Novel ceramic corundum grinding tool of low-temperature and high-strength ceramic bonding agent and preparation method thereof

A ceramic bond, ceramic corundum technology, applied in grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of not meeting the preparation requirements of new ceramic corundum abrasives, losing superior characteristics, and not being able to increase prices, etc. The effect of good shape retention, good self-sharpening and few trimming times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiment.

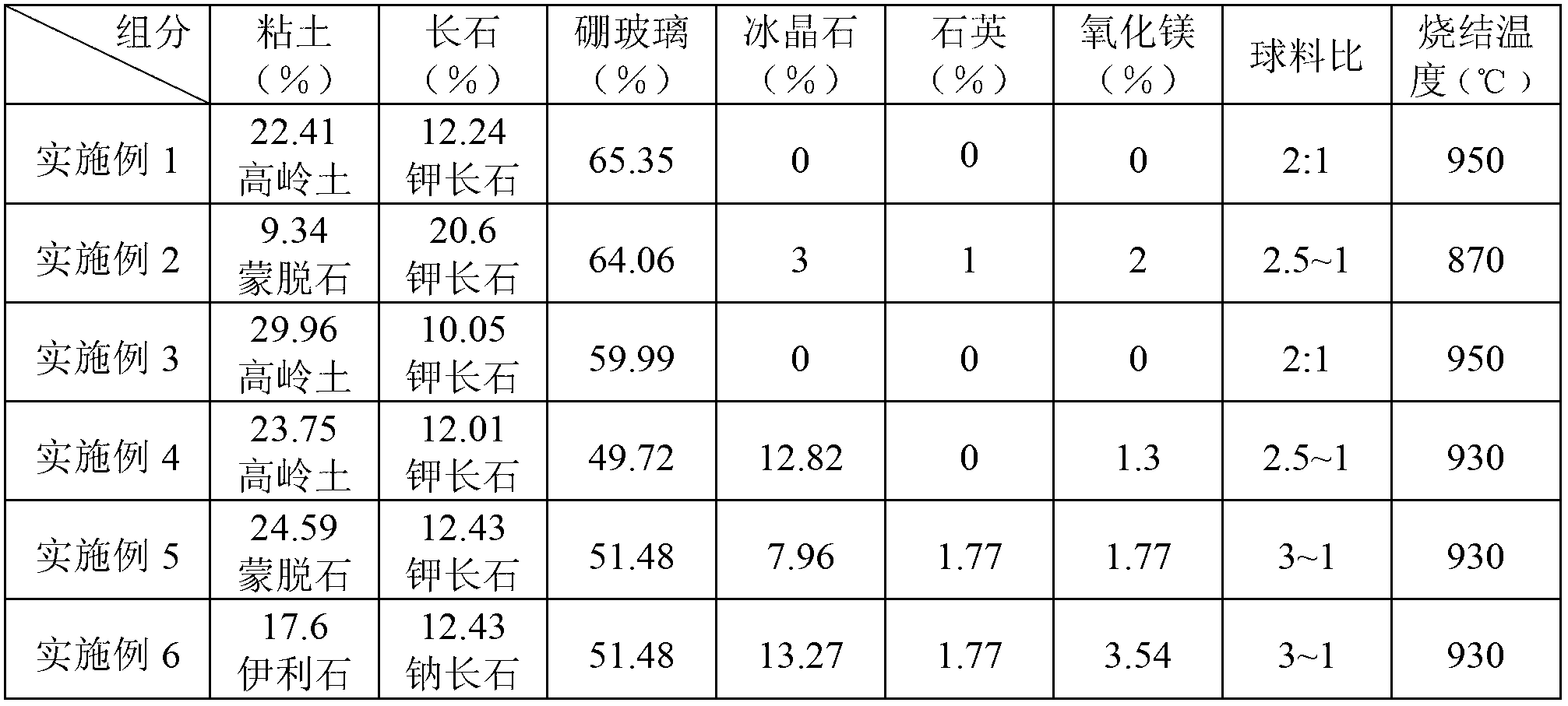

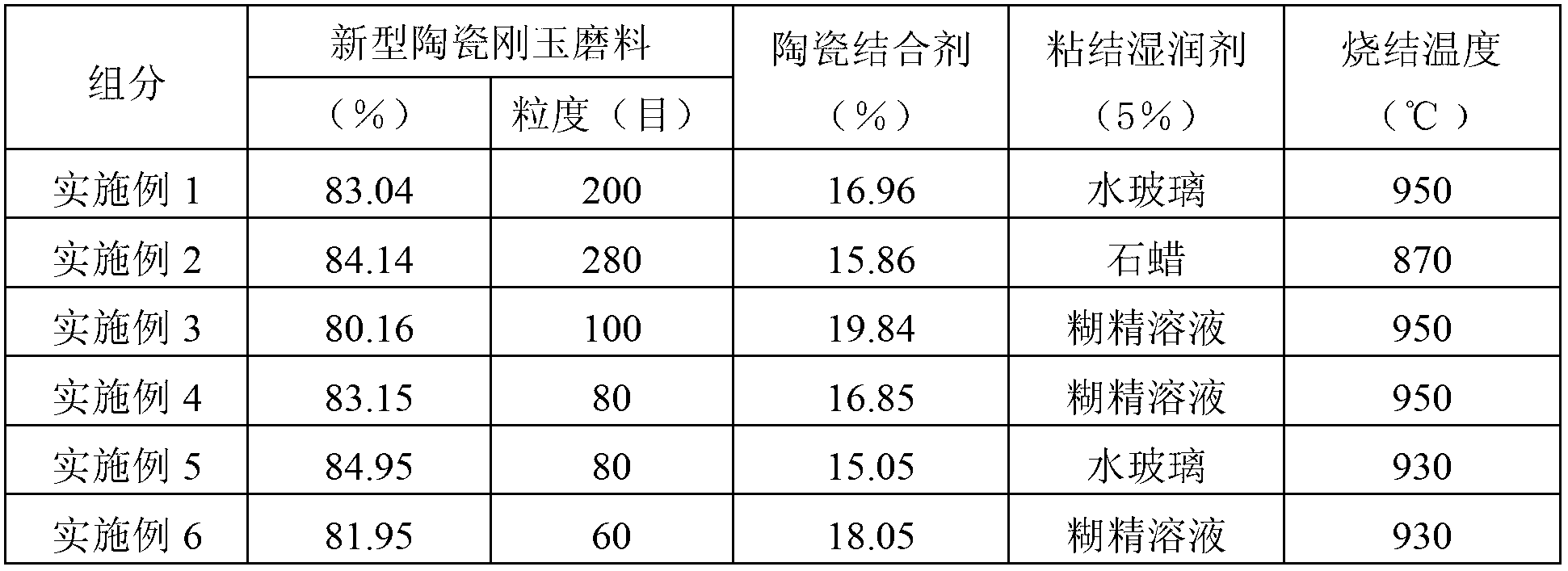

[0033] The present invention uses mineral raw materials, industrial raw materials and conventional preparation methods to firstly prepare vitrified bonding agent.

[0034] Compared with ordinary corundum abrasives, the grain size of the new ceramic corundum abrasives changes at a lower temperature (about 1000°C), which destroys the microcrystalline characteristics of the new ceramic corundum abrasives. Compared with tools, low-temperature sintering is required, that is, the refractoriness of the vitrified bond itself is lower. In addition, since this type of abrasive is usually used for large-cut, slow-feed grinding, the bond itself is required to have a high bonding strength, so as not to cause the abrasive to break during use and cause damage to personnel and machine tools.

[0035] The vitrified bond of the present invention uses minerals as raw materials. After formula calculati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com