PDC and diamond-impregnated composite block

A technology of impregnated diamond and composite blocks, which is applied in the field of PDC-impregnated diamond composite blocks, can solve the problems of low ROP, insufficient life, and large footage, and achieve high ROP, improved life, and strong cutting ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

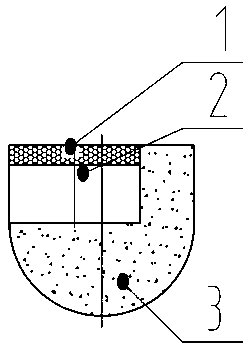

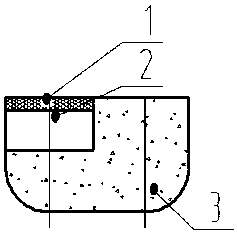

[0026] Example 1, 80 parts by weight of diamond micropowder, 10 parts by weight of cobalt, and 2.5 parts by weight of silicon adhesive in the polycrystalline diamond layer; 0.1 parts by weight of silicon, 1 part by weight of chromium, 15 parts by weight of copper, 1 part by weight of tin, 1 part by weight of iron, 5 parts by weight of cobalt, 1 part by weight of zinc, 0.1 parts by weight of phosphorus and 0.1 parts by weight of rare earth elements are binders, 12 parts by weight of diamond single crystal is used as cutting element. After fully mixing the raw materials required for the impregnated diamond layer 3 and the polycrystalline diamond layer 1, they are added together with cemented carbide materials into wedge-shaped or pyramid-shaped abrasive tools, and sintered at 20 MPa and 700°C.

Embodiment 2

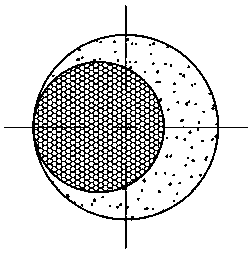

[0027] Example 2, 89 parts by weight of diamond micropowder in the polycrystalline diamond layer, 15 parts by weight of cobalt, and 5 parts by weight of silicon adhesive are sintered at 30 MPa and 1000 ° C; the impregnated diamond layer is formed by 50 parts by weight tungsten carbide and 20 parts by weight of silicon carbide as the skeleton, 10 parts by weight of nickel, 0.5 parts by weight of silicon, 3.5 parts by weight of chromium, 20 parts by weight of copper, 5 parts by weight of tin, 5 parts by weight of iron, 10 parts by weight of cobalt, zinc 2 parts by weight, 0.5 parts by weight of phosphorus and 0.5 parts by weight of rare earth element are used as binder, and 25 parts by weight of diamond single crystal is used as cutting element. After fully mixing the required raw materials for the impregnated diamond layer 3 and the polycrystalline diamond layer 1, they are added together with cemented carbide materials into a cylindrical abrasive tool and sintered at 0.2-0.6 GP...

Embodiment 3

[0028] Example 3, the diamond powder in the polycrystalline diamond layer, 5 parts by weight, 13 parts by weight of cobalt, and 2.5 parts by weight of silicon adhesive, are sintered at 25MPa and 800°C; the impregnated diamond layer is made of tungsten carbide 40 parts by weight is the skeleton, with 11 parts by weight of nickel, 0.3 parts by weight of silicon, 2.5 parts by weight of chromium, 15 parts by weight of copper, 3 parts by weight of tin, 3 parts by weight of iron, 8 parts by weight of cobalt, 1.2 parts by weight of zinc, and 0.25 parts by weight of phosphorus 20 parts by weight and 0.35 parts by weight of rare earth elements are used as binder, and 20 parts by weight of diamond single crystal is used as cutting element. After fully mixing the required raw materials for the impregnated diamond layer 3 and the polycrystalline diamond layer 1, they are added together with hard alloy materials into disc-shaped abrasive tools, and sintered at 30 MPa and 900°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com