Double-saw slot sawing machine

A technology of slot saw and saw blade, which is applied to earth moving machines/shovels, water conservancy projects, artificial islands, etc., can solve the problems of shallow slot depth, complex structure, expensive equipment, etc., and achieves simple structure and strong effect. , simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

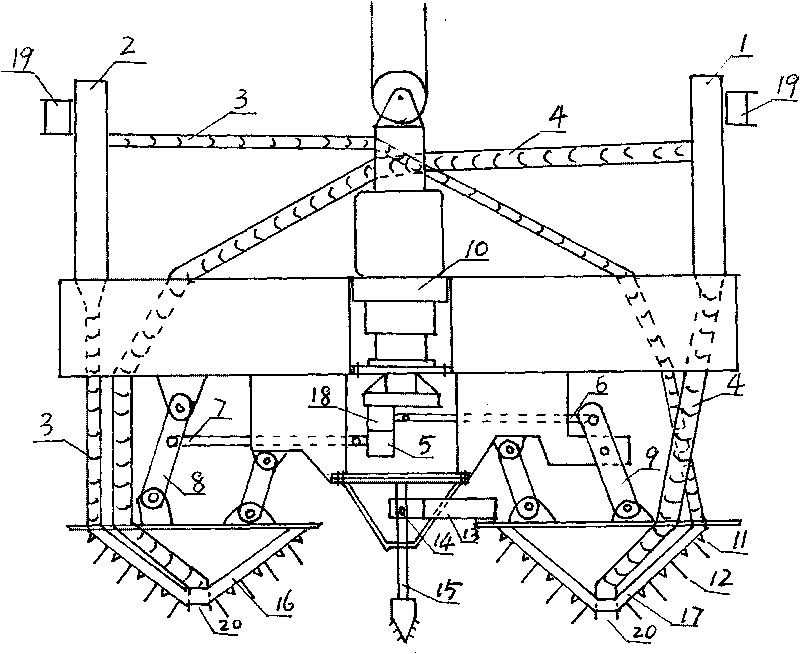

[0014] Accompanying drawing is a kind of specific embodiment of the present invention, specifically tells about through 4 below

[0015] 1. Pipeline layout

[0016] In the groove sawing process of the groove sawing machine of the present invention, the circulation mode of the slurry has positive circulation and reverse circulation, that is, water injection and suction, and the layout of the pipeline is also designed because of the two modes. The water injection pipeline is divided into water inlet pipes (2 ) and the water inlet rubber hose (3), the water inlet pipe is made of steel pipes one by one, and the two ends of each joint are provided with threaded fasteners. The water inlet hose is divided into two branches, each of which feeds water into a group of saw blades, and the water is sprayed out from the water nozzle.

[0017] The suction pipeline is divided into a sand-absorbing pipe (1) and a sand-absorbing rubber pipe (4). The sand-absorbing pipe is arranged in the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com