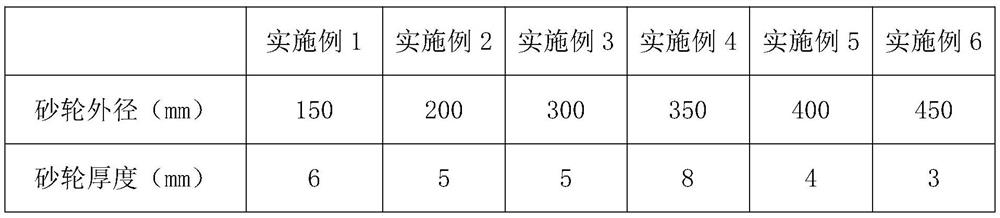

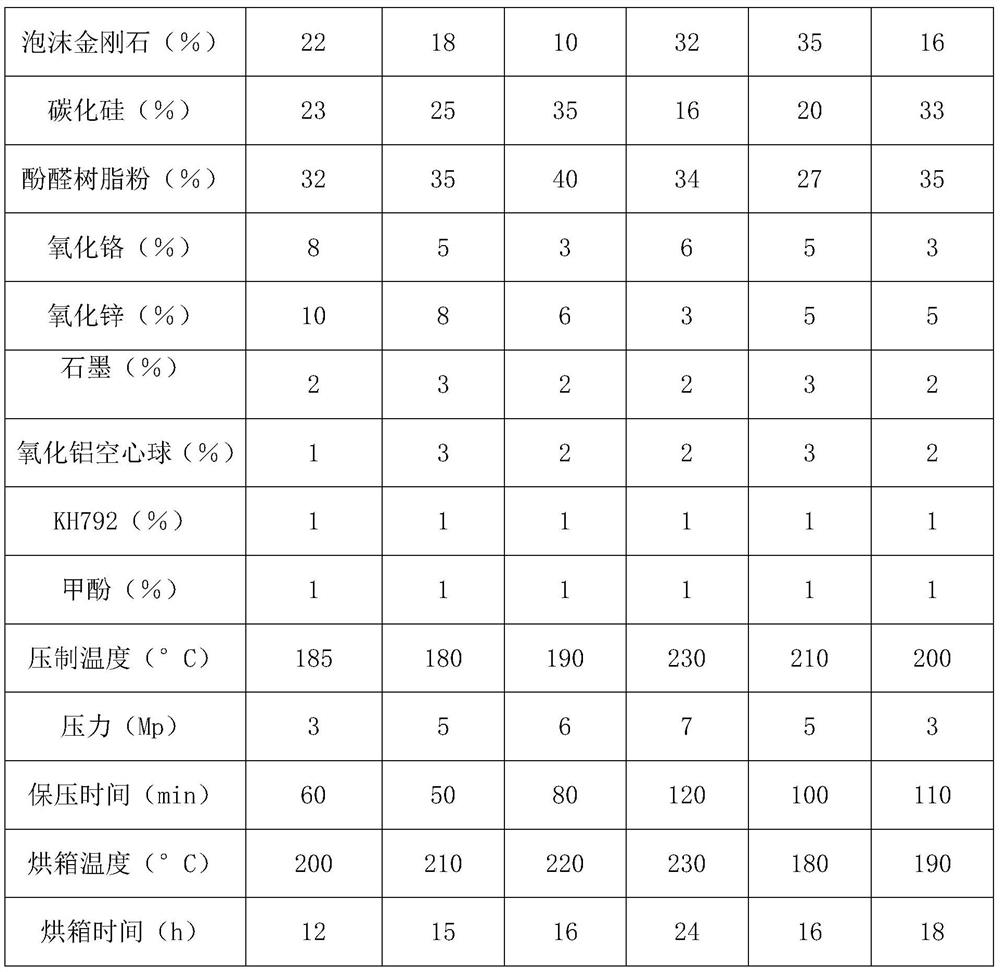

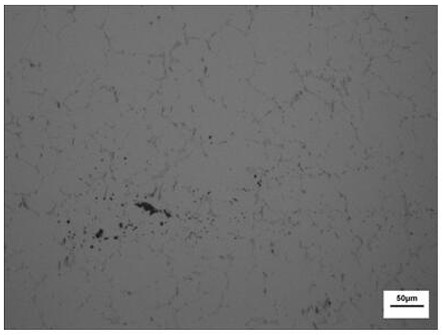

PendingCN113211334AEven consumptionWon't fall offAbrasion apparatusGrinding devicesCarbide siliconOxide zinc

The invention discloses a self-sharpening resin binder diamond grinding wheel and a preparation method thereof. The formula of the grinding wheel comprises the following components of, in percentage by volume, 15%-65% of foam diamond, 15%-45% of phenolic resin powder, 2%-15% of chromic oxide, 0%-15% of zinc oxide, 2%-10% of graphite, 16%-50% of silicon carbide, 0%-3% of pore forming agent, 0%-3% of a coupling agent, and 0%-5% of a wetting agent. According to the self-sharpening resin binder diamond grinding wheel and the preparation method thereof, compared with an existing grinding wheel, the self-sharpening resin binder diamond grinding wheel prepared through the method is characterized in that the foam diamond, the pore forming agent, the wetting agent and the coupling agent are added, the effective contact area between the foam diamond and the binder is increased, abrasive particles cannot fall off integrally due to the inlaying effect of the foam structure of the foam diamond and the binder, the diamond grinding wheel is even in consumption in the using process, the finishing frequency can be effectively reduced, good grinding force is kept, meanwhile, the self-sharpening performance of a grinding tool is improved, cutting damage is effectively reduced, and the workpiece surface machining quality is improved.

Owner:XINYA COMPOSITE SUPER HARD MATERIAL CO LTD ZHENGZHOU

A kind of preparation method of aluminum foil for automobile radiator

ActiveCN111101035BReduce corrosion potentialReduce solubilityHeat exchange apparatusMetal rolling arrangementsSilicon oxideAluminum foil

The invention discloses a method for preparing aluminum foil for automobile radiators, which comprises the following steps: preparing aluminum melt; continuous casting and rolling, during continuous casting and rolling, the contact interface between the steel strip of the casting machine and the slab is uniformly sprayed with a layer of nano-scale carbon dioxide Silicon powder; homogenization annealing; cold rolling; finished annealing. The invention provides a method for producing aluminum foil for automobile radiators by means of continuous casting and rolling, and provides more choices for producing aluminum foil for automobile radiators with 7072 alloy.

Owner:广西润泰铝业有限公司

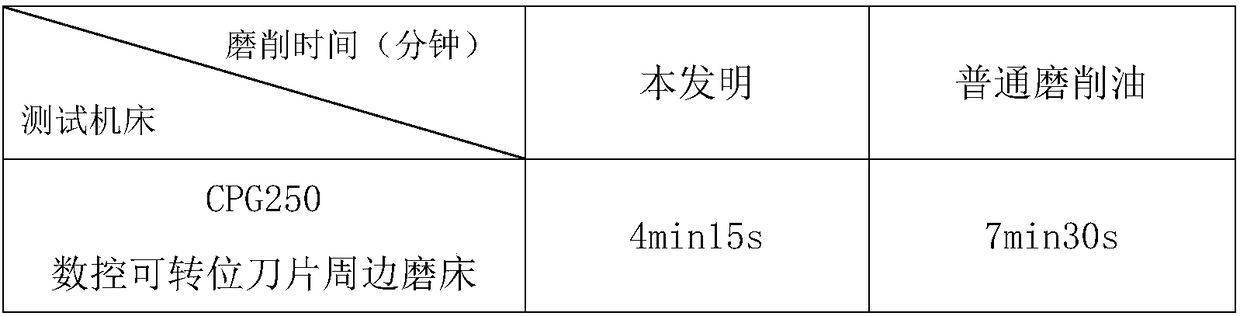

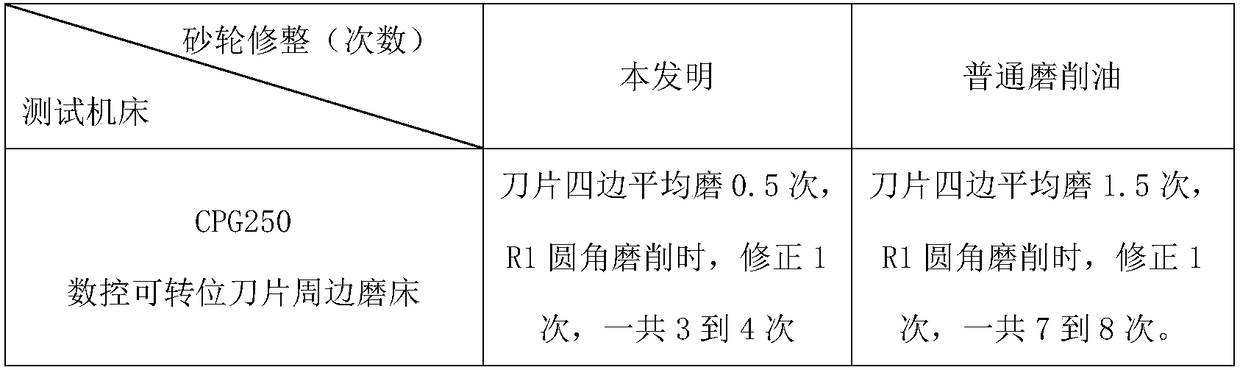

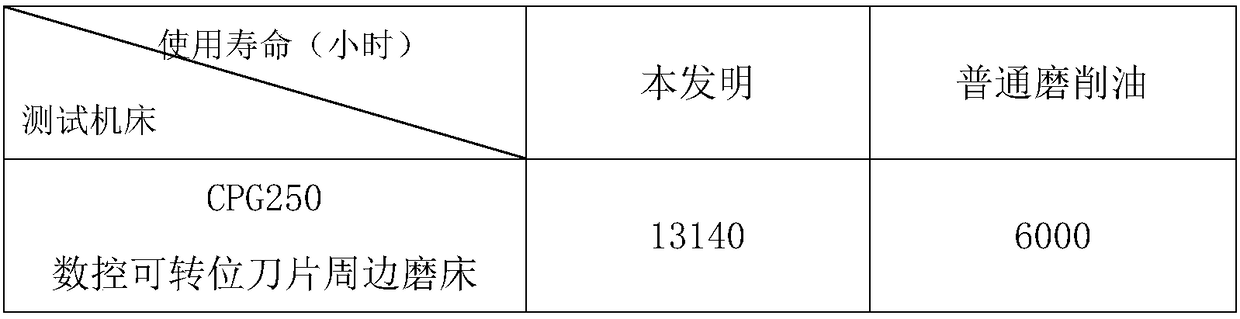

A kind of grinding oil for high hardness composite material processing and preparation method thereof

ActiveCN105838486BImprove cooling effectImprove permeabilityLubricant compositionMaterials processingGrinding wheel

The invention discloses grinding oil for machining a high-hardness composite material and a preparation method of the grinding oil. The grinding oil has the advantages that finished product has relatively good lubricating property; the heat dissipation is uniform, and the problem of bursting caused by non-uniform diffusion is prevented; the grinding oil has excellent lubricating property, extreme pressure, wear resistance and cooling property and good permeability, cleaning property and settleability; the viscosity is low, the flowing, settling, flushing deslagging effects are obvious, the oiliness is low, and the cooling speed is high; ground particles can be rapidly separated and settled, the waste rate of a grinding wheel is low, and the surface smoothness of a workpiece is high; the flash point is high and is 155 DEG C, so that the potential safety hazard is eliminated, and the grinding speed is increased; the chemical stability is strong, the service life can reach two years, and the grinding oil can be repeatedly used; the smoke and the odor are extremely little during grinding and cutting, the grinding oil has no toxicity or odor and does not stimulate skin and nervous systems; and the grinding oil is beneficial to the closed environment works.

Owner:浙江模德科技有限公司

Grinding wheel for synchronous grinding of outer circle and end face and preparation method thereof

InactiveCN107350979BEffective bondingImprove rigidityAbrasion apparatusGrinding devicesImideMetal powder

The invention discloses a grinding wheel used for grinding an outer circle and an end face synchronously. The grinding wheel comprises a base body and an abrasive material layer. The base body is prepared from, by weight, 10-20 parts of imide resin powder, 60-85 parts of metal powder, 2-10 parts of resin glue, 1-5 parts of metal glue, and 2.5-5.5 parts of a silane coupling agent. The abrasive material layer is a resin grinding wheel ring or a ceramic grinding wheel ring or a grinding wheel block. According to the grinding wheel, the resin glue and the metal glue are mixed to be used for pouring the base body, so that a resin phase and a metal phase are effectively bonded together, and thus the bonding performance and other performance are improved; and the rigidity, tenacity, heat conductivity and high-temperature performance of the base body are improved, synchronous wastage between the base body and the abrasive material layer can be achieved in the grinding process of the grinding wheel, and thus the performance of the grinding wheel and the surface quality of a machined workpiece are not affected.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Diamond grinding wheel and preparation method thereof

ActiveCN112536735BImprove wear resistanceImprove adhesionVacuum evaporation coatingSputtering coatingGraphiteSapphire

Owner:HENAN FULAIGE ULTRAHARD MATERIAL

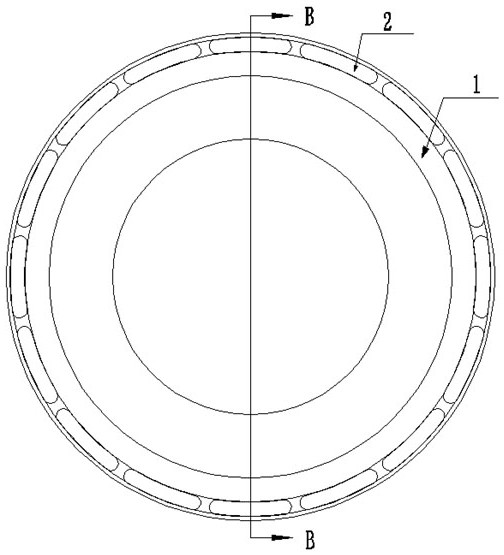

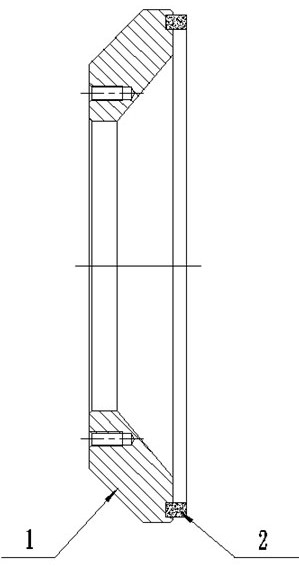

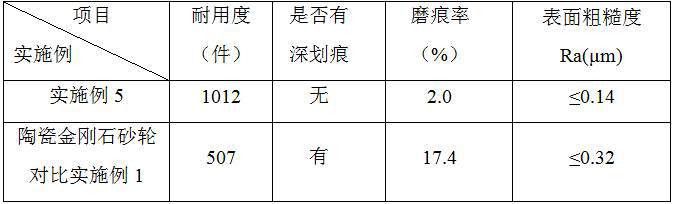

Grinding wheel for grinding electronic package substrate material and preparation method thereof

ActiveCN111300288BReduces chances of deep scratchesImprove surface qualityBonded abrasive wheelsGrinding devicesCarbide siliconElectronic packaging

The invention relates to a grinding wheel for grinding an electronic package substrate material. The grinding wheel consists of a base body and an abrasive layer. The end face of the base body is evenly spaced with a plurality of arc segments along the circumferential direction, and the arc segments form the abrasive layer. . Both ends of the arc segment block are arc structures. The abrasive layer is composed of the following raw materials by weight percentage: 10-16.2% of binder, 12-22% of silicon carbide, 3-5% of aluminum borate whiskers, 10-15% of cobalt blue, and 6-9% of temporary wetting agent , the remainder is abrasive. The grinding wheel can effectively reduce the probability of deep scratches occurring at the moment of cutting into the grinding wheel when the grinding wheel is fed. It has the advantages of high grinding efficiency, less dressing times and good surface quality of the workpiece. The grinding rate of the workpiece can be reduced to less than 5%. , which greatly improves the processing efficiency.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

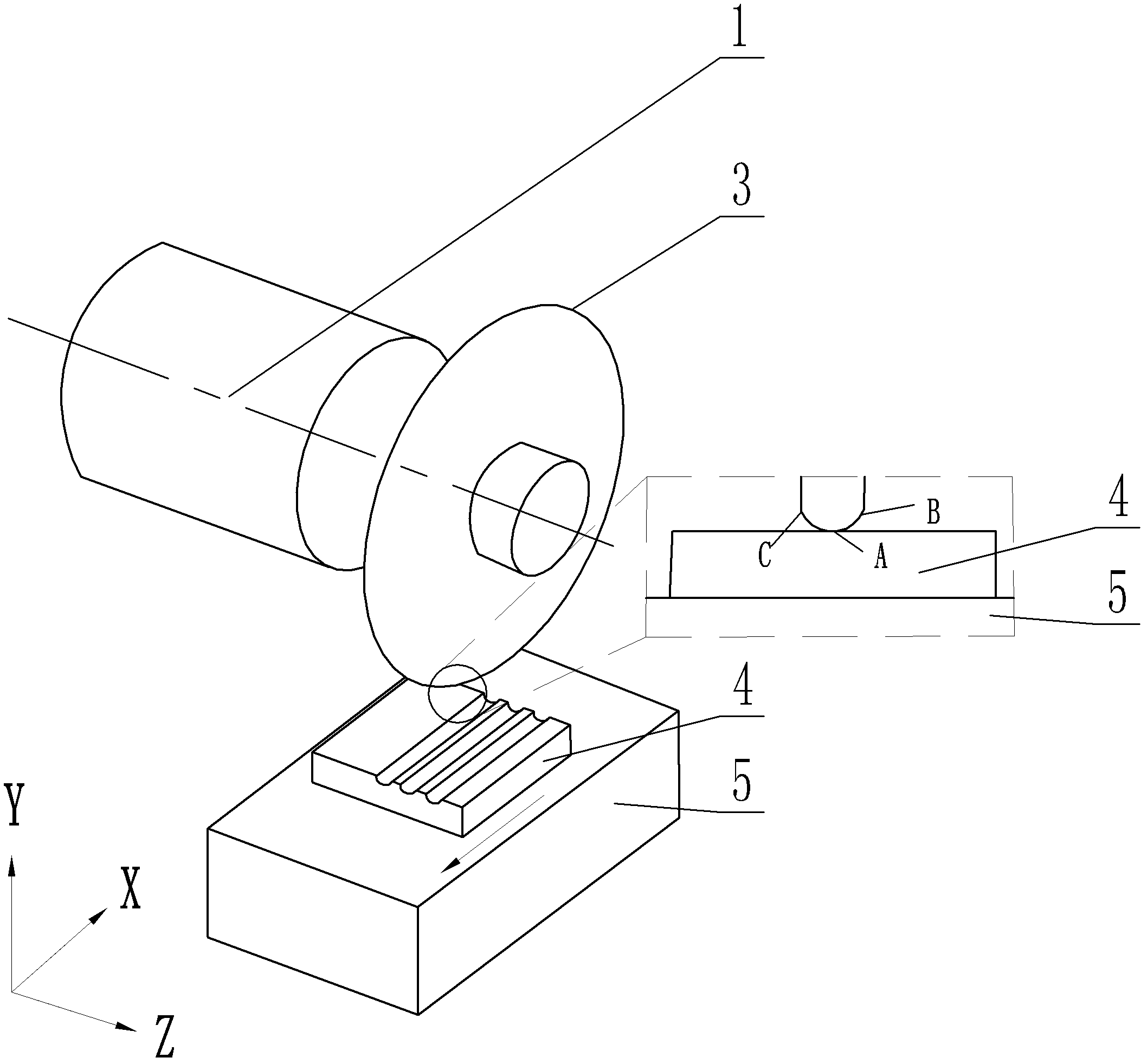

Single-direction inclined-shaft profiling precision grinding method of array optical elements of micro circular troughs

InactiveCN102513899BReduce surface roughnessImprove machining accuracyOptical surface grinding machinesSurface roughnessGrinding wheel

The invention discloses a single-direction inclined-shaft profiling precision grinding method of array optical elements of micro circular troughs, and relates to a precision grinding method of array optical elements of micro circular troughs. The invention aims at solving the problems that the surface roughness of micro circular troughs ground by the current grinding method of the array optical elements of the micro circular troughs in different feeding directions has large difference, a grinding wheel is easily abraded in processing, and the grinding processing efficiency is low. The single-direction inclined-shaft profiling precision grinding method comprises the following steps of: 1, causing the axis of rotation of a profiling grinding wheel and the upper surface of a workpiece to be ground to form an included angle of 45 degrees, and causing the first lowest point of the profiling grinding wheel to become a grinding center point; 2, causing the workpiece to be ground to feed along the reverse direction of an X axis and to process micro circular troughs of all arrays in a single direction along with a workbench of a precision grinder; 3, and causing the axis of rotation of the grinding wheel and a plane with the surface of the workpiece to form an included angle of 135 degrees, causing the second lowest point of the grinding wheel to become the grinding center point, and then processing the circular troughs according to the step 2. The precision grinding method disclosed by the invention is used for processing array optical elements of the micro circular troughs.

Owner:HARBIN INST OF TECH

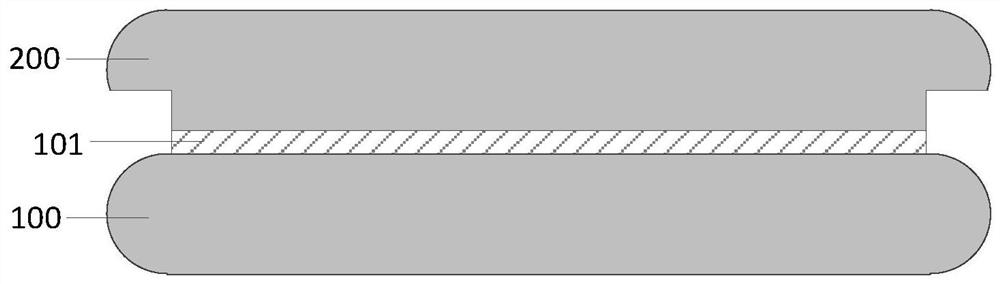

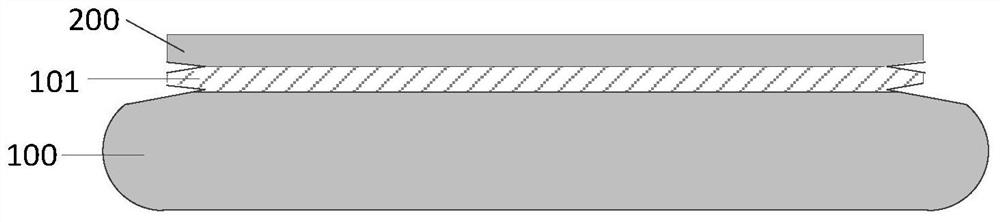

Wafer thinning method and wafer structure

ActiveCN110364430BIncrease the areaAvoid lateral undercuttingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingAcid etchingStructural engineering

The present invention provides a wafer thinning method and a wafer structure. The embodiment of the present application provides a wafer thinning method. After providing the wafer to be thinned, it can be ground from the back of the wafer, and then the The first planarization process is performed on the back of the wafer to repair the flatness of the wafer after grinding, and then the second planarization process is performed from the back of the wafer until the target thinning thickness is reached. That is to say, the embodiment of the present application can repair the flatness of the wafer through two planarization processes after removing part of the thickness of the wafer, without using an epitaxial layer as an etching stop layer, which reduces the cost of thinning, while Grinding removes most of the thickness without using acid etching, avoiding the lateral undercutting caused by acid etching, thereby reducing the number of edge trimmings caused by lateral undercutting and increasing the effective chip area.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

A kind of nanometer multi-layer structure film and preparation method thereof for blade rolling die

ActiveCN109594039BImprove wear resistanceExtended service lifeVacuum evaporation coatingSputtering coatingWear resistantThin membrane

The invention relates to a nano multilayer film for a blade rolling die and a preparation method thereof, and belongs to the technical field of surface treatment techniques and die surface strengthening. The nano multilayer film comprises a metal TiAl bottom layer, a TiAlN transition layer, a TiAlN / CrTiAlN nano multilayer coating and a CrTiAlN surface coating layer. The method comprises the stepsof performing ultrasonic cleaning after polishing, performing vapor phase deposition, wherein the vacuum degree is less than 8*10<-3>Pa, the temperature is 250 to 350 DEG C, depositing the metal TiAlbottom layer and the TiAlN transition layer in sequence, and alternately depositing the TiAlN / CrTiAlN nano multilayer coating and the CrTiAlN surface coating layer with a strict modulation period. Themultilayer coating with a proper modulation period and modulation ratio is prepared and is applied to high-speed steel for preparing a wear resistant and high-temperature resistant hard coating, thewear resistance of the die can be obviously increased, and compared with a die without a coating to strengthen, the service life is prolonged by more than 20 times.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

A resin cbn grinding wheel for processing saw blade base

InactiveCN104308755BExtend the trimming timeGood self-sharpeningAbrasion apparatusGrinding devicesBoron nitrideGrinding wheel

The invention discloses a resin CBN (cubic boron nitride) grinding wheel for machining a saw blade base body. The resin CBN grinding wheel comprises a base body and an abrasive material layer. The abrasive material layer comprises the following raw materials in percent by volume: 15%-30% of CBN abrasive materials, 30%-45% of phenolic resin powder, 3%-6% of villiaumite grinding-aiding materials, 5%-15% of heat conduction materials, 5%-25% of metallic oxide, 2%-5% of solid lubricating materials and 4%-8% of pore forming materials. Compared with a common white corundum grinding wheel, the resin CBN grinding wheel is high in grinding amount, high in machining efficiency, long in finishing interval and low in speed of loss; and the grinding wheel changing frequency is reduced. Because the grinding wheel has high self-sharpening performance, burn injury and slow grinding of the CBN grinding wheel can be eliminated in a grinding process. On a grinding machine with low revolving speed of 1450 revolutions per minute, the CBN grinding wheel is used for replacing the common white corundum grinding wheel, and the saw blade base body can be quickly ground into a saw blade base body with the given size.

Owner:江苏赛扬精工科技有限责任公司

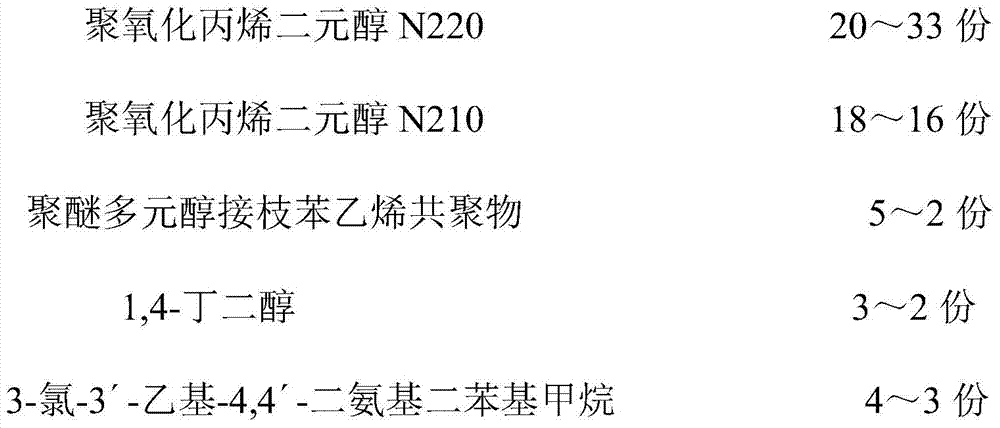

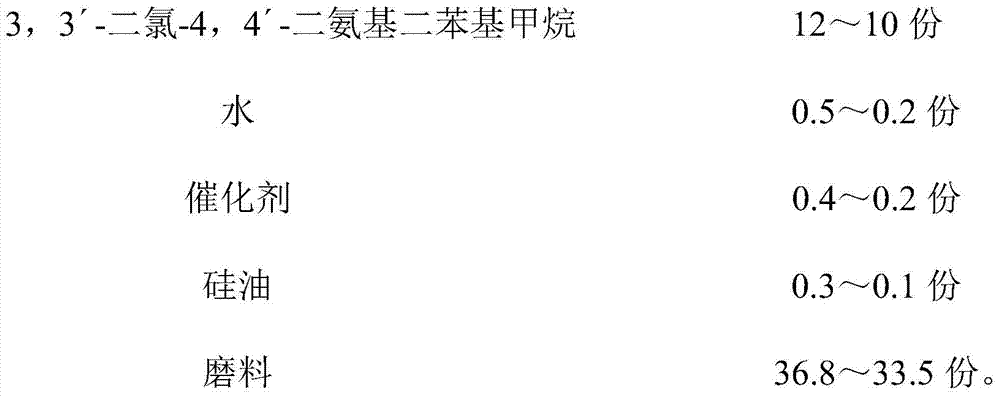

A kind of polyurethane elastomer polishing material and preparation method thereof

Owner:山西合成材料产业技术研究院有限公司

A combined land preparation machine

InactiveCN104685997BReduce the number of trimmingImprove dressing efficiencySpadesPloughsAgricultural engineeringLand leveling

Owner:SHIJIAZHUANG XINNONG MACHINERY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com