Method for preparing resin grinding wheel containing epoxy resin

A resin grinding wheel and epoxy resin technology, applied in the manufacture of tools, abrasives, metal processing equipment, etc., can solve the problems of uneven mixing of fillers and abrasives, difficult mixing of stabilizer fillers, and uneven distribution of resin grinding wheels. The effect of reducing the fatigue strength of the operation, improving the finish and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] To make resin wheel cutting discs:

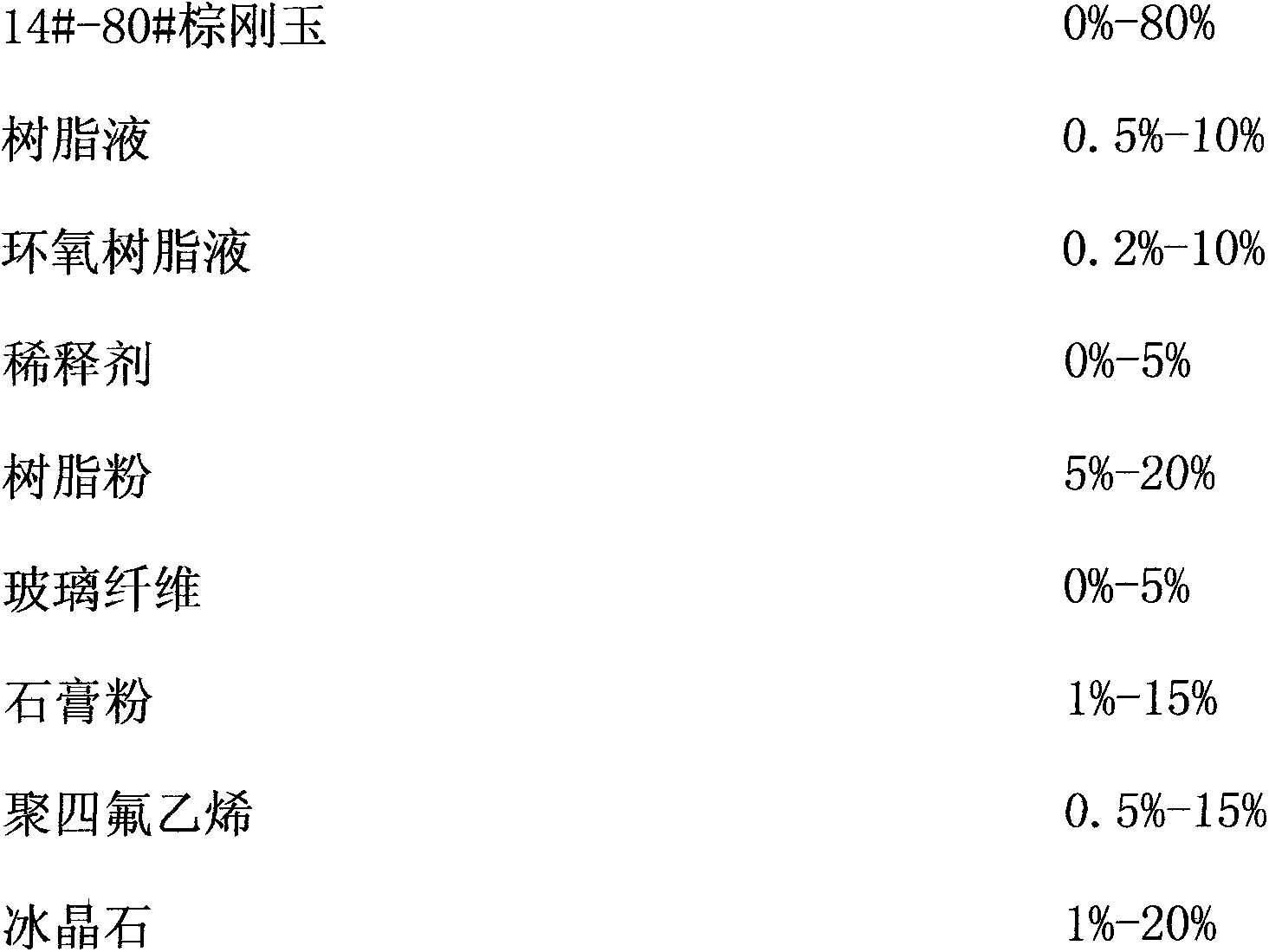

[0020] Select the bonding mixed abrasive with the following ratio, and the ratio is as follows by weight percentage:

[0021]

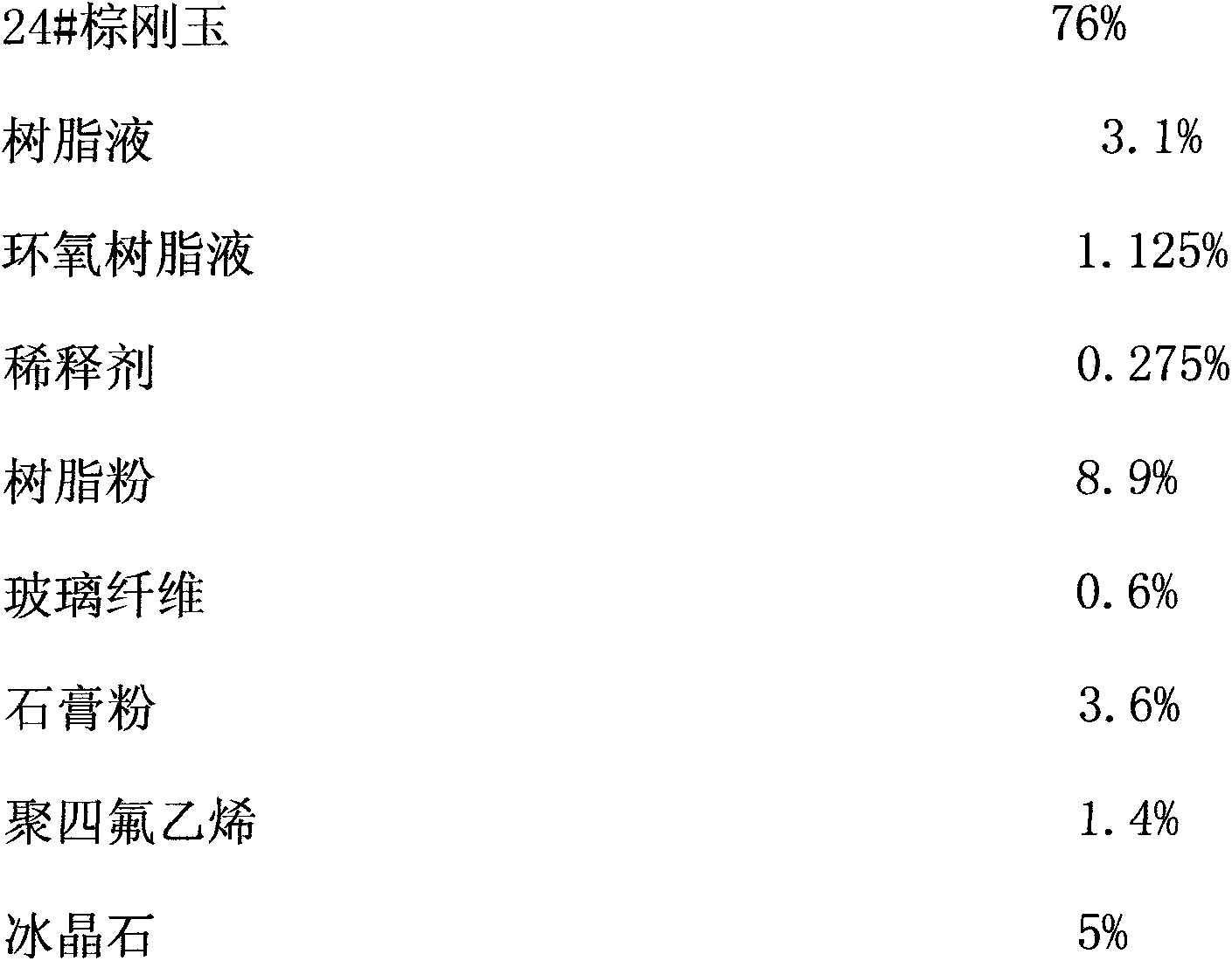

[0022] Its preparation process is as follows:

[0023] Put 24# brown corundum into the mixing pot according to the proportion and weight to mix evenly, then add the mixed solution of resin solution, diluent and epoxy resin solution, after the brown corundum abrasive is completely wetted, add cryolite and polytetrafluoroethylene powder in turn , glass fiber and gypsum powder, after mixing evenly, add resin powder and continue mixing until the powder is evenly attached to each abrasive. Then weigh according to the single weight of the cutting piece and then feed the material. Before feeding, put the grinding wheel mesh, spread the material with a scraper, put a grinding wheel mesh after it is flattened, press the pressure plate to form, and then harden.

Embodiment 2

[0025] To make a resin grinding wheel:

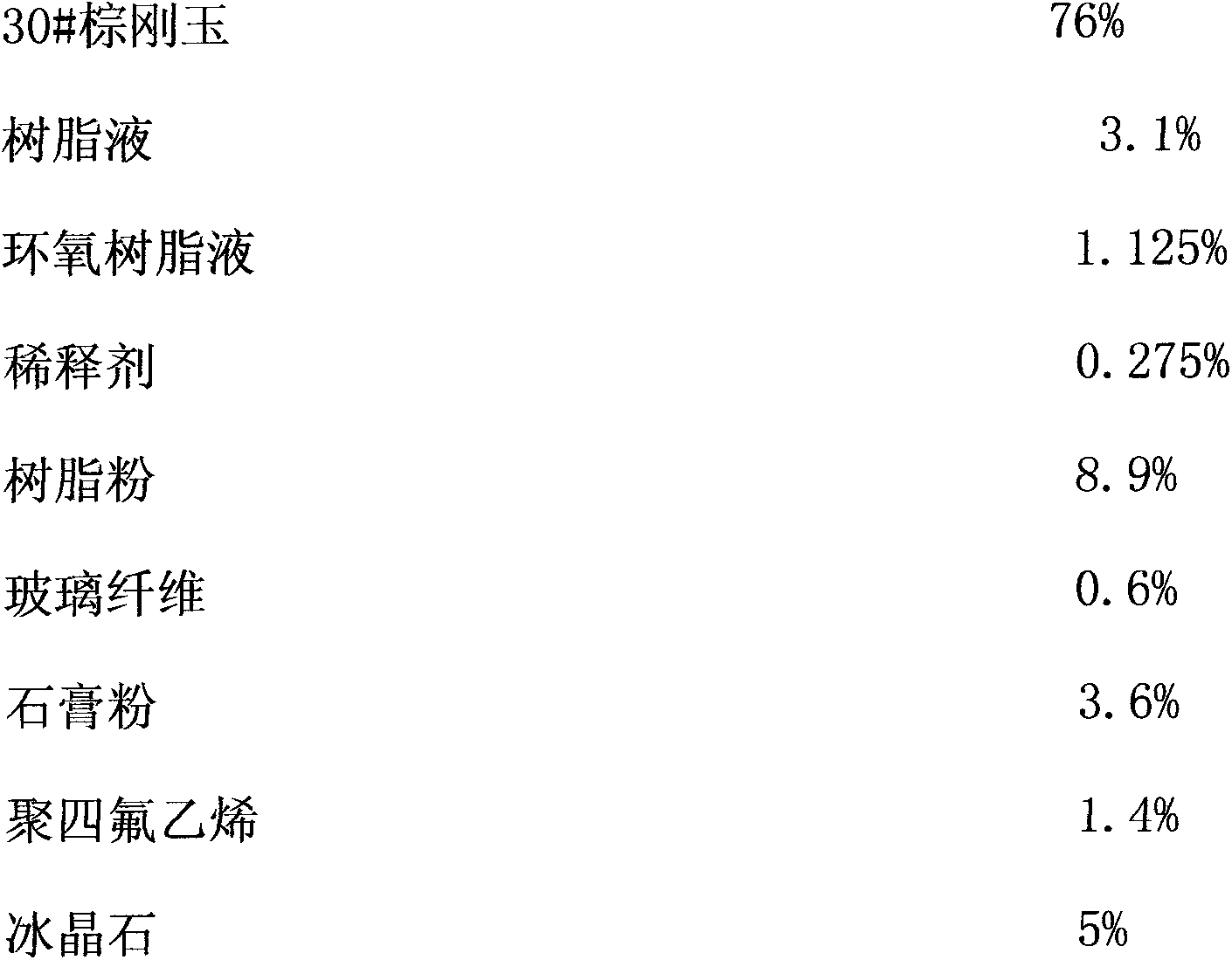

[0026] Resin grinding wheel bonded mixed abrasive formula, the ratio by weight percentage is:

[0027]

[0028] Its preparation process is as follows:

[0029] Put 30# brown corundum into the mixing pot according to the proportion and mix evenly, then add the mixed solution of resin solution, diluent and epoxy resin solution, after the brown corundum abrasive is completely wetted, add cryolite and polytetrafluoroethylene powder in turn , glass fiber and gypsum powder, after mixing evenly, add resin powder and continue mixing until the powder is evenly attached to each abrasive, and place nuts or skeletons on the operating table. Different grinding wheels have different accessories, according to the single weight specification of the grinding wheel , drop into cohesive mixed abrasive, spread the material, scrape, and harden after pressing and forming with a pressing plate, and become the resin grinding wheel of the present invention....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com