Ceramic bonding agent, preparation method thereof and application in CBN grinding wheel

A vitrified bond and grinding wheel technology, which is applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of unsatisfactory structure of grinding wheel, inability to adopt large feed rate, insufficient holding force of abrasive grains, etc. Achieve the effects of small thermal expansion coefficient, increased strength, and reduced grinding wheel dressing times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

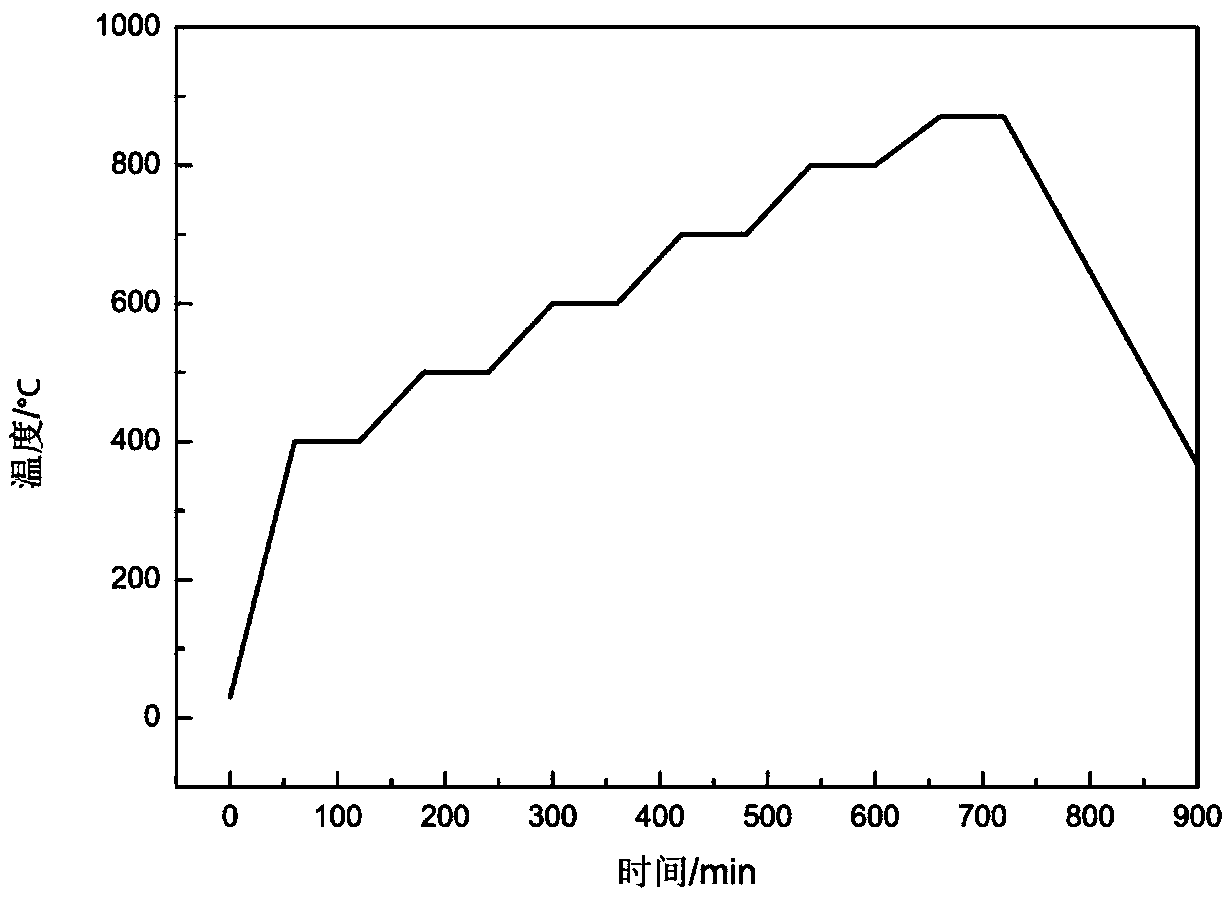

[0041] The preparation method of above-mentioned ceramic bond, comprises the steps:

[0042] The step of preparing materials: use the electronic balance to weigh the raw materials of the formula amount for standby;

[0043] Mixing step: after the weighing is completed, put the raw materials into the mixing tank, and mix them evenly on the automatic mixer; as a further embodiment, the mixing time of the mixing is 50-70min;

[0044] Melting step: put the uniformly mixed raw materials into a corundum crucible, put them into a high-temperature energy-saving frit furnace for melting; as a further embodiment, the firing temperature is 1380-1480°C, and the firing The time is 60-120min;

[0045] The step of water quenching: after the solute is kept warm, it is quenched and rapidly cooled by water to obtain glass frit; as a further embodiment, the temperature of the solute is 1425-1435°C, and the temperature is kept for 55-65min;

[0046] The step of ball milling: then glass frit is ...

Embodiment 1

[0060] A CBN grinding wheel, comprising the following components in parts by weight: 45 parts of CBN abrasive particles with a particle size of 80 / 100 mesh, 12 parts of CBN abrasive particles with a particle size of 100 / 120 mesh, 20 parts of vitrified bond, and a particle size of 80 / 100 Purpose Microcrystalline corundum SG 15 parts, binder 2 parts.

[0061] The vitrified bond is prepared from the following components in parts by weight: 41.0 parts of quartz, 4.0 parts of aluminum oxide, 19.0 parts of boric acid, 3.0 parts of zinc oxide, 6.0 parts of lithium carbonate, 2.5 parts of carbonic acid Sodium, 15.0 parts of barium carbonate, 2.0 parts of strontium carbonate.

[0062] The preparation method of this vitrified bond comprises the steps:

[0063] The step of preparing materials: use the electronic balance to weigh the raw materials of the formula amount for standby;

[0064] Mixing steps: After the weighing is completed, put the raw materials into the mixing tank and mix...

Embodiment 2

[0077] A CBN grinding wheel, comprising the following components in parts by weight: 47.1 parts of CBN abrasive particles with a particle size of 80 / 100 mesh, 15.7 parts of CBN abrasive particles with a particle size of 100 / 120 mesh, 21.0 parts of vitrified bond, and a particle size of 80 / 100 Objective microcrystalline corundum SG 16.2 parts, binder 2 parts.

[0078] The vitrified bond is prepared from the following components in parts by weight: 42.5 parts of quartz, 5 parts of aluminum oxide, 20.0 parts of boric acid, 4.0 parts of zinc oxide, 7.0 parts of lithium carbonate, 3.0 parts of carbonic acid Sodium, 16.0 parts of barium carbonate, 2.8 parts of strontium carbonate.

[0079] The preparation method of this vitrified bond comprises the steps:

[0080] The step of preparing materials: use the electronic balance to weigh the raw materials of the formula amount for standby;

[0081] Mixing steps: After the weighing is completed, put the raw materials into the mixing tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com