Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

130results about How to "Strong cutting force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel ceramic corundum grinding tool of low-temperature and high-strength ceramic bonding agent and preparation method thereof

InactiveCN102699825ASharp abrasiveStrong cutting forceAbrasion apparatusGrinding devicesGrinding wheelBorosilicate glass

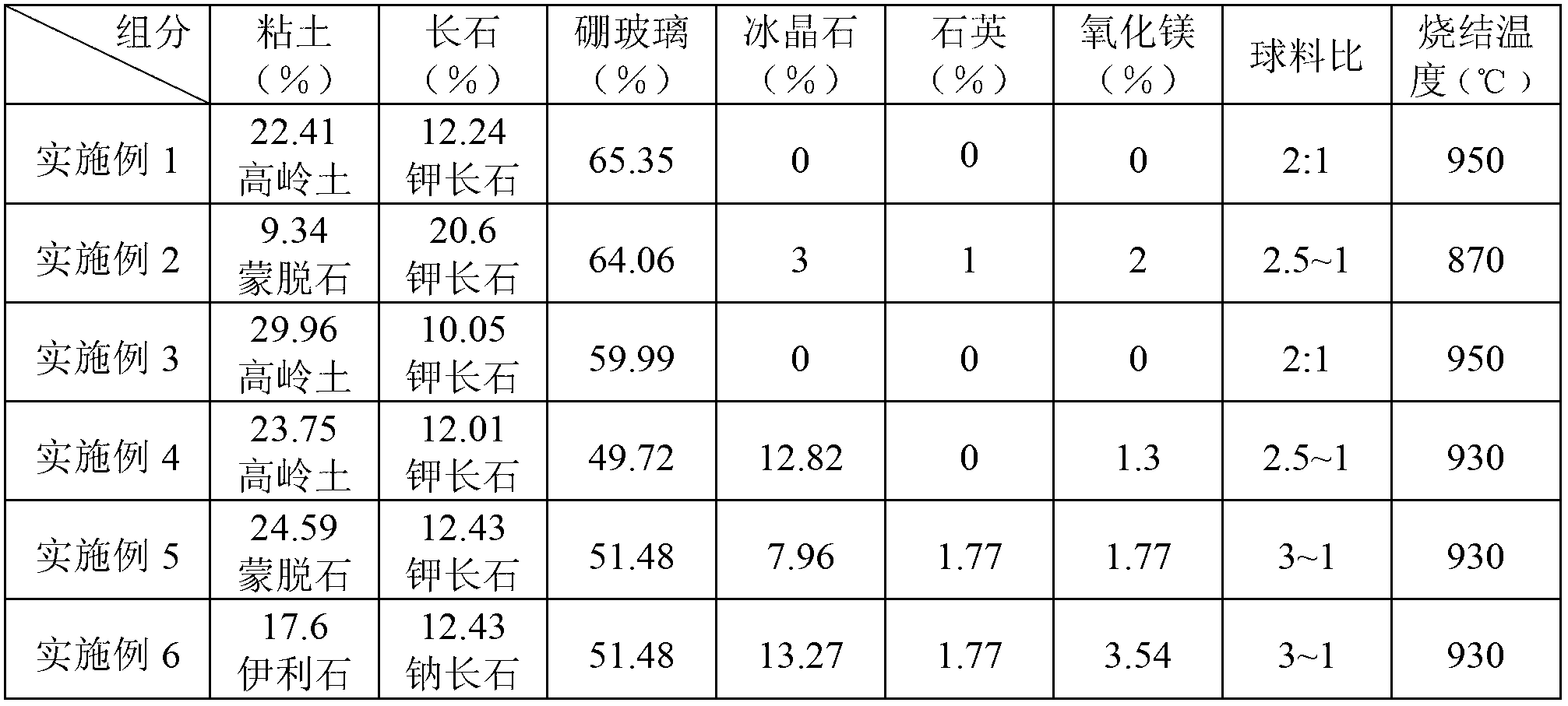

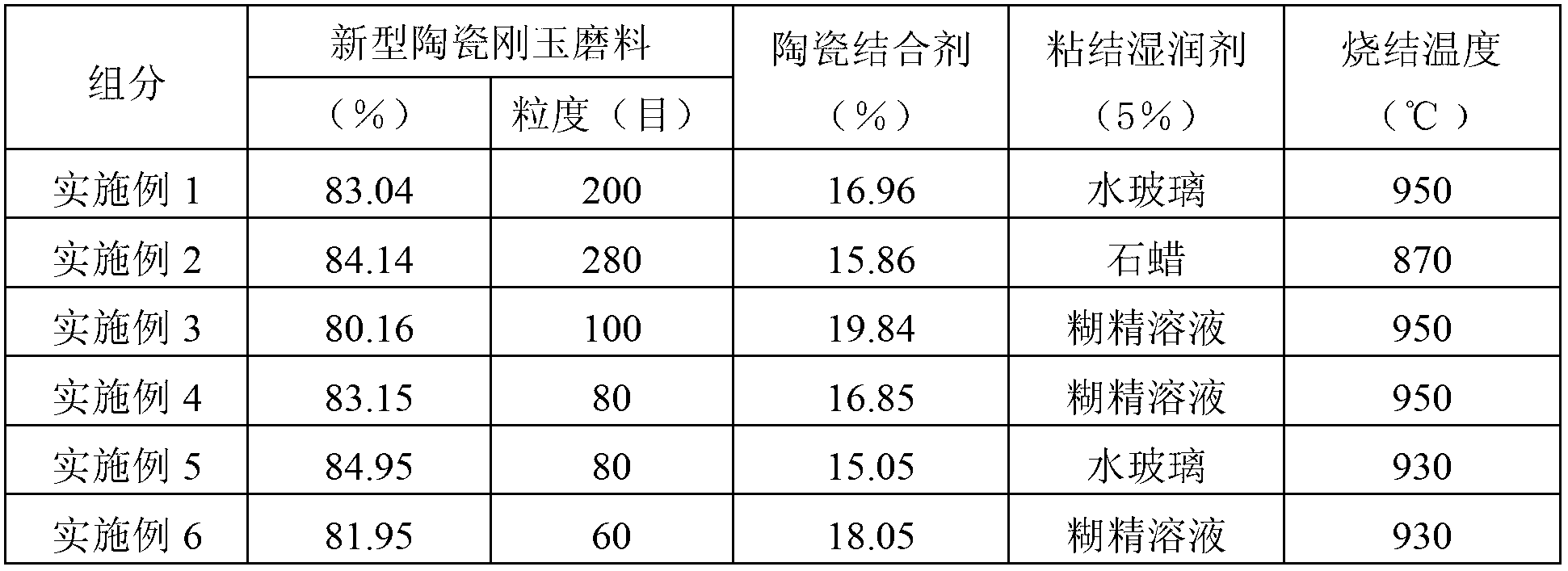

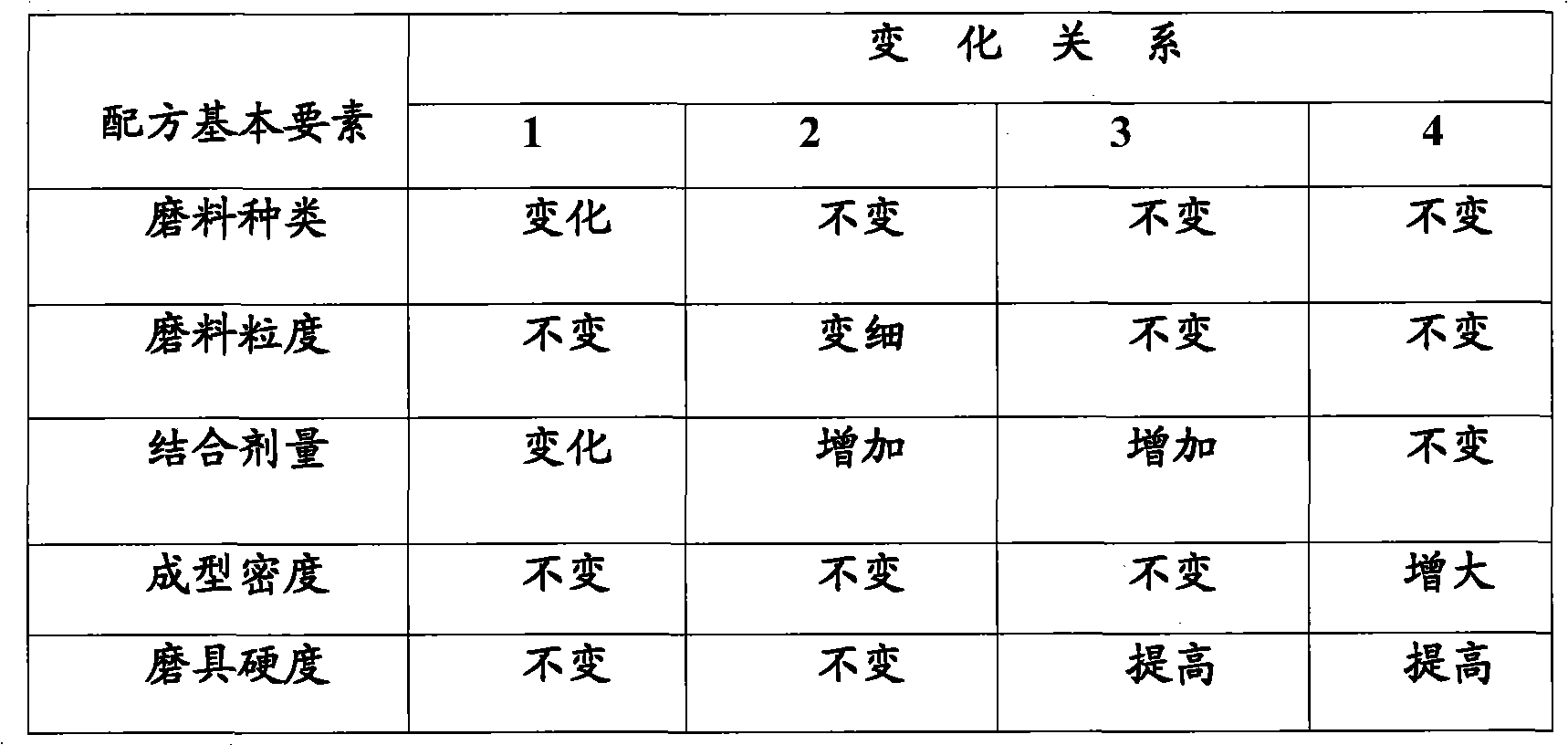

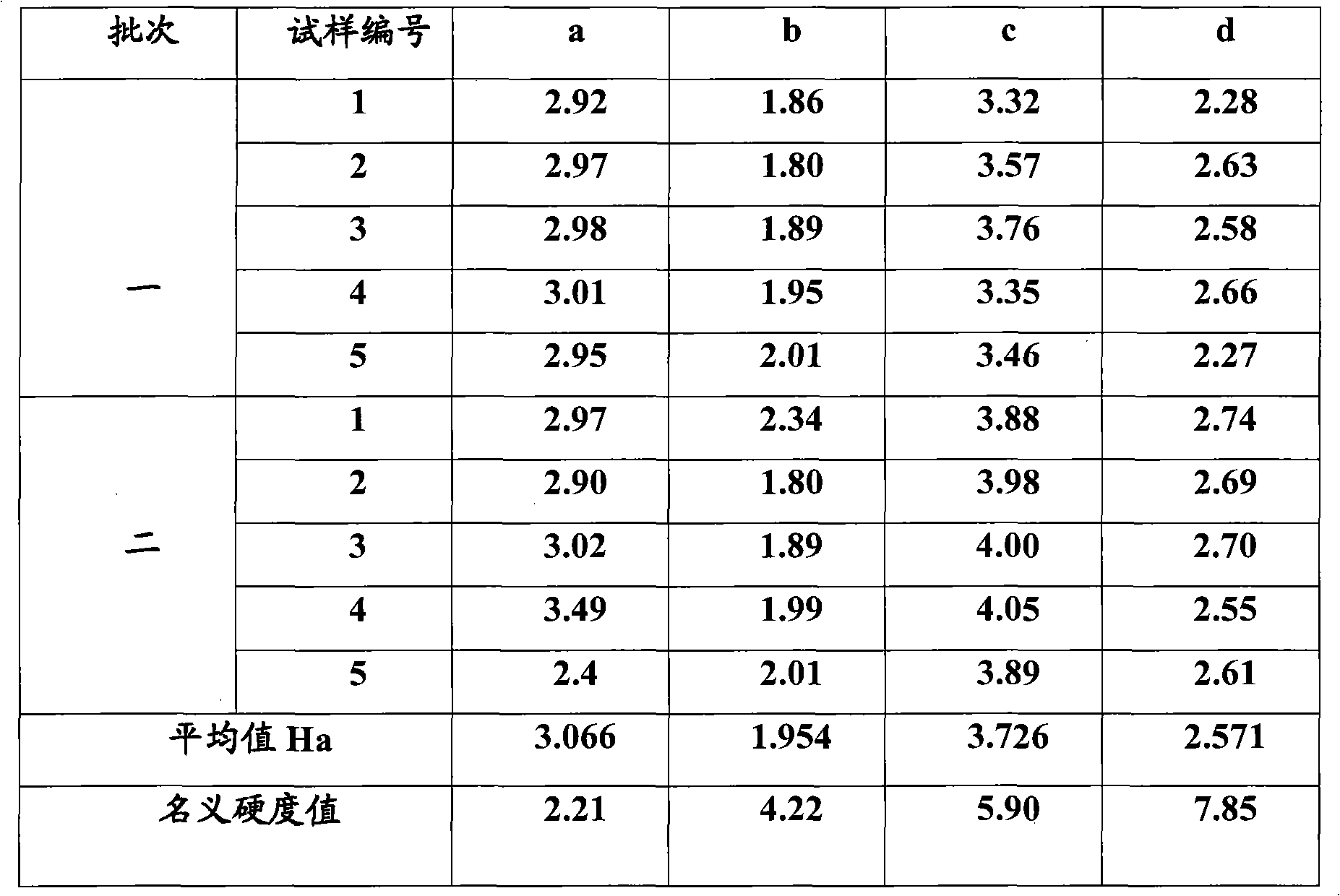

The invention discloses a novel ceramic corundum grinding tool of a low-temperature and high-strength ceramic bonding agent. The grinding tool consists of the following components in percentage by mass: 15 to 20 percent of ceramic bonding agent, 80 to 85 percent of novel ceramic corundum grinding material and 5 percent of bonding wetting agent, wherein the bonding agent consists of the following components in percentage by mass: 10 to 30 percent of clay, 10 to 30 percent of feldspar, 45 to 70 percent of borosilicate glass, 0 to 15 percent of kryocide, 0 to 5 percent of quartz and 0 to 5 percent of magnesium oxide. The novel ceramic corundum grinding tool can be sintered at the sintering temperature of 850 to 980 DEG C, and by the grinding tool, a grinding wheel can be safely used at the rotation speed of 80 to 100m / s. The single-travel feeding amount of the grinding tool can be over 0.3mm, the metal removing rate is over 3 times that of an ordinary corundum grinding wheel, the grinding interval time is 3 to 5 times that of the ordinary corundum grinding wheel, the service life is 5 to 10 times that of the ordinary corundum grinding tool, and the novel ceramic corundum grinding tool is superior to a super-hard grinding tool and the ordinary grinding tool in performance and price.

Owner:TIANJIN UNIV

Precision grinding wheel for high-efficiency aluminum oxide ceramic microcrystalline grinding materials

InactiveCN101797724AGood toughnessSmall grinding deformationAbrasion apparatusAlumina ceramicAluminium oxide

The invention relates to a precision grinding wheel for high-efficiency aluminum oxide ceramic microcrystalline grinding materials, comprising a grinding wheel basal body, grinding material particles distributed on the grinding wheel basal body and a bonding agent bonded and fixed on the grinding material particles, wherein the bonding agent comprises the following components in percentage by weight: 10-15 clay powder, 30-50 feldspar powder, 20-40 talcum powder and 10-20 high-boron glass powder. The grinding wheel has the functions of large cutting depth, high feeding strength, large load and high-efficiency grinding. According to tests, over 0.3 mm can be reached for one-way feeding and the metal removing rate is over 2 times higher than that of a common corundum grinding wheel. The grinding wheel ahs the advantages of high durability, long service life which is 5-10 times that of the common corundum grinding wheel, favorable self sharpening, no blockage and high capability of maintaining stable grinding performance.

Owner:SUZHOU FAR EAST ABRASIVES

Prepn of microcrystalline alumina ceramic grain

The preparation process of microcrystalline alumina ceramic grain includes the following steps: preparing alpha-alumina with superfine aluminum hydroxide as initial material, mixing with aluminum hydroxide and pseudoboehmite, grinding to compound suspension, preparing gel, drying, crushing, sintering at 1250-1650 deg.c, crushing and final sieving. Compared with white corundum, brown corundum and other traditional aluminum base grinding material, the present invention has the advantages of high hardness, high toughness, high wear resistance, etc. and primary crystal of 0.2-2 micron size. This grinding tool of the said grinding material has greatly raised durability.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

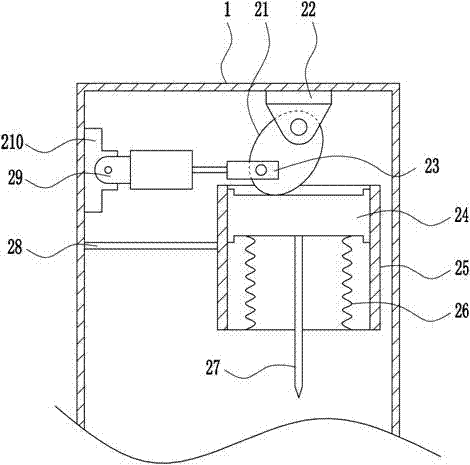

Medicinal material cutting and breaking device for pharmaceutical factory

InactiveCN106985175AEasy to collectReduce workloadGrain treatmentsMetal working apparatusProduction rateEngineering

The invention relates to a cutting and breaking device, in particular to a medicinal material cutting and breaking device for the pharmaceutical factory and aims at achieving the technical purpose of providing the medicinal material cutting and breaking device for the pharmaceutical factory, wherein the medicinal material cutting and breaking device for the pharmaceutical factory is high in cutting strength, high in breaking efficiency and capable of increasing the production rate. To achieve the above technical purpose, the medicinal material cutting and breaking device for the pharmaceutical factory is provided and comprises a first box, a cutting mechanism, a pushing mechanism, a first support column, a falling mechanism and the like. The first support column is arranged on the left side of the bottom of the first box, a second support column is arranged at the lower portion of the right side of the first box, the cutting mechanism is arranged on the top in the first box, the pushing mechanism is arranged at the bottom of the left wall in the first box, and the falling mechanism is arranged at the bottom of the first box. The medicinal material cutting and breaking device achieves the effects that the cutting strength is high, the breaking efficiency is high, and the production rate can be increased.

Owner:嘉兴嘉湖骨科医院管理有限公司

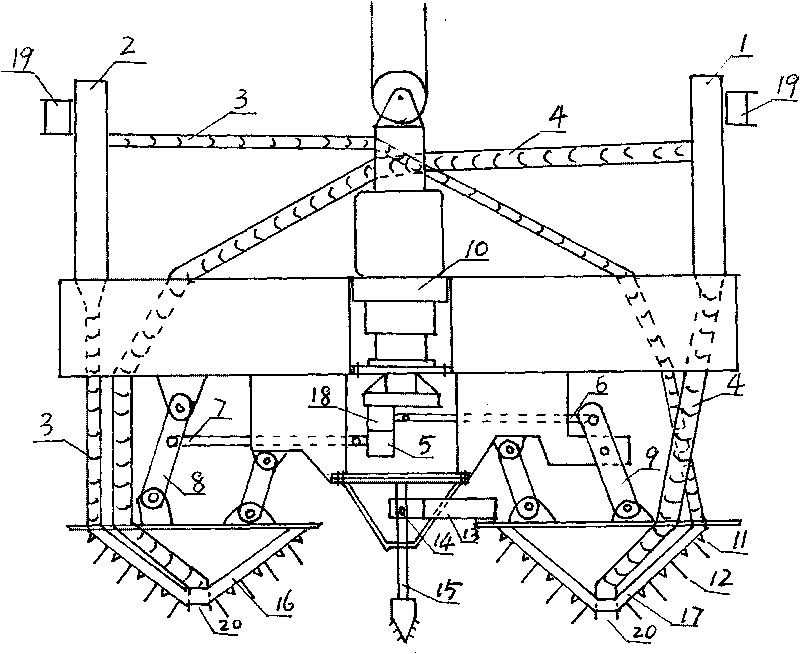

Double-saw slot sawing machine

InactiveCN101705702ASimple structurePowerfulArtificial islandsSoil-shifting machines/dredgersMachine toolWater spray

The invention discloses a double-saw slot sawing machine comprising a water inlet tube (2), a water inlet rubber (3), a sand suction tube (1) and a sand suction rubber tube (4), wherein the water inlet rubber (3) respectively supplies water to two groups of saw blades, and the sand suction rubber tube (4) adsorbs sand to two groups of saw blades. A diving reduction box (10) is positioned in the middle of the slot sawing machine; an eccentric shaft is installed below the diving reduction box and is provided with an upper sealed axle sleeve (18) and a lower sealed axle sleeve (5); two axle sleeves are respectively connected with a left connecting rod (7) and a right connecting rod (6), wherein the connecting rod (7) is hinged with the middle of a swing arm (8), and the connecting rod (6) is hinged with the upper end of a swing arm (9); a drill point (15) capable of rotating from left to right is positioned on the top center of the slot sawing machine between a shifting fork and two shifting needles; two triangle tool rests (16) and (17) are respectively positioned on the left and the right of the lower end of the slot sawing machine; inclined saw blades (12) are evenly distributed according to certain length on the bottom of the tool rest; a water spray nozzle (11) is positioned between each two saw blades. The invention is a special machine tool for building underground impervious walls.

Owner:南通同旭贸易有限公司

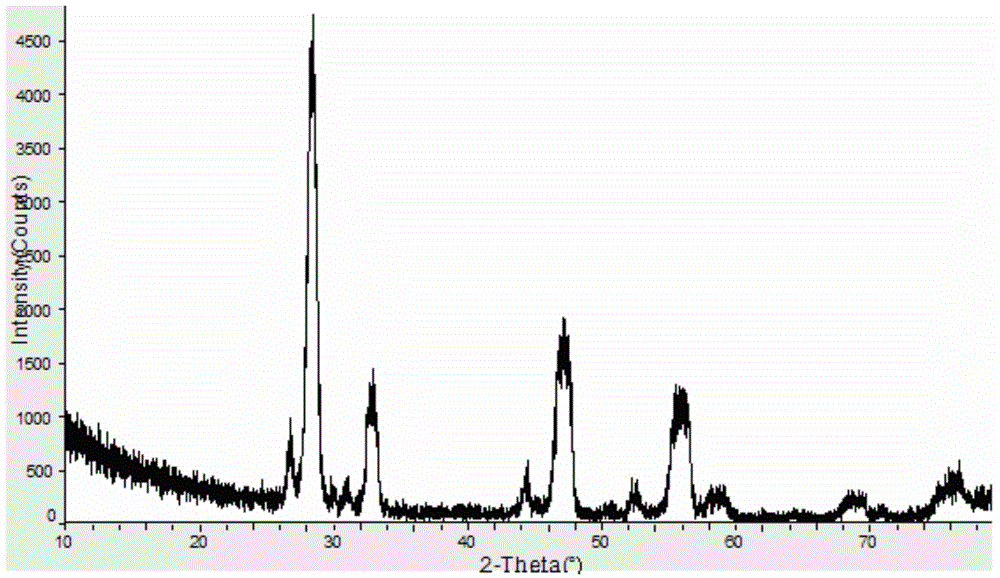

High-cutting-force diamond micro powder and preparation method thereof

ActiveCN102757044AReduce the roughness valueRoughness Ra value decreasedDiamondOptical communicationCutting force

The invention discloses high-cutting-force diamond micro powder and a preparation method thereof. A large amount of sharp cutting edges are arranged on the surfaces of grains of high-cutting-force diamond micro powder; the cutting force is 2 to 4 times of that of a common monocrystal diamond micro powder; and the specific surface area of the diamond micro powder with the particle size average of 3 microns, 6 microns, 9 microns, 15 microns or 30 microns is much larger than that of common monocrystal diamond micro powder with the particle size average of 3 microns, 6 microns, 9 microns, 15 microns or 30 microns. The high-cutting-force diamond micro powder is strong in cutting force and long in service life, the scratches on the surface of a ground and polished workpiece are less, the requirements of the modern industry on the high grinding and polishing efficiency and high grinding and polishing precision are met, and the development of a precise grinding and polishing technology can bepromoted. The high-cutting-force diamond micro powder is mainly suitable for precisely grinding and polishing in the IT (information technology) industry, the optical communication industry, the LED industry, the aerospace industry, the automobile industry and the other industries.

Owner:HENAN UNION ABRASIVES

Ceramic bonding agent, ceramic bonding agent abrasive disk and preparation method of ceramic bonding agent abrasive disk

ActiveCN106737255AImprove liquidityHigh tensile strengthAbrasion apparatusGrinding devicesBoron nitrideGraphite

The invention discloses a ceramic bonding agent, a ceramic bonding agent abrasive disk and a preparation method of the ceramic bonding agent abrasive disk. The ceramic bonding agent comprises, by weight, 20-60 parts of SiO2, 10-30 parts of B2O3, 5-20 parts of Al2O3, 3-6 parts of Li2O, 6-15 parts of Bi2O3, 5-20 parts of P2O5, 0.2-1.5 parts of TiO2 and 0.5-2 parts of Sb2O5. A grinding layer of the ceramic bonding agent abrasive disk is composed of, by volume percentage, 5-50% of cubic boron nitride (CBN) or diamond, 5-40% of white corundum, 5-30% of the ceramic bonding agent and 3-5% of whiskers. The boron, aluminum and phosphorus silicate ceramic bonding agent disclosed by the invention has the good liquidity and tensile strength, can well infiltrate and control a grinding material, and has a good cutting capacity; the whiskers are added into the ceramic bonding agent, the strength of the ceramic bonding agent is increased, the grinding durability is improved, the hardness of the bonding agent is reduced, self-sharpening performance of a grinding tool is improved, and accordingly the durability of a grinding wheel is improved and the service life of the grinding wheel is prolonged. Efficient grinding on various steel materials is achieved through the synergistic effect of the CBN, the white corundum, the silicon carbide, wollastonite and the graphite, and high durability is achieved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

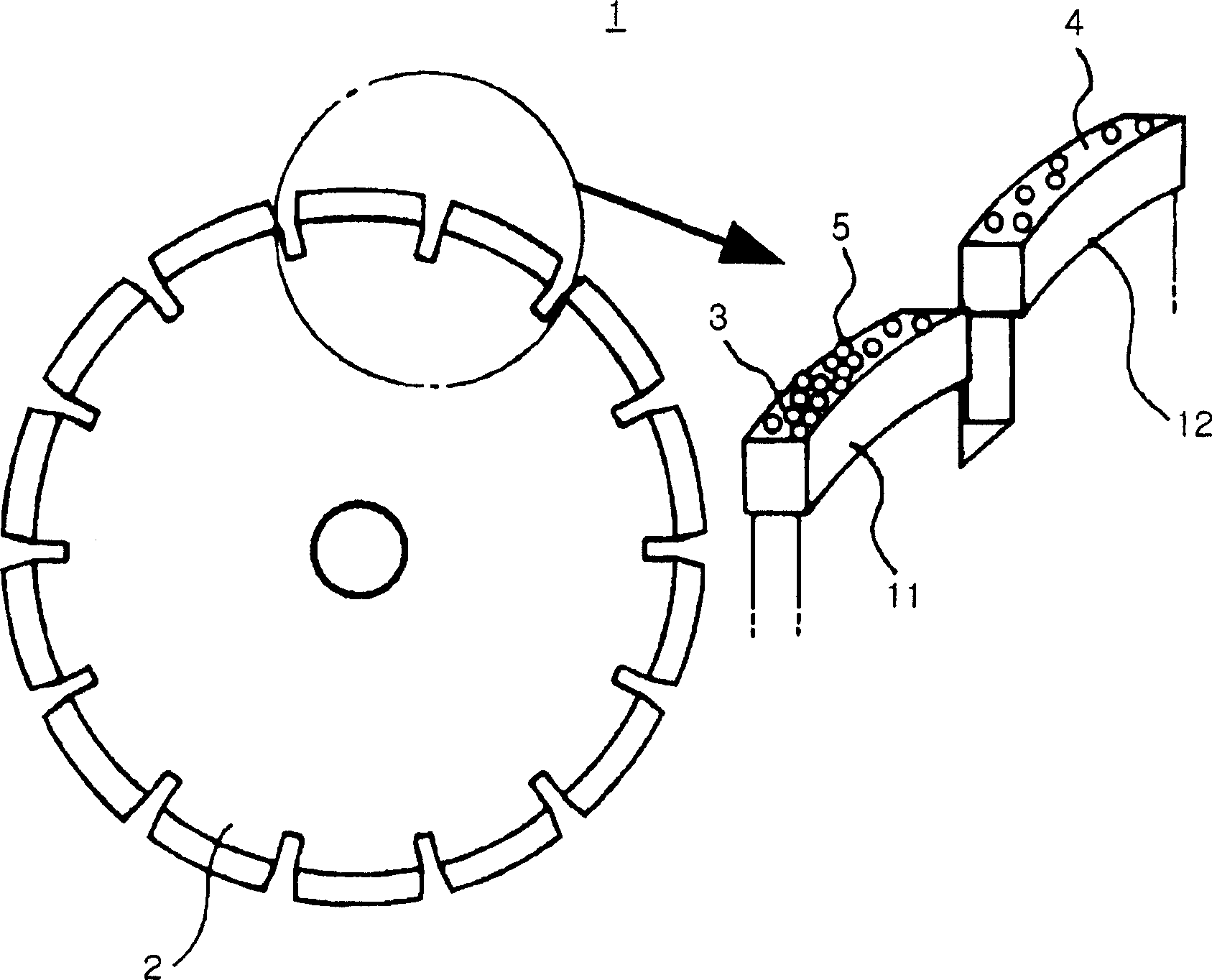

Cutting segment, method of manufacturing cutting segment, and cutting tool

ActiveCN1774311AStrong cutting forceSimplify the manufacturing processMetal sawing toolsBonded abrasive wheelsManufacturing cost reductionBrick

Disclosed are: a cutting insert for a cutting tool for cutting or drilling brittle workpieces such as stone, brick, concrete and asphalt; a method of manufacturing the insert; and a cutting tool provided with the insert. The blade comprises: a plurality of plate-like metal matrix layers laminated perpendicularly to the cutting surface of the blade while being parallel to the cutting direction of the blade, the plate-like metal matrix layers are integrated with each other and made of iron or made of non-ferrous material; and diamond particle layers, which are arranged between the plate-shaped metal matrix layers, so that the diamond particles can be arranged in an array on the cutting surface. The insert has excellent cutting ability and can be manufactured through a simplified manufacturing process, thereby significantly reducing manufacturing costs.

Owner:NIWA DAIYAMONDO INDS +1

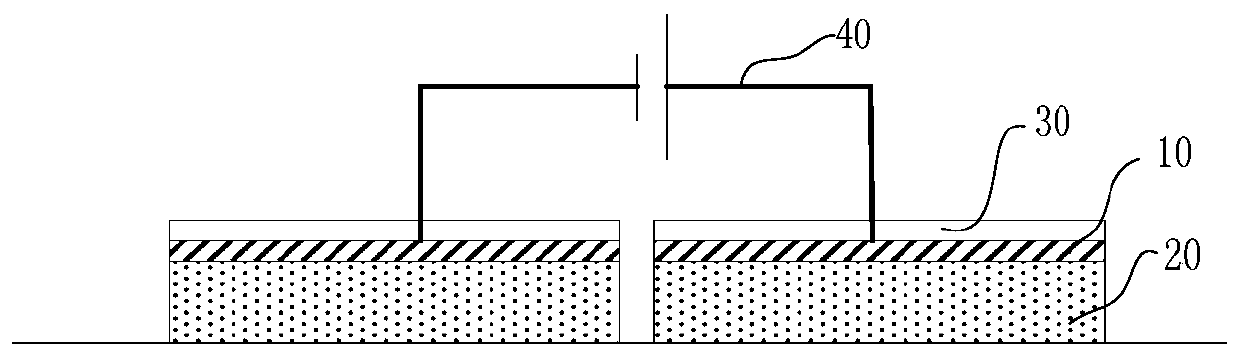

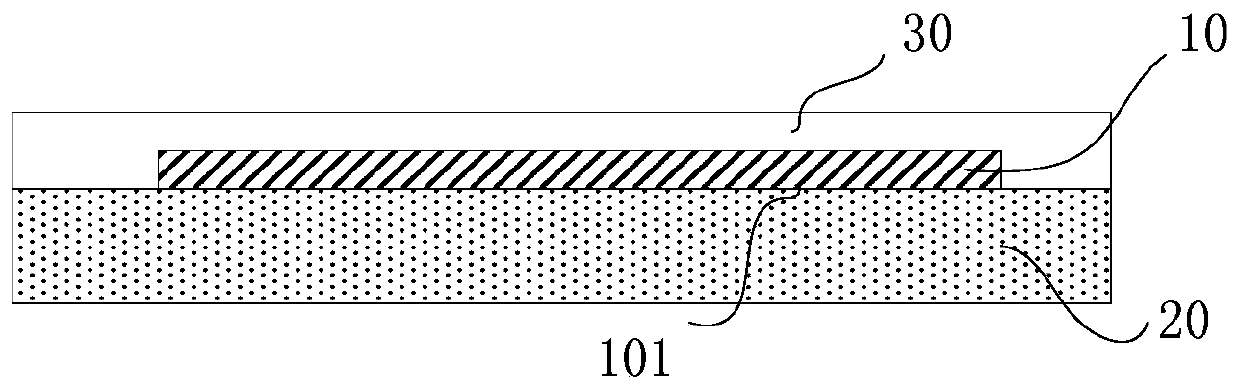

Conductive hydrogel electrical stimulation patch and preparation method and application thereof

PendingCN109771820AImprove fitGood flexibilityDiagnostic signal processingSensorsElectricityMedicine

The invention discloses an electrical stimulation patch which is of a lamellar structure. The patch comprises lamellar electronic epidermis and a conductive polymeric material layer, wherein the electronic epidermis is arranged in an intermediate layer of the electrical stimulation patch, and one side of the electronic epidermis is a discharge surface facing the human body. The discharge surface makes contact with the conductive polymeric material layer. The electric stimulation patch of the invention can uniformly stimulate the covered area, and the discharge effect is good.

Owner:CHENGDU ROUDIAN YUNKE SCI & TECH CO LTD

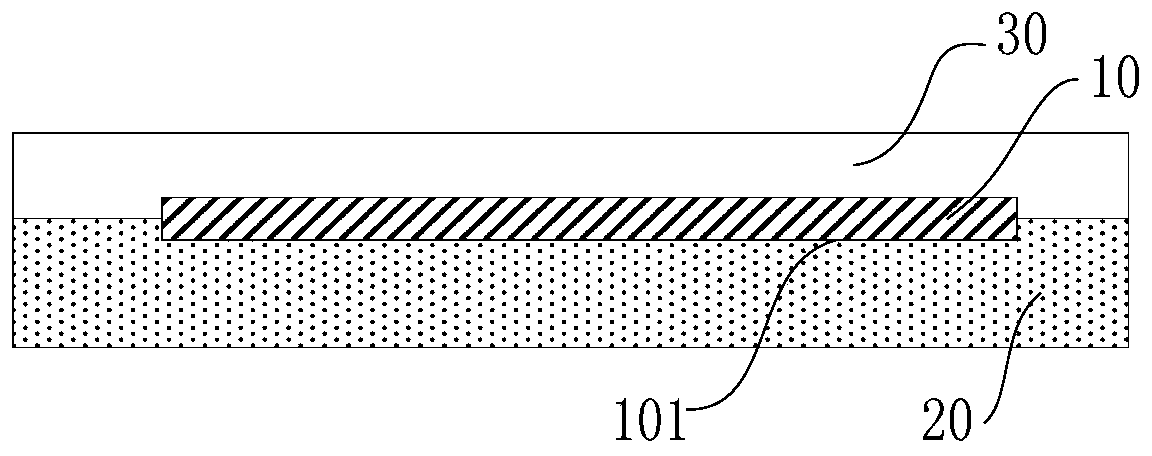

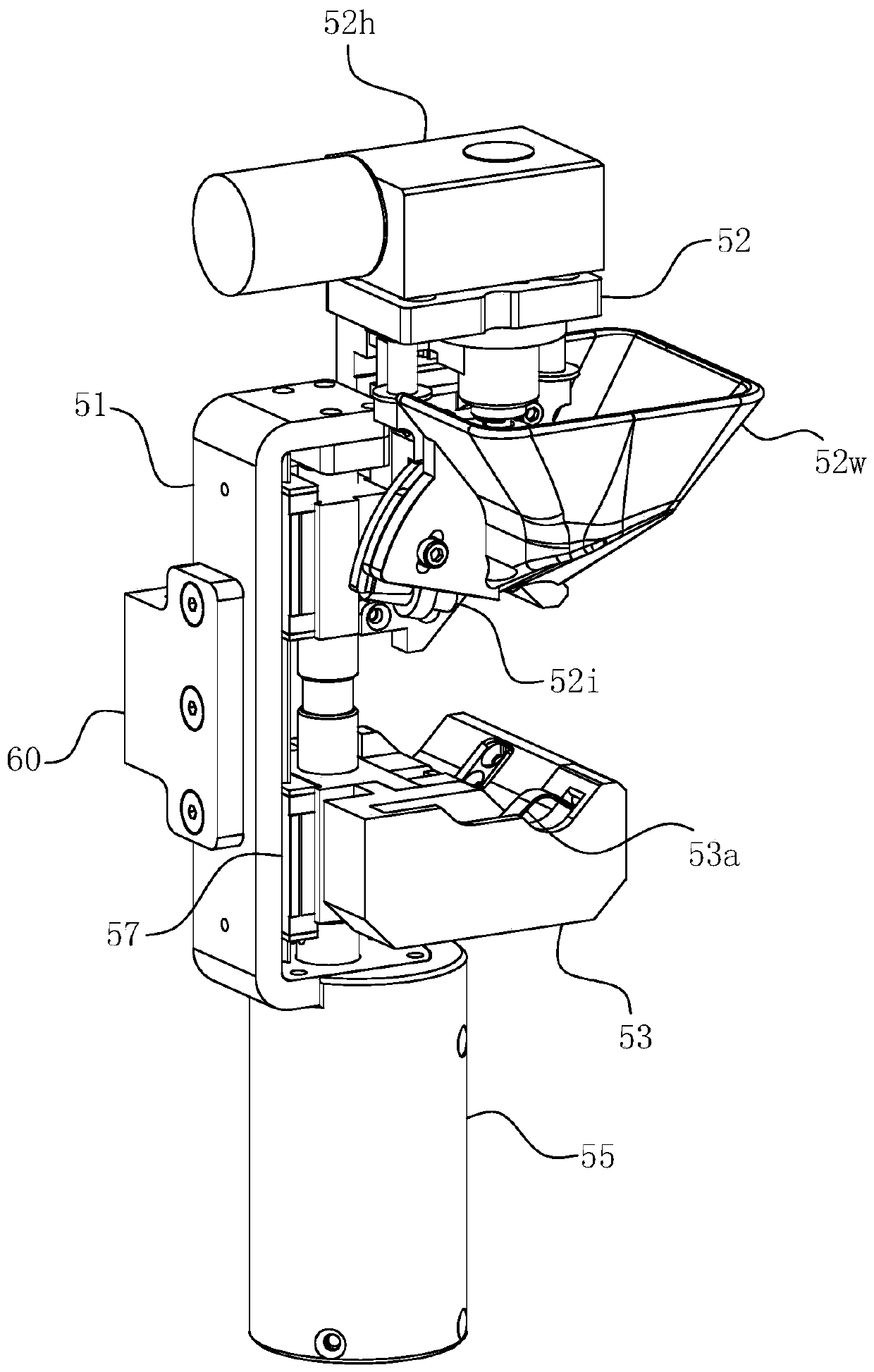

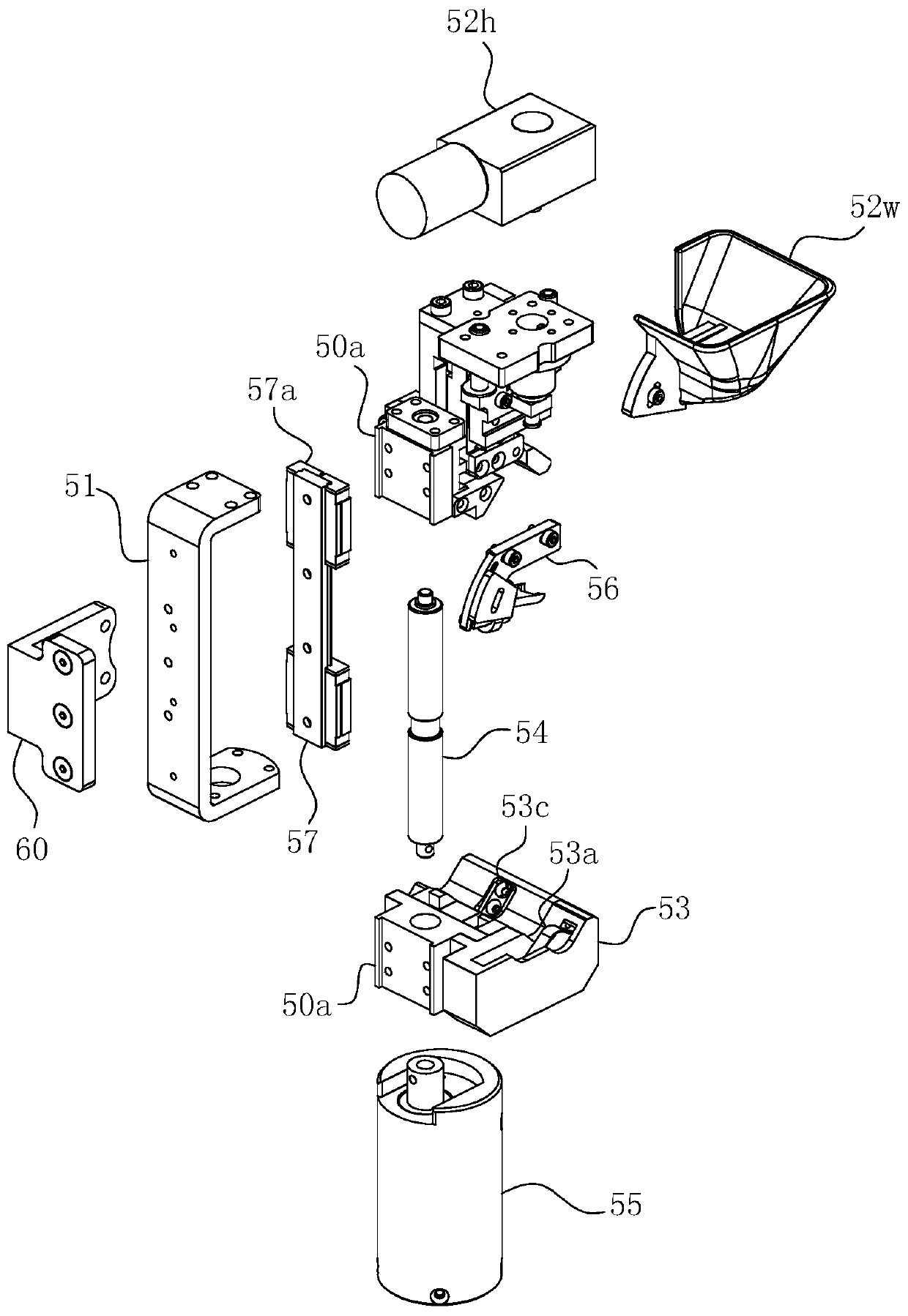

Foldable internal-cutting removing device for minimally invasive operation excision objects

InactiveCN101721239ATraumaMinimally invasive treatment is effectiveSuture equipmentsInternal osteosythesisOperations securityEngineering

The invention discloses a foldable internal-cutting removing device for minimally invasive operation excision objects. The device comprises three layers, wherein the outer layer is a transparent isolation bag, the middle layer is a cutting layer, and the inner layer is a transparent protecting layer. Two rack wires are movably connected, are perpendicular after axially rotating for unfolding, and are parallel after being folded. Each rack wire is provided with a pair of mutually perpendicular circular rings at the interval of 0.5-1mm. The pair of circular rings respectively guide cutting wires which are parallel with or perpendicular to the rack wires. The front ends and the tail ends of the cutting wires in the same travelling direction are respectively collected on two operating rods. When in use, two operators in opposite positions lift the corresponding operating rods, and cut the minimally invasive operation excision objects in the cavity into horizontal strips at one time by utilizing the net-shaped multiple wire saw cutting principle, therefore, the invention is convenient for the operators to remove the excision objects out of narrow cavascope or endoscope holes one by one, and has the advantages of small invasion, monitor and control under scopes, high operation safety and the like.

Owner:XI AN JIAOTONG UNIV

Cutting insert and cutting tool, and cut workpiece manufacturing method using same

ActiveCN102548694ASuitable for curlImprove discharge effectMilling cuttersMilling equipment detailsMechanical engineeringReference plane

A cutting insert is provided with an upper surface, a lower surface, side surfaces, and cutting edges located respectively at the intersection lines between the upper surface and the side surfaces, and comprises a main cutting edge, a flat cutting edge, and an auxiliary cutting edge that is located between the main cutting edge and the flat cutting edge. In a side view, the cutting edge inclines upward with respect to a reference plane perpendicular to the center axis of the cutting insert, starting from the flat cutting edge toward the main cutting edge, until a top section is reached, whereupon the cutting edge inclines downward with respect to the reference plane, and the outer peripheral cutting edge angle of the auxiliary cutting edge is larger than the outer peripheral cutting edge angle of the main cutting edge. Provided are a cutting tool equipped with the cutting insert, and a cut workpiece manufacturing method using the cutting tool.

Owner:KYOCERA CORP

Fluorine doping method of cerium-based rare earth polishing powder

InactiveCN104419378AAdd evenlyEasy to control particle sizeOther chemical processesPolishing compositions with abrasivesFiltrationCerium

The invention discloses a fluorine doping method of cerium-based rare earth polishing powder. The fluorine doping method comprises the following steps: (1) respectively preparing a cerium-based rare earth salt solution, a precipitator and a fluorinating agent; (2) adding the rare earth salt solution, the precipitator and the fluorinating agent into a reaction kettle through parallel flow at a certain flow velocity, controlling the pH of the reaction system through controlling the flow velocity of the precipitator, controlling the fluorine doping proportion through controlling the flow velocity of the fluorinating agent, keeping a certain temperature in the reaction process, stirring violently, carrying out ageing after the reaction, and carrying out filtration, cleaning and drying on the sizing agent to obtain a cerium-based rare earth polishing powder precursor; and (3) calcining the prepared cerium-based rare earth polishing powder precursor, and carrying out natural cooling in the furnace to obtain the cerium-based rare earth polishing powder material. The fluorine doping method is simple in process, convenient to operate and suitable for industrial production. The cerium-based rare earth polishing powder prepared through the method is spherical in particle shape and controllable in particle size of product; and products with different particle sizes and different particle size distributions can be prepared according to the requirements of rare earth polishing powder with different applications.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

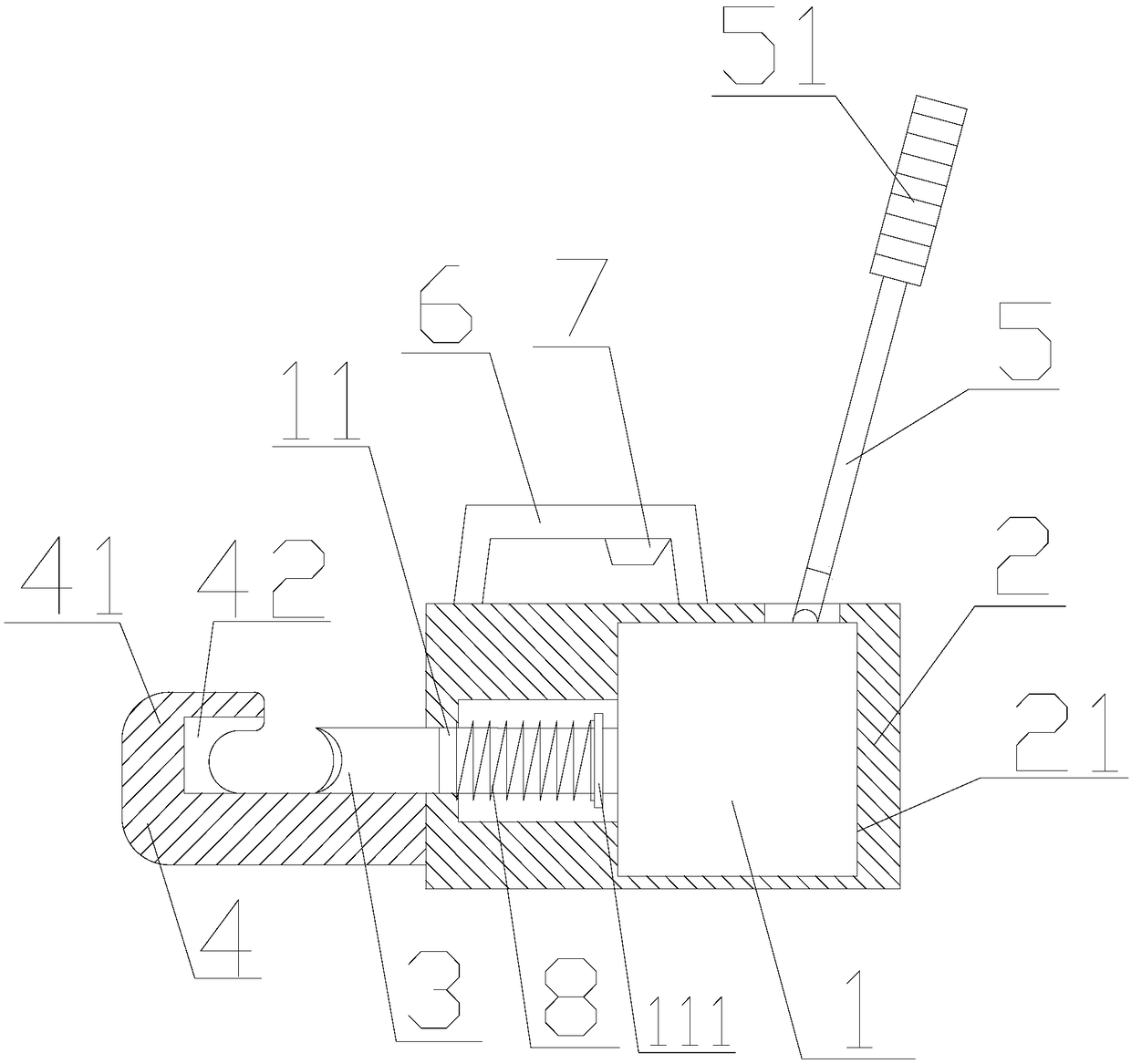

Automatic stripper

PendingCN110676767ALow rotational resistanceImprove convenienceApparatus for removing/armouring cablesElectric machineryEngineering

The invention belongs to the technical field of cable stripping, and particularly relates to an automatic stripper. The automatic stripper comprises a stripping clamp and a driving unit, wherein the stripping clamp comprises a rack, an upper clamp base and a lower clamp base; threaded holes are vertically formed in the upper clamp base and the lower clamp base in a penetrating mode, and vertical approaching and separating actions of the upper clamp base and the lower clamp base are achieved through rotating actions of two-way lead screws after the two-way lead screws are in threaded fit with threaded holes and opening and closing driving motors located at the ends of the two-way lead screws; the upper clamp base comprises a zero position reference sliding plate, a cutter depth adjusting sliding block, a pressing plate, a cutter depth adjusting threaded base, an elastic compression damping piece, a cutter depth adjusting bolt, a rotating sleeve, a cutter depth adjusting motor and a wirecore detection sensor. Thus, the purposes of self-adaptive adjustment of the feed amount of the cutter and adaptive opening adjustment of the stripping clamp can be flexibly realized, so that the stripping reliability and the stripping efficiency of the cable are greatly improved.

Owner:HEFEI CAS LANRUI TECH CO LTD +2

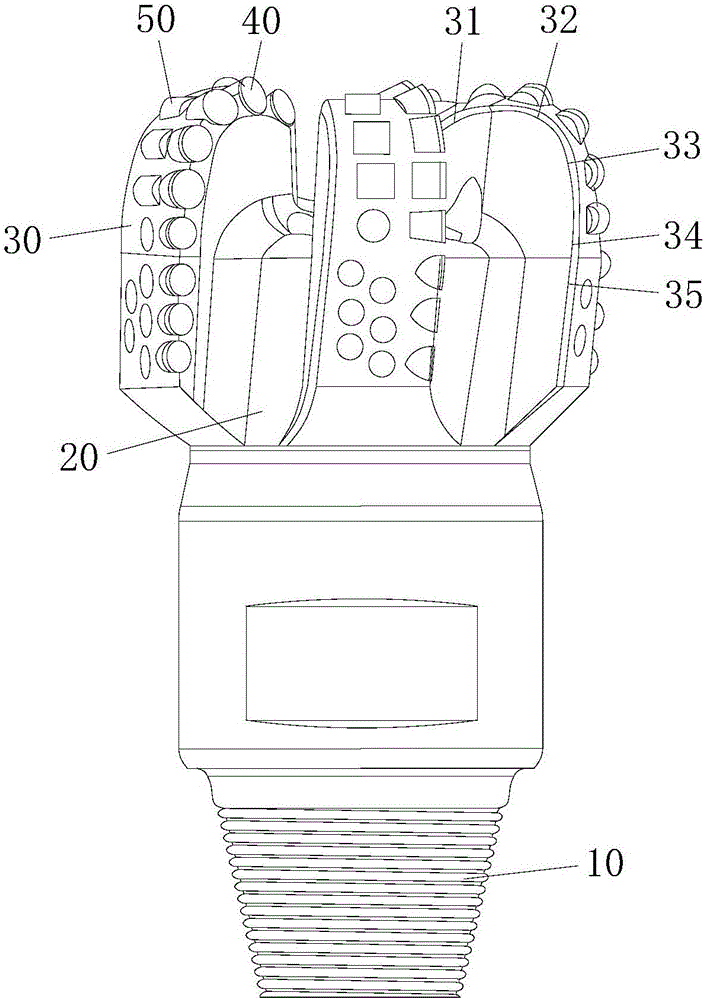

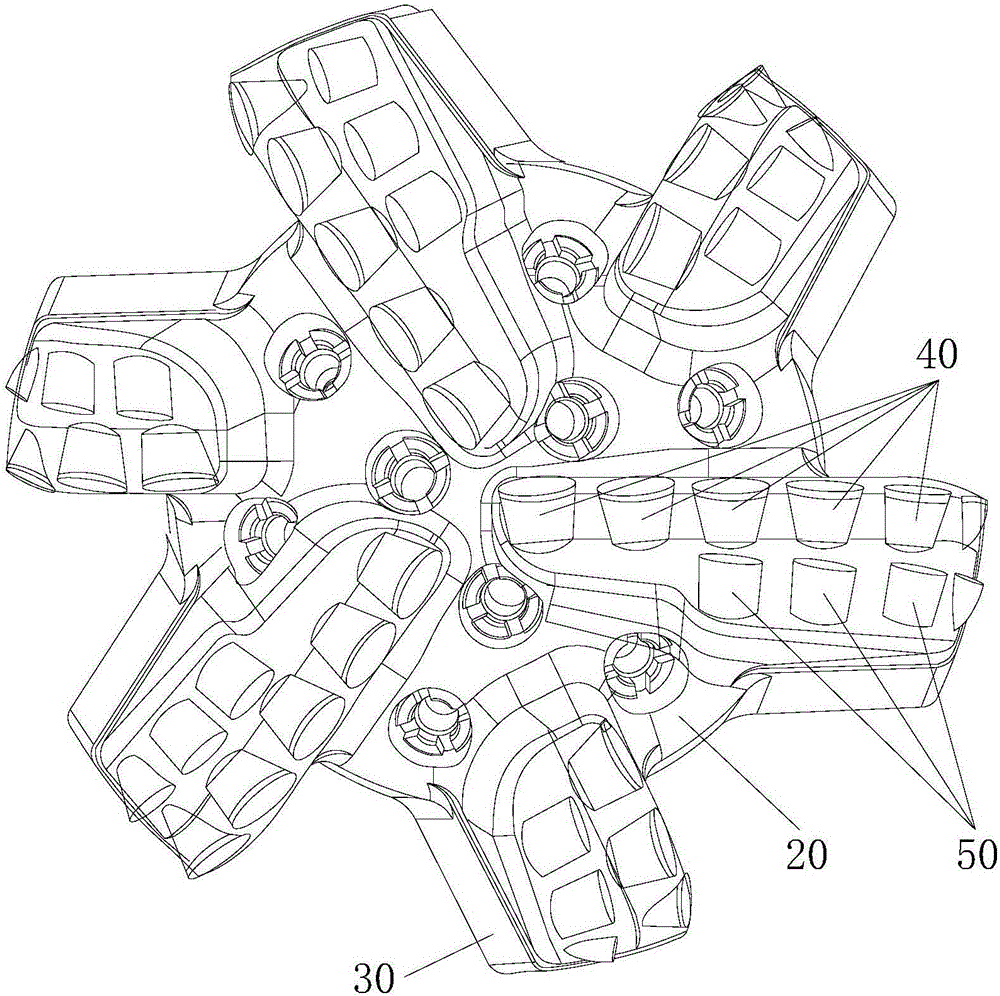

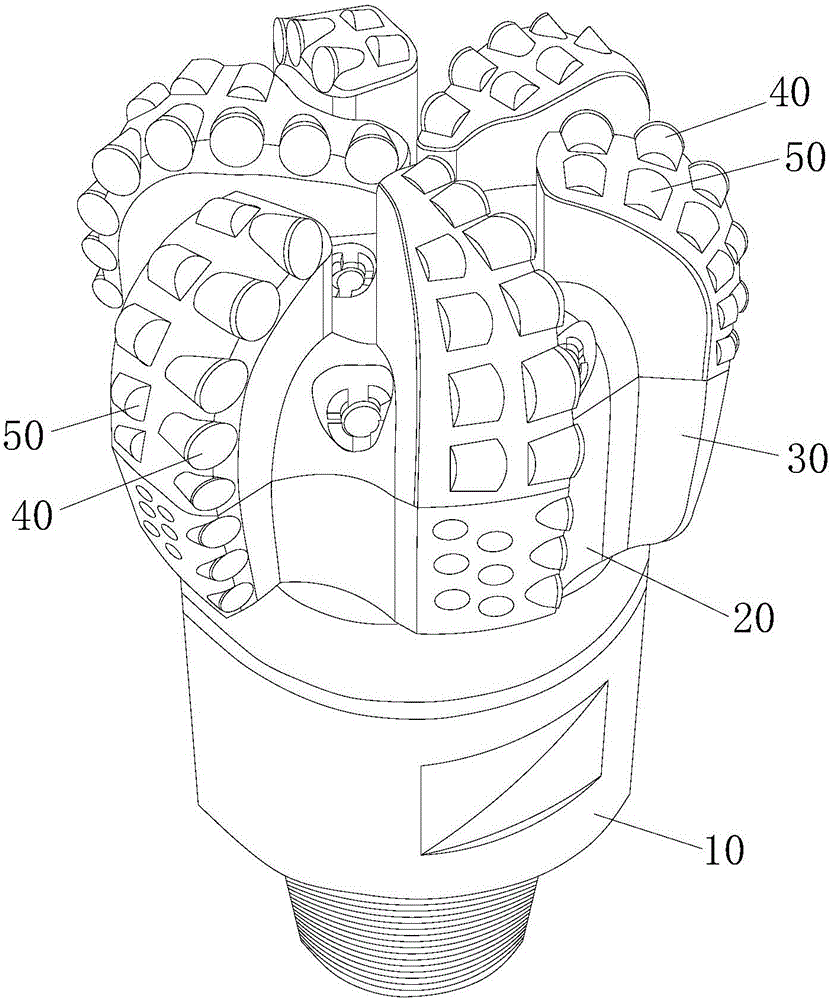

Composite drill bit

InactiveCN106639890AStrong cutting forceImprove rock breaking abilityDrill bitsConstructionsKnife bladesGrinding teeth

The invention provides a composite drill bit. The composite drill bit comprises a columnar connector and a drill bit body connected to the connector. The composite drill bit further comprises at least three knife blades arranged on the drill bit body evenly in the circumferential direction of the drill bit body. All the knife blades extend from inside to outside in the radial direction of the drill bit body. The outer side face of each knife blade is provided with a crown profile which is a curve. The composite drill bit further comprises a plurality of cutting teeth and a plurality of grinding teeth which are all fixedly arranged on the crown profiles. All the cutting teeth are arranged in a row in the extending direction of the knife blades. All the grinding teeth are arranged in a row in the extending direction of the knife blades. The row where all the grinding teeth are located is located behind the row, where all the cutting teeth are located, in the rotary direction of the drill bit body. The peak heights of all the grinding teeth are smaller than that of the cutting teeth on the same circumference. Through the composite drill bit, machine drilling speed and drill bit drilling depth are increased, the service life is prolonged, and the drilling rock breaking efficiency of the drill bit is also improved.

Owner:PETROCHINA CO LTD

Double-shaft shredding machine

The invention discloses a double-shaft shredding machine which comprises a box and a cutter. A crushing cavity is formed in the box. The two ends of the crushing cavity are each provided with an installing plate and a partition plate which are arranged in a spaced manner. A first gap is formed between each installing plate and the corresponding partition plate. The cutter comprises two cutter shafts, cutter bodies and multiple scraping cutter bodies. The two ends of each cutter shaft penetrate the partition plates and are in pivot joint with the installing plates in a bearing manner. Each cutter shaft is fixedly provided with the multiple cutter bodies. A second gap is formed between every two adjacent cutter bodies on each cutter shaft. Each cutter body comprises a cutter base and a cutting blade. The multiple cutting blades are distributed on the cutter shafts in a spiral line manner. Each scraping cutter body comprises a scraping cutter base and a scraping blade. Each scraping blade is arranged in one second gap in a one-to-one corresponding manner. The double-shaft shredding machine is high in cutting force. The scraping blades can be used for removing materials remaining on the cutter shafts, and the cutter shafts can operate more smoothly. Meanwhile, the situation that materials enter a bearing and damage the bearing is avoided.

Owner:GENOX RECYCLING TECH

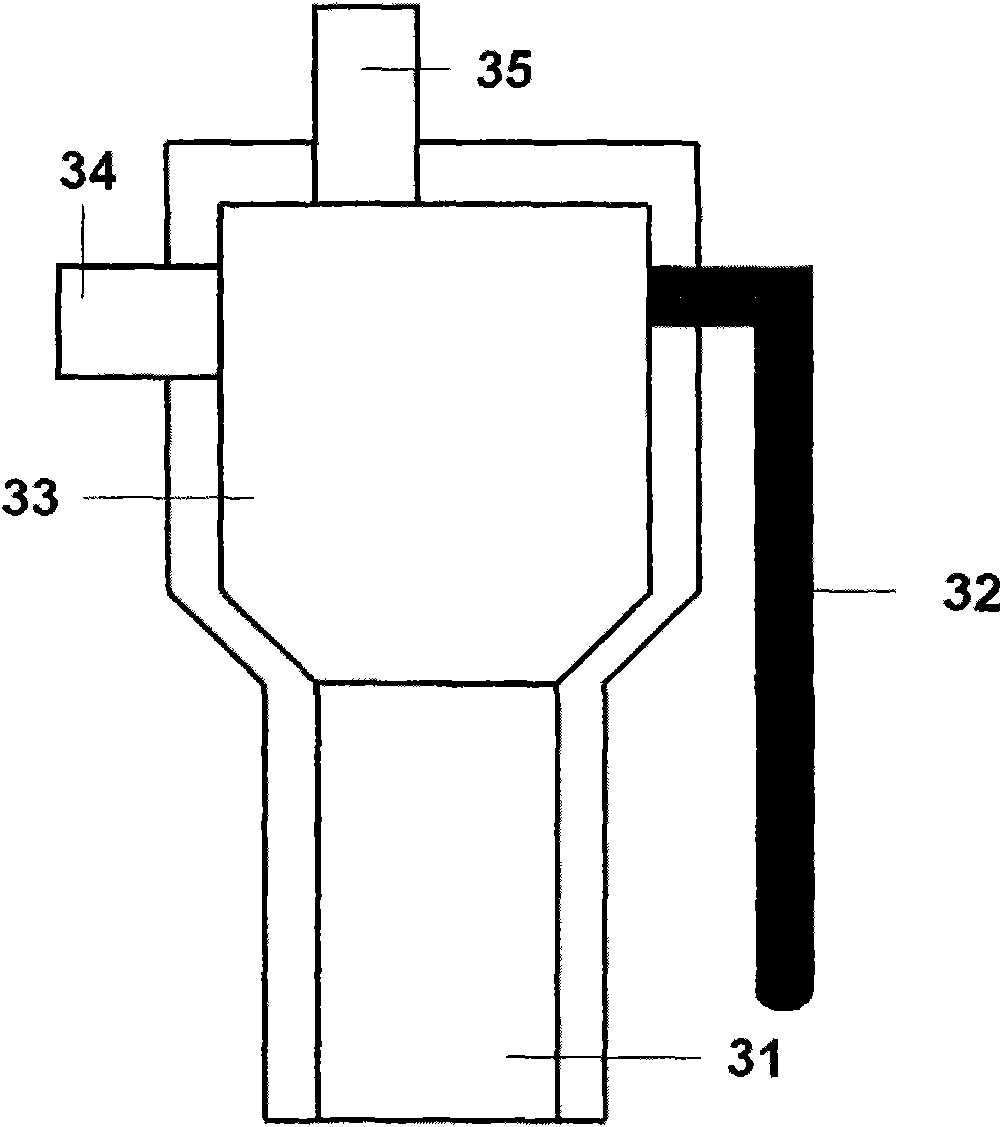

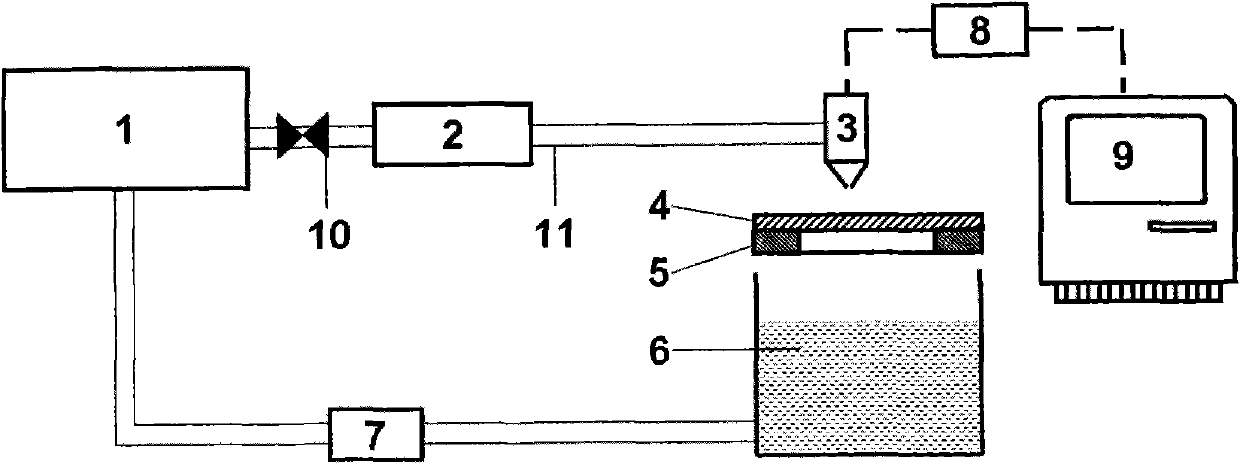

Liquid metal knife cutting system

ActiveCN102554798AAchieve the purpose of cuttingWon't happenAbrasive blasting machinesNumerical controlSpray nozzle

A liquid metal knife cutting system comprises a cutting device, wherein the cutting device comprises a cutting nozzle and a rectification cavity communicated with the upper end of the cutting nozzle. An inlet pipe communicated with the pressure pump outlet through a hose is installed on the lateral wall of the rectification cavity, a miniature camera is installed on an observation hole on the lateral wall of the rectification cavity, and the pressure pump inlet is communicated with the liquid metal storage tank outlet. A workbench is arranged below the cutting nozzle, a recycle container is arranged below the workbench, a connection pipeline at the lower portion of the recycle container is communicated with the storage tank bottom, and a recycle pump is installed on the pipeline of the recycle container. A numerical control table comprises a processor and a data base, wherein the processor is used for calculating relevant cutting parameters in cutting, and the data base is used for recording the cutting parameters corresponding to cutting materials and cutting results. The cutting nozzle of the cutting device is coaxial with a motor shaft, and a motor receives operation commands given out by the numerical control table and controls a cutting path of the cutting nozzle of the cutting device according to the commands to complete cutting of a workpiece to be cut. The cutting system is high in cutting accuracy, stable, low in noise, energy-saving and environment-friendly.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Ceramic bond CBN composite grinding wheel for grinding titanium alloys and preparation method

InactiveCN109465758AHigh bonding strengthImprovement effortsAbrasion apparatusGrinding devicesSurface finishTitanium

The invention belongs to the technical field of grinding, and in particular, relates to a ceramic bond CBN composite grinding wheel for grinding titanium alloys and a preparation method. The compositegrinding wheel comprises a basal body, and a composite patch fixed on the basal body by using an adhesive layer and used for grinding the titanium alloys. Through cooperation between ceramic microcrystal abrasives and CBN abrasives, the composite grinding wheel is prepared, sharp cutting edges can be continuously generated, more chip accommodating space is provided, the heat dissipating effect isimproved, the stable grinding effect is maintained, the finishing amount is reduced, and the production efficiency is improved; and through bonding and holding effects of low-temperature ceramic bondreinforcing abrasives with a specific ratio, the self-sharpening property is better, the chip accommodating space is larger, and the surface smoothness of grinded workpieces is further improved. Based on brand new raw material formulas, the preparation method forms a stable grid structure through low-temperature ceramic bonds, the CBN abrasives and the ceramic microcrystal abrasives to improve the mechanical strength of the composite grinding wheel.

Owner:SUZHOU FAR EAST ABRASIVES

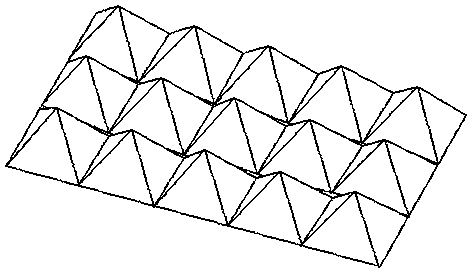

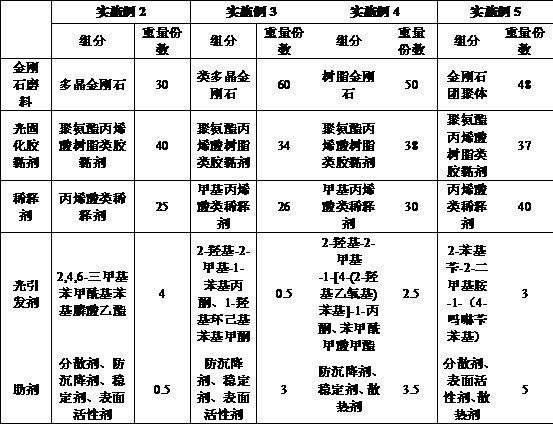

Pyramid-type solid grinding tool for grinding metallic middle frame of mobile phone and preparation method

InactiveCN108481217AEasy to processImprove sanding effectBonded abrasive wheelsGrinding devicesAdhesiveSolid structure

The invention discloses a pyramid-type solid grinding tool for polishing a metallic middle frame of a mobile phone. The pyramid-type solid grinding tool comprises a soft substrate disposed on a bottomlayer, wherein a plurality of pyramids projecting upwardly and formed by curing a diamond slurry are arranged on the soft substrate; the diamond slurry is prepared from, by weight, 30-60 parts of diamond abrasive, 30-60 parts of photocurable adhesive, 20-40 parts of diluent, 0.5-5 parts of photoinitiator and 1-5 parts of adjuvant. The present invention employs intaglio printing and photocuring techniques to coat diamond slurry onto a mold having a pyramid structure, after photocuring, to a soft substrate to obtain a soft base diamond abrasive tool having a pyramid-type stereo structure a softsubstrate diamond grinding tool having a pyramid-type solid structure is obtained by coating a mold having a pyramid structure with the diamond slurry, performing photocuring, and transferring the diamond slurry subjected to photocuring to the soft substrate with intaglio printing and photocuring techniques, and the grinding tool can be applied to polishing operation in a high-strength metallic middle frame of the mobile phone, and the processing cost can be reduced on the basis of bringing convenience for processing, improving product polishing effect and increasing processing yield.

Owner:河北思瑞恩新材料科技有限公司

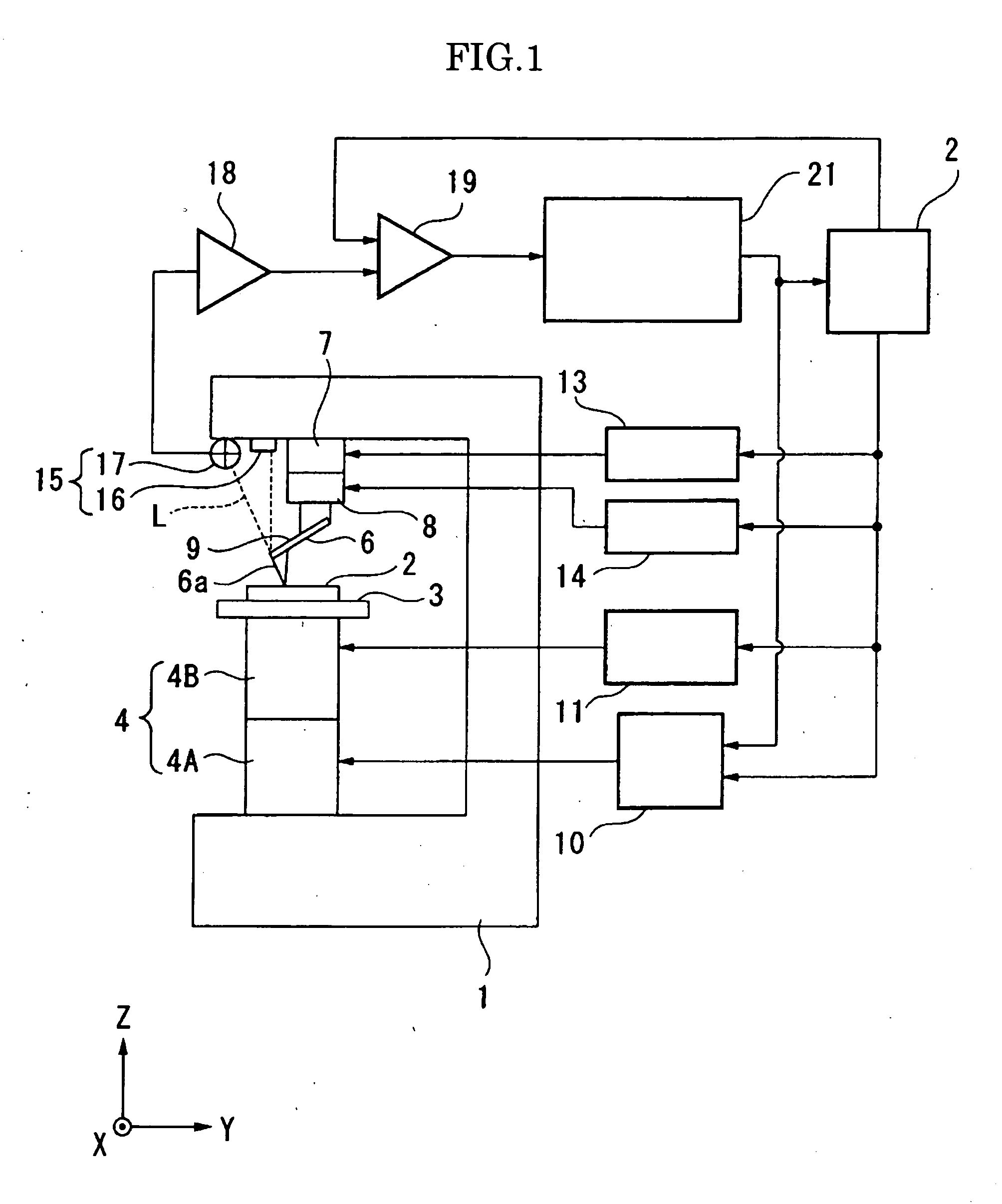

Working method using scanning probe

InactiveUS20060219901A1Reduced life-timeStrong cutting forceNanostructure manufactureMaterial analysis using wave/particle radiationCantileverLow frequency

The present invention provides a working method using a scanning probe which can enhance a working speed and prolong a lifetime of the probe. The present invention provides the working method using a scanning probe which works a sample by performing the relative scanning of a probe supported on a cantilever on the sample at a predetermined scanning speed. The working method can work the object to be worked while forcibly and relatively vibrating the probe in the direction orthogonal to or parallel to a working surface of the sample at low frequency of 100 to 1000 Hz.

Owner:HITACHI HIGH TECH SCI CORP

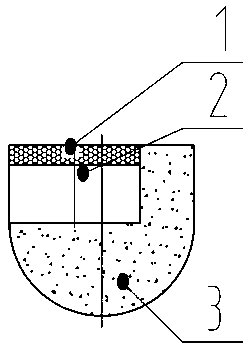

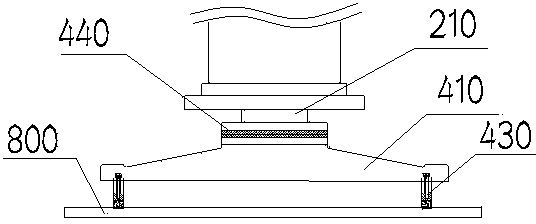

Double-layer net grinding pressing mechanism and double-layer net grinding pressing juice extractor

The invention relates to the technical field of domestic electrical appliance products, in particular to a double-layer net grinding pressing mechanism and a double-layer net grinding pressing juice extractor. The juice extractor comprises a motor box, a motor, a middle cover, a grinding pressing mechanism and an upper cover, wherein the grinding pressing mechanism is composed of a filter screen and a rotor; the filter screen is of a double-layer filter screen structure, and comprises an upper filter screen and a lower filter screen; the rotor comprises an upper coarse grinding part and a lower coarse grinding part; the motor is mounted in the motor box; the middle cover is fixed on the motor box; the filter screen is mounted in the middle cover; the rotor is positioned in the filter screen; the middle cover is covered with the upper cover, and the upper cover is used for hooding the filter screen and the rotor; the rotor is connected to the motor through a rotor shaft. The filter screen and the rotor are designed to form a structure with an upper part and a lower part corresponding to each other, and a grinding pressing structure is newly added through combination; compared with a traditional structure, fruit residues inside the double-layer net grinding pressing mechanism is great in stress, high in juice extraction speed and high in juice yield, the content of fibers is also improved, and the juice extractor has a more obvious juice extraction effect for raw materials with hard shells such as beans.

Owner:东莞溢丰电器有限公司

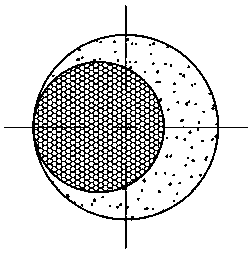

PDC and diamond-impregnated composite block

The invention discloses a PDC and diamond-impregnated composite block, which is composed of a polycrystalline diamond layer, a hard alloy layer and a diamond-impregnated layer. The polycrystalline diamond layer takes diamond micro-powder as a skeleton and cobalt and silicon as an adhesive; and the diamond-impregnated layer is formed by being subjected to hot-pressed sintering or cold-pressed sintering by adopting tungsten carbide, or a combination of the tungsten carbide and one or more of silicon carbide or silicon nitride or titanium carbide as a skeleton, nickel, silicon, chromium, copper,tin, iron, cobalt, zinc, phosphorus and rare earth elements as an adhesive, and diamond monocrystals as a cutting element. Practice proves that the PDC and diamond-impregnated composite block is usedfor a diamond drill bit, the mechanical drill speed and footage of the diamond drill bit are greatly increased, the labor intensity of workers is lowered, then the drilling cost is lowered, and the exploration and development speed of oil and gas fields and mines is increased.

Owner:中石化石油工程技术服务有限公司 +2

High-durability ceramic grinding tool

The invention discloses a high-durability ceramic grinding tool which is characterized by comprising the following components in parts by weight: 11-27 parts of zirconite, 31-50 parts of calcite, 3-14 parts of ethylene copolymer elastomer, 1-9 parts of closed-cell perlite, 15-45 parts of borate glass, 5-17 parts of solid paraffin, 11-25 parts of tourmaline concentrate micropowder, 3-4 parts of molybdenum disilicide, 34-61 parts of spodumene, 11-31 parts of mica, 3-5 parts of zinc oxide, 5-12 parts of ferric sodium pyrophosphate, 1-3 parts of calcium hydrogen phosphate and 5-9 parts of cryolite. The high-durability ceramic grinding tool has the advantages of sharp grinding grains, low trimming frequency, favorable sharpness, low grinding temperature, favorable toughness, low abrasion, high durability and long service life, and can be used for high depth, roughing feed, heavy load and high efficiency grinding.

Owner:QINGDAO XIANGHAI ELECTRONICS

Ultra-thin diamond saw blade made of rare-earth modified tungsten-base binding agent and manufacturing method of ultra-thin diamond saw blade

ActiveCN104148642ASolve temperature problemsSolve defects that are difficult to practical applicationRare-earth elementManganese

The invention discloses an ultra-thin diamond saw blade made of a rare-earth modified tungsten-base binding agent and a manufacturing method of the ultra-thin diamond saw blade. The method includes: fully mixing diamond powder and the rare-earth modified tungsten-base binding agent; subjecting the mixture to cold press molding, and then performing vacuum hot-pressing sintering at the temperature of 900-960 DEG C under the force of 90-200KN for 25-35 minutes; then performing hot isostatic pressing sintering at the temperature of 840-900 DEG C under the pressure of 80-120 Mpa for 5-10 minutes to obtain a crude product of the ultra-thin diamond saw blade; finishing the crude product of the ultra-thin diamond saw blade to obtain a finished product of the ultra-thin diamond saw blade. The rare-earth modified tungsten-base binding agent comprises 40-75 parts of tungsten, 2-6 parts of nickel, 2-5 parts of ferrum, 8-30 parts of stannum, 7-20 parts of copper, 0.4-1 part of manganese and 0.1-1 part of rare earth elements. Holding force of diamond particles can be enhanced remarkably, abrasion resistance of the ultra-thin diamond saw blade is improved, and accordingly processability is improved while service life of the ultra-thin diamond saw blade is prolonged.

Owner:南安华大石材产业技术研究院

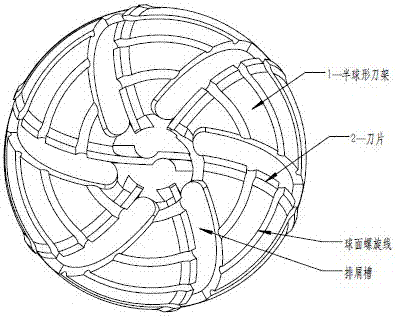

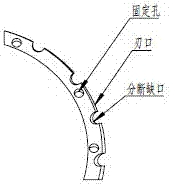

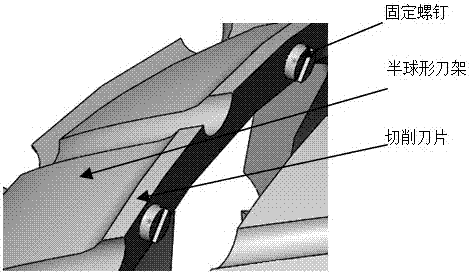

Combined acetabulum file

The invention relates to the technical field of surgery department medical instruments, and discloses a combined acetabulum file. The combined acetabulum file comprises a hemisphere tool rest and detachable blades, the axis of a hemisphere is adopted as the rotating axis of the acetabulum file, 2-5 pairs of cutting blades are mounted on the hemisphere face of the hemisphere, each pair of cutting blades are symmetrically arranged relative to the rotating axis, each cutting edge is divided into 3-6 sections by small gaps on the cutting edge, and the adjacent blades are spirally distributed along the hemisphere face. The cutting edges of the acetabulum file are not likely to be abraded and can be repeatedly used, after the blades are abraded, the blades can be replaced, and the cutting effect is good.

Owner:WUHAN YIJIABAO BIOMATERIAL CO LTD

Method for preparing nanometer tungsten carbide-cobalt hard alloy material

Provided is a method for preparing a nanometer tungsten carbide-cobalt hard alloy material. The raw material comprises, by weight percentage, 30-80% of 50-100 nm of tungsten carbide nanometer powder, 15-65% of 70-100 nm of cobalt nanometer powder and 3-10% of absolute ethyl alcohol. The method comprises a step a of performing ball-milling mixing of the tungsten carbide nanometer powder and the cobalt nanometer powder in an absolute ethyl alcohol medium, controlling the ball-milling rotating speed to be 130-170 r / min, and causing the mixing time to be 2-4 h; a step b of performing granulation; a step c of performing drying, drying the mixture powder at 50-70 DEG C, and causing the time to be 2-3 h; a step d of performing vacuum sintering, causing the sintering temperature to be 1300-1500 DEG C, and causing the time to be 1-5 s. An alloy cutter made of the material is high in compactness and cutting capability and long in service life.

Owner:江苏和田科技材料有限公司

Energy-gathered tile surface polishing machine

InactiveCN104002388AOvercoming profiling defectsDecrease stockStone-like material working toolsDiamond knifeEngineering

Owner:袁子科

Diamond circular saw blade with rare earth modified tungsten-based binding agent and manufacturing method thereof

ActiveCN104128605ASolve temperature problemsSolve defects that are difficult to practical applicationTurbinesOther manufacturing equipments/toolsRare-earth elementManganese

The invention discloses a diamond circular saw blade with a rare earth modified tungsten-based binding agent and a manufacturing method of the diamond circular saw blade with the rare earth modified tungsten-based binding agent. Diamond powder and the rare earth modified tungsten-based binding agent are fully mixed, wherein the rare earth modified tungsten-based binding agent comprises 40-75 parts of tungsten, 2-6 parts of nickel, 2-5 parts of iron, 8-30 parts of tin, 7-20 parts of copper, 0.4-1 part of manganese and 0.1-1 part of rare earth elements; after a mixture is formed in a cold pressing mode, vacuum hot-pressing sintering is carried out for 25-35 minutes under 900-960 DEG C and 140-200 KN; then hot isostatic pressing sintering is carried out for 5-10 minutes under 840-900 DEG C and 80-120 MPa, and diamond circular saw blade segments are obtained; the diamond circular saw blade segments are installed and connected to a circular saw blade base body, and then the diamond circular saw blade is obtained. The hold force of diamond particles can be improved significantly, abrasion resistance of the diamond circular saw blade is increased, and therefore the machining performance of the diamond circular saw blade is improved, and the service life of the diamond circular saw blade is prolonged.

Owner:HUAQIAO UNIVERSITY

Hydraulic shear for coaxial cable cutting

The invention discloses a hydraulic shear for coaxial cable cutting. The hydraulic shear for coaxial cable cutting comprises a hydraulic cylinder, a main machine shell, a main blade, a tool rest and ahydraulic cylinder rocker arm. A hydraulic cylinder mounting cavity is formed in the main machine shell. A hydraulic cylinder is arranged in the hydraulic cylinder mounting cavity. A telescopic arm is arranged on the hydraulic cylinder, the telescopic arm extends to the outside of the main machine shell, the main blade is arranged on the telescopic arm, and the tool rest which can be matched withthe main blade is arranged outside the main machine shell. The tool rest and the main blade form a cutting part, and the hydraulic cylinder rocker arm is arranged at the upper end of the hydraulic cylinder. According to the hydraulic shear for coaxial cable cutting, the hydraulic cylinder is arranged in the main machine shell, the main blade is pushed to move by the hydraulic cylinder, the circular cutting part is formed by the cooperation of the main blade and the tool rest, cables can be directly put into the cutting part, and the cables are cut by the driving force of the hydraulic cylinder. Compared with traditional technology, the hydraulic shear for coaxial cable cutting is convenient to carry, the hydraulic cylinder drives the blade to cut the cables, the cutting force is stronger,the cable cutting quality is improved, and the manpower is saved.

Owner:海盐明杰电子有限公司

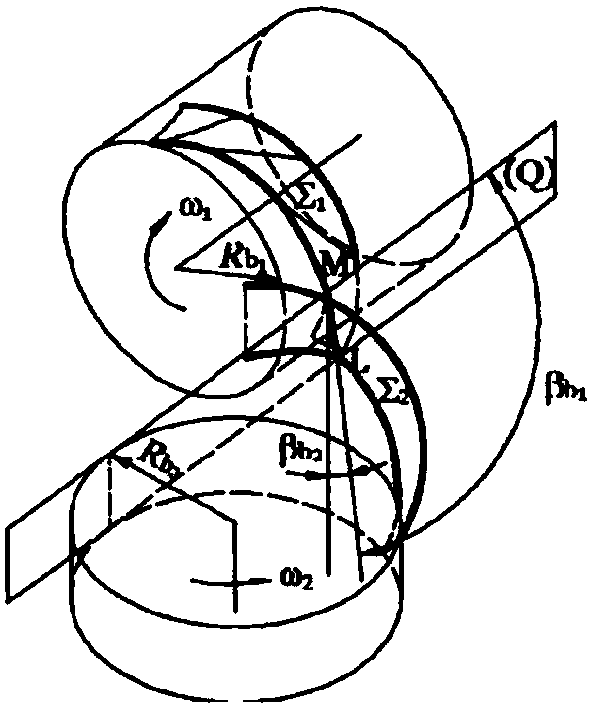

Gear honing machine tool without axial feed and gear honing method

The invention discloses a gear honing machine tool without axial feed and a gear honing method. A left tooth face honing wheel is fixedly connected with a thread at the tail end of a left tooth face honing wheel transmission shaft through a cone hole of the left tooth face honing wheel by means of a first fastening nut; a right tooth face honing wheel is fixedly connected with a thread at the tailend of a right tooth face honing wheel transmission shaft through a cone hole of the right tooth face honing wheel by means of a second fastening nut; a machined gear is placed parallel to a work table, and two cooling hoses are placed close to a grinding area. The left tooth face honing wheel and the right tooth face honing wheel are meshed with the machined helical gear, and the honing qualityand the honing allowance of the honing wheels for the machined helical gear are controlled by adjusting the rotating speed of two servo motors and the relative phase angle phi of the two servo motors.The gear honing machine tool is a special machine tool for finish machining of cylindrical hardened helical gears produced in batches or in large quantities. Compared with other similar machine tools, the gear honing machine tool has the advantages of simple mechanism, convenient operation, and low cost of manufacturing and later maintenance.

Owner:JILIN UNIV

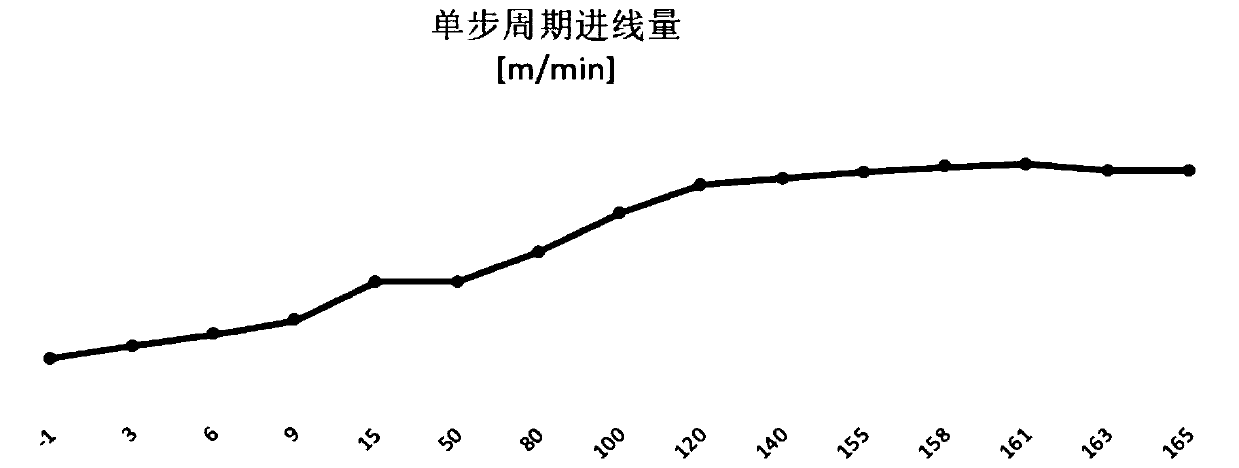

Reverse cutting process for diamond wire

InactiveCN111483067AImprove stabilityAvoid disconnection of pay-off reelFine working devicesWire cuttingEngineering

The invention belongs to the technical field of diamond wire cutting, and particularly relates to a reverse cutting process for a diamond wire. The reverse cutting process comprises the following steps: selecting and cleaning a qualified crystal bar, filling the crystal bar into a clamping guide rail of a cutter workbench, adopting the diamond wire with the diameter of 45 [mu]m-60[mu]m as a cutting wire, spreading a cutting wire net, adding cooling liquid, placing the diamond wire for cutting onto a take-up wheel from a pay-off wheel, setting diamond wire operation speed to be 600 m / min-2100m / min, and setting cutting workbench feeding speed to be 200-3500 [mu]m / min, changing a cutting direction to be reverse cutting from front cutting before cutting, starting a cutter to start cutting, andtaking down the crystal bar by an unloading vehicle after cutting is accomplished. The reverse cutting process adopted by the invention is consistent in cutting direction in the whole process, improves the problem that surface quality and chromatic aberration of a silicon slice is poor, improves silicon slice surface quality, and reduces production cost.

Owner:QINGDAO GAOCE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com