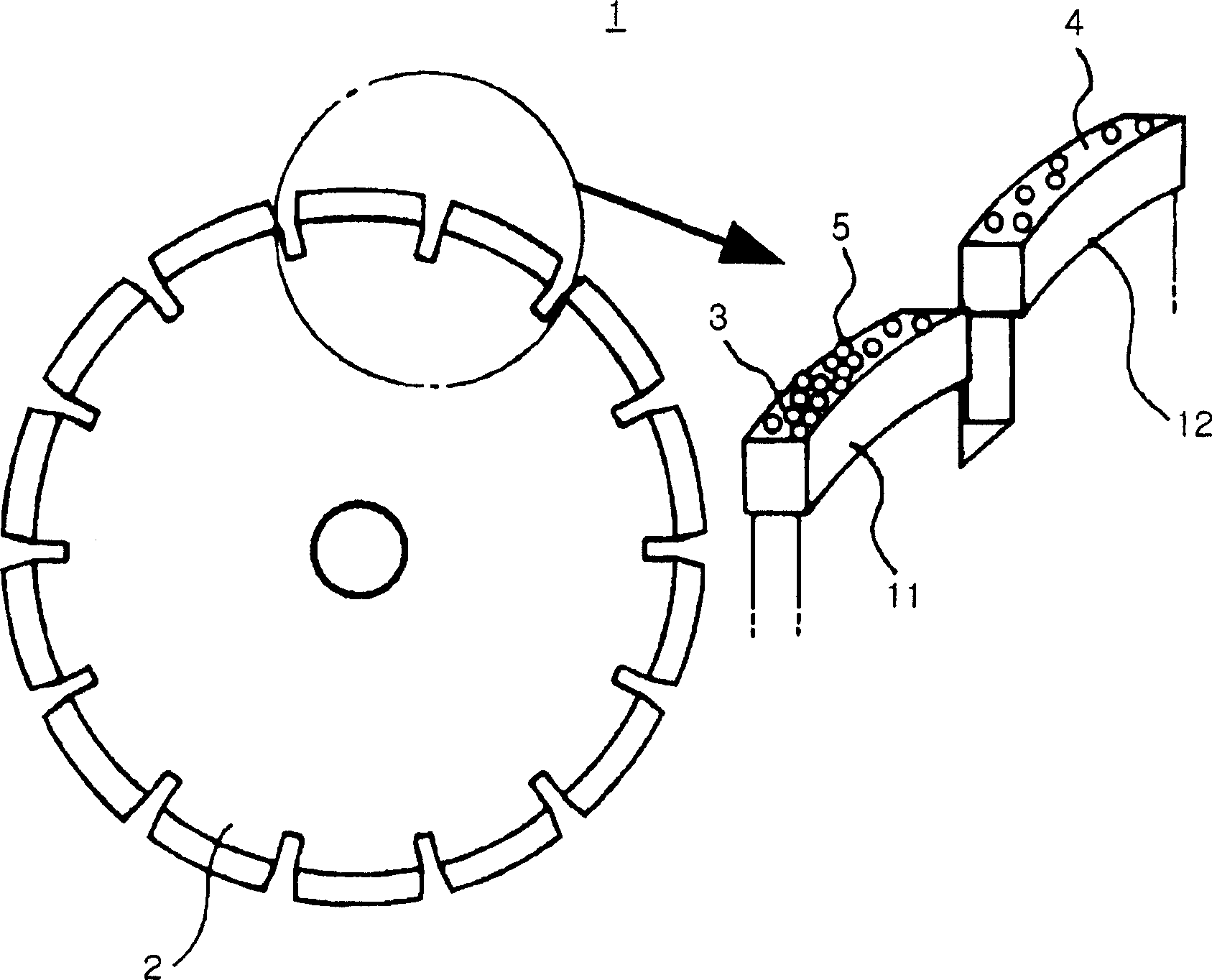

Cutting segment, method of manufacturing cutting segment, and cutting tool

A technology of cutting blades and cutting directions, applied in the direction of manufacturing tools, knives of sawing machine devices, metal sawing equipment, etc., can solve the problems of substrate thickness changes, reduced productivity, and reduced performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0129] In order to investigate the cutting ability and service life of the cutting tool according to the invention, a cutting test was carried out on a saw blade manufactured according to the invention (material 3 according to the invention) and another saw blade manufactured according to a conventional method (conventional material 2), And the test results are shown in Table 2 below.

[0130] In Table 2, the material 3 of the present invention is obtained by laminating together four SK85 steel plates each having a thickness of 0.5 mm and then arranging two metal preforms made of 100% Co between these steel plates and placing A tape with uniformly arranged diamond particles is placed between these metal preforms. Conventional material 2 is manufactured by mixing diamond particles with metal powder.

[0131] The diamond particles used in Example 1 were MBS955 available from GE in the United States.

[0132] Sintering was performed by hot pressing at a sintering temperature of...

Embodiment 2

[0139] The variation of the cutting time depending on the number of cutting cycles was investigated by carrying out a cutting test on washed concrete using saw blades made of the inventive material 3 and the conventional material 2 of Example 1, and at Figure 10 The test results are shown in .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com