Multilayer composite plate for building templates and brick pallets and preparation process thereof

A multi-layer composite and construction formwork technology, which is applied in the direction of manufacturing tools, clay preparation equipment, mixing operation control, etc., can solve the problems of high price, easy deformation, layered cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

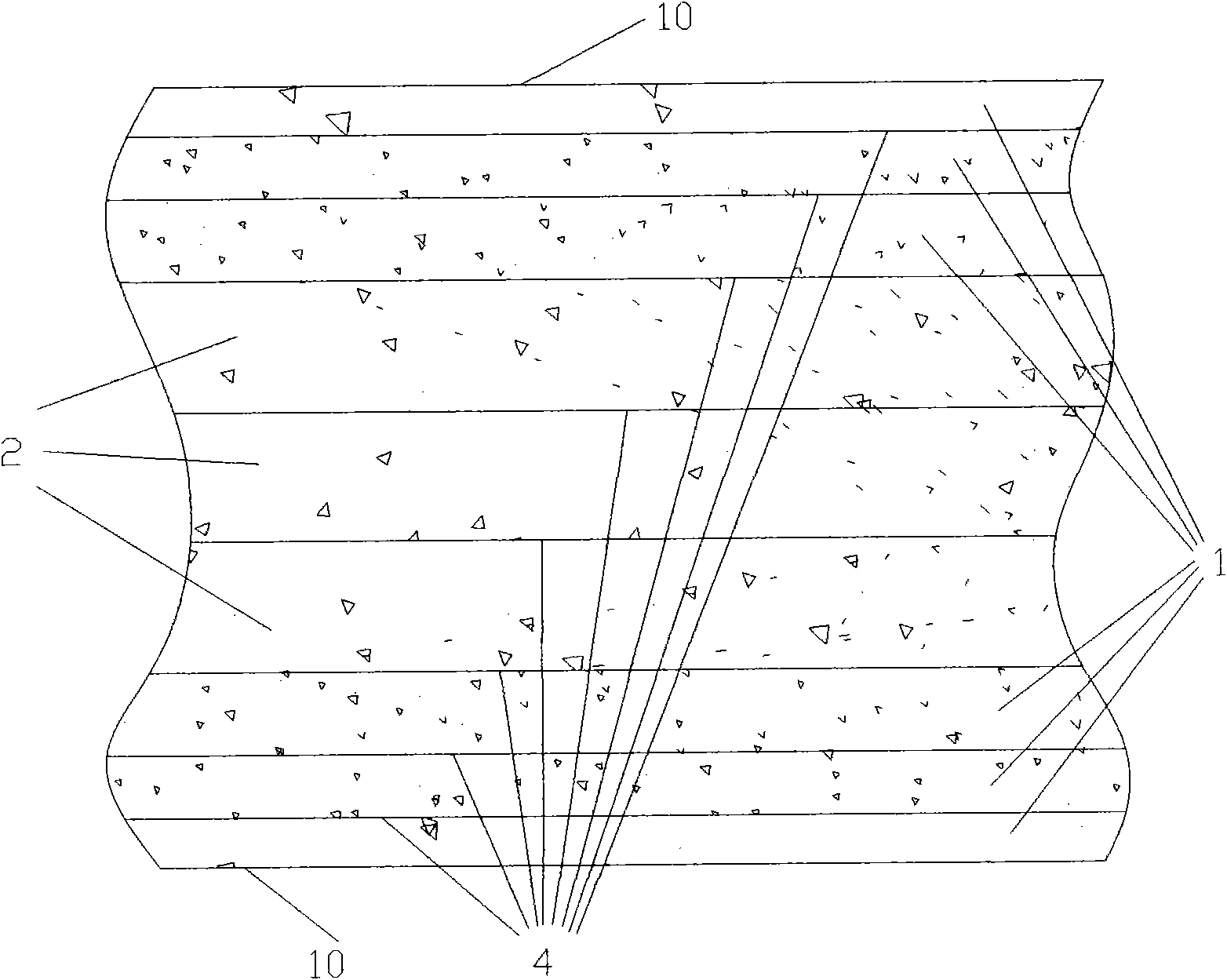

[0102] Embodiment 1 (see attached Figure 1~3 )

[0103] A multi-layer composite board, which uses magnesium cement gel as the main material, and is made by adding reinforcing materials and fillers; it is characterized in that: the multi-layer composite board specifically includes a surface layer 1 constituting the outer surface and a surface layer located on the outer surface Core layer 2 within;

[0104] The surface layer 1 is arranged on both sides of the core layer 2 respectively; each layer of the surface layer 1 or / and the core layer 2 contains fillers and reinforcing materials with uniform content; wherein, the reinforcing materials are arranged on adjacent between layers; fillers are physically and / or chemically arranged in layered materials;

[0105] The core layer 2 is arranged in the surface layer 1 on both sides, and the core layer 2 has 1 to 5 layers in total; reinforcing materials are arranged between different adjacent core layers 2 and between the surface lay...

Embodiment 2

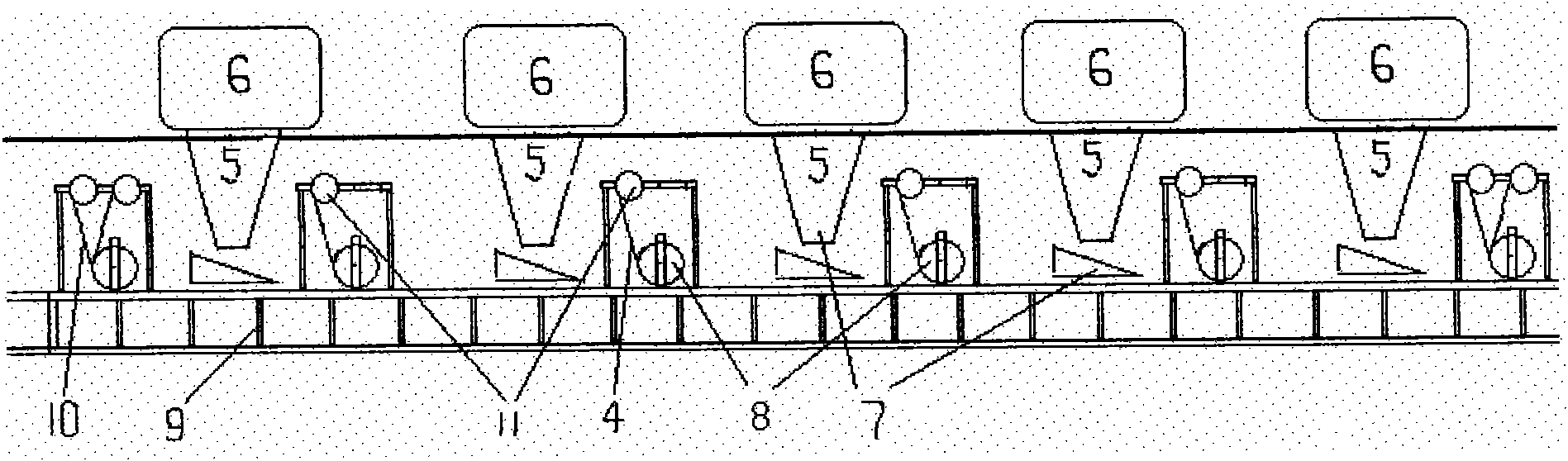

[0167] Embodiment 2 (see attached figure 1 , 2 、4)

[0168] The content of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0169] 1) The surface layer 1 of the multi-layer composite sheet is arranged on both sides of the core layer 2 or on a single side of the core layer 2; each layer of the surface layer 1 or / and core layer 2 contains a uniform Filler, the content of the filler in each of the two adjacent layers changes in a gradient;

[0170] The core layer 2 is arranged in the surface layer 1 on both sides, and the core layer 2 has three layers in total; reinforcing materials are arranged between different adjacent core layers 2 and between the surface layer 1 and the core layer 2; the reinforcing materials are arranged in The boundary between adjacent layers can be sequentially prepared by layering; the filler is physically or / and chemically arranged in the layered material;

[0171] 2) Among the raw materials of the main materi...

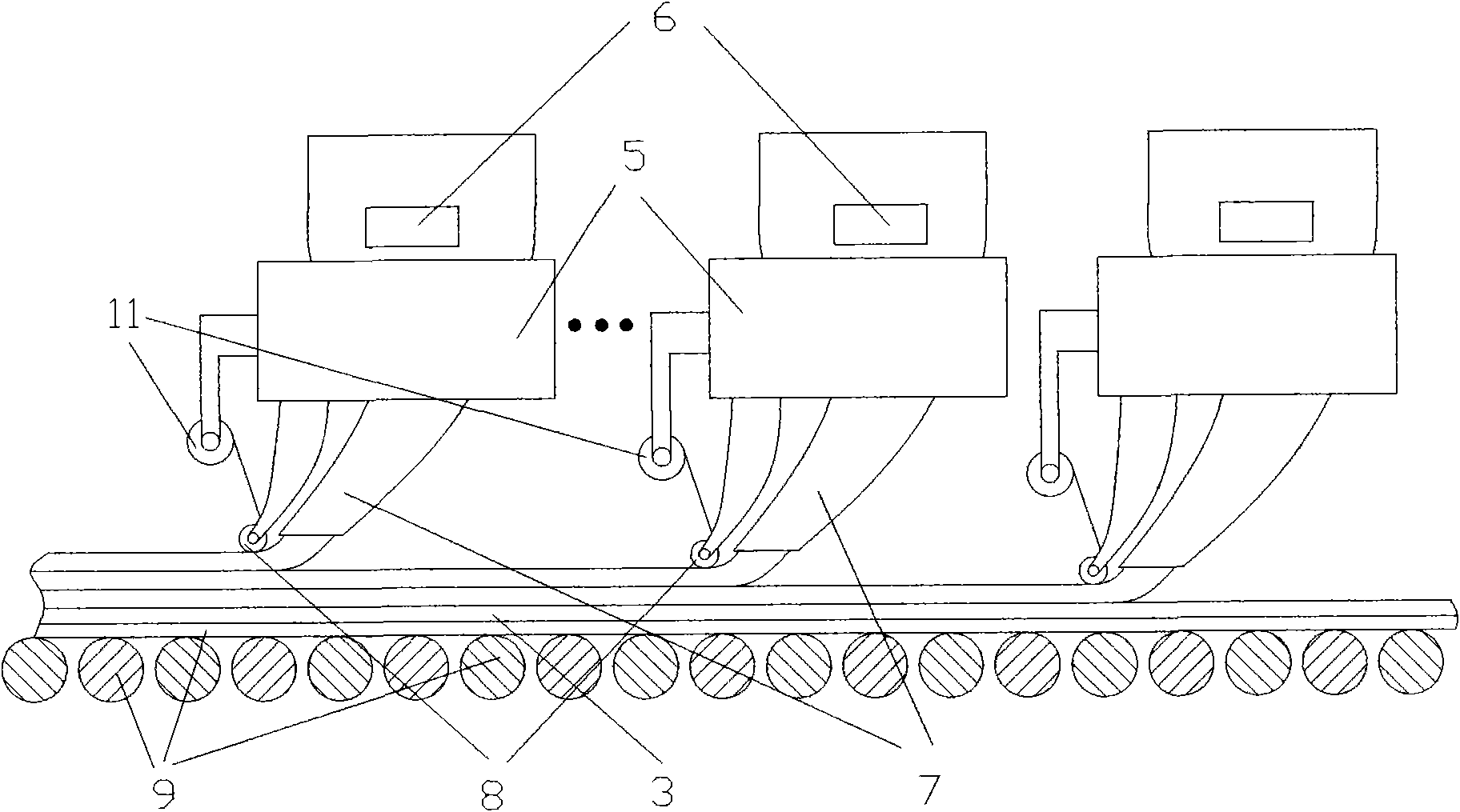

Embodiment 3

[0193] The content of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0194] 1) The upper and lower surfaces of the multilayer composite sheet (the outermost side of the surface layer 1) only have non-woven fabrics on one side or no non-woven fabrics on both sides;

[0195] 2) In the multi-layer composite board, only a few of the boundaries between different adjacent core layers 2 and between the surface layer 1 and the core layer 2 are provided with reinforcing materials: medium-alkali or alkali-free glass fiber cloth or polyester chemical fiber cloth; 2 to 3 layers of reinforcing materials can be overlapped at some boundaries: medium-alkali or alkali-free glass fiber cloth or polyester chemical fiber cloth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com